Patents

Literature

137results about How to "Reduce chemical reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating and/or treating hydraulic fracturing proppants to improve wettability, proppant lubrication, and/or to reduce damage by fracturing fluids and reservoir fluids

InactiveUS20050244641A1Reduce conductivityEfficient arrangementSynthetic resin layered productsCellulosic plastic layered productsFracturing fluidCompound (substance)

Surface modified oil and gas well hydraulic fracturing proppants for improving wettability, altering chemical reactivity, altering surface topography, imparting lubricity or controlling relative permeability to flow of fluids of such proppants. The use and preparation of such coated proppants in hydraulic fracturing of subterranean formations is also described.

Owner:CARBO CERAMICS

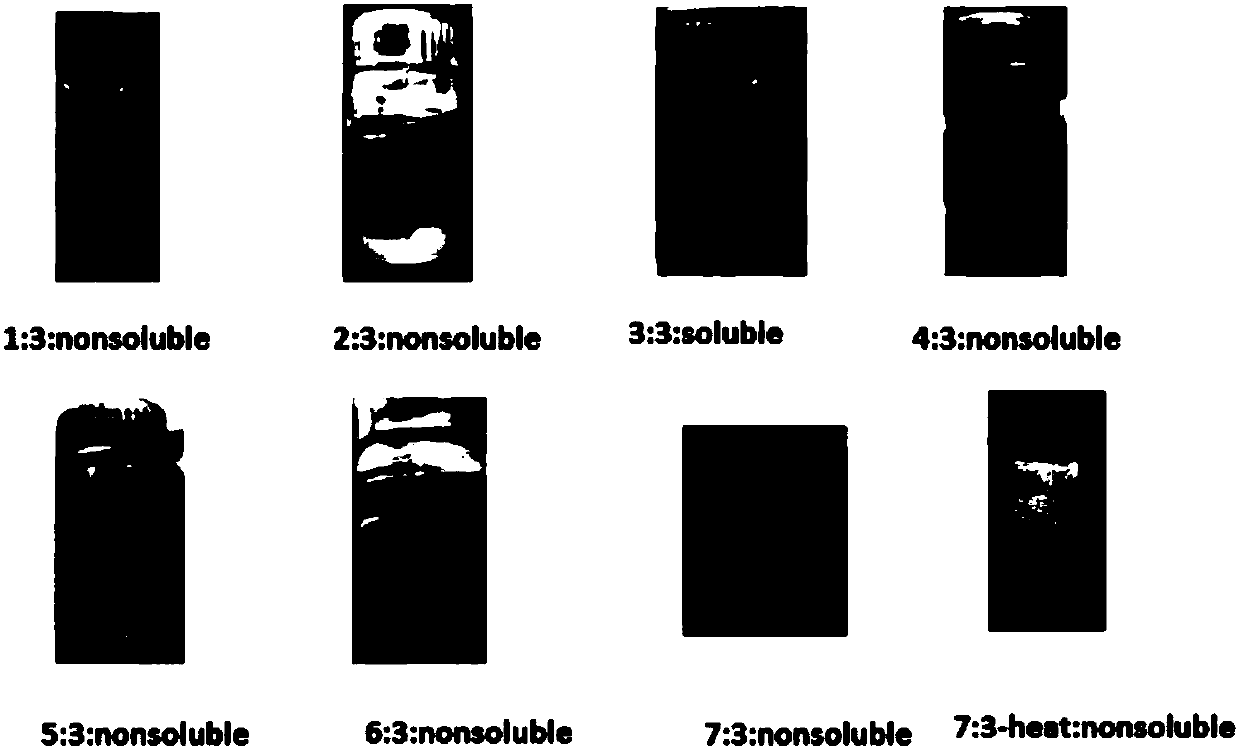

Solvent composite and preparation method and use thereof

The solvent composition consists of sodium hydroxide 5-12 wt% and urea 8-20 wt% except water. The preparation process of the solvent composition is also provided. Water solution of sodium hydroxideand water solution of urea are mixed to compound the solvent composition; or sodium hydroxide is first compounded into water solution and urea is then added to compound the solvent composition. The solvent composition may be used in directly dissolving natural cellulose and regenerated cellulose to obtain transparent cellulose solution with high dissolubility and high concentration.

Owner:WUHAN UNIV

Protective coating comprising boron nitride for refractory material members of an ingot mold for continuous casting of metals

InactiveUS6051058AImprove protectionLow wettabilityMelt-holding vesselsAlkali metal silicate coatingsIngot castingCarbon nitride

The invention relates to a protective coating for a refractory material member of an ingot mold for continuous casting of metals, especially of steel, which consists of a dispersion of particles in a solvent, said particles including essentially boron nitride and at least one of the following metal oxides: zircon, zirconia, alumina and silica, the boron nitride representing between 20 and 50% by weight of said particles.

Owner:USINOR SA +1

Process for preparing regenerated cellulose films and wires

The invention discloses a method for manufacturing cellulose film and silk. The cellulose is dissolved in mixed liquid 5-12wt% natrium oxyhydrogen and 8-20wt% ureophil, gets the cellulose liquid, then carries on film scratching and silk spraying to the cellulose, they are solidified in the solidifying bath, then the regenerated cellulose film and silk will be got after being cleaned. The cellulose thick liquid has excellent fiber textile performance and compactibiity of film, the regenerated cellulose has excellent light transmission and mechanical performance, the silk also has good mechanical performance. The method can obtain cellulose thick liquid by dissolving cellulose in room temperature. It has no contamination and its price is low, it is a kind of green manufacturing process.

