Patents

Literature

574results about How to "Reduce yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

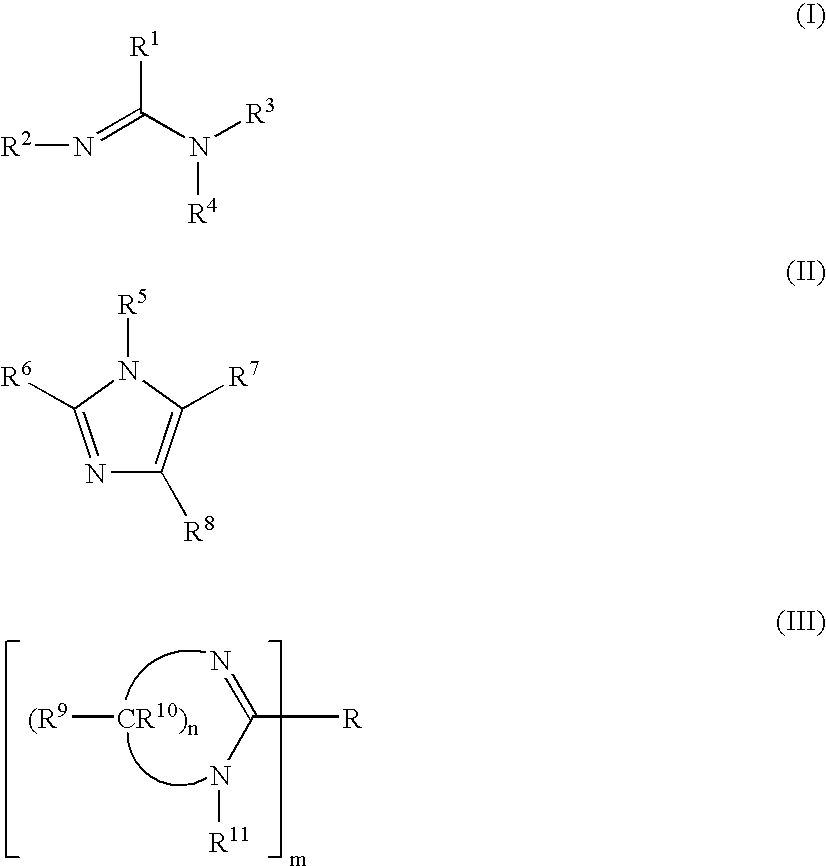

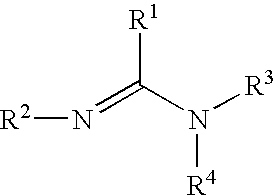

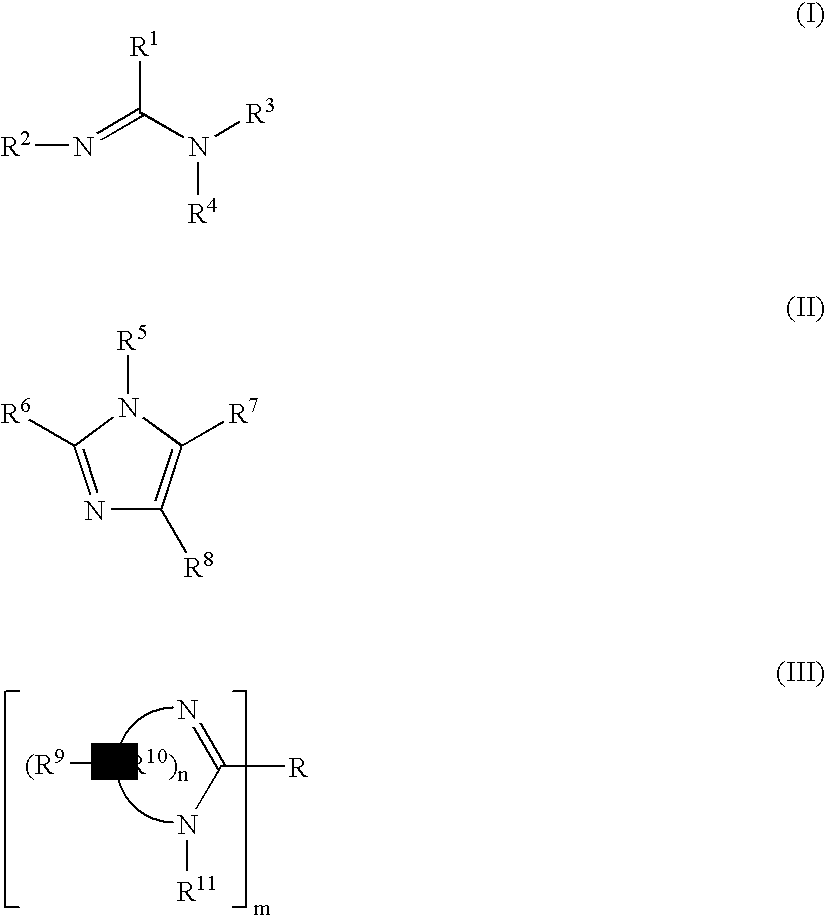

Organometallic compositions and coating compositions

InactiveUS20060247341A1Reduce yellowingImprove moisture resistanceOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsCarbamateZinc

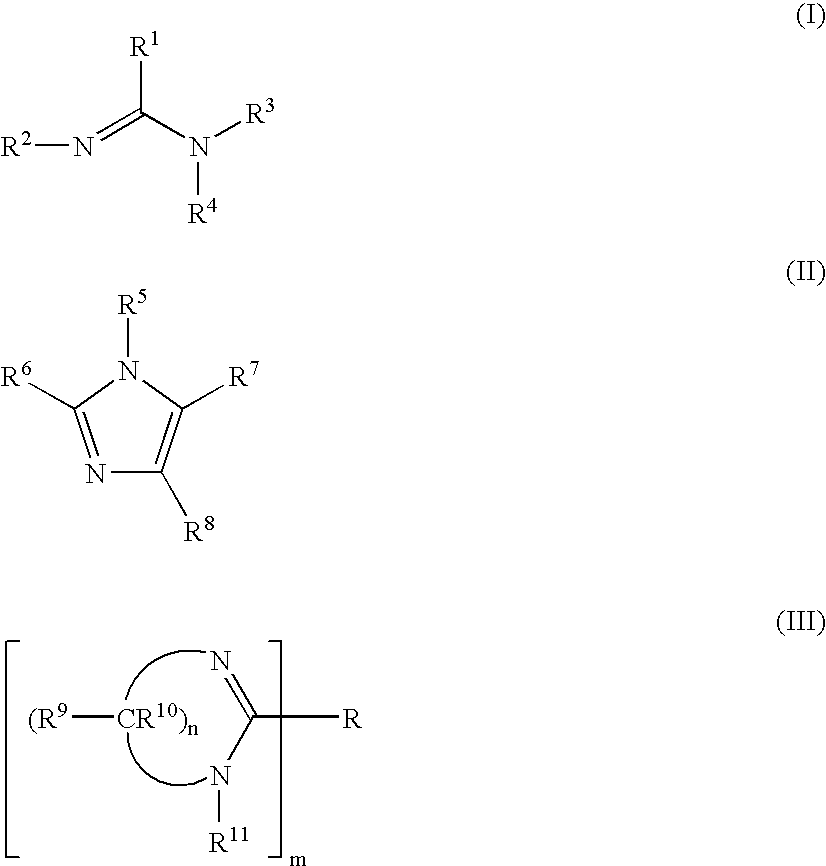

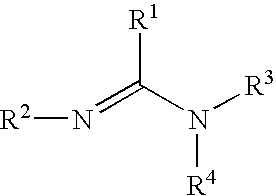

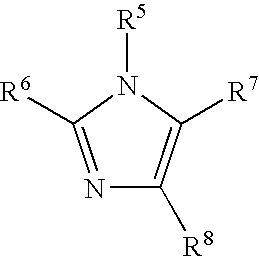

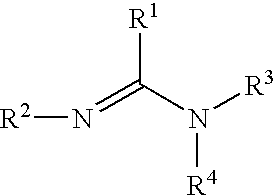

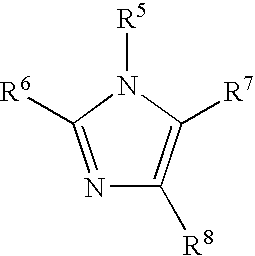

The present invention is directed to novel organometallic complexes as catalysts for the reaction of compounds with isocyanate and hydroxyl functional groups to form urethane and / or polyurethane and the process employing such catalysts. More particularly, the present invention is directed to novel complexes of zinc(II) with substituted amidines. These novel catalysts are useful for the production of urethanes and polyurethanes which are important in many industrial applications.

Owner:KING INDUSTRIES INC

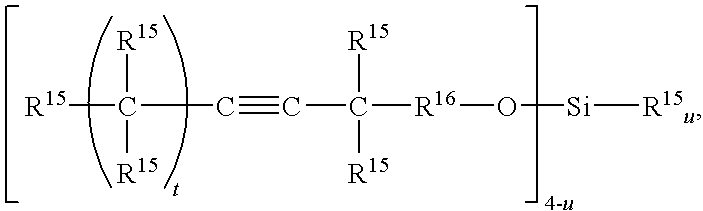

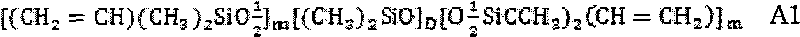

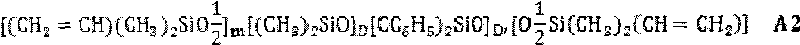

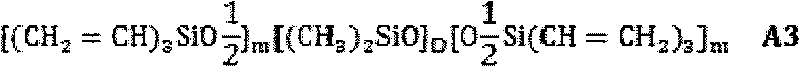

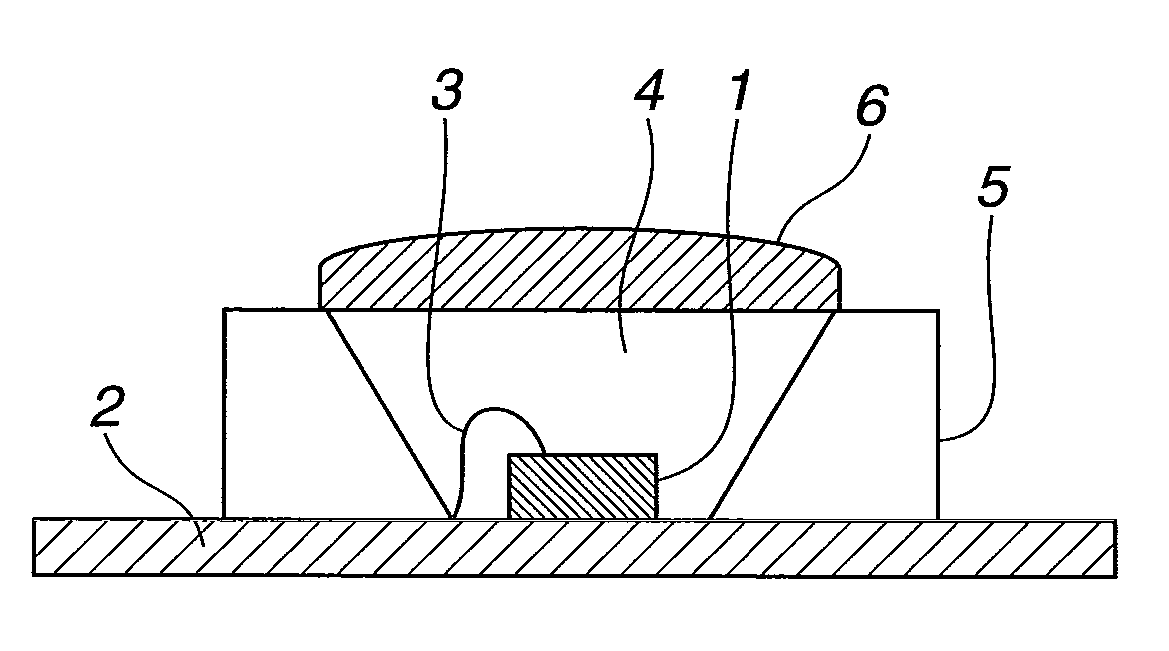

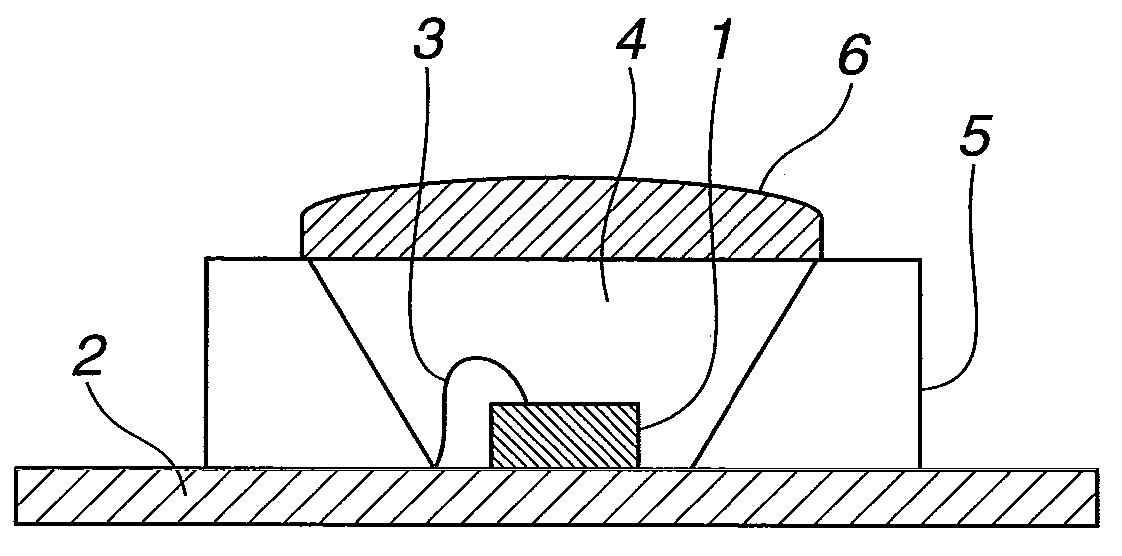

Light Emitting Device Encapsulated with Silicones and Curable Silicone Compositions for Preparing the Silicones

ActiveUS20100276721A1Improve matchAvoid viscosity increaseSolid-state devicesSemiconductor/solid-state device manufacturingHydrosilylationSealant

A composition includes: (I) an alkenyl functional, phenyl-containing polyorganosiloxane, an Si—H functional phenyl-containing polyorganosiloxane, or a combination thereof; (II) a hydrogendiorganosiloxy terminated oligodiphenylsiloxane having specific molecular weight, an alkenyl-functional, diorganosiloxy-terminated oligodiphenylsiloxane having specific molecular weight, or a combination thereof; and (III) a hydrosilylation catalyst. A light emitting device is made by applying the composition onto a light source followed by curing. The composition provides a cured material with mechanical properties suited for use as an encapsulant for a light emitting device.

