Patents

Literature

193 results about "Every Hour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Every hour. (NCI)

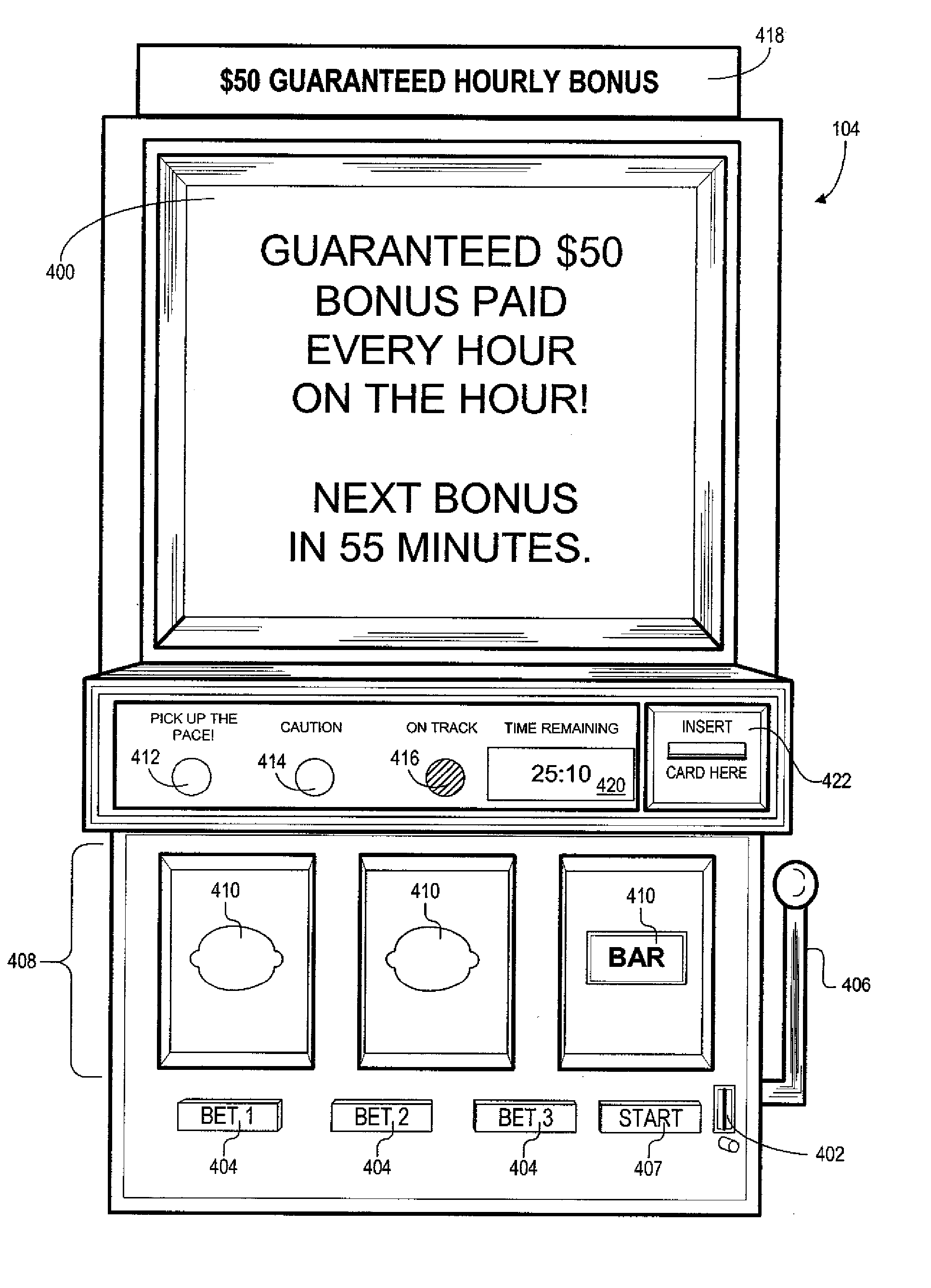

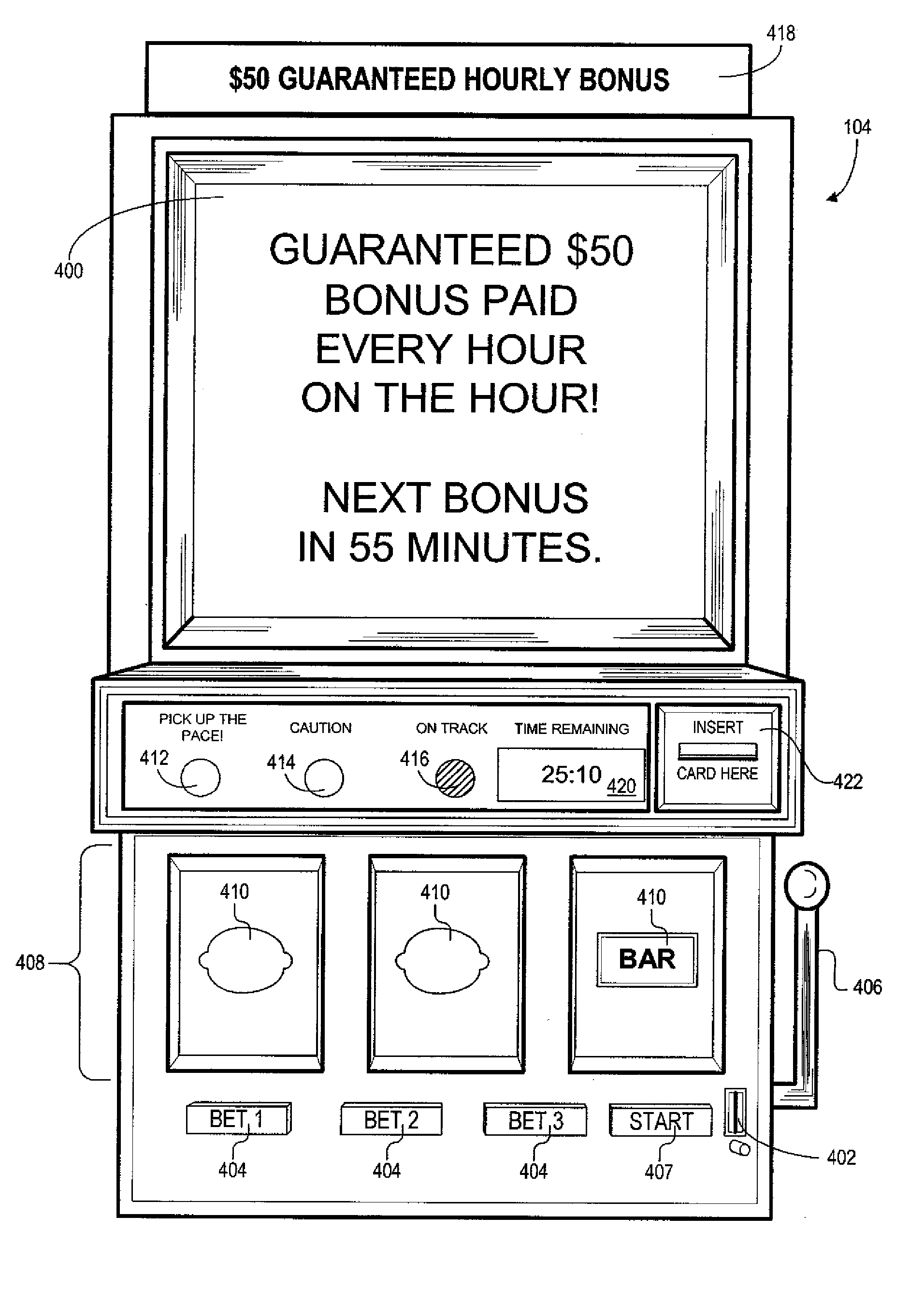

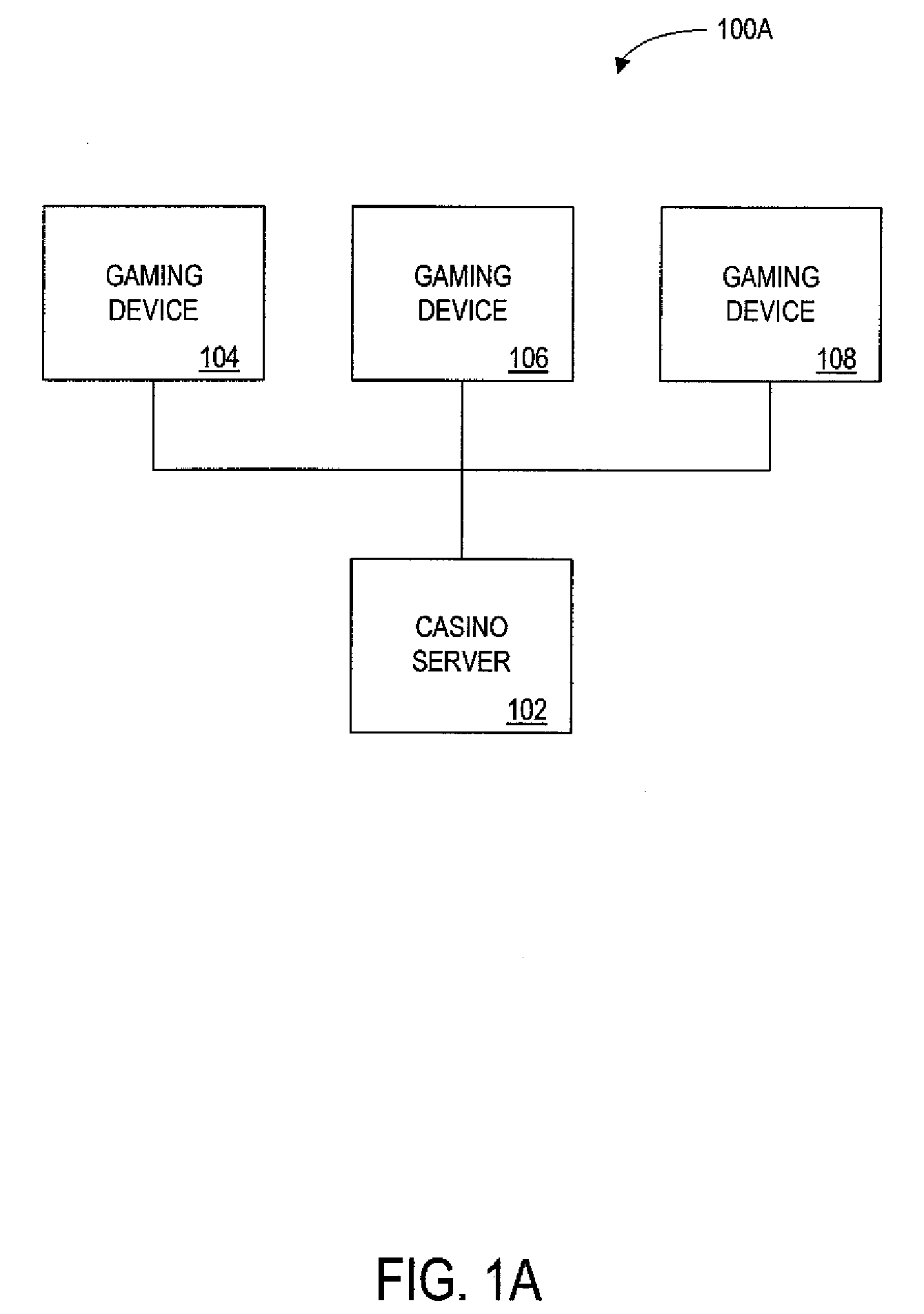

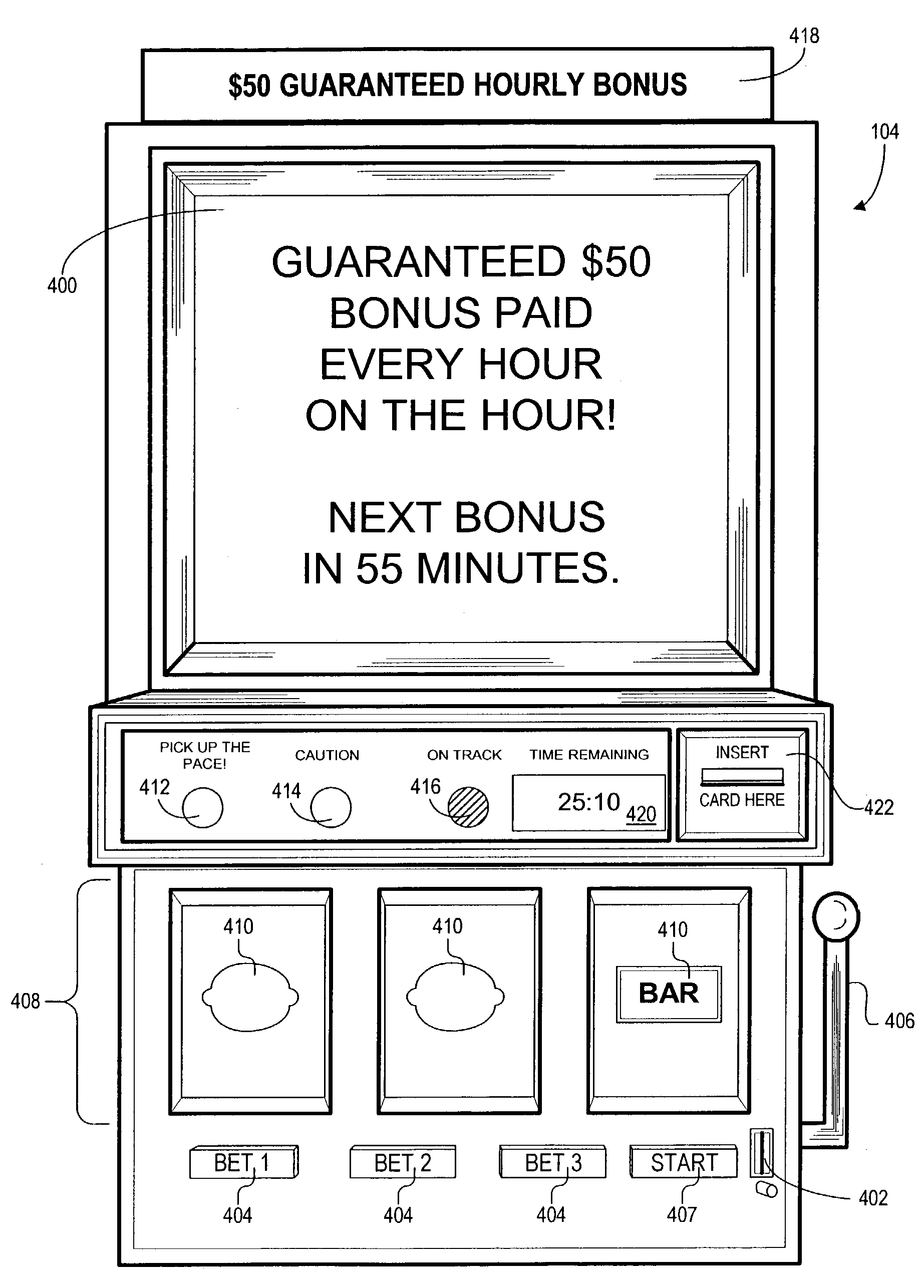

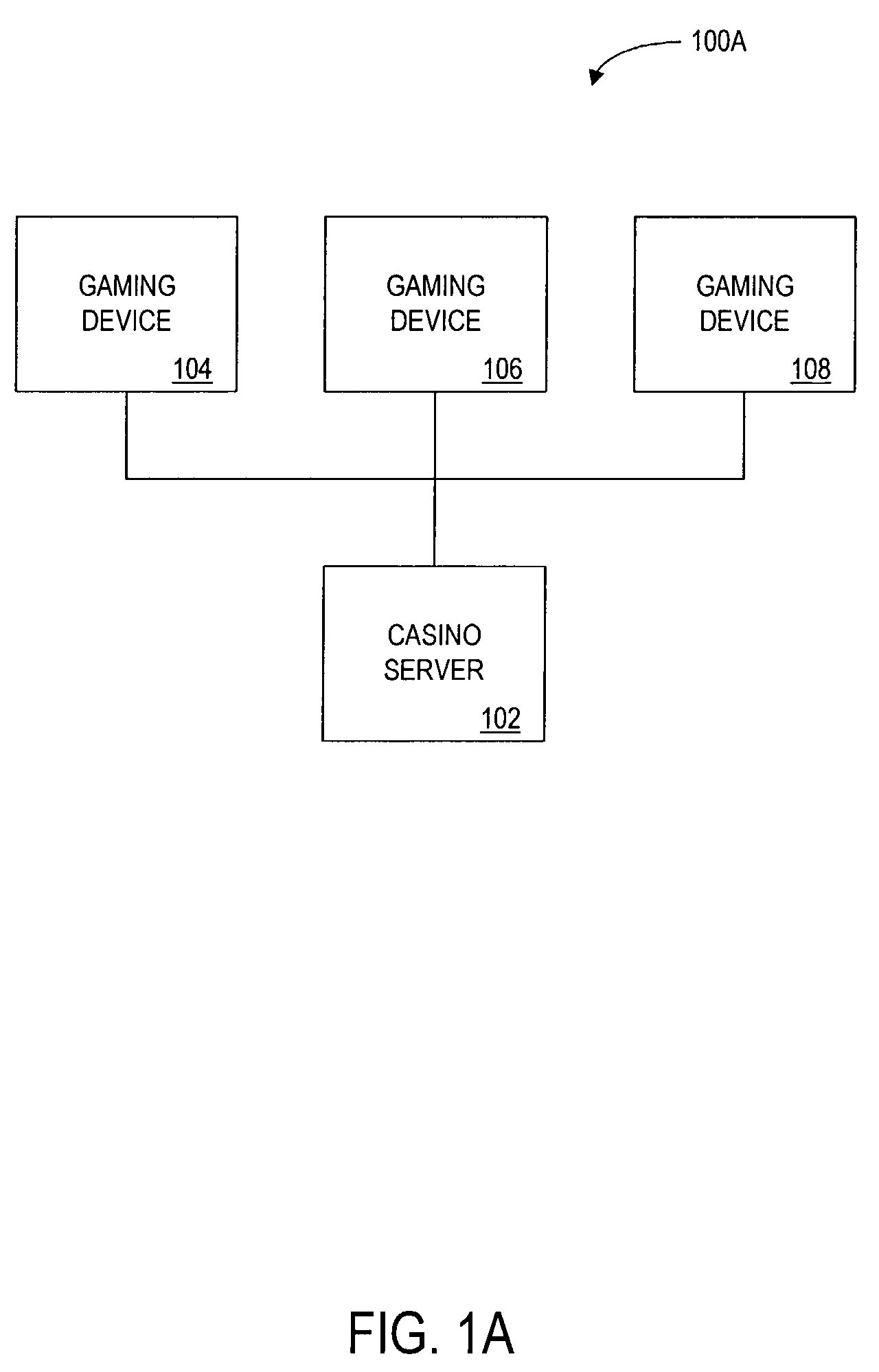

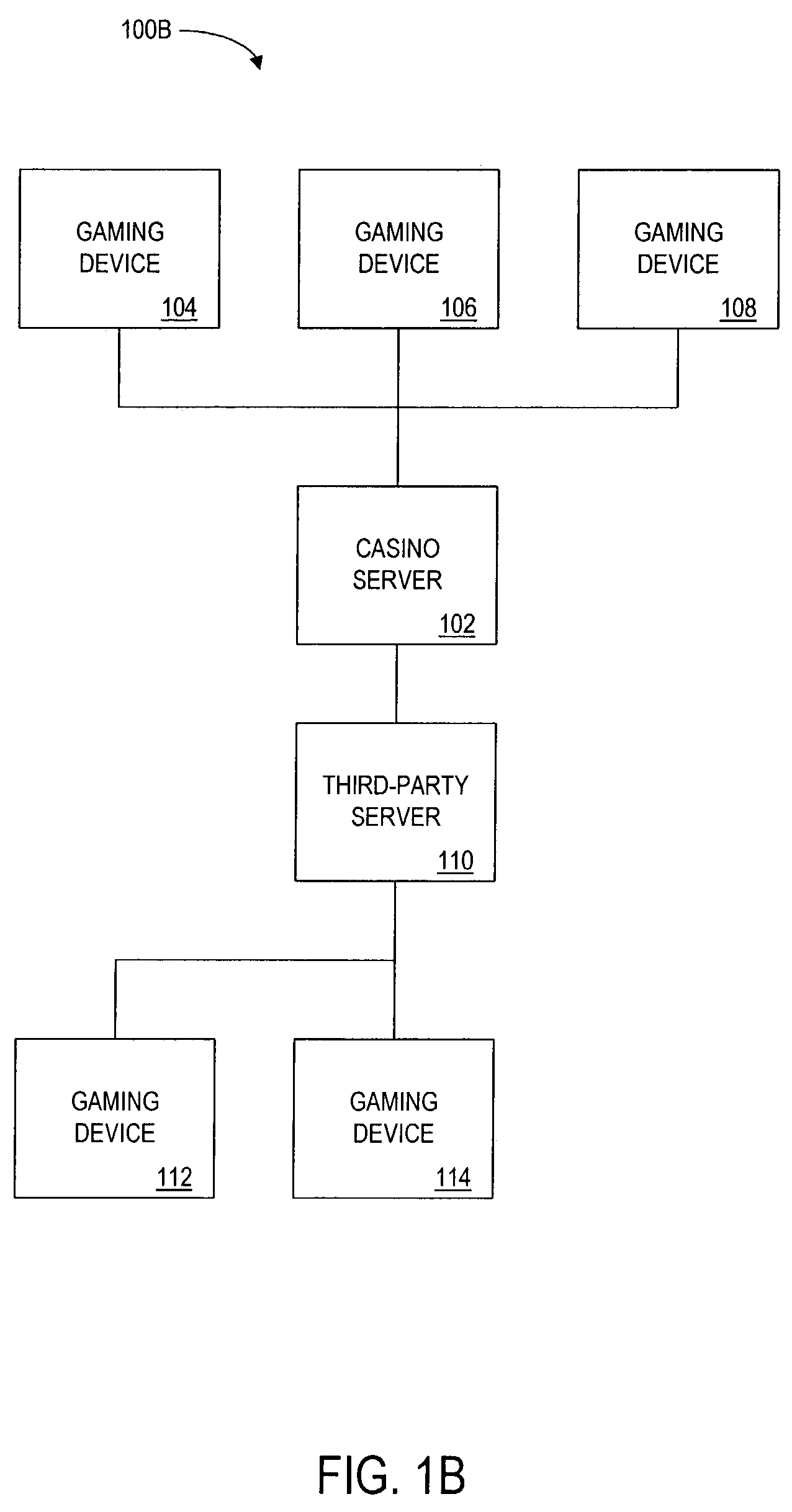

Method and apparatus for providing regular entrance into a bonus game

InactiveUS20060287045A1Apparatus for meter-controlled dispensingVideo gamesEvery HourVisual perception

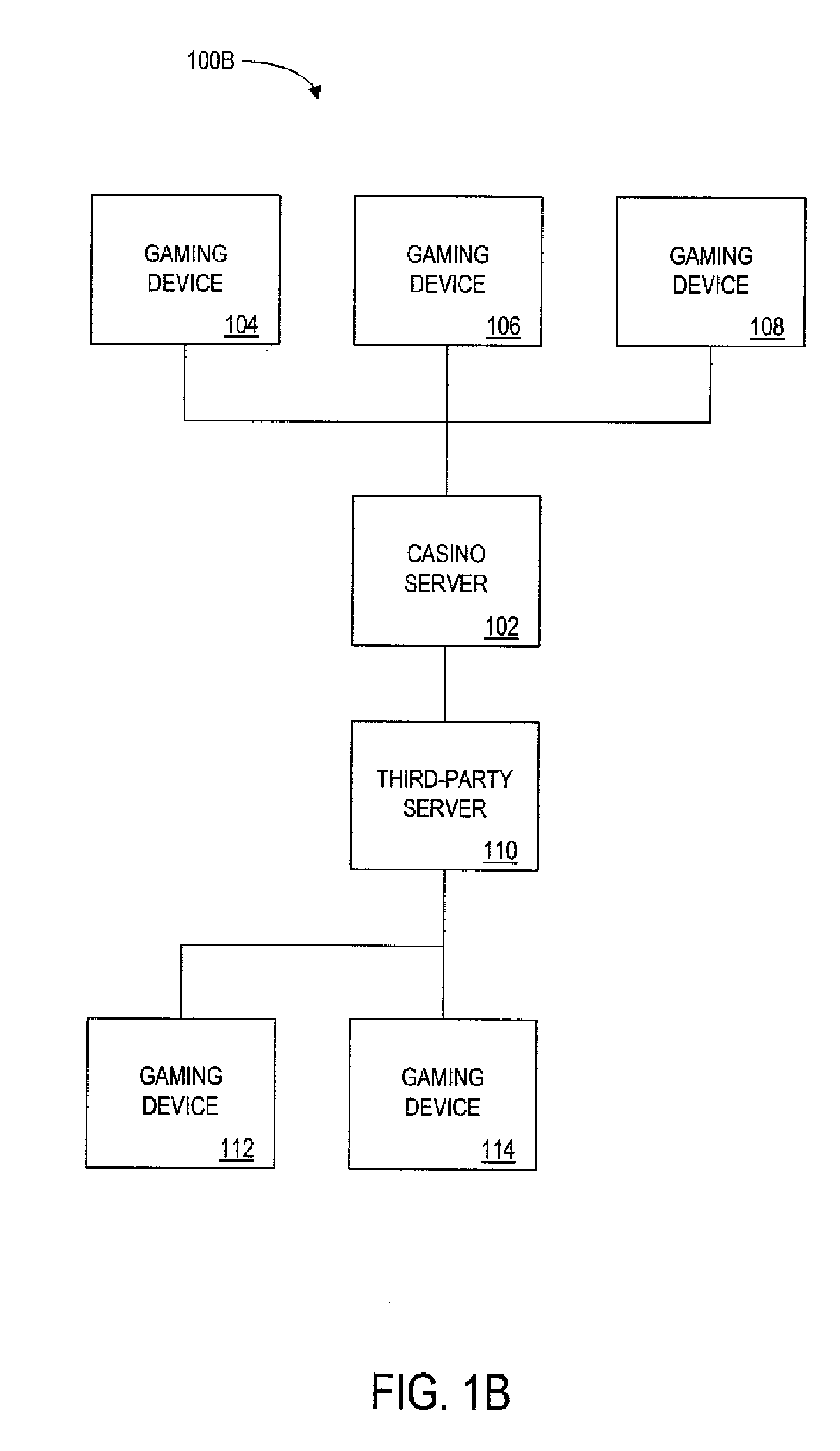

A method is disclosed for providing entry into a bonus game at a gaming device, where the bonus games may occur at predictable times and may payout predictable amounts. In one or more embodiments, a gaming device may provide a guaranteed entry into a bonus game every hour on the hour, so long as a player meets one or more criteria. Criteria may include a total amount wagered, a total number of handle pulls completed, or a total amount of time spent at a gaming device. One or more embodiments provide a method for withholding value from a player in order that the value may delivered later in the form of a guaranteed entry into a bonus game. One or more embodiments provide a method whereby multiple gaming devices may provide entry in bonus rounds simultaneously, thereby creating mutually reinforcing sounds and visual displays.

