Patents

Literature

1235results about How to "Wide range of choices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

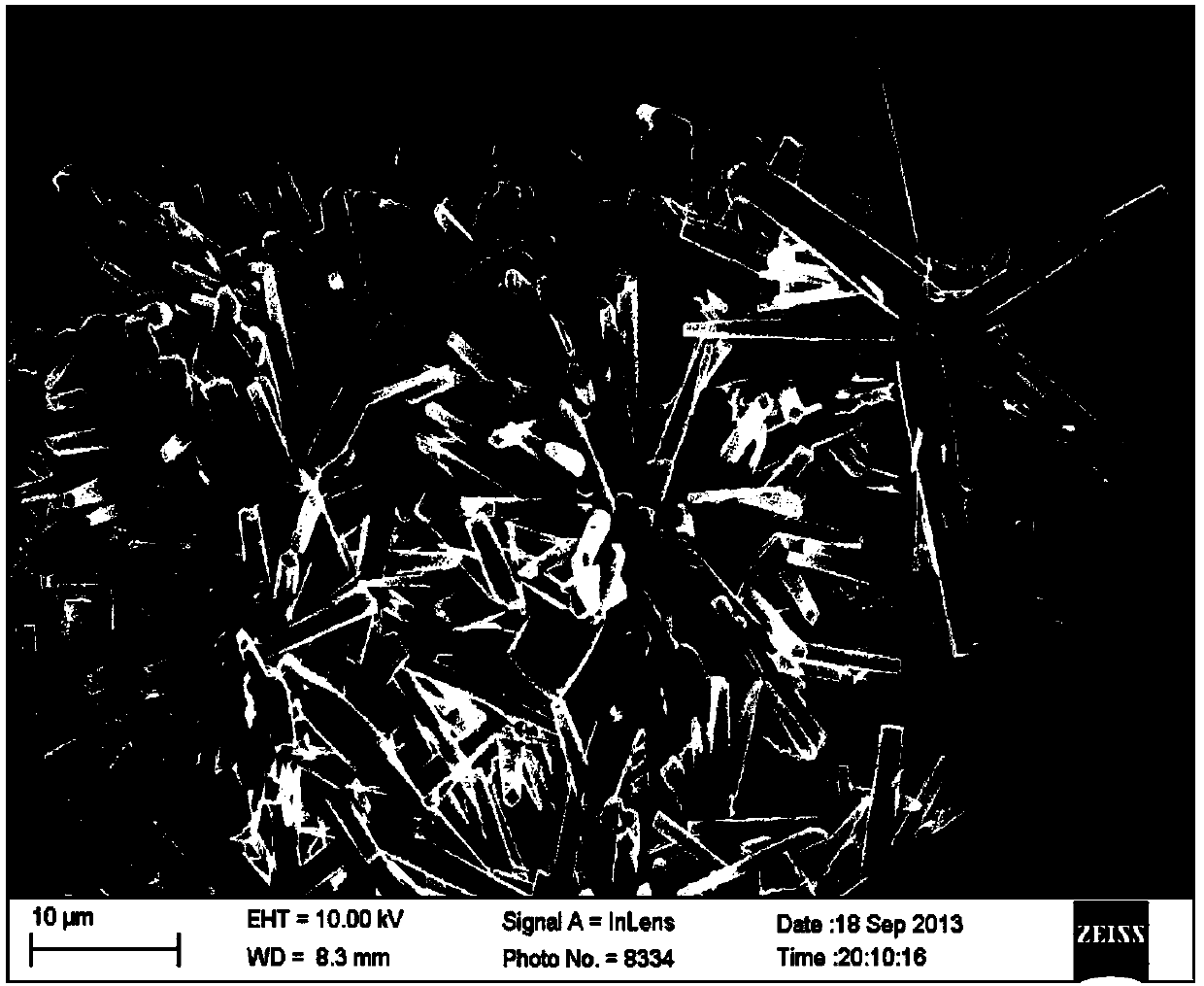

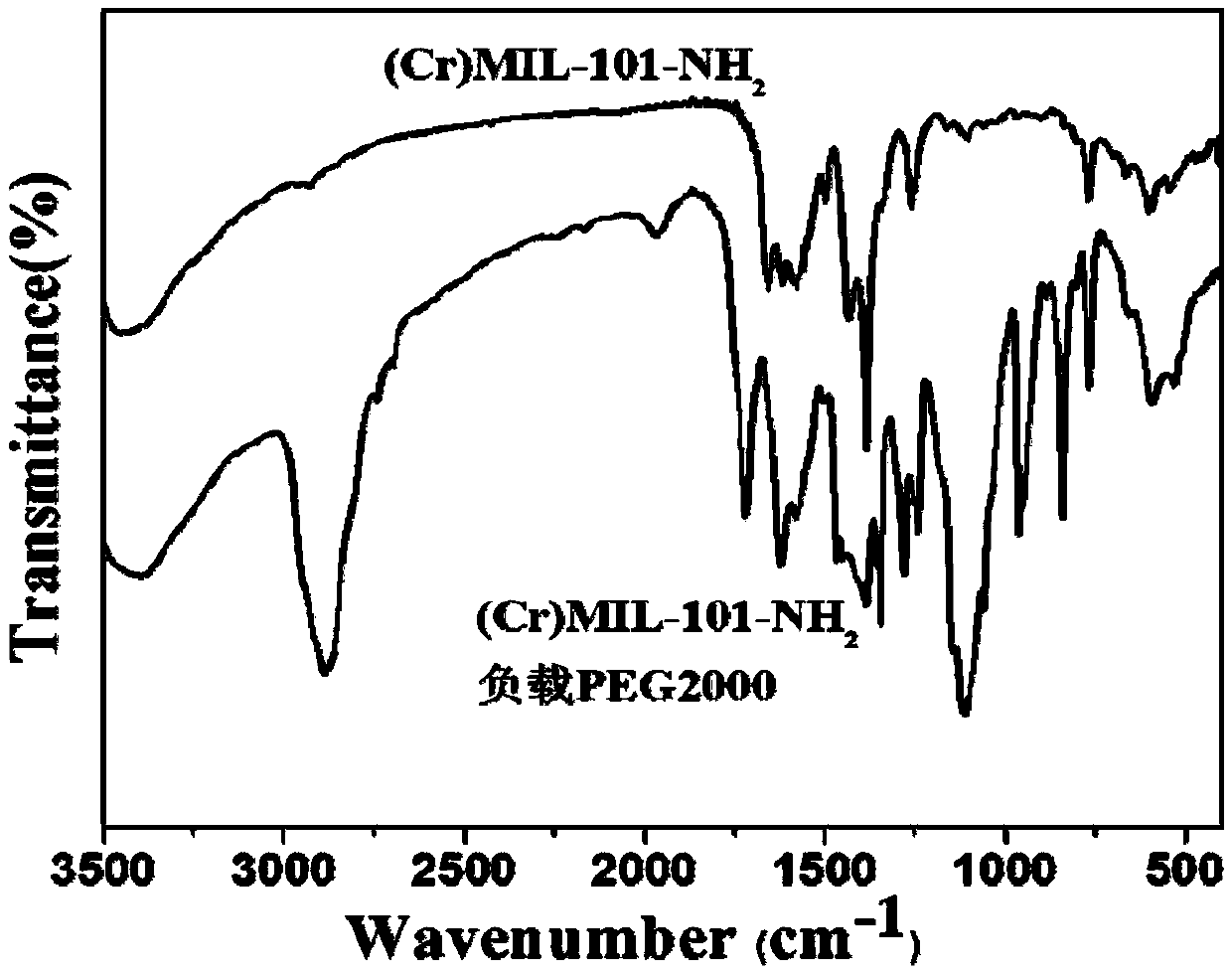

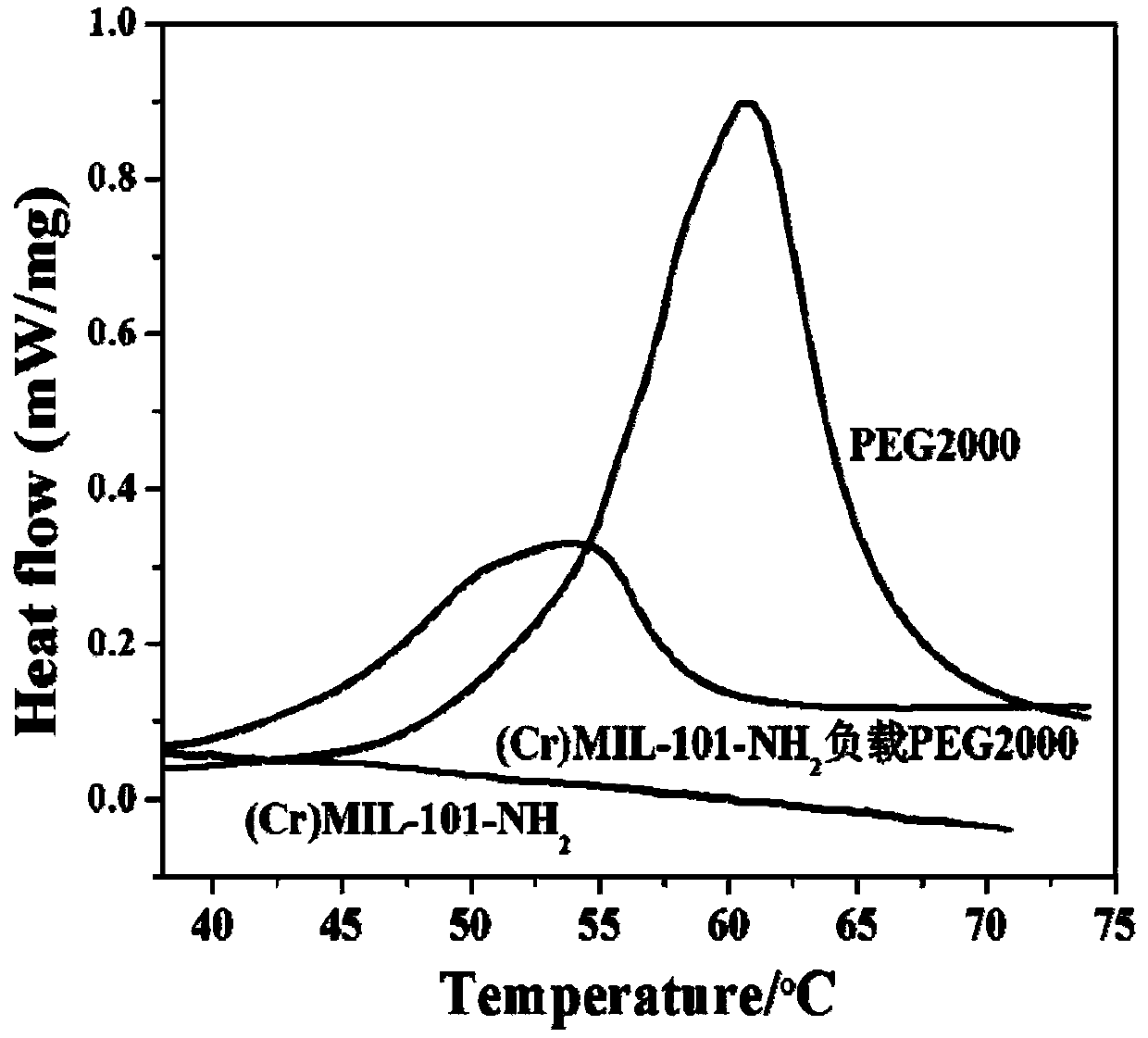

Preparation method of metal organic framework based composite phase-change material

InactiveCN103756646AWide range of choicesPrevent leakage and other issuesProductsReagentsMetal-organic frameworkElectrical polarity

The invention relates to a preparation method of a metal organic framework based composite phase-change material. The method comprises the steps that a metal organic framework material substrate is prepared selectively; hole diameter size design and hole channel polarity regulation and control are performed on the substrate according to the size and the kind of a core material, so that a phase-change core material to be loaded is matched better; the soluble phase-change core material is prepared into a solution; a metal organic framework material is dispersed in the prepared phase-change material solution; a phase-change material is adsorbed by utilizing an extra-large specific surface area and a nano hole channel structure of the metal organic framework material; drying is performed; and then the metal organic framework composite phase-change material with a shaping effect is obtained. According to the method, a novel metal organic framework based composite phase-change material is developed; the prepared metal organic framework based composite phase-change material can effectively avoid leakage and the like, and has the advantages of adjustable nano hole structure and wide core material selection range; the method is simple in technology and mild in reaction condition, and is suitable for scale production; and a raw material is cheap and easy to obtain.

