Preparation method of long-life thermal barrier coating

A thermal barrier coating, long-life technology, applied in coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of high preparation cost and high cost of arc ion plating metal targets, and reduce processing costs. , The effect of high thermal shock resistance and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

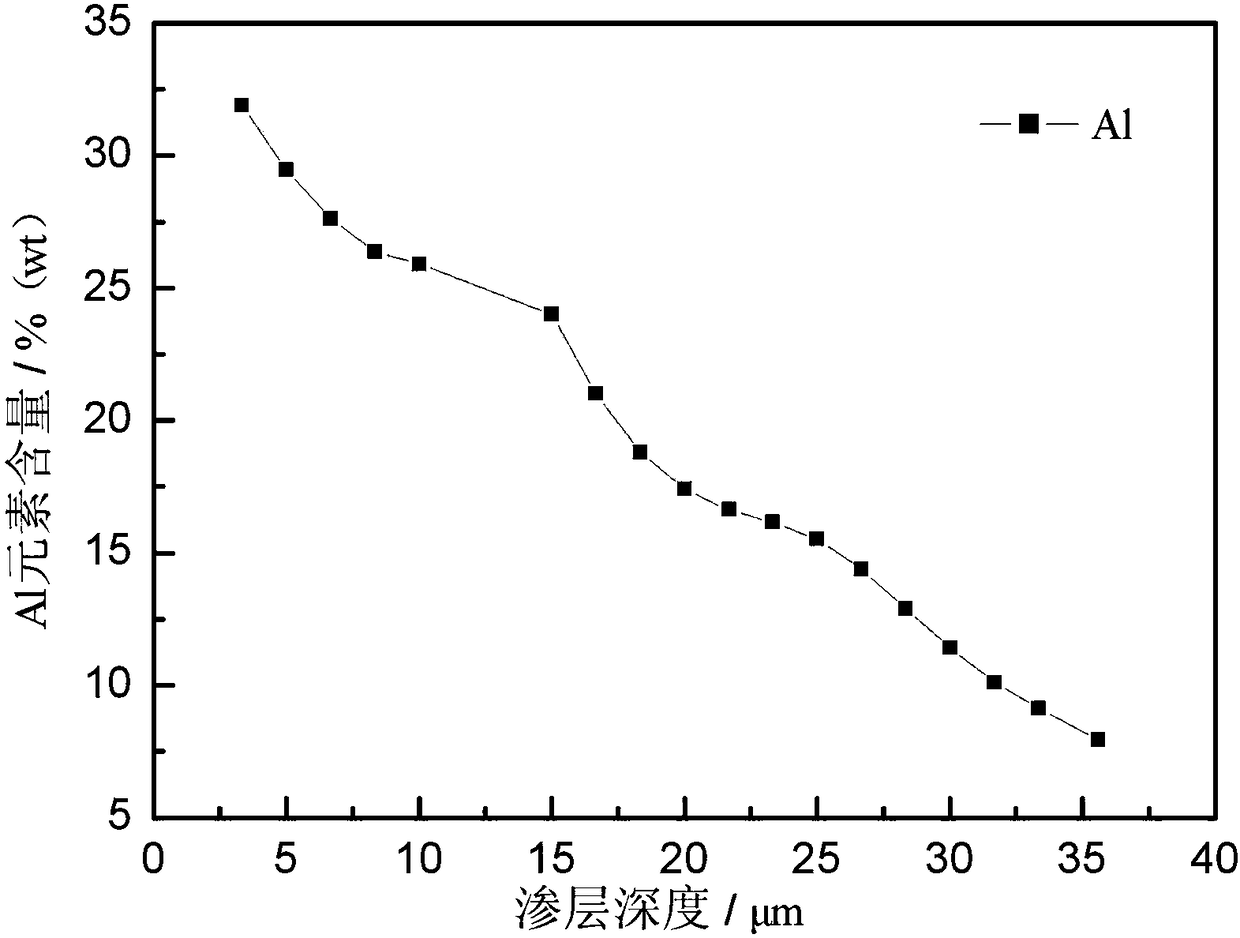

Examples

Embodiment 1

[0032] Embodiment 1 provides a method for preparing a long-life thermal barrier coating, including the following steps:

[0033] (1) Pretreatment: Before preparing the Al-infiltrated bonding layer, the parts are pretreated, and the pretreatment includes: wet sand blasting and ultrasonic cleaning.

[0034] (2) Preparation of vapor phase infiltration agent: use 3Kg of FeAl powder infiltration agent for every 10 parts, NH 4 Cl catalyst 100g, and baked at 100°C for 1 hour.

[0035] (3) Put the pre-treated blades and the baked infiltration agent into the bonding layer tooling, close the muffle furnace door, use a mechanical pump to evacuate to 1Pa, then pass in argon to 0.1MPa, use argon The air in the furnace was replaced five times, and finally argon was introduced to 0.05MPa. Heat up to 1000°C and keep it warm for 5 hours; during the heat preservation process, when the pressure is greater than 2MPa, deflate to 0.05MPa.

[0036] (4) After the holding time in the furnace is ove...

Embodiment 2

[0043] Embodiment 2 provides a method for preparing a long-life thermal barrier coating, including the following steps:

[0044] (1) Pre-treatment: Before preparing the Al-infiltrated bonding layer, pre-treat the parts. The pre-treatment includes: wet sand blasting and ultrasonic cleaning;

[0045] (2) Preparation of vapor phase infiltration agent: use 5Kg of FeAl powder infiltration agent and 200g of NH4Cl catalyst for every 20 parts; and bake at 150°C for 1 hour,

[0046] (3) Put the pre-treated blades and baked penetrating agent into the bonding layer tooling, close the muffle furnace door; use a mechanical pump to evacuate to 1Pa, then pass in neon gas to 0.2MPa, use neon gas The air in the furnace is replaced six times, and finally neon gas is introduced to 0.05MPa. Heat up to 1020°C and keep it warm for 3 hours; during the heat preservation process, when the pressure is greater than 2MPa, deflate to 0.05MPa.

[0047] (4) After the holding time in the furnace is over, v...

Embodiment 3

[0053] Embodiment 3 provides a method for preparing a long-life thermal barrier coating, including the following steps:

[0054] (1) Pre-treatment: Before preparing the Al-infiltrated bonding layer, pre-treat the parts. The pre-treatment includes: wet sand blasting and ultrasonic cleaning;

[0055] (2) Preparation of vapor phase infiltration agent: use 8Kg of FeAl powder infiltration agent and 200g of NH4Cl catalyst for every 20 parts; and bake at 100°C for 2 hours,

[0056] (3) Put the pre-treated blades and the baked infiltration agent into the bonding layer tooling, close the muffle furnace door; use a mechanical pump to evacuate to 1Pa, then pass in argon to 0.2MPa, use argon The air in the furnace was replaced seven times, and finally argon was introduced to 0.05MPa. Heat up to 1040°C and keep it warm for 2 hours; during the heat preservation process, when the pressure is greater than 2MPa, deflate to 0.05MPa.

[0057] (4) After the holding time in the furnace is over, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com