Patents

Literature

3652 results about "Carving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carving is the act of using tools to shape something from a material by scraping away portions of that material. The technique can be applied to any material that is solid enough to hold a form even when pieces have been removed from it, and yet soft enough for portions to be scraped away with available tools. Carving, as a means for making sculpture, is distinct from methods using soft and malleable materials like clay, fruit, and melted glass, which may be shaped into the desired forms while soft and then harden into that form. Carving tends to require much more work than methods using malleable materials.

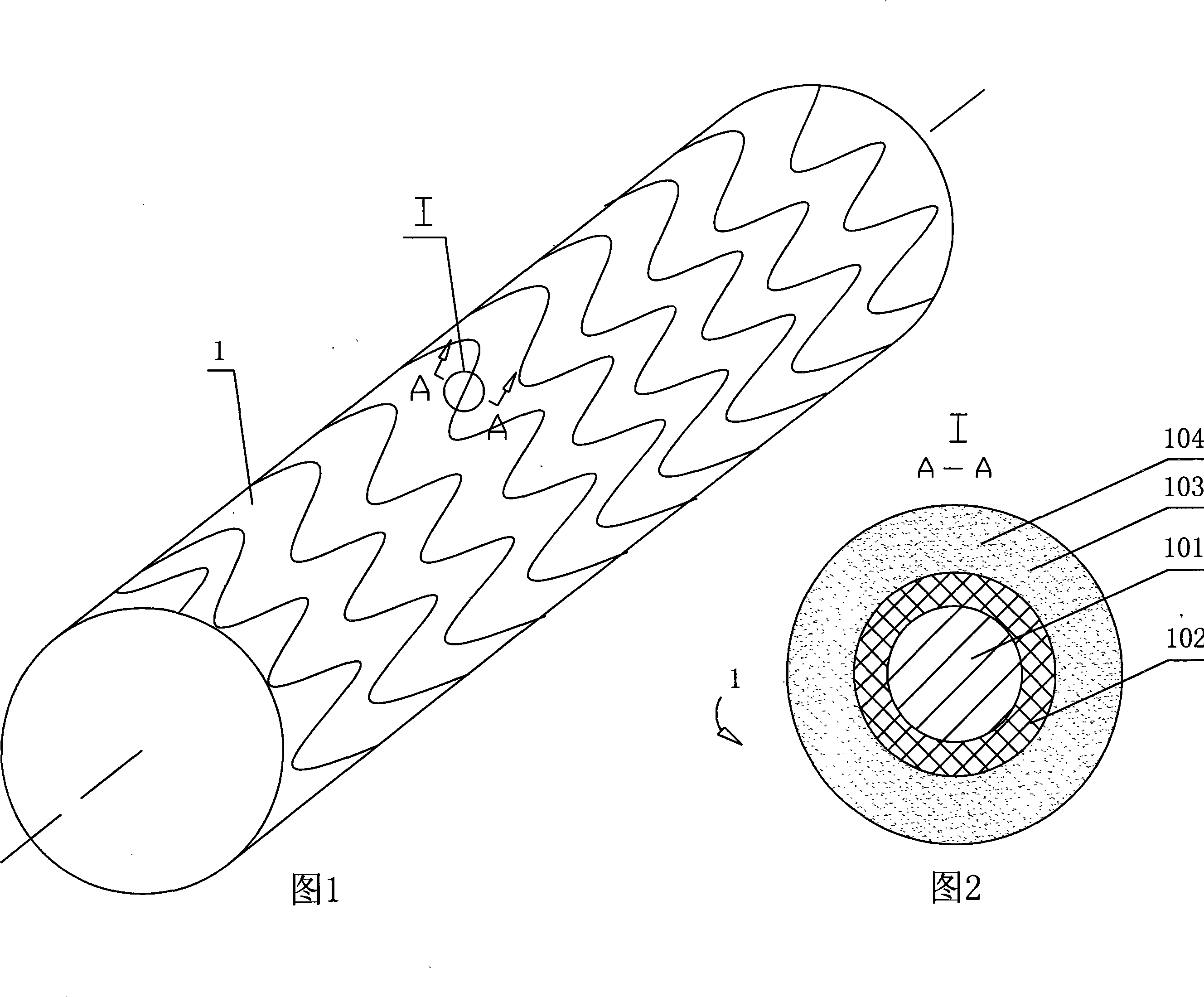

Controlled degradation magnesium alloy coating bracket and preparation thereof

InactiveCN101214396AImprove mechanical propertiesExcellent pharmacological propertiesAnodisationStentsSurface cleaningPolymer chemistry

The invention relates to a controlled degradation magnesium alloy coating stent and a preparation method. The stent body is made of medical high purity magnesium or magnesium alloy by mechanical processing or laser carving; the stent body is provided with a drug-loading coating which bears curative drug; the surface of the stent body is provided with an anti-corrosive coating; the surface of the anti-corrosive coating is provided with a degradable polymer film drug-loading coating; the preparation method includes surface cleaning, preparation of the degradable polymer film drug-loading coating, and application of curative drug; through (1)surface cleaning, (2)preparation of the degradable polymer film drug-loading coating, and (3)application of curative drug, an oxide film is formed on the surface; different drugs and dosage can be fixed by regulating the molecular weight and the thickness of the polymer layer, the drug-loading quantity is more than 30 percent, which improves the fixed stability of the drug, greatly reduces the degradation speed of the magnesium alloy and controls release of the drug, delays corrosion of the magnesium alloy, extends the service life of the stent, is safe in use, and meets the clinical requirement.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

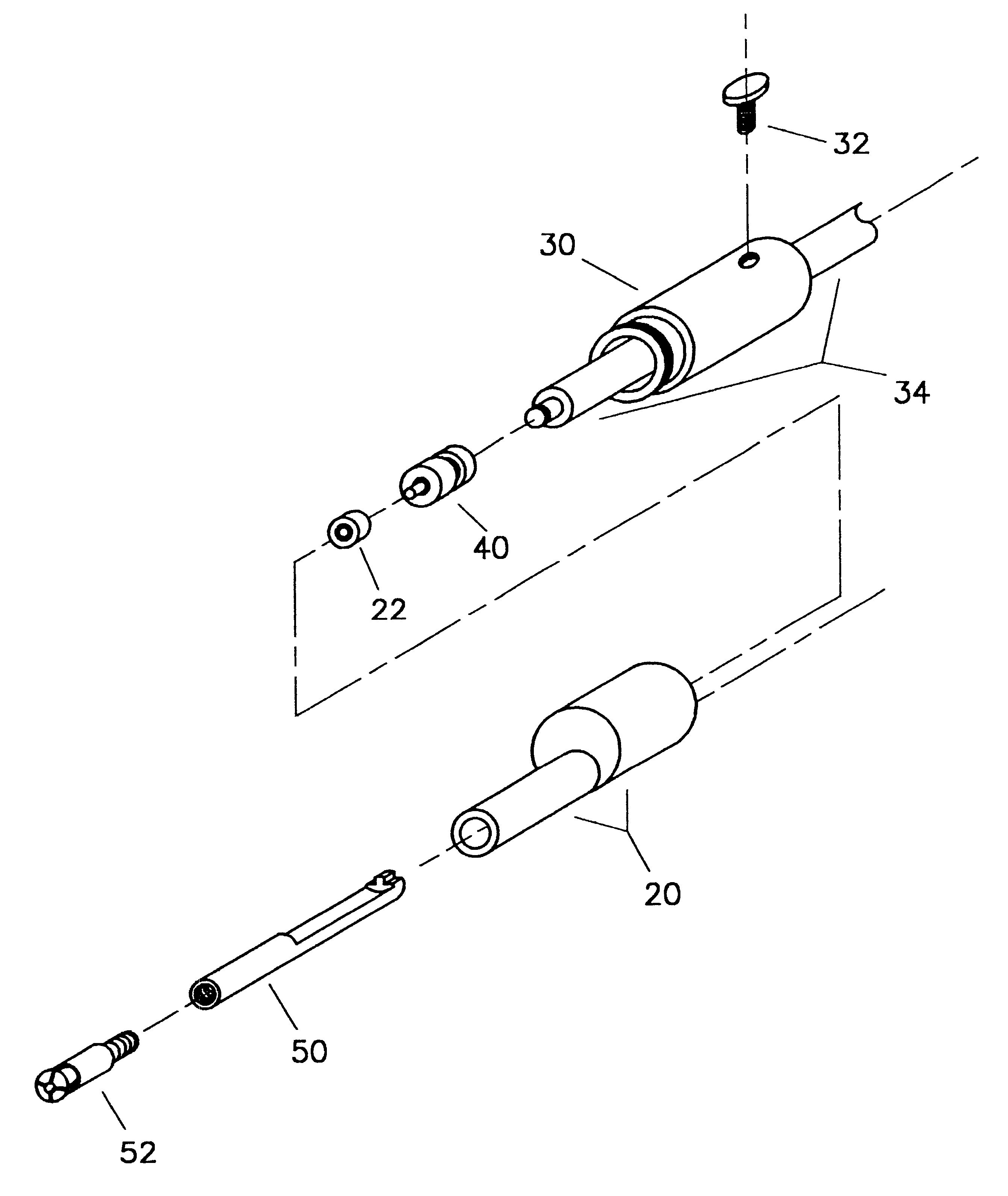

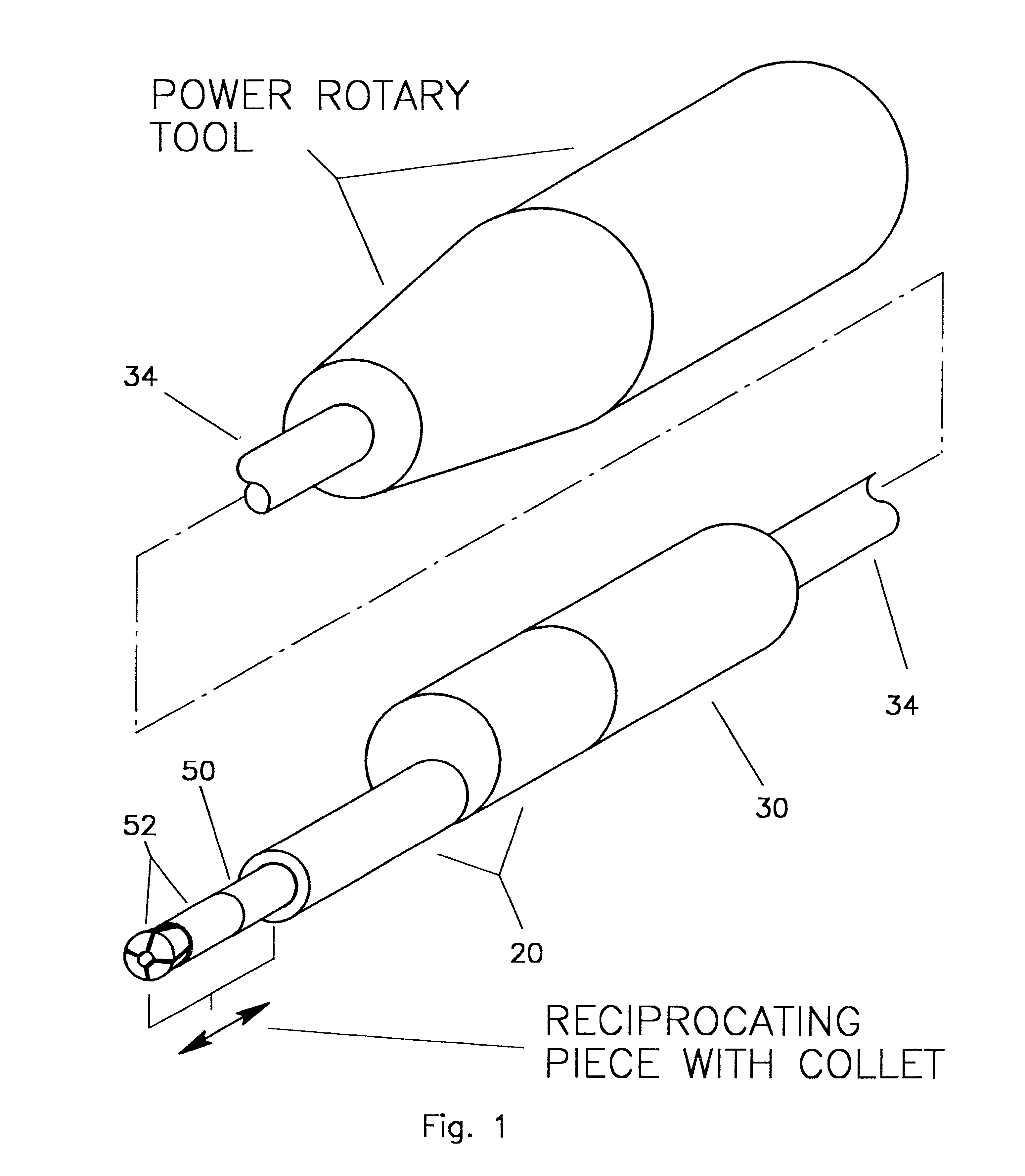

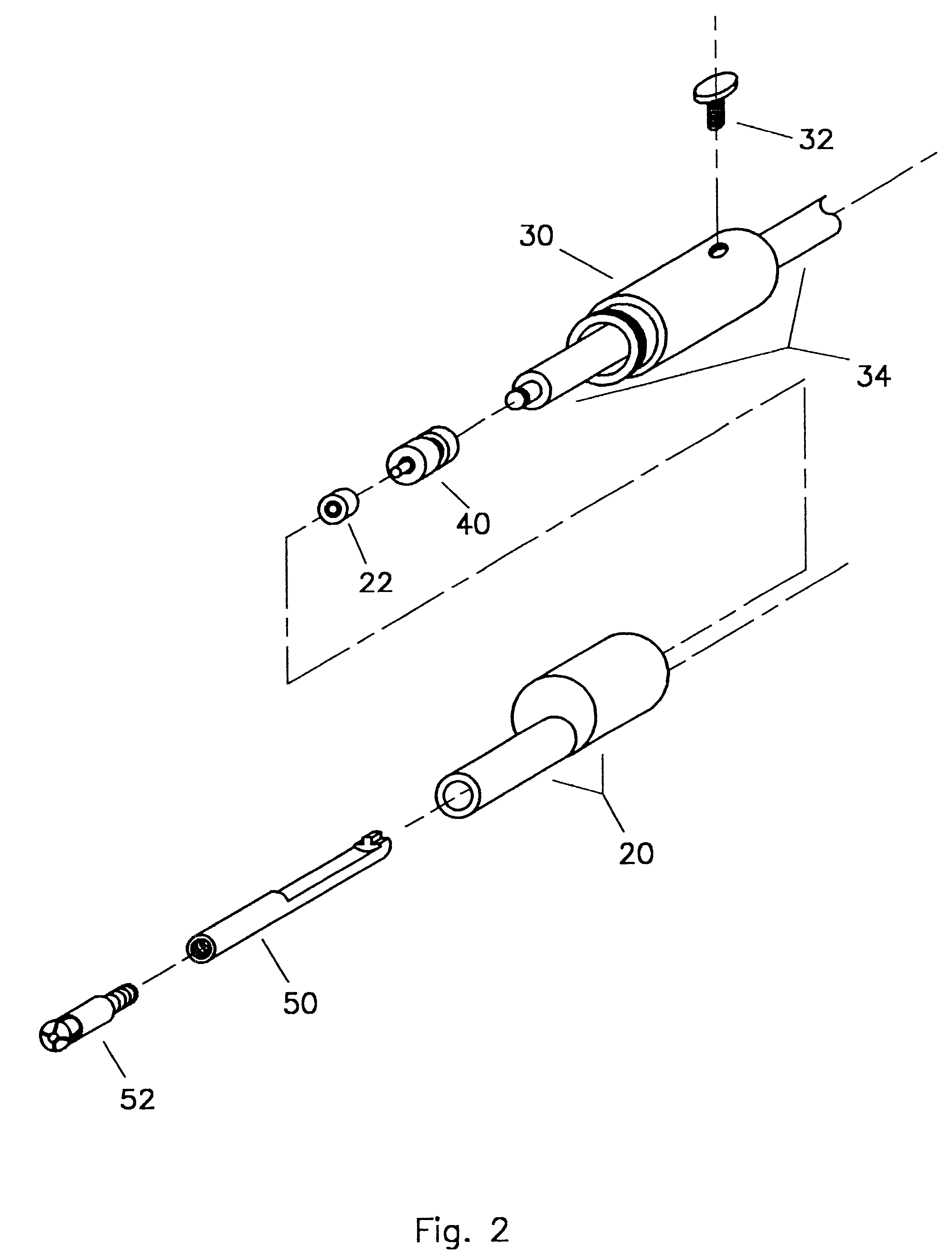

High-speed, hand-held reciprocating method for cutting, carving, sawing, chiseling, filing, sanding, and engraving

A high-speed, hand-held attachment for flex rotor shafts of power rotary tools, and also for direct attachment to power rotary tools without flex rotor shafts, that converts rotary motion to reciprocating motion for precision control of cutting, carving, sawing, chiseling, filing, sanding, and engraving on delicate work pieces. The attachment is one assembly comprising a one-piece front one-piece enclosure (20), a rear one-piece enclosure (30), a high-speed bearing (22), a one-piece rotating piece (40) with integral cam groove, a one-piece reciprocating piece (50) with an integral cam follower on one end and with its other, exposed end accomodating the attachment of a chuck or collet and with geometry to prevent rotation, and a thumbscrew (32). Rotating piece (40) attaches directly to the rotary power source and provides the cam action drive to reciprocating piece (50). Bearing (22) provides rotative support for the other end of rotating piece (40). Reciprocating piece (50) slidably mounts in front one-piece enclosure (20). Front one-piece enclosure (20) and rear one-piece enclosure (30) are attached to each other and maintain proper alignment for rotating piece (40), bearing (22), and reciprocating piece (50). Thumbscrew (32) secures the attachment to the flex rotor shaft of a power rotary tool. A tool holder / collet is attached to the exposed end of reciprocating piece (50) whereby numerous types of cutting tools may be utilized. Alternative versions of the rear one-piece enclosure, (30A) and (30B), described herein, allow for attachment directly to power rotary tools without flex rotor shafts. Alternative versions of the reciprocating piece, (50A), (50B), and (50C), and of the rotating piece, (40A), are also described herein.

Owner:JONES WILLIAM RANDOLPH

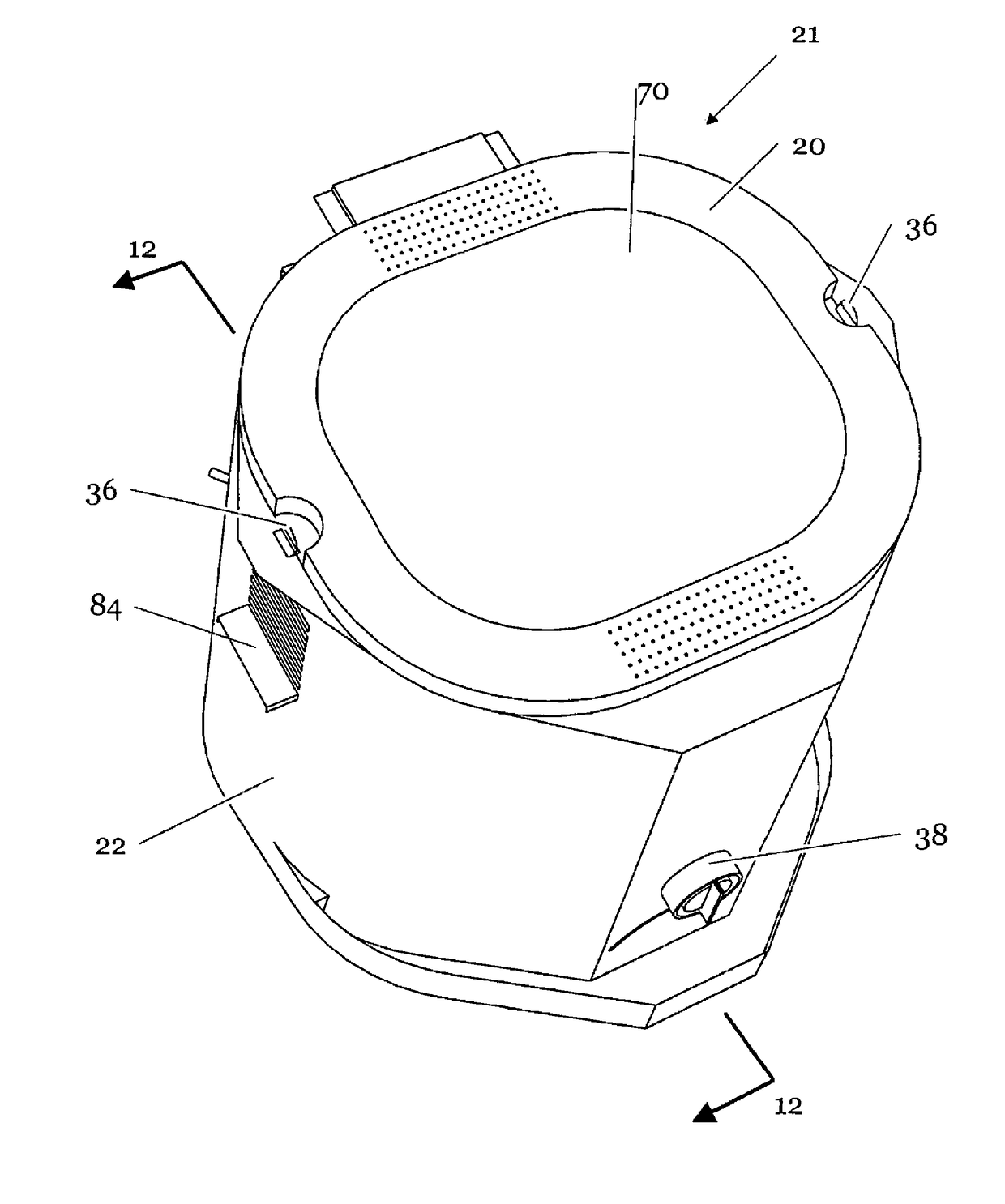

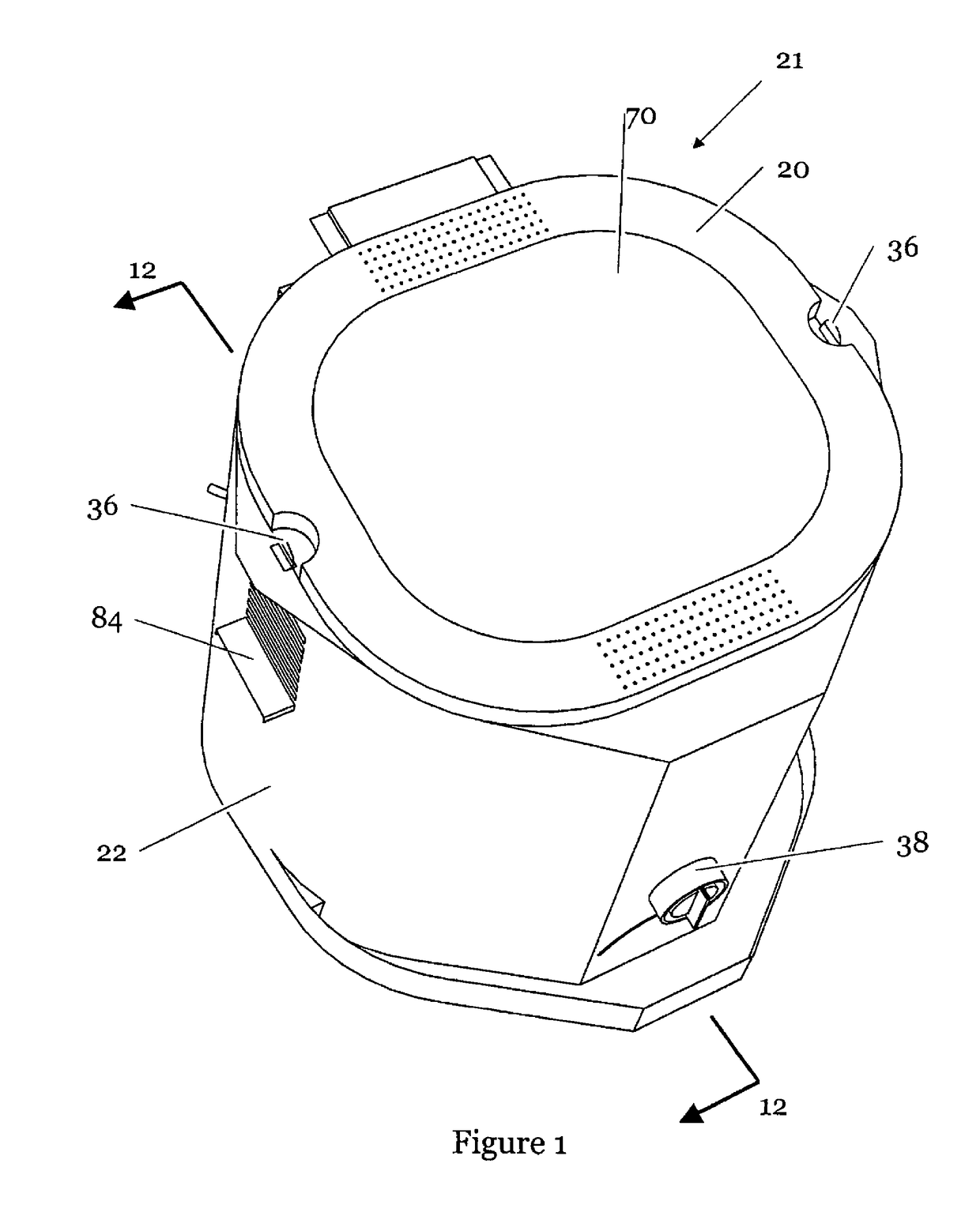

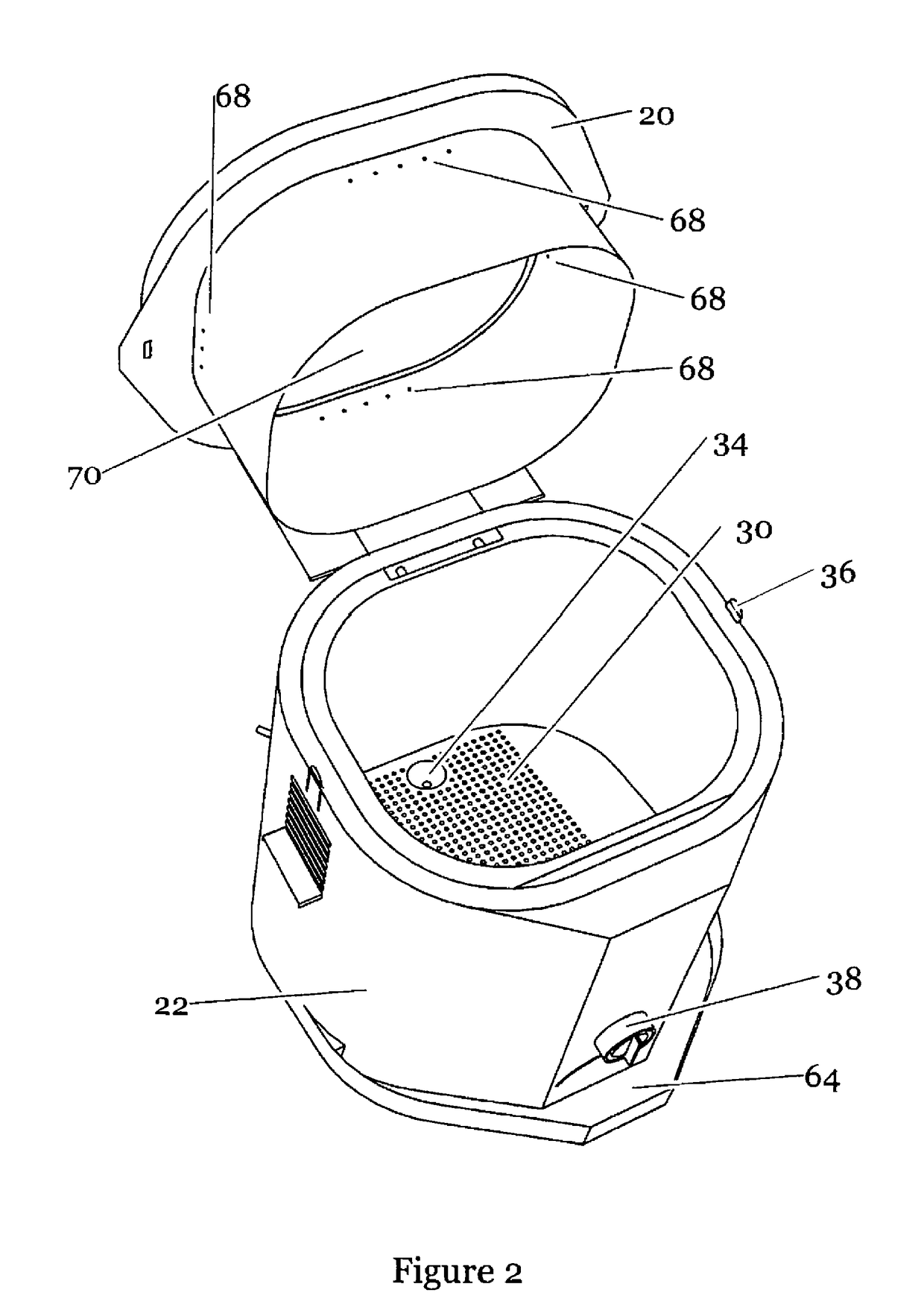

Device to efficiently cook foods using liquids and hot vapors

Embodiments teaching appliance base constructions which increase stability, using both static and dynamic base extending elements. Methods to enhance coloring of the fried foods. Food support structures which utilize two-hand manipulation to increase safety and control. Removable handle construction, which decreases storage space. Peripheral feet on appliance base, to increase safety and stability. Various means for securing unitary food items, including fowl, during cooking. Structures which help prevent accidental deep fryer oil overflow onto supporting surfaces. Lid constructions, which keep a lid in place to protect the user, even while loading oversized, vertically extending foods. Food drainage opening assist device, to help drain fowl cavities after deep frying. Collapsible food support devices, used for cooking, serving, carving, and other purposes. Movable partitions within a food support, to compartmentalize, contain, cap, and space apart foods being cooked. Structures to help align over-extending food during their loading into a cooking vessel.