Owner:UNIV OF SCI & TECH BEIJING

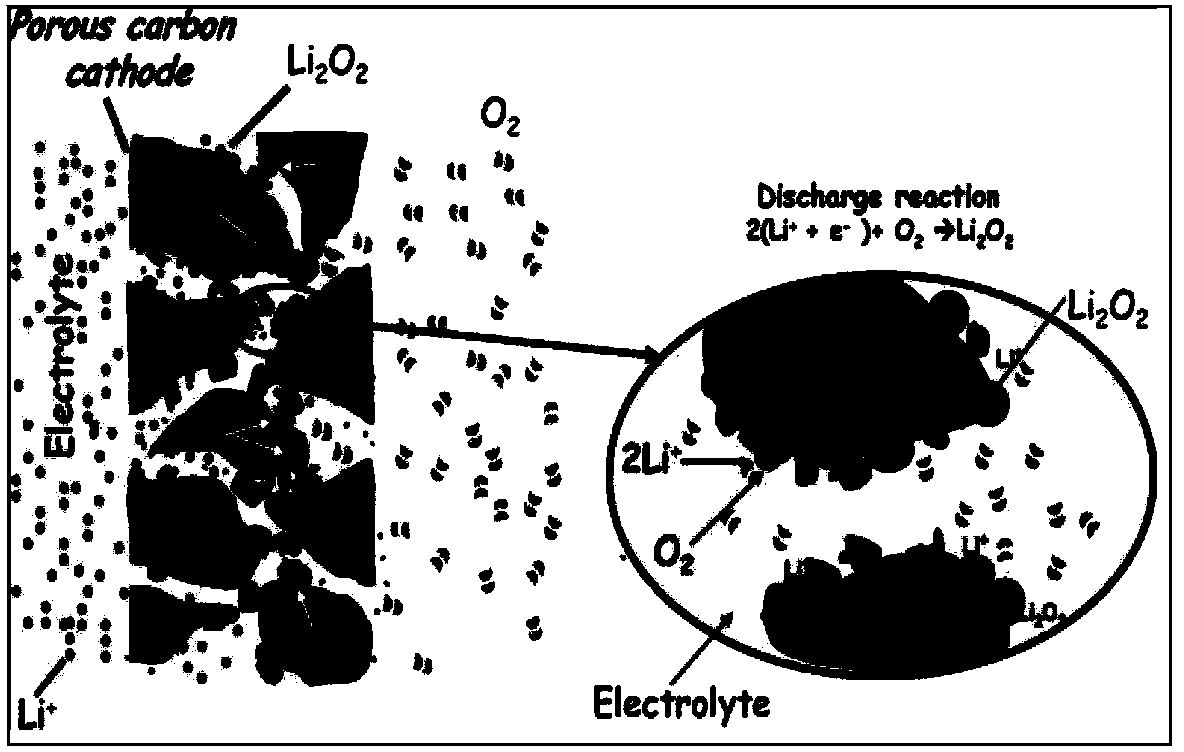

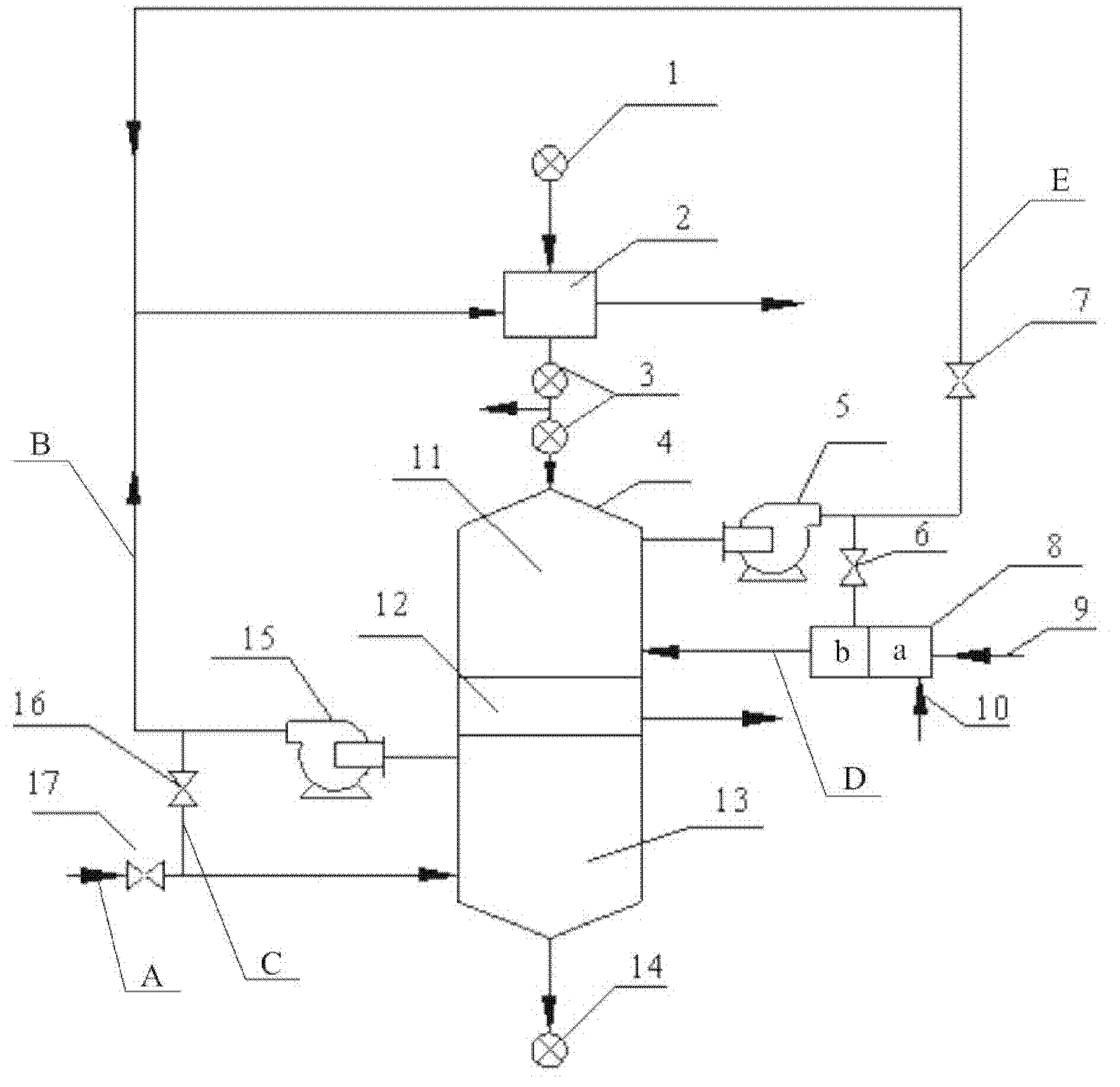

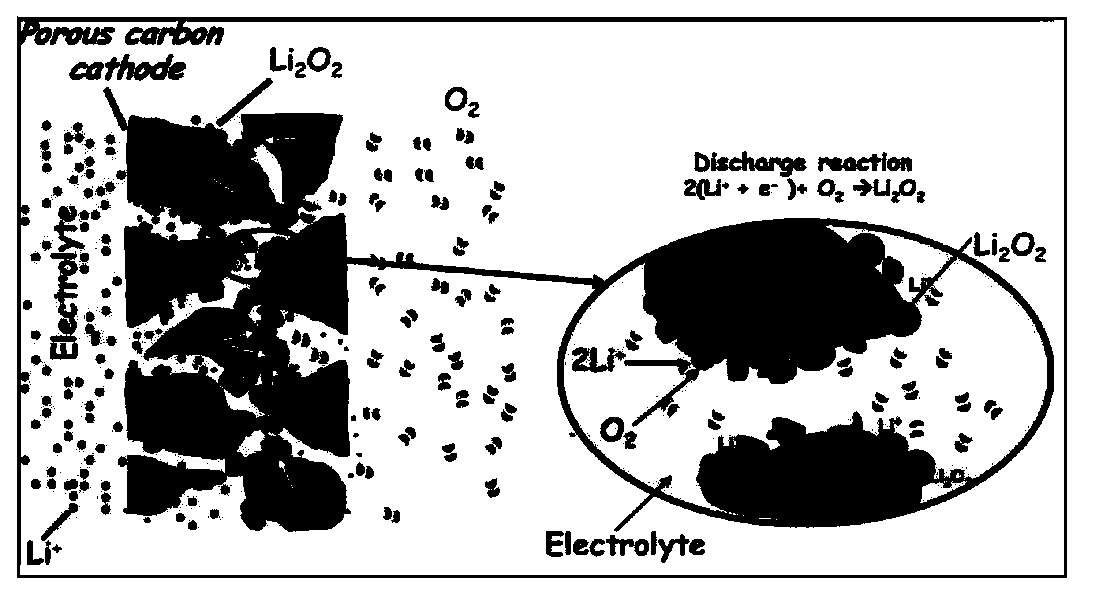

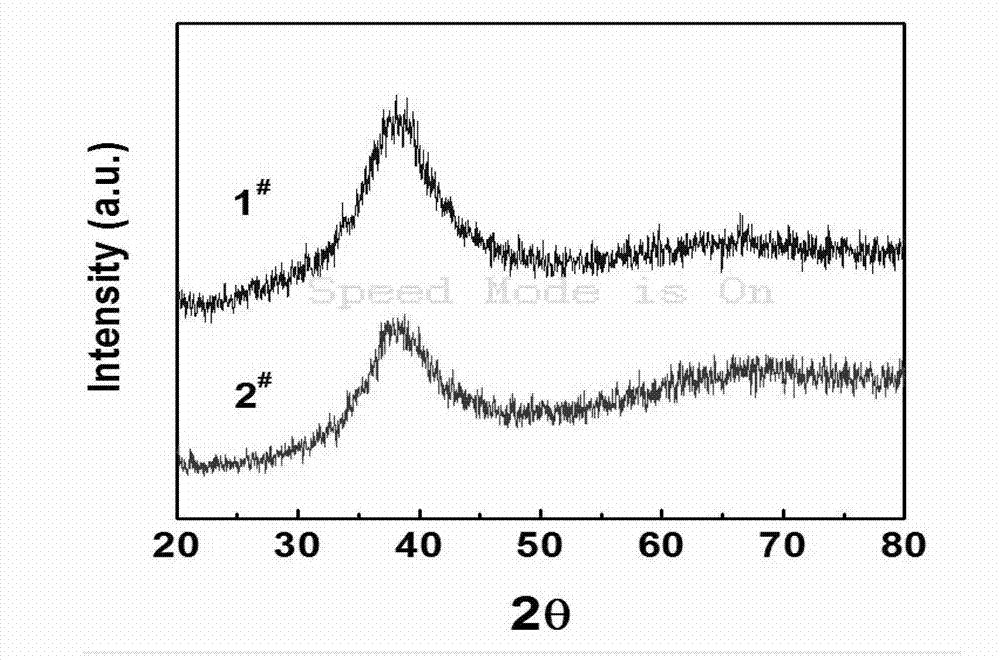

Nitrogen-doped porous carbon material for lithium-air battery positive electrode

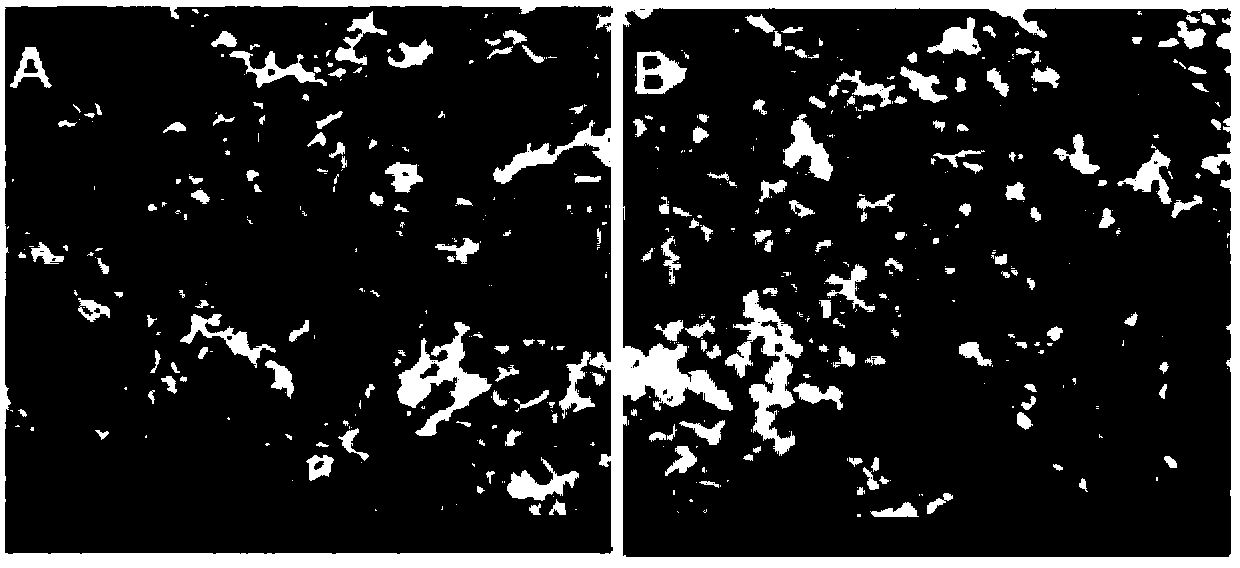

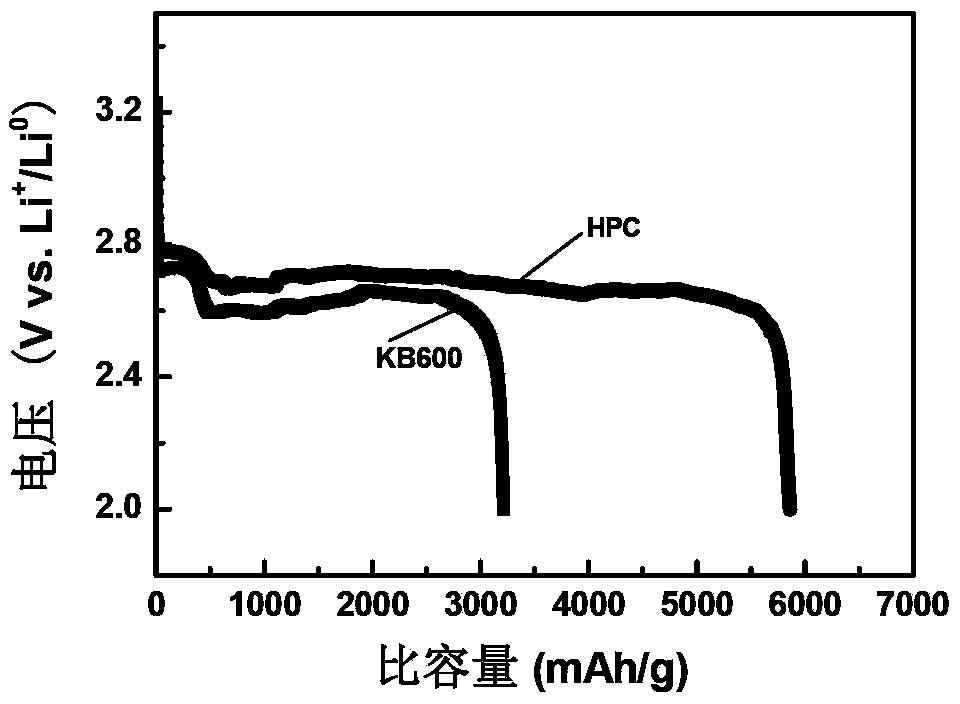

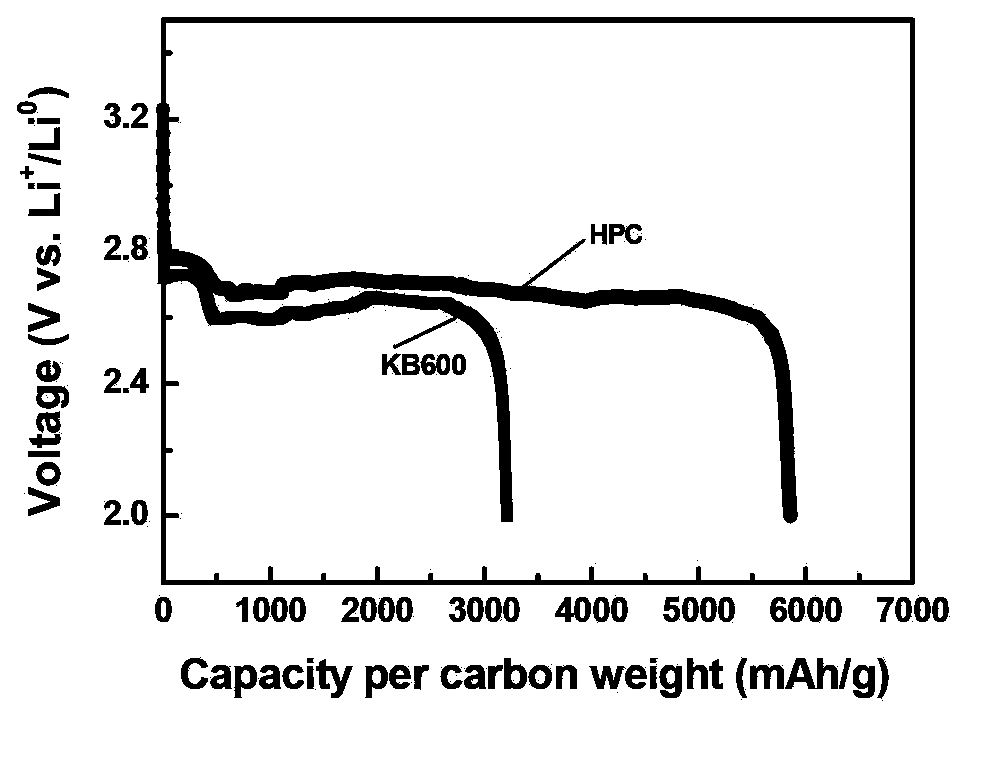

ActiveCN103855366AHigh discharge specific capacityHigh voltage platformFuel and secondary cellsCell electrodesPorous carbonCharge discharge

The present invention relates to a nitrogen-doped porous carbon material for a lithium-air battery positive electrode, wherein the nitrogen-doped porous carbon material has an interconnected graded pore structure, N is uniformly doped in the C skeleton, N accounts for 0.2-15% of the carbon material atomic ratio, the graded pores comprise mass transfer pores and deposition holes, the deposition holes account for 40-95% of the total pore volume, and the mass transfer pores account for 4-55% of the total pore volume. According to the present invention, with application of the carbon material as the lithium-air battery electrode material, the space utilization rate of the carbon material during the charge-discharge process can be increased at a maximum, and the energy density and the power density of the lithium-air battery can be effectively increased; and the preparation process is simple, the material source is wide, the pore structure of the graded pore carbon material can be regulated, the regulation manner is diverse, and the nitrogen doping manner is easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

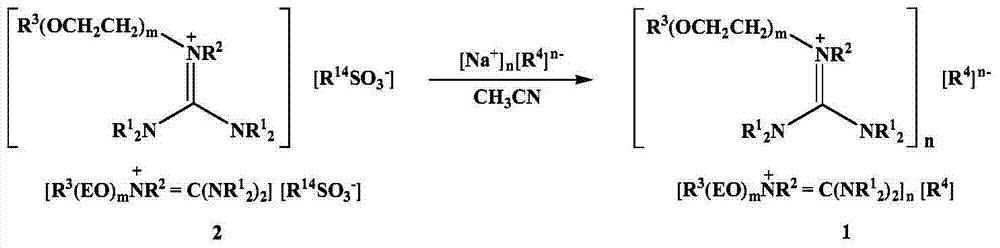

Preparation method of first-class phosphorus functionalized ionic liquid and application of ionic liquid in hydroformylation

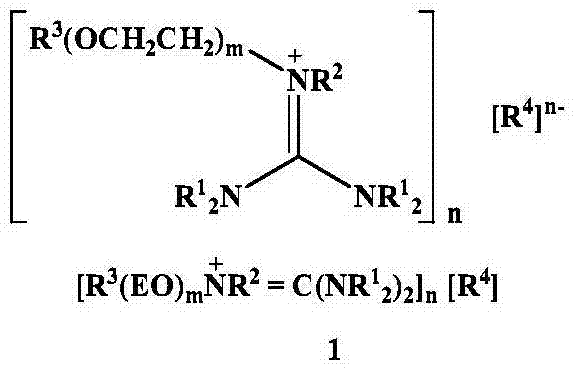

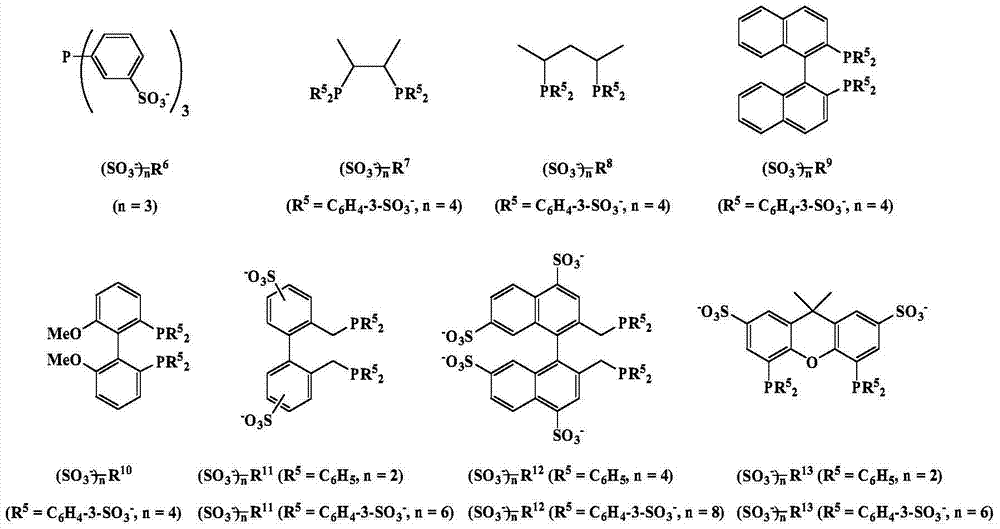

ActiveCN103483381AEasy to synthesizeThe synthetic method is matureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIon exchangeOrganic reaction

The invention relates to synthesis of first-class phosphorus functionalized polyether alkyl guanidinium ionic liquid, and an application of the first-class phosphorus functionalized polyether alkyl guanidinium ionic liquid in a homogeneous catalytic reaction. The functionalized ionic liquid of such class can be easily prepared by an ion exchange reaction between the polyether alkyl guanidinium ionic liquid and sulfonic acid type water soluble phosphine ligand. The designed phosphorus functionalized ionic liquid can be applied to organic reactions, including hydroformylation, hydroesterification, hydrocarboxylation and catalytic hydrogenation under the catalyzing of a transition metal; the dosage of the ionic liquid used in the catalytic reaction can be decreased; the activity of the catalytic reaction can be improved; a catalyst can be separated and cycled simply and conveniently.

Owner:QINGDAO UNIV OF SCI & TECH

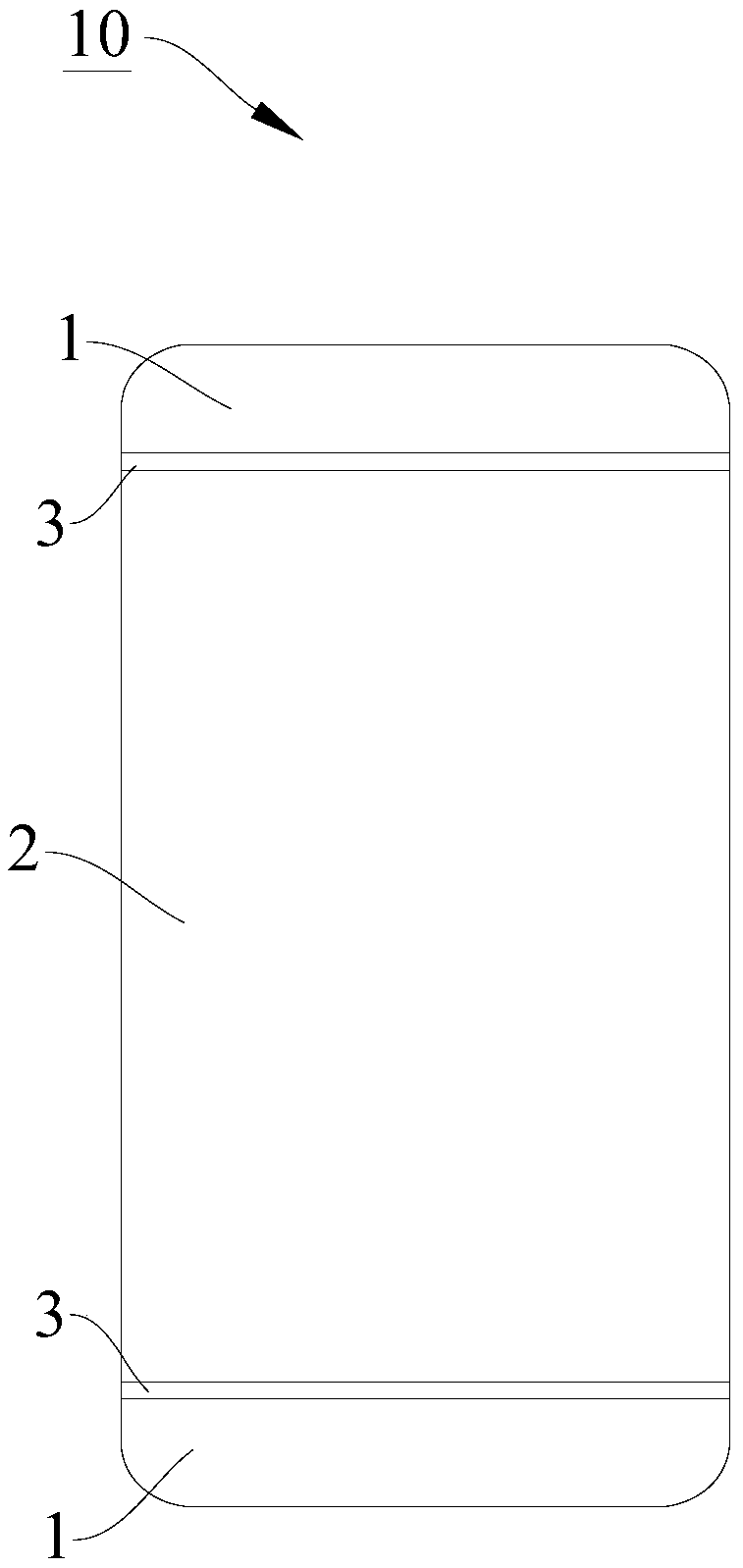

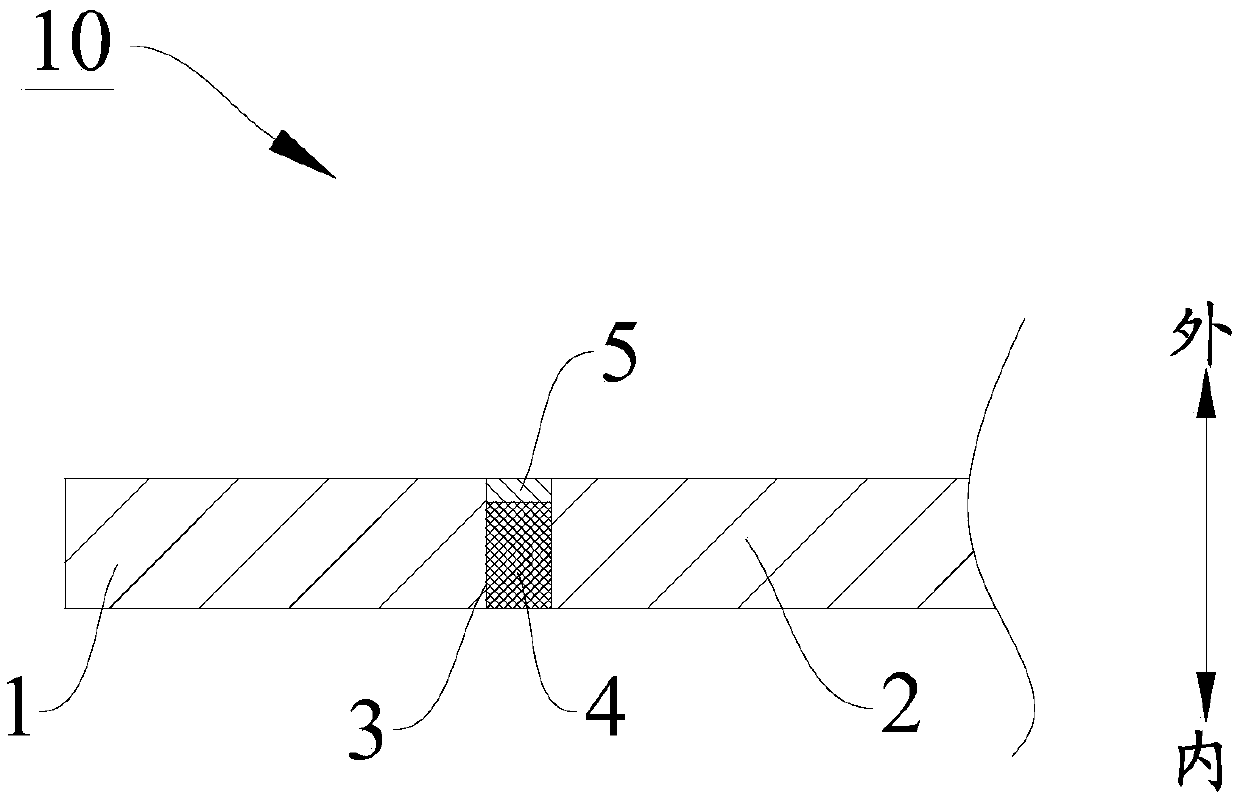

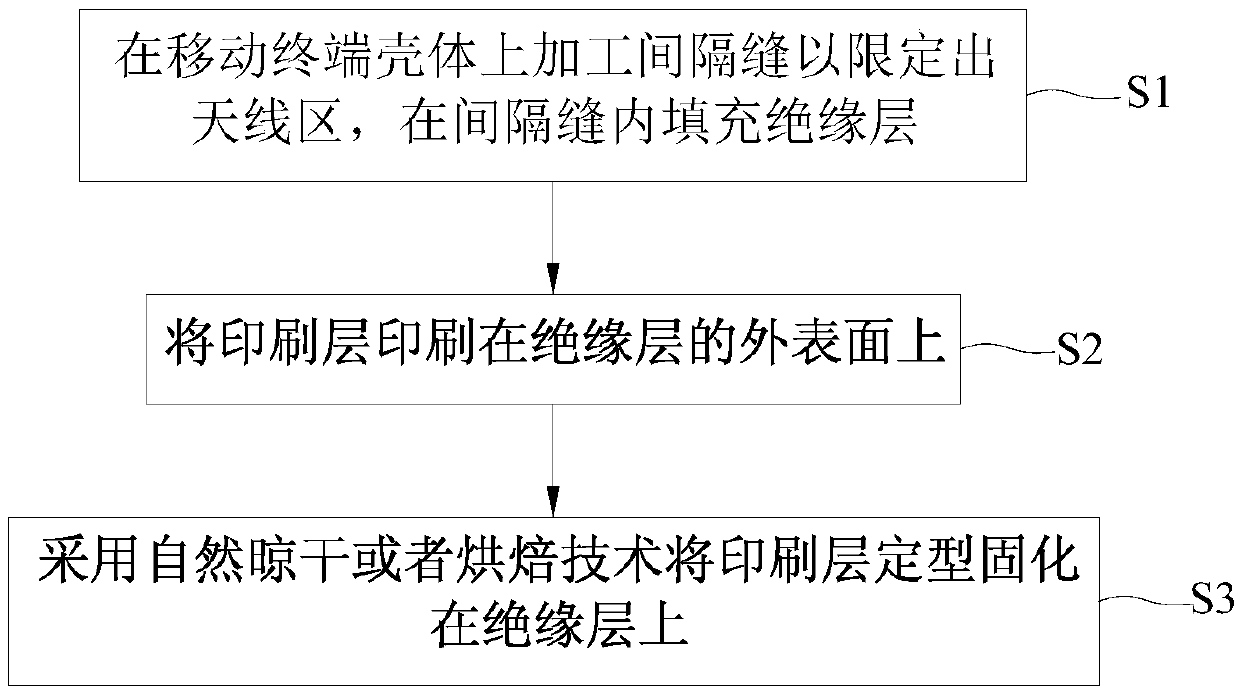

Mobile terminal housing and processing method thereof

InactiveCN105517389AColorful designLittle impact on shapeCasings/cabinets/drawers detailsMetal casingsEngineeringMetal

The invention discloses a mobile terminal housing and a processing method of the mobile terminal housing. The mobile terminal housing is a metal housing, and is provided with interval seams for dividing the mobile terminal housing into antenna areas and a remaining area; each interval seam is internally filled with an insulating layer; a printing layer is arranged on the outer surface of each insulating layer. The mobile terminal housing disclosed by the invention has the advantages that the printing layer is arranged on the outer surface of each insulating layer, and the printing layer can be formed into various types, so that the design of the mobile terminal housing is rich and colorful, and the diversification requirements of users are met; because of the decoration effect of the printing layer, the influence of the texture and color of the insulating layer to the appearance of the mobile terminal housing is reduced, therefore the material selection range of the insulating layer is wider, and a better-performace and cheaper material is beneficially selected.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

