Patents

Literature

157 results about "Alnico" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alnico is a family of iron alloys which in addition to iron are composed primarily of aluminium (Al), nickel (Ni) and cobalt (Co), hence acronym al-ni-co. They also include copper, and sometimes titanium. Alnico alloys are ferromagnetic, and are used to make permanent magnets. Before the development of rare-earth magnets in the 1970s, they were the strongest type of permanent magnet. Other trade names for alloys in this family are: Alni, Alcomax, Hycomax, Columax, and Ticonal.

Insulation for cryogenic tanks

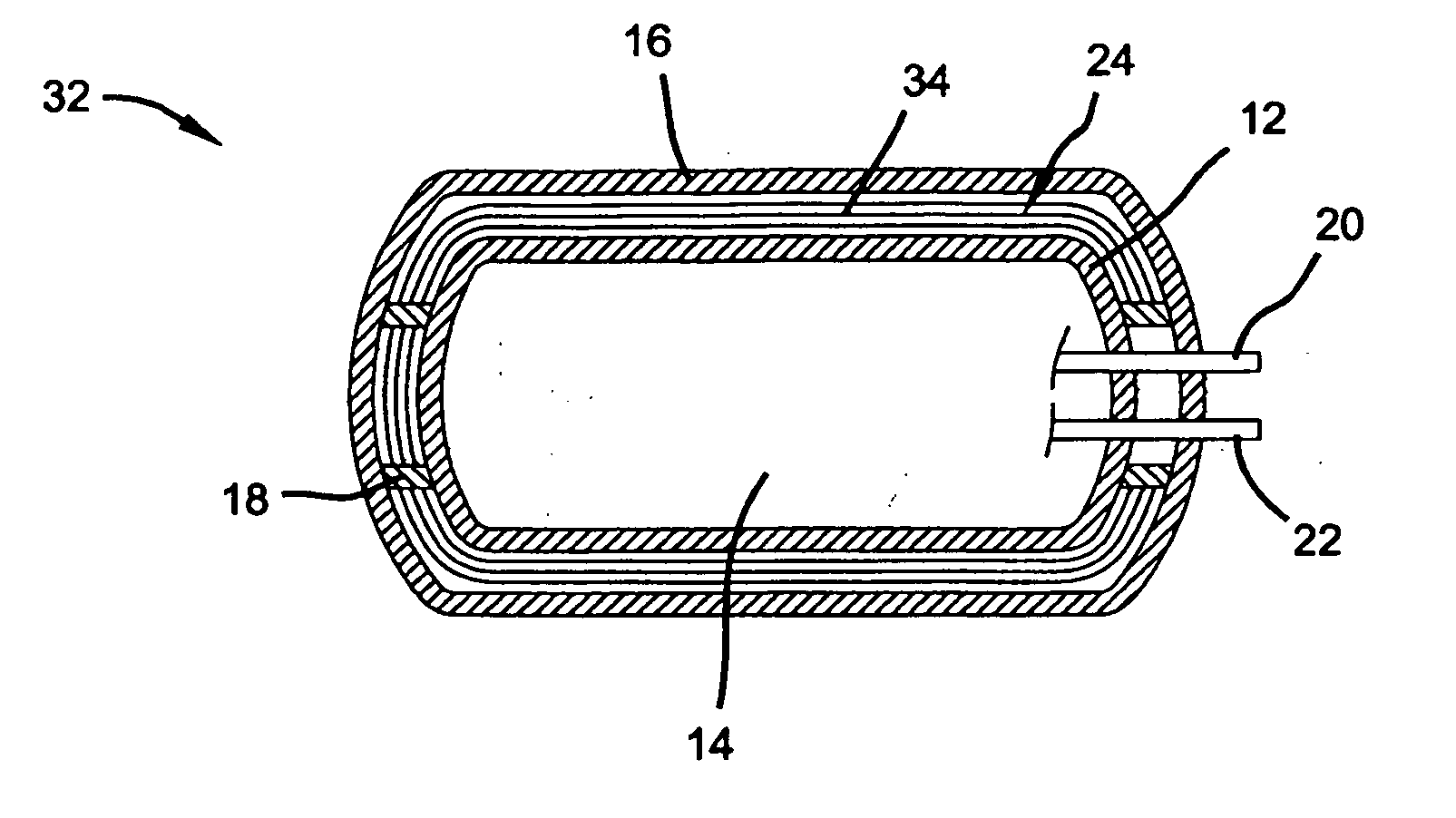

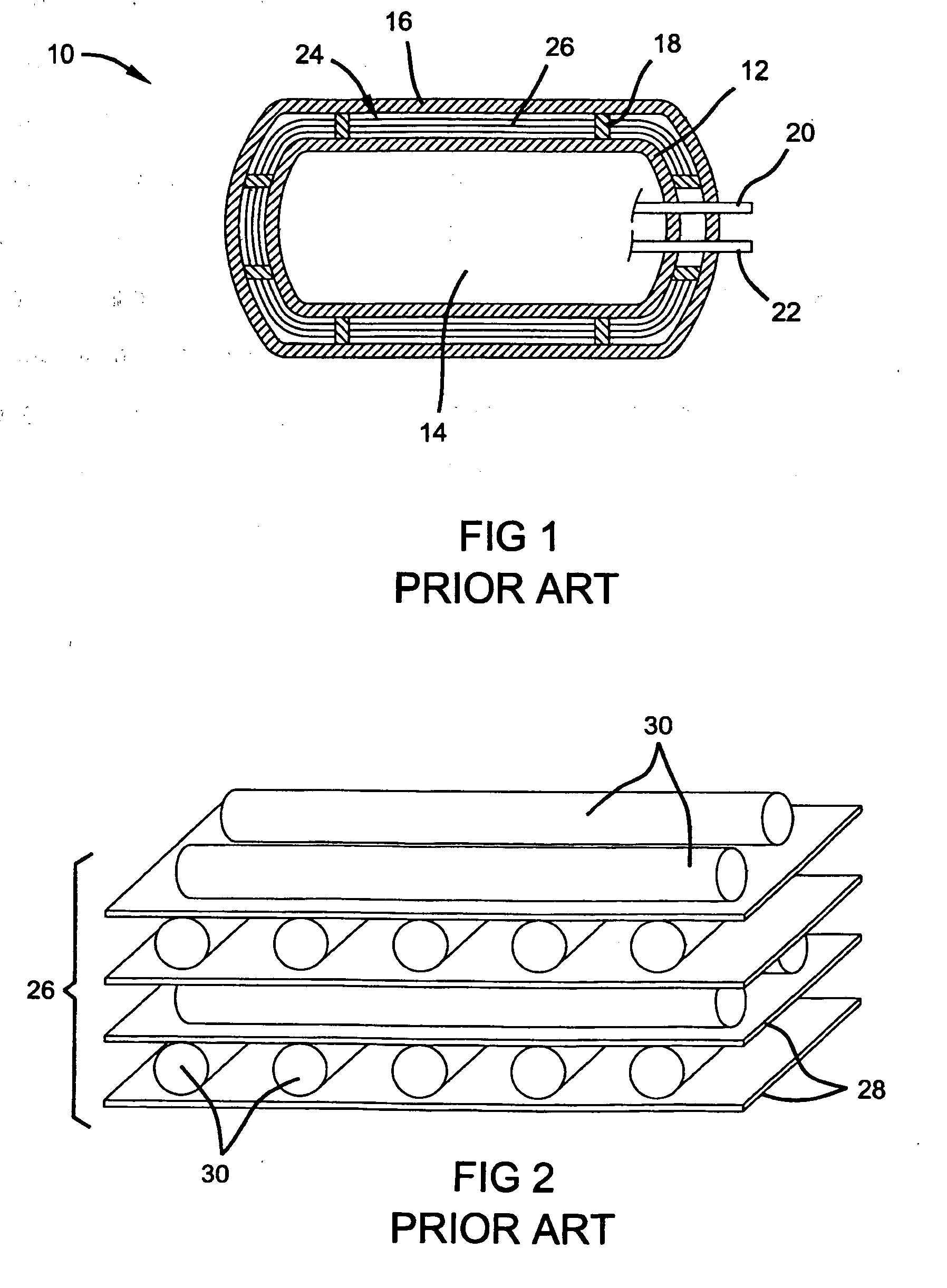

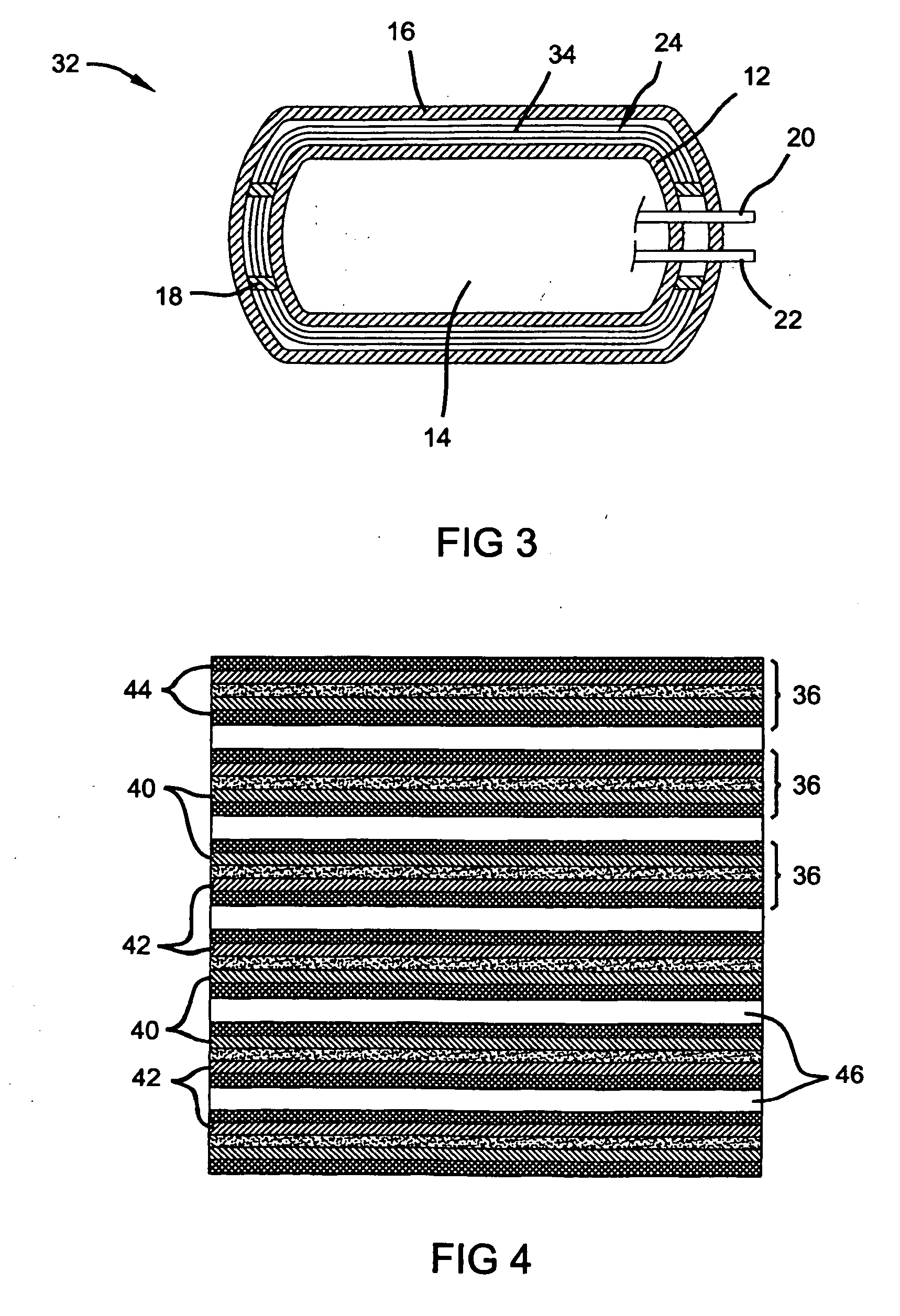

InactiveUS20060196876A1Domestic cooling apparatusLighting and heating apparatusMetal foilMagnetic poles

A magnetic multi-layer insulation system for a cryogenic storage tank. The system includes multiple layers of insulation comprising a carrier support structure disposed between a first major surface of a magnetic material defining a north pole facing away from the carrier support structure, and a second and opposite major surface of a magnetic material defining a south pole facing away from the carrier support structure. A reflective surface, or metal foil, is disposed adjacent the magnetic poles to deflect radiation. The layers are repelled from one another without the use of spacers. In various embodiments, the magnetic material is a permanent magnet selected from the group consisting of Samarium-Cobalt, Alnico, Neodymium-Iron-Boron, an alloy of the Lanthanide group of elements, and mixtures and alloys thereof.

Owner:GM GLOBAL TECH OPERATIONS LLC

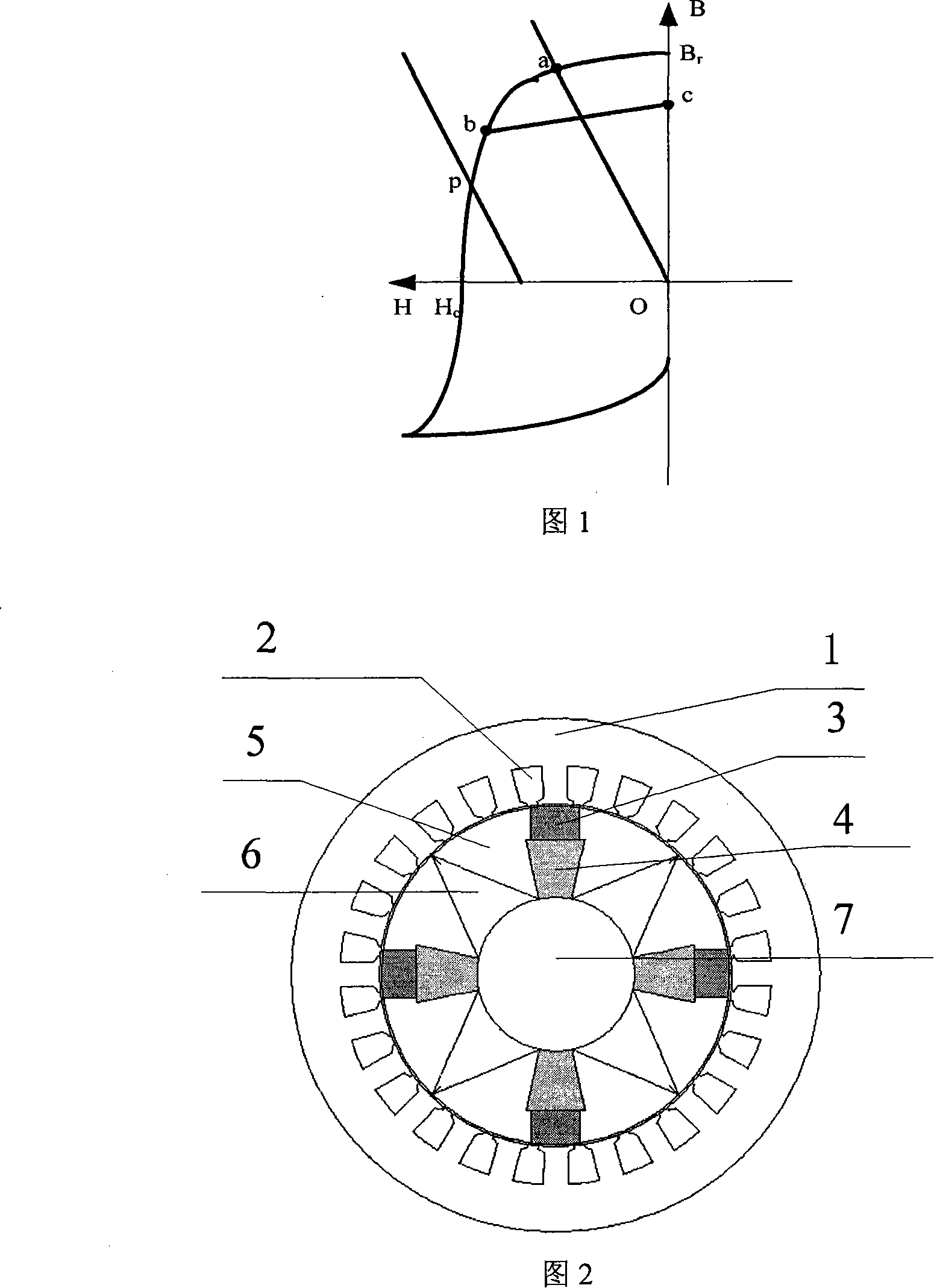

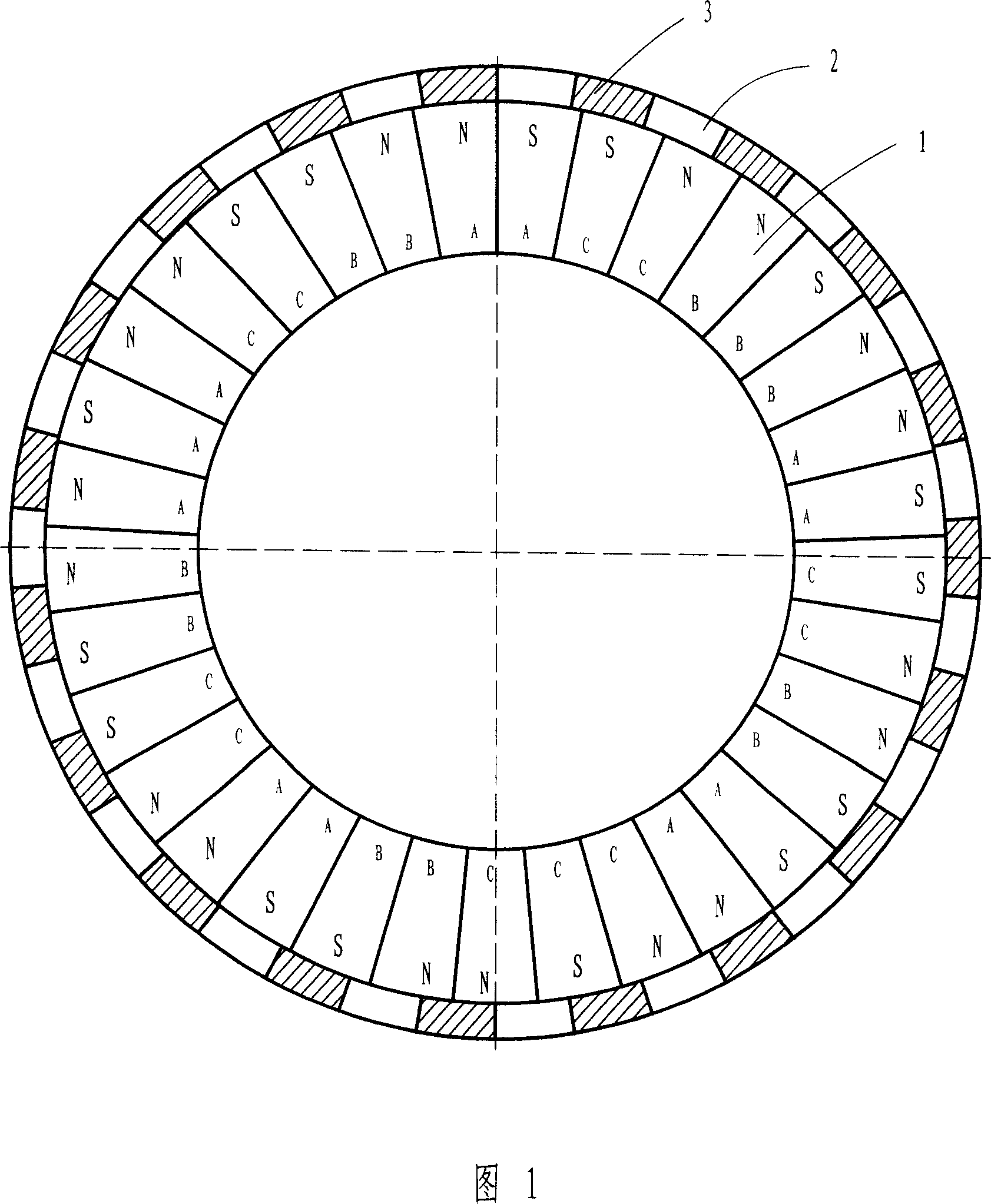

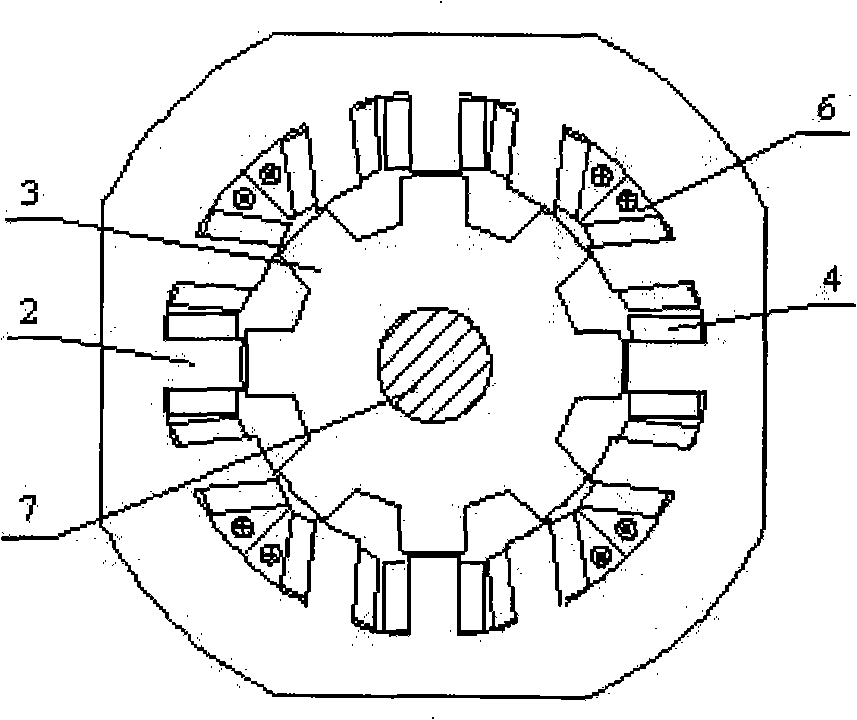

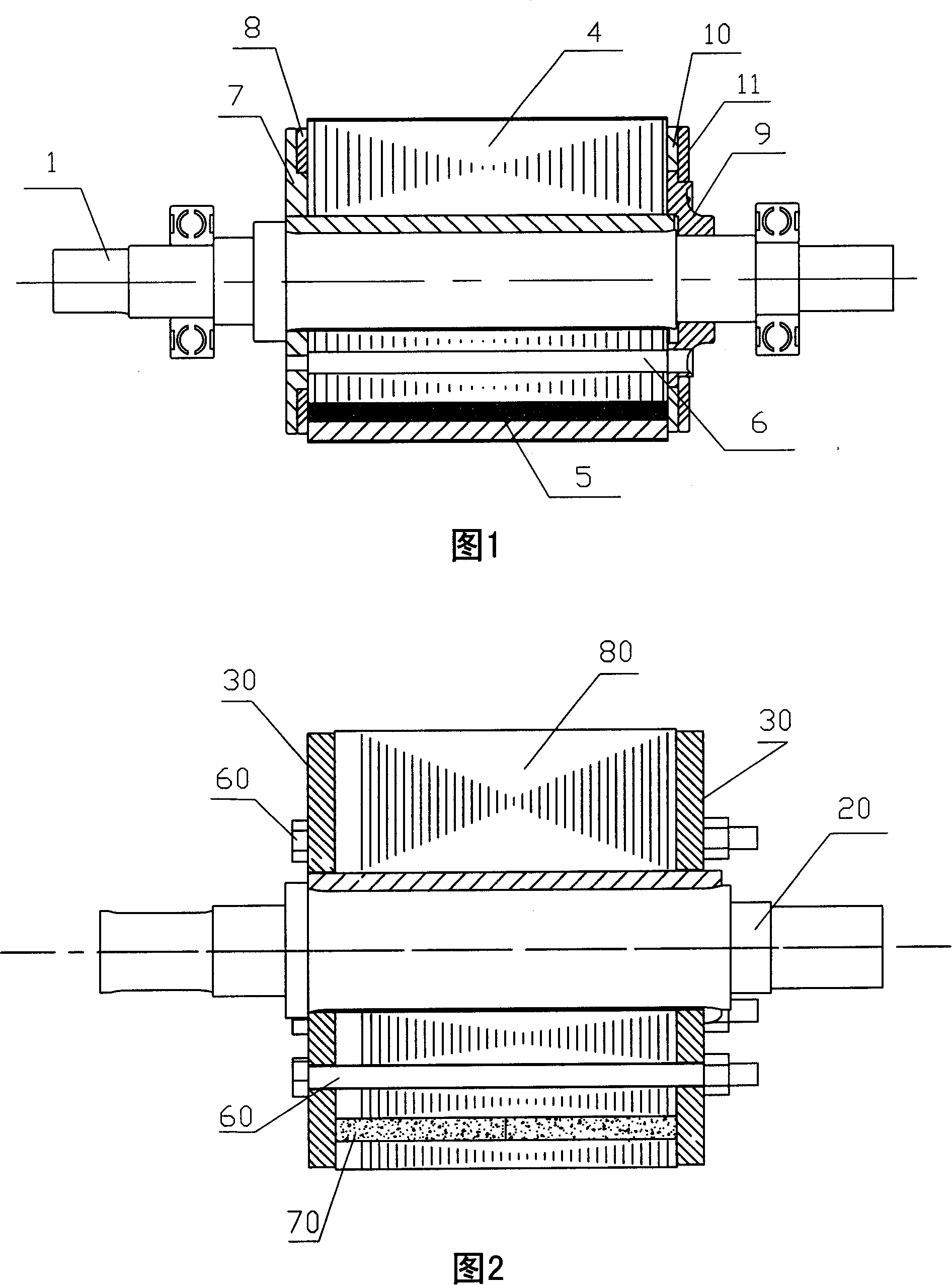

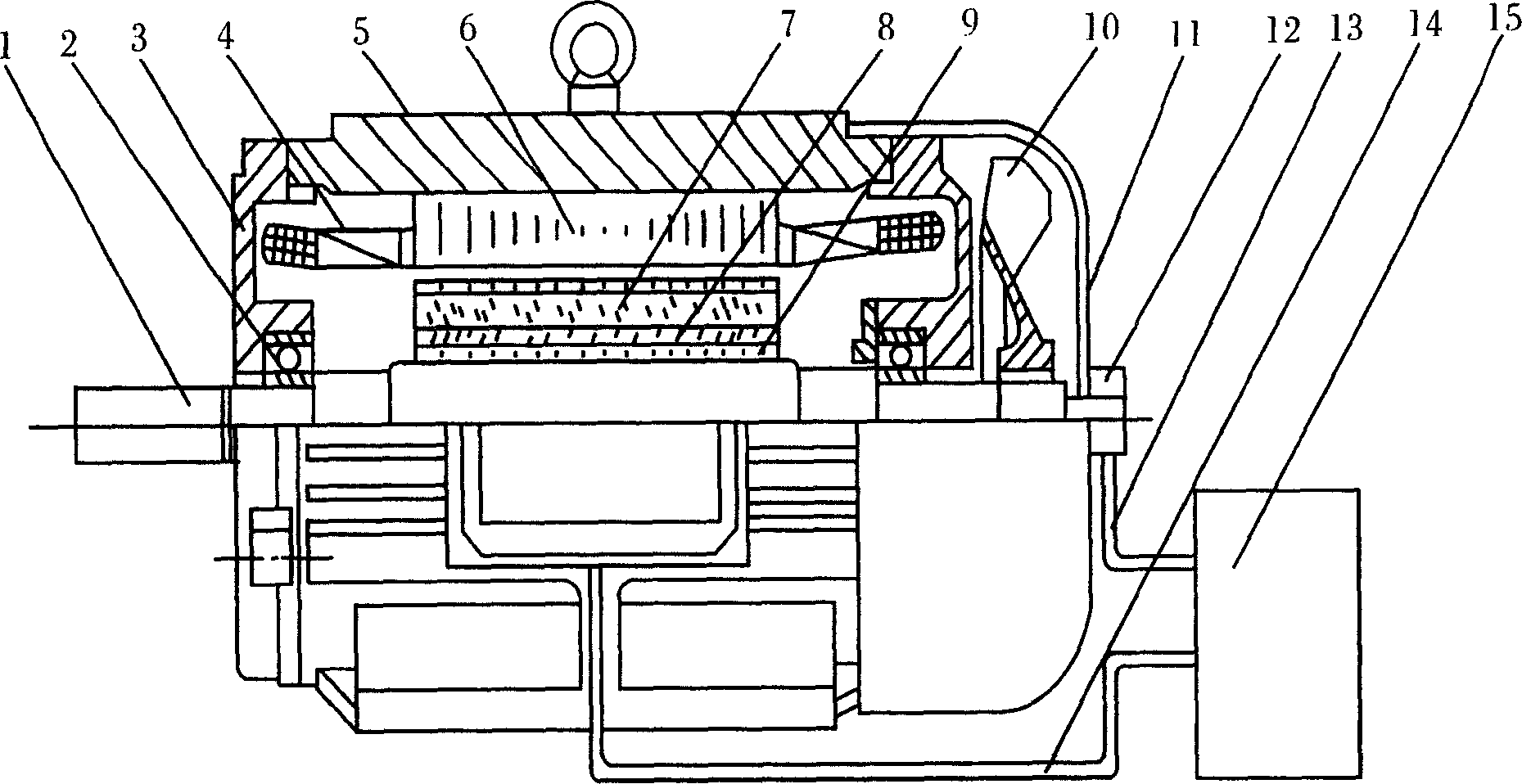

Variable flux permanent magnet synchronous motor

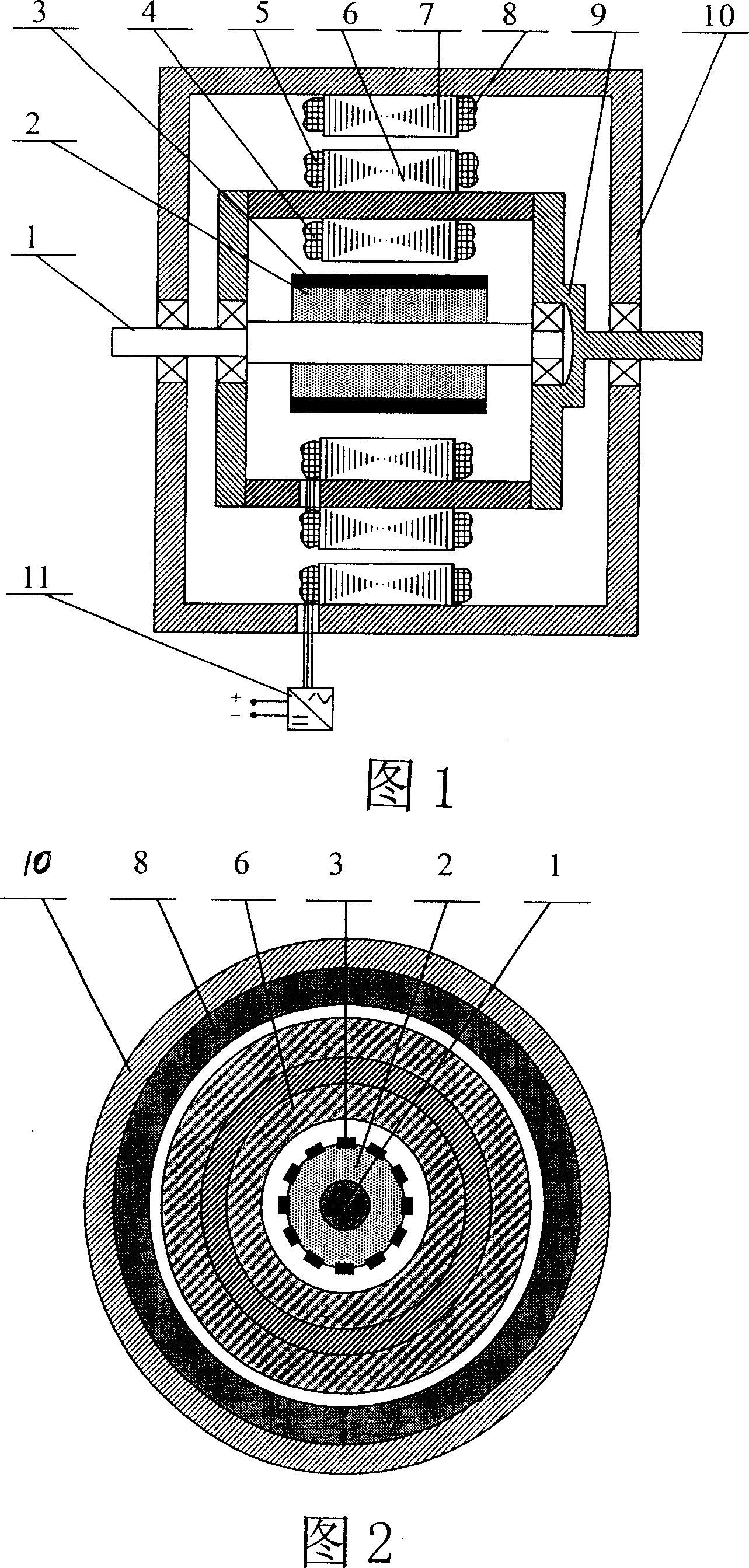

InactiveCN101232205AEasy to adjust magnetismImprove efficiencyMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsElectric machinePermanent magnet synchronous motor

