Patents

Literature

703results about How to "Fill in the gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

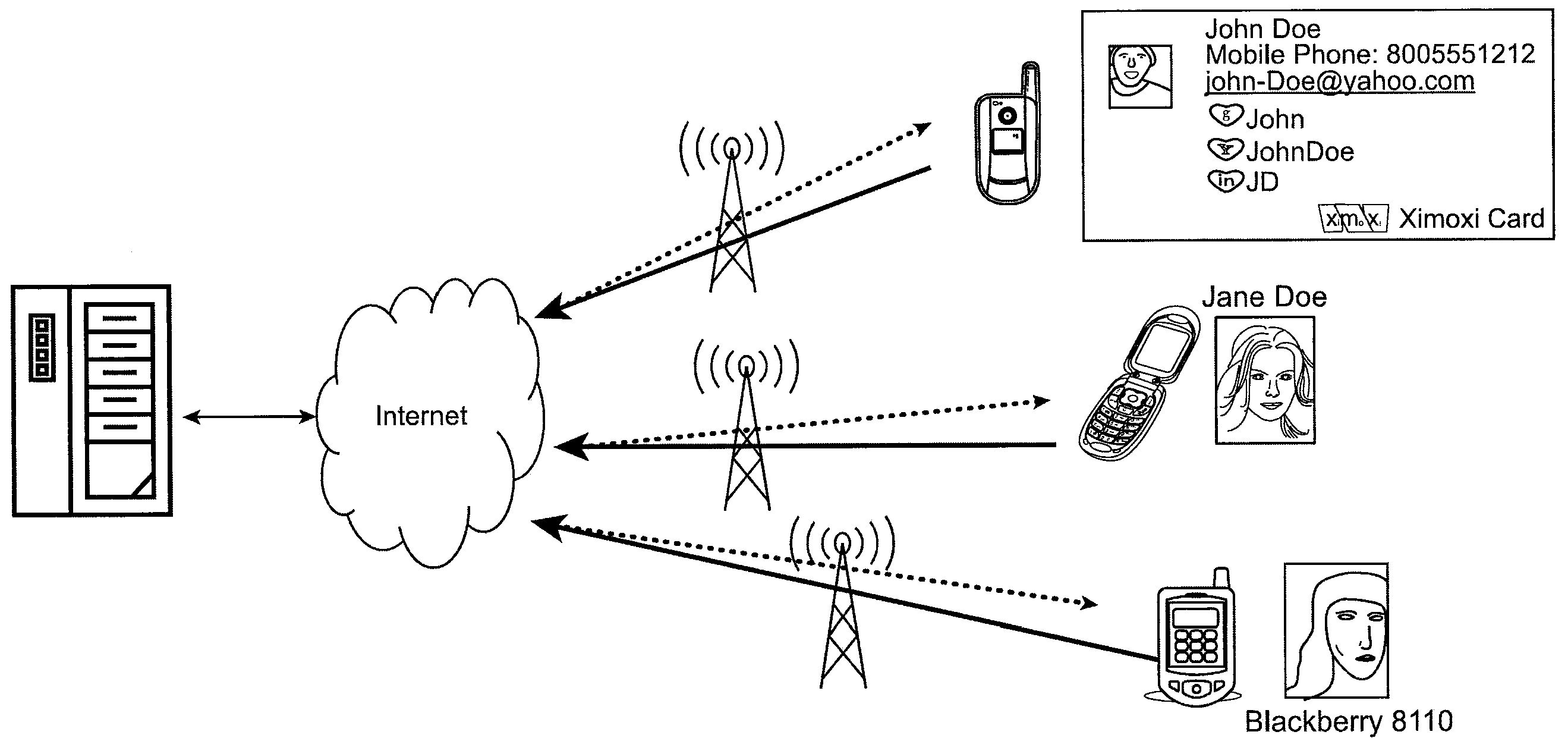

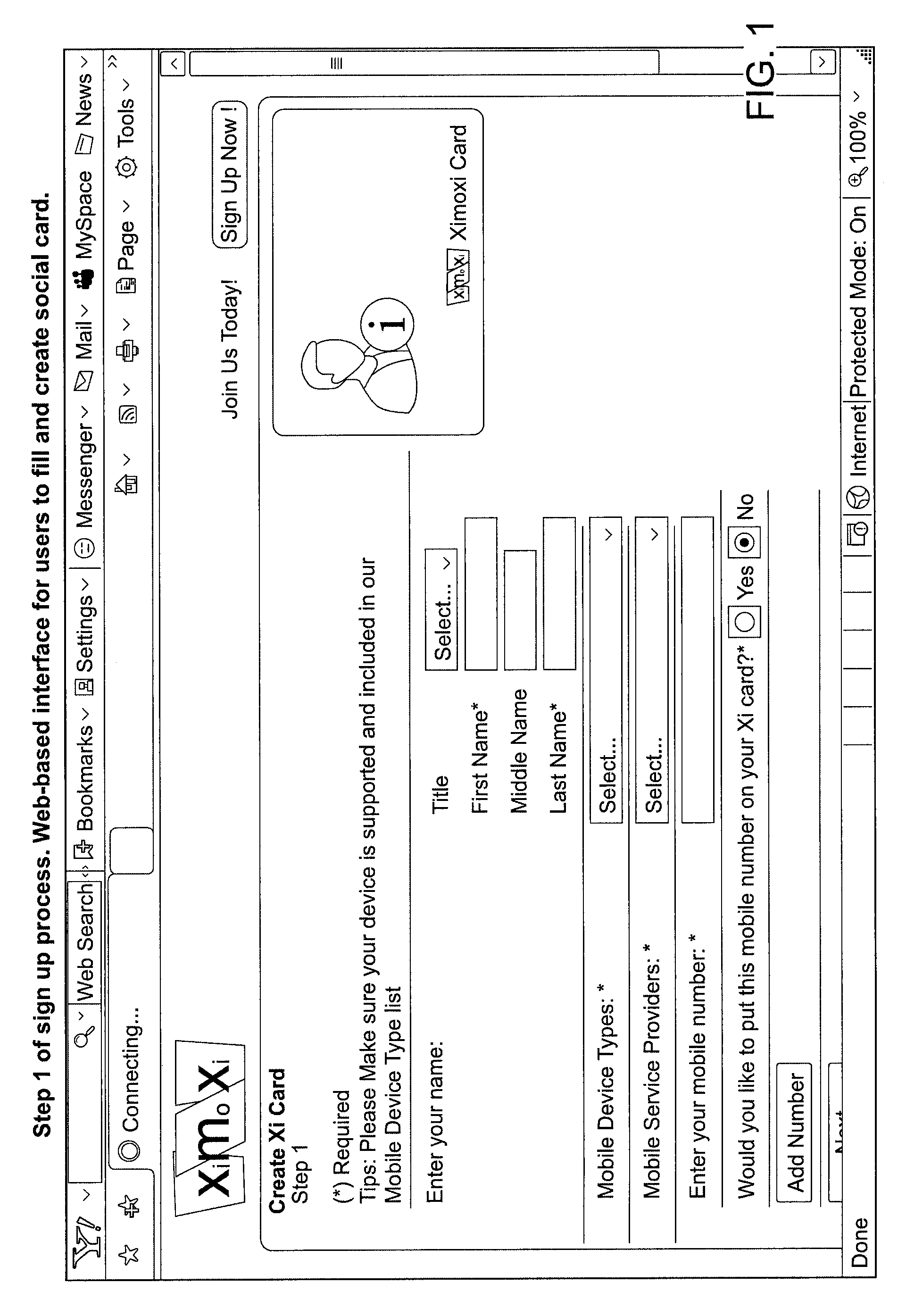

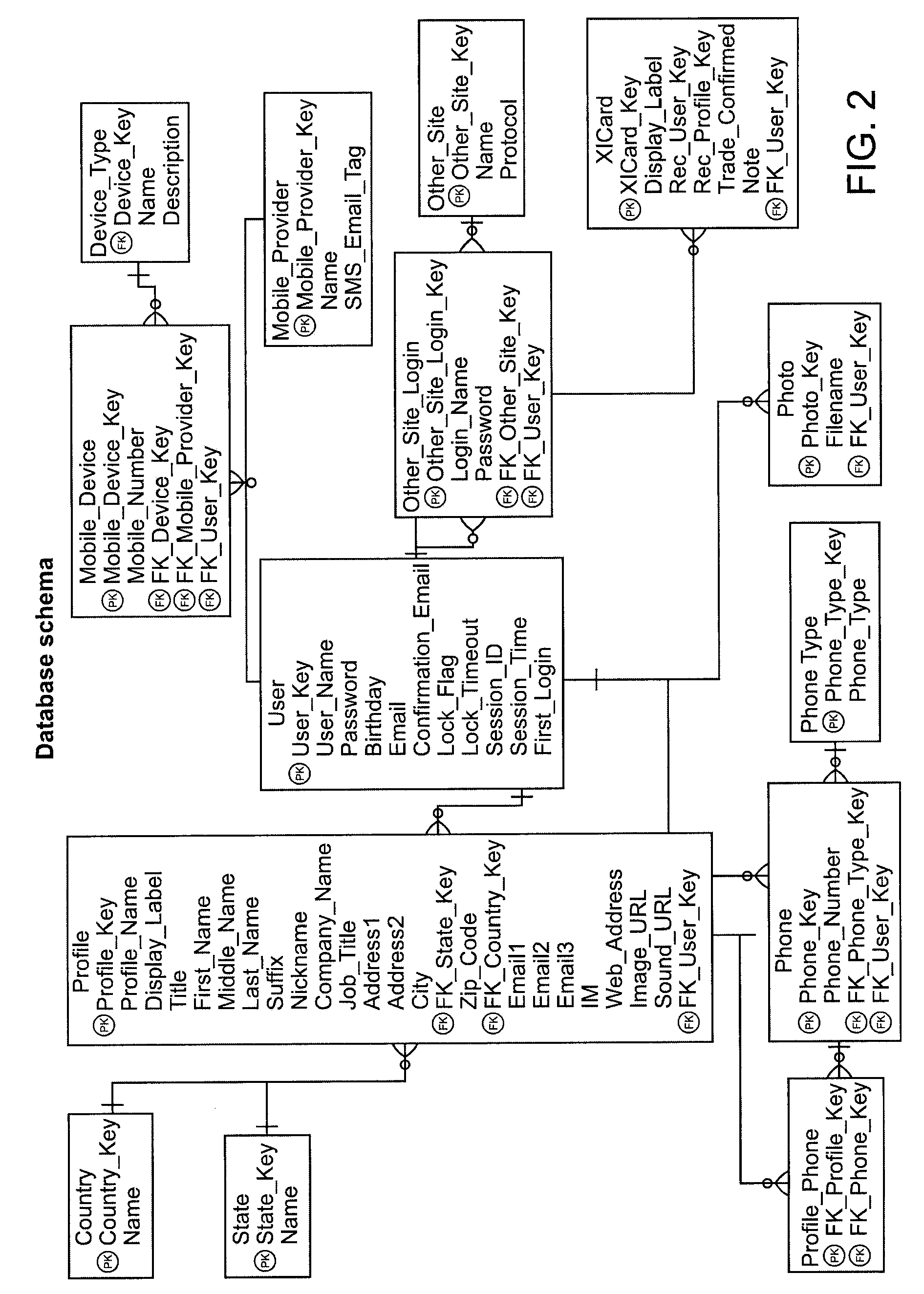

Discovery Of Network Members By Personal Attributes

ActiveUS20090181653A1Fill in the blanksReduce distanceSpecial service for subscribersRadio transmissionBluetoothComputer science

A method and application for mobile phone users provides an ability to discover personal attributes including photo of other individuals in vicinity covered by a short range wireless network, such as Bluetooth or similar signals operating in a wireless free spectrum, such as WiFi. The users can elect to exchange, send or receive contact information with ones that are in the vicinity that includes photos.

Owner:WIRELESS DISCOVERY

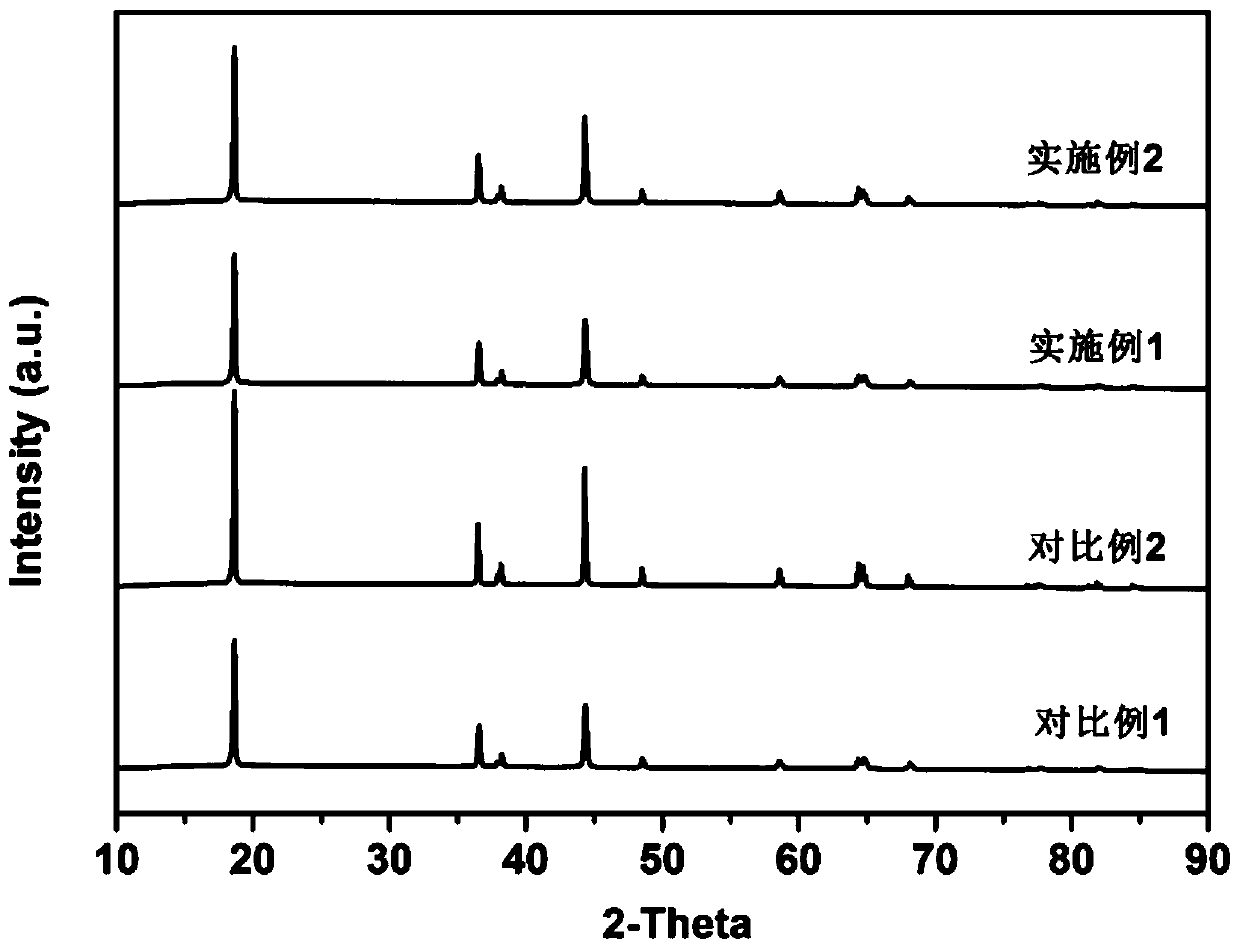

Graded high-nickel ternary anode material, and preparation method and application thereof

