Patents

Literature

190results about How to "Good batch stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

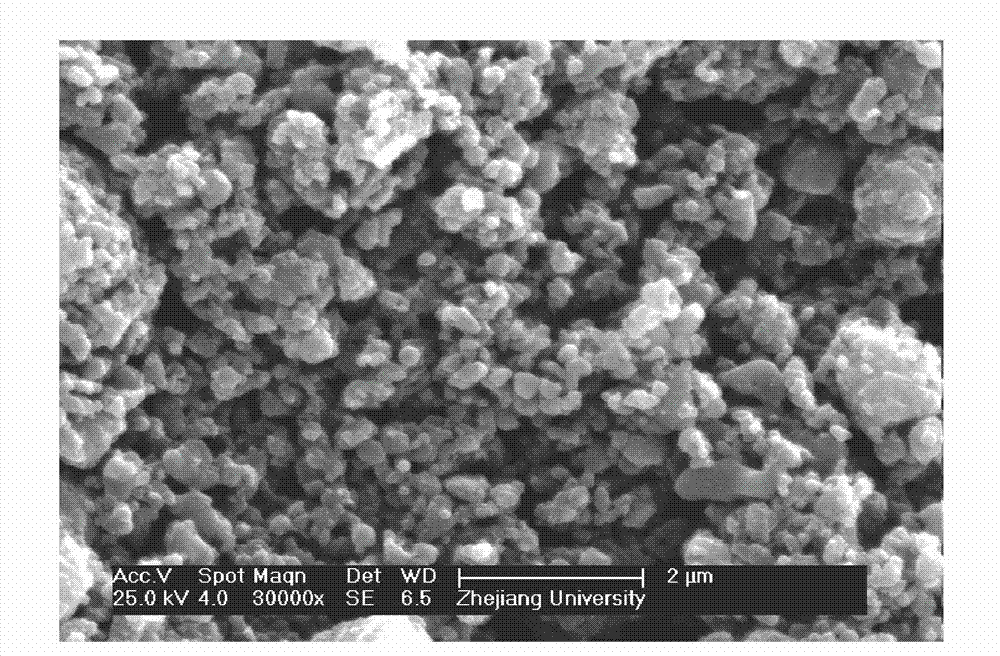

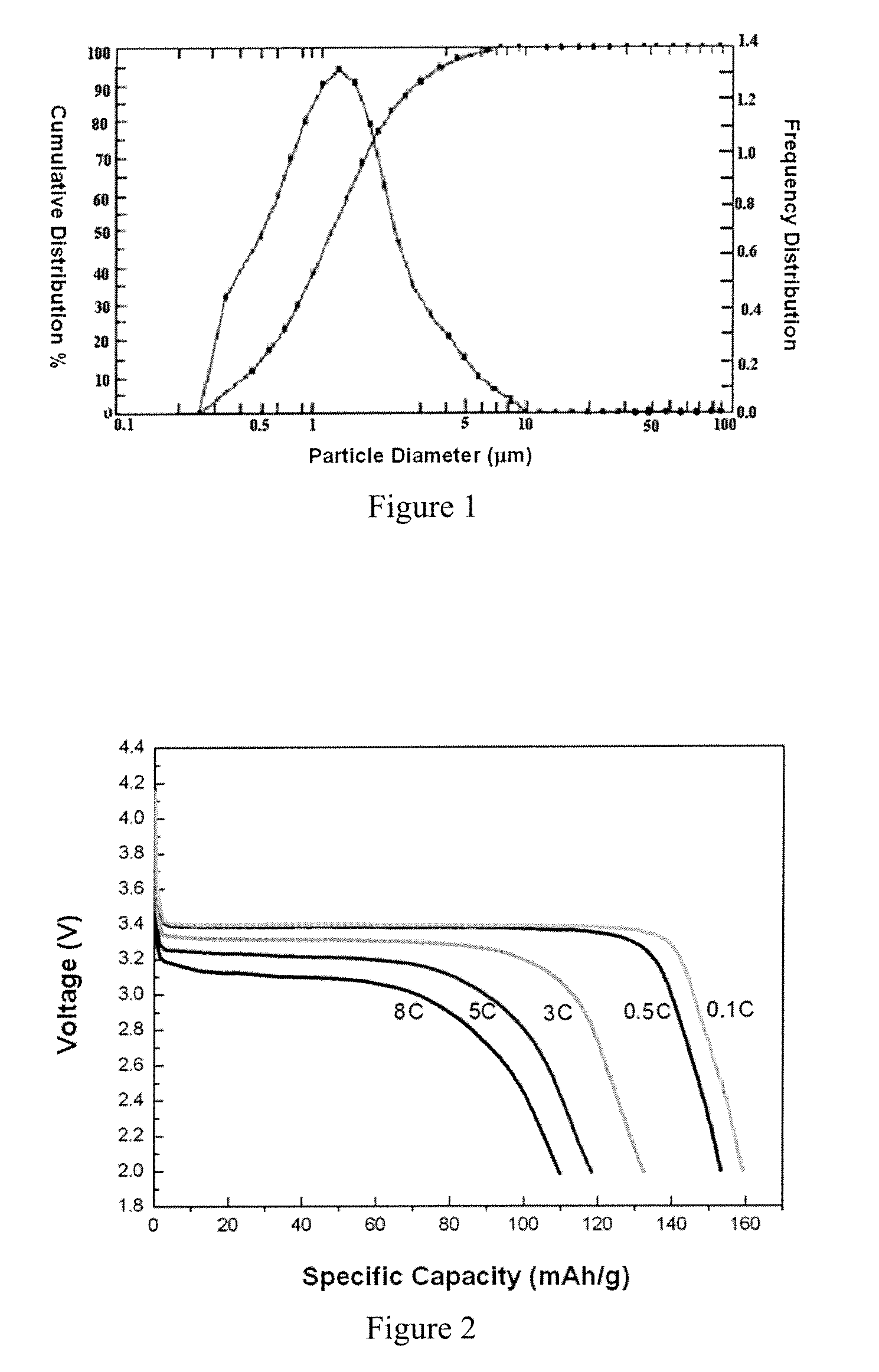

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

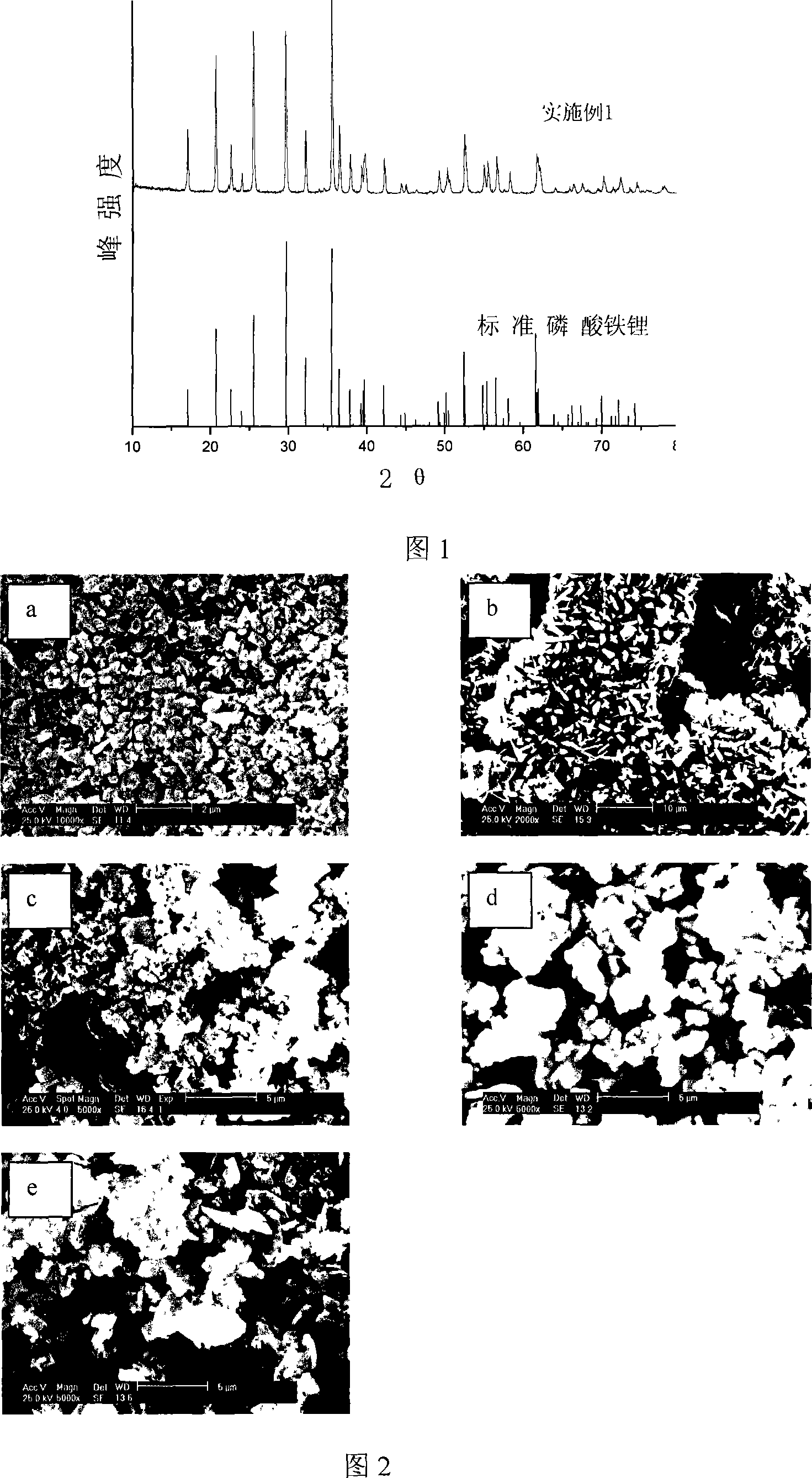

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

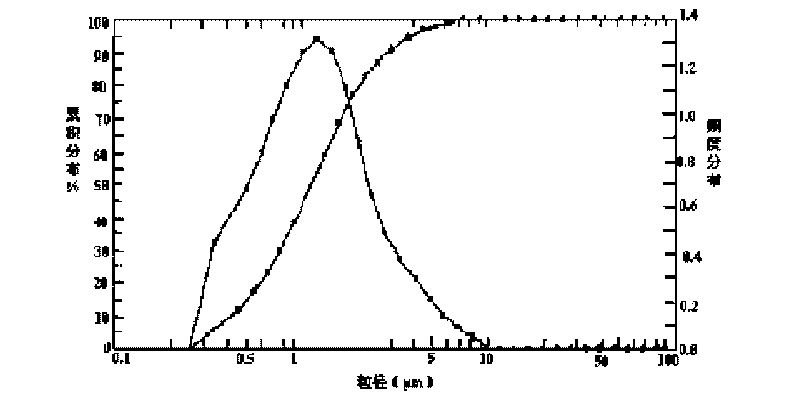

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

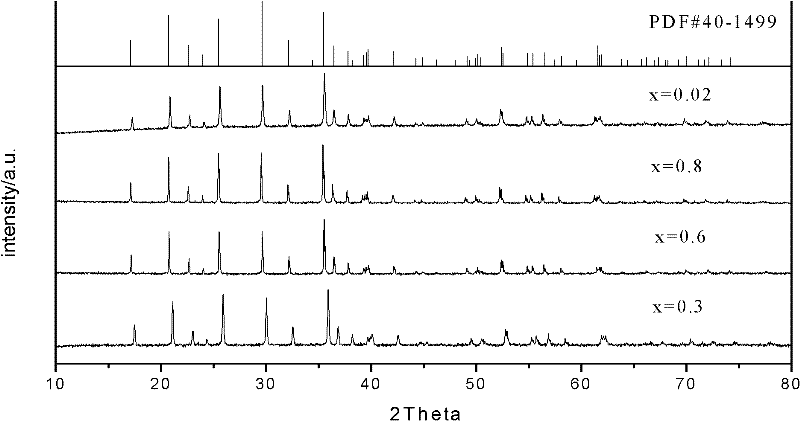

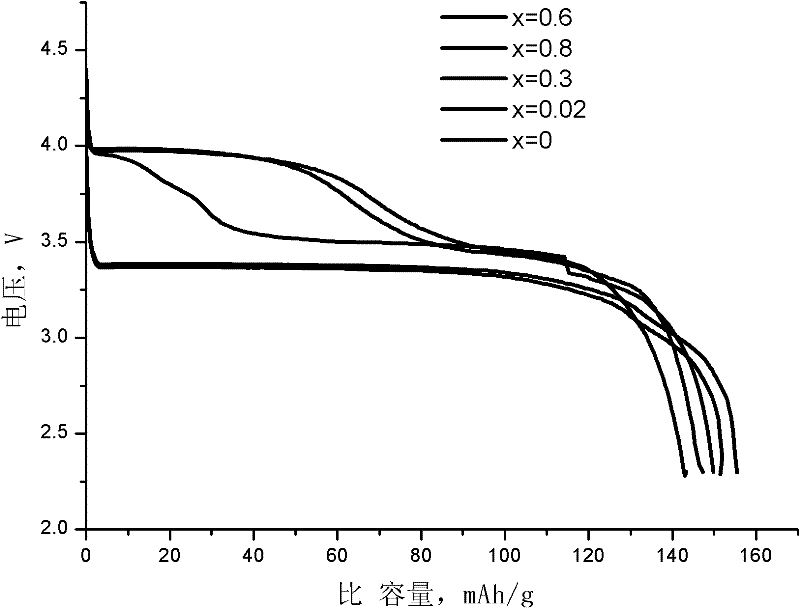

Hydrothermal synthesis method for lithium ferromanganese phosphate anode material of lithium ion battery

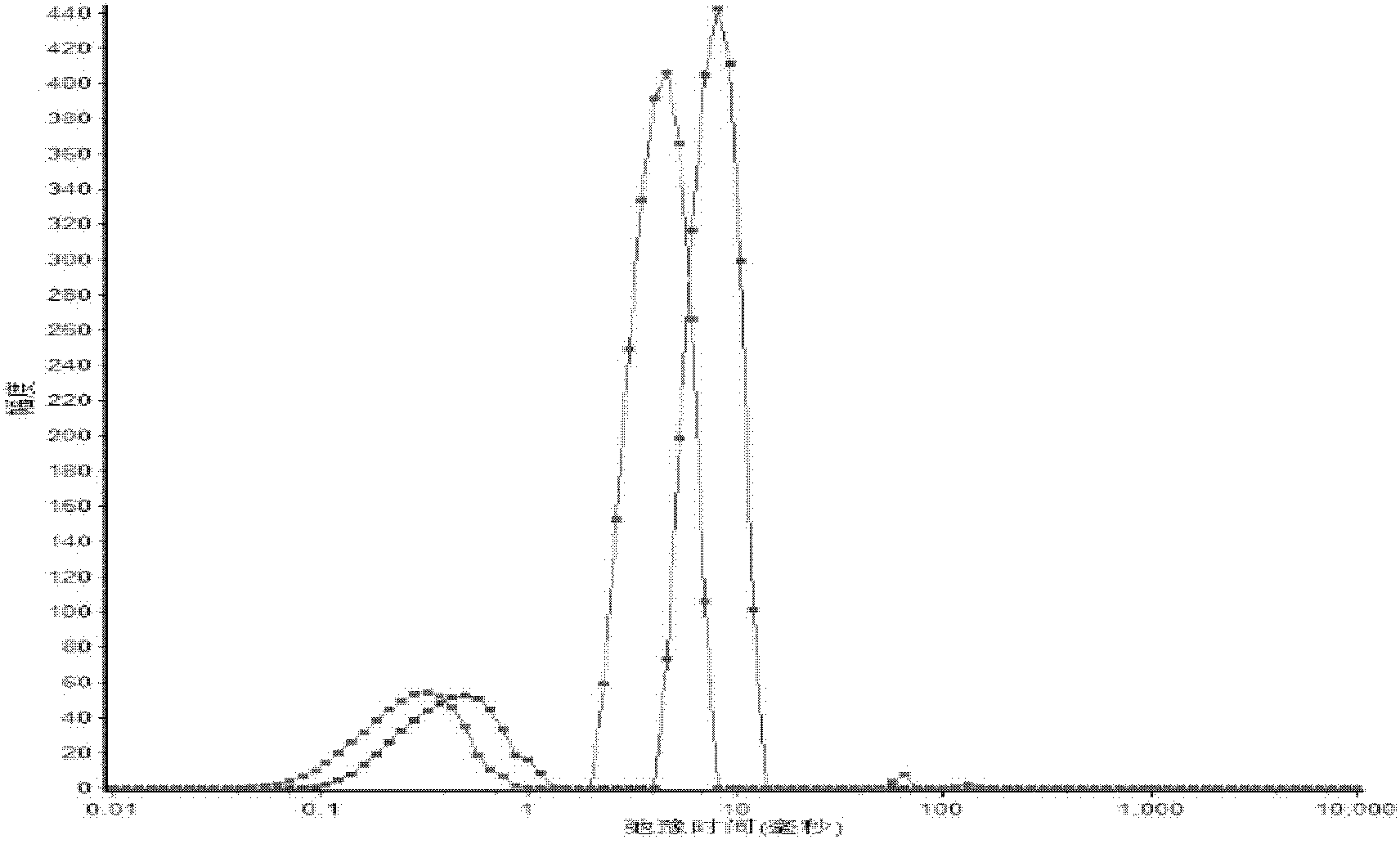

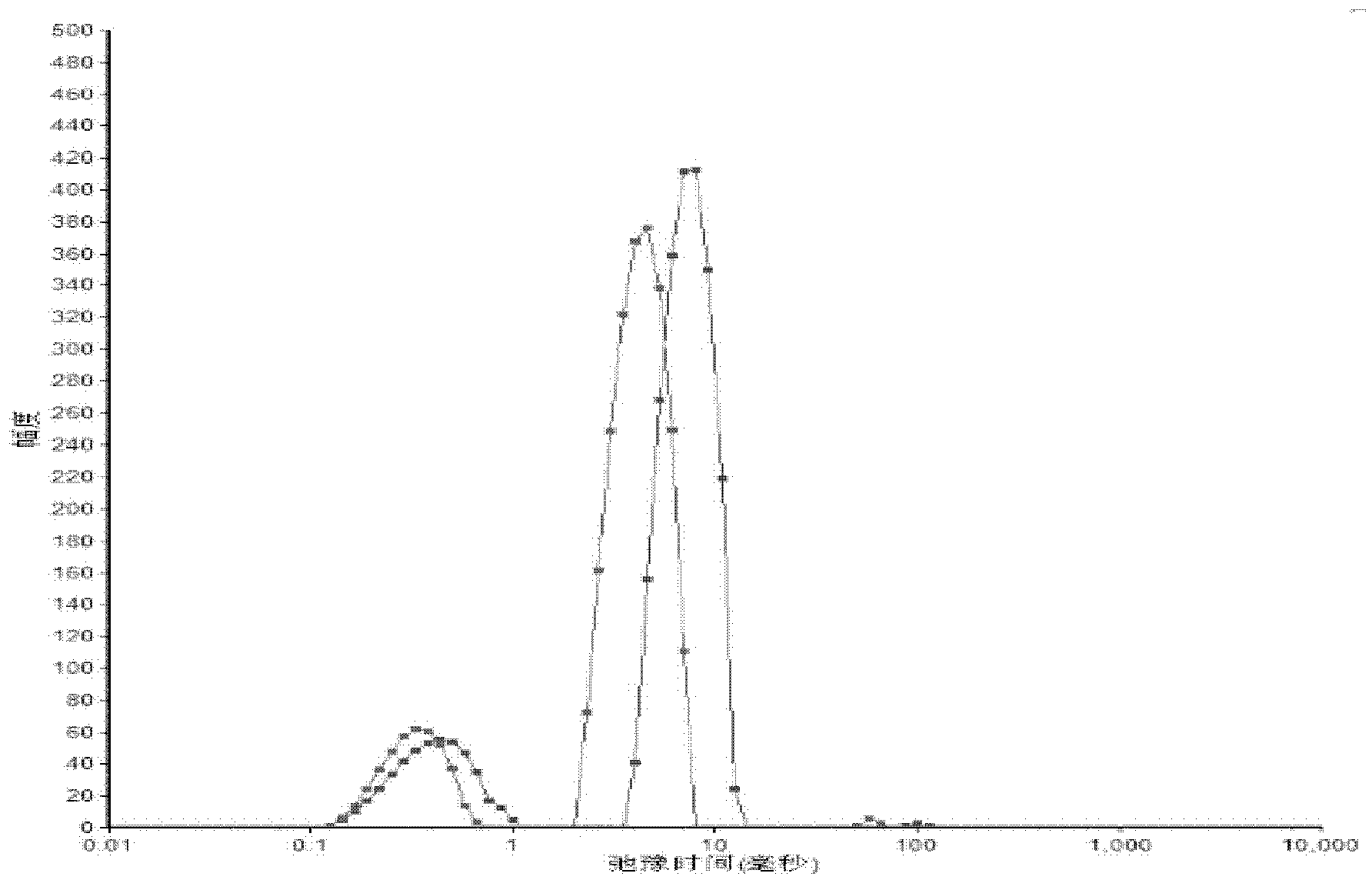

InactiveCN102249208AHigh degree of crystallinitySingle phaseCell electrodesNanotechnologyPhosphateLithium hydroxide

The invention relates to a hydrothermal synthesis method for lithium ferromanganese phosphate anode material of a lithium ion battery, belonging to the technical field of lithium ion batteries. The method has the following processing steps of: step 1, preparing LiMnxFe1-xPO4 through a hydrothermal synthesis reaction: mixing an aqueous lithium hydroxide solution, an aqueous ferrous sulfate solution and phosphoric acid under a stirring condition, after sealing, heating to 150 DEG C to 180 DEG C within 0.5 to 2 h, reacting for 0.5-4 h under the pressure of 0.48-1.0 Mpa, cooling to less than 80 DEG C, and filtering; step 2, mixing with organic matters and drying: mixing a wet filter cake with a soluble carbon source organic matter, and carrying out spray drying or expansion drying; and step 3, carrying out carbon-coated processing: roasting LiMnxFe1-xPO4 carbon source compound powder at a temperature between 600 DEG C and 750 DEG C for 4-6 h under an insert gas condition, and cooling to less than 150 DEG C to obtain a carbon-coated lithium ferromanganese phosphate anode material of the lithium ion battery. The hydrothermal synthesis method disclosed by the invention has the advantages of simple and controllable technology, convenience for operation, low cost, high crystallization degree of products, uniform dispersion, high specific capacity, high conservation rate of the cycling capacity, and the like.

