Microwave synthetic method of dodecyl methyl biethoxyl ammonium bromide

A technology of dodecyl bromide and methyldiethanolamine, applied in the field of chemistry, can solve the problems of slow reaction speed, reduced yield, longer reaction time, etc., and achieves the advantages of improving yield, being beneficial to absorption, and suppressing side reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] 1. Preparation: Dissolve 1.19g of N-methyldiethanolamine and 2.49g of dodecyl bromide in 7ml of n-butanol, boil and reflux in a microwave with a power of 636W for 23 minutes, and finally add the reaction product to the reaction solution The product was crystallized with 6 times the volume of anhydrous ether to obtain a white solid, the product. Using bromophenol blue-ethanol as an indicator, the conversion rate of the target product was measured to be 92% by hydrochloric acid-ethanol titration.

[0043] 2. The resulting white solid is identified by the following method:

[0044] (1) Identification of quaternary ammonium salt (potassium ferricyanide test)

[0045] Dissolve 0.1 g of the resulting white solid in 50 mL of water, and add potassium ferricyanide solution (3 g / L) to 10 mL of the solution to generate a yellow precipitate. Show the existence of quaternary ammonium salt, reaction formula is:

[0046]

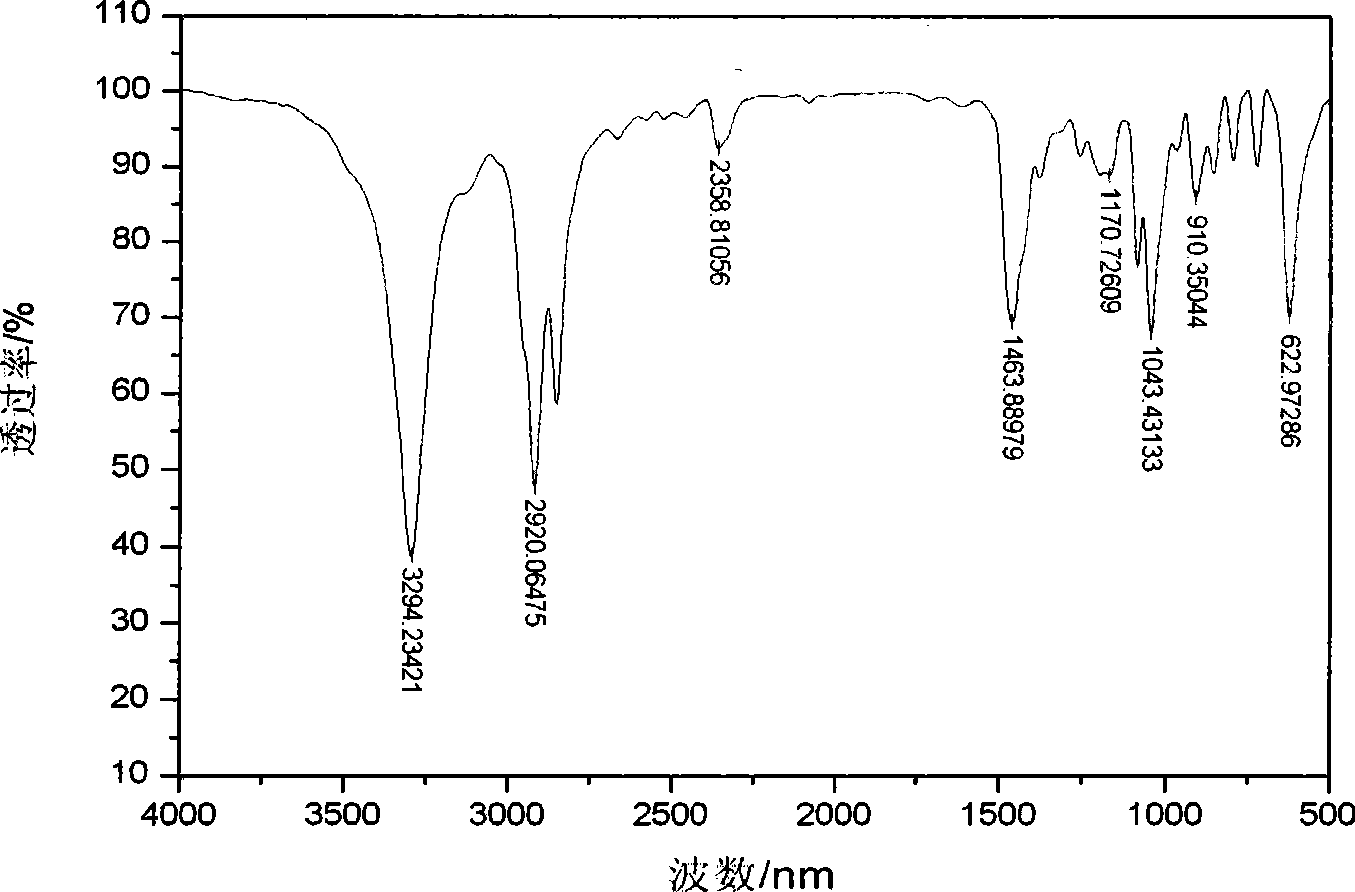

[0047] (2) Infrared spectral analysis

[0048] Take a s...

