Patents

Literature

2588results about How to "Realize automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

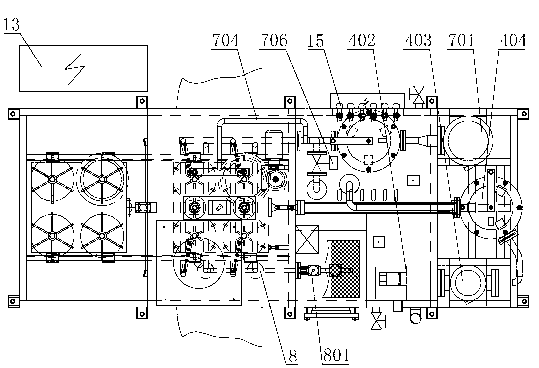

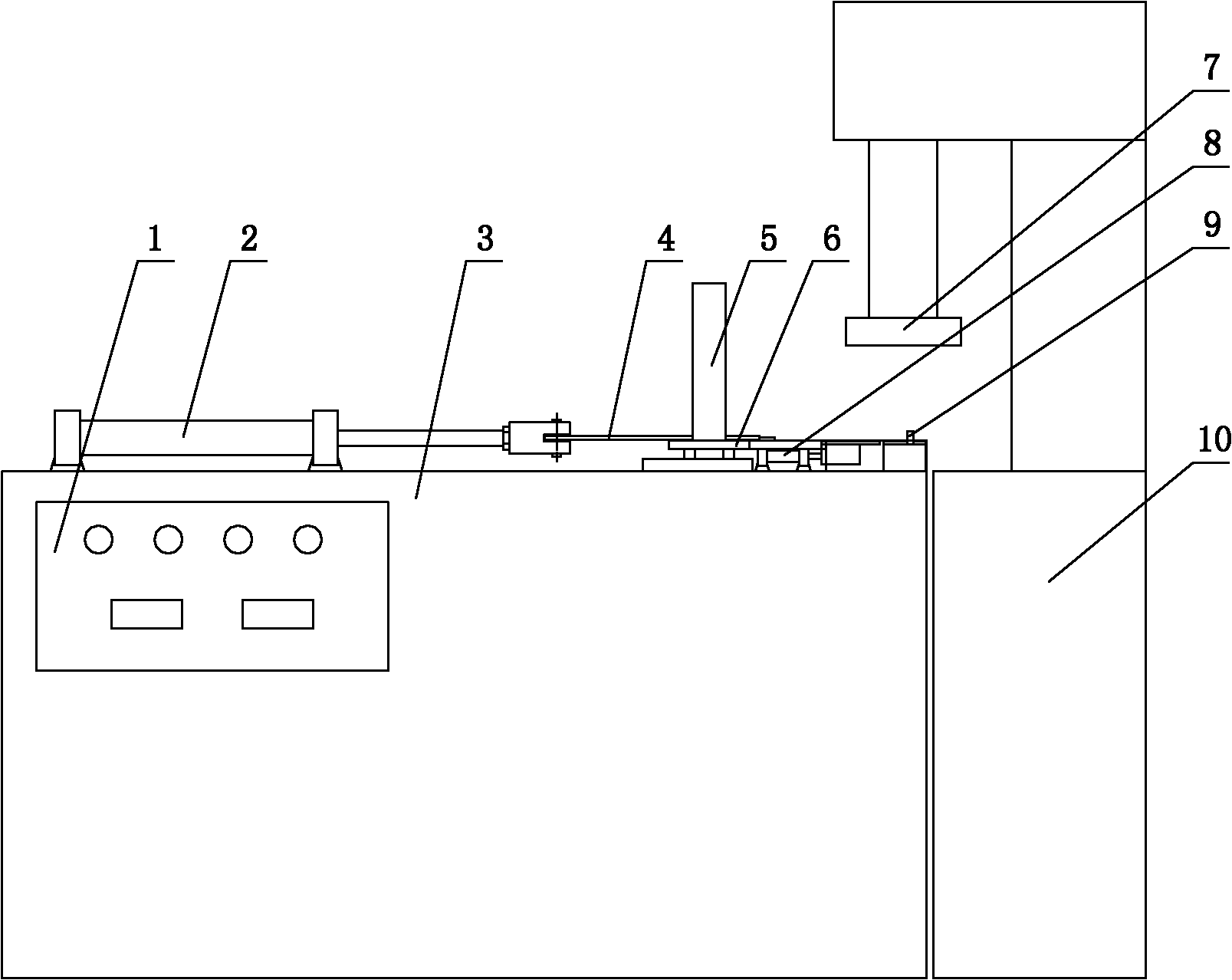

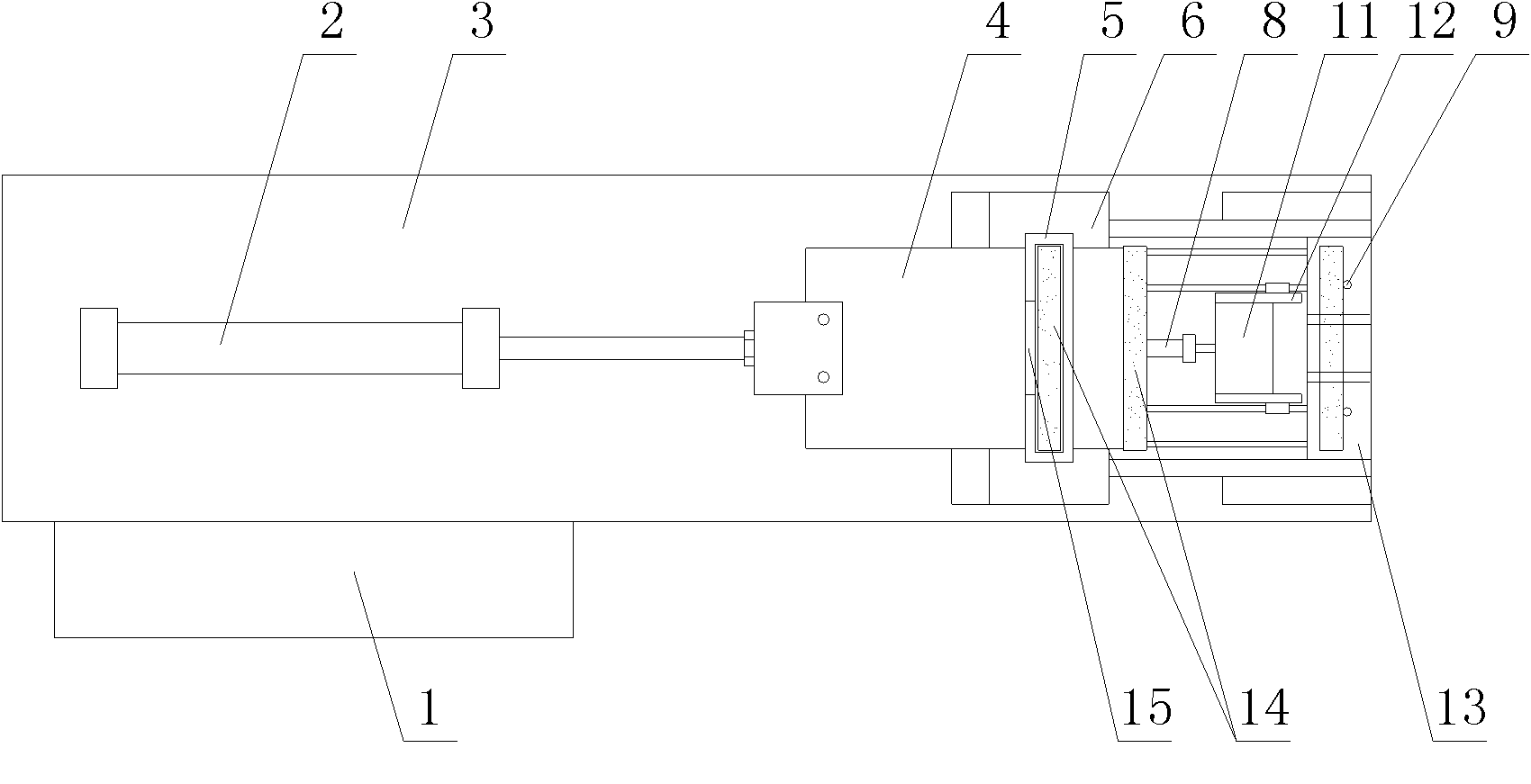

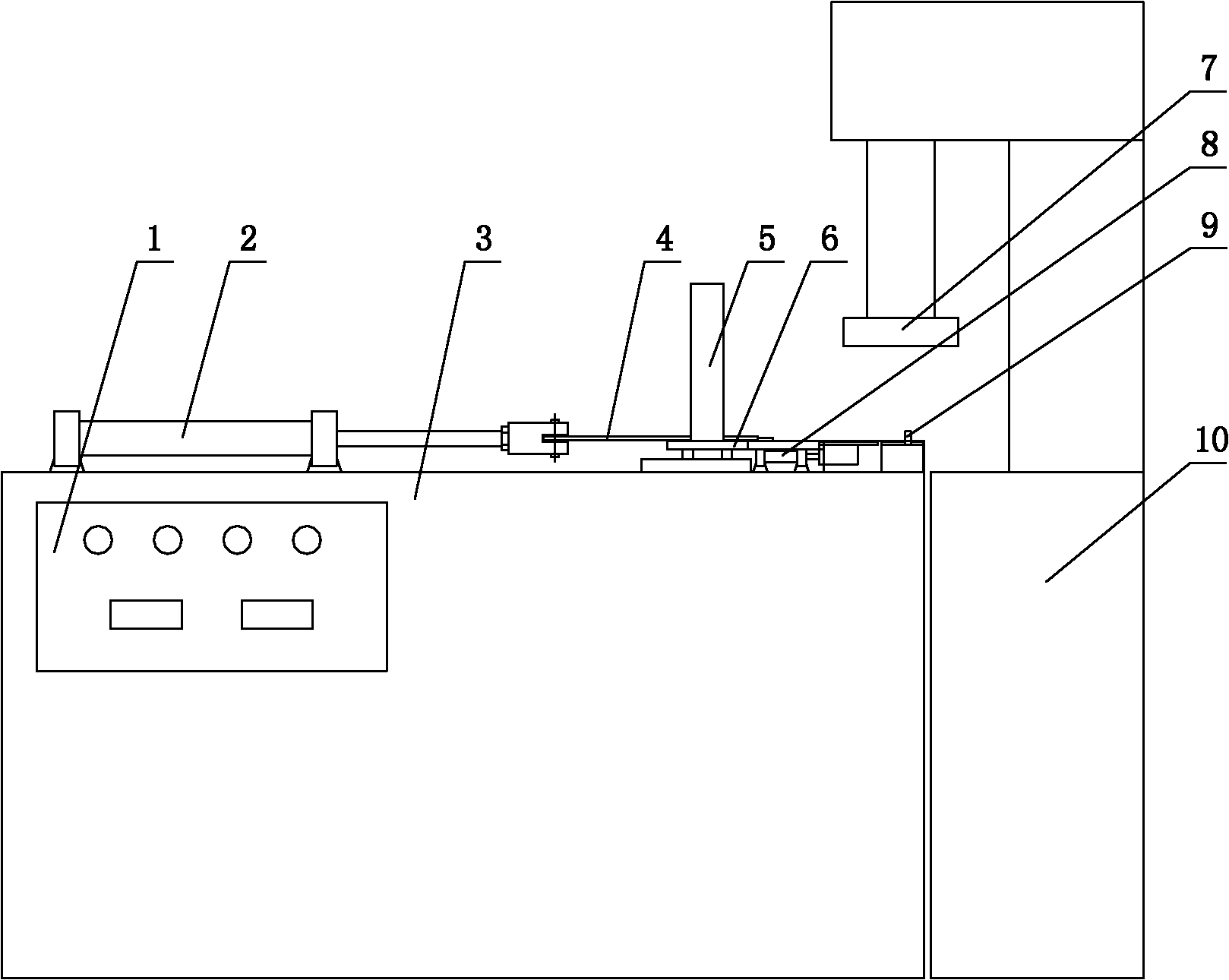

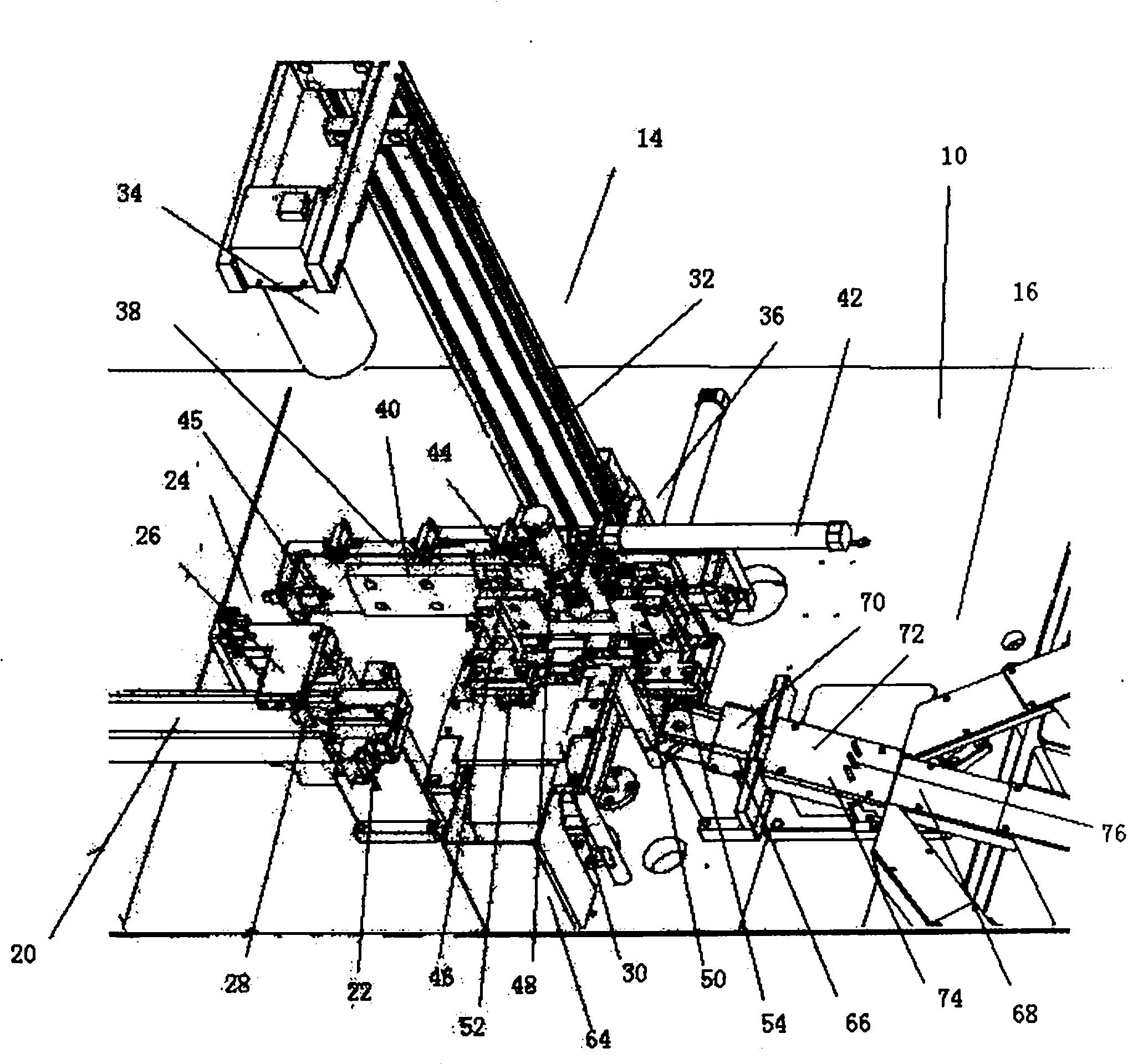

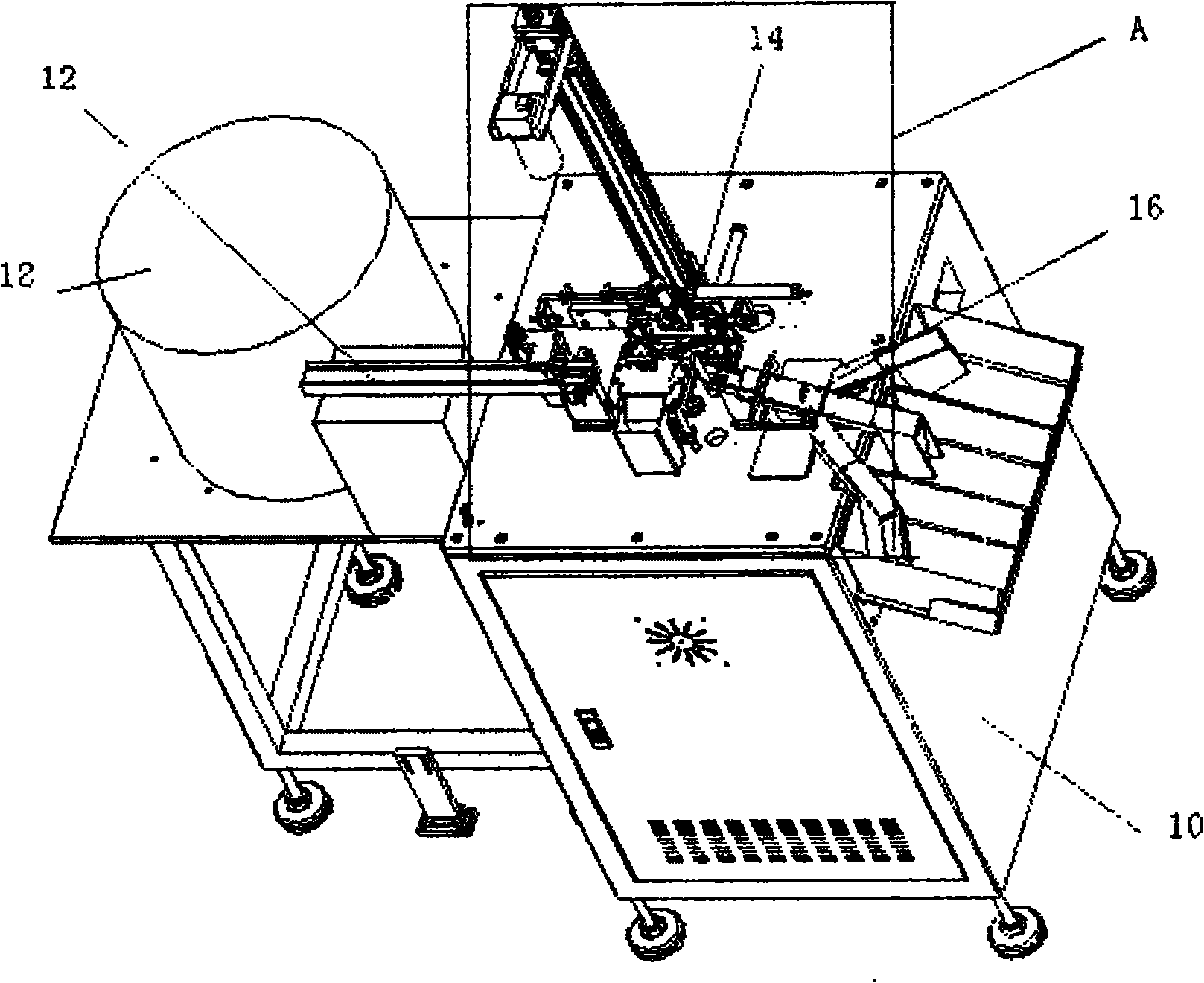

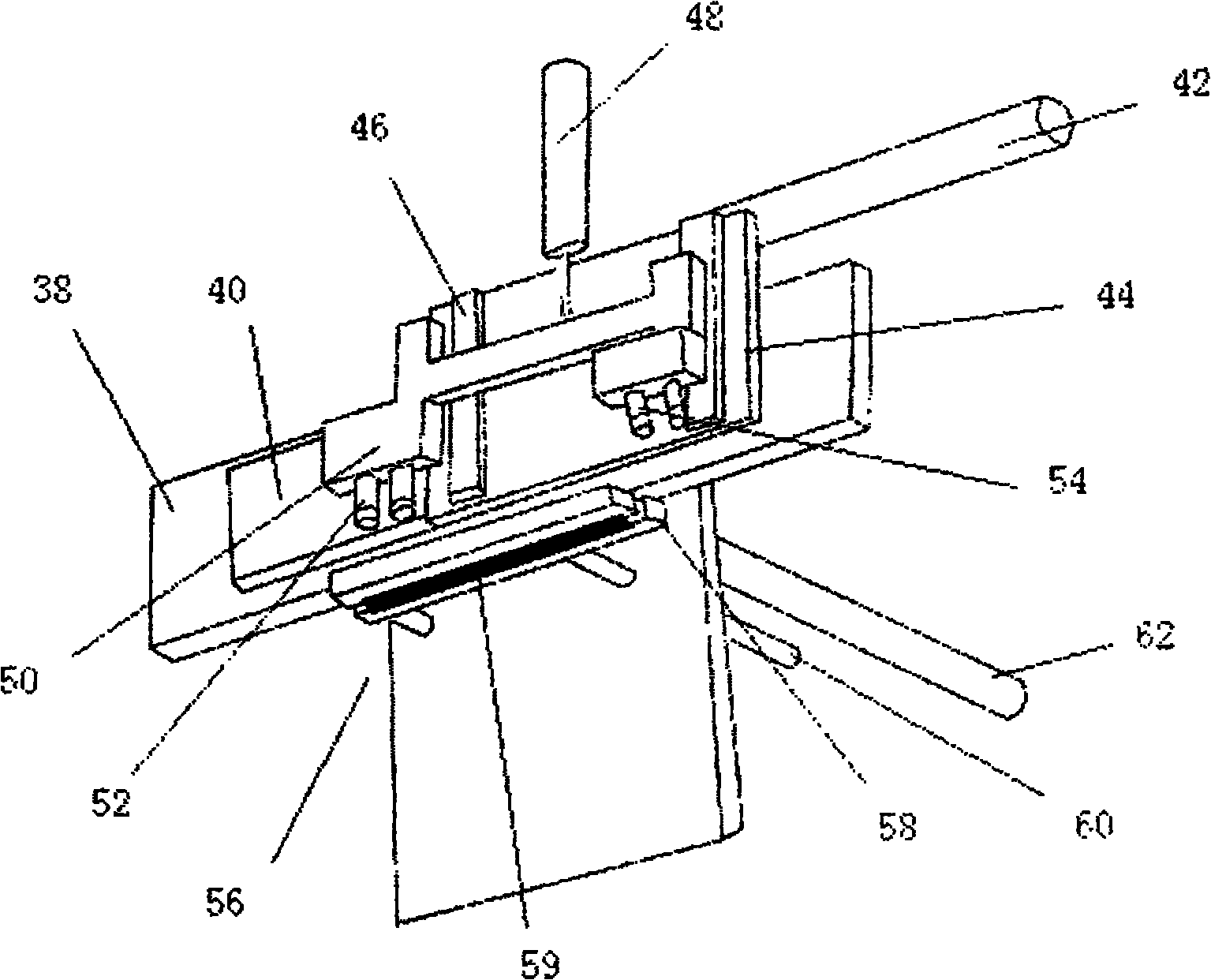

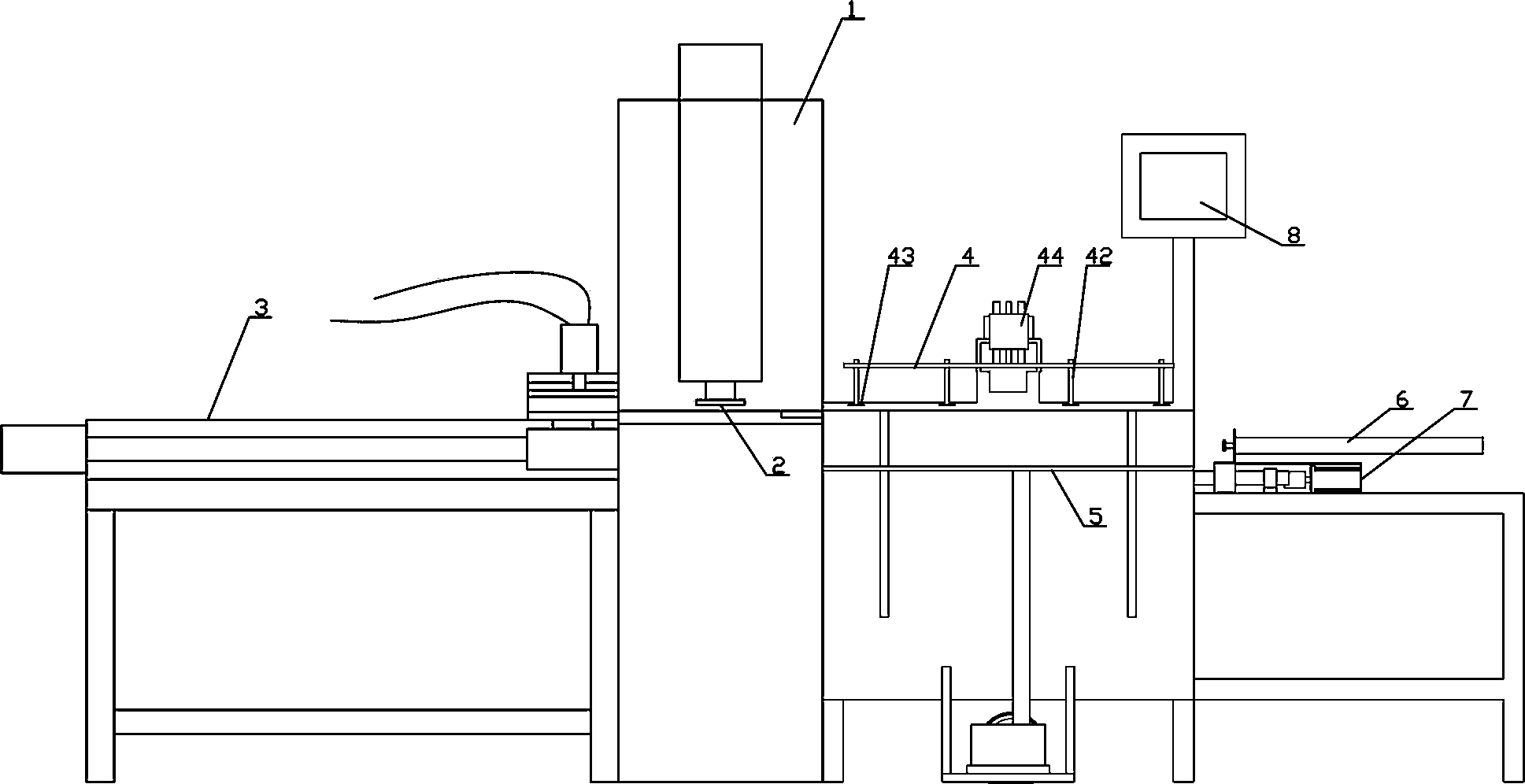

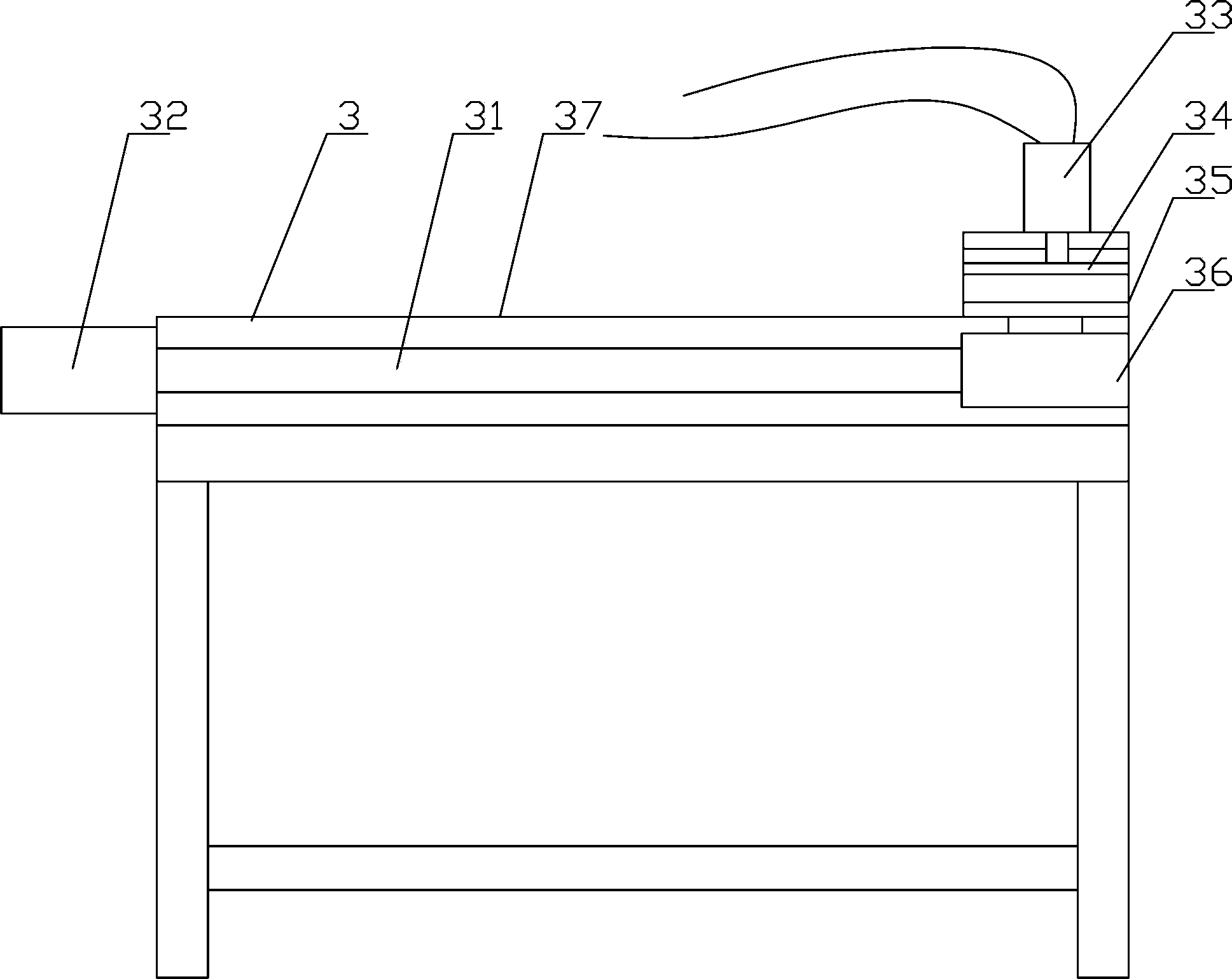

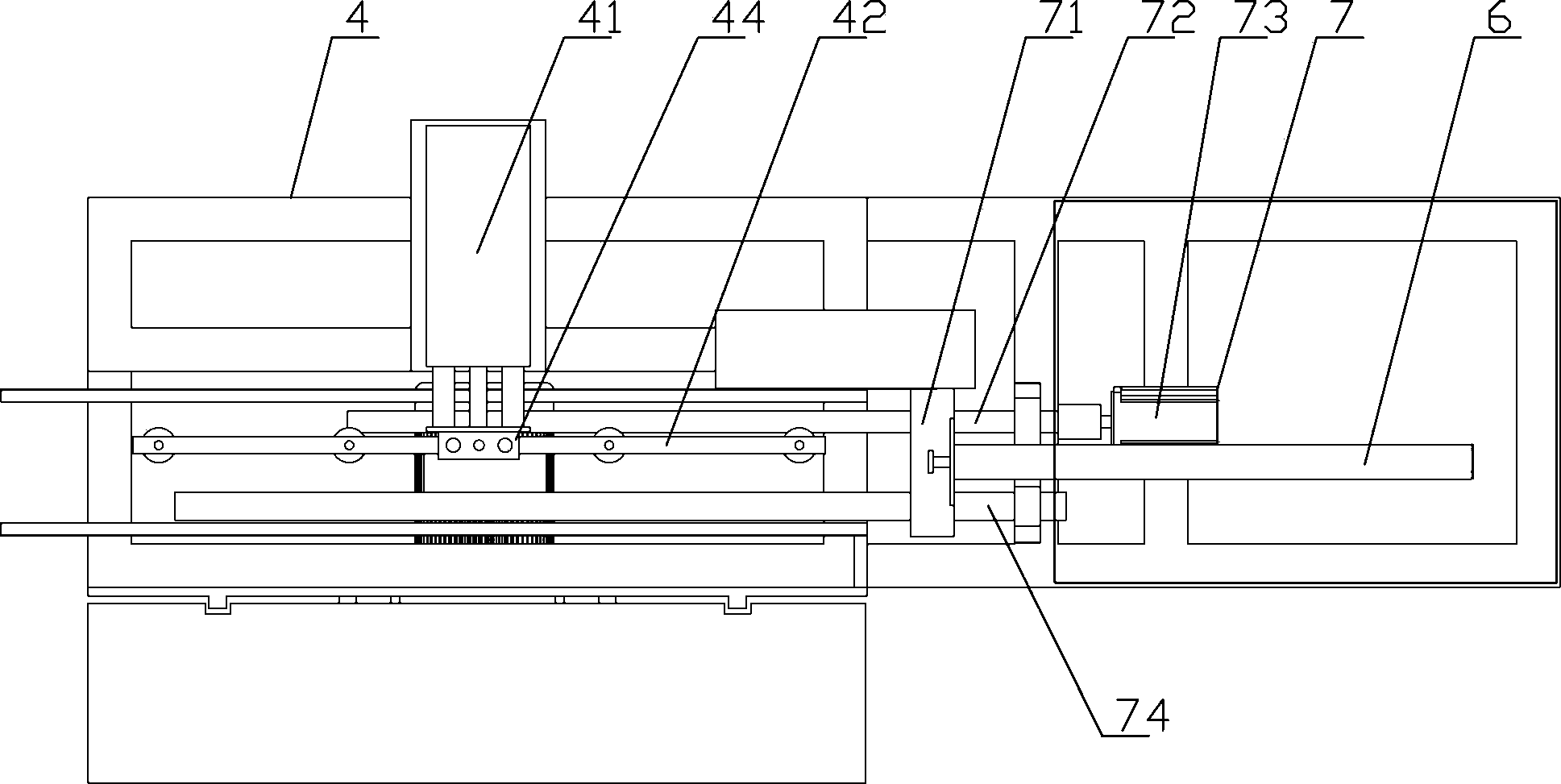

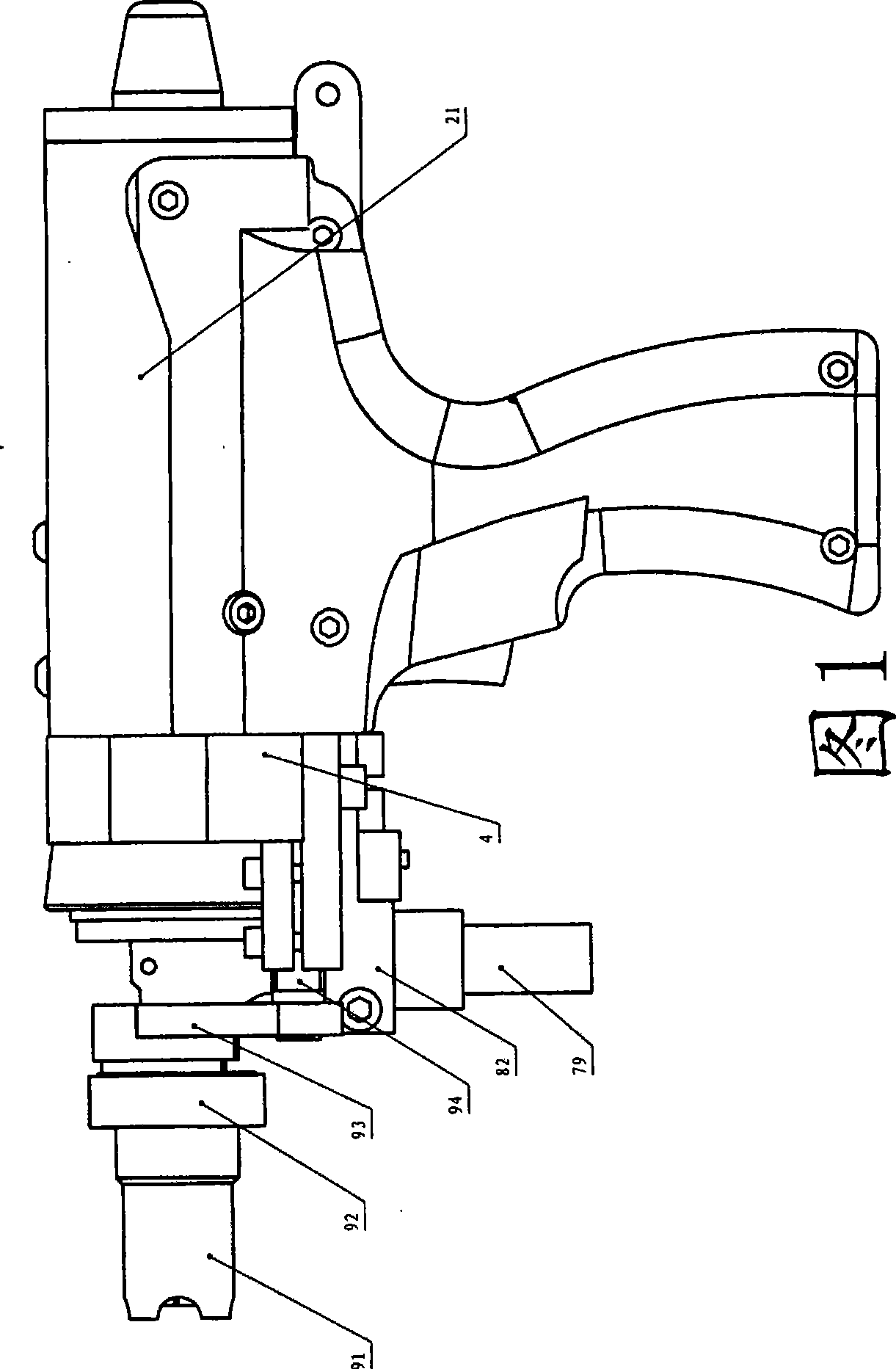

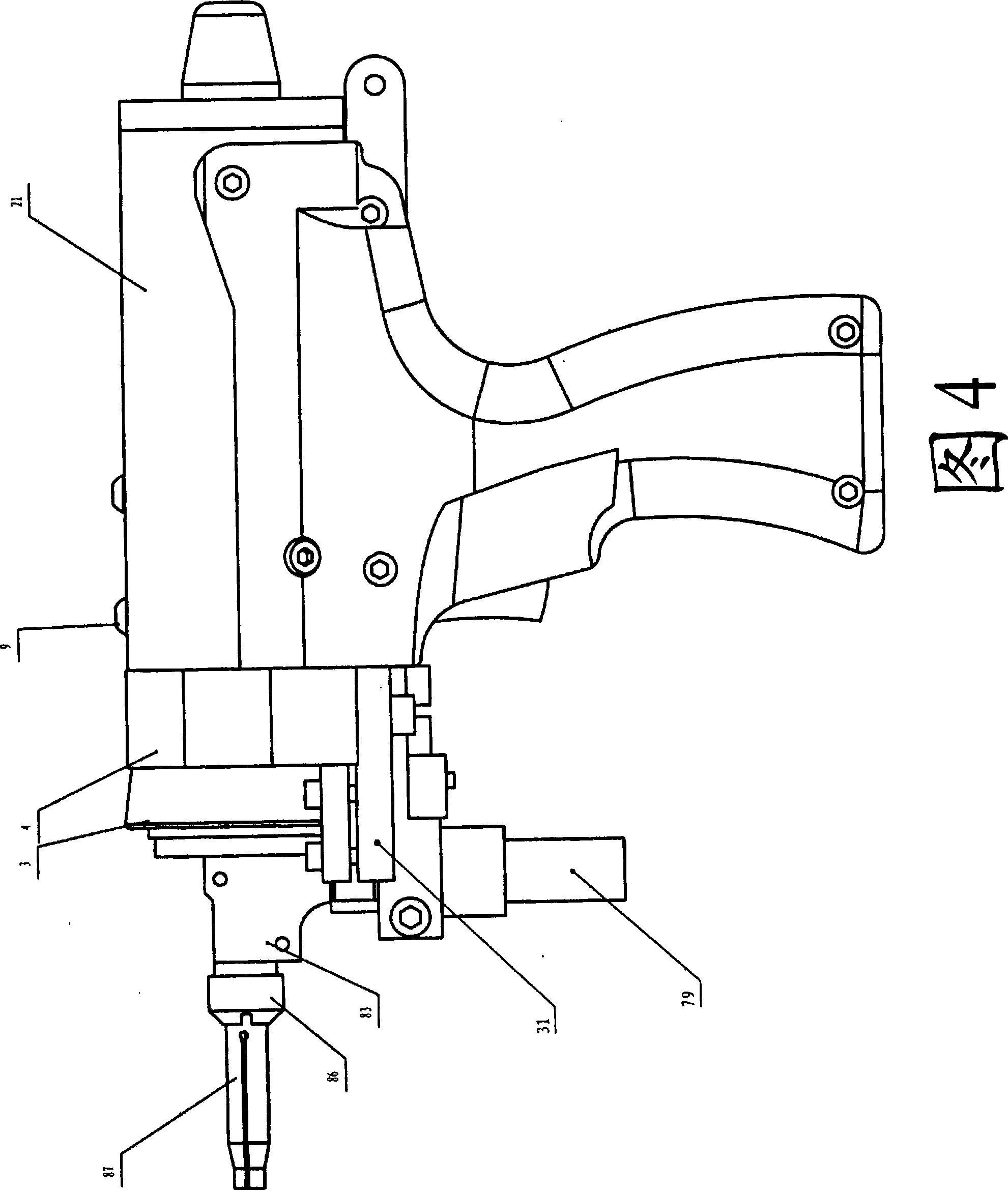

