Patents

Literature

1252 results about "Titanium plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

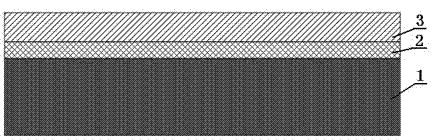

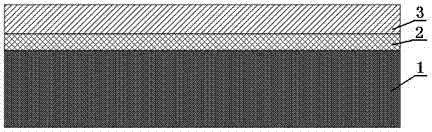

Method for obtaining release agent layer on base plate and composite material containing base plate and release agent layer

ActiveCN105238216AAvoid stickingPlay an isolation roleLayered productsEpoxy resin coatingsTitaniumMaterials science

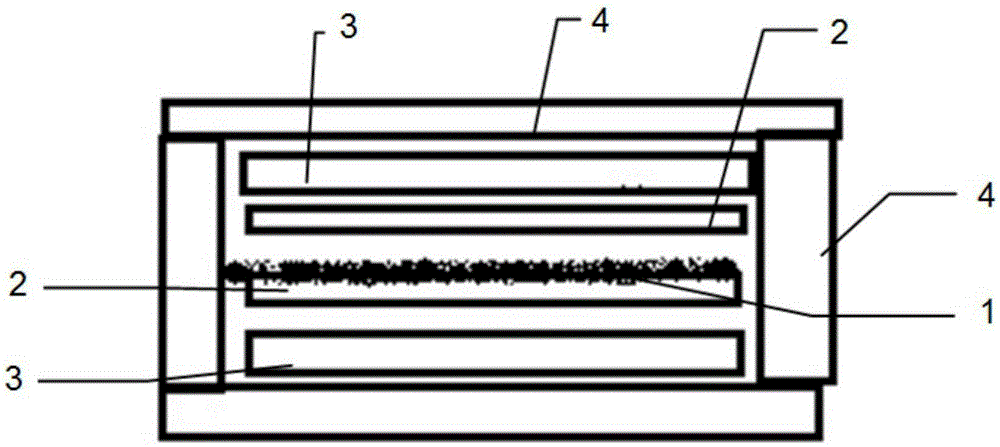

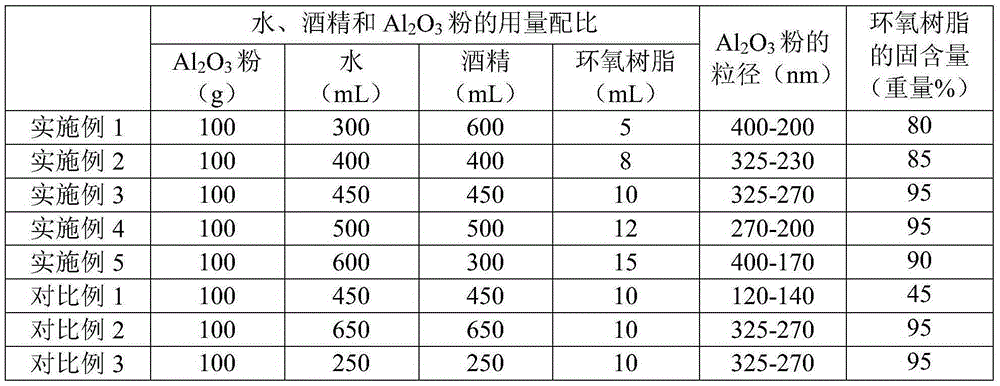

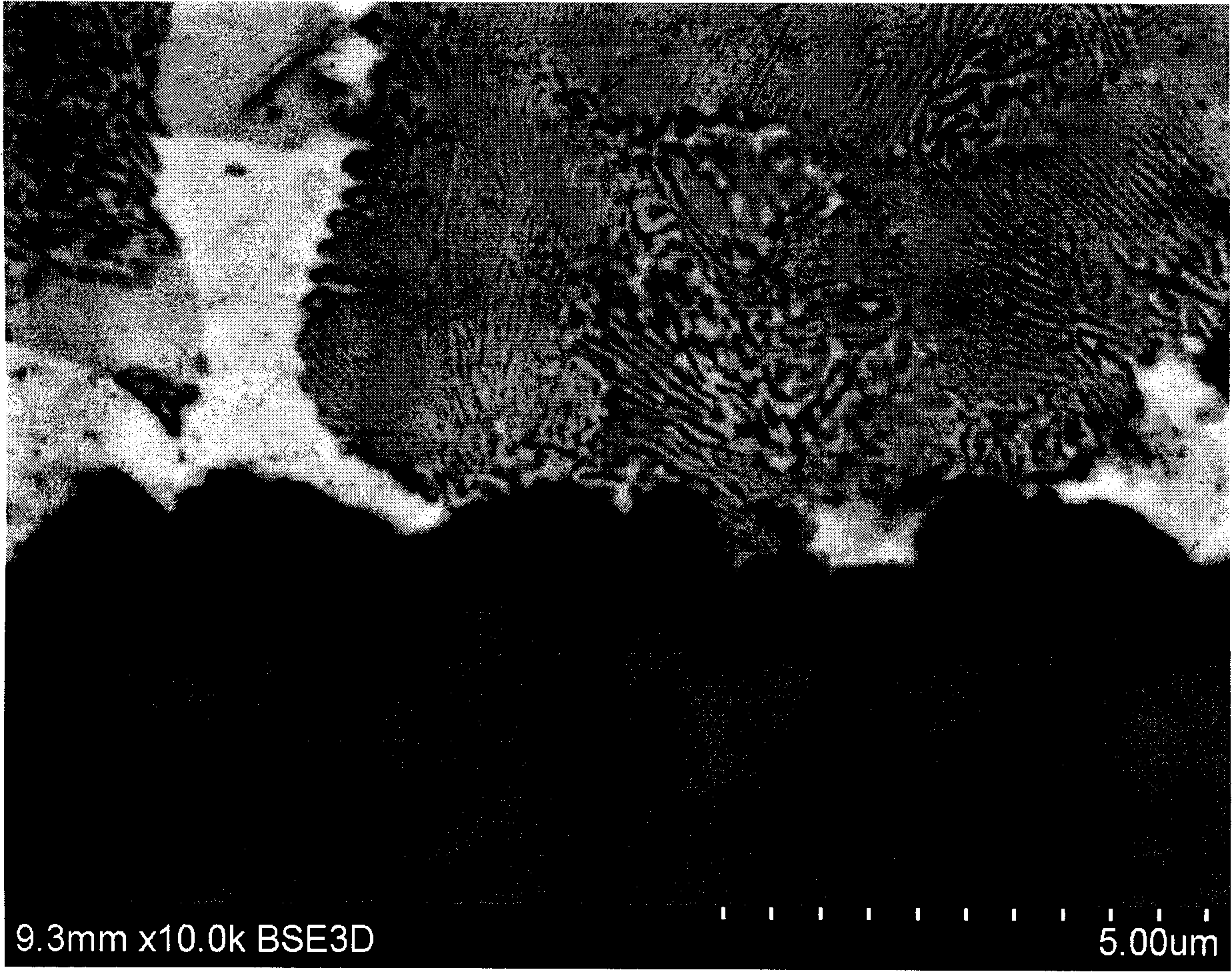

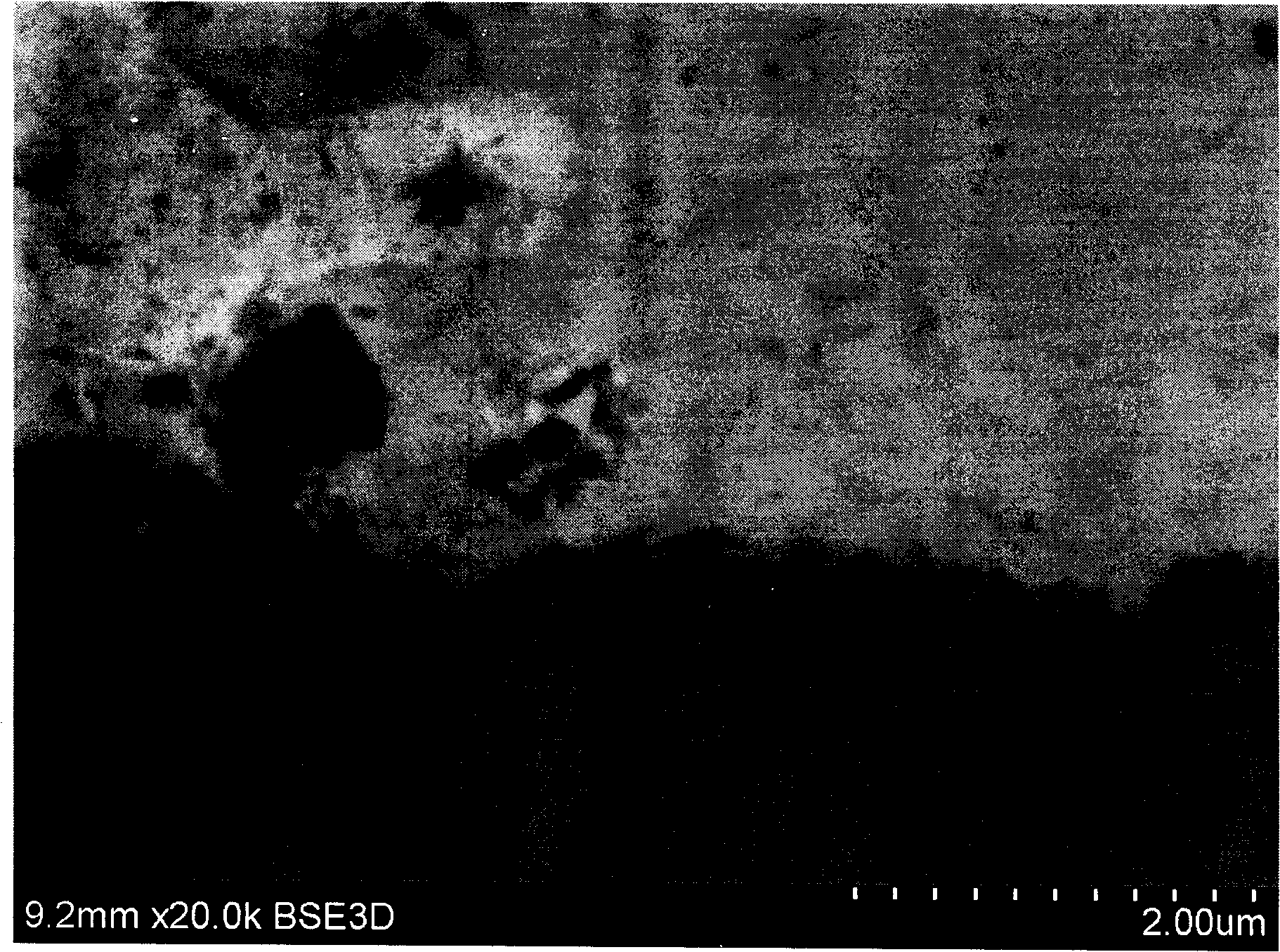

The invention relates to the field of release agents, in particular to a method for obtaining a release agent layer on a base plate and a composite material containing the base plate and the release agent layer. The method for obtaining the parting agent layer on the base plate comprises coating a release agent on the base plate, and drying to form the parting agent layer on the base plate. The method is characterized in that the release agent comprises water, alcohol, epoxy resin and Al2O3 powder, wherein relative to 100g of Al2O3 powder, the dosage of the water is 300-600mL, the dosage of the alcohol is 300-600mL, and the dosage of the epoxy resin is 5-15mL. The release agent can be online directly sprayed on the surface of a composite titanium board, and can be quickly cured to form a self-drying type coating to achieve a parting effect, so that in a 4-6h constant-temperature process at 800-1000 DEG C and a rolling process of a titanium steel composite board, adhesion and surface roughness increase phenomena of a titanium-titanium interface are avoided, and the yield and the production efficiency for titanium steel composite board processing are improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

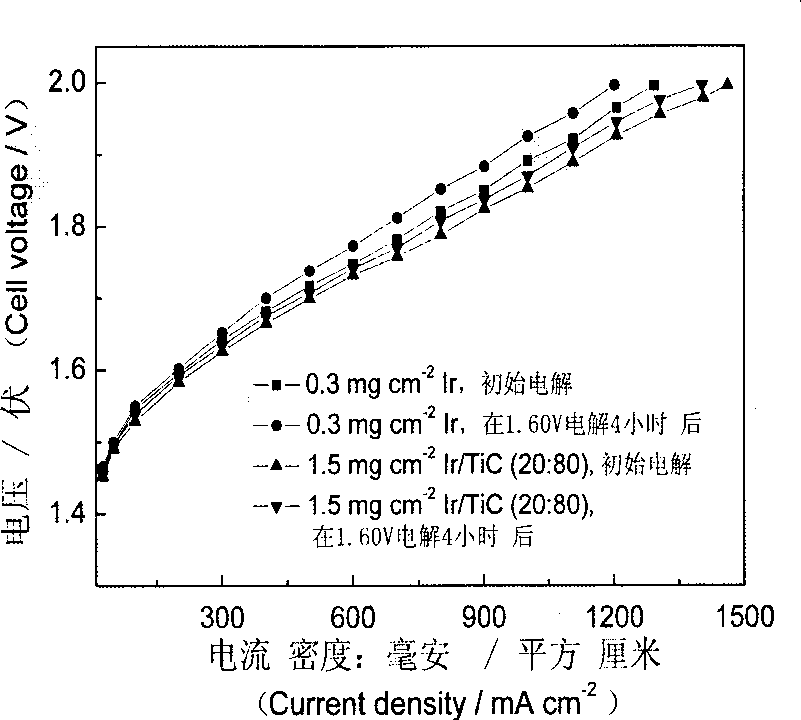

Membrane electrode for proton exchange membrane water electrolysis battery and preparation thereof

InactiveCN101388463AReduce loadReduce contact resistanceCell electrodesSolid electrolyte fuel cellsNano catalystElectrolysis

