Patents

Literature

36results about How to "Complete separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

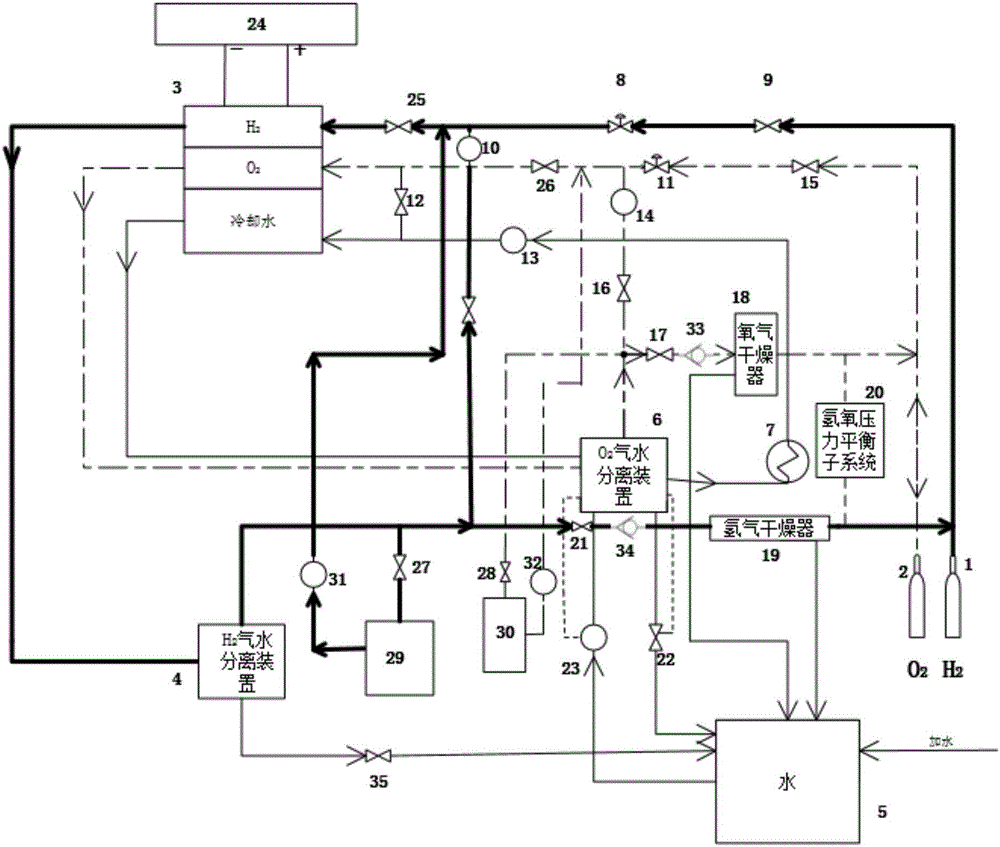

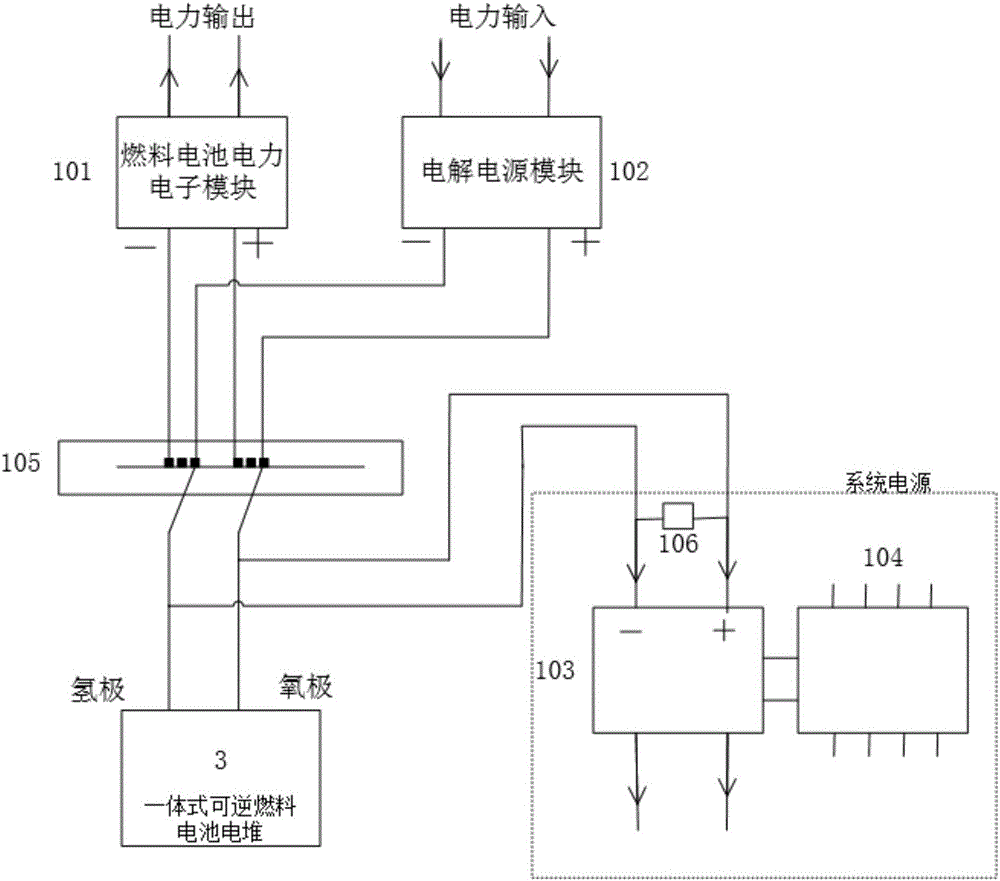

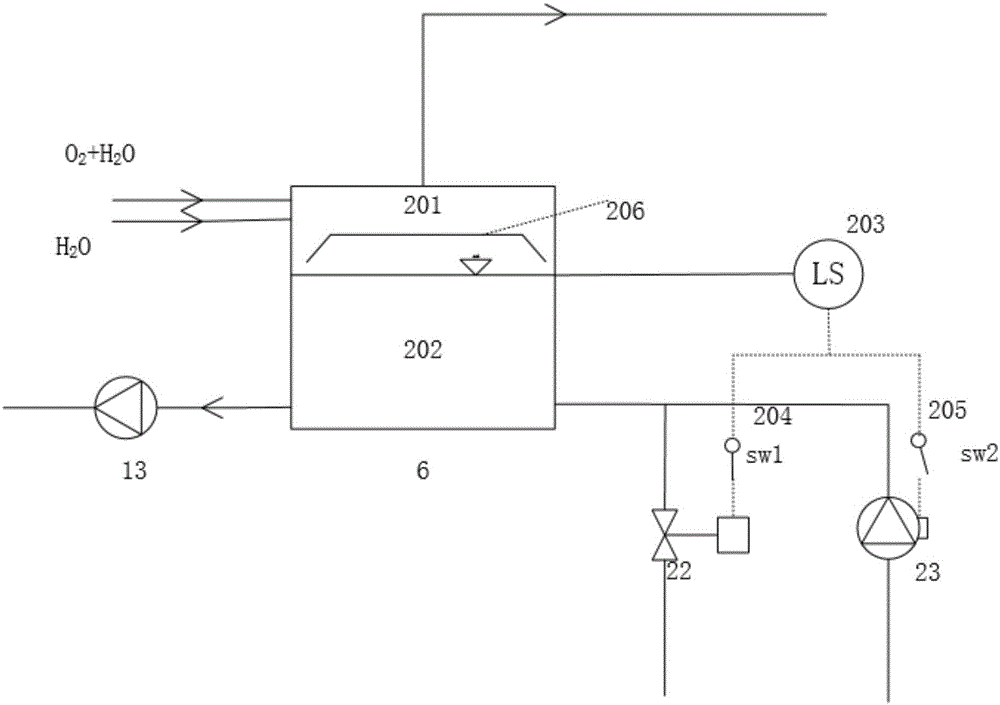

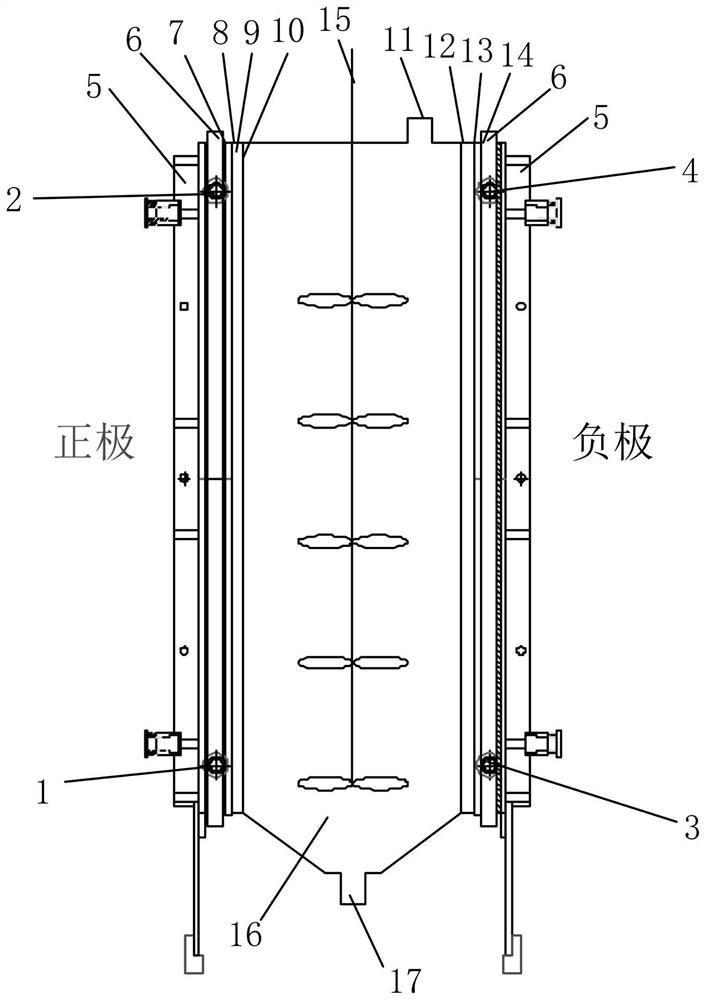

Integrated reversible fuel cell system

ActiveCN106784960AReduce water wasteComplete separationReactant parameters controlFinal product manufactureWater circulationEngineering

The invention relates to an integrated reversible fuel cell system which comprises a hydrogen production power generation module formed by a fuel cell stack, a hydrogen circulation module, an oxygen circulation module and a water circulation module. The fuel cell stack is composed of a plurality of single cells which are stacked sequentially, a hydrogen inlet, a hydrogen outlet, an oxygen inlet, an oxygen outlet, a cooling fluid inlet and a cooling fluid outlet; each single cell is composed of a conductive plate and a membrane electrode; the hydrogen circulation module is connected with the hydrogen inlet and outlet of the fuel cell stack; the oxygen circulation module is connected with the oxygen inlet and outlet of the fuel cell stack; the water circulation module is connected with the cooling fluid inlet and outlet of the fuel cell stack; and in the system, power generation by the fuel cells is carried out in a forward process, and hydrogen production by electrolyzed water is carried out in a reverse process. Compared with the prior art, the integrated reversible fuel cell system has the advantages of being simple and compact in structure, lowering the cost, recycling water, hydrogen and oxygen raw materials, and integrated in management such as gas-water separation, and the like.

