Patents

Literature

36results about How to "Fast impregnation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

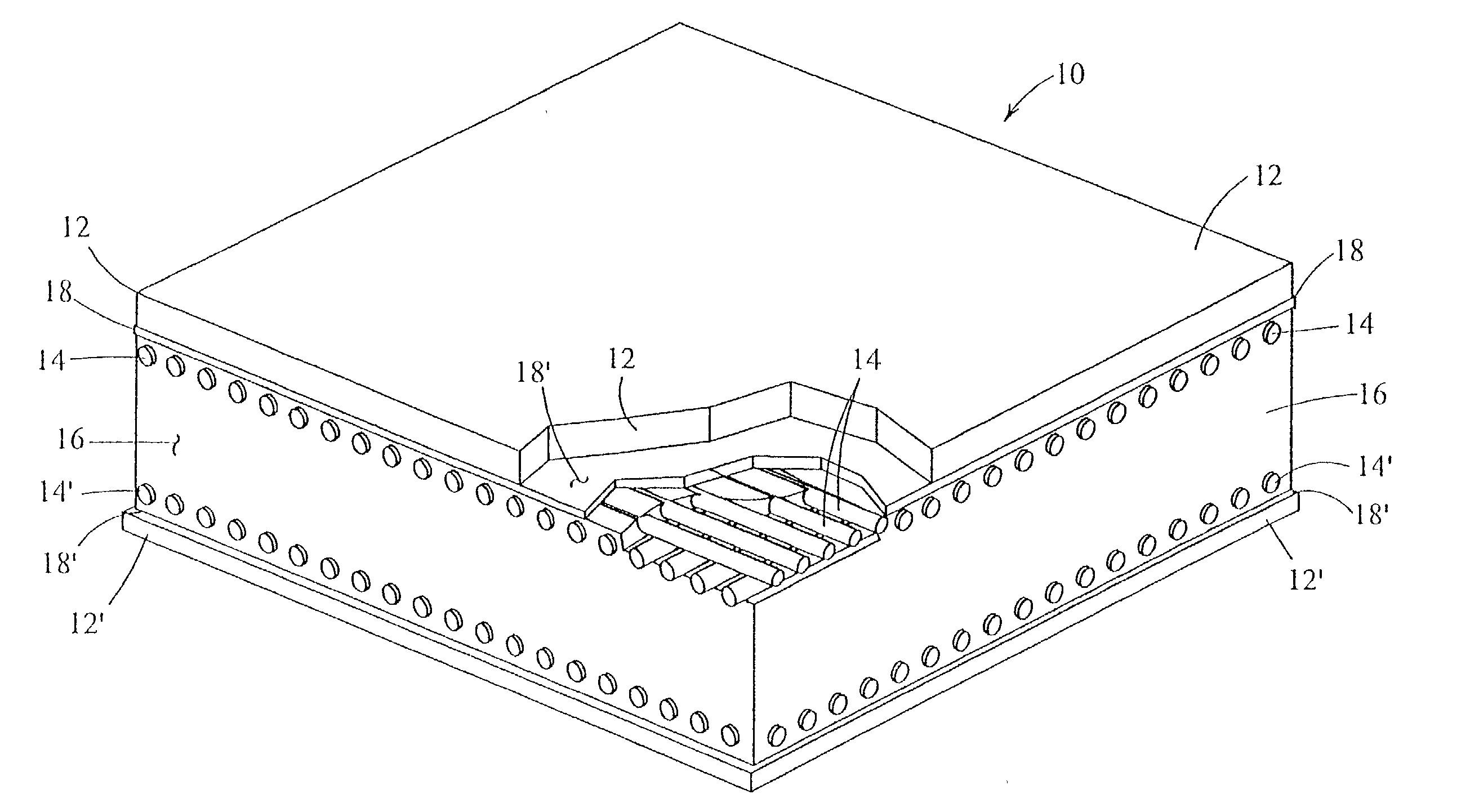

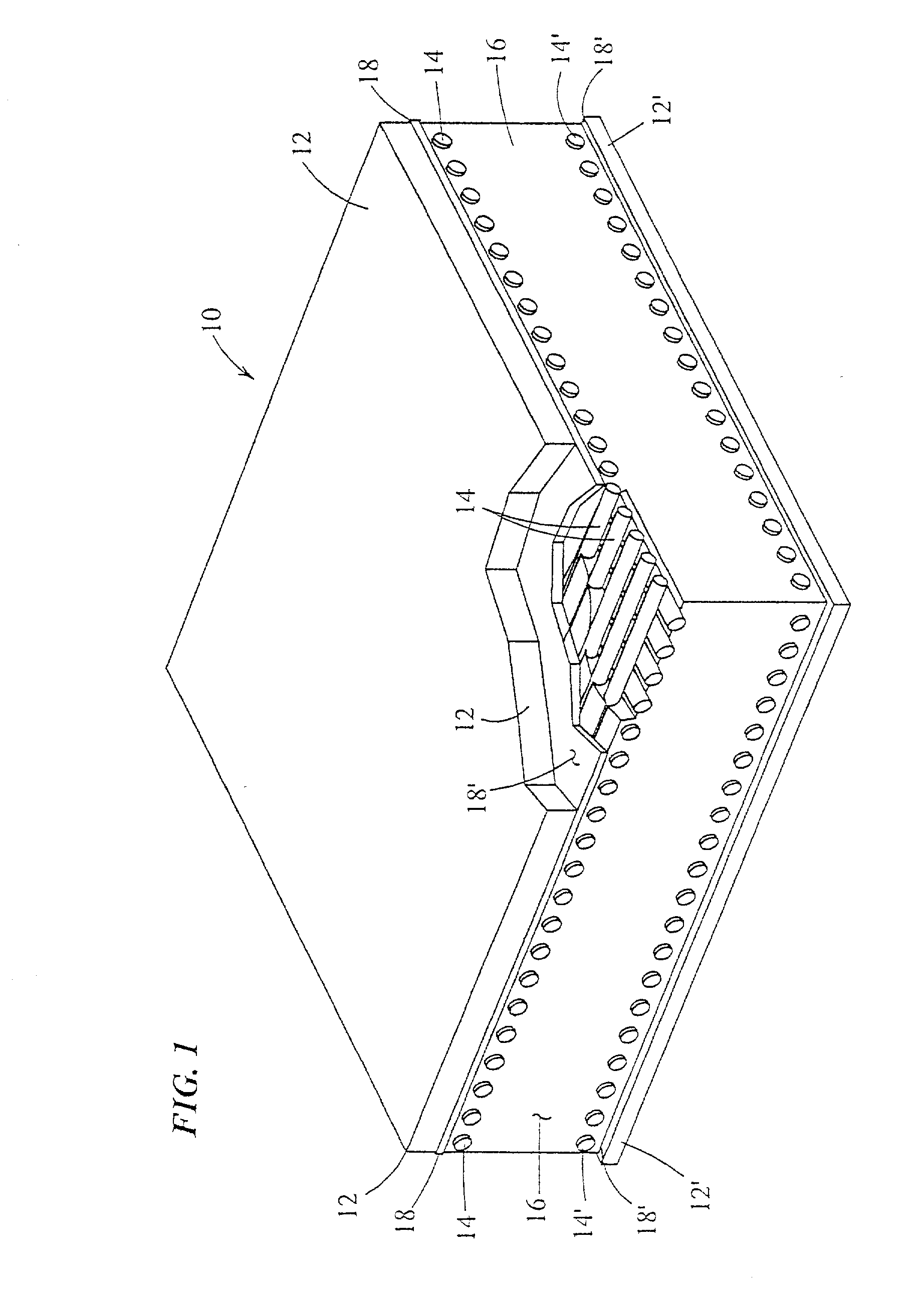

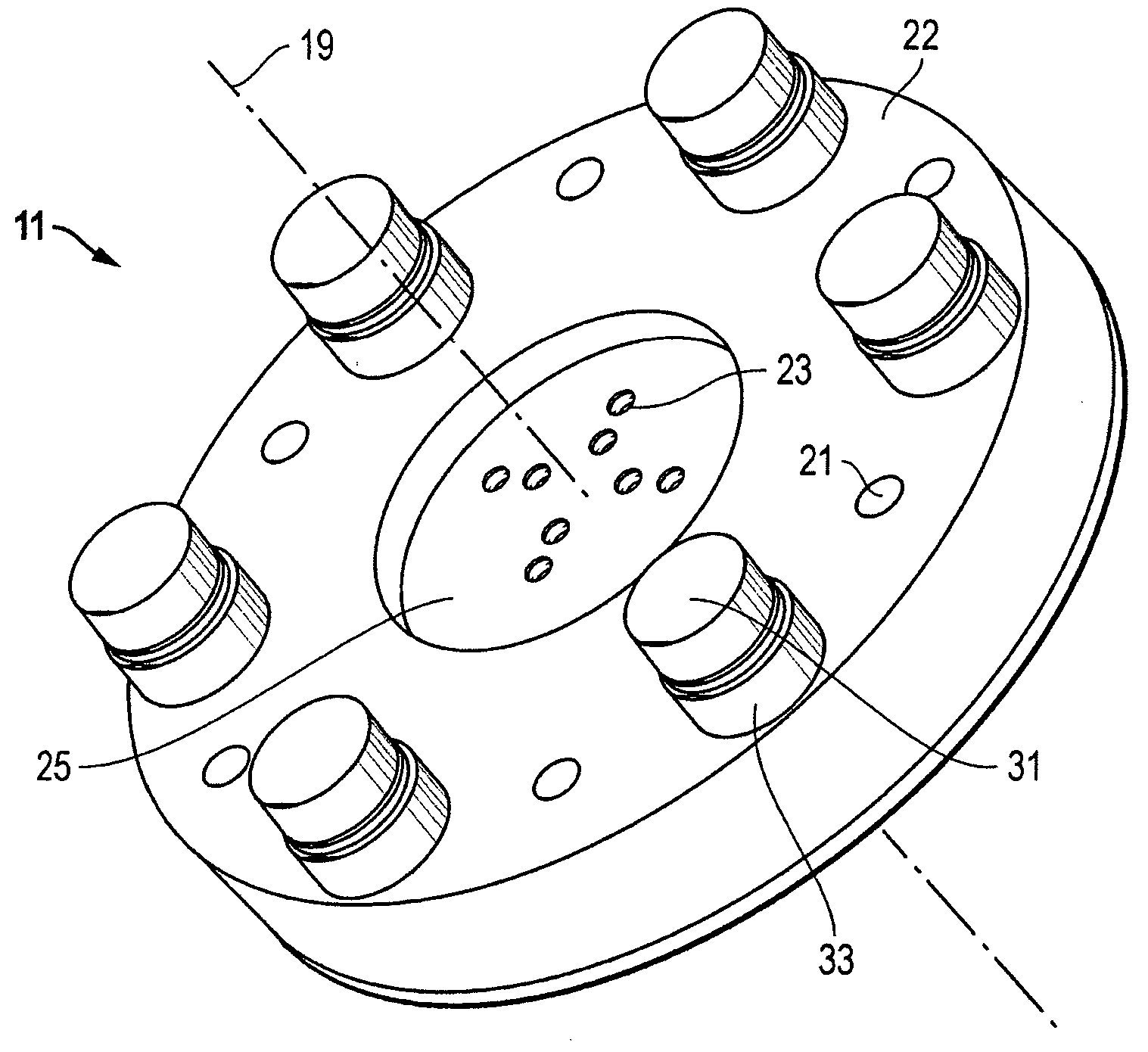

Fiber-reinforced composite structure

InactiveUS6331028B1Fast fillFast impregnationLayered productsWoven fabricsFoaming agentVacuum pressure

