Patents

Literature

9688 results about "Processing cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process costing is a management accounting cost allocation method used by companies that produce copious amounts of homogenous or extremely similar consumer goods. Examples of these types of companies include food manufacturers, bottling companies, printing companies, and other similar businesses.

Method for producing carbon coated nano stage lithium iron phosphate by precipitation

InactiveCN101393982AAvoid synthetic stepsEasy to controlElectrode manufacturing processesIron saltsPhosphate

The invention discloses a precipitation method for preparing nanometer level iron phosphate lithium coated with carbon. The method comprises the following steps: firstly, weighing iron salt, deionized water and a compound of metallic elements; after the stirring and the mixing are performed, adding a phosphorous compound and citric acid diluted with water to the mixture; after the stirring is performed again, adding a precipitation agent to the mixture and controlling to the neutrality; stirring to react in a container, and after the static placement, respectively adding the deionized water, a carbon source and lithium salt to mix uniformly after the precipitate is filtered and washed; stirring again to react, and drying the water at 30 to 160 DEG C and warming up at the heating rate under the protection of non-oxidized gas after a product is crashed; baking at a constant temperature of 450 to 850 DEG C, cooling down to a room temperature at a cooling rate or with a stove, and finally obtaining the nanometer level ferric phosphate lithium coated with the carbon after crashing is performed. The precipitation method has the advantage that the raw material cost and the processing cost are low because bivalent iron is taken as the raw material. The iron phosphate lithium prepared by using the process has the characteristics of good physical processing performance and good electrochemistry performance, and is suitable for industrialized production.

Owner:南京海泰纳米材料有限公司

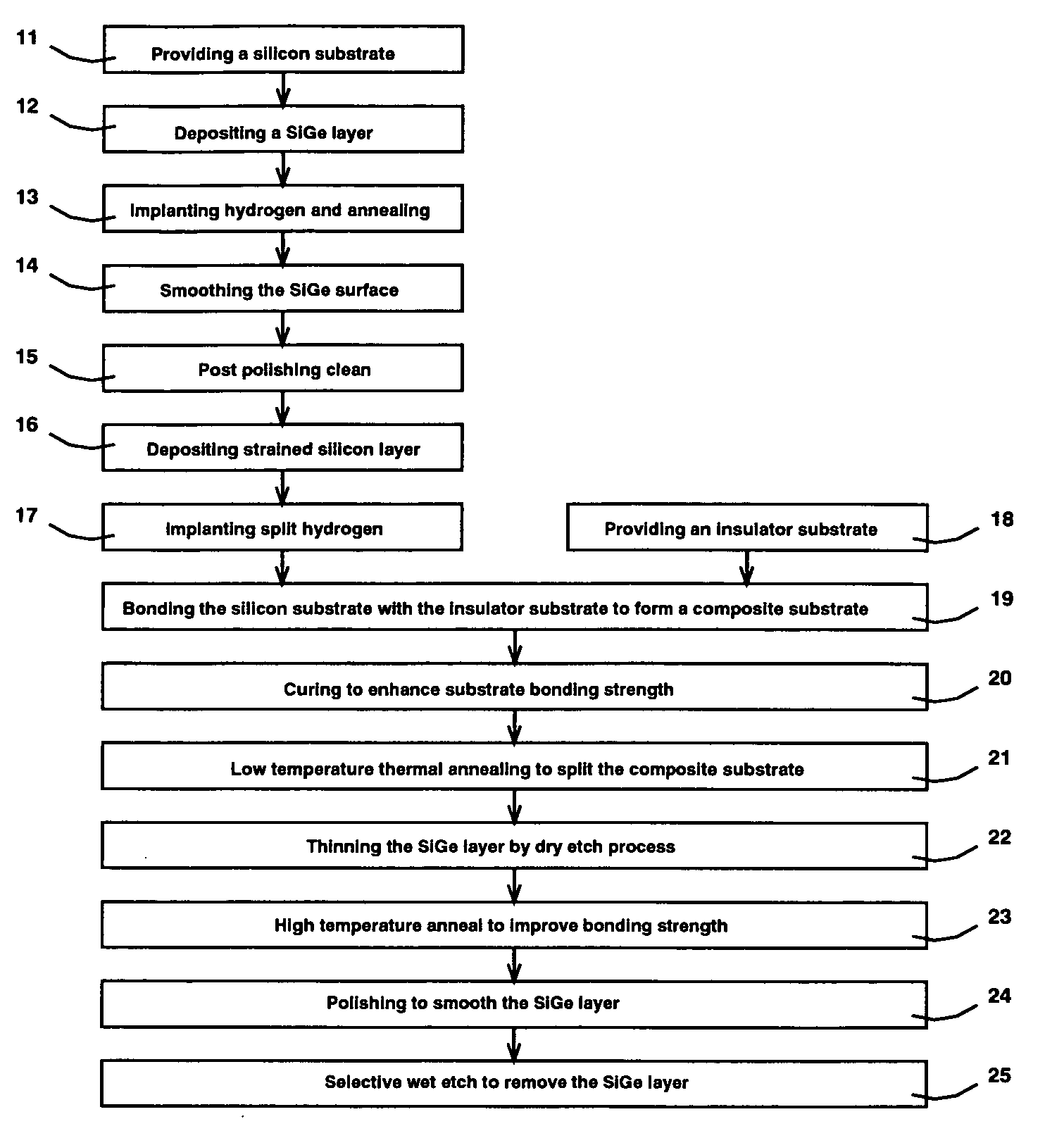

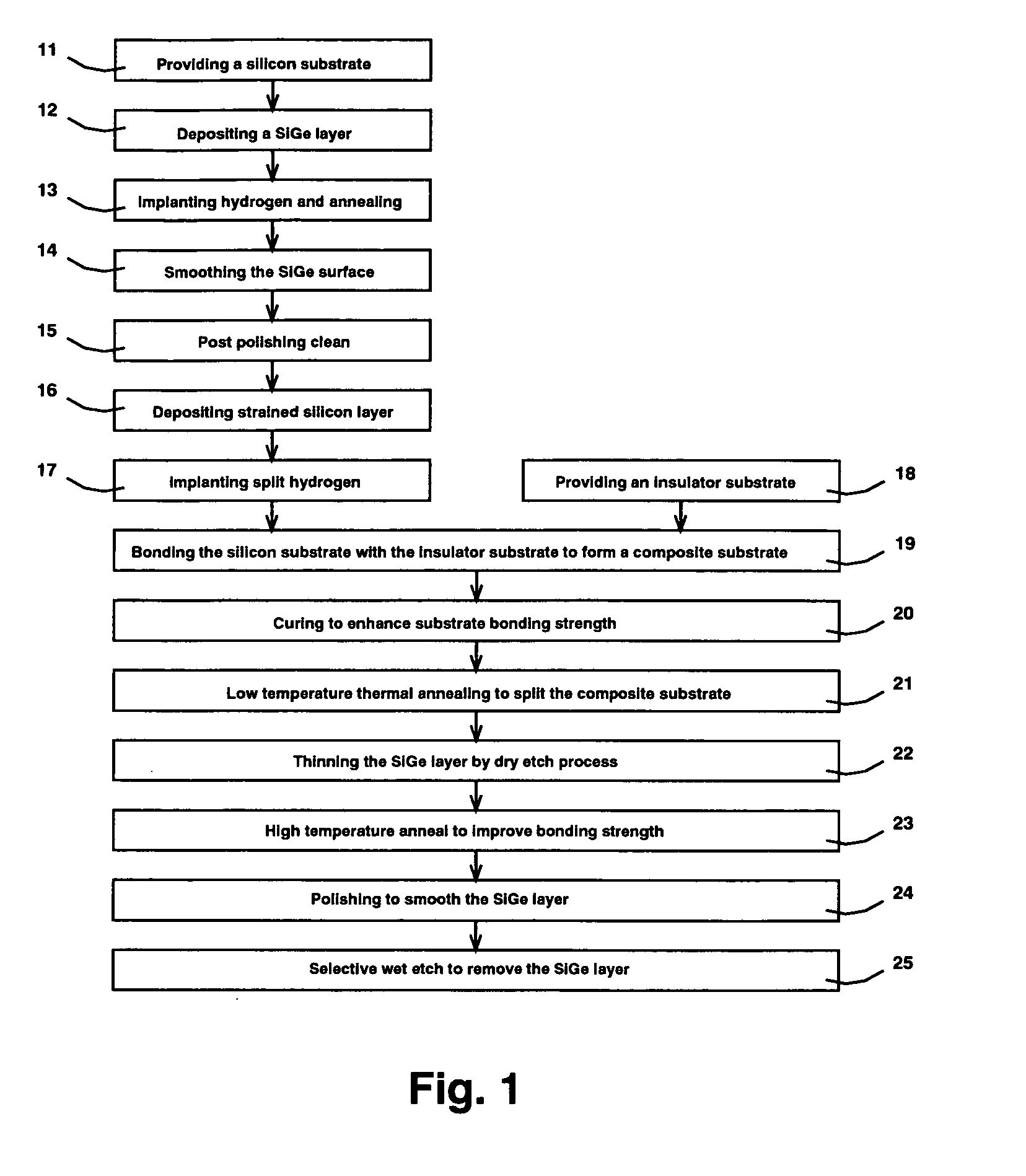

Strained silicon on insulator from film transfer and relaxation by hydrogen implantation

ActiveUS20050153524A1Easy to relaxEasy to integrateSolid-state devicesSemiconductor/solid-state device manufacturingThreading dislocationsHydrogen

Transistors fabricated on SSOI (Strained Silicon On Insulator) substrate, which comprises a strained silicon layer disposed directly on an insulator layer, have enhanced device performance due to the strain-induced band modification of the strained silicon device channel and the limited silicon volume because of the insulator layer. The present invention discloses a SSOI substrate fabrication process comprising various novel approaches. One is the use of a thin relaxed SiGe layer as the strain-induced seed layer to facilitate integration and reduce processing cost. Another is the formation of split implant microcracks deep in the silicon substrate to reduce the number of threading dislocations reaching the strained silicon layer. And lastly is the two step annealing / thinning process for the strained silicon / SiGe multilayer film transfer without blister or flaking formation.

Owner:SHARP KK

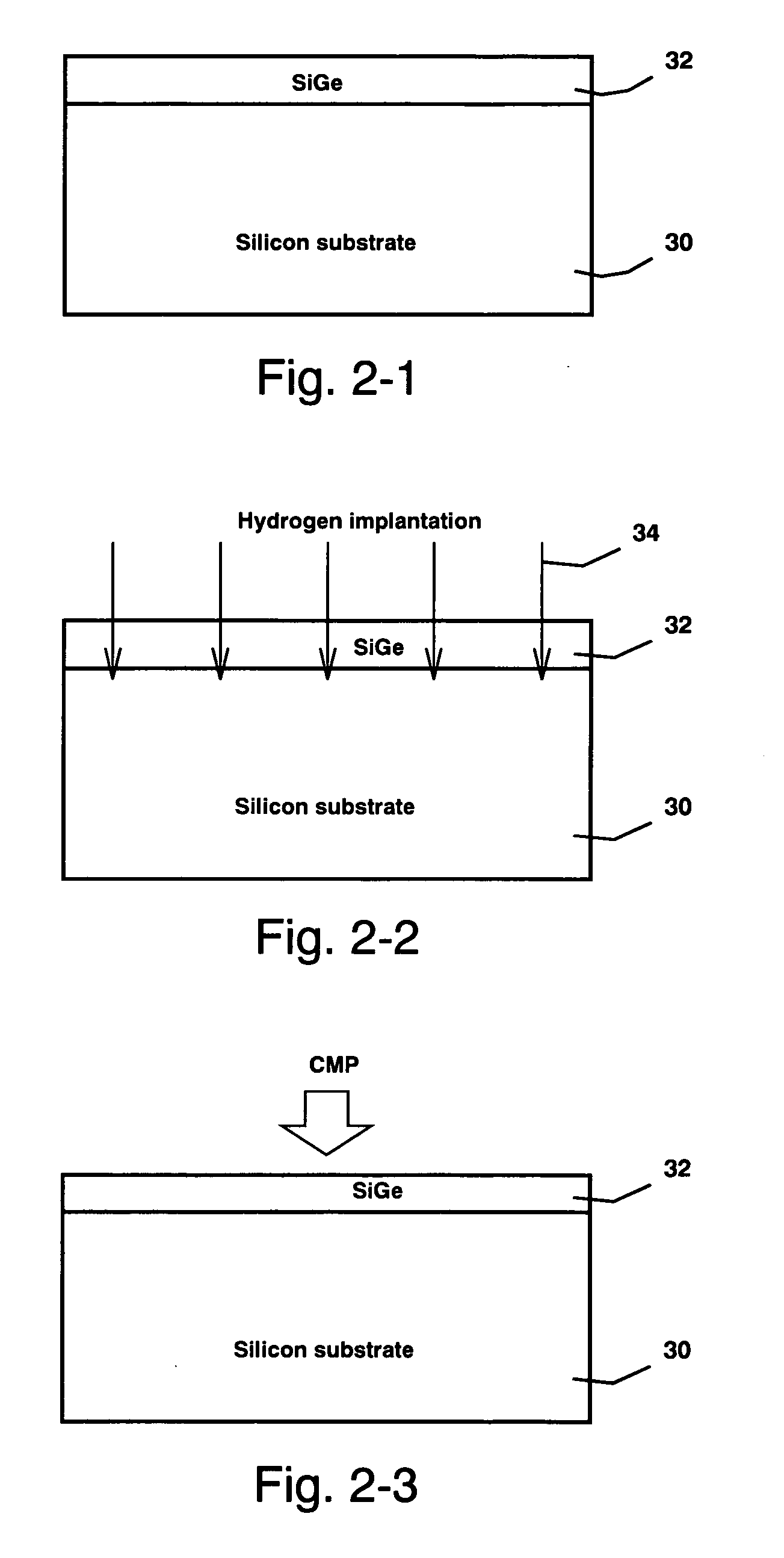

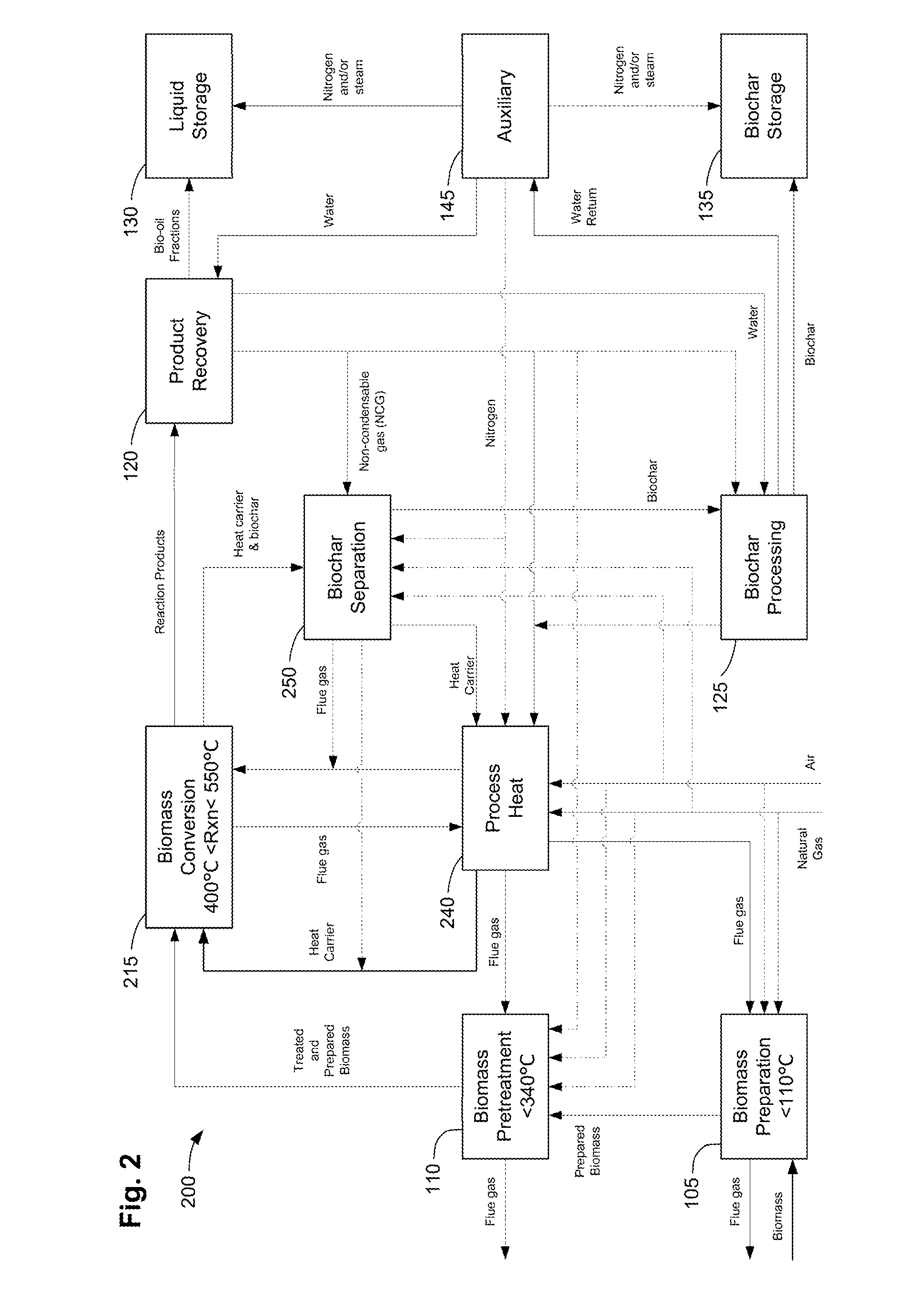

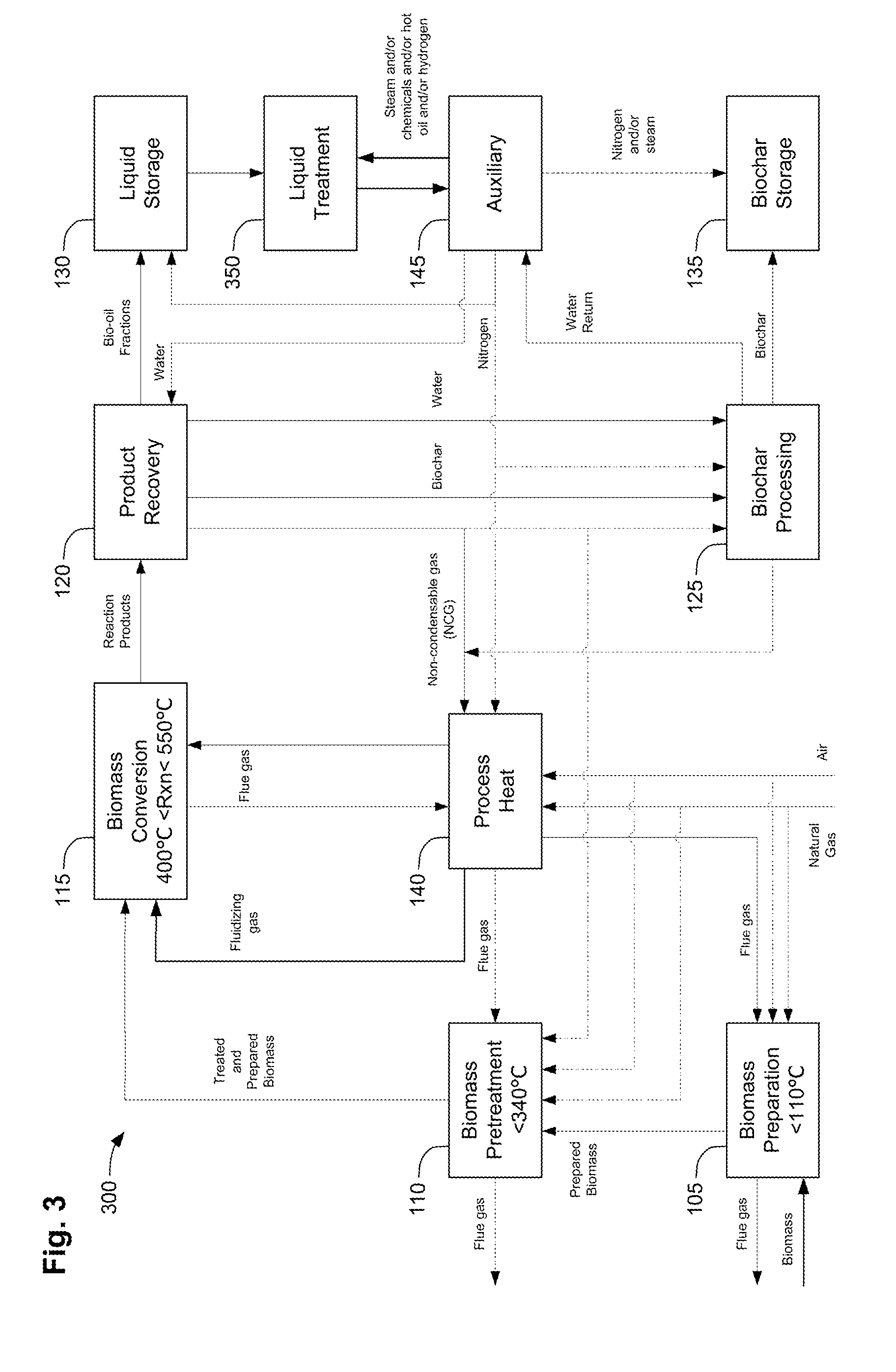

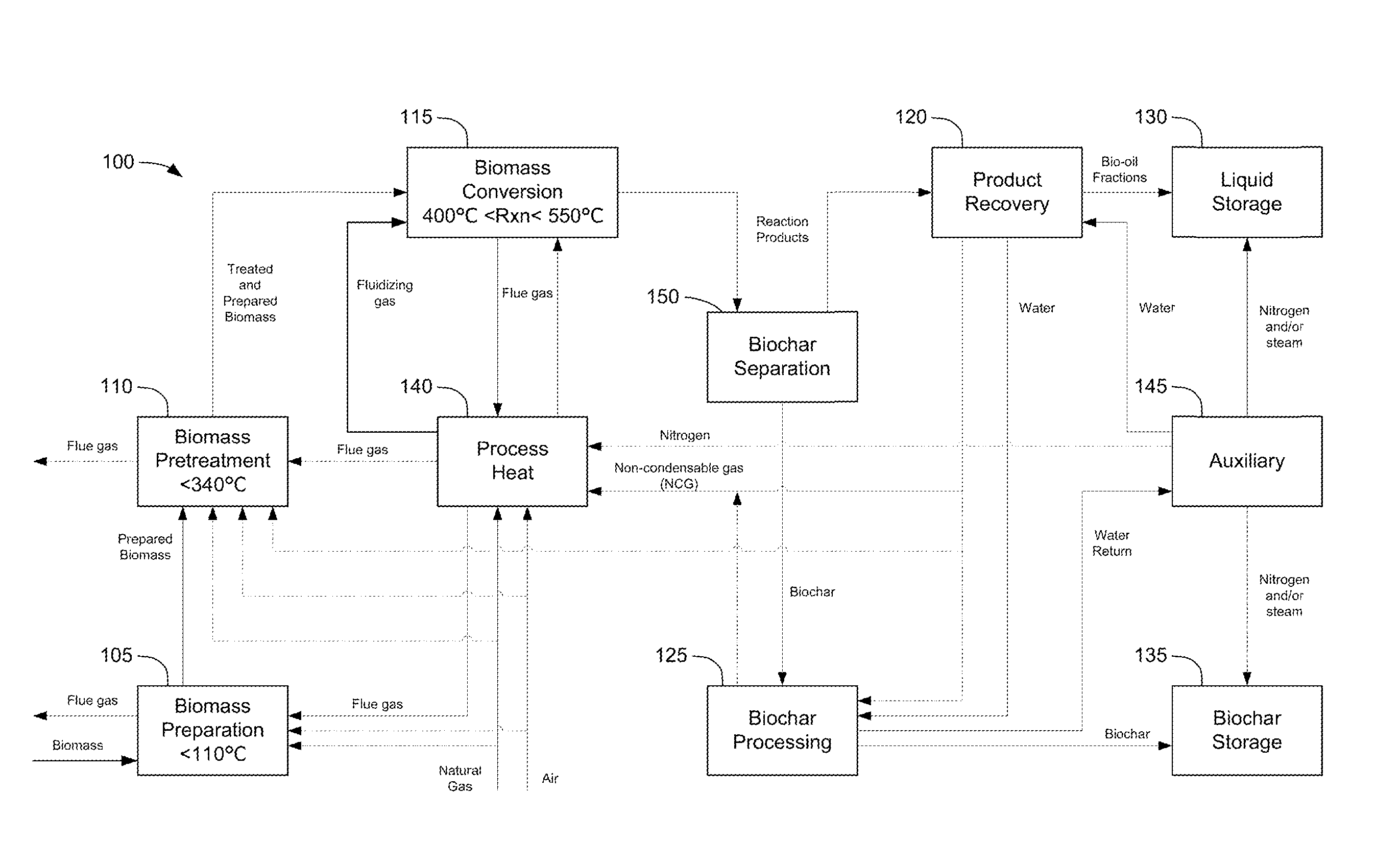

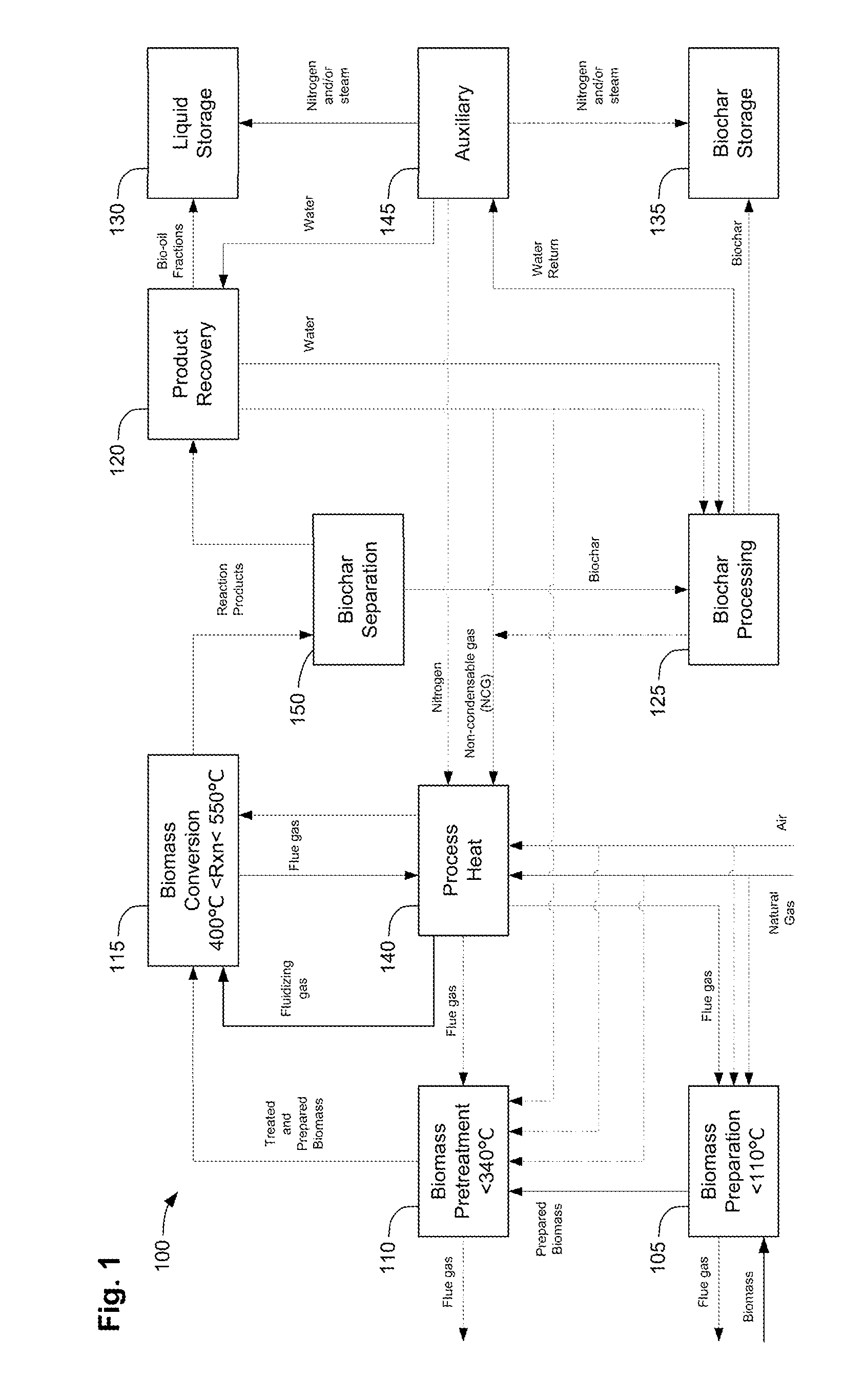

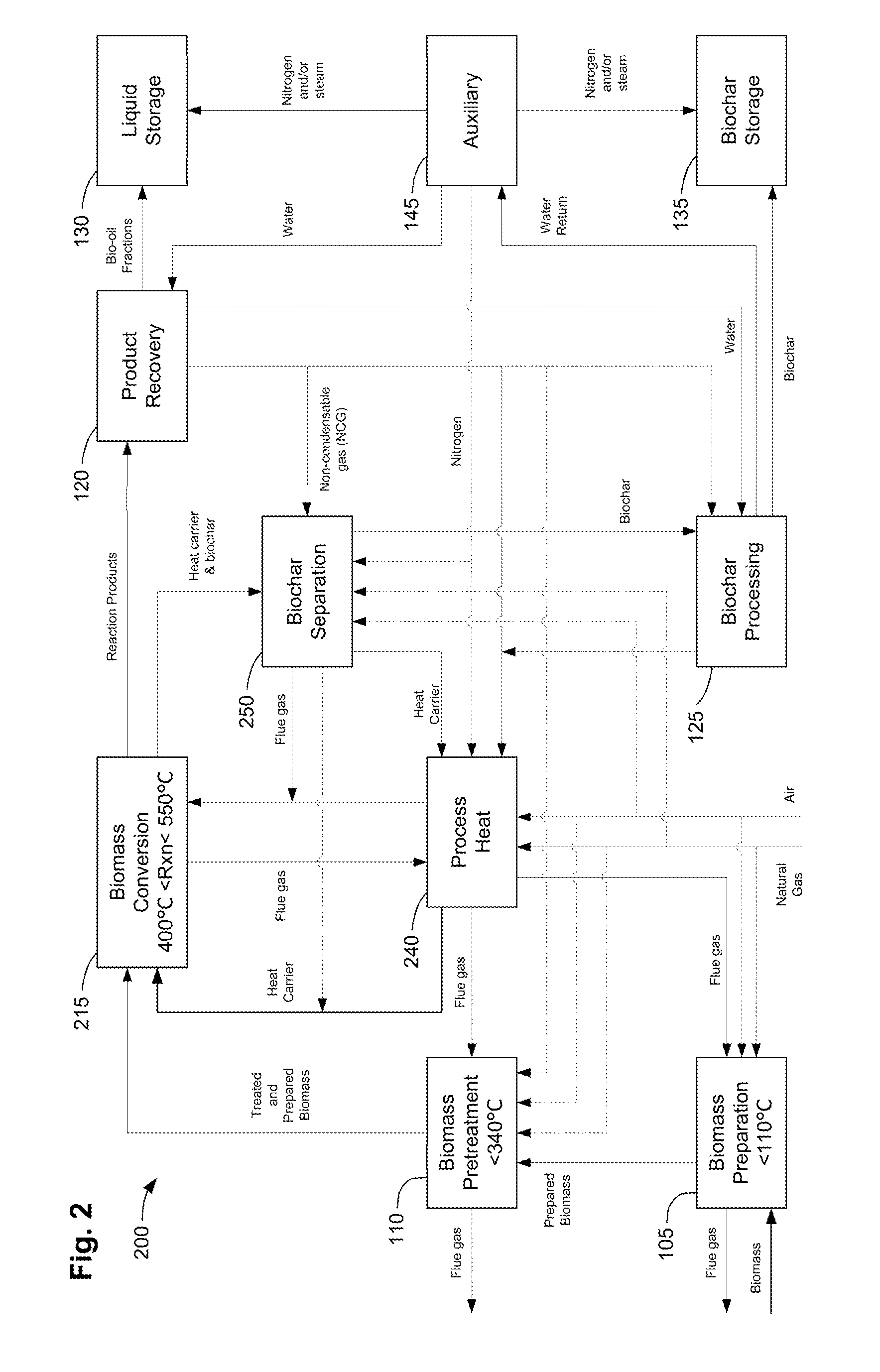

Methods for integrated fast pyrolysis processing of biomass

ActiveUS20110258914A1Improve collection efficiencyMinimizes water contentDirect heating destructive distillationBiofuelsPre treatmentSafe handling

Methods, process, apparatus, equipment, and systems are disclosed for converting biomass into bio-oil fractions for chemicals, materials, feedstocks and fuels using a low-cost, integrated fast pyrolysis system. The system improves upon prior art by creating stable, bio-oil fractions which have unique properties that make them individually superior to conventional bio-oil. The invention enables water and low-molecular weight compounds to be separated into a final value-added fraction suitable for upgrading or extracting into value-added chemicals, fuels and water. Initial bio-oil fractions from the process are chemically distinct, have low-water content and acidity which reduces processing costs normally associated with conventional bio-oil post-production upgrading since fewer separation steps, milder processing conditions and lower auxiliary inputs are required. Biochar is stabilized so that it can be handled safely. The integrated fast pyrolysis process includes biomass storage, preparation, pretreatment, and conversion, product recovery and processing to create and store stable biochar and bio-oil fractions.