Owner:朱鸥鹭

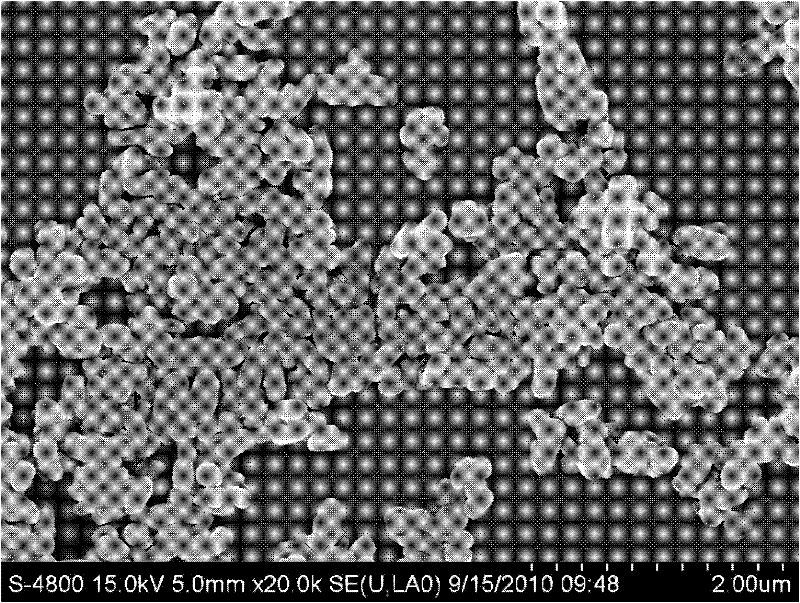

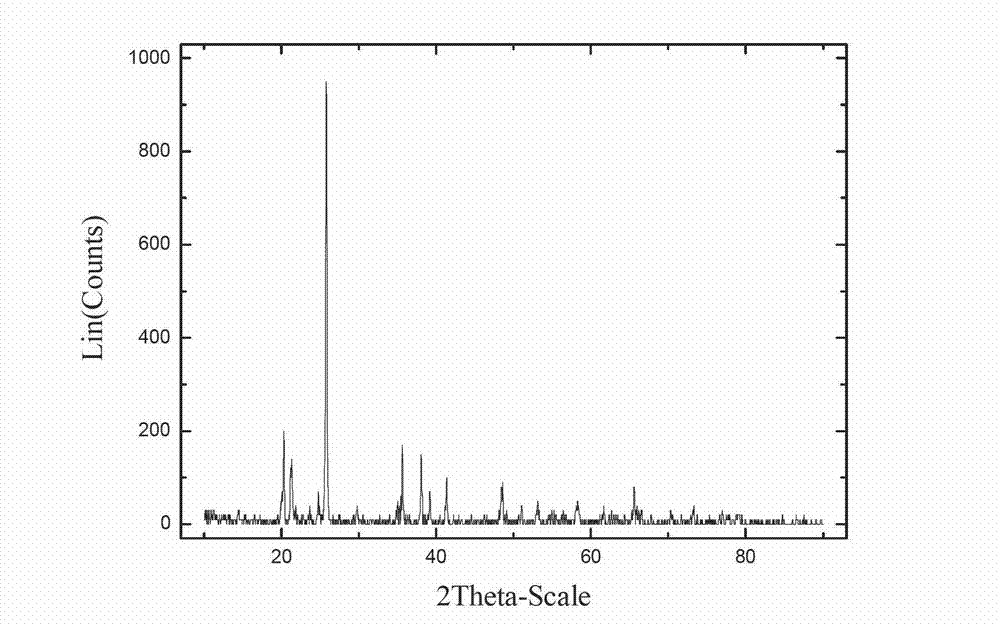

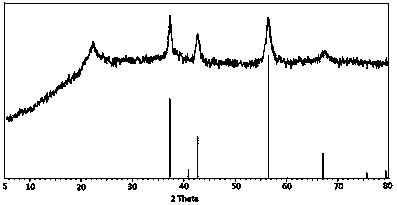

Hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure

InactiveCN101752564AImprove rate discharge performancePromote environmental protectionCell electrodesPhosphorus compoundsLithium hydroxidePhosphoric acid

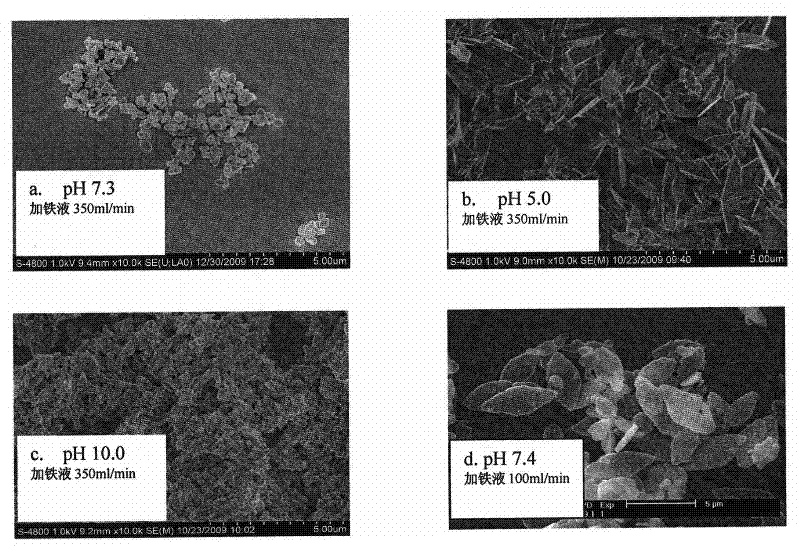

The invention discloses a hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure, which comprises the steps of: 1. respectively adding lithium hydroxide solution and phosphoric acid, evenly adding iron source solution with a certain speed, wherein the molar ratio of the proportion of the added materials Li: Fe: P is 3.0:1.0:1.0-1.15, stirring 10-30 for minutes, adding pH value adjusting agent, leading the initial pH value of a reaction system to be 6.5-8.0, and reacting for 60-480 minutes at 40-180 DEG C; 2. filtering, washing and drying resultant; and 3. packing carbon. The hydrothermal synthesis method can take raw material solution for generating ferrous sulfate as iron source, produces a product with good performance by adjusting the pH value of the reaction system and controlling the feeding speed, eliminates working procedures for crystallizing and drying the ferrous sulfate and the like, is good for reducing water electricity consumption, and has less equipment investment, simple and controllable technology and good batch stability of the product.

Owner:HEBEI UNIV OF TECH

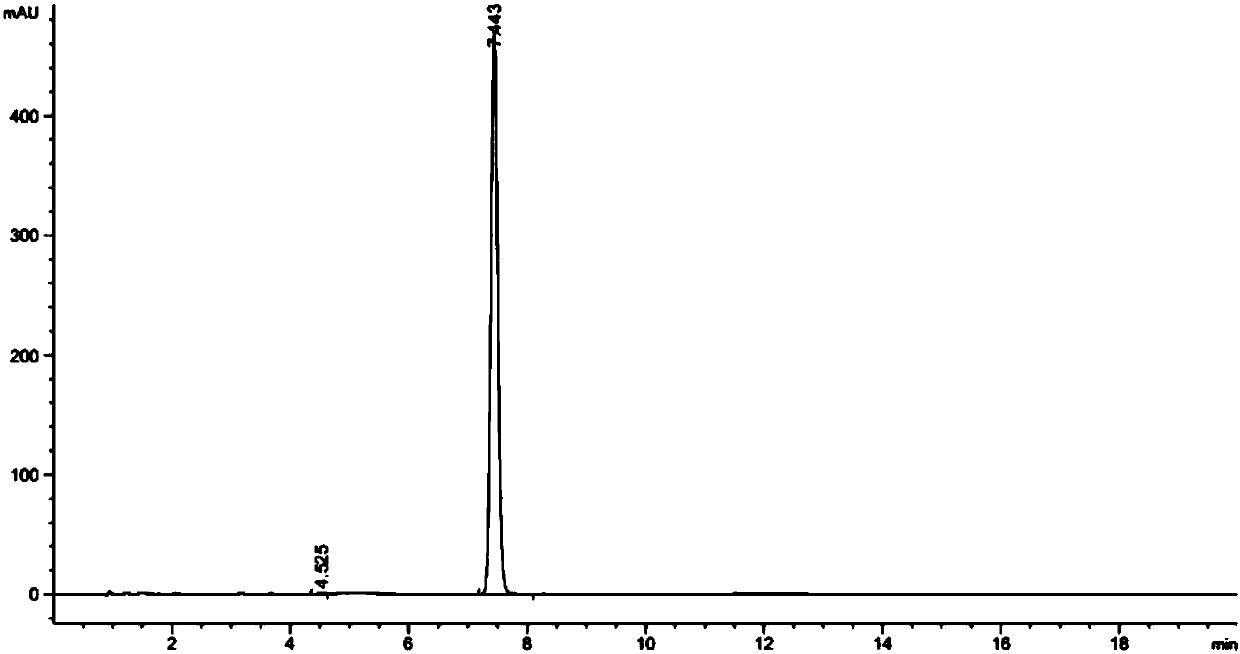

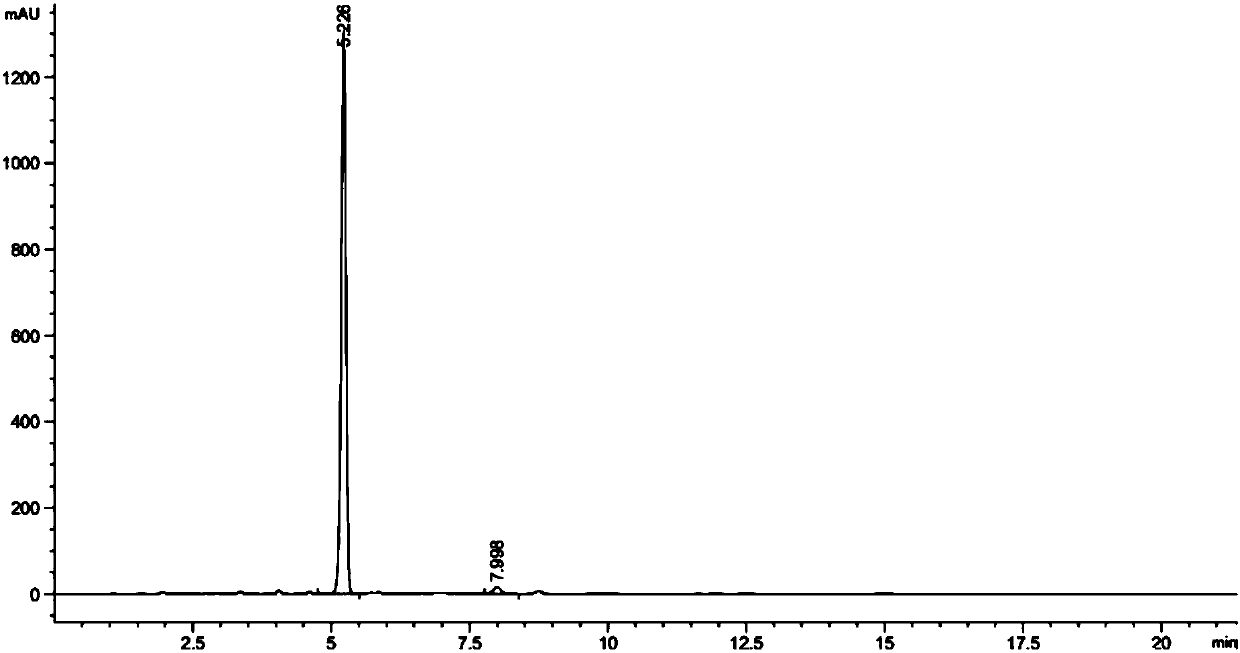

Method for extracting CBD and CBDV at same time

ActiveCN109574810AResidue reductionReduce the impactOrganic chemistryOrganic compound preparationCannabisSolvent

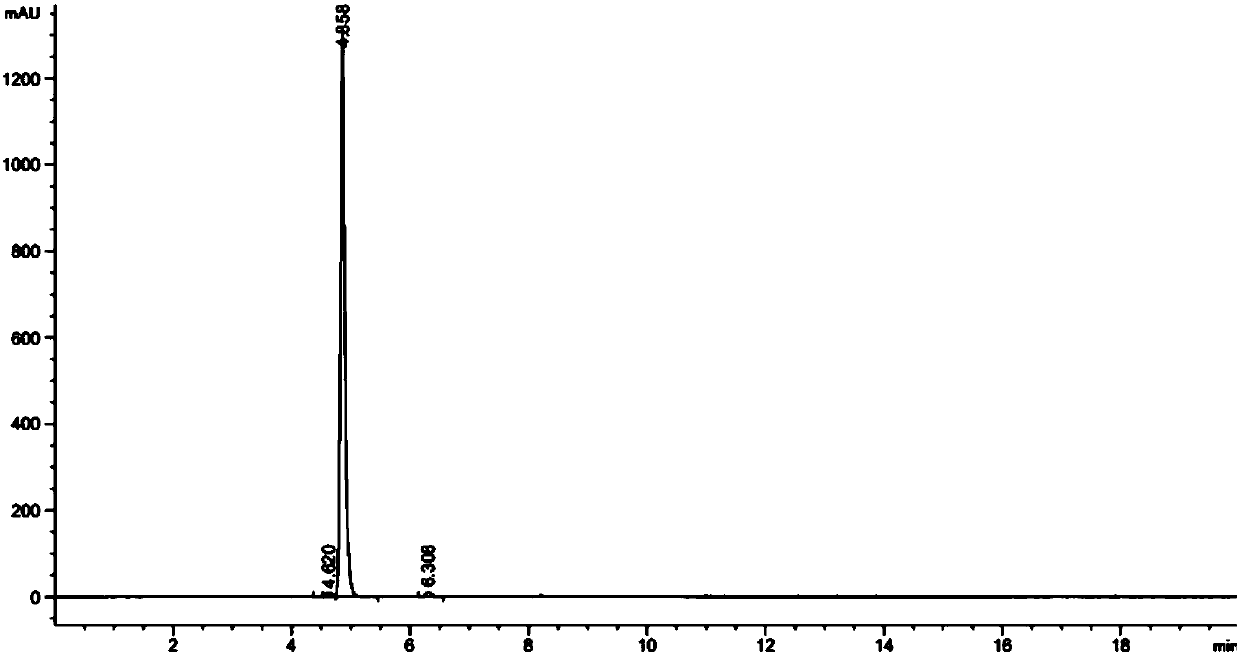

The invention discloses a method for extracting CBD and CBDV at the same time. The method includes: smashing an extracted portion of hemp, and baking to obtain medicinal material powder; using a solvent to extract the medicinal material powder to obtain extraction liquid; concentrating the extraction liquid, and performing solid-liquid separation to obtain supernate; allowing the supernate to passan adsorption column, and eluting to obtain eluate 1 and eluate 2; respectively concentrating and purifying the eluate 1 and the eluate 2 to obtain CBDV and CBD. The method is low in cost and easy inoperation, and impact on environment and operation personnel and solvent residue in CBDV and CBD; purity and yield of target products in CBDV and CBD are high, CBD purity can be up to 99.7%, and one-time crystallization purity of CBDV can reach 98%; psychotoxic ingredient THC is removed and destroyed, so that CBDV and CBD are high in safety, and the method can realize industrial amplification.

