Graphene-coated nickel lithium manganate preparation method

A technology of graphene coating and lithium nickel manganese oxide, which is applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problems of increasing resistance, corroding the surface of materials, reducing specific capacity, etc., to reduce operating steps, High specific capacity and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

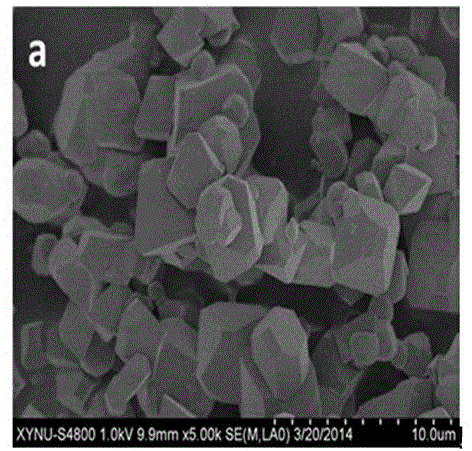

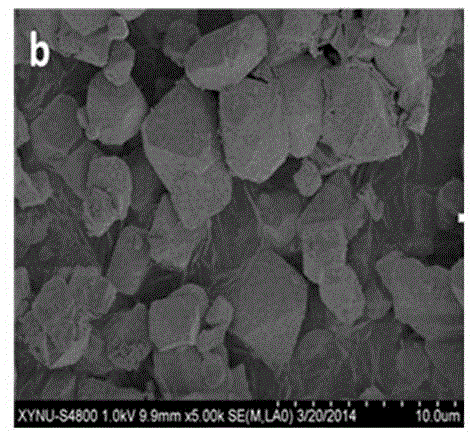

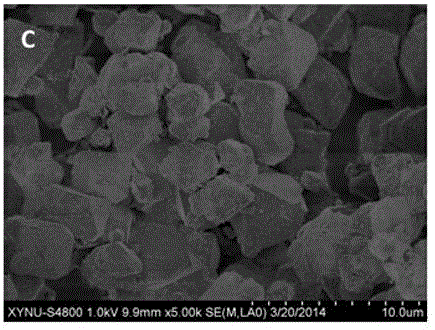

Image

Examples

Embodiment 1

[0043] A preparation method of lithium nickel manganese oxide coated with graphene as the positive electrode material of lithium ion battery. In this example, 18.30 g (0.10 mol) of LiNi coated with graphene 0.5 mn 1.5 o 4 The positive electrode material specifically includes the following process steps:

[0044] (1) Preparation of lithium nickel manganese oxide precursor

[0045] Weigh nickel acetate (C 4 h 6 o 4 Ni·4H 2 O) 12.44g (0.05mol), manganese acetate (Mn(CH 3 COO) 2 )25.95g (0.15mol), lithium acetate (C 2 h 3 LiO 2 ) 6.60g (0.1mol), mixed in 50ml of distilled water, added 0.6g of polyvinylpyrrolidone (PVP) and 3ml of citric acid, heated the solution at 40°C with constant magnetic stirring, and reacted for 6 hours before use.

[0046] (2) Configure graphene DMF solution

[0047] Weigh 0.08g of graphene flakes and disperse in 160g of dimethylformyl (DMF) amine solution at 110°C and keep the temperature at 110°C for later use.

[0048] (3) Configure lithiu...

Embodiment 2

[0056] A preparation method of lithium nickel manganese oxide coated with graphene as the positive electrode material of lithium ion battery. In this example, 36.60 g (0.20 mol) of LiNi coated with graphene 0.5 mn 1.5 o 4 The positive electrode material specifically includes the following process steps:

[0057] (1) Preparation of lithium nickel manganese oxide precursor

[0058] Weigh nickel oxalate (C 2 o 4 Ni) 14.67g (0.1mol), manganese oxalate (MnC 2 o 4 )42.89g (0.3mol), lithium oxalate (Li 2 C 2 o 4 ) 10.19g (0.1mol), mixed in 100ml distilled water, added 1.0g polyvinylpyrrolidone (PVP) and 6ml citric acid, heated the solution at 60°C with constant magnetic stirring, reacted for 3.5h and then set aside.

[0059] (2) Configure graphene DMF solution

[0060] Weigh 0.16g of graphene flakes and disperse them in 300g of dimethylformyl (DMF) amine solution at 160°C and keep the temperature at 160°C for later use.

[0061] (3) Configure lithium nickel manganese oxi...

Embodiment 3

[0069] A preparation method of graphene-coated lithium nickel manganese oxide, a positive electrode material for lithium-ion batteries. In this example, graphene-coated 54.90 g (0.30 mol) LiNi 0.5 mn 1.5 o 4 The positive electrode material specifically includes the following process steps:

[0070] (1) Preparation of lithium nickel manganese oxide precursor

[0071] Weigh 22.01g (0.15mol) of nickel oxalate (C2O4 Ni), 64.34g (0.45mol) of manganese oxalate (MnC2O4), lithium acetate (C 2 h 3 LiO 2 ) 19.80g (0.3mol), mixed in 150ml of distilled water, added 1.5g of polyvinylpyrrolidone (PVP) and 9ml of citric acid, heated the solution at 80°C with constant magnetic stirring, and reacted for 2 hours before use.

[0072] (2) Configure graphene DMF solution

[0073] Weigh 0.24g of graphene flakes and disperse in 450g of dimethylformyl (DMF) amine solution at 170°C and keep the temperature at 170°C for later use.

[0074] (3) Configure lithium nickel manganese oxide precursor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com