Grain boundary diffusion method for improving properties of sintered NdFeB magnets

A technology of grain boundary diffusion and neodymium iron boron, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of increasing the production cost of magnets, natural resource pressure, insufficient diffusion depth of diffusion process, and reducing the magnetization intensity of magnets. Achieve the effects of good fluidity, wide applicability, and large diffusion depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

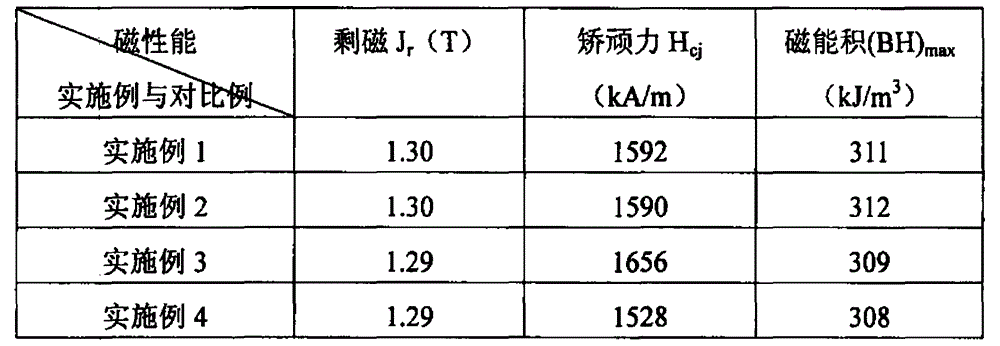

Embodiment 1

[0033] 1) Set the size to 4×7×27mm 3 The sintered samples were polished off the surface oxide layer with sandpaper, and ultrasonically cleaned with alcohol.

[0034] 2) Put a piece of Nd 63.5 Cu 30 Fe 6.5 The alloy sheet is placed under the magnet prepared in step 1, and the alloy sheet and the magnet are placed in the middle of the hot-pressing mold block, and the alloy sheet and the mold, and the magnet and the mold are separated by graphite paper.

[0035] 3) Vacuum the hot press furnace to 1×10 -2 Pa, run the heating program, wait until the temperature reaches 800°C, apply a pressure of 10Mpa, the pressure direction is parallel to the C axis, keep the pressure for 6h, cool to room temperature with the furnace, and take out the sample.

[0036] 4) Put the diffused sample into high vacuum (-3 Pa) Anneal in a tube furnace at 500°C, hold for 3 hours, and cool to room temperature with the furnace after annealing.

Embodiment 2

[0038] 1) with embodiment 1 step 1;

[0039] 2) with embodiment 1 step 2;

[0040] 3) Vacuum the hot press furnace to 1×10 -2 , run the heating program, wait until the temperature reaches 750°C, apply a pressure of 30Mpa, the pressure is parallel to the C axis, keep the pressure for 3h, cool to room temperature with the furnace, and take out the sample;

[0041] 4) Put the diffused sample into high vacuum (-3 Pa) Anneal in a tube furnace at 450°C, hold for 6 hours, and cool to room temperature with the furnace after annealing.

Embodiment 3

[0043] 1) with embodiment 1 step 1;

[0044] 2) with embodiment 1 step 2;

[0045] 3) Vacuum the hot press furnace to 1×10 -2 , run the heating program, when the temperature reaches 750°C, apply a pressure of 40Mpa, hold the pressure for 3h, cool down to room temperature with the furnace, and take out the sample;

[0046] 4) Put the diffused sample into high vacuum (-3 Pa) Anneal in a tube furnace at 550°C, hold for 2 hours, and cool to room temperature with the furnace after annealing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com