Patents

Literature

169results about How to "Realize the winding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

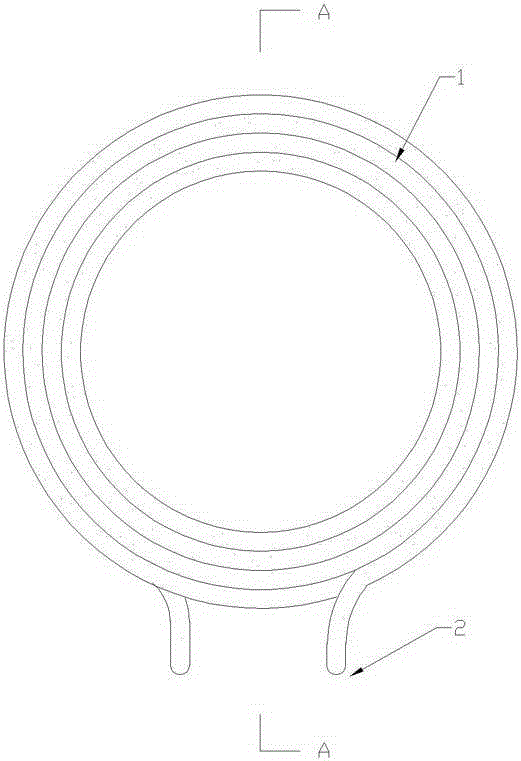

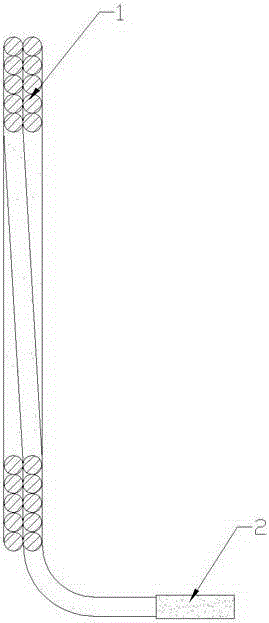

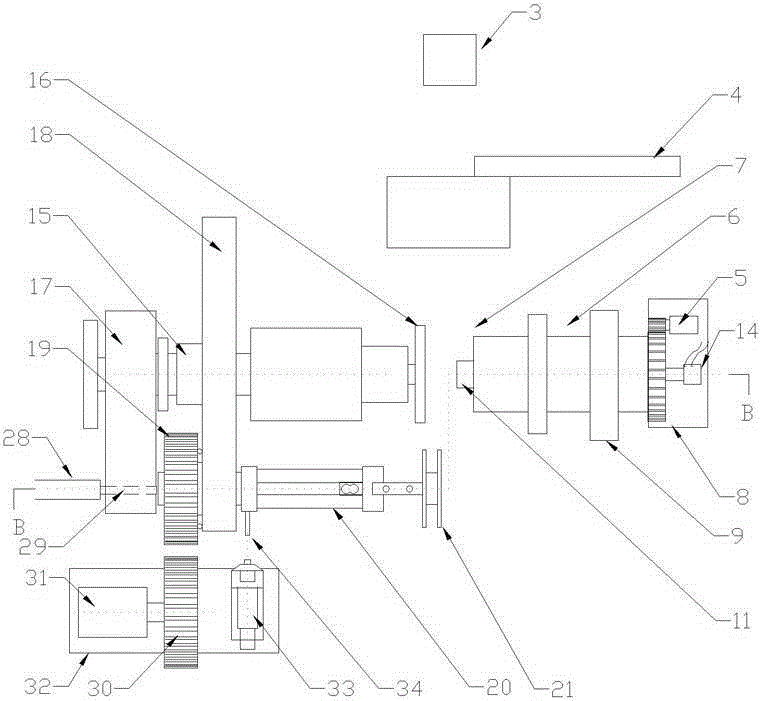

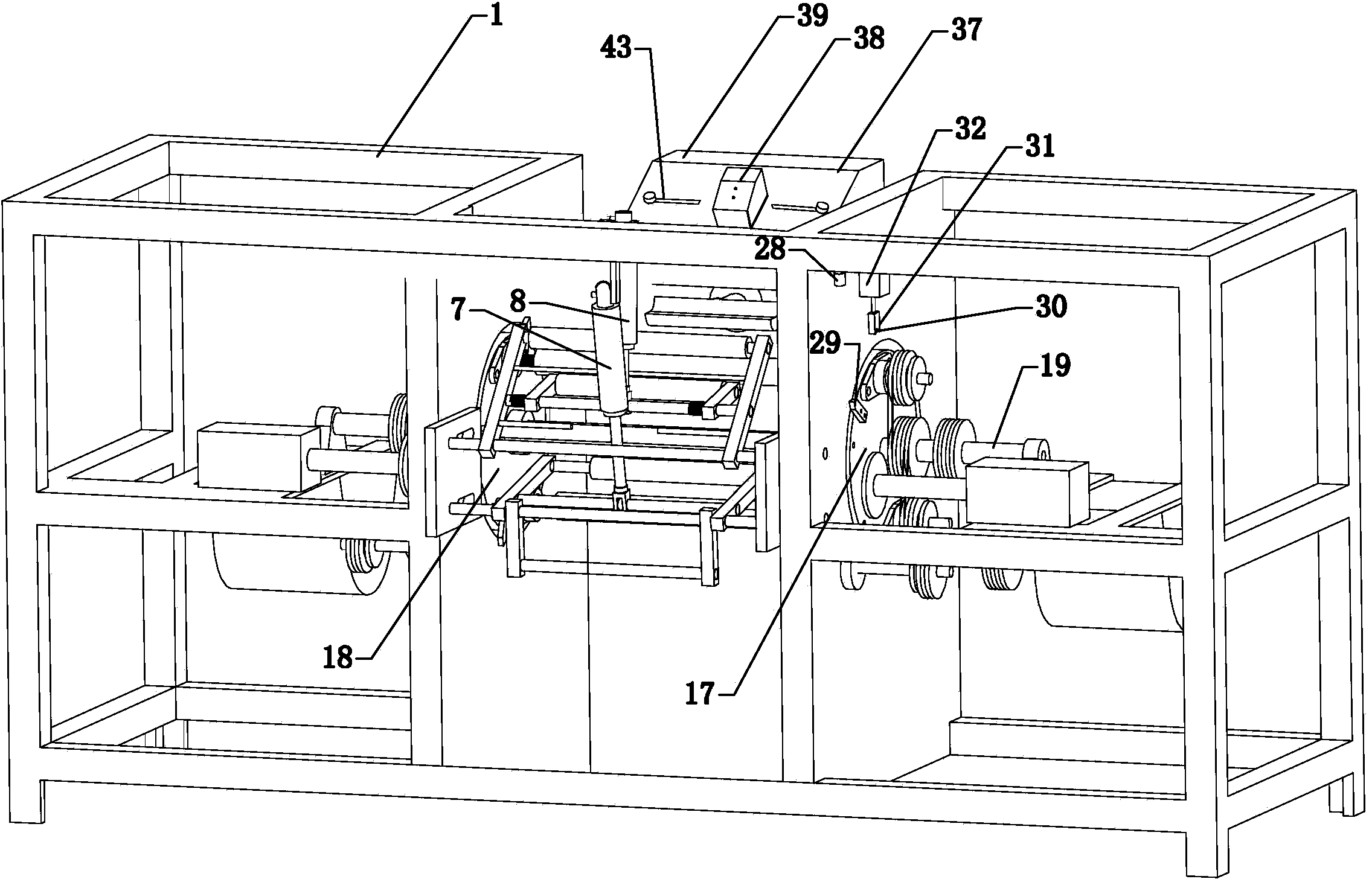

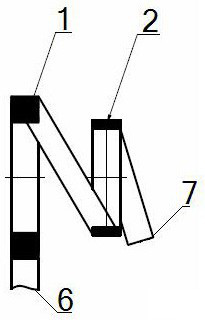

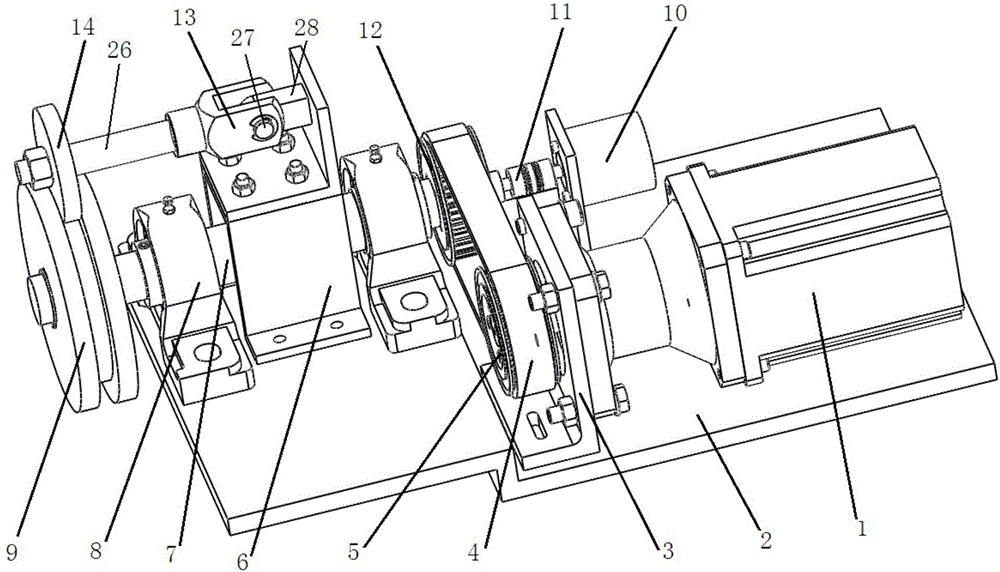

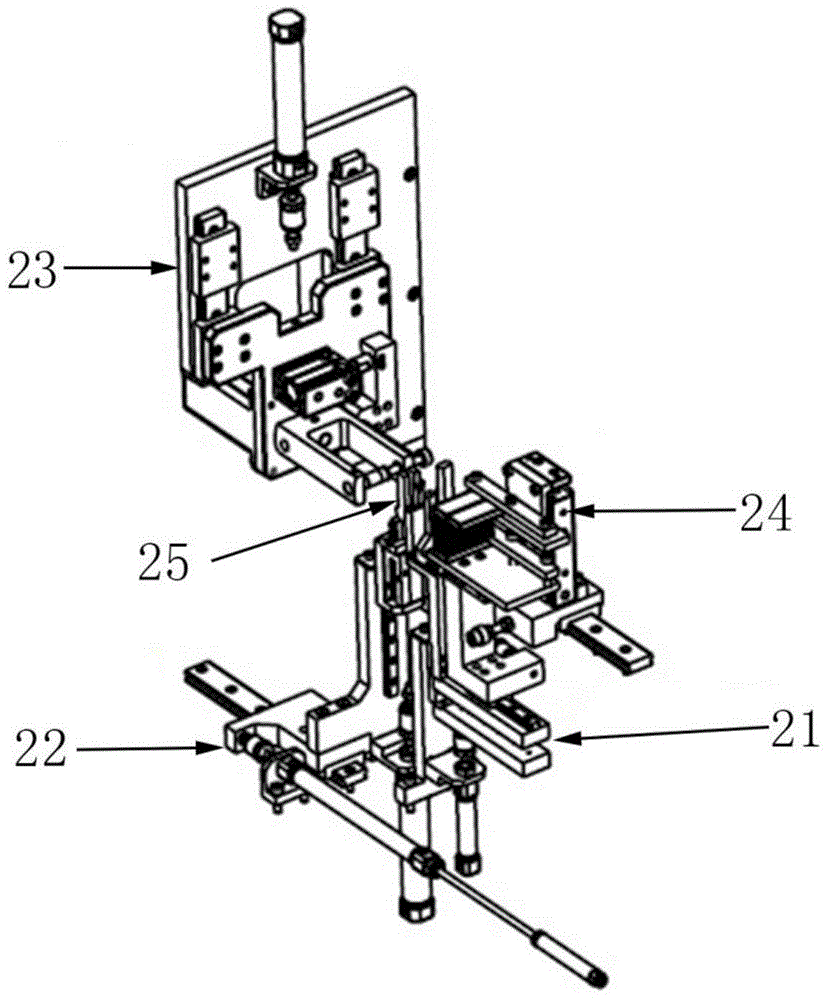

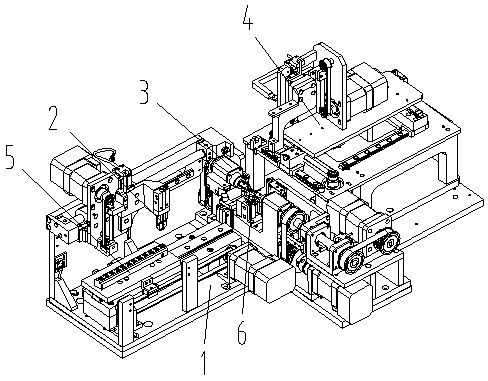

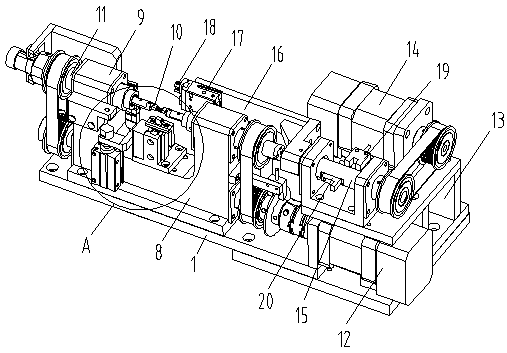

Double-outer-lead-terminal coil winding machine and winding process

ActiveCN105225829ARealize the winding processAchieve demouldingCoils manufactureWinding machineRotational axis