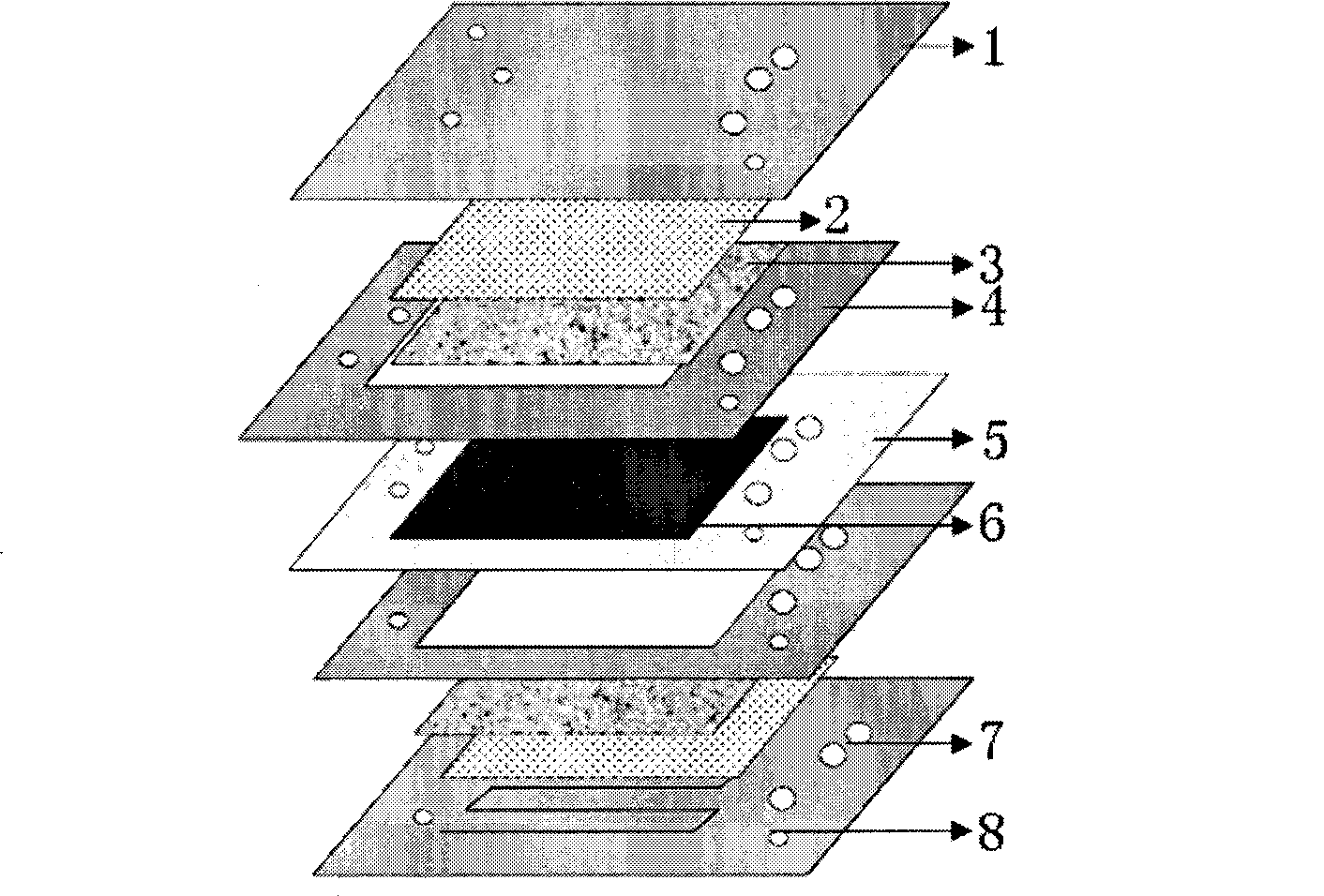

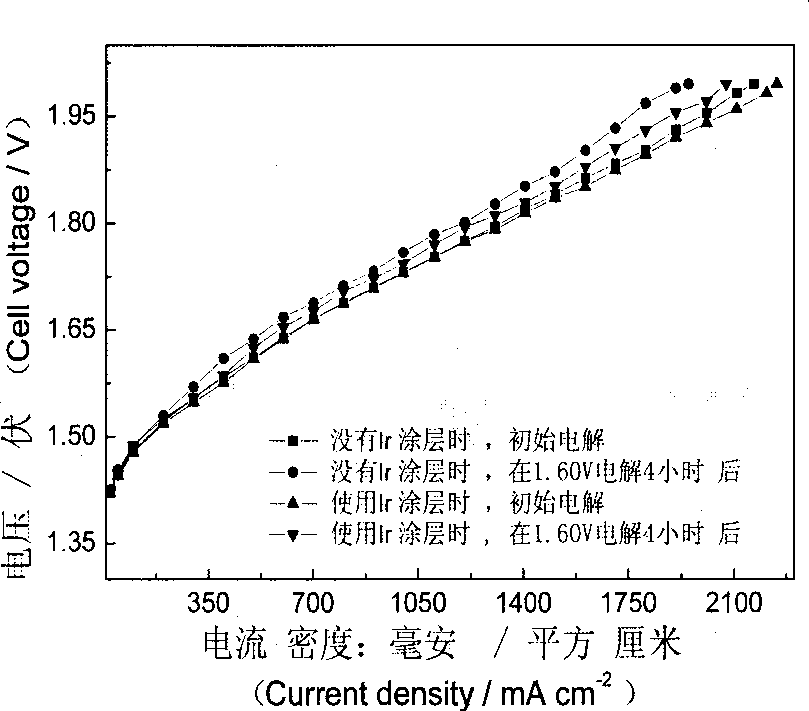

The invention discloses a proton exchange membrane water electrolyte battery membrane electrode and a process for preparation thereof, which belongs to the technical field of preparing hydrogen gas through electrolyzing water, wherein the proton exchange membrane water electrolyte battery membrane electrode comprises a polymer electrolyte membrane, an anode catalyst layer, a cathode catalyst layer, an anode diffusion layer, a cathode diffusion layer, a support layer and a flow field plate, wherein hydrophilic thin layer structures which are formed by catalyst are respectively brushed on both surfaces of the polymer electrolyte membrane. Anode catalyst is noble metal or metallic material, and the diffusion layer is carbon material or metallic material. A catalyst layer and the relative diffusion layer and the support layer are compacted in a titanium plate to prepare membrane electrode through utilizing external force under normal temperature. The invention lowers the load of catalyst, improves the operating factor of catalyst, avoids the deformation of membranes in the process of heat pressing, and is drawn supported from the catalytic and corrosion resistance property of an anti-corrosion diffusion layer with catalytic property, and the electrolytic property and the stability of a battery are improved. The invention has the advantages of simple technique, convenient operation and excellent repeatability.