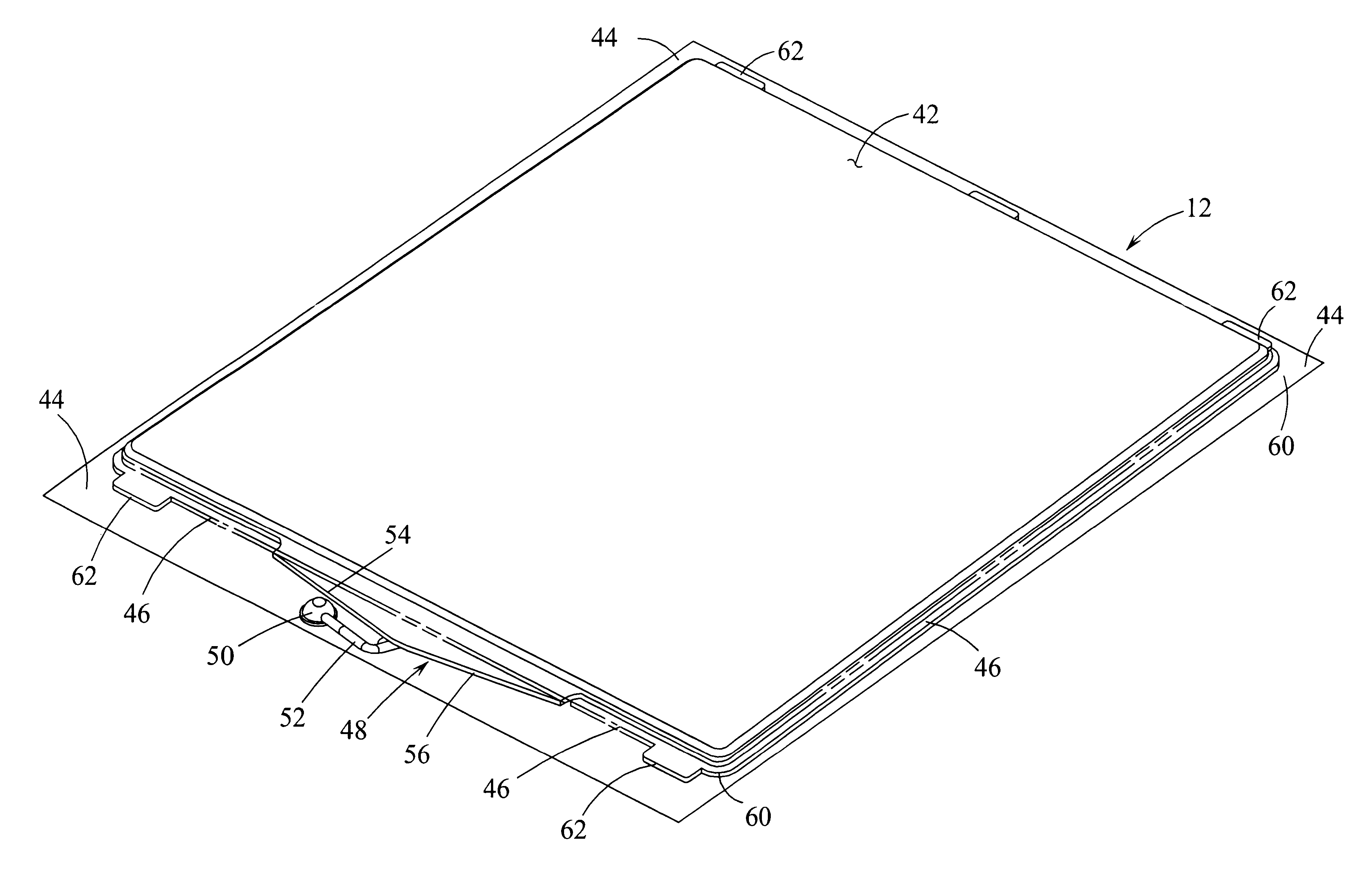

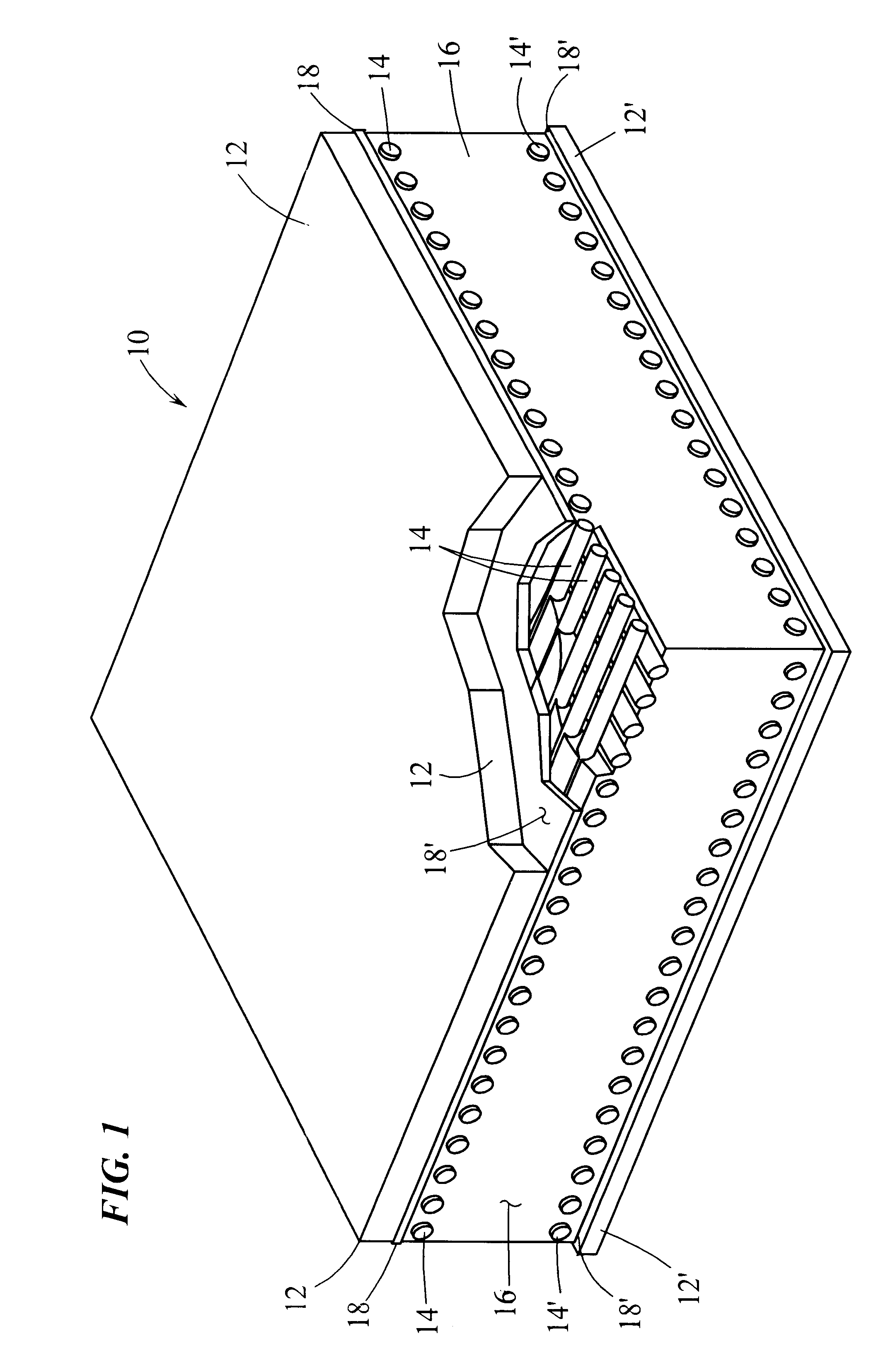

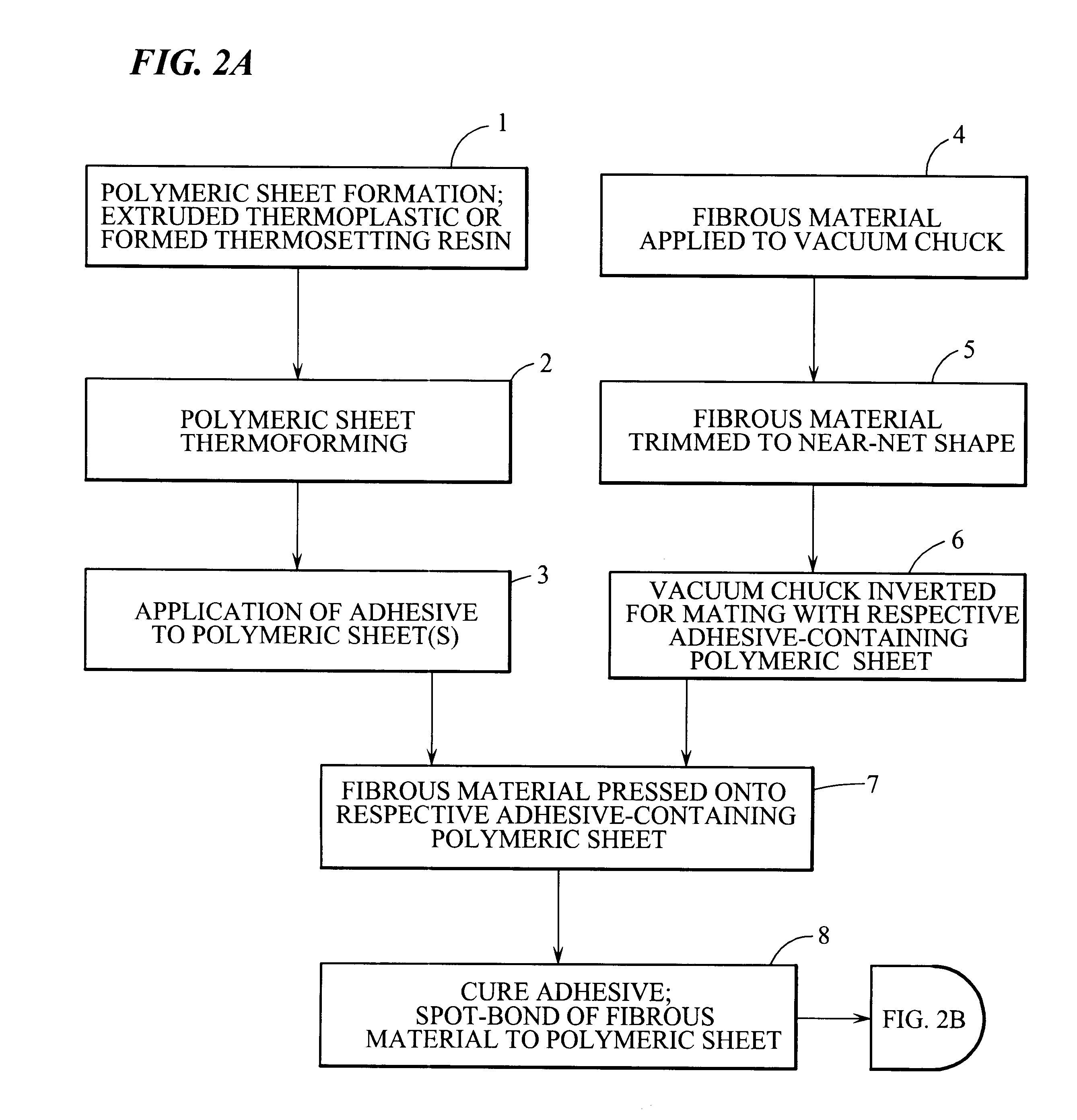

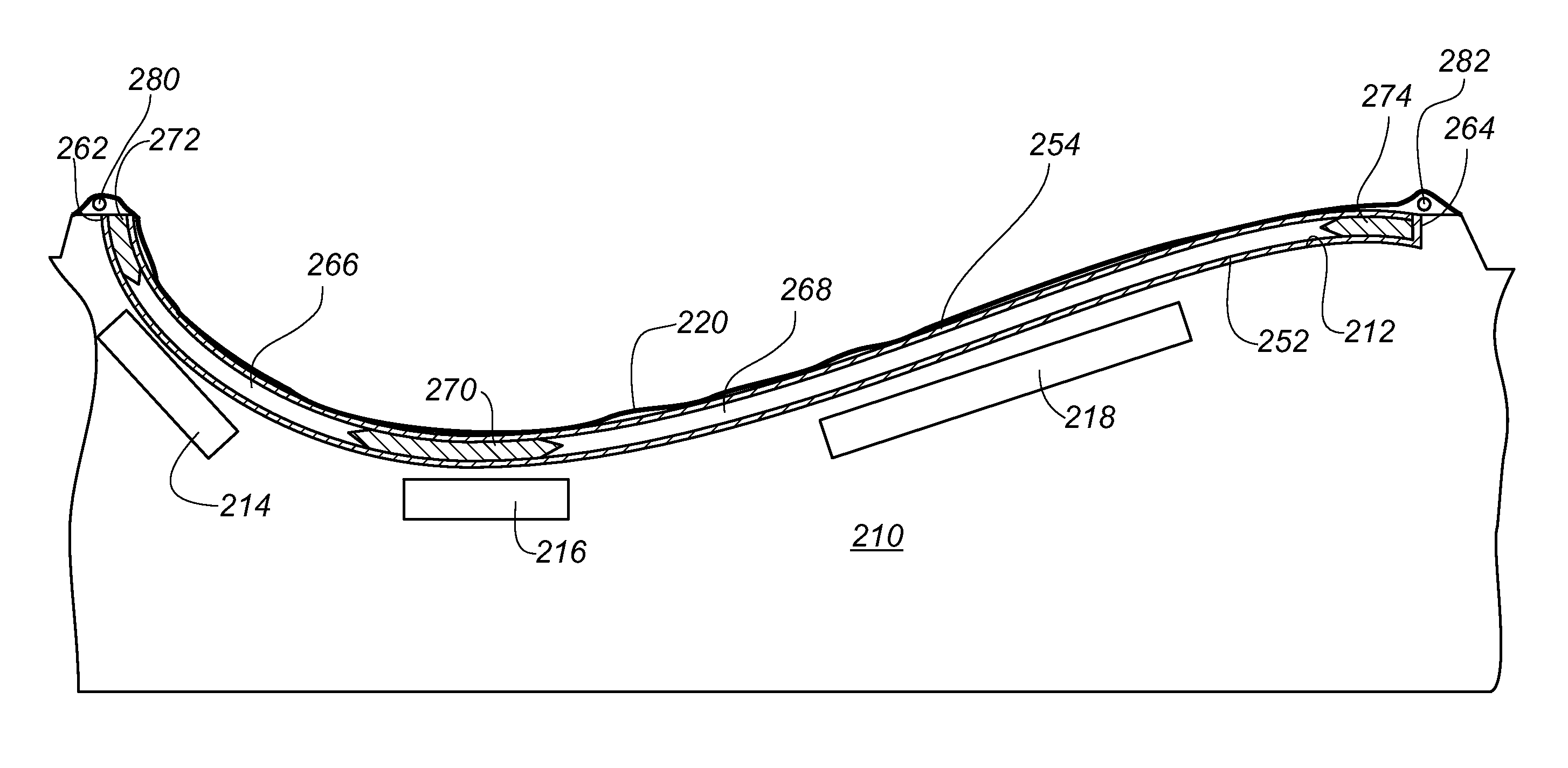

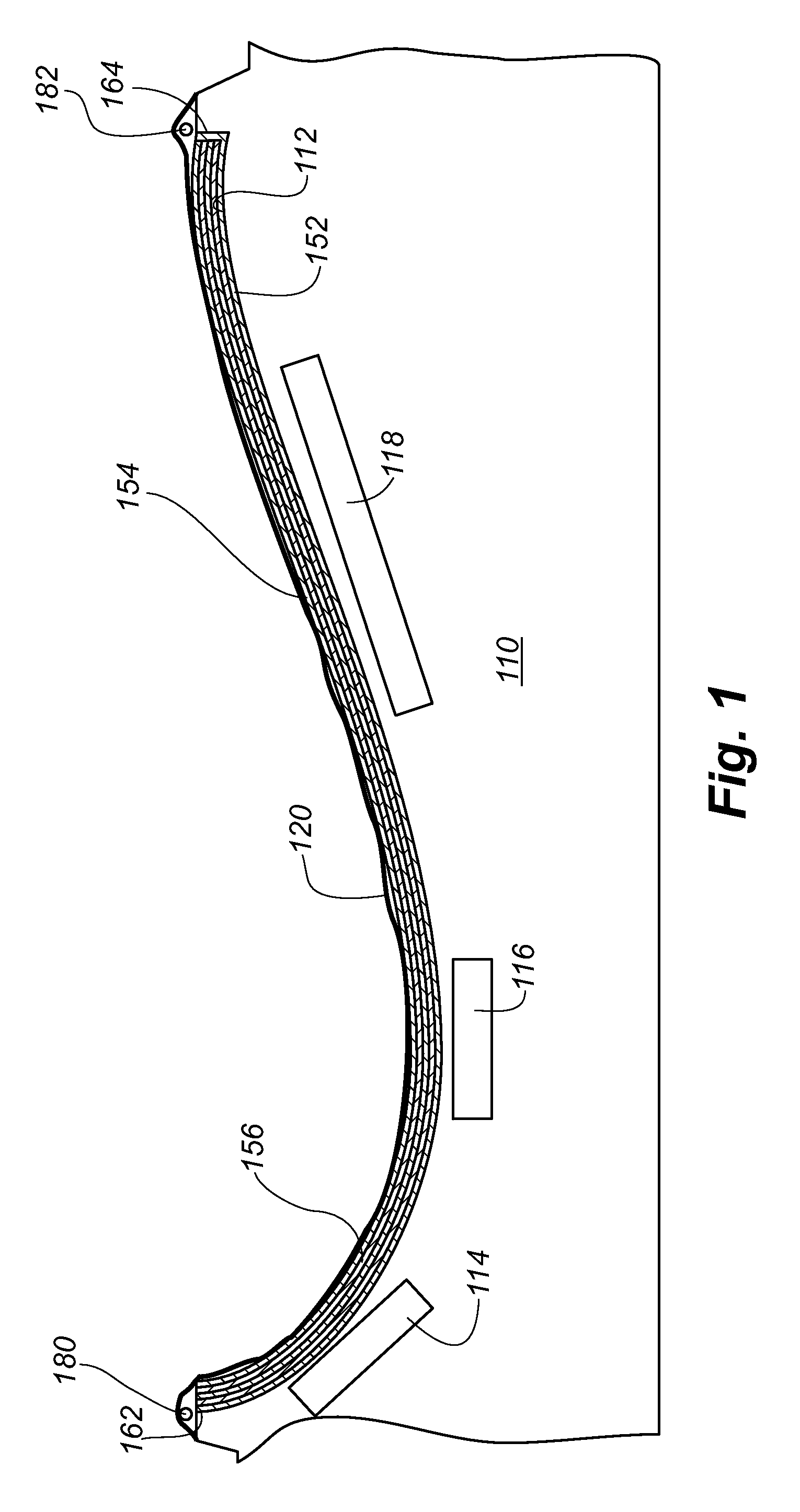

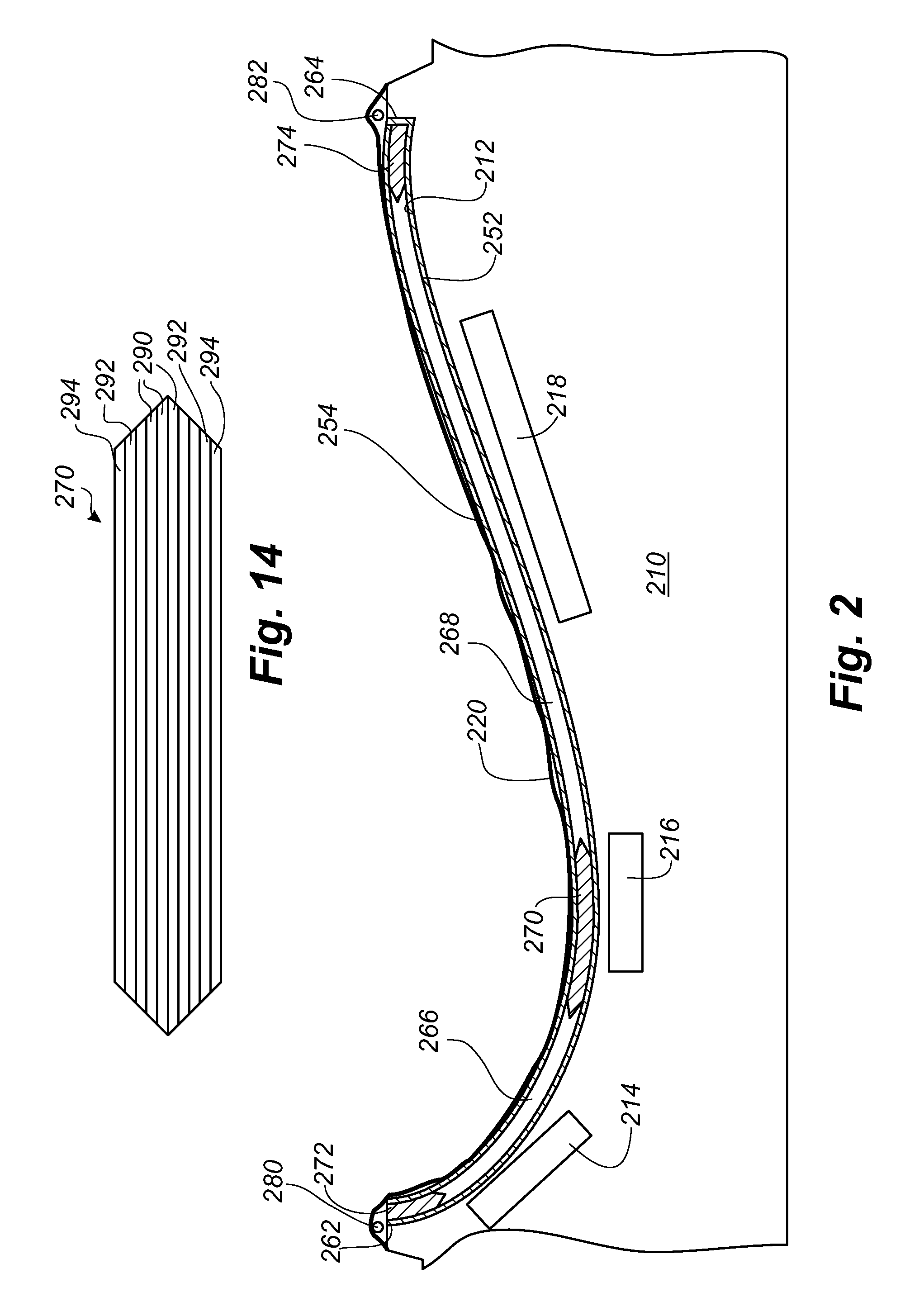

A fiber-reinforced composite structure has two molded outer polymeric layers spaced apart from each other and defining a cavity therebetween. Each molded outer polymeric layer defines a sealing surface extending about a periphery of the respective layer, and the opposing sealing surfaces cooperate to define a hermetic seal extending about a periphery of the cavity. One or more multi-directional fiber reinforcement layers are adhesively attached in a discontinuous manner to each outer polymeric layer, and define a first region of the cavity extending between each respective outer polymeric layer and adjacent fiber reinforcement layer, and a second region of the cavity extending between the fiber reinforcement layers. A core is located between the two outer polymeric layers, and is made of a resinous core material capable of exhibiting a foamed character and a resinous character. The resinous core material has a blowing agent activatable upon exposure to a predetermined vacuum pressure within the cavity to convert the core material within the second region of the cavity from a resinous character to a foamed character and thereby fill the second region of the cavity with the foamed core material. Each multi-directional fiber reinforcement layer is impregnated with the core material exhibiting a relatively dense, resinous character, and each first region of the cavity is substantially filled with the core material exhibiting a resinous character to fixedly secure the multi-directional fiber reinforcement layers to the outer polymeric layers. A structural insert, such as a rigid plate adapted to receive fasteners, is embedded within the core material for attaching other devices or structures thereto.

Owner:SABIC GLOBAL TECH BV

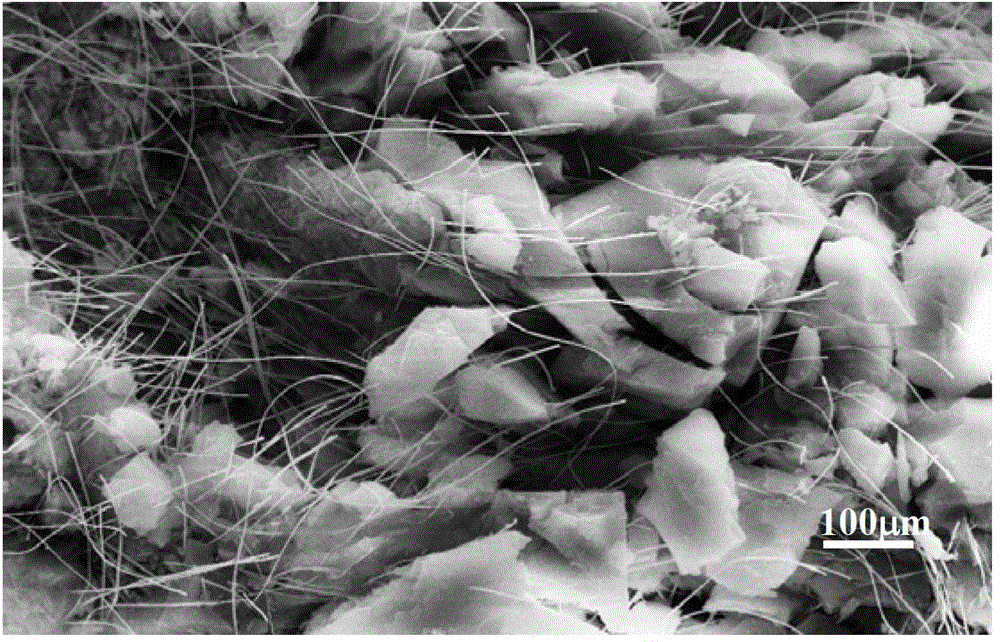

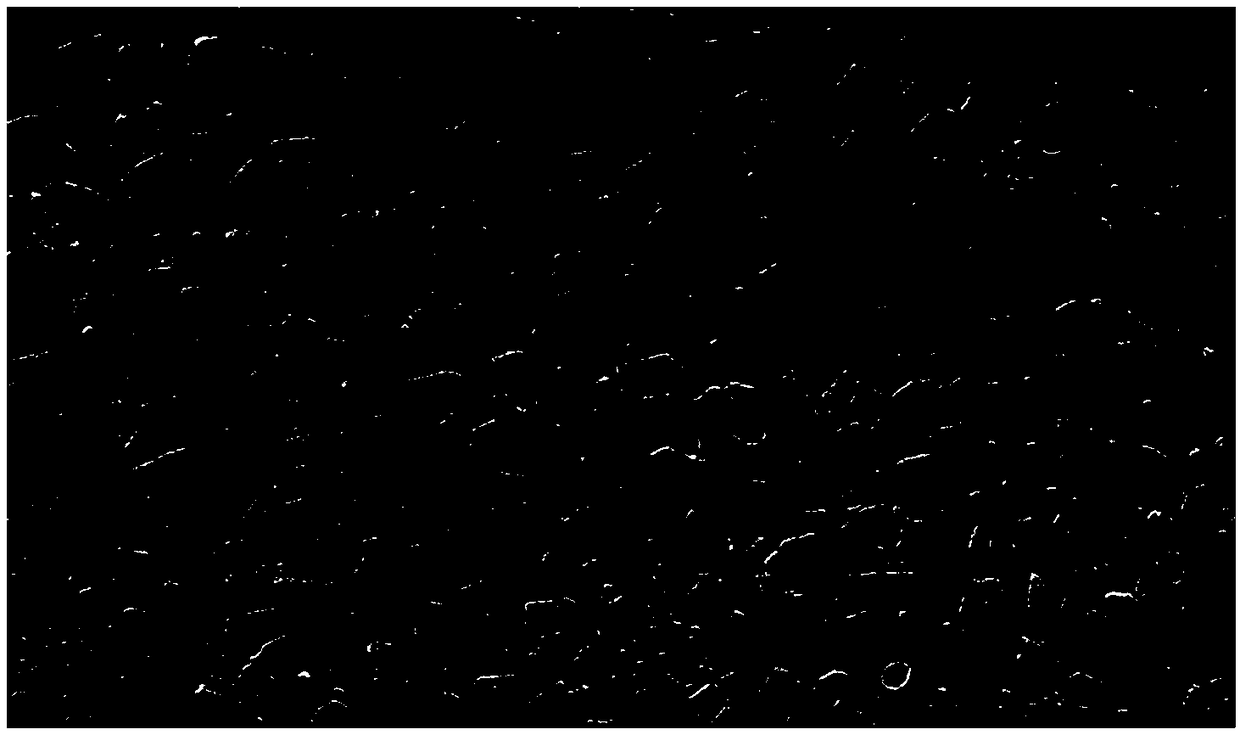

Preparation method of silicon-carbide-fibrofelt-enhanced silica aerogel composite material

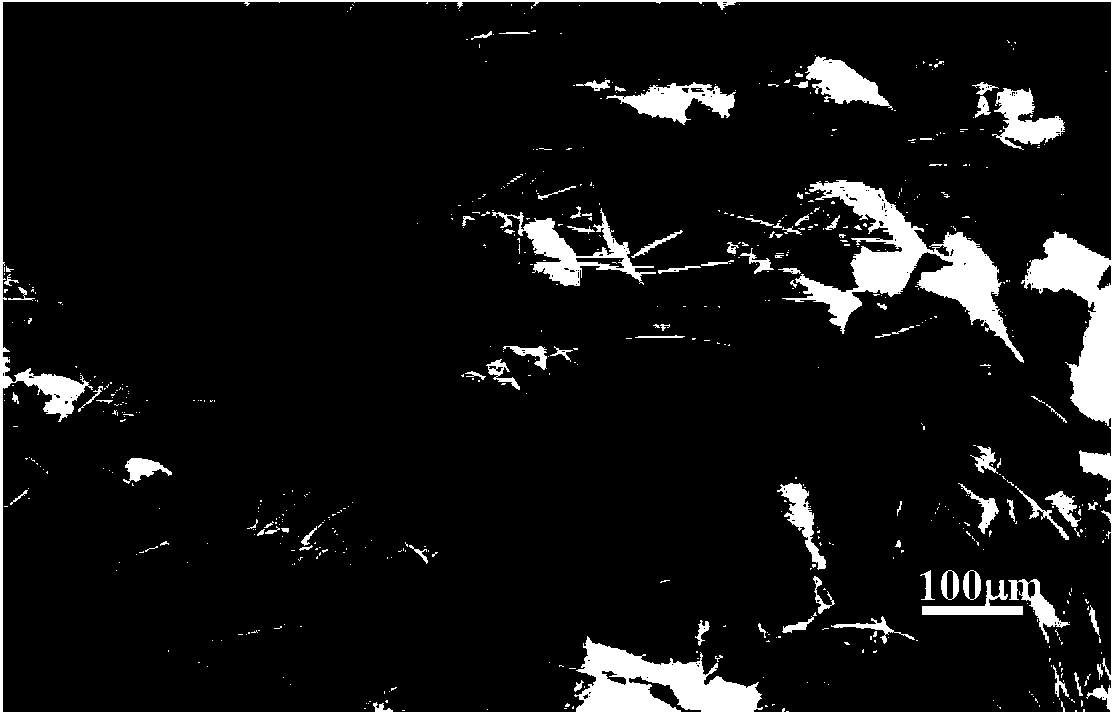

The invention relates to a preparation method of a silicon-carbide-fibrofelt-enhanced silica aerogel composite material, and relates to an aerogel composite material. According to the invention, a carbon-rich silicon carbide micro-nano ceramic fibrofelt with small fiber diameter, high porosity, communicating pores, fast impregnation speed, and good compatibility with a substrate is prepared with a static electro-spinning technology combined with a precursor conversion method; a silica sol is prepared with an acid-alkali two-step method; with an infiltration technology, the electro-spun silicon carbide ceramic fibrofelt or precast is soaked into the sol; and through processes such as gel process, aging, curing, solvent exchange, supercritical drying, and the like, the silicon-carbide-fibrofelt-enhanced silica aerogel composite material is obtained. The prepared composite material has the characteristics of low density, large specific surface area, super-hydrophobicity, low thermal conductivity, and the like. The strength and toughness of the material are also greatly improved. The carbon-rich silicon carbide fiber has an infrared shielding effect, such that composite material thermal insulation effect and ultra-high-temperature stability can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

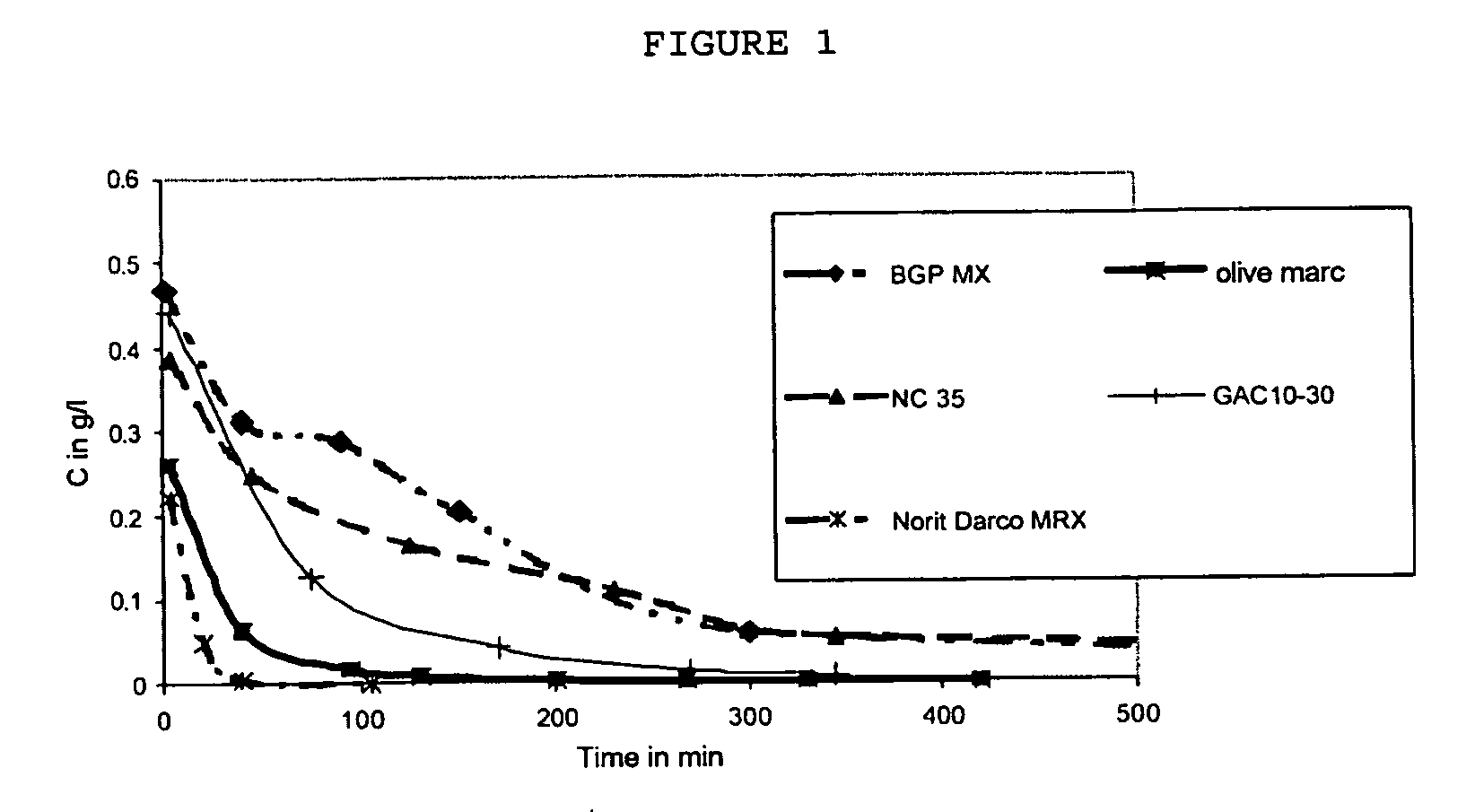

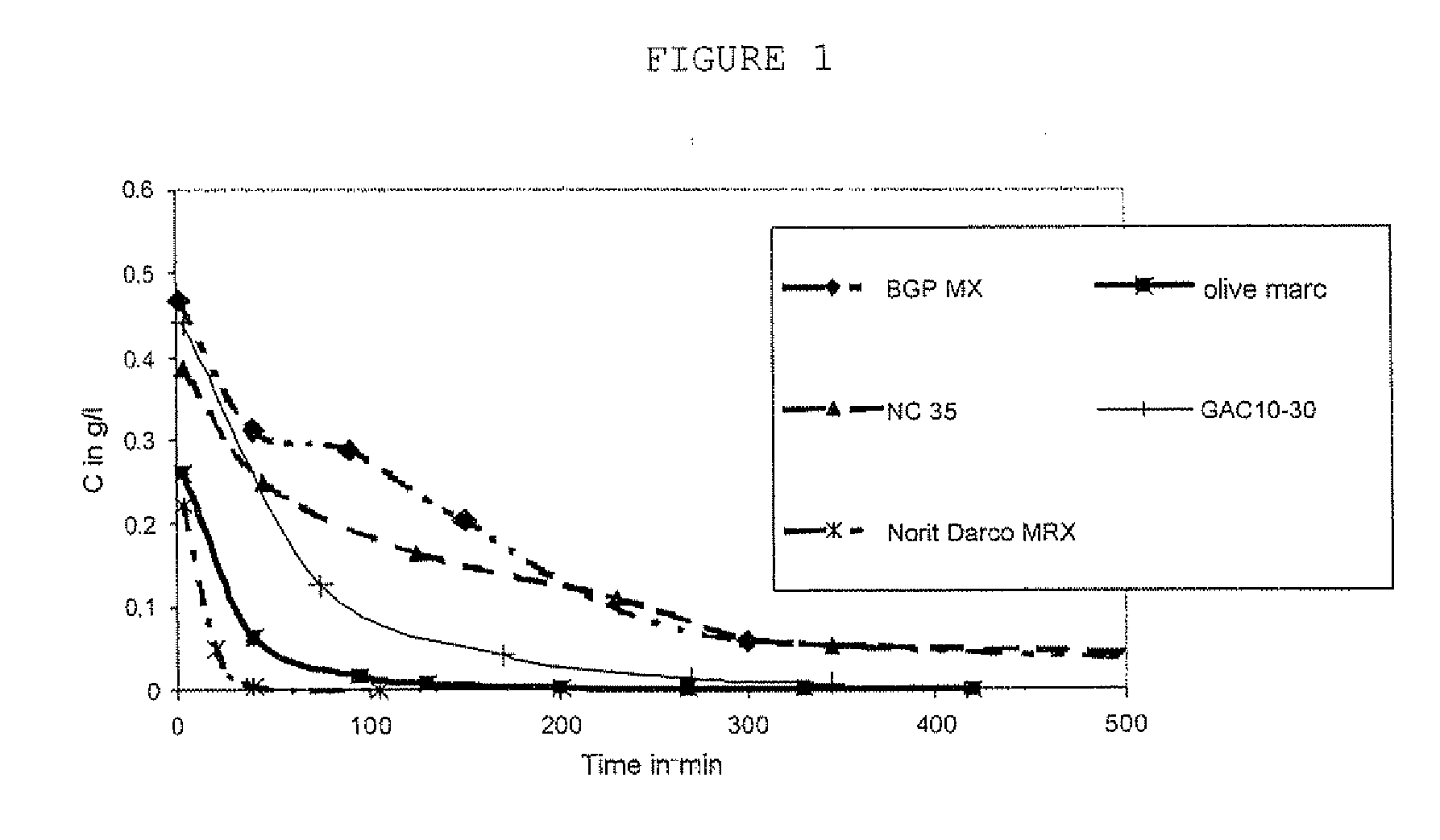

Activated carbon with improved mechanical resistance, and the uses thereof, especially as a catalyst carrier

InactiveUS20070123419A1Strong mechanical propertiesRapidly impregnated with oxidation catalystCarbon compoundsOther chemical processesGas phaseSolvent

The present invention relates to active charcoals with improved mechanical properties. They can advantageously be used in the sweetening of petroleum fractions, as oxidation catalyst support in the conversion of mercaptans to disulphides, but also in any other type of reaction, such as, for example, for the oxidation of cyanide present in water or in the synthesis of glyphosate, and in processes for purification and / or separation by selective adsorption in a liquid phase and / or in a gas phase (decolouration of liquid foodstuffs, water treatment, air treatment, recovery of solvents, and the like).