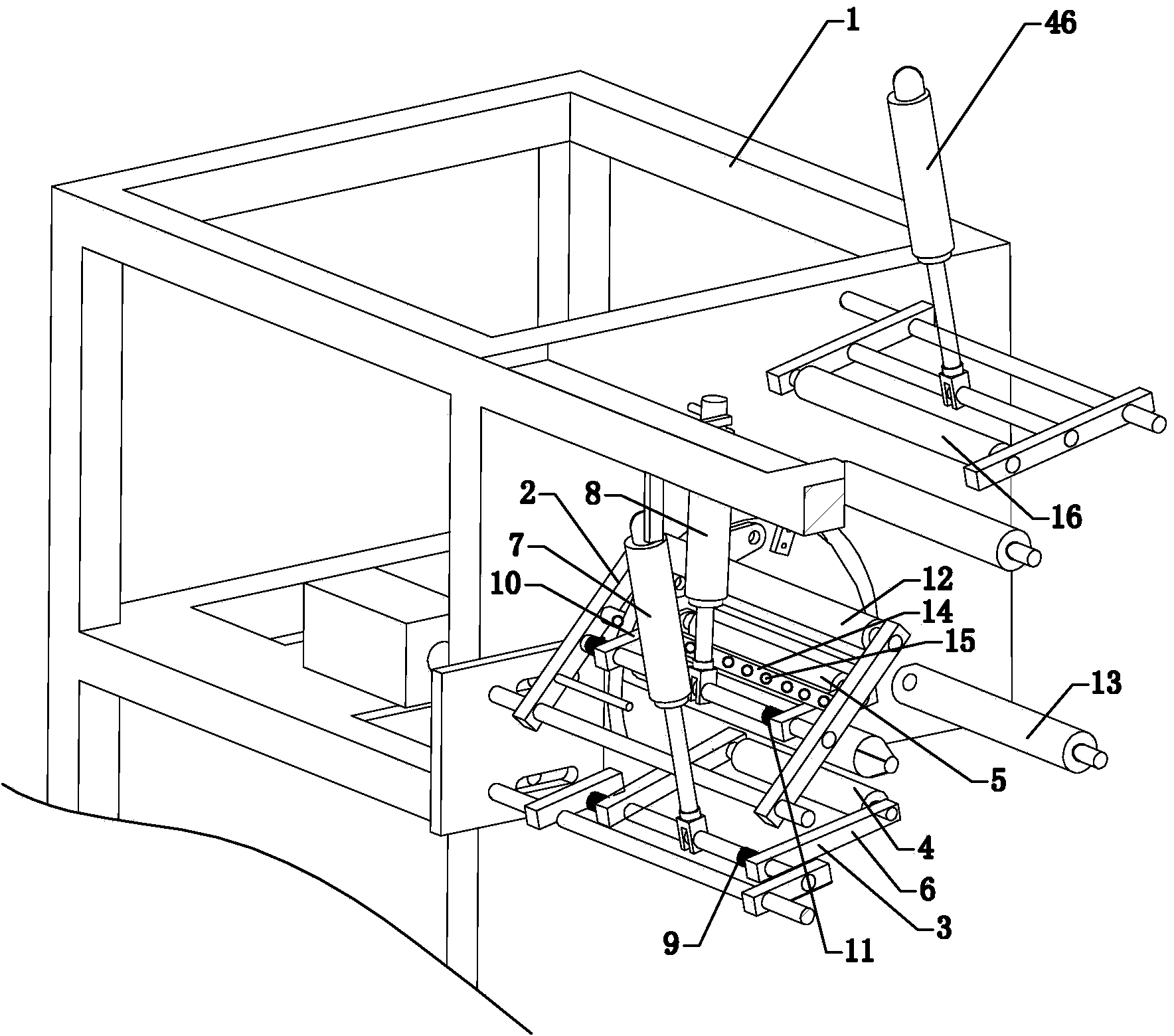

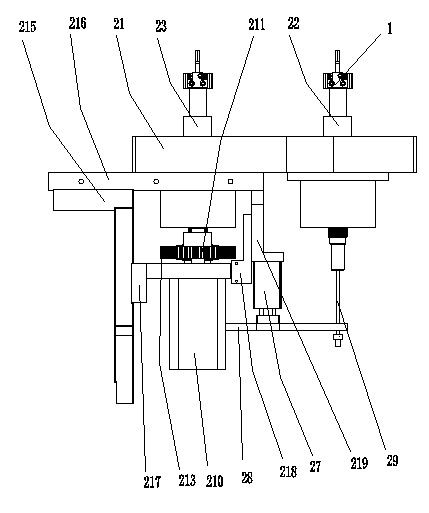

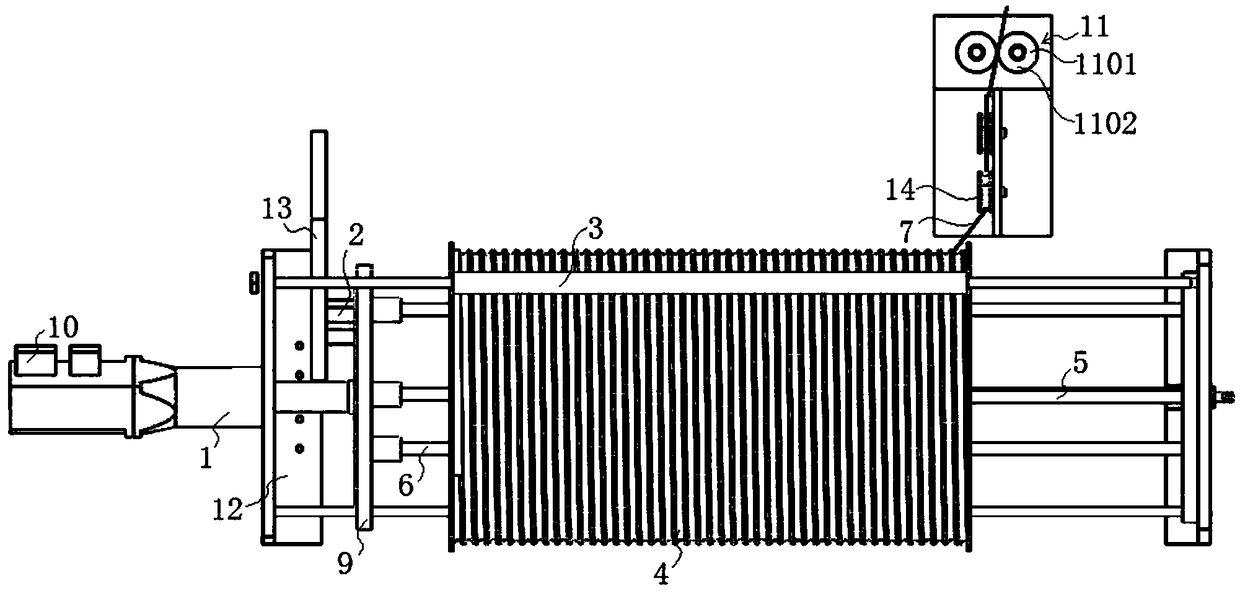

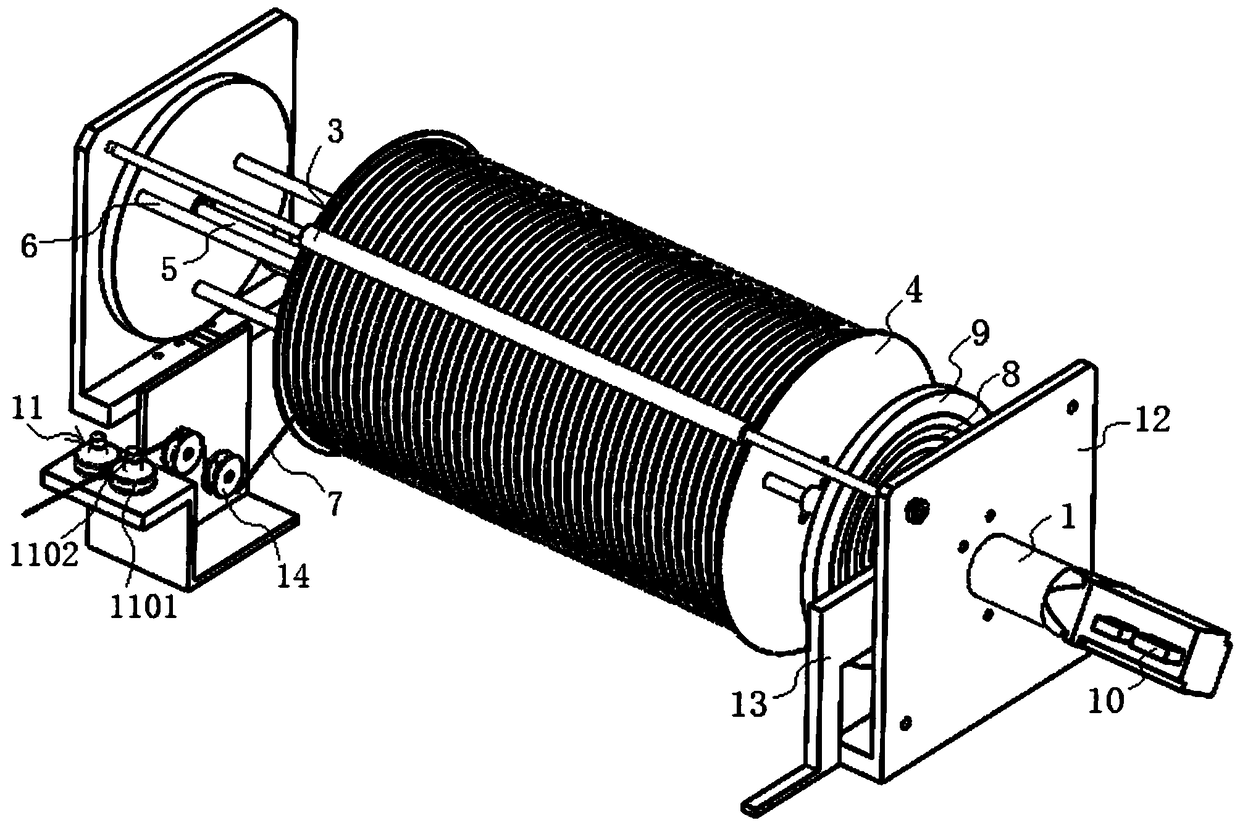

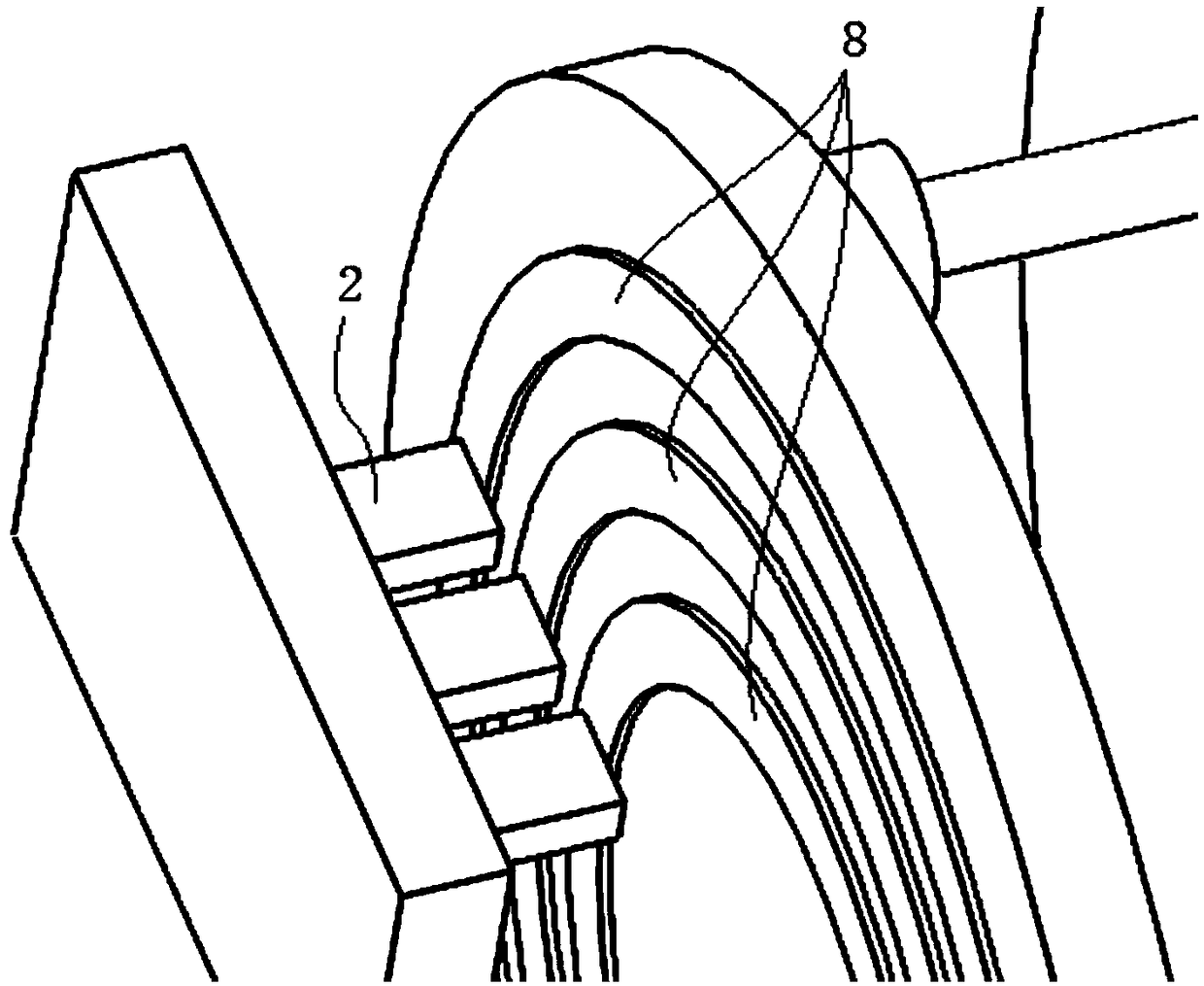

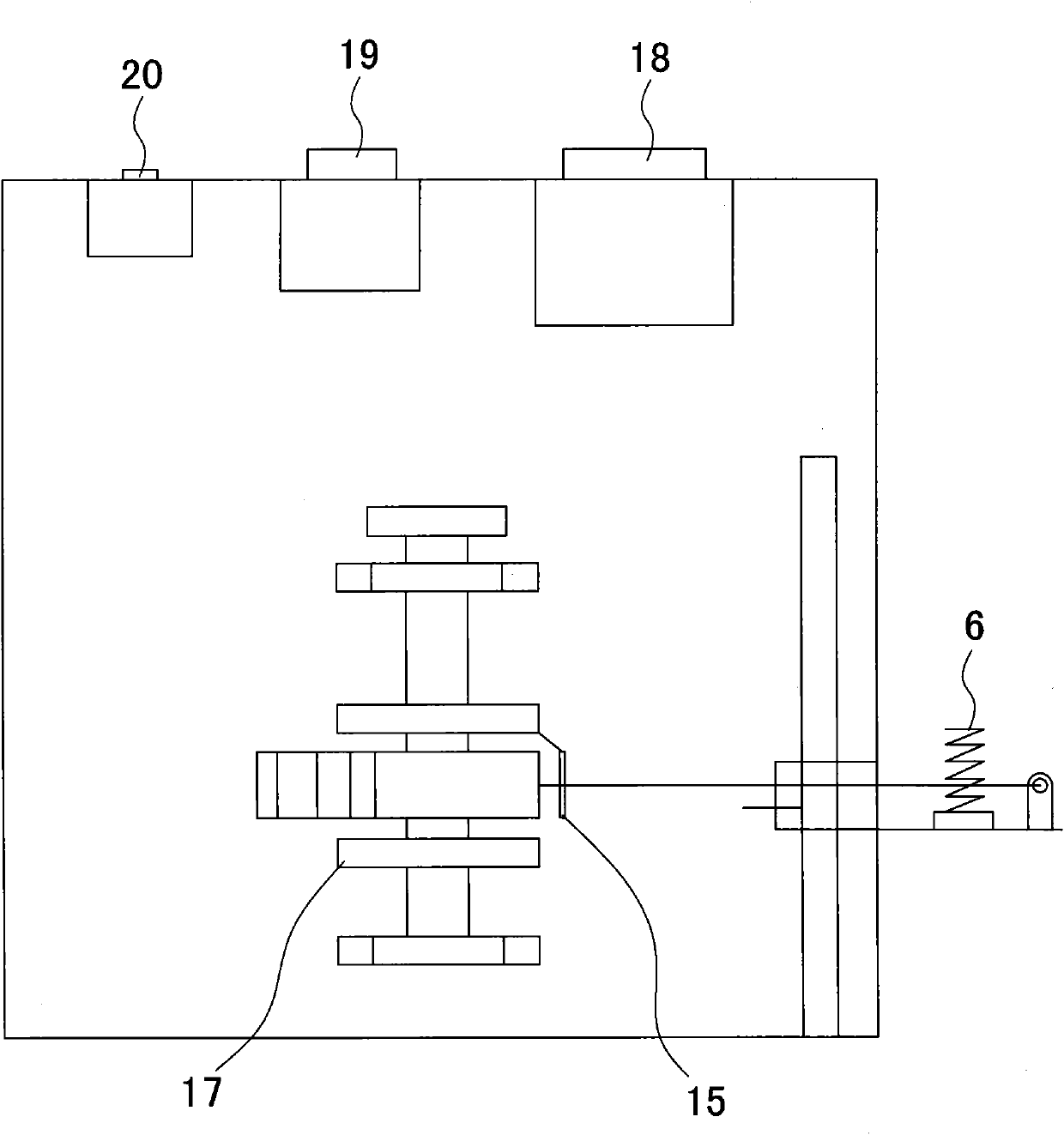

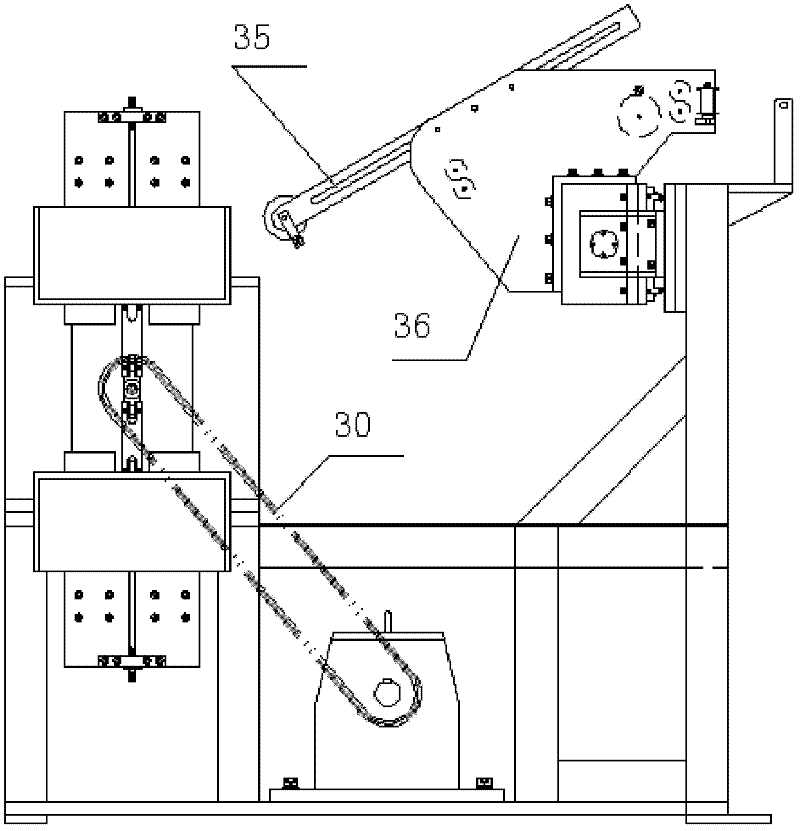

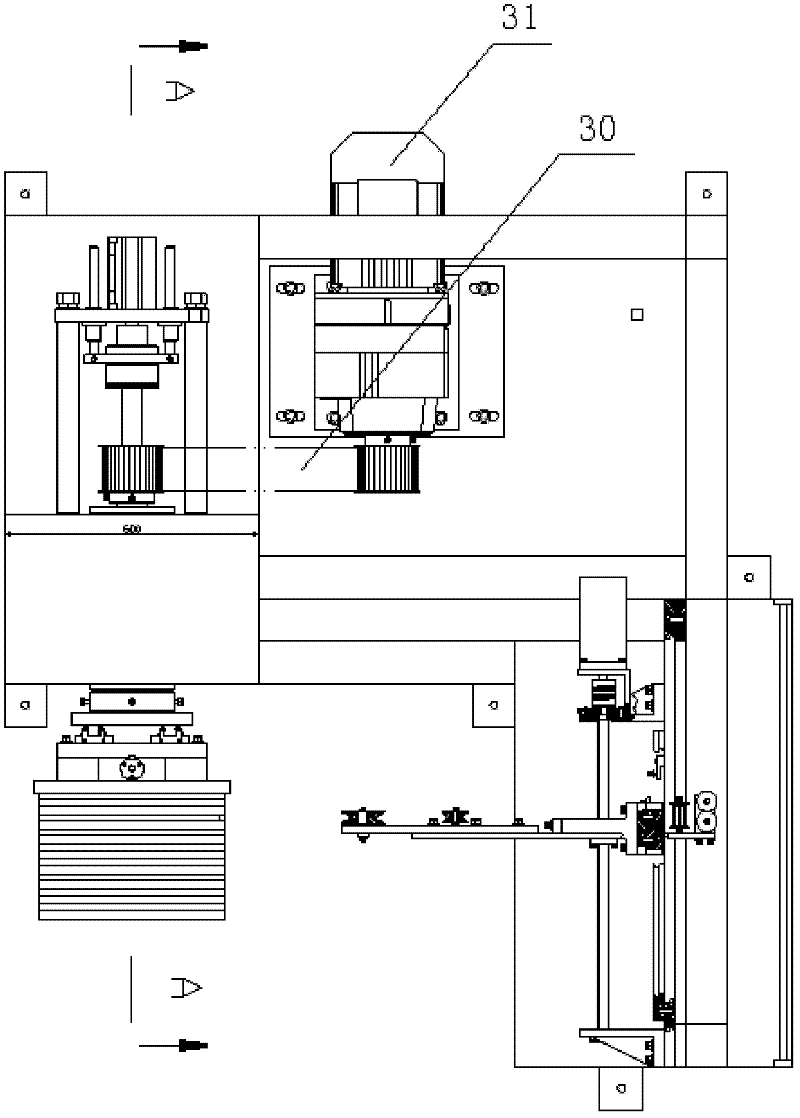

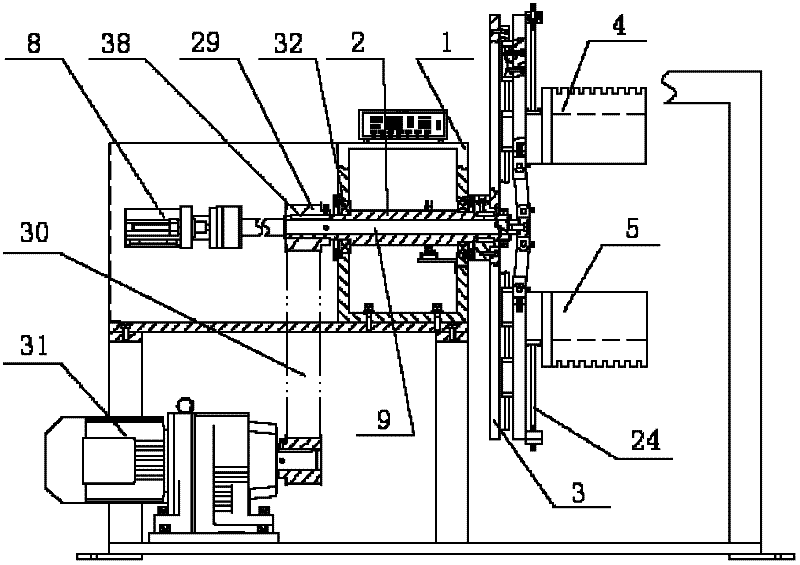

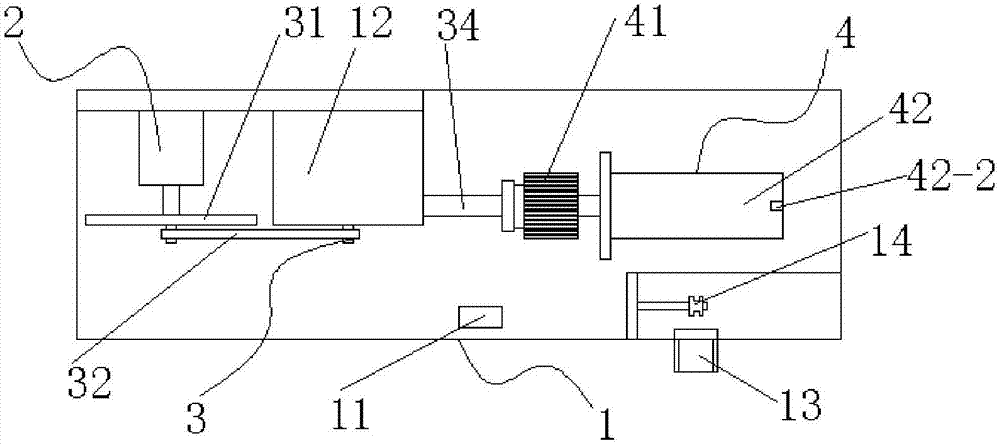

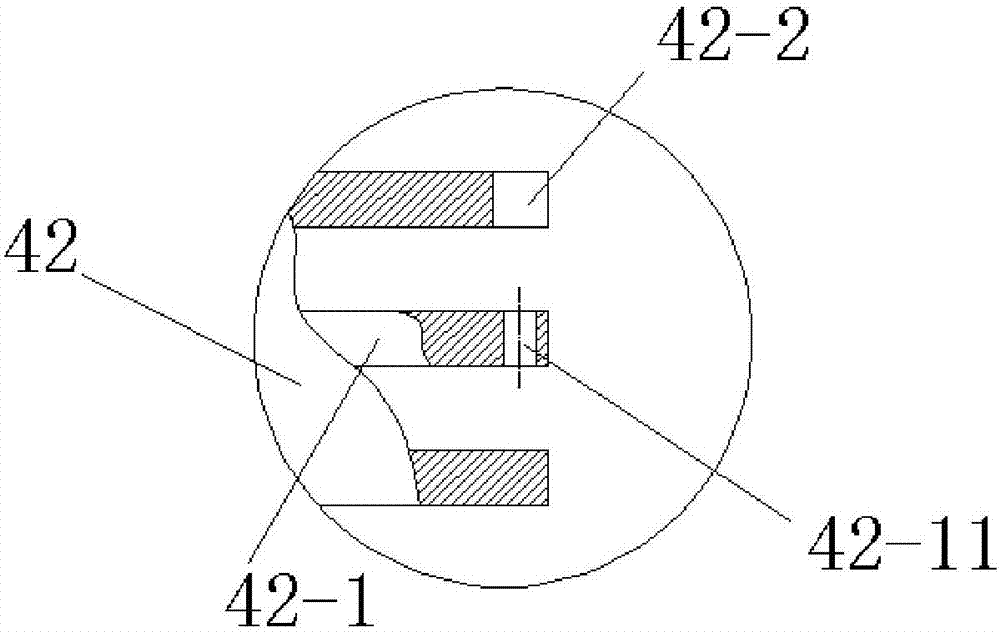

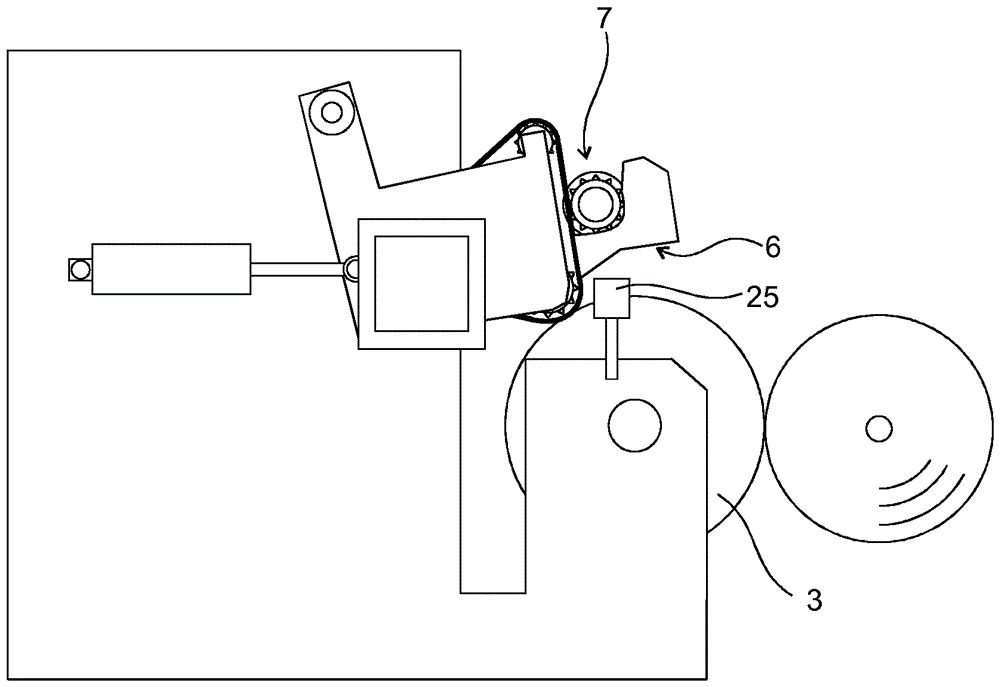

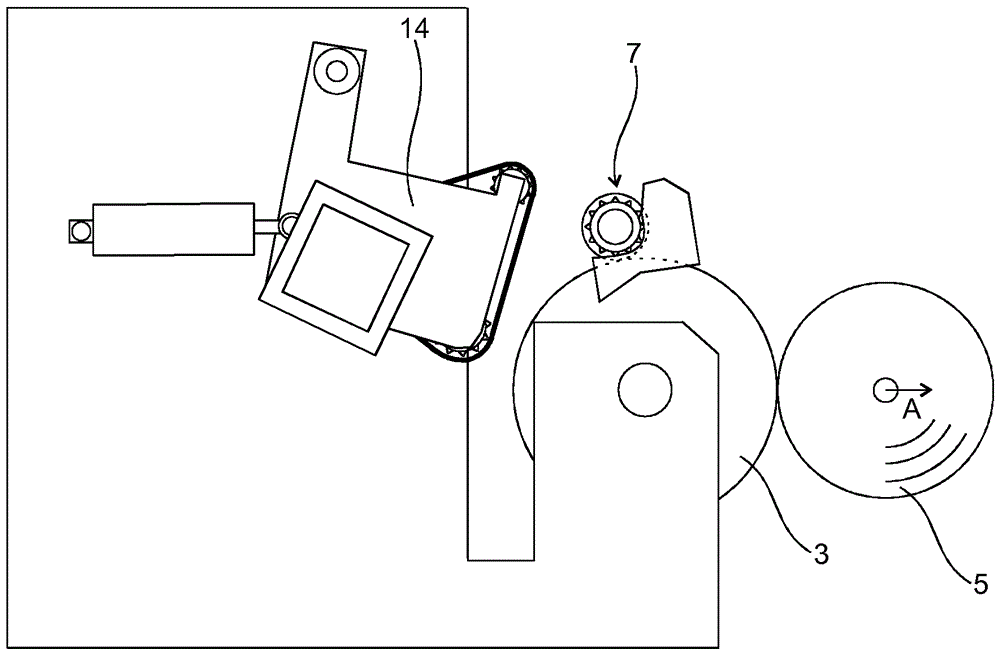

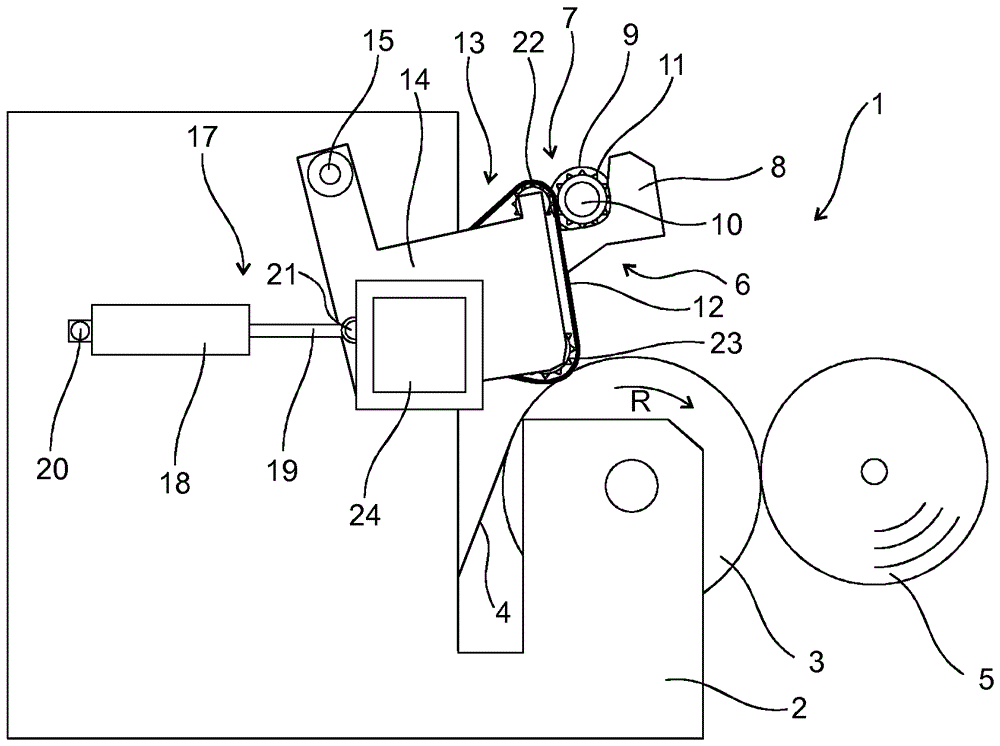

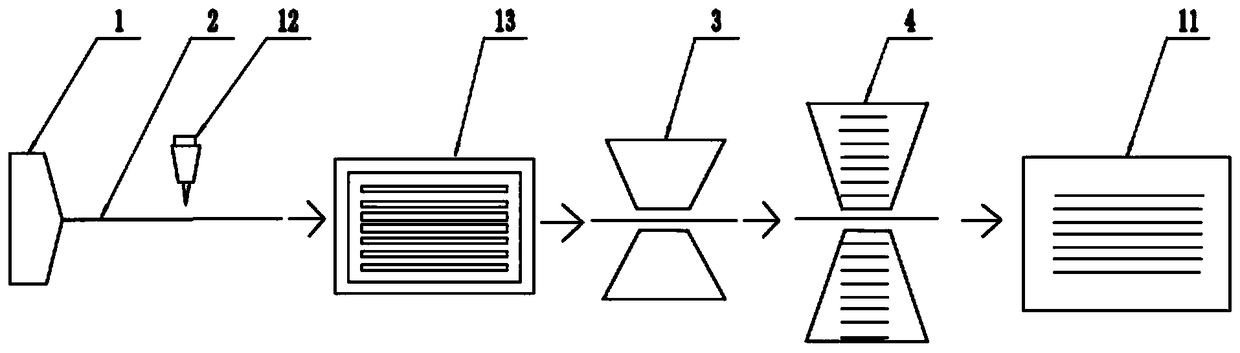

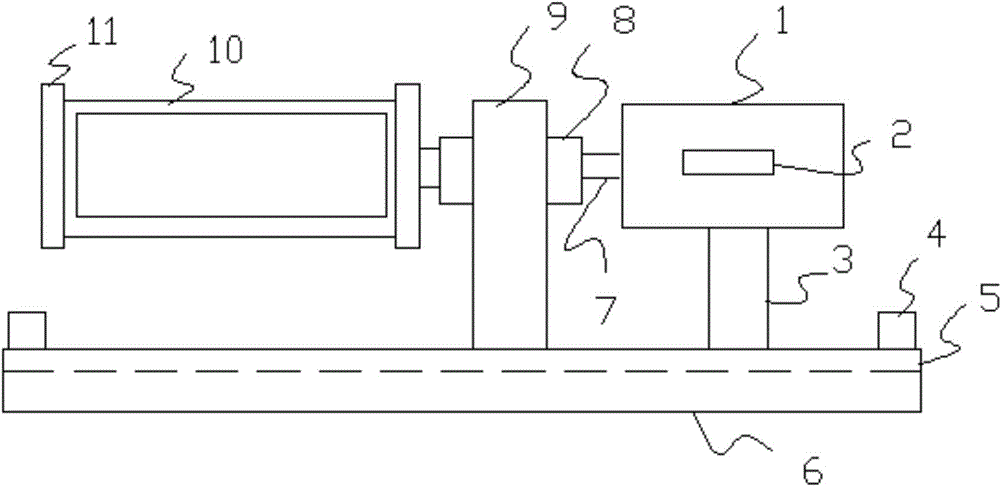

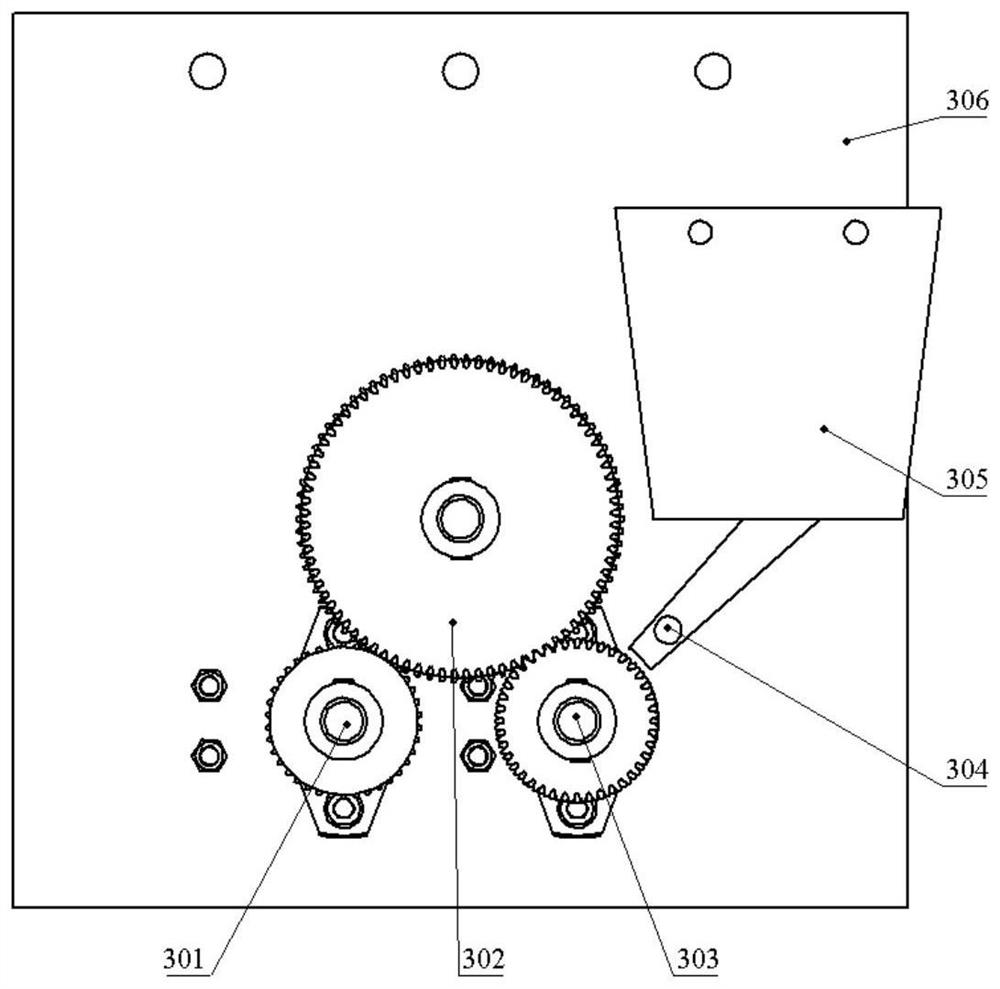

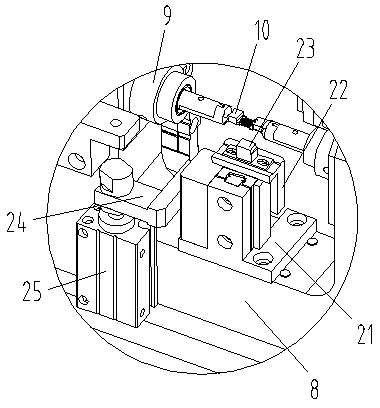

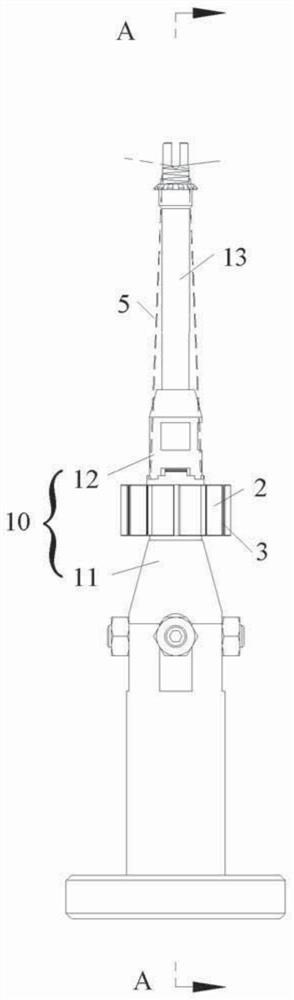

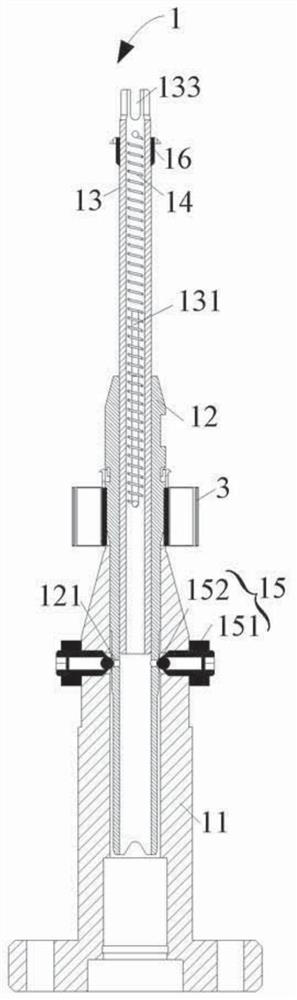

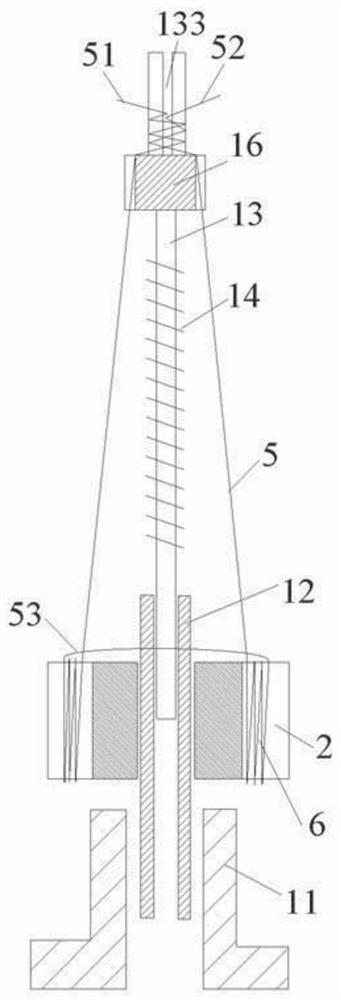

The invention relates to a double-outer-lead-terminal coil winding machine and a winding process. The winding machine structurally comprises a coil sorting component, a mechanical arm component, a left rotating and winding component, a right rotating and winding component, a clutch drive component, a machine base and a program controller. The left rotating and winding component and the right rotating and winding component are arranged on a base, and rotating shaft components in the left rotating and winding component and the right rotating and winding component are coaxially and oppositely arranged; the left rotating shaft of the left rotating and winding assembly is further fixedly provided with a rectangular rotation block provided with a pre-wind-up component. The winding process of the double-outer-lead-terminal coil winding machine includes the steps of system resetting, coil feeding, pre-winding-up, winding and demoulding. By means of the double-outer-lead-terminal coil winding machine and the winding process, double-outer-lead-terminal coils can be machined and produced conveniently and rapidly, and production efficiency is high.