Owner:RONS ENTERPRISES

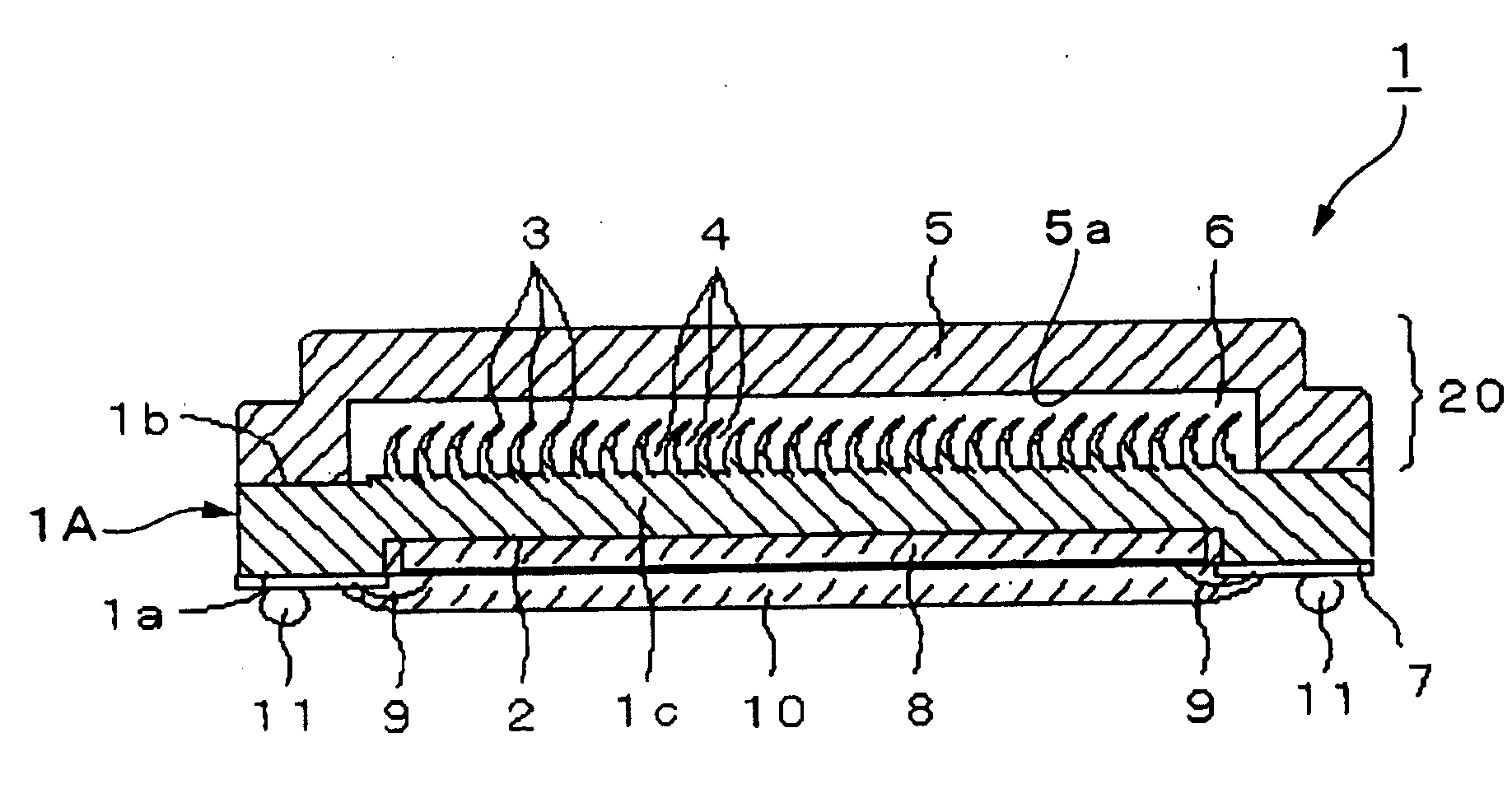

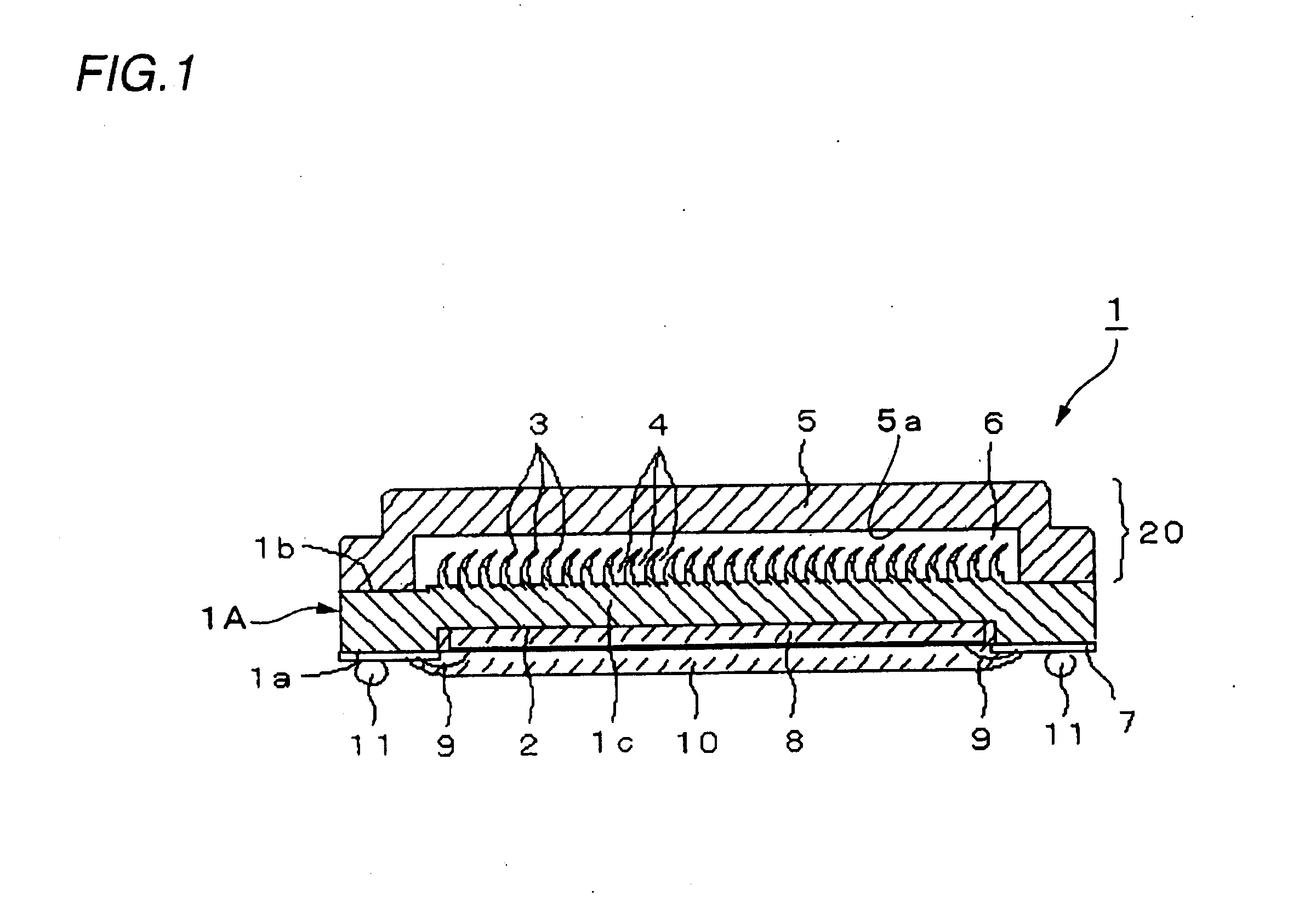

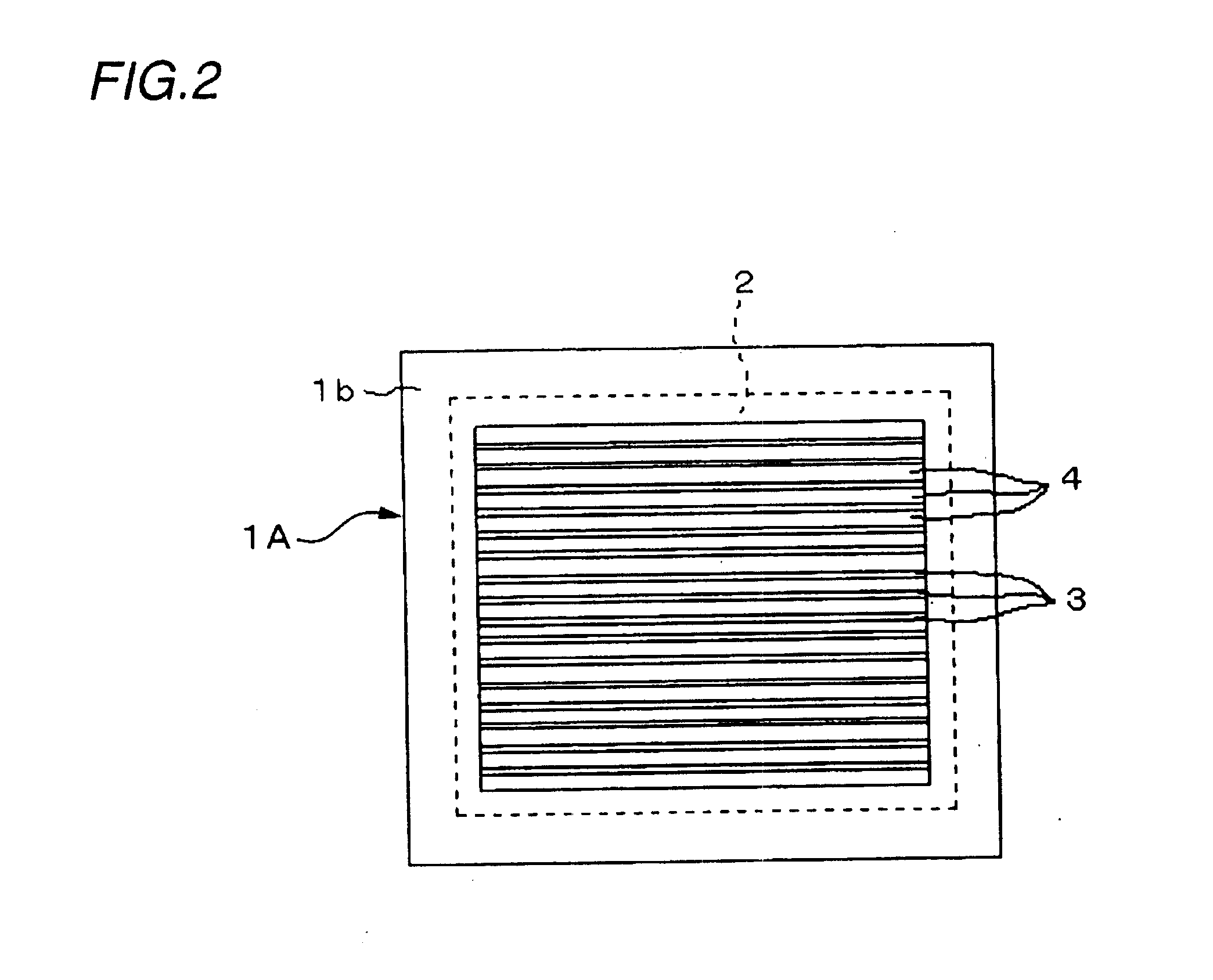

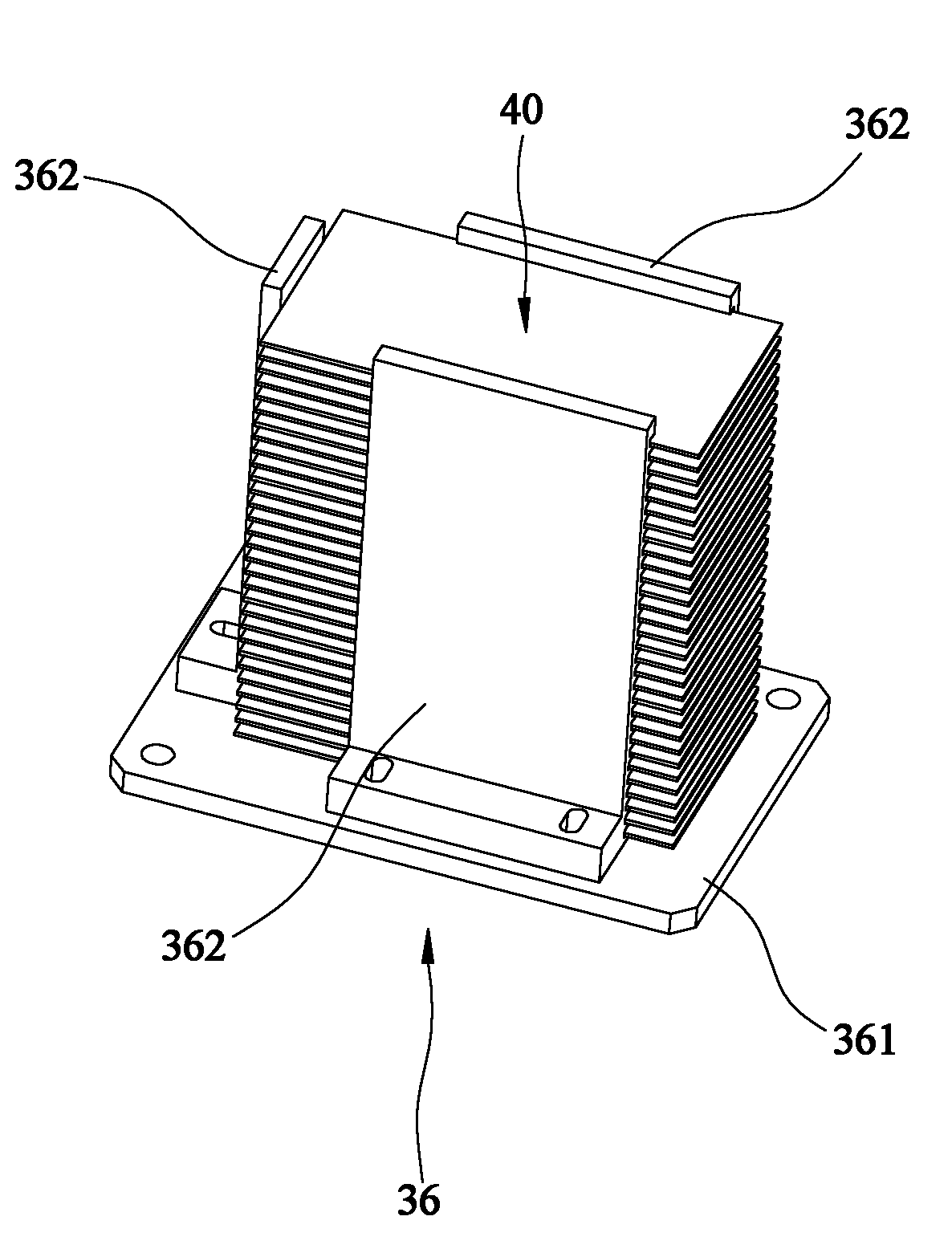

Component package having heat exchanger

InactiveUS20070163749A1Good cooling functionEfficient executionSemiconductor/solid-state device detailsSolid-state devicesWorking fluidCarve out

In an electrical component package (1) provided with a liquid-cooled heat exchanger (20), a main-body plate (1A) of the package and a crowning member (5) that are composed of metal plates are joined together, forming a hollow part (6) therebetween for use as a liquid-cooled heat exchanger in which a working fluid is sealed. A concavity (2) for use in mounting an electrical component (8) to be cooled is formed on the outer surface portion of the main-body plate (1A) of the package disposed opposite to the hollow part (6). An inner surface portion (5a) that faces into the hollow part (6) of the main-body plate (1A) of the package is carved out using a carving tool, whereby fins (3) are formed at a fine pitch on the inner surface portion. Minute channels (4) for moving the working fluid are formed between the fins. A flat electrical component package can [therefore] be provided with a liquid-cooled heat exchanger that has excellent heat-radiating functionality.

Owner:NAKAMURA IND MFG CO LTD

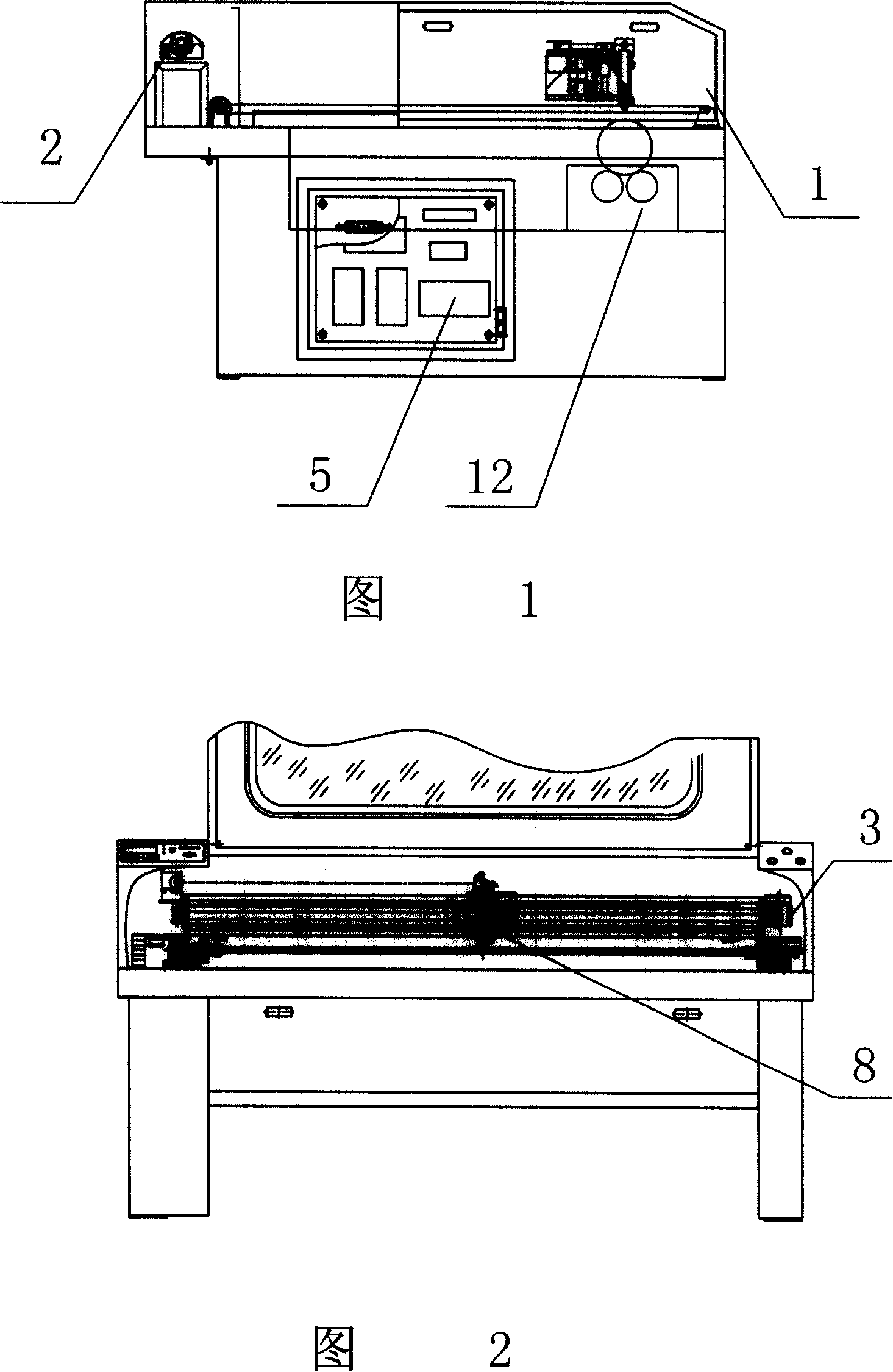

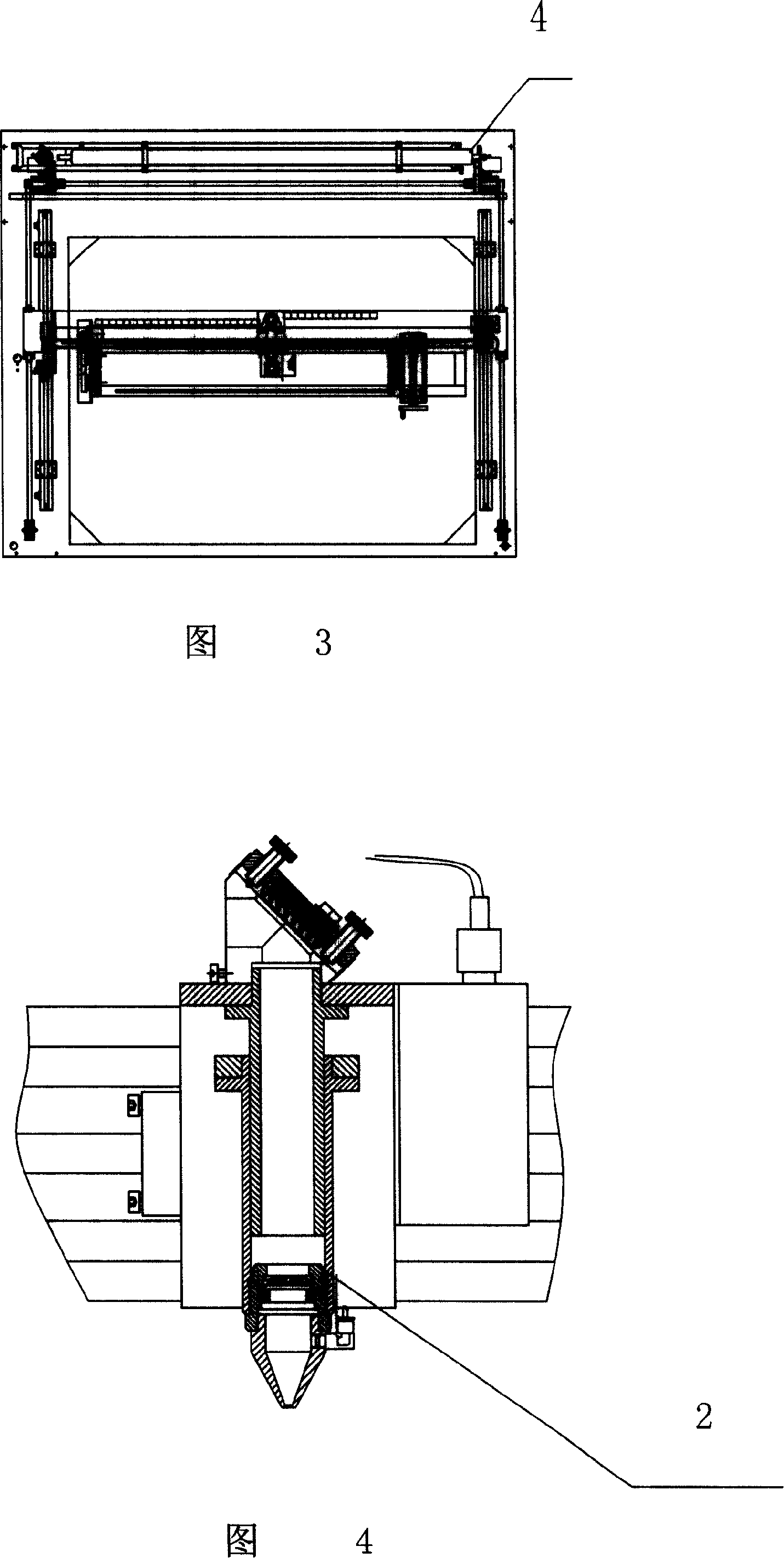

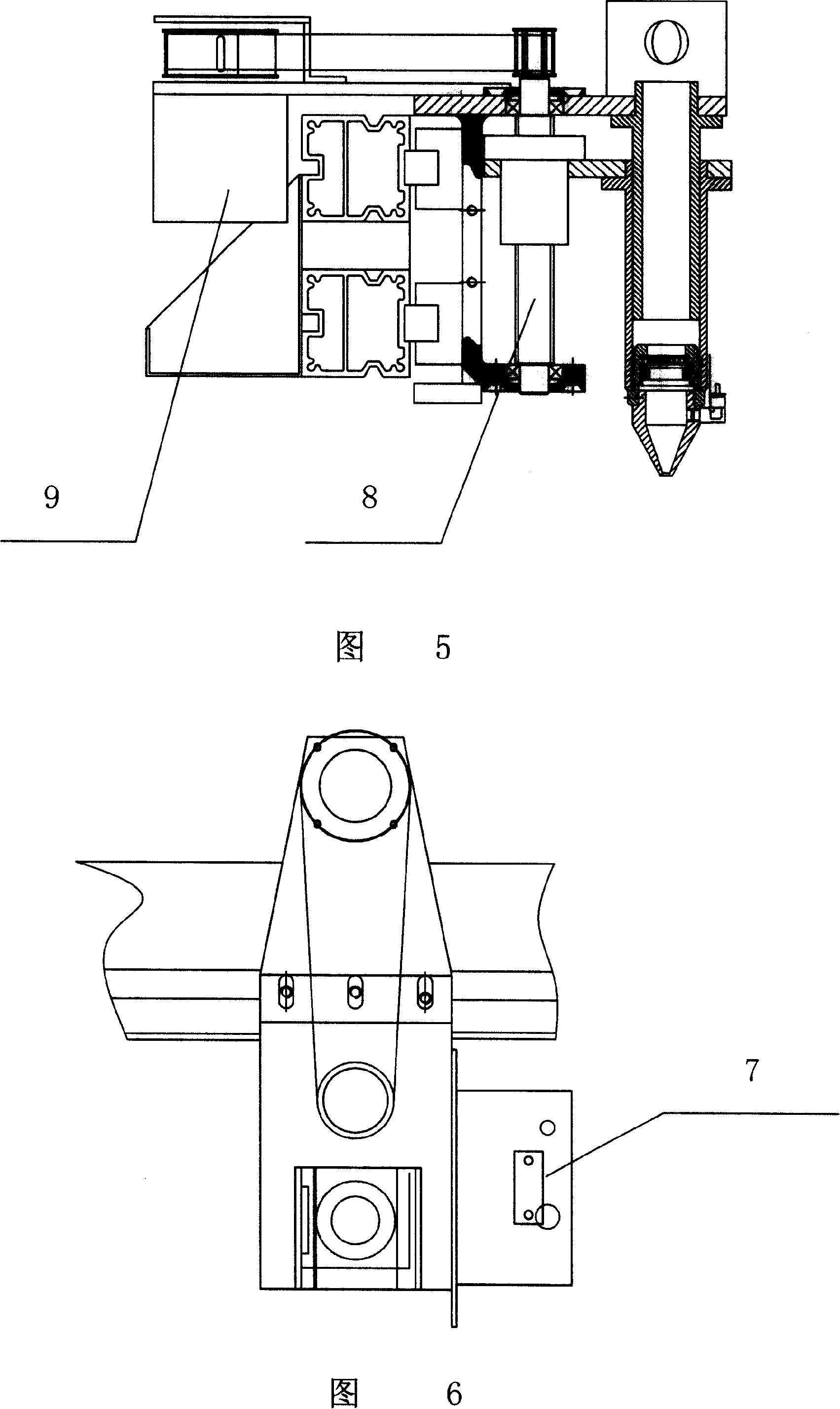

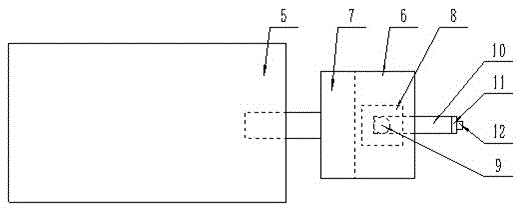

Profile modeling laser engraving process method and laser carving machine thereof

InactiveCN101138926ARealize dynamic focusRealize special-shaped plane engravingComputer controlProgramme control in sequence/logic controllersPid control algorithmLaser engraving

A method of form copying laser carving processing belongs to the laser carving processing field. The method uses a CCD laser displacement sensor to detect the distance between a laser head and a workpiece for processing to generate a three-dimensional relief map of the material for carving; a PID control arithmetic is used to control the position of the laser head to ensure that a focus of the laser falls at the surface of the workpiece for processing, so as to realize laser cutting and carving towards irregular materials. A laser carving machine is also provided, including a machine frame, a leaser head, an X-axial and Y-axial flying mechanism which is connected with the laser head, a Z-axial driving mechanism which is vertical with the surface of the workpiece, a CCD laser displacement sensor and an upper controller which is used for controlling form copying carving. The present invention provides a method of form copying laser carving processing which can realize dynamic focusing and real-time focusing during the course of carving and can realize plane carving of the irregular materials, and also provides the laser carving machine of the method.