Owner:DOW TORAY CO LTD +1

Organometallic compositions and coating compositions

InactiveUS7485729B2Reduce yellowingGood stability at room temperatureOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsCarbamateZinc

The present invention is directed to novel organometallic complexes as catalysts for the reaction of compounds with isocyanate and hydroxyl functional groups to form urethane and / or polyurethane and the process employing such catalysts. More particularly, the present invention is directed to novel complexes of zinc(II) with substituted amidines. These novel catalysts are useful for the production of urethanes and polyurethanes which are important in many industrial applications.

Owner:KING INDUSTRIES INC

Organic silicon rubber encapsulating material for high-power LED

InactiveCN101747632AHigh light transmittance durabilityImprove temperature resistanceOther chemical processesSemiconductor devicesRefractive indexTackifier

The invention relates to an organic silicon encapsulating material for a high-power LED and a preparation method thereof. The organic silicon encapsulating material is prepared by mixing a component A containing vinyl polysiloxanes, a silicone resin component B, a component C containing hydrogen polysiloxane, a platinum catalyst component D, a component E of catalytic inhibitor of acetylene alcohols and a tackifier component F. The obtained encapsulating silicon rubber with different refractive indexes of level 1.4, level 1.5 and the like can be used for the encapsulation of various high-power LEDs and the encapsulation of other optical application. The organic silicon rubber encapsulating material for the high-power LED takes the silicone resin component B as a filling material, which not only enables that the silicone rubber has high transparency, high strength and high light transmittance, but also improves the temperature resistance, the yellowing resistance, and the durability of the high light transmittance of high-power LED products. The organic silicon rubber encapsulating material for the high-power LED can be prepared into two encapsulating forms of a single component and bi-component, which improves the adaptability and the encapsulating efficiency for encapsulating equipment and process procedures, and has the characteristics of reduced cost and convenient use.

Owner:陈俊光

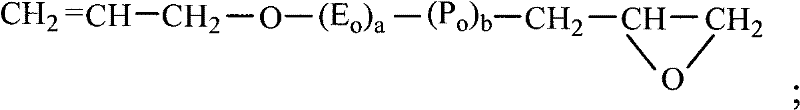

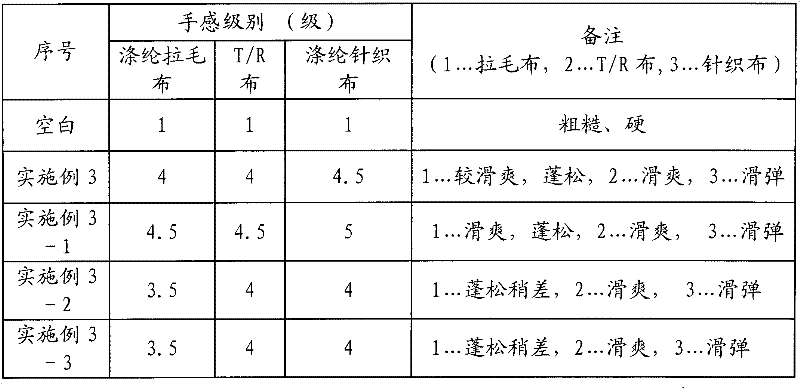

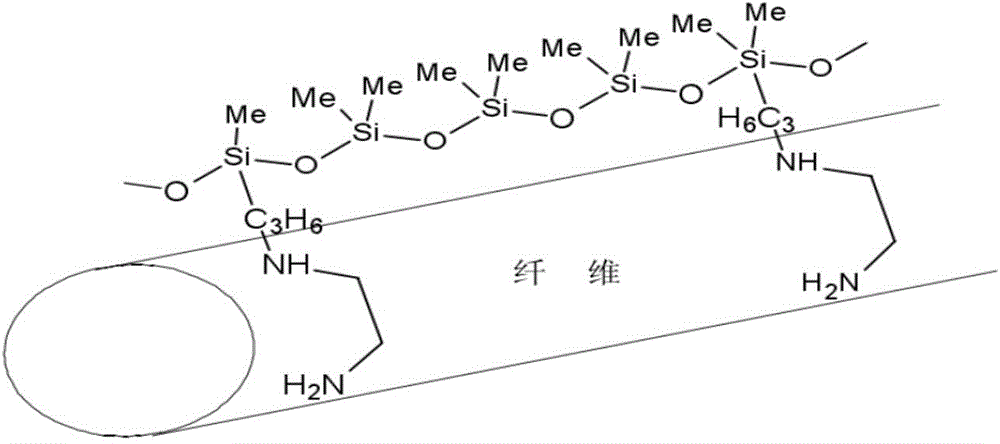

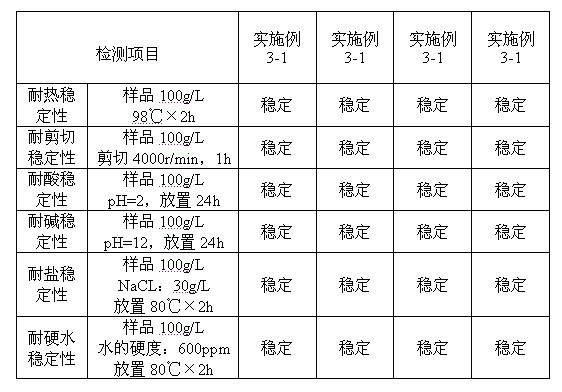

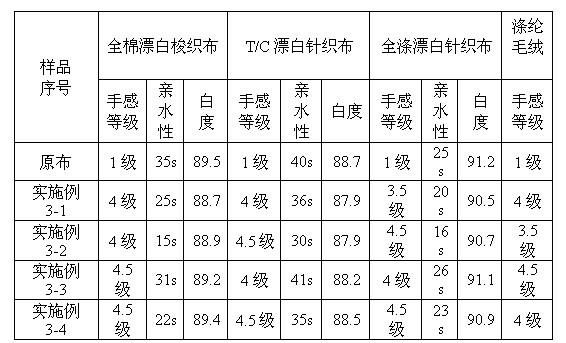

Preparation method for polysiloxanes-amidopolyether block copolymer

InactiveCN102199295ABroad encapsulationWide penetration abilityFibre treatmentPolyelectrolyteEmulsion

The invention discloses a preparation method for a polysiloxanes-amidopolyether block copolymer, comprising the steps of preparation of an intermediate of alpha, omega-hydrosiloxane, preparation of an intermediate of alpha, omega-polysiloxanes diepoxide, and preparation of the polysiloxanes-amidopolyether block copolymer. The polysiloxanes-amidopolyether block copolymer provided in the invention enables a textile finishing agent to be stable under condition of high temperature, a polyelectrolyte, a high pH value or a high shear force without breaking emulsion, sticking to a roller or a cylinder and producing oil marks, allows textiles finished to be returned for repairing, and is widely used in fields like chemical fiber, natural fiber and blended products thereof, etc.