Owner:戈瑞屋(上海)科技发展有限公司

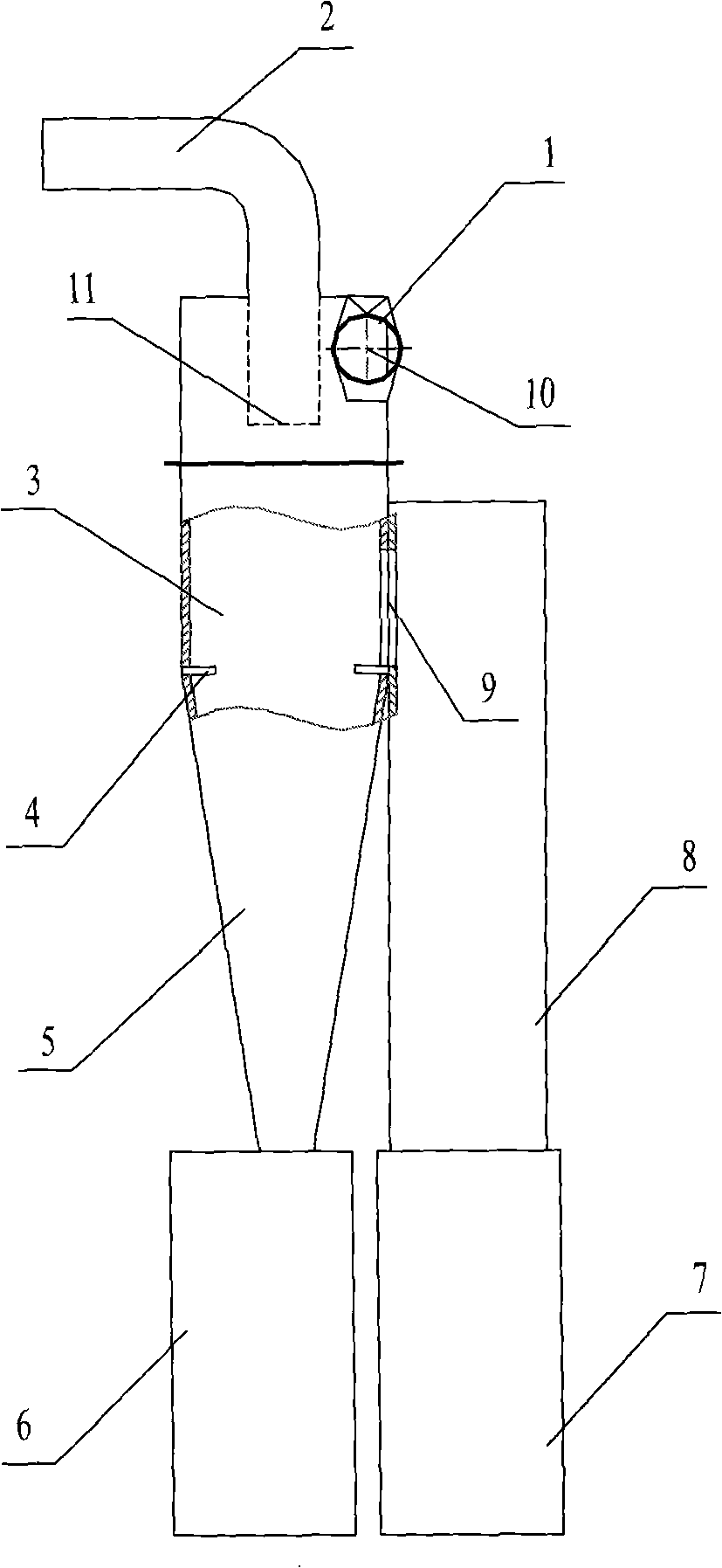

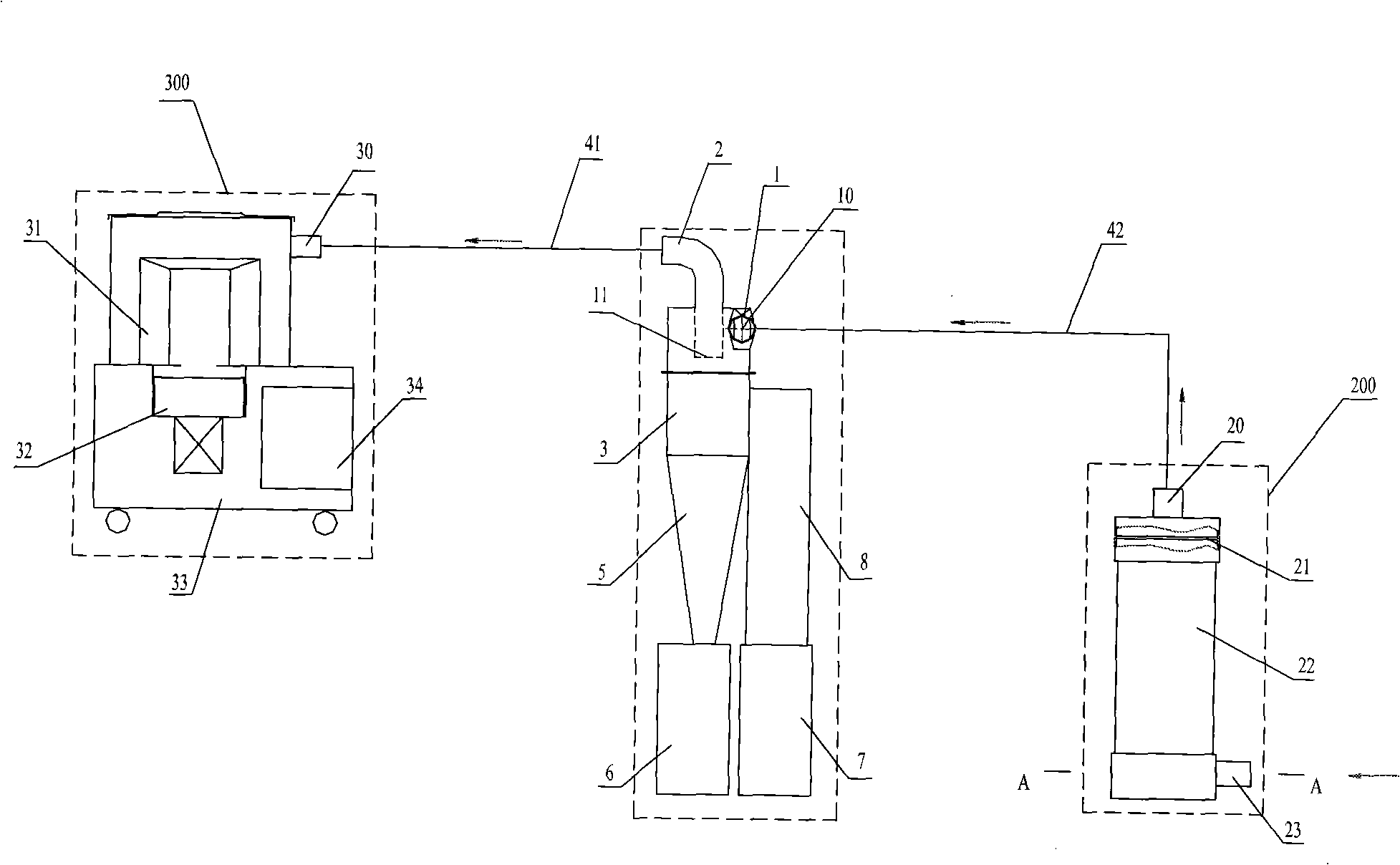

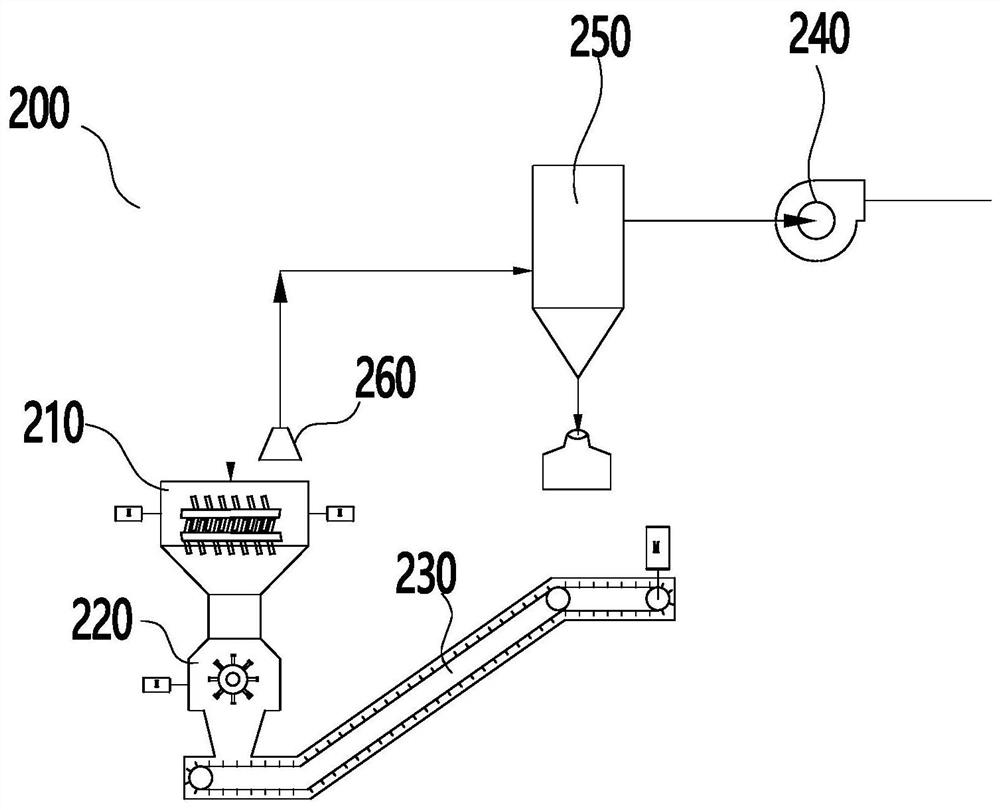

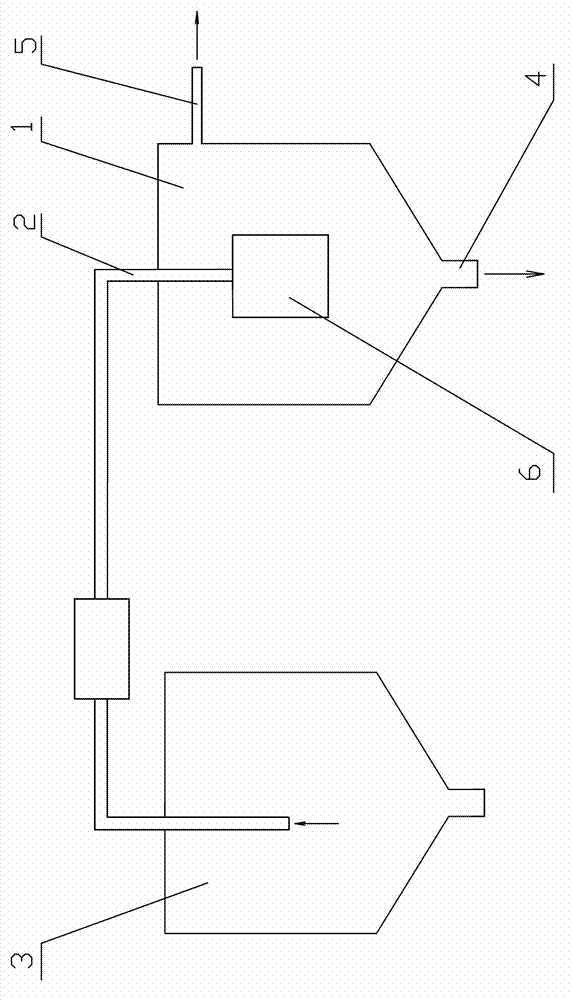

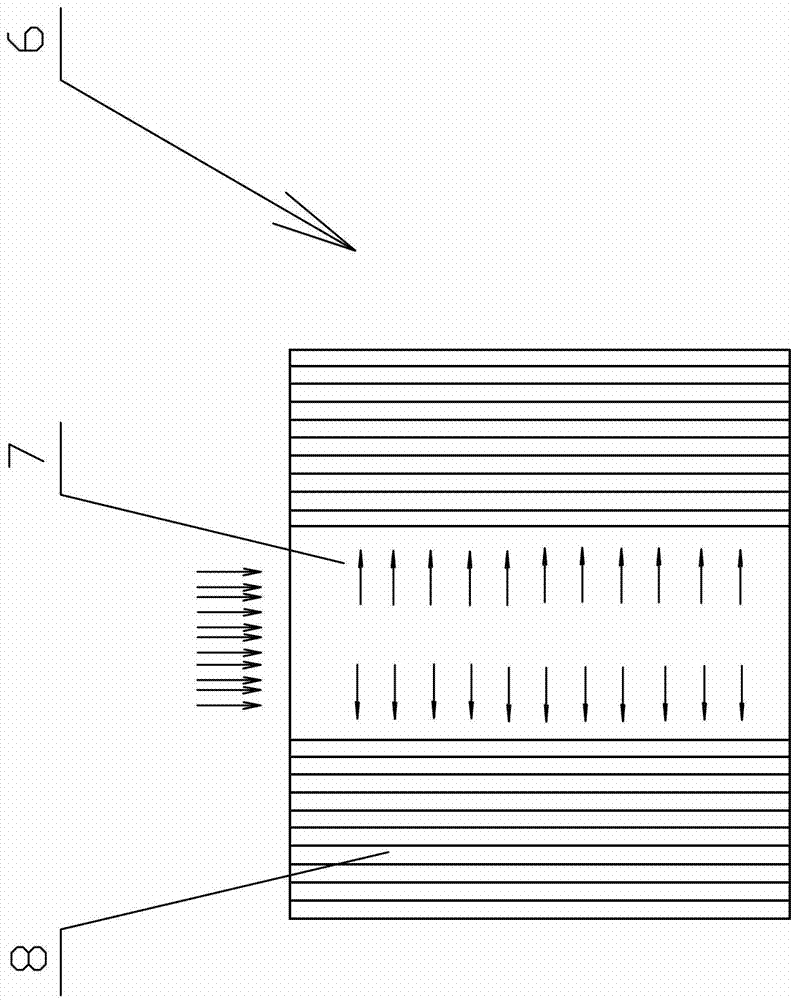

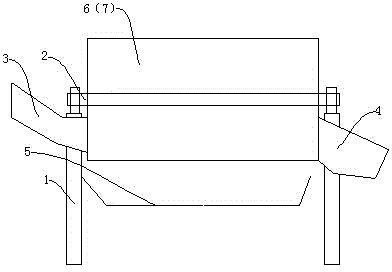

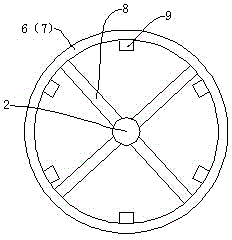

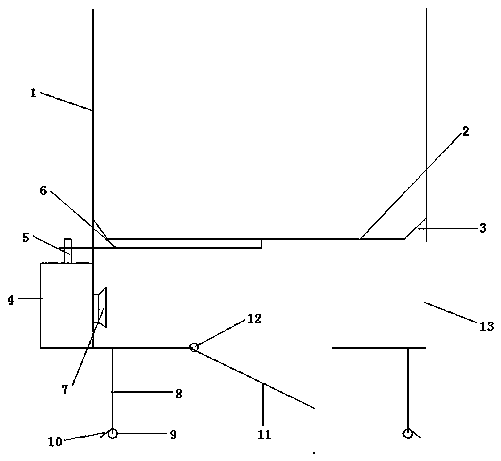

Cyclone separator and spore separation device therewith

InactiveCN101524672ASafe and Low Consumption SystemComplete separationBioreactor/fermenter combinationsBiological substance pretreatmentsAir volumePhencyclone

The invention discloses a cyclone separator, comprising a primary separator and a secondary separator (8) which are communicated by a channel (9), the bottom of the primary separator is connected with a primary collection tube (6), the bottom of the secondary separator is connected with a secondary collection tube (7); the top surface of the primary separator is provided with an air outlet channel (2), the side wall of the primary separator is tangentially provided with an air inlet channel (1), the air outlet channel (2) and the air inlet channel (1) are both communicated with the inner cavity of the primary separator; an air volume regulator (10) is arranged inside the air inlet channel (1), and the channel (9) is positioned below the air inlet channel (1). The invention also discloses a spore separation device with the cyclone separator, wherein a blower component (300) is connected with the air outlet channel (2) in a sealing way, and a swirling flow feeder component (200) is connected with the air inlet channel (1) in a sealing way. The spore separation device of the invention can efficiently separate solid fermentation fungal spore.

Owner:ZHEJIANG UNIV

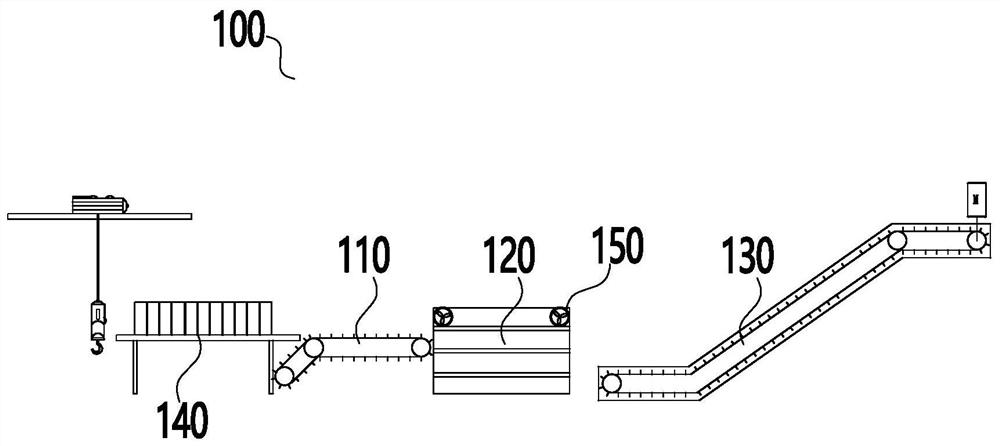

Continuous peeling method for walnut kernels

The present invention discloses a continuous peeling method for walnut kernels, the method includes the following steps: the sorted complete walnut kernels are successively soaked in a continuous alkali solution soaking machine, then the soaked walnut kernels are put into a high-pressure spraying machine, the skins of the walnut kernels on the mesh belts of the high-pressure spraying machine are subjected to continuous and all-around impacts from high-pressure water produced by a high pressure pump, then the treated walnut kernels are put into a double-effect washing machine to be soaked and rinsed, and the skins of the walnut kernels are subjected to continuous and all-around impacts by the high-pressure water, then fiber and other light impurities on the skin of the walnut kernels are further removed by constant stirring and tumbling impacts produced by a wind pump, the skins are separated from the walnut kernels under the action of a separation device and circulating water in the skin and kernel separating machine, and then the walnut kernels are put into a countercurrent dryer to evaporate water on the surface of the walnut kernels. The continuous peeling method can realize the complete separation of the kernels and the skins of walnut kernels, the process is relatively simple and easy to operate, the production cost is low, the quality of walnut kernels can be significantly improved, the waste water is greatly decreased and the production cost is substantially reduced.

Owner:郑州新力德粮油科技有限公司 +2

Silicon-carbon separation method for polysilicon carbon head materials

InactiveCN101691222AComplete separationSeparation Process SafetySilicon compoundsIonPolycrystalline silicon

The invention relates to a silicon-carbon separation method for polysilicon carbon head materials, which comprises the steps of silicon-carbon separation, cleaning and surface treatment, wherein in the silicon-carbon separation step, the carbon head materials are loaded into a mesh bag and then put into separation liquid in a weight ratio of the separation liquid to the polysilicon carbon head materials being 100:(50-200), and the carbon head materials are mixed under sealing or ventilating condition and are fully soaked for 0.5 to 8 hours; and in the surface treatment step, polysilicon after the cleaning step and removal of graphite is soaked in 5 to 10 mass percent solution of caustic soda liquid for 5 to 10 minutes, cleaned in 5 to 20 mass percent solution of pure hydrochloric acid for 1 to 5 minutes, and then washed with deionized water until the surface pH is between 5.0 and 7.0, so that the separation of the polysilicon and the graphite can be completely realized. The method has safe process, and controllable silicon-carbon separation efficiency.

Owner:隋聚勇

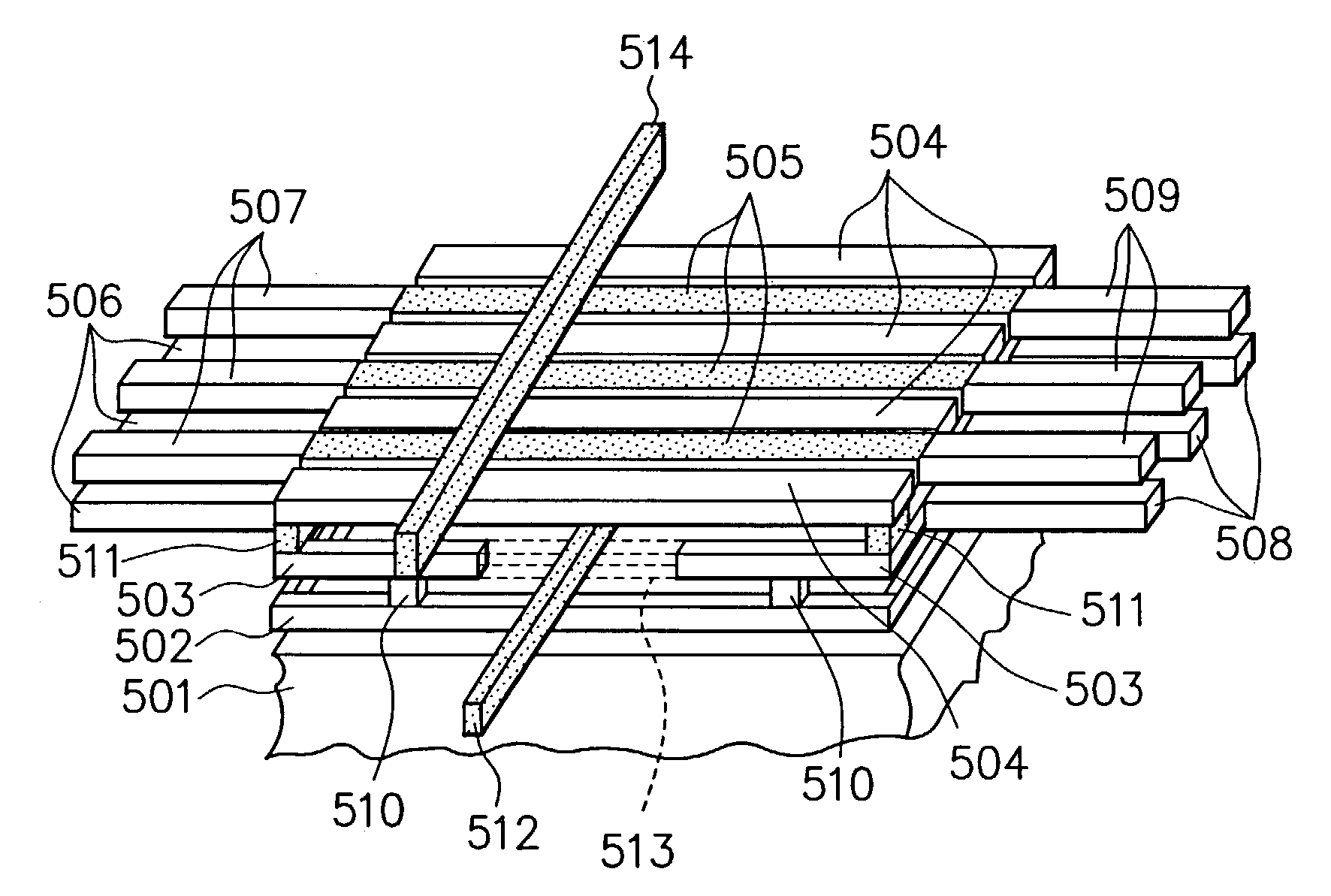

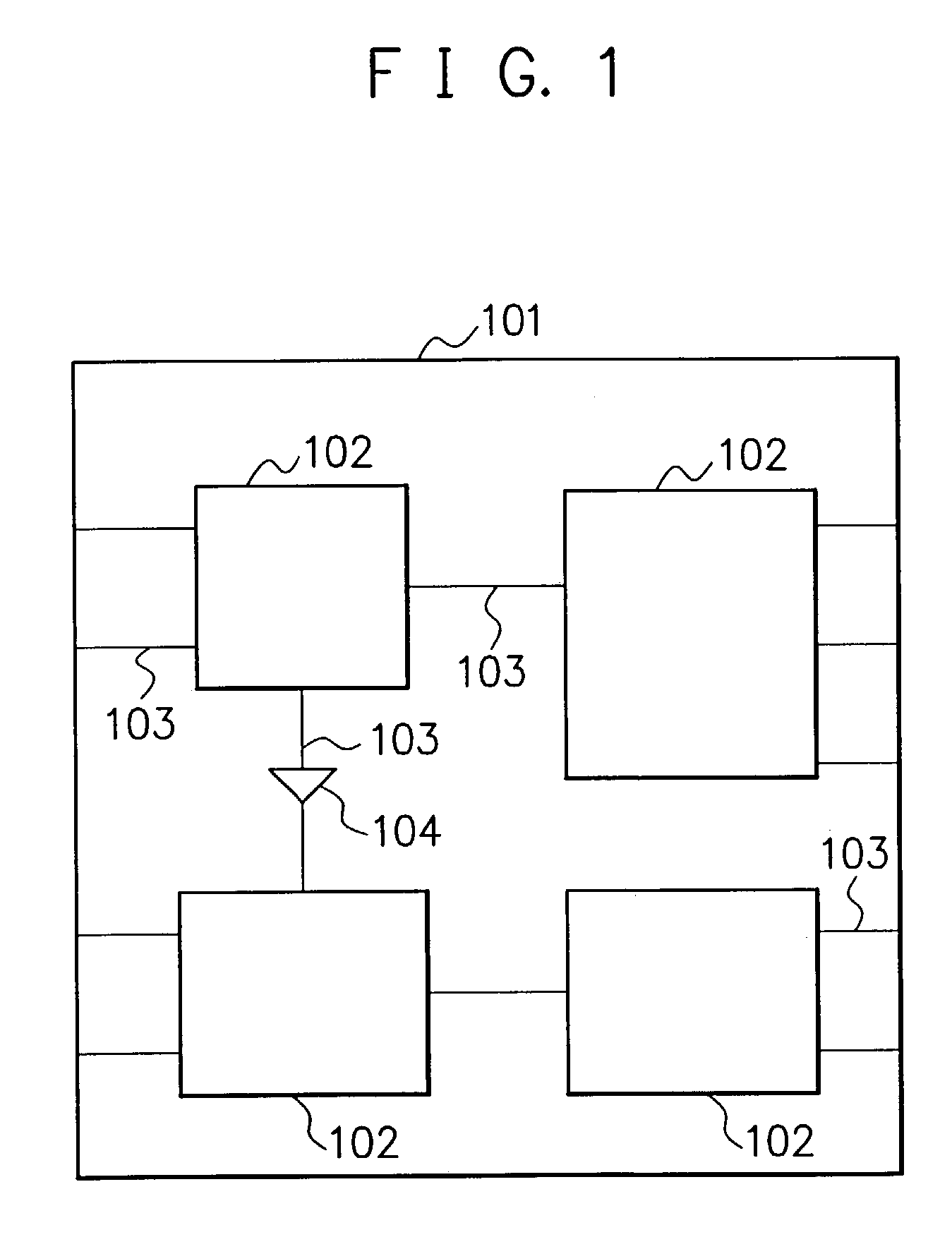

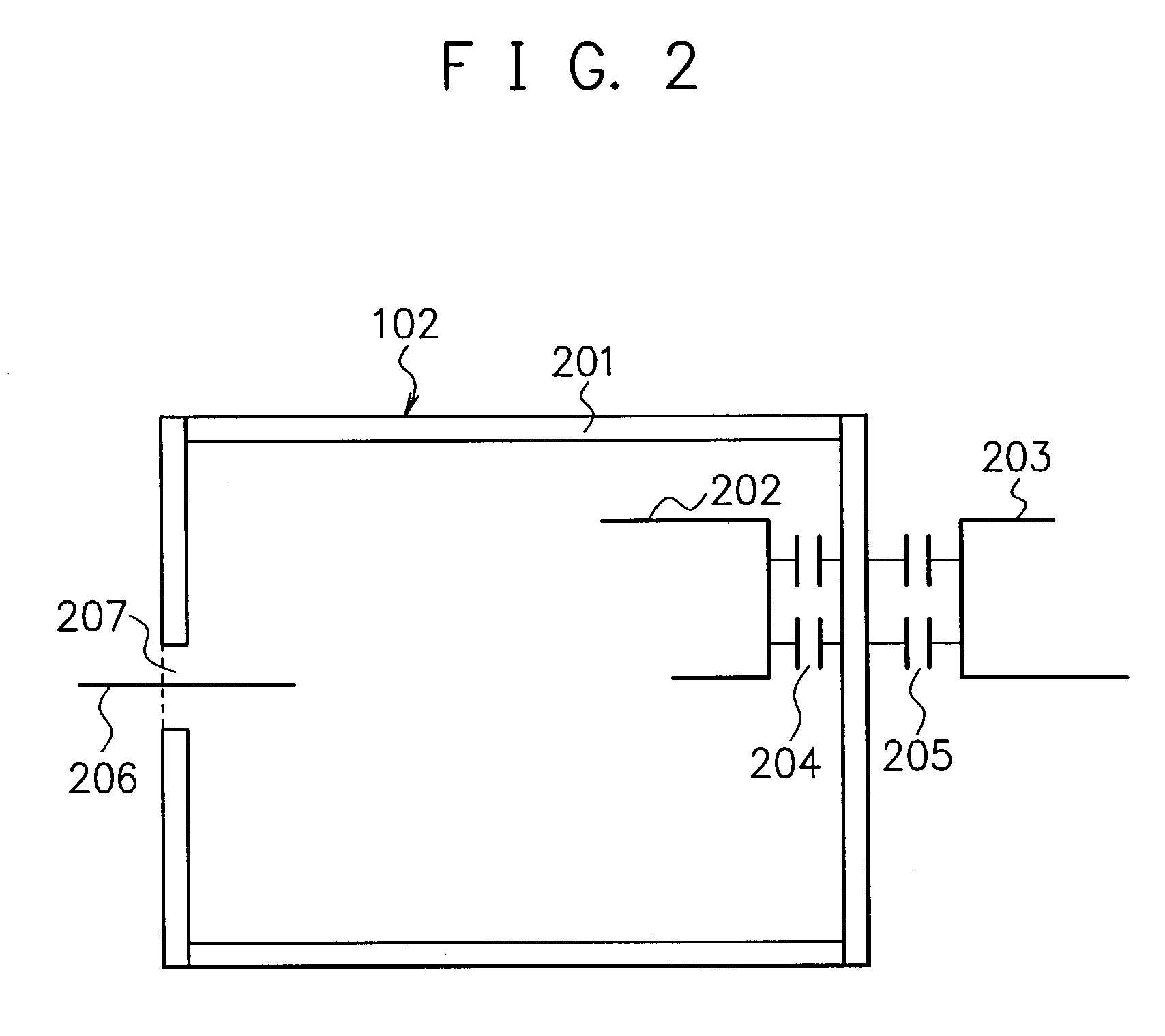

Semiconductor circuit designing method, semiconductor circuit designing apparatus, program, and semiconductor device

