Patents

Literature

51results about How to "Intact epidermis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medicinal common monkshood mother root fresh cutting processing technology

The invention discloses a medicinal common monkshood mother root fresh cutting processing technology. The technology is characterized by after harvesting medicinal common monkshood mother root, seizing the time to wash medicinal common monkshood mother root while the soil adhering to the surface of medicinal common monkshood mother root is wet, trimming the roots and the branches, tedding medicinal common monkshood mother root for 12-24 hours, cutting medicinal common monkshood mother root into circular slices or oval slices while medicinal common monkshood mother root is fresh, vacuum-packaging the slices with polyethylene plastic bags after airing the slices until the slices are dry and adding drying agents and antioxidants. The processing technology has the beneficial effects that the medicines are washed and processed while the medicines are fresh, thus avoiding losses of water-soluble active ingredients, reducing pollution of the medicines caused by microorganisms and worm eggs in the soil, simplifying the medicinal slice production process, reducing the preparation cost, guaranteeing the quality of the medicines and improving the clinical effects; and popularization and implementation of the processing technology have obvious social significance and economic benefits.

Owner:徐自升

Medicinal kusnezoff monkshood fresh cutting processing technology

The invention discloses a medicinal kusnezoff monkshood fresh cutting processing technology. The technology is characterized by after harvesting medicinal kusnezoff monkshood, seizing the time to wash medicinal kusnezoff monkshood while the soil adhering to the surface of medicinal kusnezoff monkshood is wet, trimming the roots and the branches, tedding medicinal kusnezoff monkshood for 12-48 hours, longitudinally slicing medicinal kusnezoff monkshood or slicing the top of medicinal kusnezoff monkshood, vacuum-packaging the slices with polyethylene plastic bags after airing the slices until the slices are dry and adding drying agents and antioxidants. The processing technology has the beneficial effects that the medicines are washed and processed while the medicines are fresh, thus avoiding losses of water-soluble active ingredients, reducing pollution of the medicines caused by microorganisms and worm eggs in the soil, simplifying the medicinal slice production process, reducing the preparation cost, guaranteeing the quality of the medicines and improving the clinical effects; and popularization and implementation of the processing technology have obvious social significance and economic benefits.

Owner:徐自升

Fresh-cut processing technology of largehead atractylodes rhizome crude medicine

The invention discloses a fresh-cut processing technology of a largehead atractylodes rhizome crude medicine. According to the technology, after the largehead atractylodes rhizome crude medicine is harvested, the largehead atractylodes rhizome crude medicine is washed with water when soil is attached to the surface of the medicine which is still wet, roots and branches are arranged, the largehead atractylodes rhizome crude medicine is spread for drying for 12-24 h and cut into round pieces or oval pieces when being fresh, the pieces are air-dried to dryness and subjected to vacuum packaging with a polyethylene plastic bag, and a desiccant and an antioxidant are added. The crude medicine is washed and processed when being fresh, so that loss of water-soluble effective components is avoided, pollution of the crude medicine by microorganisms and worm eggs in the soil is reduced, the process for production of decoction pieces is simplified, the preparation cost is reduced, the quality of the crude medicine is guaranteed, and the clinical effect is improved. Great social meaning and economic benefits can be produced with popularization and implementation of the technology.

Owner:徐自升

Fresh-cut processing technology for radix curcumae

The invention discloses a fresh-cut processing technology for radix curcumae. The technology comprises the steps that after being harvested, radix curcumae is washed with water while the surface of radix curcumae is adhered with mud and is wet, fibrous roots and impurities are removed, the radix curcumae is aired in a spread mode for 4-6 hours and cut into round pieces or elliptical pieces while the radix curcumae is fresh, after being aired in the sun to be dry, the round pieces or elliptical pieces are packed with polyethylene plastic bags in a vacuumized mode, and then drying agents are added in the bags. According to the technology, due to the fact that the medicine materials are washed and processed while the medicine materials are fresh, the loss of water-soluble effective components is avoided, the pollution of microorganisms and worm eggs in soil to radix curcumae is reduced, the decoction piece production procedures are simplified, the preparation cost is lowered, the medicine material quality is guaranteed, and the clinical treatment effect is improved. The popularization and implementation of the technology have significant social significance and economical benefits.