Owner:WALKER JAY S +8

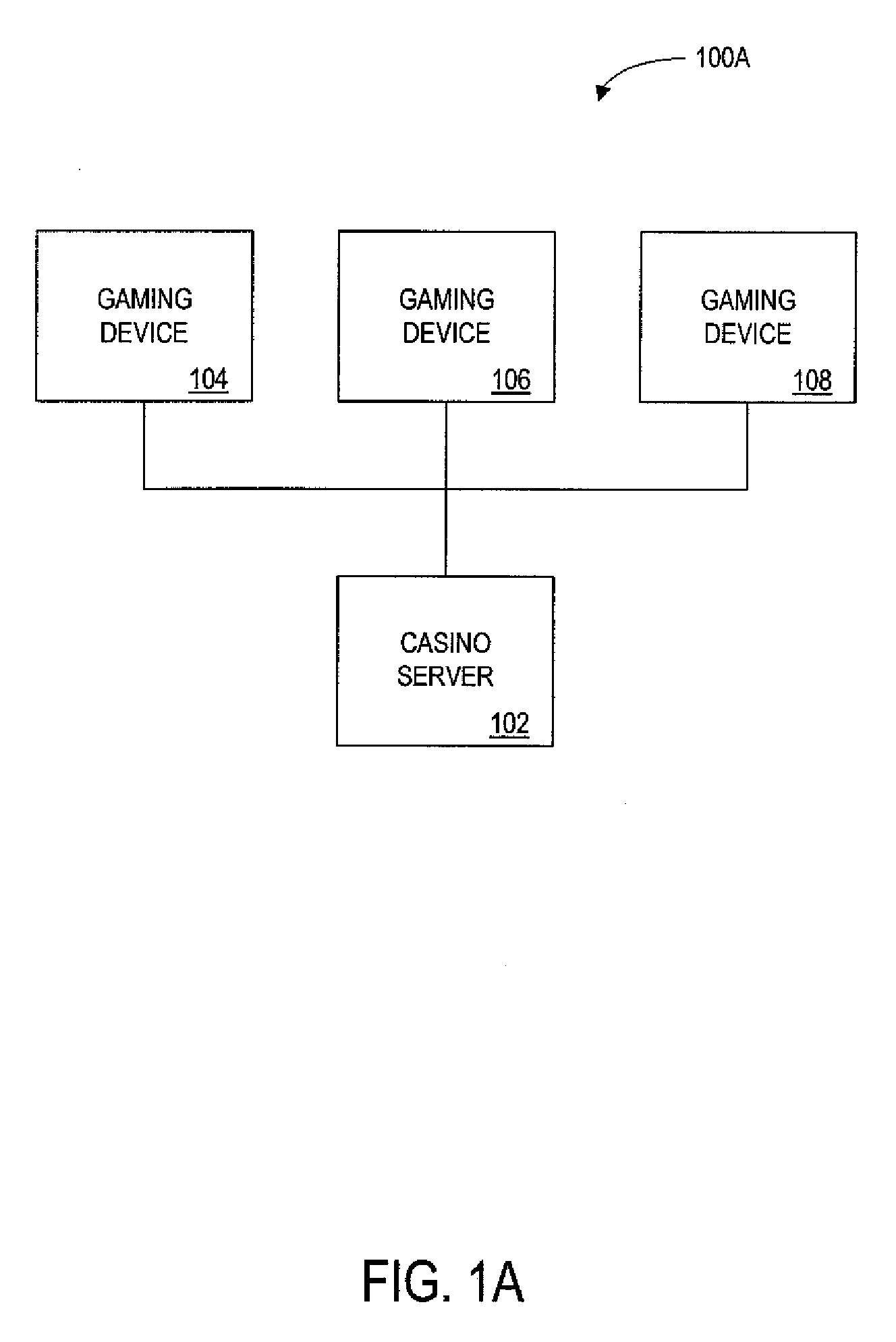

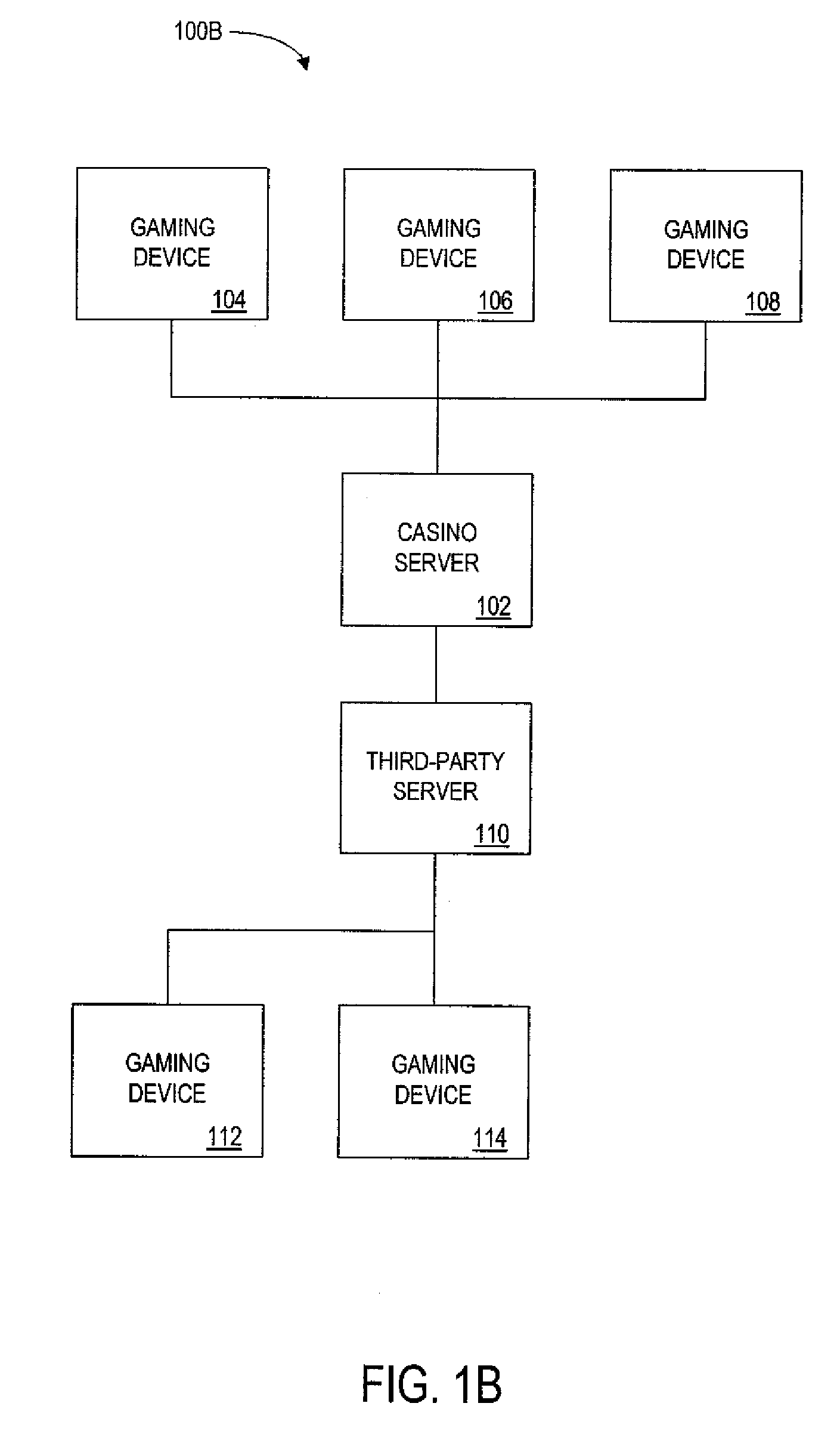

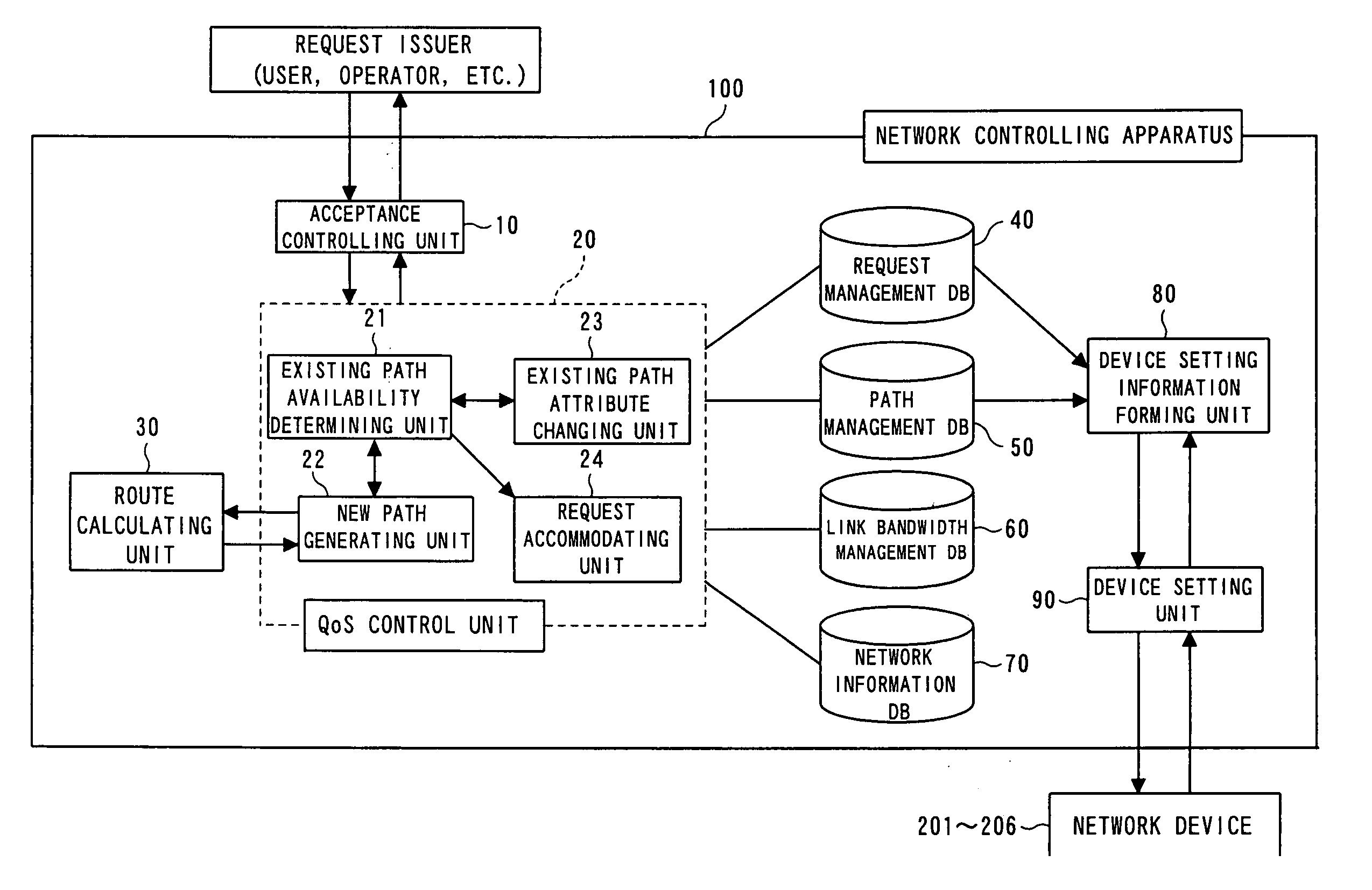

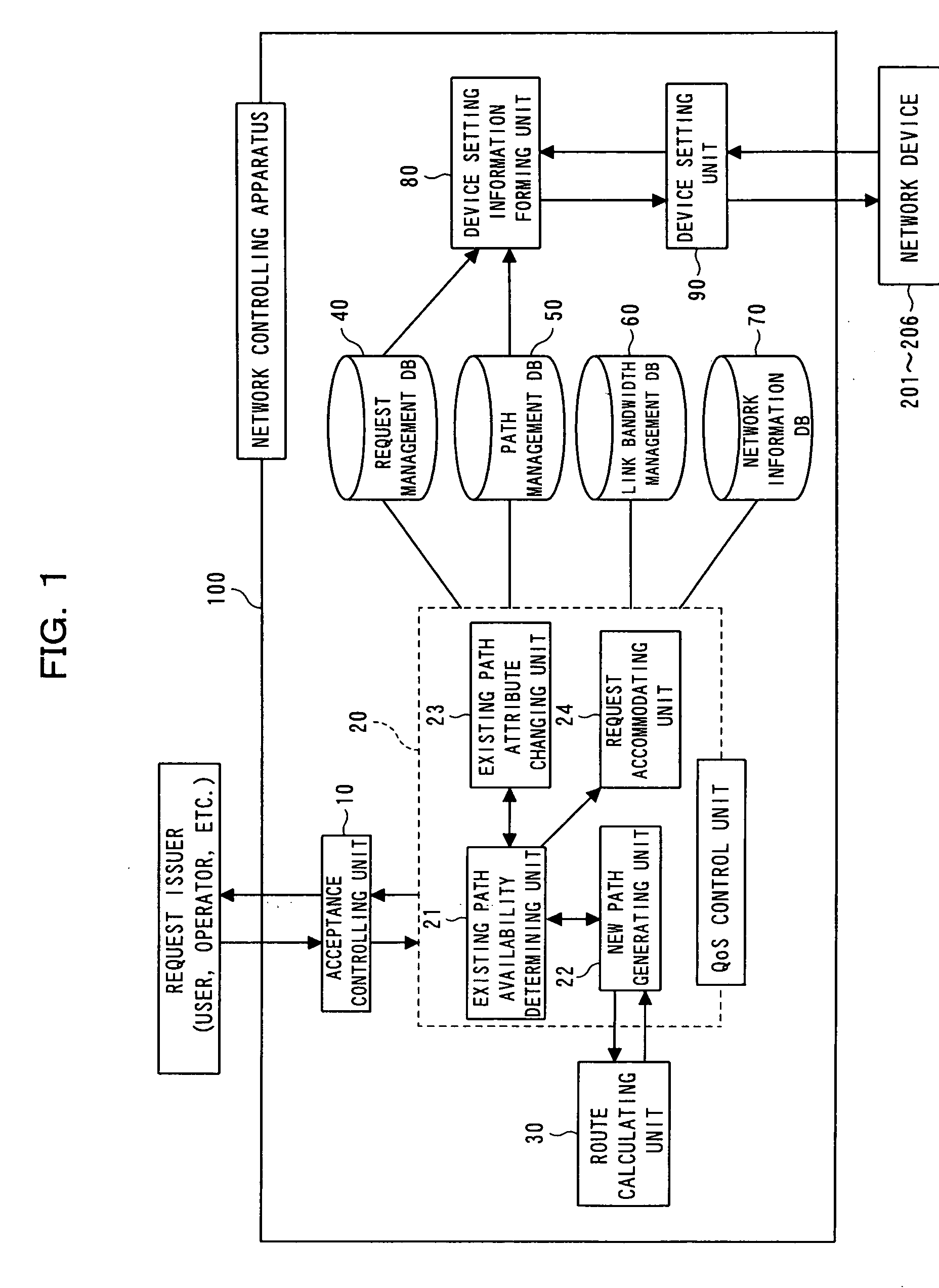

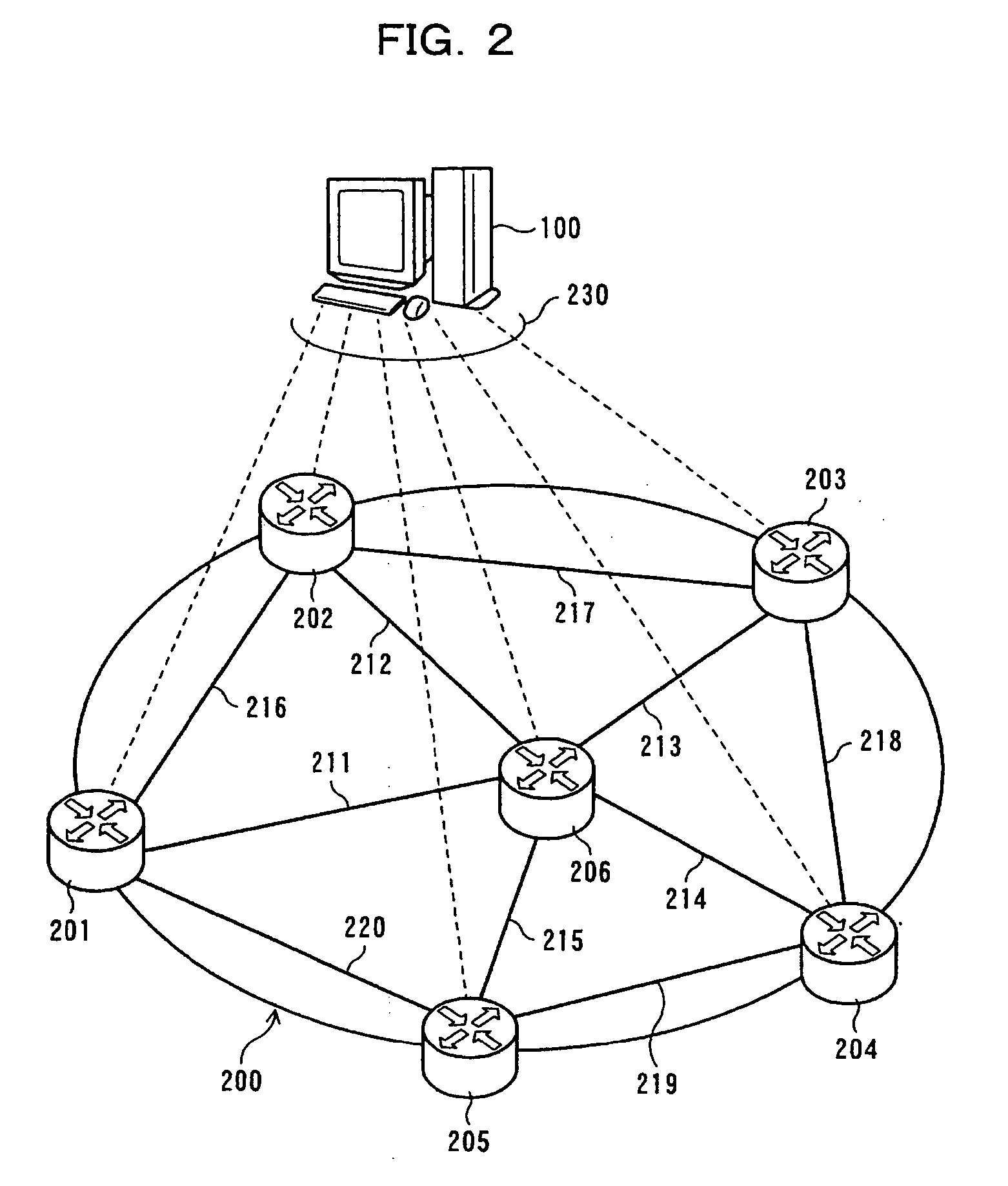

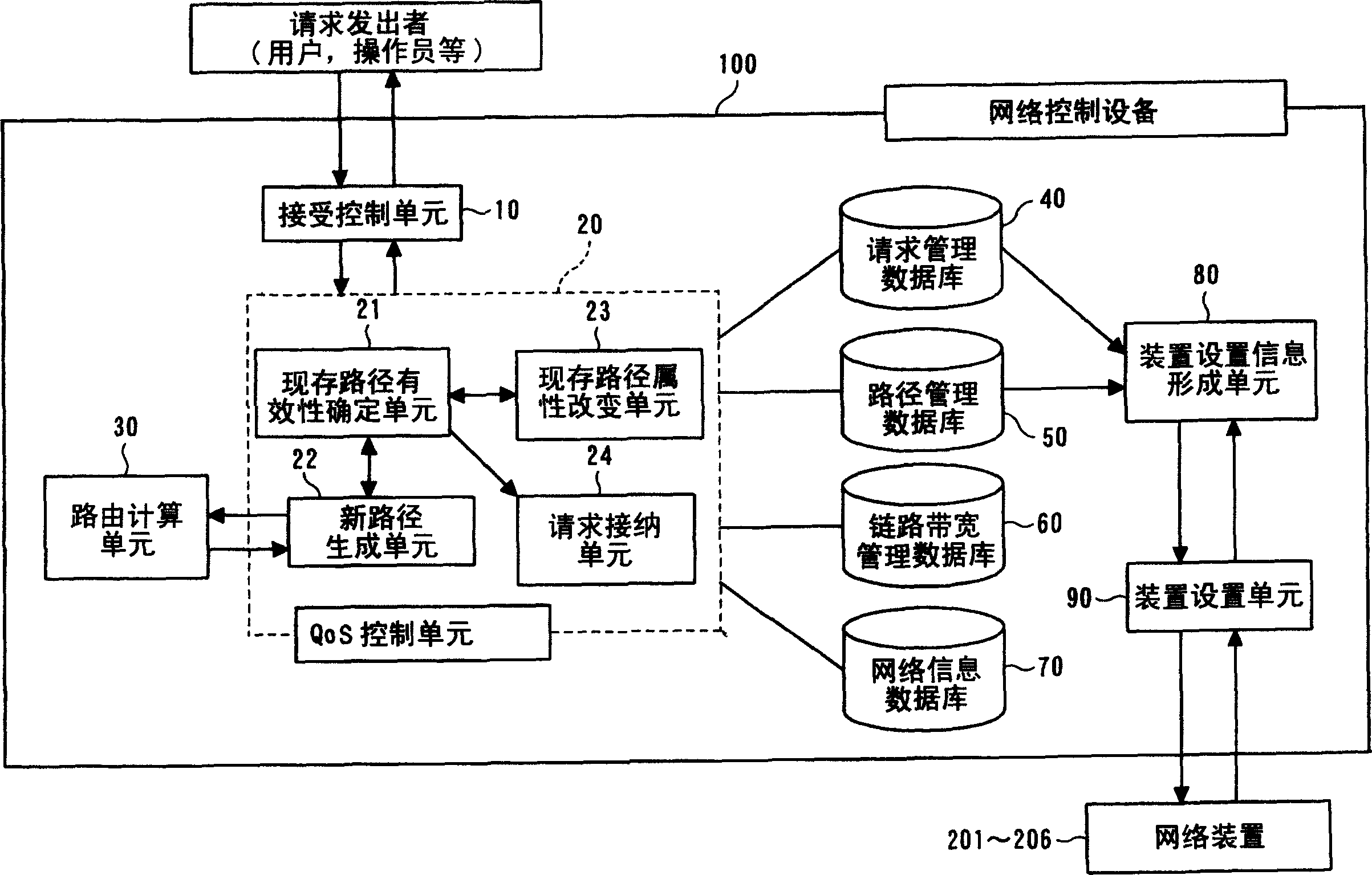

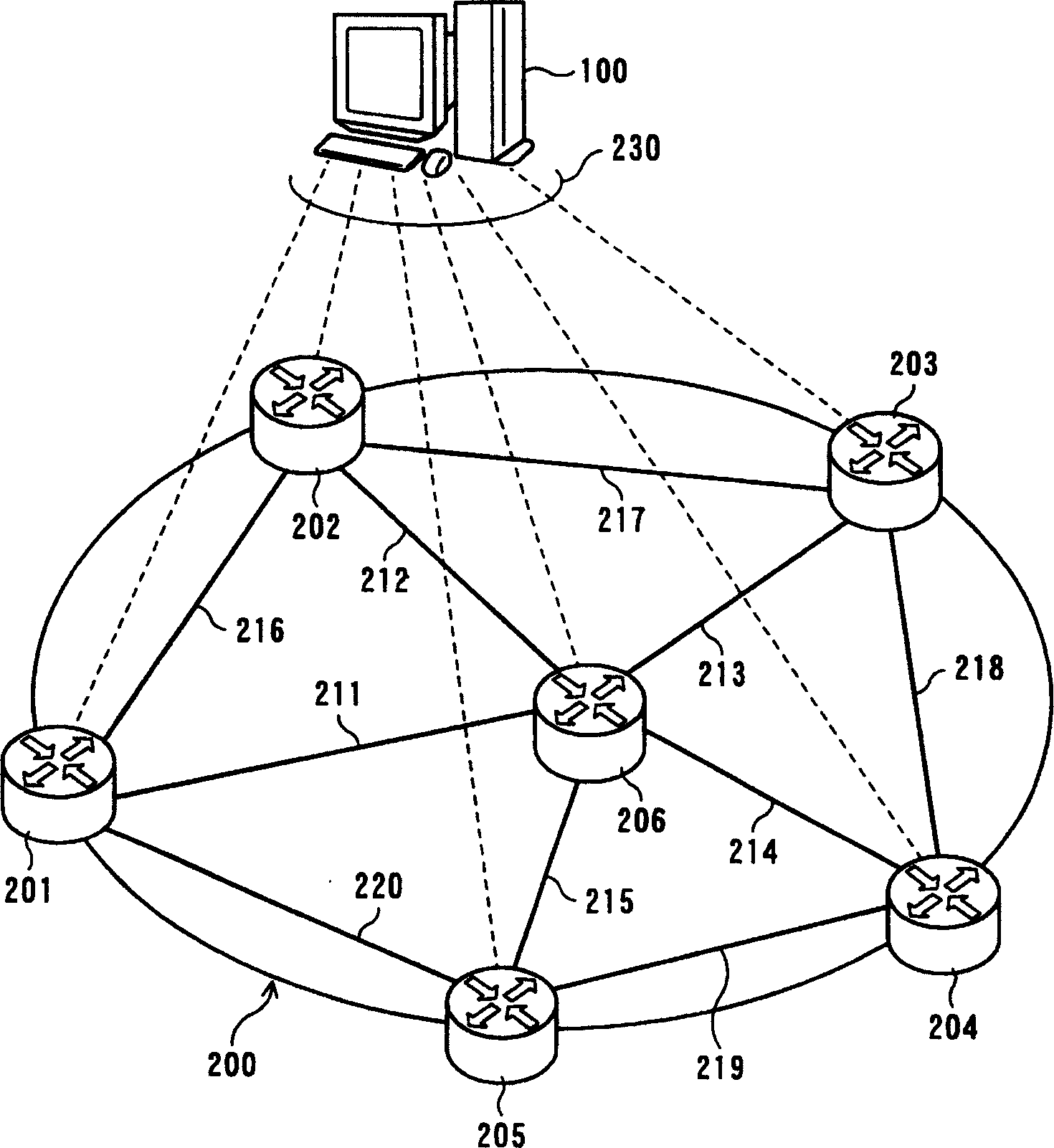

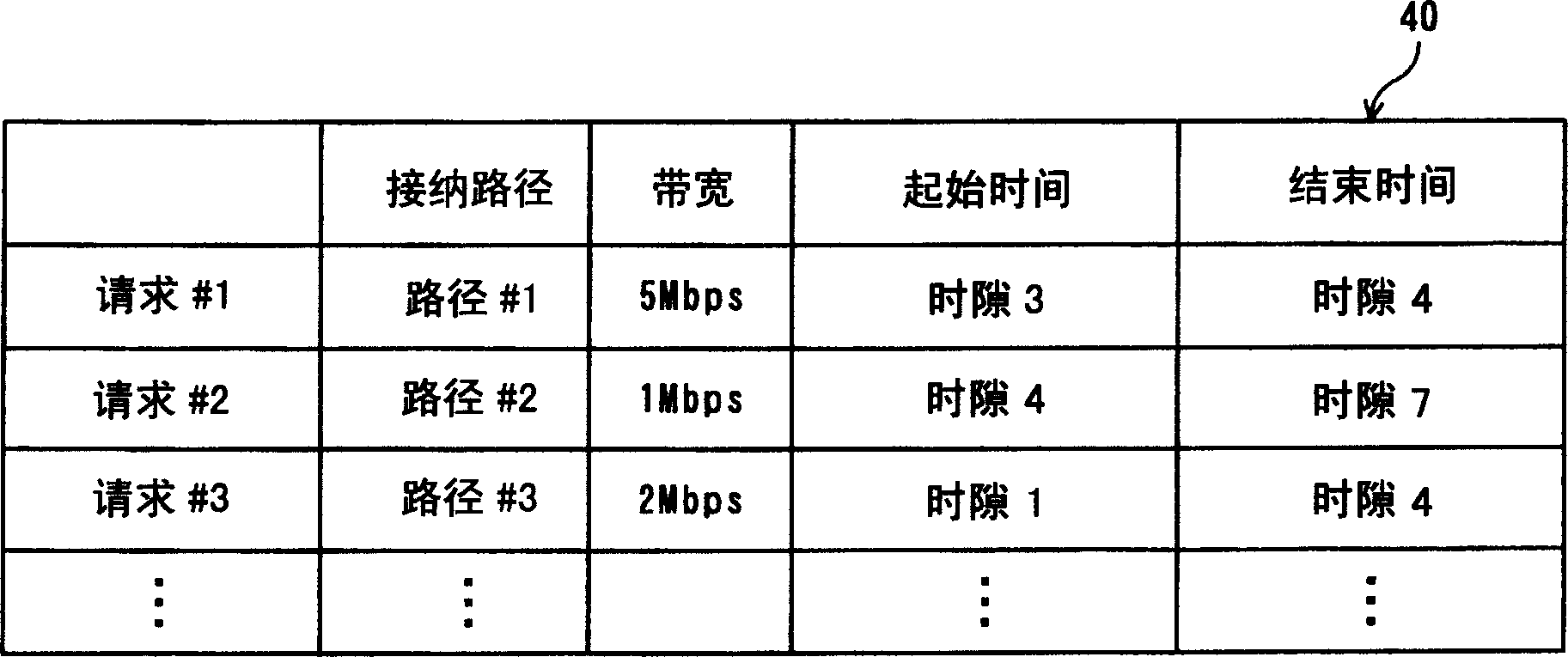

Network controlling apparatus and path controlling method therein

InactiveUS20050169313A1Improve efficiencyOptimize usageTime-division multiplexData switching by path configurationEvery HourTime segment

A network controlling apparatus appropriately arranges a generated path every hour with a change in section and bandwidth requested in each time period to flexibly generate a path according to the state of occurrence of requests. The network apparatus comprises a storing unit storing information for management of the network, and a controlling unit controlling setting of the network device relating to a connection of network devices at two edge points in the network to obtain path setting satisfying the quality guarantee request, using a path already set or scheduled to be set, or a newly generated path, by referring to the information stored in the storing unit when receiving the quality guarantee request.