Owner:HANYI BIO TECH CO LTD

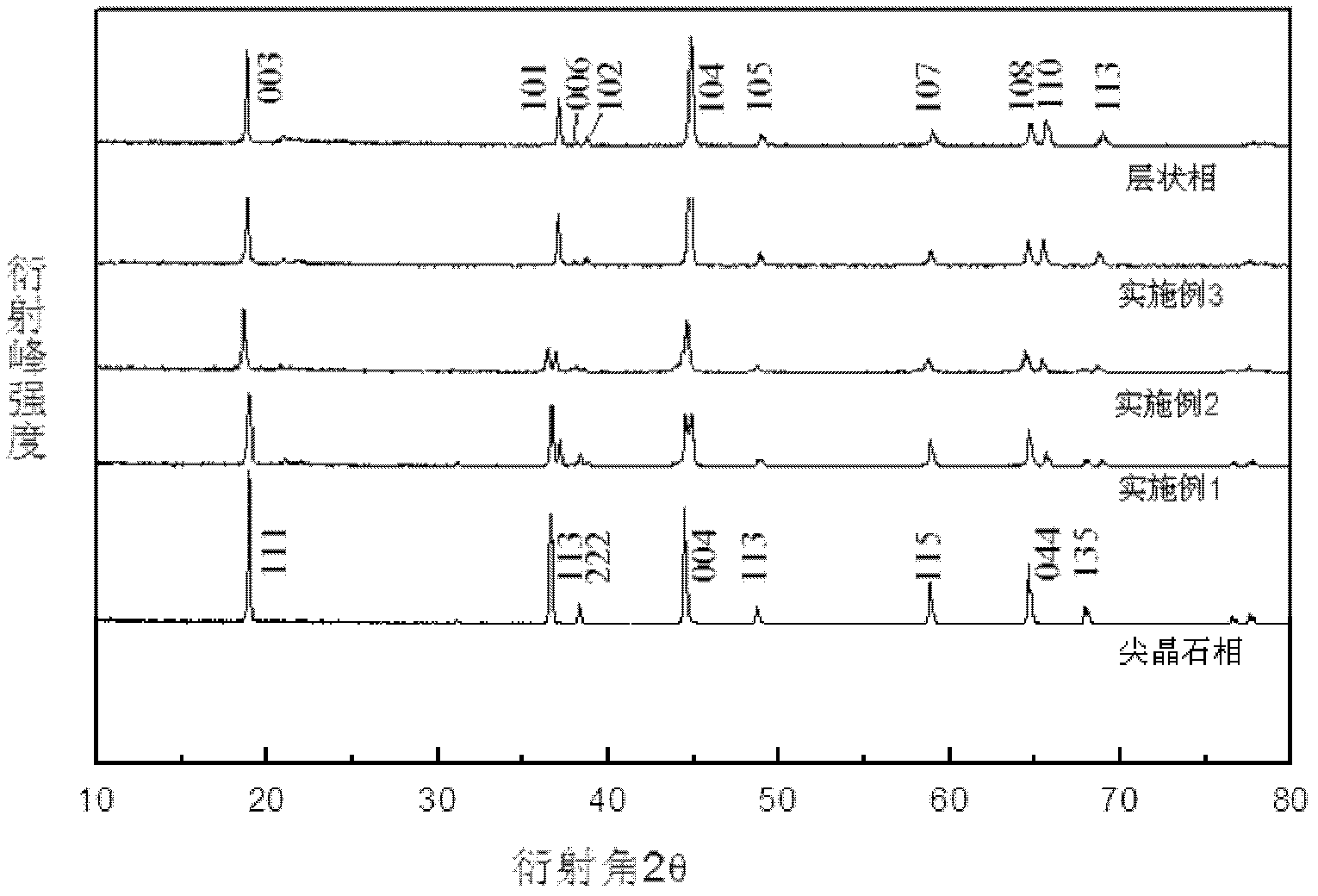

High-voltage lithium ion battery cathode material and preparation method thereof

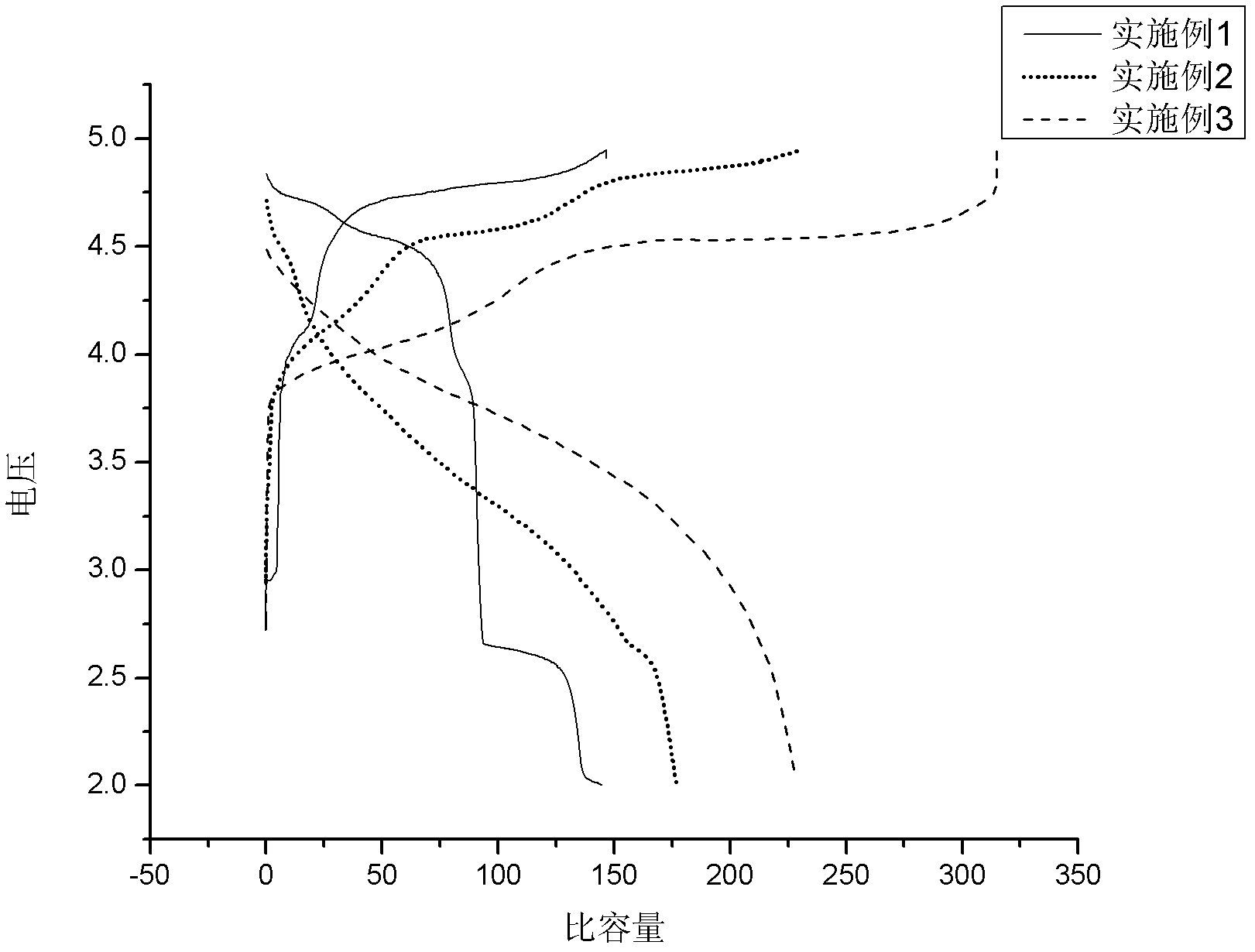

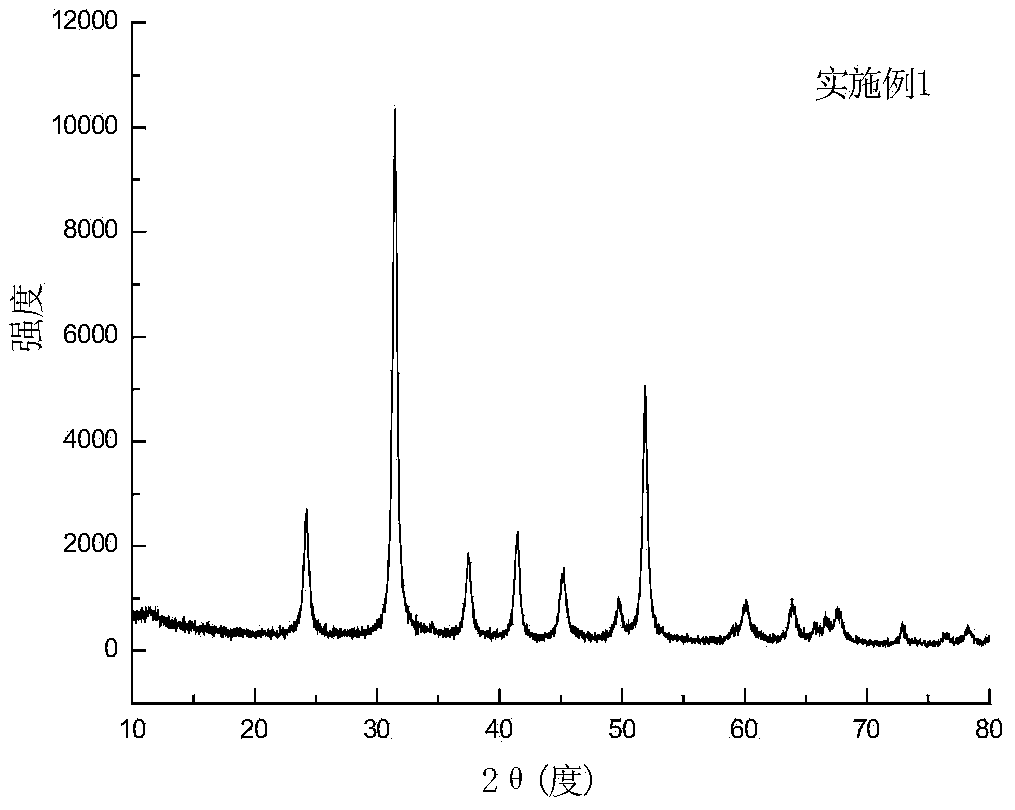

ActiveCN102569781AExpand the voltage application rangeImprove cycle stabilityCell electrodesManganeseLithium-ion battery

The invention discloses a high-voltage lithium ion battery cathode material and a preparation method thereof. The high-voltage lithium ion battery cathode material is a solid solution material with a stratiform and spinel composite structure, and the molecular formula of the cathode material is LixNi0.25-zMn0.75-zM2zOy, wherein M is one or two of doped metals of Co, Al, Cr, Mn and Ga, x is more than 0 and less than 2, y is more than or equal to 2 and less than or equal to 3, and z is more than 0 and less than or equal to 0.25. The invention has the advantages that: the cathode material has the stratiform and spinel composite structure, the high specific capacity advantage of a manganese-based solid solution material is kept, and the cycle stability and the thermal stability of the material are improved; the impedance of the cathode material is reduced by doping, so that the thermal stability of the material is further improved, and the heat release is reduced to improve the comprehensive electrochemical performance of the material; and the preparation process of the material has high controllability, the manufacturing cost is low, and the manufacturing process has high repeatability and high batch stability, production management is facilitated, and the application demands on high-voltage and high-specific-capacity materials on the market are met.

Owner:徐源庆

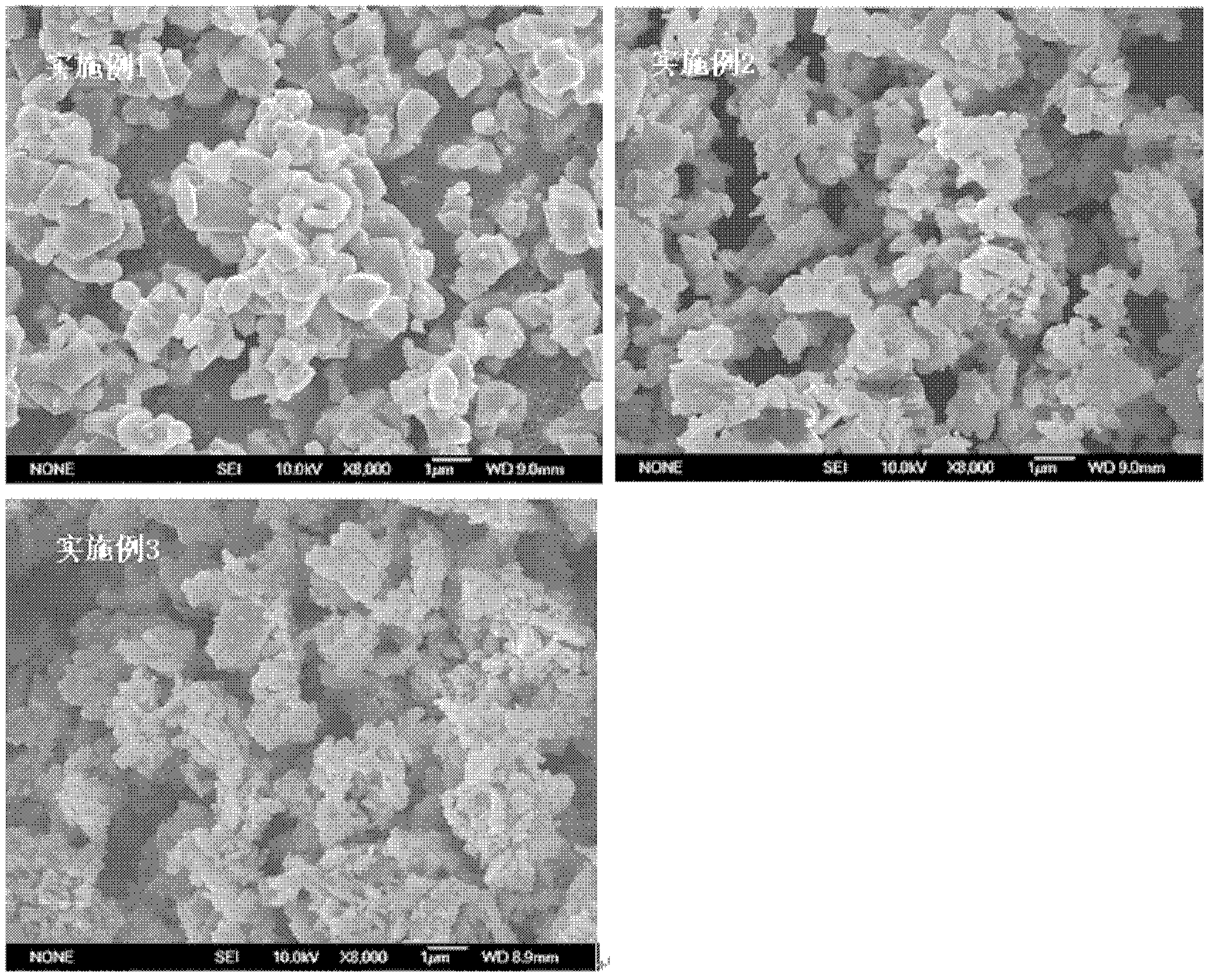

High-capacity lithium ion battery positive material with core-shell heterostructure and preparation method of material

InactiveCN103762353AImprove cycle stabilityImprove first-time efficiencyCell electrodesSecondary cellsDischarge efficiencyManganese

The invention relates to a high-capacity lithium ion battery positive material. The high-capacity lithium ion battery positive material is a laminar composite material with a core-shell structure taking a lithium-rich phase material as a shell material and a spinel phase material as a core material. The preparation method comprises the following steps: performing coprecipitation reaction on nickel-manganese salt-mixture solution, ammonium hydroxide and sodium carbonate solution to obtain manganese carbonate nickel precursor; after uniformity mixing the precursor with a powdered lithium source, calcinating to obtain the powder granular core material with spinel structure; and calcinating after uniformity mixing the core material and Li2CO3, so as to obtain the target object. The high-capacity lithium ion battery positive material provided by the invention has the advantages that the positive material is high in specific capacity, cycling stability and first discharging efficiency, and the preparation technology of the material is good in controllability, low in manufacturing costs, and is suitable for large-scale production, so as to meet the demand on materials with high voltage and high specific capacity in the market.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

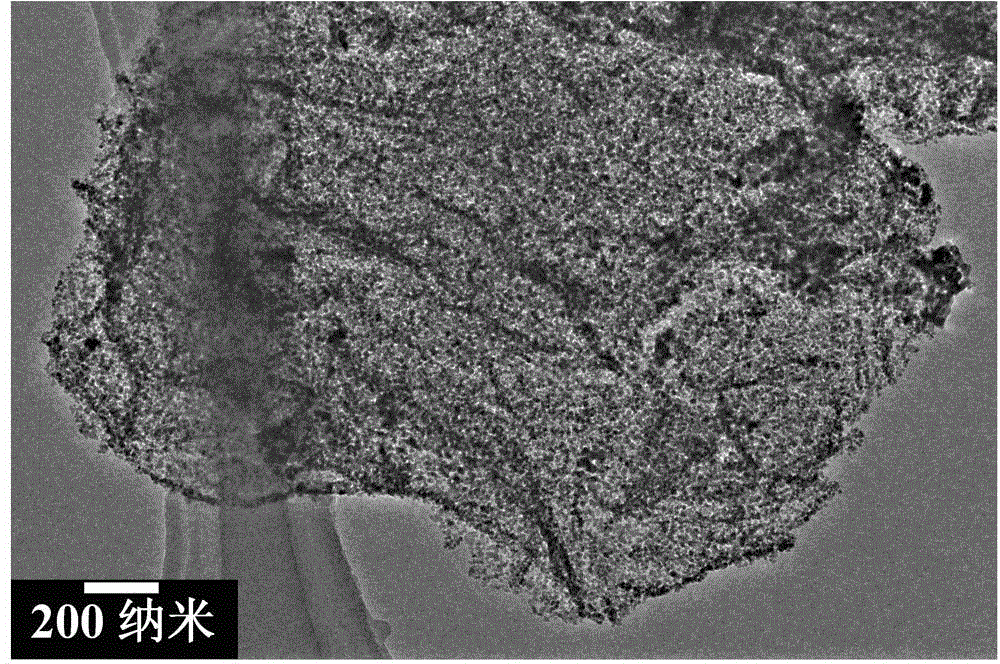

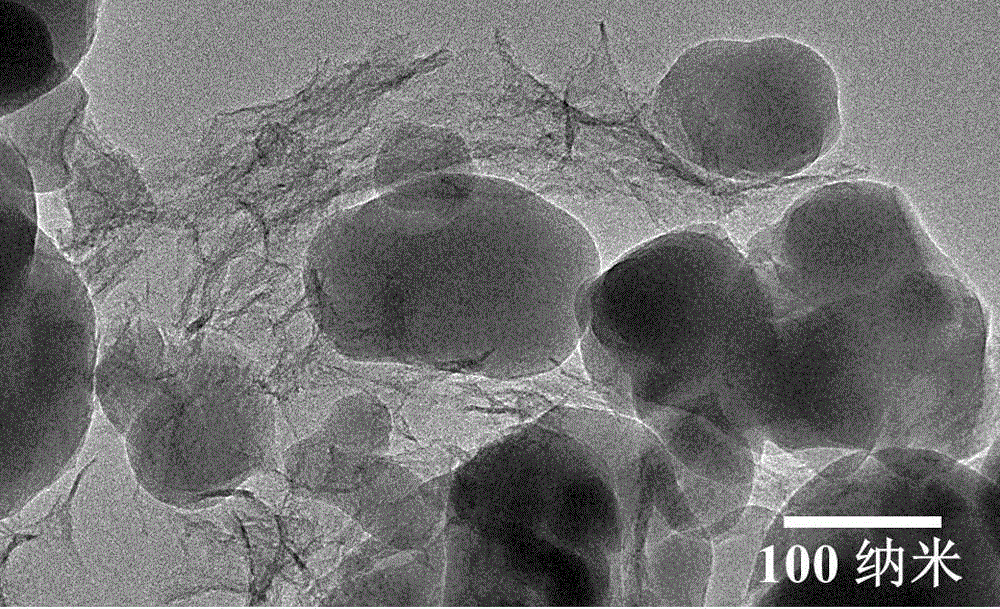

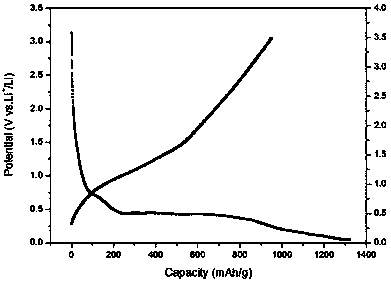

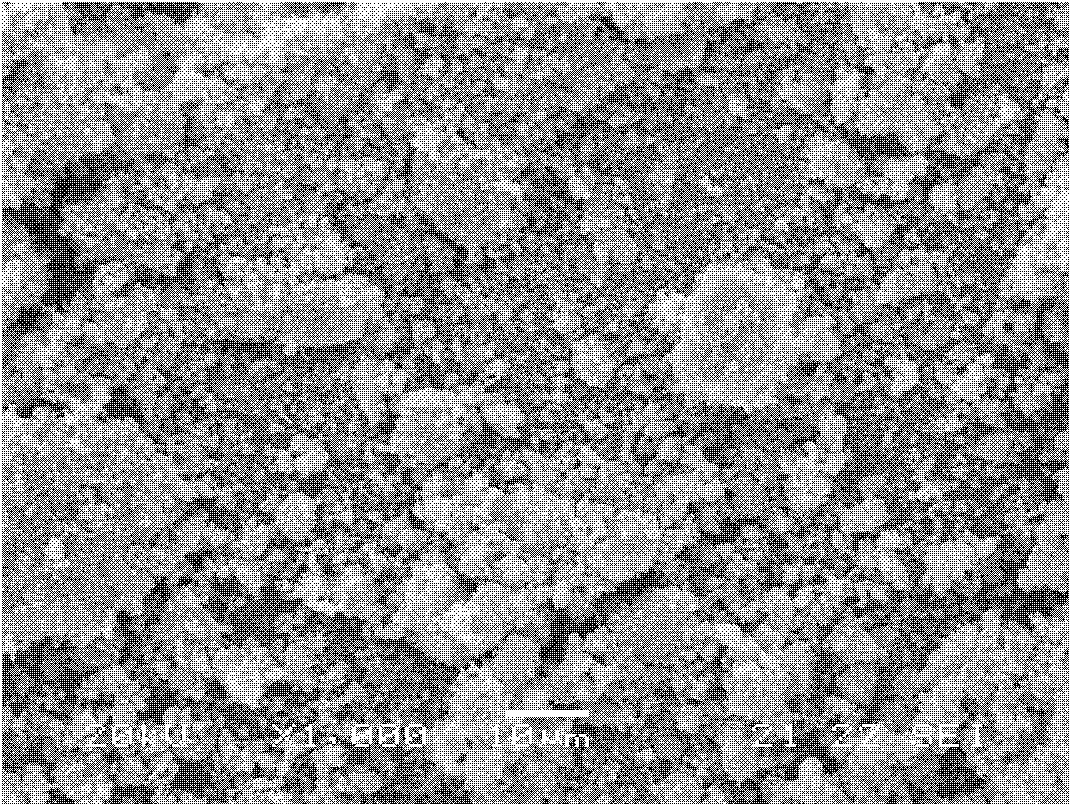

Preparation method of ultra-high density cobaltosic oxide/porous graphene nano-composite anode material for lithium ion battery

InactiveCN104934574ASolve the technical bottleneck that is difficult to grow high-density cobalt trioxide nanoparticlesImprove electronic conductivityMaterial nanotechnologyCell electrodesPorous grapheneGraphene nanocomposites

The invention relates to a preparation method of an ultra-high density cobaltosic oxide / porous graphene nano-composite anode material for a lithium ion battery and brings forward a novel low-cost in-situ growth method. According to the method, evenly distributed in plane defect sites are manufactured on the surface of oxidized graphene by means of strong oxidization of a chemical reagent; and then through a low-temperature hydrothermal reaction, in-situ growth of ultra-high density cobaltosic oxide nano-particles happens on porous graphene with the defect active sites. Cobaltosic oxide accounts for more than 92% of the compound, and adverse effects such as the drop in first coulombic efficiency and tilt of a charging / discharging platform due to addition of overmuch graphene can remarkably be improved. In the cobaltosic oxide / porous graphene nano-composite material, graphene can effectively improve conductivity insufficiency of cobaltosic oxide; and volume effect of cobaltosic oxide during the cyclic process can be well overcome due to the particle size of 5-10 nm. Thus, the material has ultra-high electrochemical performance. According to the invention, the principle is simple, and the material is easy to produce.