Owner:徐自升

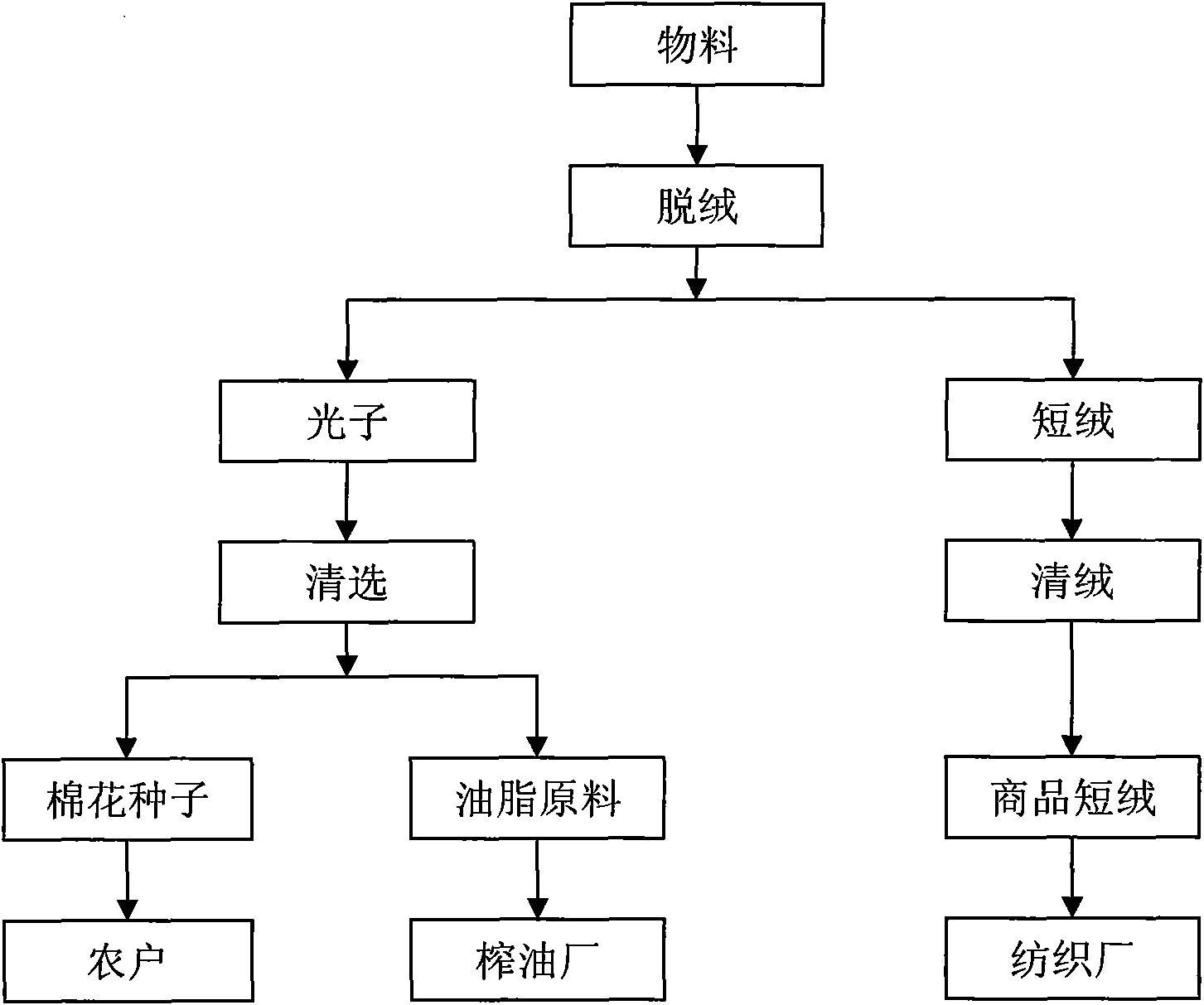

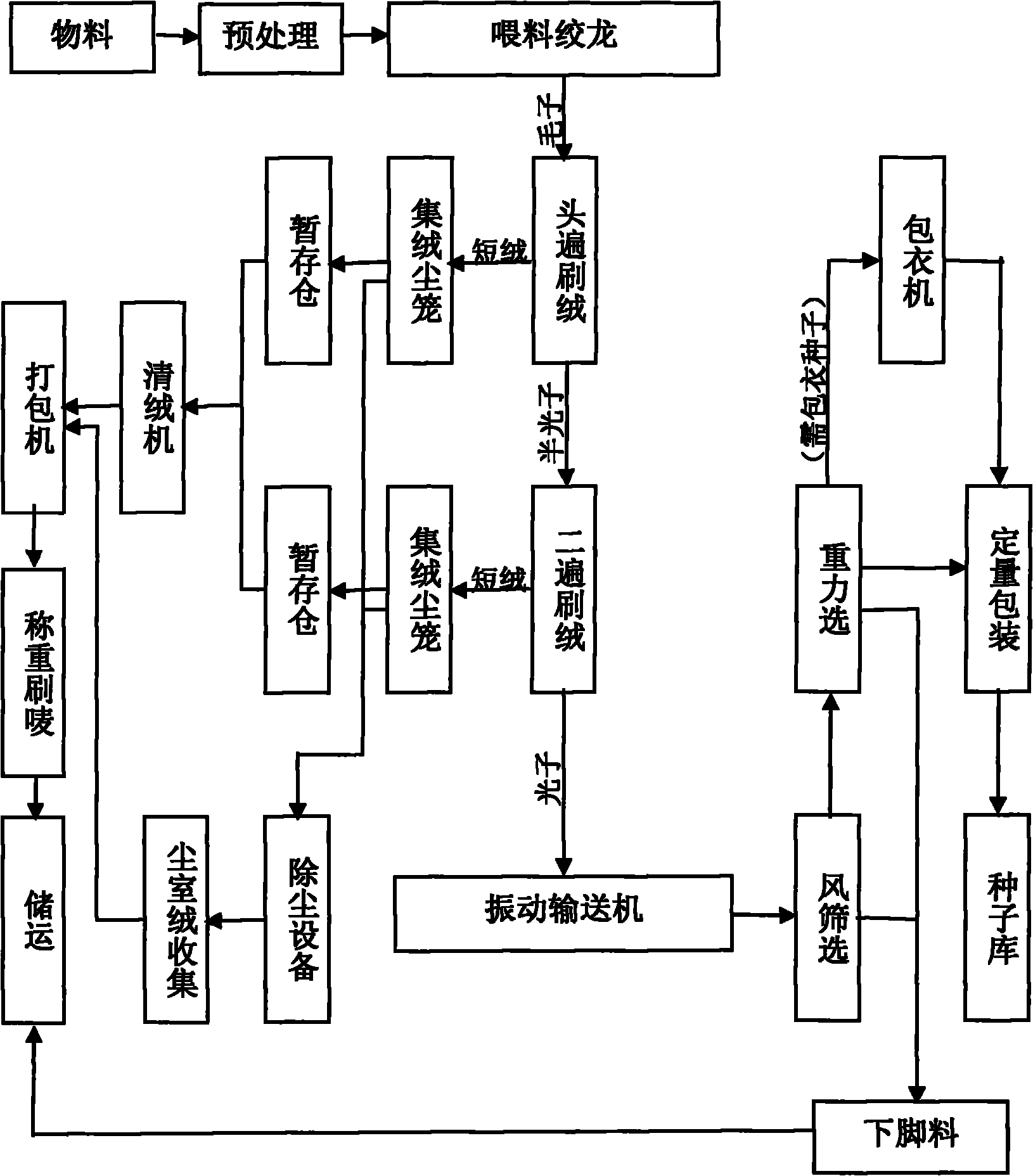

Cotton seed, commodity linter and grease raw material co-production process based on delinting technology of cylindrical brushing machine

InactiveCN101974787ASimple processShort processing routeVegetable fibre separation from seedsSeed and root treatmentEngineeringCottonseed

The invention relates to the cotton processing technical field, in particular to a cotton seed, commodity linter and grease raw material co-production process based on the delinting technology of a cylindrical brushing machine. The co-production process is characterized by producing cotton seeds, commodity linters and grease raw materials at the same time by primary processing of materials (fluff). Compared with the prior art, the co-production process has the advantages of simple process flow, short processing route, high production efficiency, low cottonseed crushing ratio, guaranteed seed quality, fewer linter impurities, easy linter cleaning, high commodity linter level, complete waste (photon) skin, convenient hulling, thorough separation between cotton hulls and cotton kernels and high oil yield. In the process, the linter obtained by double brushing is collected, cleaned and packaged respectively, thus ensuring grade quality of the commodity linter.

Owner:SHANGHAI KUDUN ELECTROMECHANICAL TECH

Processing technology of radix et rhizoma rhei fresh-cut decoction pieces

The invention discloses a processing technology of radix et rhizoma rhei fresh-cut decoction pieces. The technology comprises the following steps: after harvesting medicinal material radix et rhizoma rhei, washing the radix et rhizoma rhei while the surface of the radix et rhizoma rhei carries soil and is wet; spreading and airing for 2h to 4h; cutting the radix et rhizoma rhei into round pieces or oval pieces while the radix et rhizoma rhei is fresh; after drying, putting the radix et rhizoma rhei into a polyethylene plastic bag, and vacuumizing and packaging; then adding a drying agent and an antioxidant. According to the technology disclosed by the invention, the medicinal material is washed and processed while the medicinal material is fresh, so that the loss of water-soluble effective components is avoided, and pollution, caused by microorganisms and ova in the soil, to the medicinal material is reduced; a production procedure of the decoction pieces is simplified and the production cost is reduced; the quality of the medicinal material is ensured and the clinical curative effect is improved. The popularization and implementation of the technology have remarkable social significance and economic benefits.