Owner:HANGZHOU MEIGAO HUAYI CHEM

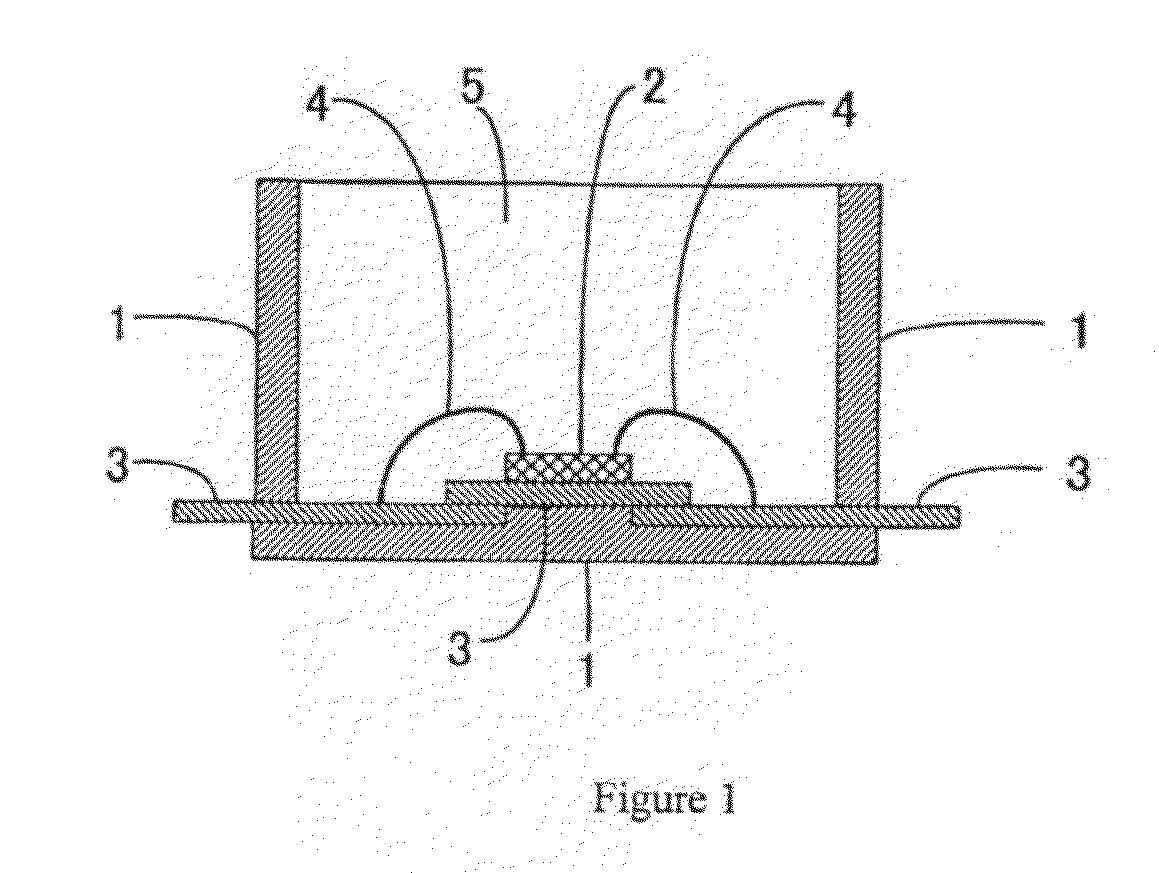

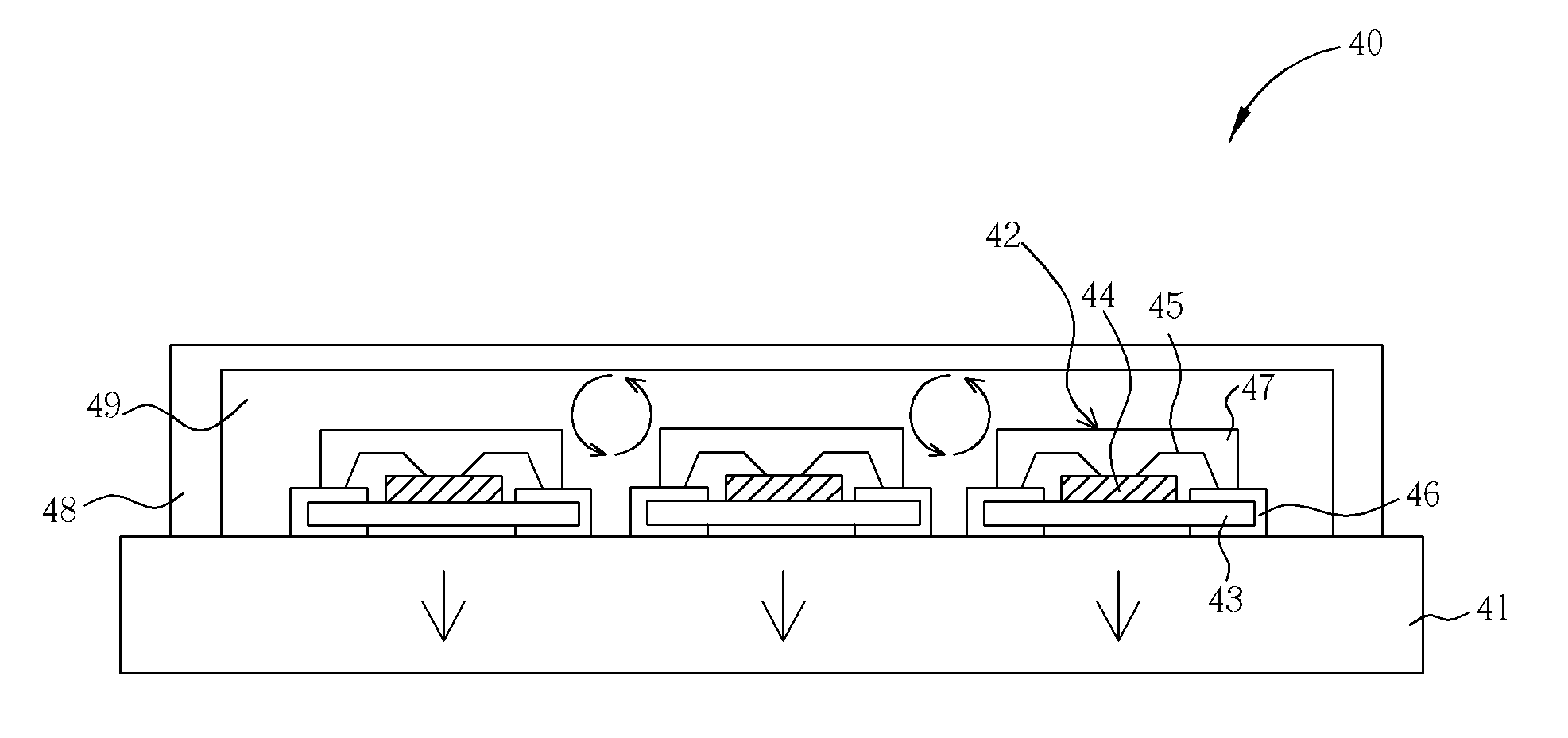

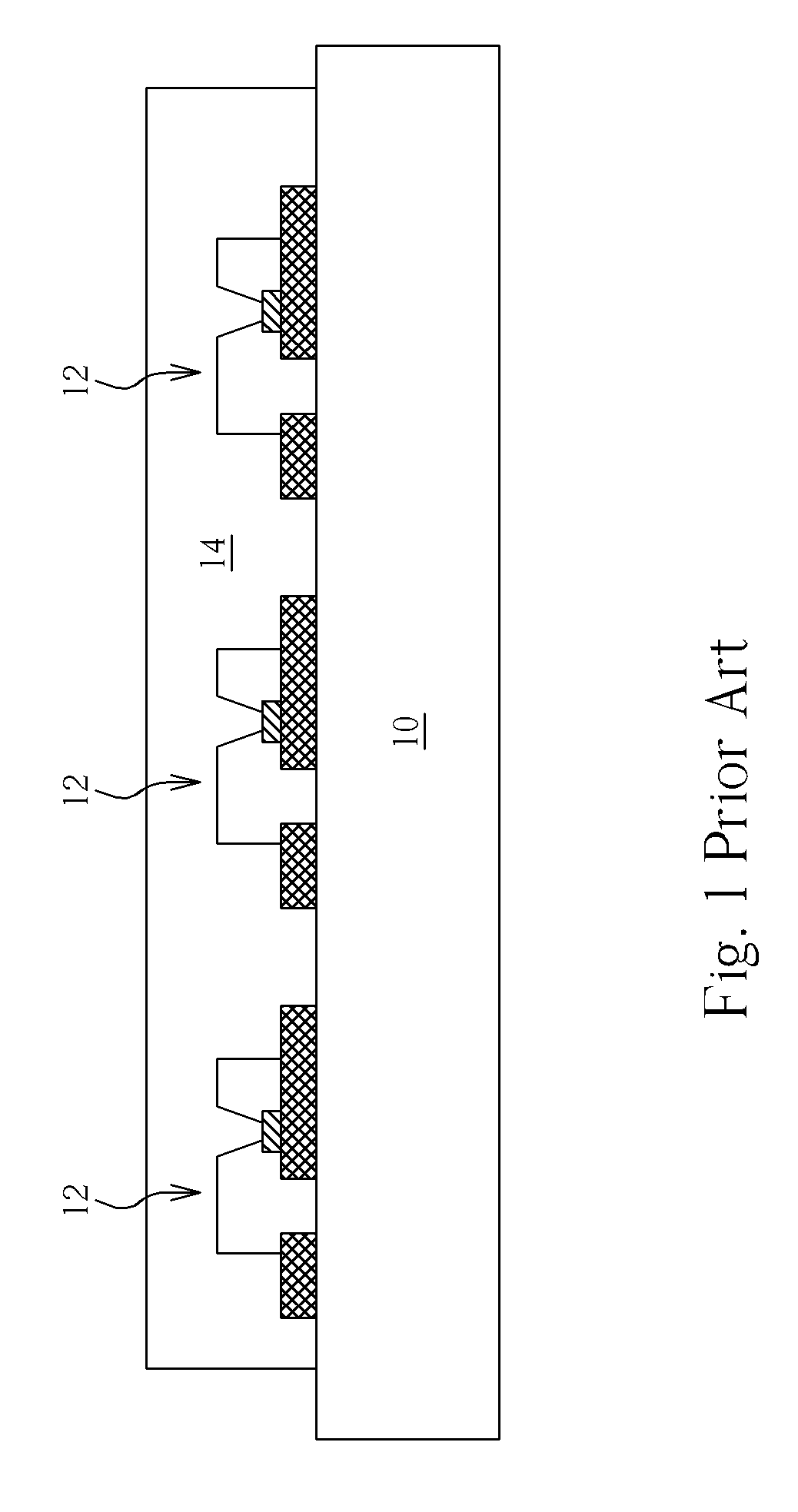

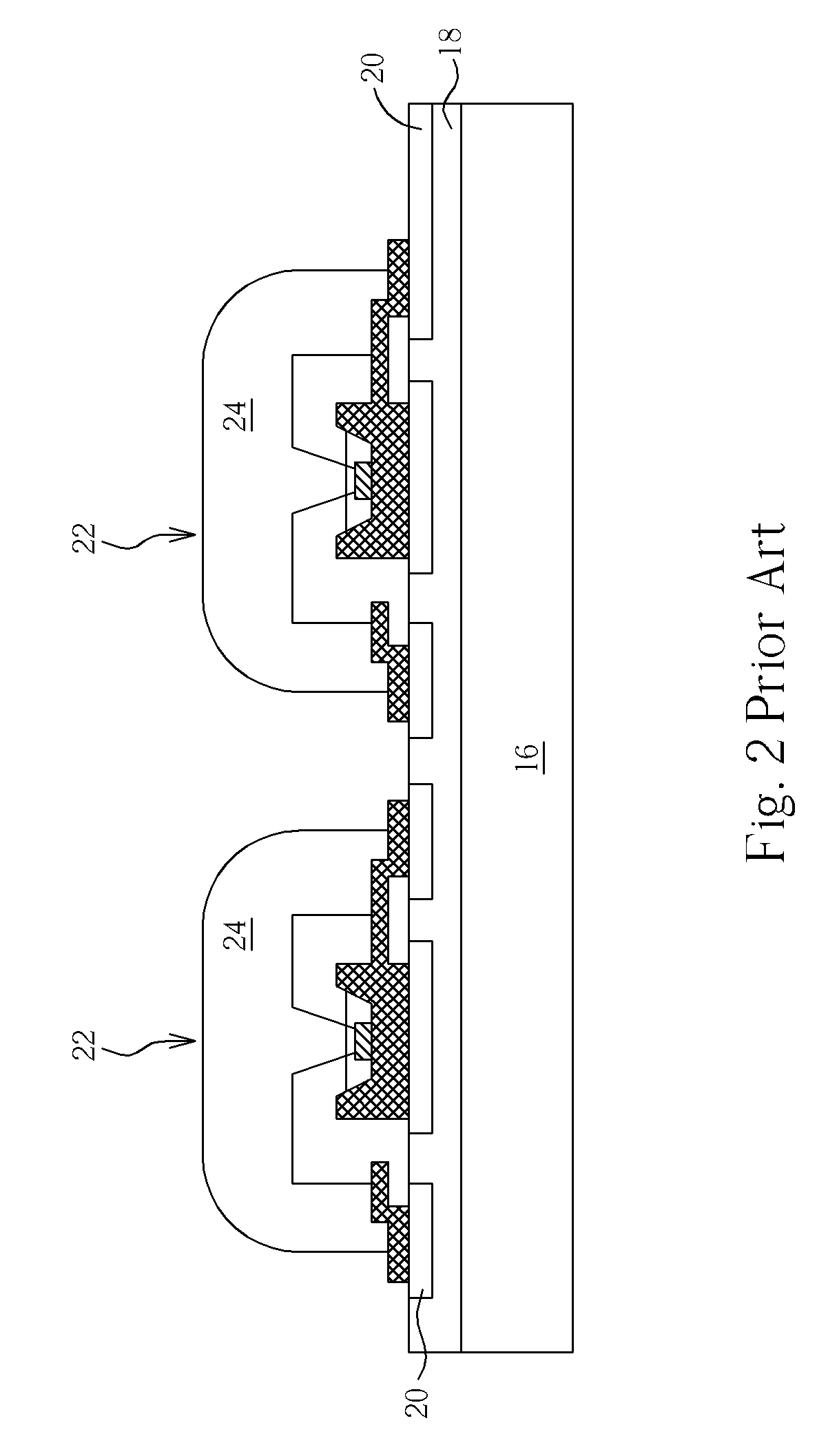

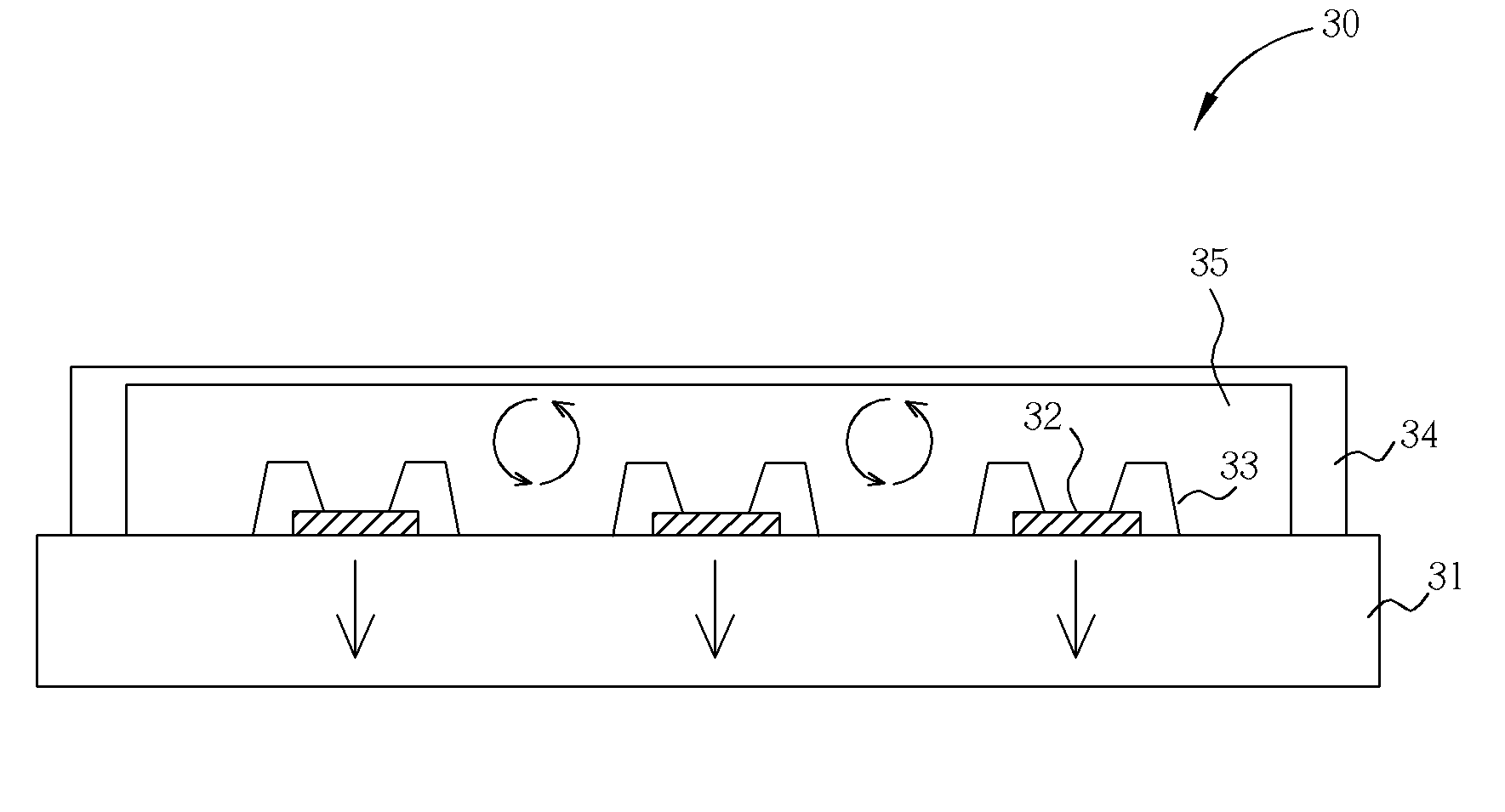

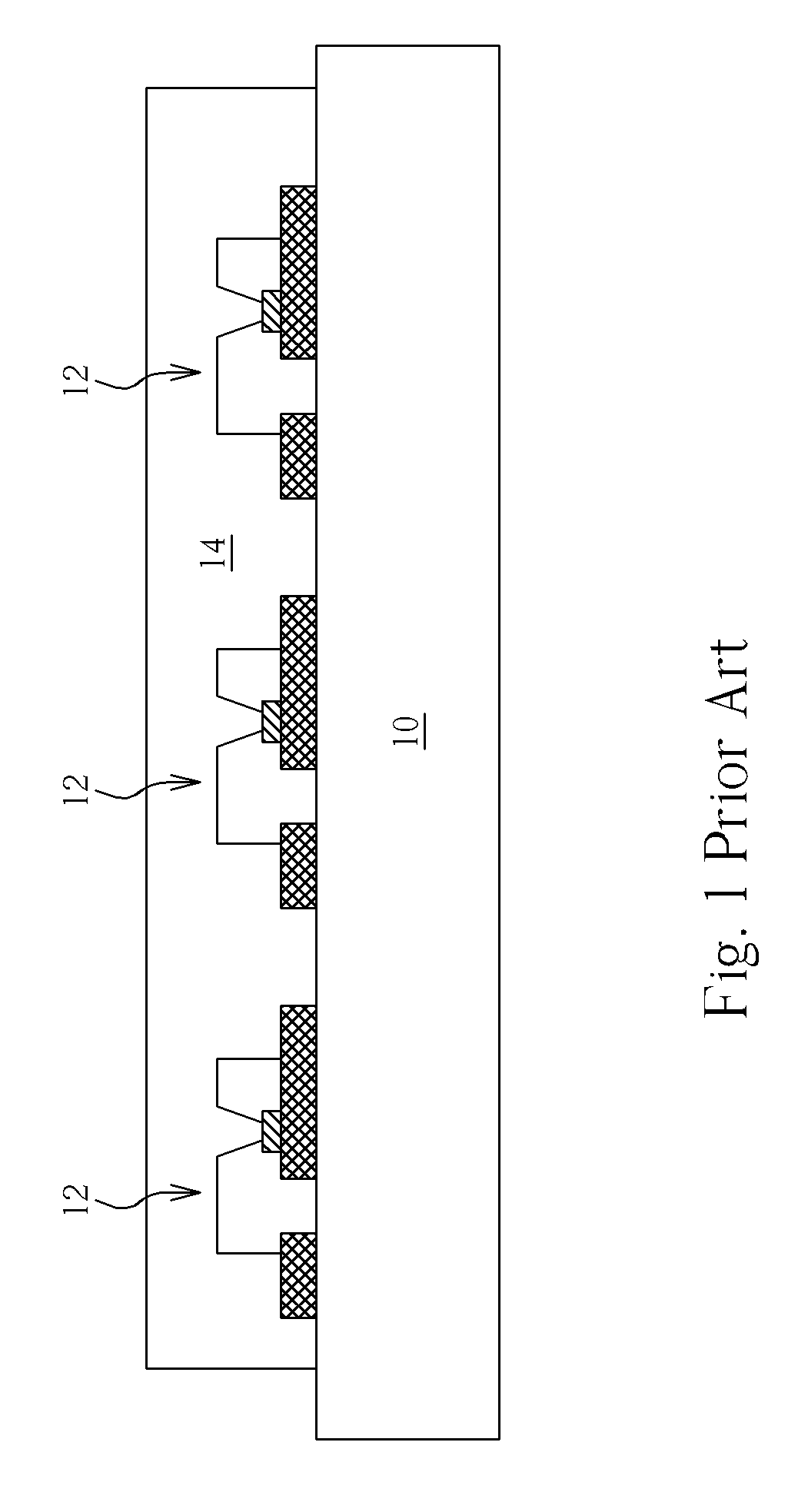

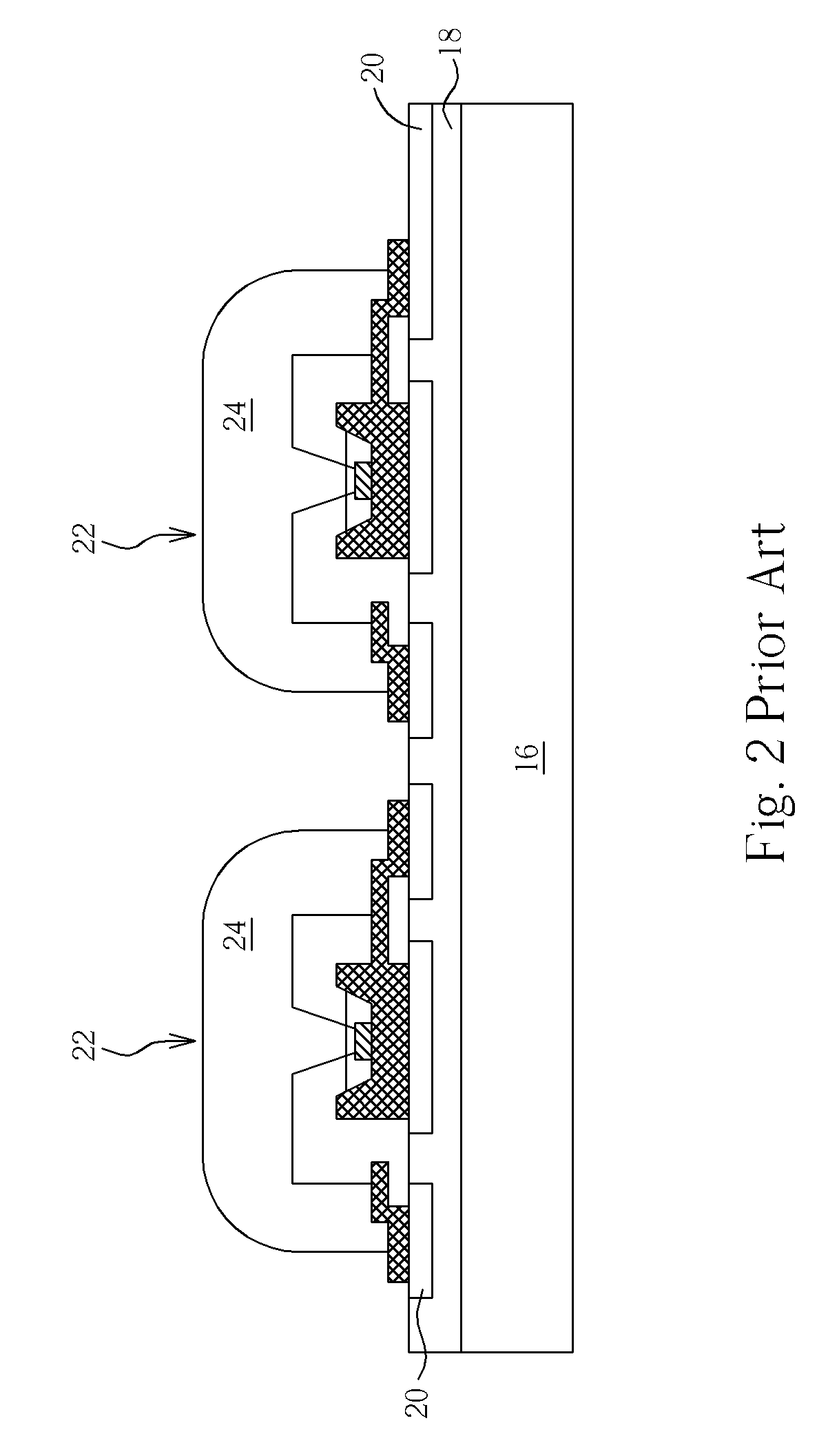

Light module

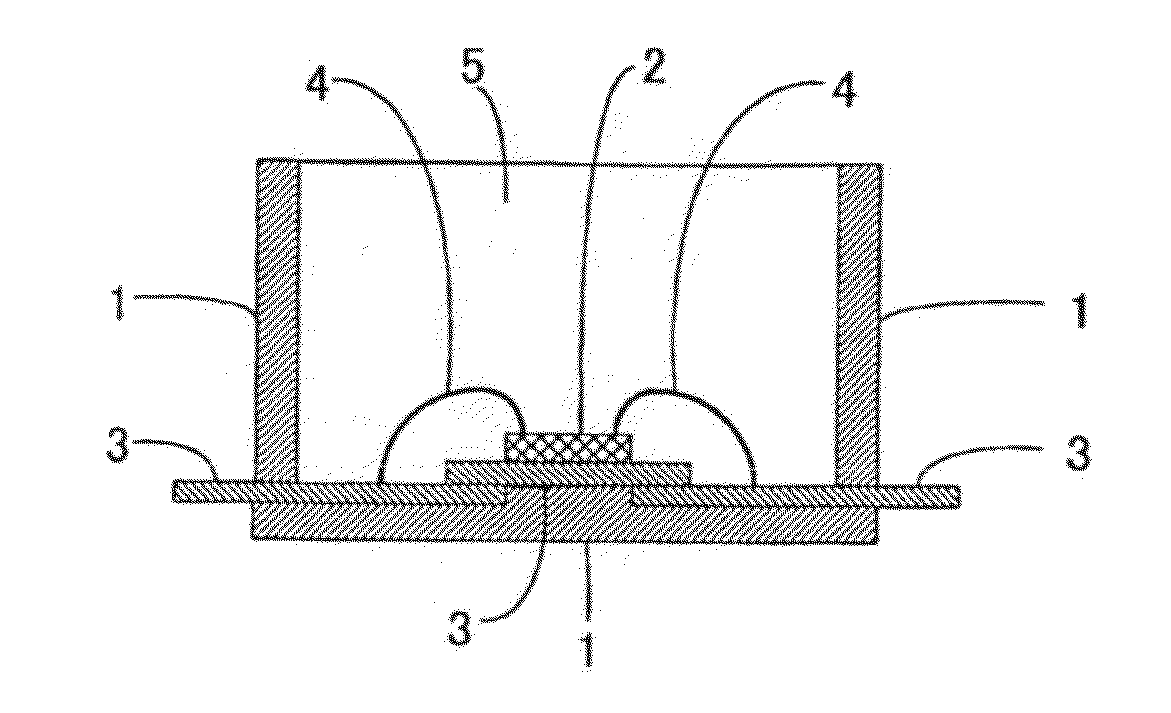

ActiveUS20060274524A1Heat dissipation fastAccelerated dissipationSemiconductor/solid-state device detailsLighting heating/cooling arrangementsEngineering

Owner:LEXTAR ELECTRONICS CORP

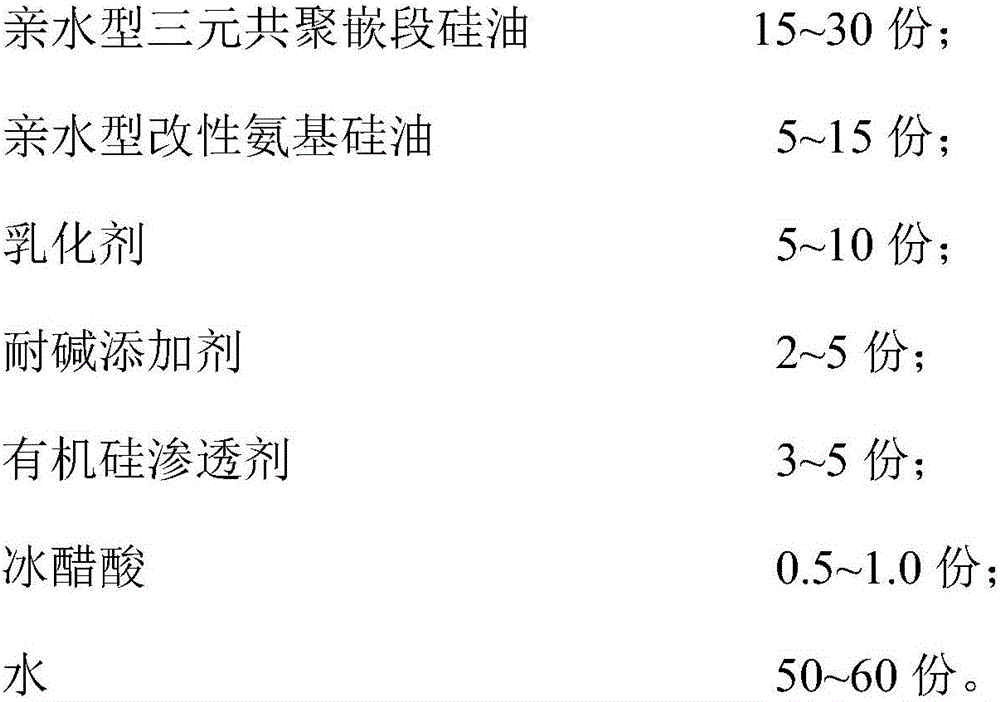

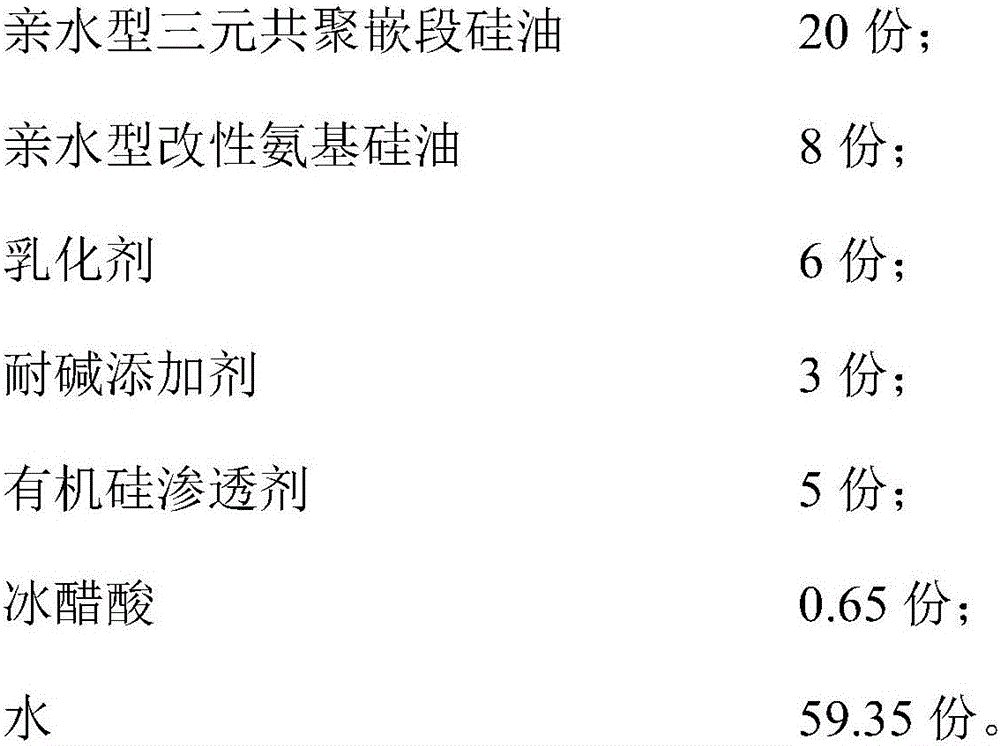

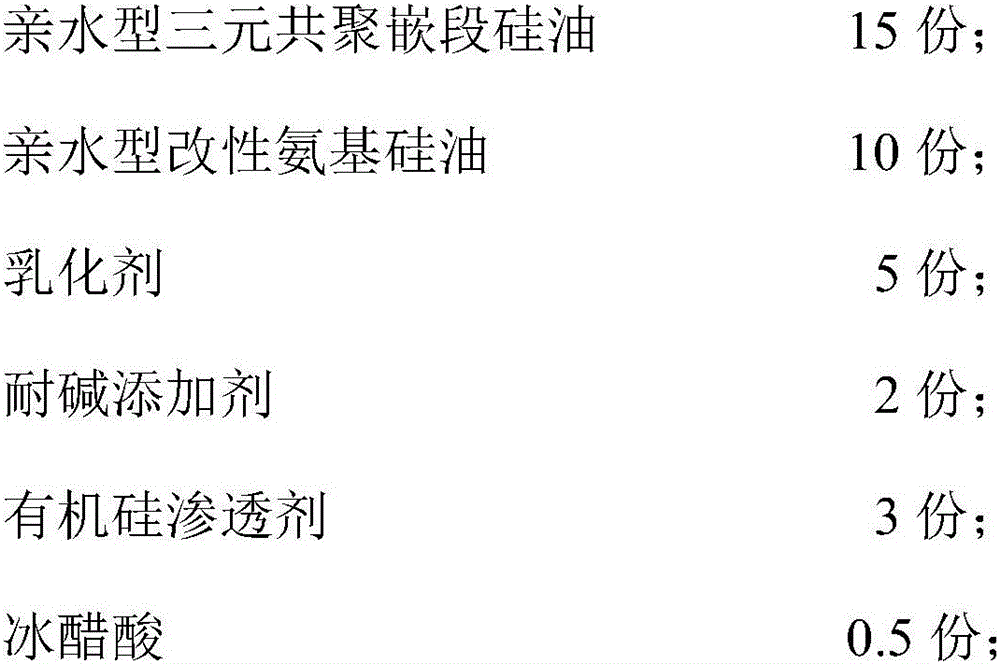

Hydrophilic ice-cold skin touch finishing agent for cotton fabric and preparation method of hydrophilic ice-cold skin touch finishing agent

ActiveCN106319975AImprove performanceIncrease elasticityGrip property fibresVegetal fibresAcetic acidAlkylphenol

The invention discloses a hydrophilic ice-cold skin touch finishing agent for a cotton fabric and a preparation method of the hydrophilic ice-cold skin touch finishing agent. The finishing agent is prepared from the following raw material formula in parts by weight: 15 to 30 parts of hydrophilic ternary polymerization block silicone oil, 5 to 15 parts of hydrophilic modified amino silicon oil, 5 to 10 parts of emulsifying agent, 2 to 5 parts of alkali-resisting additive, 3 to 5 parts of organosilicon penetrant, 0.5 to 1.0 part of glacial acetic acid and 50 to 60 parts of water. The finishing agent disclosed by the invention has a good hydrophilic effect on the cotton fabric, and can endow the cotton fabric with excellent softness, exquisite smoothness, ice-cold touch and good resilience effect; in addition, the raw material formula does not contain harmful components polluting the environment and components which are strictly prohibited by China such as APEO (Alkylphenol Ethoxylates). The preparation method has the advantages of simple process, convenience in operation and control, stable quality, high production efficiency and capability of realizing large-scale industrial production.