Owner:WUHAN UNIV

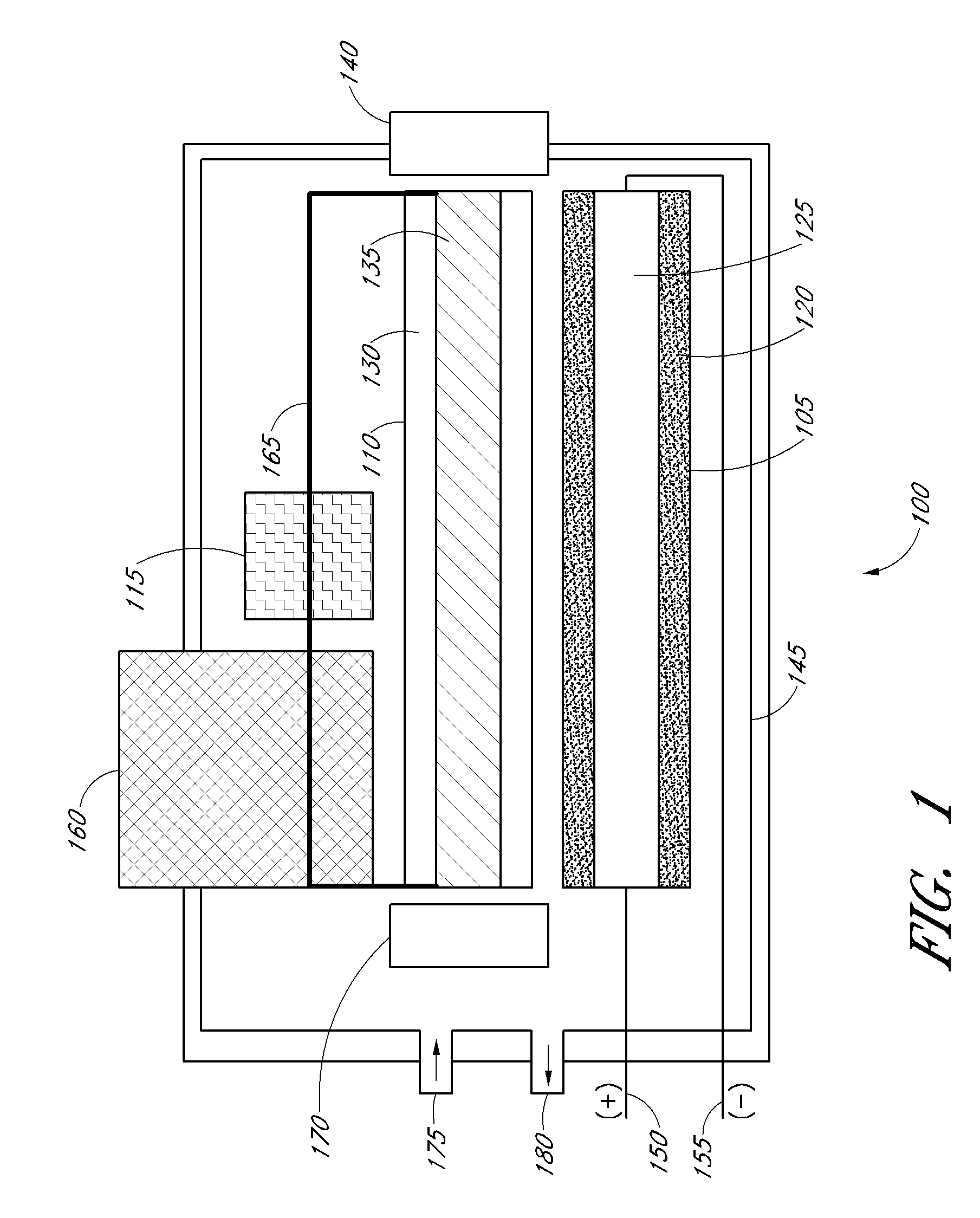

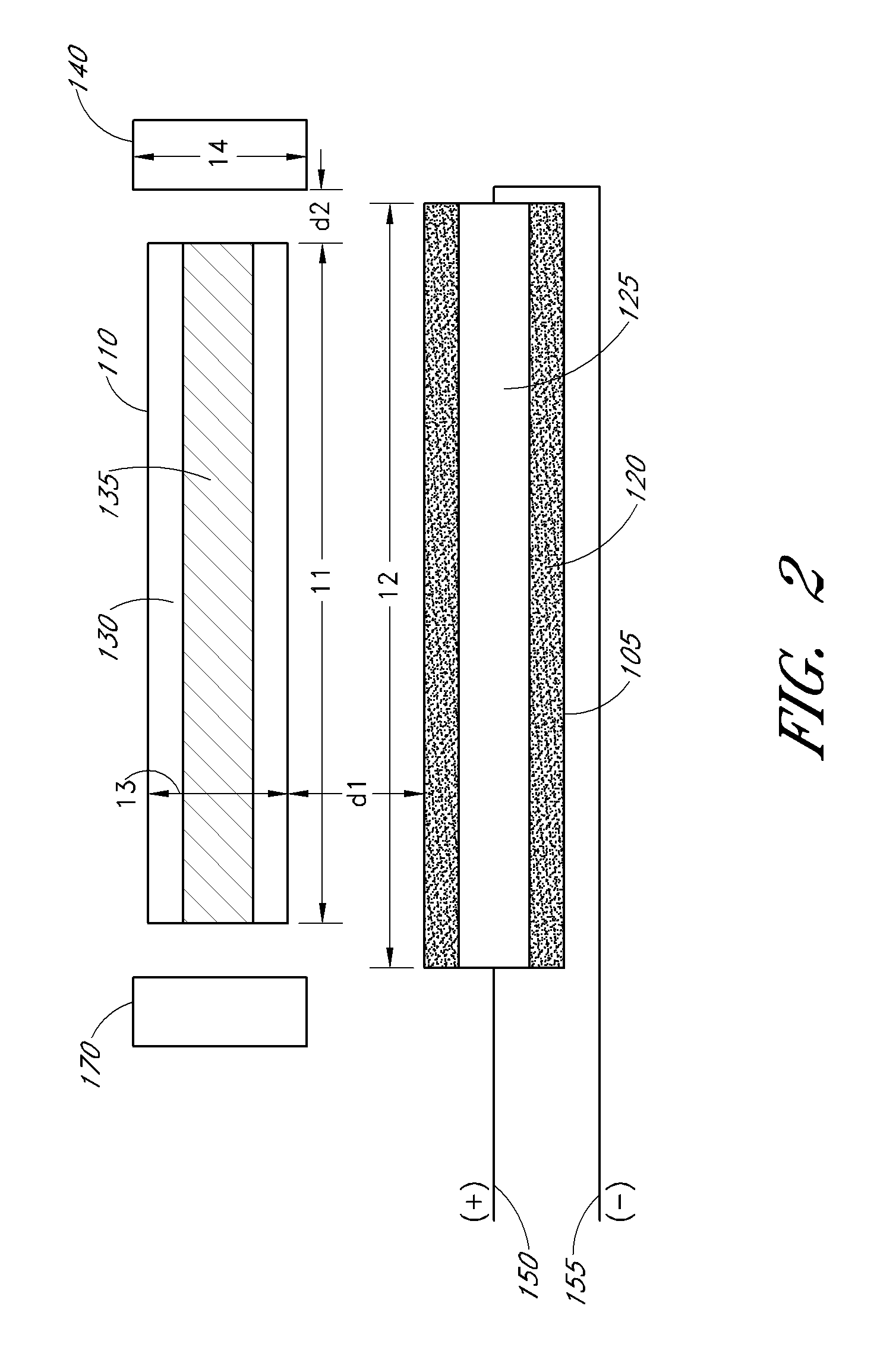

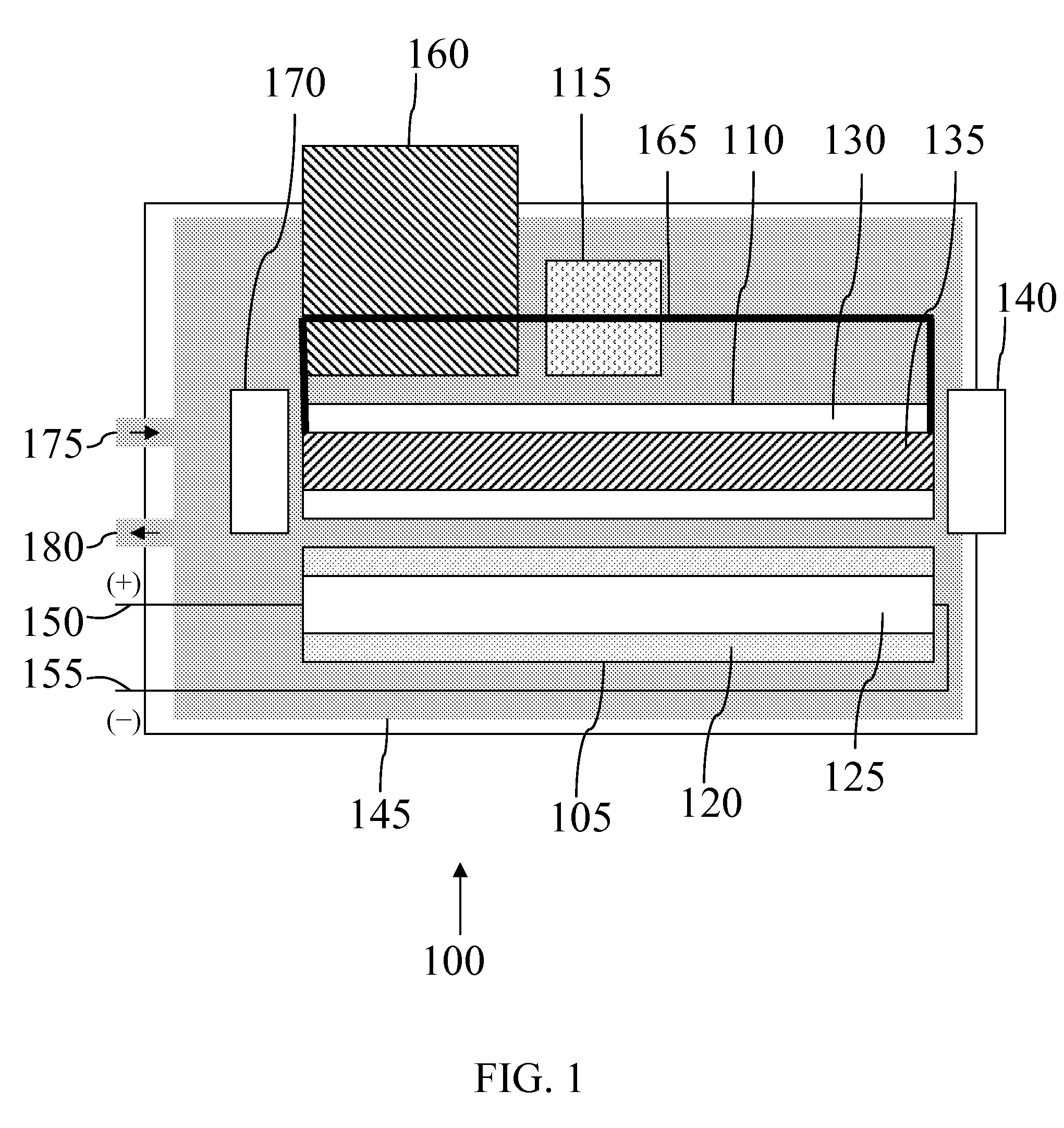

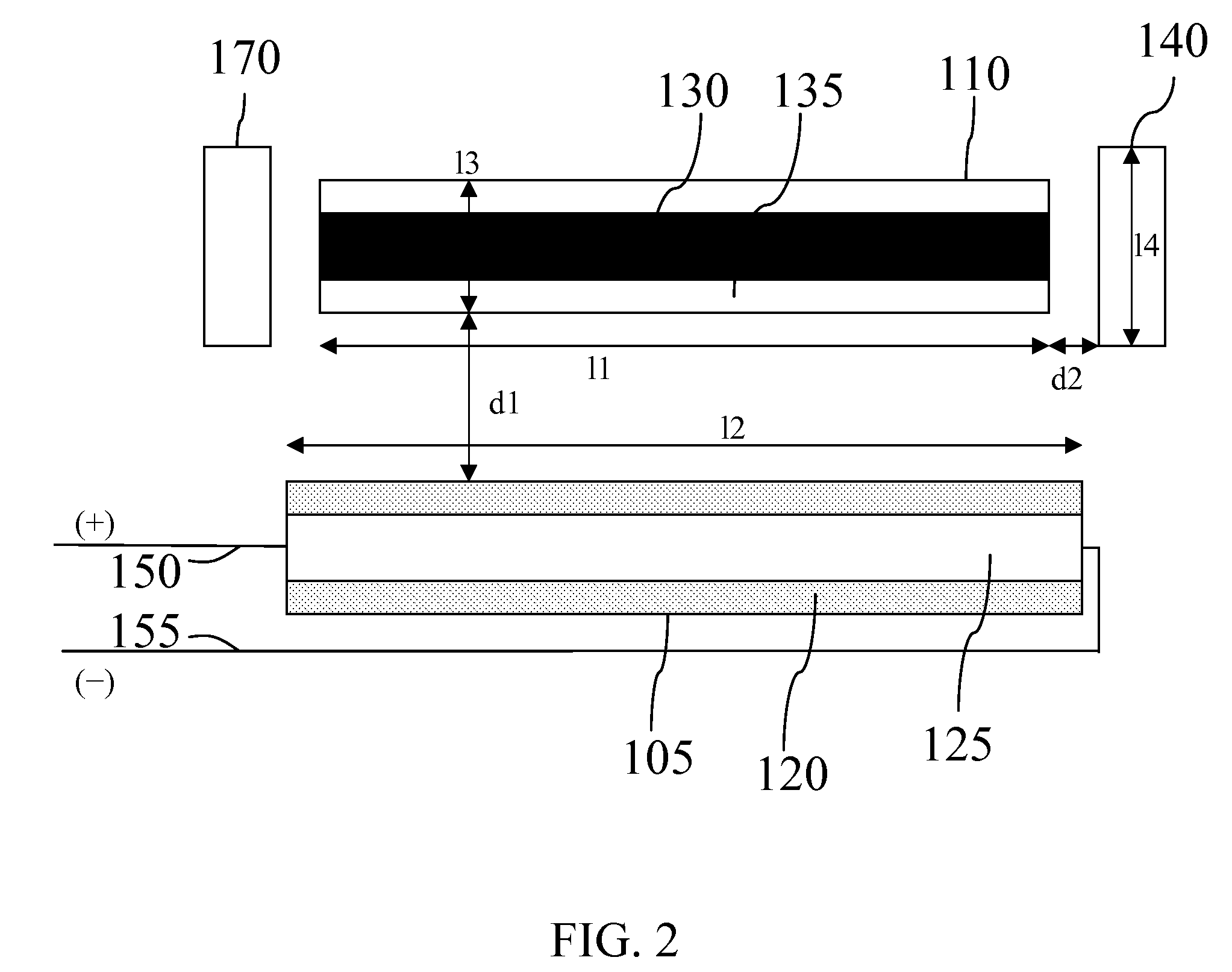

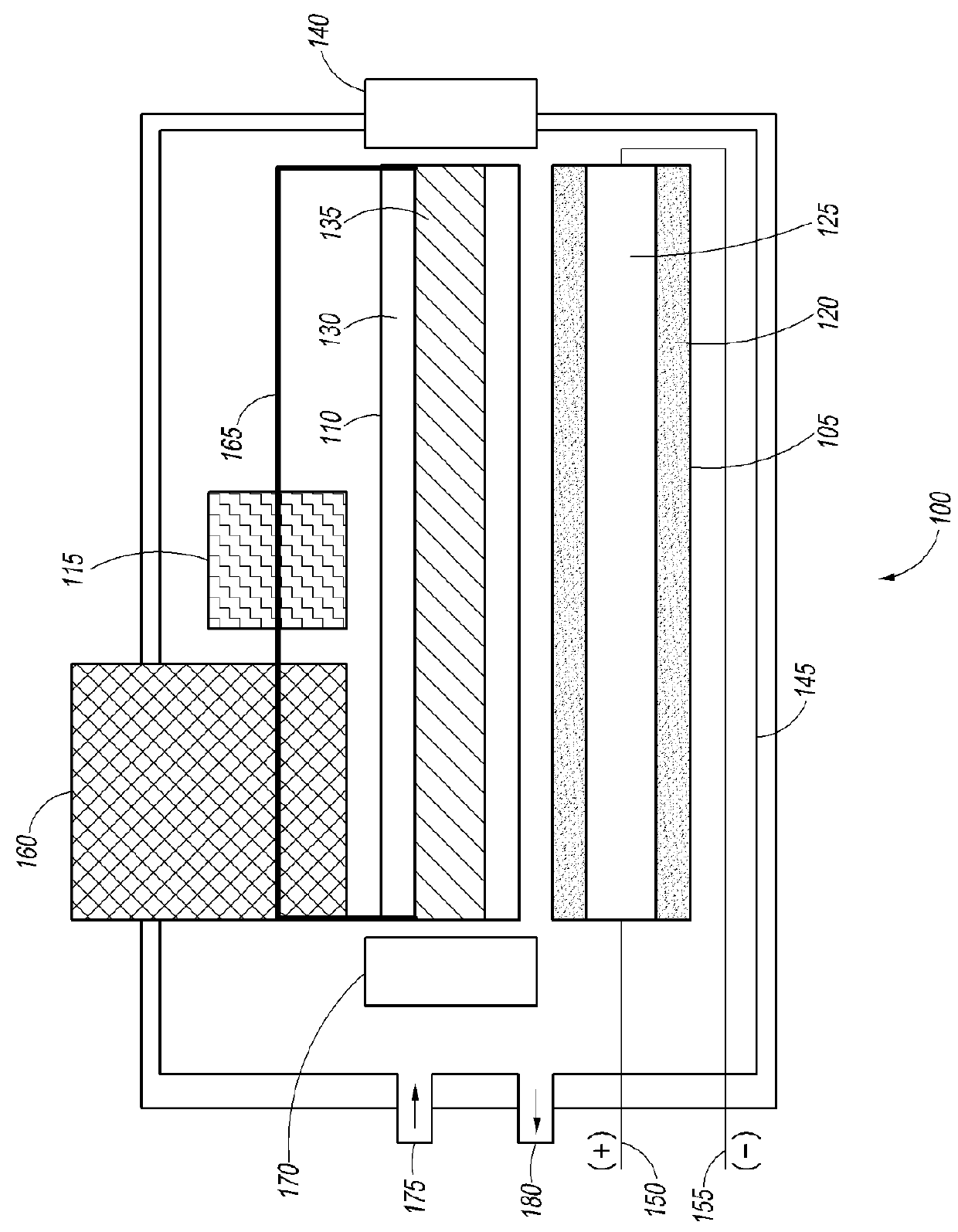

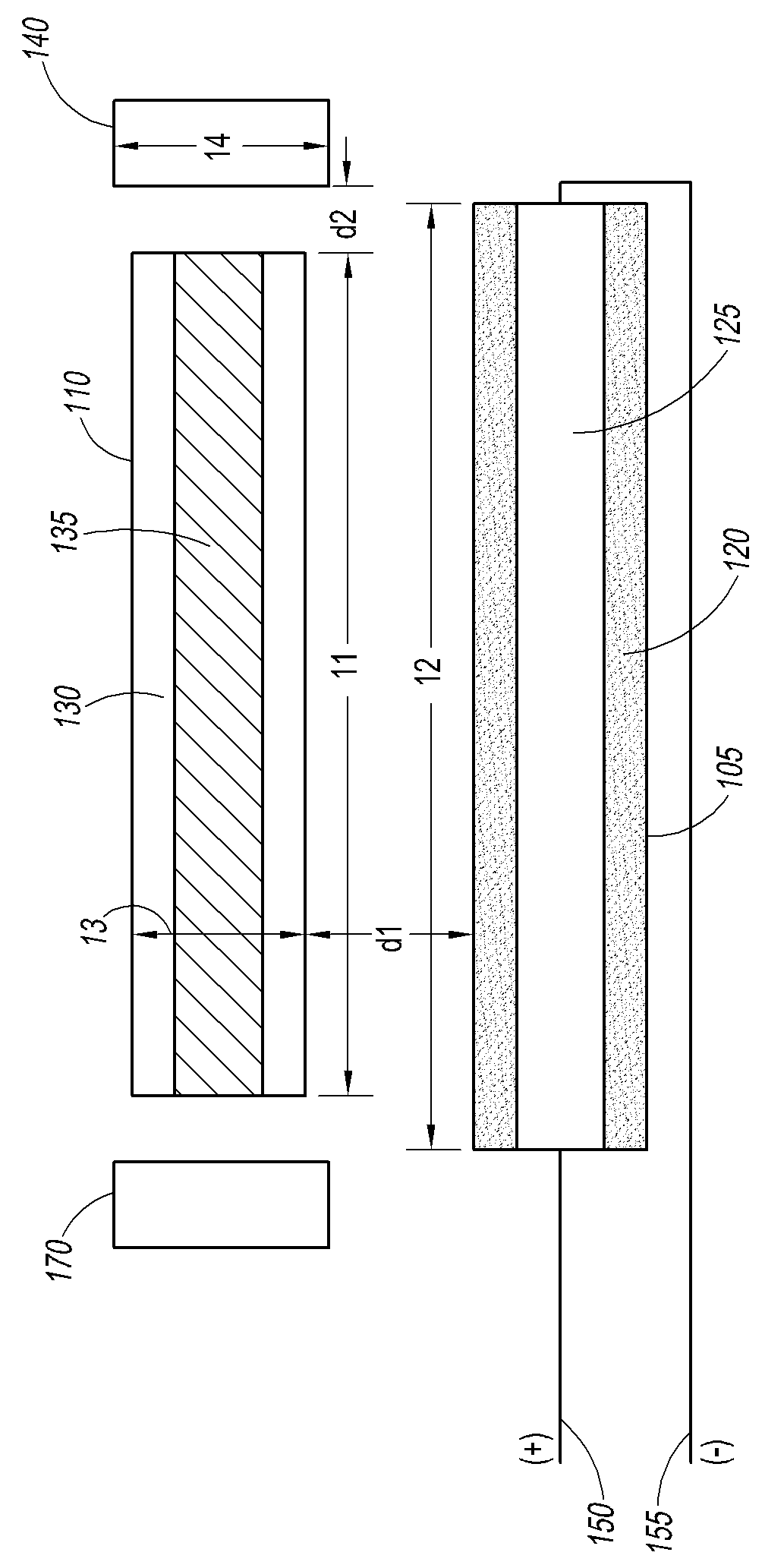

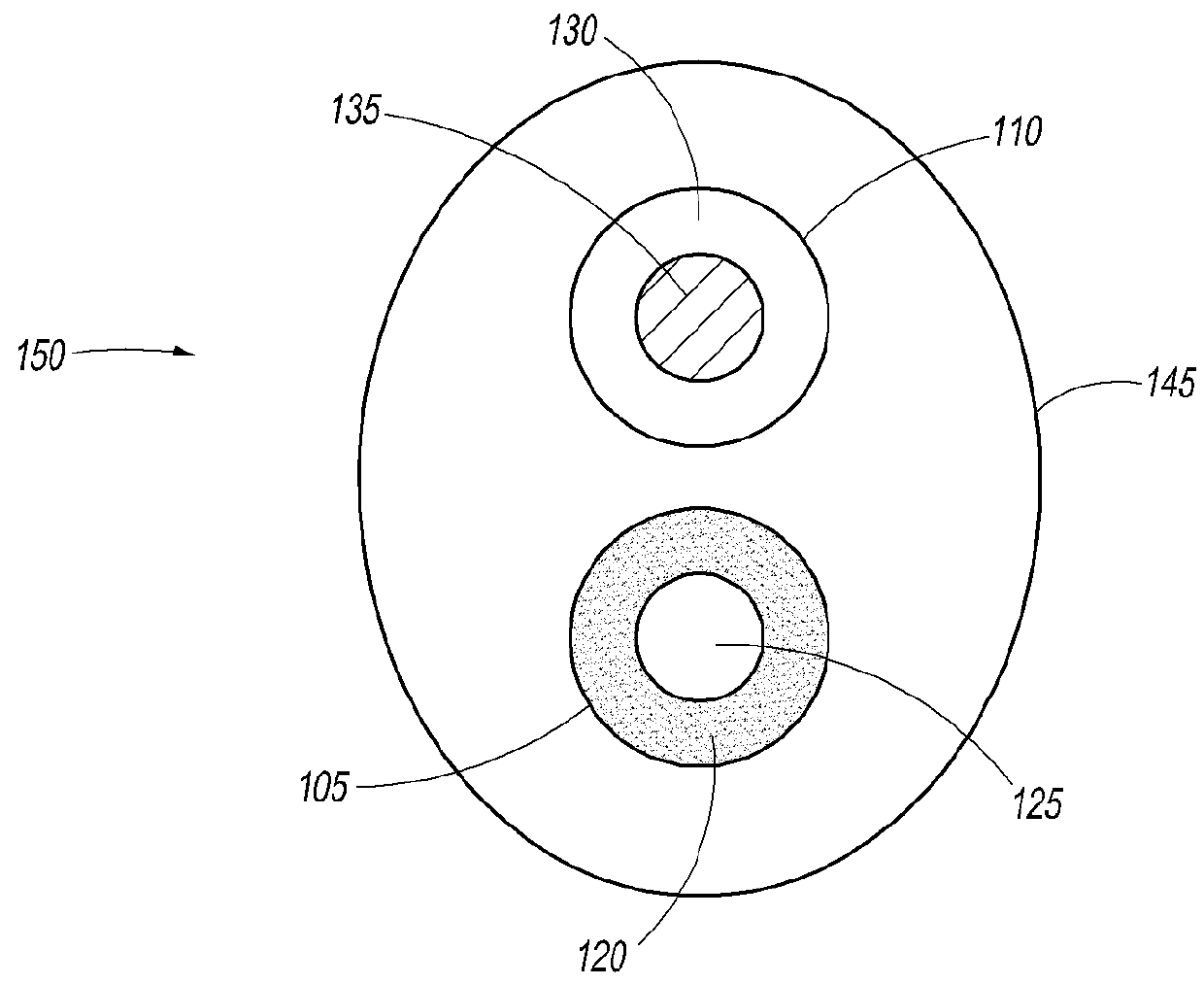

Composite film material for lithium battery and preparation method and application thereof

ActiveCN107591511AReduce manufacturing costEasy to operateLi-accumulatorsCell component detailsElectrical conductorComposite film

The invention provides a composite film material for a lithium battery. The composite film material comprises a polymer film and a conductor particle layer coating the surface of the polymer film in one side. The conductor particle layer contains one or more of particles of an ion conductor material, particles of an ion-electron mixed conductor material and particles of an electron conductor material. The invention also provides a preparation method of the composite film material and an application of the composite film material in a rechargeable metal lithium battery. The invention provides aliquid metal lithium battery and solid metal lithium battery containing the composite film material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

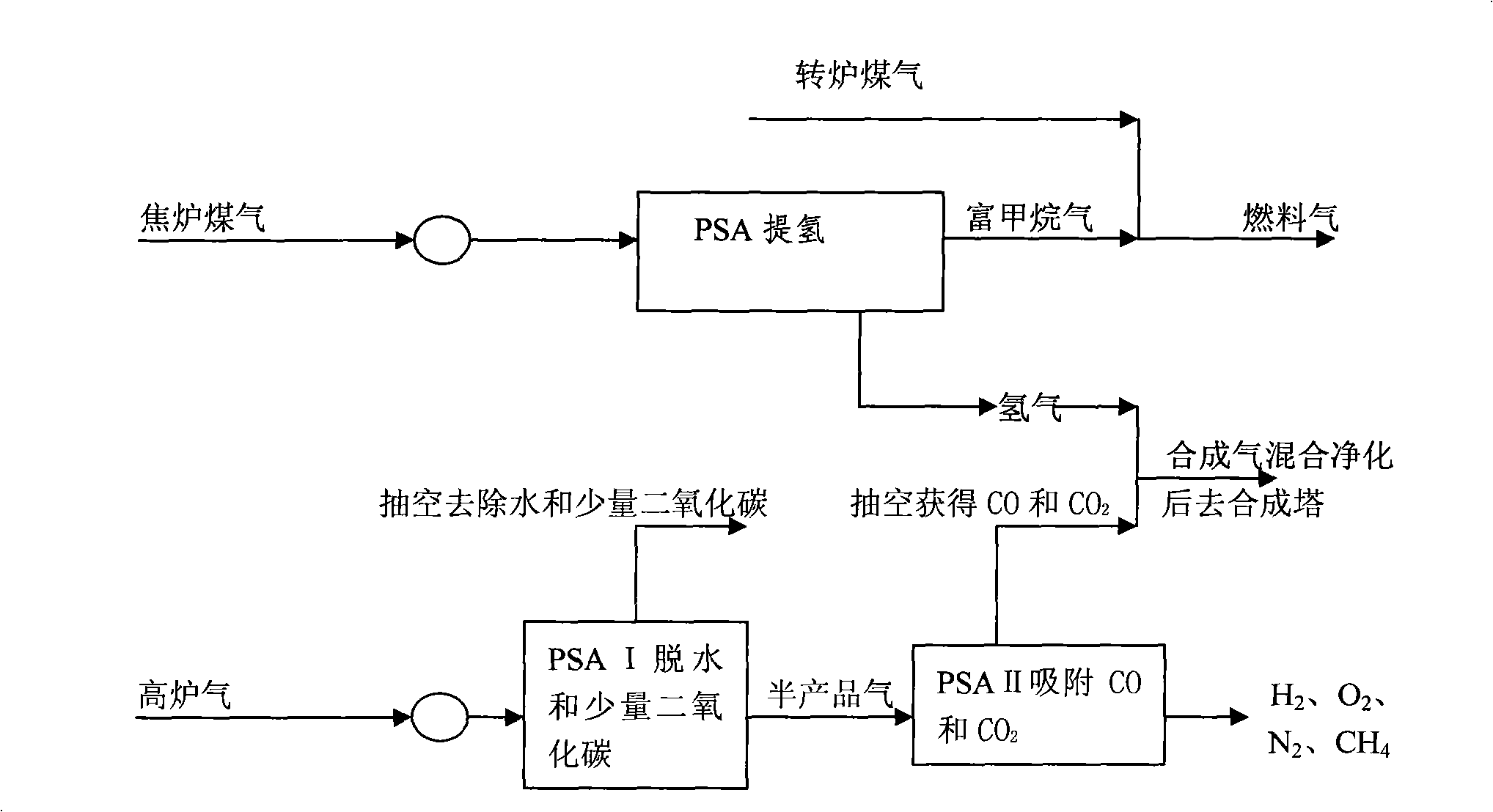

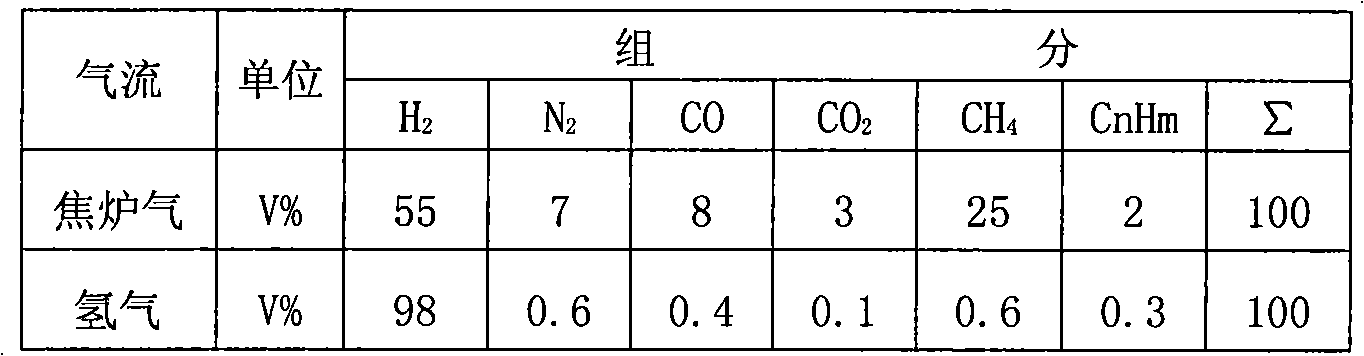

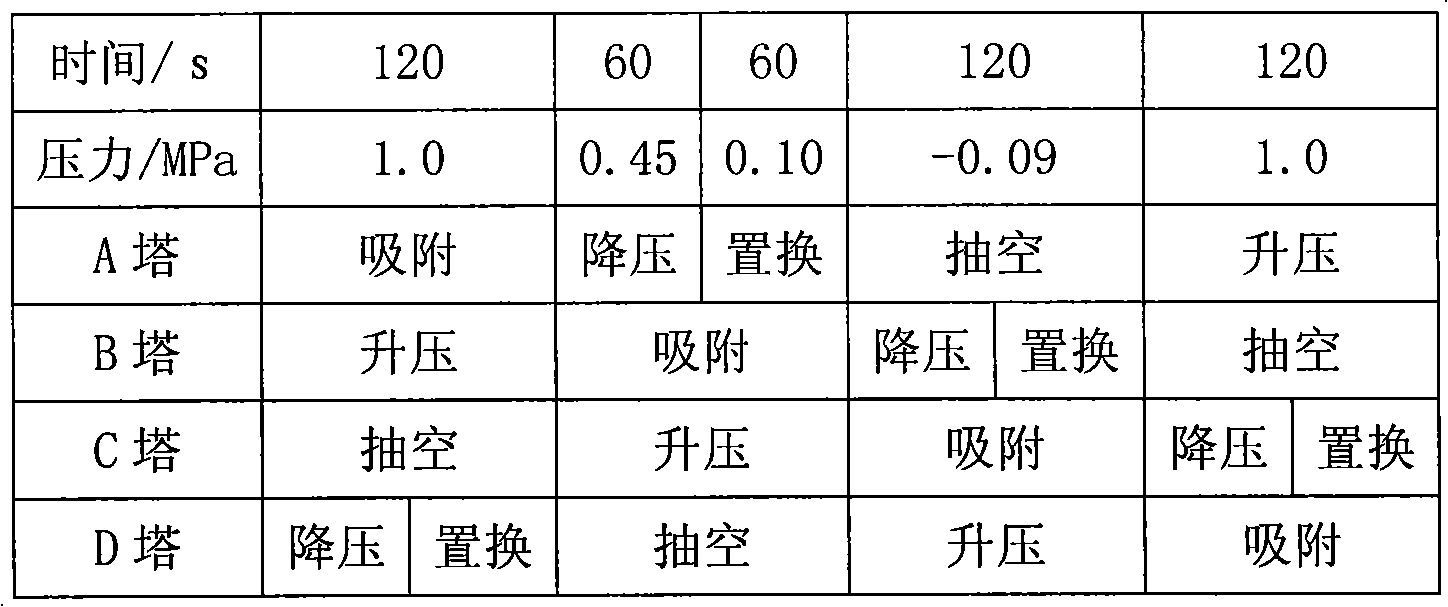

Method for preparing methanol synthesis gas with oven gas and blast furnace gas

InactiveCN101343580AEmission reductionReduce chemical reactionsGaseous fuelsChemical reactionSorbent

The invention discloses a preparation method for methanol synthetic gas through coke oven gas and blast furnace gas. The preparation method adopts coke oven gas as the raw material, and H2 is extracted through pressure swing adsorption; the blast furnace gas with high yield and relatively low calorific value is adopted as the raw material, an adsorbent which can adsorb CO and CO2 is utilized to simultaneously extract and reclaim the CO and the CO2 in the blast furnace gas, and then the H2, the CO and the CO2 are mixed and prepared into the methanol synthetic gas. The hydrogencarbon ratio f value of the methanol synthetic gas prepared according to the method is within the optimum range of 2.05 to 2.60, and the contents of nitrogen gas and other impure gases are suitable for the methanol production. The by-product gas generated during the steel production process is utilized to prepare the methanol synthetic gas, the useful components in the gas are utilized, the discharging of harmful substances into the environment is reduced, and not only the chemical reaction can not occur during the process, but also the carbon adding is not required, the technical process is short, the process is simple, and the cost is low, so the preparation method is one of the preferable methods for the preparation of methanol synthetic gas.

