Patents

Literature

97results about How to "Good surface quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

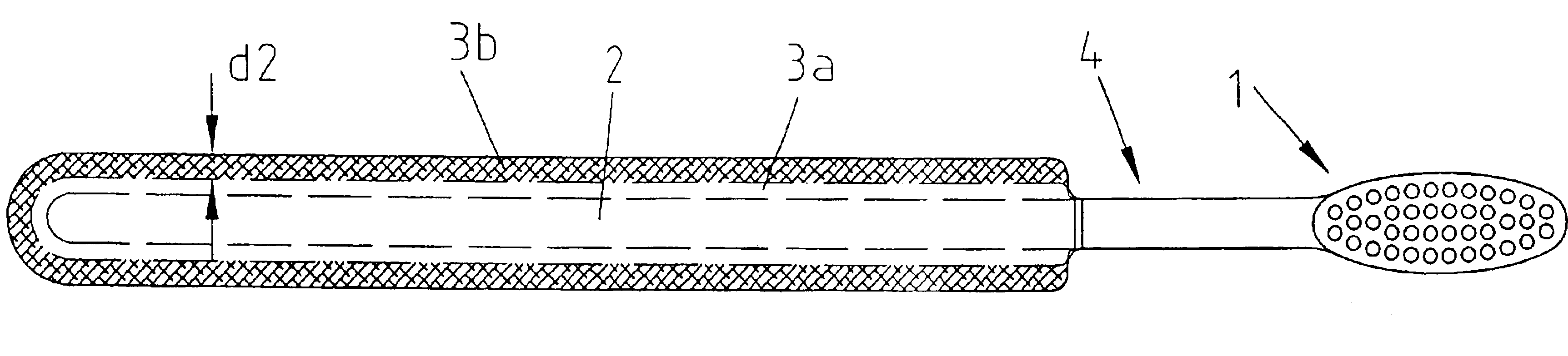

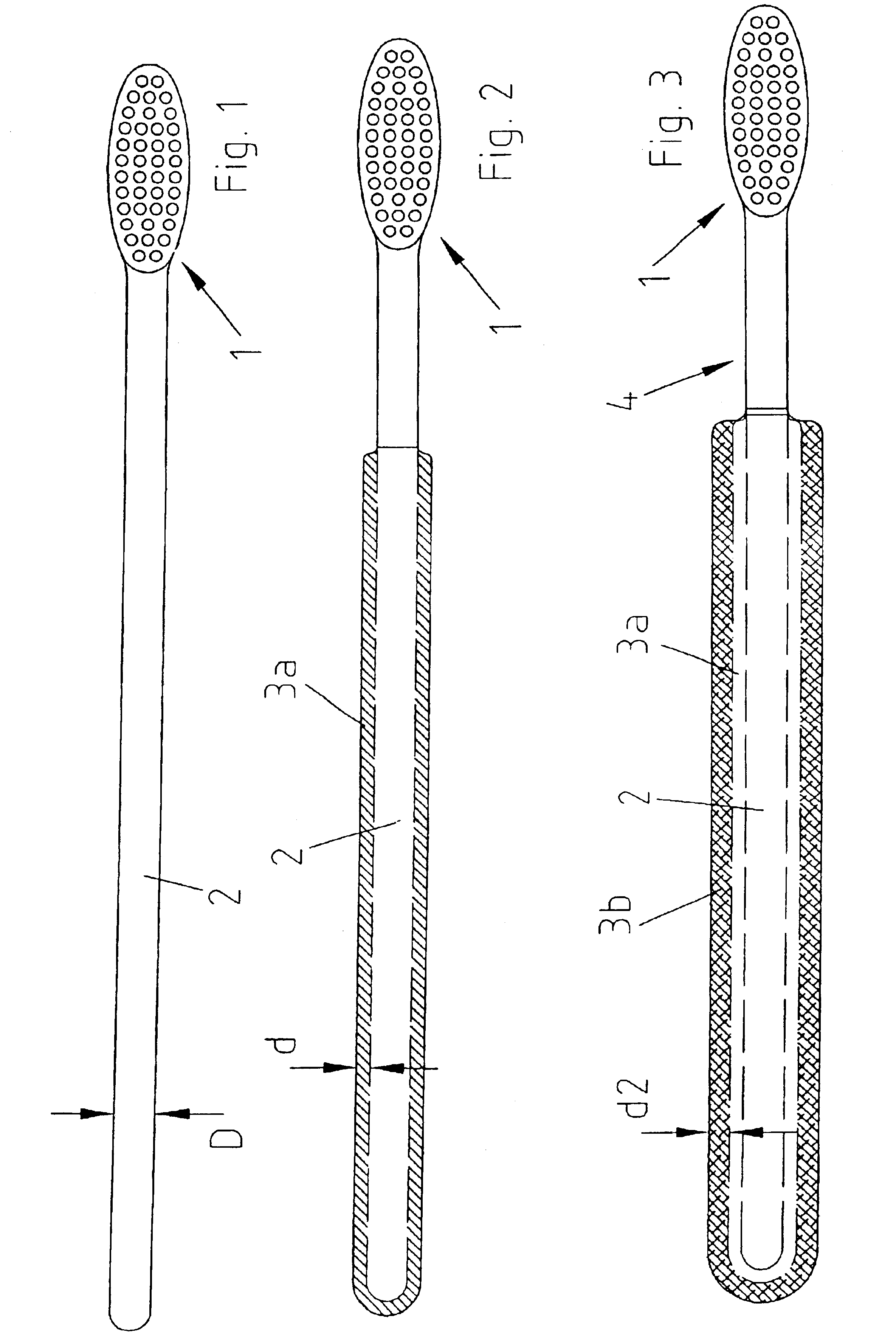

Method of producing thick-walled brushes, in particular toothbrushes

InactiveUS6919038B2High productivityGood surface qualityCarpet cleanersMouldsProduction rateEngineering

The present invention relates to a method of producing thick-walled brushes, in particular toothbrushes, with a grip piece and a brush head supporting bristle filaments. In order to increase the productivity, the method mentioned at the start is further developed by the present invention in that a core produced in a first injection molding cycle is coated with a plastic component in at least one subsequent injection molding cycle so as to form a multi-layered grip piece.

Owner:M C SCHIFFER

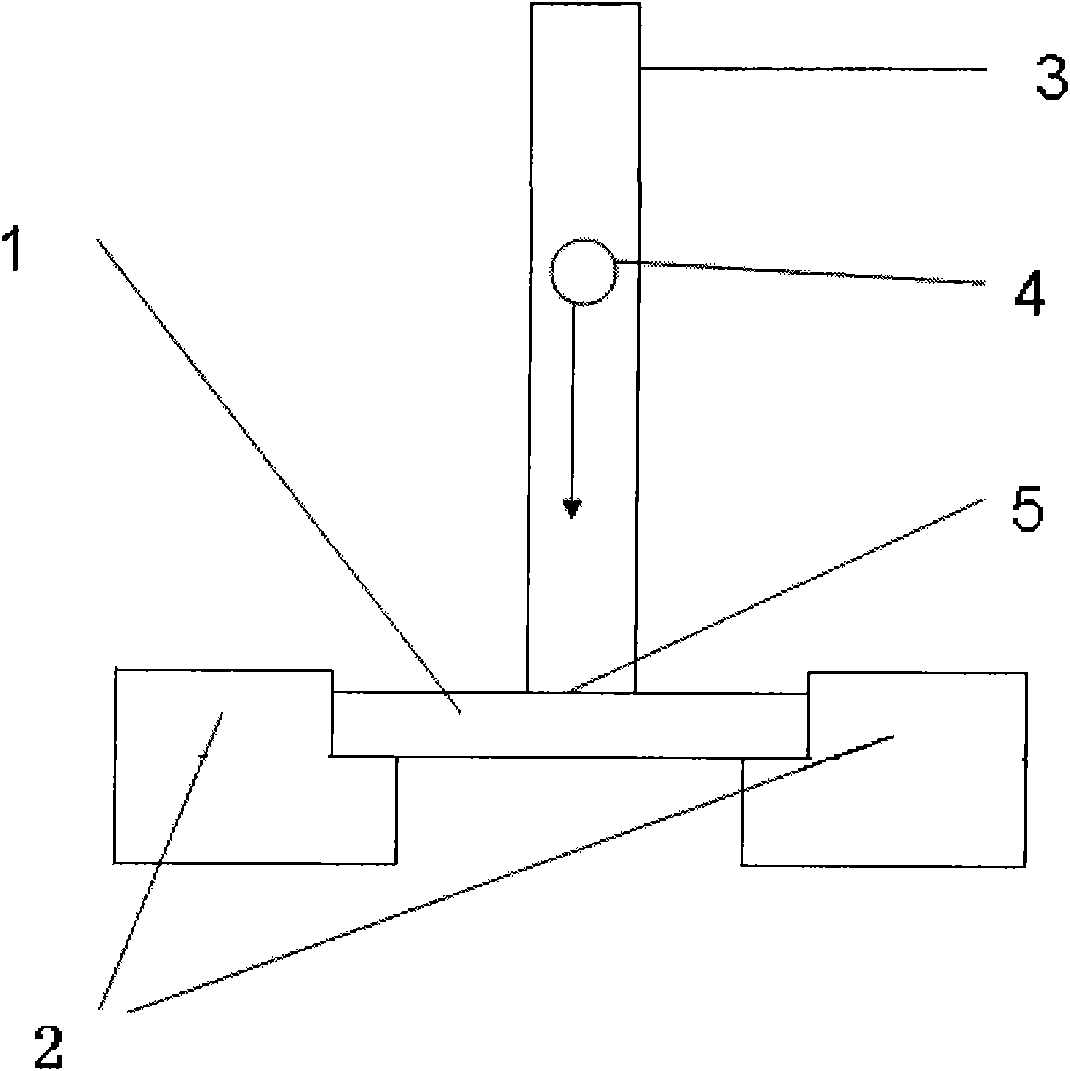

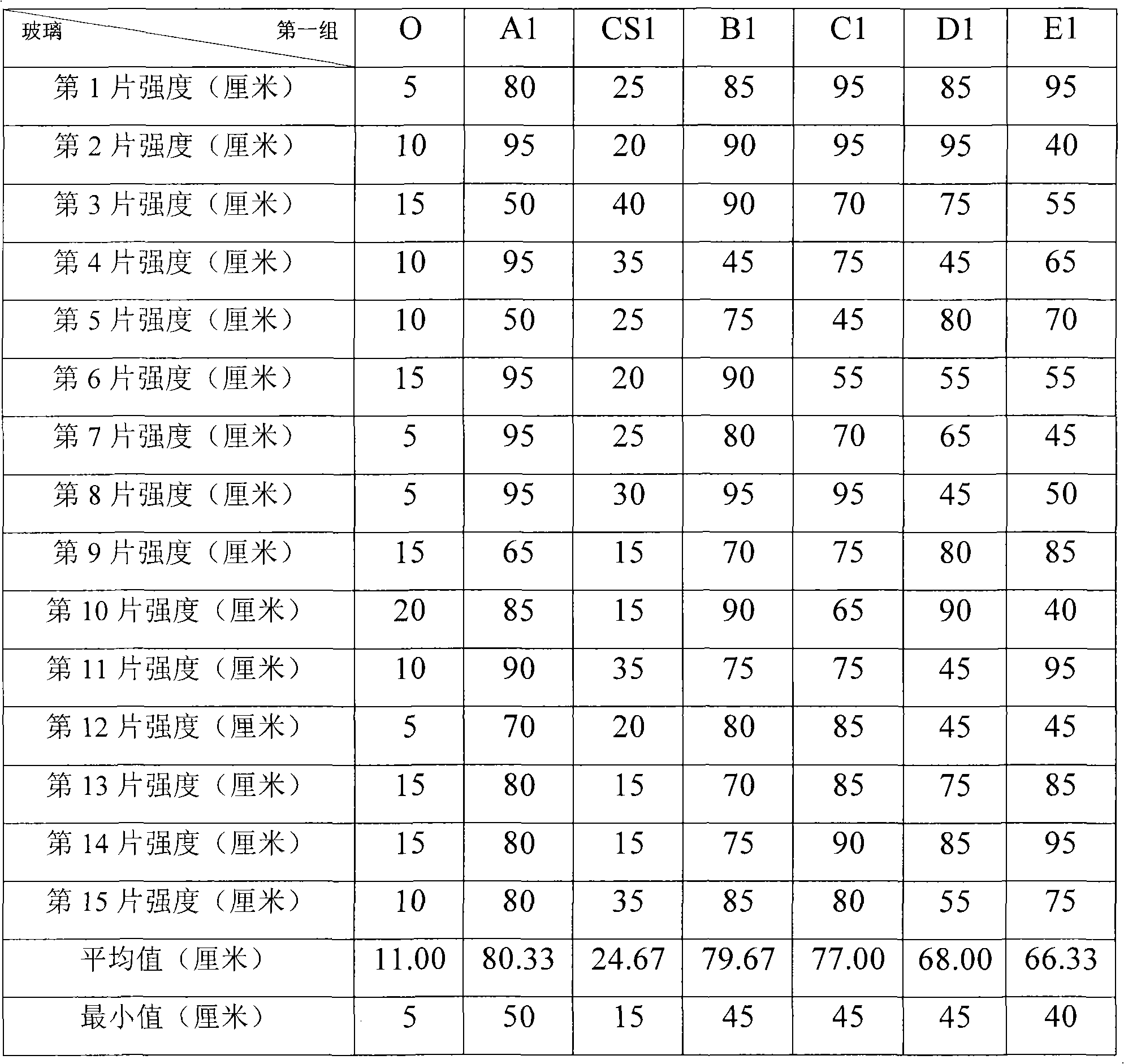

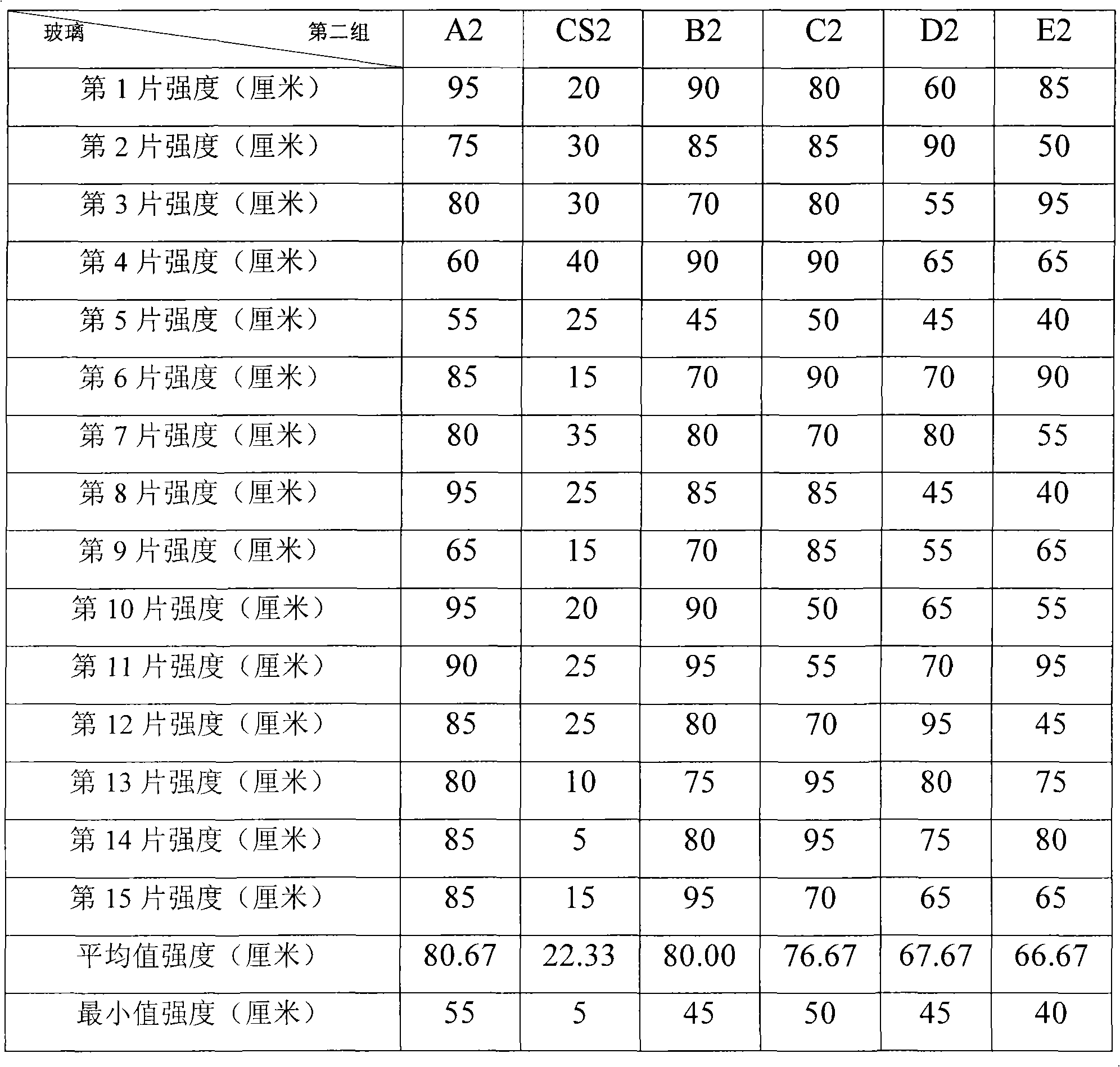

Method for improving strength of glass

The invention provides a method for improving the strength of glass. The method comprises the following steps: performing chemical strengthening on the glass; and performing mechanical polishing on atleast one surface of the glass after the chemical strengthening. According to the method for improving the strength of the glass, the strength of the glass can be greatly improved and reliably maintained only by removing a defective layer in a certain thickness on the surface of the strengthened glass; and the method has simple operation and convenient control, and is convenient for industrialized production. In addition, the method effectively reduces a defective part on the surface of the glass by performing the mechanical polishing, can better improve the strength of the glass without performing chemical strengthening repeatedly on the glass, and reduce the corrosion to the glass and the damage to the optical performance of the glass by chemical drugs so that the glass has better luster and transmittance. The glass strengthened by the method provided by the invention is particularly suitable for a mobile phone display window.