Owner:资兴市弘电电子科技有限公司

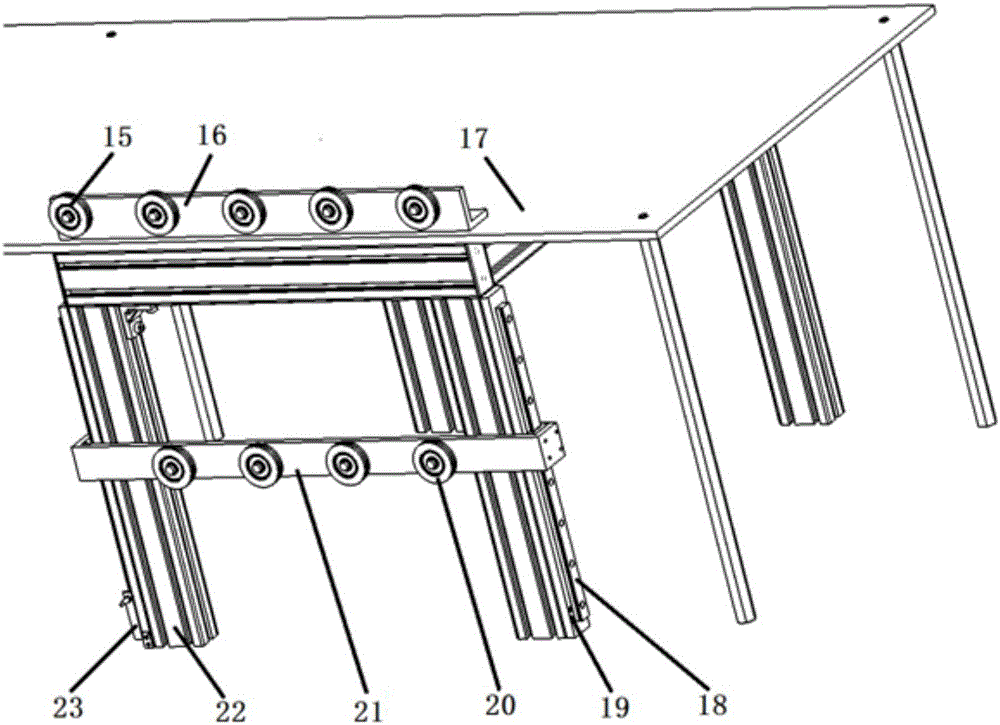

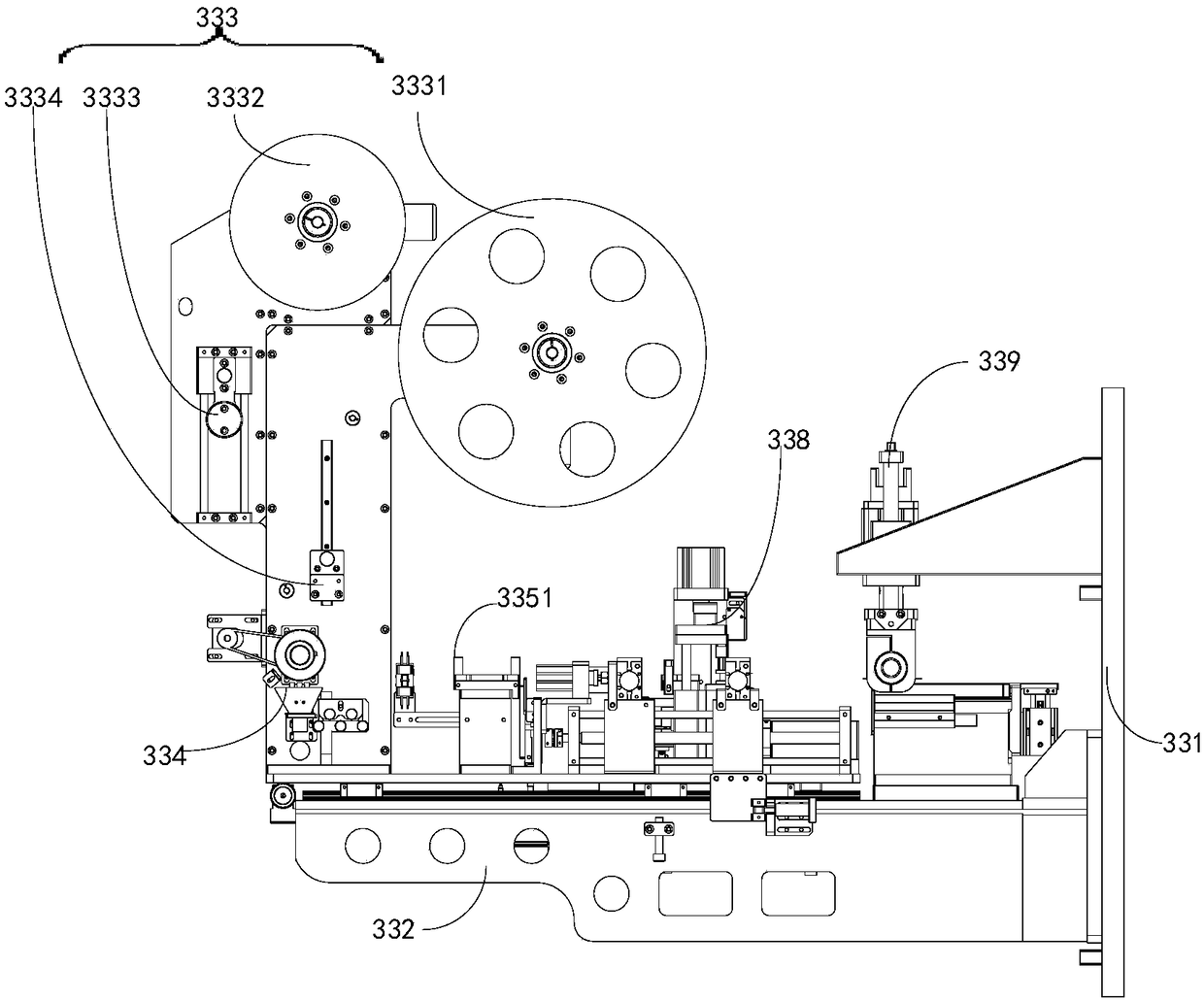

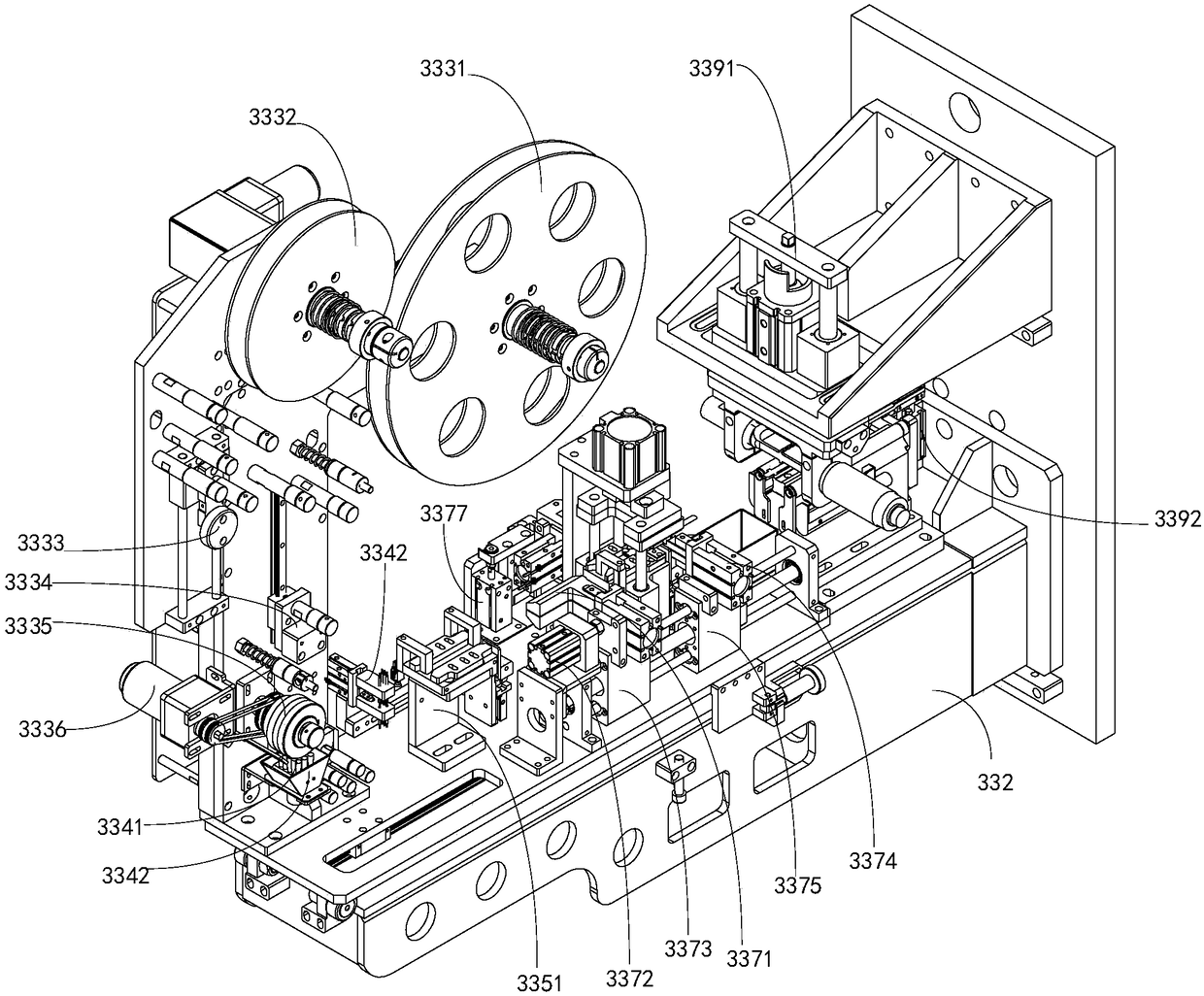

Automatic take-up and reel alternation machine for plastic bags

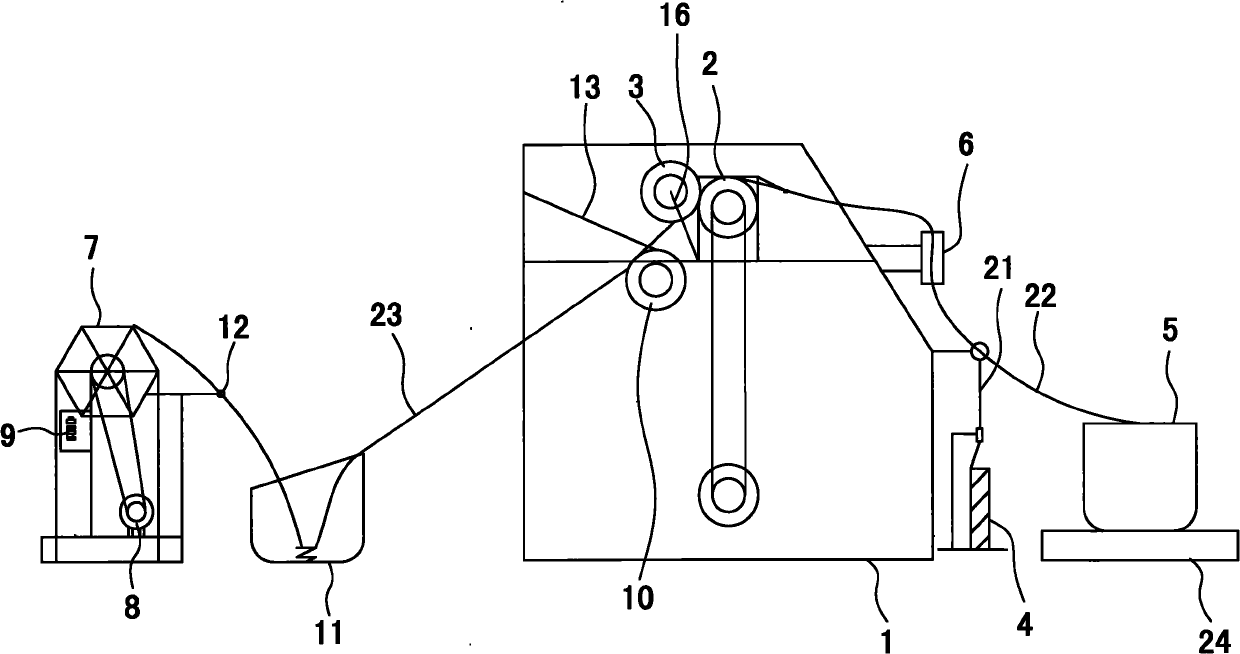

The invention discloses an automatic take-up and reel alternation machine for plastic bags. The automatic take-up and reel alternation machine comprises a machine frame and further comprises a reel-alternating mechanical arm, an overturning mechanism and a clamping mechanism in the conveying direction of plastic bag films. The reel-alternating mechanical arm is used for reel alternation of the plastic bag films and is installed on the machine frame. The overturning mechanism is used for making reels of the plastic bags reach a working position alternately, is installed on the machine frame and is arranged below the reel-alternating mechanical arm. The clamping mechanism is used for clamping and dismantling the reels alternately, is installed on the machine frame and is arranged below the reel-alternating mechanical arm. The automatic take-up and reel alternation machine for the plastic bags is used in cooperation with a bag making machine, realizes automatic take-up and reel alternation of the plastic bag films, is reliable in operation and high in automation degree, lowers the labor intensity of workers, improves the production efficiency of the plastic bag films, and greatly lowers production cost.

Owner:潍坊兴信工程项目管理有限公司

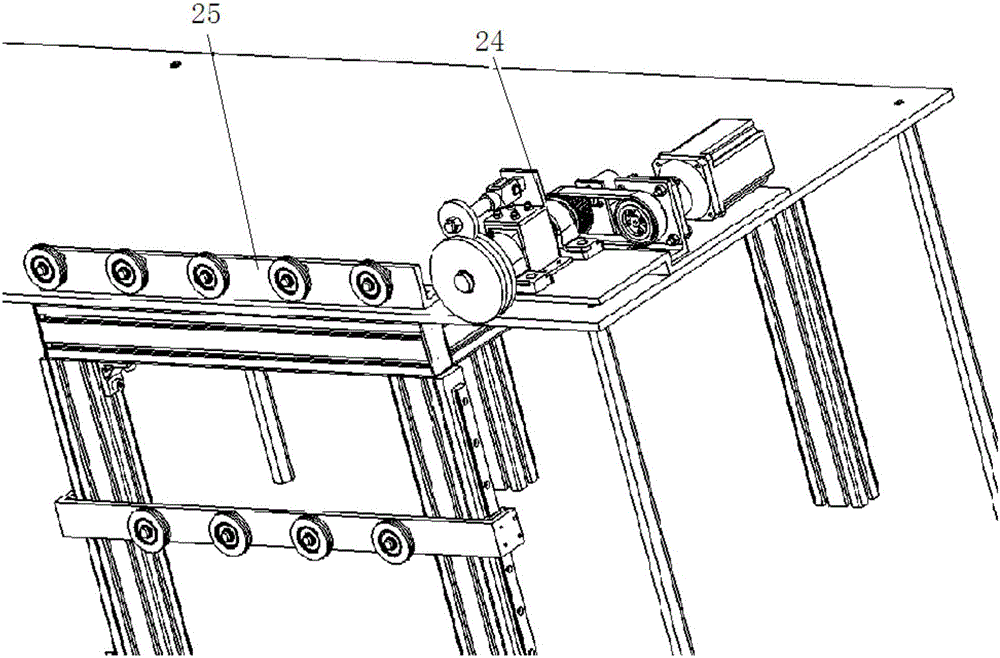

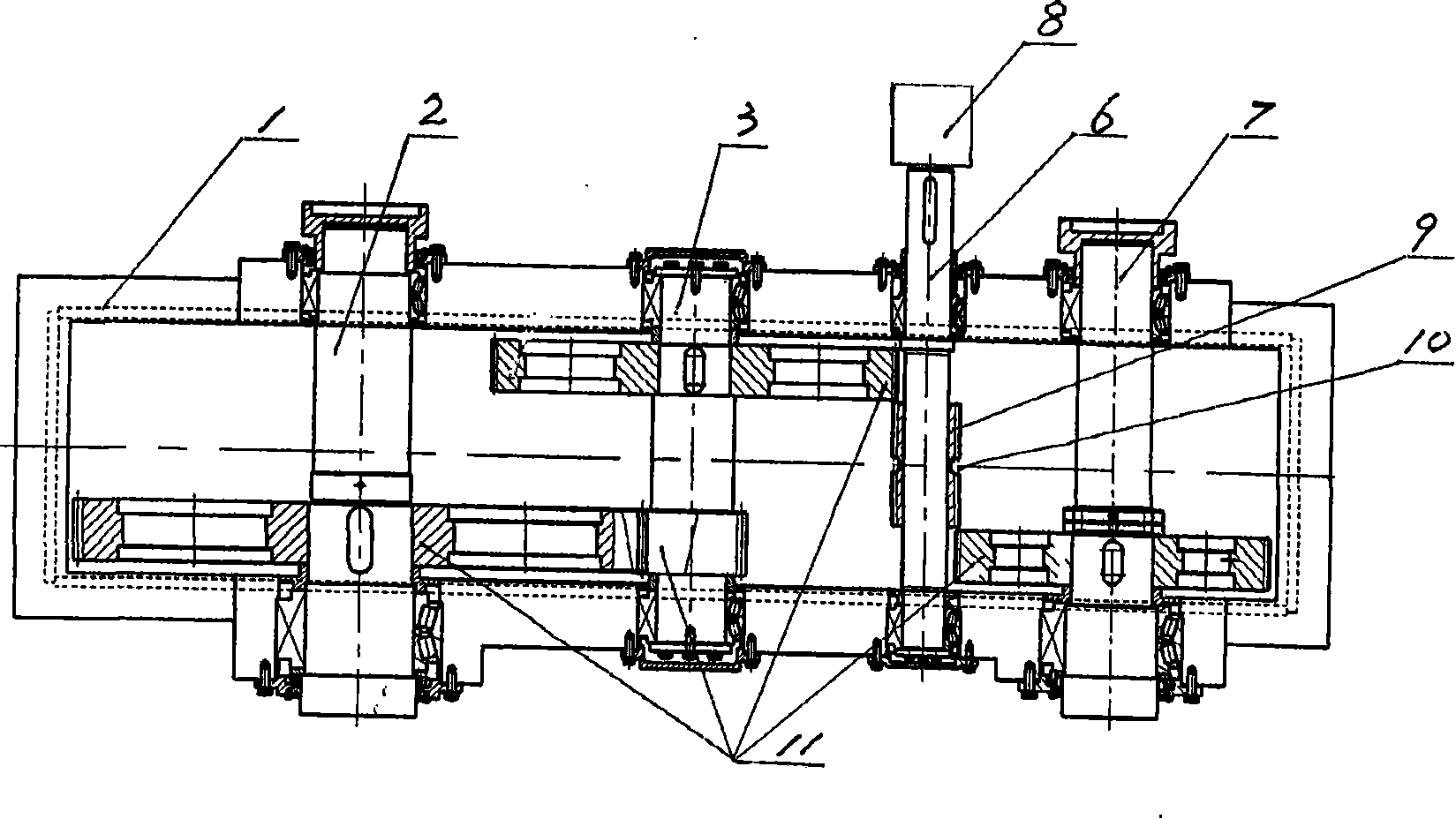

Winding system of winding machine

InactiveCN101917097ASolution to short lifeReliable and smooth windingManufacturing dynamo-electric machinesWinding machineWind system