InactiveCN109888235AImprove compactionImprove cycle stabilityCell electrodesSecondary cellsSingle crystalMixed materials

The invention discloses a graded high-nickel ternary anode material, and a preparation method and an application thereof. The graded high-nickel ternary anode material is prepared by the following method: 1) mixing a high-nickel polycrystalline precursor with anhydrous LiOH and a doping additive, performing sintering, mixing the obtained product with a coating additive, and performing sintering toobtain a high-nickel polycrystalline material; 2) mixing a ternary monocrystalline silicon precursor with a lithium source and the doping additive, performing sintering, mixing the obtained product with the coating additive, and performing sintering to obtain a ternary monocrystalline silicon material; and 3) mixing the high-nickel polycrystalline material with the ternary monocrystalline siliconmaterial, or mixing the mixed material with the coating additive, and then performing sintering. The invention further discloses an application of the graded high-nickel ternary anode material in lithium batteries. The graded material prepared by the method provided by the invention has higher compaction and cycle stability than the single polycrystalline material, has higher capacity than the single monocrystalline silicon, and the gas production and service life problems of the battery can be effectively improved after the grading modification.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

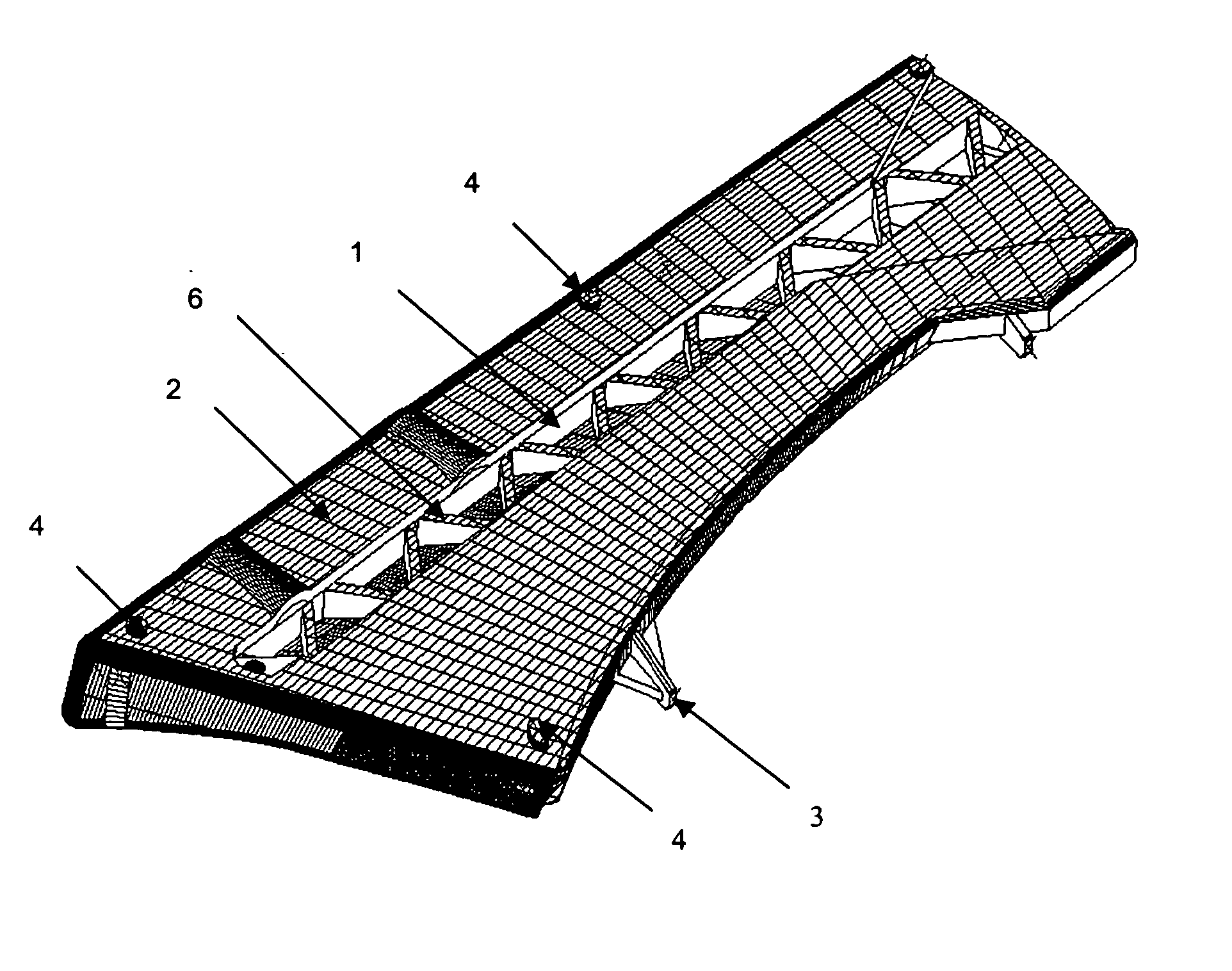

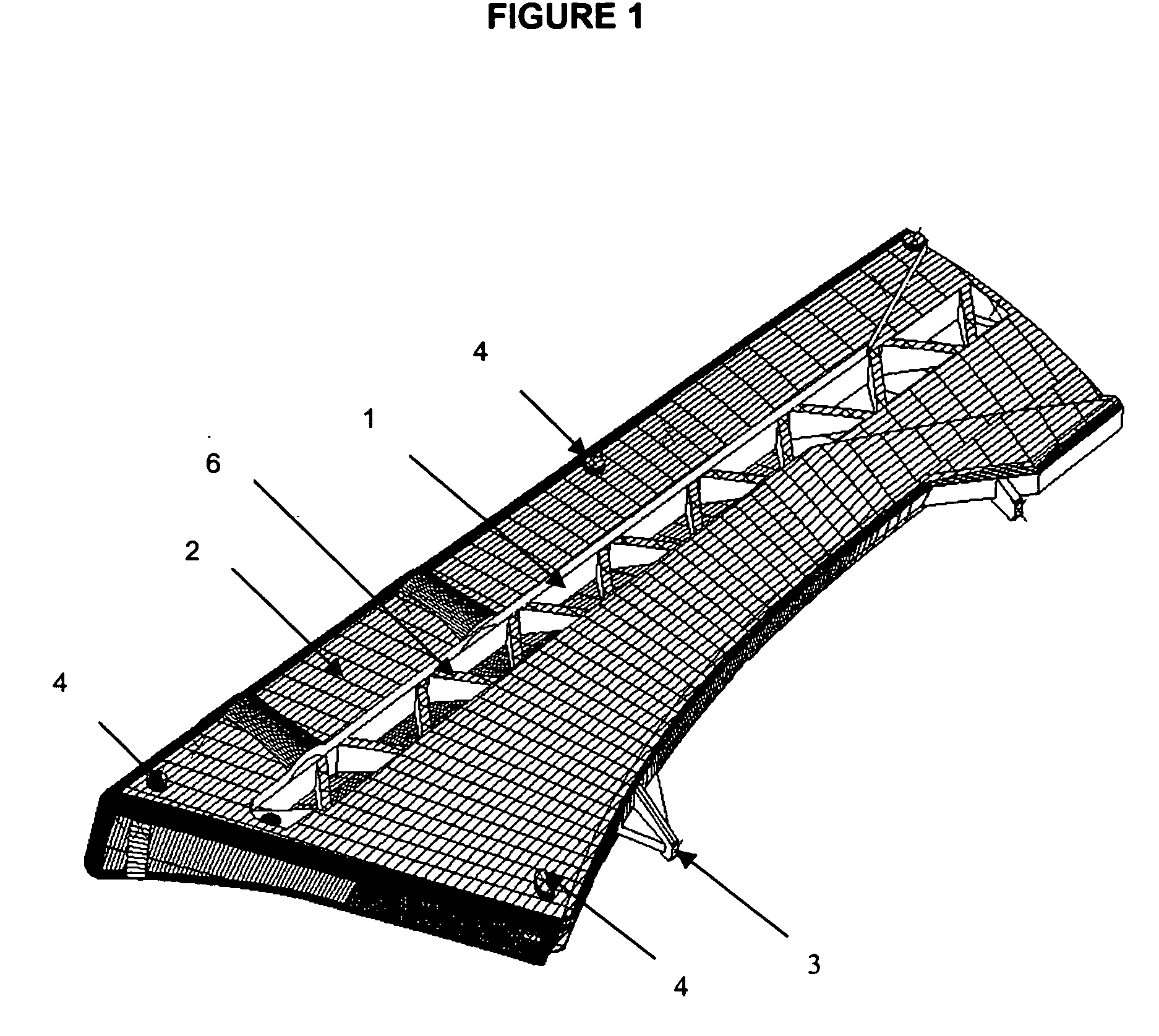

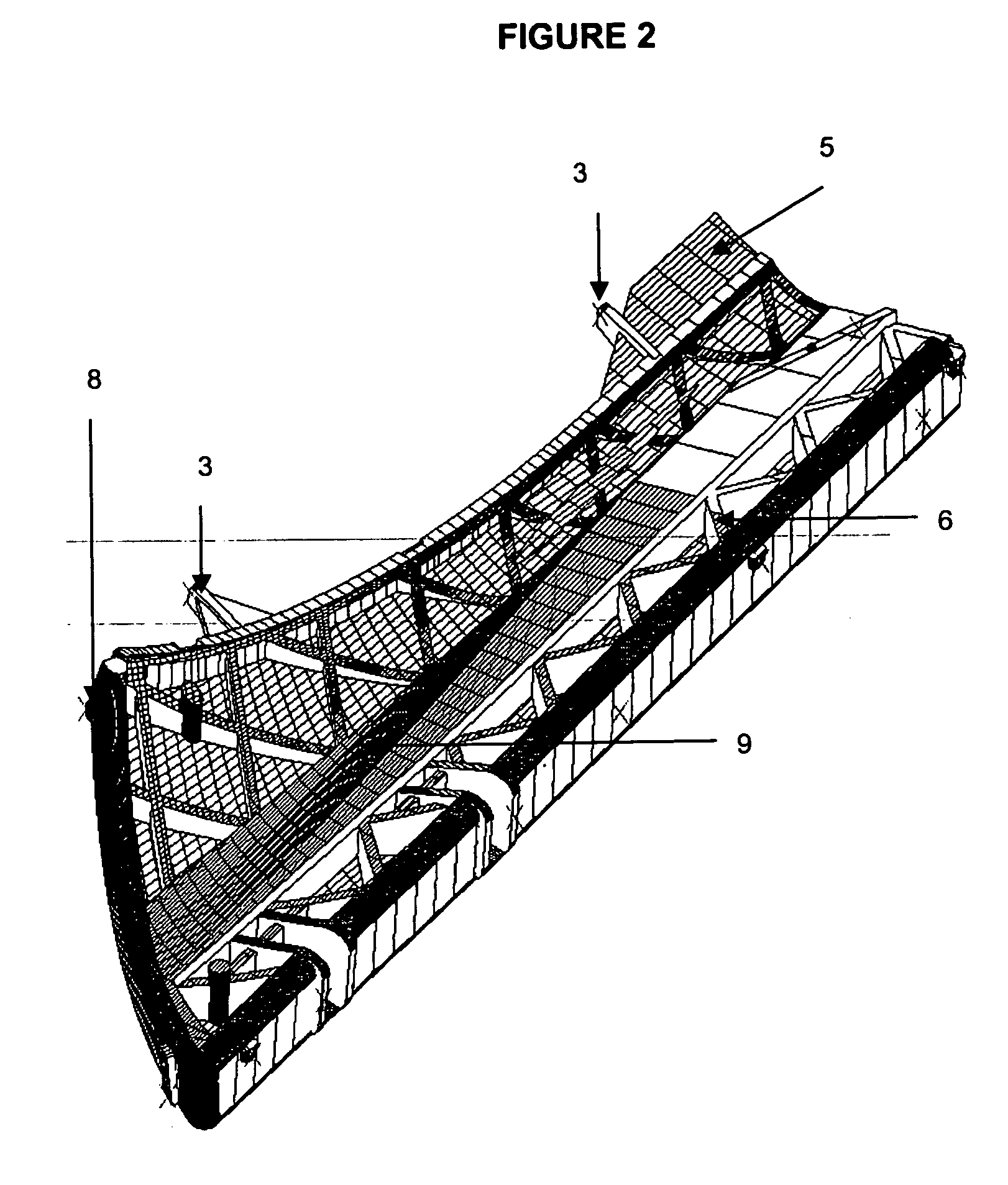

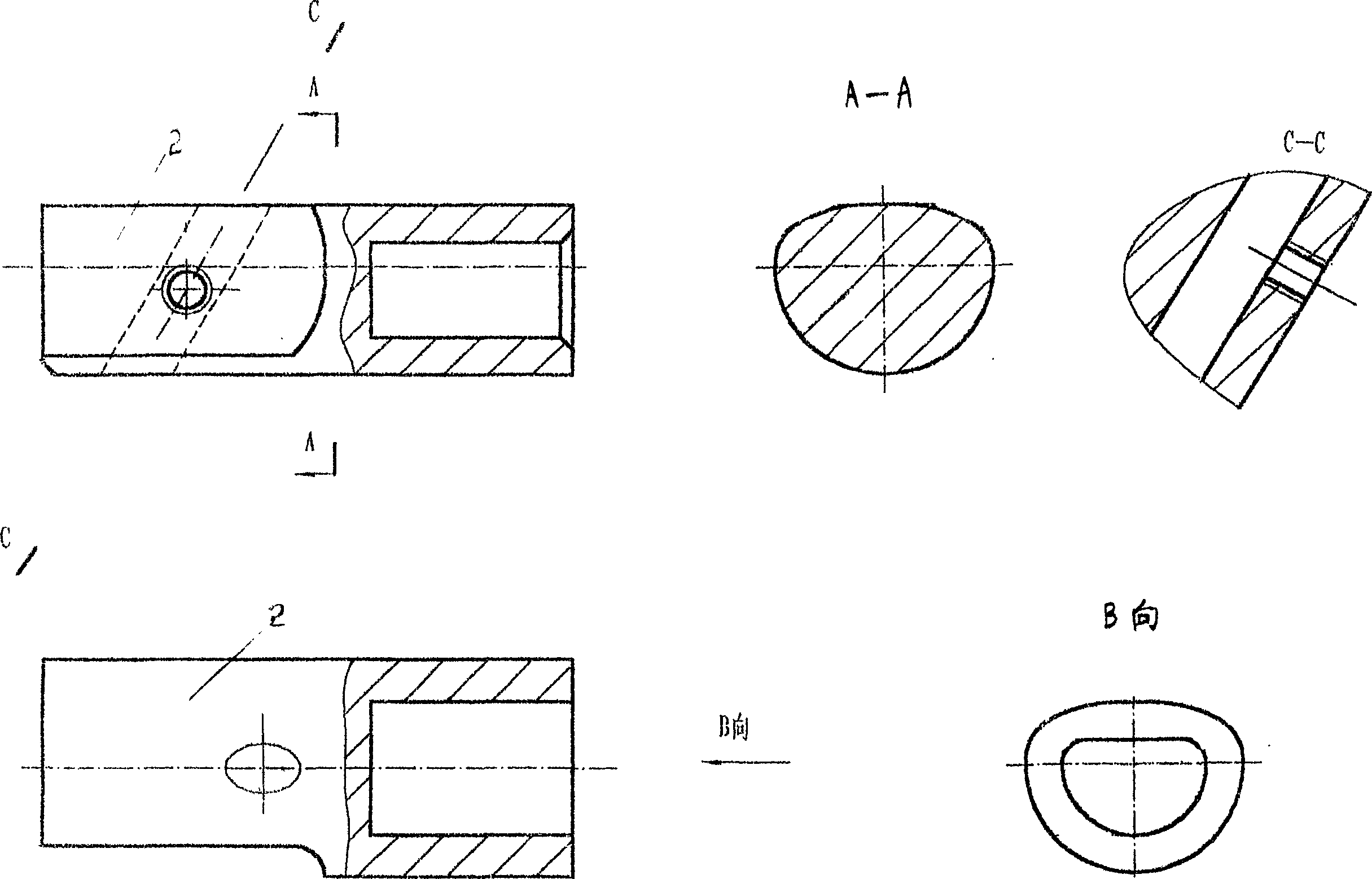

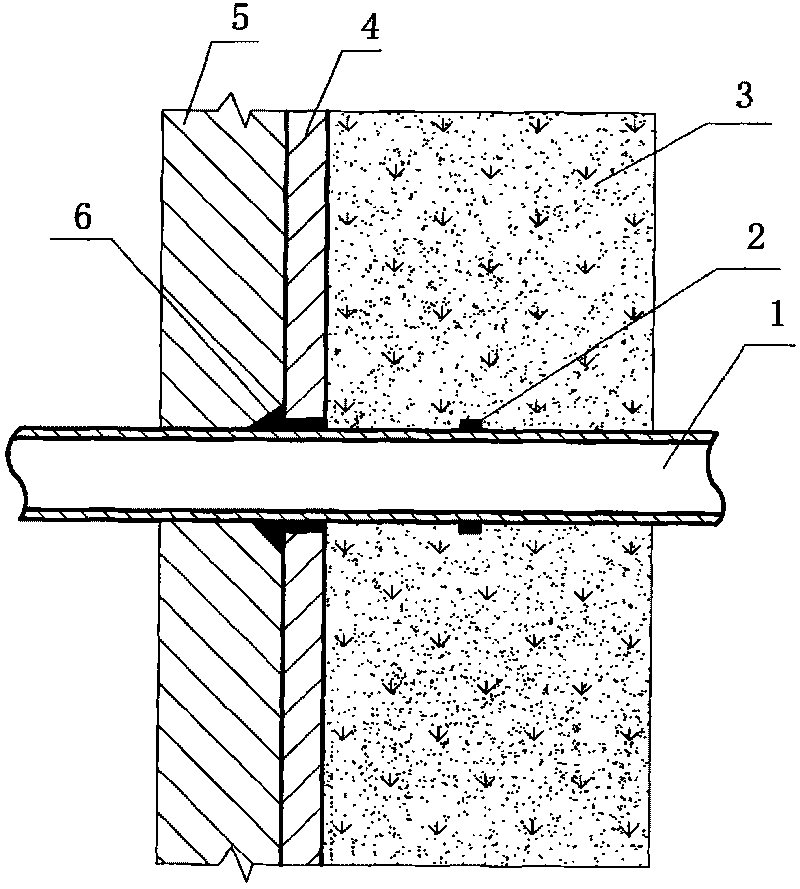

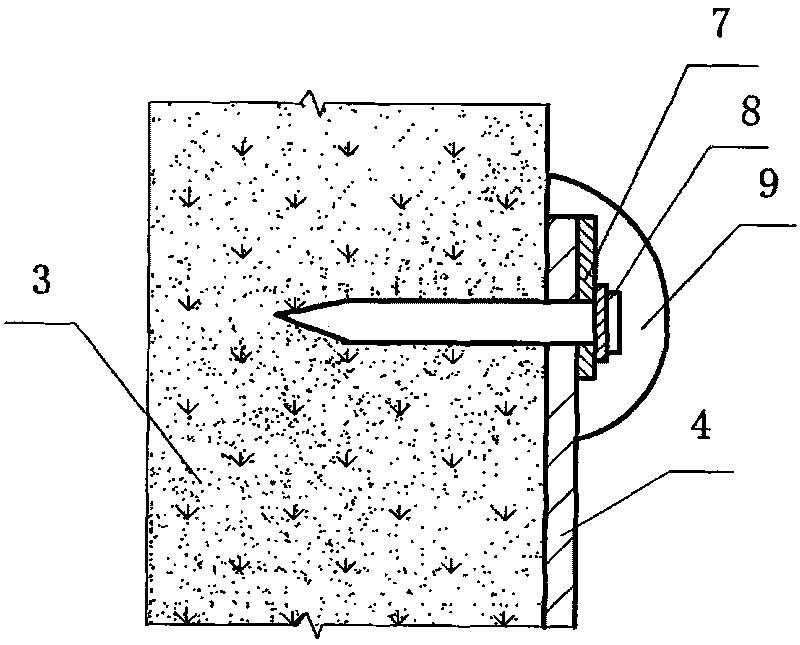

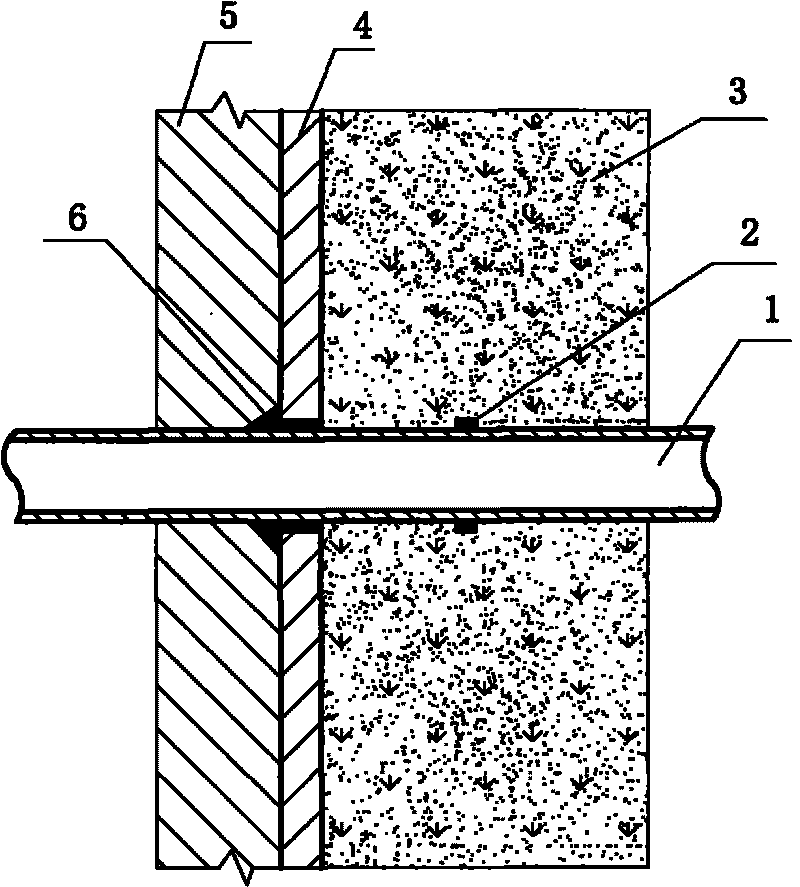

Reinforcing members

ActiveUS20040256888A1Satisfactory performanceEfficient coatingVehicle seatsSuperstructure subunitsEngineeringAdhesive materials

A structural reinforcement for a hollow section at least part of at least one of whose surfaces is the internal surface of an external panel comprising a rigid reinforcing member having a shape that substantially conforms to the cross section to be reinforced. An expandable adhesive material is provided over a portion of the surface of the rigid reinforcing member and the shape of the rigid reinforcing member and the amount and location of the expandable adhesive is such that upon foaming the foam contacts and bonds to the internal surfaces of the hollow section other than the interior surface of the external panel. In this way deformation of the external body panel during the foaming and / or cooling of the foamed expandable material is reduced or prevented.