Owner:SHANGHAI JIAO TONG UNIV

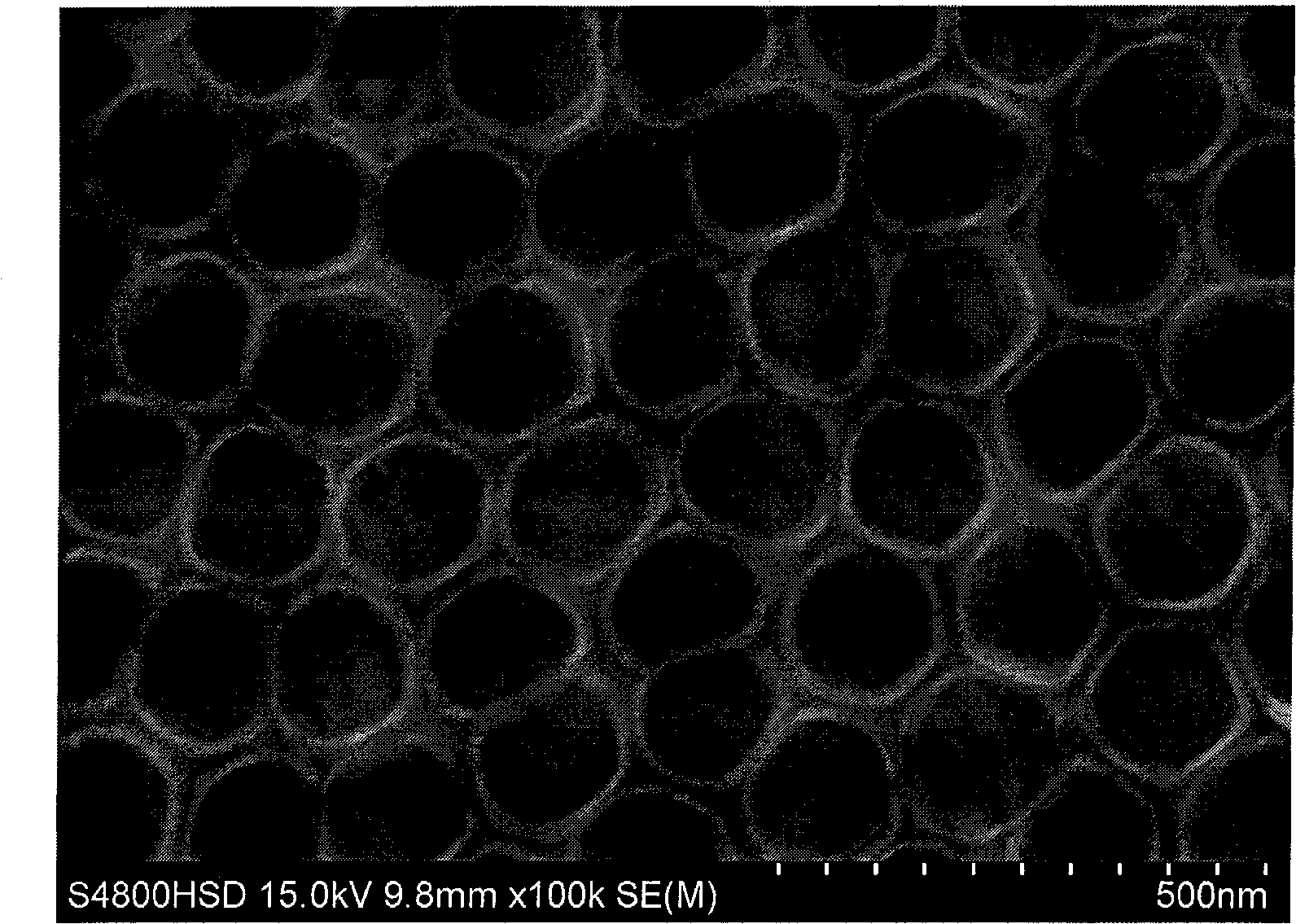

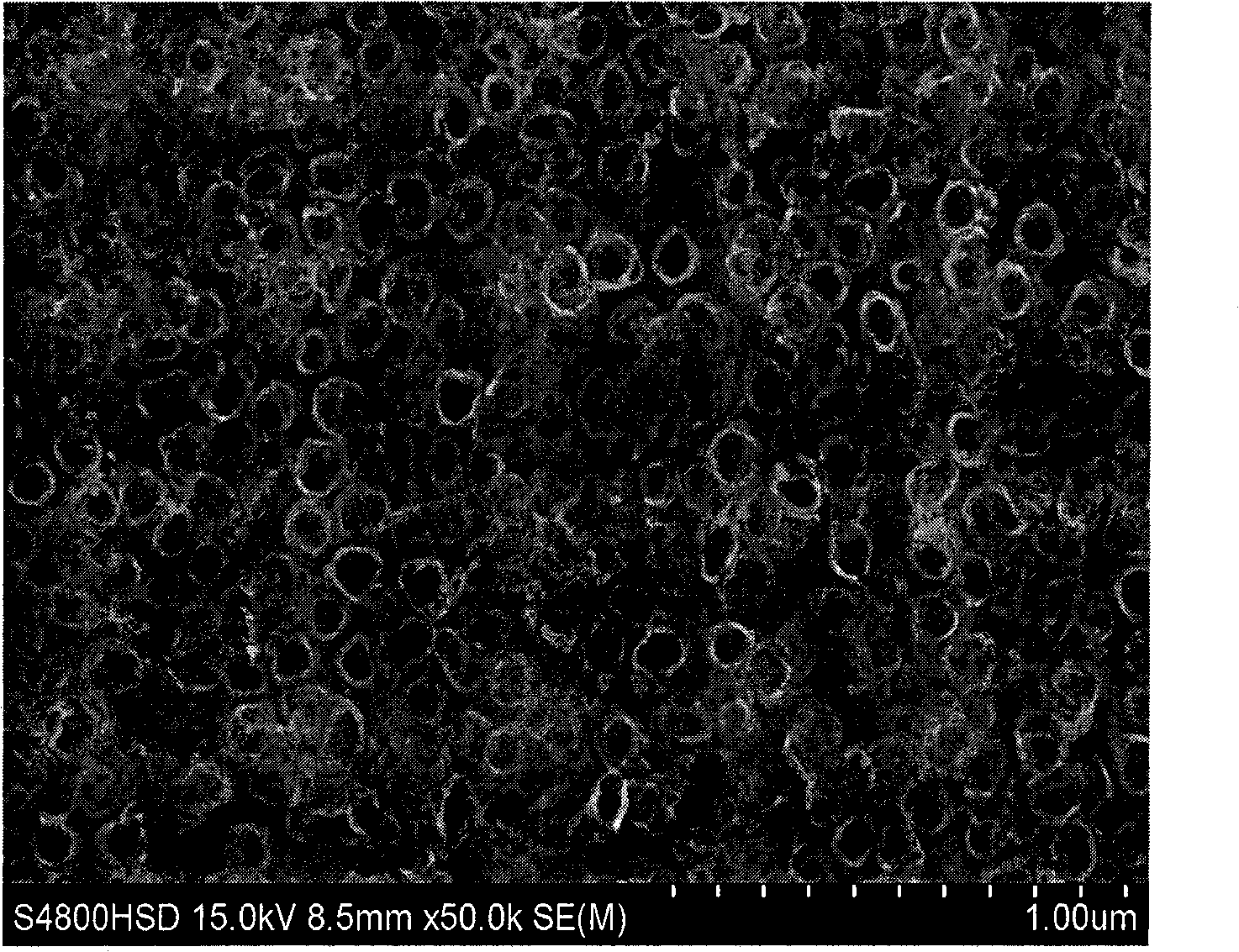

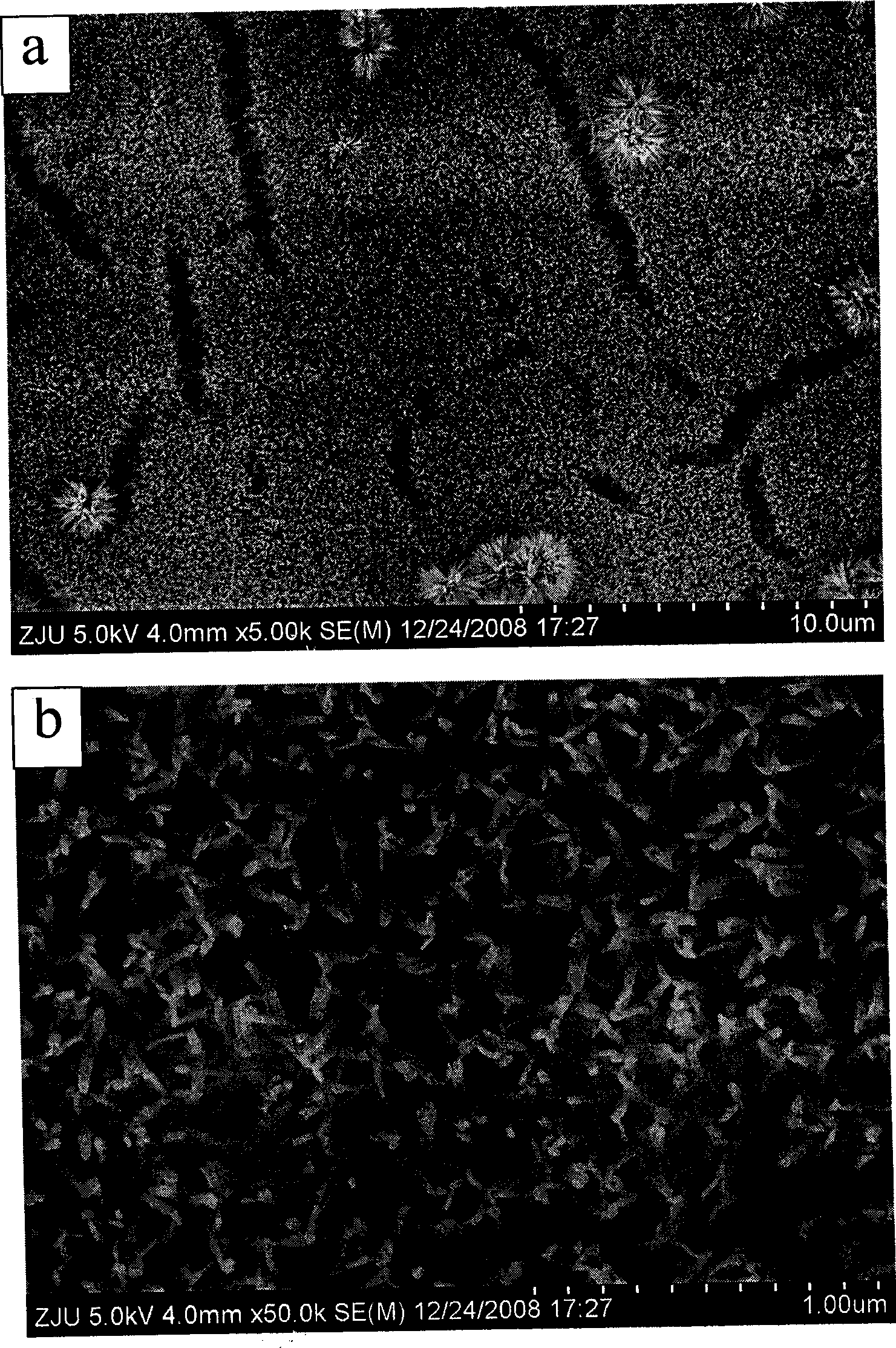

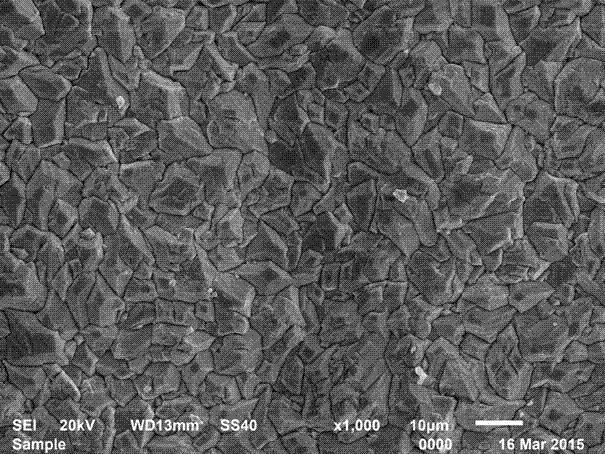

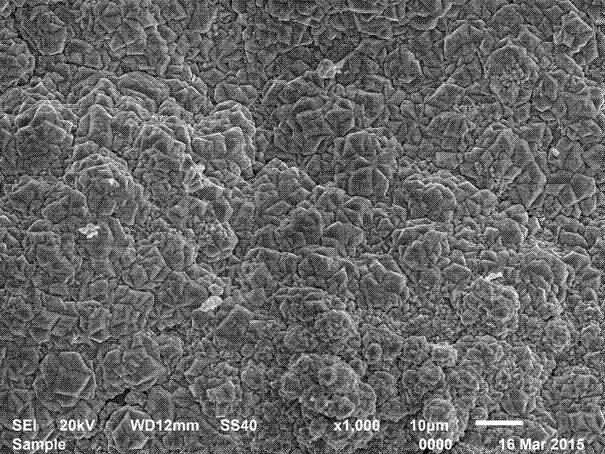

Method for preparing TiO2 nanotube array film

InactiveCN101514471ARegular microscopic morphologyNo reunionPolycrystalline material growthSurface reaction electrolytic coatingTio2 nanotubeTitanium

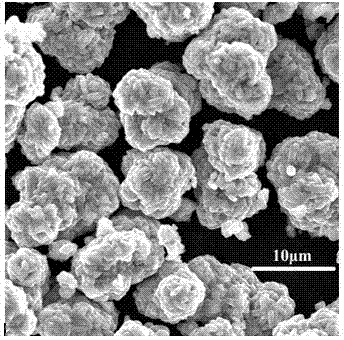

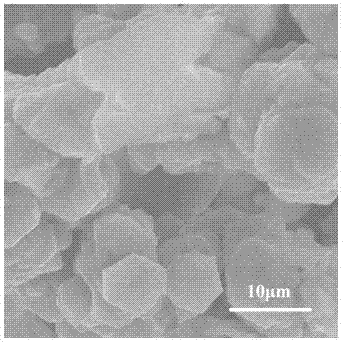

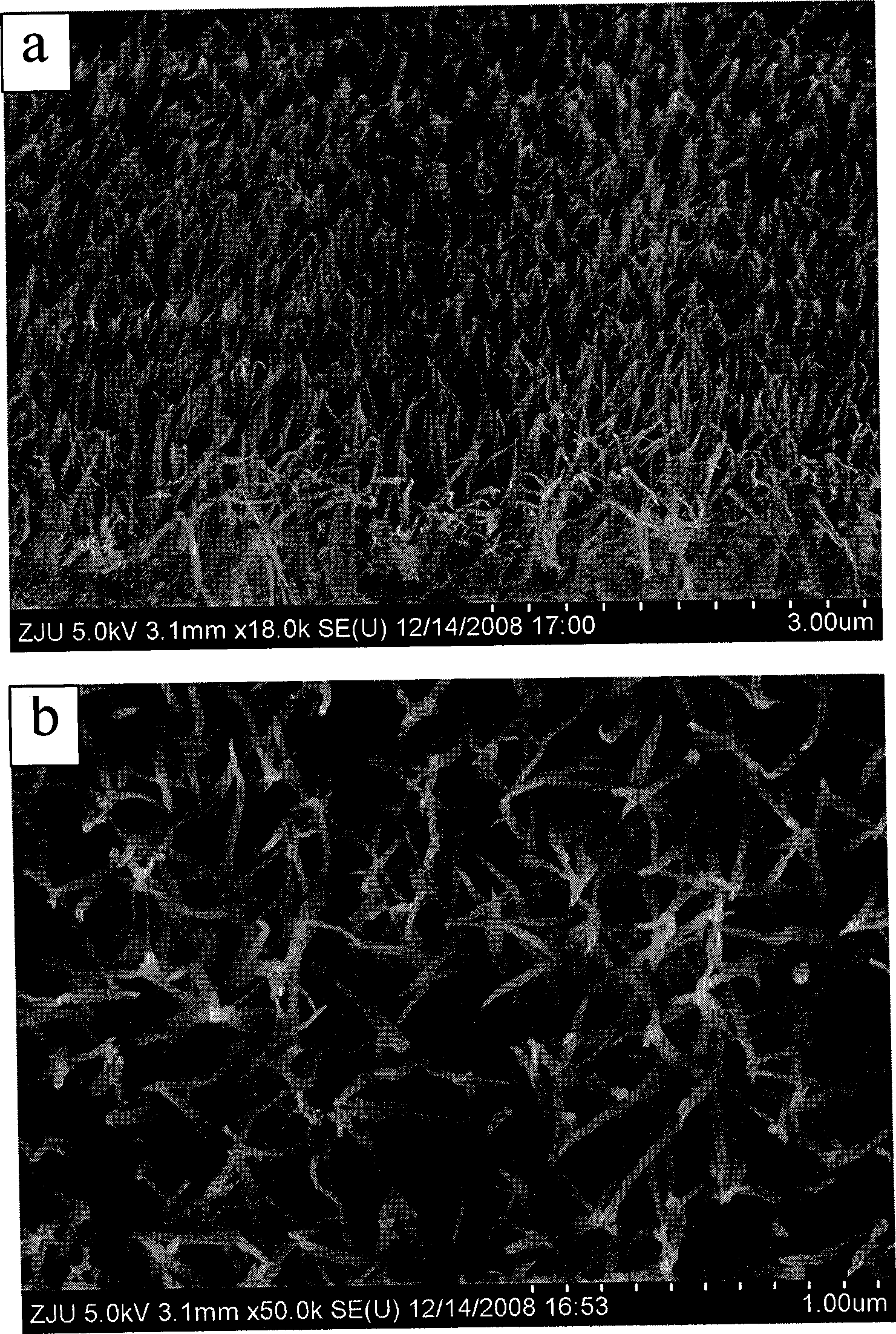

The invention provides a method for a preparing TiO2 nanotube array film, relating to a method for preparing a nanotube film. The method solves the problems of the prior art that the prepared nanotube array film features thin film, irregular micro appearance, heterogeneous length of nanotubes, reunion of tube orifice and cracking of the film. The preparation method comprises: 1. a titanium plate is cut into two titanium sheets of the same size, and polishing, ultrasound processing and washing are carried out on the two titanium sheets; 2. electrolyte is prepared; 3. primary anodic oxidation is carried out on the titanium sheets; 4. demoulding is carried out; 5. secondary anodic oxidation is carried out on the titanium sheets; 6. the titanium sheets are dried after ultrasonic processing; and 7. calcination treatment is carried out, thus obtaining the TiO2 nanotube array film. In the invention, twice anodic oxidations are carried out on the titanium sheets, thus producing the TiO2 nanotube array film featuring regular micro appearance, homogeneous, smoothness, thick film layer, reunion-free tube orifice and no cracking. The preparation method of the invention features simple technique and equipment and controllable thickness of the nanotube film.

Owner:HARBIN INST OF TECH

Oily high-temperature resistant protective coating material, application thereof and titanium ingot production method

The invention discloses an oily high-temperature resistant protective coating material. The oily high-temperature resistant protective coating material is obtained after a raw material mixture is uniformly mixed, wherein the raw material mixture contains an oxidation protecting agent and an oily film forming agent; the oxidation protecting agent contains Al powder and Fe powder which are in the weight ratio of 1: (0.01-0.1). The invention further discloses an application of the oily high-temperature resistant protective coating material in titanium ingot production and a titanium ingot production method. The oily high-temperature resistant protective coating material disclosed by the invention has the advantages that the condition that the surface of a titanium ingot is not subjected to oxidation cracking under the condition that the titanium ingot undergoes constant temperature for 8 hours at the high temperature of 1,000 DEG C can be guaranteed, the forming possibility of an oxygen dissolved layer can be greatly reduced, and the yield and production efficiency of a titanium material are increased; the construction environment is not affected; the preparation process is simple; a variety of coating manners, such as pneumatic spraying, vacuum spraying and brushing, can be adopted. The titanium ingot production method disclosed by the invention has good economic and social benefits and has relatively broad popularization and application prospects in titanium plate and titanium tube production industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Preparation method of titanium-steel composite plate

InactiveCN101992344ASolve easy oxidationIncreased interfacial shear strengthLaminationLamination apparatusComposite plateVacuum chamber

The invention relates to a preparation method of a composite steel plate, in particular to a preparation method of a titanium-steel composite plate. The preparation method comprises the following steps of: firstly selecting titanium plates and steel plates which have equal width and length and removing rusty layers and oxide layers; then making surfaces of the titanium plates and the steel plates opposite, and completely coinciding to form a combined blank; then sealing up the periphery of the combined blank by taking four titanium plates as side seal plates, and clamping the side seal plates and the combined blank by using a clamp and then putting the side seal plates and the combined blank into a vacuum chamber together; tightly welding all contact seams of the combined blank and the side seal plates, then conveying the combined blank and the side seal plates into a heating furnace together and heating to 600-1200 DEG C, and carrying out heat preservation for 0.1-2h; and finally, conveying the heated combined blank into a rolling mill for rolling to obtain the titanium-steel composite plate with the interface bonding strength of 350MPa. The invention well solves the problem that the interface of the titanium-steel composite plate is oxidized and improves the interface bonding strength of the composite plate, and moreover, argon or brazing filler metal does not need to be added, thereby saving the cost and simplifying the flow of the production process.

Owner:沈阳科安捷材料技术有限公司

Preparation method of high-performance thin clad titanium/steel compound plates

InactiveCN102489506AEasy to manufactureSimple methodWork treatment devicesAuxillary arrangementsOrganic solventTitanium

The invention discloses a preparation method of high-performance thin clad titanium / steel compound plates, and the method comprises the following steps: step 1) performing treatment on the surface to be compounded of a steel plate and the surface to the compounded of a titanium plate through a mechanical method, removing defects on the surfaces to be compounded and then washing the surfaces to be compounded of the steel plate and the titanium plate clean through an organic solvent; 2) assembling the steel plate and the titanium plate after cleaning into a rolled compact; 3) heating the rolled compact to 780 DEG C-880 DEG C and performing heat insulation for 20 min-180min; 4) sending the rolled compact after heat insulation into a rolling machine for rolling, and cooling to get the compound plate; 5) performing heat treatment on the compound plate; 6) leveling, and then cutting off the head, the tail and a weld joint part so as to get two titanium / steel compound plates, wherein the thickness of clad titanium of each titanium / steel compound plate is not more than 3.0mm, and the shear strength is not less than 180MPa. The method disclosed by the invention is simple and very easy to prepare thin clads, in particular to the titanium / steel compound plates with the clad thickness of less than 3.0mm.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

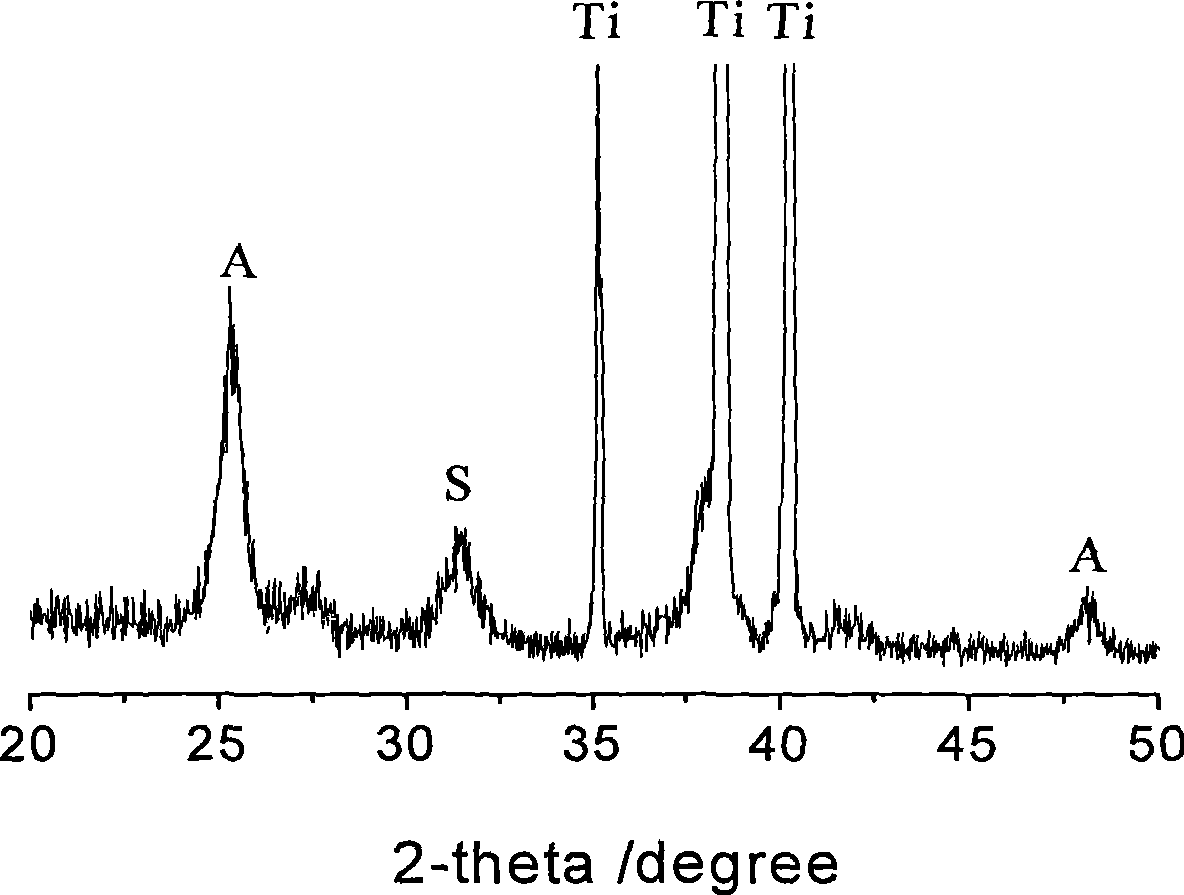

Process for reversely recycling and preparing lithium nickel manganese oxide by taking waste lithium battery as raw material

