High-voltage lithium ion battery cathode material and preparation method thereof

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems affecting the service life of materials, restricting the commercial development of materials, and difficulties in lithium manganese oxides, and achieves low manufacturing costs and improved Good cycle stability, thermal stability, and batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

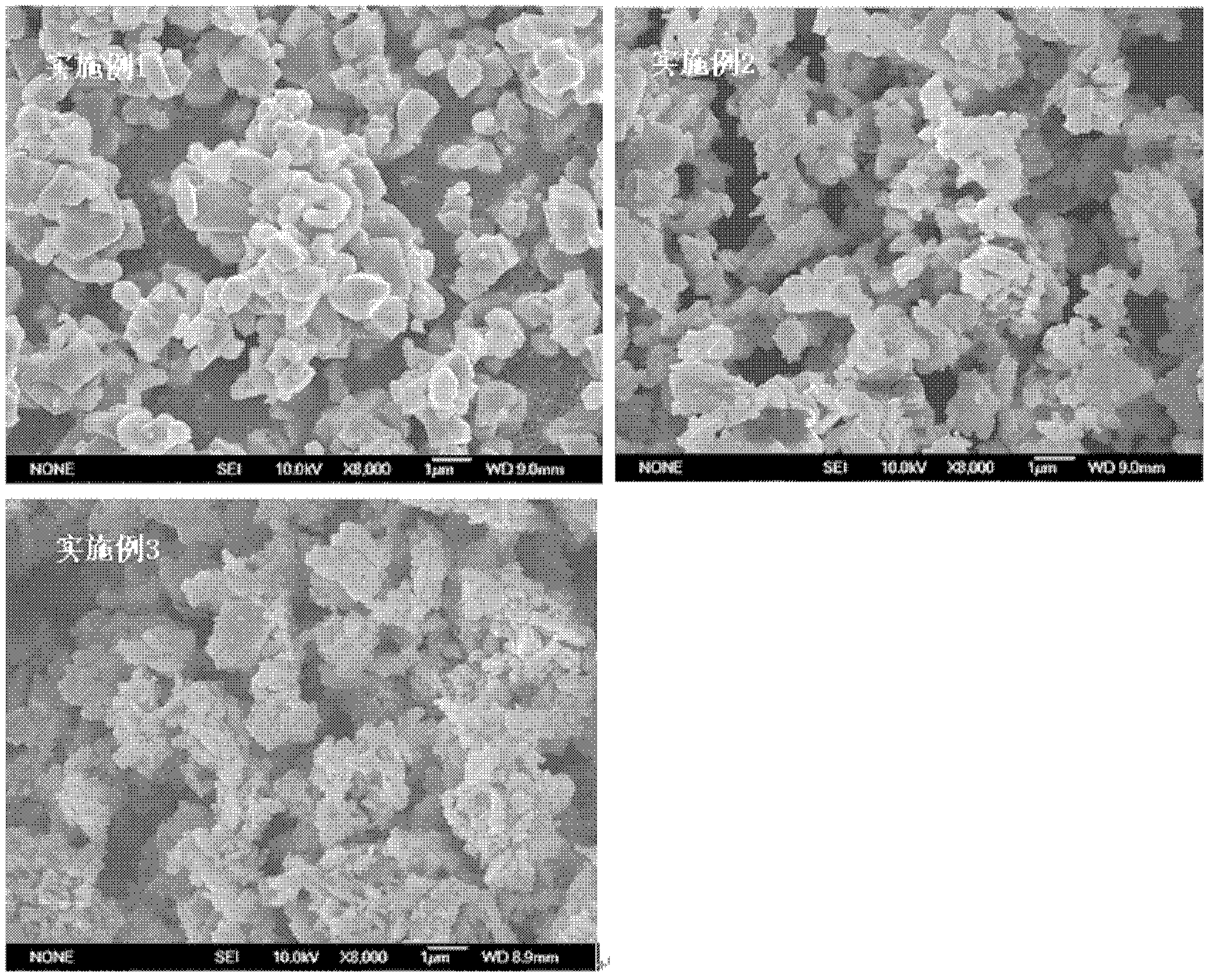

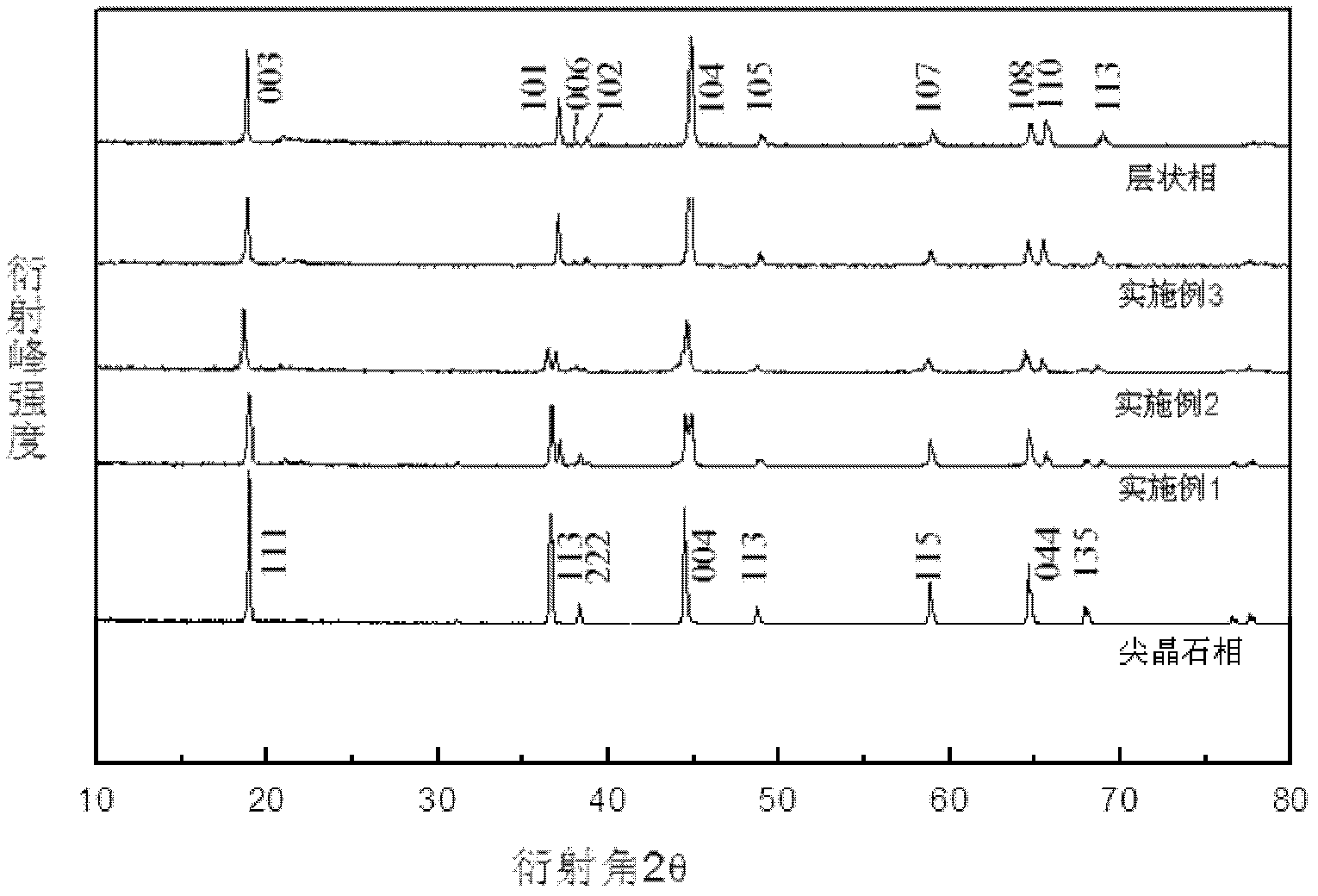

Embodiment 1

[0022] A preparation method of a high-voltage lithium-ion battery cathode material, the steps are as follows:

[0023] 1) Prepare 25L of 2M salt solution with 2656g nickel sulfate, 1437g cobalt sulfate and 5923g manganese sulfate;

[0024] 2) Inject the prepared 25L salt solution into a reaction kettle with a rotating speed of 300rps at a speed of 1L / h, and inject a mixed aqueous solution of sodium hydroxide-ammonia water at the same time, and the mixed aqueous solution of sodium hydroxide-ammonia water is a NaOH aqueous solution with a concentration of 6M Mix and prepare the ammonia water with a concentration of 10M at a volume ratio of 7:1. Pay attention to adjusting the flow rate of the alkali solution to keep the pH value between 10-11. After the salt solution is completely injected into the reactor, continue to stir and age for 24 hours. The precursor preparation reaction Complete, the solid-liquid mixture after the reaction is separated by centrifugation, washed to neutr...

Embodiment 2

[0028] A preparation method of a high-voltage lithium-ion battery cathode material, the steps are as follows:

[0029] 1) same as embodiment 1;

[0030] 2) same as embodiment 1;

[0031] 3) Lithium carbonate and solid solution material precursors were evenly mixed according to the molar ratio of lithium to metal ions of 1.2:1, pre-calcined at 500°C for 4 hours, cooled and then ground, then calcined at 900°C for 12 hours, and the material was cooled After grinding and sieving, the layered and spinel composite structure solid solution material Li 1.2 Ni 0.2 mn 0.7 co 0.1 o 2.2 .

