Roller shutter and roller shutter system manufactured by applying same

A technology of roller blinds and reels, applied in the field of roller blind systems, which can solve problems such as easy tilting and unstable operation of roller blinds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

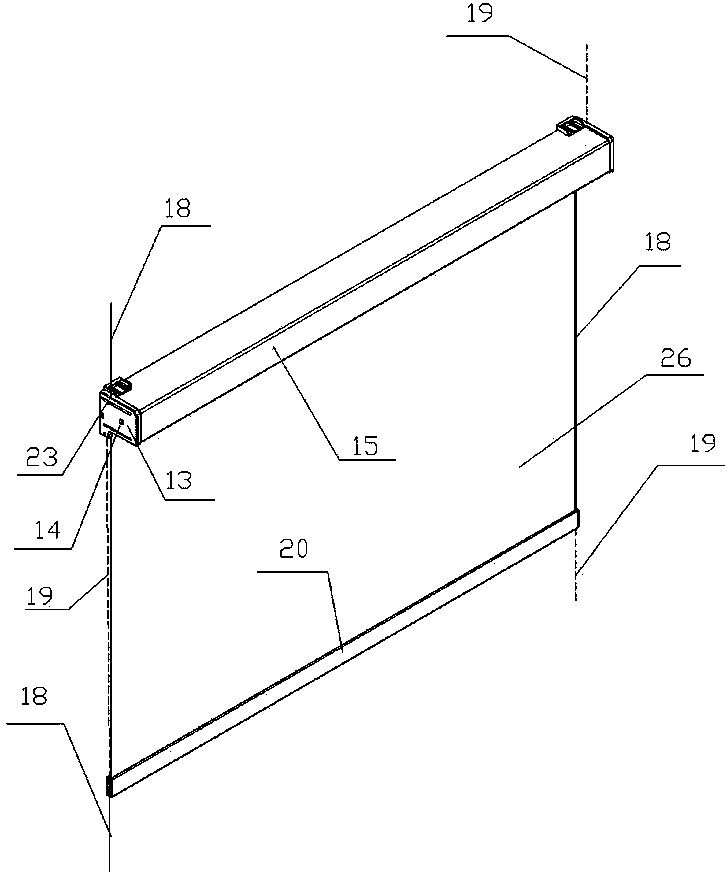

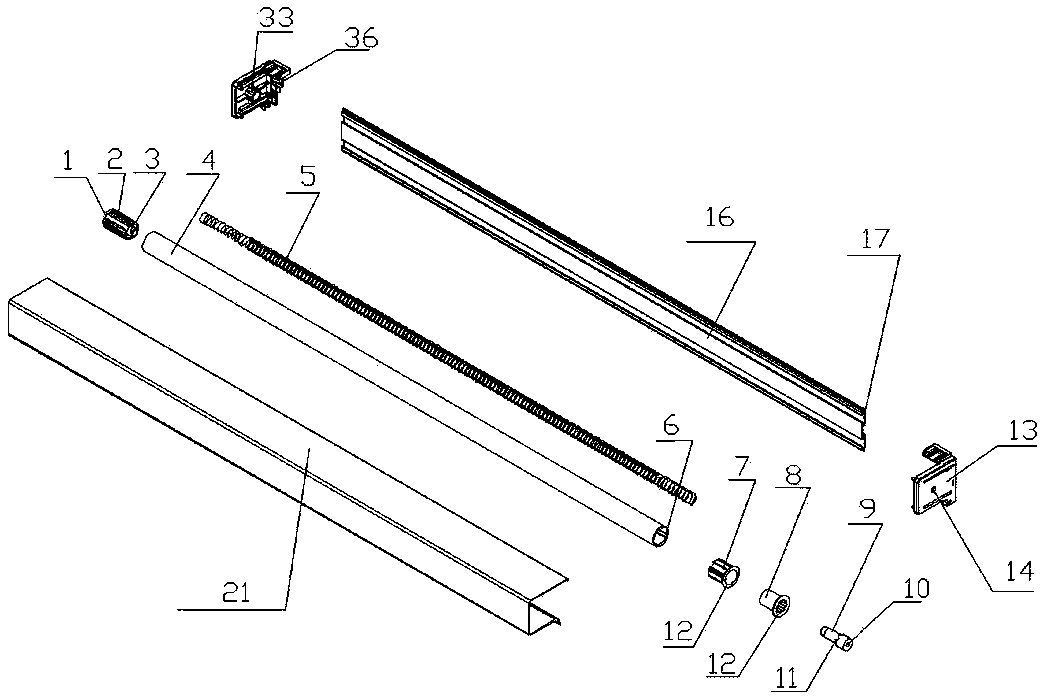

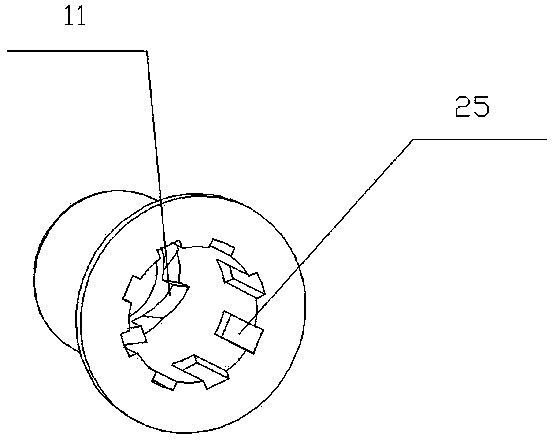

[0041] Such as figure 1 As shown, a roller blind includes a reel assembly 15 located at the upper end of the curtain 26 and a floor assembly 20 located at the lower end of the curtain 26 . The reel assembly 15 includes a reel 4 and end caps 13 located at both ends of the reel 4 , and a curtain 26 is wound around the reel 4 . A sleeve cover 21 and a reel rear cover 16 are connected between the two end covers 13. The reel cover 21 and the reel rear cover 16 form a cavity, and the reel 4 is installed in the cavity.

[0042] There are two ropes arranged at the two ends of the curtain, and the two ends of the two ropes are respectively fixed on the fixtures outside the roller blind, such as on the window frame or the wall (not shown), and the reel assembly 15 passes through the inlet on the end cover. The wire hole connects the reel assembly to the rope, and the reel assembly can move up and down on the rope. The base plate assembly passes through the wire channel 29 on the base c...

Embodiment 2

[0052] Such as Figure 8 As shown, the difference from Embodiment 1 is that the bottom plate assembly 20 is on the top, and the reel assembly 15 is on the bottom. The second wire inlet hole 22 at the lower end of the end cover 13 passes through, and the second wire inlet hole 22 is located at the rear end of the first wire inlet hole 24, which can effectively prevent the reel assembly 15 from being tilted and unstable.

Embodiment 3

[0054] Such as Figure 9 As shown, the difference from Embodiment 1 is that the rope is fixed on the reel assembly, and the reel assembly is fixed on a fixed object such as a roller blind, such as a wall or a window frame. The fixing of the reel assembly is through the end cover 13 and the end cover. The connection between the end cover cover plate 43 on the outside of 13 is realized.

[0055] There is an end cover cover 43 on the outside of the end cover 13, and the end cover cover 43 is "L" shaped. On one side of the end cover cover 43, there are two fixing holes 48 for the end cover cover. Plate 43 is fixed on the body of wall or form, just on the fixture other than roller blind, and the other limit of end cover cover plate is integrally formed with positioning protrusion 44, and the length of positioning protrusion 44 is the same as end cover 13 outer sides. The length of the positioning grooves 42 on the top is the same, because there are three positioning grooves 42 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com