Owner:HT FINE CHEM CO LTD

Light module

ActiveUS7288798B2Heat dissipation fastNot easy for yellowingSemiconductor/solid-state device detailsLighting elementsEngineering

Owner:LEXTAR ELECTRONICS CORP

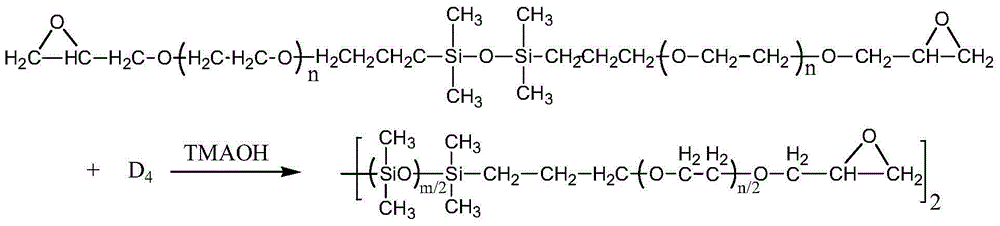

Preparation method of hyper-branched polyether amide block silicone

The invention discloses a preparation method of hyper-branched polyether amide block silicone. The preparation method comprises the following steps: preparing polyether / epoxy block silicone oil and preparing hyper-branched polyether amide block silicone. According to the preparation method, hyper-branched polymers and linear polyether amino block silicone are combined together to develop a new silicone softening agent with a newly modified silicone chemical structure; the synthesized hyper-branched material has a reticular structure which not only strengthens cohesive force between fibers, but also strengthens cohesive force between yarns; the invention is high in molecular weight, low in viscosity, rich in hydrophilic groups and capable of endowing soft, well-rounded and washable touch on fabrics; the problem of easy demulsification of traditional amino-modified silicone oil is solved; the product has self-emulsifying performance in water and is good in emulsion stability; the hyper-branched polyether amide block silicone is reduced in yellowing performance and enhanced in hydrophilicity; fabrics made accordingly has good hydrophilicity and low yellowing performance; and the hyper-branched polyether amide block silicone combines with the fabrics in a form of chemical bonds, so that the wash resistances is enhanced and the soft effect of amino silicone oil is achieved.

Owner:南通曙光染织有限公司

Organometallic compositions and coating compositions

ActiveUS20090011124A1Reduce yellowingGood stability at room temperatureOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsCarbamateZinc

The present invention is directed to novel organometallic complexes as catalysts for the reaction of compounds with isocyanate and hydroxyl functional groups to form urethane and / or polyurethane and the process employing such catalysts. More particularly, the present invention is directed to novel complexes of zinc(II) with substituted amidines. These novel catalysts are useful for the production of urethanes and polyurethanes which are important in many industrial applications.

Owner:KING INDUSTRIES INC

Silicone elastomers

InactiveUS6194508B1Reduce yellowingSpecial tyresCeramic shaping apparatusSilicone ElastomersPhysical property

Peroxidically crosslinkable silicone rubber compositions containing a filler which has covalently bound Si-H-containing groups exhibit lower tendency toward yellowing while maintaining or increasing other elastomer physical properties and processing properties.

Owner:WACKER CHEM GMBH

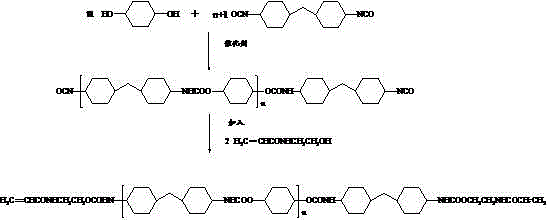

Ultraviolet curing coating

ActiveCN101967342AHigh curing activityHigh hardnessPolyurea/polyurethane coatingsPolyester coatingsPolyesterPolymer science

The invention discloses an ultraviolet curing coating. The ultraviolet curing coating is characterized by comprising basic resin, a diluting agent and a light initiator, wherein the basic resin comprises urethane acrylate resin and self-initiating polyester acrylate resin; and the light initiator comprises normal light initiator and low-yellowing light initiator. The coating provided by the invention has high curing activity; a paint film has the advantages of high hardness, high wear resistance, superior chemical resistance, low yellowing, high weather resistance and the like; and the coating is suitable for various plastic materials.

Owner:中山大桥化工集团有限公司

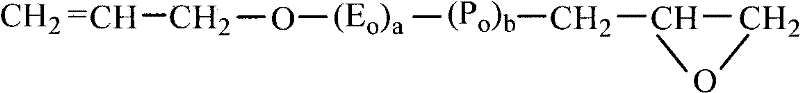

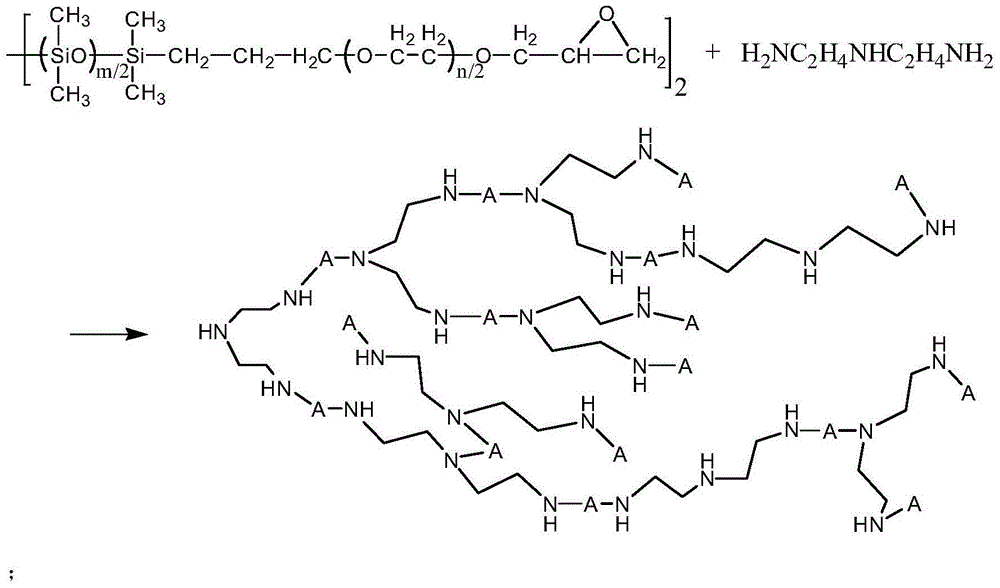

Supersoft hydrophilic block silicone oil compound and preparation method thereof

The invention relates to the field of textile finishing agent, in particular to supersoft hydrophilic block silicone oil compound and a preparation method thereof. The supersoft hydrophilic block silicone oil compound is composed of cations of the structural formula, wherein the n1 is the number of 5 to 10, the R is polyether group, and the degree of polymerization ranges from 3 to 50. The supersoft hydrophilic block silicone oil compound is applicable to handle finishing of fabric knitted by one or multiple fibers of cotton, dacron, chinlon and acrylic fibers and has softness, smoothness and looseness effects superior to those of amino-modified silicone oil, has excellent stability in acid and alkali resistance, electrolyte resistance, high temperature resistance, shearing resistance and the like and thoroughly solves the problems of easy demulsification, floating oil, roll banding, difficulty in refinishing and the like.

Owner:RUNHE ORGANICSILICONE NEW MATERIAL

Ultraviolet curing anti-drag paint in steel pipes

ActiveCN102079937AGood adhesionGood mechanical properties and chemical resistancePolyurea/polyurethane coatingsEpoxy resin coatingsPrepolymerSteel quality

The invention relates to an ultraviolet curing anti-drag paint in steel pipes. Epoxy acrylate and polyester acrylate are combinedly used as prepolymers, and phosphate-modified acrylate resin is used as an adhesion promotor, thereby greatly increasing the adhesion; a mixture of two or three of tripropylene glycol diacrylate, isobornyl acrylate and ethoxylated trimethylolpropane triacrylate is selected as an active monomer, and multiple functional group monomers are selectively added for compounding, thereby simultaneously satisfying curing speed, hardness, adhesion, flexibility and other requirements; multiple initiator compounding systems are adopted so as to simultaneously implement curing on the surface layer and deep layer; the paint provided by the invention has favorable mechanical properties and chemical resistance on a steel substrate; after coating, the surface is very smooth, has favorable anti-drag effect, can effectively enhance the salt fog resistance and corrosion resistance of the coating and the transmission efficiency of the pipeline, and can be widely used in anti-drag corrosion prevention in transmission pipelines in the fields of oil transmission, gas transmission, water supply and drainage, and the like.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

Silk afterfinishing compound softening agent and preparation method

The invention relates to a silk afterfinishing compound softening agent and a preparation method. The softening agent is nontoxic, nonirritating, very low in yellowing possibility, good in re-wettability, biodegradable, and completely harmless to an environment. The method comprises the steps that required water temperature is selected between 0 DEG C and 100 DEG C according to used different quaternization raw materials; 1-30% of ester quaternary ammonium salt is added to water, and stirred; and then 1-30% of hydrophilic amino silicone oil is added and stirred uniformly after ester quaternary ammonium salt is completely dissolved or dispersed in the water and forms a uniform white viscous emulsion. The softening agent has the advantages that 1, the softening agent adopts raw animal or plant synthetic chemicals as main components of the softening agent, and is completely nontoxic, nonirritating, very low in yellowing possibility, and good in re-wettability, and 2, the softening agent is biodegradable and completely harmless to the environment, and is an ideal silk fabric afterfinishing softening agent.

Owner:ZHEJIANG HSDP SILK TECH

Process for making a thermoplastic vulcanizate composition

InactiveUS20060229399A1Sufficient reaction rateReduce yellowingSpecial tyresMixingElastomerPolymer science

A process for making a thermoplastic vulcanizate includes blending a thermoplastic first polymer, an elastomeric second polymer, a carboxylic anhydride, a free radical generator, and a particulate reinforcing material to provide a first blend containing the thermoplastic first polymer and grafted elastomeric second polymer with the particulate reinforcing material dispersed therein, the particulate reinforcing material having sufficient surface moisture to permit coupling to the thermoplastic first polymer and the elastomeric second polymer upon reaction with a coupling agent; then, combining a coupling agent with the first blend for coupling the thermoplastic first polymer and / or grafted elastomeric second polymer with the particulate reinforcing material and / or crosslinking the grafted elastomeric second polymer.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

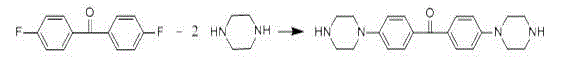

Preparation method of polyurethane trimer curing agent of low free isocyanate monomer

ActiveCN102718944AGood compatibilityRapid curing at room temperatureOrganic chemistryPolyurea/polyurethane coatingsPolymer scienceNitrogen

The invention discloses a preparation method of a polyurethane trimer curing agent of a low free isocyanate monomer, comprising the following steps of: under the protection of nitrogen, firstly putting an isocyanate monomer and an esters solvent into a reaction container to evenly stir, wherein the temperature is kept at 50-90DEG C; dropwise adding diamine into the reaction container under the condition of stirring, wherein the dropwise adding time is 1-1.5 hours; and after dropwise adding, adding a catalyst of which the mass is 0.1-0.5% of that of the isocyanate monomer once, continuing stirring and reacting at the temperature of 70-100DEG C for 3-6hours, when the NCO base content is 20%-25%, immediately adding the polymerization inhibitor of which the mass is 0.1-1% of that of the isocyanate monomer, keeping the temperature for 1-2hours, and discharging in a cooling way. The polyurethane trimer curing agent prepared by the preparation method can be better compatible with the resin, can be quickly solidified under normal temperature, and has the advantages of being higher in mechanical strength, modulus, adhesion, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

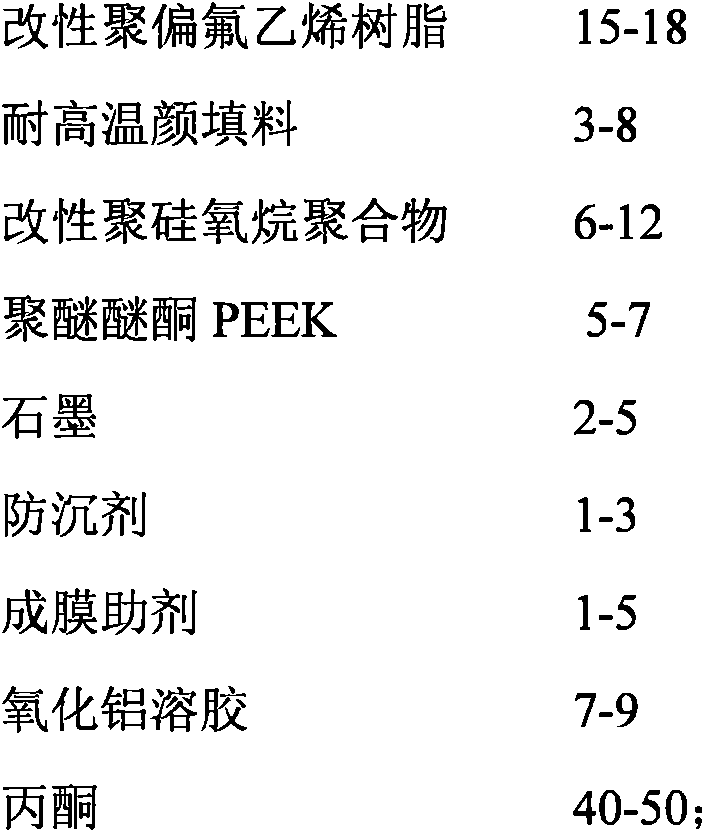

Wear-resistant and mildewproof non-stick pan coating

ActiveCN105111926AChemically stableDoes not generate PFOACooking-vessel materialsAntifouling/underwater paintsEpoxyWear resistant

The present invention relates to a wear-resistant and mildewproof non-stick pan coating. The coating comprises a bottom layer and a surface layer; The bottom layer consists of the following materials in parts by weight: polyimide resin, modified polyvinylidene fluoride resin, a high-temperature-resistant pigment filler, modified polyorganosiloxane polymer, polyetheretherketone PEEK and graphite. The surface layer consists of the following materials in parts by weight: polytetrafluoroethylene resin, phenylene sulfide, acrylate rubber latex, epoxy accelerated resin, a catalyst, fumed silica, nano silver and the like. The wear-resistant and mildewproof non-stick pan coating prepared in the invention is chemically stable at the cooking temperature and does not generate hazardous substance PFOA. The coating has relatively great hardness and the damages of spatulas or spoons to the surface coating of the non-stick pan can be avoided. The non-stick pan prepared from the coating has low cost and a long service life.

