Patents

Literature

3144 results about "Air humidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), the ideal humidity range for humans is between 30 to 60 percent relative humidity. The ideal is somewhere around 45-55%. Very high levels of humidity contribute to the growth of mold, funguses, dust mites, and other pests.

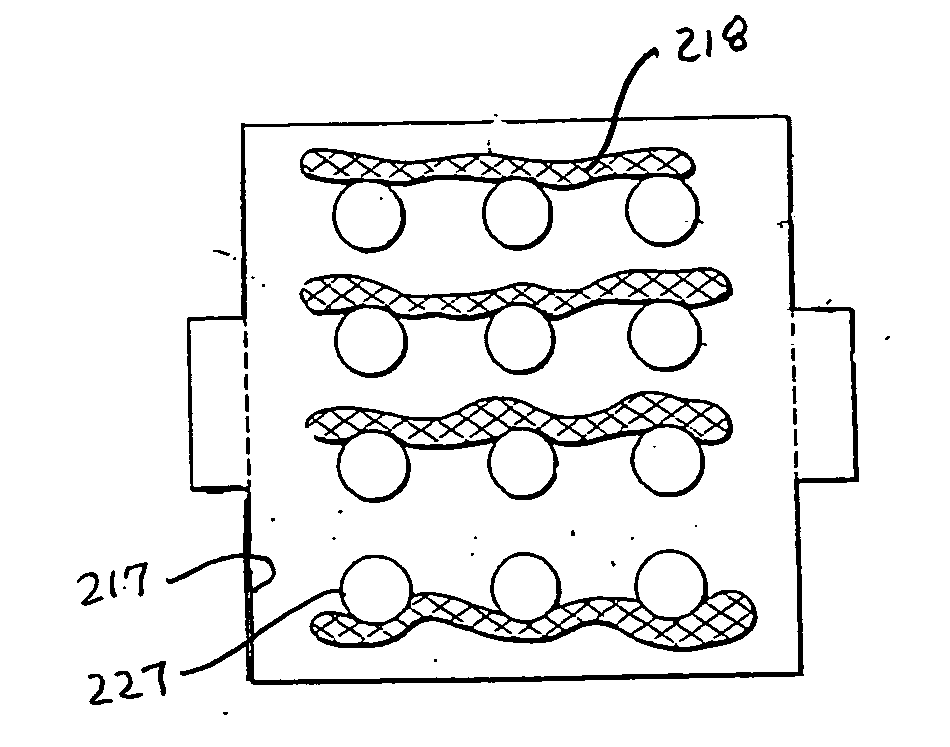

Air filter monitoring system

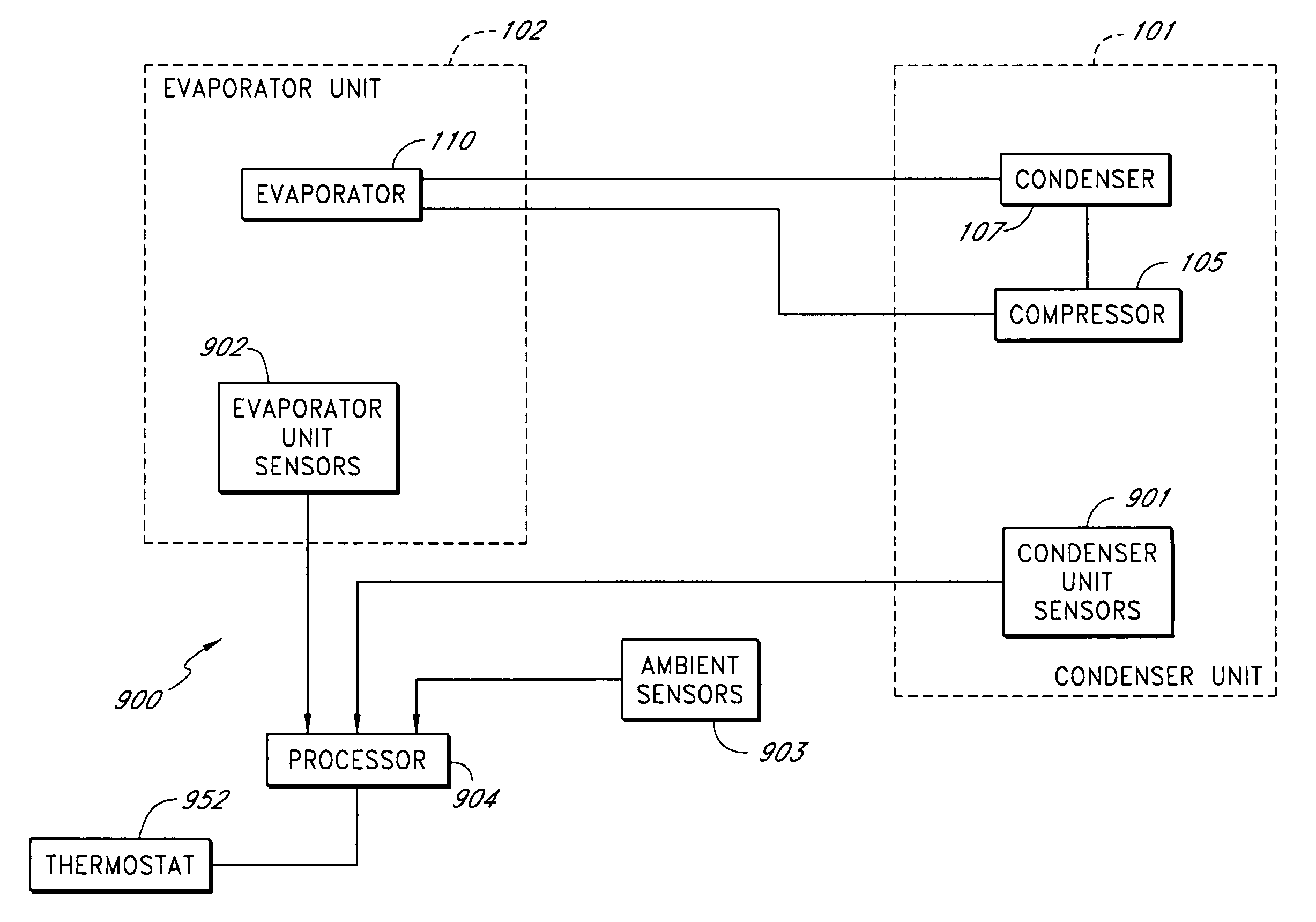

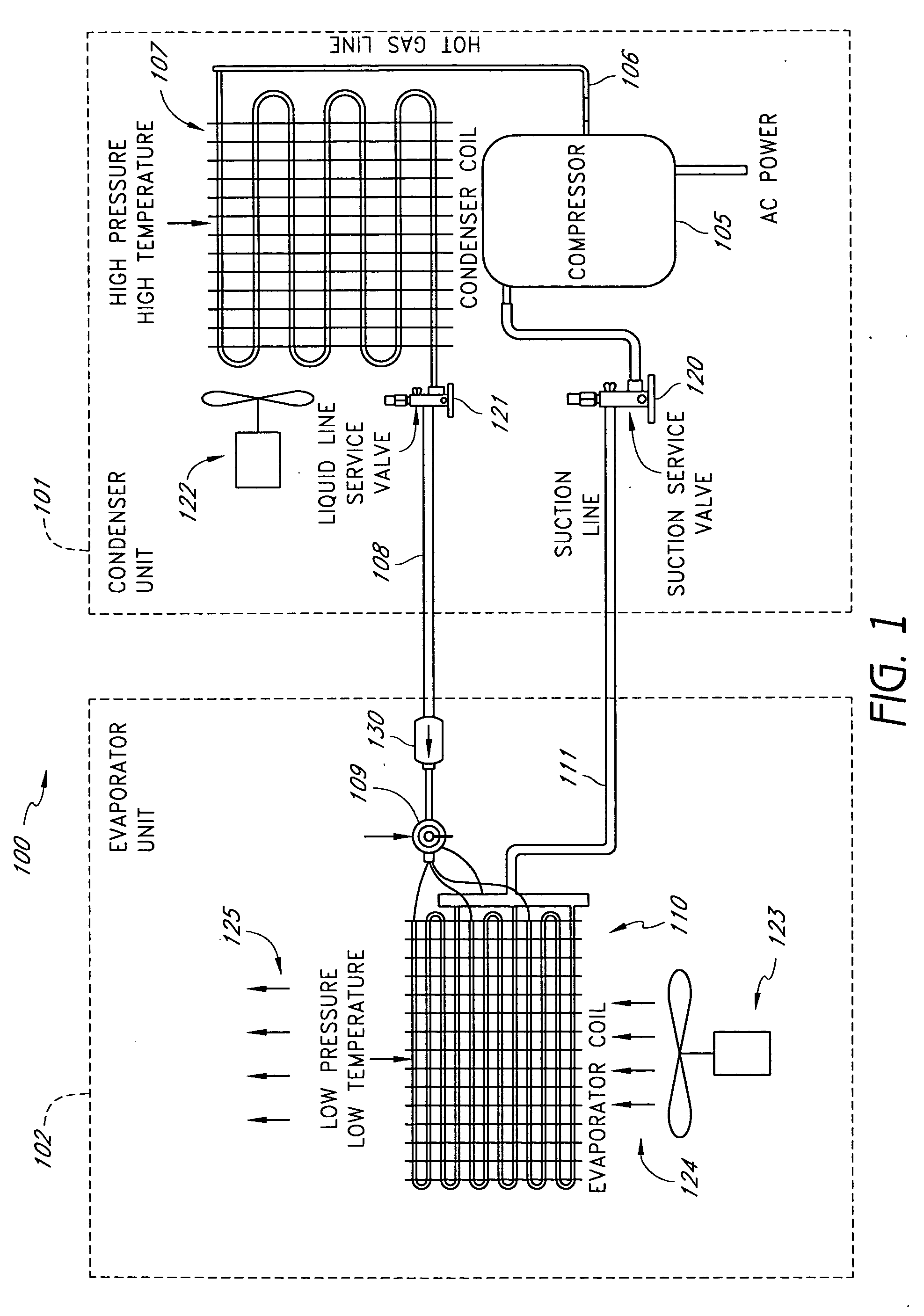

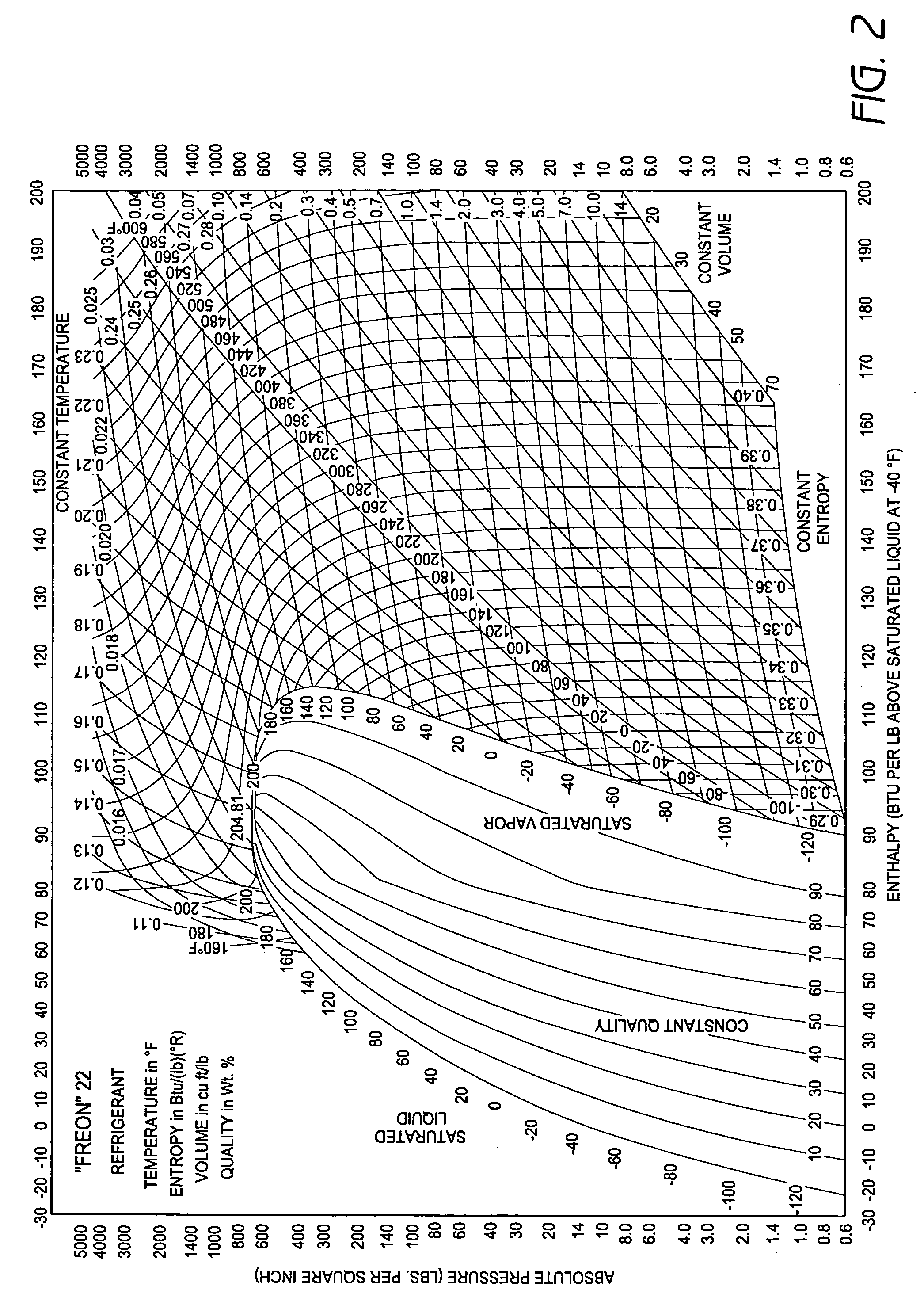

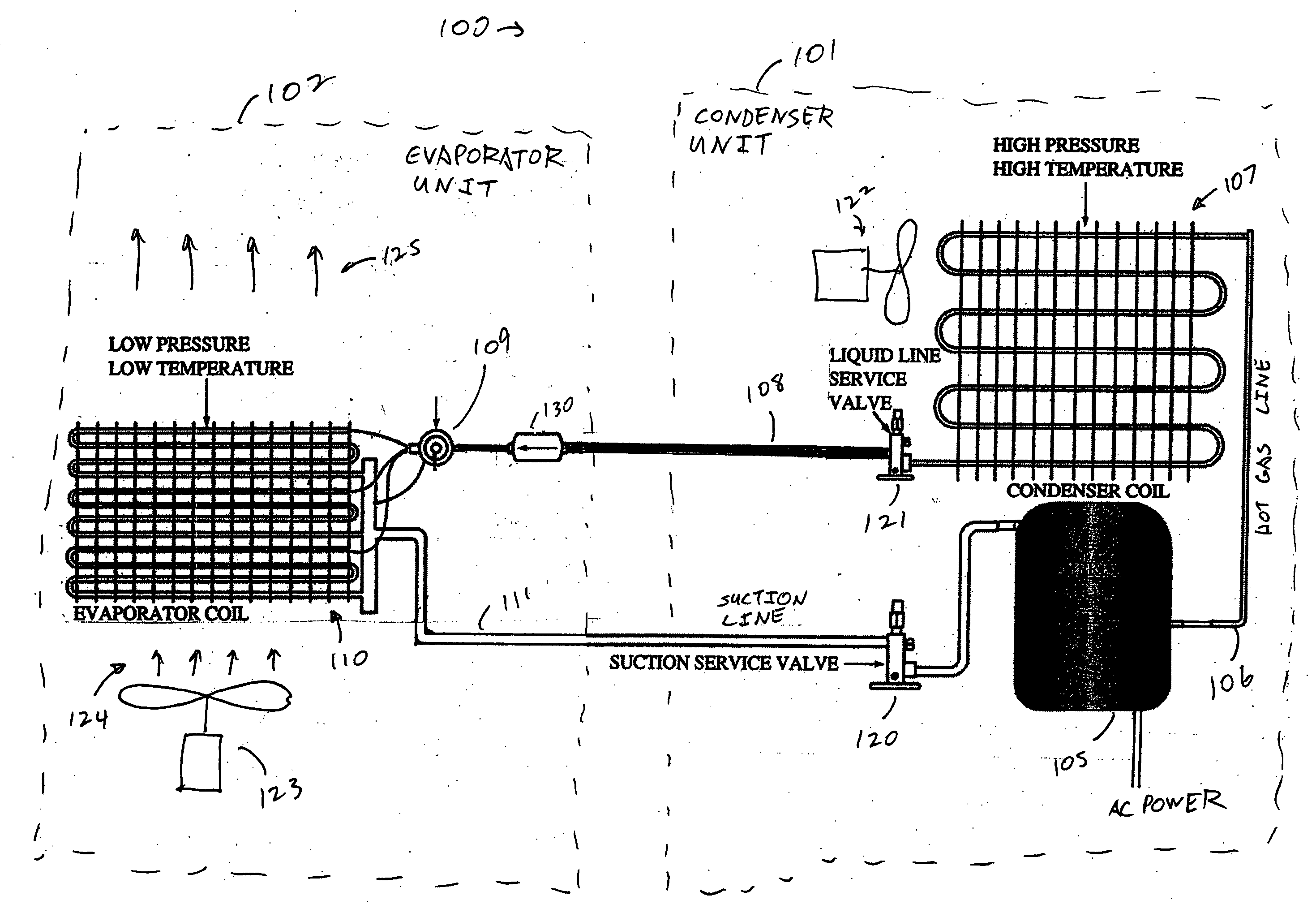

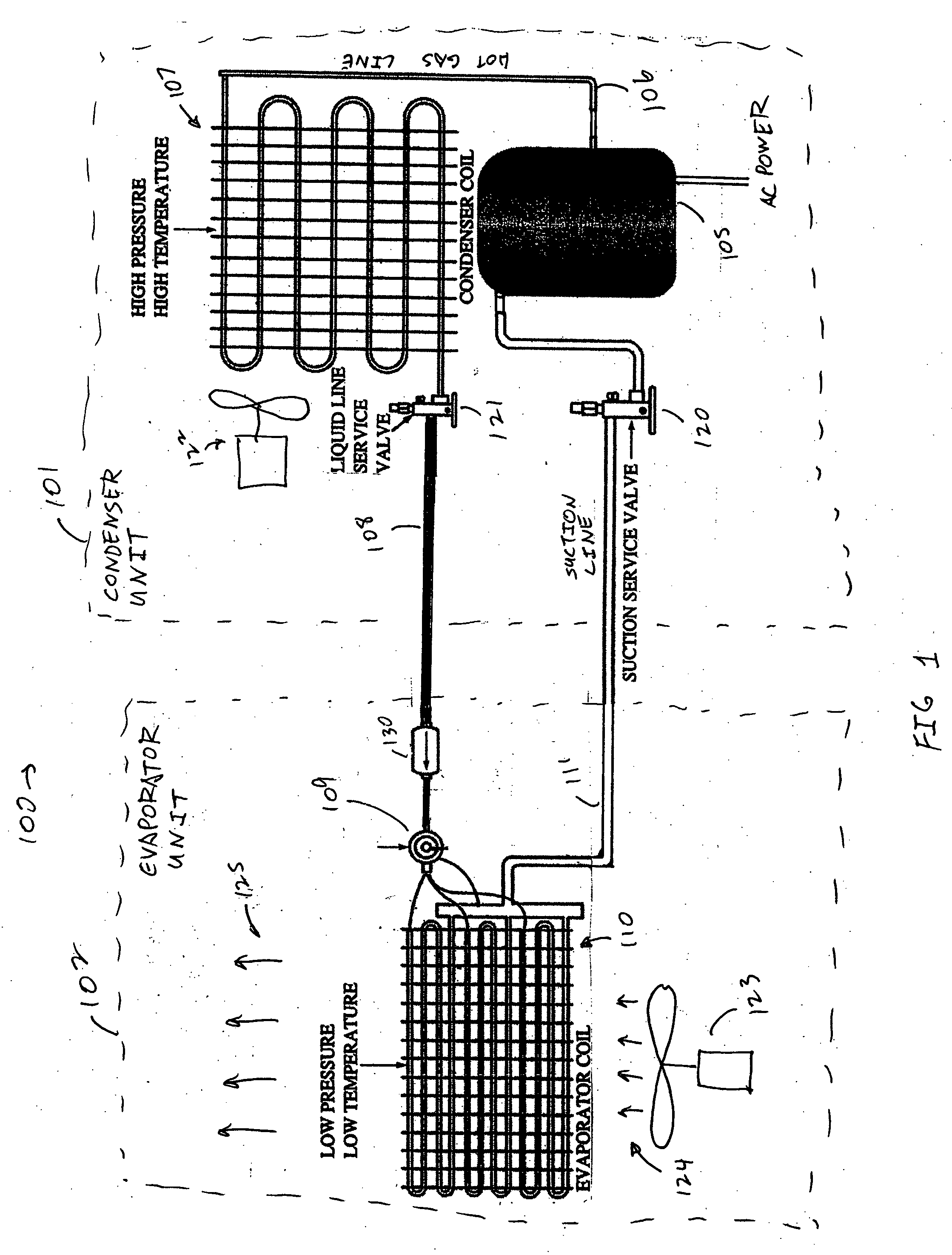

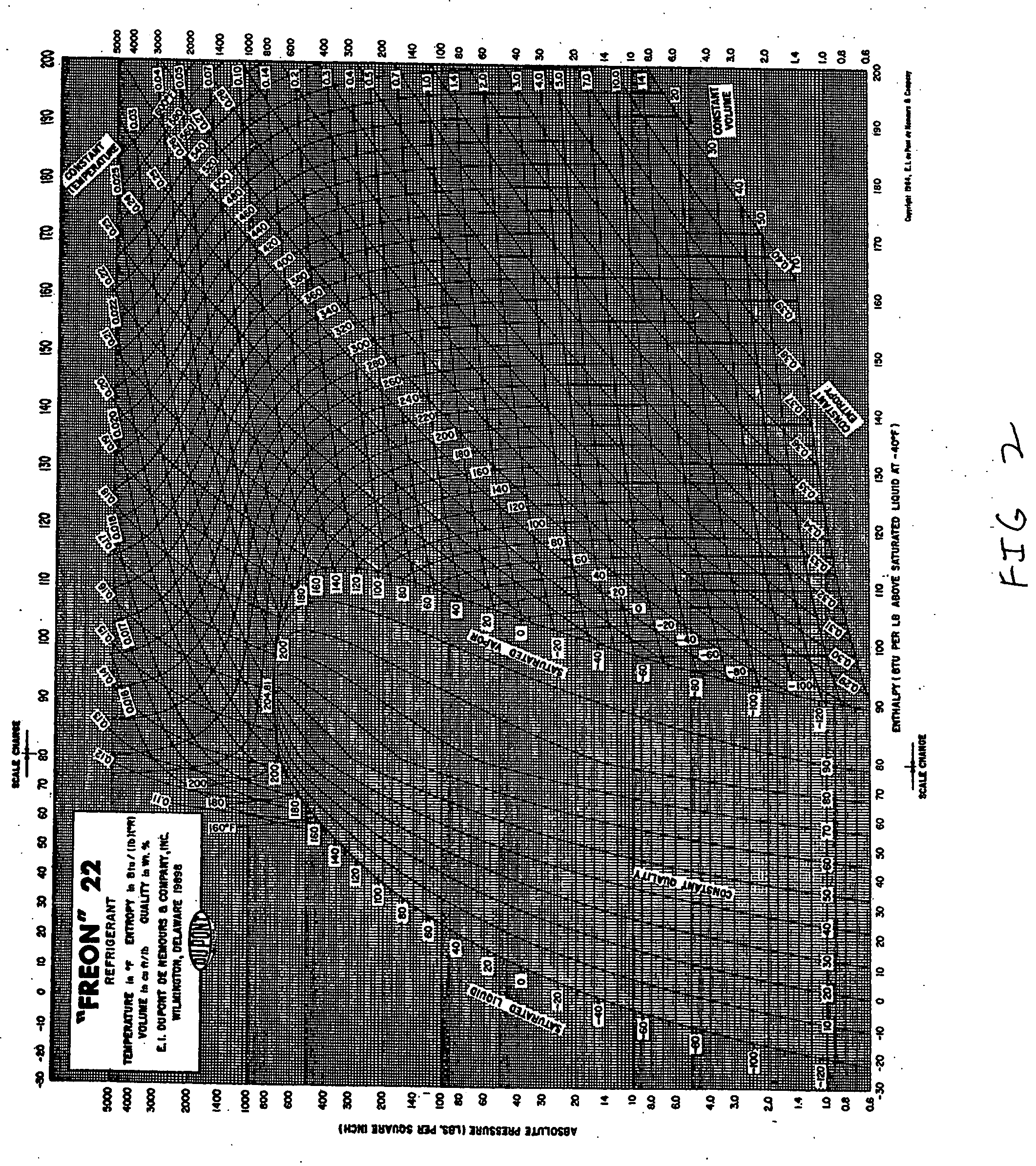

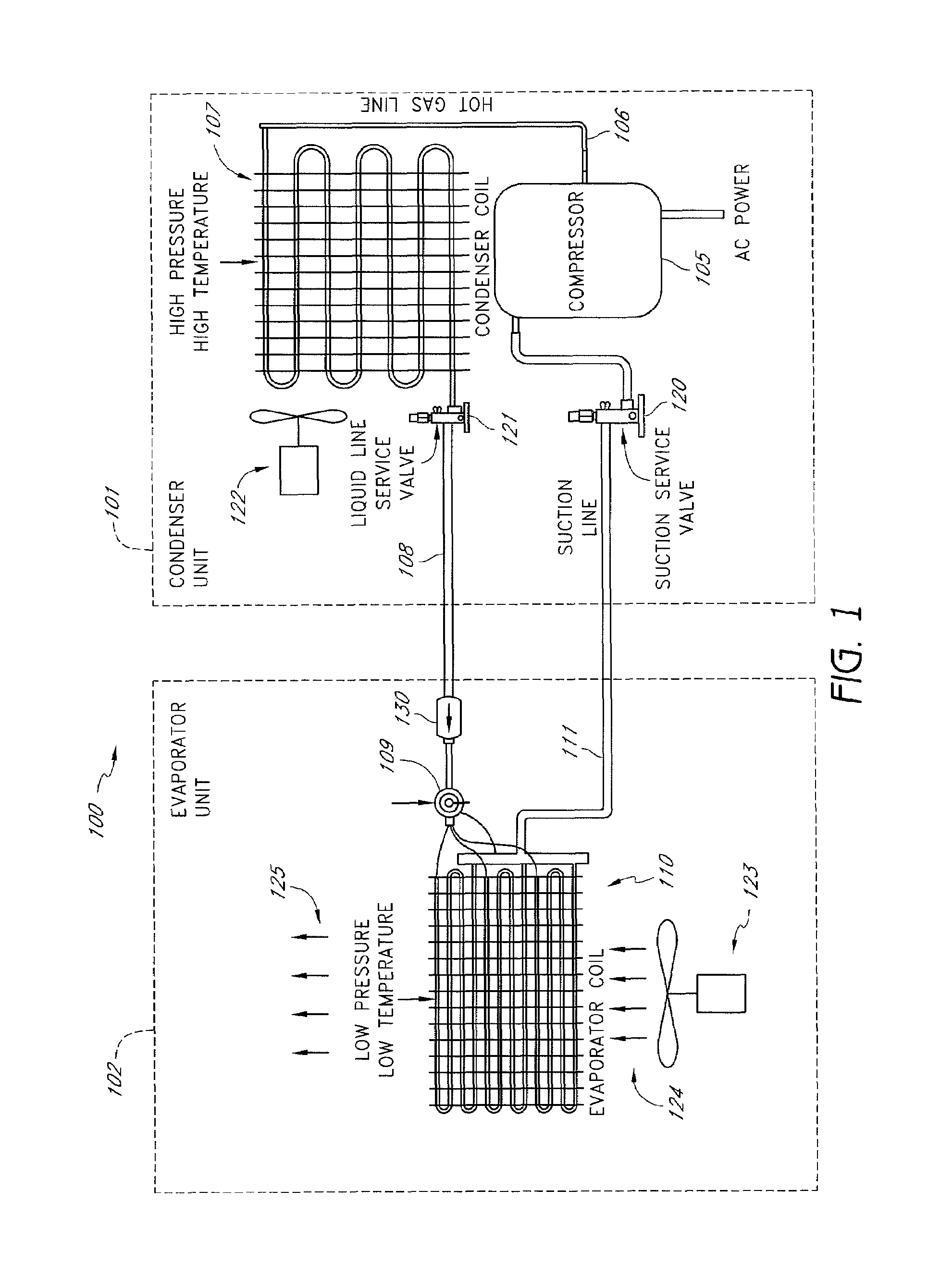