Owner:SUZHOU GREEN POWER TECH CO LTD

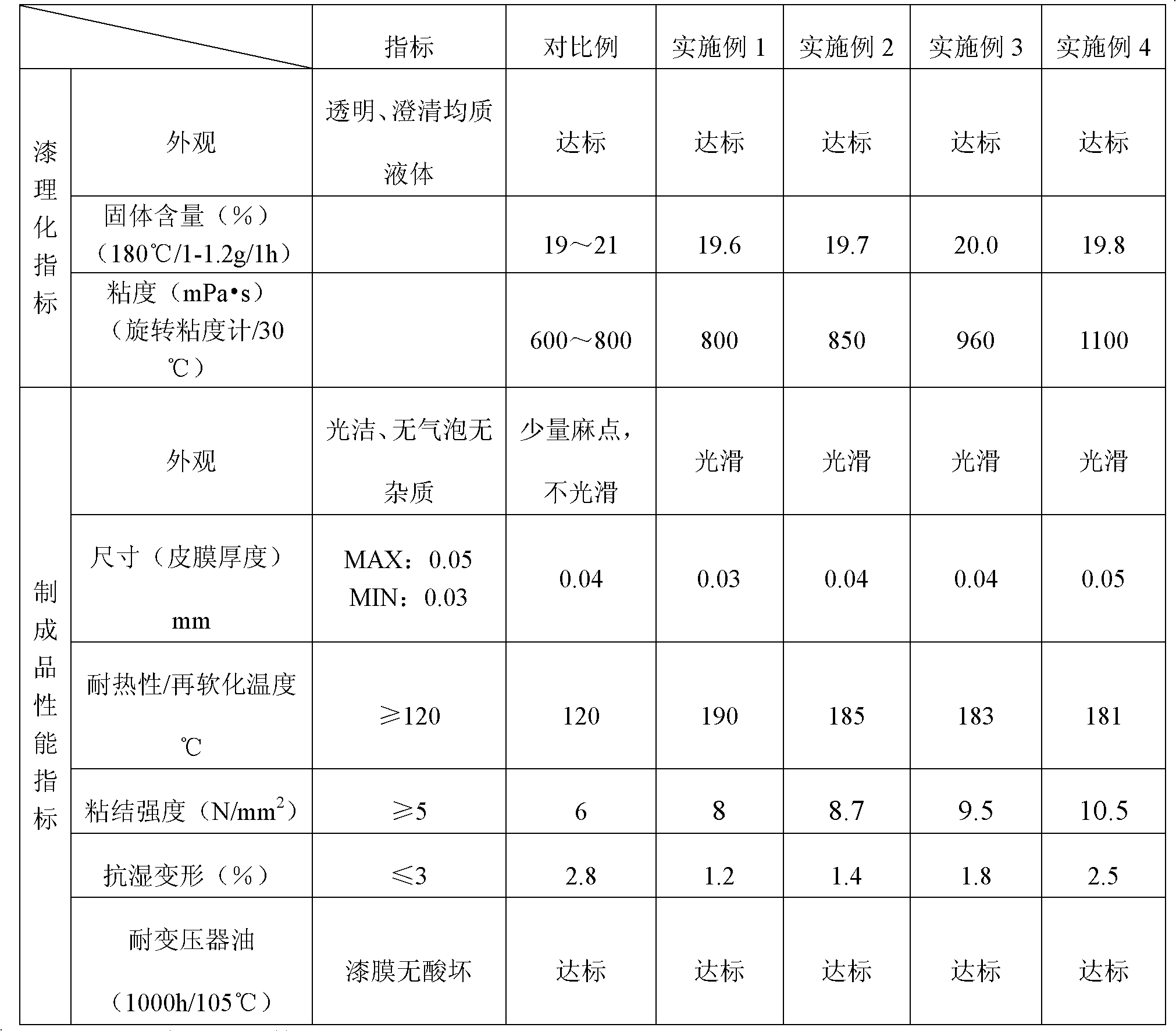

Moisture resistant oilproof electromagnetic wire epoxy self-bonding paint

ActiveCN101857764AImprove consistencyGood batch stabilityPolyurea/polyurethane coatingsInsulating bodiesPolyurethane elastomerEpoxy

The invention relates to a moisture resistant oilproof electromagnetic wire epoxy self-bonding paint meeting heat resisting requirement more than thermal level of 155 DEG C, applied to enamelled wire with high bonding strength and good surface quality. The moisture resistant oilproof electromagnetic wire epoxy self-bonding paint comprises the following components by parts by weight: 320-450 parts of methyl phenol, 350-480 parts of dimethyl benzene, 15-40 parts of polyurethane elastomer, 130-148 parts of epoxy resin, 10-30 parts of phenolic resion, 4.5-13 parts of amino resin, 0.8-1.2 parts of titanate coupling agent and 1-2 parts of flatting agent; wherein the weight-average molecular weight of the epoxy resin is 20000-30000. The main performance indexes of the manufactured product adopting the paint of the invention are as follows: 1, adhesiveness is good; 2, no cracking is produced when heat shock reaches 180 DEG C; 3, bonding strength is 11N / mm2, and the bonding strength in the JB / T6758.1-2007 standard is more than or equal to 5N / mm2.

Owner:江苏佳禾电子材料有限公司

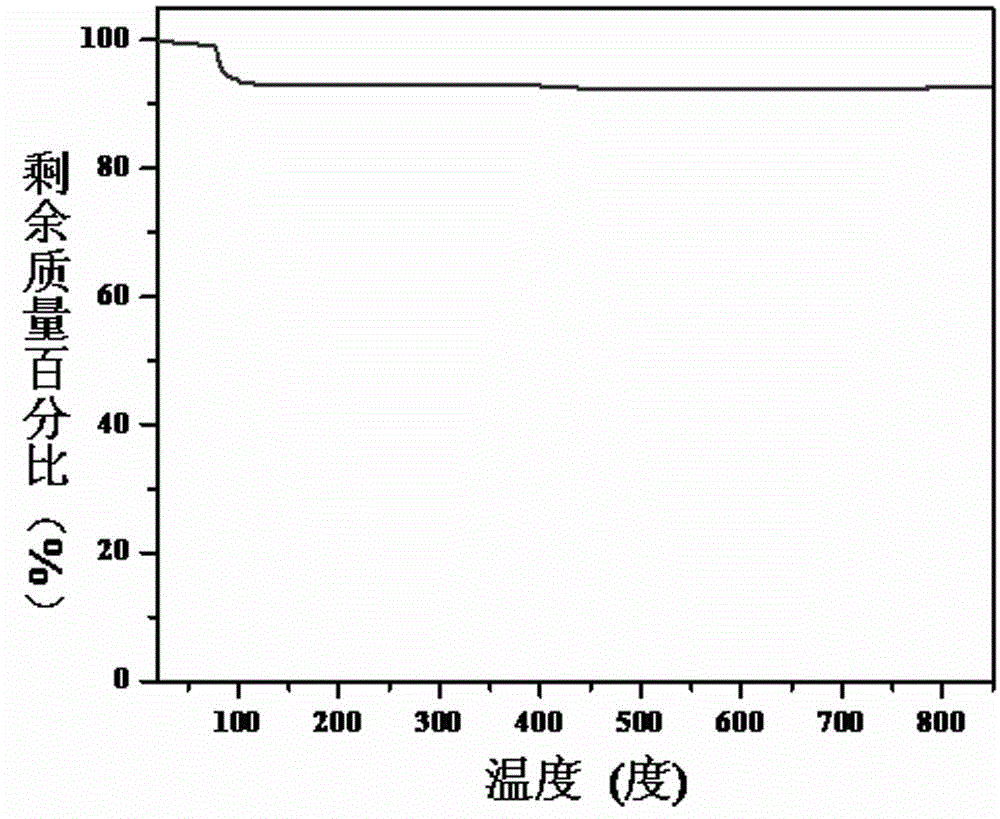

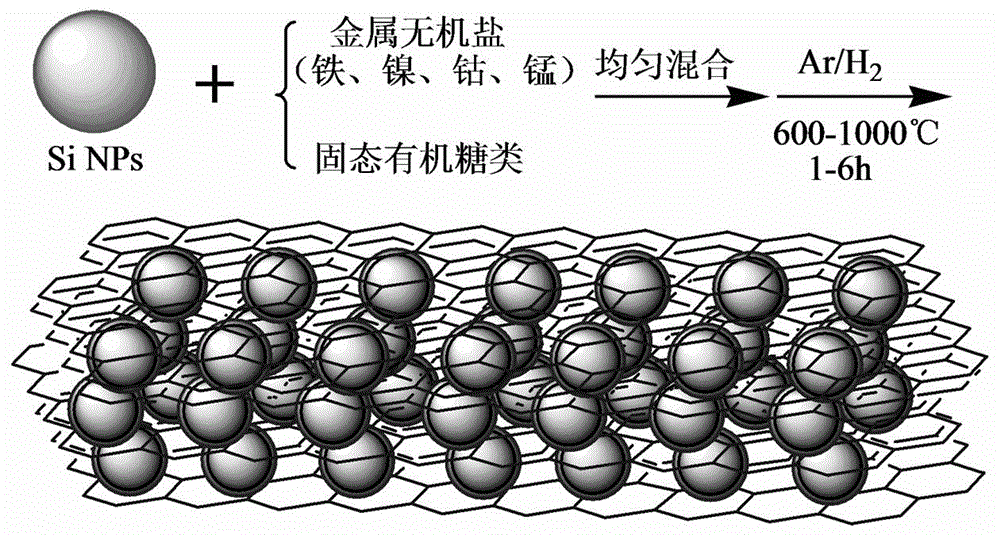

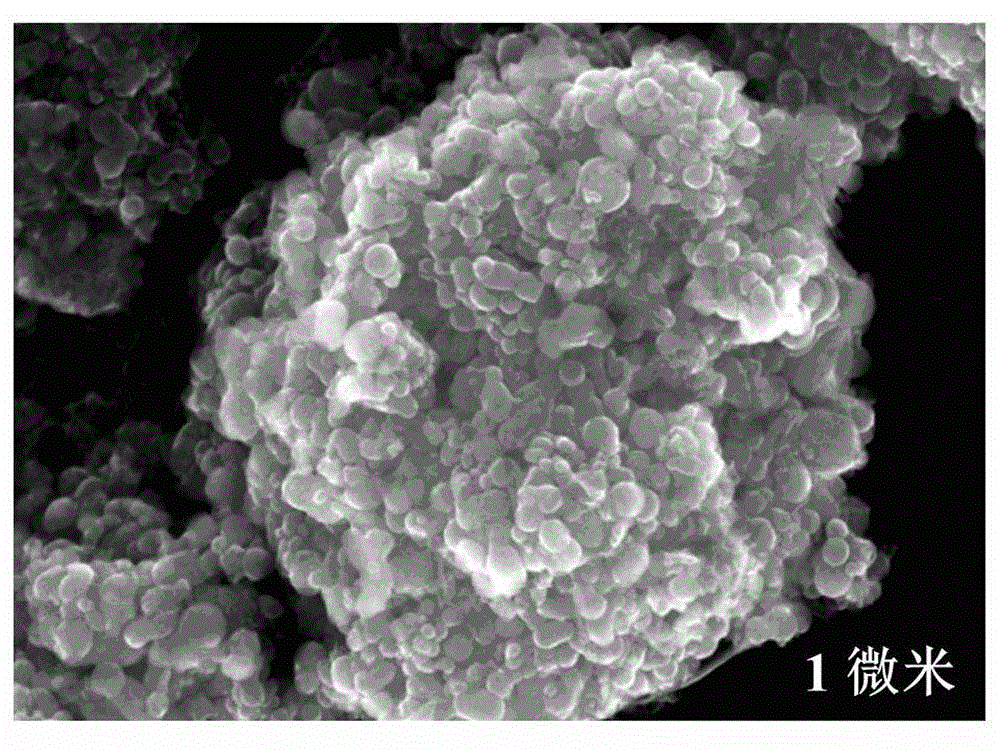

In-situ solid-phase synthesis method of silicon-graphene spheroidal composite material with multilevel structure and application thereof

InactiveCN104934573AAvoid volume effectImprove electronic conductivityCell electrodesFinal product manufacturePtru catalystElectronic conductivity

The invention brings forward a novel low-cost in-situ solid-phase preparation method. By the method, a silicon-graphene spheroidal composite material with a multilevel structure can be synthesized by one step. The composite material can be used as a high specific energy anode material to be applied in a lithium ion battery. Low-cost organic carbohydrate and inorganic transition metal salt which are respectively used as a carbon source and a metal catalyst precursor are selected to be uniformly mixed with a silicon nano-material; by a tube furnace heating method, in-situ catalytic growth of a graphene coated network happens on the surface of silicon nano-particles; and through the bridging effect of the graphene network, spheroidal micro-scale particles with a nanometer fine structure is self-assembled. The silicon-graphene spheroidal composite anode material with the multilevel structure has an advantage of high specific capacity. In addition, two main bottleneck problems such as poor electronic conductivity of a silicon anode material and severe volume effect during the cyclic process can be overcome simultaneously, and multiplying power and cycle performance of silicon anode can be raised greatly.

Owner:SUZHOU GREEN POWER TECH CO LTD

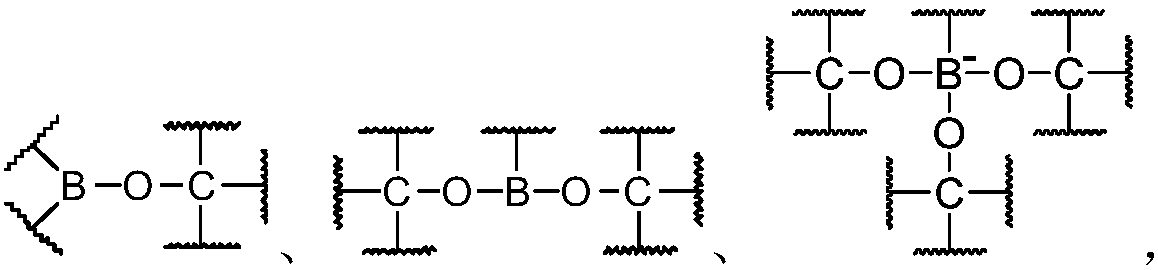

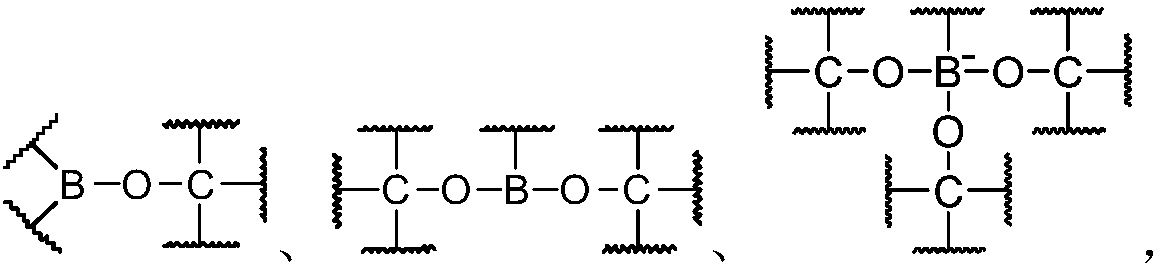

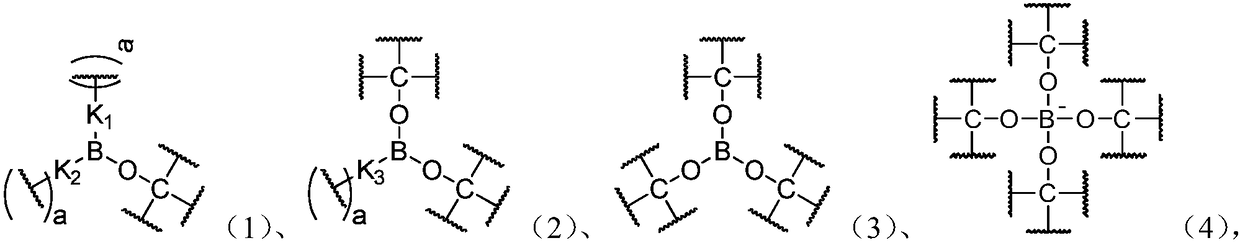

Dynamic polymer with hybrid cross-linked network and application thereof

The invention discloses a dynamic polymer with a hybrid cross-linked network. The dynamic polymer contains common covalent cross-linking and dynamic covalent organic borate bonds. The dynamic polymerintegrates the respective advantages of the dynamic covalent organic borate bonds and the common covalent cross-linking, and polymeric materials of abundant structures and with diversified propertiescan be prepared by regulating the structures of reactants. The high dynamic reversibility of the dynamic covalent organic borate bonds in the dynamic polymer allows the polymer to present the functional characteristics of stimulation responsiveness, self repair performance; the common covalent cross-linking endows the dynamic polymer with certain strength and stability; moreover, based on the dynamic nature of the dynamic organic borate bonds, the dynamic polymer has the characteristics of energy dissipation and energy absorption and the good functions of damping, shock absorption, sound insulation, impact resistance, high toughness and the like. The dynamic polymer can be used for preparing damping and buffering materials, anti-impact protection materials, self-repairing materials, toughmaterials, force transducers, etc.

Owner:厦门天策材料科技有限公司

Novel process for preparing battery-grade iron phosphate material by using iron hydroxide

InactiveCN102897739ALow self-discharge rateReduced processing performancePhosphorus compoundsPhosphoric acidIndustrial scale

The invention discloses a novel process for preparing a low-cost battery-grade iron phosphate material by using iron hydroxide. The process comprises the following steps: mixing a zero-valent iron source and corrosive acid in a molar ratio, and adding a certain amount of primary water and ammonia water; stirring to react for 0 to 24 hours, and slowly adding hydrogen peroxide until the iron source disappears and the solution turns to orange; adding surfactant which is 1 to 5 percent that of the mass of the iron source into the solution; adding a reagent containing phosphate radicals into the solution according to a certain molar ratio of iron element to phosphor element under a stirring condition to obtain iron phosphate precipitate; filtering and washing the product 3 to 5 times with the primary water which is 3 to 7 times the weight of the iron phosphate; drying in vacuum for 4 to 12 hours at 50 and 80 DEG C to obtain FePO4.2H2O. The process for preparing battery grade iron phosphate is simple and easy to carry out and low in cost; and the prepared product has good product crystal structure, few impurities and uniform granularity and is suitable for industrial scale production; moreover, the lithium iron phosphate prepared by the process has high specific capacity, low self-discharge, high tap density, stable product performance and good processing performance.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +2

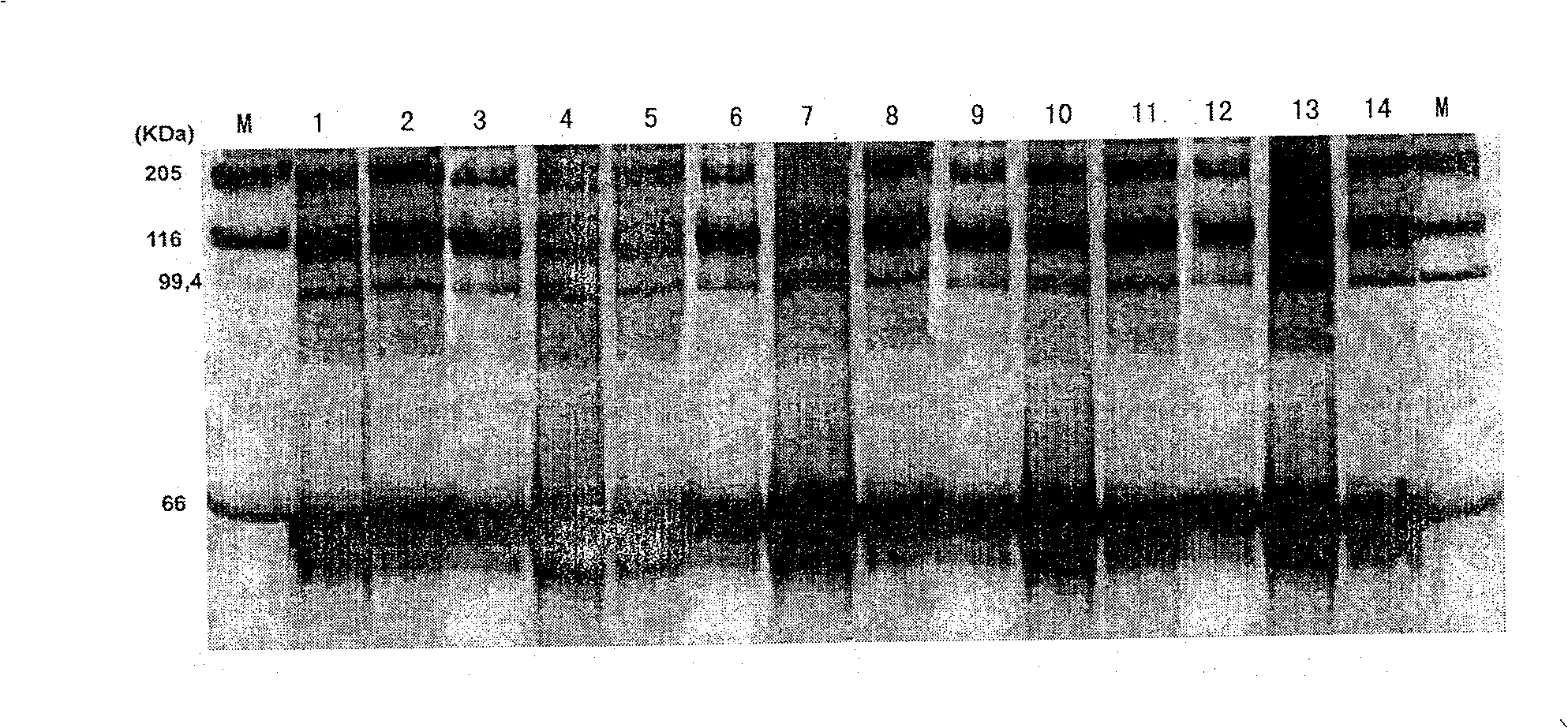

Method for extracting rabies virus

InactiveCN101270350AImprove removal efficiencyGood removal effectSsRNA viruses negative-senseMicroorganism based processesHollow fibreFiber

The invention provides a method for extracting rabies virus, and is to solve the defects that great discrepancy of quality indices of different batches occurs; removal of remaining DNA becomes difficult; the protein content of the remaining host is too high; and great side effects appear clinically when the single method of molecular sieve gel chromatography is adopted for extracting rabies virus vaccine. The essential of the invention is that a hollow fiber ultrafiltration column or ultrafiltration membrane with the molecular weight cut-off of 750KD or 500KD is used to condense and partially purify harvested liquid of virus; anion exchange chromatography or molecular sieve gel chromatography is adopted to separate and purify samples; molecular sieve gel chromatography or anion exchange chromatography is adopted to separate and purify samples got in step (2). The method for extracting rabies virus has the characteristics of great productive capacity, high product quality, excellent batch stability, being remarkably effective in removal of remaining DNA and HCP, and reducing the potential safety hazard of vaccine.