ActiveCN103199230ARealize resource utilizationGood for regulating propertiesCell electrodesWaste accumulators reclaimingElectrolysisManganese oxide

The invention discloses a process for reversely recycling and preparing lithium nickel manganese oxide by taking waste lithium batteries as raw materials. The process is characterized by comprising the following steps of: (1) preprocessing a positive battery plate of a waste lithium battery to obtain anode power; (2) dissolving the anode power in inorganic acid, and eliminating impurities to obtain mixed acid liquor containing nickel and manganese; (3) adding a nickel source or a manganese source into the mixed solution; (4) adding an acetate complexing agent, and regulating the ratio of the acetate concentration to the total metal ion concentration; (5) putting the mixed solution into an electrolytic bath to be electrolyzed, and depositing nickel manganese oxide on a titanium plate; (6) stopping the conduction of a direct current, taking the titanium plate out, separating the nickel manganese oxide on the titanium plate, and drying the nickel manganese oxide to obtain nickel manganese oxide powder; (7) and uniformly mixing the nickel manganese oxide powder and a lithium source, and then calcining the mixture to obtain lithium nickel manganese oxide. According to the process, a regenerated product having the performance the same with the performance of the original product can be obtained by the waste battery through a reverse recycling process, so that the resource utilization can be realized.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

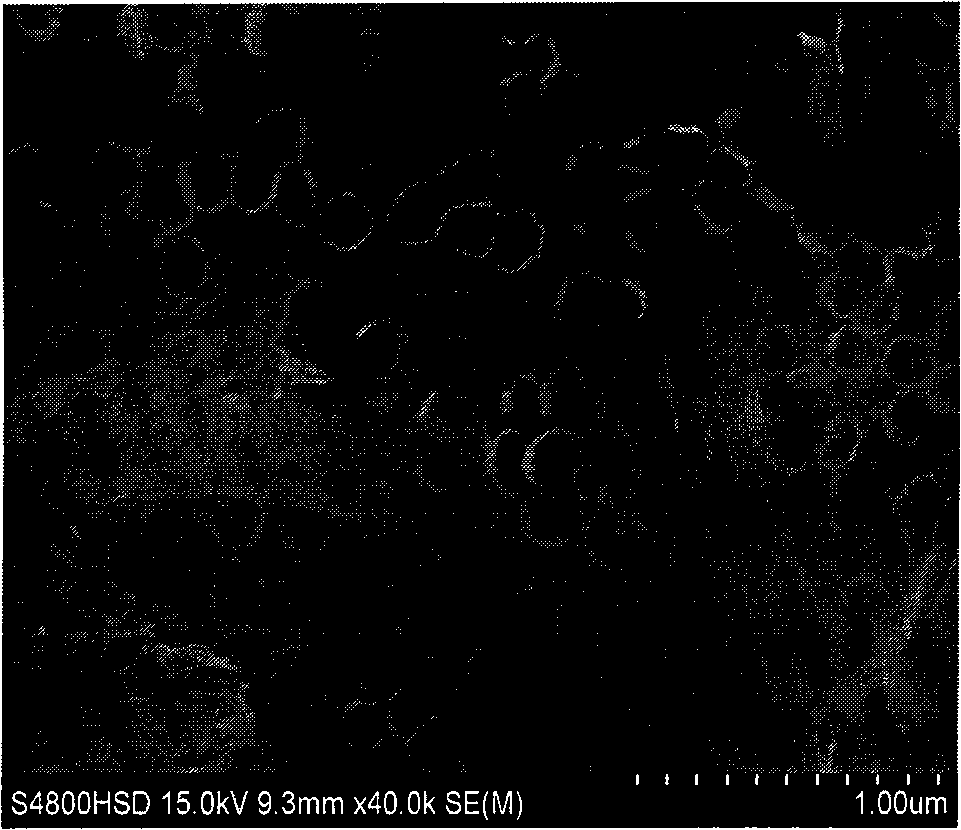

Method for producing nano-wire array film of titanium dioxide

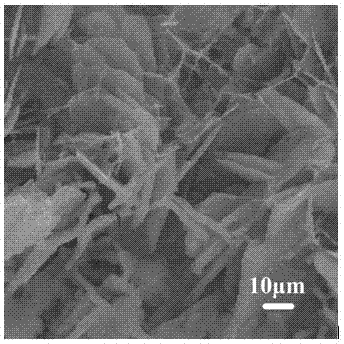

The invention discloses a method for preparing a titanium dioxide nano-wire array film. The method comprises the following steps: mixing hydrofluoric acid, nitric acid and deionized water to prepare an acid wash; adding melamine and nitric acid into a hydrogen peroxide solution to obtain a reaction solution; washing the surface of a metal titanium plate by the acid wash to be immersed in the reaction solution to react for 60 to 72 hours at a temperature of between 60 and 90 DEG C; and washing the reacted titanium plate by the deionized water to be dried, and insulating the titanium plate for 1 to 2 hours at a temperature of between 350 and 550 DEG C. The method for preparing the titanium dioxide nano-wire array film does not need a template or a catalyst, and has the advantages of simpleness and feasibility, low cost, pure film, regular size arrangement, perfect crystallization, large specific surface area and firm combination with a substrate, and the titanium dioxide nano-wire array film has wide application in photocatalysis, photoelectrocatalysis, thin-film solar cell, gas sensor, cold cathode electronic emission and other fields.

Owner:ZHEJIANG UNIV

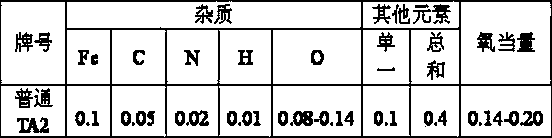

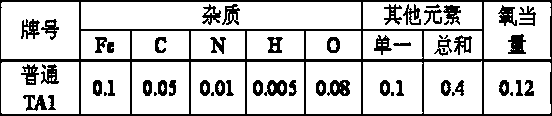

Super plastic forming method for plate type heat converter special titanium plate

InactiveCN101121178AHigh yield strengthEasy to processRoll mill control devicesFurnace typesPlate heat exchangerTitanium

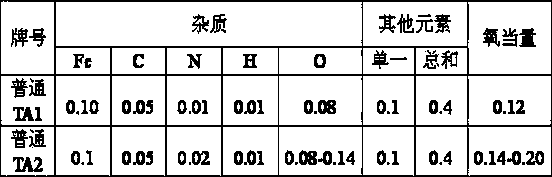

The present invention relates to a superplastic forming method for the titanium plate specially used for the plate type heat exchanger, which belongs to the field of mechanical processing technology. The present invention comprises the following steps that spongy titanium is chosen to be the melted raw material; the spongy titanium is placed in a vacuum plasma smelting furnace to be directly cast into plate base; the plate base forms a plate of a thickness of 2.0 to 2.4 mm after the process of heating, hot rolling, acid and alkali washing; second heating, hot rolling and acid and alkali washing and annealing; the plate of a thickness of 2.0 to 2.4 mm after the annealing in the vacuum smelting furnace forms a titanium plate of a thickness of 0.5 to 0.6 mm after the process of cold rolling, cleaning, second annealing and cold rolling, acid and alkali washing and third annealing. The present invention adopts the process that the spongy titanium which contains oxygen, iron and nitrogen of comparatively high content is directly processed into the titanium plate base in the plasma smelting furnace and directly rolled into the plate without forging and pressing.

