Preparation method for carbon-containing material metal organic framework-based composite phase change material

A technology of metal-organic framework and composite phase-change materials, which is applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of poor heat transfer performance and single selection of core materials, and achieve improved heat transfer performance and heat transfer performance. Excellent performance and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

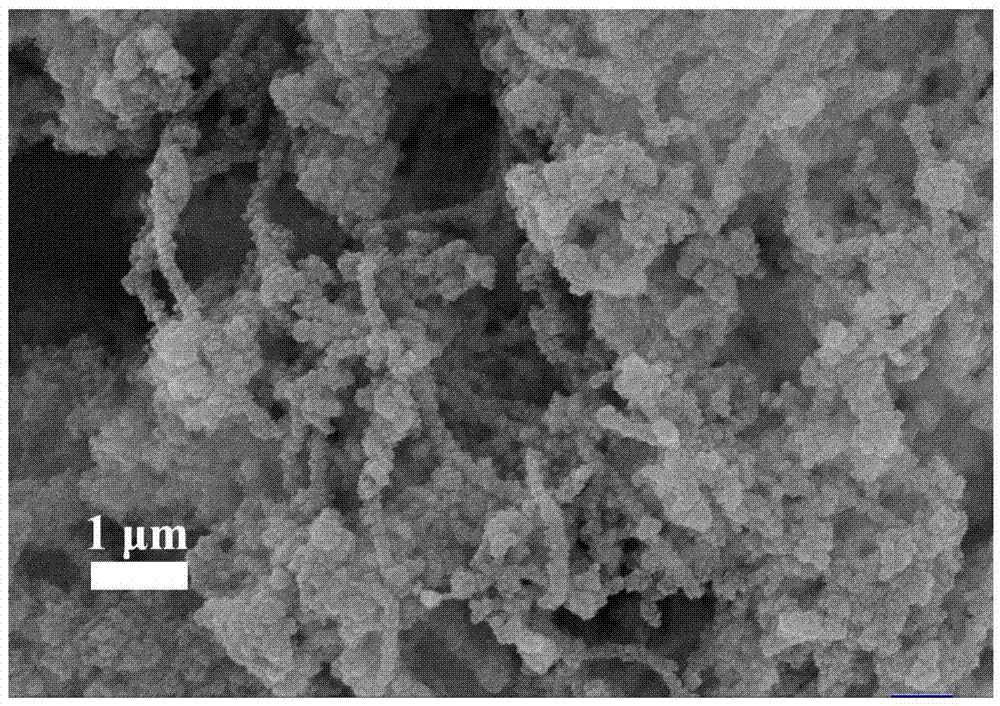

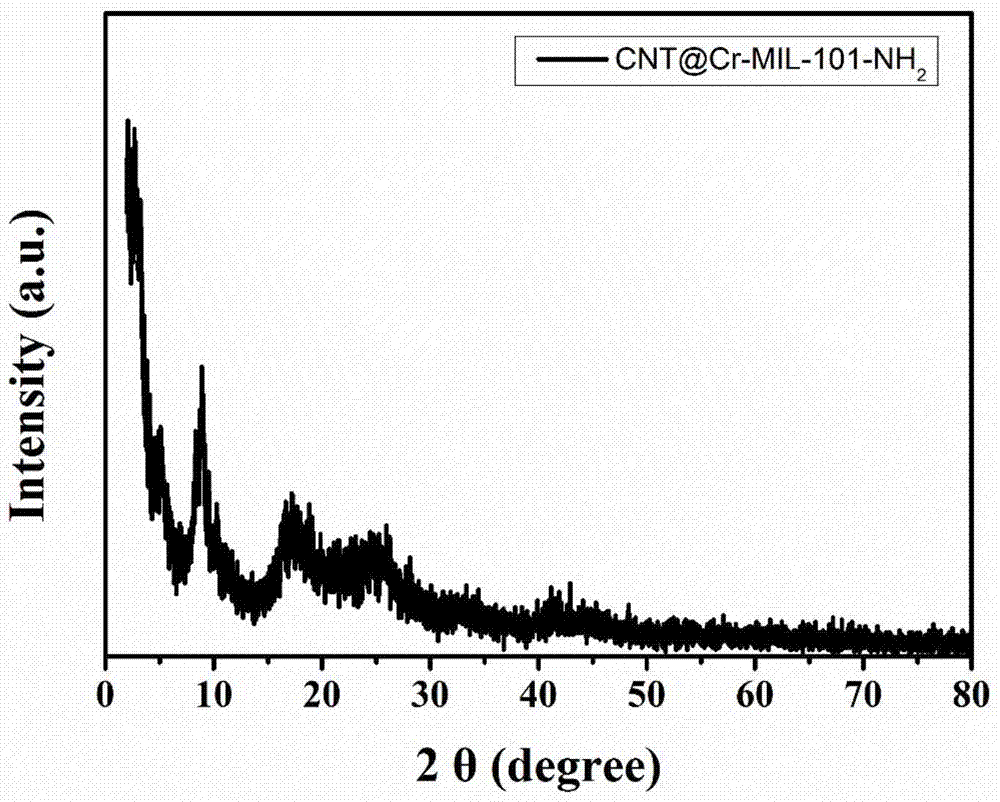

[0023] (1) Disperse 50mg of carbon nanotubes (CNT) into 40mL of PVP (average molecular weight 58000) aqueous solution (2mg mL -1 ), ultrasonically dispersed for 1 h, and then stirred overnight at room temperature. The precipitate was centrifuged and redispersed into 15 mL of water. Add 2mmol of chromium nitrate, 2mmol of terephthalic acid and 5mmol of sodium hydroxide to the mixture, stir at room temperature for 5min, move it to the reaction kettle, keep it at 150°C for 12h, filter and wash it, and put it under vacuum at 60°C CNTCr-MIL-101-NH was obtained after drying in a drying oven for 24 hours 2 carrier material.

[0024] (2) 0.107g of CNTCr-MIL-101-NH prepared above 2 Vacuumize at 150°C for 4 hours to remove small guest molecules in the pores. The carrier material after suction filtration was dispersed in 10 mL of absolute ethanol containing 0.25 g of PEG2000, and stirred at 60° C. for 2 h to obtain a homogeneous solution. Put the mixture in a drying oven at 80°C, ke...

Embodiment example 2