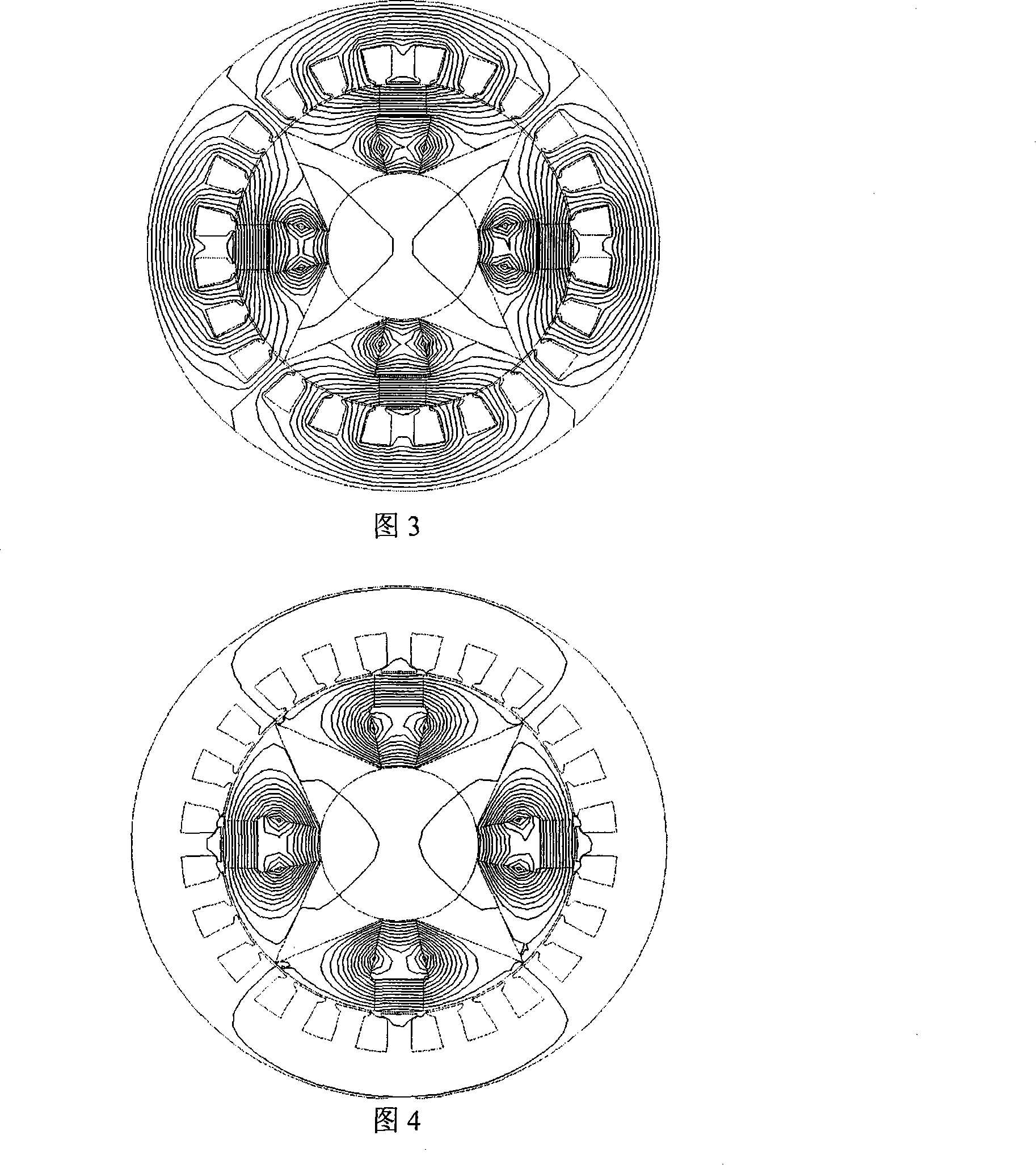

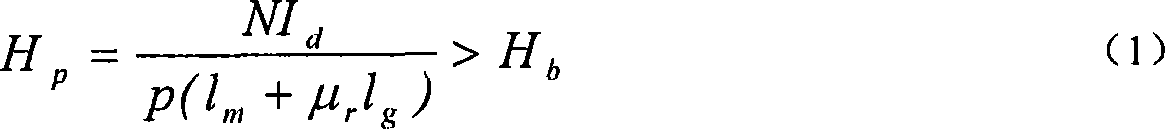

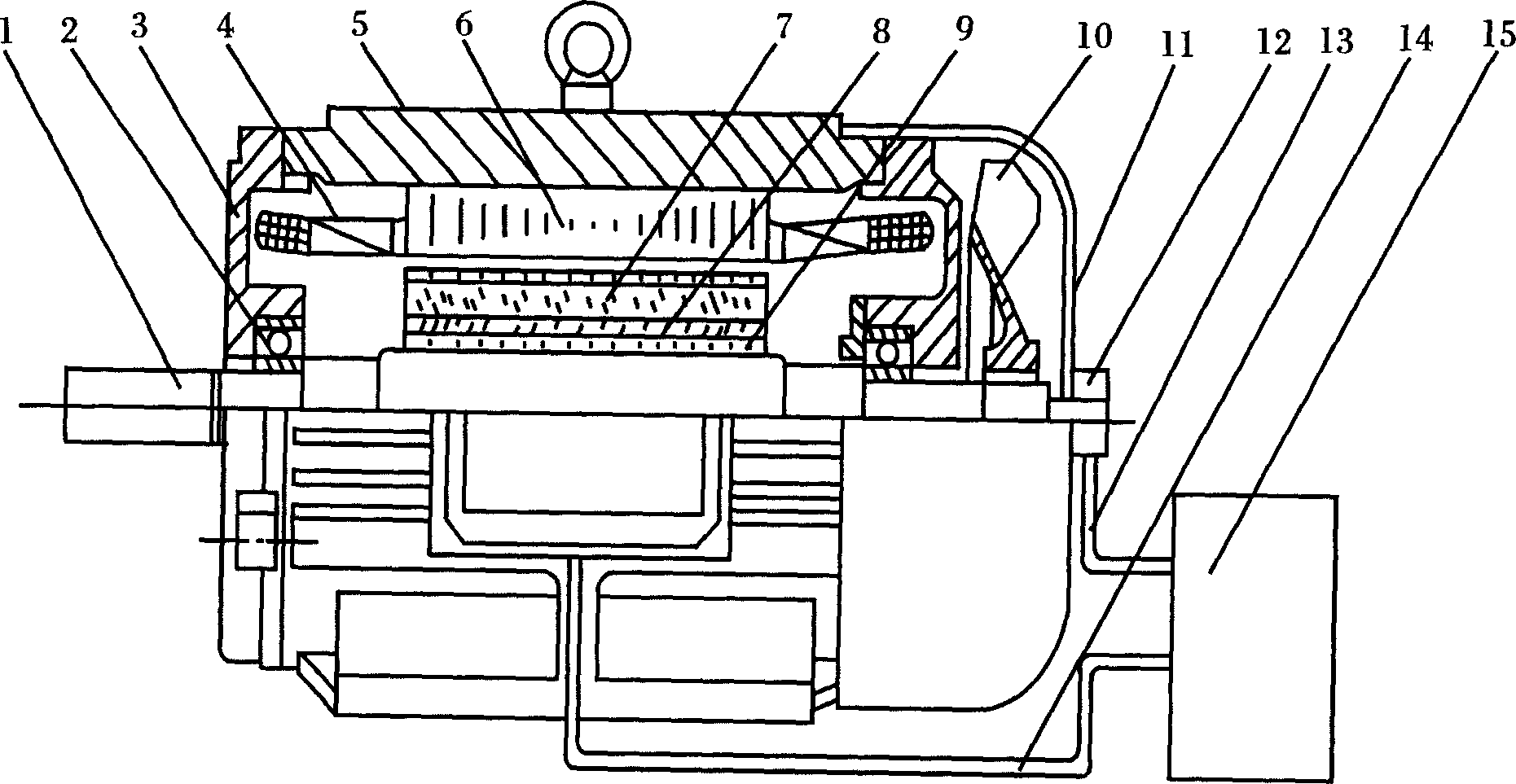

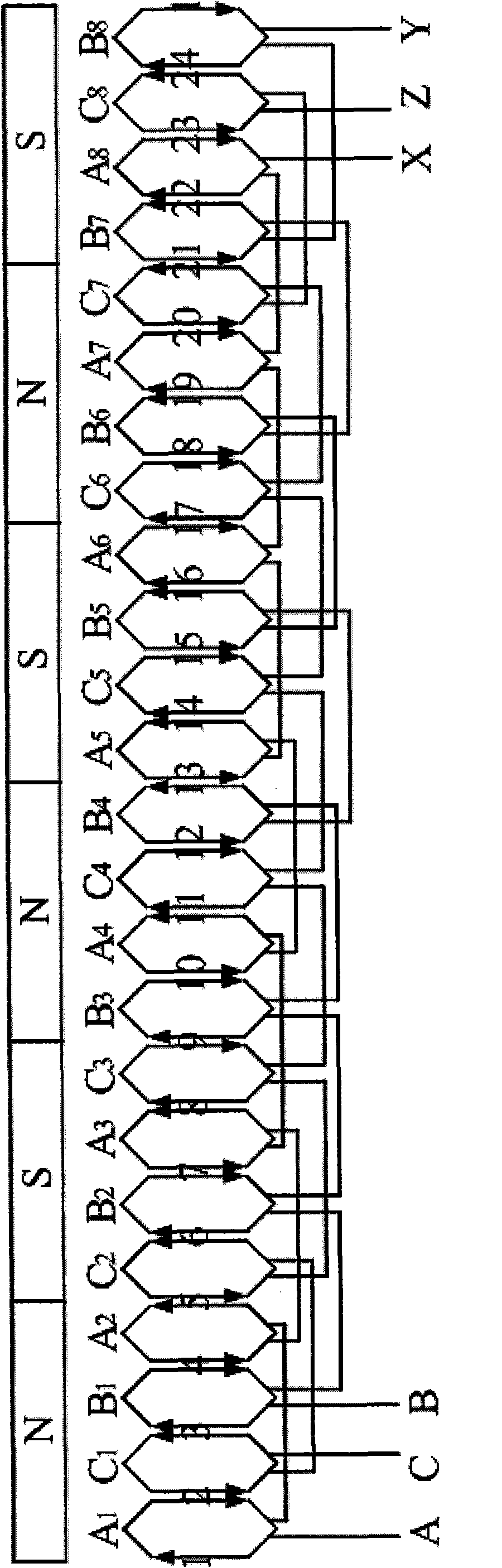

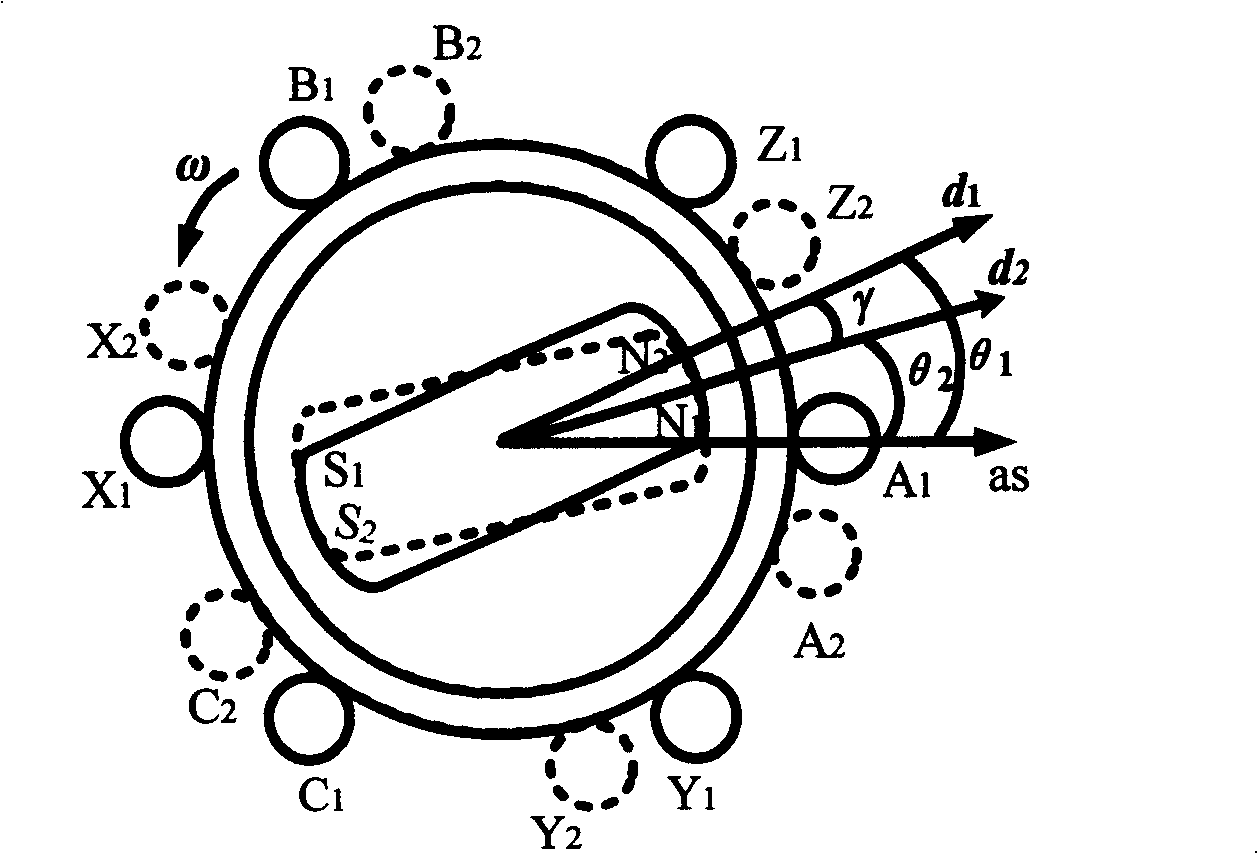

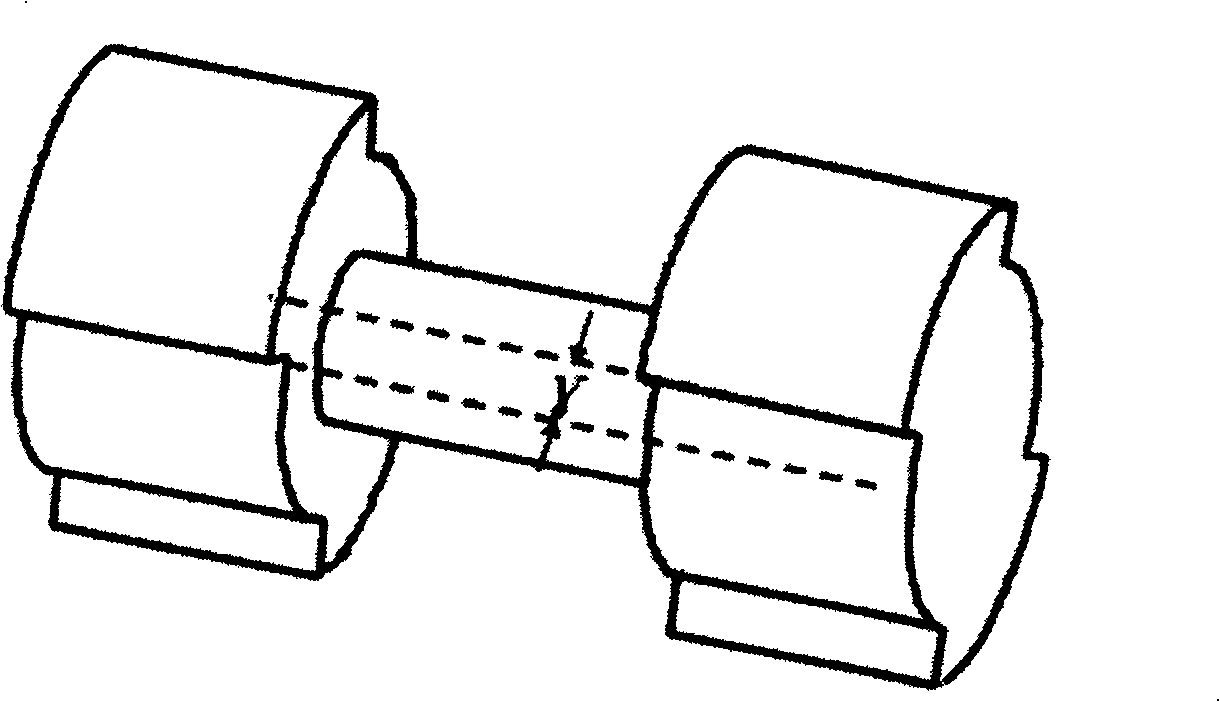

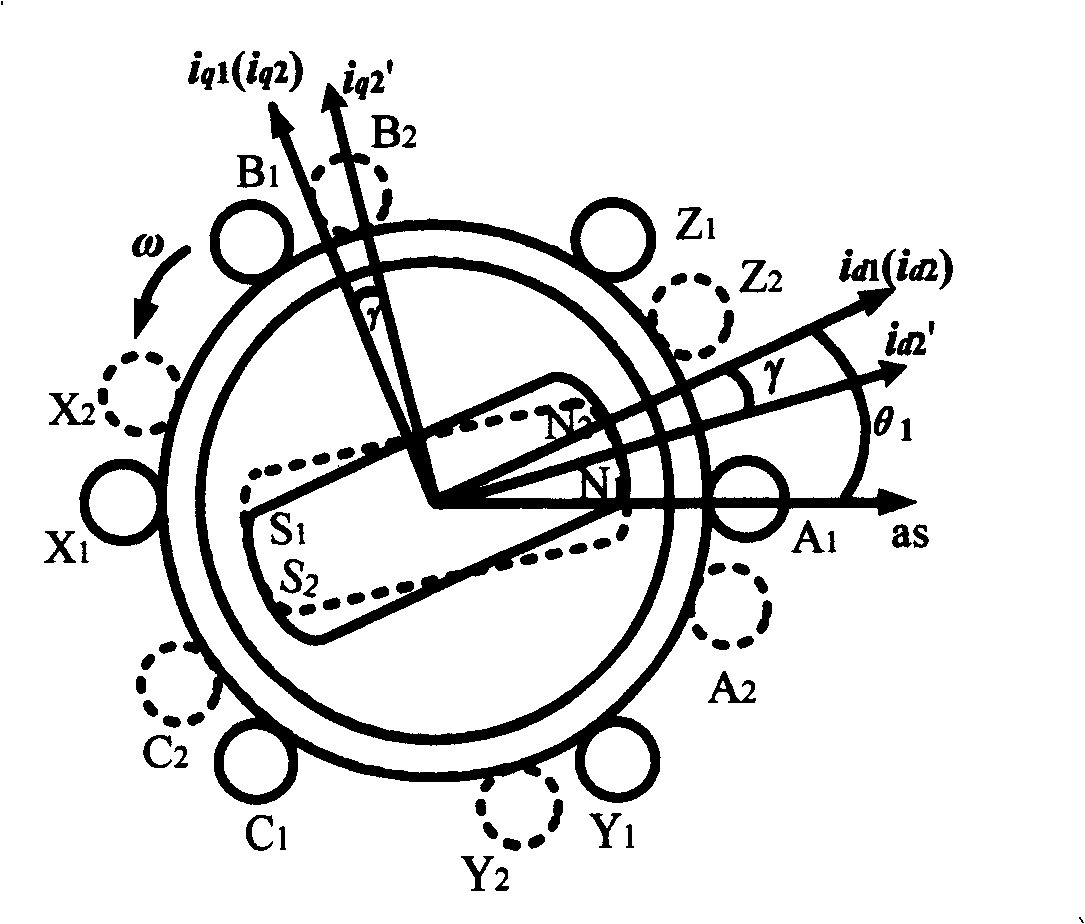

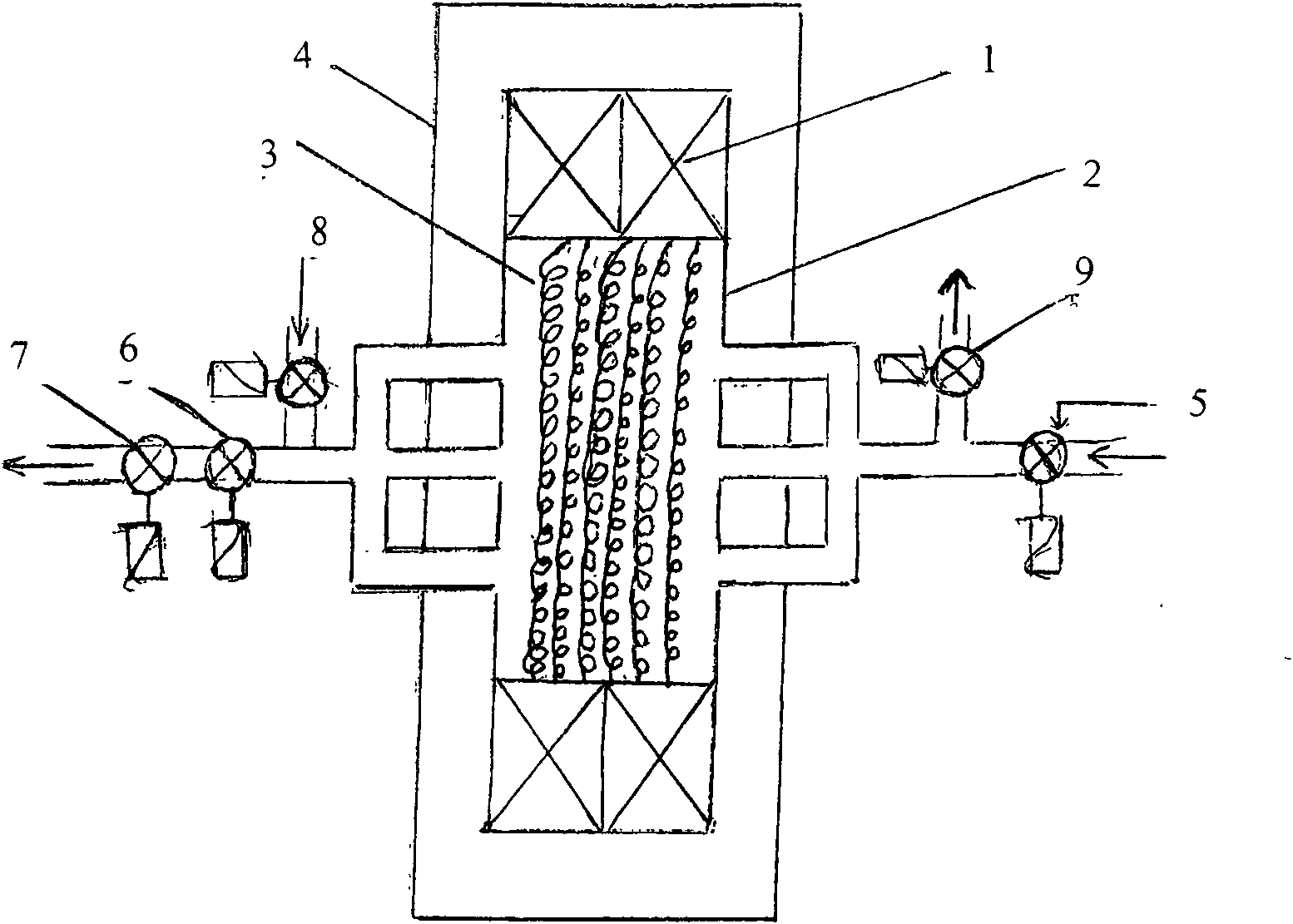

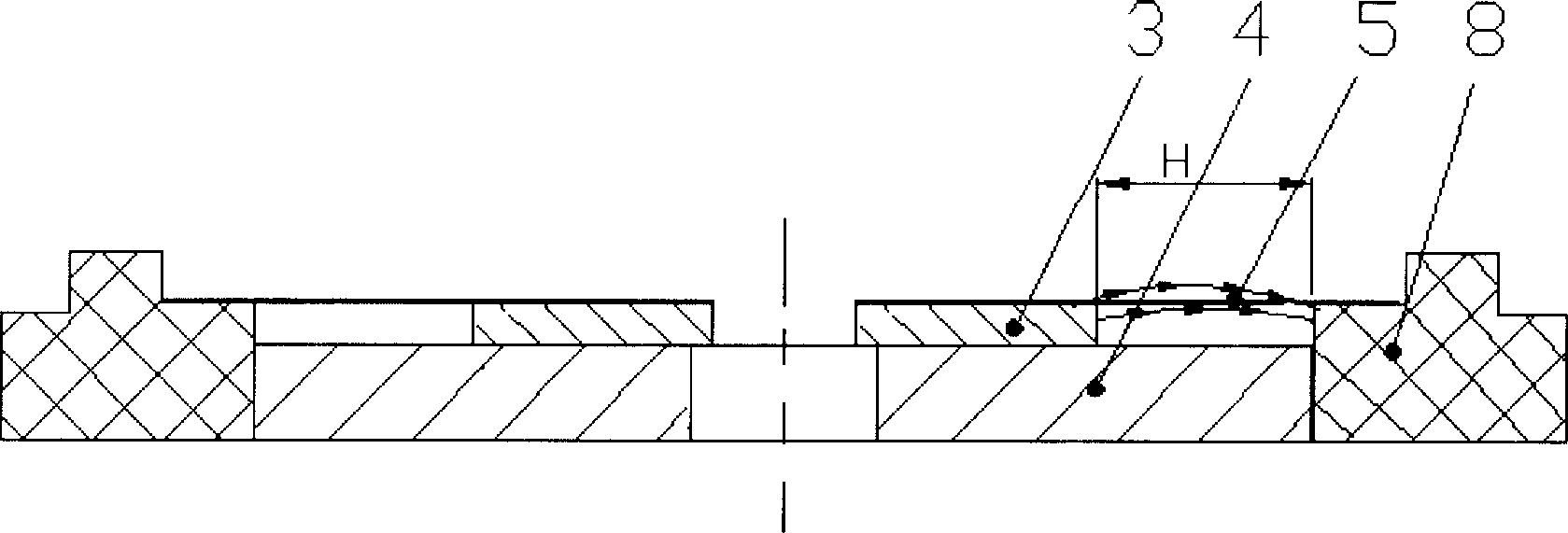

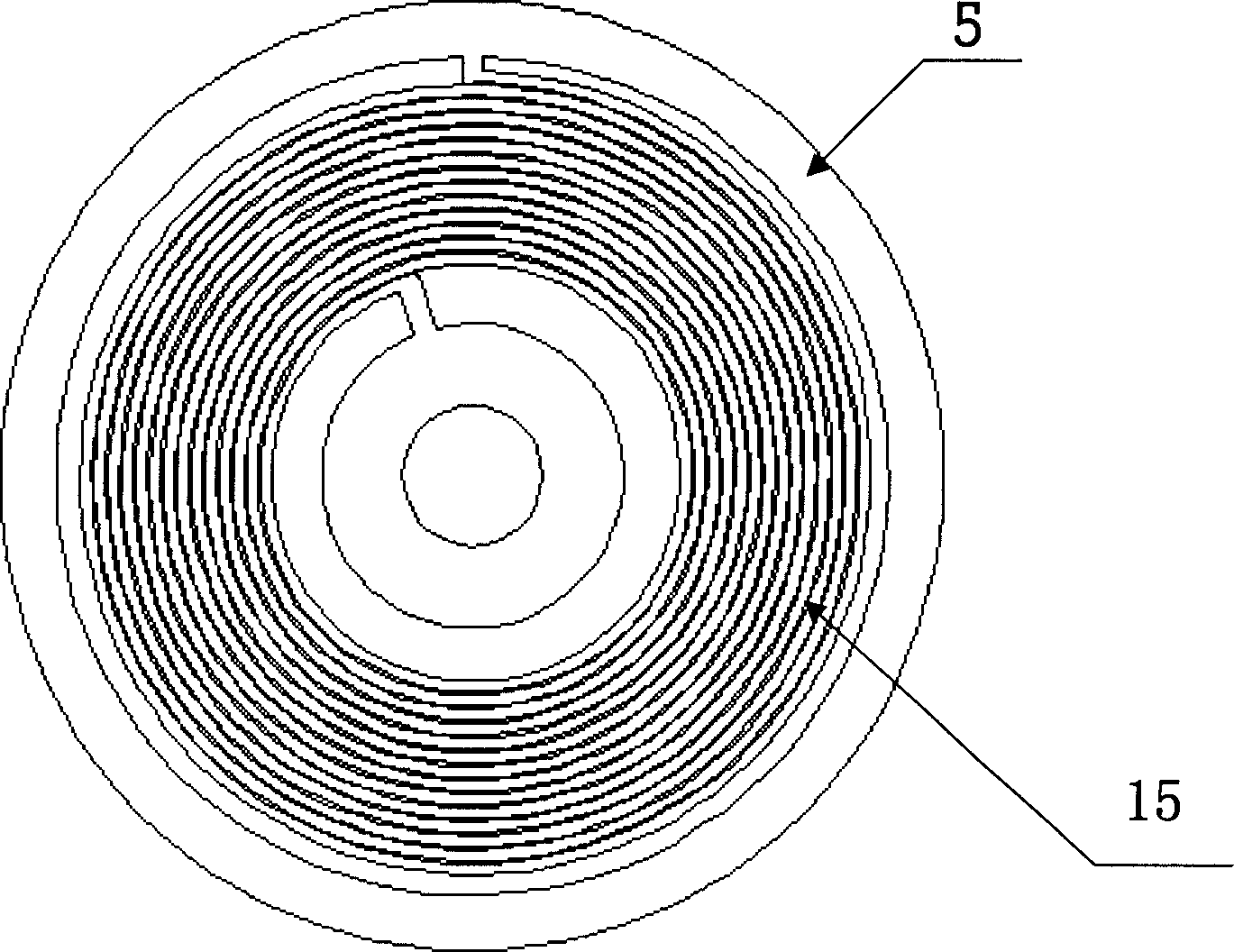

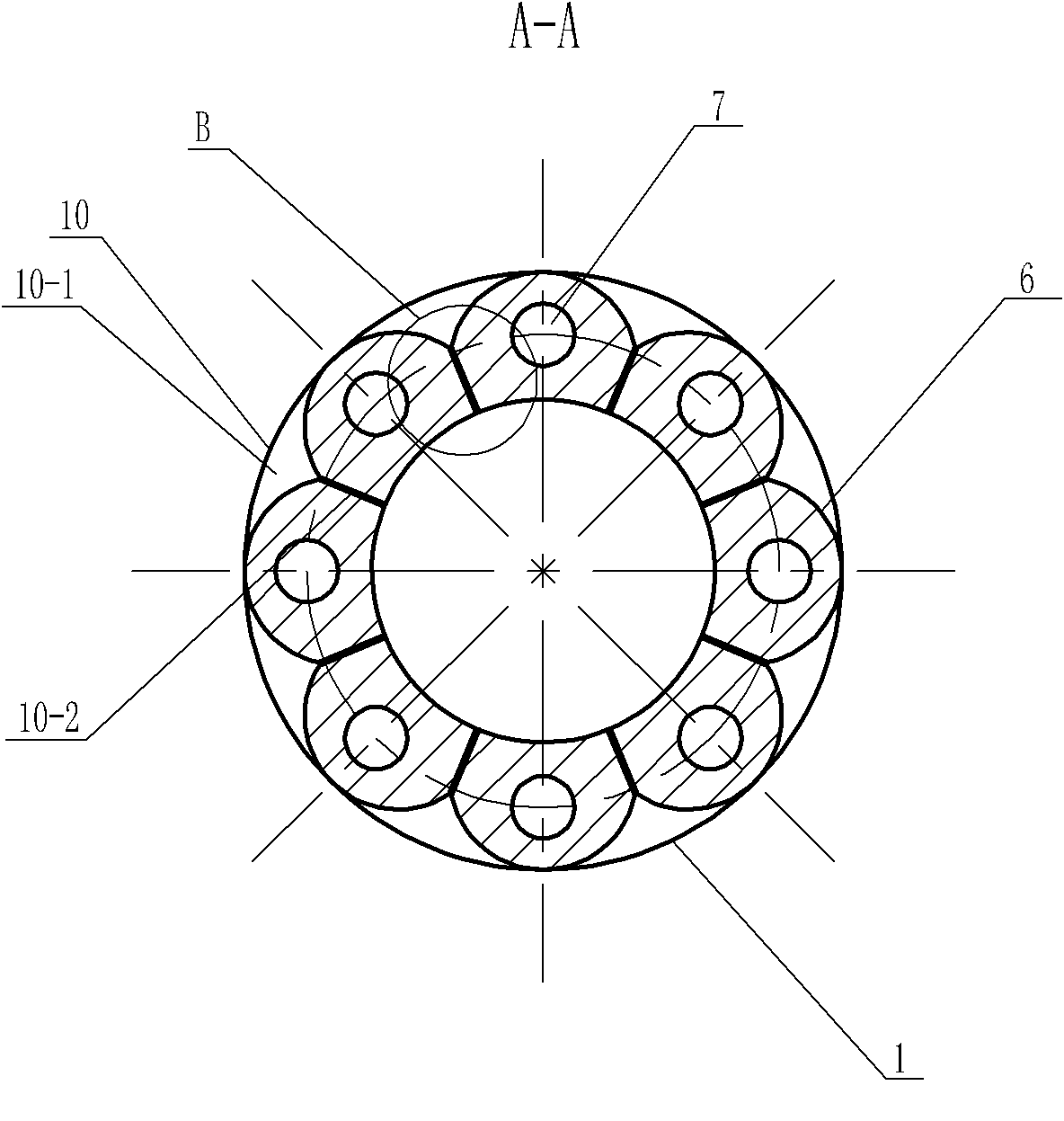

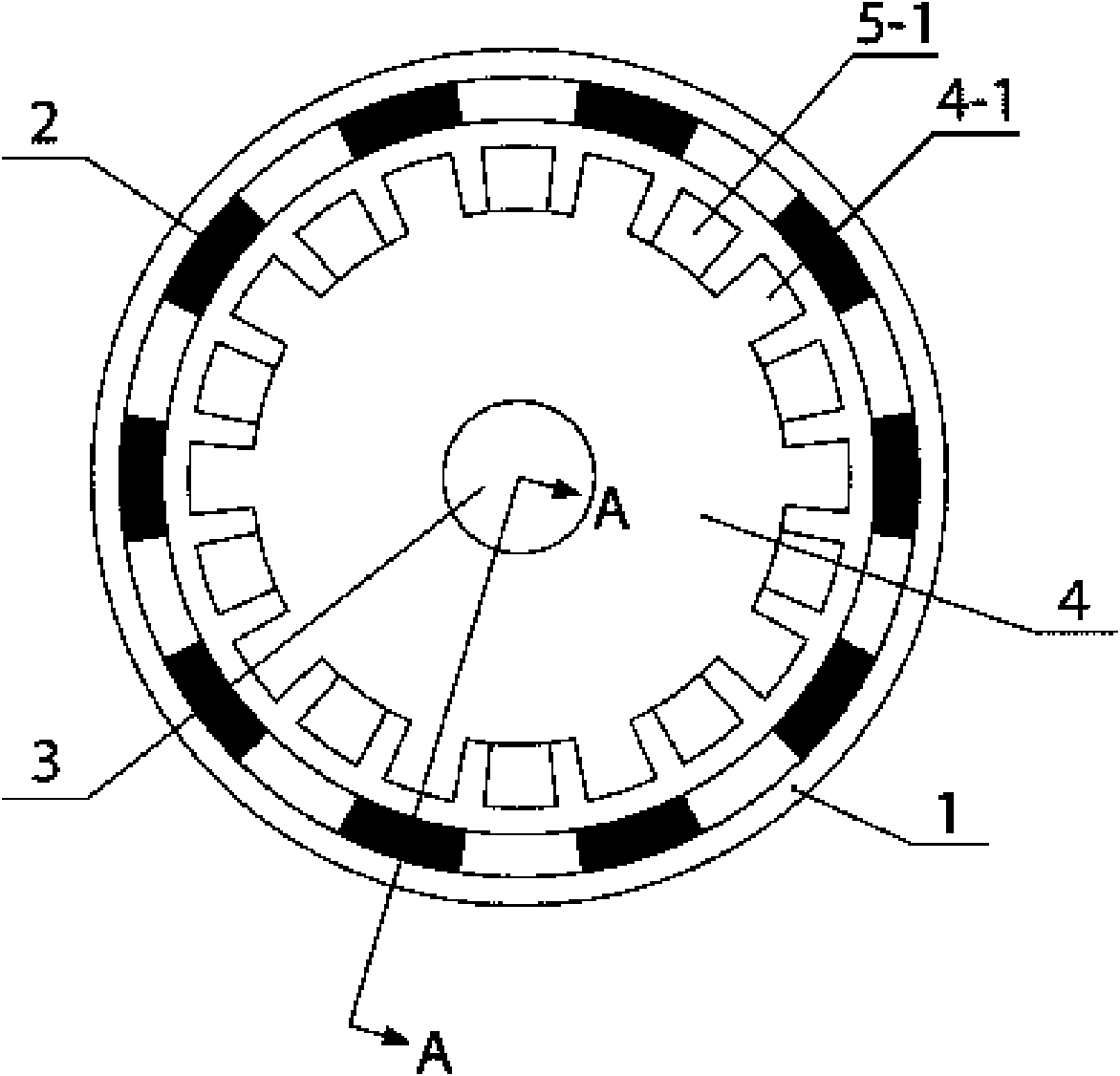

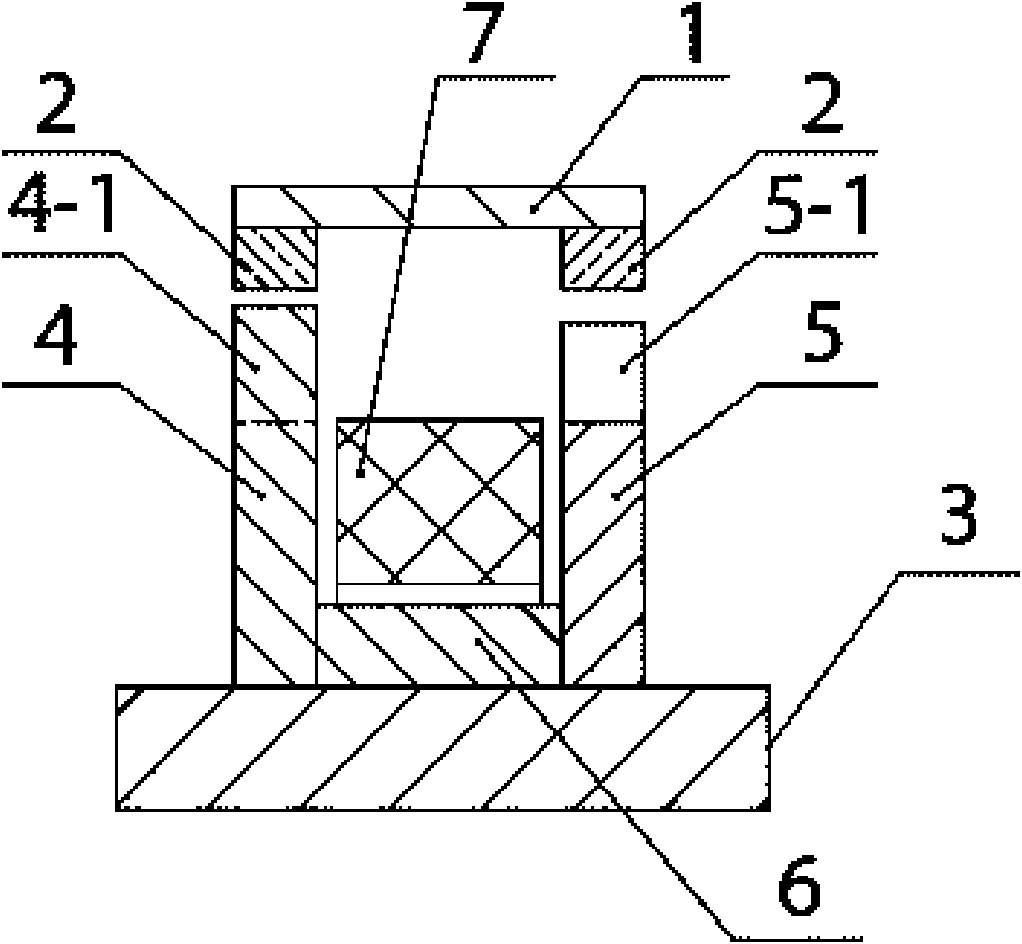

The invention relates to a motor, in particular to a permanent magnet synchronous motor with variable magnetic flux, which has the advantages of easy magnetic field adjusting, high efficiency and wide speed regulation range. The motor comprises a stator consisting of an iron core (1) and an armature winding (2), and a rotor consisting of NdFeB permanent magnet (3), AINiCo permanent magnet (4), soft iron (5), a non-magnetic interlayer (6), a non-magnetic shaft (7), etc. Each permanent magnet in the rotor is composed of two different magnets stacked on each other and tangentially magnetized. The AlNiCo permanent magnet is ladder-shaped and close to the shaft, and the NdFeB permanent magnet is rectangular-shapee and close to an air gap. The non-magnetic interlayer in the rotor is triangular-shaped and connected with the permanent magnet at a section close to the shaft. The entire rotor is packaged by a cylinder with staggered magnetic and non-magnetic regions. The magnetization state of the AlNiCo permanent magnet can be changed by applying a pulse current id to the straight shaft of the stator, thus achieving effectively the adjustment of air-gap magnetic field of the motor.

Owner:SOUTHEAST UNIV

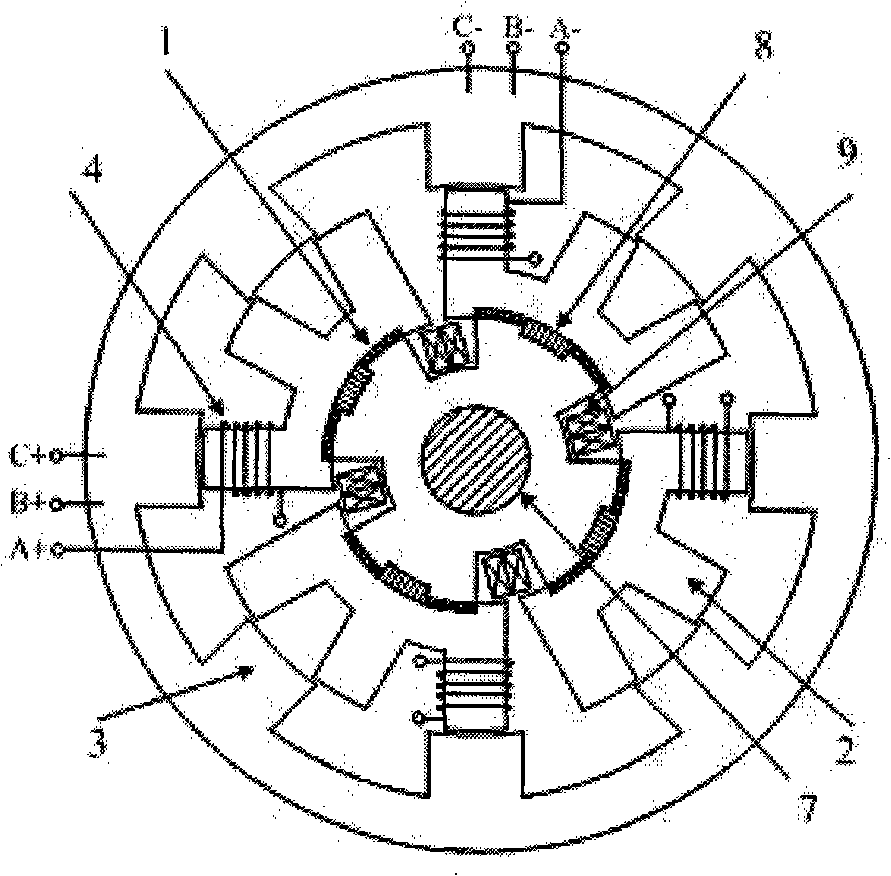

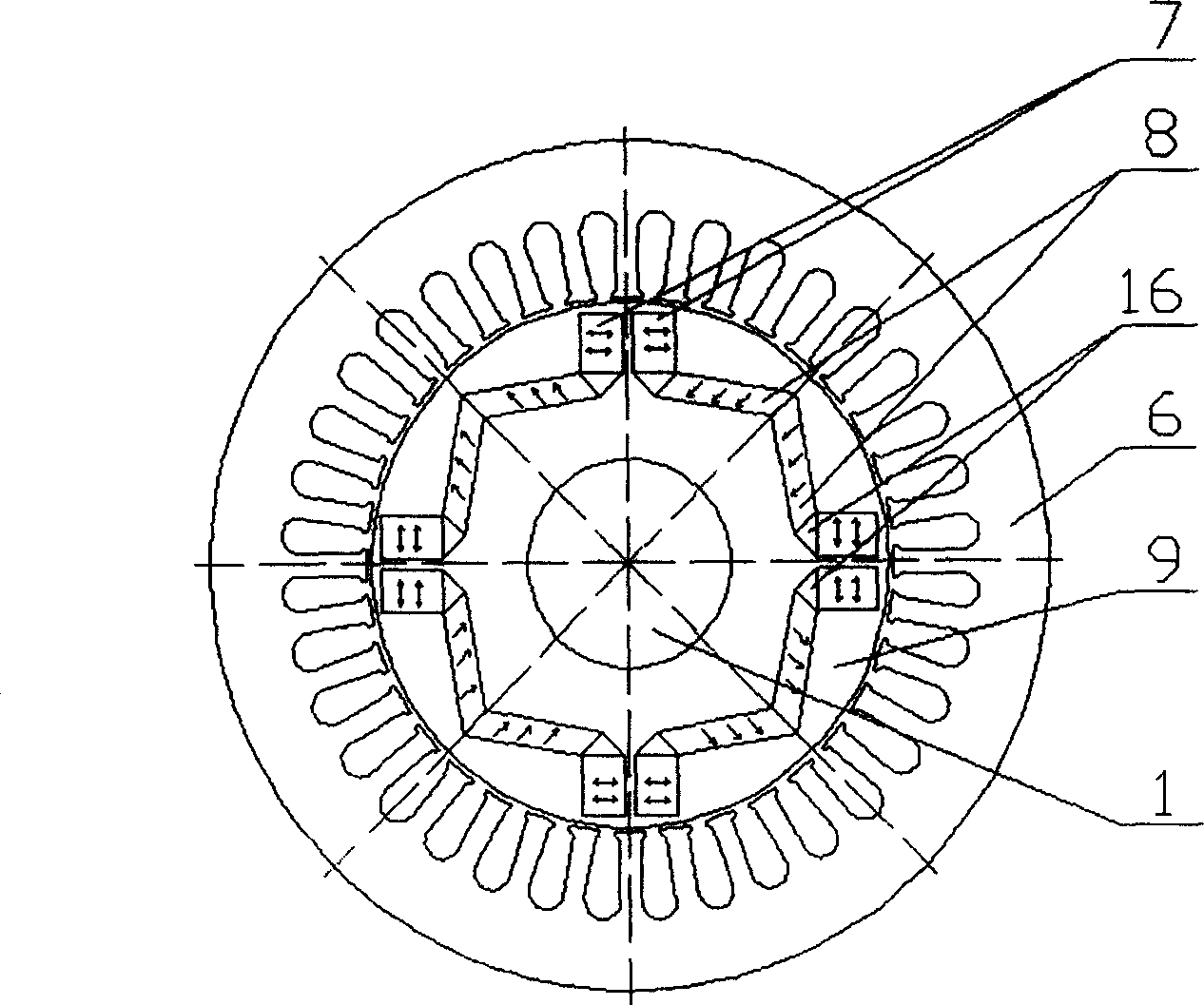

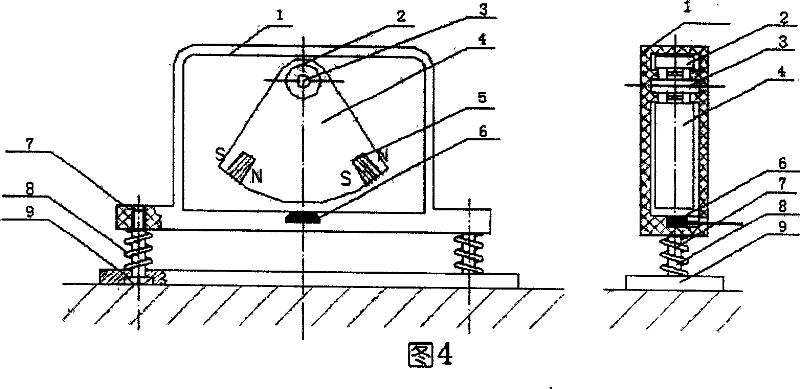

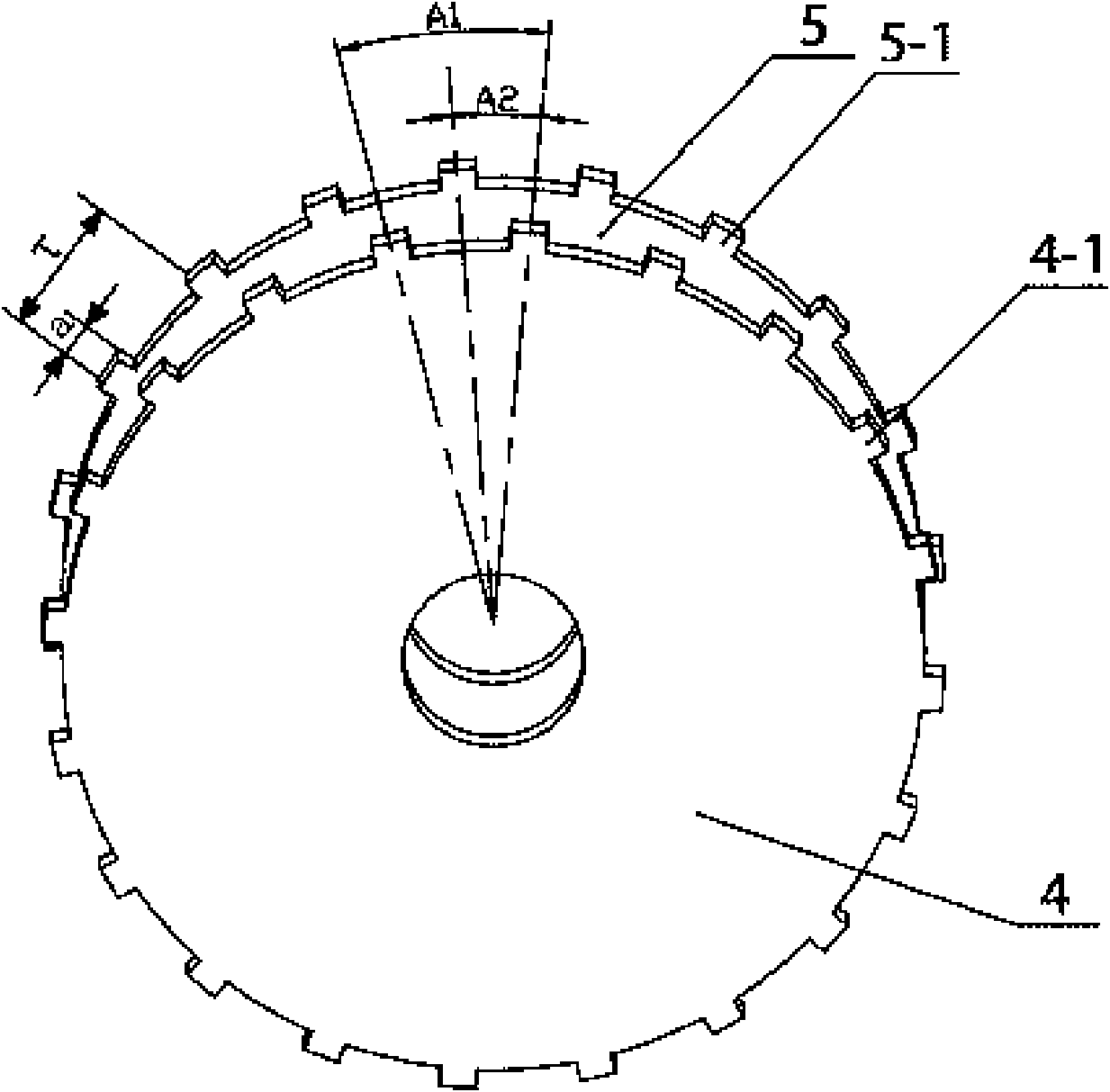

Controllable flux permanent magnetic synchronous motor of multiple pole number built-in mixed rotor magnetic path structure

InactiveCN1617422AChange the magnetizationMemoryMagnetic circuit rotating partsPermanent magnet rotorSynchronous motor

This invention provides a multiple integral hybrid rotor magnetic circuit structure controlled flux magnet synchronous motor including motor spindle, a stator winding, a stator iron core, AlNiCo magnet, A Nd FeB magent, a rotor iron core, a position sensor, a sensor cable, a motor cable and a converter. The permanent rotor is in an integral hybrid rotor magnetic circuit structure, the magnet in the rotor iron cover is set in U shape, the NdFeB is placed tangentially and the AlNiCo magnet is in radial position characterizing in being called a memory motor since it can apply an amplitude controlled d-axis current vector to change the magnetization intensity of the rotor magnet and remember the changed flux intensity.