Owner:NINGBO GRAMMY KITCHENWARE

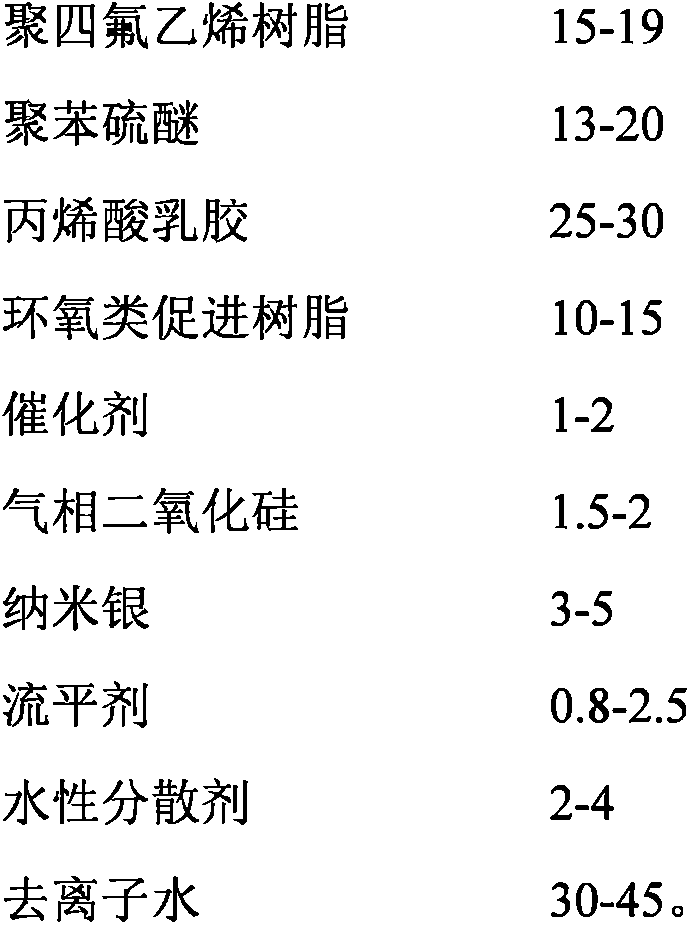

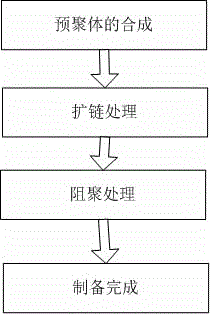

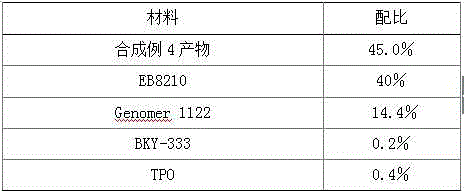

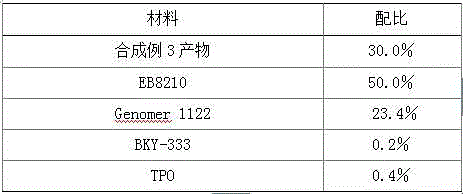

3D printing-based photo-curing material and preparation method thereof

The invention discloses a 3D printing-based photo-curing material and a preparation method thereof. The 3D printing-based photo-curing material comprises the following components in parts by weight: 50-55 parts of aqueous polyurethane acrylic resin, 20-30 parts of hydrogenated bisphenol A epoxy resin, 10-15 parts of alkoxylated pentaerythritol hexaacrylate, 10-15 parts of three-ring decane dimethyl carbinol dimethacrylate, 8-10 parts of hydroxyl ethyl methacrylate, 8-10 parts of vinyl ether, 3-5 parts of 1-hydroxy cyclohexyl phenyl ketone, 3-5 parts of 4,4'-bis(p-toly) iodonium hexafluorophosphate and 0.5-1 part of an 1080 antioxidant. The method comprises the following preparation steps: primary polymerization of a free radical-cation hybrid system, anti-shrinkage treatment, anti-yellowing treatment and post-treatment. The obtained material has the characteristics of excellent performance, low cost, good consistency and the like; and the used preparation method has the characteristics of being environment-friendly, short in production cycle and good in batch stability.

Owner:河源然生新材料有限公司

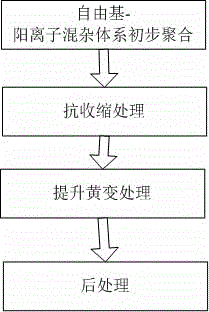

Application of low-viscosity light-cured resin in 3D (three-dimensional) printing materials

ActiveCN104893224ALow viscosityFast curing rateAdditive manufacturing apparatusPolymer scienceAcrylate ester

The invention relates application of low-viscosity light-cured resin in 3D (three-dimensional) printing materials. The low-viscosity light-cured resin is (branched) polyether acrylate or heterocyclic amine modified (branched) polyether acrylate. A 3D printing material prepared from the low-viscosity light-cured resin is of low viscosity and high curing speed, is low in curing shrinkage, low in yellowing property, moderate in rigidity and flexibility, high in forming speed and high in product dimensional precision, is free of curing incompleteness, edge warping and the like, and is very suitable for being applied to 3D printing materials based on the SLA (stereolithography) or 3DP (three-dimensional printing) technology.

Owner:新丰博兴聚合材料有限公司

Preparation method of hexamethylene diisocyanate tripolymer curing agent

InactiveCN103435778AEasy to synthesizeGood effectOrganic chemistryPolyurea/polyurethane coatingsPolymer scienceAmmonium hydroxide

The invention discloses a preparation method of a hexamethylene diisocyanate tripolymer curing agent, which comprises the following steps: putting an isocyanate monomer into a reaction vessel in a nitrogen gas protective atmosphere, dropwisely adding an isocyanate trimerization catalyst containing 2-hydroxyalkyl quaternary ammonium hydroxide within 1-1.5 hours, reacting while stirring at 30-80 DEG C for 2-24 hours, wherein the mass of the isocyanate trimerization catalyst accounts for 0.01-0.5% of that of the isocyanate monomer; when the mass percent of free NCO groups is measured to be 30-40%, adding an isocyanate trimerization inhibitor, wherein the mass of the isocyanate trimerization inhibitor accounts for 0.1-1% of that of the isocyanate monomer; and feeding the obtained polyurethane tripolymer curing agent into a separation device through a distributor at a feed rate of 1-20g / min, and separating to obtain the hexamethylene diisocyanate tripolymer curing agent. The curing agent disclosed by the invention is favorably compatible with resin, and has ultraviolet irradiation resistance, high compatibility, low viscosity and high mechanical strength.

Owner:SOUTH CHINA UNIV OF TECH

Method for improving physical and mechanical properties of oxidation-degummed ramie

ActiveCN103215655AImprove applicabilityImprove performanceFibre treatment to obtain bast fibreFiberColloid

The invention provides a method for improving the physical and mechanical properties of oxidation-degummed ramie. The method comprises the following steps of: preparing a degumming solution by using caustic soda, an oxidant, a surfactant, a fiber expanding agent, an oxidant stabilizer and water; mixing raw ramie and the degumming solution, heating, and boiling off to sufficiently remove colloid; and then cooling, adding a reduction softener, maintaining the temperature, oiling and drying after washing with clear water, and opening and carding to obtain textile ramie fiber subjected to reduction modification. According to the method disclosed by the invention, the defects of the prior art are overcome; and the reduction softener is added to raffinate obtained after oxidation-degumming, oxycellulose produced in the degumming process is reduced and softened, so that the physical and mechanical properties, such as strength, length, elongation and softness of the fiber are improved, the working procedures are simplified, and pollution and environmental pressure are lightened.

Owner:DONGHUA UNIV

Method for preparing super-smooth hydrophilic quaternary ammonium salt modified organic silicon copolymer

ActiveCN104072783AGood self-emulsifying performanceImprove hydrophilicityVegetal fibresAcetic acidOrganic solvent

The invention relates to the field of a textile finishing agent, and particularly relates to a method for preparing a super-smooth hydrophilic quaternary ammonium salt-modified organic silicon copolymer. The method comprises the following steps: synthesizing a cationic modified polyether amine intermediate by using aliphatic polyether diamine and an alkylating agent under the action of an acid catalyst; carrying out addition polymerization of amino and an epoxy group on the cationic modified polyether amine intermediate and terminated epoxy polyether silicone oil in the presence of an organic solvent, then adding a glacial acetic acid, and synthesizing ternary block silicon oil. The super-smooth hydrophilic quaternary ammonium salt modified organic silicon copolymer prepared by the method provides excellent hydrophilic performance to cotton fabric, and has an outstanding smooth effect, and the smoothness can achieve the level of common amino silicon oil, and is superior to that of most of ternary block silicon oil. The super-smooth hydrophilic quaternary ammonium salt modified organic silicon copolymer has certain antibacterial and antistatic functions by improvement of the cationization degree, meanwhile, the problem that amino is easy to yellow in a high-temperature condition can be effectively solved, and the processed fabric is small in yellowing, and applicable to finishing of white or light fabric.

Owner:GUANGDONG CHUANHUA FULIAN FINE CHEM CO LTD

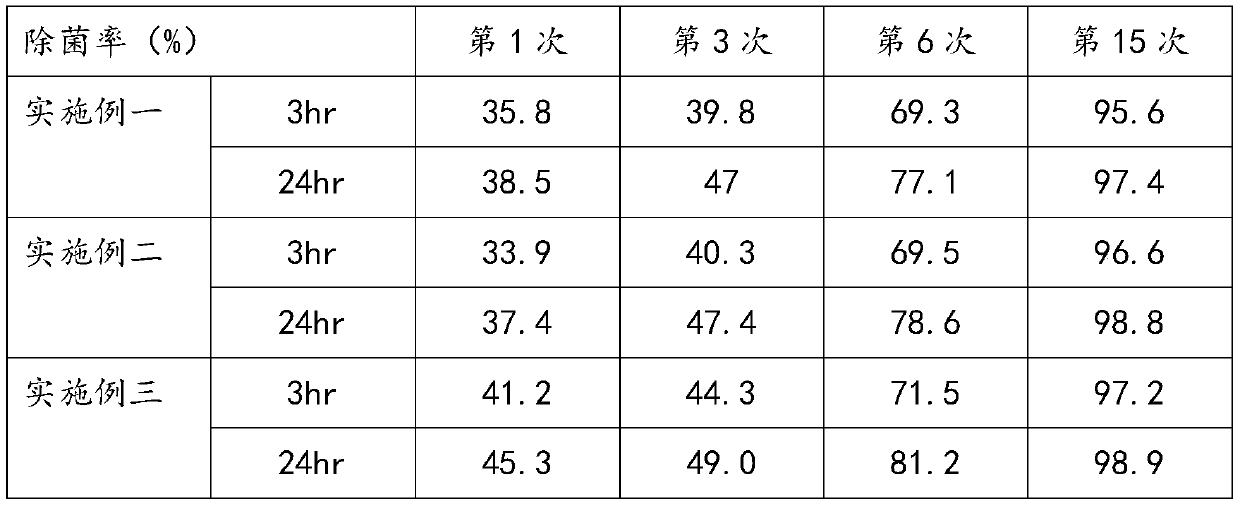

Long-acting antibacterial agent, long-acting antibacterial agent with instant effect and preparation method of long-acting antibacterial agent

ActiveCN109735154AControl release speedFacilitated ionizationAntifouling/underwater paintsPaints with biocidesCross-linkHydrophilic polymers

The invention discloses a long-acting antibacterial agent, a long-acting antibacterial agent with an instant effect and a preparation method of the long-acting antibacterial agent, and relates to thetechnical field of coating antibacterial agents. The long-acting antibacterial agent mainly comprises nano silver, carrier particles and hydrophilic polymers / a mixture of hydrophilic polymers and hydrophilic inorganic matters, and the long-acting antibacterial agent with the instant effect comprises nano silver, silver salts, other metal salts, carrier particles, hydrophilic polymers / a mixture ofhydrophilic polymers and hydrophilic inorganic matters and a cross-linking agent. By the invention, the problems that a coating film prepared by an existing antibacterial agent is not washable and poor in long-acting property, yellowing of antibacterial active component Ag ions is easily caused, an organic antibacterial agent is harmful to human bodies, pollutes the environment and the like are solved. In addition, hydrophilic polymers or a mixture of the hydrophilic polymers and hydrophilic oligomers or inorganic matters wrap the surface of the antibacterial agent, the releasing speed of silver ions is controlled, and silver simple substances can be promoted to ionize silver ions to resist bacteria.