Owner:徐事成

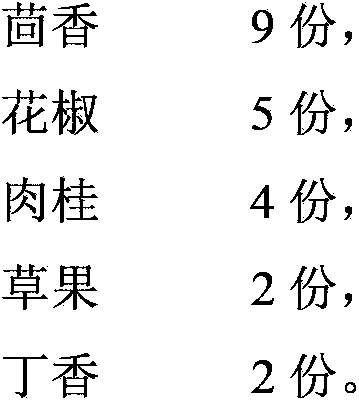

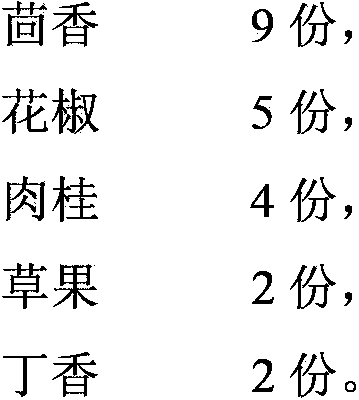

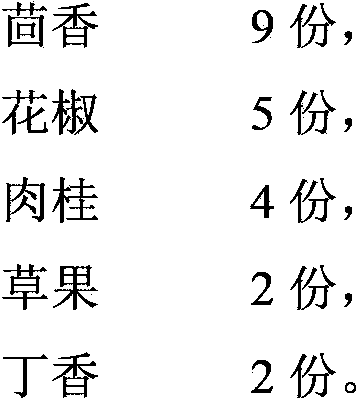

Making method Dezhou chicken

The invention discloses a making method of Dezhou chicken, and belongs to the food processing field. The method is based on a present Dezhou chicken processing technology, and is characterized in that a special flavor formula and special flavor sauce blending are adopted, two-time high pressure boiling is carried out, and fast immersion in cold water during the two-time high pressure boiling and is also carried out after secondary boiling to guarantee the quality of a Dezhou chicken product. The quality of the product is guaranteed through the two-time high pressure boiling, complete epidermis and compact meat of the product are realized after boiling, air-drying and frying, and the product is very fresh and delicious after oil drying.

Owner:重庆市夔畅食品有限公司

Medicinal radix stephaniae tetrandrae fresh cutting processing technology

The invention discloses a medicinal radix stephaniae tetrandrae fresh cutting processing technology. The technology is characterized by after harvesting medicinal radix stephaniae tetrandrae, seizing the time to wash medicinal radix stephaniae tetrandrae while the soil adhering to the surface of medicinal radix stephaniae tetrandrae is wet, trimming the roots and the branches, tedding medicinal radix stephaniae tetrandrae for 12-48 hours, cutting medicinal radix stephaniae tetrandrae into circular slices or oval slices while medicinal radix stephaniae tetrandrae is fresh, vacuum-packaging the slices with polyethylene plastic bags after airing the slices until the slices are dry and adding drying agents and antioxidants. The processing technology has the beneficial effects that the medicines are washed and processed while the medicines are fresh, thus avoiding losses of water-soluble active ingredients, reducing pollution of the medicines caused by microorganisms and worm eggs in the soil, simplifying the medicinal slice production process, reducing the preparation cost, guaranteeing the quality of the medicines and improving the clinical effects; and popularization and implementation of the processing technology have obvious social significance and economic benefits.

Owner:徐自升

Fresh-cut processing technology of polygonum multiflorum medicinal material

The invention discloses a fresh-cut processing technology of a polygonum multiflorum medicinal material. The process comprises the following steps: after collecting the polygonum multiflorum medicinal material, at the time when the surface of the polygonum multiflorum medicinal material is wet as soil is attached, rapidly washing by water; settling roots and branches; tedding for 12-48 hours; fresh-cutting to round or elliptical sheets; after airing and drying, vacuumizing and packaging by using a polyethylene plastic bag; and adding a drying agent and an antioxidant. According to the process, as the medicinal material is washed and processed when the medicinal material is fresh, the loss of water-soluble effective components is avoided, the pollution to the medicinal material caused by microorganisms and eggs in soil is reduced, the process of production of decoction pieces is simplified, the preparation cost is lowered, the quality of the medicinal material is ensured, and the clinical curative effect is improved. The technology has significant social significance and economic benefits after being popularized and implemented.

Owner:徐自升

Fresh-cut processing technology for air potato yarn medicinal material

The invention discloses a fresh-cut processing technology for an air potato yarn medicinal material. The technology comprises the following steps: harvesting the n air potato yarn medicinal material, washing quickly when the soil adhered to the surface of the air potato yarn is moist, arranging tubers, tedding for 12-48 hours, freshly cutting and preparing into round sheets or oval sheets; and airing until drying, vacuumizing and packing with a polyethylene plastic bag, and adding a drying agent. According to the method, the medicinal material is freshly washed and processed, so that the loss of water-soluble effective components is avoided; the pollution to medicinal material caused by microorganisms and eggs in the soil is reduced; the procedure of producing decoction pieces is simplified; the preparation cost is reduced; the quality of the medicinal material is ensured; the clinical curative effect is improved; and implementation and popularization of the method are of significant social significance and economic benefits.

Owner:徐自升

Pubescent angelica root medicinal material fresh cutting and processing technology

The invention provides a pubescent angelica root medicinal material fresh cutting and processing technology. According to the technology, after being harvested, pubescent angelica root medicinal materials are washed with boiled water while soil is attached to the surfaces of the pubescent angelica root medicinal materials and the surfaces of the pubescent angelica root medicinal materials are moist; the pubescent angelica root medicinal materials are spread and aired for 4-6 hours, root bodies and branches are separated and cut into slices while being fresh; after the pubescent angelica root medicinal materials are aired to be dry, a polyethylene plastic bag is vacuumized and used for packaging the pubescent angelica root medicinal materials, and drying agents are added. According to the technology, because the medicine materials are washed and processed while being fresh, loss of effective water-soluble components is avoided, and pollution of microorganisms and worm eggs in the soil to the medicine materials is reduced, the production procedures of medicinal slices are simplified, manufacturing cost is reduced, the quality of the medicine materials is guaranteed, and the clinical curative effect is improved. The technology has remarkable social significance and economic benefits after being implemented and popularized.

