Cold crucible for directional solidification of magnetic AlNiCo alloy

A magnetic alloy and directional solidification technology, applied in the field of cold crucibles, can solve problems such as low energy utilization, inability to laterally dissipate thermal compensation, discontinuous columnar crystals, etc., to improve energy utilization, optimize height, and increase transparency. magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

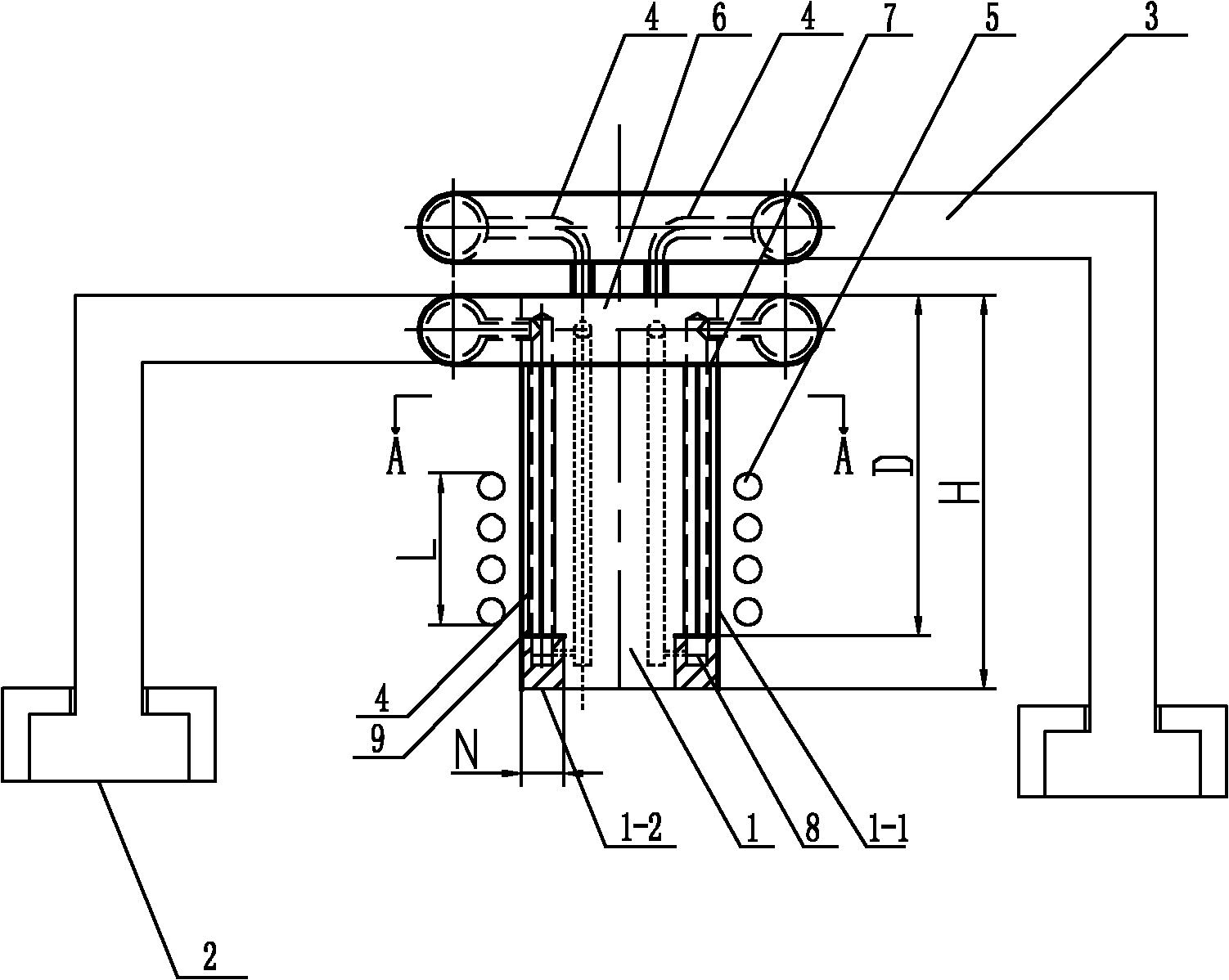

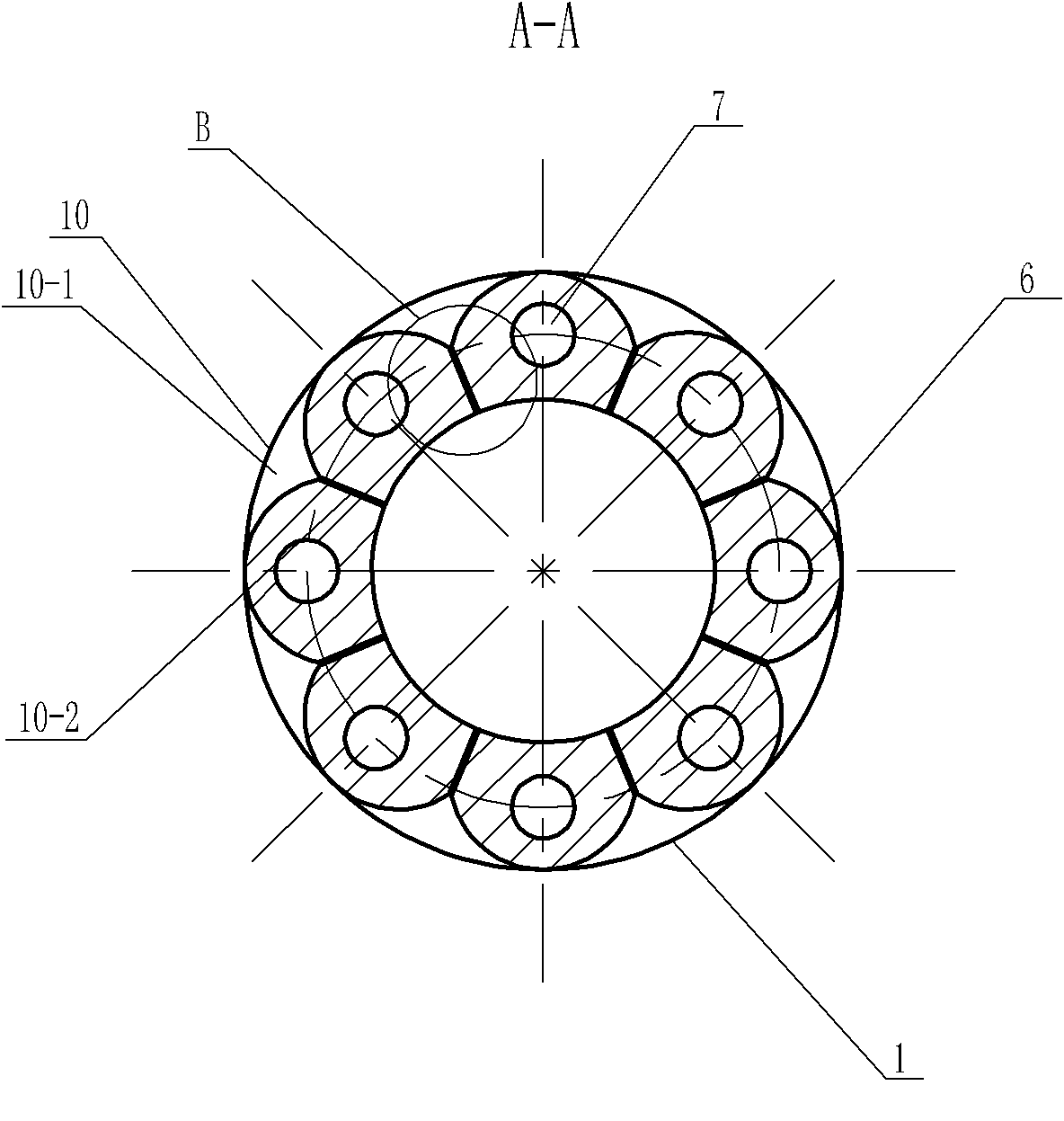

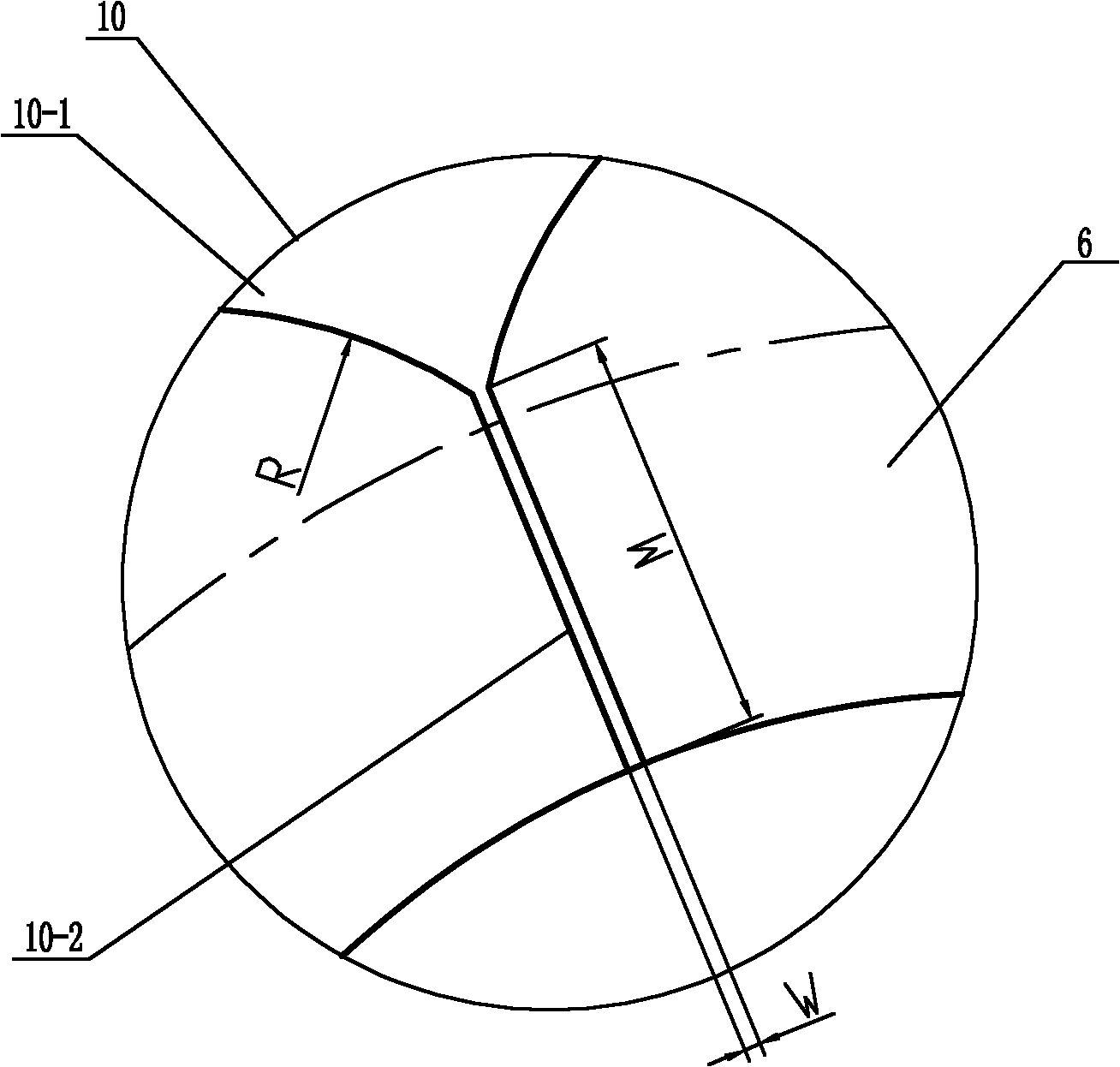

[0008] Specific implementation mode one: combine Figure 1-Figure 4 To illustrate this embodiment, a cold crucible for directionally solidified AlNiCo magnetic alloy in this embodiment includes a crucible main body 1, a water inlet pipe 2, a water outlet pipe 3, an induction coil 5 and eight cooling connecting