Reducing agent supply system for cement plant low-temperature SCR denitration and control method

A supply system and reducing agent technology, applied in the field of flue gas denitrification, to achieve good service environment, small reduction in flue gas temperature, and reduced energy consumption of heat sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

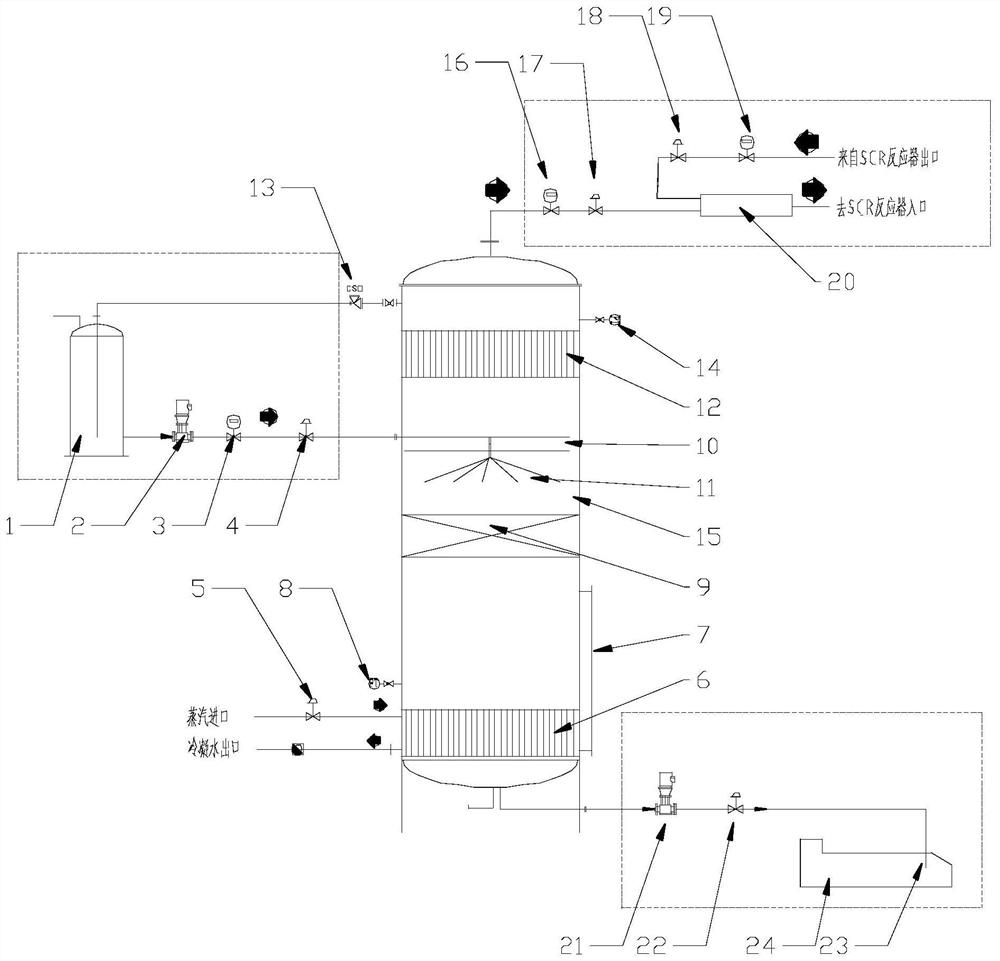

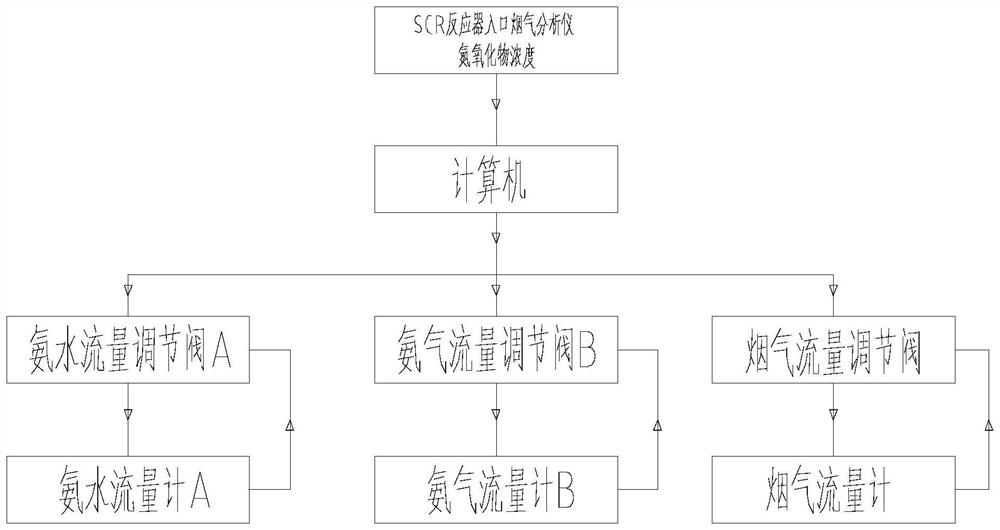

[0042] This embodiment includes an ammonia water storage and delivery module, an ammonia water low-temperature evaporation-self-cooling separation module, an ammonia gas dilution and temperature rise module, a waste water treatment module, and a control module.

[0043] The ammonia water storage and delivery module includes an ammonia water storage tank 1, an ammonia water delivery pump 2, an ammonia water flow meter A3 and an ammonia water flow regulating valve A4.

[0044] The top of the ammonia water storage tank 1 is provided with an ammonia water unloading port and an ammonia gas receiving port with a long pipe to receive the ammonia gas delivered by the ammonia gas safety valve 13. The long pipe is required to go deep into the bottom of the ammonia water storage tank and be lower than the ammonia water level. , The upper part of the ammonia water storage tank is provided with a thermometer and a pressure gauge, the side of the tank is provided with a liquid level gauge, a...

Embodiment 2

[0054] This embodiment includes the following steps:

[0055] S1, the ammonia water with a mass concentration of 15%-25% uses the ammonia water tanker's own pump to enter the ammonia water storage tank 1 through the ammonia water unloading port at the top of the ammonia water storage tank; according to the denitration requirement, the ammonia water in the ammonia water storage tank 1 passes through the ammonia water delivery pump. 2 and the ammonia water flow regulating valve A4 to adjust and control the flow, and the ammonia water whose flow meets the requirements is sent to the middle of the gas-liquid separator 15 .

[0056] S2. The ammonia water sent to the gas-liquid separator 15 is sprayed into the gas-liquid separator 15 through the multi-layer self-cooling coil 10 and the liquid distribution nozzle 11 in the middle. The sprayed ammonia water droplets conduct heat exchange with the ammonia gas evaporated from the bottom of the gas-liquid separator 15 in the heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com