Owner:BYD CO LTD

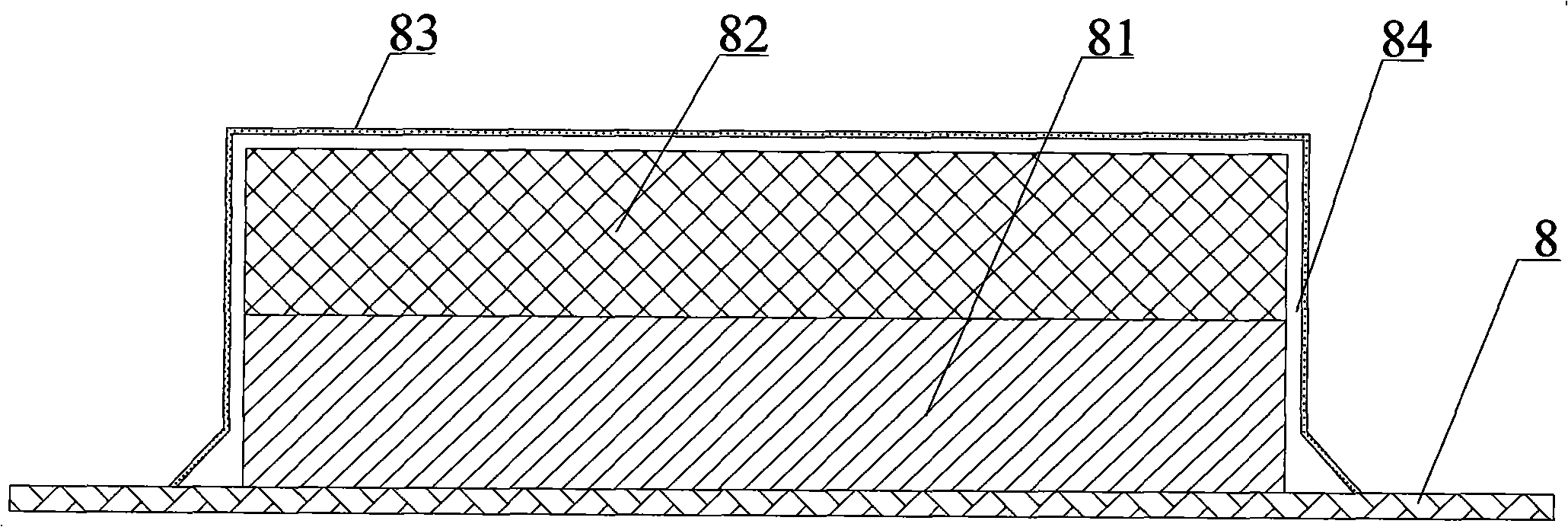

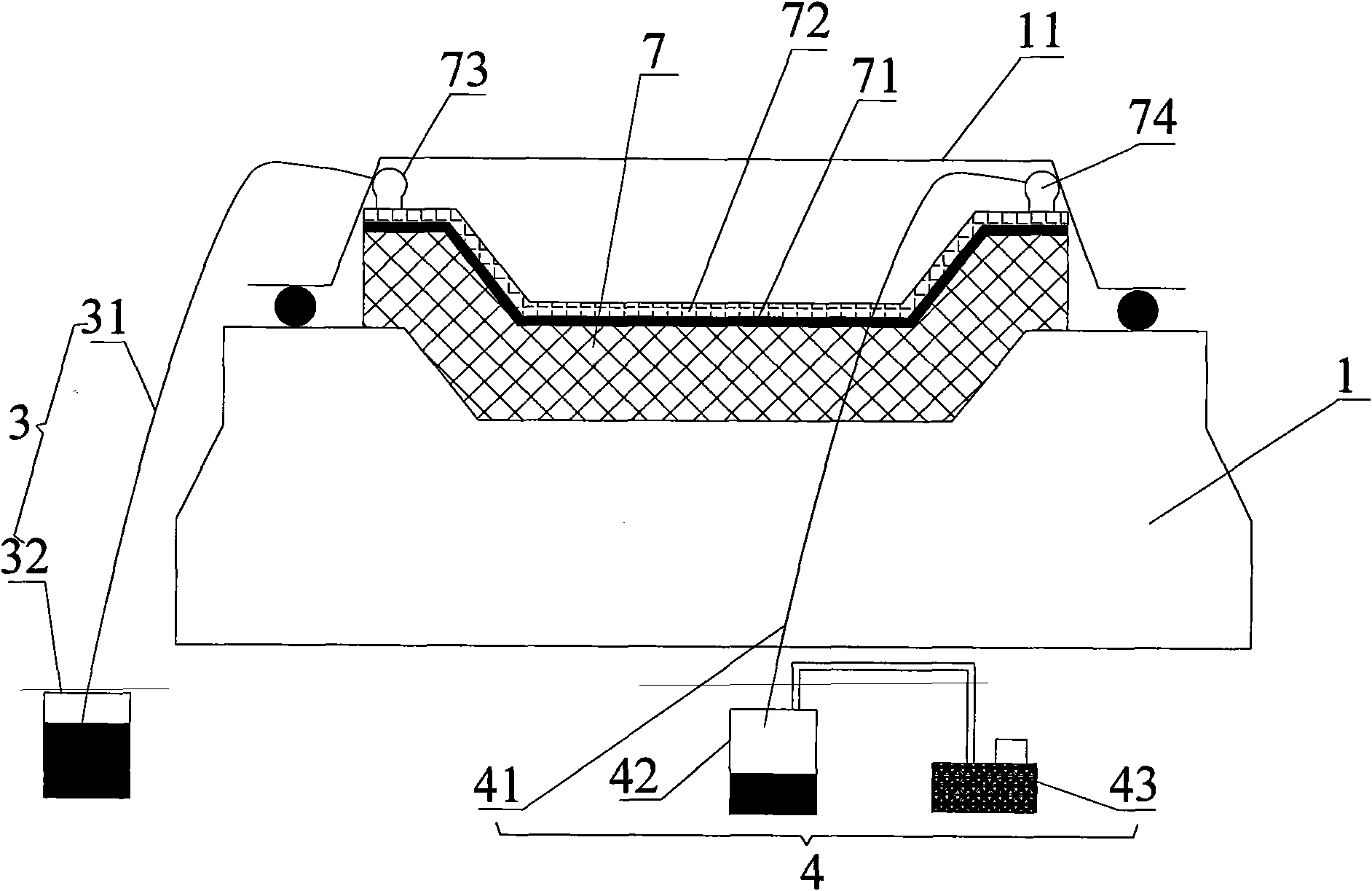

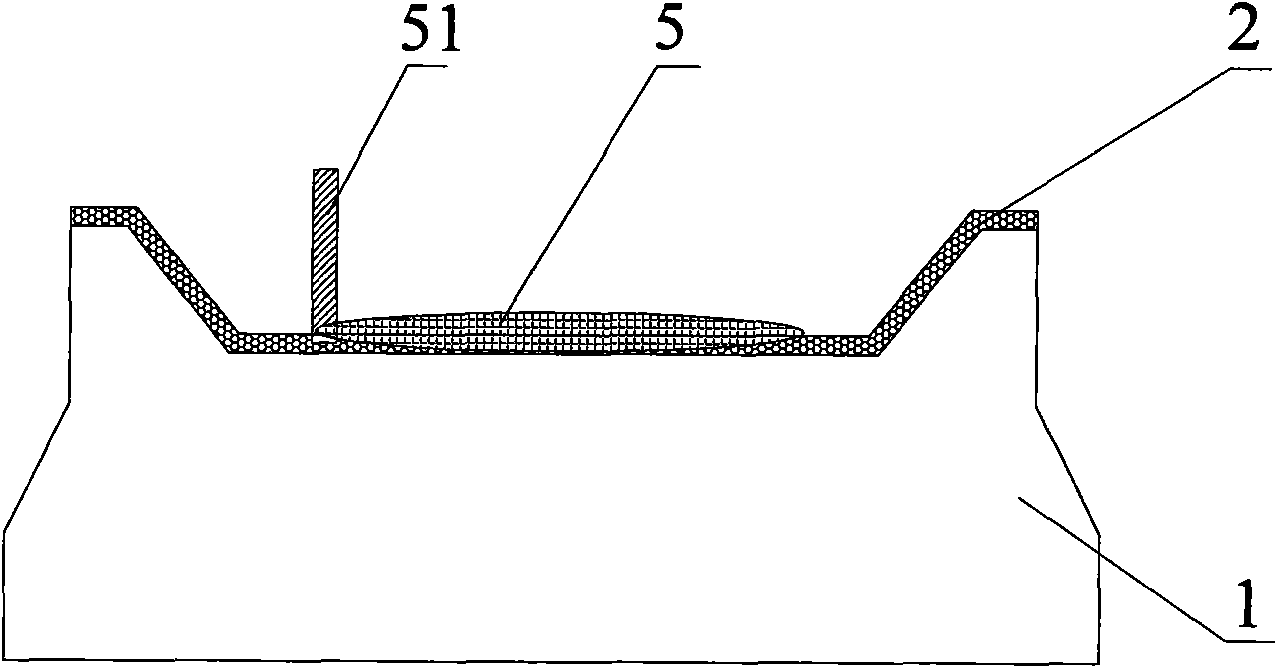

Composite material member with surface function layer and VIMP preparation method thereof

InactiveCN101830095AFast impregnationGood surface qualitySynthetic resin layered productsSurface functionMaterial system

The invention belongs to the technical field of a multilayer structural composite material member and a preparation method thereof and specifically discloses the composite material member with a surface function layer and a VIMP preparation method thereof. The composite material member comprises an outer surface layer and a main body layer, wherein, the outer surface layer and the main body layer are respectively a first composite material system and a second composite material system; and the first composite material system takes epoxy resin, phenolic resin and the like as a matrix, the second composite material system takes unsaturated polyester resin as a matrix, and the two systems take fiber cloth of carbon fiber or glass fiber as reinforcement. The VIMP preparation method comprises the following steps: firstly preparing a reinforced resin film on a die surface for vacuum dip molding by a resin film infiltration process, and then preparing the composite material member with a molding die covered with the reinforced resin film through the vacuum dip molding process. The VIMP process of the invention combines the double advantages of an RFI process and the VIMP process; and the obtained composite material member has better surface quality, better integrity and excellent comprehensive performances.

Owner:NAT UNIV OF DEFENSE TECH

Manufacturing method of nuclear nickel-base high-temperature alloy GH 4145 wire

The invention provides a manufacturing method of a nuclear nickel-base high-temperature alloy GH 4145 wire and belongs to the technical field of high-temperature alloy wire machining. The method includes the steps that after being blended according to the mass percent, raw materials are subjected to vacuum induction and vacuum consumption duplex smelting and cast into an alloy ingot; the alloy ingot is homogenized so as to be forged into an alloy ingot blank, and the alloy ingot blank is then subjected to flaw detection and finishing and hot-rolled into a wire rod with the diameter phi ranging from 8 mm to 12 mm; the wire rod is subjected to solution treatment and is rounded, peeled and coated with a film; drawing and annealing are performed sequentially, the wire rod is pulled into the alloy wire with the required diameter, and the GH 4145 alloy wire is obtained. By the adoption of the nuclear nickel-base high-temperature alloy wire, the whole process is free of acid pickling, the special nuclear requirement is met, and meanwhile the finished wire is high in size accuracy, good in surface quality, even in component and structure and excellent in mechanical performance and processing performance. The method can be widely applied to the machining field of the nuclear nickel-base high-temperature alloy wire.

Owner:CENT IRON & STEEL RES INST

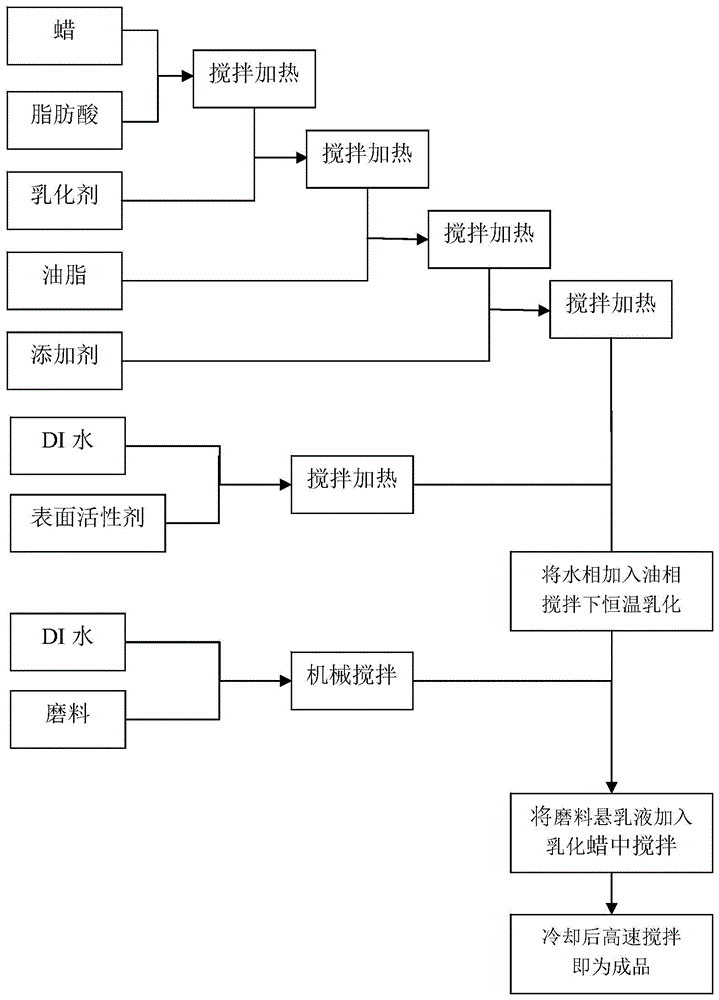

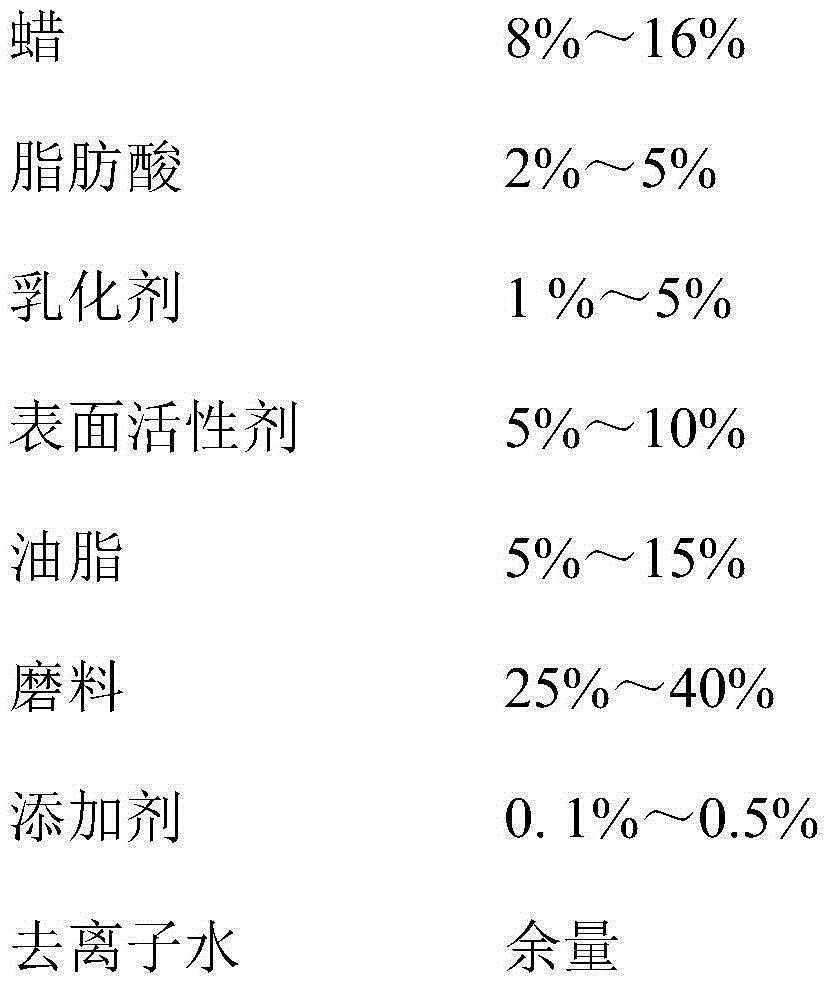

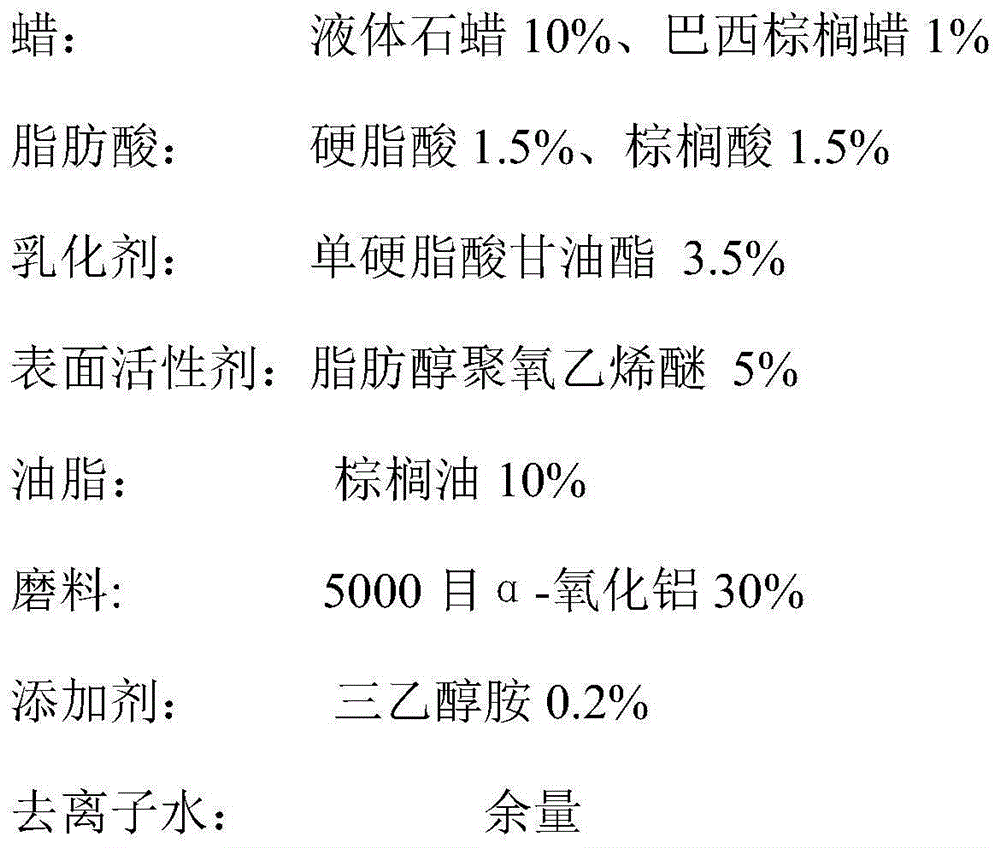

Stainless steel liquid polishing paste and preparation method thereof

The invention discloses stainless steel liquid polishing paste and a preparation method thereof. The polishing paste comprises wax, fatty acid, an emulsifier, a surface active agent, oil, a grinding material, additives and deionized water. The preparation method comprises the following steps: sequentially adding the wax, the fatty acid, the emulsifier, the oil and the additives into a thermostatic container with 80 to 90 DEG C under a stirring condition, stirring, completely dissolving to obtain a mixed solution; adding the surface active agent and the deionized water into another container, heating and stirring, and completely dissolving to obtain a surface active agent solution; slowly adding the surface active agent solution into the mixed solution, continuously stirring for 20 to 40 minutes at the temperature of 80 to 90 DEG C, and emulsifying; adding the deionized water to the grinding material to prepare a grinding material suspension; slowly adding the grinding material suspension, stirring, cooling, and then stirring for 30 to 50 minutes at a high speed to obtain a product. The polishing paste is used for mechanically polishing stainless steel, so that good surface quality and high glossiness can be obtained; moreover, a polished workpiece is simple to wash. The preparation method is simple in process and easy to operate and can produce a high-quality product.