Owner:FUJITSU LTD

Method and apparatus for providing regular entrance into a bonus game

InactiveUS20070004505A1Apparatus for meter-controlled dispensingVideo gamesEvery HourVisual perception

A method is disclosed for providing entry into a bonus game at a gaming device, where the bonus games may occur at predictable times and may payout predictable amounts. In one or more embodiments, a gaming device may provide a guaranteed entry into a bonus game every hour on the hour, so long as a player meets one or more criteria. Criteria may include a total amount wagered, a total number of handle pulls completed, or a total amount of time spent at a gaming device. One or more embodiments provide a method for withholding value from a player in order that the value may delivered later in the form of a guaranteed entry into a bonus game. One or more embodiments provide a method whereby multiple gaming devices may provide entry in bonus rounds simultaneously, thereby creating mutually reinforcing sounds and visual displays.

Owner:WALKER JAY S +8

Method for preparing a freeze-drying crisp fruit and vegetable piece

The invention discloses a method for preparing a freeze-drying crisp fruit and vegetable piece, which includes the following steps: blanching raw materials for killing enzyme; preparing a color protection liquid using citric acid concentration, sodium isoascorbate concentration, or cysteine hydrochloride concentration, sodium phytate concentration and embedding medium, wherein, the ratio between the color protection liquid and the slice liquid material is 0.25-1:1; slowly freezing fruit paste with 4-7 mm thickness below a eutectic point at minus 30 DEG C. for one hour; placing the fruit paste on a separator plate of a vacuum lyophilizer after the machine is precooled to a cold trap minus 50 DEG C. with 30 Pa vacuum degree and 40 DEG C. separator plate temperature; heating and drying by programs, wherein, 3-5 DEG C. rises every hour when the temperature is below 10 DEG C.; keeping temperature at 10 DEG C. for 1 hour; heating continuously for rising 5-7 DEG C. every hour; keeping temperature for 2 hours at 40 DEG C.; obtaining the crisp fruit and vegetable pieces with water content below 7% after refrigeration; slicing and packing products in an independent drying room with air humidity 40-50%. The invention has a distinct fruit and vegetable original flavour with larger market prospect.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

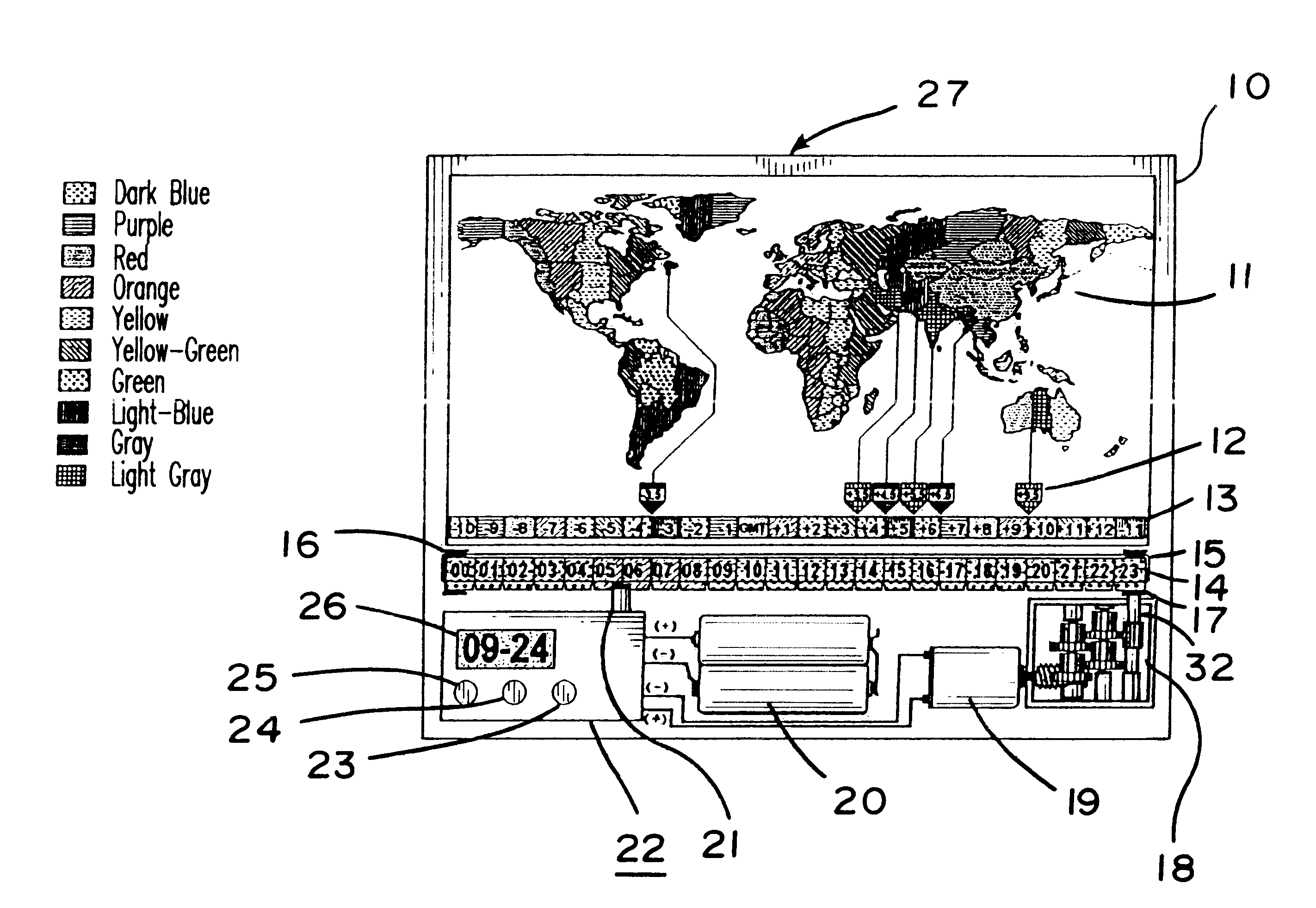

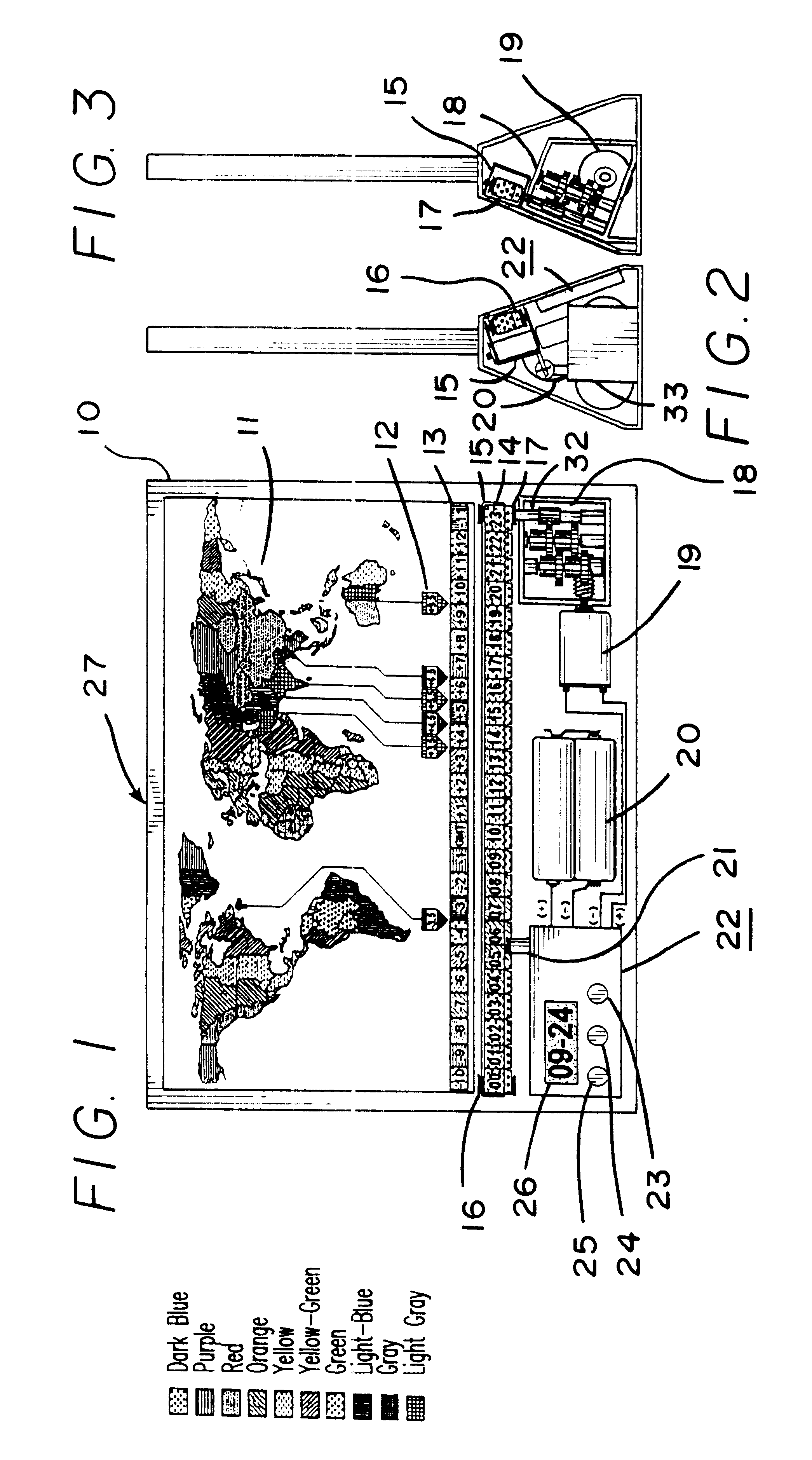

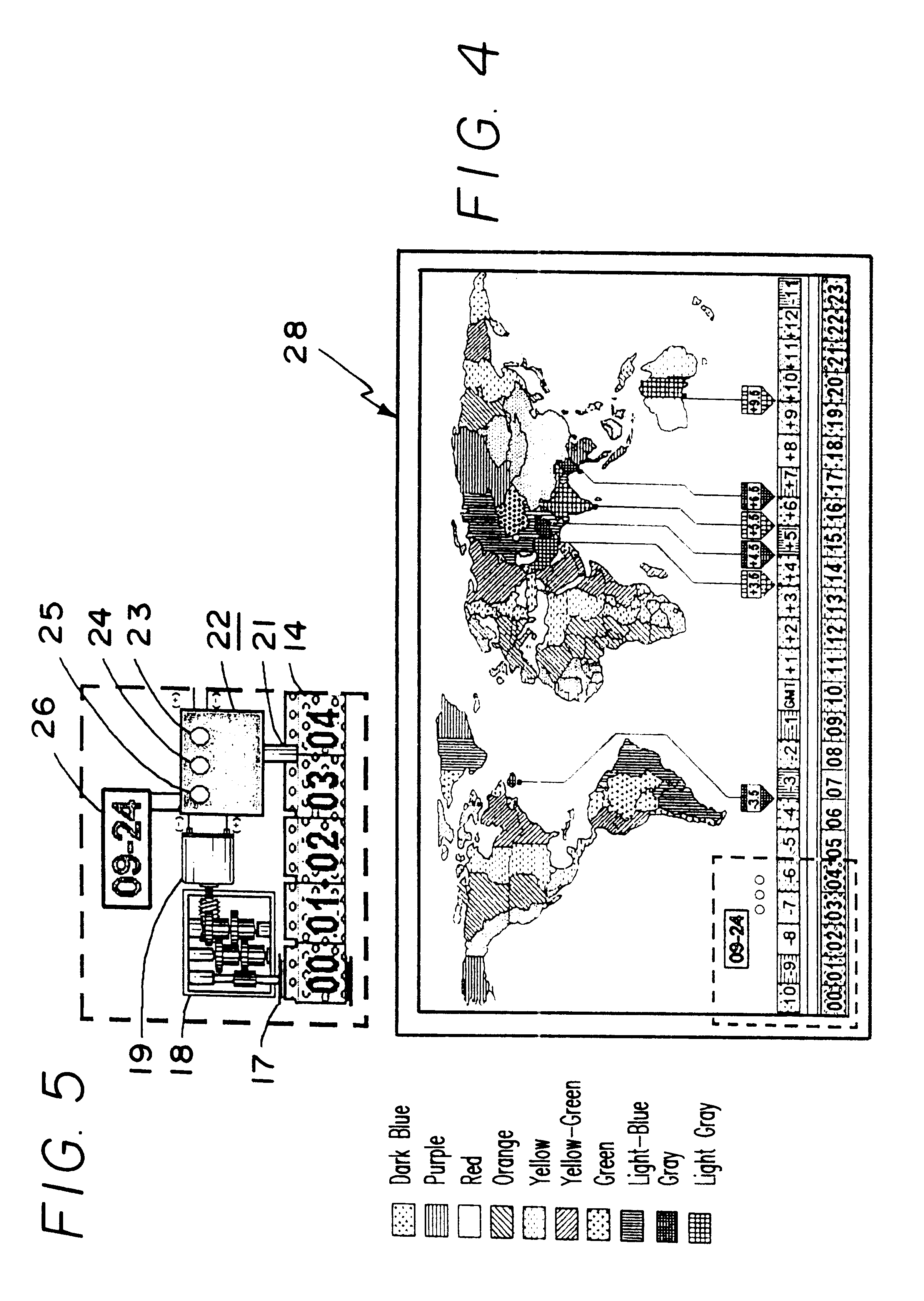

World clock with synchronous display

A world clock includes a map with markings arranged to indicate time zones for actual geographic locations and a single-row table having 24 columns for correlating the markings with hour markings on a belt. The belt is driven by a controller to move one column every hour, with stoppage of the belt below the next column being controlled by a light sensor arranged to sense blank spaces on the belt between the hour markings.

Owner:WANG RICHARD

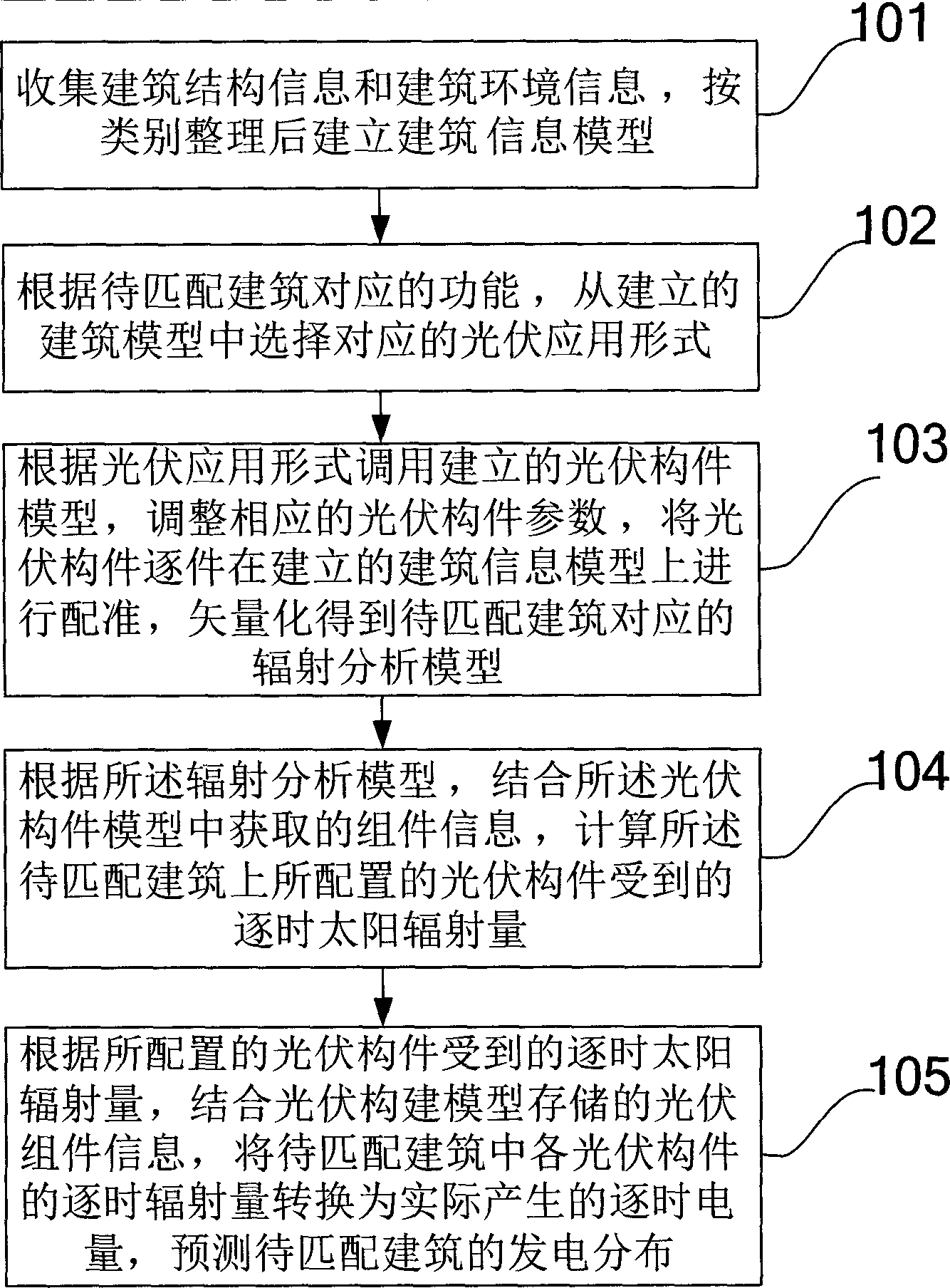

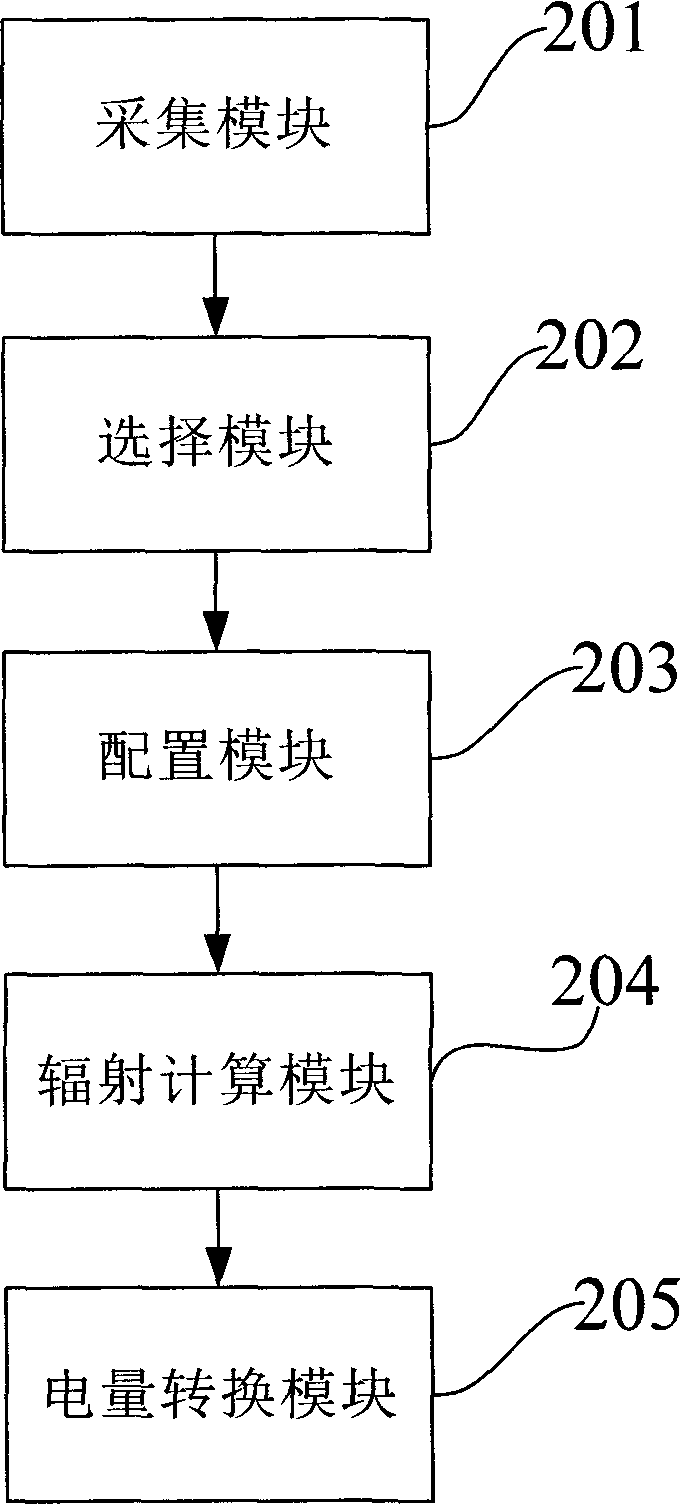

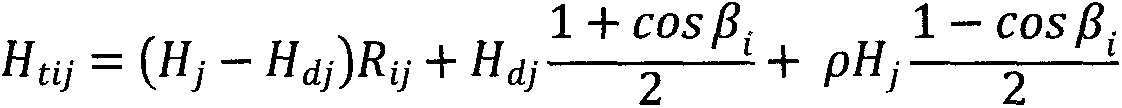

Power generation prediction method and device based on building information model

InactiveCN103440526AImprove accuracyHigh precisionForecastingInformation technology support systemEvery HourComputer science

The embodiment of the invention discloses a power generation prediction method and device based on a building information model, and belongs to the field of photovoltaic power generation. The method comprises the steps that corresponding photovoltaic application modes are selected from the built building information model; corresponding photovoltaic component parameters are adjusted; photovoltaic components are registered on the built building information model one by one, and a radiation analysis model corresponding to a building to be matched is acquired in a vectorization mode; the real-time solar radiation quantity borne by the configured photovoltaic components is calculated according to assembly information acquired from a photovoltaic component model and the radiation analysis model; after the real-time solar radiation quantity borne by the configured photovoltaic components is converted to actually generated real-time electric quantity, then power generation distribution of the building to be matched is predicted. According to the power generation prediction method and device based on the building information model, a BIM modeling and analyzing mode is adopted to calculate the radiation quantity in every hour of each photovoltaic component through typical meteorological conditions of the place where the building is located, accurate power generation quantity prediction can be carried out at the initial stage of a solar photoelectric building project plan, and calculation accuracy and precision are improved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