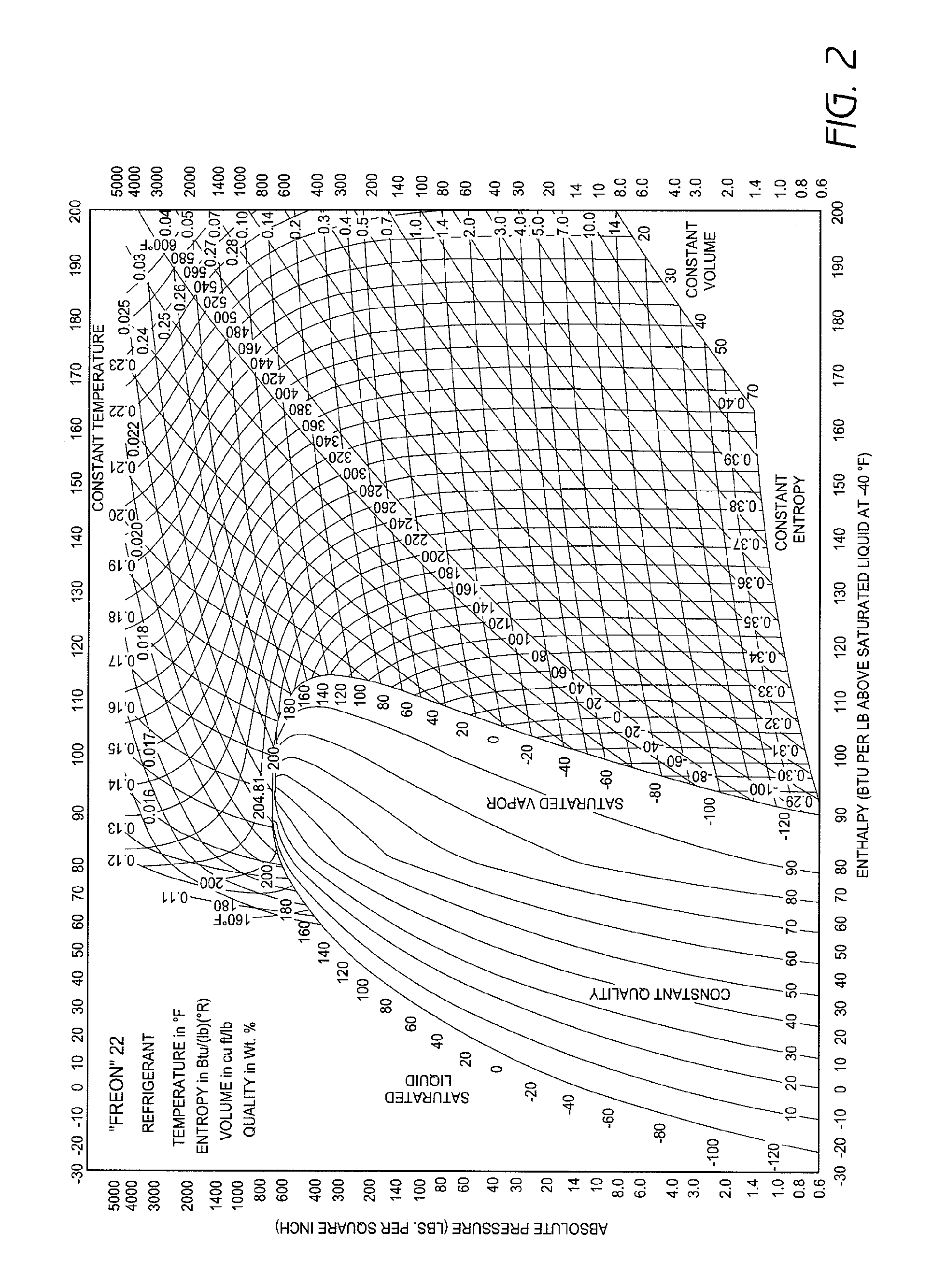

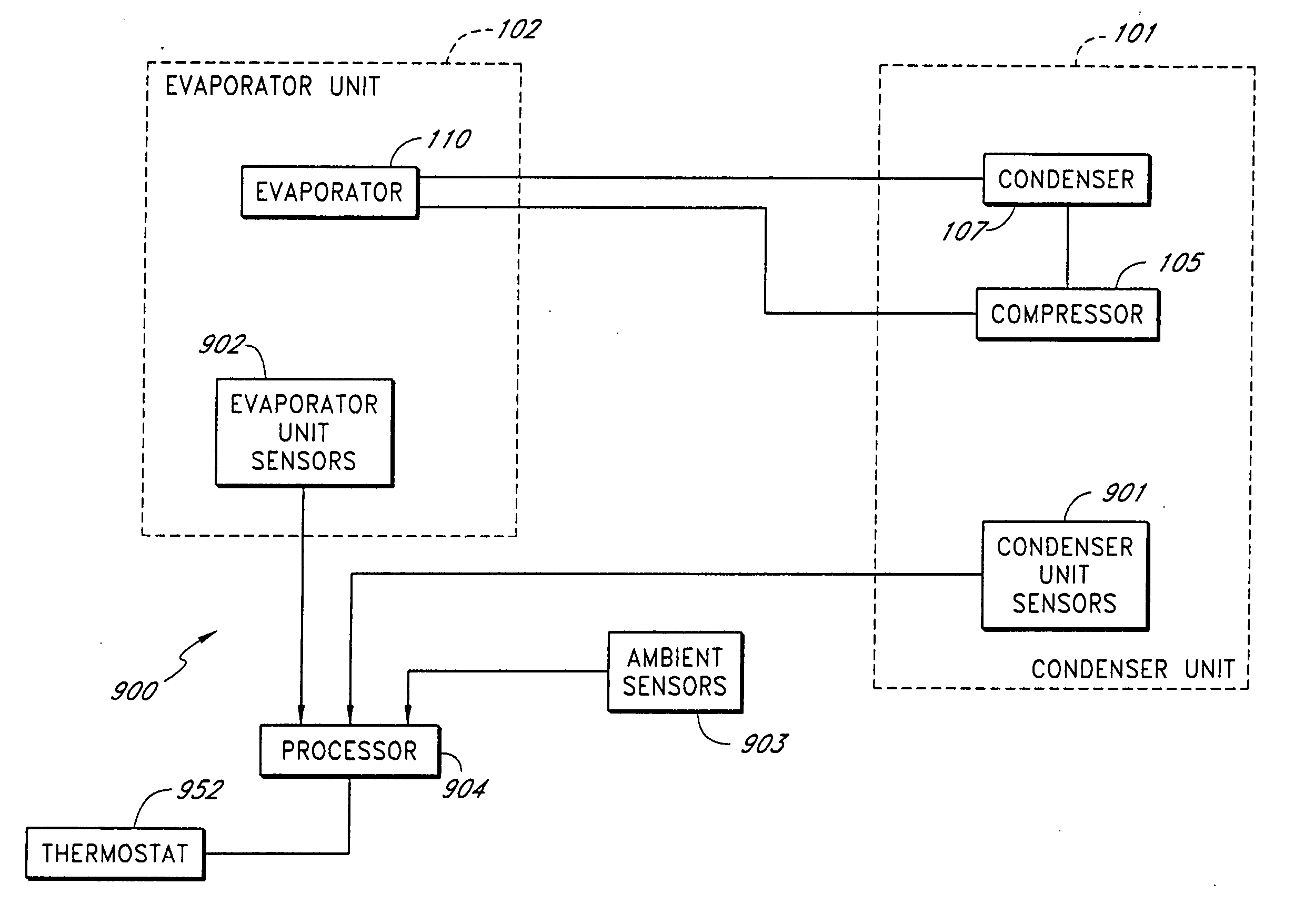

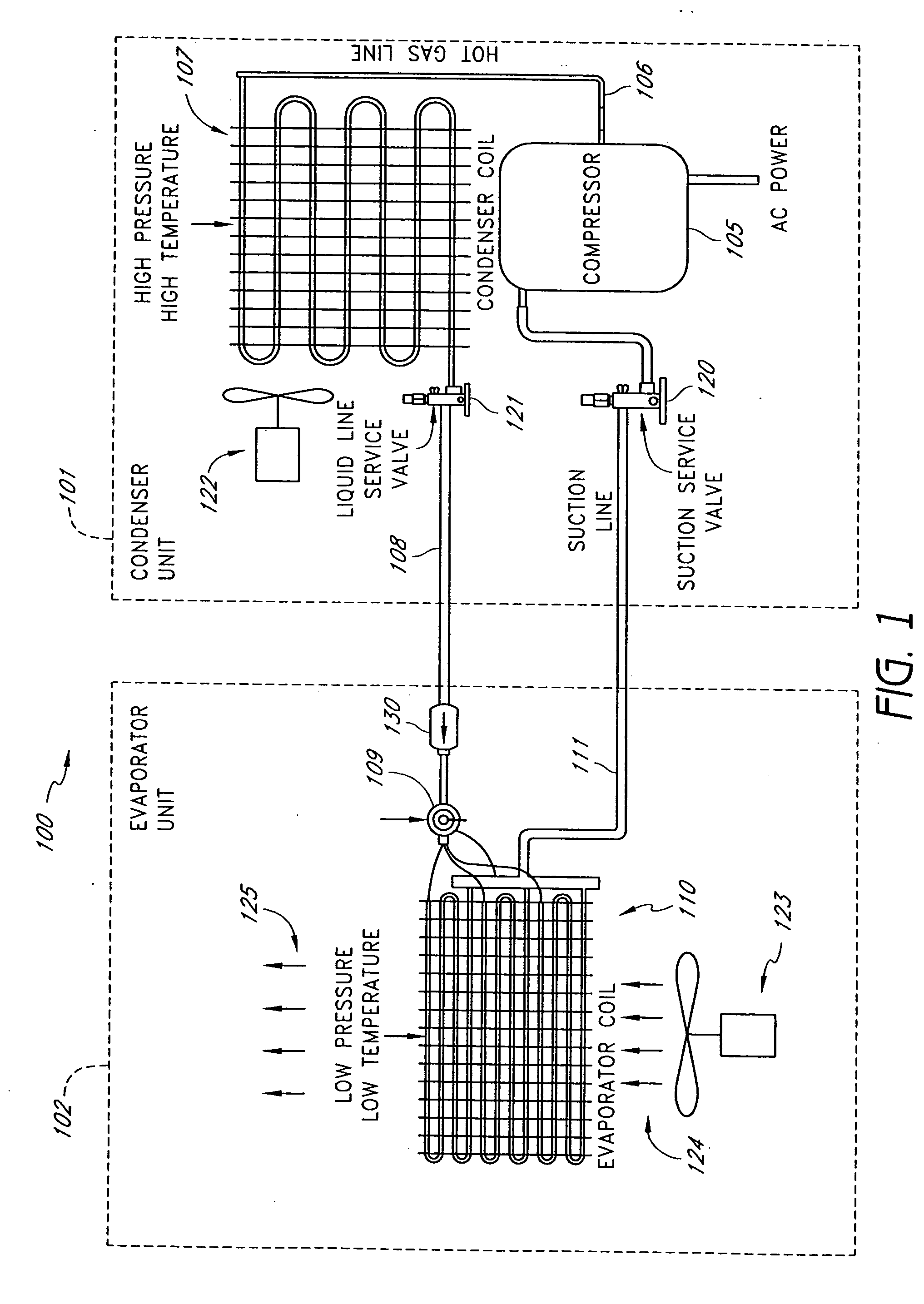

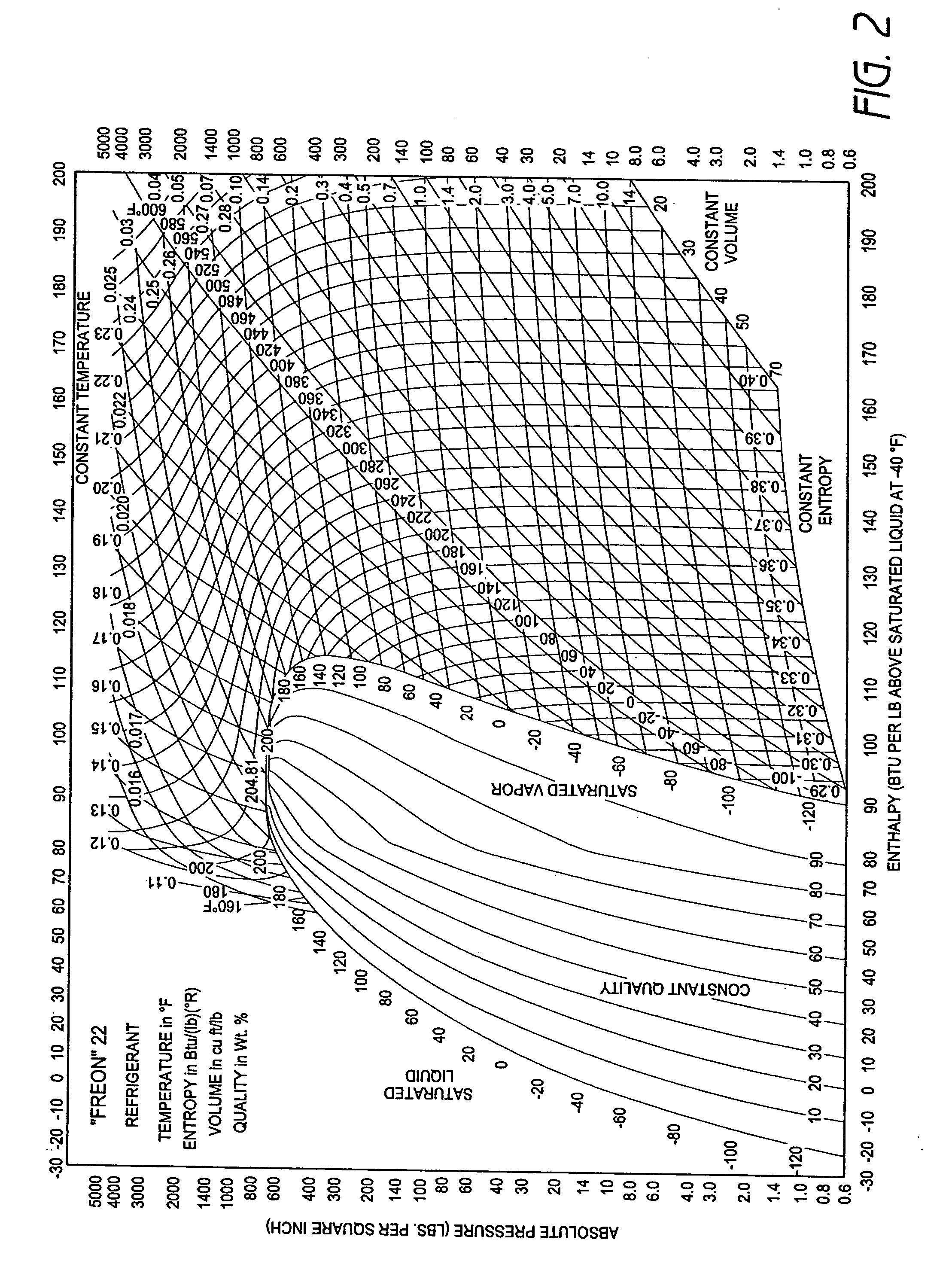

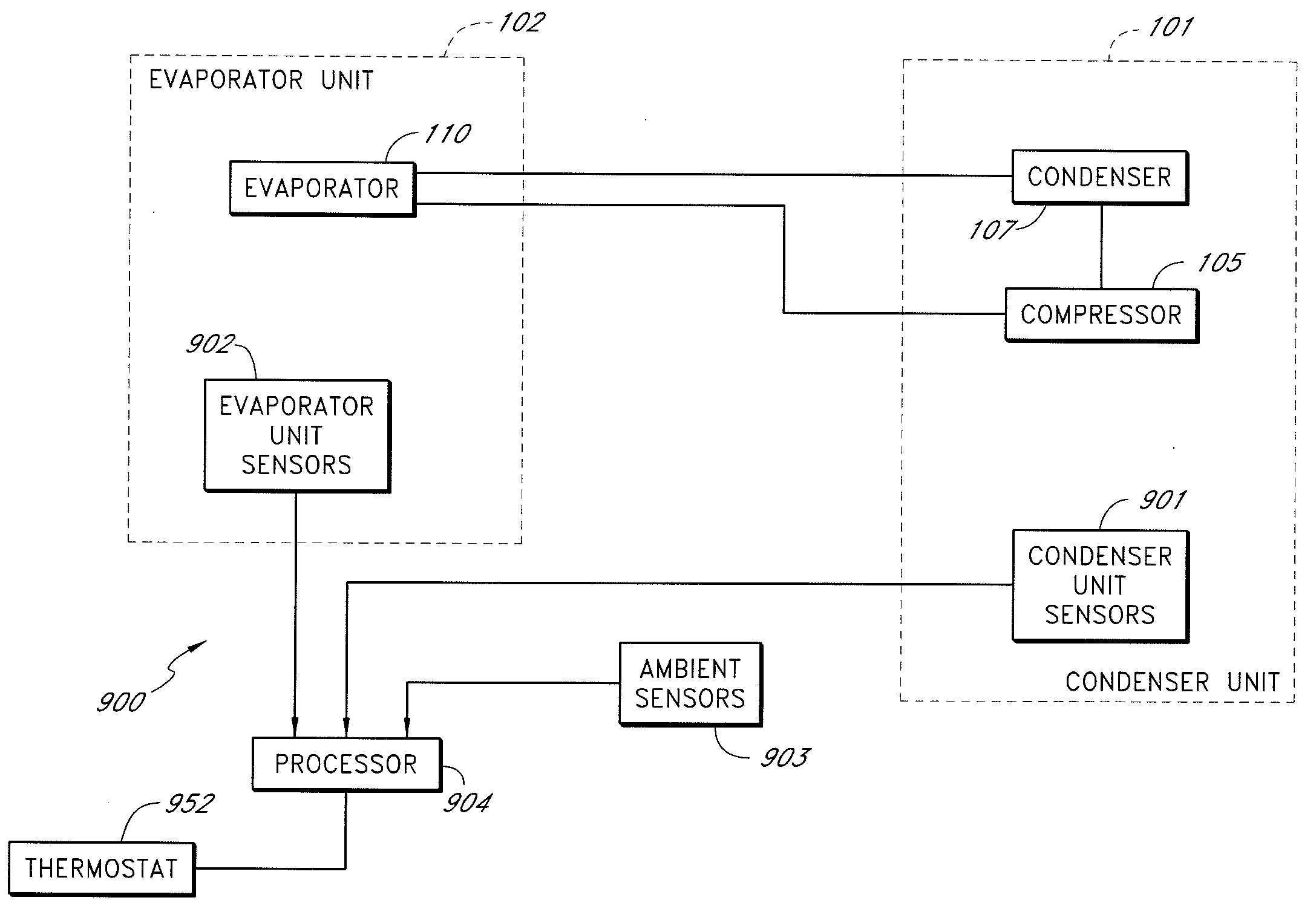

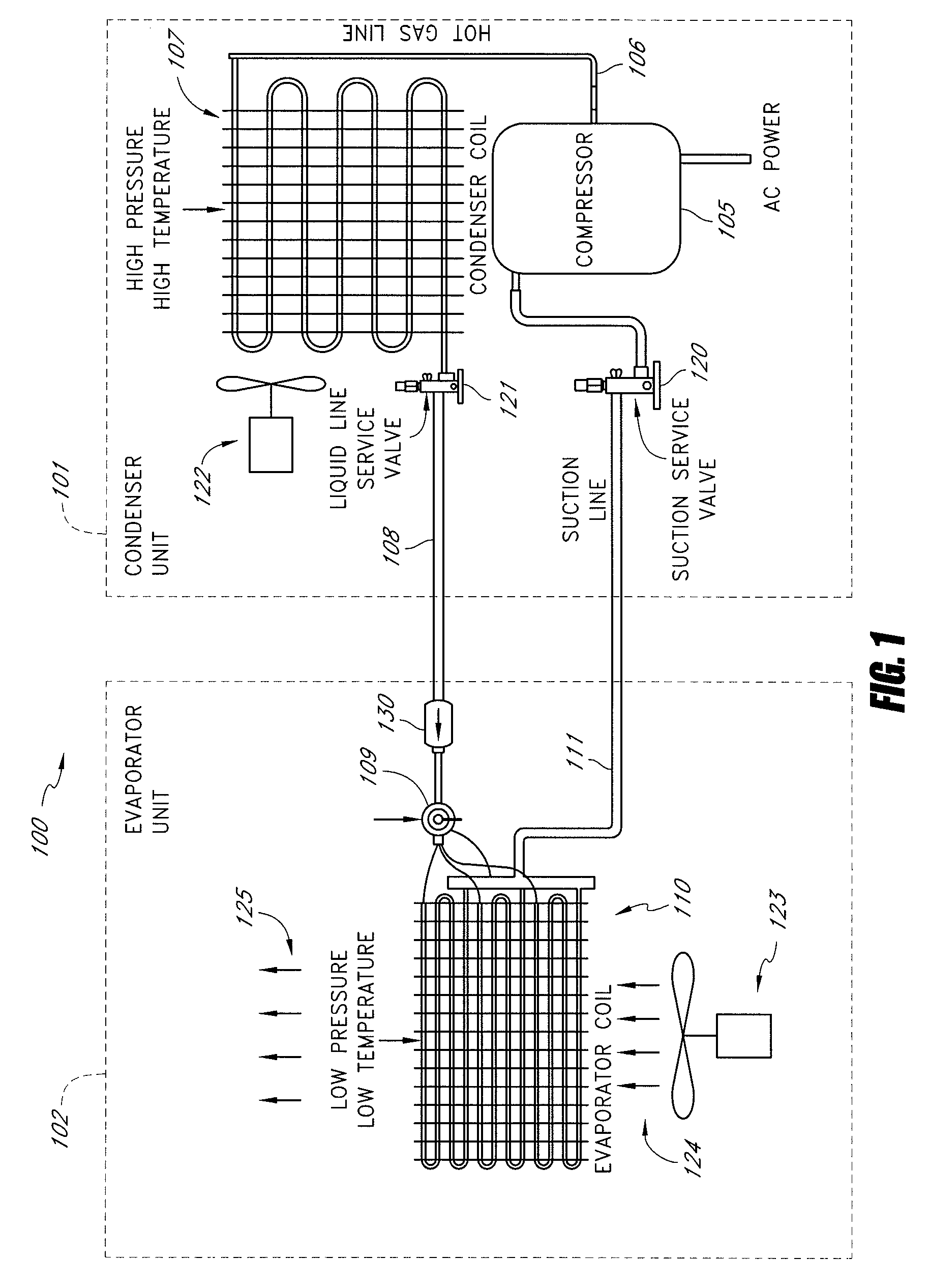

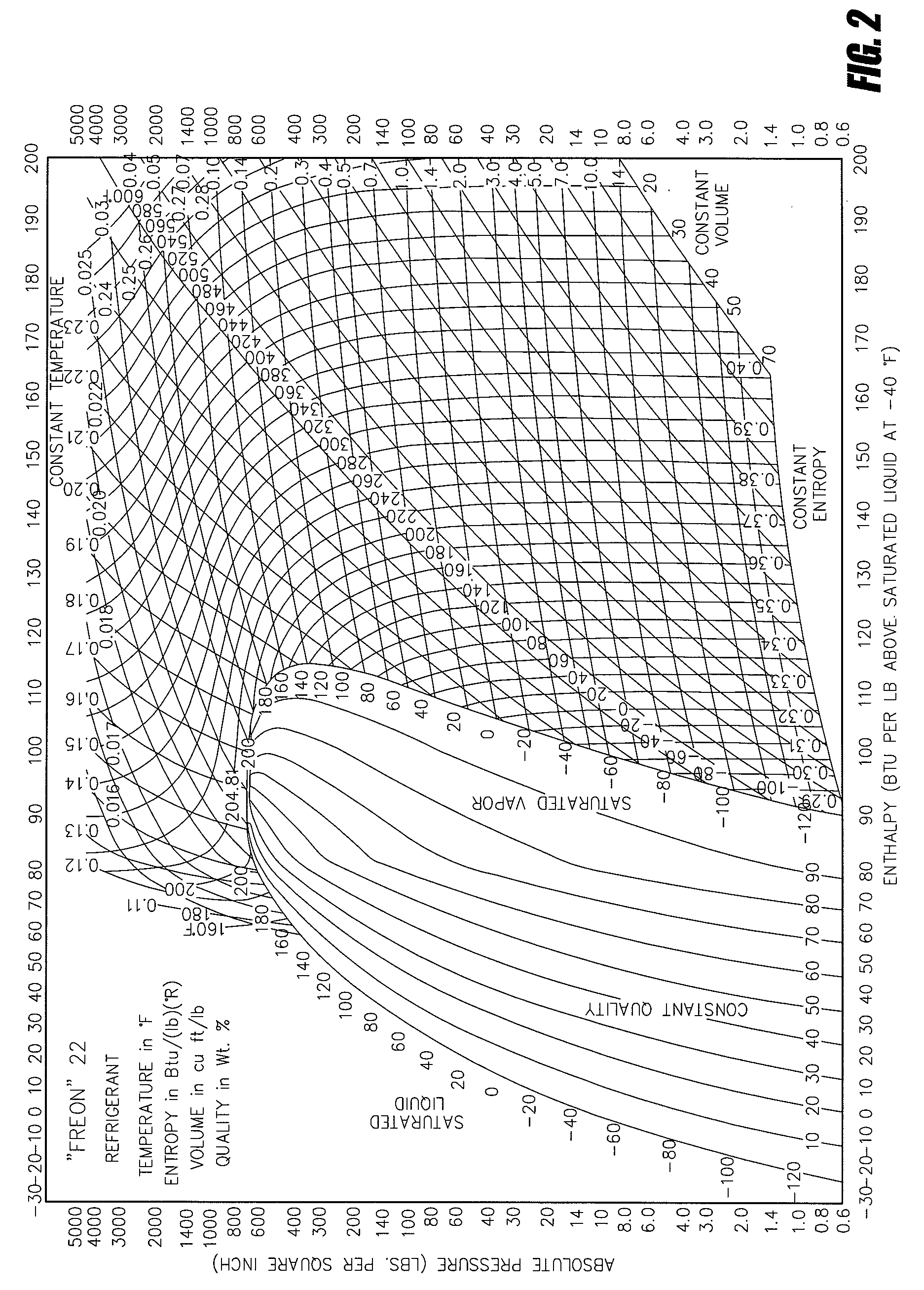

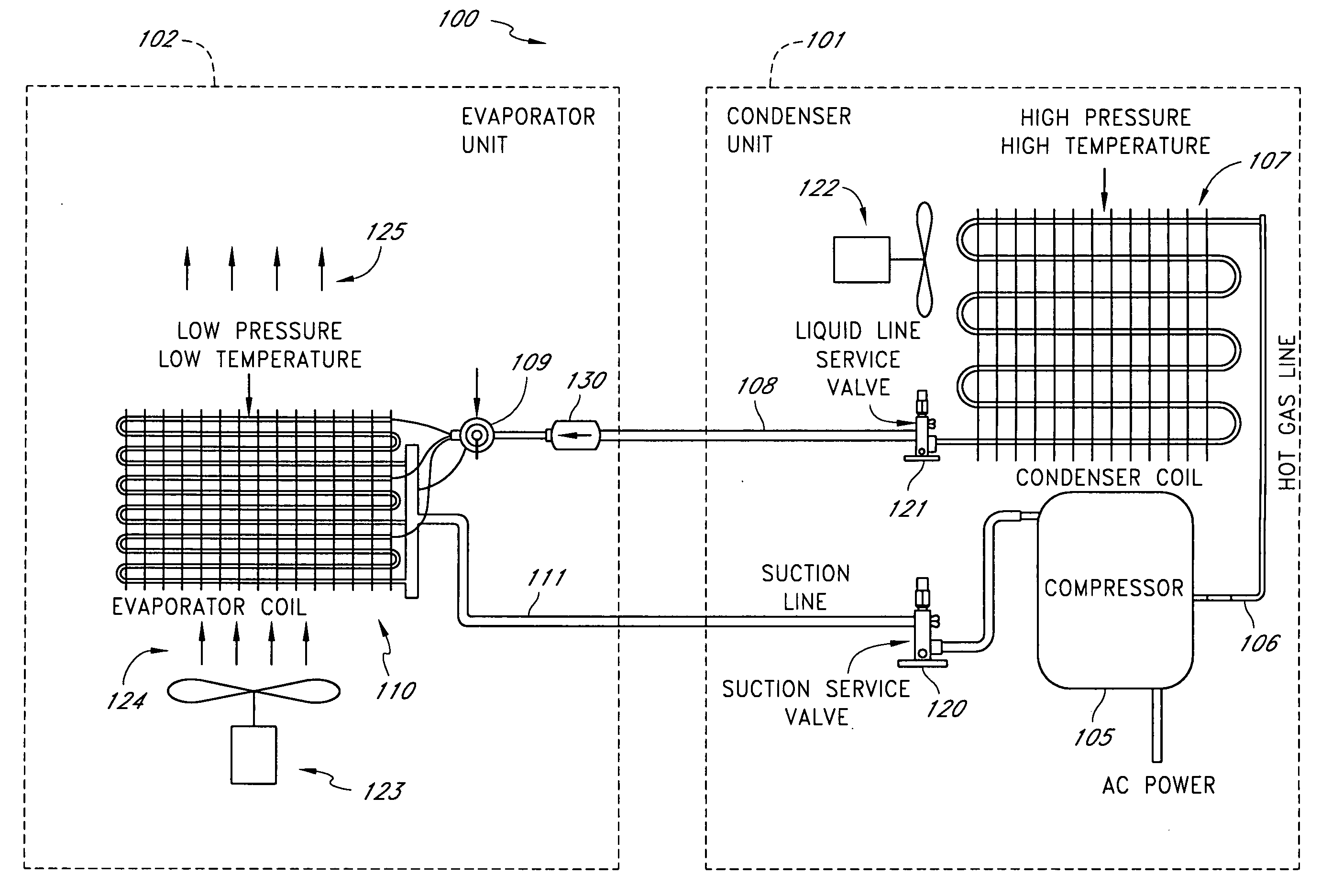

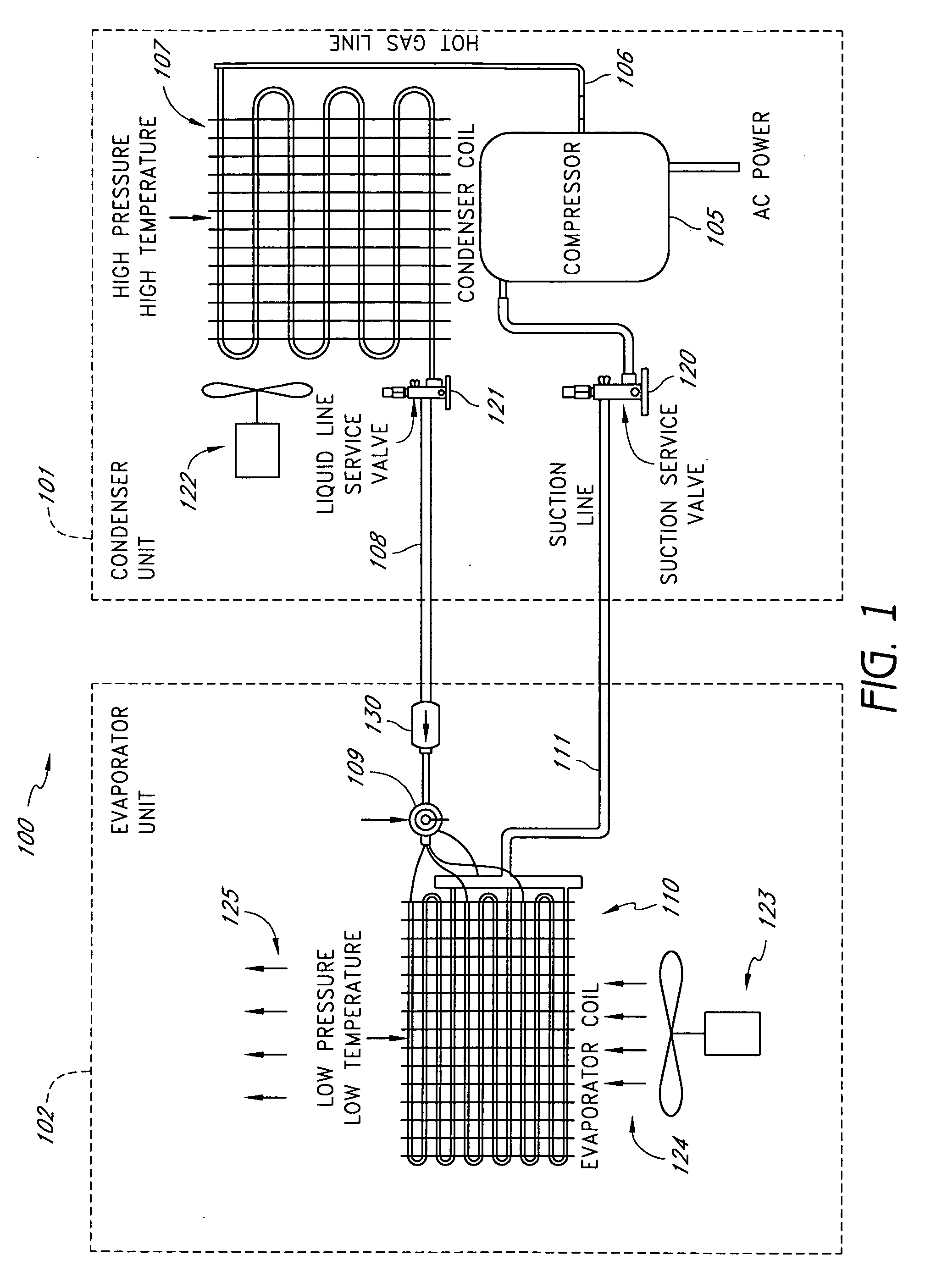

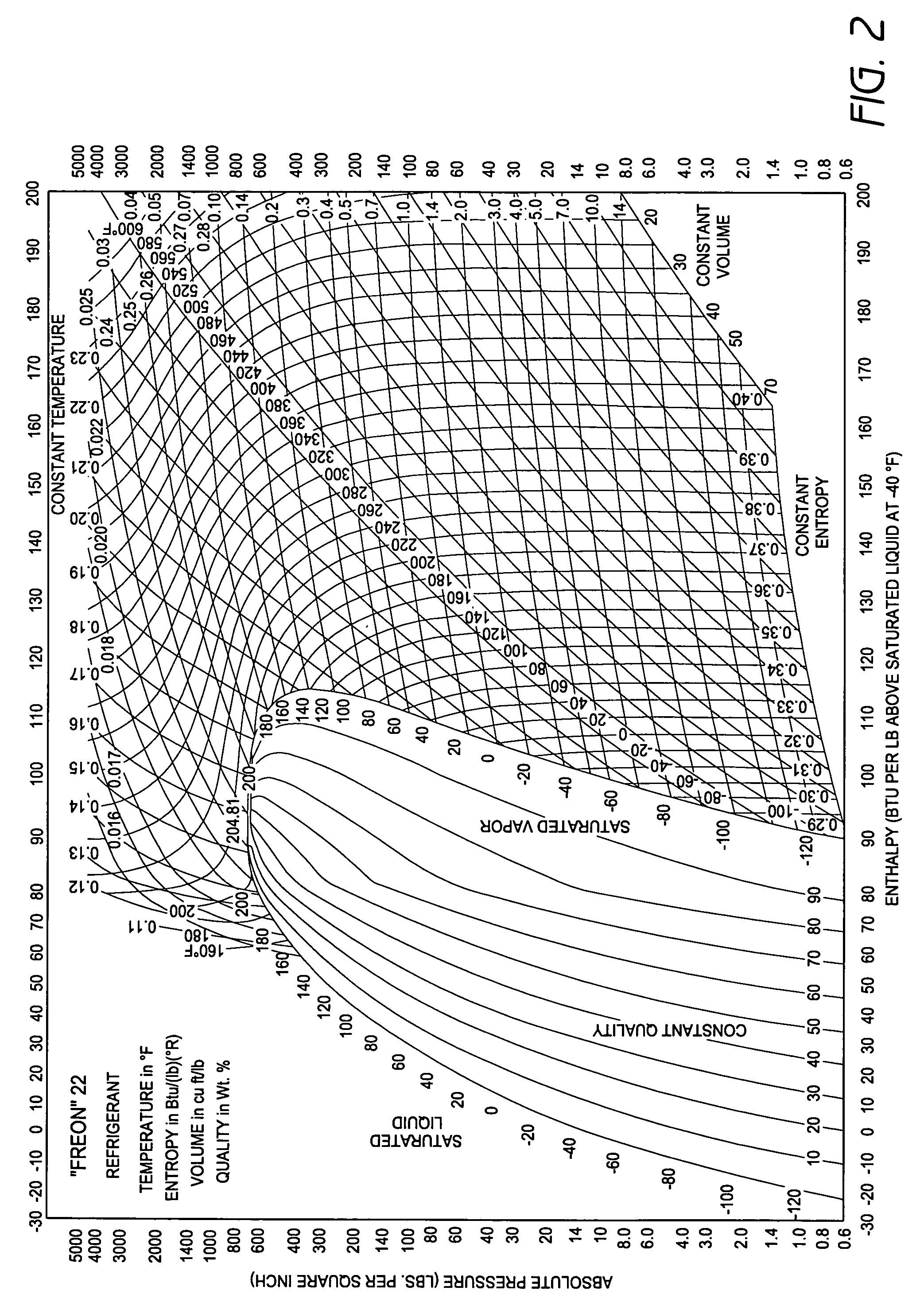

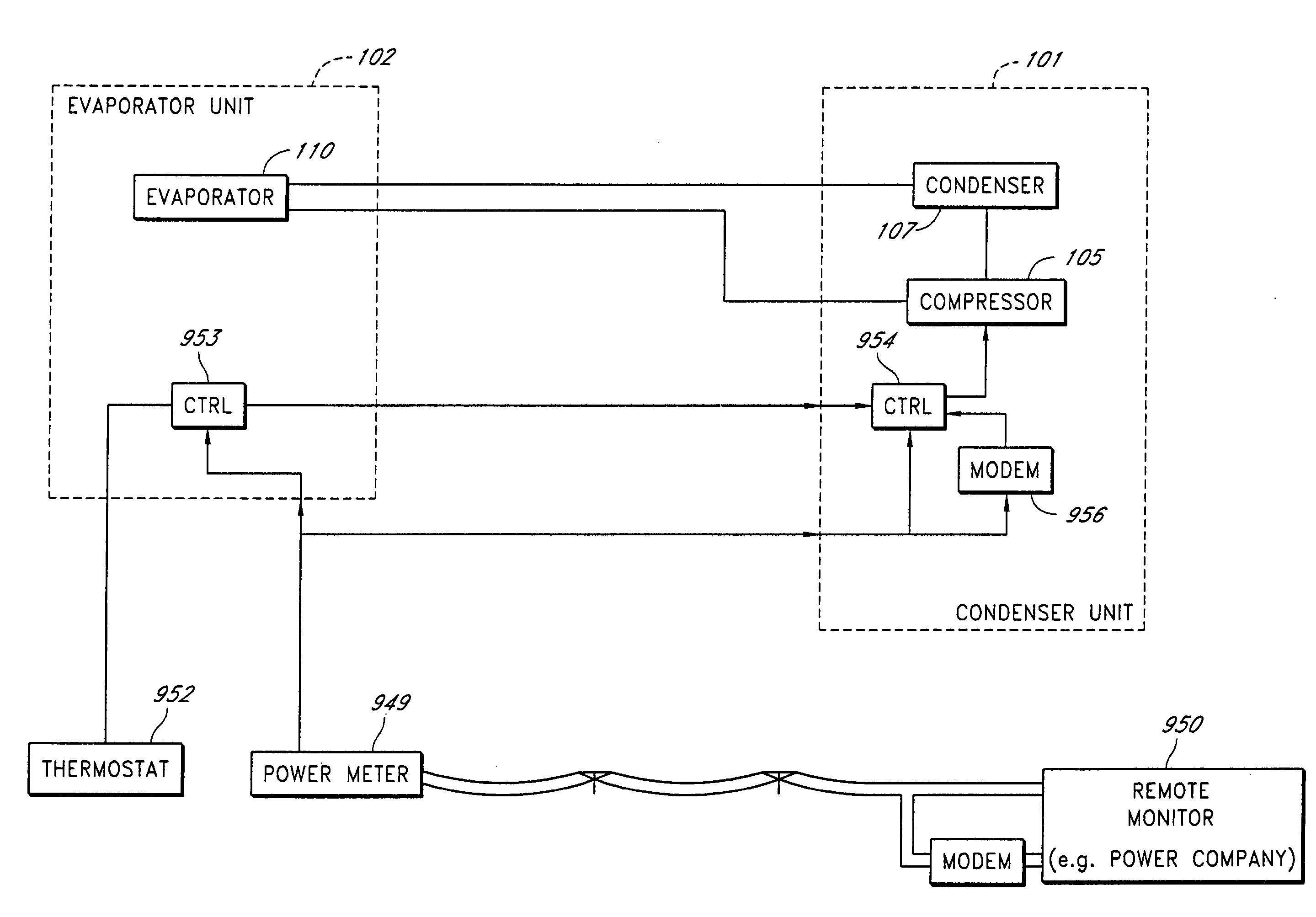

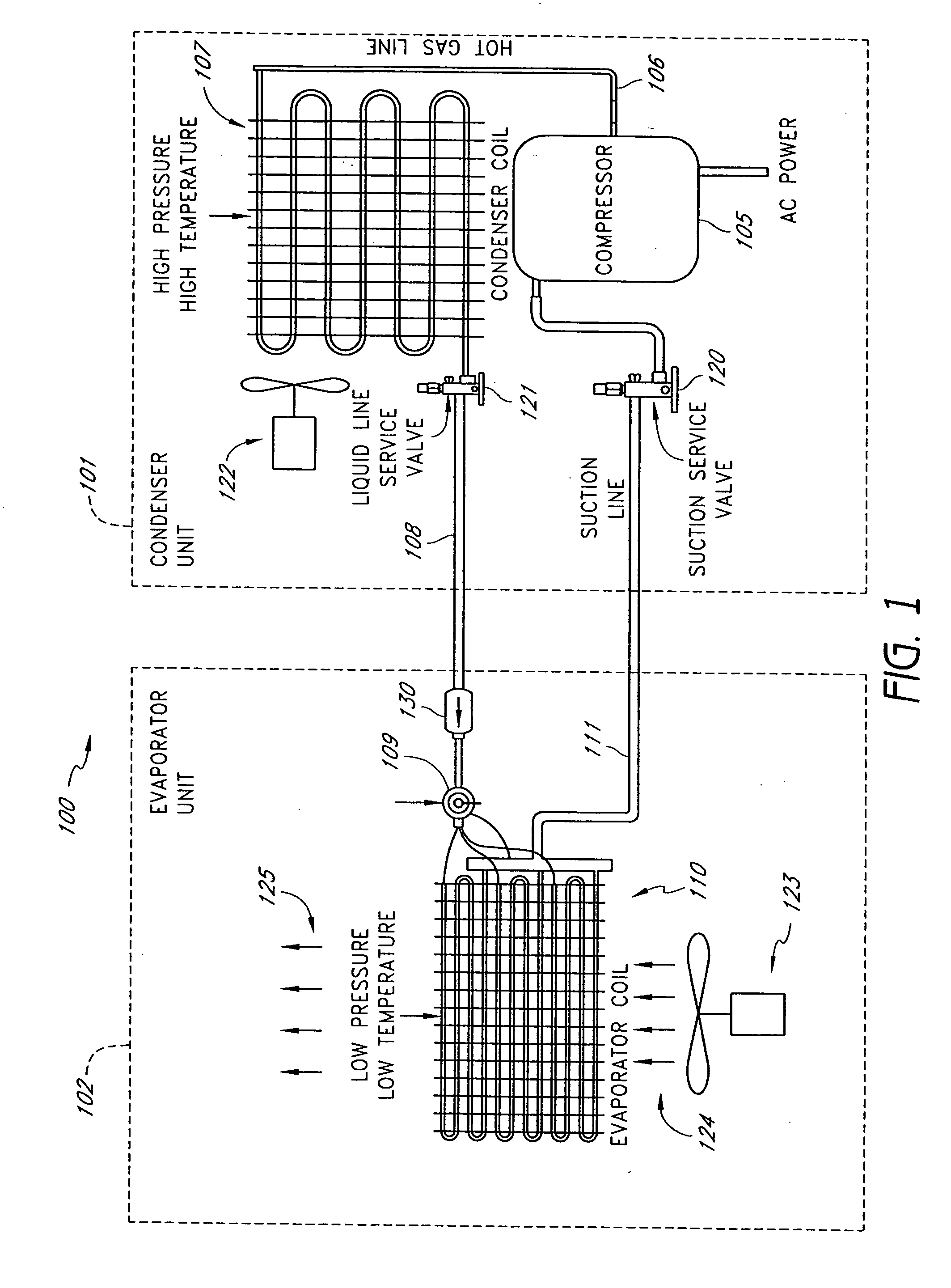

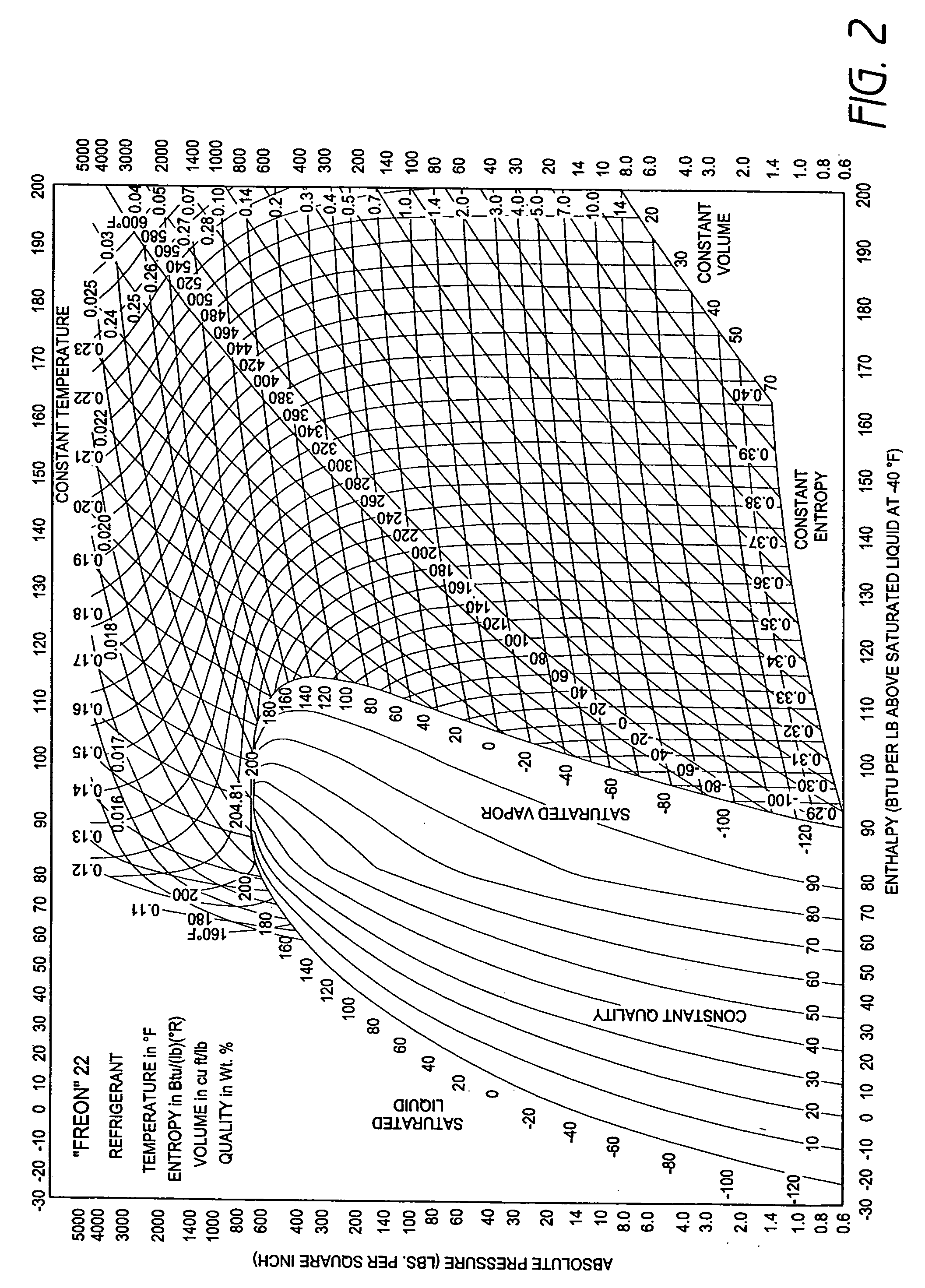

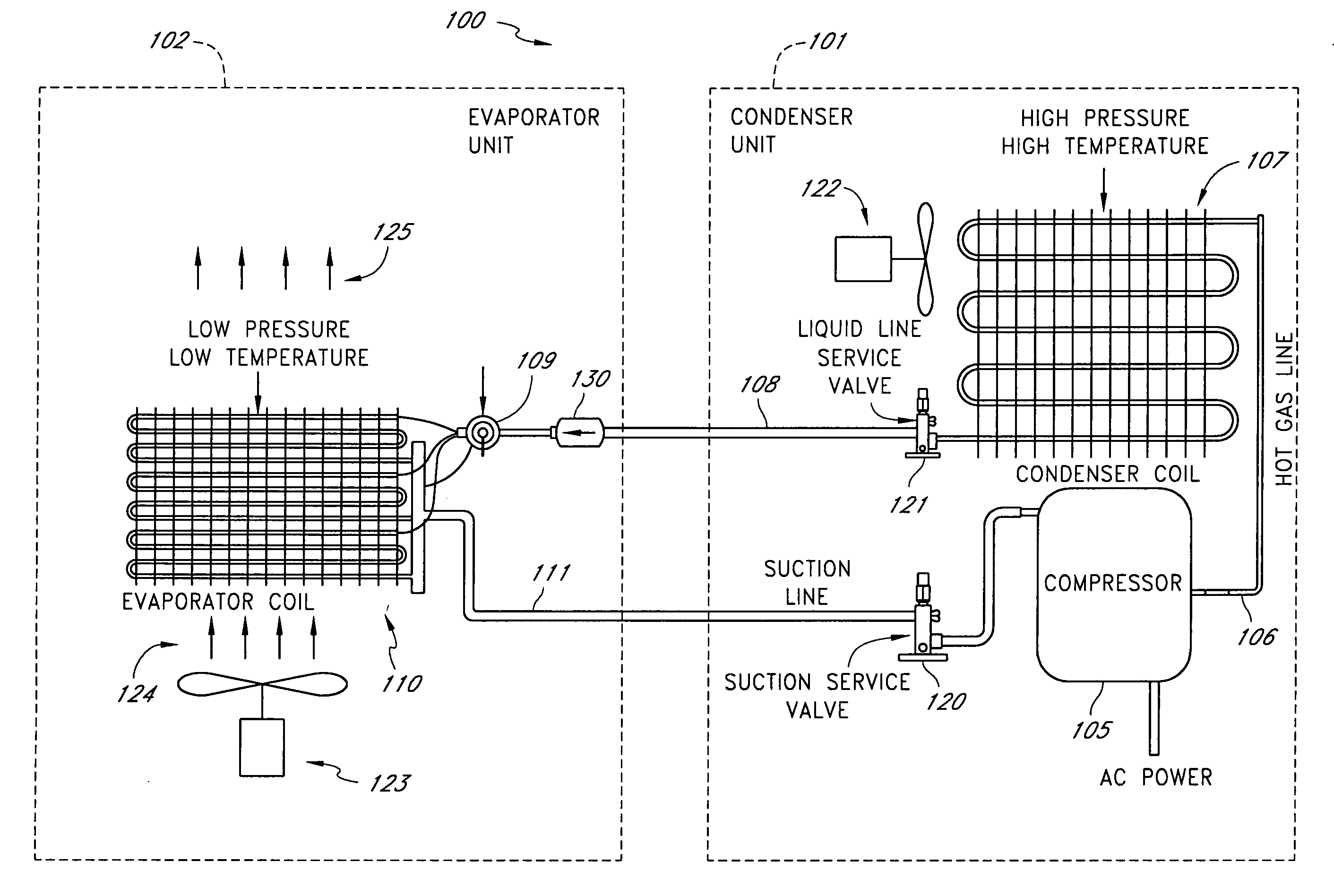

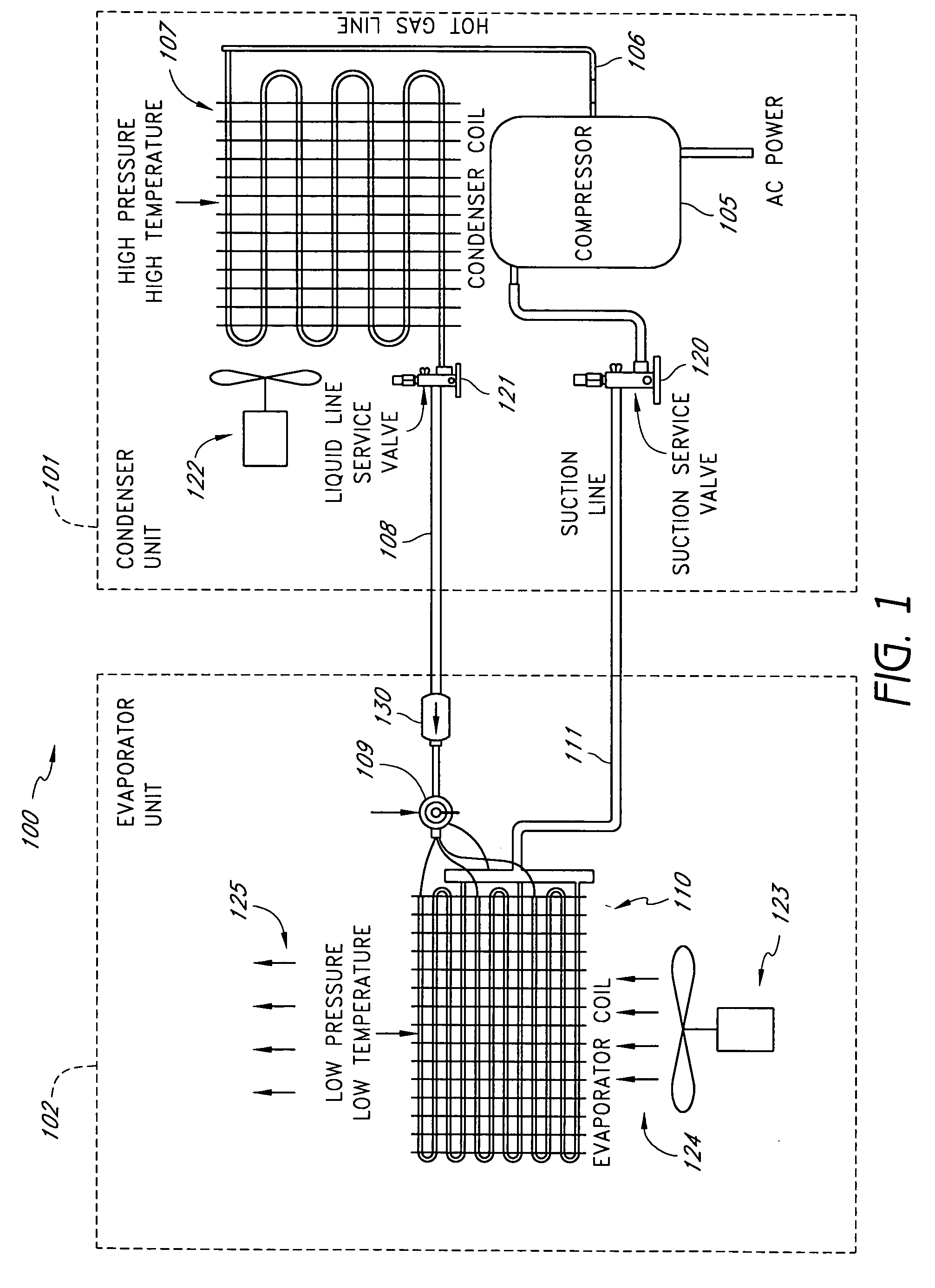

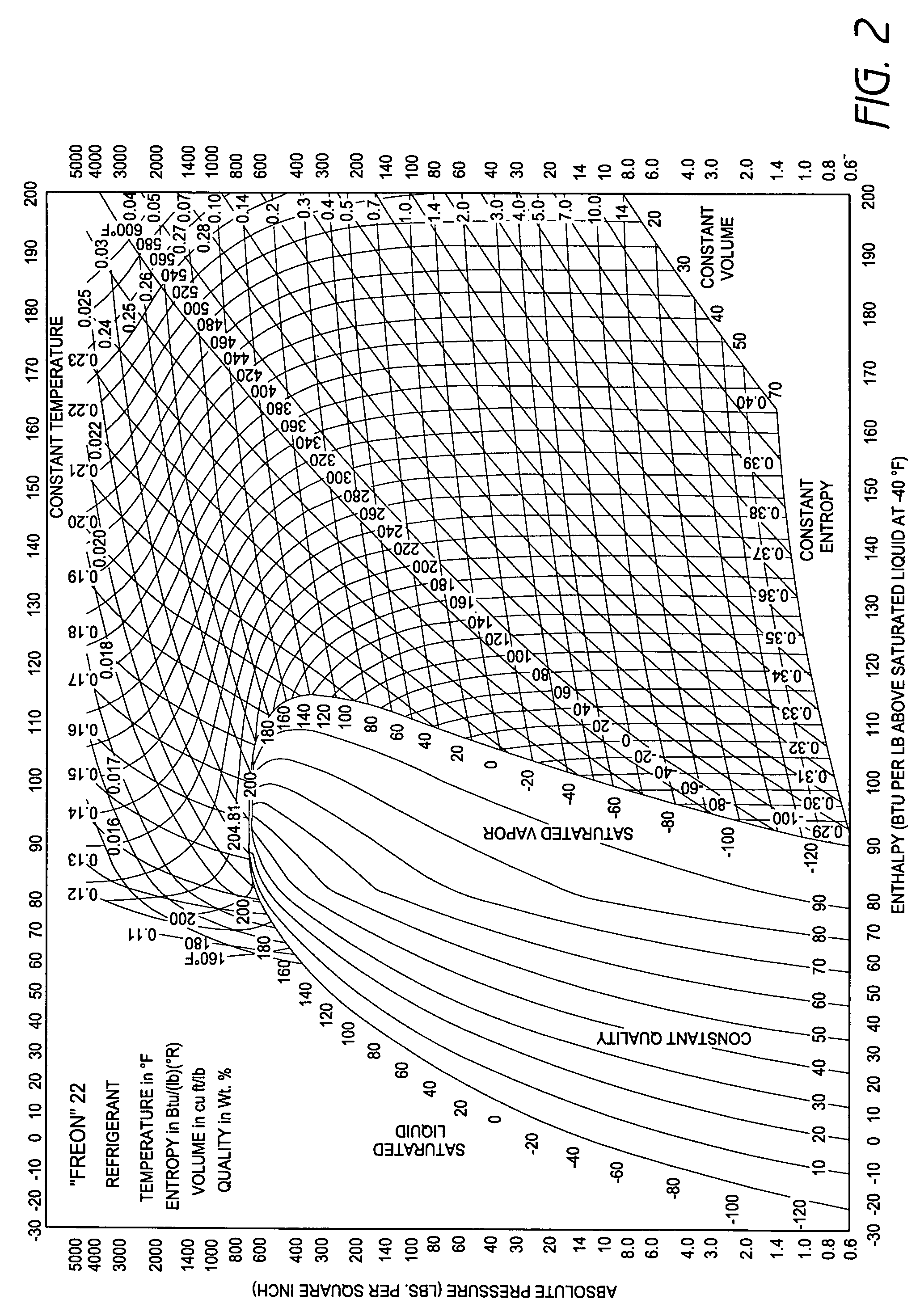

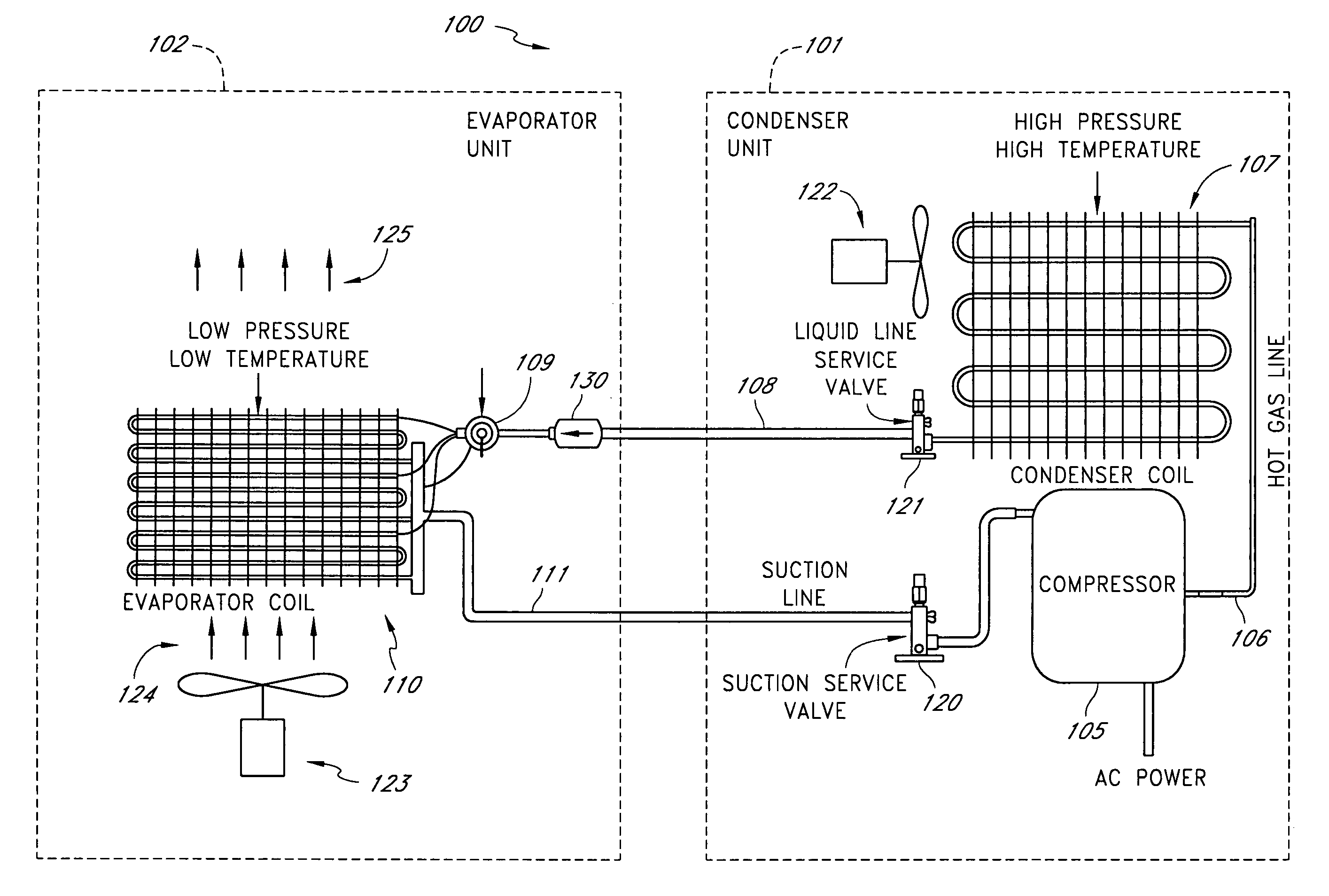