Owner:LE BEC REMY

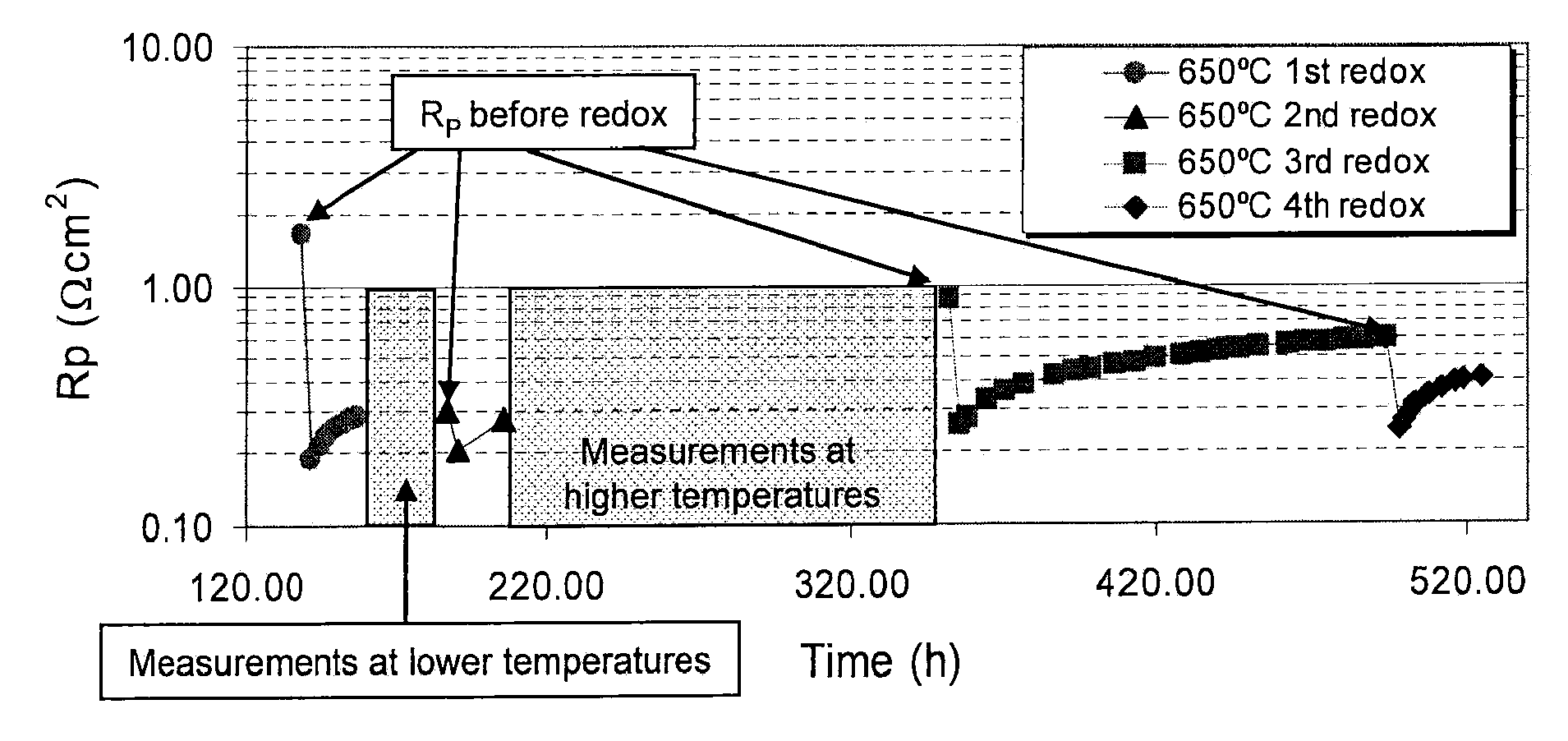

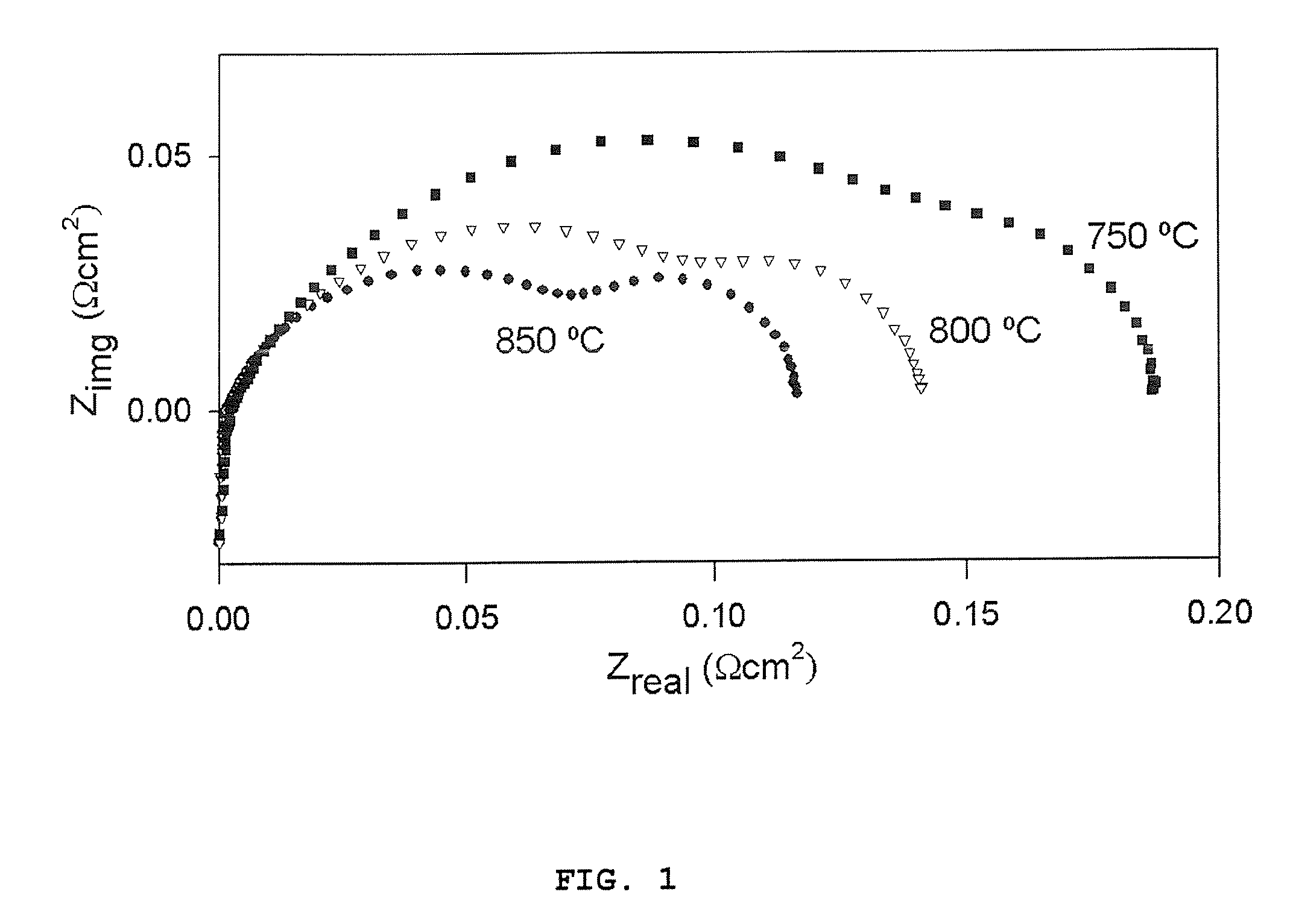

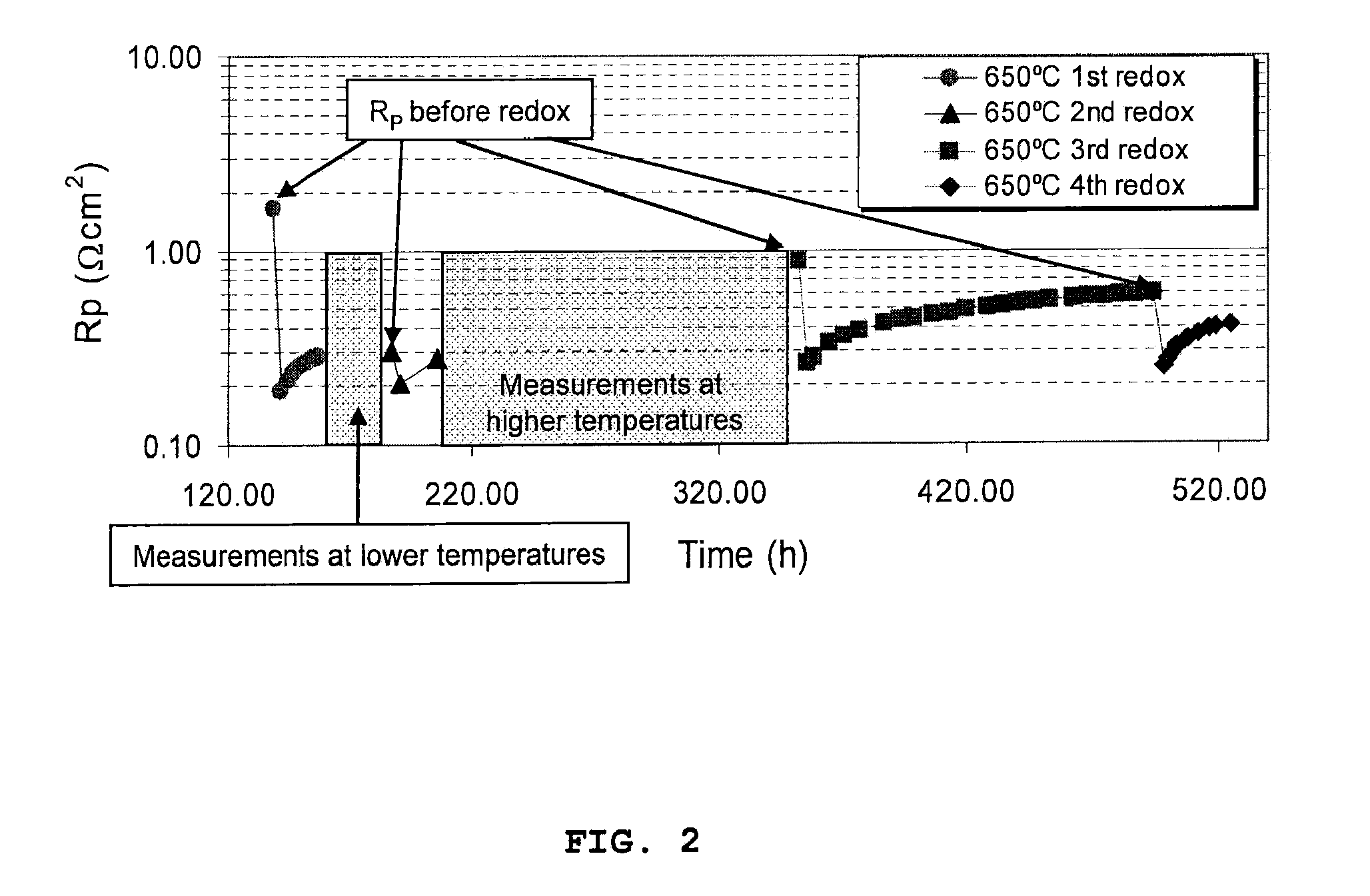

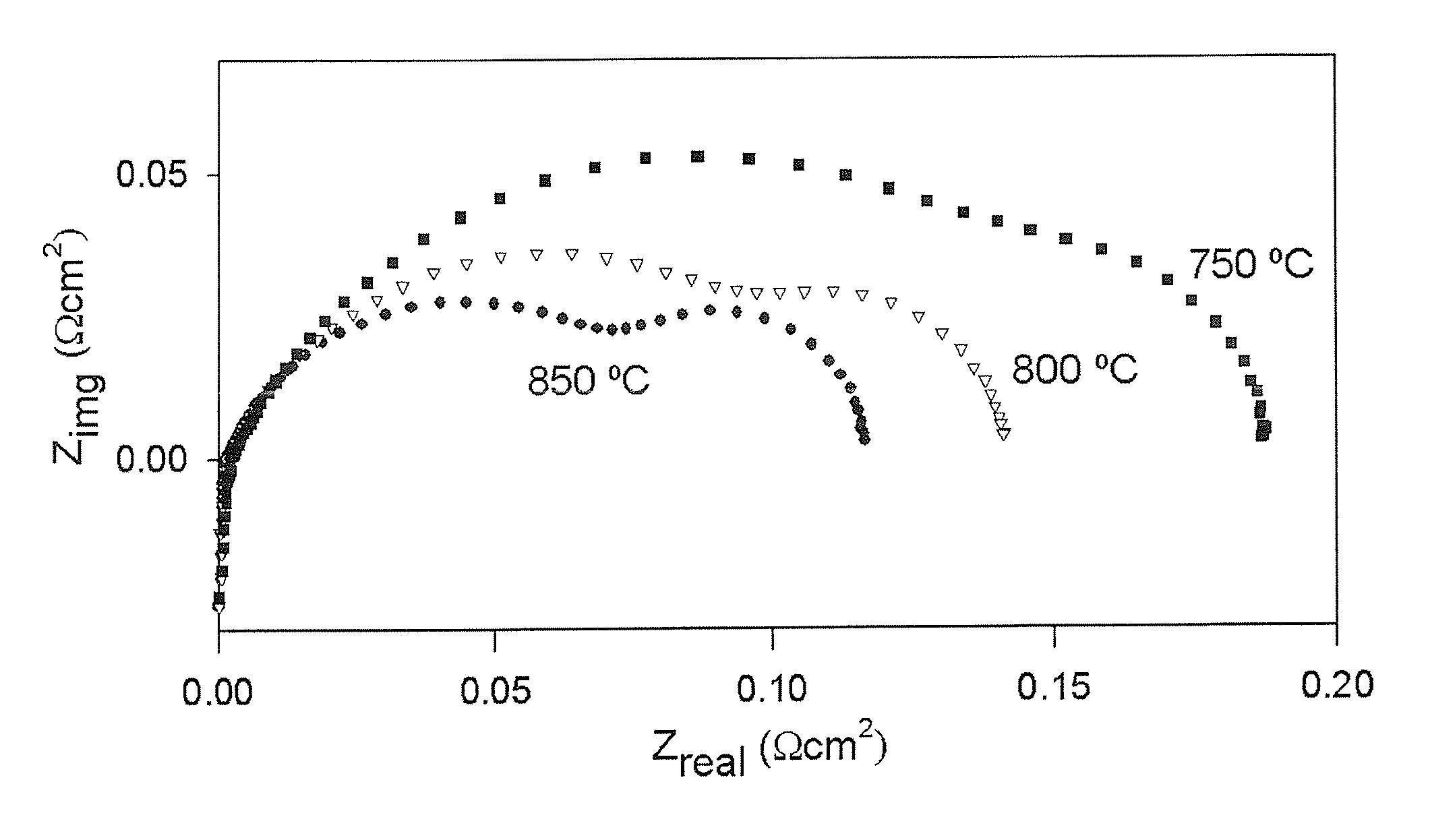

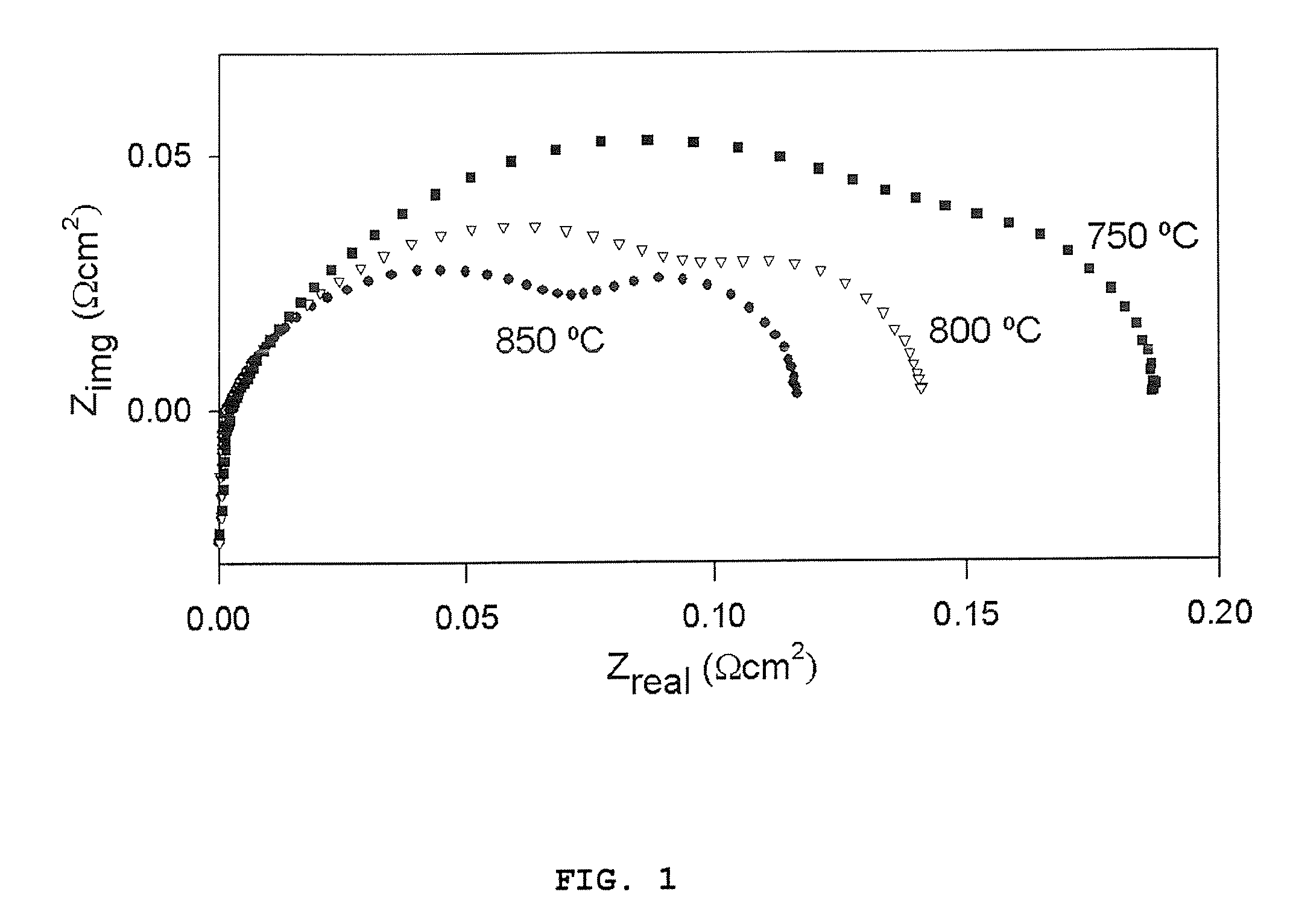

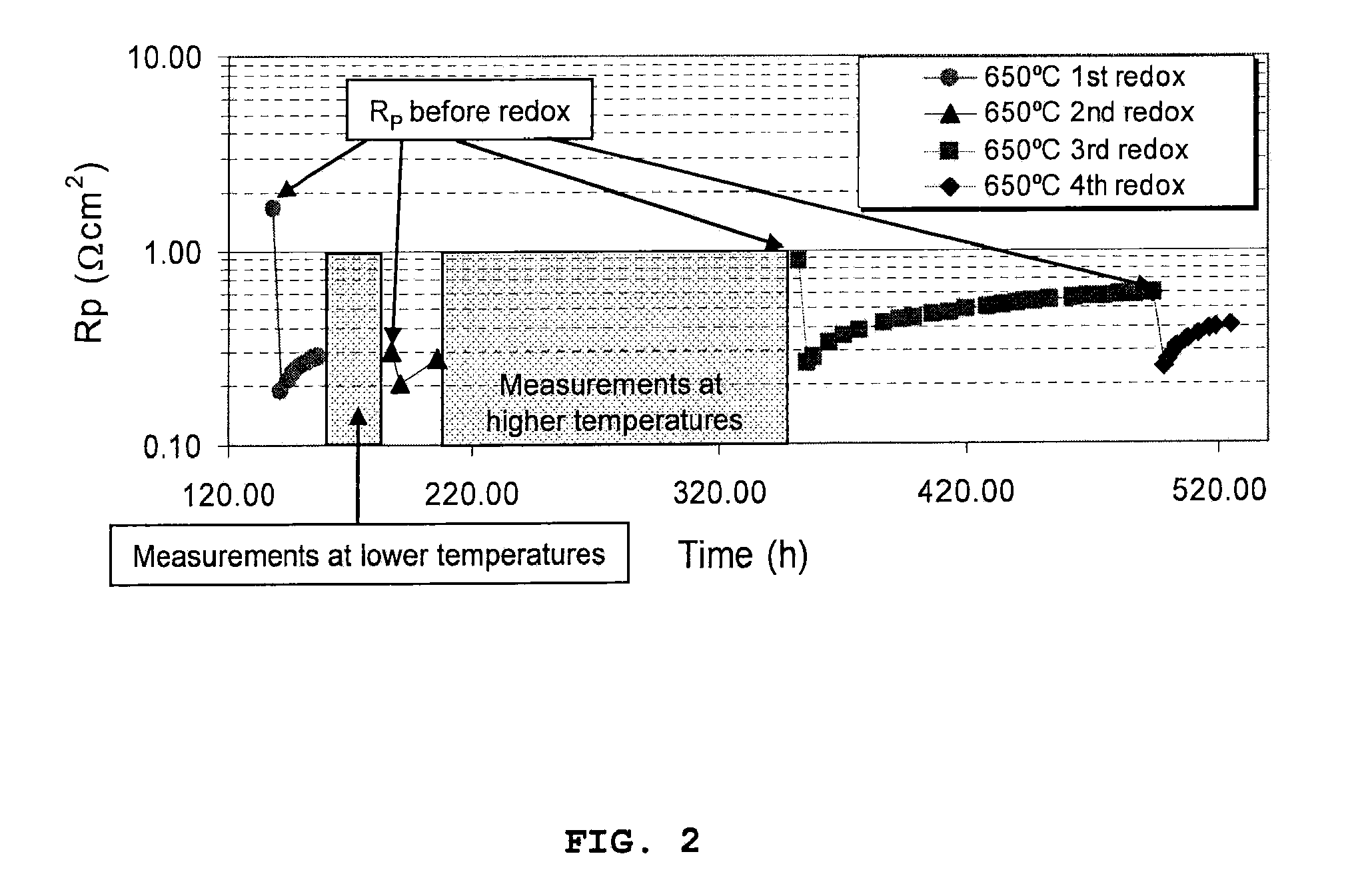

Ceria and strontium titanate based electrodes

InactiveUS20090061284A1High BET surface areaSpeed up calcination procedureFuel cells groupingCell electrodesStrontium titanateVanadium doping

A ceramic anode structure obtainable by a process comprising the steps of: (a) providing a slurry by dispersing a powder of an electronically conductive phase and by adding a binder to the dispersion, in which said powder is selected from the group consisting of niobium-doped strontium titanate, vanadium-doped strontium titanate, tantalum-doped strontium titanate, and mixtures thereof, (b) sintering the slurry of step (a), (c) providing a precursor solution of ceria, said solution containing a solvent and a surfactant, (d) impregnating the resulting sintered structure of step (b) with the precursor solution of step (c), (e) subjecting the resulting structure of step (d) to calcination, and (f) conducting steps (d)-(e) at least once.