Owner:深圳市宏达威表面处理技术有限公司

Method for manufacturing aluminum alloy free forge piece for spaceflight

The invention provides a method for manufacturing an aluminum alloy free forge piece for spaceflight and relates to a method for manufacturing an aluminum alloy free forge piece. The method aims to solve the technical problems that an existing aluminum alloy free forge piece cannot have high strength, high corrosion resistance and low density at the same time so that the requirements for high strength, corrosion resistance and light weight of aluminum alloy materials in the spaceflight field cannot be met. The method comprises the steps of 1, preparing an aluminum alloy solution; 2, manufacturing a round cast ingot; 3, carrying out dual-stage homogenizing annealing treatment; 4, manufacturing forge piece blank; 5, carrying out free forging; 6, performing solid-solution hardening treatment; 7, performing cold deformation treatment; and 8, performing two-stage aging treatment. The method has the advantages that by optimizing alloy components and adopting the optimized solid solution and aging processes after forging, the requirement for the overall performance of the aluminum alloy free forge piece is met; the manufactured aluminum alloy free forge piece is good in surface quality, the finished forge piece in industrial production is good in performance, and the overall mechanical property is good.

Owner:哈尔滨东轻特种材料有限责任公司

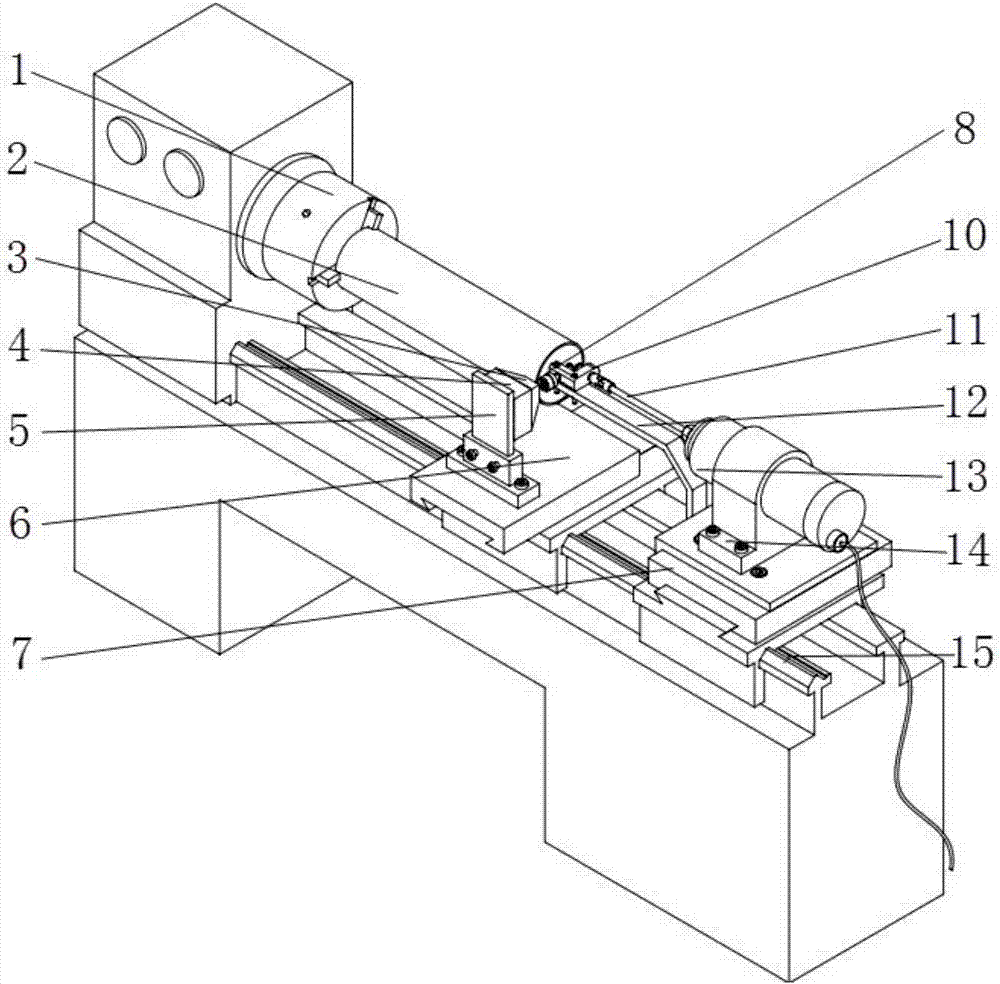

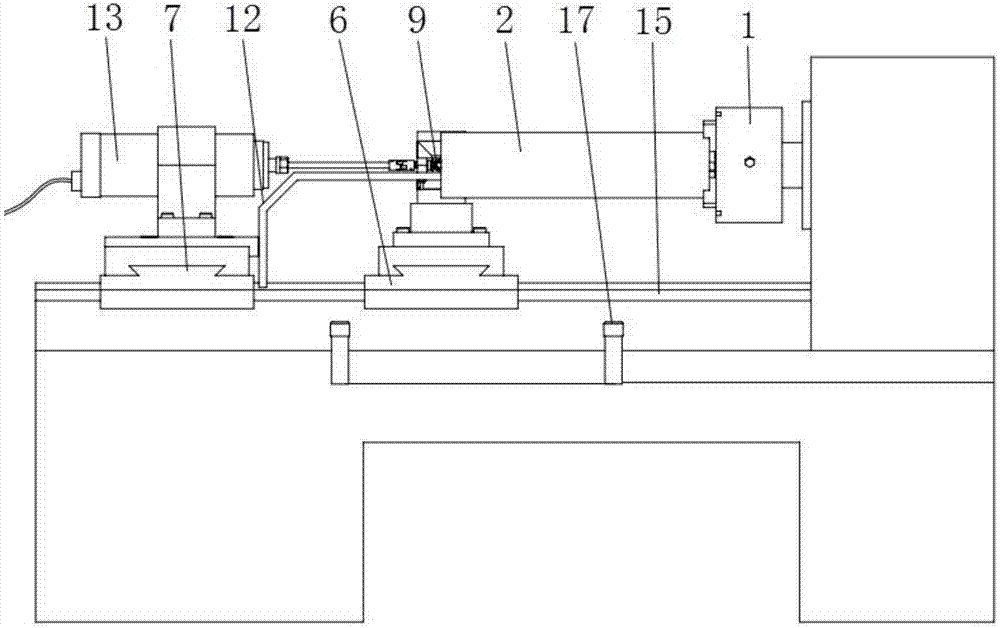

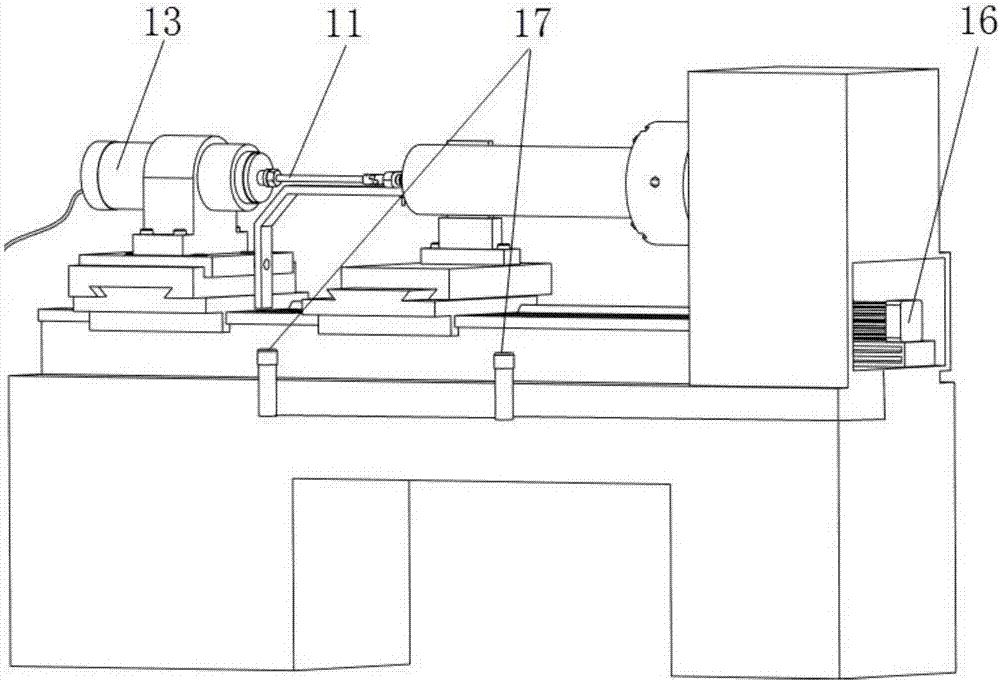

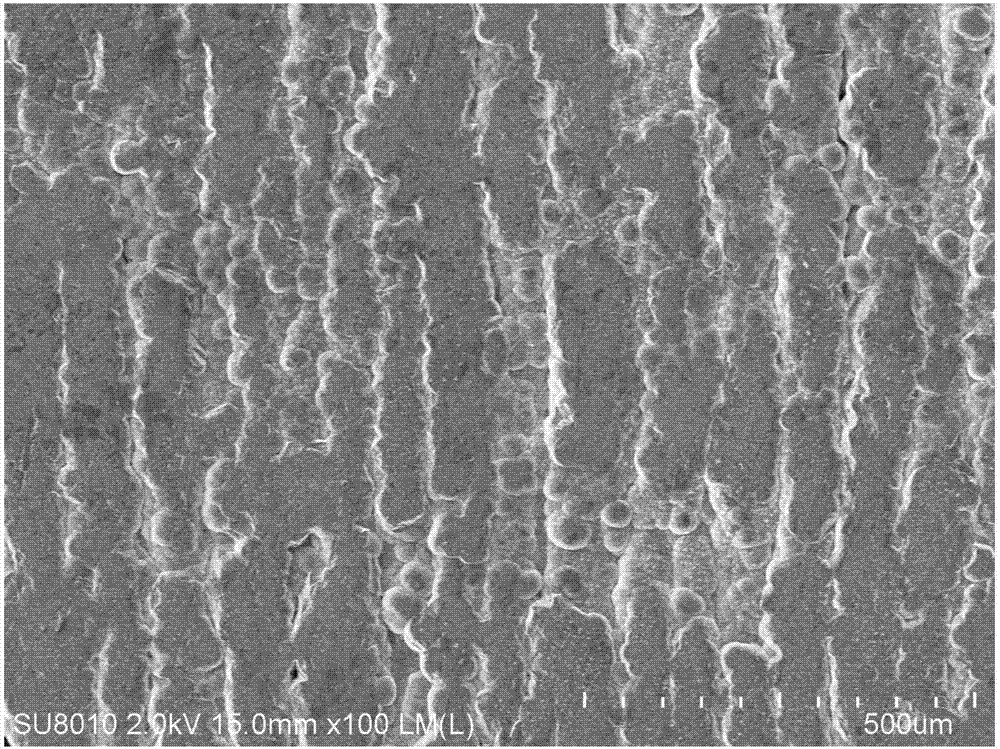

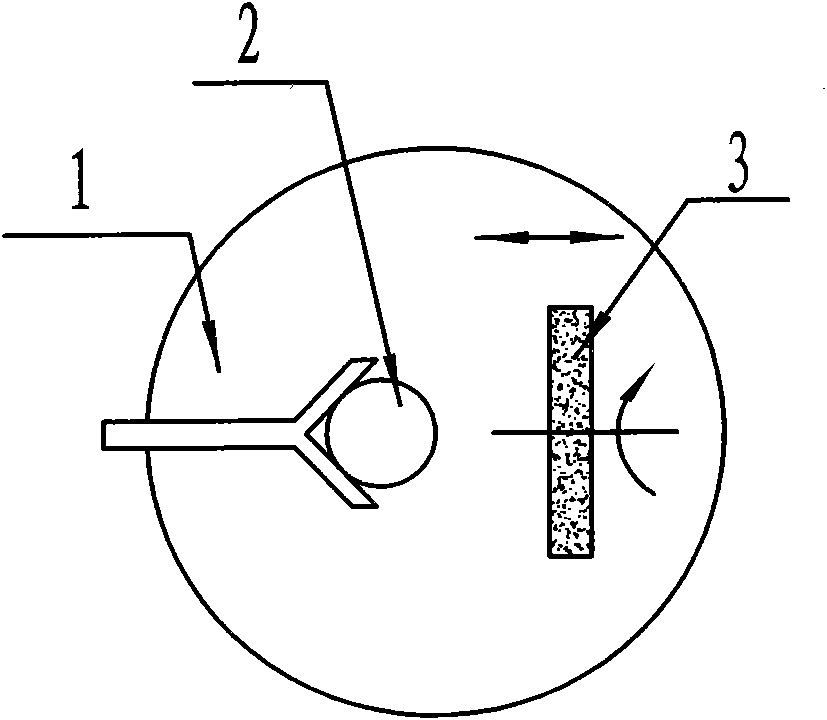

Ceramic tube inner surface polishing device and method

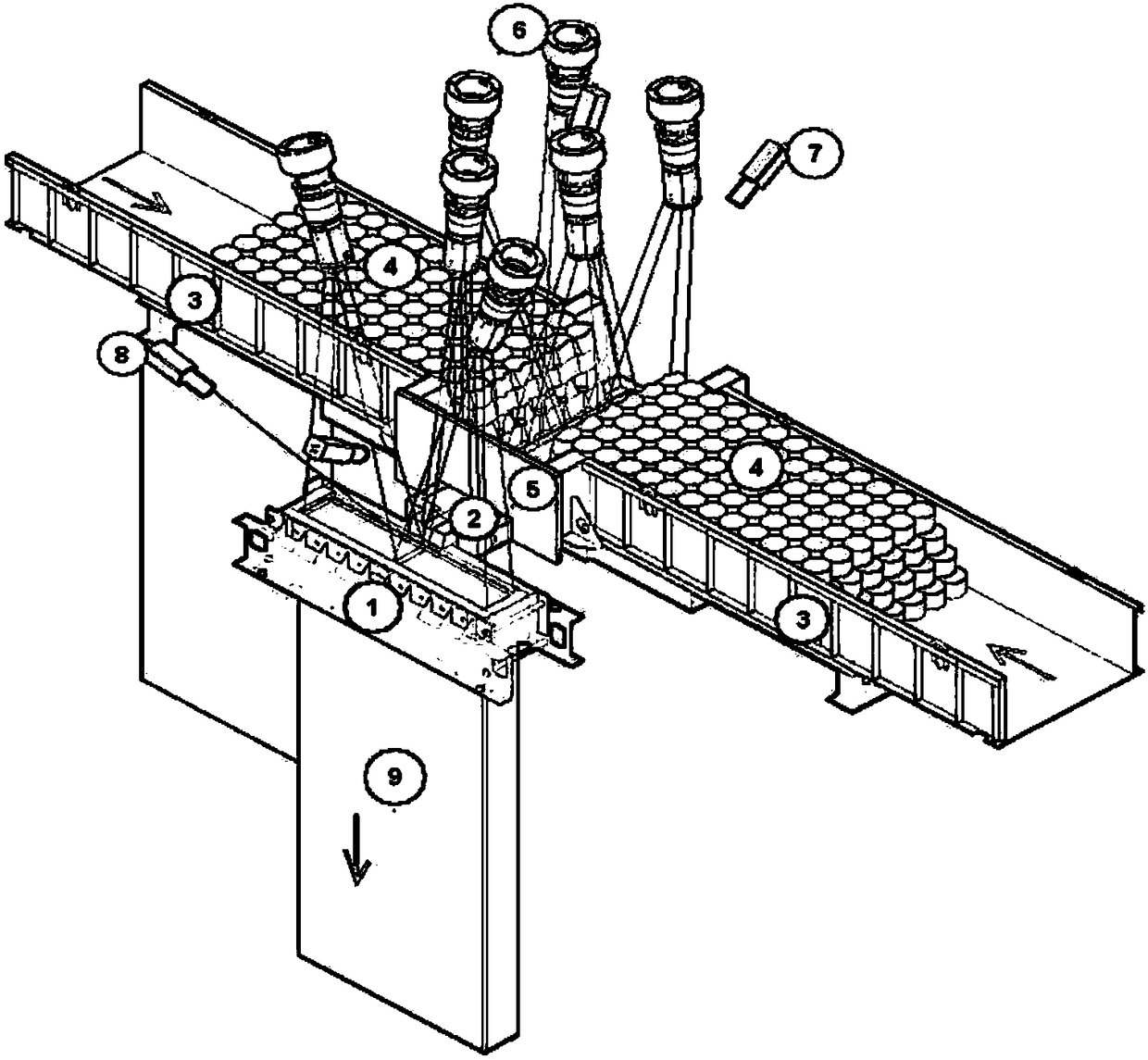

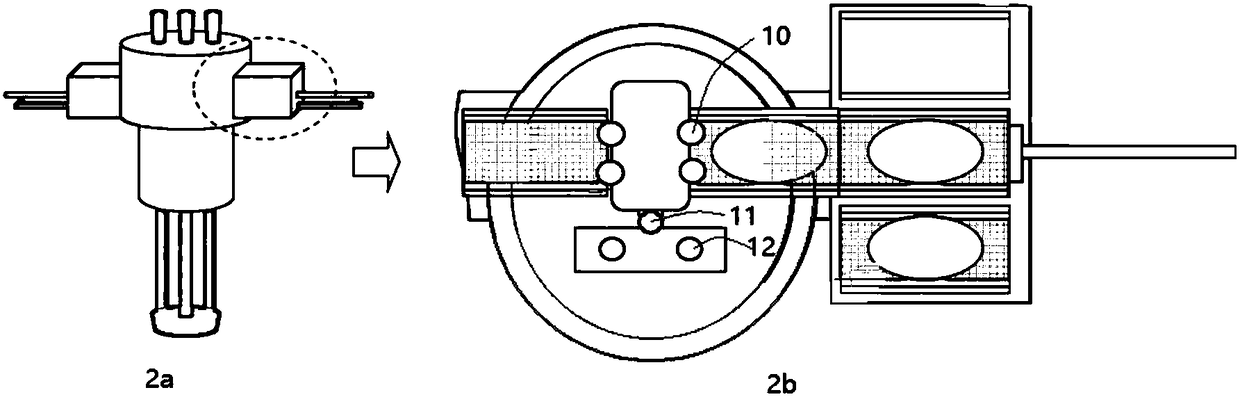

ActiveCN107186551AReduce roughnessGood surface qualityEdge grinding machinesPolishing machinesMotor driveLimit switch