Owner:徐自升

Fresh-cutting process for blackberry lily medicinal material

The invention discloses a fresh-cutting process for a blackberry lily medicinal material. The process comprises the steps of harvesting the blackberry lily medicinal material; then washing the blackberry lily medicinal material by virtue of wet soil stuck to the surface of the blackberry lily medicinal material; tidying roots, and tedding for 12-48h; cutting the blackberry lily medicinal material into circular or elliptic slices while the blackberry lily medicinal material is fresh; airing to be dry, and then, carrying out vacuum packaging by using a polyethylene plastic bag; and adding a drying agent and an antioxidant. According to the fresh-cutting process, the medicinal material is washed and processed while being fresh, so that effective water-soluble components are prevented from being lost, the pollution of microorganisms and eggs in soil to the medicinal material is reduced, the production process of a decoction piece is simplified, the production cost is reduced, the quality of the medicinal material is ensured, and the clinical effect of the medicinal material is improved. Due to the popularization and implementation of the process, remarkable social and economic benefits can be achieved.

Owner:徐自升

Fresh slicing process of radix sophorae flavescentis

The invention discloses a fresh slicing process of radix sophorae flavescentis. The fresh slicing process includes: washing the harvested radix sophorae flavescentis with water while mud still adheres to the surface of the radix sophorae flavescentis and the radix sophorae flavescentis is moist, removing fibrous roots and impurities, spreading and airing for 4-6 hours, slicing the radix sophorae flavescentis while the radix sophorae flavescentis is fresh, airing until the sliced radix sophorae flavescentis is dry, vacuum packaging with polyethylene plastic bags, and adding drying agent. The fresh slicing process has the advantages that the radix sophorae flavescentis is washed and processed while the radix sophorae flavescentis is fresh, loss of water-soluble effective components is avoided, pollution of microorganisms and worm eggs in soil to the radix sophorae flavescentis is reduced, medicinal slice production procedures are simplified, production cost is lowered, medicinal material quality is guaranteed, and clinical curative effect is increased; the popularization and implementation of the fresh slicing process have evident social and economic significance.

Owner:徐自升

Fresh cutting processing technology for radix ampelopsis medicinal material

The invention discloses a fresh cutting processing technology for a radix ampelopsis medicinal material. According to the technology, after the radix ampelopsis medicinal material is harvested, water is seized for cleaning the radix ampelopsis medicinal material while mud is stuck to the surface of the radix ampelopsis medicinal material and the surface of the radix ampelopsis medicinal material is moistened, spreading airing is conducted for 4-6 hours, the radix ampelopsis medicinal material is cut into slices while the radix ampelopsis medicinal material is fresh, the radix ampelopsis medicinal material is packaged in a vacuumized mode after being aired to be dried, and a drying agent is added. According to the fresh cutting processing technology, the medicinal material is washed and processed while being fresh, so that running of water-soluble effective components is avoided, the pollution of microorganisms and worm eggs in soil to the medicinal material is reduced, the processes for medicinal slice production are simplified, the preparing cost is reduced, the medicine quality is ensured, and the clinical effect is improved. By means of implementation and popularization of the fresh cutting processing technology, obvious social significance and economic benefits can be achieved.

Owner:徐自升

Monkshood medicinal material fresh-cut processing technology

The invention discloses a monkshood medicinal material fresh-cut processing technology. The technology comprises the following steps: picking monkshood medicinal materials, washing the monkshood medicinal materials by using water when the surfaces of the monkshood medicinal materials are adhered with soil and are wetted, tidying the roots and branches, tedding for 12-48 hours, longitudinally cutting the monkshood medicinal materials into slices while being fresh, airing, drying, vacuumizing and packaging by using polyethylene plastic bags, and adding drying agents and antioxidants. According to the method, because the medicinal materials are washed and processed while being fresh, losses of water-soluble active ingredients are avoided, pollution of microbes and eggs to the medicinal materials is reduced, the process of producing medicinal slices is simplified, the preparation cost is reduced, the quality of the medicinal materials is guaranteed, and the clinical curative effect is improved. The method is convenient to popularize and implement and has obvious social benefits and economic benefits.

Owner:徐自升

Medicinal radix cynanchi auriculati fresh cutting processing technology

The invention discloses a medicinal radix cynanchi auriculati fresh cutting processing technology. The technology is characterized by after harvesting medicinal radix cynanchi auriculati, seizing the time to wash medicinal radix cynanchi auriculati while the soil adhering to the surface of medicinal radix cynanchi auriculati is wet, trimming the roots and the branches, tedding medicinal radix cynanchi auriculati for 12-48 hours, cutting medicinal radix cynanchi auriculati into circular slices or oval slices while medicinal radix cynanchi auriculati is fresh, vacuum-packaging the slices with polyethylene plastic bags after airing the slices until the slices are dry and adding drying agents and antioxidants. The processing technology has the beneficial effects that the medicines are washed and processed while the medicines are fresh, thus avoiding losses of water-soluble active ingredients, reducing pollution of the medicines caused by microorganisms and worm eggs in the soil, simplifying the medicinal slice production process, reducing the preparation cost, guaranteeing the quality of the medicines and improving the clinical effects; and popularization and implementation of the processing technology have obvious social significance and economic benefits.

