Formaldehyde-free recombined wood integrated material for furniture, and manufacturing method thereof

A manufacturing method and technology of recombining wood, which is applied in the direction of manufacturing tools, joining of wooden veneers, wood processing appliances, etc., can solve the problems of less research and production, and achieve reduced energy consumption of hot pressing, good gluing performance, and reduced aging Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation,

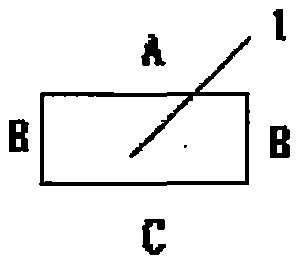

[0034] The material preparation process includes: material selection, rotary cutting, defrosting, drying, dipping, drying, cold pressing, sawing and other processes, which belong to the prior art. Process the recombined wood through the above procedures, and saw it into a chord surface width of 20mm, a diameter surface thickness of 5mm, and a length of 1200mm specification recombined wood unit (such as figure 1 shown).

[0035] (2) Diameter surface sizing of recombined wood units

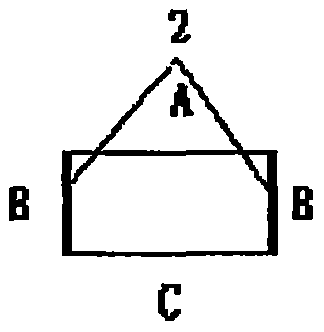

[0036] The diameter surface of the recombined wood unit is sizing, using the glue sizing method, the adhesive used is a water-based polymer isocyanate adhesive, and the sizing amount is controlled at 100 g / m2-105 g / m2 sizing surface layer Apply a quantitative amount of water-based polymer isocyanate adhesive evenly to the radial surface of the recombined wood unit (such as figure 2 shown).

[0037] (3) Dimensional splicing

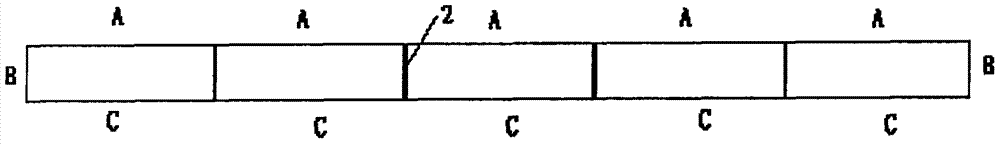

[0038] Splicing the diameter and surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com