Owner:SICHUAN TIANYI SCI & TECH

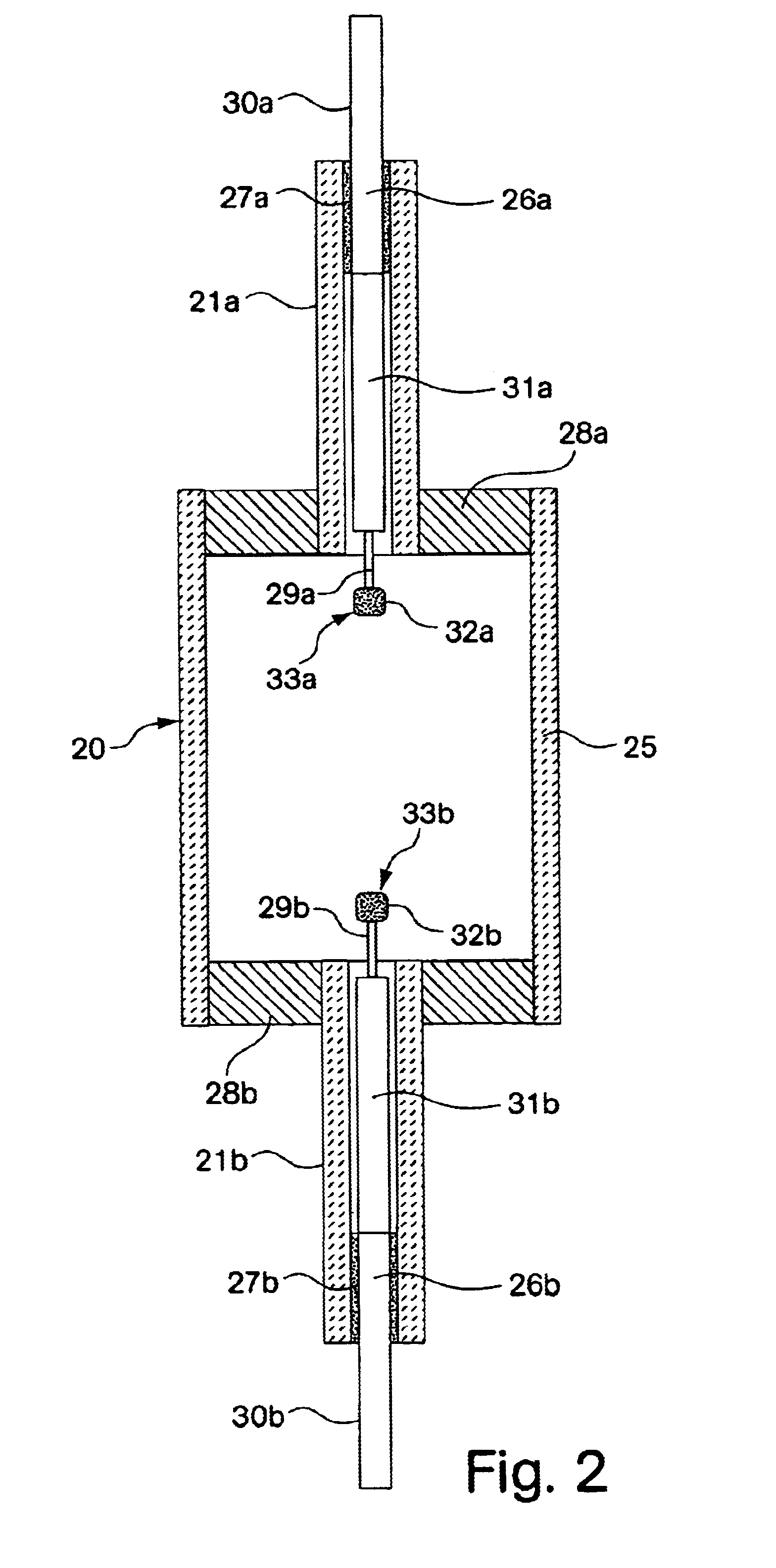

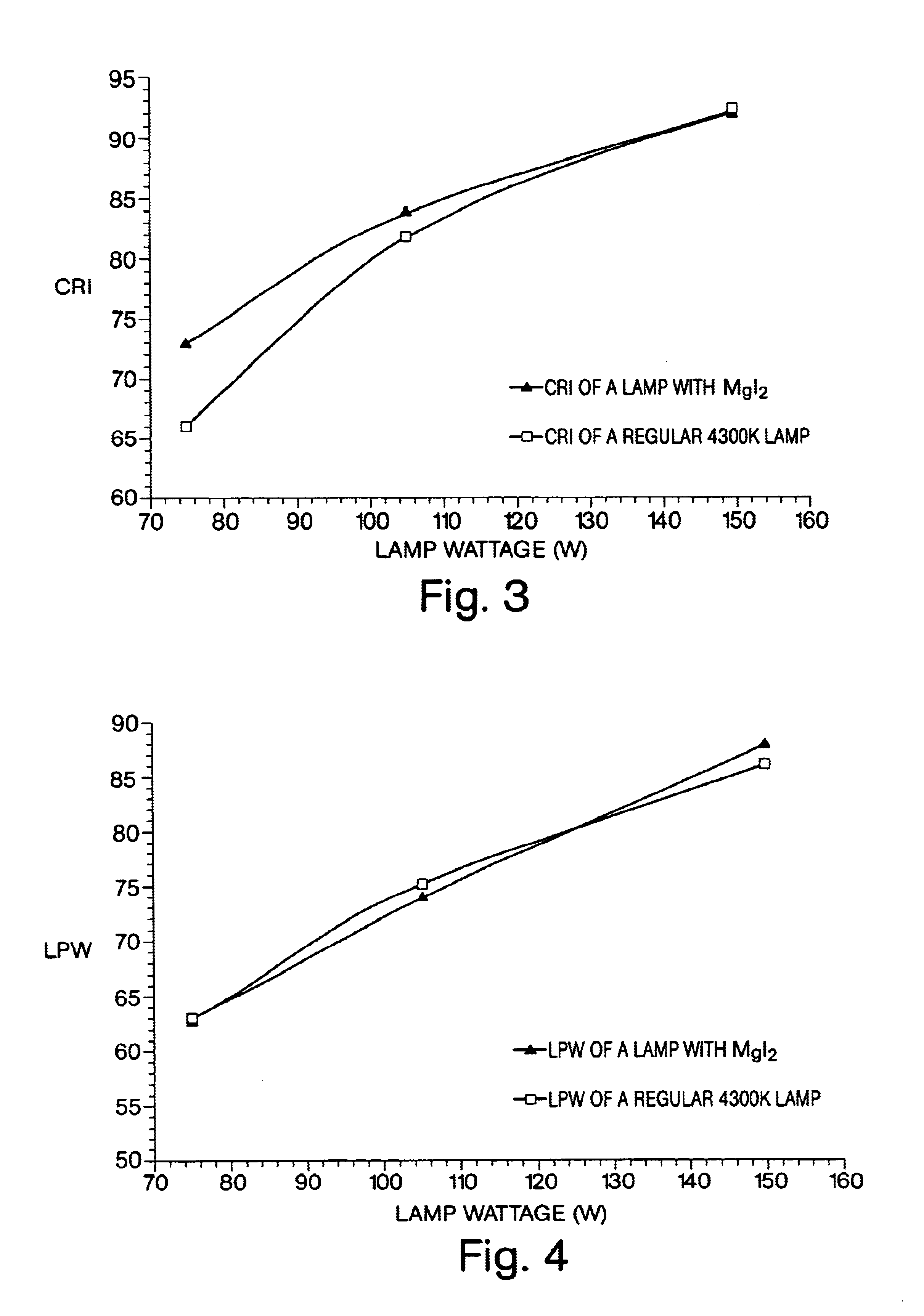

Thallium free-metal halide lamp with magnesium halide filling for improved dimming properties

InactiveUS6717364B1Lowering indexLamp performanceSolid cathode detailsGas discharge lamp detailsMetal-halide lampThallium

A [thallium free] high pressure ceramic metal halide lamp having superior dimming characteristics with a fill composition including MgI2 and / or MgBr2.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Sulfur-based electrolyte solution and application thereof in solid lithium battery

ActiveCN107591563AReduce manufacturing costReduce interface resistanceFinal product manufactureElectrolyte accumulators manufactureOrganic solventPhysical chemistry

The invention provides a sulfur-based electrolyte solution comprising a soluble polysulfide and an organic solvent, the chemical formula of the soluble polysulfide is Sy (Li2S) 100-x-y-z (LiX) z (P2S5) x, wherein, X is one or a plurality of elements of Cl, Br and I, 15<= x <= 90, 0 <=y <=80, 0<=z <=60, x-10 <=100-x-y-z<= x + 10; the mass concentration of the soluble polysulfide in the sulfur-basedelectrolyte solution is 0.1%-40%. The invention also provides a method for preparation of a solid lithium battery by using of the sulfur-based electrolyte solution and the prepared solid lithium battery.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

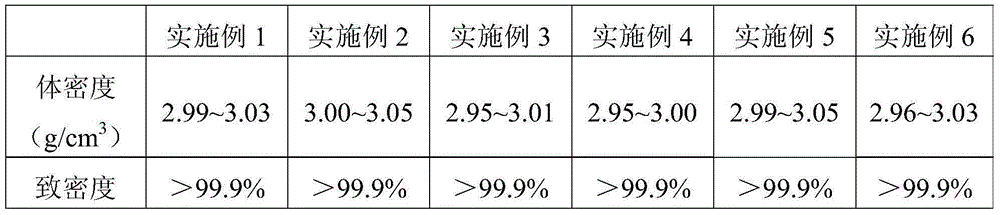

Aluminum-silicon carbide composite ceramic materials and preparation method and application thereof

ActiveCN105039912AImproves wetting and bindingImprove material performanceVacuum evaporation coatingSputtering coatingCeramic particleAluminium

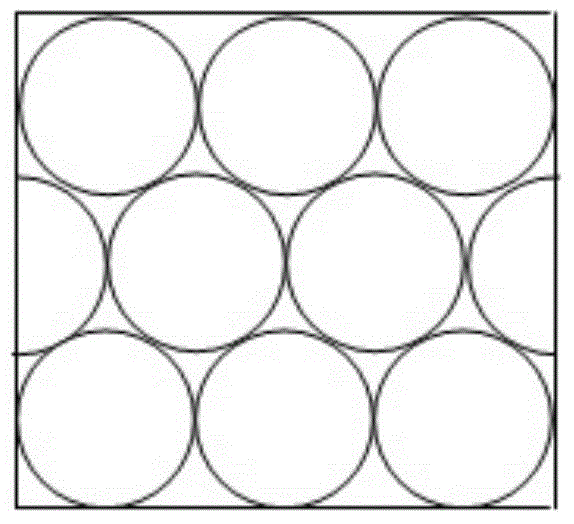

The invention relates to aluminum-silicon carbide composite ceramic materials and a preparation method and application thereof. The aluminum-silicon carbide composite ceramic materials are prepared through the following steps that (1) silicon carbide ceramics are dispersed and buried in metal titanium powder, heated to 1000-1100 DEG C in a vacuum environment, kept at the temperature for 1-3h, and then cooled, so that ceramic particles with surfaces plated with metal titanium layers in an evaporation mode are obtained; (2) the ceramic particles with the surfaces plated with the metal titanium layers in the evaporation mode are put into a container, arranged tightly to form a ceramic array, heated and then put into a compression casting machine, and metal aluminum melt is cast into the ceramic array; and (3) after mold release, the surfaces of the ceramics are cleaned, and the aluminum-silicon carbide composite ceramic materials are obtained and can be used for manufacturing bulletproof plates. Compared with the prior art, the composite ceramic materials have the characteristics of being compact in combination, simple in preparation method, suitable for industrial enlargement and the like.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

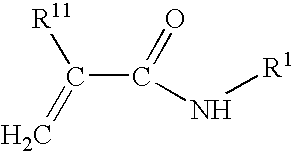

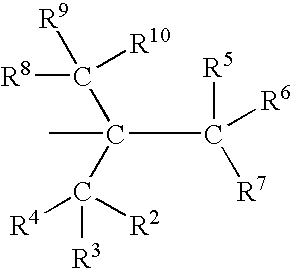

Chemotherapeutic compositions

InactiveUS6723336B1Prevention and treatmentLess weight gainPowder deliveryBiocideAdjuvantFeed additive

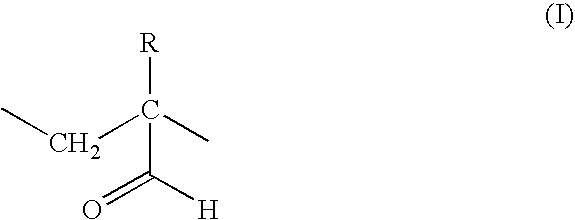

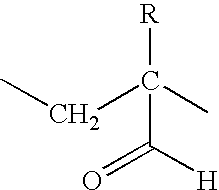

The present invention relates to the treatment of gastrointestinal disease and / or cancer, and a method of weight gain, via the ingestion of polymeric compositions in humans, animals or birds in need of said treatment. The invention provides methods for the treatment of cancer, the treatment and / or prevention of gastrointestinal disease and / or infection and / or diarrhea and a method for increasing weight gain in humans, animals or birds comprising administering to said humans, animals or birds an effective amount of a pharmaceutical or veterinary composition or feed additive, comprising an effective amount of a polymer and / or copolymer, having the repeating polymeric unit (I) wherein R is H or alkyl, usually C1 to C4, or this unit in hydrated, hemiacetal or acetal form, together with a pharmaceutically or veterinarally acceptable carrier, diluent, adjuvant, excipient and / or controlled release system.

Owner:CHEMEQ

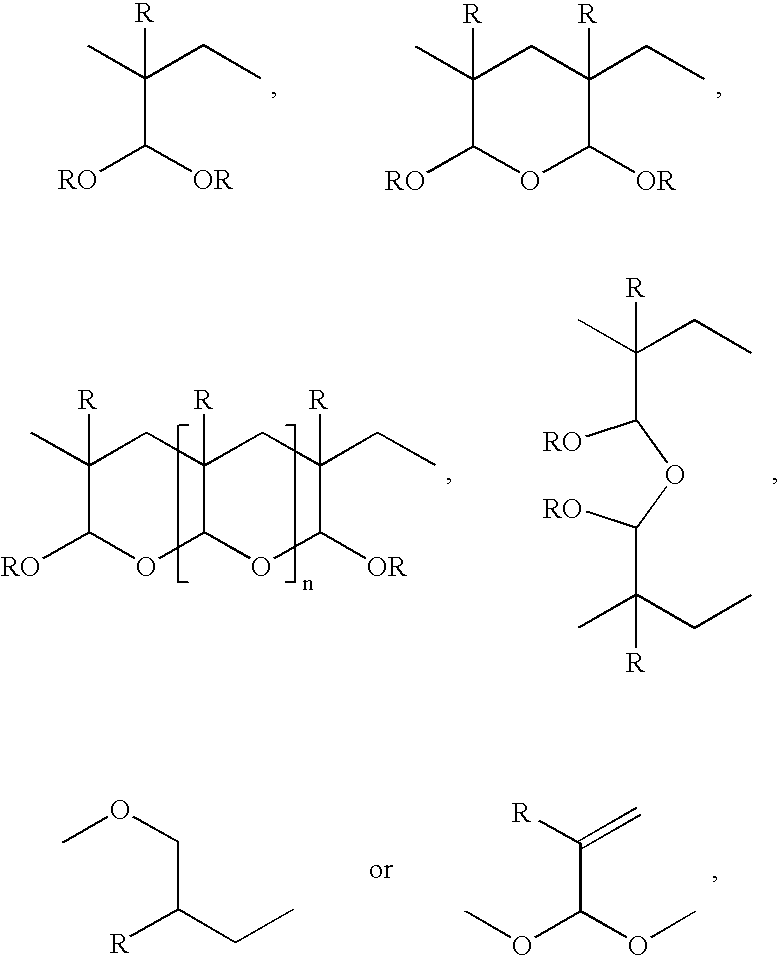

Method for separating, reclaiming and recycling CO2 in gas of blast furnace and converter

InactiveCN101603104AEmission reductionReduce consumptionBlast furnace detailsManufacturing convertersSlagTower

The invention relates to a method for separating, reclaiming and recycling CO2 in gas of a blast furnace and a converter respectively, belongs to the fields of ferrous metallurgy and greenhouse gas discharge reduction, and provides an energy-saving technique for improving the mass energy of the gas and reducing the discharge of CO2. The method integrates and optimizes the reclamation and recycle of the gas of the blast furnace and the converter; the reclamation and separation of the CO2 in the gas are executed by a gas treatment system, an absorption tower and a regeneration tower with a built-in boiler, and a chemical absorption system is additionally provided; and the reclaimed CO2 and partial external CO2 can be used for blasting in a hot-blast stove of the blast furnace and carrying gas for injection fuel, and the reclaimed CO2 also can be used for replacing N2 to carry out slag splashing protection for the converter. The method realizes the recycle of the CO2 during iron making in the blast furnace and steel making in the converter, also can use the external CO2 reclaimed from the industrial waste gas in the industries of power, chemical engineering and the like, reduces the discharge of the CO2, realizes an environment-friendly steel production process, and has remarkable social and environmental benefits.