InactiveUS7051311B2Simple and quick and accurate designingComplete separationSemiconductor/solid-state device detailsSolid-state devicesSemiconductorDesign methods

The present invention provides a semiconductor circuit designing method, comprising a lower level hierarchical designing step of designing a semiconductor circuit inside a block and an upper level hierarchical designing step of designing an external wiring of the block. The above-mentioned lower level hierarchical designing step or upper level hierarchical designing step includes a shield wiring designing step of designing to provide a shield wiring on a boundary part of the block.

Owner:SOCIONEXT INC

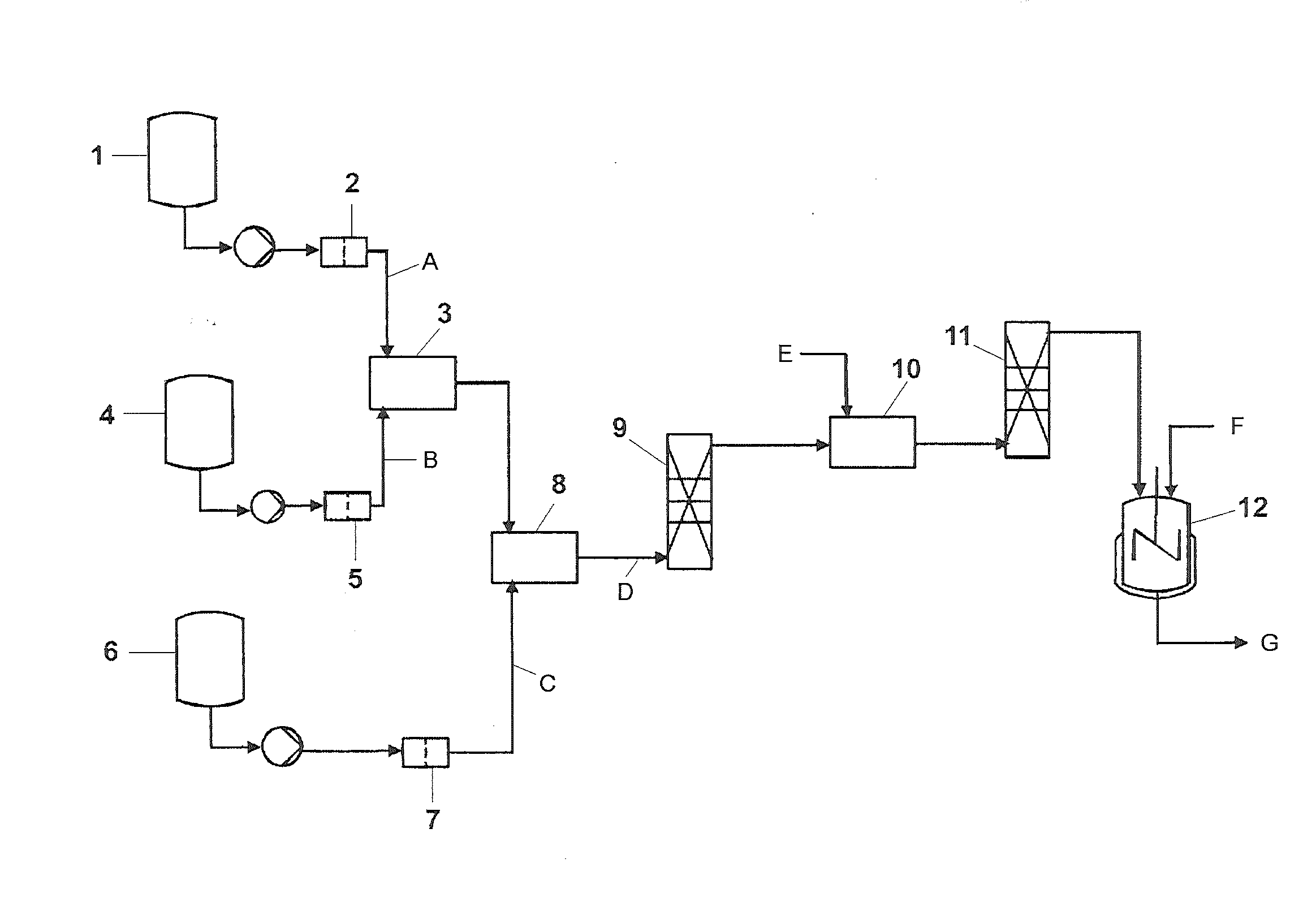

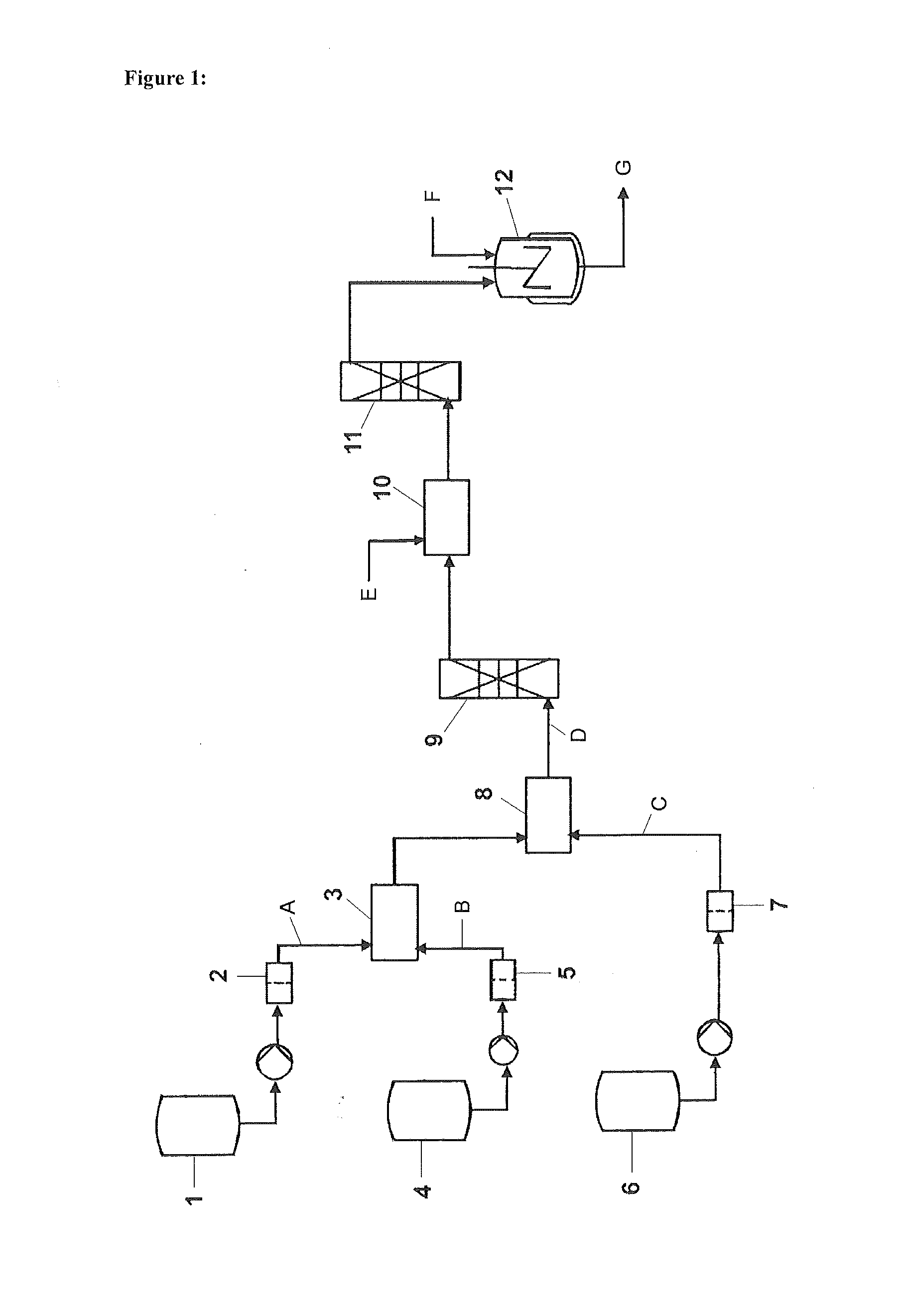

Method and Device for the Continuous Production of Polymers by Radical Polymerization

ActiveUS20140088280A1Reduced activityNarrow molar mass distributionFlow mixersTransportation and packagingPolymer scienceReaction zone

The present invention relates to a method for the continuous production of a polymer by radical polymerization, wherein at least three materials are mixed with microstructures in one or more mixers and are then polymerized in at least one reaction zone.

Owner:BASF AG

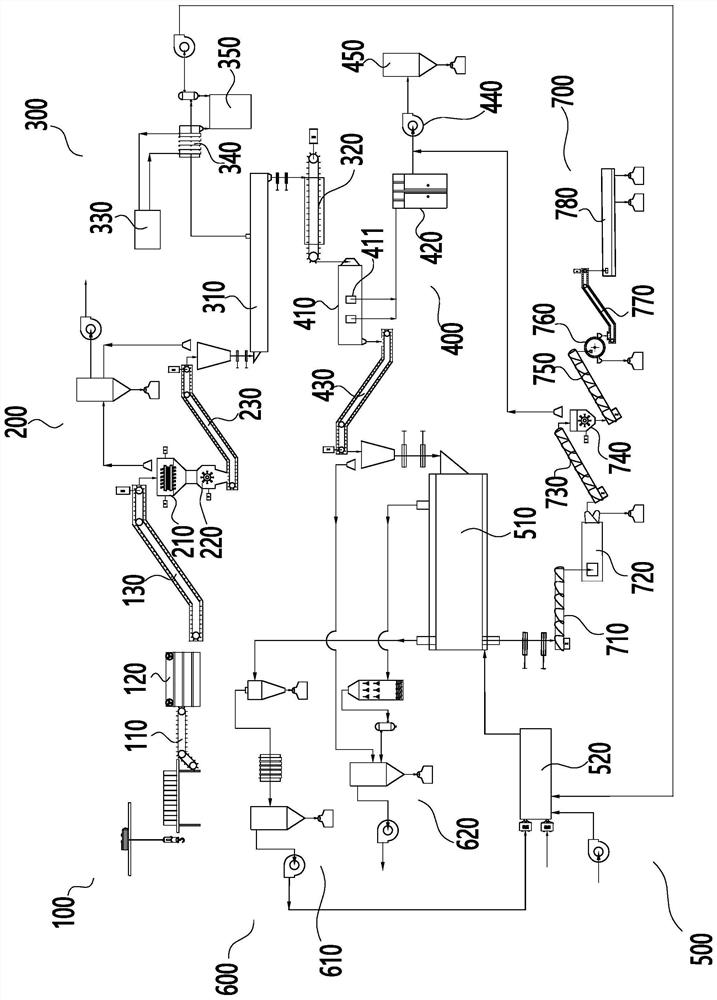

Waste power battery single body full-component recovery system

PendingCN111842410AReduce turnoverAvoid sticking inHuman health protectionCombination devicesElectrolytic agentPower battery

The invention discloses a waste power battery single body full-component recovery system which comprises a single body discharge system, a crushing system, an electrolyte recovery system, a diaphragmrecovery system, a cracking system, a tail gas purification system and a separation system. Electrolyte, diaphragm paper, battery powder and metal materials in batteries can be recovered in a full-component manner. The waste power batteries are subjected to working procedures of discharge, crushing, electrolyte recovery, diaphragm paper recovery, cracking, separation and the like to obtain final products. All the working procedures of the whole system are connected in a head and tail manner, continuous production can be achieved, material circulation is reduced, and labor and consumption costare reduced remarkably. The batteries can be recovered in a full-component manner. The batteries are crushed after being discharged, and the technology is safe and reliable. After diaphragms and the electrolyte in battery crushed materials are removed, then the cracking technology is adopted for treating the battery crushed materials, the cracking reaction is easier, the problem of material bonding caused by diaphragm melting is effectively avoided, and powder of positive and negative anodes of the batteries are separated more thoroughly.

Owner:HUNAN BRUNP RECYCLING TECH +2

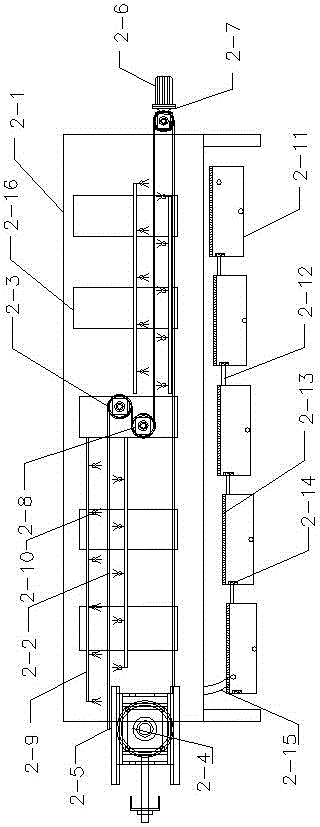

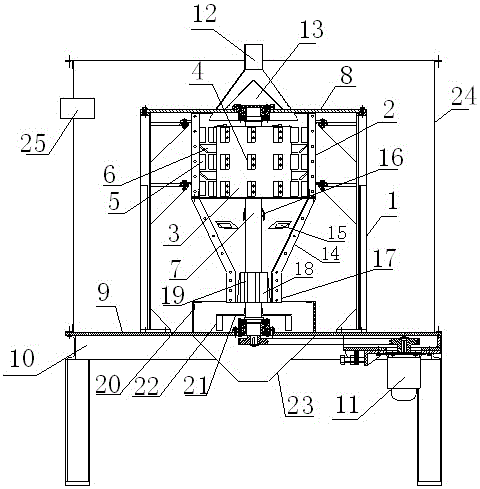

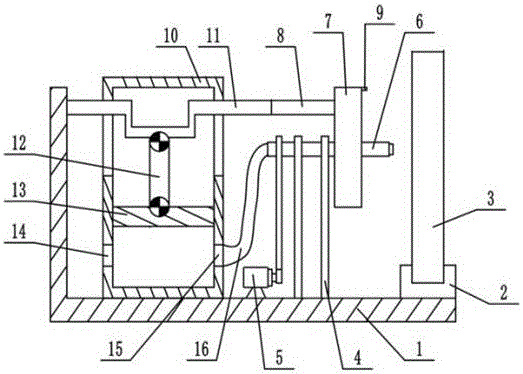

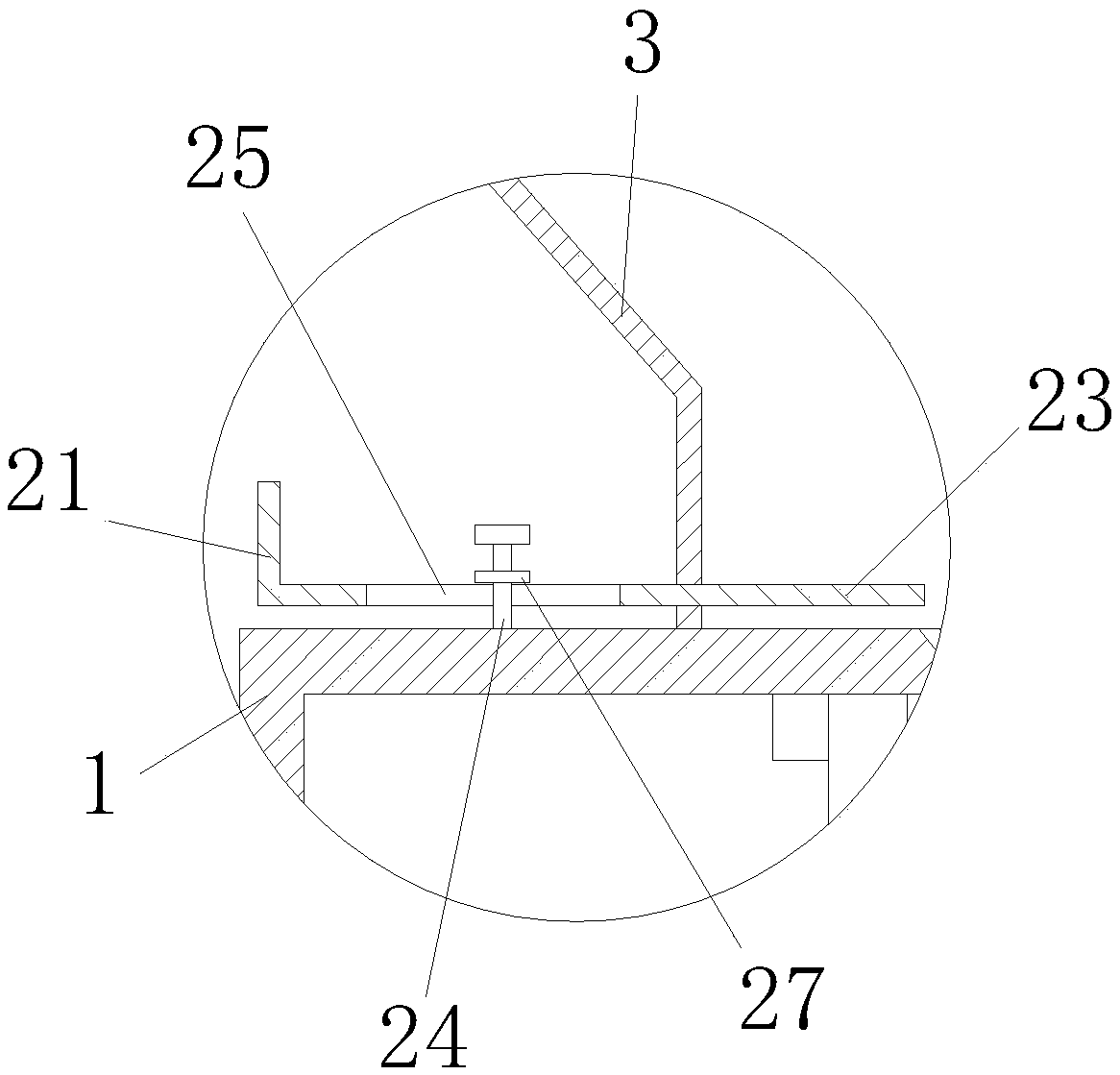

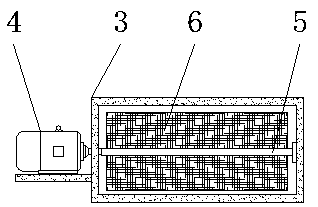

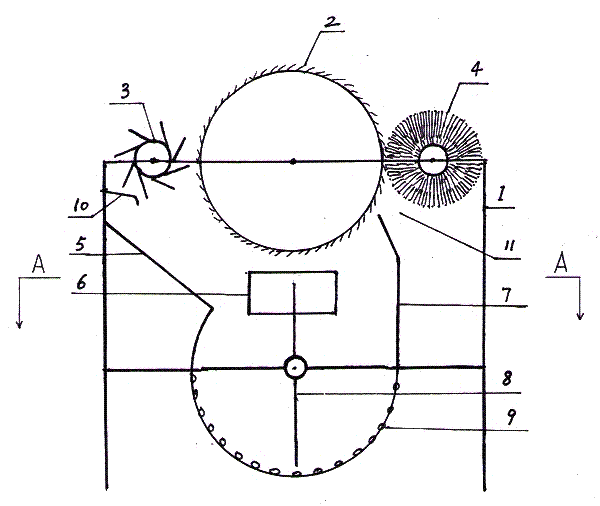

Old sand regenerator

ActiveCN105772627AImprove efficiencyComplete separationMould handling/dressing devicesEngineeringUltimate tensile strength

The invention provides an old sand regenerator, and particularly relates to a mechanical old sand regenerator. According to the old sand regenerator, membranes on the surfaces of sand can be evenly and rapidly smashed, the smashing intensity is easy to control, and sand bodies with different qualities are conveniently produced. The old sand regenerator comprises a rack, a barrel and a rotation driving device, the barrel is fixed to the rack, a roller is arranged in the barrel coaxially, and many rings of hitting plates are arranged on the roller; each ring of hitting plate is a plate body distributed in the circumferential direction of the roller, many rings of collision plates corresponding to the hitting plates on the roller are arranged in the barrel, and the position, between two rings of collision plates, of the barrel is provided with a ring of sand flow guide plate; a rotating shaft is arranged on the roller and connected with the rotating driving device. By means of the old sand regenerator, the sand is relatively uniform even though collision occurs, and the efficiency is higher. By controlling the rotating speed of the roller, the smashing intensity of the sand can be controlled, and the sane in different sizes can be obtained.