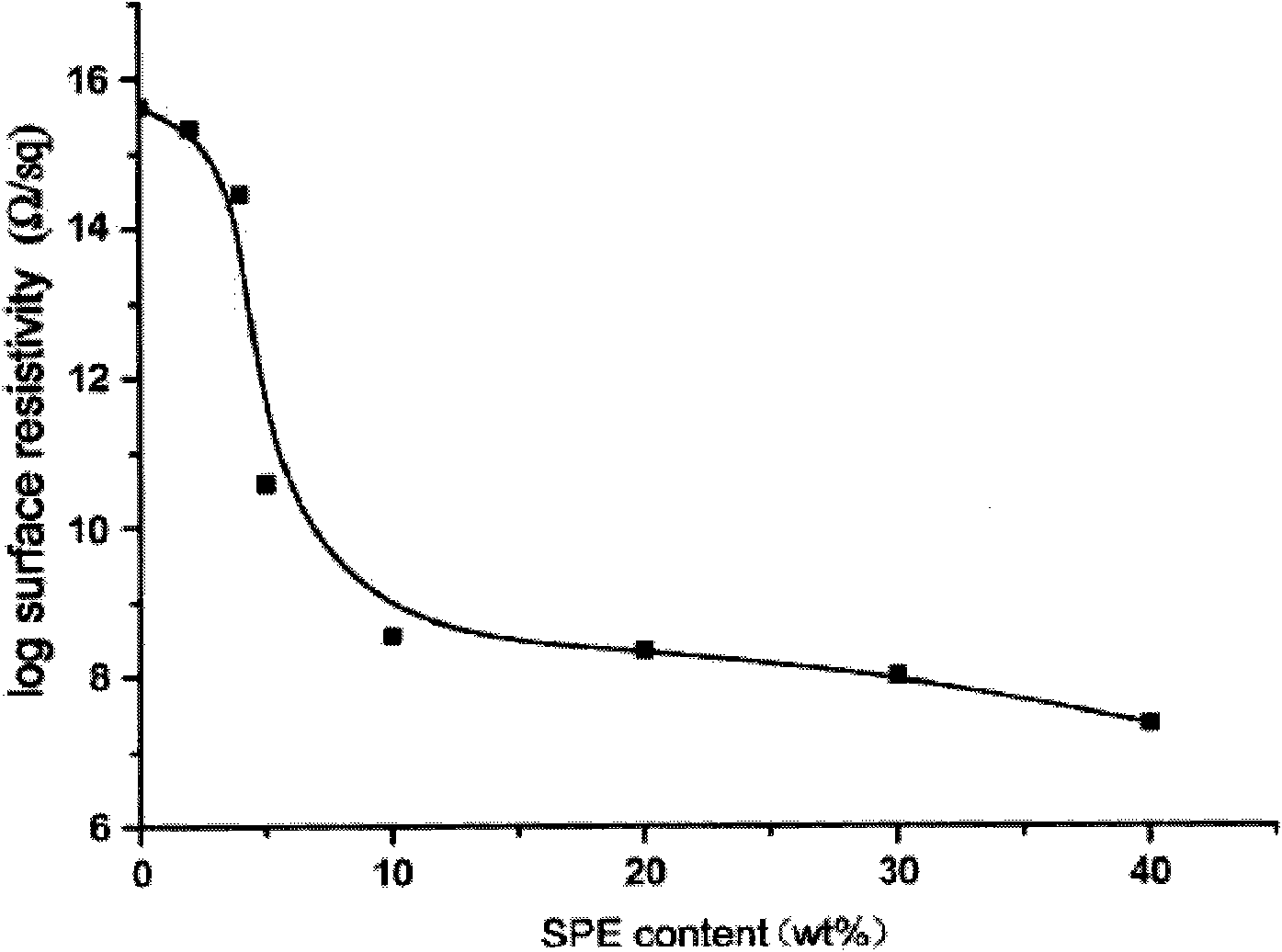

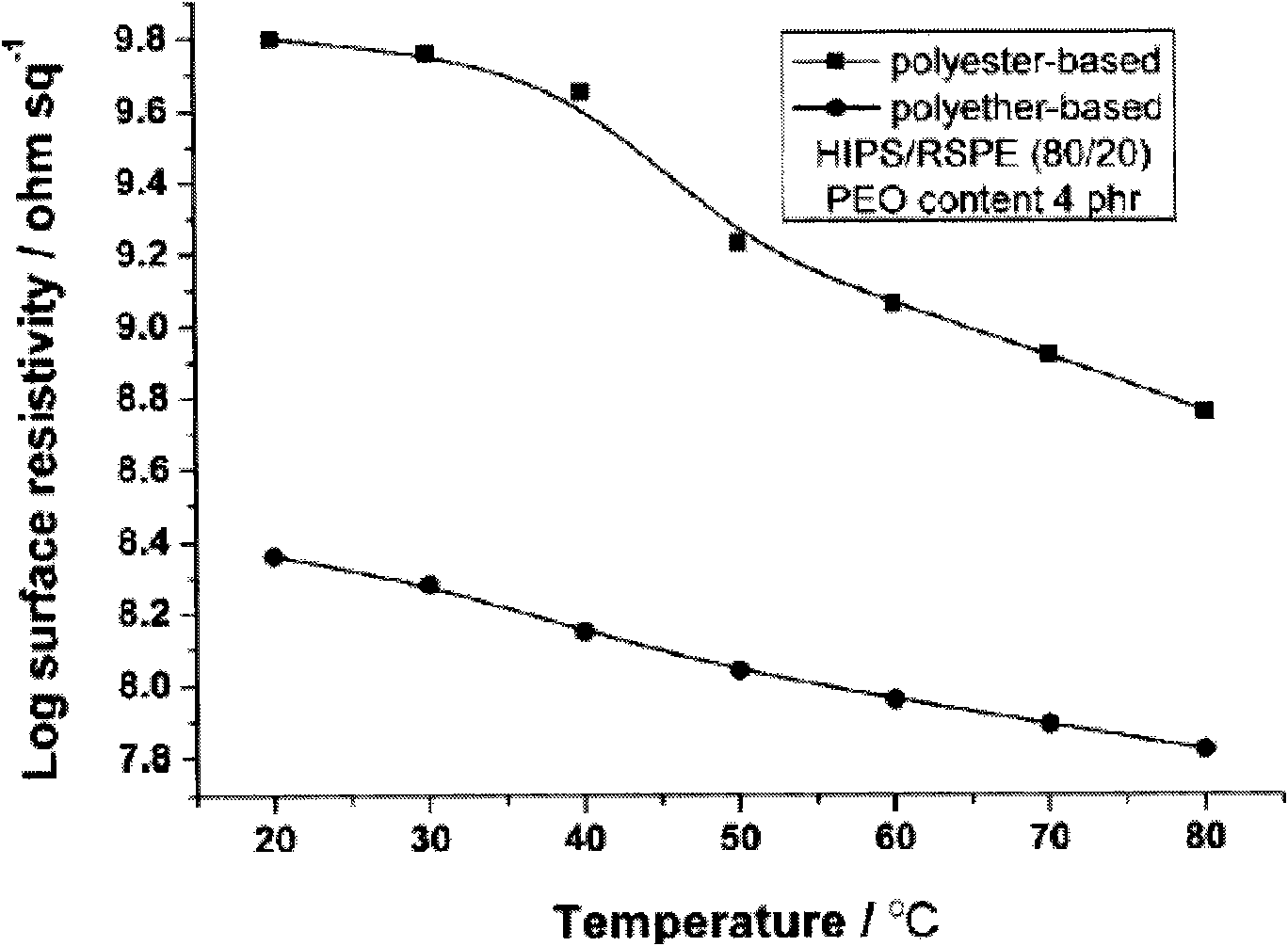

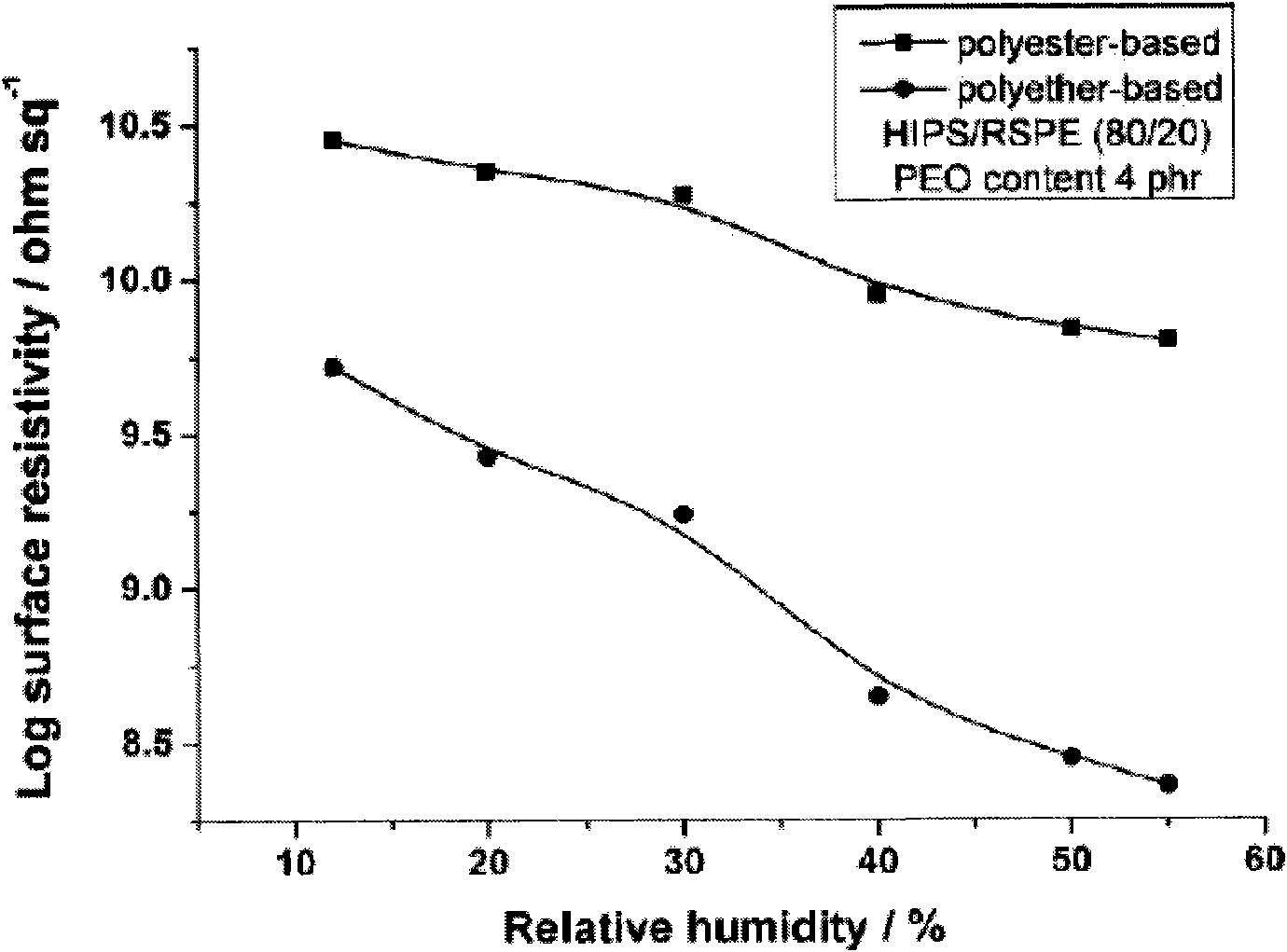

All-weather persistent antistatic master batch capable of being subjected to thermoplastic processing and antistatic composite material

The invention belongs to the field of preparation of macromolecular composite materials and particularly relates to an all-weather persistent antistatic master batch capable of being subjected to thermoplastic processing and an antistatic composite material. The antistatic master batch is prepared by forming of a low-dissociation-energy compounding agent, a processing auxiliary agent and thermoplastic macromolecular resin containing polar groups through macromolecular thermoplastic processing equipment at the temperature of 25-300 DEG C; and the mass ratio of the compounding agent to the thermoplastic macromolecular resin is equal to (1:10)-(1:50). The invention also discloses the antistatic composite material which is obtained after the persistent antistatic master batch and a macromolecular base material are formed through the thermoplastic processing equipment. The antistatic composite material has the characteristics that: 1. the antistatic composite material has light color and dyeability; 2. The master batch of the antistatic composite material and the compounding agent are wider in selection range, low in cost and easy to obtain, and the production process is simple, safe and non-hazardous; and 3. the influence of the ambient environment on the antistatic performance of the antistatic composite material is less, and the antistatic performance is persistent.

Owner:浙江三和塑料有限公司

Nitrogen-doped porous carbon and preparation method thereof

ActiveCN103265008AWide range of choicesEasy to operateCarbon preparation/purificationPorous carbonCarbonization

The invention relates to a preparation method of nitrogen-doped porous carbon, and in particular relates to a method for preparing doped porous carbon by taking a heavy organism as a carbon source, belonging to the technical field of carbon material preparation. The method comprises the following steps of: firstly, conducting a reaction between a nitrogen source and formaldehyde to generate a prepolymer; then, mixing the prepolymer with a template and the carbon source, and reacting at certain temperature; and finally, curing and carbonizing a crosslinking product to obtain nitrogen-doped porous carbon. The method provided by the invention can obtain nitrogen-doped porous carbon with different pore structures and nitrogen contents through multiple ways such as control on the nitrogen source type, temperature control, control on the mass ratio of a carbon source to a nitrogen source, control on the dosage of a template agent and the like. By adopting a chemical polymerization blending carbonization method, the method effectively controls the loss of nitrogen in a thermal treatment process and improves the utilization rate of the nitrogen source; the selection range of the raw material is wide; and the method is easy to operate and easily realizes large-scale preparation while providing a new way for efficiently utilizing heavy organic matters.

Owner:DALIAN UNIV OF TECH

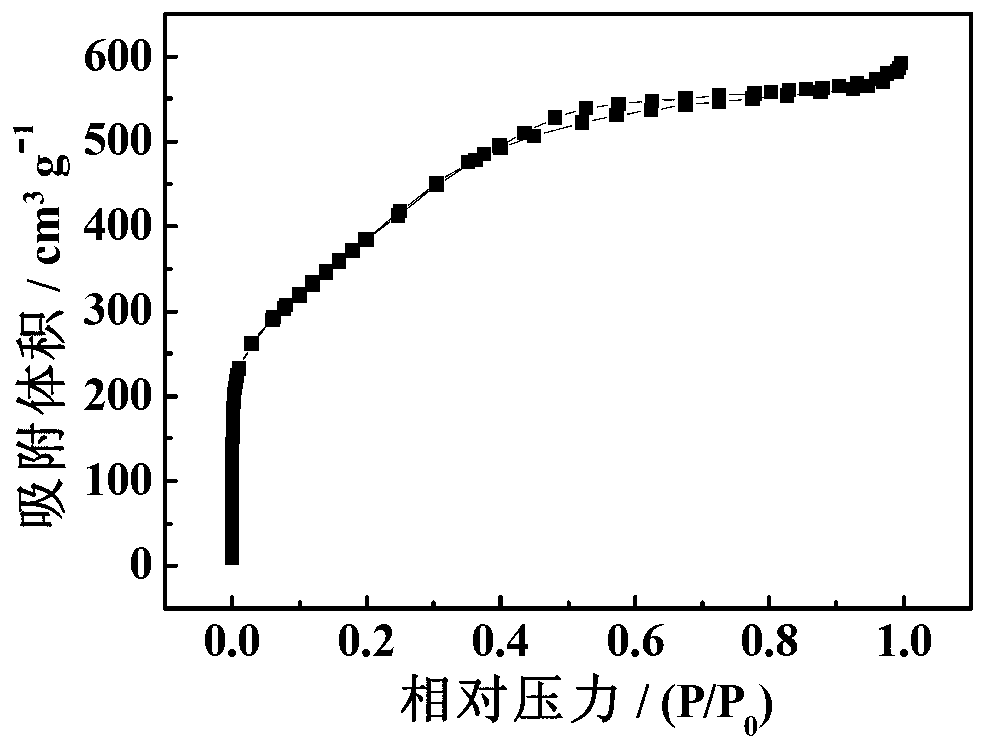

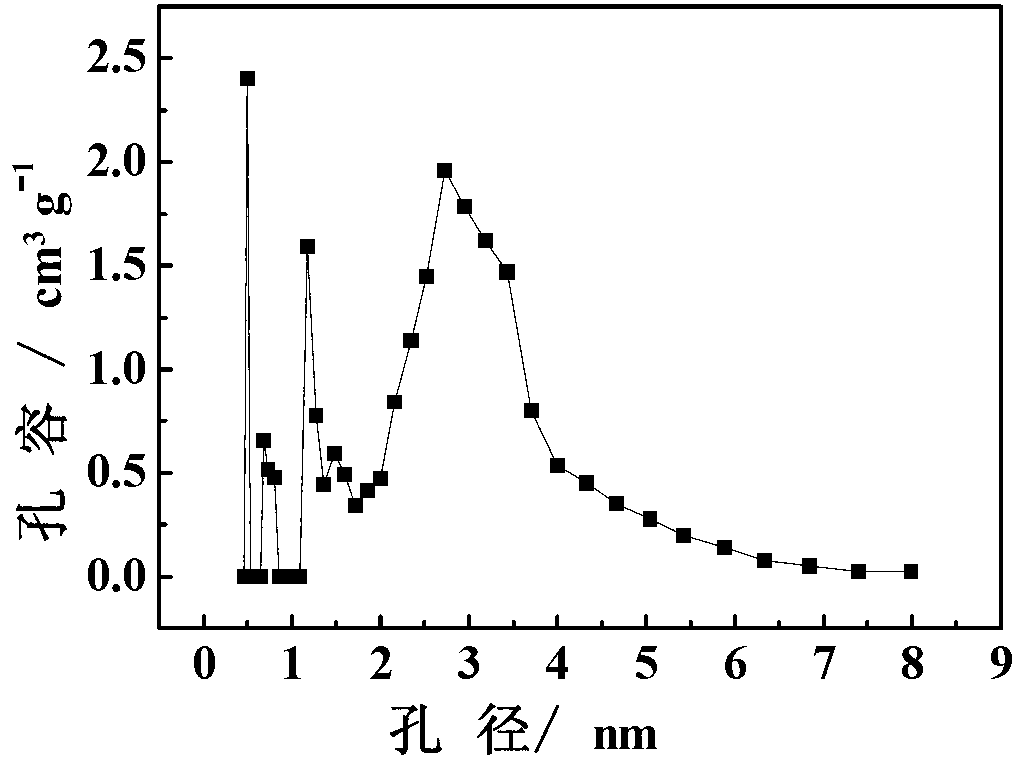

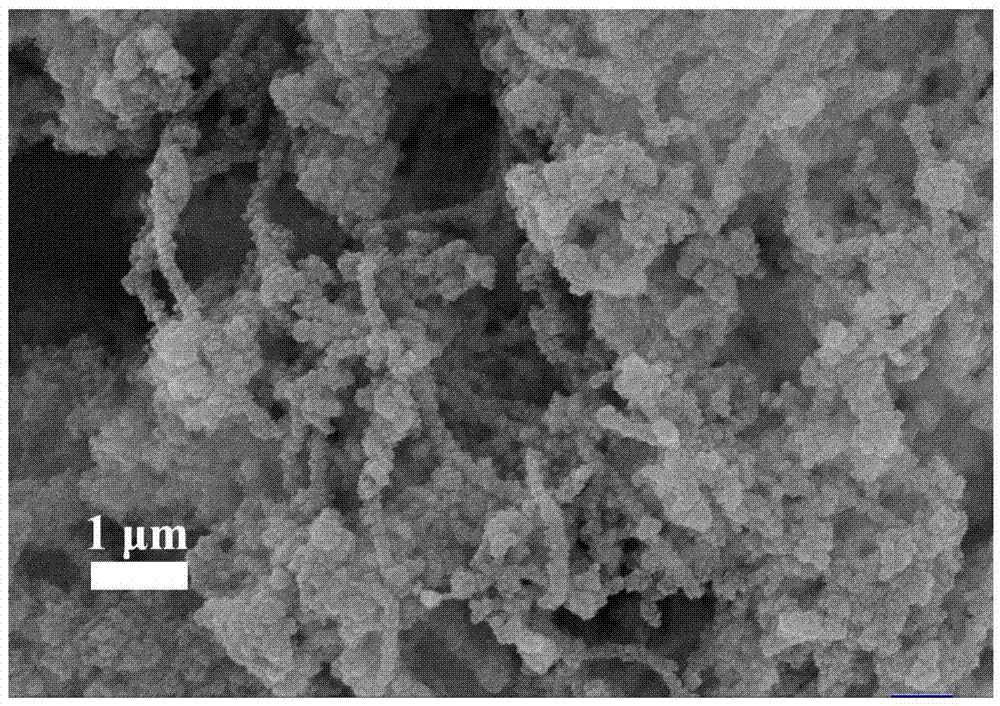

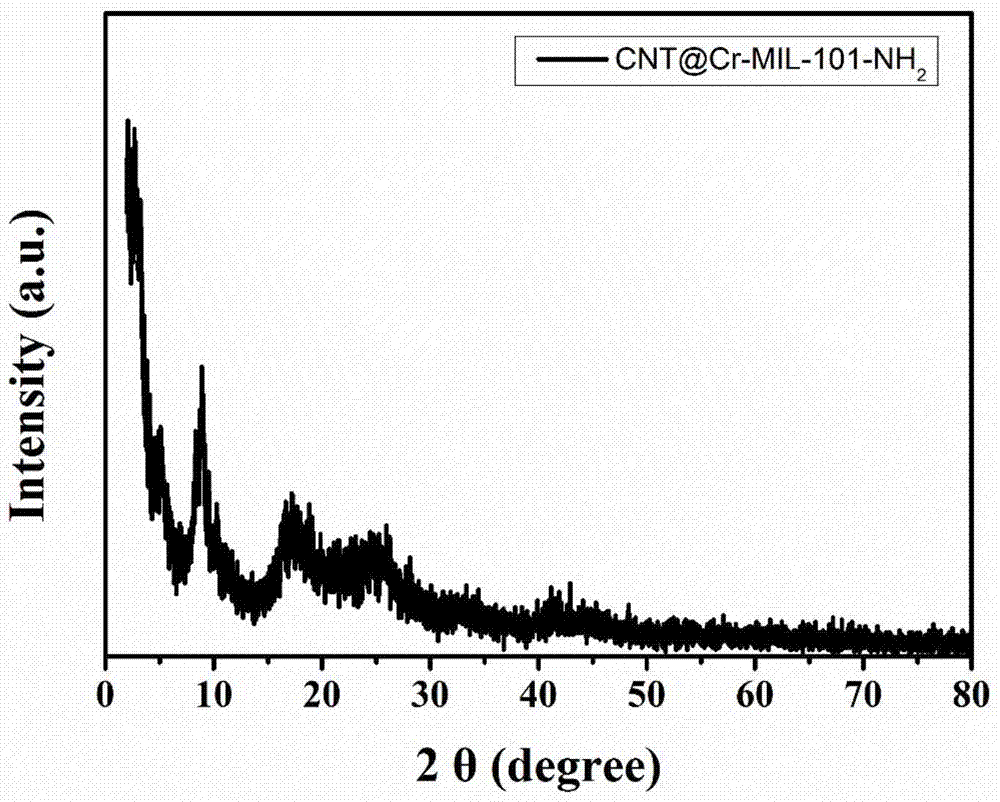

Preparation method for carbon-containing material metal organic framework-based composite phase change material

InactiveCN104745149AImprove heat transfer performanceImprove cycle stabilityHeat-exchange elementsModified carbonMetal-organic framework

The invention discloses a preparation method for a carbon-containing material metal organic framework-based composite phase change material and belongs to the field of nano composite materials and composite phase change materials. The preparation method comprises the following steps: carrying out in-situ growth of MOFs particles on a polyvinylpyrrolidone (PVP)-modified carbon material surface by adopting a hydrothermal method to prepare a carbon-containing material metal organic framework-based porous carrier material; then, dispersing a carbon material @MOFs porous carrier material into a prepared solution containing a phase change core material by adopting a solution dipping method; adsorbing a phase change core material by utilizing an oversized specific surface area of the metal organic framework material and a nao duct structure; and drying at a temperature higher than the phase change material to obtain the carbon-containing material metal organic framework-based composite phase change material. The material can be used for improving the heat transfer performances of the composite phase-change material, effectively preventing core material leakage, and has the advantages of wide core material selection range. The composite phase change material prepared by the method provided by the invention is excellent in heat transfer performance, good in circulating stability, simple in process and suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