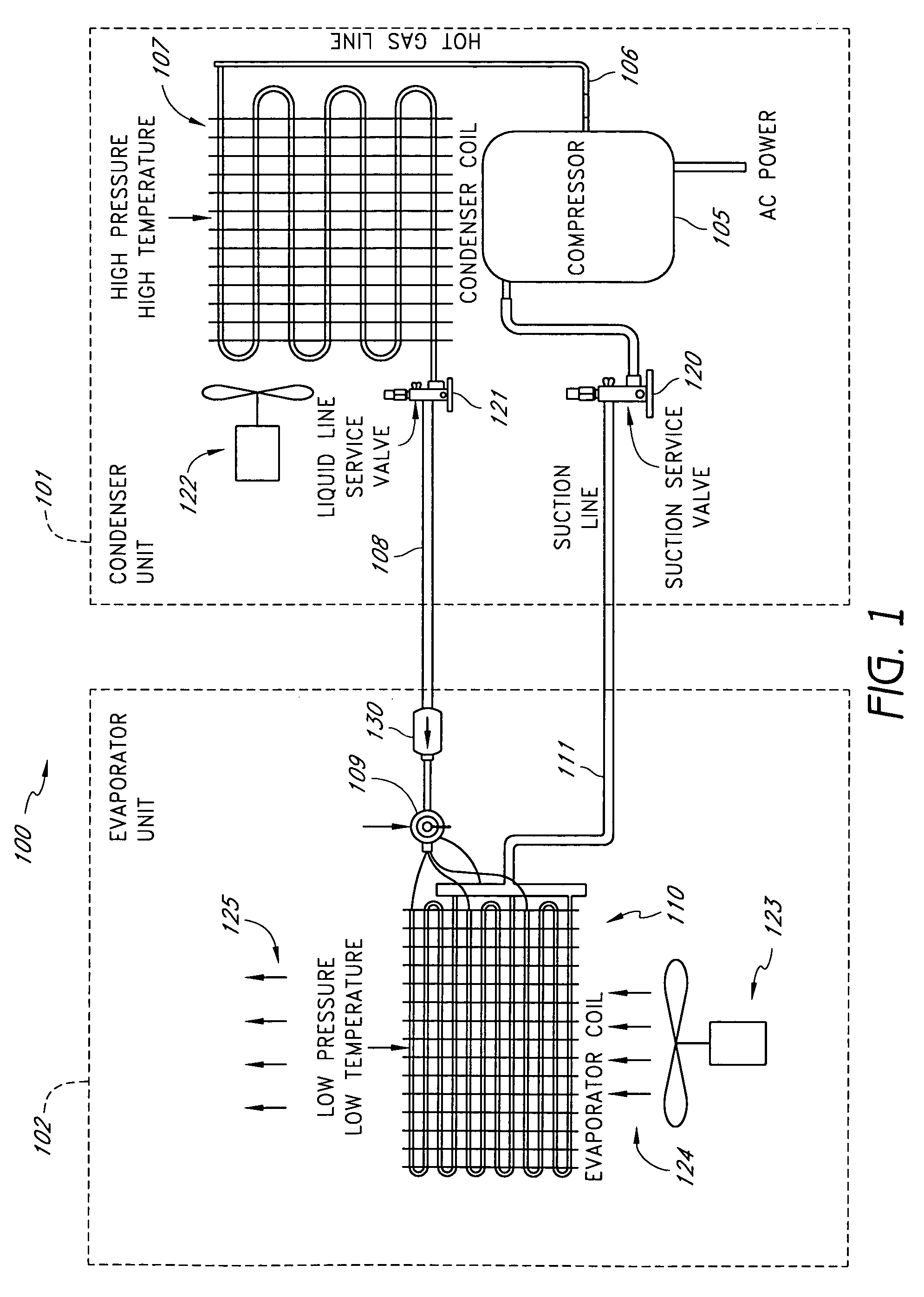

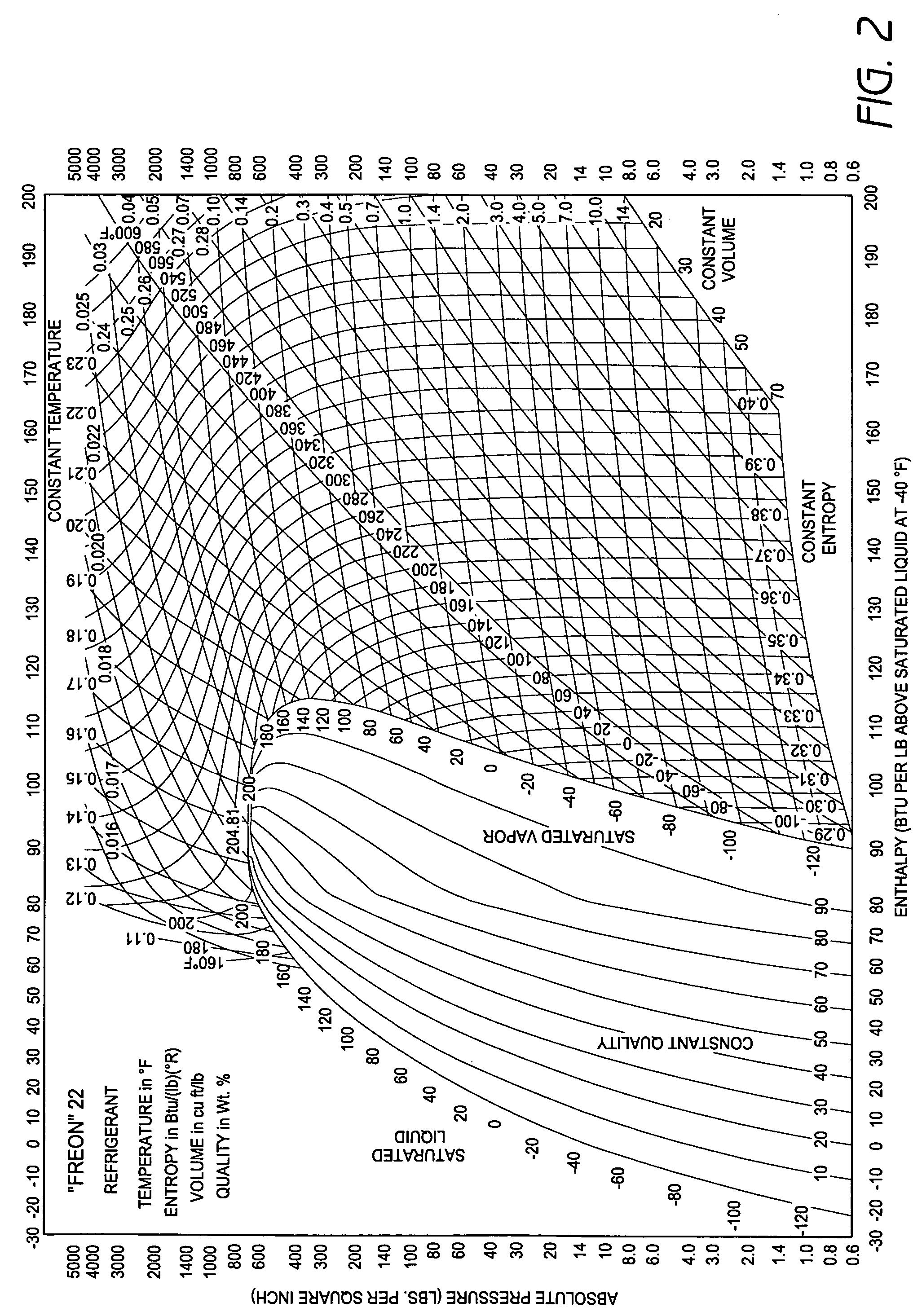

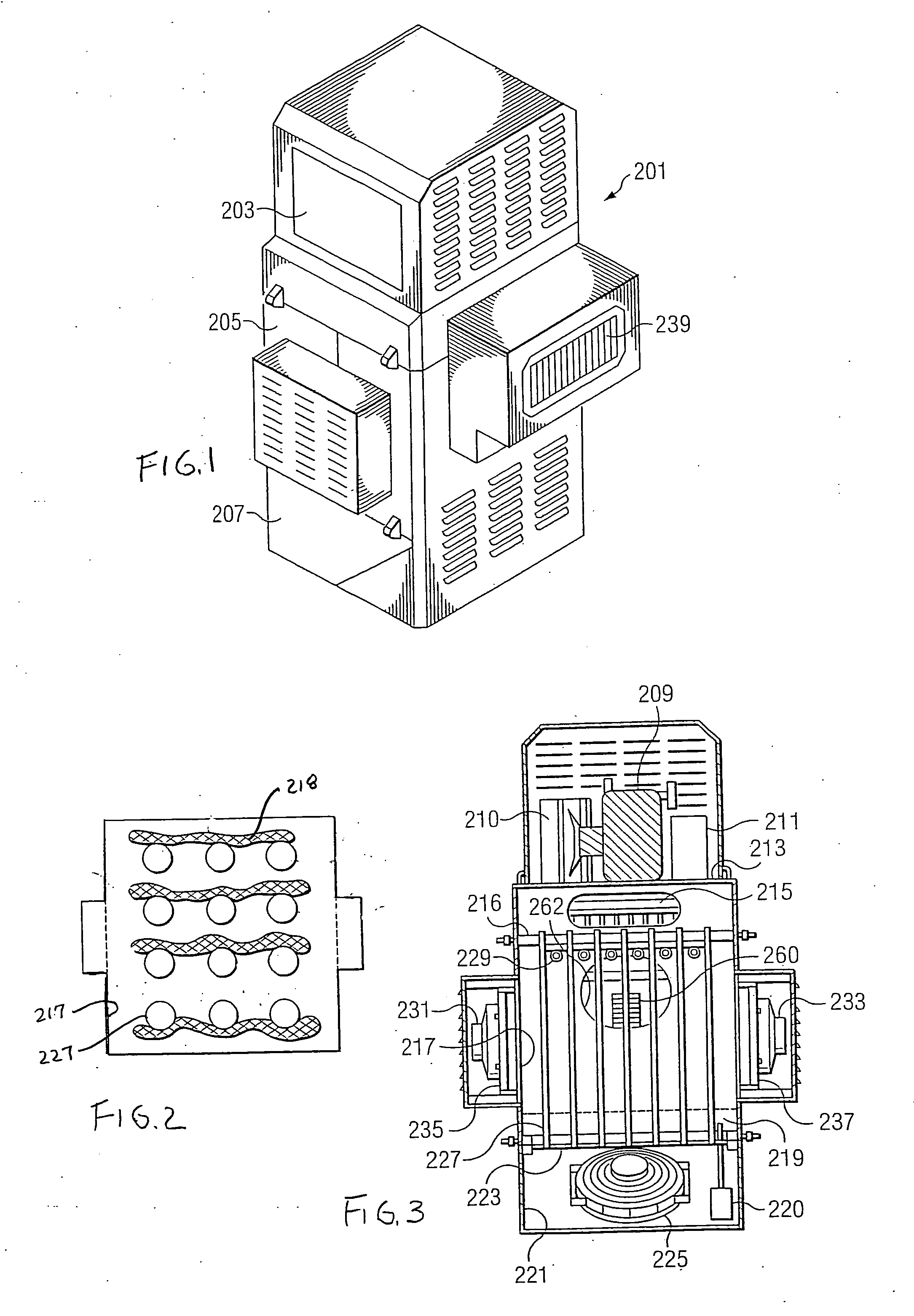

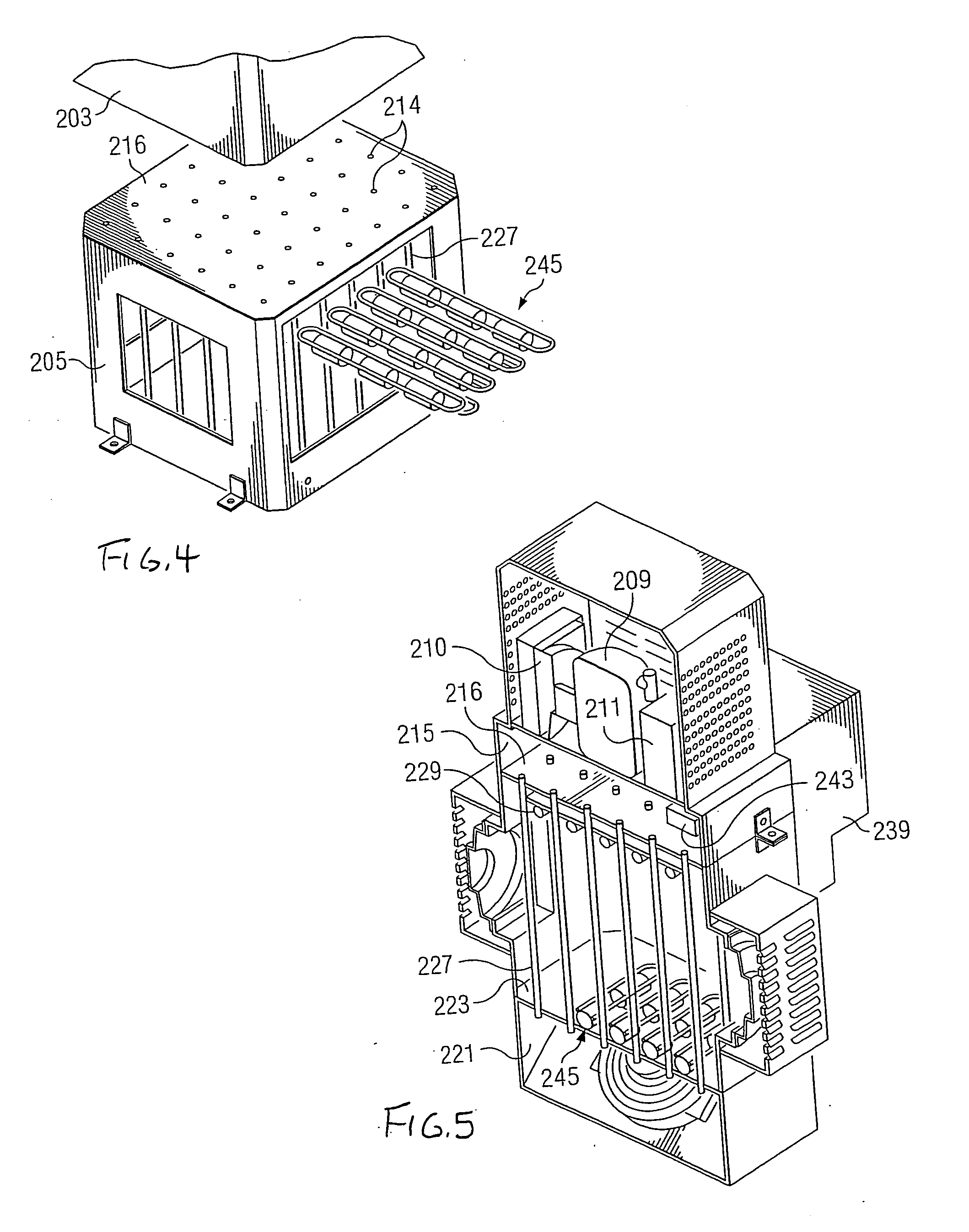

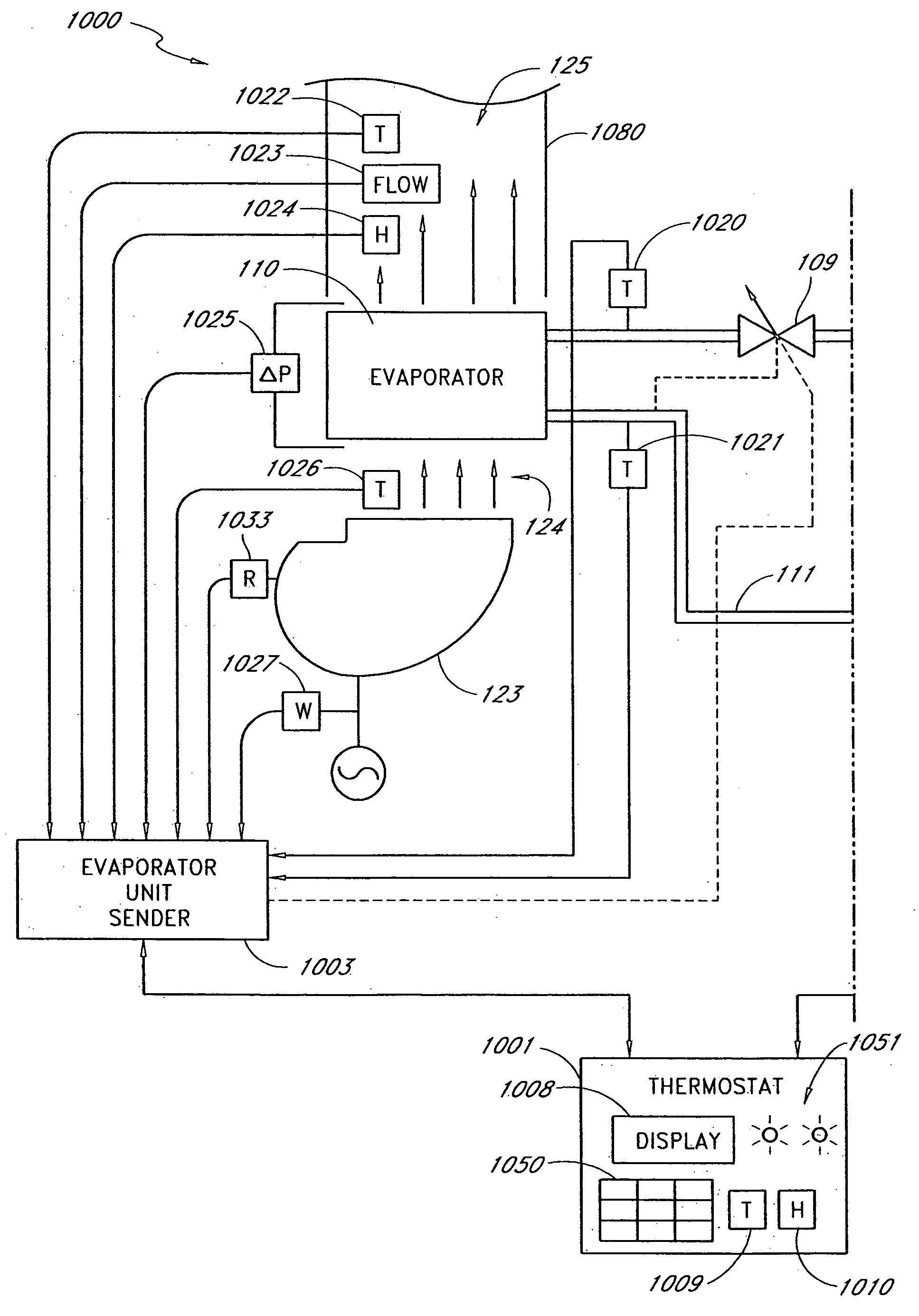

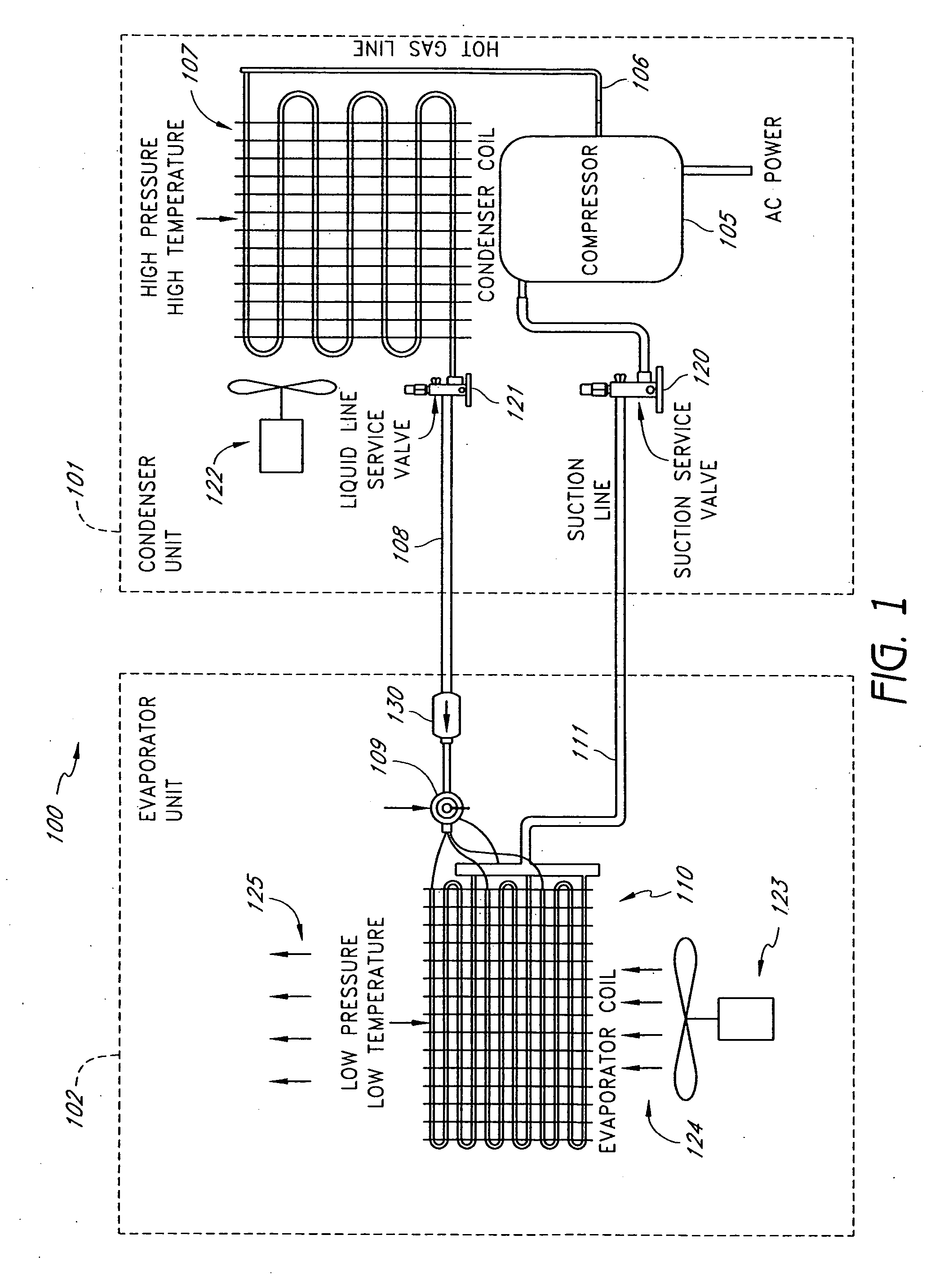

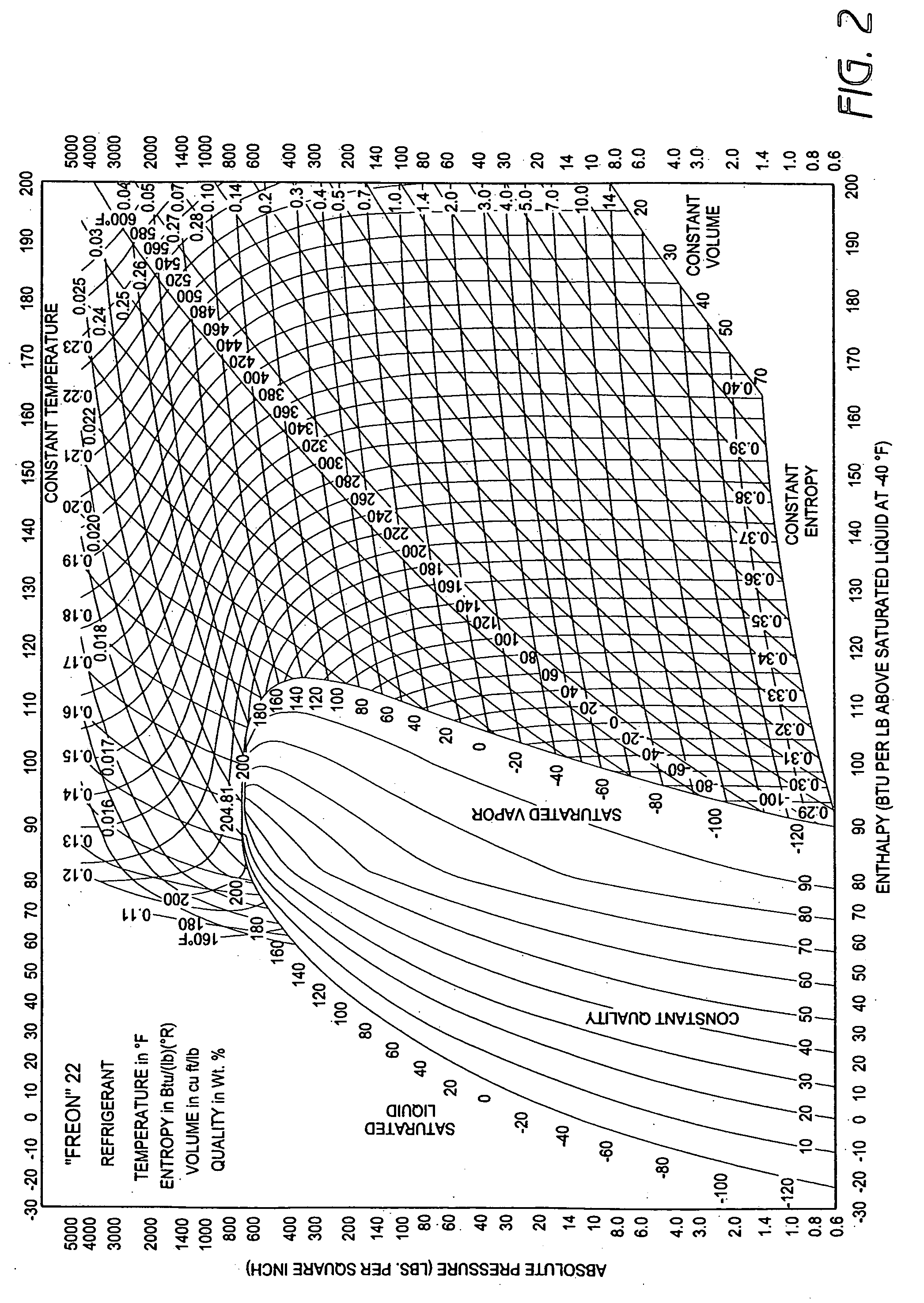

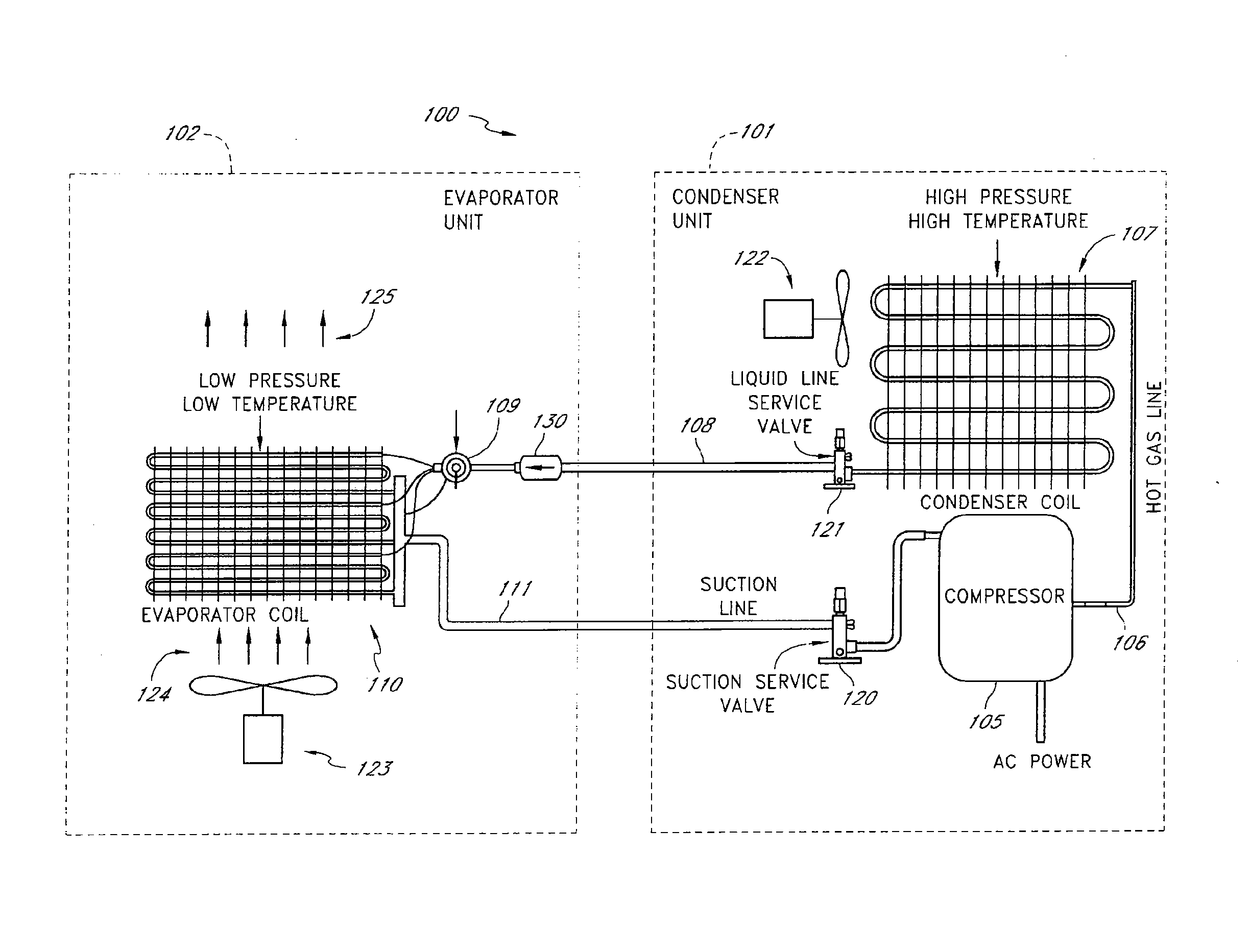

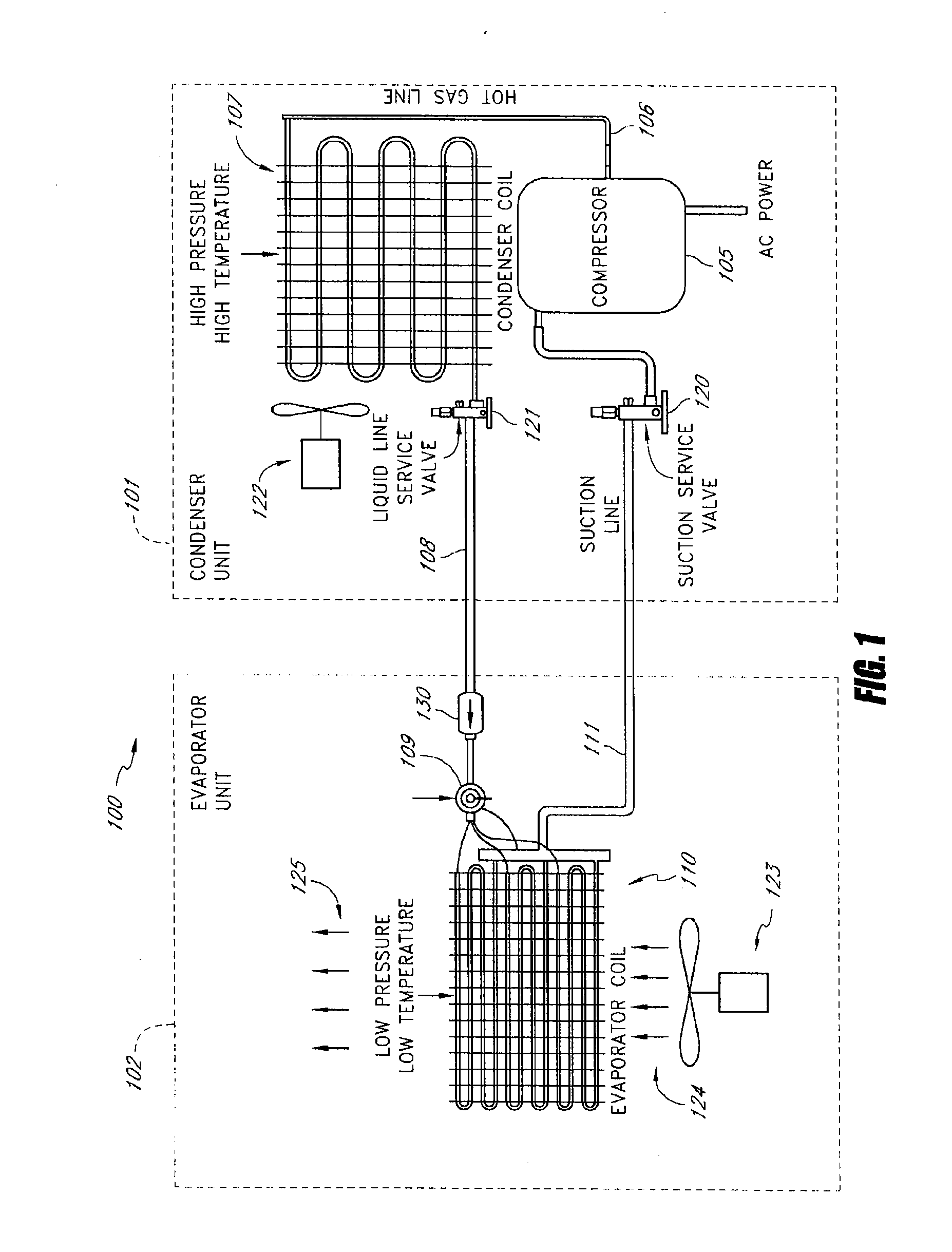

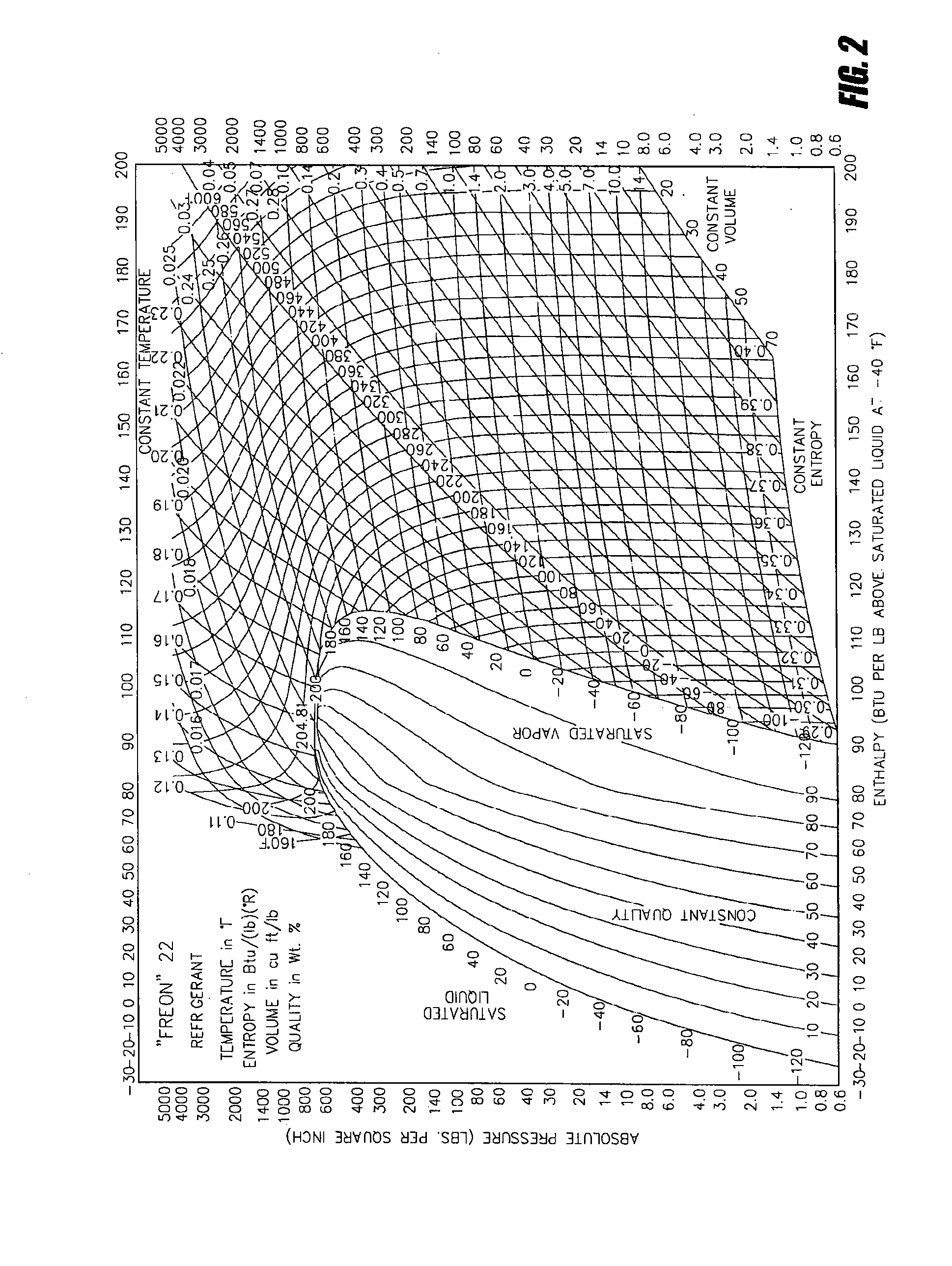

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:EMERSON CLIMATE TECH INC

Method and apparatus for monitoring refrigerant-cycle systems

ActiveUS20060032245A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

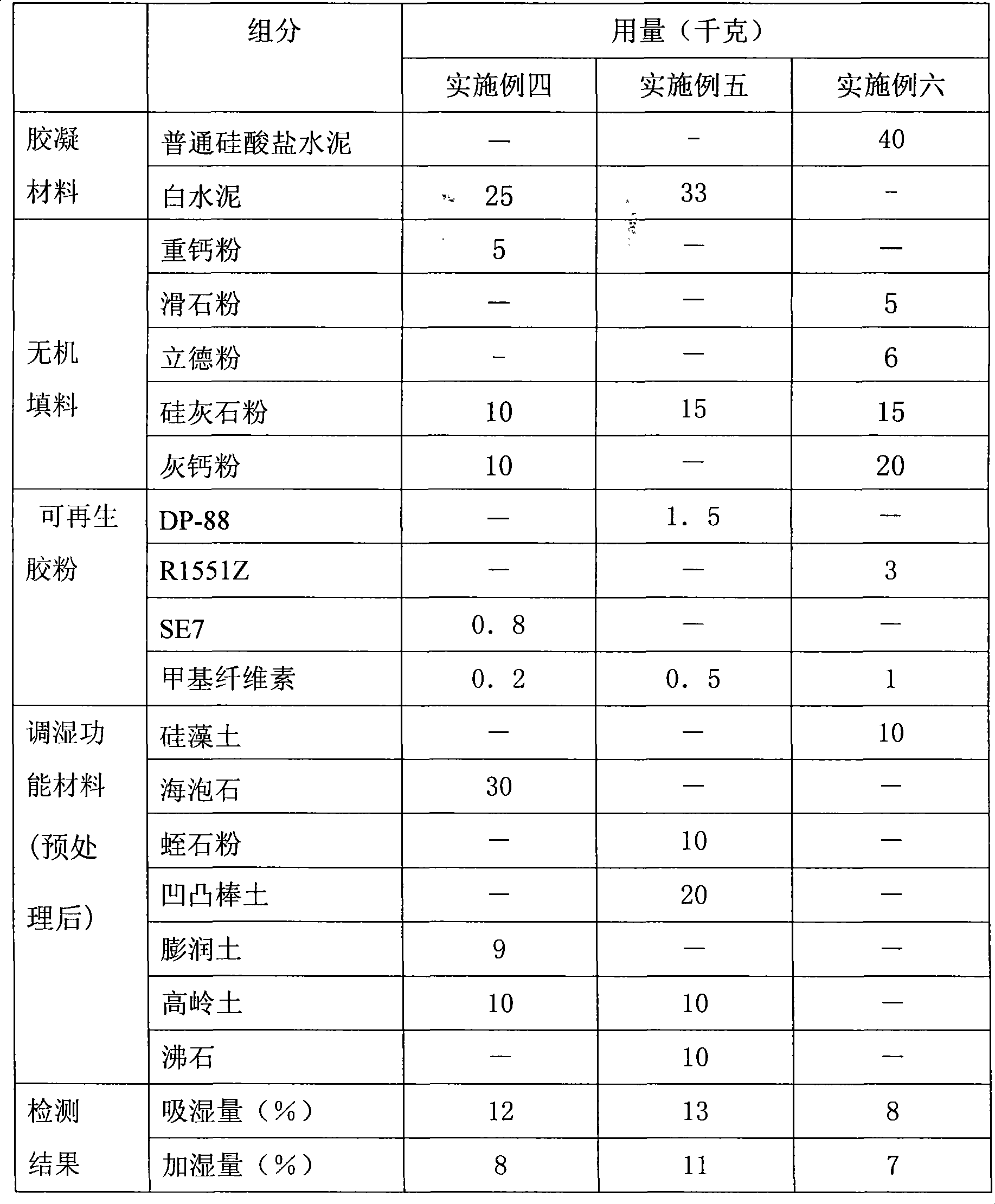

