Preparation method for multilayer dissimilar metal composite ultra-thin strip

A dissimilar metal and ultra-thin strip technology, which is applied in metal rolling, roll speed control, etc., can solve problems not involving dissimilar metal double-layer and multi-layer composite material ultra-thin strips, and meet the requirements of low equipment capacity and high thickness. Uniformity, the effect of increasing the thinning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

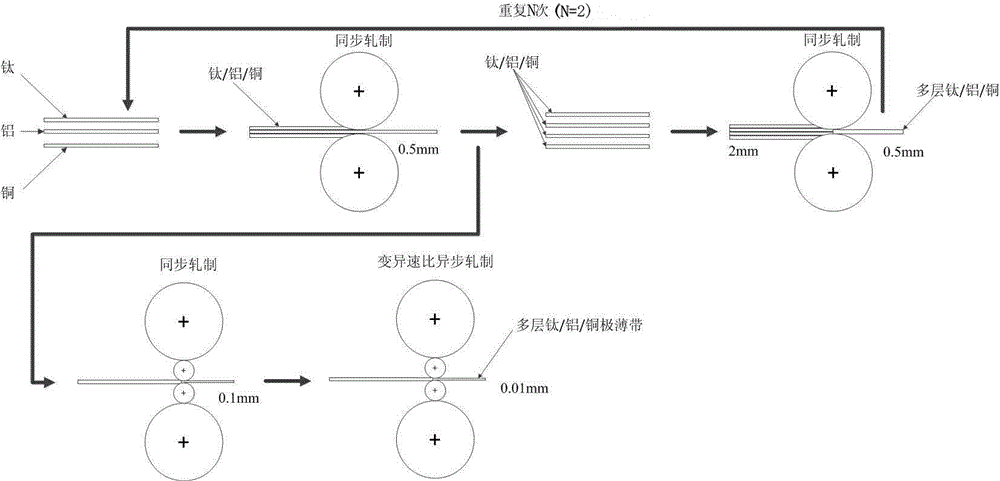

[0028] To prepare a 0.01mm thick multi-layer titanium / aluminum / copper composite ultra-thin strip, proceed according to the following process steps:

[0029] (1) Prepare copper, aluminum, and titanium with thicknesses of 2, 15, and 2 mm respectively, and use synchronous cold rolling process to reduce the thickness of copper, aluminum, and titanium to 0.3 mm, 0.3 mm, and 0.4 mm respectively after 4 to 10 passes. Synchronous cold rolling process parameters are: rolling speed 60~250mm / s, pass reduction rate 10~30%, total deformation rate ≥ 80%;

[0030] (2) Grind the upper and lower surfaces of copper, aluminum, and titanium thin strips, rinse the upper and lower surfaces of the thin metal strips with alcohol, and then use ultrasonic vibration for further cleaning. The time is 5~10min, put it in the air to dry;

[0031] (3) Select one group of the three metal thin strips in step (2) in the order of titanium, aluminum, and copper, and attach the upper and lower surfaces closely to...

Embodiment 2

[0038] To prepare a 0.02mm thick multi-layer titanium / AZ31B magnesium alloy / aluminum composite ultra-thin strip, proceed according to the following process steps:

[0039] (1) Prepare titanium, AZ31B magnesium alloy, and aluminum with thicknesses of 2, 2, and 4mm respectively, and adopt synchronous cold rolling process to reduce the thickness of titanium, AZ31B magnesium alloy, and aluminum to 0.3~0.6mm respectively after 10 passes, and synchronously cold-roll The rolling process parameters are: rolling speed 60~250mm / s, pass reduction rate 10~30%, total deformation rate ≥ 80%;

[0040] (2) Grind the upper and lower surfaces of titanium, AZ31B magnesium alloy, and aluminum thin strips, rinse the upper and lower surfaces of the thin metal strips with alcohol, and then use ultrasonic vibration for further cleaning. The parameters are set to ultrasonic water temperature 20~40°C , the cleaning time is 5~10min, and air-dried in the air;

[0041] (3) Select two groups of the three ...

Embodiment 3

[0048] To prepare a 0.02mm thick multi-layer titanium / aluminum composite extremely thin strip, proceed according to the following process steps:

[0049] (1) Prepare an aluminum plate with a thickness of 4mm and a titanium plate with a thickness of 2mm, and use the synchronous cold rolling process to reduce the thickness of aluminum and titanium to 0.5mm respectively after 4-8 passes. The parameters of the synchronous cold rolling process are: rolling speed 60~ 250mm / s, pass reduction rate 10~30%, total deformation rate ≥ 80%;

[0050] (2) Grind the upper and lower surfaces of the aluminum and titanium thin strips, wash the remaining grit and oil on the upper and lower surfaces of the thin metal strips with alcohol, and then use ultrasonic vibration for further cleaning. 5~10min, place in the air to dry;

[0051] (3) Select 5 groups of the two metal thin strips in step (2) in the order of titanium and aluminum, closely fit the upper and lower surfaces, and punch holes at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com