Owner:ZEPHYROS INC

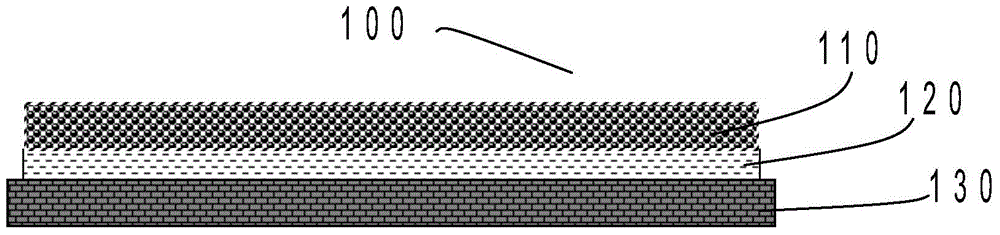

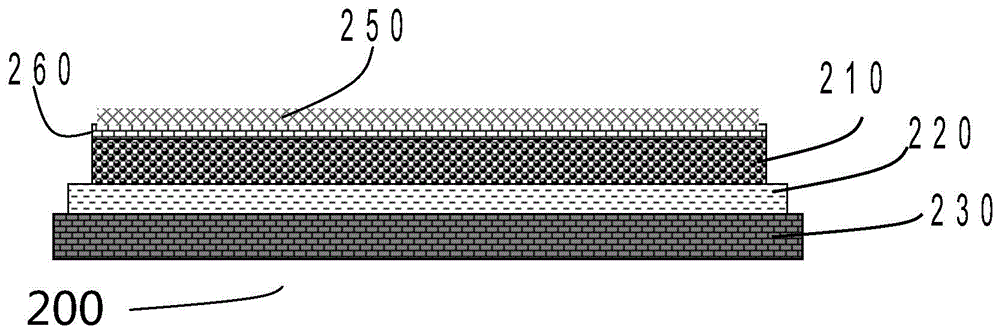

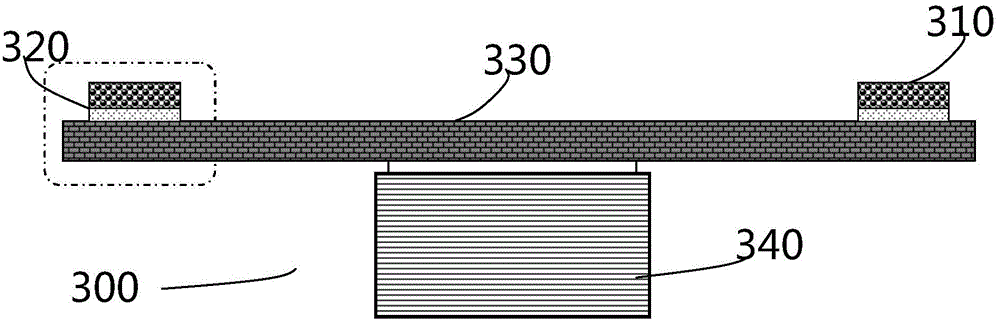

Wavelength conversion device and related light emitting device thereof

ActiveCN105322433AImprove light utilizationImprove cooling effectNon-macromolecular adhesive additivesLaser output parameters controlReflective layerHigh reflectivity

The invention discloses a wavelength conversion device and a related light emitting device thereof. The wavelength conversion device comprises a substrate, a reflecting layer and a light emitting layer which are superimposed in sequence. The light emitting layer contains a wavelength conversion material and a second binder. The reflecting layer contains reflecting particles, auxiliary particles and a first binder, wherein the reflecting particles are used for reflecting light, the auxiliary particles are used for filling the gaps of the reflecting particles, and the first binder is used for binding the reflecting particles and the auxiliary particles into a layer. The reflecting layer not only ensures high reflectivity, but also achieves small thickness. Therefore, heat generated by the light emitting layer can be better transferred to the substrate through the reflecting layer, and reduction of light conversion efficiency due to too high temperature of the light emitting layer is avoided.

Owner:APPOTRONICS CORP LTD

Fiber reinforcement fire-proof thermal insulation plate and preparation process thereof

InactiveUS20150345132A1Low production costResistance to crackingSolid waste managementClimate change adaptationThermal insulationCalcium formate

The present invention discloses a fiber reinforcement fire-proof thermal insulation plate, which is prepared by raw materials having the following weight portions: 80-100 portions of fly ash, 30-50 portions of expanded perlite, 10-20 portions of haydite, 10-20 portions of vegetable fiber, 5-10 portions of winnowing beads, 5-8 portions of sepiolite, 3-5 portions of sodium fluorosilicate, 3-5 portions of calcium formate, 3-5 portions of flame-retardant, 0.1-0.5 portion of triisopropanolamine loeate and 0.1-0.3 portion of dimethoxy-ethane. According to the present invention, industrial production wastes are adopted as main raw materials, so that the production cost is reduced; and defects in the existing building thermal insulation plates can be effectively overcome through the cooperation effect produced by organic combination of the fly ash, light aggregates and additives.