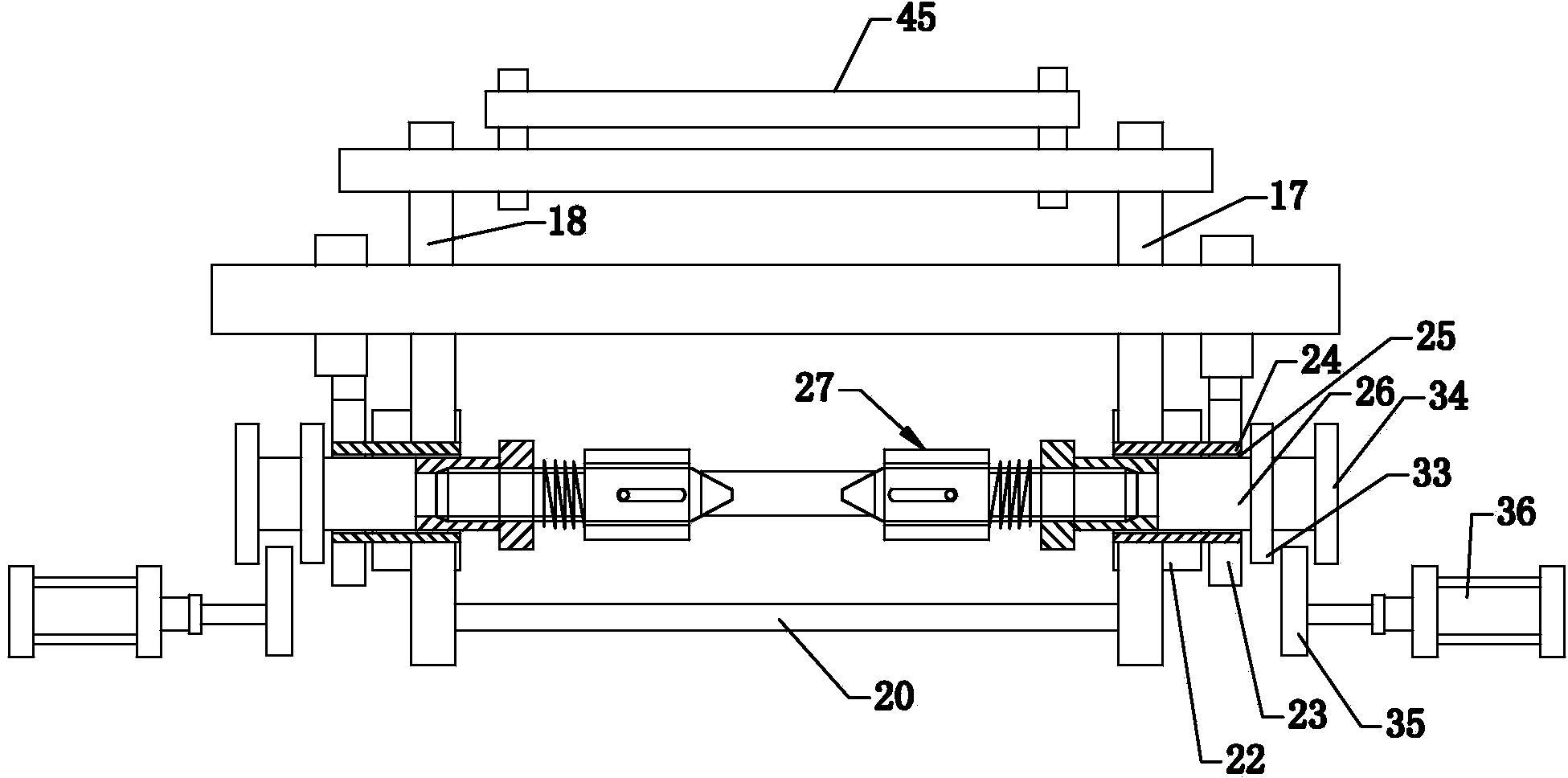

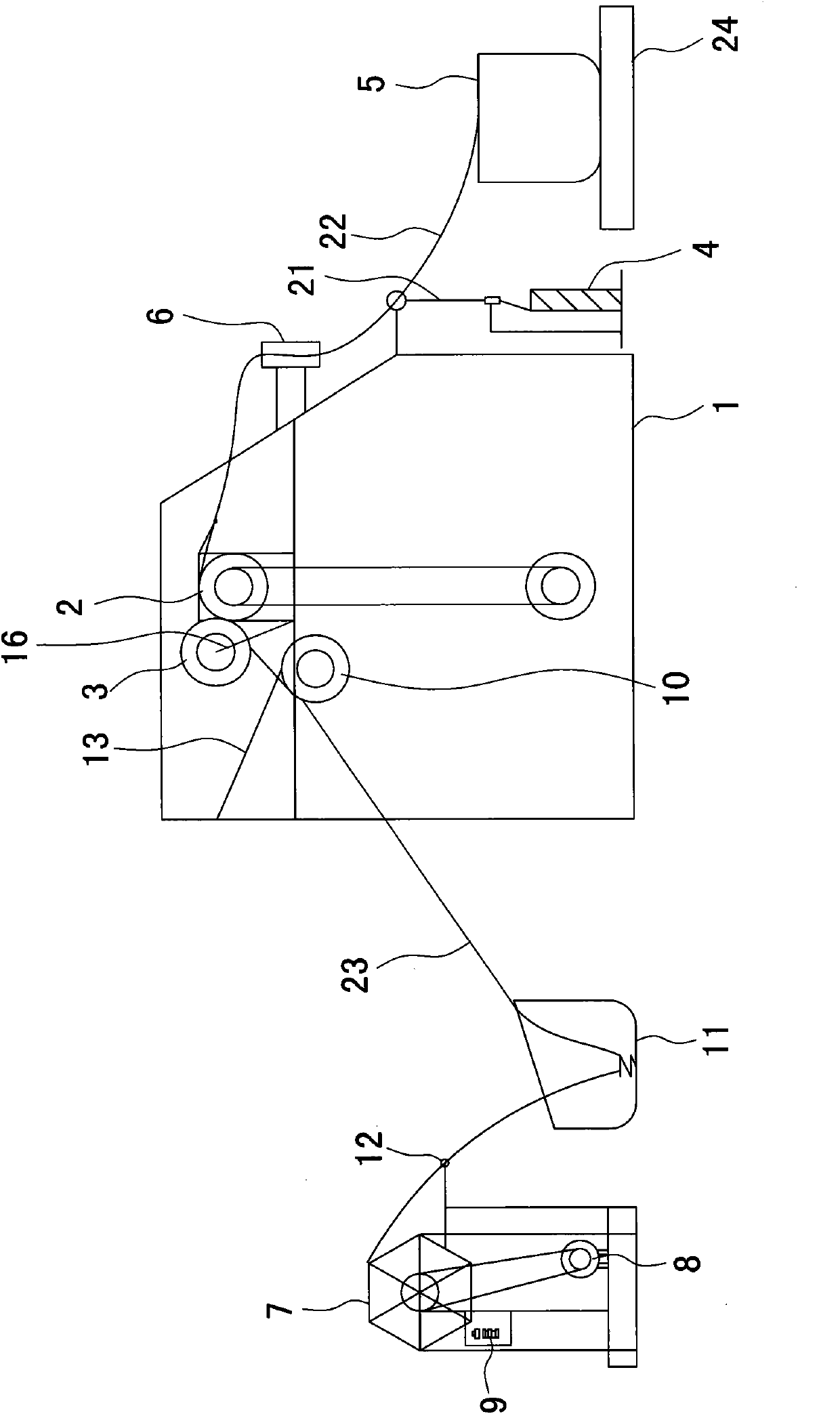

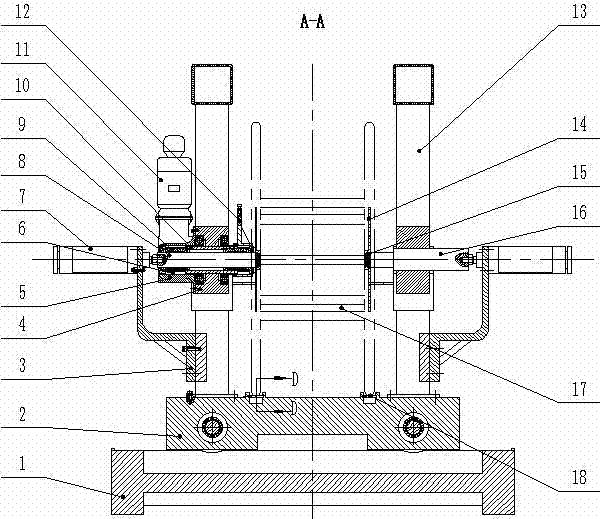

The invention discloses a winding system of a winding machine, which comprises a stand, demolding mechanisms, a demolding power mechanism and coil twisting mechanisms, wherein the demolding mechanisms and the coil twisting mechanism are both fixed on the stand; the front parts of a first winding mold fixture main shaft and a second winding mold fixture main shaft are respectively and fixedly provided with the demolding mechanisms with uniform structure; and the coil twisting mechanisms with uniform structure are respectively arranged in front of winding molds adjacent to the demolding mechanisms. The reliable and smooth winding, demolding and twisting of coils of a micromotor can be realized by reasonably installing and designing the demolding mechanisms, the demolding power mechanism and the coil twisting mechanisms, so that the automation of winding, demolding and twisting is realized. Thus, the production efficiency is greatly improved, the uniformity of products can be improved, and stale and reliable coil sheets can be provided for the subsequent rounding process. The coil demolding mechanisms, the demolding power mechanism and the coil twisting mechanisms are stable and reliable and have the advantages of long service life and high precision.

Owner:CHONGQING KNVAN ELECTRONICS

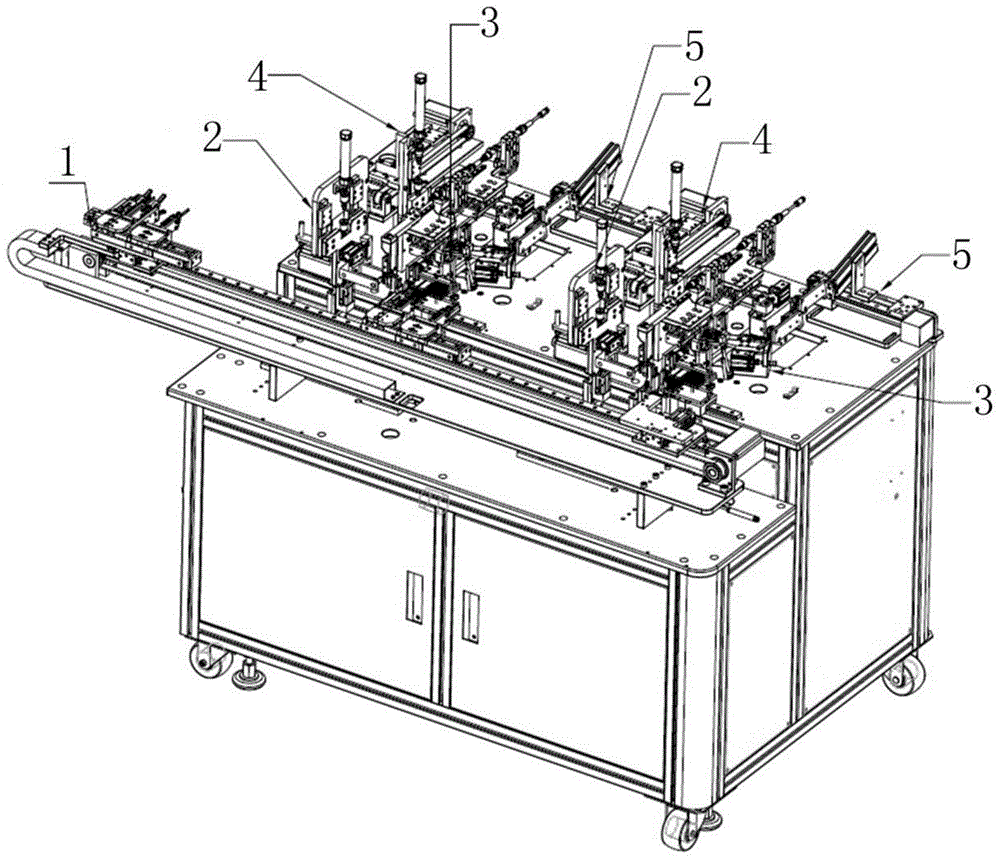

Double-group winding machine

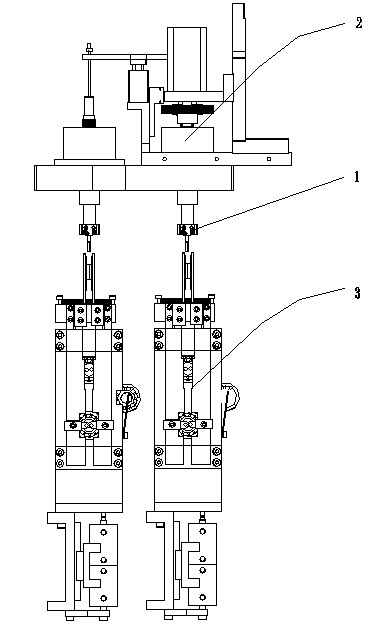

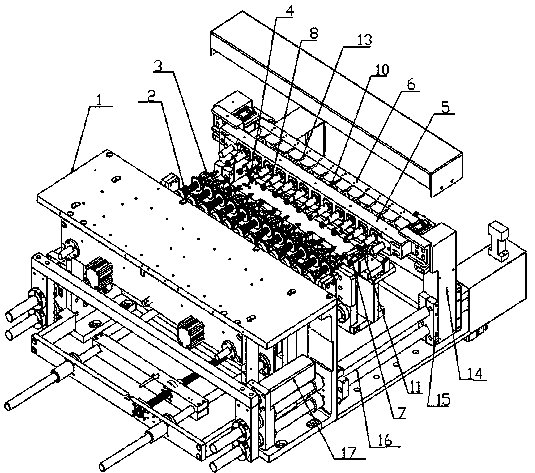

The invention relates to a double-group winding machine. The machine comprises a first rack, a plurality of main winding shafts which are horizontally mounted at equal intervals on the front side of the rack, a double-group winding mechanism, a glue covering mechanism, and a feeding mechanism in the front of the rack, wherein the double-group winding mechanism and the glue covering mechanism are arranged above the rack; each main winding shaft is provided with a jig provided with a coil framework; the feeding mechanism, the double-group winding mechanism and the glue covering mechanism are respectively matched with the jigs on the main winding shafts to perform feeding, double-group winding and glue covering. The machine has the advantages that all mechanisms are reasonably arranged and matched, so that the structure is compact, the service life is long, and the production efficiency of a product is increased.

Owner:JIANGSU FEIER ELECTRICAL TECH

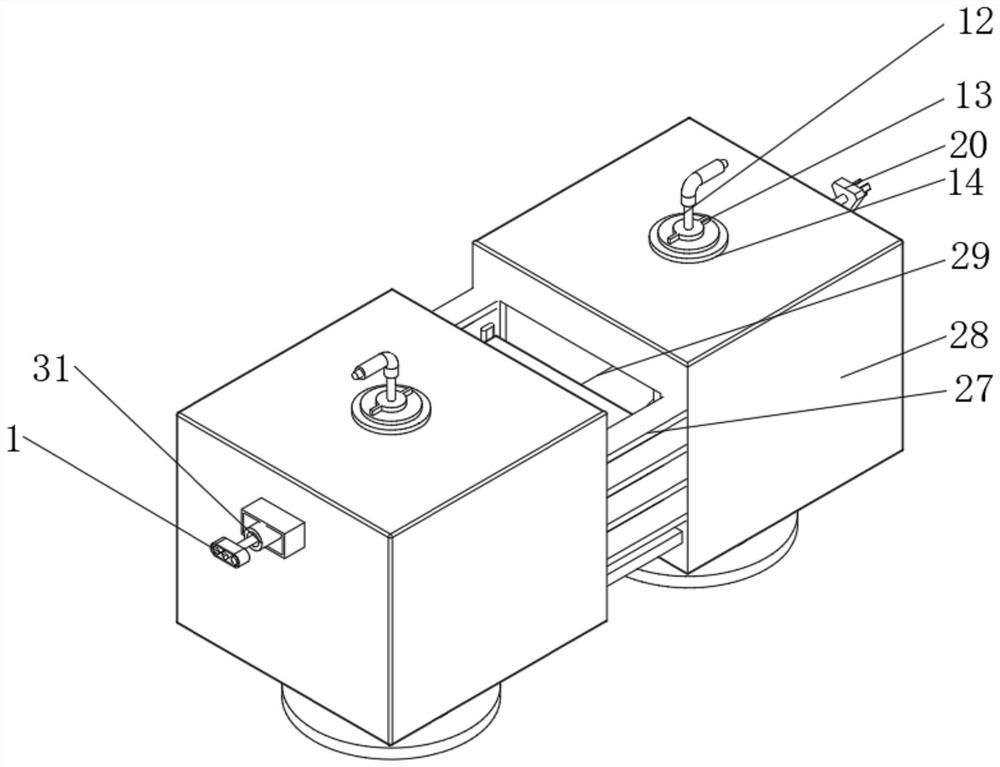

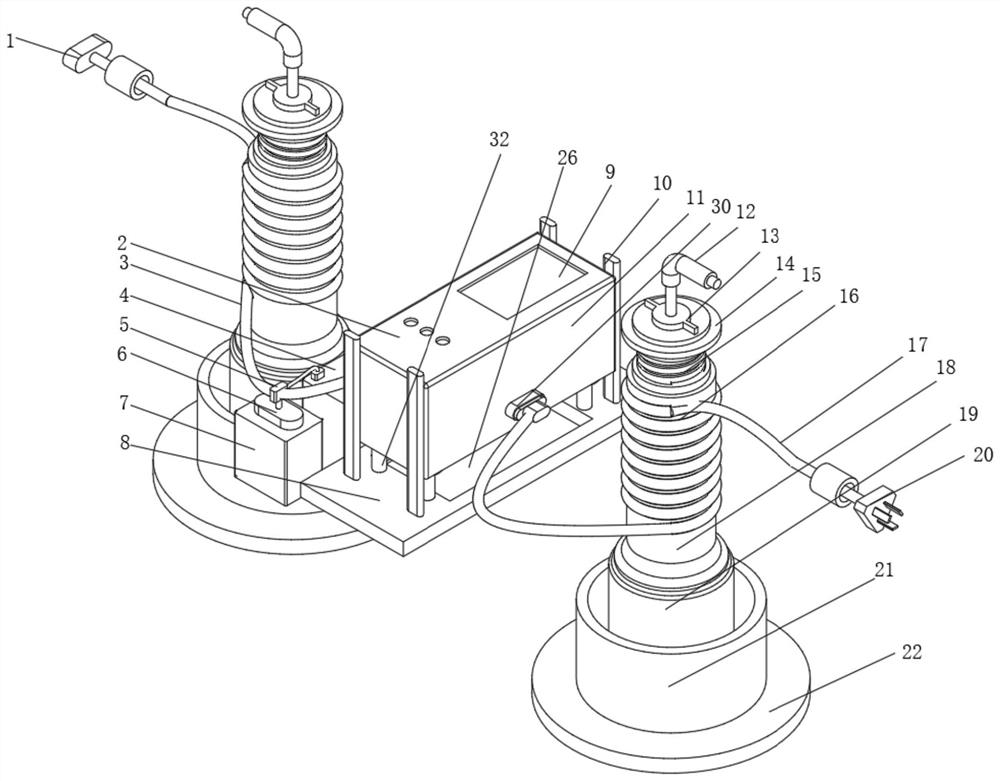

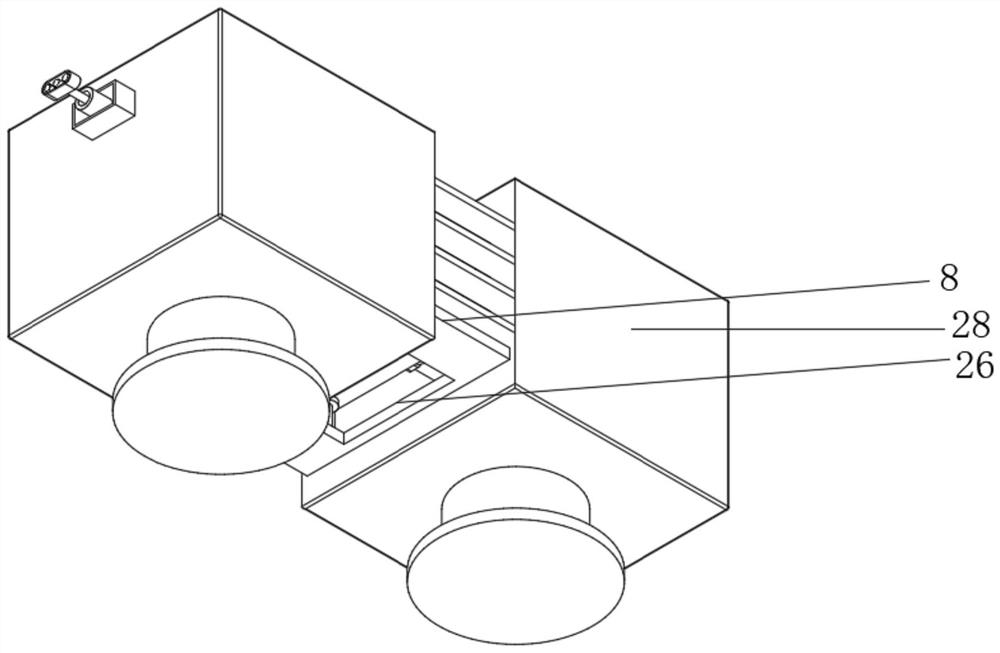

Shuttle vehicle power supply device

The invention discloses a shuttle vehicle power supply device, and belongs to the field of shuttle vehicles. The device comprises a support and a winding conductive mechanism, wherein the two heads ofthe winding conductive mechanism are fixed on the support, the device further comprises a motor, the motor is fixed at one end of the support, and an output shaft of the motor is connected with the winding conductive mechanism; a screw rod is fixedly arranged on the support away from one end of the motor and in threaded connection with a wire winding and guiding mechanism; the device further comprises a sensing device and an encoder, the encoder is connected with the motor, a wire on the wire winding and guiding mechanism penetrates through the sensing device and extends outward, and the sensing device, the encoder and the motor are all in signal connection with a control system of a vehicle-mounted terminal of a shuttle vehicle. The shuttle vehicle power supply device has the advantagesthat when power is supplied to the shuttle vehicle, the wire cannot wind and lap, through the improvement of a device structure, the wire can be neatly coiled on a reel during winding and unwinding, through the measurement of the deploying and retracting length and tightening degree of the wire, the rolling precision of the reel is higher, and lapping of the wire is further avoided.

Owner:CHINA INFORMATION & ELECTRONICSE DEV HEFEI

Preparation method and device of composite textured yarn

The invention discloses a processing method and a device of composite textured yarn, the device comprises a rack, a heating deformation mechanism arranged on the rack, a yarn guide mechanism arranged on one side of the rack, a yarn coiling mechanism arranged on the other side of the rack, wherein the heating deformation mechanism comprises a driving wheel and a matched yarn pressing wheel, the driving wheel and the yarn pressing wheel are arranged at the left and the right, the yarn pressing wheel is higher than the driving wheel, the connecting line of shaft centers forms an included angle of 20-40 degrees with the horizontal line, and heating devices are arranged on two sides of the driving wheel; the wire guide mechanism comprises a detwisting bobbin creel, a cocoon cooking pot and a tensioner; the yarn coiling mechanism comprises a yarn holding tool, a winding motor connected with the yarn holding tool and a speed regulator; and a special-shaped yarn guide wheel, a yarn storage device and a yarn guide device are sequentially arranged between the heating deformation mechanism and the yarn coiling mechanism. The processing method and the device can carry out composite deformation processing on the yarn with different components, completely realize the winding without tension, realize the continuous production of the composite textured yarn and keep the deformation effect.

Owner:SUZHOU INST OF TRADE & COMMERCE

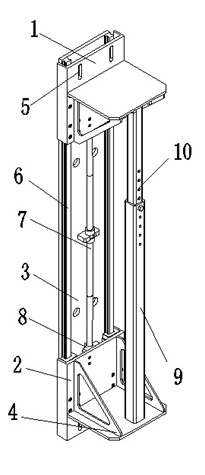

Automatic ground rail type steel wire rope winding machine without lifting device

InactiveCN104773606AThe overall structure is simpleReduce the incidence of complete machine failureFilament handlingWinding machineEngineering

Owner:UNIV OF JINAN

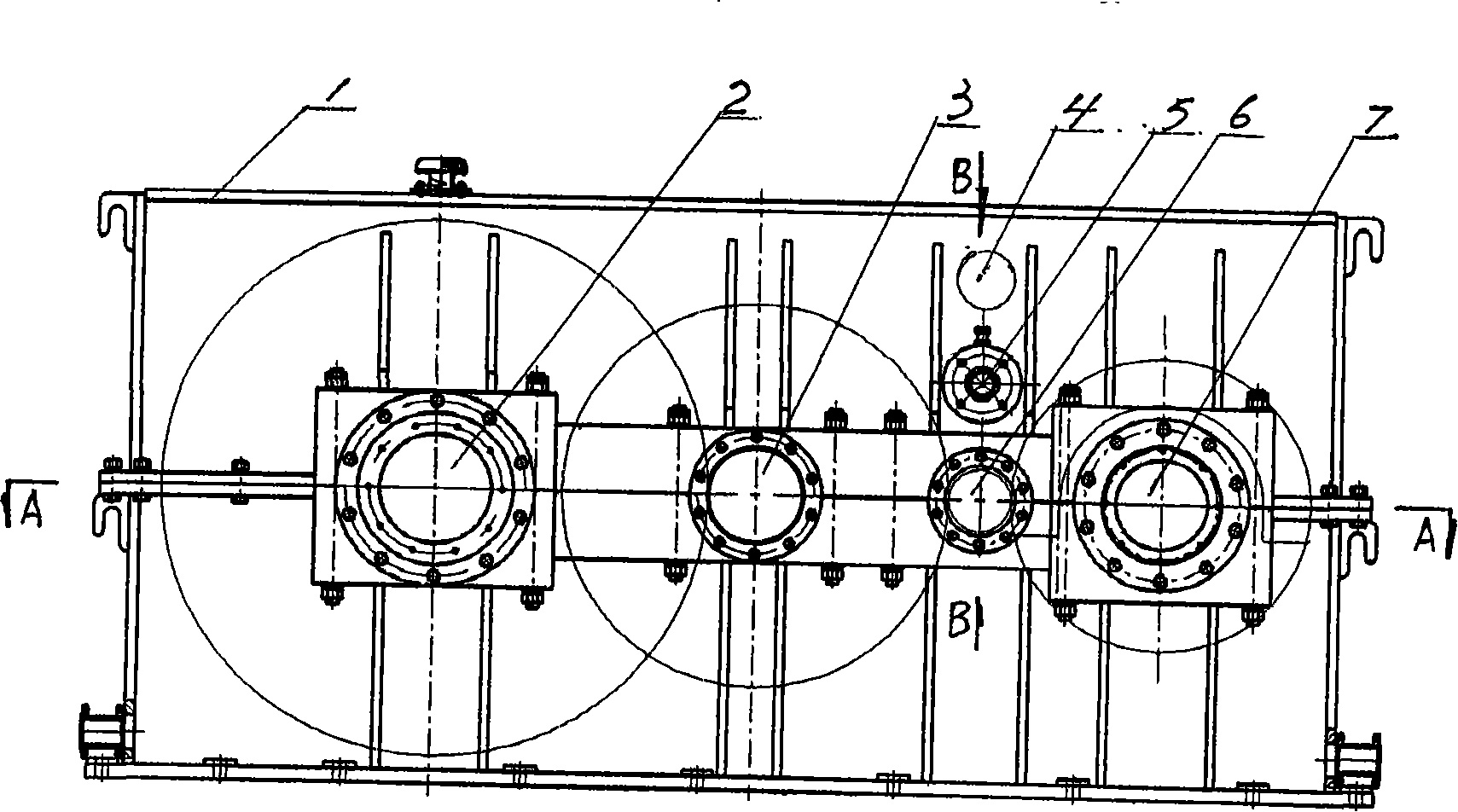

Coil winding machine for large power three-phase stator coils

InactiveCN102694442AIncrease productivityImprove coil performanceManufacturing dynamo-electric machinesWinding machineThree-phase

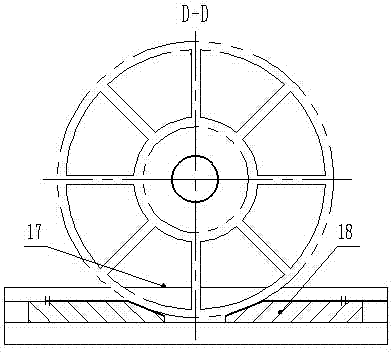

The invention discloses a coil winding machine for large power three-phase stator coils, comprising a shaft box, a wire laying mechanism, a wire hanging mechanism and a coiling die mechanism, and characterized in that the coiling die mechanism comprises an upper die and a lower die. The upper die and the lower die are symmetrically arranged to the center of a rotary main shaft. The bottom of the upper die and the bottom of the lower die are respectively provided with a pedestal. The upper die and the lower die are connected with a rotating table by a demoulding apparatus through the corresponding pedestal. The demoulding apparatus comprises a contraction cylinder, a central shaft in connection with the contraction cylinder, a contraction linkage in connection with the tip of the central shaft and a guiding mechanism vertically arranged to the rotary main shaft. The central shaft is in sliding connection with the rotary main shaft. The coil winding machine is formed by the upper die and the lower die arranged symmetrically and the dies are connected with the rotary table by the demoulding apparatus, realizing the coiling and automatic demoulding for large power coils with improved production efficiency and coil performance and mitigated labor intensity.

Owner:NIDE MECHANICAL EQUIP

Method for winding joint-free high-temperature superconducting four-cake coil

ActiveCN111613435AAdjust the diameter size at willSolve winding problemsInductances/transformers/magnets manufactureSuperconducting magnets/coilsHigh temperature superconductingEngineering

The invention discloses a method for winding a joint-free high-temperature superconducting four-cake coil. The method comprises the following steps of: 1) naming the four-cake coil as cakes I, II, IIIand IV from right to left; winding a 1 / 4 section of strip at the head part of the main wire coil on the transition wire coil, and winding a 2 / 4 section of strip in the middle of the main wire coil ona right side framework of the double-cake coil to finish winding of the second cake; 2) winding the strip on the transition wire coil to finish the winding of the cake I; 3) winding the middle 3 / 4 section of strip of the main wire coil on the left side transition framework of the double-cake coil, and winding the rest 4 / 4 section of strip of the main wire coil on the left side framework of the double-cake coil to finish the winding of the fourth cake; (4) rewinding 3 / 4 sections of strips wound on the left transition framework on the left framework of the double-cake coil, and completing winding of a third cake; 5), installing the wound left side framework on the right side framework, screwing the two frameworks, tensioning the strip between the second cake and the third cake, and completing winding of the fourth cake. The principle is simple, practical, reliable and convenient to operate, the number of superconducting joints can be reduced, variable-diameter winding is achieved, and the method can be widely applied to winding of high-temperature superconducting uniform magnets.

