Patents

Literature

96results about How to "Increase furnace capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

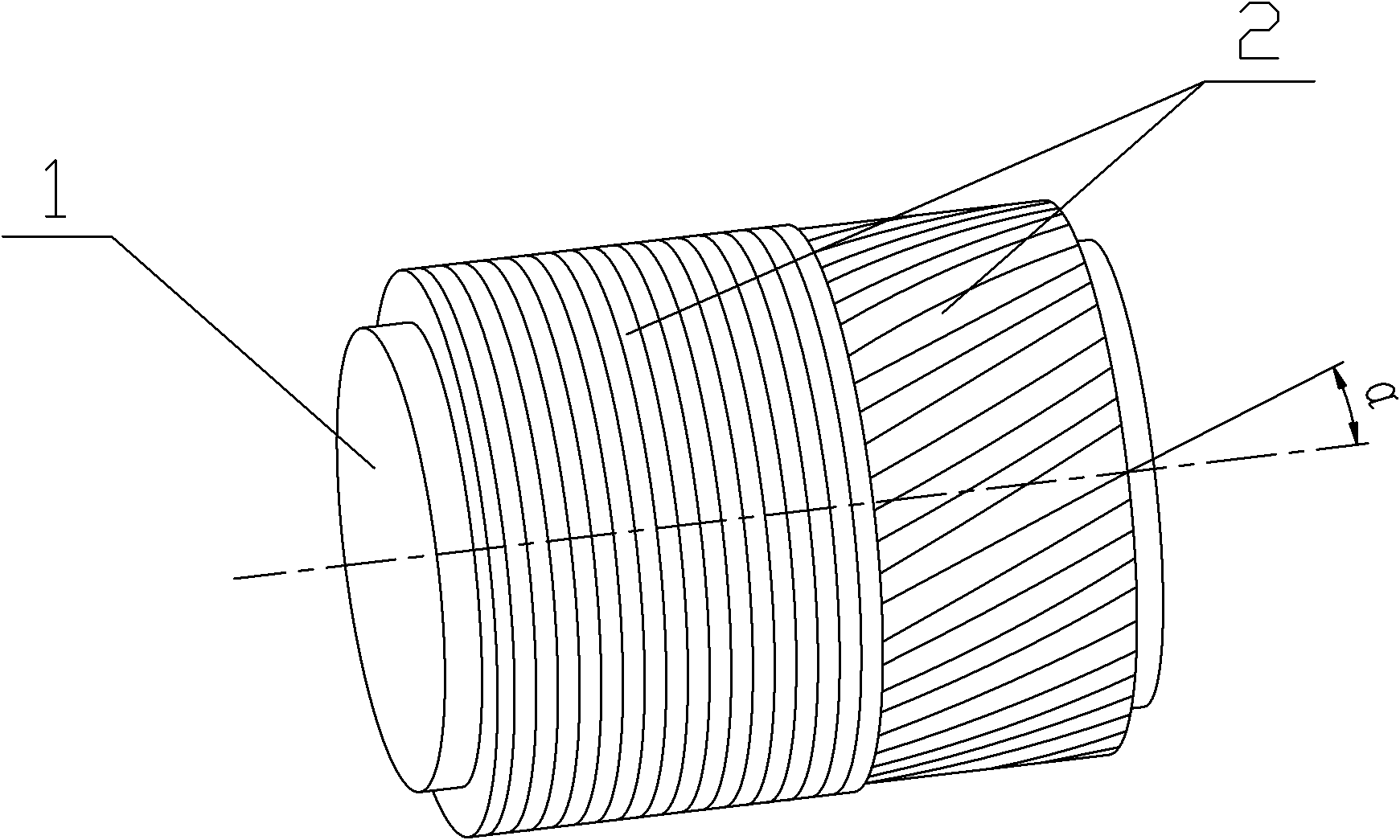

Method for manufacturing high-strength carbon/carbon hot-press die

InactiveCN102060555AMaximize Strength PropertiesEffectively develop tensile strength propertiesFiberCarbon fibers

The invention discloses a method for manufacturing a high-strength carbon / carbon hot-press die, comprising the steps of: winding dipped carbon fibers on a graphite core die alternatively in a circumferential winding manner and a longitudinal winding manner to obtain a preformed body with required diameter, curing the preformed body, and then carbonizing; dipping the carbonized preformed body, and then carrying out carbonization and vacuum high-temperature treatment; and machining the preformed body subjected to vacuum high-temperature treatment to obtain the high-strength carbon / carbon hot-press die. Compared with a simply circumferential winding structural mode, small-angle longitudinal wound fibers are added in the method, and the fibers in the direction are favorable for both circumferential acting force and longitudinal acting force, overcomes the defect of the circumferential winging structure and improves the integral performance of the product. Compared with the graphite die, the high-strength carbon / carbon hot-press die provided by the invention has the thickness reduced by almost two thirds, and has the advantages of greatly improving charging amount and production efficiency and reducing cost under the condition with a definite furnace chamber dimension.

Owner:XIAN CHAOMA SCI TECH

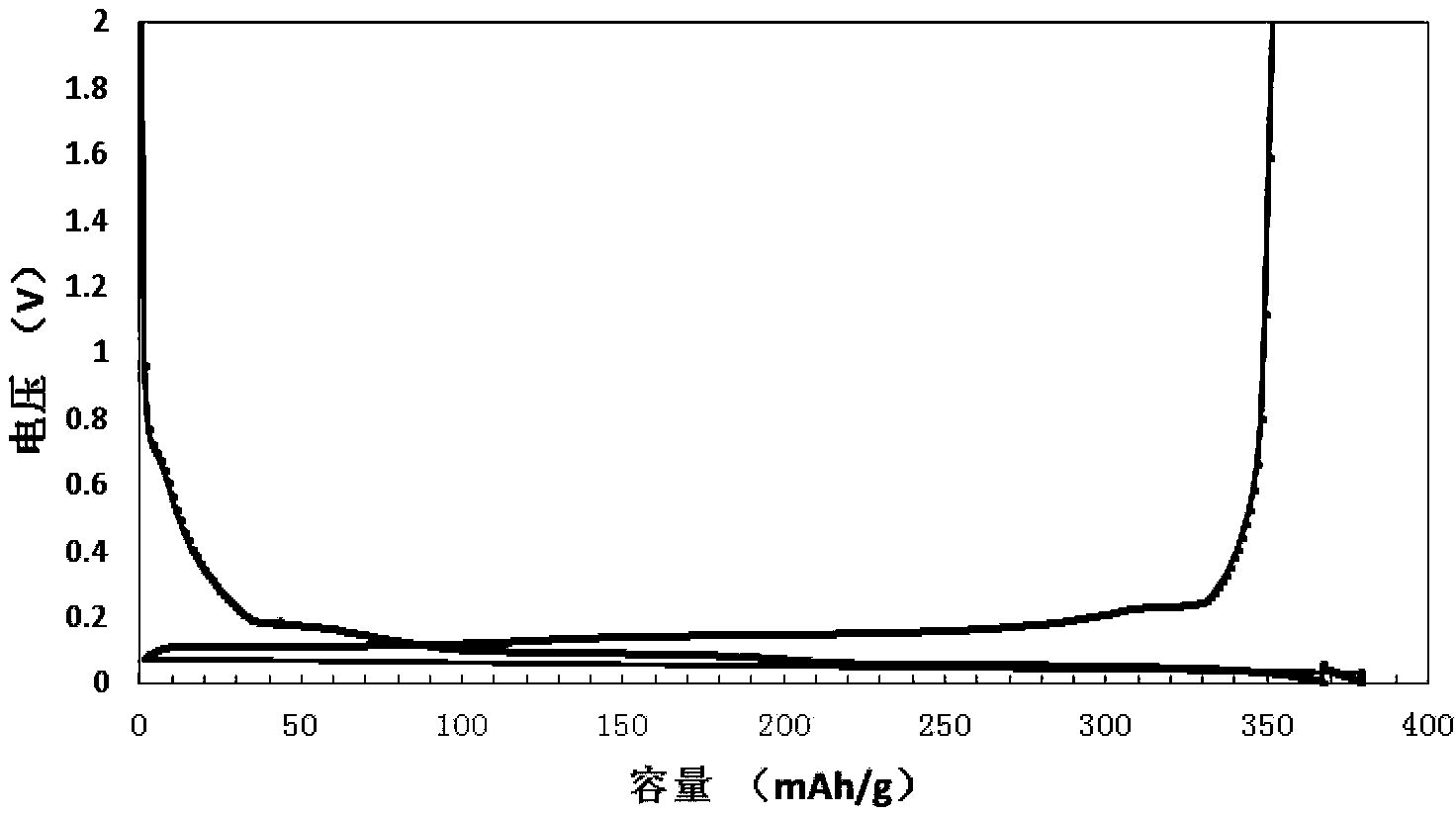

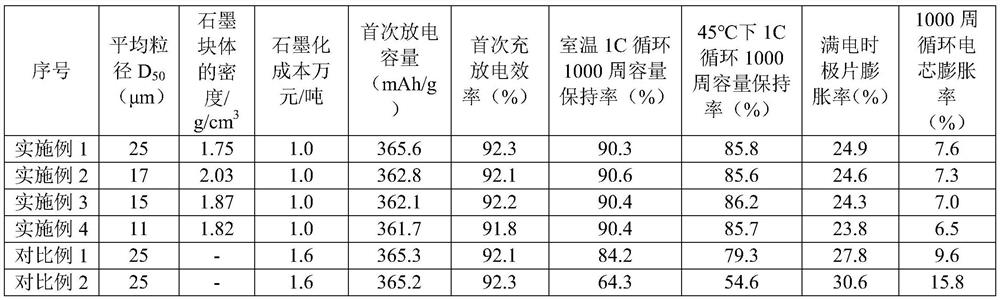

Lithium battery negative electrode material and preparation method thereof

InactiveCN103855369AIncrease energy densityHigh liquid absorptionNegative electrodesLi-accumulatorsNanotechnologyElectrode material

The invention discloses a lithium battery negative electrode material and a preparation method thereof. The preparation method of the lithium battery negative electrode material comprises the following steps of heating and stirring a mixture of carbon powder, a binder and a catalyst, pressing and molding, carbonizing, and graphitizing the mixture. The prepared lithium battery negative electrode material is high in graphitization degree, good in isotropic property, high in energy density, good in cycling property and low in preparation cost; the preparation process combining the molding graphitization and catalytic graphitization is also applicable to the graphitization process of other powder materials.

Owner:SHANGHAI SHANSHAN TECH CO LTD

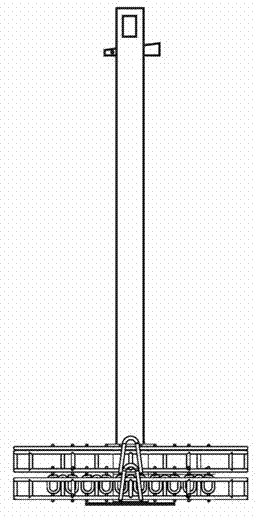

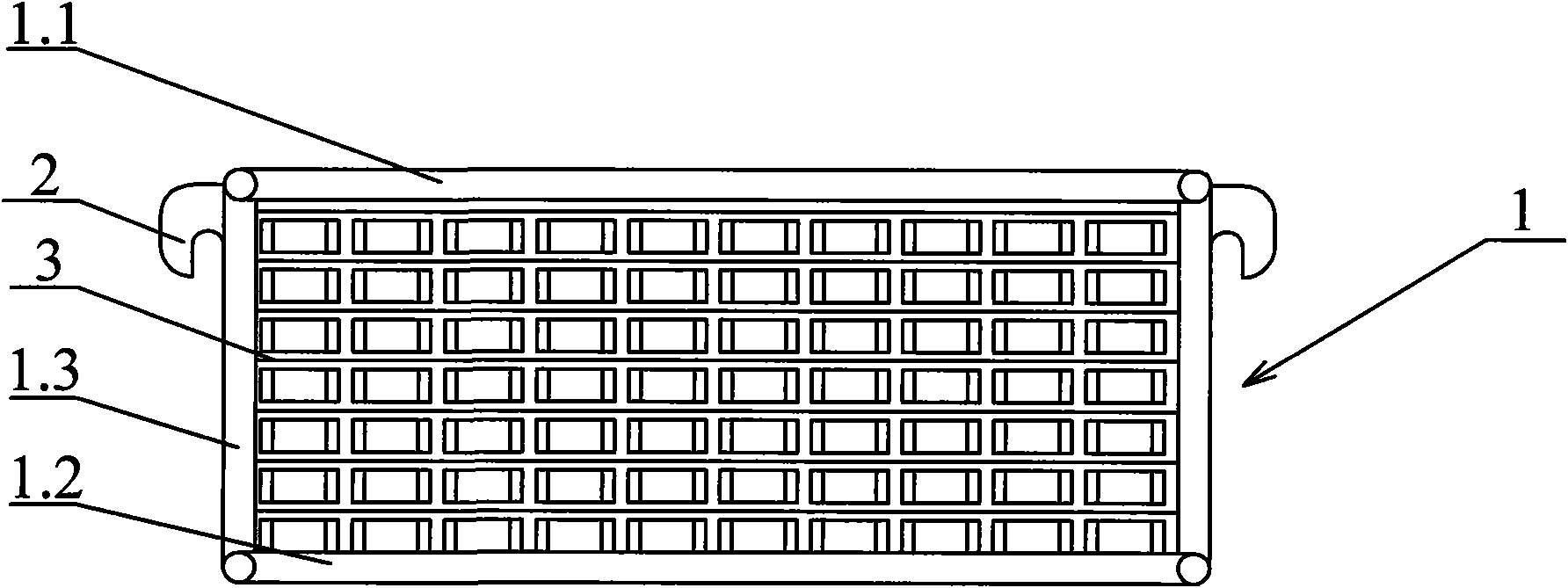

Tool for depositing coating on multi-arc ion plating equipment and usage method thereof

ActiveCN104404454AGuaranteed uniformityEasy to useVacuum evaporation coatingSputtering coatingTurbine bladeEngineering

The invention discloses a tool for depositing a coating on multi-arc ion plating equipment and a usage method thereof. The tool comprises a pull bar, positioning boxes, a connection plate and suspension hooks; two ends of the pull bar are provided with the suspension hooks, the bottom end of the pull bar is provided with the connection plate, and the positioning boxes used for putting turbine blades are arranged on the connection plate at two sides of the pull bar. The provided tool is simple in structure, convenient for maintenance, novel in design and convenient and rapid for mounting and dismounting. The tool protects a tenon, and also guarantees the uniformity of the thickness of the coating on various areas of the turbine blades and a margin plate upper surface, in other words, the usage performance of the coating is guaranteed. The tool protects the tenon through a physical shielding principle, the blade bodies simultaneous realize revolution and rotation in the coating process, two blades are arranged in a parallel way, and all blades are uniformly coated to form coatings by controlling the distance between the turbine working blades to not generate the physical shielding phenomenon.

Owner:AECC AVIATION POWER CO LTD

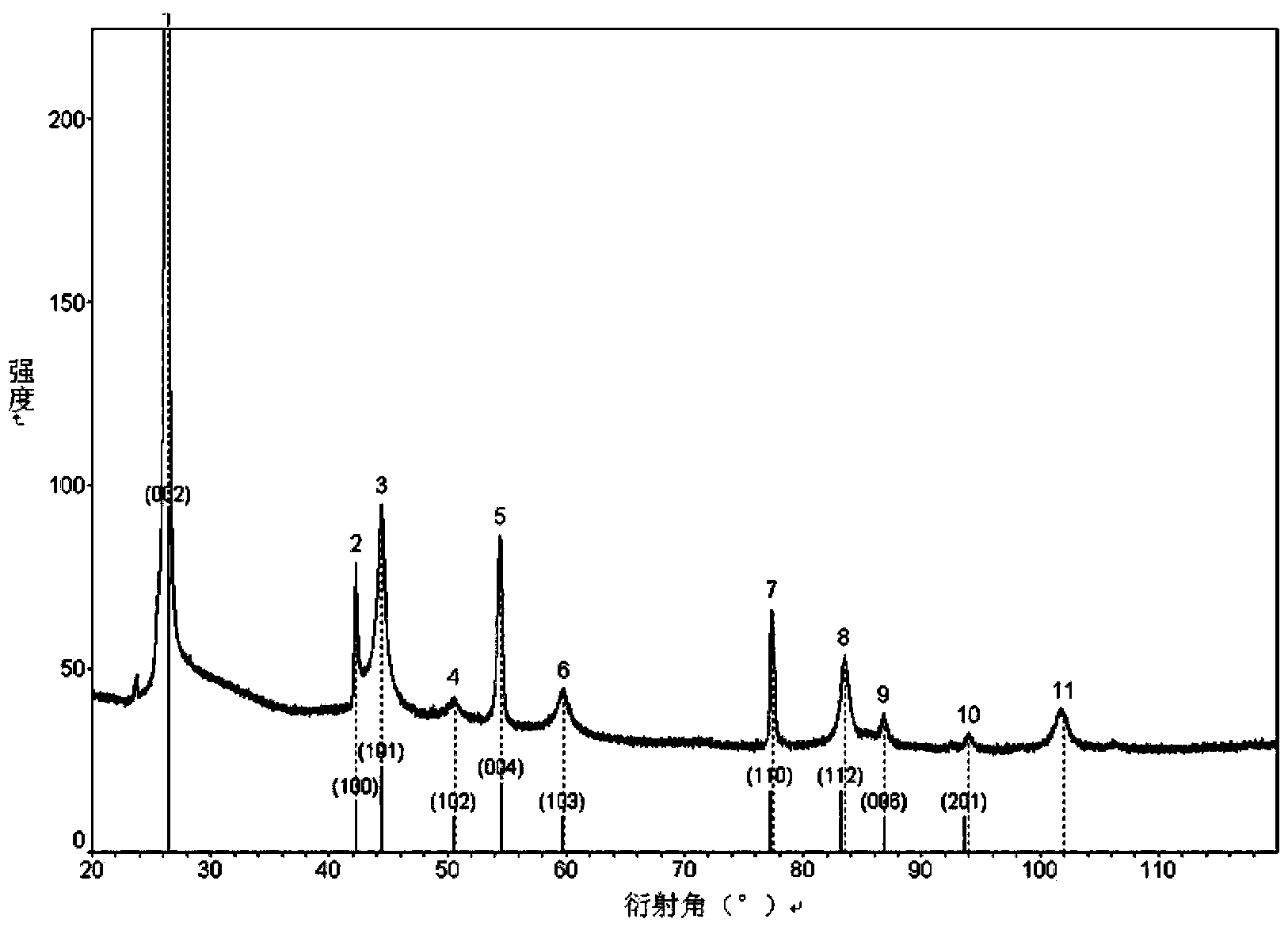

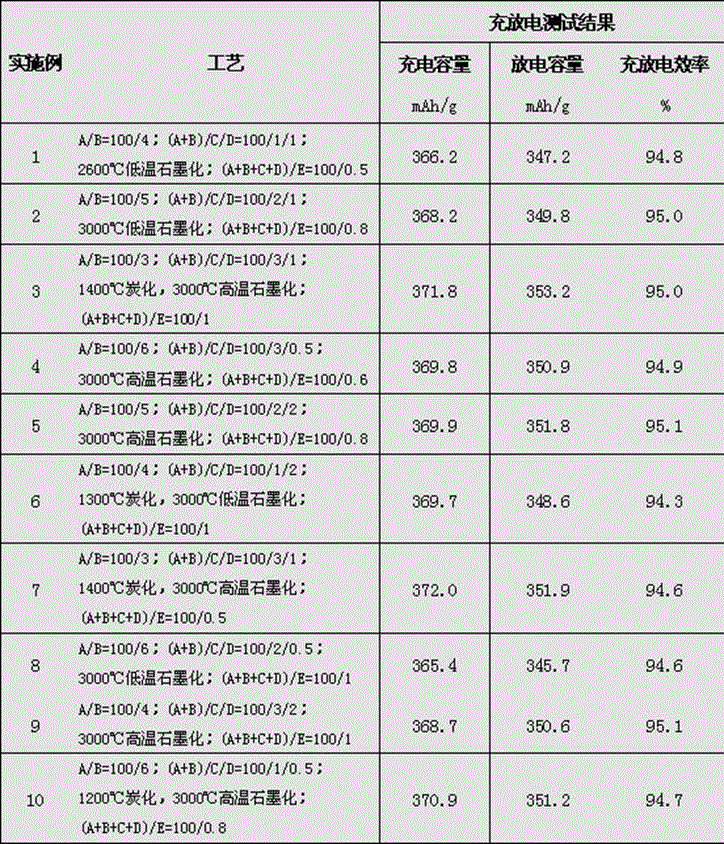

Production method for modified artificial graphite negative electrode material

ActiveCN105428615ALow costChange structureCell electrodesSecondary cellsCarbon nanotubeCarbonization

The invention provides a production method for a modified artificial graphite negative electrode material. The method comprises: taking powder obtained by grinding petroleum coke as a main raw material and performing shaping treatment; adding a certain proportion of petroleum asphalt into the shaped petroleum coke material, and performing secondary granulation treatment in an extrusion fusion way; adding the granulated material into a mixture of petroleum asphalt and coal asphalt or coal tar, and performing coating modification treatment; putting the material into a graphitization furnace in bulk to perform high-temperature graphitization treatment, or performing carbonization and graphitization treatment in sequence; performing dispersion and grading treatment after the material is cooled to the room temperature; and finally adding few carbon nanotubes to perform mixing and screening. The method has the advantages that the main raw material is ground petroleum coke powder, and the powder is recycled, so that the cost can be reduced; secondary granulation of small granules can increase the capacity of the material and improve the cycle performance of the material; and due to the adoption of a graphite plate loading mode, the graphitization degree of the material can be increased, namely, the capacity can be increased, and the energy consumption cost can be reduced.

