Patents

Literature

1671results about How to "Strong magnetism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

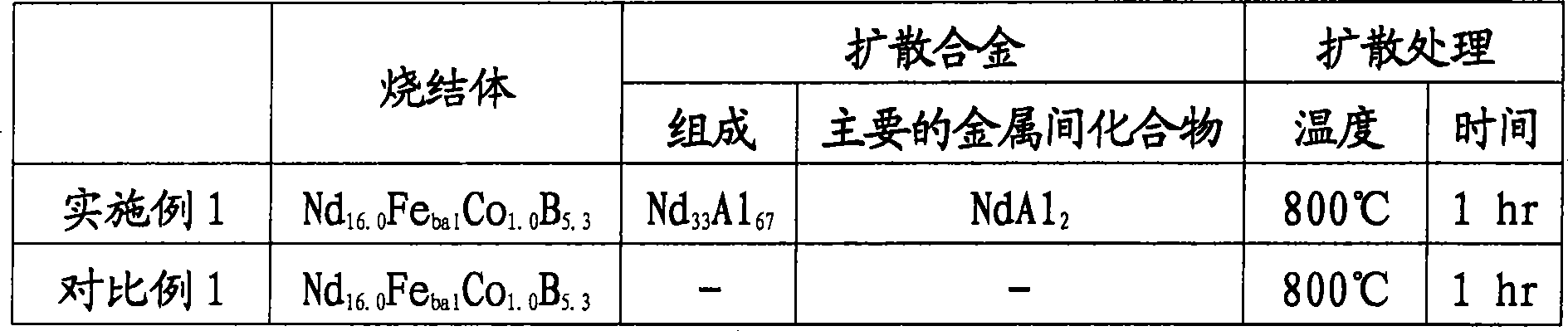

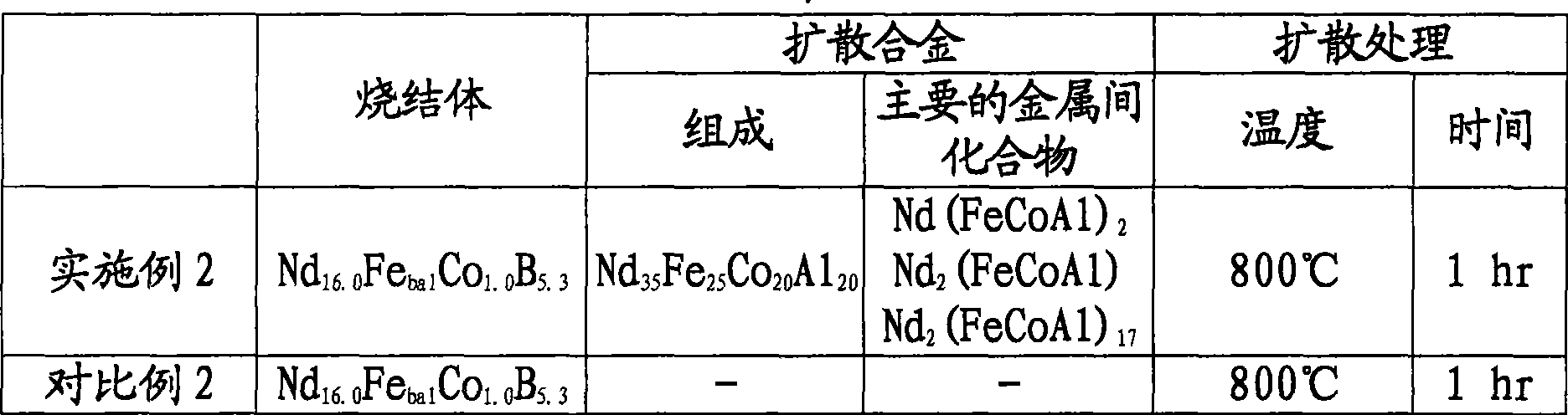

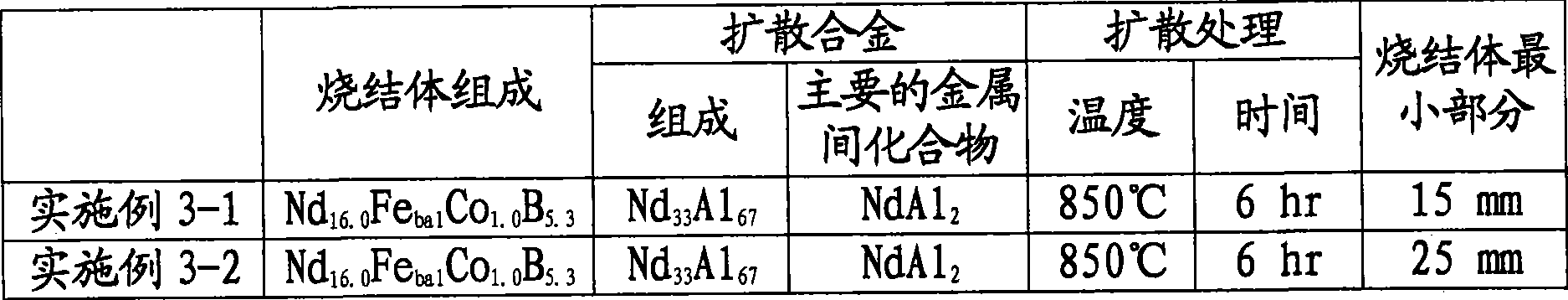

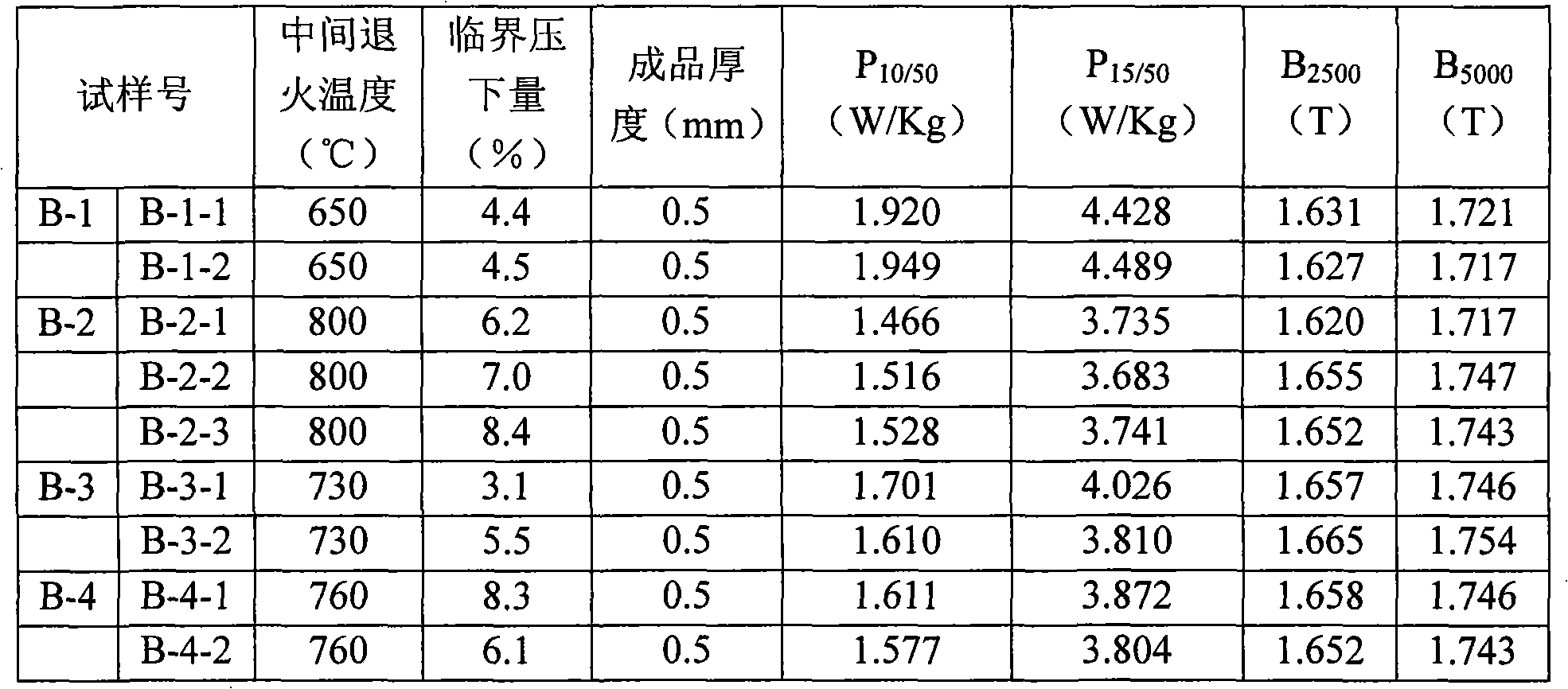

Rare earth permanent magnet and method of manufacturing the same

ActiveCN101521068AImprove productivityStrong magnetismInorganic material magnetismInductances/transformers/magnets manufactureProduction rateMetal alloy

A rare earth permanent magnet is prepared by disposing a powdered metal alloy containing at least 70 vol% of an intermetallic compound phase on a sintered body of R-Fe-B system, and heating the sintered body having the powder disposed on surface thereof below the sintering temperature of the sintered body in vacuum or in an inert gas for diffusion treatment. The advantages include efficient productivity, excellent magnetic performance, a minimal or zero amount of Tb or Dy used, an increased coercive force, and a minimized decline of remanence.

Owner:SHIN ETSU CHEM IND CO LTD

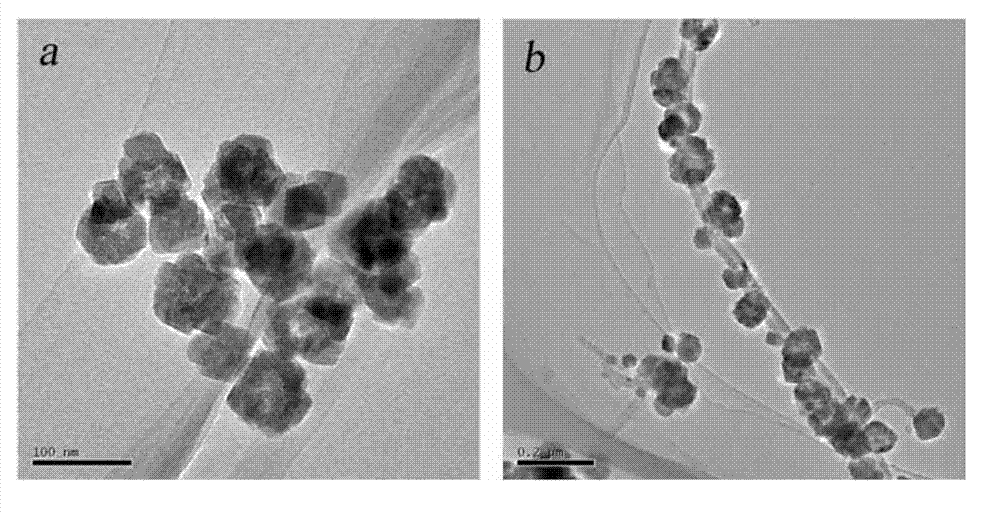

Method for preparing heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet

ActiveCN101521069AImprove coercive forceNot easily oxidizedInorganic material magnetismRare-earth elementDehydrogenation

The invention discloses a method for preparing a heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet, which belongs to the technical field of magnetic materials. The prior preparation method improves the coercive force and the temperature stability of magnets by adding heavy rare earth elements, namely terbium or dysprosium into master alloy, but the method can cause the residual magnetism of the magnets, the reduction of magnetic energy product and the increase of manufacturing cost. The method adopts heavy rare earth terbium hydride and dysprosium hydride nano-powder doping technology to prepare the sintered NdFeB permanent magnet with high coercive force and excellent magnetic property. The method comprises the following steps: preparing NdFeB powder by a rapidly solidified flake process and a hydrogen decrepitation process; preparing the terbium hydride or the dysprosium hydride nano-powder by physical vapor deposition technology; mixing the two powders, and performing magnetic field orientation and press forming; and performing dehydrogenation treatment, sintering and heat treatment on a green compact at different temperatures, and obtaining the sintered magnet. The coercive force of the magnet prepared by the method is higher than that of the prior sintered magnet with the same ingredients; and compared with the sintered magnet with the equivalent coercive force, the proportion of the terbium and dysprosium needed by the magnet prepared by the method is remarkably reduced.

Owner:BEIJING UNIV OF TECH

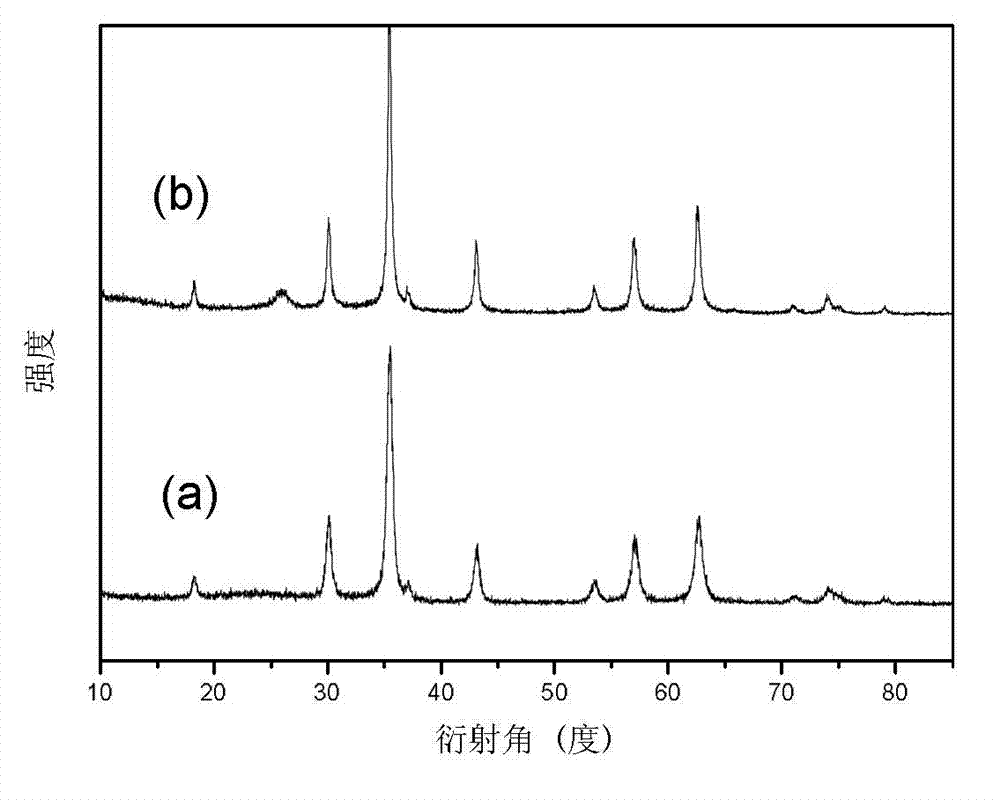

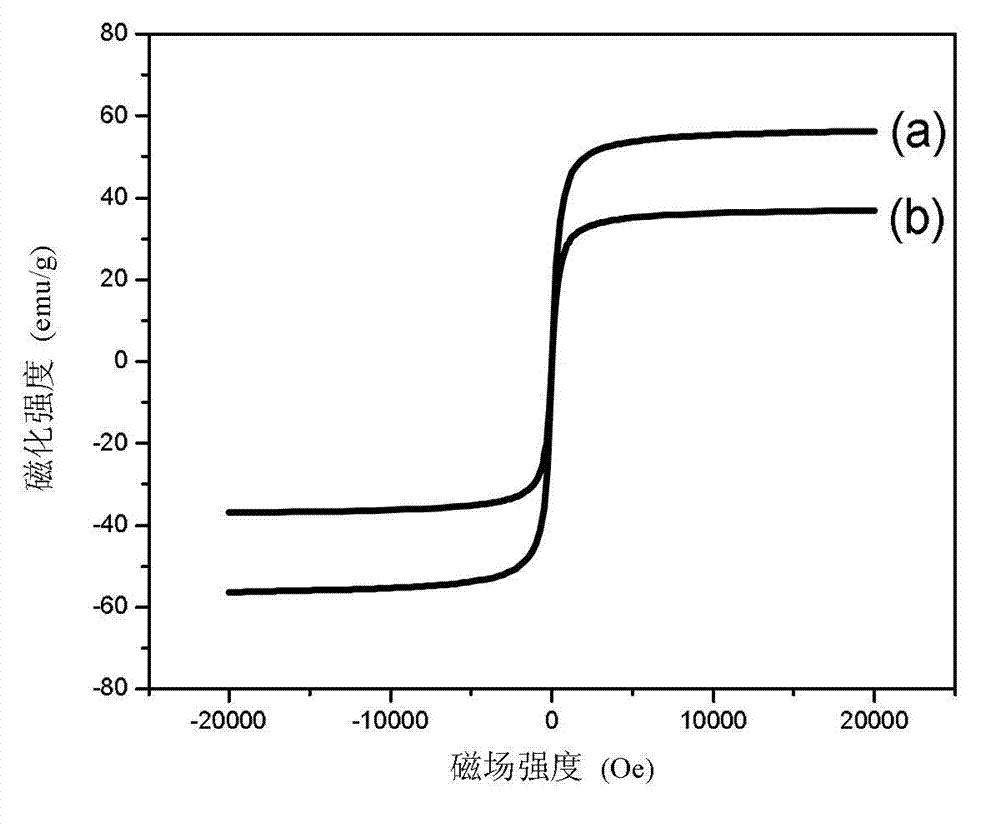

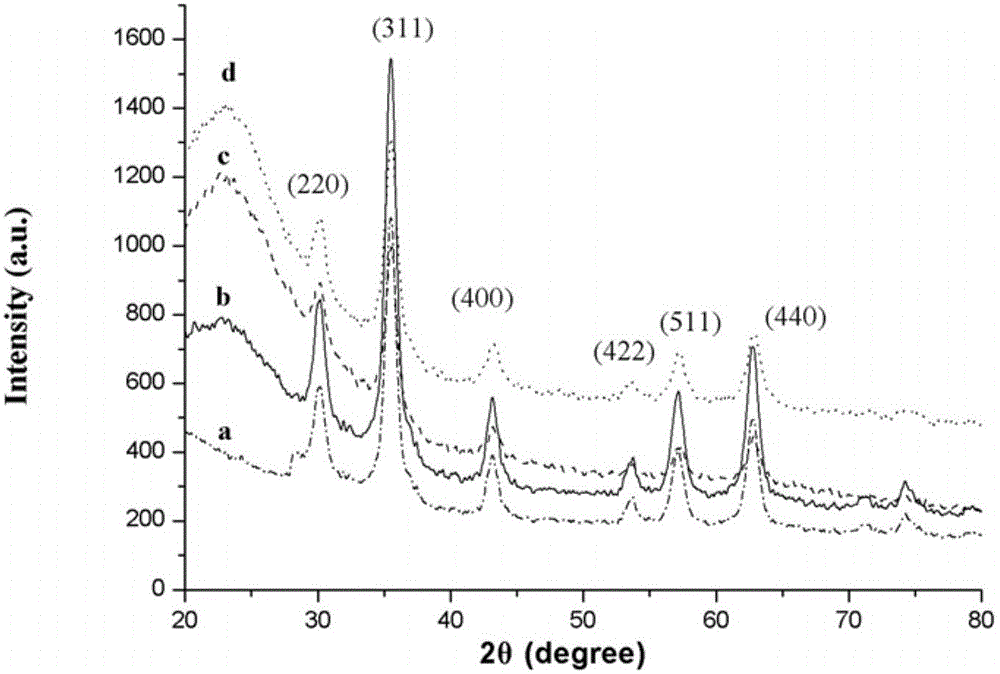

Magnetic carbon nanotube composite material and preparation method and application thereof

InactiveCN103041773AImprove bindingEasy to separateIon-exchange process apparatusComponent separationSorbentHexamethylenediamine