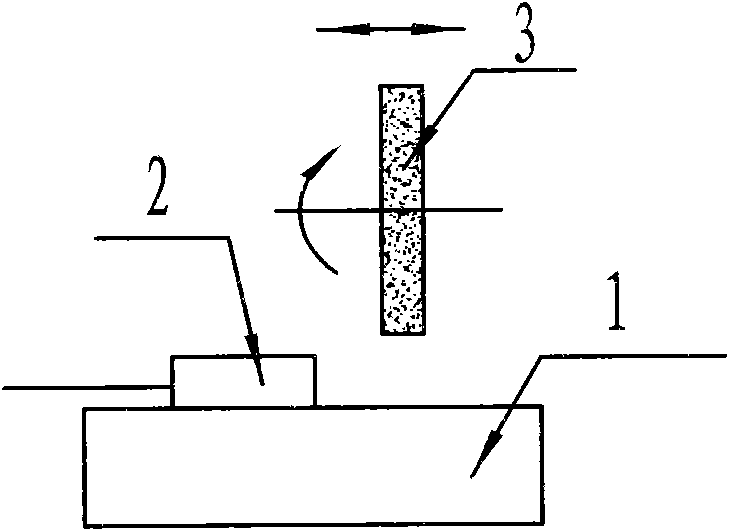

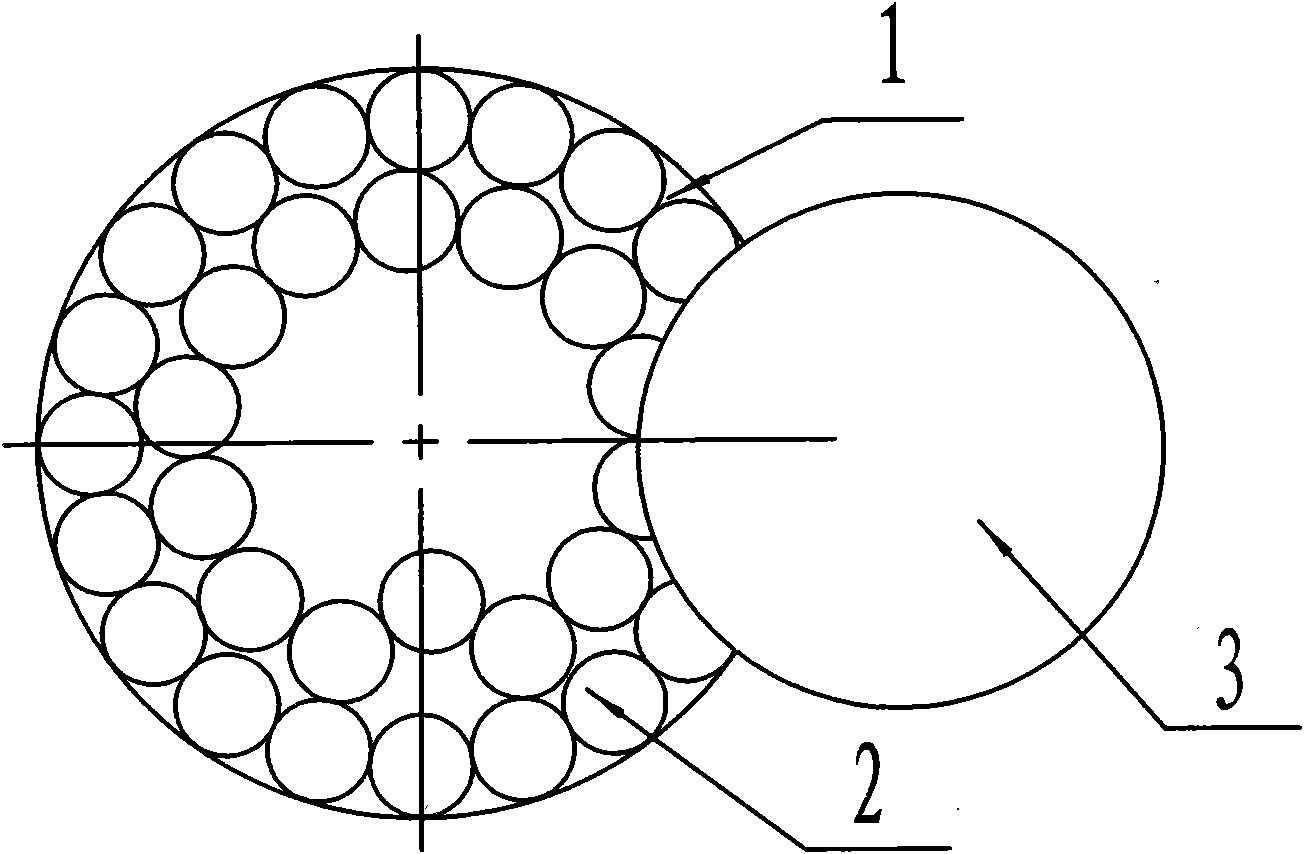

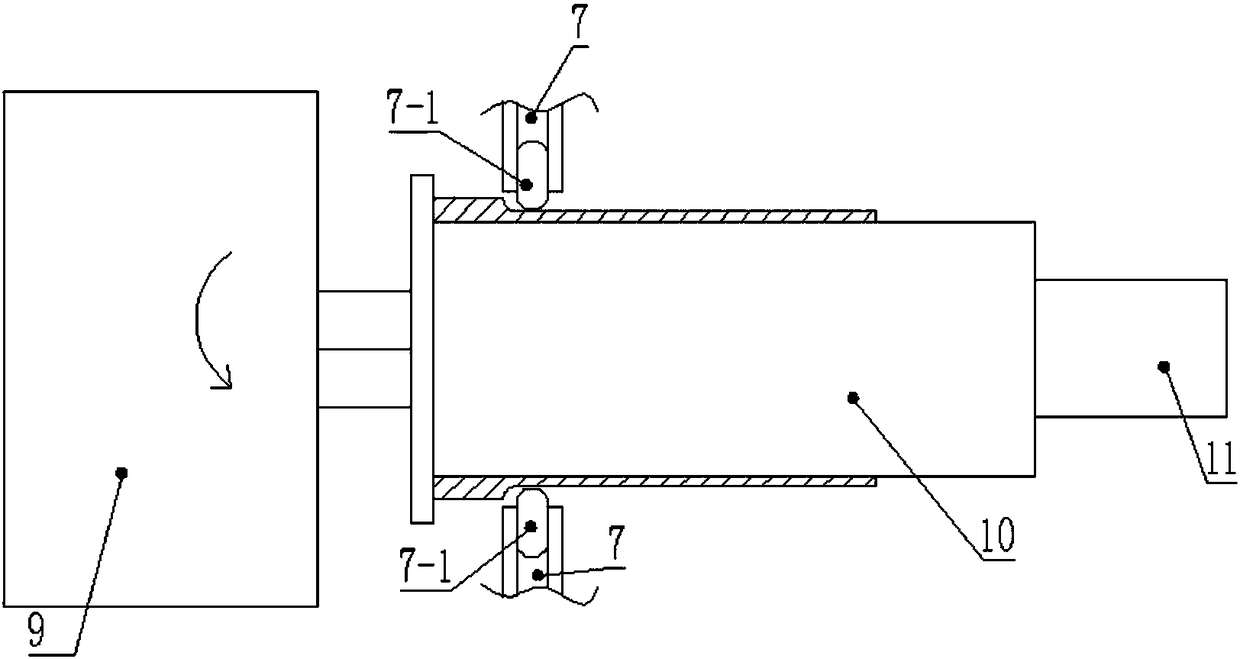

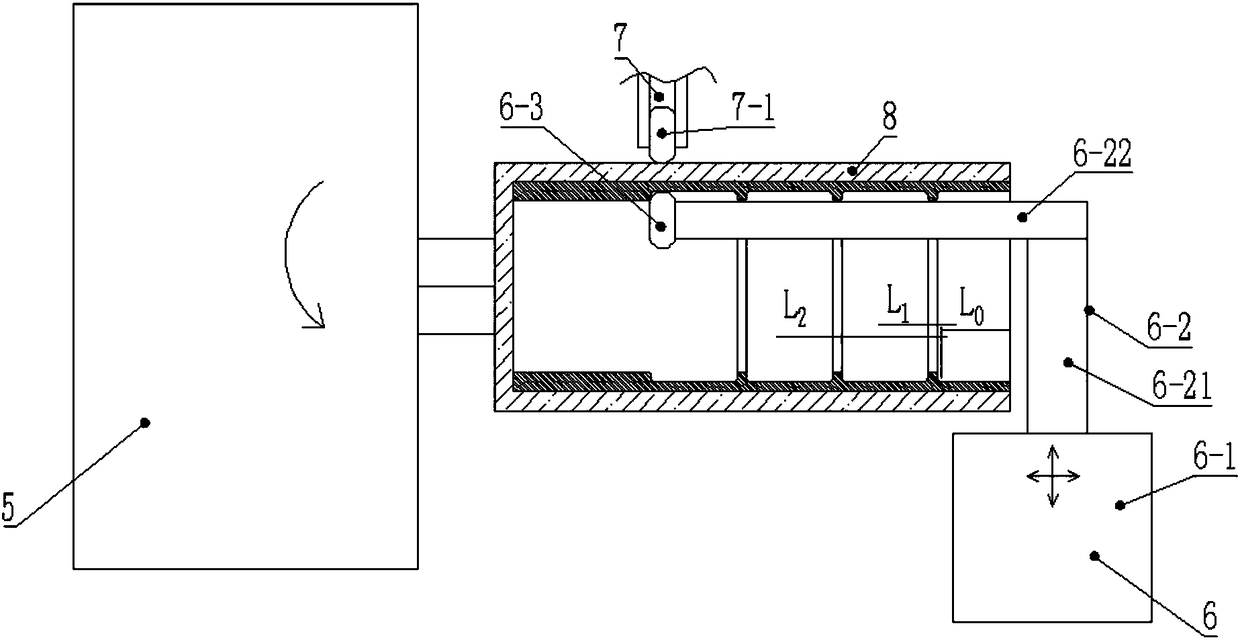

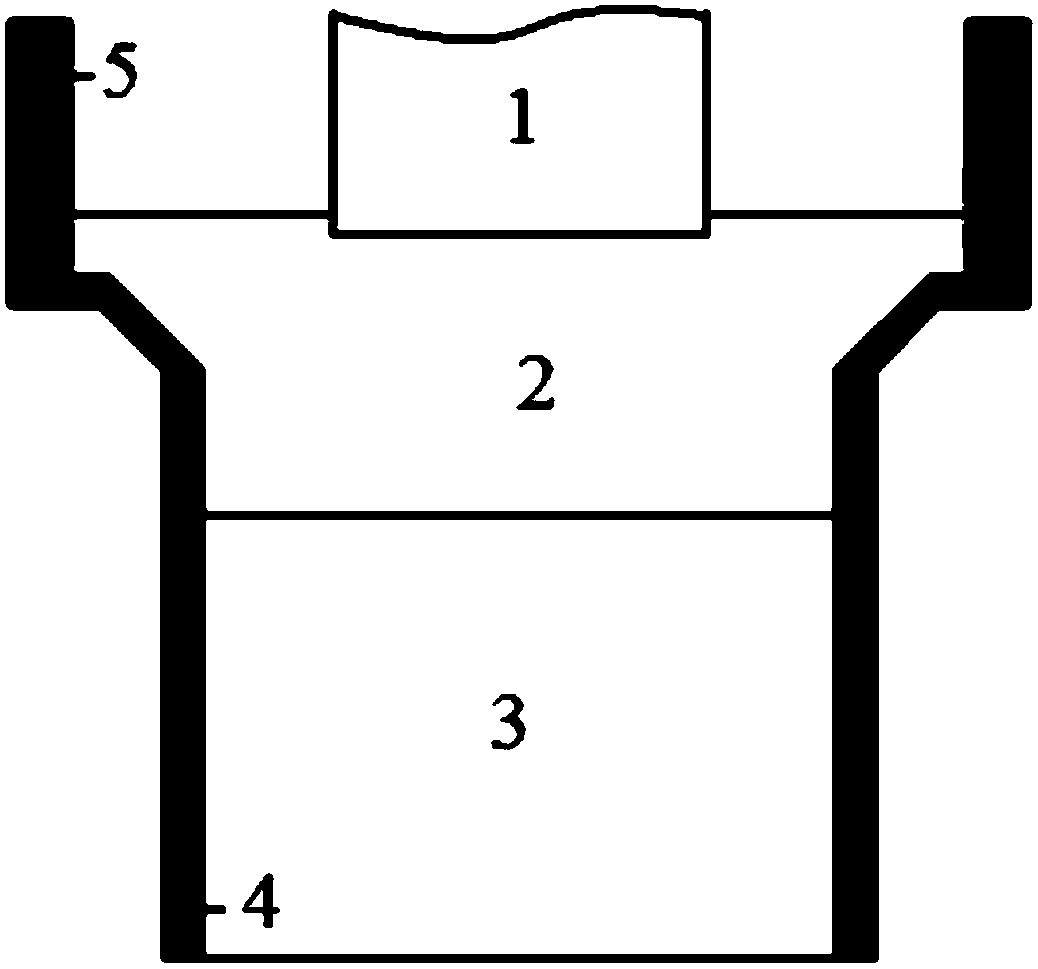

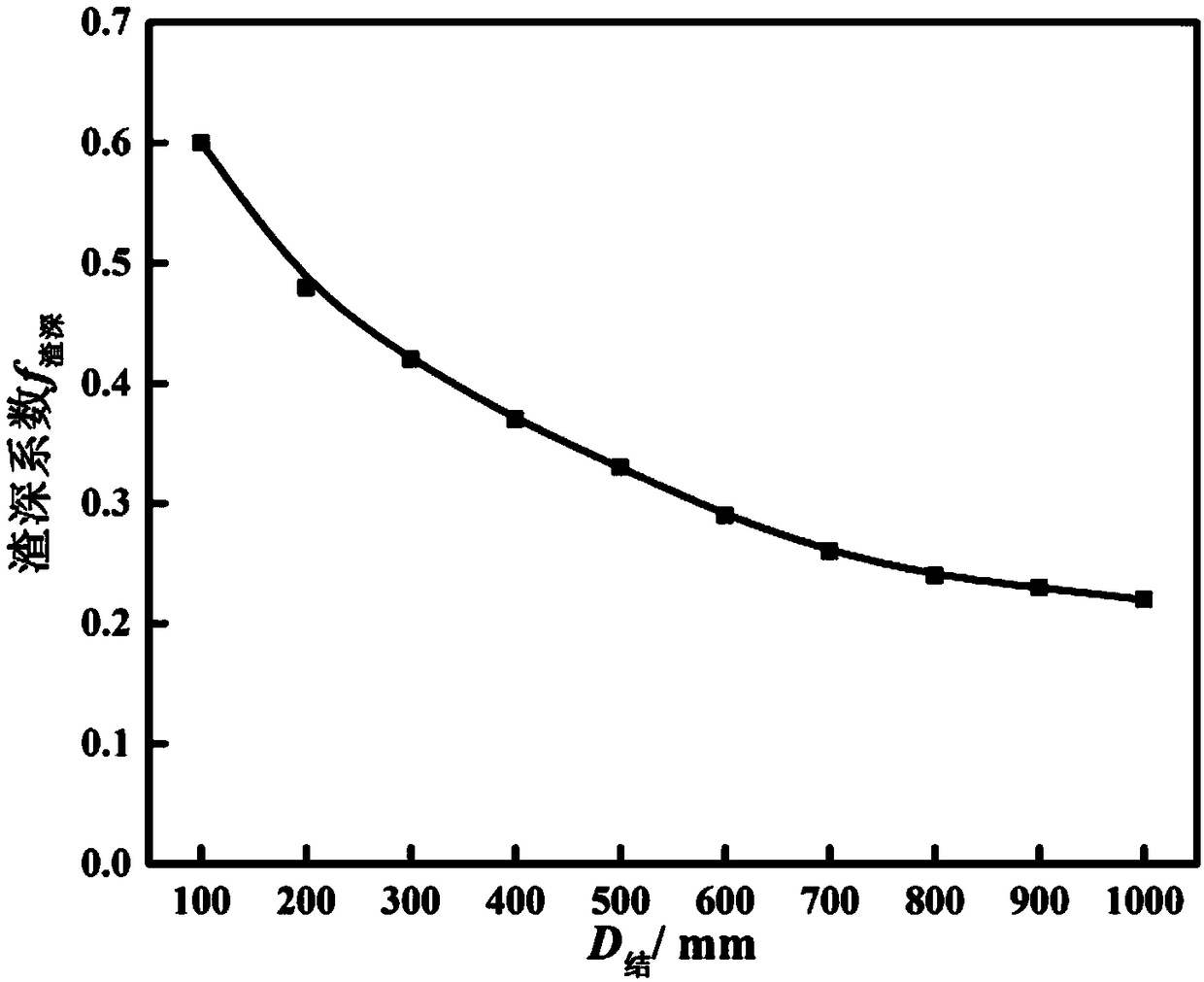

The invention relates to the technical field of ceramic tube inner surface ultra-precision machining, in particular to a ceramic tube inner surface polishing device and method. The ceramic tube inner surface polishing device comprises a lathe, a magnetism gathering device, a peripheral magnetic pole, a peripheral magnetic pole support, an auxiliary magnetic pole, an L-shaped bevel gear angle rotator, a transmission shaft, an auxiliary magnetic pole support, a high-speed motor, a high-speed motor bracket and a photoelectric limit switch. The magnetism gathering device, the peripheral magnetic pole and the peripheral magnetic pole support are fixed to a sliding box a of the lathe. The high-speed motor, the transmission shaft, the L-shaped bevel gear angle rotator and the auxiliary magnetic pole are connected in sequence and are fixed to a sliding box b of the lathe. A ceramic tube generates rotational motion under the action of the lathe. The high-speed motor drives the auxiliary magnetic pole to rotate. The auxiliary magnetic pole and the peripheral magnetic pole synchronously conduct axial feeding. Magnetic grinding particles and the inner surface of the ceramic tube part move relatively, so that ultra-precision machining of the inner surface of the ceramic tube is completed. The ceramic tube inner surface polishing device is high in machining precision and can be widely applied to polishing of inner surfaces of ceramic tubes.

Owner:UNIV OF SCI & TECH LIAONING

A method for manufacturing an aluminum alloy section bar used for aviation

The invention relates to a method for manufacturing an aluminum alloy section bar, particularly relates to a method for manufacturing an aluminum alloy section bar used for aviation, and overcomes a problem that various aluminum alloy section bars produced by conventional processes are low in tensile strength, low in proof strength at non-proportional extension, low in percentage elongation afterfracture and low in exfoliation corrosion performance. The method includes 1) smelting, 2) casting, 3) cutting off, 4) lathing to remove skin, 5) annealing, 6) heating, 7) extrusion, 8) solution treatment and water quenching, 9) stretching and 10) ageing treatment. Through alloy component optimization and through adoption of optimized solution treatment and ageing treatment processes after extrusion, integrated performance requirements of users on the alloy section bar are met, the prepared aluminum alloy section bar has a good physical dimension, good surface quality, good forming performancein industrial production and excellent comprehensive mechanical performance. The method is used for manufacturing the aluminum alloy section bar used for aviation.

