Manufacturing method of oriented silicon steel sheets for low-noise transformer

A technology of oriented silicon steel and manufacturing method, which is applied in the manufacture of inductors/transformers/magnets, parts of transformers/inductors, manufacturing tools, etc., can solve problems such as magnetic flux leakage, achieve broad application space, convenient operation and maintenance, and good application sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] (1) Laser scoring before decarburization annealing

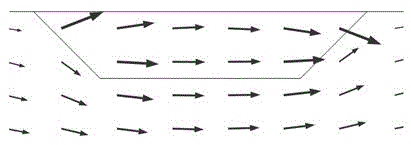

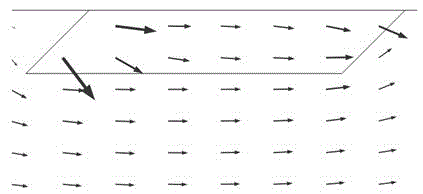

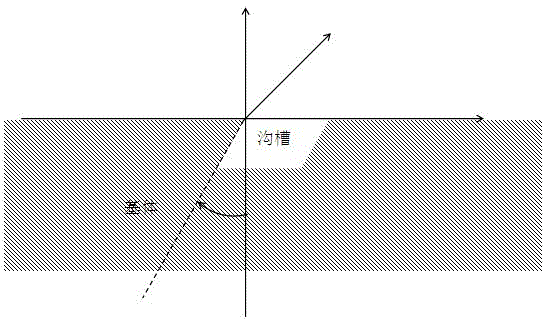

[0073] Oriented silicon steel undergoes ironmaking, steelmaking, continuous casting, hot rolling, and then one cold rolling to a final thickness of 0.25 mm. Linear micro-grooves are scored on its surface with a laser with a pulse width of 10 nanoseconds. The laser output power is 200W, the light wavelength is 1030nm, and the repetition frequency is 100KHz. The light spot focused on the surface of the steel plate is elliptical. According to formula Calculated single pulse instantaneous peak power density 8.0×10 6 W / mm 2 , by adjusting the scanning speed and the number of scans to control the total energy injected by the laser into the unit score line length on the steel plate surface, so as to control the size of the formed groove; adjust the groove shape by adjusting the incident angle of the laser beam.

[0074] The above laser beam forms oblique quadrilateral or inverted trapezoidal linear grooves on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com