Owner:XIAN JUNENG SUPERCONDUCTING MAGNET TECH

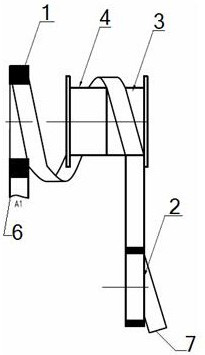

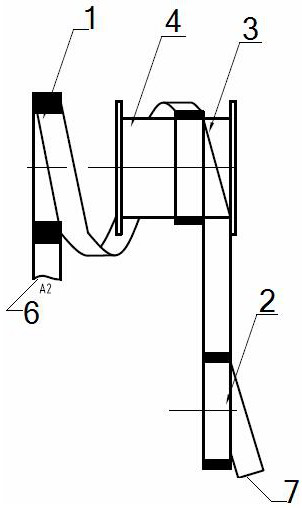

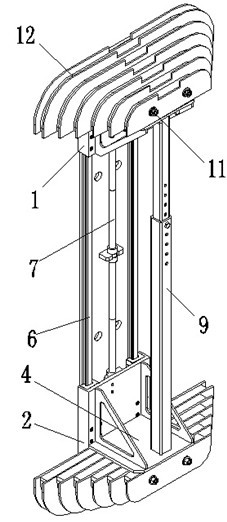

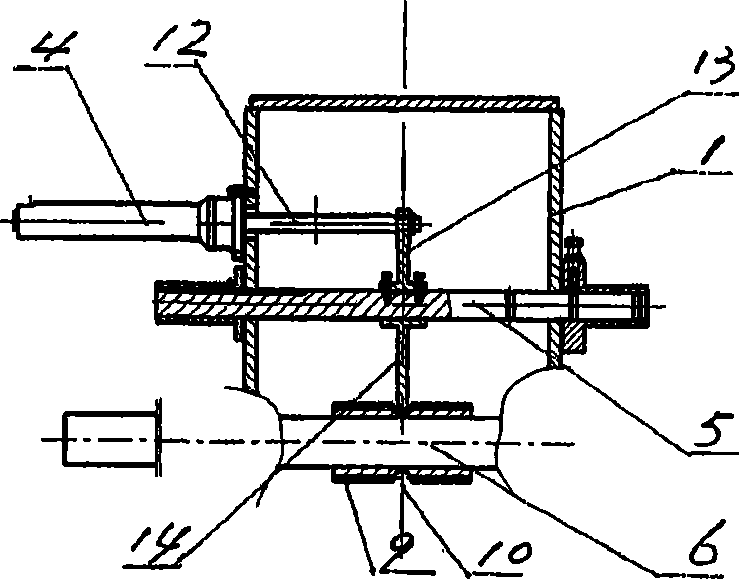

Motor stator coil winding former

ActiveCN101980430ARealize the winding processManufacturing dynamo-electric machinesStator coilConductor Coil

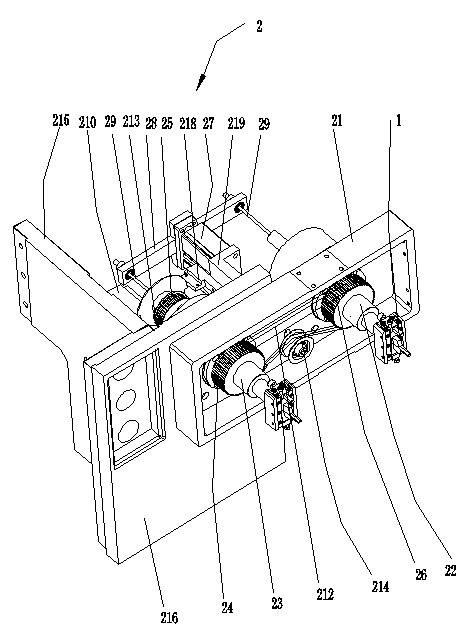

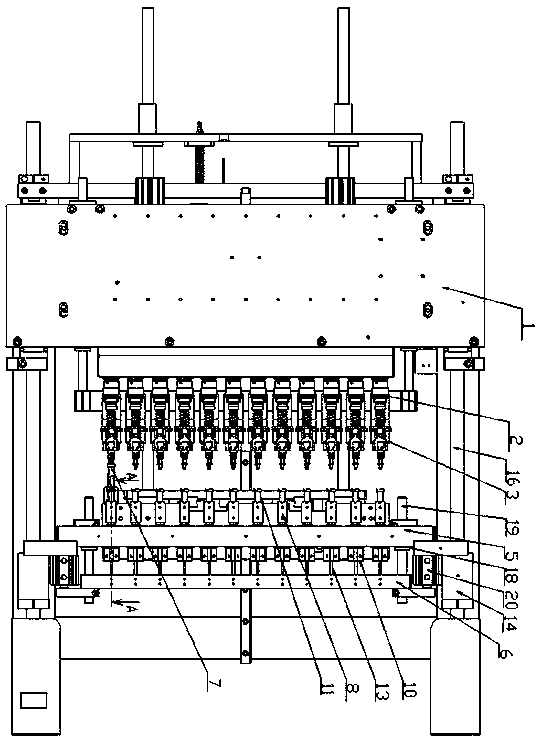

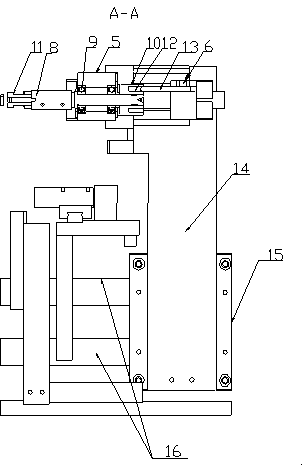

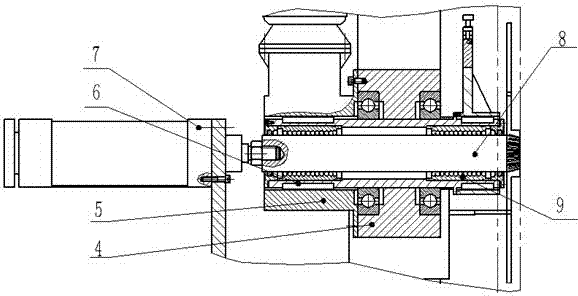

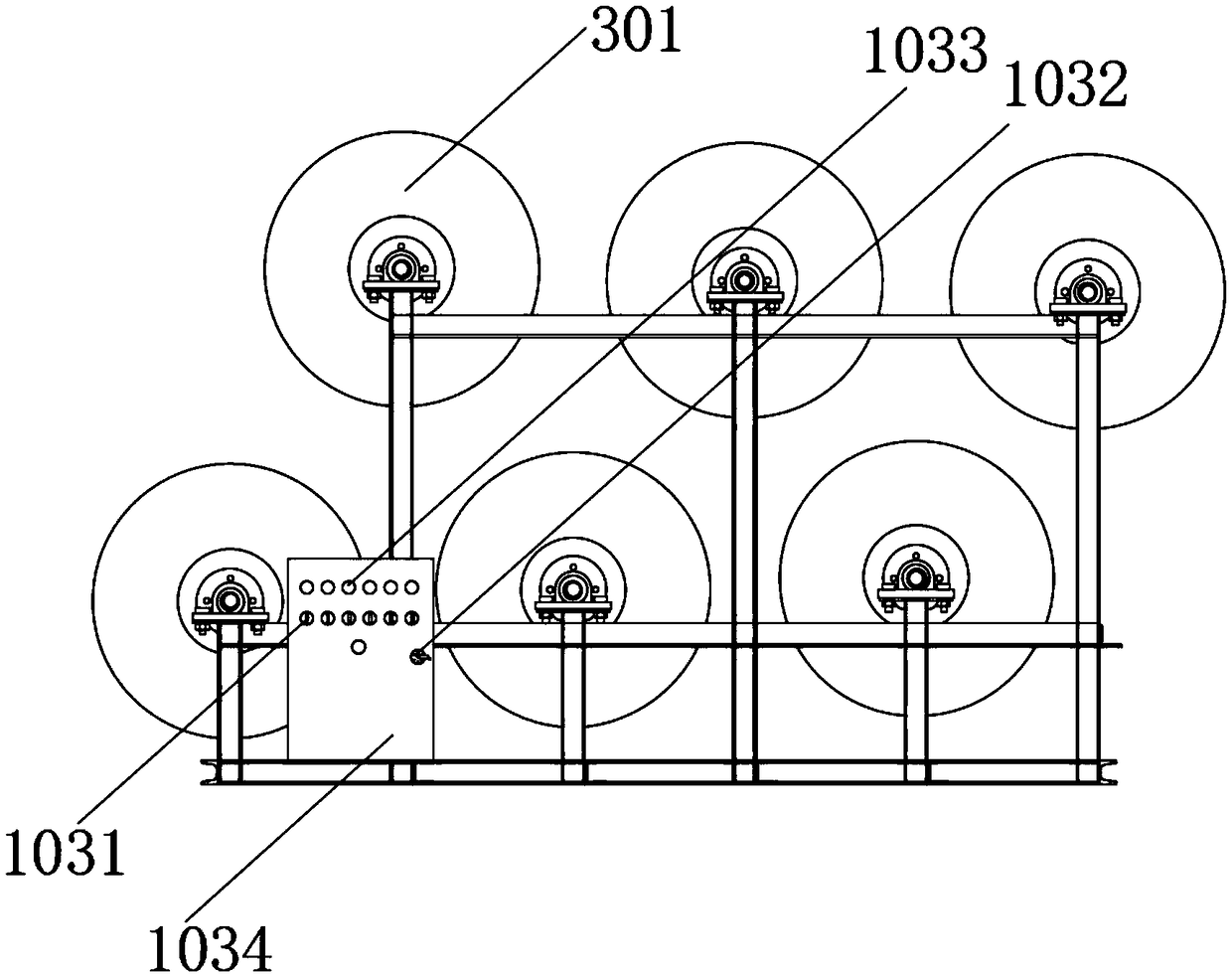

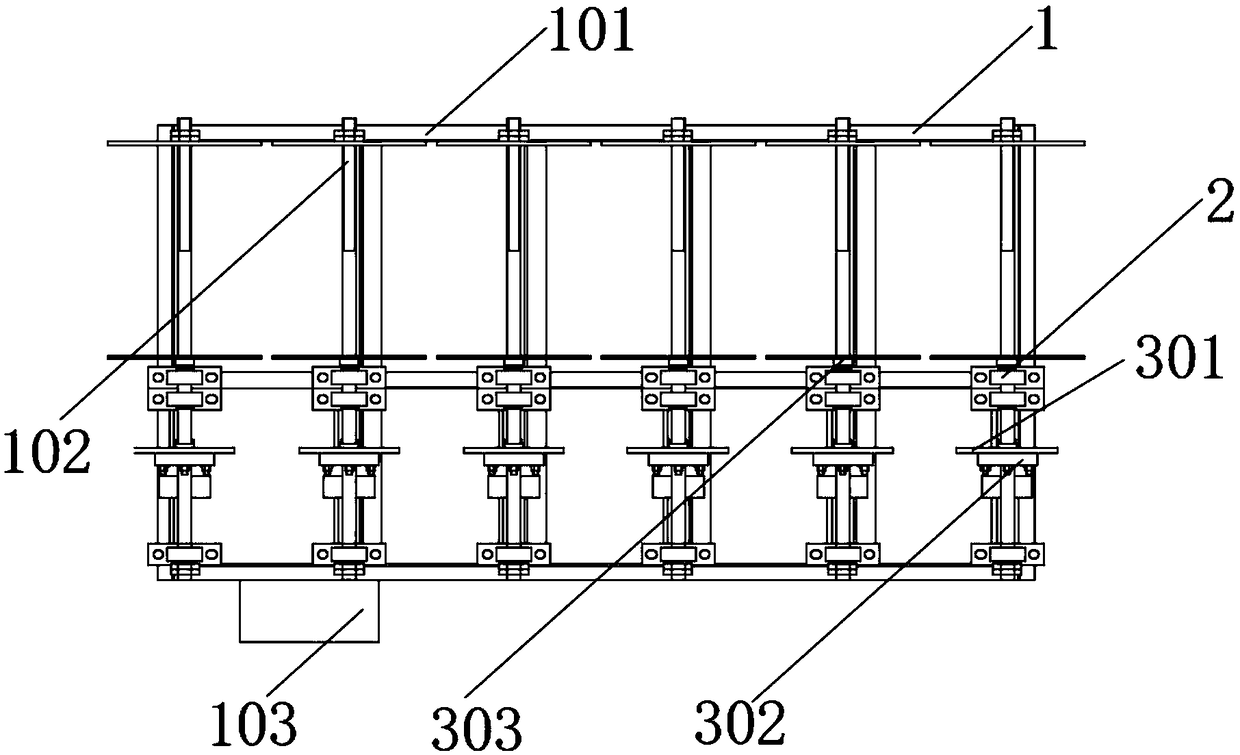

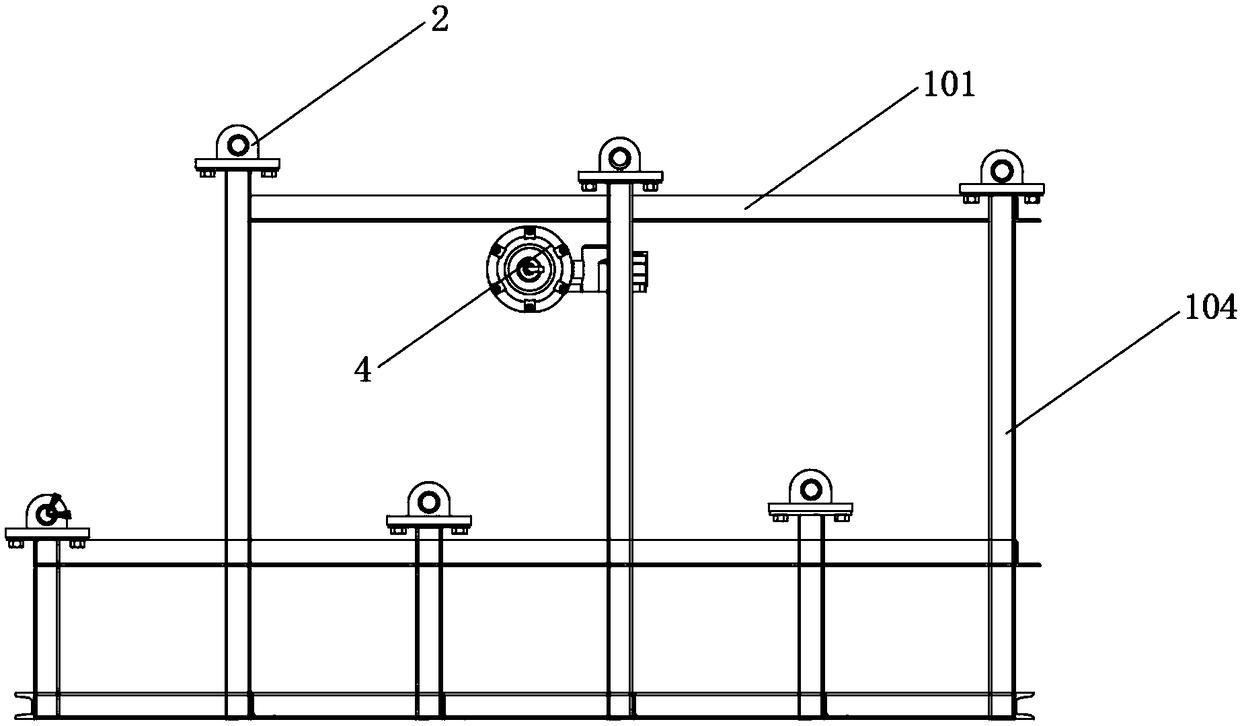

The invention discloses a motor stator coil winding former, which comprises an upper slipway seat, a lower slipway seat, double-end lead screws, a bottom plate, two guide rails, triangular support frames, and winding templates, wherein the two guide rails are arranged on the two sides of the long side of the bottom plate; the upper slipway seat and the lower slipway seat are arranged at the upper and lower ends of the guide rail respectively and can slide up and down along the guide rail; the upper slipway seat and the lower slipway seat are provided with nuts respectively, the double-end lead screws are screwed in the nuts of the upper slipway seat and the lower slipway seat, and the double-end lead screws are rotated to drive the nuts matched with the double-end lead screws to move up and down; symmetrical strip-shaped holes are formed on the upper slipway seat and the lower slipway seat, and fastening pieces for fastening the winding templates are arranged in the stripe-shaped holes; and the upper slipway seat and the lower slipway seat are provided with triangular support frames respectively, triangular support frames on the upper slipway seat and the lower slipway seat are oppositely arranged, six winding templates are arranged on each triangular support frame side by side, and the winding templates are fixed on the upper slipway seat or the lower slipway seat through fastening pieces.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

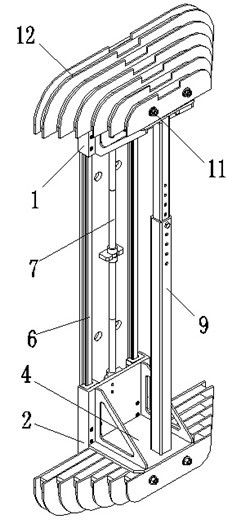

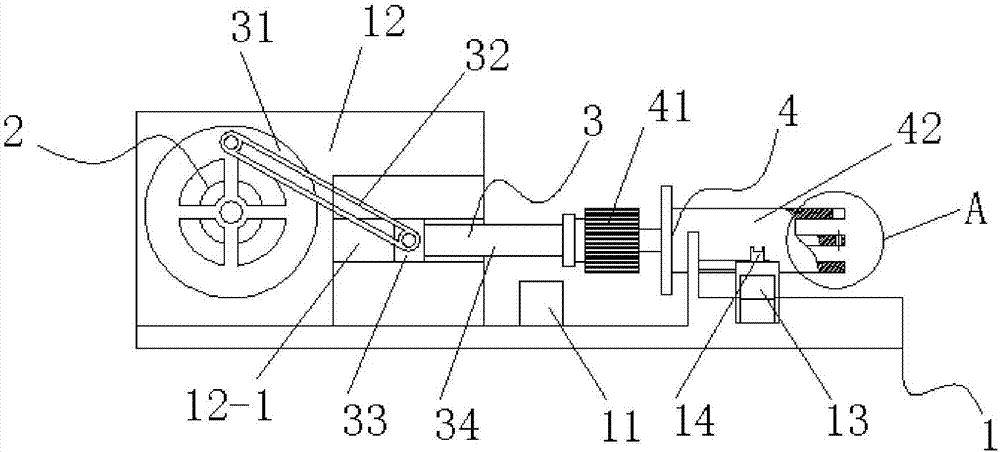

Wire feeding and storing device of detonator tube

InactiveCN105858327APrevent nonel buildup or temporary shortagesUniform length and sizeFilament handlingMechanical engineering

A nonel wire feeding and wire storage device. The invention relates to a civil explosive device, in particular to a nonel wire feeding and storage device. The invention aims to solve the problems that the existing nonel tubes are prone to accumulation or temporary shortage in the production process, it is difficult to realize active traction and wire feeding, and at the same time, the length of the nonel tubes cannot be automatically cut to a fixed length. A detonating tube wire feeding and wire storage device includes a pulling wire feeding mechanism and a wire storage buffer mechanism, and the pulling wire feeding mechanism and the wire storage buffer mechanism are respectively installed on an operation platform. The invention is used for the production of nonel tubes.

Owner:HARBIN INST OF TECH

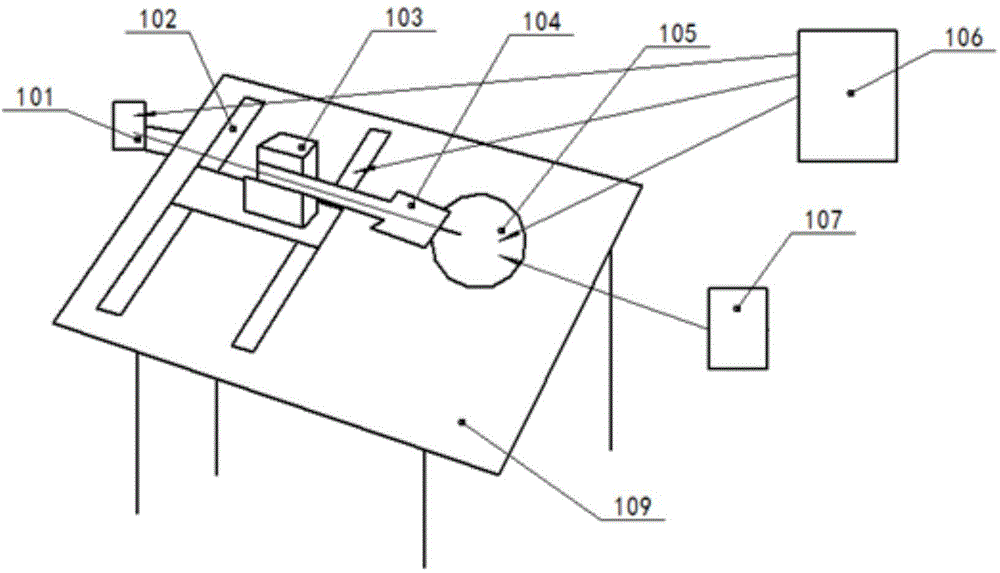

Wire winding method and device for wire winding type strainmeter

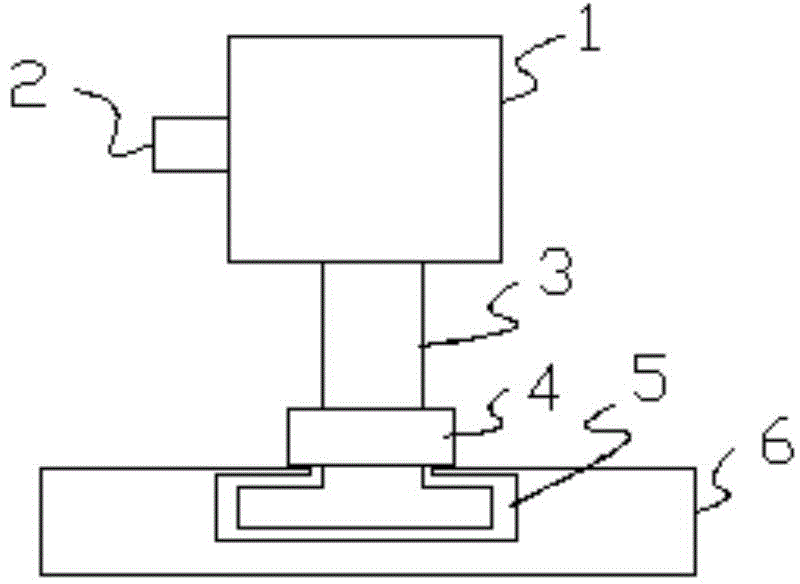

The invention relates to a wire winding method and device for a wire winding type strainmeter. The device comprises a working platform, a linear movement system is fixed to the working platform, a mechanical arm is arranged on the linear movement system and makes reciprocating movement on the linear movement system, a glue containing and wire outgoing device is connected to the mechanical arm, an end wire outlet of the glue containing and wire outgoing device is arranged close to a rotation platform, a substrate film adheres to the rotation platform, a wire to be wound stretches out of the glue containing and wire outgoing device, and the end of the wire adheres to the substrate film. In the winding process, after the wire to be wound stretches out of the glue containing and wire outgoing device, the end of the wire is made to adhere to the substrate film of the rotation platform through glue, and the wire can be spirally wound through cooperation between linear movement of the mechanical arm and rotation movement of the rotation platform.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

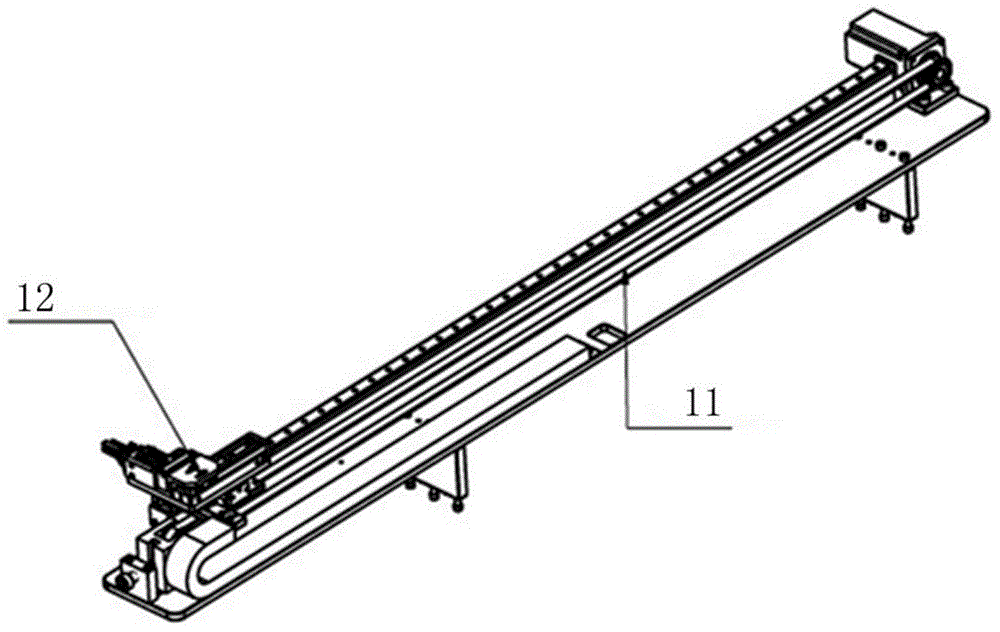

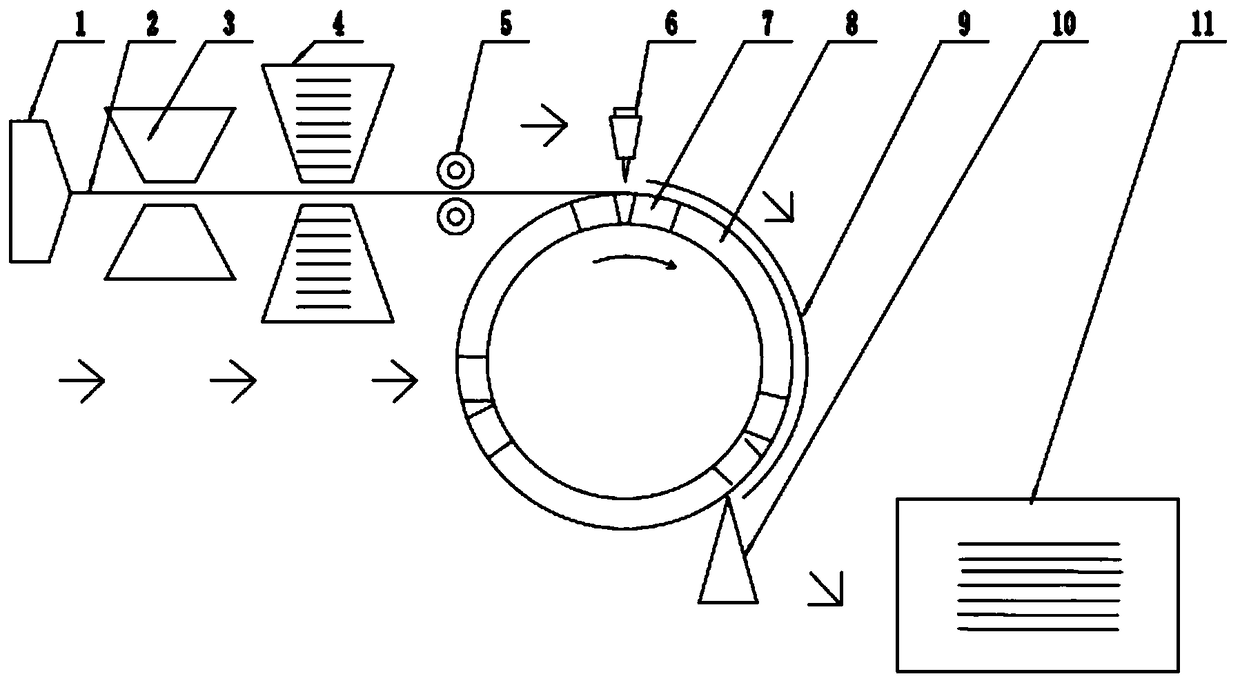

Network transformer T2 ring wire-winding machine

ActiveCN104795237ARealize the winding processCoils manufactureConveyor partsWinding machineTransformer

The invention provides a network transformer T2 ring wire-winding machine. The network transformer T2 ring wire-winding machine comprises a wire separating mechanism, a wire stranding mechanism and a wire-winding mechanism which are connected in sequence, wherein the wire separating mechanism is used for finding two longest enameled wires from enameled wires of a T1 ring wounded with wires. By the adoption of the network transformer T2 ring wire-winding machine, the two longest enameled wires can be found from eight head and rail wires of the T1 ring wounded with the wires, then wire stranding and T2 ring wire winding can be performed, and T2 ring wire winding is automatically achieved.