Owner:LIAONING YISHENG BIOLOGY PHARMACY

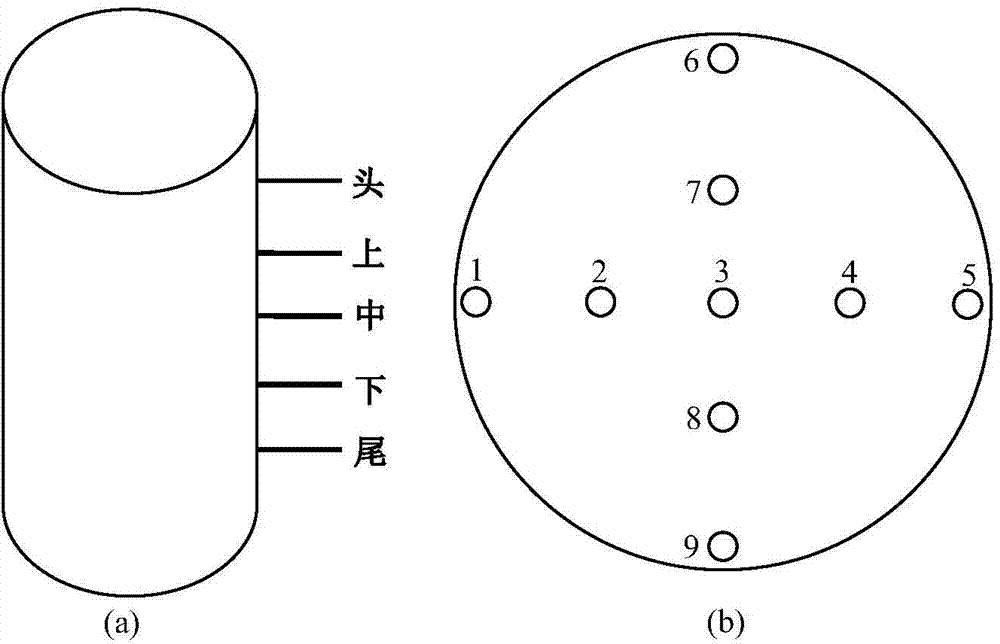

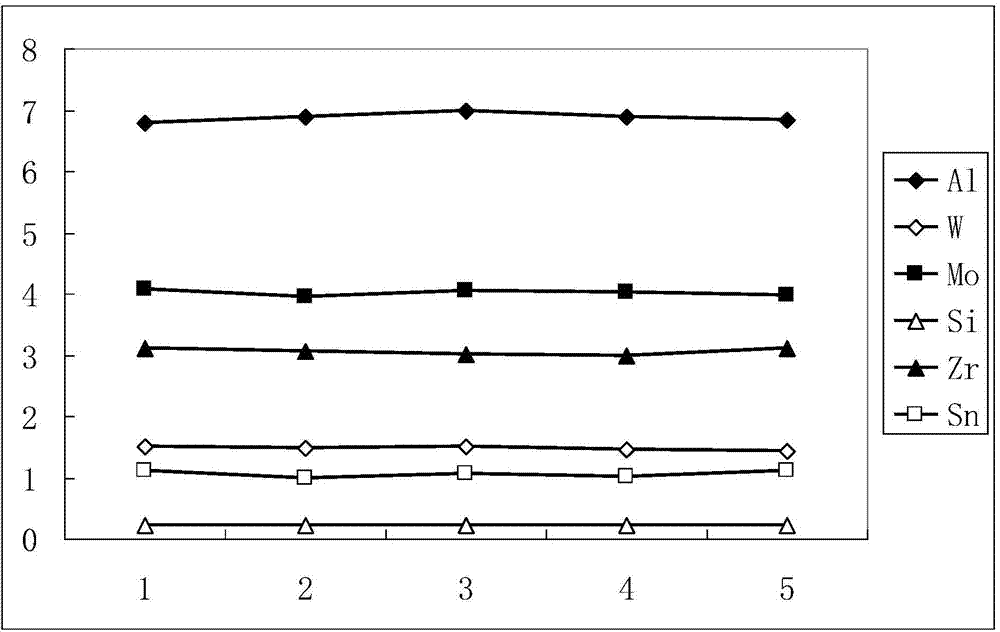

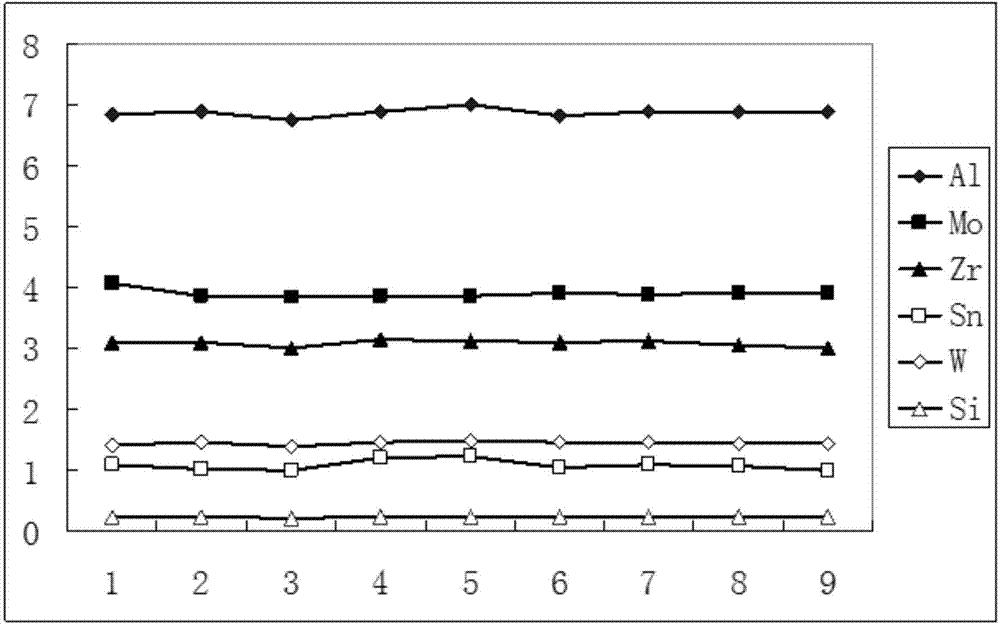

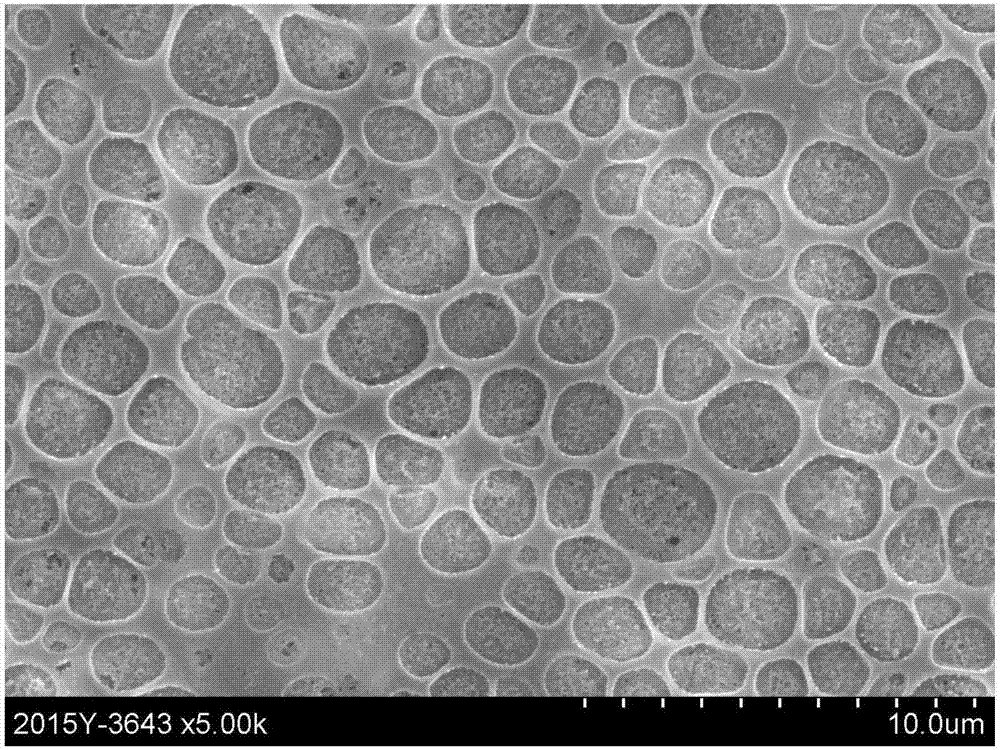

Preparation method for high-uniformity WSTi62441S titanium alloy ingot

The invention discloses a preparation method for a high-uniformity WSTi62441S titanium alloy ingot. The preparation method comprises the following steps of mixing 6.0 to 7.0 mass percent of Al, 1.0 to 2.5 mass percent of Sn, 3.5 to 4.5 mass percent of Mo, 3.0 to 4.5 mass percent of Zr, 0.20 to 0.25 mass percent of Si, 0.4 to 1.5 mass percent of W and the balance of Ti based on the total amount of 100 percent, performing electrode pressing and welding on the mixture to obtain a consumable electrode, and performing vacuum smelting on the consumable electrode for many times to obtain the high-uniformity WSTi62441S titanium alloy ingot. According to the preparation method, the problems of composition segregation, poor controllability in the content of impurities and an interstitial element and poor batch stability of the conventional preparation method are solved, the prepared WSTi62441S titanium alloy ingot is uniform in element composition and high in batch stability, and the preparation method is applied to the industrial production of WSTi62441S titanium alloy ingots in specifications of Phi560 to Phi720mm.

Owner:西部超导材料科技股份有限公司

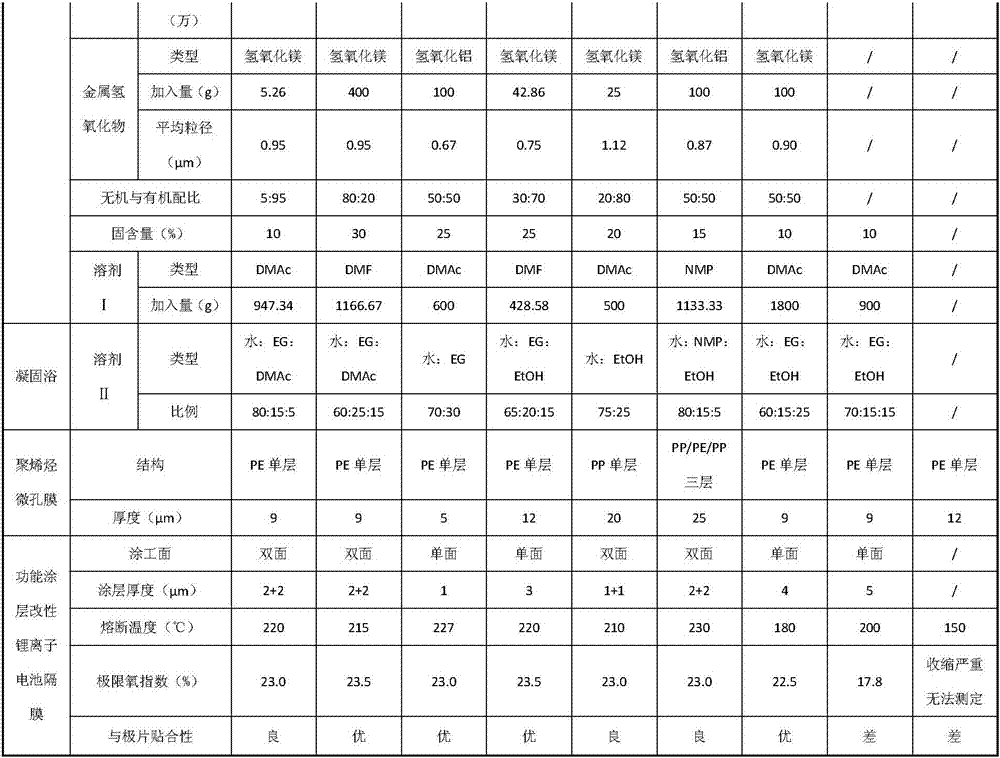

Lithium ion battery diaphragm and preparation method thereof

ActiveCN106898720AAdd flame retardant functionReduce surface temperatureCell component detailsSecondary cells servicing/maintenancePolyolefinPolyamide

The invention relates to a lithium ion battery diaphragm. The lithium ion battery diaphragm comprises a polyolefin microporous membrane and at least one functional coating applied to the polyolefin microporous membrane. Each functional coating is jointly composed of aromatic polyamide, gel polymers and metal oxides and has properties of high temperature resistance, flame retardation, easiness in fitting with battery pole pieces and the like. The lithium ion battery diaphragm is larger than or equal to 210 DEG C in fusing temperature and larger than or equal to 23% in limit oxygen index. In a battery hot-pressing process, the lithium ion battery diaphragm can well fit the battery pole pieces. The preparation method is convenient and simple in operation, and integral stability in use of batteries can be improved remarkably.

Owner:CHINA LUCKY FILM CORP +1

Moisture-resistant epoxy resin paint for transformer

ActiveCN103013269AImprove consistencyImprove surface qualityPretreated surfacesCoatingsTransformerMelamine formaldehyde resin

The invention discloses moisture-resistant epoxy resin paint for a transformer. The moisture-resistant epoxy resin paint is composed of the following raw materials in parts by weight: 125-135 parts of modified epoxy resin, 20-30 parts of phenolic resin, 15-20 parts of melamino-formaldehyde resin, 10-20 parts of anti-rust pigment zinc phosphate, 5-6 parts of phthalic acid diethylene glycol acrylate, 1-2 parts of polyacrylic acid, 0.3-0.5 part of fatty alcohol-polyoxyethylene ether ammonium sulfate, 0.2-0.4 part of isopropyl tri(dioctyl pyrophosphoric acid acyloxy) titanate, 0.1-0.3 part of dicumyl peroxide, 0.2-0.6 part of monoethanolamine, 0.1-0.3 part of defoamer polydimethylsiloxane, and 0.1-0.2 part of dioctyl sodium sulfosuccinate. According to the invention, a finished product of emulsion prepared by using the modified epoxy resin is used as a main film-forming material, so that the entire production process is stable and is easy to control, the product consistency is improved greatly, and the stability among batches is good; and the phthalic acid diethylene glycol acrylate is selected as the solvent, so that the odor of the finished product is improved greatly, and environment pollution is reduced when the phthalic acid diethylene glycol acrylate is used in production.

Owner:铜陵常江传动工具有限公司

Preparation method of hydro-thermal coupling spray pyrolysis MnO2/graphene electrode material

InactiveCN103915613AStable structureWide variety of sourcesMaterial nanotechnologyHybrid capacitor electrodesActive agentGraphene electrode

The invention discloses a preparation method of a hydro-thermal coupling spray pyrolysis MnO2 / graphene electrode material, belonging to the technical field of electrode materials for energy storage systems. The preparation method comprises the following steps: uniformly mixing graphene oxide (GO) prepared by using a Hummer method with an aqueous solution of bivalent manganese salt and a doped metal ion compound, adding a dispersing agent, an oxidant and a surfactant, and ultrasonically dispersing for a certain period of time; putting the mixed solution into a hydrothermal kettle, adjusting the temperature, and keeping for a certain period of time; filtering and washing a reaction product to obtain a precursor; adding the dispersing agent and the surfactant into the precursor, uniformly stirring for mixing, and adjusting the solid-liquid ratio, inlet temperature and outlet temperature to perform spray pyrolysis in order to obtain a metal ion-doped MnO2 / graphene nanometer composite electrode material. According to the nanometer composite electrode material prepared by using the method, components are uniform and the batch stability is high.

Owner:SHANDONG RUNSHENG POWER TECH +1

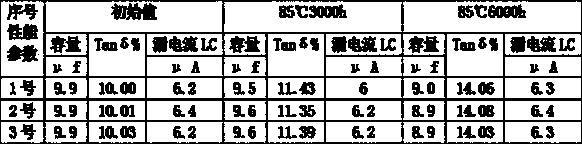

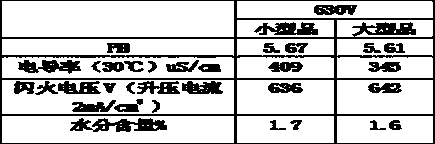

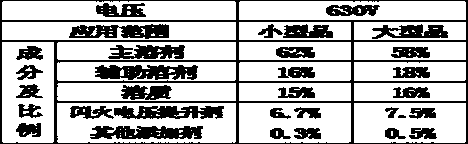

Working electrolyte of 630 V high-voltage aluminum electrolytic capacitor and manufacturing method thereof

ActiveCN103811183AIncrease working voltageSolution to short lifeElectrolytic capacitorsElectrolytic agentUltra high voltage

The invention discloses working electrolyte of a 630 V high-voltage aluminum electrolytic capacitor and a manufacturing method thereof. The working electrolyte of the 630 V high-voltage aluminum electrolytic capacitor is characterized in that the working electrolyte is composed of 38-65% of main solvent, 3-23% of secondary solvent, 8-22% of solute, 5-10% of spark voltage increasing agent and 0.2-1% of other additives by weight. The manufacturing method includes the following steps: mixing the main solvent with the secondary solvent; adding the solute under the temperature of 110 to 115 degrees centigrade, stirring and heating to 135 to 138 degrees centigrade, preserving the heat under 135 to 138 degrees centigrade, stirring and reacting for 30 to 40 minutes, and adding the spark voltage increasing agent; cooling to 70 to 90 degrees centigrade, and adding the other additives. Compared with the prior art, the working electrolyte of the 630 V high-voltage aluminum electrolytic capacitor and the manufacturing method thereof can be used under 630 V extra-high voltage, and moreover, the electrolyte performance is stable, and the batch stability is good.