Owner:天津西敦粉漆科技有限公司

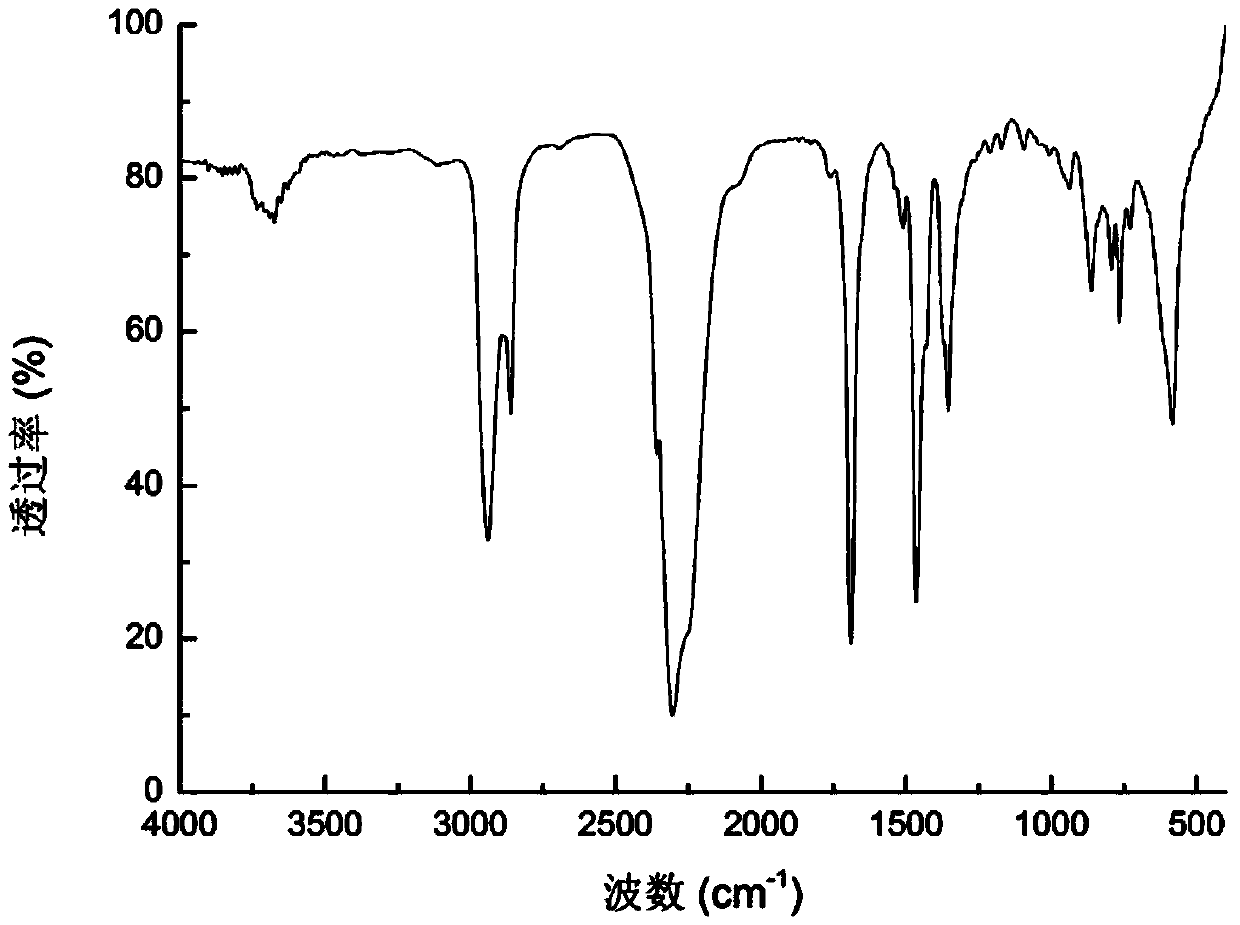

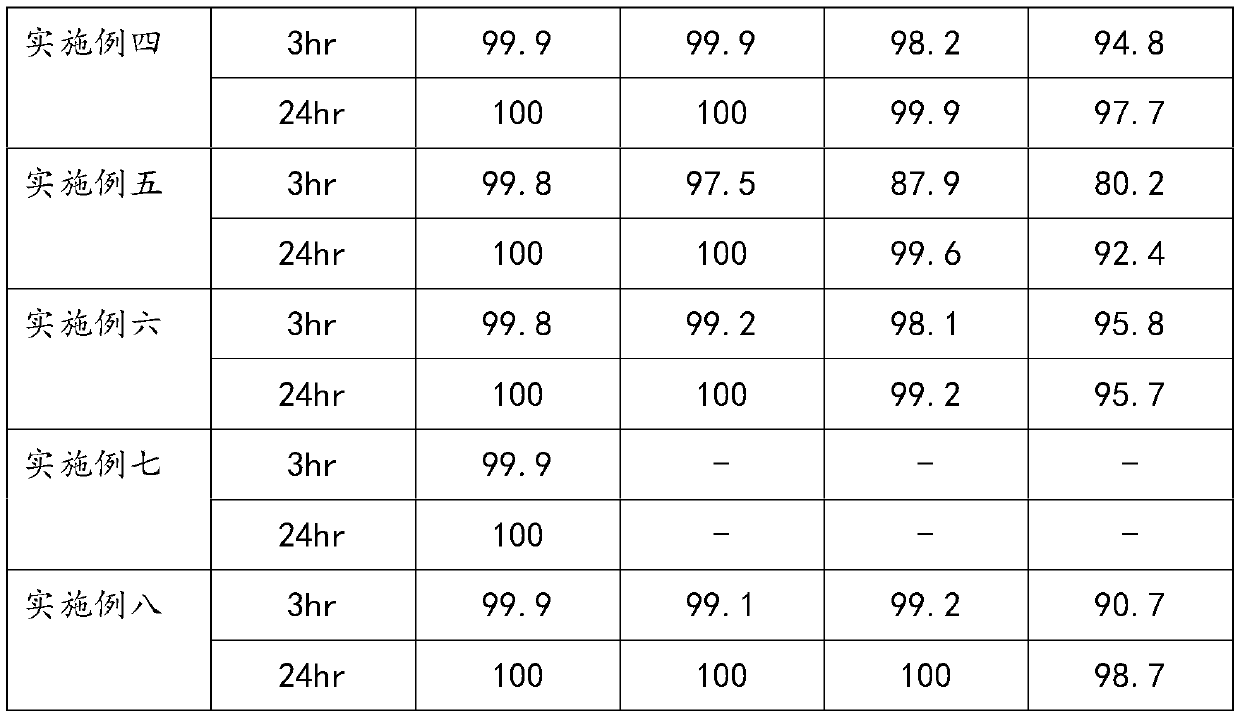

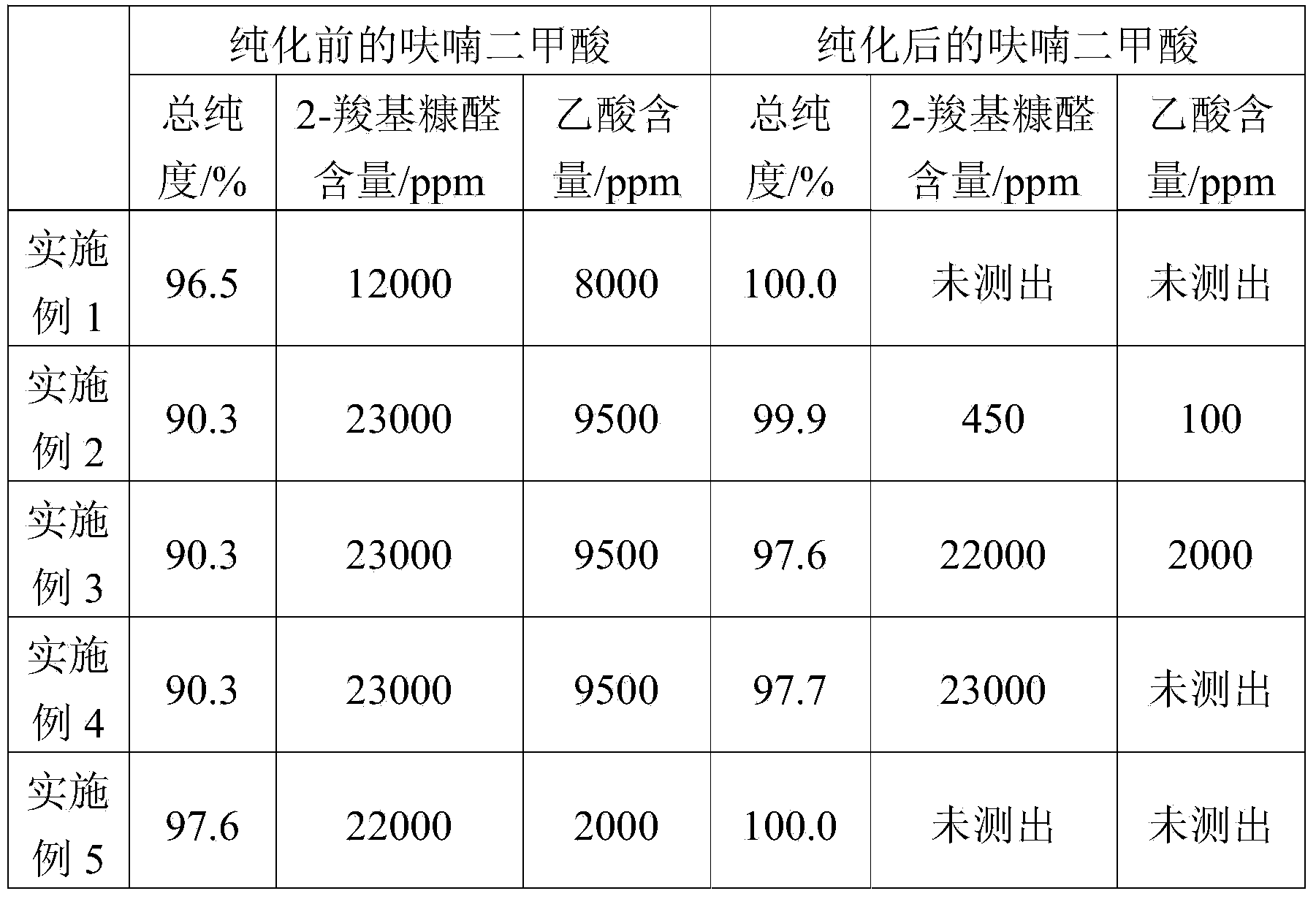

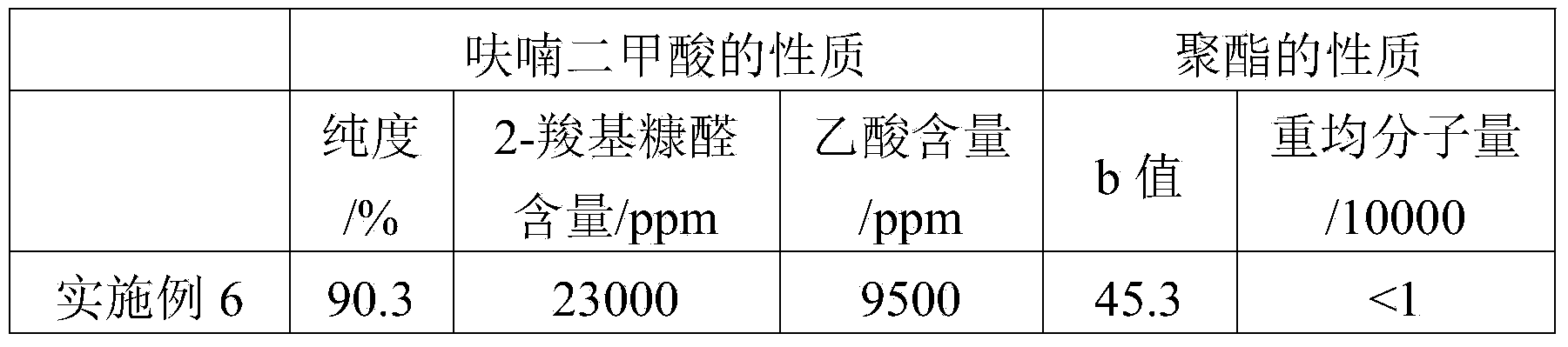

Method for purifying furandicarboxylic acid

The invention discloses a method for purifying furandicarboxylic acid. The method comprises the steps as follows: to-be-purified furandicarboxylic acid is dissolved in water through salt forming reaction; a filter liquid is acidized after filtration; and solids obtained through precipitation is filtered out, washed and dried, and the high-purity furandicarboxylic acid is obtained. Meanwhile, in order to solve the problems that the to-be-purified furandicarboxylic acid is low in purity degree and is not suitable for the method, the invention further discloses two pre-purification methods including backflow in acetic acid and recrystallization in water. The method for purifying the furandicarboxylic acid is simple in technological process and mild in reaction condition, and does not adopt an organic agent; and the prepared high-purity furandicarboxylic acid is applied to polymerization, can effectively restrain a polymer from changing color, and simultaneously facilitates acquisition of a polymerization product with a high molecular weight.

Owner:ZHEJIANG UNIV

Special slow control/release compound fertilizer for eggplant and preparation method thereof

ActiveCN103524221AIncrease productionPromote flowering and fruitingAgriculture gas emission reductionFertilizer mixturesNitrification inhibitorsRapeseed

The invention provides a special slow control / release fertilizer for an eggplant. The fertilizer is characterized by comprising, in terms of mass percent, 0.05% to 0.08% of n-butyl triamine thiophosphate, 0.05 to 0.08% of hydroquinone and 0.24 to 0.28% of dicyandiamide. According to the invention, the special slow control / release fertilizer is prepared by combining macro-element, medium-element and trace-element fertilizers like nitrogen, phosphorus, potassium, calcium, magnesium, molybdenum, boron, zinc and iron with organic fertilizers like high-quality decomposed rapeseed dregs, chicken manure and grass carbon, adding a urease inhibitor and a nitrification inhibitor and carrying out mixing; the special slow control / release fertilizer has a slow release effect in soil, is rich in a variety of nutrient elements needed in growth of the eggplant, can meet demands of the eggplant for nutrients in different growth and development phases for a long time and effectively improves output of the eggplant.