Inorganic putty powder with function of governing humidness

ActiveCN101368014AEffective regulation of relative humidityGood environmental protectionFilling pastesCement coatingsSodium BentoniteMetallurgy

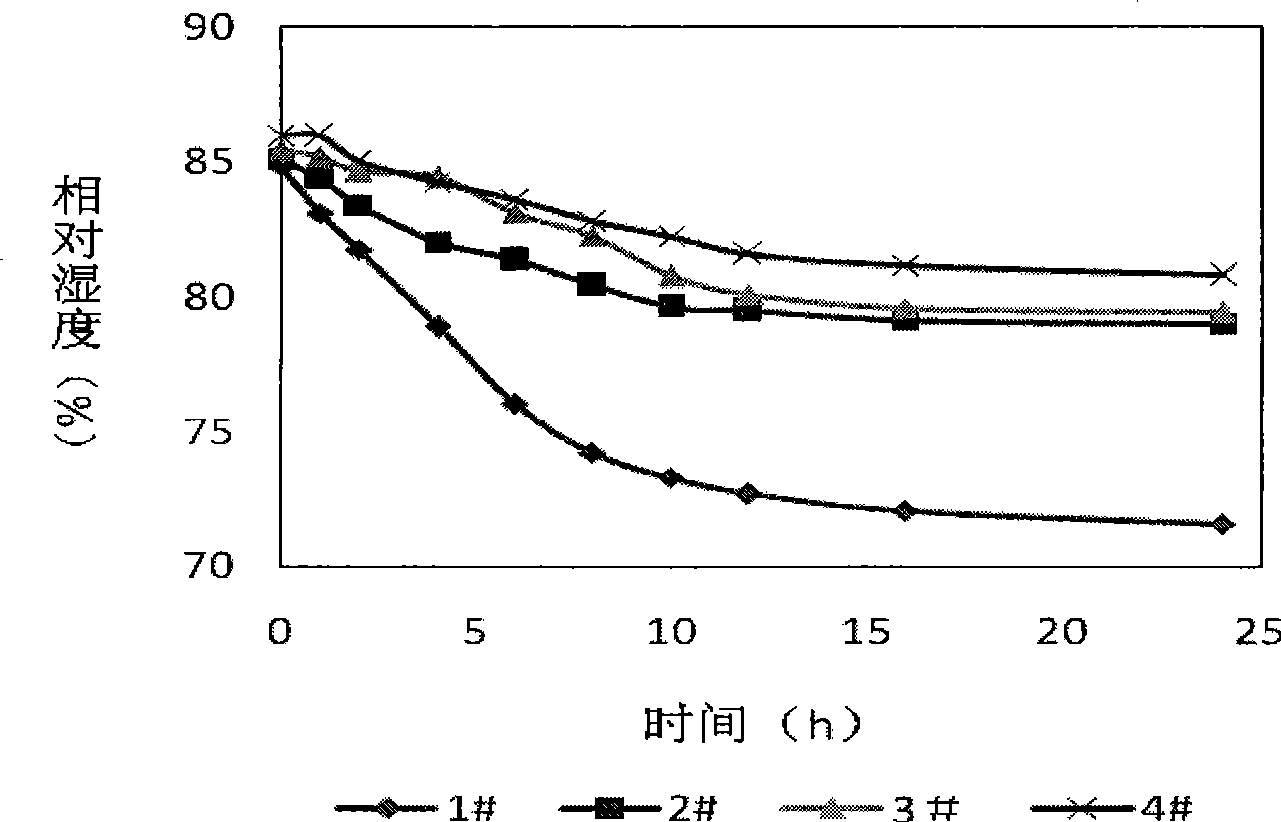

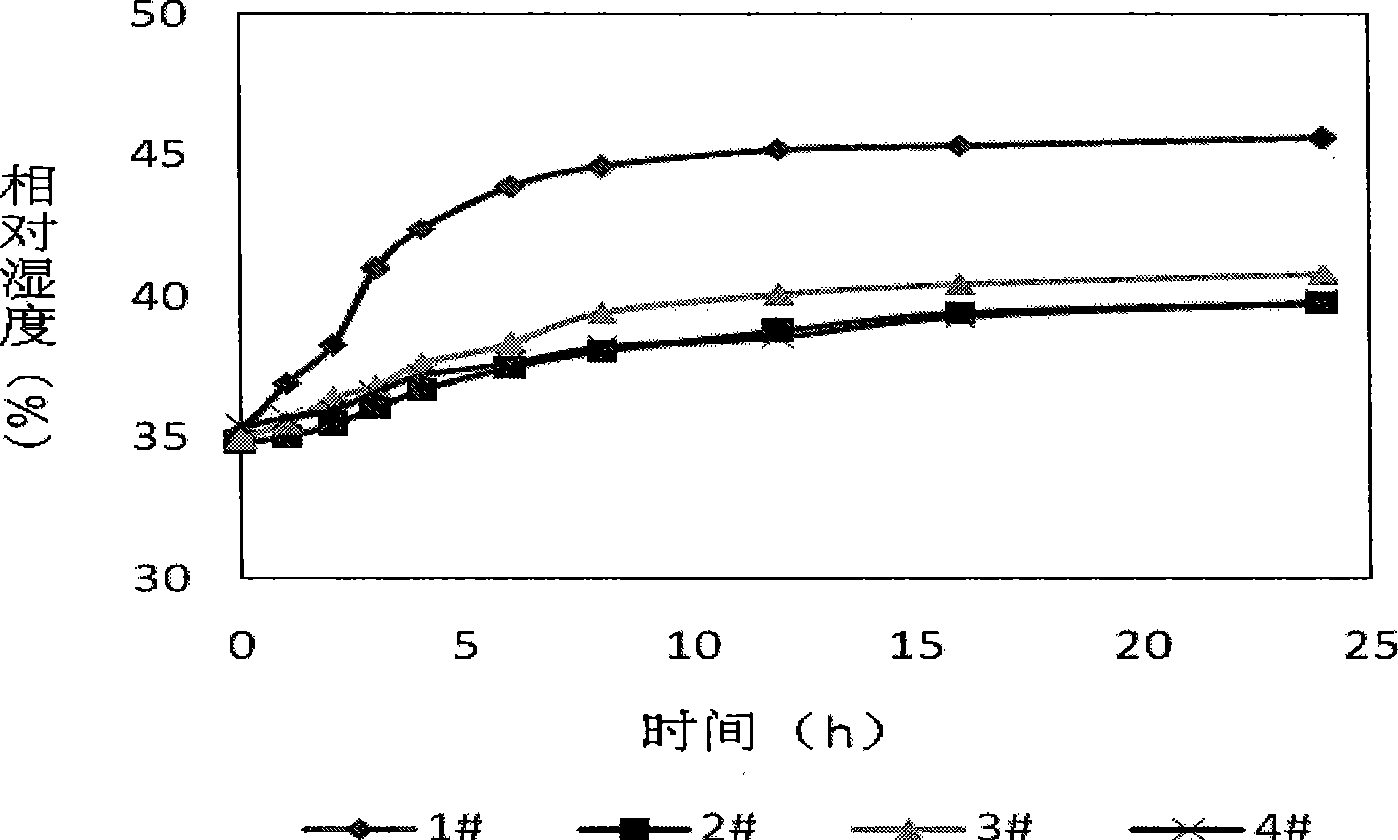

The invention relates to interior wall putty powder with air humidity regulating function, which belongs to the field of building materials. The putty powder is composed of 10 to 50 weight portions of humidity regulating material, 15 to 50 weight portions of inorganic binding material, 15 to 50 weight portions of inorganic filler, and 1 to 5 weight portions of sub divisible rubber powder; the humidity regulating material comprises one type or more than one type of diatomite, sepiolite, attapulgite, vermiculite, zeolite powder, kaolin and bentonite. Because of the environment protection and humidity regulating functions, the multi-pore inorganic mineral material is taken as humidity regulating material and applied in the building interior wall putty powder. With water added in, the putty powder is mixed into lacquer putty and applied on the wall surface, which can effectively regulate the indoor air humidity, so that the indoor air humidity is controlled within the scope which is beneficial to the health of human body; meanwhile, the putty powder has no pollution, no VOC released and can be directly used for decoration.