Owner:GUANGDONG NO 1 CONSTRUCTION ENGINEERING CO LTD

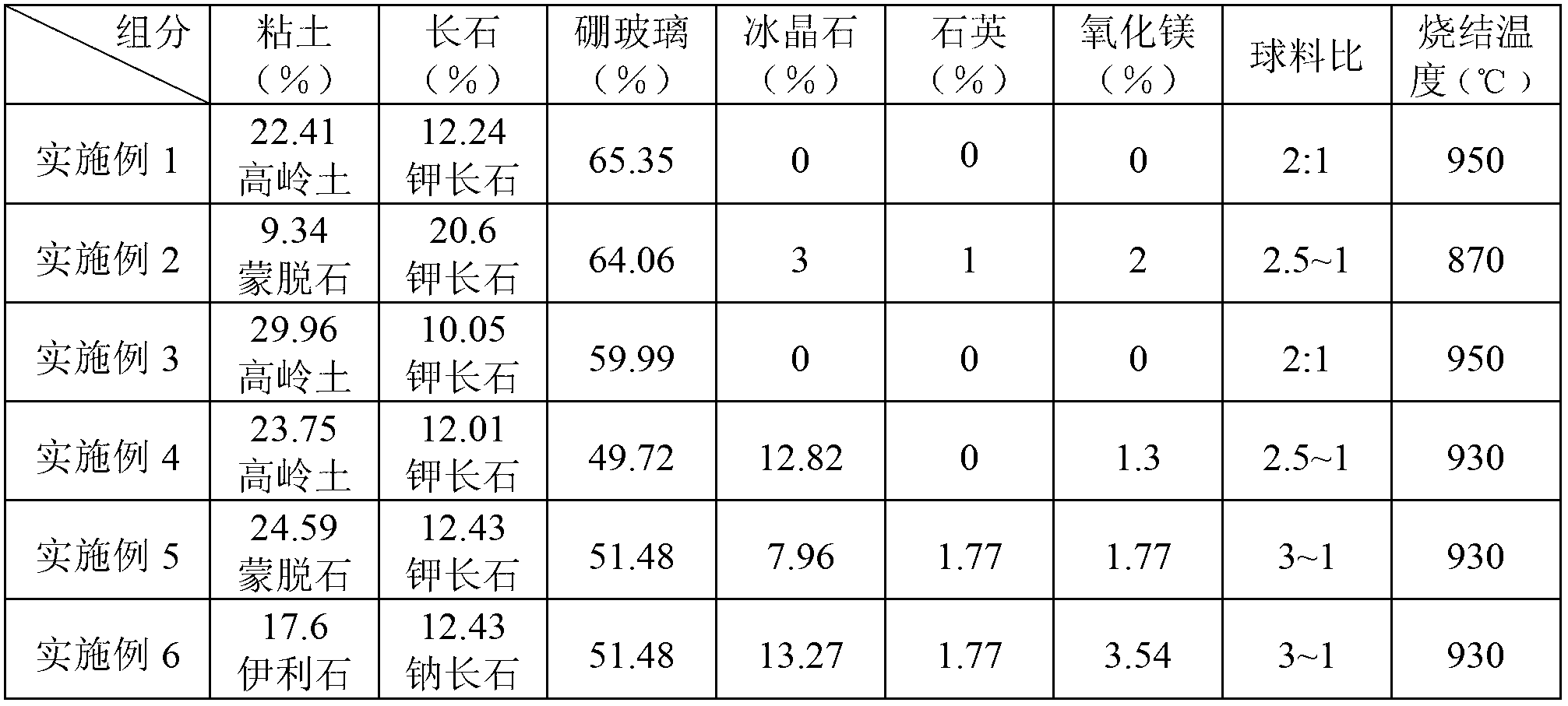

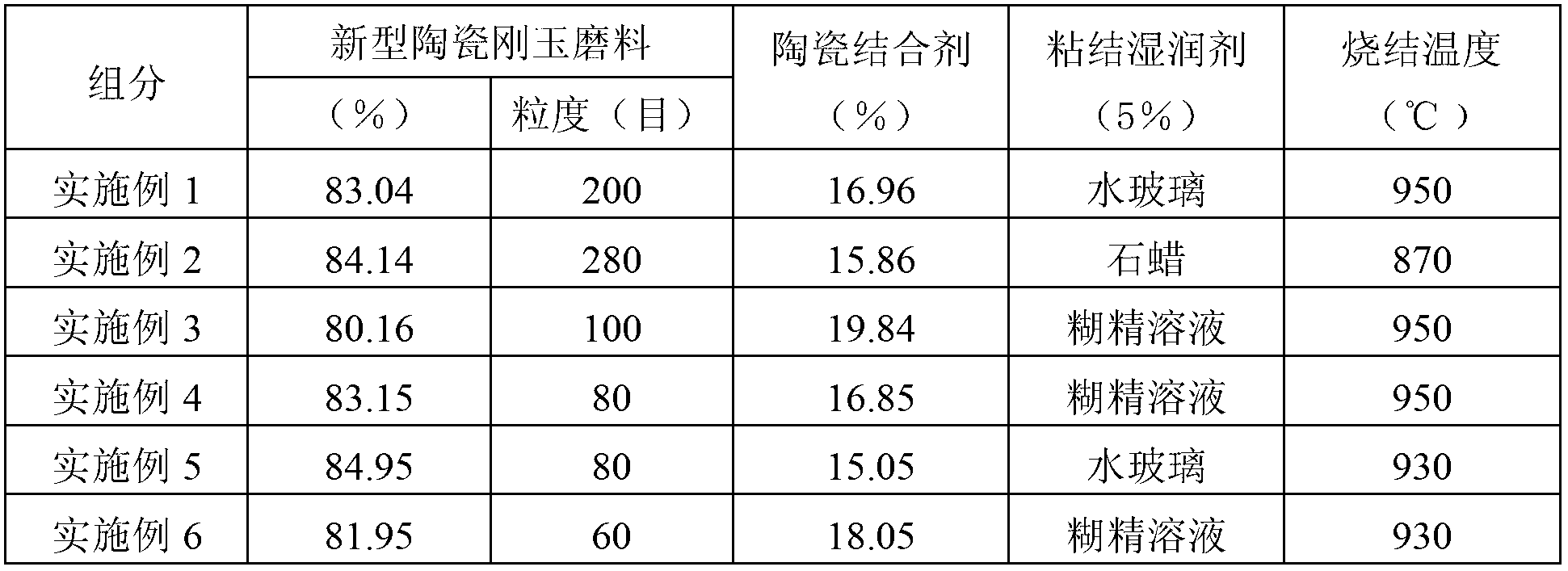

Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

InactiveCN102699825ASharp abrasiveStrong cutting forceAbrasion apparatusGrinding devicesGrinding wheelBorosilicate glass

The invention discloses a novel ceramic corundum grinding tool of a low-temperature and high-strength ceramic bonding agent. The grinding tool consists of the following components in percentage by mass: 15 to 20 percent of ceramic bonding agent, 80 to 85 percent of novel ceramic corundum grinding material and 5 percent of bonding wetting agent, wherein the bonding agent consists of the following components in percentage by mass: 10 to 30 percent of clay, 10 to 30 percent of feldspar, 45 to 70 percent of borosilicate glass, 0 to 15 percent of kryocide, 0 to 5 percent of quartz and 0 to 5 percent of magnesium oxide. The novel ceramic corundum grinding tool can be sintered at the sintering temperature of 850 to 980 DEG C, and by the grinding tool, a grinding wheel can be safely used at the rotation speed of 80 to 100m / s. The single-travel feeding amount of the grinding tool can be over 0.3mm, the metal removing rate is over 3 times that of an ordinary corundum grinding wheel, the grinding interval time is 3 to 5 times that of the ordinary corundum grinding wheel, the service life is 5 to 10 times that of the ordinary corundum grinding tool, and the novel ceramic corundum grinding tool is superior to a super-hard grinding tool and the ordinary grinding tool in performance and price.

Owner:TIANJIN UNIV

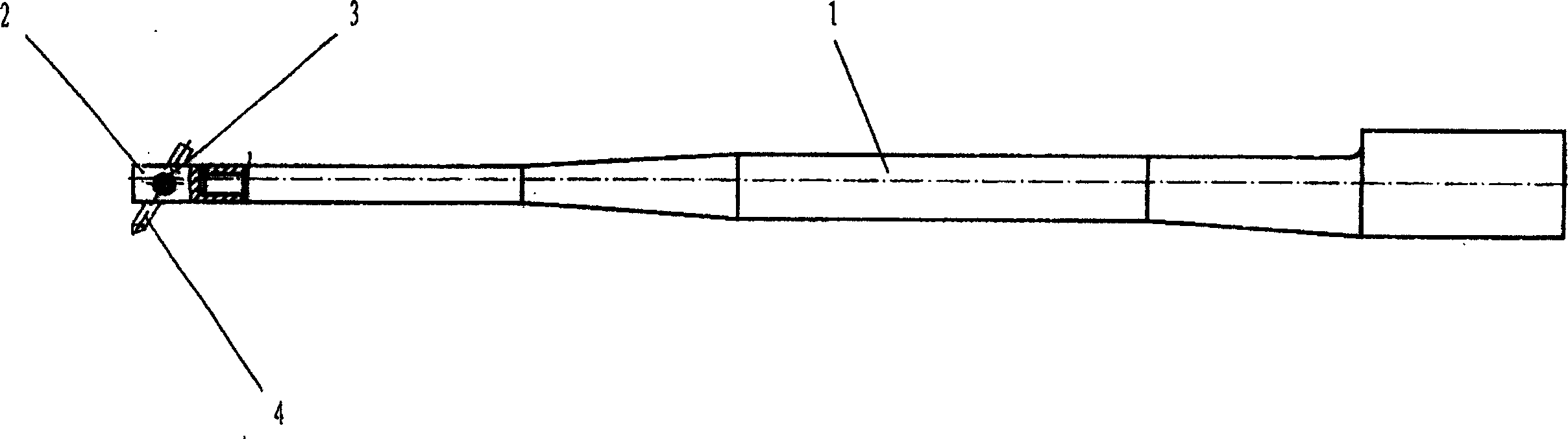

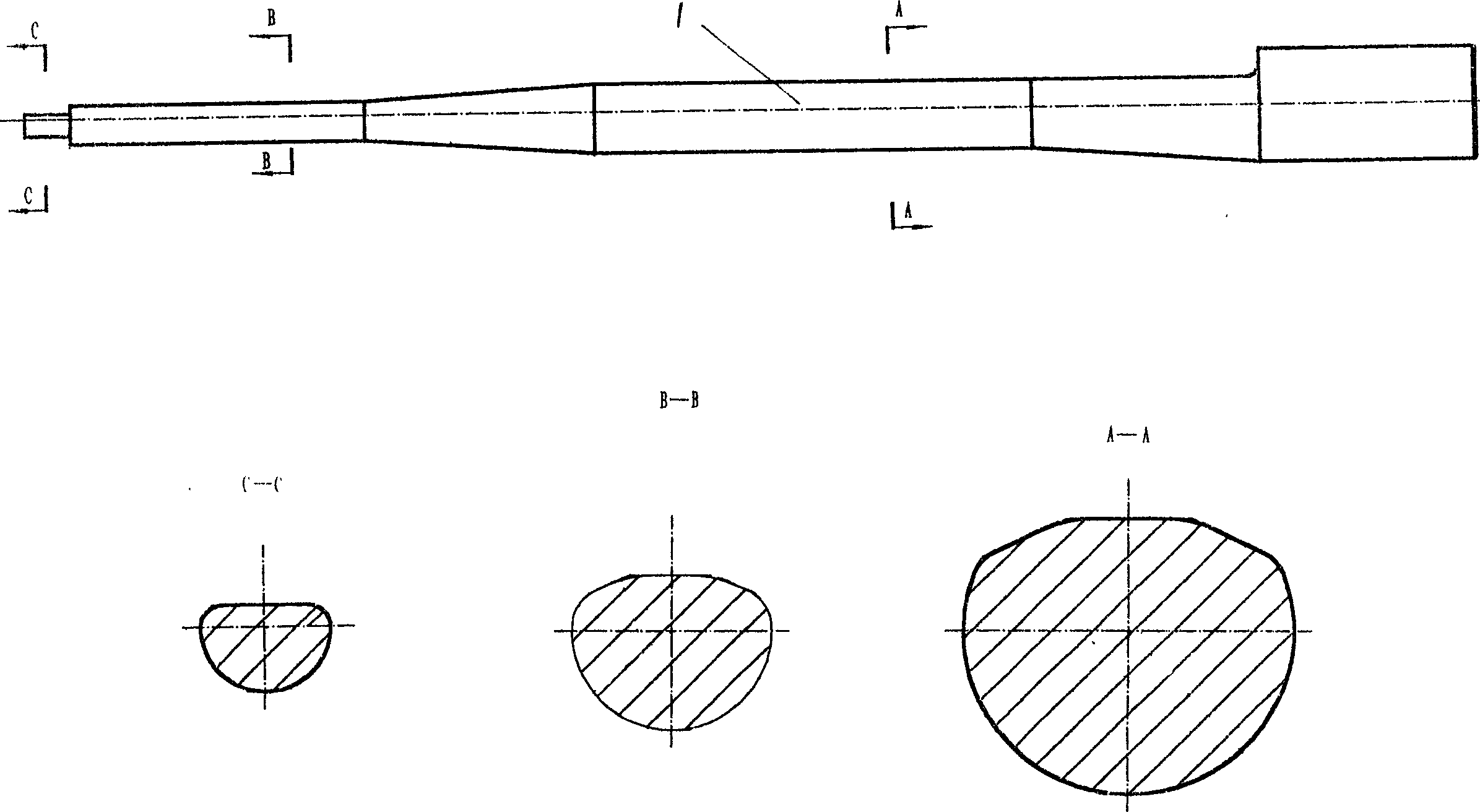

Method for machining deep hole and its special tool

InactiveCN1781653ARepair process is simpleImprove efficiencyAdhesive processes with surface pretreatmentSoldering apparatusDiameter ratioEngineering

The deep hole machining process includes the following successive steps: drilling hole, expanding, coarse reaming, boring and finish reaming. The wall thickness difference in the whole machined length is controlled in 0.02-0.10. The cutter for deep holes machining is long cutter bar of hard alloy and in the length / diameter ratio of 10-20. The deep hole machining technology of the present invention is advanced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Heat-resistant stainless steel with high-lasting strength and manufacturing method thereof

ActiveCN101705437ASimple structureMeet the requirements of the use environmentTemperature control deviceFurnace typesPower stationSuperheater

The invention discloses a heat-resistant stainless steel with high-lasting strength and a manufacturing method thereof. The heat-resistant stainless steel includes the following components by percentage: 24.00-26.00 of Cr, 17.00-23.00 of Ni, 0.05-0.75 of Si, 0.15-2.00 of Mn, less than or equal to 0.030 of P, less than or equal to 0.030 of S, 0.04-0.10 of C, 0.15-0.35 of N, 0.01-5.00 of RE, and 0.20-0.60 of M, wherein M is Nb and Ta. The manufacturing method comprises the following steps: 1. smelting: smelting molten steel in accordance with component requirements of the stainless steel; 2. pouring billet steel; 3. hot-rolling the billet steel: a. heating, the temperature of a uniform temperature section in a furnace is at the temperature of 1130 DEG C plus or minus 50 DEG C, and the soaking time is 80 minutes plus or minus 10 minutes; and b. rolling or forging, the initial rolling / initial forging temperature is at the temperature of 1100 DEG C plus or minus 50 DEG C, and the finishing rolling / finishing forging temperature is at the temperature of 860 DEG C plus or minus 50 DEG C; and 4. heat treatment, the solid solution temperature is at the temperature of 1175 DEG C plus or minus 75 DEG C, and water quenching after heat preservation. Through deduction by tests after sampling the stainless steel manufactured by the method, manufactured seamless tubes can satisfy the use requirements of superheaters and reheaters of ultra-supercritical power station boilers.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

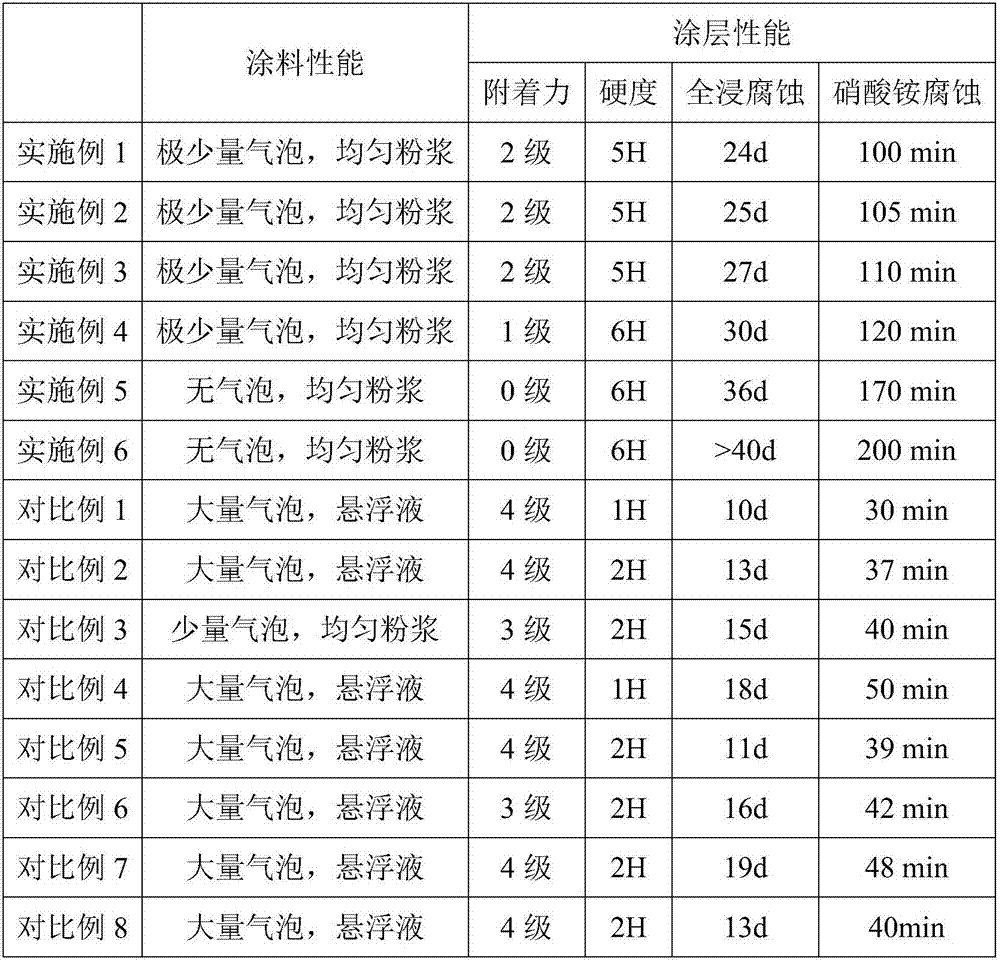

Aqueous composite zinc-aluminum anticorrosion coating

The invention relates to the field of coatings and particularly relates to an aqueous composite zinc-aluminum anticorrosion coating. The aqueous composite zinc-aluminum anticorrosion coating comprises, by weight, 40-65 parts of zinc-aluminum alloy powder, 2-5 parts of a passivating agent, 10-18 parts of a binder, 25-45 parts of a dispersing agent, 0.5-5 parts of a wetting agent, 5-15 parts of a filler, 0.5-2 parts of an additive and 100 parts by weight of a solvent. The filler comprises one or more of nano-silica, nano-titanium dioxide, nano-zinc oxide, modified graphene, nano-alumina, mica powder, talc powder, calcium carbonate, barium sulfate, kaolin, aluminum silicate and nano-cerium oxide. The solvent is a mixture of ethanol and water. The content of ethanol is 20wt% to 50wt%.