Owner:ZHUHAI HENGNUO SCI & TECH CO LTD

Automatic wire harness winding device

InactiveCN107043046ARealize the winding processReduce labor intensityFilament handlingElectric machineryDrive motor

The invention discloses an automatic wire harness winding device. The automatic wire harness winding device comprises a device base, a drive motor, an alignment sliding block mechanism and a winding mechanism. The device base is provided with a controller, a vertical wall, a wire harness inlet and a wire guiding wheel. A sliding groove is formed in one side of the vertical wall, and the drive motor is fixedly arranged on one side of the vertical arm. On one hand, the alignment sliding block mechanism is fixedly connected with an output shaft of the drive motor, and on the other hand, the alignment sliding block mechanism is fixedly connected with the winding mechanism. According to the device, workers do not need to conduct manual winding, the labor intensity of the workers is reduced, the work efficiency is improved, meanwhile, wound wire harnesses are standard in shape and size, and great convenience is brought to wire harness package standardization and transportation.

Owner:WUHU QIAOYUN & YOUXING ELECTRICAL IND CO LTD

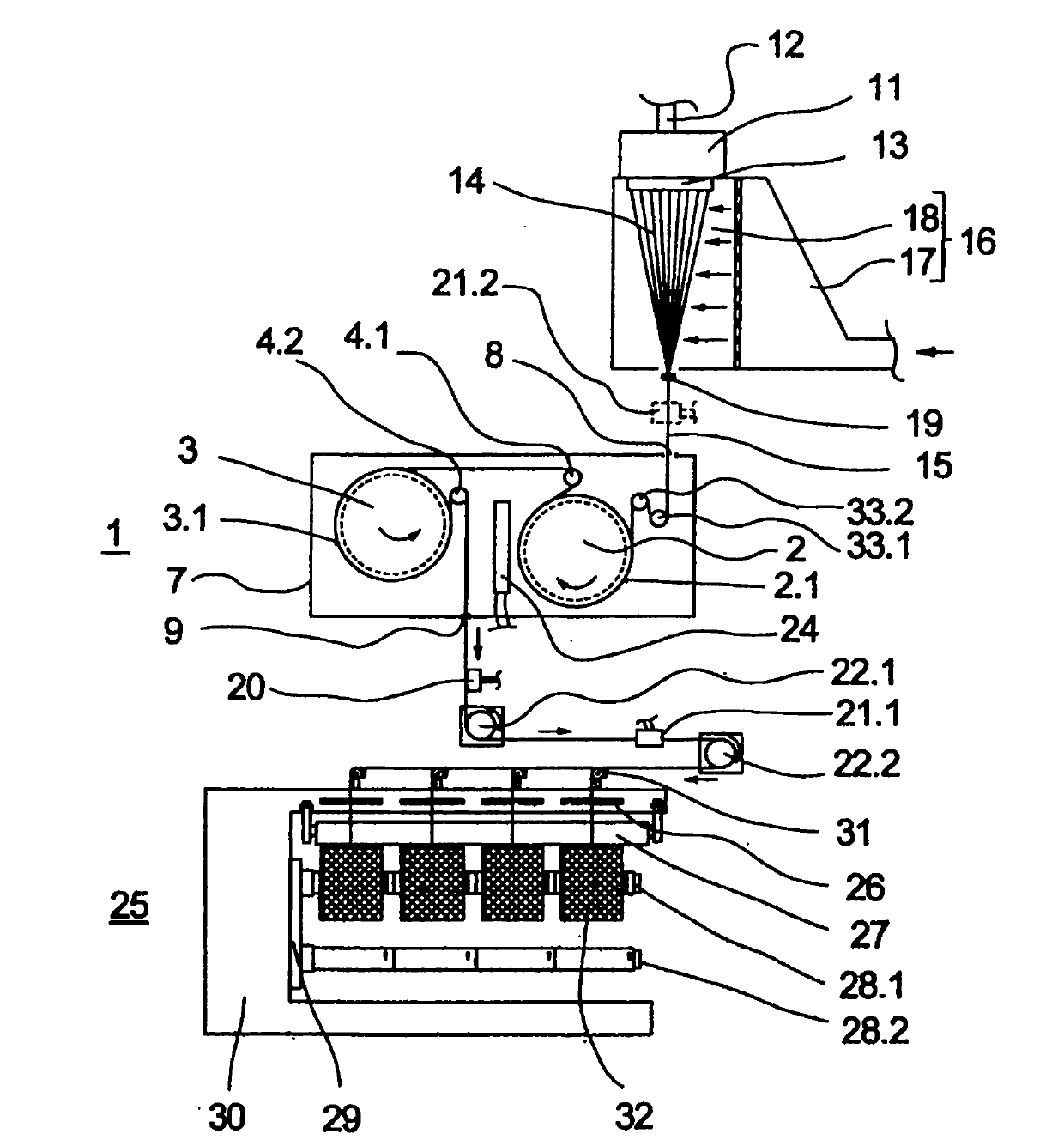

Method for taking up and drawing a multifilament during melt-spinning, and apparatus for carrying out said method

InactiveCN102016139AFull stressEnough tensionArtificial thread manufacturing machinesFilament manufacturePolymer scienceMelt spinning

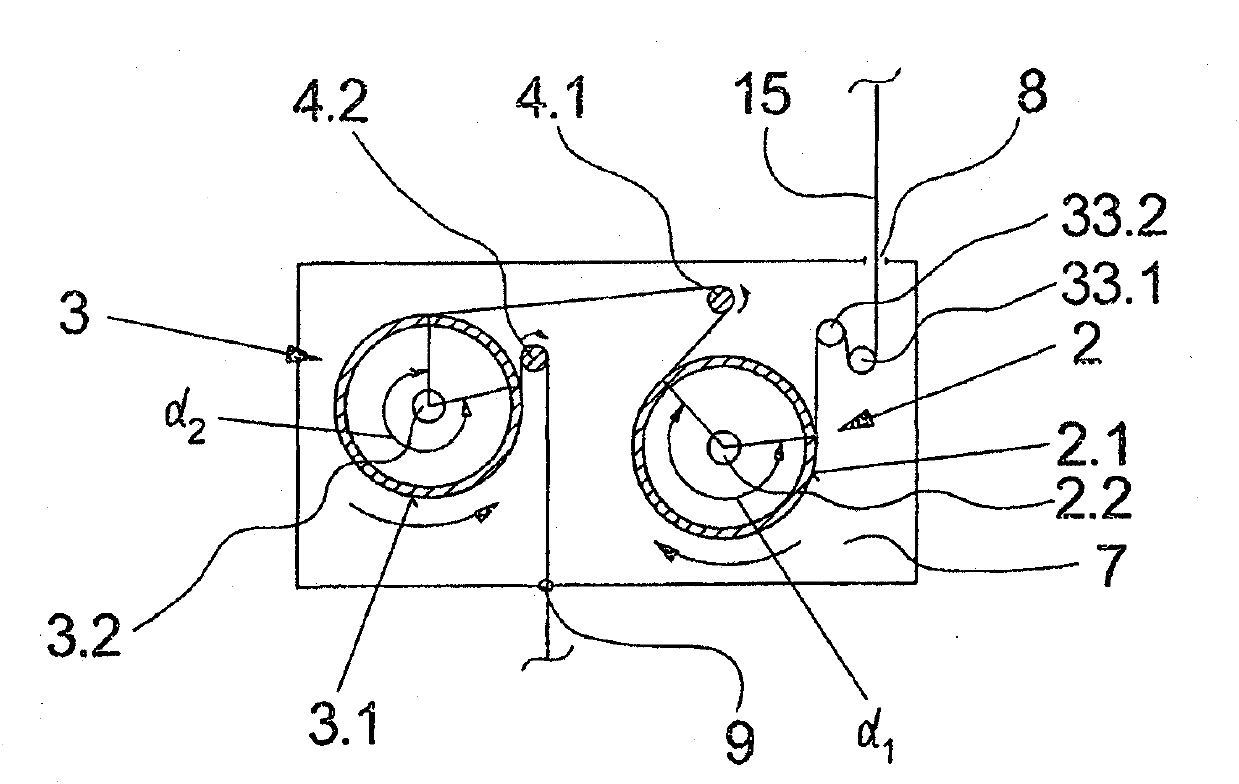

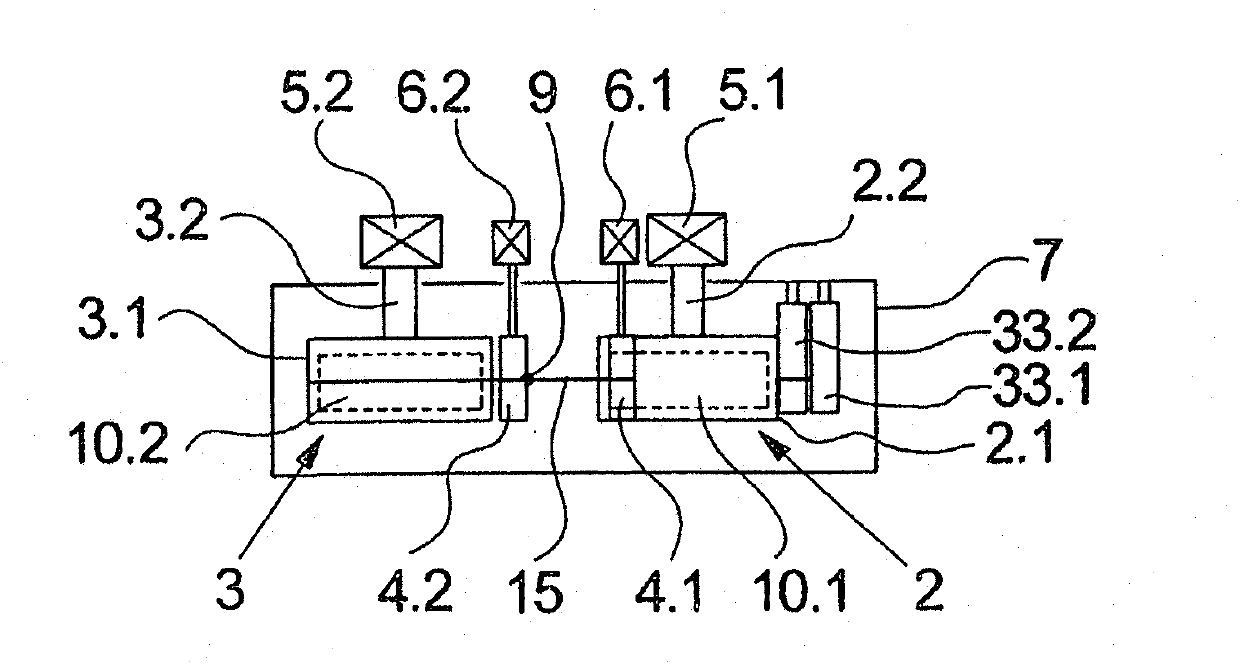

The invention relates to a method and an apparatus for taking up and drawing a multifilament during melt-spinning. In said method and apparatus, the multifilament is guided on driven guiding sleeves of several godets, at least partially going therearound. Several guiding sleeves are heated. One of the guiding sleeves is driven at a circumferential speed exceeding 1,500 m / min so as to take up the multifilament, while at least one guiding sleeve located downstream is driven at least at twice said circumferential speed so as to draw the multifilament. In order to sufficiently heat the multifilament as the same goes around the guiding sleeves once and generate a sufficient tensile force on the multifilament, the multifilament is guided on the guiding sleeve that is driven for taking up the multifilament such that the multifilament and the guiding sleeve are in uninterrupted contact for a minimum length of 650 mm, the guiding sleeve being heated to a surface temperature ranging from 80 DEG C to 200 DEG C.

Owner:OERLIKON TEXTILE GMBH & CO KG

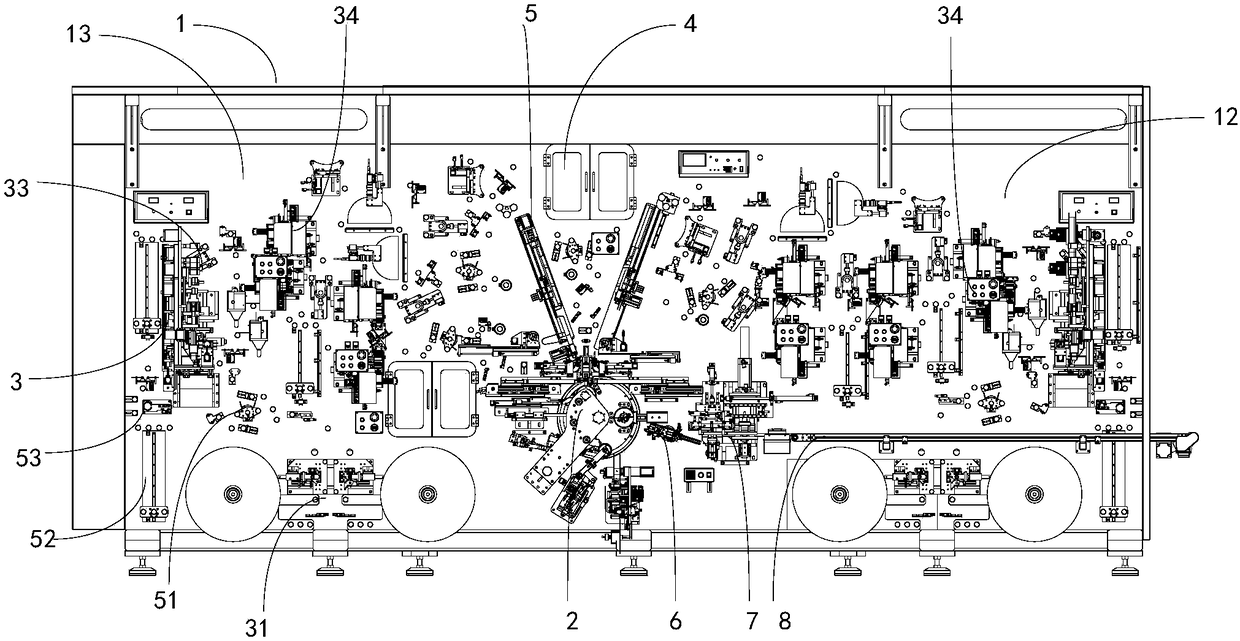

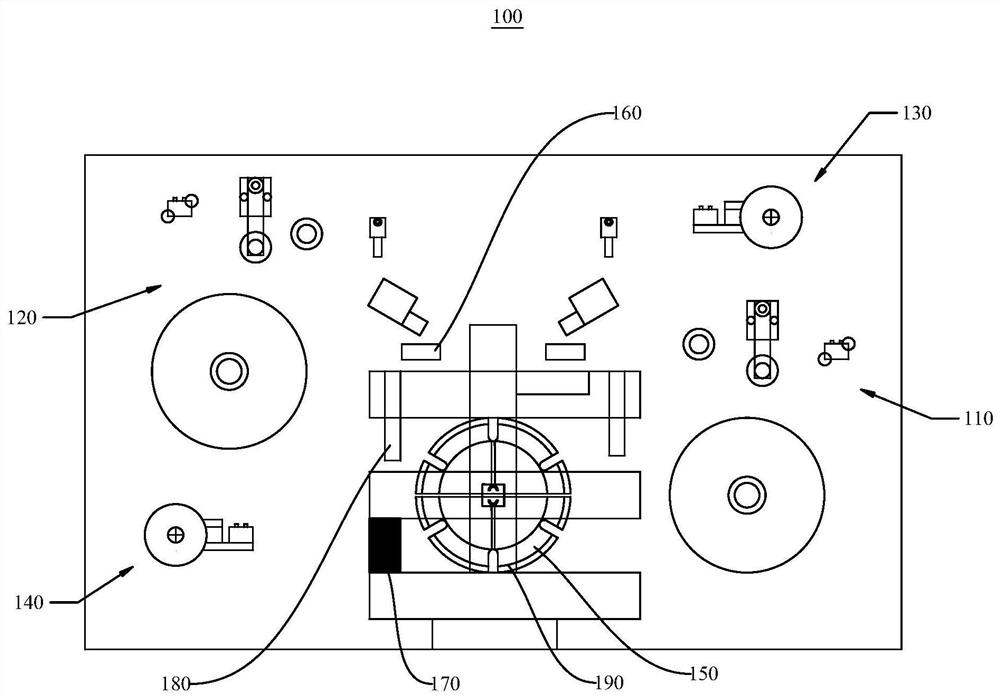

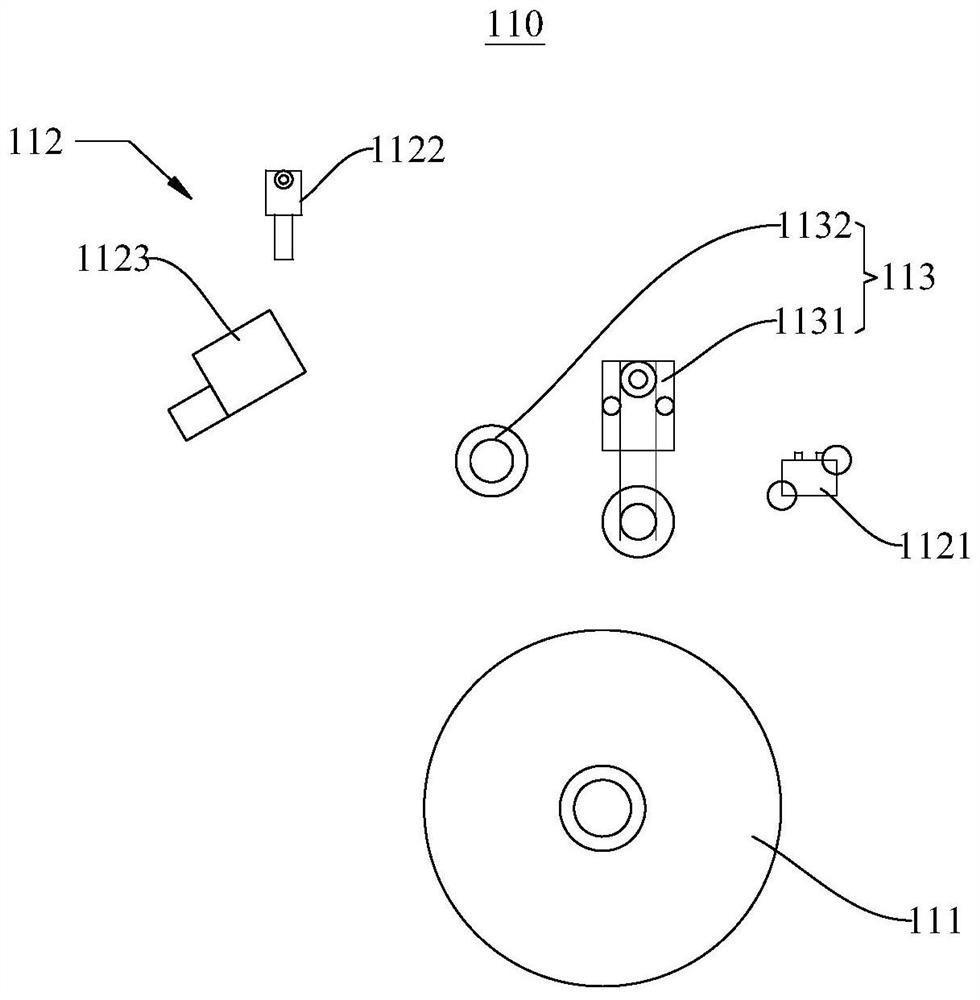

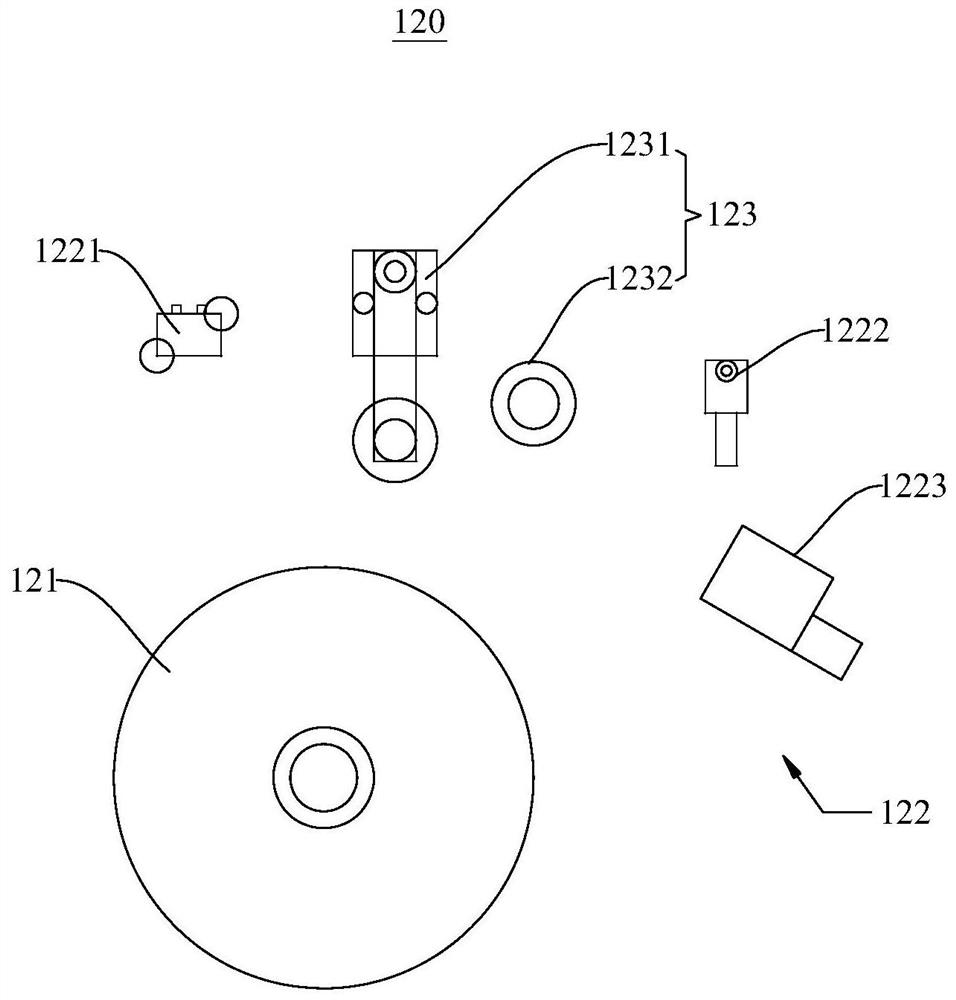

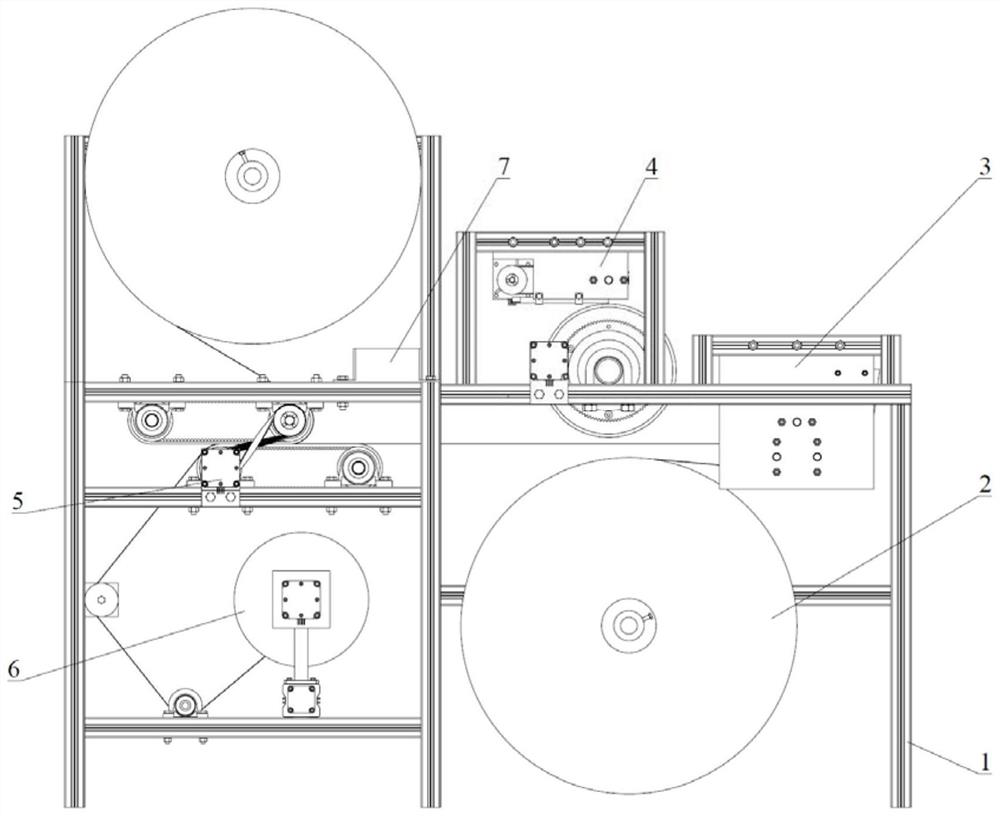

Square battery core producing and winding equipment

ActiveCN108615949AImprove production efficiencyRealize the winding processFinal product manufactureSecondary cellsPole pieceEngineering