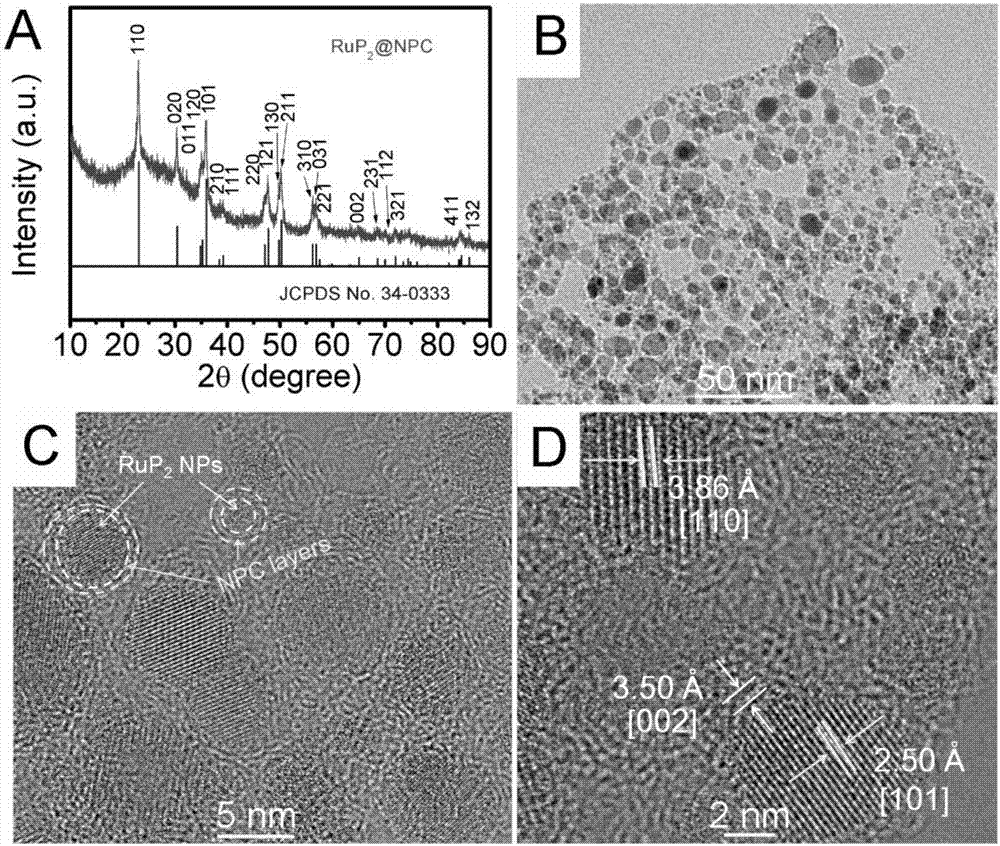

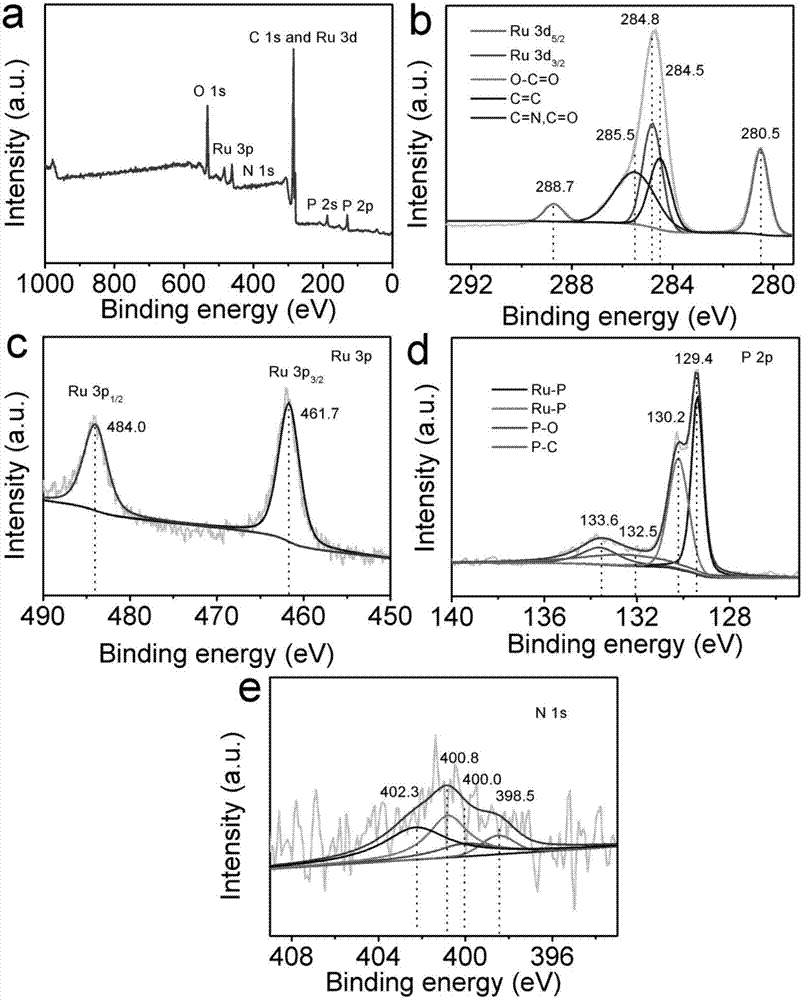

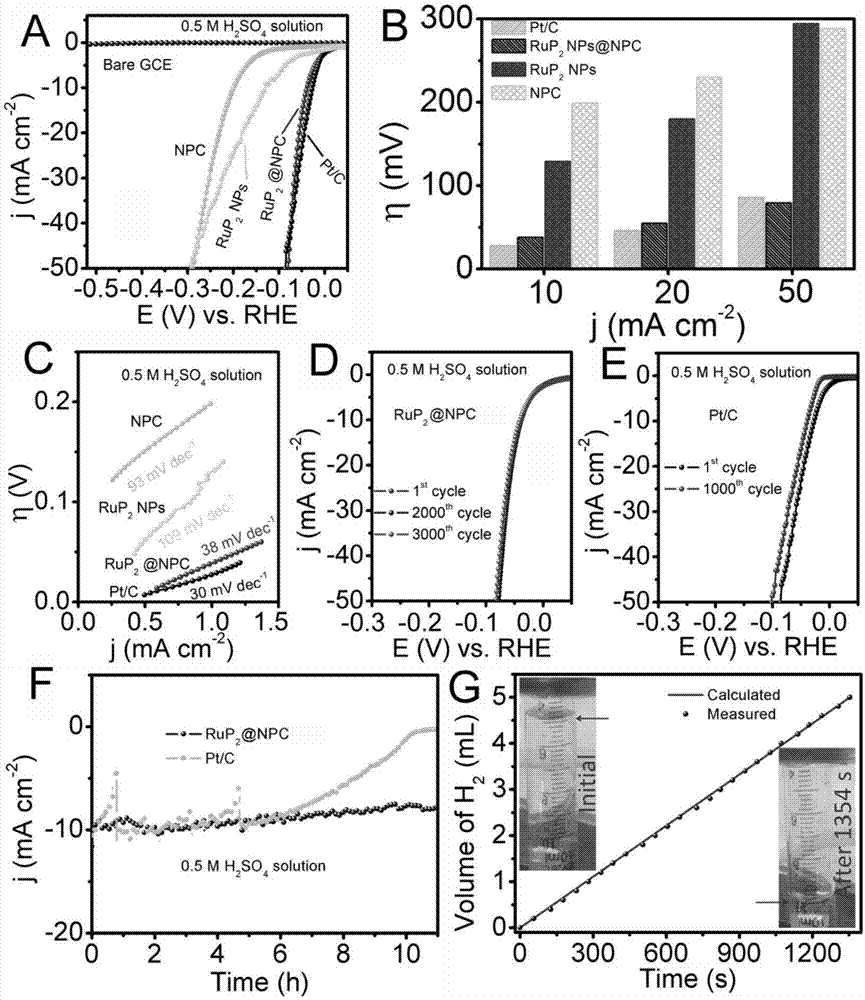

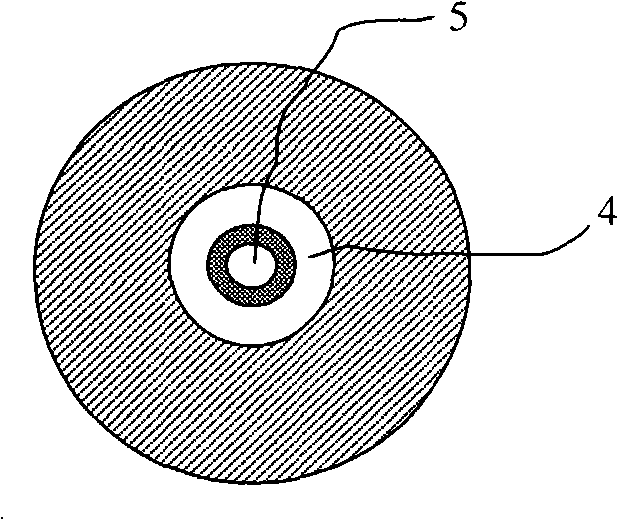

Nitrogen-phosphorus double-doped carbon-coated transition metal diphosphide hydrogen evolution catalyst and preparation method thereof

InactiveCN107362818AHigh activityImprove stabilityCatalyst activation/preparationElectrodesPlatinumStructural formula

The invention relates to a nitrogen-phosphorus double-doped carbon-coated transition metal diphosphide hydrogen evolution catalyst and a preparation method thereof. The nitrogen-phosphorus double-doped carbon-coated transition metal diphosphide is characterized in that the structural formula is MP2@NPC, a transition metal diphosphide MP2 is used as a core, nitrogen-phosphorus double-doped carbon NPC is used as a shell so that a core-shell structure is formed, the diphosphide has a nano-particle structure, the particle size is less than 50nm and good crystallinity is obtained. The composite catalyst has the electrocatalytic hydrogen evolution activity similar to that of the commercial platinum carbon and catalyst stability better than that of the commercial catalyst. The catalyst has a wide application prospect.

Owner:WUHAN UNIV OF TECH

Fuel for firing into rotary kiln cement clinker

A fuel which is used for rotary kiln cement clinker firing is composed of raw materials with the following weight percentage: coal 3-80, straw substances 0-90, forest products wastes 0-95 and food industry by-product residues 0-70. The straw substances refer to rice straws, wheat straws, cotton stalks, sesame stalks, soybean straws, corn stalks, sorghum stalks, rice husks, peanut shells, soybean shells and corn sticks, the forest products wastes refer to defective bamboo, wood, tree branches, leaves, shrubs, faggot straws and sawdust and wood wool corner scrap materials in the bamboo and wood-processing industry, the food industry by-product residues refer to bran, wheat skin, squeezing meal cake, bean dregs and wine lees, and the coal refers to bituminite, anthracite and coke coal powder. The flue raw materials which are used for the rotary kiln cement clinker firing have wide selecting range, simple preparation, convenient use and rapid burning speed and are beneficial for protecting atmosphere circumstances.

Owner:吴飞龙

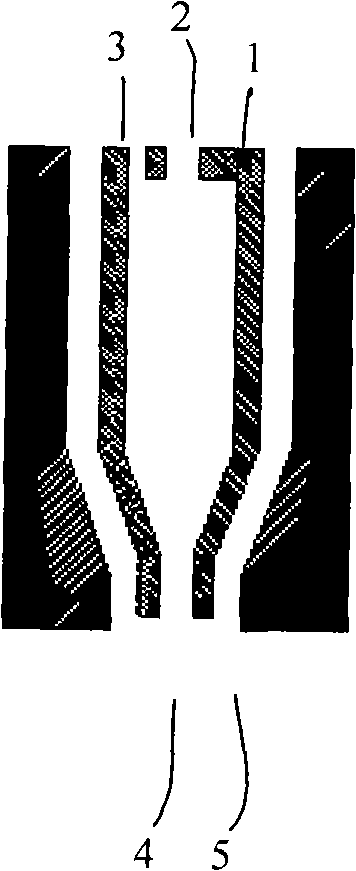

Method for achieving high-melting-point material 3D printing through nanometer ink together with laser melting

InactiveCN103407296AWide range of choicesLarge specific surface areaOther printing apparatusDevice formInk printer

The invention discloses a method for preparing the nanometer ink through ceramics, metal, semiconductors, glass and other high-melting-point materials, carrying out 3D printing and utilizing the laser heating sintering in the process of printing to obtain 3D devices formed by combining the ceramics, the metal, the semiconductors and other composite. The method comprises the first step of processing raw materials needed to prepare the device into nanometer particles of 1-500nm, the second step of preparing the particles into ink jet printing ink, the third step of carrying out 3D printing by utilizing an improved ordinary ink printer and adopting the laser heating sintering in the process of printing, and the fourth step of achieving the melting and sintering molding of the nanometer particles. According to the method, micron-level precision devices with any complex shape can be directly prepared, the high surface energy of the nanometer particles is utilized, the sintering temperature is lowered, high density is achieved, and a superior property is obtained. The method can be used for manufacturing automobile metal ceramic composite pistons, aviation engine tail pipes, and ceramic bearings and ceramal composite precise components of watches and other precision instruments and for directly printing a circuit board.

Owner:南京鼎科纳米技术研究所有限公司

Method for preparing Wood-plastic composite material by modified wood powder and waste and old plastics

The invention relates to a preparation technique of a wood plastic composite material, in particular to a method for preparing a wood plastic composite material by using modified wood powder and waste plastics. The method is characterized in that: (1) discarded agriculture and forestry wastes are crushed, milled and dried, and three different surface modification agents are added in sequence and mixed with the waste power one after another in a high-speed mixer to produce the modified water powder; and (2) waste plastics are washed and crushed into granules with the grain size of 2mm to 12mm and then dried; the modified waste powder, the waste plastic granules, a lubricant, a vesicant and a blowing promoter are mixed by weight percentage and put into the high-speed mixer for high-speed mixing and then cooled to the temperature lower than 55 DEG C for discharging so as to prepare a special premix. The composite material has super high strength and anti-bending and anti-impact capacity, wherein, the obvious enhancement of the anti-impact strength causes the great enhancement of the processing capacity of the product, thus causing products to meet different demands and ensuring an extremely wide application range.