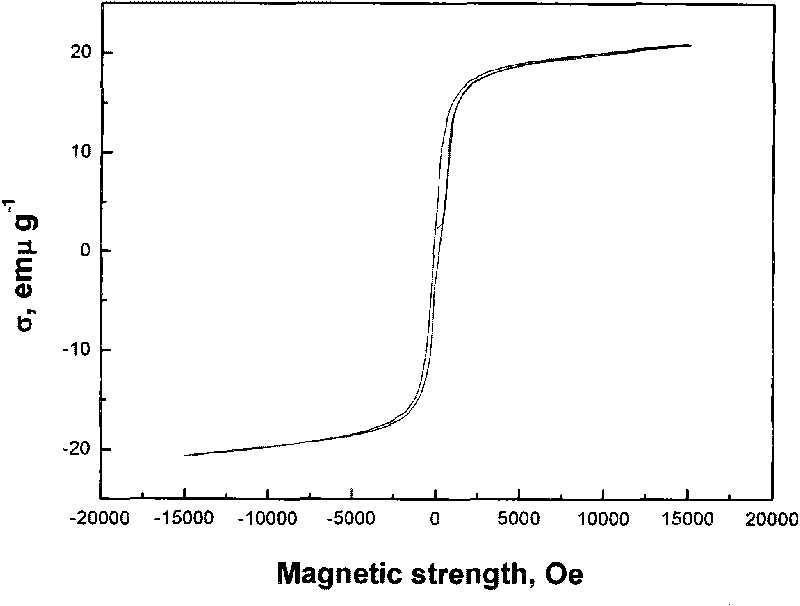

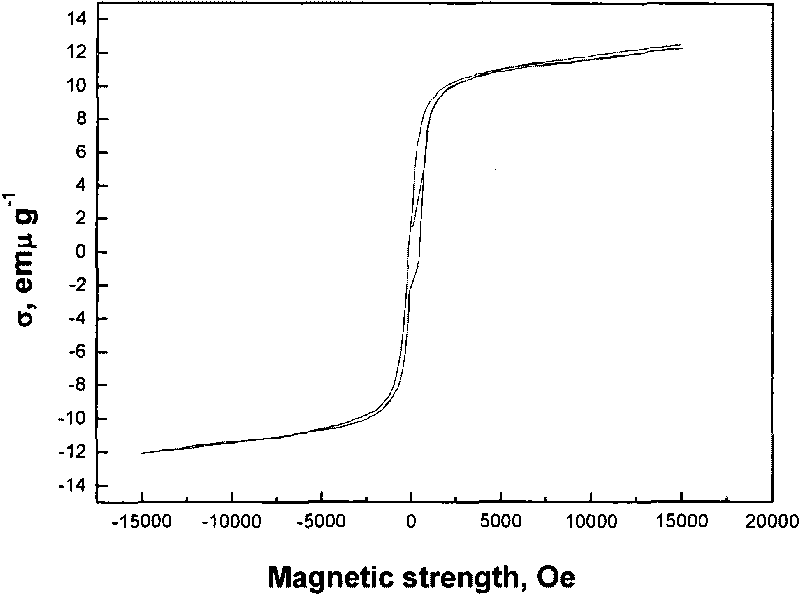

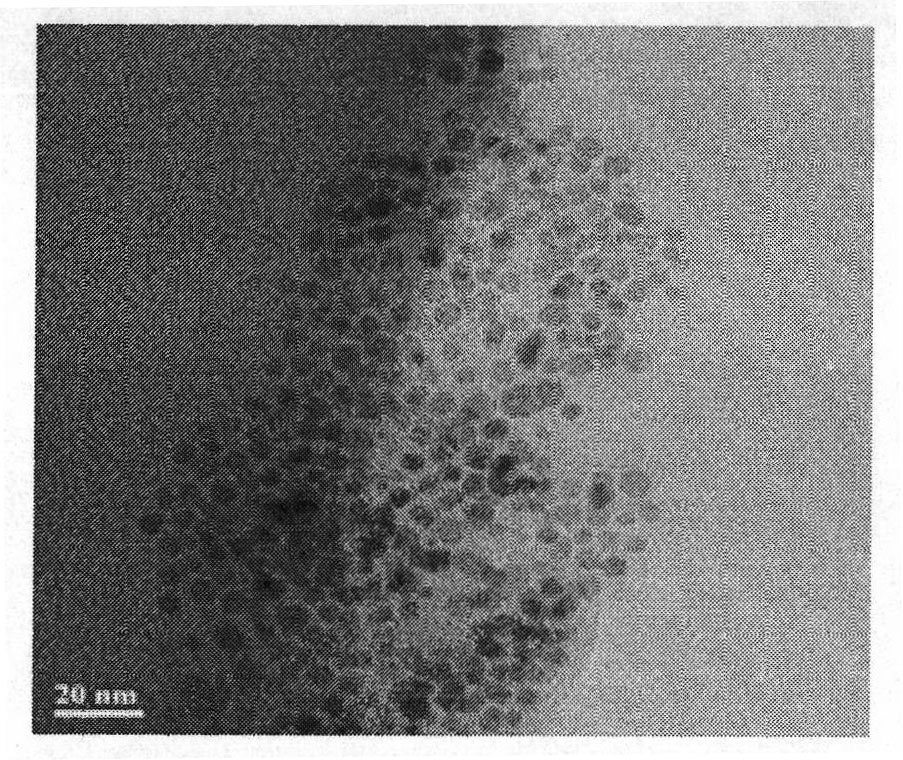

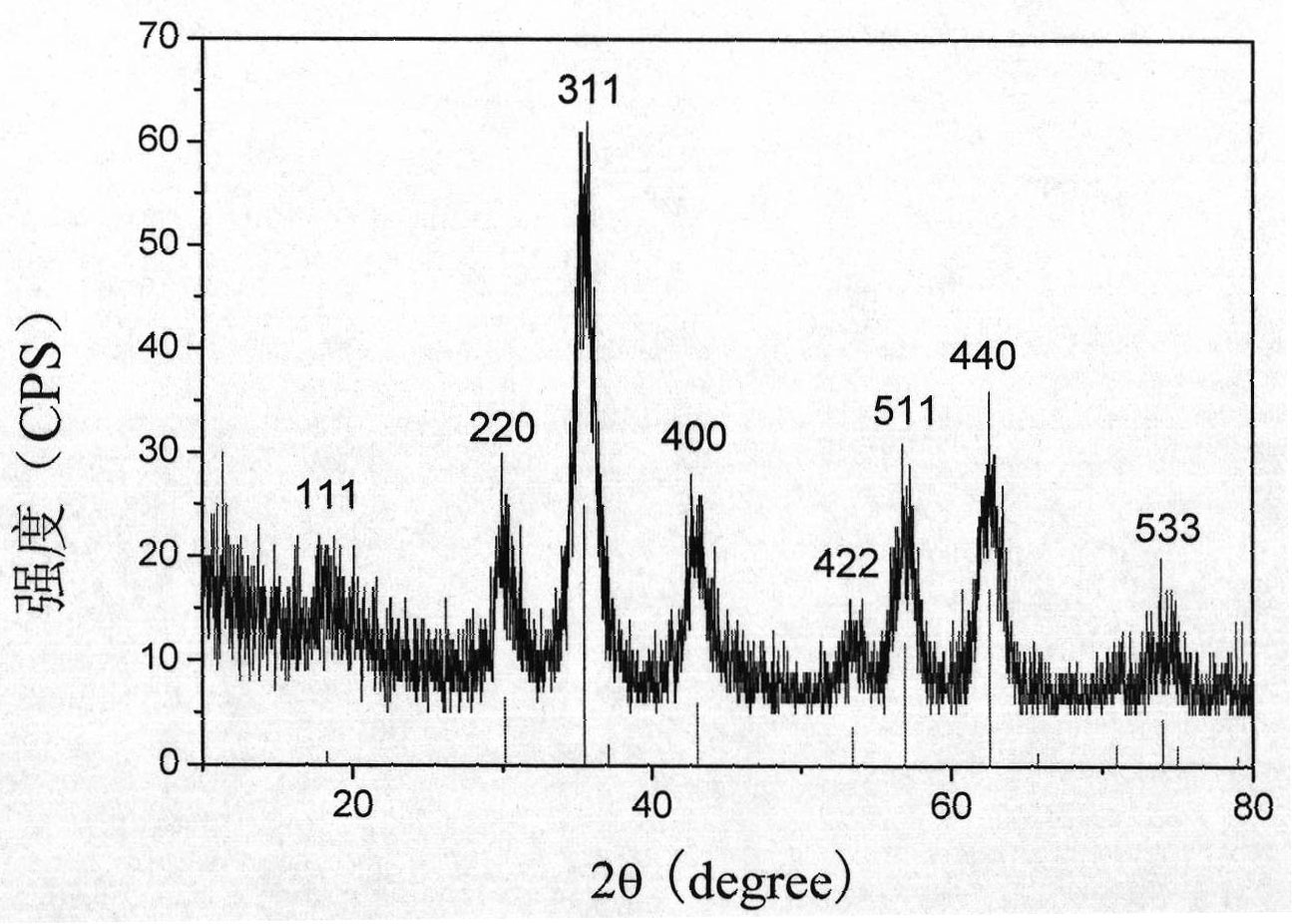

The invention discloses a magnetic carbon nanotube composite material and a preparation method and an application thereof. The preparation method comprises the following steps: adding FeCl3.6H2O to an ethylene glycol solution; then adding anhydrous sodium acetate and polyethylene glycol; adding a carboxylated multiwalled carbon nanotube; performing ultrasonic dispersion; adding hexamethylenediamine or ethanediamine; heating to 200-300 DEG C for reaction for 8-24h; and washing and performing vacuum drying to prepare the amino-modified magnetic Fe3O4-carbon nanotube composite material. The amino-modified magnetic Fe3O4-carbon nanotube composite material prepared by the invention is of nanoscale and superparamagnetism, can be stably dispersed in solutions, and can be quickly separated and enriched through a simple action of a magnetic field. As an adsorbent, the material is large in superficial area and has various active groups on the surface. The material can adsorb pigments from complex substrates through pi-pi electron interaction and hydrophobic effect of the carbon nanotube and can adsorb compounds such as organic acids and phenols through weak anion exchange effect of amino groups on the surfaces of magnetic nanoparticles.

Owner:TIANJIN UNIV

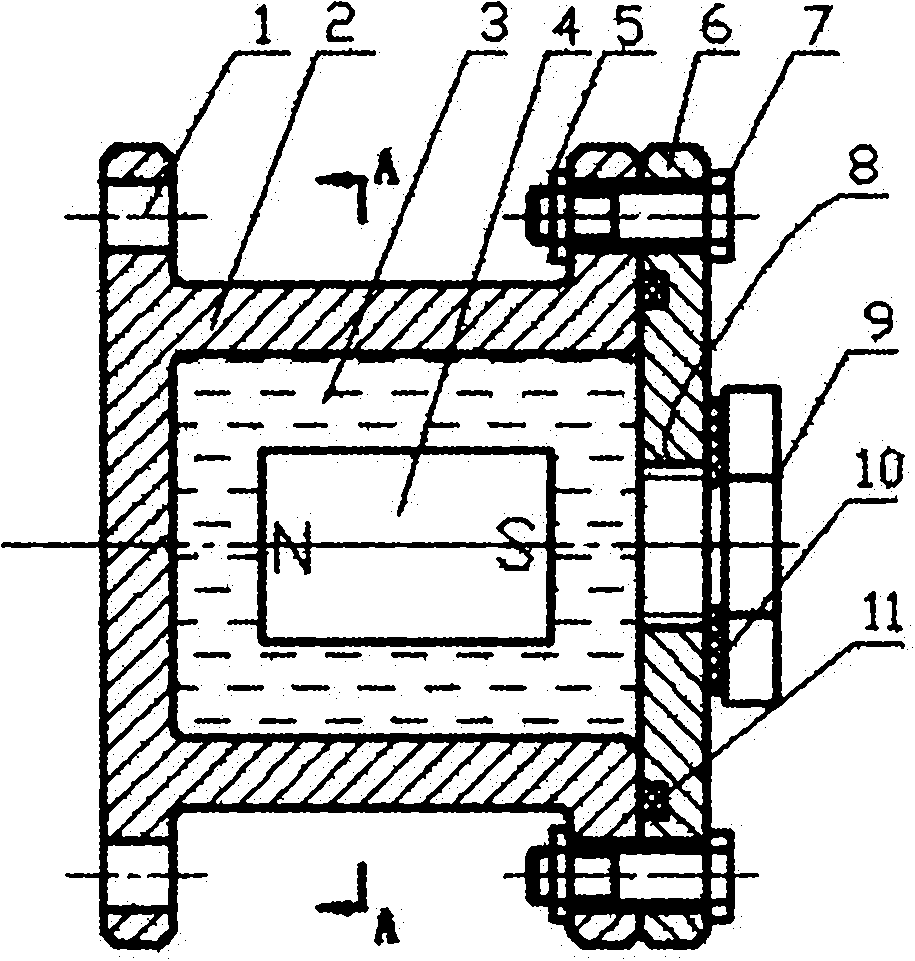

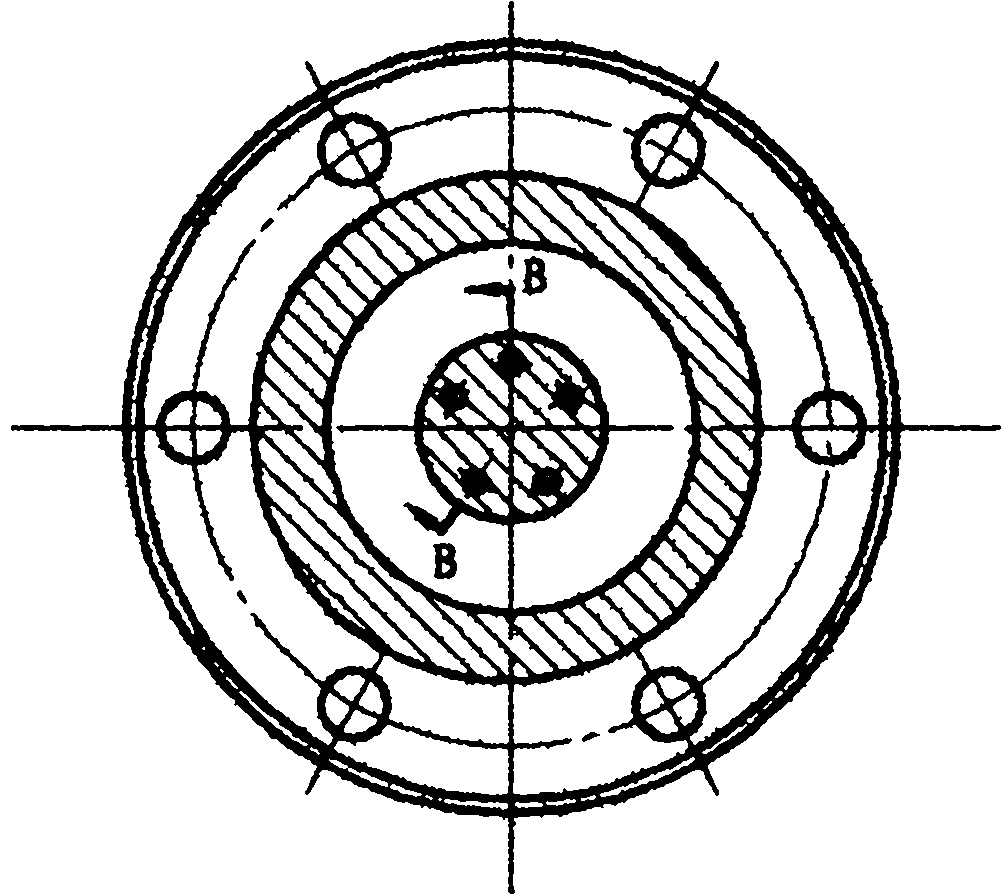

Magnetic liquid damping device

InactiveCN102042359AStrong magnetismIncrease the friction surfaceMagnetic springsMagnetic liquidsMagnet

The invention discloses a magnetic liquid damping device, relates to a damping device and aims to solving the damping problem of a longer object in a spacecraft. The device consists of a non-magnetic conducting shell (2), magnetic liquid (3), a permanent magnet (4), a nut (5), an end cover (6), a bolt (7), a screw (9), a sealing gasket (10) and an O-shaped seal ring (11), wherein the parts are connected together; the permanent magnet (4) is arranged in the cavity of the non-magnetic conducting shell (2); the end cover (6) with the O-shaped seal ring (11) is fixed on one end of the non-magnetic conducting shell (2) through the bolt (7) and the nut (5); the magnetic liquid (3) is filled in the cavity of the non-magnetic conducting shell (2) through a screwed hole (8); the screw (9) and the sealing gasket (10) are used for sealing; the permanent magnet (4) is a cylinder; and 4-8 through holes are distributed in the cylinder axially. The device disclosed by the invention has good damping effect.

Owner:BEIJING JIAOTONG UNIV

Non-oriented electrical steel produced by sheet continuous casting and rolling and method thereof

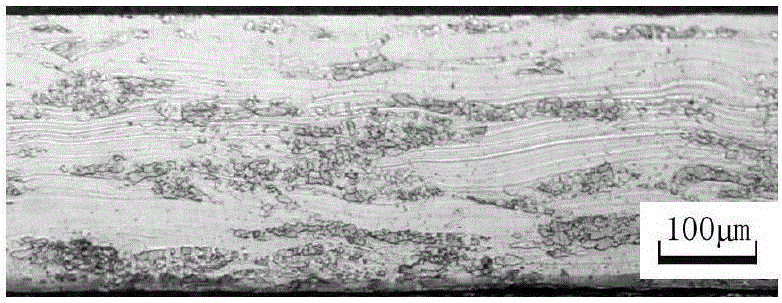

The invention relates to non-oriented electrical steel produced by sheet continuous casting and rolling and a method thereof. The steel contains the following components by in percentage of by weight: 0.0031%-0.01% of C, 1.0-1.7% of Si, 1.0-2.4% of Si+2Al, at mostnot less than 0.5% of Al, 0.5-1.5% of Mn, not less thanat most 0.10% of P, not less thanat most 0.008% of S, not less thanat most 0.005% of N, not less thanat most 0.008% of Ti, and not less thanat most 0.010% of Ca, wherein Si+2Al is 1.0-2.4%. The method comprises the following steps of: smelting and treating by in vacuum; continuously casting, and controlling the thickness of a casting blank to be thickness within 50-90mm; soaking, controlling the temperature of the casting blank to be 850-950 DEG C before entering the furnace; finish rolling; coiling at the temperature of 690-780 DEG C; prickling; cold rolling; decarburizing, and controlling at the temperature to of 800-920 DEG C; and coating or not coating as required by users. The invention has no need of additionally arranging equipment and the normalizing and secondary cold rolling of hot rolled plates, the magnetism of the steel plate is good, and the corrugated defect is not found in test.