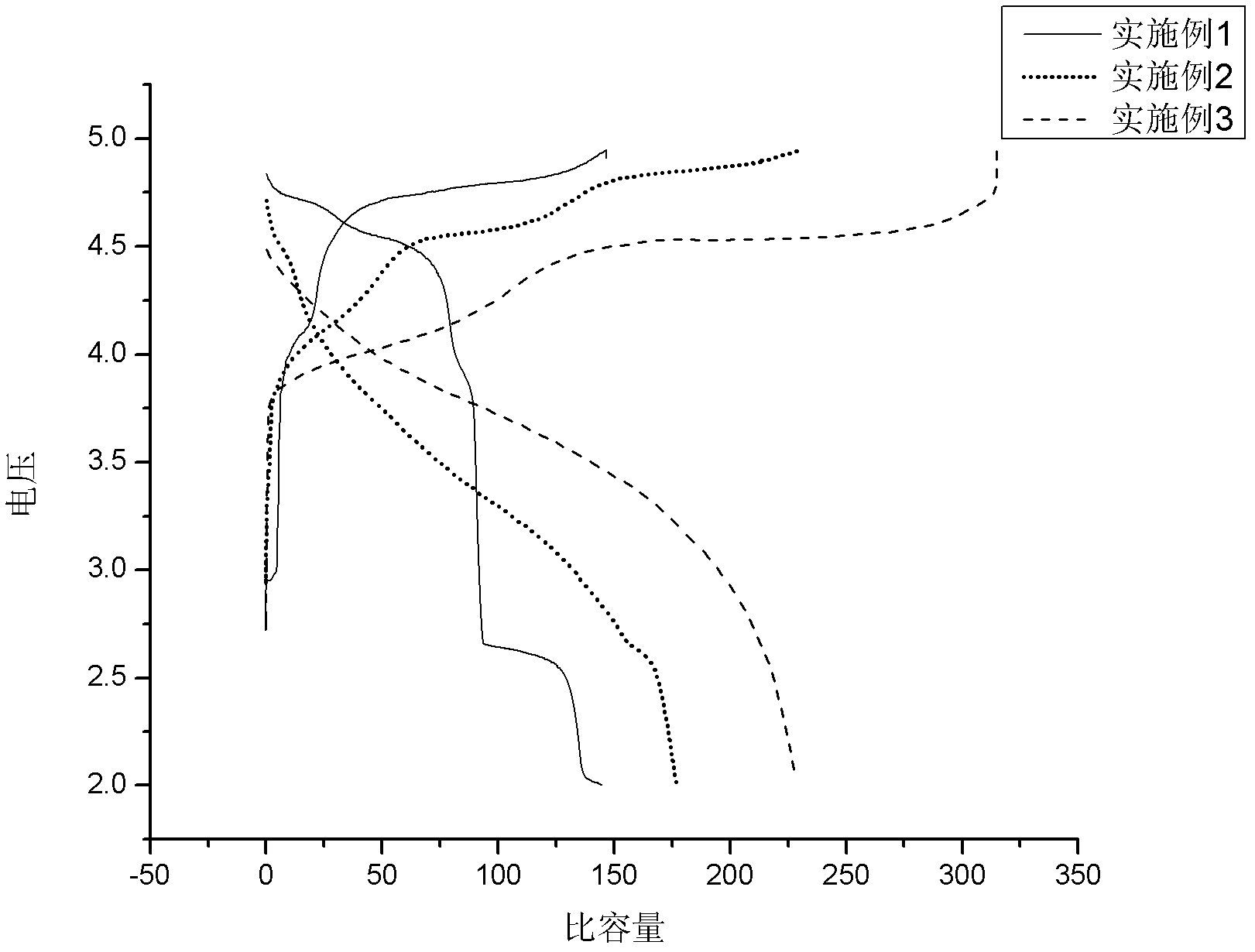

[0032] The solid solution material was made into a 2032 button battery for testing. In the voltage range of 2.0V-4.95V with a current density of 20mAh / g, the first charge specific capacity was 230.8mAh / g, the first discharge specific capacity was 177mAh / g, and the first efficiency 76.69%, 83.87% cycle retention after 50 weeks.

Embodiment 3

[0034] A preparation method of a high-voltage lithium-ion battery cathode material, the steps are as follows:

[0035] 1) same as embodiment 1;

[0036] 2) same as embodiment 1;

[0037] 3) The lithium source and the solid solution material precursor are uniformly mixed according to the molar ratio of lithium source and metal ion of 1.7:1. The lithium source is a mixture of lithium carbonate and lithium nitrate with a mass ratio of 7:3, prior to Pre-fired at 500°C for 4 hours, ground after cooling, and then calcined at 900°C for 12 hours. After the material was cooled, it was ground and sieved to obtain a layered and spinel composite structure solid solution material Li 1.4 Ni 0.2 mn 0.7 co 0.1 o 2.4 .

[0038] The solid solution material was made into a 2032 button battery for testing. In the voltage range of 2.0V-4.95V with a current density of 20mAh / g, the specific capacity for the first charge was 314.9mAh / g, and the specific capacity for the first discharge was 228.8m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com