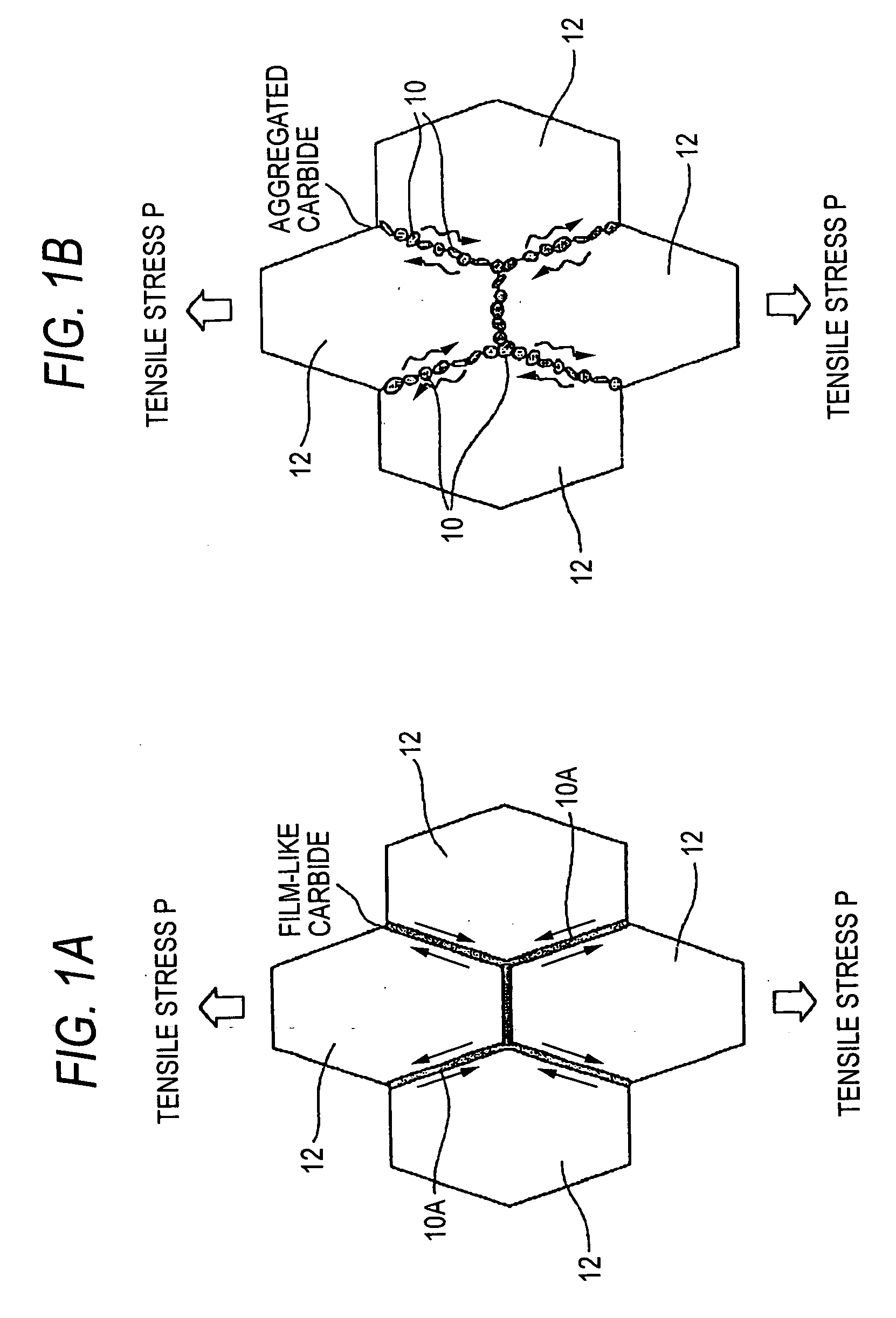

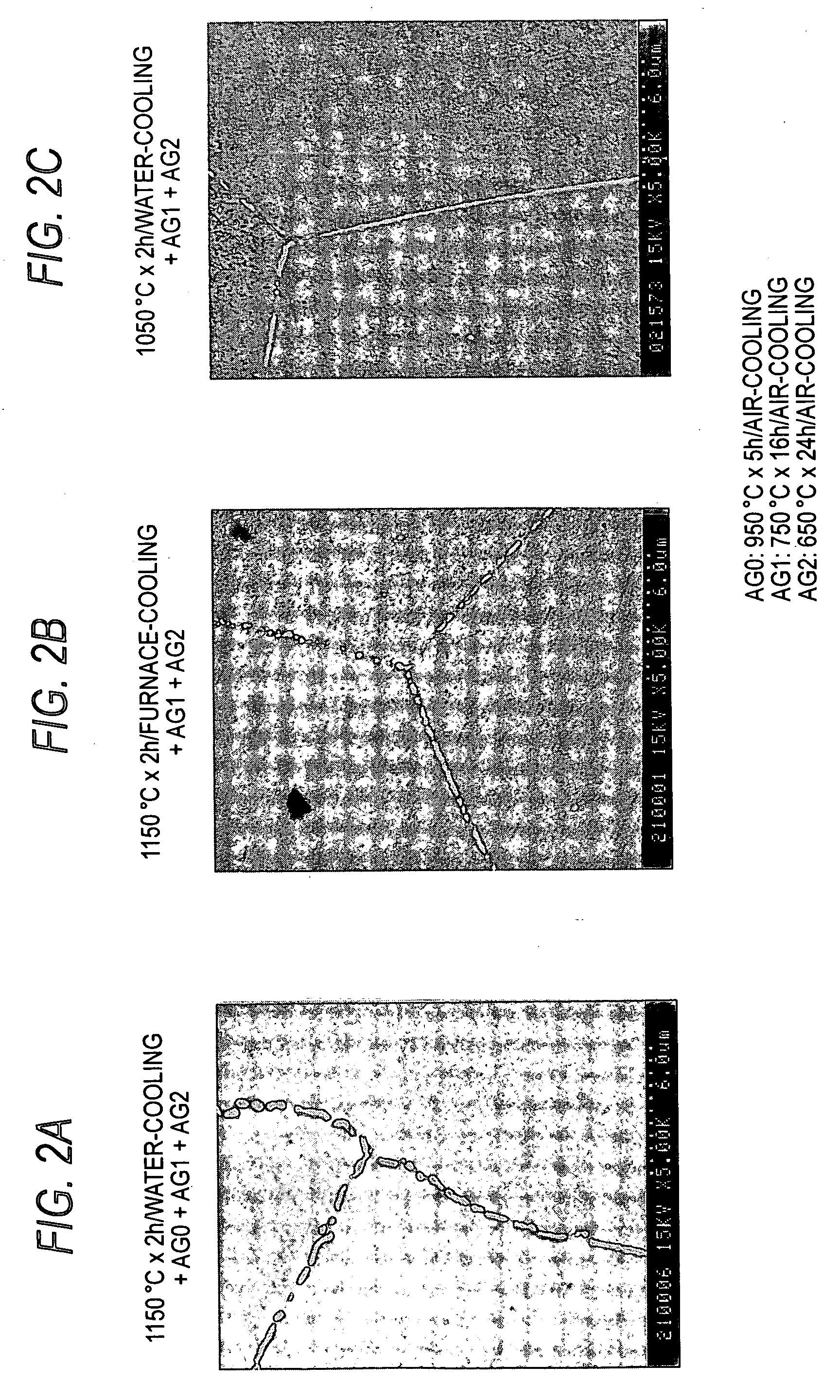

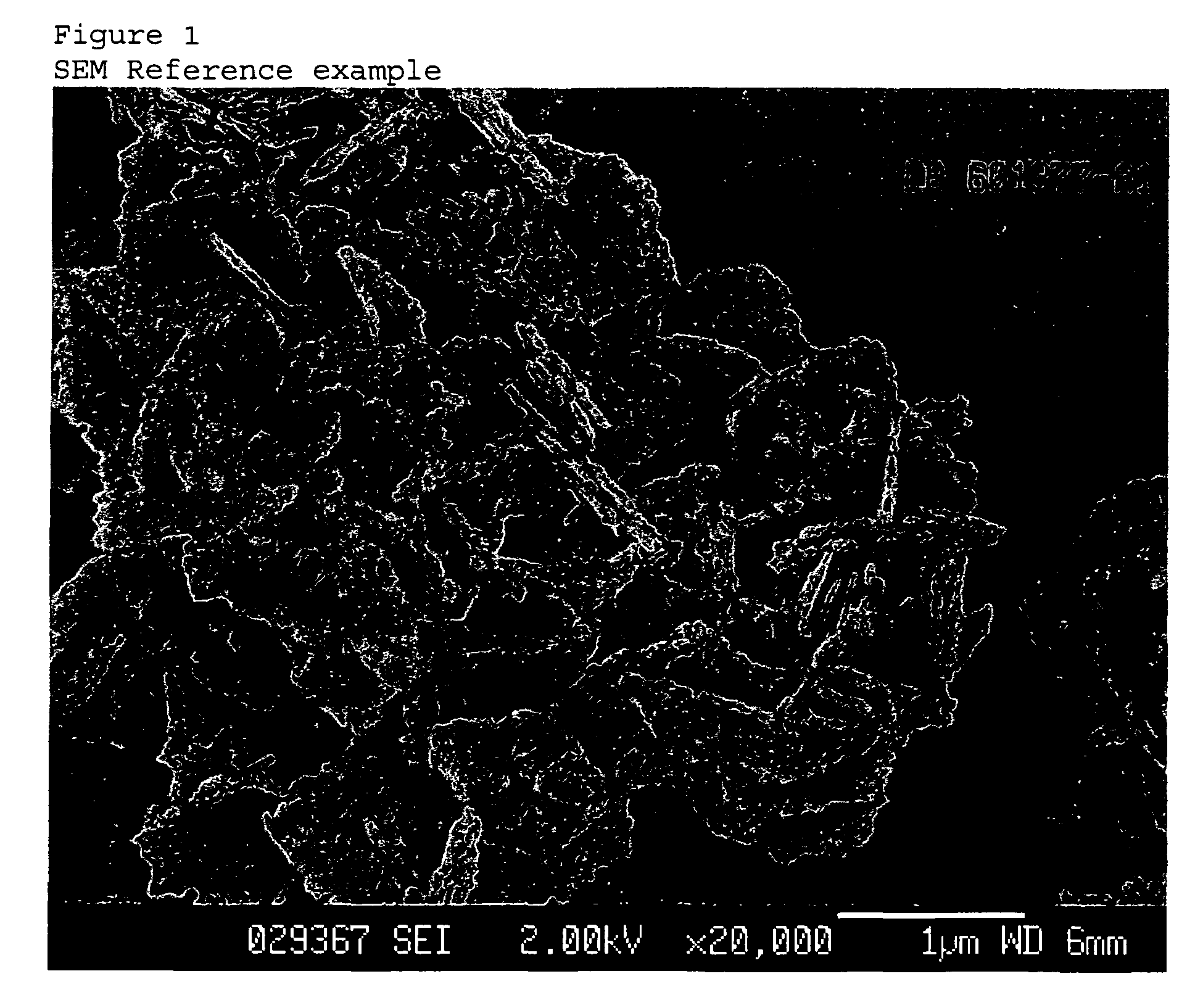

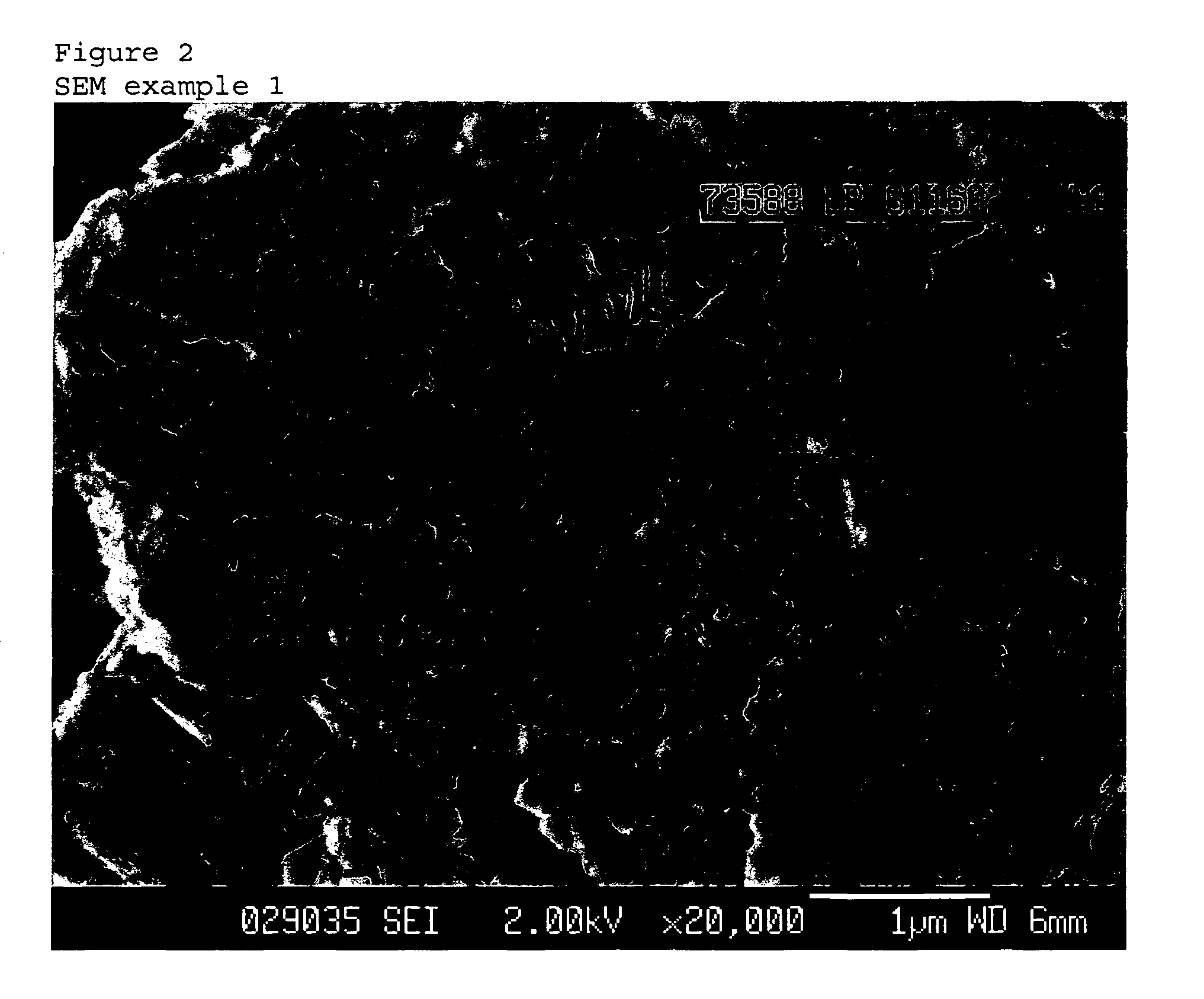

Method for producing low thermal expansion Ni-base superalloy

The present invention provides a method for producing a low thermal expansion Ni-base superalloy, which includes: preparing an alloy including, by weight %, C: 0.15% or less, Si: 1% or less, Mn: 1% or less, Cr: 5 to 20%, at least one of Mo, W and Re, which satisfy the relationship Mo+½(W+Re): 17 to 27%, Al: 0.1 to 2%, Ti: 0.1 to 2%, Nb and Ta, which satisfy the relationship Nb+Ta / 2: 1.5% or less, Fe: 10% or less, Co: 5% or less, B: 0.001 to 0.02%, Zr: 0.001 to 0.2%, a reminder of Ni and inevitable components; subjecting the alloy to a solution heat treatment under the condition of at a temperature of 1000 to 1200° C.; subjecting the alloy to either a carbide stabilizing treatment for making aggregated carbides on grain boundaries and stabilizing the carbides under the conditions of at a temperature of not less than 850° C. and less than 1000° C. and for 1 to 50 hours, or a carbide stabilizing treatment for making aggregated carbides on grain boundaries and stabilizing the carbides by cooling from the temperature in the solution heat treatment to 850° C. at a cooling rate of 100° C. or less per hour; subjecting the alloy to a first aging treatment for precipitating γ′ phase under the conditions of at a temperature of 720 to 900° C. and for 1 to 50 hours; and subjecting the alloy to a second aging treatment for precipitating A2B phase under the conditions of at a temperature of 550 to 700° C. and for 5 to 100 hours.

Owner:MITSUBISHI POWER LTD +1

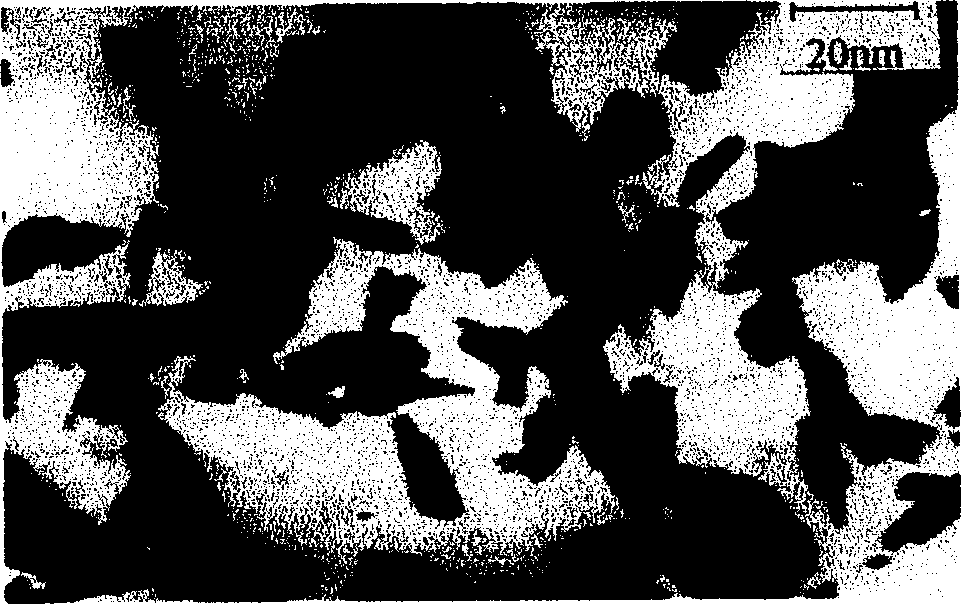

Preparation method of high specific surface area nano-cerium oxide

InactiveCN1785815ASuitable for industrial productionLow costRare earth metal compoundsEvery HourOxalate

The preparation method of nano cerium oxide with high specific surface area includes the following steps: firstly, preparing salt solution A containing cerium ions, adding surfactant F and additive T in said solution to form solution C; using one or more than two kinds of precipitants and making them in water to form solution D; mixing solution C and solution D to make chemical reaction, reaction time is 10-200min, regulating end point pH value of reaction suspension to 5-10 to produce precipitate, stirring said precipitate for 10-100min, filtering, washing and drying said precipitate, igniting said precipitate for 2-10hr at 400-1000deg.C its heating speed is 50-500deg.C for every hour, so that the nano cerium oxide whose specific surface area is greater than 100sq.m / g.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

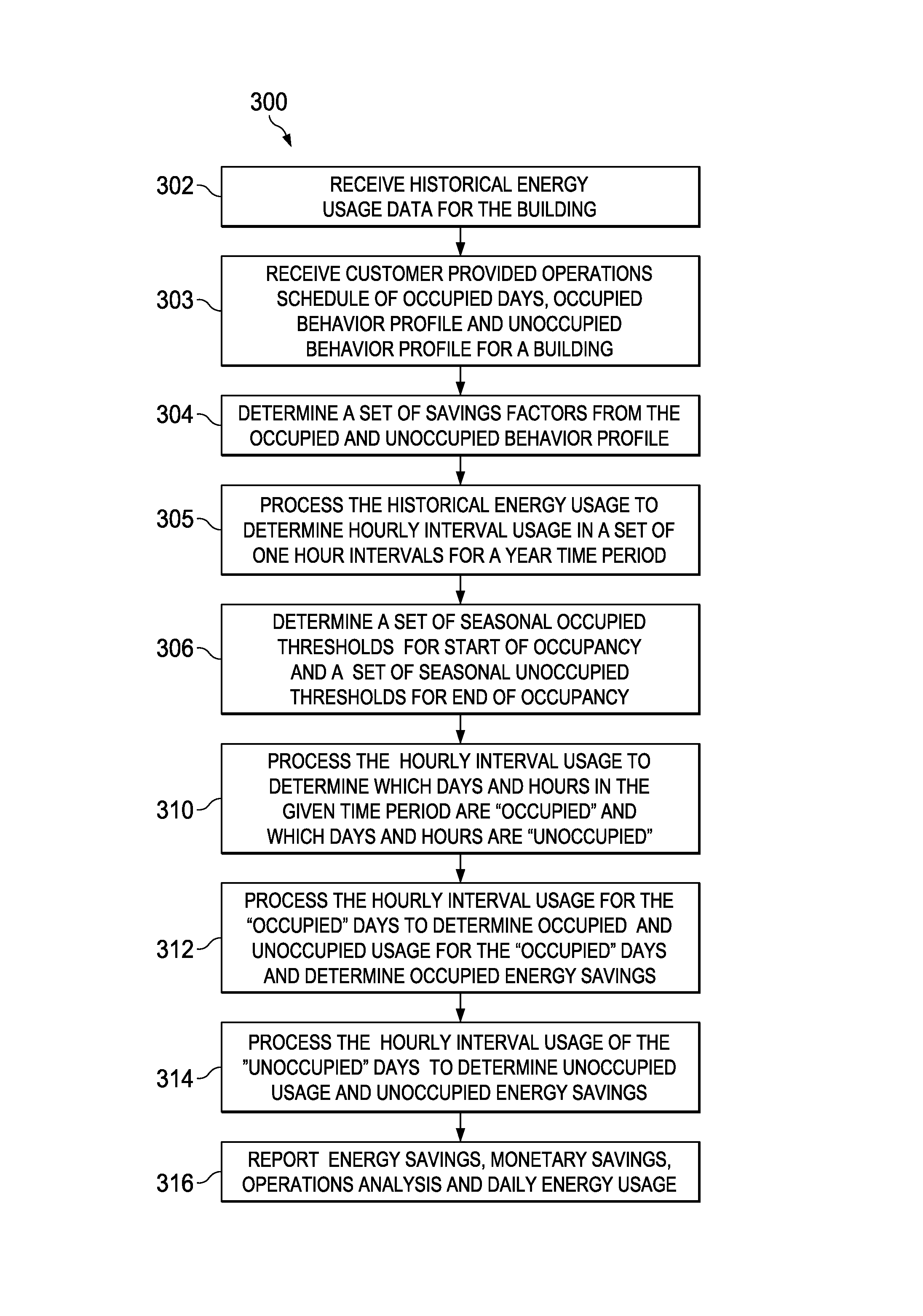

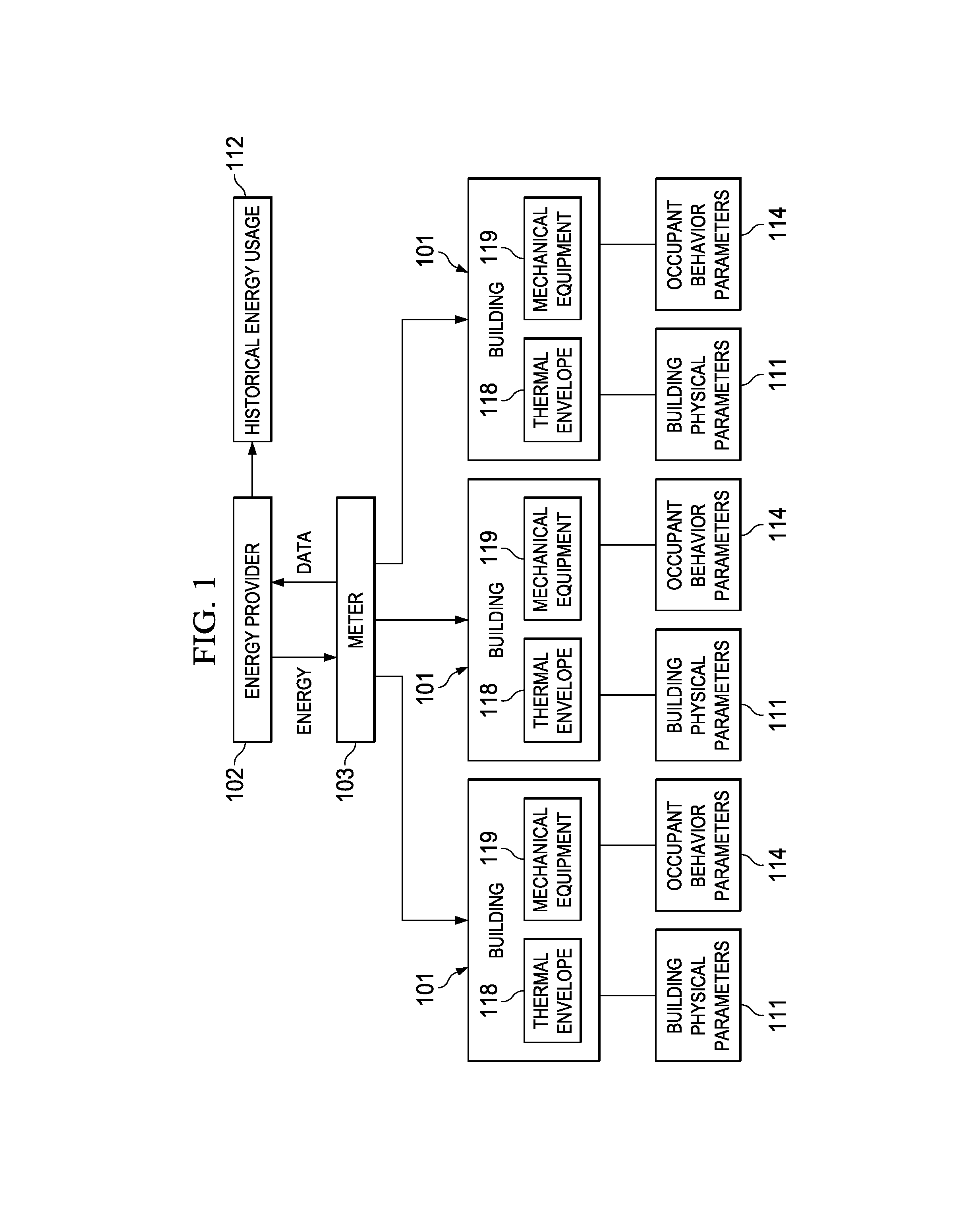

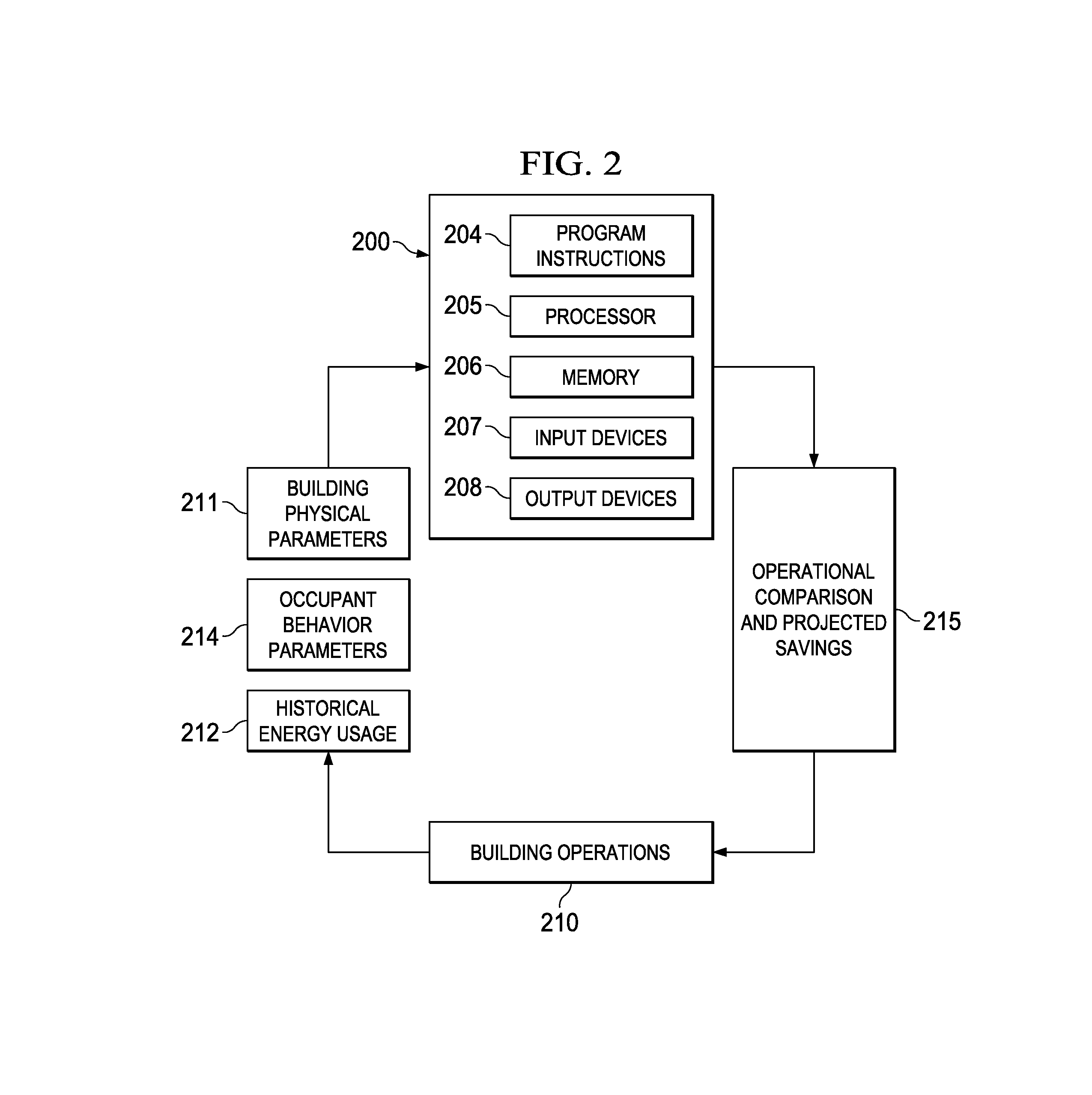

Interval analysis tool for energy consumption

A system and method for analyzing energy savings for a building is provided. The method includes receiving a schedule of occupied days, an occupancy behavior profile and historical energy usage data from which an hourly interval usage is determined. A set of occupancy thresholds is determined by season. Occupied days are determined from the set of occupancy thresholds and the hourly interval usage. The hourly interval usage is analyzed to determine occupied energy consumption in hourly intervals, occupied start and stop time savings, mechanical equipment savings and temperature setpoint savings during an occupied day. The hourly interval usage is also analyzed to determine unoccupied energy consumption in the hourly intervals and refrigeration savings, mechanical equipment savings, computer equipment savings, parking lot lighting savings, hallway lighting savings and temperature setpoint savings during an unoccupied day. Energy consumption, energy savings, operational comparisons and monetary savings are reported.