Owner:武汉钢铁有限公司

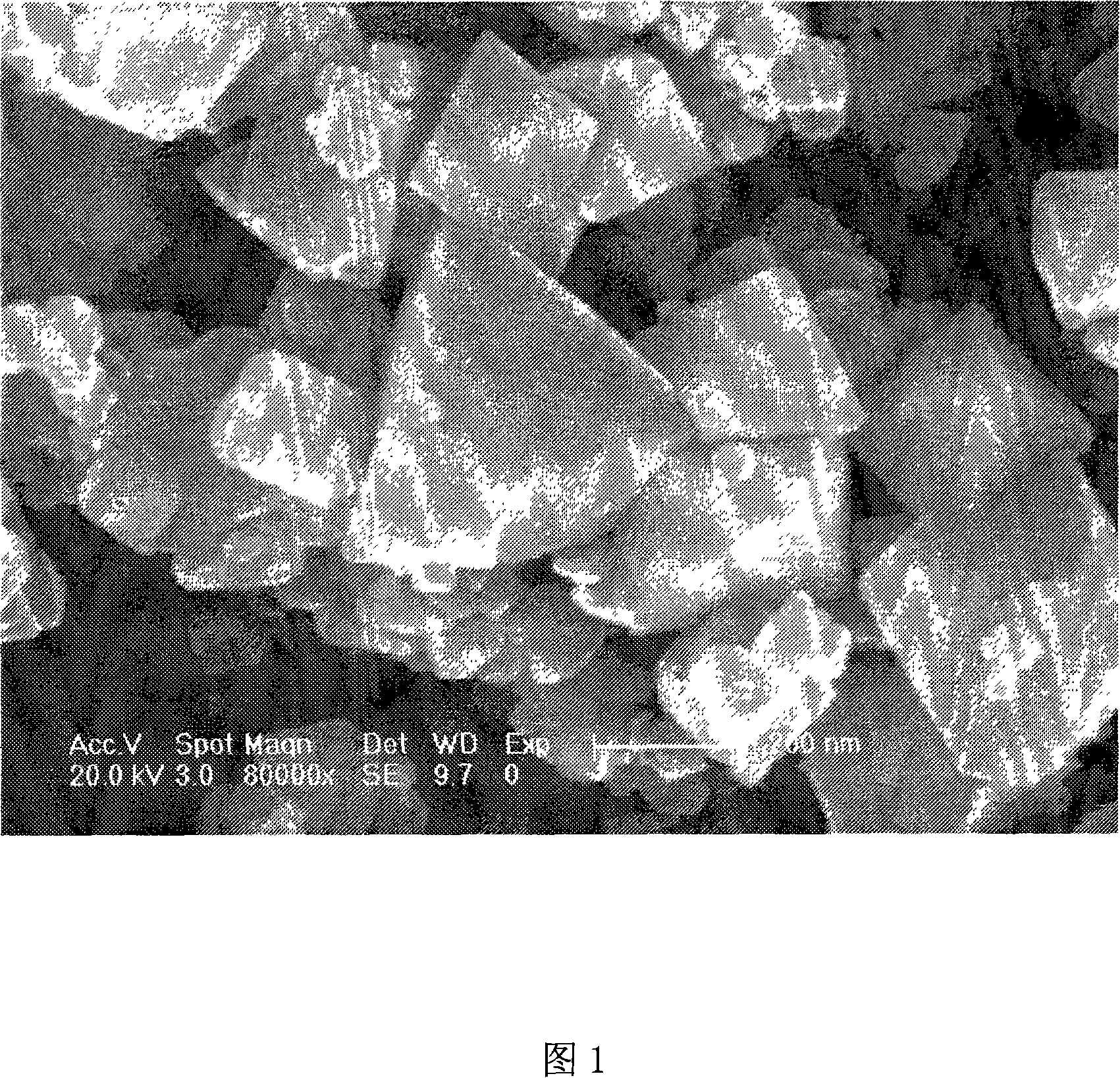

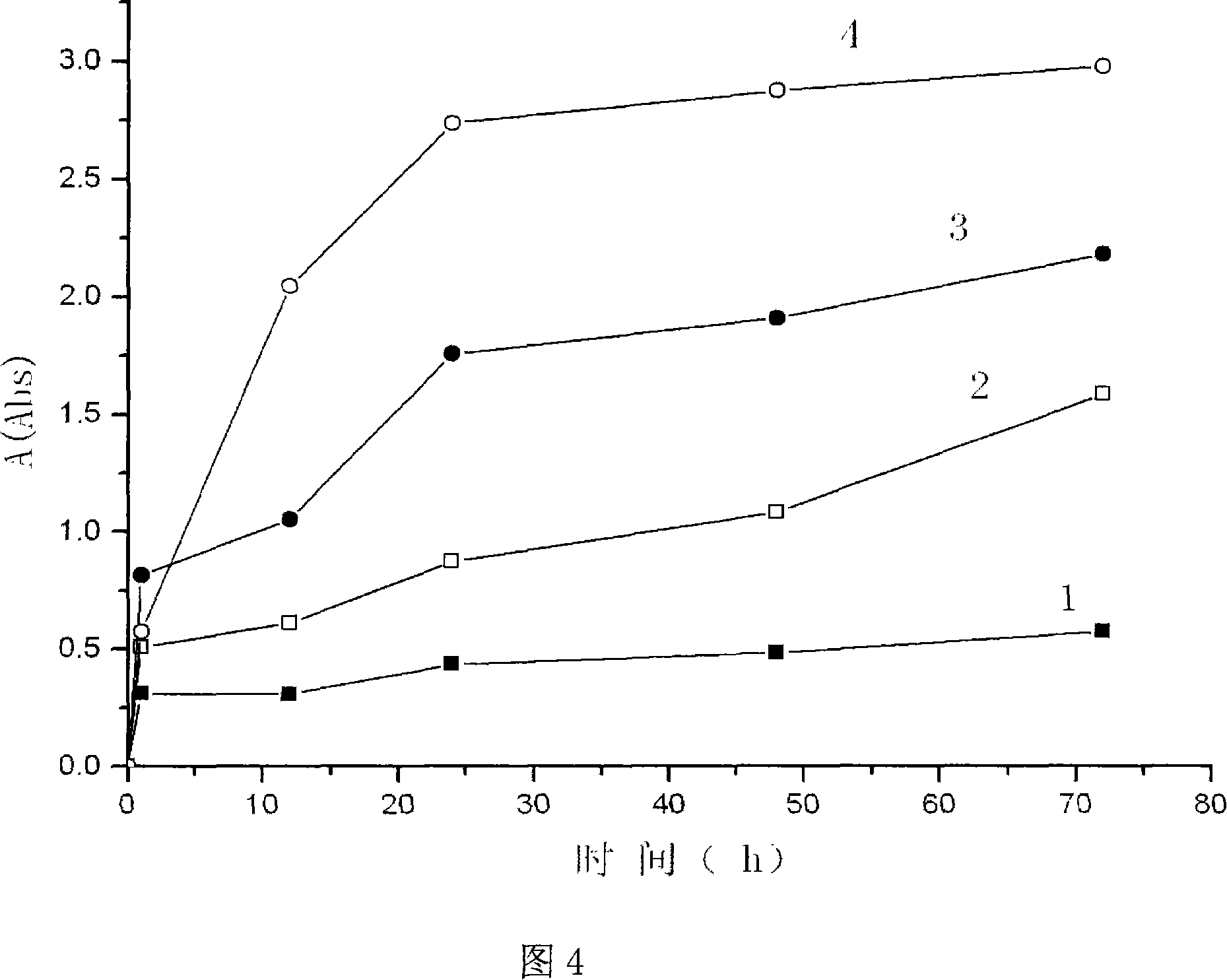

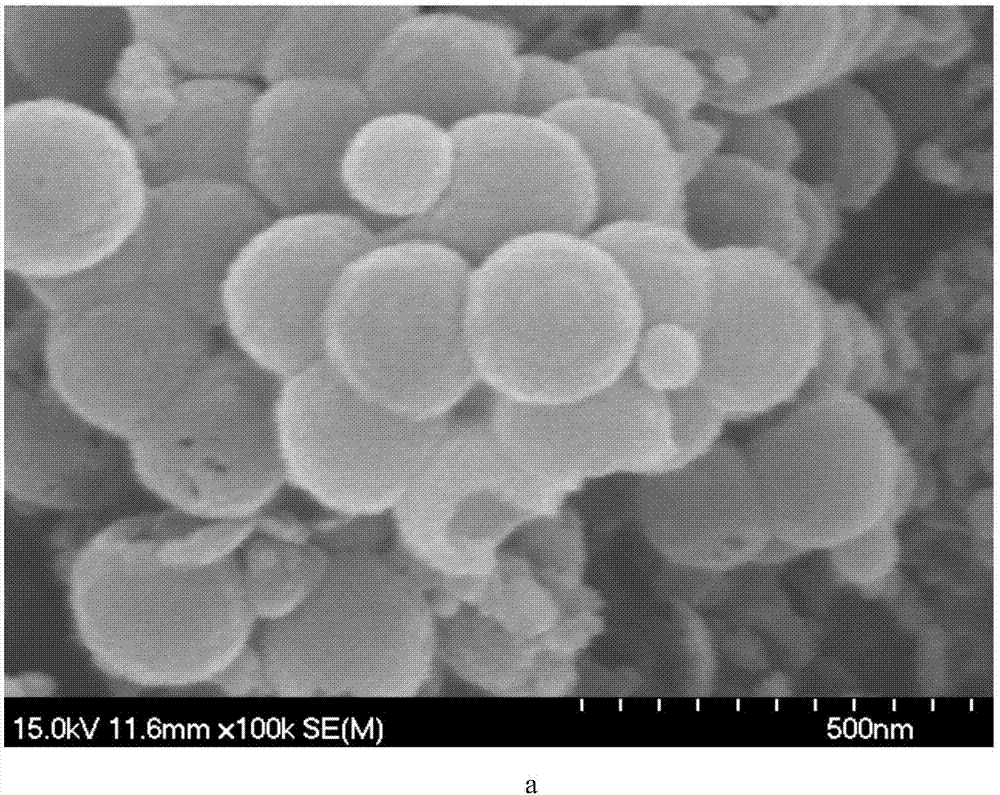

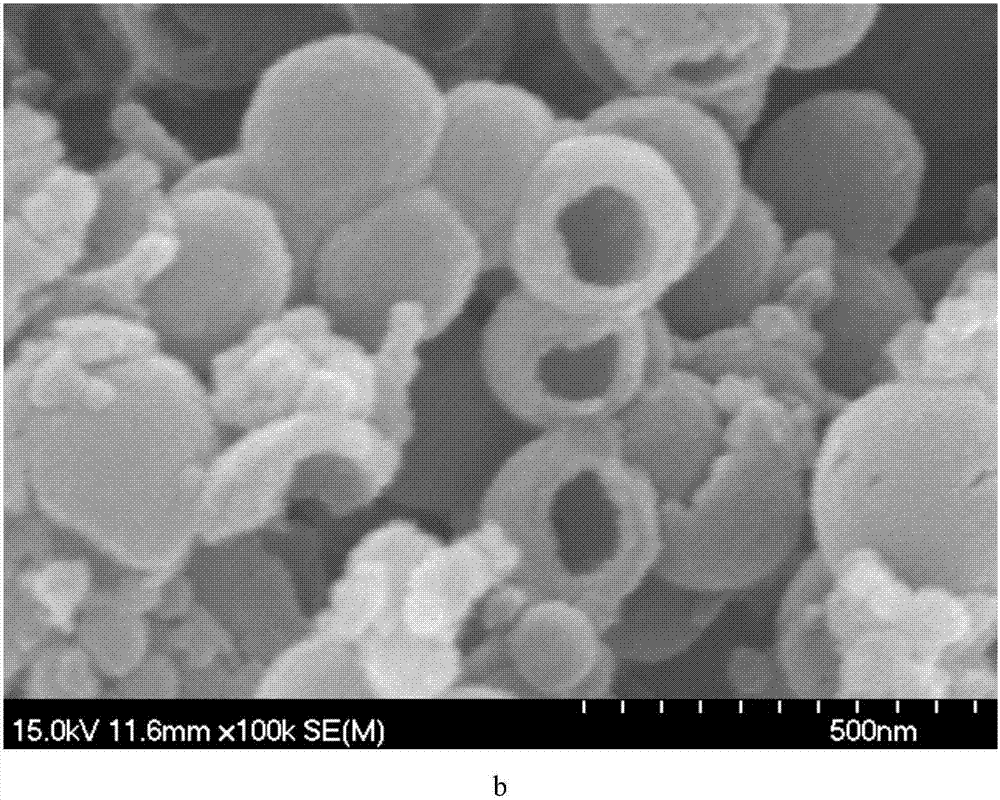

Functionalized silicon coating mesoporous magnetic carrier and preparation method and application thereof

InactiveCN101139127AHigh magnetic contentStrong magnetismOn/in inorganic carrierWater/sewage treatment by sorptionChemisorptionSilicon membrane

The present invention discloses a functionalized silicon coating mesoporous magnetic carrier. The carrier is a compound magnetic carrier having a core-shell structure formed by coating the magnetic ferroferric oxide with the silicon dioxide and an active amido or mercapto is bonded on the surface of the magnetic carrier and the active amido or mercapto can apply the selective chemisorption effect to the target chemical. The present invention simultaneously discloses a preparation method for the carrier, which in particular is that the thickness and uniformity of the silicon film are increased through two times of silicon coating processes so as to effectively protect the magnetic carrier from being corroded by acid and base in the application; the template agent on the surface of the carrier is detracted with high temperature under the inert atmosphere and the porecreating processing is applied to the surface of the carrier so as to increase the effective surface area of the carrier and enhance the processing performance. The fixed active bacterium for the funtionalized silicon coating mesoporous magnetic carrier can be applied in the treatment of the urban domestic sewage delivers good treatment effect and has important meaning to the environment protection.

Owner:SOUTH CHINA NORMAL UNIVERSITY

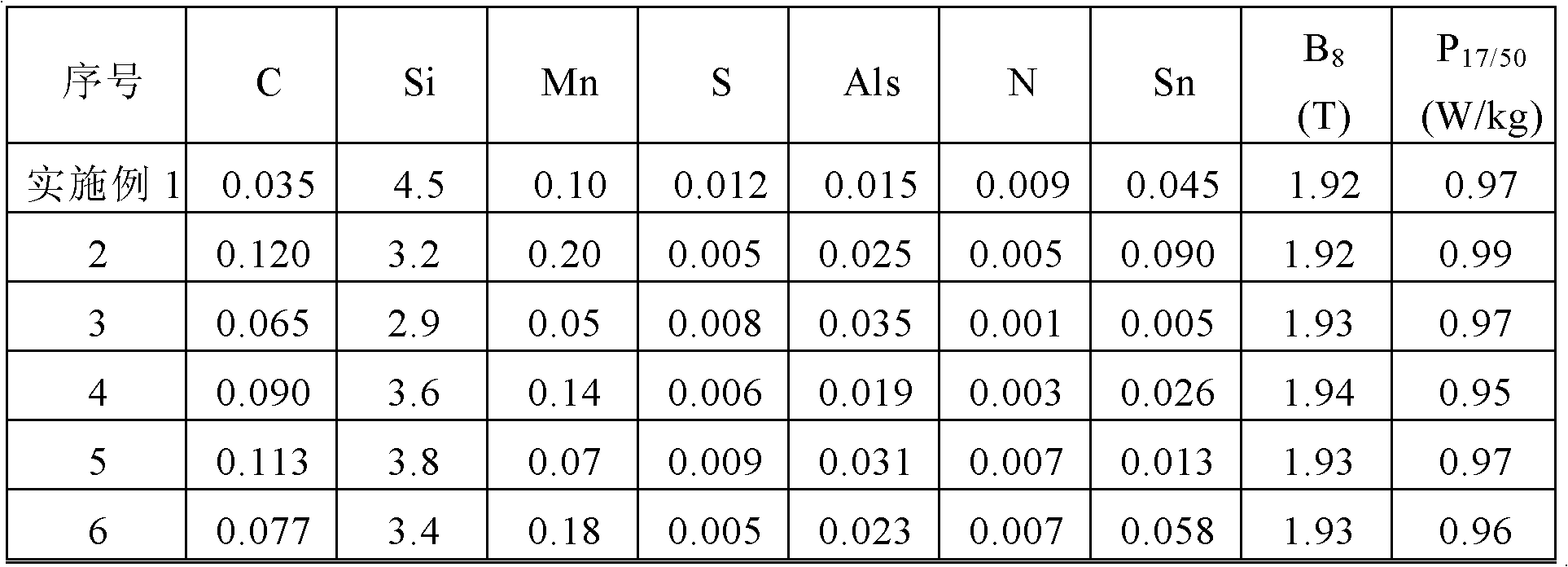

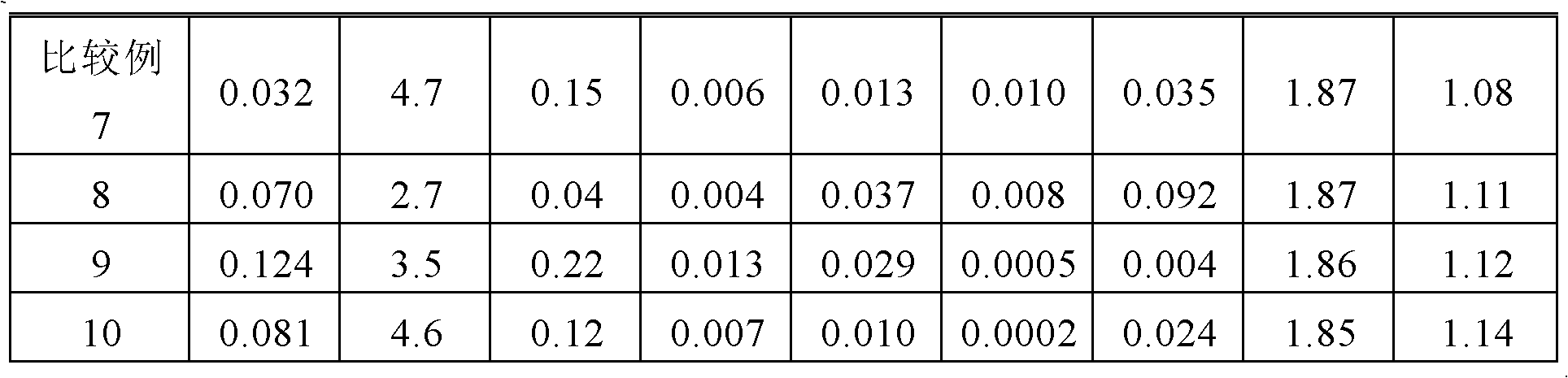

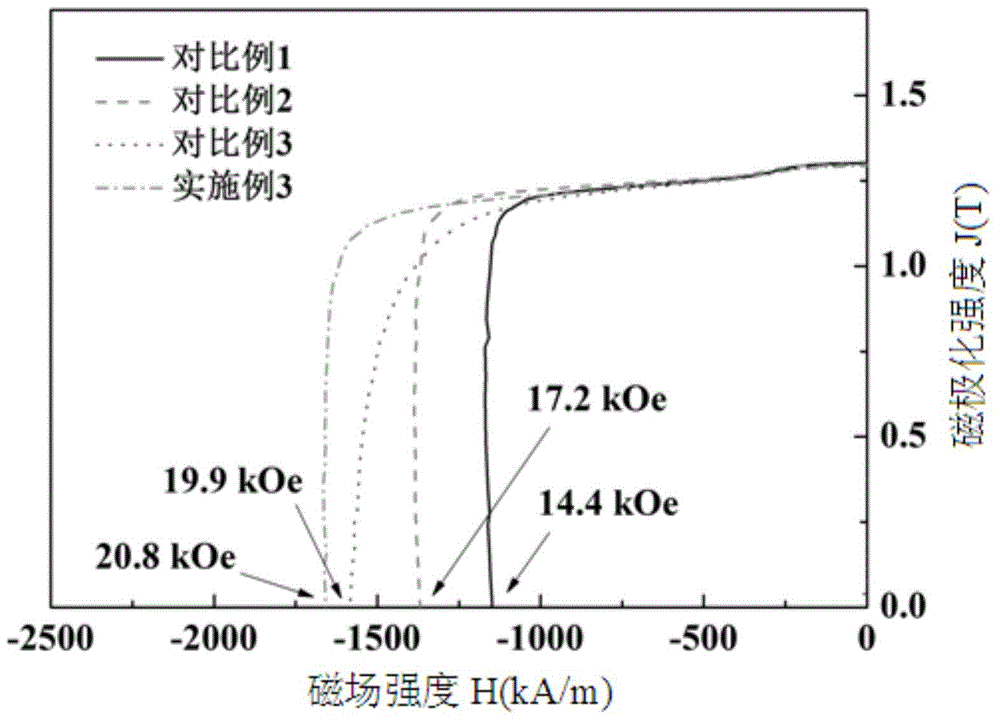

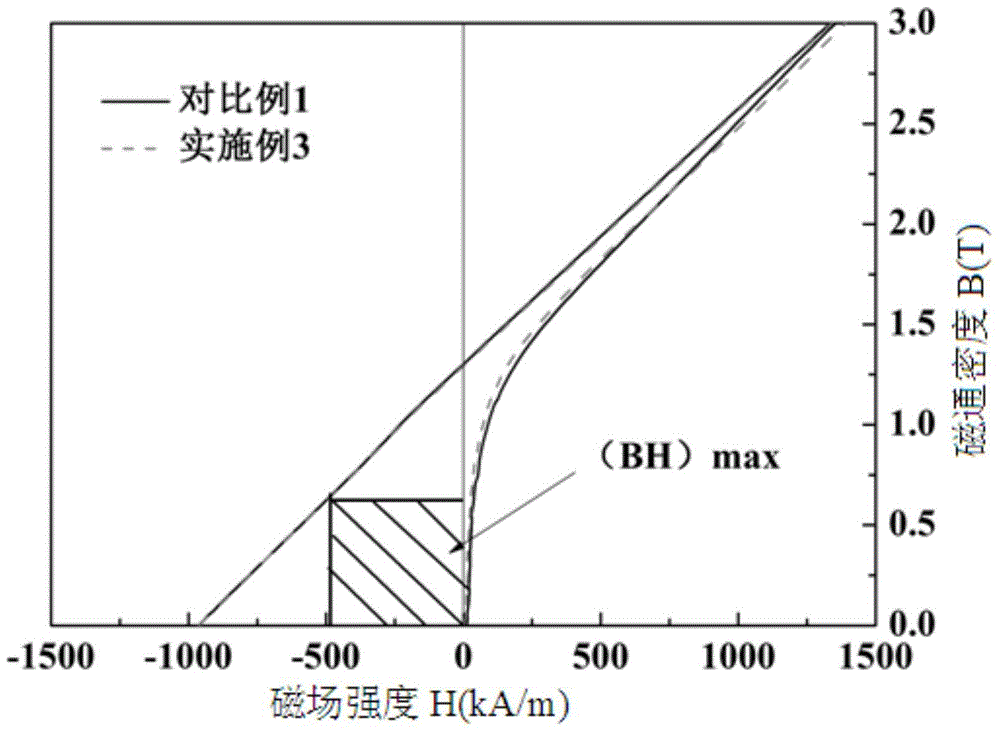

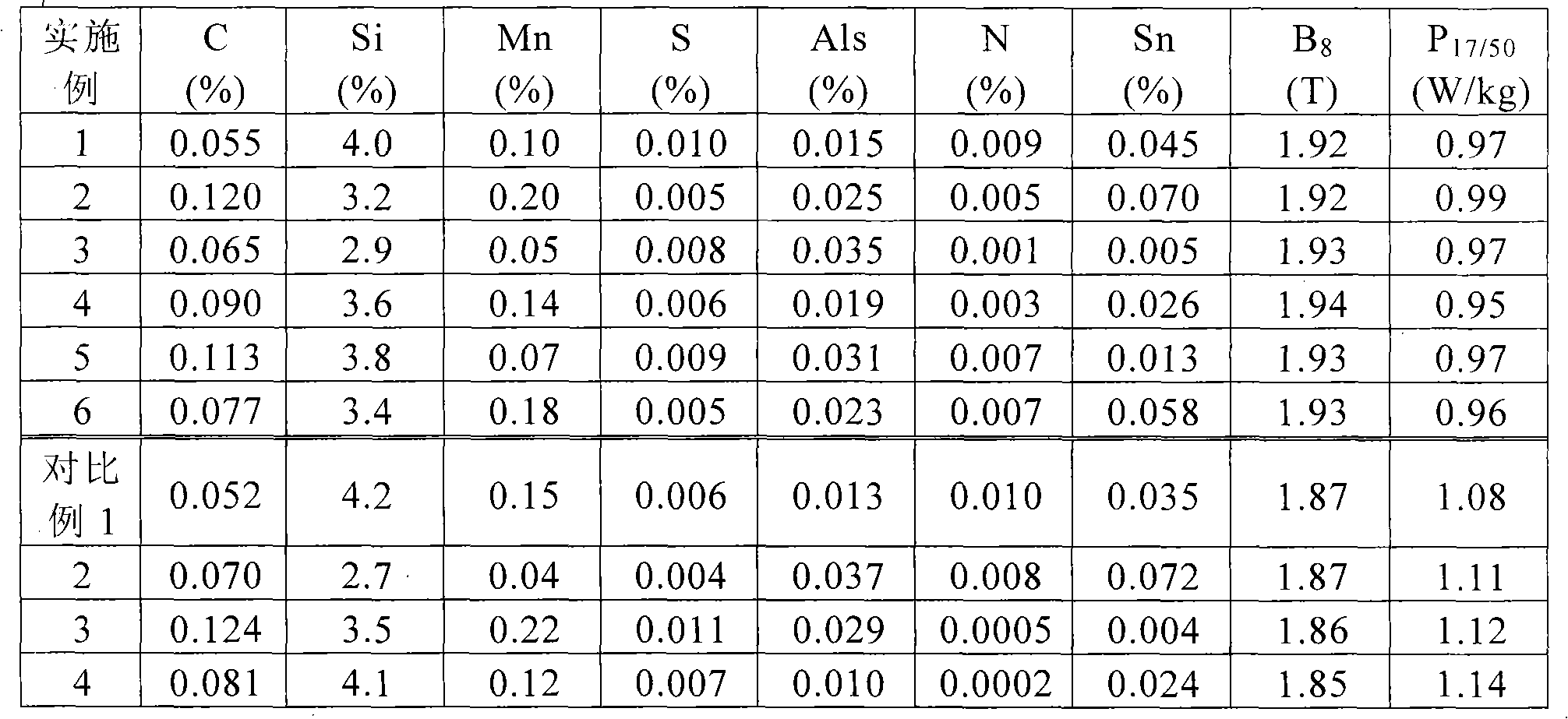

Method for producing high magnetic induction orientation silicon steel with excellent magnetic performance and good bottom layer

The invention relates to a method for producing high magnetic induction orientation silicon steel with excellent magnetic performance and a good bottom layer. The method comprises the following steps: (1) smelting, casting, making steel by using a converter or an electric furnace, and performing secondary refining and continuous casting on molten steel to obtain a plate blank; (2) performing hot rolling; (3) normalizing: performing two-section normalization, and then cooling; (4) performing cold rolling: rolling the normalized plate into the plate with the thickness of the finished product plate by a primary cold rolling method; (5) performing decarburizing annealing and nitriding annealing; (6) coating MgO coating and annealing at high temperature; and (7) coating insulating coating on the surface of a high-temperature annealing plate and performing heat drawing and flat annealing to obtain the high magnetic induction orientation silicon steel with excellent magnetic performance. According to the method, the problem of nitrogen stability in the plate after nitriding is solved, so that secondary recrystallization in the high-temperature annealing process is perfected and the high magnetic induction orientation silicon steel with excellent magnetic performance (B8 is more than or equal to 1.90 T and P17 / 50 is less than or equal to 1.00 w / kg), with the good bottom layer and without the defects of crystal exposure and frost descend is obtained finally.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of flexible anisotropy bonding rare earth permanent magnet material

InactiveCN101800106AAbundant resourcesReduce manufacturing costInorganic material magnetismInductances/transformers/magnets manufactureMagnetizationRare earth

The invention discloses a preparation method of flexible anisotropy bonding rare earth permanent magnet material, belonging to the field of magnetic materials. The material is prepared by combining the two-step approach accompanying temperature magnetic field orientation technology of which the calendaring process and the accompanying temperature magnetic field orientation process are separated. A certain quantity of anisotropy magnetic powder which is performed with surface treatment by the processing agent in advance, binder and processing agent are evenly mixed; the mixed material is calendered into flaky flexible bonding magnetic body by the calendaring technology; then, the flaky flexible bonding magnetic body is cut into parts which are heated at certain temperature under the condition of heat preservation for certain time, after that, the obtained product is put into an orientation magnetic field for accompanying temperature magnetic field orientation; and the direction of the orientation magnetic field is parallel to the plane normal direction of the flaky flexible bonding magnetic body. In the preparation technology, magnetic powder can overcome the constraint of a bonding system and rotates under the action of magnetic field force to ensure that the direction of easy magnetization of the magnetic powder generally points to the orientation direction, and the magnetic property of prepared flexible anisotropy bonding rare earth permanent magnet material can be greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

Grain boundary diffusion method for improving properties of sintered NdFeB magnets

ActiveCN104388951AIncreased diffusion kinetic energyLow melting pointInorganic material magnetismRare-earth elementDiffusion methods

The invention relates to a grain boundary diffusion method for improving properties of sintered NdFeB magnets. The grain boundary diffusion method comprises the following steps of stacking sintered NdFeB magnets and diffusion alloy sheets together and placing in a hot-pressing furnace; vacuumizing the hot-pressing furnace until the vacuum degree reaches a set value, heating the hot-pressing furnace, and when the temperature of the hot-pressing furnace reaches a set value, beginning to exert a pressure and maintaining the pressure and putting the diffused sample into a high-vacuum furnace for annealing, wherein the diffusion alloy sheets are low-melting-point eutectic diffusion alloys and are represented by R-TM, R is one or more of Sc, Y, La, Ce, Pr or Nd and TM is one or more of Ti, V, Cr, Mn, Fe, Co, Ni, Cu and Zn. Compared with the prior art, the sintered NdFeB magnets modified by the pressure diffusion method, which is provided by the invention, have the advantages of large diffusion depth of a diffusion agent, uniform distribution of grain boundary phases, high coercivity and the like, especially, low-melting-point diffusion alloys designed by the invention are free of expensive heavy rare earth element dysprosium and thus the cost of the raw materials is relatively low, the diffusion temperature is low and the energy consumption in the diffusion process is small.