Owner:上海桦厦实业有限公司

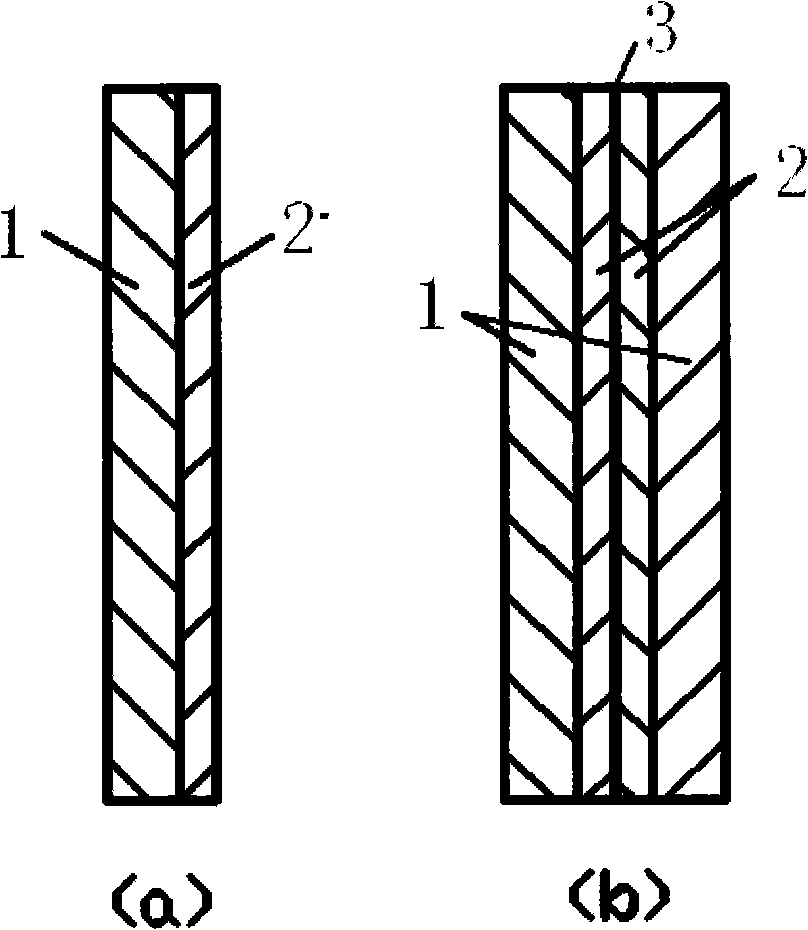

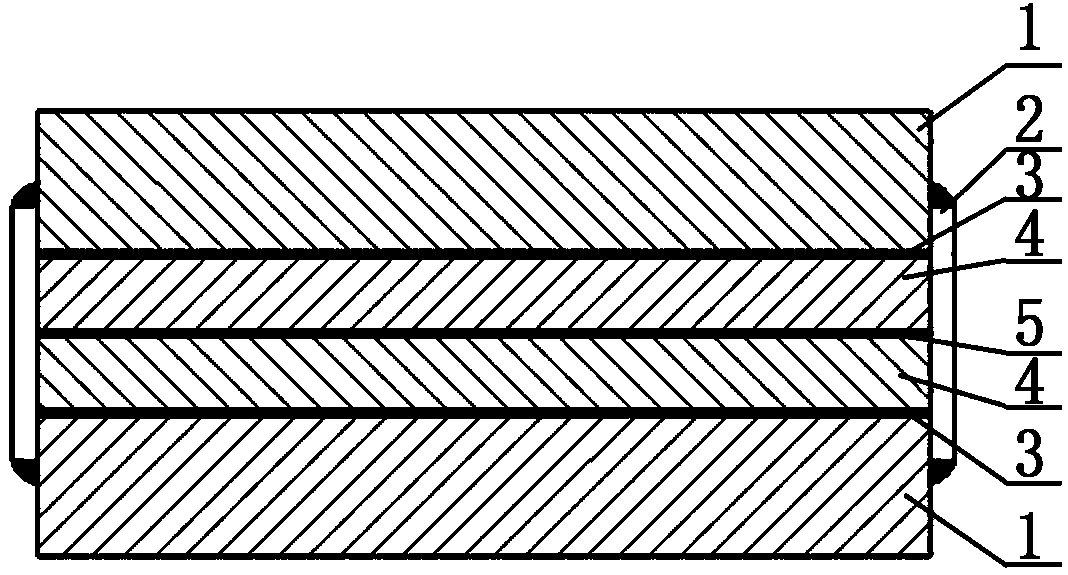

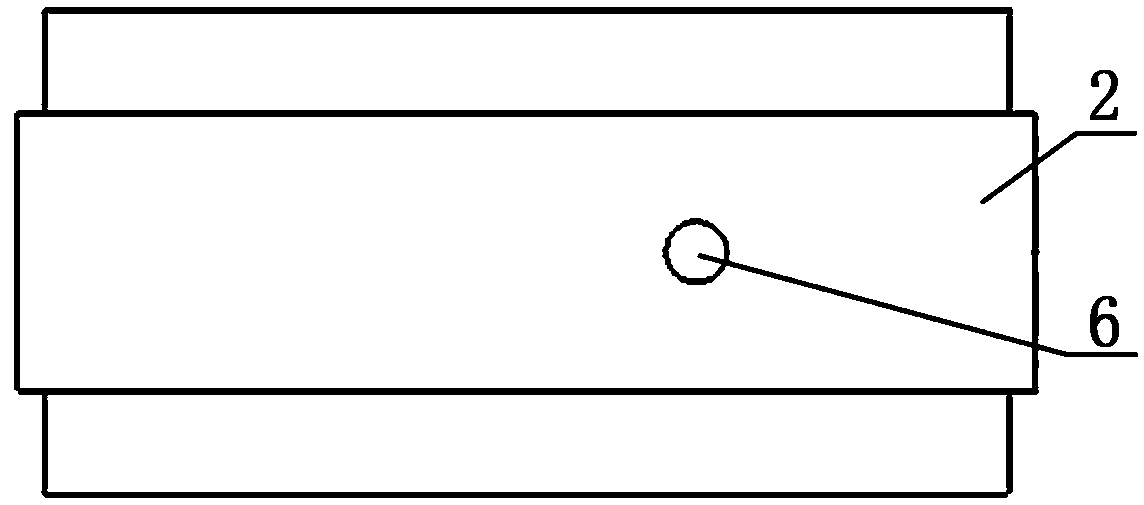

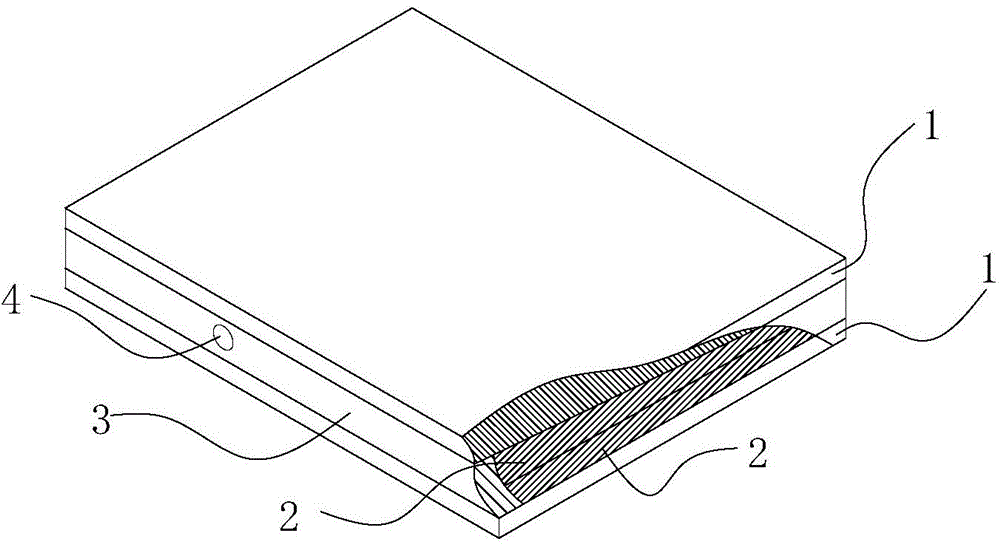

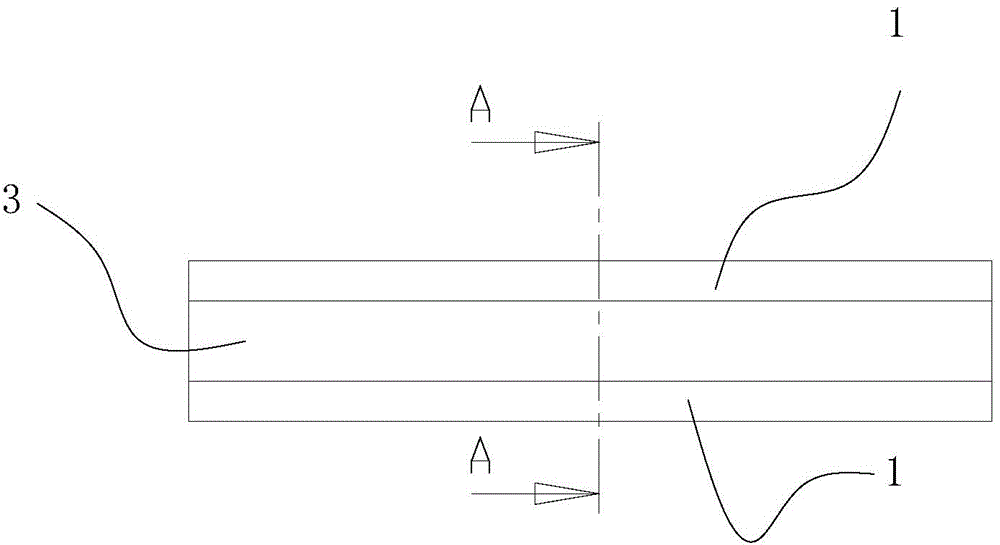

Preparation method of titanium-steel single-sided composite board

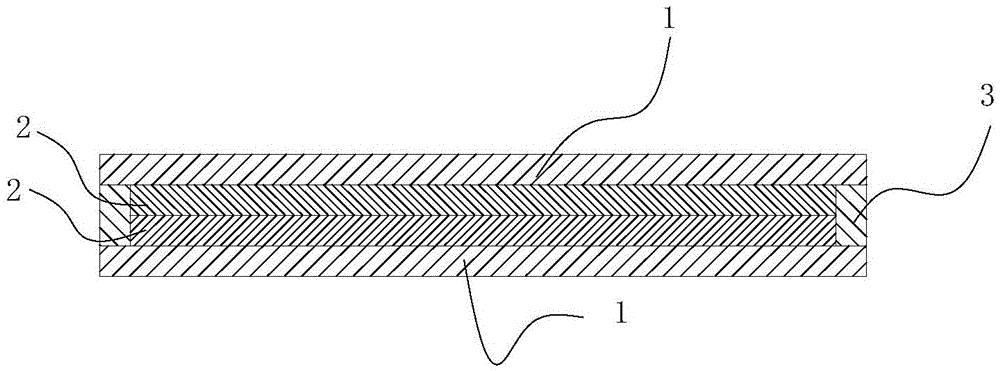

ActiveCN102773254AReasonable process designLow requirements for welding conditionsMetal rolling arrangementsLayer removalTechnical design

The invention discloses a preparation method of a titanium-steel single-sided composite board, comprising the following processing steps of: (1) respectively selecting two titanium plates with same size and two steel plates with same size and carrying out rust and oxide layer removal treatment on the surfaces of the plates; (2) assembling to form multiple layers of symmetrical combined blank sequentially including a steel plate, a transition layer, a titanium plate, a parting agent, a titanium plate, a transition layer and a steel plate, wherein a gap exists between the periphery of the titanium plate and a barrier strip in the combined blank; (3) compressing the combined blank and respectively welding the barrier strip with a first steel plate and a second steel plate to form a closed cavity among the first steel plate, the second steel plate and the barrier strip, drilling holes in the barrier strip and welding a steel tube in the holes, and communicating the steel tube and the closed cavity; (4) conveying the combined blank into a heating furnace to heat and vacuumizing; (5) sealing the outer end of the steel tube and then conveying the combined blank into a rolling mill; and (6) cutting the combined blank after rolling to obtain the titanium-steel single-sided composite board. The preparation method disclosed by the invention is rational in technical design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

Method of manufacturing thin titanium/steel composite board

InactiveCN101428389AHigh bonding strengthGuaranteed Thickness RequirementsMetal rolling arrangementsNon-electric welding apparatusSheet steelTitanium

The invention discloses a method for preparing a thin-type titanium or steel composite plate, and particularly relates to a method for preparing a composite plate manufactured by the titanium steel-based composite plate through explosion and pack rolling. The method is characterized in that in the preparation process of the thin-type titanium or steel composite plate, the titanium or steel composite plate is compounded and formed by the titanium plate and the steel plate through explosion, then two composite plates are folded and welded into a billet body, and then the thin-type titanium or steel composite plate is formed through rolling. The preparation method adopts the explosive composite process, the rolling billet body has high bonding strength after explosive compounding, the titanium or steel composite plate billet is folded and welded for rolling, and the deformation amount is in 4 to 7 times; therefore, the preparation method not only ensures higher bonding strength of the titanium or steel composite plate after rolling, but also ensures the respective thickness requirements, the prepared titanium or steel composite plate has good processing technological property, the explosive composite billets of the titanium plate and the steel plate after pack rolling have good bonding property, the bending test is performed without layering, the titanium plate surface is free from cracks and impurities, and the method has the advantages of higher bonding strength, corrosion resistance and fatigue resistance.

Owner:XIAN TIANLI CLAD METAL MATERIALS

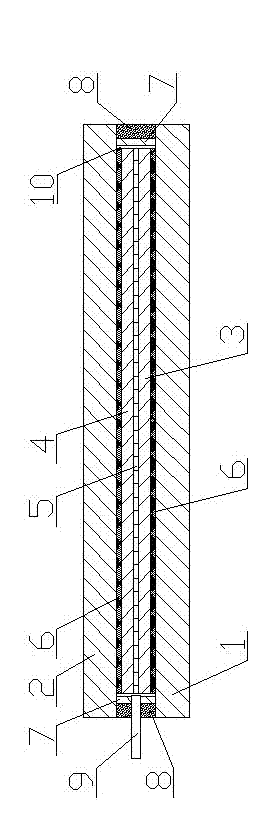

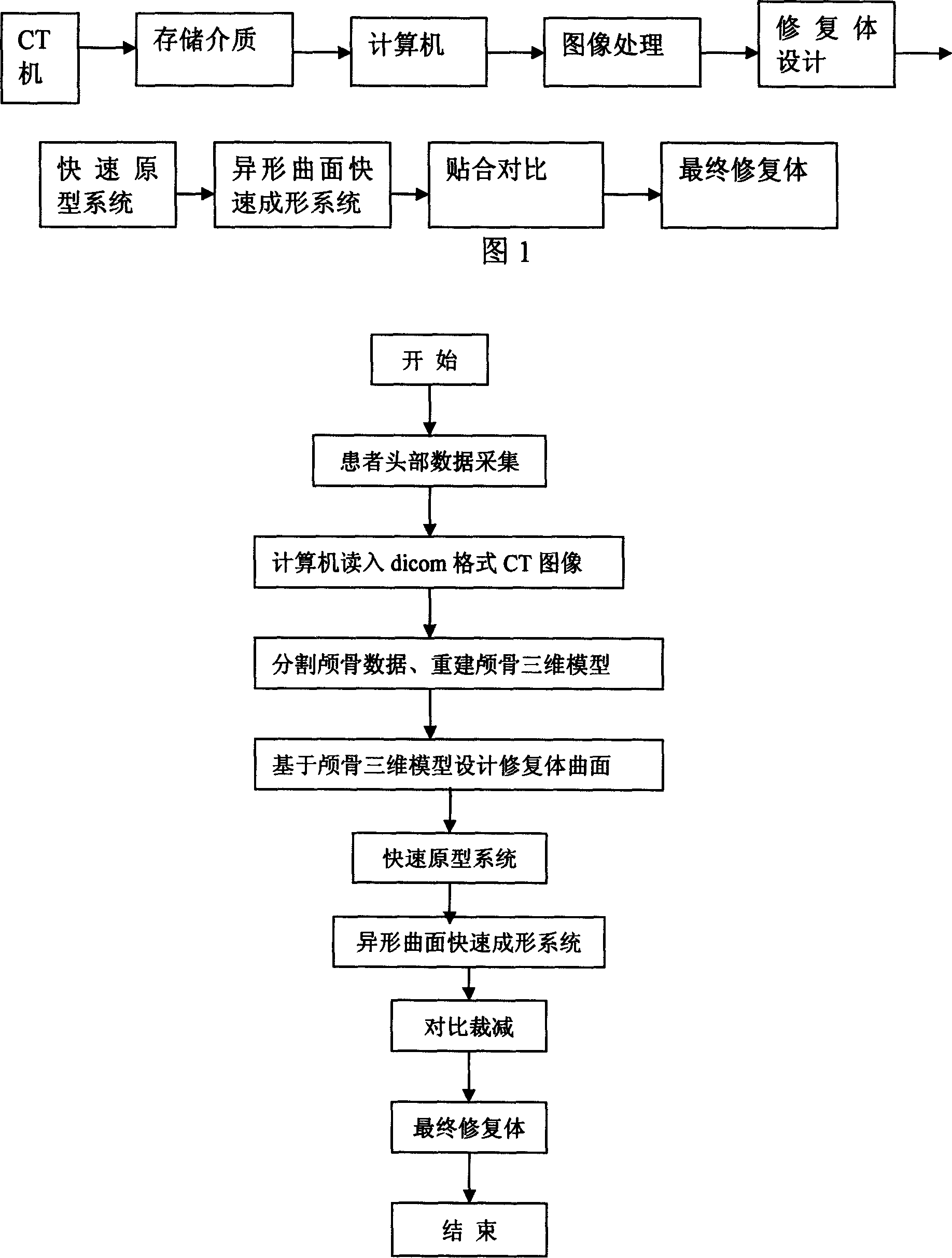

Method for preparing titanium alloy skull repairing body

InactiveCN1586432AQuality improvementSolve the problem of rapid shapingBone implantImage processing softwareDesign software

The preparation process of skull repairing body of titanium alloy for cerebral neurosurgery and other fields is based on the CT image scanning of the patient, assembling the repairing body, data analysis in computer with common image processing software and reverse design software, reconstituting the 3D prototype of the patient head, designing the repairing body based on the 3D prototype, making the repairing body mold via the fast prototype system, and pressing the netted titanium plate based on the mold to form final repairing body. The present invention features the making of the repairing body mold via digital design technology, fast forming system with special curved surface and gradually forming method to press the netted titanium plate. The repairing body of the present invention has high precision, low cost, fast making process and other advantages.

Owner:BEIJING UNIV OF TECH

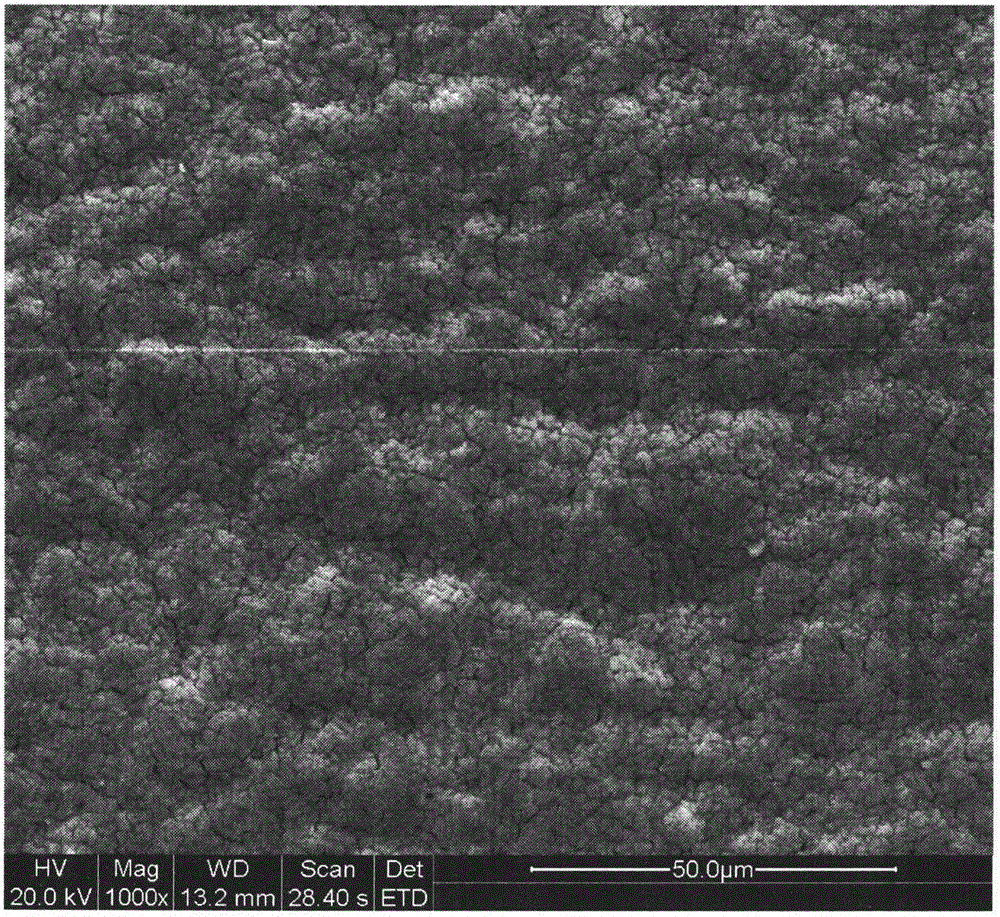

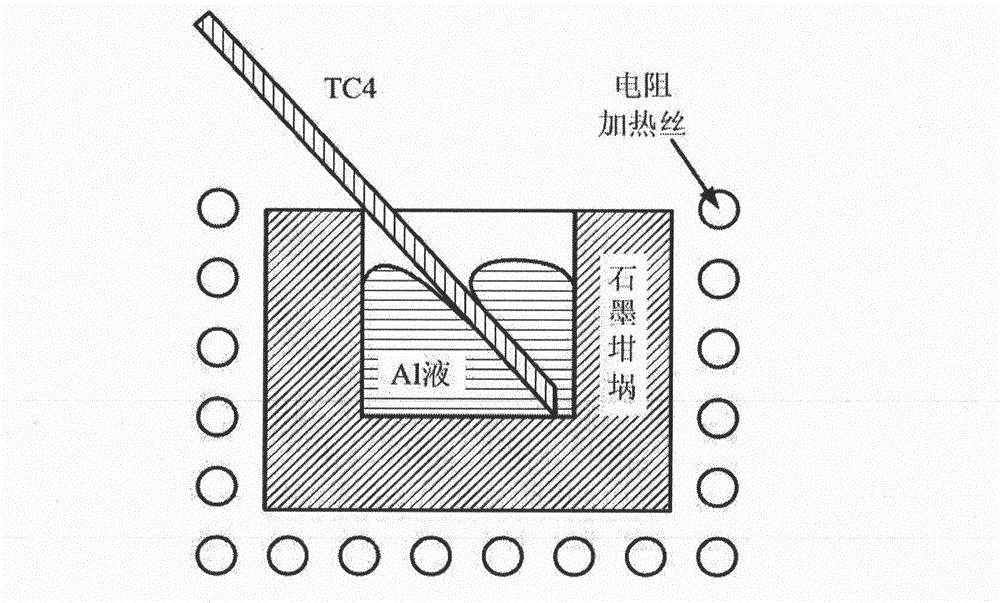

Titanium alloy and aluminum alloy or aluminum base compound material ultrasound precoating and soldering method

ActiveCN101284323AMeet various needs of connecting jointsReliable connection without breakingSoldering apparatusMetallic material coating processesTitaniumSoldering

A titanium alloy and aluminum alloy or aluminum matrix composite ultrasound pre-coating brazing method relates to a method for welding the titanium alloy and the aluminum alloy or the aluminum matrix composite, and solves the technical shortcomings with prior method for weldingthe titanium alloy and the aluminum alloy or the aluminum matrix composite, including hard, crisp and thick intermetallic compounds produced on the interface, cracks and uncontinuous micorcracks, low bonding strength of connections, expensive connecting equipment and long production period. The method comprises the steps of cleaning the surface of a titanium plate, ultrasonically pre-coating the surface, polishing and treating the coating layer, ultrasonically coating brazing filler metal on the titanium plates and aluminum plates, and ultrasonically brazing. The method has the advantages of simple process, low production cost, short production period, high mechanical property, etc.