Owner:侯松涛

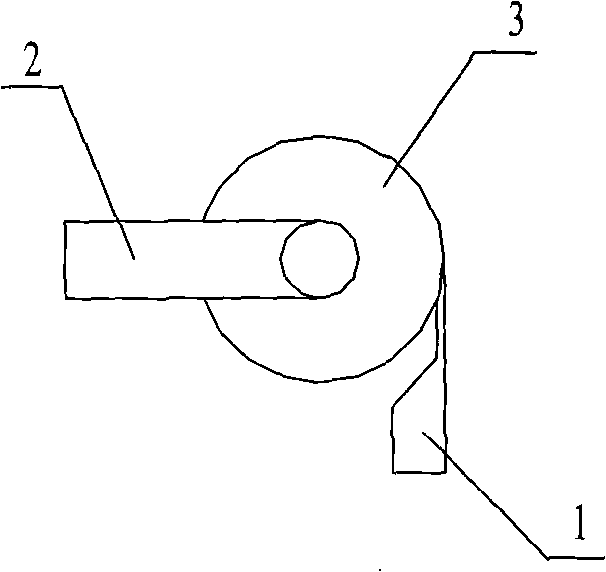

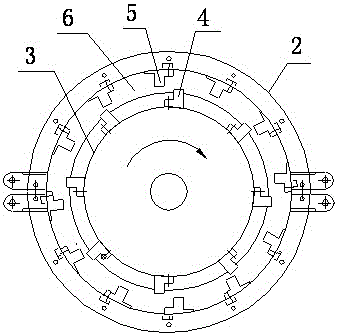

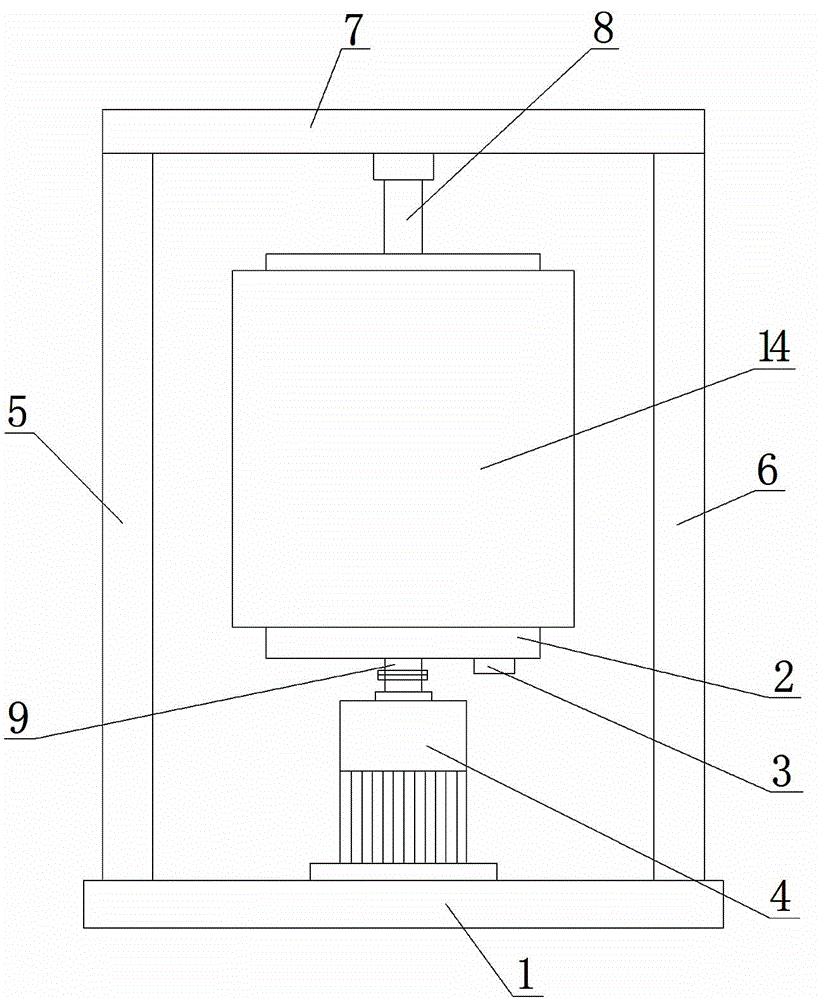

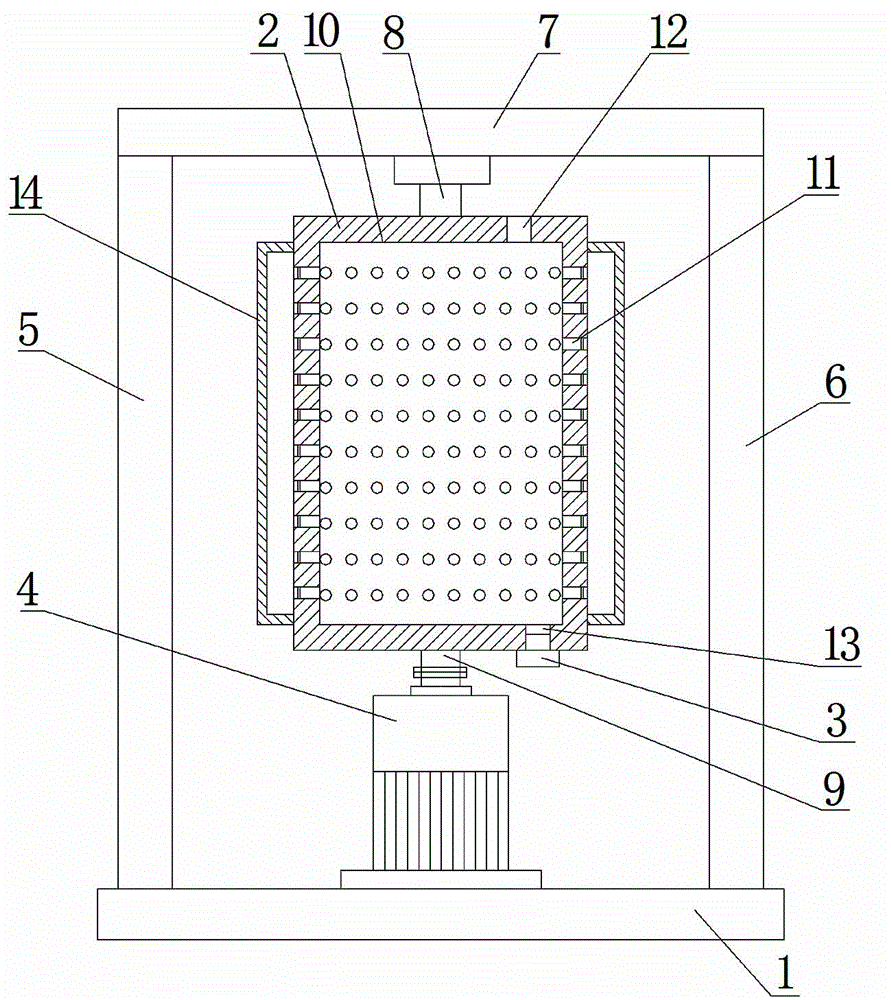

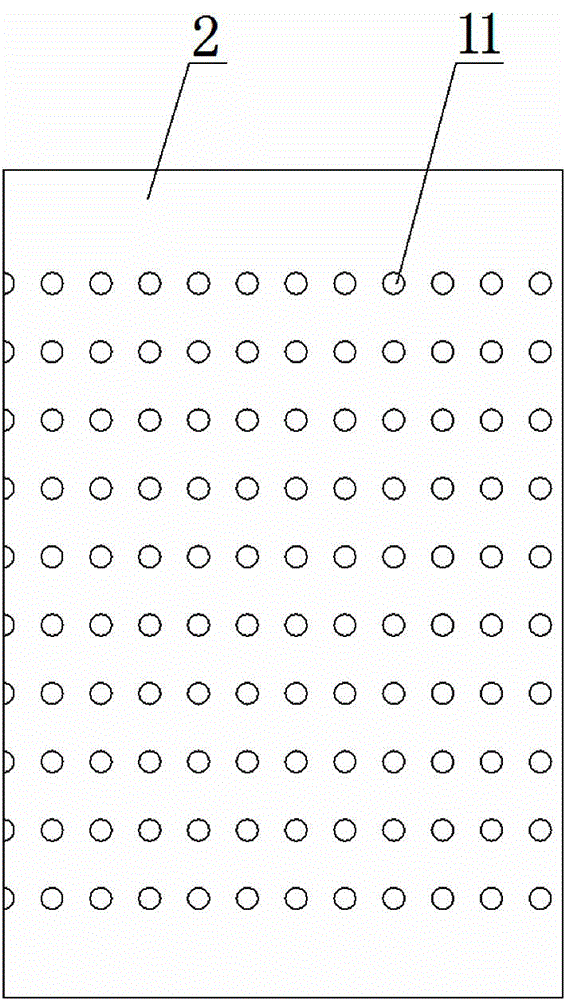

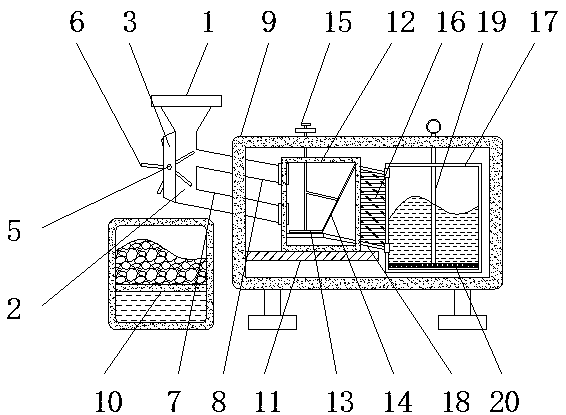

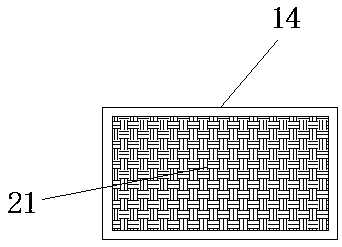

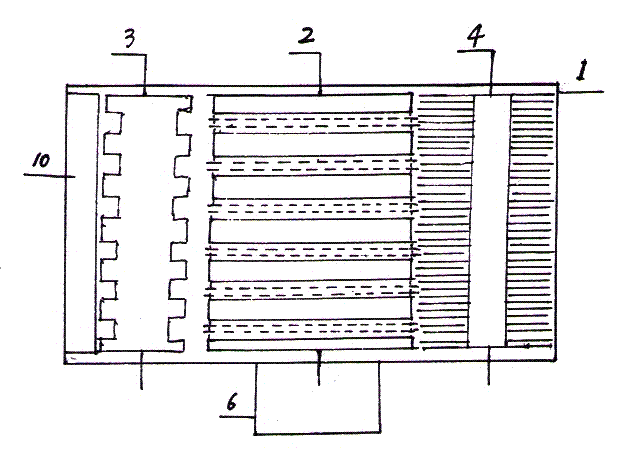

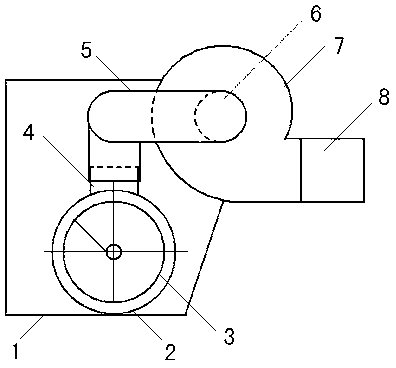

Novel device for separating copper powder from waste liquid

InactiveCN104941289AImprove separation efficiencyComplete separationMoving filtering element filtersCopperLiquid waste

The invention discloses a novel device for separating copper powder from waste liquid. The device includes a working table (1), a filter drum (2), a motor (4), as well as a stand column A (5) and a stand column B (6) which are both arranged on the working table (1), wherein a rotating shaft II (9) is connected with the output end of the motor (4); a cavity (10) is formed in the middle of the filter drum (2); a plurality of through holes (11) communicated with the cavity (10) are distributed uniformly in the cylindrical surface of the filter drum (2); a liquid inlet (12) and a discharge opening (13), which are communicated with the cavity (10), are respectively arranged formed in the upper end and the lower end of the filter drum (2); a plug (3) is arranged in the discharge opening (13); the device further includes a liquid collection bag (14) which surrounds the filter drum (2); a cavity is formed between the liquid collection bag (14) and the filter drum (2). The novel device for separating copper powder from waste liquid has the benefits that the copper powder separation is thorough, separation efficiency is high, and the operation is simple,; manual copper powder collection is facilitated and waste liquid is prevented from splashing.

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

Cooling device for automobile part cutting

PendingCN106514020AComplete separationImprove cutting effectLaser beam welding apparatusPistonLaser cutting

The invention belongs to the field of machining and particularly discloses a cooling device for automobile part cutting. The cooling device for automobile part cutting comprises a fixing seat. One end of the fixing seat is provided with a clamping mechanism. A laser cutting mechanism is arranged in the middle of the fixing seat and comprises a supporting frame. A first rotating shaft is rotationally connected to the supporting frame. The work end of the first rotating shaft is statically connected with an eccentric wheel. A laser cutter is arranged on the edge of the eccentric wheel. A second rotating shaft is further statically connected with the eccentric wheel. The other end of the fixing seat is connected with a cooling mechanism. The cooling mechanism comprises a cylinder body, a piston, a water inlet, a water outlet, a water outlet pipe, a crankshaft and a connecting rod. The work end of the water outlet pipe is arranged in the first rotating shaft in a penetrating manner and is aligned with part raw materials. The crankshaft is connected with the second rotating shaft. The cooling device for automobile part cutting can cool finished part products obtained after laser cutting and prevent the finished part products from being fused with the part raw materials in the cutting process.

Owner:重庆寅悦恒工贸有限公司

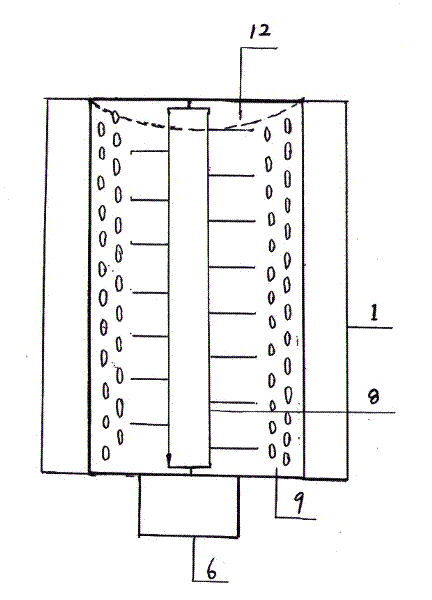

Cassia oil-water separator

InactiveCN102895802AComplete separationEasy to separateLiquid separationWater storage tankOil–water separator

The invention discloses a cassia oil-water separator for the separation of mixed liquor of cassia oil and water. The separator comprises a separation tank. A cassia oil coalescence device is arranged in the separation tank, and is communicated with a cassia oil-water storage tank through a pump pipe. An oil outlet is reserved at the bottom of the separation tank, and a water outlet is reserved on the upper part of the separation tank. The cassia oil coalescence device is a hollow filter element. The middle part of the filter element is a filter cavity communicated with the pump pipe. A filter layer formed by winding a plurality of layers of filter cloth is arranged around the filter cavity. The filter cloth is made from an anticorrosive high polymer material. The filter element is used as the cassia oil coalescence device, the oil and the water can be quickly and completely separated according to the density difference of the water and the cassia oil by using a gravity settling principle, and a separation rate reaches 99 percent.