Owner:SOUTHWEST UNIVERSITY

White thermosetting silicone resin composition for molding an optical semiconductor case and optical semiconductor case

ActiveUS8013057B2Convenient lightingIncrease resistanceSolid-state devicesOptical articlesOrganic groupGlycylxylidide

Owner:SHIN ETSU CHEM CO LTD

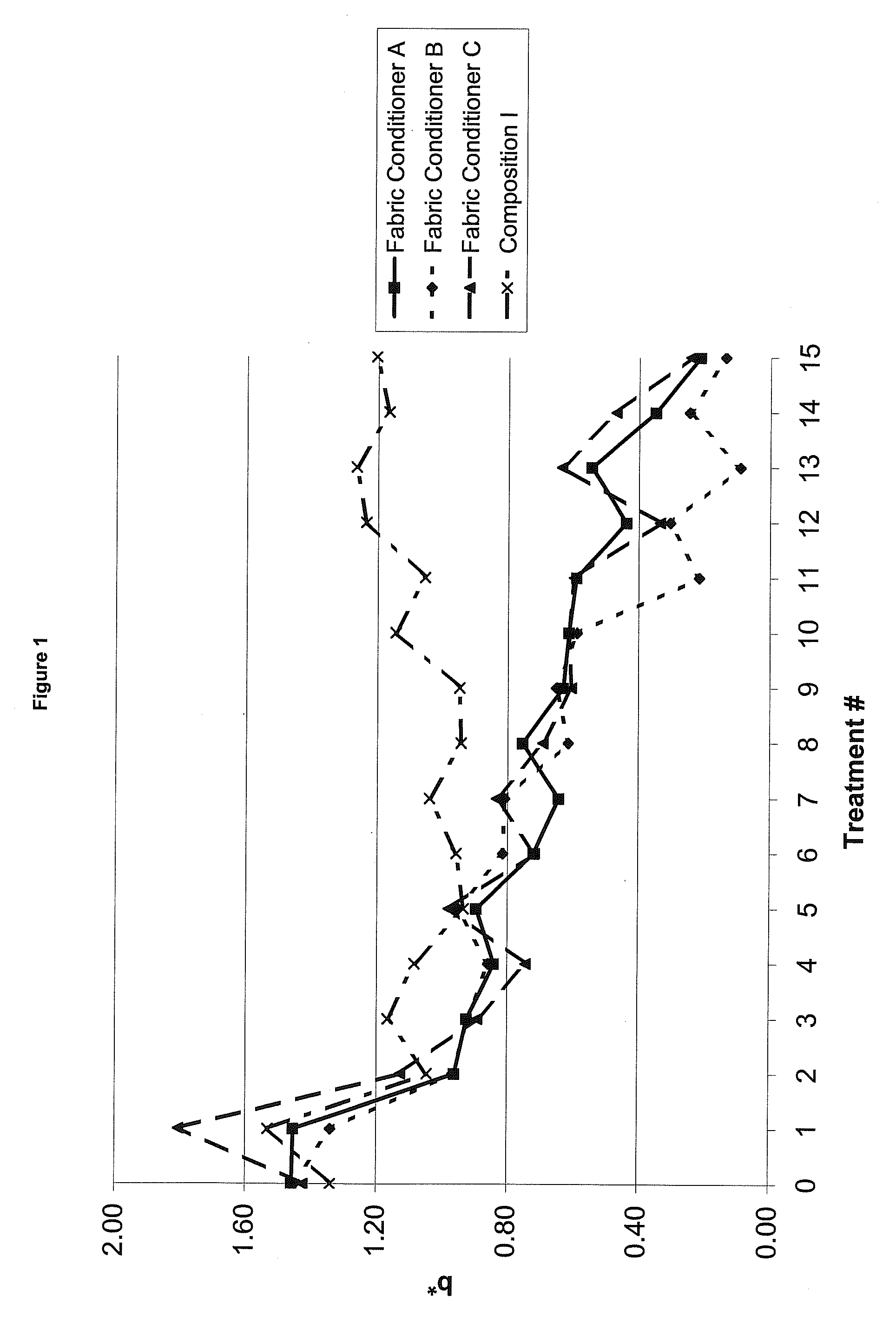

Liquid fabric conditioner composition and method of use

ActiveUS20080307586A1Reduced tendency to pickReduce discolorationCationic surface-active compoundsOrganic detergent compounding agentsResistDegree Fahrenheit

The invention includes a method of conditioning fabrics, comprising contacting fabric with a liquid composition comprising an amino-functional silicone and a quaternary ammonium, and drying said fabric at 200 degrees F. or greater. The invention includes a method of conditioning fabrics, comprising washing fabric in a detergent having a wash pH of greater than 10, contacting fabric with a liquid composition comprising an amino-functional silicone and a quaternary ammonium, and drying said fabric at less than 200 degrees F. The invention further provides a method of conditioning fabrics wherein softness, anti-static, and anti-wrinkle properties are imparted to the fabric wherein the conditioned fabric resists yellowing in industrial and institutional conditions wherein the wash pH is greater than 9 and / or the fabric temperature is 200 degrees Fahrenheit or greater.

Owner:ECOLAB USA INC

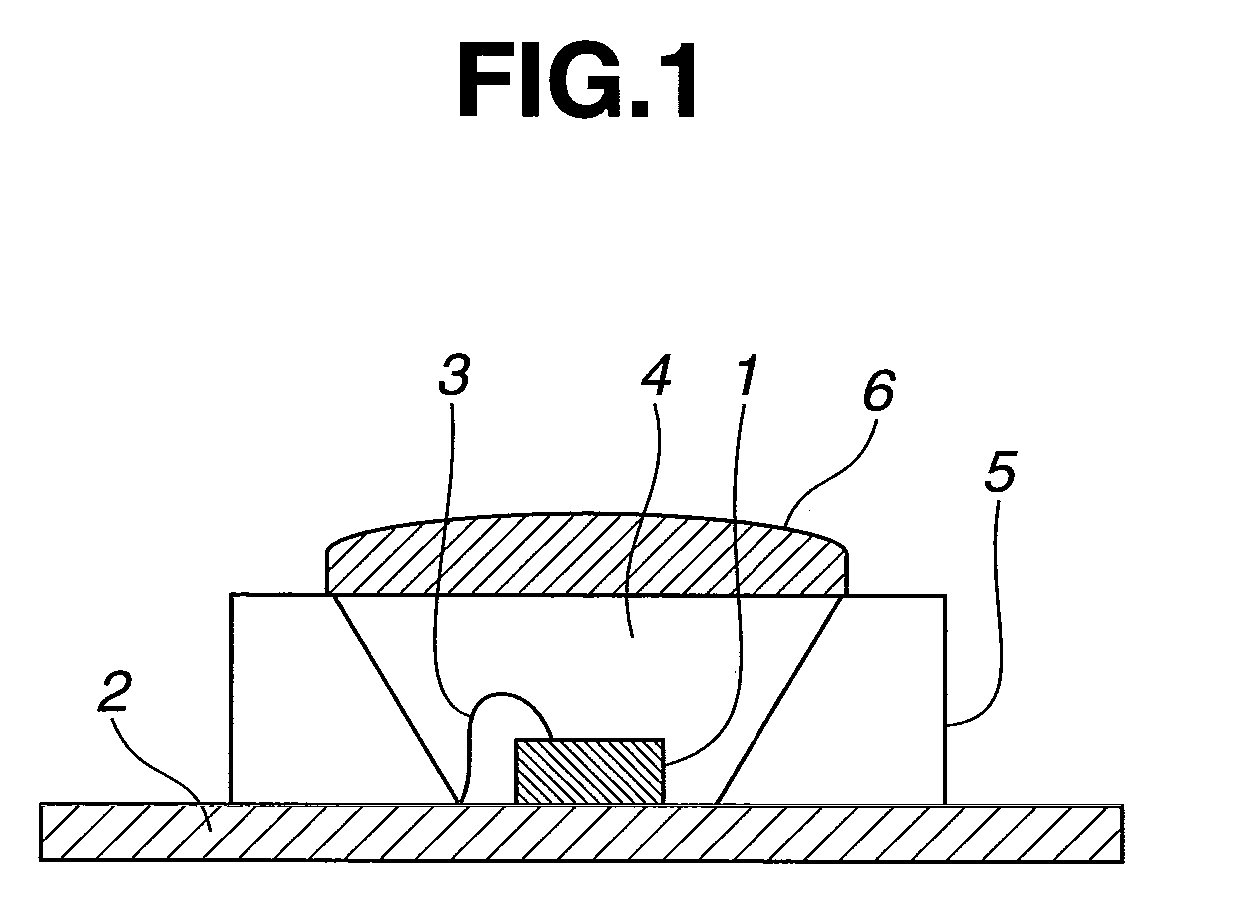

White thermosetting silicone resin composition for molding an optical semiconductor case and optical semiconductor case

ActiveUS20090239997A1Improve heat resistanceConvenient lightingSolid-state devicesOptical articlesOrganic groupGlycylxylidide

A white thermosetting silicone resin composition for molding an optical semiconductor case and a case for an optical semiconductor such as LED are provided. The composition comprises (A) a thermosetting organopolysiloxane, (B) a white pigment, (C) an inorganic filler (excluding the white pigment), (D) a condensation catalyst, and (E) a coupling agent represented by the following formula: R3dSi(OR2)e wherein R3 represents an organic group containing a mercapto group, a glycidyl group, or an amino group, R2 represents a C1-4 organic group, d represents 1 or 2, and e represents 2 or 3; wherein content of the white pigment (B) is 1 to 50% by weight in the entire composition, and total content of the white pigment (B) and the inorganic filler (C) is 70 to 93% by weight in the entire composition. When cured, it has excellent whiteness, consistency, and resistance to heat, light, yellowing, and warping.

Owner:SHIN ETSU CHEM IND CO LTD

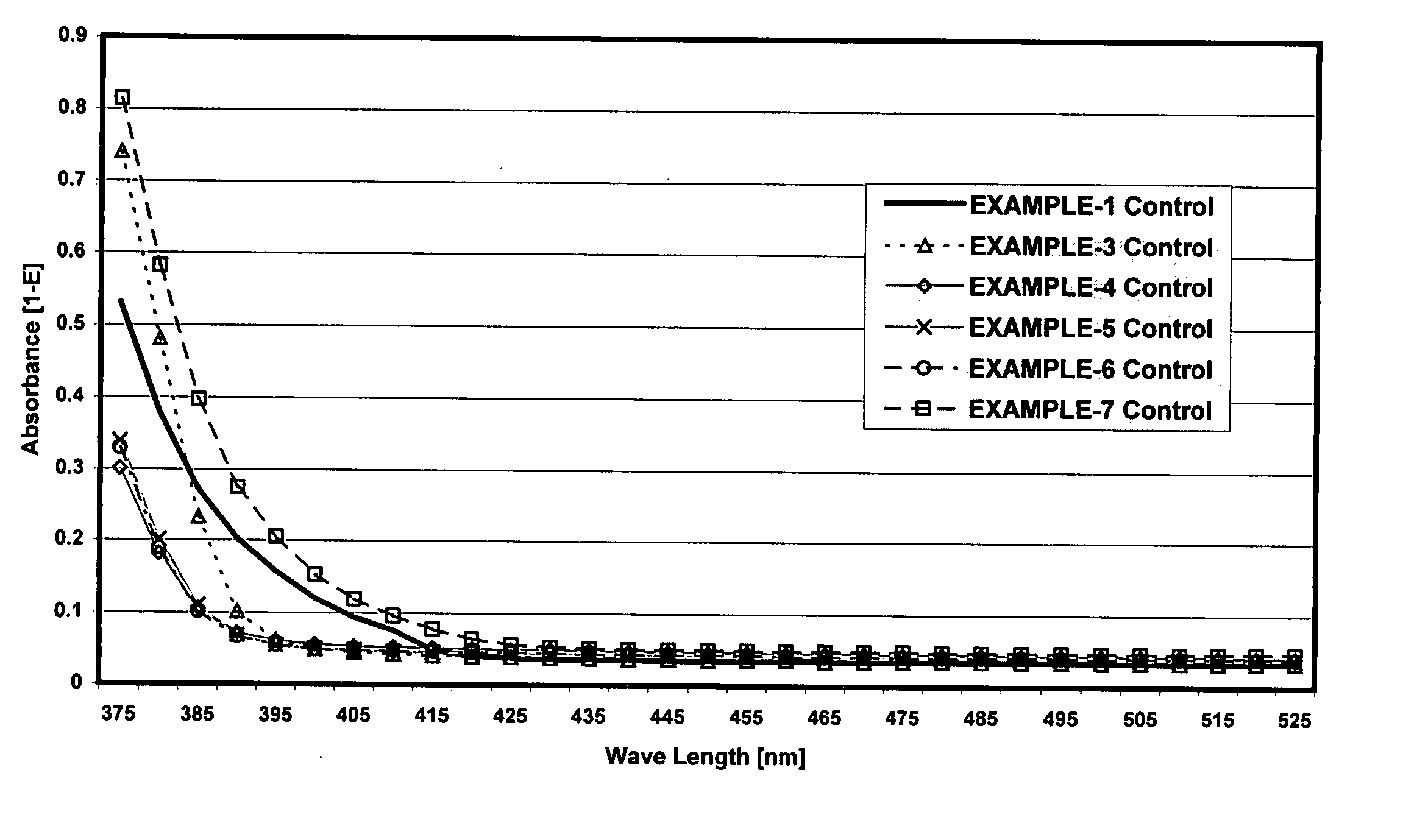

Photosensitive composition with low yellowing under UV-light and sunlight exposure

ActiveUS20070099119A1Maintain clarityReduce yellowingPhotosensitive materialsRadiation applicationsPrepolymerPhotoinitiator

This disclosure relates to a photosensitive composition useful in preparing water-developable, relief printing plates and other photosensitive articles. The compositions comprise an unsaturated polyurethane pre-polymer, which is the reaction product of at least one polyether diol, at least one aliphatic diisocyanate, at least one hydroxyl-functionalized mono-, di- and tri-(meth)acrylate, and a particular photoinitiator. The resulting photosensitive resin compositions have reduced rates and levels of yellowing if subjected to additional UV-light or sunlight after processing.

Owner:CHEMENCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com