Owner:AVELLO BIOENERGY

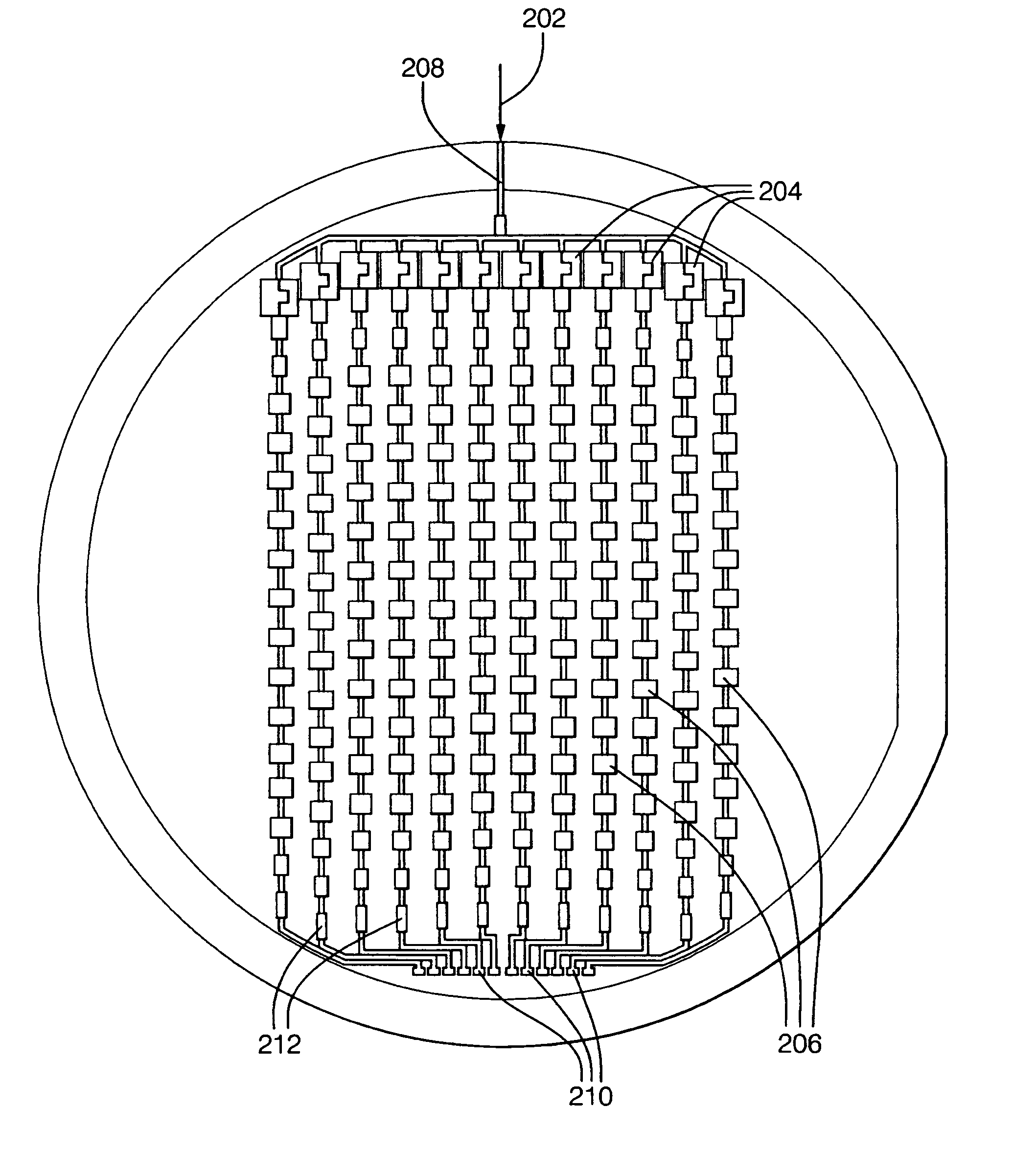

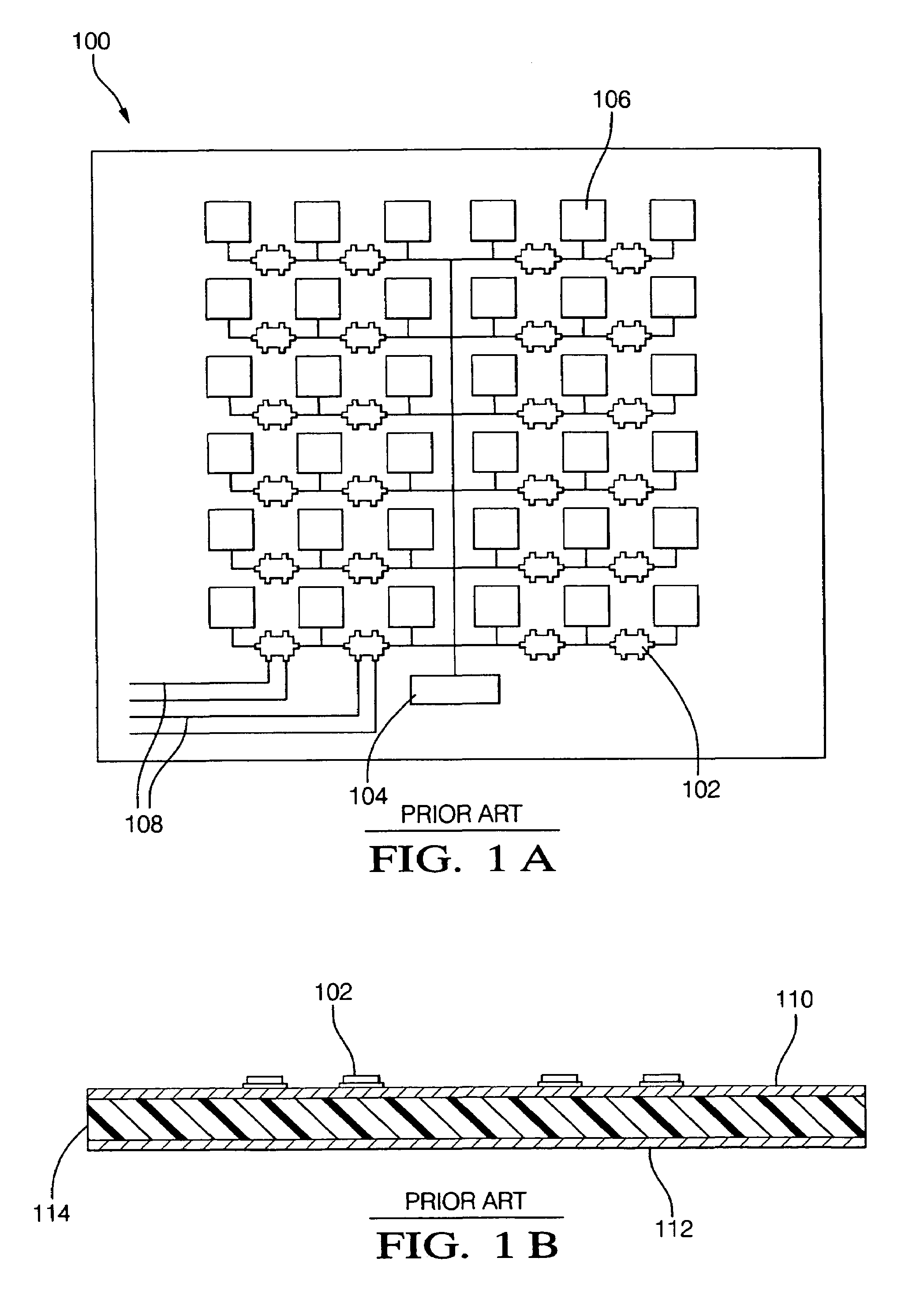

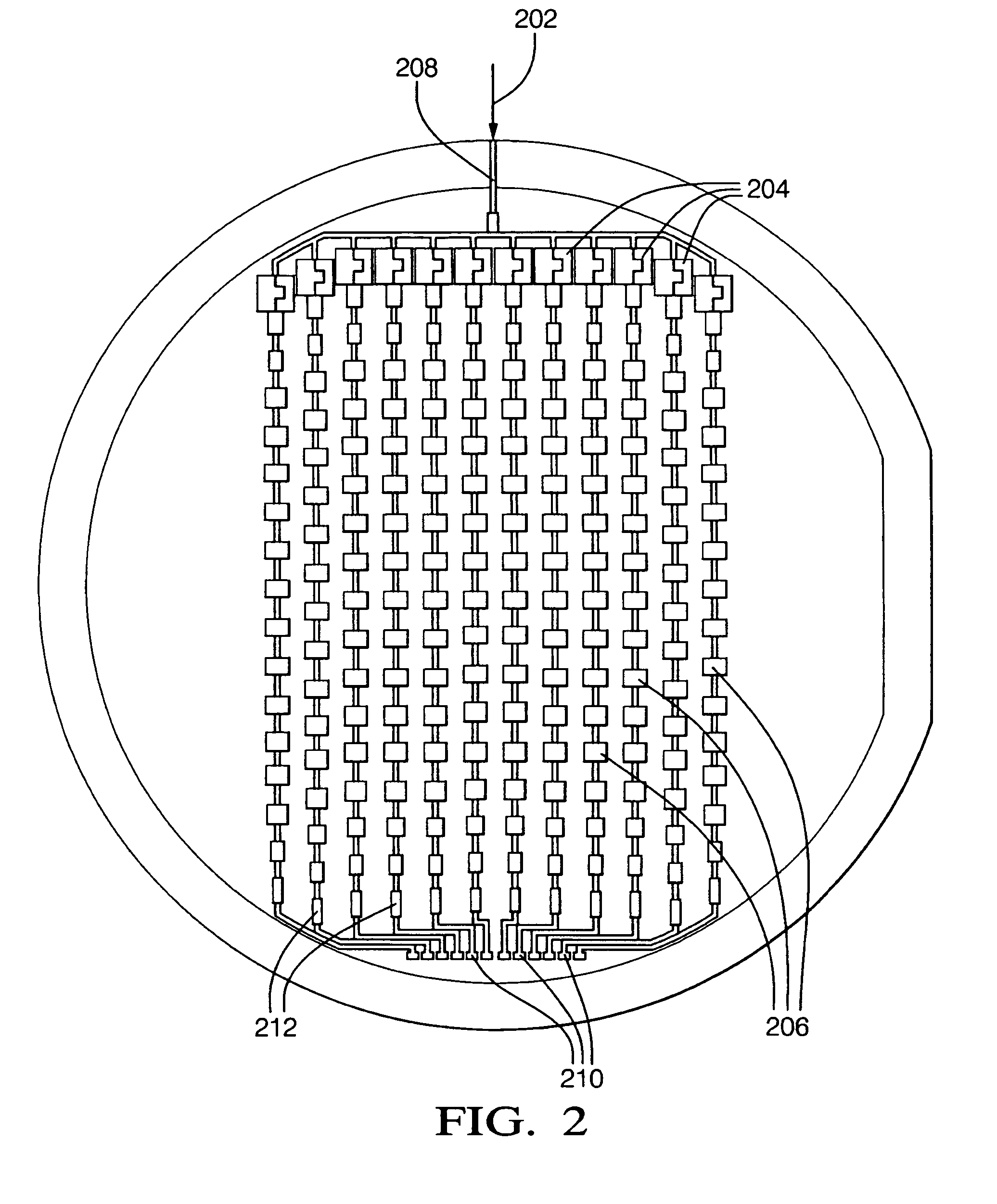

Phase shifters deposited en masse for an electronically scanned antenna

ActiveUS7324043B2Increase processing costPatterning of backsideSimultaneous aerial operationsRadiating elements structural formsDielectricEngineering

A system and method for an electronically scanned antenna is provided in which phase shifters are deposited en masse along with other electronically scanned antenna components on a wafer scale substrate using a thin film process. Alternative wafer scale sizes may be utilized to furnish a required antenna aperture area. Significant processing costs for radar and communication systems are saved utilizing the present invention as compared with contemporary discrete phase shifters that are individually mounted on an antenna. In an aspect, the phase shifter is made up of a base electrode, a barium strontanate titanate (BST) ferroelectric varactor and a top electrode. The BST ferroelectric material is a voltage variable dielectric, which generates a radiation phase. The radiation phase is regulated by a phase shifter control. The radiation phase generates an electromagnetic field about a radiating element and electromagnetic radio waves are radiated from the radiating element.

Owner:APTIV TECH LTD

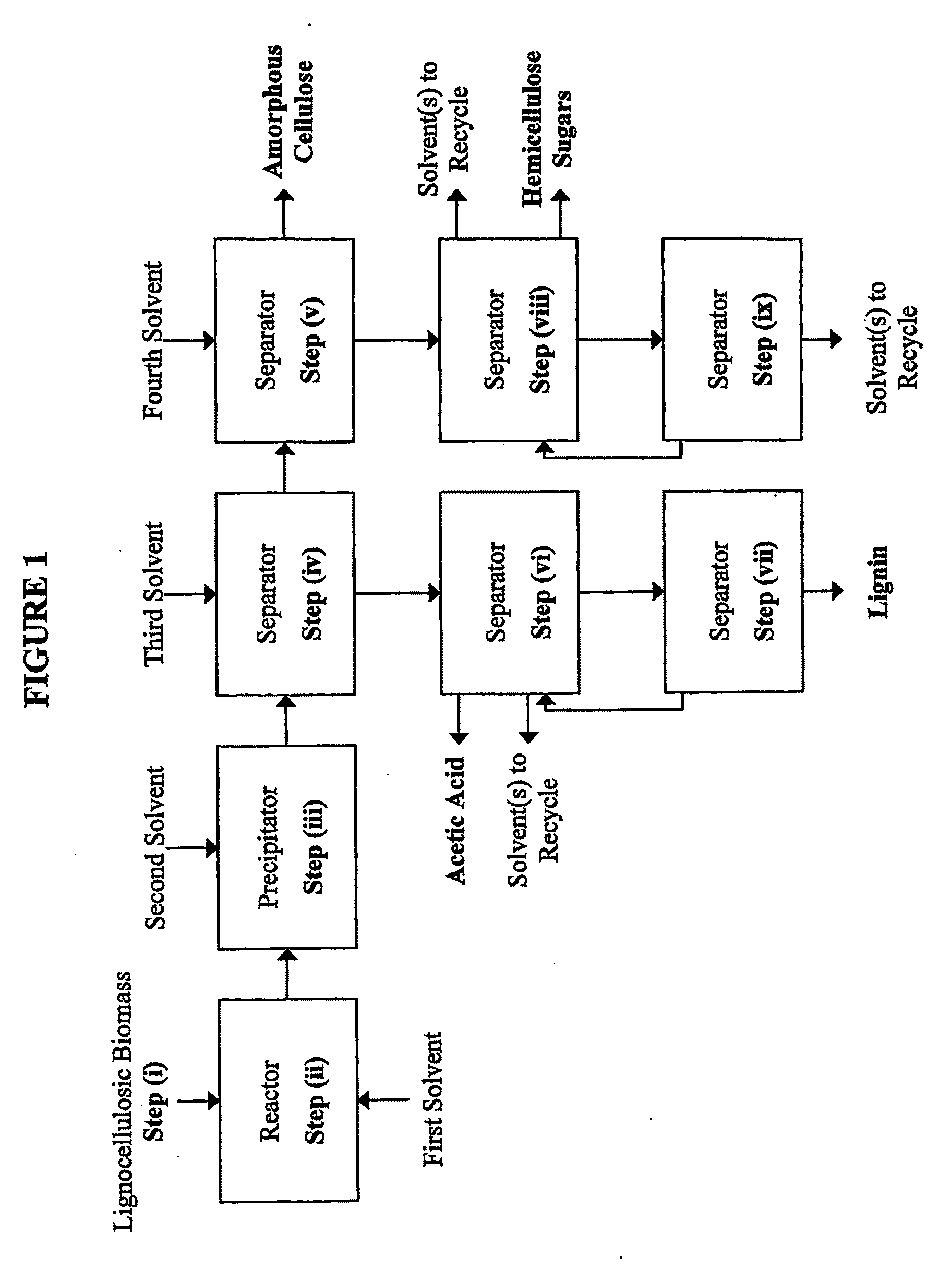

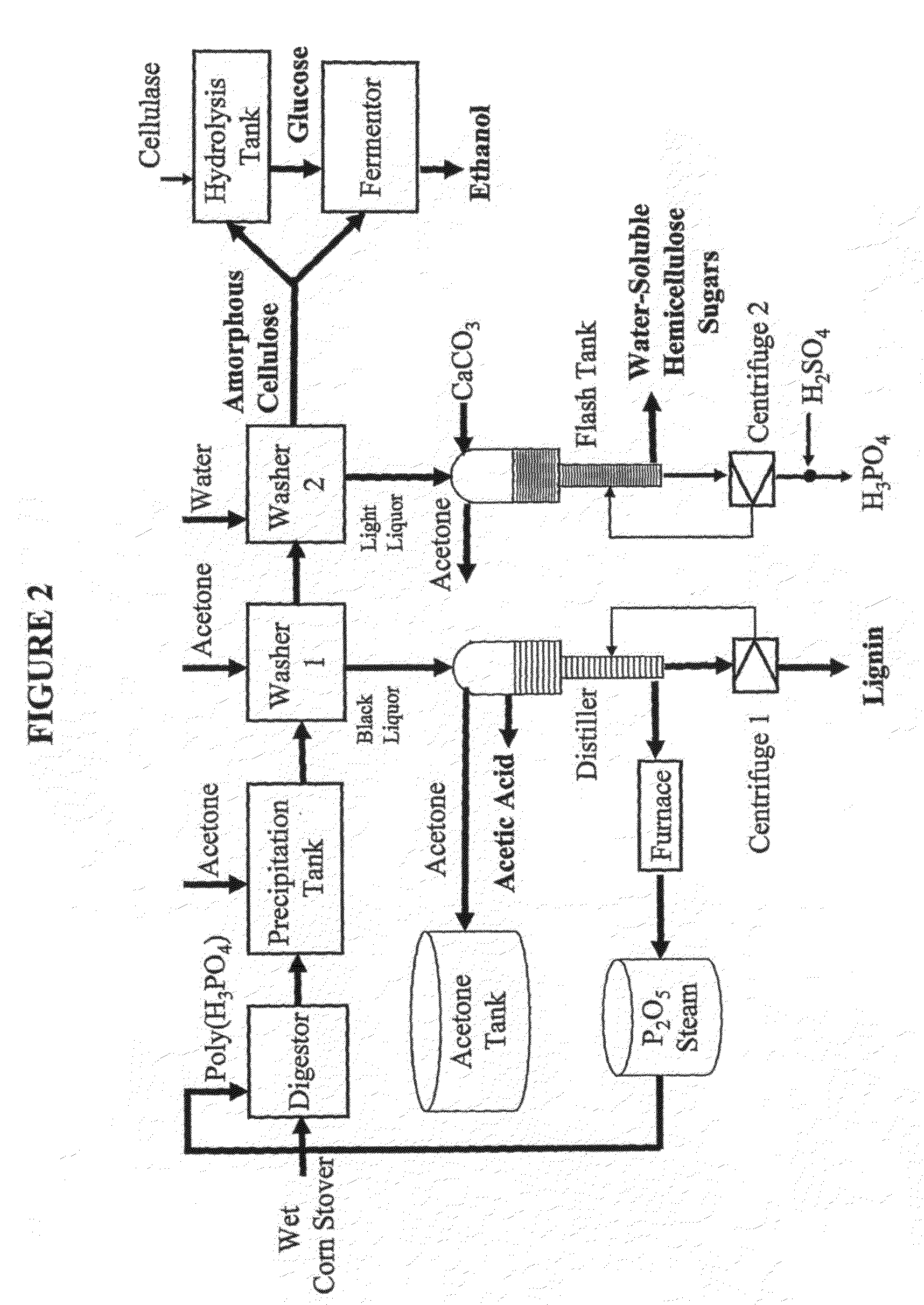

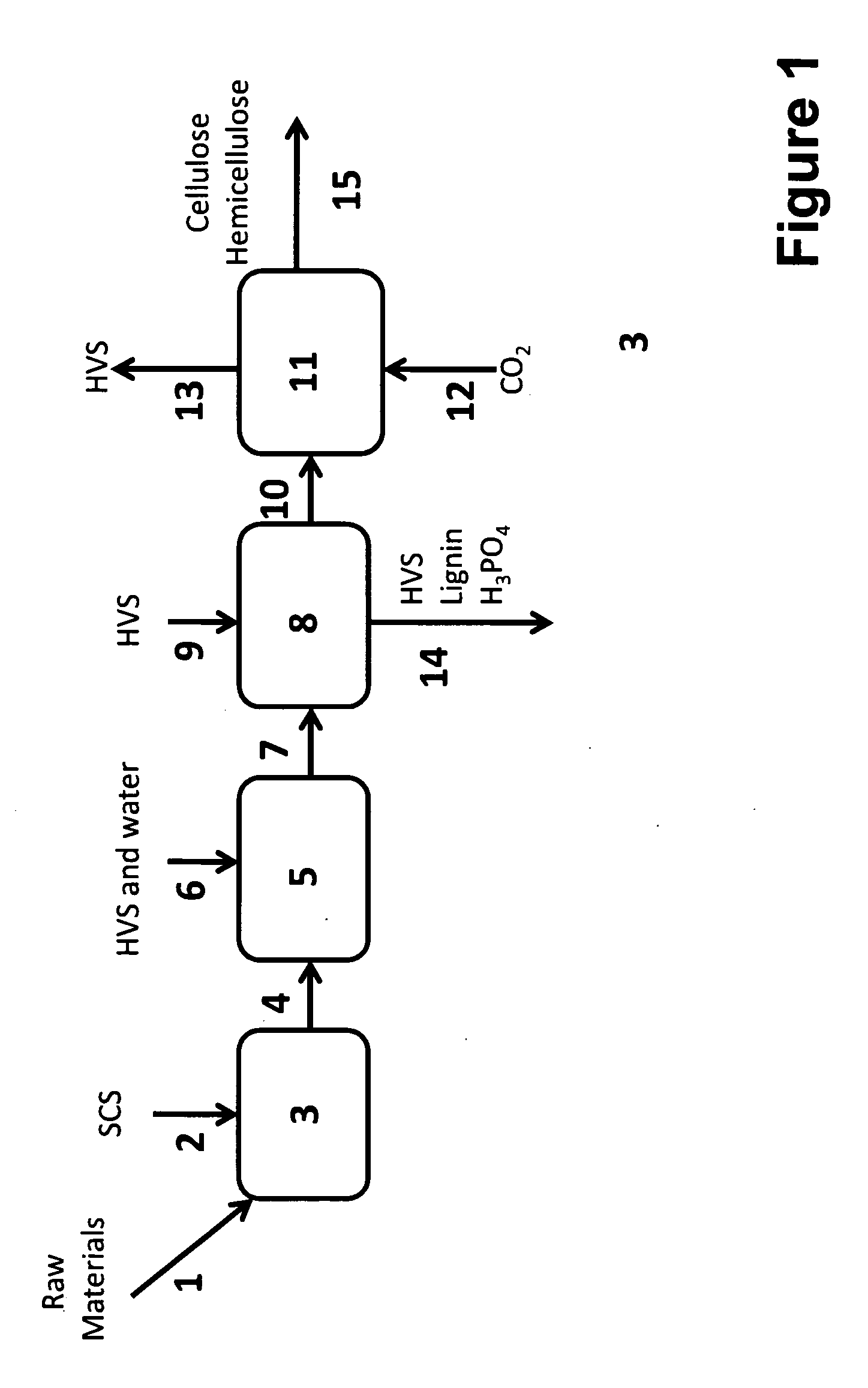

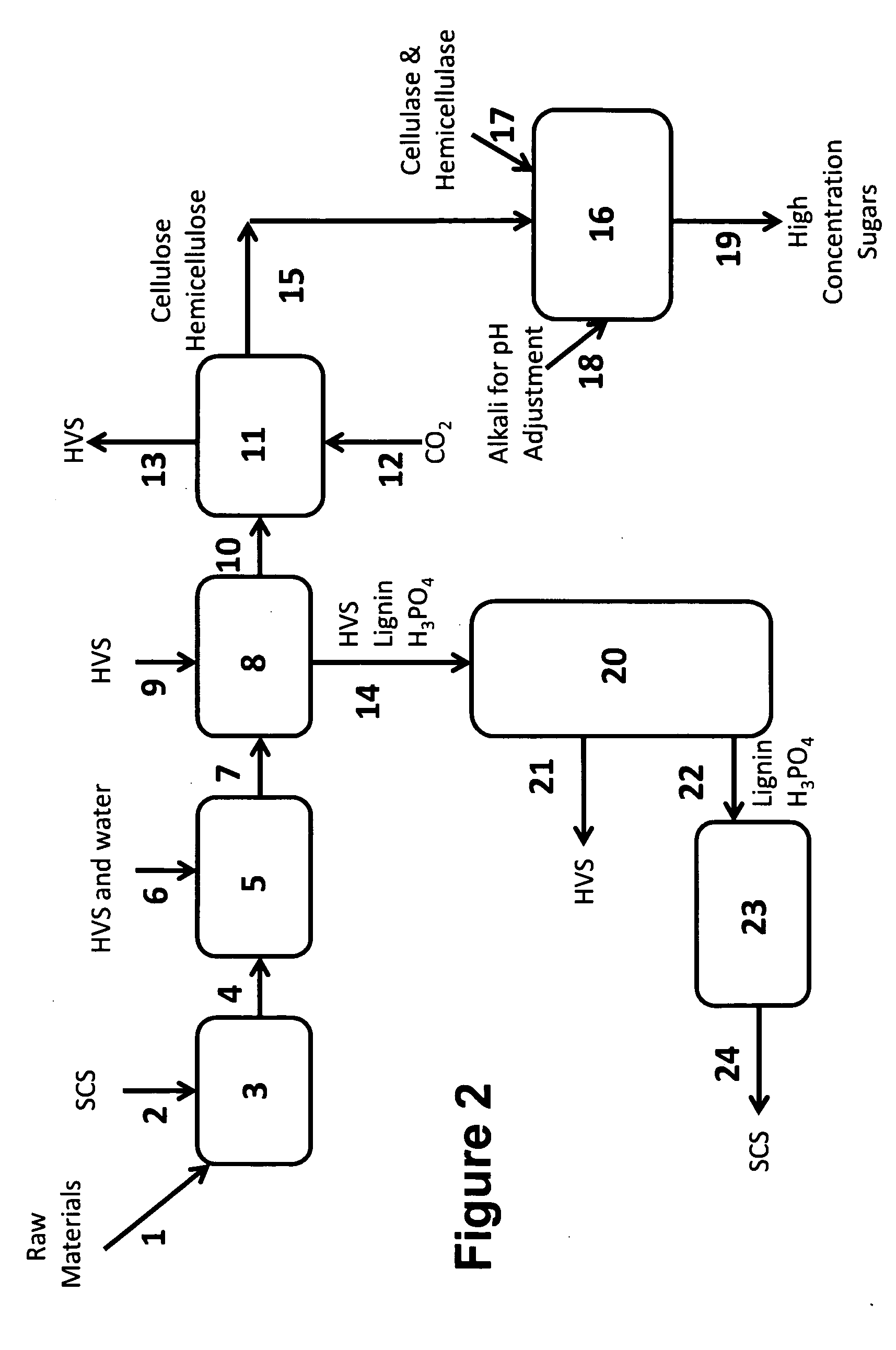

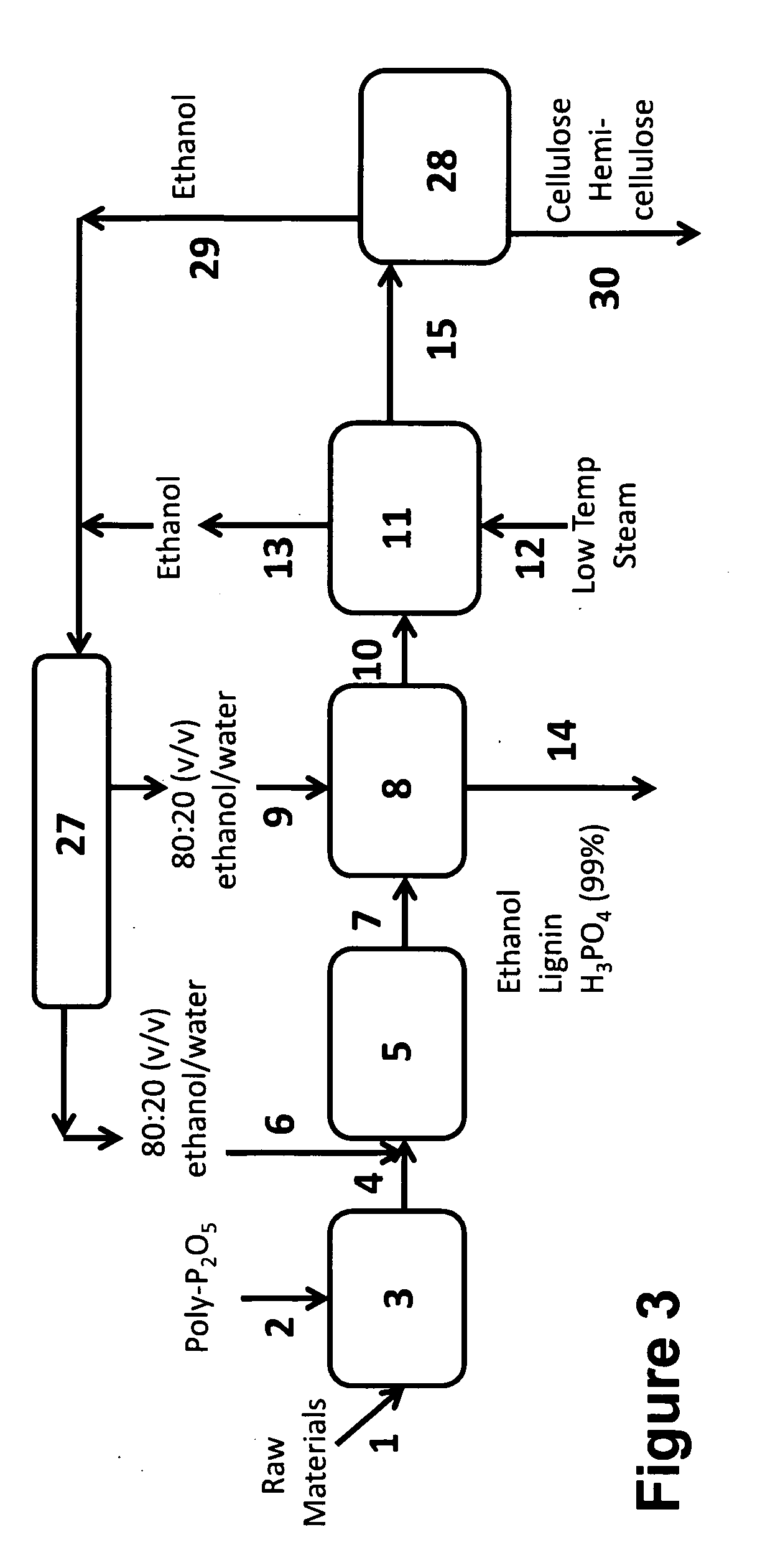

Cellulose-solvent-based lignocellulose fractionation with modest reaction conditions and reagent cycling