Owner:郝金芳

Manufacturing method of directionally organized ceramic matrix composite spare part

ActiveCN107032824AImprove production accuracyGood surface qualityCeramic shaping apparatusClay mixing apparatusSolventPyrolysis

The invention relates to a manufacturing method of a directionally organized ceramic matrix composite spare part. The manufacturing method includes steps of firstly manufacturing a spare part resin shell with two opened ends; preparing suspending slurry by monomer, crosslinking agent and ceramic powder, and pouring the suspending slurry in the spare part resin shell; cooling, solidifying and directionally crystalizing solvent in the suspending slurry along the direction of temperature gradient by arranging a temperate field; vacuum-freezing and drying the suspending slurry after being solidified completely, then preserving temperature at 900-1200 DEG; removing organic matters to obtain a ceramic spare part porous body; depositing a SiC interface on the inner fiber surface of the ceramic spare part porous body by a CVD / CVI method; applying precursor infiltration and pyrolysis to densify the ceramic spare part porous body deposited with the SiC interface to obtain the directionally organized ceramic matrix composite spare part. Through controlling solvent crystal under low temperature, and rapid shaping, fiber enhancement, precursor infiltration and pyrolysis and other technical steps, the directional organization is formed; the reinforcement and toughening can be realized effectively.

Owner:XI AN JIAOTONG UNIV

Magnesium alloy microcapillary and preparation method thereof

The invention discloses a magnesium alloy microcapillary and a preparation method thereof and belongs to the field of metal material precision machining. The method comprises the following steps that(1) a magnesium alloy blank is extruded to obtain a seamless extruded pipe blank; (2) the obtained seamless extruded pipe blank is subjected to stress relief annealing; and (3) the annealed seamless extruded pipe blank is subjected to multiple passes of drawing and intermediate annealing, and the magnesium alloy microcapillary is obtained. The magnesium alloy microcapillary prepared through the preparation method provided by the invention is good in surface quality, precise in size, uniform in wall thickness and excellent in mechanical property; the machining method is simple in process, low in cost, high in machining efficiency, and capable of performing large-scale production; and the magnesium alloy microcapillary can be used as a structural component to be applied to the fields of automobiles and electronics, and can also be used as a medical implant used for preparing an intravascular stent.

Owner:BEIJING UNIV OF TECH

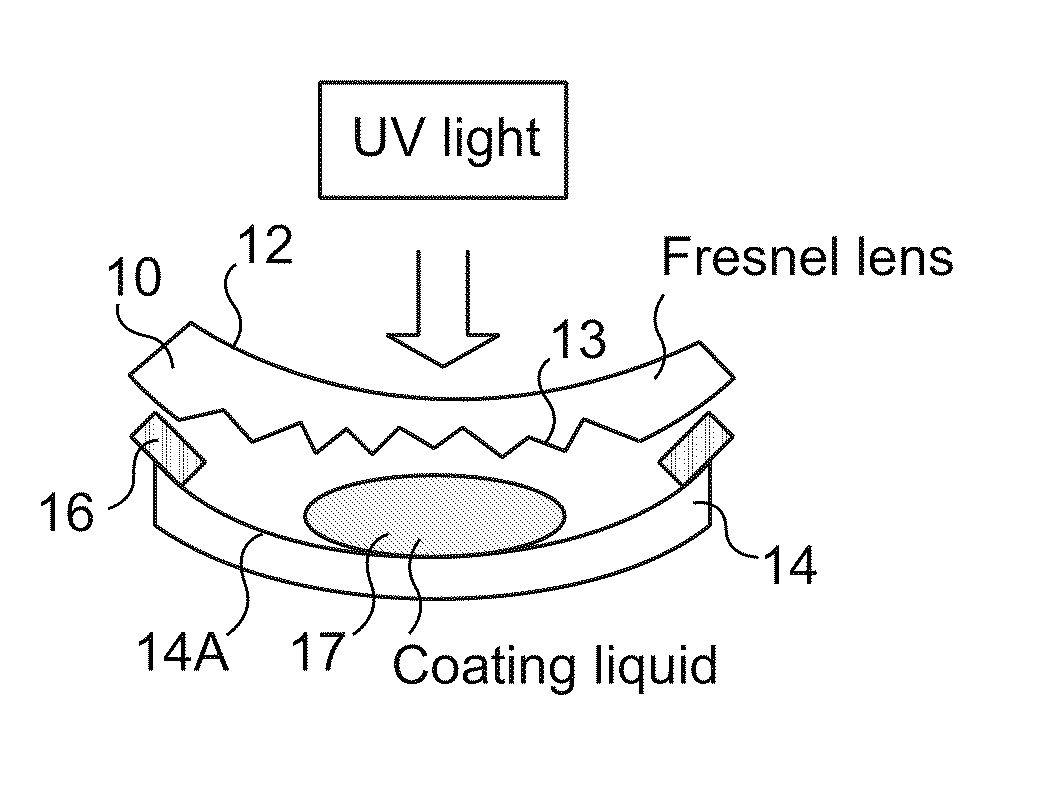

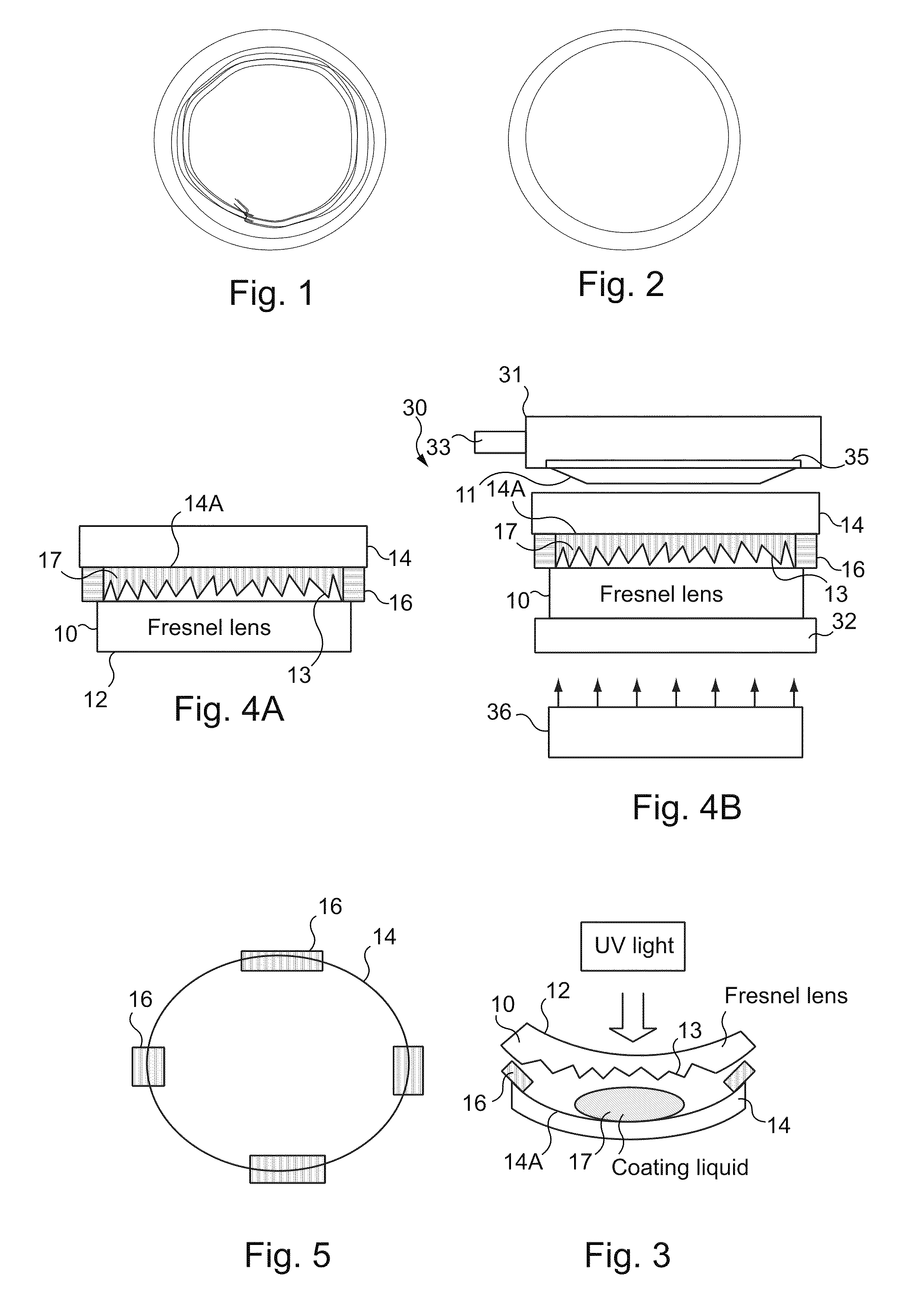

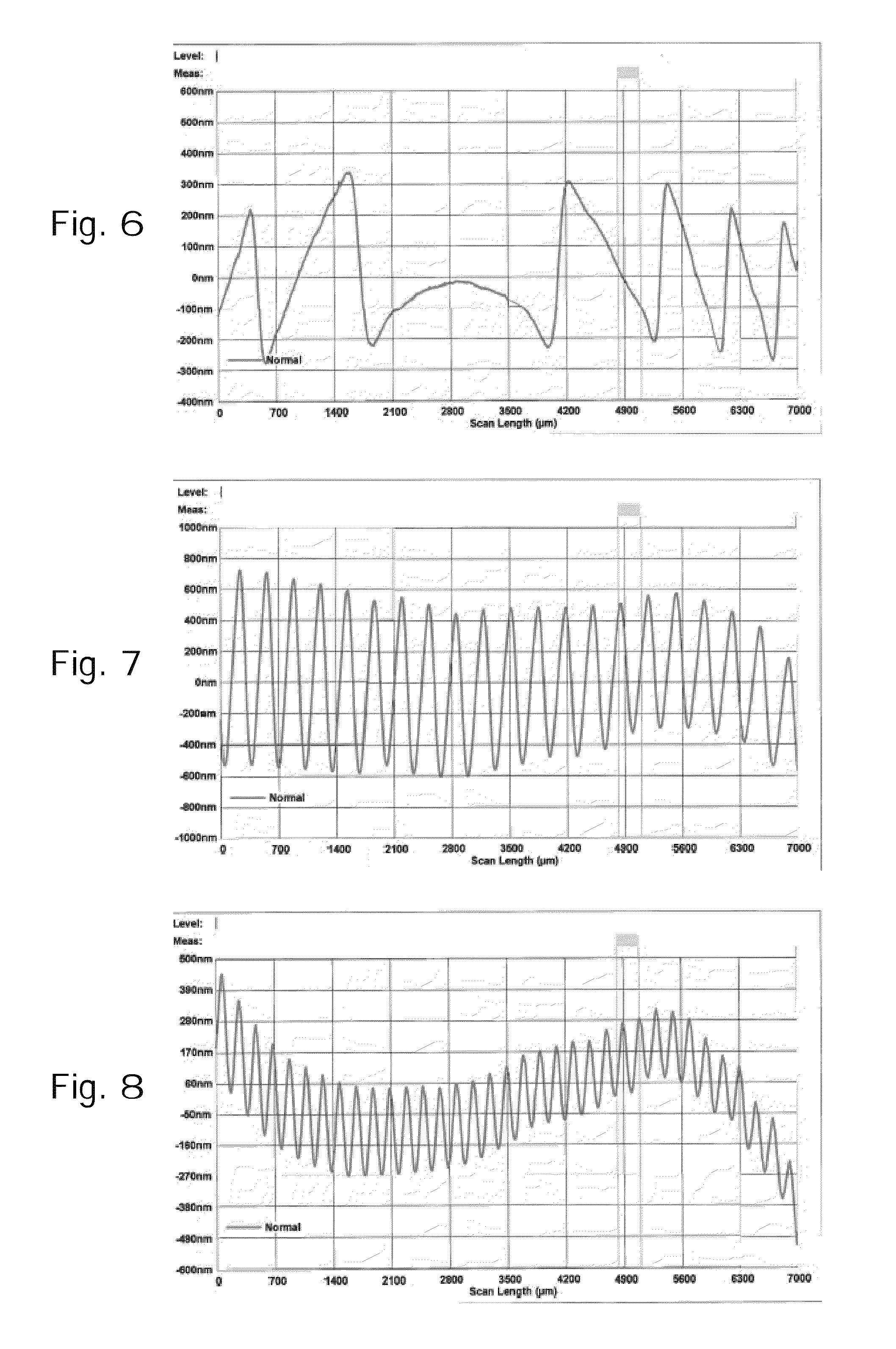

Fresnel lens coating process

InactiveUS20110164329A1Good surface qualityReduce surface roughnessPretreated surfacesCoatingsOptical powerDouble coating

The present method for coating a Fresnel lens blank includes providing an uncoated Fresnel lens blank having a structure surface and a non-structured surface, providing a transparent mold part having molding surface substantially matching the base curvature of the Fresnel lens, depositing a metered quantity of coating resin between the molding surface and the structured surface of the Fresnel lens, applying pressure between the Fresnel lens and the mold part while maintaining the distance between the molding surface and the structure surface so that the thickness of the coating is greater than 1.5 times the Fresnel structural height of the structured surface and less than 5 times of the Fresnel structure height of the structured surface and curing the resin coating in situ by directing the incident UV radiation at the Fresnel lens. A double coating may be employed for obtaining both higher optical power and better mechanical properties.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Processing process of ball bag-shaped stainless steel retainer

InactiveCN101913061AGood benchmarkGood surface qualityTurning toolsBoring/drilling machinesDrill holeEngineering

The invention belongs to the technical field of bearing processing and provides a processing process of a ball bag-shaped stainless steel retainer. The process comprises the following steps of: roughly turning end surfaces, the inner diameter and the outer diameter and cutting off; turning cut-off surfaces; softly grinding the outer diameter; softly grinding the two end surfaces; fine turning the inner diameter; drilling rivet holes and installing rivets; finally turning the outer diameter; finally turning the inner diameter; drilling; and boring. The invention has the advantages of simple process flow, convenient processing, reliable quality, higher efficiency and low cost. The parallel difference of the end surfaces can be guaranteed within 0.015mm by adopting the process, and the roughness is guaranteed within 0.5mum, thus good size and surface precision are obtained.

Owner:LUOYANG LYC BEARING

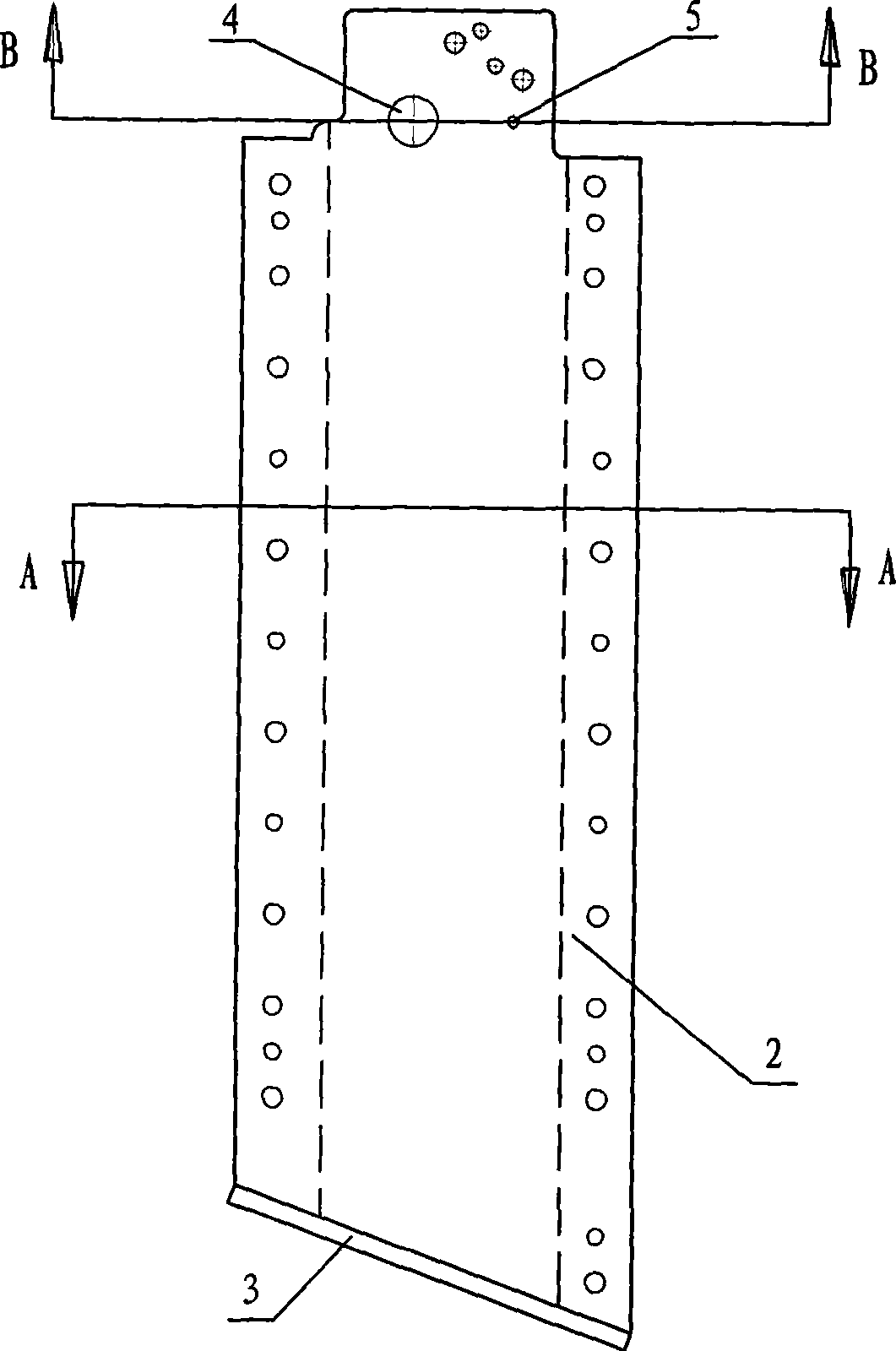

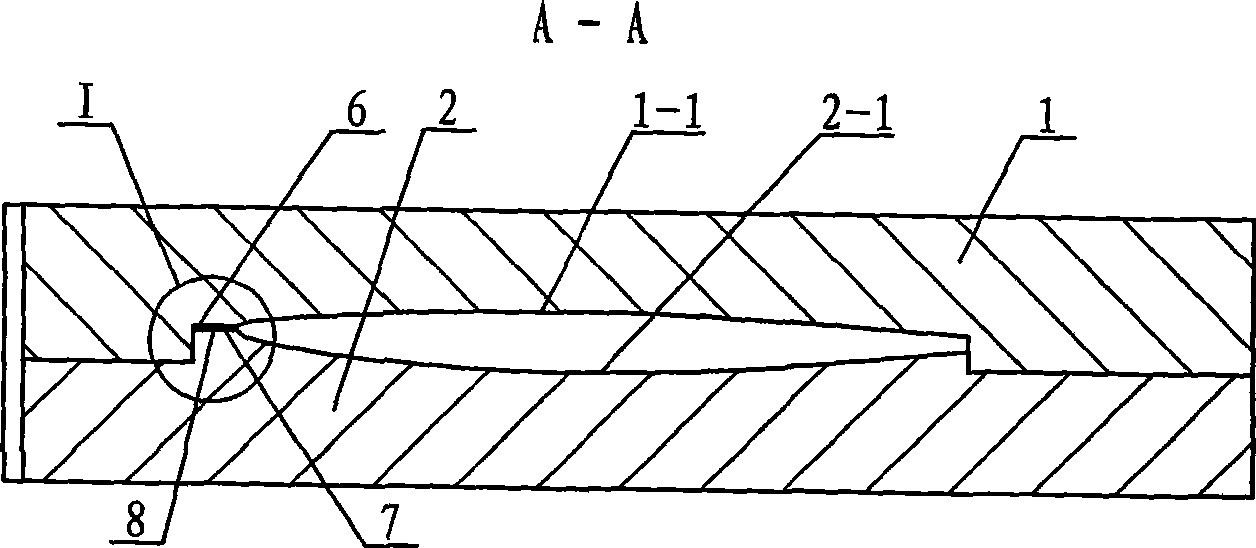

Fibre reinforced resin based composite material fin piece molding mould

InactiveCN101367257AProduct porosity reductionGood surface qualityDomestic articlesPorosityResin-Based Composite

The invention provides a molding die for fiber reinforced resin-based composite vanes. The invention relates to molding die for composite vanes, which aims to solve the problems that the prior composite vane molding die is insufficient in die assembly and too tight to seal die cavities, can not discharge air in a product, can not guarantee the geometrical size of the airfoil surface of a vane and the relative position of a vane handle, and causes that the product is large in porosity or has air holes on surface. A parting surface of an upper die and a lower die is provided with an upper model groove; a parting surface of the lower die and the upper die is provided with a lower model groove; a first positioning pin is arranged in a first positioning pinhole and a third positioning pinhole; a second positioning pin is arranged in a second positioning pinhole and a fourth positioning pinhole; and a gap between the parting surfaces of the upper die and the lower die is configured as a material overflow groove. The material overflow groove can ensure that the upper and lower dies are sufficient in die assembly; die cavities are incompletely sealed; the air in the product can be smoothly discharged; the geometrical size of the airfoil surface of the vane and the relative position of the vane handle are guaranteed; and the product is good in surface quality.