Owner:DANMARKS TEKNISKE UNIV

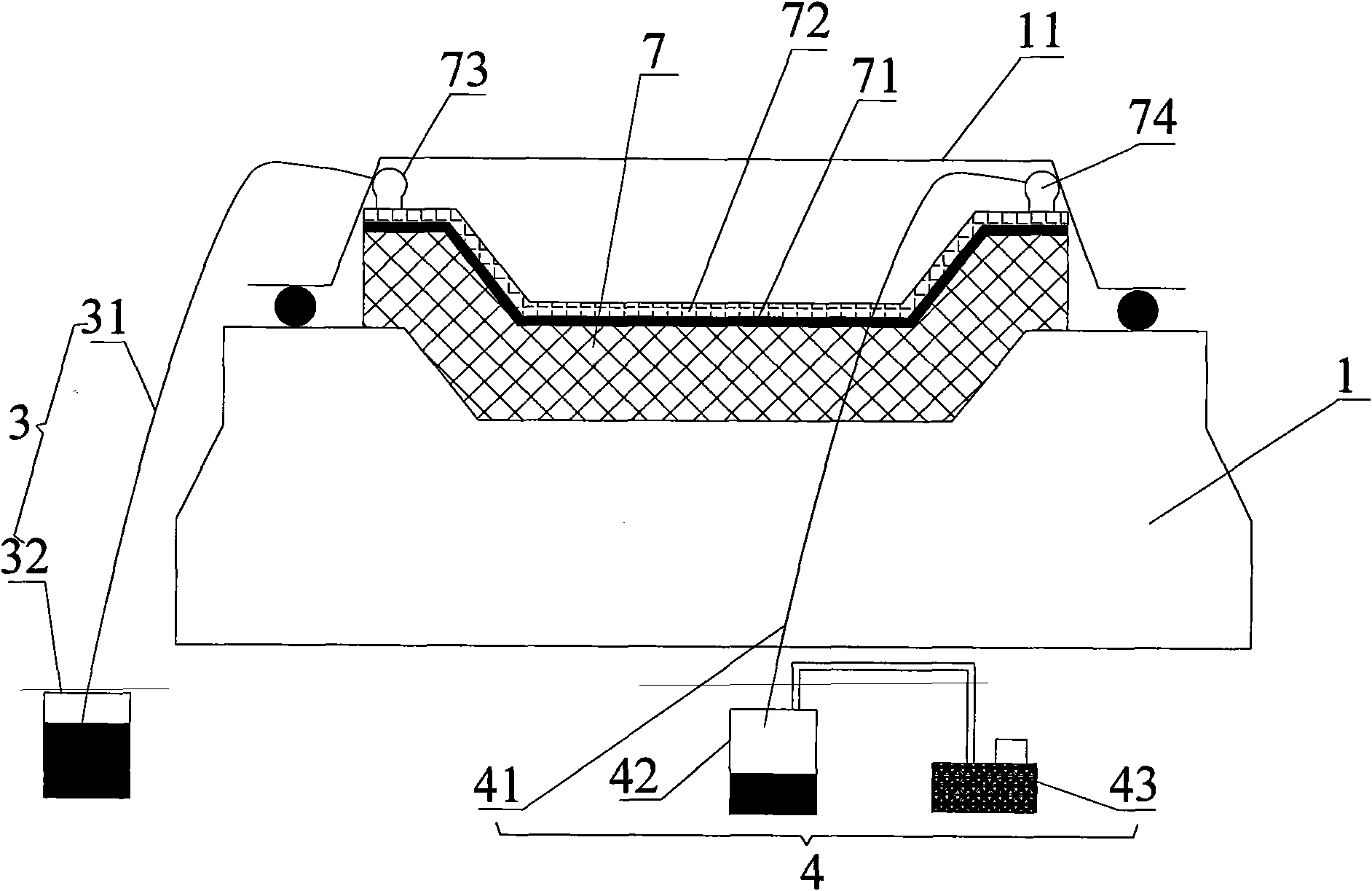

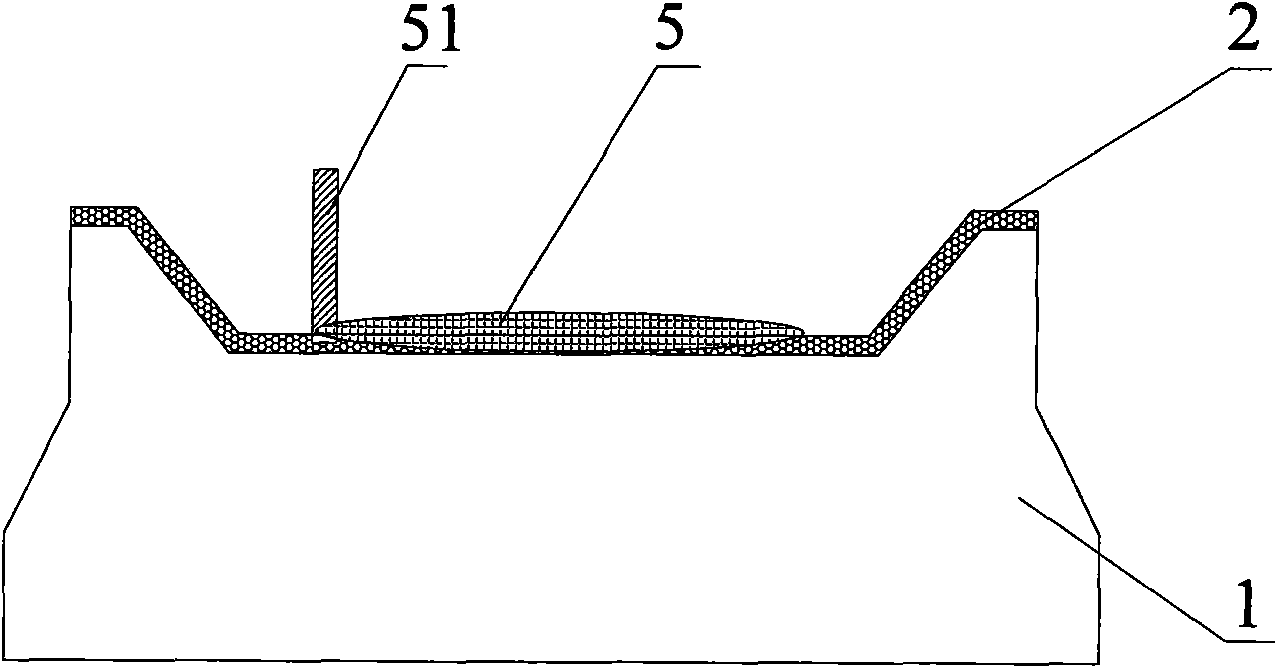

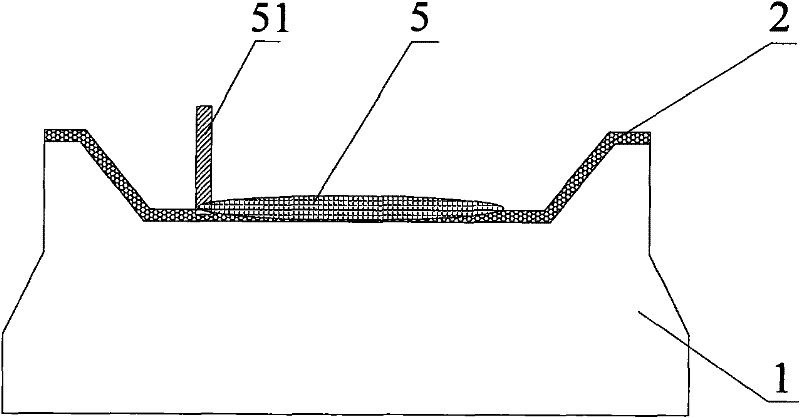

Composite material member with surface function layer and VIMP preparation method thereof

InactiveCN101830095AFast impregnationGood surface qualitySynthetic resin layered productsSurface functionMaterial system

The invention belongs to the technical field of a multilayer structural composite material member and a preparation method thereof and specifically discloses the composite material member with a surface function layer and a VIMP preparation method thereof. The composite material member comprises an outer surface layer and a main body layer, wherein, the outer surface layer and the main body layer are respectively a first composite material system and a second composite material system; and the first composite material system takes epoxy resin, phenolic resin and the like as a matrix, the second composite material system takes unsaturated polyester resin as a matrix, and the two systems take fiber cloth of carbon fiber or glass fiber as reinforcement. The VIMP preparation method comprises the following steps: firstly preparing a reinforced resin film on a die surface for vacuum dip molding by a resin film infiltration process, and then preparing the composite material member with a molding die covered with the reinforced resin film through the vacuum dip molding process. The VIMP process of the invention combines the double advantages of an RFI process and the VIMP process; and the obtained composite material member has better surface quality, better integrity and excellent comprehensive performances.

Owner:NAT UNIV OF DEFENSE TECH

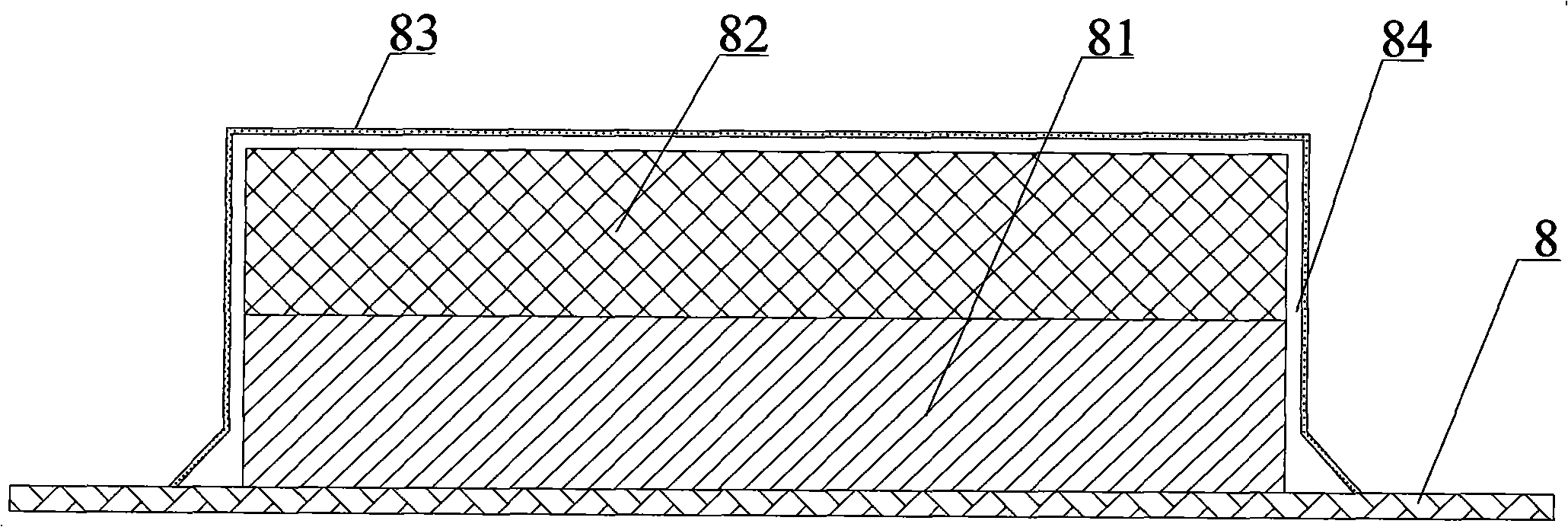

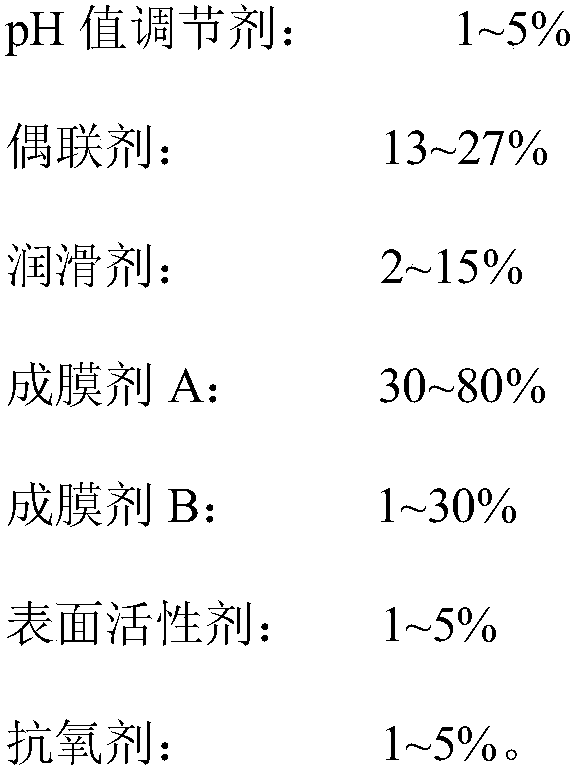

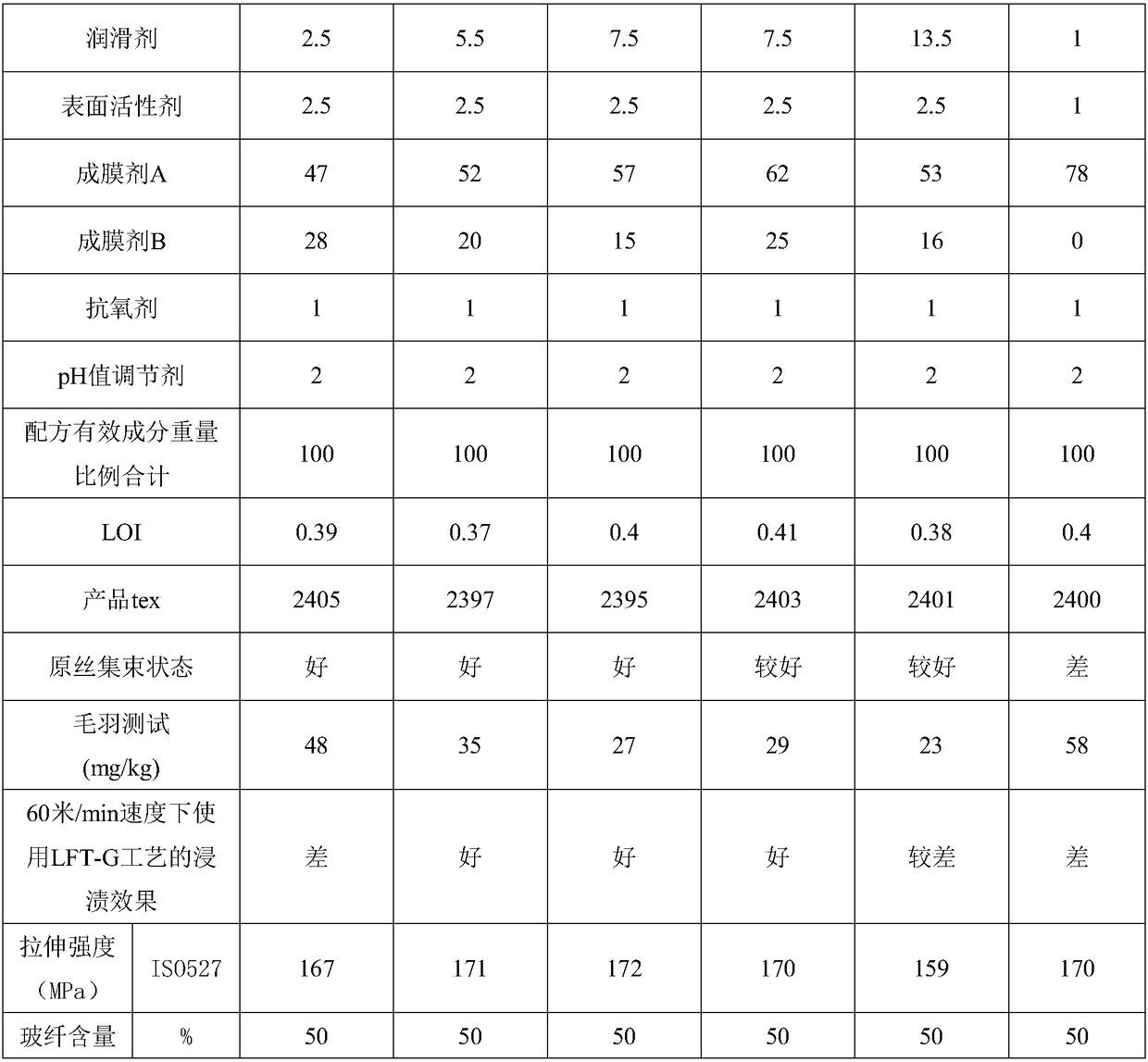

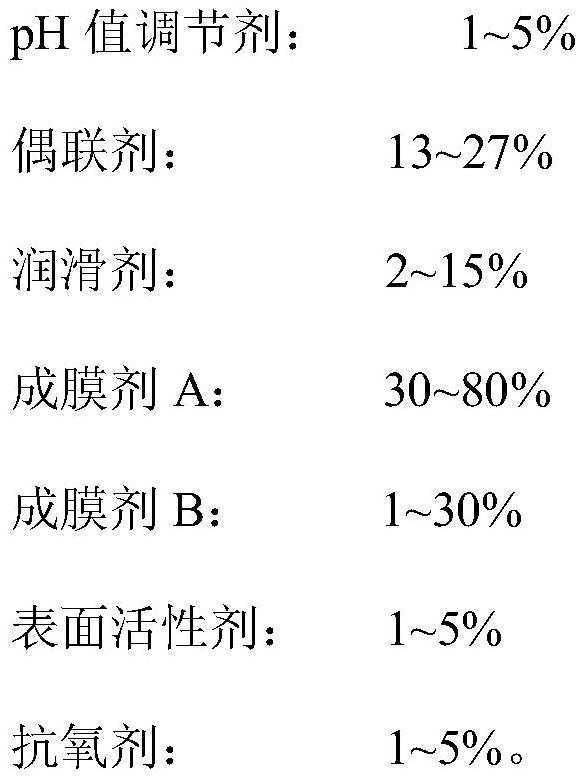

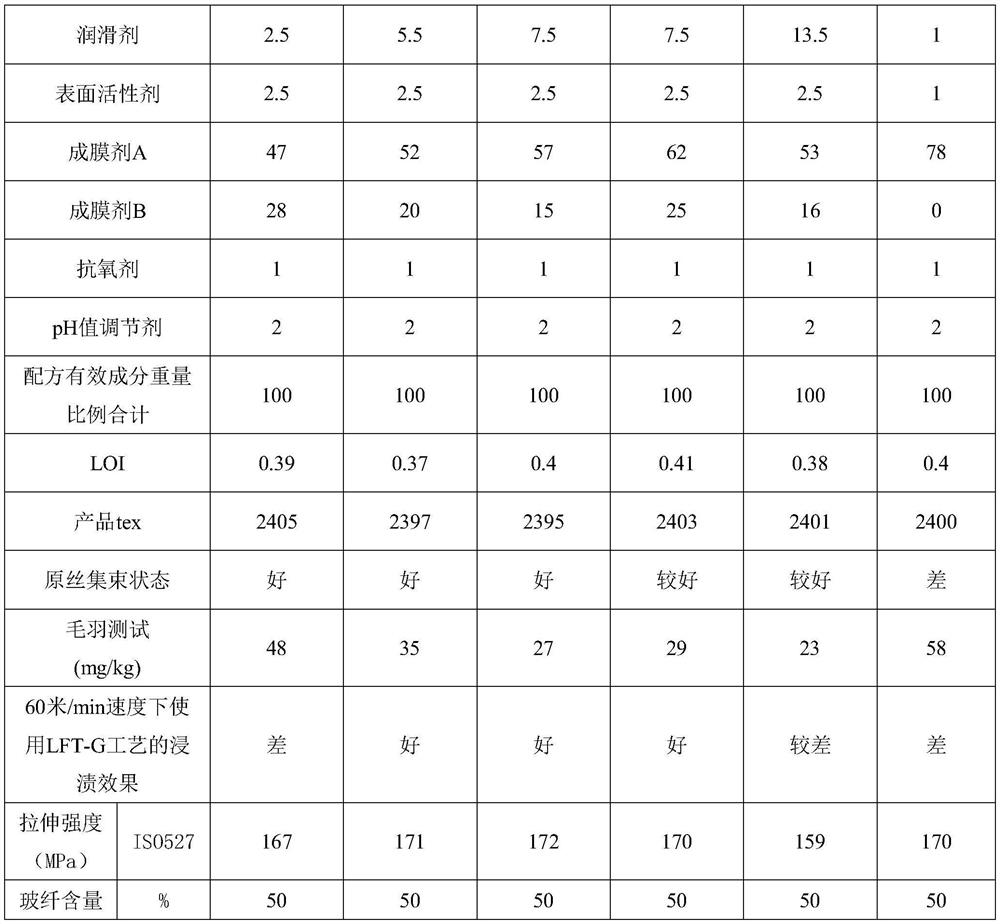

High-dipping-property alkali-free glass fiber impregnating agent for LFT reinforced polypropylene as well as application thereof

ActiveCN108996923AIncrease productivityImprove interface compatibilityAlkali freeMicrocrystalline wax

The invention relates to a high-dipping-property alkali-free glass fiber impregnating agent for LFT reinforced polypropylene as well as the application thereof. The impregnating agent comprises a pH value regulator, a silane coupling agent, a film-forming agent A, a film-forming agent B, a lubricating agent, a surfactant, an antioxidant and deionized water, wherein the film-forming agent A is a maleic anhydride grafted and modified polypropylene wax emulsion; the film-forming agent B is a maleic anhydride grafted and modified polyethylene emulsion; the lubricating agent is the combination of aPEG lubricating agent and a mineral oil lubricating agent; the surfactant is the combination of microcrystalline wax emulsion and cationic polyacrylamide emulsion; and the antixodiant hypophosphite is hypophosphite. The invention also provides the application of the impregnating agent to production of alkali-free glass fiber for the LFT reinforced polypropylene. The glass fiber produced by the impregnating agent has a high interface bonding property, can be rapidly fused with polypropylene resin at high temperature, is high in dipping speed, has good processing property, high wear resistanceand little filoplume, and has a high dipping property, so that the production efficiency can be improved and the production cost can be reduced.

Owner:JUSHI GRP CO

Fiber-reinforced composite structure

InactiveUS20020102390A1Fast fillFast impregnationCellulosic plastic layered productsSuperstructure subunitsVacuum pressureHermetic seal

A fiber-reinforced composite structure has two molded outer polymeric layers spaced apart from each other and defining a cavity therebetween. Each molded outer polymeric layer defines a sealing surface extending about a periphery of the respective layer, and the opposing sealing surfaces cooperate to define a hermetic seal extending about a periphery of the cavity. One or more multi-directional fiber reinforcement layers are adhesively attached in a discontinuous manner to each outer polymeric layer, and define a first region of the cavity extending between each respective outer polymeric layer and adjacent fiber reinforcement layer, and a second region of the cavity extending between the fiber reinforcement layers. A core is located between the two outer polymeric layers, and is made of a resinous core material capable of exhibiting a foamed character and a resinous character. The resinous core material has a blowing agent activatable upon exposure to a predetermined vacuum pressure within the cavity to convert the core material within the second region of the cavity from a resinous character to a foamed character and thereby fill the second region of the cavity with the foamed core material. Each multi-directional fiber reinforcement layer is impregnated with the core material exhibiting a relatively dense, resinous character, and each first region of the cavity is substantially filled with the core material exhibiting a resinous character to fixedly secure the multi-directional fiber reinforcement layers to the outer polymeric layers. A structural insert, such as a rigid plate adapted to receive fasteners, is embedded within the core material for attaching other devices or structures thereto.

Owner:SABIC GLOBAL TECH BV

Electronic grade glass fiber cloth surface treating agent and method for producing glass fiber cloth

InactiveCN103422356AImprove heat resistanceStrong water resistanceFibre treatmentGlass fiberWater resistant

The invention discloses an electronic grade glass fiber cloth surface treating agent. The surface treating agent comprises the following ingredients, by weight, 0.3%-0.9% of silane coupling agents, 0.3%-0.8% of acidity regulators, and 0.1%-0.5% of surfactants, the balance being deionized water. The glass fiber cloth after treated by the electronic grade glass fiber cloth surface treating agent has good heat resistant performance, good water resistant performance and good wetting property, and has good combination with resins.