InactiveUS20100170504A1Lower cost of capitalReduce operating costsBiofuelsChemical recyclingFractionationProcessing cost

Embodiments of the present invention overcome the well-known recalcitrance of lignocellulosic biomass in an economically viable manner. A process and system are provided for the efficient fractionation of lignocellulosic biomass into cellulose, hemicellulose sugars, lignin, and acetic acid. The cellulose thus obtained is highly amorphous and can be readily converted into glucose using known methods. Fermentable hemicellulose sugars, low-molecular—weight lignin, and purified acetic acid are also major products of the process and system. The modest process conditions and low solvent / solid ratios of some embodiments of the invention imply relatively low capital and processing costs.

Owner:VIRGINIA TECH INTPROP INC

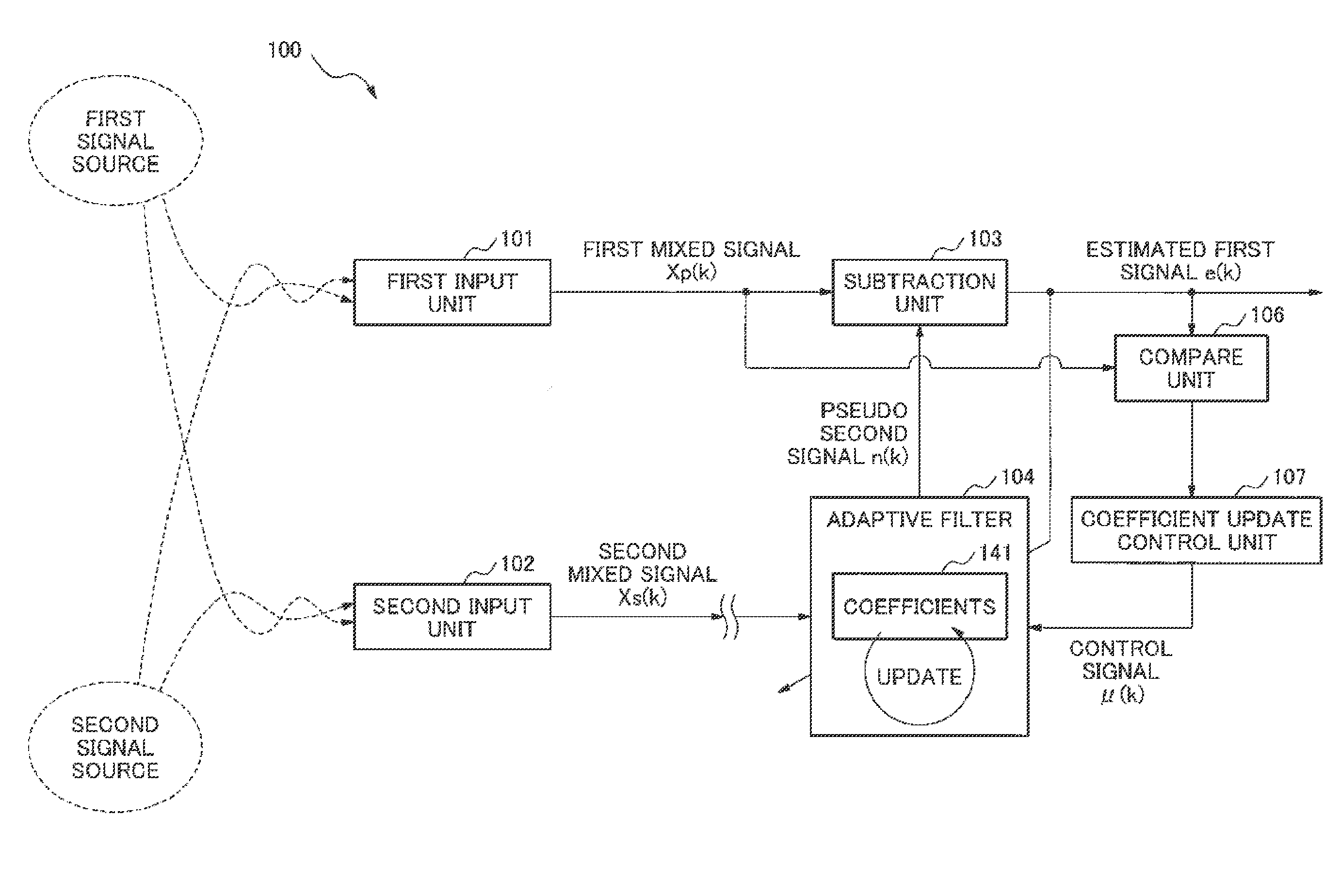

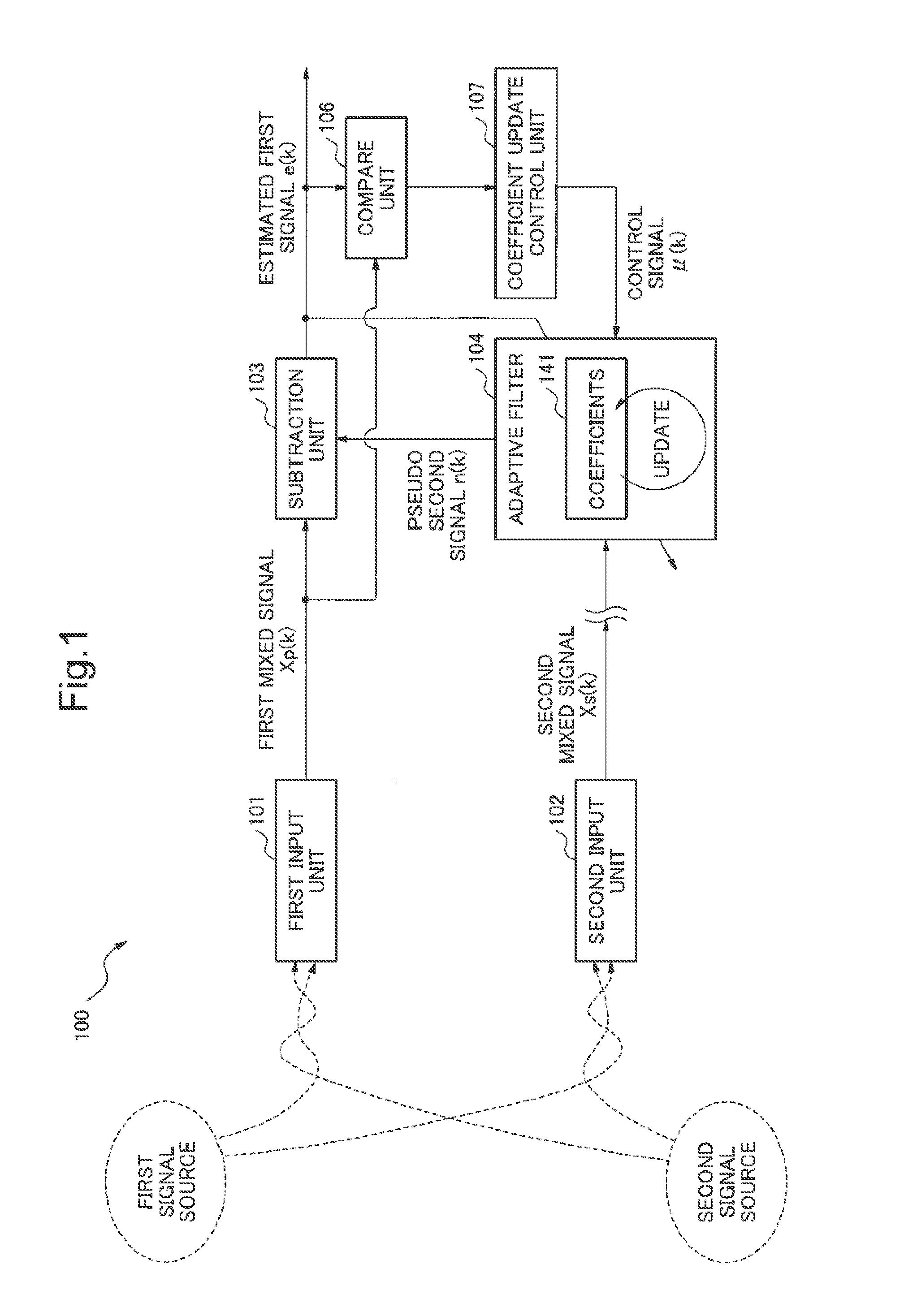

Signal processing device, signal processing method and signal processing program

ActiveUS20130191119A1Reduce processing costsWithout delayInterconnection arrangementsDigital adaptive filtersAdaptive filterLow distortion

From a mixed signal in which a first signal and a second signal are mixed, the second signal is removed at low processing cost and without delay. As a result, an estimated first signal which has low residue of the second signal and low distortion is obtained.An estimated first signal is generated by subtracting a pseudo second signal which is estimated to be mixed in a first mixed signal in which a first signal and a second signal are mixed from the first mixed signal. The pseudo second signal is obtained by a first adaptive filter using a second mixed signal in which the first signal and the second signal are mixed in a different proportion from the first mixed signal. A coefficient update amount of the first adaptive filter is made smaller as compared with a case when the estimated first signal is smaller than the first mixed signal, in case the estimated first signal is larger than the first mixed signal.

Owner:NEC CORP

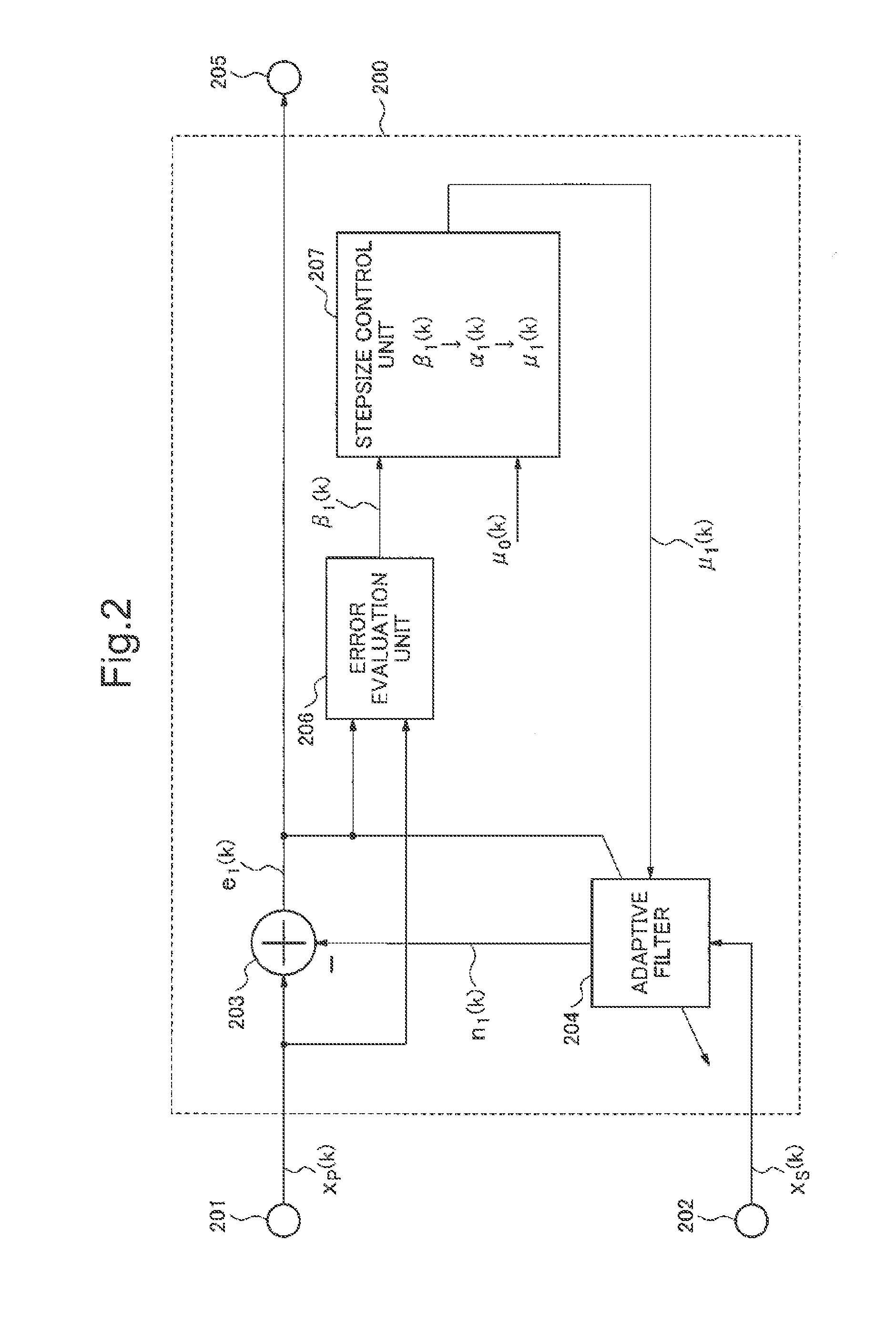

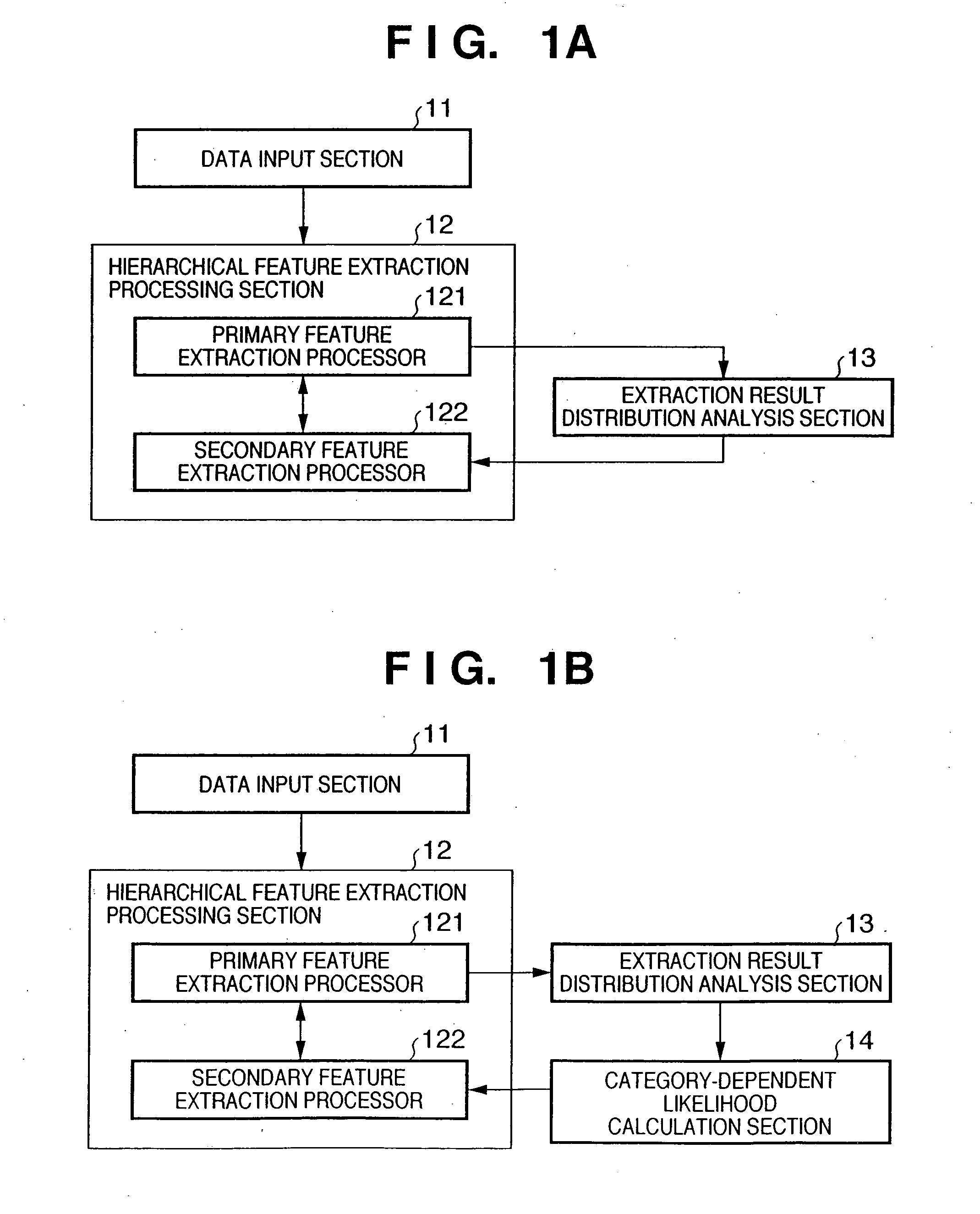

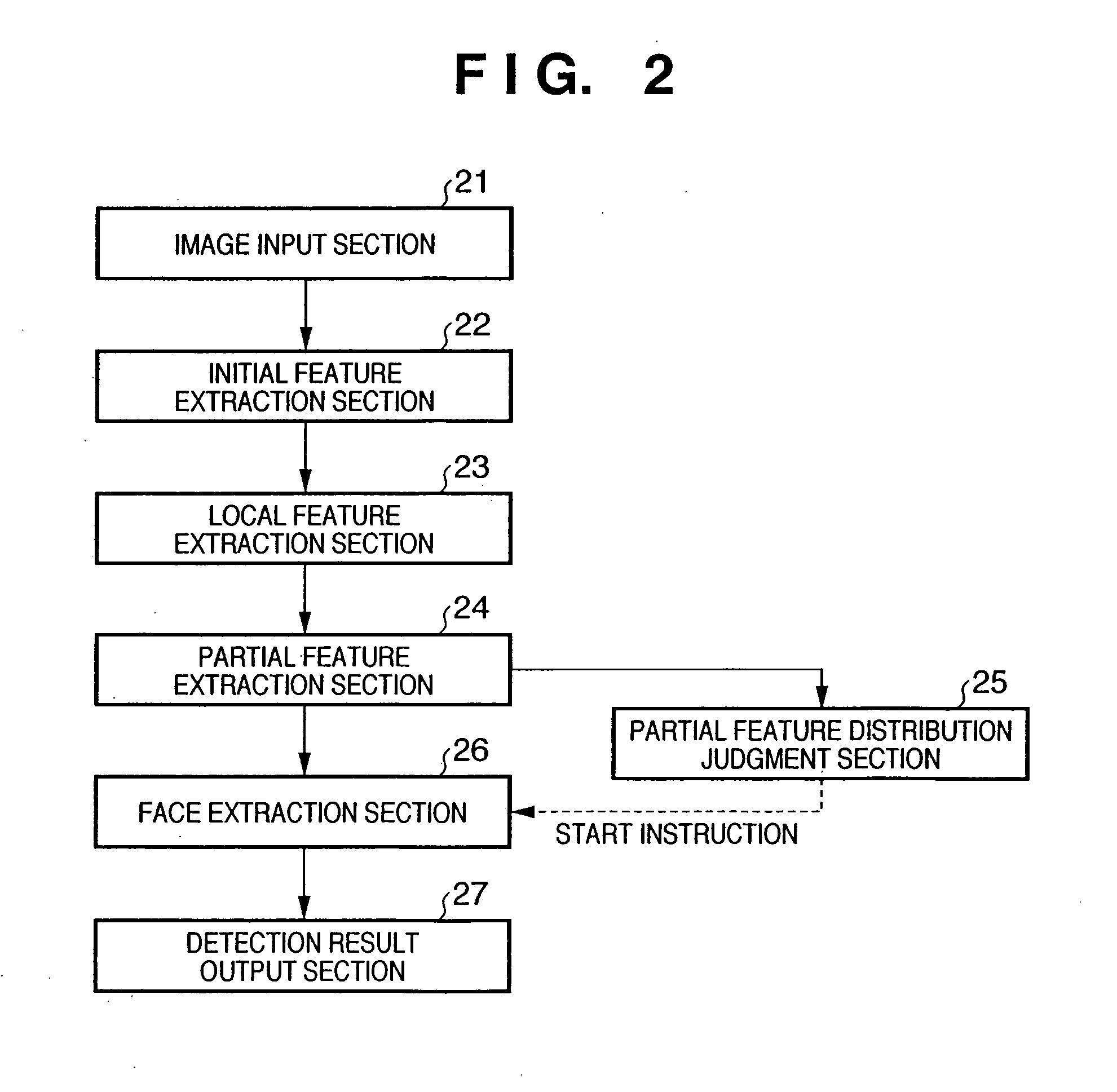

Pattern identification method, device thereof, and program thereof

InactiveUS20060204053A1Reduce processing costsReduce the possibilityCharacter and pattern recognitionFeature extractionProcessing cost

In a pattern identification device performing pattern identification of data which has been input by hierarchically extracting features, a primary feature is extracted and distribution of at least one feature extraction result extracted is analyzed, a secondary feature is extracted according to this analysis result. Thus, it is possible to perform pattern identification robustly against fluctuations of the input pattern at a reduced processing cost while reducing the probability of occurrence of incorrect identification.