Owner:上海洪微电子科技有限公司

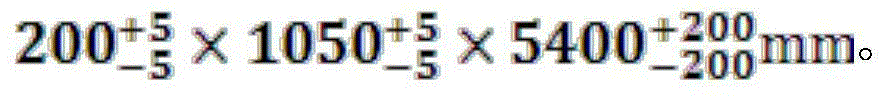

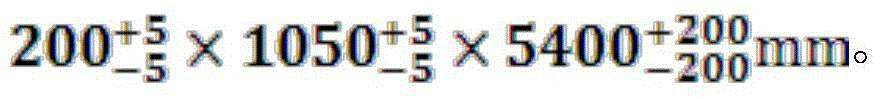

Production technology for medical TA3 sheet materials

The invention relates to a production technology for medical TA3 sheet materials. The technology comprises the following steps: slabs are subjected to production and roll type hot rolling, strip coils are subjected to annealing, shot blasting, acid pickling, cold rolling, degreasing and cutting and splitting, the sheet materials are subjected to annealing and shot blasting, and the TA3 sheet materials are obtained. According to the invention, one-chip production is replaced by a roll type production; for medical TA3 sheet materials of 4.0-6.2 mm, 2-3 heating numbers and semi-finished product processing procedures between firing can be omitted; for TA3 sheet materials of 2.0-4.0 mm, 2-3 heating numbers can be omitted, and 2-3 rolling processes and semi-finished product processing procedures can be omitted, and the total processing procedures can be reduced by more than 30%; 4-6 tons of the TA3 sheet materials can be produced for one batch; the production technology has the advantages of low cost and high efficiency.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

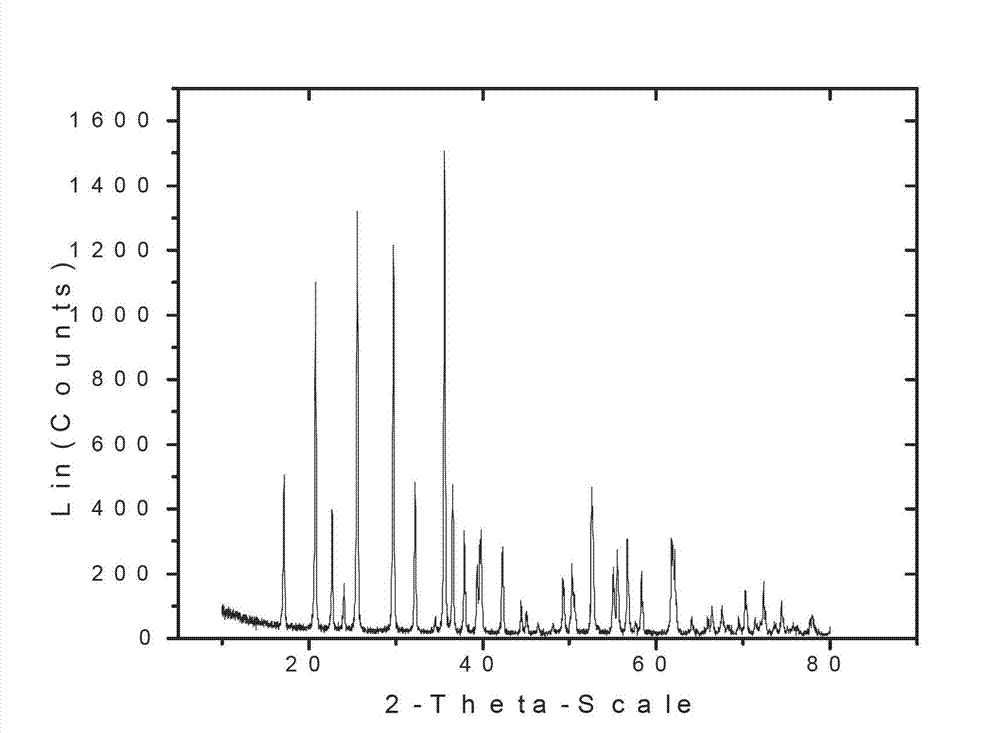

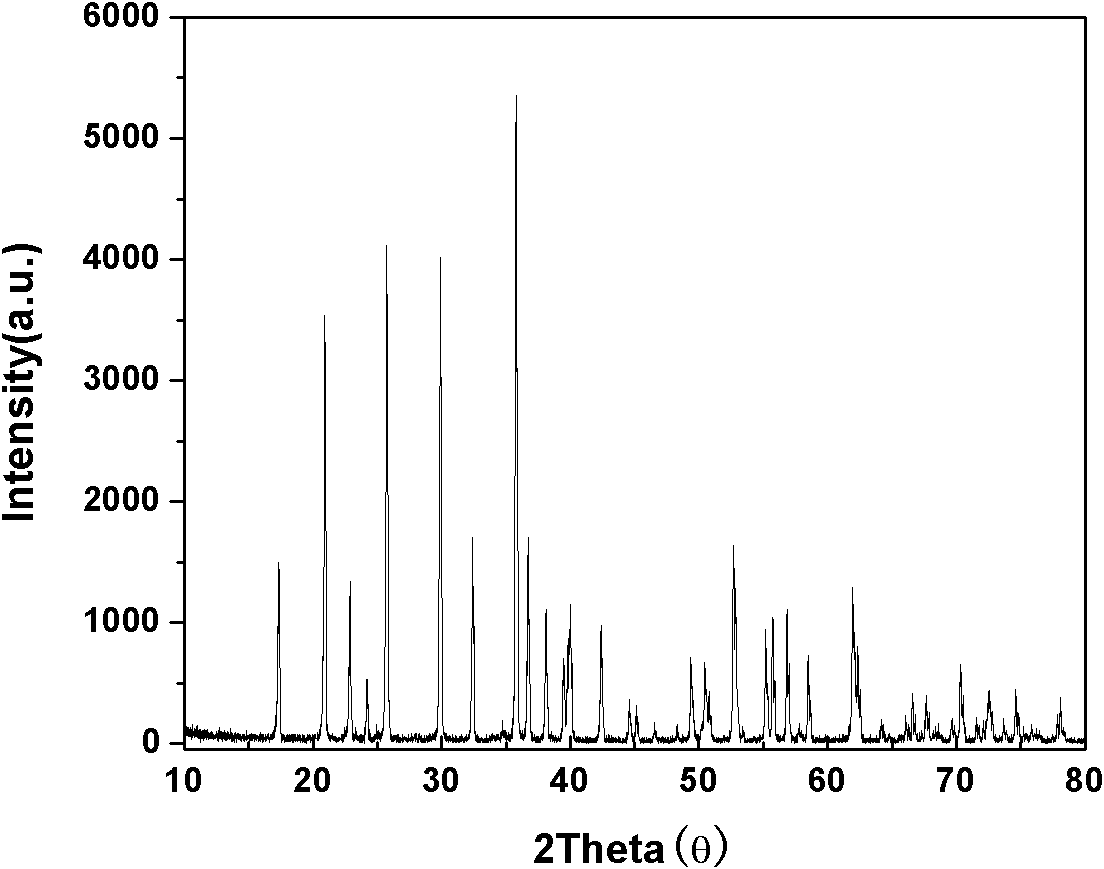

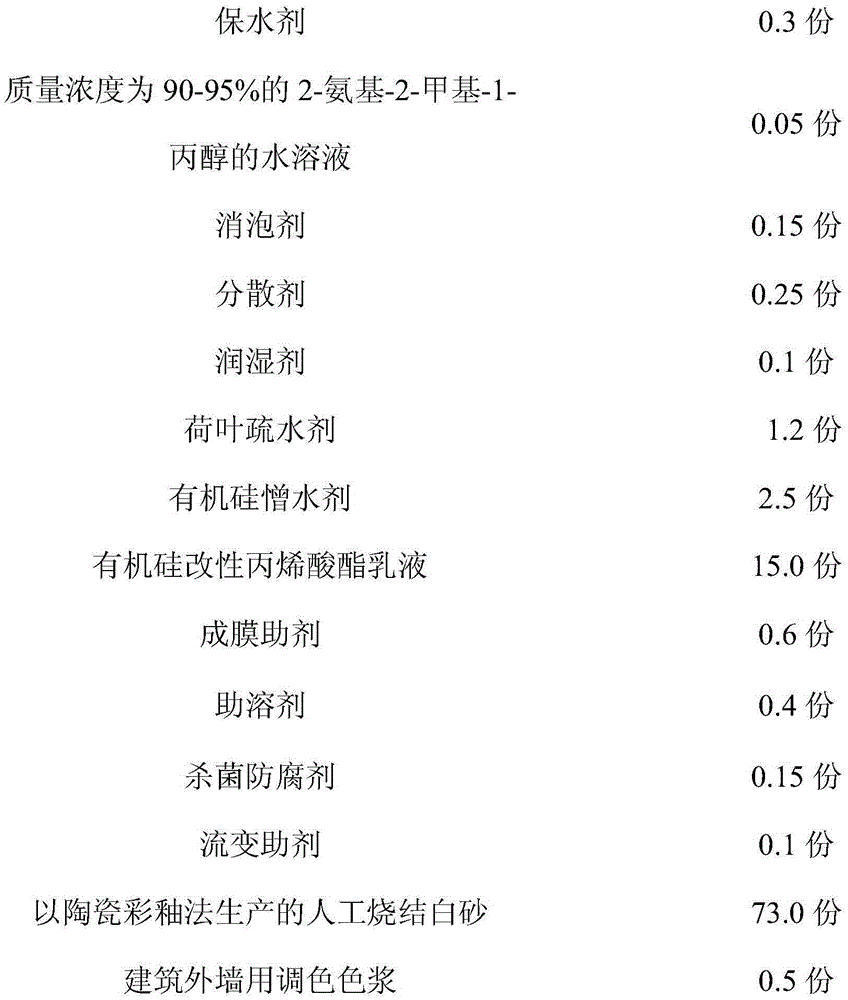

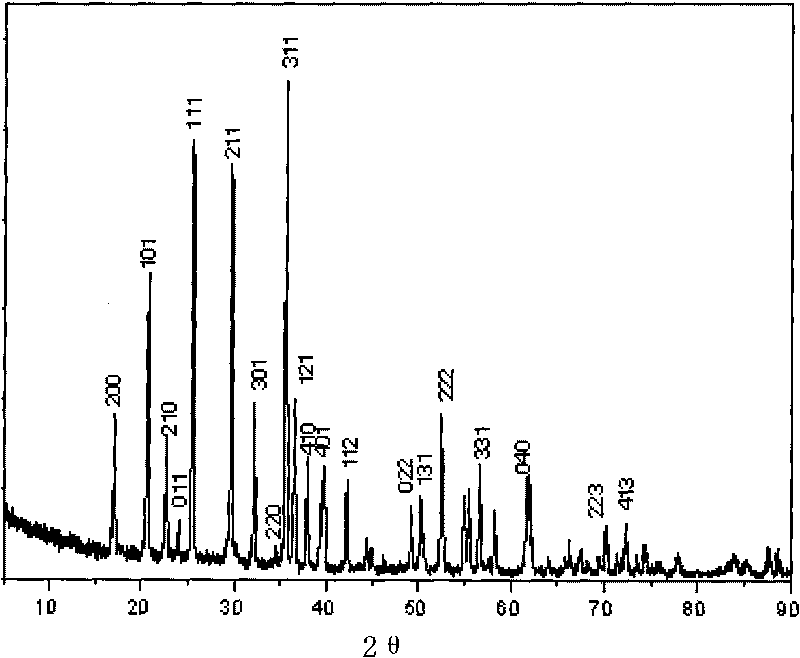

Oxygen vacancy-contained and Fe site-doped lithium ferric phosphate and rapid solid-phase sintering method thereof

ActiveCN101764226AImprove electronic conductivityImprove ionic conductivityFinal product manufactureCell electrodesLithium iron phosphateOxygen vacancy

The invention relates to an oxygen vacancy-contained and Fe site-doped lithium ferric phosphate as a lithium ion anode material and a rapid microwave sintering preparation method thereof. The formula of the invention product is LiFe1-x-aMeaMxPO4-yNz, wherein Me is one or more of Mg, Mn or Nd, and M is one or more of Li, Na, K, Ag, Cu; 0<=x<=0.1, 0<a<=0.1, 0<y<=0.5, 0<=z<=0.5 (4.9), wherein x and z can not be 0 at the same time. The rapid microwave sintering preparation method of the invention has high production efficiency, low energy consumption, good stability of prepared product batches, as well as excellent rate capability and cycle performance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Energy-absorbing method based on hybrid cross-linked network dynamic polymer

The invention discloses an energy-absorbing method based on a hybrid cross-linked network dynamic polymer. The method is characterized in that the hybrid cross-linked network dynamic polymer containing common covalent cross-linking, a dynamic covalent bond and an optional supramolecular hydrogen bond is used as an energy-absorbing material for energy-absorbing protection, wherein the dynamic covalent bond is an inorganic borate bond. The dynamic polymer provided by the invention integrates the respective advantages of the common covalent cross-linking and the dynamic covalent bond; the commoncovalent cross-linking endows the dynamic polymer with certain strength and stability; the dynamic covalent bond in the dynamic polymer has good dynamic reversibility, so the dynamic polymer has the characteristics of energy dissipation and energy absorption and can provide the functions of damping, shock absorption, sound insulation, impact resistance, noise abatement, impact resistance, high toughness and the like as an energy-absorbing material; and the dynamic polymer is especially applicable to the body protection of people during exercises, daily life and working, the body protection ofthe military police, explosion prevention, protection in airborne landing and aerial delivery, collision prevention of automobiles, anti-impact protection of electronic products and electric appliances, etc.

Owner:厦门逍扬运动科技有限公司

Method for making steamed buns through utilizing Lactobacillus plantarum

ActiveCN103284063AImprove growth characteristicsIncrease inoculum volumeFood preparationBiotechnologyYeast

The invention relates to a method for making steamed buns. The method comprises the following steps: activating Lactobacillus plantarum, making a sour dough containing Lactobacillus plantarum, fermenting by utilizing Lactobacillus plantarum to make a steamed bun dough, fermenting small doughs obtained after dividing the steamed bun dough, and steaming the small doughs. The method uses the Lactobacillus plantarum CCFM8661 to ferment in order to make steamed breads and uses no commercial yeasts, the steamed buns made through the method have a rich flavor, and an insufficient flavor disadvantage caused by the use of a single yeast to ferment of products mode in the present market is overcome; and the steamed buns made through the method have the advantages of fine construction structure, good batch stability, and high safety.

Owner:JIANGNAN UNIV

Preparation method of lithium iron phosphate of cathode material of lithium ion secondary battery

ActiveCN102208625AEasy dischargeImprove cycle performanceCell electrodesLithium iron phosphateRoom temperature

The invention provides a preparation method of lithium iron phosphate of a cathode material of a lithium ion secondary battery, which comprises the following steps: well mixing a trivalent iron source, a carbon source, a phosphate source, a lithium source, and doped ions, performing working procedures such as drying and the like to obtain a lithium iron phosphate precursor mixture, heating the mixture in reducing atmosphere with a heating rate of 0.1-10 DEG C / min, calcining the mixture at 200-800 DEG C for 5-25 hours, cooling the mixture to room temperature in the furnace, grinding the mixture to obtain the cathode material of a lithium ion electrode. The preparation method has simple process, and low cost, and the prepared cathode material of a lithium electrode has good discharge and cycle performance; the process parameters are easy to control; the batch has good stability; and the preparation method is suitable for large-scale industrial production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

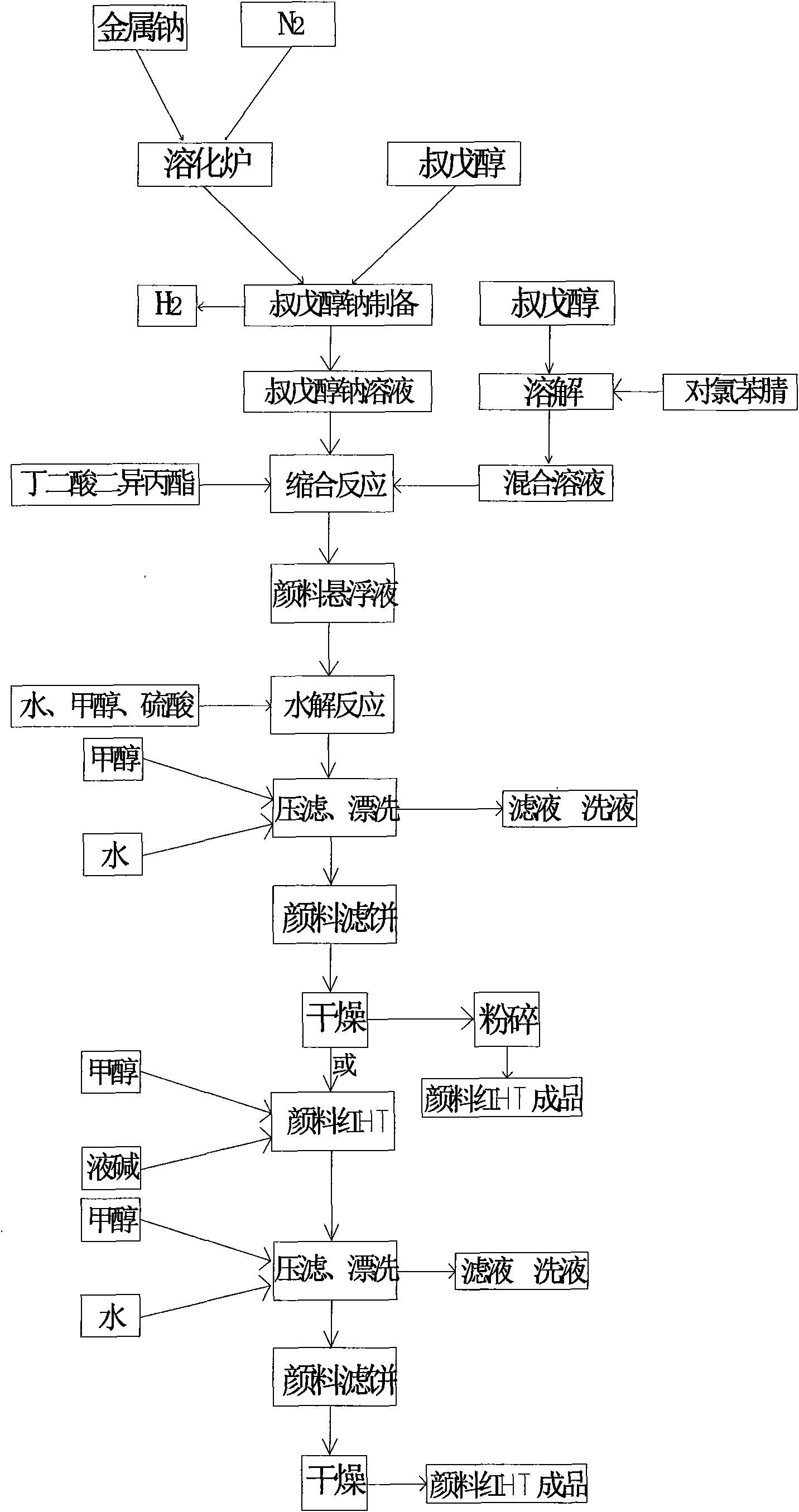

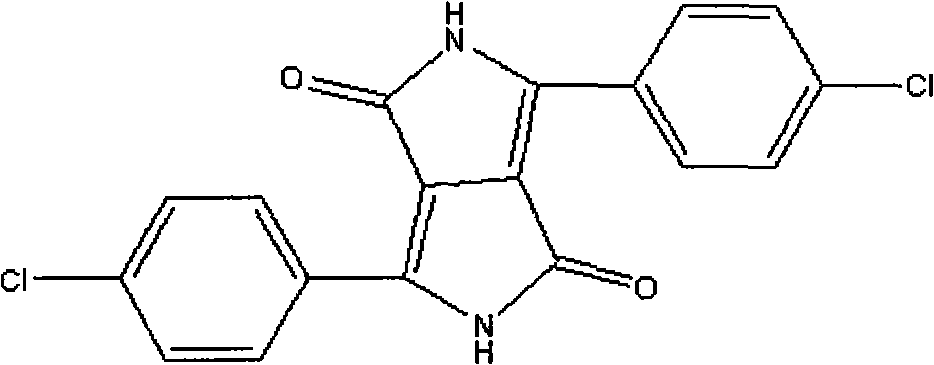

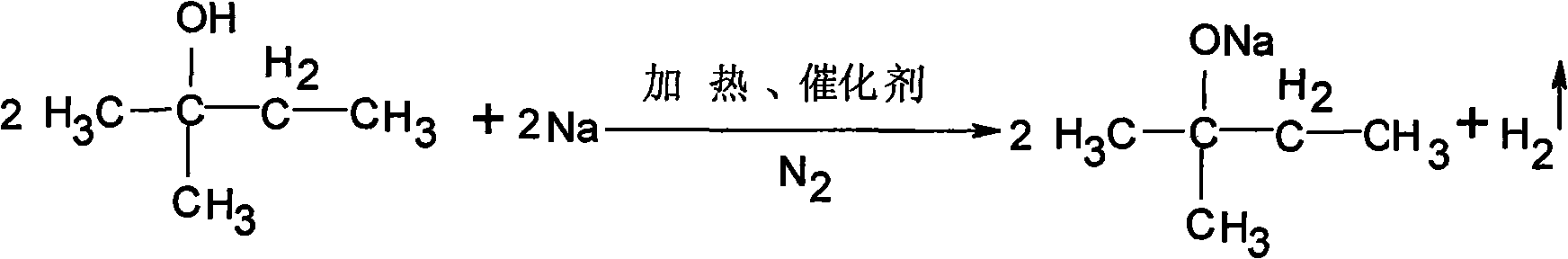

Production process of pigment red HT

The invention relates to a production process of pigment red HT, comprising steps of redox reaction, condensation reaction and hydrolysis reaction. The redox reaction step is realized by gradually adding 90-110ml of ferric trichloride tert-amyl alcohol solution with a concentration of 5 percent as a catalyst, introducing N2 at a temperature of 115-122 DEG C, and maintaining redox reaction for one hour to obtain tert-amyl alcohol sodium; the hydrolysis reaction step is realized by adding 180-200kg of concentrated sulfuric acid with a mass concentration of 96 percent and hydrolyzing the concentrated sulfuric acid for 2-4 hours at a temperature of 40-60 DEG C, filtering, rinsing, drying and breaking to obtain the product. The invention has the advantages of short technique process, high efficiency and little side product; and the prepared pigment red HT has extremely fine particles and high transparency and is bright in color.