Owner:大连宏光锂业有限责任公司

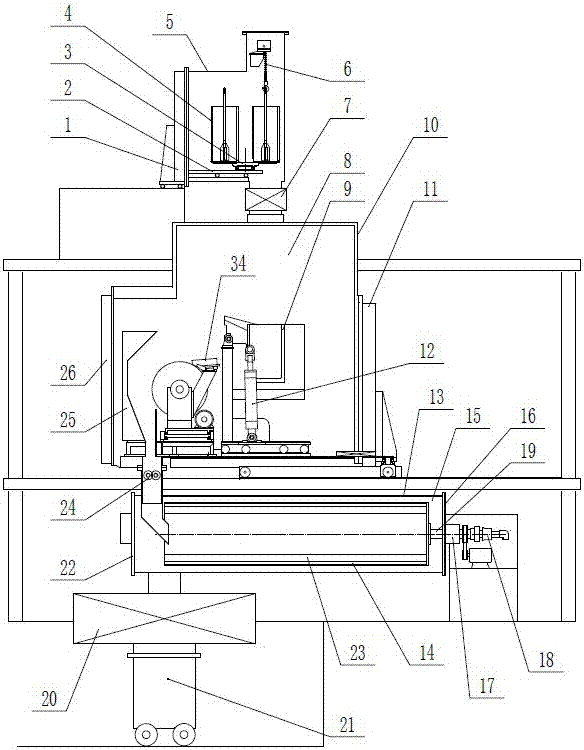

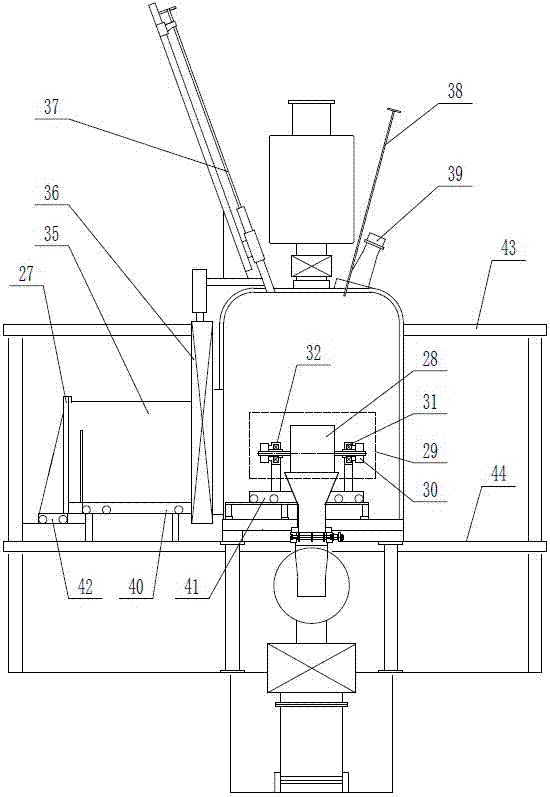

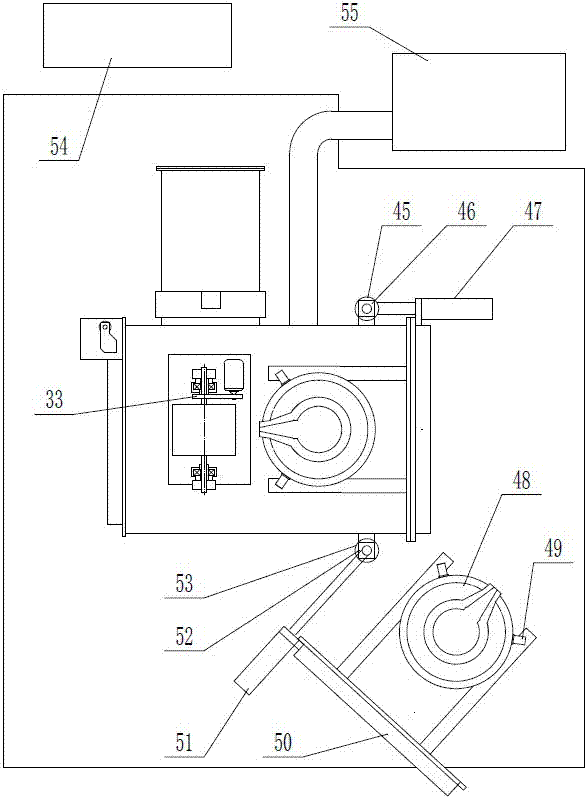

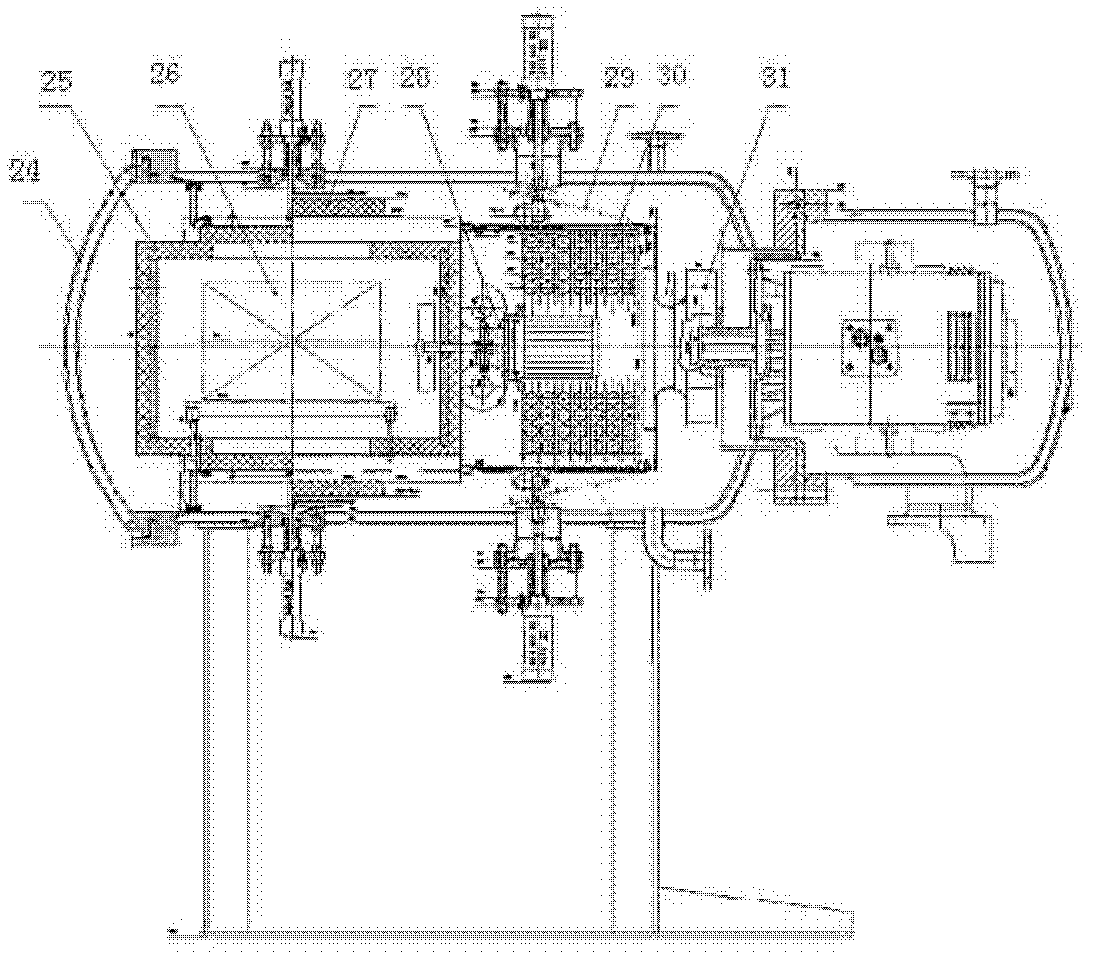

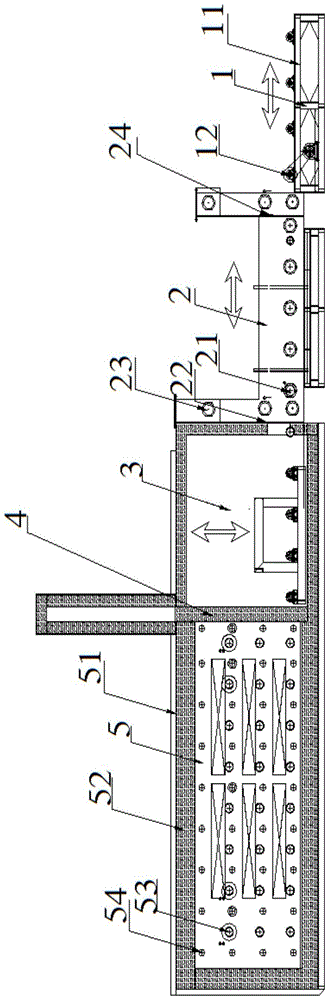

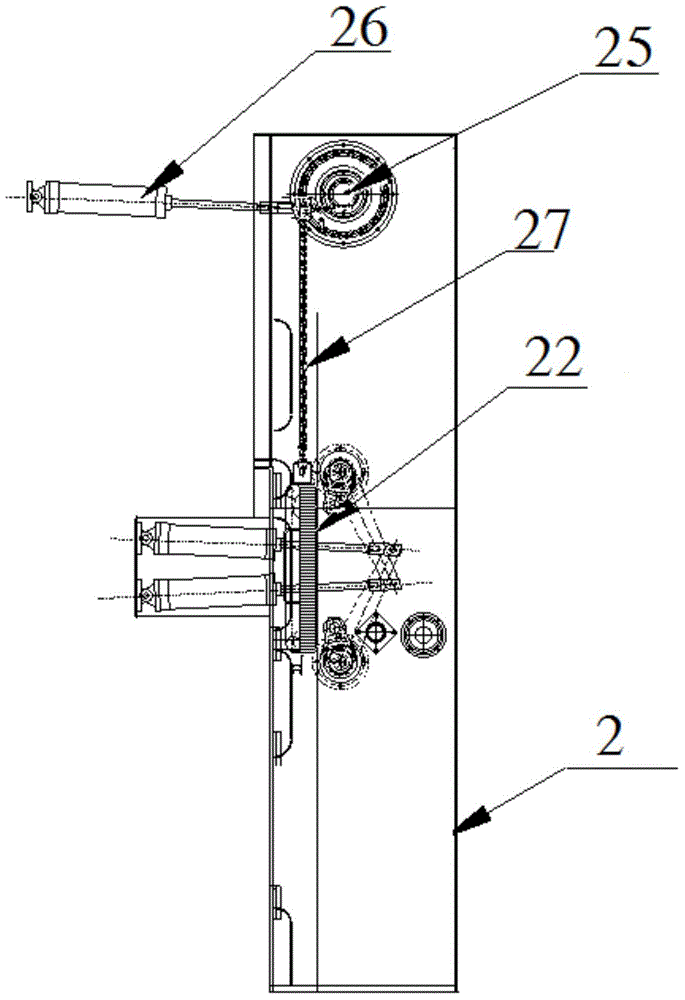

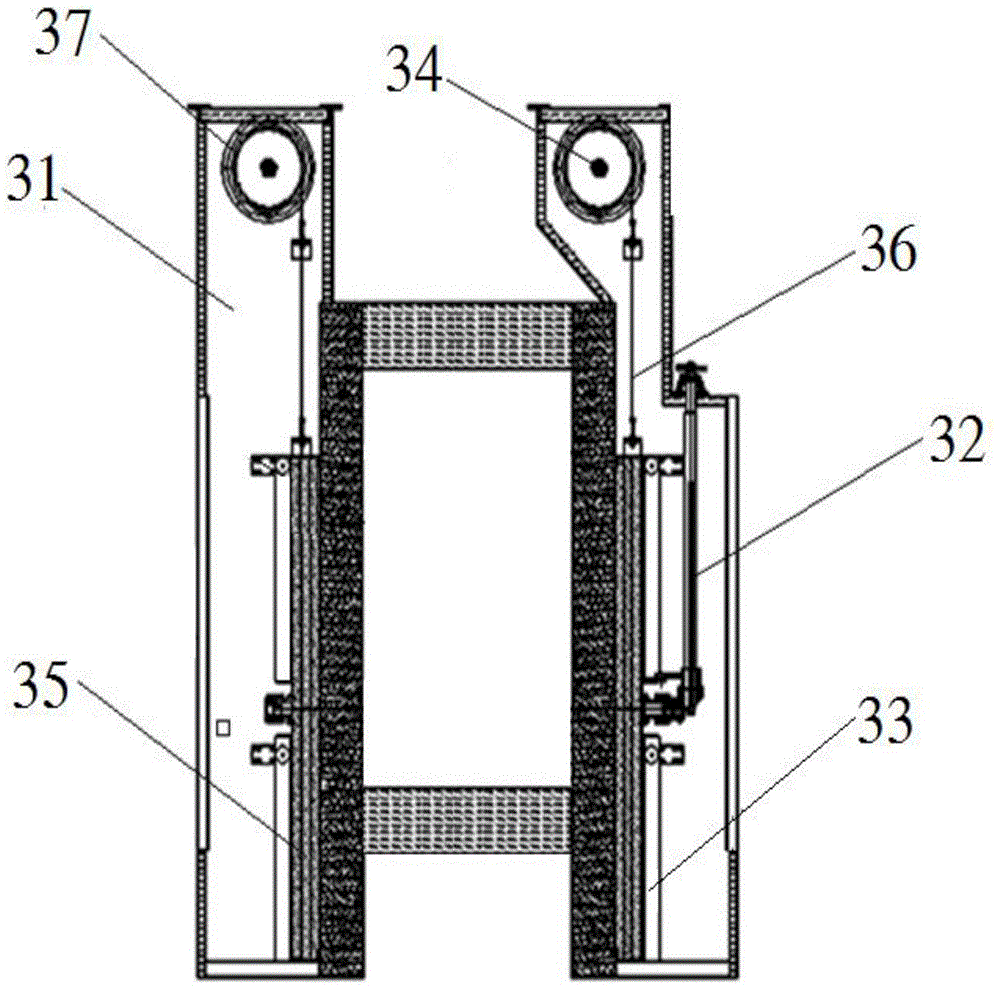

Vacuum melting rapid hardening equipment and manufacturing method of rapidly hardened alloy

ActiveCN107262687AReduce in quantityImprove performanceInductances/transformers/magnets manufactureMagnetic materialsCooling chamberAlloy

The invention discloses vacuum melting rapid hardening equipment and a manufacturing method of rapidly hardened alloy. The vacuum melting rapid hardening equipment comprises a vacuum feeding chamber, a vacuum melting chamber, a rotating roll moving chamber, an alloy plate cooling chamber and a storage device. A basket lifting mechanism, a multi-station rotary table and a trolley which moves in a reciprocating manner are arranged in the vacuum feeding chamber; during working, a water-cooled rotating roll device moves to the vacuum melting chamber from the rotating roll moving chamber; the alloy plate cooling chamber is connected with the vacuum melting chamber; a breaking device and a cooling drum are arranged in the alloy plate cooling chamber; and the storage device is connected with the alloy plate cooling chamber through a guiding valve. The manufacturing method of the rapidly hardened alloy can be used for manufacturing sintered neodymium iron boron rapidly hardened alloy, rapidly quenched neodymium iron boron permanent magnetic powder and soft magnetic nanocrystal magnetic powder, and can further be used for manufacturing neodymium iron boron permanent magnets by using neodymium iron boron waste materials.

Owner:沈阳中北真空技术有限公司

SiC ceramic thin-layer bullet-resistant material for laminated armor, and preparation method of material

The invention relates to a SiC ceramic thin-layer bullet-resistant material for a laminated armor and a preparation method of the SiC ceramic thin-layer bullet-resistant material. The SiC ceramic thin-layer bullet-resistant material is a gel-casting sheet prepared from the following raw materials: silicon carbide micro powder, boron carbide micro powder, acrylamide monomer, N'N-methylene bisacrylamide, tetramethyl ammonium hydroxide, tributyl phosphate, deionized water and ammonium persulfate. The invention also provides the preparation method of the SiC ceramic thin-layer bullet-resistant material. According to the SiC ceramic thin-layer bullet-resistant material, a silicon carbide ceramic sheet which is large in size, compact and smooth can be prepared; the SiC ceramic thin-layer bullet-resistant material is adjustable in size, good in hardness and good in fracture toughness, and is high in protective capability as a bullet-resistant material for the laminated armor.