Owner:CANON KK

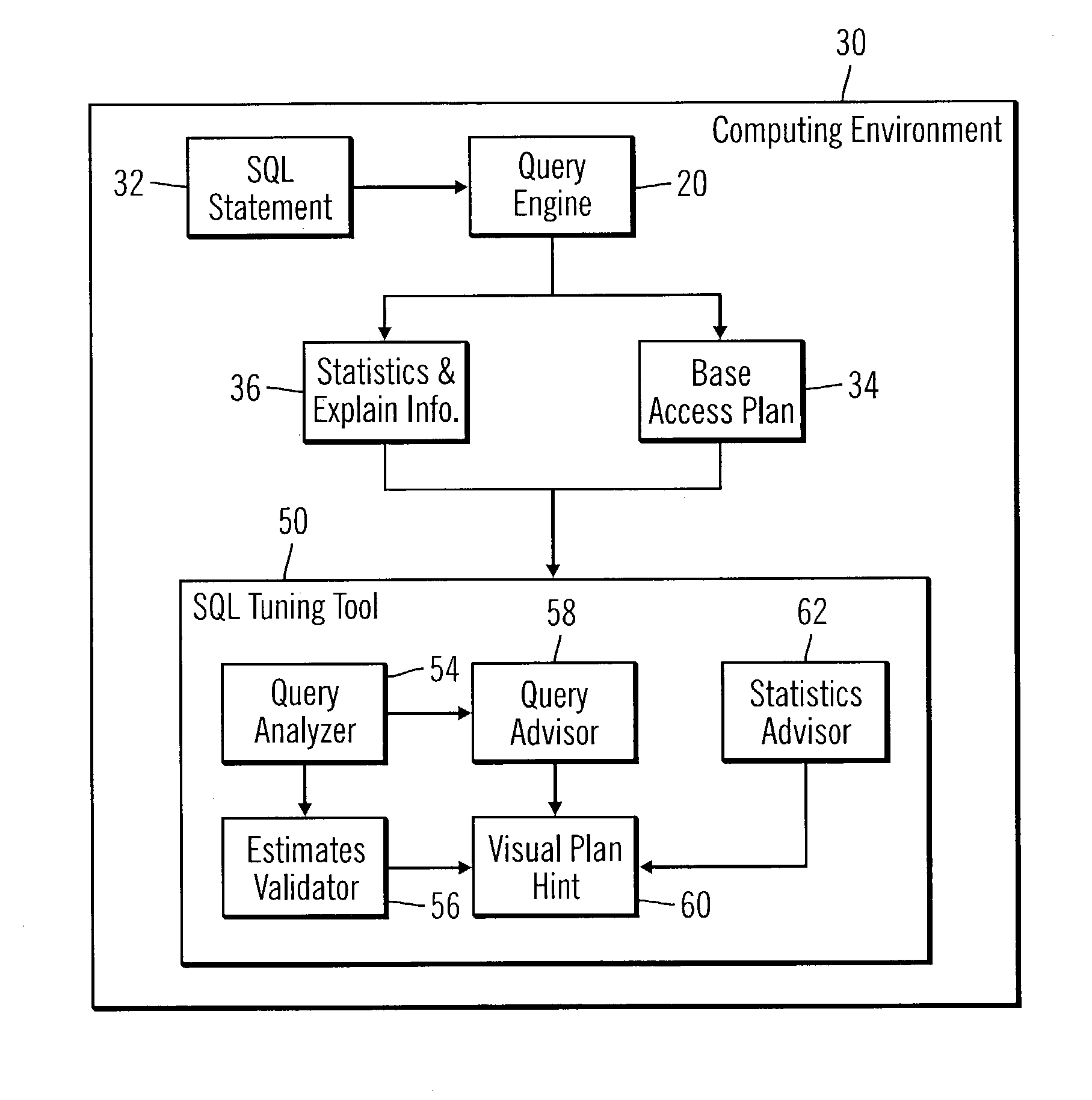

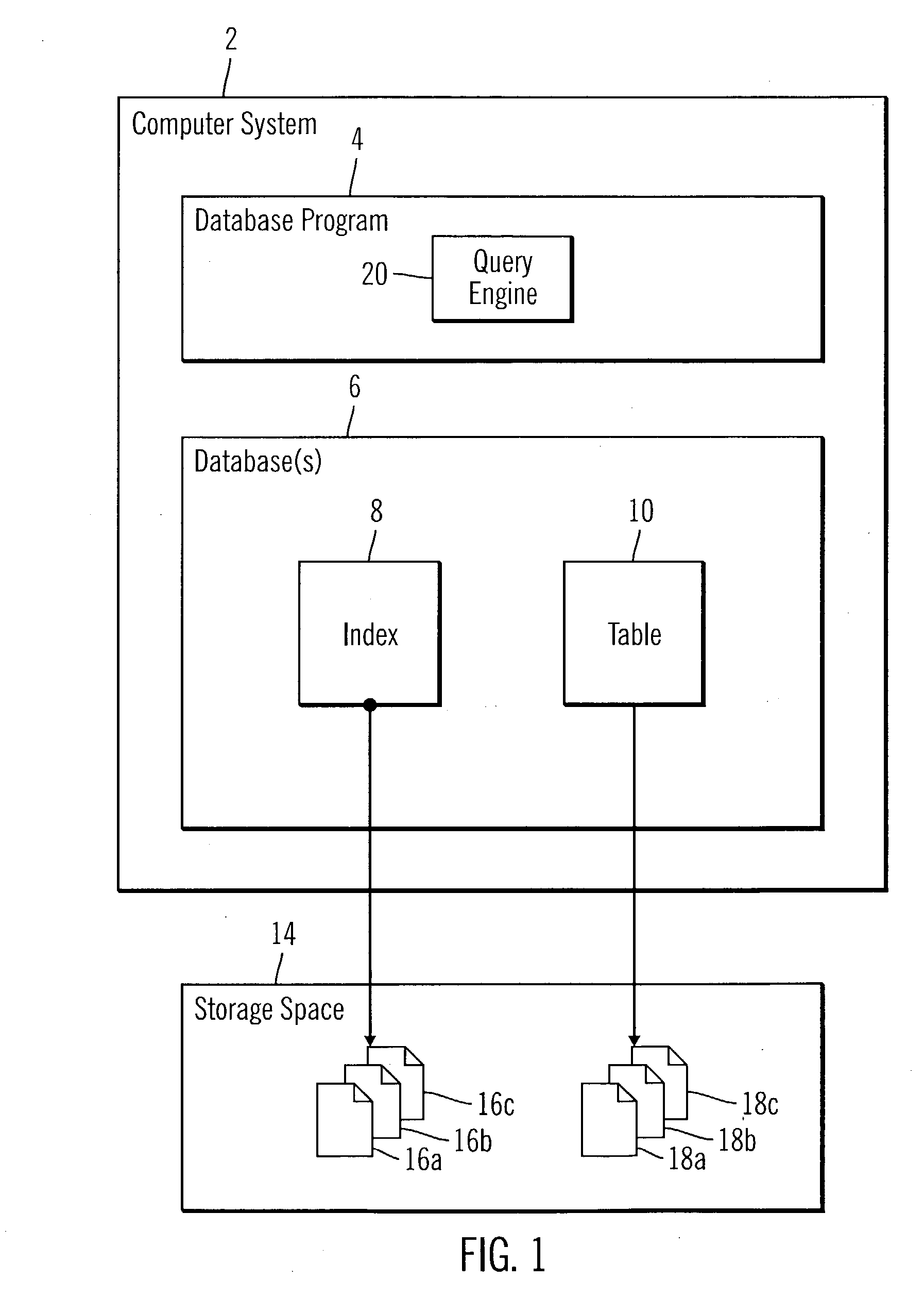

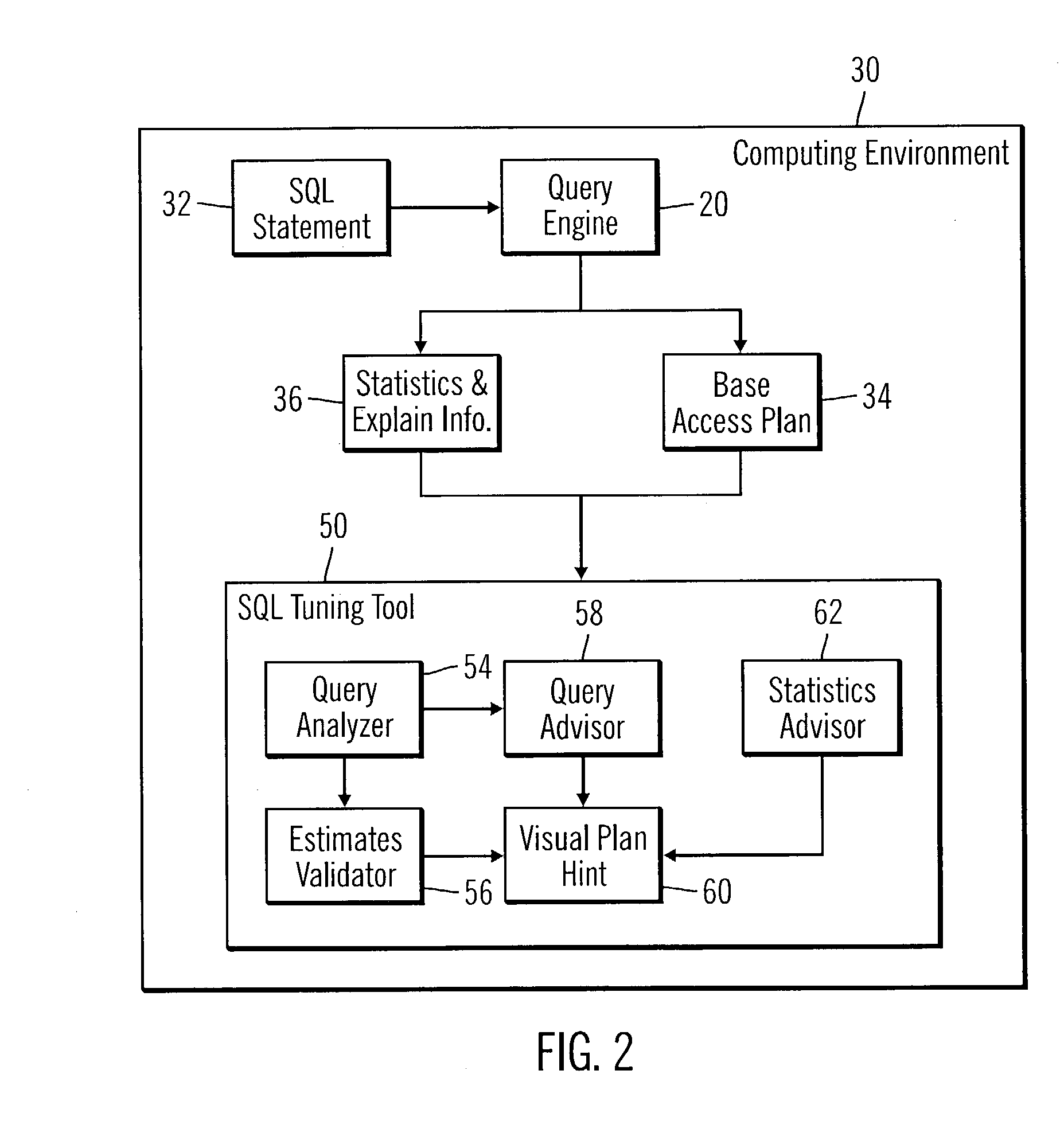

Method, system, and program for performance tuning a database query

ActiveUS7139749B2Improve performanceData processing applicationsDigital data information retrievalDatabase queryIssues treatments

Provided are a method, system, an program for tuning a database query. Provided are a base access plan to implement the database query and statistics including information on a layout of the database against which the query will be executed. The statistics are processed to determine performance problems with the base access plan as part of a first analysis of the base access plan and the determined performance problems are processed as part of a second analysis to provide an analysis of the determined performance problems and processing cost of the base access plan. Recommendations are generated to tune the base access plan to improve performance.

Owner:MICROSOFT TECH LICENSING LLC

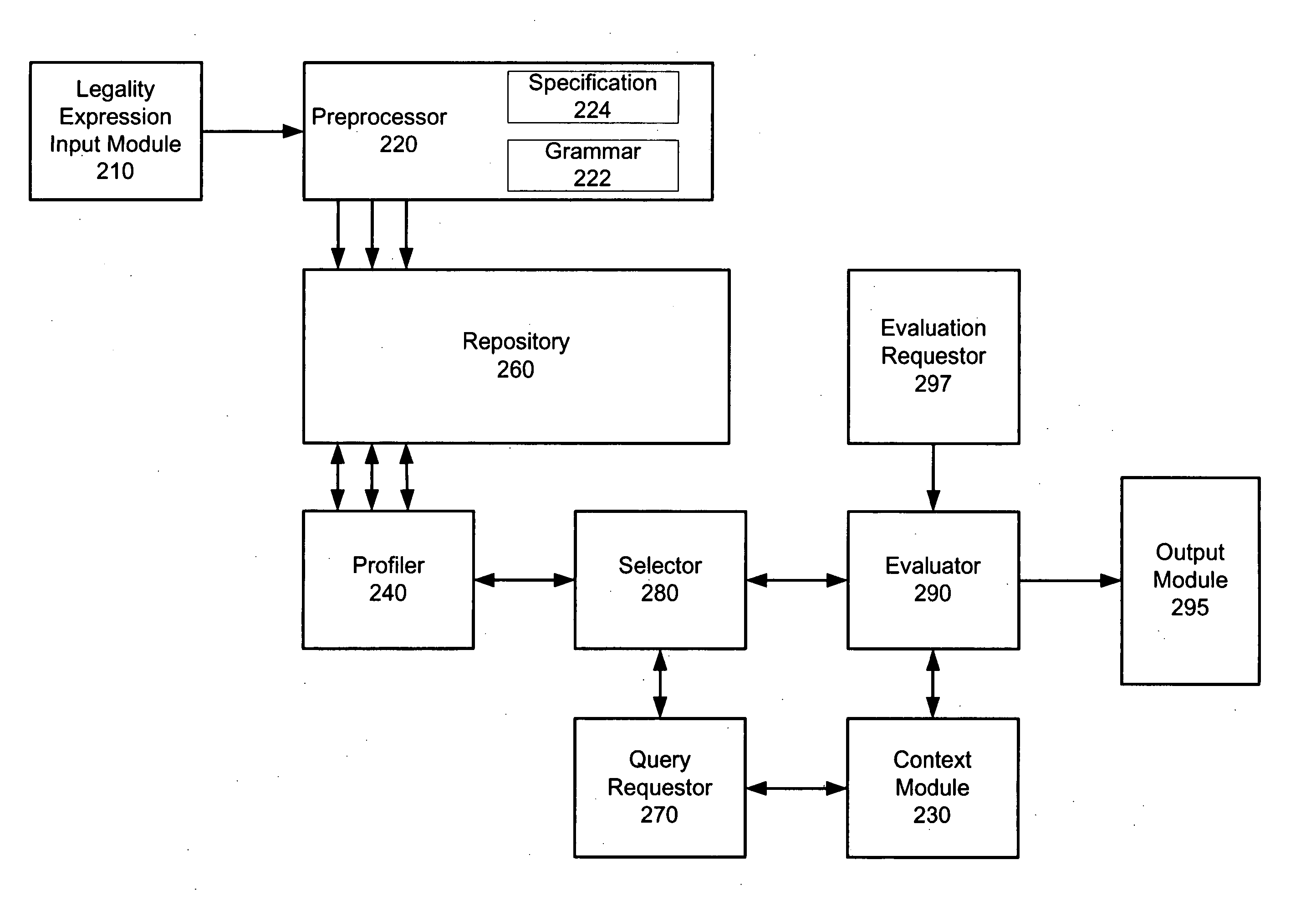

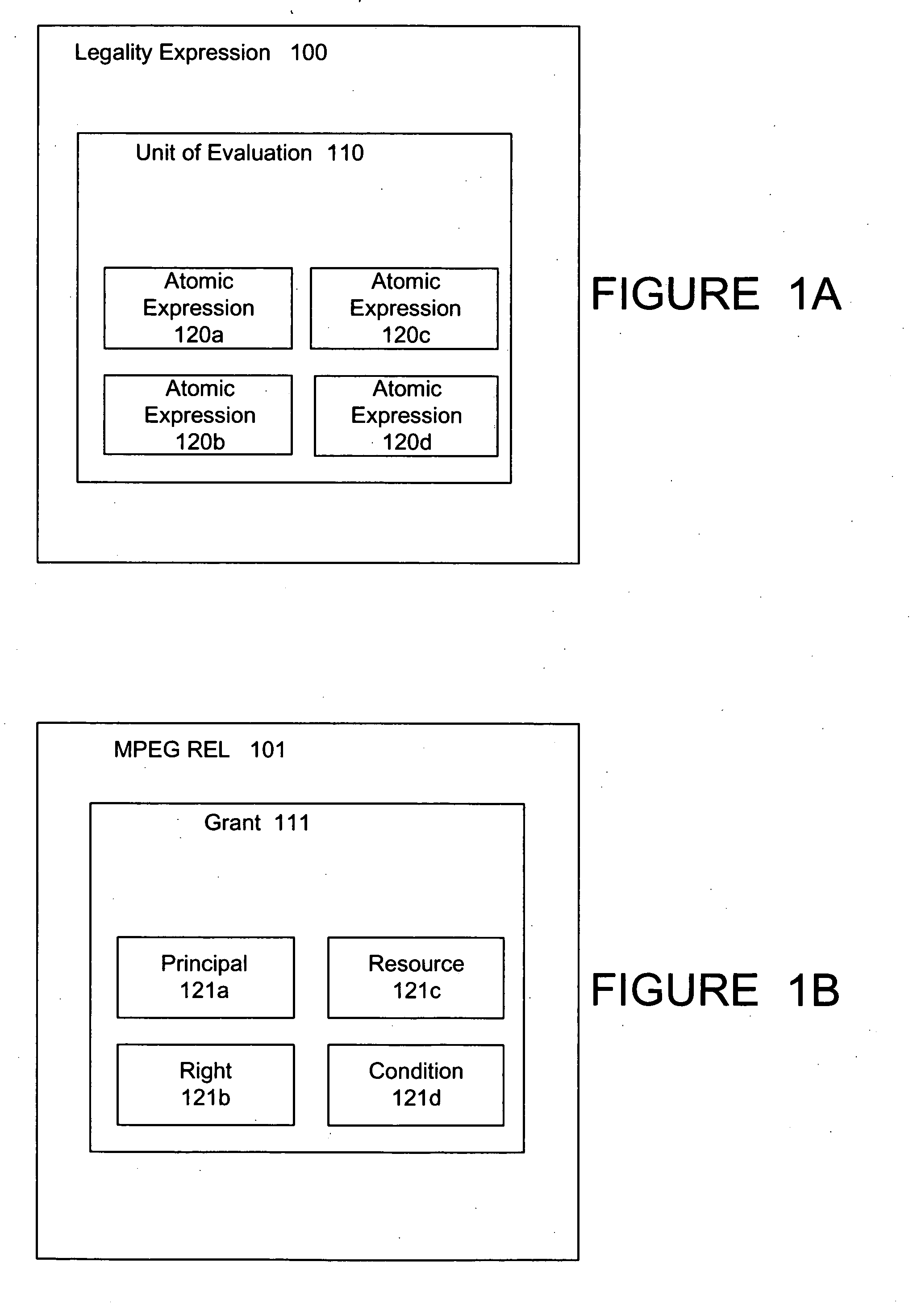

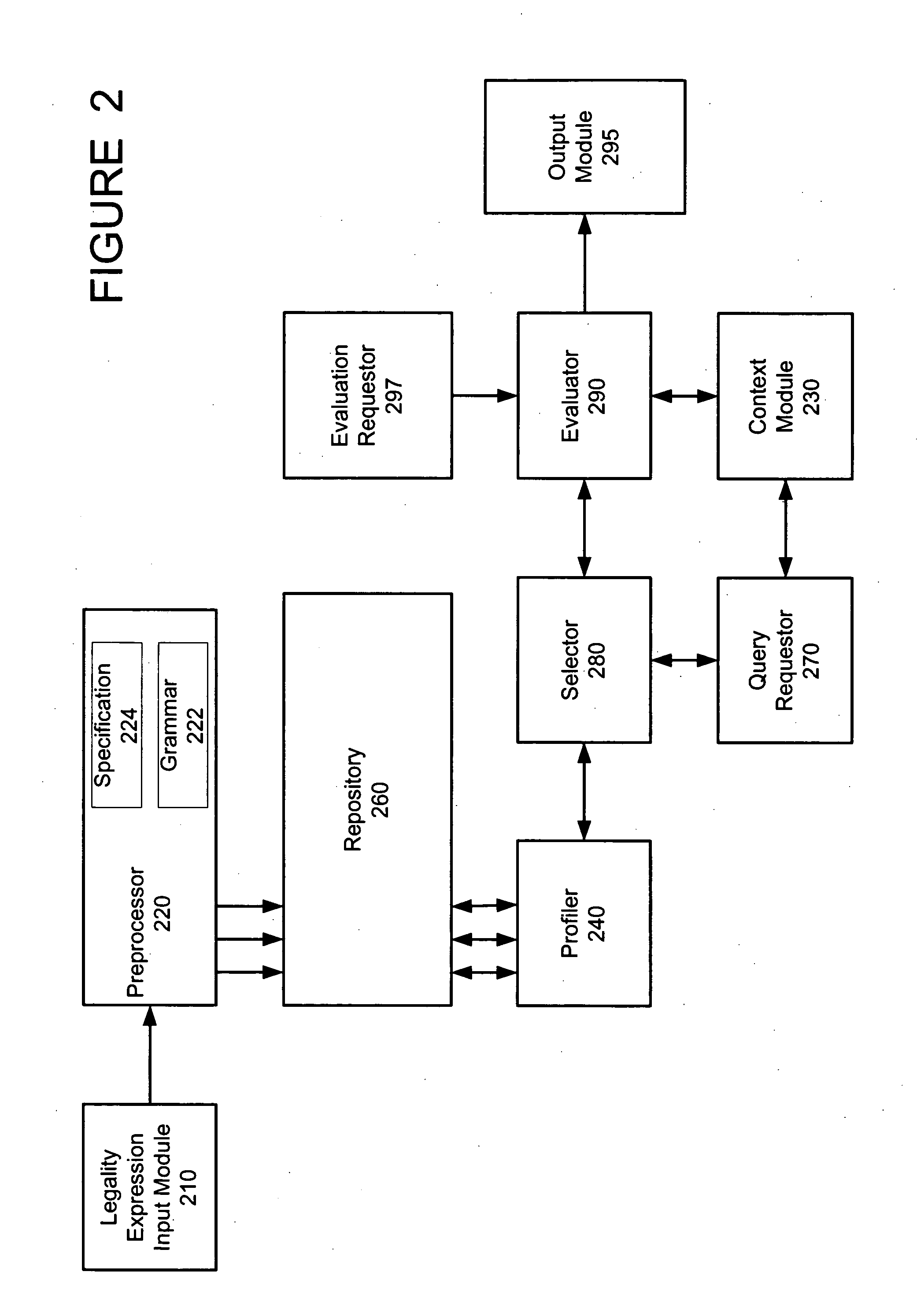

Method and system for processing grammar-based legality expressions

ActiveUS20060041421A1Efficient storageExceptional integrityProgram/content distribution protectionSpecial data processing applicationsTime responsePredictability

Legality expressions are systematically pre-processed, organized, and stored to achieve faster real-time response, improved predictability, and increased reliability for queries against a large volume of legality expressions. Exponential improvements in both the time to locate the set of legality expressions matching specified search criteria and the processing costs of evaluating the request against the matching legality expressions are achieved using the disclosed systems, devices, and methods. The systems, devices, and methods are unique to the optimization of legality expression processing, but they can also enable the use of other optimization techniques for processing large amounts of data.

Owner:CONTENTGUARD HLDG

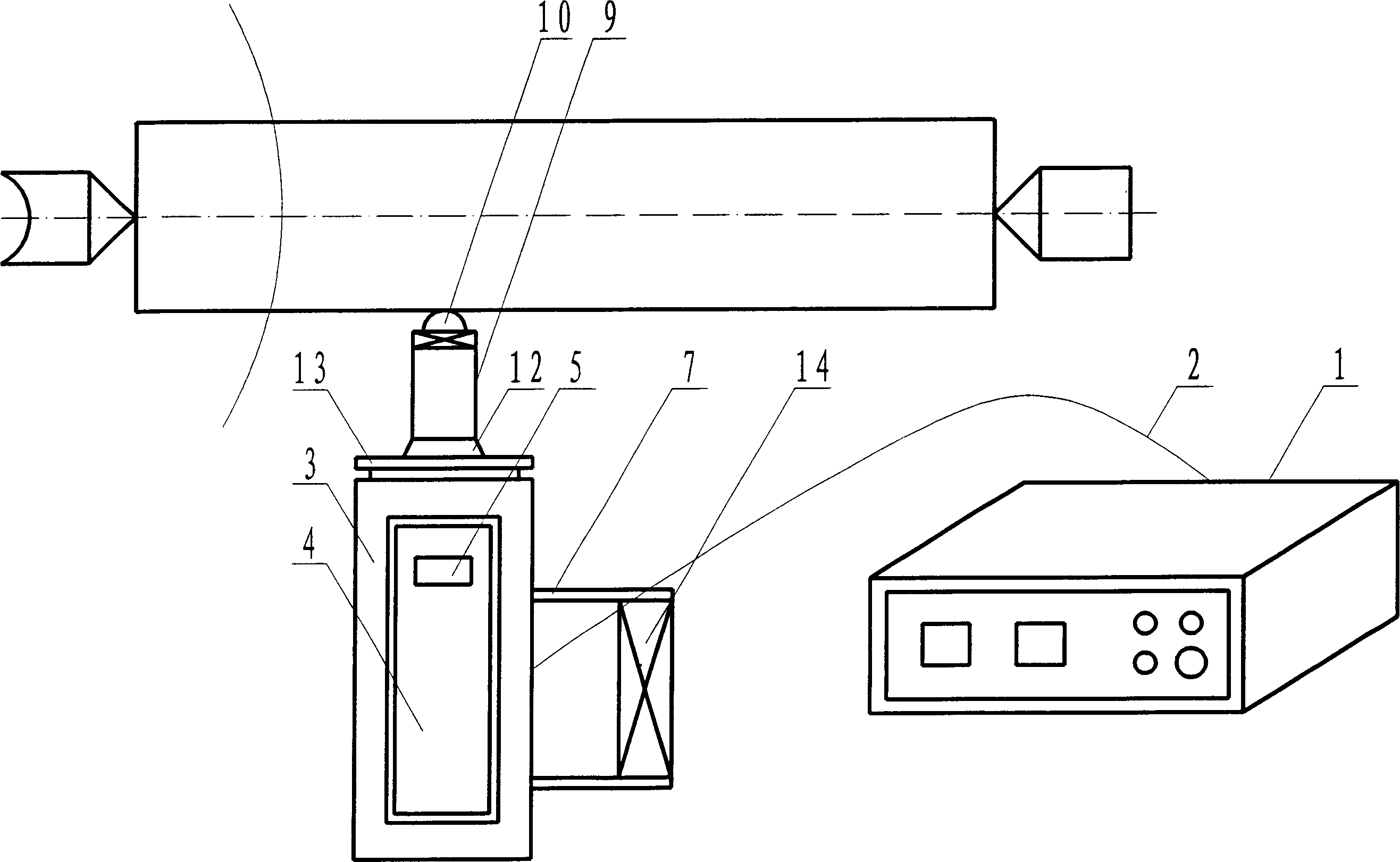

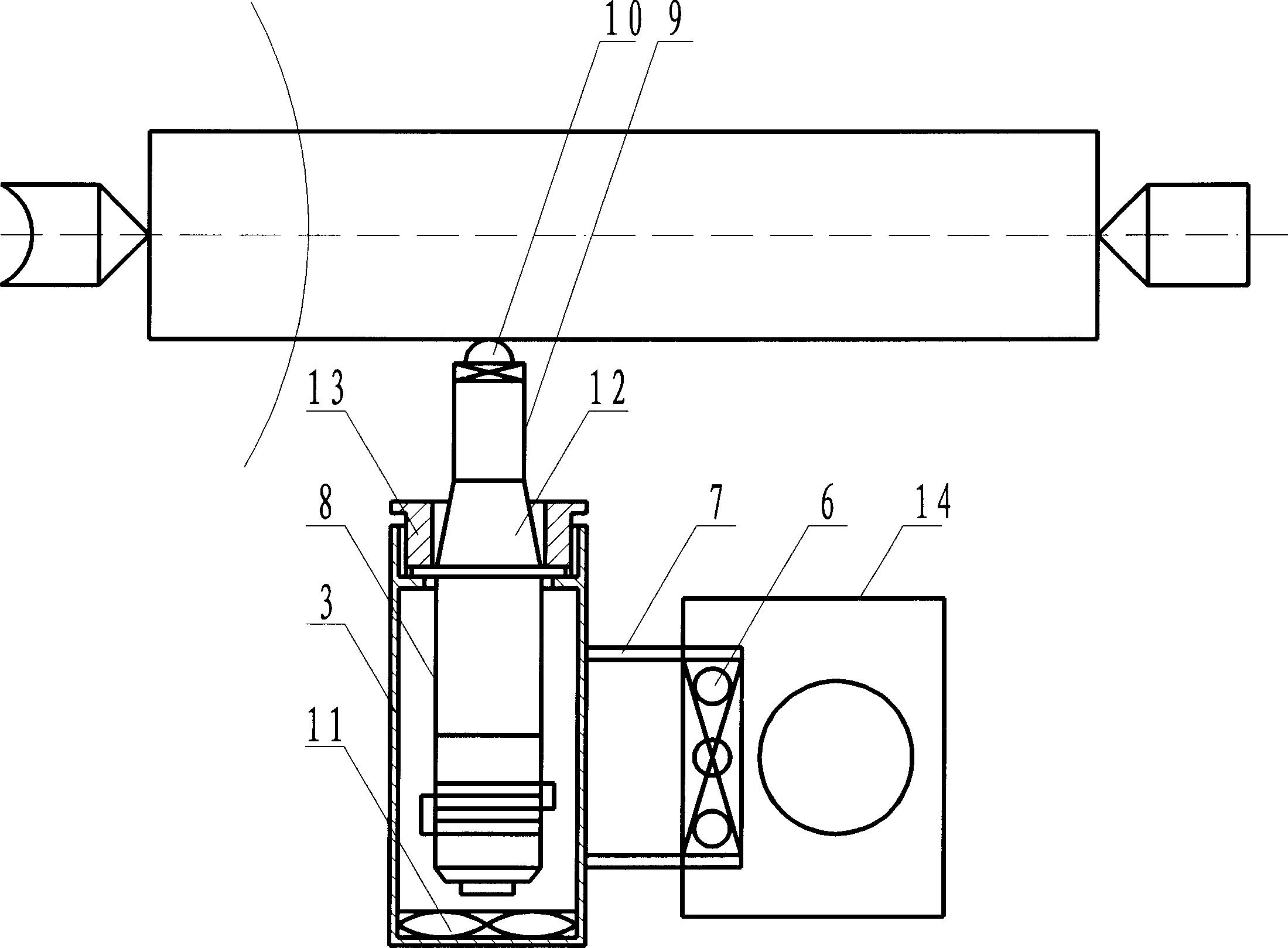

Ultrasonic metal surface processing device

ActiveCN1690231AIncrease productivityReduce investmentMechanical vibrations separationElectricityTransducer

The invention provides a ultrasonic working device for metallic surface, which comprises ultrasonic generator and ultrasonic working device linked together by cable conductor. The ultrasonic generator is existing device, and ultrasonic working device comprises shell which is equipped with spring connected to checkout gear for pressure one side and to briquette the other side besides with checkout gear for pressure and display for pressure, checkout gear for pressure, display for pressure, briquette, spring, piezoelectric ceramic transducer equipped in the shell and connected tight to one end of the half-wavelength complex varying amplitude pole by screw, half-wavelength complex varying amplitude pole whose outlet connected tight to tool caput by screw, tool caput and draught fan equipped on other end of the shell. Producing with the device for metallic surface can reduce the processing cost rapidly and effectively, simplify the productive technology, and advance the productive efficiency, as a result, it takes on a nice extendable and applicable value.

Owner:SHANDONG HUAWIN ELECTRICAL & MECHANICAL TECH

Process of converting rendered triglyceride oil from marine sources into bland, stable oil

Triglyceride oil derived from marine sources, mammalian and fish, is treated with a silica at relatively low temperature under vacuum and is then further treated with a bleaching clay under vacuum and at higher temperature. The silica and the bleaching clay are then separated from the oil. The oil treated by this method is essentially free of proteinaceous materials, phosphatides and mucilage, pro-oxidant metals and very low in colored compounds, and is suitable for deodorizing. The deodorized oil is completely bland, unchanged in the concentration of the long-chain highly unsaturated fatty acids (EPA, DPA and DHA), very low in color, peroxides and secondary oxidation products, free of pesticides and has very good flavor stability. The method avoids the use of any chemicals, such as in the acid and base treatments required in conventional degumming and alkali refining of oils of marine origin. This avoids the formation of artifacts in the oil and trace contamination with chemicals. It also reduces the number of process steps required to produce deodorized food oil from marine sources, which is advantageous in respect to oil quality, process losses and processing costs. The method is especially environmentally advantageous, since it avoids the need for soapstock and waste water processing entirely. Refined oil produced by the method is useful as a nutritional supplement and in methods of therapy or medical treatment.

Owner:MAG TED

Scratch-resistance French white filled polypropylene composition and its preparing method

InactiveCN1580115AImprove scratch resistanceImproves UV resistanceProcedure AgentsSilicone Elastomers

This invention refers to a kind of component of nick resistant talcum-powder-filling polypropylene, is characterized with strengthened toughness through latex and is composed of the following materials in amounts of weight: between 50 and 80 of polypropylene, between 5 and 35 of filler, between 5 and 25 of latex, between 0.5 and 5 of high molecular silicone elastomer, between 0.05 and 0.5 of nucleater, between 0.1 and 1.0 of stabilizer, between 0.2 and 1.5 of talcum powder surface passiation agent, between 0.05 and 1.0 of processing agent and between 0.3 and 2.0 of toner. The manufacturing method is to weigh the materials in amounts of weight, to mix polypropylene, filler, latex, high molecular silicone elastomer, nucleater, stabilizer, talcum powder surface passiation agent, processing agent and toner in homo mixer, then put them into double-screwed extruder for melting and extruding. After cooling, drying and pelleting, we can get the turnoff. The invention improves the nick resistance of polypropylene, ultraviolet radiation endurance and thermal endurance and the toughness and rigidity of the material reach good balance. It can meet the requirements of the material of automobile limbs. It can demold at a relatively high temperature, improves the moulding efficiency greatly and reduces the processing cost.