Owner:SHANGHAI JIAO TONG UNIV

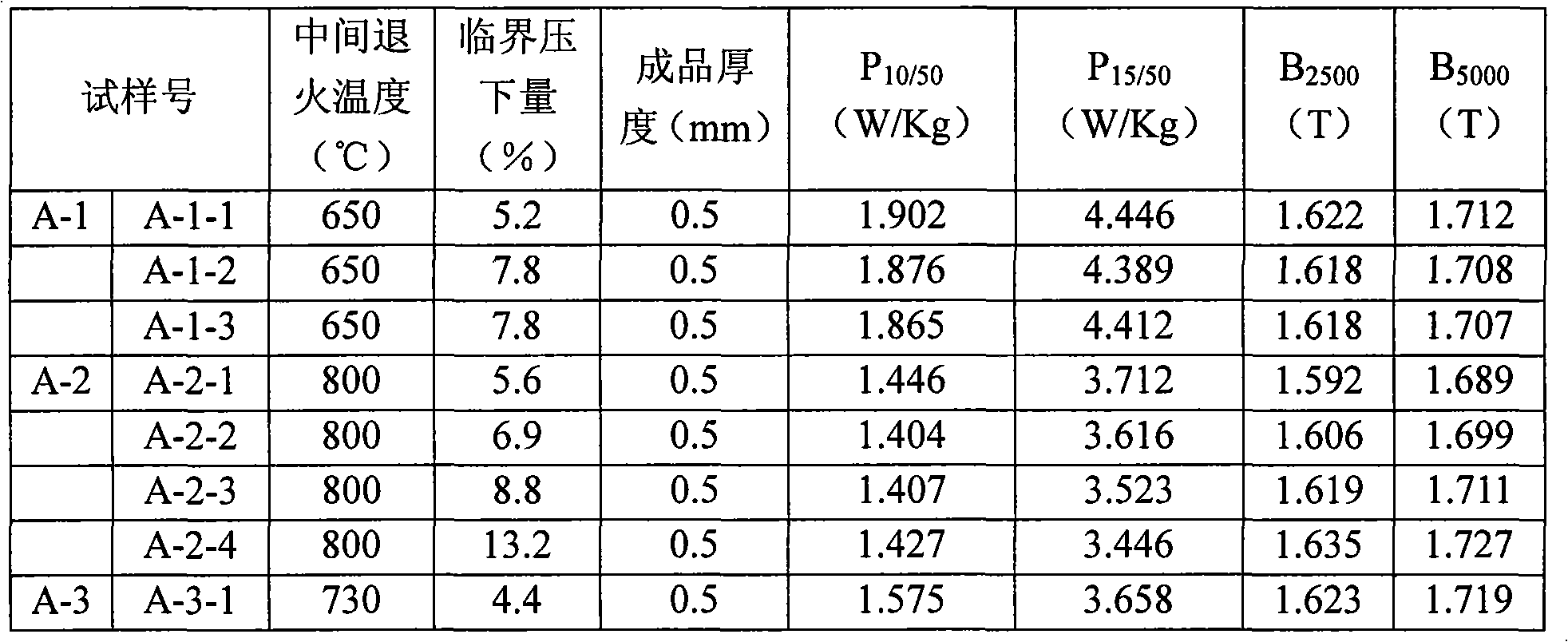

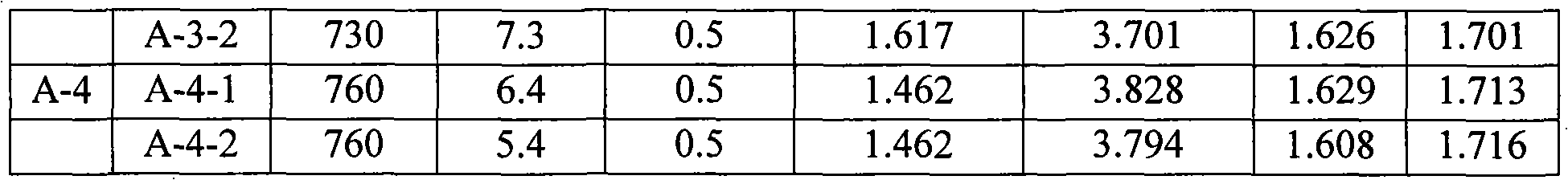

Preparation method of low carbon low silicon no-aluminum half-technique non oriented electrical steel

ActiveCN101306434AStrong magnetismLow costTemperature control deviceMetal rolling arrangementsRare-earth elementChemical composition

A method for preparing low-carbon low-silicon non-aluminum semi-process non-oriented electrical steel belongs to the technology field of the electrical steel with good magnetic performance. The preparation method includes the processing steps of meeting the requirements for the casting blank, such as the chemical components comprise less than or equal to 0.005% of C, 0.1%-1.0% of Si, less than or equal to 0.35% of Mn, less than or equal to 0.08% of P, less than or equal to 0.01% of S, less than or equal to 0.008% of N, less than or equal to 0.015% of O, inevitable impurities and Fe in balancing amount, according to the composition design for the hot rolling raw material; hot-charging and hot-rolling of the casting blank; acid-cleaning and cold-rolling of the steel plate after the hot-rolling; intermediate-annealing of the steel strip; cold-rolling of the critical deformation; relieving stress and annealing by users; and obtaining the semi-process non-oriented electrical steel with good magnetic performance. The method has the advantage that the final product has good magnetic performance: P15 / 50 is equal to 3.45-5.05 W / Kg, and B5000 is equal to 1.69-1.76 T. The casting blank contains no alloying elements such as Al, Sn, Sb, Cu, Cr, Ni, B, rare earth elements, etc., thus considerably reducing the production cost. The larger critical rolling reduction is adopted, the annealing technique is optimized, and the prepared finished products have better magnetic performance.

Owner:SHOUGANG CORPORATION

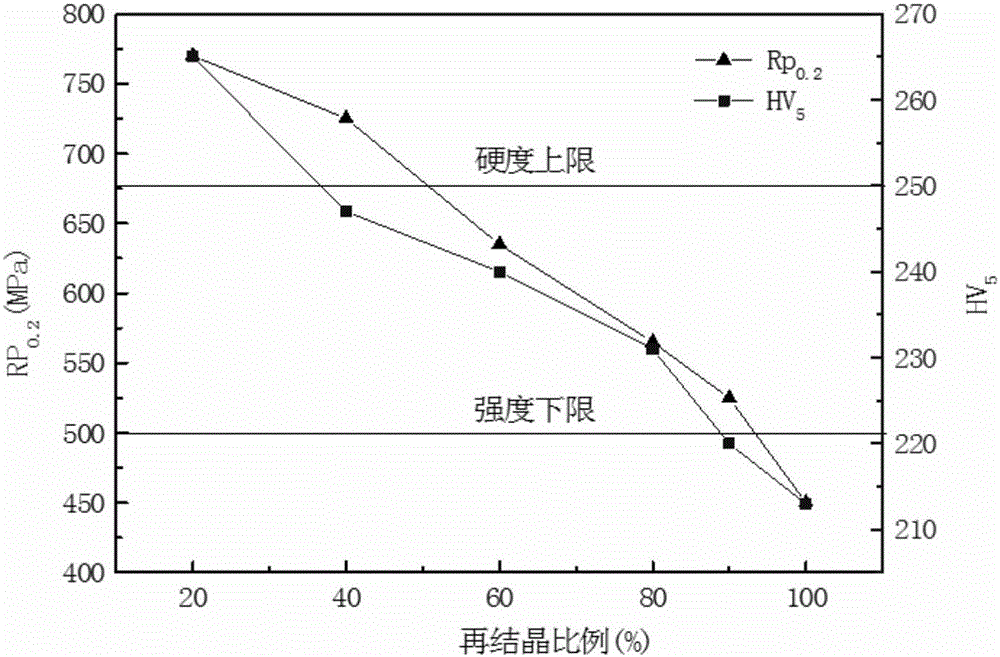

Non-oriented silicon steel for drive motor of electric automobile and preparation method thereof

The invention discloses non-oriented silicon steel for a drive motor of an electric automobile and a preparation method thereof. The performance of a silicon steel strip is controlled by optimizing chemical compositions and controlling the soaking time and soaking temperature of incomplete recrystallization annealing to regulate the recrystallization proportion. According to a rotor core made of the non-oriented silicon steel strip obtained after incomplete recrystallization annealing, the yield strength can reach 500 MPa or above, the Vickers hardness is 250 or below, and abrasion to a die is fully considered on the premise of guaranteeing the rotor strength. In addition, after stress annealing of the non-oriented silicon steel strip obtained after incomplete recrystallization annealing, a stator core manufactured from the steel strip is quite excellent in magnetic performance, i.e., the magnetic level of the stator core product after stress annealing is equivalent or even superior to that of a traditional full-process product.

Owner:武汉钢铁有限公司

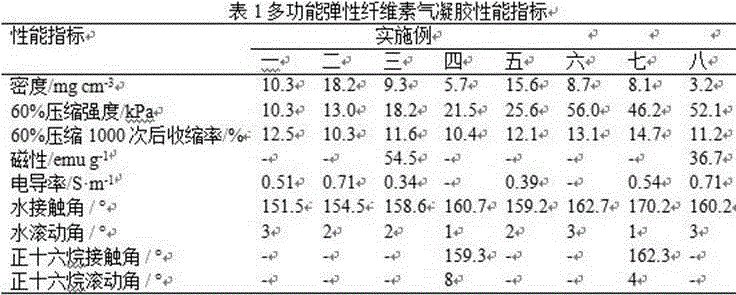

Preparation method of multifunctional cellulose elastic aerogel

The invention discloses a preparation method of a multifunctional cellulose elastic aerogel, belonging to the field of aerogel materials. The preparation method comprises the following steps: dispersing cellulose in water, carrying out pretreatment by adding sodium chlorite or / and in a solvothermal way, and cleaning with deionized water to obtain a purified cellulose dispersion solution; adding a modifier to perform chemical modification, thereby obtaining a modified cellulose suspension; dispersing the modified cellulose suspension in an organic solvent, forming, drying to form a modified cellulose gel, and finally, carrying out heat treatment on the modified cellulose gel to obtain the multifunctional cellulose elastic aerogel. The cellulose is subjected to pretreatment and chemical modification, thereby lowering the density of the aerogel, greatly enhancing the elasticity and mechanical strength of the aerogel, endowing the aerogel with excellent magnetism, electric conductivity, superhydrophobicity, superoleophobicity and many other functions, and widening the application range of the traditional cellulose aerogel.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

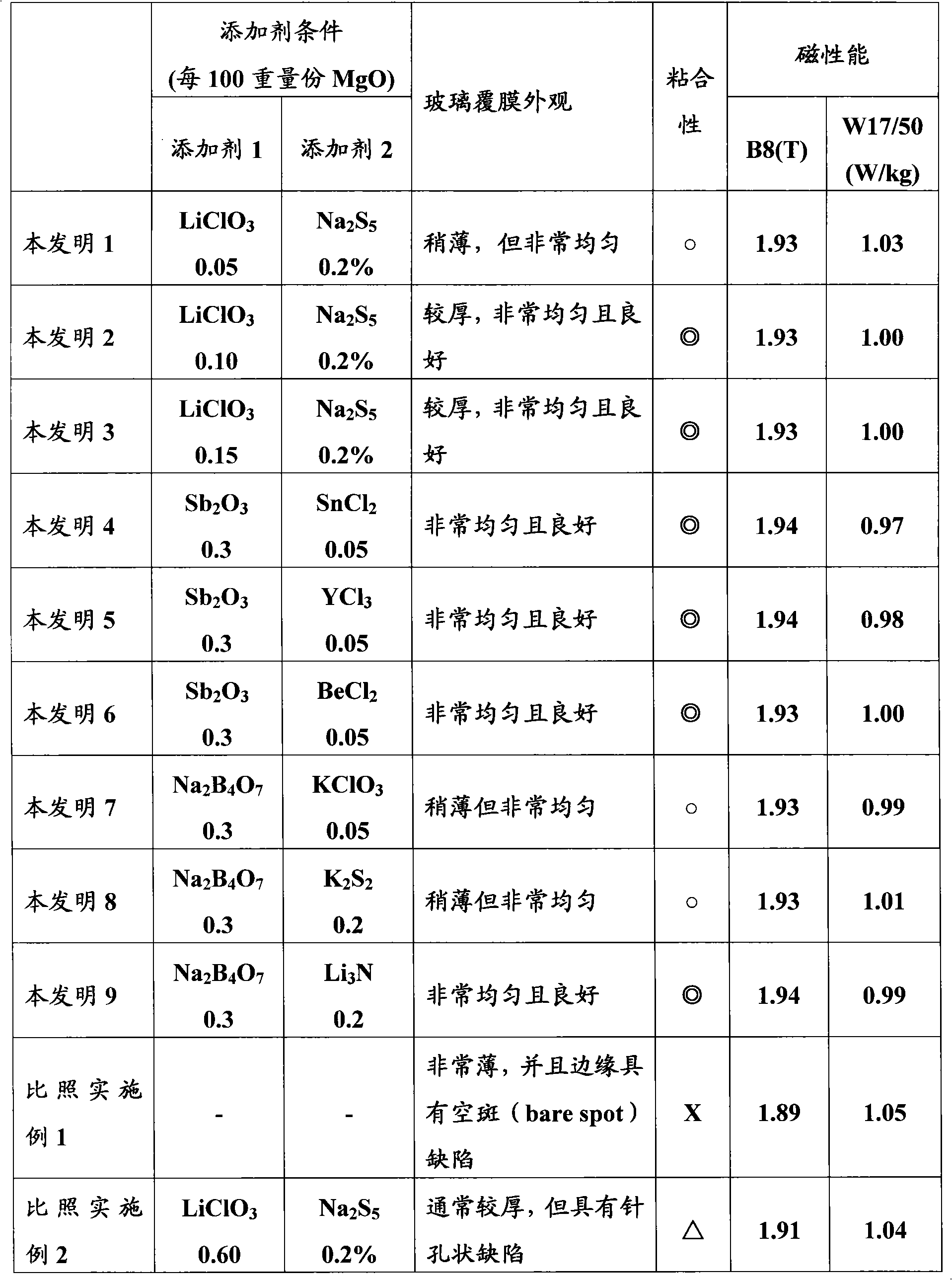

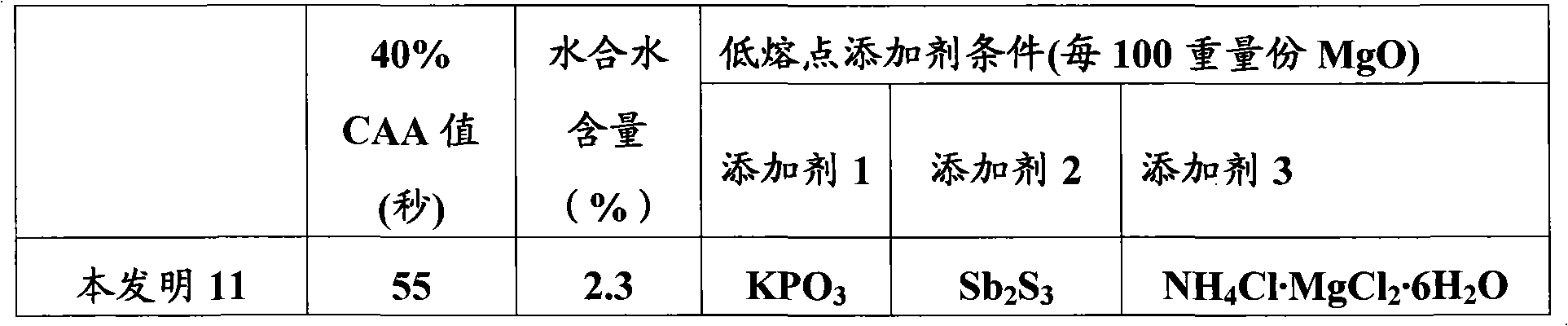

Annealing separating agent for grain oriented electrical steel sheet having uniform glass film and excellent magnetic properties and method of manufacturig the same

ActiveCN101528950APromote formationGood coating effectSolid/suspension decomposition chemical coatingSheet steelElectrical steel

Disclosed herein are an annealing separator for grain-oriented electrical steel sheets having excellent surface properties and a method for producing grain-oriented electrical steel sheets using the same. More particularly, the annealing separator comprises: 100 parts by weight of MgO, consisting of 40-95% of active MgO and 5-60% of inactive MgO; and 0.01-5 parts by weight of a low-melting-point compound having a melting point lower than 900 DEG C. The method for producing grain-oriented steel sheets comprises applying said annealing separator in the form of slurry to a steel sheet, after stirring the annealing separator in a mixing tank at a revolution speed of 1500-3000 rpm for more than 10 minutes.

Owner:浦项股份有限公司

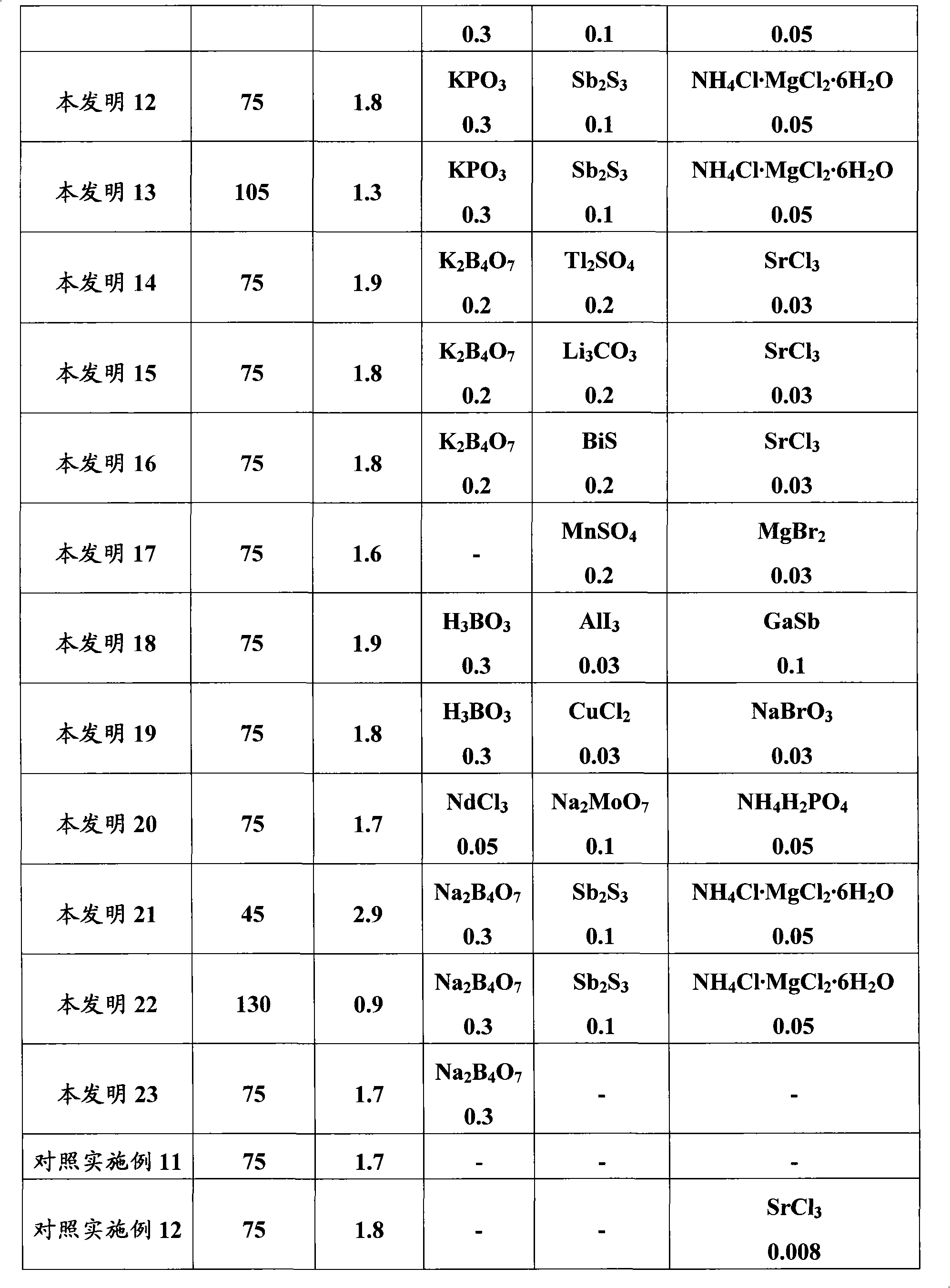

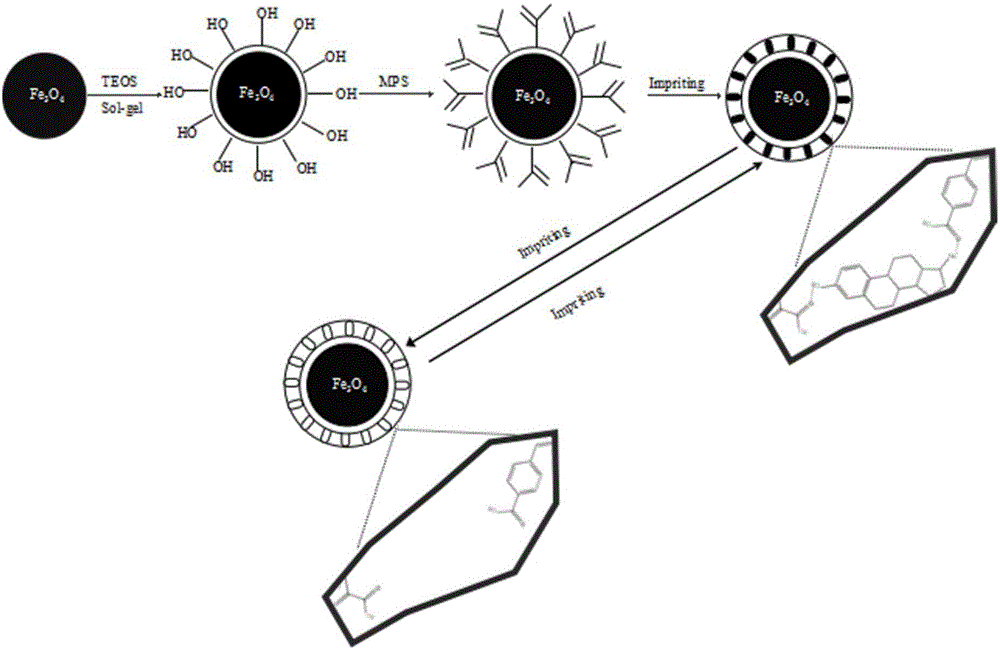

Preparation method for molecular imprinting material and molecular imprinting material prepared through preparation method

InactiveCN105107482AGood biocompatibilityImprove antioxidant capacityOther chemical processesAlkali metal oxides/hydroxidesSolubilityFunctional monomer