Owner:SHANDONG UNIV

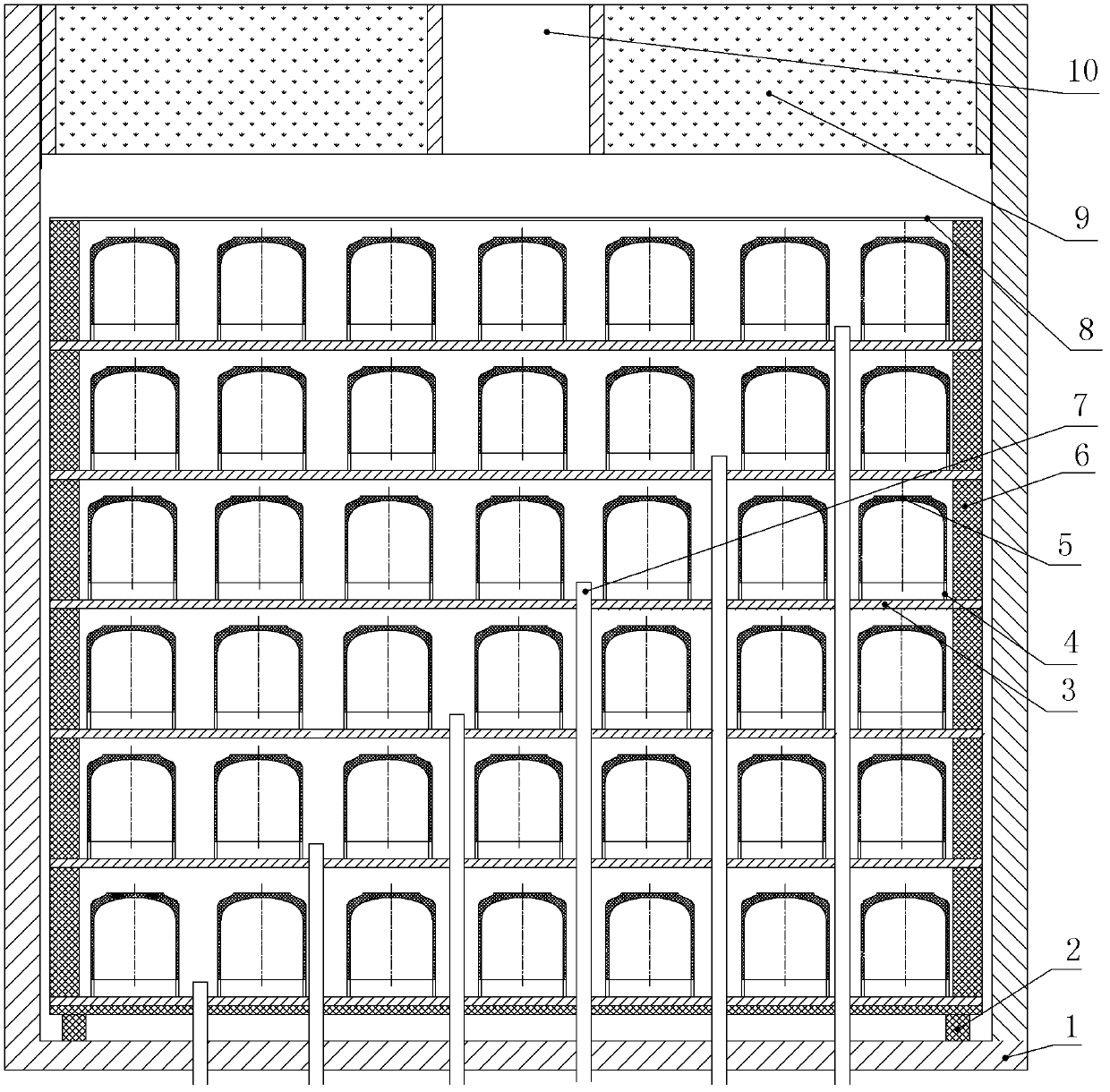

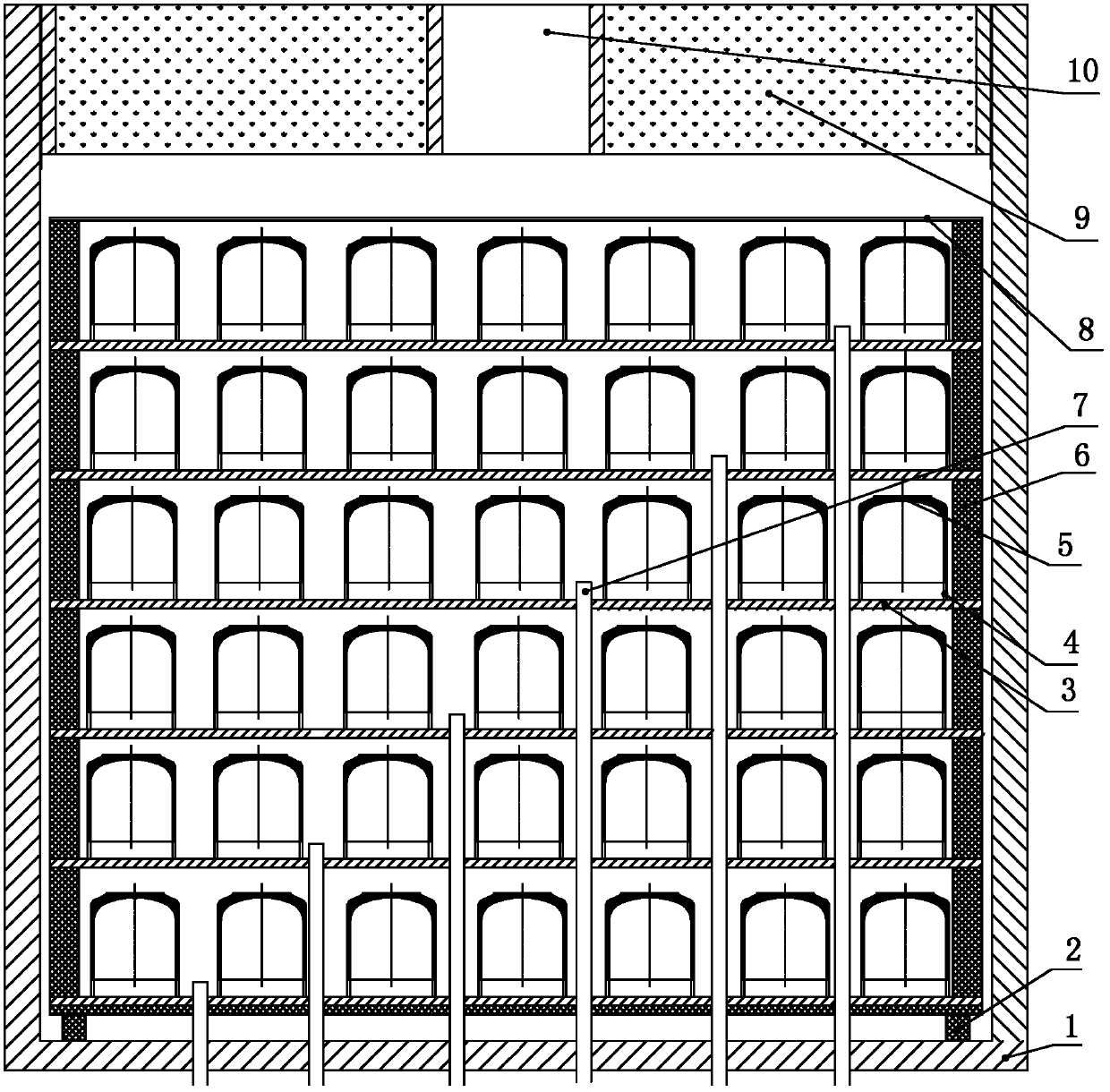

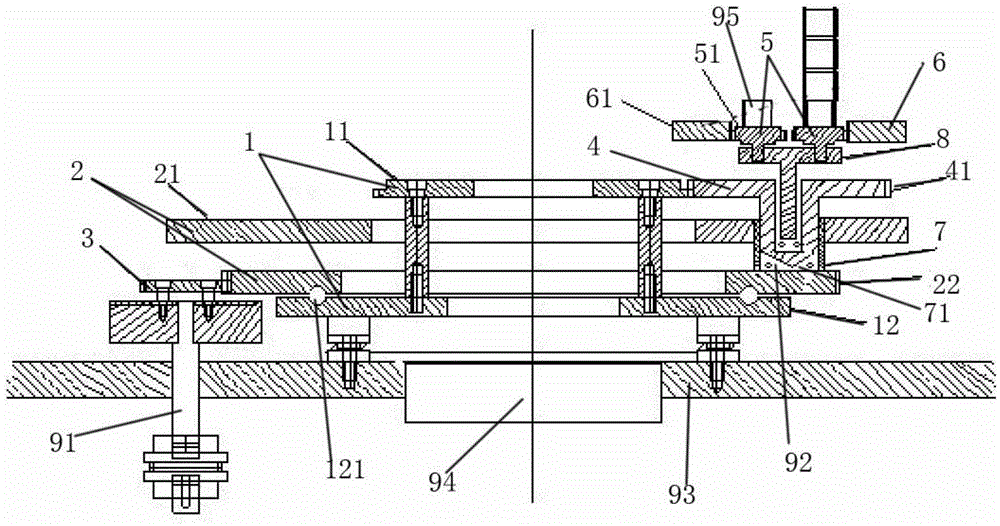

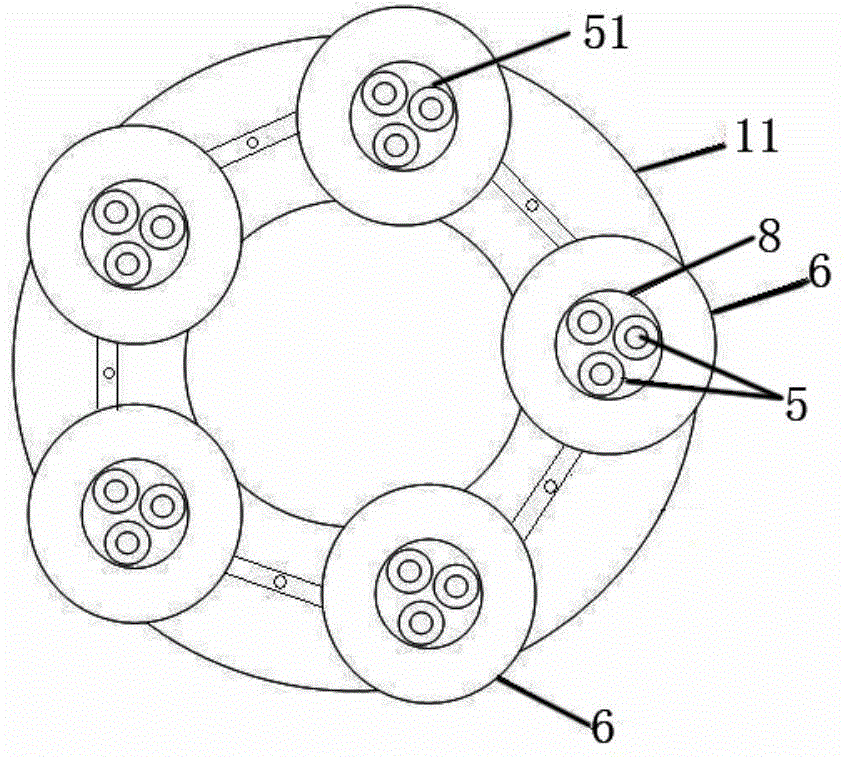

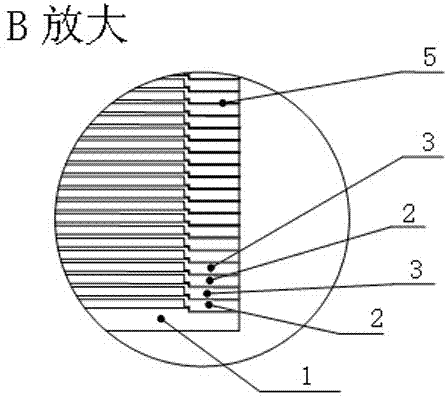

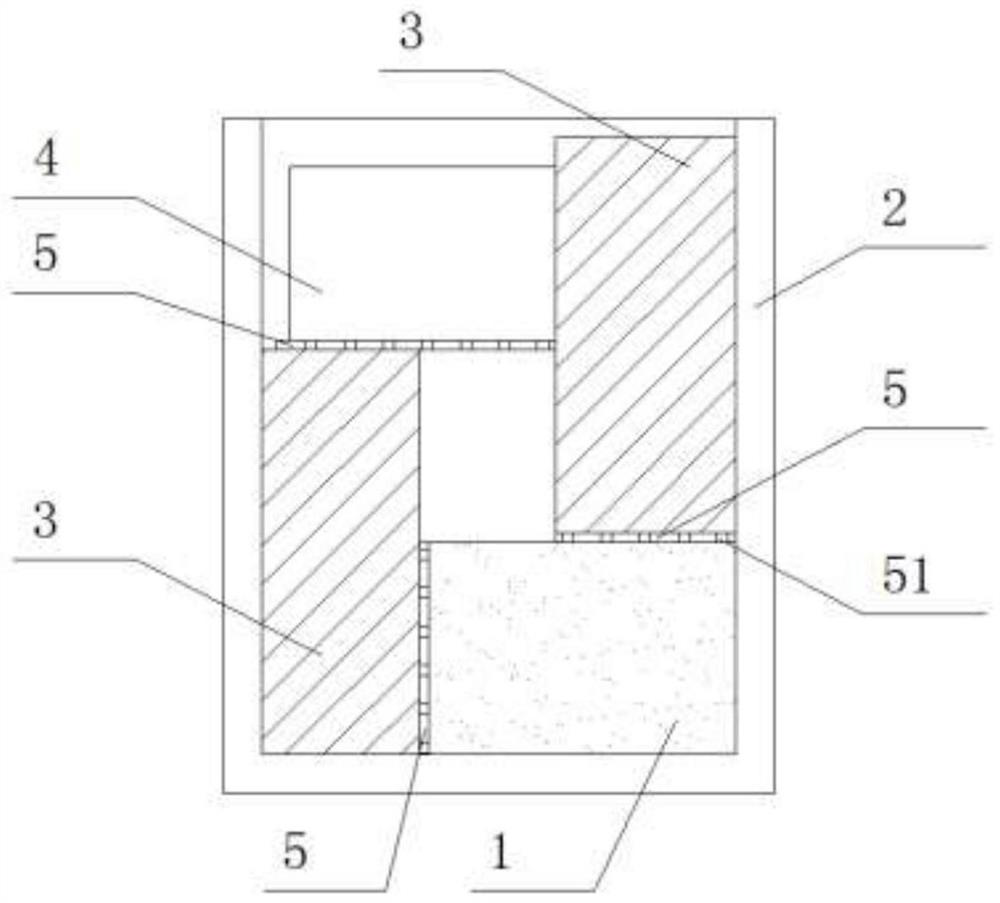

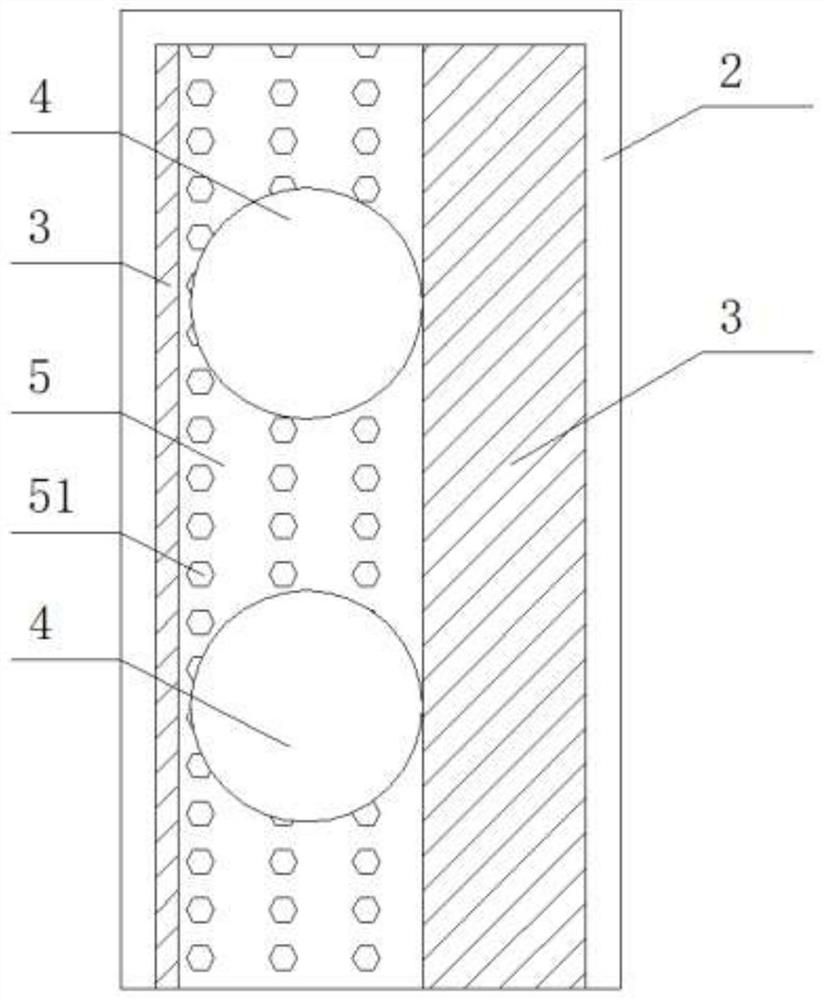

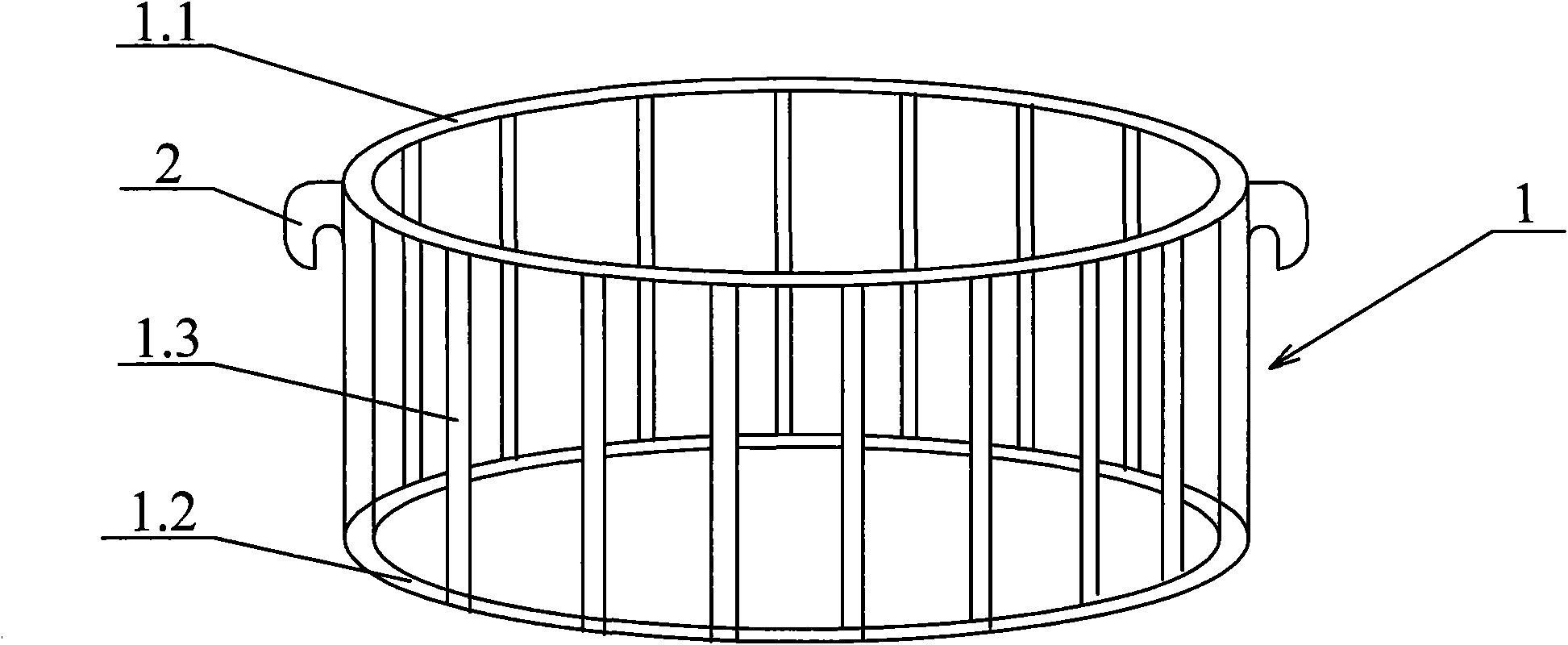

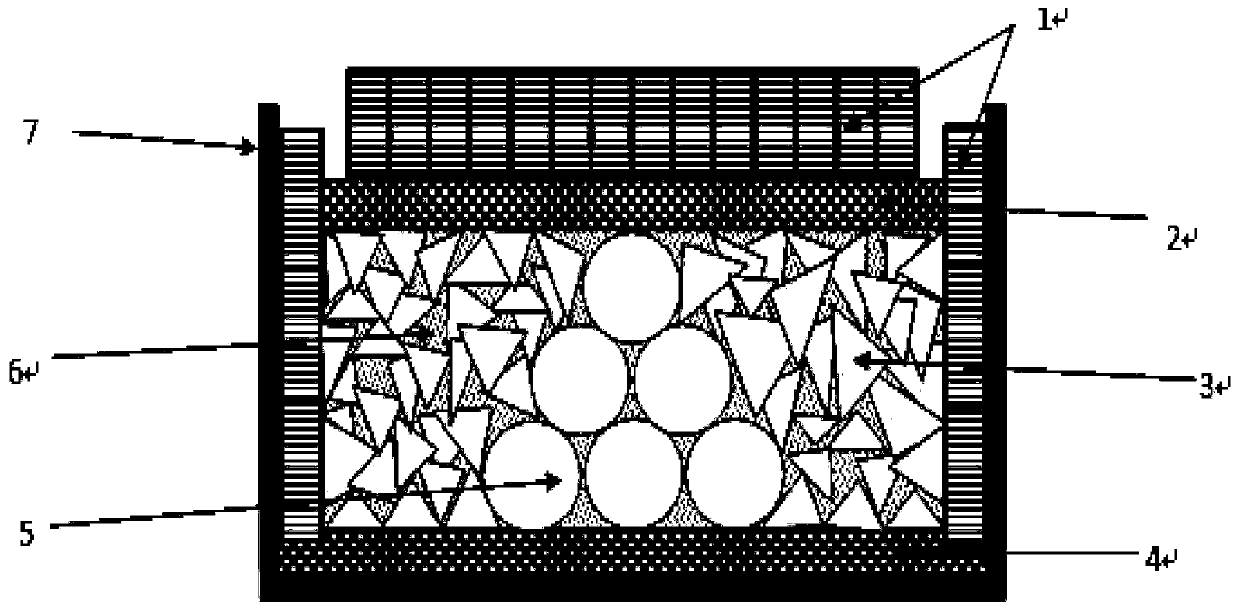

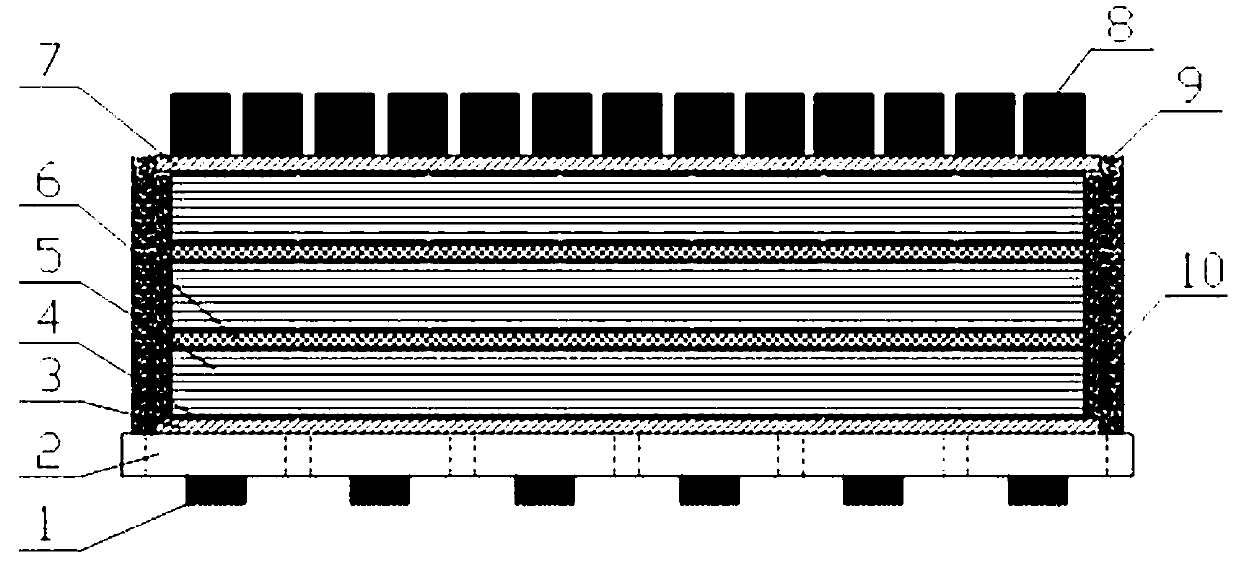

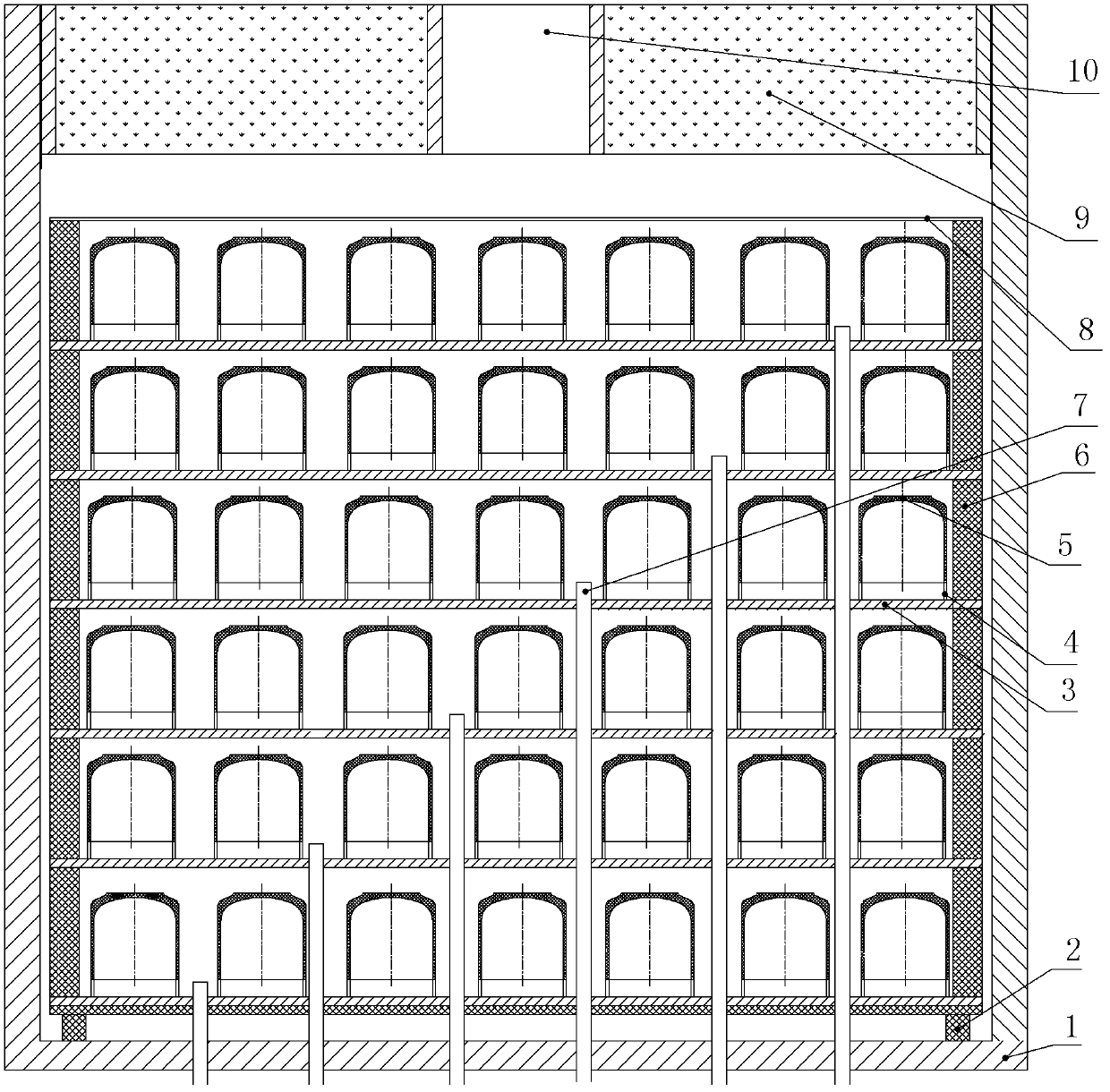

Multi-deposition-chamber CVI (chemical vapor infiltration) device for compacting carbon/carbon crucible and method using same

ActiveCN102433543ASimple structureEasy to processBy pulling from meltChemical vapor deposition coatingCrucibleGraphite

The invention discloses a multi-deposition-chamber CVI (chemical vapor infiltration) device for compacting a carbon / carbon crucible and a method using the same. The device comprises a chemical vapor deposition furnace consisting of an outer furnace tank and an inner furnace tank and also comprises multiple layers of graphite partition plates which are distributed in the inner furnace tank from bottom to top and multiple intake tubes which are inserted in the inner furnace tank from bottom to top; adjacent two layers of graphite partition plates are isolated by multiple graphite shores; the upper part of the graphite partition plate arranged on the most-top layer is provided with a gas-sealing plate; dependant deposition chambers are respectively formed between adjacent two layers of graphite partition plates and between the gas-sealing plate and the graphite partition plate arranged on the most-top layer; multiple deposition chambers are distributed from top to bottom; and the multiple intake tubes are respectively inserted into the multiple deposition chambers from bottom to top. The compacting method comprises the following steps: 1, charging of a crucible prefabricated body; and 2, compacting treatment. The device disclosed by the invention has simple structure, reasonable design, good use effect, good compacting effect, good density uniformity, large charging amount and the like, is convenient for assembling and easy to use and operate.