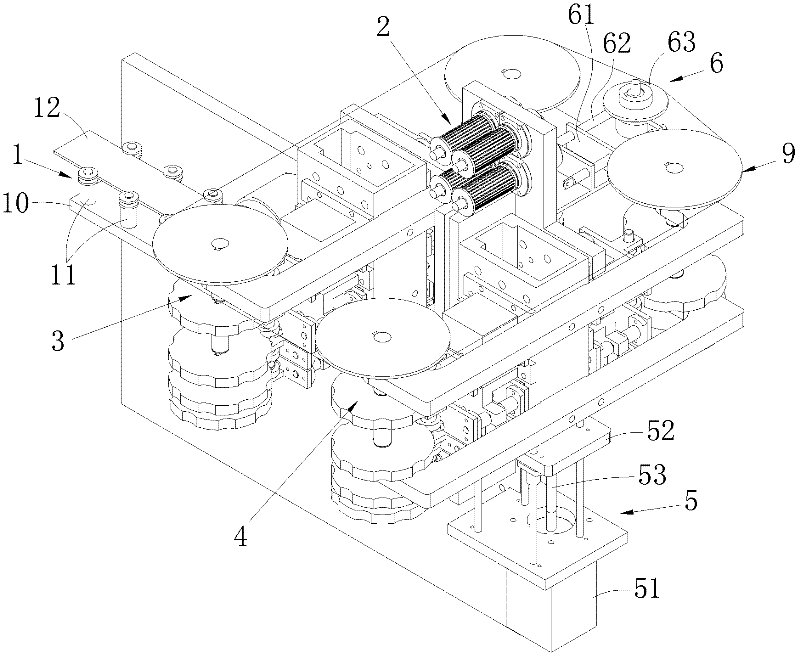

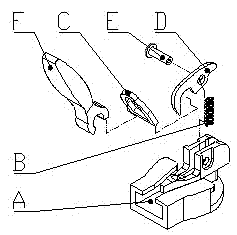

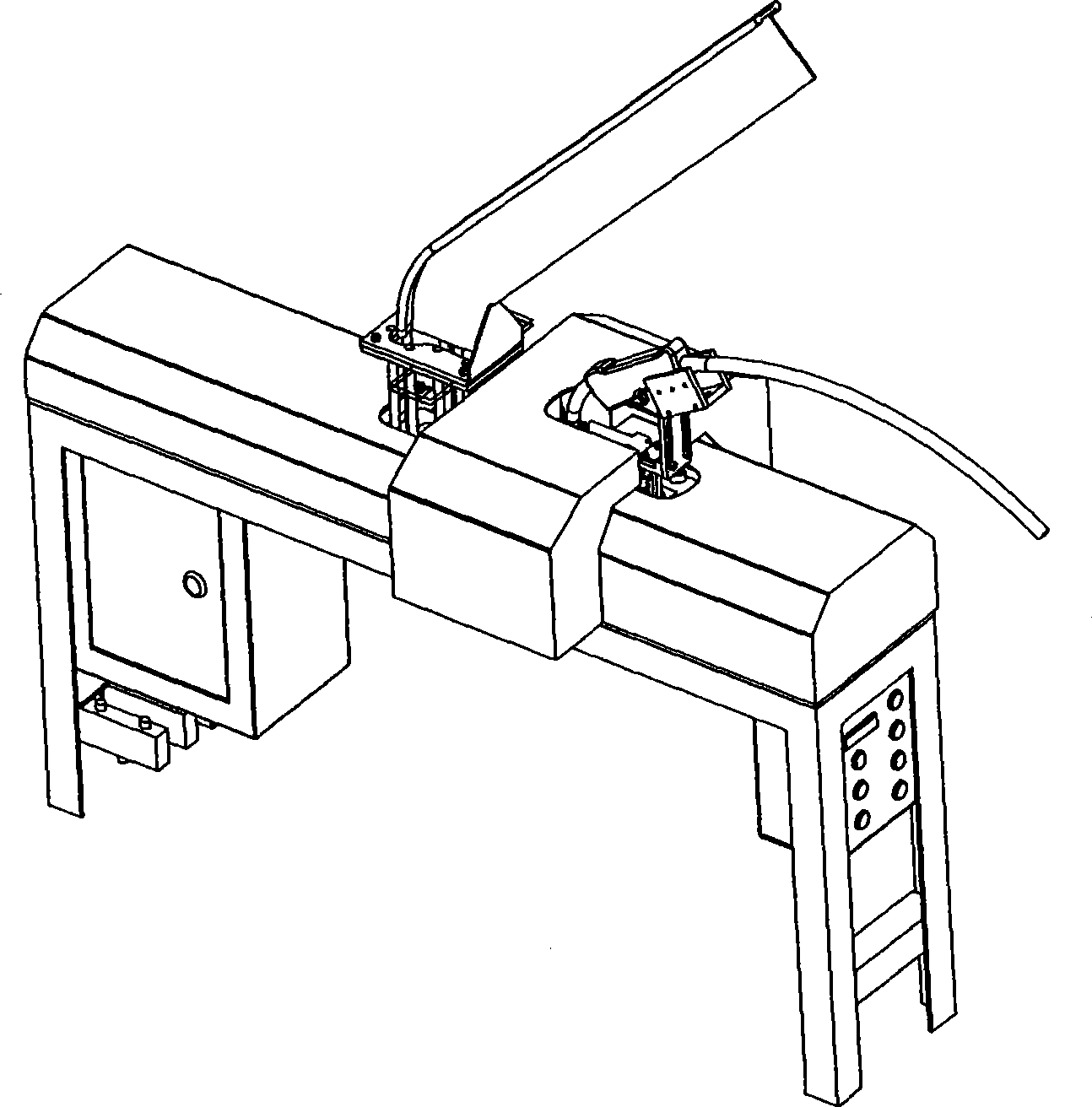

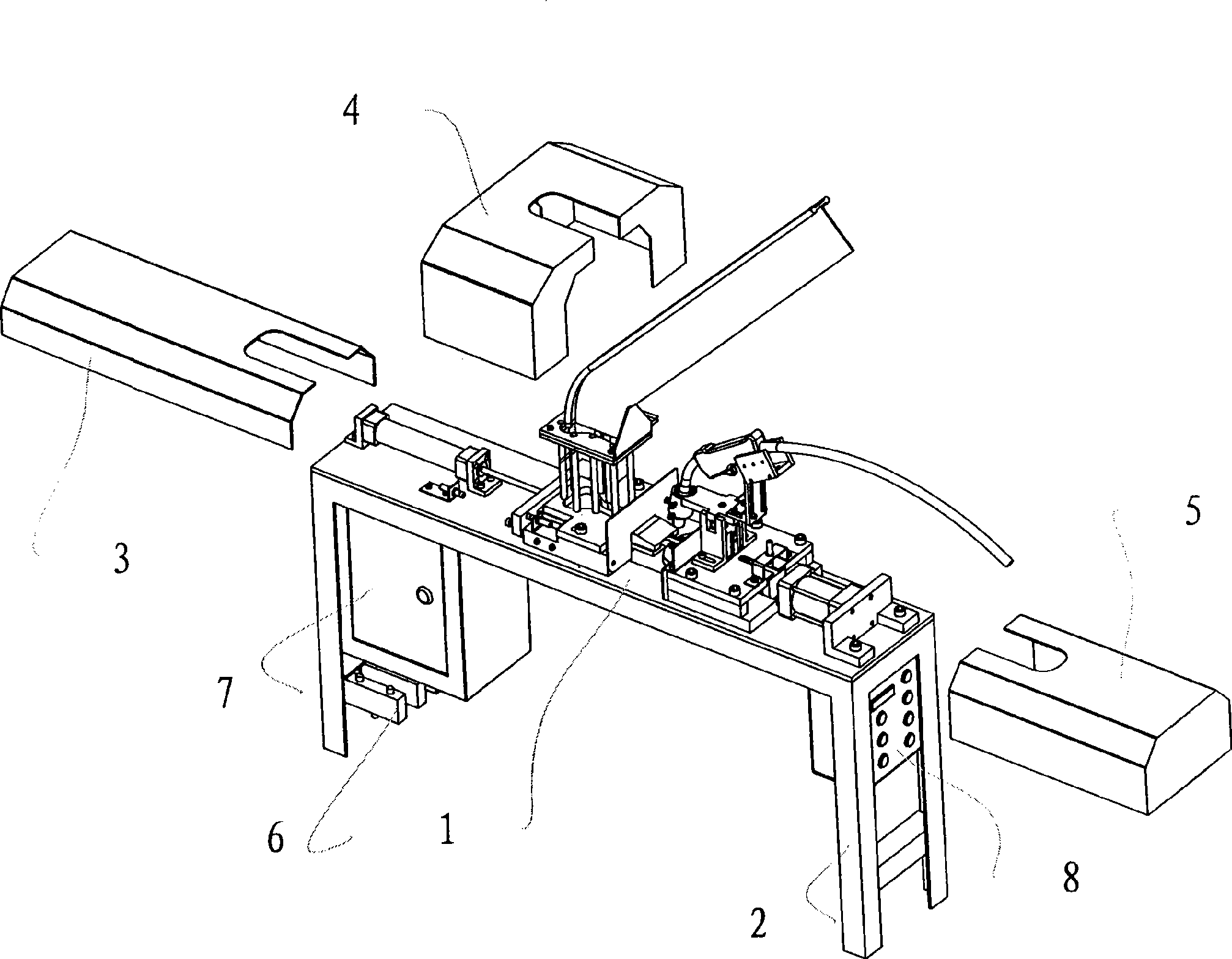

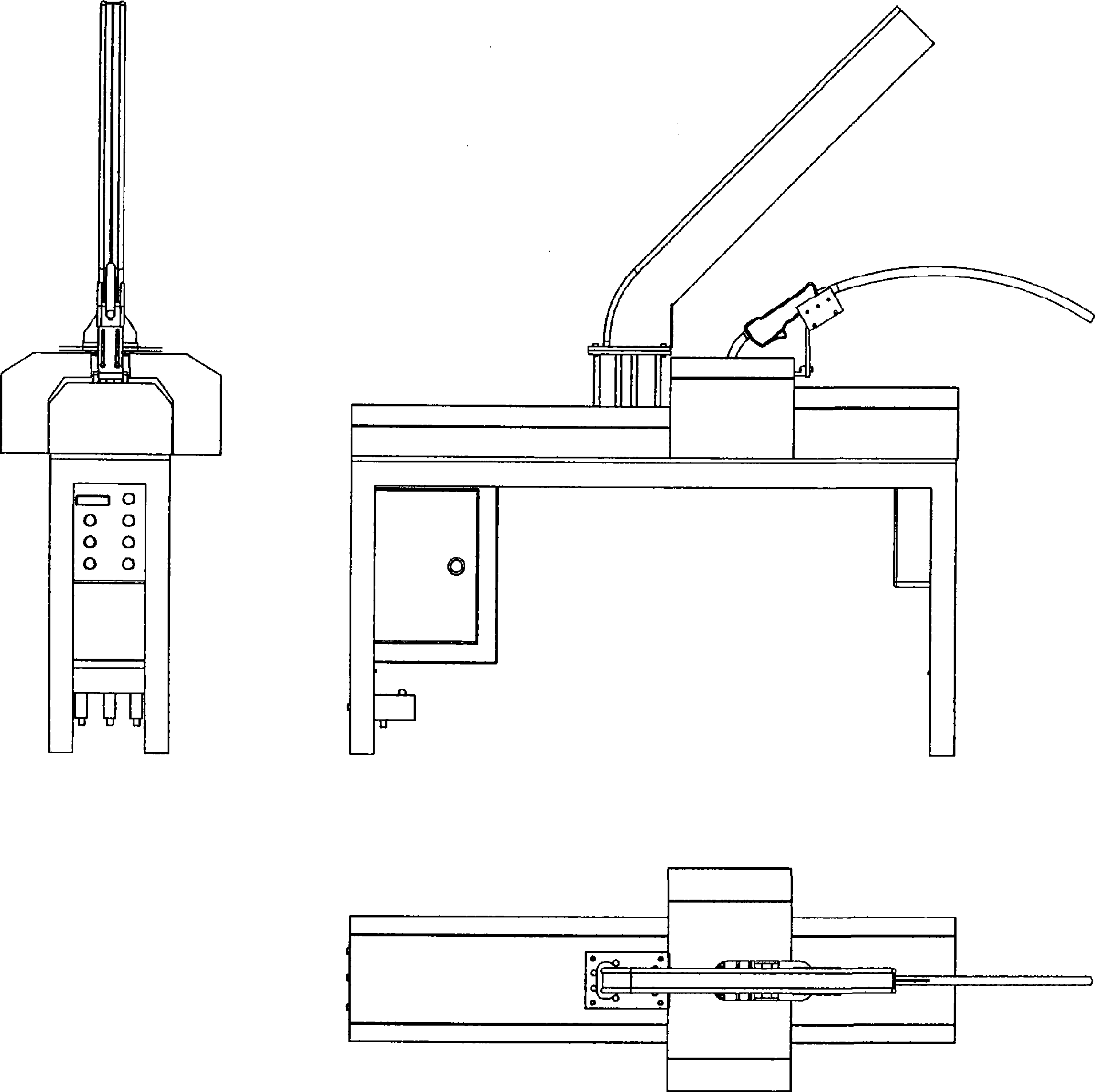

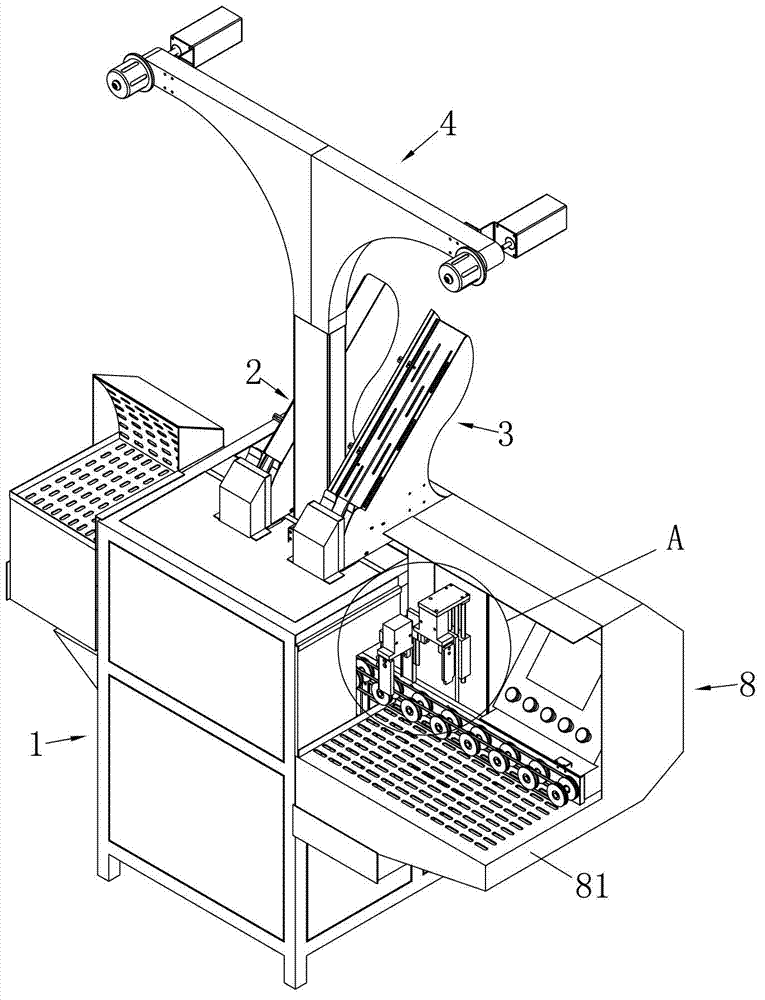

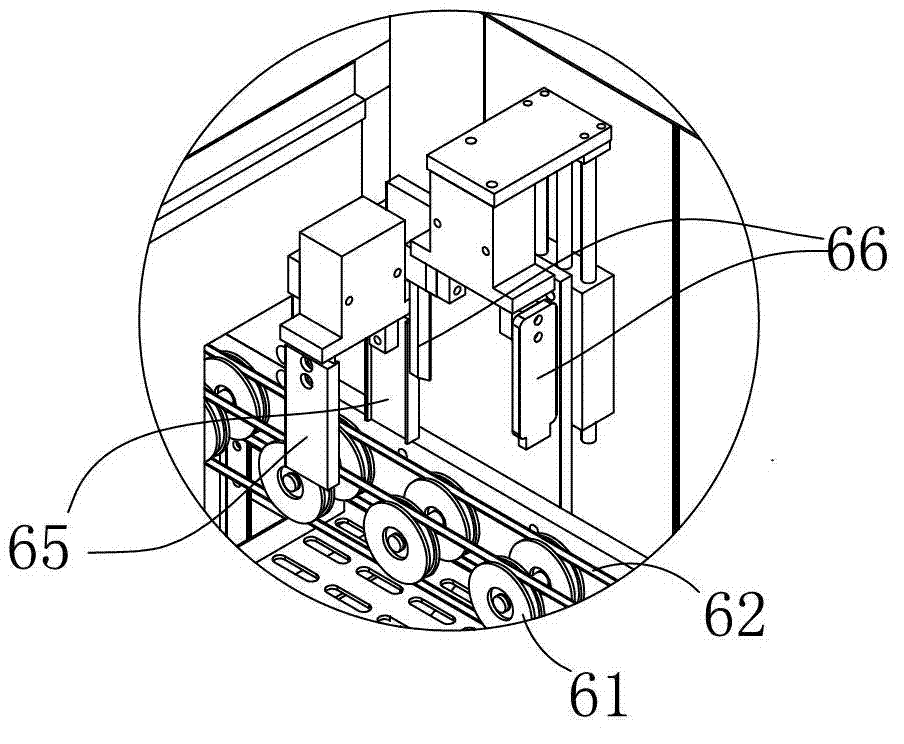

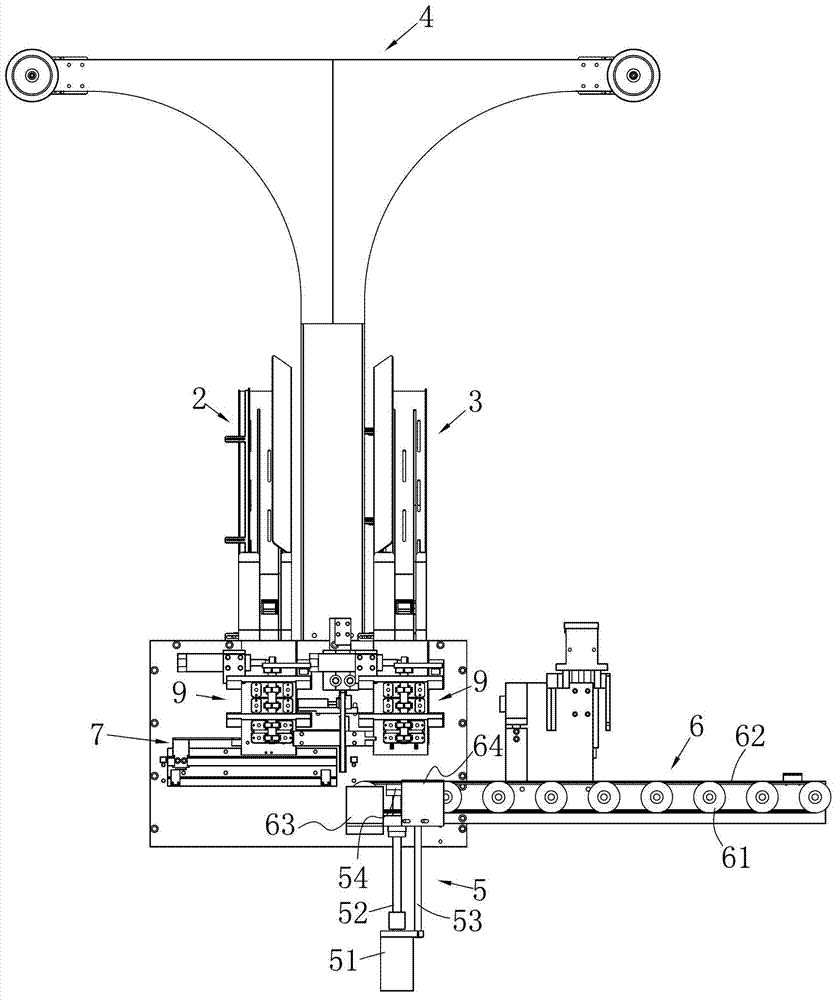

Folding key assembling machine

InactiveCN101972932ARealize automatic feedingRealize the assemblyAssembly machinesSemi automaticControl circuit

The invention relates to a folding key assembling machine, which comprises a worktable, and a plastic