Owner:FUJIAN NORMAL UNIV

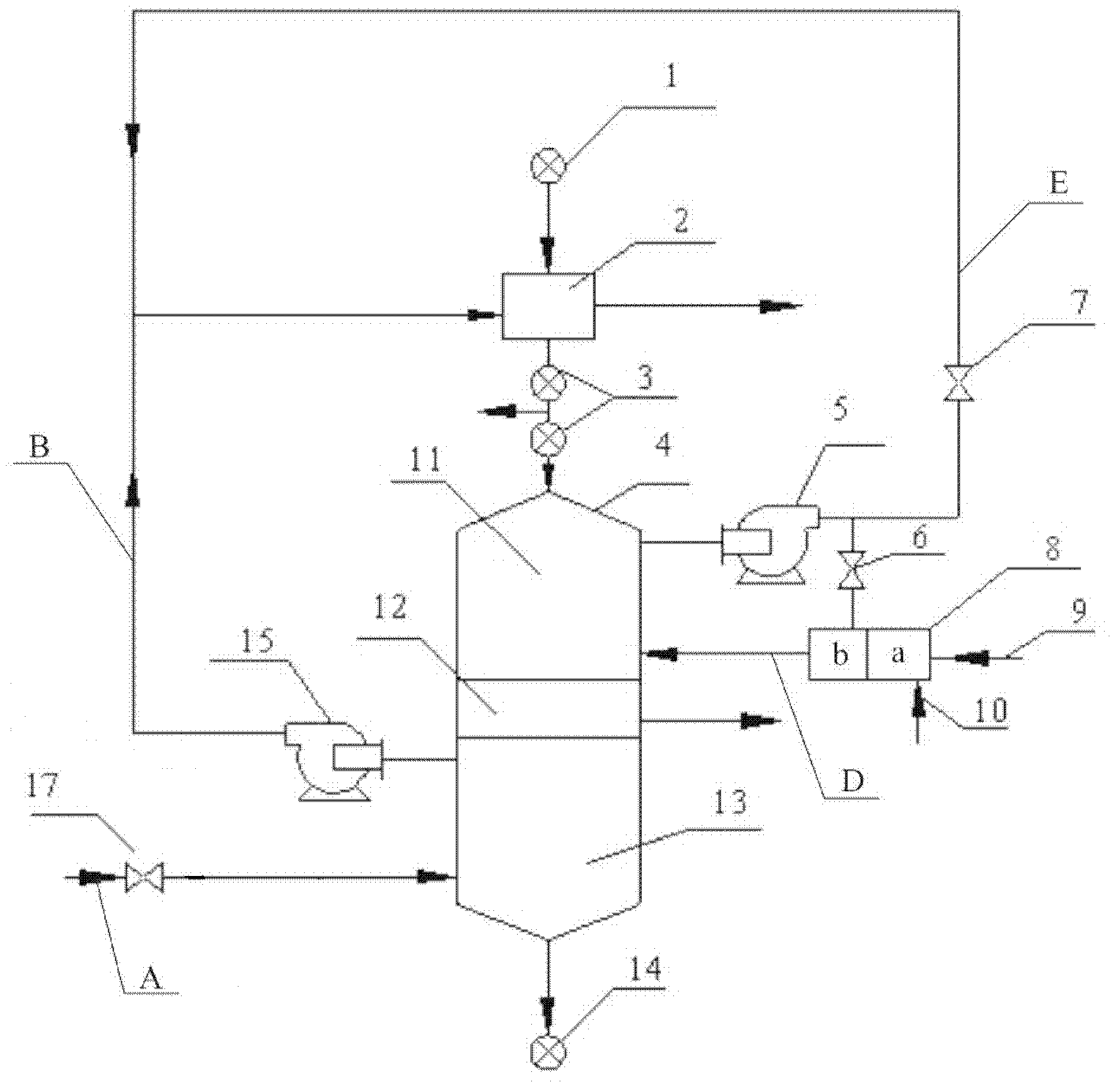

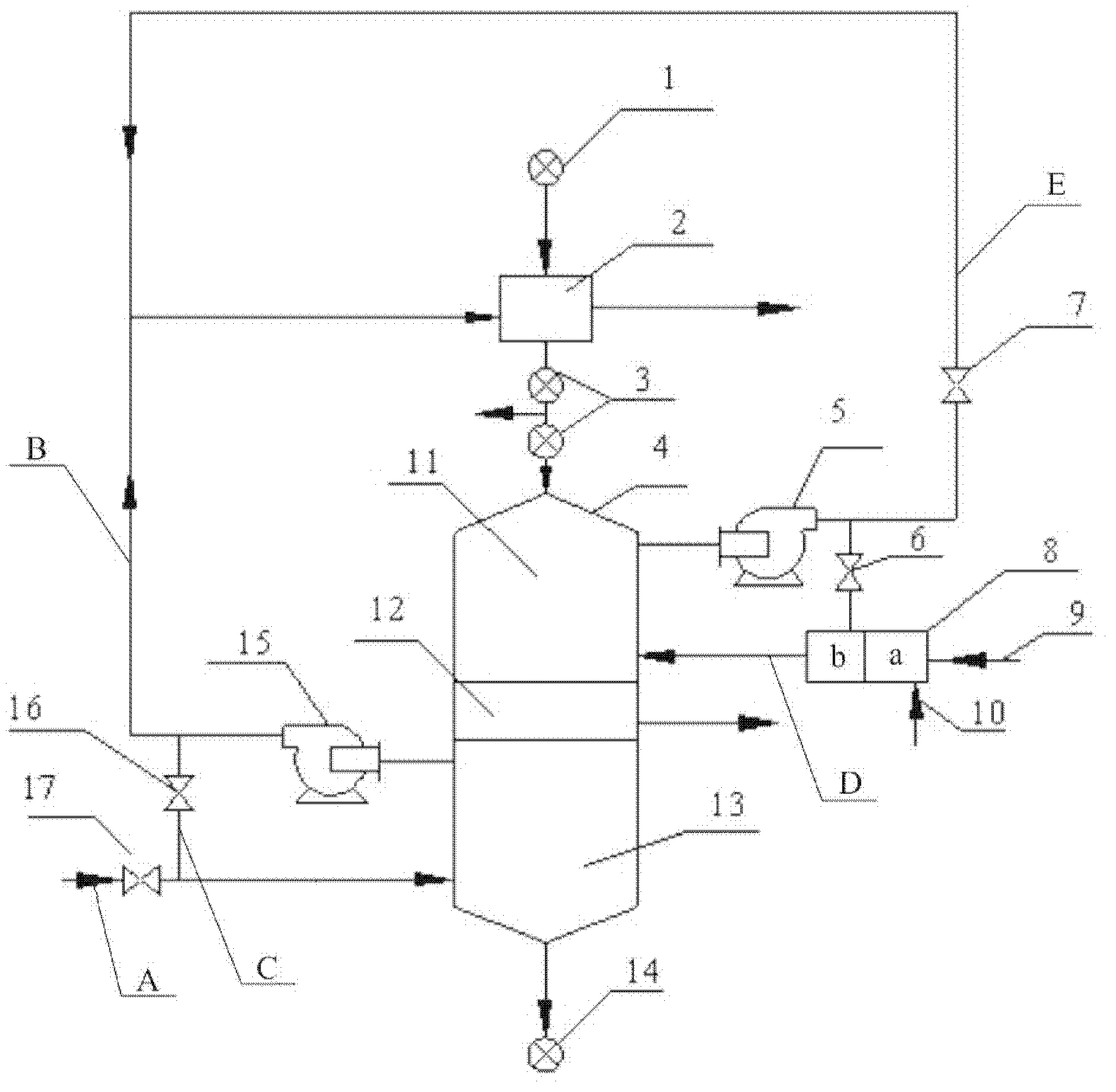

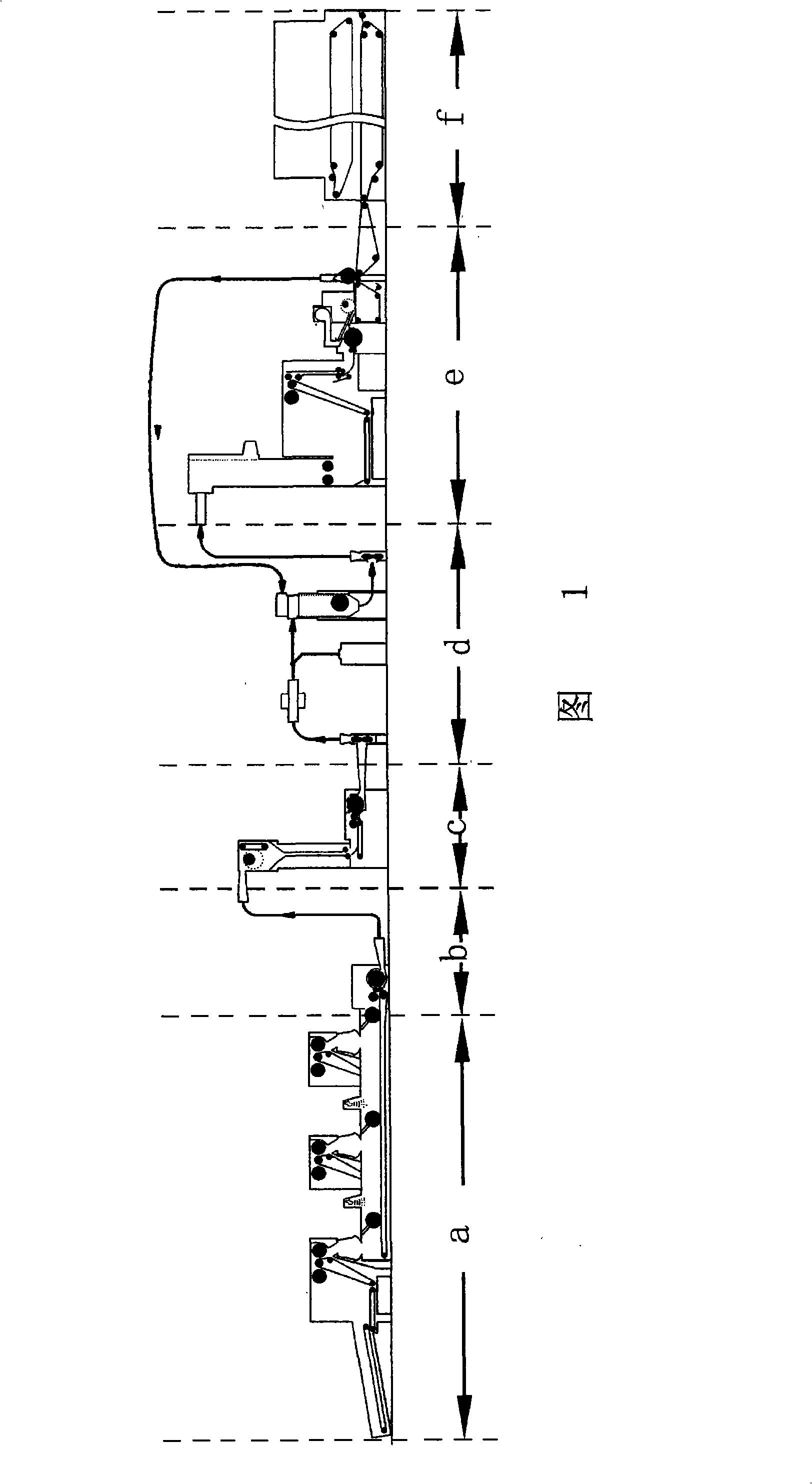

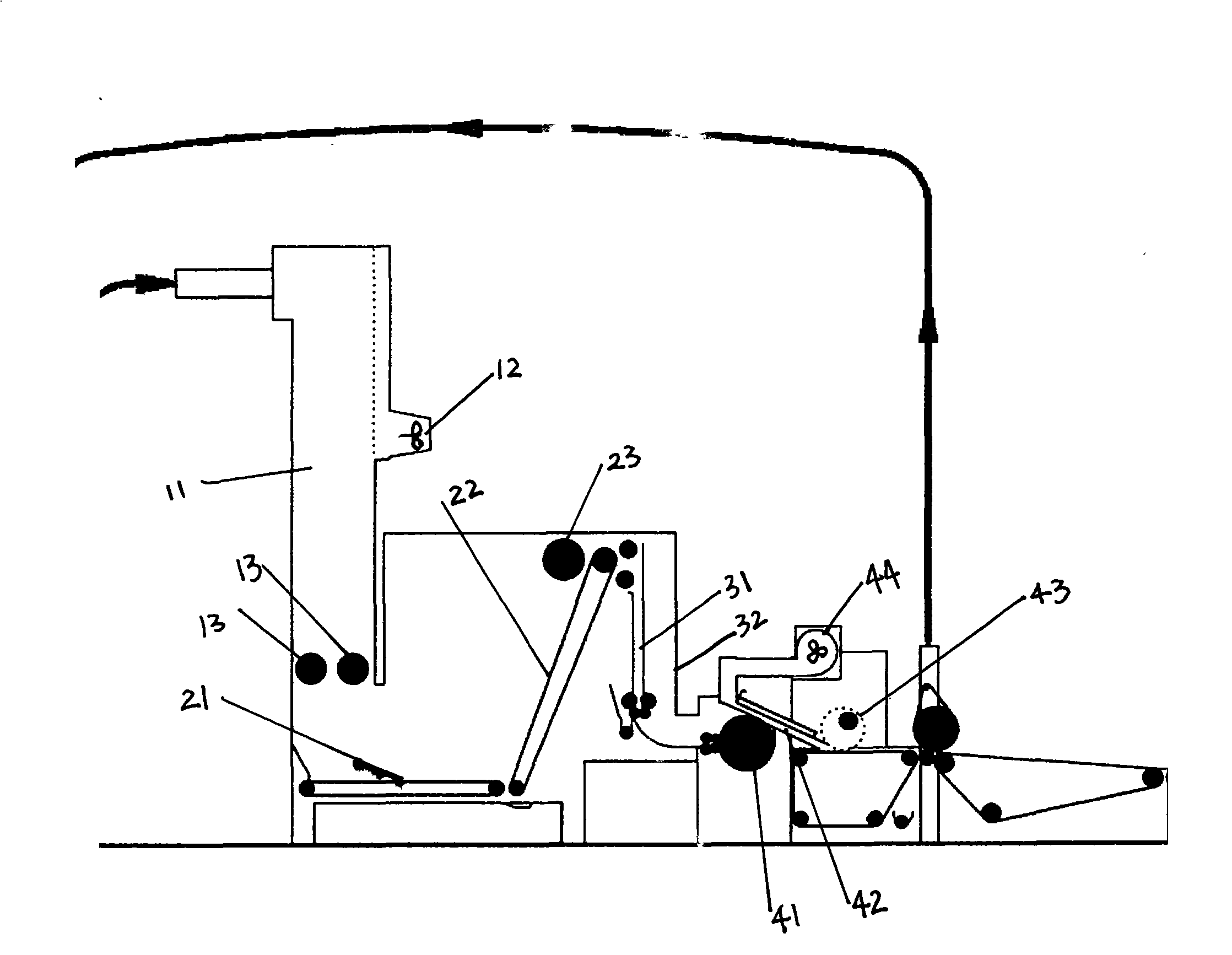

Comprehensive heat energy utilizing type active coke purifying and regenerating process system and active coke purifying and regenerating process method

ActiveCN102580705AImprove regeneration efficiencyIncrease profitOther chemical processesDispersed particle separationProcess systemsHeat conducting

The invention discloses a comprehensive heat energy utilizing type active coke purifying and regenerating process system and an active coke purifying and generating process method. The process system comprises a regenerating device, a preheating device, a heating device and a heat exchanging device, wherein the regenerating device comprises a regenerating tower; the preheating device comprises a drying tower; the heating device comprises a hot-blast stove and a first fan; and the heat exchanging device comprises a second fan, a normal-temperature air input pipeline and a hot air output pipeline, wherein the second fan is used for sending the hot air after heat exchange to the drying tower so as to preheat the active coke. The method comprises the following steps: (1) preheating: preheating the active coke in the drying tower; (b) heating: heating the active coke due to the action of a high-temperature heat-conducting medium; (c) regenerating; and (d) cooling: cooling the regenerated active coke entering a cooling section. The system and method disclosed by the invention are suitable for restoring and regenerating the active coke.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

Porous carbon material used for lithium-air cell anode

ActiveCN103855413AShorten the diffusion distanceImprove space utilizationFuel and secondary cellsCell electrodesPorous carbonAir cell

The invention relates to an application of a porous carbon material with a grading pore structure in a lithium-air cell anode, and is characterized in that the carbon material has mutually communicated grading pore structure distribution which has a mesoporous structure for depositing the discharge products and a macroporous structure suitable for transmission of oxygen and an electrolyte. When the carbon material is taken as a material of the lithium-air cell anode, the space utilization rate of carbon material can be increased at maximum limitation during a charge and discharge process, specific discharge capacity, voltage platform and multiplying power discharge capability of the cell can be effectively increased, so that the energy density and power density of the lithium-air cell can be increased. The porous carbon material has the advantages that the preparation technology is simple, the material source is wide, the grading pore carbon material pore structure enables regulation and control, the regulation and control modes are various, and the doping of metal / metal oxide can be easily and simultaneously realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

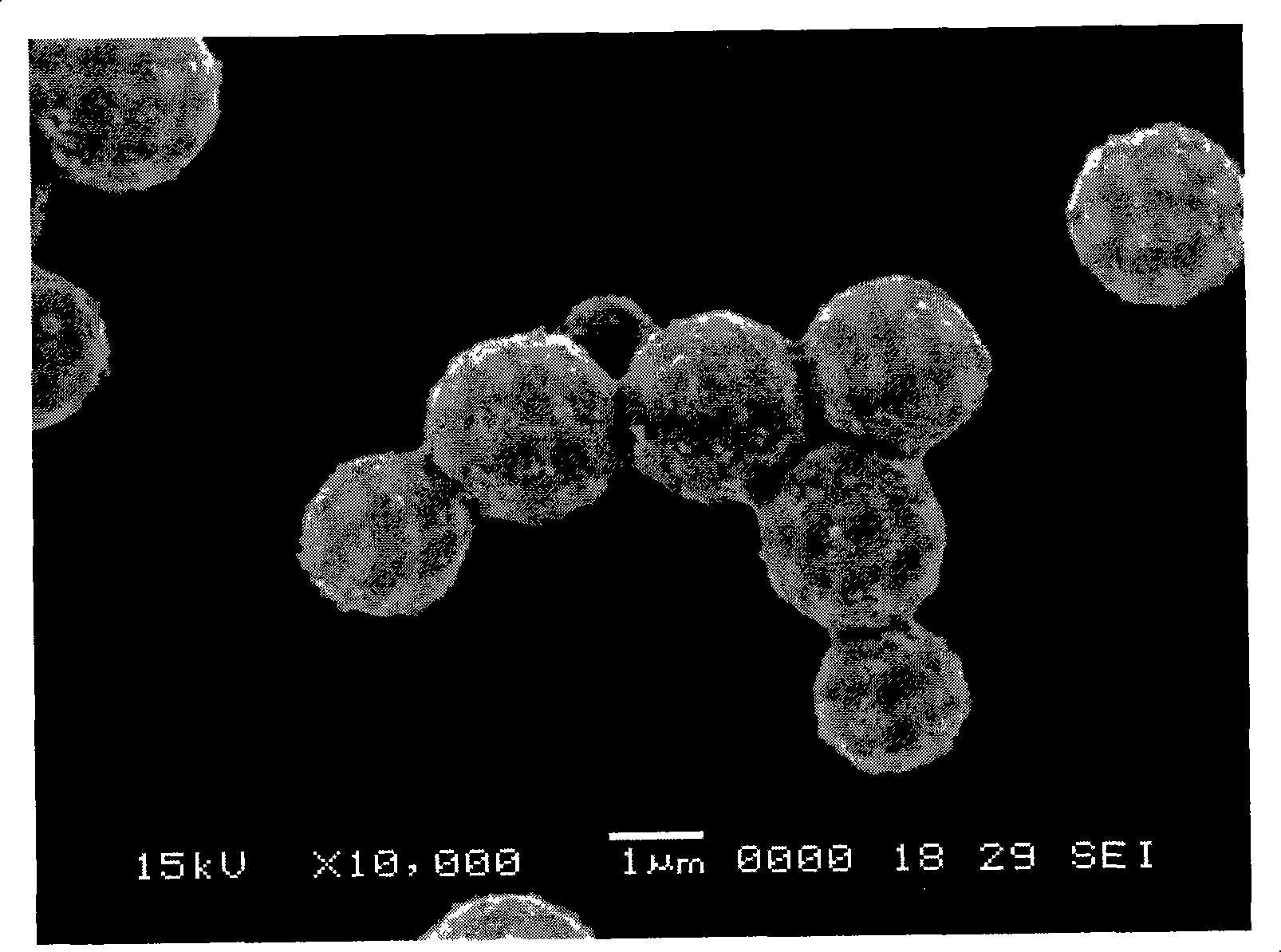

Preparation of organic-inorganic composite microballoons

InactiveCN101249410AEvenly dispersedWide range of choicesMicroballoon preparationMicrocapsule preparationPolymer scienceMicrosphere

The invention provides a method for preparing composite microspheres with the particle diameter of 0.01-100Mum and adjustable particle size distribution. The method is characterized in that one or more kinds of superfine particles is added to two or more kinds of polymer (or performed polymer) with fluxible processability to form composite microspheres by reaction mixing and oriented dispersion technique of superfine particles. The composite micropheres have the advantages of even dispersion of superfine particles and large embedding amount. The preparation method has the advantages of continuous preparation and low cost, and has wide application prospect in fields such as biological medical treatment, electronic message, daily life, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

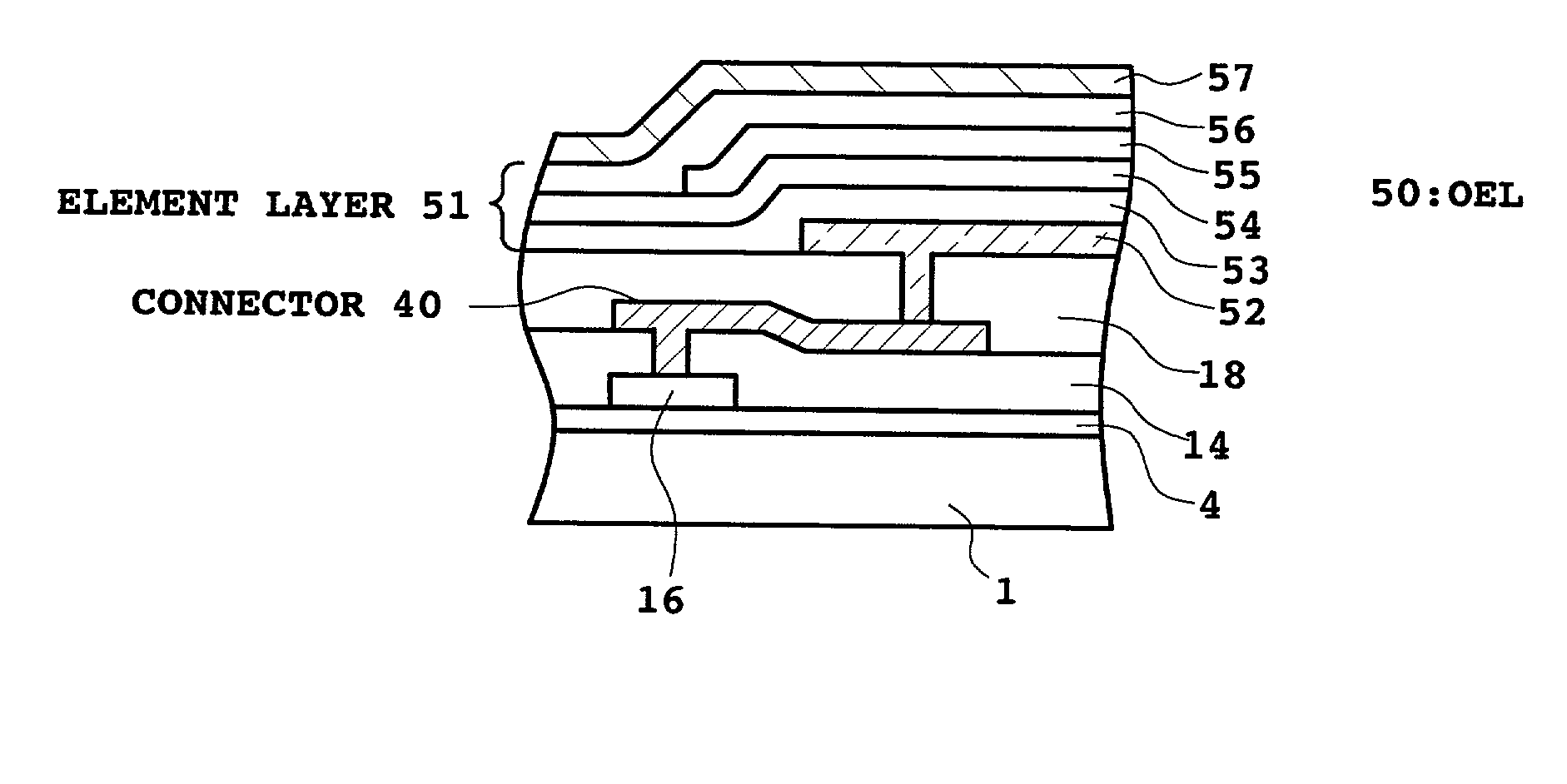

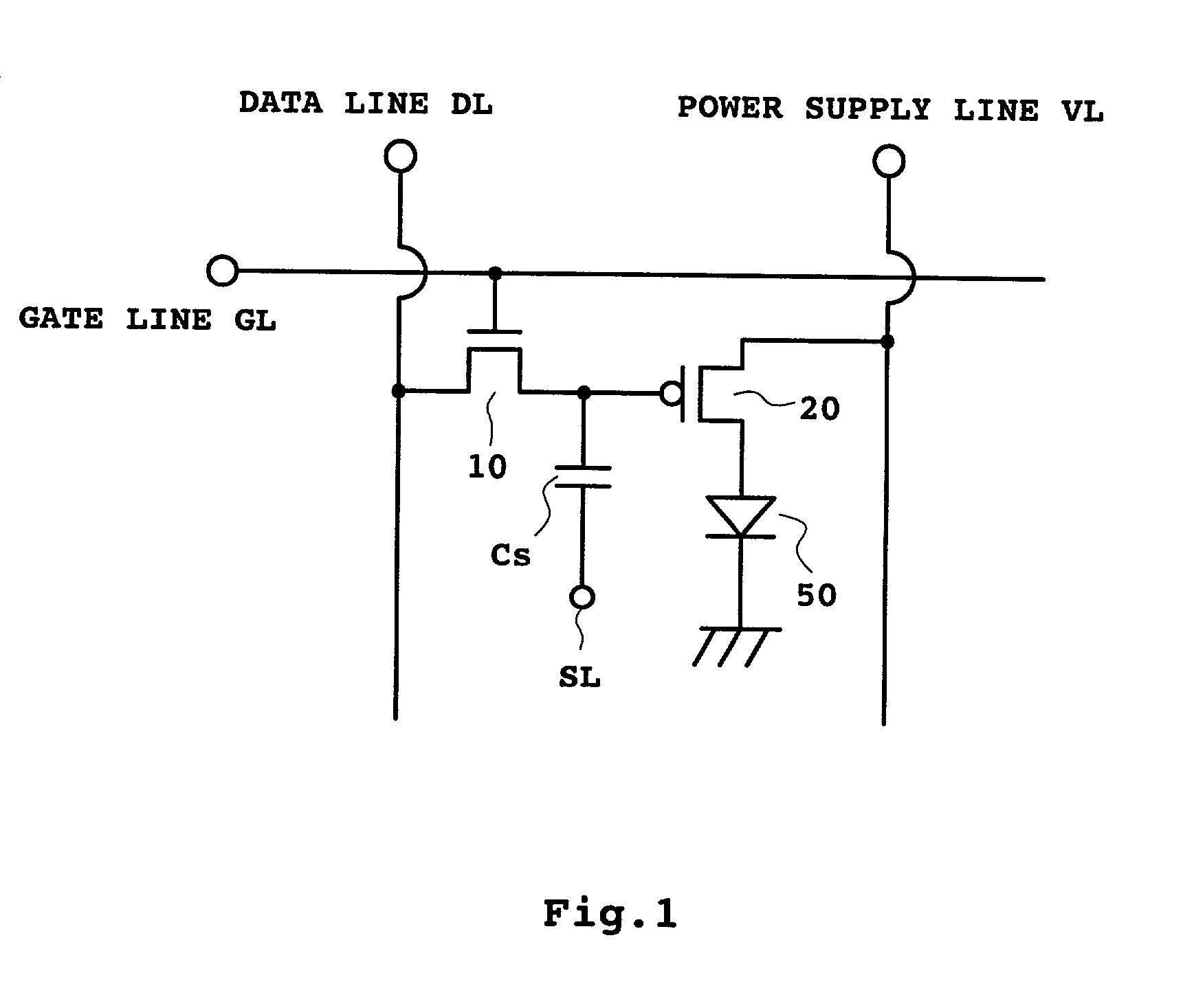

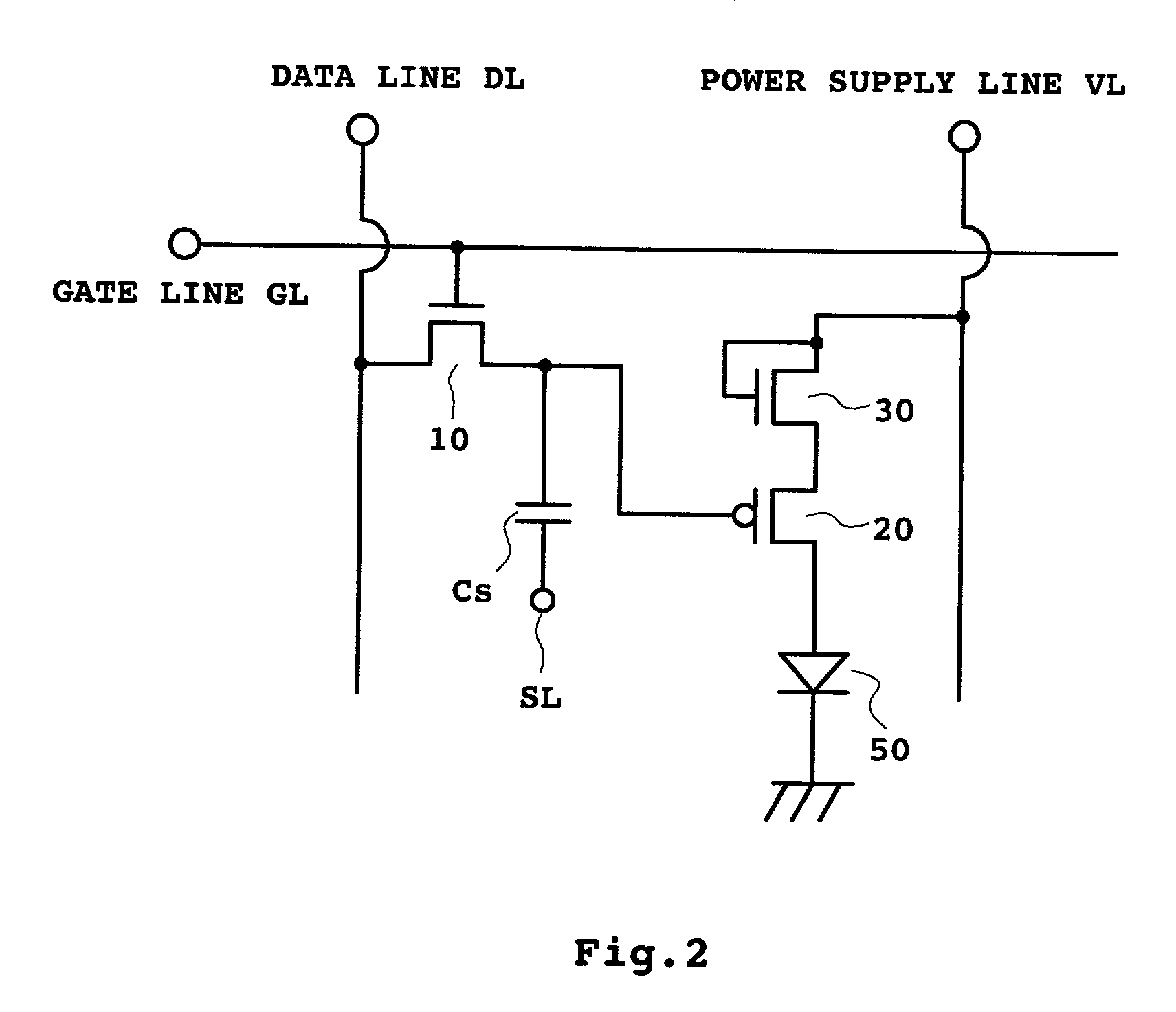

Contact between element to be driven and thin film transistor for supplying power to element to be driven

InactiveUS20020084746A1Flat surface is facilitatedImprove flatnessTransistorDischarge tube luminescnet screensElectricityEngineering

A TFT (20) for controlling the power supplied to an element to be driven (50), such as an organic EL element which operates based on the supplied power, is provided between the element to be driven (50) and a power supply line VL. The TFT (20) and the element to be driven (50) are electrically connected by a wiring layer (40). The contact position between the wiring layer (40) and the TFT (20) and the contact position between the wiring layer (40) and the element to be driven (50) are positioned so as to be distant from each other. Alternatively, at least the contact hole region of a first electrode (52) of the element (50) is covered by a flattening layer. With this structure, it is possible to realize a flatter surface on which to form, for example, the emissive layer of the element to be driven.

Owner:SANYO ELECTRIC CO LTD

Method for growing graphene film by using low-temperature chemical vapor deposition

ActiveCN103184425AReduce roughnessReduce nucleation densityPolycrystalline material growthFrom chemically reactive gasesGas phaseMaterials science

The invention relates to a method for preparing a graphene film in a low-temperature condition. The method at least comprises the following steps: (1), performing smooth treatment on a metal substrate; (2), performing doping of a chemical reagent on the surface of the metal substrate obtained in the step (1); (3), under a protective atmosphere, performing annealing treatment on the metal substrate obtained in the step (1); (4), contacting the metal substrate with a carbon source, and performing chemical vapor deposition in the low-temperature condition to obtain the graphene film; and optionally, after the step (4), performing step (5), stopping heating, cooling to the room temperature, and taking out the metal substrate with the graphene film thereon, wherein the chemical reagent is a precursor salt of metal. The method for growing the graphene film is low in growth temperature, low in cost, high in industrialized feasibility and wide in select range of the substrate, and can prepare the complete single-layer or multi-layer graphene film with high quality.