water pipes 4, and the crucible main body 1 includes an upper The half body 1-1 and the lower half body 1-2, the upper half body 1-1 and the lower half body 1-2 are fixedly connected, the induction coil 5 is set on the upper half body 1-1, and the crucible main body 1 The cross-section is a ring-shaped hollow body, and the outer wall of the upper body 1-1 is divided into eight petal-shaped cylinders 6 with arc-shaped cross-sections, and the eight petal-shaped cylinders 6 with arc-shaped cross-sections are along the crucible The horizontal axis and the vertical axis on the horizontal section of the main body 1 are arranged symmetrically, the intersection point of the hori...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 The present embodiment will be described. The height D of the upper body 1-1 of the present embodiment is 85mm-105mm. Such setting makes the position of the solid-liquid interface of the AlNiCo magnetic alloy close to the maximum magnetic field of the coil, and at this time, the utilization rate of energy is the best. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 The present embodiment will be described. The induction coil 5 of the present embodiment is wound by a red copper wire, and the diameter of the red copper wire is 10 mm. With such setting, the conduction effect is the best. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0011] Specific implementation mode four: combination figure 1 The present embodiment will be described. The height L at which the induction coil 5 of the present embodiment is wound is 50mm-70mm. Such setting can effectively support the alloy melt of 20mm-30mm. Other compositions and connections are the same as those in the third embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com