Owner:ZHEJIANG FORESTRY ACAD +1

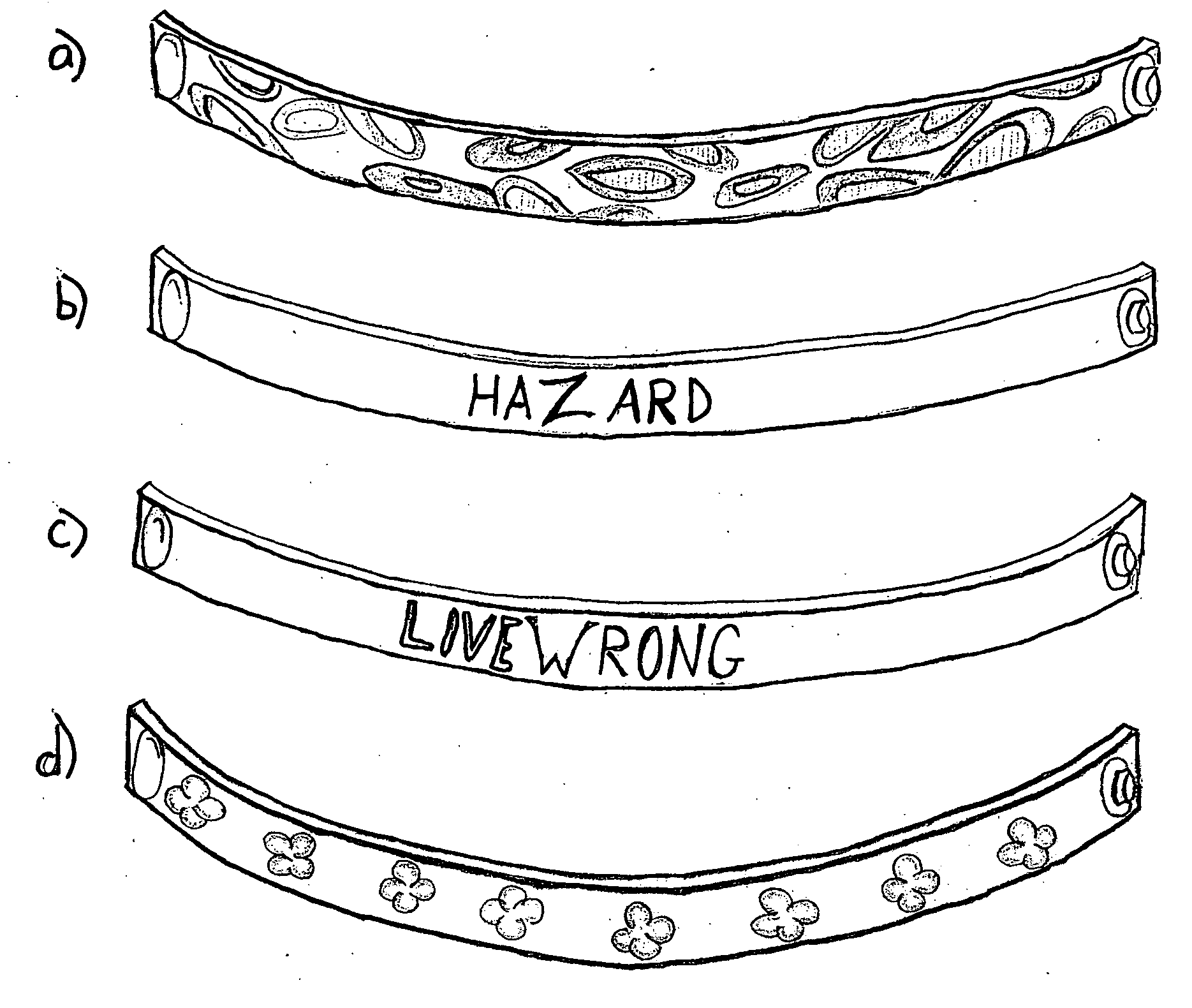

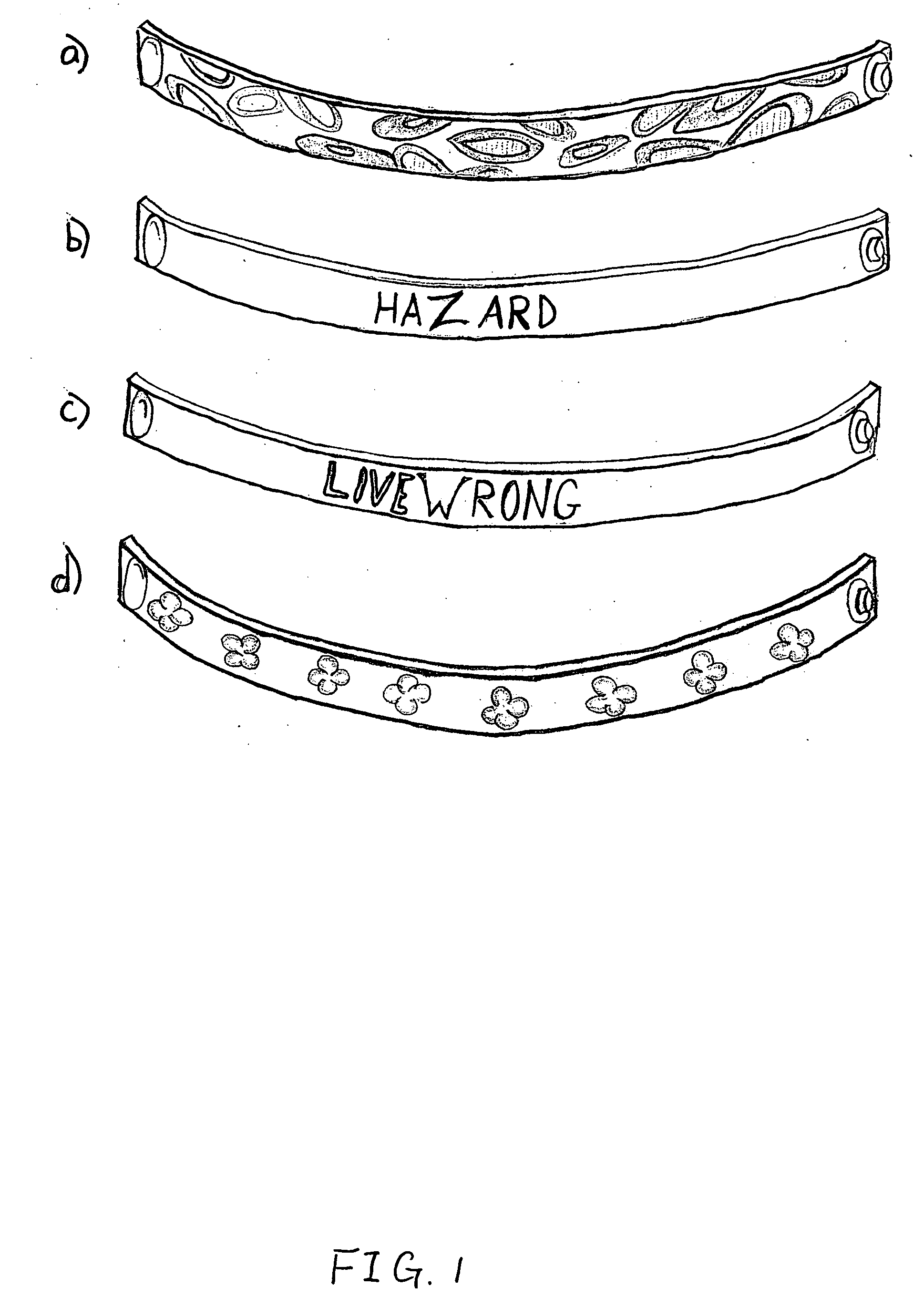

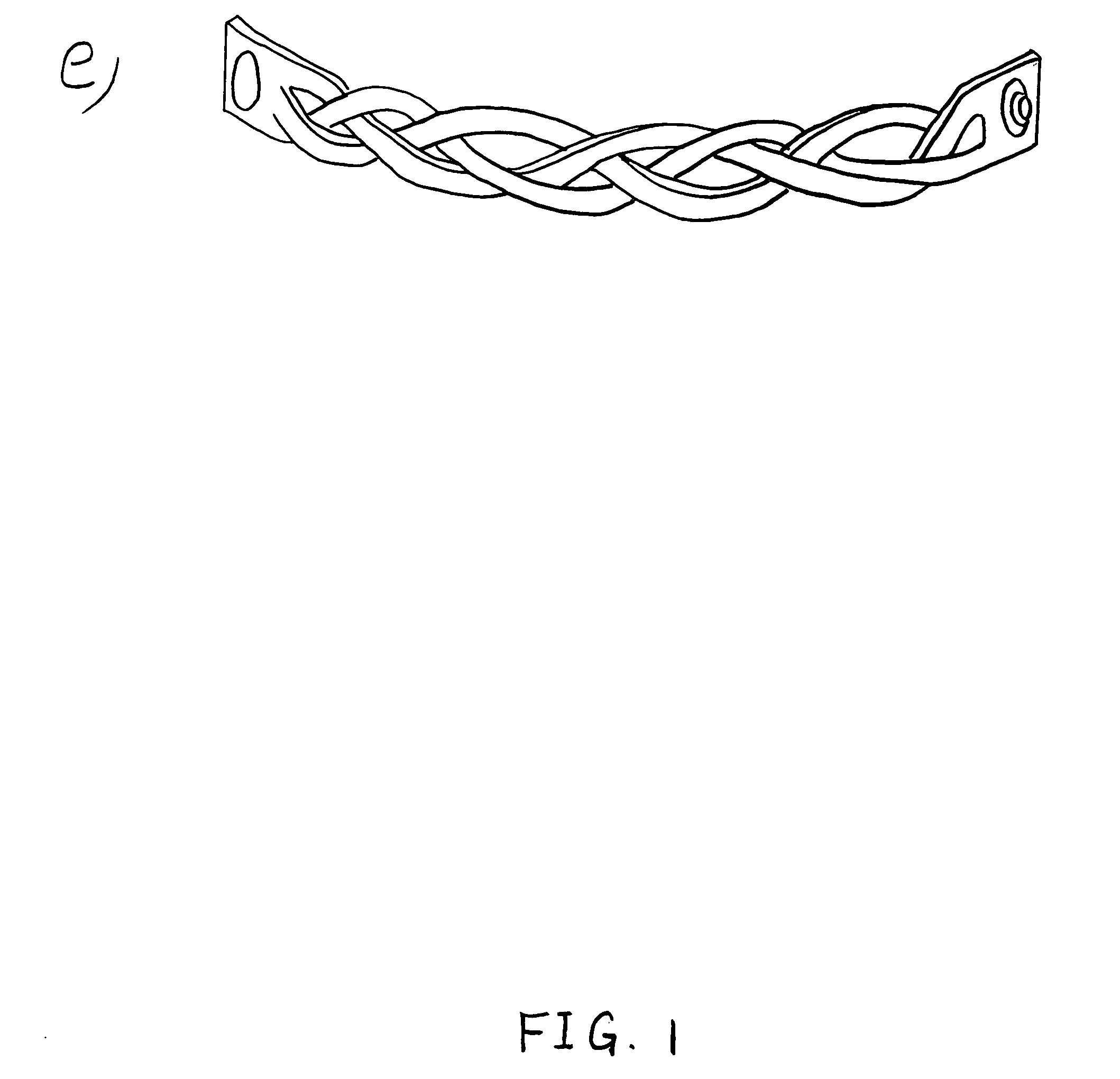

Fashion accessories made from traffic cone rubber

InactiveUS20100285283A1Satisfies needEasy to manufactureSnap fastenersSlide fastenersEngineeringCarving

The present invention relates generally to fashion accessories designed and made from traffic cone rubber, more particularly related to Bracelets, Key Chains, Necklace Pendants, Earrings, Rings, Wallet, Belts, Zipper Pulls, Belly Button Piercing, Bookmarks, Bra, Door Hanger, Cell phone / Beeper / Pager Holder, Ipod Case, Cell Phone Charm, Wall Mask, Winter Hat / Beanie Hat, Baseball Cap, Tie, Hoodie, Satchel Bag, Sneaker, Decal Snaps, Money Clip, Magnet, Backpack, Watch Band, Relief Carving, Eyeglass Case, Headband, Coaster, Car Decoration, Ornament, Pet Products, Hair Clip, Change Purse, Purse, Pins / Buttons, Anklet, Lanyard, Nose Piercing, Charms, Button, and Cufflinks.

Owner:KINGSBURY NICHOLAS SCOT

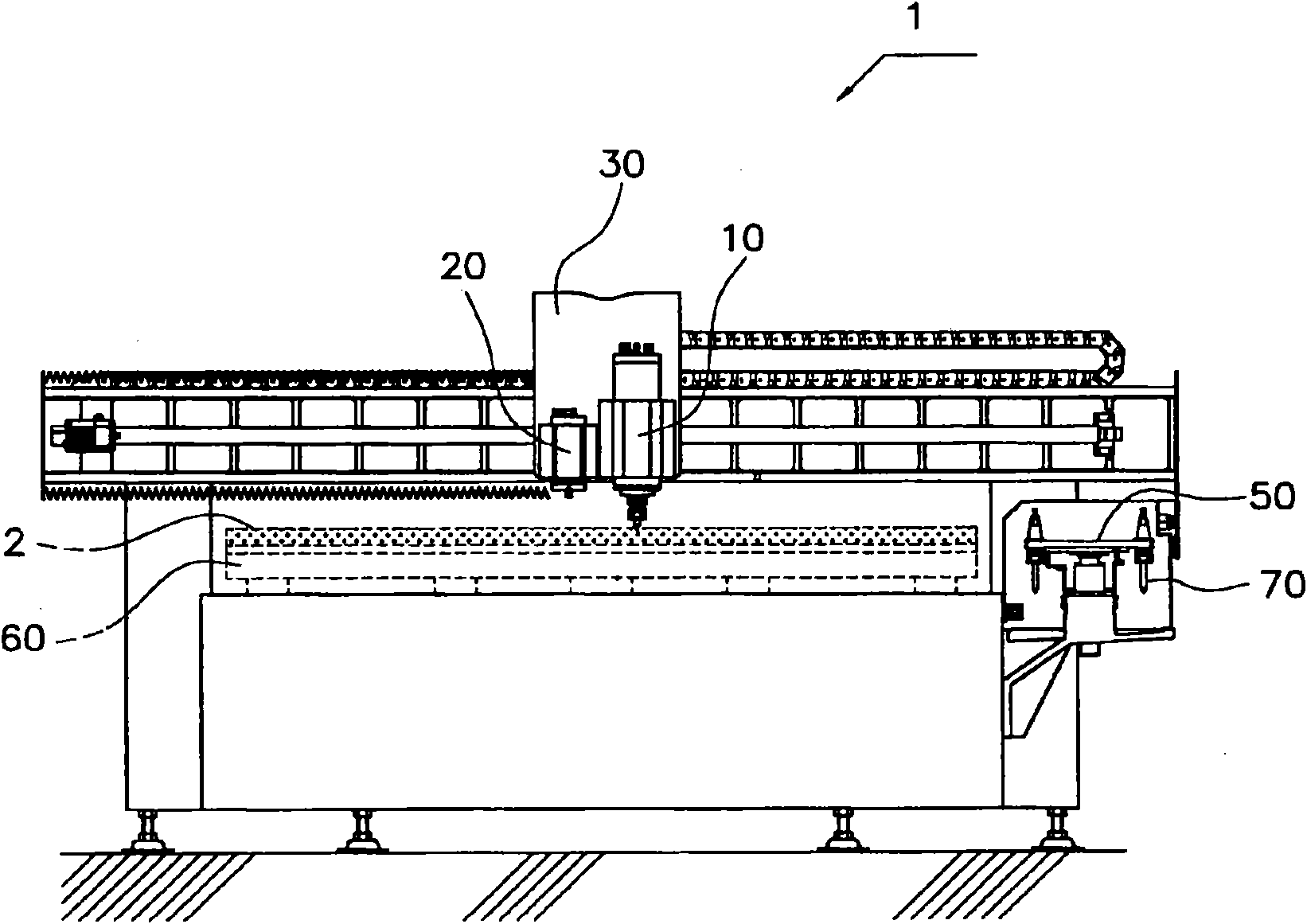

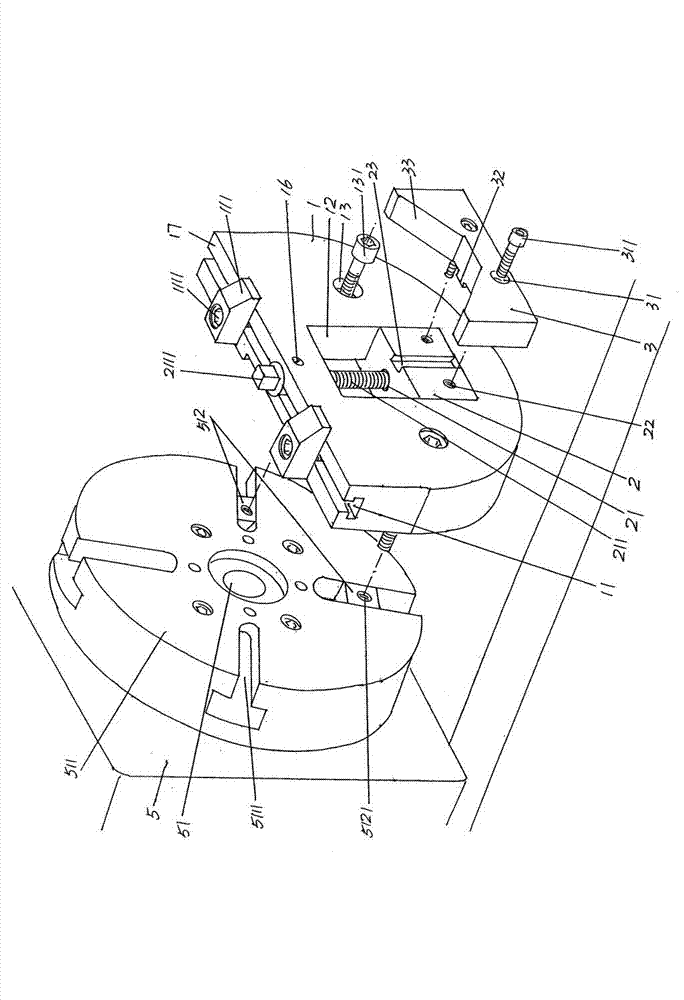

Complex machining center

InactiveCN101959639ASolve the need for a separate engraving machineSolve the problems of conventional technology such as cutting machinesMilling machinesOther manufacturing equipments/toolsEngineeringMachining

The present invention relates to a complex machining center in which at least one machining unit is mounted on one or more X-direction positioning blocks which are fixed or movable about a base frame, one or more Y-direction positioning blocks arranged on at least one side of the X-direction positioning block, and a Z-direction positioning block connected to the Y-direction positioning block in such a manner that the Z-direction positioning block is movable in the upward and downward directions. The complex machining center is capable of performing carving, precision cutting, V-shape cutting and groove forming work.

Owner:金福仁

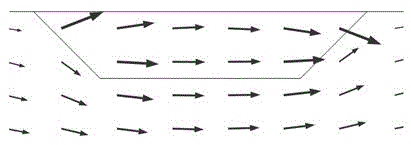

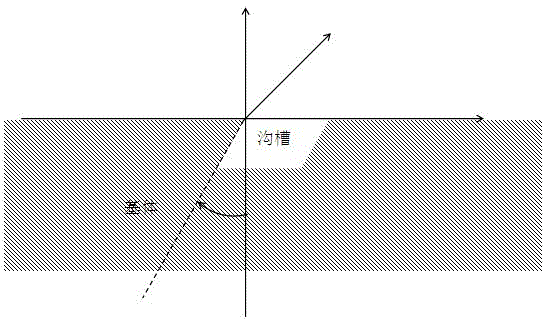

Manufacturing method of oriented silicon steel sheets for low-noise transformer

ActiveCN106282512AReduce noise levelReduce iron lossTransformers/inductances detailsInductances/transformers/magnets manufactureLow noiseTransformer

The invention discloses a manufacturing method of oriented silicon steel sheets for a low-noise transformer. Grooves in special shaped are formed in a single side or double sides of silicon steel sheets in a mark carving method; the bottom surfaces of the grooves are parallel to approximately parallel to the surfaces of the silicon steel sheets; the angle with the maximum absolute value in included angles between the single side or multiple sides of the inner walls of the groove and the normal plane is defined to be the included angle theta; the include angle theta is in a range of being greater than or equal to -60 degrees but smaller than 0 degree; the included angle theta of each side edge is identical or different; the normal plane refers to a plane vertical to the rolling direction of the silicon steel sheets. The mark carving processing mode is set before or after the decarburizing annealing, or is after the high-temperature annealing, or is after the insulation coating flattening annealing. Pulse laser beams with the single-pulse instantaneous peak value power density not lower than 2.0*10<6>W / mm<2> are used for processing on the surface of the silicon sheets; the laser injection total energy is between 0.002J / mm to 1.3J / mm. The oriented silicon steel sheets manufactured by the method have the advantages that the iron loss is low; after the stress relief annealing, the performance is not reduced; in addition, under the same manufacturing and test conditions, the noise level of the transformer is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method for multicolor oxide film

InactiveCN101619477APerformance impactAccelerated corrosionAnodisationArtistic surface treatmentWear resistanceCarving

The invention relates to a preparation method for multicolor oxide film, comprising that an anode oxide film forming step is repeatedly carried out. The anode oxide film forming step comprises: oxidizing color anode, and forming a protective layer and laser carving on a color anode oxide film. The color anode oxidation comprises anode oxidation, dyeing and hole sealing are carried out in turn on the surface of a base material so as to obtain a color anode oxide film. The protective layer is used for separating electrolyte oxidized by a color anode and a color anode oxide film formed previously. The laser carving is used for removing at least one part of color anode oxide film formed previously so as to cause the surface of parts of base material to be exposed. The integral corrosion resistance and abrasion resistance of the oxide film on the surface of the base material, which is prepared according to the method of the invention, are high, and no other macromolecule materials need to be coated, so that the texture of the oxide film is kept.

Owner:BYD CO LTD

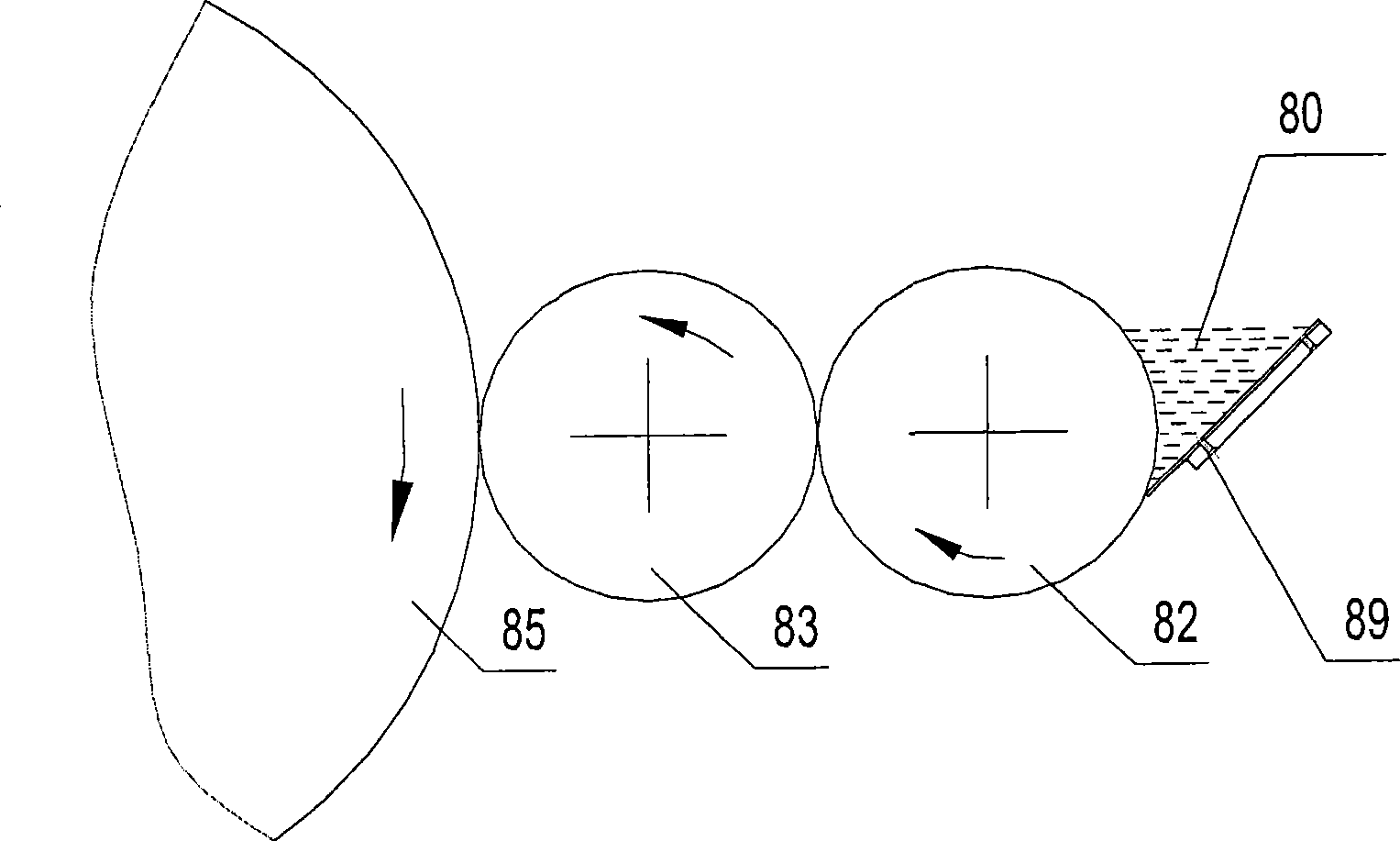

Ink fountain roller, ink distributing unit and ink distributing system of carving photogravure press

ActiveCN101544098AMolushortNot easy to jamRotary intaglio printing pressPrinting press partsPhotogravurePrinting press

The invention provides an ink fountain roller, an ink distributing unit and an ink distributing system of a carving photogravure press. The ink duct roller is a cavity-die inking roller with quasi-grains at the surface, and the quasi-grains correspond to forme grains; the ink distributing unit comprises an ink fountain, the ink fountain roller, a hook type scraper and an elastic color model roller, wherein the ink fountain roller contacts with ink in the ink fountain, the scraper is arranged at one side of the ink fountain roller, the elastic color model roller is arranged at the other side of the ink fountain roller and is in rolling transmission with the ink fountain roller; and the ink distributing system also comprises a gravure roller and an impression roller. The ink fountain roller of the ink distributing unit transmits ink grains which correspond to the gravure grains and have different thicknesses to the color model roller to form basso-relievo-shaped quasi-grain ink; the basso-relievo-shaped quasi-grain ink is transmitted into the gravure grains on the gravure roller; and the gravure roller and the impression roller mutually press to carry out printing. The invention has short ink path, easily ensures the accuracy of ink distribution and easily maintains the printing adaptability without ineffective circulation for the ink.

Owner:CHINA BANKNOTE PRINTING & MINTING

Method for manufacturing gravure printing roller with electronic carving method

InactiveCN101402275AImprove color saturationIncrease volumePrinting pre-treatmentForme preparationEngravingCopper plating

The invention discloses a method for manufacturing a gravure roller by an electronic engraving method. The method comprises the following steps: firstly, manufacturing a printing plate substrate and plating copper on a printing plate roller, and forming a plate making copper layer on the surface of the printing plate roller; secondly, plating a chrome layer on the plate making copper layer, and engraving; thirdly, eroding an engraved V-shaped ink cell, so as to deepen and widen the plate making copper layer corresponding to the V-shaped ink cell and enlarge the volume of the ink cell; and fourthly, removing chrome from the eroded printing plate roller; and lastly plating the chrome layer functioning as protection. Compared with the prior art, the gravure roller manufactured by the method has the ink cell with larger volume and larger ink capacity, has good color saturation of printed matters when transfer printing, and has higher printing quality.