The invention provides a preparation method for a molecular imprinting material and the molecular imprinting material prepared through the preparation method. The preparation method comprises the steps that silicon oxide is coated on the surfaces of magnetic ferroferric oxide nanometer particles, the magnetic ferroferric oxide nanometer particles are modified with gamma-(methacryloyl chloride) amino propyl trimethoxy silane to obtain magnetic ferroferric oxide nanometer particles with propenyl on the surfaces, the magnetic ferroferric oxide nanometer particles with the propenyl on the surfaces serve as carriers, estrogen receptors are simulated, functional monomers are optimized, a surface imprinting technology is adopted, and then the molecular imprinting material which can simultaneously identify seven kinds of environmental endocrine disrupting chemicals is prepared. According to the preparation method, the easy separation of a magnetic nanometer material, the good water solubility of a silicon oxide nanometer material, the specific recognition ability of molecular imprinting polymers and the surface imprinting technology are mutually combined, the preparation technology is simple, the conditions are mild, the prepared molecular imprinting material is large in adsorption capacity, fast to respond, high in magnetism, good in chemical stability and high in repeating utilization rate, and the problems that at present, multiple trace, steroid and phenol environmental endocrine disrupting chemicals are difficult to simultaneously identify, separate and enrich are solved.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

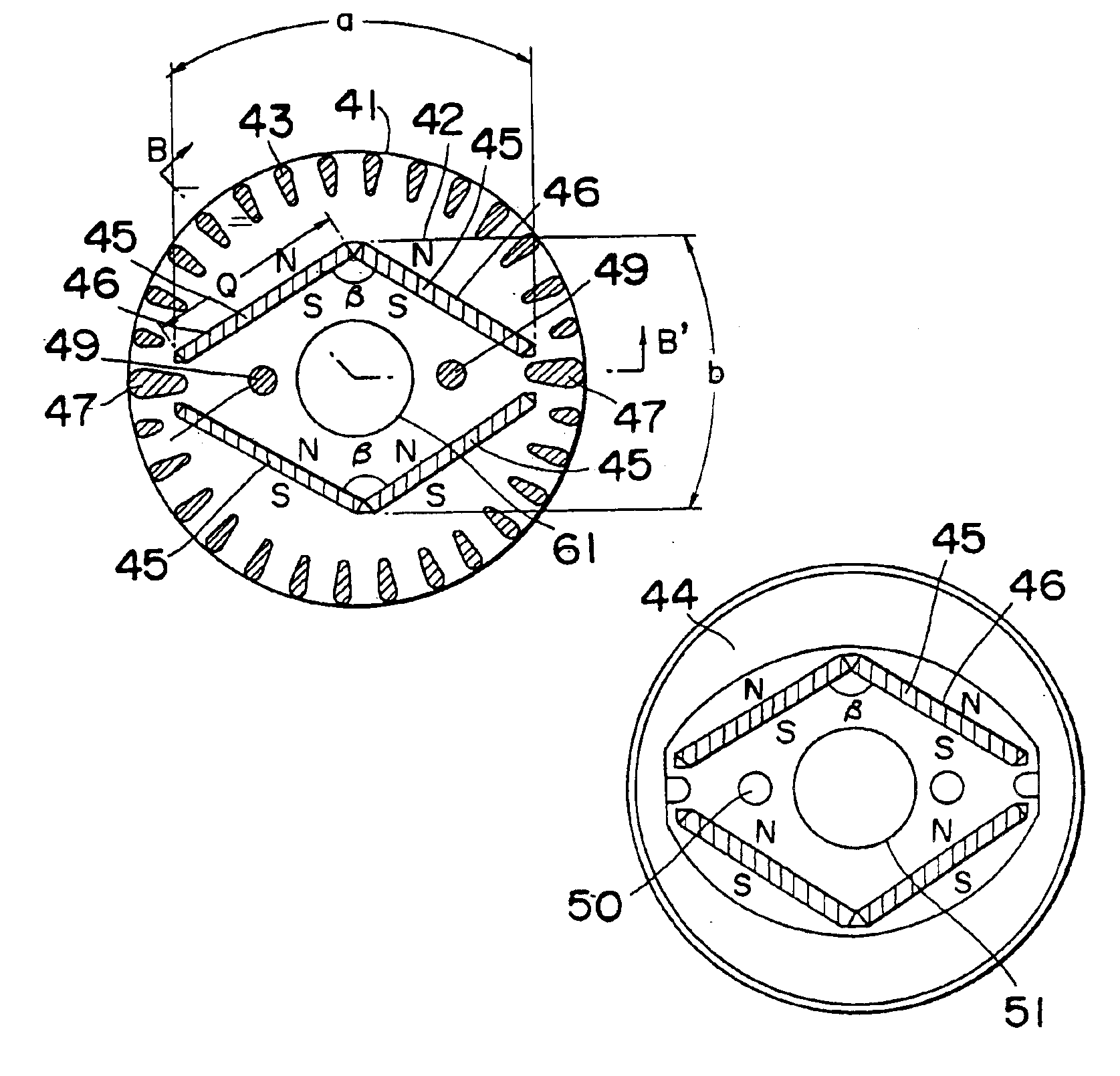

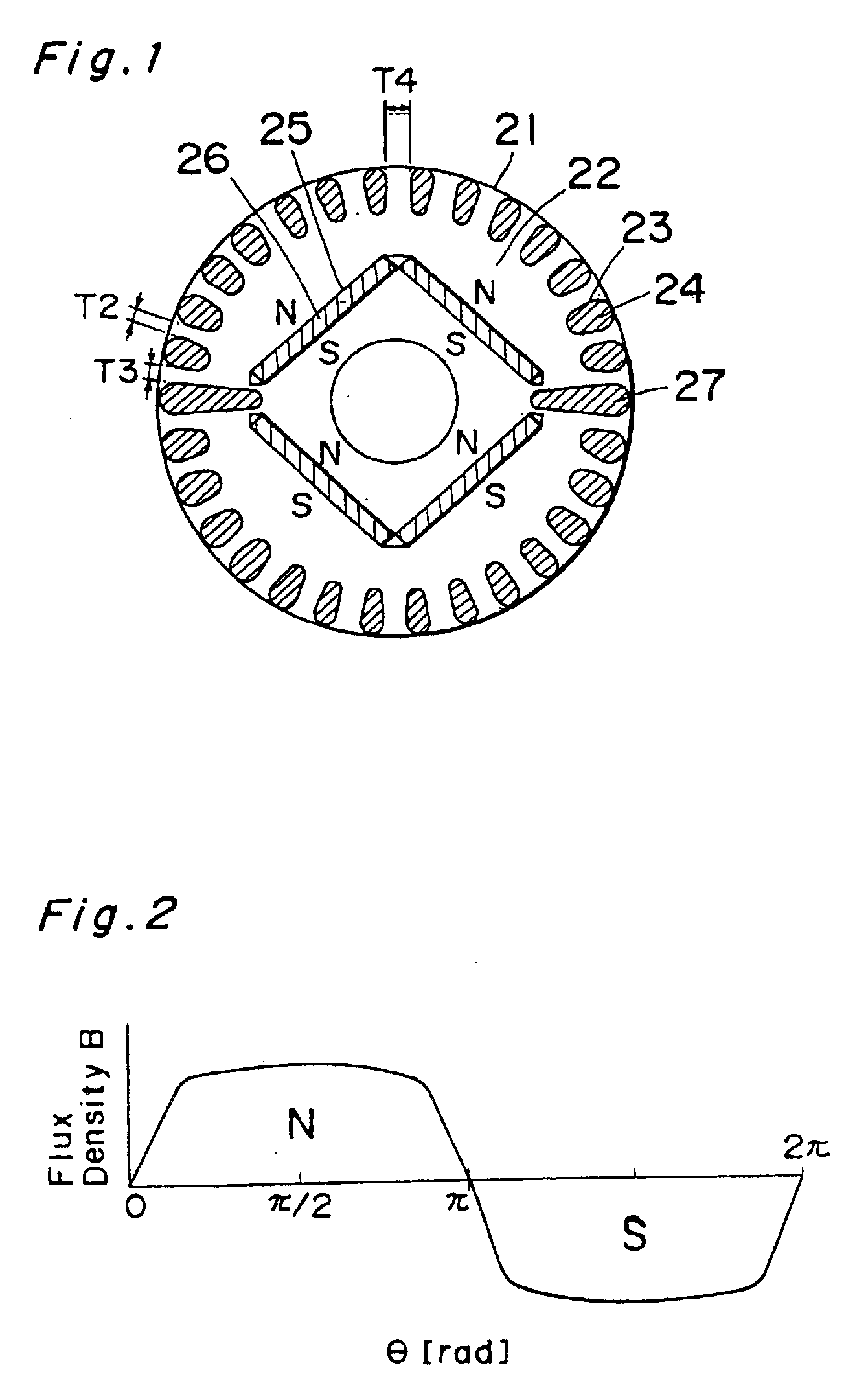

Permanent magnet synchronous motor

InactiveUS6876119B2Reduce in quantityWork lessMagnetic circuit rotating partsSynchronous motorsElectrical conductorSynchronous motor

A synchronous motor includes a stator, a rotor and permanent magnets. The rotor includes a rotor iron core and rotatable relative to the stator, a plurality of conductor bars accommodated within corresponding slots in the rotor iron core. The conductor bars have their opposite ends shortcircuited by respective shortcircuit rings to form a starter cage conductor. The rotor also has a plurality of magnet retaining slots defined therein at a location on an inner side of the conductor bars, in which hole permanent magnets are embedded.

Owner:PANASONIC CORP +1

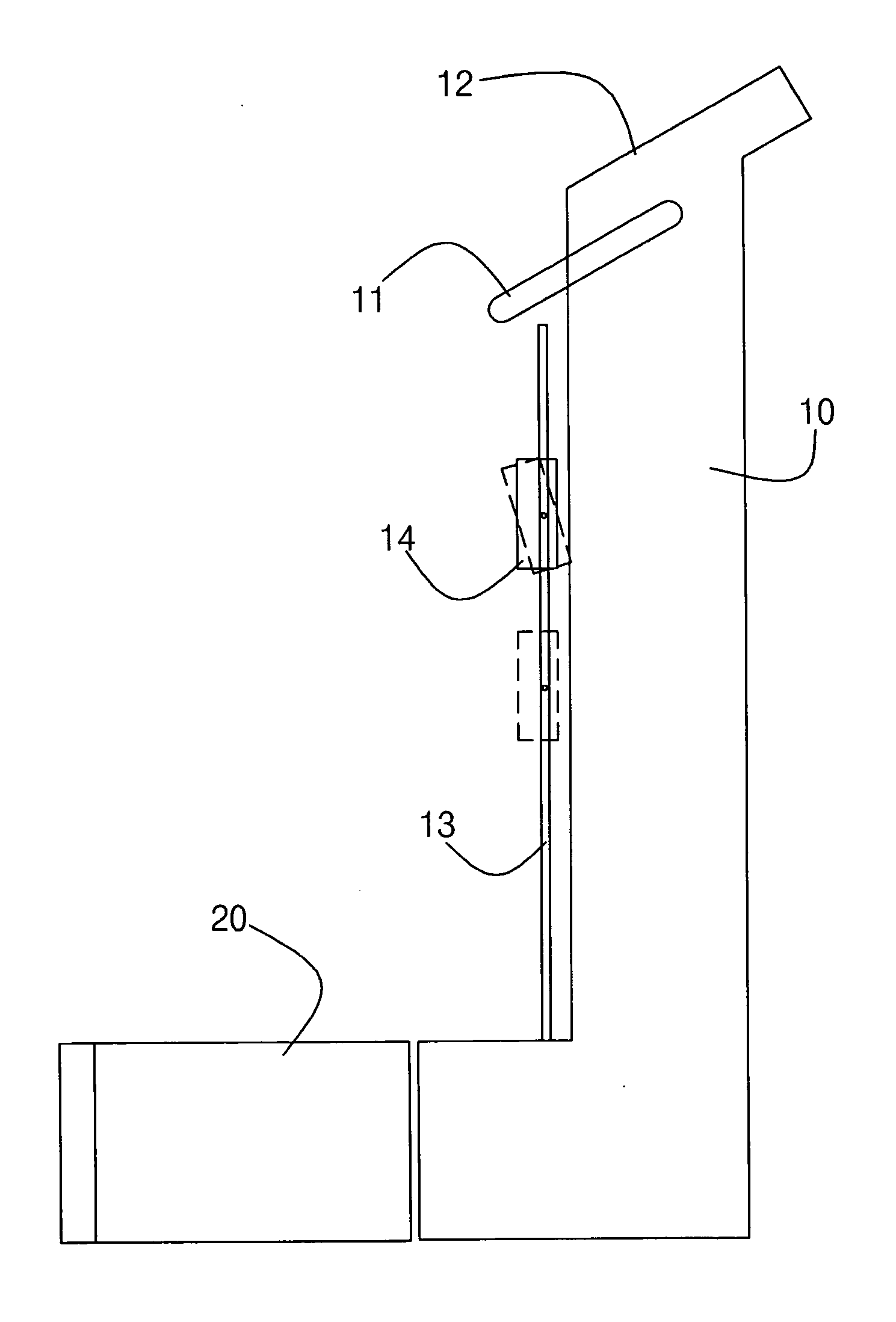

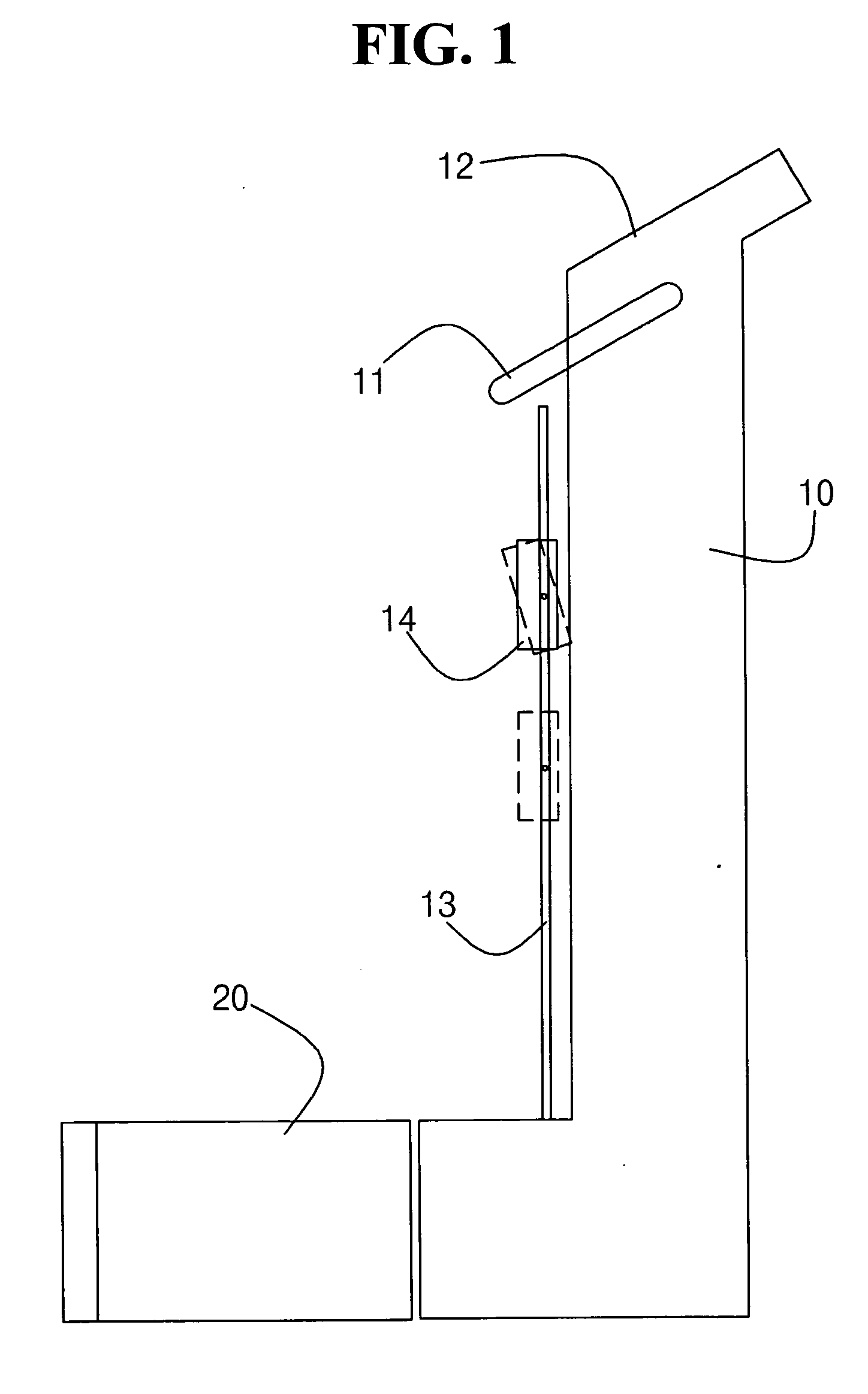

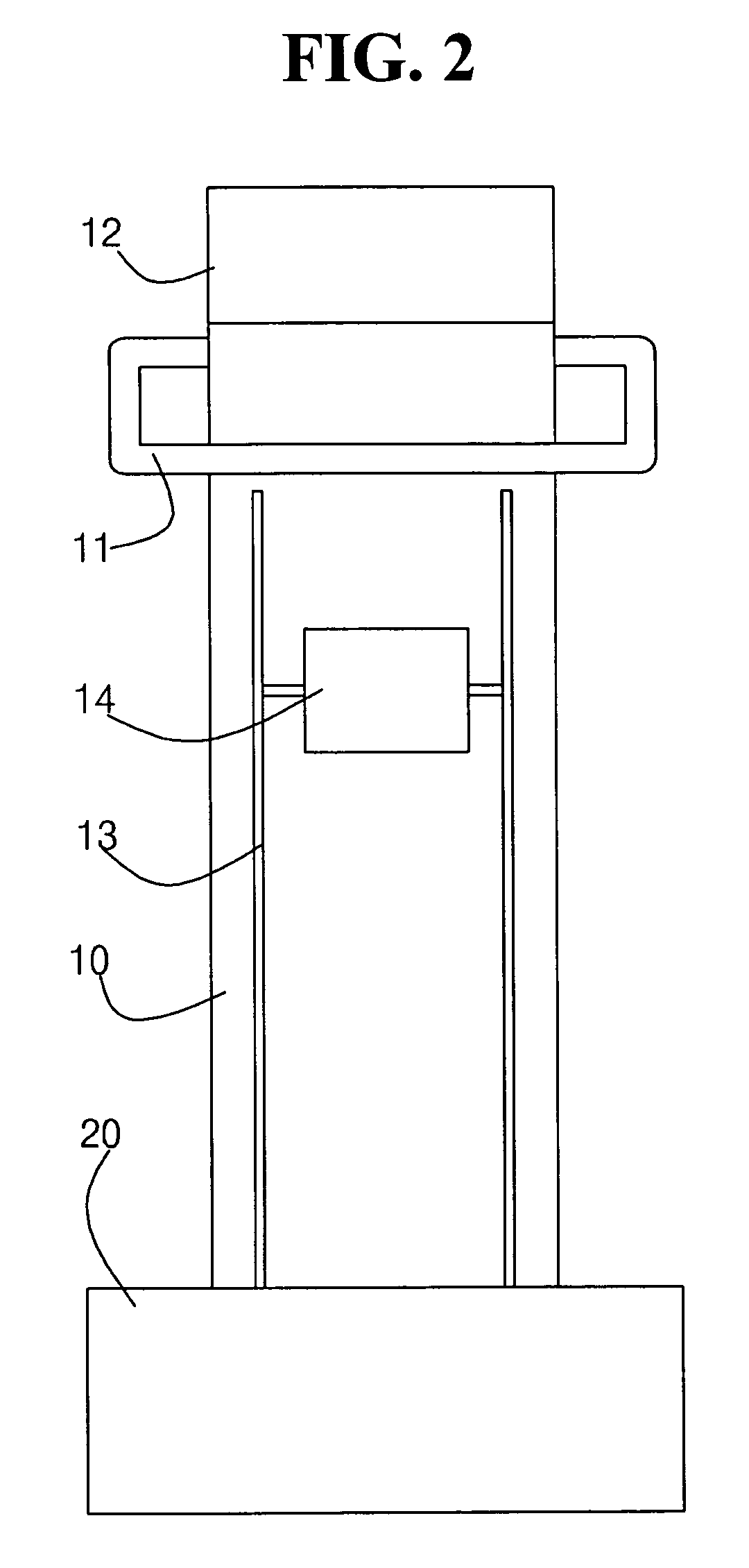

Vibratory apparatus of exercise

ActiveUS20060094990A1Good linear responseLow noise smallChiropractic devicesVibration massageVertical vibrationBobbin

A vibratory exercise apparatus capable of providing a sufficient vertical movement force is provided, which adopts a structure that a bobbin coil connected with a vibration plate is employed in a magnetic gap of a magnetic circuit using a permanent magnet which can generate a strong magnetic force. The vibratory exercise apparatus includes a magnetic gap type vertical vibrator which generates vertical vibration by a permanent magnet and a bobbin coil, a bobbin guide which is installed at the center of a yoke, a bobbin guide rod which is reciprocally movably coupled with the bobbin guide and whose one end is coupled with the upper portion of a bobbin, a joint whose one end is coupled with the upper portion of the bobbin, a vibration plate which is coupled with the other end of the joint, a guide which guides vertical movement of the vibration plate, and a spring which limits a range of movement of the vibration plate and absorbs impact when the vibration plate descends.