head feeding mechanism, a hardware press-in mechanism, a key handle feeding mechanism, a pin feeding mechanism, a pin pressing mechanism, a loading mechanism and an assembling and conveying mechanism which are arranged on the worktable, wherein the assembling and conveying mechanism is provided with a key holder; the hardware press-in mechanism, the key handle feeding mechanism and the pin pressing mechanism are connected with the assembling and conveying mechanism in turn; the output end of the plastic head feeding mechanism is connected with the hardware press-in mechanism; the output end of the pin feeding mechanism is connected with the pin pressing mechanism; and the mechanisms are connected with the main control circuit electrically. In the invention, the automatic feeding mechanism and the automatic assembling mechanism are combined scientifically; the operation mechanicals form a continuous operation streamline for automatically feeding and assembling folding keys in place of the manual and semi-automatic ways of assembling the folding keys; thus, the production efficiency of the folding keys is improved obviously, assembly quality is improved, production cost is saved and labor intensity is lowered.

Owner:周俊雄

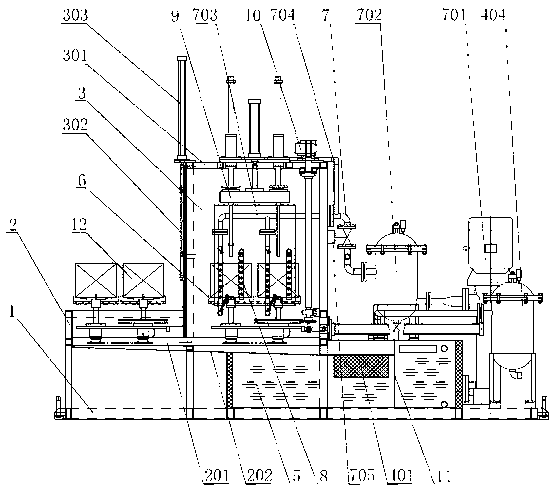

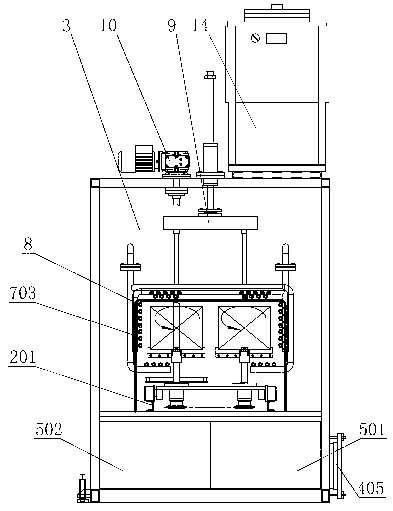

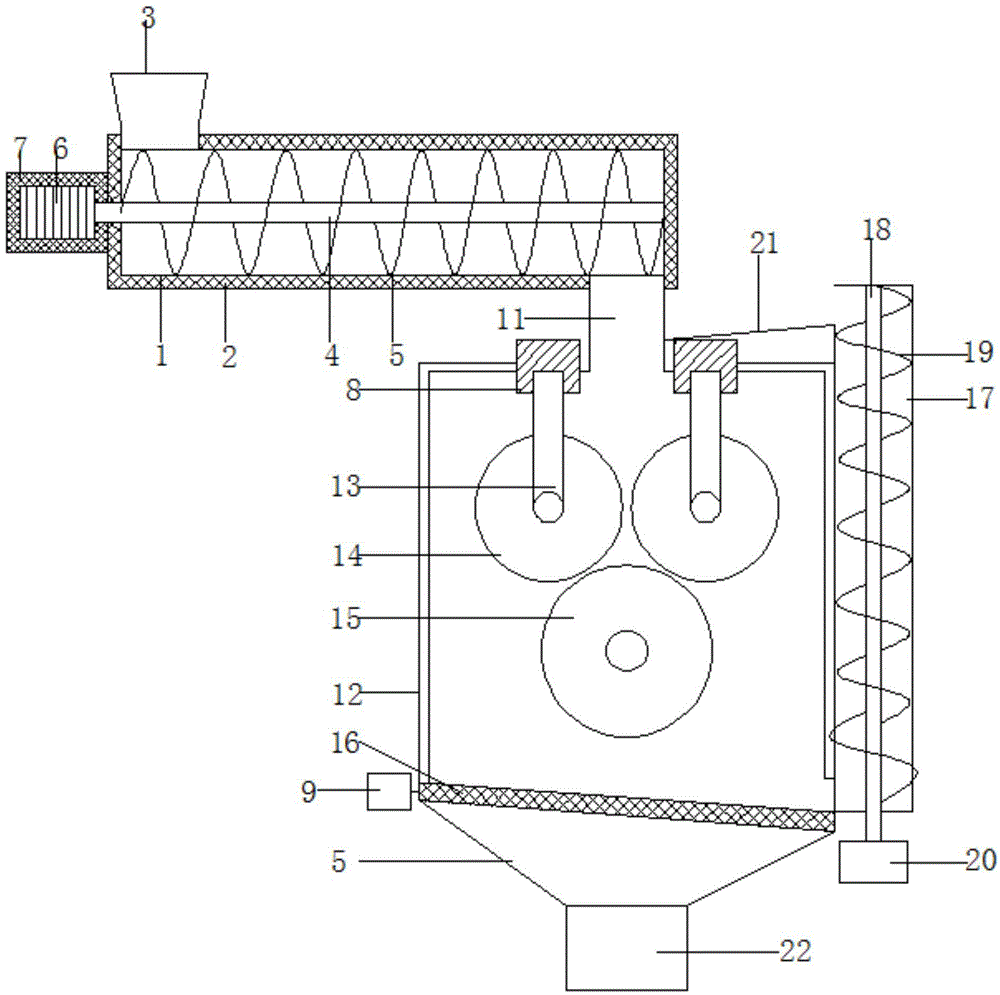

Cylinder part cleaning machine

ActiveCN103008274AImprove cleaning efficiencyRealize automatic feedingDrying gas arrangementsMultistage water/sewage treatmentElectric heatingEngineering

The invention discloses a cylinder part cleaning machine, which comprises a frame and an electric control cabinet, wherein the frame is horizontally provided with a workpiece station, a cleaning chamber and a water treatment system; a water tank is arranged below the cleaning chamber, extends to the water treatment system and comprises a waste water tank and a clear water tank; an electric heating tube is arranged in the clear water tank; the workpiece station is provided with a track which extends to the cleaning chamber to be fixedly connected with the inner wall of the cleaning chamber; and a guide plate is arranged below the track. The cleaning machine further comprises a conveying vehicle assembled on the track, and a cleaning pipeline, a drying pipeline, a lifting probe cleaning device and a driving device which are arranged in the cleaning chamber, wherein the conveying vehicle is provided with a plurality of bearing disks which can rotate 360 degrees; and the cleaning pipeline is divided into two paths, one of which directly leads to the cleaning chamber to clean the outer surface of a cylinder part, and the other of which enters the probe cleaning device through a pipe to clean the inner chamber of the cylinder part. The cylinder part cleaning machine can clean the inner and outer surfaces of a plurality of cylinder parts and is low in labor intensity, high in cleaning efficiency and good in cleaning effect.