Owner:CENERGISTIC LLC

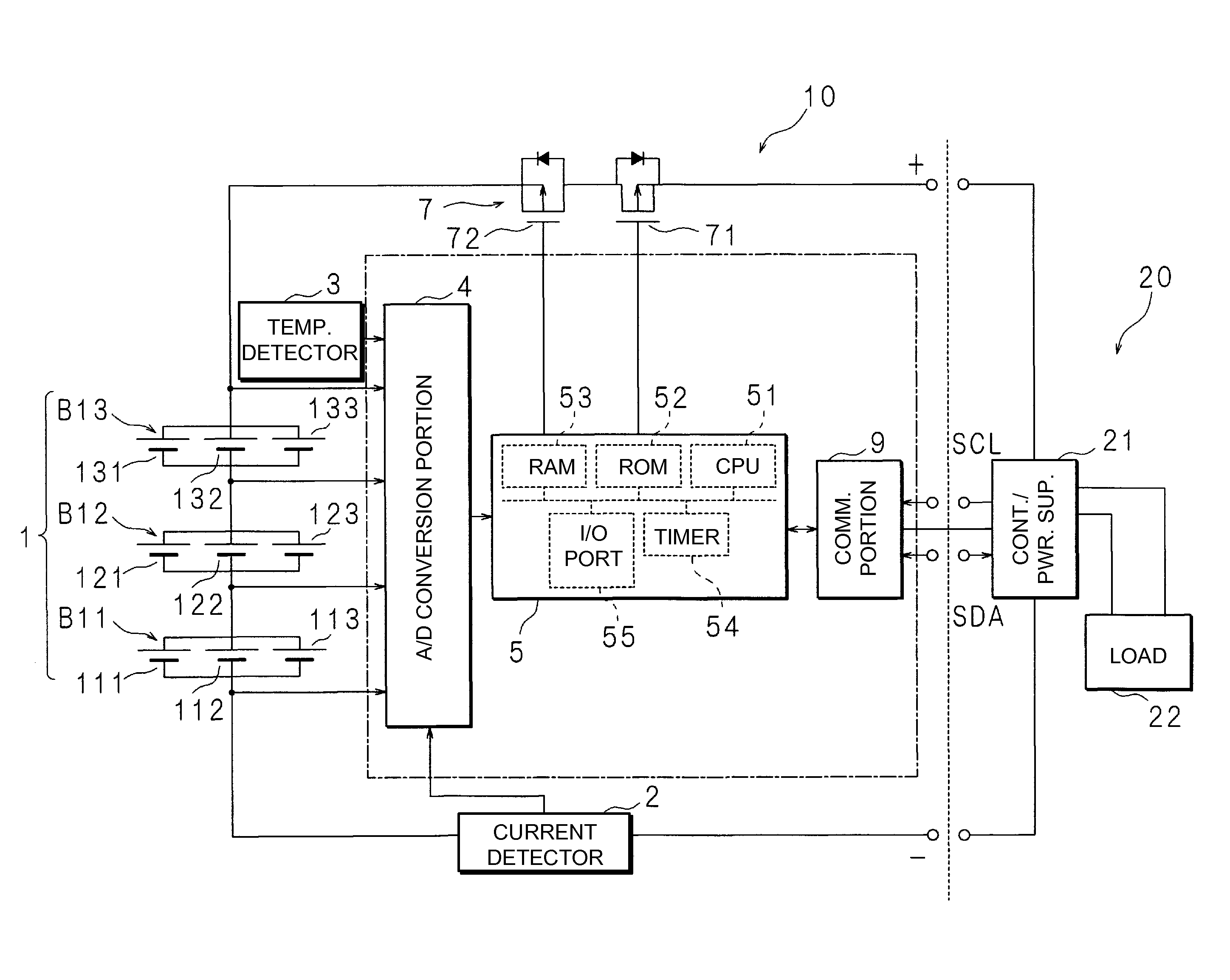

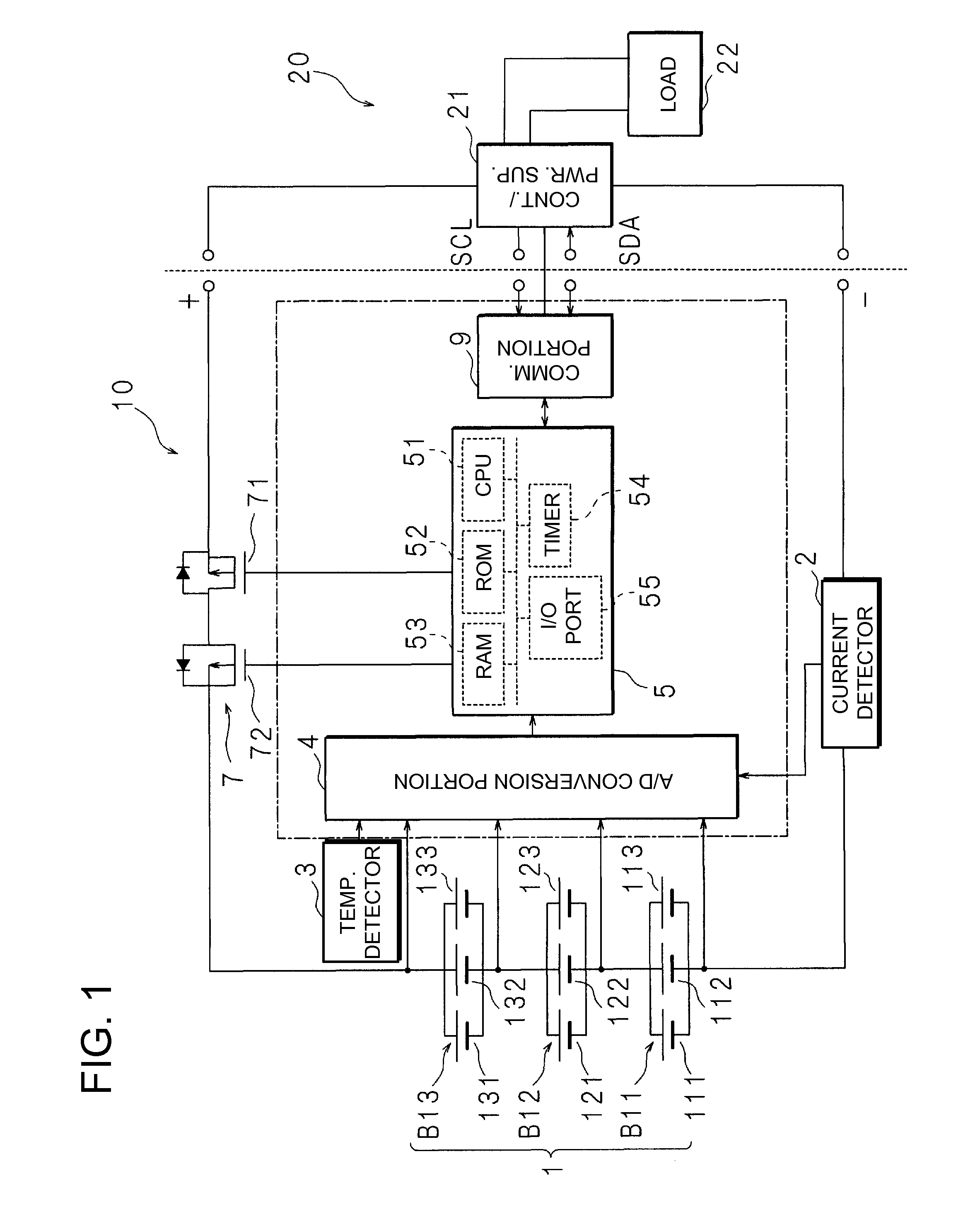

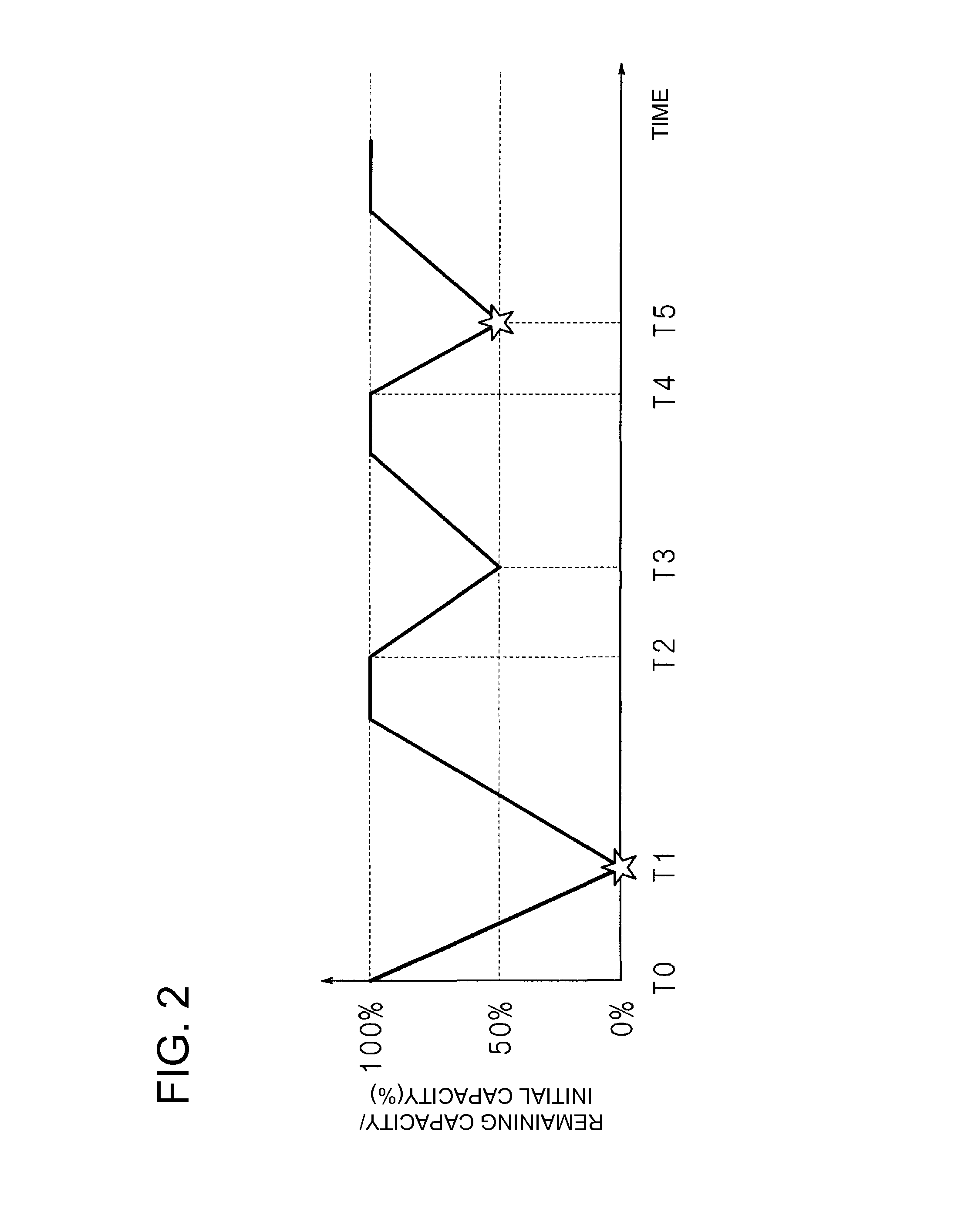

Rechargeable battery charging method and battery pack capable of suppressing deterioration degree

InactiveUS20120049804A1Suppressing deterioration degreeAffect deterioration of the rechargeable batterySecondary cellsElectric powerTerminal voltageEvery Hour

One cycle is corrected every charging / discharging cycle in accordance with a cycle deterioration accelerating coefficient. The corrected one cycles are accumulated. A storage period is corrected in accordance with a storage deterioration accelerating coefficient every hour. The corrected storage periods are accumulated. In the storage period, a rechargeable battery is stored with the terminal voltage higher than a predetermined voltage. A deterioration coefficient is obtained as the product of a cycle deterioration coefficient calculated in accordance with the accumulated cycle number, and a storage deterioration coefficient calculated in accordance with the accumulated value of the storage periods (Step S42). If the deterioration coefficients falls within the range 0.3 to 0.7 (Step S43, 44: NO), the setting voltage in constant-voltage and constant-current charging operation is decreased from 4.2 to 4.1 V (S45). If it is smaller than 0.3 (S43: NO, S44: YES), the setting voltage is decreased to 3.8 V (S46).

Owner:SANYO ELECTRIC CO LTD

Method and apparatus for providing a time based payment from a gaming device

A method is provided for providing payments at a gaming device, where the payments may occur at predictable times and are of predictable amounts. In one or more embodiments, a gaming device may provide a guaranteed payment every hour on the hour, so long as a player meets one or more criteria. Criteria may include a total amount wagered, a total number of handle pulls completed, or a total amount of time spent at a gaming device. One or more embodiments provide a method for withholding value from a player in order that the value may delivered later in the form of a guaranteed payment. One or more embodiments provide a method whereby multiple gaming devices may provide payments simultaneously, thereby creating mutually reinforcing sounds and visual displays.

Owner:IGT

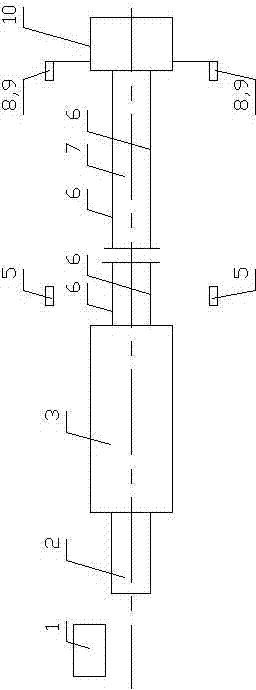

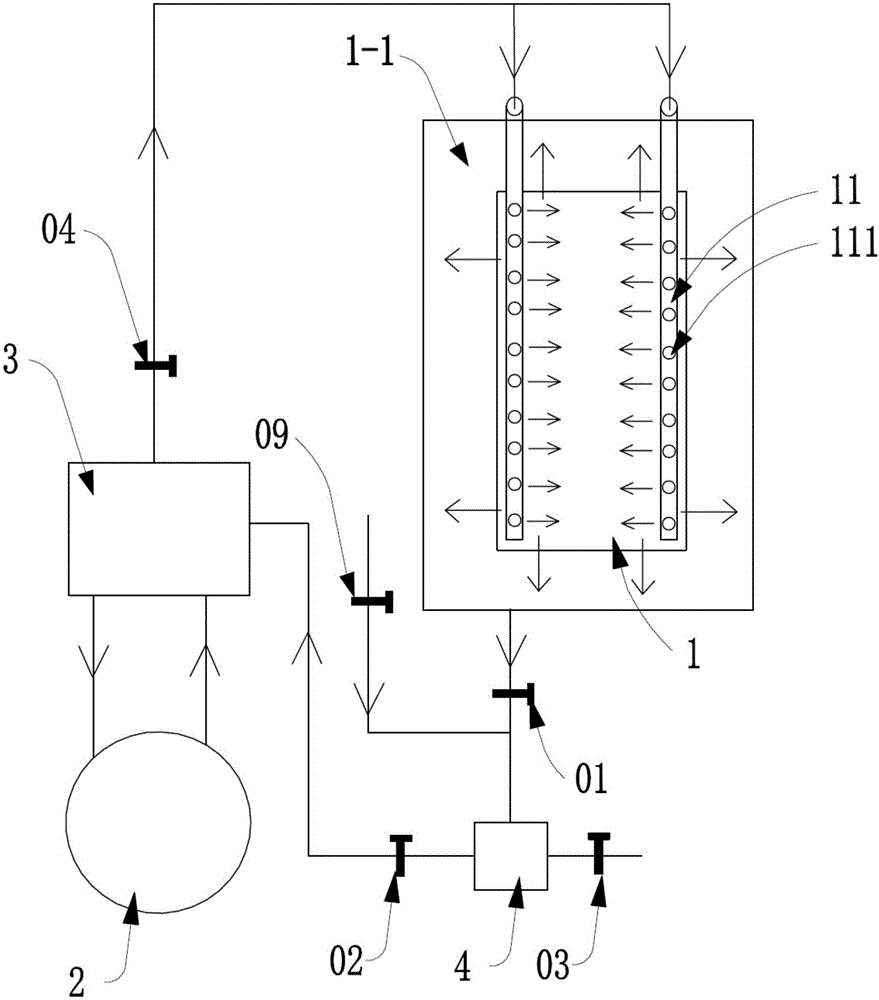

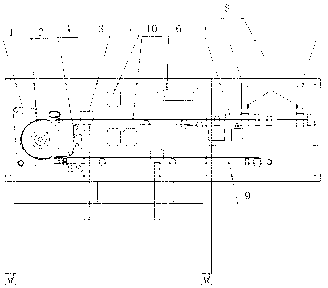

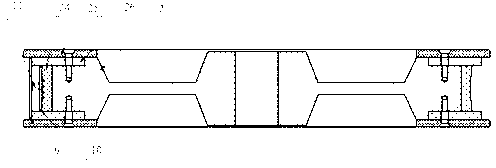

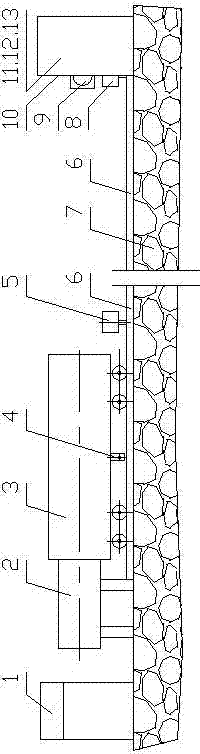

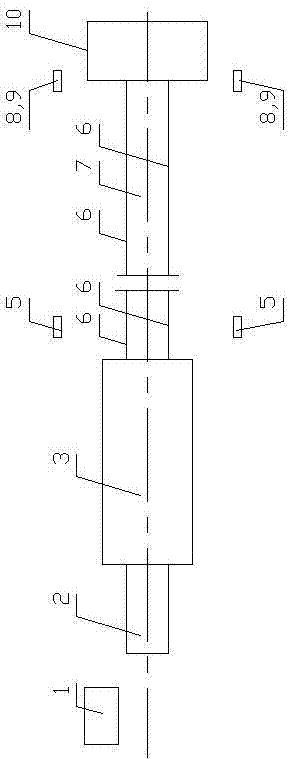

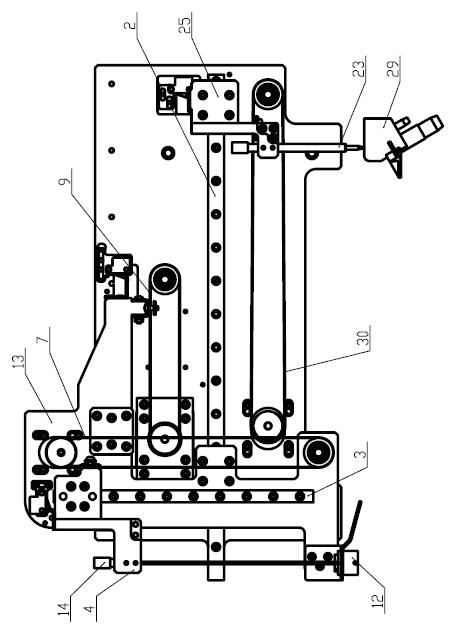

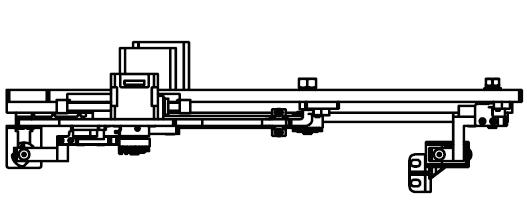

Real vehicle collision test system of rail vehicles

ActiveCN103940570AScientific and reasonable structureEasy to operateRailway vehicle testingShock testingSensor arrayRear-end collision

A real vehicle collision test system of rail vehicles comprises a central control platform, a transmitter, a real vehicle and a simulation vehicle; special software is arranged on the central control platform; the real vehicle and the simulation vehicle are placed on the same steel rail; one end of the real vehicle, which is back to the simulation vehicle, is provided with the transmitter; a uniform force plate and a force measurement sensor array are arranged at one end of the simulation vehicle from outside to inside in turn, wherein the end of the simulation vehicle faces to the real vehicle and a collision speed measuring device and a high-speed photography device are arranged on the lateral side of the end portion in a cantilever mode; in the collision test process, the simulation vehicle is static, the real vehicle accelerates within the effective stroke through the transmitter, the real vehicle collides with the simulation vehicle which is static on the rail after a certain distance of unpowered free sliding, and the free sliding distance of the real vehicle is at least 1.1 times of the effective stroke of the transmitter; the test collision speed during the collision of the real vehicle and the simulation vehicle is 1 to 2 times of the set collision speed and the lowest test collision speed is not less than 25 miles every hour; the facing or rear-end collision test of two moving objects on the same rail can be achieved after the simulation vehicle is provided with the transmitter.

Owner:CENT SOUTH UNIV

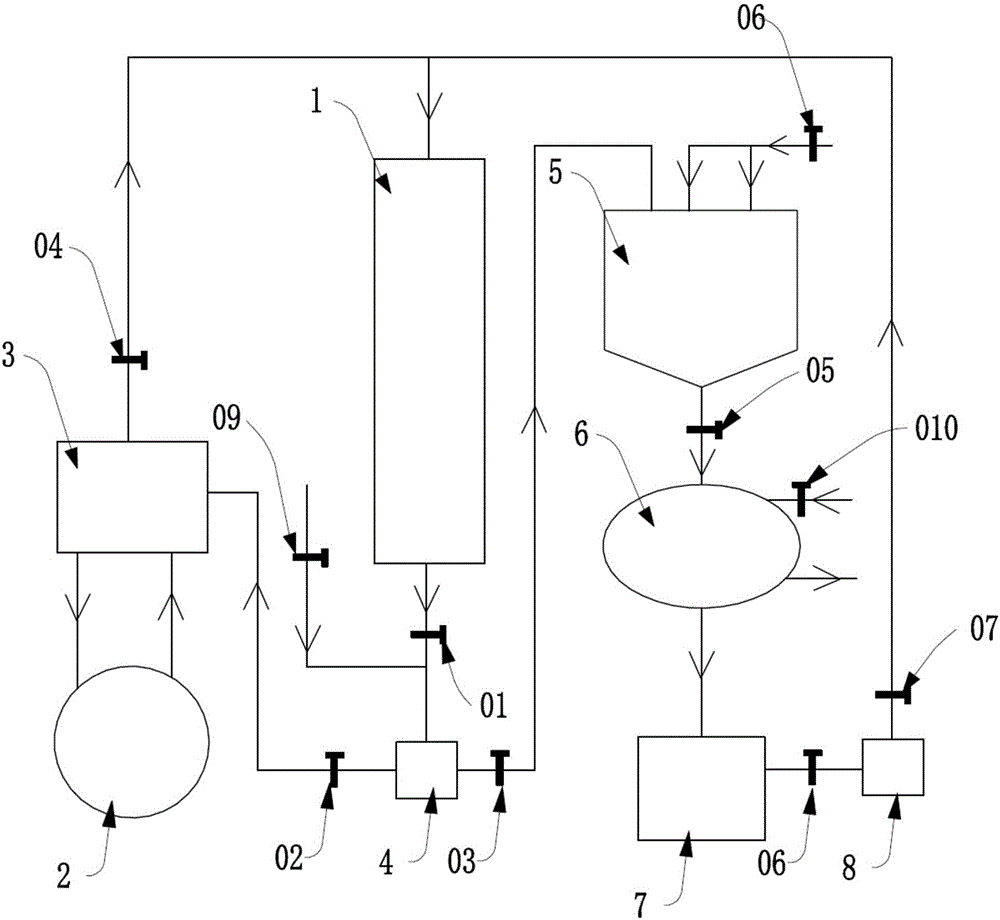

Method for treating production solvent-containing waste liquid from production of m-aramid fibers

ActiveCN101774721ASave energyReduce corrosionMultistage water/sewage treatmentNature of treatment waterLiquid wasteEvery Hour

The invention discloses a method for treating production solvent-containing waste liquid from m-aramid fiber production, which comprises the following steps: (1), filtering production solvent-containing waste liquid produced in the production of m-aramid fibers; (2), delivering liquid obtained by the step (1) to an extracting device to perform extraction separation in an extraction ratio of (1-3):1 and directly discharging the waste water; (3) delivering an extractive phase in a container used in the step (2) to a distillation tower, and subjecting the extractive phase to reduced pressure distillation separation, wherein the filler accounts for 15 to 25 percent of the volume of the distillation tower, the feeding speed is 8.4 to 16.8 percent of the volume of the distilled tower per hour, the temperature in the tower is 80 to 120 DEG C, the temperature at the bottom of the tower is 130 to 150 DEG C, the refluxing speed is 1.7 to 8.5 percent of the volume of the distillation tower per hour, and the discharge speed is 0.7 to 2.5 percent of the volume of the distillation tower per hour; and (4) rectifying the production solvent obtained by the step (3). The method can save energy and causes little corrosion of rectifying device.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

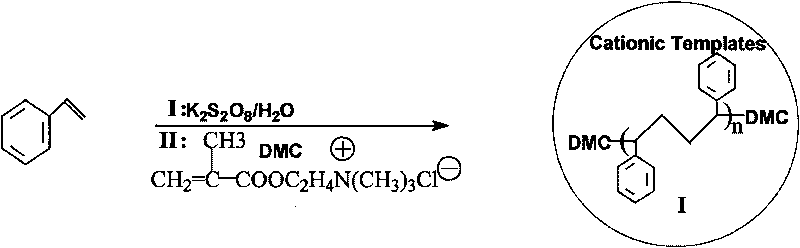

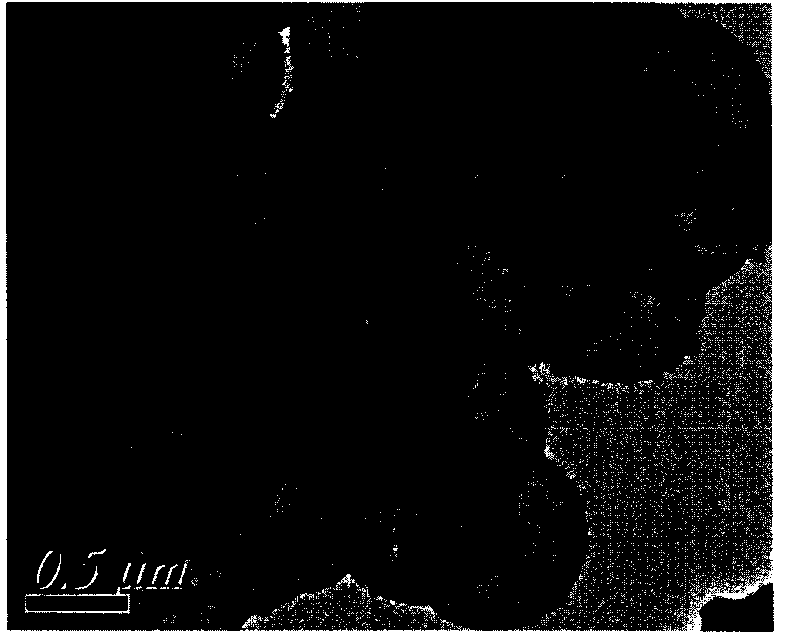

Method for preparing cation polystyrene template based on porous materials

The invention discloses a method for preparing a cation polystyrene template based on porous materials, which comprises the following steps: by utilizing soap-free emulsion polymerization, after styrene monomer polymerization is carried out for 1.5 hours, starting to inject the mixture of cation DMC and deionized water (with volume ration being 2:1) into a reaction system by a micro sample injector. The first three times of injections are respectively carried out with the interval of half an hour, and the later two times of injections are carries out with the interval of one hour. Subsequently, a plurality of times of DMC mixtures can be continuously injected every three minutes, 50 Mul of the DMC mixture is injected each time, and the highest content of the injected DMC can reach up to 30-50% (compared with the mass of St). Aqueous millipore filter membrane (0.2 mu m) is then used for centrifuging and separating the prepared cation template, and finally a cation nano polystyrene template with monodispersity is obtained. The template can be applied to the synthesis of the porous materials, is extremely easy to be dissolved in alcohol and little dichloromethane solvent, and is beneficial to removing the template of the porous materials.