Owner:CHINA BUILDING MATERIALS ACAD

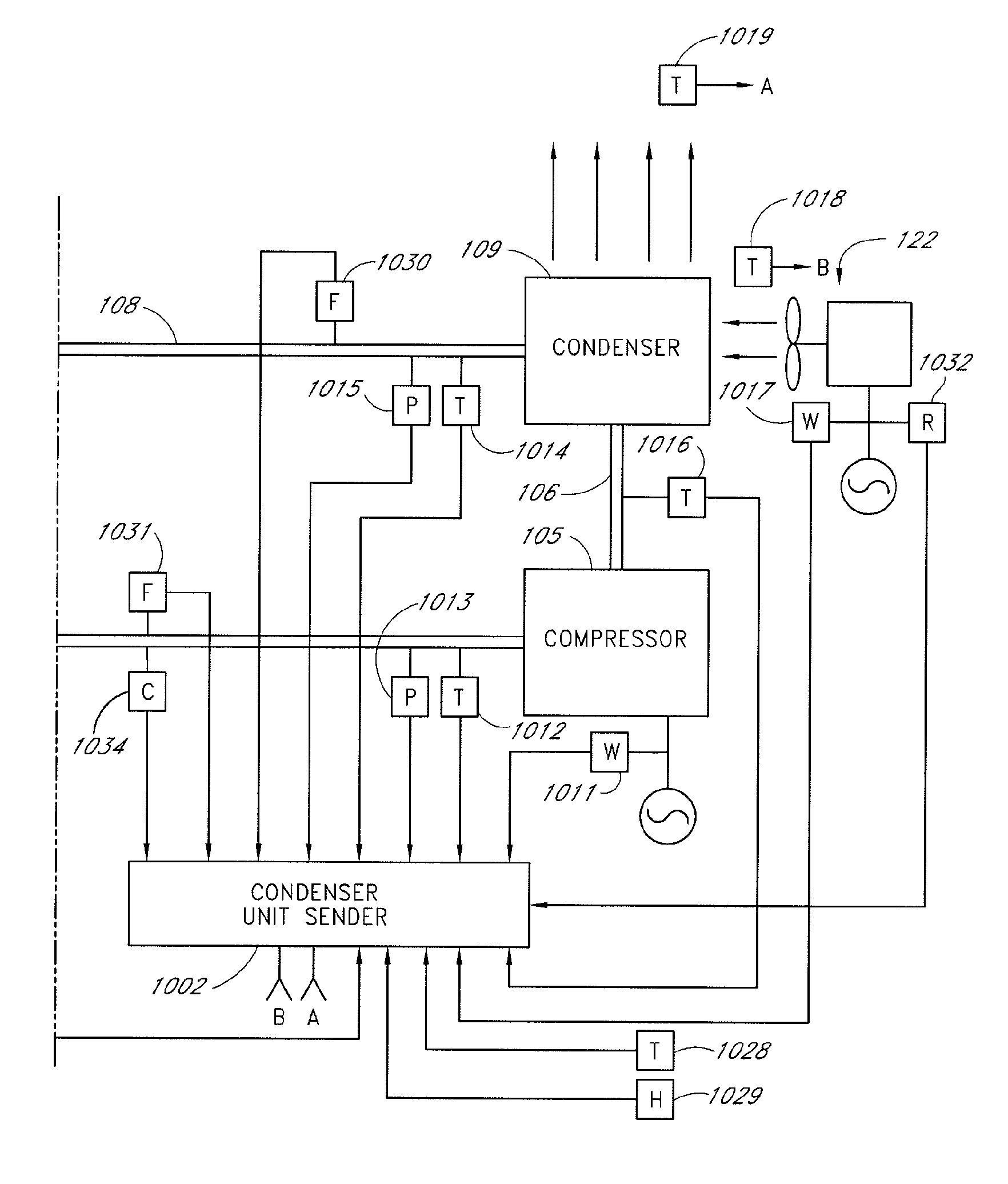

Method and apparatus for monitoring a calibrated condenser unit in a refrigerant-cycle system

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Method and apparatus for monitoring a calibrated condenser unit in a refrigerant-cycle system

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Conditioning deodorization antibiotic mildew-proof wallpaper

The present invention relates to a humidity-regulating, odor-removing, antibacterial and mould-proof wallpaper, which can effectively regulate the air humidity, absorb the polluting gases in the air and inhibit the reproduction of bacteria and mould. The wallpaper is produced by the drying, cooling and embossing of a basal paper and pasty material coated on the basal paper. According to weight percentages, the pasty material is made from 20 percent to 60 percent of PVC, 25 percent to 50 percent of filling, 5 percent to 15 percent of titanium pigment, 3 percent to 5 percent of the mixture of nano-ZnO and nano-TiO2, 1.5 percent to 3.5 percent of mould inhibitor, 1.5 percent to 3.5 percent of plasticiser, 0.5 percent to 2.5 percent of viscosity depressant, 1.5 percent to 2.5 percent of stabilizer and 0.5 percent to 1.0 percent of bisphenol A. Firstly, the PVC is made into paste and then uniformly mixed with the bisphenol A and the plasticiser; secondly, after being uniformly mixed with the filling, the paste is uniformly mixed with the titanium pigment, the nano-ZnO, the nano-TiO2 and the mould inhibitor and then the stabilizer; and finally, the viscosity depressant is added to regulate the viscosity of the paste in order to obtain the pasty material, which is then coated on the basal paper. The wallpaper has the advantages of no toxicity, no offensive odor, environment-friendliness, long service life, waterproofness and no deformation.

Owner:HONGQIJU CONSTR GRP CO LTD

Portable method and apparatus for monitoring refrigerant-cycle systems

InactiveUS20090037142A1Mechanical apparatusComplex mathematical operationsMonitoring systemEngineering

A portable monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the measurements performed by the monitoring system include one or more of: an evaporator input air temperature, an evaporator output air temperature, evaporator air flow, evaporator air humidity, condenser air input temperature, condenser air output temperature sensor, electrical power. In one embodiment, the portable monitoring system receives information about the refrigerant-cycle system from either the system itself or from a computer network.

Owner:KATES LAWRENCE

Method and apparatus for monitoring air-exchange evaporation in a refrigerant-cycle system

ActiveUS20060032248A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEvaporation

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

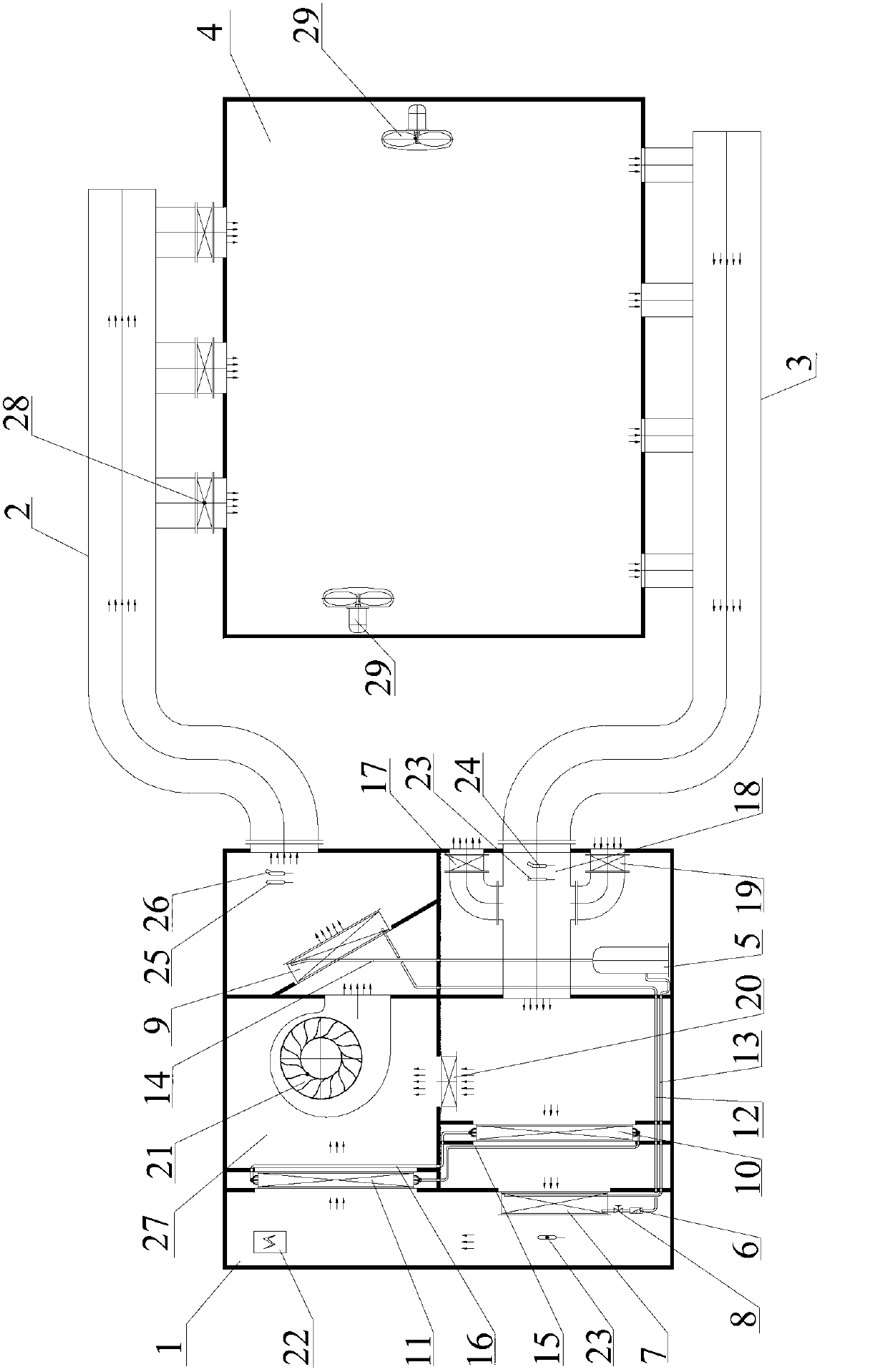

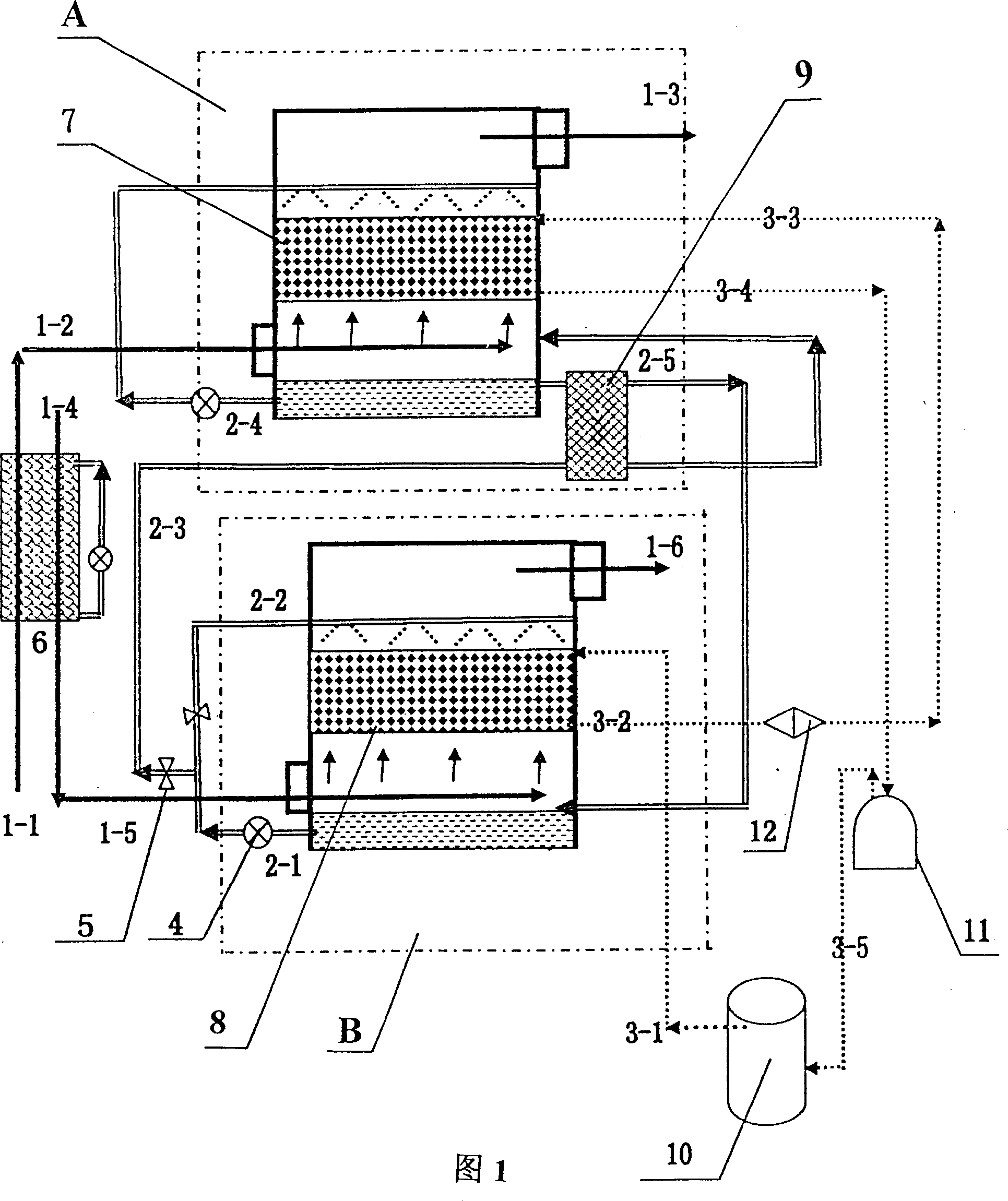

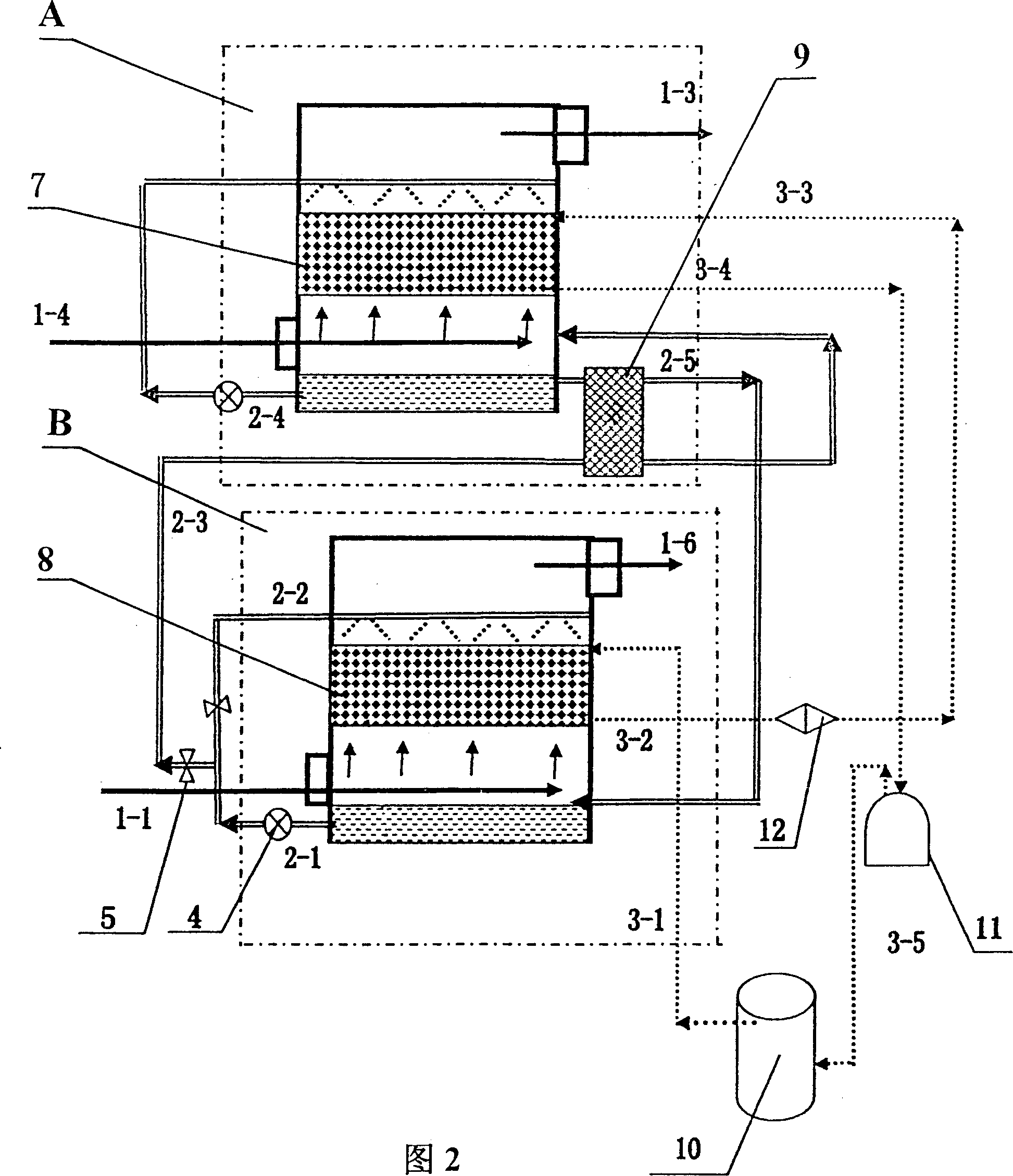

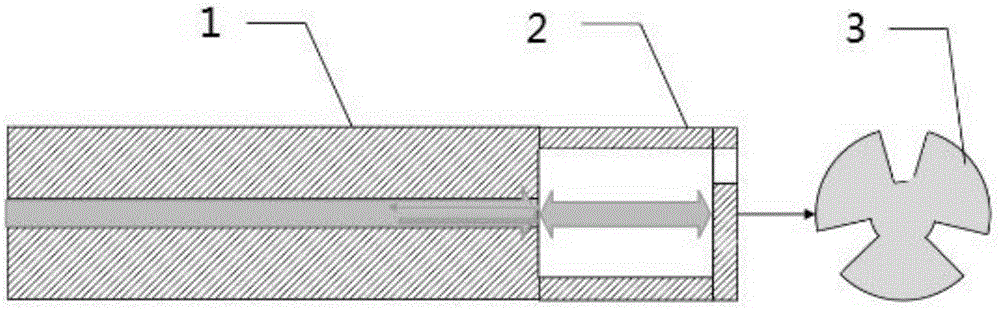

Intelligent hot-air drying control device

InactiveCN103123215AReduce energy consumptionReduced dehumidification loadDrying gas arrangementsEngineeringAir blower

The invention discloses an intelligent hot-air drying control device which comprises a heat exchange box and a drying chamber, wherein he heat exchange box is separated into multiple spaces, and the drying chamber is connected with the heat exchange box through an air supplying main pipe and a general air return pipe. A heat pump dehumidifying and heating system, a heat pipe return heat exchange system, a hot air circulating system and an intelligent control system are arranged in the heat exchange box. The heat pump dehumidifying and heating system which is composed of a compressor, a drying filter, a dehumidifying evaporator, a throttle valve and a heating condenser. The heat pipe return heat exchange system is composed of a heat pipe evaporator and a heat pipe condenser. The hot air circulating system is composed of a high-pressure refrigerant liquid connecting pipe, a low-pressure refrigerant return gas connecting pipe, a high-pressure refrigerant gas connecting pipe, a liquid refrigerant connecting pipe, a gas refrigerant connecting pipe, an air exhaust regulating valve, a mixed air box, a fresh air regulating valve, a secondary air flow regulating valve and an air blower assembly. The intelligent control system is composed of the a temperature sensor, a humidity sensor, a hot air temperature sensor and a hot air humidity sensor, wherein the temperature sensor, the humidity sensor, the hot air temperature sensor and the hot air humidity sensor are connected in the various systems. The intelligent hot-air drying control device can regulate the temperature and the humidity of drying air automatically and improve the material drying efficiency.

Owner:孙应真

Intelligent thermostat system for load monitoring a refrigerant-cycle apparatus

ActiveUS20060196197A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Intelligent thermostat system for monitoring a refrigerant-cycle apparatus

ActiveUS20060032246A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureThermostat

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Method and apparatus for monitoring a condenser unit in a refrigerant-cycle system

ActiveUS20060032247A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Method and apparatus for generating drinking water by condensing air humidity

InactiveUS20070175234A1Efficient workIdeal for useSteam/vapor condensersStationary conduit assembliesElectricityRural location

A system and method are shown which utilize a hybrid mechanical and evaporative air conditioning system to produce potable drinking while cooling an enclosure. The system operates on direct current, making it suitable for use in areas effected by natural disaster, power outage, or simply rural locations without access to electricity. The conditioning system includes both evaporative air conditioning and mechanical air conditioning functioning components to produce a water discharge. The system is operated to cool an enclosure. A portion of the water discharge is then drawn off and purified for use as drinking water.

Owner:GPM INC

Method and apparatus for airflow monitoring refrigerant-cycle systems

InactiveUS20060196196A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:KATES LAWRENCE

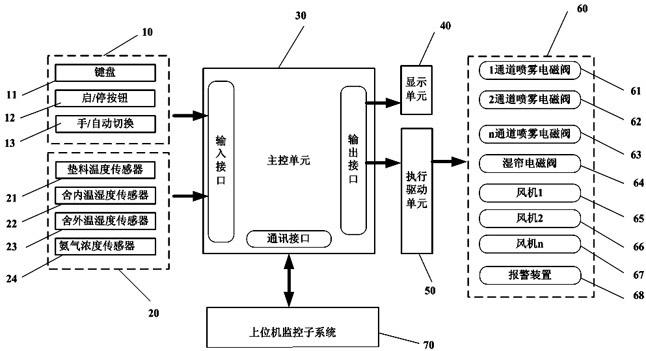

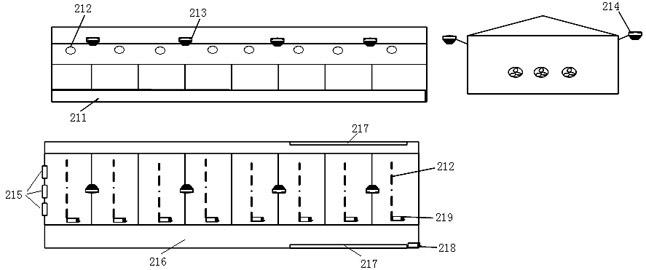

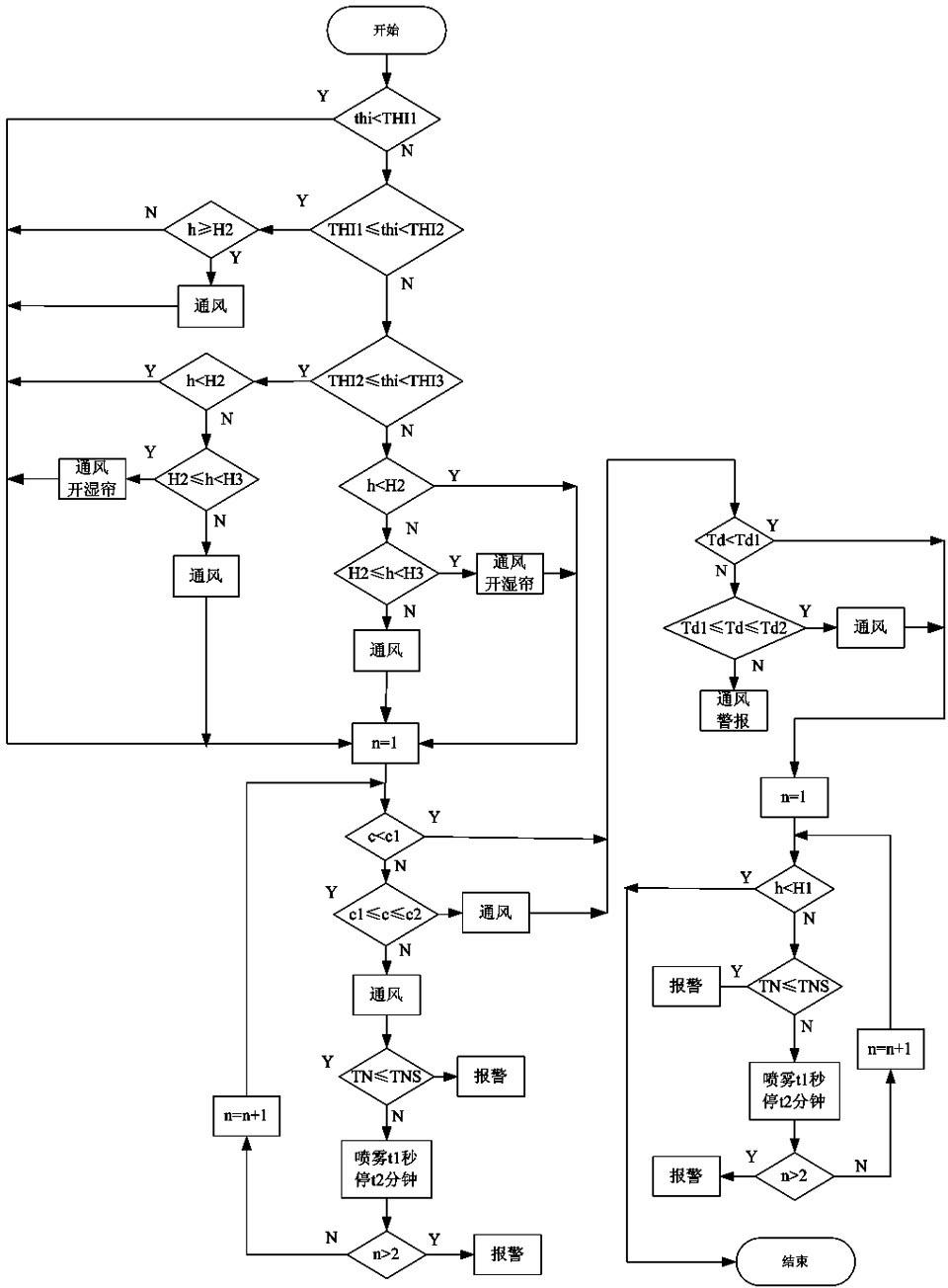

Intelligent microclimate control system for biological fermentation hog house

InactiveCN102511402AReduce heat stressNo high ammonia concentrationAnimal housingSimultaneous control of multiple variablesComputer monitoringEngineering

The invention relates to an environmental control system, in particular to a house microclimate control system for a biological fermentation hog house, which comprises a lower computer subsystem and an upper computer monitoring subsystem. The lower computer subsystem comprises an input device, a detection unit, a master control unit, a display unit, an executive drive unit and an executive unit. The system is mainly functionally capable of automatically acquiring environment factors, such as interior air temperature, interior air humidity, interior ammonia concentration of the hog house, temperature of padding of a biological fermentation bed, exterior air temperature and exterior humidity of the hog house, and the like, capable of starting and stopping ventilation operation, water curtain cooling operation and interior sprinkling operation to effectively regulate house temperature and ammonia concentration according to physiological comfort of hogs, and capable of intelligently sprinkling to effectively regulate humidity of the biological fermentation bed according to physiological comfort of the hogs and the humidity of the biological fermentation bed.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for air conditioning by solution dehumidifying with cold-hot two-side energy of refrigerating compressor

ActiveCN1743769AAchieve heat recoveryReduce concentrationAir conditioning systemsRefrigeration machinesLithiumRefrigeration compressor

A method for air condition utilizing cold and heat energy of solution combined with refrigeration compressor, which features utilizing the double side cold and heat energy of refrigeration compressor to process air and adjusting temperature, utilizing lithium salt solution to spraying air adjusting air humidity, then utilizing compressor energy condensing a d regenerating diluted solution to complete the process of sterilizing, dust removing and filtering.