Owner:XIAN CHAOMA SCI TECH

Method for rolling large-sized aluminum alloy ring piece and performing solid solution treatment by using electric furnace

InactiveCN102409270AIncrease furnace capacityImprove production flexibilityElectrical resistance and conductanceElectric arc furnace

The invention relates to a process method for rolling and molding a large-sized aluminum alloy ring piece and performing solid solution treatment by using an electric furnace, and belongs to the field of manufacturing of non-ferrous alloys. The method comprises the following steps of: determining the aluminum ingot rolling specification and the rolling process upsetting deformation ratio of an aluminum alloy ring piece blank and heating temperatures and temperature preservation time process parameters during solid solution aging treatment of the electric furnace through the rolling and molding ingot specification and the rolling process parameter of an aluminum alloy, wherein in the determined process, the upsetting deformation ratio of the rolled and molded aluminum ingot with the specification of phi 410*1,000mm is 85 to 88 percent; performing a solid solution process at the temperature of between 475+ / -5 DEG C for 500 minutes in a resistance furnace; performing water quenching at the temperature of 65 DEG C, wherein the straightening cold deformation amount is 3 to 4 percent; and performing aging treatment by using the electric furnace at the temperature of 130+ / -5 DEG C for 7 hours, and raising the temperature to 170+ / -5 DEG C for 8 hours. By the novel process method for rolling and molding a large-sized aluminum alloy and producing a blank through solid solution thermal treatment of the electric furnace, feeding amount is reduced by 38 percent, and the efficiency is improved by 30 percent; and the method has the characteristics of short production period, high quality stability and the like, is safe, energy-saving and environment-friendly, has obvious economic benefits and is positioned in a leading level in China.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

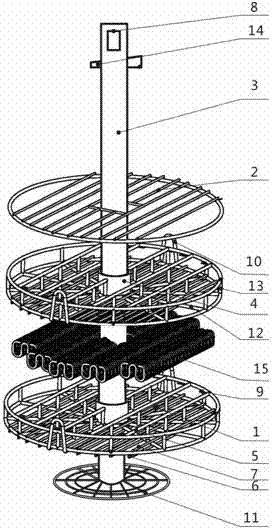

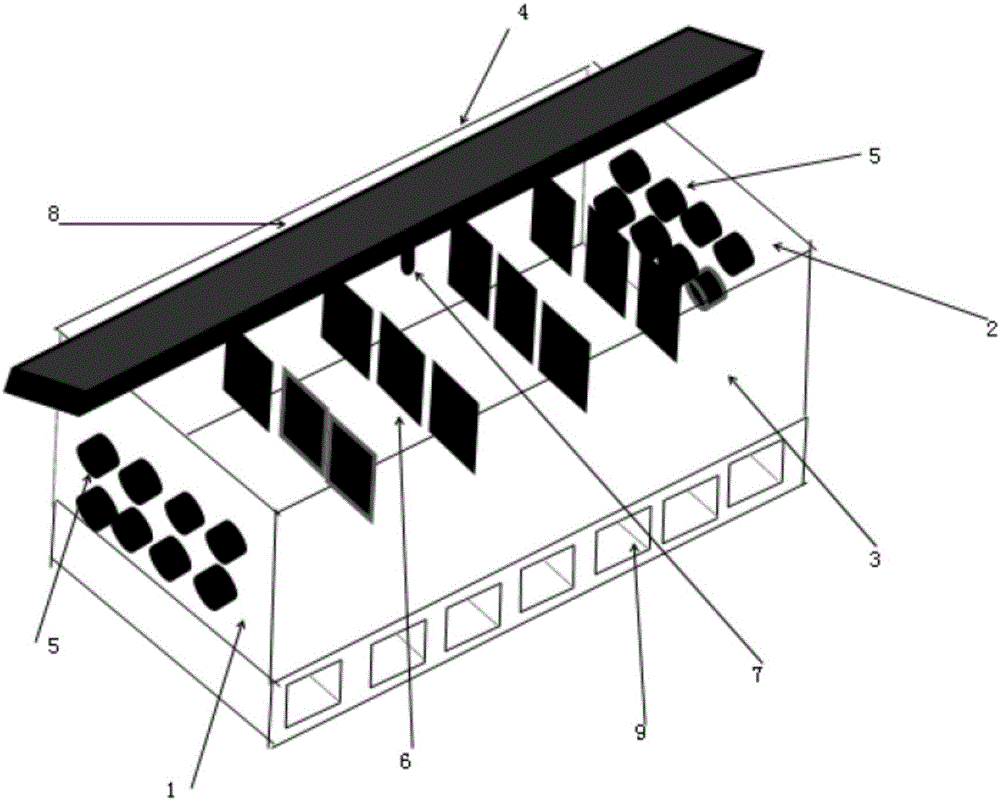

Three-shaft rotation base frame device in vacuum film plating cavity

ActiveCN104818468AGuaranteed coating uniformityIncrease furnace capacityVacuum evaporation coatingSputtering coatingGear driveEngineering