Owner:泉州运城制版有限公司

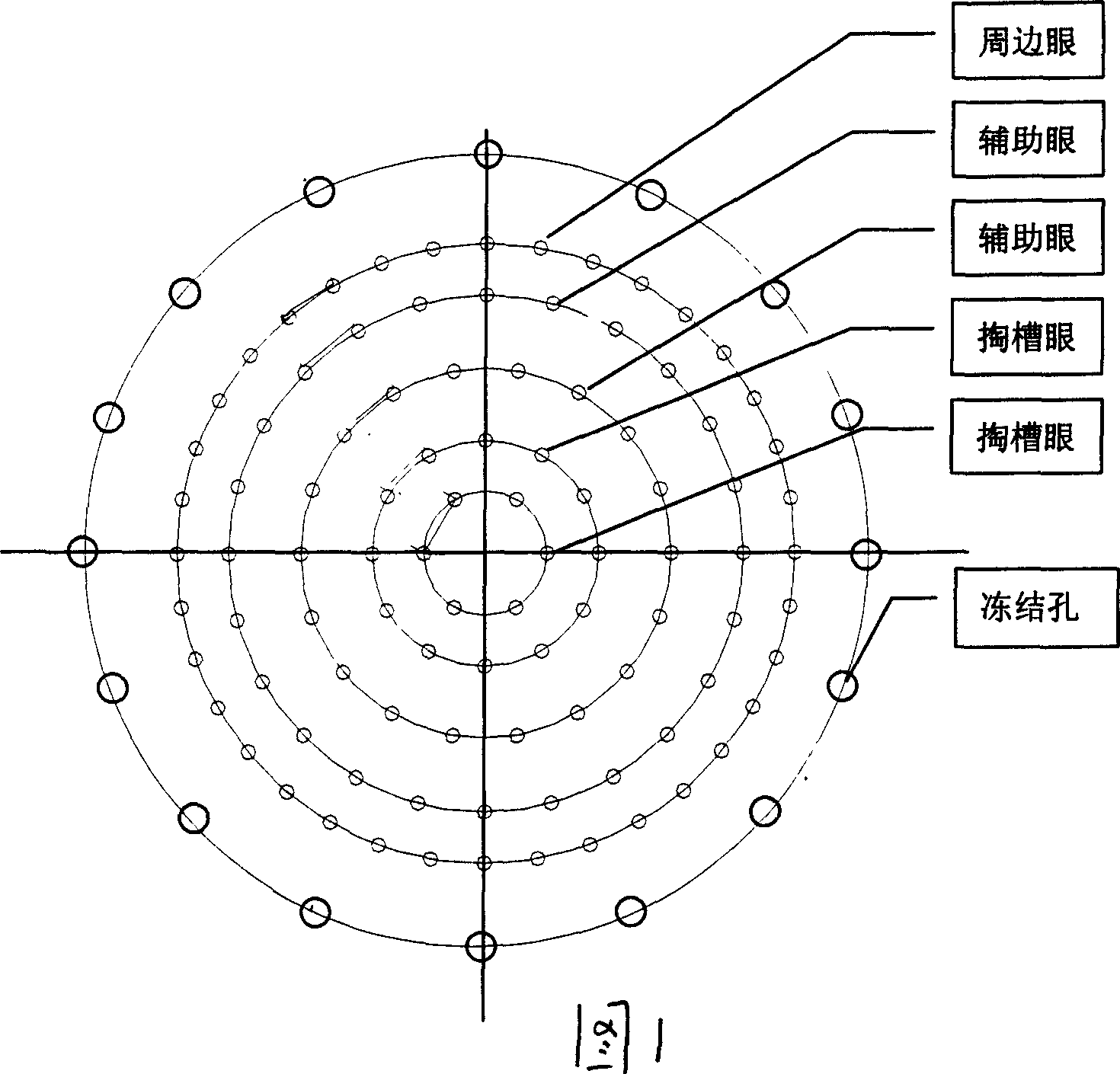

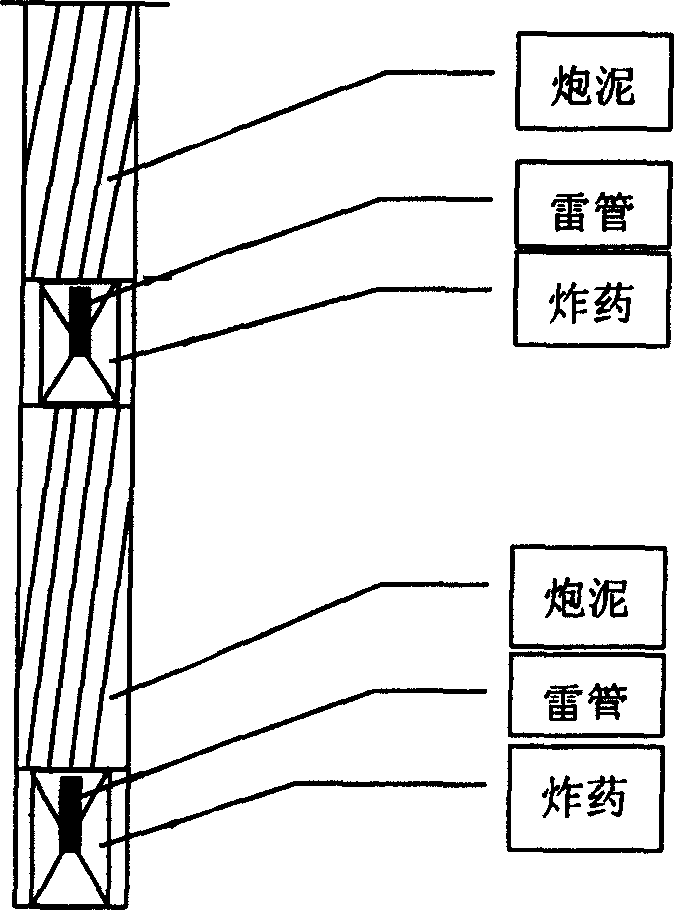

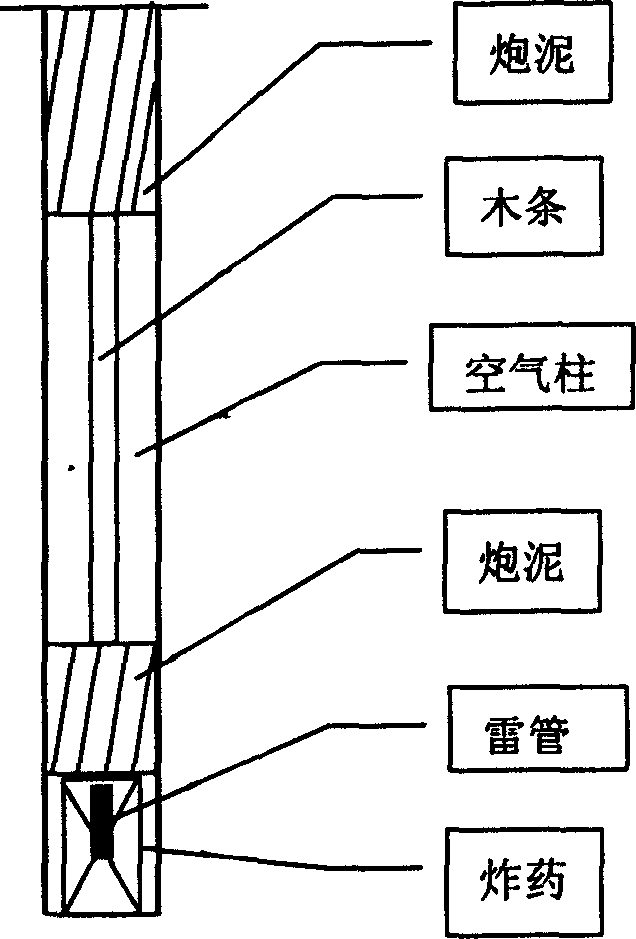

Technology method of artificial frozen soil control blasting by deep surface forzen method

InactiveCN1560557AReduce labor intensityIncrease the speed of excavationBlastingEngineeringSurface freezing

The invention relates to a process method for manual frozen soil control blast with deep and thick surface freezing method; one or several circles of slot carving apertures are arranged in the centre of the cylinder which is frozen; a circle of side apertures is arranged on the excavation wild path, the around apertures are distributed evenly, at least one circle of assistant apertures are arranged between the peripheral apertures and the slot apertures; the slot aperture uses powder filling inner micro difference blast divided into upper and subjacent two parts.

Owner:马芹永

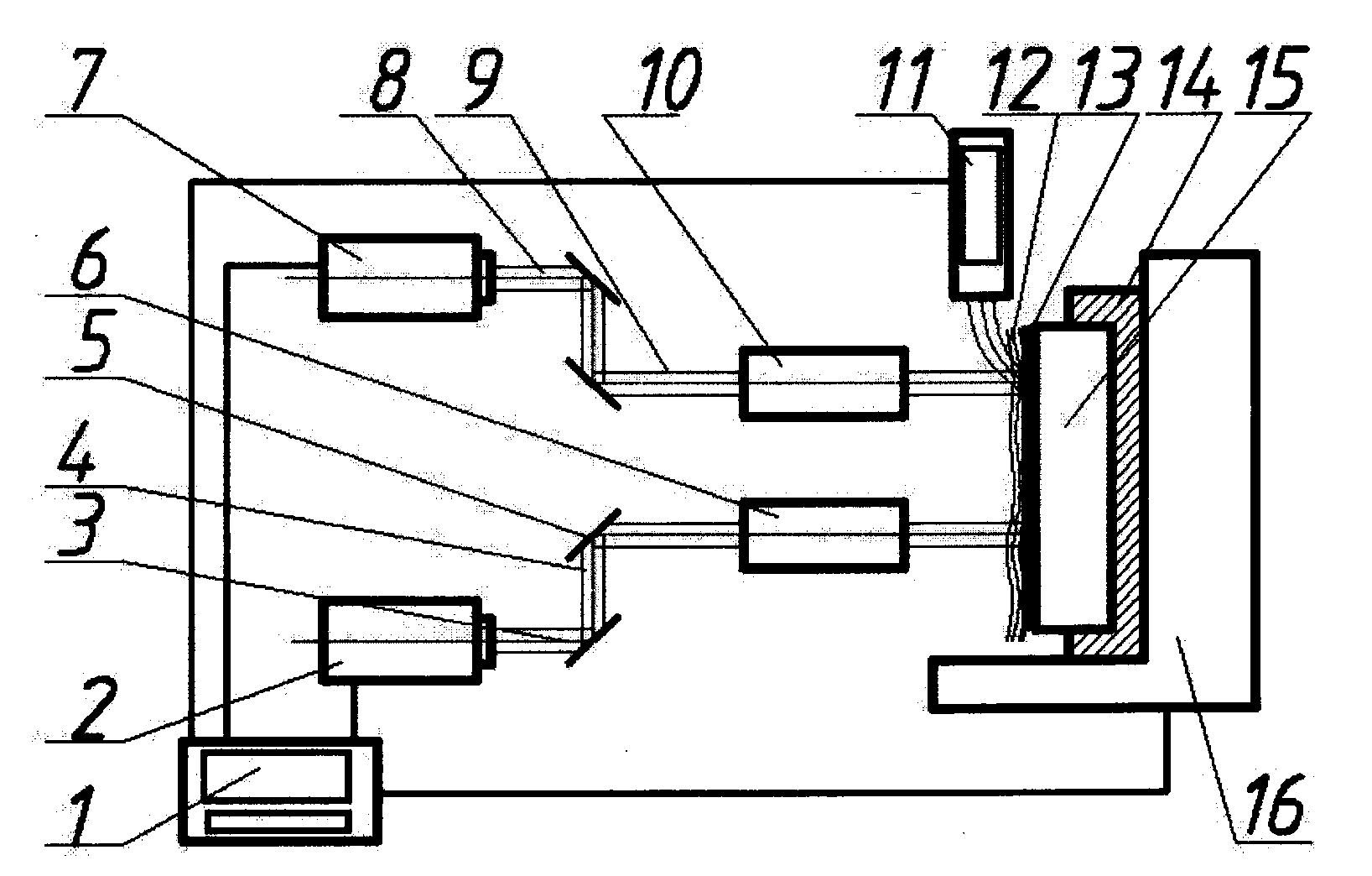

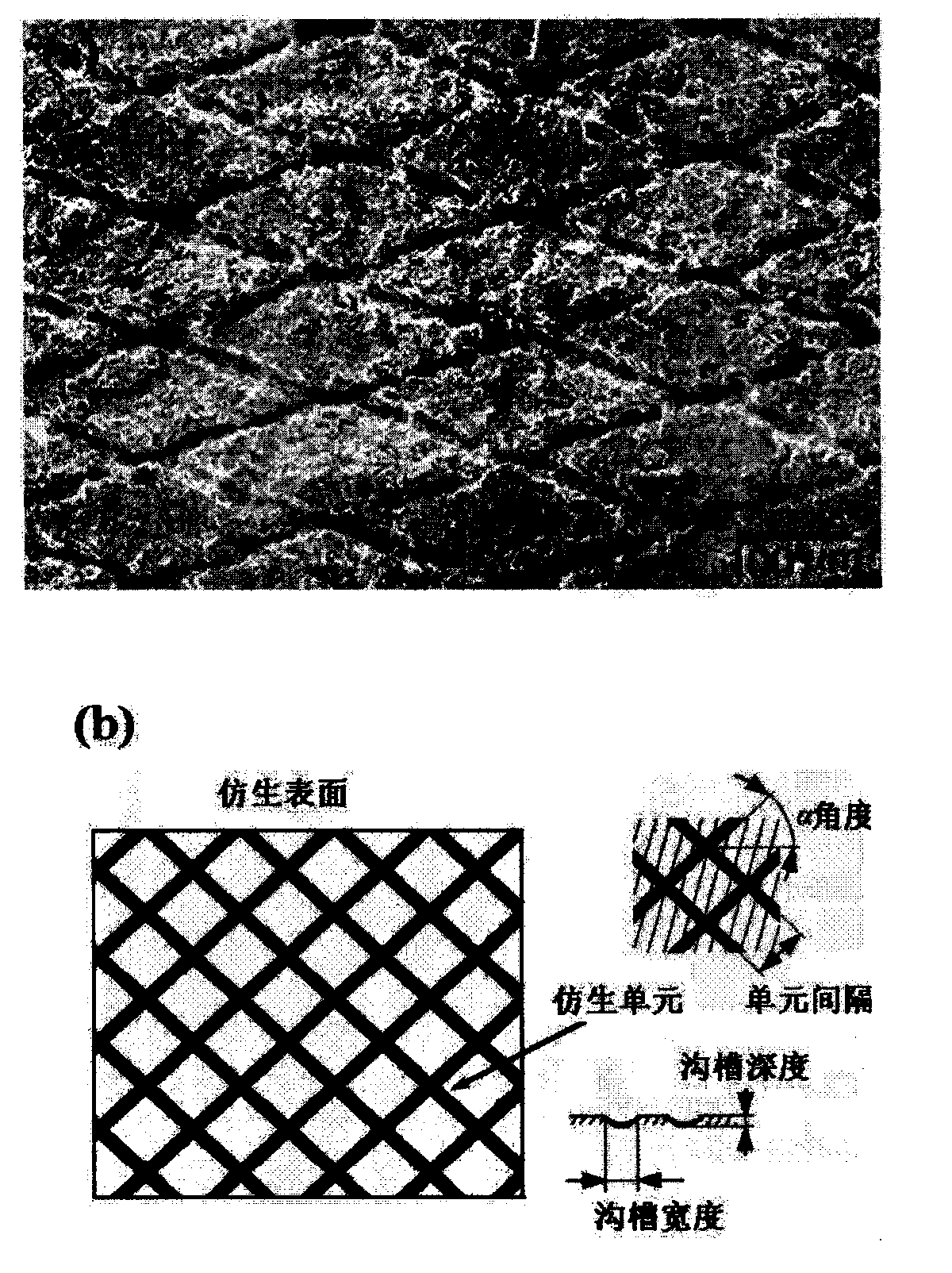

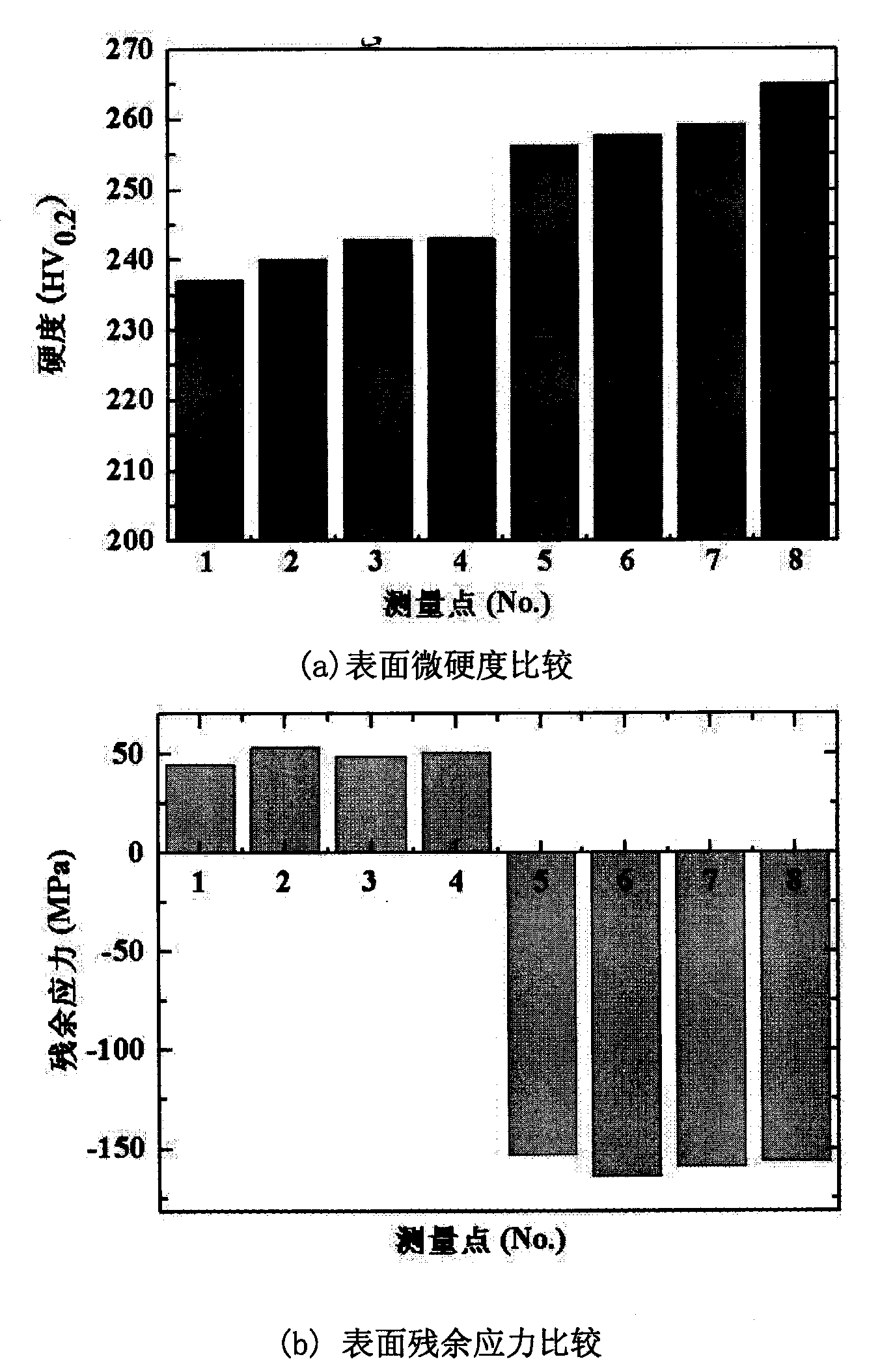

Method and device for compositely preparing surface-layer biomimetic structure by laser

InactiveCN101590569ANo wearNo consumptionLaser beam welding apparatusLight spotVolumetric Mass Density

The invention relates to the field of laser processing, in particular to a method and a device for compositely preparing a surface-layer biomimetic structure by mechanical effects based on laser carving and laser shock, which are particularly suitable for processing a biomimetic surface and a friction pair surface. The method is characterized by comprising the following steps: firstly preparing a regular micro geometrical appearance with certain density (space), width, depth, angle and shape on the surface of a workpiece by the laser carving technology; and then forcedly processing the micro geometrical appearance area by laser shock to process a microstructure which has the required shape and management mode and is optimally matched with the requirement of lubricating property on the surface of the workpiece. The device for the implementation method comprises a control device, a nanosecond laser generator, a laser beam I, a light guide tube I, a totally reflecting mirror I, a light spot adjusting device I, a fiber laser, a laser beam II, a light guide tube II, a totally reflecting mirror II, a light spot adjusting device II, an automatic spraying device, a restrain layer, an absorption layer, the workpiece, a workpiece fixture system and a five-axis working platform.

Owner:JIANGSU UNIV

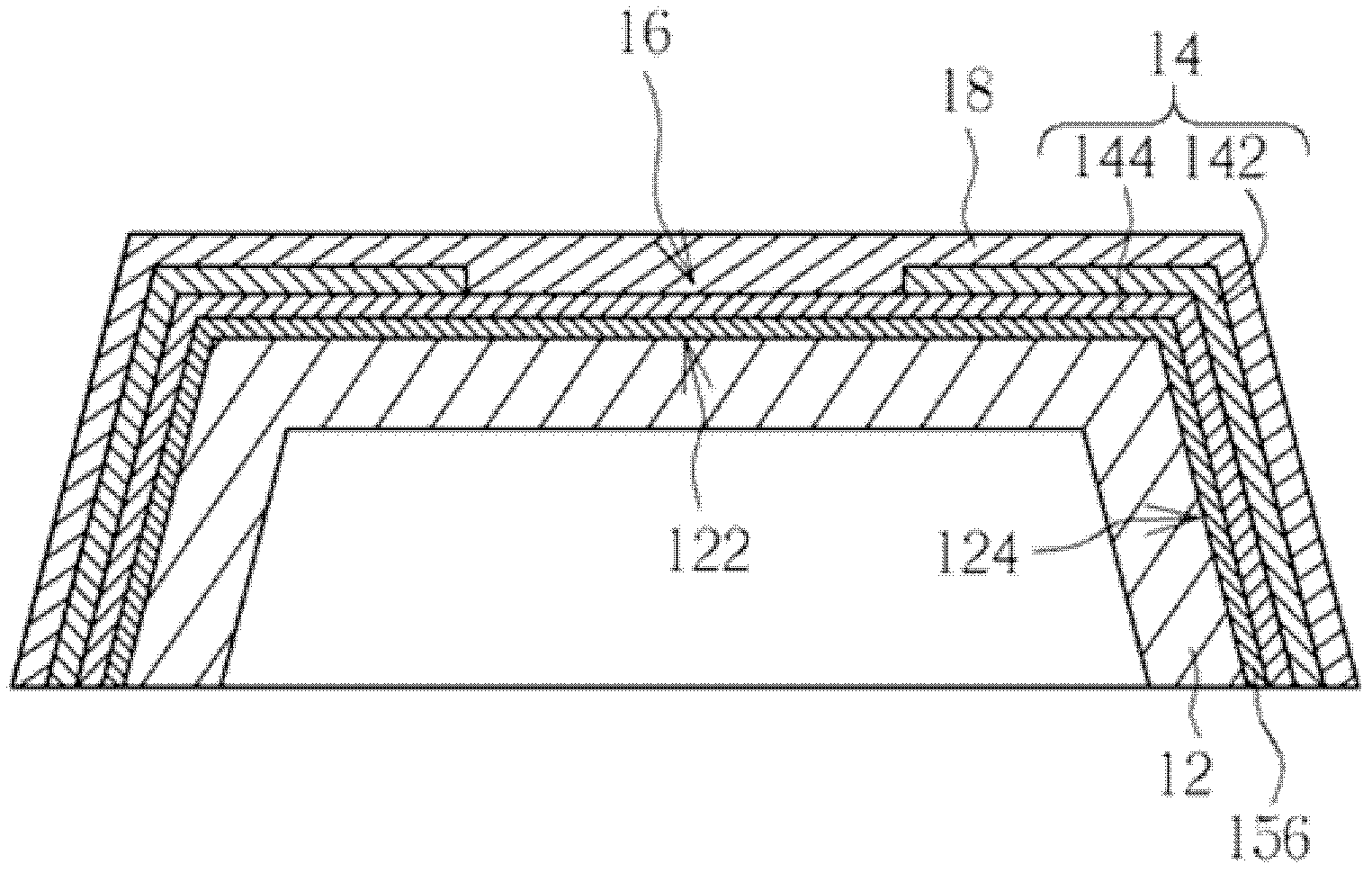

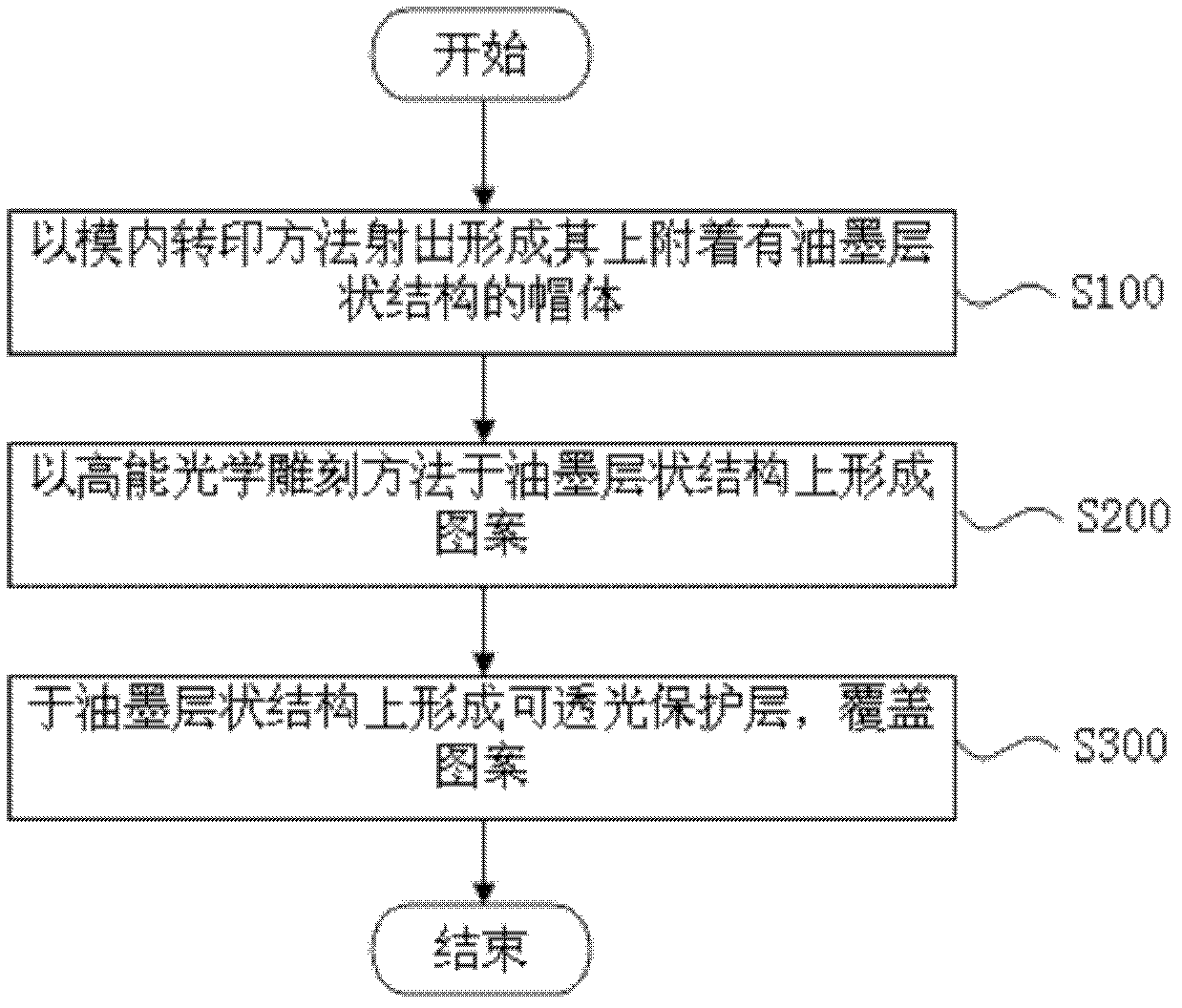

Key cap and method for making key cap

InactiveCN102629527AReduce processing timePrevent peelingDecorative surface effectsPattern printingHigh energyProtection layer

The invention relates to a key cap and a method for making the key cap. According to the manufacture method, an in-mold transfer printing method is used for injecting and forming a cap body, and an ink layer type structure is attached on the cap body; then, patterns are formed on the ink layer type structure by a high-energy optical carving method; and finally, a light transmission protection layer is formed on the ink layer type structure and covers the patterns. Compared with the prior art, the key cap and the method have the advantages that the manufacture time of forming the cap with patterns at the upper sides, such as key caps used by backlight keyboards and the like can be shortened, in addition, the in-mold transfer printing method is utilized, the combination intensity between the ink layer type structure and the cap body can be enhanced by using the in-mold transfer printing method, and the peeling possibility of the ink layer type structure is effectively inhibited.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

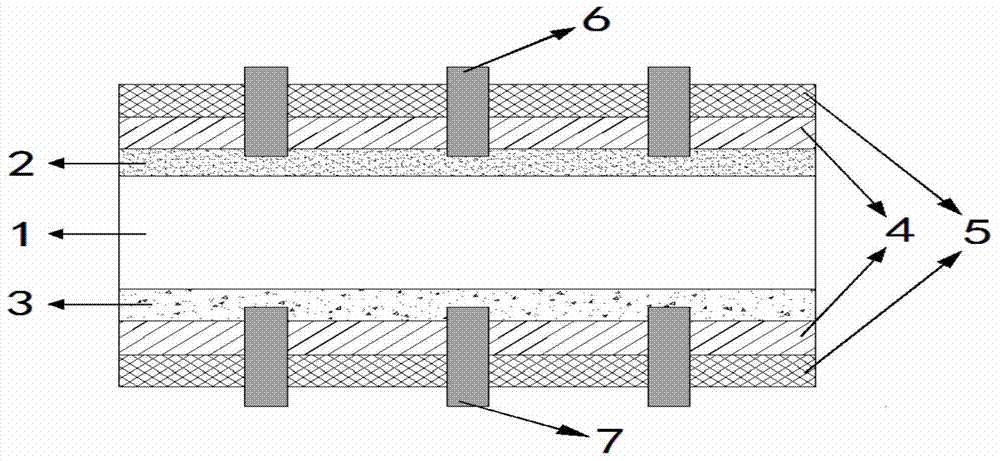

High efficiency N-type double-faced solar cell and preparation method thereof

ActiveCN104733555AIncrease the open circuit voltageInhibited DiffusionFinal product manufacturePhotovoltaic energy generationPhosphorSilicon dioxide

The invention relates to a high efficiency N-type double-faced solar cell and a preparation method thereof. The structure of the solar cell comprises an N-type silicon slice substrate, a front side boron doping layer, a back side phosphor doping layer, double-faced silicon dioxide passivation layers, doubled-faced silicon nitride antireflection layers and double-faced electrodes. The invention further discloses a preparation method for the solar cell, the preparation method particularly comprises the first step that double-faced texturization is conducted; the second step that front side boron diffusion is conducted; the third step that front side film masking is conducted; the fourth step that back side washing is conducted; the fifth step that back side phosphorus diffusion is conducted; the sixth step that a mask film is removed; the seventh step that double-faced passivation is conducted; the eighth step that double-faced film coating is conducted; the ninth step that the front side electrodes and the back side electrodes are formed; the tenth step that laser edge carving is conducted. According to the high efficiency N-type double-faced solar cell and the preparation method thereof, knots are formed on both the front side and the back side of the N-type silicon slice, the front side and the back side both have high photoelectric converting rates, the output power of an assembly of the high efficiency N-type double-faced solar cell is 20% higher than the output power of a common solar cell, and meanwhile the high efficiency N-type double-faced solar cell is applicable to large-scale industrial production due to the fact that the preparation technology is simple and practical.