Owner:WUXI GRAPHENE FILM +1

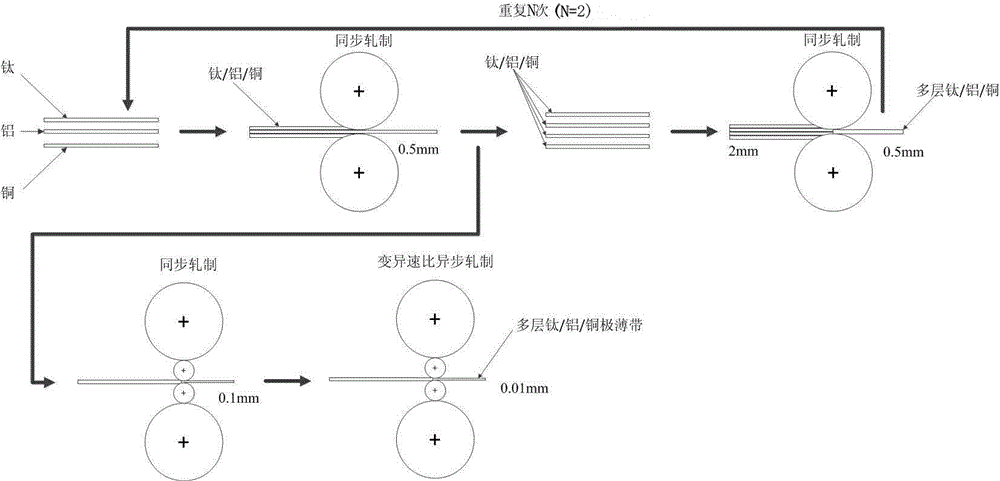

Preparation method for multilayer dissimilar metal composite ultra-thin strip

ActiveCN105170652AWide range of choicesEliminate intermediate heating processMetal rolling arrangementsRoll speed control deviceThinningMetal

The invention provides a preparation method for a multilayer dissimilar metal composite ultra-thin strip. The preparation method includes the process steps that (1) different metal materials are synchronously cold-rolled for first thinning; (2) metal thin strips are polished and cleaned; (3) the upper surfaces and lower surfaces of two or more metal thin strips are closely attached; (4) two-roll synchronous cold rolling is conducted on dissimilar metal combined strips; (5) the upper surfaces and lower surfaces of 2-10 dissimilar metal thin strips subjected to preliminary combination are closely attached and then the procedures of the step (1) to the step (4) are repeated 2-10 times; (6) reversible four-roll synchronous cold rolling is conducted on a multilayer dissimilar metal composite thin strip; and (7) reversible four-roll asynchronous cold rolling is conducted on the multilayer dissimilar metal composite thin strip, and the multilayer dissimilar metal composite ultra-thin strip with the thickness being 0.01 mm-0.02 mm is obtained. According to the method, the selection range of the metal materials is wide, the requirement for equipment capacity is low, and the surface quality of the ultra-thin strip can be improved remarkably; besides, production resources are saved, production cost is reduced, and the method is suitable for large-scale industrial production.

Owner:NORTHEASTERN UNIV

Airflow air laid fiber cotton preparing process and manufactured fibre cotton

ActiveCN101307529AWide selection of materialsImprove product qualityLap forming devicesNon-woven fabricsEngineeringWaste material

The invention discloses a method for preparing air-laying cellucotton and cellucotton produced by the method. Taking low melting point fibers and other fibers as raw material, the cellucotton is produced by rough shape cutting, coarse opening, fine opening, air laying, hot binding and parting cut packaging, wherein the air laying is as follows: the loose fibers which are distributed evenly in a cotton box after fully mixed by the fine opening are further mixed by airflow and delivered by pressurized airflow to between the net forming curtain and the net forming roller to be formed into a required retiform structure. The preparing process has wide range of material selection, is suitable for not only all the raw materials adopted in the prior process, but also the plant fiber widely existing in the natural world which are not used in the prior art such as couch grass, reed, cornstock, straw and bagasse as raw materials, and the waste materials such as wood wool, crushed sponge and wool manufacturing crushed aggregates to reuse and regenerate; in addition, the preparing process has high production efficiency and low energy consumption, and produces the cellucotton with great improvement in the performance, thereby being applied to wider fields.

Owner:广东美梦思床具有限公司

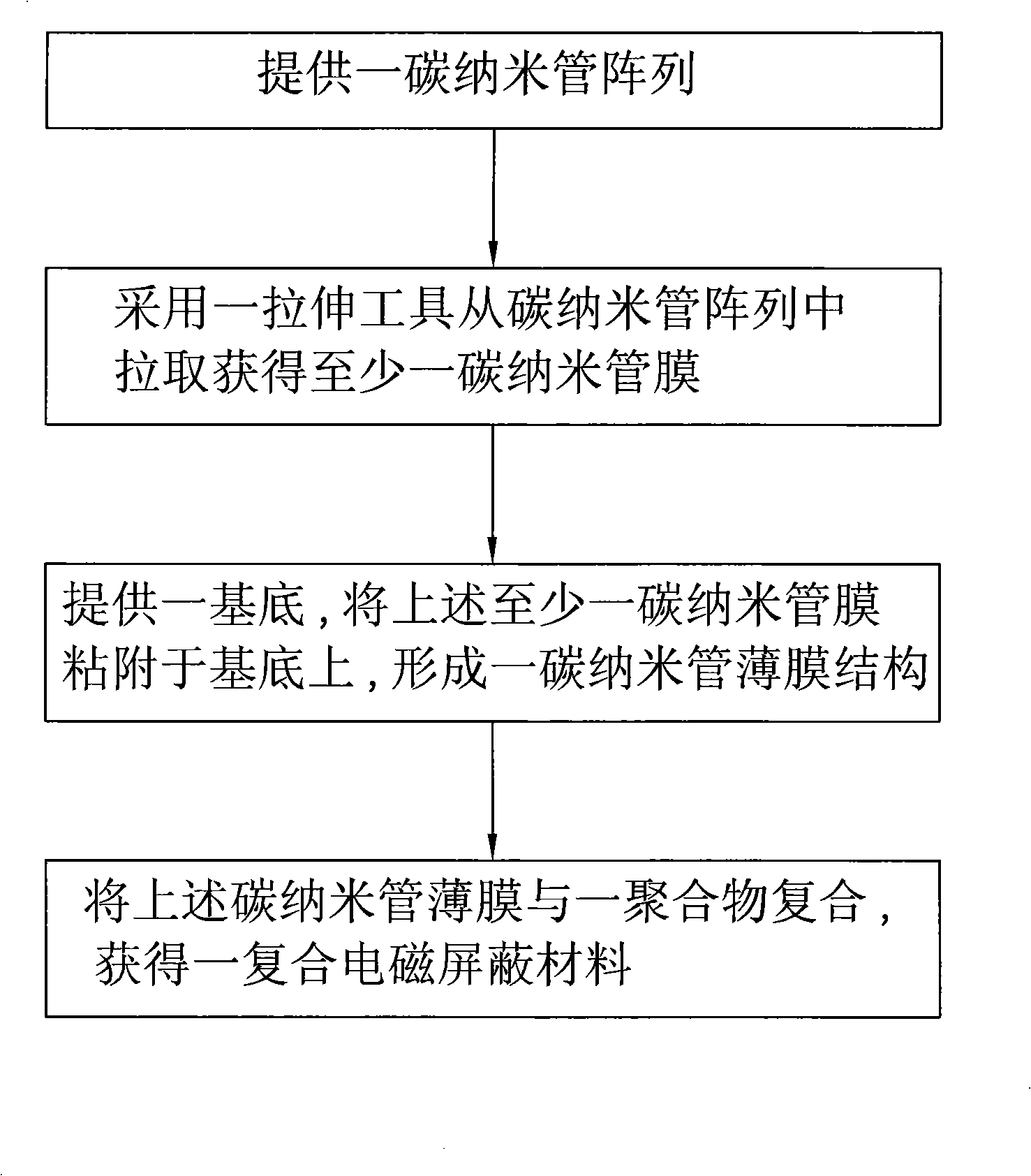

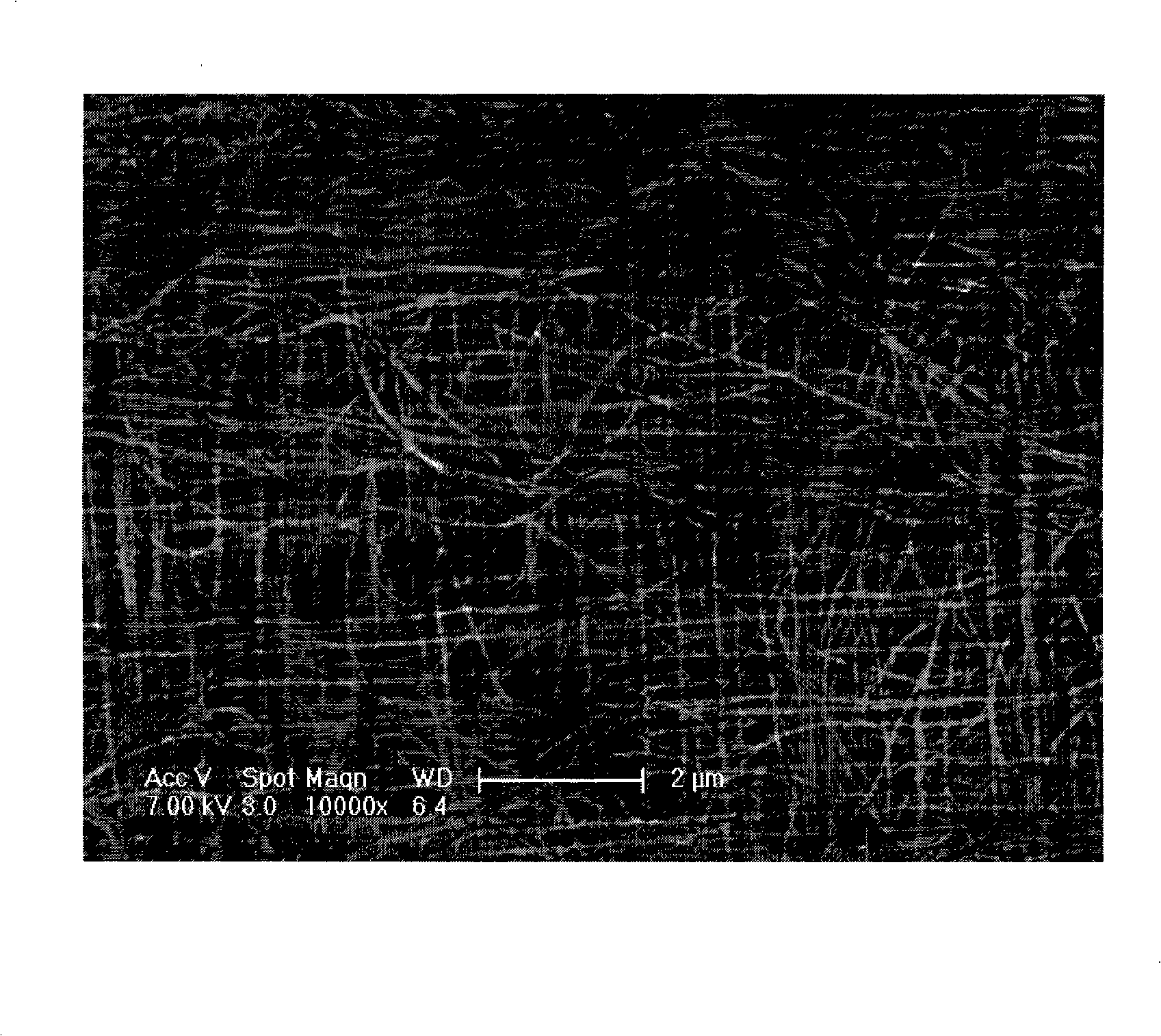

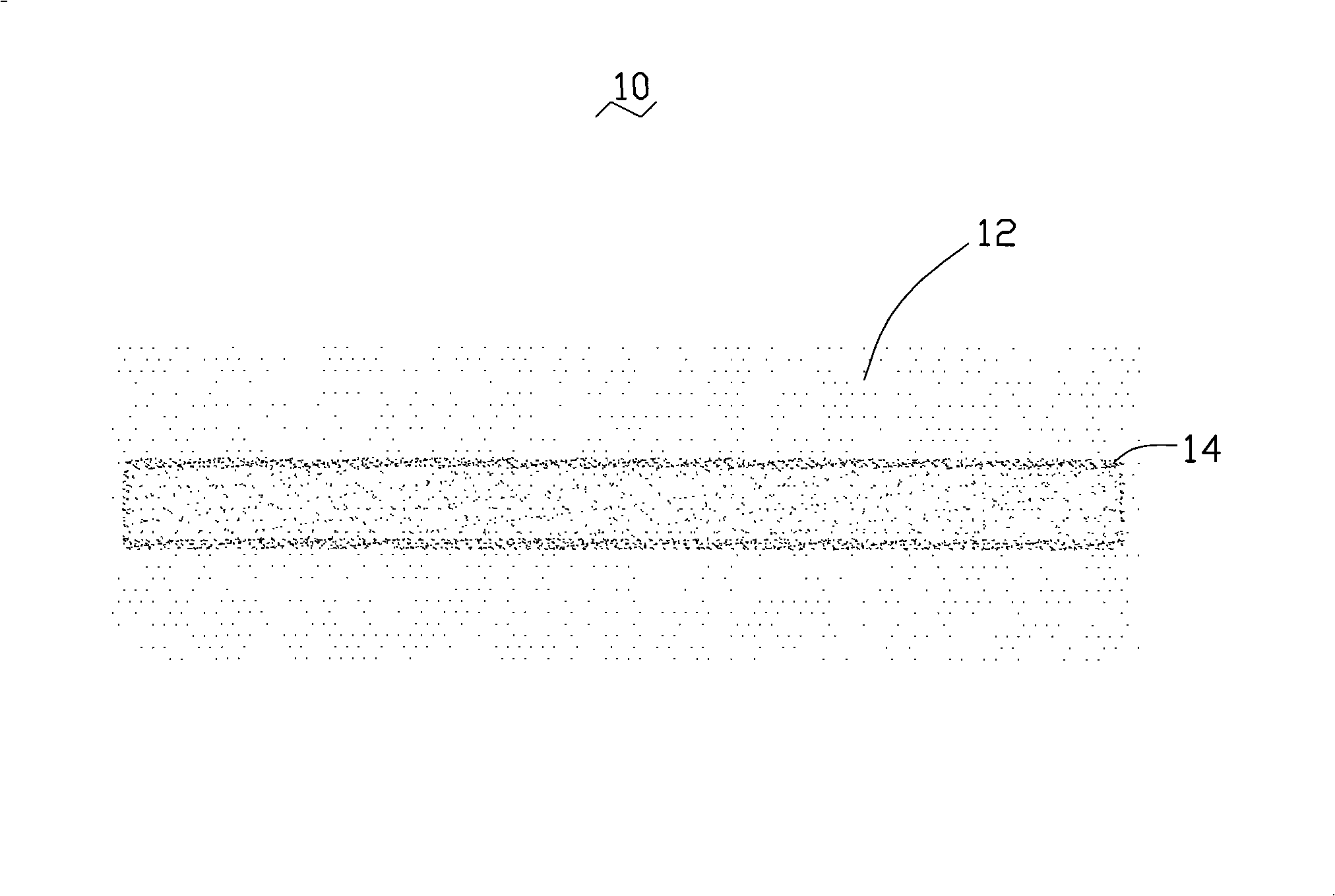

Composite electromagnetic shielding material and preparation method thereof

ActiveCN101409999AUnrestricted contentWide range of choicesLamination ancillary operationsMagnetic/electric field screeningResidual carbonCarbon nanotube

The invention provides a composite electromagnetic shielding material, comprising a polymer and a plurality of carbon nano-tubes; wherein, a plurality of carbon nano-tubes are arranged in the polymer in the form of carbon nano-tube film. A preparation method used for preparing the composite electromagnetic shielding material comprises the steps as follows: a carbon nano-tube array is provided; atleast a carbon nano-tube film is gained by the pulling in the carbon nano-tube array by a tensile tool; a substrate is provided; at least a carbon nano-tube film is attached to the substrate, thus forming the carbon carbon-tube film structure and removing the residual carbon nano-tube film structure out of the substrate; the carbon nano-tube film structure is composed with the polymer, thus gaining the composite electromagnetic shielding material.

Owner:TSINGHUA UNIV +1

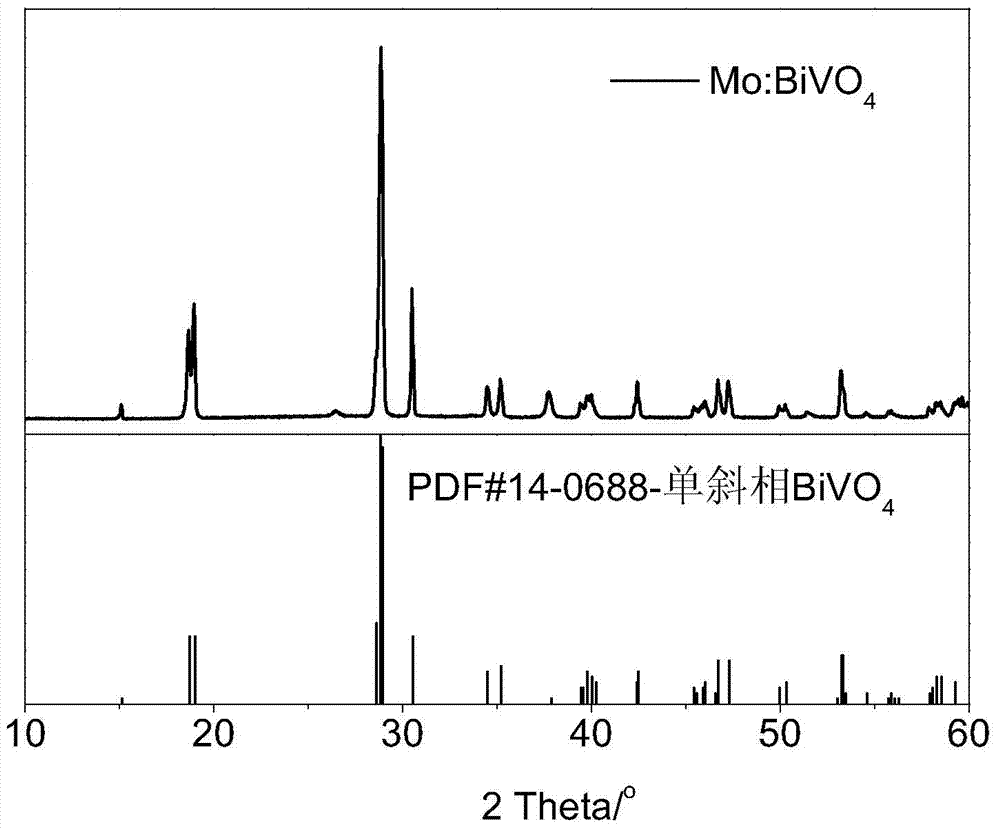

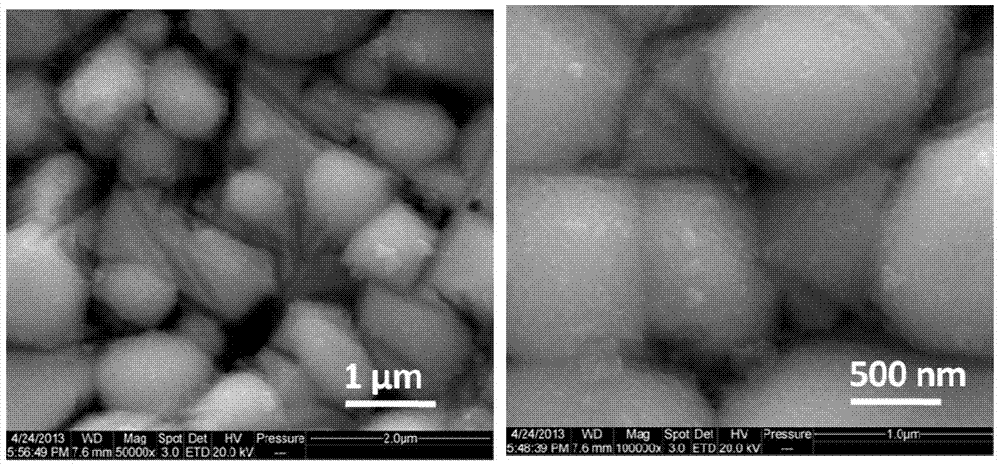

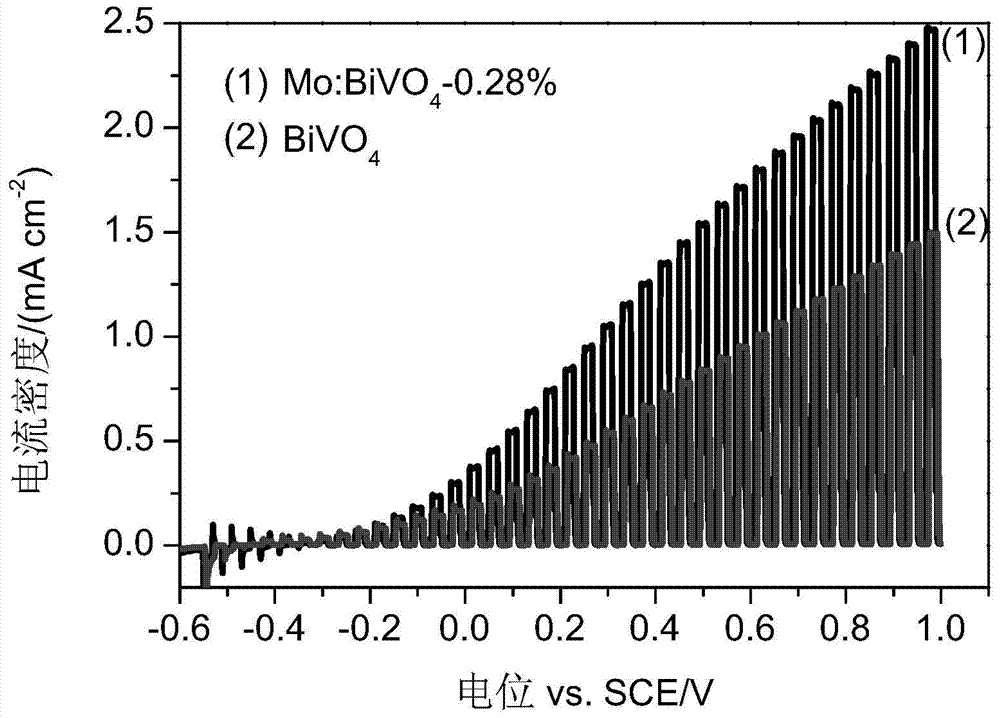

Method for preparing hydrogen through photoanode-photovoltaic battery coupled dual-illumination fully-photic-driven decomposition of water

InactiveCN104711627AImprove visible light absorptionHigh catalytic activityElectrolysis componentsLight-sensitive devicesSemiconductor materialsHydrogen

The invention relates to a method for preparing hydrogen through photoanode-photovoltaic battery coupled dual-illumination fully-photic-driven decomposition of water. Efficient decomposition of water is realized under sunlight illumination conditions by using coupling of a photoelectrocatalysis technology with a photovoltaic battery technology, adopting a water oxidation cocatalsyt modified semiconductor material as a photoanode, placing a proton reduction cocatalyst modified Si battery in an electrolyte as a photocathode, directly connecting the positive electrode of the Si battery with the anode through a lead and allowing the surface of the cathode to contact with the electrolyte. The method realizes fully photic driven decomposition of water without applied bias conditions, and the solar energy utilization efficiency STH of the method reaches 2.2% or above.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

