Blocking remover of gas well shaft

A plugging agent and wellbore technology, which is applied in the field of organic-inorganic composite plugs, can solve the problems of slow dissolution of organic matter, limited solubilization ability, and easy volatilization, and achieves the effects of fast speed, good thermal stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A wellbore plugging remover for gas wells, the components and parts by mass are as follows:

[0027] N, N dimethylformamide: 65 parts; Ethylene glycol-diethyl ether: 20 parts; Dispersant: 5 parts; Propylenediamine: 5 parts; Sodium citrate: 5 parts. Mix and stir N, N dimethylformamide, ethylene glycol-ethyl ether, dispersant, propadienediamine and sodium citrate according to the above ratio, and then let it stand for 1 to 3 hours to obtain the wellbore plugging remover for gas wells .

[0028] According to the severity of gas well wellbore blockage, first put in temporary plugging rods, pump the prepared gas well wellbore plugging remover into the wellbore and soak for 4-8 hours until it completely dissolves and disperses the blockage in the wellbore, and then backwash the dissolved matter in the wellbore to the ground Storage devices are fine.

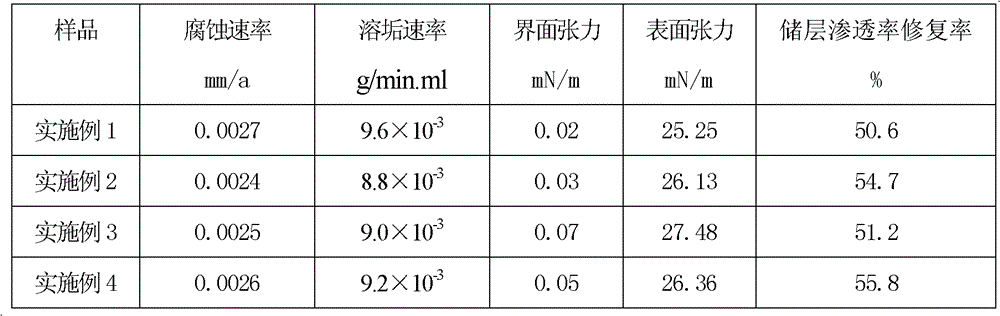

[0029] After testing, the corrosion rate, scale dissolution rate, interfacial tension, surface tension, reservoir permeabili...

Embodiment 2

[0031] The gas well wellbore plugging remover as described in Example 1, the difference is that the components and parts by mass are as follows:

[0032] N, N dimethylformamide: 55 parts; Ethylene glycol-propyl ether: 25 parts; Dispersant: 5 parts; Acetonitrile: 10 parts; Sodium citrate: 5 parts.

[0033] After testing, the corrosion rate, scale dissolution rate, interfacial tension, surface tension, reservoir permeability repair rate and other test data of the gas well wellbore plugging removal agent are shown in Table 1.

Embodiment 3

[0035] The gas well wellbore plugging remover as described in Example 1, the difference is that the components and parts by mass are as follows:

[0036] N, N dimethylacetamide: 60 parts; Ethylene glycol-butyl ether: 20 parts; Dispersant: 7 parts; Acetonitrile: 10 parts; EDTA: 3 parts.

[0037] After testing, the corrosion rate, scale dissolution rate, interfacial tension, surface tension, reservoir permeability repair rate and other test data of the gas well wellbore plugging removal agent are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com