Owner:南通市埃唯卡新材料有限公司

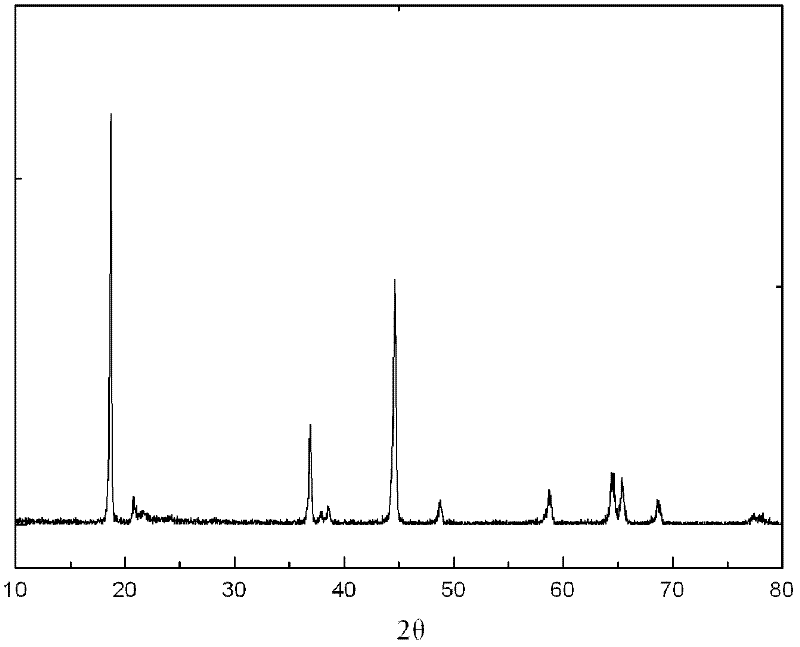

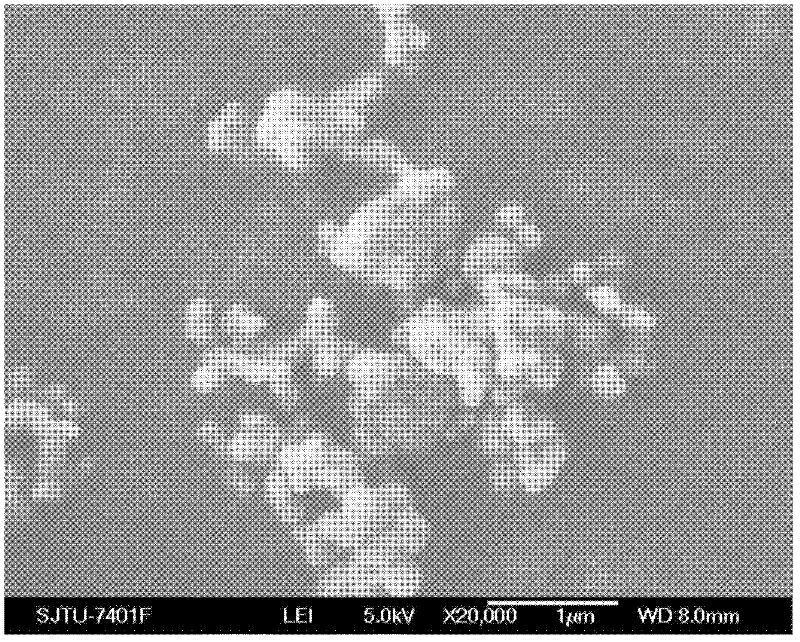

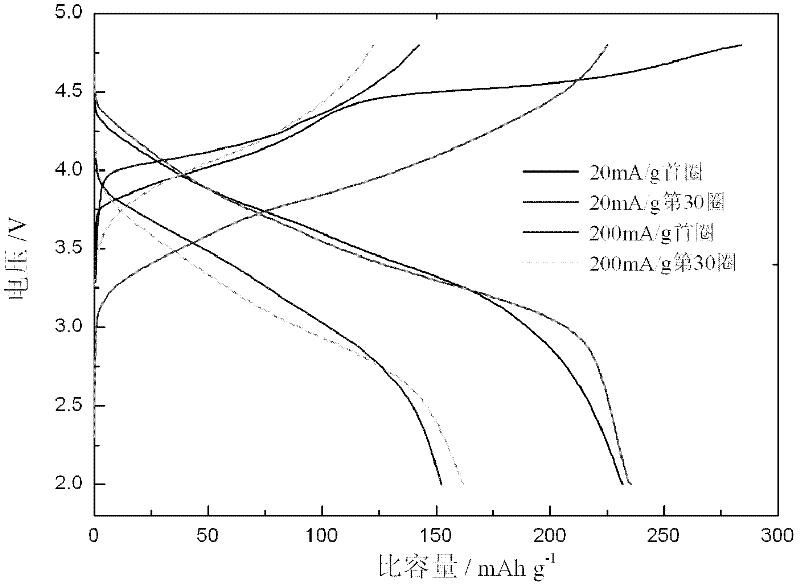

Preparation method of lithium abundant cathode material for lithium ion battery

InactiveCN102364732AShorten the diffusion pathGreen environmental particle sizeCell electrodesAir atmosphereNickel salt

The invention discloses a preparation method of a lithium abundant cathode material for a lithium ion battery. The preparation method comprises the following steps of: performing spray drying on manganese salt, cobalt salt, nickel salt and lithium salt which are dissolved in deionized water by a spray drying process to obtain precursor powder; and putting the precursor powder into a high temperature furnace, sintering under an air atmosphere, naturally cooling to room temperature, and thus obtaining a product, namely the lithium abundant cathode material Li[Ni2 / 5-xLixMn3 / 5-x / 2Cox / 2]O2 (x is more than 0 and less than 2 / 5). The lithium abundant cathode material prepared by the method has uniform particles with the average size of 200nm; and the cathode material of the lithium ion battery reflects extremely high discharging specific capacity, has the current charging / discharging density of 20mA / g and the initial-circle discharging capacity of 247mAh / g, and has the capacity retention rate of 99 percent after 10-time circulation. Compared with the conventional lithium abundant cathode material prepared by a co-precipitation method, the lithium abundant cathode material prepared by the method has a higher electrochemical property and high batch stability and is suitable for industrial mass production.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH +1

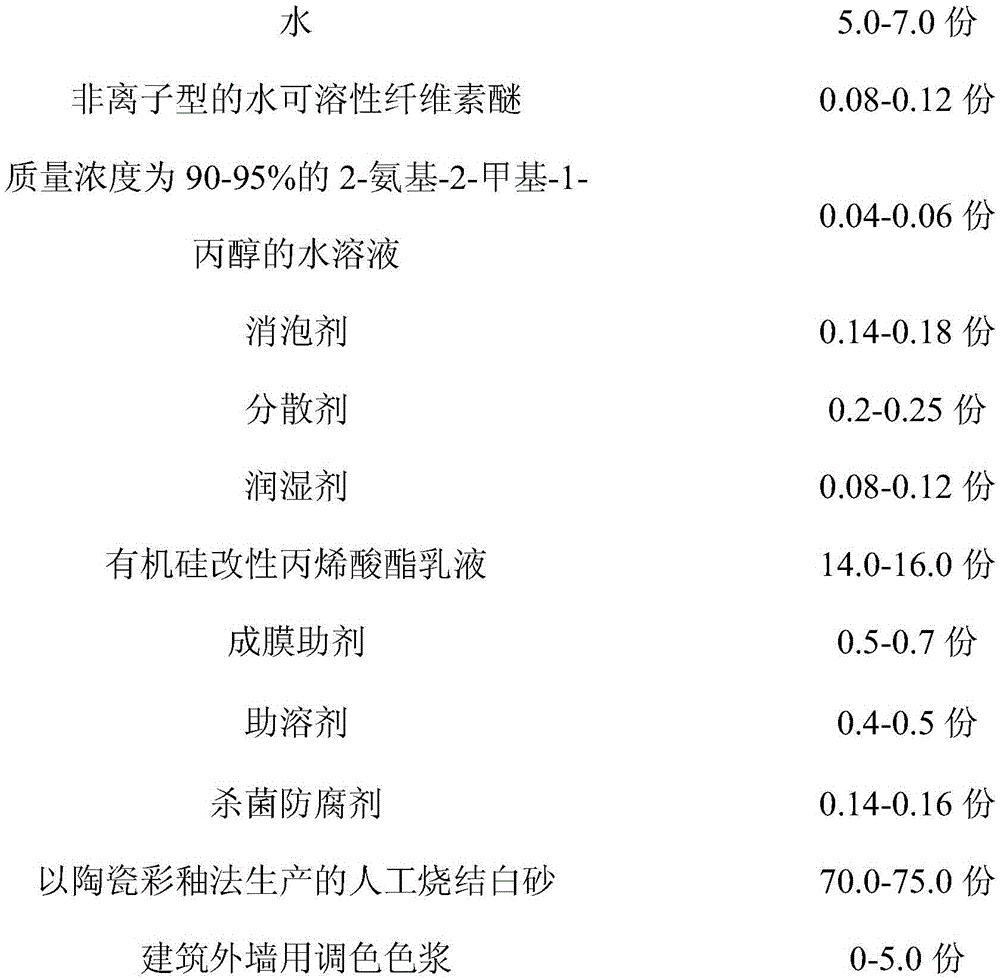

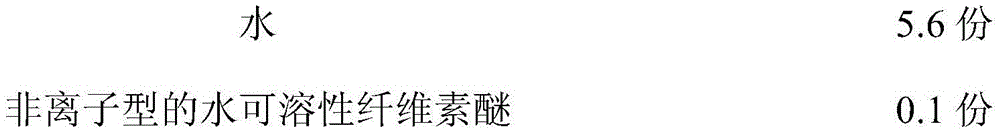

Bright and beautiful-color real-stone-feeling paint and preparation method thereof

The present invention relates to bright and beautiful-color real-stone-feeling paint which comprises the following components: water, non-ionic water-soluble cellulose ether, a 2-amino-2-methyl-1-propanol aqueous solution with the concentration of 90-95%, a defoamer, a dispersant, a wetting agent, silicone-modified acrylate emulsion, a film formation aid, a cosolvent, a sterilization preservative, artificial sintering white sand and building exterior wall color paste. The bright and beautiful-color real-stone-feeling paint overcomes the shortcomings of being dependent on increasingly scarce resources of natural color sand, poor in stability in batches, easy-to-crack in paint film, and poor in water weather resistance, and has the advantages of high gloss, good color retention, rich source of raw materials, good water and weather resistance, good crack resistance and simple production method.

Owner:SKSHU PAINT

Method for synthesizing lithium ferrous phosphate in solution

InactiveCN101696001AAvoid impuritiesReduce manufacturing costCell electrodesPhosphorus compoundsPhosphatePhosphoric acid

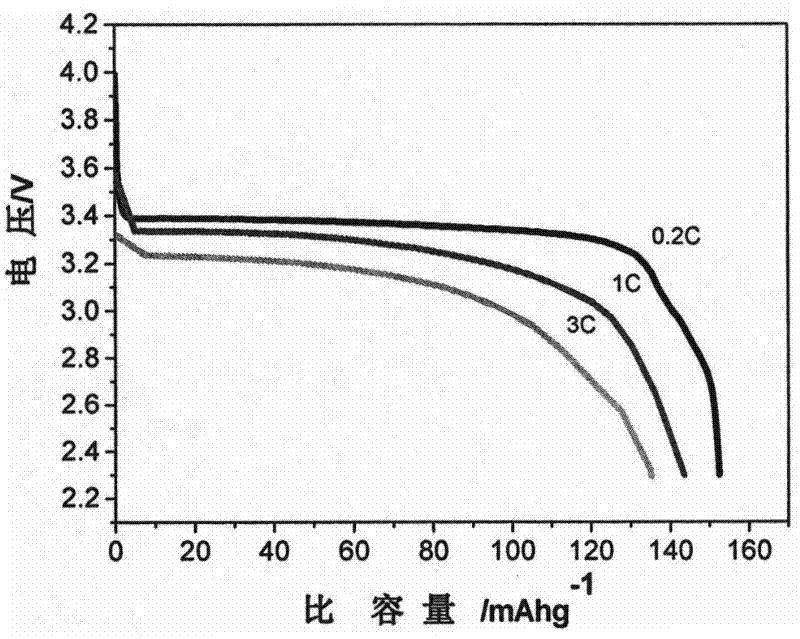

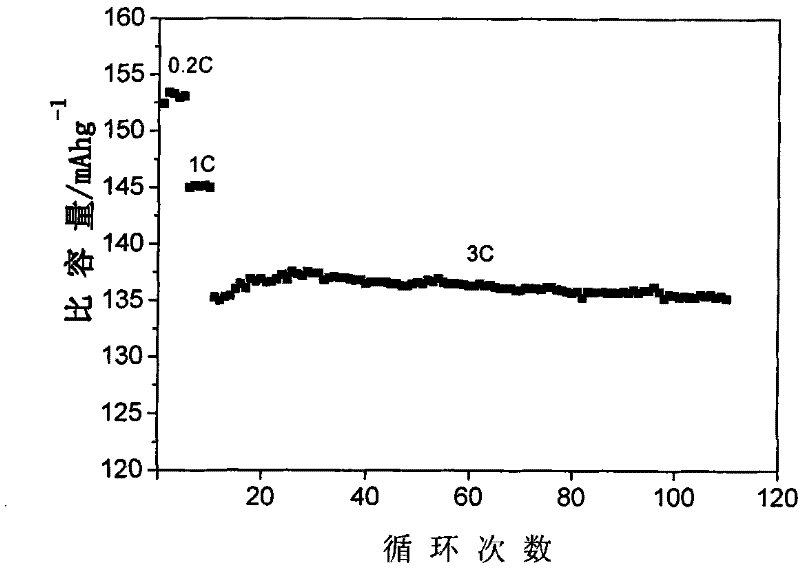

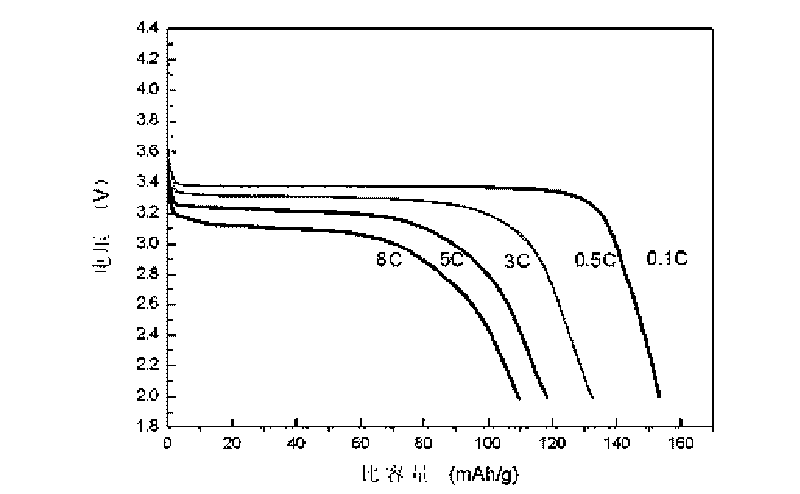

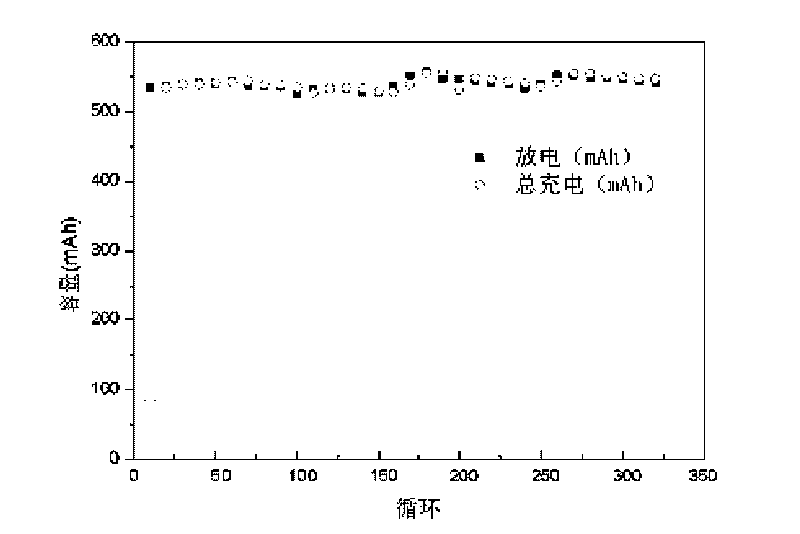

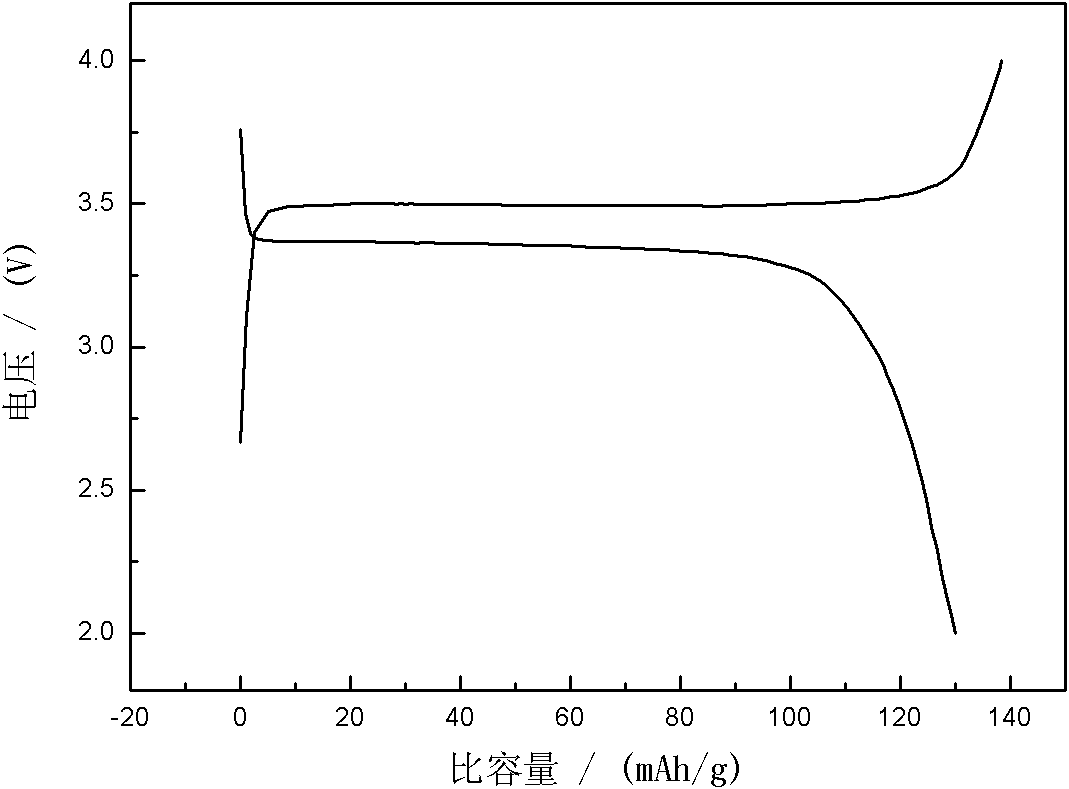

The invention discloses a method for synthesizing lithium ferrous phosphate in a solution, which relates to an anode material of a lithium ion battery, and the method belongs to the technical field of chemical material preparation. The method comprises the following steps: reacting phosphoric acid, iron trioxide with reduced iron powder at a certain temperature, adding a lithium source and a carbon source, continuing the reaction to obtain a mixing solution, and filtering, drying and calcining the mixing solution to obtain the lithium ferrous phosphate. Compared with a synthetic method of using the reduced iron powder as an iron source, the method adopts the iron trioxide as most of iron sources so as to reduce the cost of raw materials greatly; the obtained product is uniform in component and good in batch stability, and the synthesized lithium ferrous phosphate material serving as the anode material of the lithium ion battery has the excellent electrochemistry performance; 3C multiplying power discharging specific capacity is more than 130mAh / g at room temperature; the synthesized lithium ferrous phosphate material is suitable for being used as power lithium ion batteries; and the method has short sintering period, simple production process, less energy consumption and no pollution, such as tail gas and waste liquor, and is suitable for mass industrial production.