The invention discloses square battery core producing and winding equipment, which comprises two groups of membrane unwinding devices, two groups of production devices and a winding device, wherein each production device comprises two groups of pole piece unwinding mechanisms, two groups of lug welding mechanisms and two groups of opposite pasting mechanisms; a controller controls one pole piece unwinding mechanism, one lug welding mechanism and one opposite pasting mechanism to be combined on a pole piece to carry out production of an even number of lugs, and controls another pole piece unwinding mechanism, another lug welding mechanism and another opposite pasting mechanism to be combined on the pole piece to carry out production of an odd number of lugs; each lug welding mechanism is provided with a lug dedusting component and a lug detection component; the winding device comprises at least one square winding needle component and a shaping mechanism; positive and negative pole piecestrips, provided by the production devices, with the lugs and two membrane strips provided by the membrane unwinding devices are clamped on the square winding needle component of the winding device;and the shaping mechanism opens the square winding needle component to wind and mold square battery cores. According to the square battery core producing and winding equipment, high-quality winding and fast and efficient hot-pressing of square batteries of different specifications can be achieved.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

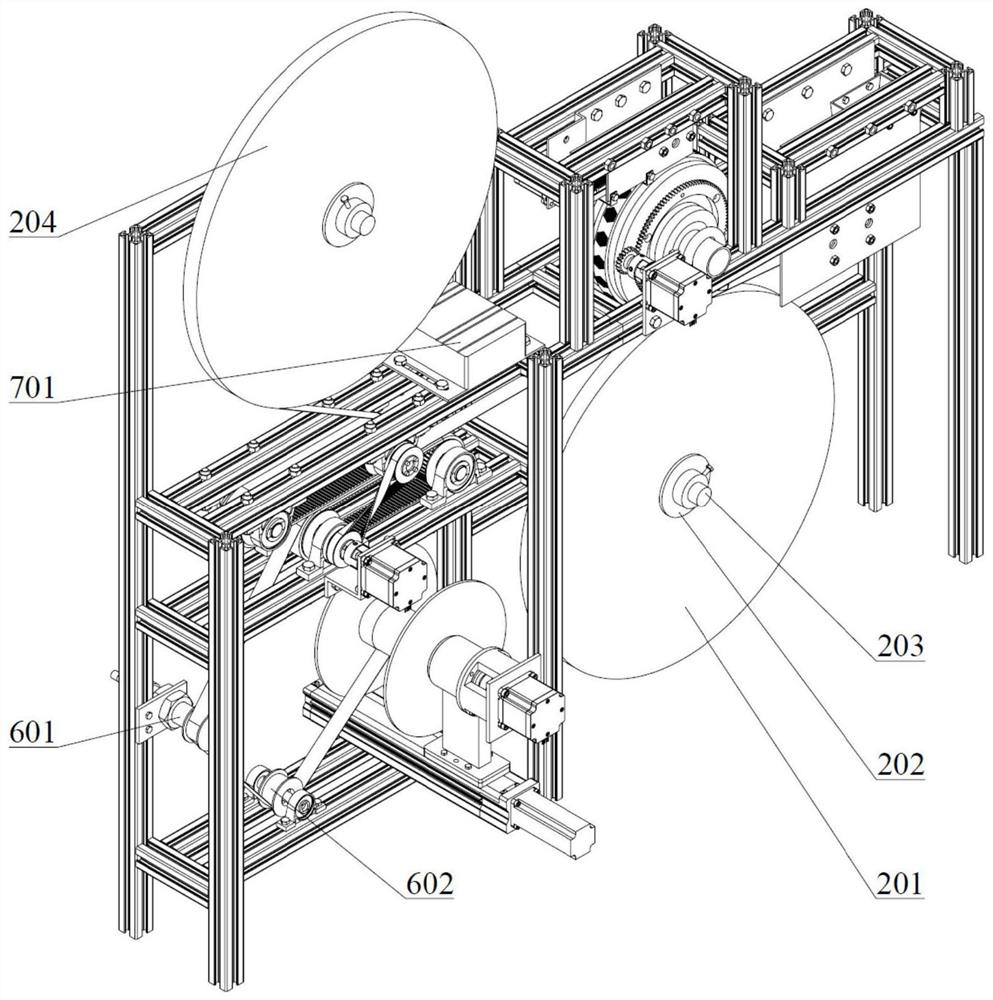

Winding device for winding a web-shaped material and method for changing a spool in a winding device

InactiveCN105813963ARealize the winding processSimple design and fairly reliableWebs handlingEngineeringPlastic film

The invention relates to a winding device for winding a web-shaped material, preferably a plastic film, comprising: a spool for receiving the web-shaped material, a contact roller for leading the web-shaped material to and pressing the web-shaped material onto the spool, a device for rotationally driving a still empty spool, a device for leading the still empty spool to the contact roller. The still empty spool can be simultaneously acted upon by means of the device for rotationally driving the still empty spool and by means of the device for leading the still empty spool to the contact roller.

Owner:WINDMOELLER & HOELSCHER GMBH

Magnetic type rolling cutting device capable of being continuously magnetized of lanthanon permanent magnet strip

PendingCN109300682ARealize automatic feedingRealize the winding processMagnetic bodiesInductances/transformers/magnets manufactureRare earthEngineering

The invention discloses a magnetic type rolling cutting device capable of being continuously magnetized of a lanthanon permanent magnet strip. The device comprises an extruder, the extruder is used for extruding the lanthanon permanent magnet strip out, and a pre-magnetizing machine and a magnetizing machine are successively arranged on the back side of the extruder; an automatic rolling disc is arranged on the back side of the magnetizing machine, several sets of magnets uniformly distributed are embedded in the automatic rolling disc and used for driving the lanthanon permanent magnet stripto rotate around the automatic rolling disc, and each magnet set comprises two magnets; a cutting blade is arranged at the top end of the automatic rolling disc, a wedge cutter is arranged below the automatic rolling disc, and an analyzing tray is further arranged on the back side of the automatic rolling disc. The device can continuously work, the production efficiency is improved, the machiningamount can be adjusted, and the cost is reduced.

Owner:BGRIMM TECH CO LTD

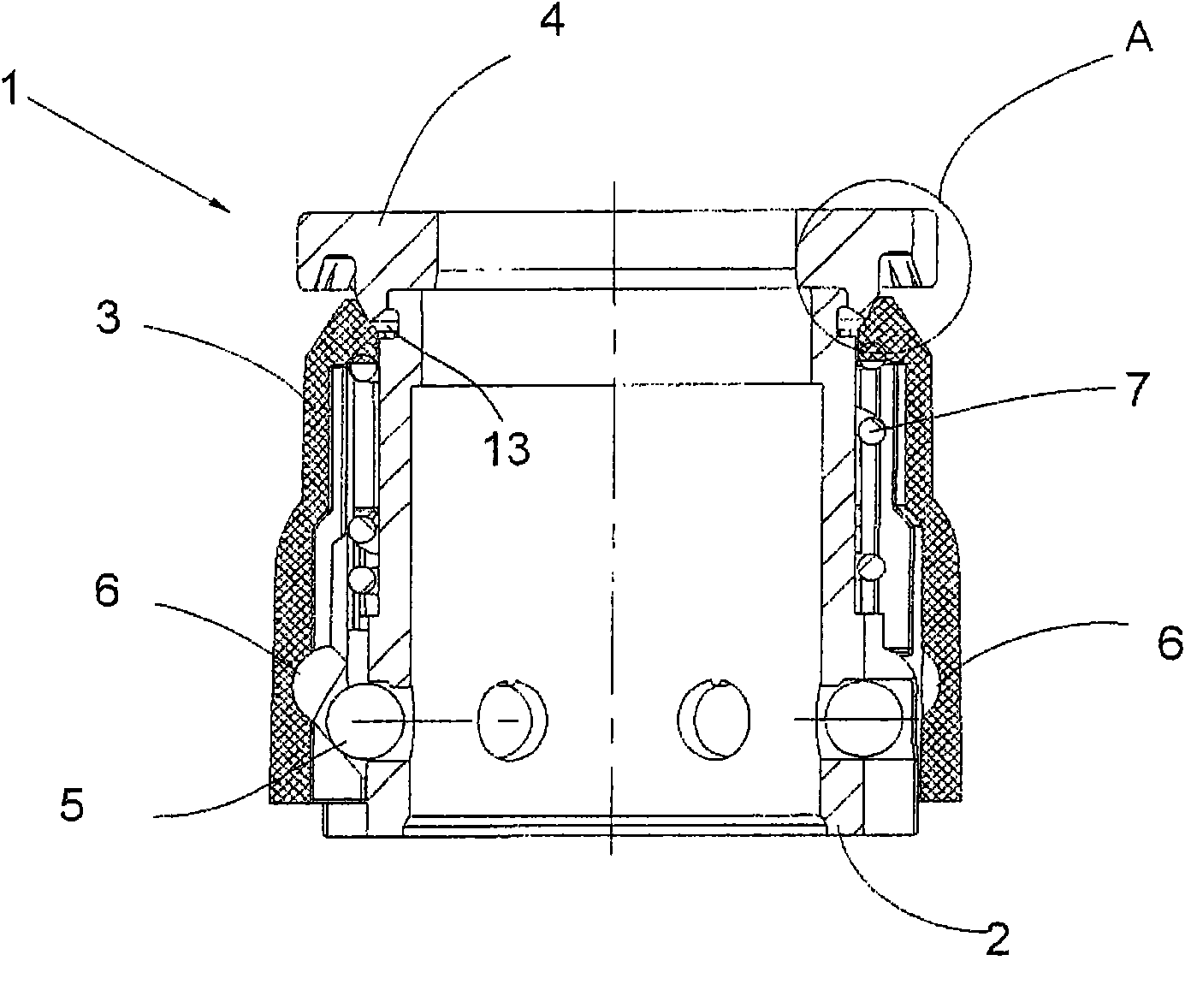

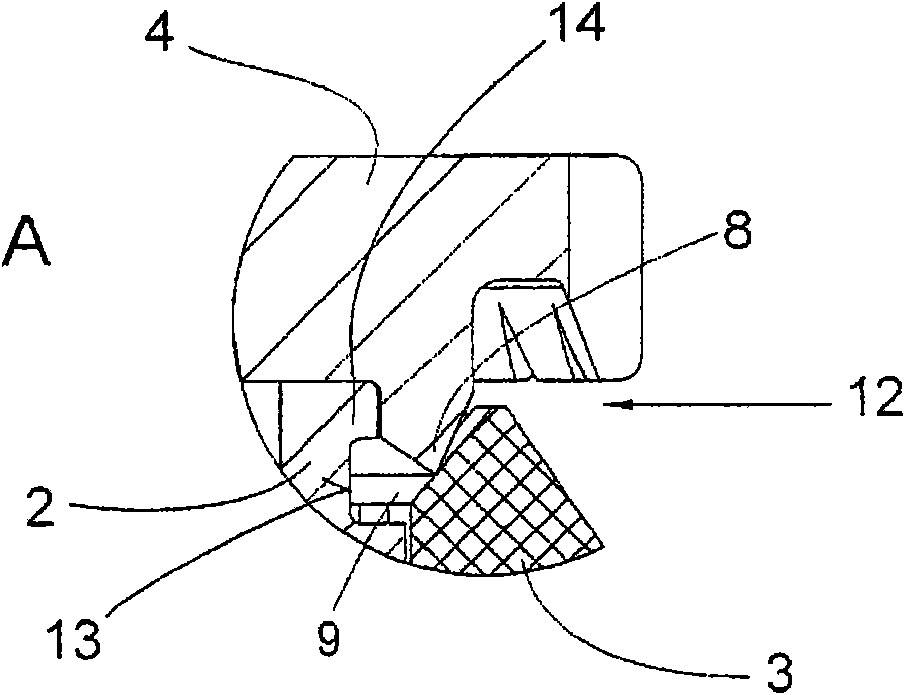

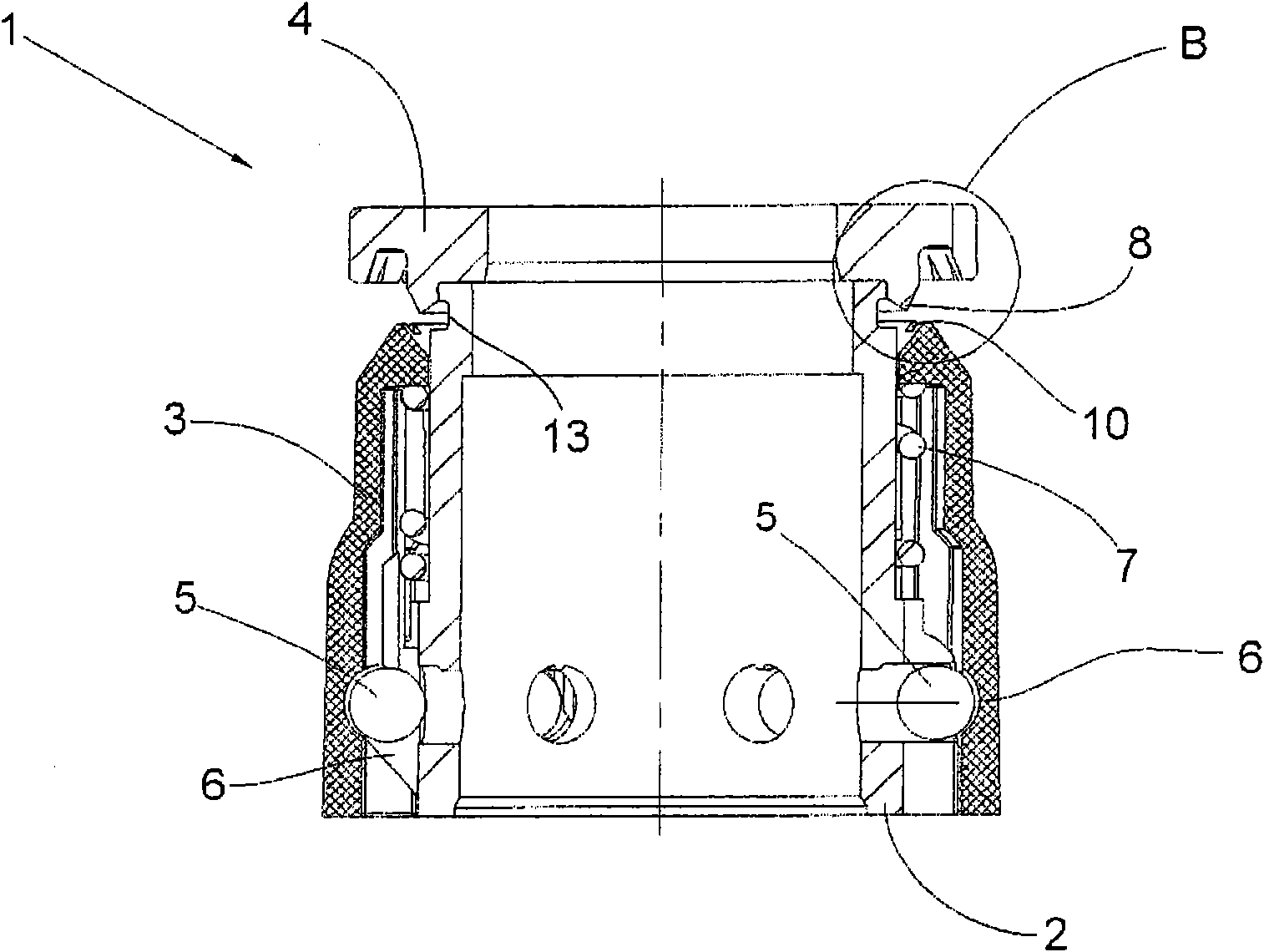

Clamping device

ActiveCN101654825ARealize the winding processThe clamping effect is stable and reliableContinuous wound-up machinesYarnEngineering

The invention relates to a clamping device 1 on spindle of a spinning machine and a twisting machine for yarning, wherein, a basically cylindrical clamping device 1is provided on the upper par to the spindle, the clamping device 1 includes a fixed clamping element 4 and a clamping element 3 that can be pressed on the fixed clamping element 4 and can move in the axial direciton, an orientation force can be applied to the the clamping element 3, the orientation force makes the movable clamping element 3 to maintain a space from the fixed clamping element 4 in the axial direciton, namely, a clamp clearance is formed between these clamp elements,the yarn to be clamped can be introduced into the clamp clearance, wherein, the clamping device 1 has a ring projecting part 8 pointing to the clamp clearance 12 on one of these clamp elements 3,4, the ring projecting part 8 is supported on contact faces 9,11 with uninterrupted surface of the other clamp element to clamp the yarn.

Owner:SAURER COMPONENTS GMBH

Spinning winding device

InactiveCN104973449AGood value for promotionDesign rationalizationFilament handlingElectric machineryWinding function

The invention relates to the field of spinning products, in particular to a spinning winding device which can effectively solve the problems of yarn twisting and the influence on forming effects. The spinning winding device structurally comprises a base, the base is provided with a slideway. A first sliding part and a second sliding part are arranged in the slideway, a motor is fixedly arranged at the upper end of the first sliding part, a bearing is embedded in the second sliding part, and a motor shaft of the motor penetrates the bearing to be connected with a square frame. The motor shaft is movably connected with the square frame and can be dismantled. Rubber baffles are positioned at the two ends of the square frame respectively, and limiting blocks are arranged at the two ends of the slideway respectively. The spinning winding device achieves a winding function through overall sliding and the driving by the motor, is simple in structure and convenient to use, works reliably, and is suitable for various occasions.

Owner:SUZHOU DONGMAO TEXTILE IND

Sliding and rolling mechanism, manufacturing method thereof and display device

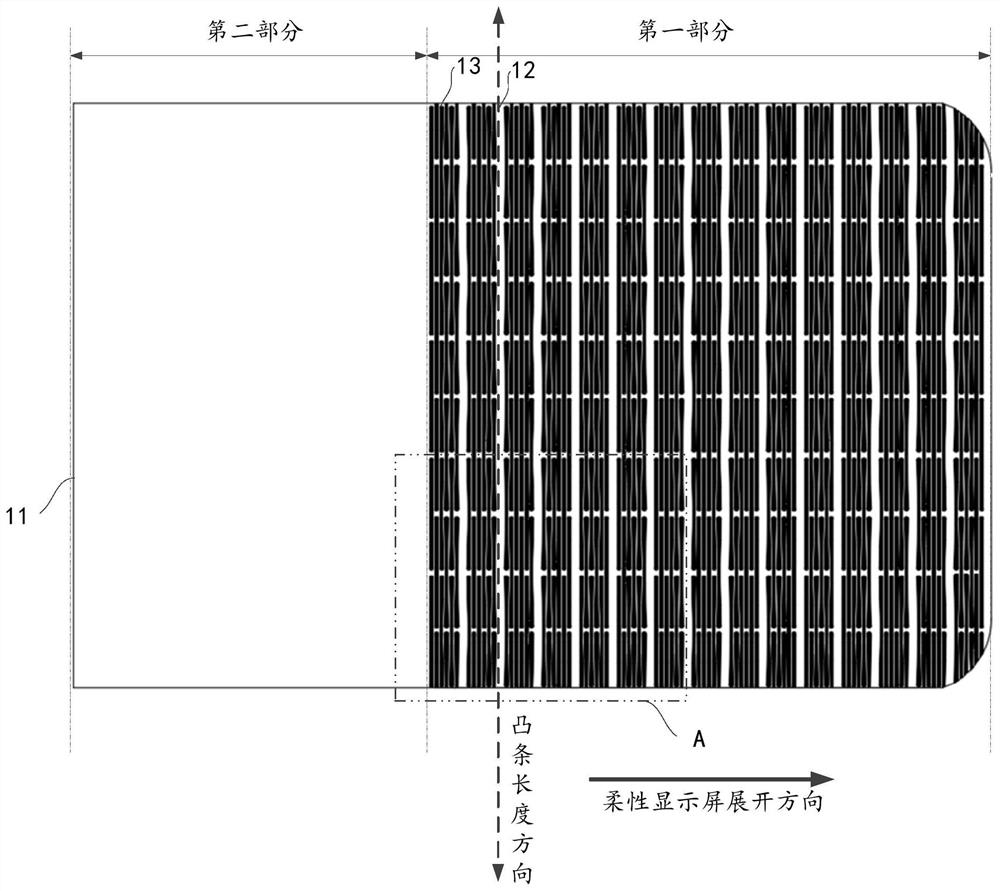

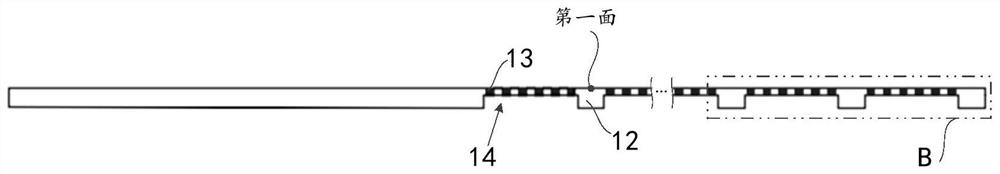

The invention discloses a sliding and rolling mechanism, a manufacturing method thereof and a display device, and belongs to the technical field of display. The sliding and rolling mechanism is used for supporting a flexible display screen and comprises a supporting substrate, the flexible display screen is arranged on the first face of the supporting substrate, and the supporting substrate can drive the flexible display screen to unfold or wind around a first axis; a plurality of protruding strips arranged at intervals in the unfolding direction of the flexible display screen are arranged on the face, away from the flexible display screen, of the supporting substrate, the length direction of the protruding strips is the same as the extending direction of the first axis, and a first groove is formed between every two adjacent protruding strips. In the embodiment of the invention, the raised lines are directly formed on the surface, deviating from the flexible display screen, of the supporting substrate instead of independent metal strips adopted in the prior art, so that adhesive connection is not needed; and the condition that the flexible display screen cannot normally slide and roll due to contact aggregation between the metal strips caused by easy debonding after long-time use or under high-temperature and high-humidity conditions is avoided.

Owner:BOE TECH GRP CO LTD +1

Automatic winding and contracting structure for charging wire of battery car

InactiveCN112408116ARealize automatic winding storageAffect the charging experienceBatteries circuit arrangementsElectric powerConvertersDrive shaft

The invention discloses an automatic winding and contracting structure for a charging wire of a battery car. The structure comprises a placing plate, a charging converter is arranged at the top of theplacing plate through supporting legs, outer boxes are fixedly arranged at two sides of the placing plate, winding openings are formed at one sides, close to the placing plate, of the outer boxes, winding columns are longitudinally arranged in the outer boxes, a servo motor is arranged under each winding column, a mounting groove is formed in the bottom of the winding column, a free end of a transmission shaft of the servo motor is clamped in the mounting groove, a bearing is fixedly mounted at the top of the outer box, the top of the winding column penetrates through the outer box and is rotatably mounted in the bearing, a winding groove is formed in the winding column in an up-down surrounding mode, the winding grooves are spirally distributed in the winding columns, a first wire is wound in the winding groove in the winding column at one side of the placing plate, and a second wire is wound in the winding groove in the winding column at the other side of the placing plate.

Owner:天长市万科电器配件厂

Battery winding device

ActiveCN113363553AImprove performanceImprove securityAssembling battery machinesElectrostatic separationElectrical batteryDust control

The embodiment of the invention provides a battery winding device, and relates to the field of battery manufacturing. The battery winding device comprises: a positive pole piece unreeling module which is used for unreeling a positive pole piece; a negative pole piece unwinding module which is used for unwinding a negative pole piece; an upper diaphragm unwinding module which is used for unwinding an upper diaphragm; a lower diaphragm unwinding module which is used for unwinding a lower diaphragm; a turret module which is used for winding the positive pole piece, the negative pole piece, the upper diaphragm and the lower diaphragm; a dust collection module which is used for carrying out electrostatic dust collection on the positive pole piece, the negative pole piece, the upper diaphragm and the lower diaphragm; and a glue outlet rolling module which is used for spraying glue and rolling. According to the embodiment of the invention, the battery performance and safety can be improved; compared with a lamination process, the embodiment of the invention can also reduce waste and has better economic benefits.

Owner:BATTERO TECH CORP LTD

Double-speed recoiler

The invention discloses a double-speed winding machine, comprising a frame, a power shaft, a power device and a winding shaft. The power shaft is connected with the power device. The power shaft is parallel with the winding shaft. The winding shaft comprises a high-speed winding shaft and a low-speed winding shaft. The two winding shafts are respectively positioned on both sides of the power shaft. A gear sleeve is arranged on the power shaft. The gear sleeve is slidingly fitted with the axial direction of the power shaft and is fixedly fitted with the circumferential direction of the power shaft. A slide bar and a cylinder are arranged above the power shaft. The cylinder is connected with the slide bar and drives the slide bar to shift vertically. A shift fork is arranged on the center of the slide bar and is connected with the gear sleeve. Gears are arranged on both the high-speed winding shaft and the low-speed winding shaft. The diameter of the gear on the high-speed winding shaft is smaller than the diameter of the gear on the low-speed winding shaft. The gear sleeve on the power shaft is respectively meshed with the gear on the high-speed winding shaft and the gear on the low-speed winding shaft under the function of the shift fork. The double-speed winding machine has the advantages of reducing the equipment investment, saving the space, lowering the production cost, and being applicable for mills rolling belt materials.

