Self-adaptive magnetic-conducting slot wedge and preparation method thereof

A magnetic groove and self-adaptive technology, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of limited bonding force, easy loosening and falling off, etc., to achieve enhanced magnetic permeability, good bonding force, The effect of improving motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

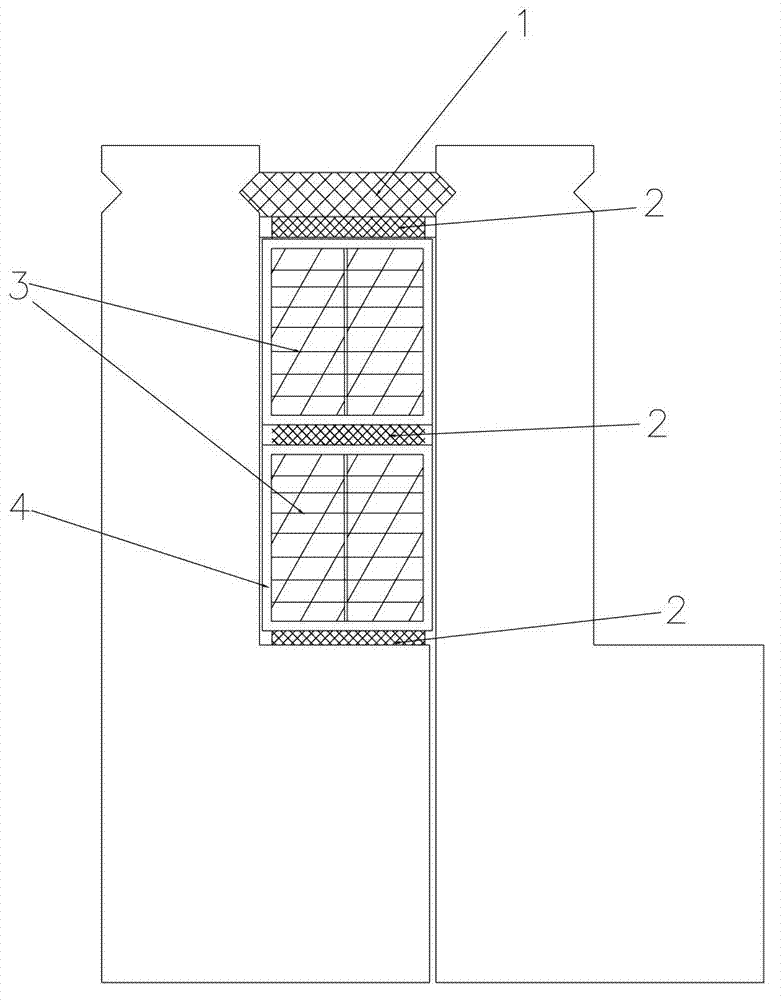

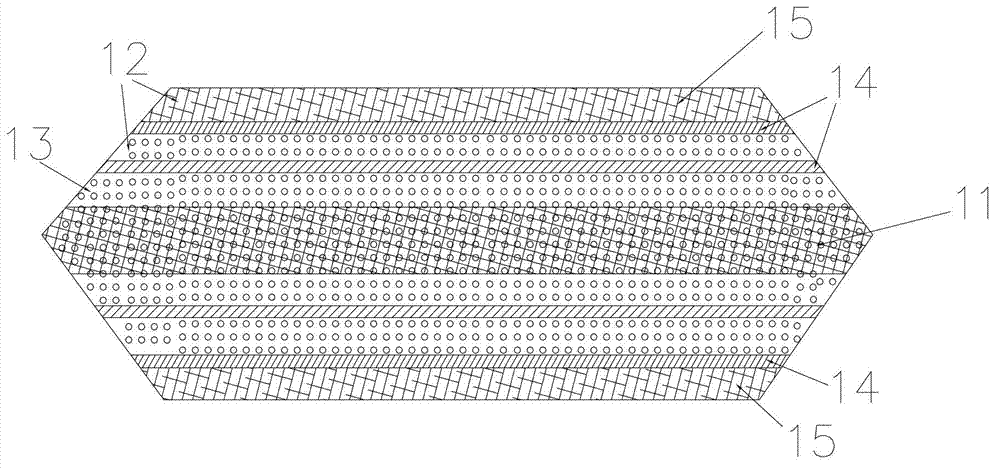

[0051] Such as figure 1 and as figure 2 As shown, a self-adaptive magnetically conductive slot wedge is installed at the notch on the stator and rotor of the motor, and is suitable for VPI process treatment, including a magnetically conductive layer 11 and two layers of second expansive felt 13 with expansion effect , the second expansive felt 13 is arranged on the outside of the magnetic permeable layer 11, and the first expansive felt 12 is arranged on the outside of the two layers of the second expansive felt 13; the first expansive felt 12 includes The glass fiber cloth layer 15 and the common expansive felt with expansion function; the second expansive felt 13 and the common expansive felt form an expansive layer; an adhesive layer 14 is arranged between the various material layers.

[0052] The stator and the rotor of the motor are provided with a slot cavity, and a wire 3 is arranged in the slot cavity, and the wire 3 is covered with an insulating layer 4, and pad strip...

Embodiment 2

[0082] The rest are the same as in Example 1, except that the volume of the magnetic permeable layer 11 accounts for 50% of the total volume of the slot wedge, the volume of the expansion layer accounts for 39.5% of the total volume of the slot wedge, and the glass fiber The volume of the cloth layer 15 accounts for 5% of the total volume of the slot wedge, and the volume of the adhesive layer 14 accounts for 5.5% of the total volume of the slot wedge.

[0083] The magnetic permeable layer 11 includes multiple groups of metal wires and metal meshes, the metal wires are arranged in parallel with the metal meshes, and the metal wires are arranged alternately with the metal meshes, and a layer of metal meshes is arranged on both sides of the metal meshes The metal wire, the second expansive felt that acts as a spacer is arranged between the metal wire and the metal mesh. After the second expansive felt is glued, the fiber holes are all impregnated with glue. Two expansion felts, ...

Embodiment 3

[0103] The rest are the same as in Example 2, except that the volume of the magnetic permeable layer 5 accounts for 41% of the total volume of the slot wedge, the volume of the expansion layer accounts for 30% of the total volume of the slot wedge, and the glass fiber The volume of the cloth layer 15 accounts for 20% of the total volume of the slot wedge, and the volume of the adhesive layer 14 accounts for 9% of the total volume of the slot wedge.

[0104] The present invention also provides a preparation method of self-adaptive magnetically permeable slot wedge, the preparation method is specifically as follows:

[0105] (1) Prepare expansive felt and glass cloth;

[0106] The expansive mat is a roll material, the raw material is electrical alkali-free glass filament, the thickness is 0.5-10 mm, and the width is 900 mm or 1000 mm;

[0107] The glass cloth can be selected from various brands of electrical alkali-free glass cloth with a thickness of 0.14mm and a width of 900m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com