Owner:SHANGHAI PRET COMPOSITES

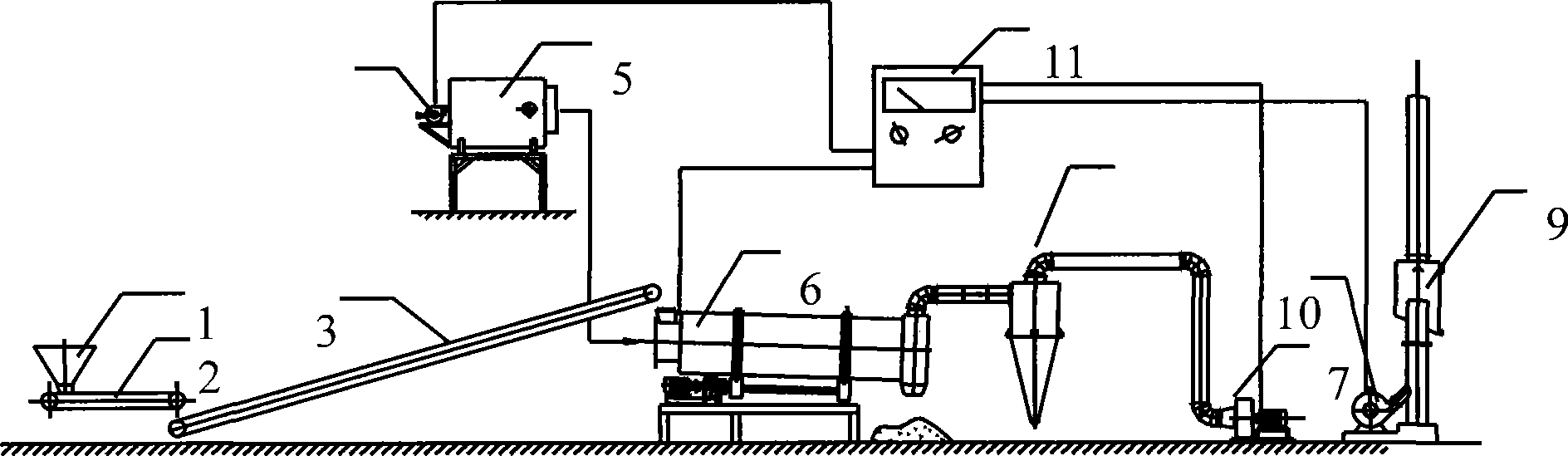

Soil pollution thermal desorption restoration processing system

InactiveCN101530858AAvoid secondary pollutionImprove applicabilityContaminated soil reclamationEngineeringProcessing cost

The invention relates to a soil pollution thermal desorption restoration processing system, which belongs to a soil restoration processing system. The system comprises a feed system, a heat source system and a control system, and is characterized by further comprising a thermal desorption system and a tail gas processing device, wherein the thermal desorption system consists of a draught fan and a thermal extraction converter, and the tail gas processing device consists of a dust remover and an absorption tower. When the system is applied to processing polluted soil with main pollutants of volatile / semi-volatile organic compounds, compared with the like products in other countries, the equipment cost is only 1 / 3 to 1 / 5 of the same; the problem of secondary pollution probably brought about in the process of processing the polluted soil is thoroughly avoided; a temperature control system has better practicability; the running cost for each ton of the polluted soil is between 300 and 500 RMB, which is far low than the processing cost for hazardous landfilling and incineration of the polluted soil; and half of the purification effect of processing the polluted soil with the main pollutants of the volatile / semi-volatile organic compounds can reach between 70 and 80 percent.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

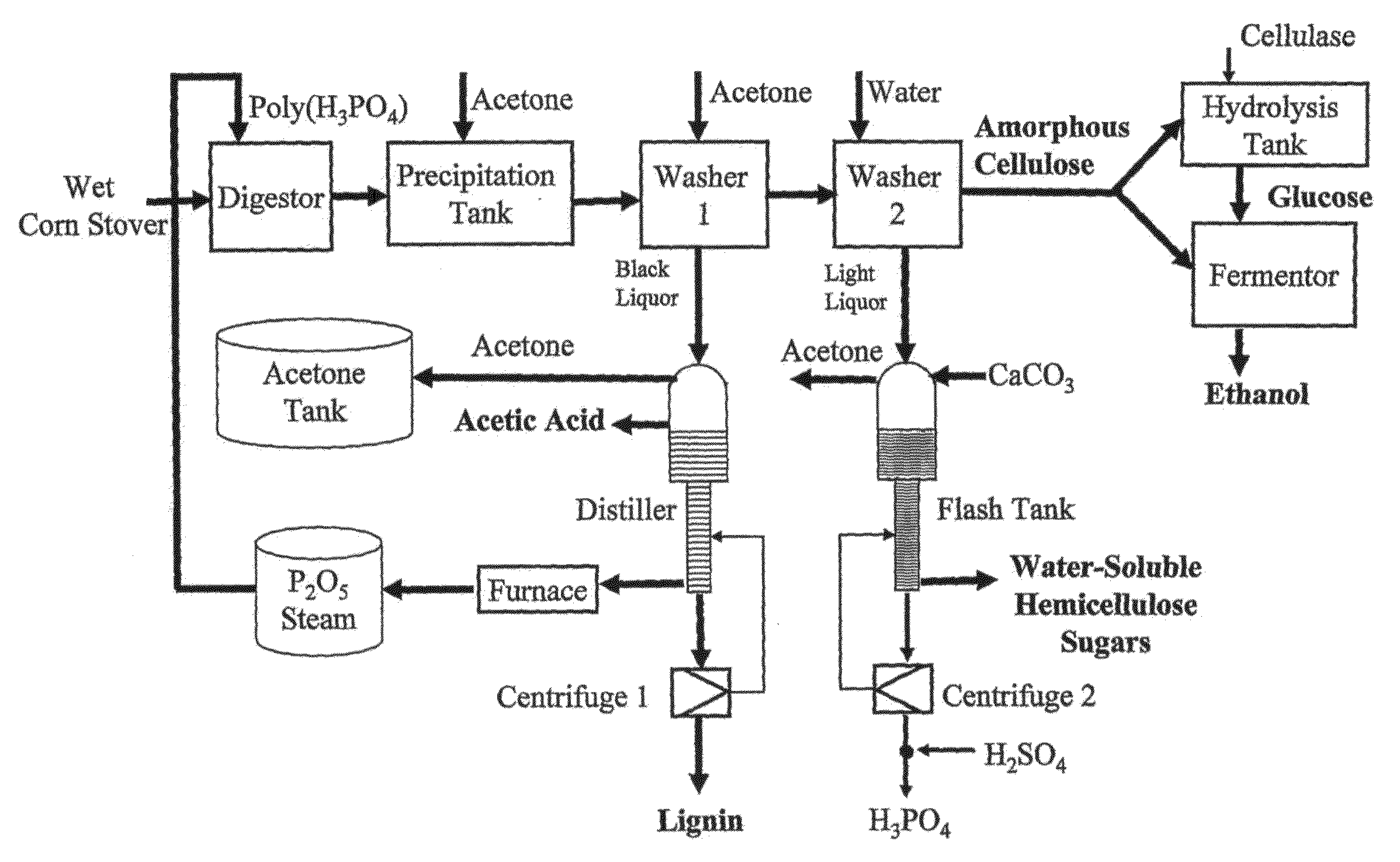

Method and apparatus for lignocellulose pretreatment using a super-cellulose-solvent and highly volatile solvents

InactiveUS20090229599A1Overcome shortcomingReduce solvent usagePressurized chemical processBiofuelsAlcoholGram

Embodiments of the present invention overcome the well-known recalcitrance of lignocellulosic biomass in an economically viable manner. A process and a system are provided for the efficient fractionation of lignocellulosic biomass into cellulose, hemicellulose, and lignin. The cellulose and hemicellulose thus obtained are highly amorphous and can be readily converted into highly concentrated mixtures of five and six carbon sugars using known methods. Typical yields of sugars exceed 100 grams of sugars per liter of sugar solution. Other products, such as alcohols, can easily be prepared according to methods of the invention. The modest process conditions and low solvent / solid ratios of some embodiments of the invention require relatively low capital and processing costs.

Owner:VIRGINIA TECH INTPROP INC

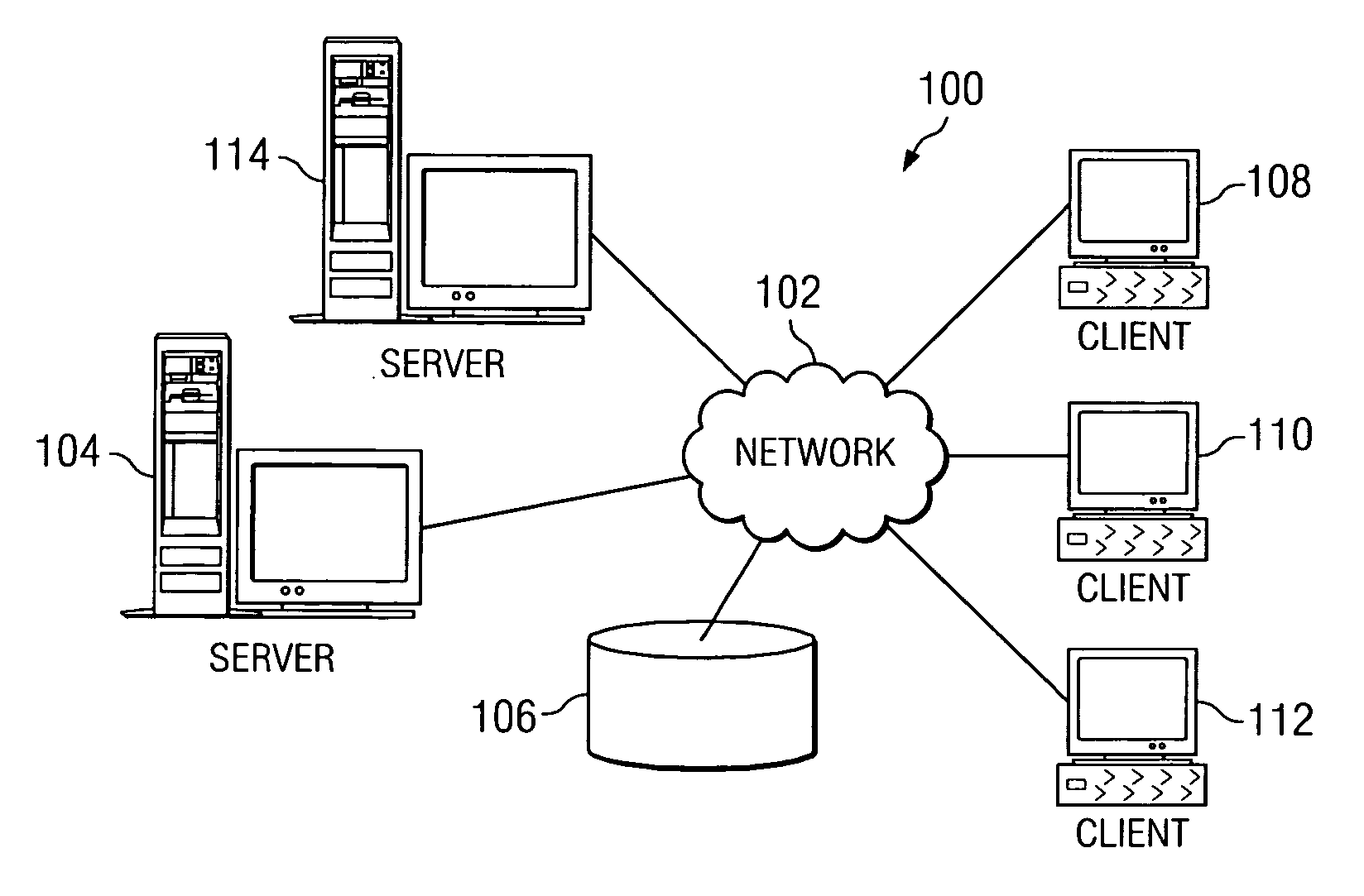

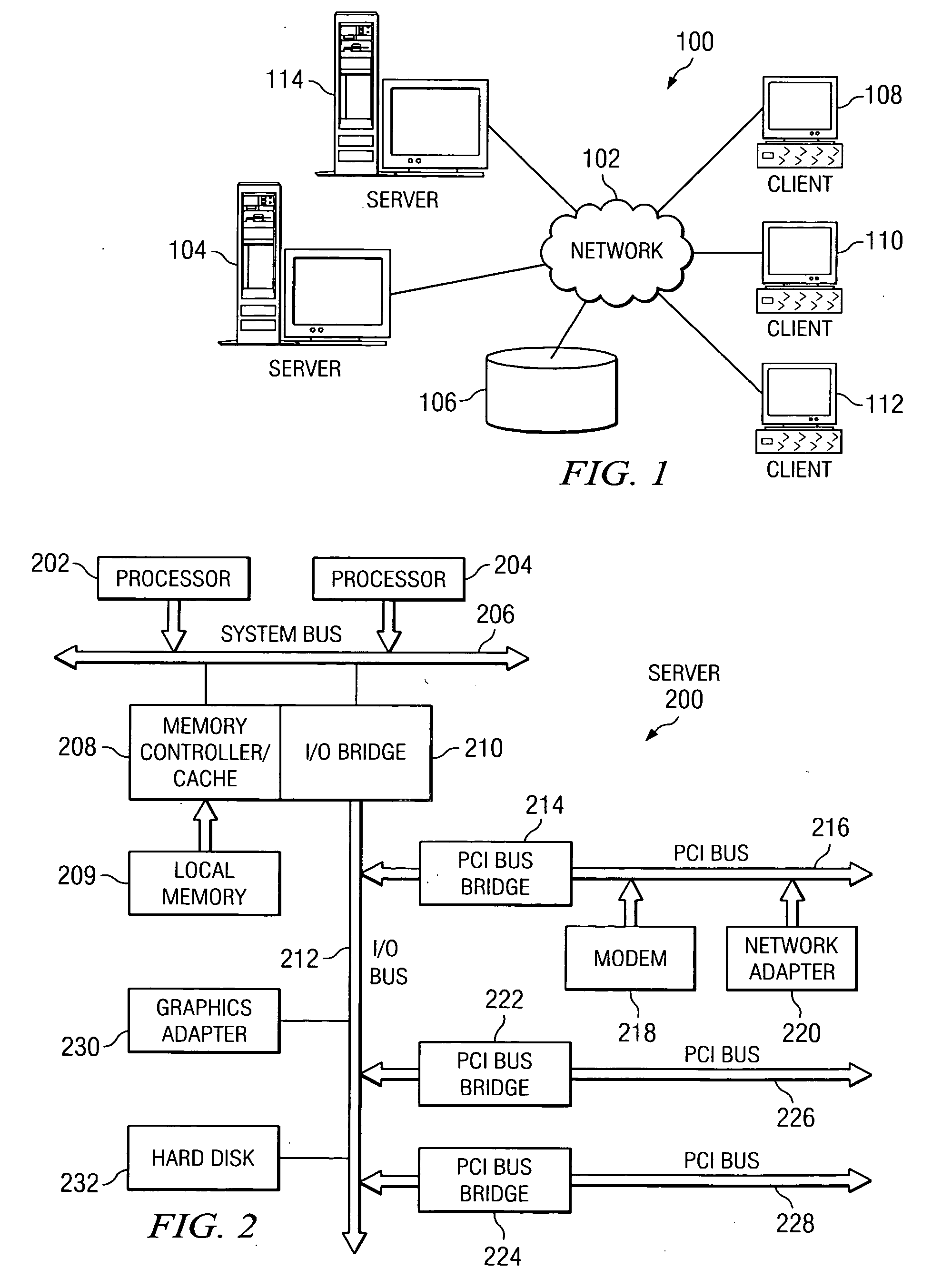

Component model for batch computing in a distributed object environment

ActiveUS20050256826A1Easy to implementEnhanced advantageProgram initiation/switchingResource allocationBatch processingDistributed object

A batch component model is provided within a distributed object environment. The batch component is designed to capture the iterative logic of a batch program as it reads from one or more input streams, invokes operations on other business component functions, and generates output to one or more output streams. Deployment descriptors express declarative policies for the component that will influence how the component is managed including the streams it uses, business components it depends on, how processing costs are accounted for, the resource demands the job will put on the system, and the like. Input streams and output streams are encapsulated in objects that hide the actual source of input and output data so that the component can be redeployed in different execution environments to different physical data sources without requiring the program to be changed. A batch container enforces the deployment policies declared for the batch component.

Owner:IBM CORP

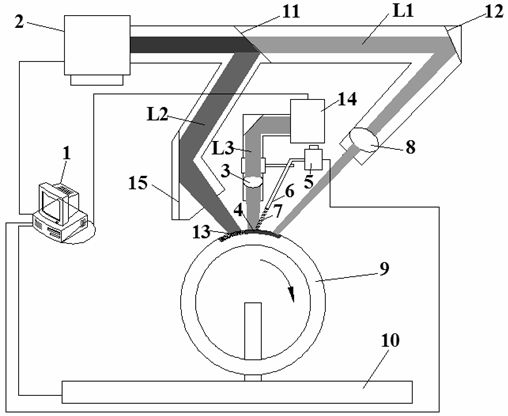

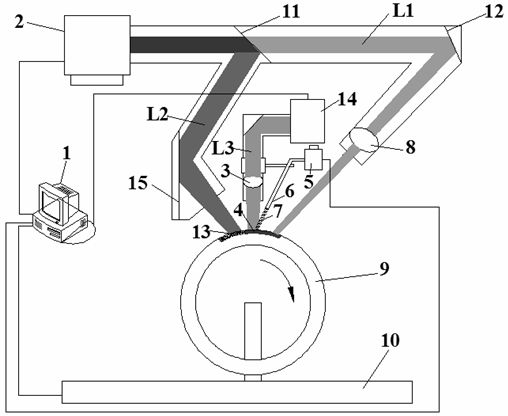

Method with functions of preheating and postheating for forming crack-free coating with high efficiency by three-light-beam laser-cladding technique

InactiveCN102383126ALow and adjustable dilution rateSmall heat affected zoneMetallic material coating processesLaser beam welding apparatusMelting tankHeat-affected zone

The invention discloses a method with functions of preheating and postheating for forming crack-free coating with high efficiency by a three-light-beam laser-cladding technique. The method comprises the following steps of: splitting a laser beam emitted by an Nd: YAG laser into two laser beams by using a laser beam splitter, namely a preheating laser beam for preheating the surface of a base material and a postheating laser beam for postheating the formed coating; then blowing alloy powder into a molten pool which is formed by focusing a laser beam emitted by a CO2 laser and acting the focused laser beam on the surface of the base material by using a powder nozzle, wherein after the CO2 laser beam moves away, a molten layer is cured and crystallized quickly to form the coating; and postheating the formed coating by adopting the postheating laser beam. The method has the advantages that: (1) the dilution rate of the coating is low and adjustable, and the coating is metallurgically combined with the base material, so the base material has a small thermal influence area and is deformation-free and crack-free; (2) residual inner stress in the coating can be eliminated effectively, a tissue can be improved, and the coating has high abrasion resistance, high corrosion resistance, high anti-cracking performance and high thermal shock resistance; and (3) relative to the processing efficiency in the conventional laser cladding technology, the processing efficiency in the method can be improved by 50 times to the maximum extent, so the processing cost is reduced greatly, and a large-scale industrialized application potential is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

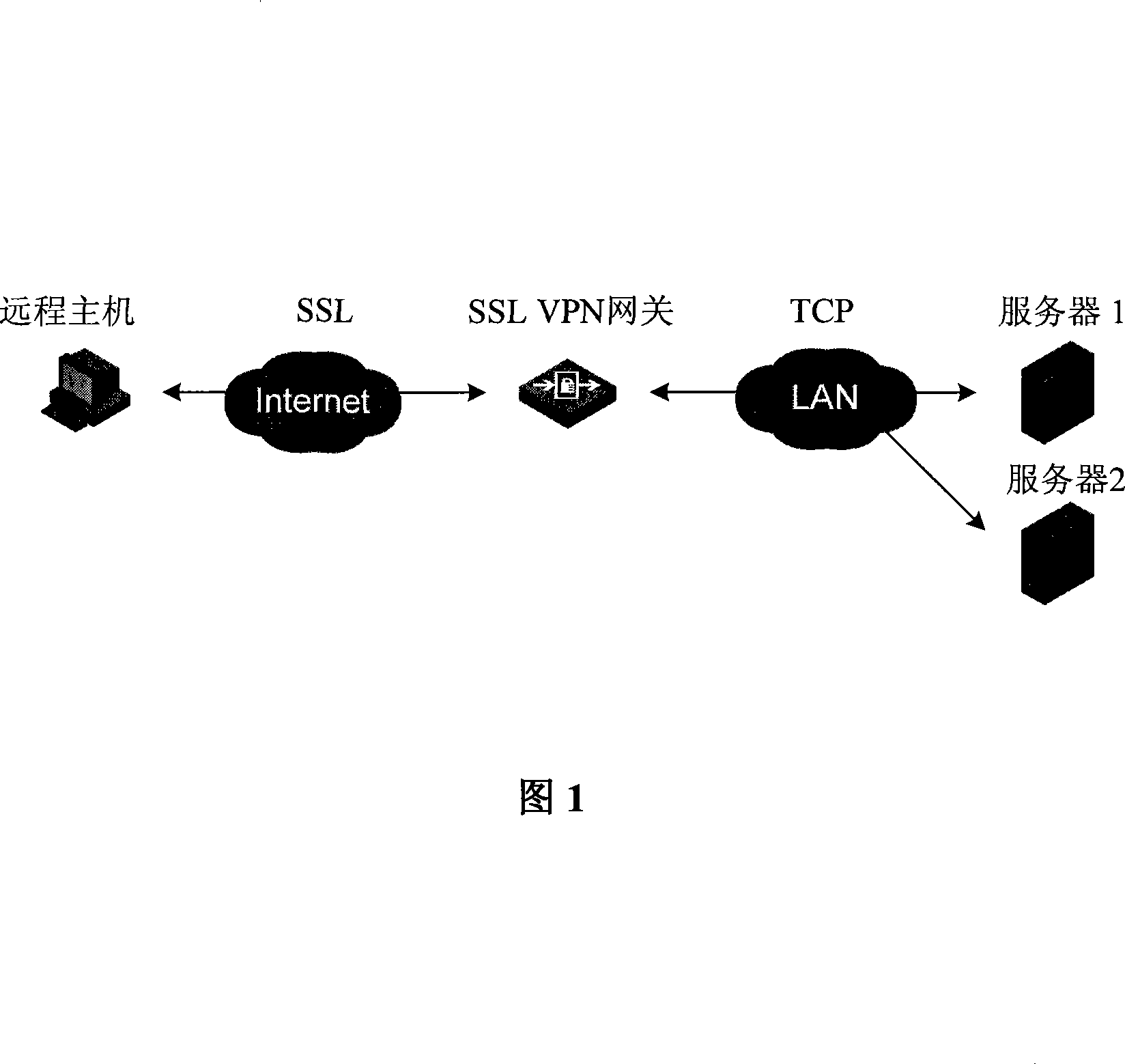

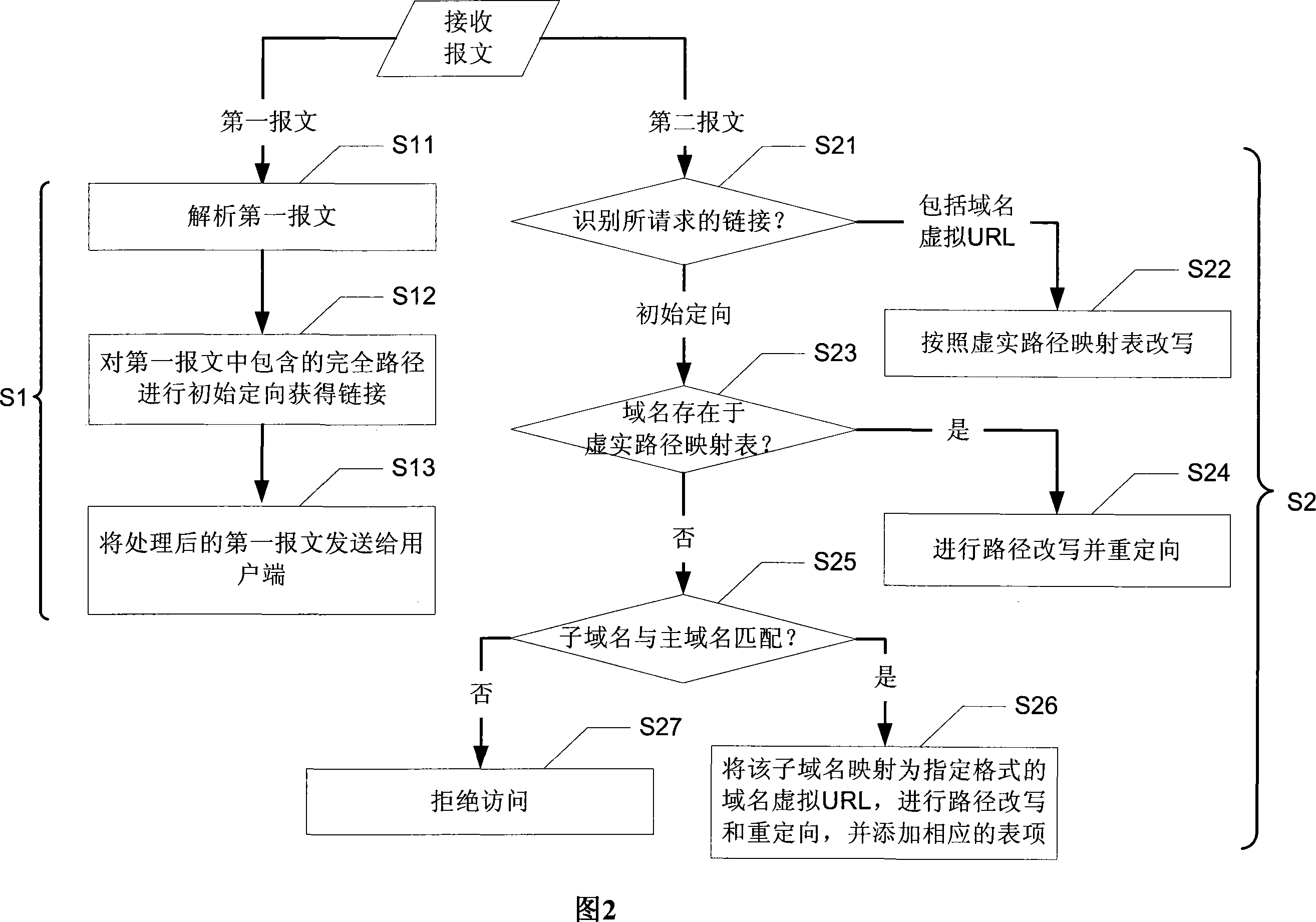

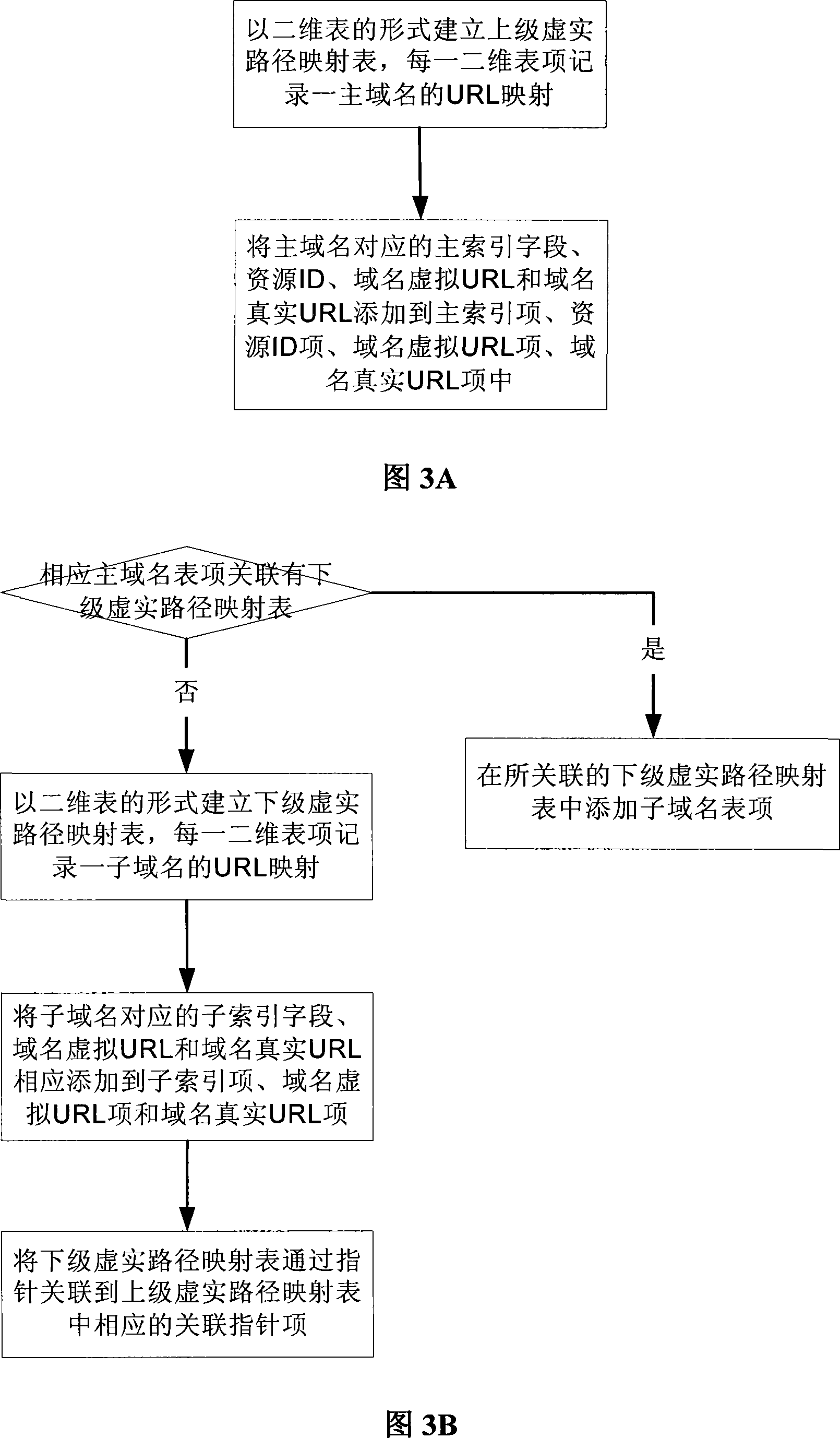

Method for remote access to intranet Web server and Web proxy server

ActiveCN101242336AAvoid confusionRealize differentiated rewritingNetworks interconnectionDomain nameWeb service

The invention discloses a method for remote accessing intranet web server, a web proxy server gateway executes the steps: initially orienting a complete path contained a first message sent to the user terminal by a web server to obtain a link; carrying out a rewrite from domain name virtual URL to a domain name real URL for a second message sent to the user terminal by a web server, or extracting the domain name from a initial orienting complete path to directly perform a reorienting or perform a specified format virtual URL mapping and reorienting for a sub domain name when a preset fuzzy policy match succeeds. The invention also discloses a web proxy server. The invention can avoid a Cookie confusion of a user terminal, increases processing efficiency of the web proxy server, and reduce a processing cost of the system.