Owner:AOLAN FUJIAN IND

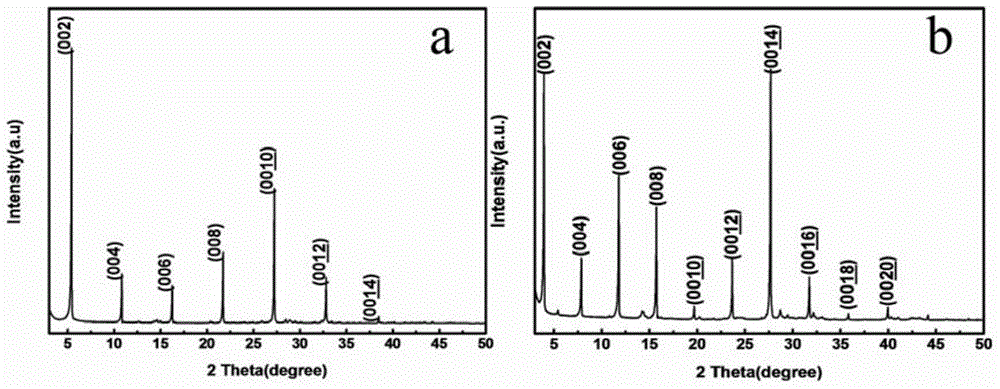

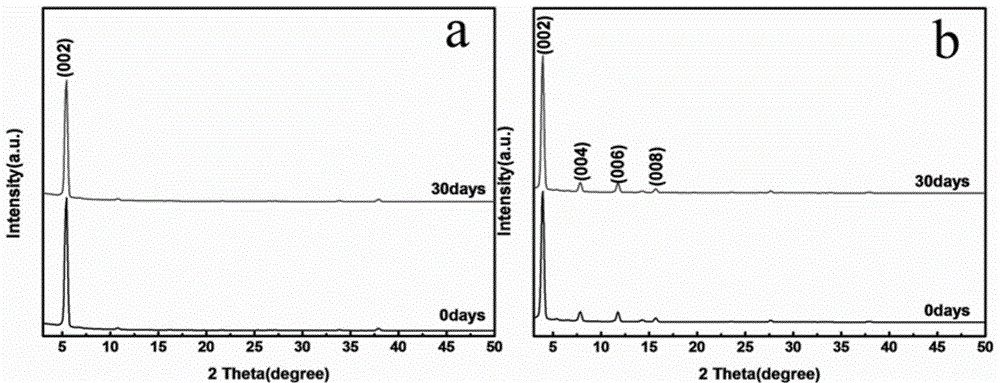

Perovskite solar cell and method for manufacturing same

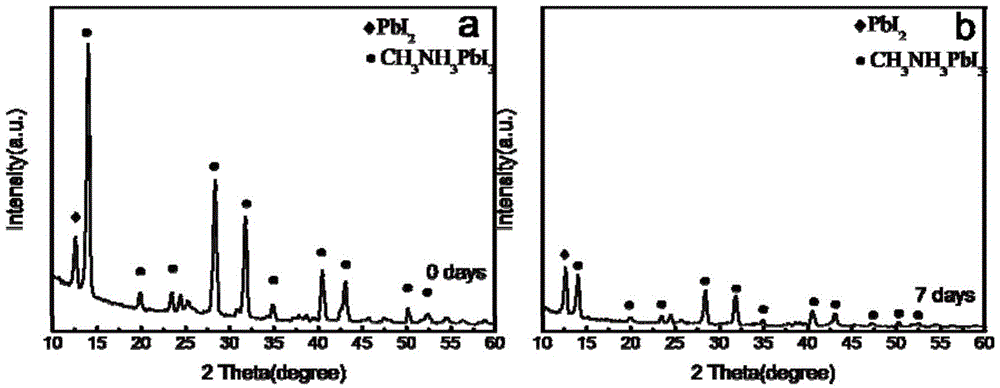

InactiveCN104795501ASimple and fast operationLow costFinal product manufactureSolid-state devicesHole transport layerMetal electrodes

The invention relates to a perovskite solar cell and a method for manufacturing the same. The perovskite solar cell comprises an FTO (fluorine-doped tin oxide) transparent conducting glass substrate, an electron transport layer, a light absorption layer, a hole transport layer and a metal electrode. The light absorption layer is made of (C<6>H<5>CH<2>CH<2>NH<3>)<2>(CH<3>NH<3>)<n-1>Pb<n>I<3*n+1> (the n is equal to 1 or 2) materials which are of two-dimensional layered structures. The perovskite solar cell and the method have the advantages that the layered perovskite light absorption layer is manufactured by the aid of a spin coating process, the method is simple and is excellent in film-forming property, the materials of the light absorption layer can be changed along with the layer number n, gaps of the materials can be adjusted, and the materials are excellent in chemical stability and still can keep the excellent layered structures without chemical decomposition after being exposed at high air humidity (50-80%) for 30 days, solar cell prototype devices with excellent and stable performance can be obtained, and the perovskite solar cell and the method are favorable for promoting perovskite solar cell commercialization progress.

Owner:WUHAN UNIV OF TECH

Portable method and apparatus for monitoring refrigerant-cycle systems

A portable monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the measurements performed by the monitoring system include one or more of: an evaporator input air temperature, an evaporator output air temperature, evaporator air flow, evaporator air humidity, condenser air input temperature, condenser air output temperature sensor, electrical power. In one embodiment, the portable monitoring system receives information about the refrigerant-cycle system from either the system itself or from a computer network.

Owner:COPELAND LP

Method for preparing a freeze-drying crisp fruit and vegetable piece

The invention discloses a method for preparing a freeze-drying crisp fruit and vegetable piece, which includes the following steps: blanching raw materials for killing enzyme; preparing a color protection liquid using citric acid concentration, sodium isoascorbate concentration, or cysteine hydrochloride concentration, sodium phytate concentration and embedding medium, wherein, the ratio between the color protection liquid and the slice liquid material is 0.25-1:1; slowly freezing fruit paste with 4-7 mm thickness below a eutectic point at minus 30 DEG C. for one hour; placing the fruit paste on a separator plate of a vacuum lyophilizer after the machine is precooled to a cold trap minus 50 DEG C. with 30 Pa vacuum degree and 40 DEG C. separator plate temperature; heating and drying by programs, wherein, 3-5 DEG C. rises every hour when the temperature is below 10 DEG C.; keeping temperature at 10 DEG C. for 1 hour; heating continuously for rising 5-7 DEG C. every hour; keeping temperature for 2 hours at 40 DEG C.; obtaining the crisp fruit and vegetable pieces with water content below 7% after refrigeration; slicing and packing products in an independent drying room with air humidity 40-50%. The invention has a distinct fruit and vegetable original flavour with larger market prospect.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

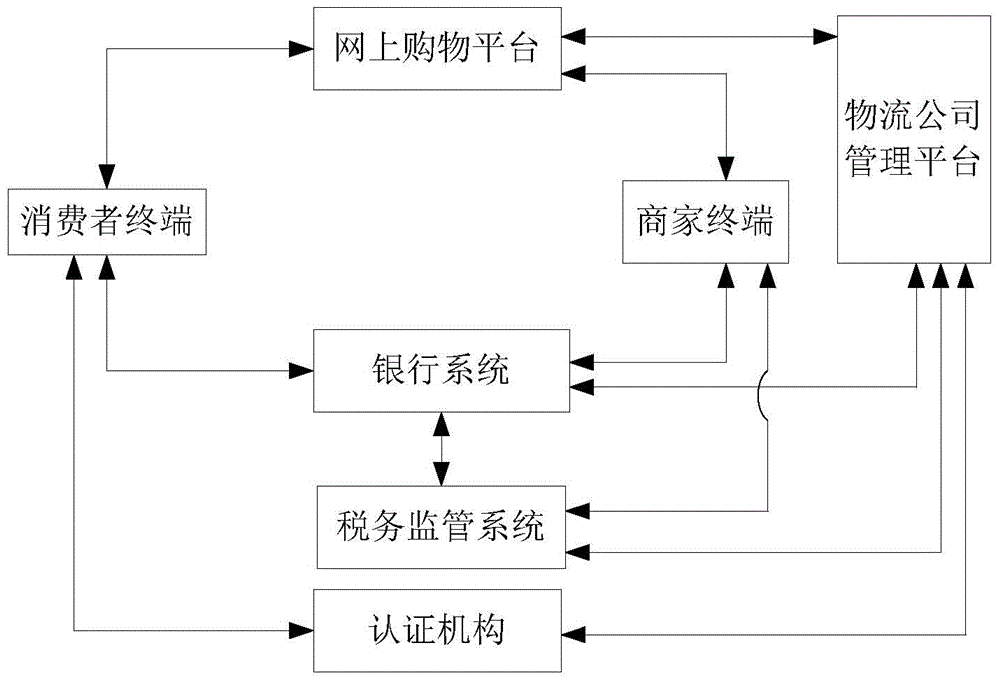

Business logistics safe payment method based on cash on delivery

InactiveCN105787718AGuaranteed legal statusGuarantee property securityPoint-of-sale network systemsProtocol authorisationLogistics managementPayment transaction

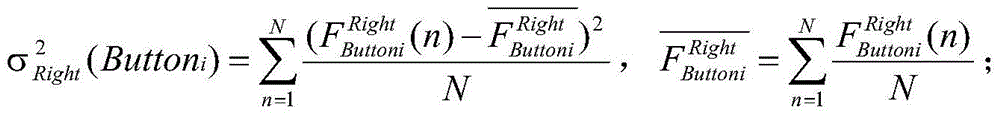

The invention relates to a business logistics safe payment method based on cash on delivery. After a hand-held POS terminal of a delivery man is connected with a mobile intelligent terminal of an addressee, the hand-held POS terminal and the mobile intelligent terminal respectively send their respective current positions, current position noise and air humidity to an authentication mechanism, the authentication mechanism, when determining that two payment sides are disposed within a safe transaction space distance and a current position noise difference and an air humidity difference between the two sides are within safety scopes, sends transaction secret keys to the two payment sides of cash on delivery, and the mobile intelligent terminal, according to conditions of already constructed left and right hand-pressing pressure databases of each button, when determining that a current payment password is input by a legal owner, transferring a fee to the account of a logistics company. In a cash-on-delivery transaction process, a tax supervision system monitors in real time a transaction order completion condition, and after a transaction succeeds, a banking system plays the role of deducting business taxes for a trade company and the logistics company.

Owner:ZHEJIANG WANLI UNIV

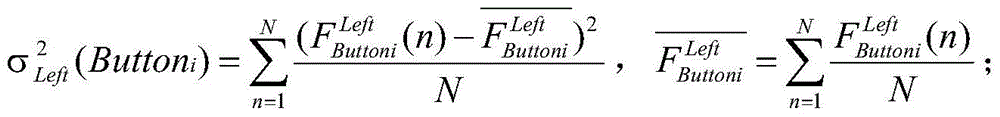

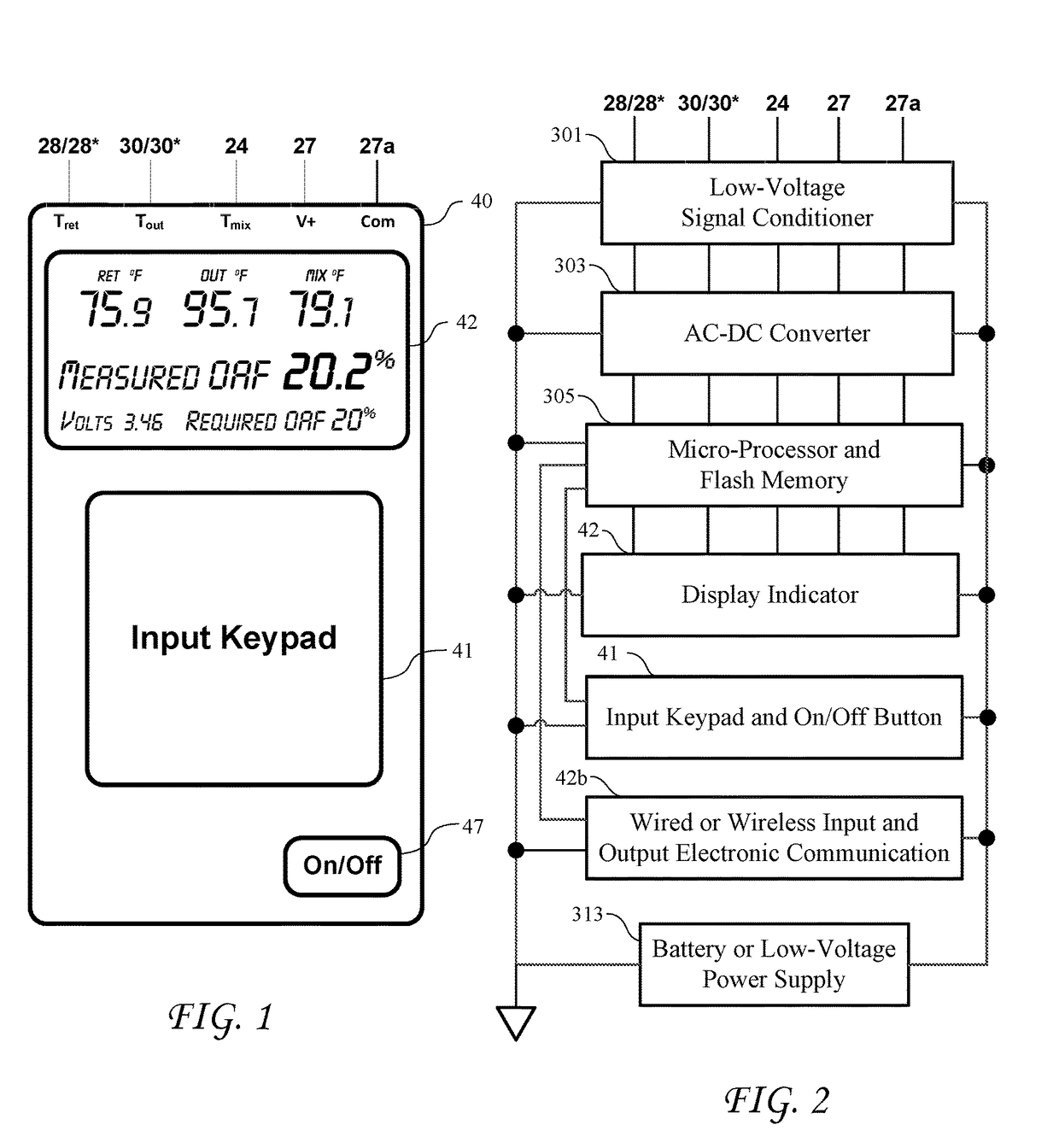

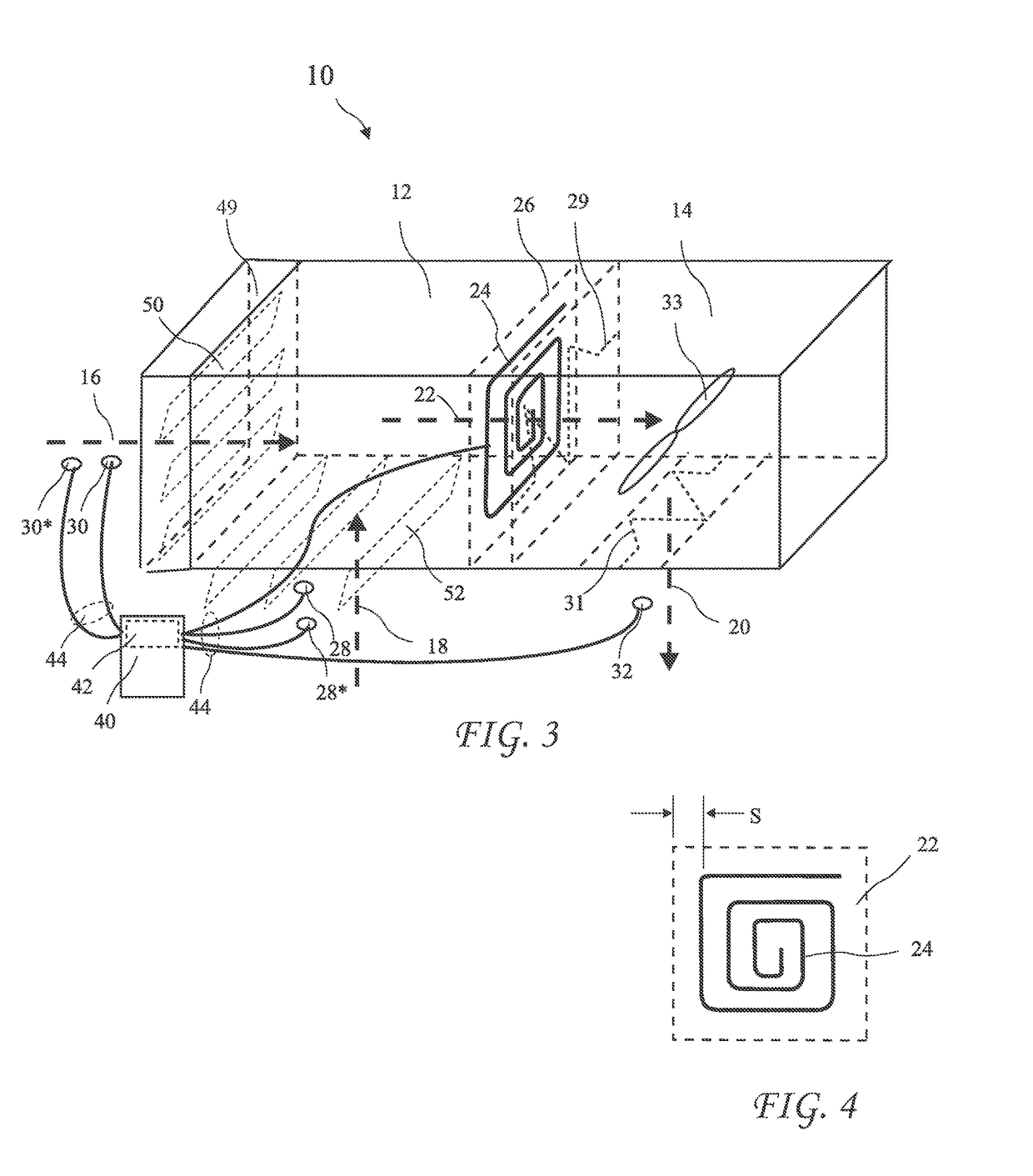

Apparatus and Methods to Measure Economizer Outdoor Air Fractions and Fault Detection Diagnostics of Airflow, Cooling Capacity, and Heating Capacity

ActiveUS20170343227A1Accurate temperatureLow accuracyMechanical apparatusSpace heating and ventilation safety systemsActuatorControl theory

An apparatus and method for measuring or controlling the Outdoor Air Fraction (OAF) ratio through economizer or outdoor air dampers and cabinet to total system airflow and mixed-air humidity ratio and wetbulb temperature for HVAC equipment. An OAF exceeding the minimum regulatory requirements wastes energy and contributes to global warming. OAF is used to optimize economizer damper position either manually or automatically using an economizer Fault Detection Diagnostic controller and actuator to meet minimum outdoor airflow requirements. After the outdoor air damper position is optimized, the mixed-air humidity ratio and mixed-air wetbulb temperature are determined and used with the measured mixed-air drybulb and supply-air drybulb temperatures to evaluate evaporator airflow, cooling capacity, and heating capacity, and, if necessary, provide a visual or electronically-transmitted error code signal indicating maintenance requirements to check or correct economizer damper position, cabinet leakage, airflow, cooling or heating capacity, and / or other faults for the HVAC system.

Owner:MOWRIS ROBERT J

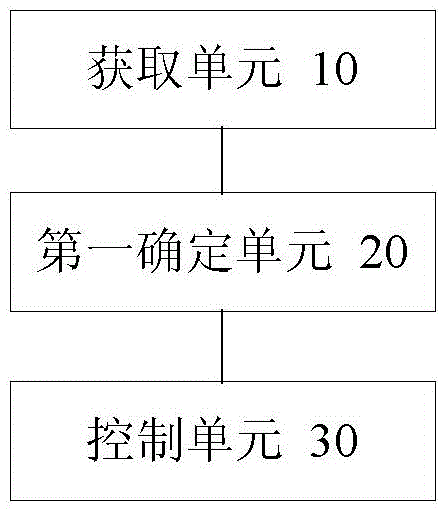

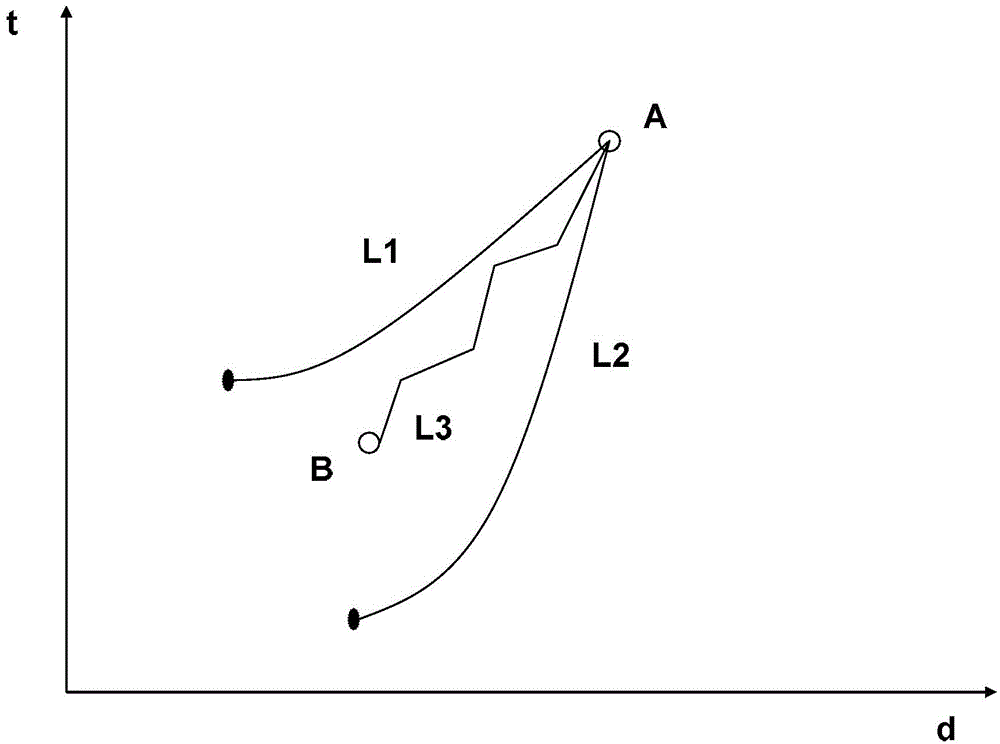

Air conditioning temperature and humidity control method and device

ActiveCN104807137ASolve the problem of not being able to take into account the energy saving of air conditionersMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention discloses an air conditioning temperature and humidity control method and device. The air conditioning temperature and humidity control method comprises obtaining the current air temperature values and the current air humidity values of the indoor environment in which an air conditioning is located and the outdoor environment; determining energy-saving control parameters according to the current air temperature values and the current air humidity values, wherein the energy-saving control parameters are used for controlling the air conditioning to adjust the current air temperature and the current air humidity in the indoor environment in the preset energy-saving state; controlling the air conditioning to operate the energy-saving control parameters. According to the air conditioning temperature and humidity control method and device, the problem that the energy conservation of the air conditioning cannot be achieved when the indoor temperature and the indoor humidity is simultaneously controlled in the related technologies is solved.

Owner:张迎春

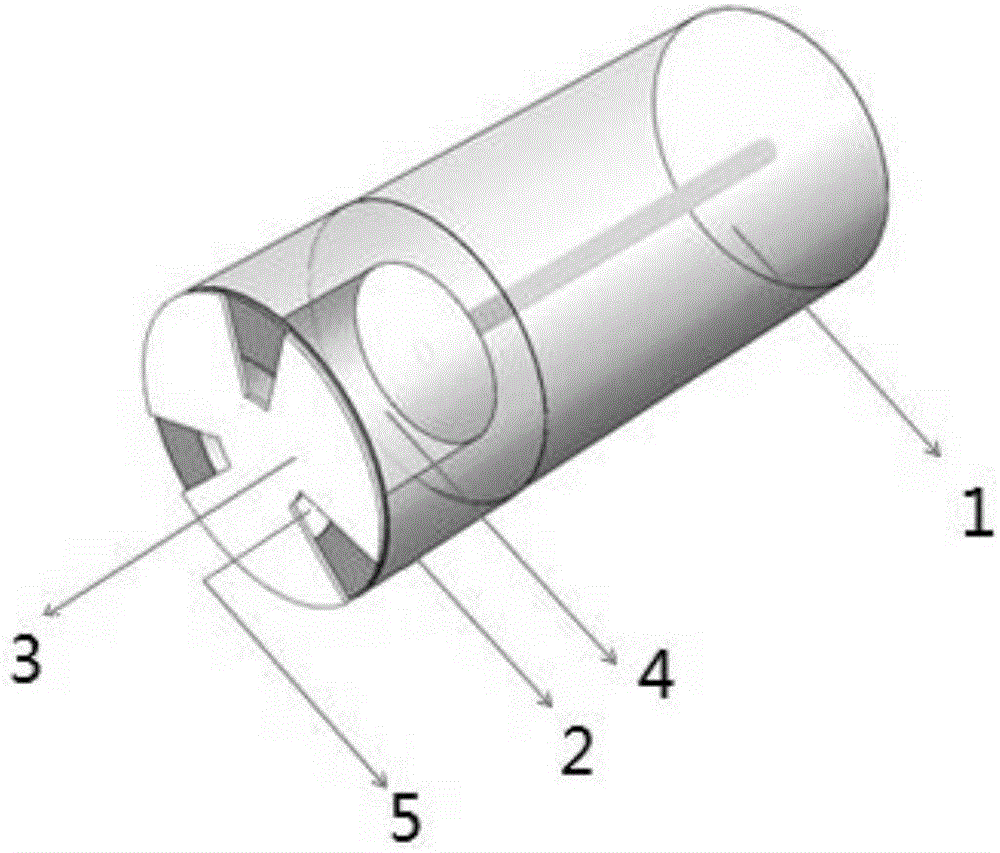

Optical fiber F-P multifunctional sensor based on microporous optical reflection diaphragm

ActiveCN104596559AAvoid tearingAvoid damageSubsonic/sonic/ultrasonic wave measurementPhase-affecting property measurementsOptical reflectionDiaphragm structure

The invention provides an optical fiber F-P multifunctional sensor based on a microporous optical reflection diaphragm. The optical fiber F-P multifunctional sensor based on the microporous optical reflection diaphragm is characterized in that the design of an F-P cavity structure formed by sequentially connecting a single-die optical fiber, an optical capillary tube and the microporous optical reflection diaphragm and a special microporous optical reflection diaphragm structure is adopted to develop a built-in optical fiber F-P multifunctional sensor which can highly sensitively detecting liquid refractive index, air humidity and ultrasound under common air pressure and external high pressure conditions. The sensor has a micro size, is simple in structure, integrated, high in sensitivity, fast to respond, high in resistance to electromagnetic interference, applicable to the fields of environmental monitoring, and biochemical detection and ultrasonic detection, has a good market prospect, and is high in market value.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