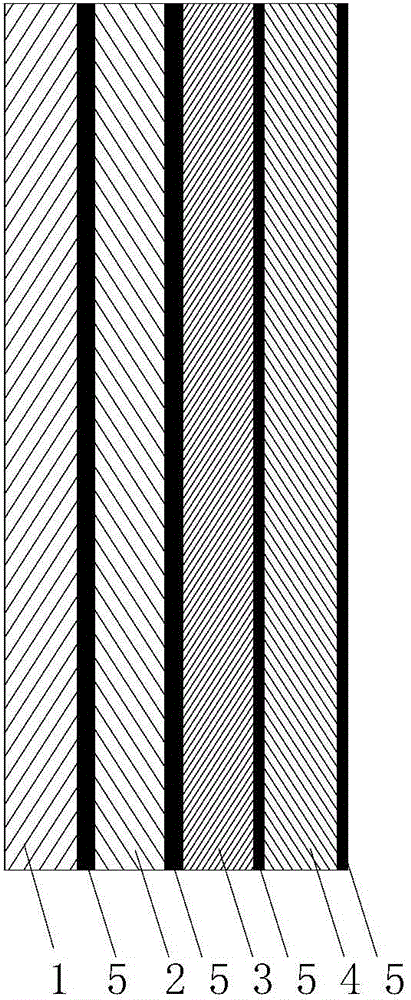

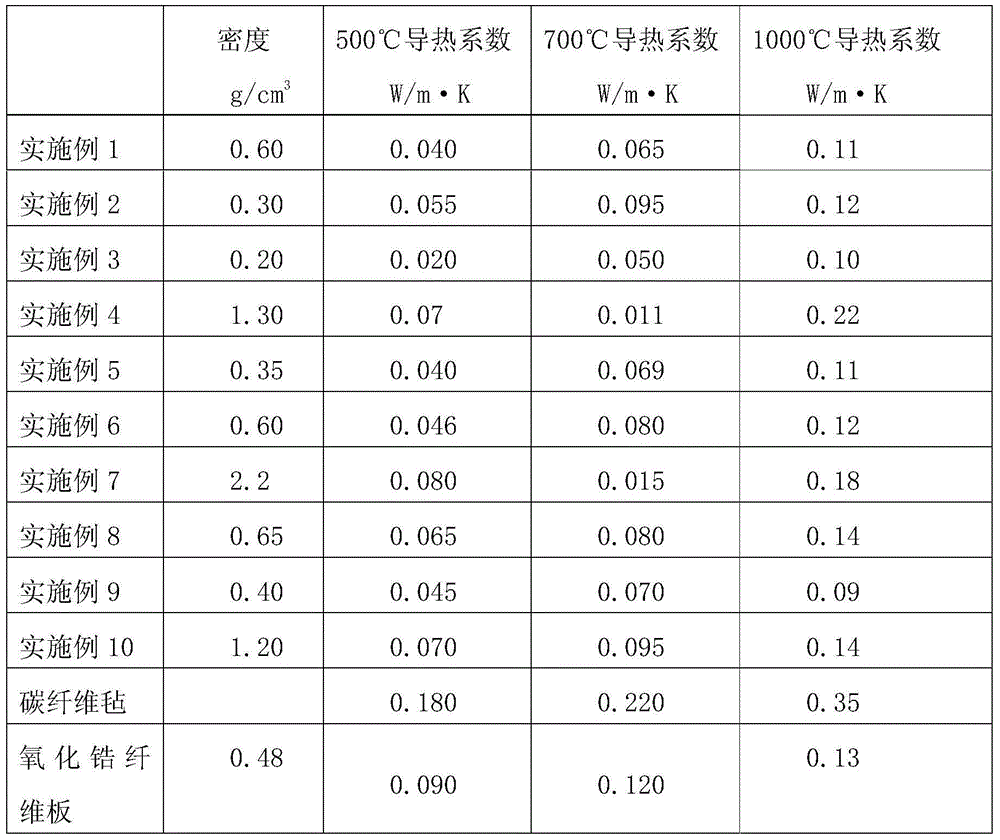

Ultrahigh-temperature gradient heat insulation material and preparation method thereof

ActiveCN104553102AWide range of choicesShorten the production cyclePaper/cardboard layered productsMetal layered productsInsulation layerPhase change

The invention discloses an ultrahigh-temperature gradient heat insulation material and a preparation method thereof. The ultrahigh-temperature gradient heat insulation material comprises an ultrahigh-temperature heat insulation material layer which is positioned at one high-temperature side, a phase-change heat absorbing insulation material layer positioned at the outer side of the ultrahigh-temperature heat insulation material layer, a medium-temperature heat insulation layer positioned at the outer side of the phase-change heat absorbing insulation material layer, a low-temperature heat insulation layer positioned at the outer side of the medium-temperature heat insulation layer, and radiating shielding layers which are respectively arranged between two adjacent layers of the ultrahigh-temperature heat insulation material layer, the phase-change heat absorbing insulation material layer, the medium-temperature heat insulation layer and the low-temperature heat insulation layer and positioned at the outer side of the low-temperature heat insulation layer; the radiating shielding layers are used for resisting radiation; the layers are integrally combined. The ultrahigh-temperature gradient heat insulation material has the characteristics of being resistant to ultrahigh temperature and long in service life.

Owner:CHINA BUILDING MATERIALS ACAD

Light-weight and high-strength plastic steel sandwich board and its making method

ActiveCN102991046ALight in massQuality improvementSynthetic resin layered productsLaminationThermoplasticAdhesive

The invention belongs to the technical field of building decoration and transportation, and discloses a light-weight and high-strength plastic steel sandwich board and its making method. The plastic steel sandwich board comprises two panels and a sandwich layer fixed between the two panels. The making method of the plastic steel sandwich board comprises the following steps: placing the sandwich layer between the two panels, and respectively bonding the two panels with the right and wrong surfaces of the sandwich layer through an adhesive to prepare the plastic steel sandwich board, wherein each of the panel is obtained through compounding one side of a continuous fiber reinforced thermoplastic plastic board with a non-woven fabric through hot-press molding. The plastic steel sandwich board has the advantages of light weight, high strength, heat insulation, fire resistance, moisture resistance, corrosion resistance and the like.

Owner:滁州格美特科技有限公司

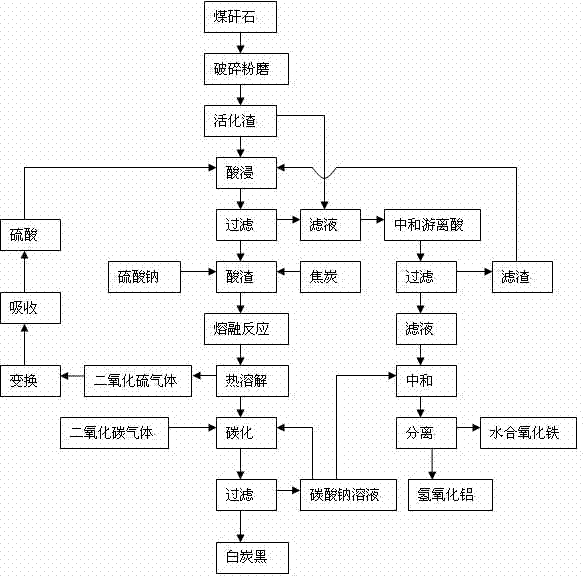

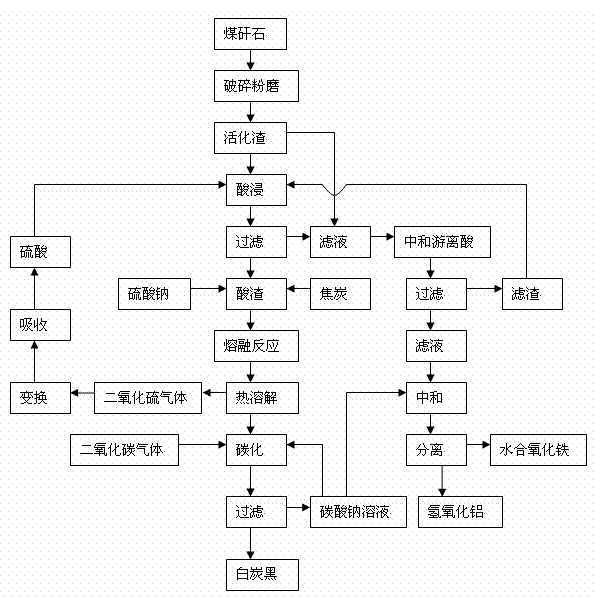

Comprehensive extraction method of ferro-silico-aluminum in gangue

ActiveCN102515279AGood slag activityMeet operating conditionsSilicaIron oxides/hydroxidesAluminium hydroxideSlag

The invention discloses a comprehensive extraction method of ferro-silico-aluminum in gangue, comprising the following steps of: using gangue as a raw material, crushing, grinding, activating, carrying out acid leaching, filtering, neutralizing free acid in the acid leaching filtered solution by the use of active slag, filtering to obtain a neutralized acid leaching solution, adding a sodium carbonate solution into the neutralized acid leaching solution, adjusting pH value, separating iron and aluminium to obtain hydrous iron oxide, aluminium hydroxide and a by-product sodium sulphate, adding sodium sulphate and coke into the acid leaching slag which has undergone acid leaching and filtration, carrying out a high-temperature melt reaction to recover silicon so as to prepare soluble glass, simultaneously recovering sulfur dioxide to prepare sulfuric acid, reusing sulfuric acid for the acid leaching treatment, diluting the soluble glass by the use of a sodium carbonate solution, carrying out carborization to obtain white carbon black, and reusing the carbonating solution for iron-aluminium separation. The method provided by the invention has characteristics of wide application range of the raw material gangue, high comprehensive recovery rate, no output of by-products, less residue amount and the like, provides a novel technological process for high-efficiency recovery of ferro-silico-aluminum from gangue, and expands the ways of gangue application.

Owner:KUNMING UNIV OF SCI & TECH +1

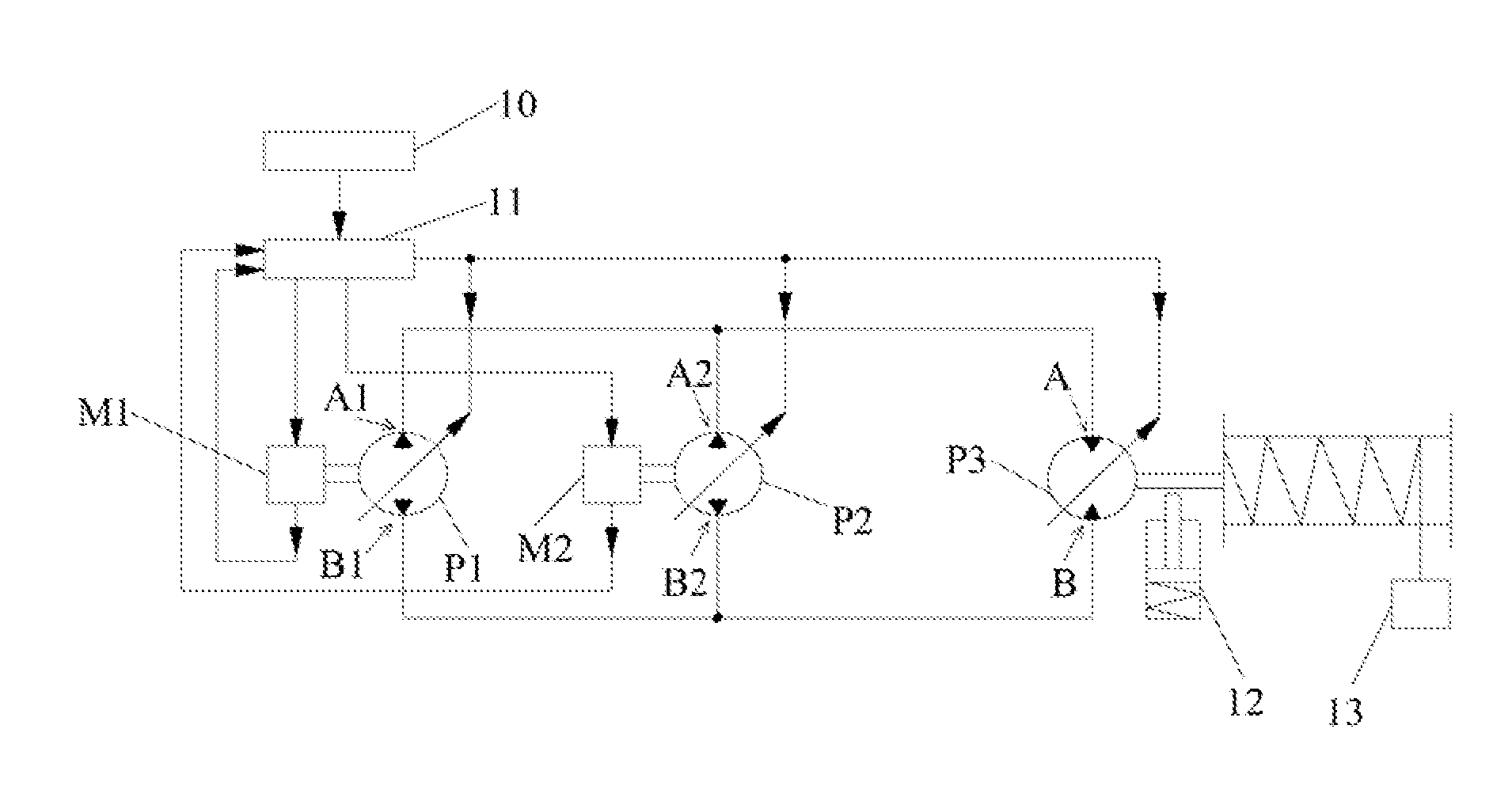

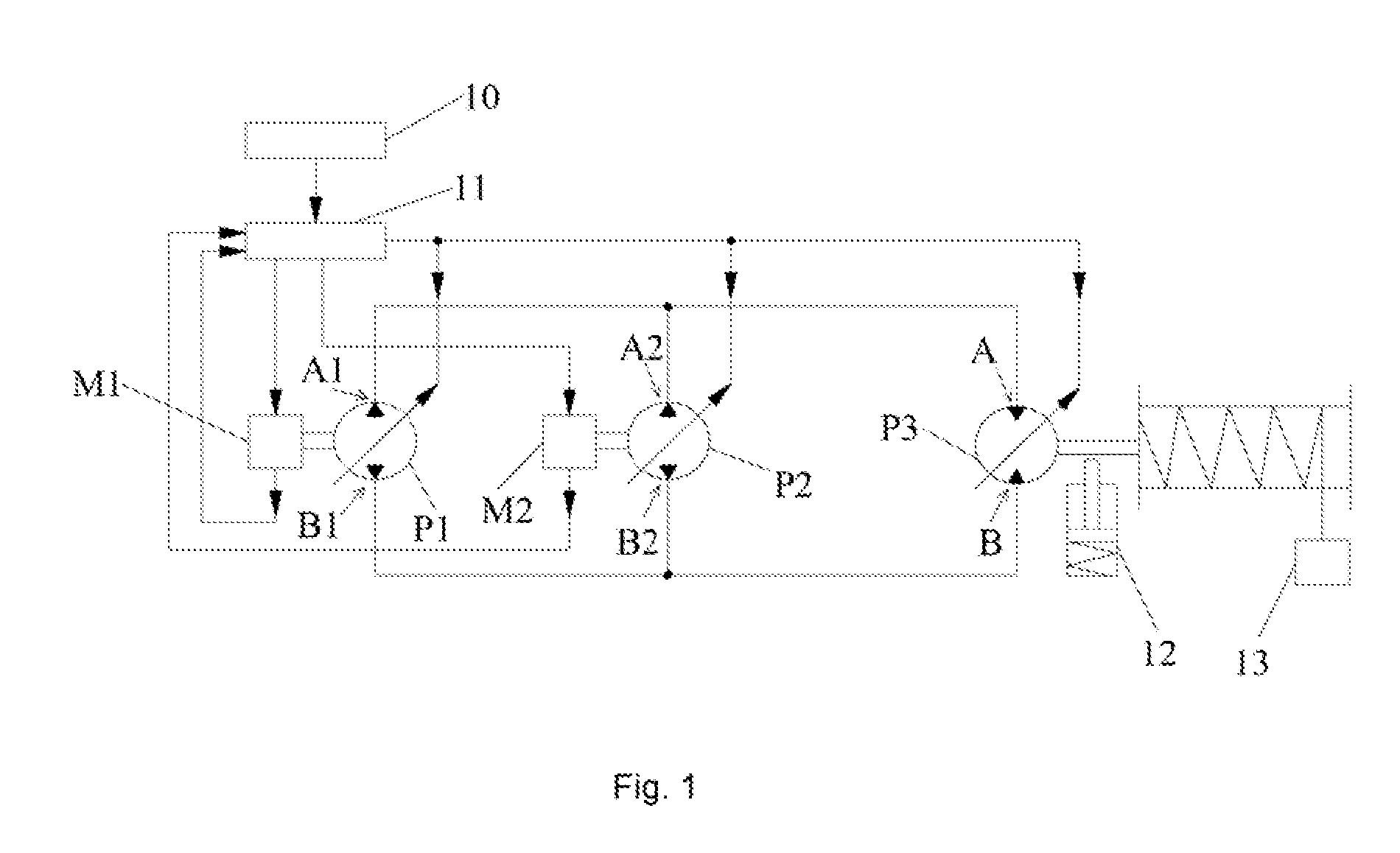

Hydraulic control system and hydraulic control method

InactiveUS20130091833A1Wider engine model selection rangeLess fault sourceRotary clutchesTelemotorsHydraulic motorModel selection

A hydraulic control system and a hydraulic control method are disclosed. The hydraulic control system comprises a first closed pump (P1) and a first engine (M1) connected with each other, a second closed pump (P2) and a second engine (M2) connected with each other, and a hydraulic motor (P3). The first closed pump (P1), the second closed pump (P2) and the hydraulic motor (P3) are connected in parallel. Compared with the prior art, the present hydraulic control system has advantages of wider engine model selection range, higher reliability and better micro-motion performance.

Owner:ZOOMLION HEAVY IND CO LTD +1

Zirconium-based amorphous alloy

The invention relates to a zirconium-based amorphous alloy. Composition of the zirconium-based amorphous alloy is (Zr, Hf, Nb)aCubNicAldRee, wherein a, b, c, d and e are corresponding contents in atomic percent of each element in the zirconium-based amorphous alloy, a is more than or equal to 45 and less than or equal to 65, b is more than or equal to 15 and less than or equal to 40, c is more than or equal to 0.1 and less than or equal to 15, d is more than or equal to 5 and less than or equal to 15, e is more than or equal to 0.05 and less than or equal to 5, the sum of a, b, c, d and e is less than or equal to 100, Re is one or combination of more than one of La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb and Lu elements, or Re is one or combination of Y with more than one of La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb and Lu elements.

Owner:HUAWEI TECH CO LTD

Reinforced tubular porous body compound film, method of preparing the same and use thereof

InactiveCN101254420AHigh tensile strengthWide range of choicesSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPorous compositePolymer

The invention discloses a reinforced tubular porous composite film, as well as a preparation method and an application thereof. The composite film consists of a tubular porous body, a first polymer material film and a second polymer material film. The composite film is obtained by coating the first polymer material film and the second polymer material film on the tubular porous body. The reinforced tubular porous composite film has the advantages of no surface defect, high water permeability, high tensile strength, wide selection range of the tubular porous body and easy production.