Owner:TIANJIN UNIV

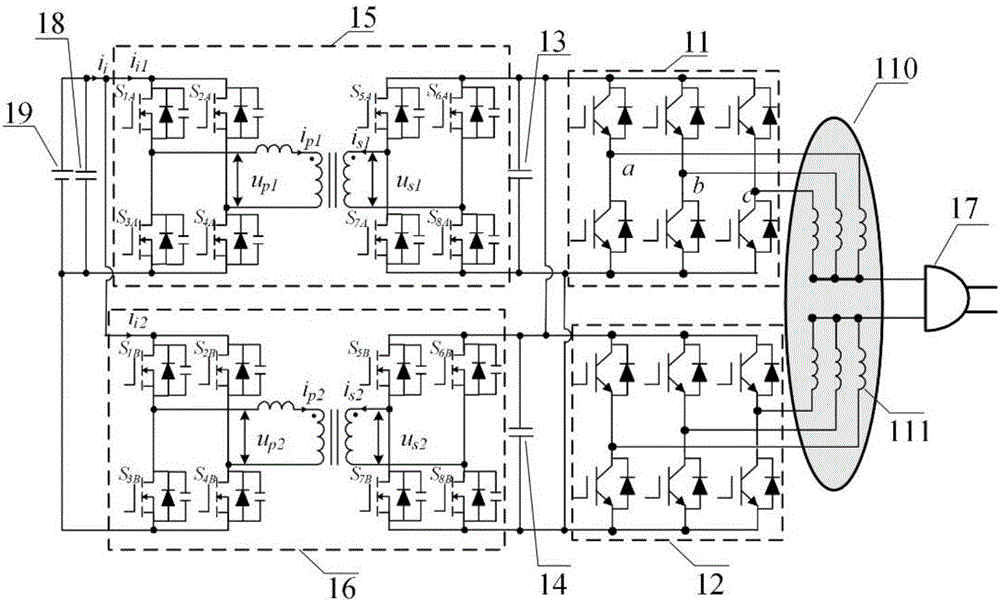

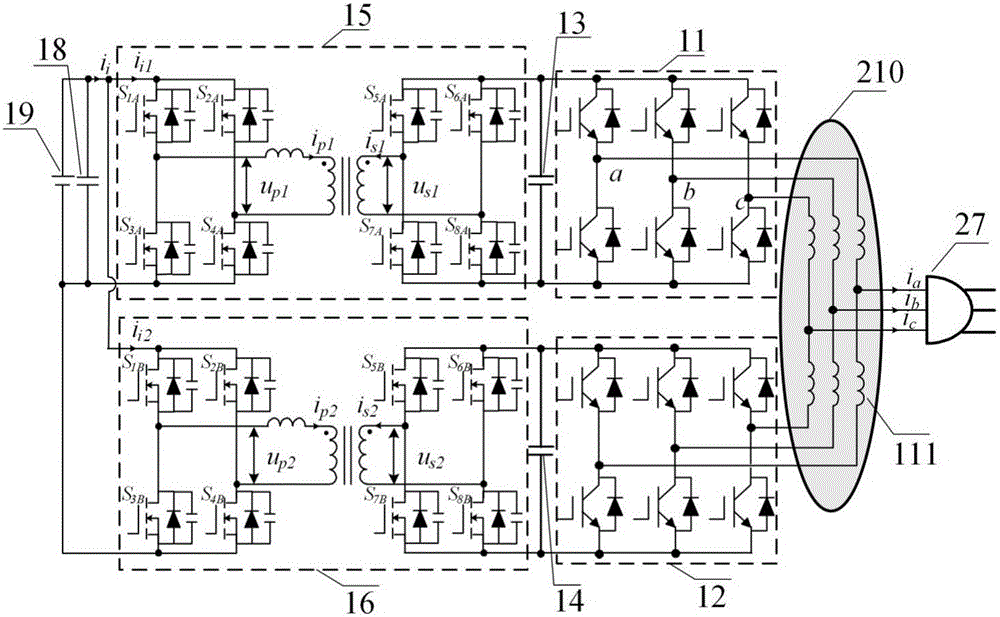

Novel electric vehicle drive system of integrating charger functions

ActiveCN105743175ASpace weight limitReduce torque rippleBatteries circuit arrangementsDc-dc conversionLow voltageOn board

The invention discloses a novel electric vehicle drive system of integrating charger functions. A motor driver and a charger share a power electronic conversion circuit between energy storage units, and also share a motor winding inductor, so that an electric vehicle motor driver and an on-board charger are organically integrated into a whole; and the limitation of an electric vehicle on the space weight is avoided. Double three-phase motors meet the low-voltage and high-current design requirements of electric vehicle motors, have relatively small torque ripples, meet the comfortable and smooth operating requirements of the electric vehicle, have relatively good fault tolerant capability and meet the high-reliability operating requirements of the electric vehicle. Permanent magnets NdFeB and AlNiCo are organically compounded on a rotor, so that the novel electric vehicle drive system has the advantage that the magnetic field of the permanent magnet AlNiCo is easy to adjust; the characteristic of high energy density of the permanent magnet NdFeB is reserved; the large starting torque and flux-weakening speed expansion operating requirements of the electric vehicle are met; the double three-phase windings can provide a torque current and a magnetization current respectively; and the magnetization efficiency is relatively high.

Owner:SOUTHEAST UNIV

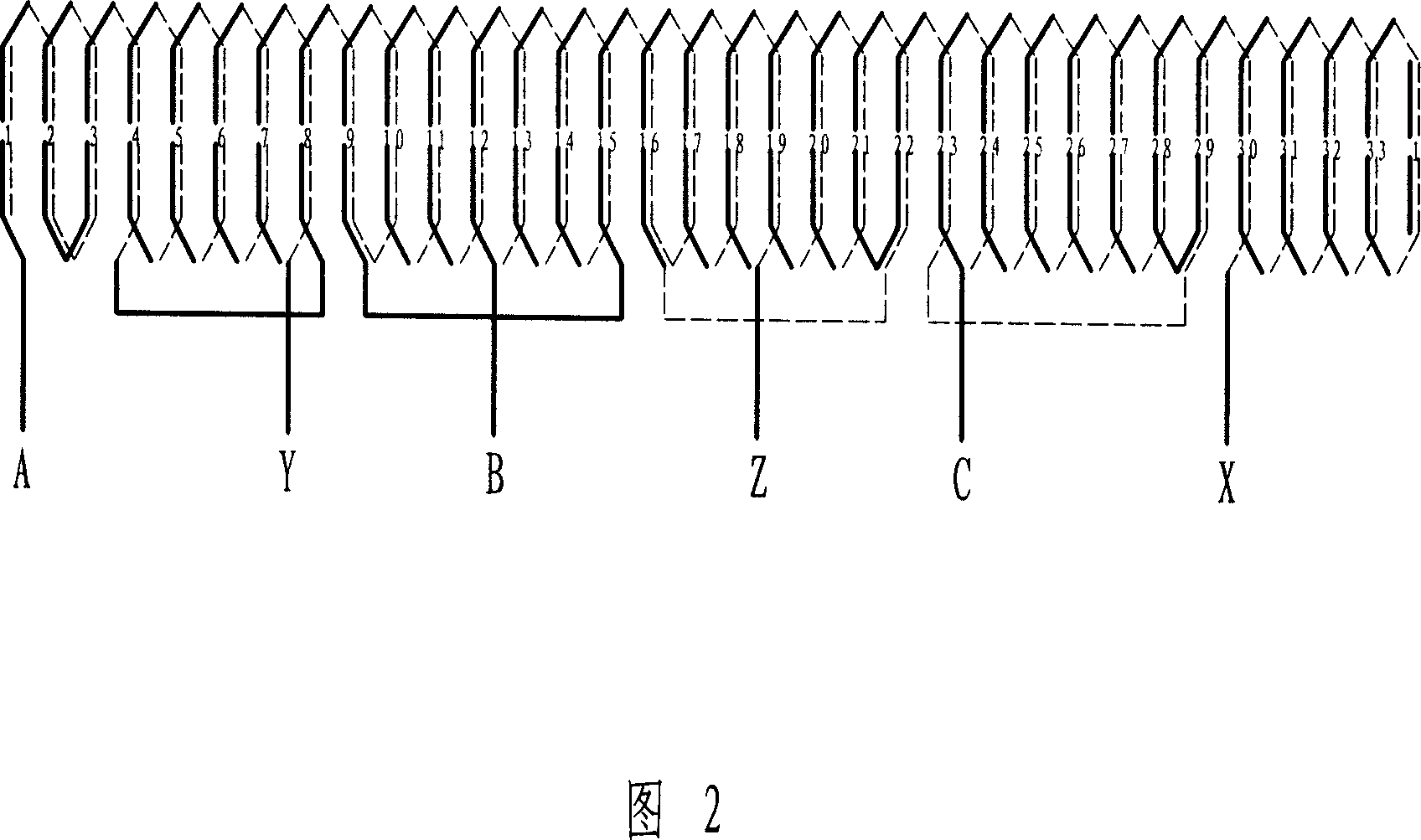

Assembled scheme for brushless DC motor slot number and magnetic steel number

InactiveCN101030721AMagnetic circuit stationary partsWindings conductor shape/form/constructionMagnetic polesCopper

The invention is concerned with combination project for slot number of the non-brush direct current machine and the alnico number, the characteristic is: the slot number of the stator iron core is equal to the phase number multiply the prime number K that is smaller that the phase number of the electronic machine; alnico pole number of the rotor is equal to the slot number add the prime number that is not equal to 1 and phase number and smaller than K. the invention is: forms several closing magnetic circuit between the teeth in the electrify magnetic pole, which is not only increase the magnetic circuit conducting area effectively and short the magnetic circuit timely, but also reduce the loss of iron and copper.