Owner:徐自升

Mandragora chinhaiebsis epidermal sand removal process

InactiveCN102805383AThin skinThe epidermis is thin and soft but remains largely intactFood preparationAdditive ingredientCuticle

The invention discloses a mandragora chinhaiebsis epidermal sand removal process which comprises the following steps: step 1, preprocessing mandragora chinhaiebsis; step 2, warming and enzyme adding: putting the preprocessed mandragora chinhaiebsis into a heating container, adding enzyme into the heating container after heating, ensuring that the addition amount of the enzyme is 0.05-0.5 percent of mass of the preprocessed mandragora chinhaiebsis or 0.05-0.1 percent of mass of the preprocessed mandragora chinhaiebsis, keeping the temperature of water to be 45-50 DEG C and carrying out enzyme treatment on the preprocessed fresh mandragora chinhaiebsis for 20-100 minutes or carrying out enzyme treatment on the preprocessed dry mandragora chinhaiebsis for 1-3 hours and removing sand in the mandragora chinhaiebsis; step 3, enzyme inactivation; putting the mandragora chinhaiebsis of which the sand is removed into the heating container and boiling for 5-10 minutes, so that the enzyme is inactivated; and step 4, taking out the mandragora chinhaiebsis and refrigerating for storage; or directly taking the mandragora chinhaiebsis as a raw material for subsequent processing. The mandragora chinhaiebsis of which the sand on the surface is removed by adopting the process has thin and soft surface, is smooth and is free from sand, the meat quality and the nutritional components of the mandragora chinhaiebsis are intactly kept, and the condition and the character are better improved.

Owner:SUZHOU MUTENG COMMERCE & TRADE

Processing technique for fresh-cut cistanche deserticola decoction pieces

The invention discloses a processing technique for fresh-cut cistanche deserticola decoction pieces. The processing technique for the fresh-cut cistanche deserticola decoction pieces comprises the steps that after being harvested, cistanche deserticola medicinal materials are washed in boiling water while soil still adheres to the surfaces of the cistanche deserticola medicinal materials and the cistanche deserticola medicinal materials are wet, then the cistanche deserticola medicinal materials are spread to be aired for 2-4 hours and prepared into round pieces or oval pieces while the cistanche deserticola medicinal materials are fresh, a polyethylene plastic bag is vacuumized to be used for packaging the pieces after the pieces are dried, and a drying agent and an antioxygen are added into the polyethylene plastic bag. According to the processing method for the fresh-cut cistanche deserticola hook decoction pieces, the medicinal materials are washed and processed while being fresh, so that water-soluble effective components are prevented from being lost, and contamination of microorganisms and worm eggs in soil to the medicinal materials is reduced; and the production procedures for the decoction pieces are simplified, the preparation cost is reduced, the quality of the medicinal materials is ensured, and the clinic curative effect is improved. By implementing and popularizing the processing technique, remarkable social significance and economic benefits can be achieved.

Owner:徐璐

Rhizoma polygoni cuspidati medicinal material fresh-cut processing technic

The invention discloses a rhizoma polygoni cuspidati medicinal material fresh-cut processing technic. The technic is characterized by comprising the steps: after harvesting a rhizoma polygoni cuspidati medicinal material, washing the rhizoma polygoni cuspidati medicinal material with water while the surface of the rhizoma polygoni cuspidati medicinal material is stained with mud and is wet; trimming roots and branches; tedding for 12-48 hours; making into round pieces or oval-shaped pieces by fresh-cut; airing the round pieces or oval-shaped pieces to be dry, then performing vacuum package by using a polyethylene plastic bag, and adding a drying agent. According to the method, the medicinal material is washed and processed while the medicinal material is fresh, so that loss of water-soluble active ingredients is avoided, pollution to the medicinal material caused by microorganism and worm eggs in soil is reduced, the production process of prepared herbal medicine in small pieces ready for decoction is simplified, the manufacturing cost is reduced, the quality of the medicinal material is guaranteed, and the clinical curative effect is improved. The popularization and implementation of the processing technic have remarkable social significance and economic benefits.

Owner:徐自升

Processing technology of fresh-cut rhizoma sparganii decoction pieces

The invention discloses a processing technology of fresh-cut rhizoma sparganii decoction pieces. The processing technology comprises the following steps: harvesting the rhizoma sparganii, washing the rhizoma sparganii when wet soil are stuck on the surface of the rhizoma spargani, spreading and drying for 2 to 4 hours, cutting the rhizoma spargani into round pieces or oval pieces while the the rhizoma spargani is fresh, drying the pieces, then vacuum packaging the pieces by using a polyethylene plastic bag, and adding a drying agent and antioxidant. According to the processing technology, since the herb is washed and processed when the herb is fresh, the loss of water-soluble active ingredients is avoided, the pollution of microorganisms and eggs in the soil to the herb can be reduced, the production procedure of the decoction pieces can be simplified, the production cost is decreased, the quality of the decoction materials is ensured, and the clinical curative effect can be improved. The popularization of the processing technology has significant social benefit and economic benefit.