Owner:WINSTAR CHEM SHANGHAI

Water-based environment-friendly porcelain glaze-like plastic coating and preparation method thereof

The invention discloses water-based environment-friendly porcelain glaze-like plastic coating and a preparation method thereof. The water-based environment-friendly porcelain glaze-like plastic coating adopts a formula comprising the following materials by mass: 20 to 40 percent of a water-based acrylic emulsion, 10 to 20 percent of water-based silica sol, 35 to 50 percent of water-based inorganic silicon dioxide nanodispersion, 0.1 to 0.3 percent of a wetting dispersant, 1 to 5 percent of silane, 0.1 to 0.5 percent of an amine neutralizing agent, 5 to 10 percent of lead-free pigment, 0.5 to 2.5 percent of a film-forming additive, and 5 to 25 percent of deionized water. The water-based environment-friendly porcelain glaze-like plastic coating can be coated on the surfaces of various materials in the form of porcelain glaze, and can be applied on the surfaces of the materials of various shapes through roller-applied coating, shower coating, spraying, blade coating, brush coating, dip coating and the like; moreover, the formed porcelain glaze coating is unique and free from hydrolysis, and cannot be melted at a certain temperature, so that a base material can be effectively protected from corrosion, abrasion, scraping, acid-alkali, impact, inflaming and fire.

Owner:吕标

Fiber reinforcement aerated thermal insulation plate and preparation process thereof

InactiveUS20150343666A1Simple stepsGood heat insulationWood working apparatusBuilding constructionsCalcium formateThermal insulation

The present invention discloses a fiber reinforcement aerated thermal insulation plate, which is prepared by raw materials having the following weight portions: 80-100 portions of fly ash, 30-50 portions of expanded perlite, 10-20 portions of haydite, 10-20 portions of vegetable fiber, 5-10 portions of winnowing beads, 5-8 portions of sepiolite, 3-5 portions of sodium fluorosilicate, 3-5 portions of calcium formate, 2-4 portions of foaming agent, 0.1-0.5 portion of triisopropanolamine loeate and 0.1-0.3 portion of dimethoxy-ethane. According to the present invention, industrial production wastes are adopted as main raw materials, so that the production cost is reduced; and defects in the existing building thermal insulation plates can be effectively overcome through the cooperation effect produced by organic combination of the fly ash, light aggregates and additives.

Owner:GUANGDONG NO 1 CONSTRUCTION ENGINEERING CO LTD

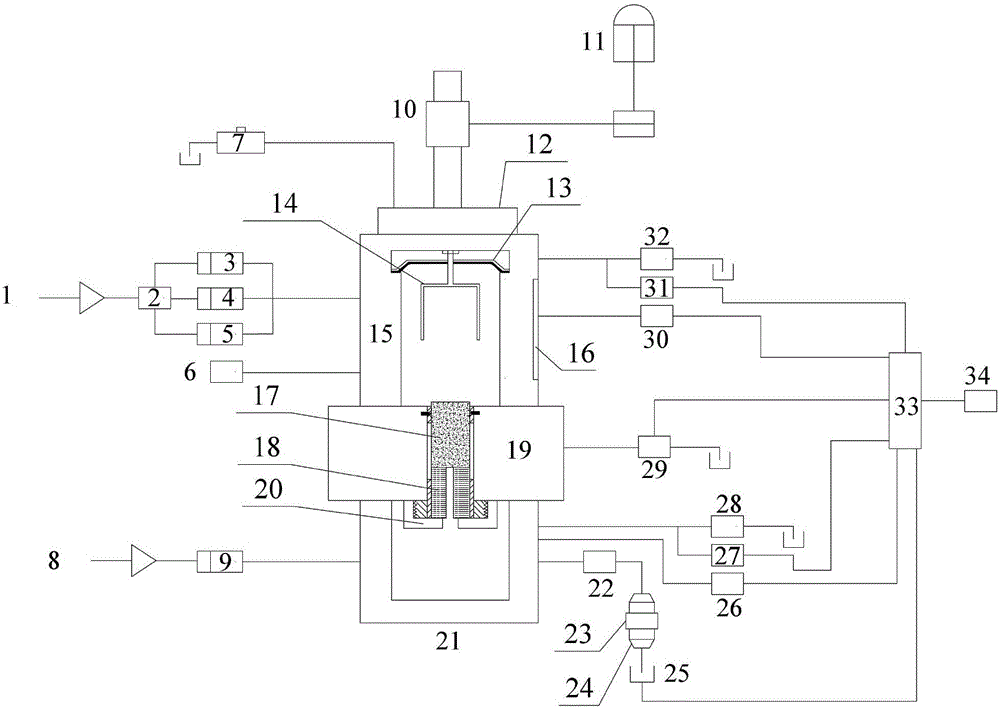

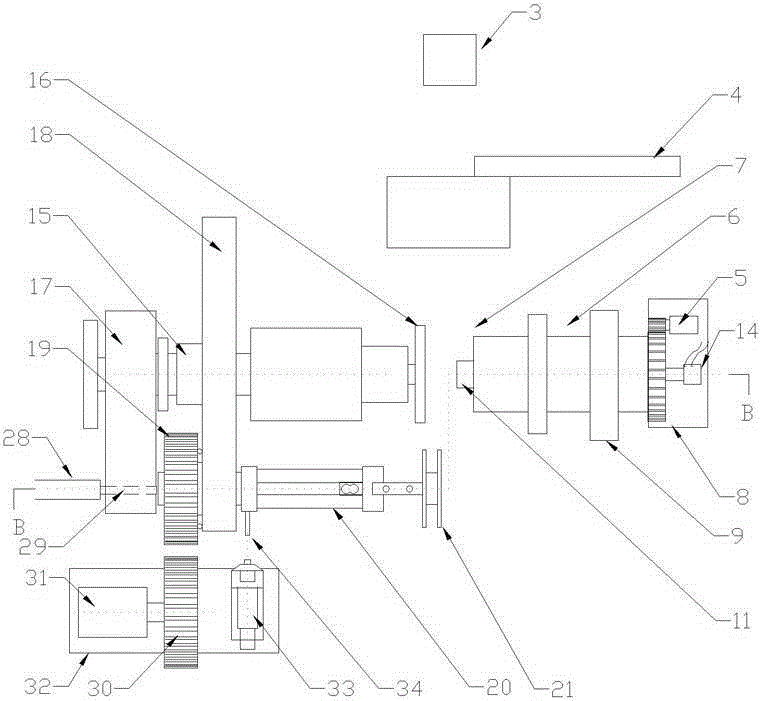

Evaluation device and evaluation method for simulating damage of cementing slurry to reservoirs

InactiveCN106522933AEfficient collectionOvercoming injury deficienciesBorehole/well accessoriesData displayCement slurry

The invention discloses an evaluation device and an evaluation method for simulating damage of cementing slurry to reservoirs. The device mainly comprises an upper kettle 15, a lower kettle 21, a middle component 19, a core clamp 20, a variable frequency motor 11, an upper kettle high-pressure pump 32, a confining pressure pump 29, a lower kettle high-pressure pump 28, a central processing system 33, a data display system 34, a formation water middle container 9, a working solution middle container group, a waste liquid collecting kettle 6, a liquid collecting tank 24, a kettle heating and cooling system 16, an upper kettle temperature sensor 30, a lower kettle temperature sensor 26, an upper kettle pressure sensor 31 and a lower kettle pressure sensor 27. The device simulates damage of various working solutions to the reservoirs under complicated working conditions such as different temperature, pressure and loss in the drilling and completion process, and a cement slurry system matched with underground environments and other working solutions is optimally selected. According to the device, cementing quality can be effectively improved, and high-efficient mining of oil and gas wells is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

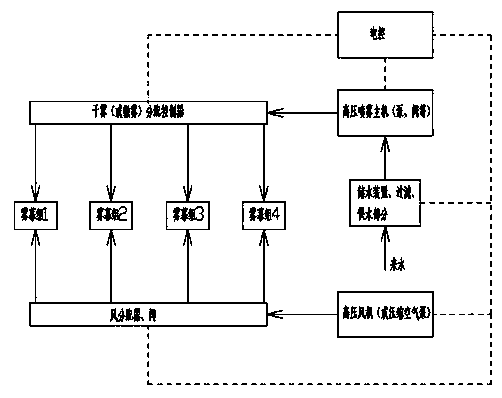

Fog screen dust suppression device

InactiveCN105498401AFill in the gapsUsing liquid separation agentDust removalAutomotive engineeringWater storage tank

The invention provides a fog screen dust suppression device which comprises a wind screen system, a fog system and an electric control system. The fog system comprises a water storage tank, a water feeding pump, a fog main engine, a fog distributor and fog generators, wherein each fog generator is composed of a water pipeline and a spraying head set. The wind screen system comprises a wind main engine, wind screen generators and a wind distributor, wherein each wind screen generator is composed of a wind pipeline and a fog screen wind port or a wind screen machine. The wind screen system and the fog system are controlled by an electric control box, the water storage tank is connected with the fog main engine, the fog main engine is connected with the fog distributor, and each pipeline of the fog distributor is connected with the corresponding fog generator through the corresponding water pipeline. The wind main engine is connected with the wind distributor, and each pipeline of the wind distributor is connected to the corresponding wind screen generator. The fog screen dust suppression device is automatically or manually started to generate dry fog or mist, a fog screen of a wind screen and water fog is formed under the action of wind at the wind screen port and surrounds dust to be generated, mud drops are formed by the dry fog or the mist and the dust and fall to a dust suppression point, and the effects of suppressing dust and removing dust from the source are achieved.

Owner:QINHUANGDAO CAPITAL STARLIGHT ENVIRONMENTAL TECH CO LTD

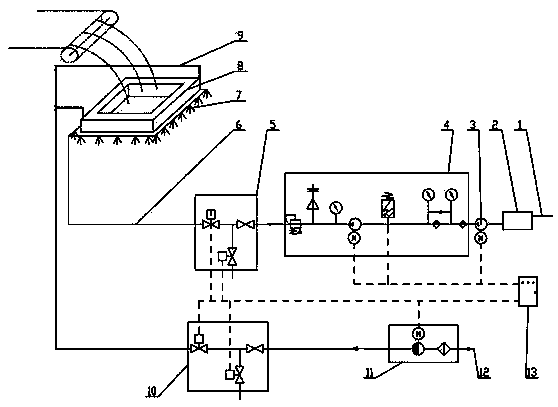

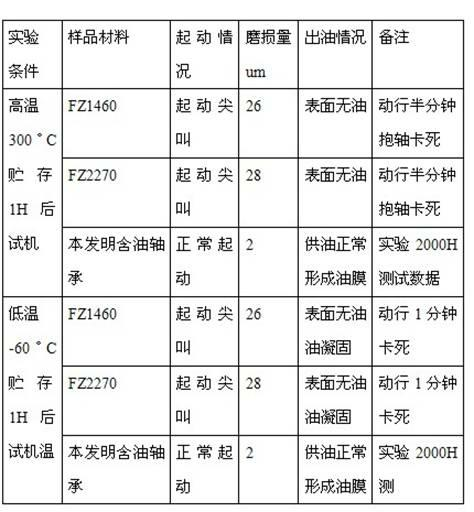

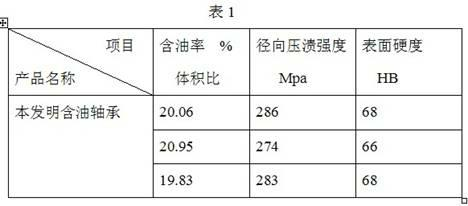

High low temperature resistant oil-retaining bearing made of powder metallurgy material and manufacturing method thereof

The invention discloses a high low temperature resistant oil-retaining bearing made of powder metallurgy material and a manufacturing method thereof. The high low temperature resistant oil-retaining bearing is characterized in that the metallurgy material is prepared from the following raw materials in percent by weight: 35-40% of C, 35-40% of Cu and balance of Fe, wherein the percent by weight of C is the same with that of Cu. The invention also provides a manufacturing method of the oil-retaining bearing, comprising the steps of: electroplating coating, mixing, compression moulding, reducing and sintering, finishing, cleaning and immersing oil. The powder metallurgy material in the invention improves content of graphite, the oil-retaining bearing made of the powder metallurgy material can adapt to the environment at the temperature of being lower than 300 DEG C and higher than minus 60 DEG C and can be continuously used, and the gap of requirement of high temperature and low temperature to the oil-retaining bearing is filled.

Owner:CHONGQING HEDA TECH

Reovirus inactivated vaccine and its preparation

ActiveCN1895667AFill the vaccine gapFill in the gapsViral antigen ingredientsInactivation/attenuationReovirus InfectionsInactivated vaccine

A deactivated Avianreovirus vaccine for fowls is prepared from the Avianreovirus (ARV) RS13 (CGMCC No.1713) through separating said virus from the organ of infected chicken, serum test, reproduction of virus, deactivating, and emulsifying.