Owner:苏州扬名机电有限公司 +1

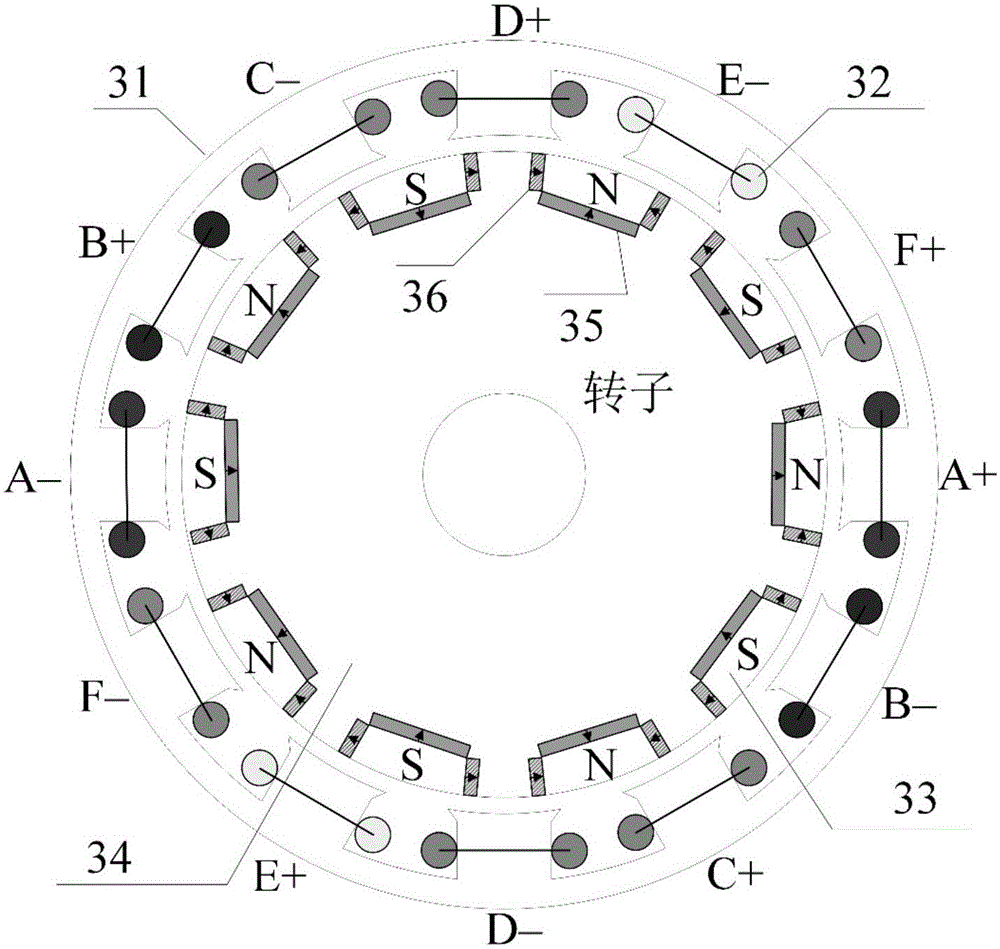

Permanent magnetism type motor of wide speed-adjusting magnetic flux memory type stator

InactiveCN101325349AHigh power densityHigh torque densityElectric machinesMagnetic circuit stationary partsMemory typeConstant power

The invention belongs to the technical field of the permanent-magnet brushless machine manufacture, particularly to a stator permanent-magnet machine adaptable to the application fields of wide speed regulation and high efficiency, such as the mixing dynamic car and the electric automobiles, composed of a stator, a rotor, an armature winding and an NdFeB permanent magnet, characterized in that, the original NdFeB permanent magnet is saved, an ALNiCo permanent magnet and a magnetizing winding for adjusting the magnetic field strength and the magnetic flux density of the ALNiCo permanent magnet are arranged on the stator. The invention has the advantage that, the ALNiCo permanent magnet and the magnetizing winding are first inducted in the stator permanent-magnet, to cause that the flux memory type stator permanent-magnet machine inherits the advantages of large power intensity and good fault tolerant performance of the stator permanent-magnet machine, meanwhile solves the defect that it is difficult to realize the weak magnetic control, the range of the constant power speed control is small and the operating efficiency of the constant power operation is low.

Owner:JIANGSU UNIV

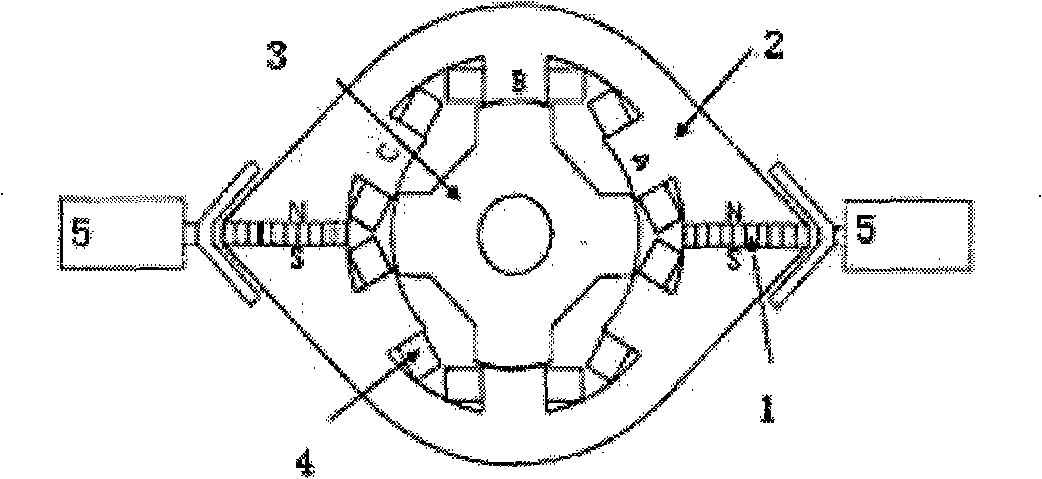

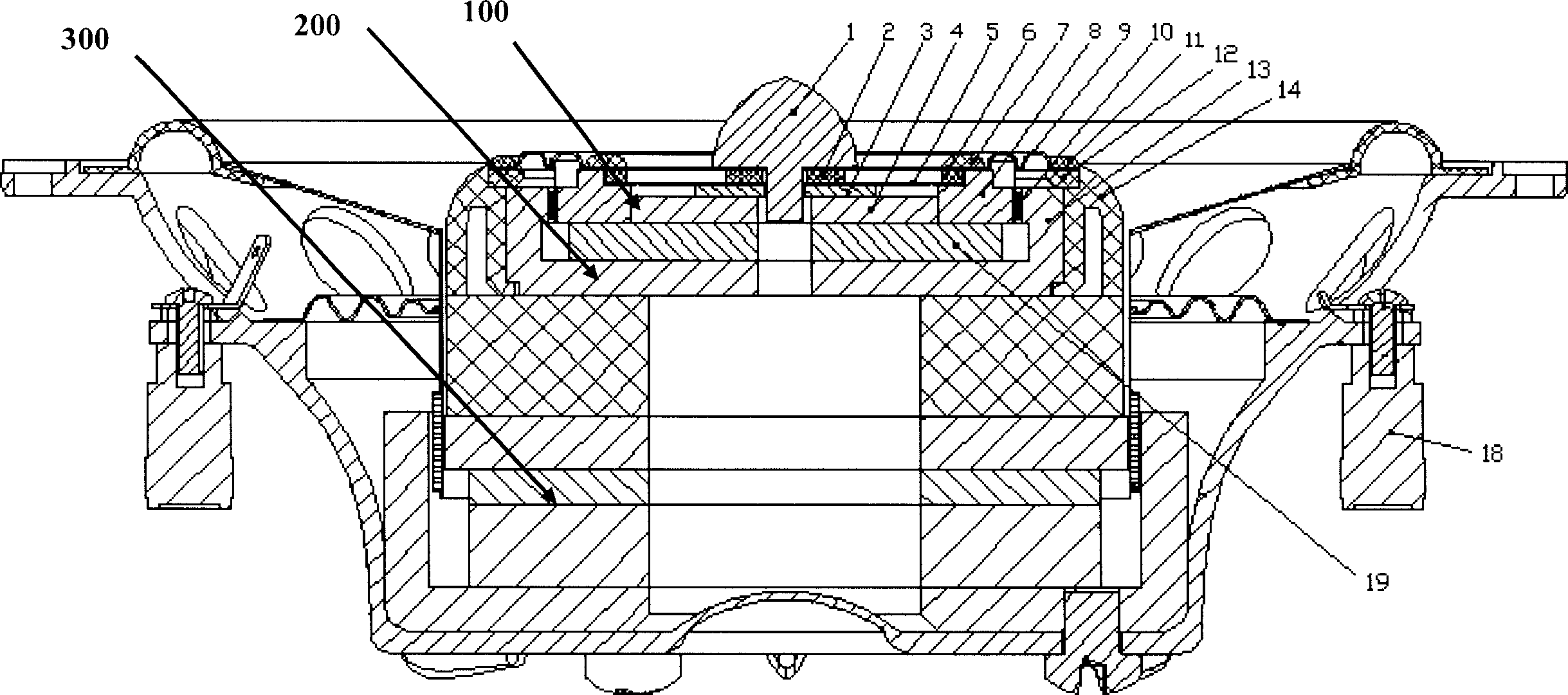

Brushless double-rotor machine

This invention relates to a brushless dual-rotor motor composed of an inner motor of an axial magnet circuit structure and an outer motor of excitation circuit structure, in which, the inner motor is composed of an input shaft, an inner rotor core, an inner magnet alnico of an inner rotor, an outer rotor core and an inner winding of an outer rotor, the outer rotor is composed of a stator winding, a stator core, an outer rotor core and an outer winding of the outer rotor, which are placed in the following sequence from inside: the input shaft, the inner rotor core, the magnet alnico of the inner rotor, a core of the outer rotor, the inner winding of the outer rotor, the outer winding of the outer rotor, the stator core, the stator winding and the shell, and the core of the inner rotor is fixed on the input shaft and rotates together with it, the stator core is fixed on the shell, the core of the outer rotor is connected with the output shaft rigidly and rotates together with it, the inner winding of the outer rotor and the outer winding of the outer rotor form a circuit.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

Hybrid excitation-type stator partition-type hybrid permanent magnet flux switching memory motor

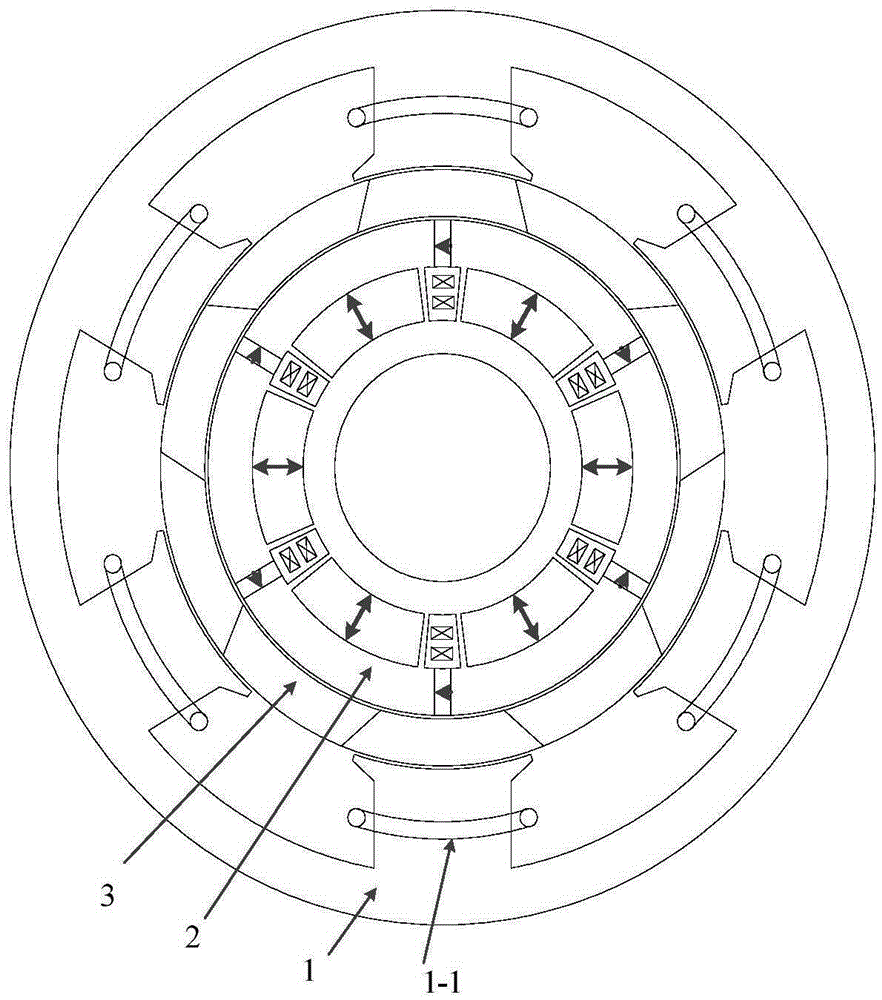

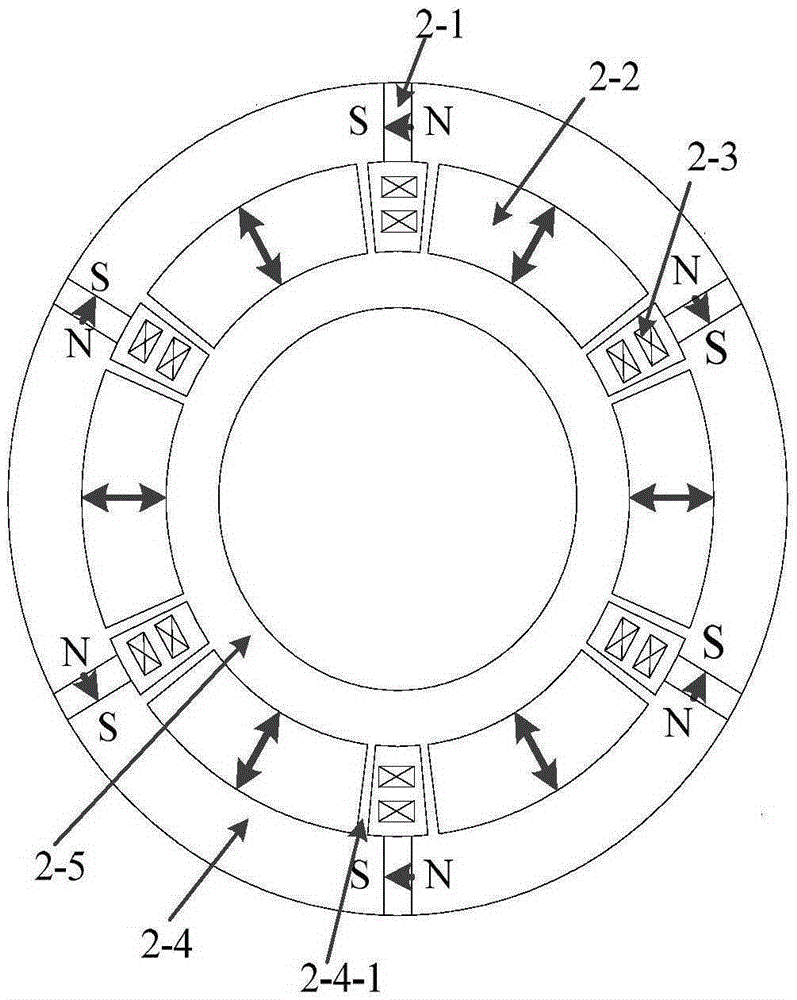

ActiveCN105337429ASolve the problem of mutual limitation of dosageIncrease dosageMagnetic circuit stationary partsWindings conductor shape/form/constructionTorque densityMemory motor

The invention discloses a hybrid excitation-type stator partition-type hybrid permanent magnet flux switching memory motor, which comprises an outer stator, an inner partition stator and a middle rotor, wherein the inner partition stator has a structure of an inner layer and an outer layer closely attached together, the outer layer is formed by an inner stator iron core and NdFeB permanent magnets, the NdFeB permanent magnets are uniformly embedded in the inner stator iron core along the circumferential direction, the NdFeB permanent magnets are magnetized tangentially, and the magnetizing directions of two adjacent NdFeB permanent magnets are opposite; and the inner layer is formed by pulse magnetizing windings and AlNiCo permanent magnets capable of being magnetized and demagnetized in an online mode, the AlNiCo permanent magnets are uniformly arranged along the circumferential direction, an inner stator groove is arranged between adjacent two AlNiCo permanent magnets, and the pulse magnetizing windings serially connected from beginning to end in sequence are placed in the inner stator grooves and are wound on the AlNiCo permanent magnets. Thus, under the same motor size, the amount of permanent magnets and the amount of armature windings can be increased to enhance torque density, the magnetic strength of the AlNiCo permanent magnets can be adjusted in an online mode, and a wide speed regulation range is provided.

Owner:JIANGSU UNIV

Manufacturing technology of isometric aluminium nickel cobalt titanium permanent magnet alloy

A process for preparing the permanent-magnet AlNiCo alloy with equiaxed crystals includes such steps as proportionally mixing Al, Ni, Co, Cu, Ti, NbFe (1: 1), Fe, Si, FeS and SmCo, charging the mixture in furnace, preparing casting mould, vacuumizing, electric heating, filling Ar gas, casting, annealing, two-stage preheating, solution treating, magnetic field controlled cooling and three-stage tempering.

Owner:宁波盛事达磁业有限公司

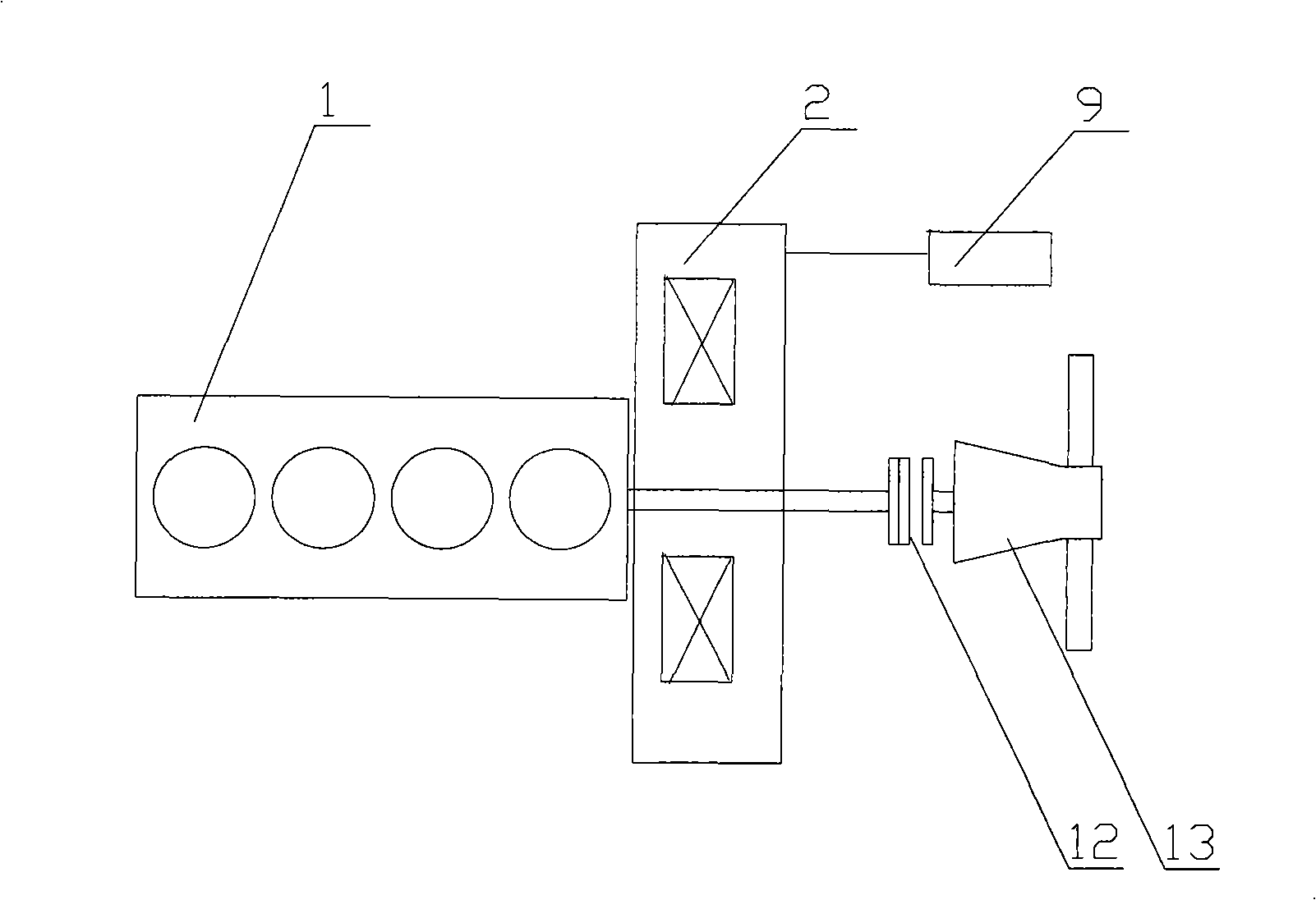

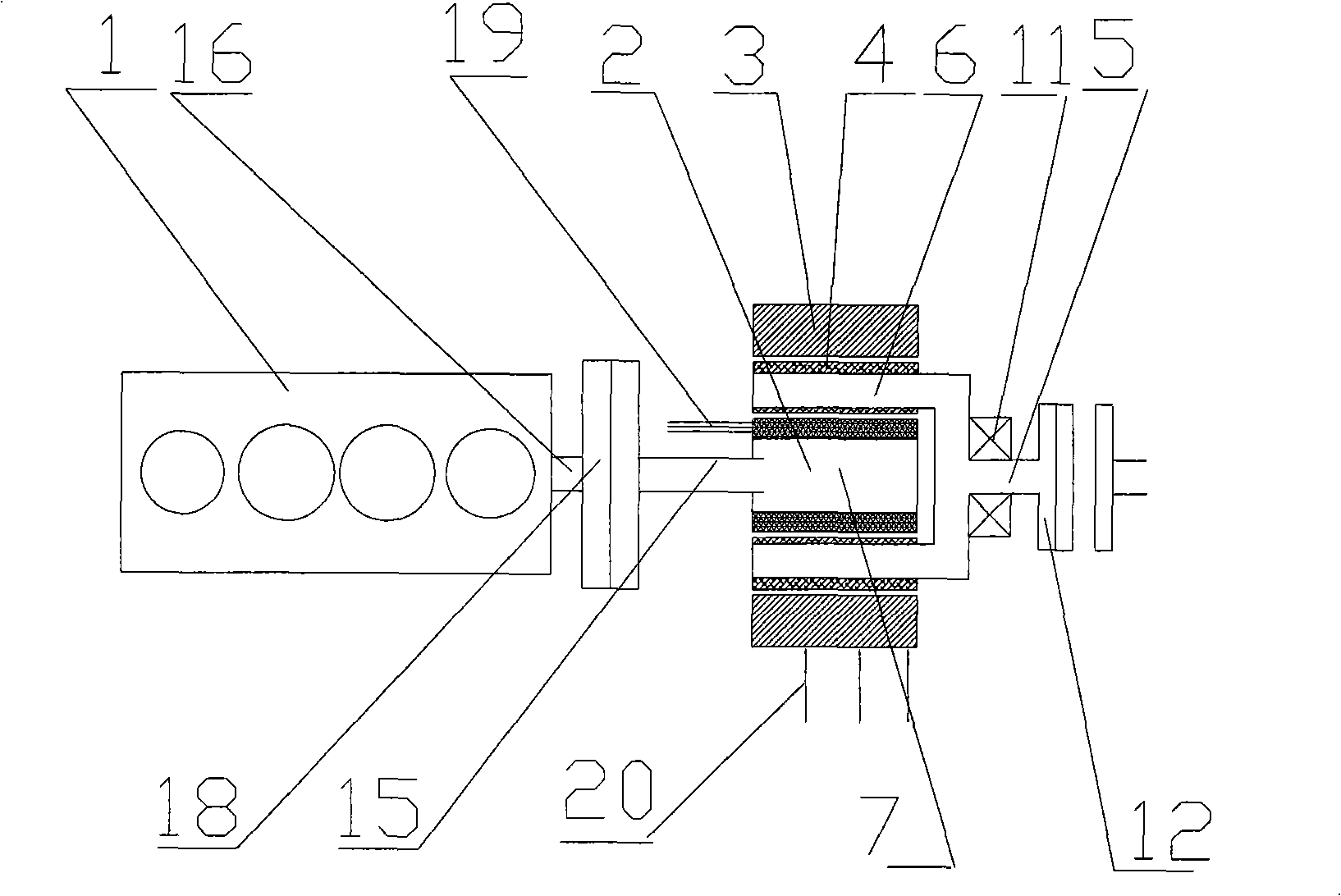

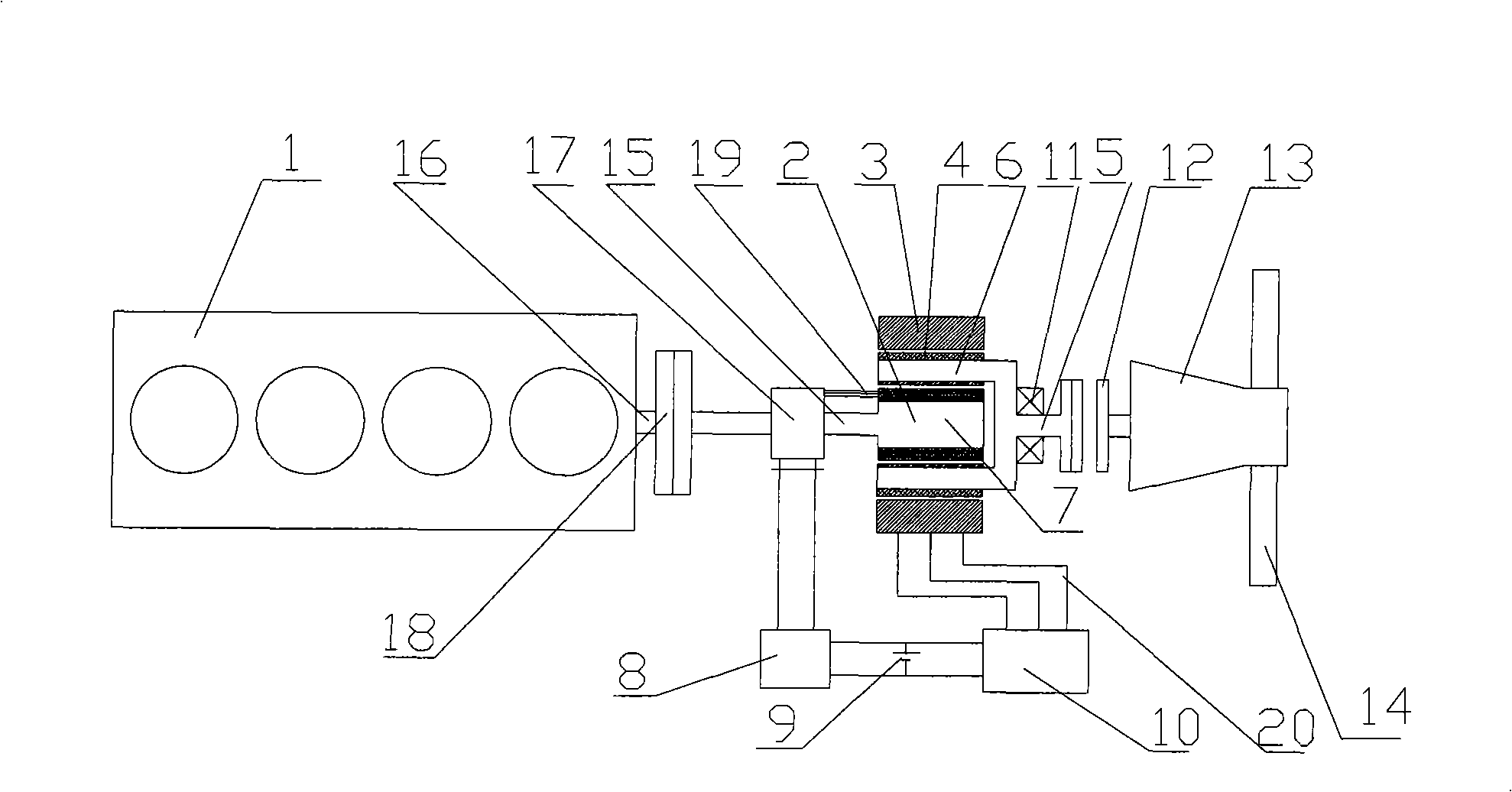

Power assembly of hybrid power automobile

ActiveCN101318460AGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingRegenerative brakeElectric vehicle

The invention discloses a power assembly of a hybrid electric vehicle which includes an engine, a double-rotor motor, a battery, etc. The power assembly of a hybrid electric vehicle is characterized in that the double-rotor motor includes a stator and a loop, an outer rotor, an inner rotor and a loop; a stator loop is twisted on the stator and surrounds the periphery of the outer rotor; the innersurface and the outer surface of the outer rotor are embedded with alnico; the loop of the inner rotor is twisted on the inner rotor; the inner rotor of an output shaft, the outer rotor and the stator are coaxial with the output shaft of the engine. The output shaft of the outer rotor is supported on a shell by a bearing and is connected with the drive end of a clutch; the inner rotor is fixed with the output shaft of the engine from the other end; the battery is respectively and electrically connected with the stator loop and the loop of the inner rotor. The power assembly of a hybrid electric vehicle can be utilized not to drive the engine to rotate idly when the vehicle is driven singly by the motor or by the power generated from regenerative braking.

Owner:CHERY AUTOMOBILE CO LTD

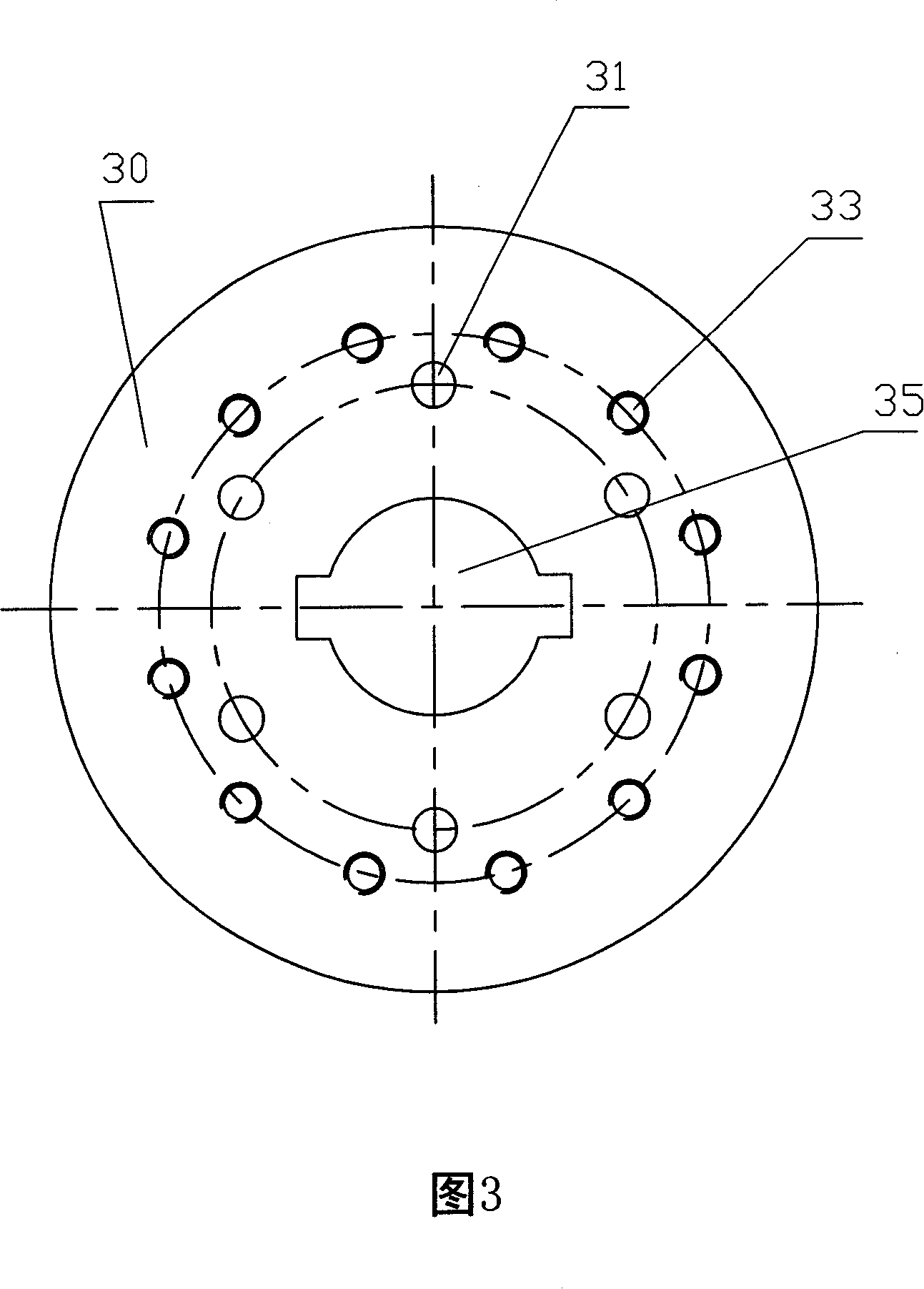

Permanent-magnetic electric machine rotor magnet steel fixing structure

ActiveCN101083411AImprove mass to powerSimple designMagnetic circuit rotating partsRotor magnetsDynamic balance

The invention discloses a permanent motor rotor alnico fixing structure, mainly comprising: rotating shaft, rotor iron core, two alnico pressure plates and magnet, where the two alnico pressure plates are separately arranged on two end surfaces of the rotor iron core and fixed, the rotating shaft runs through the middles of the alnico pressure plates and the rotor iron core and is fixed, and especially, the alnico pressure plate is formed with several screw holes for regulating dynamic balance, where the axes of these screw holes are distributed on a circle coaxial with the rotating shaft. And it has simple structure and is convenient to dynamic balancing.