Owner:徐璐

Fresh cutting process for orobanche medicinal materials

The invention discloses a fresh cutting process for orobanche medicinal materials. The process comprises the steps of after the orobanche medicinal materials are harvested, rushing to clean the orobanche medicinal materials with water while the surfaces of the orobanche medicinal materials are adhered with soil and are wet, finishing roots and branches, tedding for 12-24 hours, cutting into circular slices or elliptical slices while the orobanche medicinal materials are fresh, drying in the air until the circular slices or elliptical slices are dried, then, packaging with polyethylene plastic bags while vacuumizing, and adding desiccants and antioxidants. According to the process, the medicinal materials are cleaned while the medicinal materials are fresh, so that the loss of water-soluble effective ingredients is avoided, the pollution to the medicinal materials caused by microorganisms and worm eggs in the soil is reduced, procedures of decoction piece production are simplified, the preparation cost is reduced, the quality of the medicinal materials is guaranteed, and the clinical treatment effect is improved. With the popularization and implementation of the process, remarkable social significance and economic benefit can be obtained.

Owner:徐自升

Fresh-cut processing technology for rhizoma atractylodis medicinal materials

InactiveCN105055481AReduce qualityReduce churnSenses disorderAntipyreticMedicinal herbsClinical efficacy

The invention discloses a fresh-cut processing technology for rhizoma atractylodis medicinal materials. According to the technology, after the rhizoma atractylodis medicinal materials are harvested, while soil adheres to the surfaces of the rhizoma atractylodis medicinal materials and the rhizoma atractylodis medicinal materials are moist, the rhizoma atractylodis medicinal materials are placed in boiling water to be cleaned and then are laid to be dried for 4-6 hours in the sun; fibrous roots are removed through fire in a burning mode, and the rhizoma atractylodis medicinal materials are cut and made into slices while being still fresh; after being aired to be dry, the rhizoma atractylodis medicinal materials are packaged through polyethylene plastic bags in a vacuumizing mode, and drying agents are added. According to the technology, due to the fact that the medicinal materials are washed and processed when being still fresh, water-soluble effective components are prevented from being lost, pollution of microorganisms and worm eggs in soil to the medicinal materials is reduced, the production procedures of the medicinal slices are simplified, manufacturing cost is reduced, the quality of the medicinal materials is guaranteed, and the clinical effect is guaranteed. By means of popularization and implementation of the technology, the technology has remarkable social meaning and economic benefits.

Owner:徐自升

Processing technology for fresh sliced edible tulip decoction piece

The invention discloses a processing technology for a fresh sliced edible tulip decoction piece. The processing technology comprises the following steps: harvesting the edible tulip medicinal material; cleaning with water when the edible tulip medicinal material is moistened by the soil adhered to the surface thereof; airing for 2-4 hours; freshly slicing into disc or oval sheets; and drying and then using a polyethylene plastic bag for performing vacuum packing and adding a dryer and an antioxidant. According to the method, the medicinal material is freshly washed and processed, so that the loss of the water-soluble active ingredient is avoided, the pollution to the medicinal material caused by microorganism and pest eggs in soil can be reduced, the process of decoction piece production is simplified, the manufacturing cost is lowered, the quality of the medicinal material is guaranteed and the clinical effect is promoted. The popularization and implementation of the method have obvious social significance and economical benefit.

Owner:徐事成

Processing technology of fresh-cut herbal piece of rhizoma et radix notopterygii

InactiveCN107441133AReduce churnIntact epidermisPlant ingredientsClinical efficacyAdditive ingredient

The invention discloses a processing technology of a fresh-cut herbal piece of rhizoma et radix notopterygii. The processing technology comprises the following steps: after the medicinal material of rhizoma et radix notopterygii is harvested, when the surface is adhered to soil and is wet, cleaning by water, spreading and airing for 2 to 4h, cutting into round or elliptical pieces while the rhizoma et radix notopterygii is fresh, drying, vacuumizing a polyethylene plastic bag after drying, packaging, and adding a desiccant and an antioxidant. The processing technology has the advantages that the medicinal material is washed and processed in the fresh way, so that the loss of water-soluble effective ingredients is avoided, the pollution to the medicinal material by microorganisms and ova in soil is reduced, the production procedure of the herbal piece is simplified, the preparation cost is reduced, the quality of the medicinal material is guaranteed, and the clinical therapy effect is improved; the popularizing and implementing of the processing technology can create obvious social meaning and economic benefits.

Owner:徐事成

Processing process of fresh-cut radix ginseng decoction pieces

InactiveCN107375375AReduce manufacturing costGuaranteed clinical efficacyPlant ingredientsClinical efficacyAntioxidant

The invention discloses a processing process of fresh-cut radix ginseng decoction pieces. The process comprises the following steps: harvesting radix ginseng; rapidly cleaning in boiling water when the surface of the radix ginseng is adhered with soil and moist; spreading and drying in the air for 2-4 hours; cutting into pieces while the radix ginseng is fresh; vacuumizing and packaging with polyethylene plastic bags after drying; and adding desiccants and antioxidants. The method avoids loss of water-soluble active ingredients, reduces pollution of microorganisms and worm eggs to the medicinal materials, simplifies production processes of decoction pieces, reduces production costs, ensures quality of the medicinal materials, and improves clinical efficacy as the medicinal materials are washed and processed while the medicinal materials are fresh; the promotion and implementation of the method will have significant social significance and economic benefits.