Owner:TAIJIA GLASS FIBER

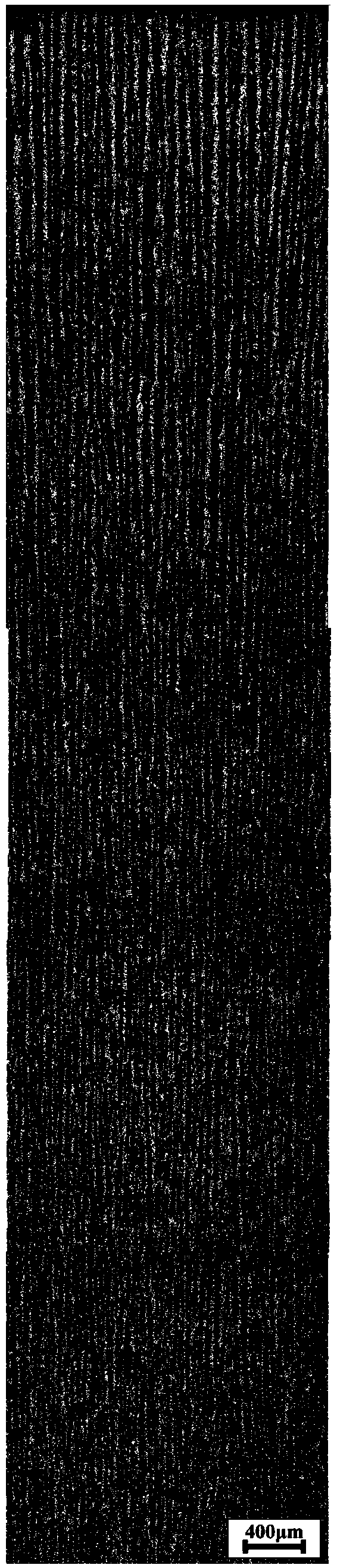

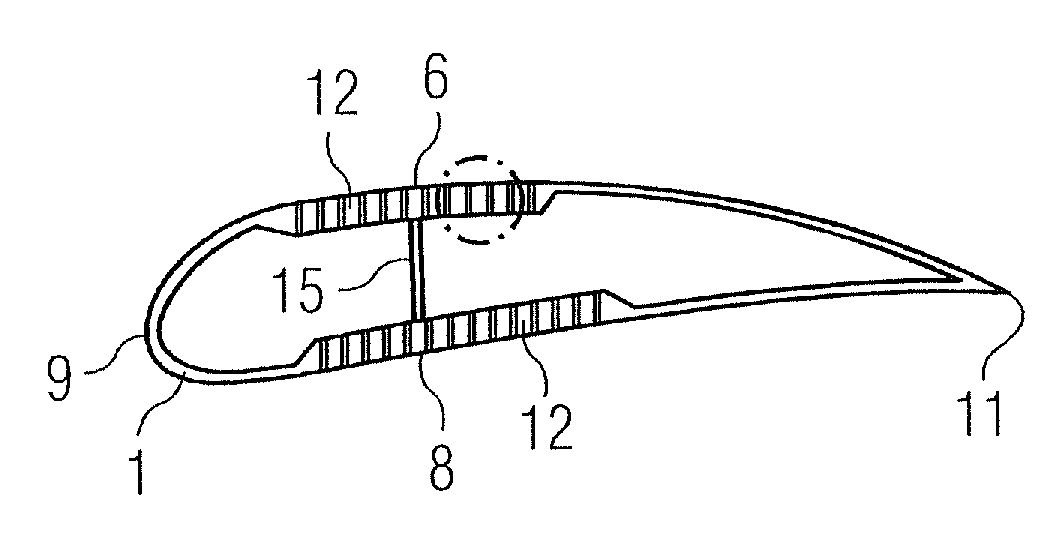

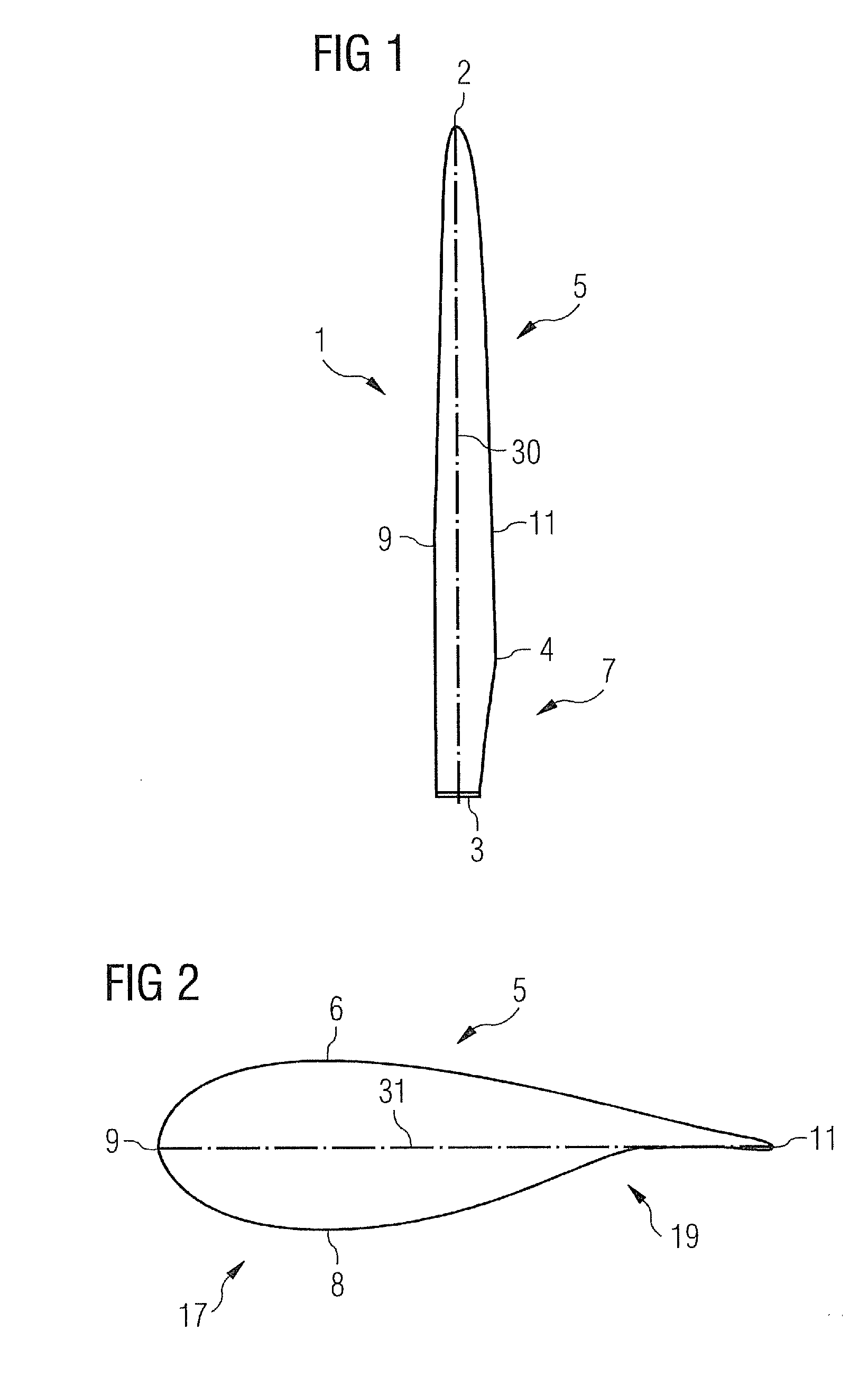

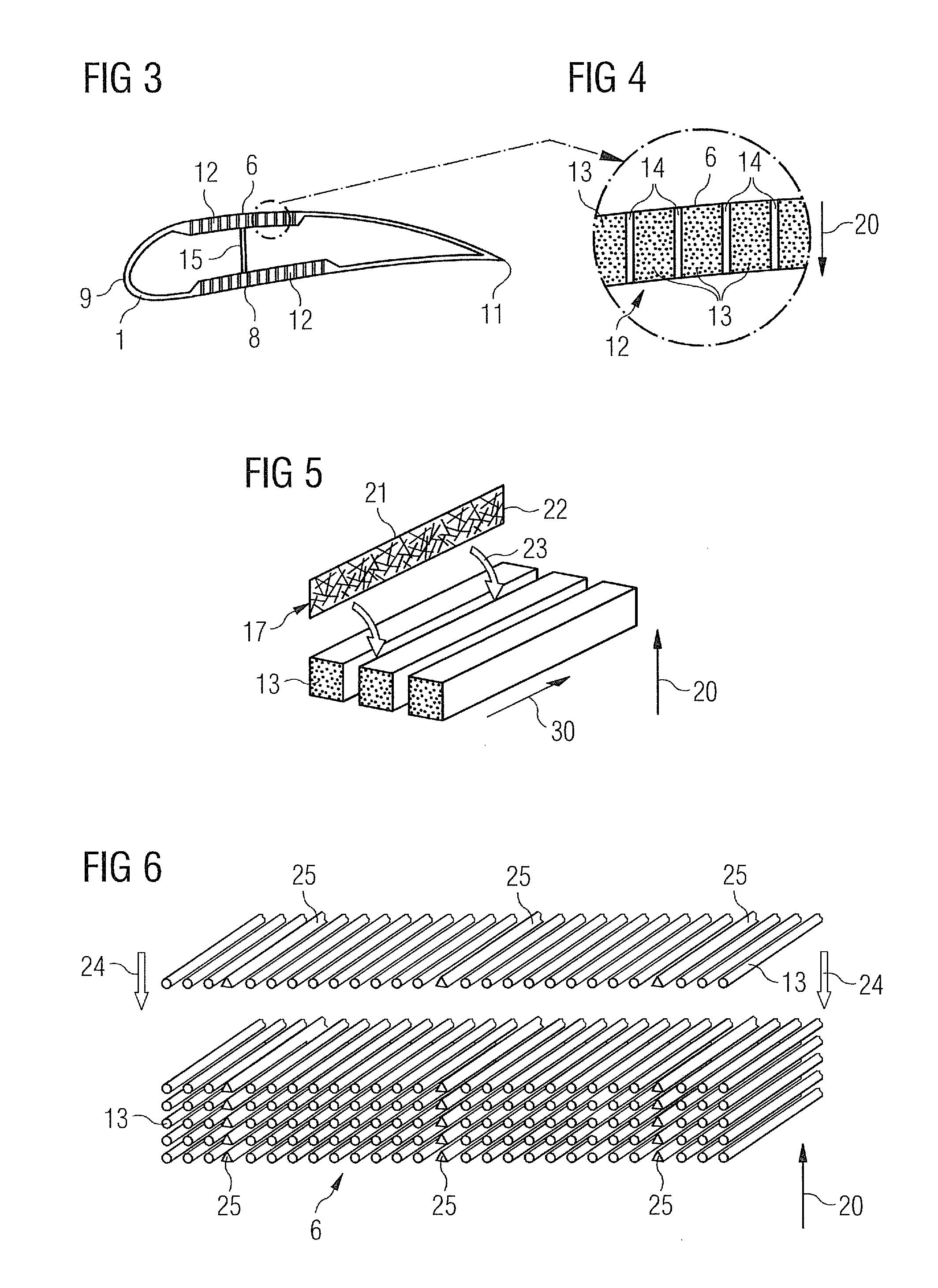

Method of manufacturing a wind turbine blade comprising steel wire reinforced matrix material

ActiveUS9181923B2Faster rateShorten the timeFinal product manufactureWood working apparatusTurbine bladePolymer

A method of manufacturing a shell construction part of a wind turbine blade, the shell construction part being made of a fibre reinforced polymer material including a polymer matrix and fibre reinforcement material embedded in the polymer matrix. The method comprises the steps of a) providing a forming structure comprising a mould cavity and having a longitudinal direction, b) placing the fibre reinforcement material in mould cavity, c) providing a resin in the mould cavity simultaneously with and / or subsequently to step b), and d) curing the resin in order to form the composite structure, wherein at least 20% by volume of the fibre reinforcement material consists of metallic wires.

Owner:LM GLASSFIBER

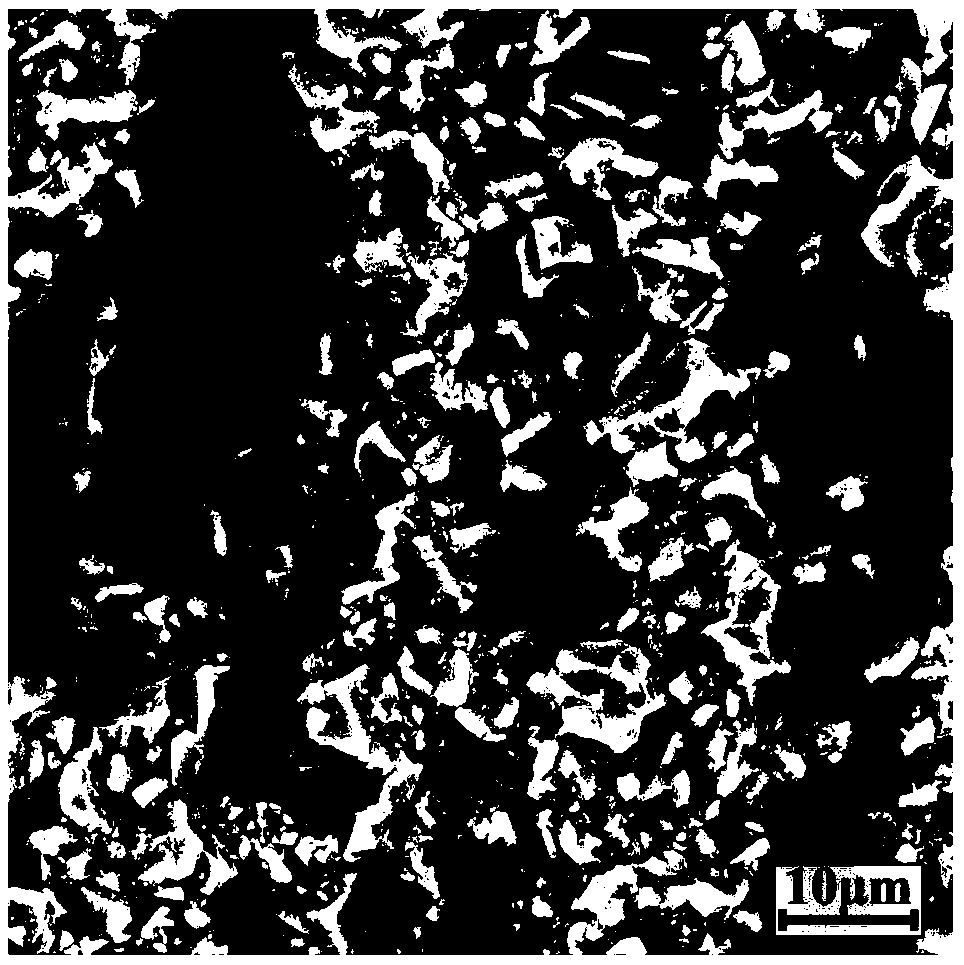

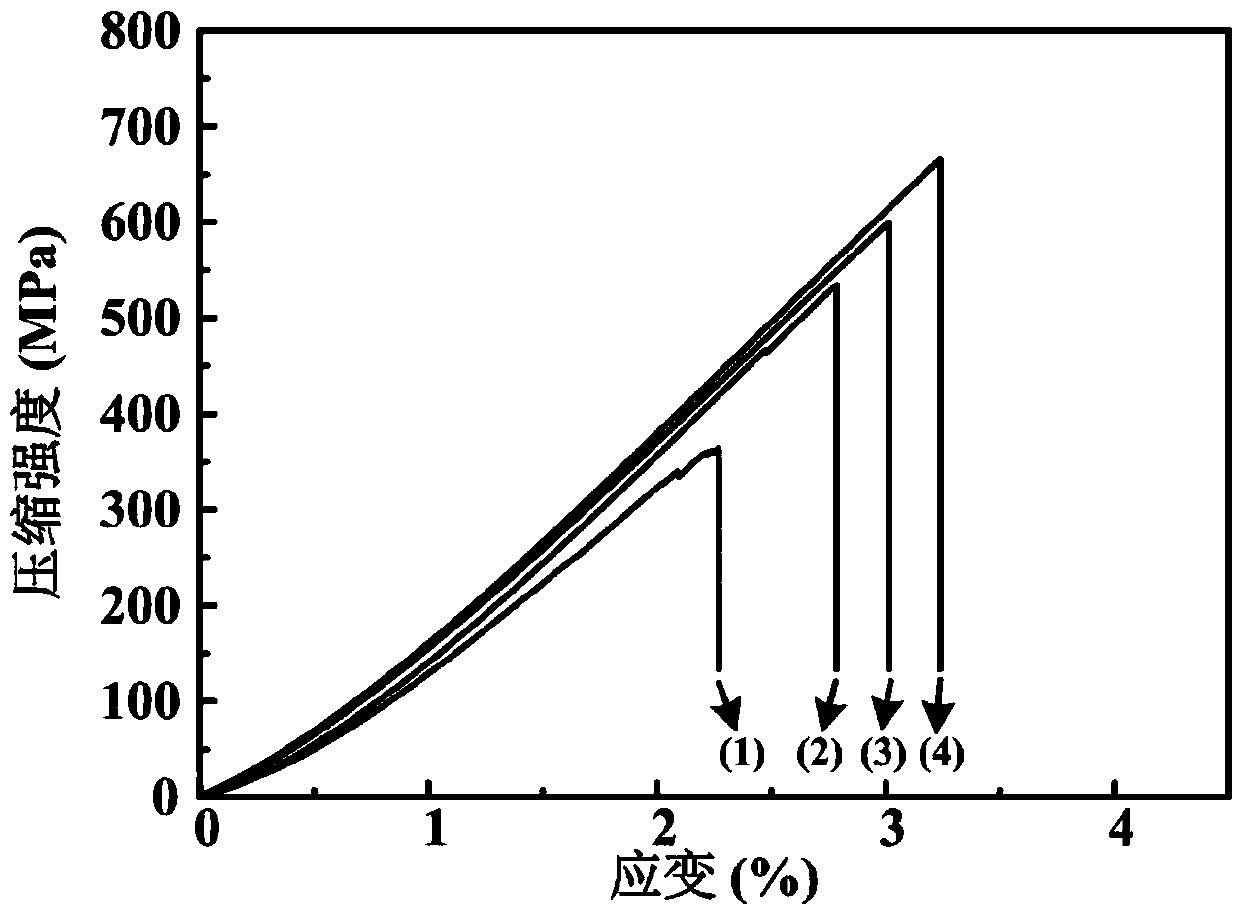

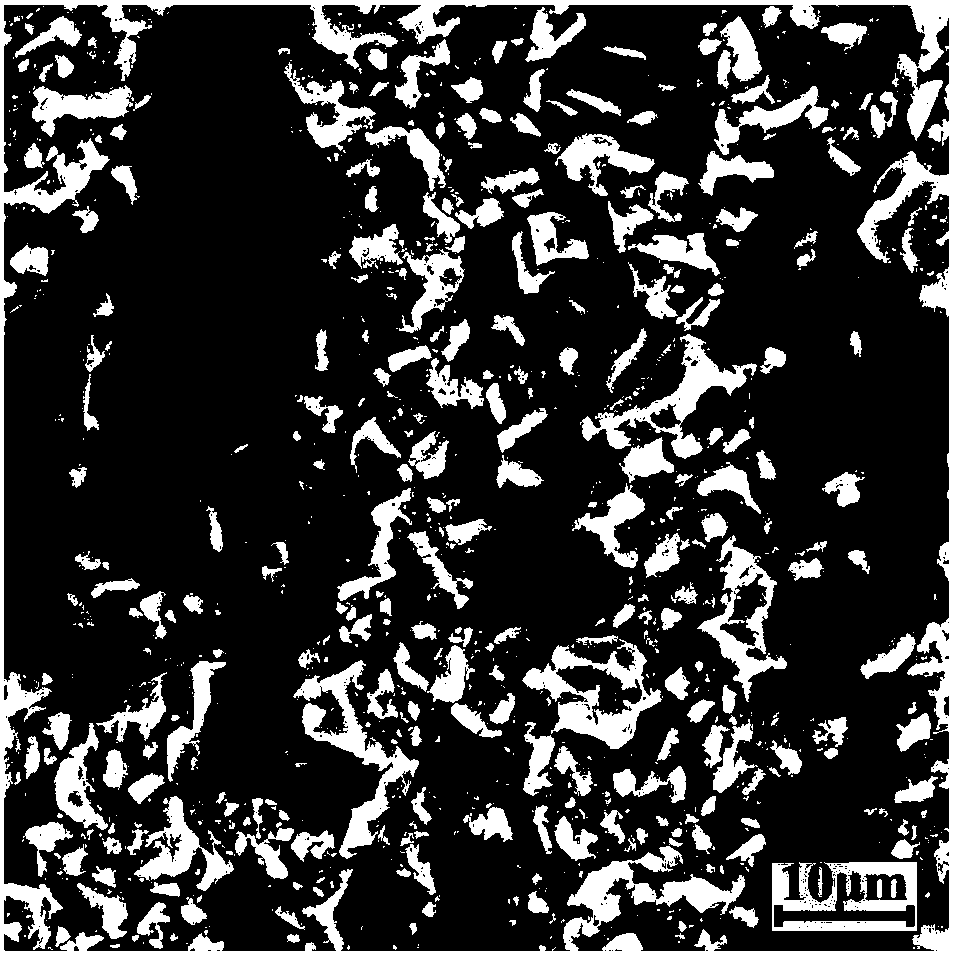

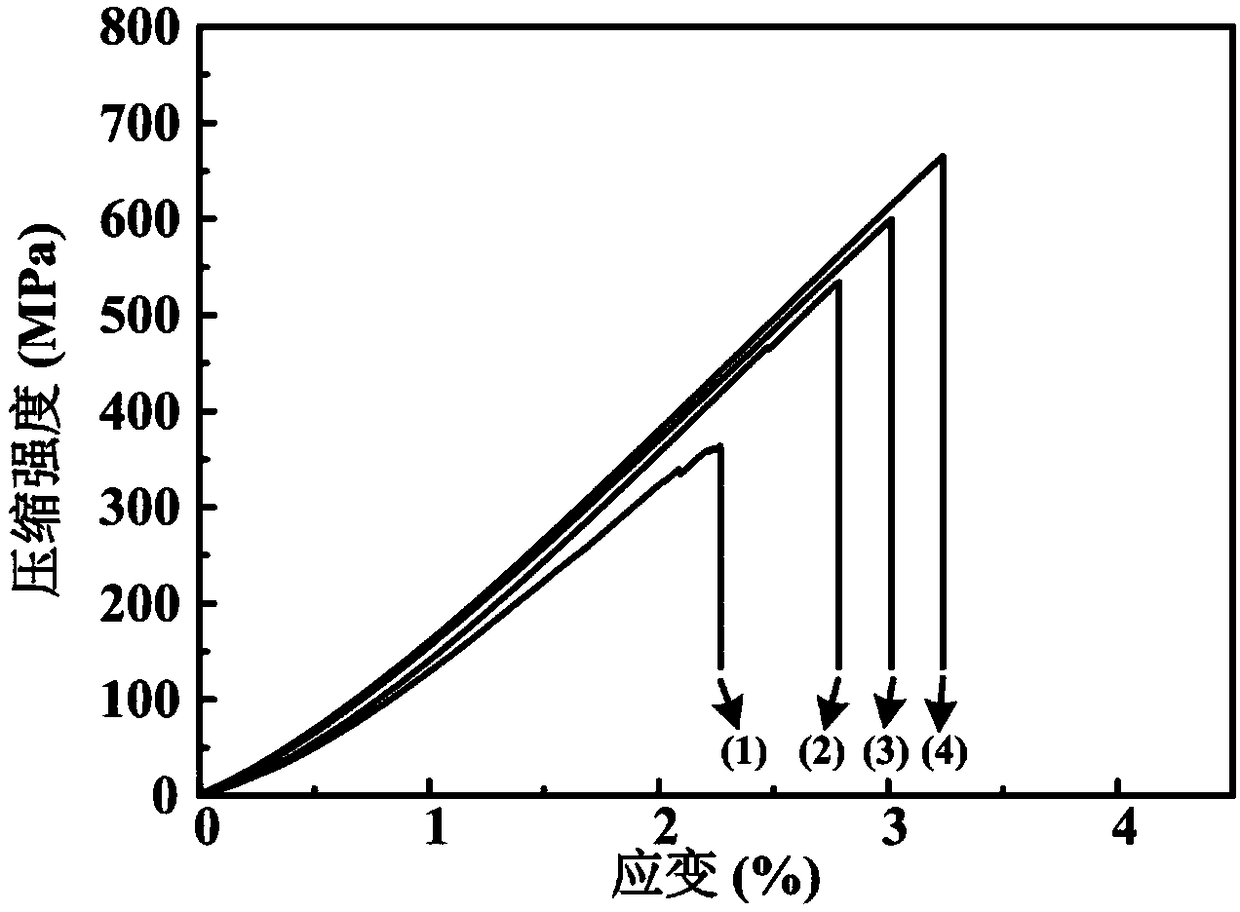

Mg alloy/Al2O3 composite and preparation method thereof

The invention relates to an Mg alloy / Al2O3 composite light in weight and high in strength, in particular to an Mg alloy / Al2O3 composite and a preparation method thereof. The Mg alloy / Al2O3 composite is composed of a lamellar structure Al2O3 substrate prepared by an ice template method and Mg alloy composited in lamellar spacing of the substrate by impregnation, and is obtained by soaking in a silica sol a lamellar structure Al2O3 base made by ice template oriented solidification so that nano SiO2 covers the surface of Al2O3 lamellas, and carrying Mg alloy impregnation in Ar atmosphere. This composite has high specific strength and has compressive strength up to 697 MPa when its density is 2.57 g / cm<3>.

Owner:JILIN UNIV

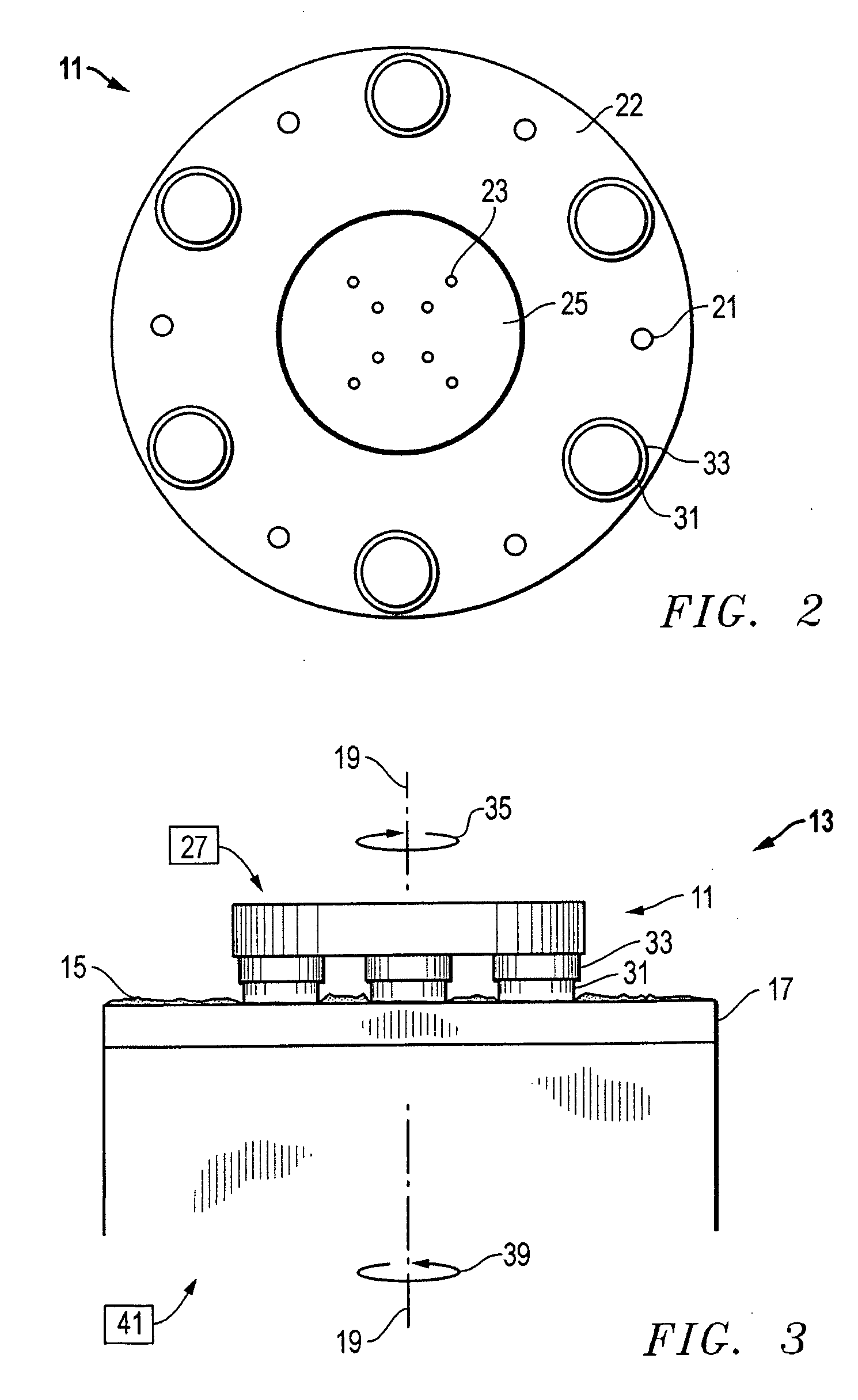

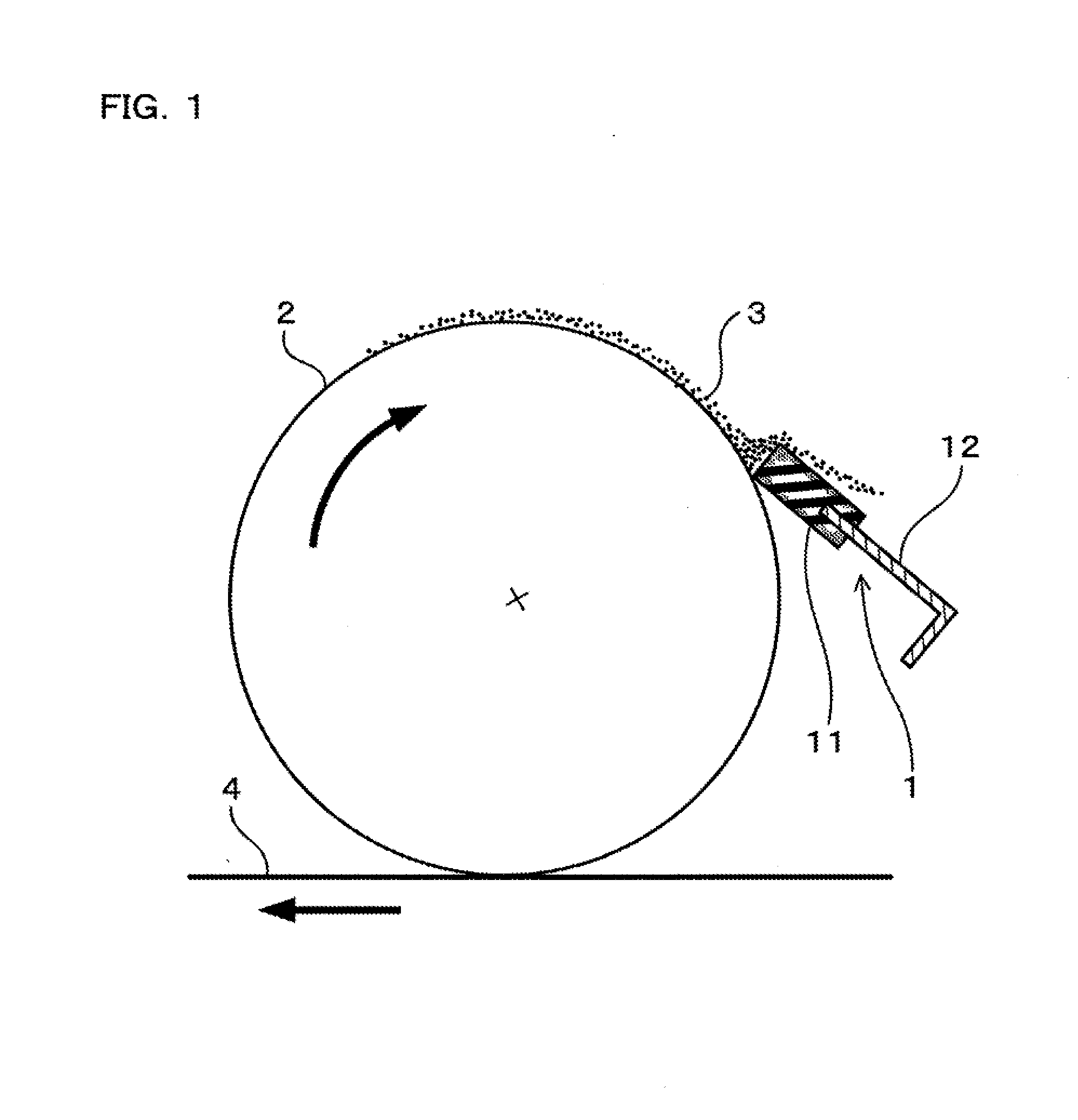

System, method, and apparatus for non-traditional kinematics/tooling for efficient charging of lapping plates