Owner:KIM SEONG BAE

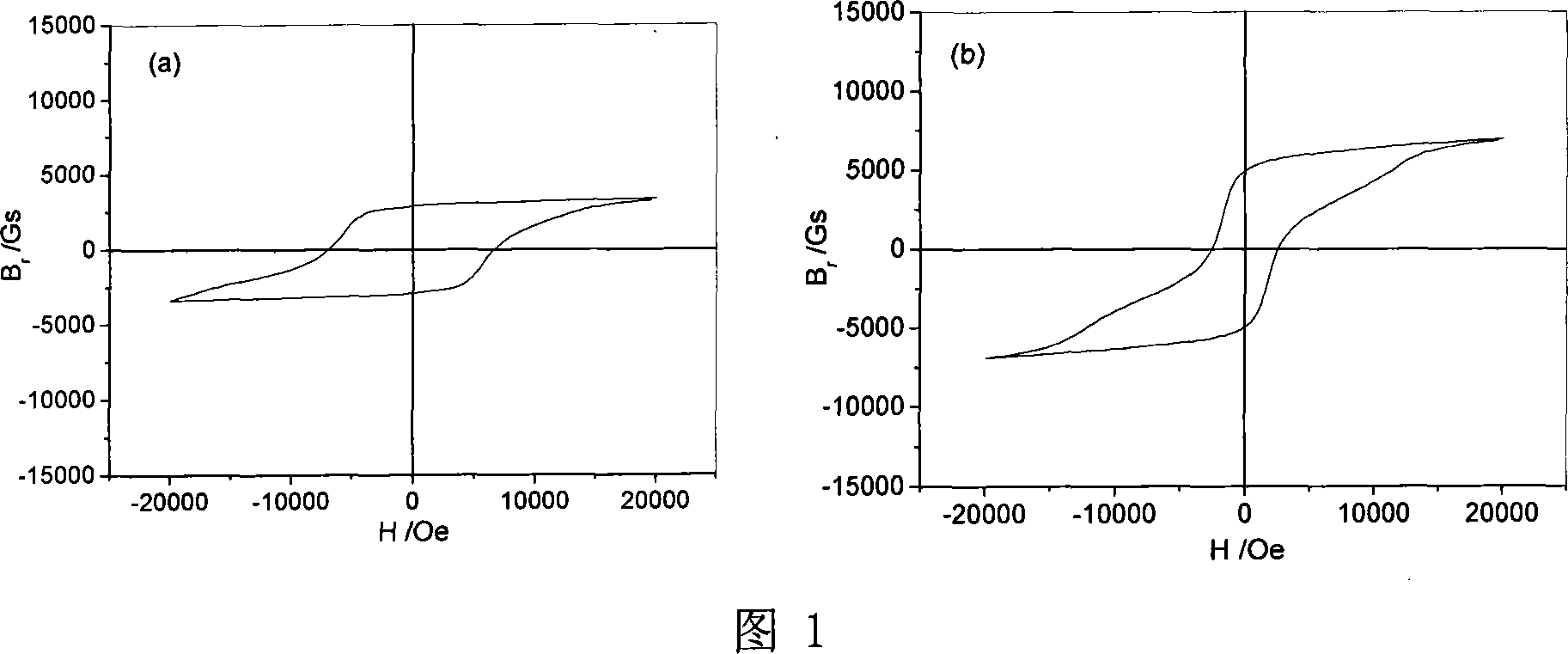

Preparation method of iron strontium oxide magnetic nanoparticles and magnetic damping rubber thereof

ActiveCN101913855AStrong magnetismGood compatibilityPigment treatment with organosilicon compoundsMagnetic dampingMolten salt

The invention discloses a preparation method of iron strontium oxide magnetic nanoparticles and a magnetic damping rubber thereof, which solves the problem that the existing magnetic damping rubber fails to meet the requirements for excellent physical-mechanical properties and good magnetic damping effect simultaneously. In the preparation method of the iron strontium oxide magnetic nanoparticles, a chemical coprecipitation method is organically combined with a molten salt method to obtain surface-modified nano-grade iron strontium oxide in a regular shape, and then the obtained iron strontium oxide is used for preparing the magnetic damping rubber. The invention has the following advantages: the magnetic particles have nano-scale particle size and excellent magnetic property, and can be uniformly dispersed in a rubber matrix; a nitrile-butadiene rubber is taken as the matrix, thus having excellent oil resistance; and the magnetic damping rubber has excellent mechanical property.

Owner:ZHONGBEI UNIV

Method for manufacturing low-iron loss high-magnetic strength non-oriented electrical steel

Disclosed is a manufacturing method for low iron loss and high magnetic induction non-oriented electric steel, which belongs to the technical field of the electric steel. The invention adopts the process steps: the heating temperature for casting billet is between 900 DEG C to 1150 DEG C, a hot rolled plate is cold-rolled to 0.50 mm after being normalized and acid-cleaned and is positioned in hydrogen-nitrogen mixed gas to undergo the stress removal and annealing treatment, and the low iron loss and high magnetic induction non-oriented electric steel product can be obtained. The invention has the advantages that the final magnetic property of the product is good, namely P15 / 50 equals to 3.1 to 3.8 W / Kg and B5000 equals to 1.69 T to 1.81 T; Si accounts for 1.0 percent to 2.0 percent, Al accounts for 0 percent to 0.60 percent and Si and 3Al equals to or is larger than 1.5 percent and equals to or is less than 3.2 percent in the casting billet, alloying elements of Sn, Sb, Bi, Cu, Cr, Ni, B, Ca, Ce and the like are not contained in the product, the manufacturing cost is greatly reduced, and the magnetic property of the finished product is excellent.

Owner:SHOUGANG CORPORATION

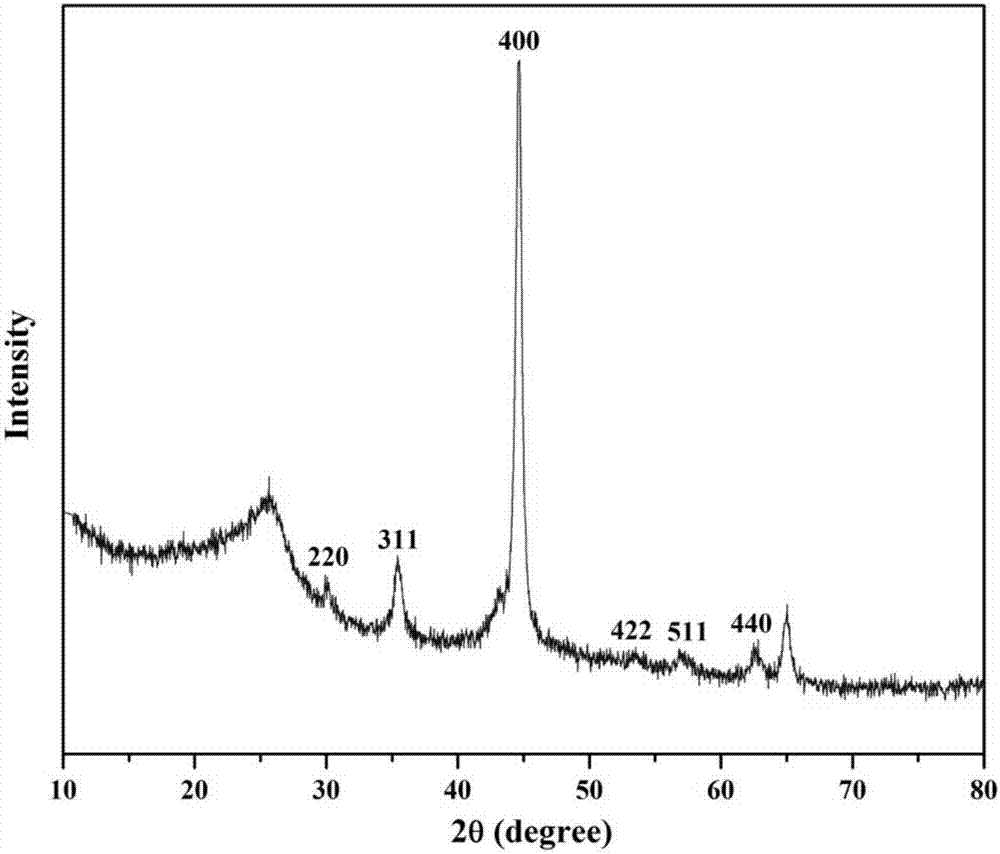

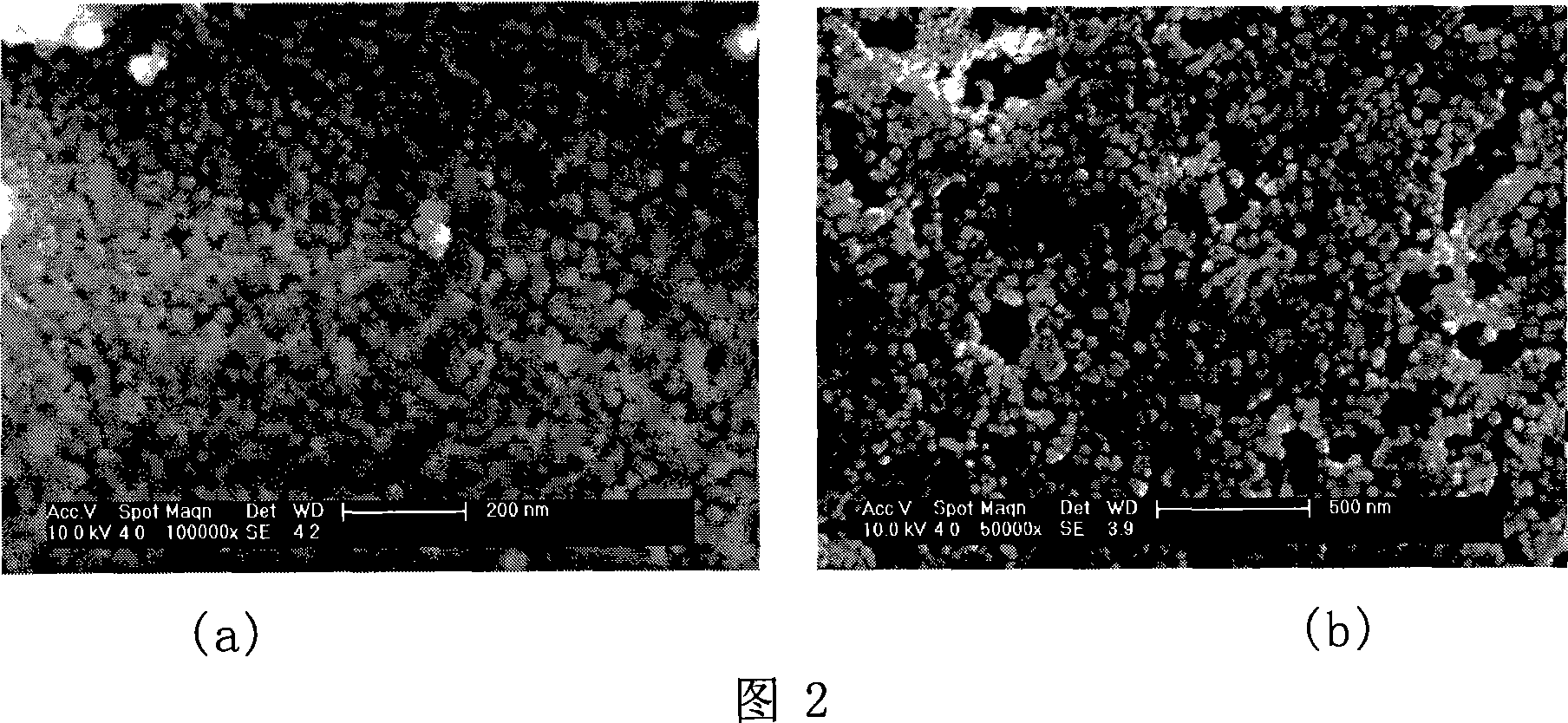

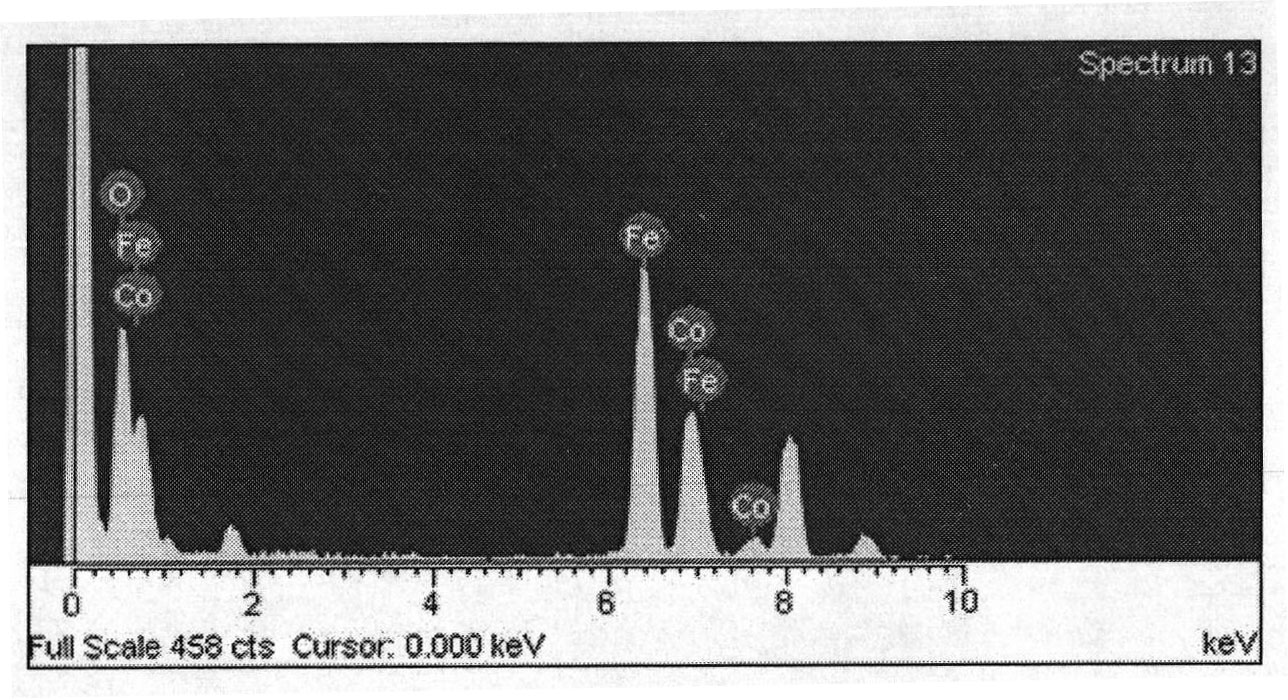

CoFe2O4/N/C hollow nanosphere and preparation and application thereof

InactiveCN106984261AImprove distributionImprove adsorption capacityPhysical/chemical process catalystsOther chemical processesMicrosphereCarbonization

The invention discloses a CoFe2O4 / N / C hollow nanosphere and preparation and application thereof. The preparation comprises: complexing dopamine with cobalt and iron metal ions under the condition of pH8-9 on a template as a SiO2 nanometer sphere to form a polymer shell layer, carbonization annealing to form N-doped carbon material loaded with CoFe2O4 metal nanoparticles, and finally, removing the SiO2 template with strong alkali to obtain CoFe2O4 / N / C hollow nanosphere. In the invention, the N / C matrix hollow structure is prepared by using the SiO2 nanosphere as the sacrificial template, theCoFe2O4 / N / C hollow nanosphere has a relatively large specific surface area and porosity, and can improve the distribution of CoFe2O4 nano metal particles loaded on the shell layer, enhance adsorption and catalytic activity on organic pollutants in waste water, and broaden the pH application range; the CoFe2O4 / N / C hollow nanosphere can be recycled due to magnetic performance, thus saving resources.

Owner:ZHEJIANG UNIV OF TECH

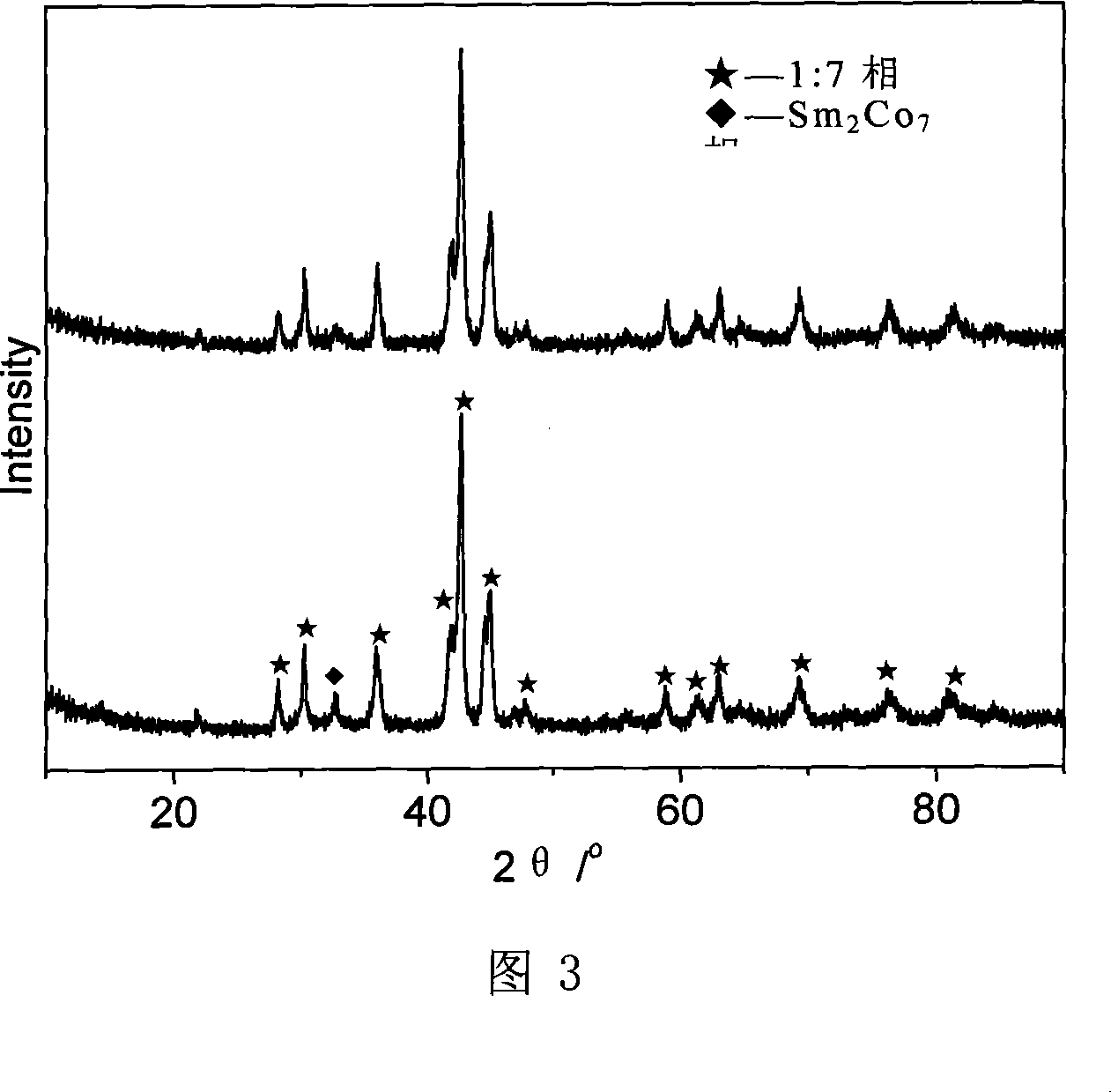

Method for preparing SmCo7 permanent-magnetic alloy with particle size smaller than 20nm

The invention discloses a preparing method of SmCo7 permanent magnet alloy whose grain size is smaller than 20nm, the RE, Co, Fe, Cu, T whose fineness is bigger than 99. 9% is mixed together just as proportion of RE(CobalFexCuyTw)z and placed in the induction furnace, the alloy ingoting which is after the fusion is cased into the quartz tube equipped with nozzle at the bottom to be melt, ejected to the surface of copper roller which is tail-wagging via the nozzle at the bottom of the quartz tube to form amorphous state alloy belt, the film belt obtained is airproofed in the quartz tube, then it is placed to the microwave welding furnace for crystal process, the temperature and time range of crystal process in the microwave welding furnace is 400-900deg.C and 10min-180min, then it is placed into water for cooling. The craftwork of the invention is simple, the cost is low, the grain size of nanometer crystal magnet which includes SmCo7 main phase is about 20nm, and it is lower than grain size obtained by general heat treatment method, the exchange coupled function between grains is increased greatly.

Owner:CENT SOUTH UNIV

Preparation method of magnetic aluminum pigment

InactiveCN103319917AStrong magnetismCover tightlyPigment treatment with non-polymer organic compoundsKetone solventsSilicon dioxide

The invention provides a preparation method of magnetic aluminum pigment. The preparation method comprises the following steps of: washing flaky aluminum pigment through a ketone solvent, and performing press filtering to obtain a filter cake; placing the filter cake, an alcohol solvent, a magnetic powder material and a silane coupling agent into a reactor to be stirred and dispersed; simultaneously dropwise adding an alcohol diluent of ammonia water and an alcohol diluent of tetraethoxysilane for reaction; aging and performing press filtering on the mixed solution to obtain magnetic aluminum pigment coated by silicon dioxide; placing a ester solvent into the reactor, uniformly dispersing the magnetic aluminum pigment coated by the silicon dioxide into the ester solvent, dropwise adding acrylate monomers and an azo initiator into the reactor, sealing the reactor, and introducing inert gas into the reactor to wrap the mixture; performing press filtering on the mixture to obtain the double-layer coated magnetic flaky aluminum pigment. The magnetic aluminum pigment has excellent magnetism, the compactness in wrapping is achieved, a wrapping film is thin and uniform, the dispersion performance of the pigment in paint is good, and the magnetic aluminum pigment can be applied to 3D (three-dimensional) magic art paint.

Owner:HEFEI SUNRISE PIGMENTS

Method for producing oriented silicon steel with good bottom by low-temperature heating

ActiveCN1978707AGuarantee normal implementationEfficient formationSolid state diffusion coatingFurnace typesHot TemperatureSilicon

The invention supplies a method used to produce orientation silicon steel by low temperature heating. It includes the following steps: heating the plate blank under 1280 degree centigrade; hot rolling; once or double cold rolling to gain finished product sheet thickness; nitriding treatment; decarburizing annealing; coating insulator; high temperature annealing. In the nitriding technology, heating area dew point is controlled at -15-40 degree centigrade. The invention has the advantages of high nitriding efficiency, no influence from the surface oxide film, excellent MgO coat formula which makes the magnesium silicate substrate have good magnetic property, ensure the implementation for the next hot leveling annealing and insulating coating.

Owner:BAOSHAN IRON & STEEL CO LTD

Insulative adhesive for preparing metallic and soft magnetic composite material and using method thereof

ActiveCN104031601AImprove thermal stabilityImprove insulation performanceNon-macromolecular adhesive additivesInorganic material magnetismAdhesiveOrganosilicon

The invention discloses an insulative adhesive for preparing a metallic and soft magnetic composite material and a using method thereof. The insulative adhesive disclosed by the invention is a nano-modified organic silicon resin insulative adhesive which comprises organic silicon resin and an inorganic nano dispersion liquid. The insulative adhesive greatly improve the heat-resisting temperature of the organic silicon resin and improve the mechanical strength of a magnetic powder core, is reasonable in component selection and good in using effect and has a good insulative adhering effect to Fe-based, nickel-based and metallic soft magnetic powder of other metals. The magnetic powder core prepared by the insulative adhesive prepared by the invention has excellent magnetic performance and mechanical performance.

