A kind of non-alkali glass fiber sizing for LFT reinforced polypropylene with high impregnability and its application

A technology of alkali-free glass fiber and sizing, applied in the field of sizing, which can solve problems such as low efficiency and affecting the mechanical properties of final products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

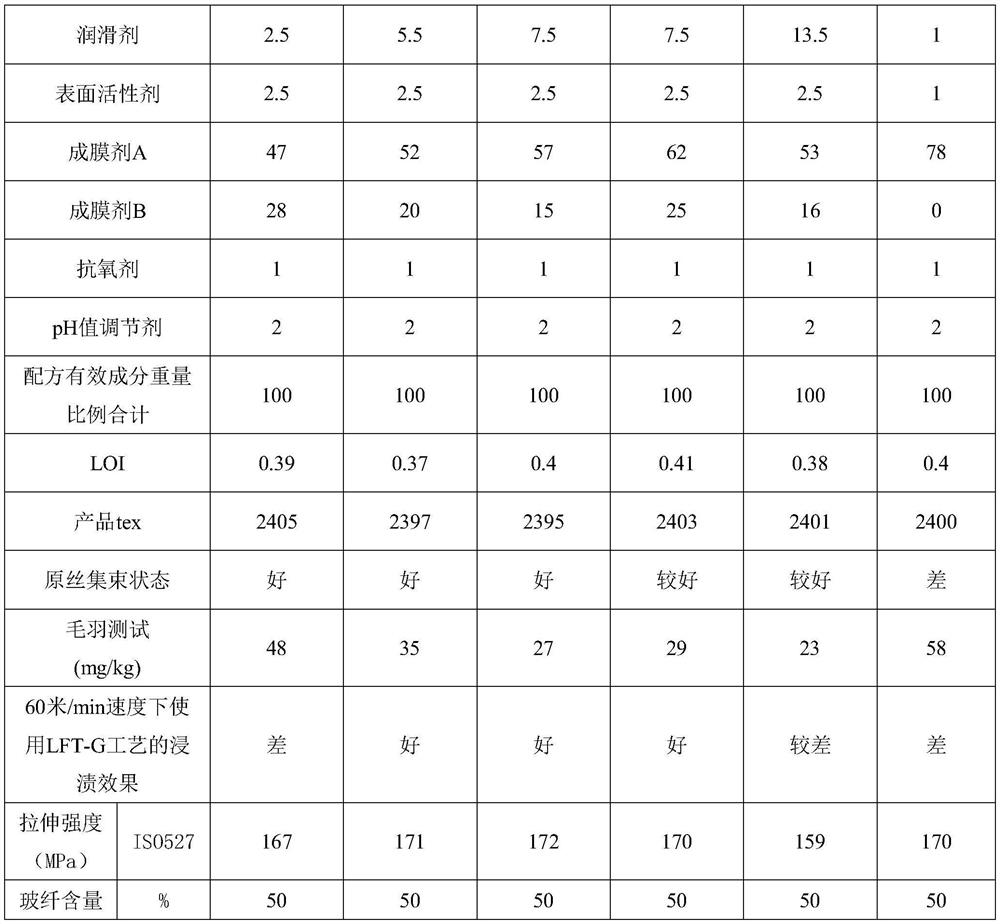

[0048] The following is the determination of the specific formula and the description of the experimental method, but the content of the present invention is not restricted by the following examples.

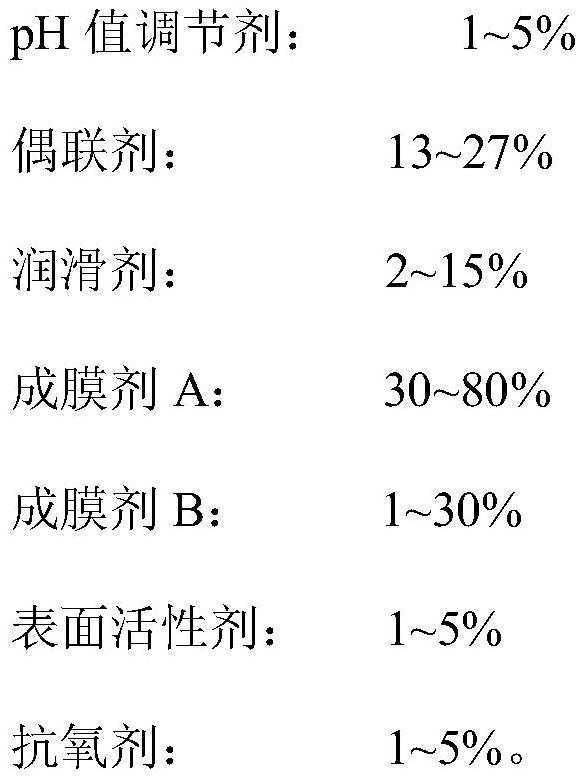

[0049] The components of the wetting agent used in the embodiments of the present invention are as follows:

[0050] The coupling agent is selected from aminosilane coupling agent, and the product brand is A1100 of Momentive.

[0051] The lubricant is selected from PEG400 and modified mineral oil, the compounding ratio is 2:1 based on the solid mass ratio, and the product grades are Kekai 2640 and STANTEX G 7607.

[0052] The film-forming agent A is selected from maleic anhydride modified PP wax emulsion, and the product grade is selected from American michelman ME91735.S-OP.

[0053] The film-forming agent B is selected from maleic anhydride modified polyethylene, and the product grade is selected from Emulsion 29730.

[0054] The selected surfactants are microcrystalline wax...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com