Owner:NEW H3C TECH CO LTD

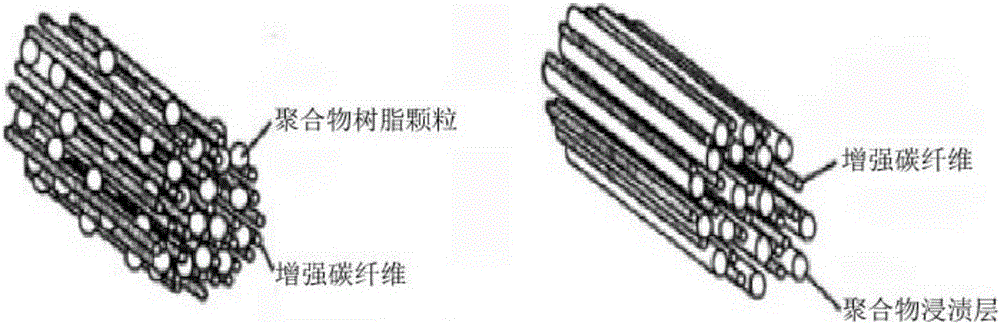

Continuous long carbon fiber reinforced thermoplastic nanocomposite and preparation method and application thereof

The invention discloses a continuous long carbon fiber reinforced thermoplastic nanocomposite and a preparation method and application thereof. The nanocomposite comprises, by weight, 40 to 70% of long carbon fiber (LCF), 25 to 40% of thermoplastic resin, 3 to 15% of a filler and 2 to 5% of an auxiliary agent; and an isostatic pressing fusion resin impregnation compound process is employed to prepare the multi-component blend composite with a multi-phase structural characteristic. In a processed and shaped part product, the reservation length of LCF is 0.5 to 15 mm and meets the requirement that normal distribution is no less than 80%. The nanocomposite provided by the invention has excellent performances and characteristics like small specific gravity, high strength, good toughness, good thermal and heat conductivity, wear resistance, corrosion resistance, fatigue resistance, simple production technology and low processing cost of the product.

Owner:河南中煌节能电器有限公司

Methods for integrated fast pyrolysis processing of biomass

ActiveUS8100990B2Minimizes water contentImprove collection efficiencyDirect heating destructive distillationBiofuelsPre treatmentSafe handling

Methods, process, apparatus, equipment, and systems are disclosed for converting biomass into bio-oil fractions for chemicals, materials, feedstocks and fuels using a low-cost, integrated fast pyrolysis system. The system improves upon prior art by creating stable, bio-oil fractions which have unique properties that make them individually superior to conventional bio-oil. The invention enables water and low-molecular weight compounds to be separated into a final value-added fraction suitable for upgrading or extracting into value-added chemicals, fuels and water. Initial bio-oil fractions from the process are chemically distinct, have low-water content and acidity which reduces processing costs normally associated with conventional bio-oil post-production upgrading since fewer separation steps, milder processing conditions and lower auxiliary inputs are required. Biochar is stabilized so that it can be handled safely. The integrated fast pyrolysis process includes biomass storage, preparation, pretreatment, and conversion, product recovery and processing to create and store stable biochar and bio-oil fractions.

Owner:AVELLO BIOENERGY

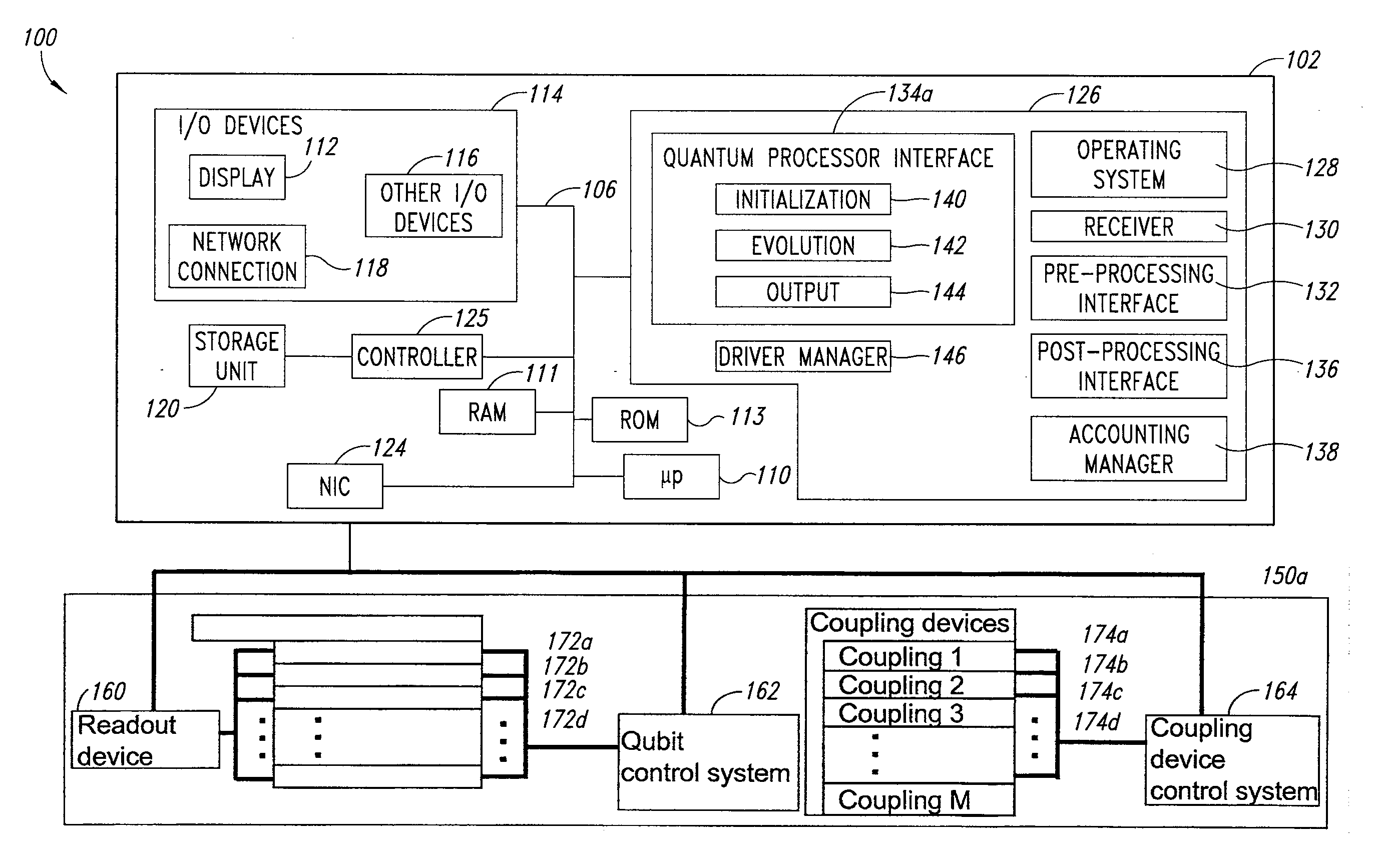

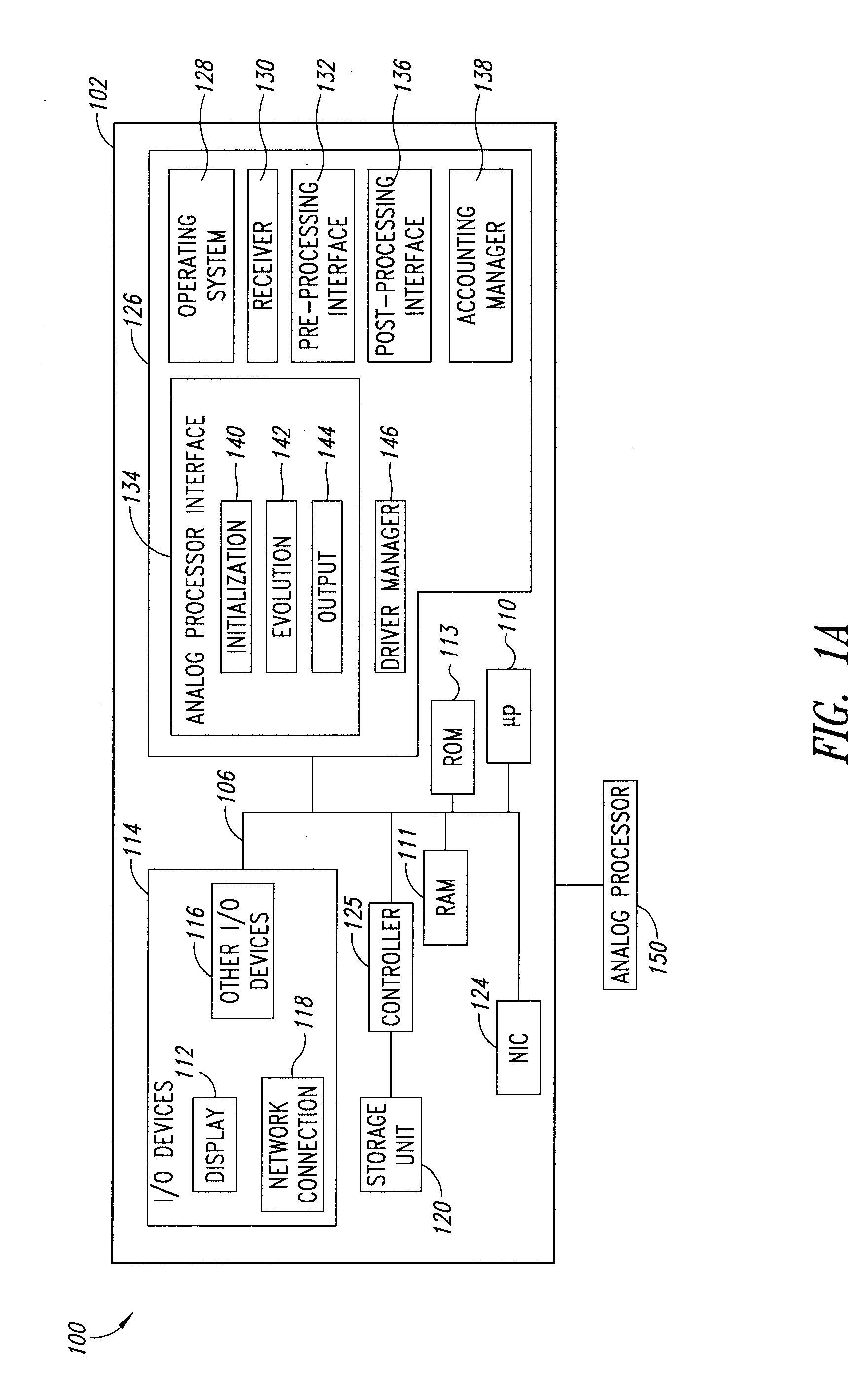

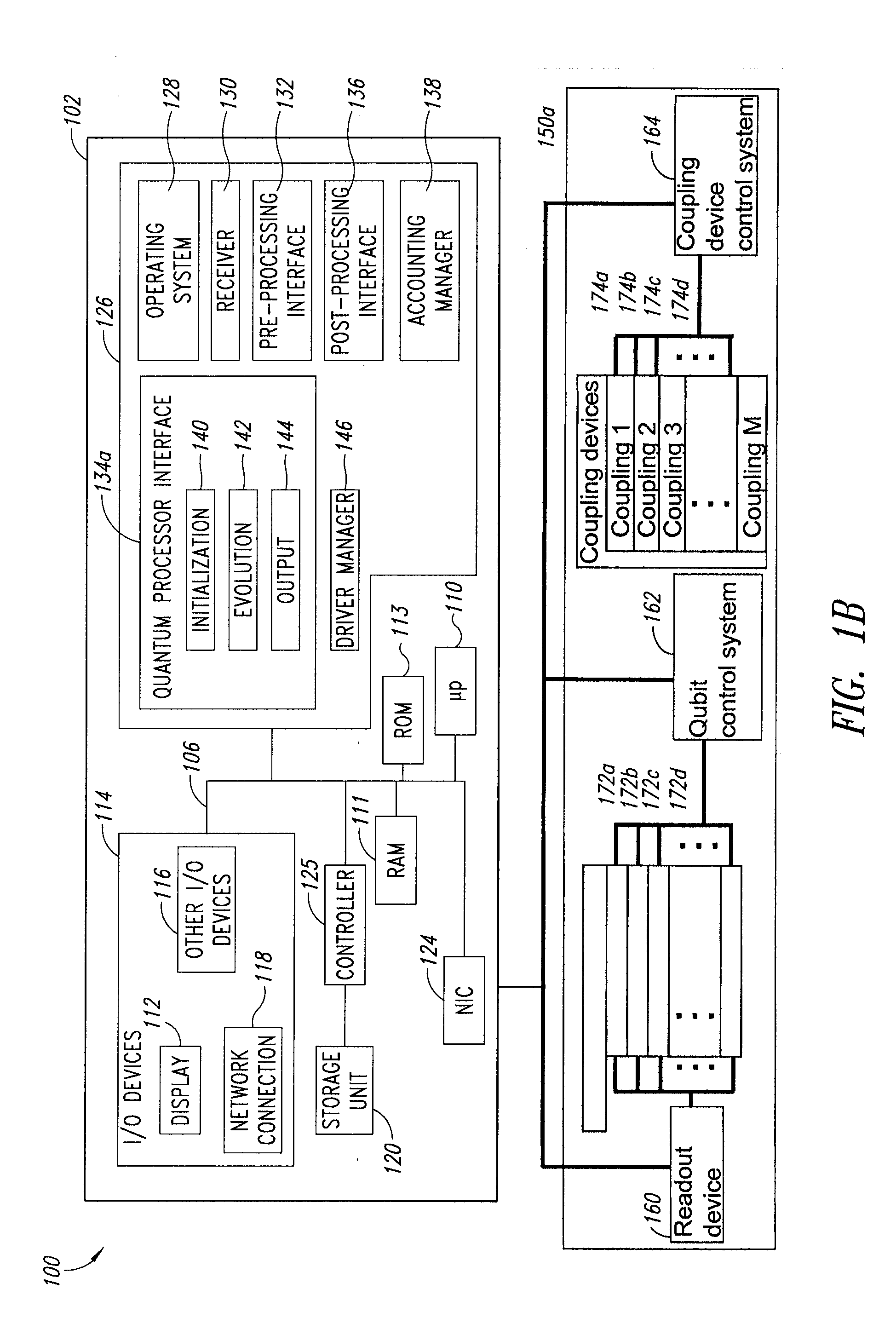

Systems, devices, and methods for solving computational problems

Systems, devices, and methods for using an analog processor to solve computational problems. A digital processor is configured to track computational problem processing requests received from a plurality of different users, and to track at least one of a status and a processing cost for each of the computational problem processing requests. An analog processor, for example a quantum processor, is operable to assist in producing one or more solutions to computational problems identified by the computational problem processing requests via a physical evolution.

Owner:D WAVE SYSTEMS INC

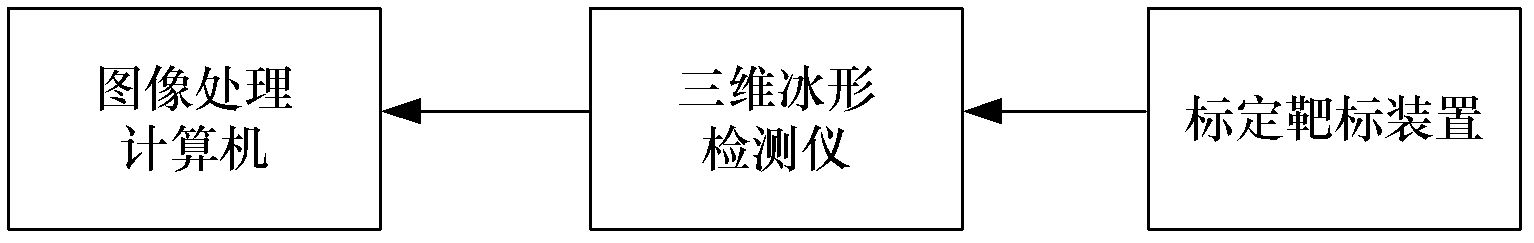

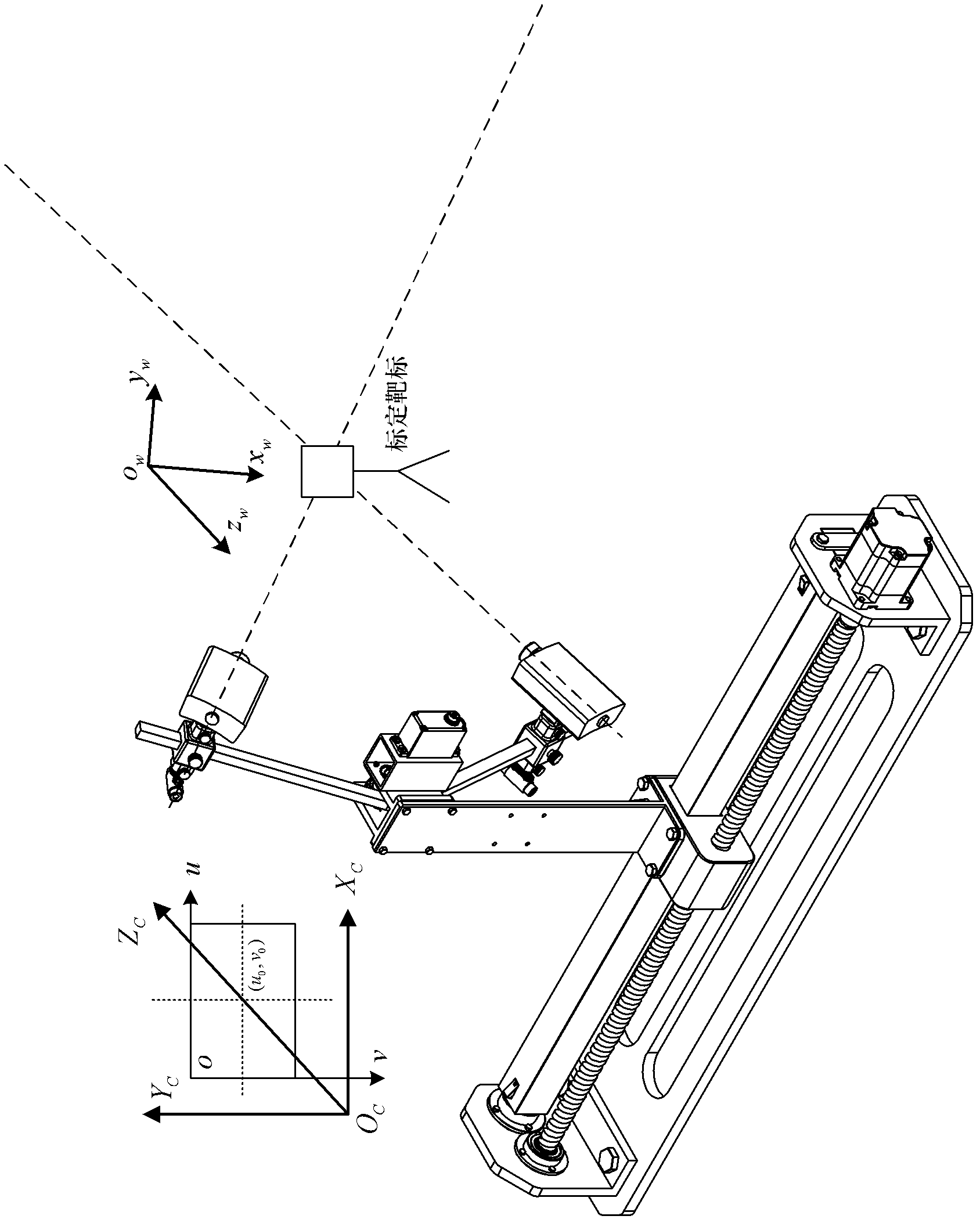

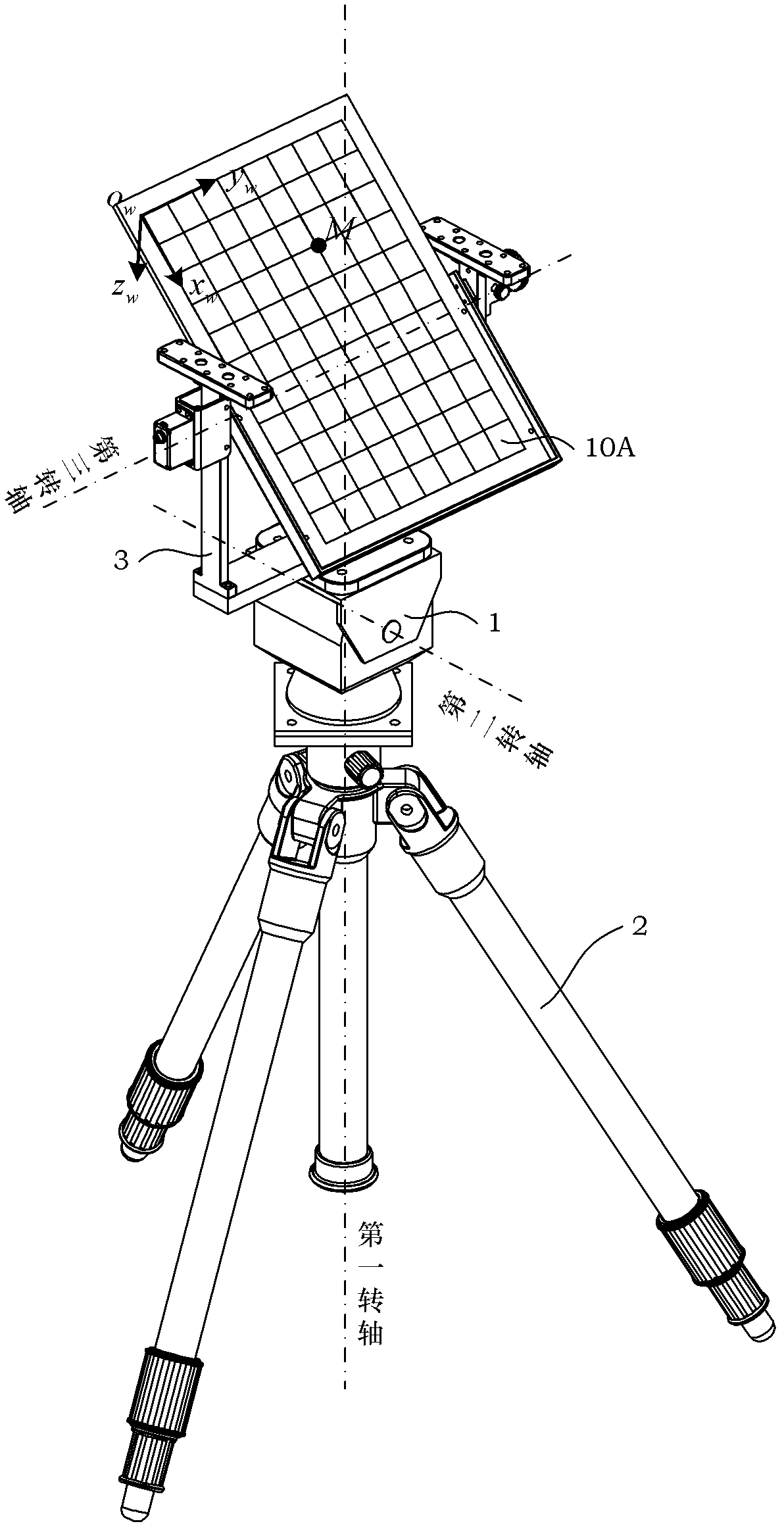

Calibration target device and calibration method for three-dimensional ice-shaped digital image system

InactiveCN102322816ARealize integrated designQuick calibrationImage analysisUsing optical meansIntegrated designDigital image

The invention discloses a calibration target device and a calibration method for a three-dimensional ice-shaped digital image system. The calibration target device comprises a rotary cloud deck, a lampstand, a movable calibration assembly and a calibration plate, wherein the rotary cloud deck is arranged on the lampstand; the rotary cloud deck is provided with the movable calibration assembly; and the movable calibration assembly is provided with the calibration plate. By adopting the calibration device, the on-site rapid calibration of a three-dimensional ice-shaped detector can be realized, and the calibration on the internal parameter and the relative positional relation of a camera can be finished through acquiring several images at a time, thereby, the experiment efficiency is greatly improved. By adopting the mechanical device disclosed by the invention, a traditional calibration mode of holding a free target is changed, the calibration error brought by the jitter of hands is avoided, and the calibration precision is improved. Moreover, the device not only is capable of realizing the calibration of a three-dimensional ice-shaped detector but also can be used as a fixed platform for an object to be measured, thereby, the integrated design of the calibration and the measurement is realized, and the manufacturing material and the processing cost of the device are saved.