Owner:哈尔滨工大光电科技有限公司

Method for producing metallic titanium plate using medium-wide strip hot rolling machine set

ActiveCN101412038ALow investment costRoll force/gap control deviceTemperature control deviceSocial benefitsProduction line

The invention discloses a method for producing a metallic titanium plate by adopting a medium-wide band heat rolling set. The method comprises the following steps: heating a titanium plate blank with a thickness of between 50 and 90 millimeters in a roller-hearth type soaking furnace to between 800 and 1,000 DEG C, controlling inlet temperature of the titanium plate blank entering the medium-wide band heat rolling set at a temperature of between 800 and 950 DEG C, controlling process temperature to between 700 and 950 DEG C, and keeping final rolling temperature at a temperature of between 700 and 800 DEG C after fine rolling for seven times; and well controlling roll gap width, depressing rate, roll force and roll (rolling) speed of each stander of the heat rolling set, controlling the rolling speed of the titanium plate rolled by the tail stander of the heat rolling set at between 4.0 and 8.0 meters per second, and coiling the titanium plate by a coiling machine after cooling the titanium plate by water, wherein the coiling temperature is between 550 and 680 DEG C. The method uses a CSP production line to produce the non-ferrous metallic titanium plate (coil) for domestic initiation, and has extremely great economic and social benefits.

Owner:湖南湘投金天钛金属股份有限公司 +1

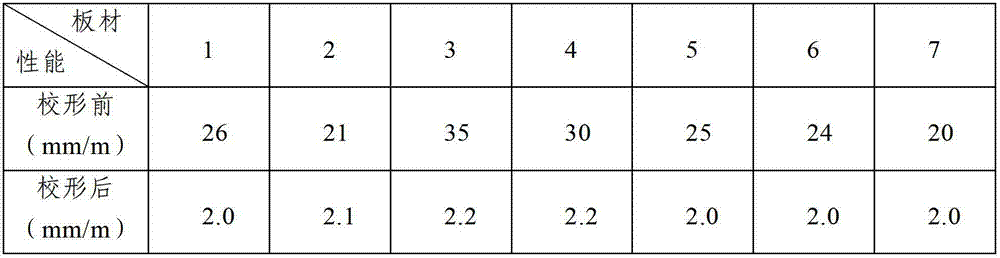

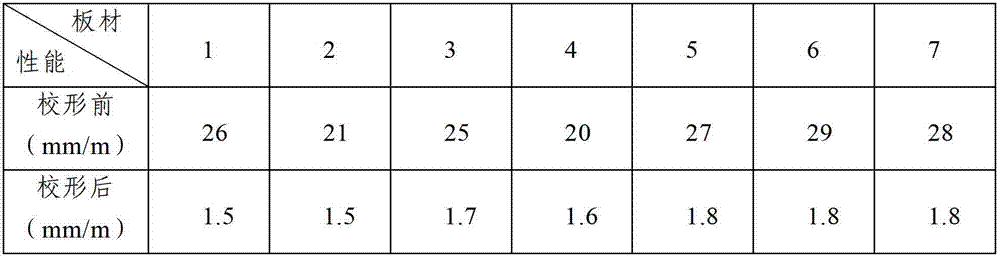

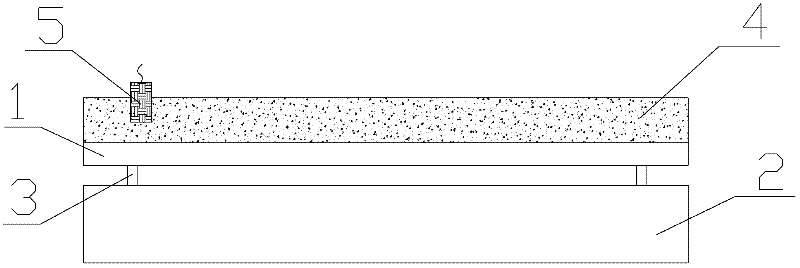

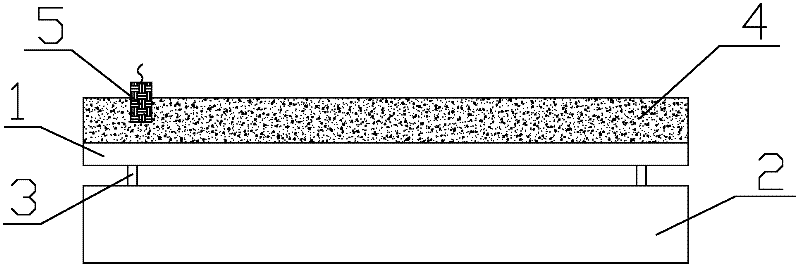

Hot shaping method of large-specification titanium plate

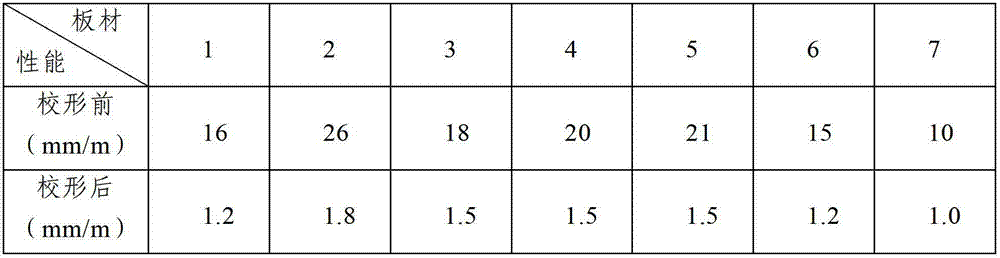

ActiveCN102861788AIncrease furnace capacityLarge furnace loading under atmospheric annealing conditionsThermal insulationTitanium

The invention provides a hot shaping method of a large-specification titanium plate. The hot shaping method includes the following steps of firstly, placing a shaping base plate in an annealing furnace and stacking the large-specification titanium plate on the shaping base plate; secondly, laying a shaping pressing plate at the top of the titanium plate; and thirdly, performing hot shaping treatment by using a gradient heating and thermal insulation process to obtain the large-specification titanium plate with unevenness smaller than or equal to 3mm / m. According to the hot shaping method of the large-specification titanium plate, the shaping base plate, the shaping pressing plate and a separation backing plate which are cheap and are made of carbon steel are used, so that the requirement of shaping strength required during a shaping process can be satisfied, the titanium plate is simple in re-shaping and easy to process when the plate is deformed during a repeat usage process, the service life is prolonged, and simultaneously, production costs are greatly reduced; and by means of a gradient heating mechanism and a cooling mode, full release of stress of the surface and the inside of the large-specification titanium plate is facilitated, mechanical properties and process properties of the plate are guaranteed, and simultaneously, the shape of the leveled plate can be well kept in follow-up processing.

Owner:WESTERN METAL MATERIAL

Titanium-coated aluminium laminated composite plate and preparation method thereof

InactiveCN101574861AGood surface bindingImprove conductivityHot-dipping/immersion processesMolten spray coatingInternal resistanceComposite plate

The invention discloses a titanium-coated aluminium laminated composite plate used for an insoluble anode in electrolysis process and a preparation method thereof, belonging to the technical field of wet-process metallurgy. The preparation method comprises the following steps of: adopting one or more of techniques of electric arc spraying, spray deposition, composite rolling, melt plating and thelike to coat an aluminium layer on the single surface of the surfaces of the titanium plate, obtaining two titanium / aluminium composite plates which are then prepared into the titanium-coated aluminium laminated composite electrode material which takes aluminium as an inner core (for improving the electric conductivity of the electrode) and is coated by titanium at the outer layer. The prepared titanium-coated aluminium laminated composite plate has the advantages of excellent interface coherency, good electric conductivity, good corrosion resistance, low cost and the like, a coating titaniumanode prepared by adopting the laminated composite plate as a substrate leads the internal resistance of inert electrode to be reduced, the current distribution to be even and the electrolytic productpurity to be improved, thus achieving the effects of saving energy and reducing consumption; and the bath voltage is reduced by 10 to 30 percent compared with that of the pure titanium coating anode.

Owner:KUNMING UNIV OF SCI & TECH

Pack rolling production method of titanium steel composite board

The invention discloses a pack rolling production method of a titanium steel composite board. The technical key point is that the pack rolling production method comprises the following steps that 1, a steel plate, a titanium plate and a pure iron plate are cut and polished for standby use; 2, the materials in the step 1 are combined to form a composite board blank, a separant is coated, a sealing ring is arranged on the outer part, guide pipes are welded in degassing holes, and the gas tightness is detected; 3, one guide pipe is connected with a vacuum pump, a vacuum thermocouple is mounted on the other guide pipe, and after vacuumizing, the guide pipes are sealed; 4, a composite board is heated, thermal insulation is performed, hot rolling and calendaring recombination is performed, and rolling is carried out for three times; 5, the step 4 is repeated until an ideal size is obtained; 6, the composite board is heated to 720-780 DEG C, the temperature is kept for 1-3 h, and diffusion annealing is performed; 7, the diffusion annealing is moved, the oxide layer of the surface of the composite board is calendered, and cold rolling and press polish are performed; 8, the composite board is heated again, the temperature is kept, and the diffusion annealing is performed; 9, the edge is trimmed and sealed to obtain a finished product. The method is free of the influence of seasons and environmental pollution, the production scale and the product specification are controllable, and the boundedness that only a thin plate can be manufactured by a continuous hot rolling manufacturing method is avoided.

Owner:沈阳和世泰通用钛业有限公司

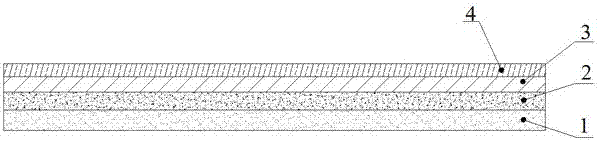

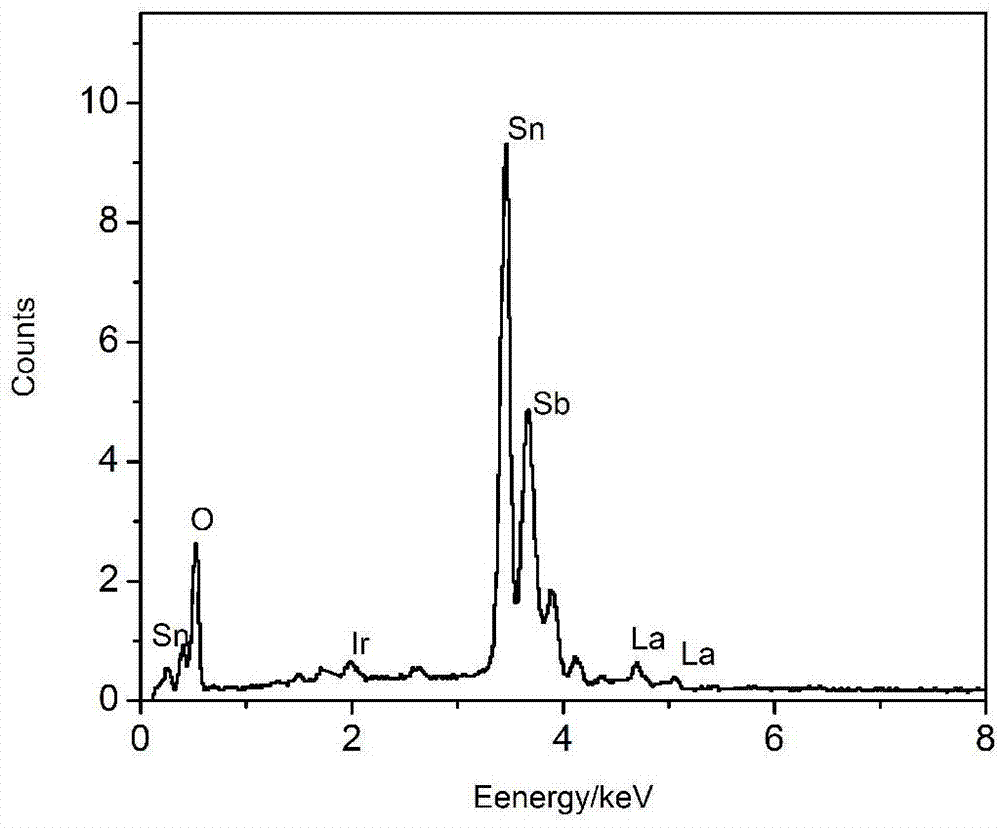

Graphene modified fluorine-contained lead dioxide electrode and preparation method thereof

ActiveCN106868509AImprove conductivityFast transferElectrolytic coatingsWater contaminantsLead dioxideMaterials science

The invention provides a graphene modified fluorine-contained lead dioxide electrode and a preparation method thereof. A tin antimony oxide bottom layer, an alpha-PbO2 middle layer and a beta-PbO2 active layer of the electrode all contain graphene. The preparation method comprises the steps of titanium plate pretreatment, thermal deposition of the tin antimony oxide bottom layer containing the graphene, acoustoelectric deposition of the alpha-PbO2 middle layer containing the graphene, and acoustoelectric deposition of the beta-PbO2 active layer containing the graphene. The graphene modified fluorine-contained lead dioxide electrode has the following advantages: the prepared graphene modified fluorine-contained lead dioxide electrode greatly is improved in electrocatalytic oxidation activity and largely prolonged in service life compared with a general fluorine-contained lead dioxide electrode, and is an anode material with development potential and suitable for electrocatalytic oxidation and degradation of organic pollutants in waste water.