Owner:JIANGSU UNIV

Fast organic waste recycling hot enzyme aerobic treatment technology

ActiveCN103304281AEfficient enzymatic fermentationEfficient and environmentally friendly processFertiliser formsOrganic fertilisersEvery HourDecomposition

The invention discloses a fast organic waste recycling hot enzyme aerobic treatment technology. The fast organic waste recycling hot enzyme aerobic treatment technology comprises the steps of: according to the proportion of (6-8):(2-4), respectively placing organic wastes and crop straw or wood chips into a hot enzyme reactor for stirring for 5-10min, respectively adding 0.05%-0.2% of heat-resistant enzyme and 0.05%-0.3% of thermophilic bacteria according to the weight percentage of the organic wastes and crop straw or wood chips, carrying out primary enzymatic fermentation, thorough decomposition and exhausting through the reactor, controlling the temperature of materials at 70-80 DEG C, controlling the humidity of the materials in the reactor to be 60%-70%, wherein the first-time exhausting amount is 100-500m<3> of per tonnage per hour, the exhausting time is 16-18 hours, and the rotating speed of stirring blade of the reactor is 1-20r / min; 16-18 hours later, finely adjusting the parameters of the hot enzyme reactor automatically, carrying out secondary enzymatic fermentation, thorough decomposition and exhausting, controlling the temperature of the materials to be 80-95 DEG C, the rotating speed of the stirring blade of the reactor to be 1-20r / min for 6-8 hours, wherein the second-time exhausting amount is 150-750m<3> of per tonnage per hour, and the exhausting time lasts for 6-8 hours; and then cooling and sieving, or further pelletizing or embedding to obtain the finished product.

Owner:BIOMAX ECOLOGICAL ENG

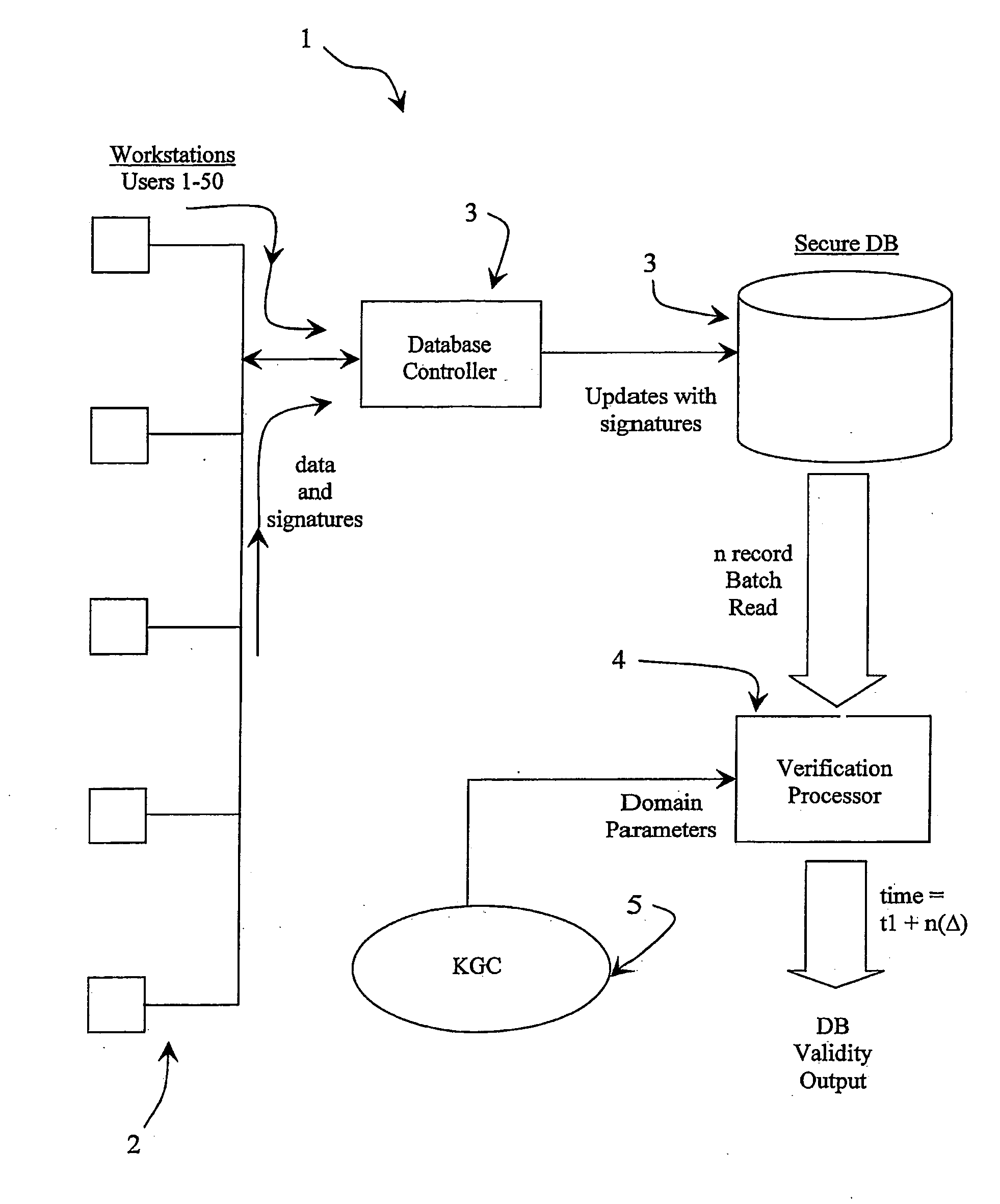

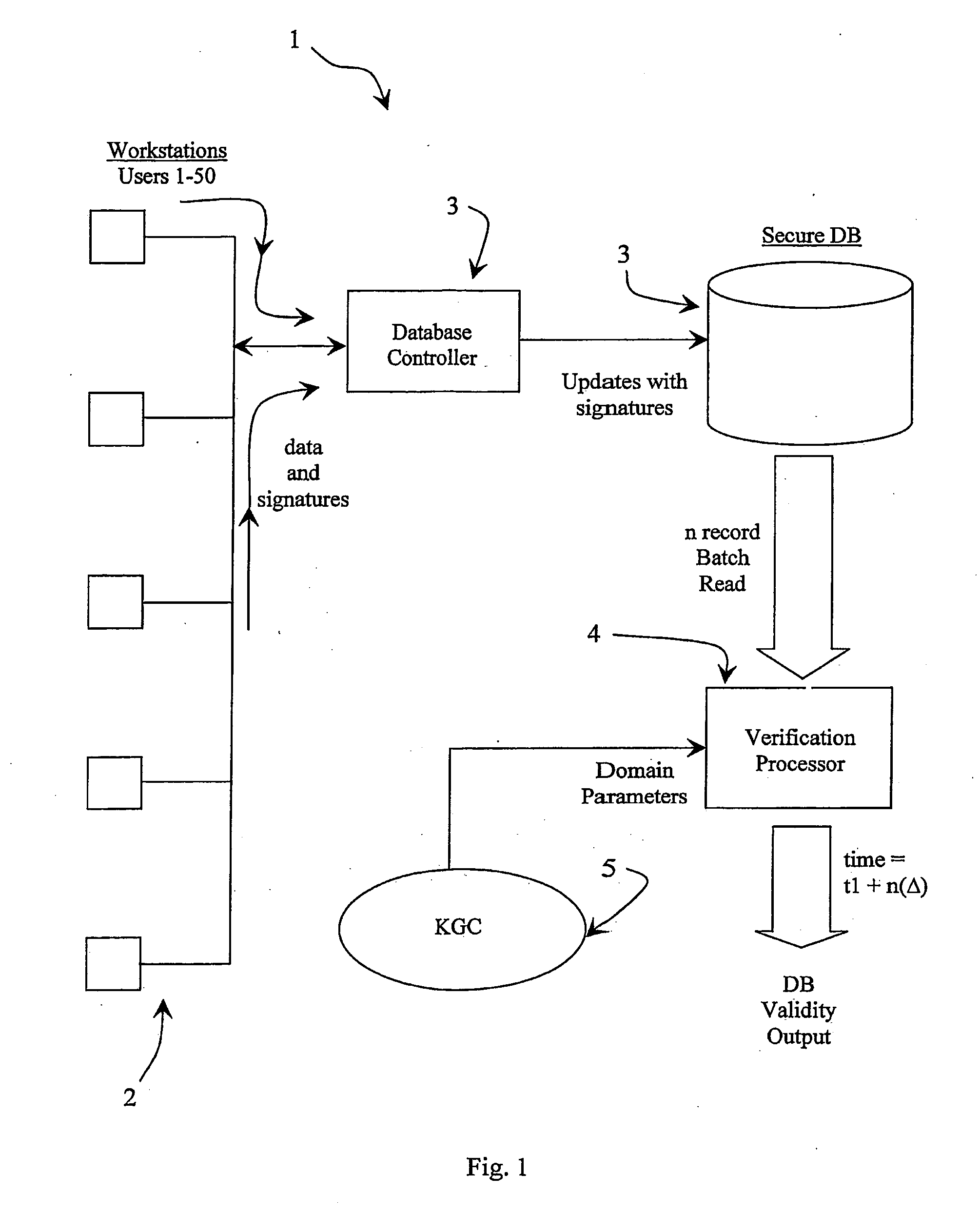

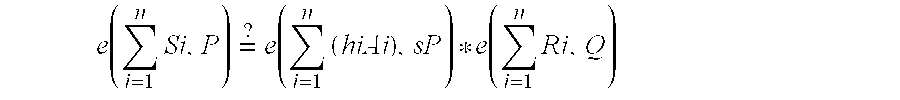

Verification of identity based signatures

ActiveUS20070028114A1Key distribution for secure communicationUser identity/authority verificationMedical recordEvery Hour

A database management system (1) comprises up to fifty or more workstations (2), each for a user. The environment may, for example, be a hospital and the system manages medical records in a secure manner. Each user has a private key issued by a KGC (5). A database controller (3) updates a secure database (3) with data and associated signatures generated by the user workstations (2). Thus every record of the secure database (3) has a signature to provide full traceability and non-repudiation of data edits / updates. It -is important for the system (1) that the signatures are verified on a regular basis, say every hour. Such a task would be extremely processor-intensive if the database (3) is large. However this is performed by a verification processor (4) of the system (1) in a much shorter time than heretofore, t1+n(&Dgr;), where t1 is the time for one verification, n is the number of signatures, and &Dgr; is a time value which is a very small proportion of t1 (less than 1%).

Owner:DUBLIN CITY UNIVERSITY

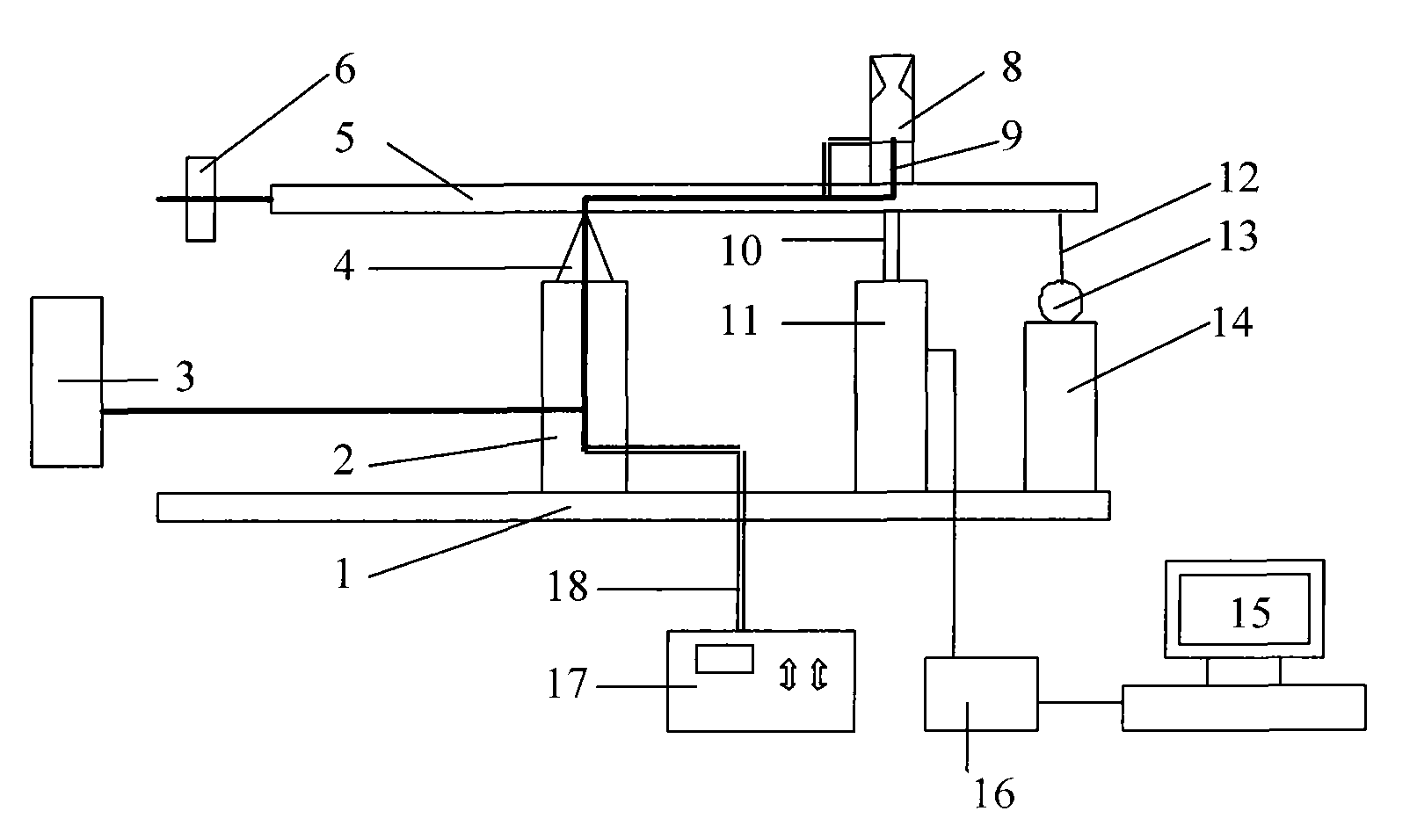

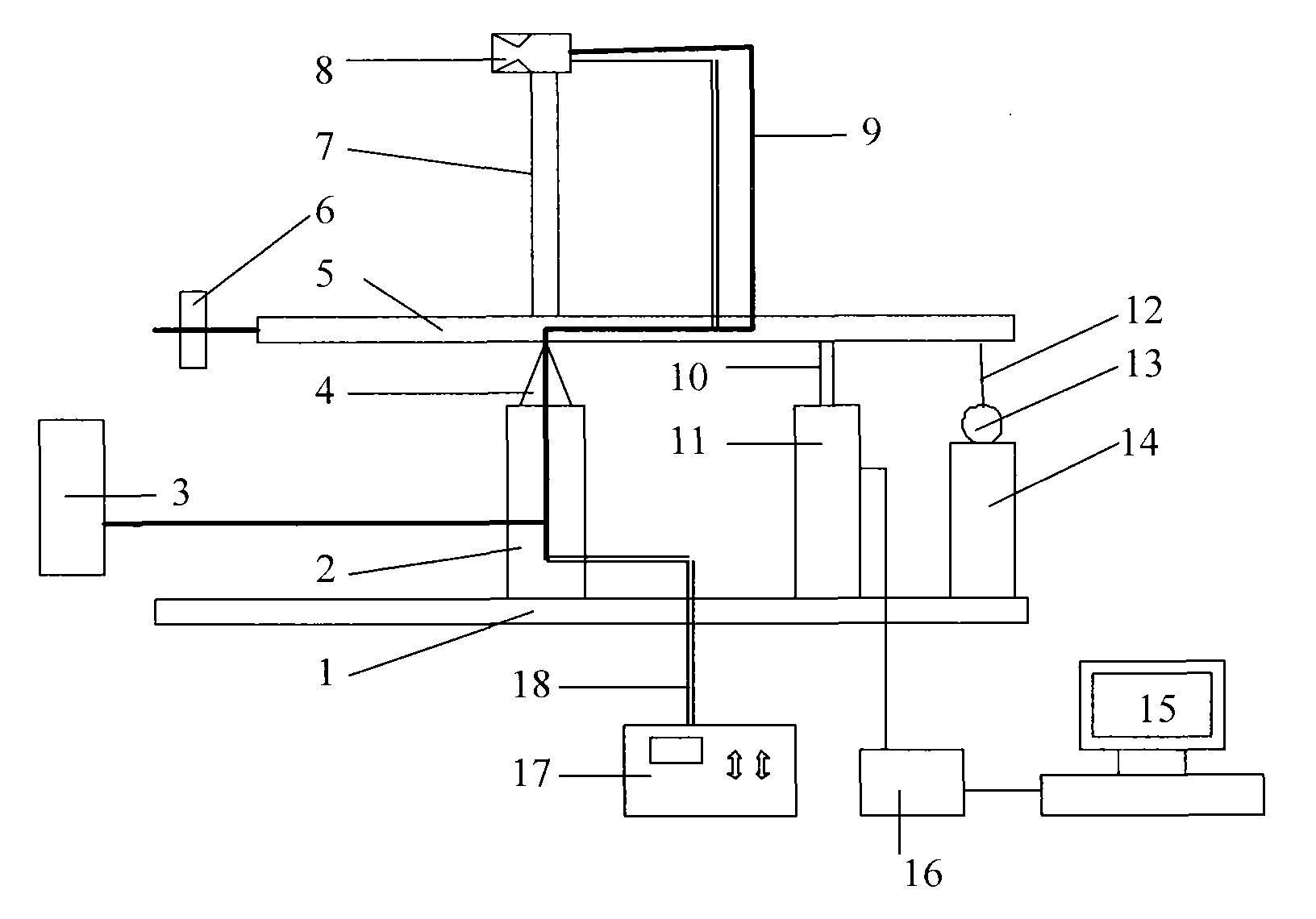

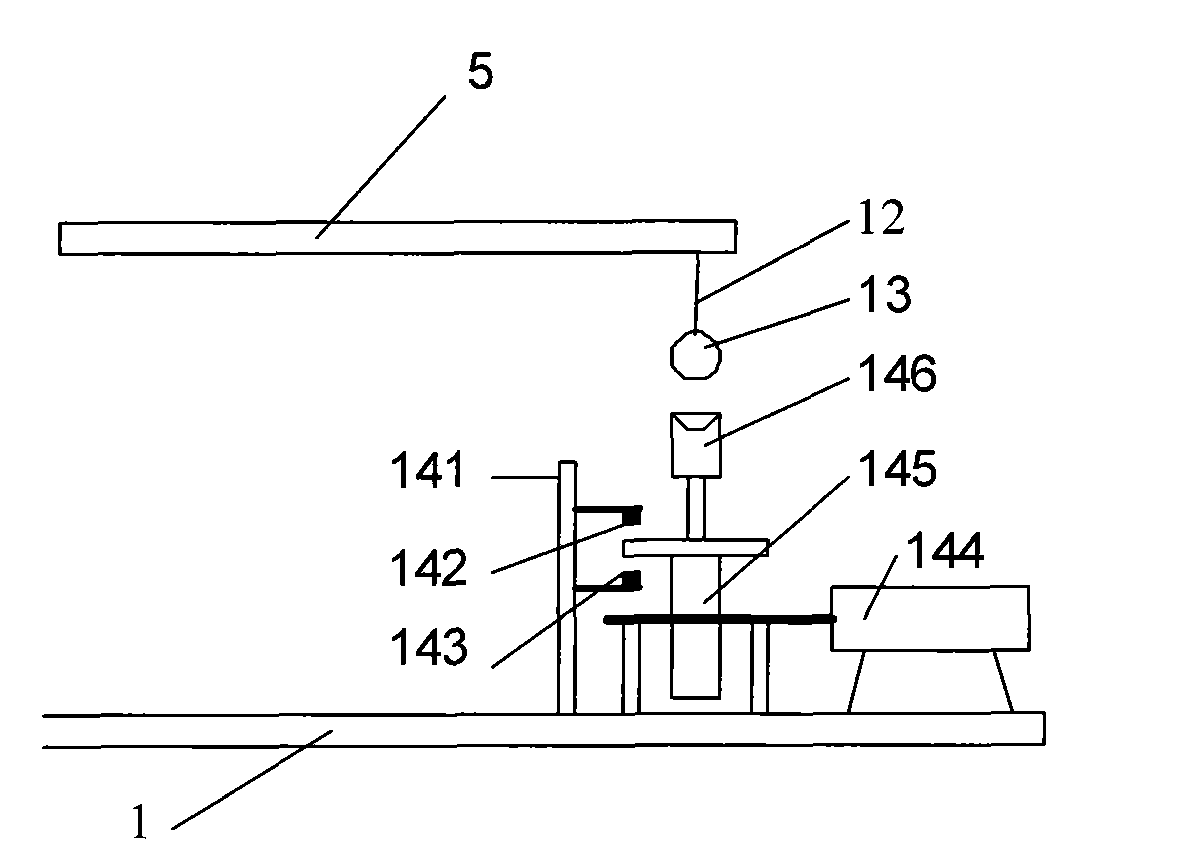

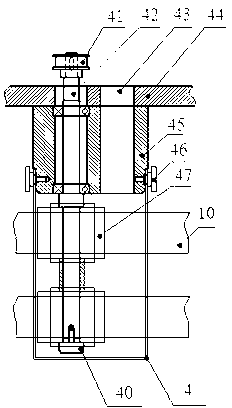

Device for measuring micro thrust of engine

ActiveCN102012292AEliminate the effects of self-weightHigh measurement accuracyApparatus for force/torque/work measurementControl lineElectric control

The invention discloses a device for measuring micro thrust of an engine, and relates to force measurement equipment. The device comprises a pedestal, a vertical beam with a knife edge, a propellant storage box, a cross beam, a balance weight, the engine, an electric control box, a force transducer, a signal processing unit and a calculator, and is characterized in that: the dead weight of the engine is balanced by using a knife edge structure and the balance weight; and the influence of a propellant pipeline and a control line on measurement accuracy is eliminated through relation between force and force arm according to a mechanical principle. When the range of the force to be measured is at the scale of hundreds of millinewtons, zero drift of the force is less than + / -1 percent F.S. every hour, the stable state measurement error is less than + / -1 percent of a full range, and high repeatability is guaranteed. The device can meet the accuracy requirement of small satellite attitude control engine thrust measurement and has broad application prospect in micro thrust measurement of the engine.