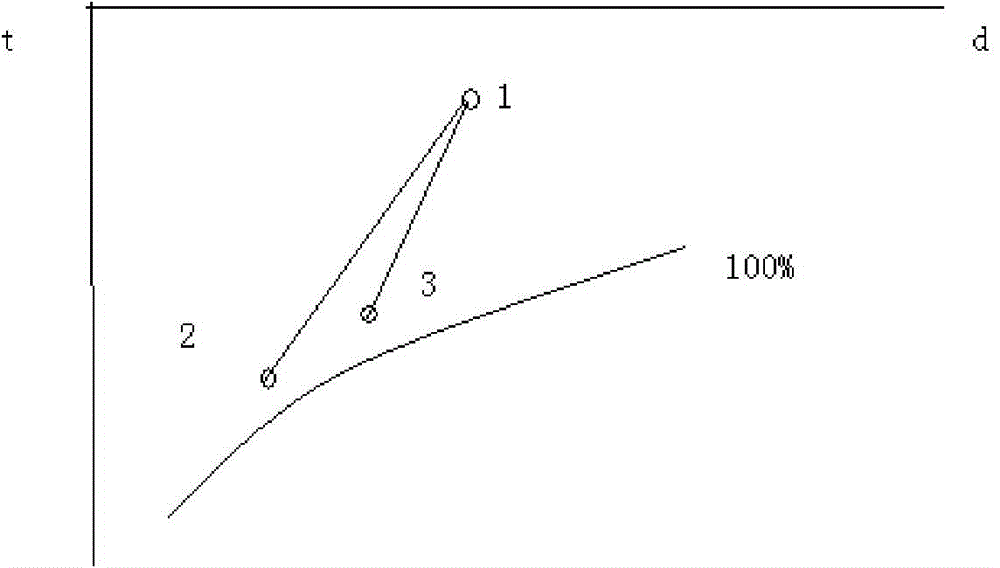

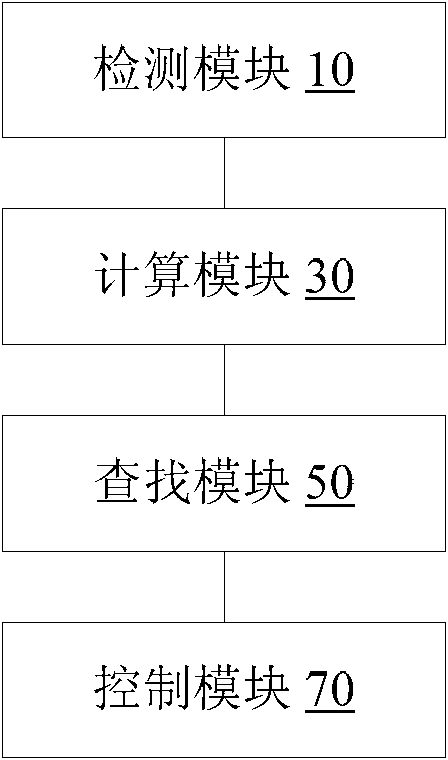

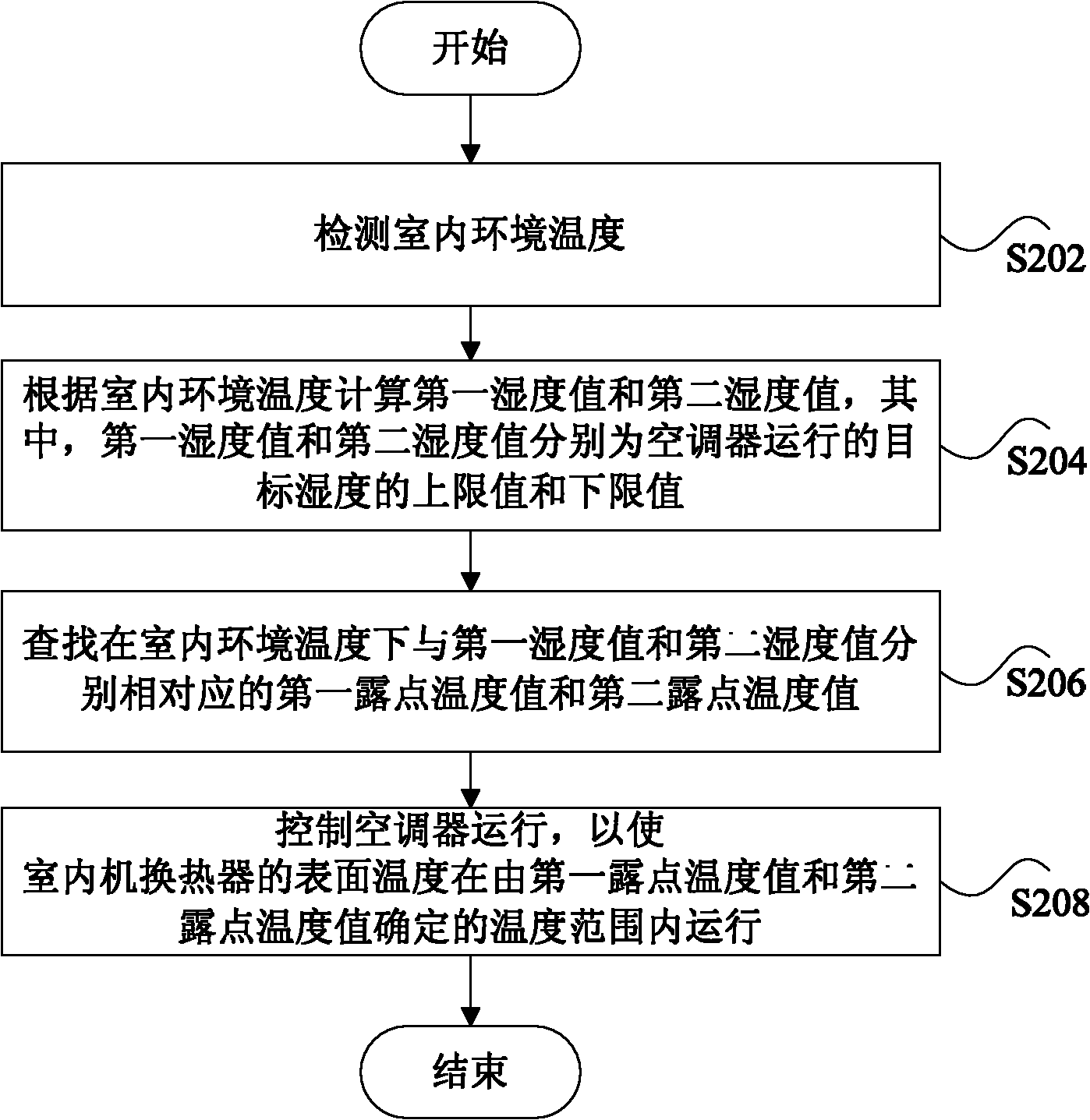

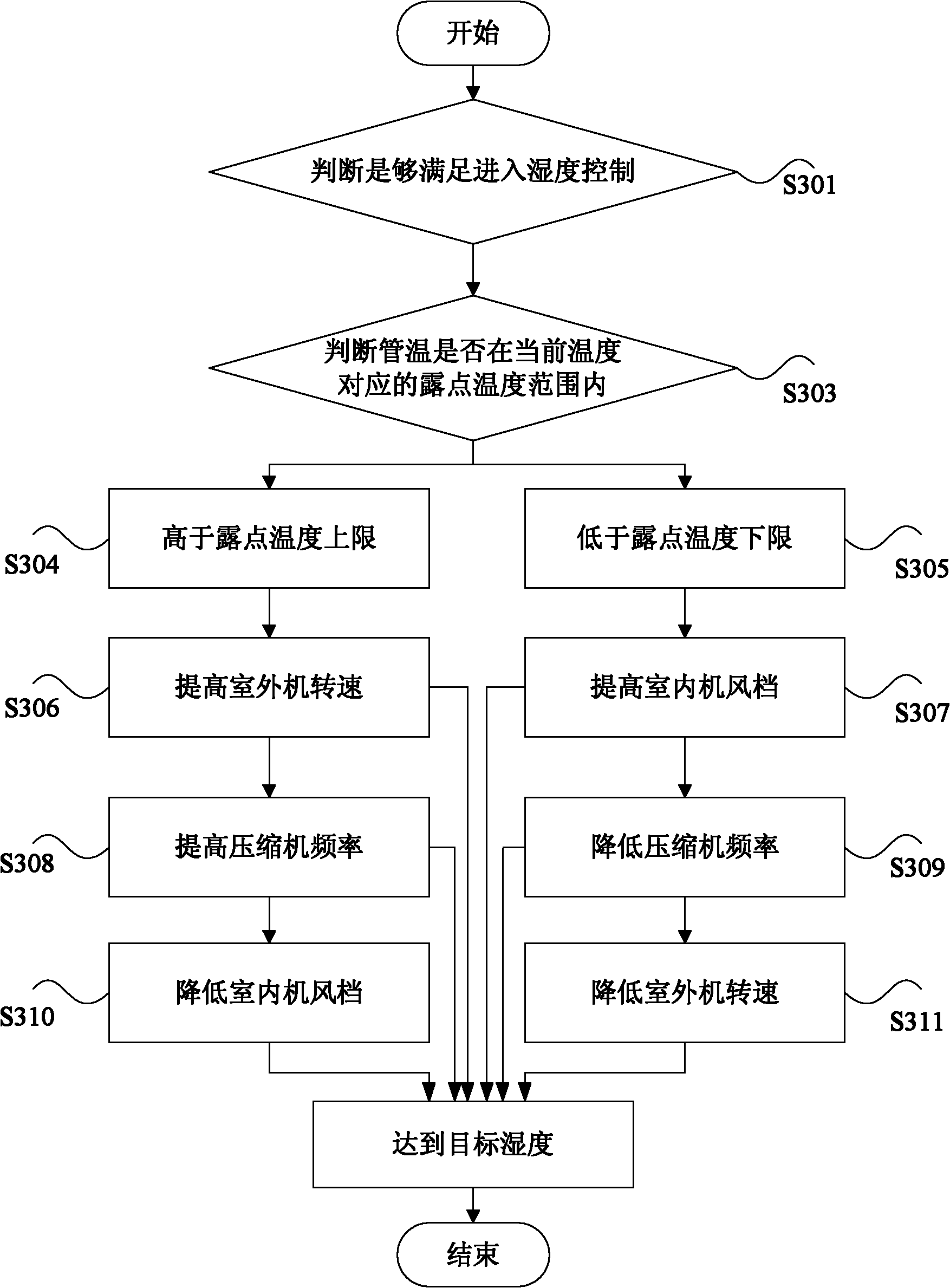

Air conditioner as well as humidity control method and device for air conditioner

ActiveCN103185384ASolve the problem of difficult to control indoor air humiditySpace heating and ventilation safety systemsLighting and heating apparatusLower limitEngineering

The invention discloses an air conditioner as well as a humidity control method and a humidity control device for the air conditioner. The humidity control method for the air conditioner comprises the following steps of: detecting indoor environment temperature; calculating a first humidity value and a second humidity value according to the indoor environment temperature, wherein the first humidity value is an upper limit value of target running humidity of the air conditioner, and the second humidity value is a lower limit value of the target running humidity of the air conditioner; searching for a first dew-point temperature value corresponding to the first humidity value and a second dew-point temperature value corresponding to the second humidity value at the indoor environment temperature; and controlling the running of the air conditioner to make the surface temperature of a heat exchanger of an indoor unit within a temperature range determined by the first and second dew-point temperature values. According to the air condition as well as the humidity control method and the humidity control device for the air conditioner, the problem of difficulty in control over indoor air humidity during the running of the air conditioner in the prior art is solved, and an effect of controlling the air humidity within a range of humidity under which a user feels comfortable is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

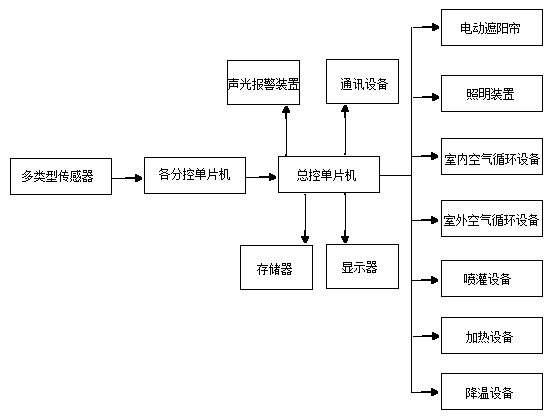

Greenhouse environment intelligent control and management system based on information acquisition

ActiveCN104238602AImprove balanceEasy to adjustSimultaneous control of multiple variablesAir cycleDisplay device

The invention discloses a greenhouse environment intelligent control and management system based on information acquisition. The system comprises various types of sensors arranged in a greenhouse, a memory, a display, a sound and light alarm apparatus and a communication device. The various types of sensors include air temperature sensors, air humidity sensors, illuminance sensors, carbon dioxide sensors, soil moisture sensors and soil temperature sensors, a sub-control single-chip microcomputer is arranged for each type of sensors, all the sub-control single-chip microcomputers are connected with a master control single-chip microcomputer, window shades and / or lighting devices are arranged on the top and the side faces of the greenhouse, an indoor air circulating device, an outdoor air circulating device, a spray irrigation device, a heating device and a cooling device are arranged in the greenhouse, and the window shades are driven by motors. Through the system, various types of environmental data of the greenhouse can be monitored, and environmental parameters of the greenhouse can be automatically adjusted accurately and rapidly according to information acquired by all the sensors.

Owner:JIANGSU YONGLIAN MODERN AGRI DEV

Method for directly seedling dendrobe seedlings by using plastic greenhouse

ActiveCN103004445AImprove seedling rateLow costSeed and root treatmentClimate change adaptationDiseaseSymbiotic bacteria

A method for directly seedling dendrobe seedlings by using a plastic greenhouse comprises the following steps: constructing a greenhouse; making a seedling bed; preparing a base material and performing sterilization, which can be realized by mixing pine barks and sheep manure, filtering the pine barks and the sheep manure through a screen after completely fermenting the pine barks and the sheep manure, soaking the pine barks and the sheep manure by using carbendazim, spreading the pine barks and the sheep manure on the seedling bed, placing the pine barks and the sheep manure on the seedling bed for 5-10 days, and controlling the water content; inoculating the symbiotic bacteria, which can be realized by taking a two years old base material of the dendrobe and uniformly scattering the two years old substrate on the seedling bed on which a new substrate is laid; pre-treating seeds, which can be realized by completely moisturizing the seeds by using sterile water containing naphthyl acetic acid; sterilizing the seeds in the greenhouse, which can be realized by fumigating every cubic meter of seeds by using 4 g mushroom protector, fumigating the seeds for one time before sowing, and fumigating the seeds every half a month in the future; scattering, which can be realized by after the seeds are scattered and before the seedlings are transplanted, controlling temperature in the greenhouse, water content of the seedling bed and air humidity, treating the seeds by weak lights within the first month of the scattering, and gradually enhancing illumination after budding; managing water, fertilizers and diseases of the seedlings; and transplanting the seedlings. The method for directly seedling the dendrobe seedlings by using the plastic greenhouse, provided by the invention has the advantages that as the dendrobe are transplanted after directly becoming to the seedlings, the seedling breeding cost is effectively reduced, the seedling rate of the seeds is more than 90 percent, and the transplanting survival rate of the seedlings is 100 percent.

Owner:戴亚峰

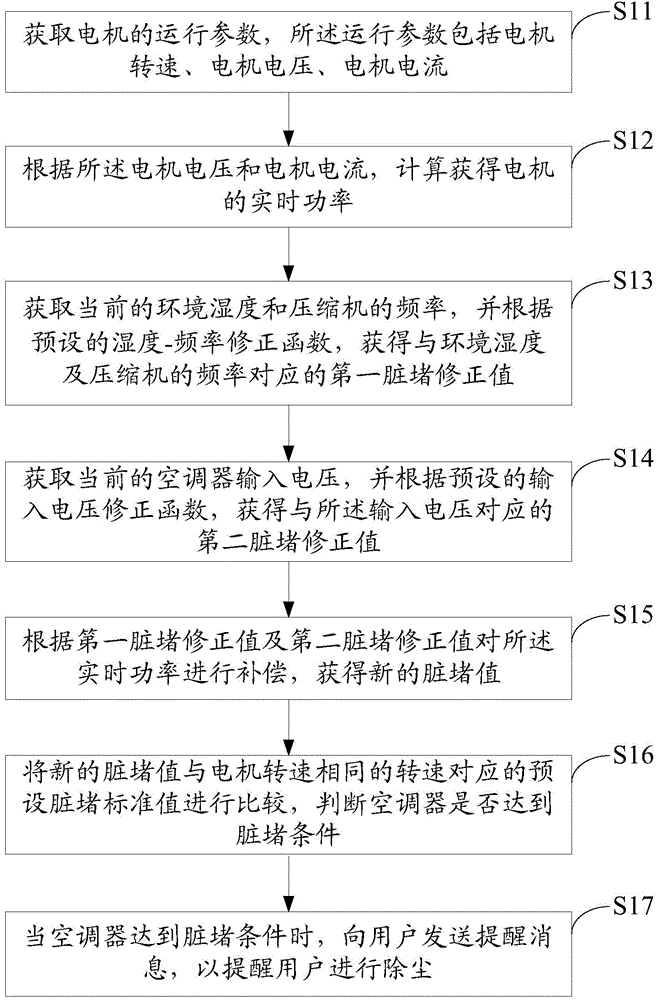

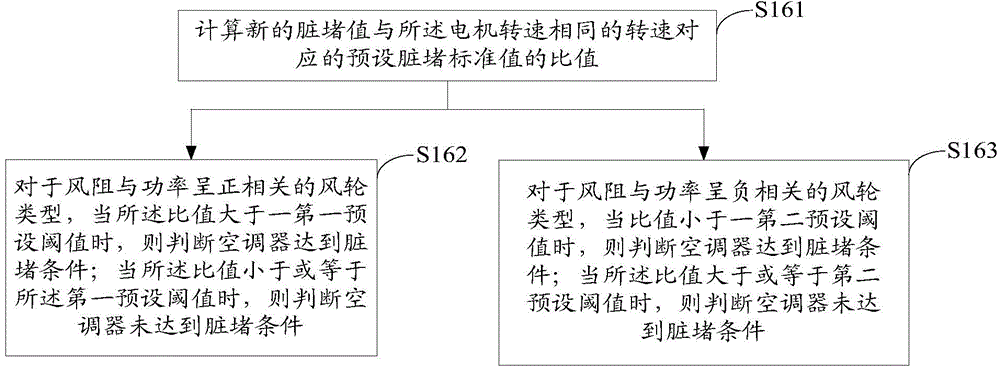

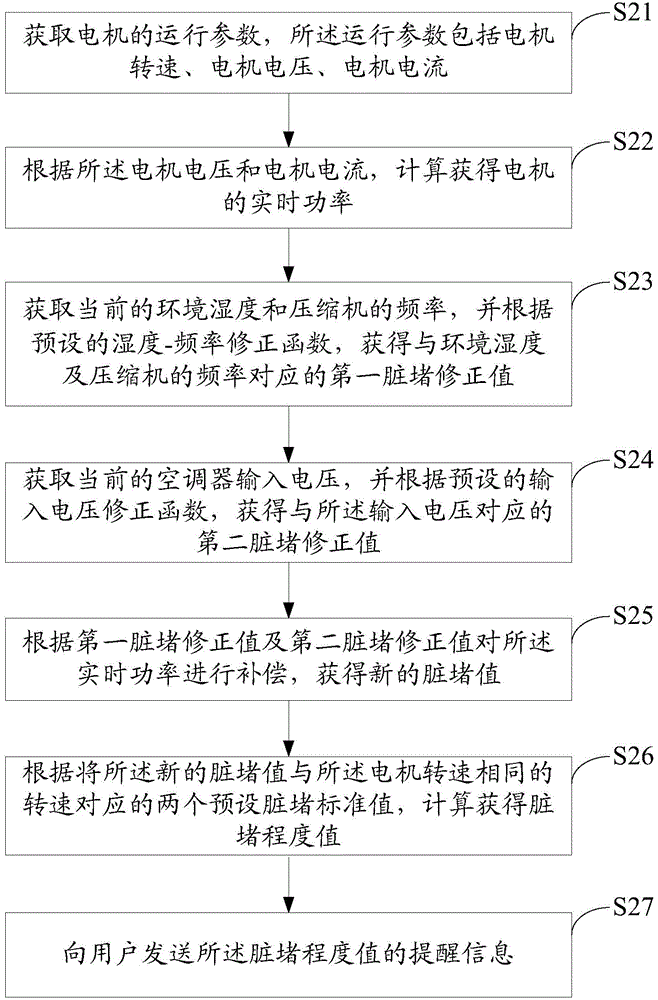

Air conditioner indoor unit and filth blockage control method thereof

ActiveCN105352027AGuaranteed cooling effectGuaranteed heating effectSpace heating and ventilation safety systemsLighting and heating apparatusPower gridElectric machinery

The invention discloses a filth blockage control method of an air conditioner indoor unit. According to the filth blockage control method, firstly real-time power of a motor is obtained; then the influence of air conditioner input voltage, humidity and compressor frequency on motor power is considered, the real-time power of the motor is modified, and therefore a new filth blockage value is obtained; the new filth blockage value is compared with a preset filth blockage standard value corresponding to the rotating speed equal to that of the motor, and whether an air conditioner meets the filth blockage condition or not is judged; when the air conditioner meets the filth blockage condition, a warning message is sent to a user so as to warn the user to remove dust. Factors such as network voltage, environment humidity and compressor frequency which affect filth blockage judgment are considered so that the filth blockage situation of an outdoor heat exchanger and the demands for removing dust timely can be accurately detected; the influence of the factors such as user network voltage, air humidity and compressor frequency is avoided; the refrigeration and heating effects of the air conditioner are guaranteed, and the health degree and comfort of the user are further improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Quick regenerating method for vegetation of returning farmland to grassland zone in extremely cold areas

The invention relates to a quick regenerating method for vegetation of returning farmland to grassland zone in extremely cold areas, which comprises the following steps of: (1) mixing and seeding annual pasture oat and perennial pasture on the farmland returning to grassland zone, and building an artificial pasture integrating mowing and grass seed harvesting functions; (2) ploughing and raking the artificial pasture; (3) sowing the seeds and applying base fertilizer; and (4) mowing the oat forage grass in the first year and harvesting the grass seeds and mowing the perennial pasture in the second year or later after covering and compacting the grass seeds in the step (3). The method utilizes the annual oat and perennial pasture to form different biotypes of pasture mixing and seeding community, so that the weed spreading can be obviously suppressed, the soil humidity and air humidity are obviously improved, the evaporation capacity and water loss and soil erosion intensity are reduced, therefore, the soil exposure time is short after regeneration of the grassland zone, the vegetation covering is quick, the water retention and preservation of soil moisture effect is obvious, and the ecological and economic benefits are remarkable.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST +1

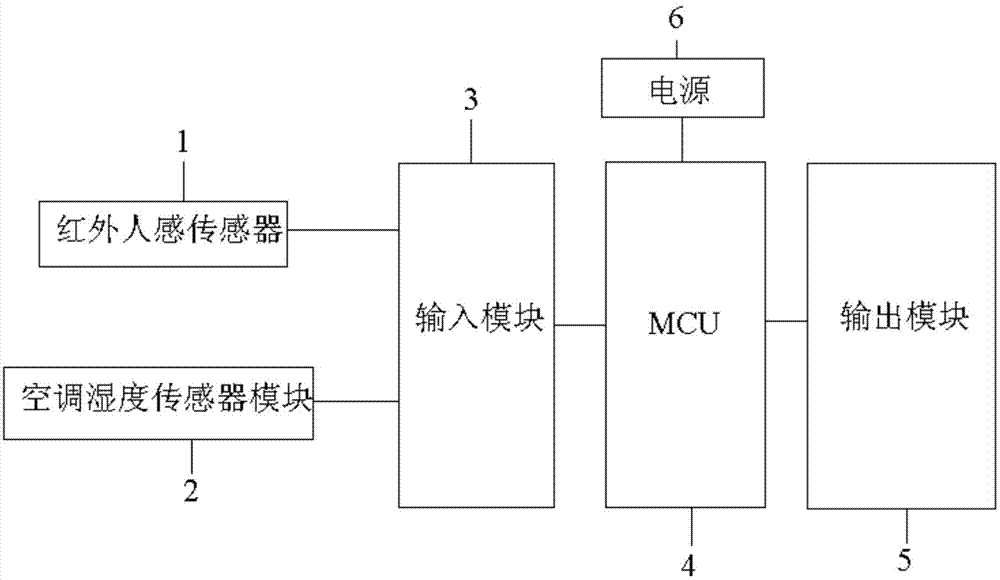

Air-conditioner and method for controlling sleep environment

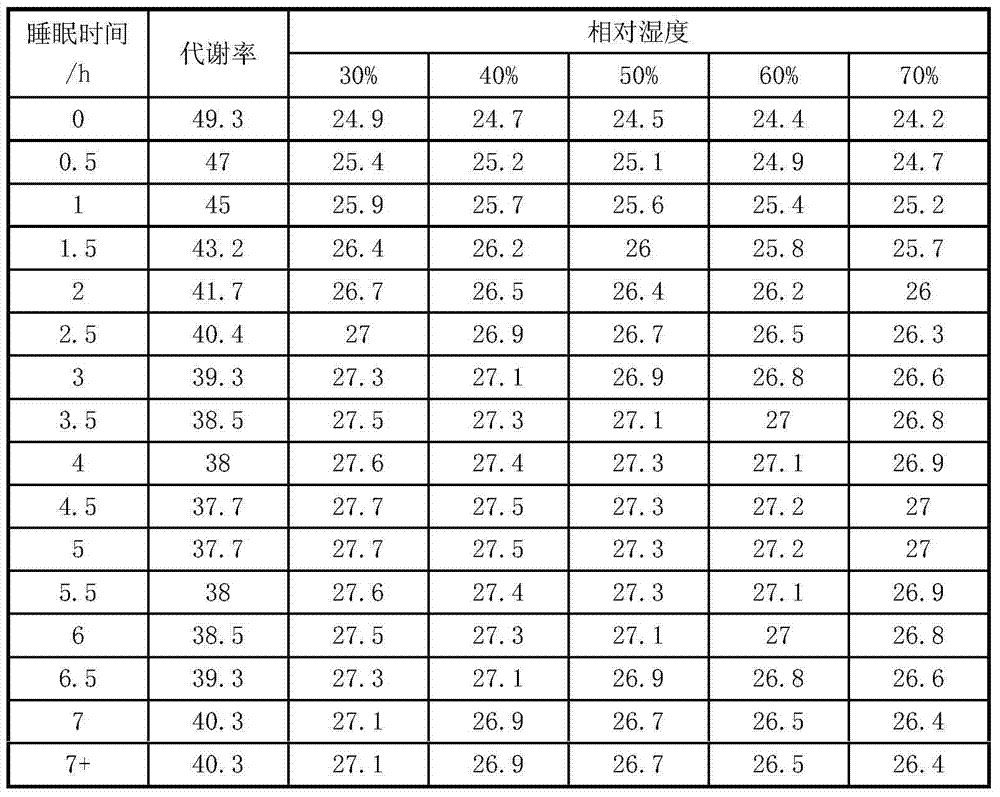

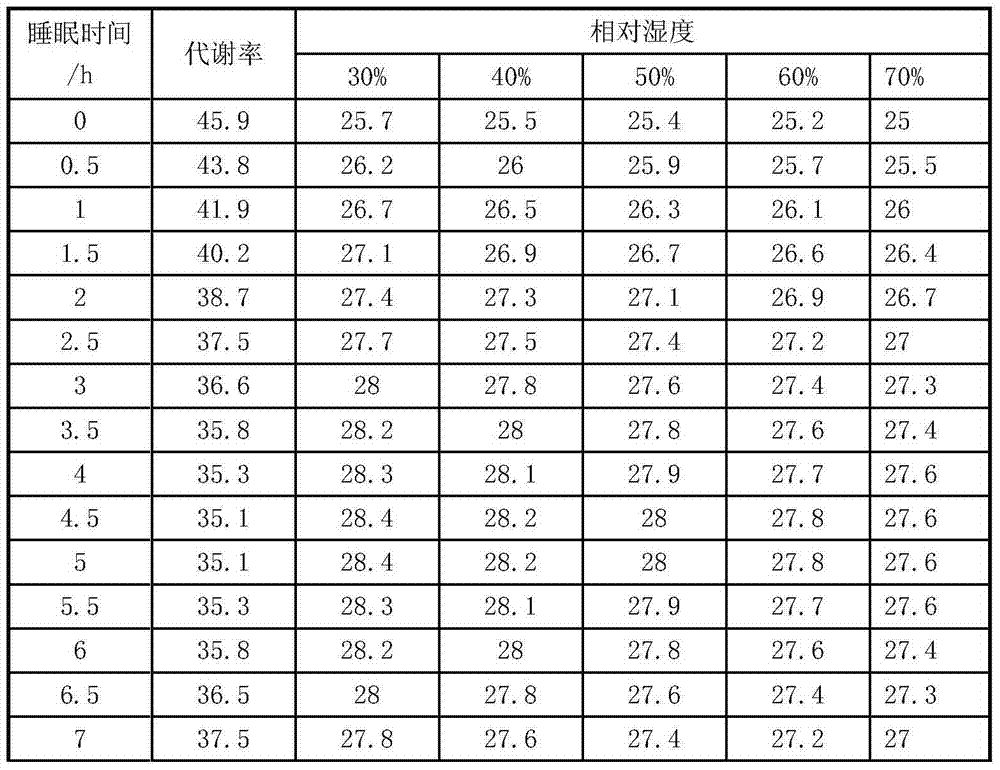

InactiveCN104764165AAdapt to sleep comfort needsMechanical apparatusSpace heating and ventilation safety systemsMetabolic rateOlder people

The invention discloses a method for controlling a sleep environment. The method comprises the steps: acquiring body type and person location information parameters through an infrared body sensor; detecting air humidity in a room through an air-conditioning humidity sensor module; bringing metabolic rates of different bodies and different humidity values into an PMV (Predicted Mean Vote) equation to calculate comfortable sleep temperature of males, females, children and old people; starting an air-conditioner to run at a low-wind state, enabling a wind direction to keep away from human bodies and regulating the present sleep setting temperature according to a setting temperature reading table calculated according to the PMV equation. The invention further discloses an air-conditioner for controlling the sleep environment. An input module, an output module and a power supply are respectively connected with an MCU (Micro Controller Unit); the infrared body sensor and the air-conditioning humidity sensor module are respectively connected with the input module. The beneficial effect is as follows: the air-conditioner is applicable to controlling different people to enter comfortable sleep state.

Owner:FUYANG NORMAL UNIVERSITY

Method for treating cow dung with Hermetia illucens to prepare organic fertilizer

InactiveCN104844288ARealize resource utilizationIncrease productivityBio-organic fraction processingOrganic fertiliser preparationHermetiaResource utilization

The invention provides a method for treating cow dung with Hermetia illucens to prepare an organic fertilizer. The method comprises the following steps: dehydrating cow dung with a dehydrater; adding swill or kitchen waste of which the addition amount is 10-15% of the mass of dehydrated cow dung; and then adding lactic acid bacteria dry powder for fermentation treatment for 1-2 days, wherein the addition amount of lactic acid bacteria dry powder is 0.1% of the mass of dehydrated cow dung; and finally adding 3-4-day old Hermetia illucens larva, culturing for 5-6 days at 30-35 DEG C under the condition that the air humidity is 75-85%, and separating out mature Hermetia illucens larva, thus obtaining an organic fertilizer. The method has the advantages of high treatment capacity, short cycle and low energy consumption in the treatment process, and can be used for realizing the resource utilization of cow dung and kitchen waste and changing waste material into things of value. In addition, since the nutritional value of cow dung is higher than that of horse dung and lactic acid bacteria are used for fermentation treatment, cow dung becomes loose and is improved in palatability, the intake rate of Hermetia illucens is increased and the yield of mature Hermetia illucens larva can be improved by 50% or above. By virtue of the method, the environment sanitation is improved and moreover organic fertilizer and bioprotein are produced; and thus, the method has a very bright application prospect.

Owner:CHONGQING GUANGYAO AGRI SCI & TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com