Owner:BYD CO LTD

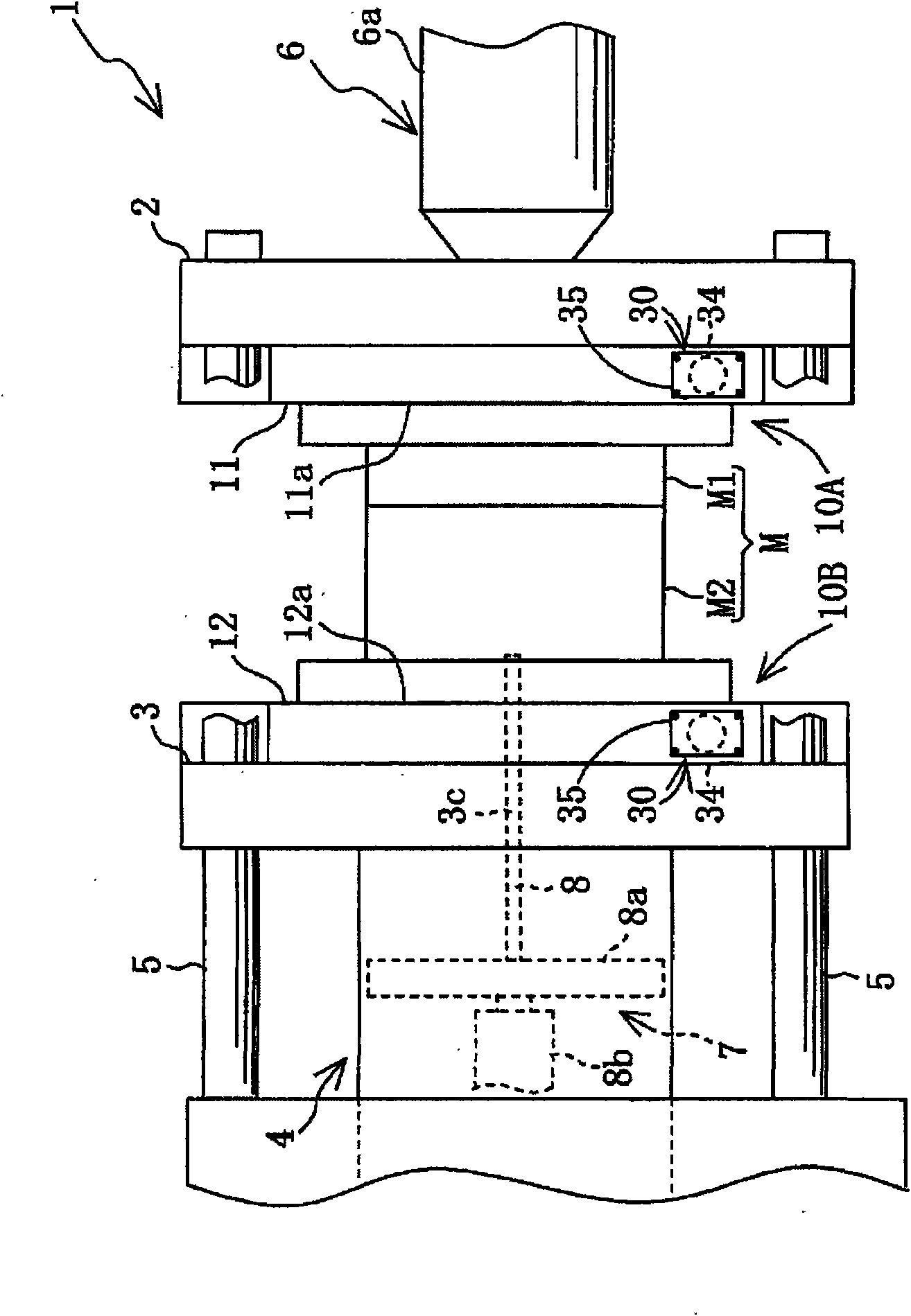

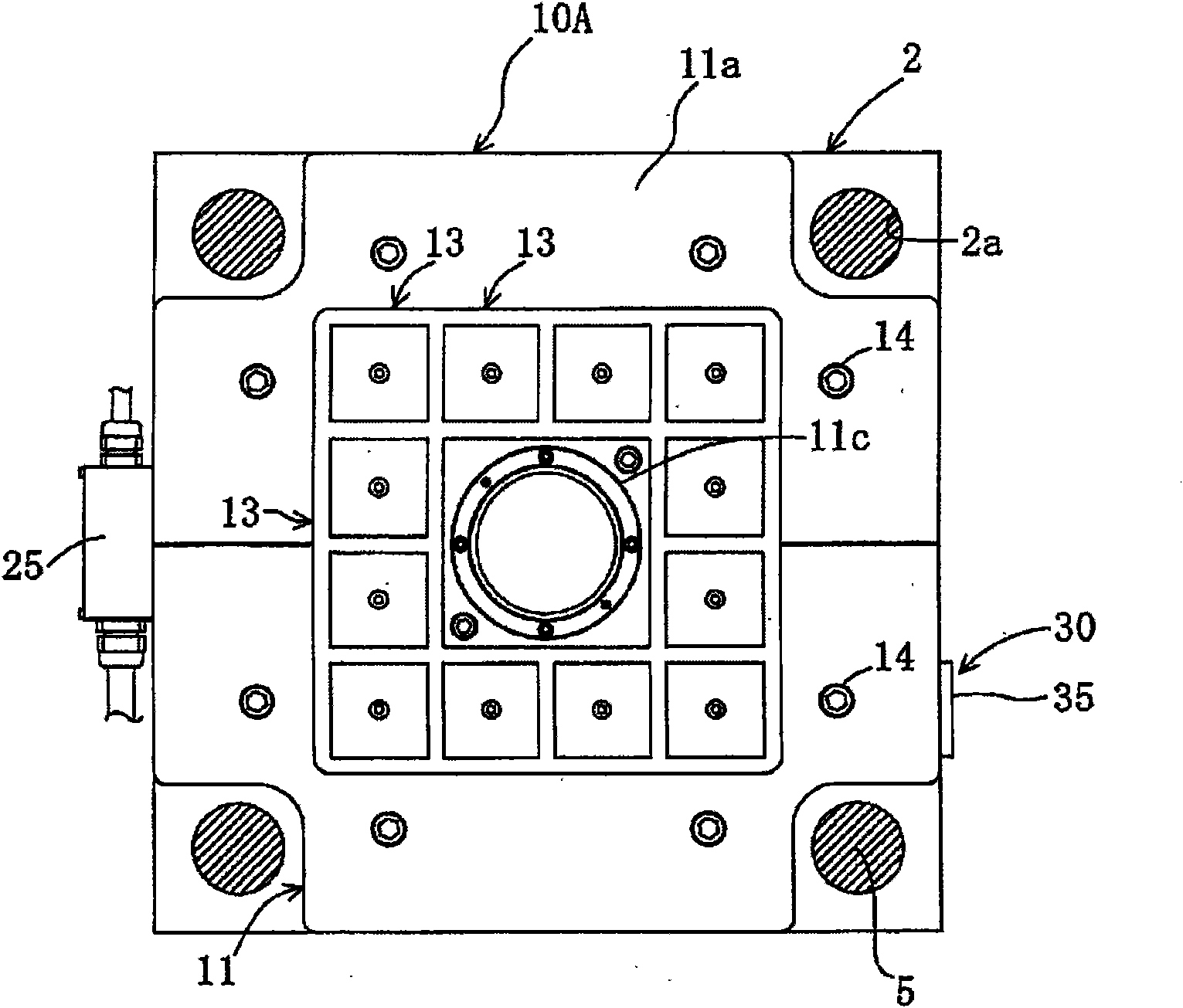

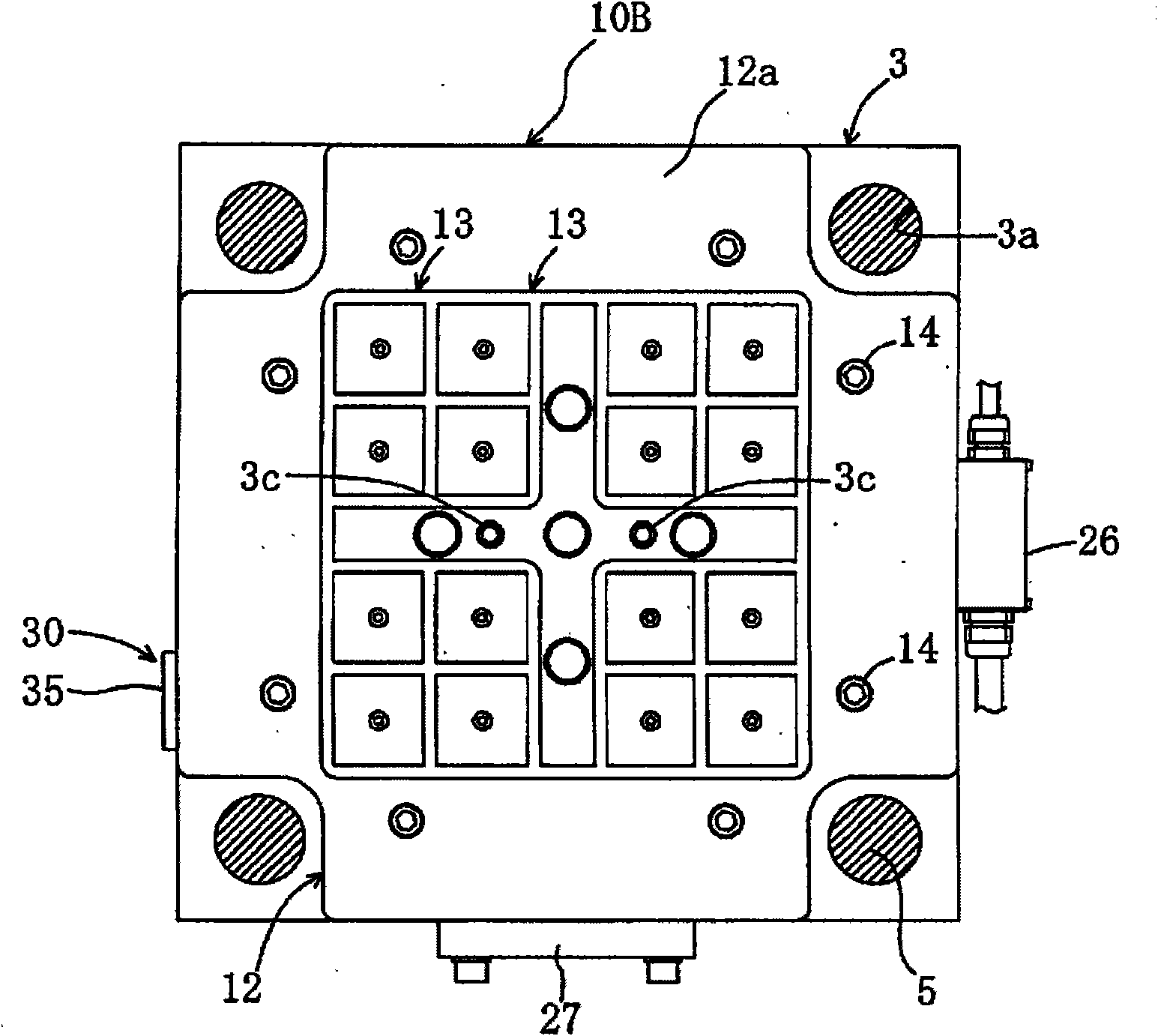

Magnetic fixing device

ActiveCN101610873AEasy to identifyPositioning apparatusMetal-working holdersMagnetic tension forceForce generation

A magnetic fixing device comprises a clamp plate having a fixing surface for fixing a clamping object, and a plurality of magnetic force generation mechanisms. Each magnetic force generation mechanism has a magnetic member facing the fixing surface, a plurality of permanent magnets arranged on the outer circumferential side of the magnetic member, a first alnico magnet arranged on the back side of the magnetic member, and a first coil for switching the polarity of the first alnico magnet. The magnetic force generation mechanism is arranged to be switched between a state where the clamping object is attracted, and a state where the clamp object is not attracted. On the fixing surface or the outer circumferential surface of the clamp plate, an operating state indication mechanism indicatingan index showing whether the plurality of magnetic force generation mechanisms are in the attracting state or non-attracting state is provided.

Owner:PASCAL ENG

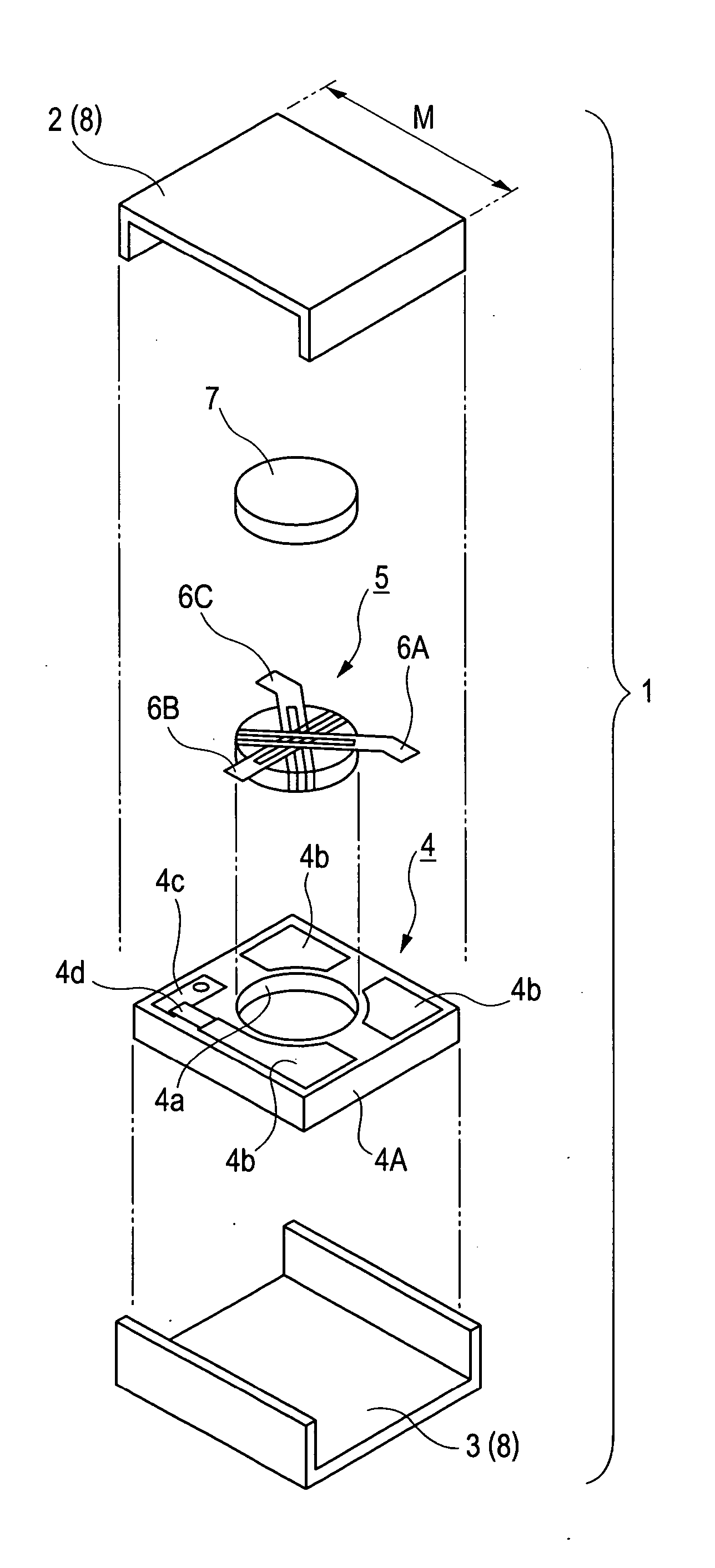

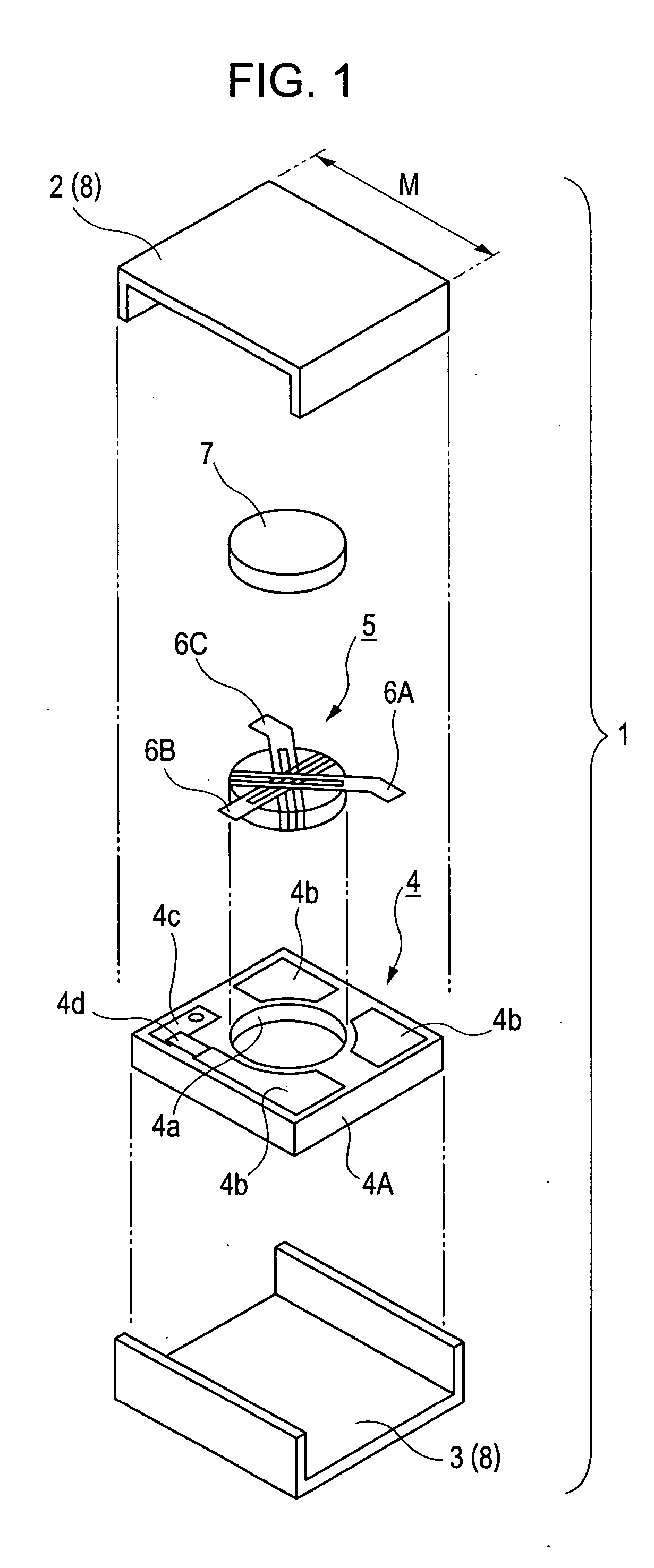

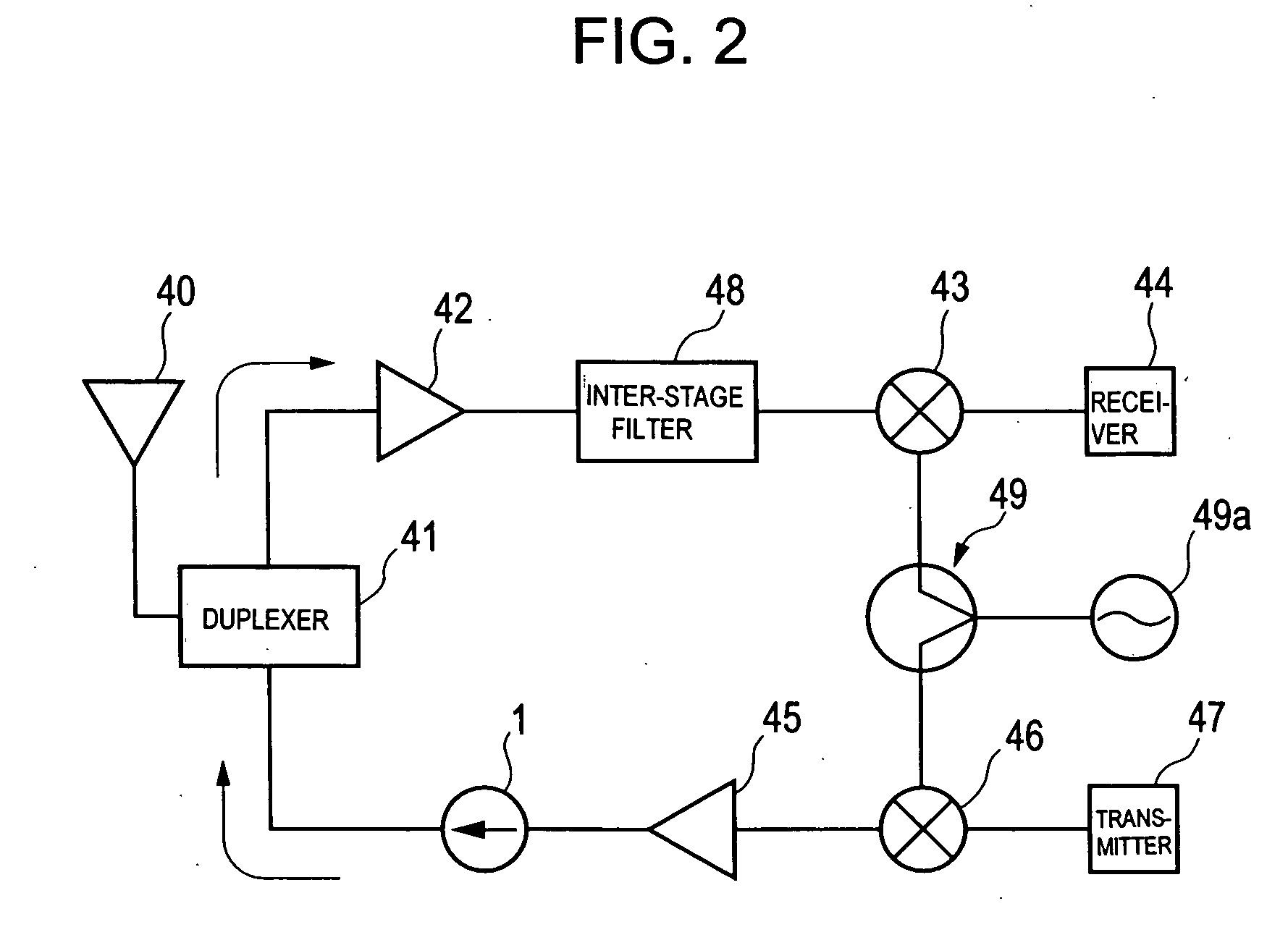

Non-reciprocal circuit device having small absolute value of temperature coefficient of out-of-band attenuation and small absolute value of temperature coefficient of maximum- isolation frequency

InactiveUS20050128023A1Improve performanceReduce stepsDifferential amplifiersWaveguide type devicesUltrasound attenuationElectrical conductor

A non-reciprocal circuit device includes a magnetic disk; a plurality of central conductors intersecting each other on a surface of the magnetic disk; a plurality of matching capacitors connected to the respective central conductors; and an SmCO-based or AlNiCo-based magnet that is stacked on the magnetic disk, the SmCO-based or AlNiCo-based magnet applying a bias magnetic field to the magnetic disk. The magnetic disk is composed of garnet ferrite represented by any one of the following Formulae (1) to (3): Y3-xGdxFet-2y-zCoySiyAlzO12 (1) Y3-x-uGdxCauFet-2y-u-zCoySiyDuAlzO12 (2) Y3-xGdxFet-2y-v-zCoySiyInvAlzO12 (3)

Owner:ALPS ALPINE CO LTD

Technique for plating alnico in copper plate type of crystallizer of conticaster

InactiveCN1796609AImprove general performanceWide range of applicationsDissolutionCurrent technology

This invention provides a continuous caster copperplate slot electroplating of nickel-cobalt alloys, with the main characteristic of a slot electroplating facility. In this technique, amino-sulfonate system is adopted as electroplating fluid and nickel is adopted as anode. Nickel ion is supplemented in an anode dissolution manner, and cobalt ion is supplemented in a cobalt amino-sulfonate continuous addition manner. The current density is 0.5~25A / sq dm, the temperature is 45~60 deg.C and the pH value is 4.0~5.5. Compared to current technologies, this invention has the advantages of large universality of the facility, wide application, high efficiency, low internal stress of coatings and high toughness. It furthest reduces the generation of thermal cracks and allows a current density of as high as 25A / sq dm. Besides, the cobalt content can be variated at different sites and thickness of the copperplate in a range of 5~80% according to the requirements.

Owner:XIANGYANG HUATONG CHEM

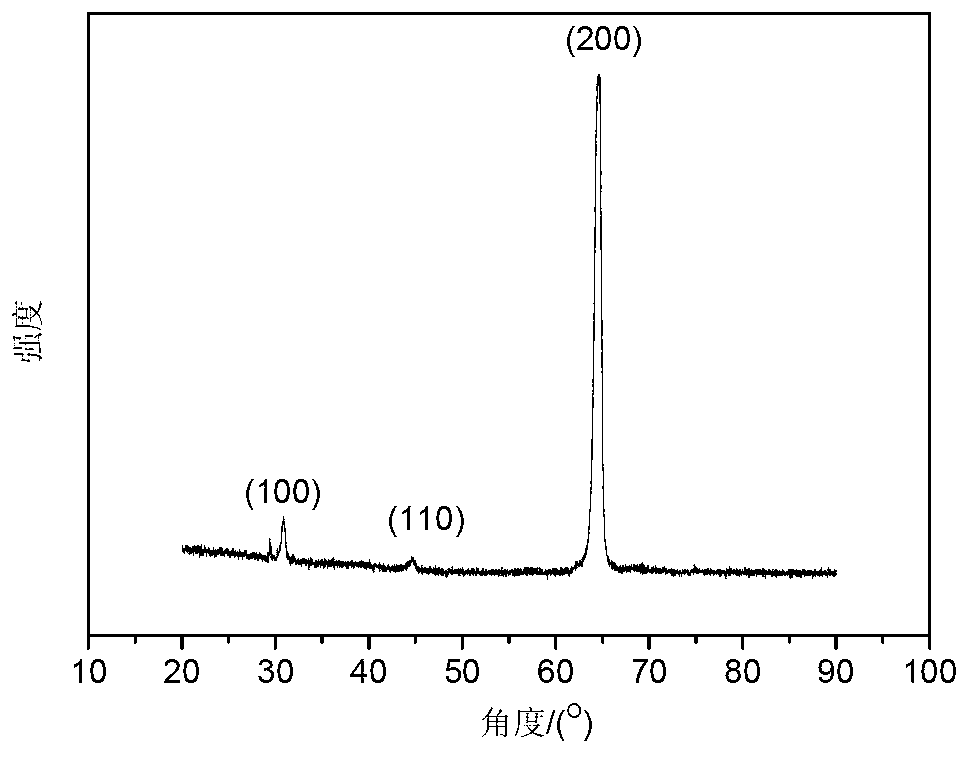

Aluminum-nickel-cobalt permanent magnet alloy with low temperature coefficient and preparation method of alloy

ActiveCN103266257AExcellent grain orientationImprove temperature stabilityInorganic material magnetismRemanenceAlloy

The invention belongs to the technical field of preparation of permanent magnet alloy and in particular relates to an aluminum-nickel-cobalt permanent magnet alloy with a low temperature coefficient and a preparation method of the alloy. The aluminum-nickel-cobalt permanent magnet alloy with the low temperature coefficient comprises the following chemical components in percentage by weight: 30%-34% of Co, 11.5%-14.5% of Ni, 2.4%-4.5% of Cu, 4%-6.2% of Ti, 5.4%-7.5% of Al, 0.02%-0.1% of C, 0.05%-0.4% of S, 0.05%-0.2% of Si and the balance being Fe. According to the aluminum-nickel-cobalt permanent magnet alloy disclosed by the invention, the AlNiCO permanent magnet alloy has excellent grain orientation by strictly controlling smelting and casting process conditions and magnetic field thermal treatment conditions. Under the condition that the magnetism does not change much, the absolute value of temperature coefficient of remanence is greatly lowered, wherein the temperature coefficient of remanence alpha is (-)0.4*10<-4> / DEG C to (-)0.6*10<-4> / DEG C at 25 DEG C-120 DEG C, and the temperature coefficient of remanence alpha is (-)0.6*10<-4> / DEG C-0.8*10<-4> / DEG C at 25 DEG C-180 DEG C.