Owner:防城港市防城区那梭香料厂

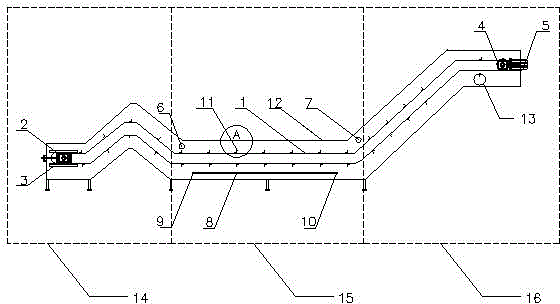

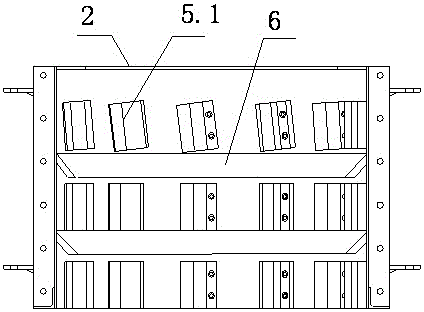

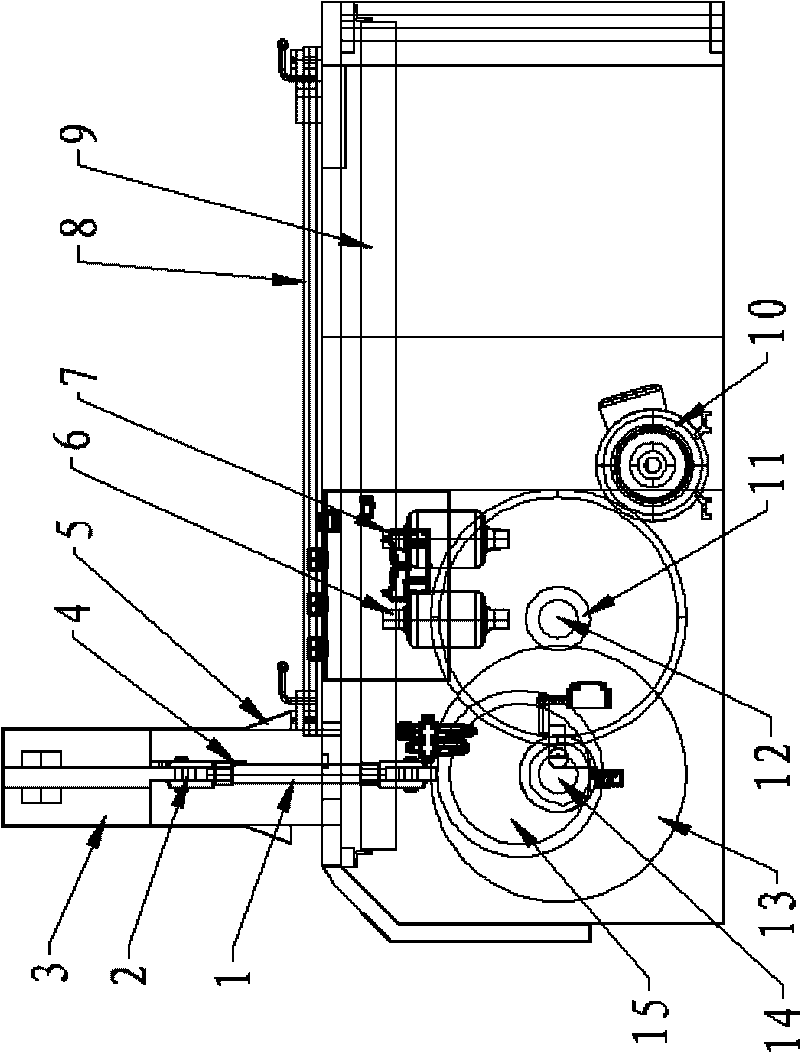

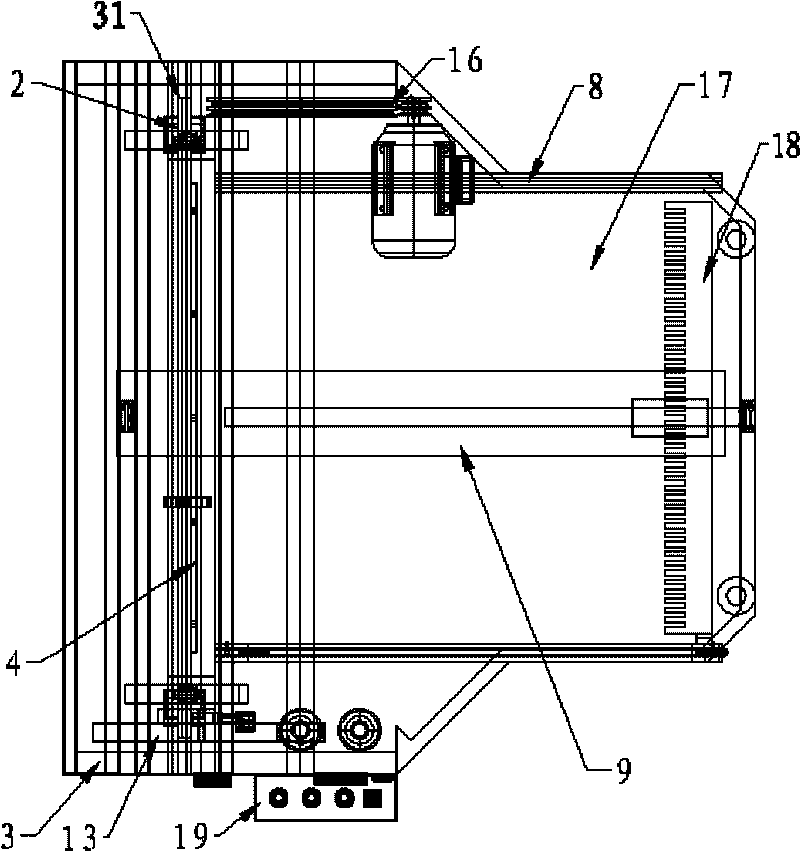

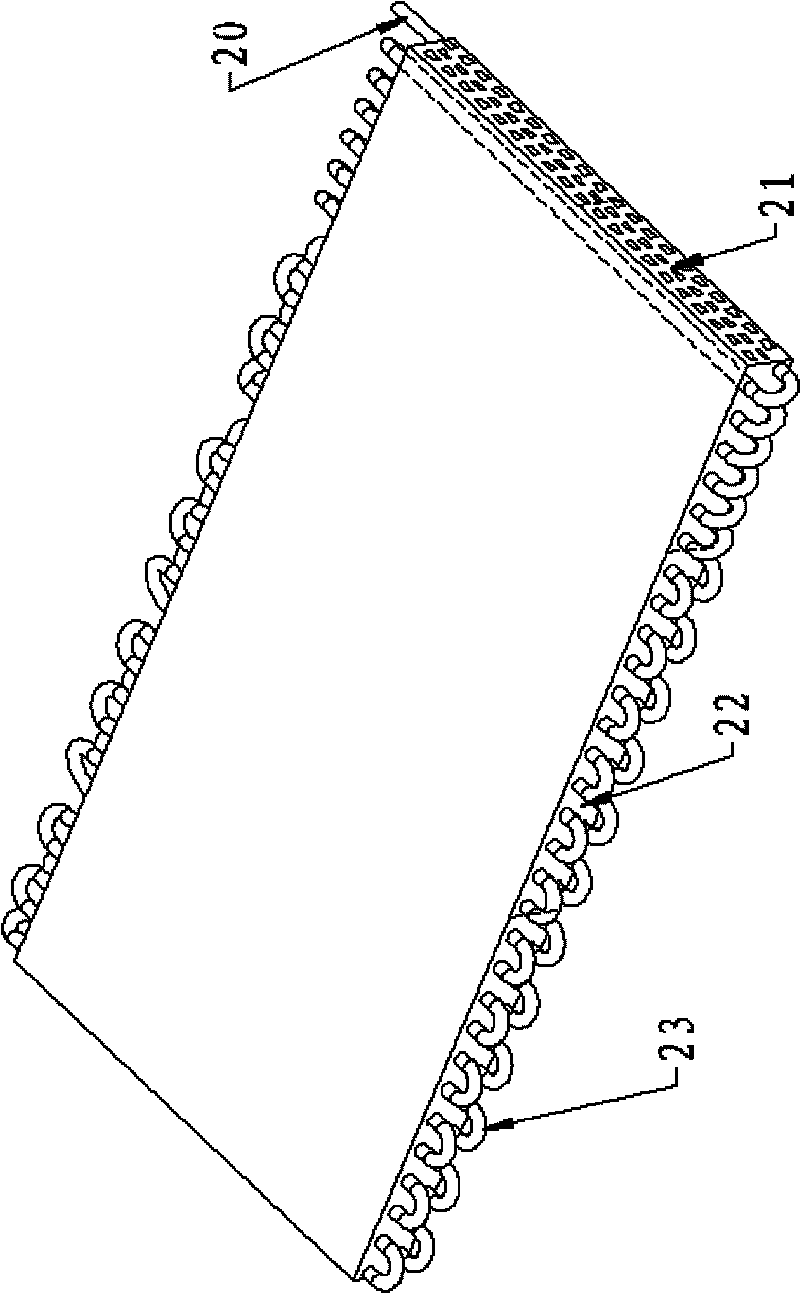

Copper and aluminum separating equipment of waste air conditioner heat exchanger

ActiveCN101695771AComplete separationImprove processing efficiencySolid waste disposalShearing machinesWorkbenchPower apparatus

The invention discloses copper and aluminum separating equipment of a waste air conditioner heat exchanger, which does not need manual disassembly and realizes more thorough separation. The copper and aluminum separating equipment comprises a workbench, and a stand, a sectioning mechanism and a feed mechanism are arranged on the workbench, wherein the stand is vertical to the workbench; the sectioning mechanism comprises a power device, a knife bed connected with the power device and a sectioning knife arranged on the knife bed; the knife bed is slidably connected with the stand; the feed mechanism consists of the table-board of the workbench and a feeder arranged on the terrace; the feeder is connected with a step controller and linearly moves along the table-board; the moving direction of the feeder is vertical to the cutting surface of the sectioning knife, which can realize the separation of copper and aluminum of a trimmed heat exchanger, the separation is thorough, and the treatment efficiency is high. Feed actions and sectioning actions of the equipment are closely matched, and the feed step quantity can be adjusted, thereby expanding the universality of the equipment. The equipment has simple structure, convenient use and maintenance and high safety.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

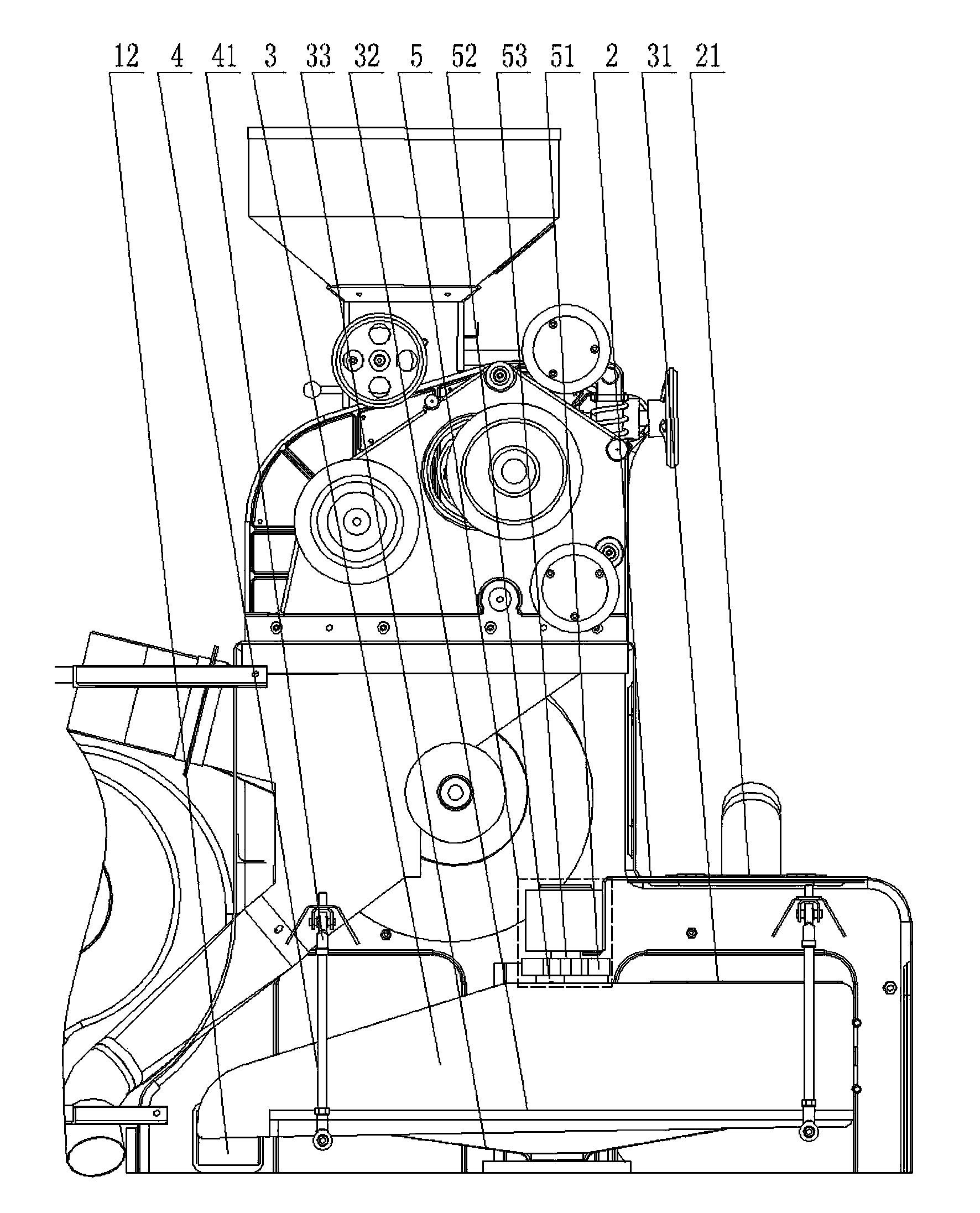

Vertical conical emery roll rice mill

The invention discloses a vertical conical emery roll rice mill comprising a mill body. A feeding port is formed in the top end of the mill body, the bottom end of the left side of the mill body is provided with a bran outlet, conical emery rolls are mounted on the outer sides of an upper support plate and a lower support plate, and vertical screen cloths are mounted on the outer sides of the conical emery rolls. A transverse screen cloth is mounted below the vertical screen cloths, and a rice outlet is mounted at the bottom end of the right side of the mill body. According to the vertical conical emery roll rice mill, through matching of the conical emery rolls, the vertical screen cloths and the transverse screen cloth and relative movement of the conical emery rolls and the vertical screen cloths, rice is driven to rotate to generate friction between the conical emery rolls and the vertical screen cloths so as to ground bran shells of the rice off; a main shaft drives an impeller torotate, the impeller rotates to enable the interior of the mill body to form the negative pressure so as to discharge the bran shells from the bran outlet, and a bran collecting bag is used for collecting the bran shells discharged from the bran outlet so as to prevent the bran shells from being flied out; and the milled rice is output from the rice outlet and collected, the rice and the bran shells are thoroughly separated to enable the bran shells and the rice to be better collected, and the using requirement of a user can be met.