Owner:PEKING UNIV

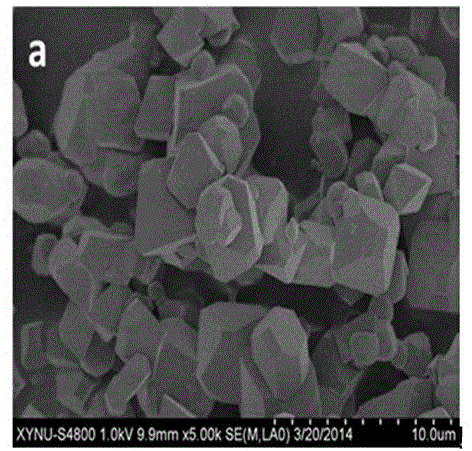

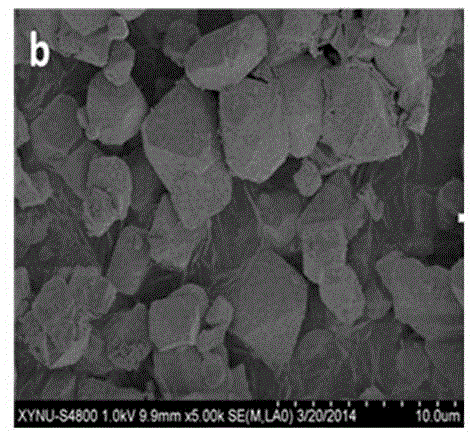

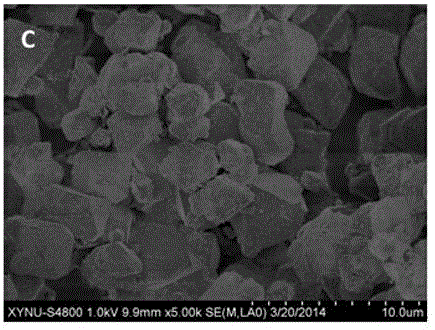

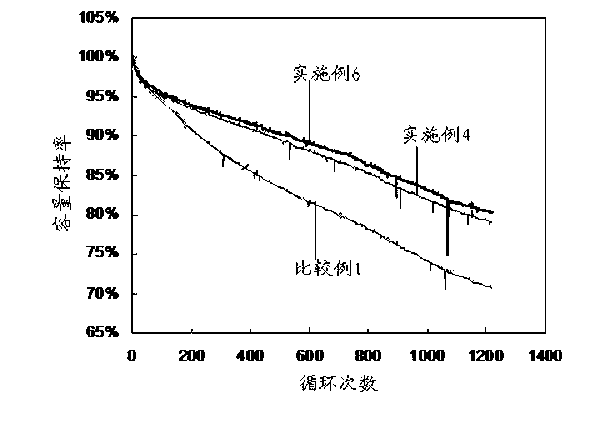

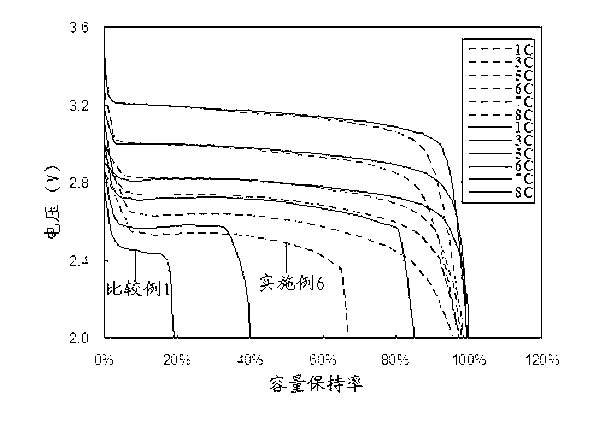

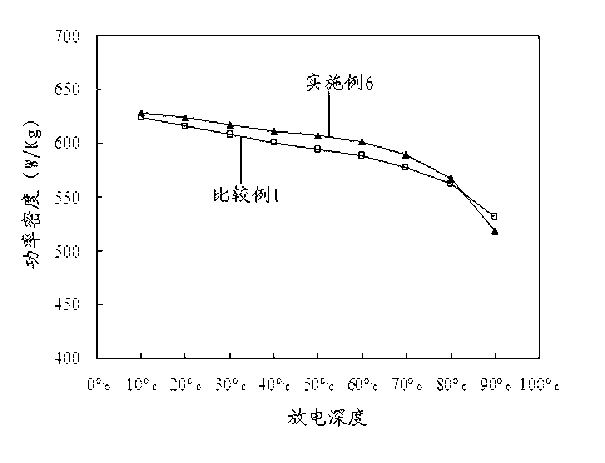

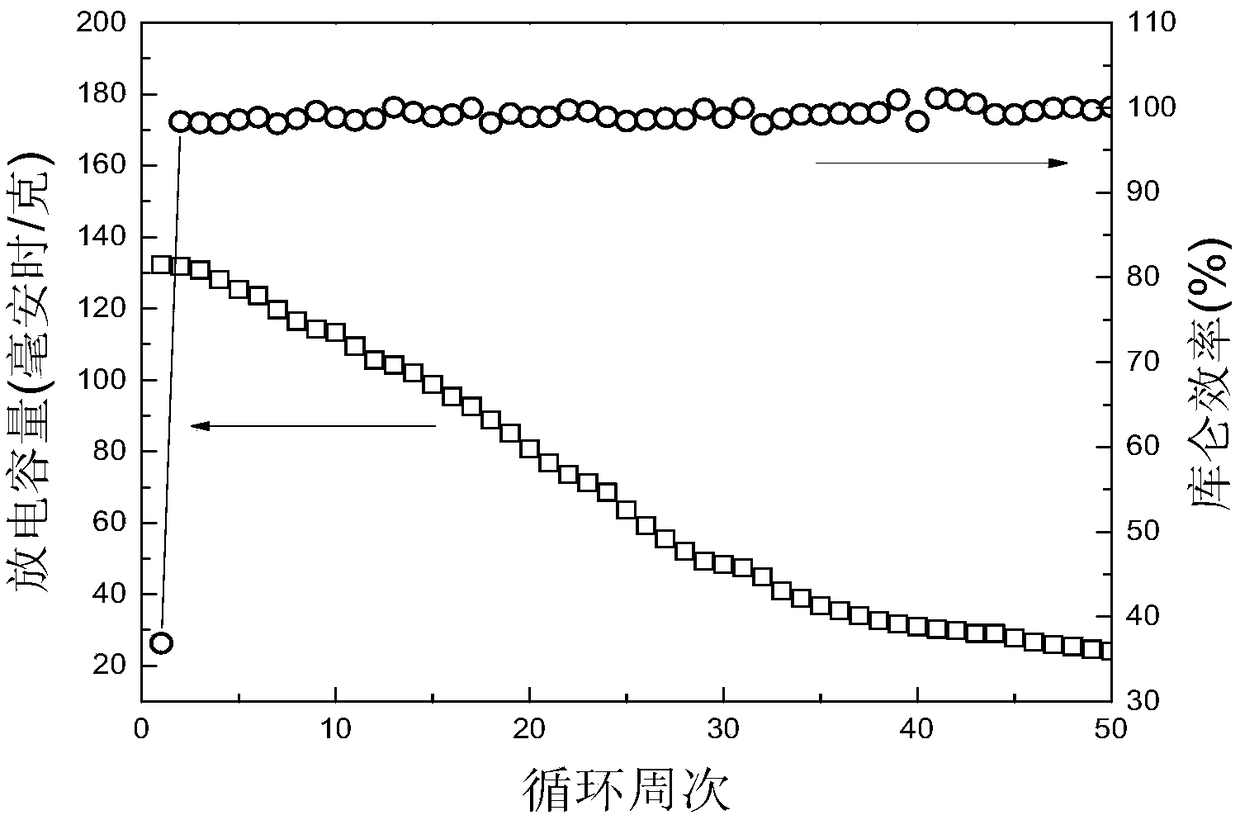

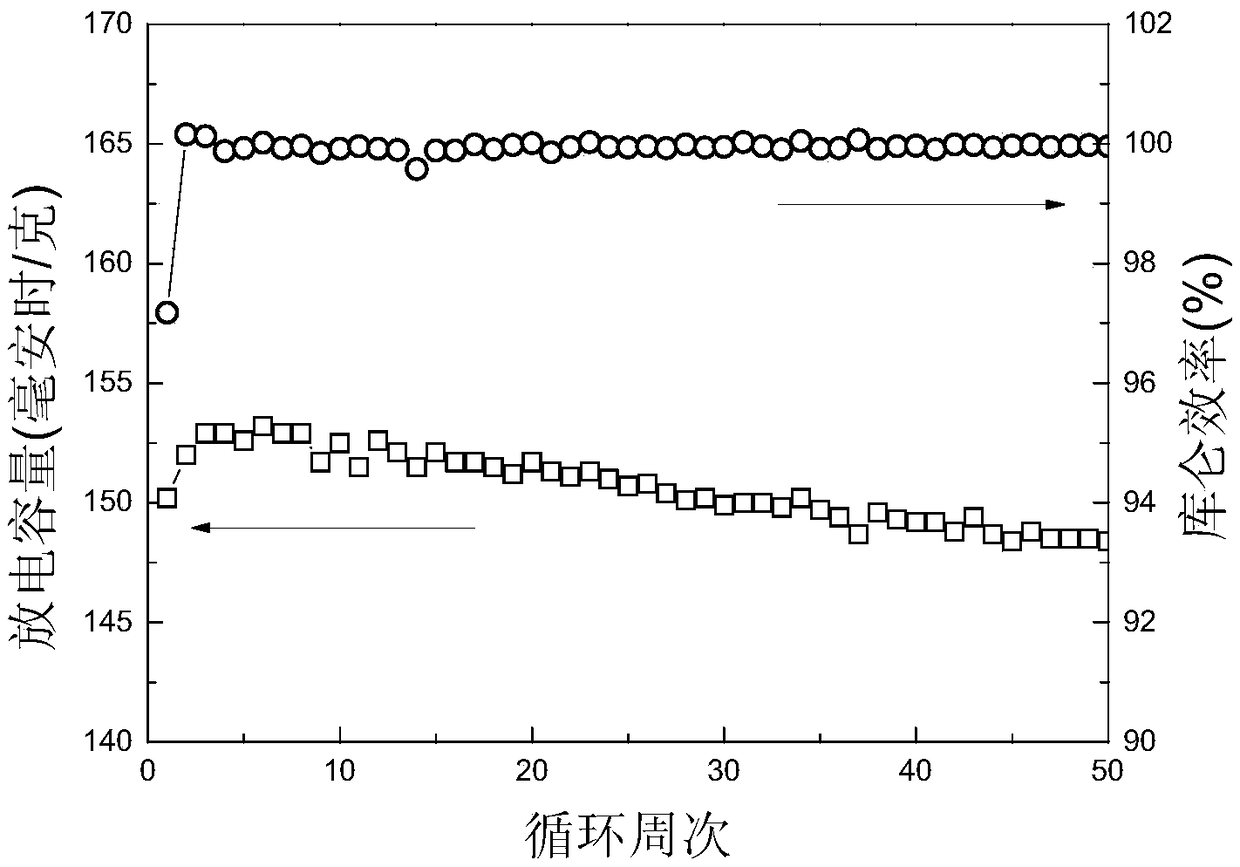

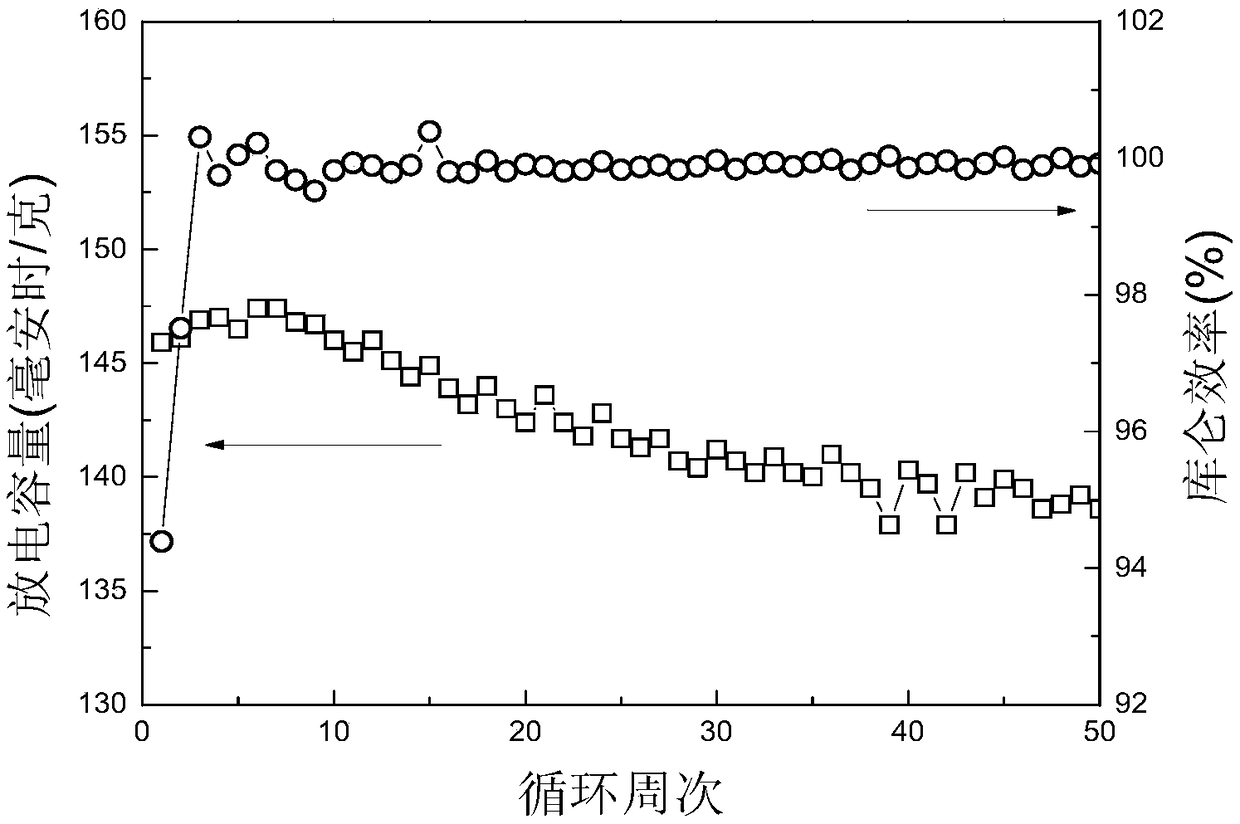

Graphene-coated nickel lithium manganate preparation method

ActiveCN104828878AGood removal effectHigh purityCell electrodesNickel compoundsManganatePhysical chemistry

The invention relates to a lithium ion battery cathode material graphene-coated nickel lithium manganate preparation method. The lithium ion battery cathode material graphene-coated nickel lithium manganate preparation metho belongs to the lithium ion battery technical field, and comprises the following steps: (1) preparing a nickel lithium manganate precursor; (2) preparing a graphene dimethyl formamide solution; (3) dropping the graphene dimethyl formamide solution obtained by the step (2) into the nickel lithium manganate precursor obtained by the step (1), and volatilizing to dry to obtain a nickel lithium manganate precursor mixed with graphene sheets; and (4) calcining the nickel lithium manganate precursor mixed with the graphene sheets obtained by the step (3) to prepare the lithium ion battery cathode material graphene-coated nickel lithium manganate. The lithium ion battery cathode material graphene-coated nickel lithium manganate preparation method has the advantages of low cost, simple process conditions, high covering rate, high purity, high specific capacity and good cyclic stability and the like.

Owner:YANCHENG TEACHERS UNIV

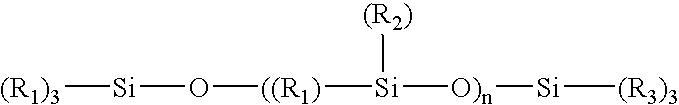

Curable fluids for forming coatings and adhesives

InactiveUS20030232187A1Good lookingImproved resistance to damageCosmetic preparationsMaterial nanotechnologyPolymer scienceAdhesive

Provided is a curable fluid with relatively low viscosity capable of forming a polymeric composition, subsequent to exposure to cure conditions. Also provided are coated articles made of substrates coated by such compositions, and further provided are composite articles made of substrates bonded by such compositions; further provided are methods of making such coated and composite articles.

Owner:KAUFFMAN THOMAS FREDERICK +1

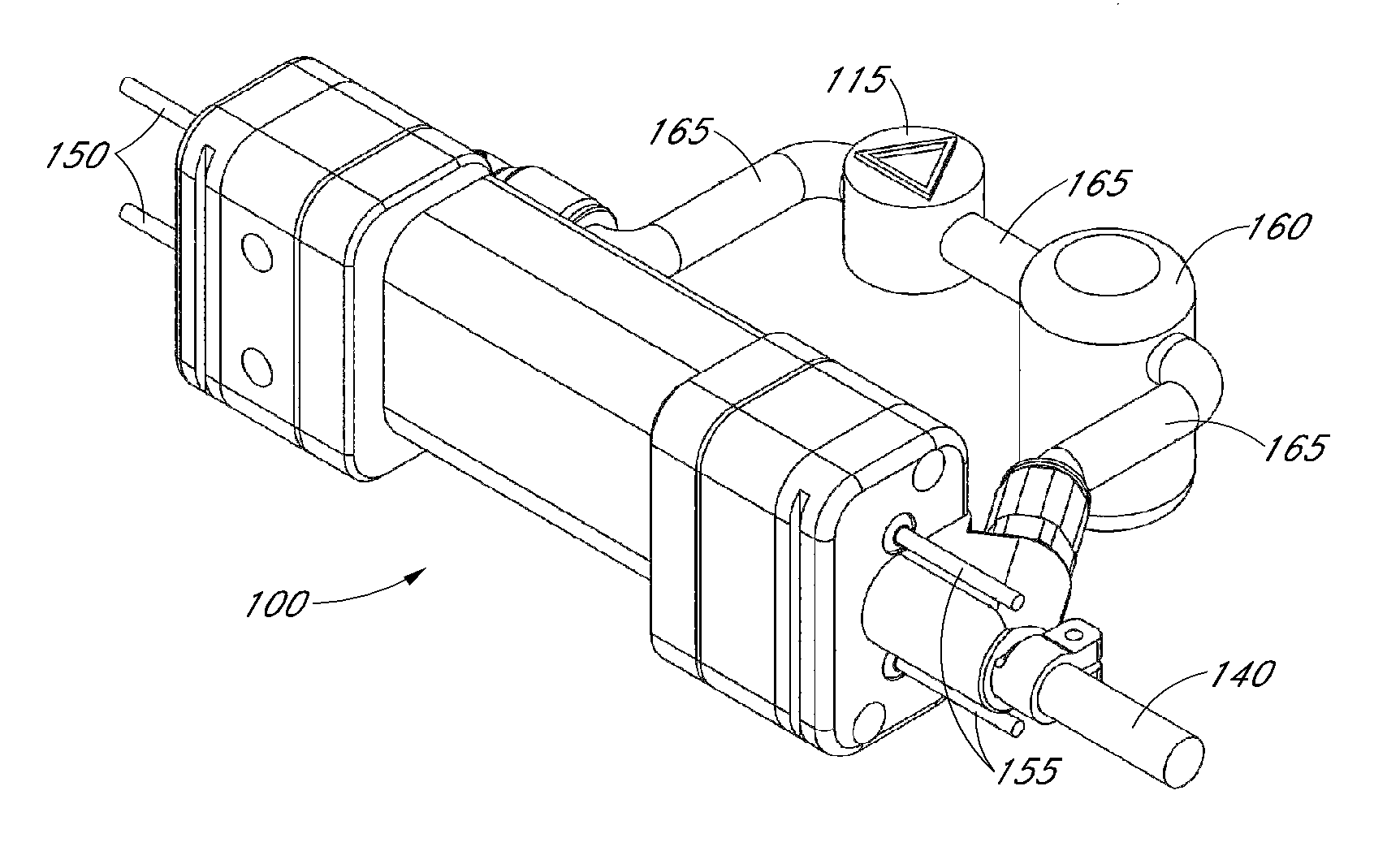

Fluorescent handpiece

ActiveUS20120215292A1Extended service lifeReduce chemical reactionsLight therapyFluorescenceBiological tissue

A handpiece can treat biological tissue using electromagnetic radiation, which can be substantially fluorescent light. The handpiece includes a source of electromagnetic radiation and a waveguide. The waveguide is adjacent the source, receives electromagnetic radiation from the source, and delivers the electromagnetic radiation to the biological tissue. The handpiece also includes a system for moving a fluorescent substance through the waveguide. The fluorescent substance includes a fluid base and a fluorescing agent and is capable of modulating at least one property of the electromagnetic radiation. A method is described for removing the fluorescing agent from the fluorescing substance and replacing it with a second, different fluorescing agent.

Owner:GUSTAVSSON NEVADA HLDG LLC

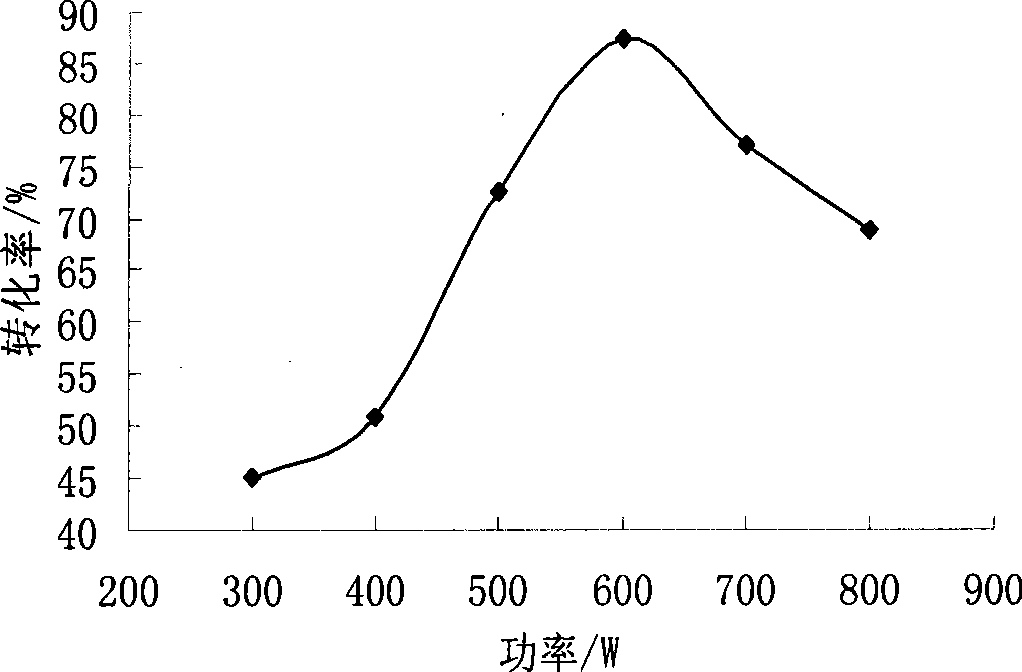

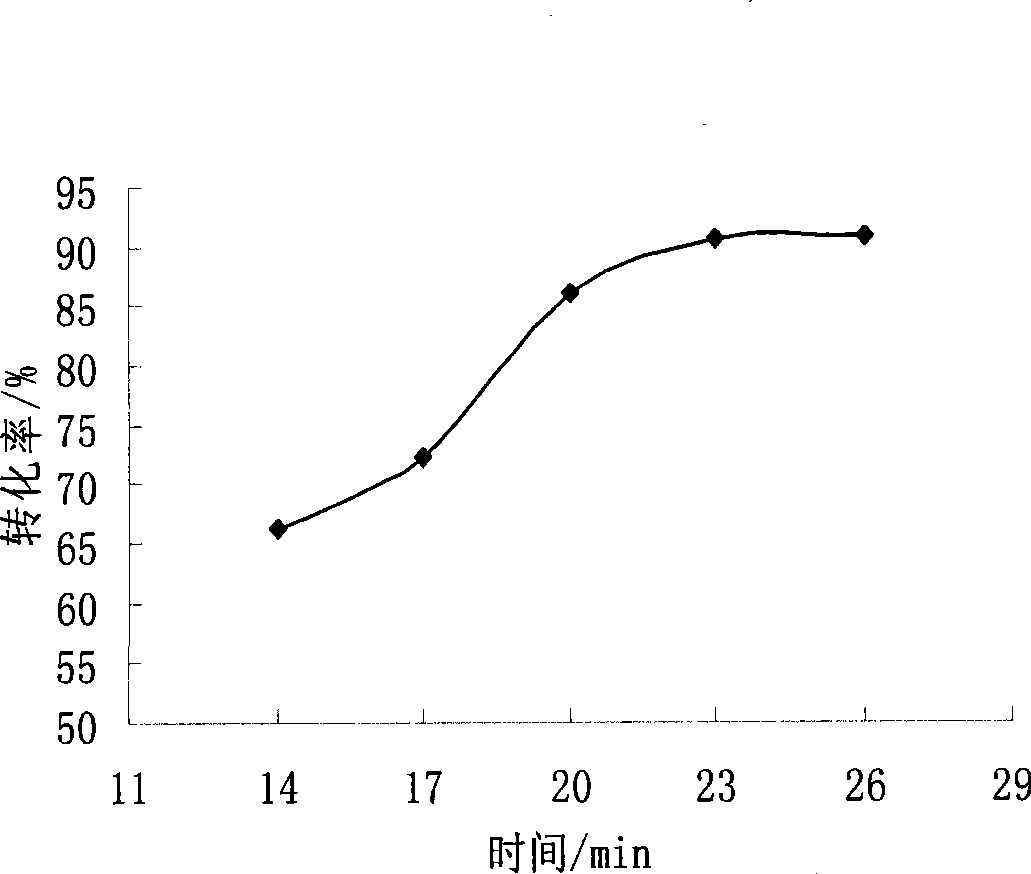

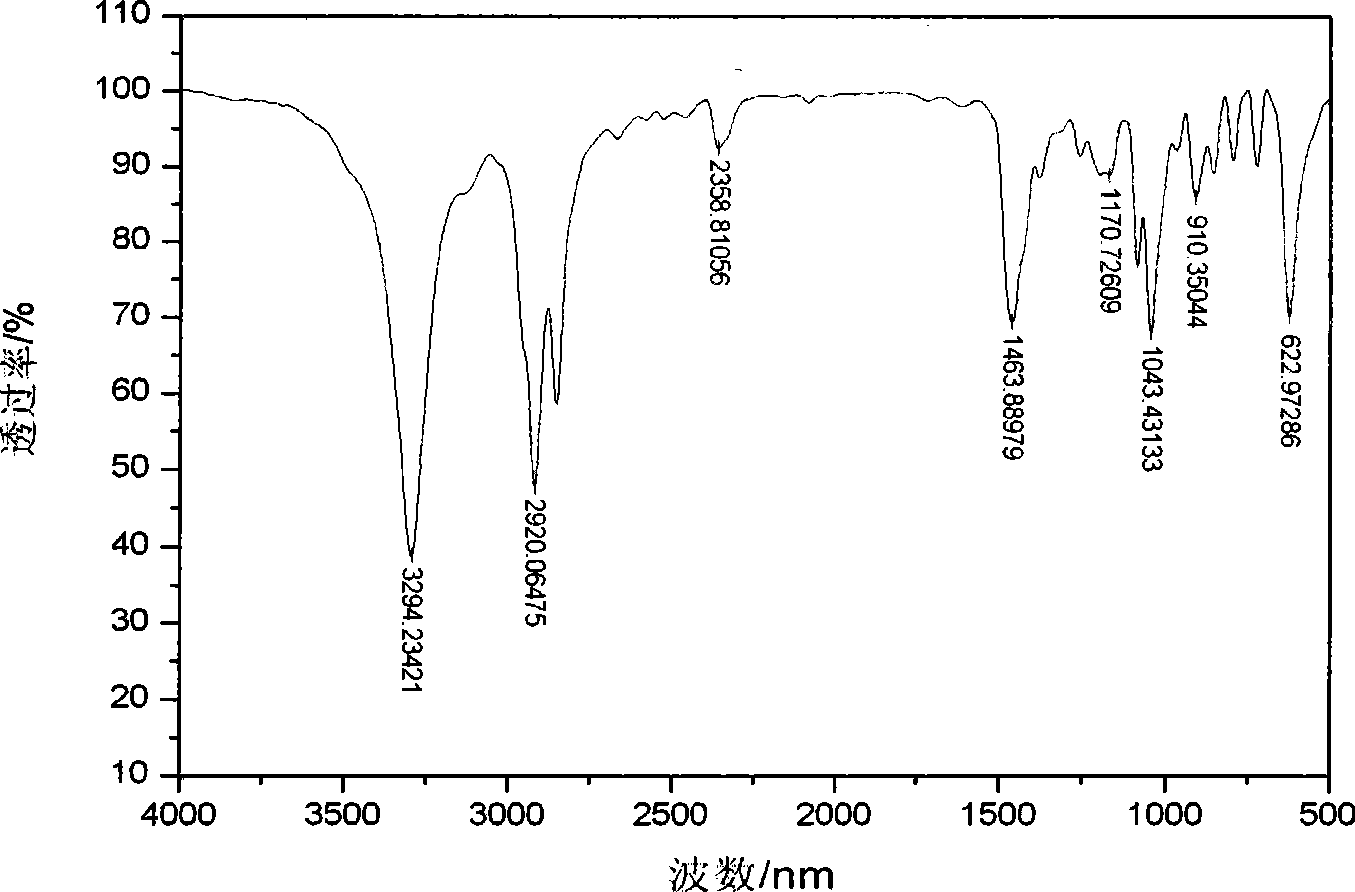

Microwave synthetic method of dodecyl methyl biethoxyl ammonium bromide

InactiveCN101381318AHigh yieldShort reaction timeOrganic compound preparationAmino-hyroxy compound preparationEtherAmmonium bromide

The invention provides a method for synthesizing dodecyl methyl dihydroxyethyl ammonium bromide by microwave. The method comprises the following steps: dissolving N-methyl diethano lamine and dodecyl bromide in normal butanol with the volume times of between 1.5 and 3; refluxing the mixed solution for 17 to 23 minutes in microwave with the power of between 500 and 700W; and adding absolute ether in the reaction solution after the reaction is completed to cause the product to be crystallized, thereby obtaining white solid. In the process of refluxing reaction, continuous action of the microwave and boiling of the reaction solution are maintained all along. By the prior method, the rate of conversion of the target product of the method is equivalent to that of the prior method, or even improved, but the reaction time required by the method is only about 5 percent of that of the prior method.