Owner:TSINGHUA UNIV

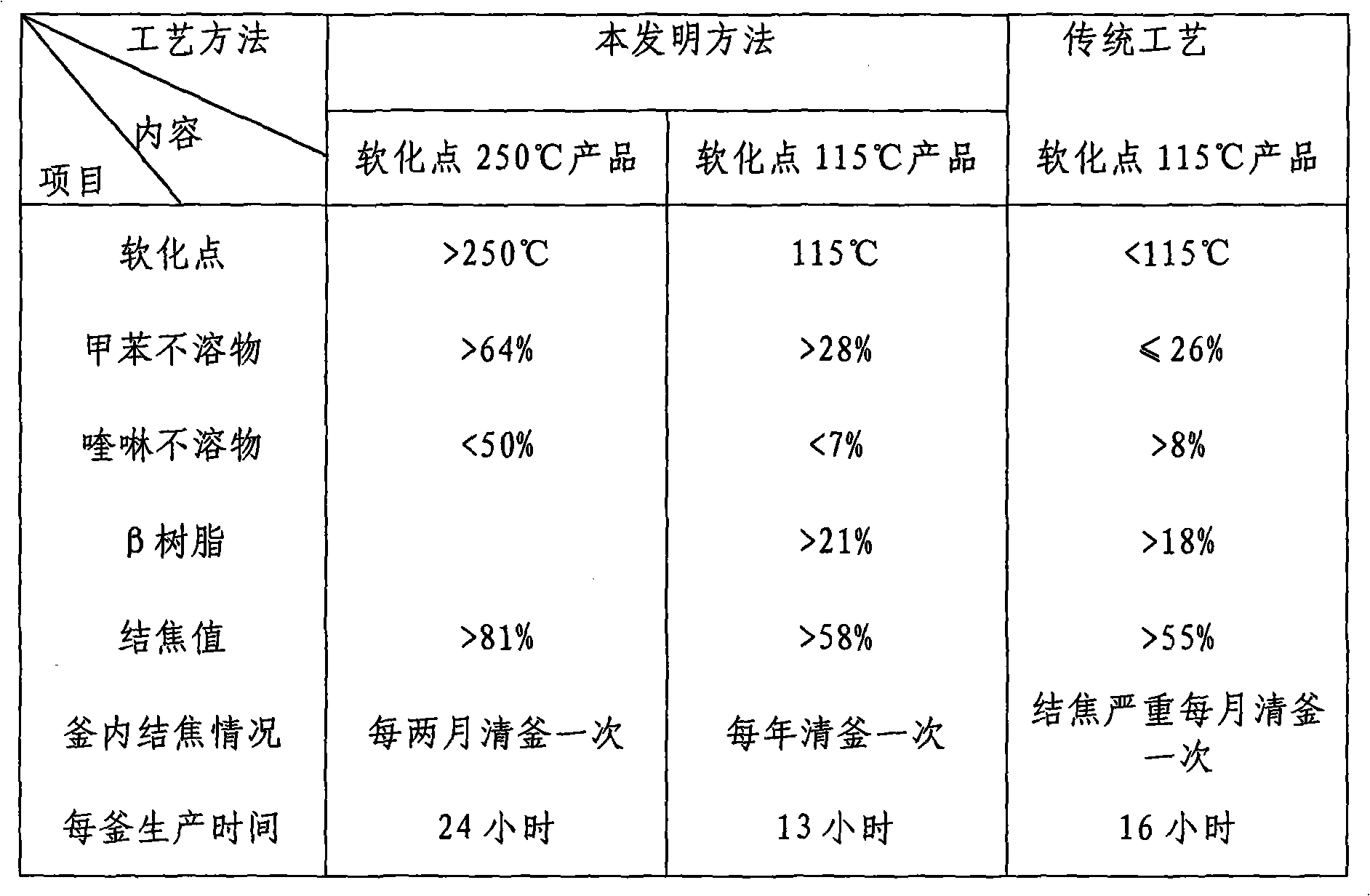

Manufacturing method of ultra-temperature pitch

ActiveCN101838542AEvenly heatedEvenly distributedWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansEvery HourDistillation

The invention relates to a manufacturing method of ultra-temperature pitch using coal pitch as a raw material, comprising the following steps of: a, evenly heating a medium-temperature liquid coal pitch raw material insulated at the temperature of 180 DEG C at the speed of 13-15 DEG C per hour and mixing by starting a mixing device when the temperature raises to 250 DEG C in a kettle; b, carryingout oxidation reaction when the temperature raises to 320 DEG C in the kettle and carrying out reduced pressure distillation after the distillate quantity is stable; c, when the temperature raises to375+ / -5 DEG C, stopping raising the temperature, maintaining the temperature, sampling, analyzing softening points until the softening points satisfy product requirements, wherein the total oxidationreaction time reaches 5-10 hours; stopping heating, introducing air and evacuating, discharging, and cooling to the normal temperature. The manufacturing method of ultra-temperature pitch can not cause local overheating concentration, leads aggregated molecules to have even distribution and stable quality, can produce high-temperature and ultra-temperature pitch according to requirements, shortens the production time, prolongs the service life of a device, and greatly improves the product quality.

Owner:镇江新光新材料科技有限公司

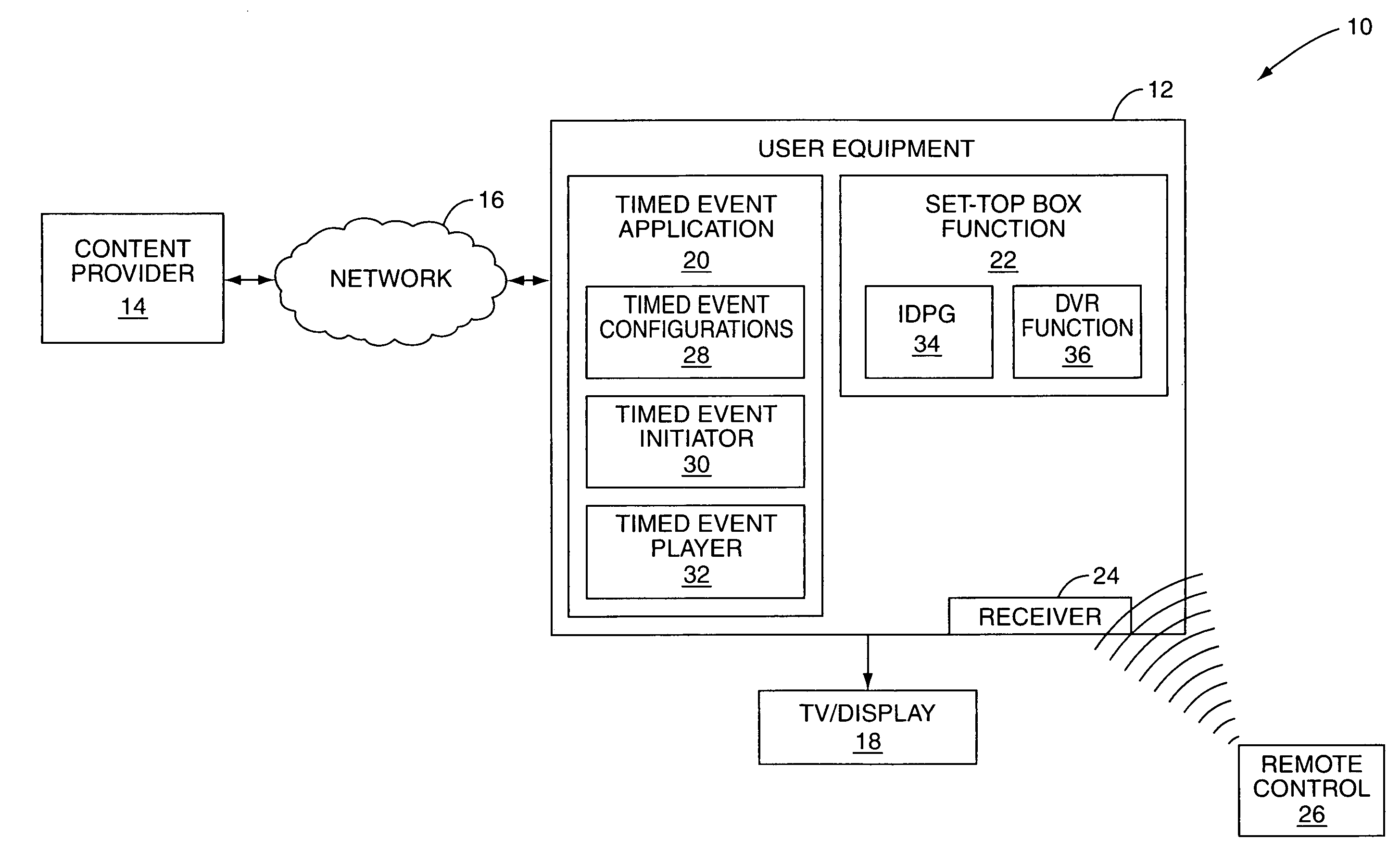

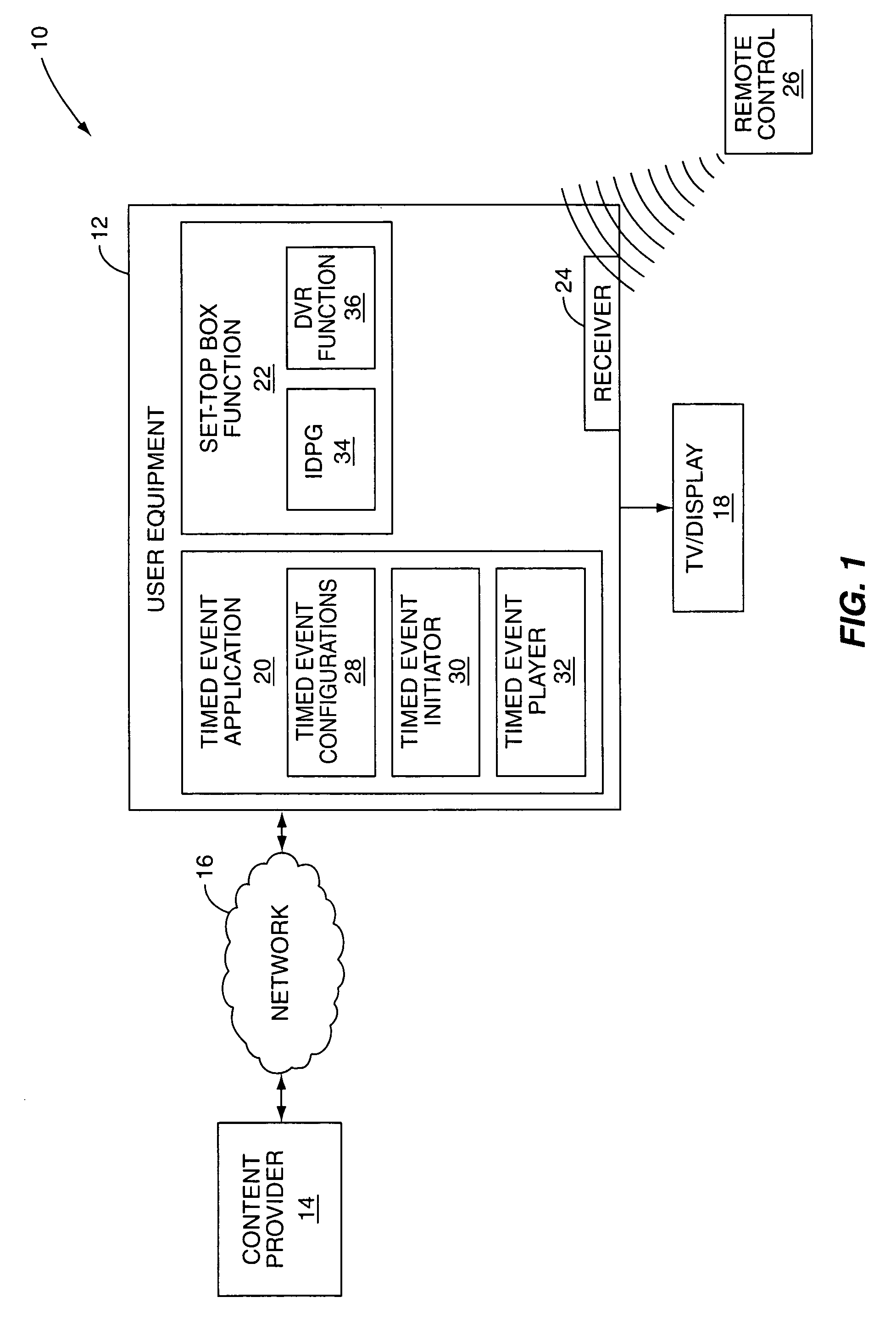

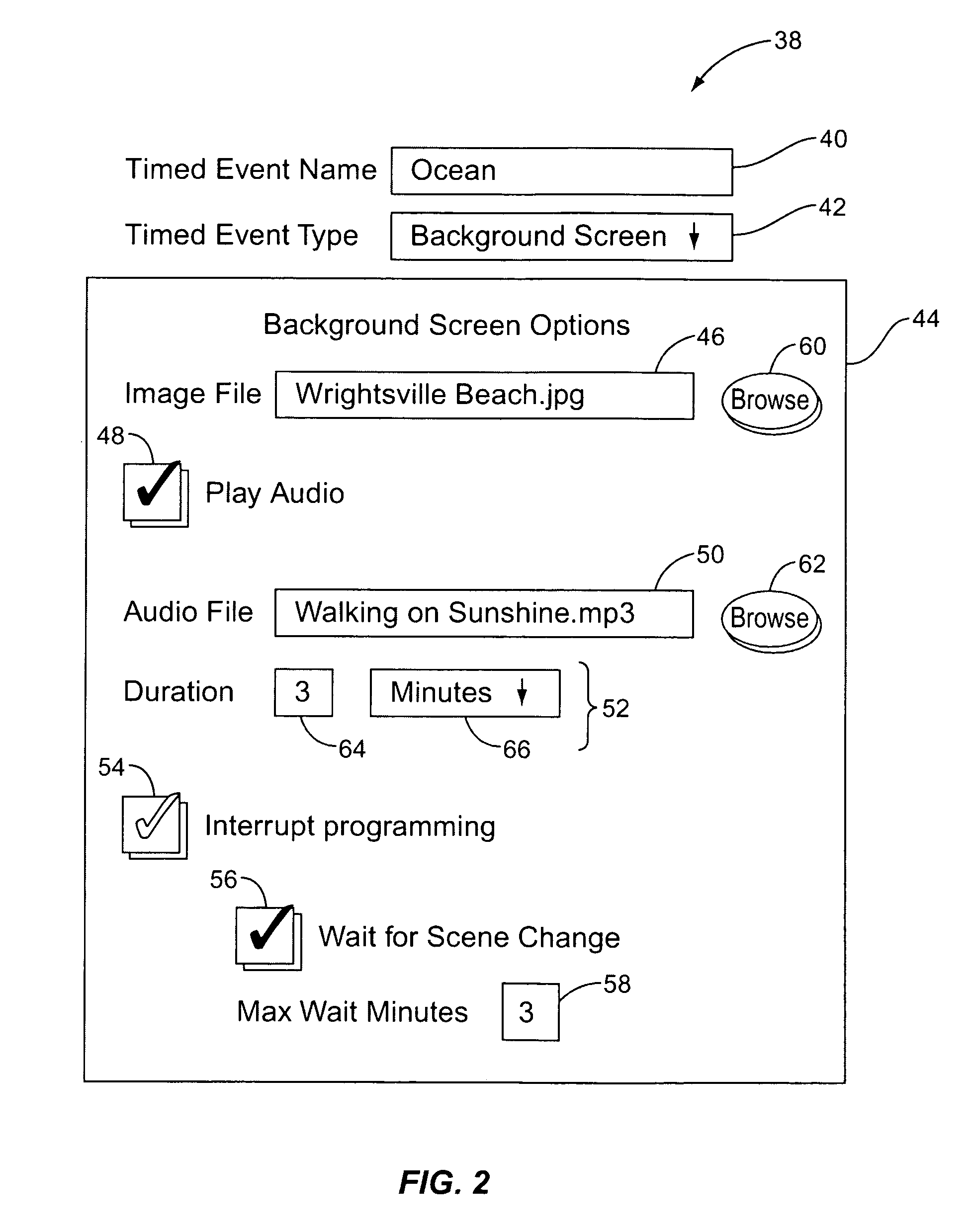

Timed events during recorded media playback

ActiveUS20070237492A1Television system detailsColor television signals processingEvery HourDigital video

A system and method are provided for providing a timed event to a user viewing recorded media content at a defined time interval. The recorded media content may be any media viewed on a time-shifted basis. For example, the recorded media may be television content recorded by a Digital Video Recorder (DVR), media content recorded on a Digital Video Disc (DVD), streaming media content providing by a network such as the Internet, or the like. In general, the timed event may be, for example, presenting audio, visual, or audio-visual content and is configured to occur periodically at a time interval such as, but not limited to, every half-hour, every hour, or once a day. Once the timed event is configured, the timed event is periodically effected at the time interval to provide an indication of time while the user is viewing recorded media content.

Owner:QURIO HLDG

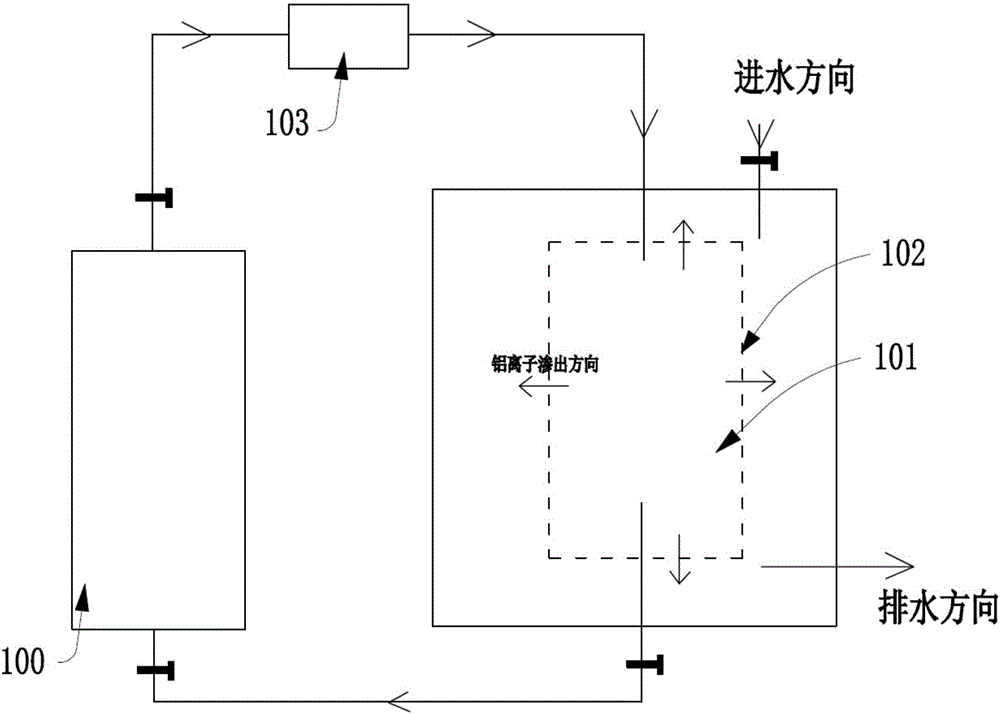

Oxidation energy-saving method for recycling aluminium ions and sulphuric acid of oxidation tank and improving current density

ActiveCN106757255AReduce the amount of dissolutionHigh densityCellsAnodisationHigh current densityEvery Hour

The invention discloses an oxidation energy-saving method for recycling aluminium ions and sulphuric acid of an oxidation tank and improving current density. The method comprises an oxidation solution circulating cooling step, an aluminium ion crystal product recycling step, a sulphuric acid oxidation solution recycling step, a gas stirring step, a defrosting step and a current density adjusting step; the current density adjusting step comprises the following steps: adjusting the flow of a variable frequency pump to be that the oxidation solution is circulated not more than six times every hour; adjusting the current density in an anodic oxidation tank. The invention provides an oxidation energy-saving method for recycling the aluminium ions and the sulphuric acid of the oxidation tank and improving the current density, the oxidation current density is improved, the oxidation time is shortened, the dissolving amount of oxidation films is reduced, and the oxidation energy consumption is reduced for the first time on the premise of blowing cold an oxidation film interface by fully utilizing a cathode cooling pipe.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

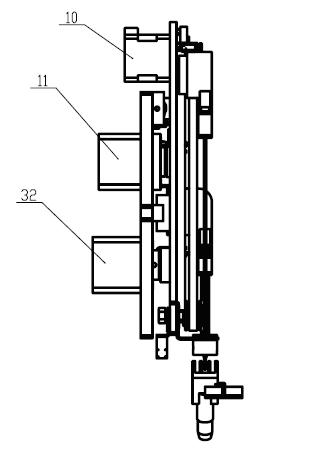

Full-automatic troche detector

ActiveCN102798727AEvenly arrangedEasy to disassemble and cleanMaterial analysisEvery HourEngineering

The invention provides a full-automatic troche detector, wherein the front end of a rack is provided with a troche turnover mechanism (1), a troche flaw identifying device (5) and a flawed troche removing device (3) are arranged above the horizontal part of an upper-side belt A (9) or an upper-side belt B (10), and the front end of the belt B (10) arranged at the back end of the rack is provided with a troche sequence arranging device (7). A troche transporting device, a troche detecting device and a troche removing device are combined with the automatic high-speed work, so that the even arrangement of troches can be guaranteed due to a rotation mode, the detector is easy to disassemble and clean, the front and the back of the detector are respectively joined with a rotating troche press device and a troche counting machine, the troches can be automatically detected, the appearance of the troches with visible flaws and various specifications can be detected by the imaging of an imaging camera at 360 degrees, the troches can be quickly and exactly monitored and classified, and 300000 troches can be detected every hour.

Owner:上海秉拓智能科技有限公司

Synthesizing method for tough epoxy vinyl ester resin

The invention belongs to the technical field of high-molecular polymers, and relates to a synthesizing method for tough epoxy vinyl ester resin. The synthesizing method is characterized by comprising the following steps of: (1) adding 45-50 percent by weight of bisphenol type A epoxy resin, 8.2-20.3 percent by weight of unsaturated monocarboxylic acid, 2.5-11.1 percent by weight of long chain saturated dibasic acid and a small amount of catalyst and polymerization inhibitor into a reaction kettle in sequence; (2) controlling the temperature between 100 DEG C and 130 DEG C, and measuring the acid value once every hour till the acid value is lowered below 10 mgKOH / g; and (3) cooling to about 100 DEG C, adding 26-40 percent of a crosslinking agent, and uniformly stirring at the temperature of 60-80 DEG C to obtain the tough epoxy vinyl ester resin. The synthesizing method has the advantages that: unsaturated monocarboxylic acid is replaced by a long chain saturated dibasic acid part for reacting, so that the synthesizing method is simple, a destination is specified, side reactions are reduced, 'three wastes' are not produced, the quality is stable, and a product is particularly suitable for manufacturing high-speed railway elastic gaskets, large-sized wind-driven generator blades, high-speed boats, high-pressure gas cylinders and the like.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Surface chemical plating Ni-P process using nickel sulfate as main salt

InactiveCN101187020ALow costPlating solution formula is simpleLiquid/solution decomposition chemical coatingEvery HourSulfate

The invention relates to a chemical Ni-P plating technique on the surface of magnesium alloy which takes nickel sulfate (NiSO4, 6H20) as the main salt. The technique process is as follows, ultrasonic cleaning, alkali cleaning, acid cleaning, activation, and chemical nickel phosphorus plating (water cleaning is employed among steps), dispensations of plating solution are NiSO4, 6H2O (20 grams per liter), HF (40%, 12 milliliter per liter), Na3C6H5O7, 2H2O (20 grams per liter), NH4HF2 (10 grams per liter), NH3, H20 (25%, 30 milliliters per liter), and NaH2PO2, H2O (20 grams per liter), and the plating temperature is 88 +-2 DEG C. The plating speed on the surface of magnesium alloy is 20 micrometers per hour, and the plated rigidity is 300-500 HV. The invention is low in cost and simple in plating solution dispensation, and is applicable to the magnesium alloy in Mg-Al-Zn series (AZ series).