Owner:安徽省中日农业环保科技有限公司

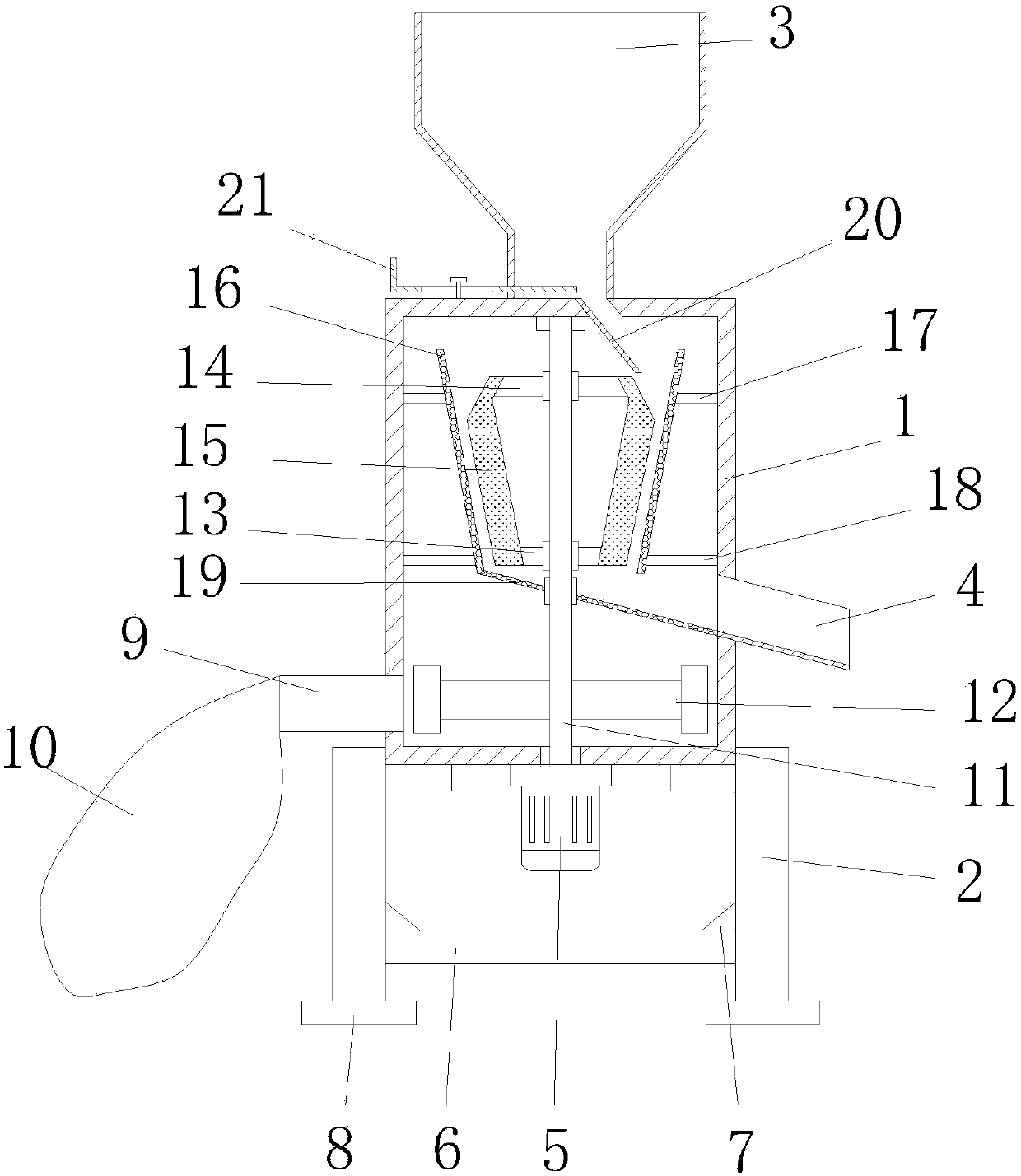

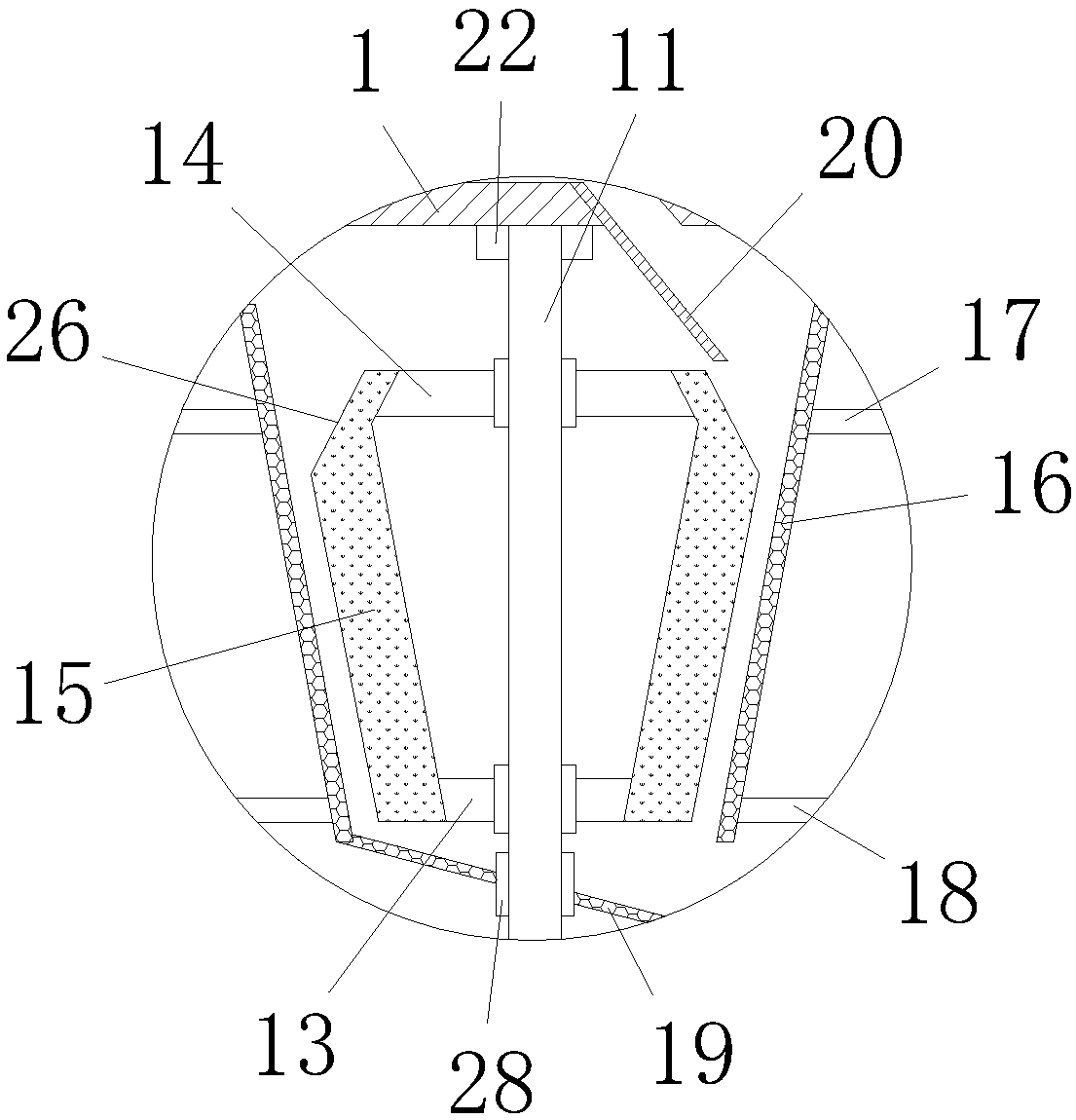

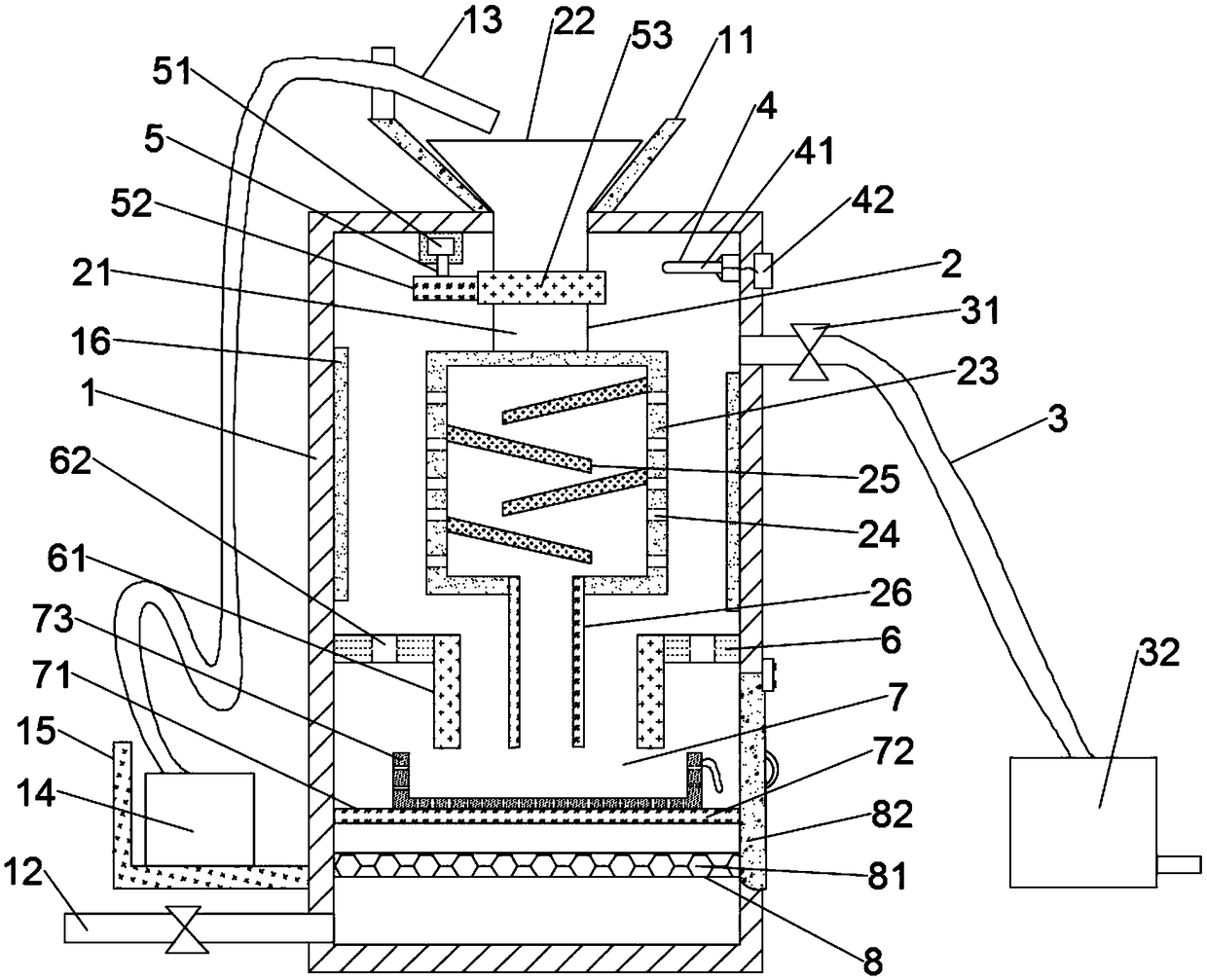

Foreign material separation equipment for sewage treatment

InactiveCN109020023AExtended Separation PathComplete separationWater/sewage treatment by centrifugal separationTreatment involving filtrationMaterial SeparationSewage

The invention discloses foreign material separation equipment for sewage treatment. The equipment comprises a separator cartridge, the top of which is provided with a feed hopper. A centrifuging device, an annular floatboard, a utility room and a secondary filter unit are successively arranged from top to bottom inside the separator cartridge. The sidewall of the separator cartridge is provided with a water outlet pipe, an exhaust pipe and a heating device. After the centrifuging device pumps sewage and sludge into a rotating cylinder through a sludge pump, the rotating cylinder is driven by arotary driving mechanism to drive sewage and foreign materials therein to rotate. Under the action of centrifugal force, sewage is thrown out of the rotating cylinder and foreign materials slowly falls down into a foreign material drawer under the action of an inclined guide plate. It is convenient and fast to clean up foreign materials in the foreign material drawer, and the secondary filter unit can perform secondary filtration on sludge and sewage, thereby more quickly separating sludge in the sewage. With the heating device and the exhaust device, toxic gases in the sewage are effectivelydischarged. The equipment of the invention has a simple structure and is low-cost.

Owner:芜湖通全科技有限公司

Medical sewage treatment and impurity separation device

The invention discloses a medical sewage treatment and impurity separation device. The medical sewage treatment and impurity separation device comprises a pipeline inlet, a main separation box and a connection plate, wherein the pipeline inlet is arranged at the top end of a communication pipeline; a motor and an impurity collection box are arranged at the left side and lower side of a fixed framerespectively; a stopping net is arranged on the outer surface of a connection shaft; a first-layer separation box and a second-layer separation box are distributed in the main separation box; the first-layer separation box and the second-layer separation box are connected through a baffle plate; a first filtering plate and a first connection rod are fixed at the right side and on the upper surface of the connection plate respectively; gauze meshes are distributed at the inner sides of the first filtering plate and a second filtering plate; the first connection rod and a second connection rodare fixed at the top end of the main separation box through transverse rods. According to the medical sewage treatment and impurity separation device disclosed by the invention, the stopping net witha rotary structure is arranged in the communication pipeline; when sewage passes through the communication pipeline, relatively large impurities are rotatably driven into the impurity collection box by rotating the stopping net.

Owner:长沙雾谷智能科技有限公司

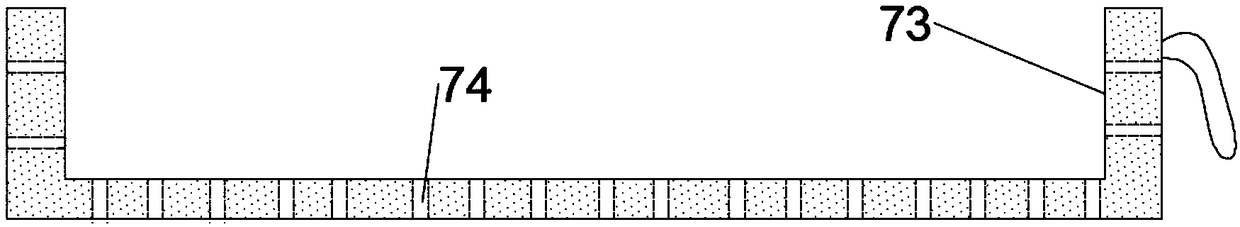

Method and special device for separating fly maggots from substrates

The invention relates to the field of fly maggot feeding devices and methods, in particular to a method and a special device for separating fly maggots from substrates. The special device for separating the fly maggots from the substrates comprises a crude substrate separator and a fine substrate separator, wherein the crude substrate separator comprises a crude substrate separation net, a rack, a rotary shaft and a power drive mechanism, the crude substrate separation net is of a cylinder structure, the rotary shaft is arranged on the rack and is in transmission connection with the power drive mechanism, and the rotary shaft passes through the interior of the crude substrate separation net to be connected with the crude substrate separation net through a connecting rod; the size of each mesh of the fine substrate separation net is smaller than the length of a straightened fly maggot. According to the method and the special device for separating the fly maggots from the substrates, fly maggots are in a straightening state when turning over in the separation net, so that the lengths of the fly maggots are basically consistent; that substrates of larger grains and substrates of smaller grains are completely separated through different sizes of the meshes of the separation nets is ensured, so that the integral separation is more complete, and the separation rate is high.

Owner:ZHEJIANG HENGYI BIOLOGICAL TECH CO LTD

Purifying method of 2, 3-dichloropyridine

ActiveCN103193703AComplete separationTo achieve the separation effectOrganic chemistryMethanolLiquid phase

The invention discloses a purifying method of 2,3-dichloropyridine. The purifying method comprises the following steps of: mixing a crude 2, 3-dichloropyridine product, a treating agent and an organic solvent to form a liquid phase reaction system, and enabling the liquid phase reaction system to react at the temperature of 20-90DEG C; extracting a sample from the liquid phase reaction system, detecting the sample by using liquid chromatography under the detection conditions that the wavelength is 235nm and the volume ratio of methanol to water in a moving phase is 70:30, and when the content of 2,3,6-trichloropyridine in the sample is less than 0.5 percent, ending the reaction, or continuously reacting; and preparing a product solution after the reaction is ended, then cooling the product solution so that a crystallized product is sufficiently separated out, carrying out solid-liquid separation to obtain the crystallized product, adding the crystallized product to water so as to form a dispersed system, adjusting the pH of the dispersed system to be 1-4 by using inorganic acid, and filtering the dispersed system to obtain solid matters, namely the purified 2, 3-dichloropyridine.

Owner:SHANDONG TIANXIN CHEM

Cotton boll shucker

InactiveCN102477589ASimple structureComplete separationVegetable fibre separation from seedsFibre cleaning/opening by toothed membersMechanical engineeringUltimate tensile strength

The invention provides a cotton boll shucker, wherein a feed opening and a shucking chamber in a machine body are communicated, and a dash roller is arranged in the shucking chamber; a cotton holding roller is positioned above the dash roller, and a brush roller and a comb roller are arranged on two sides of the cotton holding roller; the lower end of the comb roller is communicated with the shucking chamber; and a cotton outlet is arranged at the top edge of the shucking chamber and below the brush roller. By adopting the cotton boll shucker, shucking and cotton collection are performed nearly at the same time, so that as long as shucking is finished, the obtained cotton is collected; and within a short period of process, each cotton boll can be repeatedly shucked and repeatedly subjected to cotton collection, until the cotton is completely shucked and collected. The cotton boll shucker disclosed by the invention has the advantages of simple structure, convenience in operation, high efficiency, low energy consumption, improved labor efficiency, and lowed work intensity of personnel.

Owner:襄阳市丰禾田农机有限公司

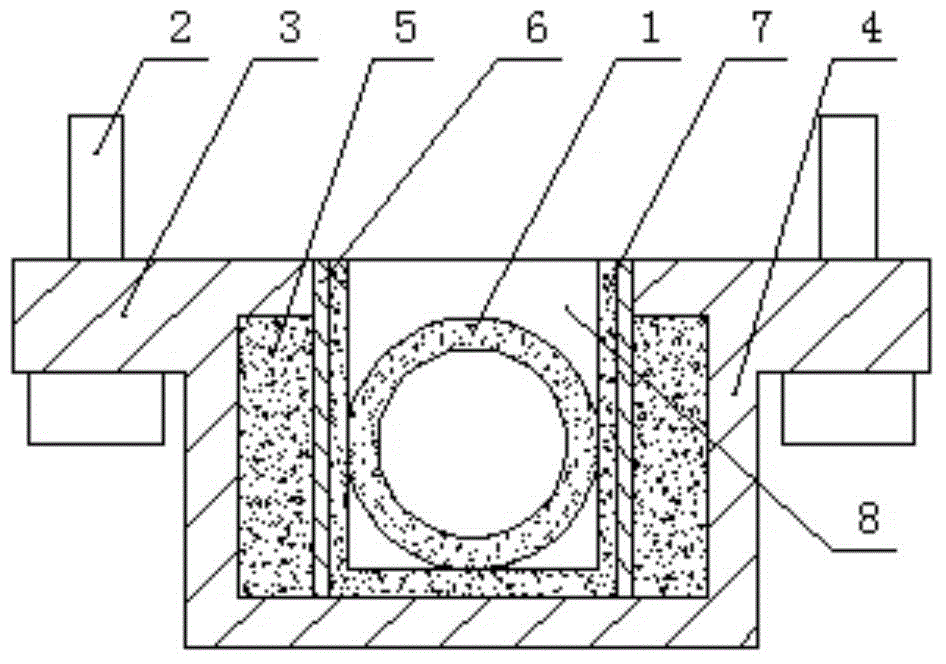

Automobile fuel-saving device capable of reducing fuel consumption through magnetic fields

InactiveCN104421059AComplete separationReduce noiseCombustion-air/fuel-air treatmentMachines/enginesExhaust gasFuel oil

The invention relates to an automobile fuel-saving device capable of reducing fuel consumption through magnetic fields. The automobile fuel-saving device comprises a base and strong magnets. A groove is machined in the middle of the base, and an automobile fuel pipe is embedded into the groove; each of the positions, located on the two sides of the groove, of the side walls of the base is provided with a cover plate; the strong magnets are embedded into the positions beside the cover plates and in the base; and a plurality of fixing bolts are arranged at the upper ends of the two sides of the base. According to the invention, the groove where the fuel pipe is embedded is formed in the base, and each of the surfaces of the two sides of the groove is provided with one cover plate; the position, beside each cover plate, inside the base is provided with one strong magnet in an embedding manner; the opposite end faces of the two strong magnets are opposite in polarity, that is, the polarity of one end face is the N pole, and the polarity of the other end face is the S pole; and the cover plates and the bottom face of the groove are each provided with an elastic layer. The strong magnetic fields between the two strong magnets change the arrangement structure of fuel molecules in the fuel pipe, and therefore agglomerate fuel and gas molecules are separated more thoroughly, so that the noise of an engine is reduced by about 10 decibels, and the fuel oil is saved by 8 percent. Tail gas emissions are reduced, and the device is safe and reliable and does not damage a fuel path and a circuit of an original automobile.

Owner:TIANJIN DAXINSHENG FUEL ECONOMIZING EQUIP TECH CO LTD

Rice processing method capable of reducing energy consumption

InactiveCN112844517AComplete separationReduce rice milling energy consumptionGrain huskingGrain polishingBroken riceAgricultural engineering

The invention discloses a rice processing method capable of reducing energy consumption. The rice processing method capable of reducing the energy consumption is characterized by sequentially comprising the following steps: (1) cleaning: specifically, screening to remove blighted grains, magnetically separating to remove magnetic impurities in unhulled rice, and removing stones; (2) hulling the rice: hulling the rice through a rice huller, and separating rice and brown rice after rice hulling; (3) milling the rice: milling the brown rice into white rice through a rice milling machine, and atomizing through a cellulose aqueous solution before rice milling; and (4) performing post-treatment: wiping the rice, cooling the rice, grading the white rice and packaging. According to the rice processing method capable of reducing the energy consumption, the amount of broken rice and left brown rice in the rice milling process can be reduced, and the rice milling energy consumption can also be reduced.

Owner:湖南金泰米业有限公司

Husk and seed separating device of corn husker

The invention discloses a husk and seed separating device of a corn husker and relates to a corn husker. The husk and seed separating device comprises a power transmission mechanism and a stirring barrel, wherein a pipe orifice is arranged in a barrel wall at the position of a stirring barrel outlet; and the pipe orifice is connected with an air inlet of an exhaust fan. Furthermore, a plurality of seed leaking holes are arranged in the barrel wall of the lower part at the position of a stirring barrel outlet and are used for downwards leaking corn seeds. The pipe orifice is arranged above the barrel wall at the position of the stirring barrel outlet; and relative to the pipe orifice, the seed leaking holes are arranged under the pipe orifice. The husk and seed separating device of the corn husker has the beneficial effects that: with the arrangement of an air suction device above the outlet of the husker and the seed leaking hole under the outlet, on one side, husks husked by the corn husker are sucked, on the other side, the corn seeds are downwards leaked, so that the corn husks and the corn seeds are separated. In particular, because the corn husks run upwards, the corn seeds wrapped in the corn husks drop down under the action of gravity and are collected by the leakage of the seed leaking holes, so that the corn husks and the corn seeds are thoroughly separated.

Owner:张希槐

Rice ultra-separation impurity removing device

InactiveCN103658029AComplete separationImprove work efficiencySievingScreeningImpurityPulp and paper industry

The invention relates to a rice ultra-separation impurity removing device which comprises a rack. A feeding port is formed in the top of the rack, a screening box is lifted below the feeding port, an impurity discharging port is formed in the left end portion of the screening box, a screening plate is arranged at the bottom of the screening box, the two lateral portions of the screening box are hinged to a swinging rod, a cardan joint is hinged to the end portion of the swinging rod and lifted at the top of the rack, and the top of the screening box is connected with an eccentric rotating mechanism fixed on the rack. The rice ultra-separation impurity removing device has the advantages of being thorough in separation, high in working efficiency and the like. The eccentric rotating mechanism is used, the screening plate performs the 360-degree full-direction oscillating motion, impurities in rice can be sufficiently removed, leaves and large stone in the rice can be completely removed, the rice ultra-separation impurity removing device is small in size and is used in a rice processing device, and the height of the rice ultra-separation impurity removing device can be greatly reduced.

Owner:HUBEI XIANLIANG MACHINERY

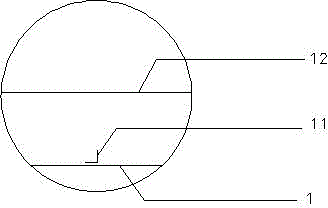

Improved electric grain screening machine

InactiveCN105499118AComplete separationSpeed up screeningSievingScreeningElectric machinerySteel plates

The invention relates to the technical field of agricultural machinery, in particular to an electric machine which can be used for carrying out screening operation on grains. The improved electric grain screening machine comprises a cylindrical machine body made of a stainless steel plate. The improved electric grain screening machine is characterized in that the top of the machine body is opened for pouring to-be-screened grains, wherein the middle of the bottom of the machine body is provided with a circular discharge hole; the side edge of the discharge hole is provided with a baffle plate; the baffle plate is connected to the bottom of the machine body through a rotary shaft; the middle position of the machine body is provided with a screen; the screen is fixed to the inner wall of the machine body through a flexible belt-shaped object; the outer side of the machine body is further provided with a motor; the rotary shaft of the motor is connected to the middle position of the bottom of the screen through a transmission rod; the inner wall of the position, below the screen, of the machine body is provided with a fan; and the position, corresponding to the machine body, at an air outlet of the fan is provided with a chaff outlet. The improved electric grain screening machine adopts the motor for driving the screen on the inner part of the screening machine to work through the transmission rod, so that the grains and the crushed chaff are separated more completely, and therefore, the screening speed is greatly increased, and the labor cost is reduced.