Owner:JILIN NORMAL UNIV

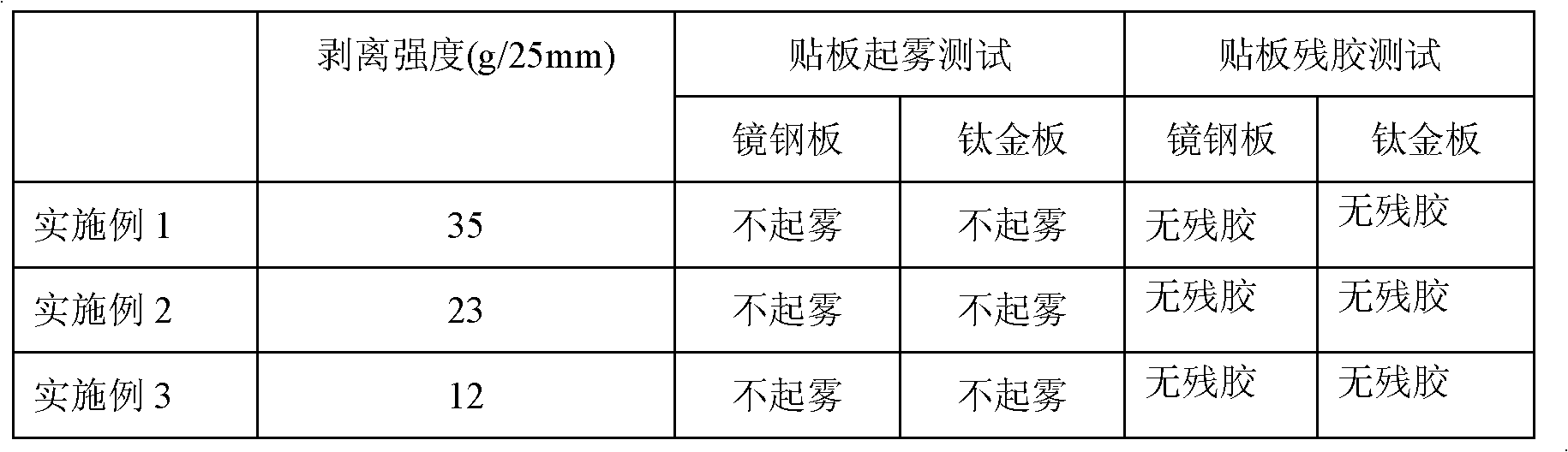

Fog-resistant aqueous pressure-sensitive adhesive and polyethylene protection film containing same

ActiveCN102492379APromote migrationResidue reductionFilm/foil adhesivesEster polymer adhesivesCross-linkTectorial membrane

The invention discloses a fog-resistant aqueous pressure-sensitive adhesive for a polyethylene protection film. The adhesive is prepared by using the manner of seeded emulsion polymerization. According to the invention, seeded emulsion is prepared at first, then pre-emulsion is added into the seeded emulsion drop by drop, the seeded emulsion and the pre-emulsion fully react by replenishing an initiator, cooling and pH value adjusting are carried out, and a discharged material is filtered. The invention also provides a polyethylene protection film containing the fog-resistant aqueous pressure-sensitive adhesive and a preparation method thereof. Through adjusting utilization amount of a cross-linking agent and gelatinizing content, an appropriate peeling strength of the emulsion pressure-sensitive adhesive prepared in the invention can be obtained; the prepared protection film has good fog resistance when applied on sheet materials like steel plates and titanium plates.

Owner:无锡达美新材料有限公司

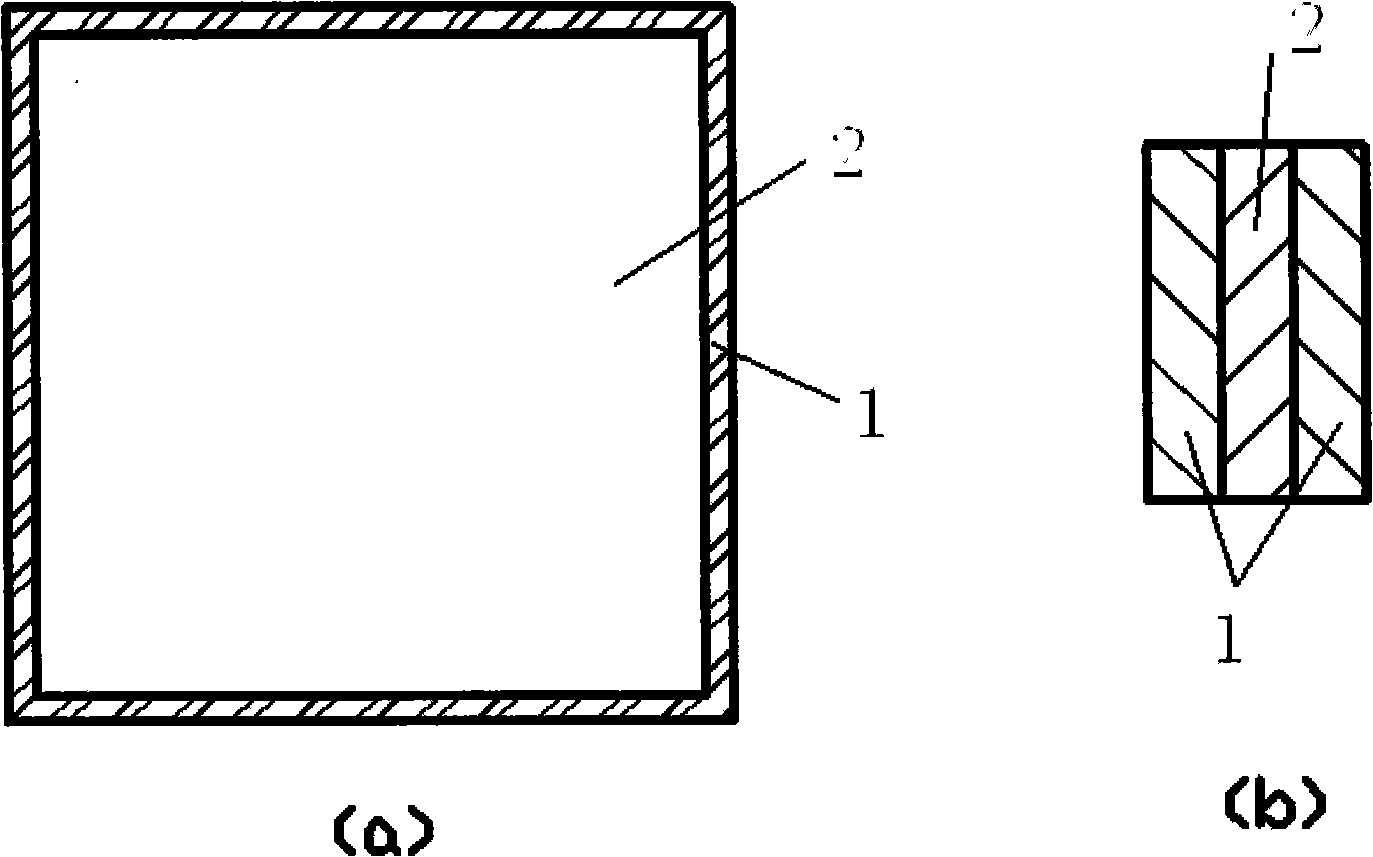

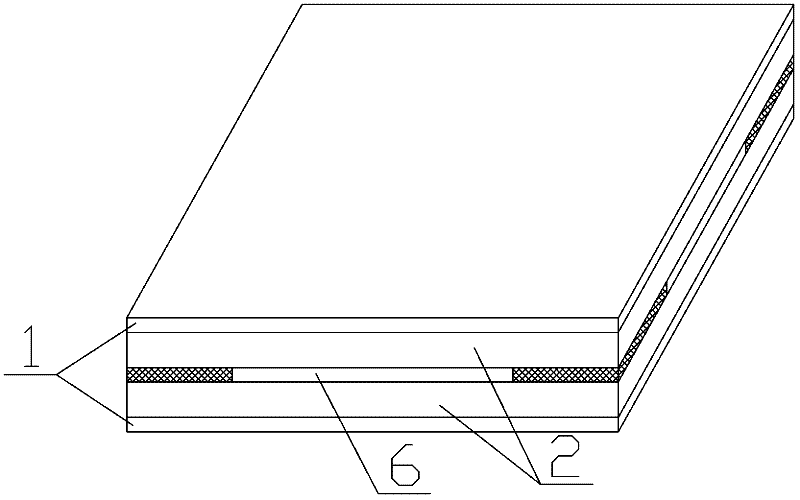

Material assembling method and rolling method for titanium-steel clad plate

InactiveCN104874634ASolve the problem of interface oxidationHigh bonding strengthMetal rolling arrangementsSurface oxidationTitanium

The invention relates to a material assembling method and rolling method for a titanium-steel clad plate and belongs to the field of titanium-steel clad plate manufacturing and processing. The material assembling method comprises the following steps: a, preparing two steel plates, two titanium plates and four side plates and removing an oxidation layer and oil stains on the surface of each plate; b, forming a hole in at least one side plate and welding a seamless carbon steel pipe at each opening hole; c, symmetrically assembling a blank from one steel plate, the two titanium plates and the other steel plate in sequence, and welding the blank into a combination body; d, after welding, connecting each seamless carbon steel pipe with a vacuum pump, vacuumizing to reach a pressure value no greater than 1*10<-2>Pa and sealing the seamless carbon steel pipe to obtain an assembled blank material. According to the material assembling method of the titanium-steel clad plate, the internal vacuum treatment of the blank material can be completed without the help of a vacuum electron beam welding box, and thus the production procedure is simplified, the cost is saved, the assembling effect is good and the problem of the interface oxidation of the titanium-steel clad plate can be effectively solved.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Production method for ultralong thin titanium/steel compound plate

InactiveCN102441769AEasy to useGuaranteed lengthAuxillary arrangementsMetal rolling arrangementsSheet steelTitanium

The invention provides a production method for an ultralong thin titanium / steel compound plate, which comprises the following steps: firstly, correcting the shape of a multi-layer titanium plate and performing heat treatment; secondly, cleaning and polishing a basic-layer steel plate and the multi-layer titanium plate after the heat treatment; thirdly, explosively welding the basic-layer steel plate with the multi-layer titanium plate to prepare a compound plate; fourthly, leveling the compound plate and mechanically cutting to guarantee that the compound plate binding fraction gets to 100%; fifthly, relatively superposing and assembling the steel surfaces of two qualified compound plates with the same sizes, and welding to obtain a blank; sixthly, rolling the blank; and seventhly, leveling and machining to obtain the ultralong thin titanium / steel compound plate. The method provided by the invention is lower in production cost and high in production efficiency; and the method adopts a combination method of the explosive welding process and the superposing rolling process, so that the using performance of the compound plate can be guaranteed and the length and the thickness of the compound plate also can be guaranteed. Therefore, the qualified ultralong thin titanium / steel compound plate can be produced by using a general rolling process only.

Owner:XIAN TIANLI CLAD METAL MATERIALS

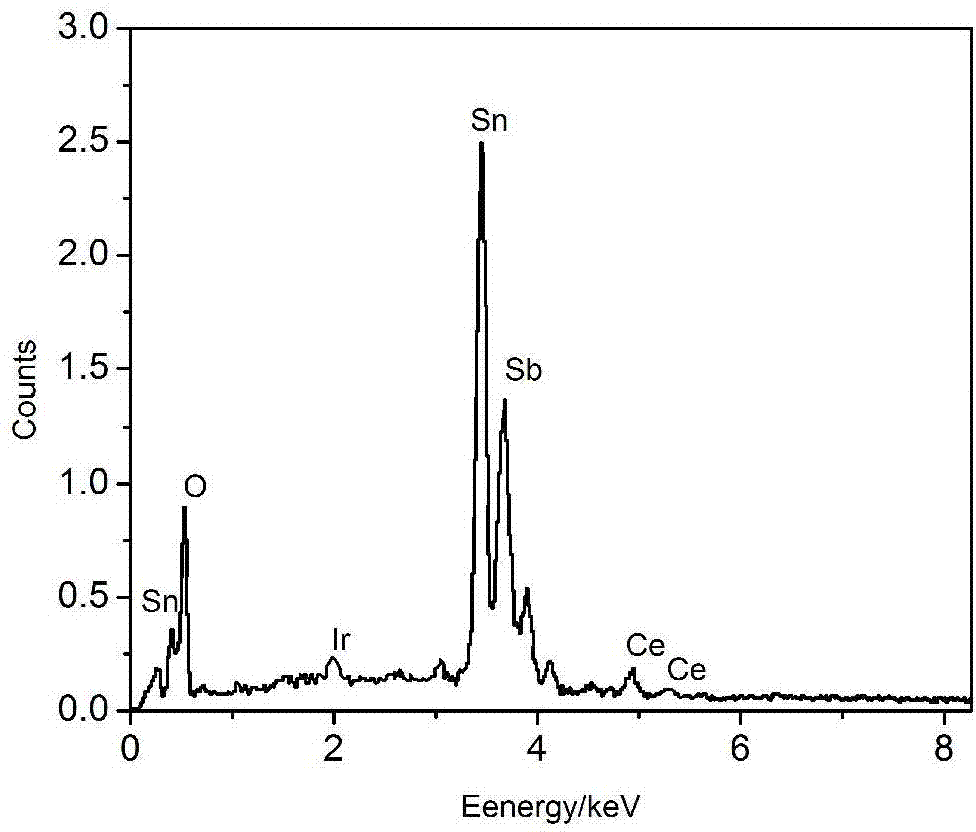

Rare earth doped Ti-based manganese dioxide electrode and preparation method thereof

InactiveCN102225797AImprove stabilityImprove conductivityWater/sewage treatmentRare-earth elementAntimony

The invention discloses a rare earth cerium doped Ti-based manganese dioxide electrocatalytic electrode and a preparation method thereof. The electrode consists of an internal layer of Ti substrate, an interlayer of tin-antimony oxide and a surface coating of cerium doped manganese dioxide, wherein, the internal layer of Ti substrate is a pure titanium plate, the interlayer of tin-antimony oxide is a mixture consisting of SnO2 and Sb2O5, the molar ratio of tin to antimony is 3.7:1, and in the surface coating, the molar ratio of cerium to manganese dioxide is 1:25-50. The preparation method comprises the following steps: polishing, alkali washing, pickling and acid embossing the pure titanium plate, then repeatedly painting a coating solution, carrying out a thermal decomposition process on the Ti substrate to prepare the interlayer of tin-antimony oxide and the surface coating of cerium doped manganese dioxide in order. The cerium doped Ti-based manganese dioxide electrode disclosed in the invention has low potential of chlorine evolution and high electrocatalysis capability, and can be used for treating the dyeing and finishing effluents.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

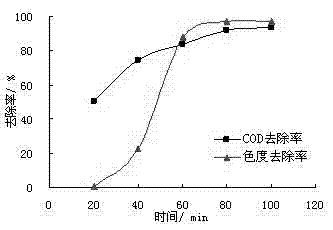

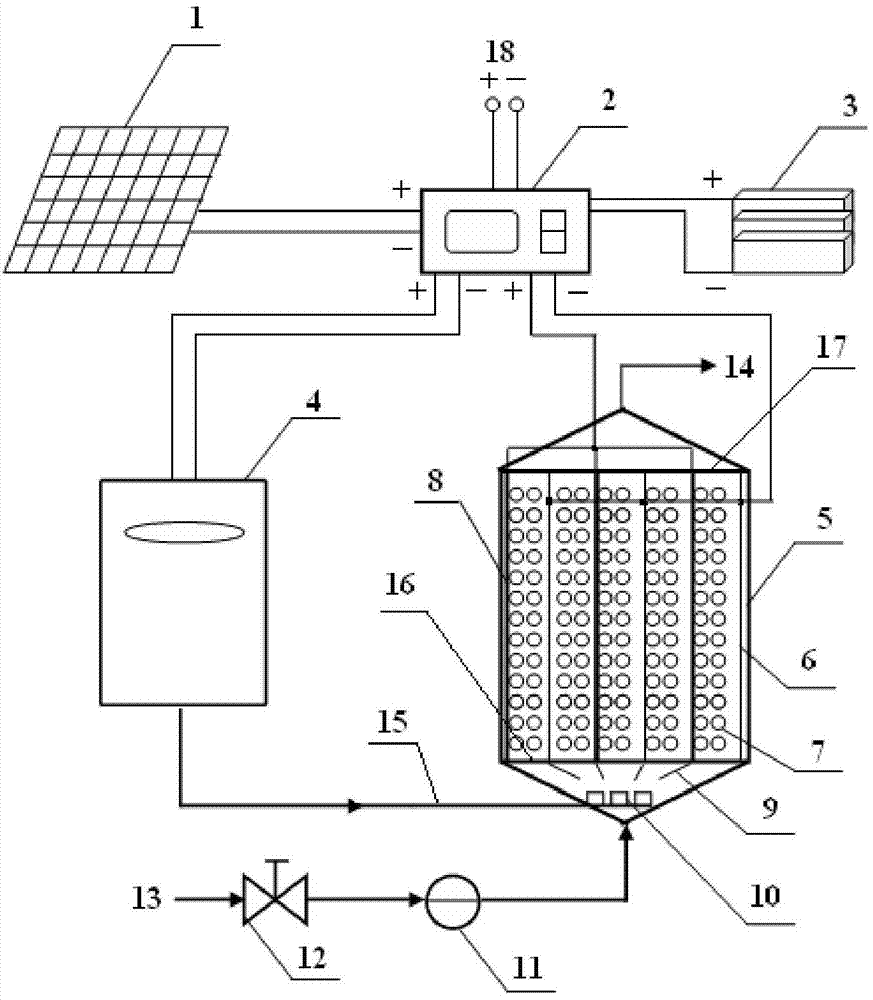

Device for compositely catalytic oxidation treatment of organic wastewater and preparation method of catalytic anode