Owner:TIANJIN RINGPU BIO TECH

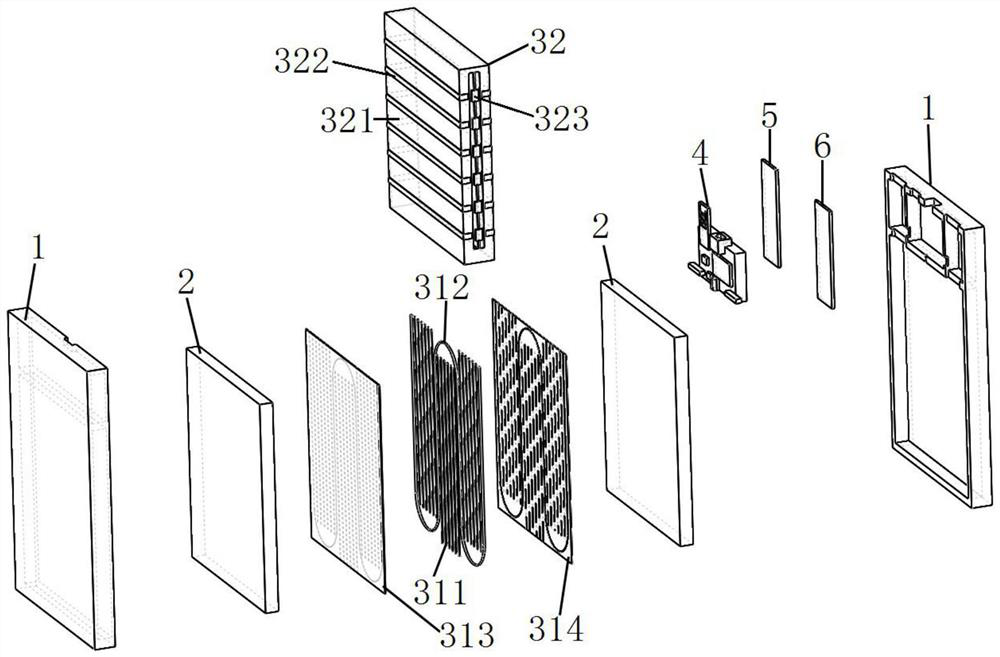

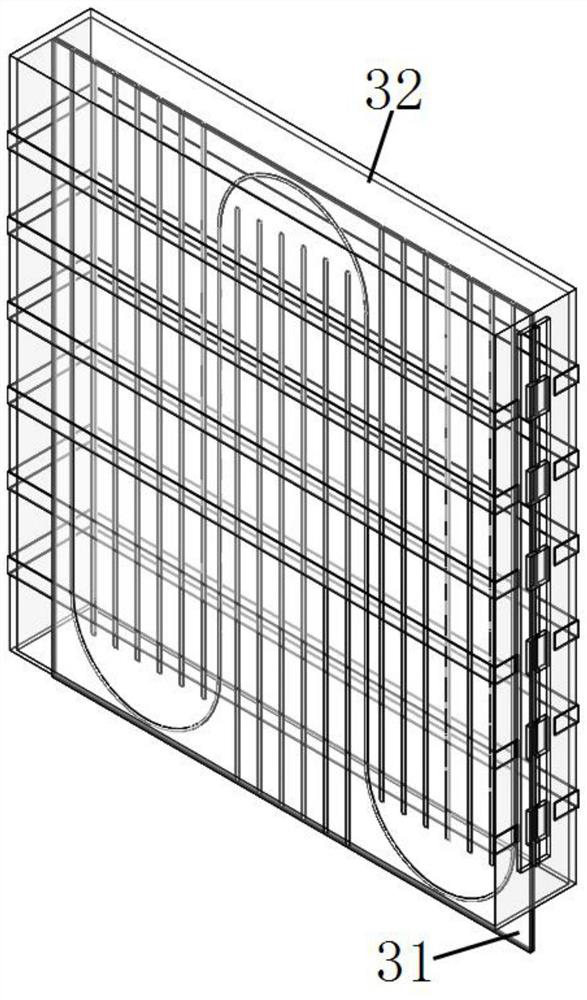

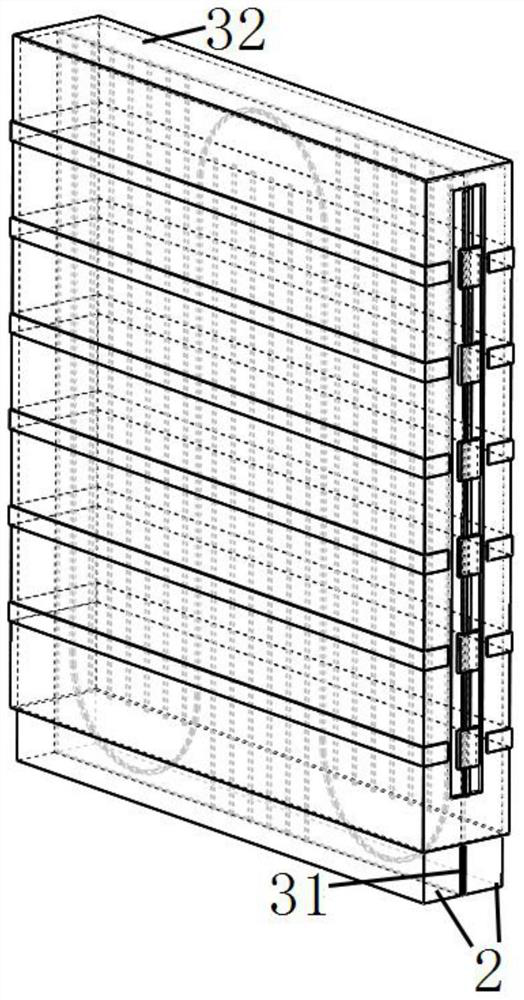

Intelligent battery

ActiveCN112103576AImprove securityImprove reliabilityBatteries circuit arrangementsElectrical testingComputer scienceEmbedded system

The invention relates to an intelligent battery. The intelligent battery comprises a battery shell, a layered battery cell, a positive electrode, a negative electrode, an embedded multi-source sensorgroup and an intelligent chip, wherein the battery shell, the layered battery cell, the positive electrode and the negative electrode are arranged on a common battery. According to the intelligent battery provided by the invention, by adopting the intelligent chip and the embedded multi-source sensor group, the core pressure, the core temperature, the current and other working information of the battery can be detected in real time, so that the real-time monitoring of the working state and the safety state of the battery is realized, and the safety of the battery is improved on the basis of realizing the self-sensing function of the battery. Therefore, the use safety and reliability of the battery are improved. Moreover, according to the intelligent battery provided by the invention, the traditional battery structure is modified by adding the intelligent chip and the embedded multi-source sensor group, so that the blank state of research on research on research and development, manufacturing, production and the like of the intelligent battery is filled up on the premise of ensuring that the volume of the battery is not changed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

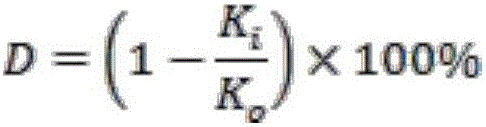

Inorganic functional coating for degrading formaldehyde by negative ions and preparation method of coating

ActiveCN103289454AImprove wear resistanceHigh hot hardnessAlkali metal silicate coatingsPhysical chemistryInorganic materials

The invention relates to an inorganic functional coating for degrading formaldehyde by negative ions and a preparation method of the coating. The coating comprises a component A and a component B, wherein the component A contains negative ion powder. The coating is high in abrasion resistance, hardness and high-temperature hot hardness, adhesive force and peeling strength and can be abraded for 9 hours, cross-linking density is greatly enhanced and compactness of the coating is increased as the coating is compounded with inorganic materials with different particle sizes, gaps among large-particle-size raw materials are filled up as the raw materials with different particle sizes are mixed, thermal stress dispersion among the large-particle-size raw materials is absorbed and buffered by small-particle-size raw materials, thermal stress concentration of the small-particle-size raw materials is resisted and isolated by the large-particle-size raw materials, the coating is environment-friendly and green, VOC (volatile organic compound) is avoided, a large number of negative ions can be generated, and the coating is superior to other products in the field.

Owner:华夏贝能(北京)生态科技有限公司

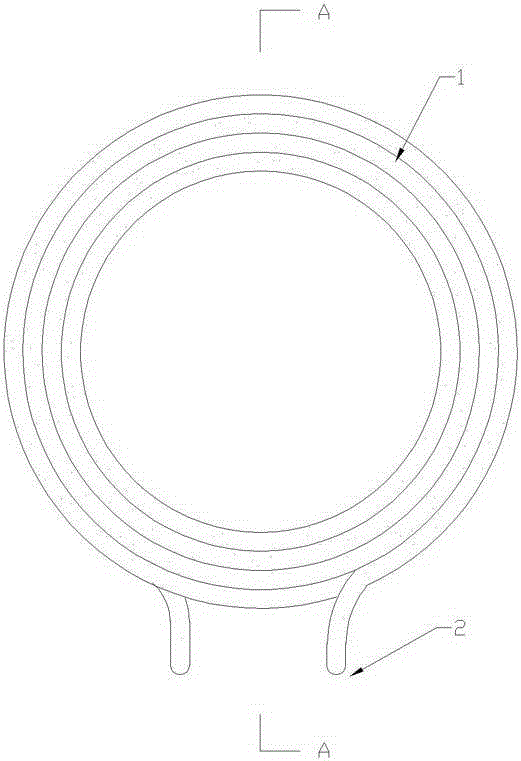

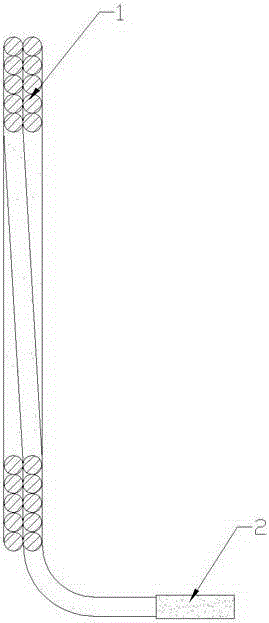

Double-outer-lead-terminal coil winding machine and winding process

ActiveCN105225829ARealize the winding processAchieve demouldingCoils manufactureWinding machineRotational axis

The invention relates to a double-outer-lead-terminal coil winding machine and a winding process. The winding machine structurally comprises a coil sorting component, a mechanical arm component, a left rotating and winding component, a right rotating and winding component, a clutch drive component, a machine base and a program controller. The left rotating and winding component and the right rotating and winding component are arranged on a base, and rotating shaft components in the left rotating and winding component and the right rotating and winding component are coaxially and oppositely arranged; the left rotating shaft of the left rotating and winding assembly is further fixedly provided with a rectangular rotation block provided with a pre-wind-up component. The winding process of the double-outer-lead-terminal coil winding machine includes the steps of system resetting, coil feeding, pre-winding-up, winding and demoulding. By means of the double-outer-lead-terminal coil winding machine and the winding process, double-outer-lead-terminal coils can be machined and produced conveniently and rapidly, and production efficiency is high.

Owner:资兴市弘电电子科技有限公司

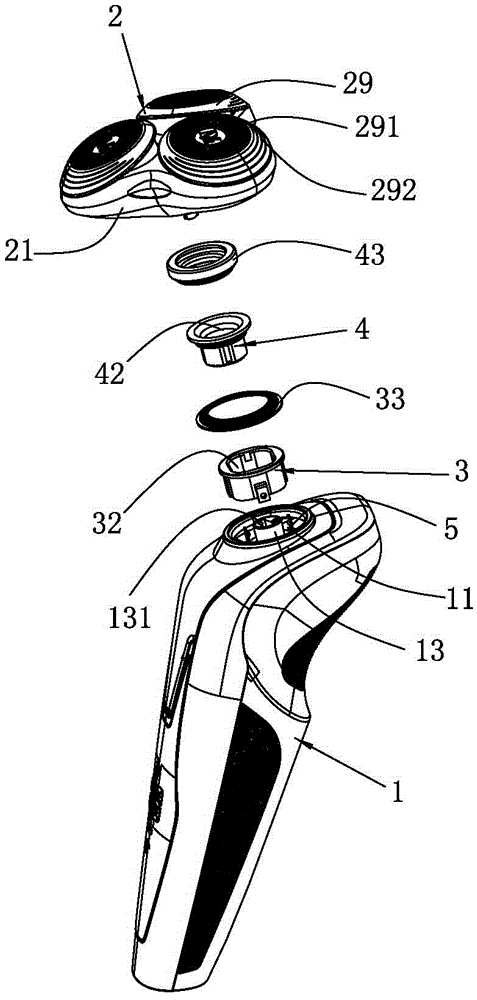

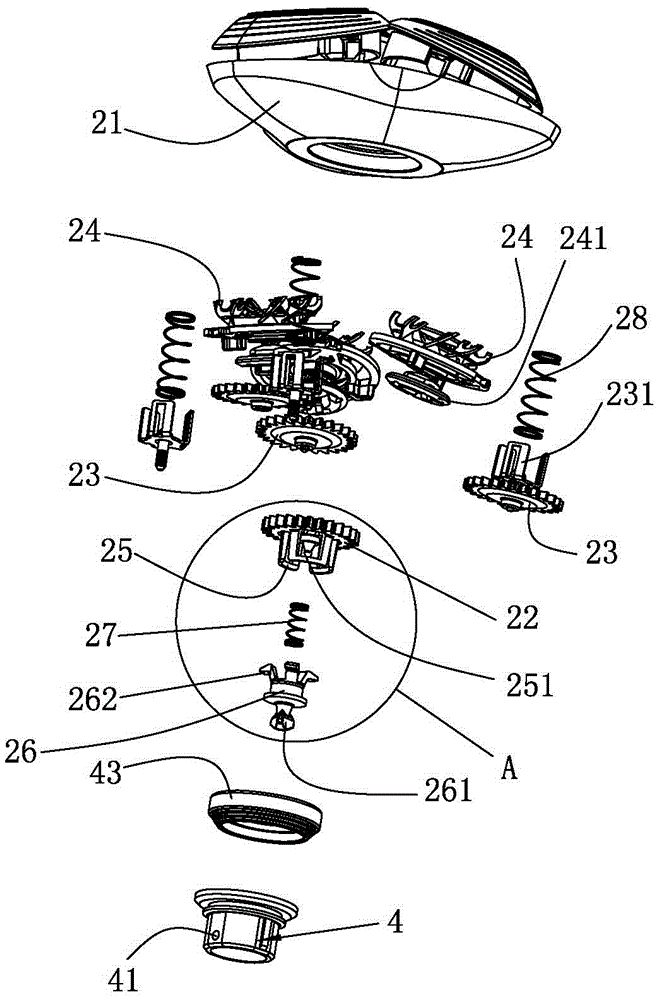

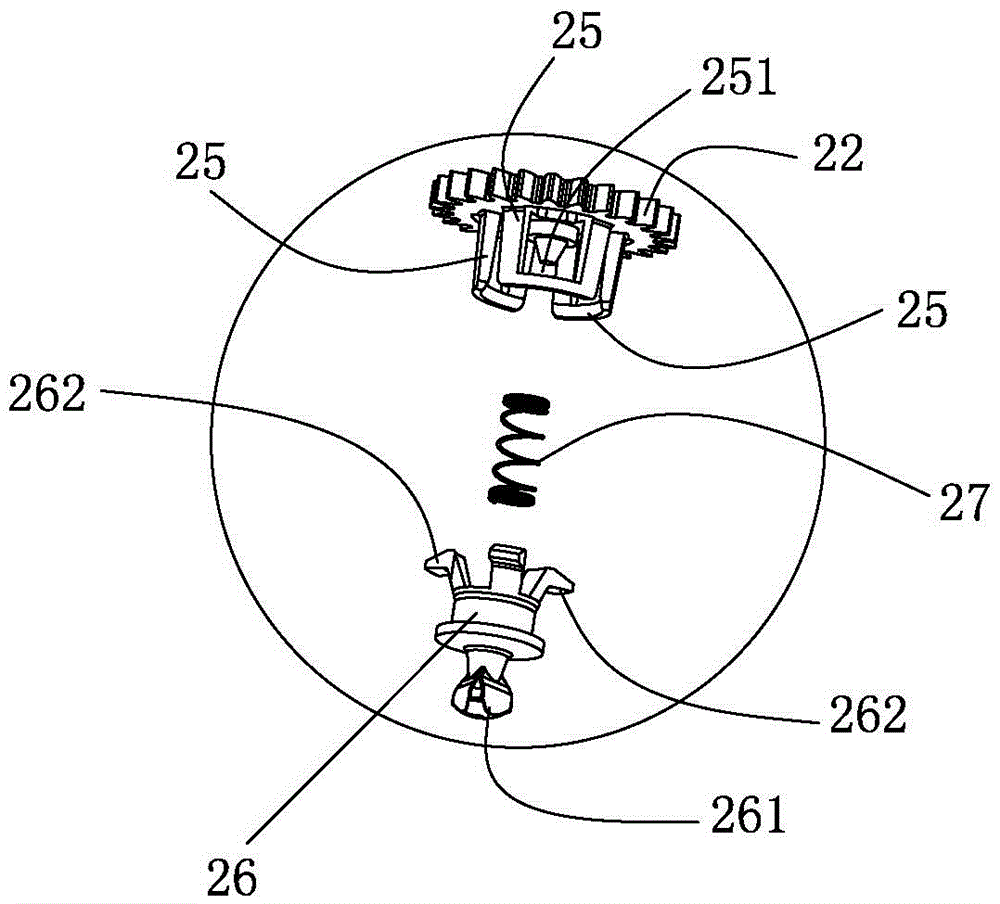

Floating type shaver

ActiveCN106514732ARealize the reset functionTo achieve the reset effectMetal working apparatusRazor stropEngineering