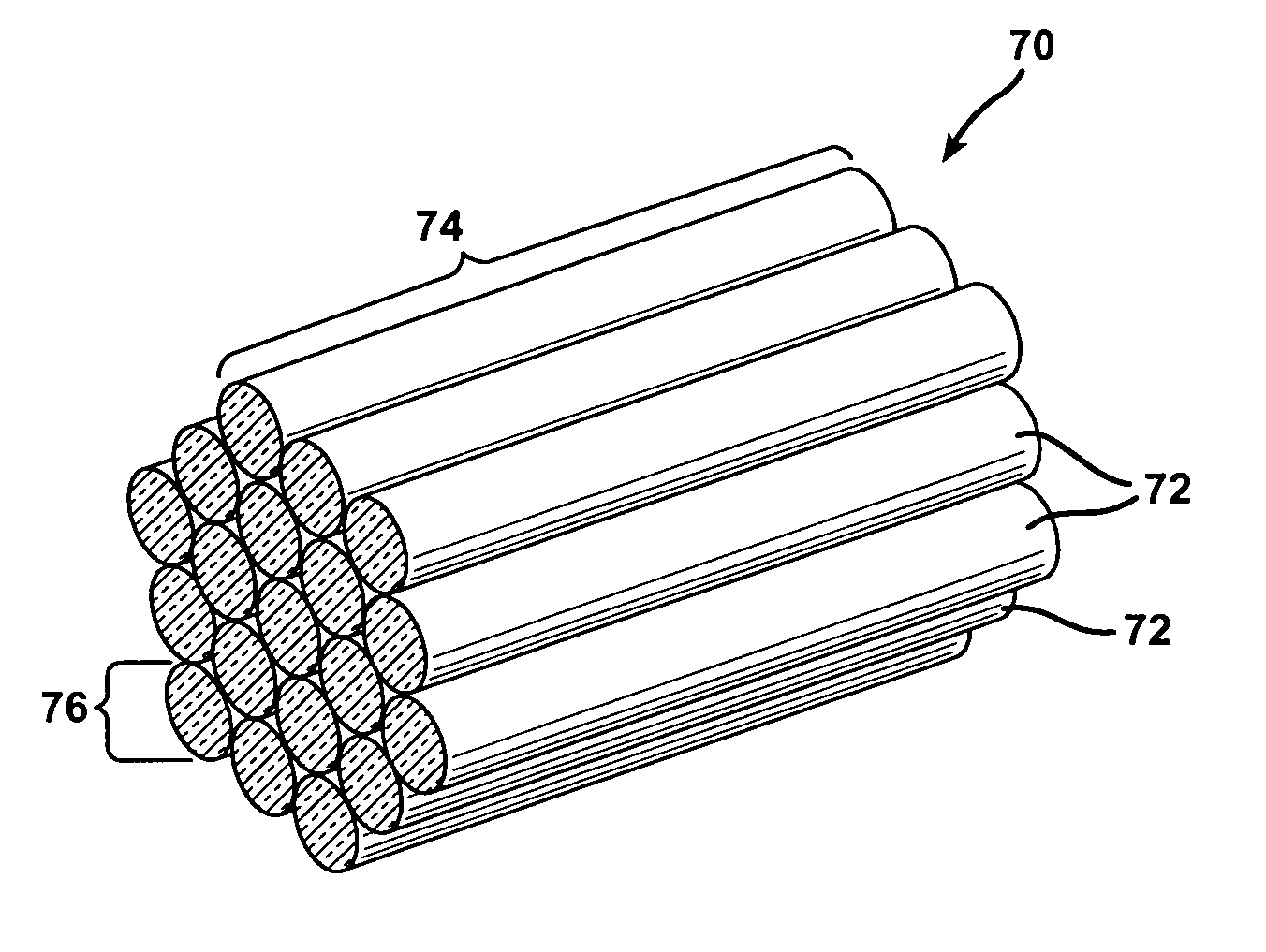

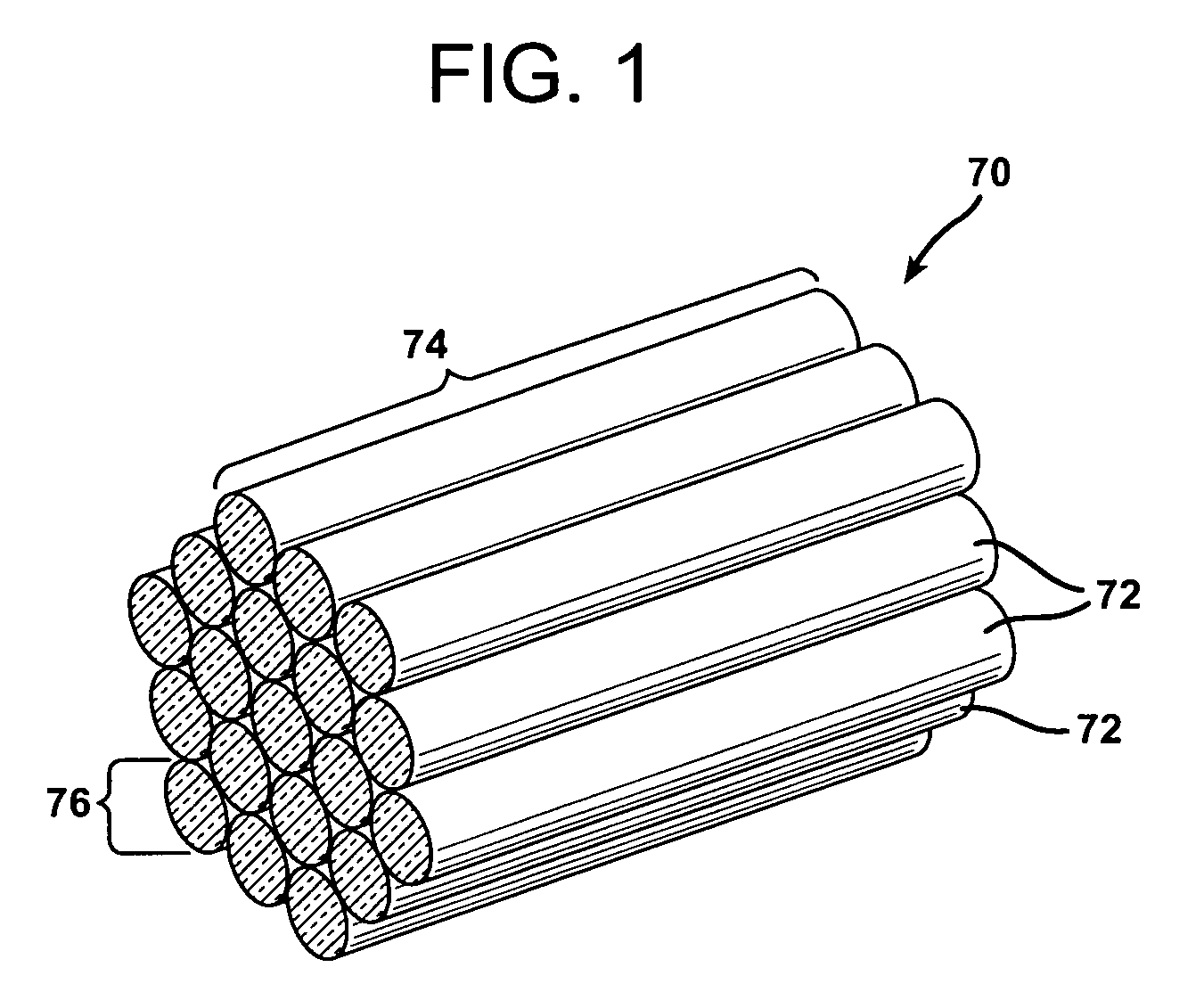

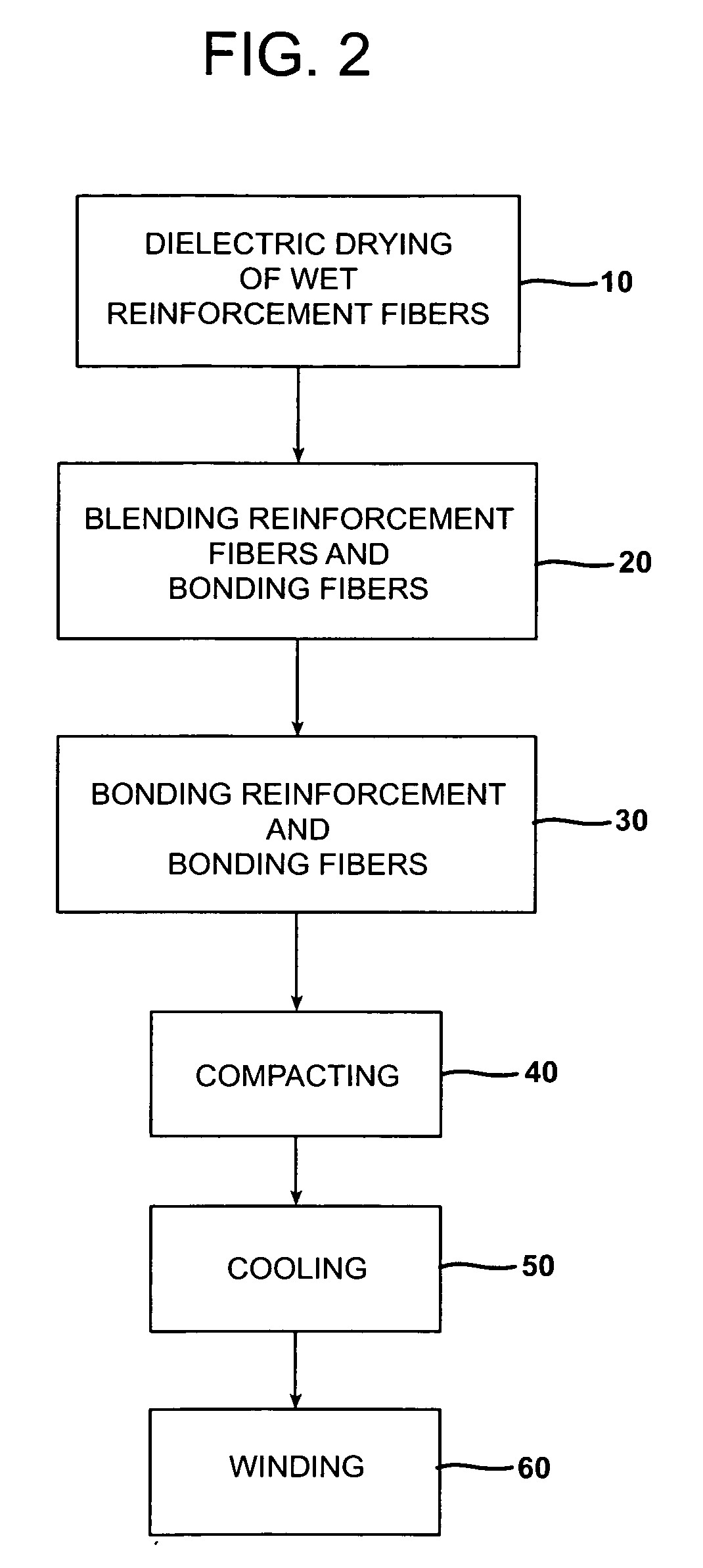

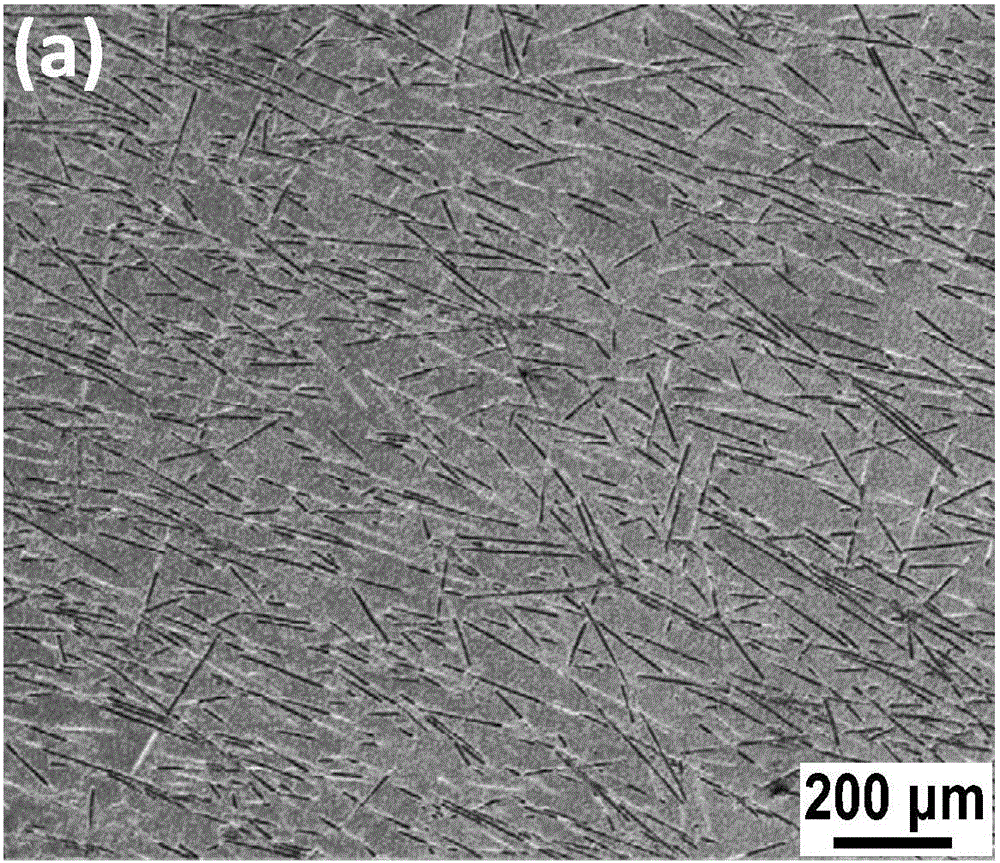

Polymer/WUCS mat and method of forming same

InactiveUS20070009722A1Lower costReduce adhesionSynthetic resin layered productsCeramic shaping apparatusFiber bundlePolymer

A chopped strand mat formed of bundles of dielectrically dried reinforcing fibers and bonding fibers is provided. The reinforcing fibers may be formed as bundles of wet reinforcing fibers with a bundle tex of about 10 to about 500. The reinforcing fibers may be formed of a single chop length of about 1 to about 1½ inches or a multi-chop length of fibers of about ½ to about 2 inches. The bonding materials may be any thermoplastic or thermosetting material having a melting point less than the reinforcing fiber. The chopped strand mat may be formed by dielectrically drying the wet reinforcement fibers, blending the reinforcement and bonding fibers, bonding the reinforcement and bonding fibers to form a chopped strand mat, compacting the mat, cooling the mat, and winding the mat into a continuous roll. The chopped strand mat contains a uniform or nearly uniform distribution of bonding fibers and bundles of dried reinforcement fibers.