InactiveCN102923826ALow running costComplies with low voltageWater contaminantsWater/sewage treatment by electrochemical methodsCatalytic oxidationTitanium plate

The invention discloses a device for compositely catalytic oxidation treatment of organic wastewater and a preparation method of a catalytic anode. The device comprises a solar photovoltaic power system, a control system, a storage battery pack, an ozone generator and an electric field ozone catalytic composite reactor, wherein the electric field ozone catalytic composite reactor comprises a shell, a wastewater inlet is formed on the lower end of the shell, and a wastewater outlet is formed on the upper end of the shell; a lower septal pore plate and an upper septal pore plate are arranged in the shell; a catalytic anode and a catalytic cathode are arranged between the lower septal pore plate and the upper septal pore plate; catalytic particles are filled between the catalytic anode and the catalytic cathode; and a gas-water mixer is arranged between the lower septal pore plate and the wastewater inlet. The preparation method comprises the following steps: taking a titanium plate and using the titanium plate as a substrate; uniformly coating mixed precursor solution of an inner layer onto the titanium plate and forming a film on the titanium plate, drying, thermally oxidizing and annealing to form an inner layer; and coating the mixed precursor solution of an outer layer onto the inner layer, drying, thermally oxidizing and annealing to a room temperature.

Owner:SOUTHEAST UNIV

Method for melting titanium scraps and pure titanium wastes of thin titanium plates by electron beam cold hearth melting furnace

InactiveCN103866130AAvoid high and low density inclusionsClear high and low density inclusionsProcess efficiency improvementTitaniumIngot

The invention discloses a method for melting titanium scraps and pure titanium wastes of thin titanium plates by an electron beam cold hearth melting furnace, and relates to methods for melting pure titanium by electron beam cold hearth melting furnaces. The method comprises the following steps: preparing raw materials; selecting and proportioning; mixing by a mixer; vacuumizing and melting the vacuumized raw materials by the electron beam cold hearth melting furnace to obtain slab ingot formed by recovering and melting the wastes. According to the method, the utilization rate of the block-shaped titanium wastes is effectively increased, the process is simplified, the cost is reduced, high-and-low-density impurities in the wastes are effectively removed, and the waste recovering and melting quality is improved.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

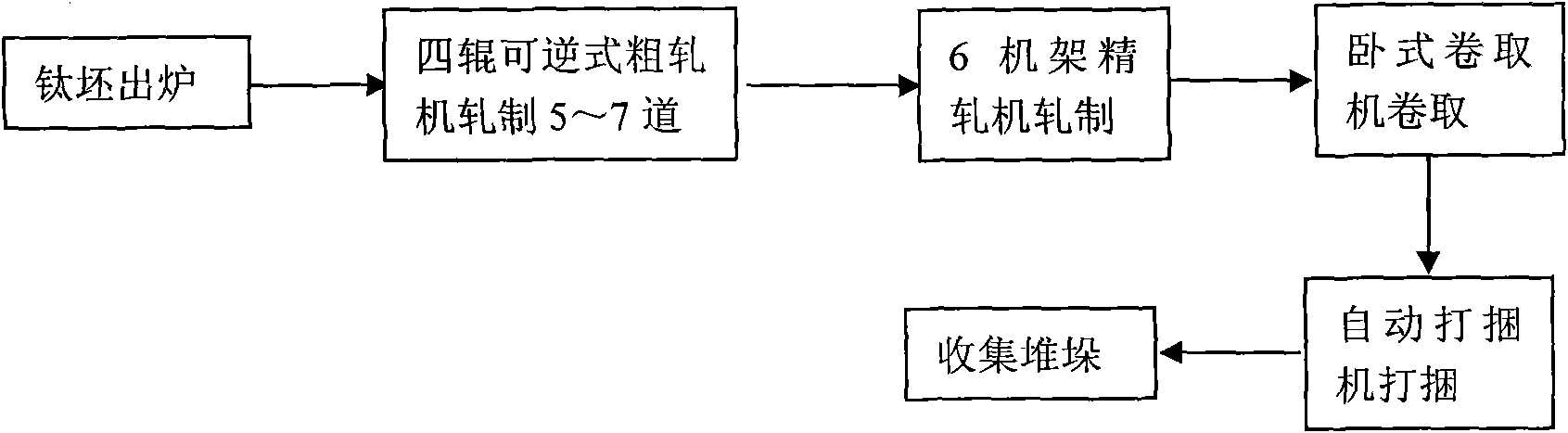

Method for producing titanium strip by adopting conventional hot continuous rolling machine set

InactiveCN101811135AAbundant resourcesReduce manufacturing costTemperature control deviceTension/compression control deviceSocial benefitsTitanium

The invention discloses a method for producing a titanium strip by adopting a conventional hot continuous rolling machine set, wherein the method comprises the following steps: heating a titanium plate blank with the thickness of 150 to 250mm to the temperature of 800 to 900 DEG C in a walking beam type heating furnace, manufacturing the titanium strip with the thickness of 2.5 to 20mm through five passes of rough rolling and continuous rolling of six stands, and coiling into a strip coil through a coiler, wherein the finishing temperature is larger than 650 DEG C, the coiling temperature is larger than 550 DEG C, and the coil weight is 5 to 15 tons. Producing the titanium strip through the conventional hot continuous rolling machine set belongs to domestic initiation and has great economic and social benefits.

Owner:SHANDONG IRON & STEEL CO LTD

Method for leveling titanium board coil

InactiveCN101486051AStress reliefEliminate its influenceTension/compression control deviceRoll speed control deviceNational standardTitanium

The invention provides a method for levelling a titanium plate coil, which comprises the following steps: delivering the titanium plate coil subjected to annealing treatment to a levelling machine, and directly carrying out levelling extension on the titanium plate coil by a levelling roll on the levelling machine or carrying out wet levelling on the titanium plate coil by the levelling roll under the conditions that the rolling speed is 50 to 200 meters per minute, the uncoiling tension is 0.5 and 4 tons, the curling tension is between 3.0 and 5.0 tons, and the extension rate is between 0.80 and 2.0 percent. After the cold-rolled and annealed titanium plate coil is subjected to leveling extension by the levelling roll on the levelling machine, the levelling method can eliminate stress and influence of the stress, level plate surfaces, and obtain better surface quality; and all the plate shape, dimension, surface quality, mechanical property, and the like of the leveled titanium plate coil achieve national standard requirements, and completely meet market demand.

Owner:YUNNAN TITANIUM IND

Preparing method of high-thermal-conductivity graphite/aluminum composite

InactiveCN106916985AEnhanced interface bindingImprove performanceTransportation and packagingMetal-working apparatusHeat managementTitanium

The invention relates to a preparing method of a high-thermal-conductivity graphite / aluminum composite and belongs to the technical fields of high-thermal-conductivity electronic packaging material preparing technologies and heat management materials. The method comprises the following steps: plating graphite powder with titanium; rolling aluminum and / or aluminum alloy powder into a flake; carrying out ball milling and mixing on the titanium-plated graphite powder and the flaky aluminum and / or aluminum alloy powder according to a ratio so as to obtain composite powder; then, filling a graphite die with the uniformly mixed graphite / aluminum powder, and adopting powder metallurgy hot-pressing; and after cooling the composite powder with the die, carrying out demoulding to obtain the high-thermal-conductivity graphite / aluminum composite. The method solves the problem that the thermal conductivity of the existing graphite / aluminum composite is low, improves the thermal conductivity of the graphite / aluminum composite, and is simple in technology, high in efficiency and low in cost.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Slag-free low-temperature rapid electrolytic phosphorizing liquid and phosphorizing process thereof

ActiveCN102719872AIncrease productivityPhosphating temperature is lowPhosphatisationWire rodZinc phosphate

The invention provides slag-free low-temperature rapid electrolytic phosphorizing liquid and a phosphorizing process thereof. The phosphorizing liquid comprises, by mass, zinc ions 10-80g / L, phosphate radicals 10-120g / L, accelerators 41-160g / L, organic acid 0-5g / L and dissolved metal elements 0.1-10g / L, wherein the phosphate radicals refer to P2O5. According to the process, inert titanium plates or titanium nets serve as anodes while treated steel wire rods serve as cathodes, a zinc phosphate film is uniformly formed on the surfaces of the steel wire rods by applying a certain current, and the film weight is higher than 4g / m<2> so as to meet drawing requirements. The phosphorizing temperature ranges from 10 DEG C to 60 DEG C, the phosphorizing time is 5-120 seconds, phosphorized slags are avoided, and accordingly the phosphorizing process has the obvious advantages of high efficiency, energy conservation and environmental protection.

Owner:派诺(湖北)绿色化学智造有限公司

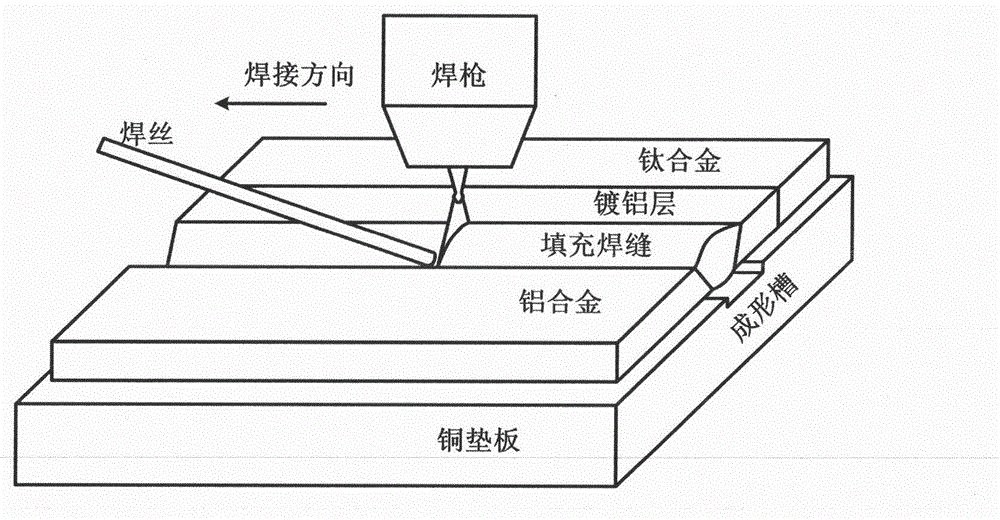

Arc welding-brazing method for pre-coating titanium alloy and aluminum alloy

InactiveCN103143803AImprove mechanical propertiesSimple processing methodArc welding apparatusWelding/cutting media/materialsSurface cleaningAlloy composite

The invention relates to an arc welding-brazing method for pre-coating a titanium alloy and an aluminum alloy, which comprises the following steps that surface cleaning is conducted on a titanium plate; surface aluminizing is then conducted on the titanium plate; an aluminum alloy welding wire is added in an arc welding-brazing manner; a fusion welded joint is formed on the side of the aluminum alloy by controlling a welding speed and heat input quantity; a brazed joint is formed on the side of the titanium alloy; and the titanium alloy is connected with the aluminum alloy. Growth of an intermetallic compound is controlled in immersion coating and welding processes, mechanical properties of the joints are improved, and the connection is reliable without fracture, so that various requirements on a titanium alloy and aluminum alloy composite structure in engineering can be further met. The method has the advantages of simple technological method, low manufacturing cost, short production period and the like.

Owner:HARBIN INST OF TECH

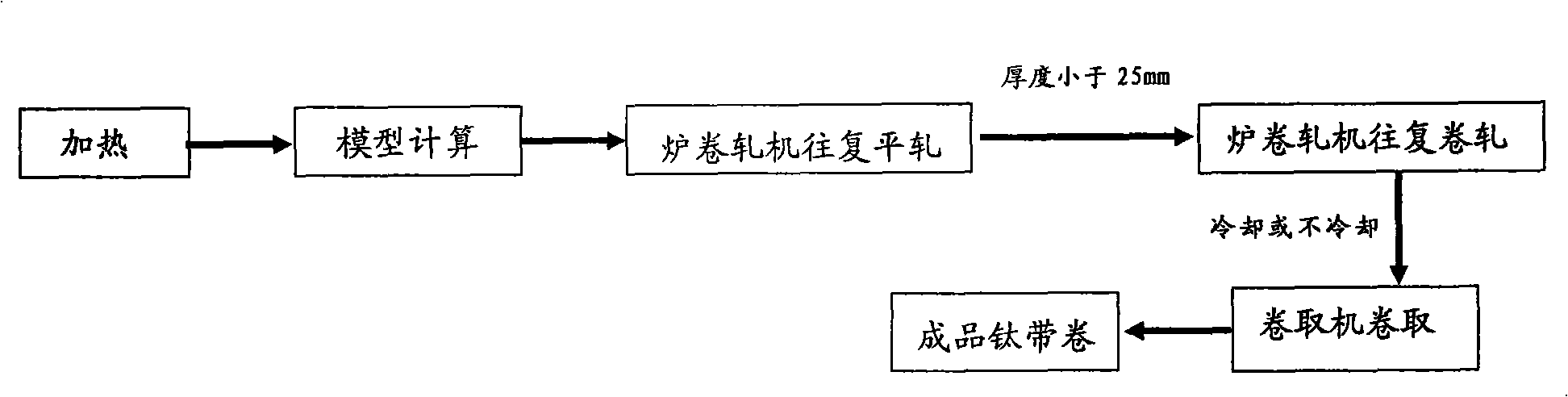

Reversible hot-rolling process of titanium plate coil

InactiveCN101628297ATake advantage ofFulfil requirementsMetal rolling arrangementsTitanium plateSteckel mill

The invention provides a hot-rolling process for manufacturing a titanium plate coil, which comprises the following steps: heating titanium plate blank to tapping temperature; automatically generating process parameters for rolling the titanium plate blank by using a model computation module according to known parameters and predetermined target parameters; repeatedly rolling the titanium plate blank by a steckel mill according to the process parameters, wherein the titanium plate blank has the opening rolling temperature of 800 DEG C to 950 DEG C and the finishing rolling temperature of 500 DEG C to 695 DEG C; and coiling rolled titanium plate strips by using a coiler so as to produce the titanium plate coil.

Owner:WUKUN STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com