Owner:占才明

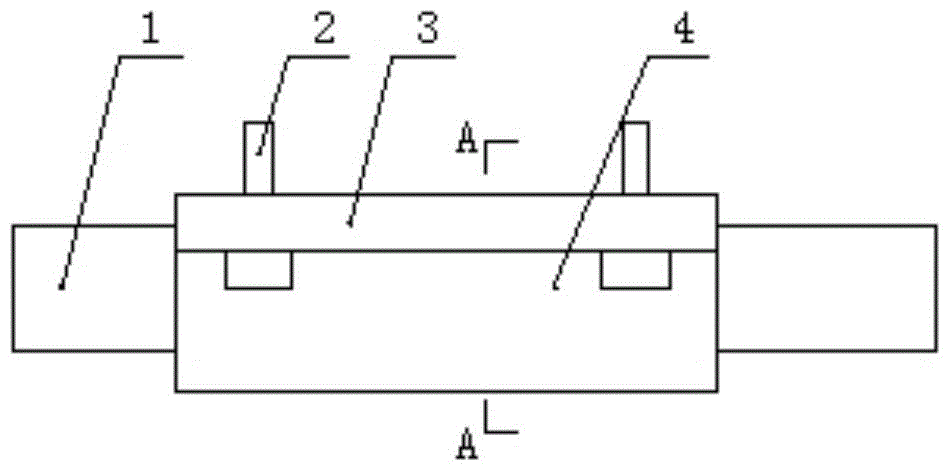

Iron removal device for acid-containing copper sulfate solution

PendingCN114180688AHigh recovery rateComplete separationWater contaminantsDispersed particle separationPerfluorosulfonic acidWater treatment

The invention belongs to the technical field of water treatment, and particularly relates to a device for removing iron in acid-containing copper sulfate. The device comprises a positive electrode plate and a negative electrode plate, wherein an anode porous plate and a cathode porous plate are respectively placed on two sides of an iron removal chamber; a perfluorosulfonic acid positive membrane, a positive electrode plate, an electrode chamber water distribution net, a water distribution plate and a locking device are sequentially arranged outside the anode porous plate; a bipolar membrane, a negative electrode plate, an electrode chamber water distribution net, a water distribution plate and a locking device are sequentially arranged outside the cathode porous plate; the locking device fixes the whole device through the water distribution plates on the two outer sides and is in a cuboid shape. The method has the advantages that the membrane separation method is high in recovery rate, thorough in separation, simple to operate, high in automation degree and good in working environment, economic benefits can be brought, better environmental benefits are achieved, the use amount of alkali is saved while acid is recovered, the sludge output is greatly reduced, and the application prospect is wide.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

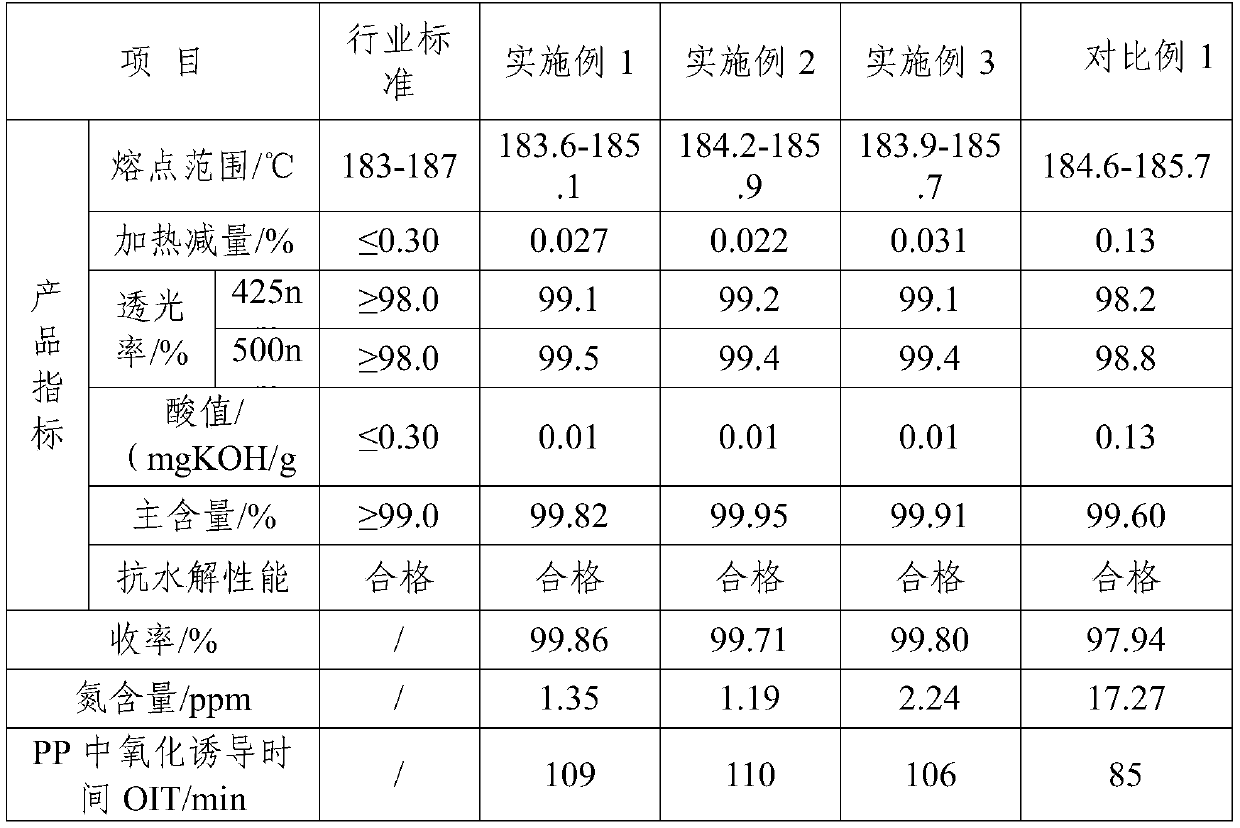

Preparation method of antioxidant 168

ActiveCN110590834ASimple process operationComplete separationGroup 5/15 element organic compoundsSolventChemistry

The invention belongs to the field of preparation of antioxidants, and particularly relates to a preparation method of an antioxidant 168. The specific preparation method comprises the following steps: (1) adding 2,4-di-tert-butylphenol, a solvent and a resin catalyst into a reaction kettle, and carrying out heating while stirring at a constant speed; dropwise adding phosphorus trichloride into the reaction kettle at a constant speed, and after the reaction is finished, adding resin as a neutralizer to neutralize the reaction solution to be neutral; (2) filtering the reaction solution obtainedin the step (1) to filtering out solid resin, and treating the filtrate to obtain an antioxidant 168 product; and (3) directly using one part of the resin filtered out in the step (2) as a catalyst for a next batch of synthetic reaction, and recycling the rest resin to be used as a neutralizer. The catalyst used in the method can be simply, conveniently, quickly and thoroughly separated from a system after the reaction is finished, can be continuously and mechanically used, and does not generate solid wastes; the product quality of the antioxidant 168 can effectively improved; and environmental pollution is reduced.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

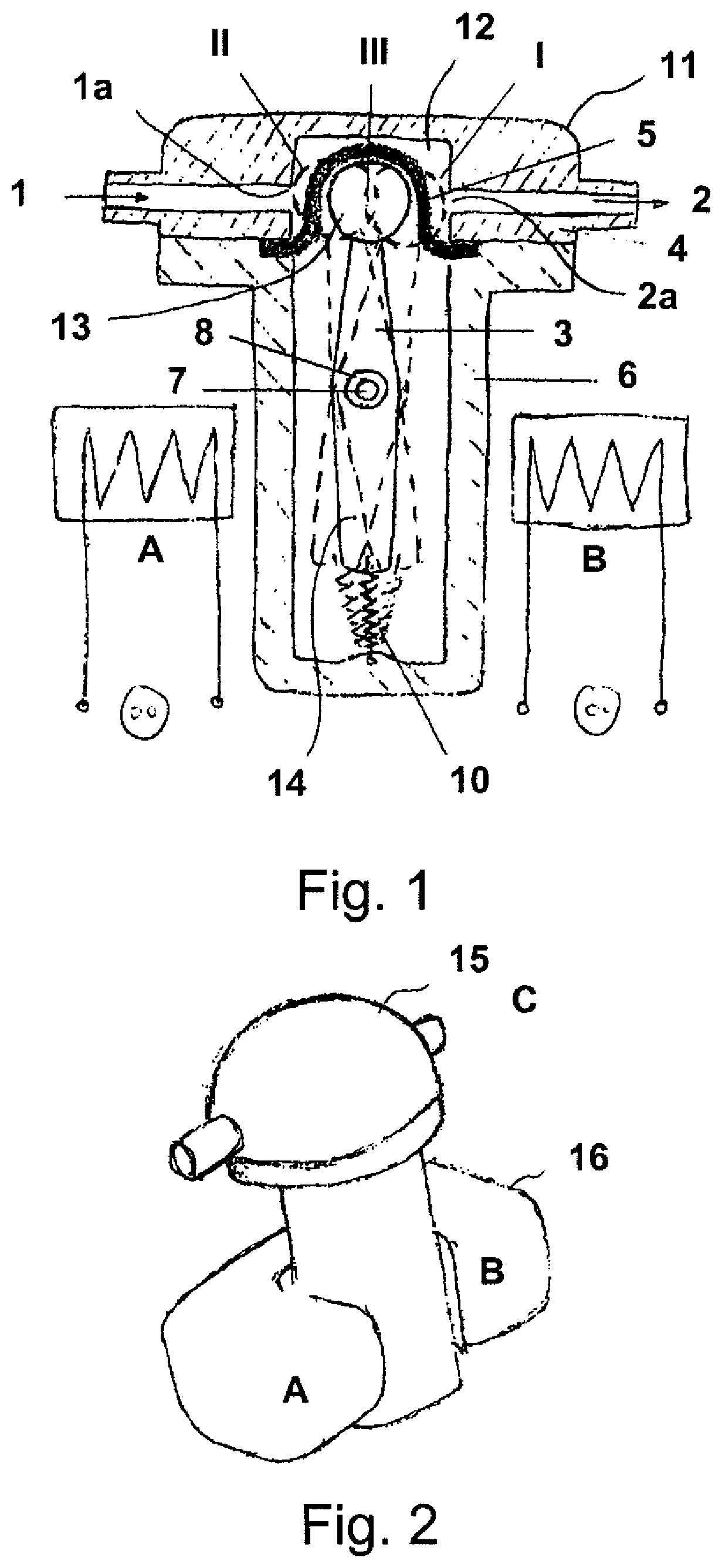

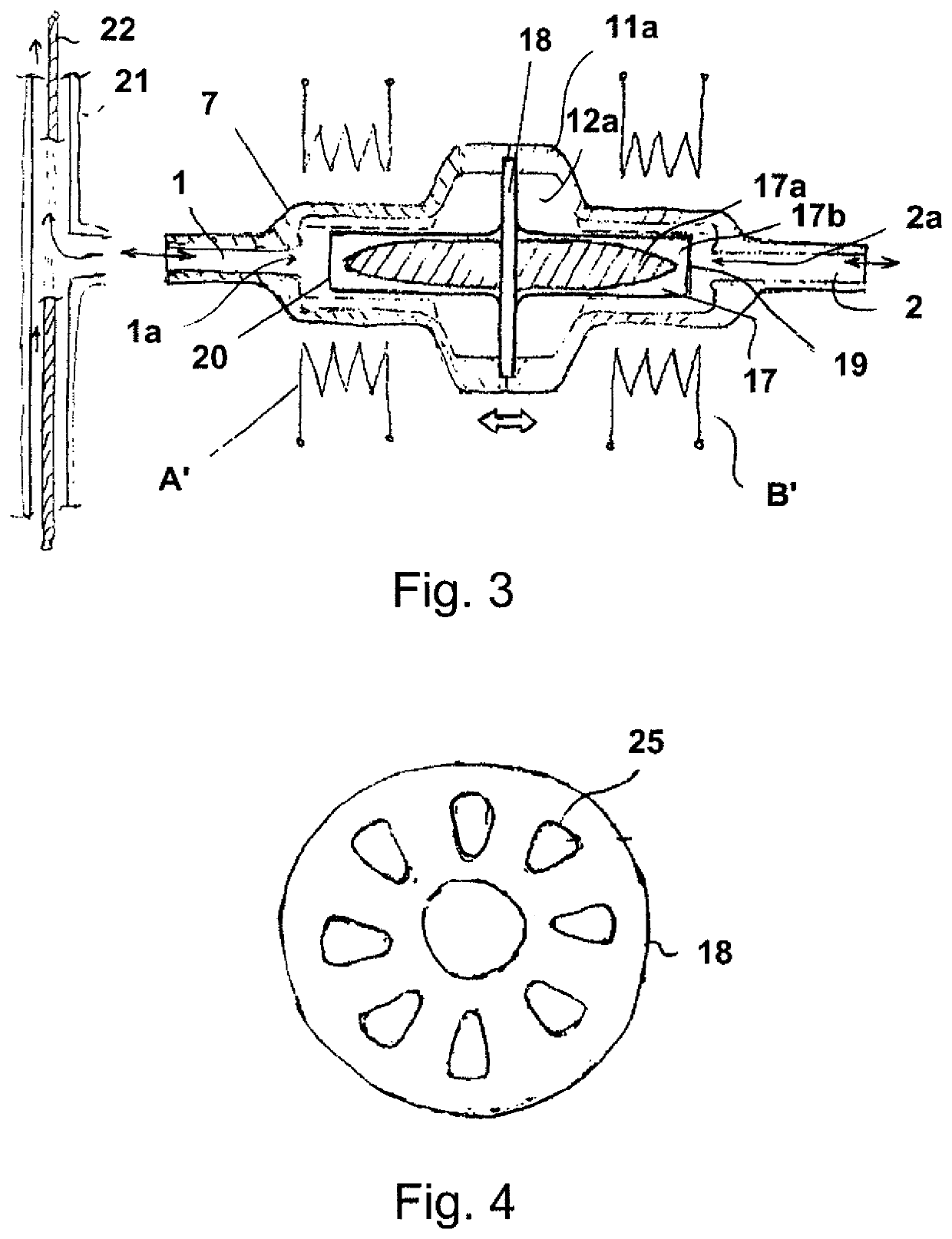

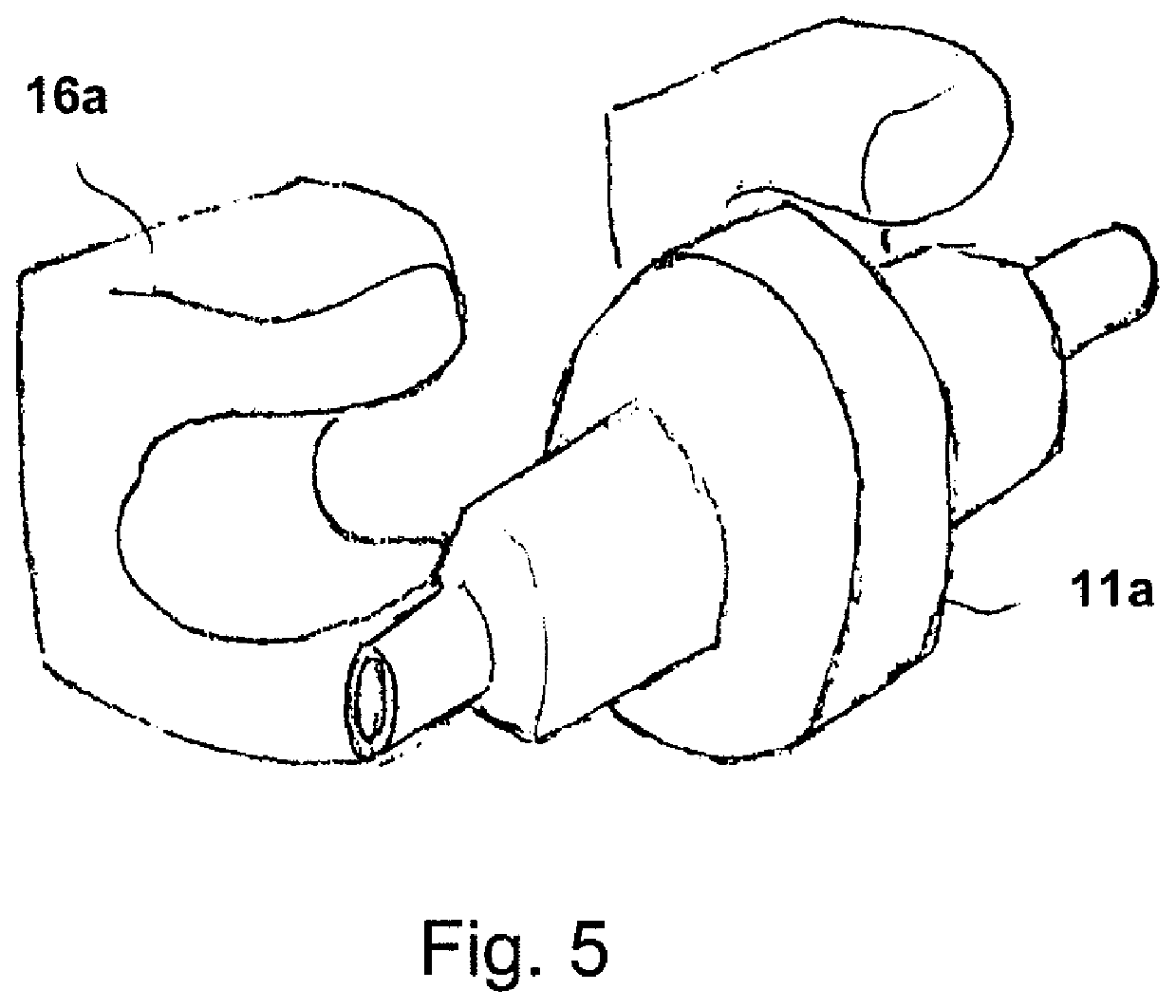

Catheter device, comprising a valve for controlling a fluid flow through a catheter

ActiveUS11045641B2Complete separationPrecise processMulti-lumen catheterControl devicesEngineeringVALVE PORT

The invention relates to a catheter device (100) comprising a catheter (68) for insertion into a living being and at least one lumen (69, 70, 74, 79) for guiding a fluid flow within a section of the catheter device, and comprising a valve for controlling a fluid flow, in particular through a catheter, having a valve control chamber (12, 12a), into which an inlet opening (1a) of an inlet channel (1) and an outlet opening (2a) of an outlet channel (2) open, and further having a closure element (5, 13, 17) which can be moved in the valve control chamber (12, 12a) in a controlled manner and which, in at least a first position (I), closes the outlet opening (2a), in at least a second position (II) closes the inlet opening (1a), and which, in at least a third position (III), keeps open a connecting channel between the inlet opening (1a) and the outlet opening (2a), a valve train (A, A′, B, B′, 3, 14, 18) being provided and optionally moving the closure element (5, 13, 17) to at least the first, second or third position, and the at least one lumen (68, 70, 74, 79) being fluidically connected to the inlet channel or the outlet channel.