Owner:OCV INTELLECTUAL CAPITAL LLC

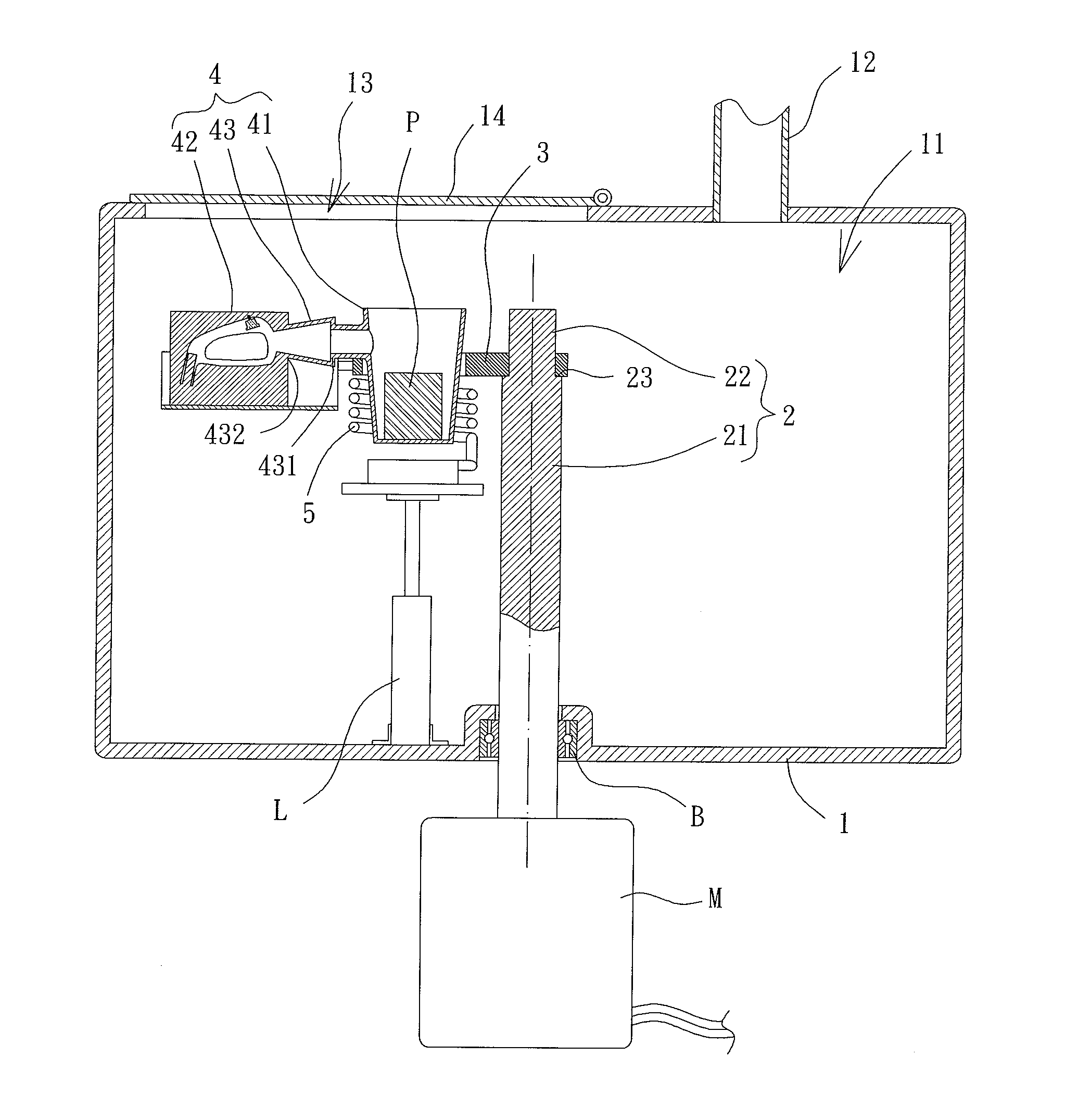

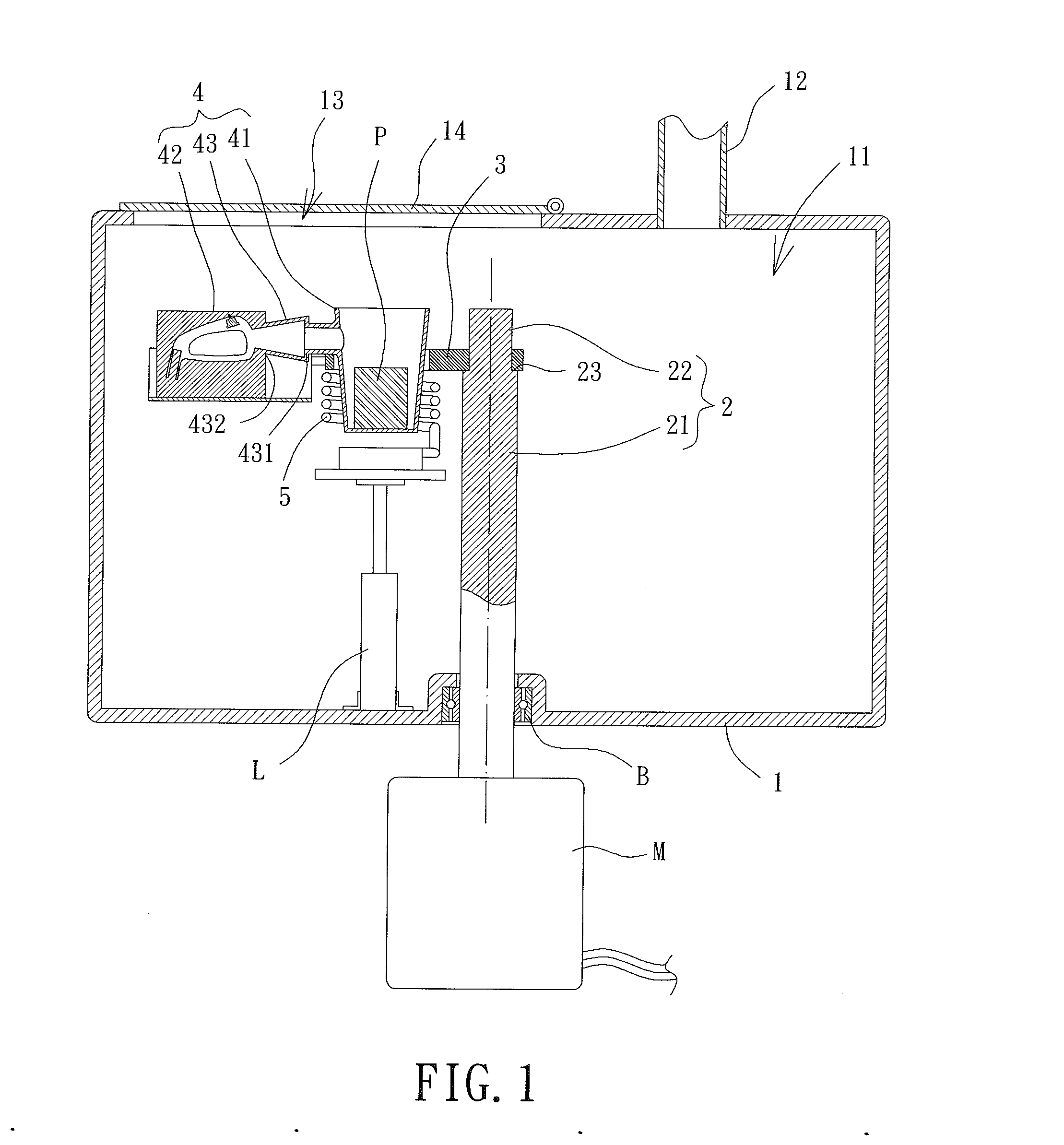

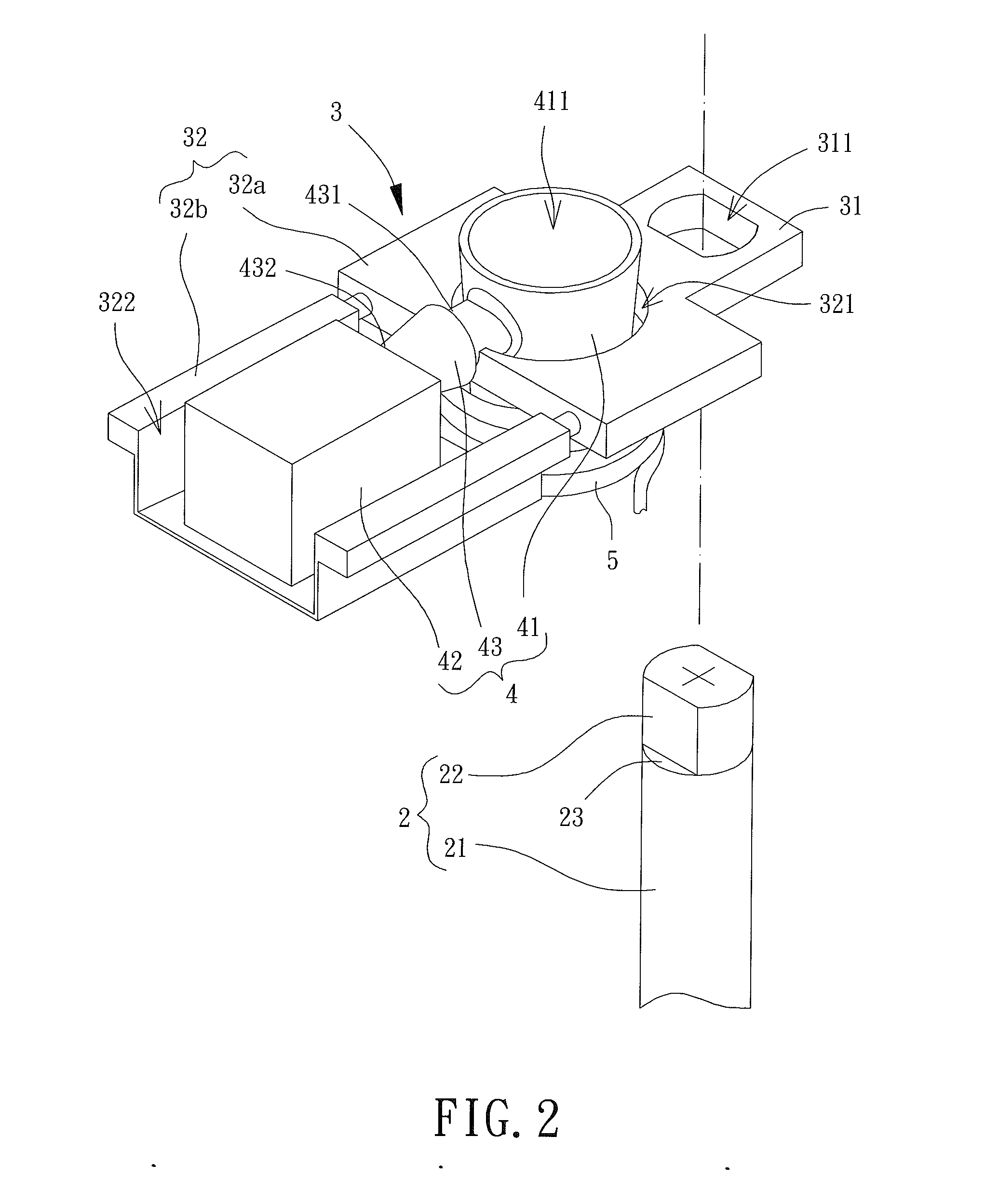

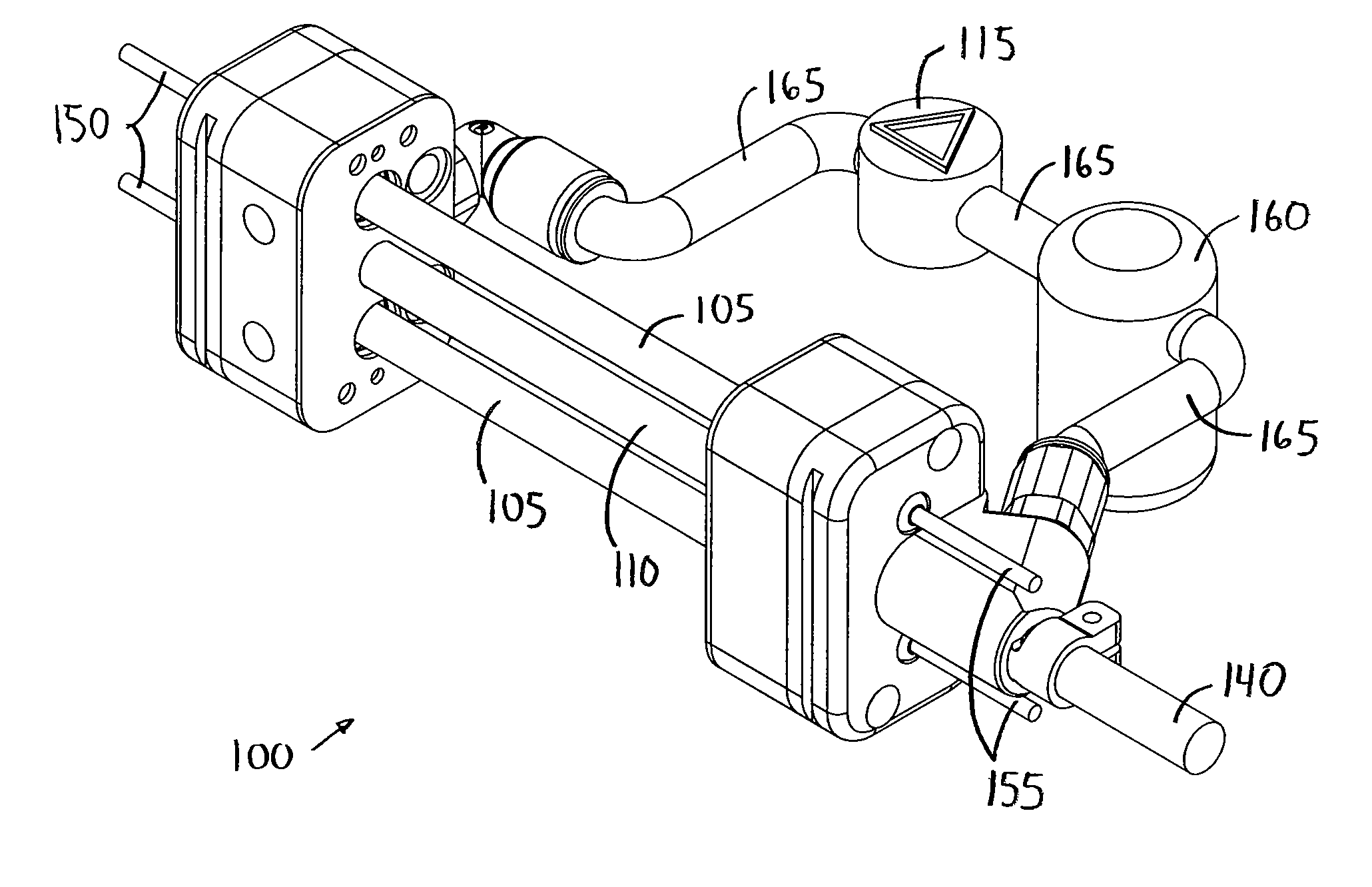

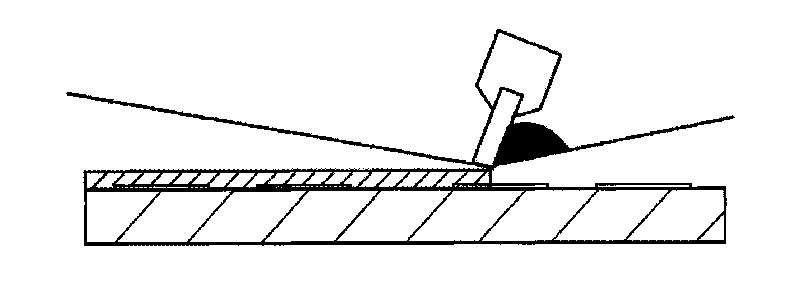

Casting Method for Manufacturing a Golf Club Head having an Embedded Heterogeneous Material

ActiveUS20150190686A1Reduce chemical reactionsImprove coupling strengthFoundry mouldsFoundry coresCrucibleInstability

A method for manufacturing a golf club head to solve a problem of coupling instability between cast materials and heterogeneous materials is disclosed. The method includes placing a shell mold with a crucible portion and a casting portion in communication with the crucible portion on a rotary table, with the casting portion including a cavity, with the heterogeneous material comprising an embedded portion inlaying in the casting portion of the shell mold and a non-embedded portion locating in the cavity of the casting portion, placing a metal ingot into the crucible portion, followed by melting the metal ingot into molten metal in a vacuum environment, driving the rotary table to rotate the rotary table, causing the molten metal to flow into the cavity, destroying the shell mold after the molten metal solidifies to obtain a casting including a cast product portion, separating the cast product portion from the casting to obtain a cast product of golf club head, and removing the embedded portion of the heterogeneous material protruding from a outer periphery of the cast product of golf club head.

Owner:FUSHENG PRECISION

Lithium ion battery and anode thereof

InactiveCN102709521AReduce the generation of HFInhibits decomposition and leaching of ironCell electrodesSecondary cellsPhysicsMolecular sieve

The invention belongs to the technical field of lithium ion batteries and particularly relates to an anode of a lithium ion battery. The anode comprises a current collector and an anode diaphragm arranged on the current collector, wherein the anode diaphragm comprises an anode active substance, a bonding agent and a conductive additive, the anode active substance comprises lithium iron phosphate, the anode diaphragm further comprises a lithiation molecular sieve which accounts for 0.1-10wt% relative to the total mass of the anode diaphragm. Compared with the prior art, the invention has the advantages that by addition of the lithiation molecular sieve in the anode, on one hand, the occurrence of side effects between electrolyte and trace moisture in a battery can be reduced effectively, the production of HF is reduced, the dissolution of ion elements in a cyclic process is reduced, and the cyclic stability of a material is increased; and one the other hand, the molecular cage structure of the lithiation molecular sieve provides lithium ion migration channels, so that the electric conduction of lithium ions is increased, and the high temperature performance and the multiplying performance of the lithium ion battery are increased favorably. In addition, the invention further provides the lithium ion battery comprising the anode.

Owner:NINGDE AMPEREX TECH

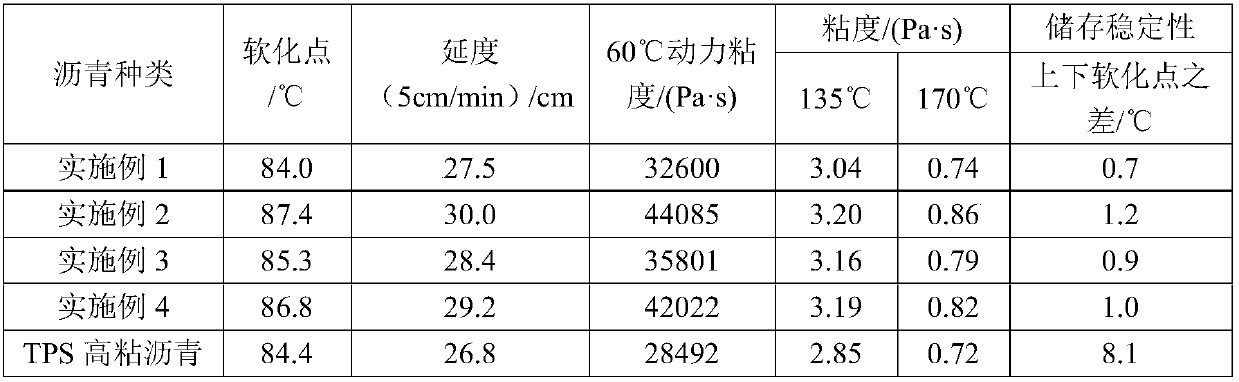

High-viscosity modified asphalt based on SBS/polyurethane compounding and preparation method thereof

InactiveCN109553991AImproved high temperature and bonding propertiesGood storage stabilityBuilding insulationsPrepolymerCarbamate

The invention discloses high-viscosity modified asphalt based on SBS / polyurethane compounding and a preparation method thereof. The preparation method includes: a) heating matrix asphalt to molten, adding a SBS modifier and uniformly mixing the components to make a mixture A, thus providing SBS-modified asphalt with incomplete swelling development; b) shearing the mixture A to obtain swelling-developed SBS-modified asphalt, adding a stabilizer to guarantee stability of a mixture B; c) adding a chain extender and a coupling agent, wherein the chain extender is a key factor of forming binding force after a curing reaction on a polyurethane prepolymer, and the coupling agent can reduce the chemical reactions between the polyurethane compound and micro amount of water in air, thus reducing theinfluence on storage stability and modification effect on the asphalt due to generated gas; d) finally, adding the polyurethane prepolymer, of which a molecular structure contains an active isocyanate group, which can react with a hydroxyl group, in the asphalt, to generate a carbamate group, therefore, a chemical reaction is carried out with amino groups in the matrix asphalt to generate allophanate.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS +1

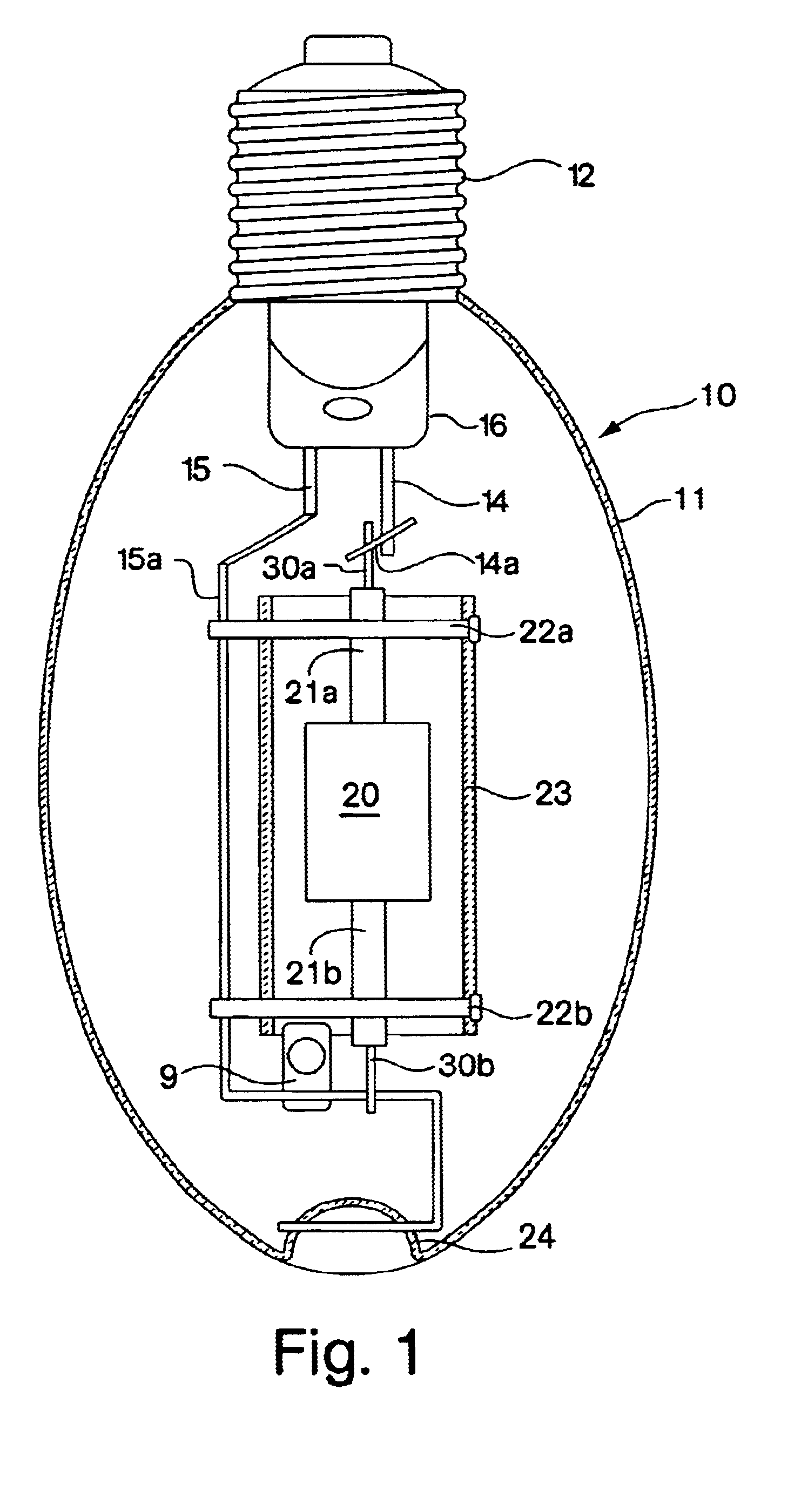

Fluorescent handpiece

ActiveUS7955367B2Extended service lifeLess expensiveSurgical instrument detailsLight therapyNonlinear waveguideElectromagnetic radiation

A handpiece can treat biological tissue using electromagnetic radiation, which can be substantially fluorescent light. The handpiece includes a source of electromagnetic radiation and a nonlinear waveguide. The nonlinear waveguide is adjacent the source, receives electromagnetic radiation from the source, and delivers the electromagnetic radiation to the biological tissue. The handpiece also includes a system for circulating a fluorescent substance through the nonlinear waveguide. The fluorescent substance is capable of modulating at least one property of the electromagnetic radiation.