Owner:CENT IRON & STEEL RES INST

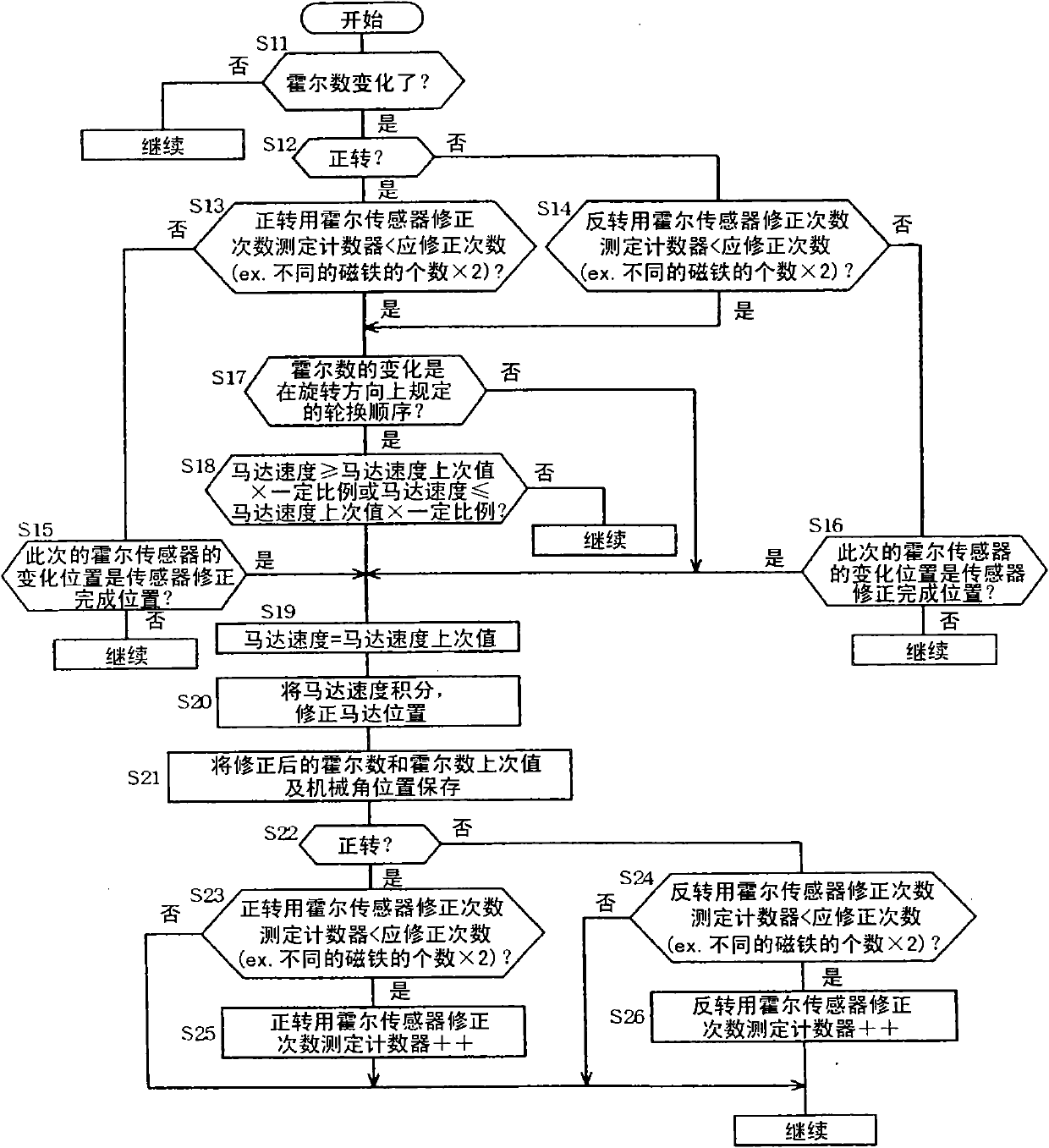

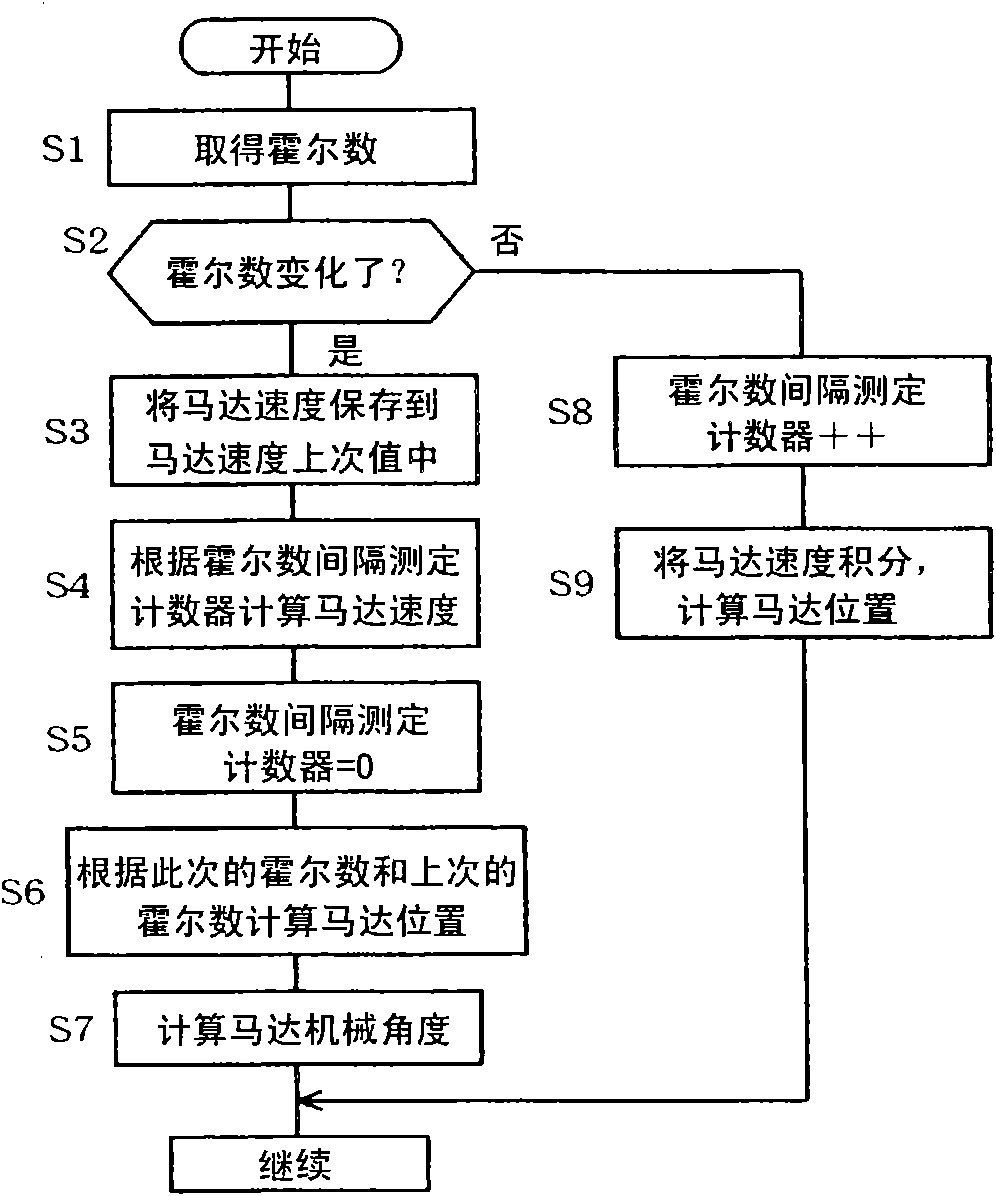

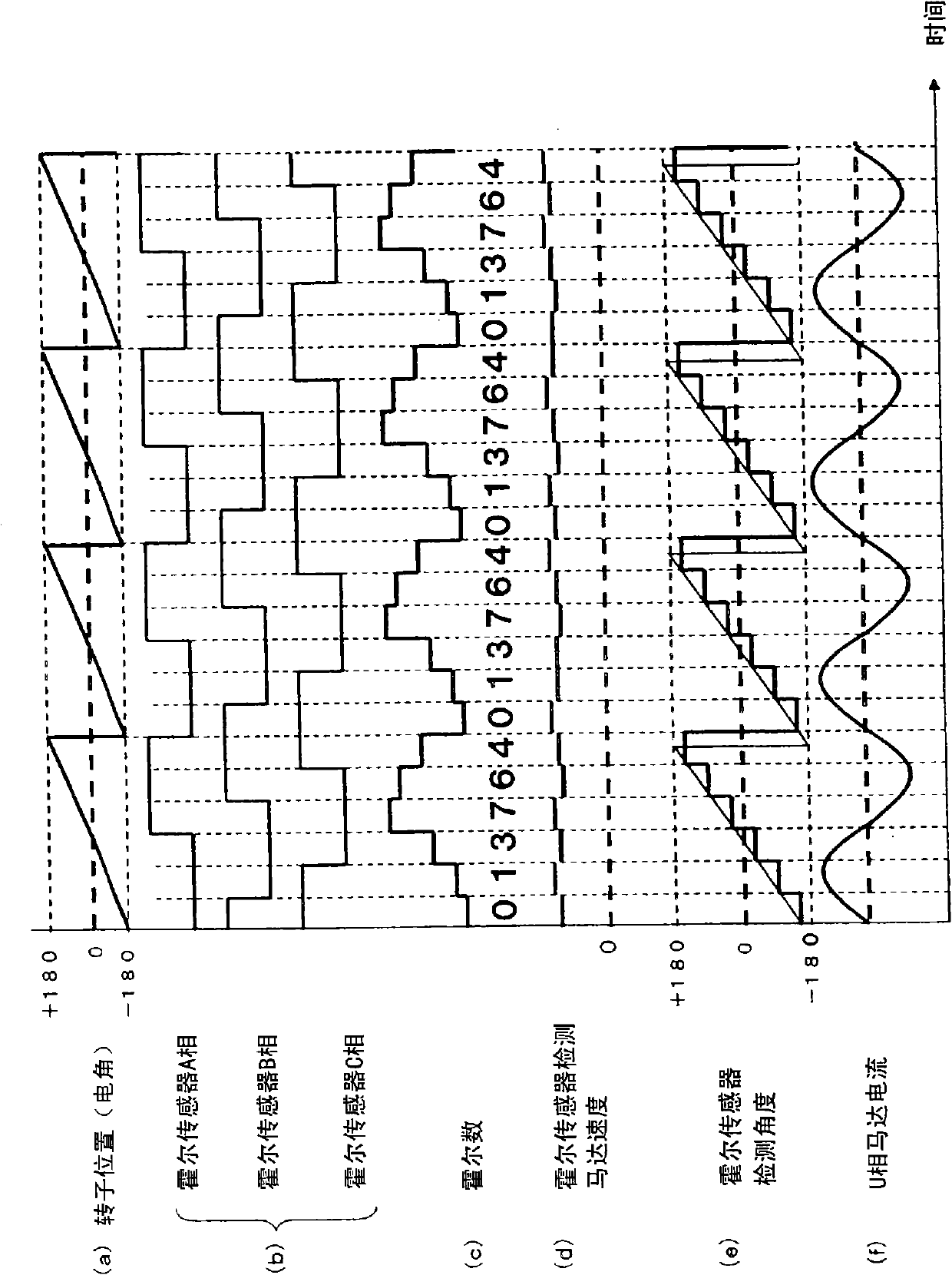

Rotor position detection device

ActiveCN102025252AAccurately getVector control systemsSingle motor speed/torque controlLocation detectionMagnetic tension force

The invention relates to a rotor position detection device. A magnetic detection sensor with low costs can be used to detect the position of a rotor correctly, when a permanent magnet motor disposed in the rotor is provided with a plurality of permanent magnets, parts of which have different magnetic forces. The permanent magnet motor (1) disposed in the rotor (3) is provided with two magnets, one is a neodymium magnet (9a) and the other is an alnico magnet (9b). 3 Hall sensors (68) (A,B,C) can be used by a speed. position detection part (55) to detect the rotation speed of the permanent magnet motor (1), and the position of the rotor (3) can be detected based on the rotation speed. The rotation speed or the position of the rotor, which are detected by the speed. position detection part (55), can be corrected, when the speed. position detection part (55) detects the boundary between the neodymium magnet (9a) and the alnico magnet (9b) according to the changing state of the sensor signal output by the Hall sensors (68).

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP +1

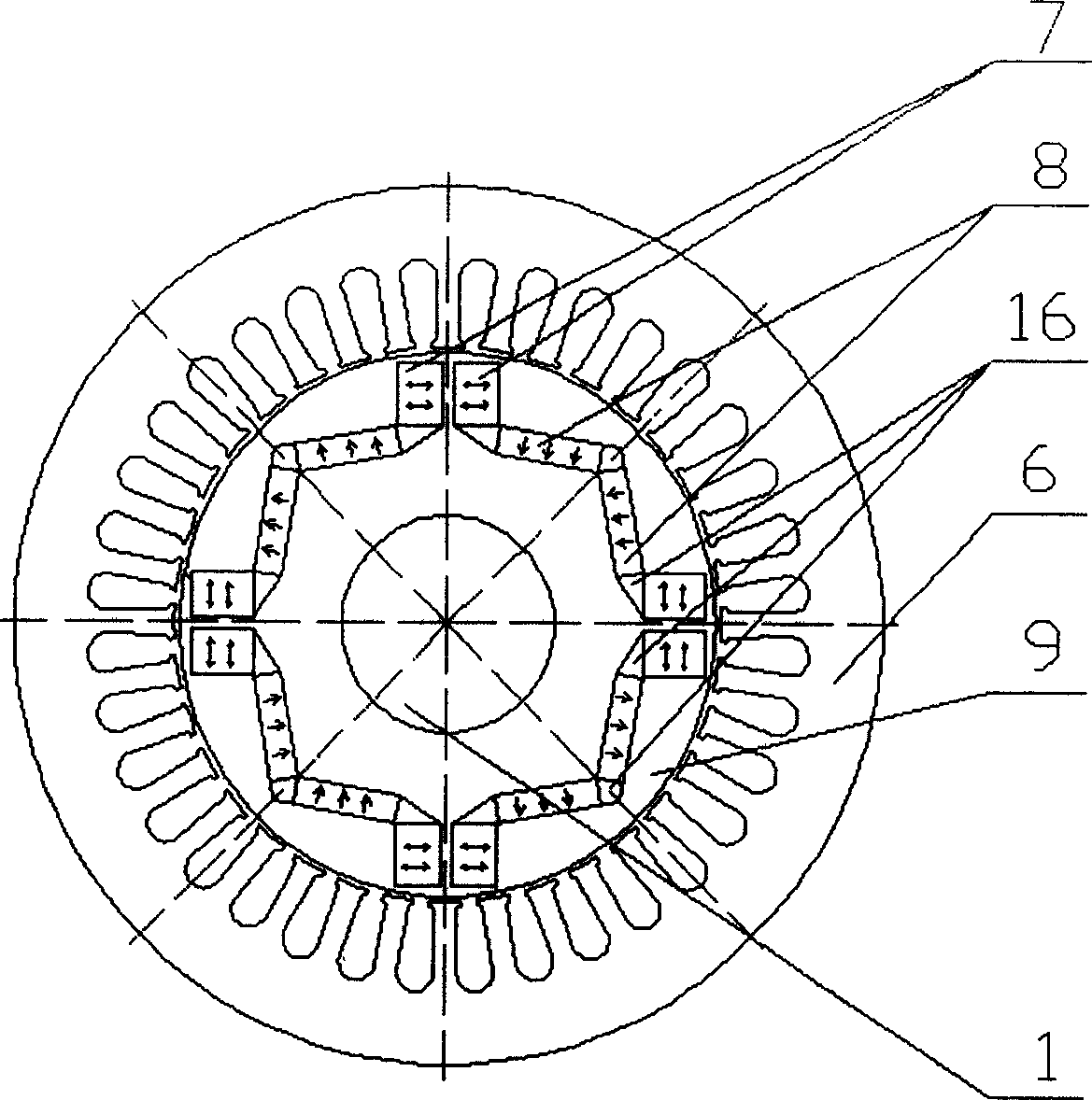

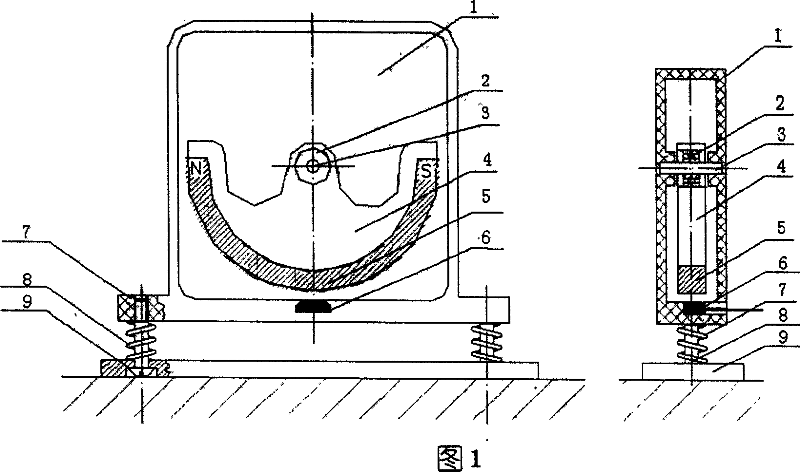

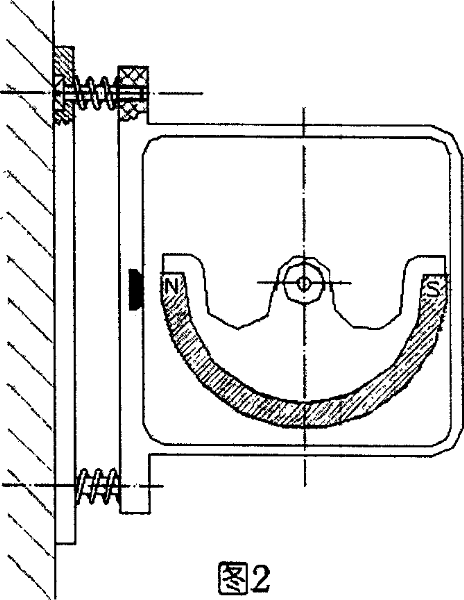

Controllable flux permament magnetic synchronous motor of built-in mixed rotor magnetic path structure

InactiveCN1617423AChange the magnetizationMemoryMagnetic circuit rotating partsSynchronous motorRotor magnets

This invention provides a controlled flux magnet synchronous motor of integral hybrid rotor magnetic-circuit structure including a motor splindle, a stator winding, a rotor iron core, a AlNiCo magnet, NdFeB magnet and a rotor iron core, in the rotor iron core, the magnets are place in W shape, AlNiCo is set tangentially and the NdFeB is set in radial position which can be a parallelogram or a rectangle considering the limit of the rotor space. The advantage is that an ampltude controlled d-axis vector is applied to alter the magnetization intensity of the rotor magnet and memerizes the altered flux density.

Owner:TIANJIN UNIV

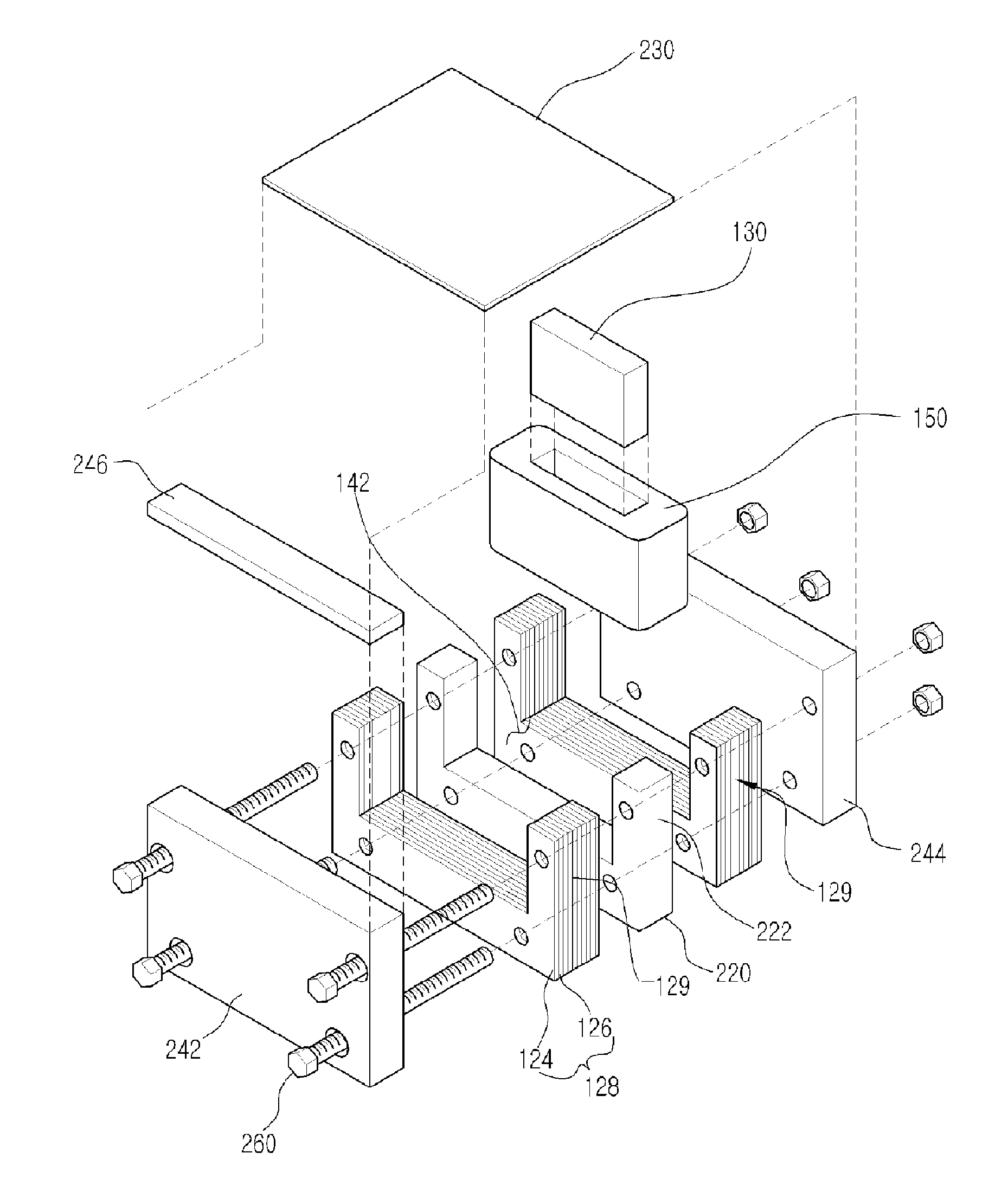

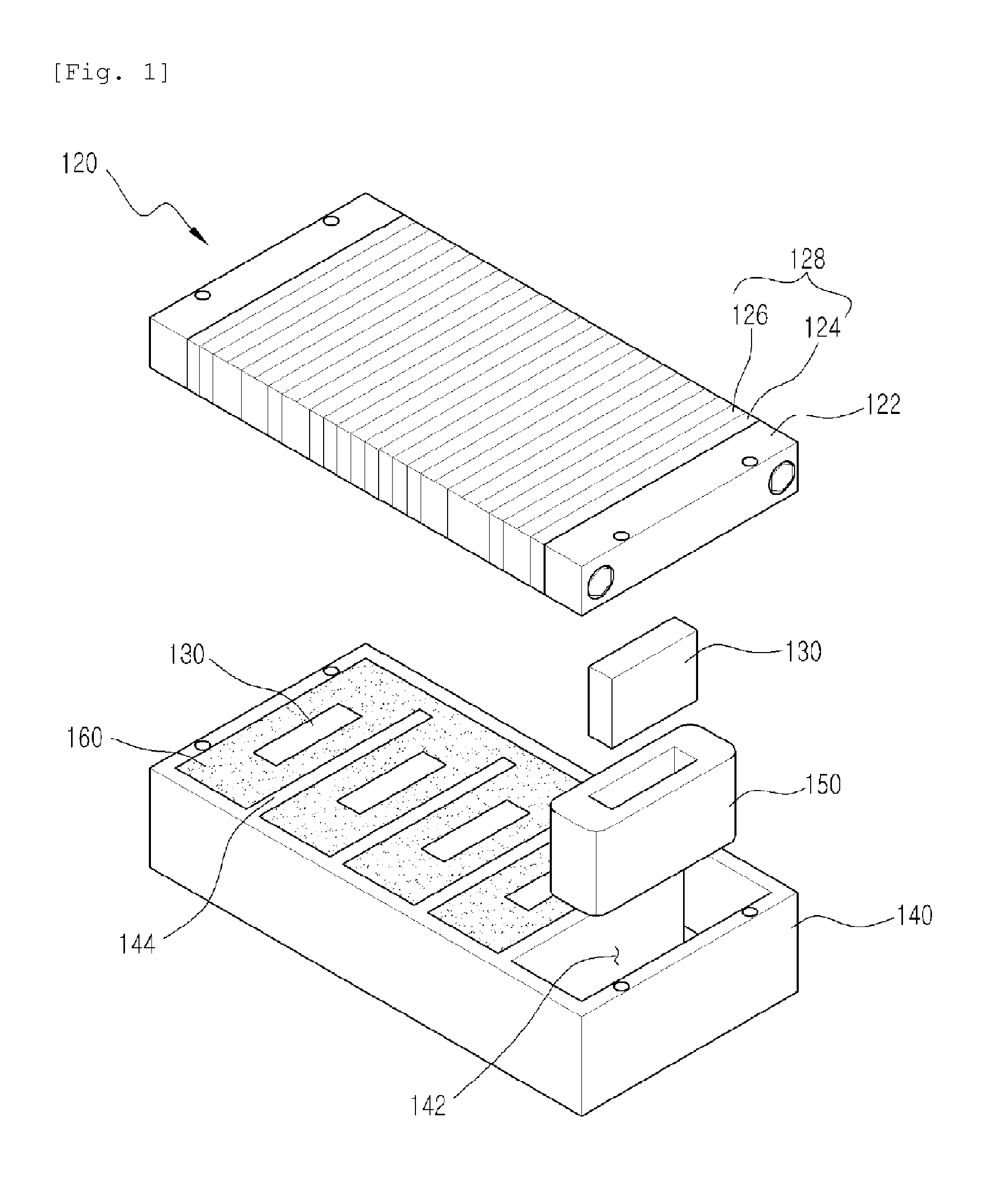

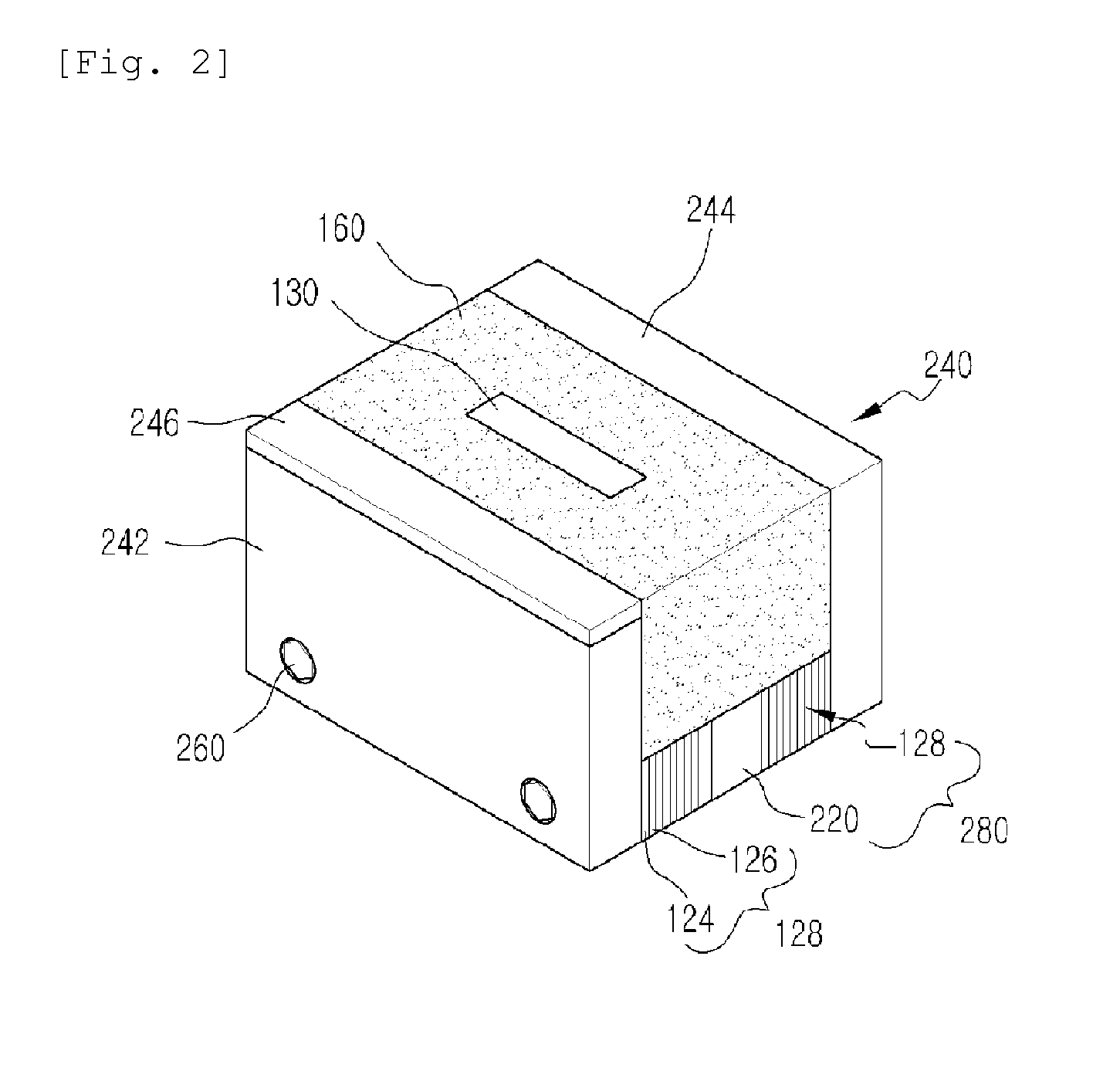

Magnetic chuck

InactiveUS20140043123A1Easy to assembleCost time be reducedElectromagnets without armaturesPermanent magnetsNon magneticCoil insertion

The present invention relates to a magnetic chuck. The present invention provides a magnetic chuck capable of attaching and processing a workpiece by magnetism, and the magnetic chuck comprises: a small-sized magnetic member which includes a magnetic substance having magnetic properties, and panel units that are respectively positioned on both sides of said magnetic substance through heat treatment and in which non-magnetic panels are inserted between a plurality of magnetic panels; a sidewall unit which has accommodation grooves by positioning respectively a first sidewall and a second sidewall on both sides of said small-sized magnetic member; coupling members which are coupled by penetrating said small-sized magnetic member and the sidewall unit; alnico magnets which are inserted into said accommodation grooves; coils which are inserted into said accommodation grooves, and enclose the alnico magnets; fillings which mutually couple said alnico magnets and said coils, and are filled in the accommodation grooves such that one side of the alnico magnets is exposed; and a first insulator which is equipped on one side of said first sidewall to allow magnetism, which flows into the first sidewall, to flow in another direction.