Owner:常州顺风太阳能科技有限公司

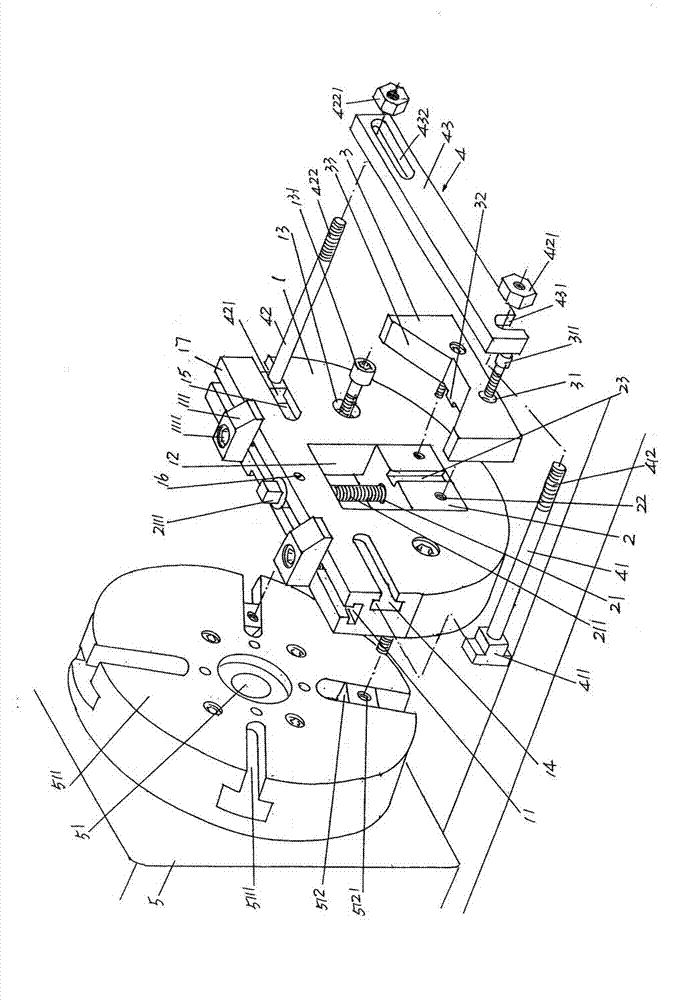

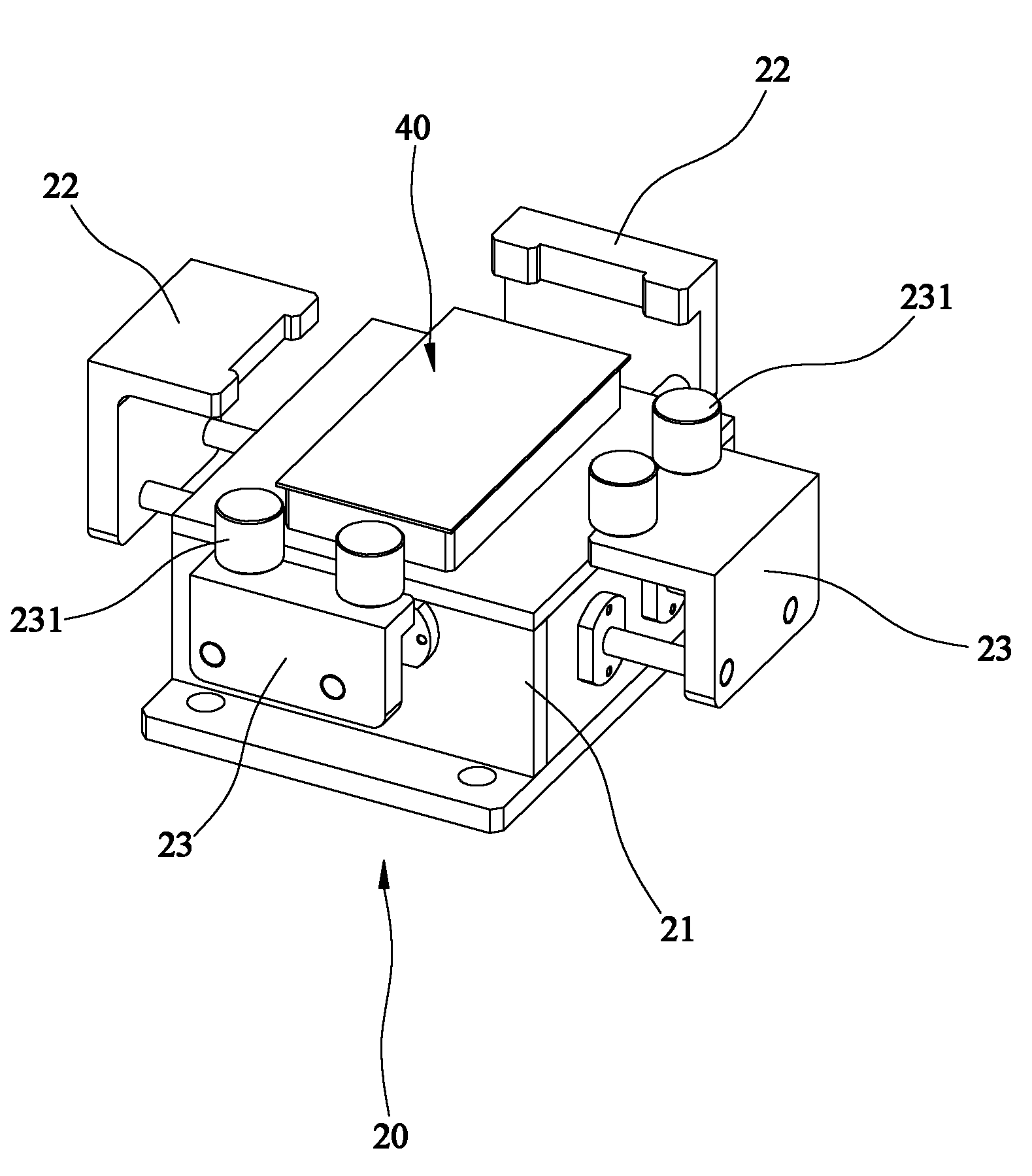

Clamping mechanism for machining glass die

ActiveCN102848245AQuality assuranceGuarantee efficiencyPositioning apparatusMetal-working holdersEngineeringCarving

The invention discloses a clamping mechanism for machining a glass die and belongs to the field of frock clamps. The clamping mechanism comprises a base, a support module fixing seat and a support module, wherein a pressure foot sliding chute is formed in a flat surface; a pressure foot is arranged in the pressure foot sliding chute; a support module fixing seat sliding cavity is formed in the base; the support module fixing seat is matched with a support module sliding cavity; a support module fixing seat nut is matched and arranged on the support module fixing seat; one end of a support module fixing seat lifting screw is connected onto the support module fixing seat nut; the other end of the support module fixing seat lifting screw is supported on the flat surface; the support module is fixedly connected with one side of the support module fixing seat; one end of the pressure foot extends out of the surface of one side of the base; a first guide sliding chute and a second guide sliding chute are formed in one side of the base; and a bottle die end surface positioning mechanism is matched and arranged on the other side of the base. The clamping mechanism has the advantages that the carving machining for an inner cavity of the glass die is realized without adopting a traditional an electric spark mode; the carving quality and efficiency are ensured; the clamping mechanism is convenient and quick in operation and is favorable in clamping adaptability; resources are saved and the interference influence on the die cavity is avoided.

Owner:CHANGSHU JIANHUA MOLD TECH

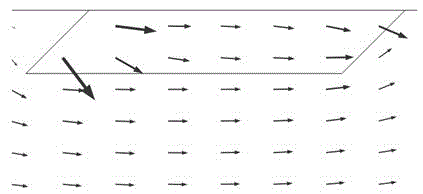

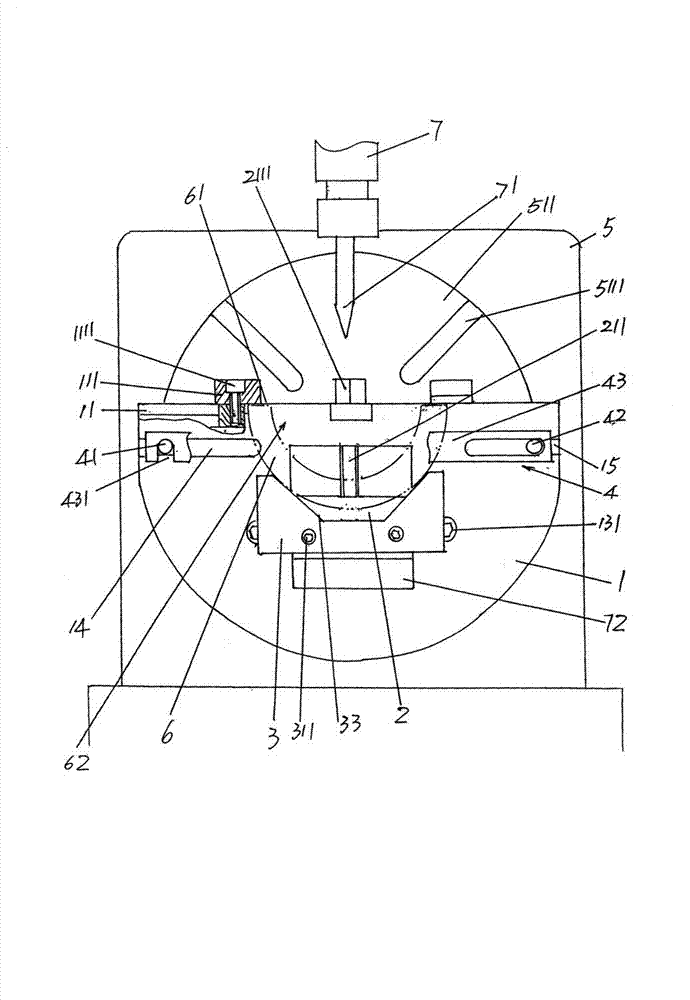

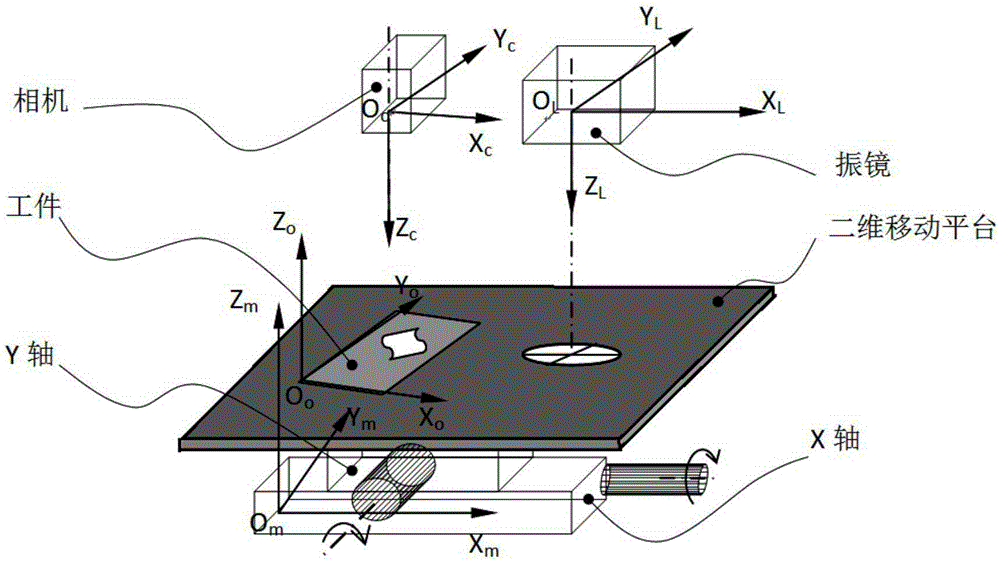

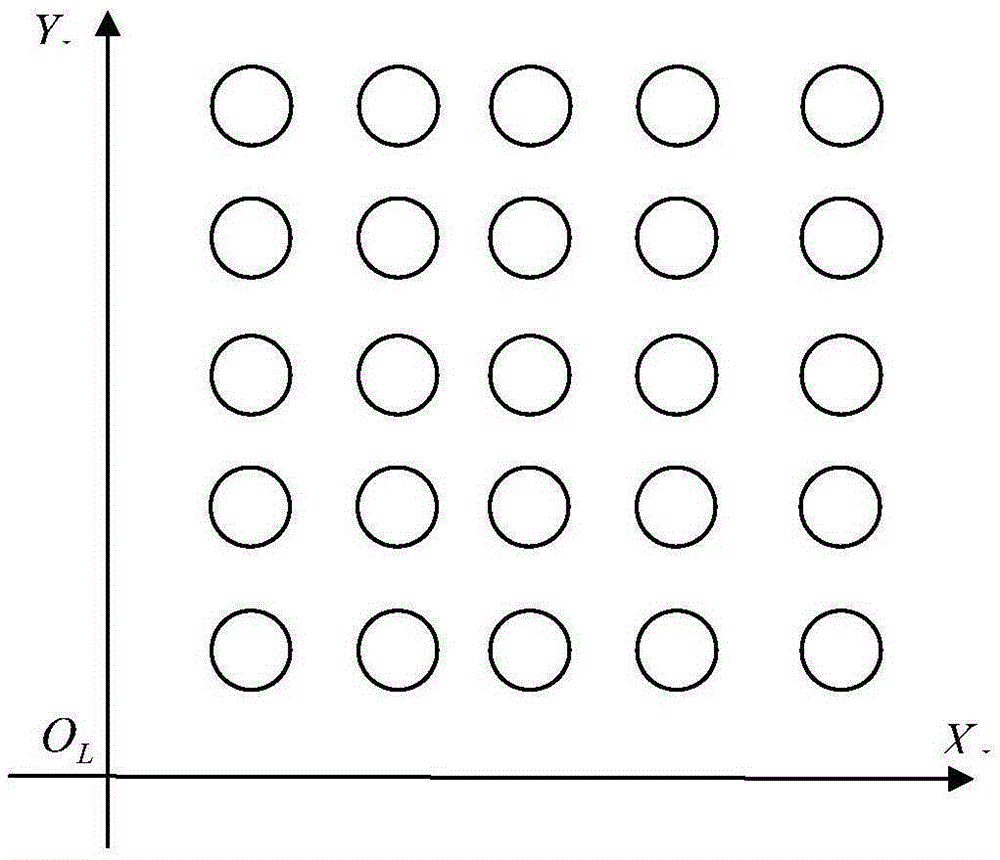

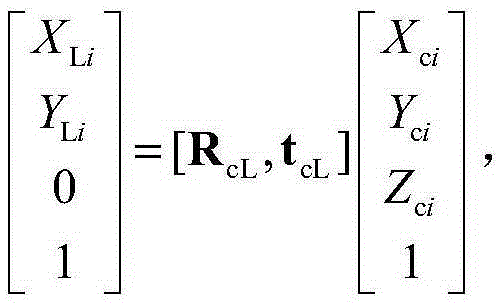

Calibration method for positional relation between paraxial type visual system and laser vibrating mirror machining system

InactiveCN105345254AReduce calibration efficiencyReduced Calibration AccuracyLaser beam welding apparatusCamera imageMachining system

The invention discloses a calibration method for the positional relation between a paraxial type visual system and a laser vibrating mirror machining system. The calibration method comprises the steps that a test-carving target is put in the field of view of a vibrating mirror, and the coordinates of a marked point in a vibrating mirror coordinate system at the moment are obtained; the test-carving target is put in the field of view of a calibration camera, and the coordinates of the marked point in the vibrating mirror coordinate system at the moment are obtained; according to the image of the marked point, in combination of a camera imaging principle, the coordinates of the initial position marked point in a calibration camera coordinate system are obtained; and the positional relation between the vibrating mirror coordinate system and the calibration camera coordinate system is represented through a matrix vector McL=[RcL, tcL], and based on the coordinates of the initial position marked point in the vibrating mirror coordinate system and the calibration camera coordinate system, the matrix vector is optimally obtained through a levenberg-marquardt (LM) method. According to the calibration method, no complex mechanical adjustment is needed, and the problems that the calibration efficiency and calibration precision are not high due to manual operation are solved. That is to say, the calibration method has the advantages of convenience, quickness, high efficiency and high calibration precision.