Owner:GUANGDONG ROMAN TECH CO LTD

Environmentally friendly surface sizing agent capable of improving paper smoothness and barrier property and a preparation method and application of environmentally friendly surface sizing agent

InactiveCN108708207AFill in the gapsImprove surface propertiesWater-repelling agents additionPulp beating methodsMicro nanoCellulose

The invention discloses an environmentally friendly surface sizing agent capable of improving paper smoothness and barrier property and a preparation method and application of the environmentally friendly surface sizing agent. The method comprises the following steps: (1) preparation of micro-nano celluloses: pretreating bleaching wood pulp by a mechanical method, and carrying out enzymolysis treatment, nano grinding and homogenization treatment on the pretreated material to obtain the micro-nano celluloses; and (2) preparation of the surface sizing agent: pasting cationic starch under heatingand stirring conditions at first, cooling to a certain temperature, then adding the micro-nano celluloses, and continuously stirring at the temperature until the material is uniform to obtain the environmentally friendly surface sizing agent. An application process comprises the following steps: sizing paper by using a roll coater, naturally air-drying the sized paper, carrying out press polish treatment on the dried paper, and detecting influences of the sizing agent to the surface performance of the paper. By the disclosed environmentally friendly surface sizing agent with micro-nano cellulose / starch, the smoothness and barrier property of paper can be improved effectively.

Owner:SOUTH CHINA UNIV OF TECH

Alcohol-group dry powder sand mould foundry coating

InactiveCN102873266AGood high temperature strength and stabilityLow gas productionFoundry mouldsFoundry coresBrown iron oxideAluminium

The invention discloses alcohol-group dry powder sand mould foundry coating, which comprises the following components in percentage by weight: 60-75% of bauxite, 2-10% of amorphous graphite, 3-15% of lamellar graphite, 2-10% of iron oxide red, 1-5% of attapulgite, 0.5-1.5% of sodium bentonite, 1-5% of polyvinyl butyral, 0.1-0.5% of surfactant and 0.1-0.5% of dispersing agent. The dry powder coating has the advantages of simple preparation technology, convenience in use and good high-temperature sand adhesiveness resistance.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Construction method of bentonite waterproof blankets

InactiveCN101748757AReasonable workmanshipIncrease the permeability coefficientProtective foundationRebarBase plane

The present invention relates to a construction method of bentonite waterproof blankets. The method comprises the steps of processing a base plane, paving waterproof blankets, processing lapped seams, protecting and connecting swing ends, folding ends, processing empty bumps, etc. The waterproof blankets are naturally lapped during the lapped seam processing, the lapped width is not smaller than 100mm, and the lapped seams can not be arranged in corners. The allowed length of the swing ends of the waterproof blankets is 200mm to 400mm longer than the allowed length of reinforcing steel bars, and is from 500mm to 800mm. The ends are lined and sealed by edgings. Facade swing ends and plane swing ends are temporarily protected. The swing ends are folded, sealed and fixed when the waterproof blankets are paved to the facade top. The construction method has the advantages of reasonable technique, permanent waterproofing, simple method, labour and material saving, long service life, long structure, secondary waterproof properties, capability of forming active water-proof system, low construction cost, high efficiency and broad application range. The present invention is suitable for various water-proof requirements of underground waterproof engineering.

Owner:HENAN GUOJI CONSTR GRP

Sampling and indoor in-situ testing method for soft intercalated layer undisturbed sample

InactiveCN105628431AEasy to carrySimple indoor test operationWithdrawing sample devicesMaterial strength using steady shearing forcesTangential forceRock sample

The invention provides a sampling and indoor in-situ testing method for a soft intercalated layer undisturbed sample. By a top cement cover, a bottom cement cover and a sampling tube closed cube rock sample, the soft intercalated layer undisturbed sample is obtained; the tube wall of a sampling tube is peripherally subjected to truncation cutting in the middle of the sampling tube to form both an upper part and a lower part so as to form an upper disk and a lower disk of a shearing-resistant test; a top concrete cushion block and a bottom concrete cushion block are placed and the soft intercalated layer undisturbed sample is placed in a shear box of a direct shear apparatus, so that the upper disk is positioned in an upper shear box, and simultaneously, the lower disk is positioned in a lower shear box; a normal force is applied to the symmetry center of the top concrete cushion block, and simultaneously, a positive tangential force and a reverse tangential force are respectively applied to two opposite surfaces of the upper shear box and the lower shear box so as to carry out the shear-resisting test. The method is an in-situ test of a soft intercalated layer; shear strength and a shear strength testing result which are obtained by the test accord with the practical condition; accurate physical and mechanics parameters can be provided for stability analysis of a slope.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Processing method of nutritional potato mixed rice

ActiveCN104273432AIncrease consumptionGreat tasteFood shapingFood preparationBiotechnologyCorn flour

The invention discloses a processing method of nutritional potato mixed rice. The processing method comprises the following steps: uniformly mixing 70-90 parts of rice meal, 10-30 parts of mashed potato and 10-20 parts of corn flour in parts by mass, wherein the finenesses of the rice meal, the mashed potato and the corn flour are respectively 70-90 meshes, 100-150 meshes and 70-120 meshes; feeding the mixed raw materials into a double-screw extrusion forming device, wherein the double-screw extrusion forming device is divided into six heating regions, and the heating temperatures from a first region to a sixth region are respectively 20-25 DEG C, 50-60 DEG C, 90-100 DEG C, 100-115 DEG C, 110-115 DEG C and 85-95 DEG C; cooling for 1-2 hours by virtue of a cooling fan, and drying at 20-30 DEG C for 4-6 hours, so as to obtain the finished nutritional potato mixed rice. According to the processing method of the nutritional potato mixed rice, by adding the mashed potato into mixed rice, the taste of the mixed rice is improved, the consumption of potatoes is increased, the development of potato industries is promoted, and the food security is guaranteed.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

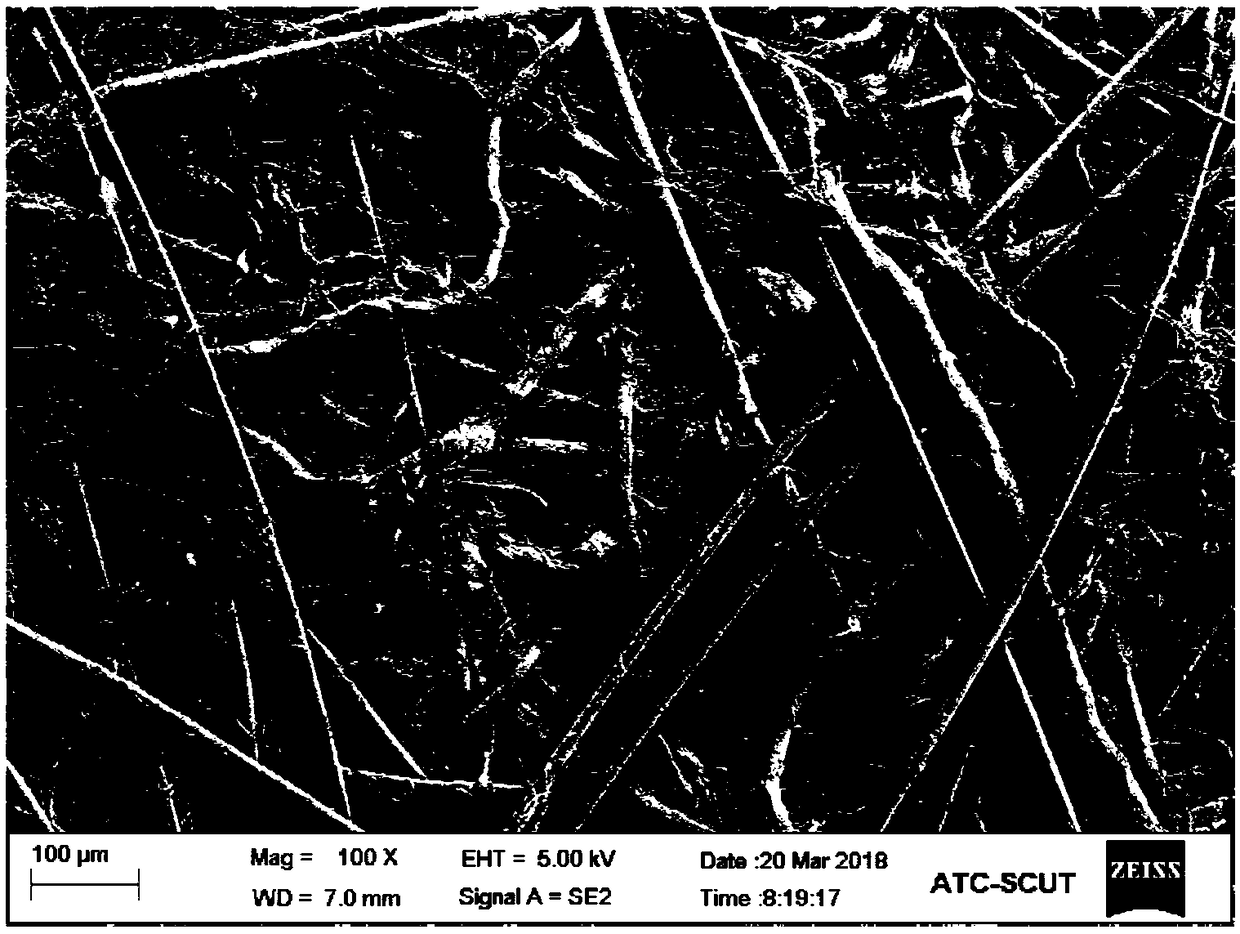

Preparation method of regenerated aramid composite paper

ActiveCN109457533AImprove hydrophilicityFacilitate the grafting reactionPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperHigh pressureAramid

The invention discloses a preparation method of regenerated aramid composite paper. The preparation method includes: pretreating para-aramid chopped fiber, para-aramid pulp fiber and meta-aramid pulpfiber, mixing, loosening to form a uniform fiber / aqueous suspension, adding a papermaking aid into the suspension, dewatering, and molding to obtain composite aramid raw paper; dissolving the meta-aramid fiber by using organic solvent / inorganic salt solution to obtain an aramid solution, dropwise adding the prepared aramid solution into the structure of the aramid composite raw paper, putting thearamid composite raw paper into the air for regeneration, after the regeneration is completed, hot pressing the paper a high temperature and high pressure, and cleaning residual organic solvent and inorganic salt by using water to obtain high-strength aramid composite paper. The quantity of the high-strength aramid composite paper is 20 to 200 g / m2, the thickness is 10 to 300 micrometers, the mechanical strength is greatly improved, and the tensile strength is improved by 20 times.

Owner:SOUTH CHINA UNIV OF TECH +1

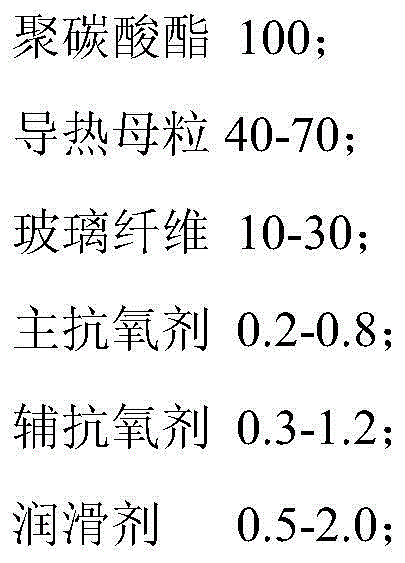

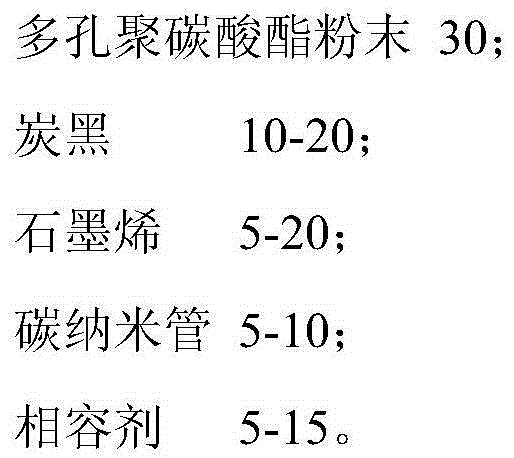

Polycarbonate heat-conducting composite material and preparation method thereof

ActiveCN104559109AImprove thermal conductivityImprove stabilityHeat-exchange elementsGlass fiberMasterbatch

The invention provides a polycarbonate heat-conducting composite material and a preparation method thereof. The composite material comprises components in parts by weight as follows: 100 parts of polycarbonate, 40-70 parts of heat-conducting masterbatch, 10-30 parts of glass fibers, 0.2-0.8 parts of a main antioxidant, 0.3-1.2 parts of an auxiliary antioxidant and 0.5-2.0 parts of a lubricant, wherein the heat-conducting masterbatch comprises components in parts by weight as follows: 30 parts of porous polycarbonate powder, 10-20 parts of carbon black, 5-20 parts of graphene, 5-10 parts of carbon nano-tubes and 5-15 parts of a compatilizer. The preparation method comprises steps as follows: A, preparation of the heat-conducting masterbatch; B, machining of the heat-conducting composite material: the polycarbonate, the heat-conducting masterbatch obtained in Step A, the main antioxidant, the auxiliary antioxidant and the lubricant are mixed in a high-speed mixer, the glass fibers are laterally fed through accurate calibration and extruded by a twin-screw extruder for granulation, and the polycarbonate heat-conducting composite material with higher heat conductivity is prepared.