Owner:朱惠兴

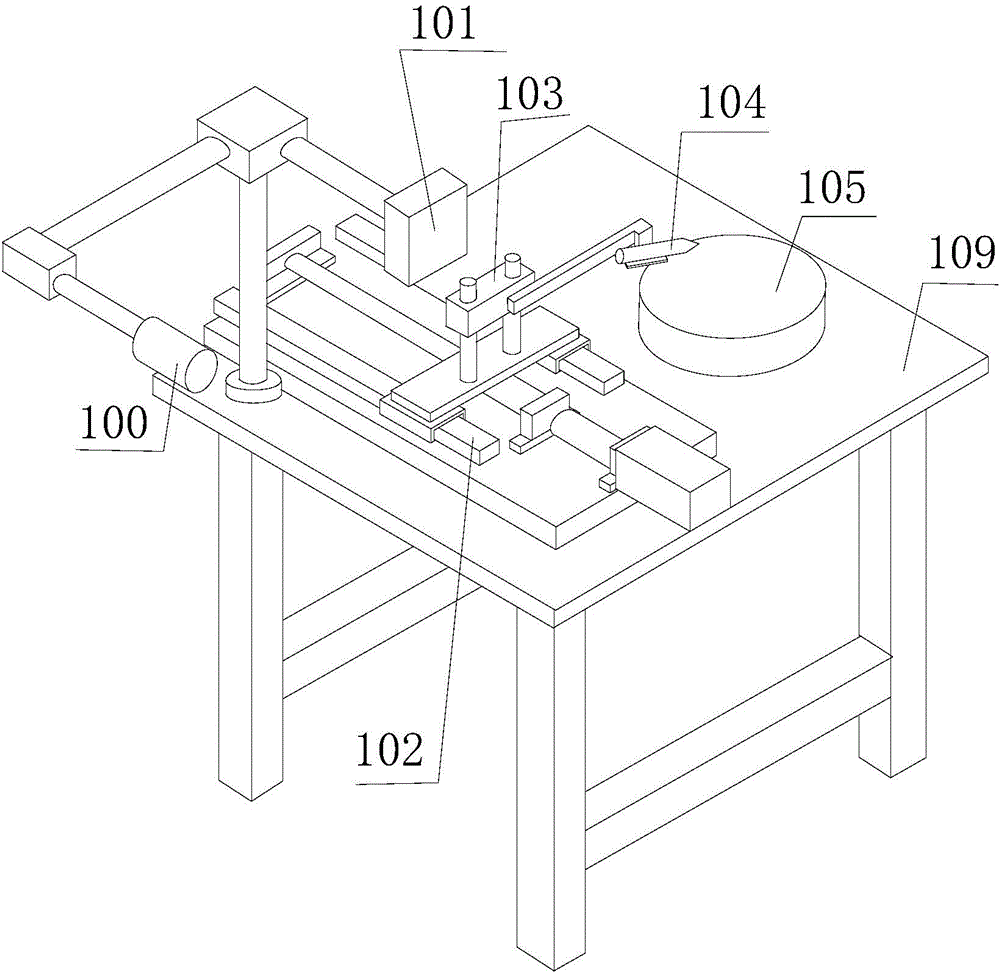

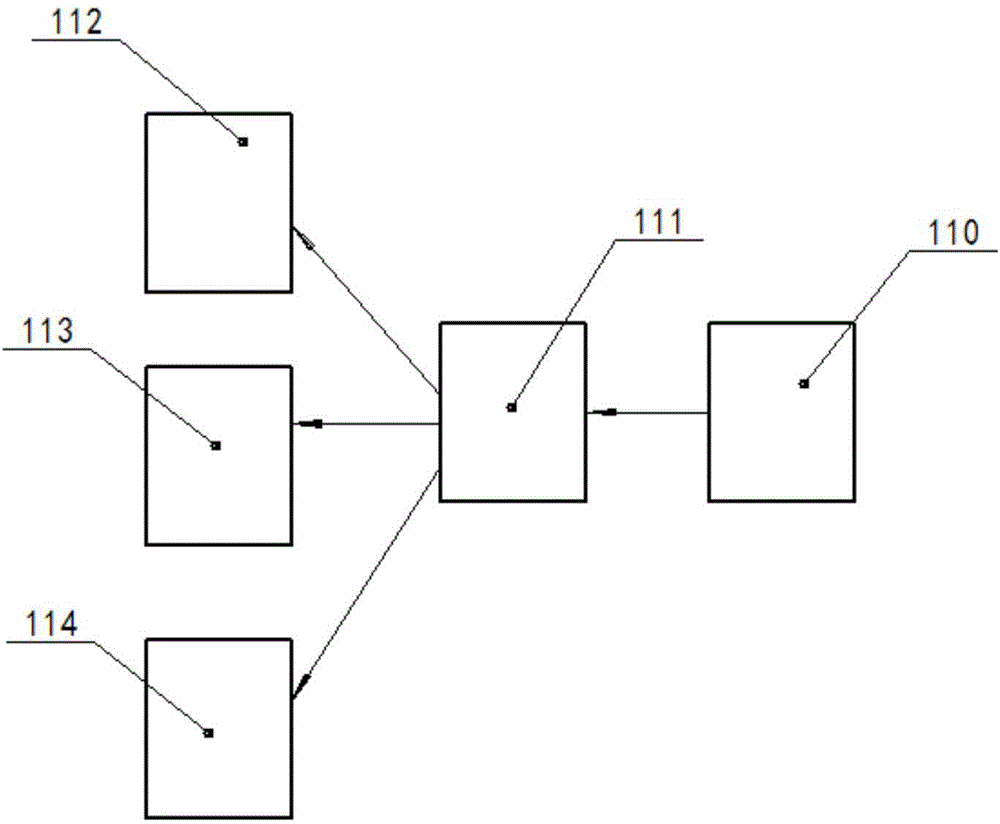

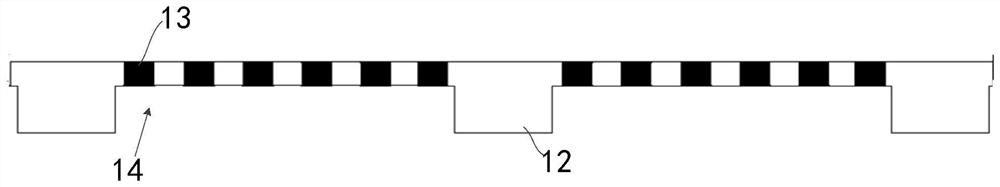

Seed tape preparation device for directional seeding corns

The invention discloses a seed tape preparation device for directional seeding corns. The seed tape preparation device for directional seeding corns comprises a working rack, a paper tape unwinding mechanism, a gluing mechanism, a directional zero-speed seed feeding mechanism, an upper and lower paper tape bonding mechanism, a winding mechanism and a control system; the working rack is formed by splicing a plurality of aluminum profiles; The paper tape unwinding mechanism comprises a lower paper tape, two material blocking disks, two optical shafts I and an upper paper tape; the upper paper tape is concentrically arranged on one optical shaft I through the material blocking disk, one optical shaft I is arranged on an upper left side of the working rack, the lower paper tape is concentrically arranged on the other optical shaft I through the material blocking disk, and the other optical shaft I is arranged on a lower right side of the working rack; and the gluing mechanism is arranged on an upper right side of the working rack, the directional zero-speed seed feeding mechanism is arranged on an upper middle part of the working rack, the upper and lower paper tape bonding mechanism is arranged on a middle part of a left side of the working rack, the winding mechanism is arranged on a lower part of the left side of the working rack and located below the upper and lower paper tape bonding mechanism, and the control system is arranged on an upper middle part of the working rack.

Owner:CHINA AGRI UNIV

A low-voltage wire-wound pneumatic brake tension device

PendingCN109216016AReduce interventionImprove product qualityInductances/transformers/magnets manufactureCopper wireFlywheel

A low-voltage wire-wound pneumatic brake tension device is provided. The invention relates to the technical field of transformer winding automation equipment. The low-voltage winding pneumatic brake tension device comprises a main support frame assembly, a main winding wheel assembly is vertically arranged on the top of the main support frame assembly, an end of the main winding wheel assembly issleeved with a support shaft base assembly, and a brake assembly is arranged on one side of the main winding wheel assembly. The flywheel of the whole equipment is clamped by a pneumatic butterfly brake, so as to realize the clamping of the whole equipment, thereby realizing the tension of the conductor, and realizing 1- 12 groups of different copper wires are used for winding operation so as to realize the winding operation of copper wires with different number of wire groups, and the whole equipment is controlled by adopting electric equipment, so as to reduce manual intervention, improve product quality and increase product production efficiency.

Owner:昆明供电设计院有限责任公司

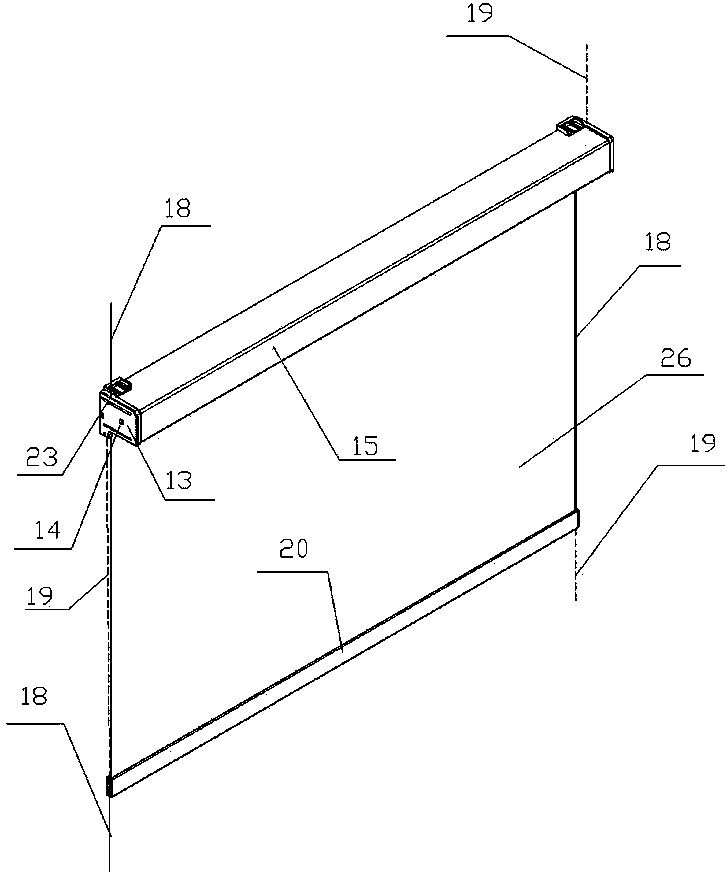

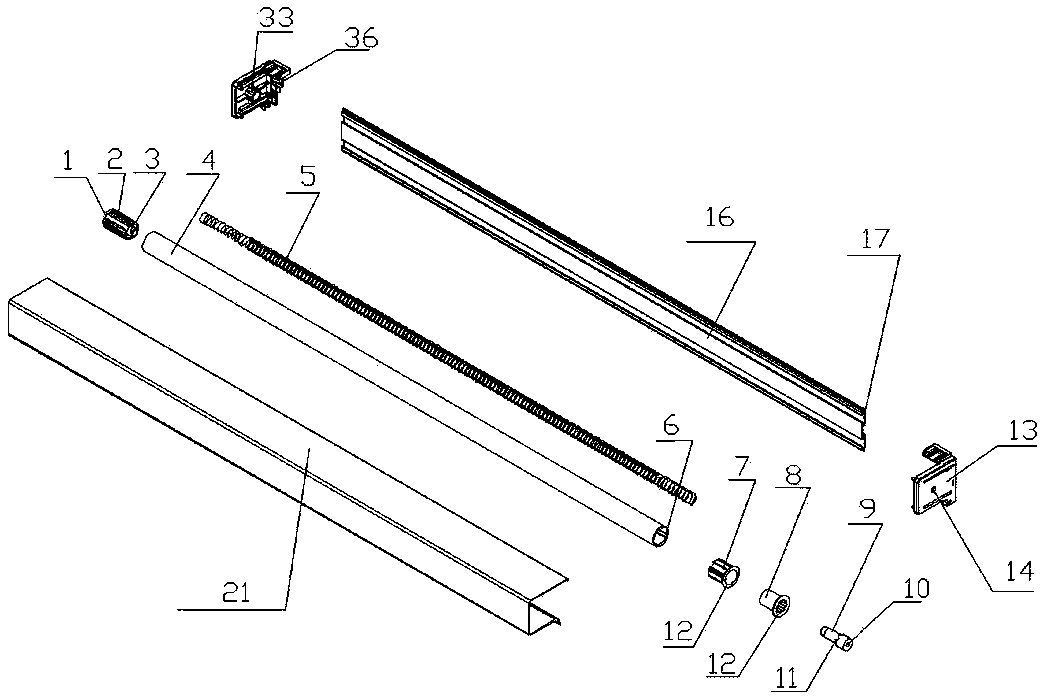

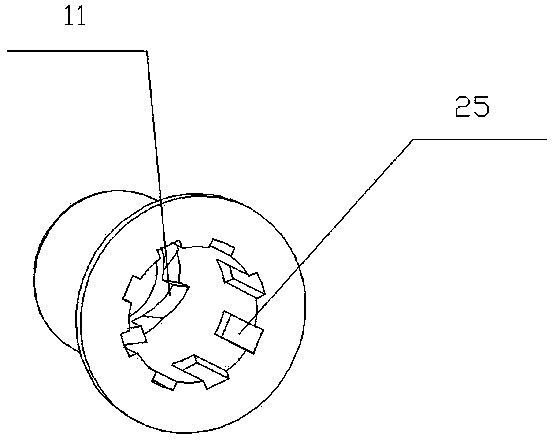

Roller shutter and roller shutter system manufactured by applying same

ActiveCN103993819ASimple structureIncrease flexibilityLight protection screensPulp and paper industryFixed position

The invention relates to a roller shutter structure, in particular to a roller shutter and a roller shutter system manufactured by applying the roller shutter. The roller shutter comprises roller shutter cloth, one end of the roller shutter cloth is wound around a reel assembly, the other end of the roller shutter cloth is fixed to a bottom plate assembly, the two sides of the roller shutter are respectively provided with a guide part, the guide parts are connected to the reel assembly and the bottom plate assembly in a wound mode respectively, and at least one of the reel assembly and the bottom plate assembly which are located at the two ends of the roller shutter cloth can move up and down along the guide parts. The roller shutter system is of the structure formed by connecting more than two roller shutters through one guide part. The roller shutter system is simple in structure and convenient to operate, the shielding position can be selected freely, the fixing positions of the two ends of the roller shutter cloth of the roller shutter can be adjusted directly, and the roller shutter system is manufactured by applying the roller shutter; the technical problems that in the prior art, shielding has to be performed from top to bottom according to the shielding position of the roller shutter cloth, the winding mode of the roller shutter cloth is single, and a winding structure is complex are solved.

Owner:HD4U SMART HOME CO LTD

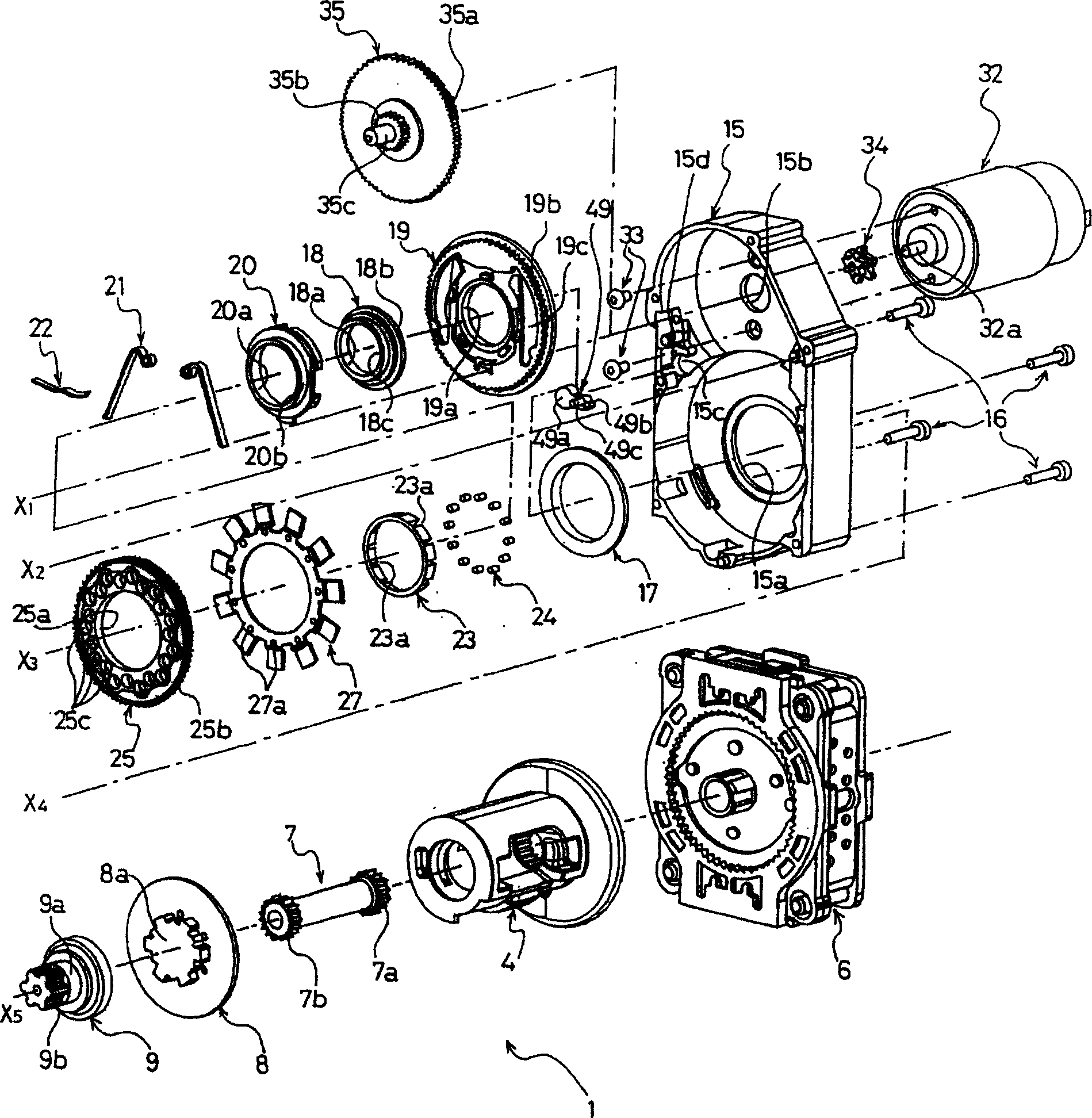

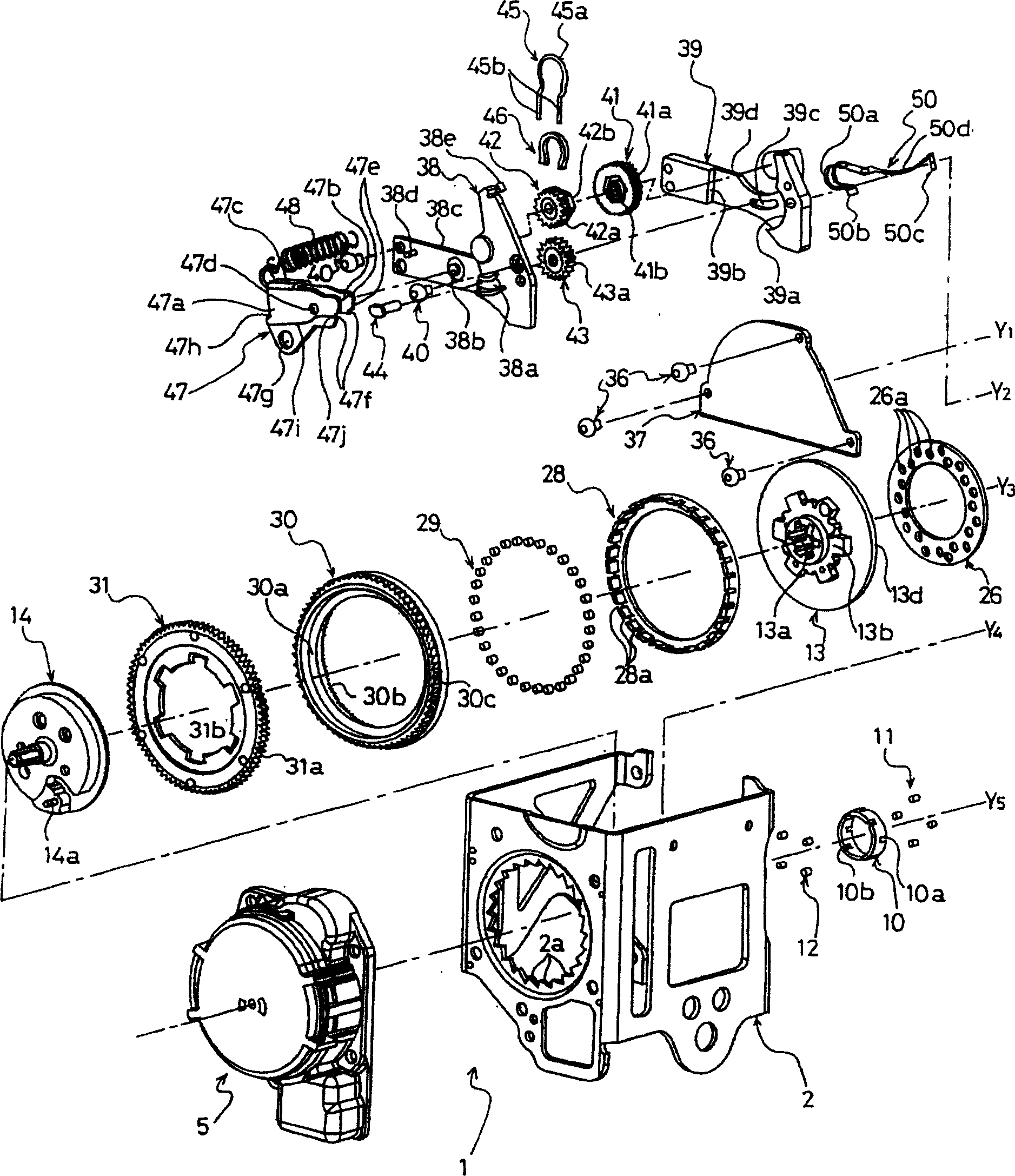

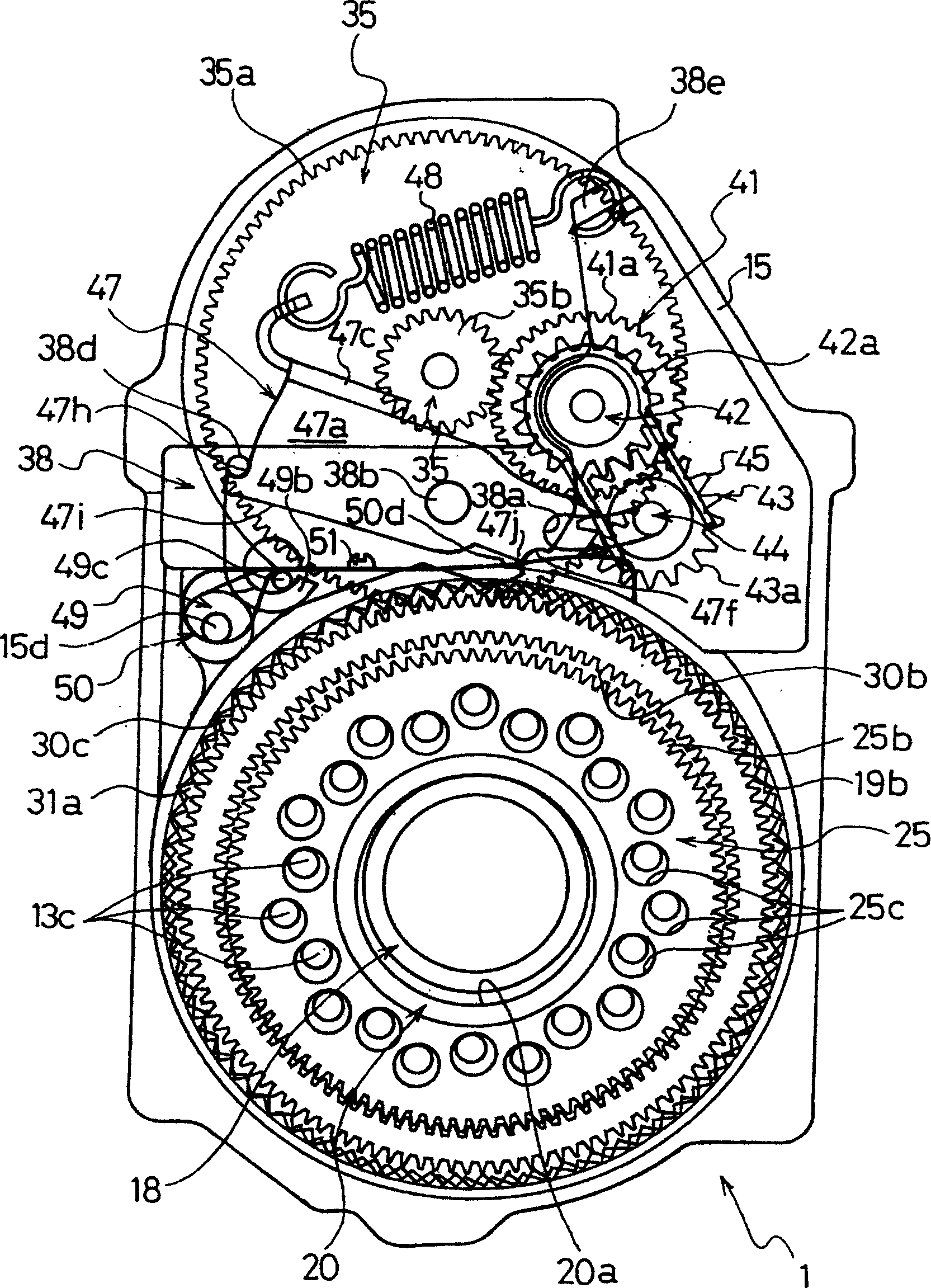

Seat belt retractor and seat belt device using the same

InactiveCN1765666ARotation torque reductionReduce power consumptionBelt retractorsLow speedPower flow

The present invention provides a seat belt retractor and a seat belt device capable of reducing the electric current consumption of the motor and controlling the motor more simply, and realizing two winding performances of rapidly winding the seat belt and winding the seat belt with a high torque . In the state where the clutch pawl (49) and the internal gear (30) are not engaged, the clutch gear (43) is meshed with the planet carrier gear (31) by making the motor rotate forward in the direction of winding the safety belt. Thus, the low reduction ratio transmission mode is set, and the seat belt can be wound at high speed and with low torque. When the seat belt is tensioned and the load of the seat belt rises, the clutch pawl (49) can be engaged with the internal gear (30). Moreover, when the motor current increases and exceeds the set value, the motor is reversed, and the clutch gear (43) is separated from the transmission gear (31). As a result, the transmission mode with a high reduction ratio is set, and the seat belt is wound at a low speed and with a high torque.

Owner:TAKATA CORPORATION

Convenient-to-clamp winding machine for transformer skeleton

Owner:XUZHOU SANHE AUTOMATIC CONTROL EQUIP

Wire winding core and wire unwinding mechanism

ActiveCN111615782ARealize the winding processRealize cardingManufacturing dynamo-electric machinesClassical mechanicsWire wrap

A wire winding core (1) and a wire unwinding mechanism (4) are disclosed. The wire winding core (1) comprises a base assembly (10), a first drive device, and a telescopic rod (13). The base assembly (10) is used for mounting an iron core (2). The first drive device is connected to the base assembly (10) to drive the base assembly (10) to rotate. The telescopic rod (13) is connected to the base assembly (10), and can extend / retract with respect to the base assembly (10) along an extension direction of the telescopic rod (13). When the first drive device drives the base assembly (10) to rotate,the iron core (2) rotates along with the base assembly (10) to wind a lead-out wire (5) on the iron core. Because the telescopic rod (13) can extend / retract with respect to the base assembly (10), thelead-out wire (5) can be in a straight suspension state after passing through the telescopic rod (13), thereby providing a foundation for subsequent automatic assembling of a PCB board (9), automaticsoldering of the lead-out wire (5), and automatic breaking of a tail.

Owner:SZ DJI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com