Electrode paste, electrode made from same, manufacturing methods thereof and PDP display screen provided with electrode

An electrode slurry and pigment technology, which is applied in the manufacture of electrode systems, the manufacture of discharge tubes/lamps, conductive materials dispersed in non-conductive inorganic materials, etc. Increase, the electrode pattern does not meet the accuracy requirements and other problems, to achieve the effect of reducing yellowing phenomenon, bright room contrast, and inhibiting migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

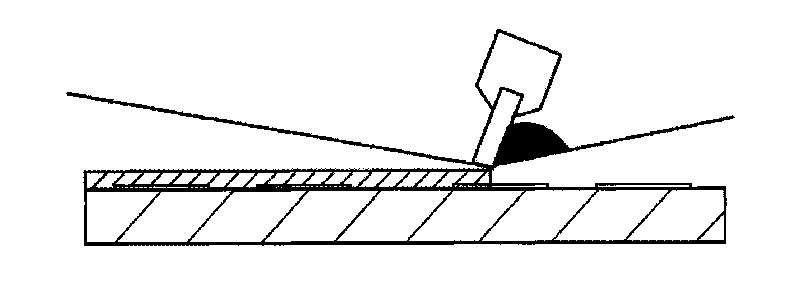

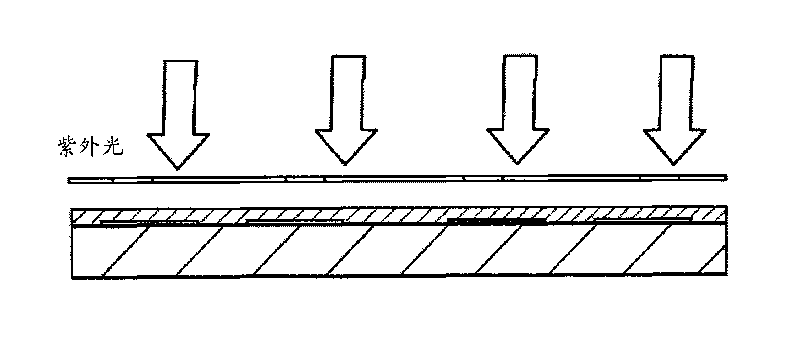

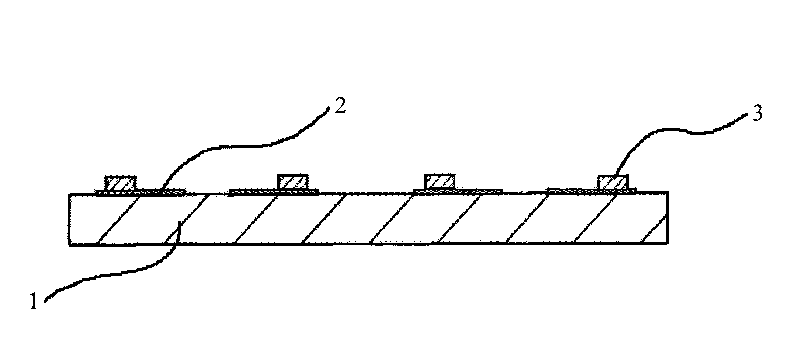

Method used

Image

Examples

Embodiment 1

[0031] High tap density spherical silver powder : The tap density reaches 4.2g / cm 3 , Spherical silver powder with a particle size of 1.5 microns. Based on the total weight of the conductive paste, the high tap density spherical silver powder is used in an amount of 59 wt%, that is, 590 grams.

[0032] Microcrystalline silver powder : The tap density reaches 1.8g / cm 3 , High crystallinity microcrystalline silver powder with a particle size of 0.4 microns. Based on the total weight of the conductive paste, the microcrystalline silver powder is used in an amount of 6 wt%, that is, 60 grams. Then the high tap density spherical silver powder and the microcrystalline silver powder are fully mixed in a mixer.

[0033] Black low melting point glass powder : Black glass pigment and low-melting glass powder are mixed according to the formula shown in Table 1 and smelted to obtain molten glass. After the glass liquid is cooled, it is processed into a black glass powder with a ...

Embodiment 2

[0042] Except using 52wt% (520 grams) with a tap density of 4.5g / cm 3 , The particle size is 1.8 micron high tap density spherical silver powder and the tap density of 13wt% (130 grams) is 2.0g / cm 3 , particle size is 0.6 micron high crystallinity microcrystalline silver powder and it is fully mixed, embodiment 2 is carried out in the same way as embodiment 1. The results are shown in Table 2.

Embodiment 3

[0044] Except using 48wt% (480 grams) with a tap density of 3.8g / cm 3 , The particle size is 1.2 micron high tap density spherical silver powder and the tap density of 13wt% (130 grams) is 1.6g / cm 3 , particle size is the high crystallinity microcrystalline silver powder of 0.6 and it is fully mixed, and the consumption of black low-melting point glass powder is 17wt%, embodiment 3 is carried out in the same way as embodiment 1. The results are shown in Table 2.

[0045] Table 2: Comparison between the conductive paste of the present invention and the traditional paste

[0046] parameter

[0047] As can be seen from Table 2, since the present invention adds high crystallinity microcrystalline silver powder to the high tap density spherical silver powder of the traditional method, it actually plays the role of fluxing silver powder. Therefore, the sintering temperature of the conductive paste of the present invention is 30-50° C. lower than 550-560° C. of the conven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com