Owner:BEIHANG UNIV

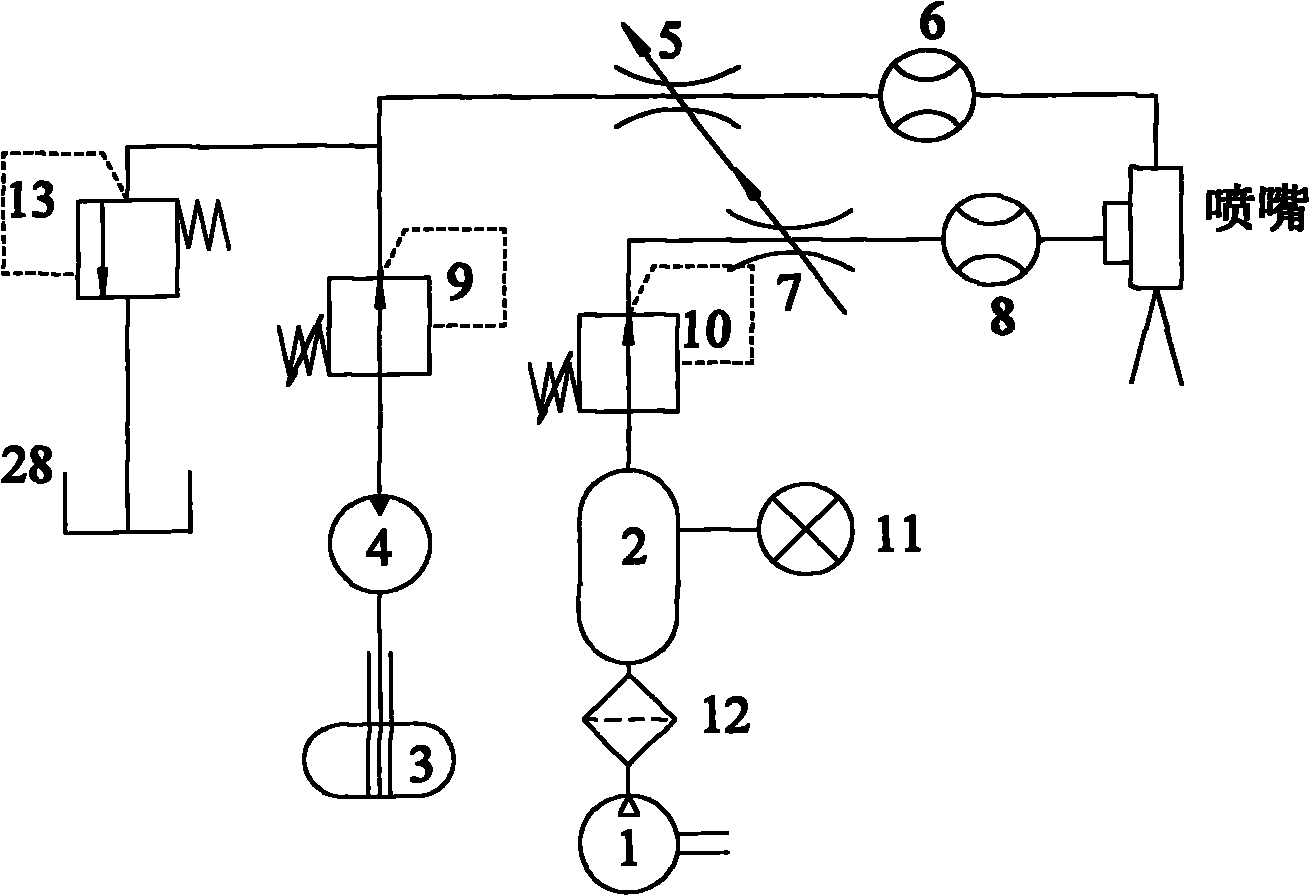

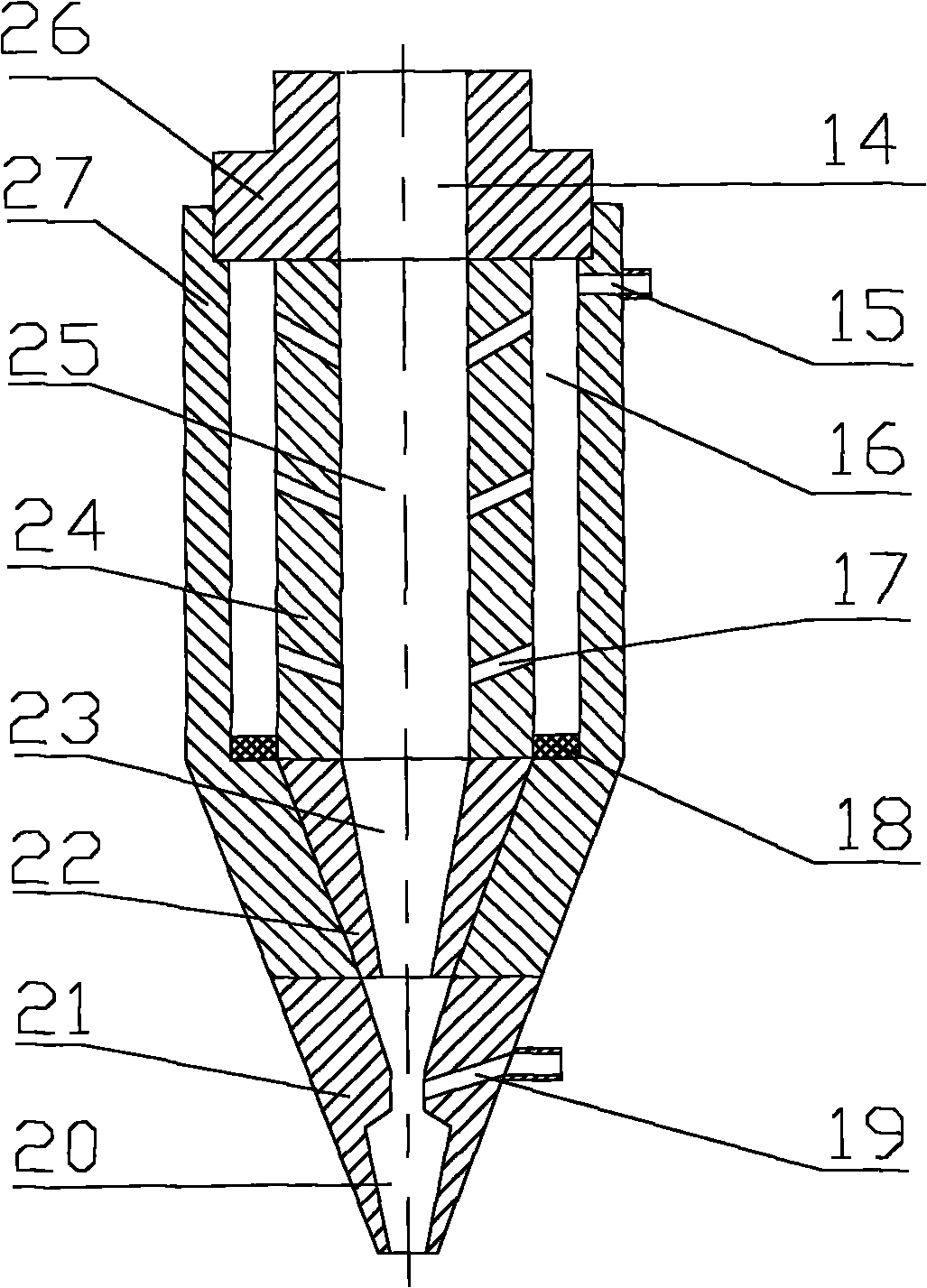

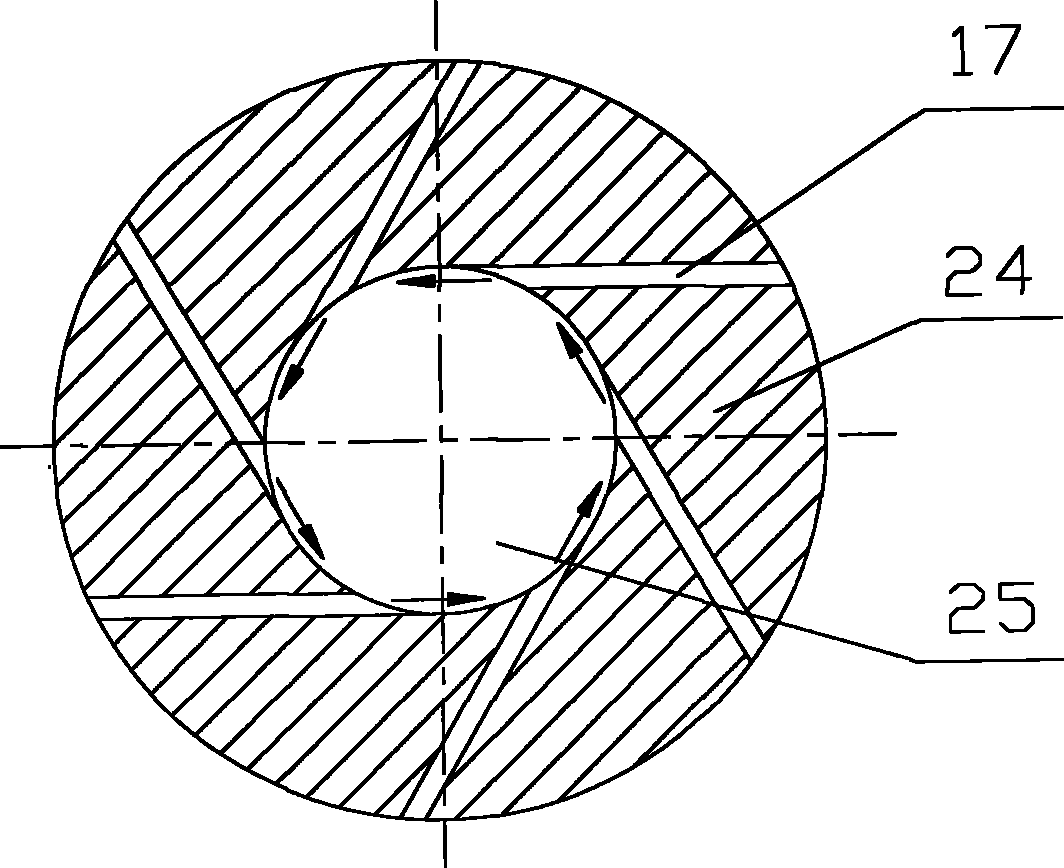

Three-phase flow supply system for nanoparticle jet micro-lubrication grinding

ActiveCN102287606AWell mixedIncrease the diameterConduits/junctionsLubrication check valvesEngineeringHigh pressure

The invention relates to the field of machining, in particular to a nano particle jet flow micro-scale lubricating and grinding three-phase flow supply system. The system is characterized in that: nano fluid is conveyed to a nozzle by a liquid path, high temperature gas enters the nozzle through a gas path at the same time, the high pressure gas and the nano fluid are fully mixed and atomized in the mixing room of the nozzle, the mixed high pressure gas and nano fluid are accelerated in an acceleration room and enter a vortex room, compressed gas enters from the vent hole of the vortex room, and a three-phase flow is further mixed and accelerated by rotating, and is jetted in the form of atomized liquid drops to a grinding area through the outlet of the nozzle. The system has the advantages that: the helical vent hole of the mixing room of the nozzle is tangent to the wall surface of the mixing room, and the nano fluid and the gas are uniformly mixed; pressure adjusting valves, throttles and flow meters are arranged in the gas path and the liquid path, and the pressure and the flow of the nano fluid and the high pressure gas can be adjusted as required so as to achieve an optimal micro-scale lubricating effect; and the problems of insufficient cooling capability in micro-scale lubricating, the large using quantity of a lubricant in pouring type grinding, high waste liquid processing cost and heavy environment pollution are solved.

Owner:青岛前瞻产业园区运营管理有限公司

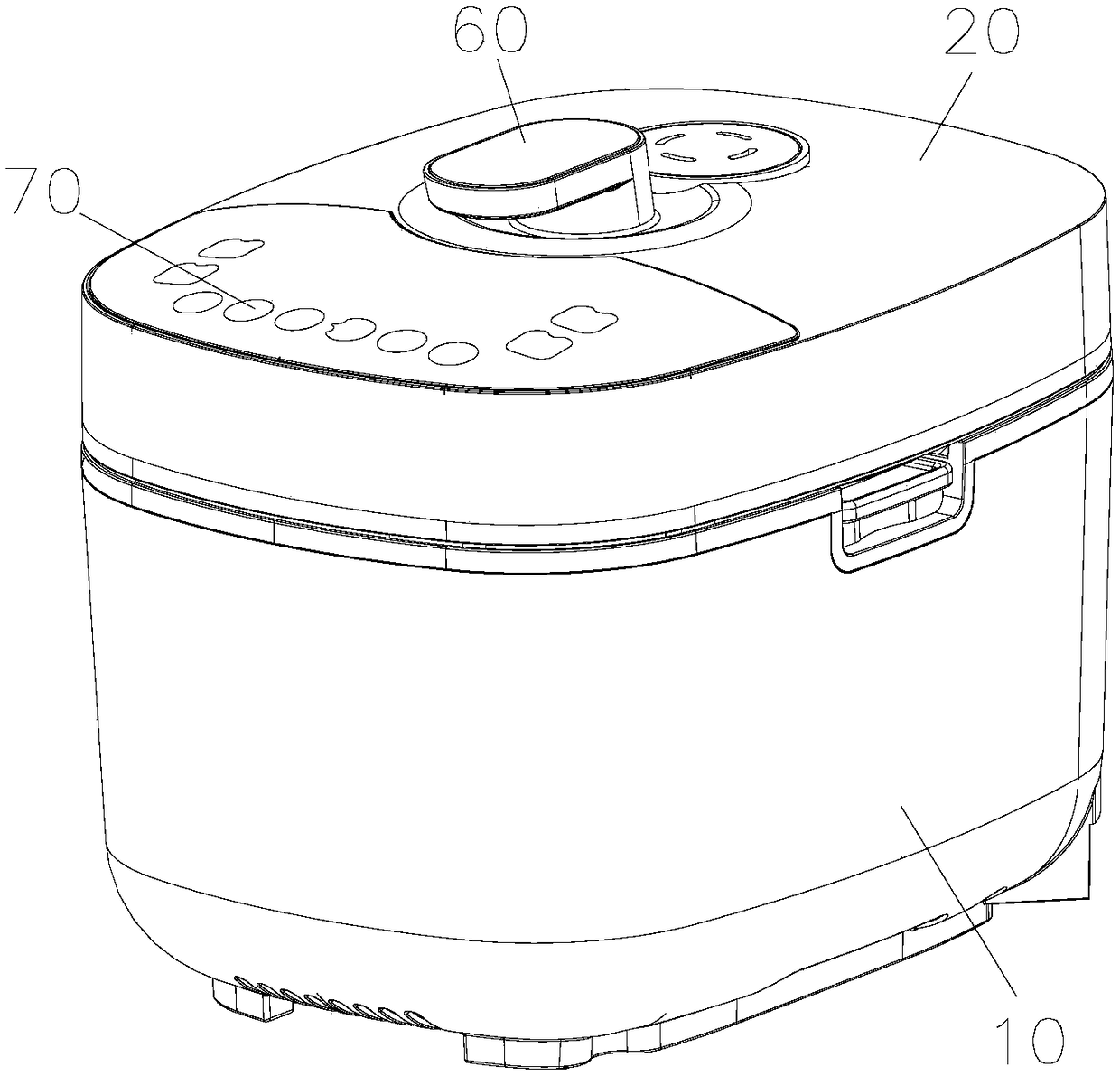

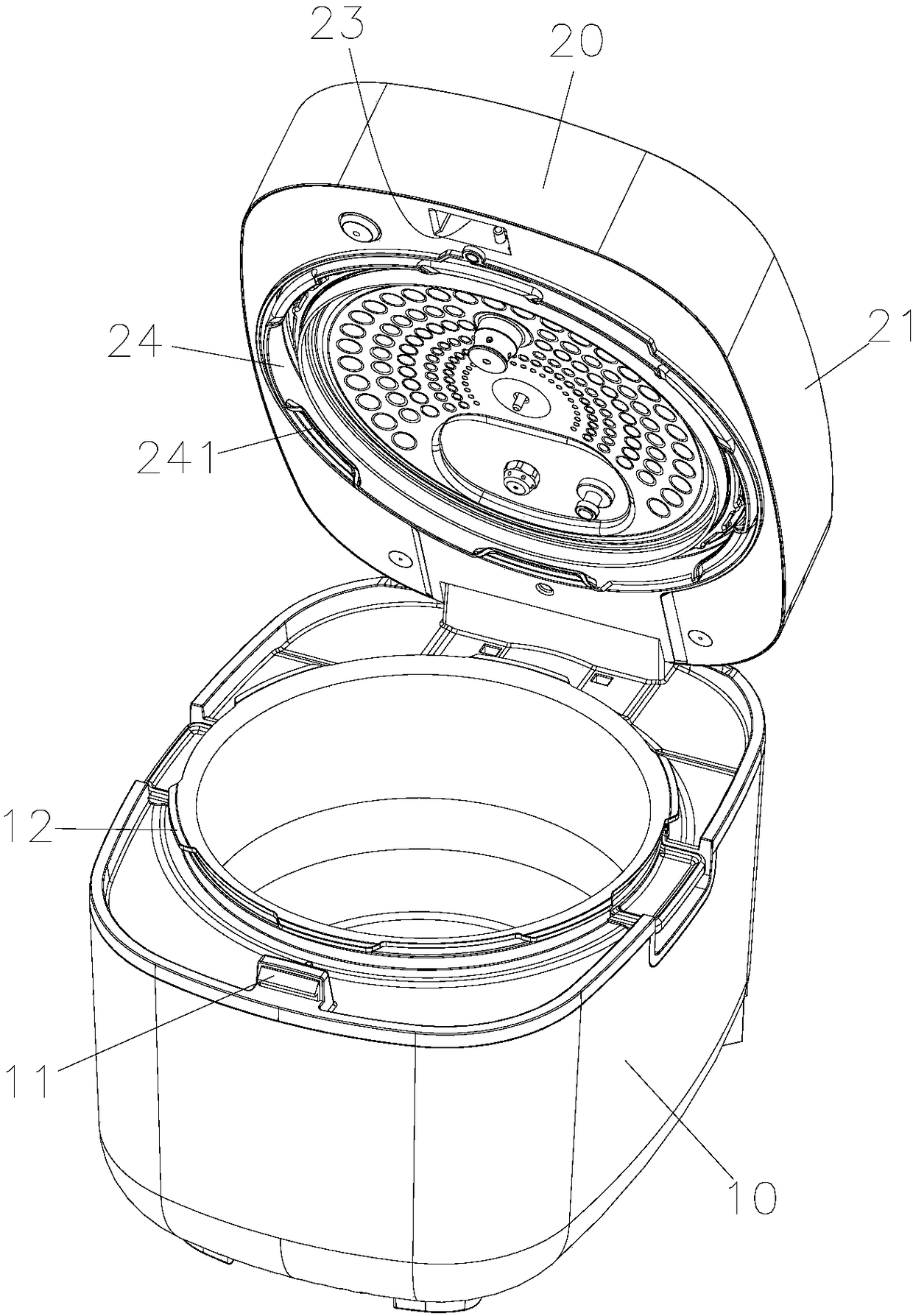

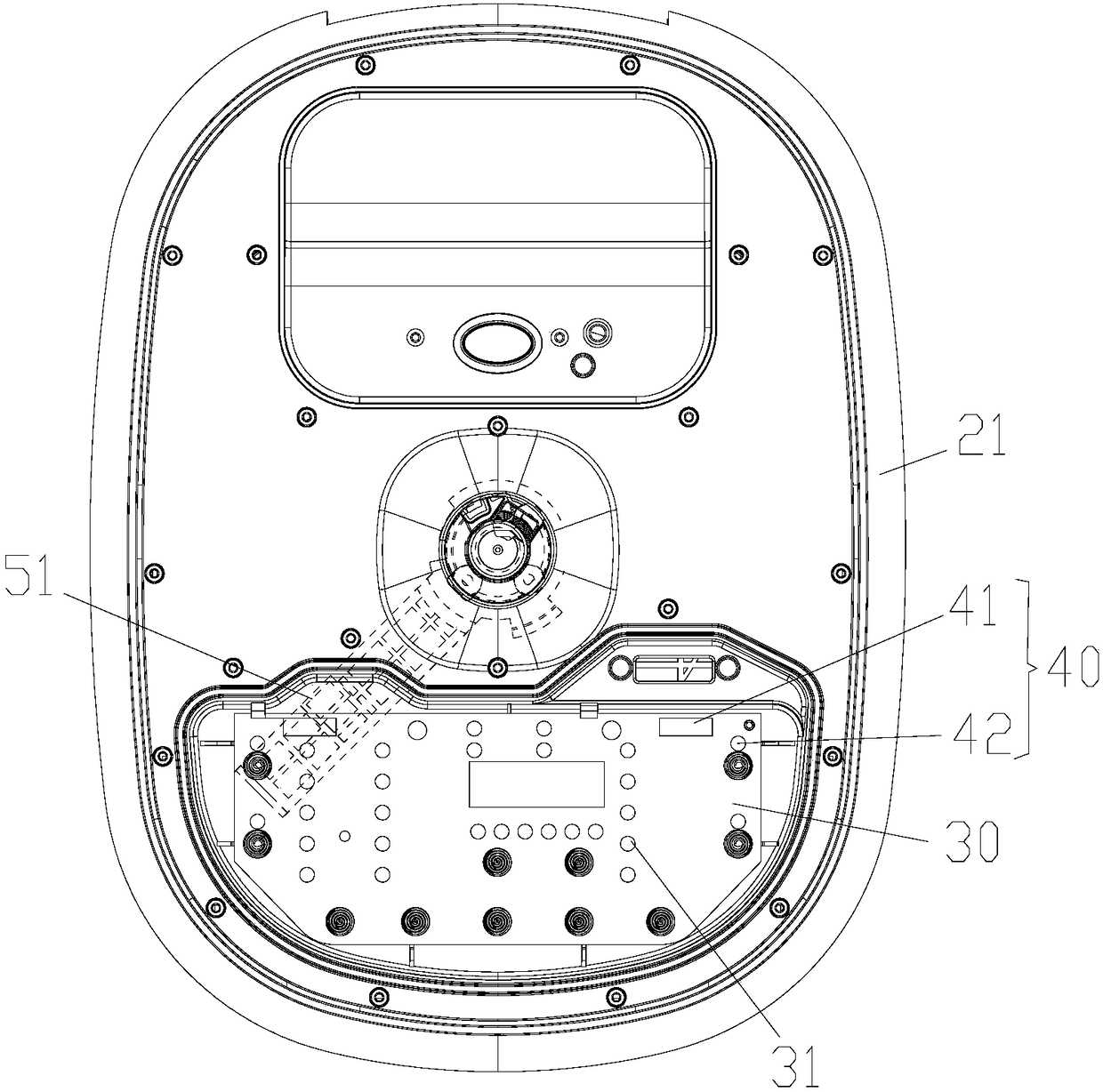

Cooking utensil

The invention provides a cooking utensil. The cooking utensil comprises a pot body and a pot cover, wherein the pot body is used for accommodating food to be cooked; the pot cover is arranged on the pot body, a circuit board containing cavity is arranged in the pot cover, a circuit board is arranged in the circuit board containing cavity, a magnetic induction element is welded or inserted on the circuit board, a mounting hole communicating with the pot body is arranged in the pot cover, the cooking utensil further comprises a pressure measuring column movably arranged in the mounting hole in apenetrating manner, a first magnetic part is arranged on the pressure measuring column, and the magnetic induction element comprises a first magnetic induction element matched with the pressure measuring column. When the cooking utensil works, steam in the pot body is jacked up by the pressure measuring column, so that the first magnetic part moves from the position, outside the induction range,of the first magnetic induction element to the position, within the induction range, of the magnetic induction element. With the technical scheme, the problem that in the prior art, a detecting element of an electric pressure cooker is high in processing cost and difficult in processing is solved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

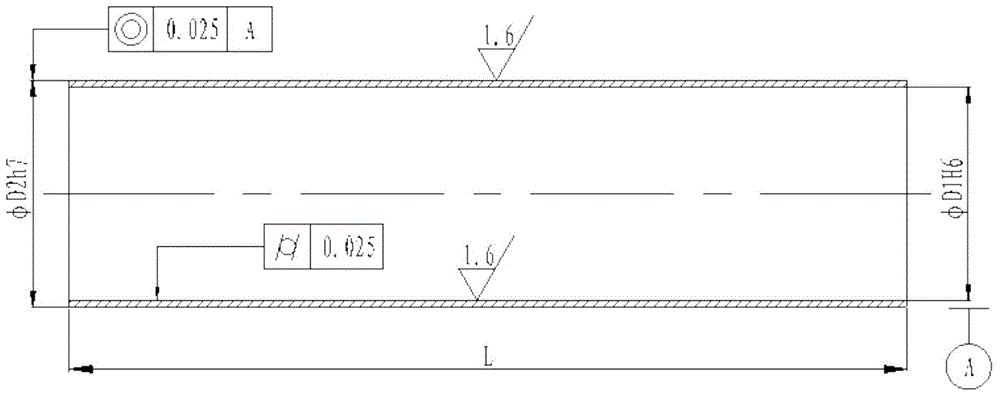

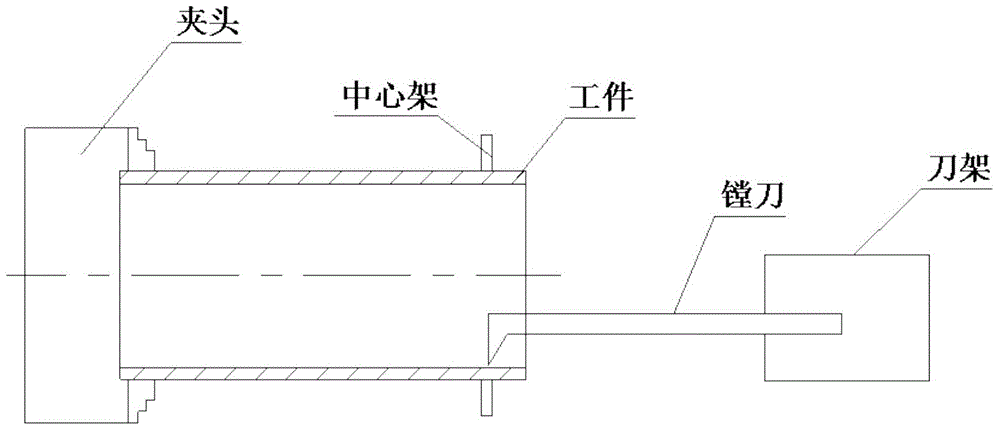

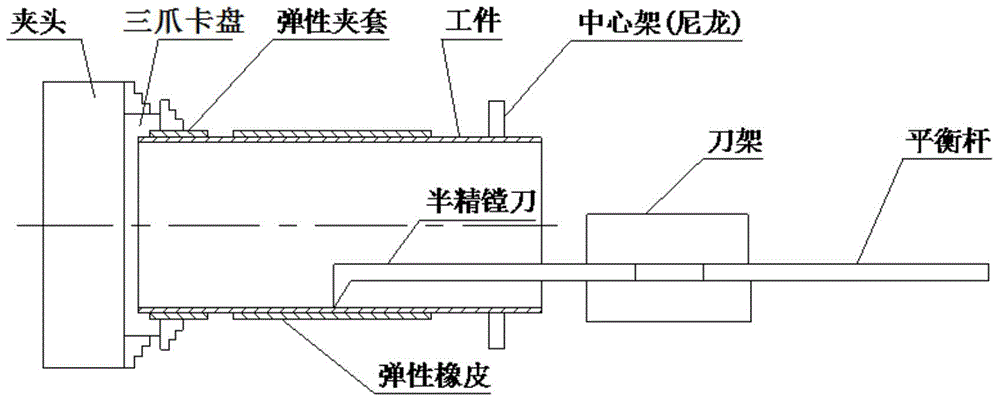

Processing method of aluminum alloy thin-wall cylindrical part

The invention discloses a processing method of an aluminum alloy thin-wall cylindrical part. The method comprises the following steps of blanking, tool selection, rough machining, excircle semi-finish machining, aging treatment, internal-hole semi-finish machining, internal-hole finish machining, excircle finish machining and the like. According to the method, as a special clamp is adopted to guarantee clamping precision, the clamping deformation is reduced and the internal stress of part processing is eliminated; moreover, the method is simple to operate; for a workpiece, procedures of keeping a technological chuck and removing the technological chuck are omitted, so that the material and the processing time are saved; meanwhile, the aluminum alloy thin-wall cylindrical part processed by using the method is stable in quality, low in processing cost and high in efficiency; in addition, the influence that a product generates deformation due to directly suffering three-point clamping force can also be avoided, the rotation heat stress deformation and the pressure damage can be reduced, the flexible deformation of the tools can be reduced, the raw material consumption of the product can be reduced, and the qualification rate and the production efficiency of the workpiece can be improved; moreover, the processing cost can be lowered.

Owner:贵州凯星液力传动机械有限公司

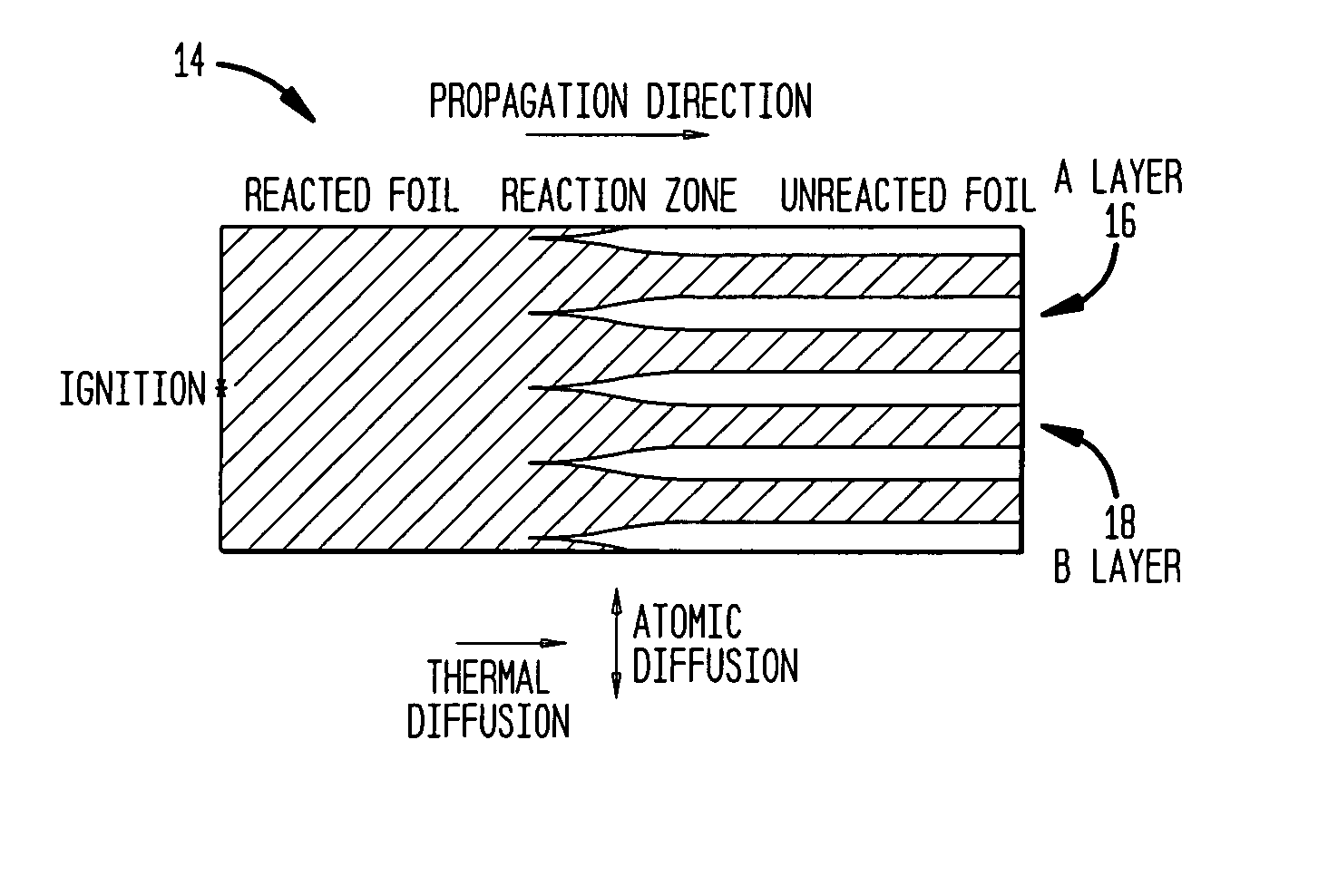

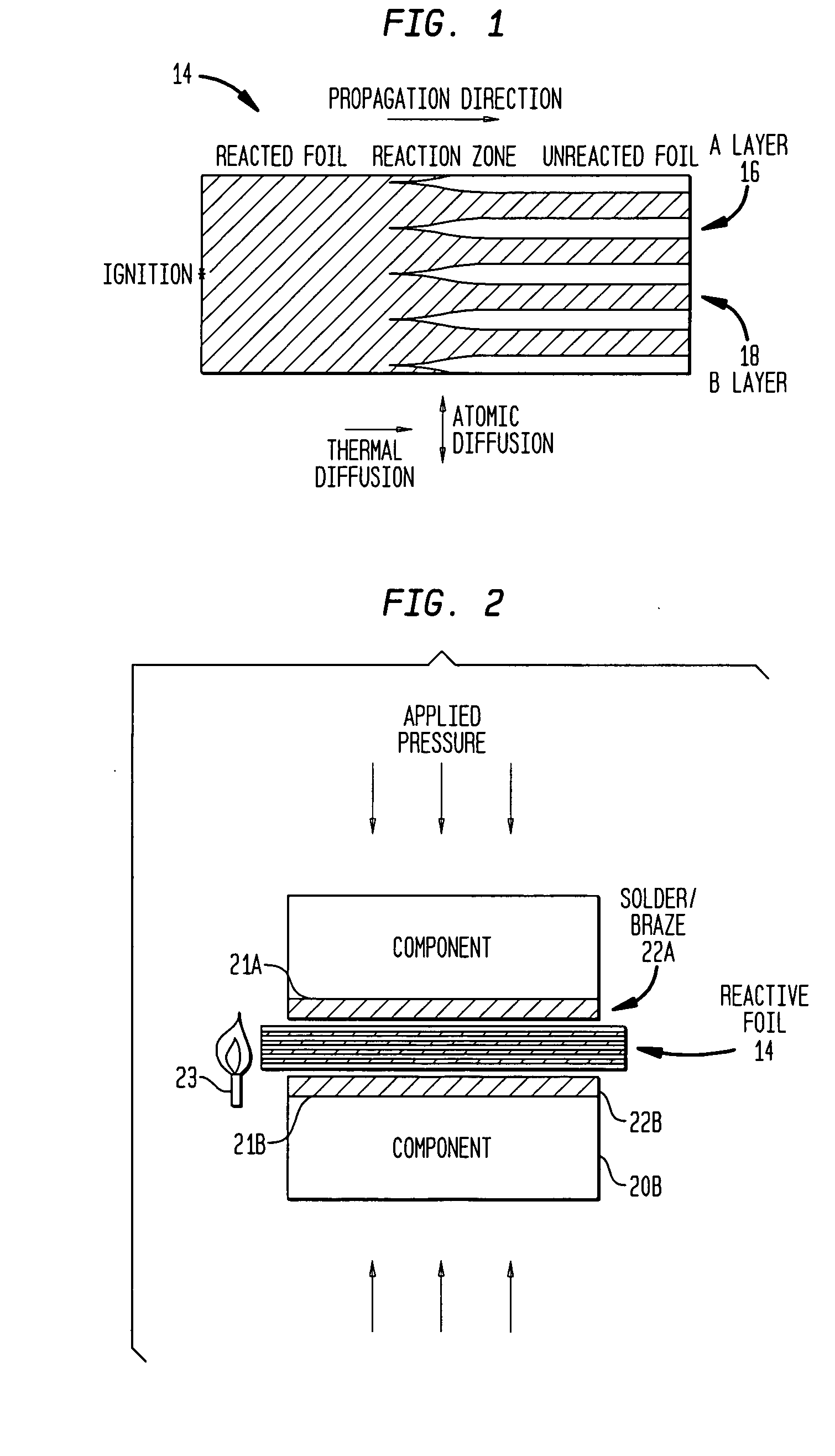

Method of joining using reactive multilayer foils with enhanced control of molten joining materials