Owner:JIN YOUNG PRECISION MACHINE

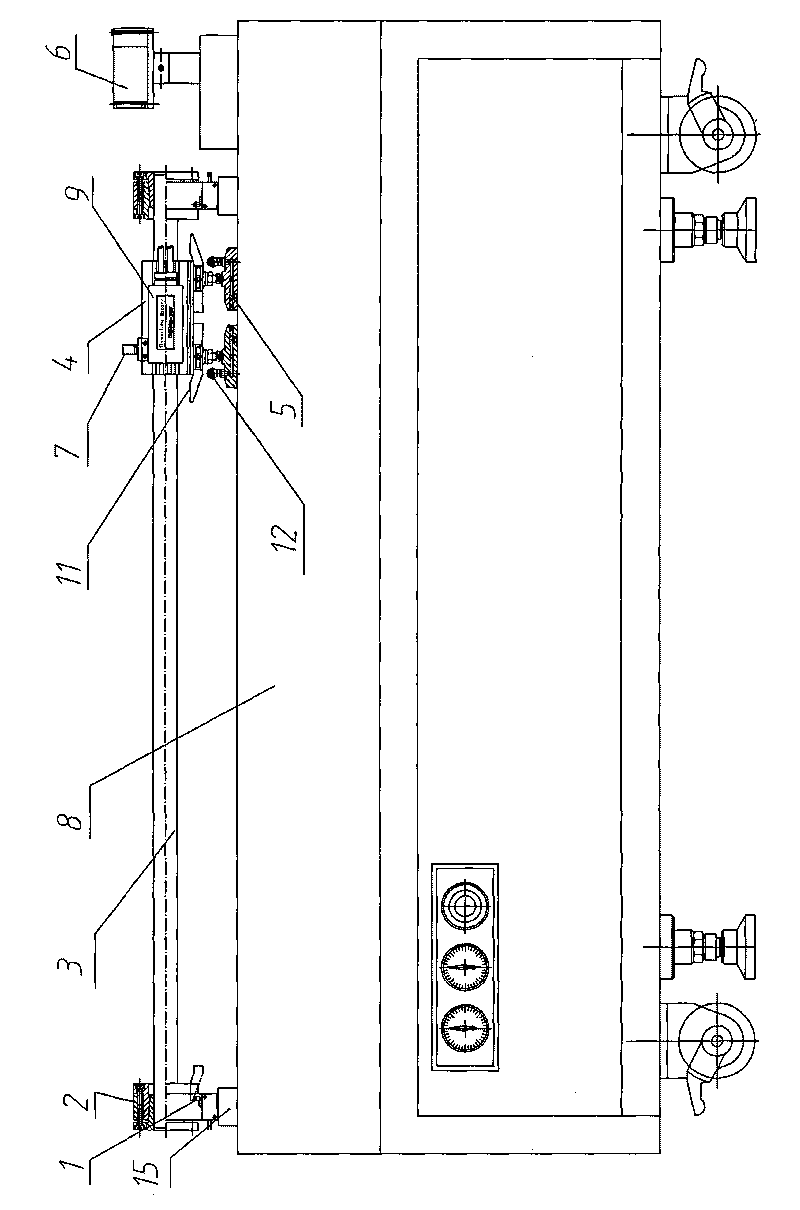

Device for calibrating high-speed motion measuring instrument

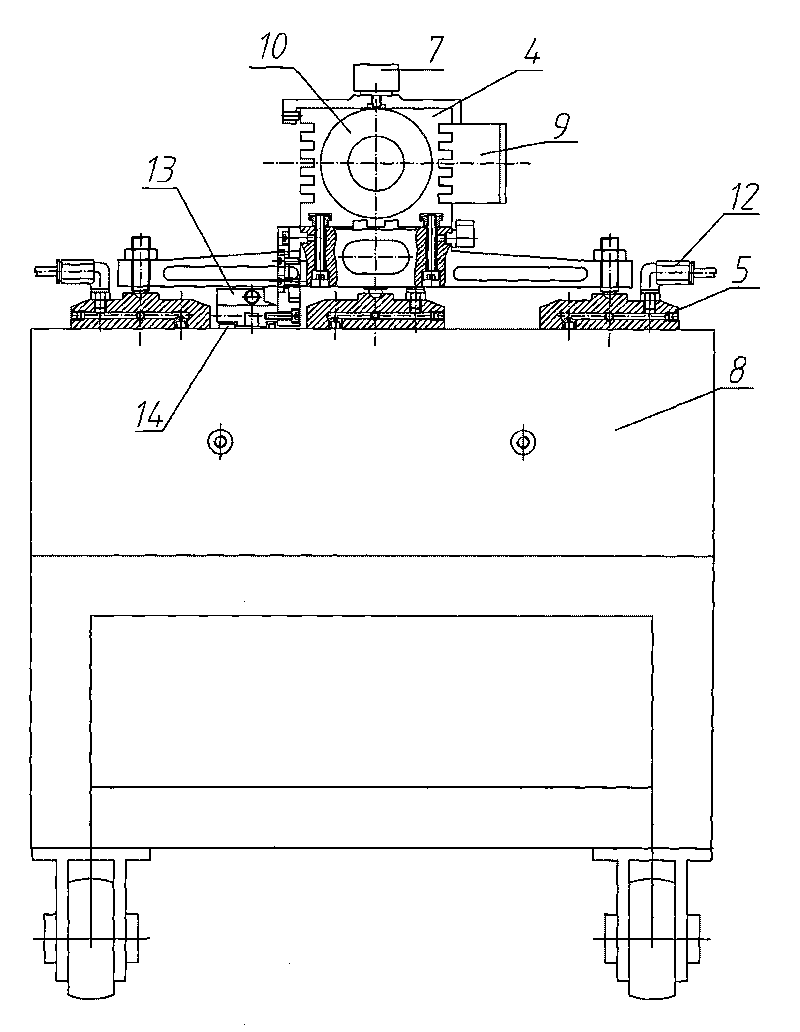

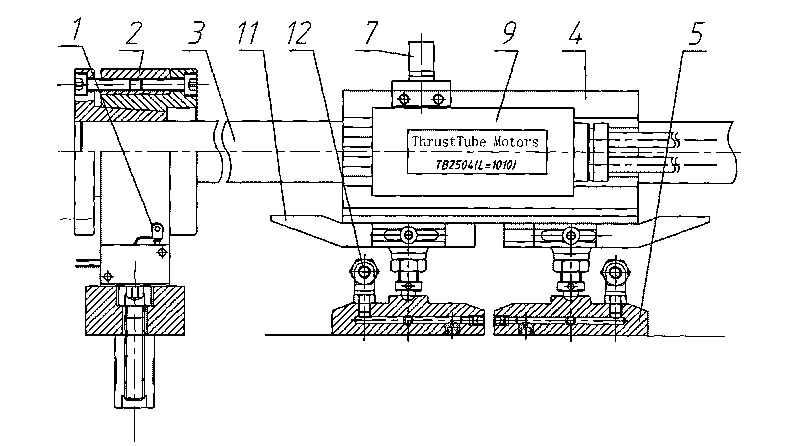

InactiveCN101738498AAccurate CalibrationEasy CalibrationTesting/calibration of speed/acceleration/shock measurement devicesGratingMeasuring instrument

The invention discloses a high-speed motion measuring instrument calibrating device capable of conveniently and accurately calibrating and measuring a conventional high-speed motion measuring device. The device comprises a worktable of which the upper surface is a smooth horizontal plane; two sides of the upper surface are provided with a bearing respectively; a permanent alnico thrust bar is horizontally arranged between the two bearings; the permanent alnico thrust bar is sleeved with a linear motor rotor; the lower end of the linear motor rotor is provided with an air floatation bearing which forms non-contact type supporting with the upper surface of the worktable; the device also comprises a metal strip raster measuring system, wherein a metal strip raster read head is arranged on the lower end face of the linear motor rotor; a metal strip raster is arranged on the upper surface of the worktable and corresponds to the metal strip raster read head; the device also comprises a microcomputer control system which is connected with the metal strip raster measuring system and the linear motor rotor respectively and can read a measuring result of the metal strip raster measuring system and control the motion of the linear motor rotor.

Owner:CHONGQING JIANSHE IND GRP +1

Novel doubly-salient memory electrical machine

InactiveCN101662173AResolve asymmetryImprove Potential WaveformMagnetic circuit rotating partsMagnetic circuit stationary partsConductor CoilPhase number

The invention relates to a novel doubly-salient memory electrical machine comprising an outer rotor with tooth and an inner stator with tooth, wherein permanent magnets are arranged on the inner stator. The number of tooth Nr of the outer rotor, the number of tooth Ns of the inner stator and the number Np of the permanent magnets should satisfy the relational expression: (m+k1)*Np=Ns=mk2 and 360Nr / Ns=360k3+ / -alpha, wherein m is a phase number and is bigger than or equal to 3, alpha is a slot pitch angle the span of which is 0-360 degrees, k1 belongs to an integer from 1 to 1-m, and k2 and k3 are respectively a random positive integer. AlNiCo is adopted as the permanent magnets, and current pulses with different sizes and polarities are charged to a plurality of separated direct current windings to realize on-line magnetism charge demagnetization, thereby realizing multiple functions. Due to the fact that the duration of the current pulse is short, and the induced loss almost can be neglected, as an electromotor, the electrical machine can realize on-line magnetism modulation in the real sense while in running, and as a generator, the electrical machine can realize high-efficiency constant-voltage output while in running.

Owner:SHANGHAI UNIV

Angle compensation process for dual-motor redundancy control system

InactiveCN101256414ALarge output torqueControl using feedbackMultiple dynamo-electric motors speed regulationControl systemPosition angle

The invention relates to an angle compensation method for a double motor redundancy control system, which is a control scheme in redundancy transmission filed. Directed at the alnico asymmetry phenomena possibly existing in a coaxial redundancy motor system, the invention effectively improves the running efficiency of the redundancy motor system with an angle compensation strategy. A front rotating angle gamma0 and a back rotating angle gamma1 of the redundancy motor system are measured, and the equation gamma = gamma1 - gamma0 is satisfied, then gamma is recorded as the initial position angle of the redundancy motor system, ensuring the current decoupling relationship in the torch control of the double redundancy motor system is established, thus the running efficiency of the redundancy motor system is effectively improved. The method has simple digital realization, good universality is good, and practical value to the redundancy transmission system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for measuring incline angle

InactiveCN101038161ASimple structureLarge dynamic rangeIncline measurementMeasurement deviceHall element

The present invention provides a measuring method of the inclination angle by adopting linear Hall element and a rotatable alnico to form the set of equipment. A heavy hammer which can be vibrated freely in a certain range in the casing is provided in the equipment, and an alnico is installed on the heavy hammer, and a linear Hall element is installed on the casing of the measuring device. The heavy hammer is perpendicular to the horizontal plane because of the function of the gravity, thus, when the installing surface of the equipment and the level plane form a certain angle, the linear Hall element forms an offset relative to the alnico, and the voltage which has a value that is in direct proportion to the incline angle between the incline device and the level plane and which is output from the linear Hall element is changed, thus, the incline angle is measured. The technique characteristics are: a structure of the heavy hammer which can be vibrated freely and which includes alnico and a Hall magnetism sensory technology are adopted; the devices are packaged in a casing; the devices which is not easy to be destroyed have a simple structure, a low cost, a high reliability, a long using lifetime. The method can also be used in the design and manufacture of the angle sensor.

Owner:上海瑞可运动器材有限公司

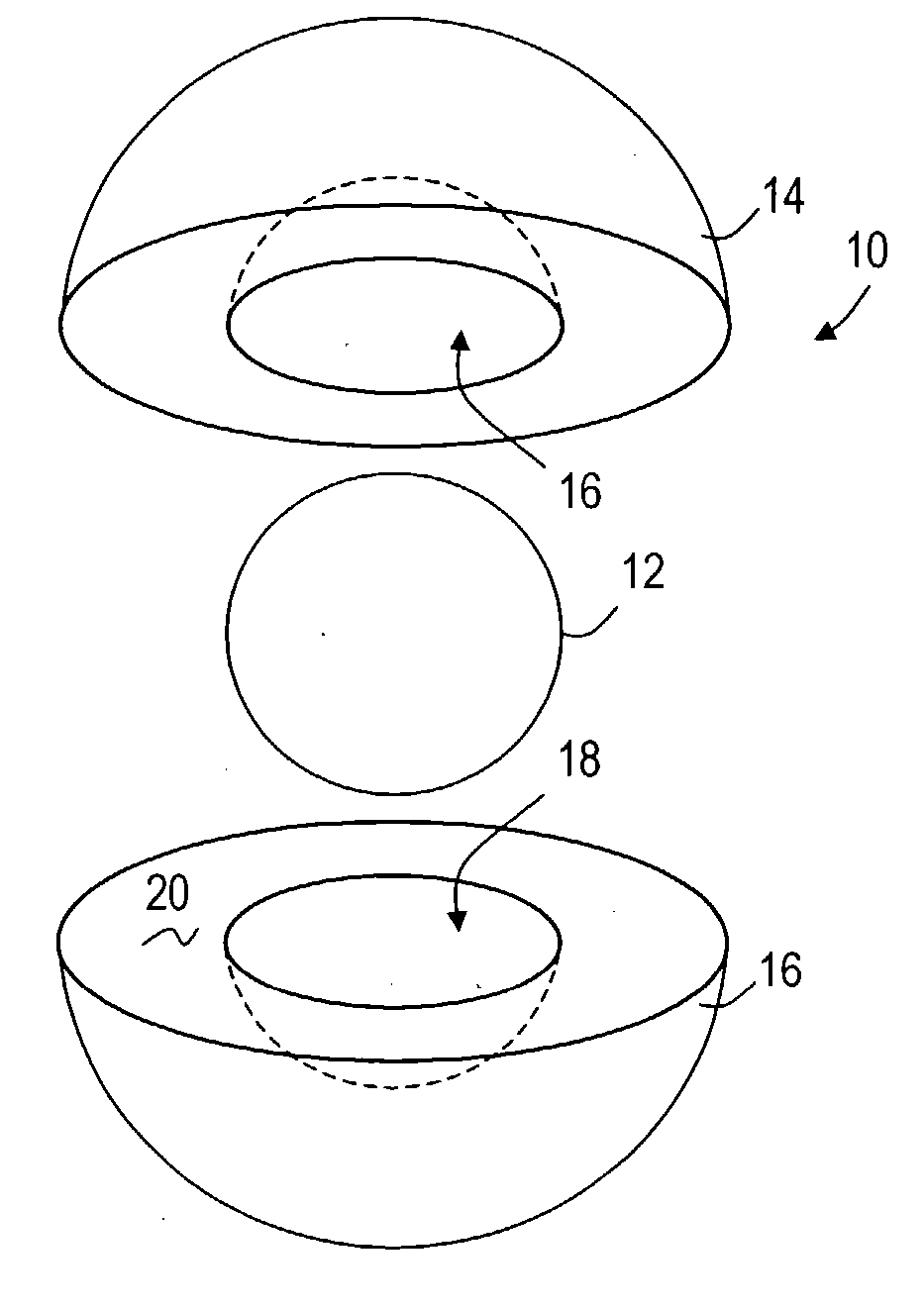

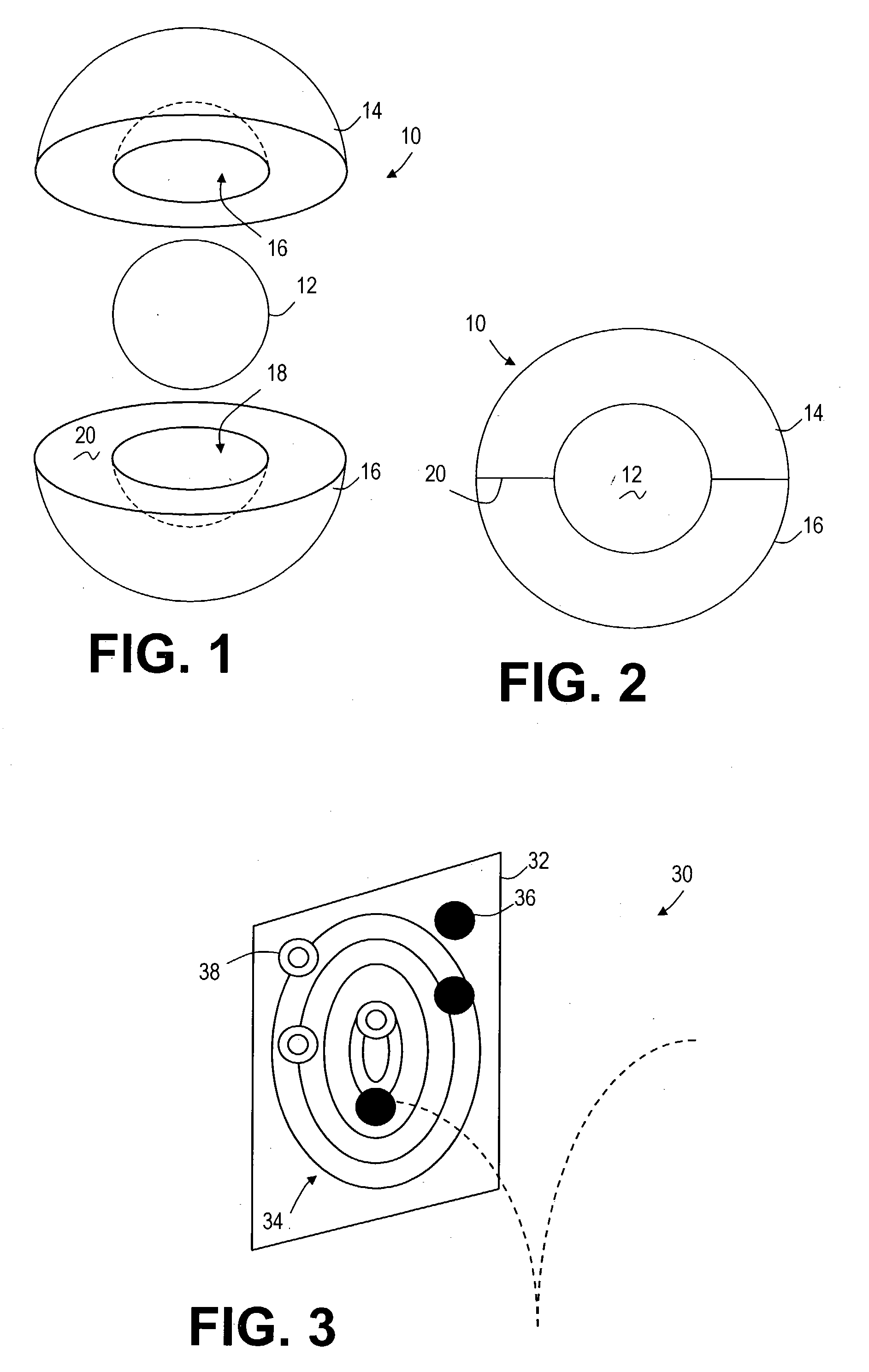

Magnetic bouncing ball and target game

InactiveUS20050009438A1Increase elasticityStrong magnetic fieldIndoor gamesToysFree rotationHigh probability

A magnaball toy is advantageously formed from an embedded spherical rare earth magnet (e.g., NdFeB, SmCo, AlNiCo, etc.) placed within an elastopolymer shell. A pair of balls may be dropped from about a meter and have a high probability of sticking together as they bounce. In some applications, allowing for free rotation of a spherical magnet inside the ball allows for a predictable attractive behavior of the ball. This feature brings various novel gaming aspects to the magnaball toy.

Owner:4LICENSING CORPORATION

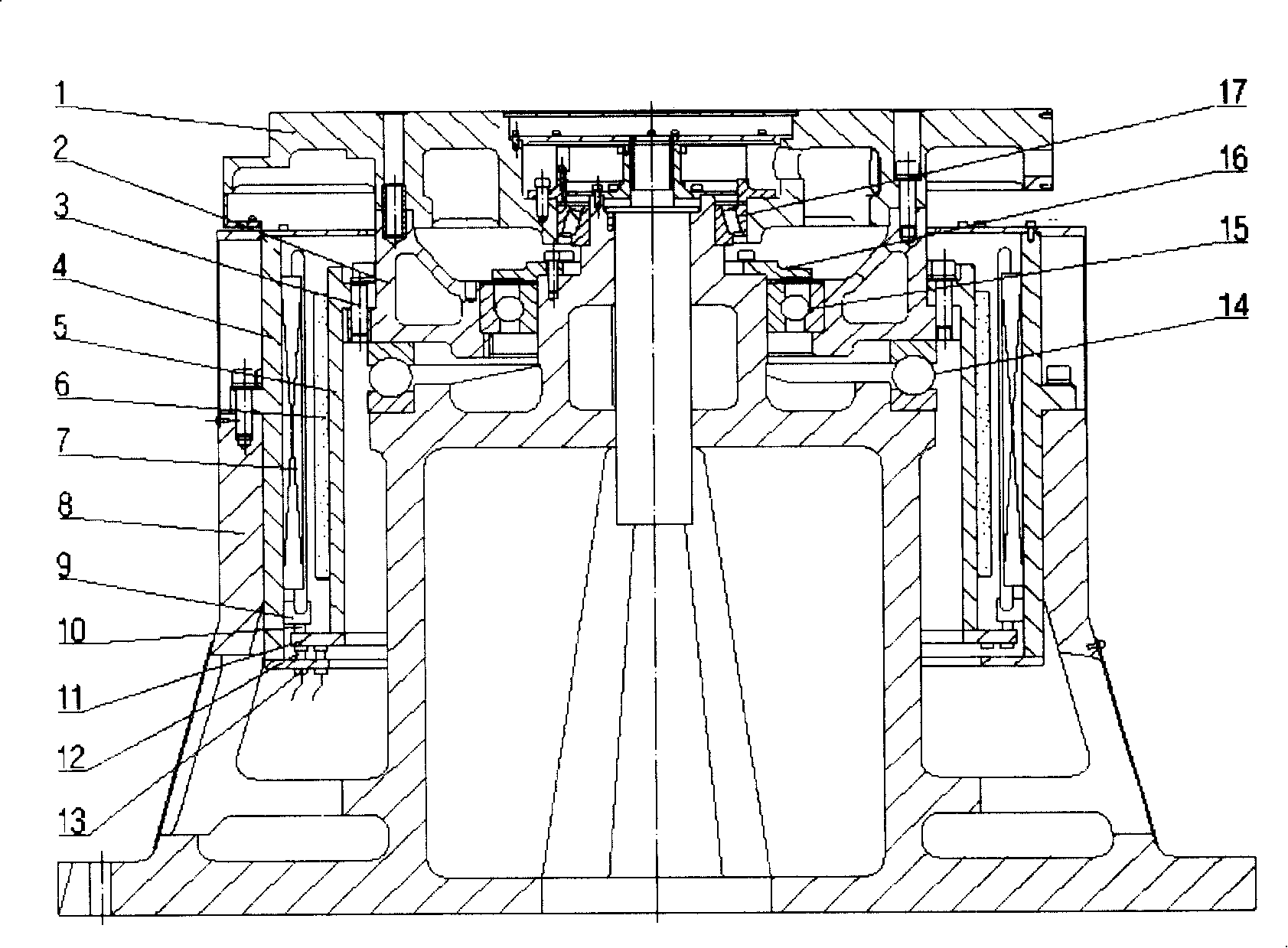

Novel direct current driving turntable structure

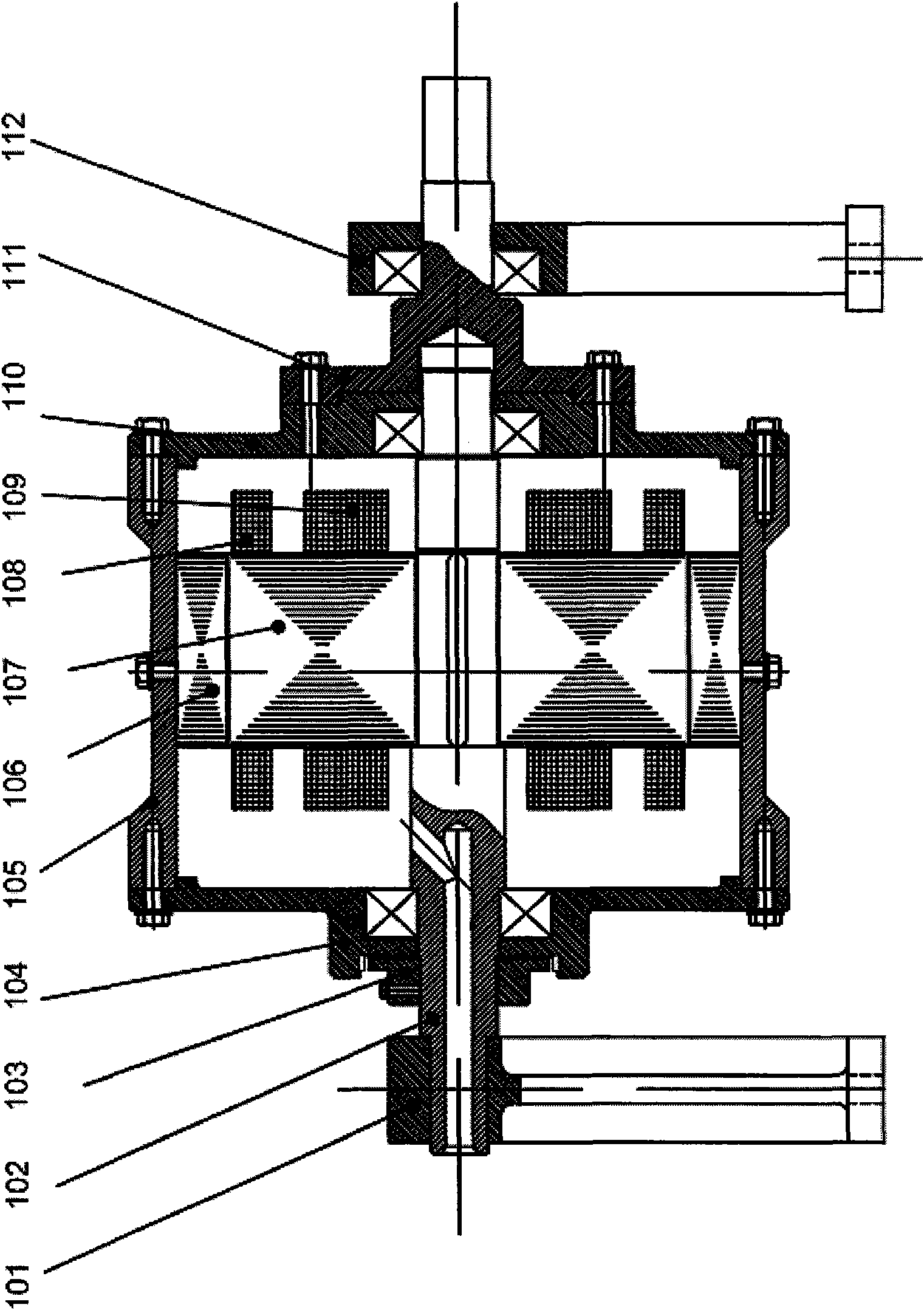

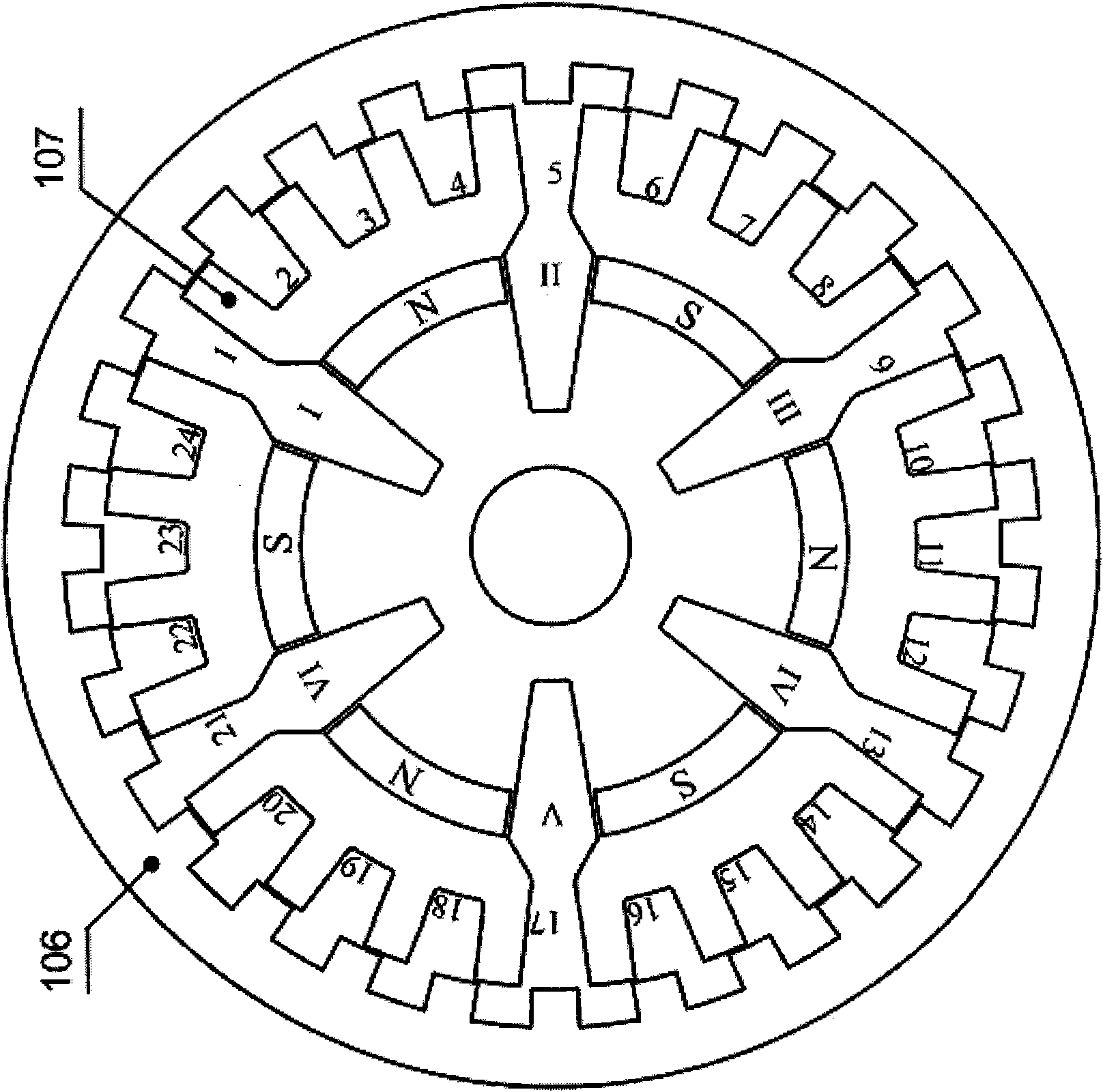

InactiveCN101162857ASmall moment of inertiaSmall torque fluctuationMagnetic circuit rotating partsDC commutatorBall bearingThrust bearing

The invention relates to a novel rotary table driven by a DC motor. The motor stator is mounted on a frame, windings and an iron core are mounted on the inner side of the stator, and a commutator is arranged at the lower end of the windings. The wire inlet terminal and the brush of the conducting ring are fixed on the lower end of the stator; the motor stator is fixed on the main shaft; the worktable face is connected to the main shaft by bolts; an alnico is fixed on the stator, the brush with a conducting ring is mounted on the bottom of the stator by a frame; the brush of the commutator is mounted on the brush frame provided with a conducting ring, and the brush of the commutator contacts with the commutator; and the conducting-ring brush contacts with the conducting ring arranged on the brush frame provided with a conducting ring. The part between the main shaft and the frame is supported by a thrust ball bearing and an angular-contact ball bearing, and the part between the worktable face connected with the main shaft and the frame is supported by a tapered roller bearing. The rotary table with such structure has the advantages of that the rotor has small moment of inertia, the fluctuation of moment is small, the speed is low, the performance is sound, and the cost is low; particularly when load acceleration requires relatively high control accuracy, such structure is easy to meet the technical requirements of the rotary table and reduce the cost.

