Transferring device and transferring method

A transshipment device and horizontal technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of high labor intensity, increased processing time, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

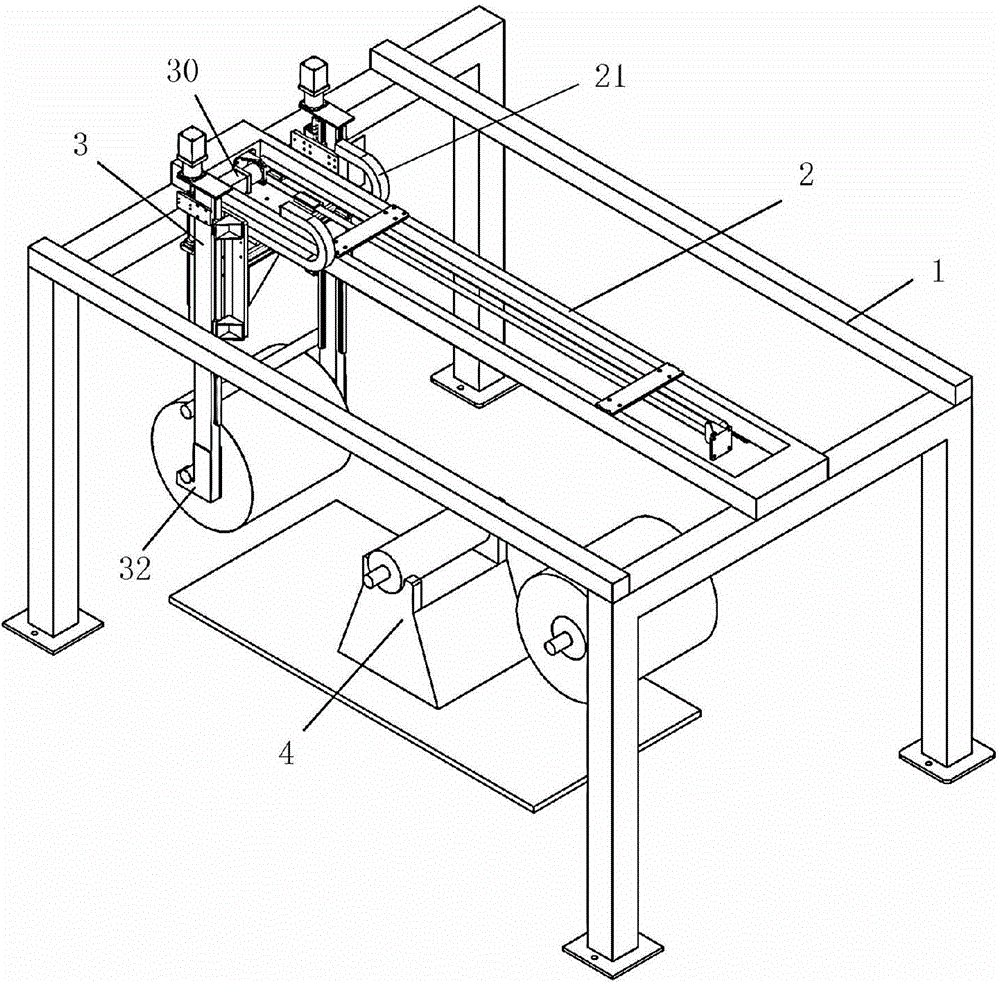

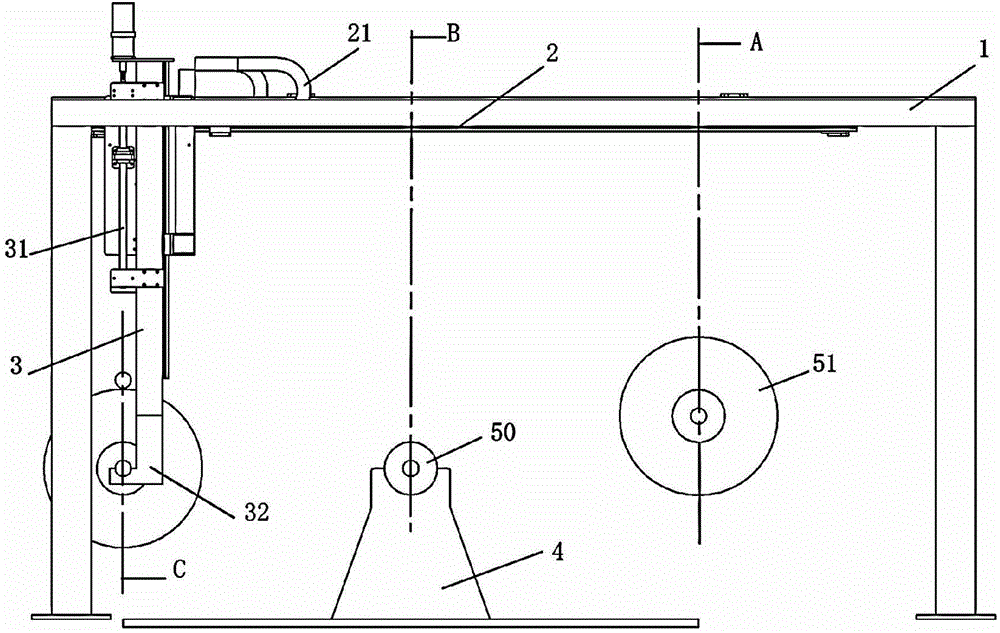

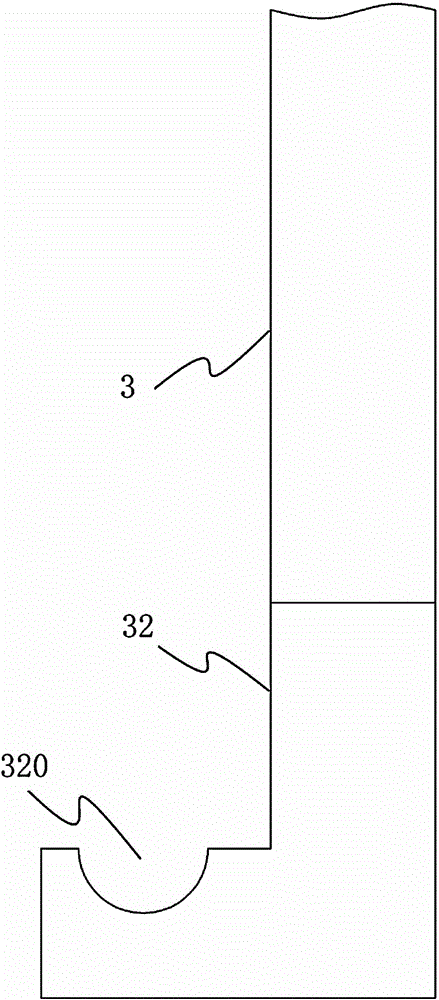

[0022] An embodiment of a transfer device of the present invention: as Figure 1-3 As shown, a fixed frame 1 is included, the fixed frame 1 is a rectangular frame with four legs, a sliding guide rail 2 is extended on the fixed frame 1 in the left and right direction, and the sliding guide rail 2 includes two tracks arranged side by side at relative intervals, so The sliding guide rail 2 is provided with a sliding guide seat 21 respectively connected to the two rail transmissions, and the two rails are respectively provided with an embedded synchronous mechanism extending along the extending direction of the track for driving the sliding guide seat 21 to guide and move in the left and right direction. Belt or inlaid rack, the sliding guide seat 21 is provided with a manipulator, and the manipulator includes a horizontal drive mechanism 30 fixed on the slide guide seat 21, a vertical drive mechanism 31 and two clamping arms 3 respectively located on the outside of the two rails ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com