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

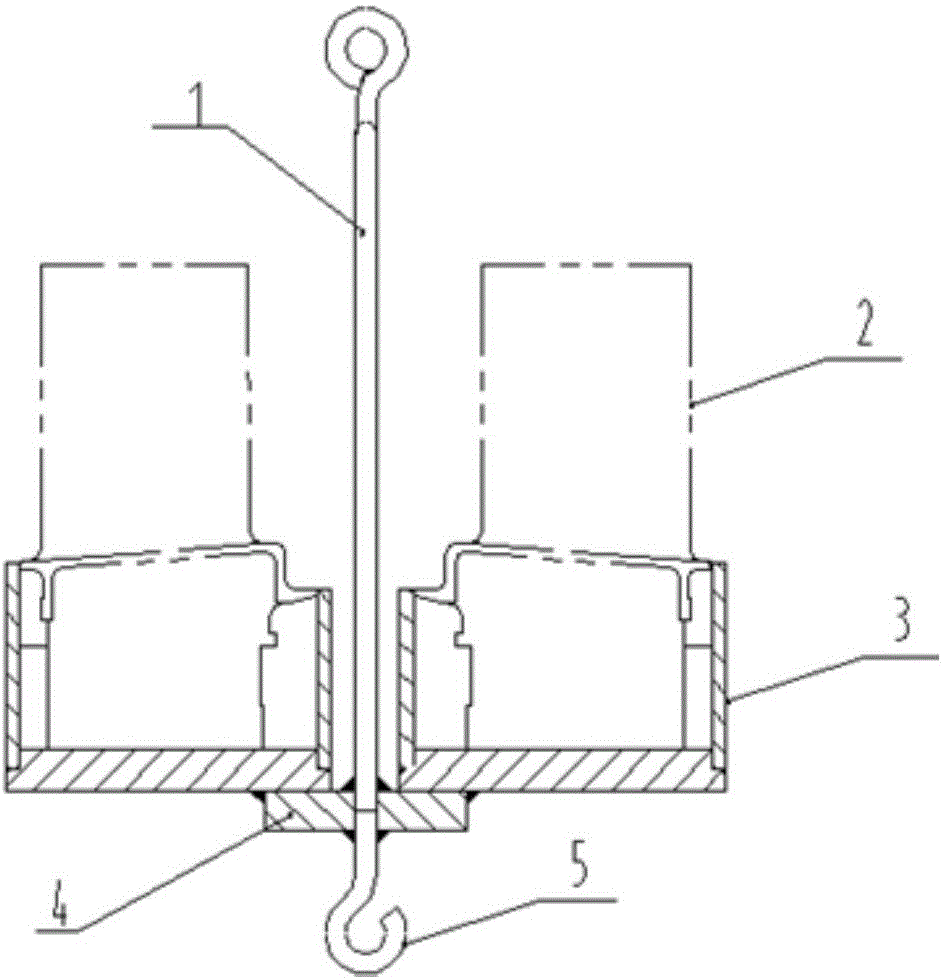

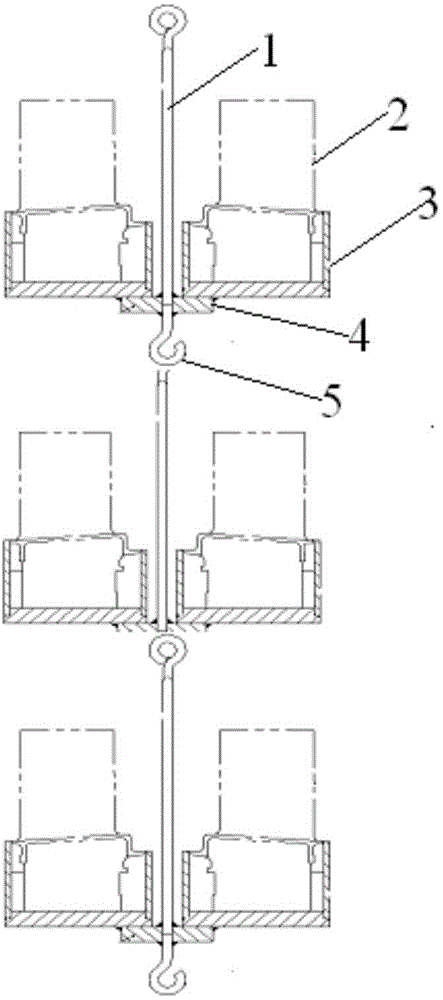

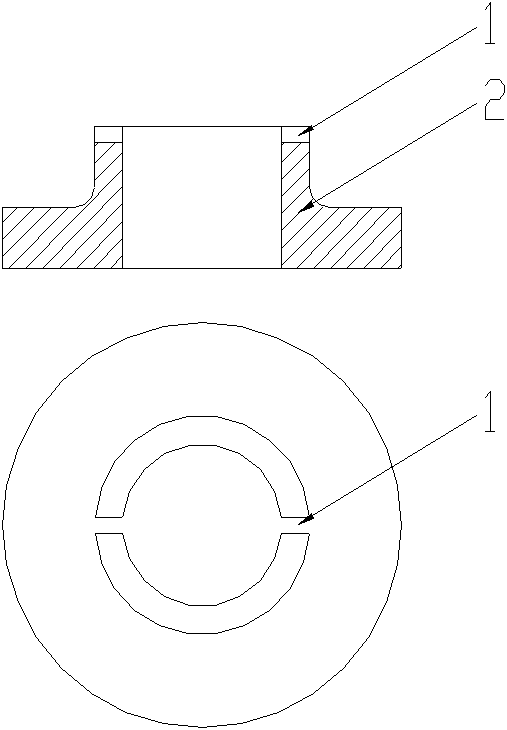

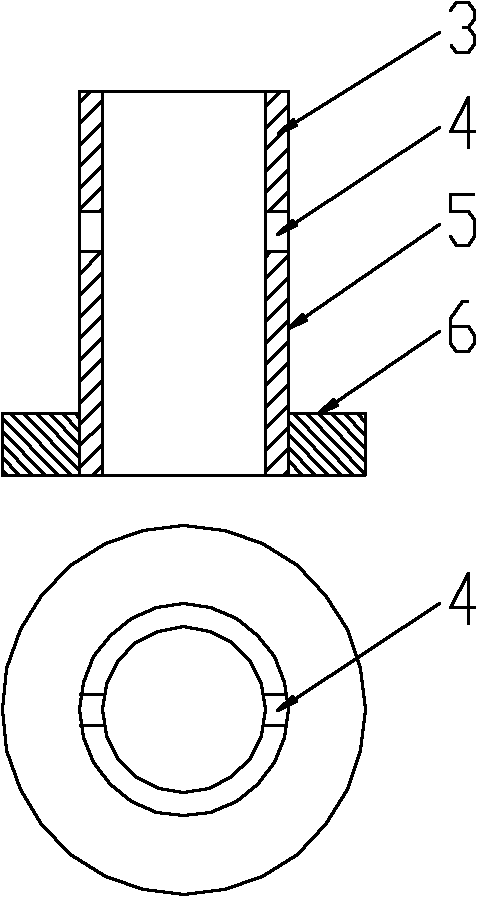

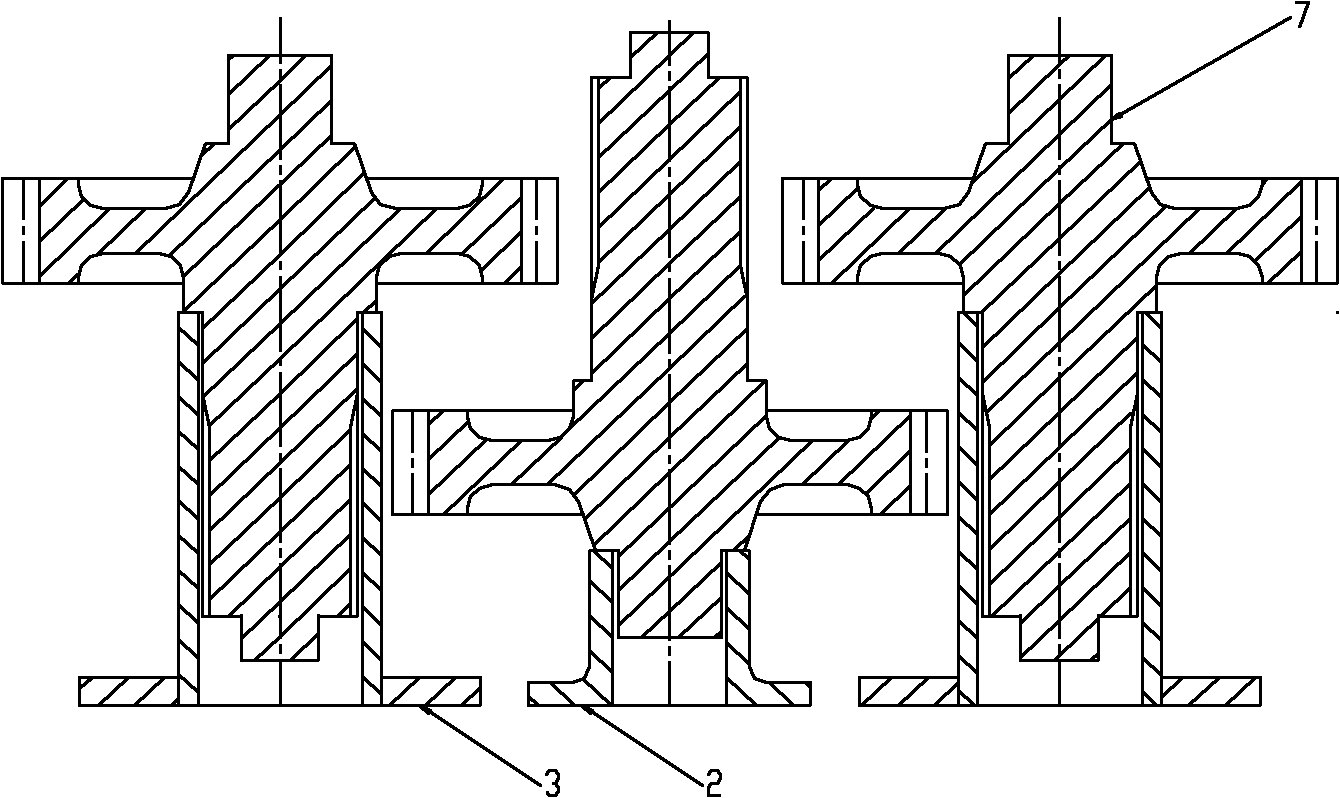

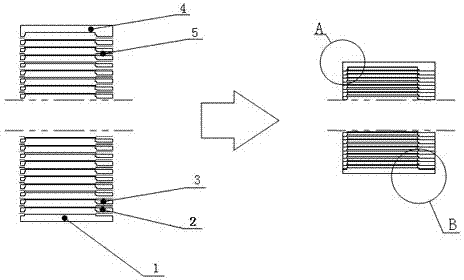

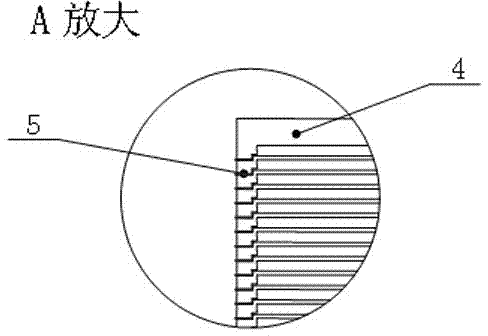

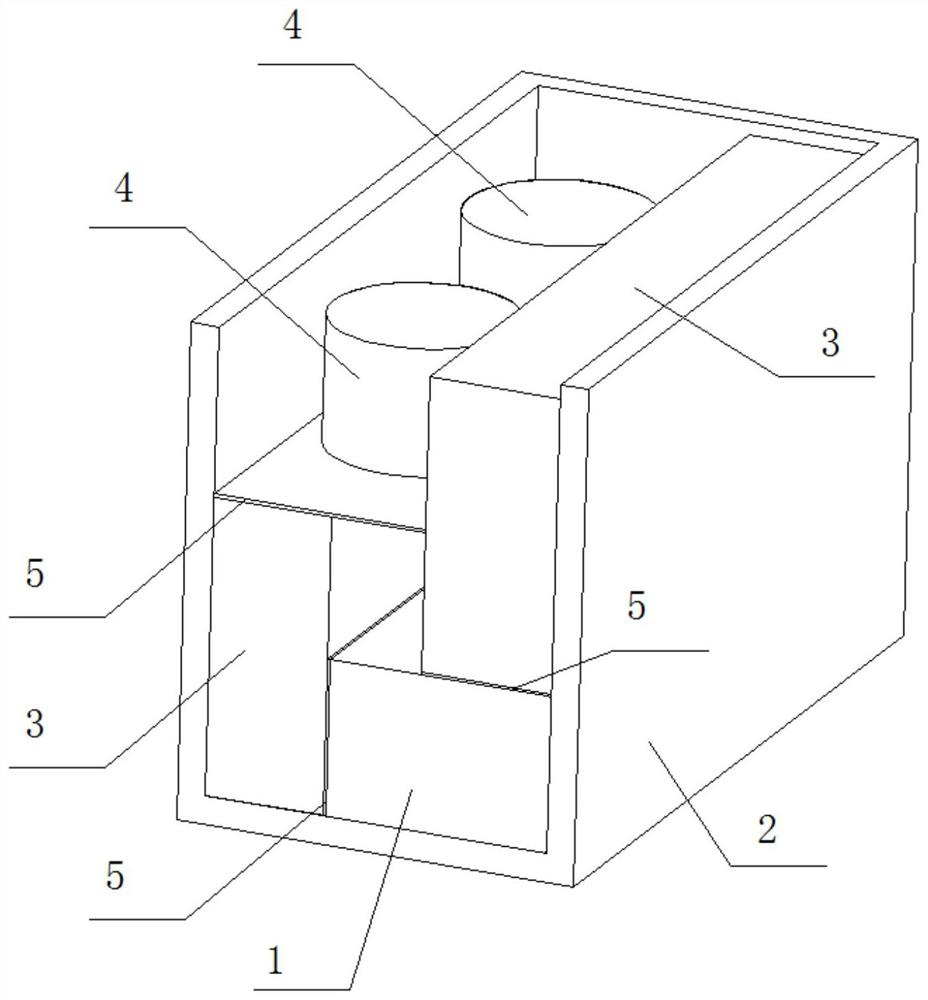

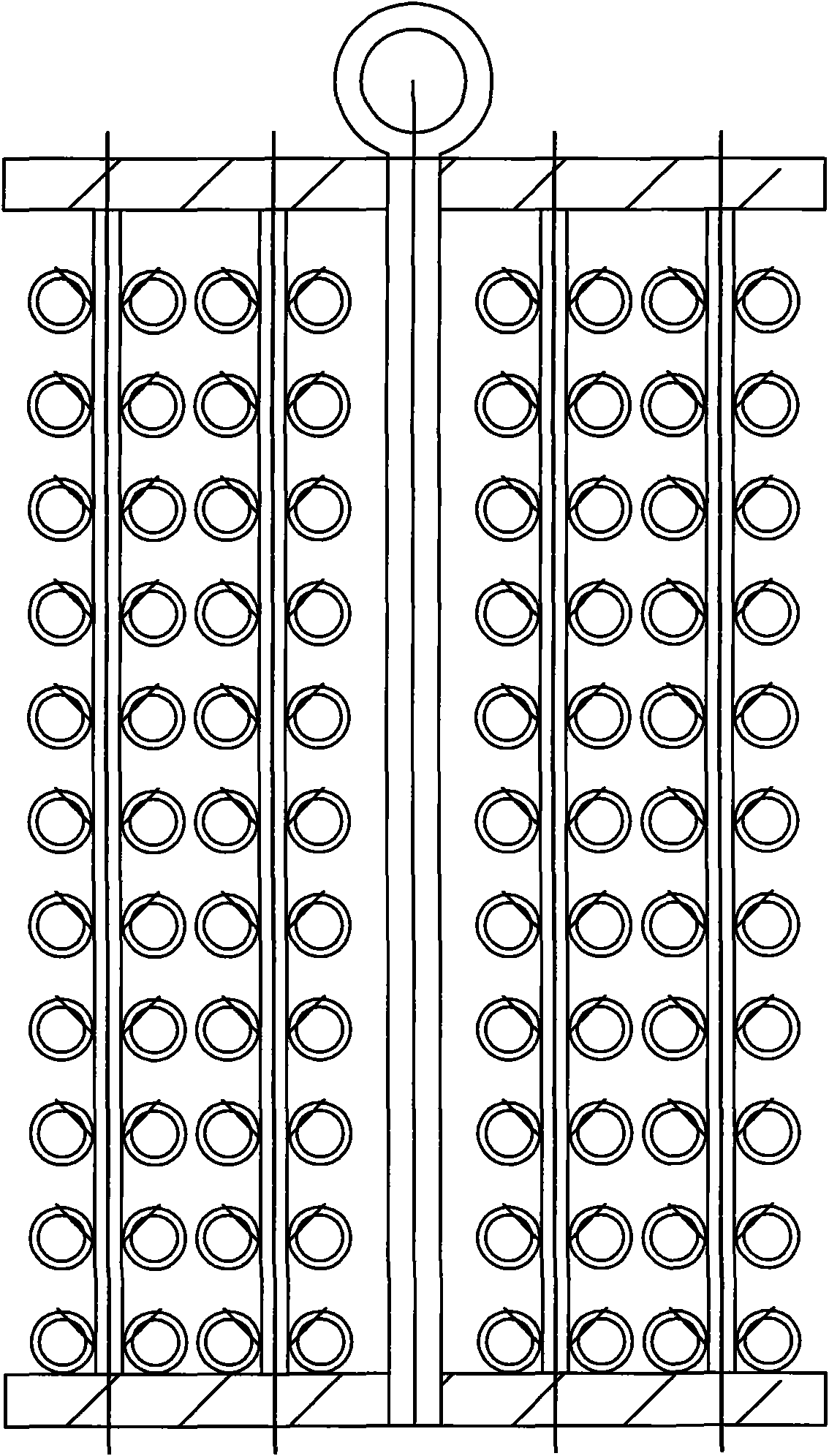

Thermal treatment carburization charge tooling

InactiveCN101984138AIncrease furnace capacityCarburizing quality qualifiedSolid state diffusion coatingFurnace typesCarburizingThermal treatment

The invention aims to provide thermal treatment carburization charge tooling capable of vertically placing axle gears. The technical scheme is that: two types of the thermal treatment carburization charge tooling are utilized; tooling (2) is integrally processed; a 4 mm notch (1) is formed on the upper part of the tooling (2); tooling (3) is formed by welding a chassis (6) and a sleeve (5); and a hole (4) with 8 mm diameter is formed on the middle part of the sleeve (5). A short axle end of the gear is vertically placed in the tooling (2), and a long axle end is placed in the tooling (3); the tooling (2) and the tooling (3) are alternately arranged on a charging basket bottom for carburization quenching treatment; and after the quenching, the gear is fetched out, and the tooling (2) and the tooling (3) can be reused. When the tooling is used, the gear can be vertically placed in the tooling, the charge amount is greatly increased and the thermal treatment carburization quality is guaranteed.

Owner:大连创新齿轮箱制造有限公司

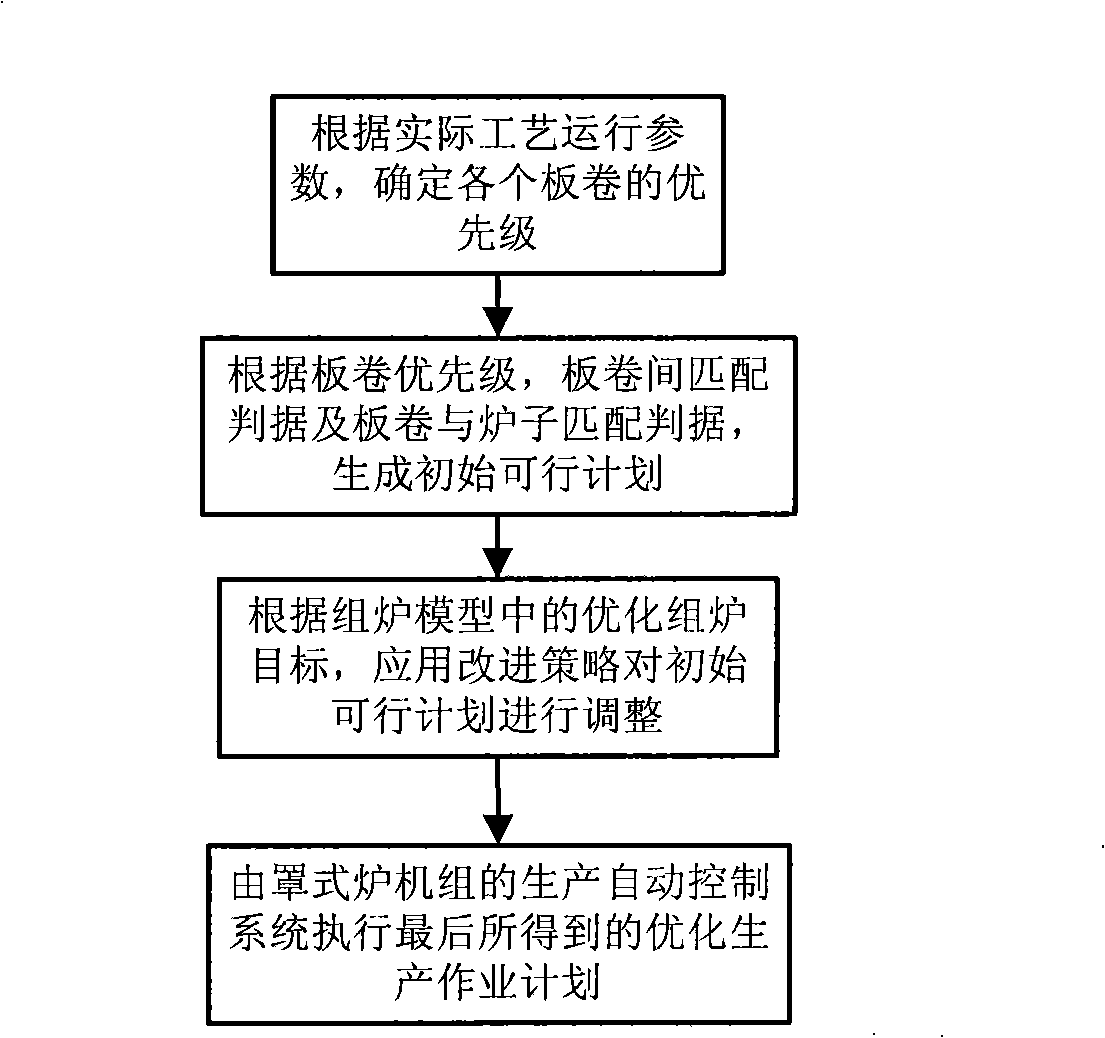

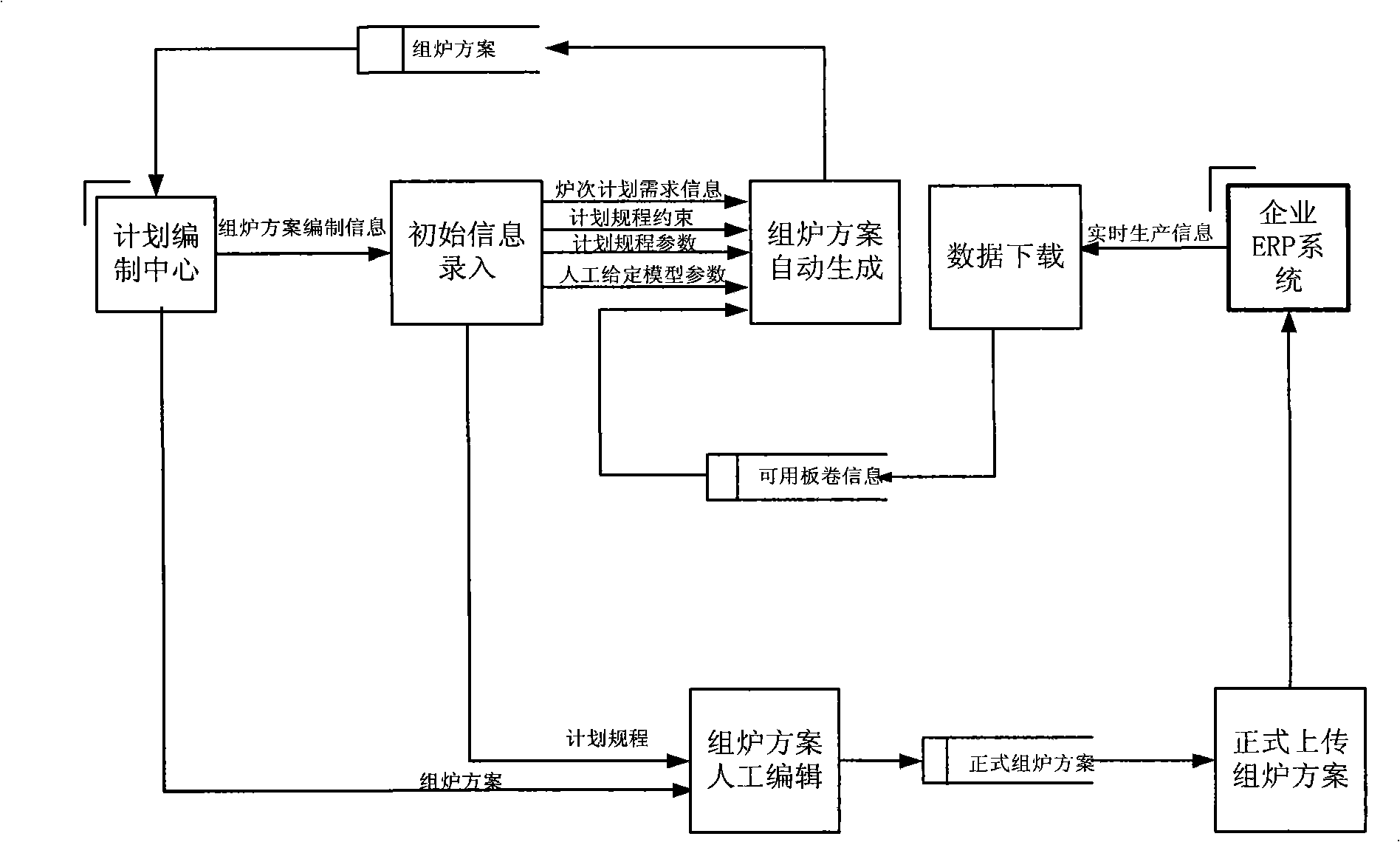

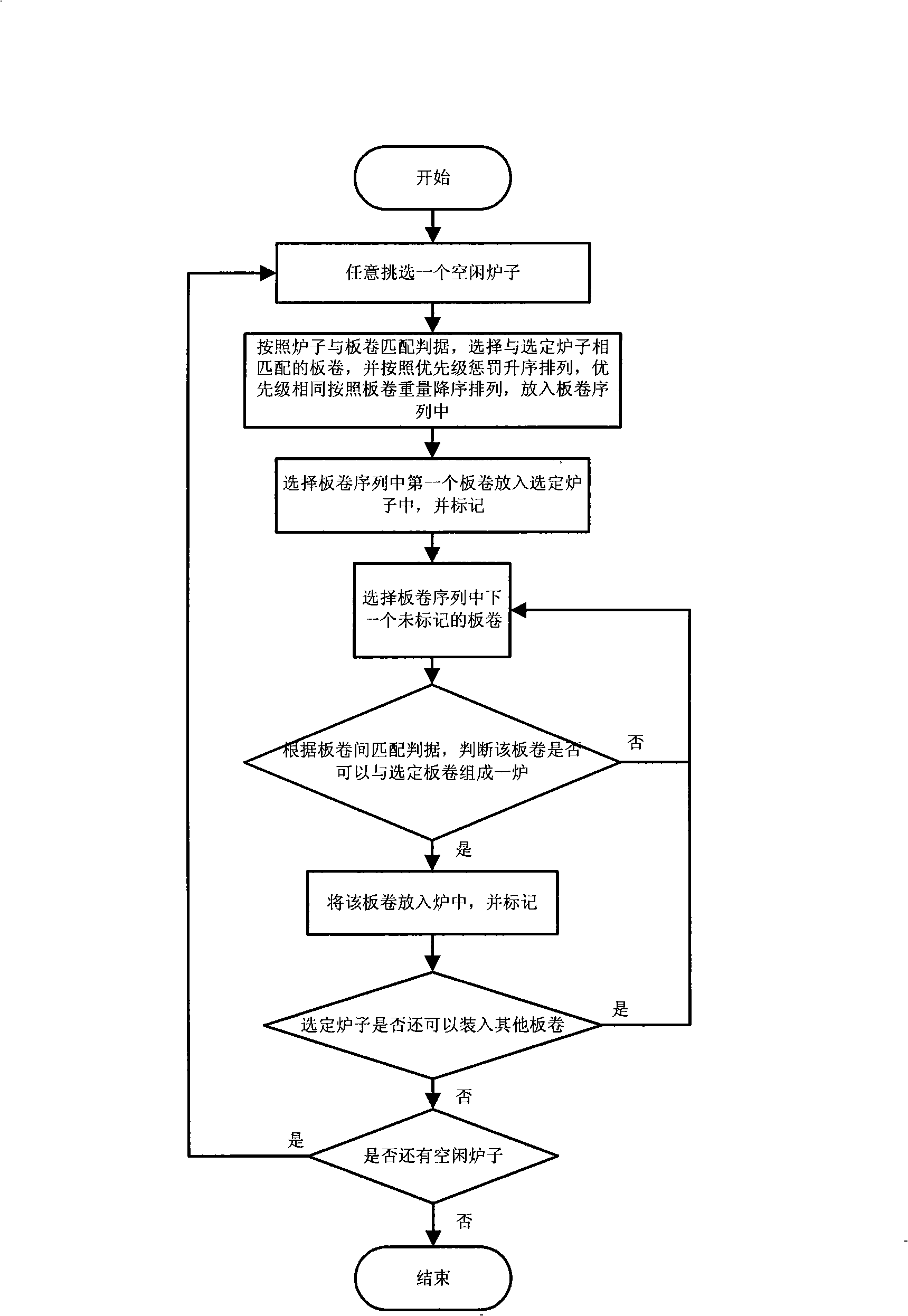

Optimized furnace combination method and system for cold rolling hood type annealing furnace unit

ActiveCN101344780AHigh-efficiency group furnace methodFeasible Group Furnace MethodTotal factory controlProgramme total factory controlManufacturing execution systemNitrogen gas

A furnace group optimizing method and a system for cold-rolling bell annealing furnace sets belong to the field of steel material processing information technology. The method comprises the following steps of: (1) according to practical technological parameters, performing priority settings on coiled sheets to be annealed; (2) furnace pre-grouping: arranging coiled sheets according to priority penalty values in ascending order; placing the coiled sheet with the minimum priority into a furnace according to the coiled sheet-furnace matching criteria; according to the coiled sheet-coiled sheet matching criteria, selecting, from the residual coiled sheets, coiled sheets that can form a furnace group with the coiled sheet in the furnace sequentially, and when the height reaches the maximum height of the bell furnace, forming a furnace grouping scheme; repeating the procedure until the demanded furnace group scale is formed; (3) adjusting the initial feasible furnace grouping scheme; and (4) using the developed system to upload the obtained optimized furnace grouping scheme to the manufacture execution system for implementation. The method and the system of the invention increase the productivity of the bell furnace set, improve the annealing quantity of the coiled sheets and effectively lower the consumption of energy resources such as hydrogen, nitrogen, water, coal and power, etc.

Owner:NORTHEASTERN UNIV

Method for manufacturing vacuum brazing cooler

The invention relates to a method for manufacturing a vacuum brazing cooler. The method is characterized by omitting the process that aluminum wrapped welding rods are arranged among aluminum or aluminum alloy sheets to perform separation, and forming aluminum profile or aluminum plate materials with two ends provided with matched bosses and grooves through extrusion or stamping; stacking the aluminum profile or aluminum plate materials in pieces to form a cooler blank, embedding thin films in two ends among the stacked materials, clamping the brazing thin films, and performing vacuum brazing on the clamped workpieces to form a closed body of the cooler; performing face milling, hole drilling, tapping, nut screwing and detection to obtain the cooler product. By means of the method, the obtained vacuum brazing cooler is compact in structure, high in cooling efficiency and yield, low in comprehensive cost and suitable for cooling high-power frequency converters and inverters.

Owner:ALNAN ALUMINIUM CO LTD

Tool for performing preservative treatment on zinc-nickel seeping layers of steel rail fastener elastic strips

ActiveCN103510044ANo hooking upIncrease productivitySolid state diffusion coatingLocking mechanismEngineering

The invention discloses a tool for performing preservative treatment on zinc-nickel seeping layers of steel rail fastener elastic strips. The tool comprises a suspension shaft and a plurality of charging baskets, wherein a column pipe core allowing the suspension shaft to penetrate and be suspended is arranged in the center of each charging basket; an opening of the next charging basket is covered by the bottom of the previous charging basket; the opening of the uppermost charging basket is covered by a cover net which is inserted into the suspension shaft; all the charging baskets and the cover net are locked by a locking mechanism on the suspension shaft. A plurality of parallel elastic strip supporting ribs for suspending the elastic strips are distributed in the charging baskets uniformly; clamping brackets for clamping the elastic strips are arranged at the two ends of each elastic strip supporting rib. The elastic strips are not hooked mutually, so the workload of manual separation is greatly reduced. Workpieces are placed neatly and orderly and one set of tool can load hundreds of elastic strips, so the charging quantity of the steel rail fastener elastic strips is increased, the workload of charging the workpieces into the tool is reduced, and the production efficiency of the zinc-nickel seeping layers is improved.