Owner:GUSTAVSSON NEVADA HLDG LLC

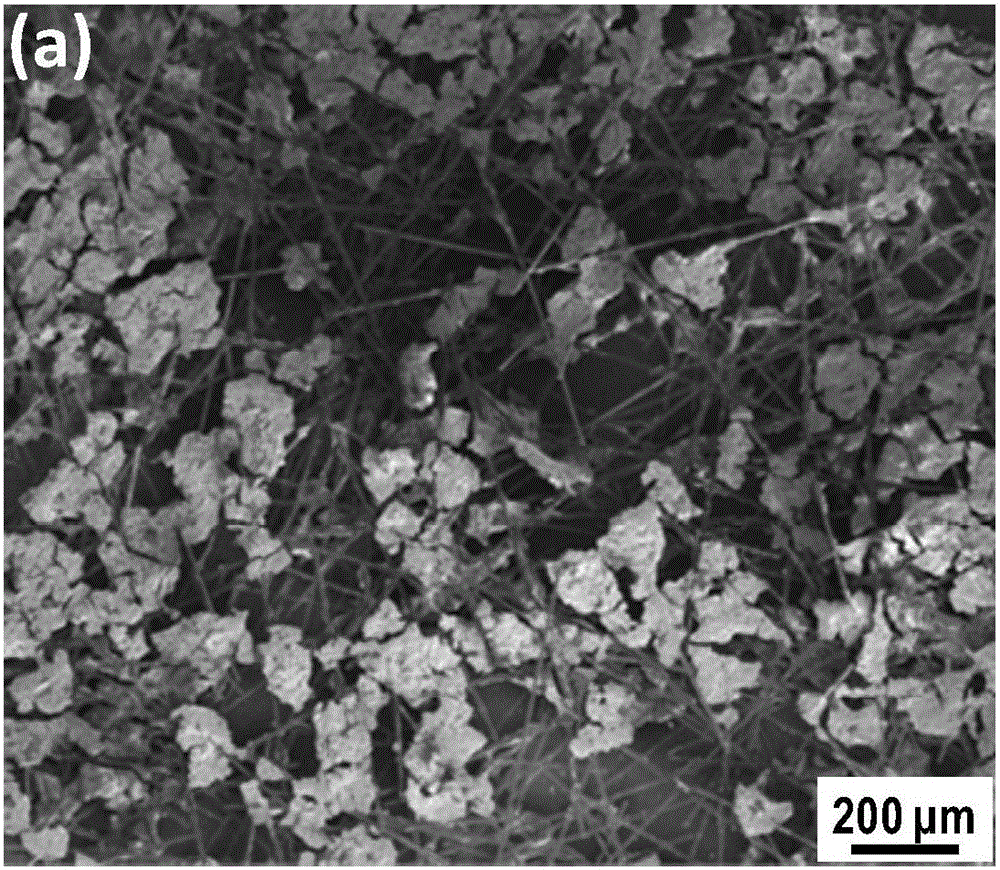

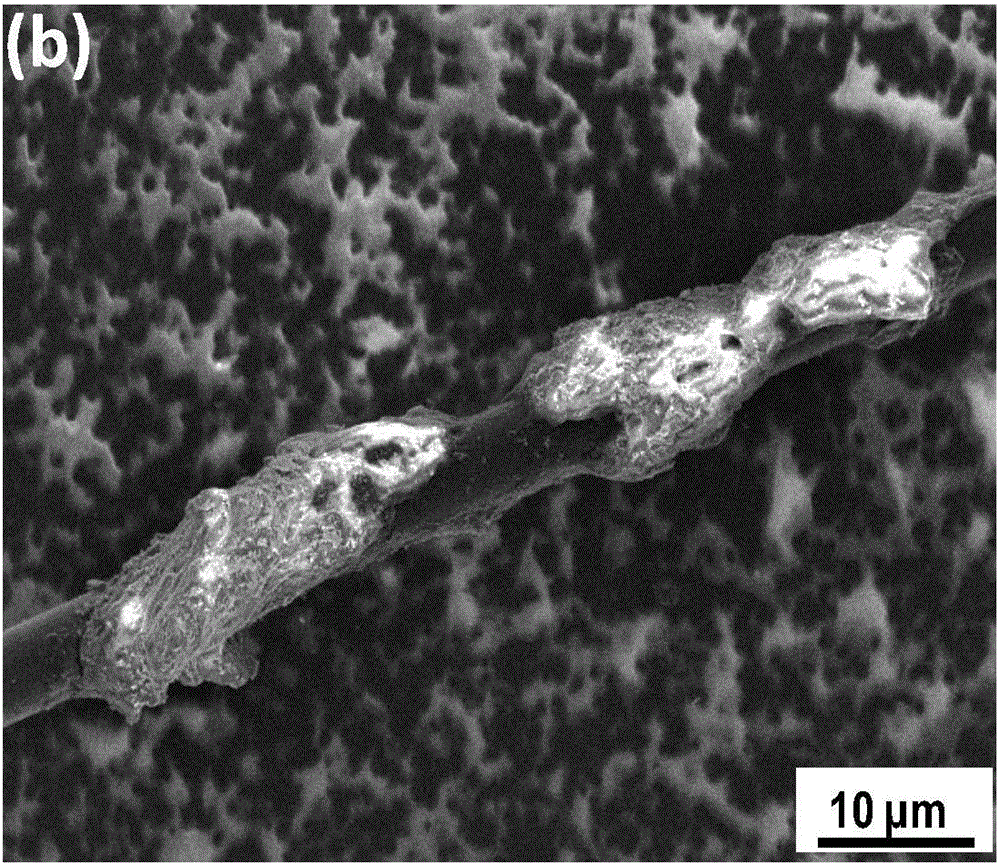

Zirconium diboride-based composite material toughened by colloid-dispersed chopped carbon fibers and preparation method thereof

ActiveCN105906360AReduce the degradation rateReduce chemical reactionsPhenol formaldehyde resinAnhydrous ethanol

The invention discloses a zirconium diboride-based composite material toughened by colloid-dispersed chopped carbon fibers and a preparation method thereof and belongs to the technical field of ultrahigh-temperature ceramic-based composite materials. The zirconium diboride-based composite material is prepared from the raw materials including, by mass, 1-3 parts of the chopped carbon fibers, 15-25 parts of nano zirconium diboride powder, 1-3 parts of nano silicon carbide powder, 1-5 parts of phenolic resin, 0.1-0.5 parts of polyethyleneimine, and 60-100 parts of anhydrous ethanol. In the invention, the phenolic resin and the polyethyleneimine are subjected to a crosslinking reaction, wherein the short carbon fibers are uniformly dispersed in the colloid, thereby overcoming a problem of abrasion of the fibers during conventional ball-milling material blending. Through the colloid dispersion method, a high-temperature protective layer is formed on the surface of the carbon fibers, and further degradation rate during high-temperature sintering of the carbon fibers is reduced, interface bonding among fiber substrates is weakened, and debonding, bridge connection and pulling-out of the fibers are promoted. The zirconium diboride-based composite material has high compactness, high strength and high toughness.

Owner:DALIAN UNIV OF TECH

Fluorescent handpiece

ActiveUS20140309717A1Easy to handleExtended service lifeLight therapyElectromagnetic radiationWaveguide

A handpiece can treat biological tissue using electromagnetic radiation, which can be substantially fluorescent light. The handpiece includes a source of electromagnetic radiation and a waveguide. The waveguide is adjacent the source, receives electromagnetic radiation from the source, and delivers the electromagnetic radiation to the biological tissue. The handpiece also includes a system for moving a fluorescent substance through the waveguide. The fluorescent substance includes a fluid base and a fluorescing agent and is capable of modulating at least one property of the electromagnetic radiation. A method is described for removing the fluorescing agent from the fluorescing substance and replacing it with a second, different fluorescing agent.

Owner:GUSTAVSSON NEVADA HLDG LLC

Compound membrane for lithium battery, preparation method and application thereof

ActiveCN109411681AGrowth inhibitionReduce chemical reactionsMaterial nanotechnologyLi-accumulatorsMetallic lithiumChemical reaction

The invention discloses a compound membrane for a lithium battery, a preparation method and an application thereof. The compound membrane comprises a polymer matrix membrane, a polyacrylonitrile sulfide ionic conductive particle coating located on one side of the polymer matrix membrane and an inorganic ceramic particle coating and / or polymer modifying layer arranged on the other side of the polymer matrix membrane. The compound membrane can be singly used as a lithium battery membrane matched with a conventional electrolyte and also can be used together with a functional electrolyte; the compound membrane can form a solid electrolyte in the manner of formation and can form a quasi-solid or all-solid metal lithium battery; the compound membrane is capable of effectively restraining the growth of lithium dendrites, restraining the puncturing of lithium dendrites to membrane, stopping the lithium dendrites to reach positive pole side, reducing further chemical reaction between metal lithium and electrolyte, effectively protecting a metallic lithium electrode and promoting thermal stability, mechanical stability and safety; the compound membrane is suitable for high-energy density lithium ion batteries, metal lithium batteries and compound metal lithium batteries.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

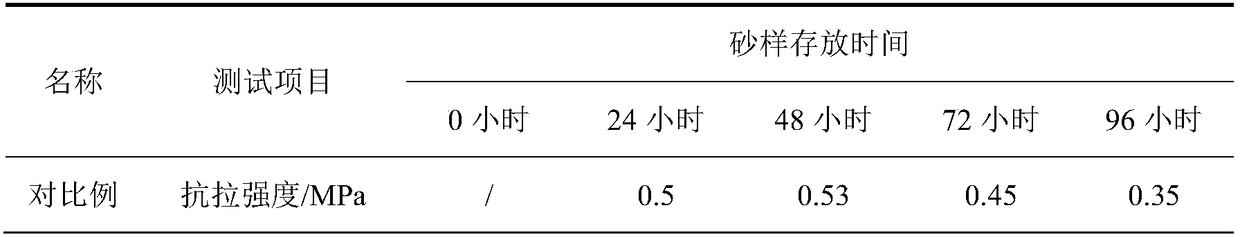

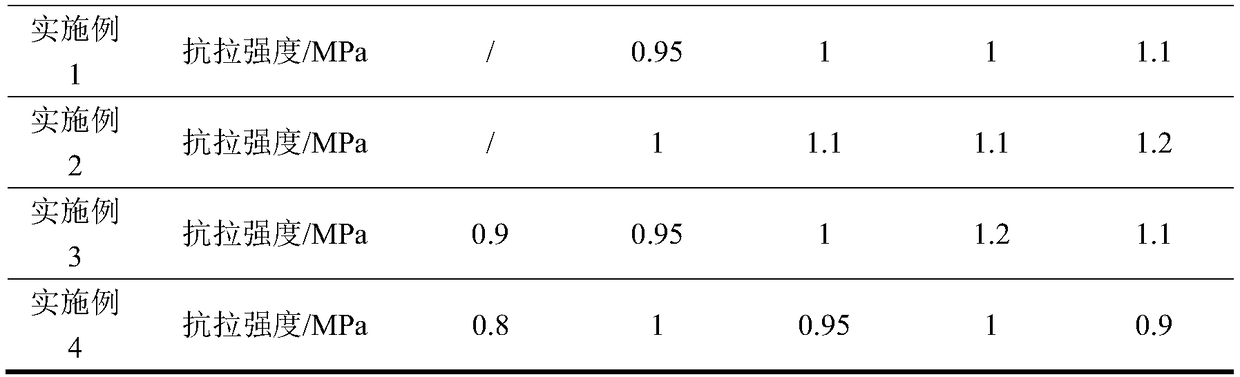

Liquid curing agent for phosphate bonding agent and application thereof

ActiveCN109454200AWith initial strengthHigh strengthFoundry mouldsFoundry coresPhosphateCalcium Binder

The invention discloses a liquid curing agent for a phosphate bonding agent and application thereof. The curing agent comprises two components, wherein 45.16%-55.17% of silane coupling agent serves asthe component I; 44.83%-54.84% of the component II comprising water and citric acid, and the component II, the citric acid accounts for 9.68%-17.24%, and the water accounts for 27.59%-45.16%. The liquid curing agent disclosed by the invention is wide in ram material source, low in cost and simple in preparation and application process. The liquid curing agent is long in using time when used for self-hardening sand production and short in demolding time and is used for bowing hardening of cold core boxes. The adopted compressed air is low in cost, environment-friendly and free of pollution.

Owner:HUBEI UNIV OF TECH

Electrode paste, electrode made from same, manufacturing methods thereof and PDP display screen provided with electrode

InactiveCN101728148ASimple manufacturing processLower sintering temperatureGas discharge electrodesAlternating current plasma display panelsSilver electrodeMetallurgy

The invention provides electric paste and preparation method thereof. The electrode paste comprises silver powder, black glass paint, low melting point glass powder and organic matter ingredients, wherein the black low melting point glass powder comprises 5-20 percent of black glass paint and low melting point glass powder by weight; the silver powder comprises 40-70 percent of high tap density spherical silver powder and 5-10 percent of microcrystal silver powder by weight; and the organic matter ingredients comprises high molecular copolymer, photoinitiator, a solvent, a defoaming agent, a surfactant and a pH regulating agent, and the like. The invention also provides a photosensitive silver electrode made from the electrode paste, a manufacturing method thereof and a PDP display screen provided with the electrode. By using the electrode paste, the electrode with high electrical conductivity can be obtained only by using one layer of paste and carrying out once drying and sintering process.