Owner:ZHEJIANG UNIV

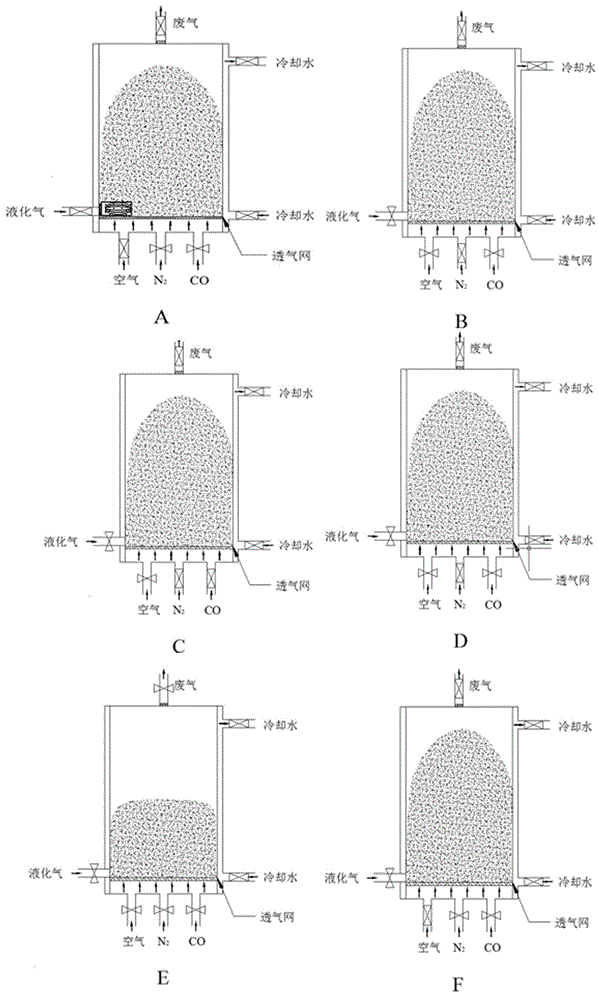

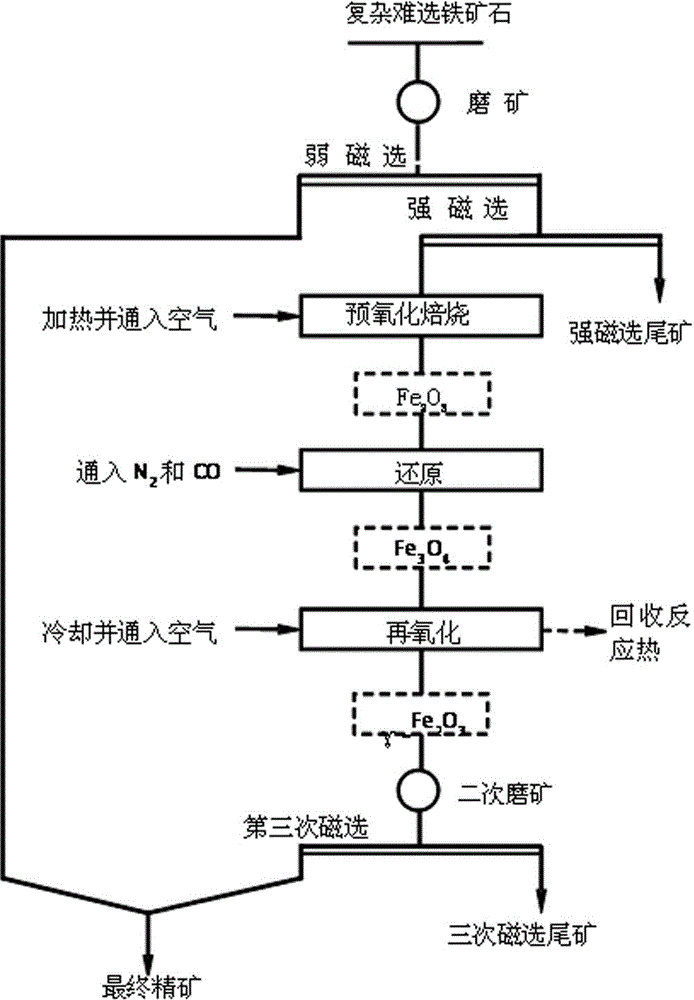

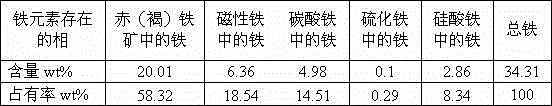

Preenrichment-three segment suspension roasting-magnetic separation treatment method of complex refractory iron ores

The invention discloses a preenrichment-three segment suspension roasting-magnetic separation treatment method of complex refractory iron ores, and belongs to the technical field of mineral processing. The method comprises the following steps: 1, levigating the complex refractory iron ores, carrying out weak magnetic separation, and carrying out strong magnetic separation on mine tailings; 2, putting concentrate obtained after strong magnetic separation in a suspension roasting furnace, and heating to 450-800DEG C in a suspension state in order to carry out pre-oxidation roasting; 3, introducing nitrogen to displace air, and introducing a reducing gas to carry out reduction in a suspension loose state; 4, introducing air when the temperature decreases to 250-400DEG C in order to oxidize, taking out the obtained material when the temperature decreases to below 100DEG C, and carrying out ore milling; and 5, carrying out third segment magnetic separation, and mixing concentrate obtained after three segment magnetic separation with concrete obtained after the weak magnetic separation to obtain finial concentrate. The method has the advantages of simple process, improvement of the recovery rate of the complex refractory iron ores, strong adaptability, safe and reliable process, uniform and stable product quality, energy saving and consumption reduction.

Owner:上海逢石科技有限公司

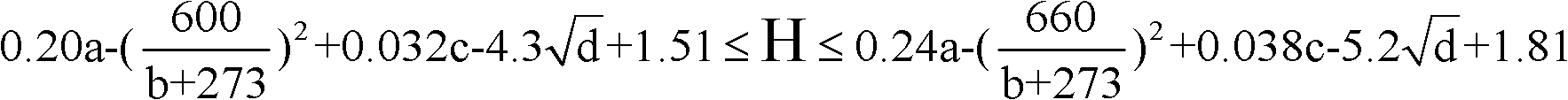

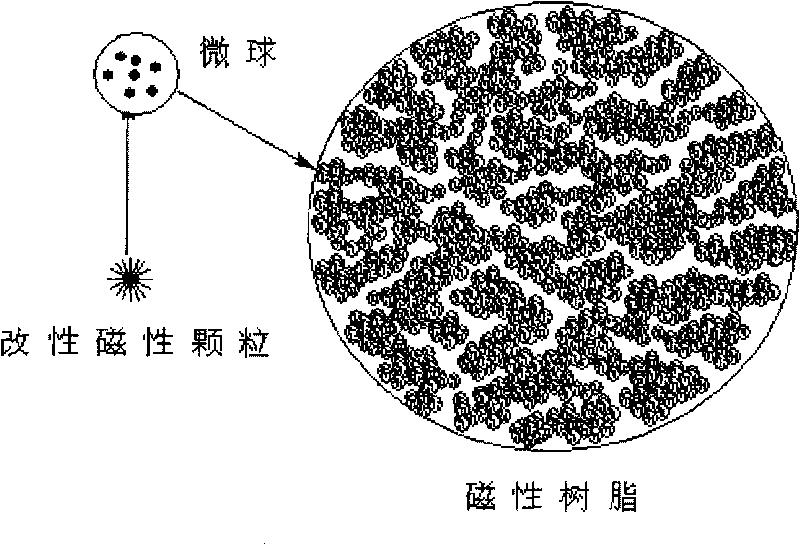

Magnetic cation exchange resin catalyzer and preparation method and application thereof

ActiveCN101733152AStrong magnetismEasy to wrap and fixOrganic-compounds/hydrides/coordination-complexes catalystsParticulatesHydration reaction

The invention relates to a magnetic cation exchange resin catalyzer and a preparation method and application thereof. In the method, nanometer magnetic metal oxide and long-chain fatty acid are mixed in the water the pH of which is 9-12, the pH is regulated to 4-5, and modified nanometer magnetic particulate is obtained after the nanometer magnetic metal oxide and the long-chain fatty acid react; monomer, evocating agents, crosslinking agents and pore-foaming agents are mixed with the modified nanometer magnetic particulate which accounts for 5-65% of the total weight of the monomer and the crosslinking agents, magnetic resin is obtained after polymerization, and the catalyzer is obtained through sulphur reaction of the magnetic resin. The catalyzer can be used for catalyzing olefin hydration reaction, ether hydrolysis reaction, esterification reaction, etherealization reaction, condensation reaction or aromatic hydrocarbon alkylation reaction in a magnetic reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

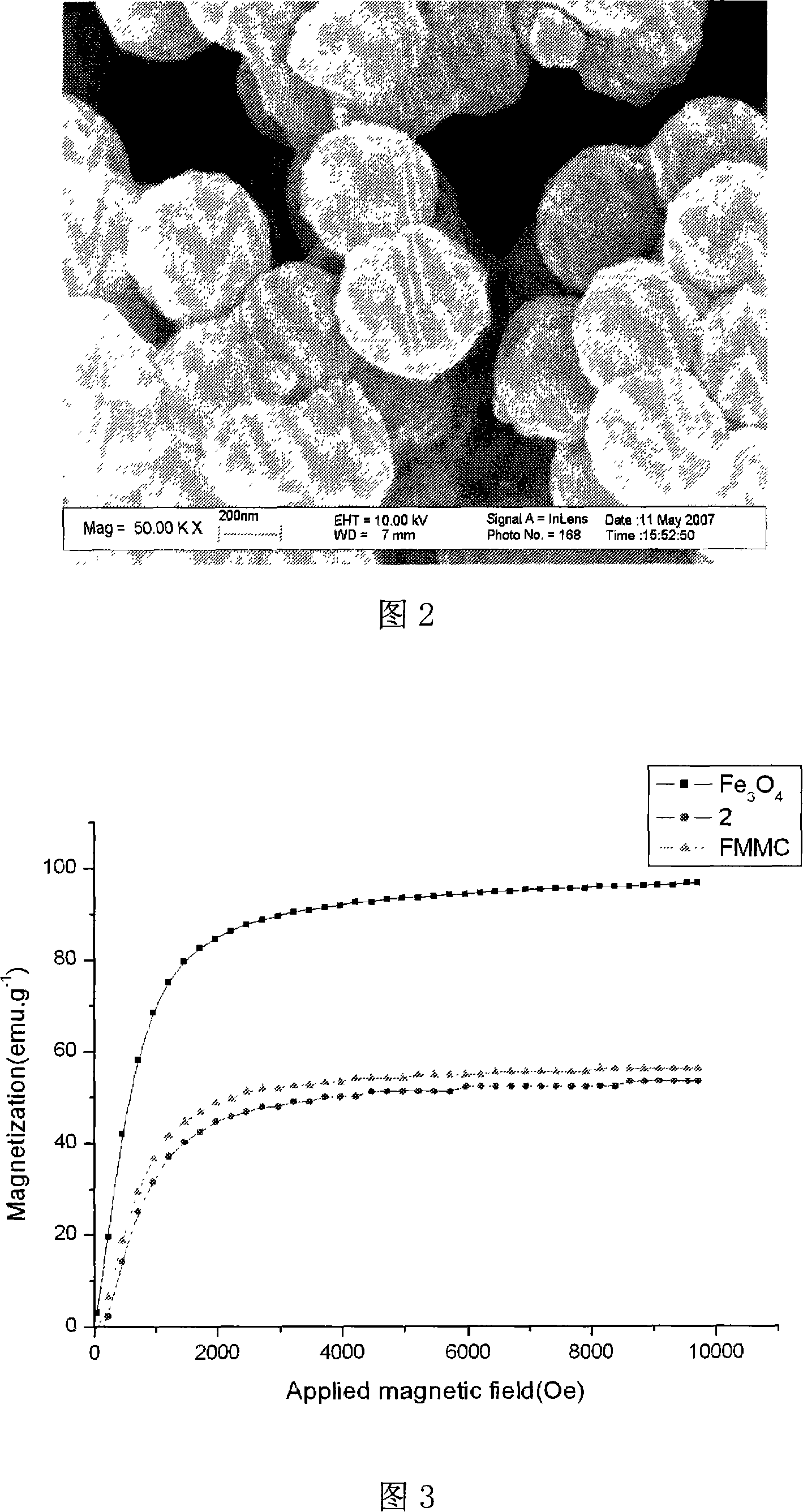

Water-soluble nuclear-shell magneto-optic dual-function nanoparticle and preparation method thereof

InactiveCN101775280AGood water solubilityGood dispersionInorganic material magnetismLuminescent compositionsSolubilityDansyl chloride

The invention relates to the technical field of the composite material, and discloses a water-soluble nuclear-shell magneto-optic dual-function nanoparticle. In the structure of the water-soluble nuclear-shell magneto-optic dual-function nanoparticle, magnetic CoFe2O4 is used as a core, amorphous SiO2 is used as a shell, the surface of the shell is connected with an organic light-emitting material dansyl chloride, and the particle size is 25-50nm. The preparation method comprises the following steps: preparing a monodisperse magnetic cobalt ferrite nanoparticle through thermal decomposition, coating silica on the surface of the nanoparticle, carrying out modification of amino on the surface of the silica, and connecting an organic light-emitting material through the amino on the peripheryof the magnetic nanoparticle. The nanoparticle of the invention has a nuclear-shell structure and a uniform particle size, and can be well dispersed in water. Moreover, the nanoparticle of the invention has good water solubility, good magnetic properties, light-emitting effect and good biocompatibility.

Owner:SHANGHAI NORMAL UNIVERSITY

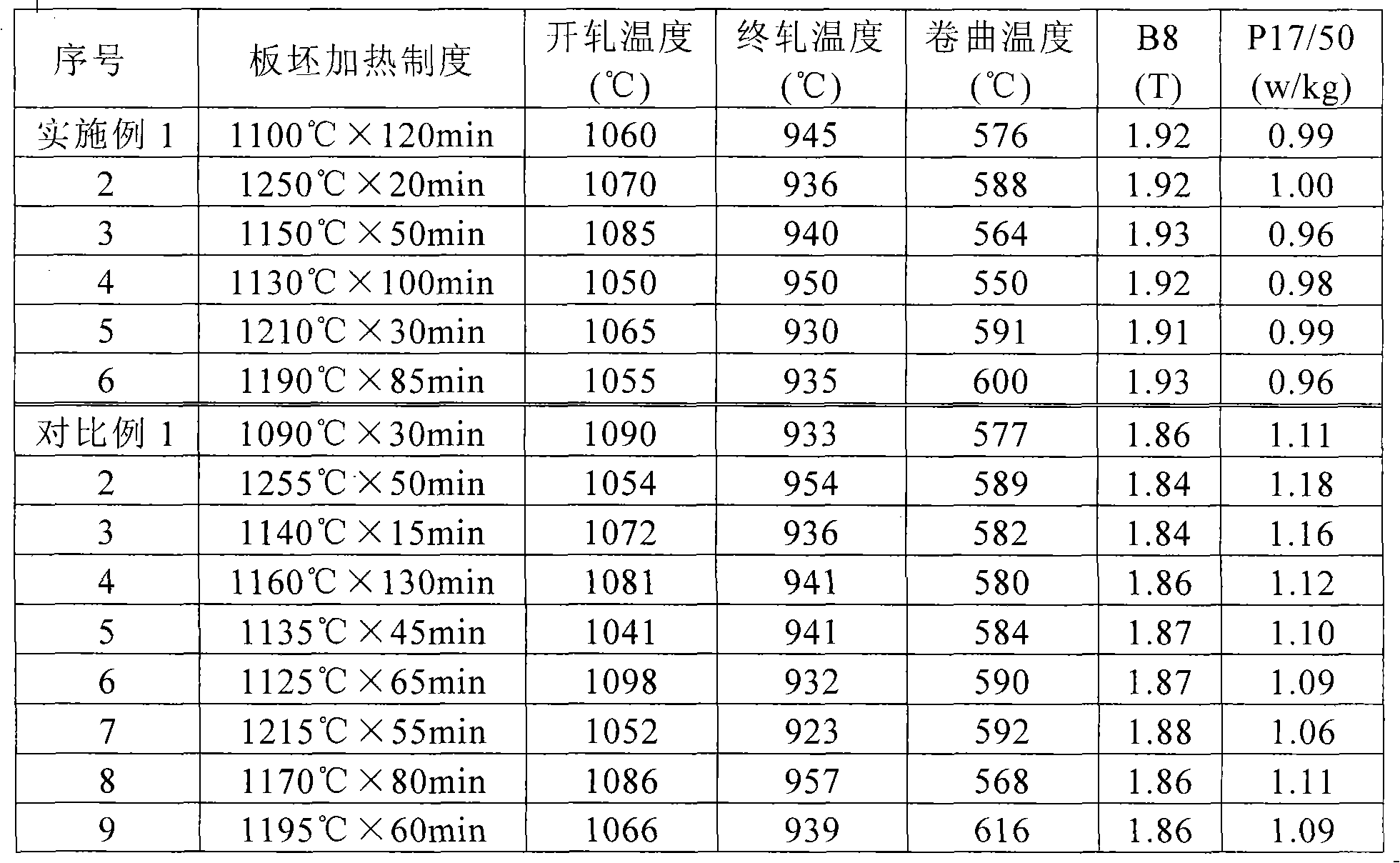

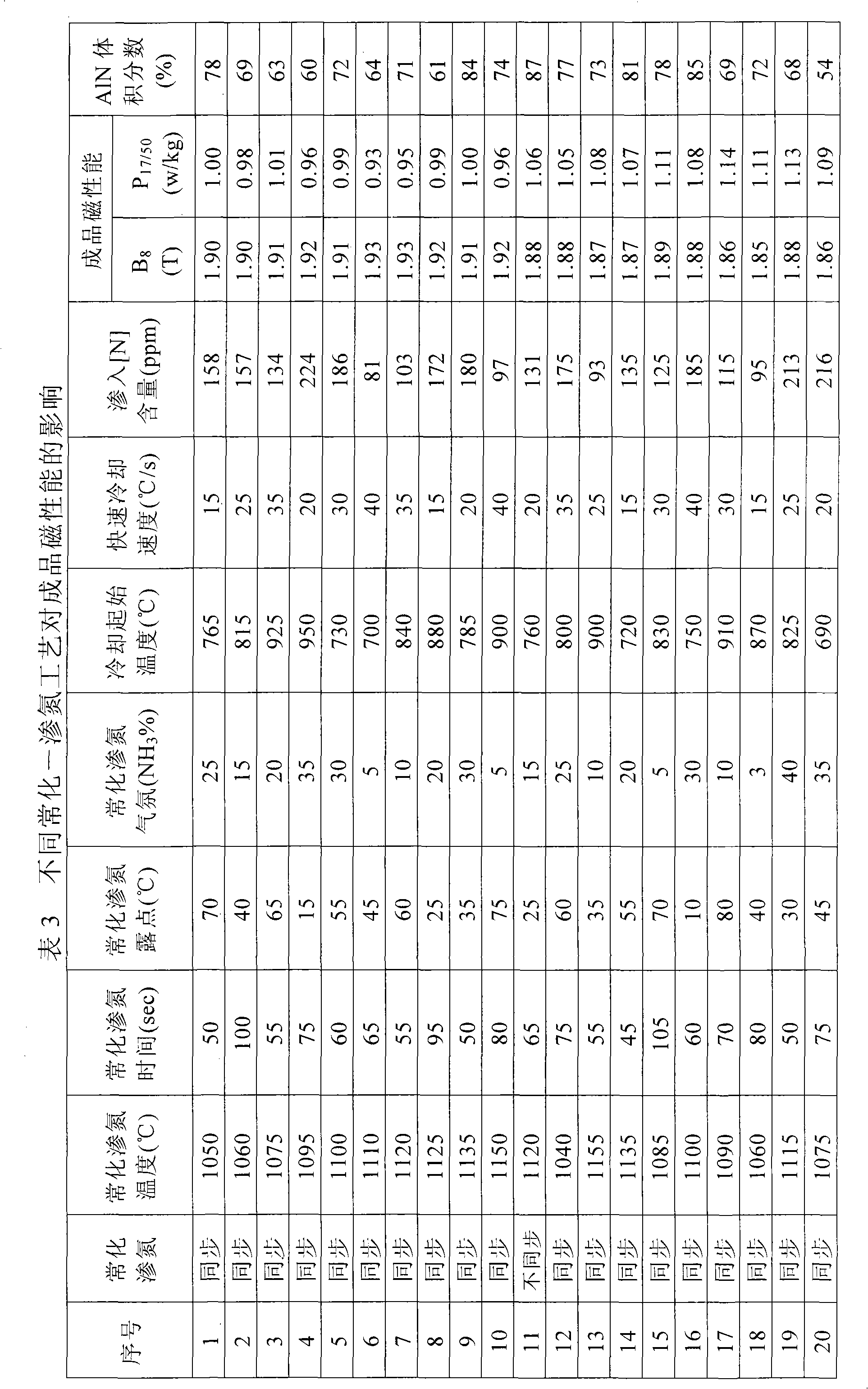

Production method of high magnetic induction oriented silicon steel

ActiveCN101845582AIncrease contentPrevent transverse crackingSolid state diffusion coatingSiliconAtmosphere

The invention relates to a production method of high magnetic induction oriented silicon steel, comprising the steps of smelting, continuous casting, hot rolling, normalization, decarbonization and annealing, MgO coating, high-temperature annealing and insulation coating, wherein the normalization comprises the steps that: normalization is carried out on a hot rolling plate, nitridation is finished synchronously, the temperature of normalization and nitridation is 1050-1150 DEG C, the atmosphere is 5-35% NH3 (volume percentage), and the balance of gas is N2; after the normalization and nitridation, the N content nitrided into the hot rolling plate is 60-250ppm; and normalization cooling is carried out, the initial temperature of fast cooling is 700-950 DEG C, and the fast cooling speed with the temperature of being reduced to 550 DEG C is 15-40 DEG C / sec. The production method solves the problem of difficult nitridation in the decarbonization procedure when a low-temperature plate blank heating technology is used for producing the high magnetic induction oriented silicon steel, carries out synchronous nitridation on the hot rolling plate in the normalization procedure, and leads the following procedure of decarbonization and annealing techniques to be simplified and easily controlled, thus not only being capable of obtaining a high magnetic induction oriented silicon steel product with excellent performance and simultaneously leading the production cost to be reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

