3D printing-based photo-curing material and preparation method thereof

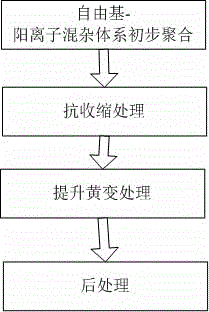

A light-curing material and 3D printing technology, applied in the field of 3D printing-based light-curing material and its preparation, can solve the problems of large shrinkage rate, low shrinkage rate, and small temperature effect, so as to shorten the product manufacturing cycle and batch Good stability and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

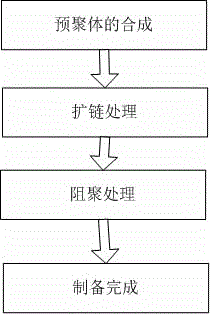

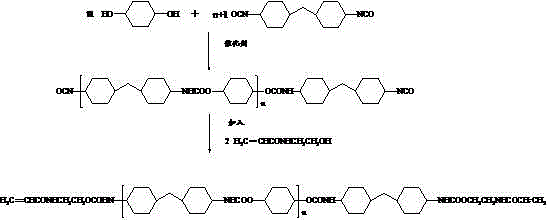

[0049] In order to prepare photocurable materials based on 3D printing, water-based polyurethane acrylic resin is prepared first, and the process flow is as follows: figure 2 Shown, the preparation of described aqueous polyurethane acrylic resin comprises the following steps:

[0050] Step 1, the synthesis of the prepolymer, adding an appropriate amount of hydroxyethylacrylamide as a reactive diluent in the reaction kettle, and then adding 39-45 parts of diisocyanate and 0.05-0.15 parts of dibutyltin dilaurate as a catalyst to the reactive diluent , adjust the temperature control of the reactor so that the temperature of the material is 60-90 °C;

[0051] Step 2, chain extension treatment, slowly drop 18-22 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com