InactiveUS20050176351A1Fast impregnationEfficiently usLapping machinesPlane surface grinding machinesKinematicsHigh pressure

A system for charging lapping plates incorporates the use of individual ceramic inserts that are mounted into a stainless steel frame to form a novel charging tool. The charging tool is rotated clockwise against a counterclockwise rotating tin plate. This configuration performs a rapid diamond impregnation into the plate without scraping off the diamond slurry from the plate. This design uses the diamond material in the plate charging slurry very efficiently. The inserts may be formed from high density ceramic in a round or cylindrical pad-like design. This design allows high pressure contact between the inserts and the tin plate. As a result, the amount of time required to charge a plate is greatly reduced and only a small fraction of the diamond slurry is wasted, thereby producing a higher yield than prior art systems.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Method for manufacturing a work piece by vacuum assisted resin transfer moulding

InactiveUS20120263600A1Reduce manufacturing costLow costFinal product manufactureLayered productsFiberVacuum assisted

A method for manufacturing a work piece by Vacuum Assisted Resin Transfer Moulding is includes the steps of placing fibre rovings in a mould of a closed mould system which comprises a mould cavity, placing at least one resin distribution device between the fibre rovings, and applying vacuum to the closed mould system and injecting resin into the mould cavity.

Owner:SIEMENS AG

Block metal composite and its prepartion method

InactiveCN1480551ANo moisture problemsReduce chemical reactionsHigh volume manufacturingMetallic materials

A composite metal block is prepared from the powdered material with high smelting point and the metallic material with lower smelting point through loading them in an infiltration container, putting the container in heater, vacuumizing while preheating, heating untile the temp is higher than the smelting point of metallic material bue lower than the smelting point of powdered material for smelting the metallic material to become liquid, holding the temp while pressurizing, and cooling. Its advantages are high infiltration speed, high uniformity, and large size of product.

Owner:周照耀

Preparation method of silica airgel composite material reinforced by silicon carbide fiber mat

The invention relates to a preparation method of a silicon-carbide-fibrofelt-enhanced silica aerogel composite material, and relates to an aerogel composite material. According to the invention, a carbon-rich silicon carbide micro-nano ceramic fibrofelt with small fiber diameter, high porosity, communicating pores, fast impregnation speed, and good compatibility with a substrate is prepared with a static electro-spinning technology combined with a precursor conversion method; a silica sol is prepared with an acid-alkali two-step method; with an infiltration technology, the electro-spun silicon carbide ceramic fibrofelt or precast is soaked into the sol; and through processes such as gel process, aging, curing, solvent exchange, supercritical drying, and the like, the silicon-carbide-fibrofelt-enhanced silica aerogel composite material is obtained. The prepared composite material has the characteristics of low density, large specific surface area, super-hydrophobicity, low thermal conductivity, and the like. The strength and toughness of the material are also greatly improved. The carbon-rich silicon carbide fiber has an infrared shielding effect, such that composite material thermal insulation effect and ultra-high-temperature stability can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

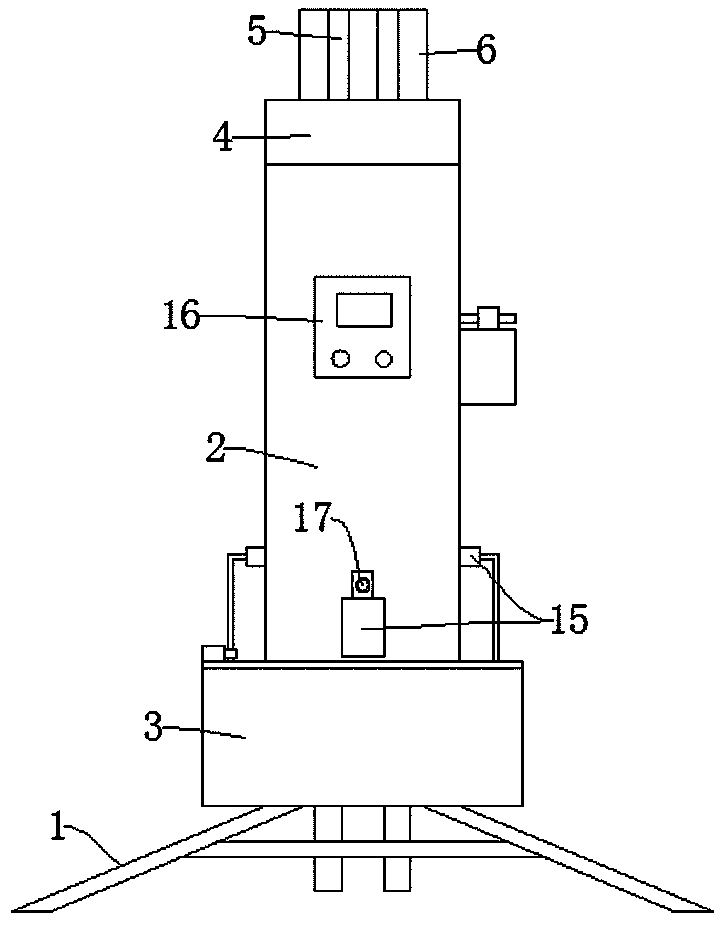

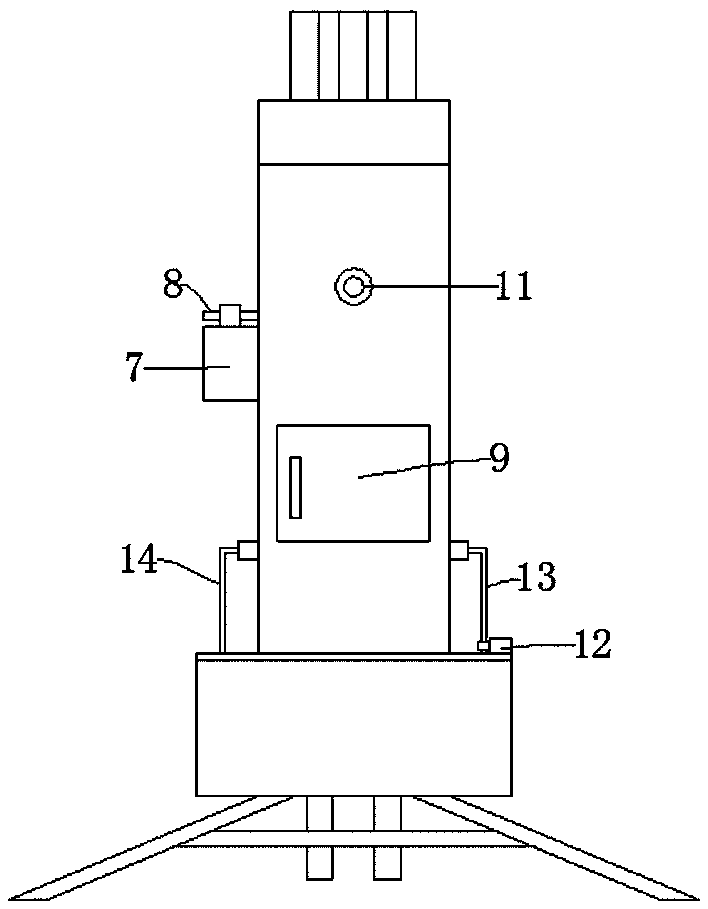

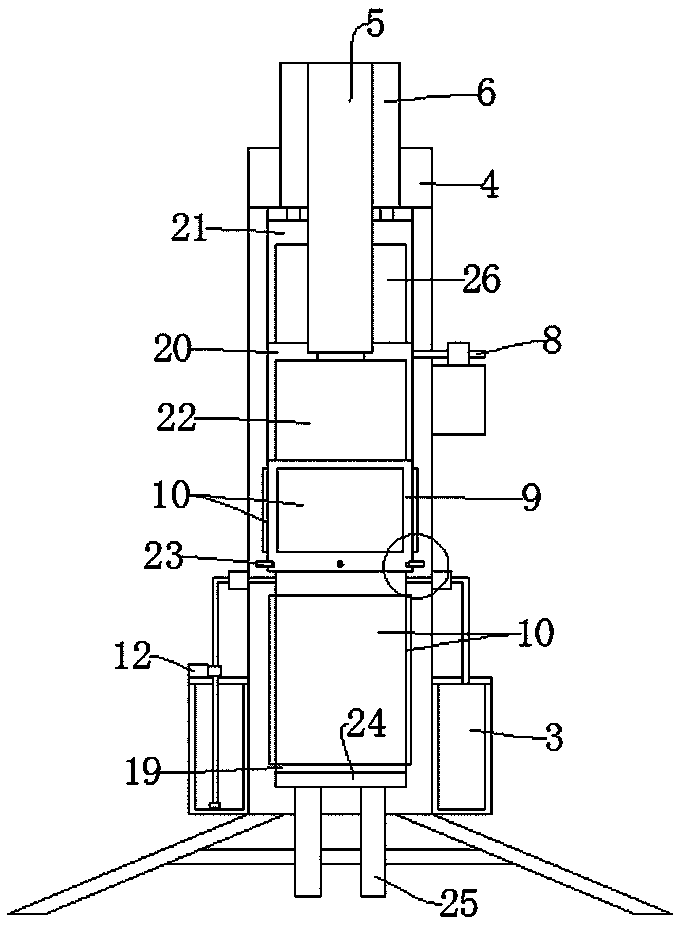

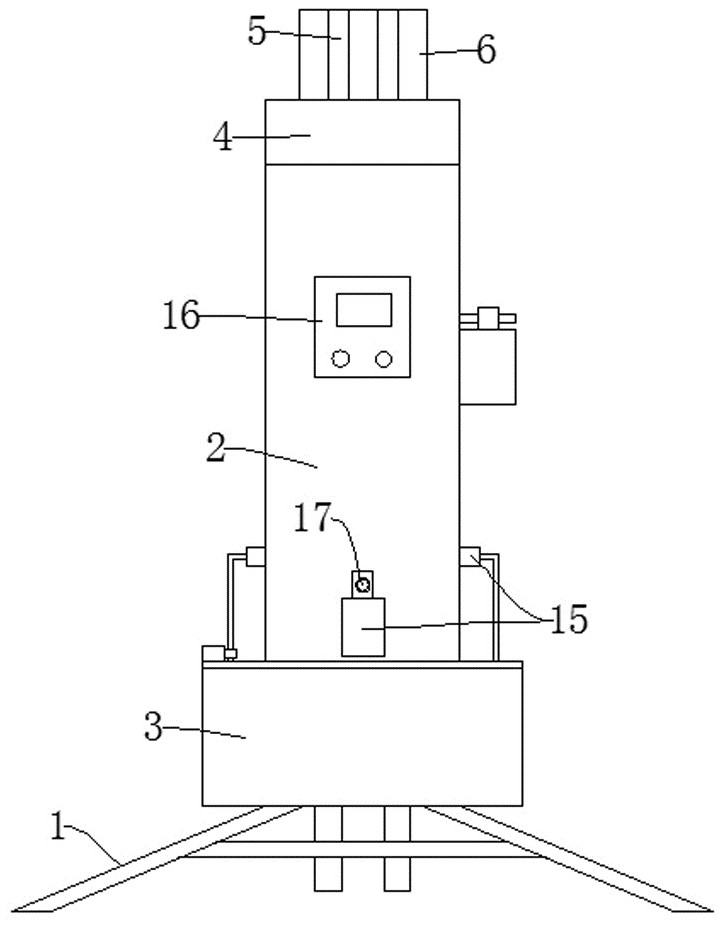

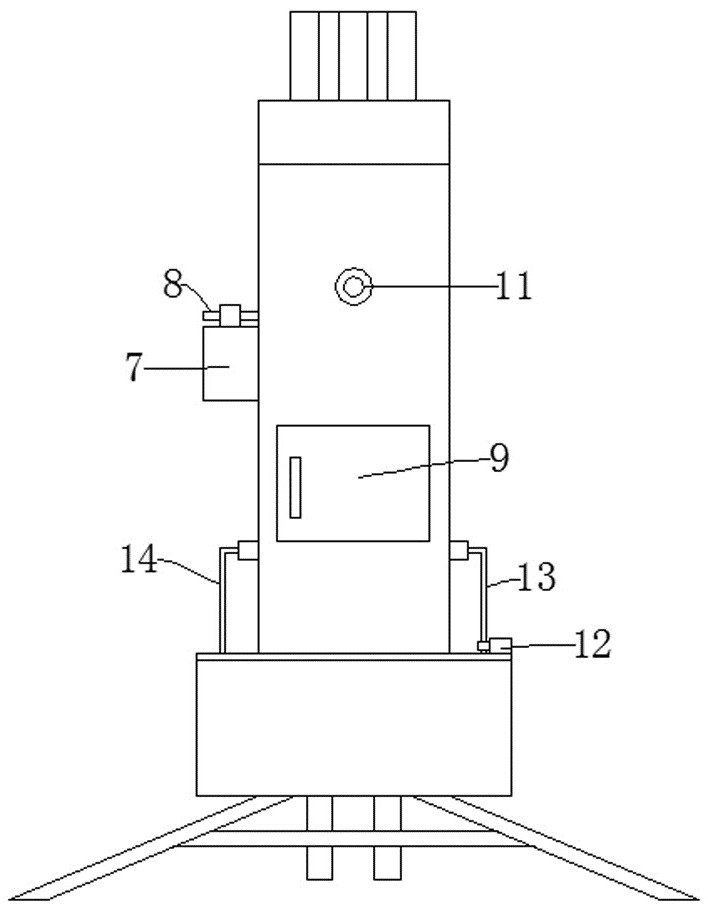

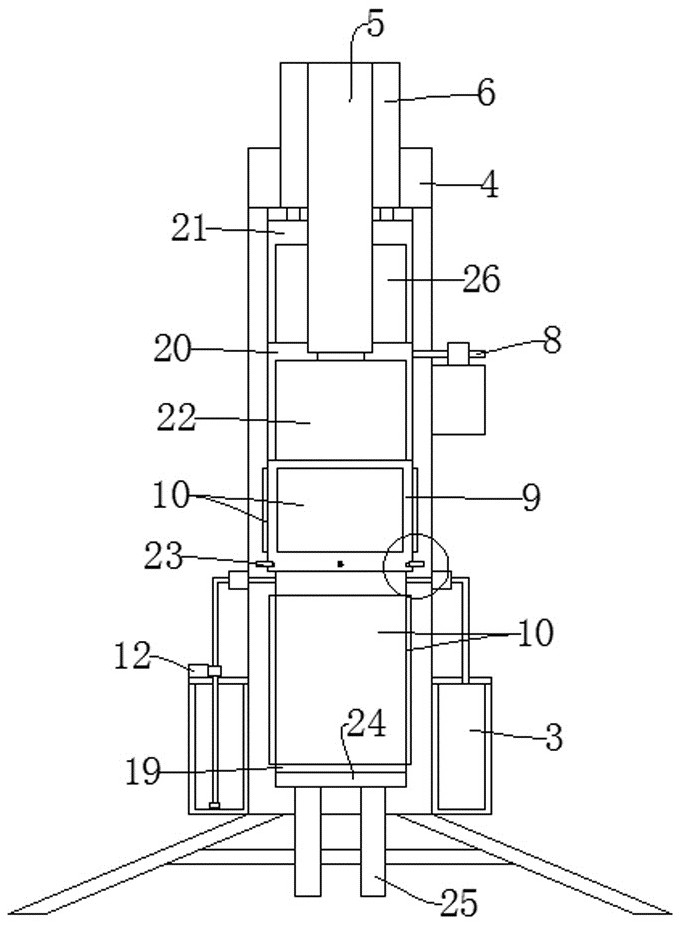

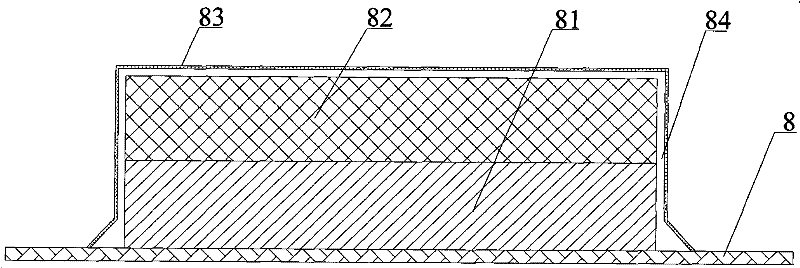

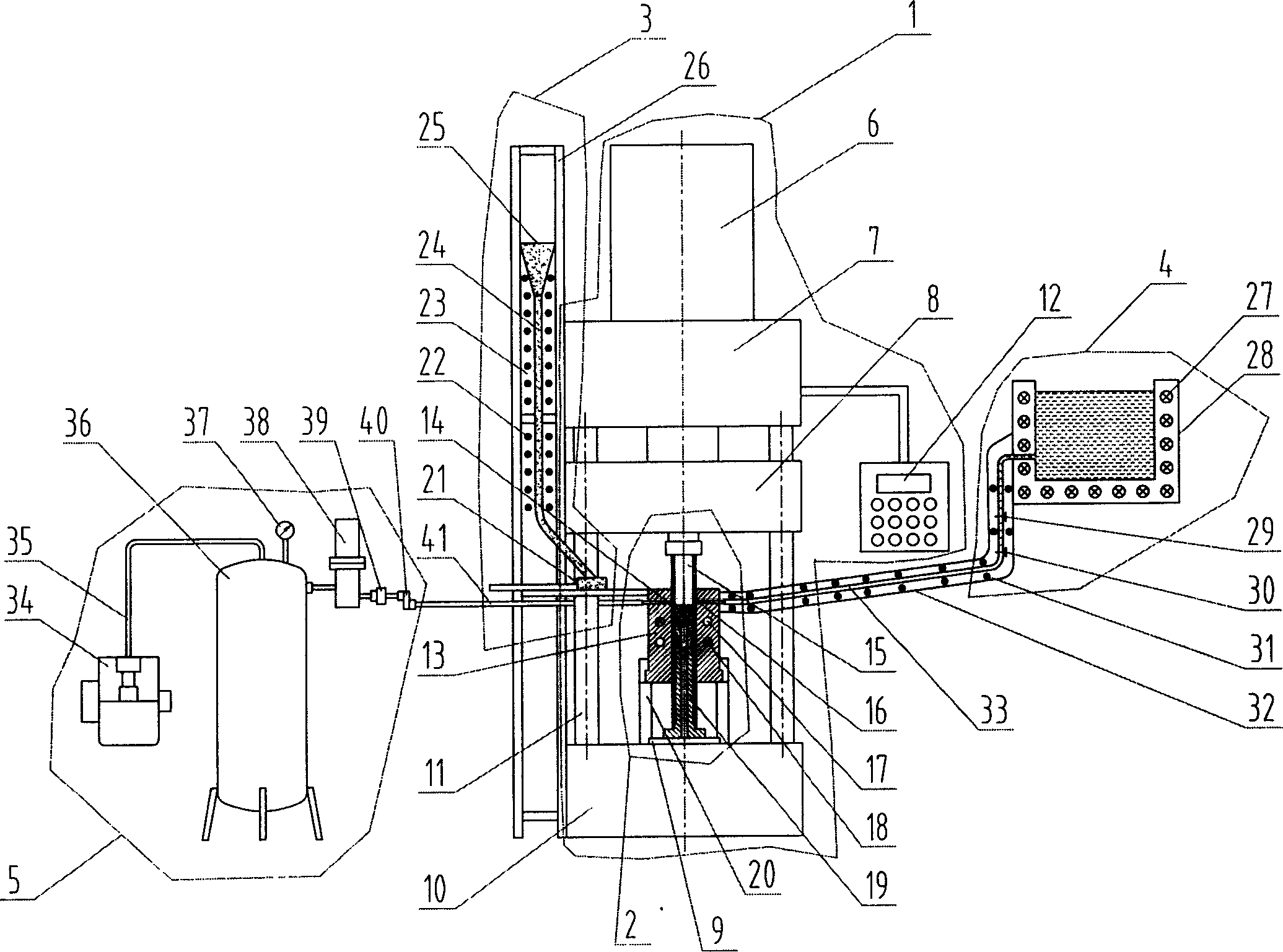

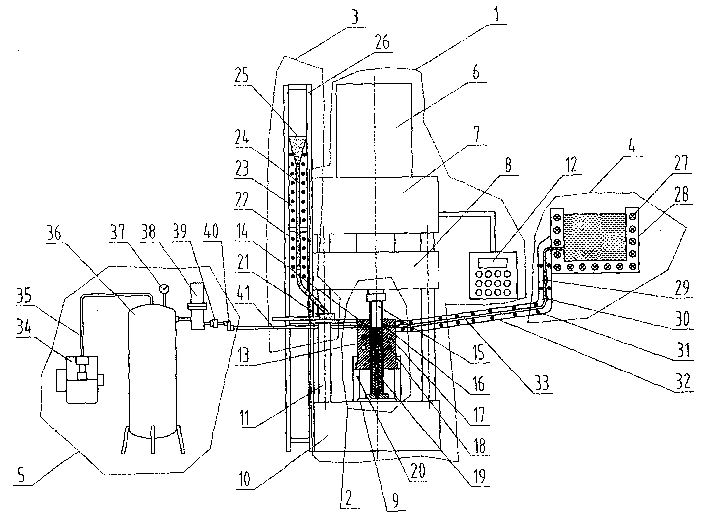

Ultra-high power graphite electrode pressing device with dipping function, and pressing method thereof

ActiveCN109454917AIncrease productivityImprove efficiencyShaping pressGraphite electrodeLiquid storage tank

The invention discloses an ultra-high power graphite electrode pressing device with a dipping function. The ultra-high power graphite electrode pressing device with the dipping function comprises a base, wherein a pressing tank and a liquid storage tank are fixedly arranged on the base; a sealed cap is fastened to the upper end of the pressing tank in a sealing way; an electric-hydraulic push rodI and multiple electric-hydraulic push rods II distributed circumferentially by adopting the electric-hydraulic push rod I as the center are vertically and fixedly arranged on the sealed cap; the pressing tank is internally divided into a dipping chamber on the upper part and a pressing chamber on the lower part; and the inner diameter of the pressing chamber is smaller than the inner diameter ofthe dipping chamber. The ultra-high power graphite electrode pressing device with the dipping function has the beneficial effects that an ultra-high power graphite electrode block blank can be pressedand dipped in the pressing device, so that the trouble of conveying the block blank is saved, the production time is saved, the production efficiency of an ultra-high power graphite electrode is improved, the steps of the pressing and dipping processes are less, the pressing and dipping speed is fast, the efficiency is high, and the practicability is good.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

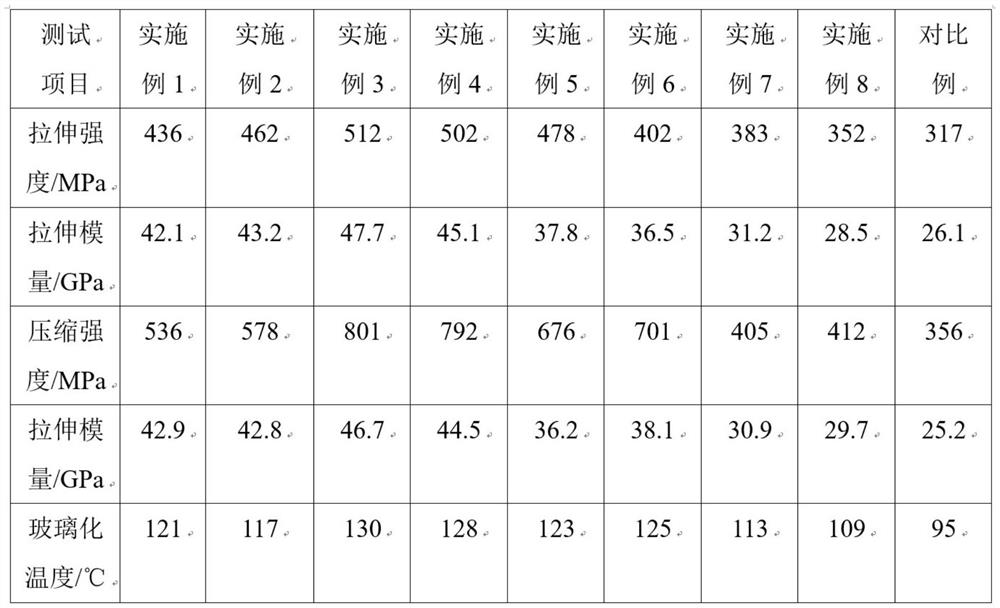

Epoxy resin composition capable of being rapidly cured at medium and low temperatures, epoxy resin-based composite material and preparation method thereof

ActiveCN113292819AFast medium and low temperature curing speedHigh glass transition temperaturePolymer scienceFirming agent

The invention provides an epoxy resin composition capable of being rapidly cured at medium and low temperatures, an epoxy resin-based composite material and a preparation method thereof. The epoxy resin composition capable of being rapidly cured at medium and low temperatures comprises the following components in parts by weight: 100 parts of epoxy resin, 0.1-5 parts of an imidazole accelerant, 2-40 parts of filler, 30-200 parts of an anhydride curing agent, 1-40 parts of a toughening agent and 0.5-10 parts of a release agent. According to the epoxy resin composition capable of being rapidly cured at medium and low temperatures, the epoxy resin-based composite material and the preparation method of the epoxy resin-based composite material, the medium and low temperature curing time of the epoxy resin-based composite material can be obviously shortened through cooperation of the anhydride curing agent, the imidazole accelerant and other raw materials in the epoxy resin composition; meanwhile, the pultrusion speed of the composite material in a pultrusion process is remarkably improved, and the composite material is excellent in mechanical property and high in glass transition temperature.