Owner:TSINGHUA UNIV

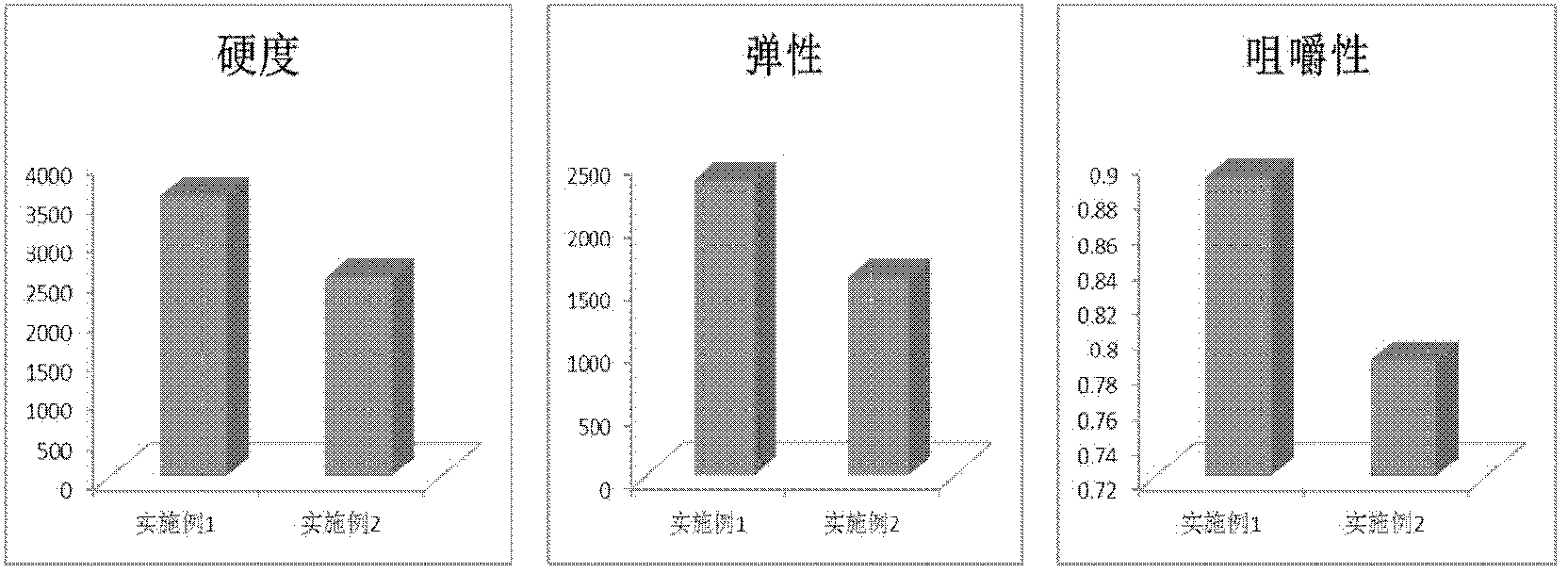

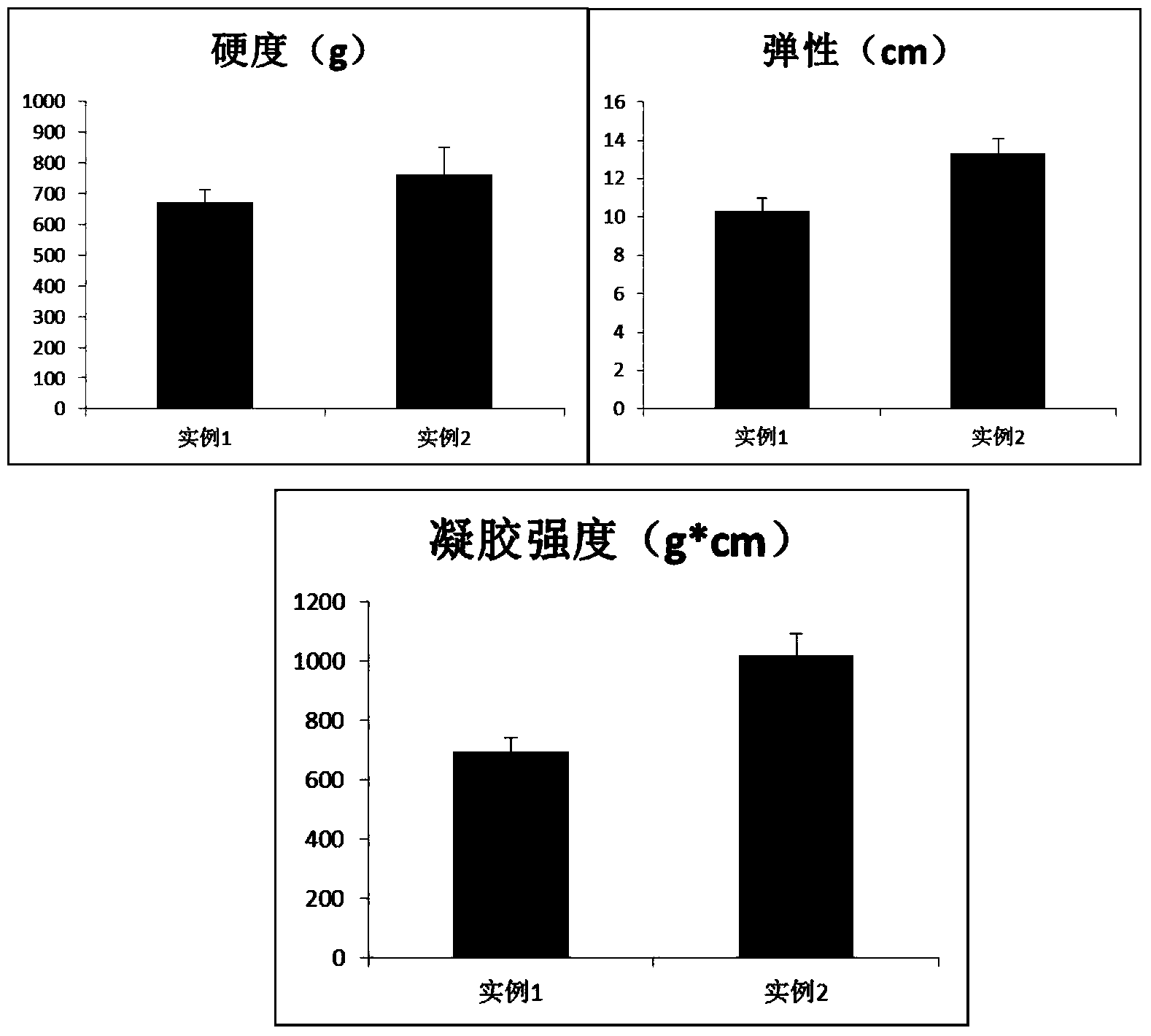

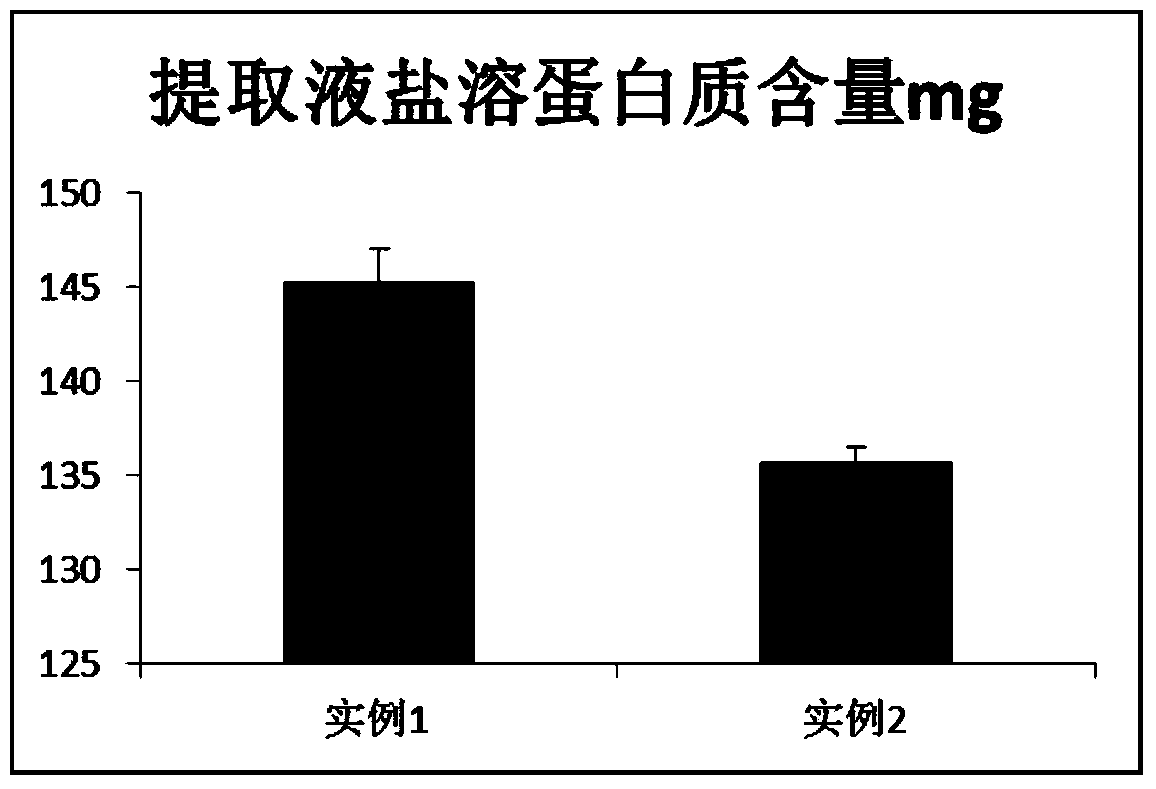

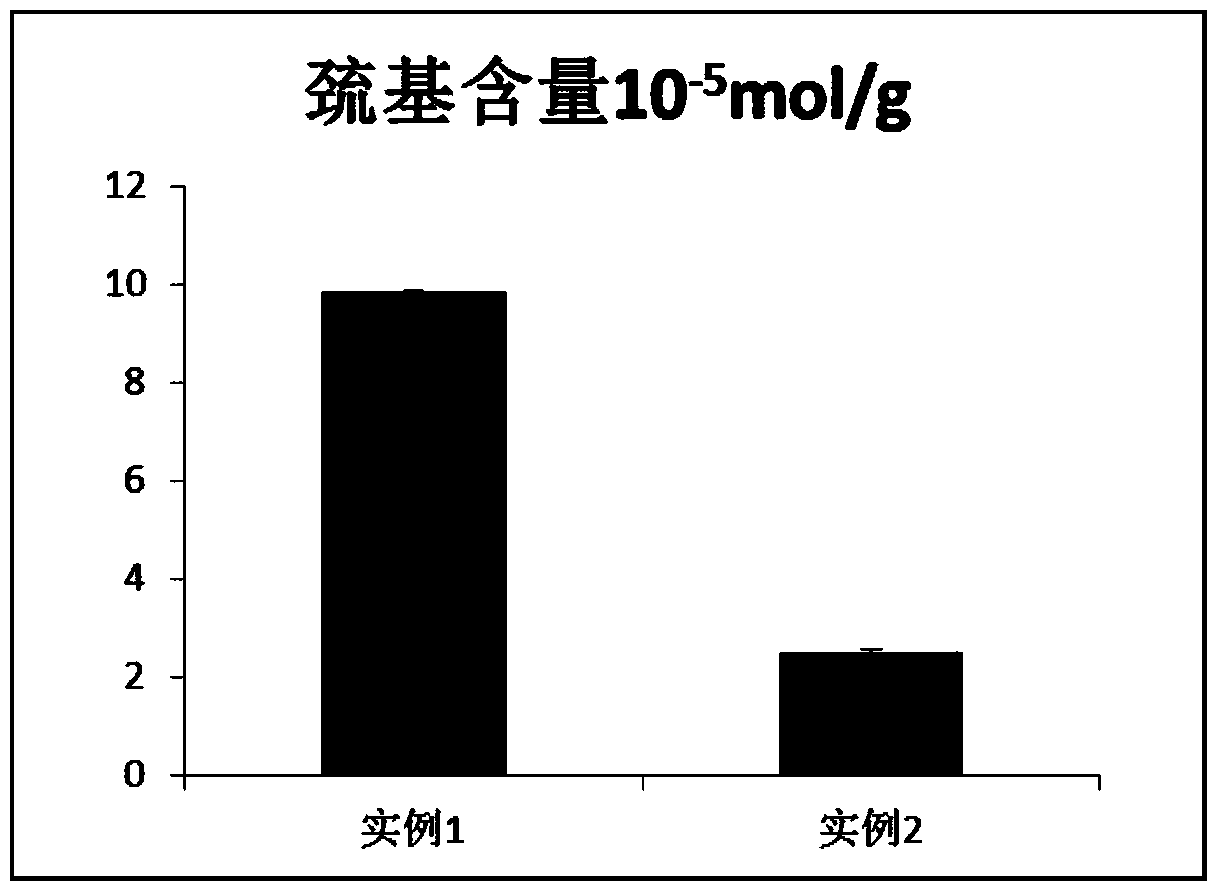

Surimi-based product with high jelly strength and preparation method thereof

InactiveCN104286964ADelicate organizational structureTaste full of elasticityFood preparationFlavorGram

The invention relates to a surimi-based product with high jelly strength, and a preparation method thereof. The method comprises the steps of cutting and mixing, cutting and mixing with salt, cutting and mixing with a water solution, and forming. The surimi-based product is 1010-1020 g*cm in the jelly strength 78-80 in the whiteness, and 82%-84% in water-holding capacity; the content of hydrosulphonyl in each one gram of protein is 2.0*10<-5> to -3.0*10<-5> mol / g. The surimi-based product provided by the invention is more elastic in taste, and is purer in flavor; the tissue structure is fine and smooth, and nutrition and health are realized; stability in batch is good, and safety is high.

Owner:JIANGNAN UNIV

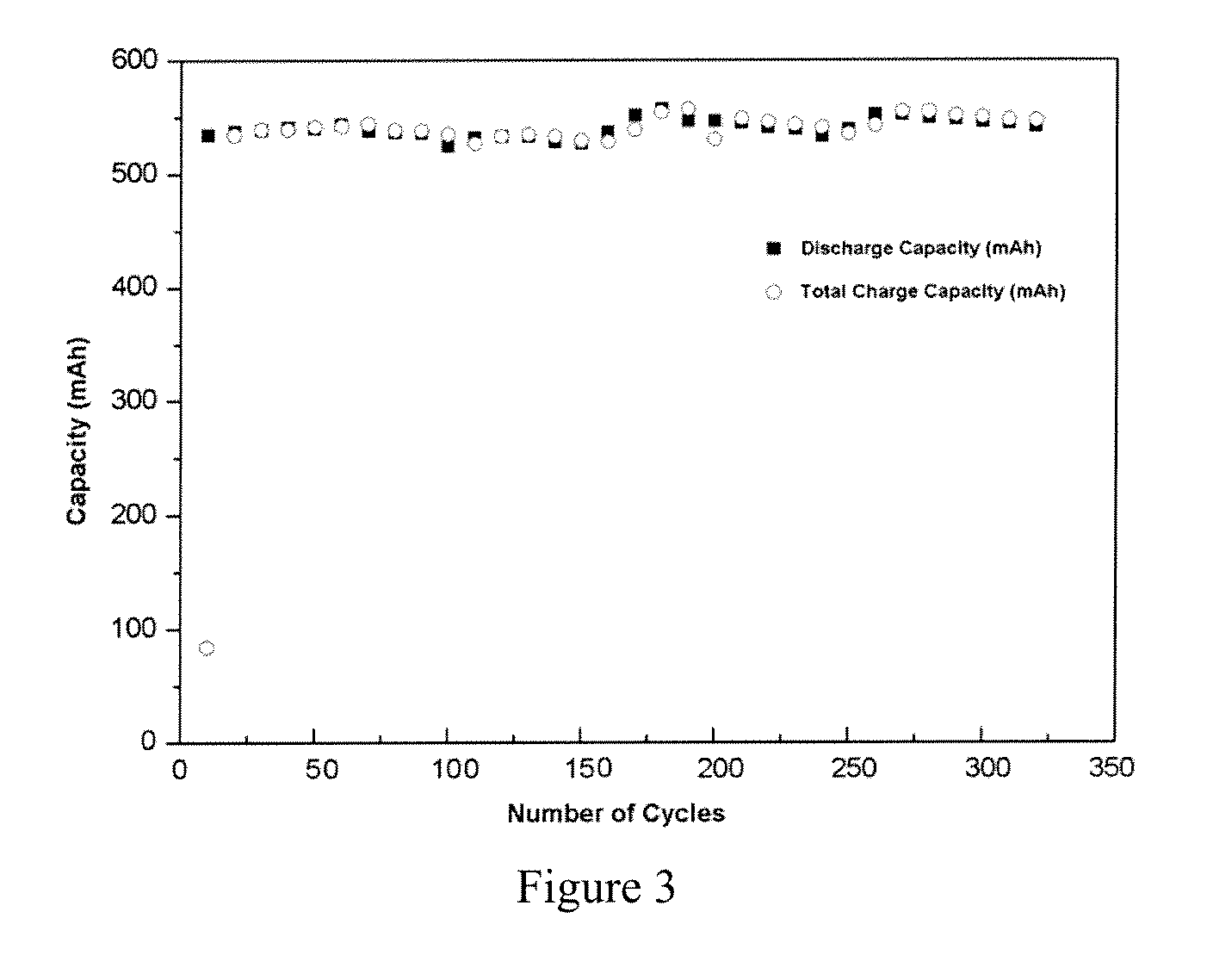

Lithium iron phosphate having oxygen vacancy and doped in the position of fe and method of quick solid phase sintering for the same

ActiveUS20100171071A1Good batch stabilityHigh tap densityCell electrodesSynthetic resin layered productsLithium iron phosphateMicrowave

The present invention relates to a lithium ion cathode material lithium iron phosphate having oxygen vacancy and doped in the position of Fe and a preparation method of quick micro-wave sintering for the same. The molecular formula of the product in present invention is expressed as LiFe1-x-aMeaMxPO4-yNz, wherein Me is one or more elements selected from Mg, Mn or Nd, and M is one or more elements selected from Li, Na, K, Ag or Cu; 0≦x≦0.1, 0<a≦0.1, 0<y≦0.5, 0≦z≦0.5, wherein x and z can not be 0 simultaneously. The quick micro-wave sintering preparation method in the present invention has advantages of high production efficiency, low energy consumption, good batch stability of the prepared product, excellent rate performance and cycle performance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Gas-sensitive membrane and preparation method and application thereof

InactiveCN109813768AIncrease the interaction areaLarge specific surface areaMaterial resistancePorosityGas detector

The invention relates to a gas-sensitive membrane and a preparation method and application thereof. The gas-sensitive membrane is a single-layer porous mesh gas-sensitive membrane. The method is a mask sputtering method and specifically comprises the steps that a single layer of organic microspheres is flatly laid on a whole sensor substrate to serve as a mask plate, then an oxide gas-sensitive thin film is deposited, and finally the single-layer organic microsphere mask plate is removed to obtain the single-layer porous gas-sensitive membrane. According to the method, a gas-sensitive sensor wafer of a suspended structure can be further obtained by adopting a traditional back etching process, and laser cutting and splitting packaging are adopted to obtain a gas-sensitive sensor device. According to the method, a traditional dense two-dimensional thin film is cut into a porous net structure, the specific surface area is large, the porosity is increased, the interaction area between thethin film and gas is increased, and then the sensitivity is improved. Meanwhile, the gas-sensitive membrane prepared through the sputtering method is consistent in performance and relatively good in batch stability and has good application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

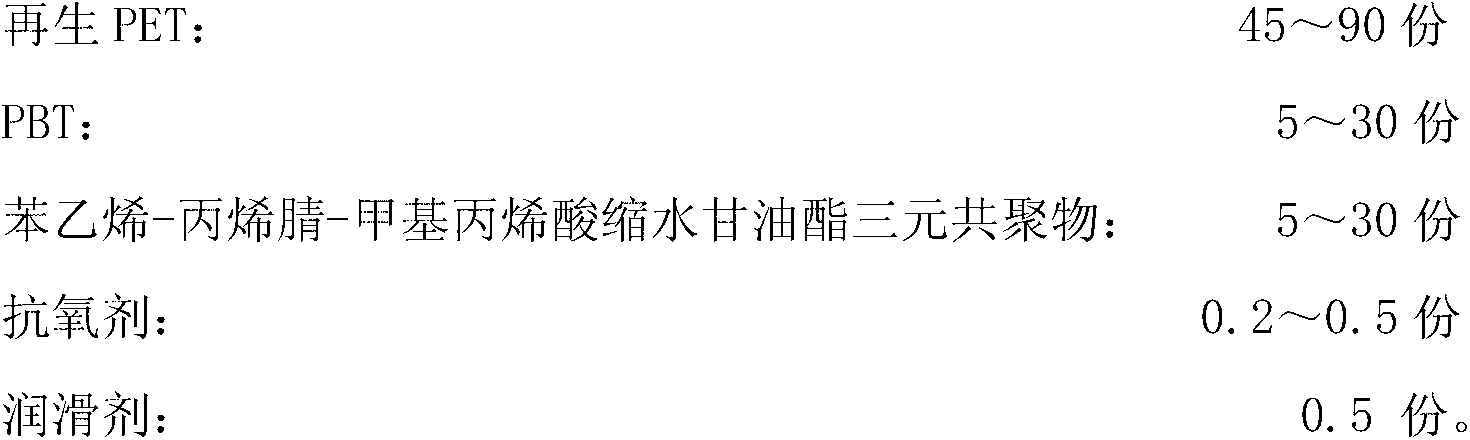

High impact recycled PET/ABS alloy composition and preparation method thereof

The present invention discloses a high impact recycled PET / ABS alloy composition and a preparation method thereof. The alloy comprises the following components, by weight, 20-50 parts of recycled PET, 5-30 parts of ABS powder, 10-70 parts of ABS, 0-20 parts of PBT, 0.5-10 parts of PET ester exchange master batch, 0.5-5 parts of a compatilizer, 0.1-1 part of an antioxidant, 0.1-1 part of a lubricant, and 0.1-3 parts of a nucleating agent. The preparation method comprises: preparing the materials according to the ratio, placing the materials into a medium speed mixer to mix for 5-30 min to obtain a mixed material, pouring the mixed material into a twin-screw extruder, and carrying out melt extrusion and granulation to obtain the product, wherein a screw rotation speed is controlled to 300-600 rpm. Compared with the high impact recycled PET / ABS alloy composition in the prior art, the PET / ABS alloy material of the present invention has the following characteristics that: the specific ABS content and the self-made ester exchange master batch are adopted so as to improve an impact performance of the PET / ABS alloy.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com