Owner:DONGGUAN HONOUR E P

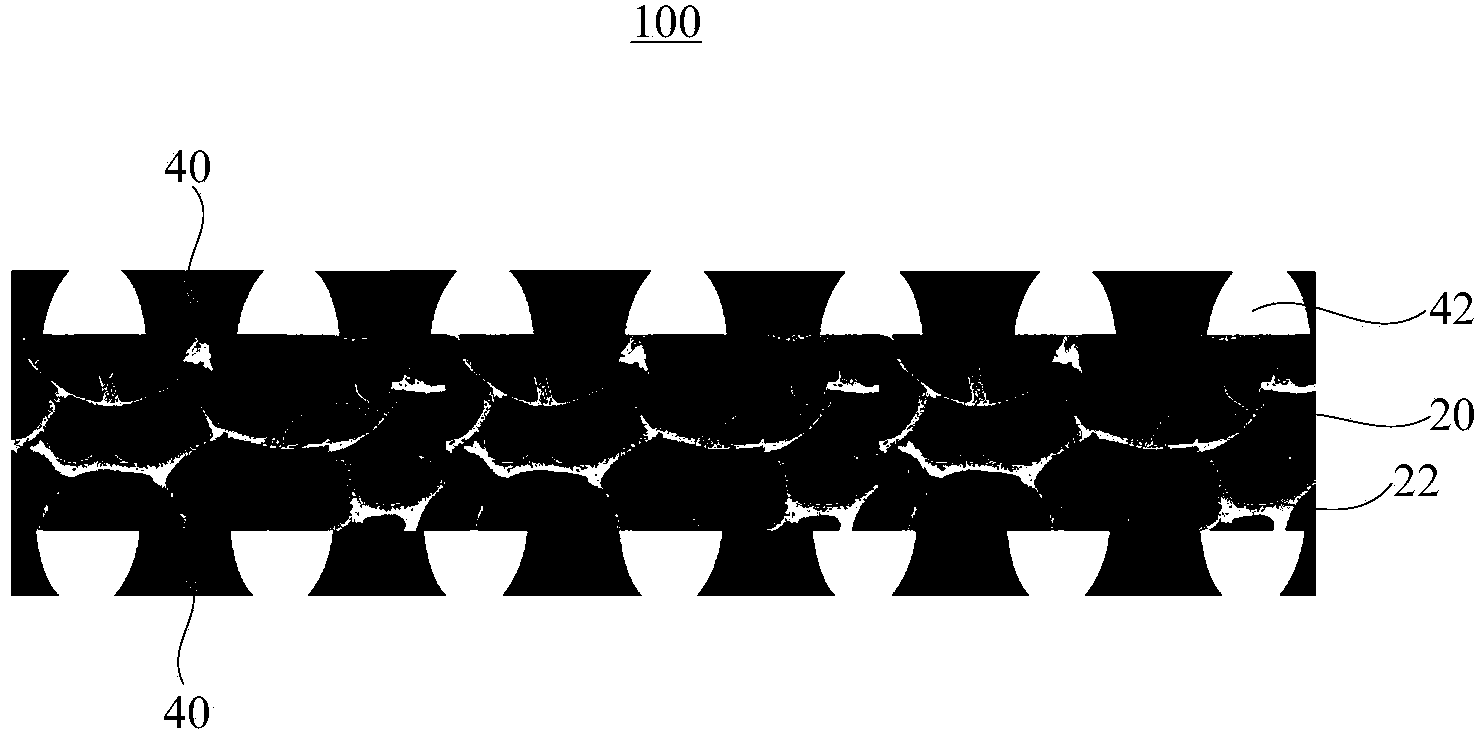

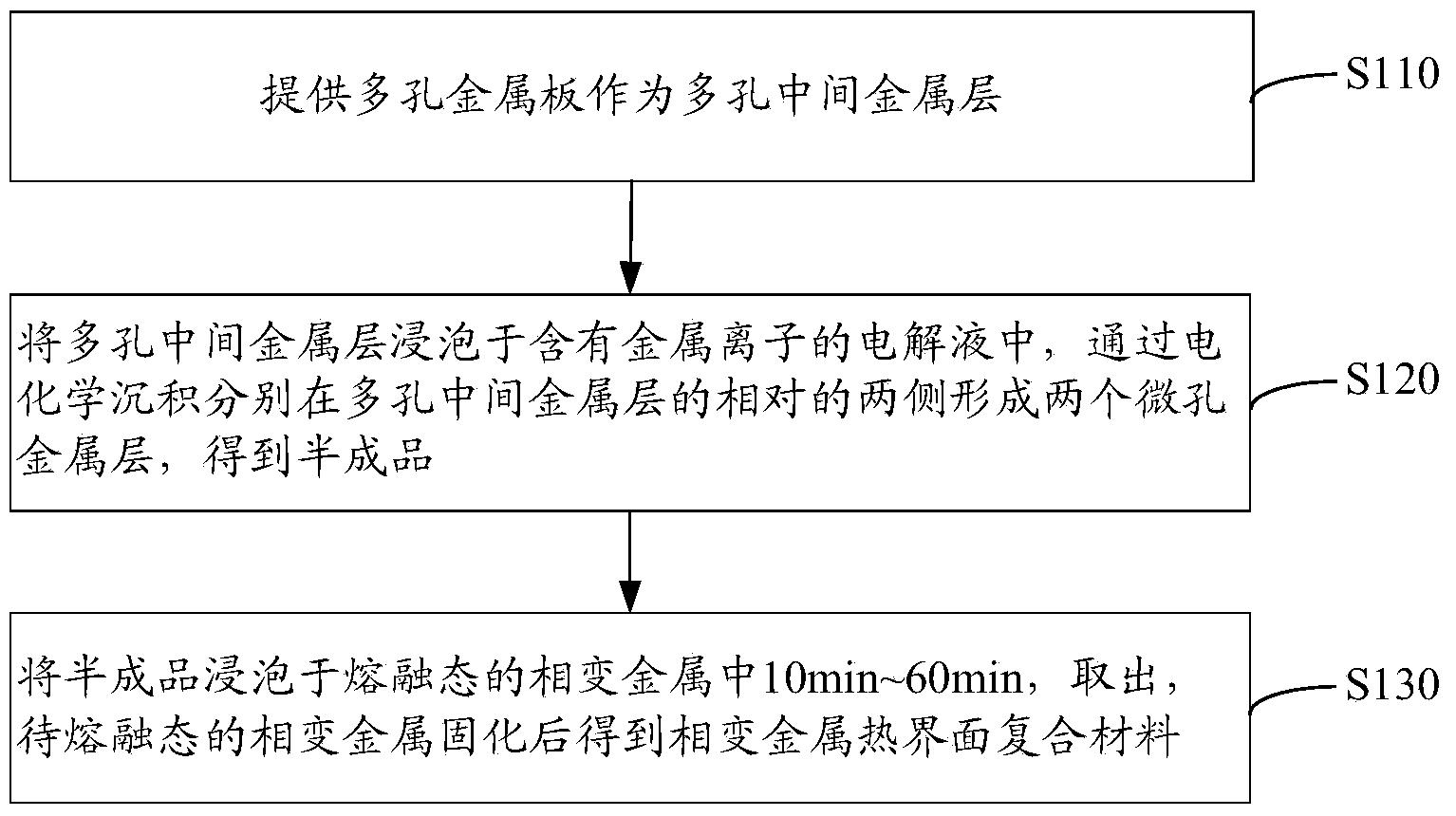

Phase-change metal thermal interface composite material and preparation method thereof

ActiveCN103862742AWon't overflowSuppress overflowSemiconductor/solid-state device detailsSolid-state devicesMolten statePhase change

The invention relates to a phase-change metal thermal interface composite material and a preparation method thereof. The phase-change metal thermal interface composite material comprises a porous middle metal layer, two microporous metal layers respectively arranged at two opposite sides of the porous metal layer, and phase-change metal, wherein the the porous middle metal layer and the two microporous metal layers are filled with the phase-change metal. The composite material has the advantages that the porous middle metal layer serving as a structure supporting layer can bear certain pressure to ensure that the phase-change metal in a molten state cannot be extruded and overflown and the phase-change metal can run through up and down to ensure that the phase-change metal thermal interface composite material has the low thermal resistance and the high heat-conducting property; the phase-change metal can be effectively prevented from being overflown by adopting the two microporous metal layers, after being molten and expanded, the phase-change metal can be oozed from micropores of the microporous metal layers to effectively fill up gaps in the composite material and no hole occurs in the using process.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

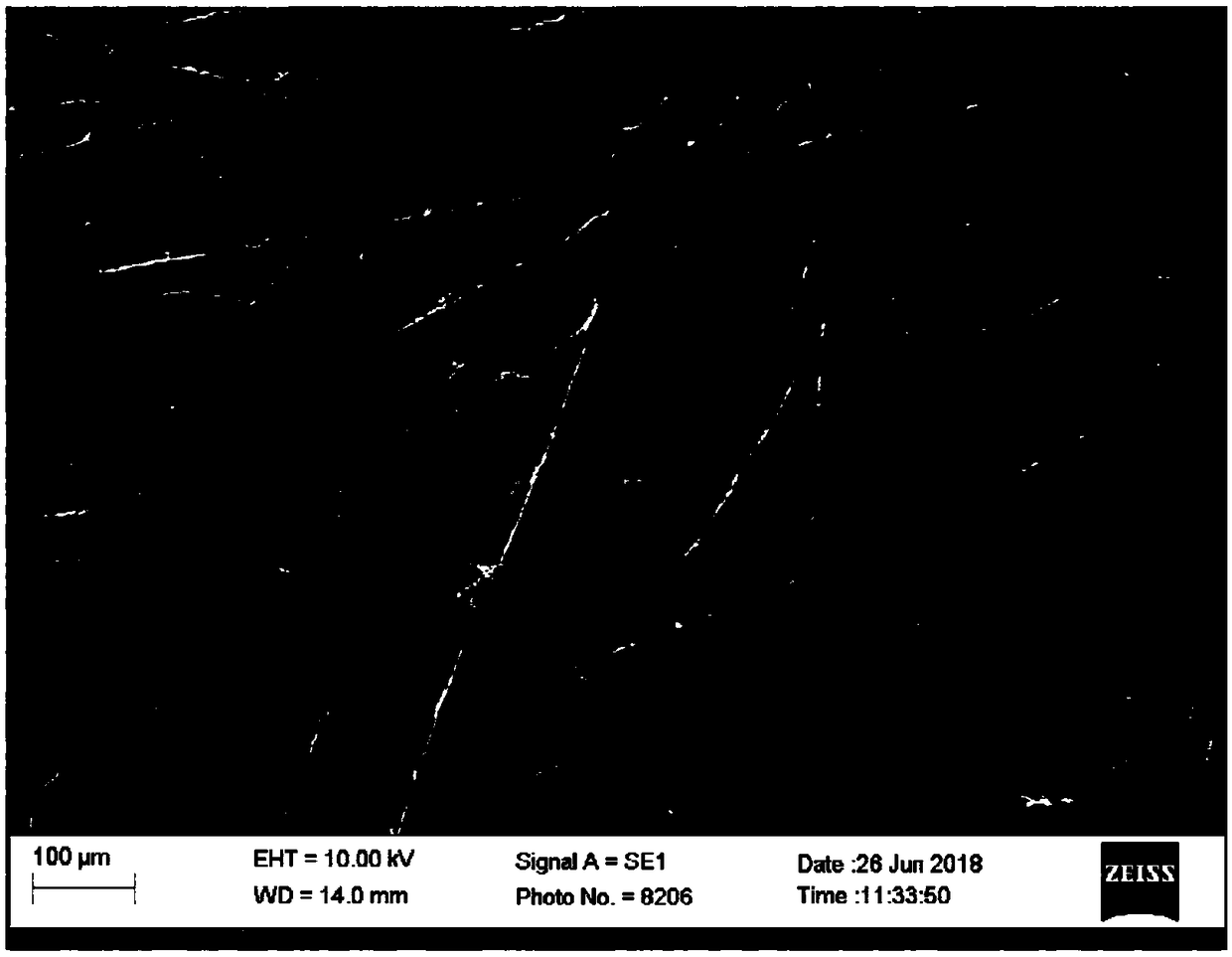

Preparation method of silver nanowire modified flexible fiber sensor electrode

ActiveCN107525832AHigh tensile strengthExcellent electrical performanceElectroconductive/antistatic filament manufactureFibre typesConductive materialsGraphene

The invention relates to the field of sensors, and discloses a preparation method of a silver nanowire modified flexible fiber sensor electrode. A flexible conductive fiber is prepared with a solution mixing method, wherein SBS (styrene-butadiene-styrene) is taken a as flexible substrate, poly 3,4-ethylenedioxythiophene-polystyrene sulfonate-graphene is taken as a conductive material, the electrode is modified with a silver nanowire, and the silver nanowire modified flexible fiber sensor electrode containing SBS / graphene / poly 3,4-ethylenedioxythiophene-polystyrene sulfonate is obtained. The sensor electrode can be applied in the fields of medical biological monitoring, environment and hygiene monitoring and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Composite papermaking nano reinforced aramid paper and preparation method thereof

PendingCN112609493AImprove dispersion compatibilityImprove evennessPulp beating methodsDryer sectionAdhesivePapermaking

The invention belongs to the technical field of papermaking, and particularly relates to composite papermaking nano reinforced aramid paper and a preparation method thereof. By utilizing the characteristics of easy dispersion, large specific surface area and the like of the para-aramid nanofibers in a solution, the para-aramid nanofiber composite wet paper sheet replaces the traditional pulp wetting agent and adhesive, and the para-aramid nanofiber composite wet paper sheet is prepared from the traditional chopped fibers and pulp or fibrids. Then the para-aramid nanofiber dispersion liquid is subjected to spraying sizing treatment on the surface of the aramid wet paper sheet, then compounding and drying forming are carried out, and the sprayed and compounded paper sheet can significantly improve the uniformity, dielectric property and mechanical strength of aramid paper, improve the forming thickness of finished aramid paper, improve the production efficiency and the like; and the negative influence on the performance of the paper sheet due to the introduction of a third adhesive or a wet strength agent is avoided.

Owner:山东聚芳新材料股份有限公司

Preparation method of steel fiber composite bar

The invention discloses a preparation method of a steel fiber composite bar. The steel fiber composite bar is obtained by compounding a thread steel bar inner core, a fiber cloth and a basalt fiber bundle and has a reasonable construction structure; the fiber cloth and the basalt fiber bundle used as reinforcing materials are fully dipped in resin, so the design strength of the reinforced concrete structure can be effectively met; and the method overcomes the defects of strong brittleness, high price and the like of present fiber reinforced composite materials (FRP), and is suitable for wide popularization use. The preparation method is simple, the circumferential winding of the basalt fiber bundle can effectively fills a gap between the projection rib of the thread steel bar inner core and the fiber cloth, and substantially reduces the strength and rigidity weakening due to the local bending of the fiber cloth during the compounding of the vertical fiber (fiber cloth) with the thread steel bar.

Owner:SICHUAN AEROSPACE WU YUAN COMPOSITE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com