Owner:北玻院(滕州)复合材料有限公司

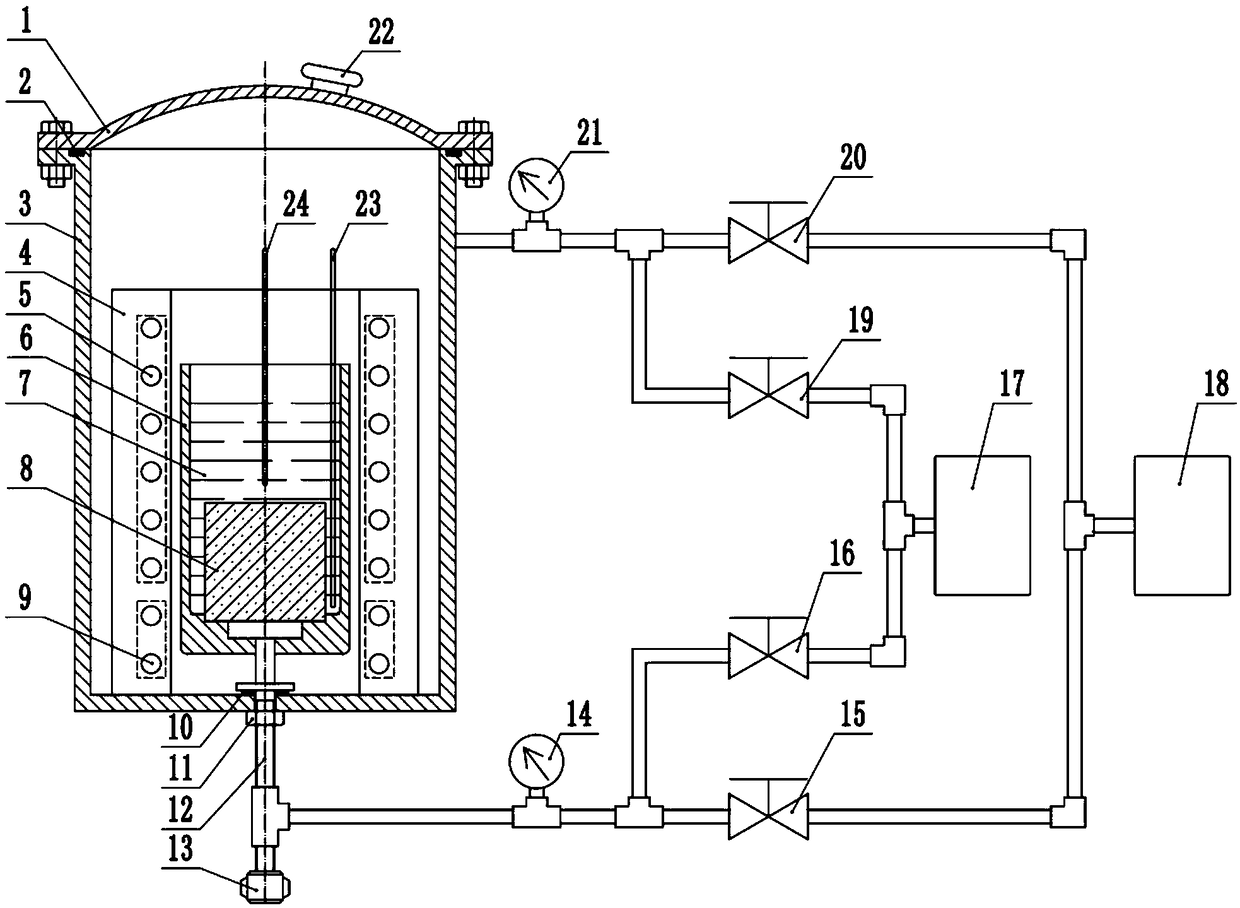

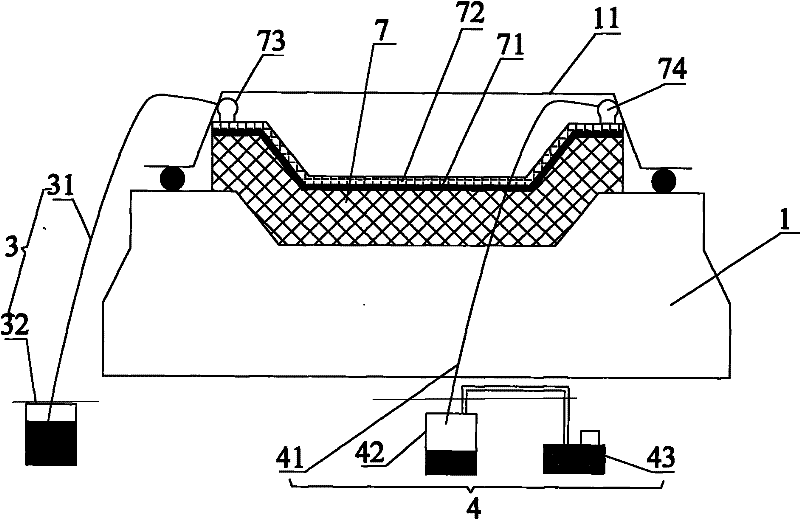

Preparation device and preparation method for pressure infiltration-negative pressure adsorption combined metal-matrix composite material

InactiveCN109396399ALow infiltration pressureFast impregnationMetal matrix compositeMaterials science

The invention discloses a preparation device and a preparation method for a pressure infiltration-negative pressure adsorption combined metal-matrix composite material, and belongs to the field of metal-matrix composite materials. The invention aims at the problems of low infiltration speed and difficulty to prepare a metal-matrix composite material with uniform reinforcement phase distribution due to low wettability of many matrix metals (such as aluminum alloy), when the metal-matrix composite material is prepared through a pressure infiltration method, and designs a preparation device and apreparation method for a pressure infiltration-negative pressure adsorption combined metal-matrix composite material. The preparation device and the preparation method are capable of realizing the simultaneous progress of low-pressure infiltration and negative-pressure adsorption, and the metal-matrix composite material with the uniform reinforcement phase distribution is prepared.

Owner:JILIN UNIV

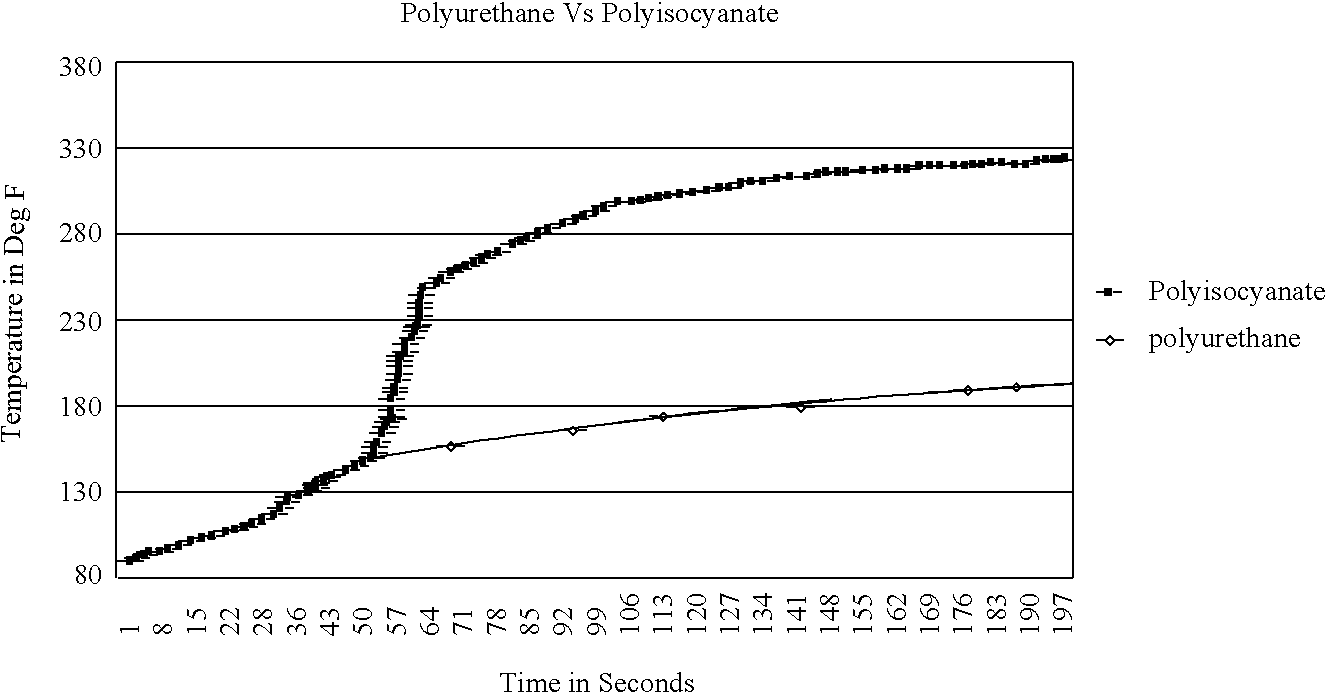

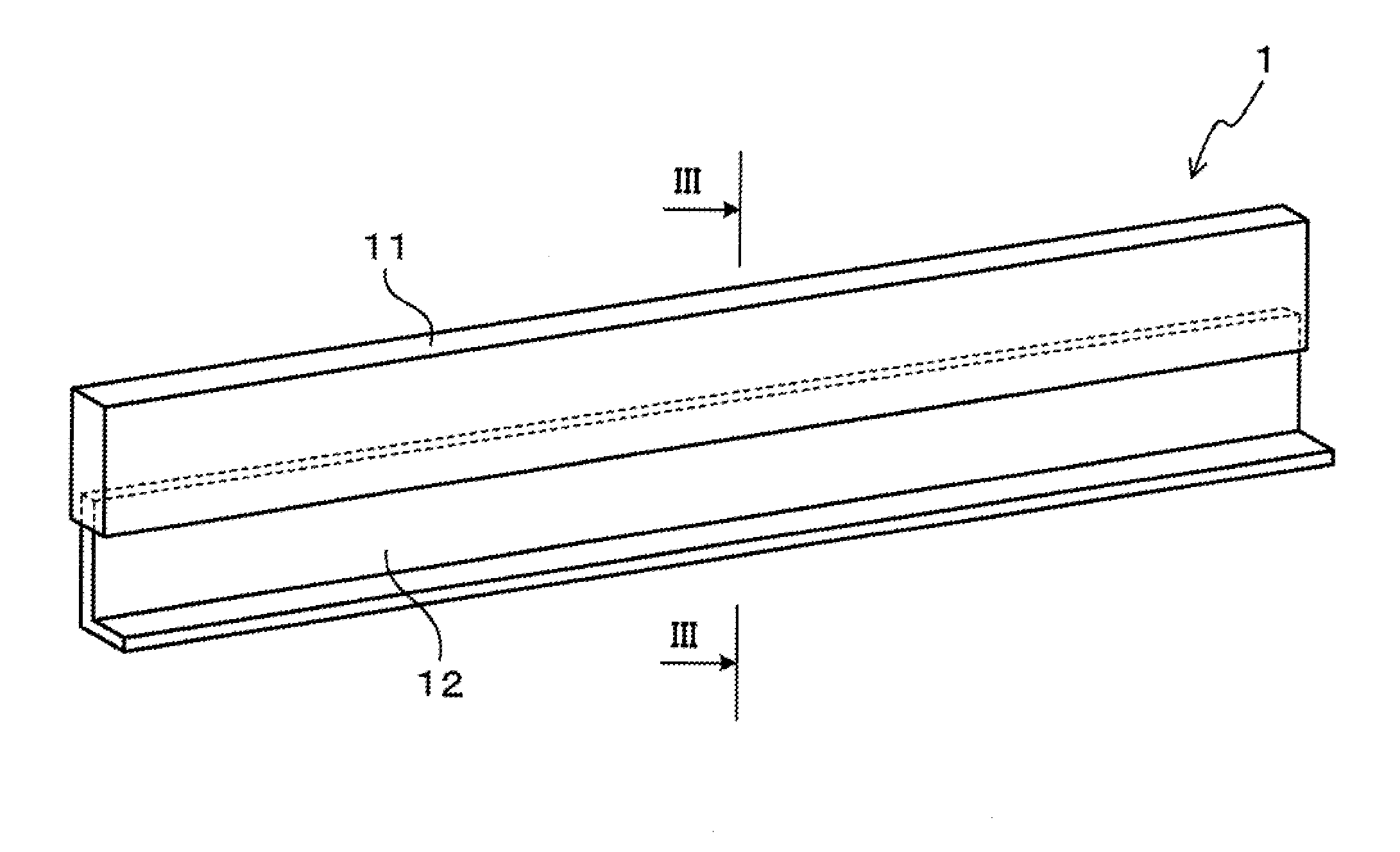

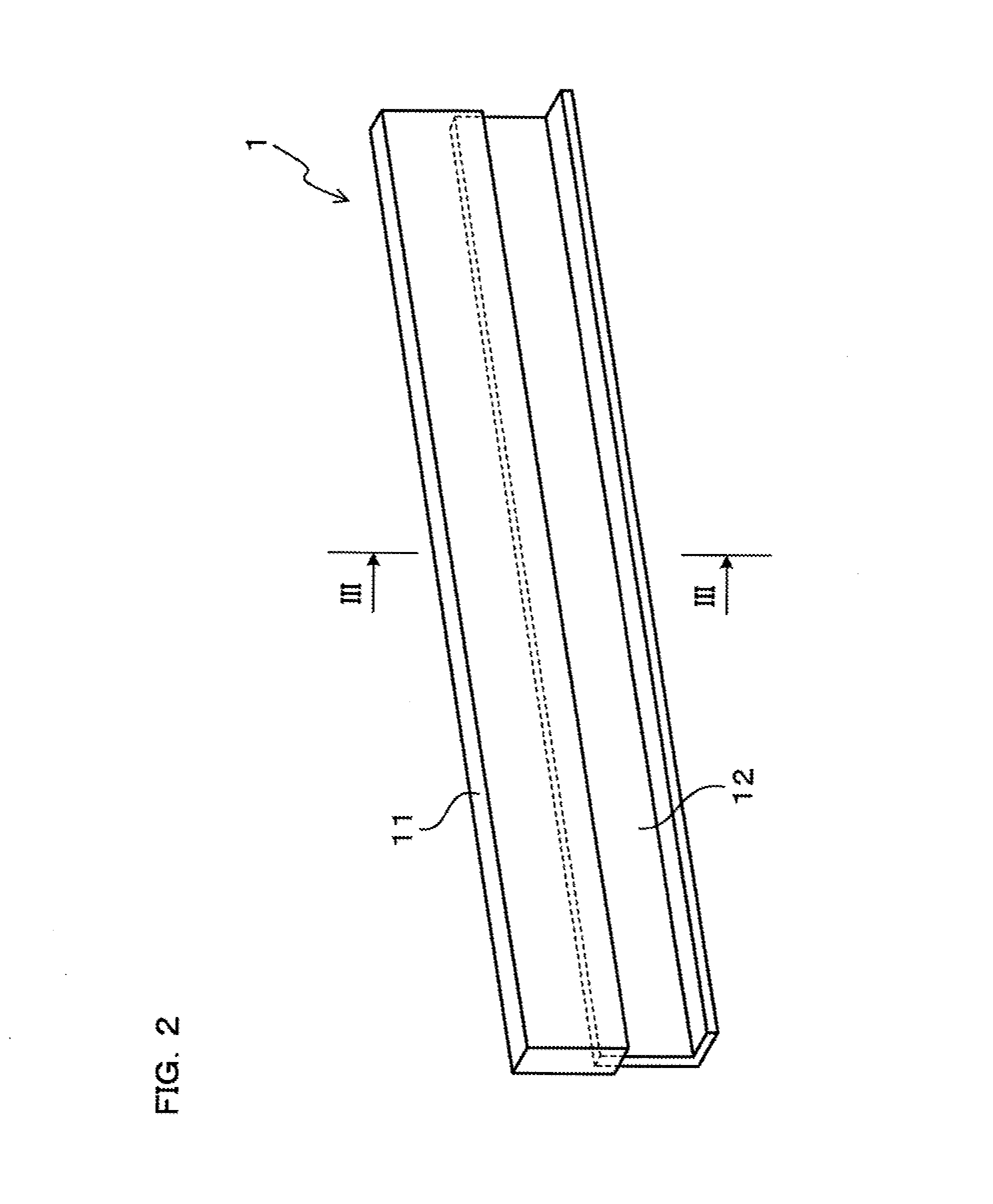

Method for producing blade member

ActiveUS20160297989A1Avoid PolymerizationEasy to usePolyurea/polyurethane coatingsElectrography/magnetographyChemistryIsocyanate compound

A method for producing a blade member 1 includes an impregnation step of impregnating at least a portion of a surface of a blade portion 11 made of a polyurethane rubber with a surface treatment liquid that includes a salt of diazabicycloundecene and a carbodiimide-modified polyvalent isocyanate compound including a carbodiimide-modified polyvalent isocyanate dimer and a carbodiimide-modified polyvalent isocyanate trimer or higher multimer, in which a content of the trimer or higher multimer is 50% by mass or less, and a cured layer formation step of heating and curing the carbodiimide-modified polyvalent isocyanate compound which is impregnated into the blade portion 11, to form a cured layer 110.

Owner:SUMITOMO RIKO CO LTD

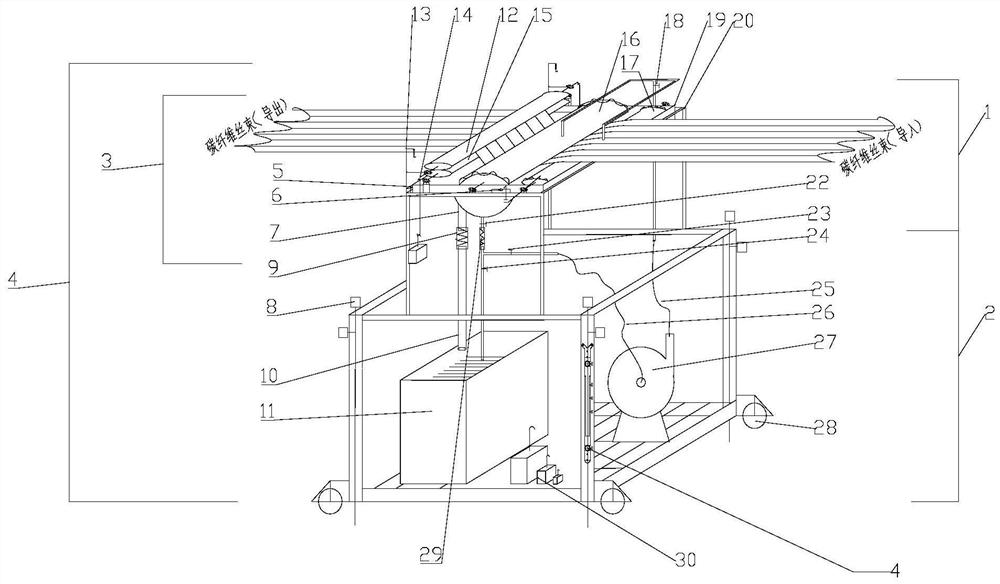

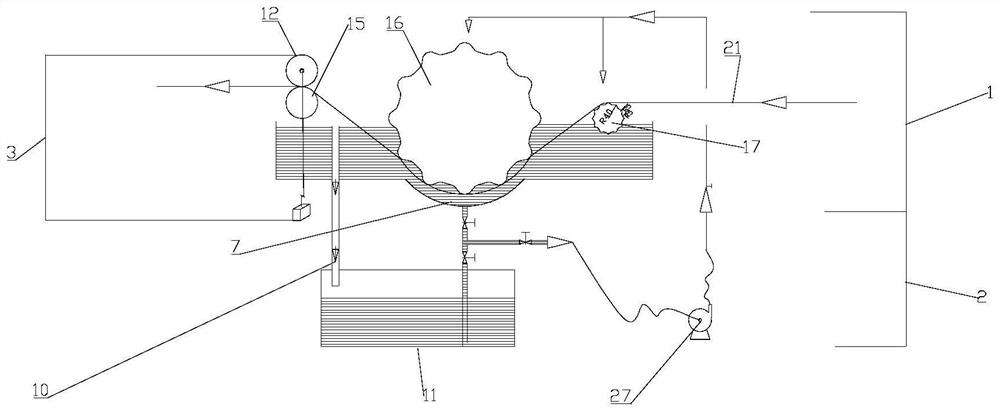

Industrial sizing device for carbon fibers

PendingCN113046955ASmooth operation spaceDevice stableTextile treatment containersTextile treatment machine arrangementsCarbon fibersElectrical energy consumption

The invention discloses an industrial sizing device for carbon fibers. The industrial sizing device comprises a sizing system, a slurry supply system, a slurry control system and a movable and fixed base frame system, The device can be conveniently grafted to an industrial production line, and sizing production and test of various novel sizing agents and carbon fibers with various sizing rates are realized. By using the industrial sizing device for sizing carbon fibers, the spreading and expanding efficiency of carbon fiber tows is high, the impregnating speed of the sizing agent is high, sizing is uniform, the net-shaped dividing performance of monofilaments is good, and no electric energy is consumed and no waste sizing agent is discharged in a whole sizing production process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ceria and strontium titanate based electrodes

InactiveUS8945793B2Improve electrochemical activityLower resistanceFuel cells groupingActive material electrodesStrontium titanium oxideNiobium

A ceramic anode structure obtainable by a process comprising the steps of: (a) providing a slurry by dispersing a powder of an electronically conductive phase and by adding a binder to the dispersion, in which said powder is selected from the group consisting of niobium-doped strontium titanate, vanadium-doped strontium titanate, tantalum-doped strontium titanate, and mixtures thereof, (b) sintering the slurry of step (a), (c) providing a precursor solution of ceria, said solution containing a solvent and a surfactant, (d) impregnating the resulting sintered structure of step (b) with the precursor solution of step (c), (e) subjecting the resulting structure of step (d) to calcination, and (f) conducting steps (d)-(e) at least once.