Owner:AVIC BEIJING CHANGCHENG AVIATION MEASUREMENT & CONTROL TECH INST +1

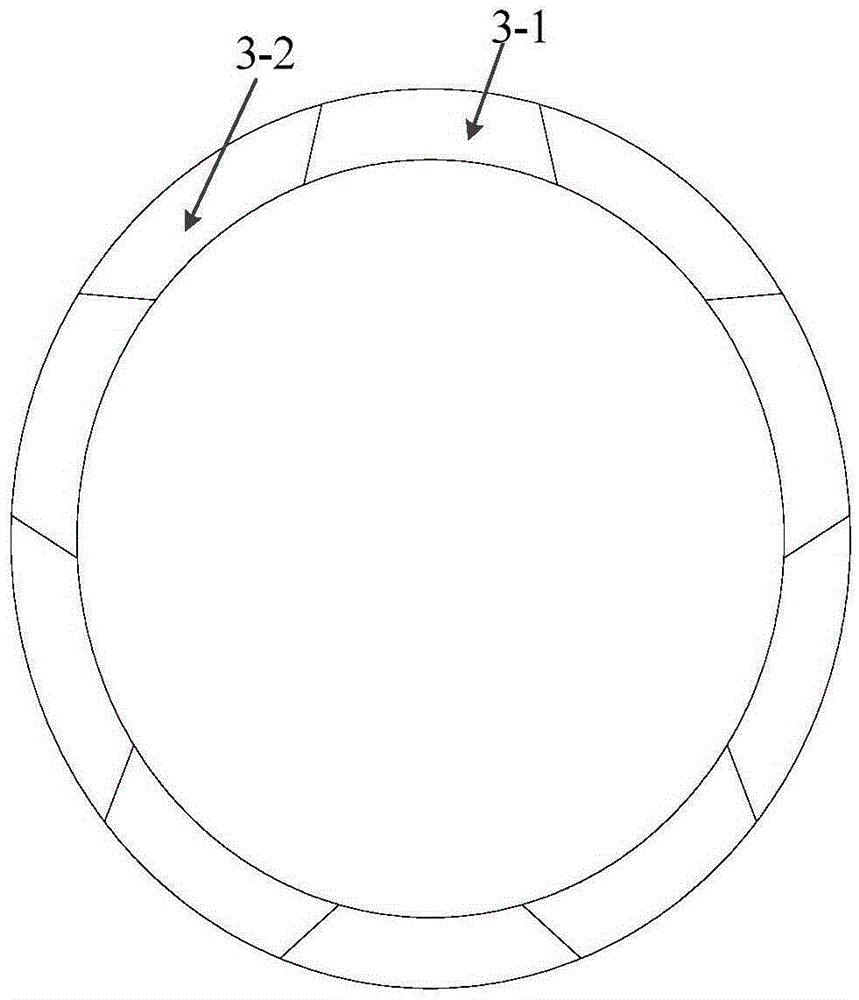

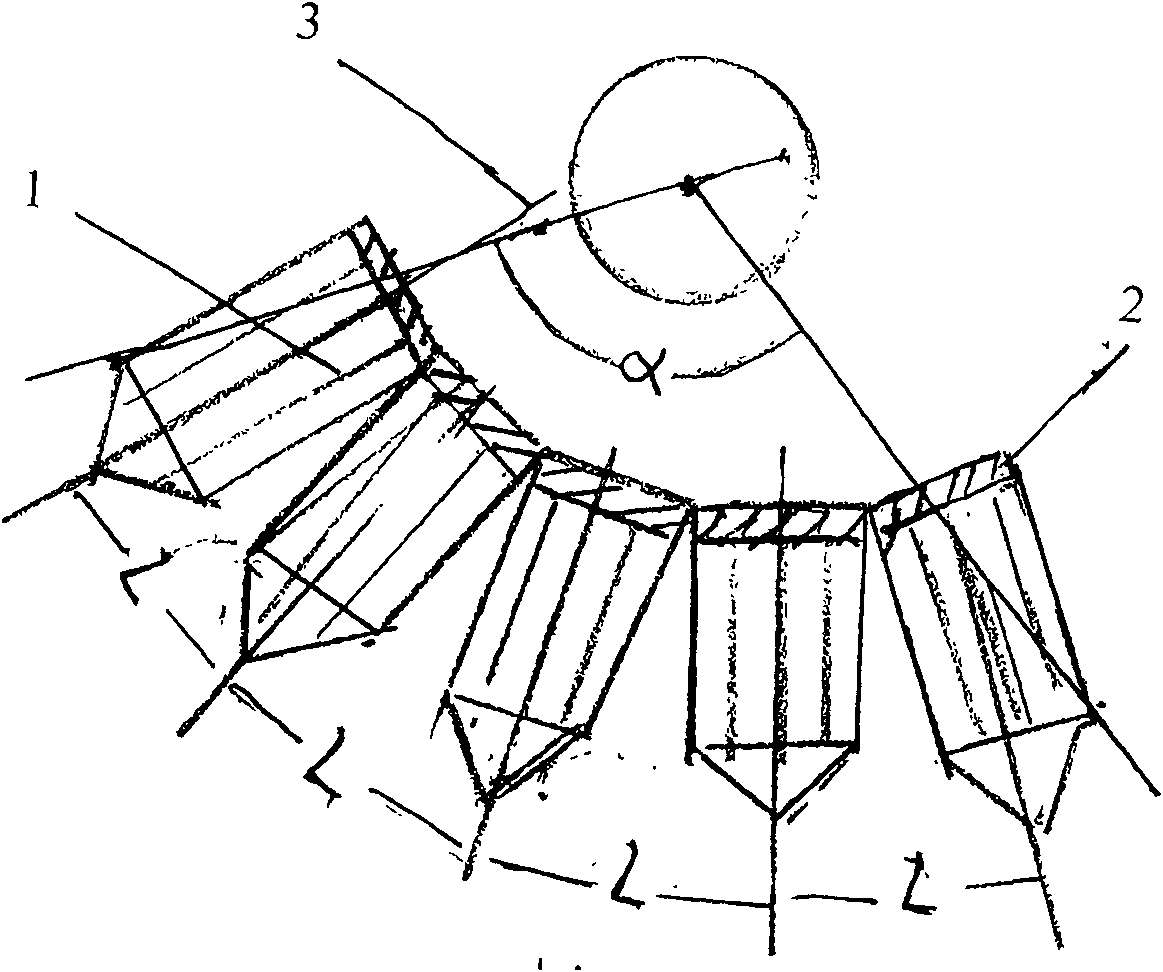

Production method of radiation-orienting magnet ring

InactiveCN101174503AImprove magnetismImprove yieldInorganic material magnetismInductances/transformers/magnets manufactureRare earthAlnico

The invention relates to a manufacturing method for a radiation-oriented magnetic ring, belonging to the technical field of the rare earth permanent magnet material. Aiming at the disadvantage that the radiation-oriented magnetic ring prepared by the prior art is easy to be broken up, the invention radiates, orients and molds anisotropic nanocrystal magnetic particles with powder particle size of 1 to 100 micron under a magnetic field, the anisotropic nanocrystal magnetic particles are pressurized and sintered with discharge plasmas or a direct current, the temperature is 500 to 960 DEG C, the time is 0.5 to 10.0 minutes, the pressure is 30 to 200 MPa, after the sintering, the temperature is rapidly reduced; magnetic powder is single alloy or double alloy (at least one kind of magnetic powder is anisotropic nanocrystal), the alloy is chosen from R1T5, R1T7, R2T17 R2T14M1, AlNiCo, FeCrCo, permanent magnetic ferrite and soft magnetic alloy with high saturation magnetization. The manufacturing method of the radiation-oriented magnetic ring is also suitable to prepare micron crystal R1T5, R2T17, R2T14M1, AlNiCo, FeCrCo radiation-oriented magnetic rings, the powder particle size is 1 to 20 micron, the magnetic ring is at least required to be thermally treated for one time. The finished product rate of the magnetic ring is higher.

Owner:NINGBO UNIV

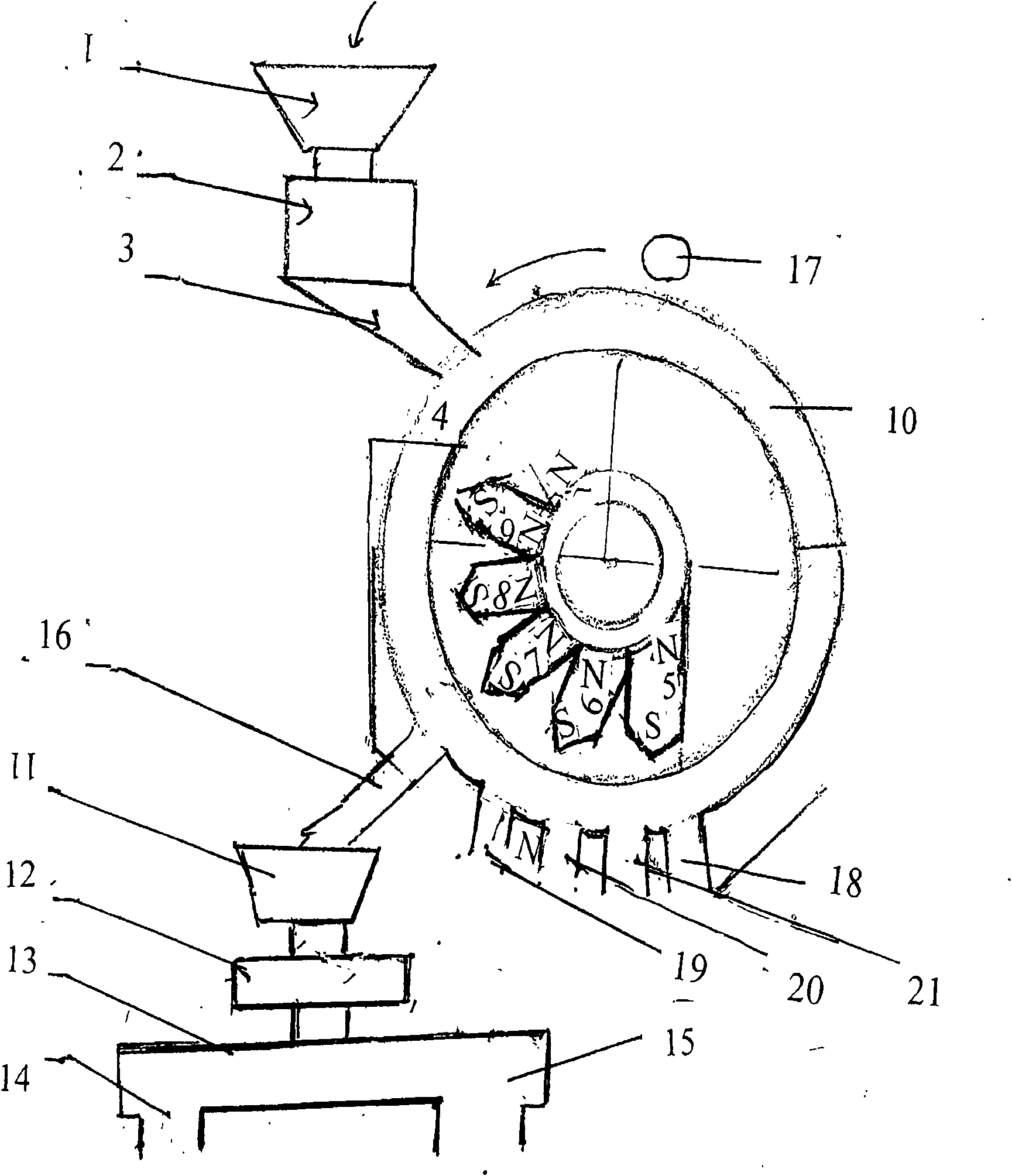

Manufacture process and application technical process of energy-saving and emission-reducing high-gradient magnetic separating machine with ultrastrong magnetic field

InactiveCN102211058AEliminate mechanical inclusion problemsReduce generationHigh gradient magnetic separatorsWater/sewage treatment by magnetic/electric fieldsRare earthSlurry

The invention provides a manufacture process and an application technical process of a high-gradient magnetic separating machine with an ultrastrong magnetic field. Set magnetic separating magnet materials comprise ferrite, alnico, SmFeN and a rare earth permanent magnet material. A magnetic separating chamber is made of non-magnet-conducting materials, a slurry outlet and a slurry inlet are respectively arranged on the upper part and the lower part of the magnetic separating chamber, and magnetic separating media put in the separating chamber are steel wool. An emission-reducing and energy-saving ball mill saves energy and reduces the emission of exhaust gas. Multiple times of fine separation are adopted in the technical process for improving iron content. After tailings are ground by using the ball mill to reduce the iron content in the tailings, the tailings enter a sorting machine, and a high-gradient magnetic separating technical process of stainless steel wool is adopted for treating waste water. The magnetic separation and mine sewage treatment technical indexes of the process provided by the invention reach an advanced level.

Owner:潘树明

Band type loudspeaker and all band coaxial loudspeaker containing same

InactiveCN1905758ASmall diaphragmImprove directivityFrequency/directions obtaining arrangementsEngineeringFull band

The invention relates to a band loudspeaker and a full-band coaxial speaker. The band speaker includes a magnetic board, an alnico, a magnetic ring and a diaphragm covered with loops, which are all annular. The magnetic board locates on the upper surface of the alnico. The magnetic ring is outside the alnico and forms magnetic gap with the magnetic ring where the diaphragm is. The full-band coaxial speaker consists of treble, alto and bass loudspeakers which are coaxial. Among them, the treble one is the band loudspeaker.

Owner:ZHUHAI HIVI TECH

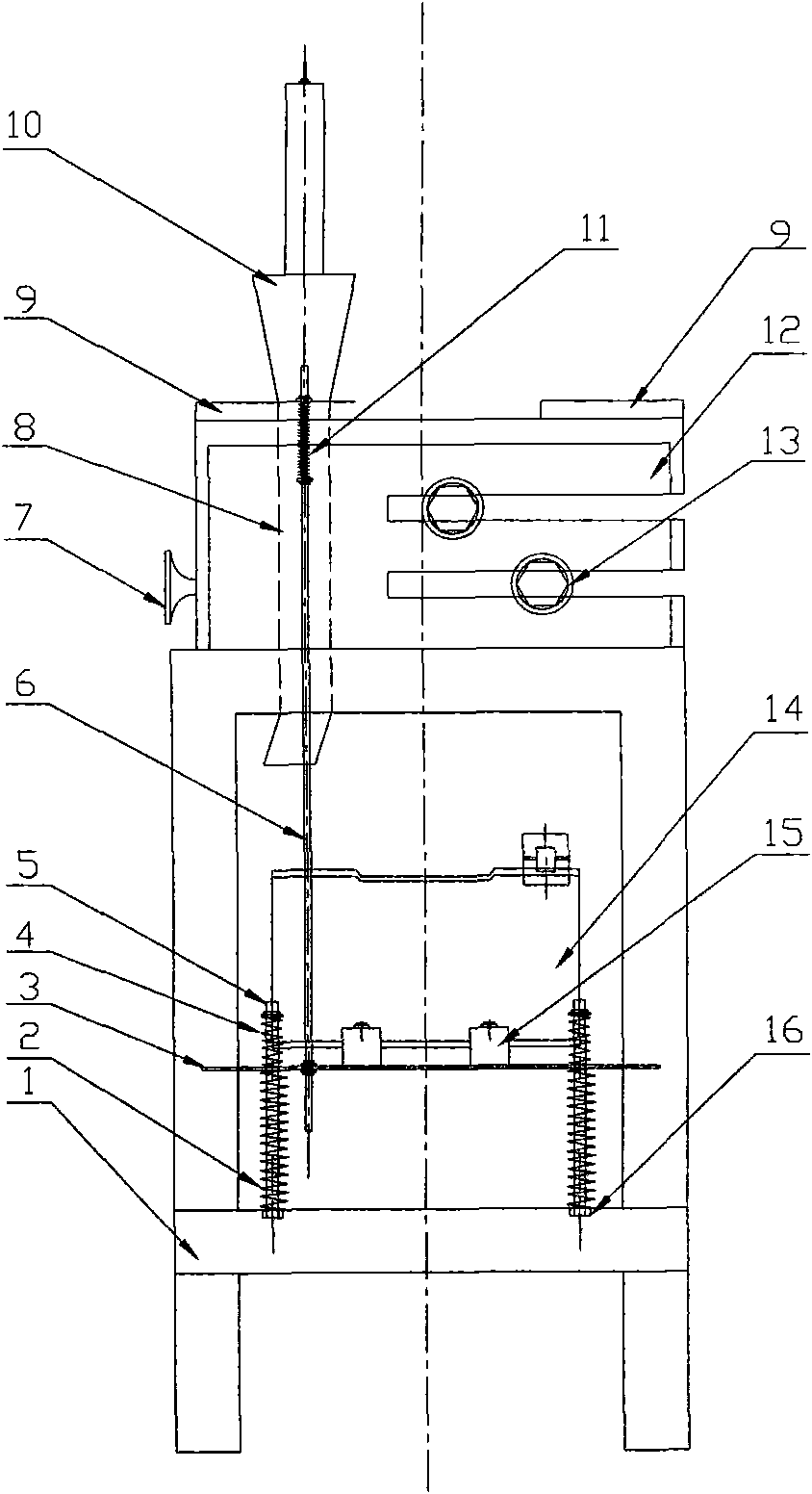

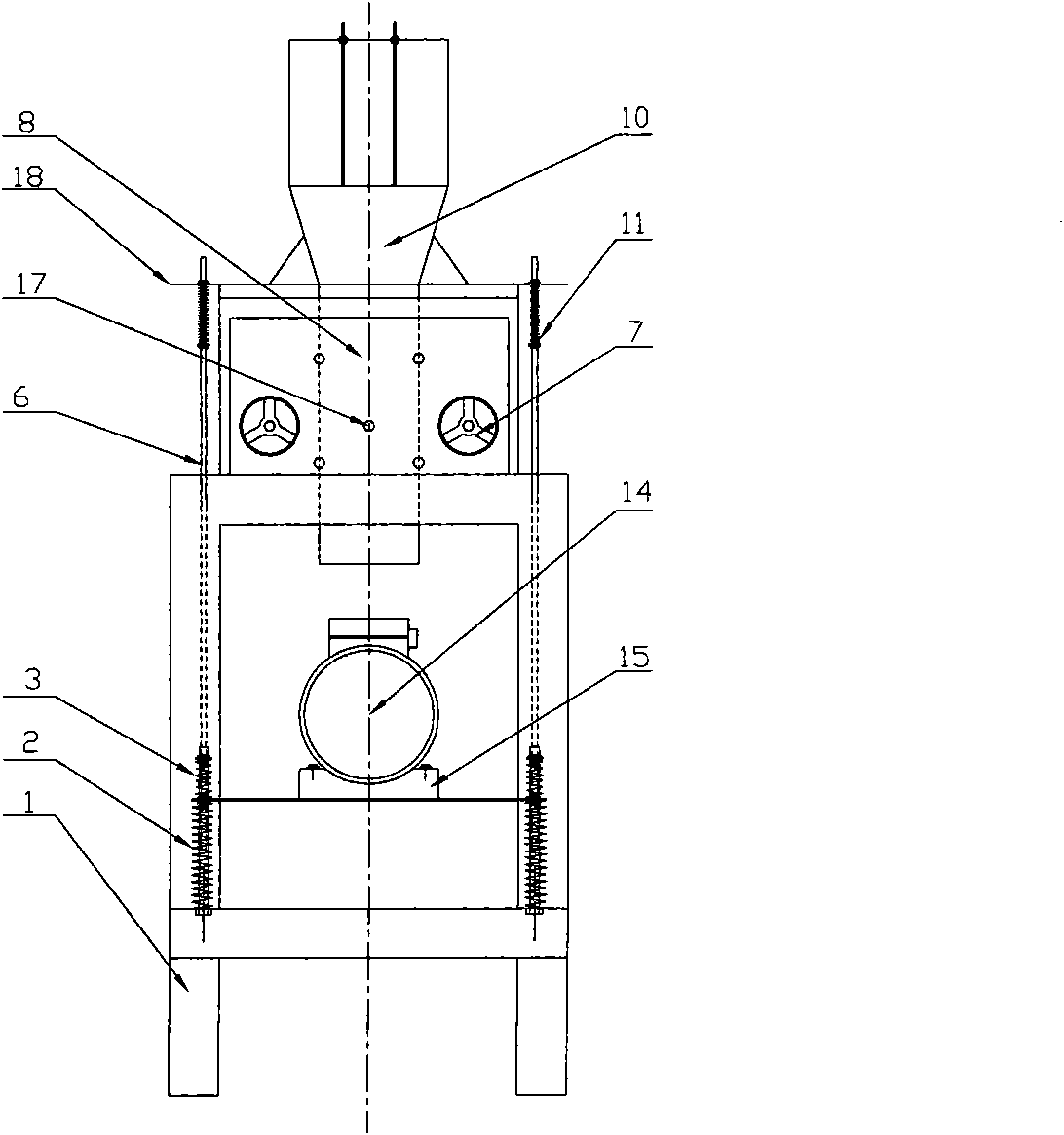

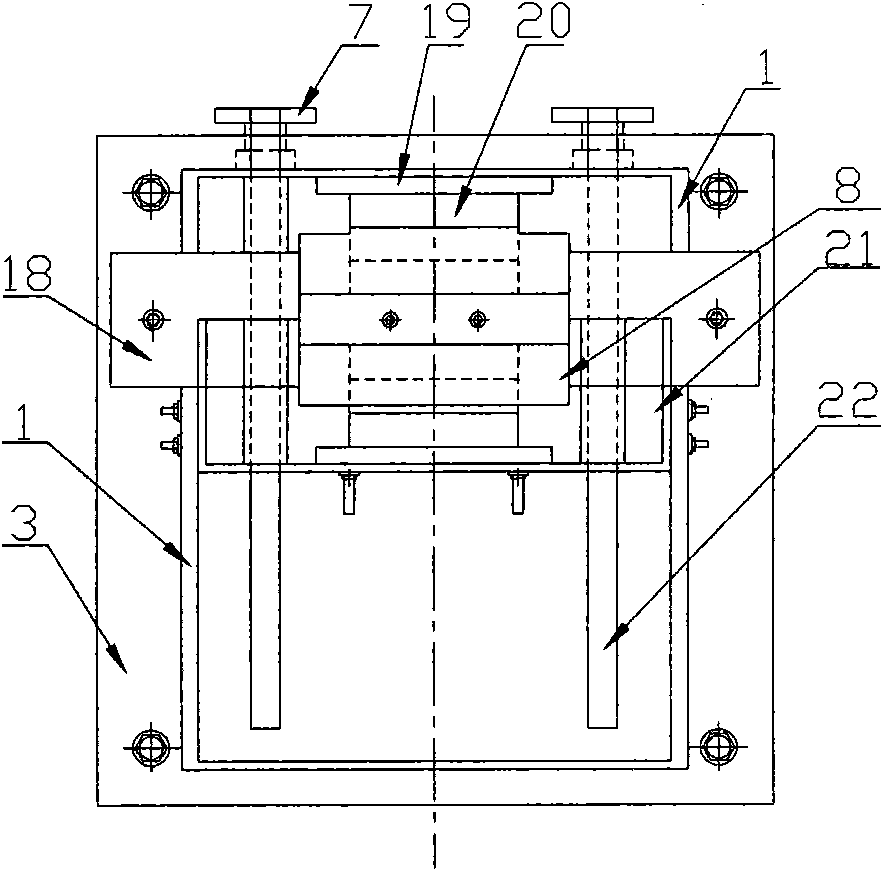

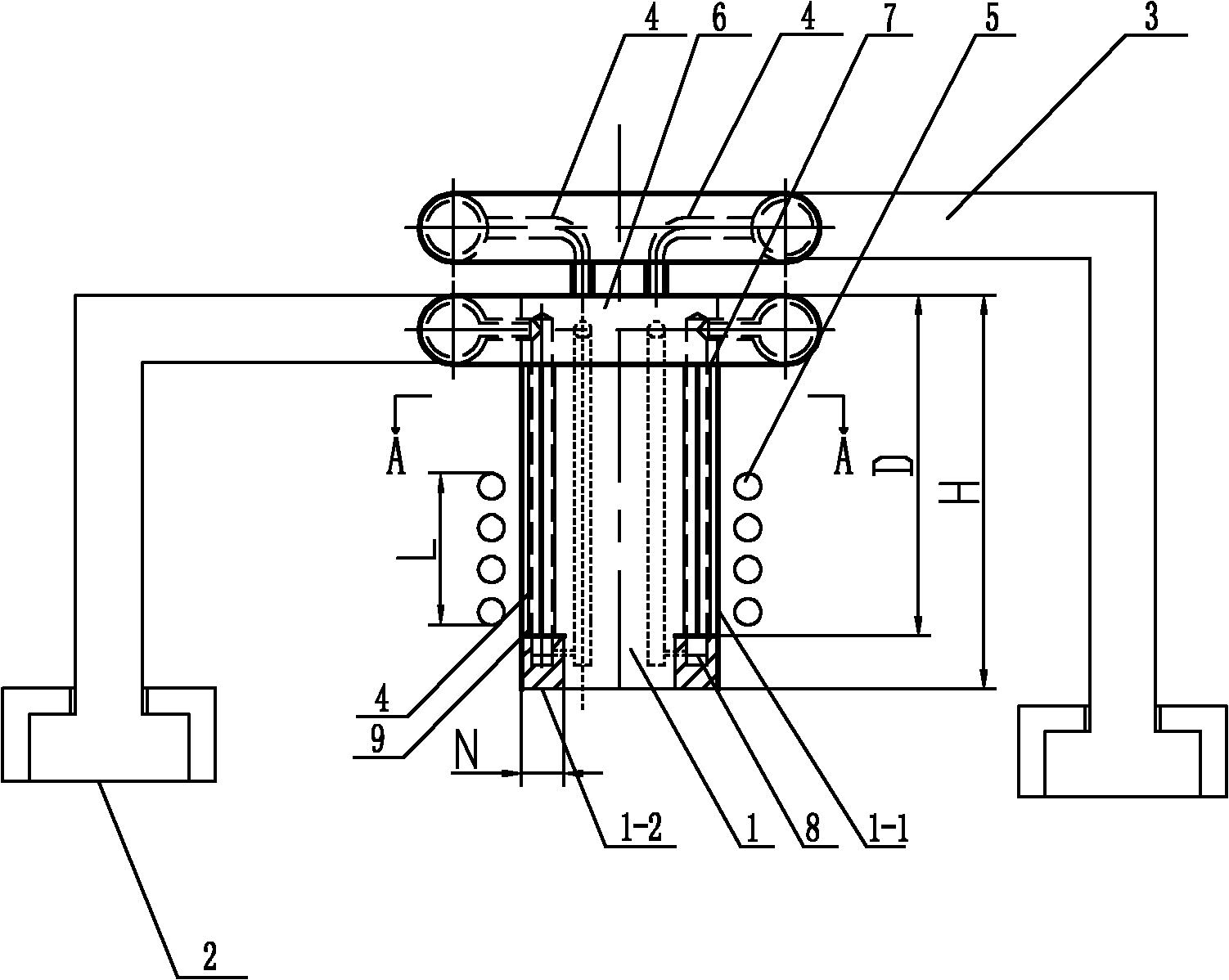

Anti-podal permanent magnetic high-intensity magnetic separator

InactiveCN101554614AFully adsorbedReasonable structureMagnetic separationElectricityElectrical polarity

An anti-podal permanent magnetic high-intensity magnetic separator is characterized in that the magnetic separator comprises a frame (1), a power vibration mechanism arranged at the middle part of the frame, a permanent magnetic system arranged at the top of the frame, and a vibration supporting frame (18) which is arranged above the permanent magnetic system and is used for installing a feeding funnel (10) and a magnetism-collecting medium box (8); the vibration supporting frame is combined with the power vibration mechanism by a connecting and supporting rod (6); the permanent magnetic system is characterized in that a plurality of axial permanent magnetic alnicos (20) with the same specification are superposed by an extrusion way in two groups and arranged at two sides of the magnetism-collecting medium box (8) in the horizontal direction, the polarity arrangement of each group is N-S-N-S-N-S or S-N-S-N-S-N, the external surfaces of the permanent magnetic alnicos form an antipodal magnetic separation space and a closed magnetic circuit, and the internal surface of each group of the permanent magnetic alnico is clamped between two bakelite boards (19) after being extruded, assembled and positioned precisely; and the Bakelite boards (19) are fixedly arranged on a chute vibration board (12) and a sliding plate (21) by a connecting bolt.

Owner:HENAN POLYTECHNIC UNIV

Cold crucible for directional solidification of magnetic AlNiCo alloy

InactiveCN102174707AImprove magnetic permeabilityIncrease profitEutectic material solidificationCrucibleDirectional solidification

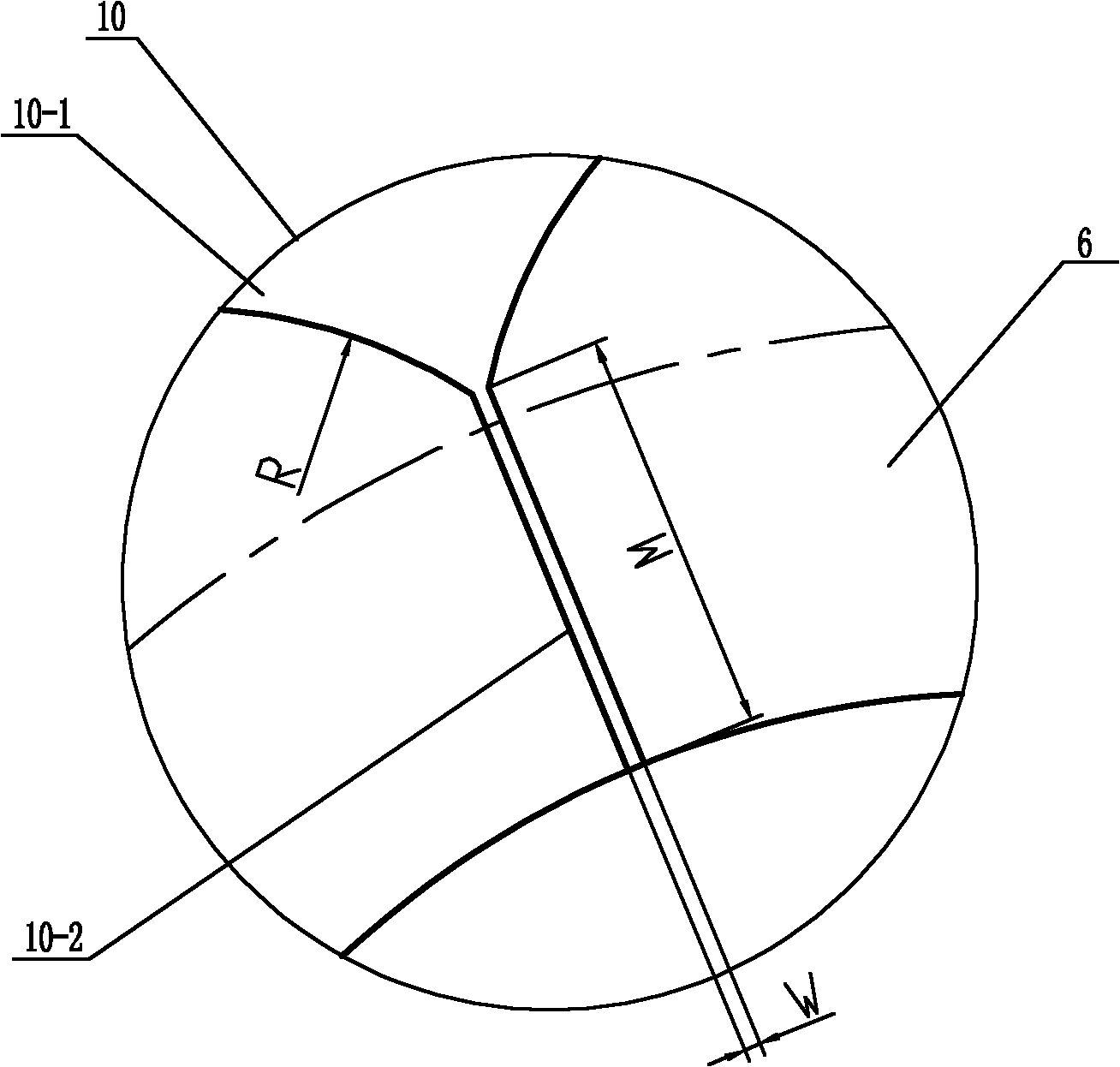

The invention discloses a cold crucible for directional solidification of magnetic AlNiCo alloy, relating to a cold crucible. The invention aims to solve the problems that when the existing cold crucible is used for directional solidification of magnetic alloy, the utilization rate of energy is low, and the side heat dissipation cannot have well thermal compensation, thereby resulting in discontinuous columnar crystals. The outer wall of the upper half of the cold crucible is divided into eight cylinders with arc petal-shaped sections, an opening seam is arranged between every two adjacent cylinders with the arc petal-shaped sections, the arc radius of each arc petal-shaped cylinder is 9 mm, the opening seam length of the opening seam is 4 mm, the opening seam width is 0.5 mm, a through hole is arranged inside each cylinder with the arc petal-shaped section, every odd number of cooling connection water pipe in eight cooling connection water pipes is communicated with a water inlet pipe, every even number of cooling connection water pipe in the eight cooling connection water pipes is communicated with a water outlet pipe, the height of the main body of the crucible is 110mm-130mm, and the wall thickness of the main body of the crucible is 12mm-15mm. The cold crucible is suitable for directional solidification of magnetic alloy.

Owner:HARBIN INST OF TECH

Permanent-magnet switch flux-linkage generator of three-dimensional magnetic structure

InactiveCN101626186AIncrease profitImprove performanceMagnetic circuit rotating partsSynchronous machine detailsLow speedSingle-phase generator

The invention relates to a permanent-magnet switch flux-linkage generator of a three-dimensional magnetic structure, belonging to the field of electric motors and aiming to solve the problems of low power density, complex winding construction, difficult insulation manufacture, and the like which are existed in a low-speed permanent-magnet generator. A single phase generator of the invention has the technical scheme that two stator cores are arranged along the axial direction of the outer surface of a main shaft and are connected by a magnetic-inductive-connection toroidal core to form a toroidal groove in which a stator winding is arranged, salient poles on the two stator cores are mutually staggered a distance of half stator, an outer rotor consists of a rotor yoke and two rows of alnico arrays arranged at the inner surface of the rotor yoke, one row of the alnico arrays is respectively arranged in the same level with one of the stator cores, and the axial center line of the two stator cores and the two rows of alnico arrays are overlapped. A two-phase generator of the invention consists of two single phase generators, rotor yoke connection pieces, supporting rings and main shaft connection pieces, and the two single phase generators are of quadrature winding structures. On the basis of the two-phase generator, by distribution of number of windings and connection of the windings, a three-phase generator can be formed.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com