example 2~21

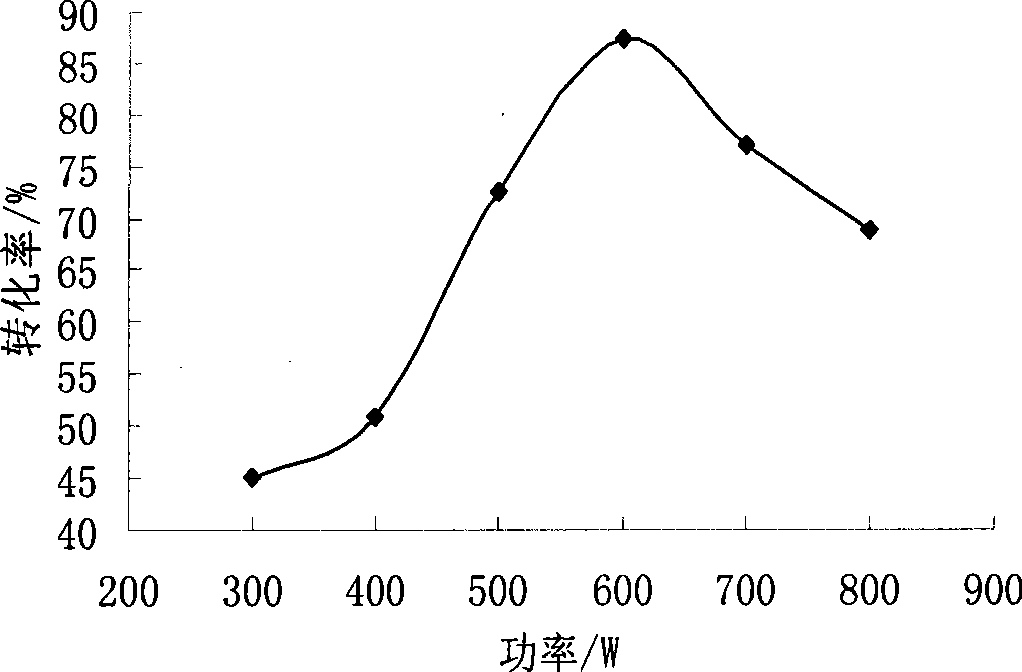

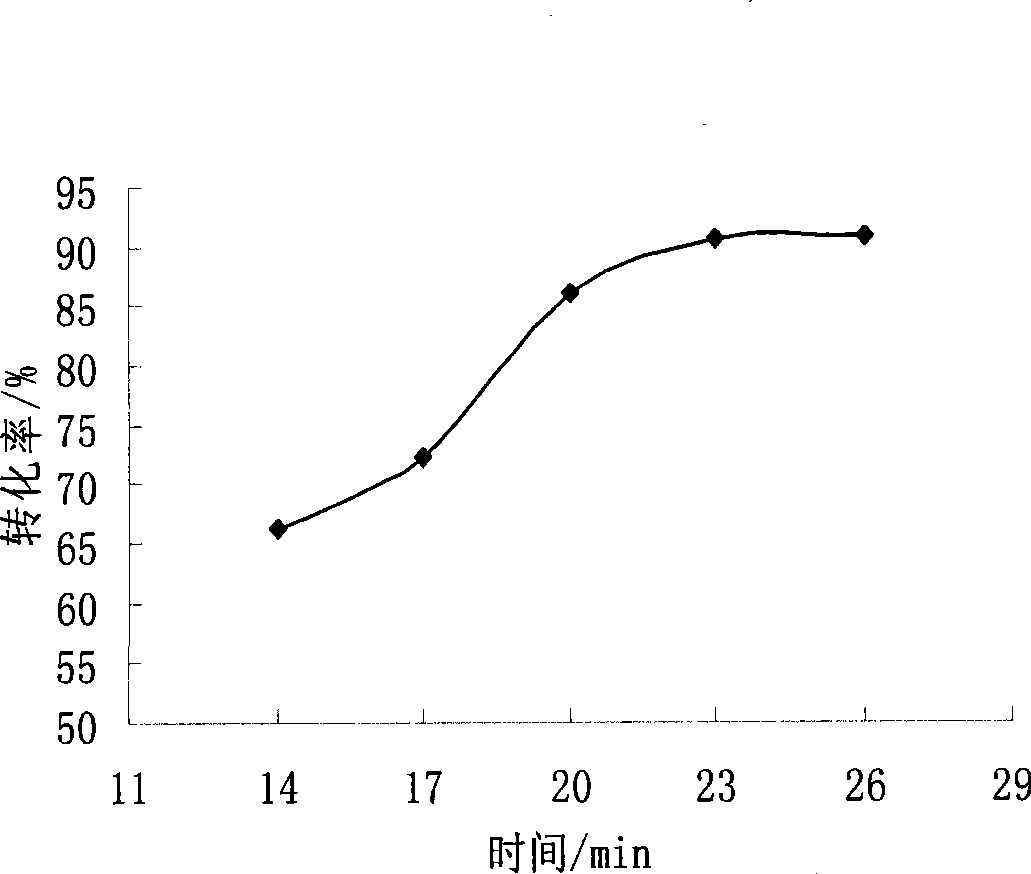

[0064] N-methyldiethanolamine and dodecyl bromide are mixed and dissolved in n-butanol, boiled and refluxed in the microwave for reaction, and finally anhydrous ether which is 6 times the volume of the reaction product is added to the reaction solution to crystallize the product to obtain white solid. Each parameter and reaction result in the reaction are as shown in table 3, wherein a, b, A, B, C, D and R represent respectively the amount of N-methyldiethanolamine, the amount of lauryl bromide, the amount of n-butanol amount, microwave power, yield and conversion of the desired product (i.e. the resulting white solid).

[0065] table 3

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com