Owner:HARBIN FRP INST

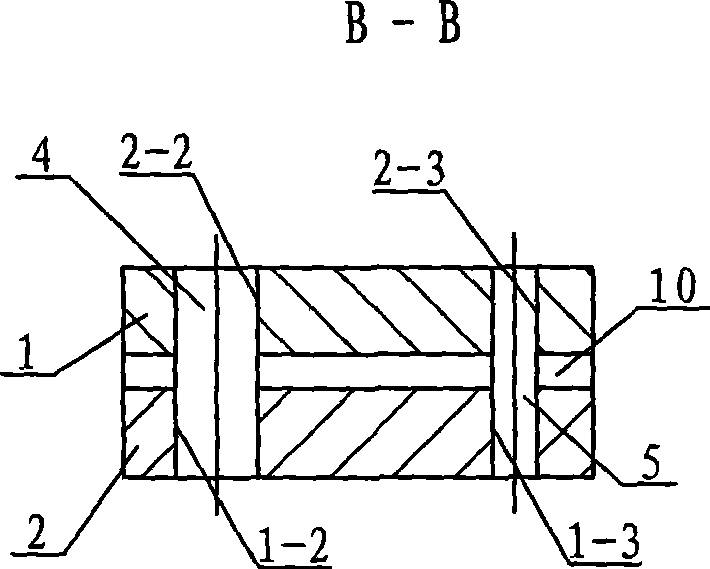

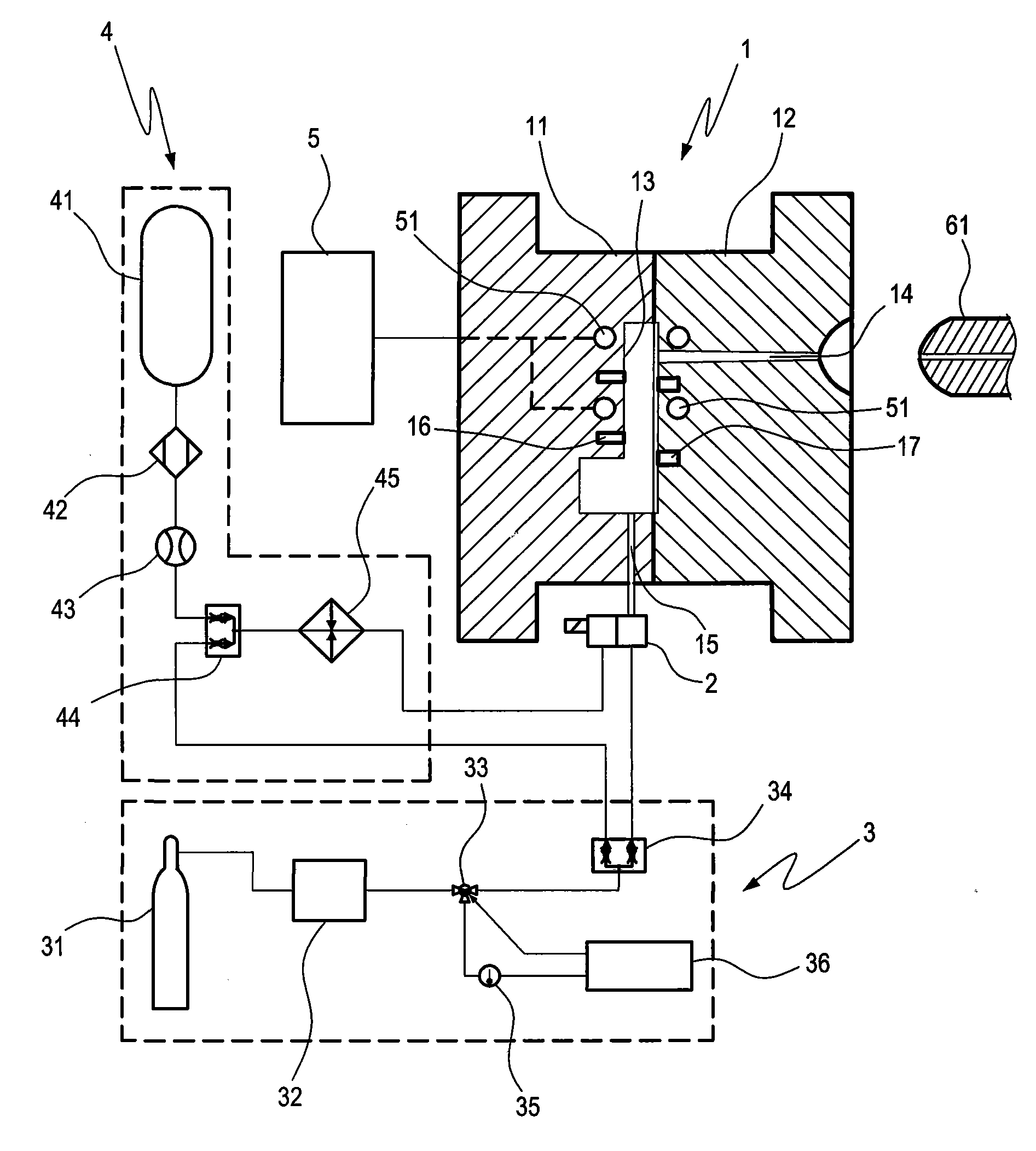

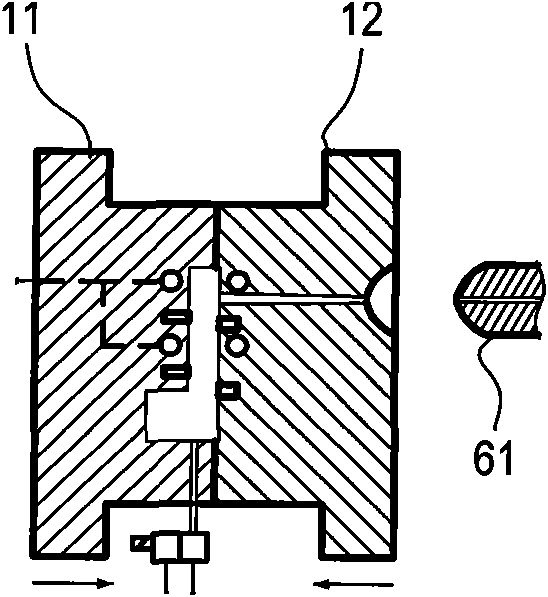

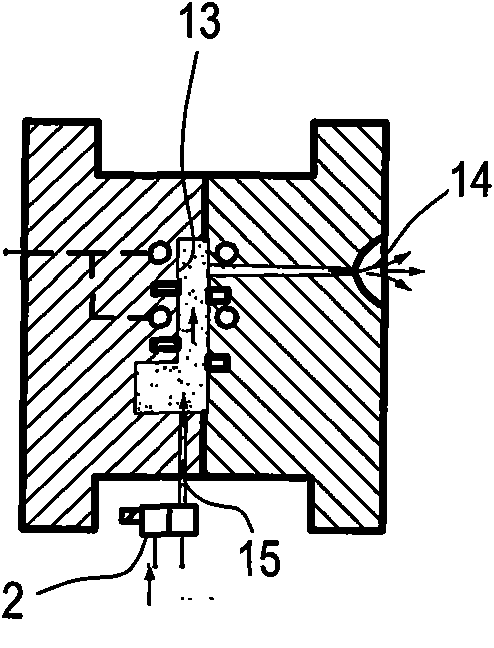

Cavity gas back pressure and temperature control device

The invention provides a cavity gas back pressure and temperature control device, mainly comprising a mold, a program control valve, a back pressure gas supply unit and a high temperature gas supply unit, wherein, the mole is provided with injection channels which penetrate to the cavity and at least one air passage, the program control valve is arranged in the air passage of the mold for controlling high temperature gas and / or high pressure gas to get in and out from the cavity through the air passage, the back pressure gas supply unit supplies back pressure gas to the cavity through the program control valve, and the high temperature gas supply unit supplies high temperature gas to the cavity through the program control valve. According to the invention, the surface of the cavity is heated by the high temperature gas supply unit through cooperative control, and back pressure is provided by the back pressure gas supply unit when injection molding, so that a finished product with good surface quality is obtained, and the foaming size and uniformity are controlled.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

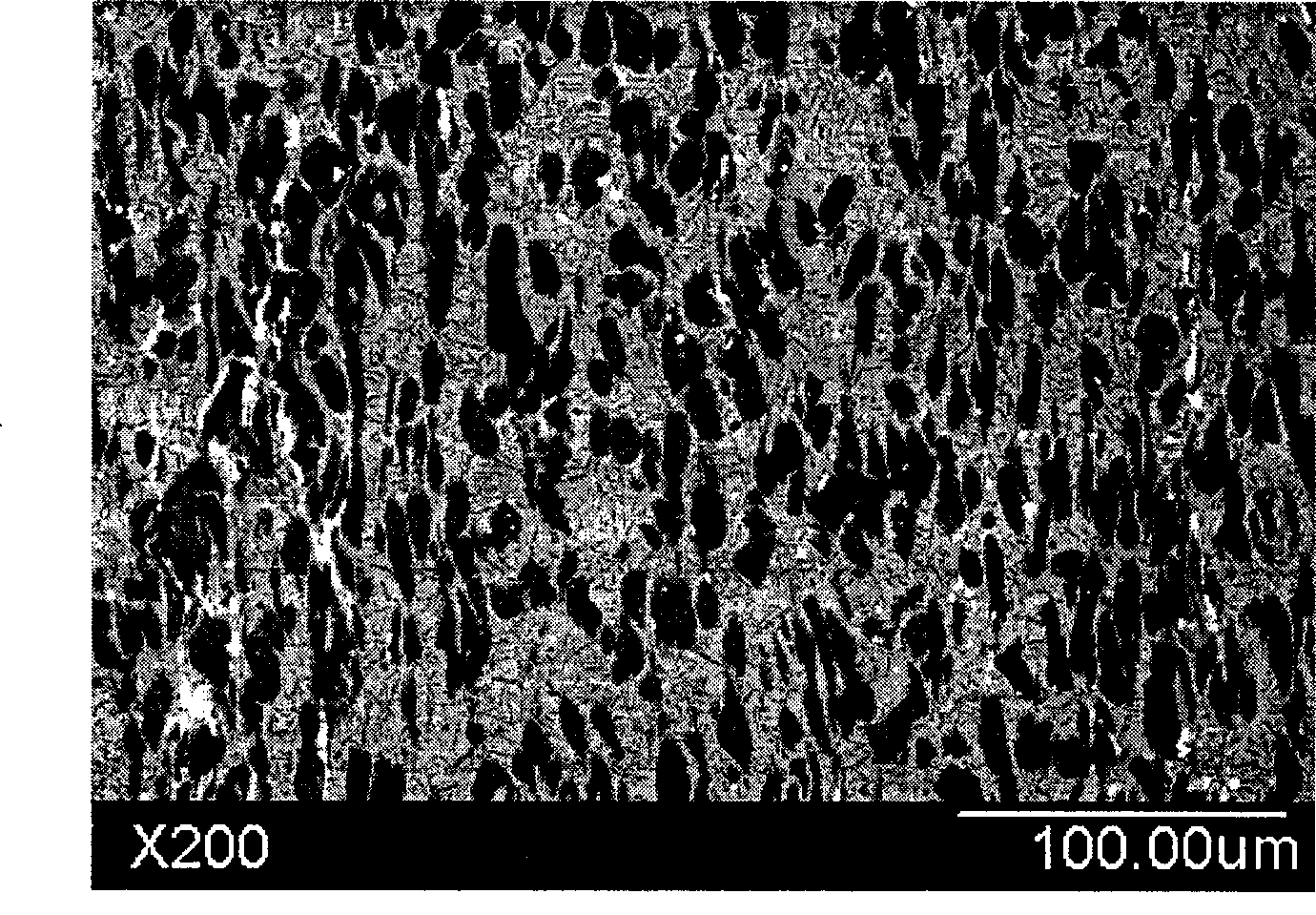

Ductile iron bar for increasing number of graphite nodules with SiC and preparation method thereof

The invention discloses a ductile iron bar for increasing the number of graphite nodules with SiC. The ductile iron bar comprises, by weight, 3.1%-3.6% of C, 2.4%-3.3% of Si, 0.2%-0.4% of Mn, 0-0.10% of P, 0-0.06% of S and the balance Fe. The weight percentage sum of the compositions is 100%. The invention further discloses a preparation method of the ductile iron bar. According to the ductile iron bar for increasing the number of the graphite nodules with the SiC and the preparation method thereof, surface quality of the ductile iron bar for increasing the number of the graphite nodules with the SiC is good, dimensional precision is high, and the casting defects of sand inclusion, slag inclusion, air holes, shrinkage cavities and the like are avoided; the structure is compact and even from the center to the edge, the number of the graphite nodules of a core part is increased by 20% or above compared with the number of graphite nodules without SiC, the graphite nodule diameter is about grade 6-7, and no obvious large-diameter graphite exists; and the edge hardness of the ductile iron bar is lowered by HB20 or above, the core part and surface layer hardness difference is decreased to HB20 or below, and processing performance of the ductile iron bar can be improved.

Owner:陕西西理华铸新材料科技有限公司

Dumping and sintering process for 3D printing ceramic body

The invention relates to a dumping and sintering process for a 3D printing ceramic body. The process comprises the steps that 1, the ceramic body with the 3D printing solid content being 20-95 wt.% is placed into a crucible, and raw material powder with the same component as the ceramic body is used for embedding and filling the ceramic body; 2, the crucible which contains the ceramic body is placed into a muffle furnace, and segmented dumping is carried out in an air atmosphere; 3, the temperature is raised to sintering temperature at the temperature rise rate of 1-3 DEG C per minute, and sintering time is 1-12 hours, wherein the densification temperature is 300-1,000 DEG C lower than the sintering temperature of the ceramic body. The raw material powder with the same component as the ceramic body is used for embedding and filling the ceramic body, the raw material powder needs to wrap the ceramic body, and holes and other hollow structures in the ceramic body need to be filled with the raw material powder so that the ceramic body can be heated uniformly and slowly to prevent sudden change of temperature, prevent internal stress from being generated inside the ceramic body and reduce the probability of collapse.

Owner:江苏先进无机材料研究院

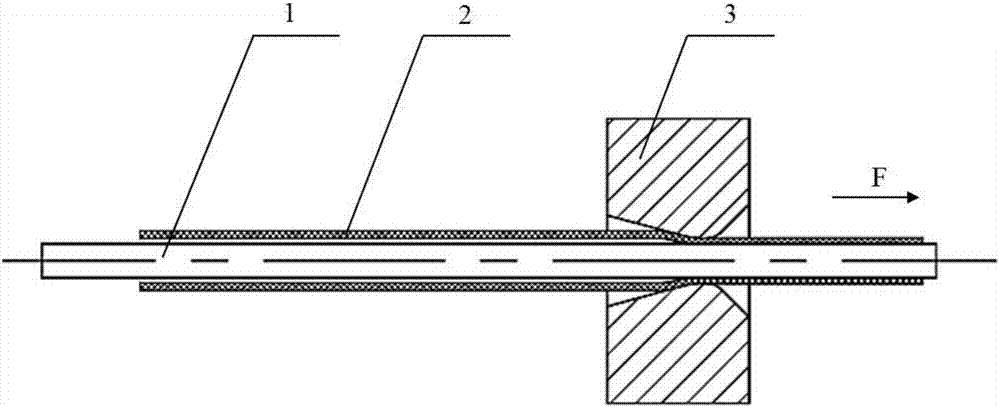

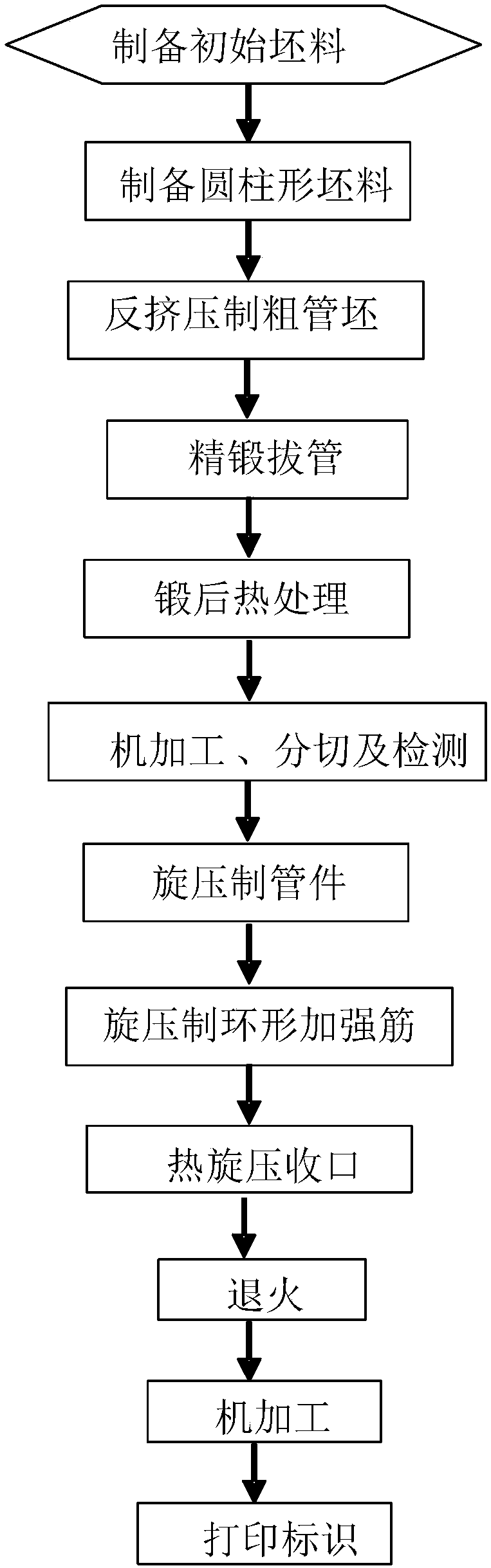

Preparation method of seamless high-pressure gas cylinder and gas cylinder

ActiveCN108188301ASimple processGood surface qualityPressure vesselsHollow articlesTube drawingHigh pressure

The invention relates to a preparation method of a seamless high-pressure gas cylinder. The preparation method comprises the following steps of 1, preparing a blank; 2, extruding the blank reversely to machine a rough tube blank; 3, carrying out precision forging and tube drawing to form a precision forging tube blank; 4, carrying out heat treatment on the precision forging tube blank; 5, carryingout spinning to prepare a tube, reducting the thickness of the tube blank subjected to precision forging to a required thickness by thickness reduction spinning equipment, forming the tube, and preparing annular reinforcing ribs integrally formed with the tube on the inner wall of the tube through spinning; and 6, sealing the opening by hot spinning, and preparing the gas cylinder. The inventionfurther relates to the seamless high-pressure gas cylinder prepared by the method, the inner wall of the gas cylinder is provided with the integrally-formed annular reinforcing ribs, so that the pressure-bearing capacity of the tube is improved, and the tube is attractive in appearance and easy to install; and materials are saved, the cost is low.