Owner:徐事成

Production technology of gastrodia elata fresh-cut medicinal slices

The invention discloses a production technology of gastrodia elata fresh-cut medicinal slices. The technology comprises the following steps: after harvesting gastrodia elata materials, rapidly cleaning the harvested gastrodia elata materials when wet soil are adsorbed on the surfaces with water, airing for 2 to 4 hours, freshly cutting into slices, drying and then vacuumizing and packaging with polyethylene plastic bags, and adding a desiccant and an antioxidant. According to the method, the loss of water-soluble active ingredients can be avoided due to fresh washing and processing of medicinal materials, the pollution of microorganism and insects in soil to the medicinal materials is reduced, the production procedures of the medicinal slices can be simplified, the production cost can be lowered, the quality of the medicinal materials can be guaranteed, and the clinical efficacy can be improved. The popularization and implementation of the method have remarkable social significance and economic benefits.

Owner:徐璐

Processing technology for fresh-cut rhizoma cibotii medicinal slices

InactiveCN107375355AReduce churnIntact epidermisPteridophyta/filicophyta medical ingredientsPlant ingredientsHerbWater soluble

The invention discloses a processing technology for fresh-cut rhizoma cibotii medicinal slices. The processing technology is characterized in that after harvesting of rhizoma cibotii, while soil attached onto the surface of rhizoma cibotii is wet, cleaning is performed, rhizoma cibotii is spread and aired for 2-4 h and then cut into round pieces or elliptical pieces while being fresh, the cut pieces are dried and subjected to vacuum package by a polyethylene plastic bag, and a drying agent and an anti-oxidant are added. As the herb is washed and processed while being fresh, loss of water-soluble effective components is avoided, pollution of microbes and worm eggs in soil to the herb is reduced, the production procedure of the medicinal slice is simplified, the manufacturing cost is lowered, the quality of the herb is guaranteed, and the clinical curative effect is improved. By popularized implementation of the processing technology, remarkable social significance and economic benefits are achieved.

Owner:徐事成

Fresh-cut processing technology of dysosma crude medicine

The invention discloses a fresh-cut processing technology of a dysosma crude medicine. According to the technology, after the dysosma crude medicine is harvested, the dysosma crude medicine is washed with water when soil is attached to the surface of the medicine which is still wet, roots and branches are arranged, the dysosma crude medicine is spread for drying for 12-24 h and cut into round pieces or oval pieces when being fresh, the pieces are air-dried to dryness and subjected to vacuum packaging with a polyethylene plastic bag, and a desiccant and an antioxidant are added. The crude medicine is washed and processed when being fresh, so that loss of water-soluble effective components is avoided, pollution of the crude medicine by microorganisms and worm eggs in the soil is reduced, the process for production of decoction pieces is simplified, the preparation cost is reduced, the quality of the crude medicine is guaranteed, and the clinical effect is improved. Great social meaning and economic benefits can be produced with popularization and implementation of the technology.

Owner:徐自升

Processing technique for fresh coptis chinensis decoction piece

InactiveCN107362209AReduce churnIntact epidermisSenses disorderNervous disorderMicroorganismClinical efficacy

The invention discloses a processing technique for a fresh coptis chinensis decoction piece. The technique comprises the following steps: harvesting coptis chinensis medicinal material and then cleaning with water while the soil is attached to the surface and is still wet; airing for 2-4 hours; cutting into circular sheets or oval sheets under a fresh state; drying and then using a polyethylene plastic bag for vacuumizing and packaging; adding a drying agent and an antioxidant. According to the method, the medicinal material is cleaned and processed under the fresh state, so that the loss of the water-soluble effective constituent is avoided, the pollutions of microorganisms and eggs in soil to the medicinal material are reduced, the production process of the decoction piece is simplified, the manufacturing cost is lowered, the quality of the medicinal material is guaranteed and the clinical effect is promoted. The popularization and implementation of the method have significant social meaning and economic benefit.

Owner:徐事成

Paris rhizome fresh cutting process

The invention discloses a paris rhizome fresh cutting process. The process includes: after paris rhizome is collected and soil on the surface of the paris rhizome is wet, cleaning with boilding water, tidying, spreading for airing for 12-24 hours, slicing fresh paris rhizome into round or oval slices, using polyethylene plastic bags for vacuum packaging of dried paris rhizome, and adding a drying agent and an antioxidant. Since the paris rhizome is washed and processed when being fresh, loss of water-soluble active ingredients is avoided, contamination caused by microorganisms and worm eggs in soil is reduced, a process for production of medicinal slices is simplified, manufacturing cost is reduced, medicinal quality is guaranteed, and clinical efficacy is improved. Popularization and application of the paris rhizome fresh cutting process have remarkable social significance and economic benefits.

Owner:徐自升

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com