Owner:HUBEI UNIV OF TECH

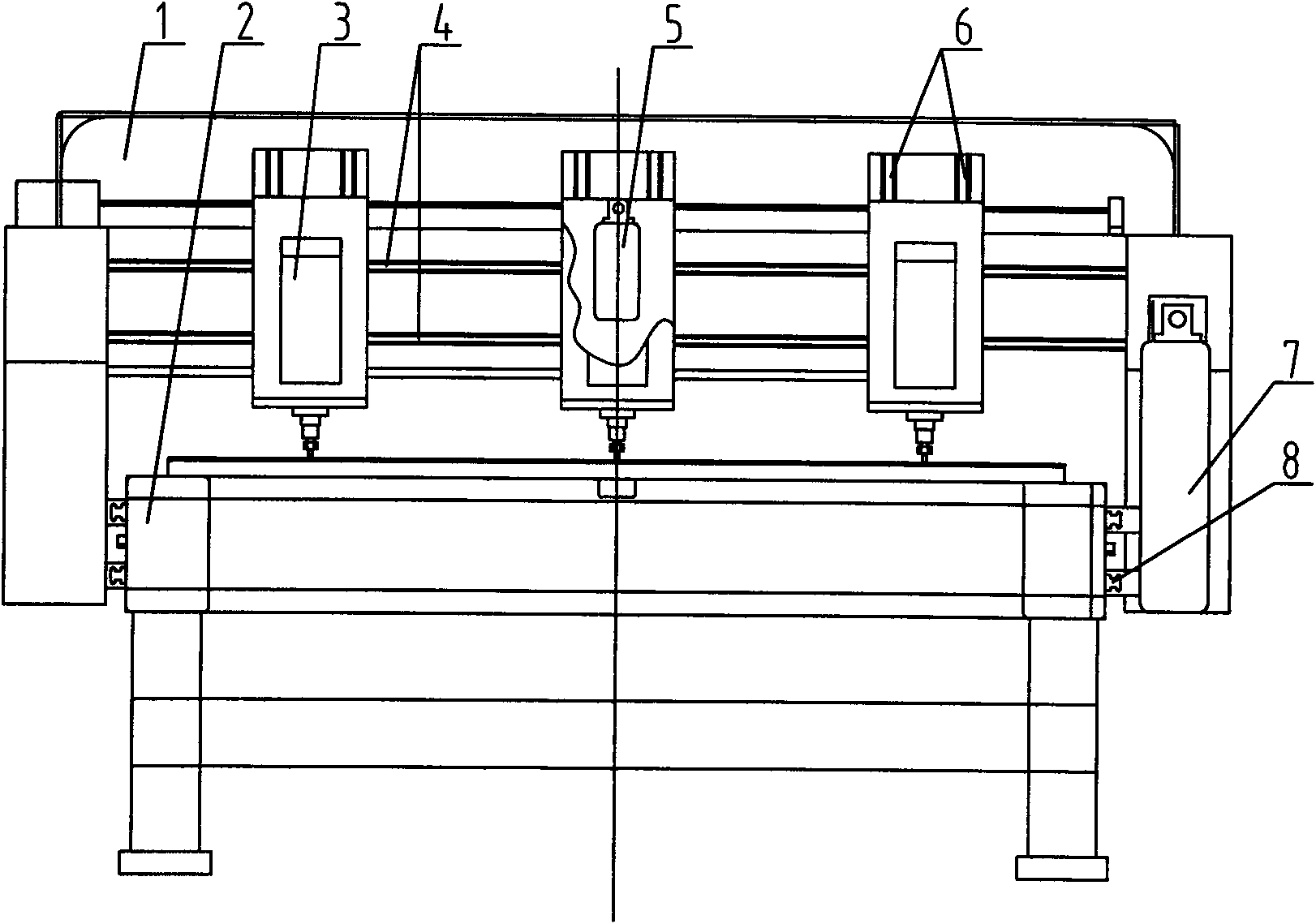

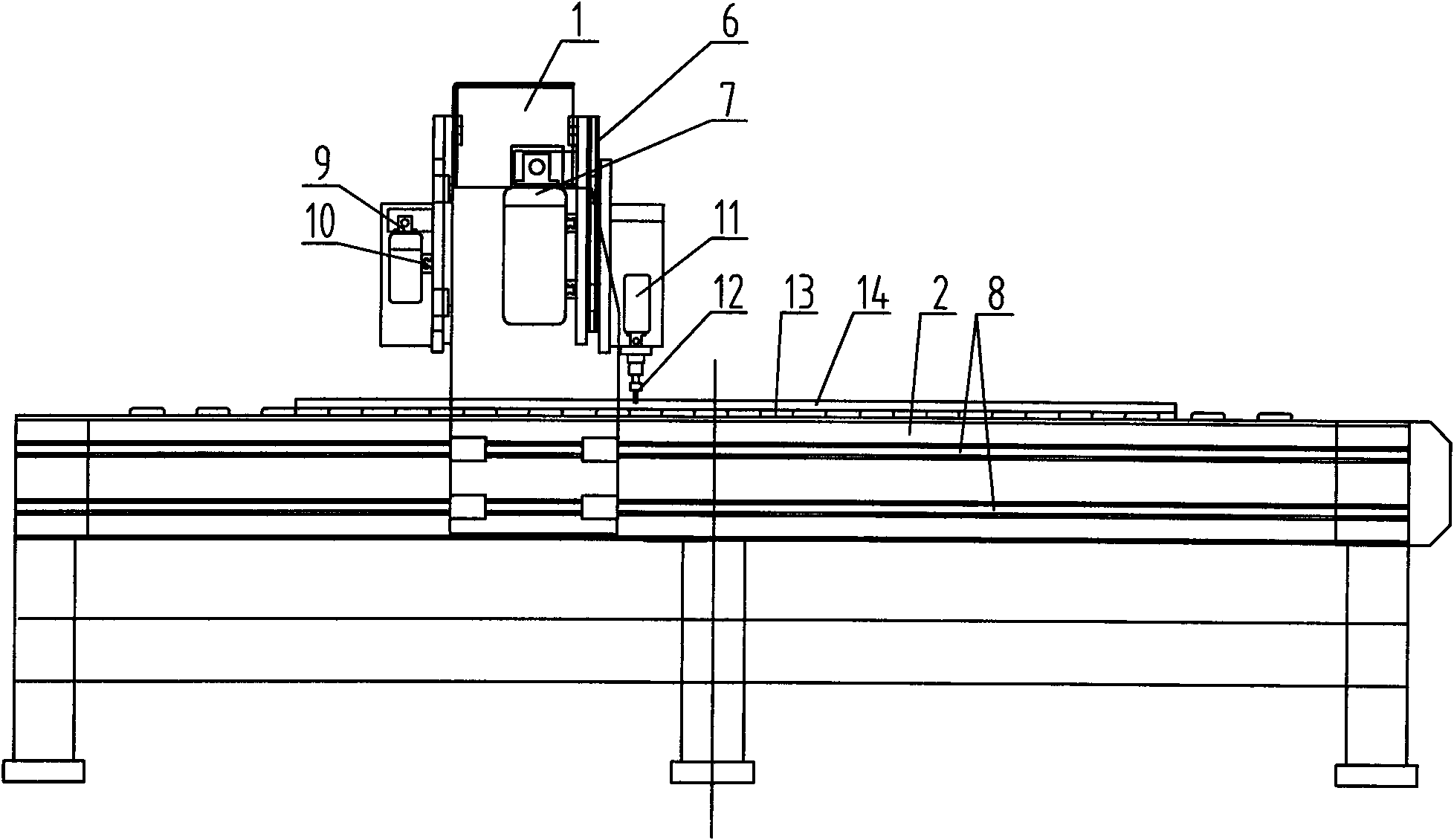

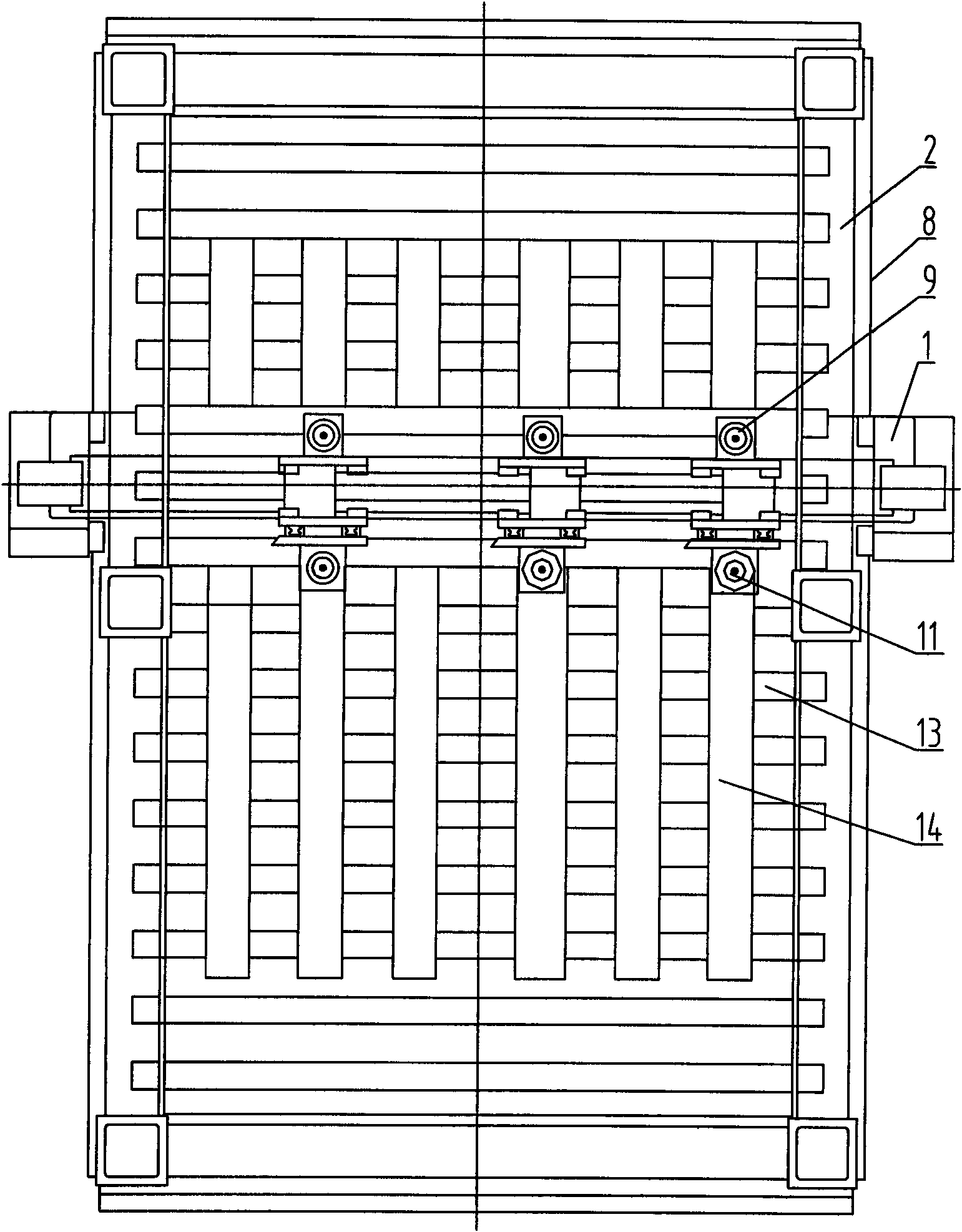

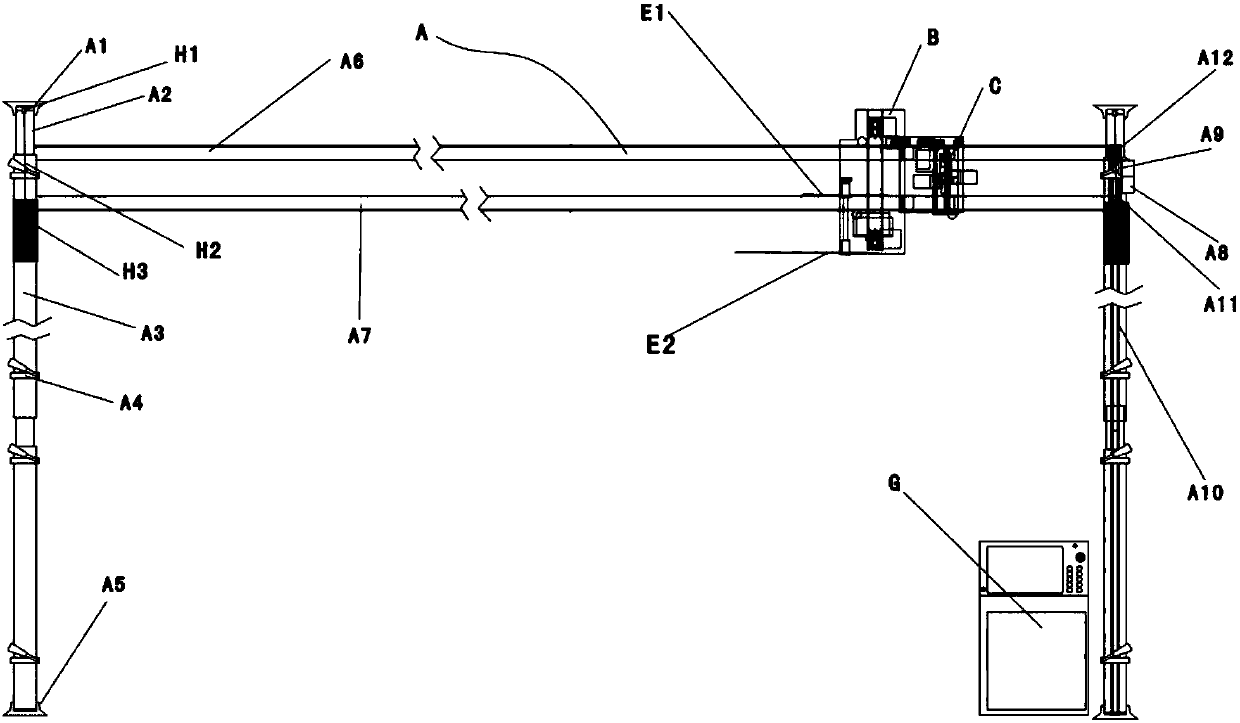

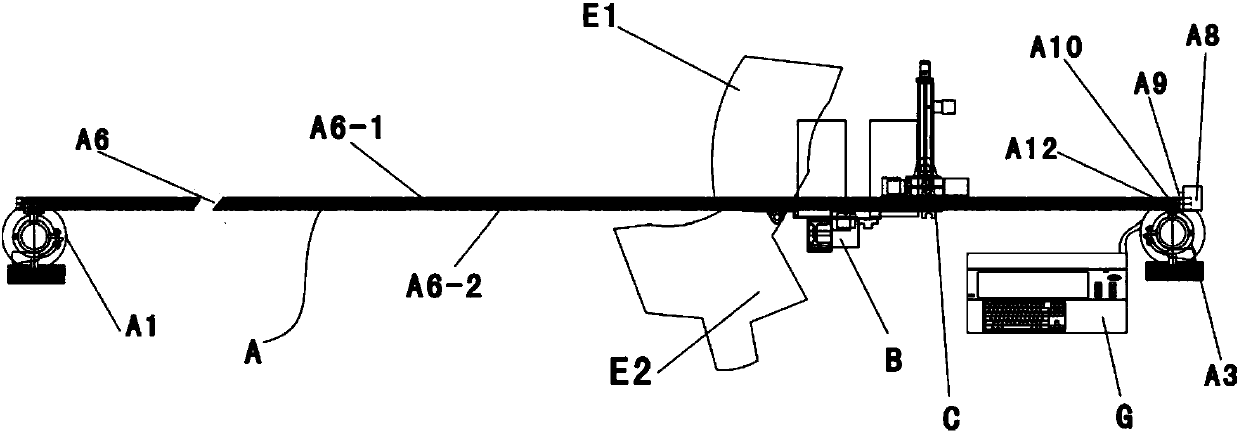

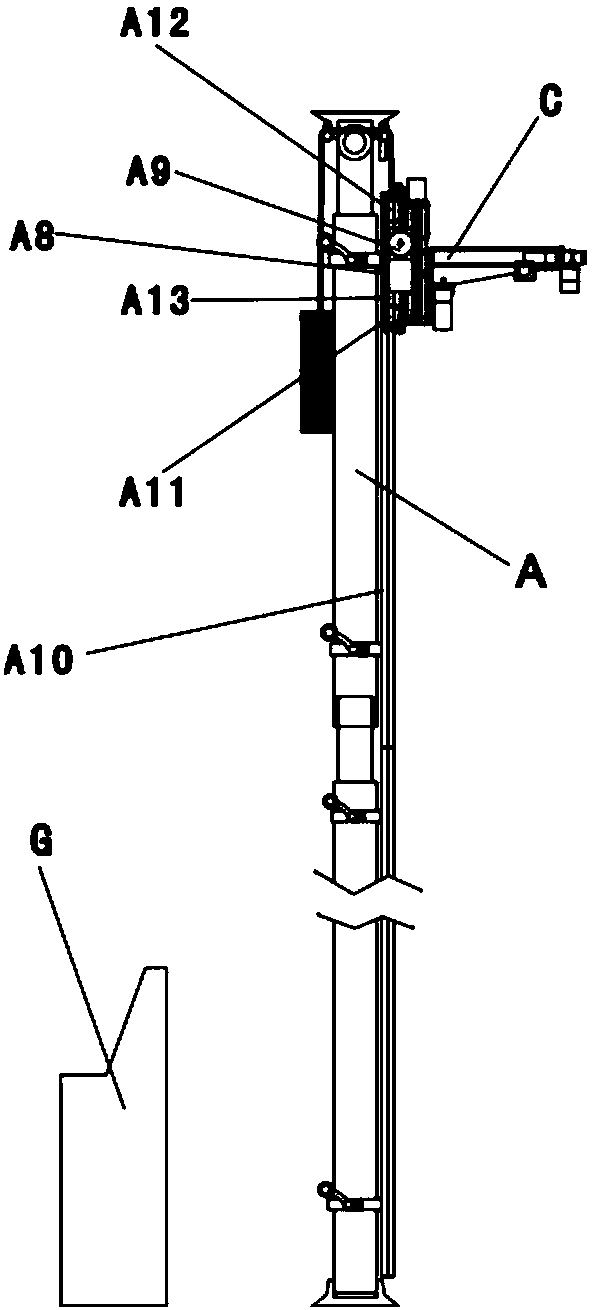

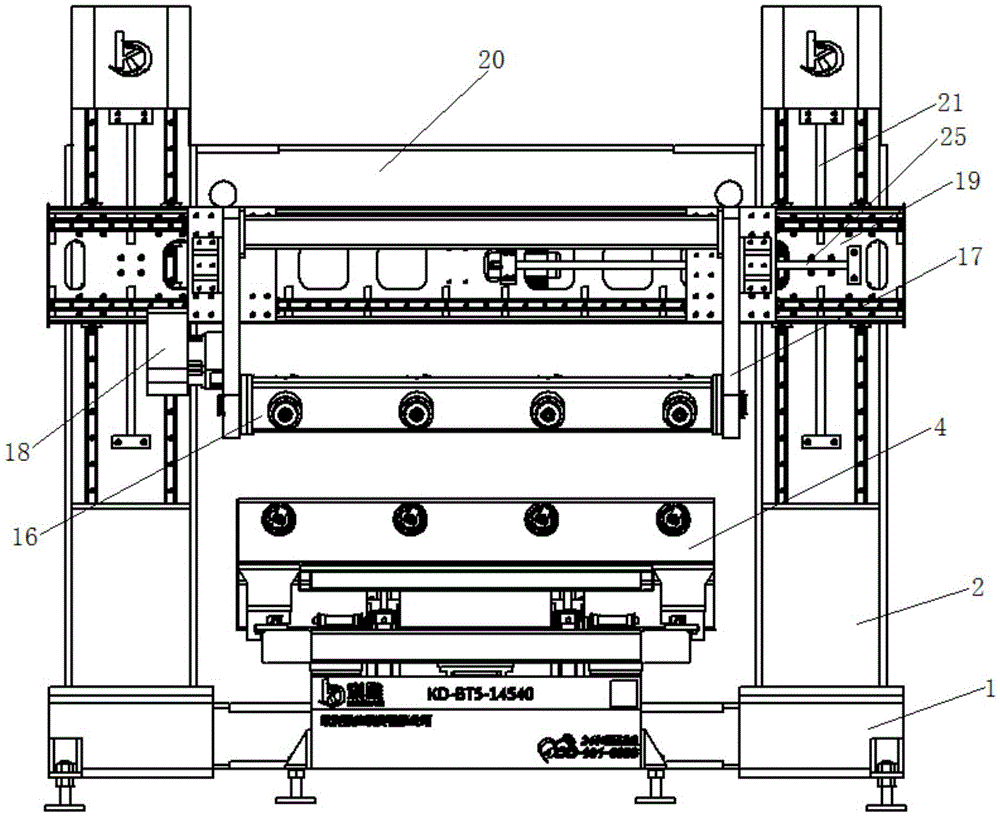

Multihead synchronous or asynchronous carving (drilling) milling numerical control processing equipment

InactiveCN102151883ASimple structureLow costMilling machinesLarge fixed membersNumerical controlControl system

The invention discloses multihead synchronous or asynchronous carving (drilling) milling numerical control processing equipment which comprises a portal frame, a lathe bed, a numerical control unit, a transmission system and x-axle, y-axle and z-axle guide rails, wherein the numerical control unit comprises an x-axle drive motor, a y-axle drive motor and a z-axle drive motor which are arranged on the portal frame. The multihead synchronous or asynchronous carving (drilling) milling numerical control processing equipment is characterized in that left and right sides of the portal frame are respectively provided with two y-axle guide rails, and the portal frame is also provided with 2-6 independent synchronous or asynchronous power heads and multiple sets of tools matched with the power heads, a lathe generates a three-dimensional processing figure by using a computer, the computer controls each power head respectively for processing after processing coordinates are input, a corresponding control system is provided with a servo motor or a stepping motor, the power heads move on the three guide rails along the x-axle direction, three points are fixed; and a screw or rack structure is adopted in the transmission system. The multihead synchronous or asynchronous carving (drilling) milling numerical control processing equipment has the advantages of simple structure, low cost, high processing accuracy, good stability, high processing efficiency, wide application range and the like.

Owner:ALNAN ALUMINIUM CO LTD

Three-dimensional high simulation ceramic tile with matte glaze surface and preparation method thereof

ActiveCN108727037AExtended service lifeGood three-dimensionalCeramic shaping apparatusAdobeComputer printing

The invention discloses a three-dimensional high simulation ceramic tile with matte glaze surface and a preparation method thereof, the method comprising the following steps: 1) adopting a laser four-dimensional fine carving system to finely carve a digital mold; 2) Positively pressing green body molding; 3) Controlling the water absorption rate of the ceramic tile before glazing at 15%-20% by controlling the drying temperature of the ceramic tile adobe or the biscuiting temperature of the ceramic tile adobe; 4) spraying a small amount of high-titanium impervious ground coat under high pressure; 5) spraying a small amount of matte glaze under high pressure; 6) using a digital ink jet printer to print decorative ink and functional ink; 7) decorating the dry particle frit, and adopting a controllable negative pressure absorbing dry particle frit equipment to absorb excess dry particle frit; 8) sintering to obtain the three-dimensional high imitation ceramic tile with matt glaze surface,the preparation method provided by the invention obtains the three-dimensional high simulation ceramic tile with matte glaze surface with three-dimensional simulation, 2-6 glossy units of glaze surface gloss and lifelike surface decoration effect through the collaborative and innovative preparation including mold sculpture, glaze formula control, high-pressure glaze spraying and effect decoration.

Owner:广东协进陶瓷有限公司

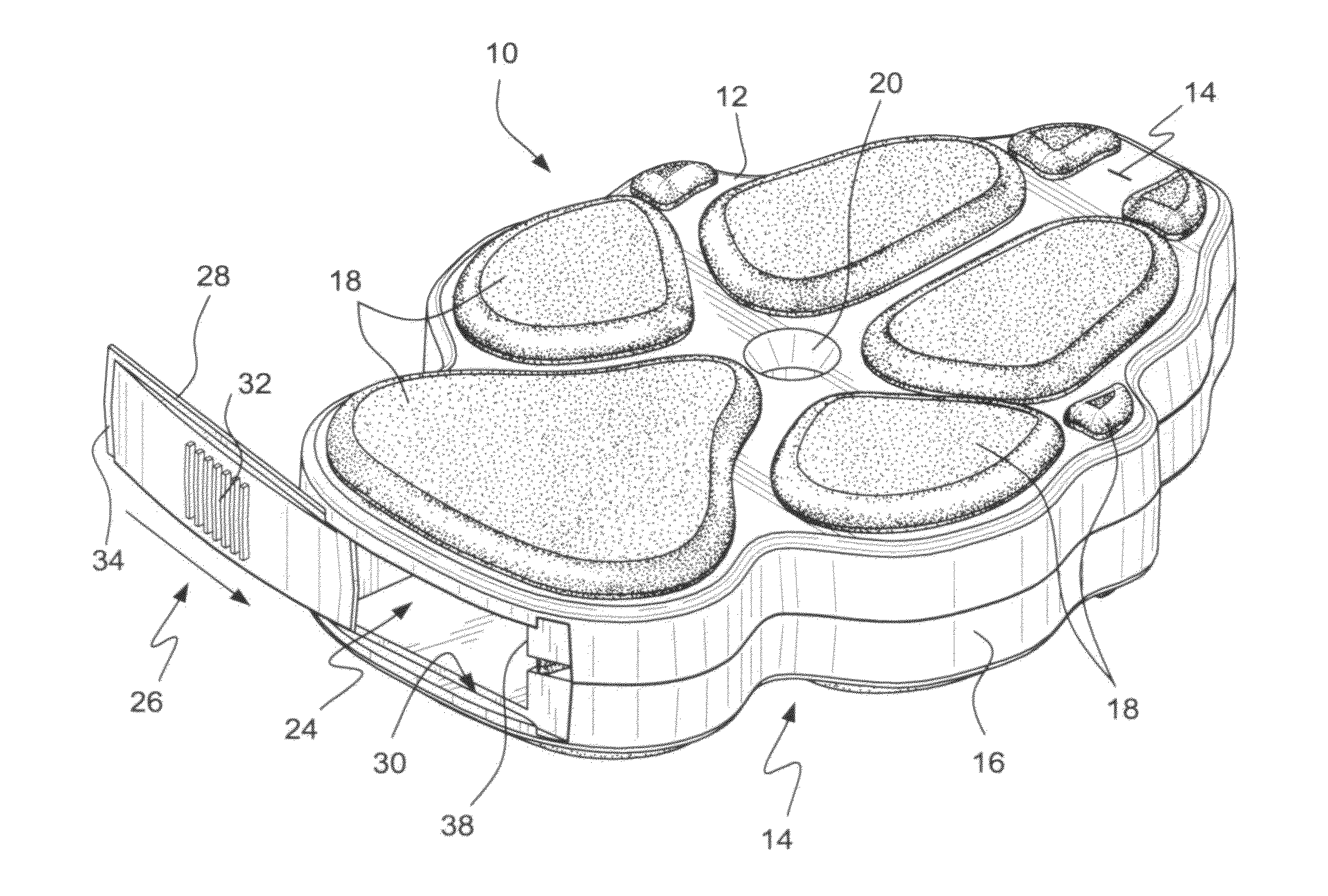

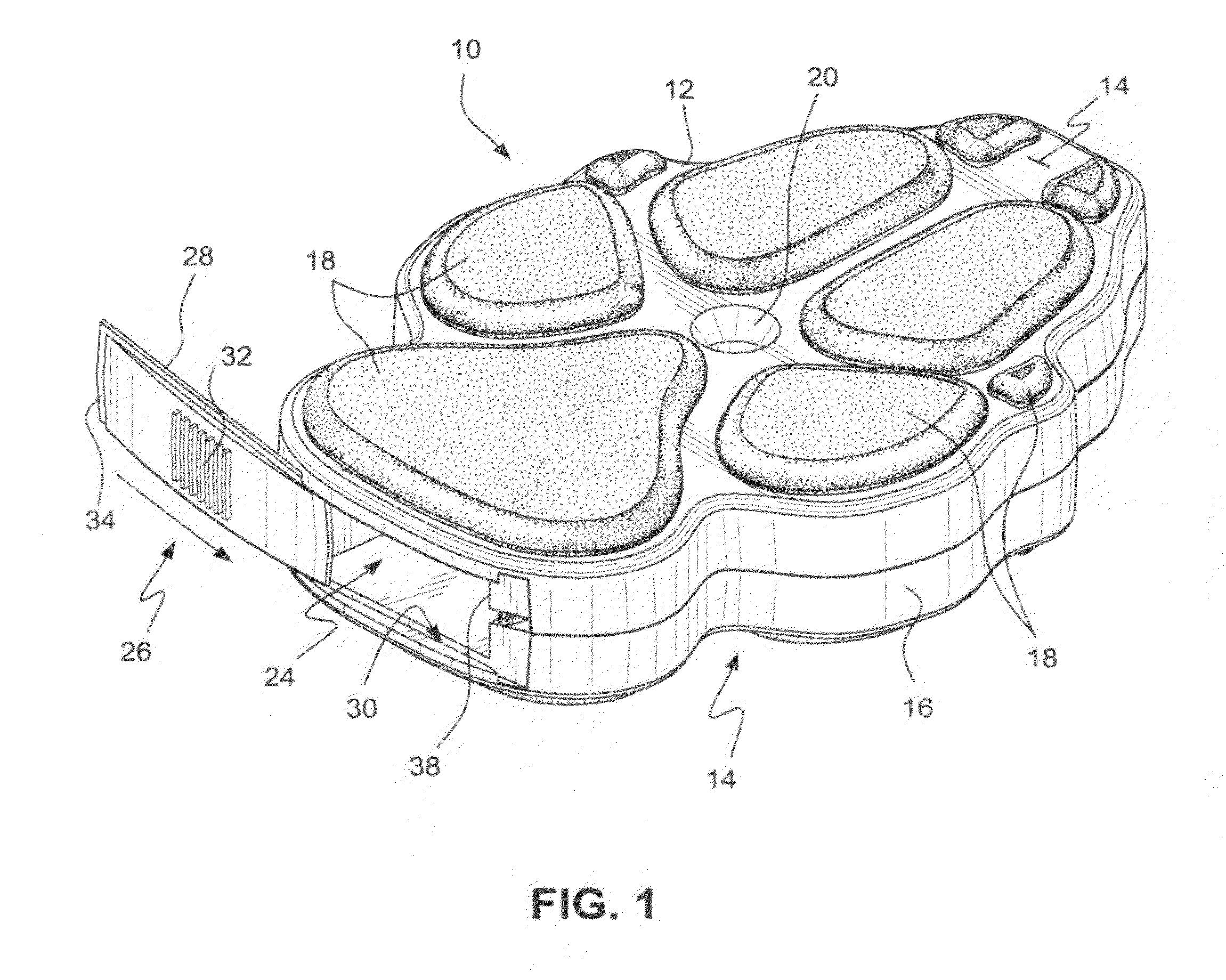

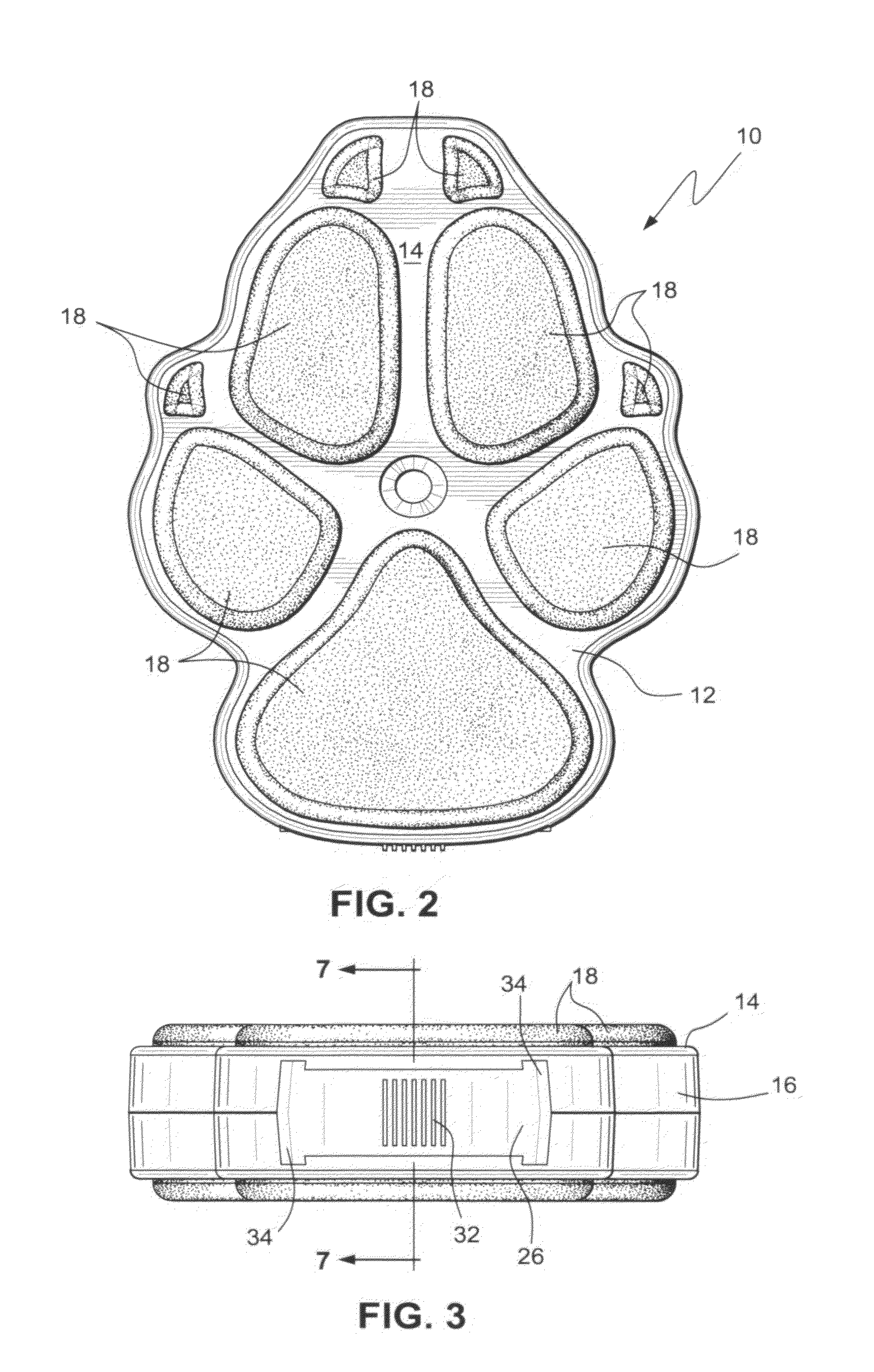

No-mar workpiece support

A workpiece support that presents a generally planar workpiece contacting surface having high friction, gripping pad(s) that will not mar a workpiece surface, and thus provides a versatile accessory for home hobbyists and artisans alike that protects the supported surface of the workpiece. By providing a non-marring workpiece support, such as that illustrated in FIGS. 1, 8 and 13, to support a workpiece with respect to a work bench surface, the workpiece can be kept from slipping while routing, sanding, carving and the like. It can elevate workpieces for edge work and finishing, or simply suspend and protect projects from marring during drying or between work sessions.