Owner:烟台台海材料科技有限公司

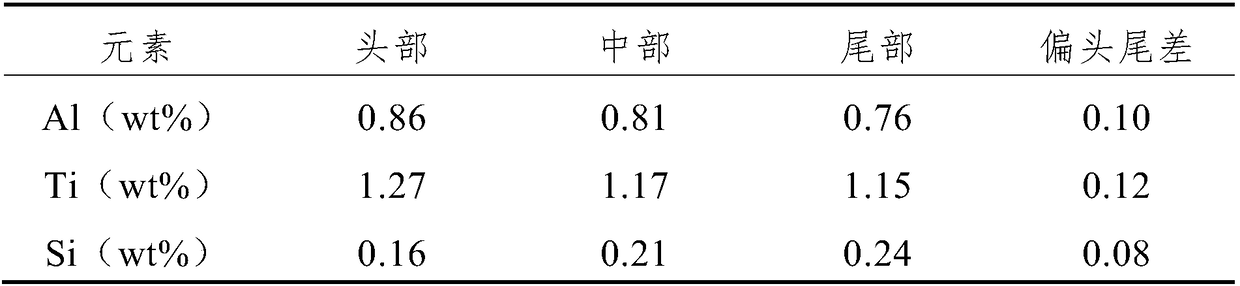

Slag system for smelting GH984G nickel base alloys and application method thereof

The invention relates to a slag system for smelting GH984G nickel base alloys and an application method thereof. The slag system comprises the following components in percentage by weight: 25-30% of CaO, 20-25% of Al2O3, 2-5% of MgO, 4-7% of TiO2, 1-3% of SiO2 and the balance of CaF2. The slag system is suitable for smelting GH984G high-temperature alloys through remelting of T-shaped crystallizeringot extracting electroslag. The slag system can preferably solve the problems of nonuniform distribution of easy-oxidized elements at the heads and the tails of ingots in the process of smelting the GH984G high-temperature alloys through remelting of the ingot extracting electroslag and weaker surface quality of ingots.

Owner:NORTHEASTERN UNIV

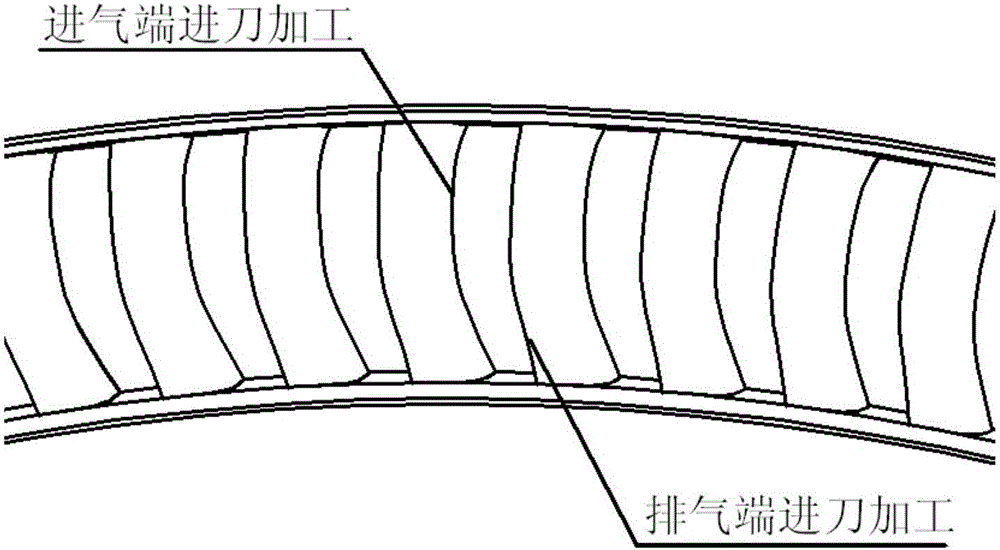

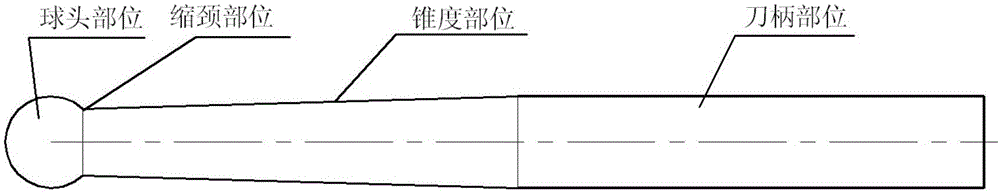

Milling method of blade of high-temperature alloy whole blade ring

ActiveCN106513804AGood surface qualityImprove surface qualityWorkpiecesMilling equipment detailsEngineeringMilling cutter

The invention discloses a milling method of a blade of a high-temperature alloy whole blade ring. The method comprises following steps: firstly, a manufacturing procedure is selected, and the milling technology path of the whole blade ring comprises air inlet end rough milling slotting, exhaust end rough milling slotting, air inlet end blade type and flow way accurate milling and exhaust end blade type and flow way accurate milling; secondly, according to the length and the maximum thickness of the blade of the whole blade ring blade type, the machining allowance reserved for accurate milling after rough milling slotting is determined; thirdly, a tool is selected, wherein during rough milling, an end milling cutter of phi 6R0.5 to phi 6R1.5 is selected for machining, and during accurate milling, a taper ball head milling cutter with the shrinking neck is selected for machining; fourthly, cutting parameters are selected; fifthly, the accurate milling step is selected. Machining of the blade of the high-temperature alloy blade ring part is effectively achieved, the method can ensure that the machined part has the good surface quality and meets the design required form and location tolerance, and the method also can be applied to milling of complex curve deep cavities.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

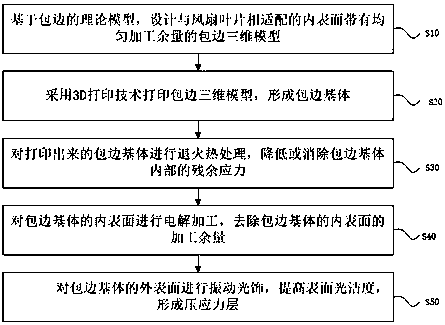

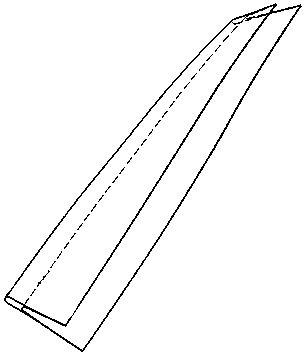

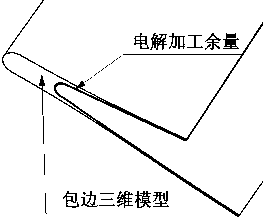

Method for manufacturing covered edge of fan blade

InactiveCN109202373AIncrease profitLow costAdditive manufacturingIncreasing energy efficiencySurface finishMachine parts

Aiming at a composite material fan blade, the invention provides a method for manufacturing the covered edge of the fan blade. The method comprises the following steps that for a theoretical model based on the covered edge, an edge covering three-dimensional model which is matched with the fan blade and is provided with a uniform machining allowance is designed; a 3D printing technology is adoptedto print the edge covering three-dimensional model to form an edge covering base body; annealing heat treatment is carried out on the printed edge covering base body, so that residual stress inside the edge covering base body is reduced or eliminated; electrolytic machining is conducted on the inner surface of the edge covering base body, so that the machining allowance of the inner surface of the edge covering base body is removed; and vibration finishing is carried out on the outer surface of the edge covering base body, so that the surface smoothness is improved, and a compressive stress layer is formed. The method aims to fully utilize the 3D printing technology to achieve the following advantages that the material utilization rate is high, the surface quality of an electrolytic machining part is good, the residual stress and deformation are small, the surface quality of a part machined through vibration finishing is good, and the anti-fatigue strength can be improved to a certaindegree; and near-no-allowance machining of edge covering is realized, the material utilization rate and the machining precision are improved, and the cost is saved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

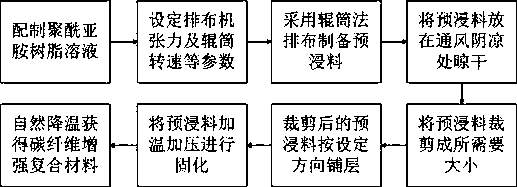

Preparation method for carbon fiber reinforced polyimide resin composite material

The invention discloses a preparation method for a carbon fiber reinforced polyimide resin composite material, and belongs to the field of material preparation. The preparation steps comprise: preparing a polyimide resin solution; setting parameters of a roller arrangement machine, and employing a roller arrangement method to prepare a prepreg; putting the prepreg at a ventilated shade place for air drying; cutting the dried prepreg into a demanded size, and laying up according to a set direction; heating and pressurizing the laid-up prepreg for solidification; and after solidification is finished, naturally cooling to obtain the carbon fiber reinforced polyimide resin composite material. The key point of the preparation method comprises that the carbon fiber reinforced polyimide prepreg is prepared in an appropriate parameter scope by setting the tension force of the roller arrangement machine, the roller rotating speed and other parameters. By utilizing the provided parameter scopes, the prepared carbon fiber reinforced polyimide prepreg is good in surface quality, carbon fiber is completely soaked by polyimide resin, and also the composite material prepared by using the prepreg for processing is superior in mechanical properties and good in heat resistance.

Owner:JIANGSU CHENGFEI PRECISION ALLOY +1

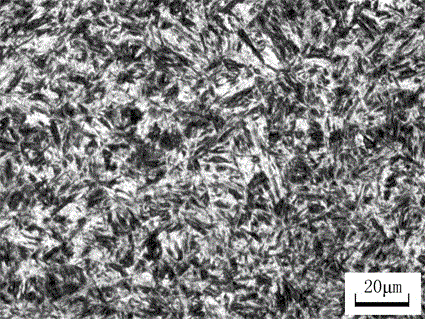

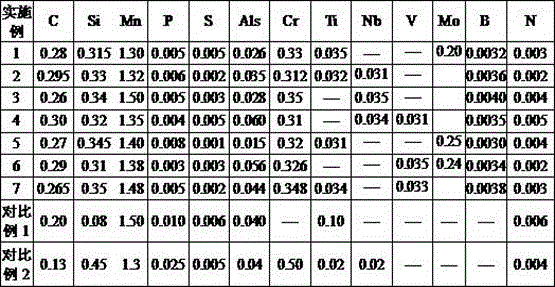

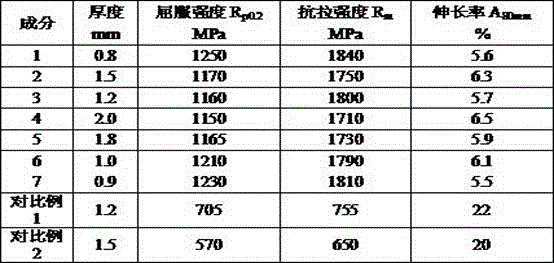

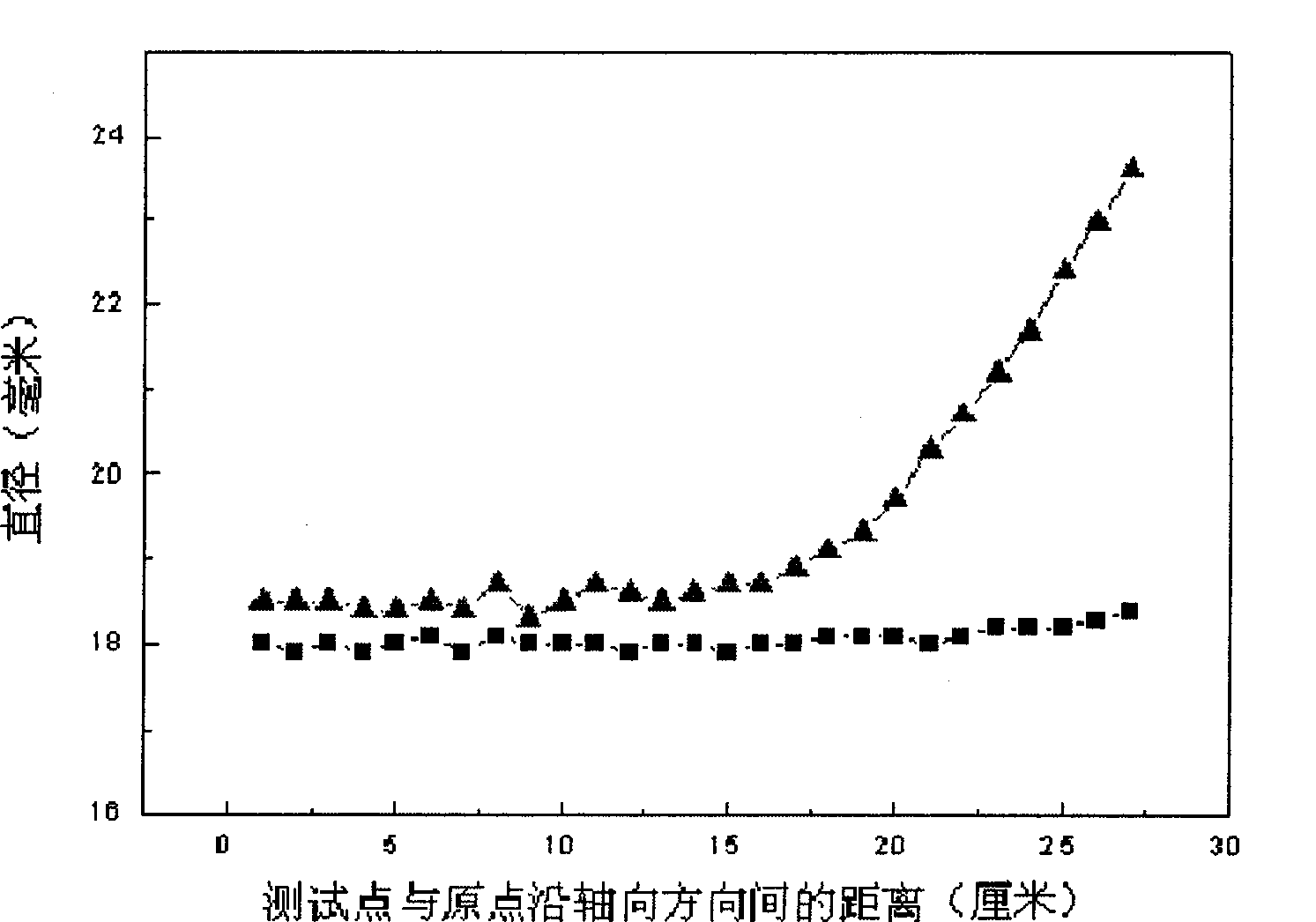

Thin thermoformed steel with tensile strength being not lower than 1700 MPa directly rolled by sheet billet and production method of thin thermoformed steel

The invention provides thin thermoformed steel with tensile strength being not lower than 1700 MPa directly rolled by a sheet billet. The thin thermoformed steel with tensile strength being not lower than 1700 MPa directly rolled by the sheet billet comprises the following components, in percentage by weight, 0.26-0.30% of C, 0.31-0.35% of Si, 1.3-1.5% of Mn, not higher than 0.008% of P, not higher than 0.005% of S, 0.015-0.060% of Als, 0.31-0.35% of Cr, 0.031-0.035% of Ti or 0.031-0.035% of Nb or 0.031-0.035% of V or a mixture mixed by more than two of the three components in any proportion, 0.003-0.004% of B, 0.20-0.25% of Mo, 0.06-0.10% of Ni and not higher than 0.005% of N. The production method of the thin thermoformed steel comprises the steps of desulfurizing molten iron; smelting the molten iron by an electric furnace smelting or a rotating furnace and refining the molten iron; performing continuous casting; performing descaling treatment before putting the molten iron into a soaking pit furnace; performing soaking; performing heating; performing high pressure water descaling before putting the molten iron into a rolling mill; performing rolling; performing cooling; performing coiling; performing austenitizing; performing mould stamping forming; and performing quenching. The steel is high in strength, short in manufacture process and good in quality of product surface, the accuracy of thickness can be controlled within + / -0.03mm and the energy consumption can be greatly reduced; moreover, the steel has great significance to realize automobile lightweight.

Owner:武汉钢铁有限公司

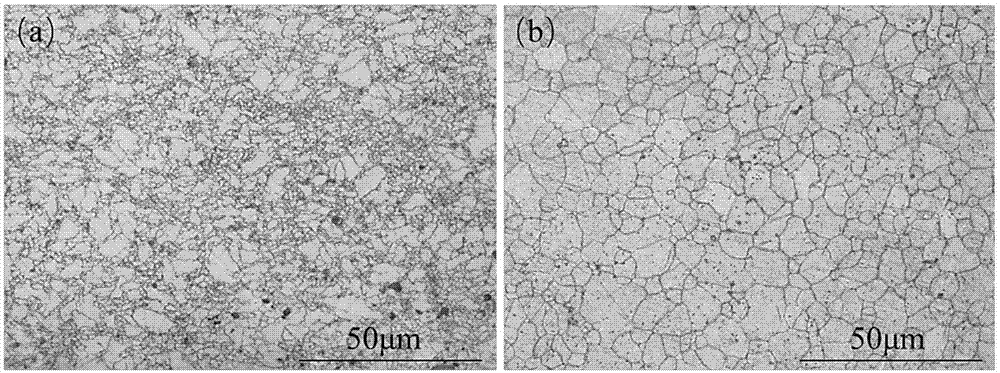

Production method for Gamma-TiAl alloy bar

InactiveCN101518794APrevent surface oxidationGood surface qualityExtrusion control devicesBase-materialsCrystalliteFiber

The invention relates to a production method for a bar, in particular to a production method for a Gamma-TiAl alloy bar. The production method solves the problems that a Gamma-TiAl alloy bar produced by the prior method has the defects of surface cracks, uneven diameter, uneven size of crystal grains and easy fusion caused by the reaction of Gamma-TiAl alloy and blank at high extrusion temperature. The production method comprises the steps: heating a cast ingot, keeping temperature and annealing; cutting a cylinder in the cast ingot, packaging aluminum silicate fibers, placing in the middle of a stainless steel pipe, and sealing both ends to obtain the blank; washing the sheathed blank, drying and heating the sheathed blank, keeping temperature, placing the sheathed blank in the air, putting the sheathed blank into a cup pre-pressured by glass lubricant, putting the sheathed blank into a mould to extrude to obtain the bar; annealing the bar, taking the bar out of a blast furnace for air cooling, and obtaining the Gamma-TiAl alloy bar. The obtained bar has the advantages of no surface cracks, even diameter, even size of crystal grains and no fusion caused by the reaction of the Gamma-TiAl alloy and the sheath.