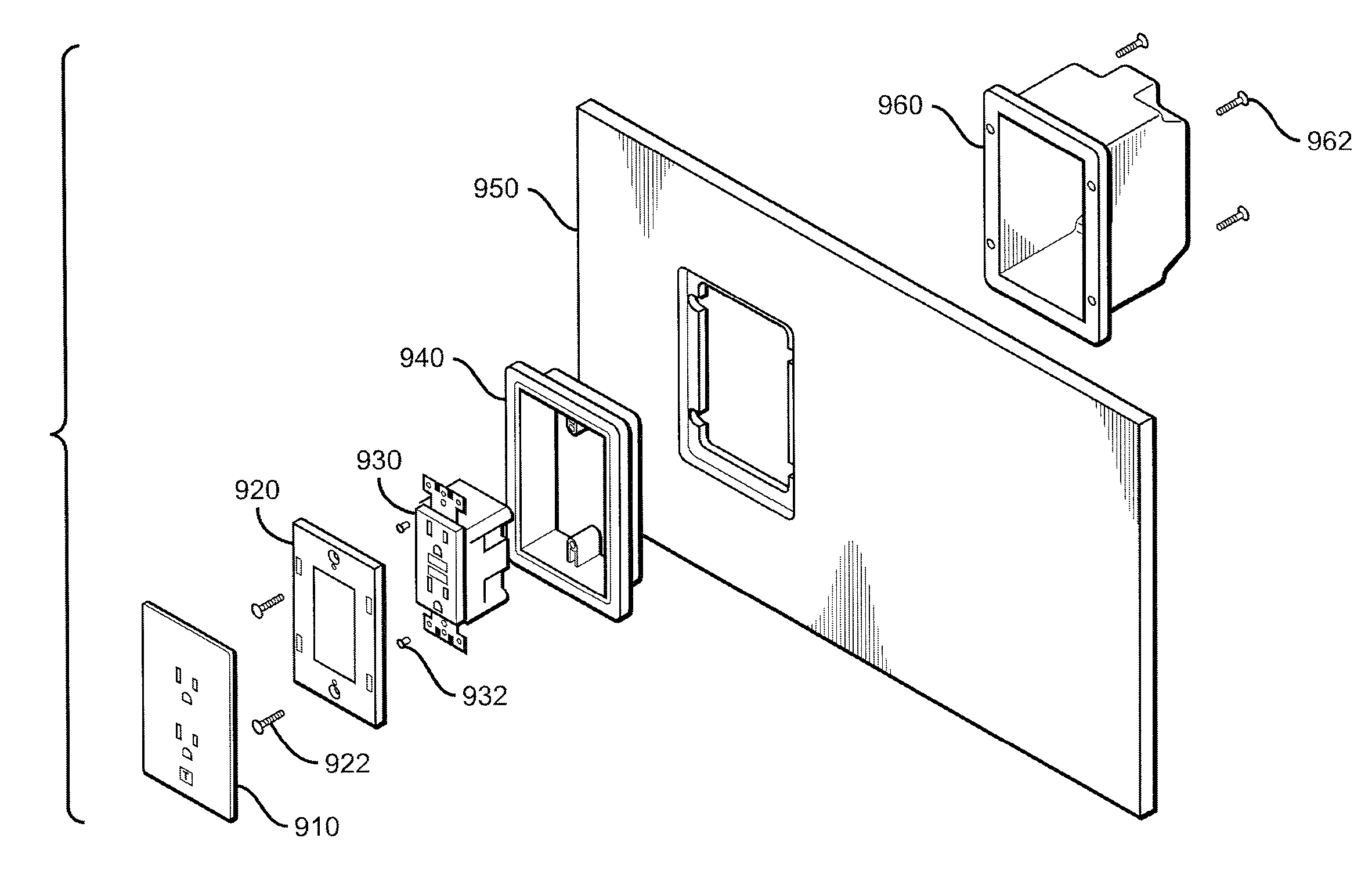

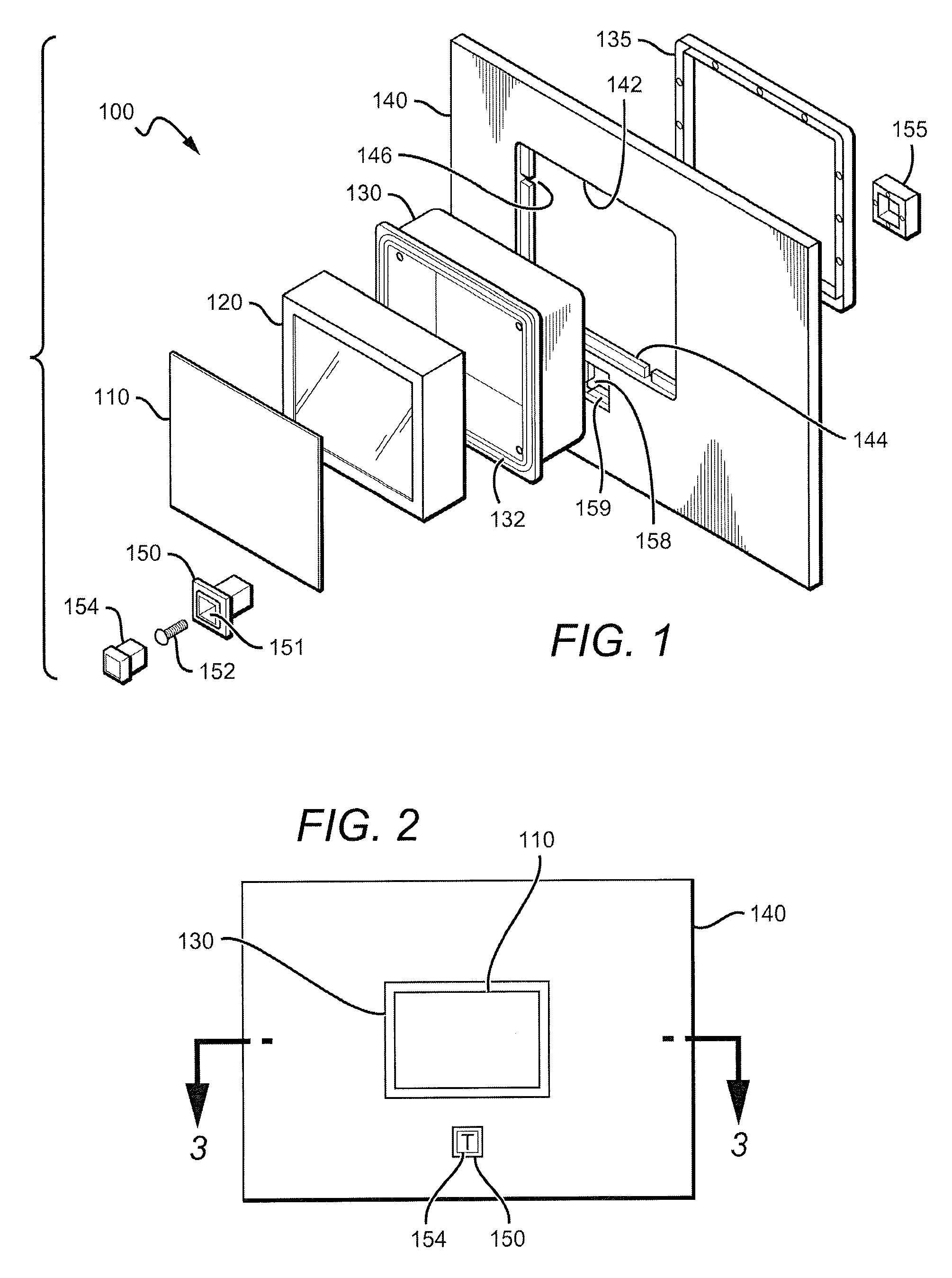

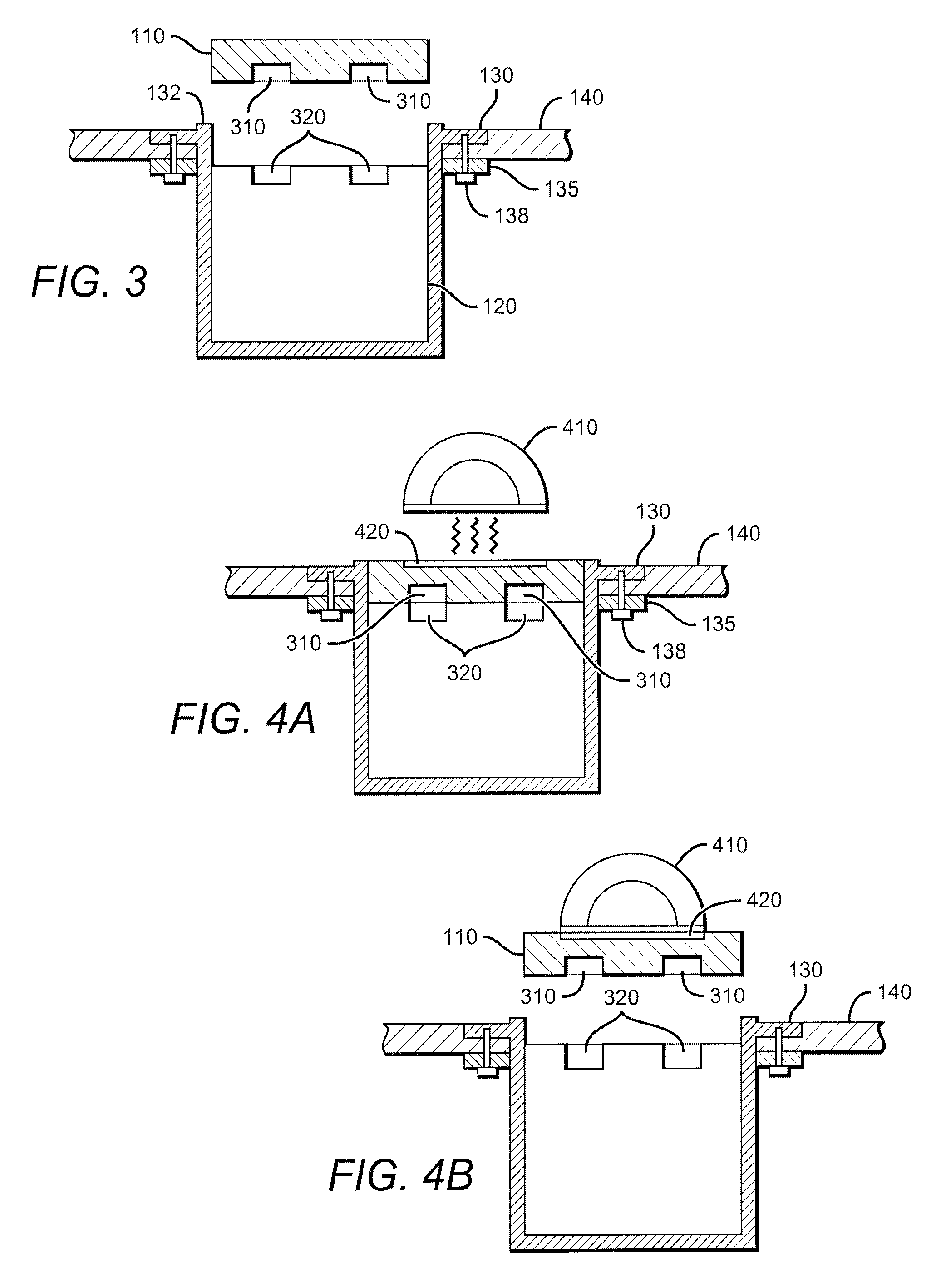

Flush Mounting Apparatus And Methods Using Component Cover

ActiveUS20090193724A1Avoid scratchesEasy to installMicrophonesPicture framesFully coupledEngineering

A panel with a bracket is used to install a component to a wallboard. The panel is inserted into an opening to a wallboard, and the junction between the panel and the wallboard is taped and spackled so that the wallboard and panel appear to be a single object. When the component is fully coupled to the bracket, the front of the component is slightly recessed from the front of the panel. A component cover could then be inserted into the newly created recess so that the component appears to be completely flush with the wallboard.

Owner:DANA INNOVATIONS

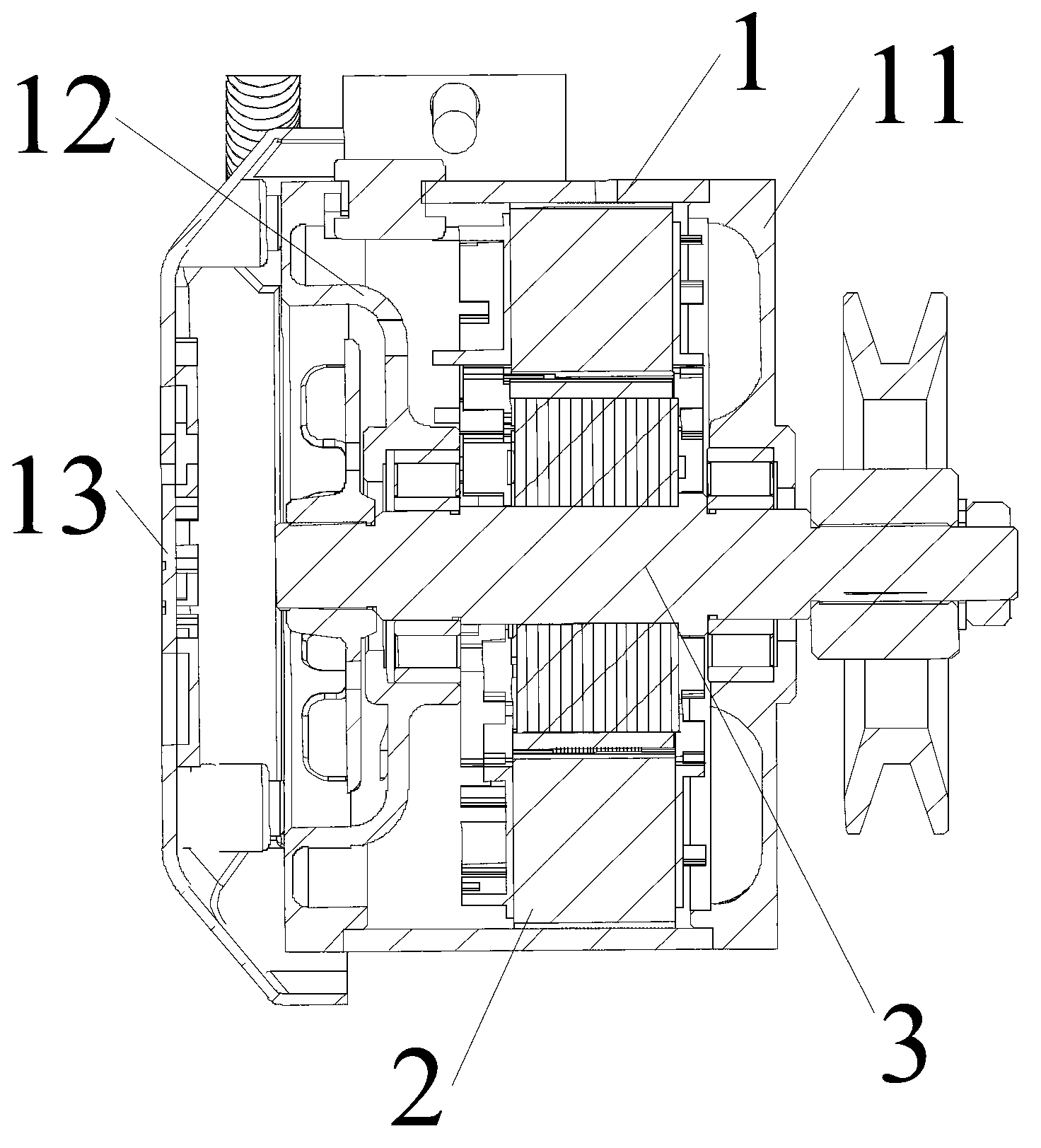

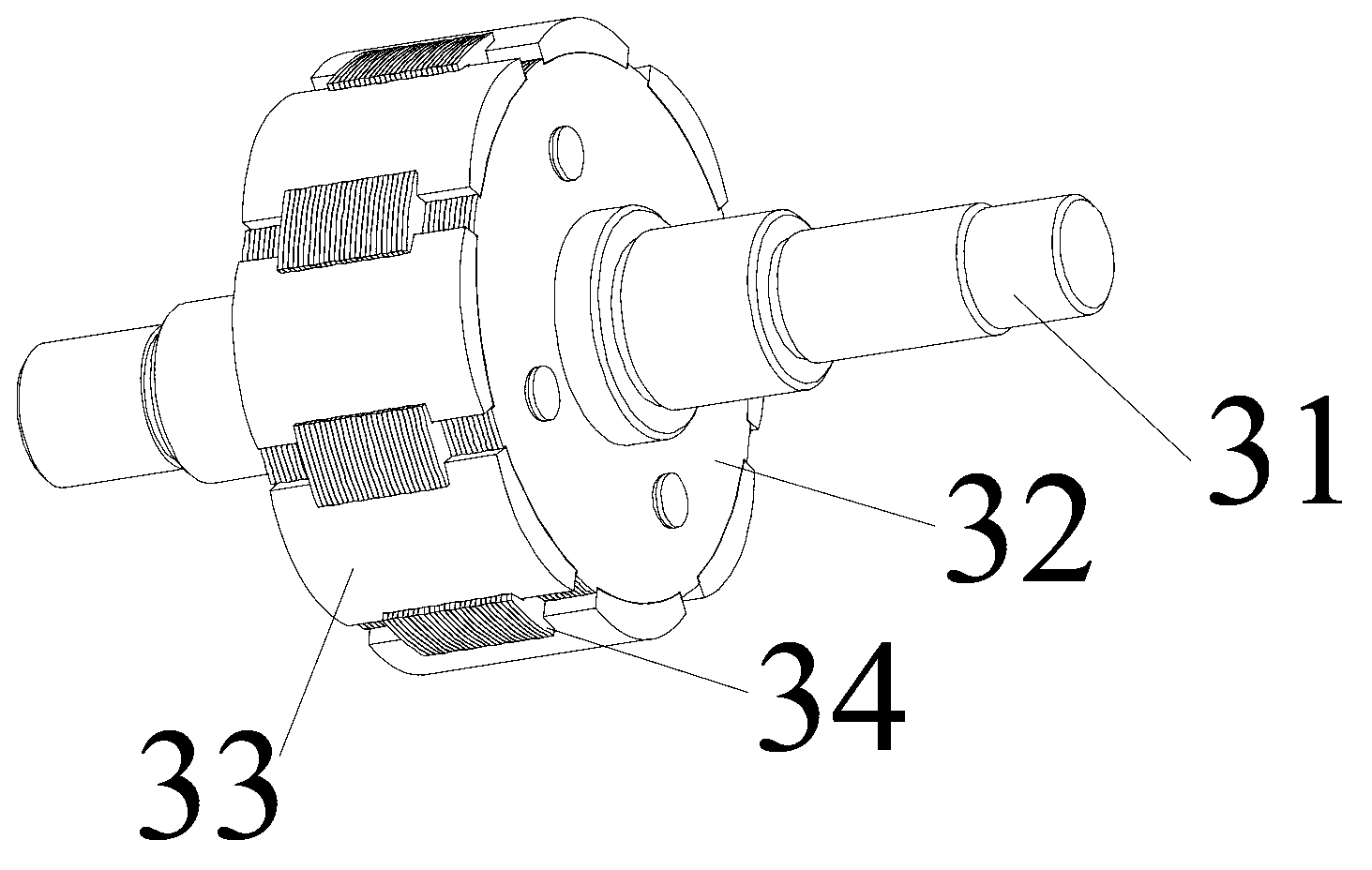

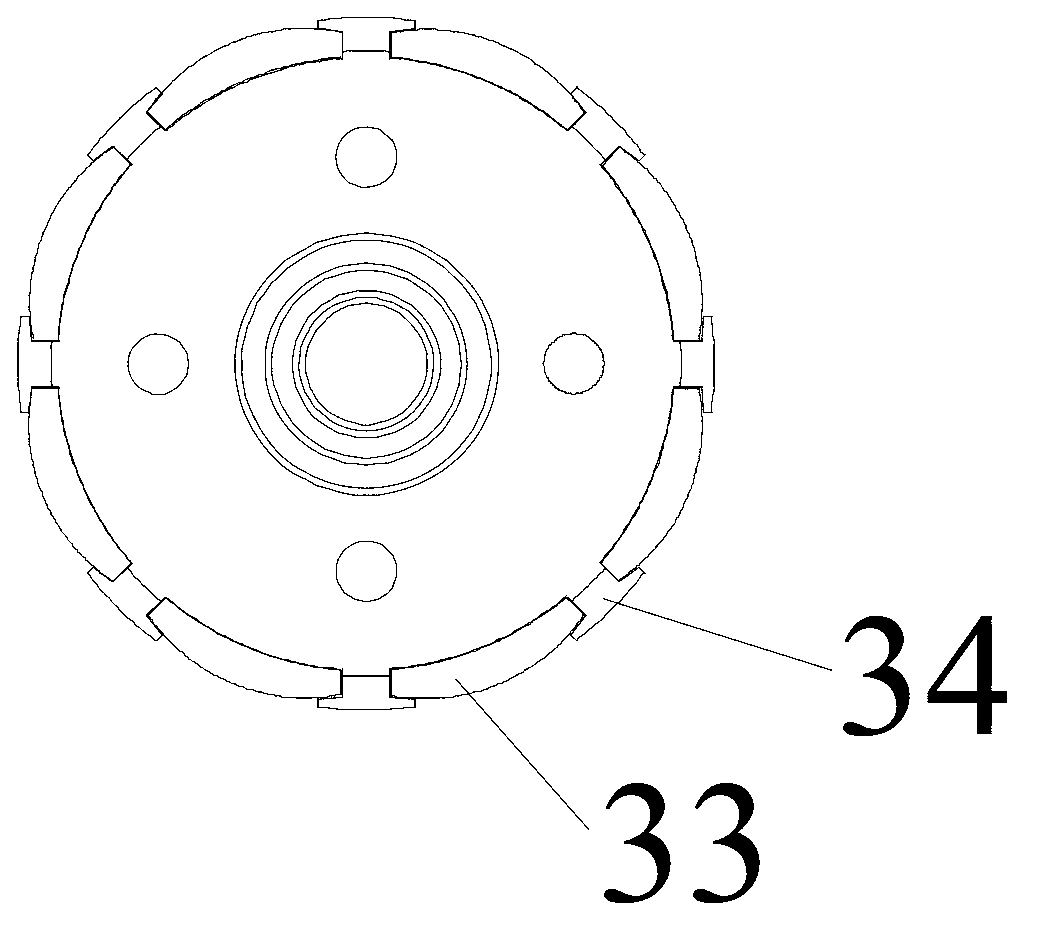

Energy-saving servo motor

InactiveCN103312068AGood energy saving effectEnergy saving effectMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringMagnetic energy

The invention discloses an energy-saving servo motor which comprises a case, a stator assembly and a rotor assembly. The rotor assembly comprises a motor shaft and a rotor iron core, the rotor iron core is fixedly sleeved on the motor shaft, a plurality of silicon steel sheets are laminated to form the rotor iron core, a plurality of steel magnets made of neodymium, iron and boron materials are mounted on the rotor iron core, T-shaped lugs which are distributed circumferentially are arranged on the circumferential surfaces of the silicon steel sheets in the middle of the rotor iron core, the quantity of the T-shaped lugs is identical to that of the steel magnets, the lugs on the silicon steel sheets are laminated to form clamp grooves, and the steel magnets can be embedded into the clamp grooves. Compared with the prior art, the energy-saving servo motor has the advantages that the steel magnets made of the neodymium, iron and boron materials are mounted on the rotor iron core of a rotor of the servo motor, excitation windings are omitted, the neodymium, iron and boron steel magnets are superior in magnetic properties such as high magnetic energy products and high coercivity, the lengths of air gaps can be maximized owing to the high coercivity of the materials, and accordingly an energy-saving effect of the servo motor is improved by 20% as compared with the traditional ferrite motor and other types of motors, and is excellent.

Owner:WUHU WEITE MOTOR

Method for producing high magnetic induction grain-oriented silicon steel

The invention relates to a method for producing high magnetic induction grain-oriented silicon steel, and belongs to the technical field of silicon steel production. The process comprises the following steps of: smelting, refining, and performing continuous casting to obtain a casting blank; performing hot rolling; normalizing, namely performing normalizing annealing and cooling; performing cold rolling at one time, wherein the cold rolling reduction ratio is 85 to 90 percent; nitriding by using a nitriding medium, namely dry NH3 at the temperature of between 600 and 740 DEG C for 5 to 40 seconds; decarburizing at the temperature of between 750 and 850 DEG C for 60 to 360 seconds, wherein the dew-point temperature is 25 DEG C; and annealing at a high temperature, and coating a stress coating. The method has the advantages that: a plate blank low-temperature heating process of nitriding at the temperature of between 600 and 740 DEG C and decarburizing annealing is adopted, the nitriding of a steel plate is not influenced by an oxidation film, the steel plate is uniformly nitrided, and efficiency is high; by controlling the nitriding and decarburizing processes, an appropriate amount of effective (Al, Si) N inhibitor is formed, and high magnetic property is achieved; and nitriding is performed at a low temperature, so energy consumption is low, and production cost is reduced.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com