Owner:WOODWORKERS SUPPLY

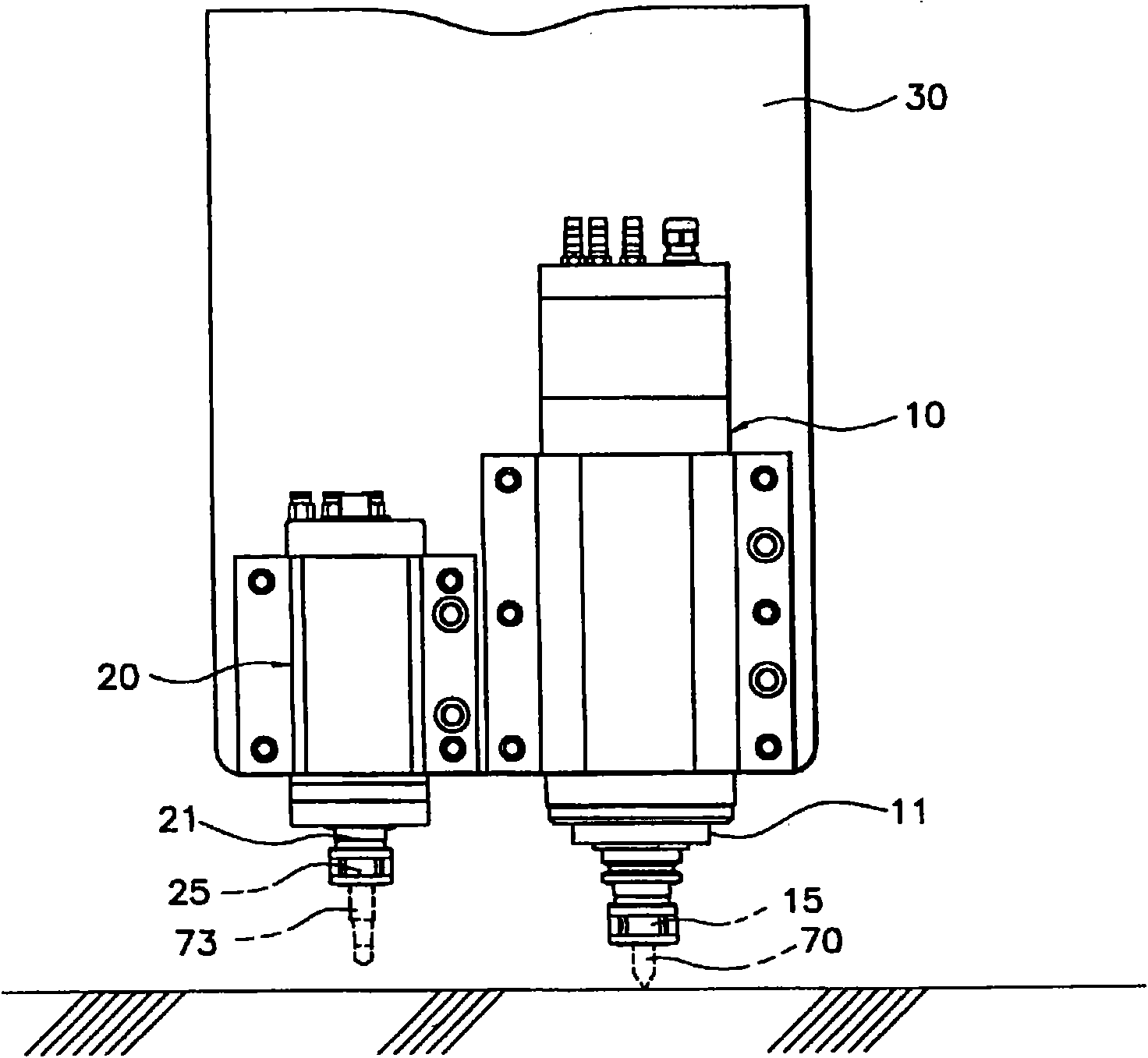

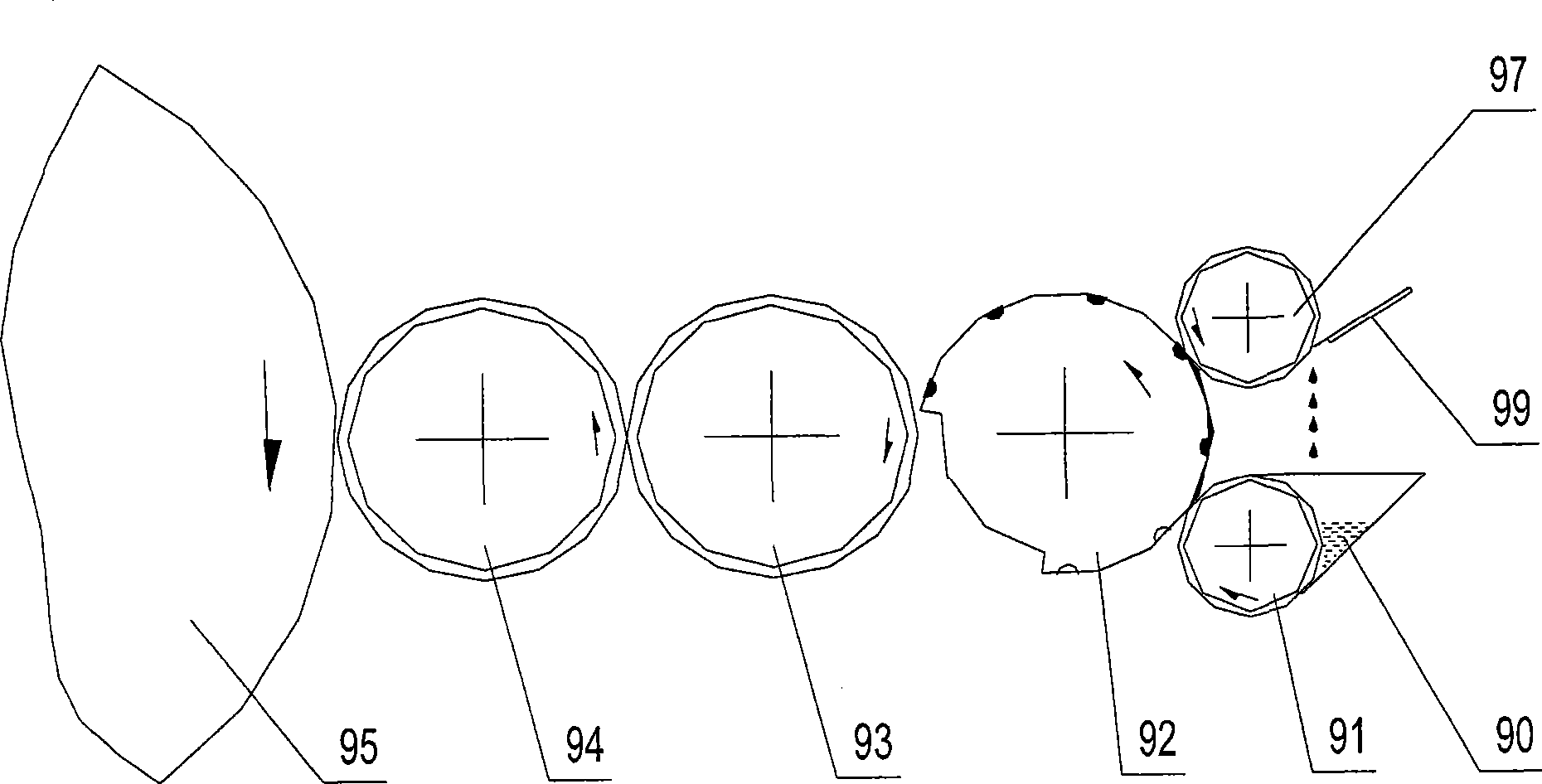

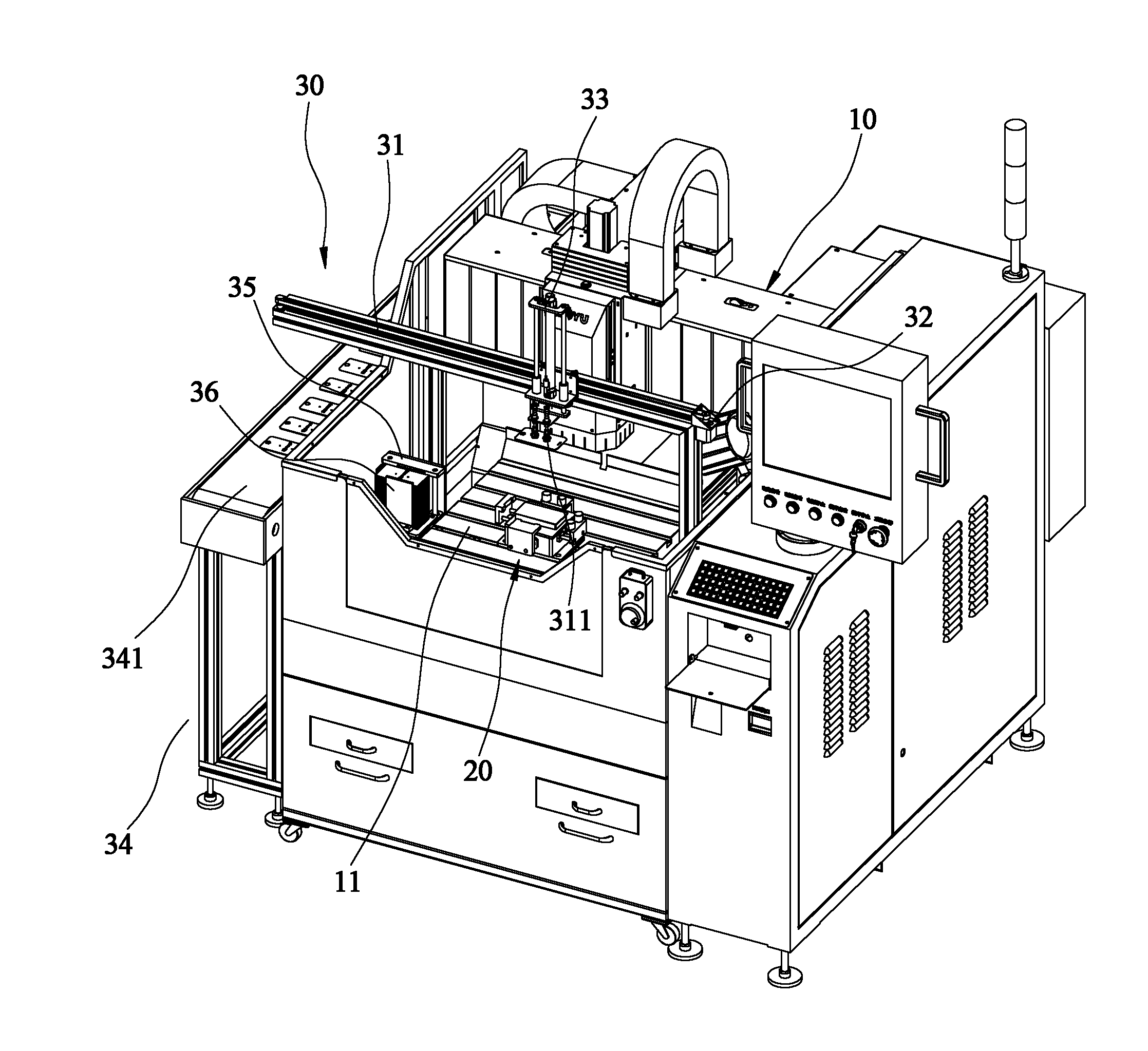

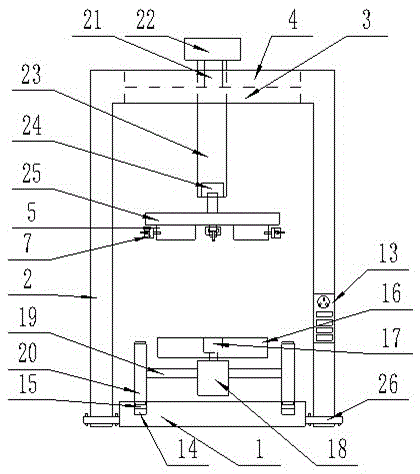

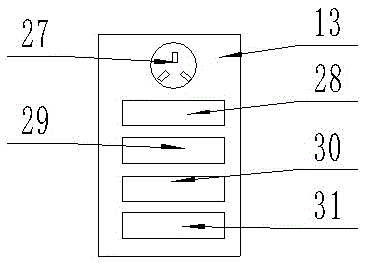

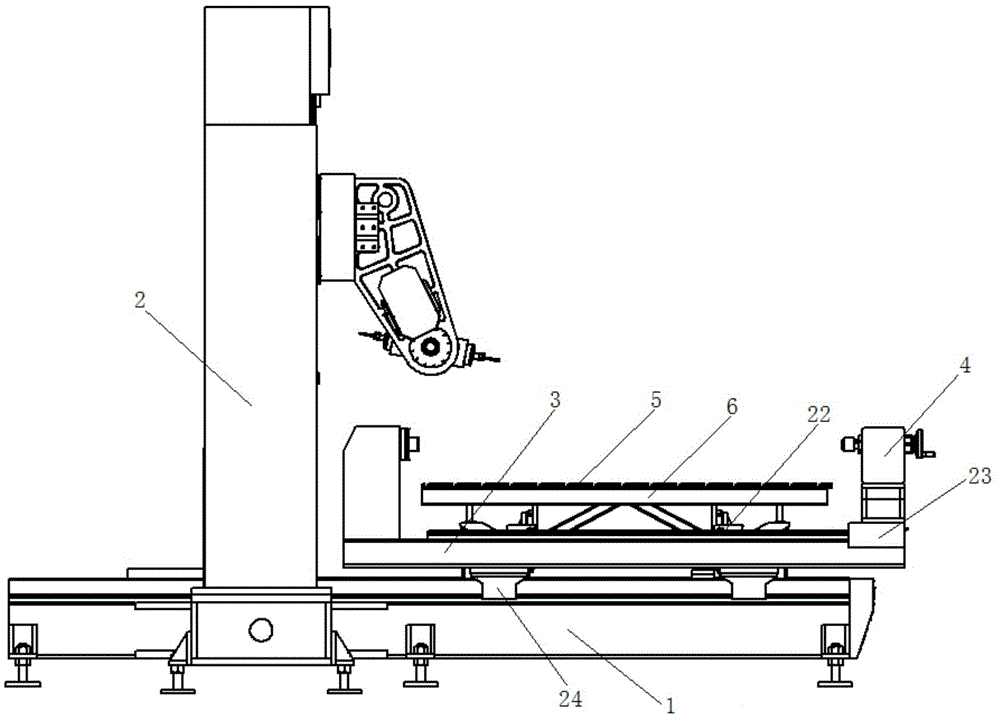

Fine-engraving machine capable of loading and unloading automatically

The invention discloses a fine-engraving machine capable of loading and unloading automatically, comprising a base and a fine-carving assembly as well as a control assembly mounted on the base. The control assembly includes an industrial personal computer (IPC) used for controlling the fine-carving assembly to work and an operating panel used for inputting commands to the IPC. The IPC is electrically connected with the fine-carving assembly. The fine-carving machine further comprises an automatic loading and unloading device which is mounted on the base. Thereby, the fine-engraving machine capable of loading and unloading automatically disclosed by the invention realizes the automatic loading and unloading function through the automatic loading and unloading device. Compared with the artificial loading and uploading way, the fine-engraving machine disclosed by the invention greatly improves production efficiency and reduces production cost.

Owner:SHENZHEN DAYUCNC TECH

Production method of 3D glass cover plates of mobile phones

The invention belongs to the technical field of mobile phone accessories, and specifically relates to a production method of 3D glass cover plates of mobile phones. The production method of 3D glass cover plates of mobile phones includes the steps: engineering, cutting, fine carving, grinding and polishing, cleaning, double face sweeping, primary detection, chemical strengthening, secondary detection, UV transfer printing, film plating and the other steps. The production method of 3D glass cover plates of mobile phones utilizes an ultrasonic cleaning machine to clean the residues on the glasssurface, thus being clearer in cleaning effect, being higher in the cleaning speed and improving the production efficiency.

Owner:WENSHAN KETAIFENG ELECTRONICS CO LTD

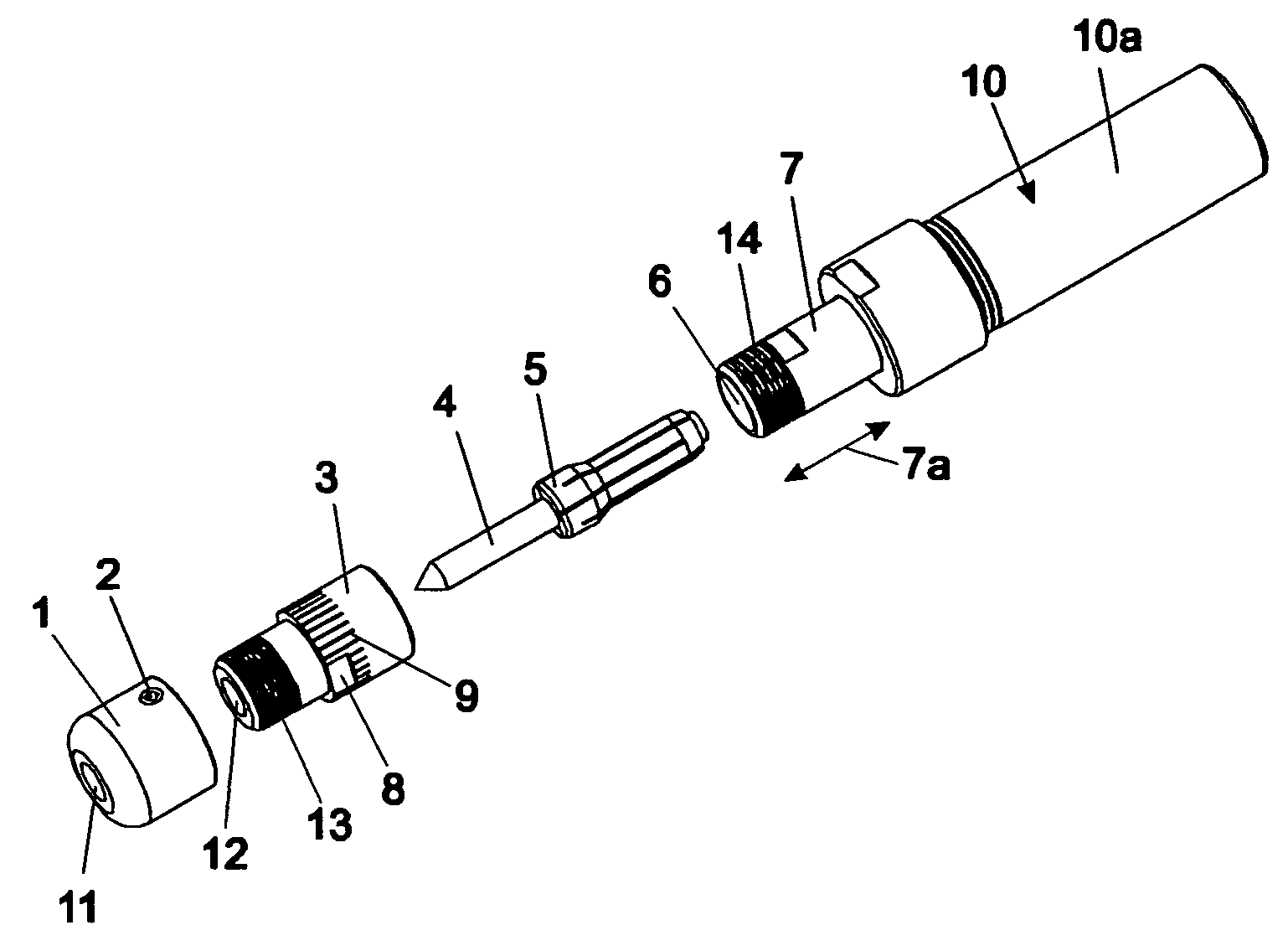

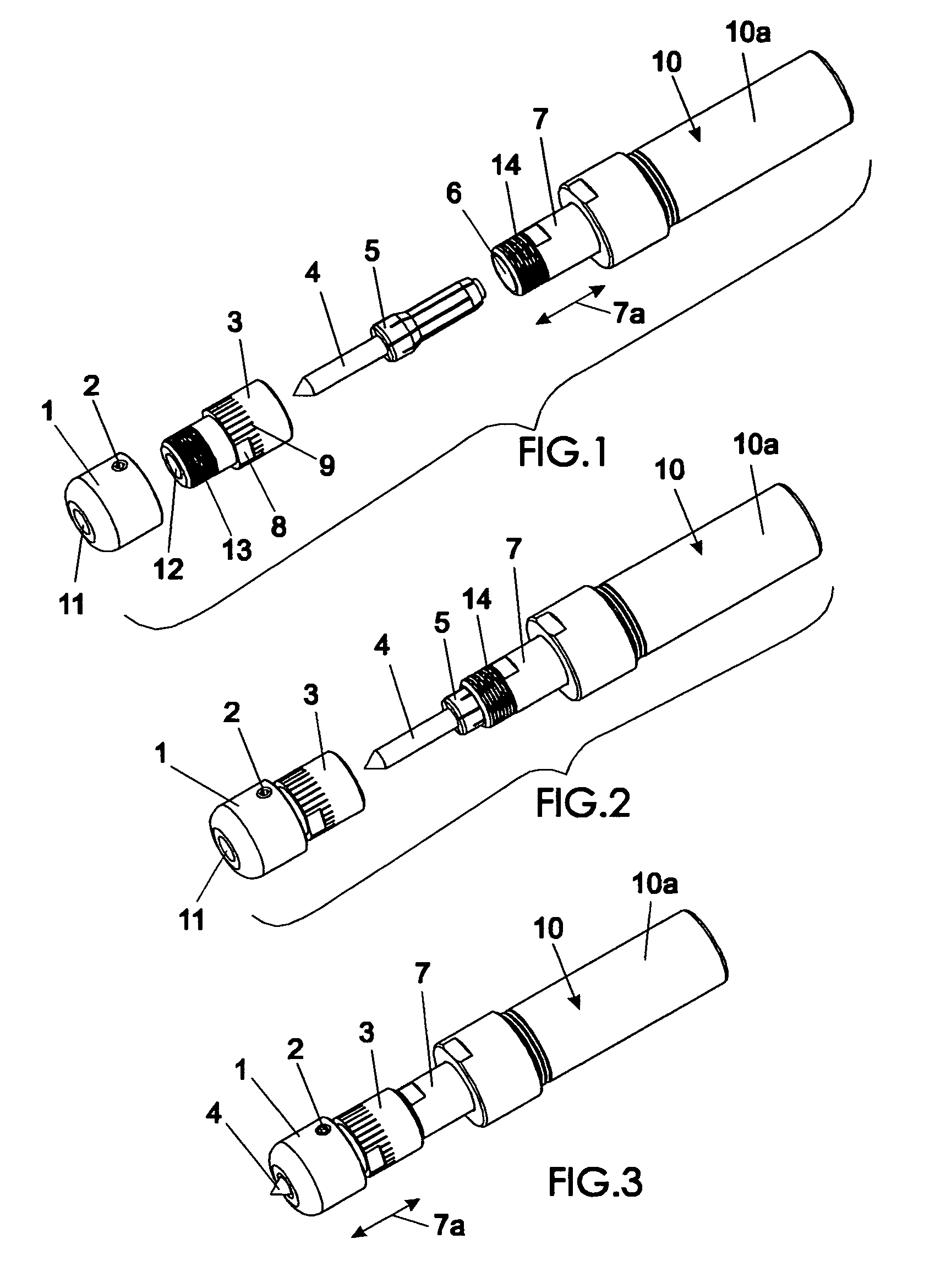

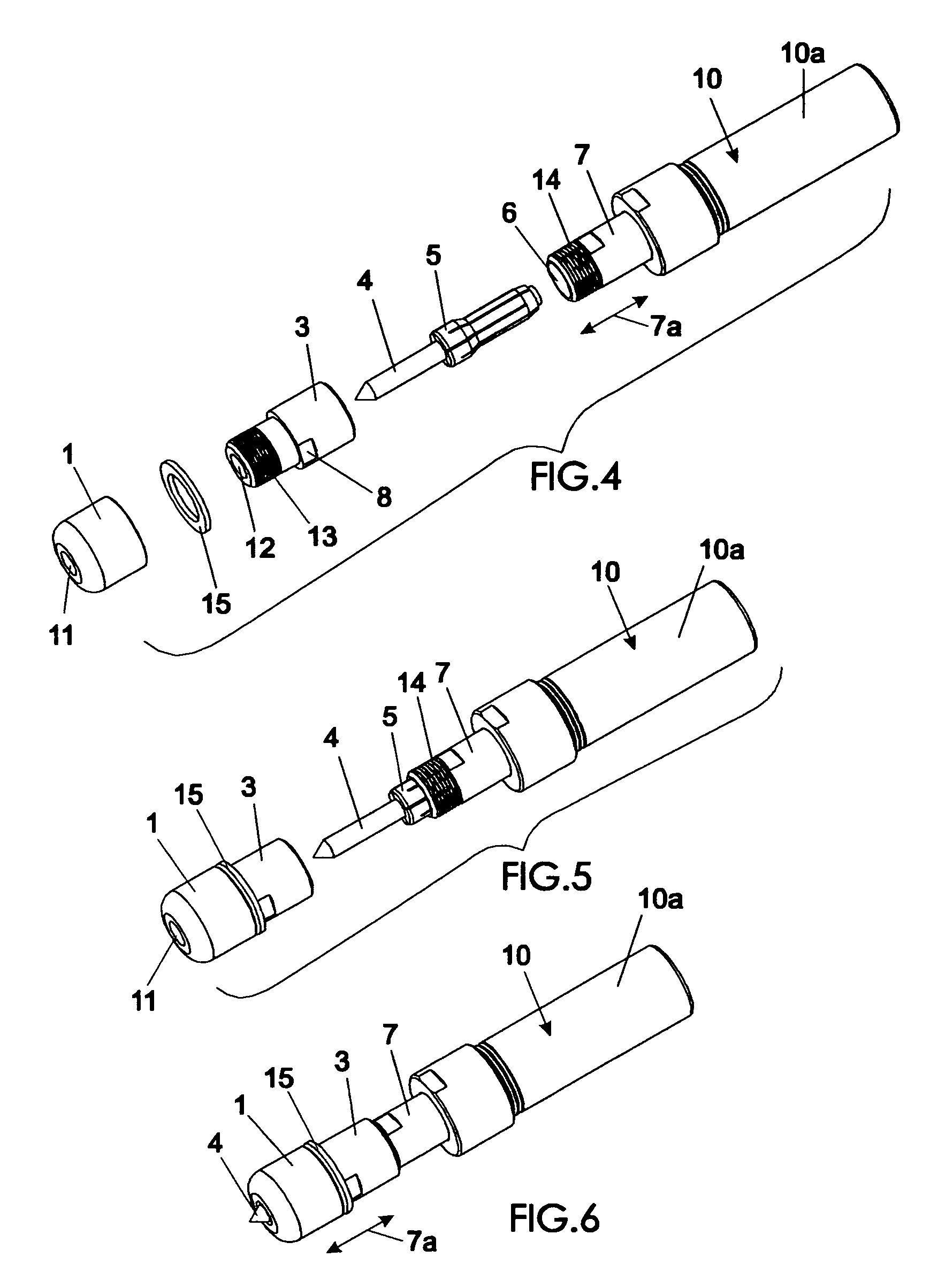

Engraving tool depth control nosepiece for enhancing line uniformity

Engraving tool bit depth controlling nosepiece adjustment devices establish a precise protrusion distance that an engraving tool bit protrudes from the end of the nosepiece of a spring loaded engraving tool, that is in turn inserted within and driven by a standard machine tool such as a cnc type milling machine. One rotational adjustment device establishes the axial position of the nosepiece with respect to a collet nut of the engraving tool and another adjustment device employs annular ring spacers in the form of washers between the nosepiece and collet nut to precisely establish the desired engraving tool bit protrusion distance from the end of the nosepiece. This modification of a spring loaded engraving tool beneficially prevents the engraving tool bit from being able to plunge too deeply into the workpiece, particularly at the start of each engraved line, to thus ensure that all the lines will be consistent.

Owner:NELSON LANCE

Mechanical device applied to building inside space building and decoration technology improvement

InactiveCN107675891AReasonable designEliminate hidden dangersBuilding material handlingCeramic tilesWorking environment

The invention discloses a mechanical device applied to building inside space building and decoration technology improvement. Through the numerical control mechanical device, the building and decoration functions of various wall bodies can be provided. The mechanical device has various functions of brick wall building, wall body rendering, wall body plastering, wall body grinding, wall body paint spraying, wall body ceramic tile pasting, wall body engraving and the like. The brick wall building function is used and is matched with the use of a pipeline passage prefabricated element; the brick wall roof building can be completed in one step, and a space and a position for passing a passing pipeline can be precisely reserved; next, other functions can be selected and used for completing the wall body rendering, plastering, grinding, paint spraying, ceramic tile pasting or even the wall body engraving decoration work; the construction period can be greatly shortened; the wall body qualitycan be ensured; the work efficiency is improved; the cost is reduced; meanwhile, the work environment of construction sites is improved; and the work coefficient of workers is optimized.

Owner:张明祥

Ceramic carving process

InactiveCN101088777AEasy to useGood collection valueDecorative surface effectsOrnamental structuresChina clayCarving

The present invention relates to ceramic carving making process. The ceramic carving making process includes the steps of forming biscuit with high quality china clay, carving patterns with sharp tools, blowing special color glaze and baking. The ceramic carving may be made through porcelain carving, underglaze carving or mold carving. The novel ceramic carving has strong stereo sensation, clear pattern, and high use and collection value.