Owner:CHONGQING DAYOU SURFACE TECH

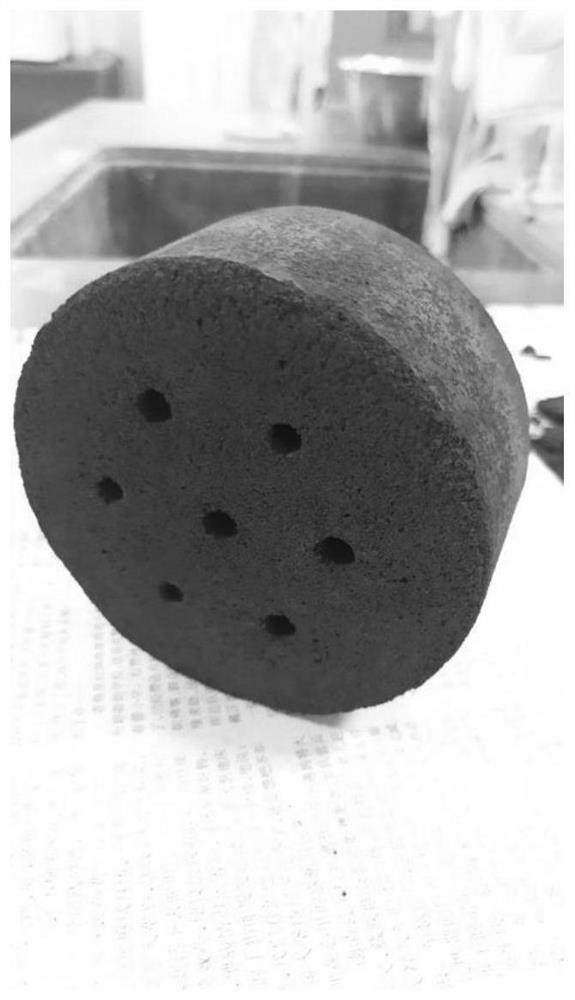

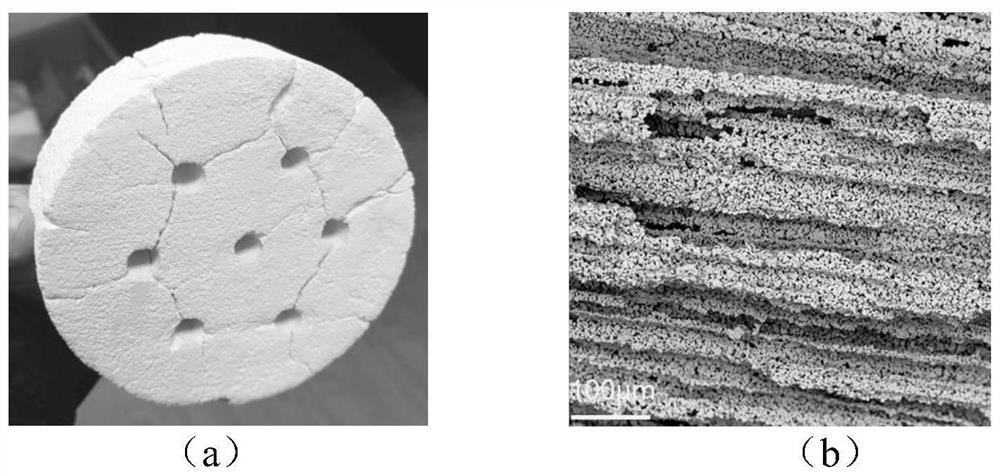

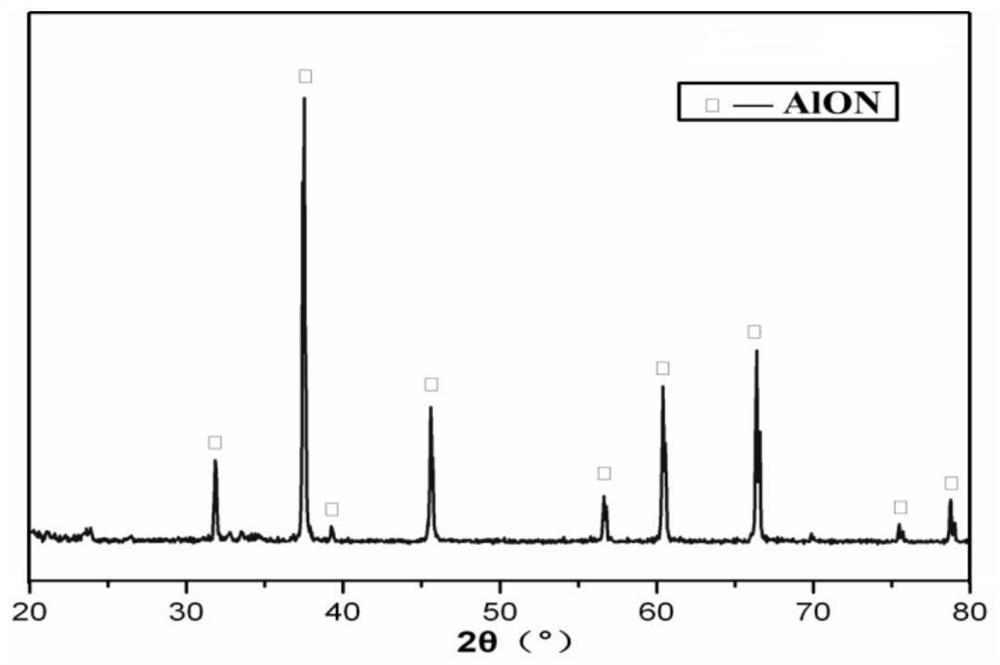

Ceramic powder preparation method based on freeze casting molding

ActiveCN112390653AFacilitated DiffusionRealize gas-solid reactionCeramic shaping apparatusNitrogen oxidesFreeze-drying

The invention discloses a ceramic powder preparation method based on freezing casting molding. The method comprises the following steps: (1) mixing a powder raw material, a solvent and an additive toobtain slurry with the solid phase content of 30-70wt%; (2) converting the slurry into a raw material blank with an internal through hole structure by adopting freezing casting molding and vacuum freeze drying processes and utilizing a temperature gradient formed by a mold; (3) putting the raw material blank into a reaction device with airflow control and anti-pollution functions in a high-temperature graphite sintering furnace, and carrying out high-temperature synthesis in a controlled reaction environment; and (4) carrying out ball milling and carbon removal process treatment on the raw material blank synthesized at high temperature to obtain the high-purity ceramic powder. The method can be used for macroscopic preparation of ceramic powder such as nitride and nitric oxide based on high-temperature gas-solid synthesis reaction, and has good application prospect and popularization value.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

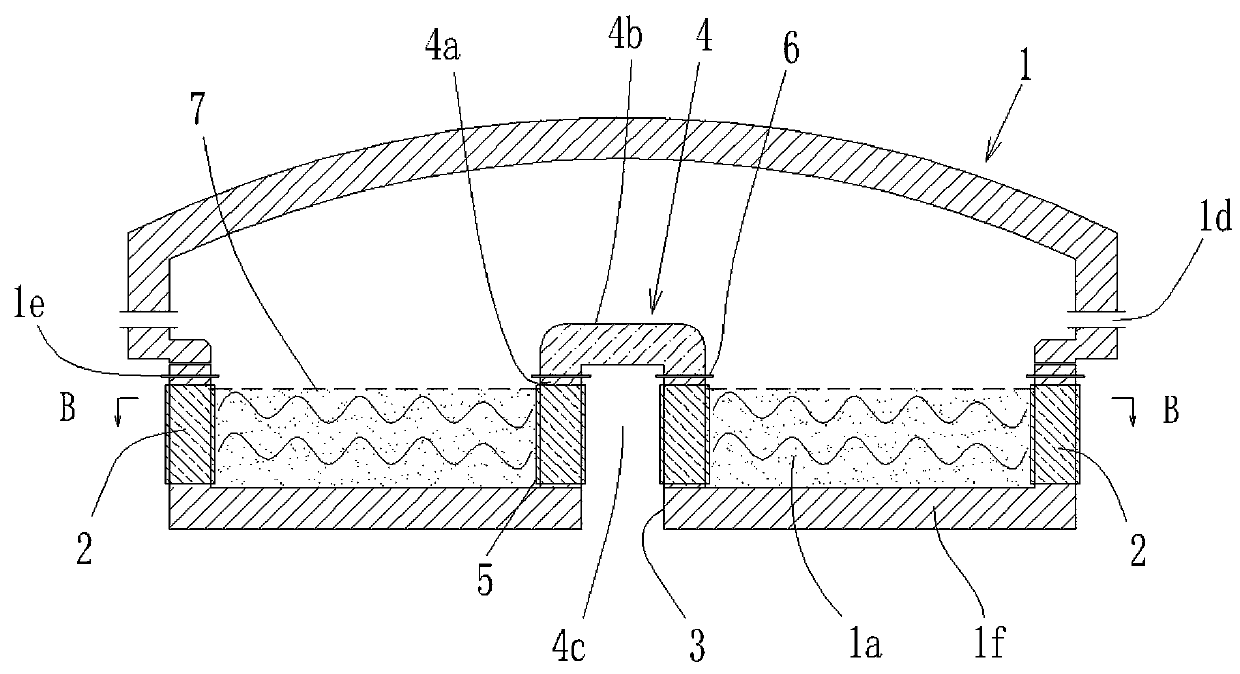

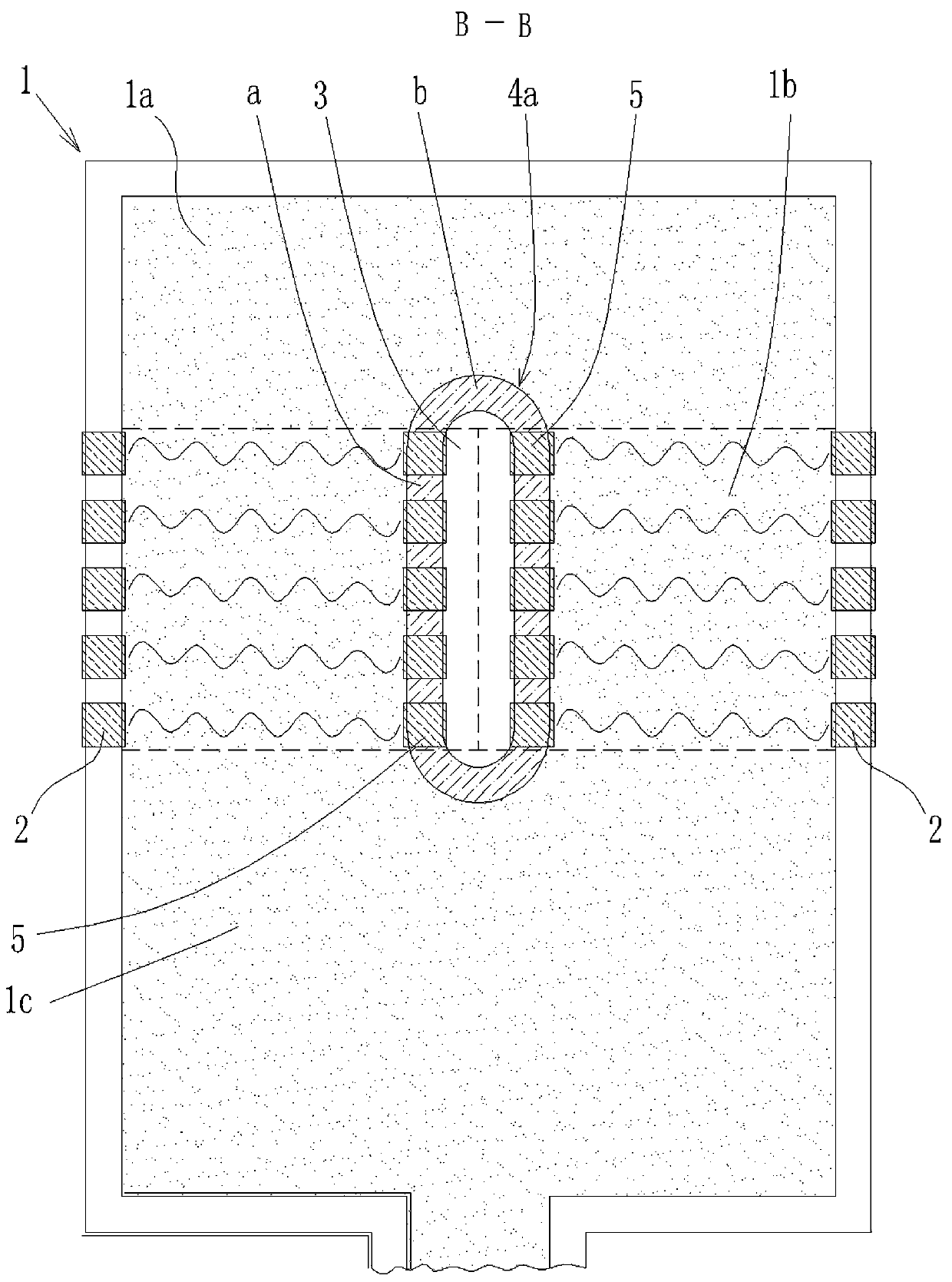

Wide-body melting furnace for producing electronic display glass

ActiveCN110818225AEasy to modifyIncrease furnace widthGlass furnace apparatusElectric furnaceGlass productionMelting furnace

The invention provides a wide-body melting furnace for producing electronic display glass. The wide-body melting furnace comprises a melting furnace (1), the interior of the melting furnace (1) is divided into a feeding part (1a), a melting part (1b) and a clarifying part (1c) in the flowing direction of raw materials; a group of first heating electrodes (2) are symmetrically arranged on the tankwall of the melting part (1b); and a group of first oxygen-enriched gas guns (1e) are also symmetrically arranged on the tank wall of the melting part (1b); the wide-body melting furnace is characterized in that an opening (3) is formed in the bottom of the melting part (1b), a cover body (4) covering the opening (3) is arranged in the melting part (1b), a cavity (4c) communicated with the outsideis formed by the cover body (4) and the opening (3); and a group of second heating electrodes (5) distributed corresponding to the group of first heating electrodes (2) and a group of second oxygen-enriched gas guns (6) are arranged on the cover body (4). The melting furnace is simple in structure and convenient to modify, and the capacity of the melting furnace is improved by increasing the width of the melting furnace without changing heating process conditions.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

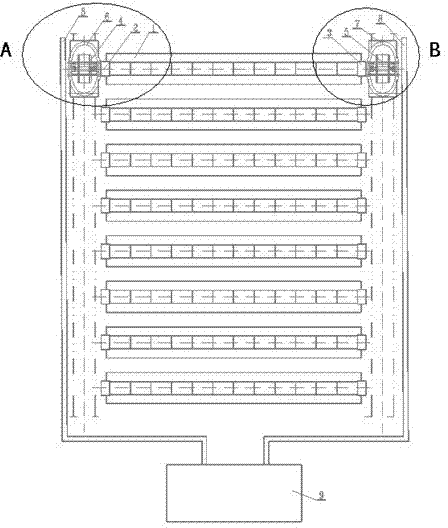

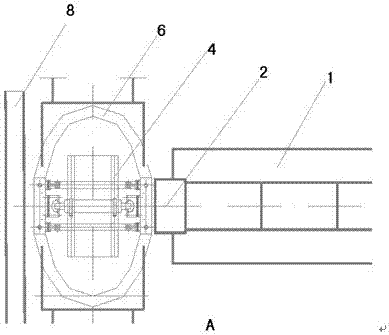

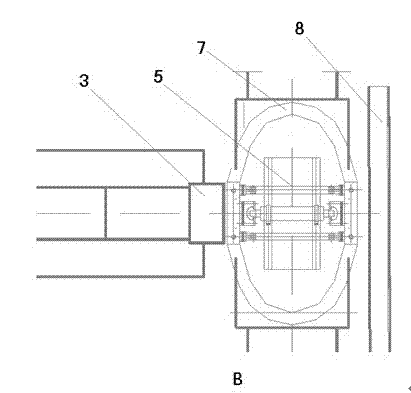

Special carbon material internal heat serial graphitizing production apparatus

The invention discloses a special carbon material internal heat serial graphitizing production apparatus, which comprises a graphitization furnace (1), a furnace head conductive electrode (2) and a furnace end conductive electrode (3) are respectively provided at two ends of the graphitization furnace, a furnace head bidirectional push apparatus (4) and a furnace end bidirectional push apparatus (5) are respectively arranged at external side of the furnace head conductive electrode and the furnace end conductive electrode, two ends of the furnace head bidirectional push apparatus are connected to a furnace head flexible busbar (6), two ends of the furnace end bidirectional push apparatus are connected to a furnace end flexible busbar (7), and the fixed bus (8) are provided at external side of the furnace head bidirectional push apparatus and the furnace end bidirectional push apparatus. The production apparatus has the advantages of short conduction time, large charge batch, low energy consumption, no furnace end bridge connection electrode, simple connection mode of the bus and the conductive electrode, less cooling water amount and low maintenance cost.

Owner:GUIYANG AL-MG DESIGN & RES INST

Method for manufacturing electron beam welding copper-tungsten contact piece by utilizing tungsten powder

ActiveCN112530724ASmall sizeRegular shapeElectric switchesIncreasing energy efficiencyElectro conductivityUltimate tensile strength

The invention discloses a method for manufacturing an electron beam welding copper-tungsten contact piece through tungsten powder, and the method comprises the steps: S1, powder mixing, S2, forming, S3, skeleton firing, S4, sintering, S5, match milling, and S6, electron beam welding. A traditional production mode is changed, a needed copper layer is sintered and welded only at the copper-tungstenalloy end, the size specification of the copper-tungsten alloy end is reduced, the charging quantity is increased, the base body and the copper-tungsten alloy are connected in an electron beam weldingmode, the appearance of a welded blank is regular, and the later machining efficiency is greatly improved. and the problem that the strength of a sintering bonding surface is affected by precipitation of chromium in the sintering process is solved, and the hardness, the conductivity and the like meet the use requirements.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Bearing tuffitriding frame

InactiveCN101876051AIncrease furnace capacitySmall footprintSolid state diffusion coatingCapacitanceBarrel Shaped

The invention relates to a device for tufftriding of a loading bearing, in particular to a bearing tufftriding frame. According to the technical scheme provided by the invention, the bearing tufftriding frame comprises a barrel-shaped frame, wherein vent holes are formed on the side wall and the barrel bottom of the barrel-shaped frame; the top end part of the side wall of the barrel-shaped frame is fixedly provided with two or more than two suspension clasps; and a plurality of separation net layers are arranged in the barrel-shaped frame. The bearing tufftriding frame can effectively improve the charge batch for bearing tufftriding, so a bearing with the same charge batch occupies less space, and a nitrogenization furnace with the same capacitance can perform the tufftriding process of more bearings. Thus, the production efficiency is improved.

Owner:WUXI NO 2 BEARING

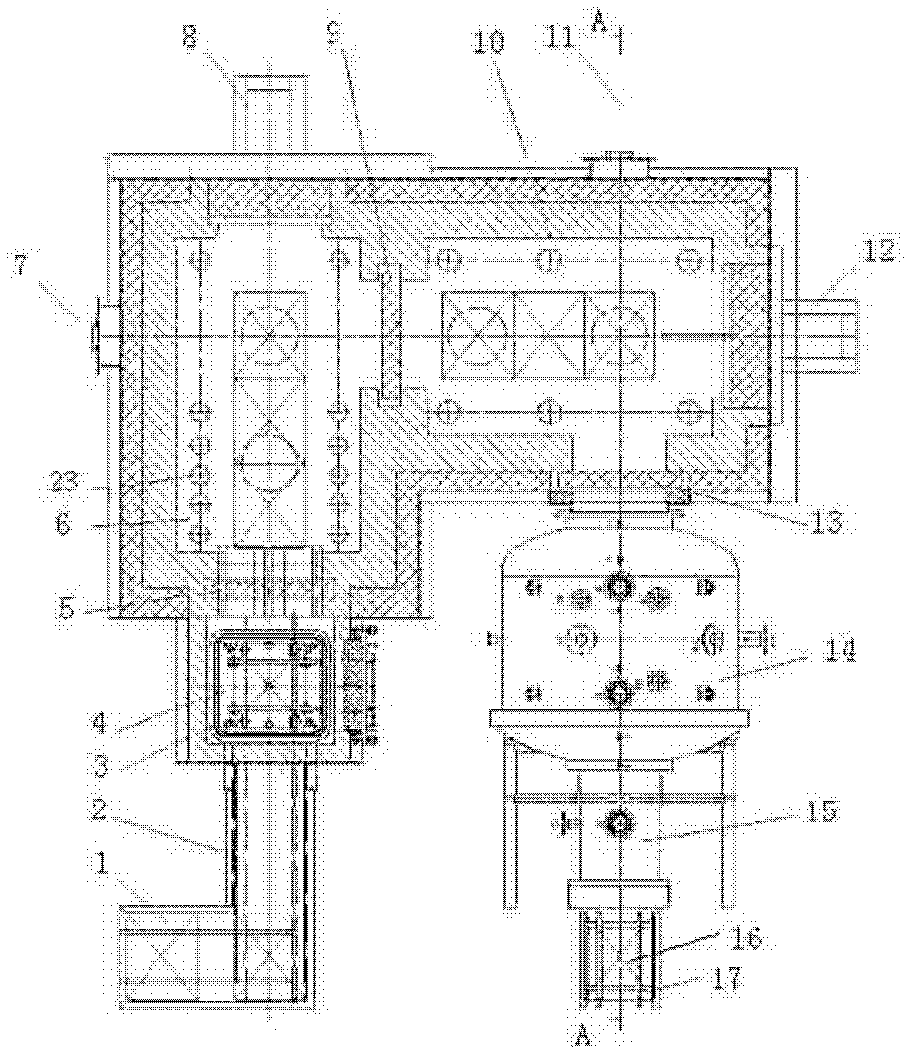

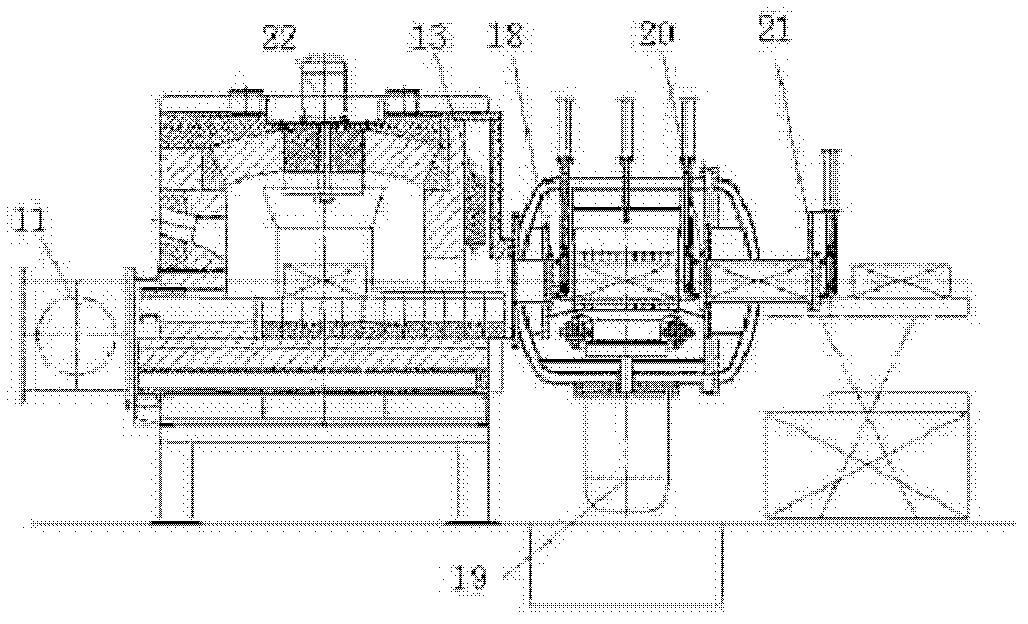

Continuous protective atmosphere heating high-pressure gas quenching furnace

The invention discloses a continuous protective atmosphere heating high-pressure gas quenching furnace which is characterized by comprising a continuous protective atmosphere heating furnace, wherein the protective atmosphere heating furnace comprises a vacuum air exchange antechamber, a heating zone and a heat preserving zone; the heat preserving zone of the continuous protective atmosphere heating furnace is in sealed connection with a high-pressure gas quenching chamber; and the high-pressure gas quenching chamber is hermetically connected with a vacuum air exchange discharging chamber. The vacuum air exchange antechamber plays the roles of preventing the air entering the heating zone, shortening the air exchange time and reducing the nitrogen consumption; the heating zone and the heat preserving zone play the role of protecting the protective atmosphere heating furnace, wherein the protective gas can be nitrogen and methanol atmosphere or nitrogen and ammonia cracking gas; and the vacuum air exchange discharging chamber plays the role of preventing the air from entering the high-pressure gas quenching chamber. The furnace disclosed by the invention has the advantages of reducing the equipment investment cost and the energy consumption, increasing the high-pressure gas quenching intensity, increasing the equipment automation degree and reducing the labor intensity and the labor cost.