Owner:ZHONGYUAN ENGINEERING COLLEGE

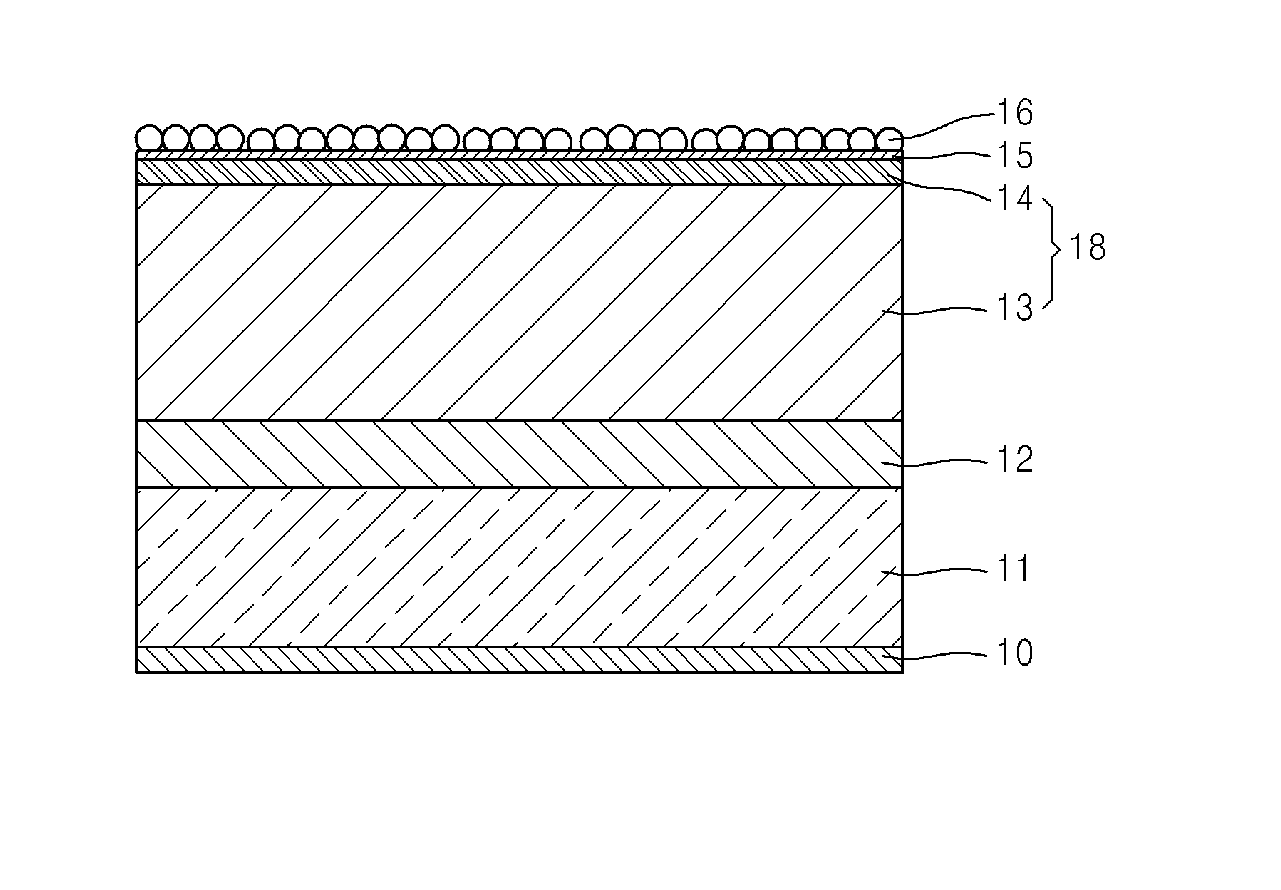

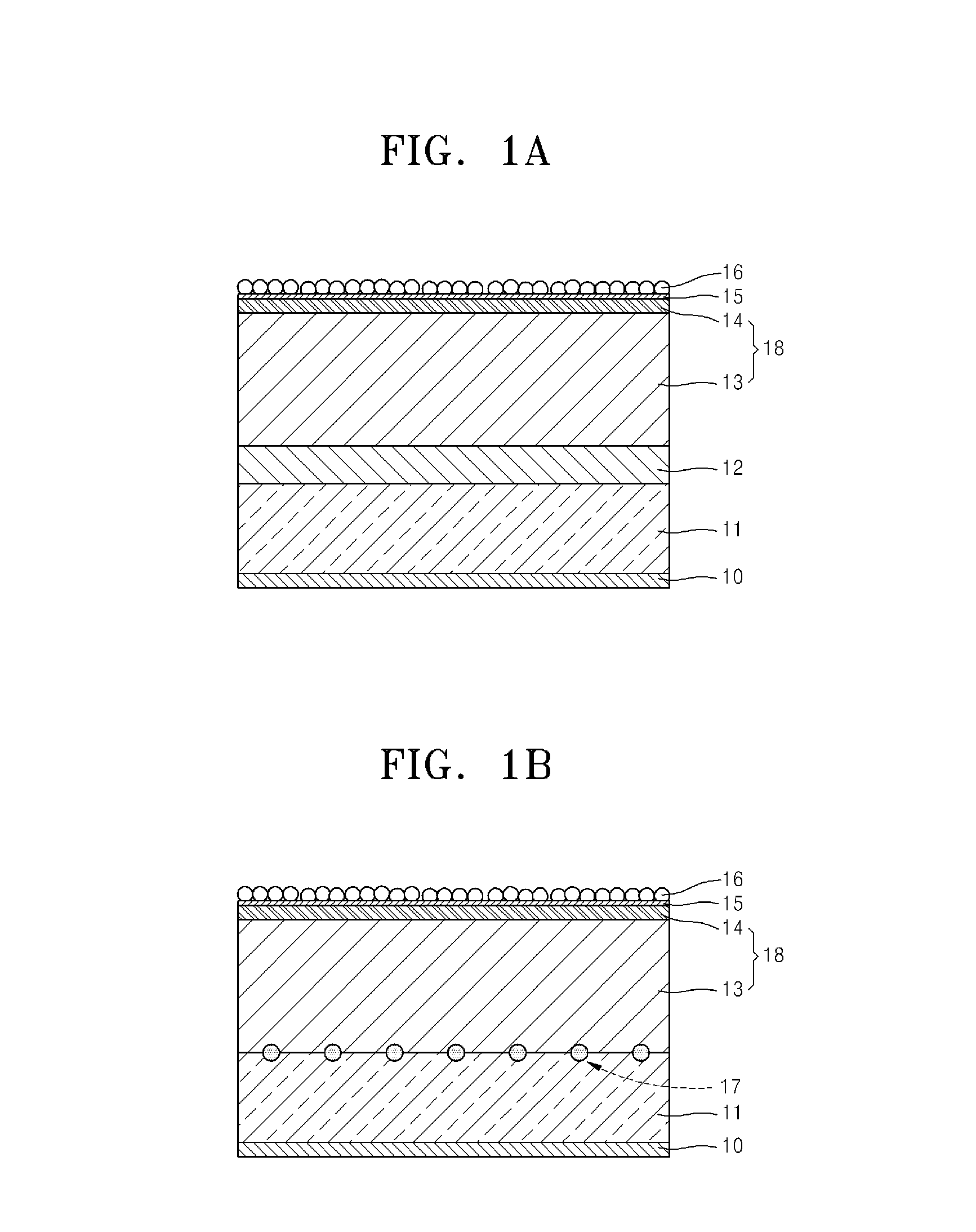

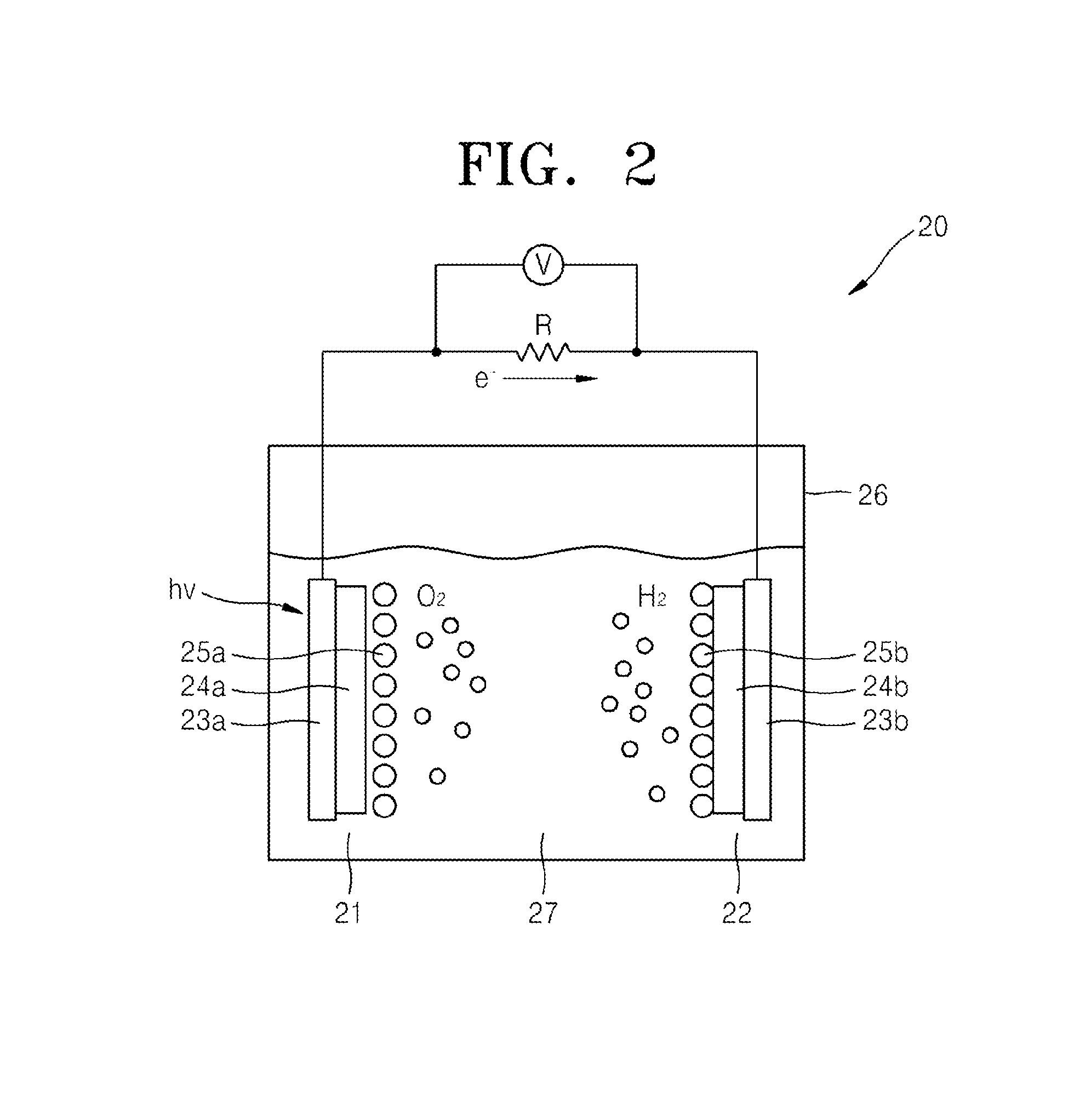

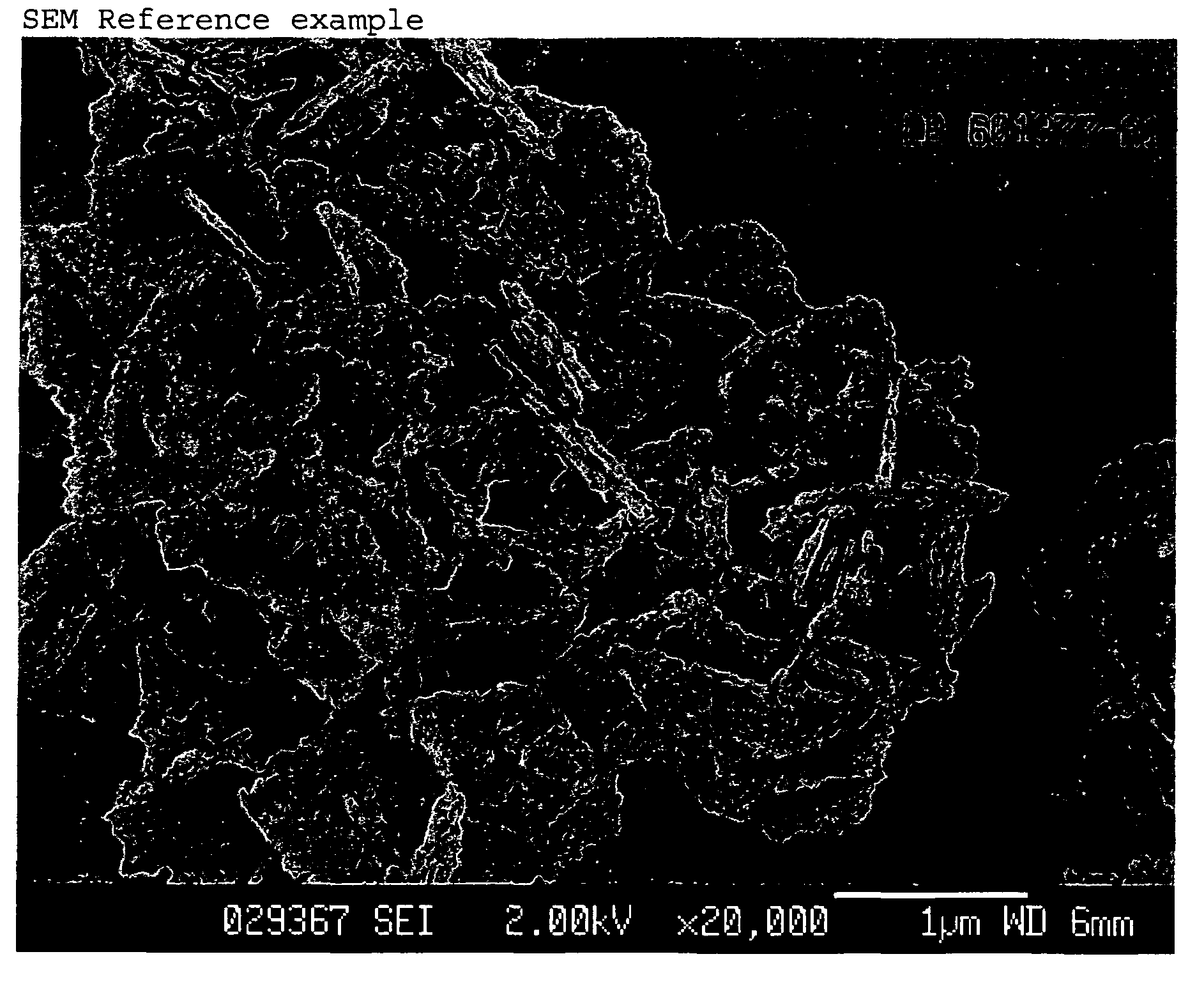

Composite protective layer for photoelectrode structure, photoelectrode structure including the composite protective layer, and photoelectrochemical cell including photoelectrode structure

A composite protective layer for a photoelectrode, the composite protective layer including a chemical protective layer; and a physical protective layer, wherein the chemical protective layer has corrosion rate of 0.1 Coulombs per square centimeter per 10 hours or less when evaluated at a water decomposition potential, and the physical protective layer has a moisture transmittance rate of 0.001 grams per square meter per day or less and has an electrical conductivity.

Owner:SAMSUNG ELECTRONICS CO LTD

Process for manufacturing molecular sieve of MFS framework type and its use

A method of making a crystalline molecular sieve of MFS framework type, said method comprising the steps of (a) adding at least one source of ions of tetravalent element (Y), at least one source of ions of trivalent element (X), at least one hydroxide source (OH−), at least one structure-directing-agent (R), at least one seed source (Seed), and water (H2O) to form a mixture having the following mole composition (expressed in term of oxide):YO2:(n)X2O3:(x)OH−:(y)R:(z)H2O+(m)Seedwherein the m is in the range of from about 10 wtppm to about 2 wt. % (based on total weight of the synthesis mixture), the n is in the range of from about 0.005 to 0.05, the x is in the range of from about 0.01 to about 0.3, the y is in the range of from about 0.03 to about 2; and the z is in the range of from about 3 to about 30; and (b) treating said mixture under crystallization conditions to form said crystalline molecular sieve substantially free of non-MFS material, wherein said crystallization conditions comprise a temperature in the range of from about 150° C. to about 250° C., and crystallization time less than 100 hr, the weight hourly throughput is at least 0.001 hr−1.

Owner:EXXONMOBIL CHEM PAT INC

Method for producing Nixing pottery by stacking and carving

The invention discloses a method for producing a Nixing pottery by stacking and carving. The method comprises the steps of preparing a blank material, forming a blank body, finishing the blank body, decorating the blank body, drying the blank body and firing the blank body, wherein the step of decorating the blank body comprises the sub-steps of moisturizing the blank body, preparing a stacking and carving material, stacking and carving; and the step of firing the blank body comprises the following sub-steps of: 1) placing a dry blank body into a kiln, gradually heating at a speed of 20-30 DEG C per hour, when heating to be 80-120 DEG C, stopping heating, and keeping for 20-28 h; 2) gradually heating again at a speed of 20-30 DEG C per hour, when heating to be 350-500 DEG C, stopping heating, and keeping for 0.5-2 h; 3) gradually heating again at a speed of 20-30 DEG C per hour, when heating to be 550-700 DEG C, stopping heating, and keeping for 0.5-2 h; 4) gradually heating again at a speed of 30-60 DEG C per hour, and heating to be 1060-1100 DEG C; and 5) naturally cooling.

Owner:钦州市三鸿陶艺厂

Real vehicle collision test system of rail vehicles

ActiveCN103940572AScientific and reasonable structureEasy to operateRailway vehicle testingShock testingEvery HourCollision test

A real vehicle collision test system of rail vehicles comprises a central control platform, a transmitter, a real vehicle and a collision wall; the real vehicle is placed on a rail which is arranged between the transmitter and the collision wall; the lateral side of the collision wall is provided with a collision speed measuring device and a high-speed photography device; in the collision test process, work of the transmitter, the collision speed measuring device, the high-speed photography device and a measured force collection device of the collision wall is controlled by a program of the central control platform and related data are received and stored; the real vehicle accelerates within the effective stroke through the transmitter, the real vehicle collides with the collision wall after a certain distance of unpowered free sliding, and the free sliding distance of the real vehicle is at least 1.1 times of the effective stroke of the transmitter; the test collision speed during the collision of the real vehicle and the collision wall is 1 to 2 times of the set collision speed, the set collision speed is 20 to 40 % of the real vehicle operating speed, and the lowest test collision speed is not less than 25 miles every hour; analytical calculation is performed after the test is achieved and a test result is output.

Owner:CENT SOUTH UNIV

Automatic reagent dropping system of urine analysis meter

ActiveCN102221627AAccurate sampling positionImprove cleanlinessMaterial analysisEvery HourEngineering

The invention relates to an automatic reagent dropping system of a urine analysis meter, belonging to the field of the urine analysis meter. The automatic reagent dropping system provided by the invention is of a double-probe structure and comprises a sampling mechanism, a dropping mechanism, a sampling cleaning mechanism and a dropping cleaning mechanism. The automatic reagent dropping system provided by the invention effectively enhances the speed of dropping and realizes the testing result of 480 parts every hour. In the automatic reagent dropping system provided by the invention, the sampling and dropping system drives a synchronous belt to make a motion by adopting a motor in a transmission mode, and the extraction and sampling of samples are carried out by utilizing an injection pump, an electromagnetic valve and a pipeline. In the automatic reagent dropping system provided by the invention, the accuracy of the sampling and the dropping is improved to the great extent; and the double probes are alternately operated in parallel, thereby greatly improving the work efficiency. The two paths of cleaning mechanisms avoids the cross contamination among the samples to the great extent and improves the accuracy of the test result.

Owner:DIRUI MEDICAL TECH CO LTD

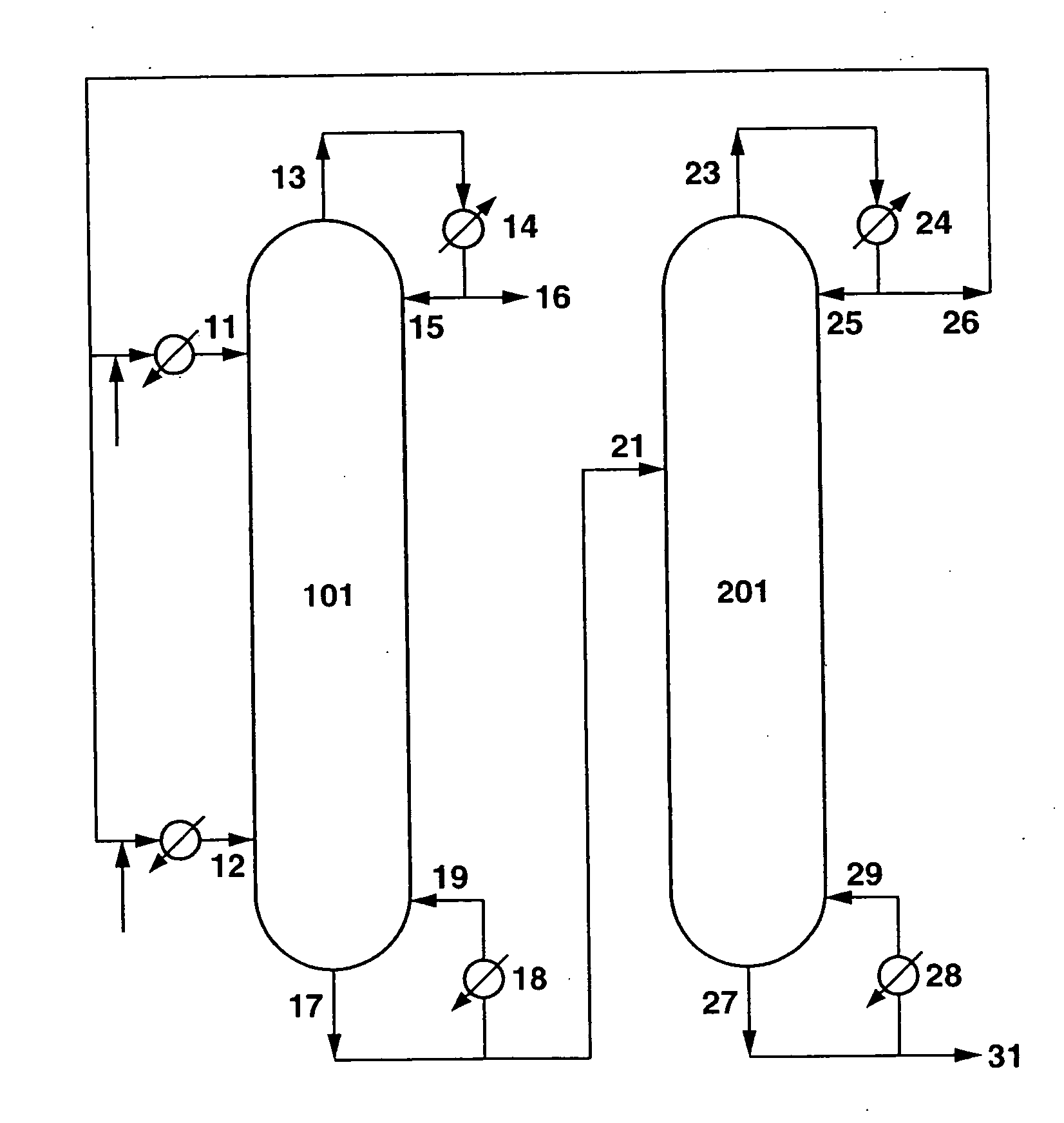

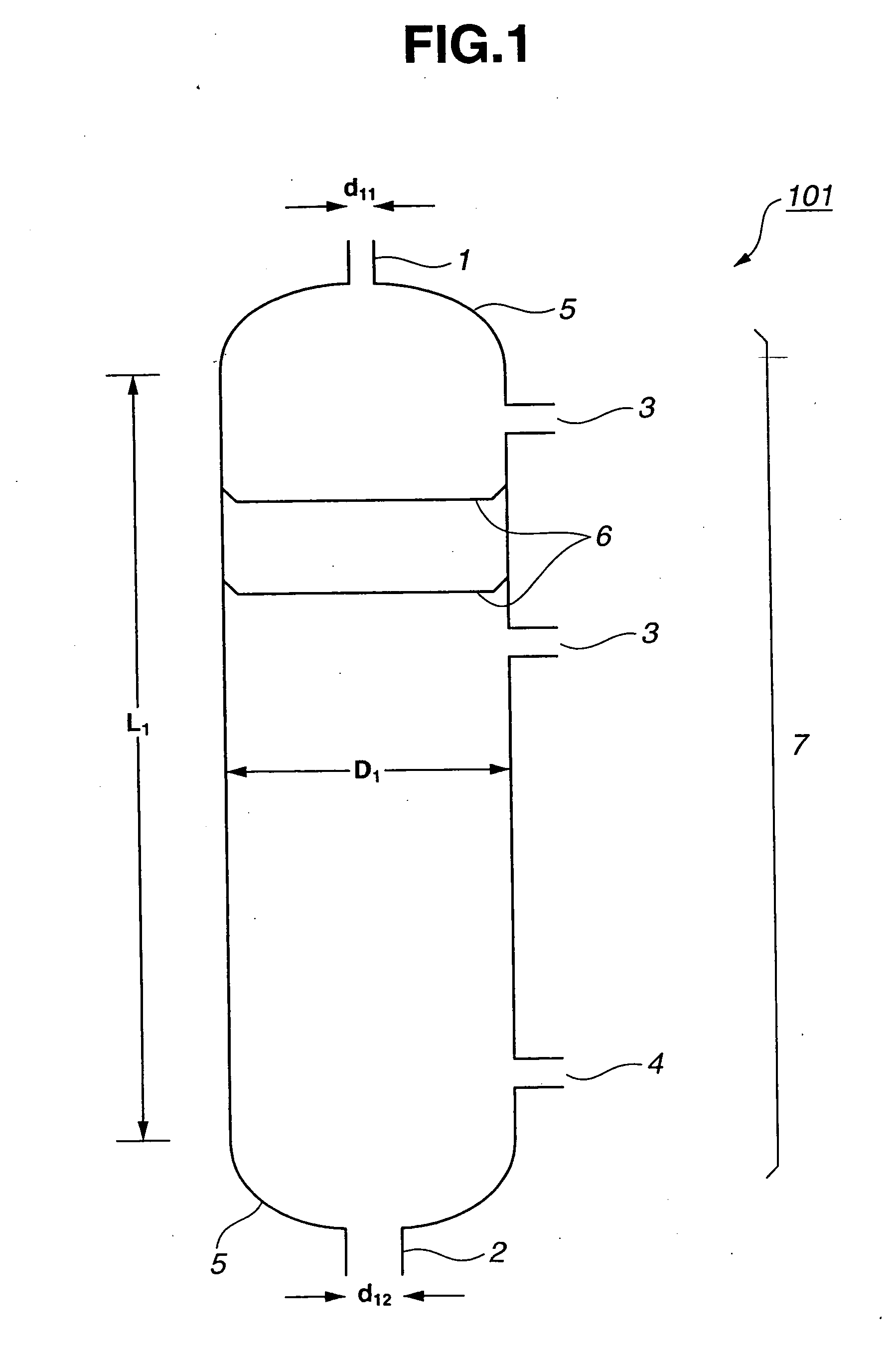

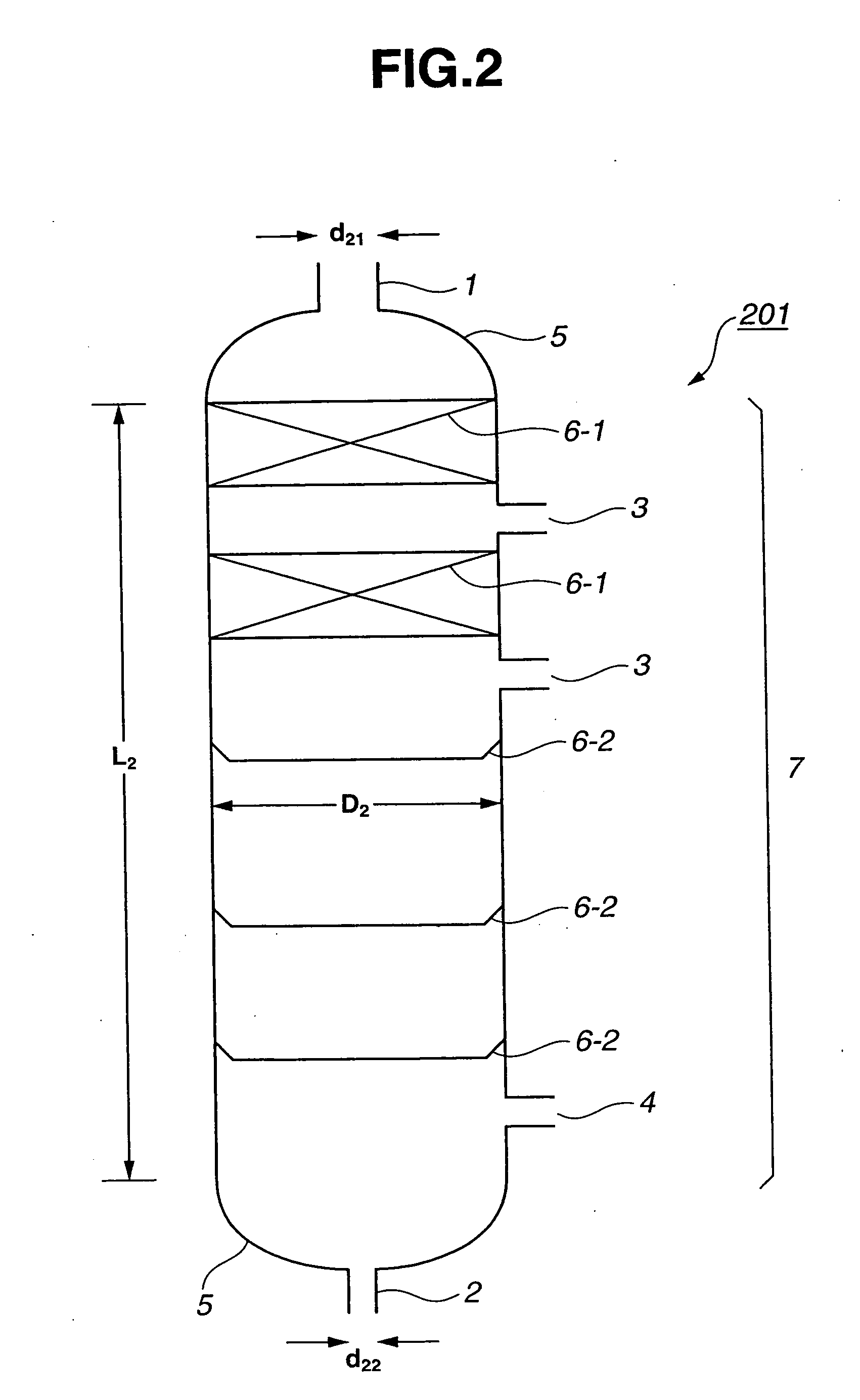

Process for industrial production of an aromatic carbonate

ActiveUS20070191623A1High selectivityHigh purityChemical industryDistillation separationEvery HourProduction rate

It is an object of the present invention to provide a specific process that enables aromatic carbonates to be produced with high selectivity and high productivity stably for a prolonged period of time on an industrial scale of not less than 1 ton per hour from a dialkyl carbonate and an aromatic monohydroxy compound using two continuous multi-stage distillation columns. Although there have been various proposals regarding processes for the production of aromatic carbonates by means of a reactive distillation method, these have all been on a small scale and short operating time laboratory level, and there have been no disclosures whatsoever on a specific process or apparatus enabling mass production on an industrial scale. According to the present invention, there are provided two specified continuous multi-stage distillation columns, and there is also provided a specific process that enables aromatic carbonates to be produced with high selectivity and high productivity stably for a prolonged period of time on an industrial scale of not less than 1 ton per hour from a dialkyl carbonate and an aromatic monohydroxy compound using a apparatus in which these two continuous multi-stage distillation columns are connected together.

Owner:ASAHI KASEI KK

Network controlling apparatus and path controlling method therein

InactiveCN1649315AImprove efficiencyEfficient utilizationTime-division multiplexData switching by path configurationEvery HourNetwork control

A network controlling apparatus appropriately arranges a generated path every hour with a change in section and bandwidth requested in each time period to flexibly generate a path according to the state of occurrence of requests. The network apparatus comprises a storing unit storing information for management of the network, and a controlling unit controlling setting of the network device relating to a connection of network devices at two edge points in the network to obtain path setting satisfying the quality guarantee request, using a path already set or scheduled to be set, or a newly generated path, by referring to the information stored in the storing unit when receiving the quality guarantee request.

Owner:FUJITSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com