Method for improving magnetic performance of samarium-cobalt permanent magnet material

A technology of permanent magnetic materials and magnetic properties, which is applied in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc. Magnetic energy product and other issues, to achieve the effect of regulating and optimizing element distribution, ensuring diffusion temperature, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

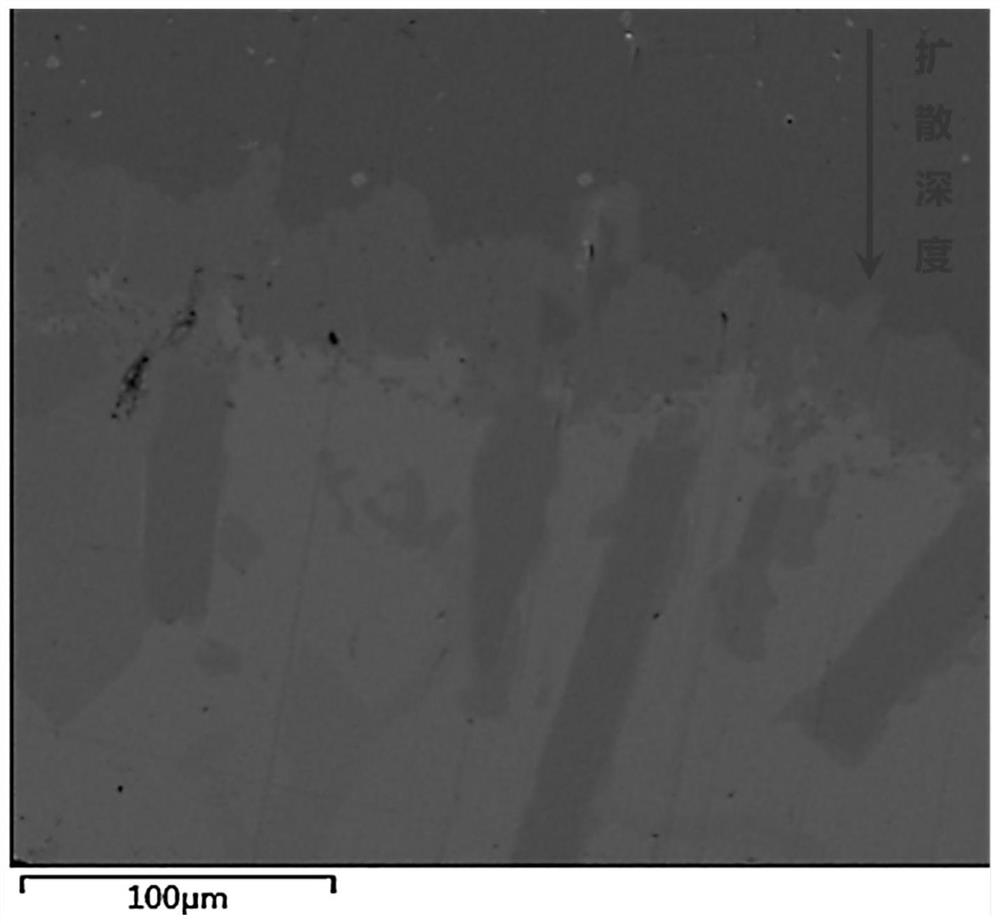

Image

Examples

preparation example Construction

[0032] In some more specific embodiments, the preparation method includes:

[0033] Put the base material with the low melting point phase diffusion source in a vacuum of 1×10 -1 ~1×10 -5 The thermal diffusion treatment is carried out under the condition of Pa.

[0034] Further, the preparation method includes: under an inert atmosphere with a pressure of 0.02-0.15 MPa, performing thermal diffusion treatment on the base material applied with a low melting point phase diffusion source, or performing a thermal diffusion treatment on the base material applied with a low melting point phase diffusion source A pressure of 5-20N is applied and thermal diffusion treatment is performed.

[0035] Further, the thermal diffusion treatment includes: under vacuum or pressurized conditions, the temperature is raised to 350-450°C at a rate of 5-7°C / min, heat preservation treatment is performed for 1.5-2.5h, and then the temperature is increased at a rate of 5-7°C / min Cool down to 750-850°...

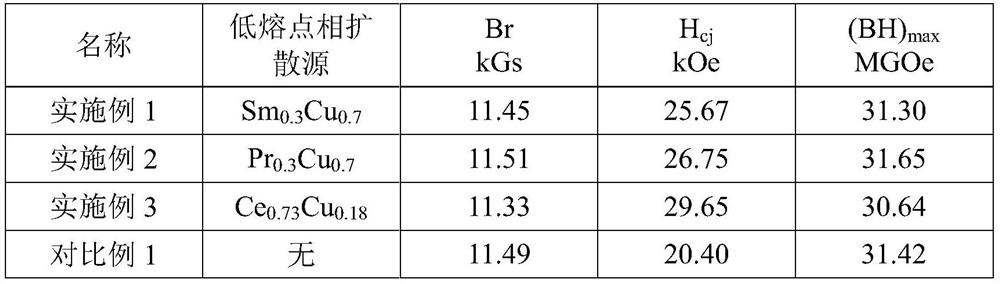

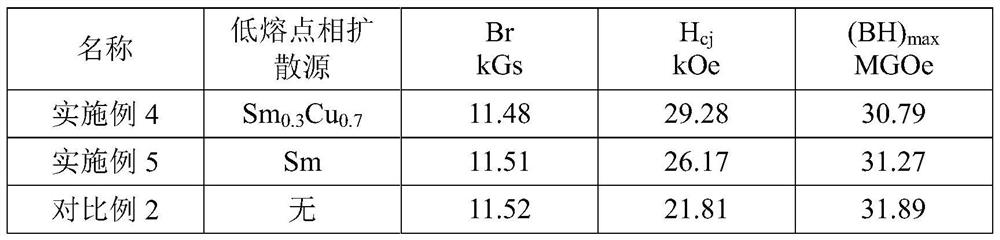

Embodiment 1

[0056] Diffusion treatment under vacuum conditions:

[0057] (1) Select 4μm rare earth-transition alloy Sm 0.3 Cu 0.7 (melting point at 600°C) low melting point powder as low melting point phase diffusion source, weigh 10g of alloy powder and alcohol in a mass ratio of 3:1 and mix thoroughly to form a suspension, wherein the viscosity of the suspension is 50-700mPa.s ;

[0058] (2) The samarium cobalt green body Sm(Co 0.7 Fe 0.05 Cu 0.05 Zr 0.05 ) 7 Processed into 20mm × 20mm × 1mm matrix sheet (i.e. powder oriented green body) after isostatic pressing, coated with a 0.4mm thick diffusion source on the surface layer of the matrix sheet, after that in 3 × 10 -2 Dry at 50°C for 30 minutes under a vacuum environment of Pa, and then put it into a high vacuum sintering furnace;

[0059] (3) Vacuumize the sintering furnace, when the vacuum degree reaches the required set value of 4×10 -3 Start heating at Pa, heat up to 400°C at a rate of 6°C / min, heat preservation treatment...

Embodiment 2

[0063] The preparation method of Example 2 is basically the same as that of Example 1, except that the low melting point phase diffusion source in step (1) of Example 1 is changed to Pr with an average particle size of 4 μm 0.3 Cu 0.7 Low melting point alloy powder (different from Sm in example 1 0.3 Cu 0.7 ), and its alloy melting point is 710°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com