Owner:HARBIN INST OF TECH

Production process capable of effectively reducing cracks of antimony-containing weather-proof round steel

ActiveCN106756494AReduce antimony-containing weathering round steel cracksGood surface qualityProcess efficiency improvementSuperficial massPrecipitation

The invention belongs to the technical field of metallurgy and particularly relates to a production process capable of effectively reducing cracks of antimony-containing weather-proof round steel. According to the production process, antimony precipitation and segregation are reduced by properly increasing the S content, decreasing the O content and controlling the Ti content; the oscillation mark depth is decreased by increasing the electromagnetic stirring current of a crystallizer, increasing the non-sinusoidal vibration frequency, decreasing the amplitude and shortening the negative strip time; Fe and Sb are prevented from being precipitated before straightening by increasing the casting blank straightening temperature; and the C solid content of casting powder is increased, the compression ratio is controlled through billet continuous casting, the heating speed is increased, and the tapping interval is shortened. The antimony-containing weather-proof round steel produced through the production process is good in surface quality and high in production efficiency, barreling treatment is not needed, and the one-time flaw detection percent of pass can reach 92% or above.

Owner:ZENITH STEEL GROUP CORP +1

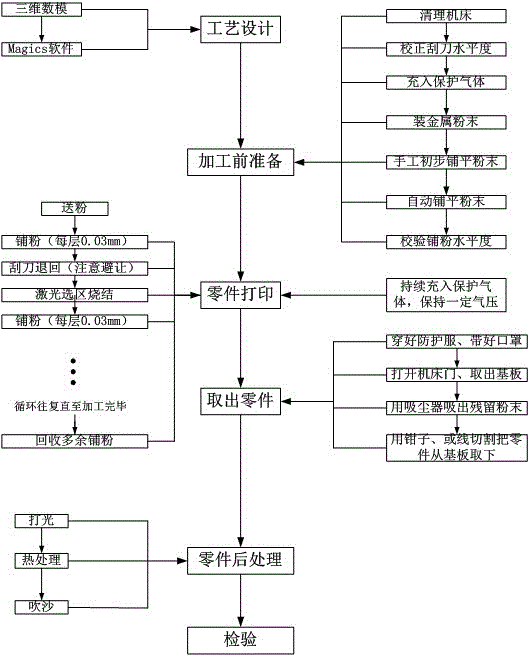

Process for manufacturing Ti6Al4V powdered 3D printing additive material

InactiveCN106270514AGood surface qualityHigh dimensional accuracyAdditive manufacturing apparatusIncreasing energy efficiencyHigh surface3D printing

The invention relates to a process for manufacturing a Ti6Al4V powdered 3D printing additive material, and belongs to the field of 3D printing additive material manufacture. The process comprises the steps of process designing, preparing before processing, part printing, part fetching, part post-treatment and inspecting. The process can be used for effectively solving the problem of a Ti6Al4V powder selective laser sintering process method, and provides a complete process solution for Ti6Al4V powder selective laser sintered 3D printing molding, so that a printed part has high surface quality and high size precision, and the application of the Ti6Al4V powder selective laser sintered 3D printing technology in the field of aeronautical manufacture can be further improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

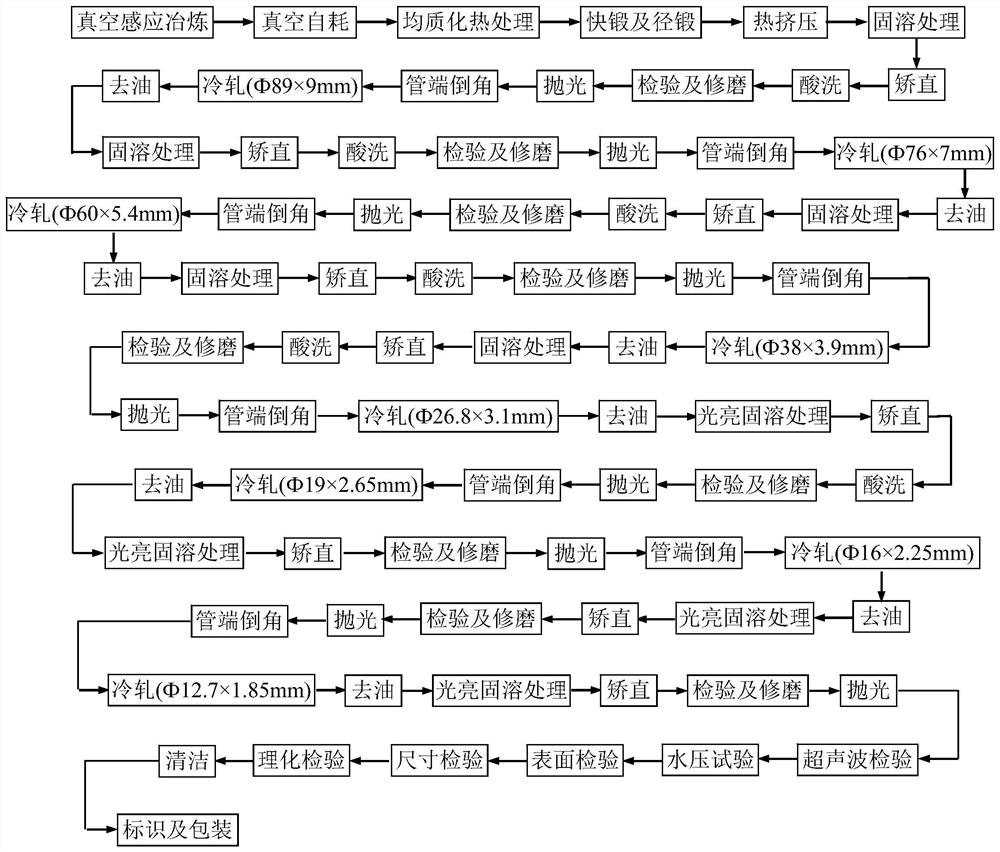

Novel nickel-chromium-cobalt-molybdenum high-temperature alloy seamless tube for power station and manufacturing method

PendingCN111636013AAvoid uneven deformationGood surface qualityMetal rolling arrangementsChromiumSmelting process

The invention discloses a novel nickel-chromium-cobalt-molybdenum high-temperature alloy seamless tube for a power station. The novel nickel-chromium-cobalt-molybdenum high-temperature alloy seamlesstube comprises the following components in percentage by weight: 0.03-0.10% of C, less than or equal to 1.0% of Si, less than or equal to 0.70% of Mn, less than or equal to 0.012% of P, less than or equal to 0.008% of S, 20.00-24.00% of Cr, 10.00-15.00% of Co, 0.70-1.50% of Al, 0.20-0.70% of Ti, 8.00-10.00% of Mo, less than or equal to 2.00% of Fe, less than or equal to 0.5% of Cu, 0.001-0.006% ofB, less than or equal to 0.005% of Pb, less than or equal to 0.005% of Sb, less than or equal to 0.001% of Bi, less than or equal to 0.010% of Sn, less than or equal to 0.010% of As and the balance Ni and trace elements, wherein the sum of the components is 100%. According to the nickel-chromium-cobalt-molybdenum high-temperature alloy seamless tube disclosed by the invention, a certain amount ofCo, Mo, B and other elements are added by controlling and limiting the components, a smelting process adopts vacuum induction and vacuum self-consumption, a tube manufacturing process adopts hot extrusion and full cold rolling, and finally solution treatment is performed; and by adopting the way, the alloy seamless tube has good structure stability, mechanical properties and process properties and can meet the using requirements of a heat exchange tube for the novel power station.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

Method for manufacturing aluminum alloy rivet rod for aerospace product

The invention relates to a method for manufacturing a high shear-resistant strength and high percentage elongation after fracture aluminum alloy rivet rod for the aerospace product, belonging to the method for manufacturing an aluminum alloy rod, and aiming to solve the problems of low non-proportional extension strength, shearing strength, tensile strength and extension at break of the existing aluminum alloy rivet rod for the aerospace product. The method comprises the following steps: (1) preparing molten alloy; (2) casting an alloy rod; (3) cutting off the cast alloy rod; (4) turning the peel of the cast alloy rod; (5) carrying out homogenizing annealing; (6) heating the cast alloy rod; (7) extruding; (8) carrying out cold-drawing by using a mold; (9) quenching; (10) straightening; and (11) aging to obtain the aluminum alloy rivet rod for the aerospace product. The aluminum alloy rivet rod manufactured by adopting the method has the tensile strength of not less than 431N / mm<2>, the non-proportional extension strength of not less than 265N / mm<2>, the extension at break of not less than 16% and the shearing strength of not less than 255N / mm<2> and meets the application requirement of the aerospace product. The method can be used for processing and manufacturing the aluminum alloy rivet for the aerospace product.

Owner:哈尔滨东轻特种材料有限责任公司

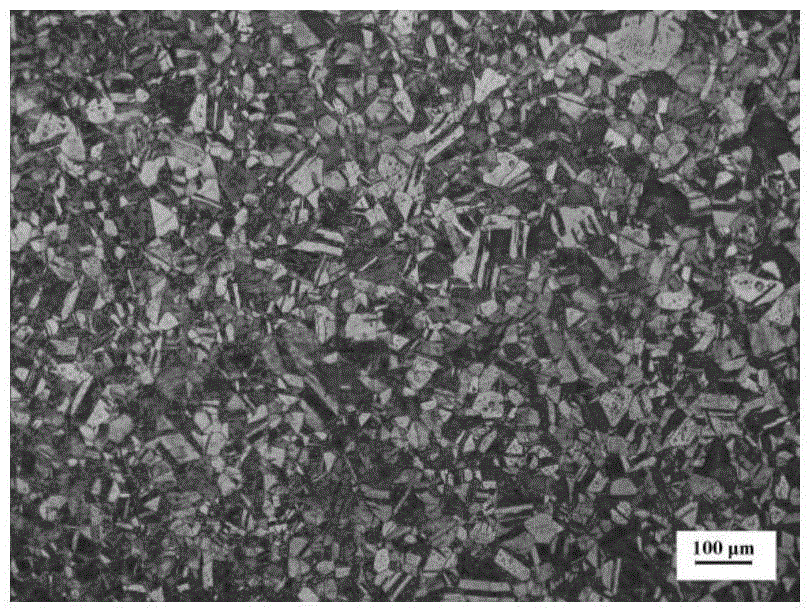

Niobium alloy target material and preparation method thereof

ActiveCN103866245AGood lubrication effectGood surface qualityVacuum evaporation coatingSputtering coatingLubricationNiobium alloy

The invention provides a preparation method of a niobium alloy target material. The preparation method comprises the steps: firstly, carrying out hot extrusion of a niobium alloy tube blank, then carrying out inner hole processing of the niobium alloy tube blank after hot extrusion, and thus obtaining the niobium alloy target material. In the preparation process of the niobium alloy target material, firstly, the surface of the niobium alloy tube blank is coated with a glass powder; because the surface of the niobium alloy tube blank is spray-coated with the glass powder, the niobium alloy tube blank is allowed to have relatively good lubrication effect in the hot extrusion process, and thus the surface quality of the niobium alloy tube blank is relatively good; the subsequent hot extrusion processing and heat treatment are conducive to refinement and homogenization of crystal grains of the niobium alloy tube blank; and finally, the niobium alloy tube blank after hot extrusion is subjected to mechanical processing, and an inner hole of the niobium alloy tube blank is bored and milled by selected special tools, so that chip breaking can be allowed to be continuously discharged from the inner hole, the problem that chip breaking is accumulated in the inner hole to affect processing of the inner hole surface is avoided, and thus the niobium alloy target material with uniform and fine internal crystal grains and relatively low surface roughness value is obtained. The invention also provides the niobium alloy target material.

Owner:NINGXIA ORIENT TANTALUM IND

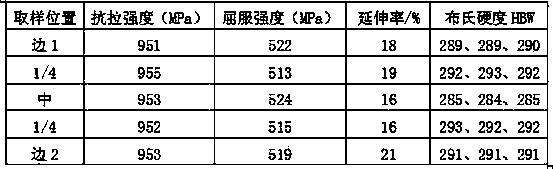

75Cr hot-rolled plate coil produced from thin sheet billets through continuous casting and continuous rolling and production method thereof

The invention discloses a 75Cr hot-rolled plate coil produced from thin sheet billets through continuous casting and continuous rolling and a production method thereof. The 75Cr hot-rolled plate coil comprises the following chemical ingredients in percentage by weight: 0.73-0.78% of C, 0.25-0.40% of Si, 0.65-0.90% of Mn, not higher than 0.020% of P, not higher than 0.012% of S, 0.30-0.60% of Cr, 0.015-0.03% of Als and the balance of Fe and inevitable impurities. The production method has the advantages that the production problems of large liquid level fluctuation, caking, unstable heat flow and the like appearing during the continuous casting of thin sheet billets under the condition of high pulling rate and the quality problems of surface crackle, center segregation, center porosity and the like of casting blanks are solved, and a stable production technology for 75Cr steel in a thin-sheet continuous casting and continuous rolling production line is realized. The 75Cr plate coil has the advantages that the surface quality is good, cracks and slag inclusions are not discovered, the structure property is uniform, the tensile strength is 920-1010MPa, the yield strength is 490-820MPa, the elongation percentage is 13-24%, and the Brinell hardness is 270-320HBW.

Owner:HEBEI IRON AND STEEL

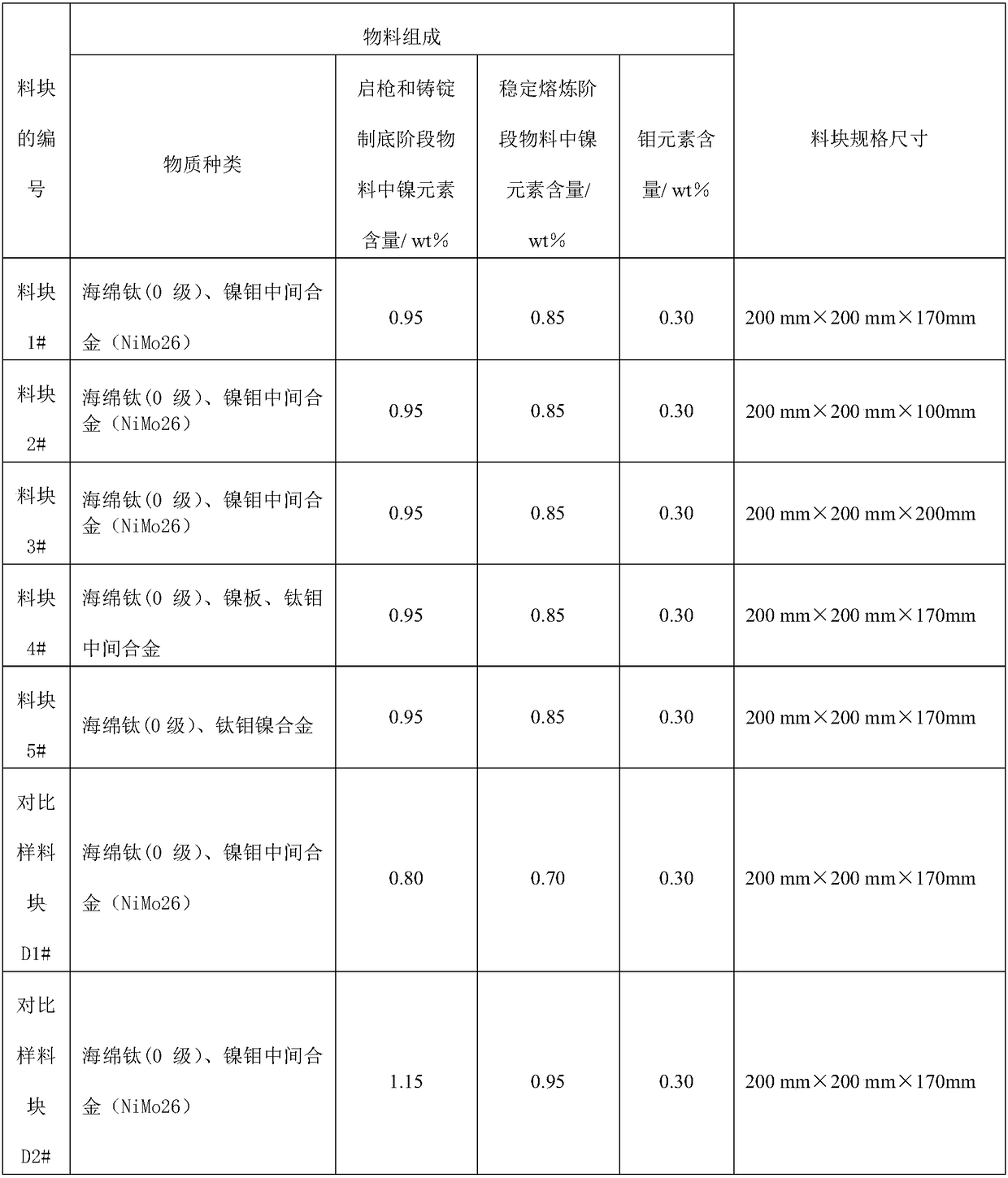

Method for smelting TA10 titanium alloy by using electron beam cold hearth

The invention discloses a method for smelting a TA10 titanium alloy by using an electron beam cold hearth, and belongs to the field of titanium alloys. The method comprises the following steps that (1), materials containing titanium, nickel and molybdenum are mixed and pressed into a material block, and then the material block is dried; and (2) the dried material block is subjected to smelting byusing the electron beam cold hearth, and the TA10 titanium alloy is obtained. Electron beam cold hearth smelting comprises a gun starting stage, a casting ingot bottom making stage, and a stable smelting stage; and the electron beam cold hearth comprises a melting zone, a refining zone and a crystallization zone which are sequentially adjoined, the power of the melting zone in the stable smeltingstage is 800-1100 Kw, the power of the refining zone is 150-180 Kw, and the power of the crystallization zone is 180-210 Kw. The TA10 titanium alloy prepared through the method is good in element distribution uniformity and surface quality.

Owner:QINGHAI JUNENG TITANIUM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com