Owner:谢开强

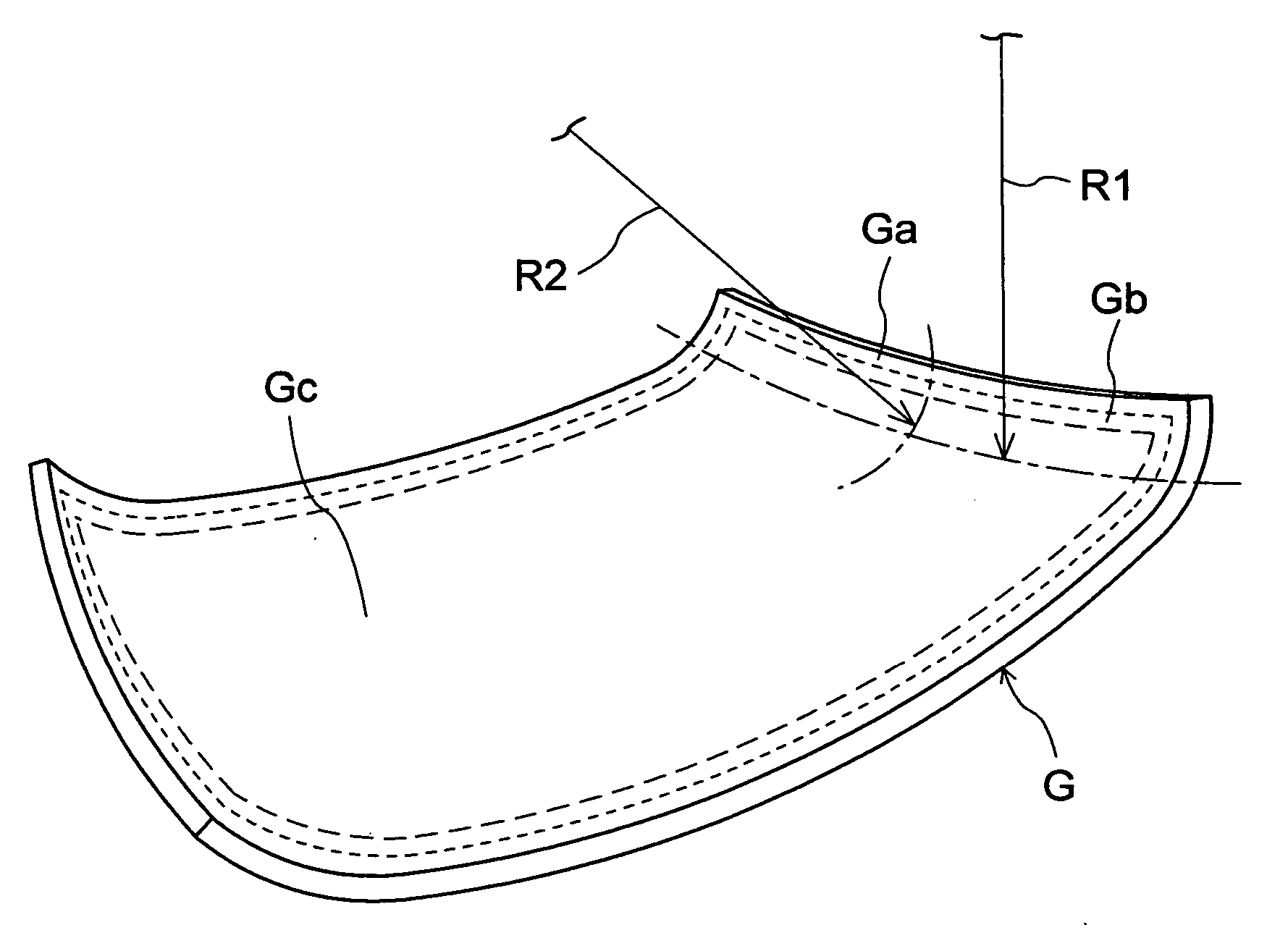

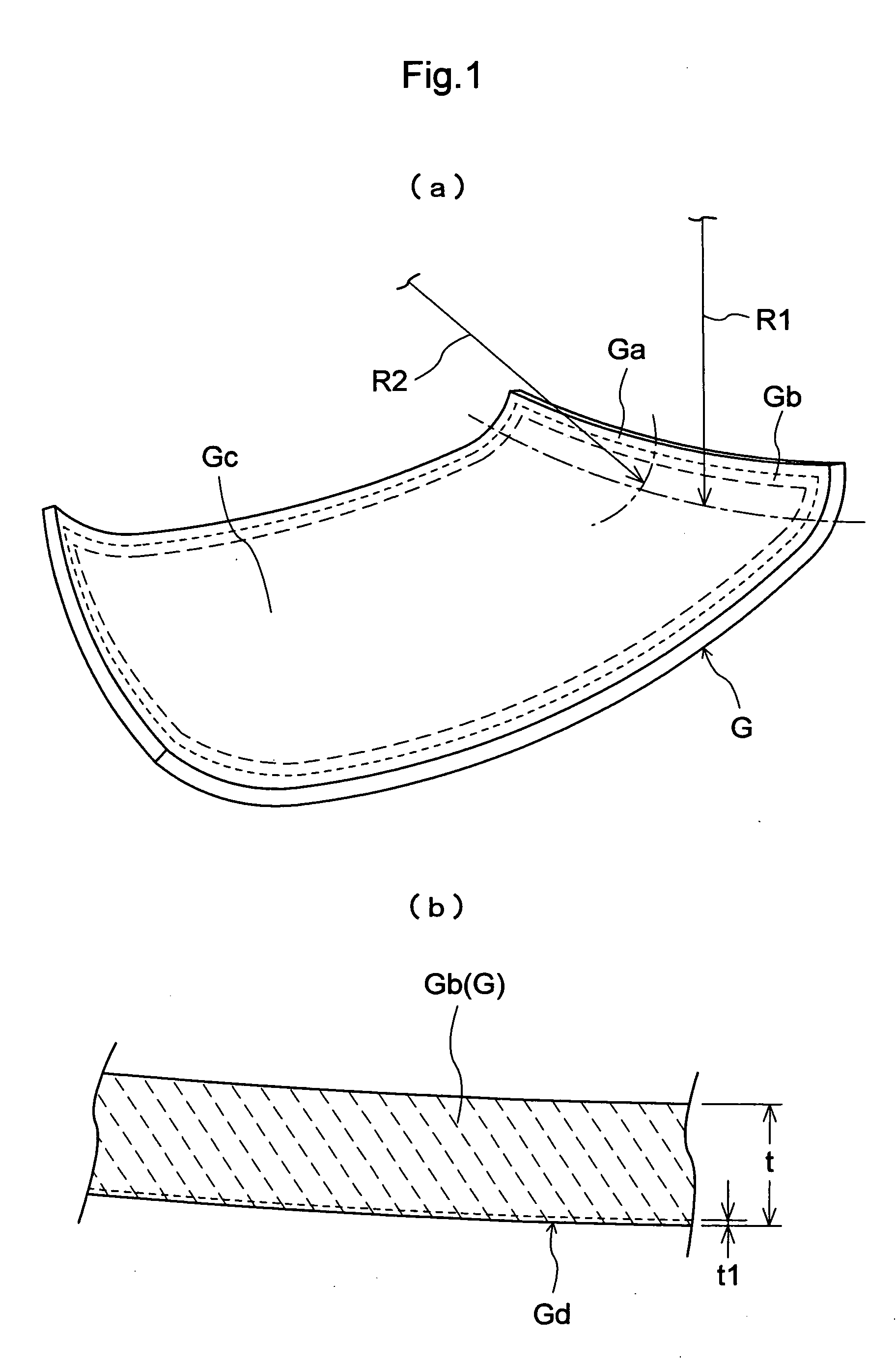

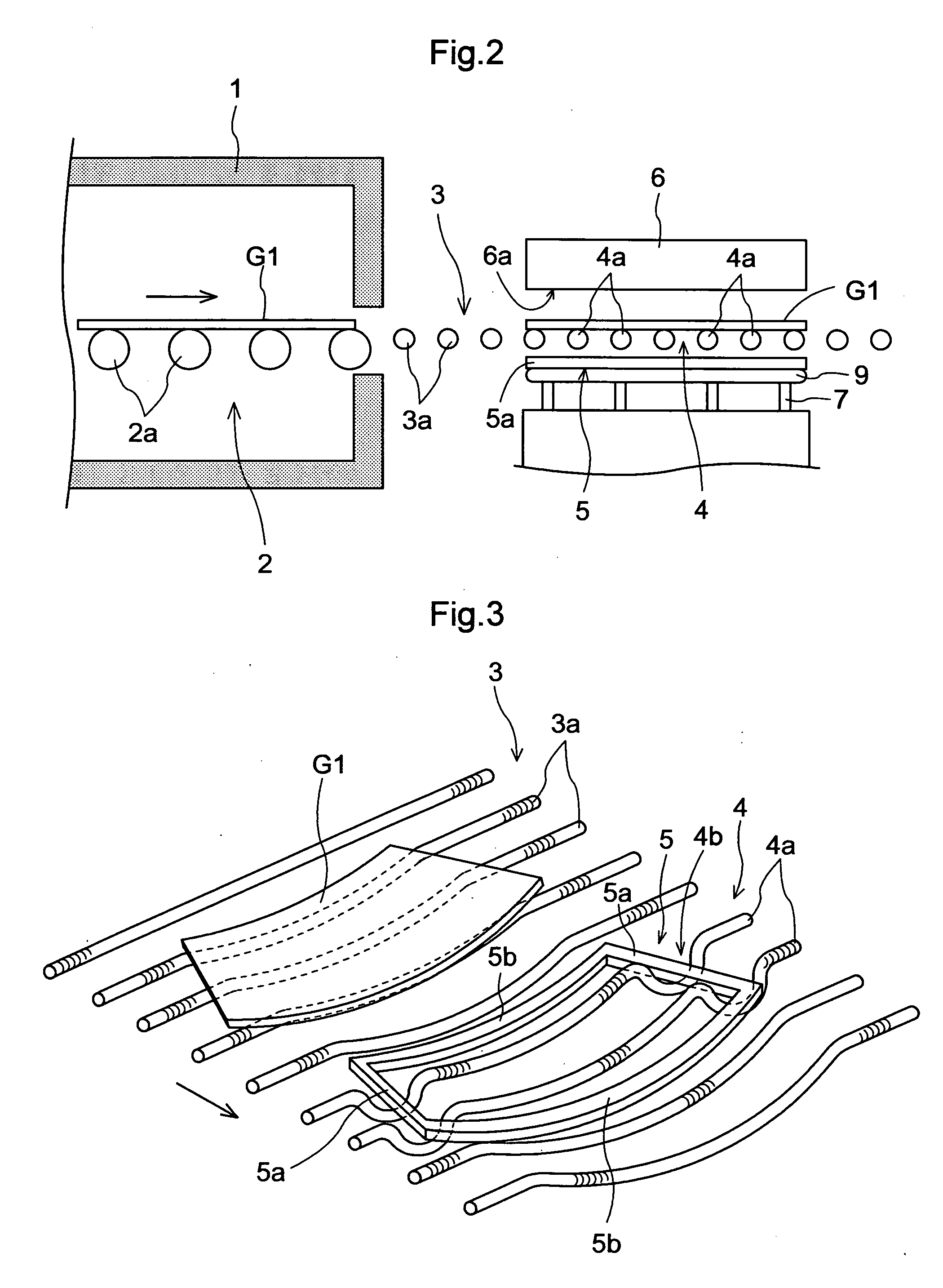

Curved glass plate

InactiveUS20050266247A1Likely can be damagedAvoid damageGlass/slag layered productsGlass reforming apparatusEngineeringGlass sheet

A carved glass plate ha a curved peripheral spice portion where R1×R2 is 1,500,000 m2 or less, R1 being a radius of curvature determined in a direction parallel to an edge of the glass plate, R2 being a radius of curvature determined in a direction normal to the direction. The curved peripheral surface portion includes a residual plane compressive stress zone and a residual plane tensile stress zone on the inner side of the residual plane compressive stress zone, the residual plane tensile stress zone having a tensile stress value below 8 MPa The glass plate has also a central portion located on the inner side of the residual plane tensile stress zone. This entire central zone is a residual surface compressive stress zone having a residual surface compressive stress value ranging from 10 MPa to 30 MPa.

Owner:NIPPON SHEET GLASS CO LTD

Manufacturing technique of stereoscopic underglaze multicolor ceramic

The invention relates to a manufacturing technique of stereoscopic underglaze multicolor ceramic, which comprises the following steps: carrying out ball milling on a selected ceramic raw material, screening, slurrying, carrying out injection forming on a mold to obtain a required shape, preparing a blank, and carrying out bisque firing to obtain a biscuit; carving out a stereoscopic multilayer plain color picture on the biscuit with a carving tool; dipping a drawing tool into underglaze multicolor pigments, and drawing and decorating on the stereoscopic picture of the biscuit to obtain a colored biscuit; carrying out color depth gradation treatment on the picture of the colored biscuit by using a special brush; and covering a glaze layer on the surface of the colored biscuit subjected to color treatment; and firing the glaze-covered colored biscuit in a kiln again to obtain the finished product. The technique adopts the two modes of biscuit carving and mold carving. The ceramic article prepared by the technique has the advantages of strong stereoscopic effect, abundant colors, high color layering effect and glossy and bright glaze.

Owner:HUNAN NEW CENTURY CERAMICS

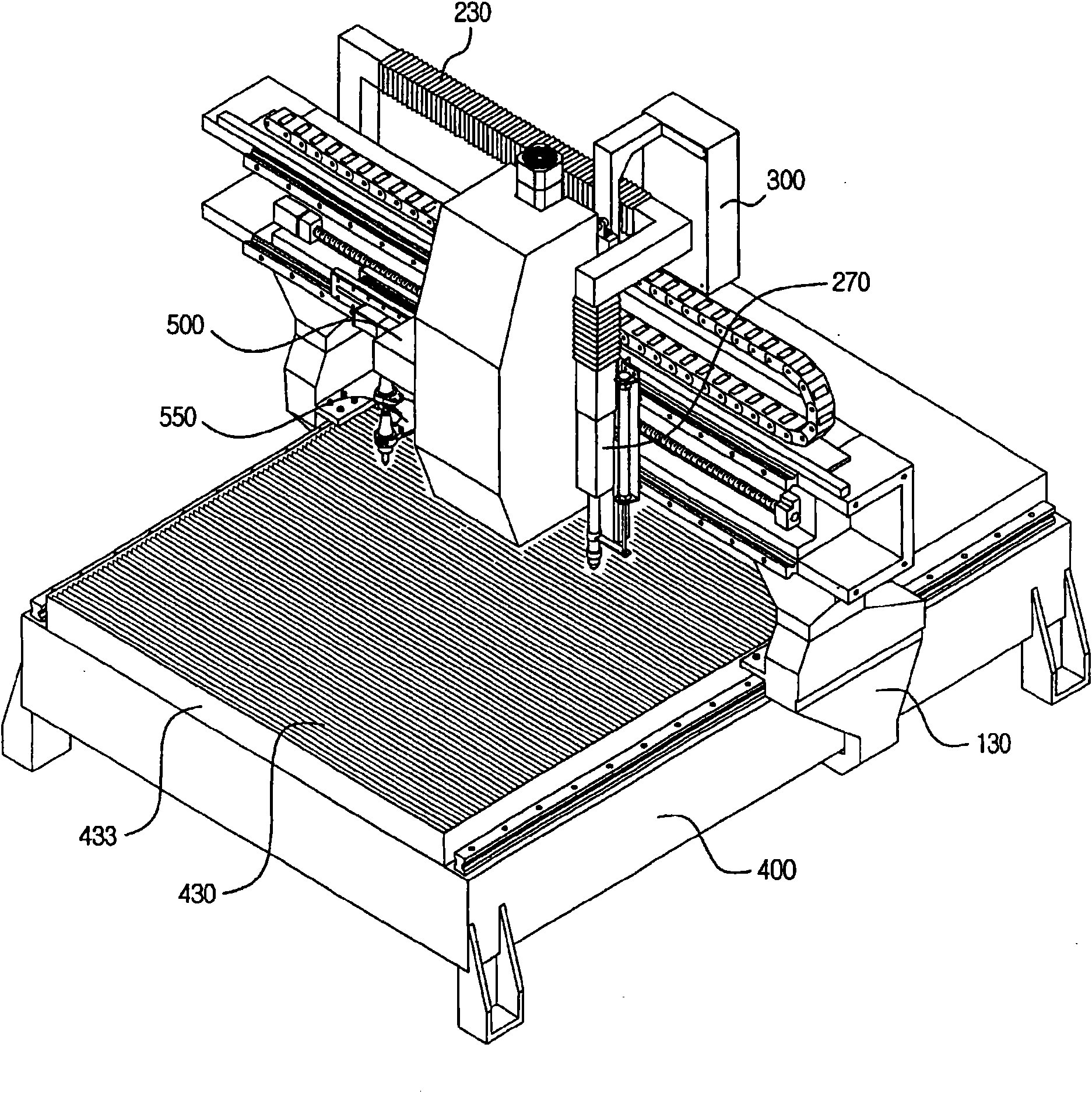

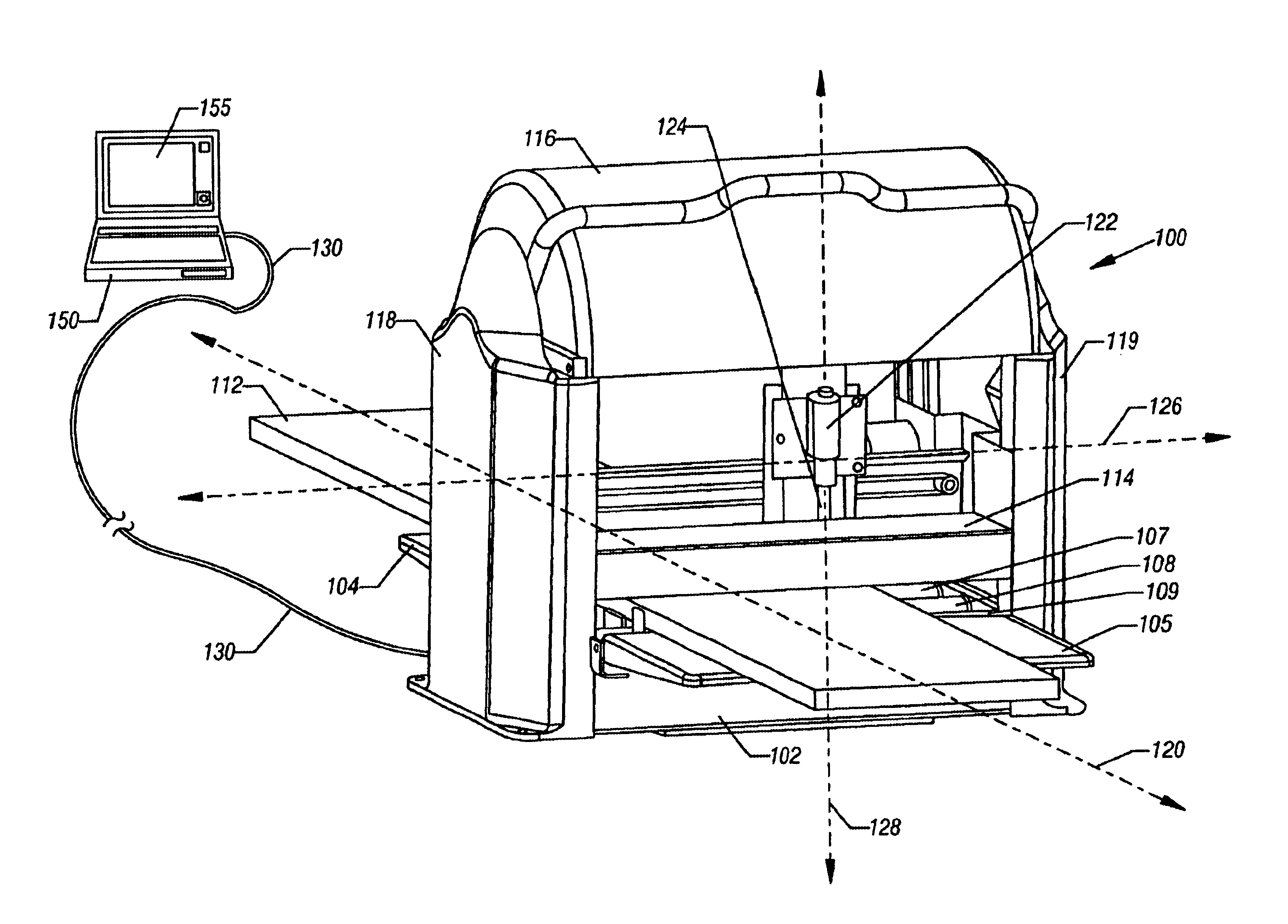

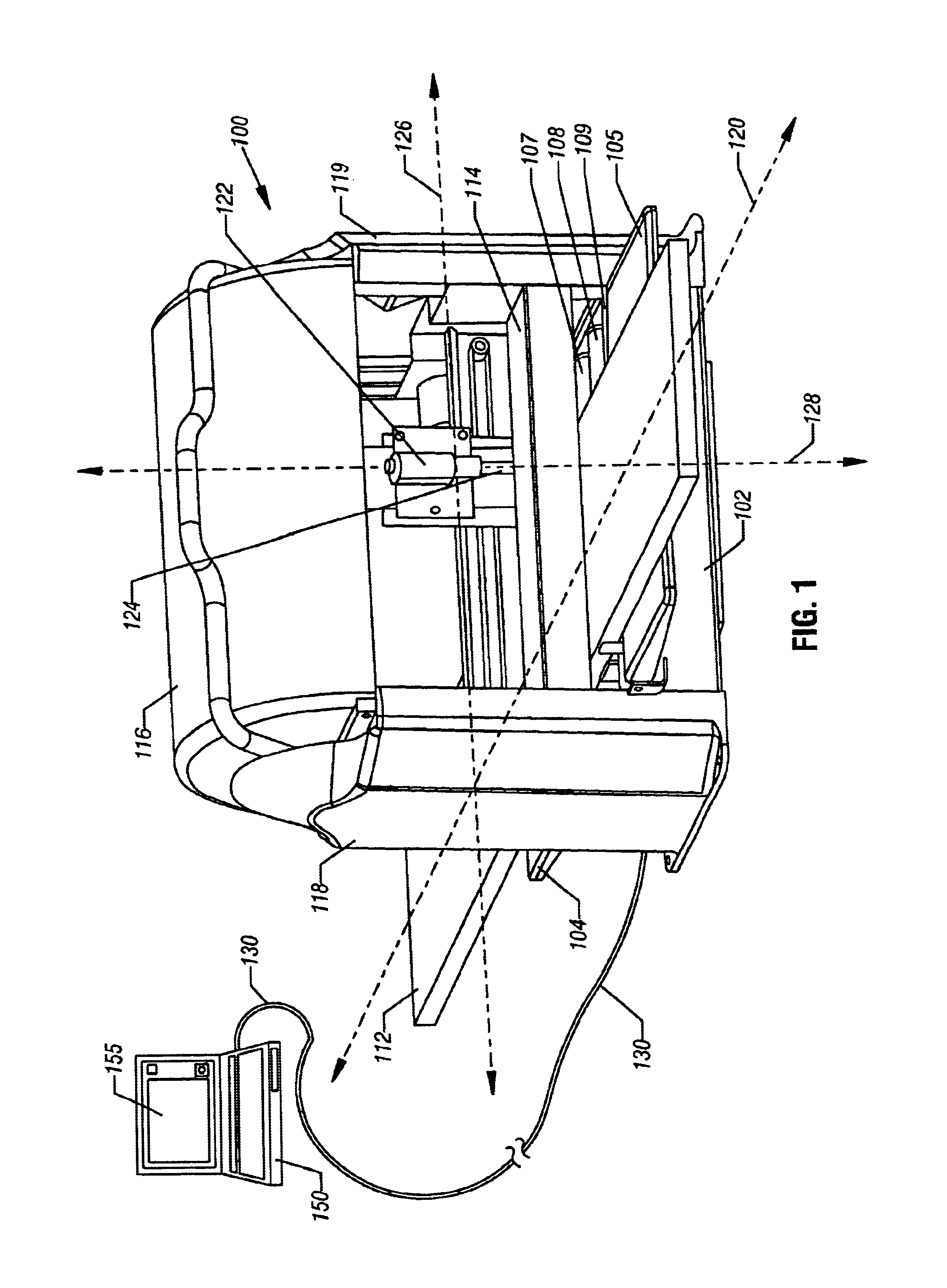

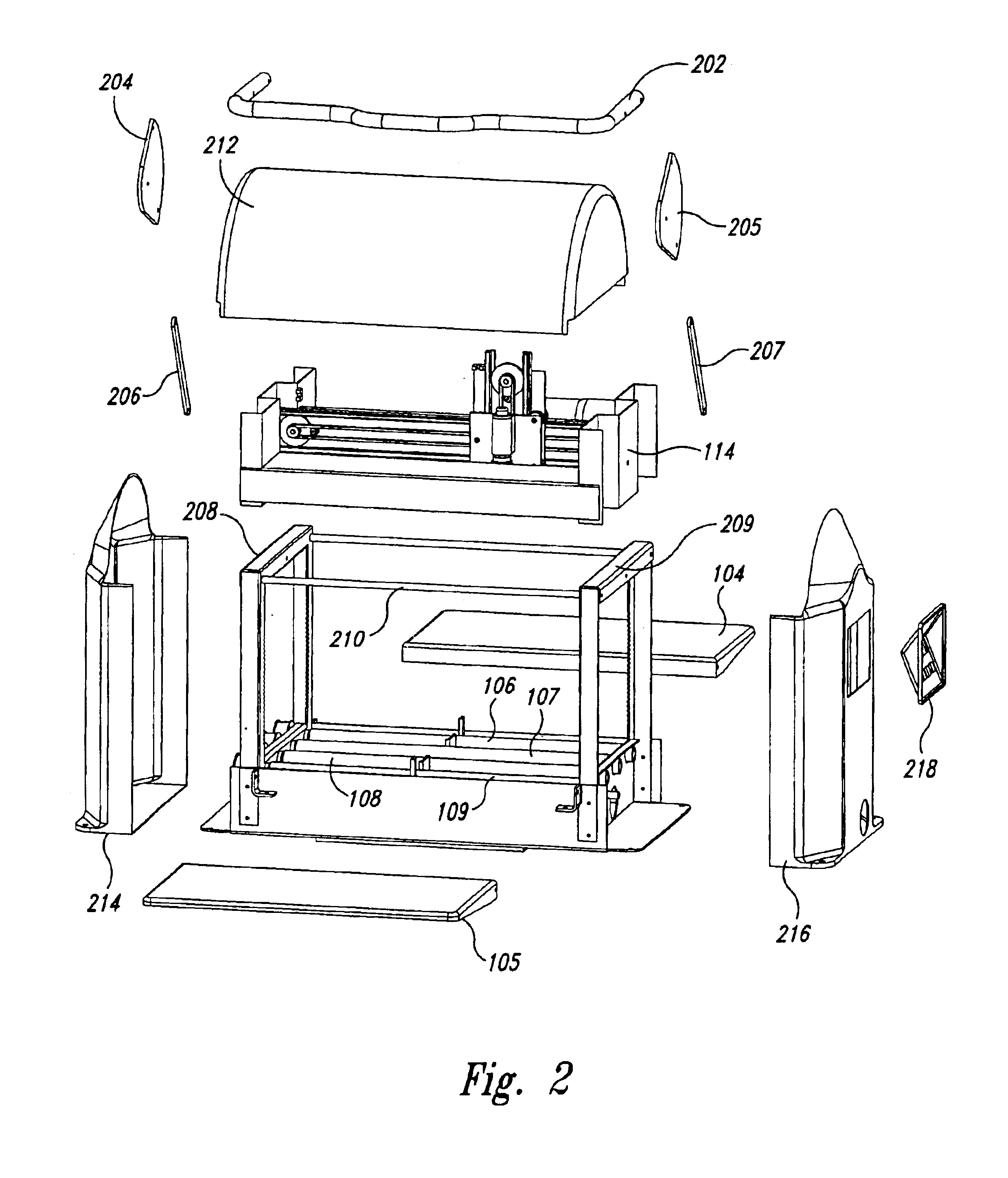

Processor-controlled carving and multi-purpose shaping device

InactiveUS6859988B2Easy to operateFineness is limitedSawing apparatusGearingComputer printingEngineering

Owner:LHR TECH

Board carving machine

ActiveCN105562935AImprove machining accuracyNo manual controlLaser beam welding apparatusEngineeringCarving

The invention discloses a board carving machine. The board carving machine comprises a base; the base is fixedly mounted on the ground; a movable worktable mechanism is arranged on the surface of the base; a door-shaped bracket is arranged above the base; the bottom ends of stand columns of the door-shaped bracket are fixedly mounted on parts, on two sides of the base, of the ground; a through groove is formed in the upper surface of a cross beam of the door-shaped bracket in the length direction; concave grooves as long as the through groove are respectively formed in the upper surface of parts, on two sides of the through groove, of the cross beam; slide mechanisms are mounted in the concave grooves; lifting rotating mechanisms are fixedly mounted at the lower ends of the slide mechanisms; a multi-arm carving mechanism is fixedly mounted below the lifting rotating mechanism; a controller is arranged on the surface of one stand column of the door-shaped bracket; and the controller is electrically connected with the movable worktable mechanism, the slide mechanisms, the lifting rotating mechanisms and the multi-arm carving mechanism. The board carving machine has the beneficial effects of simple structure and high practicability.

Owner:广东沃维伽家居科技有限公司

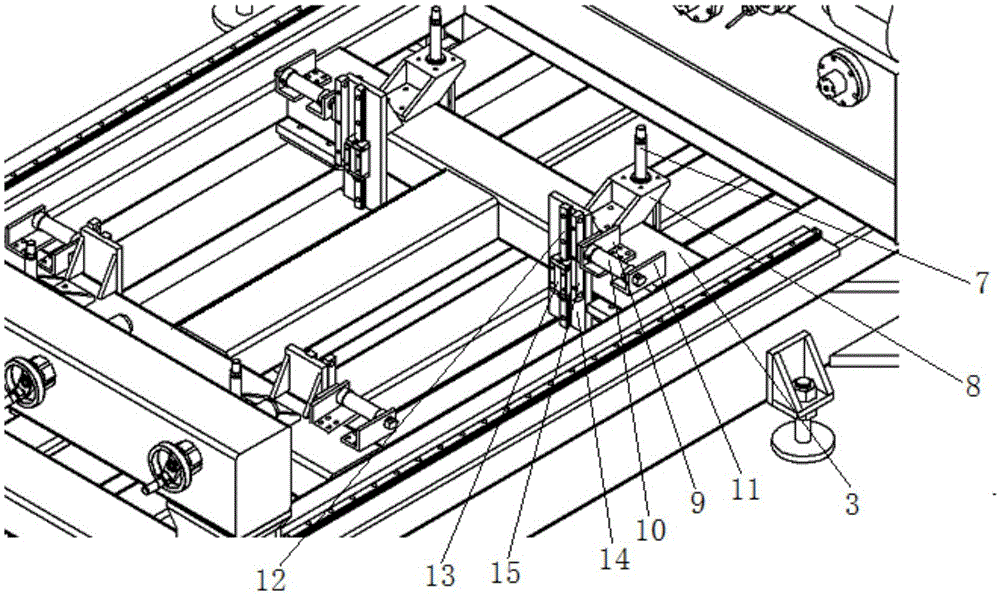

Multifunctional carving machine

ActiveCN105620148AHigh degree of automationWide range of usesModel makingEngravingMarine engineeringMachining

The invention relates to the field of machining, in particular to a multifunctional carving machine which comprises a base, stand columns, a carving platform and a cutter mechanism. The carving platform comprises a movable platform and a workpiece clamping device; an automatic lifting platform is arranged on the movable platform, and comprises a platform board, a platform board lifting rack and automatic platform board lifting mechanisms; the automatic platform board lifting mechanisms are fastened on a cross beam in the middle of the movable platform; the platform board lifting rack is fixed to the automatic platform board lifting mechanisms; and the platform board is fixed to the platform board lifting rack. The multifunctional carving machine is additionally provided with the platform board capable of being lifted automatically on the basis of an existing high-precision three-dimensional carving machine; the lifting platform can be automatically lifted through program codes, and the platform board is lifted up when a plane is carved and is automatically lifted down when a three-dimensional structure is carved. The multifunctional carving machine is high in automation degree, wide in application and convenient and safe to operate.

Owner:NANTONG OUKE CNC EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com