InactiveUS20050082343A1Reducing applied pressureExtended durationExothermal chemical reaction heat productionVacuum evaporation coatingCopperMaximum pressure

In accordance with the invention, bodies of materials are joined by disposing between them a reactive multilayer foil and one or more layers of meltable joining material such as braze or solder. The bodies are pressed together against the foil and joining material, and the foil is ignited to melt the joining material. The pressing is near the critical pressure and typically produces a joint having a strength of at least 70-85% the maximum strength producible at practical maximum pressures. Thus for example, reactively formed stainless steel soldered joints that were heretofore made at an applied pressure of about 100 MPa can be made with substantially the same strength at a critical applied pressure of about 10 kPa. Advantages of the process include minimization of braze or solder extrusion and reduced equipment and processing costs, especially in the joining of large bodies.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

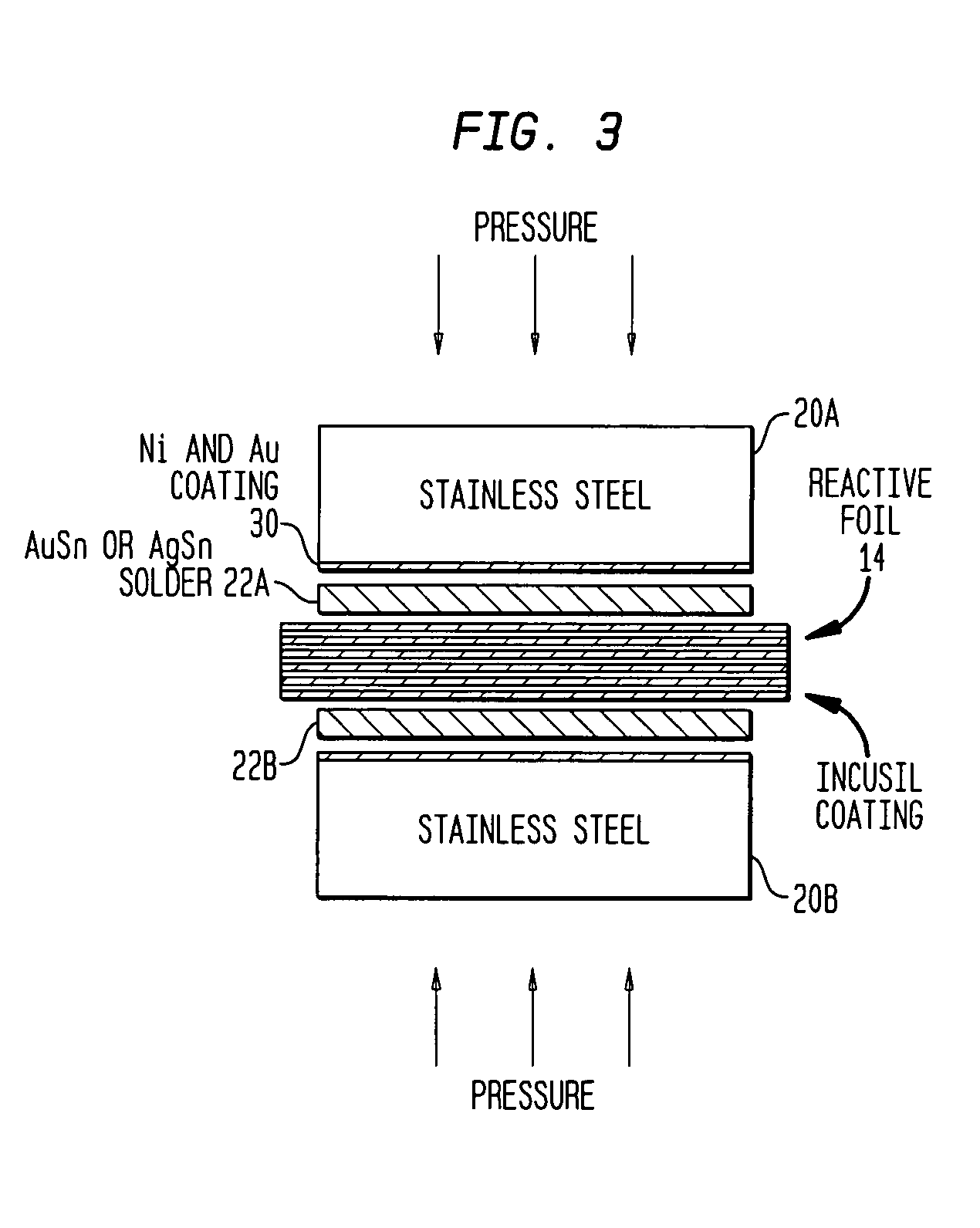

Compound antimicrobial and preparation method thereof

The invention provides a compound antimicrobial and a preparation method thereof. The compound antimicrobial comprises micro-nano particles and guanidine polymers by the weight ratio of 1:1 to 1:50, wherein the micro-nano particles at least have the one-dimensional average dimension of 1nm to 1000 mu m; the guanidine polymers are coated on the surfaces of the micro-nano particles and / or embedded in holes or among layers of the micro-nano particles; inorganic or organic particles comprising micro-nano particles are added to a solution of the guanidine polymers; organic alkali is added or not added; the particles and the solution are uniformly mixed and dried for obtaining the compound antimicrobial. When applied to plastics, fibers and rubber, the antimicrobial has high sterilization efficiency, also largely reduces the processing cost of antibacterial materials, and has simple and convenient preparation method.

Owner:CHINA PETROLEUM & CHEM CORP +1

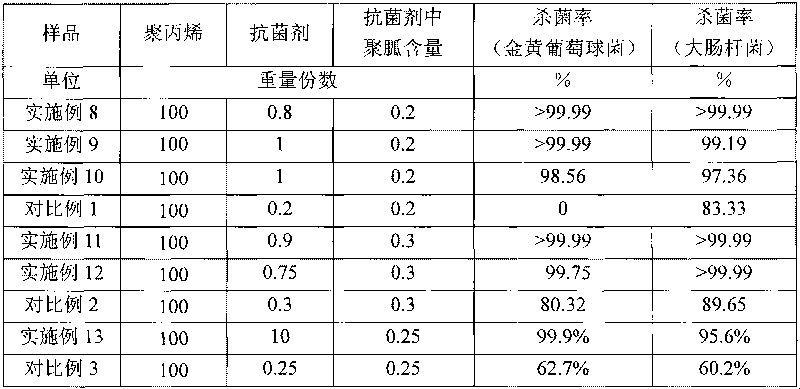

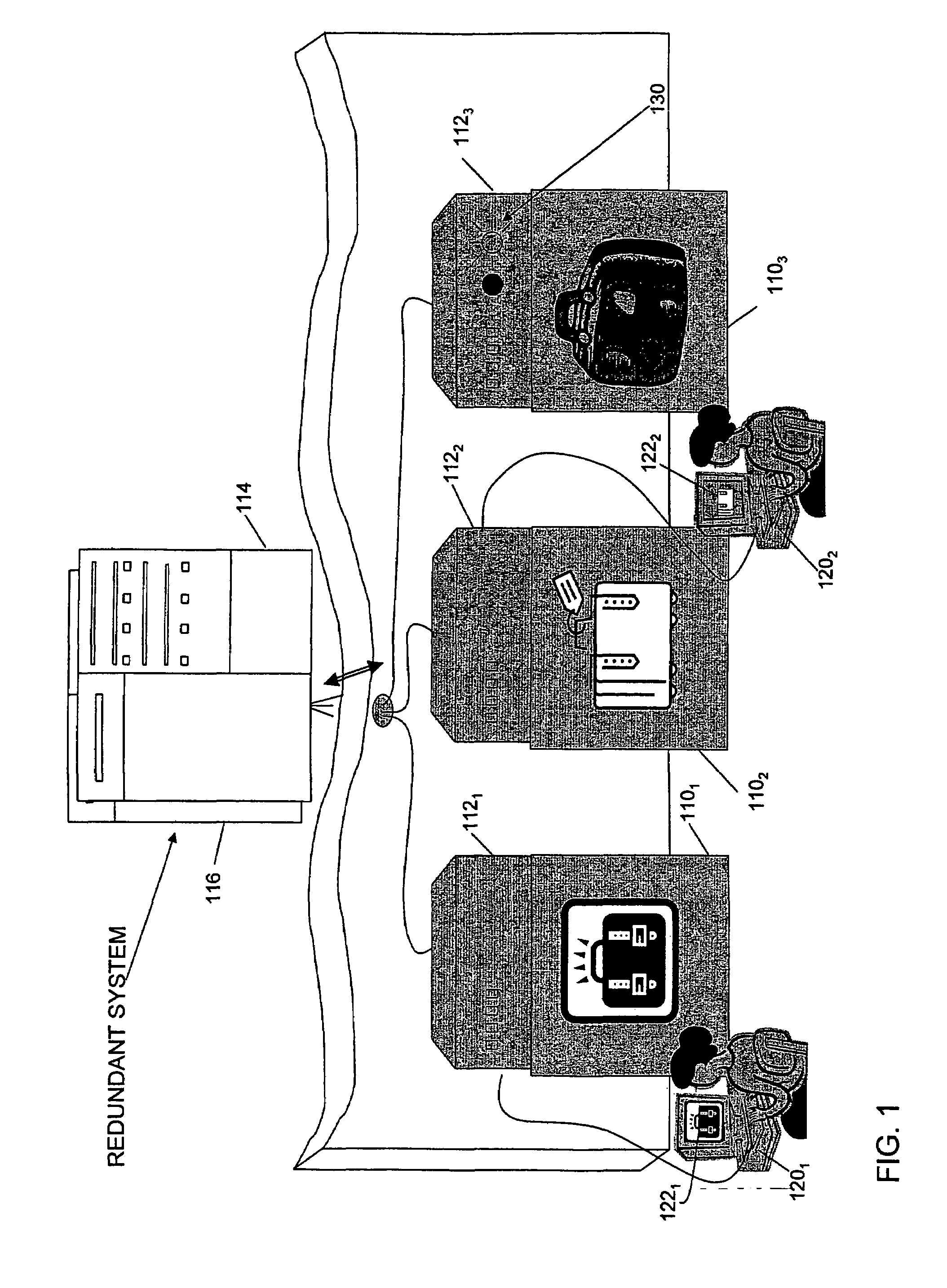

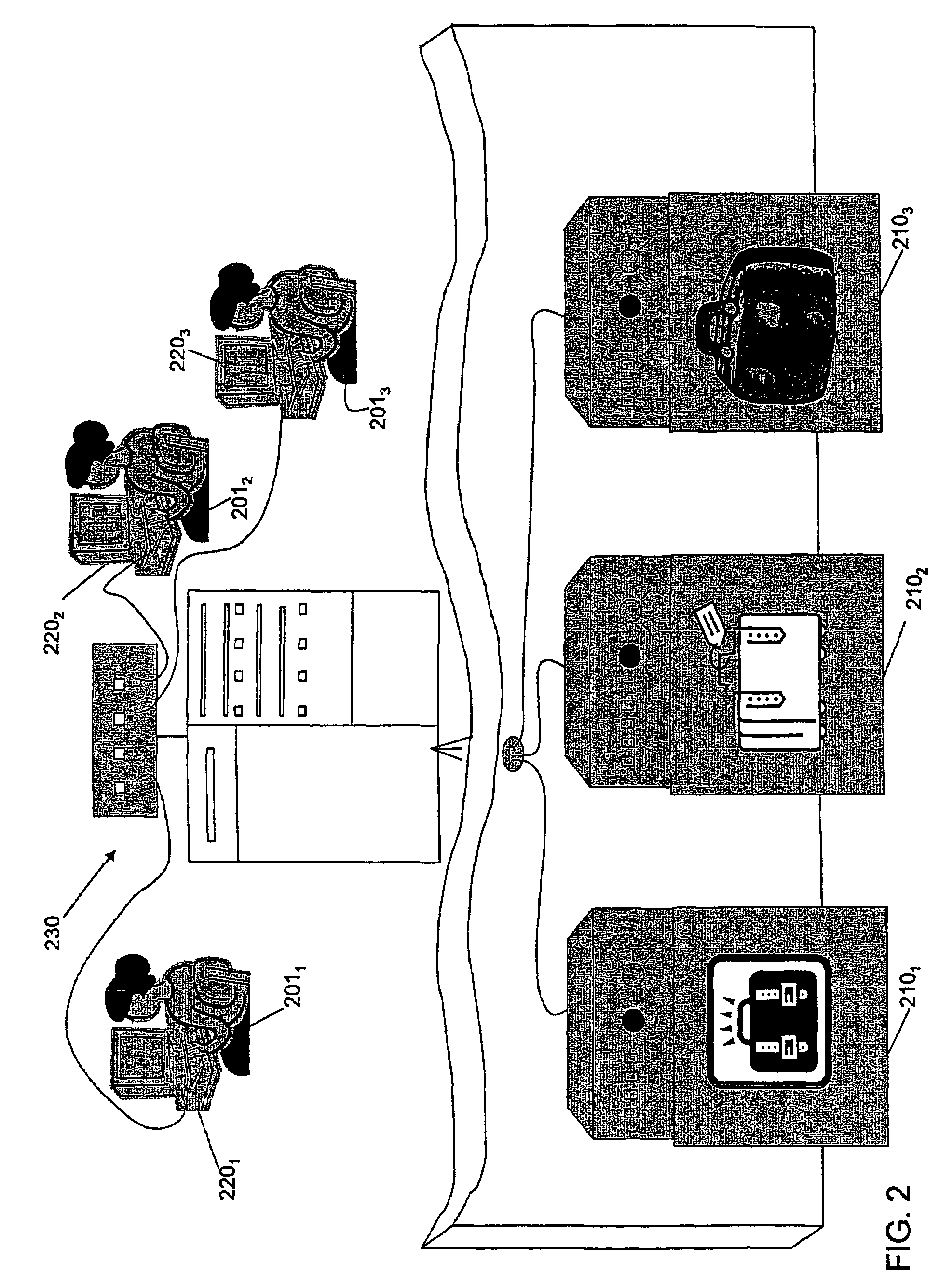

Security system with distributed computing

A security system with a processor that receives information from multiple sources. The system is illustrated by a network of inspection machines at multiple locations in an airport, such as at check-in desks. These machines provide data to the processor for threat detection processing. The processor provides a central control and data integration point. Centralized control may be used to readily adapt threat detection programs and data integration may allow more accurate or more thorough threat determinations to be made. Moreover, centralized processing of computation intensive operations, such as image reconstruction, may provide for more efficient processor utilization throughout the system, providing a lower total processing cost. Additionally, centralized processing allows for human decision makers to be readily integrated into the system.

Owner:LEIDOS SECURITY DETECTION & AUTOMATION INC

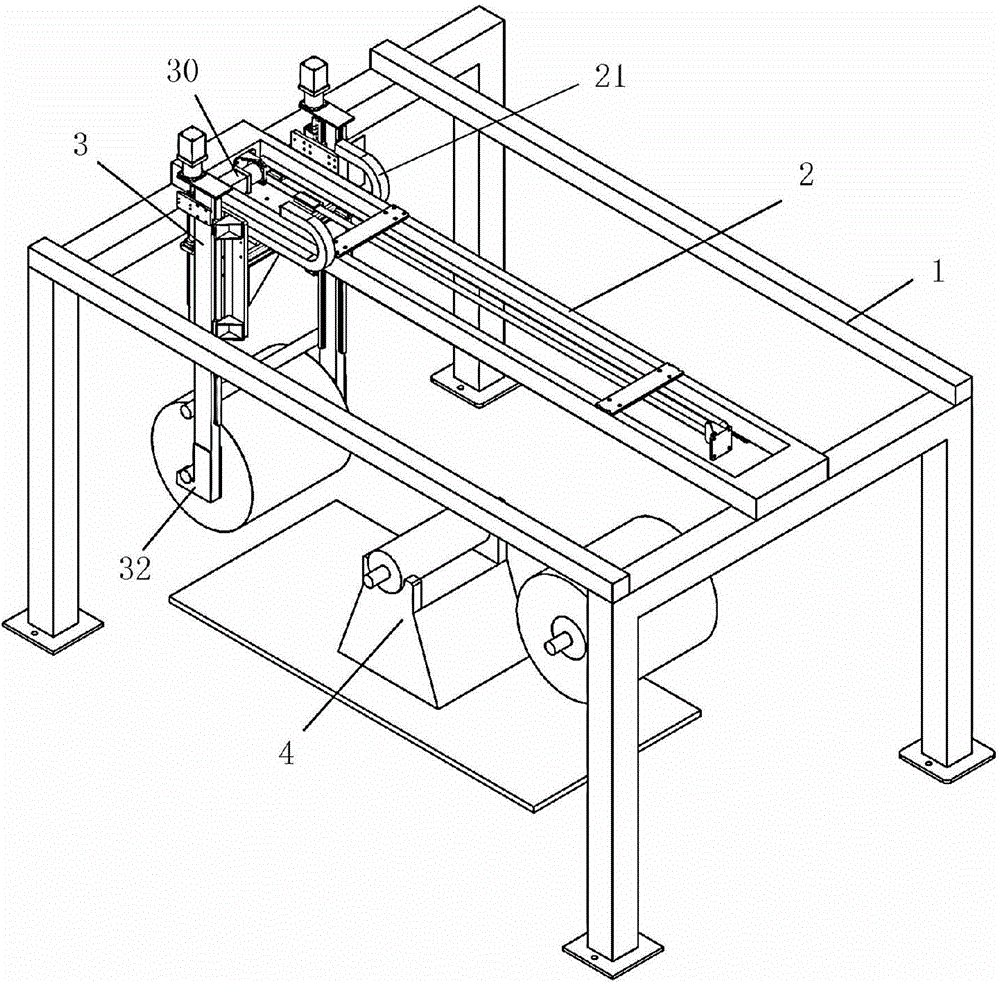

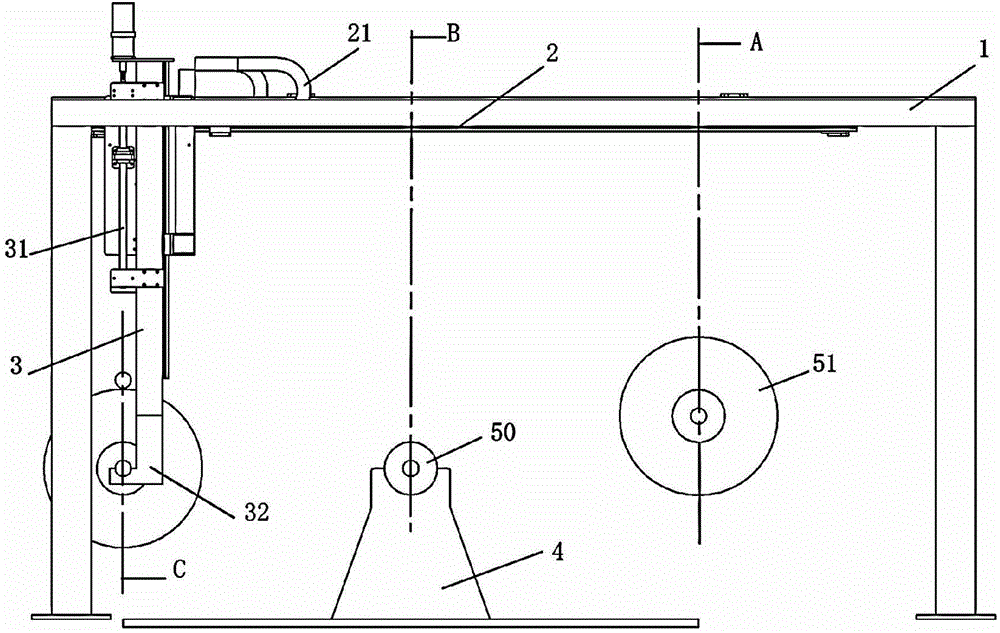

Transferring device and transferring method

ActiveCN104692113AImprove work efficiencyReduce processing costsConveyor partsRobot handControl engineering

The invention discloses a transferring device and a transferring method. The transferring device comprises a fixing rack, wherein the fixing rack is provided with a mechanical arm used for grabbing and placing material rollers, a horizontal driving device used for driving the guiding move of the mechanical arm in the horizontal direction and a vertical driving mechanism used for driving the mechanical arm to extend and retract in the vertical direction; the mechanical arm has a first station and a second station in the guiding move process in the horizontal direction; a third station used for temporarily storing idle material rollers is arranged between the first station and the second station on the fixing rack; a bracket used for supporting the idle material rollers is arranged at a part corresponding to the third station on the fixing rack. According to the transferring device, the third station is arranged between the first station and the second station; two material rollers can be operate at the same time; the working efficiency is improved; the processing cost is reduced.

Owner:CAMALUOYANGELECTROMECHANIC

Five-axis plunge milling method of aeroengine crankcase

InactiveCN101767218AImprove processing efficiencyReduce processing costsMilling equipment detailsNumerical controlNumerical controlMilling cutter

The invention discloses a five-axis plunge milling method of an aeroengine crankcase, which is characterized by comprising the technical processes of part processing technology analysis, technology route formulation, cutter selection, cutting parameter selection, numerical control programming and processing. The invention overcomes the key technique of generating the paths of five-variable-axis plunge milling cutters of complex crankcase pieces, provides an effective means for crankcase processing, improves the crankcase processing efficiency and reduces the processing cost. The method can be used in the technical filed of numerical control processing of the parts of the aeroengine crankcases.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

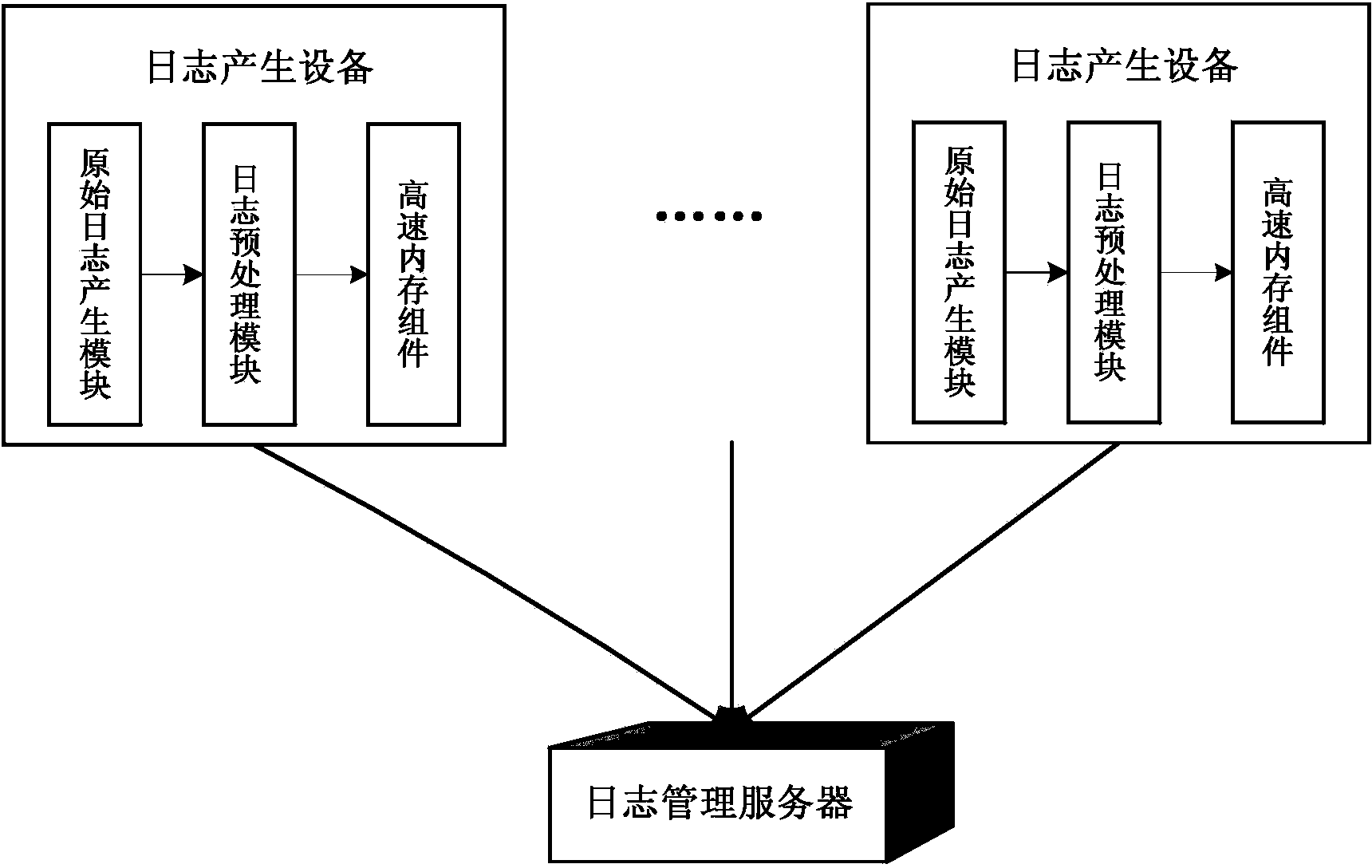

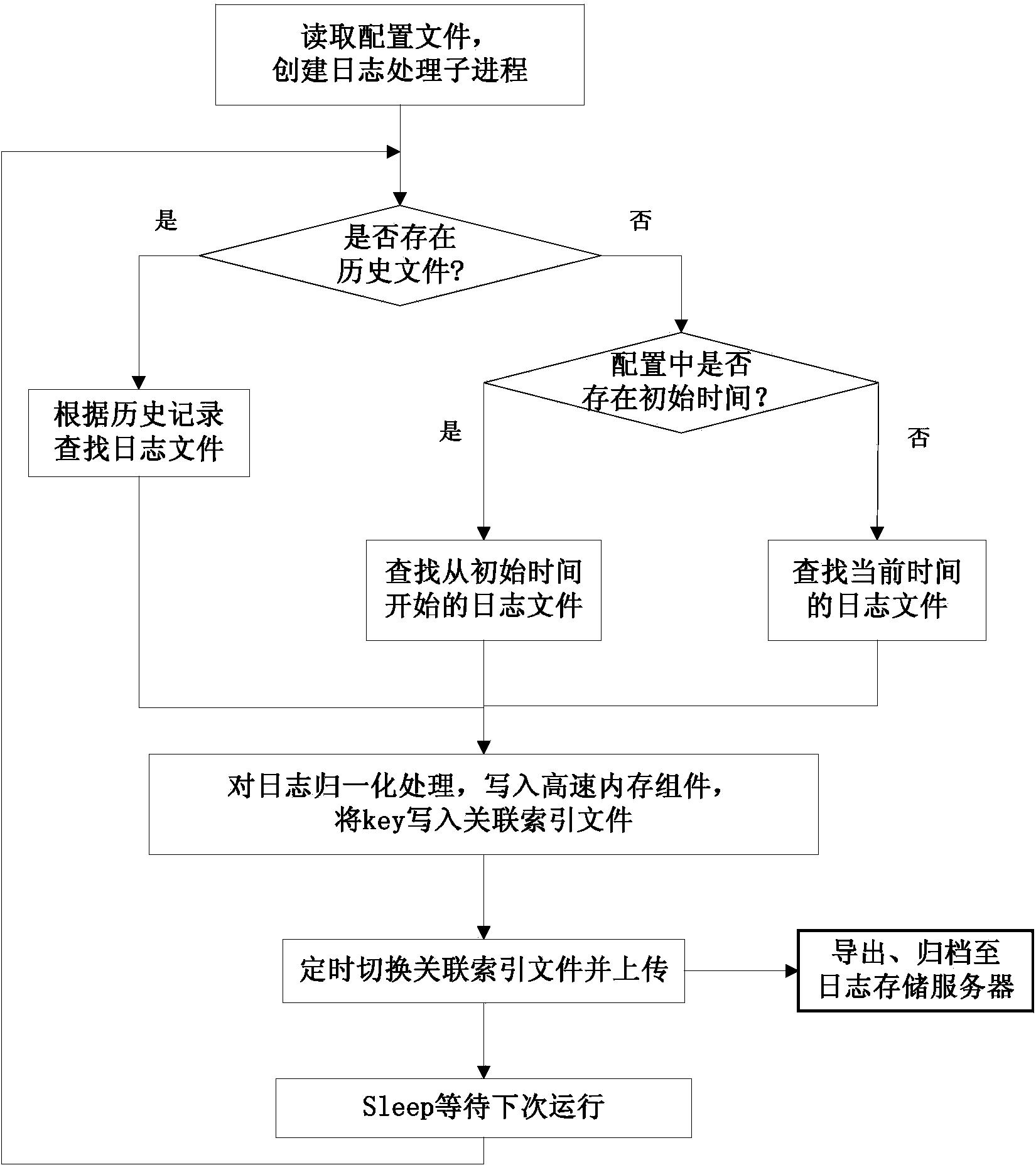

System and method for high-speed memory and distributed type processing of massive logs

ActiveCN103532754AEasy to handleReal-time processingData switching networksHigh speed memoryLog management

The invention discloses a system and a method for high-speed memory and distributed type processing of massive logs. The system comprises a plurality of log generating devices and a log management server, wherein the log generating devices are dispersed in all network elements and are used for carrying out format normalization on various original logs, caching the original logs into high-speed memory components and uploading the original logs to the log management server periodically; each log generation device is respectively provided with three parts, i.e., an original log generation module, a log pre-processing module and a high-speed memory component. The log management server is responsible for unified derivation and filing storage of the logs beyond the caching period in the high-speed memory components distributed in all the log generating devices so as to be used for inquiring and analyzing the logs by other systems. The system and the method disclosed by the invention have the beneficial effects that a plurality of types of logs can be processed in real time with high-efficiency and low cost, and both the expandability and the actionability are better. Compared with the mode of adopting a relational database to store the logs, the system and the method disclosed by the invention have the advantages that the processing cost is reduced, the bottleneck problem of the database with large data volume is also solved, and the efficiency of querying and analyzing the logs is improved.

Owner:BEIJING CAPITEK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com