Owner:SICHUAN COC DISPLAY DEVICES

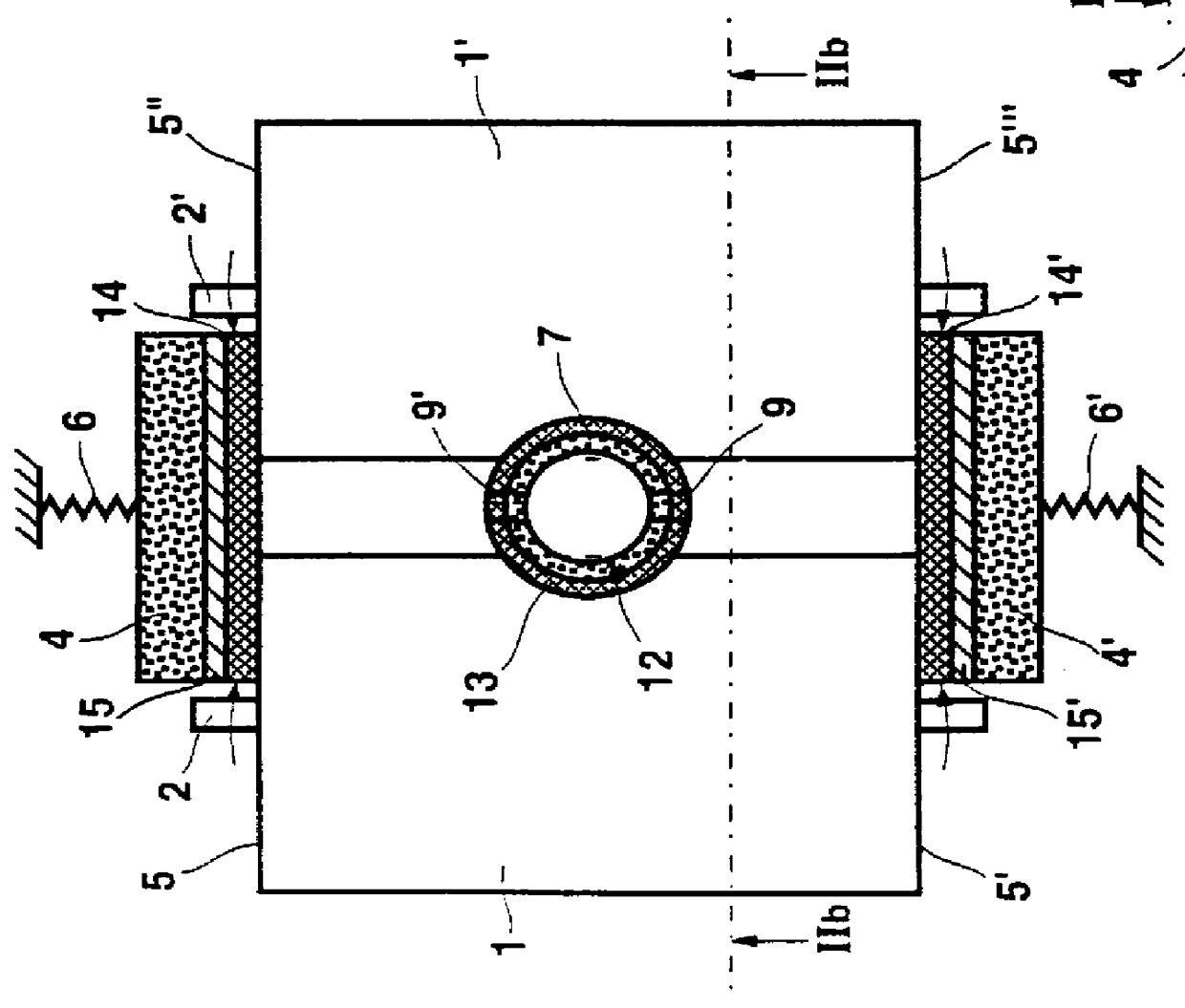

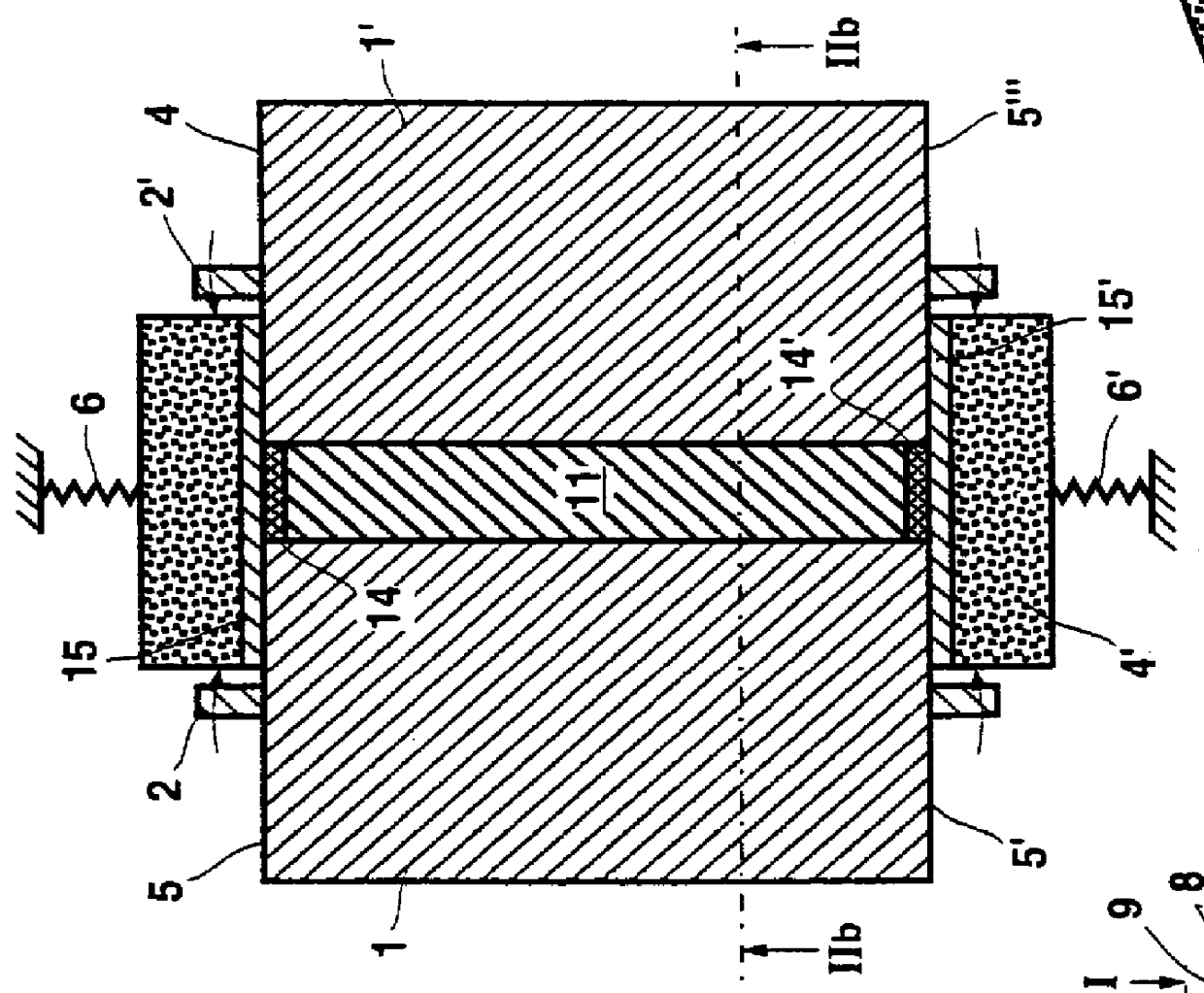

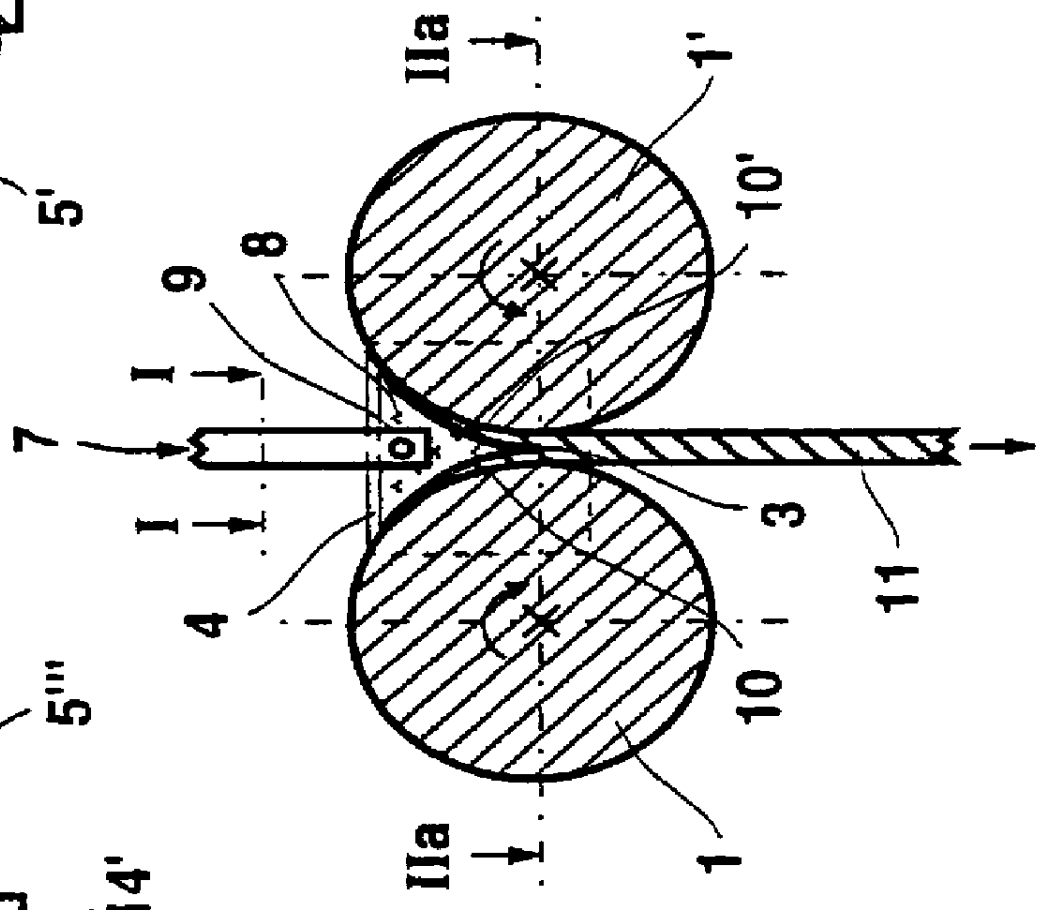

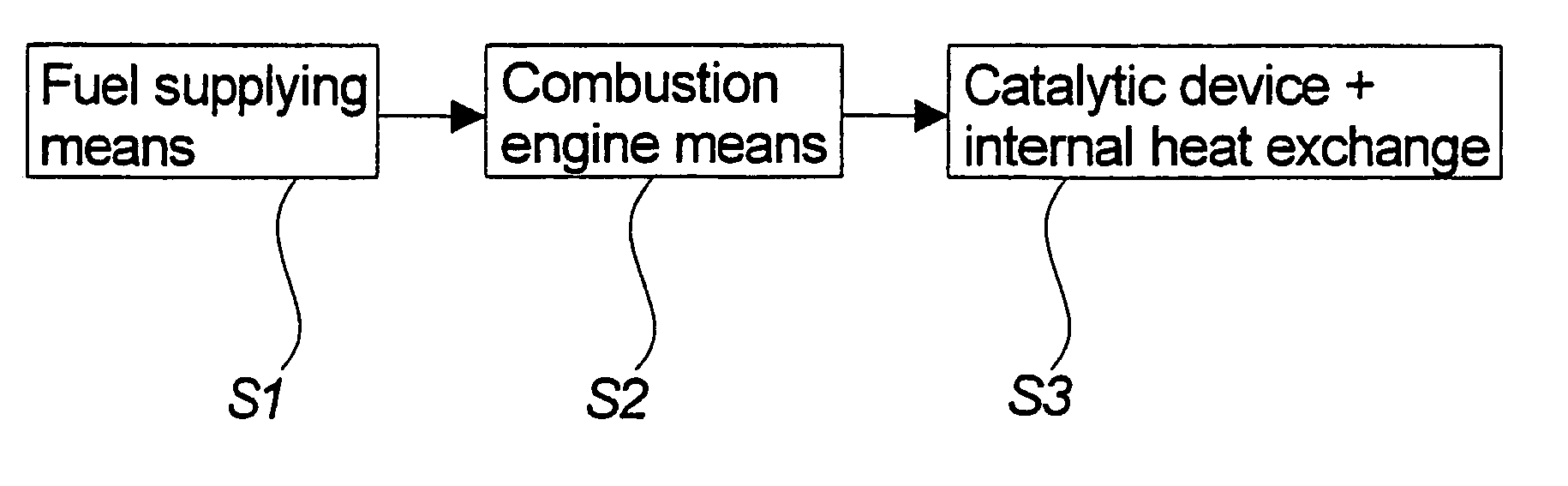

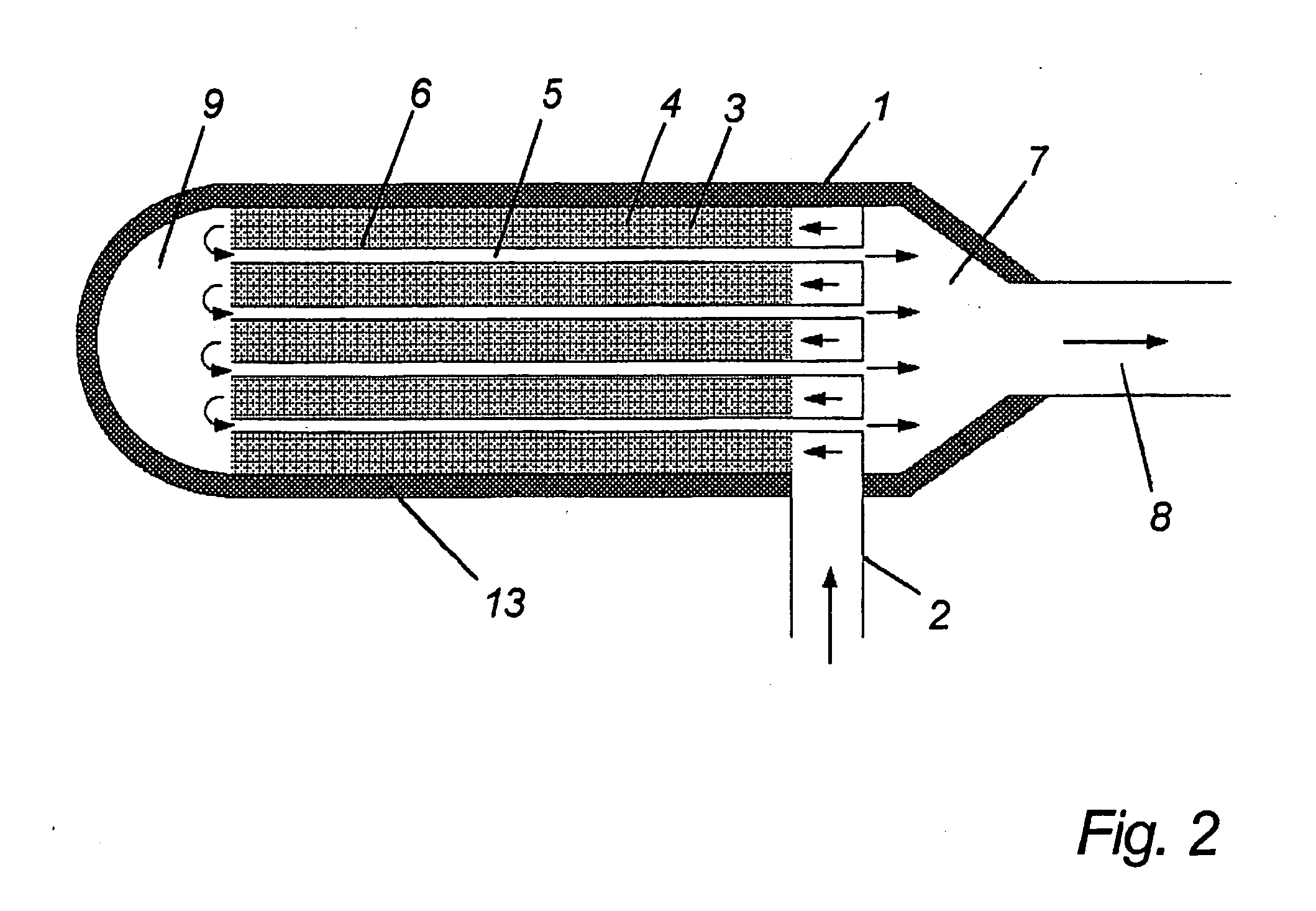

Catalytic device with internal heat exchange

InactiveUS20060048501A1Reduce and control heat exchangeSafer burnoutFuel cell auxillariesDispersed particle separationExhaust fumesEngineering

The invention relates to a catalytic device with internal heat exchange that among other things can be used for vehicles with an internal combustion engine or for stationary engines where there is a certain amount of unburned gas components in the exhaust that can be converted in the catalyst. By the invention it is obtained that the maximum temperature in the catalyst is always nearly constant whatever the inlet temperature. Hereby, the catalyst can be designed to work at a very specific temperature, by which it is possible, partly to ensure a better and safer burnout of the unburned components, and partly to save expenses for catalyst materials. The exhaust gas is guided through the catalyst by at least three passage sections that have a mutual internal heat exchange. In the main reaction passage section there are catalytic materials of one or several kinds, in which the gas can react, and in which the gases heat exchange with the succeeding main heat transfer passage section passage.

Owner:RECCAT

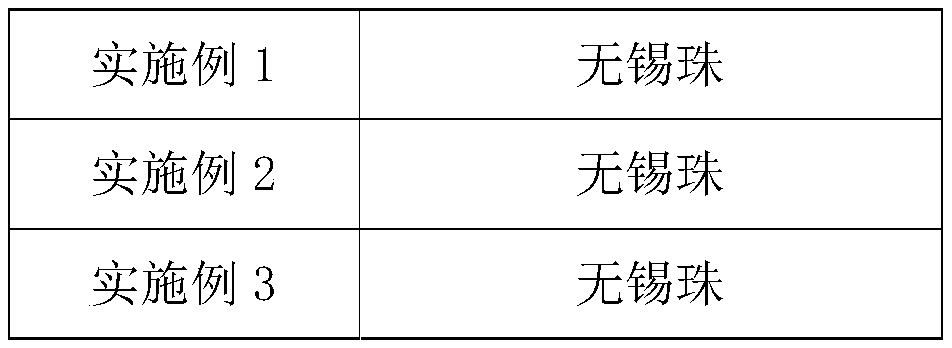

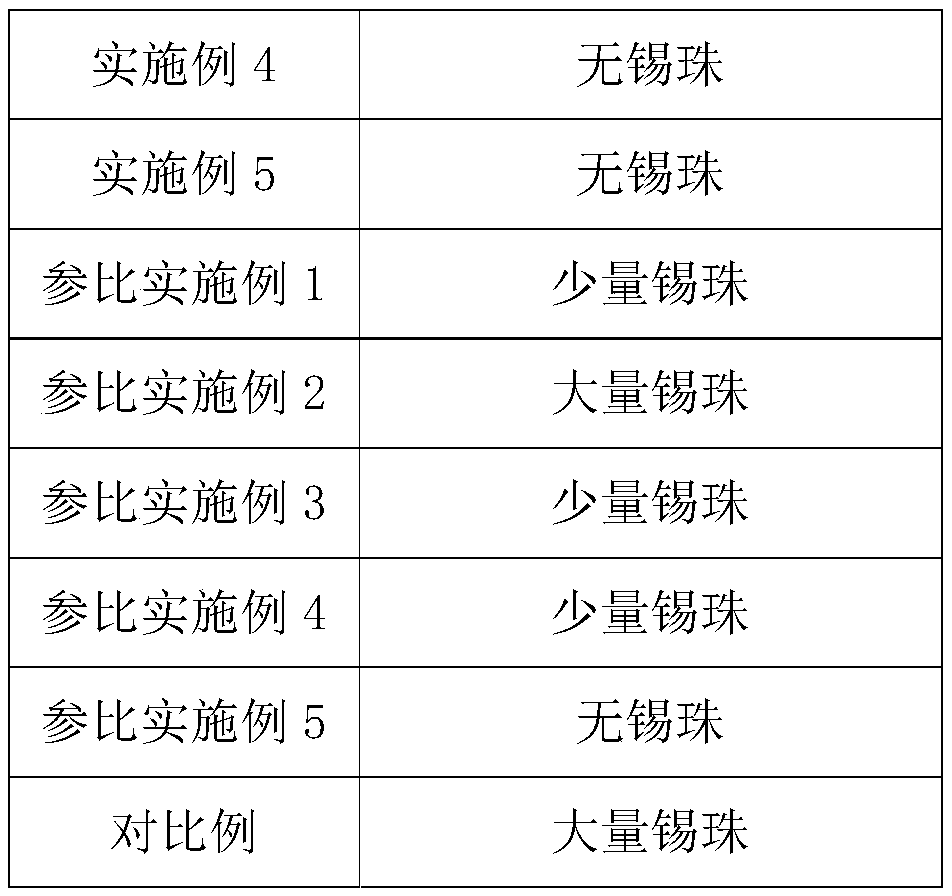

Anti-splashing laser soldering paste and preparation method thereof

ActiveCN111571064AIncrease moistureReduce oxidationWelding/cutting media/materialsSoldering mediaOrganic acidAlloy

The invention provides anti-splashing laser soldering paste. The anti-splashing laser soldering paste is prepared from raw materials in percent by weight: 87%-90% of alloy powder and 10%-13% of scaling powder. The alloy powder is formed by mixing one or more kinds of tin-based alloy powder and has a eutectic composition. The scaling powder is prepared from components in percent by weight: 35%-55%of rosin, 4%-9% of a thixotropic agent, 3%-9% of organic acid, 2%-8% of organic amine, 2%-6% of a high-boiling-point additive, 1%-2% of a compound X and the balance being a solvent. The invention further provides a preparation method of the anti-splashing laser soldering paste. The anti-splashing laser soldering paste can achieve instant welding, and has good wettability, and the problems of tin blasting, splashing, tin balls, non-tin-melting and the like are avoided.

Owner:深圳市唯特偶新材料股份有限公司 +1

Amorphous copper catalyst and preparation method and application thereof

ActiveCN101733130AImprove belt yieldLow costOrganic compound preparationAmino-carboxyl compound preparationDehydrogenationAlloy

The invention relates to an amorphous copper catalyst and a preparation method and application thereof. The preparation method comprises the following steps: heating copper, aluminum, and an alloy consisting of a transition metal M and aluminum to melt; rapidly cooling and curing the melts; and performing extraction treatment on the cured alloy by using alkali solution so as to extract most aluminum to obtain the catalyst. The catalyst prepared by the method has high catalytic activity and stability and excellent abrasion resistance, and can be applied to catalytic dehydrogenation oxidation reaction of diethanol amine.

Owner:CHINA PETROLEUM & CHEM CORP +1

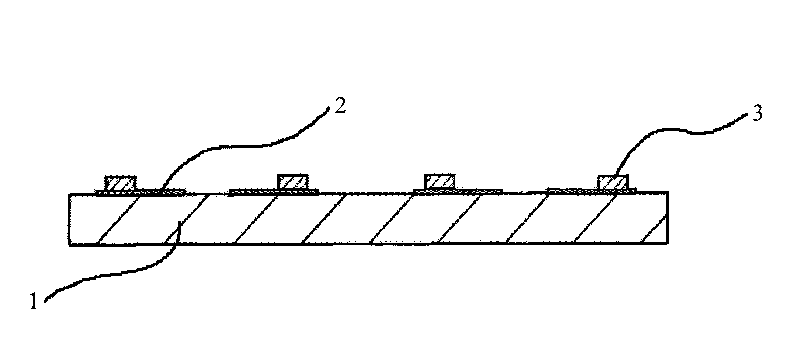

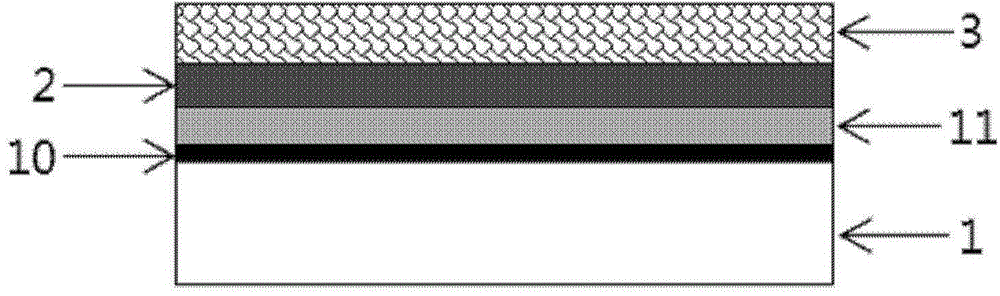

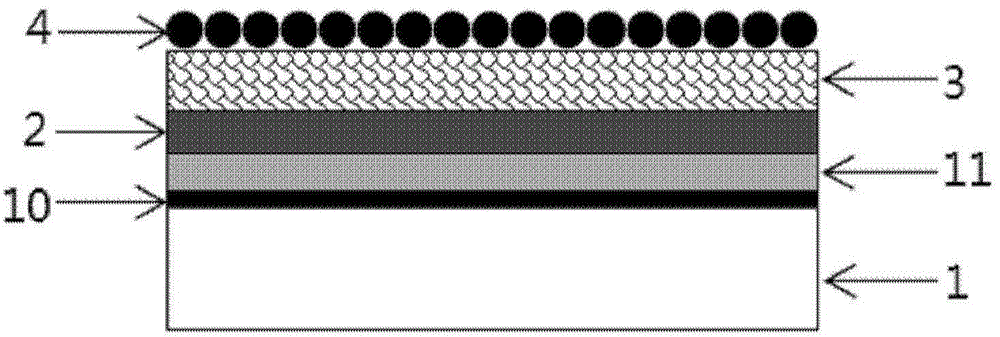

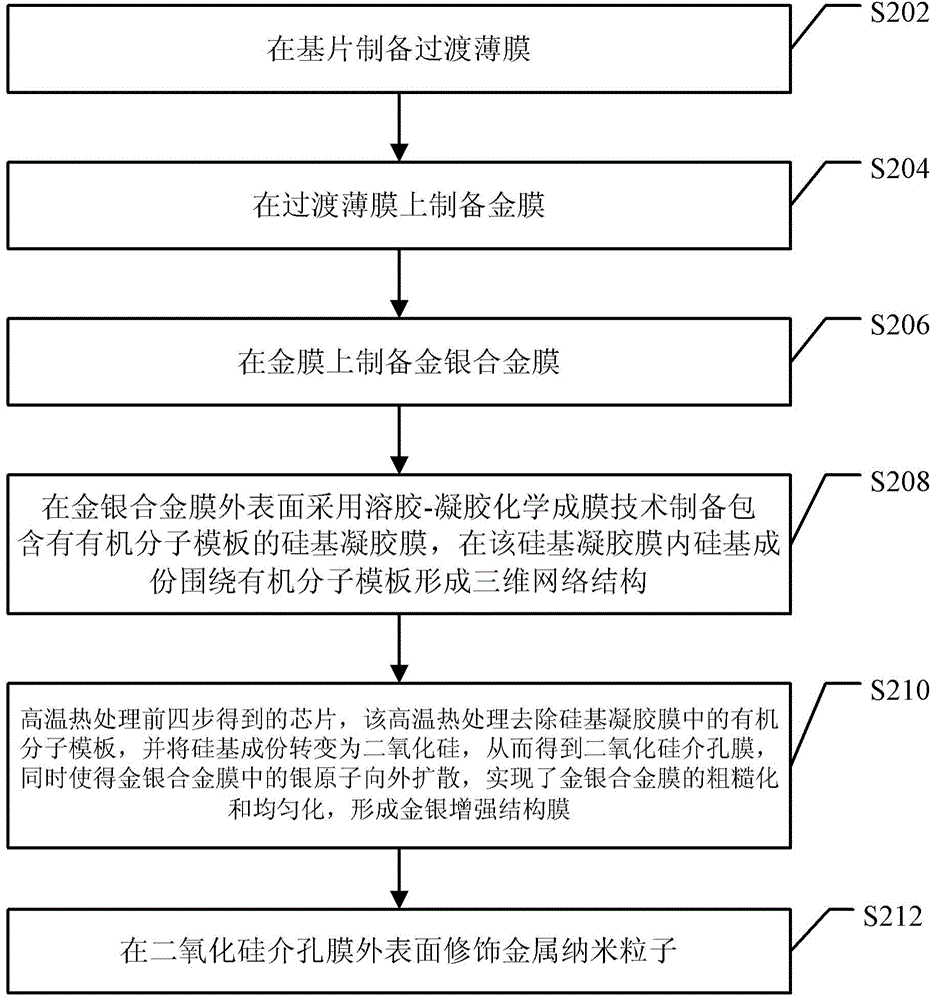

Large-area uniform raman detection chip for porous membrane sensitivity enhancing and preparation method for large-area uniform raman detection chip

ActiveCN104406953AImprove Raman detection sensitivityIncrease the number of molecules to be testedRaman scatteringNanoporous membranePorous membrane

The invention provides a large-area uniform raman detection chip for porous membrane sensitivity enhancing and a preparation method for the large-area uniform raman detection chip. The raman detection chip comprises a substrate, a gold-based enhanced structural membrane which is formed on the substrate and is used as an electromagnetic enhancement layer of the raman detection chip, and a nano porous membrane which is formed on the outer surface of the gold-based enhanced structural membrane so as to enrich molecules to be detected. According to the large-area uniform raman detection chip for porous membrane sensitivity enhancing, the nano porous membrane serving as a molecule enriching layer can obviously increase the quantity of the molecules to be detected within a local enhanced electric field working range, so that the raman detection sensitivity of the chip is improved; the large-area uniform raman detection chip is particularly suitable for detection on small-molecular substances with ultralow concentration. The raman detection chip disclosed by the invention has the advantages of low preparation cost, high large-area uniformity and the like, and can suppress interference on a raman fingerprint diagram of the molecules to be detected due to metals.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Method for processing coal gangue and red mud

ActiveCN102671906AReduce chemical reactionsReduce pollutionSolid waste disposalCoal gangueMaterials science

The invention discloses a method for processing coal gangue and red mud, which belongs to the technical field of pollution treatment of the coal gangue and the red mud, and aims at solving the technical problem to provide a layer upon layer piling method which is low in cost and can reduce environment pollution of the coal gangue and the red mud in maximum limit. The technical scheme is that the coal gangue and the red mud are laminated and piled, wherein a bottom first layer is provided with the coal gangue, a bottom second layer is provided with the red mud, and then the coal gangue and the red mud are alternately laminated and piled layer upon layer, at last the red mud is laminated and piled on a top layer, the thickness of the coal gangue on the first layer on the bottom first layer is 60-500cm, the thickness of the red mud on the bottom second layer is 5-100cm, the thickness of the red mud on the top layer is 30-50cm, and the thicknesses of the other layers are 5-15cm. The method for processing the coal gangue and the red mud can pile and process two kinds of production wastes such as the coal gangue and the red mud at the same time, and achieves the purpose of reducing environment pollution by neutralizing the coal gangue and the red mud with each other.

Owner:段明丰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com