Owner:BEIJING ORIGINWATER TECH CO LTD

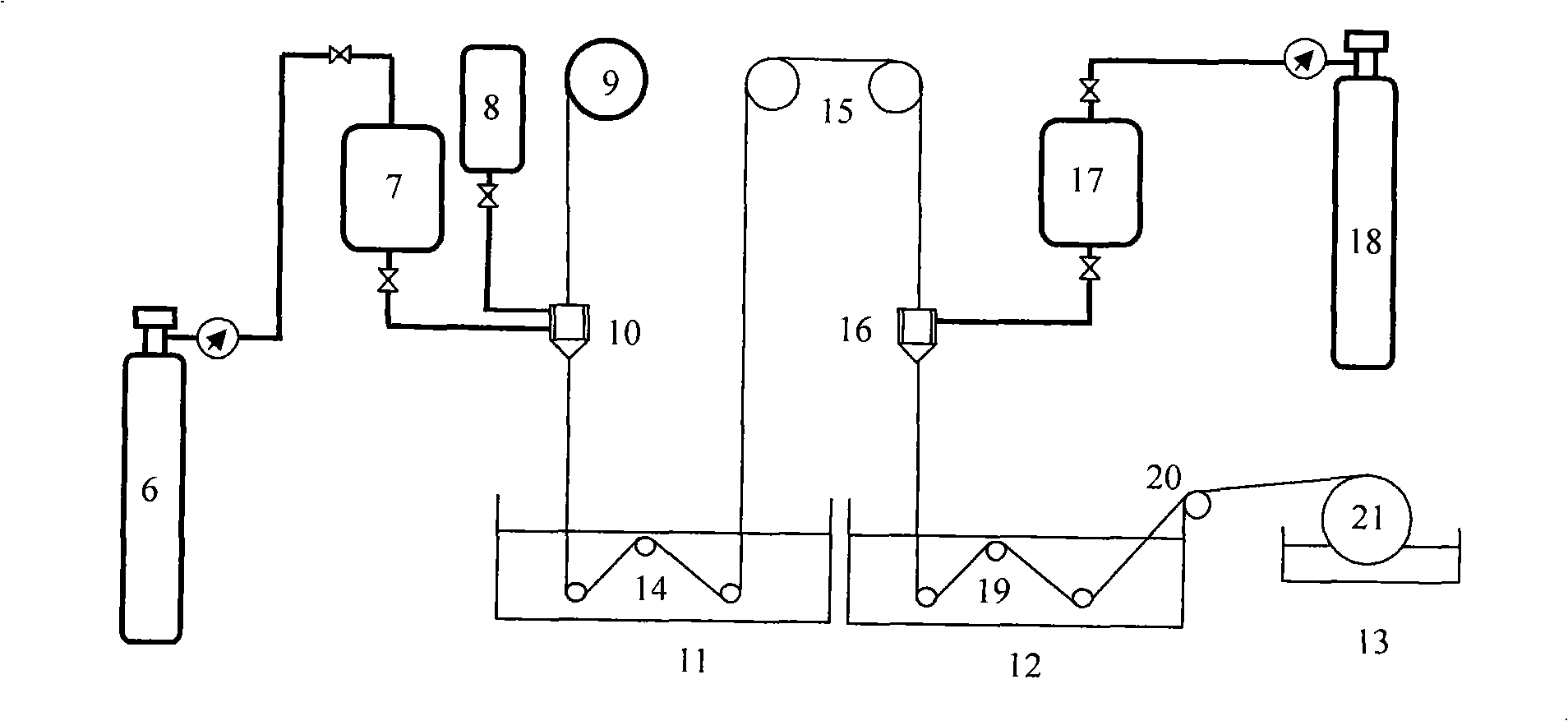

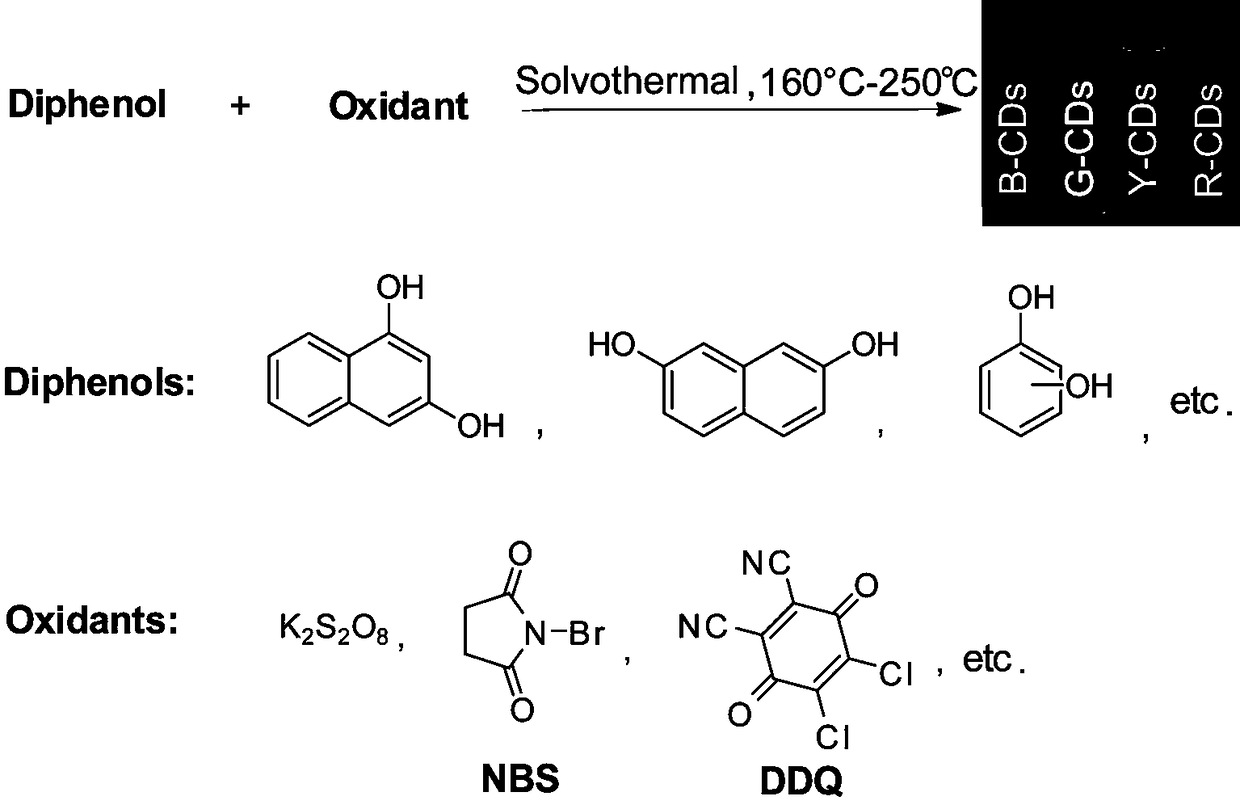

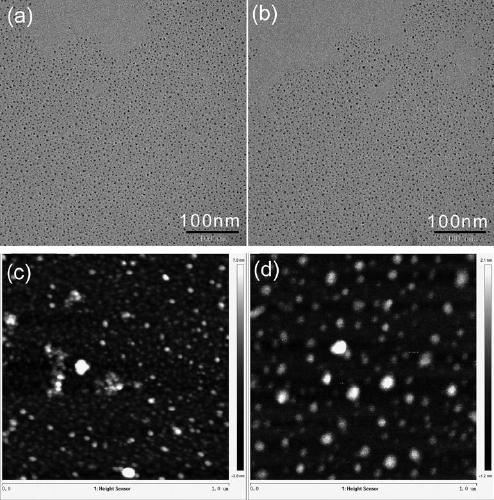

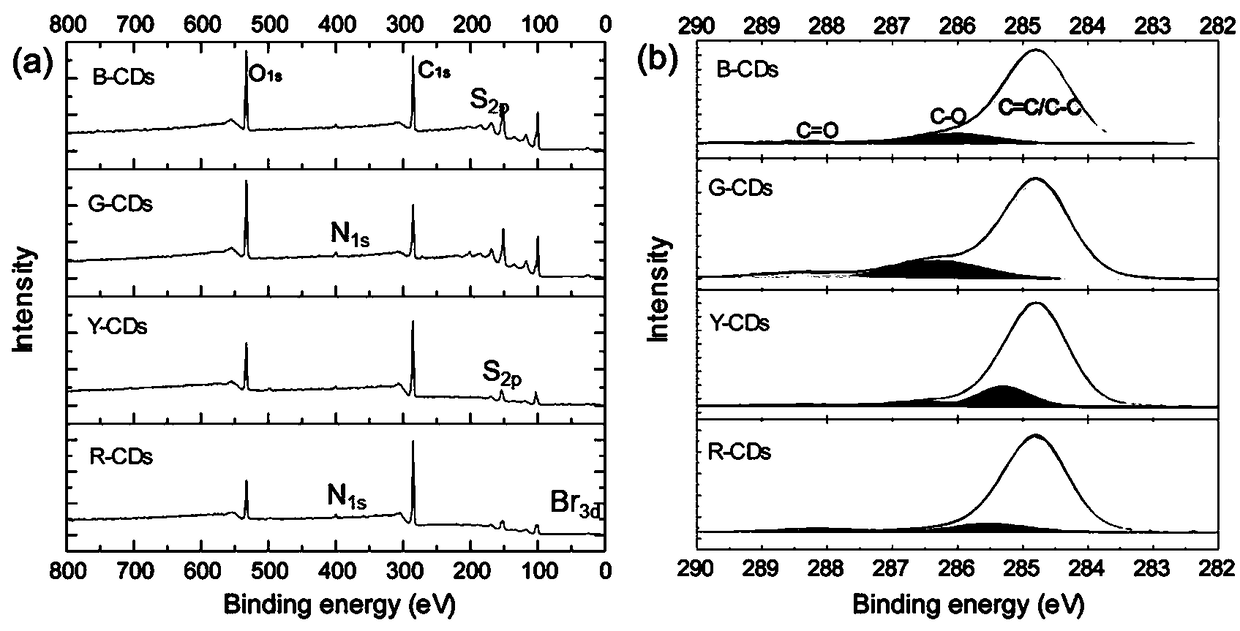

Method for preparing fluorescence color adjustable carbon dots

ActiveCN109294569AWide range of choicesImprove quantum efficiencyNanoopticsFluorescence/phosphorescenceQuantum efficiencyRed fluorescence

The invention relates to a method for preparing fluorescence color adjustable carbon dots. According to the method, a diphenol compound is used as a carbon source, and under the action of an oxidizingagent, a carbon dot mixed liquor is generated by a solvothermal one-pot reaction; and then, the carbon dot mixed liquor is purified by column chromatography to obtain the carbon dots emitting variousfluorescence colors. By regulating the combination of the diphenol compound and the oxidizing agent, the fluorescence colors of the carbon dots are adjusted. By the method, long-wavelength luminescence of the carbon dots can be realized, and quantum efficiency is improved. Quantum efficiency of the carbon dots having blue fluorescence color is 66%, quantum efficiency of the carbon dots having green fluorescence color is 81%, quantum efficiency of the carbon dots having yellow fluorescence color is 36%, and quantum efficiency of the carbon dots having red fluorescence color is 7%.

Owner:HENAN UNIVERSITY

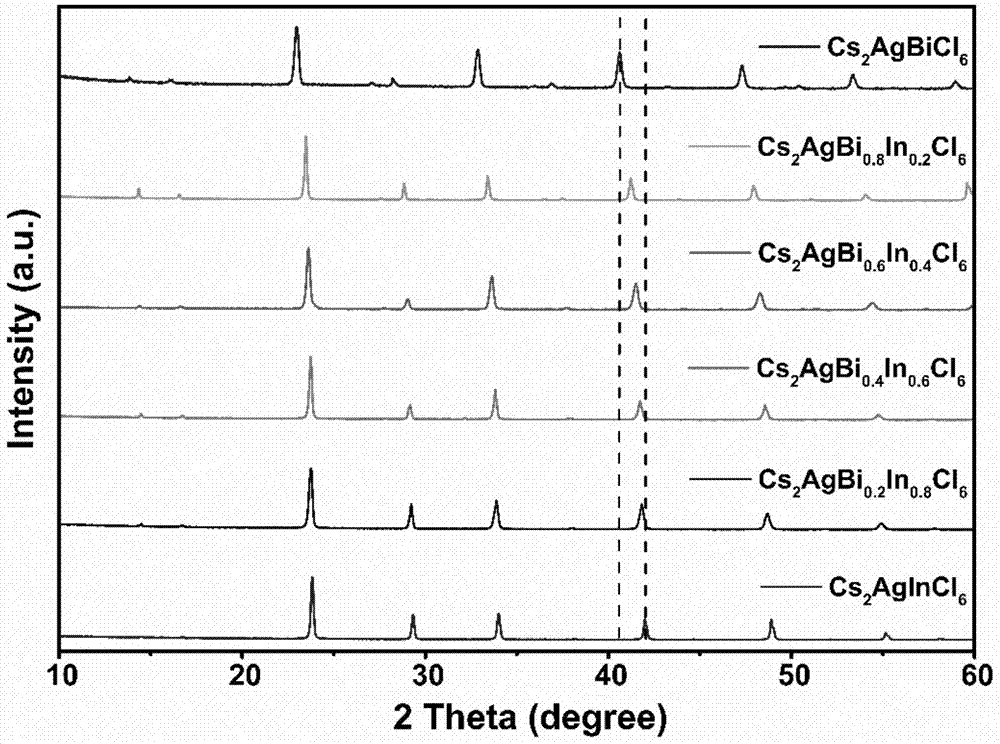

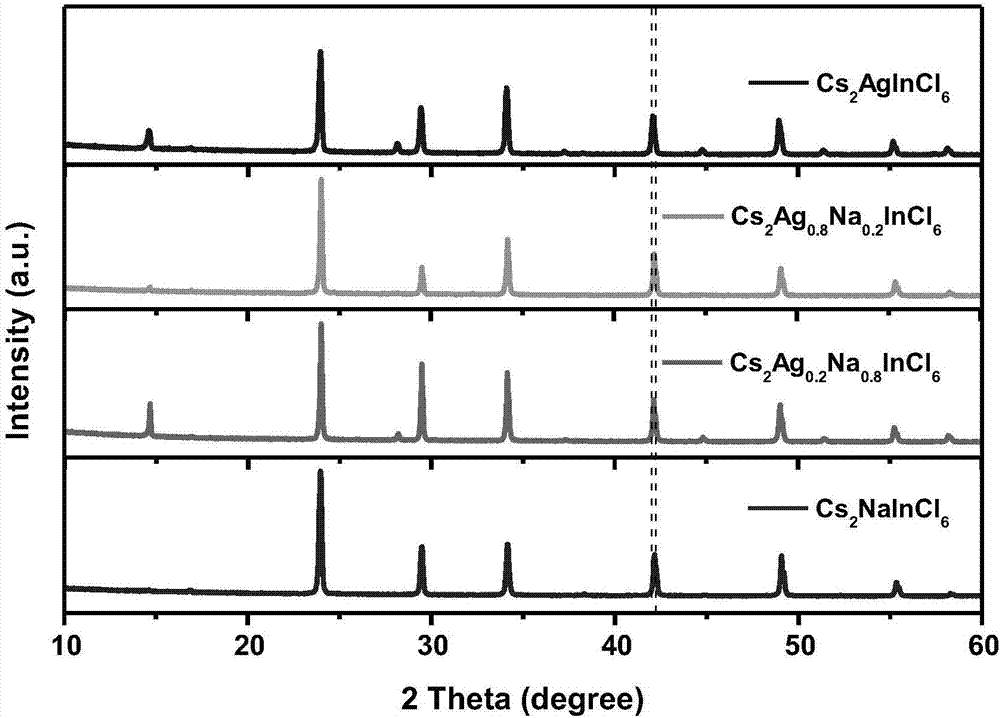

Multi-element perovskite material, as well as preparation and application thereof

ActiveCN107299393ABroaden applicationReduce pollutionPolycrystalline material growthFrom normal temperature solutionsHalogenChemical element

The invention discloses a multi-element perovskite material, as well as preparation and application thereof. The multi-element perovskite material is multi-element fully-inorganic metal non-lead halide salt and has a perovskite structure; the chemical formula of the multi-element perovskite meets: (the formula is shown in the description), wherein x is greater than or equal to 0 and less than or equal to 1, y is greater than or equal to 0 and less than or equal to 1, A is Cs<+>, B1, B2, B3 and B4 are Na<+>, Ag<+>, In<3+> and Bi<3+> respectively, and X is a halogen element. Through improvement on the varieties and proportion of the key chemical elements of the perovskite material, being compared with the prior art, the multi-element perovskite material can effectively solve the problems that the conventional multi-element perovskite material has few varieties, and is difficult to regulate and control, and high in environmental pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

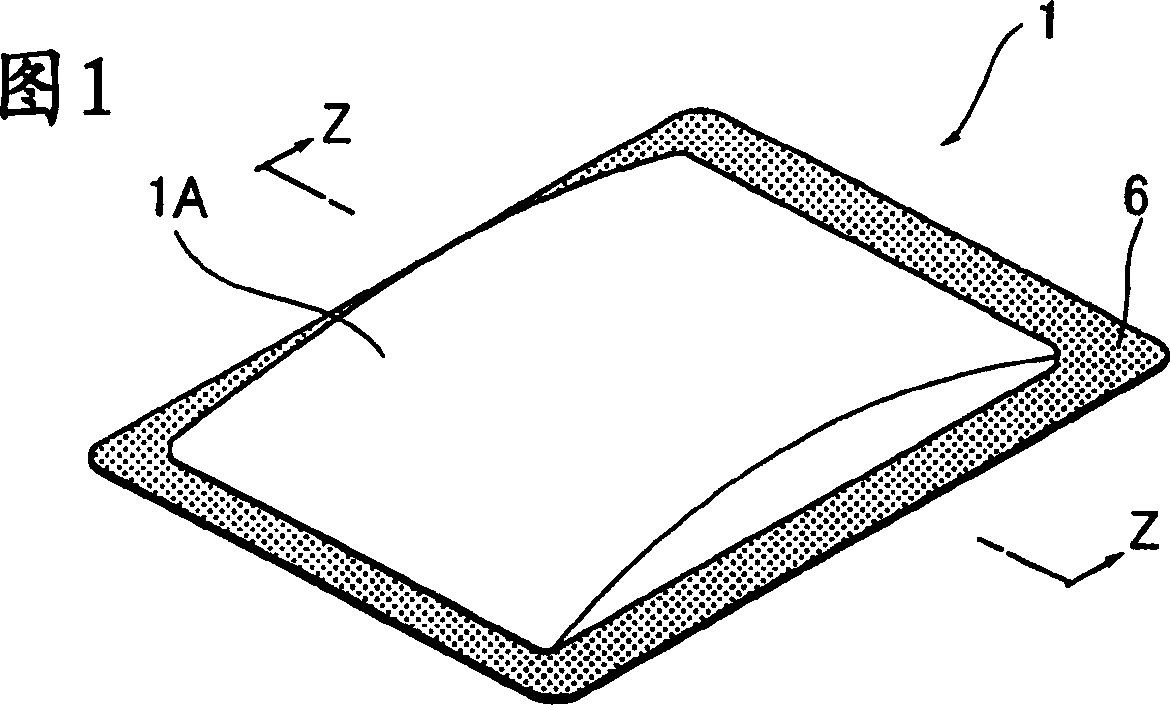

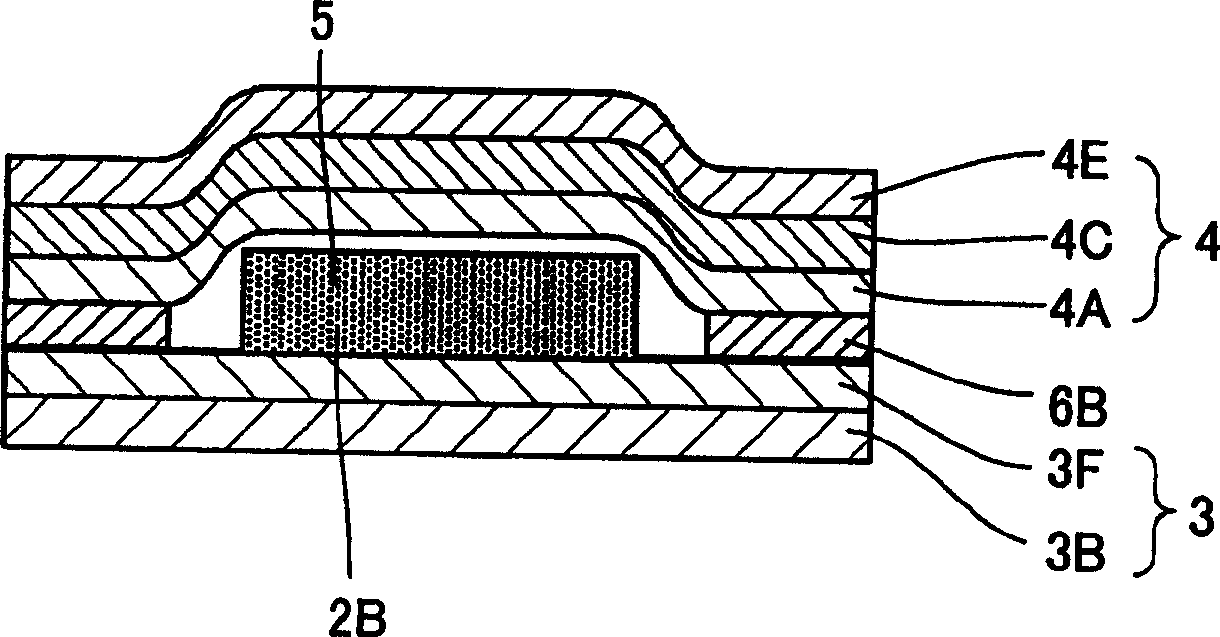

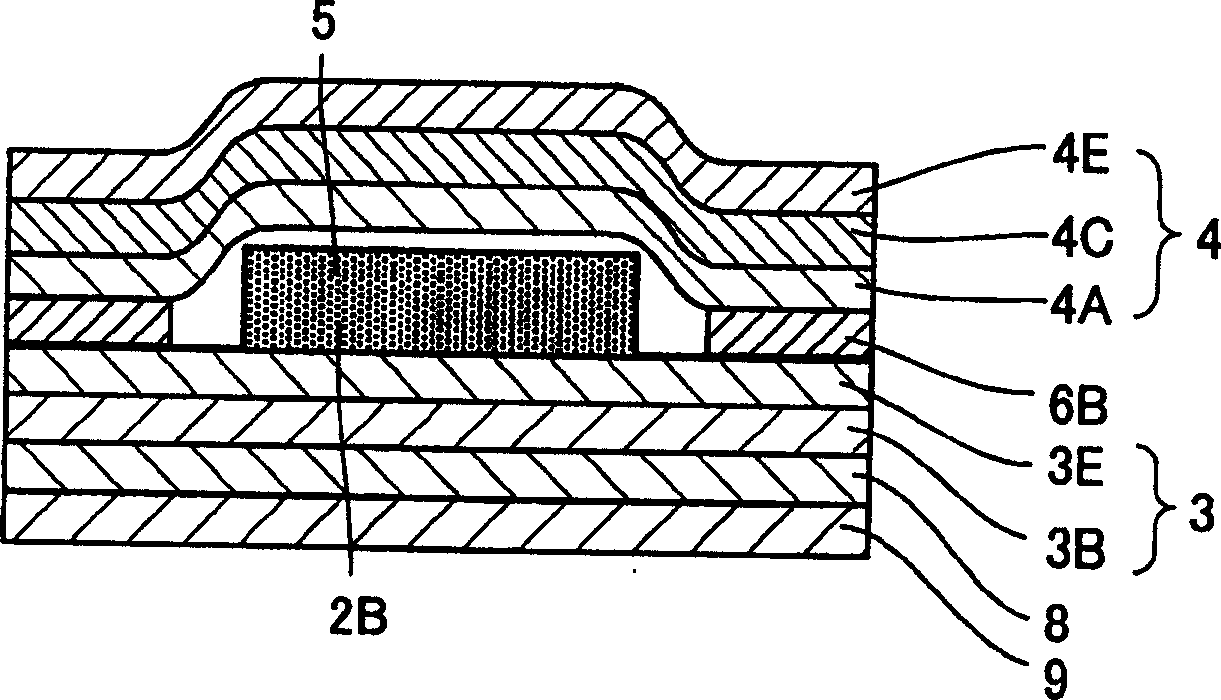

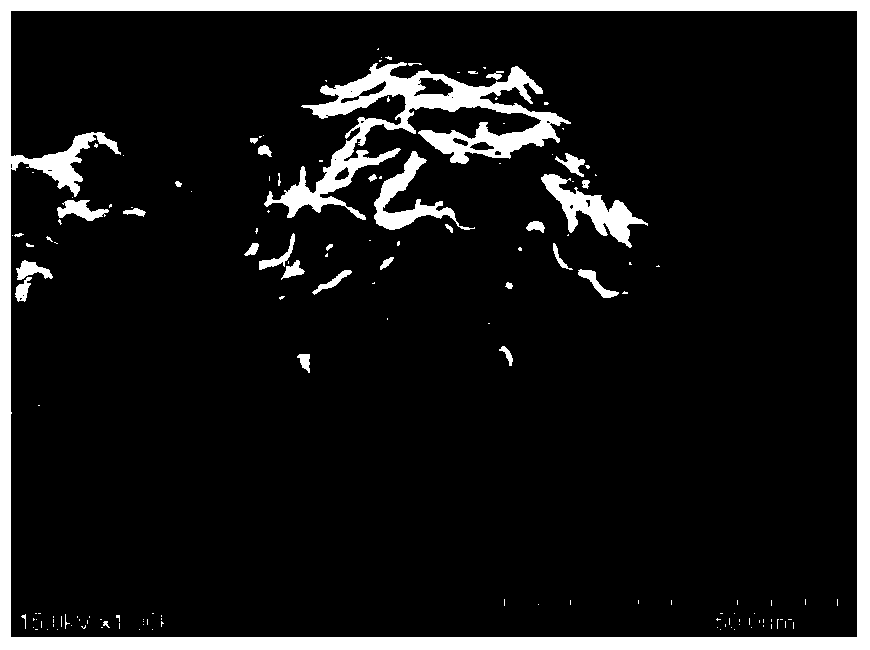

Exothermic composition and exothermic body

InactiveCN1496395AMaintain shape retentionMaintain propertiesHeat-exchange elementsTherapeutic coolingInternal pressureEngineering

There are provided a heat-generating composition excellent in moldability, shape retaining property and heat-generating characteristics, and a heat-generating body using the same that can maintain the shape of a molded article of the heat-generating composition irrespective to the pressure inside the container bag and has excellent heat-generating characteristics and long-term heat generation maintaining property. It is a non-viscous heat-generating composition having excessive water characterized in that the heat generating composition generating heat in contact with air comprises, as essential components, a water absorbing polymer, a carbon component, a heat-generating promoter, water and a heat-generating substance, has excessive water, and has an incremental degree of viscosity of less than 1,000 cP and a liquid permeation degree of 5 or more.

Owner:艾饰庭株式会社

Organic/inorganic composite microspheres with core-shell structures and preparation method and application thereof

InactiveCN103626897AImprove surface affinityEasy to useMicroballoon preparationPigment treatment with macromolecular organic compoundsEmulsionControllability

The invention relates to organic / inorganic composite microspheres with core-shell structures and a preparation method and application thereof. The preparation method of the organic / inorganic composite microspheres comprises the steps of firstly, carrying out surface activation treatment on inorganic particles by using an organic coupling agent, so as to prepare lipophilic active inorganic particles with molecular bridges; adding the active inorganic particles into a homogeneous good solution where an organic polymer is dissolved, and thoroughly stirring and mixing, so as to form a monodisperse emulsion; slowly adding a non-solvent into the emulsion, so as to enable the organic polymer in the solution to be uniformly attached to the surfaces of the inorganic particles through the molecular bridges, repeatedly washing with the non-solvent, and drying, thereby preparing free-flowing organic / inorganic composite microspheres with the core-shell structures. Compared with the prior art, the preparation method disclosed by the invention has the characteristics of rapidness, simplicity, convenience, flexibility, controllability and the like, and can be applied to the preparation of any composite microsphere with an inorganic core-organic shell structure.

Owner:SHANGHAI RES INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com