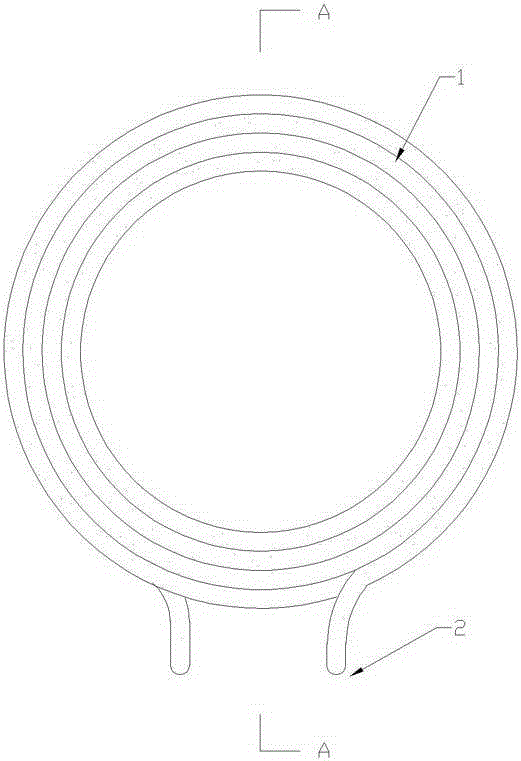

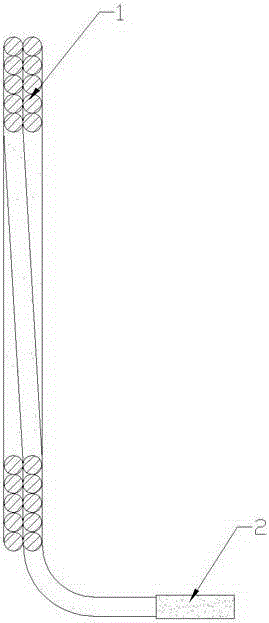

Double-outer-lead-terminal coil winding machine and winding process

A technology of double outer leads and winding machine, applied in the direction of coil manufacturing, etc., to achieve the effects of high production efficiency, rapid processing, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

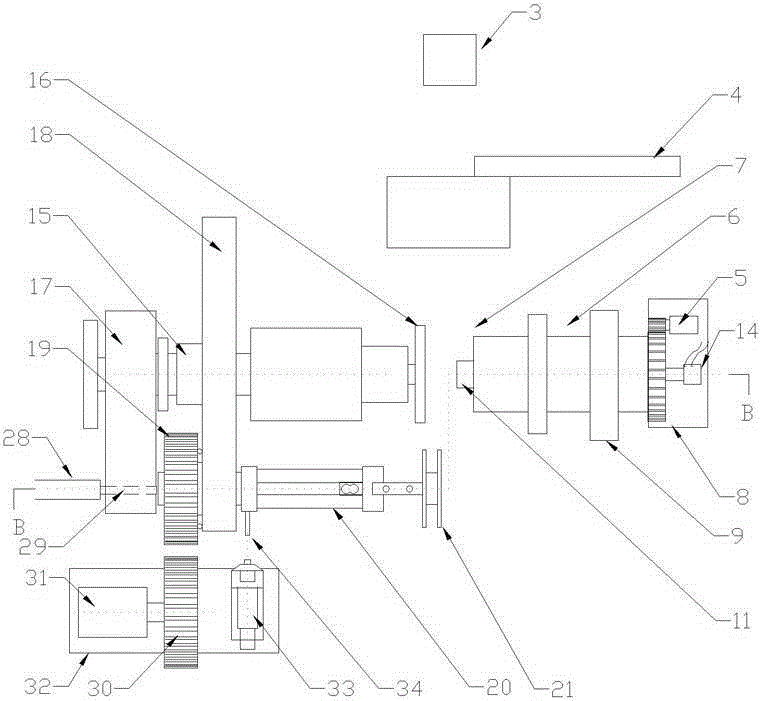

[0020] Reference attached Figure 3-4, a coil winding machine with double outer lead terminals, comprising a whole line part 3, a manipulator assembly 4, a left-hand winding assembly, a right-hand winding assembly, a clutch drive assembly, a base and a program controller; it is characterized in that: the whole The wire part 3 is composed of a wire bracket, a wire holder and a pressing block buckled above the wire holder; the upper surface of the wire holder and the lower pressing surface of the pressing block are covered with wool pads; Installed on the base, and the rotating shaft parts in the left and right revolving assemblies are coaxially facing; when the left revolving assembly and the right revolving assembly are relatively close together, the left die head 16 of the left revolving assembly and the The right die head 7 and core mold 11 of the right turn winding assembly form a coil winding mold; the left turn winding assembly is composed of a left drive motor, a left ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com