Owner:SHANGHAI HUISEN MTH INDAL FURNACES

Multi-layer roller hearth waste heat utilization cyclic furnace and waste heat recovery method thereof

ActiveCN104975159AReduce heat lossIncrease furnace capacityIncreasing energy efficiencyFurnace typesProcess engineeringTransmission system

The invention relates to a multi-layer roller hearth waste heat utilization cyclic furnace and a waste heat recovery method applied to the multi-layer roller hearth cyclic furnace. The multi-layer roller hearth waste heat utilization cyclic furnace comprises a furnace body, an elevator, a vacuum ventilation chamber, a material inlet and outlet table, a transmission system and a control system. The transmission system comprises a transmission device which is connected with a motor. The material inlet and outlet table, the vacuum ventilation chamber, the elevator and the furnace body are sequentially connected. An electric furnace door is arranged between the furnace body and the elevator. A furnace shell is arranged outside the furnace body. Multiple heating bodies and at least two layers of in-furnace carrier rollers are disposed in the furnace body. The in-furnace carrier rollers of each layer are arranged on the transmission device. The control system controls forward and reversing transmission of the transmission device and ascending and descending of a lifting movable table. Compared with a continuous furnace and a cyclic furnace in the prior art, the multi-layer roller hearth waste heat utilization cyclic furnace has the advantages that charge capacity is large, the application range is wide, energy consumption for production is low and production efficiency is high.

Owner:浙江鼎诚炉业科技有限公司

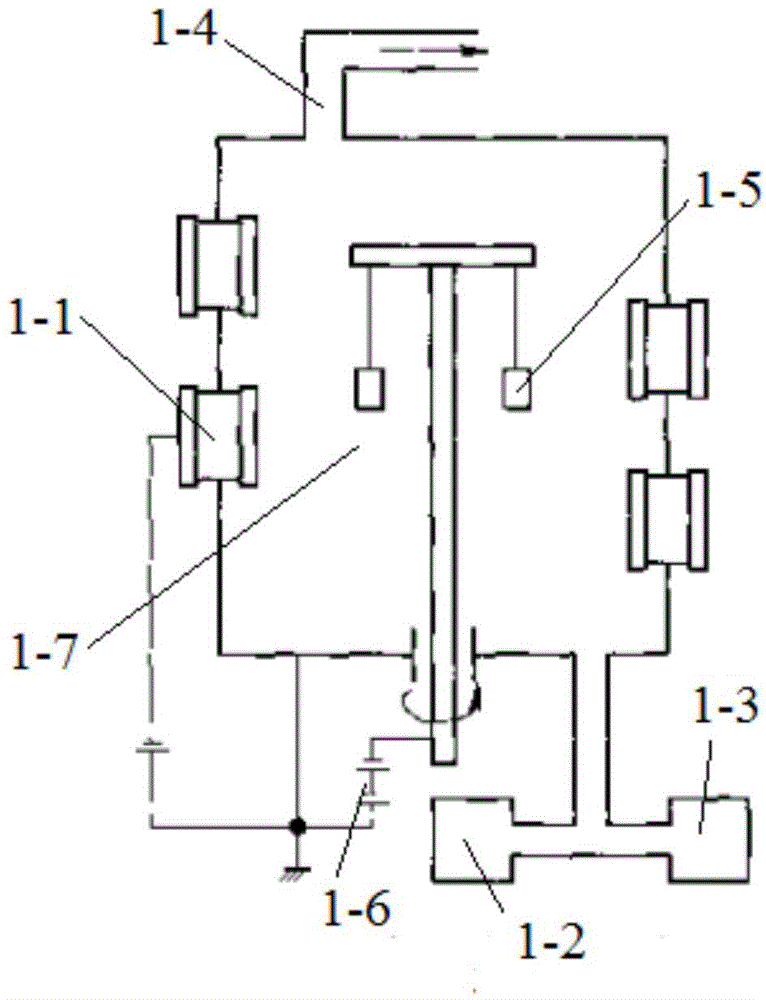

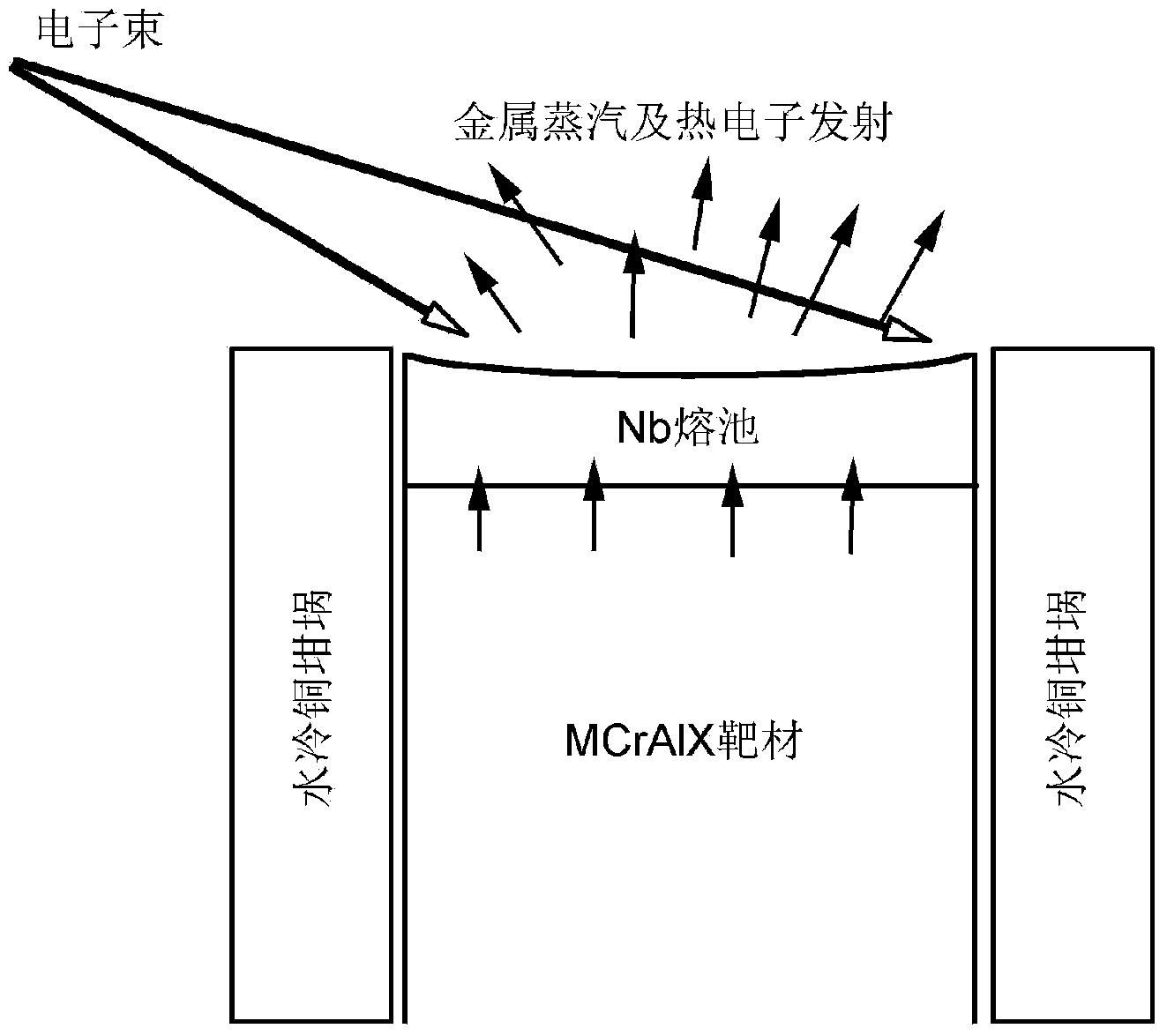

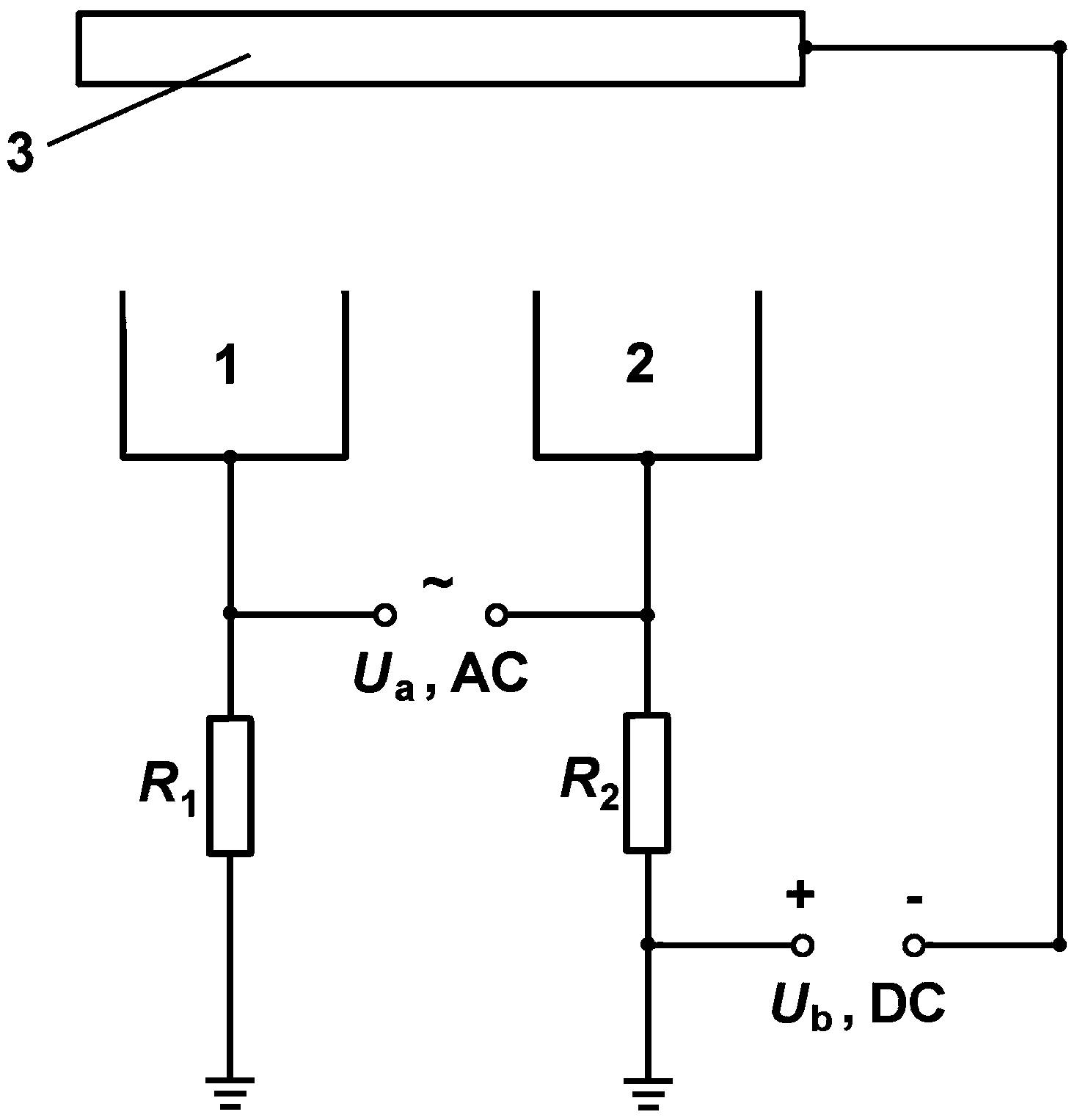

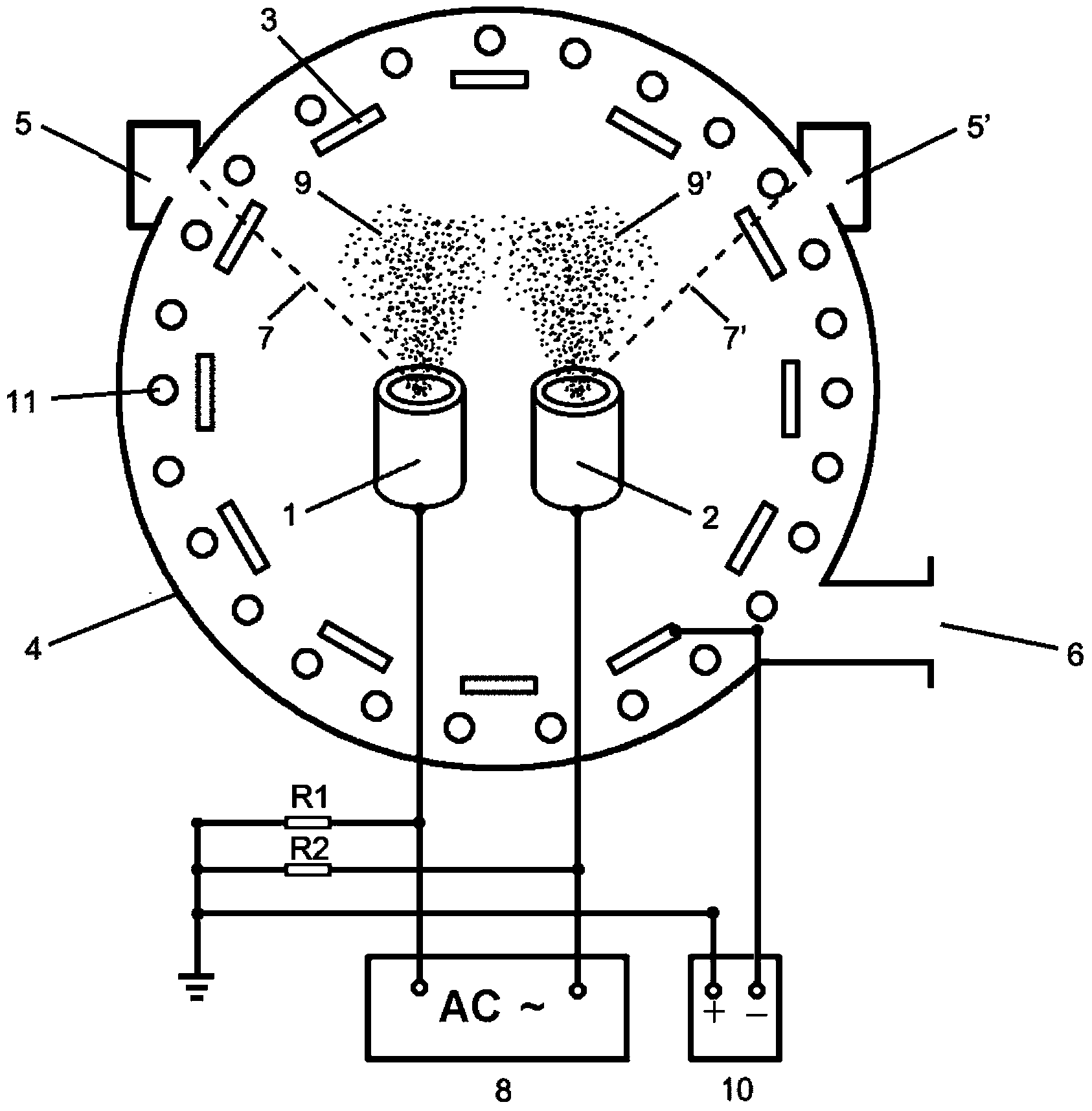

Method for realizing MCrAlX protective coating through ion plating deposition and device

ActiveCN103966556AQuality improvementIncrease furnace capacityVacuum evaporation coatingSputtering coatingHigh densityCrucible

The invention discloses a method for realizing a MCrAlX protective coating through physical vapor deposition of electron beams activated by plasmas in a vacuum environment and a device for realizing the method. The method comprises the steps of arranging at least two crucibles with MCrAlX targets in a vacuum cavity, and placing a proper amount of metal Nb above the targets; bombarding the two crucibles by using an electronic gun to melt the metal Nb and evaporate the MCrAlX targets. A high-temperature molten pool formed by the metal Nb emits a great number of hot electrons and MCrAlX steam under the action of an alternating current arc source, the hot electrons and the MCrAlX steam act together to trigger a hot cathode arc to discharge to form high-density MCrAlX plasma steam, and the two crucibles are alternately used as an anode and a cathode in the process. The plasma steam is deposited under the action of bias voltage of a base plate to form a MCrAlX coating, and the base plate can be preheated through radiation in a coating process.

Owner:成都航大新材料有限公司

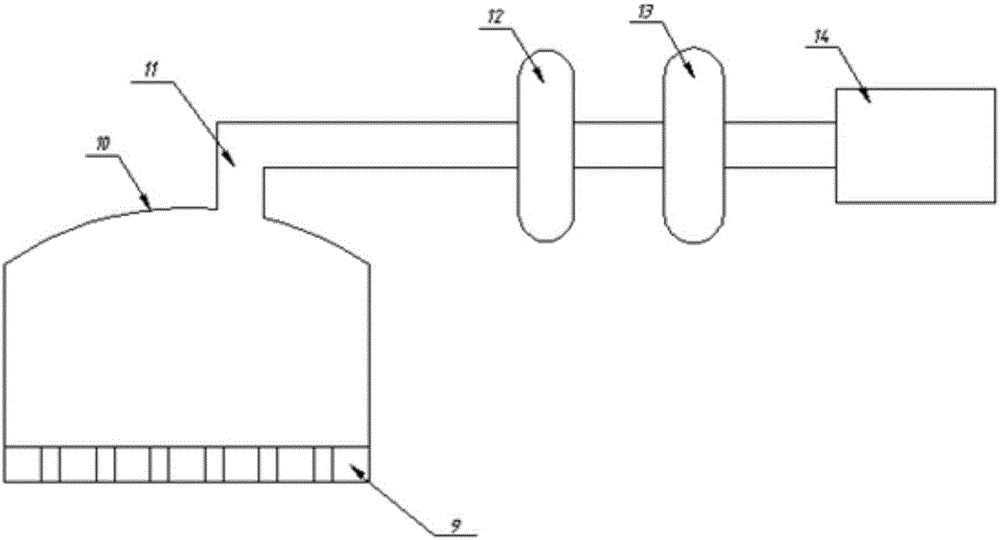

Graphitization furnace and graphitization production method for synthetic graphite negative electrode material

InactiveCN106219522AImprove cooling effectFast power deliveryChemical industryThermal insulationClean energy

The invention discloses a graphitization furnace and a graphitization production method for a synthetic graphite negative electrode material. The furnace body of the graphitization furnace is of a case structure with an open upper end; the open end of the furnace body is sealed with a furnace lid; conductive electrodes are installed on two opposite side walls of the furnace body; and a plurality of graphite current-conducting plates are distributed in the furnace body. The graphitization production method does not use a material container or material boat and directly places a raw material to be graphitized into a hearth for graphitization instead, so the charging amount of the material can be increased and output is increased by 25%; heat loss is small during heating, power consumption is greatly reduced, and unit power consumption of the graphitization furnace is reduced by at least 1000 kw / h compared with common furnaces; the periphery in the graphitization furnace is not filled with a thermal insulation material, so introduction of impurities in discharging is avoided, and product purity is high; concentrated guiding of flue gas for treatment is carried out, tailings are recycled, clean energy production is realized, and the degree of environmental protection is improved by 95% or above; and an air cooling system is utilized, the furnace body is simple in structure, and water resources are saved.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

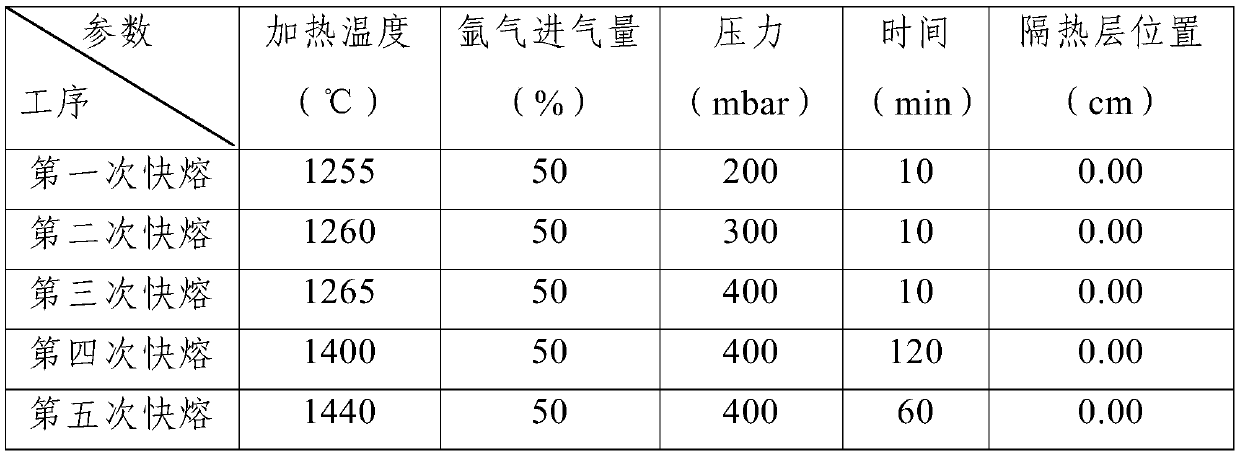

Application of silica powder to polycrystalline silicon cast ingot preparation

ActiveCN109811408ALow costIncrease furnace weightPolycrystalline material growthSingle crystal growth detailsSeed crystalMaterials science

The invention discloses application of silica powder to polycrystalline silicon cast ingot preparation. A preparation method of the polycrystalline silicon cast ingot comprises the following steps: step 1, the silica powder, silicon reuse materials, silica particles, polycrystalline silicon block materials, polycrystalline silicon bar materials, and silicon seed crystal are fed in the quartz crucible of an ingot furnace to serve as silicon materials used for the cast ingot; step 2, the ingot furnace is subjected to vacuum pumping and heating; step 3, the silicon materials used for the cast ingot are melted; step 4, argon is introduced to the ingot furnace, and pressure maintaining and cooling are performed for controlled directional solidification crystal growth; step 5, the argon is continuously introduced to the ingot furnace to perform anneal, and step 6, the argon is continuously introduced to the ingot furnace to cool to obtain the polycrystalline silicon cast ingot. According tothe application of silica powder to polycrystalline silicon cast ingot preparation, the silica powder is taken as one of the preparing silicon materials for the polycrystalline silicon cast ingot, unique charging mode is adopted, the charge batch of the silicon materials and the silica powder is effectively increased, the heat transfer effect among silicon materials is improved, sufficient meltingof the silica powder is guaranteed, rate of finished products of the polycrystalline silicon cast ingot is improved, thereby the minority carrier lifetime of the polycrystalline silicon is improved,and meanwhile, the silica powder need not to be pressed into a powder cake in advance, thereby lowering the preparation cost.