[0027] (1) Disperse 50mg of expanded graphite into 40mL of PVP (average molecular weight is 58000) aqueous solution (2mg mL -1 ), ultrasonically dispersed for 1 h, and then stirred overnight at room temperature. The precipitate was centrifuged and redispersed into 15 mL of water. Add 2mmol of chromium nitrate, 2mmol of terephthalic acid and 5mmol of sodium hydroxide to the mixture, stir at room temperature for 5min, move it to the reaction kettle, keep it at 150°C for 12h, filter and wash it, and put it under vacuum at 60°C After drying in a drying oven for 24 hours, expanded graphite Cr-MIL-101-NH was obtained 2 carrier material.

[0028] (2) 0.107g of the above-mentioned expanded graphite Cr-MIL-101-NH 2 Vacuumize at 150°C for 4 hours to remove small guest molecules in the pores. The carrier material after suction filtration was dispersed in 10 mL of absolute ethanol containing 0.25 g of stearic acid, and stirred at 80° C. for 2 h to obtain a homogeneous solution. Put t...

Embodiment example 3

[0030](1) Disperse 50mg of carbon fiber into 40mL of PVP (average molecular weight 58000) aqueous solution (2mg mL -1 ), ultrasonically dispersed for 1 h, and then stirred overnight at room temperature. The precipitate was centrifuged and redispersed in 15 mL of water. Add 2mmol of chromium nitrate, 2mmol of terephthalic acid and 5mmol of sodium hydroxide to the mixture, stir at room temperature for 5min, move it to the reaction kettle, keep it at 150°C for 12h, filter and wash it, and put it under vacuum at 60°C Carbon fiber Cr-MIL-101-NH was obtained after drying in a drying oven for 24 hours 2 carrier material.

[0031] (2) 0.107g of the above-prepared carbon fiber Cr-MIL-101-NH 2 Vacuumize at 150°C for 4 hours to remove small guest molecules in the pores. The carrier material after suction filtration was dispersed in 10 mL of dichloromethane containing 0.25 g of paraffin 58, and stirred at 40° C. for 2 h to obtain a homogeneous solution. Put the mixture in a drying ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com