Owner:DANMARKS TEKNISKE UNIV

mg alloy/al2o3 composite material and preparation method

Owner:JILIN UNIV

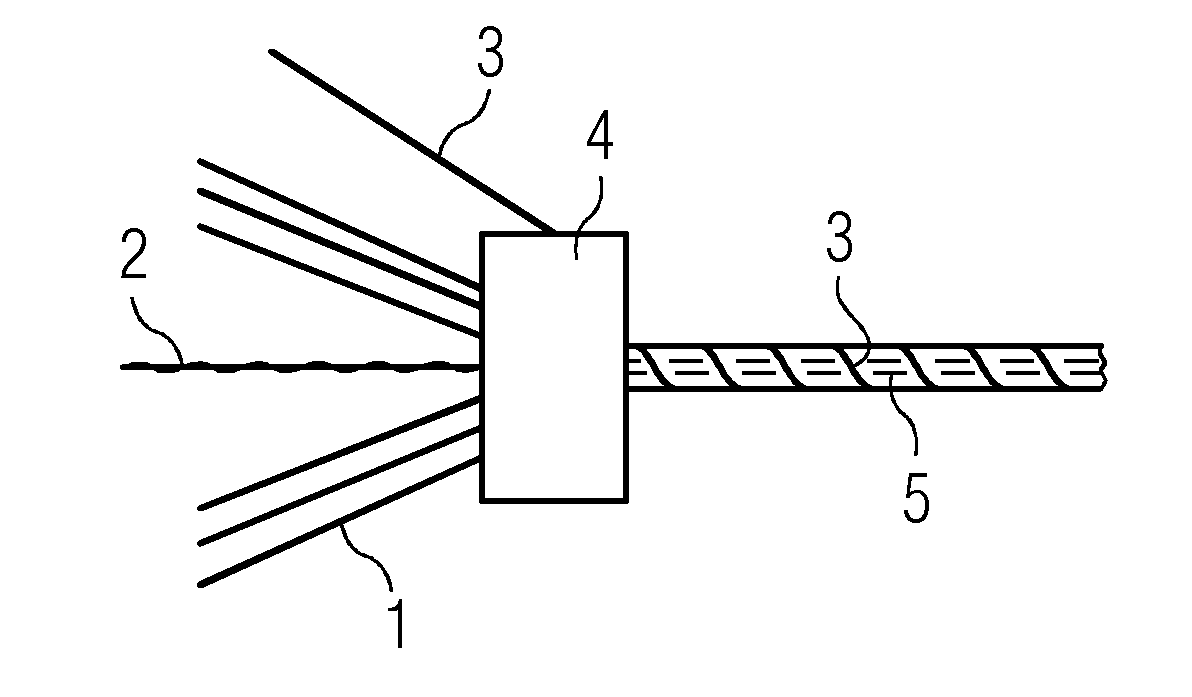

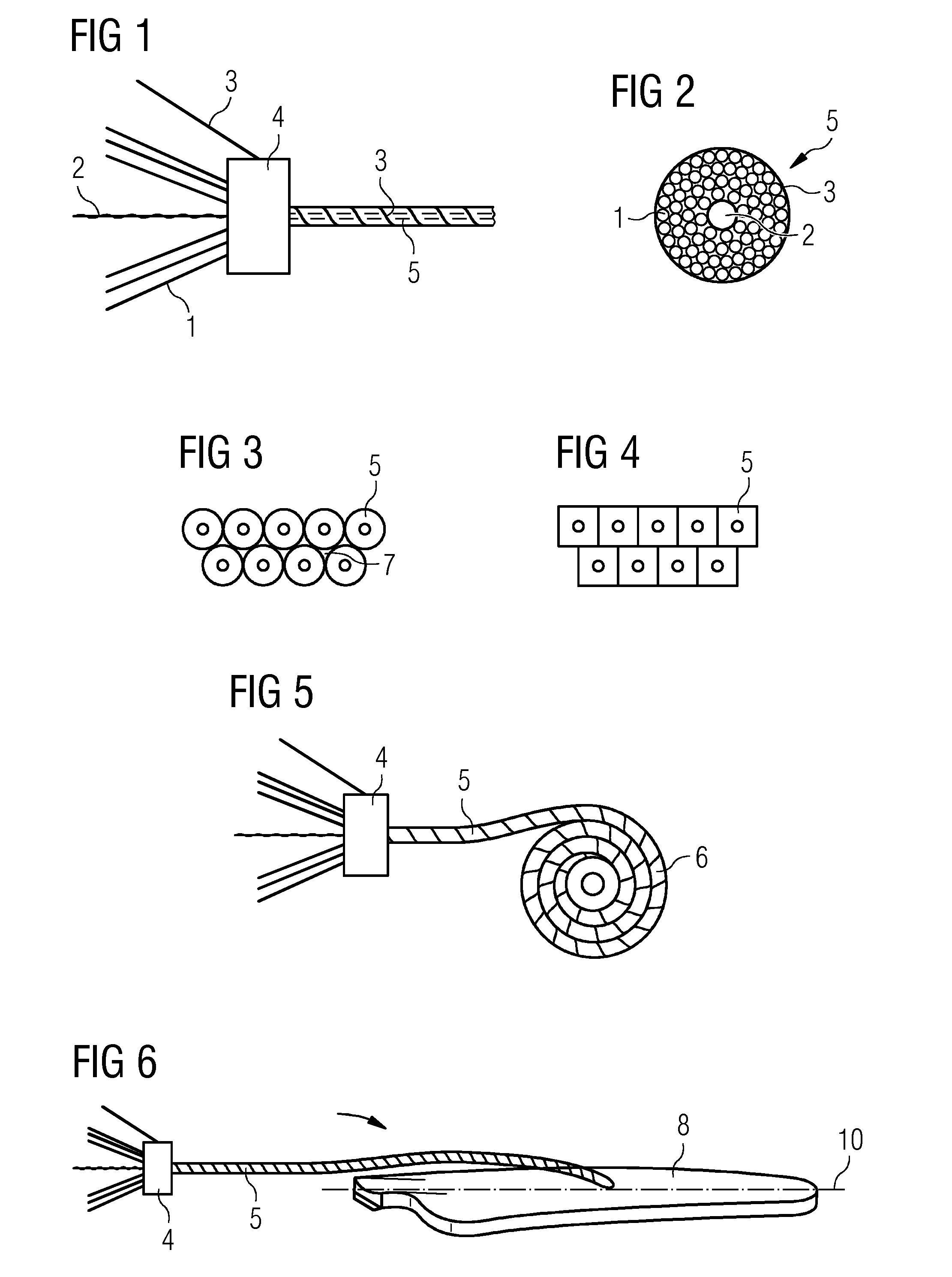

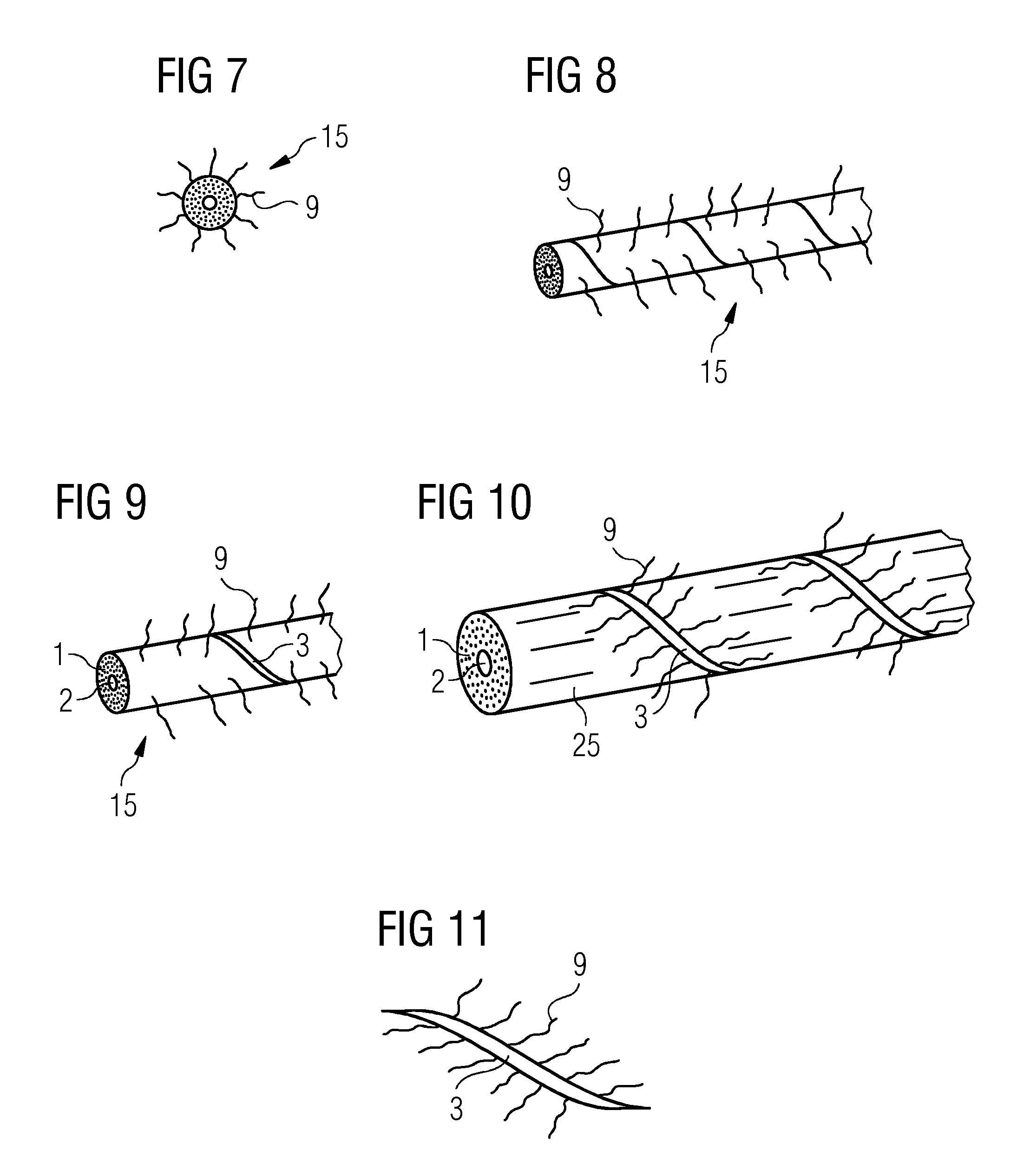

Bundle of roving yarns, method of manufacturing a bundle of roving yarns and method for manufacturing a work piece

InactiveUS20120261854A1Cheap and easily methodReduce manufacturing costFibre treatmentRenewable energy generationFiberYarn

A method of manufacturing a bundle of roving yarns is described. The method is characterised in assembling a number of roving yarns of longitudinal unidirectional fibres and an additional component in a bundle. For example, at least one resin distribution means or a thermoplastic material may be placed as the additional component in the bundle.

Owner:SIEMENS AG

A kind of non-alkali glass fiber sizing for LFT reinforced polypropylene with high impregnability and its application

ActiveCN108996923BIncrease productivityImprove interface compatibilityPolymer scienceMicrocrystalline wax

A high-impregnation non-alkali glass fiber sizing agent for LFT reinforced polypropylene and its application, the sizing agent includes a pH regulator, a silane coupling agent, a film-forming agent A, a film-forming agent B, a lubricant, a surface Active agent, antioxidant and deionized water, film-forming agent A is polypropylene wax emulsion modified by maleic anhydride grafting, film-forming agent B is polyethylene emulsion modified by maleic anhydride grafting, lubricant is PEG The combination of lubricants and mineral oil lubricants, the surfactant is a combination of microcrystalline wax emulsion and cationic polyacrylamide emulsion, and the antioxidant is hypophosphite. The present invention also provides the application of the sizing agent in the production of alkali-free glass fibers for LFT-reinforced polypropylene. The glass fibers produced by the sizing agent have good interfacial bonding properties and can be rapidly compatible with polypropylene resin at high temperatures. The impregnation speed is fast, and it also has good manufacturability, good wear resistance, less hairiness, and high impregnation properties, which can improve production efficiency and reduce production costs.

Owner:JUSHI GRP CO

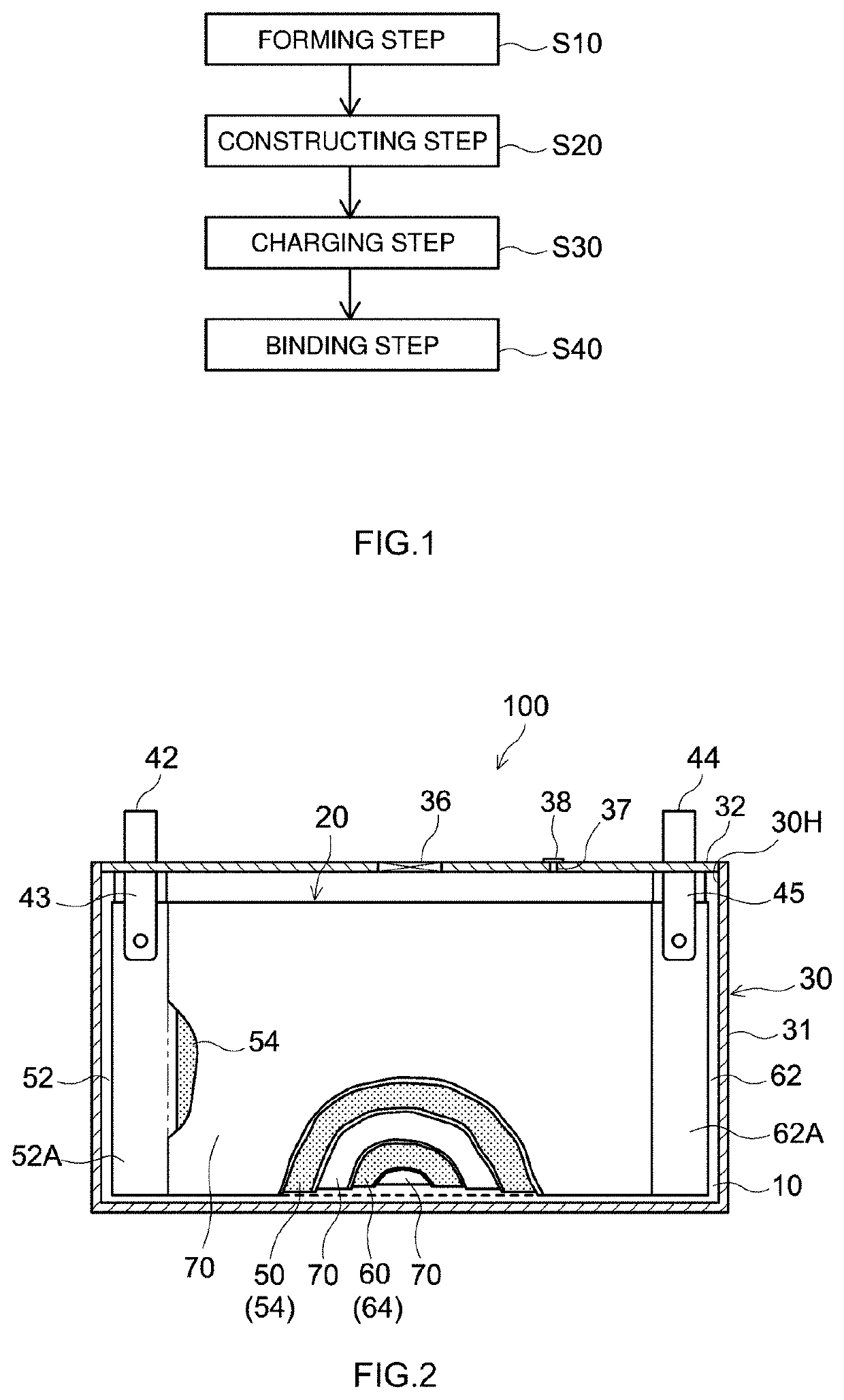

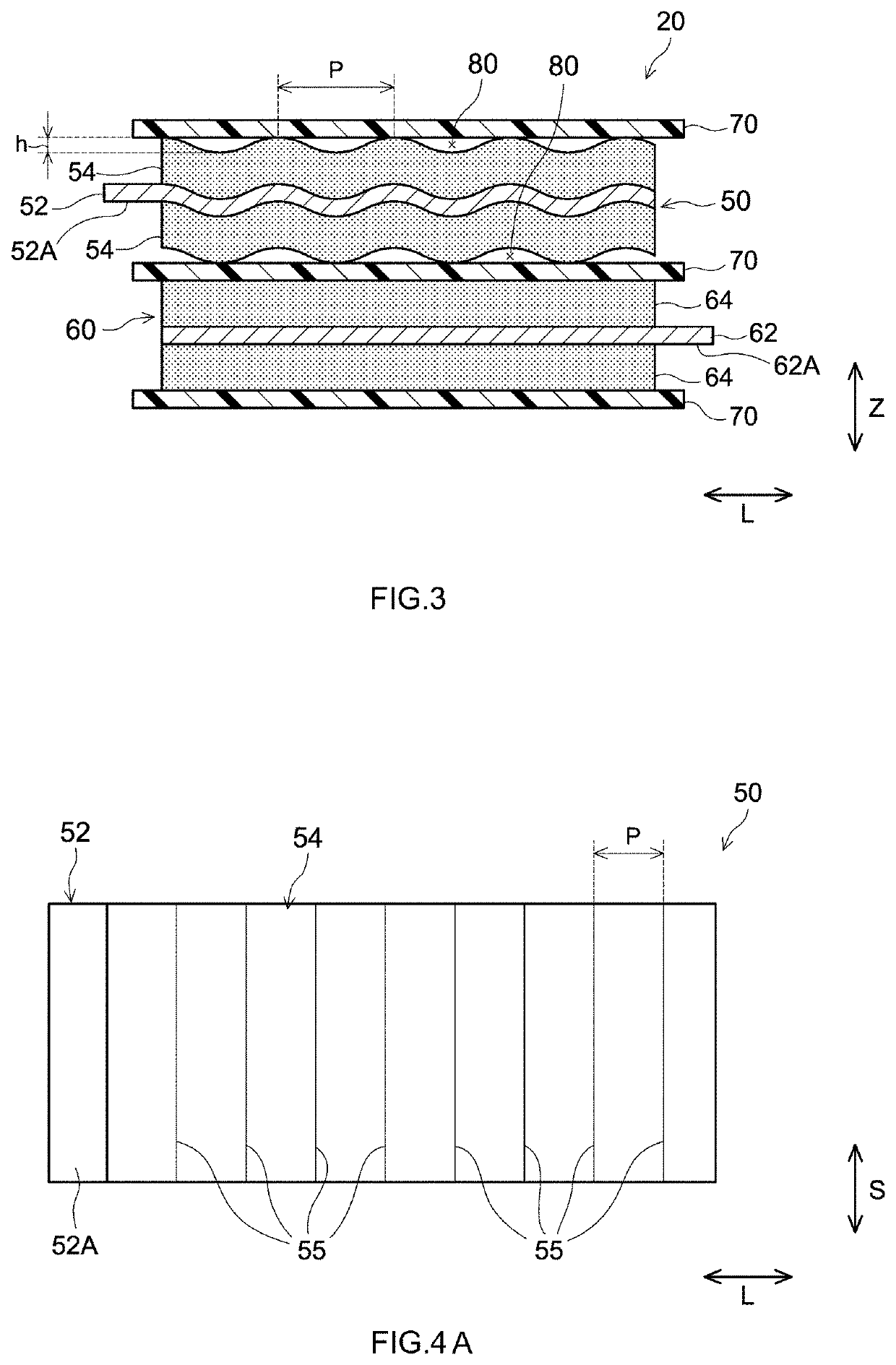

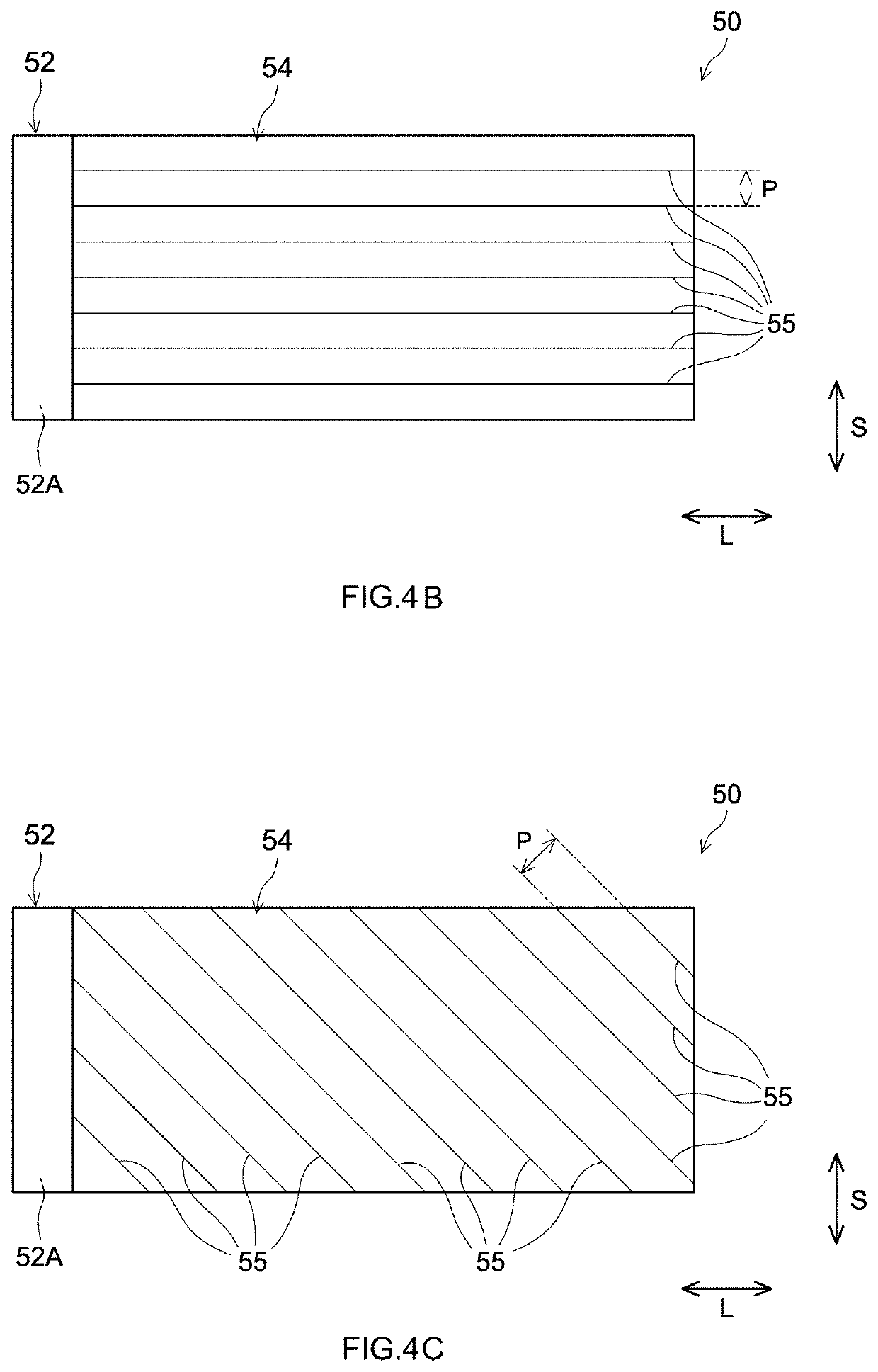

Method for manufacturing secondary battery

PendingUS20220263139A1Reduce the ratioReduced strengthCell electrodesFinal product manufactureElectrolytic agentElectrical battery

The manufacturing method herein disclosed includes a forming step of stacking a positive electrode sheet including a positive electrode active material layer on a positive electrode collector, a negative electrode sheet including a negative electrode active material layer on a negative electrode collector, and a separator sheet, thereby forming an electrode body; a constructing step of accommodating the electrode body in a battery case, and pouring an electrolyte into the battery case, thereby constructing a battery assembly; and a charging step of charging the battery assembly. At least any one of the positive electrode active material layer and the negative electrode active material layer has an undulating shape in a stacking direction, and a pit depth of the undulation is 10 μm or more.

Owner:PRIME PLANET ENERGY & SOLUTIONS INC

A kind of high-capacity aluminum electrolytic capacitor and preparation method thereof

ActiveCN110993351BGood co-solubilityFast impregnationLiquid electrolytic capacitorsCapacitor electrolytes/absorbentsElectrolytic agentPolyethylene glycol

Owner:CENT SOUTH UNIV

Activated carbon with improved mechanical resistance, and the uses thereof, especially as a catalyst carrier

InactiveUS20100278987A1Strong mechanical propertiesFast impregnationCarbon compoundsSolid sorbent liquid separationBisulfideGas phase

The present invention relates to active charcoals with improved mechanical properties. They can advantageously be used in the sweetening of petroleum fractions, as oxidation catalyst support in the conversion of mercaptans to disulphides, but also in any other type of reaction, such as, for example, for the oxidation of cyanide present in water or in the synthesis of glyphosate, and in processes for purification and / or separation by selective adsorption in a liquid phase and / or in a gas phase (decolouration of liquid foodstuffs, water treatment, air treatment, recovery of solvents, and the like).

Owner:LE BEC REMY

Membrane and process

PendingUS20200303753A1Improve the immunityIncreased durabilityFinal product manufactureFuel cellsFuel cellsPhysical chemistry

A reinforced ion-conducting membrane comprises a planar reinforcing component which comprises a porous polymer material; an ion-conducting component embedded in at least a region of the planar reinforcing component, which ion-conducting component comprises an ion-conducting polymer material; and linking groups which are chemically bonded to both the planar reinforcing component and the ion-conducting component. The reinforced ion-conducting membrane is useful as the membrane in a membrane-electrode assembly for example as used in fuel cells.

Owner:JOHNSON MATTHEY HYDROGEN TECH LTD

A kind of ultra-high power graphite electrode pressing equipment with self-impregnating function and pressing method thereof

ActiveCN109454917BIncrease productivityImprove efficiencyShaping pressGraphite electrodeLiquid storage tank

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Composite member vimp preparation method with surface functional layer

InactiveCN101830095BIncrease stiffnessImprove surface qualitySynthetic resin layered productsFiberEpoxy

The invention belongs to the technical field of multi-layer composite material components and preparation methods thereof, and specifically discloses a VIMP preparation method of a composite material component with a surface functional layer. The composite material component includes an outer layer and a body layer. The layers are the first and second composite material systems; the first composite material system is based on epoxy resin, phenolic resin, etc., the second composite material system is based on unsaturated polyester resin, and each system is based on carbon fiber Or fiberglass cloth as reinforcement. The VIMP preparation method is to firstly adopt the resin film infiltration process to prepare a reinforced resin film on the surface of a vacuum dip molding process molding mold, and then use the molding mold covered with the reinforced resin film to prepare a composite product through a vacuum dip molding process. Material components. The VIMP process of the present invention combines the double advantages of the RFI process and the VIMP process, and the prepared composite material component has better surface quality, better integrity and excellent comprehensive performance.

Owner:NAT UNIV OF DEFENSE TECH

Method integrated Preparation of extruding and impregnating composite material with parts forming and its device

The present invention is an integrated method and equipment for the preparation of extrusion-impregnated composite materials and parts forming. The temperature is lower than the melting point of the powder. When the metal liquid infiltrated into the powder is cooled and solidified, a part made of composite material with the same shape and size as the cavity is obtained; the equipment consists of a press, a mold, a powder feeding device, and a liquid supply device. , The vacuum device is connected with each other. The invention has few technological processes, small equipment footprint, high production efficiency and high material utilization rate, is suitable for automatic mass production, can produce large parts, is convenient for manufacturing parts with complex shapes, and can produce dense multi-component materials. The composite material parts prepared by the invention have high precision, fine and uniform microstructure, repeatability, and the porosity content can reach the same level as that of dense materials, thereby reducing possible defects in the casting structure.

Owner:周照耀

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com