Owner:ECP ENTWICKLUNGSGMBH

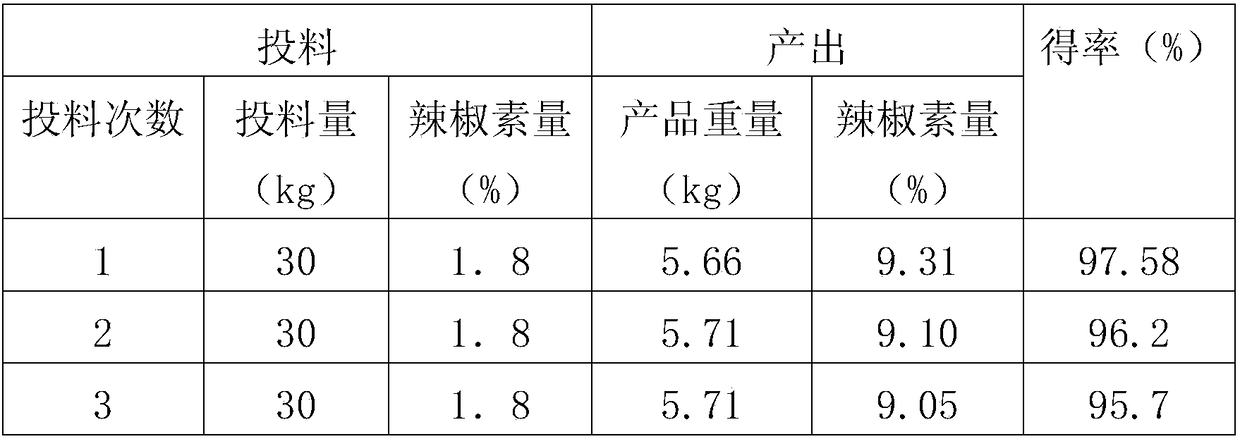

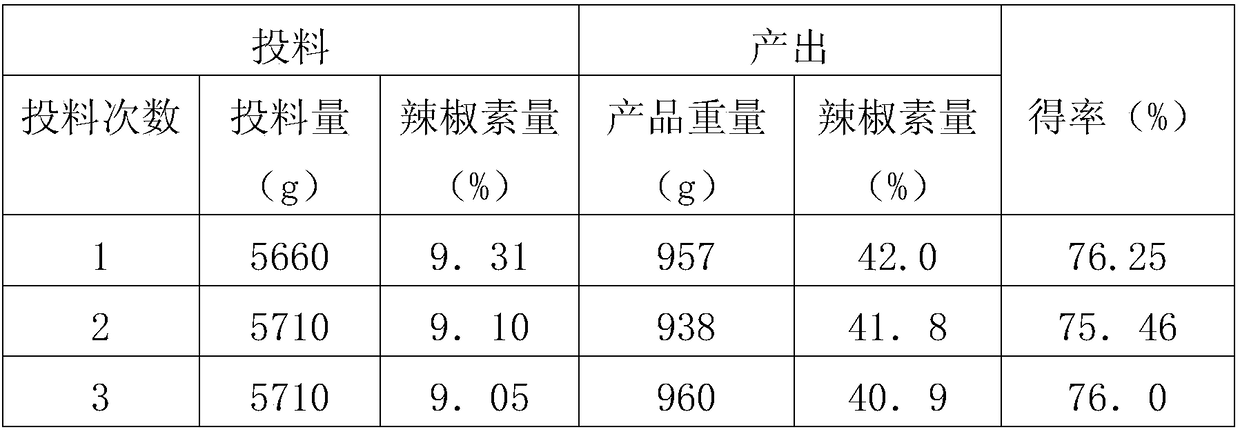

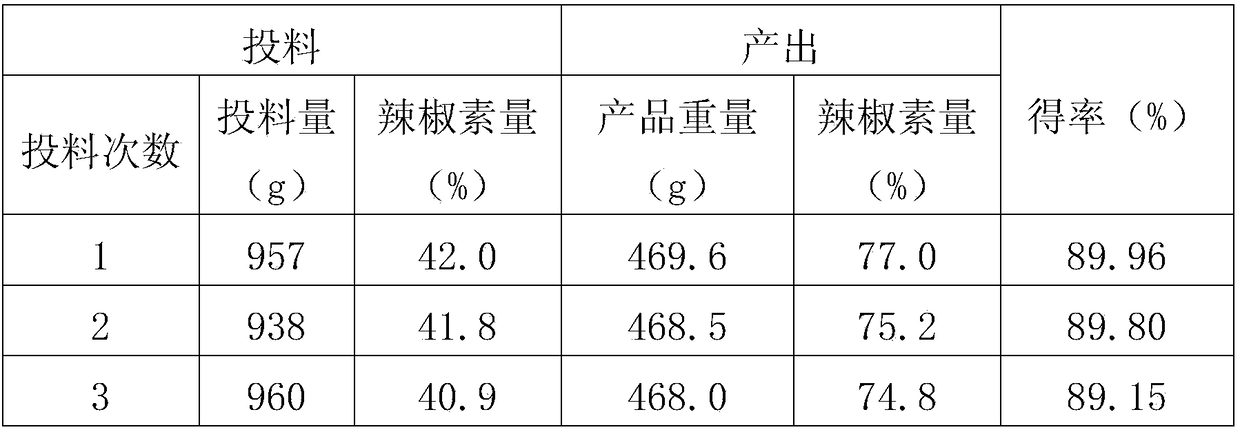

Preparation method of capsaicin

InactiveCN108218737ASimple production processComplete separationCarboxylic acid amide separation/purificationSolventAfter treatment

The invention relates to a process method for preparing a high-pungency degree chili extract or capsaicin from natural chilies, in particular to a method for preparing capsaicin by taking a low- pungency degree chili extract as a basic raw material. The invention adopts the technical scheme that the process method comprises the three process steps of extracting a medium-pungency degree chili extract, preparing an oily capsaicin mixture and preparing high-purity capsaicin; the content of capsanthin in the prepared product is greater than 95 percent; the total yield is greater than 60 percent, the production process is simple, and the separation is complete; the yield of the capsaicin is high, and a byproduct obtained in each step can be used as a chili extract after treatment and is free from wastes; a solvent used in the production process is an ordinary solvent and is easy to recycle and free from environmental pollution; a selected chromatographic medium can be reused after regeneration and is low in production; by adopting the chili extract as the raw material, not only is the added value of the chili extract improved, but also a chili processing industry chain is prolonged.

Owner:刘明明

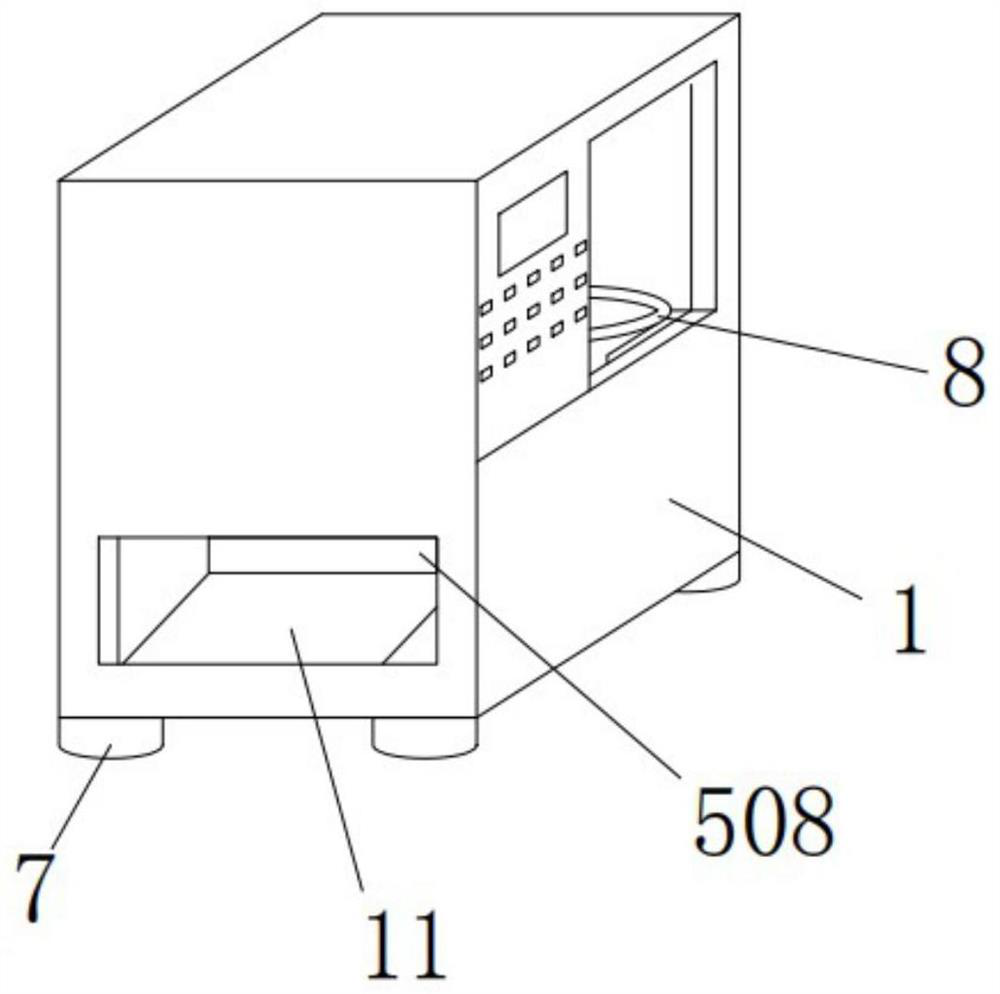

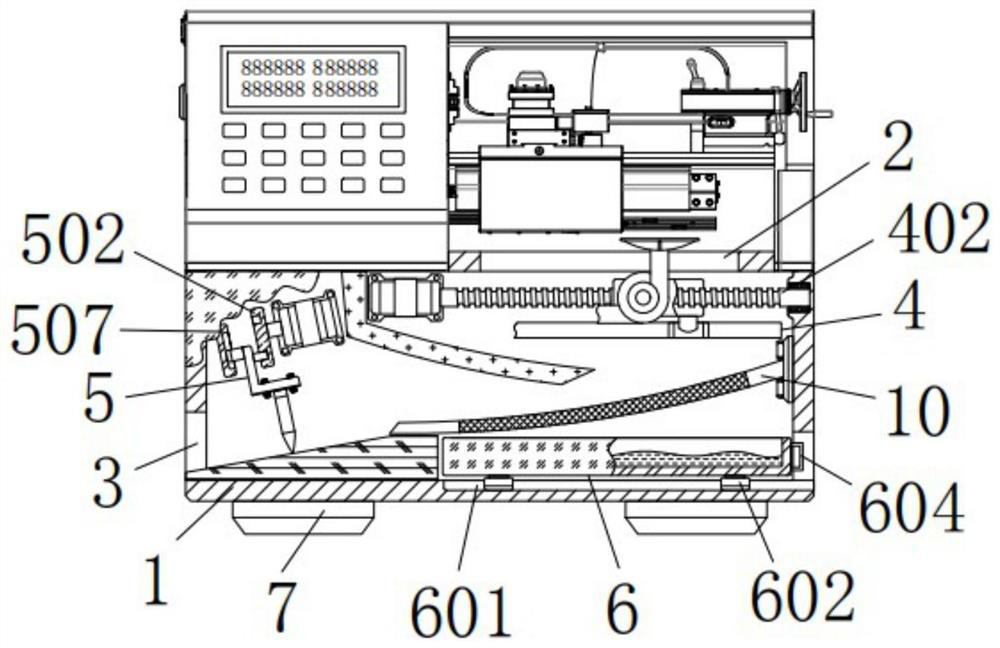

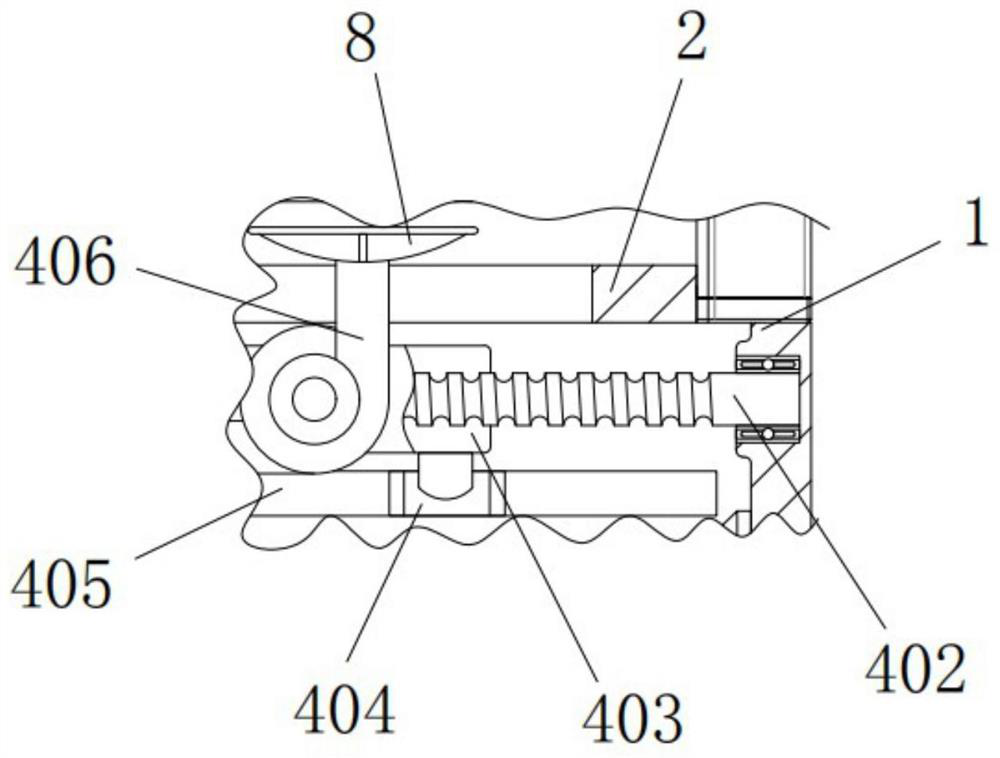

Multi-axis linkage machining center machine

PendingCN113770795AComplete separationScientific and reasonable structureMaintainance and safety accessoriesElectric machineryScrap

The invention discloses a multi-axis linkage machining center machine which comprises a shell, a collecting mechanism is arranged on one side of an inner cavity of the shell, the collecting mechanism comprises a first motor, a screw rod, a threaded sleeve, a sliding block, a sliding groove and a fan, the sliding groove is formed in the rear end face of the inner cavity of the shell, the fan is fixedly arranged on the front end face of the outer wall of the threaded sleeve, and one end of the outer wall of the fan is slidably connected to the inner wall of a groove plate. According to the multi-axis linkage machining center machine, through cooperation of the first motor, the screw rod, the threaded sleeve, the sliding block, the sliding groove, the fan and a collecting cover, when the multi-axis linkage machining center machine is used, through sliding connection of the fan and the groove plate, the threaded sleeve can drive the fan to stably move left and right, and therefore when the fan moves, cooling liquid and scraps can be completely collected through the collecting cover, which solves the problem that the cooling liquid and the scraps need to be manually cleaned by workers after machining is completed due to the fact that the cooling liquid and the scraps are difficult to thoroughly collect.

Owner:马秀兵

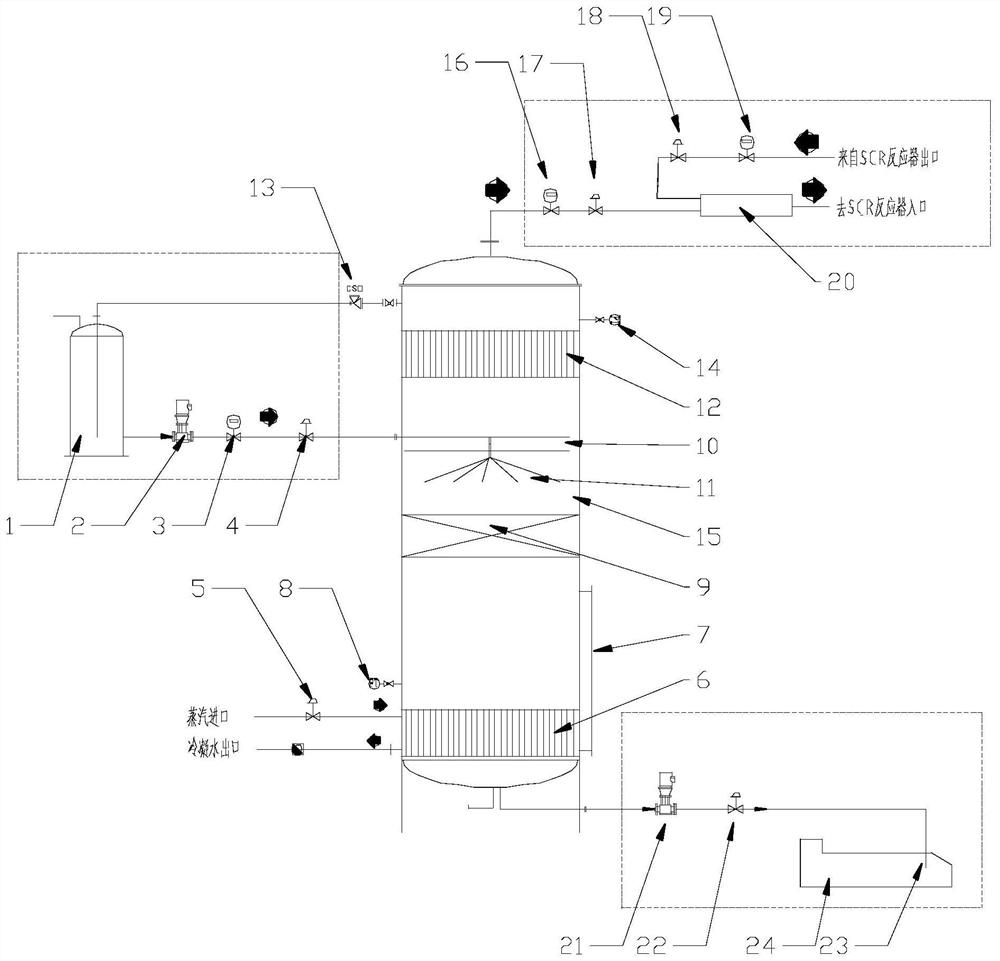

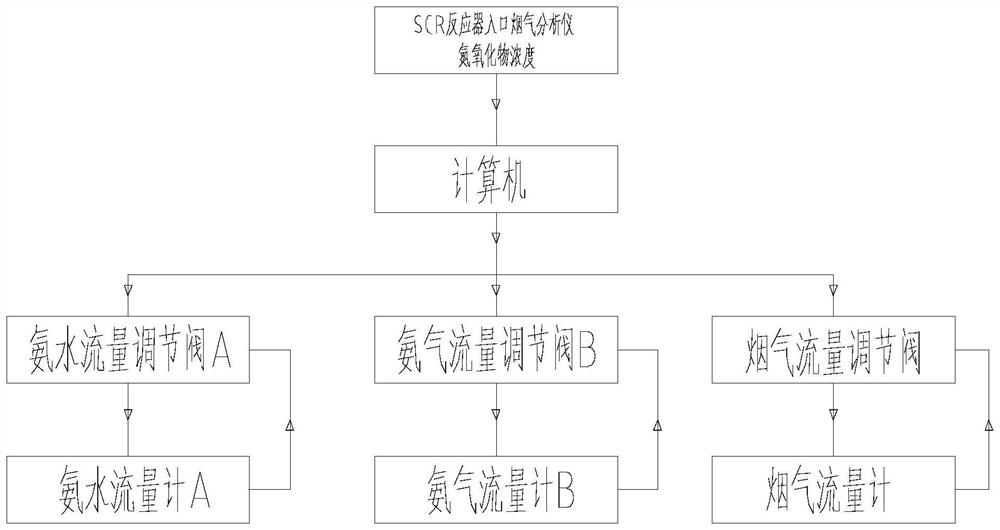

Reducing agent supply system for cement plant low-temperature SCR denitration and control method

PendingCN114669193AReduce heat energy consumptionComplete separationGas treatmentDispersed particle separationCooling coilDemister

The invention belongs to the technical field of flue gas denitration, and particularly relates to a reducing agent supply system for low-temperature SCR denitration of a cement plant and a control method.The ammonia water low-temperature evaporation-self-cooling separation module comprises a gas-liquid separator, a heater is arranged at the bottom of the gas-liquid separator and connected with a steam pipeline, and the steam pipeline is connected with the ammonia water low-temperature evaporation-self-cooling separation module; a steam flow regulating valve is arranged on the steam pipeline, a heat exchange packing layer is arranged in the middle of the gas-liquid separator, a self-cooling coil connected with the ammonia water pipeline is arranged above the heat exchange packing layer, and a demister is arranged at the top of the gas-liquid separator. The invention provides a reducing agent supply system for cement plant low-temperature SCR denitration and a control method. According to the reducing agent supply system and the control method, ammonia water with the mass fraction ranging from 15% to 25% forms high-purity ammonia gas in a low-temperature evaporation-self-cooling mode.

Owner:天津中材工程研究中心有限公司 +1

Flotation agent for extracting silicon carbide micropowder

The present invention proposes a flotation agent for silicon carbide micropowder extraction, the raw materials of which include by weight: 50-80 parts of naphthenic acid, 20-40 parts of glycerin, 5-15 parts of diesel oil, 2-8 parts of xylene, alkane 3-8 parts of sodium succinate sulfonate, 2-9 parts of diethylene glycol benzoate, 1-5 parts of octylphenol polyoxyethylene ether, 5-15 parts of methanol, thiazonitrile 8-12 parts, 1-3 parts of isopropyl ethyl thiocarbamate, 3-6 parts of p-benzoquinone dioxime, 5-9 parts of liquid rosin, 2-5 parts of benzoxazole mercaptan, 1- 4 parts, 30-60 parts of water. The recovery rate of silicon carbide is high and the purity of silicon carbide is high.

Owner:ANHUI ZHENGFENG RENEWABLE RESOURCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com