Owner:无锡坤硅新能源科技有限公司

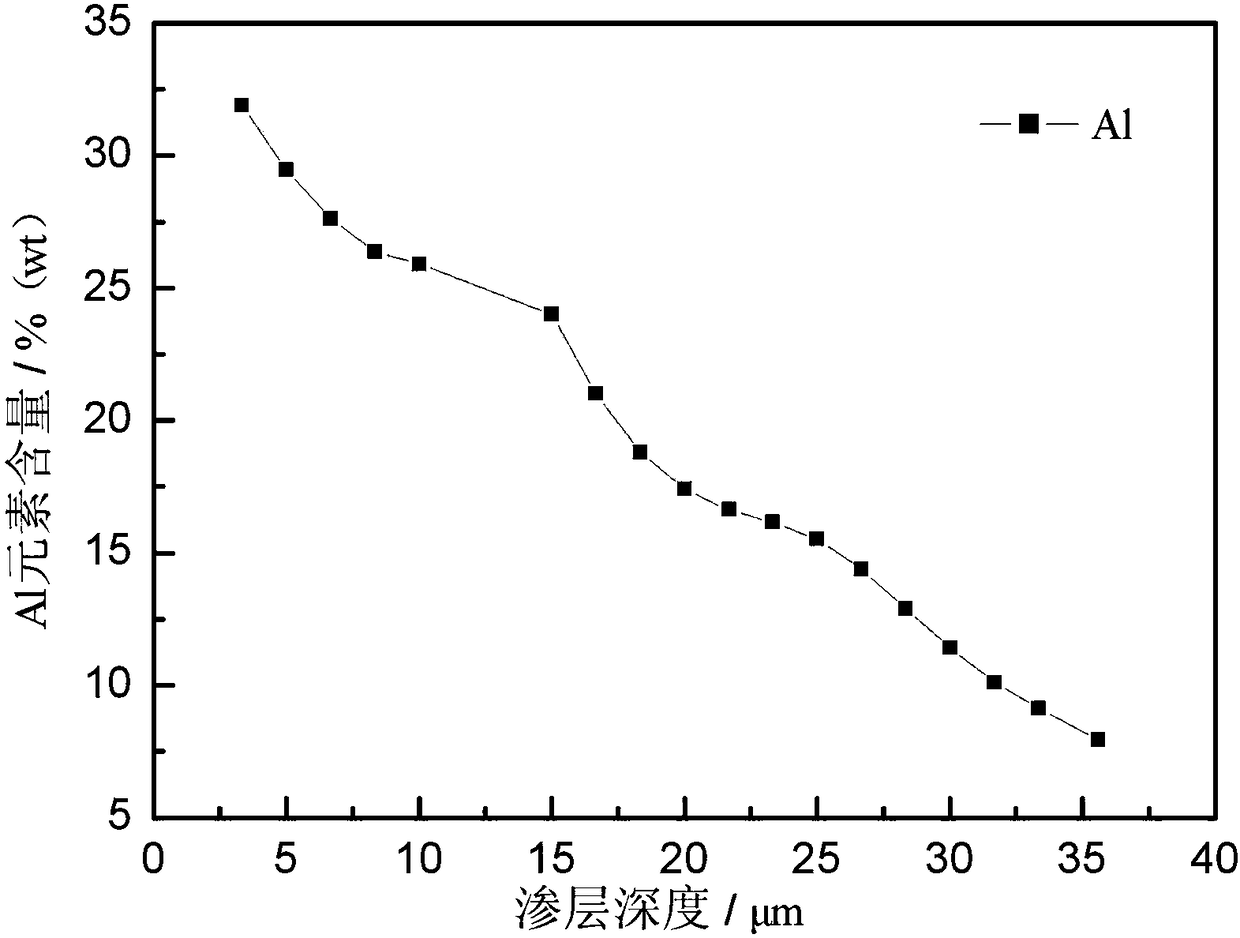

Preparation method of long-life thermal barrier coating

InactiveCN108130515AImprove thermal shock resistanceExtended service lifeVacuum evaporation coatingSputtering coatingGas phaseCeramic coating

The invention discloses a preparation method of a long-life thermal barrier coating, belonging to the technical field of thermal barrier coatings for aero-engine turbine blades. A bonding layer of thethermal barrier coating is prepared by using a lower-cost gas-phase infiltration Al method; when being prepared, the bonding layer is in an inert atmosphere, and is subjected to heat preservation andvacuum heat treatment; a ceramic layer of the thermal barrier coating is prepared by using an electron beam vapor deposition method. The gas-phase infiltration Al method is used for replacing an arcion plating method to prepare the bonding layer of the thermal barrier coating, so that the coating processing cost is greatly reduced, and the prepared gas-phase infiltration Al bonding layer has higher Al content; after the ceramic coating is deposited, the thermal shock resistance of the coating is higher, and the service life of the coating is greatly prolonged.

Owner:AECC AVIATION POWER CO LTD

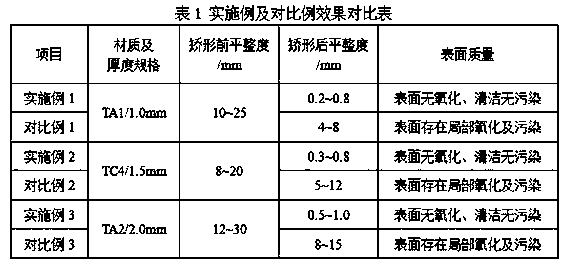

Titanium sheet vacuum hotpressing shape righting technology

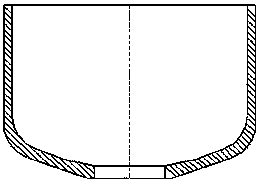

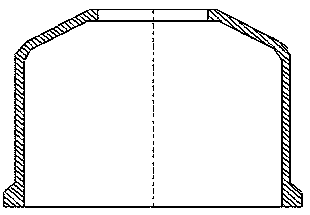

A titanium sheet vacuum hotpressing shape righting technology includes a placing procedure and a vacuum hotpressing righting procedure for titanium sheets, wherein the placing procedure includes the following steps: placing a material tray on a material tray support inside a hotpressing shape righting furnace, placing a bottom plate on the material tray, fully distributing liner plates on the bottom plate and reserving intervals among the liner plates; step II, stacking the titanium sheets stack by stack vertically on the liner plates, a baffle is arranged between every upper stack of titaniumsheets and lower stack of titanium sheets, and liner plates are placed between every baffle and the titanium sheets above and between every baffle and the titanium sheets below according to the manner of step I, so as to obtain the titanium sheet stack; step III, placing liner plates at the top of the titanium sheet stack according to step I, placing pressure plates on the liner plates, placing pressure blocks on the pressure plates, and reserving intervals among the pressure plates; step IV, placing cleaned and fully dried titanium scraps surrounding the titanium sheet stack, fixing by a metal net and completing the placing procedure. According to the invention, high flatness and surface quality, low cost vacuum hotpressing shape righting of the titanium sheets can be realized, besides,surface oxidation and pollution can be avoided.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Rapid CVD compacting method of carbon/carbon heat field structure product for single crystal furnace

InactiveCN108218461ASolve the problem of low output in independent productionImprove deposition efficiencySingle crystalGraphite

The invention discloses a rapid CVD compacting method of a carbon / carbon heat field structure product for a single crystal furnace. The rapid CVD compacting method comprises the following steps: (1) assembling a single crystal furnace heat field, wherein the single crystal furnace field comprises a graphite charging tray, an air manifold tool, a insulated barrel, a guiding barrel, a crucible, an air guiding barrel, and an air limiting tool; (2) CVD compacting; (3) repeating the step (2), and repeatedly compacting for multiple times until the density is not less than 1.35g / cm<3>. The rapid CVDcompacting method has the following beneficial effects: 1, by innovatively adding an airflow control element and integrating the advantages of the small-distance (slit flow and narrow flow) depositionand air guiding deposition, the method has the characteristic of high deposition efficiency, the cost is decreased, and the production period is shortened; 2, the furnace is innovatively assembled according to the appearance characteristics of the product, so that the product loading capacity can be greatly increased, and the yield is increased; and 3, the method has the characteristics of high practicability and easy in mass production and popularization and is easy to accept by single crystal heat field manufacturers.

Owner:AEROSPACE RUITIAN CARBON MATERIALS CO LTD

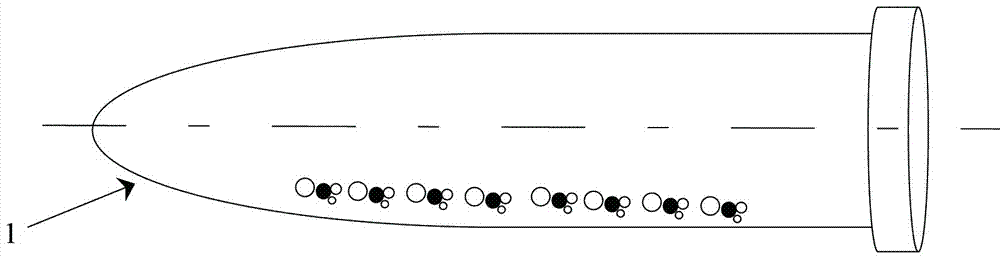

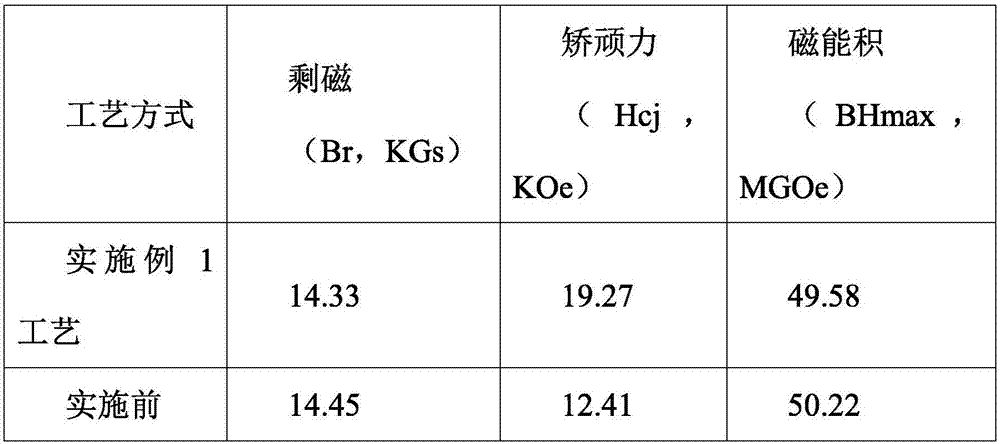

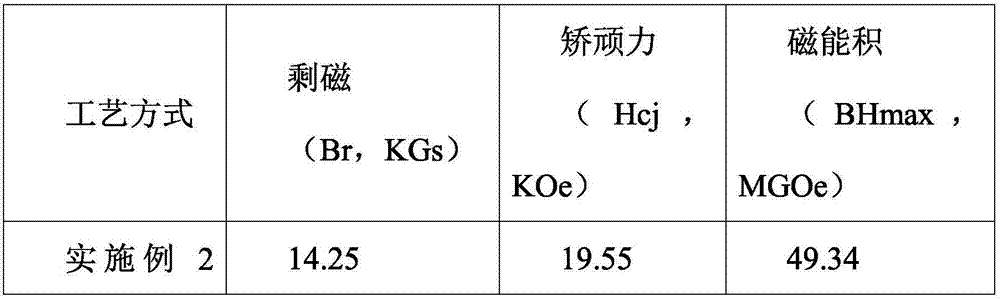

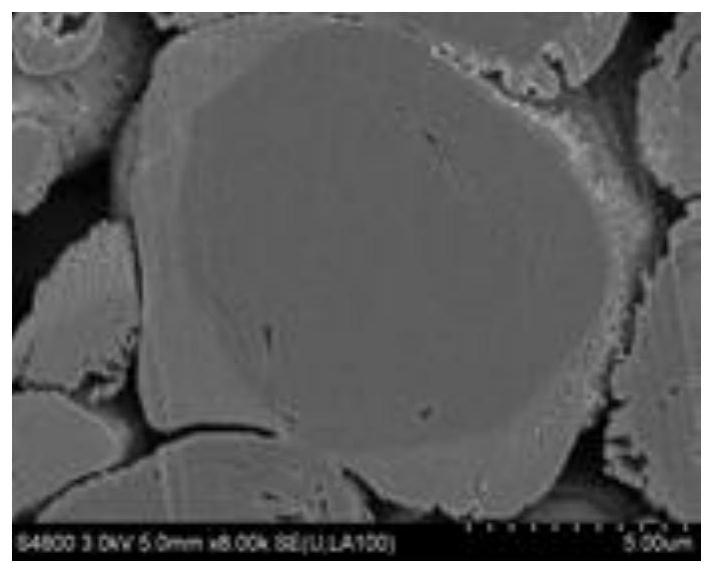

A method and device for preparing r-t-b rare earth permanent magnets

ActiveCN106298219BAvoid mutual adhesionAvoid sticking to each otherInductances/transformers/magnets manufactureMagnetic materialsRare earthAlloy

The invention discloses a method for preparing an R-T-B rare earth permanent magnet. The method comprises the following steps: a) preparing an R<L>uR<H>vFe100-u-v-w-zBwMz rare earth alloy serving as a diffusion source, wherein R<L> represents at least one element of Pr and Nd, R<H> represents at least one element of Dy, Tb and Ho, M represents at least one element of Co, Nb, Cu, Al, Ga, Zr and Ti, and u, v, w and z satisfy the following relations: u is greater than or equal to 0 and smaller than or equal to 10, v is greater than or equal to 35 and smaller than or equal to 70, w is greater than or equal to 0.5 and smaller than or equal to 5, and z is greater than or equal to 0 and smaller than or equal to 5; b, smashing the rare earth alloy to form alloy powder; c), putting the alloy powder together with an R-T-B magnet in a rotary diffusion device for heat diffusion; and d) carrying out aging treatment. The method has the beneficial effect that efficient and low-cost production of an R-T-B rare earth permanent magnet material with high coercive force and low heavy rare earth content is realized.

Owner:宁波永久磁业有限公司

A low-cost low-expansion long-cycle natural graphite-based composite material and its preparation method and application

ActiveCN111463416BImprove cycle performanceReduce expansionSecondary cellsNegative electrodesCarbon layerCrucible

The invention provides a low-cost low-expansion long-cycle natural graphite-based composite material and its preparation method and application. In the method of the invention, by adding a modifier and adopting cold isostatic pressing or warm isostatic pressing The modifier is pressed into the voids inside the spherical graphite to realize the densification of the voids inside the spherical graphite curled carbon layer, and at the same time, the spherical graphite particles are formed into blocks. During the graphitization process, the blocks can be directly put into the graphitization process. In the furnace, the furnace loading capacity is increased and the crucible is not used, which greatly reduces the cost of the product, and at the same time further improves the cycle performance of spherical graphite.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

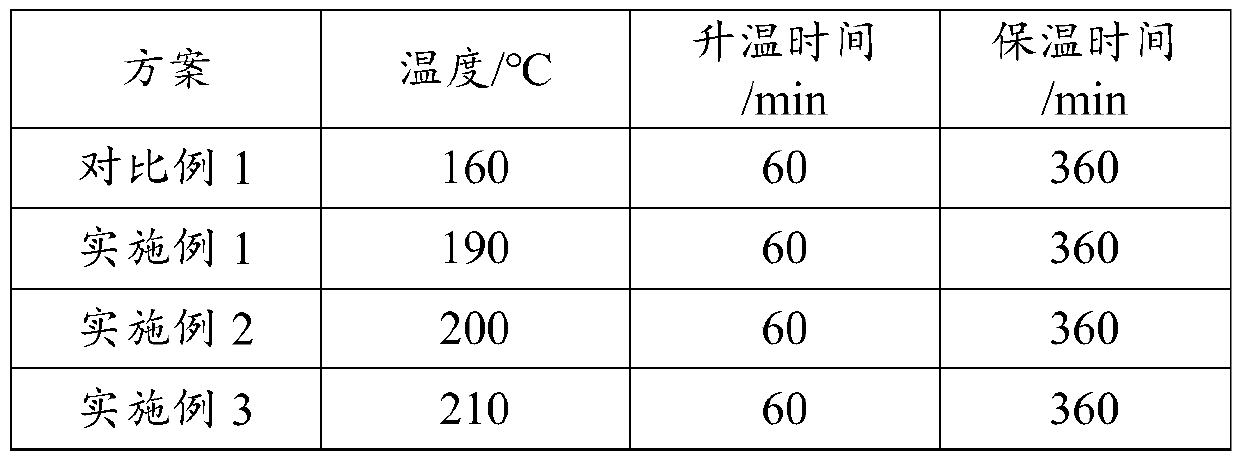

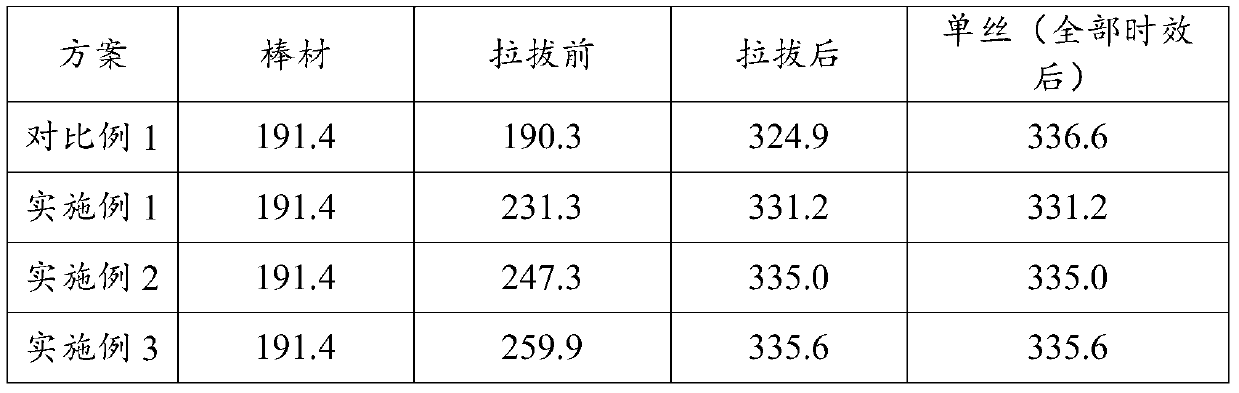

High-strength and high-conductivity aluminum alloy used for overhead conductors and preparation method for aluminum alloy

InactiveCN111270112AImprove conductivityReduce scratchesConductive materialMetal/alloy conductorsBoridingContinuous rolling

The invention discloses a preparation method for a high-strength and high-conductivity aluminum alloy used for overhead conductors. The preparation method comprises the steps: S1, material preparing is performed with the following components in weight percent: 0.60%-0.80% of Si, not greater than 0.50% of Fe, 0.05%-0.10% of Cu, 0.60%-0.90% of Mg, not greater than 0.03% of Cr, not greater than 0.03%of Mn, not greater than 0.03% of V, not greater than 0.03% of Ti and the balance Al; S2, after an aluminum source is boronized, the boronized aluminum source is melted in a holding furnace together with other raw materials, and molten aluminum is sampled and detected to confirm whether the content of each element reaches a target value or not; S3, when each of the elements of the molten aluminumreaches the target value, casting is started, and then continuous rolling is performed on a casting blank obtained by casting to make an aluminum alloy rod of which the wire diameter is 9.5mm; and S4,the aluminum alloy rod is aged at 180-220 DEG C, wherein the heating rate of 3-5 DEG C / min and the holding time is 5-12h; and then, the aluminum alloy rod is drawn at room temperature to form an aluminum alloy monofilament. The invention further discloses the aluminum alloy prepared by the method. The aluminum alloy monofilament prepared by the invention has high strength and high conductivity, and can realize 56.5% international annealed copper standard (IACS) on the basis of 315MPa strength.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD

Multi-deposition-chamber CVI (chemical vapor infiltration) device for compacting carbon/carbon crucible and method using same

ActiveCN102433543BSimple structureEasy to processBy pulling from meltChemical vapor deposition coatingCrucibleGraphite

The invention discloses a multi-deposition-chamber CVI (chemical vapor infiltration) device for compacting a carbon / carbon crucible and a method using the same. The device comprises a chemical vapor deposition furnace consisting of an outer furnace tank and an inner furnace tank and also comprises multiple layers of graphite partition plates which are distributed in the inner furnace tank from bottom to top and multiple intake tubes which are inserted in the inner furnace tank from bottom to top; adjacent two layers of graphite partition plates are isolated by multiple graphite shores; the upper part of the graphite partition plate arranged on the most-top layer is provided with a gas-sealing plate; dependant deposition chambers are respectively formed between adjacent two layers of graphite partition plates and between the gas-sealing plate and the graphite partition plate arranged on the most-top layer; multiple deposition chambers are distributed from top to bottom; and the multiple intake tubes are respectively inserted into the multiple deposition chambers from bottom to top. The compacting method comprises the following steps: 1, charging of a crucible prefabricated body; and 2, compacting treatment. The device disclosed by the invention has simple structure, reasonable design, good use effect, good compacting effect, good density uniformity, large charging amount and the like, is convenient for assembling and easy to use and operate.

Owner:XIAN CHAOMA SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com