Owner:安徽宝辉清洗设备制造有限公司

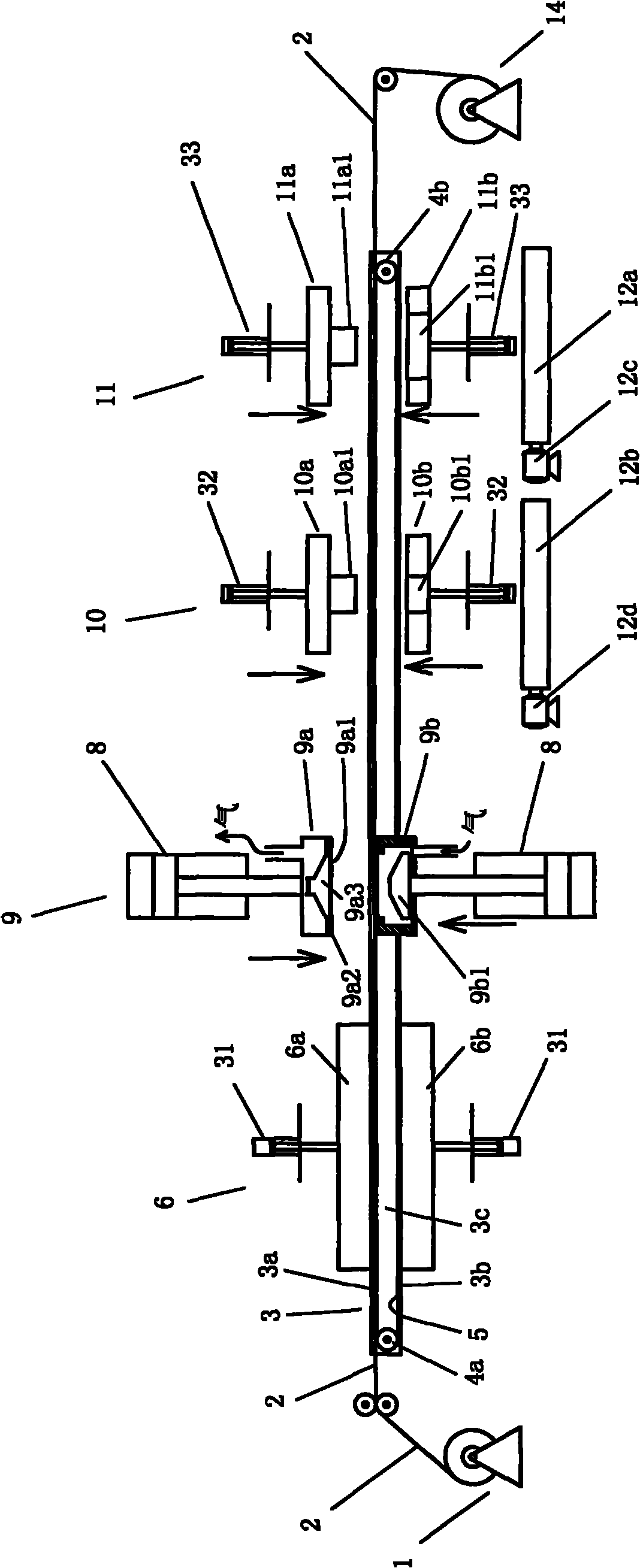

Plastic sucking production line and production process thereof

The invention belongs to plastic sucking equipment and the technical field of a plastic sucking process, and relates to a plastic sucking production line. The production line comprises two mutually-parallel guide rails of which the opposite side is provided with an opening, wherein an annular conveying device for conveying sheet raw materials is arranged in the opening of each guide rail; a heating drying oven, a plastic sucking molding and in-mould die cutting device, a punching device and a stacking device are sequentially arranged between the two guide rails from one side to the other side; the heating drying oven is in an annular sealing type; and the plastic sucking molding and in-mould die cutting device has an integral structure. The plastic sucking production line comprises the production process of preparation, heating, molding, die cutting, stacking and discharging. The plastic sucking production line has the advantages of simple structure, high utilization factor of the raw materials, simple, convenient and quick operation, high automaticity, capability of saving electricity by over 65 percent and replacing required product dies according to the requirements of producing different products and wide application.

Owner:林士顺

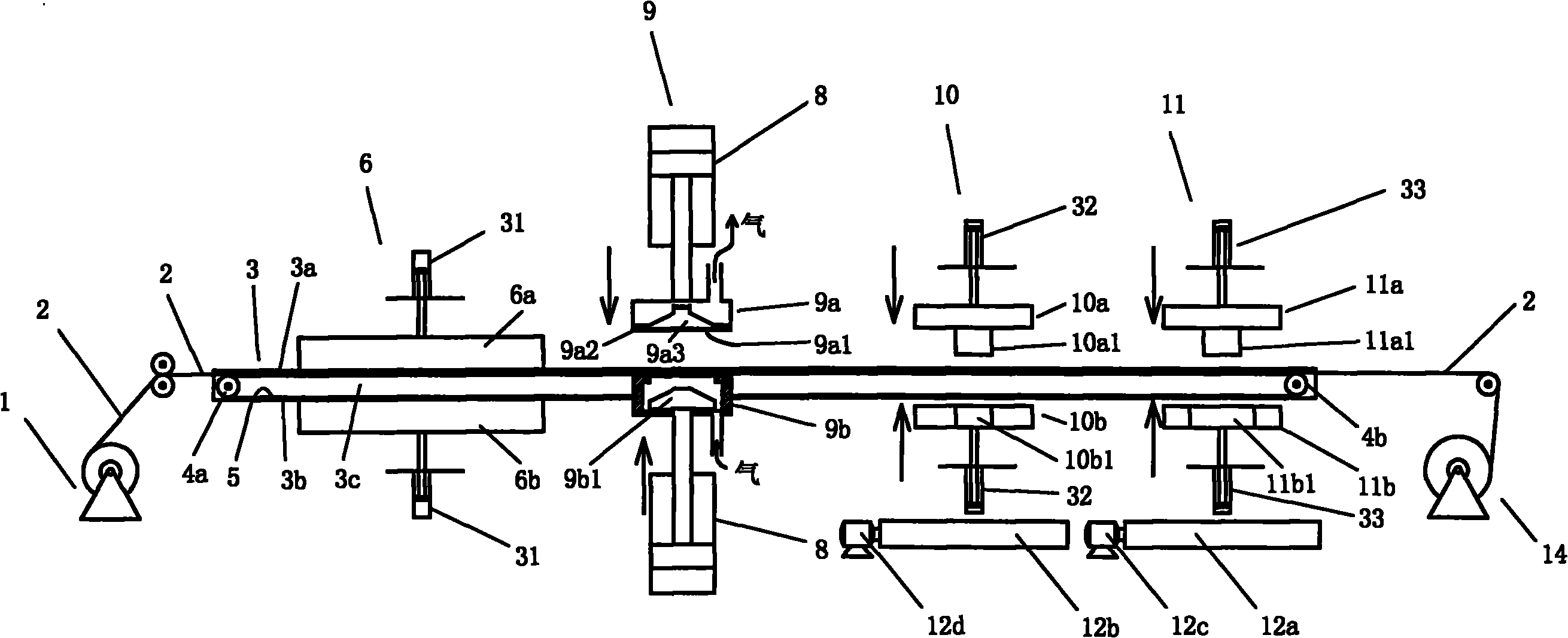

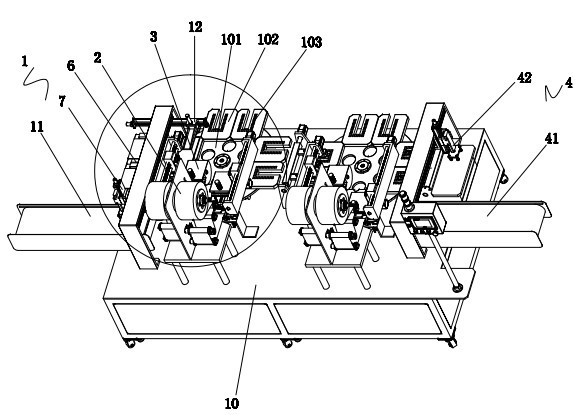

Automatic adhesive sticking machine of flexible packaged lithium battery

ActiveCN102593521ARealize automatic feedingIncrease productivityFinal product manufactureElectrolyte accumulators manufactureAdhesiveEngineering

The invention relates to an automatic adhesive sticking machine of a flexible packaged lithium battery. The automatic adhesive sticking machine comprises a workbench arranged on a frame, wherein a conveyer chain is arranged on the workbench, a clamp for clamping the battery to be adhesive-stuck is arranged on the conveyer chain, and a driving mechanism for driving the clamp to open and close is arranged on the workbench; and a conveying mechanism for conveying the battery to be adhesive-stuck to the clamp, a cutting mechanism for cutting aluminum-plastic film surplus edge on the adhesive sticking side of the battery to be adhesive-stuck, a rubber belt conveying mechanism, an adhesive sticking mechanism for sticking an adhesive tape to the aluminum plastic film of the battery, an adhesive bending mechanism for bending the adhesive tape stuck on the battery, a base material tearing mechanism for tearing off the base material of double-sided glue of the adhesive tape, a folding mechanism for folding the adhesive tape and a product discharging mechanism are sequentially arranged on the workbench, and the mechanisms are respectively connected with a master control circuit. The adhesive sticking machine realizes automatic conveying, cutting, adhesive sticking, adhesive bending, folding and discharge of the battery, greatly improves the production efficiency and the adhesive-stuck battery quality, and reduces the labor difficulty and intensity.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

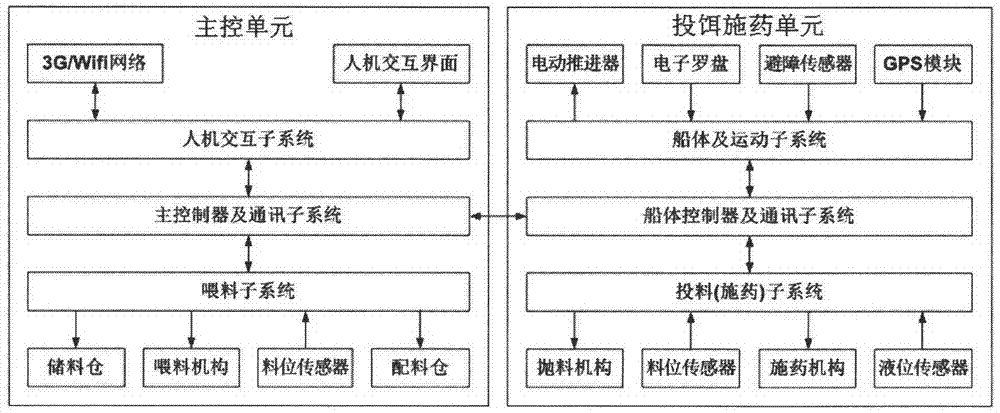

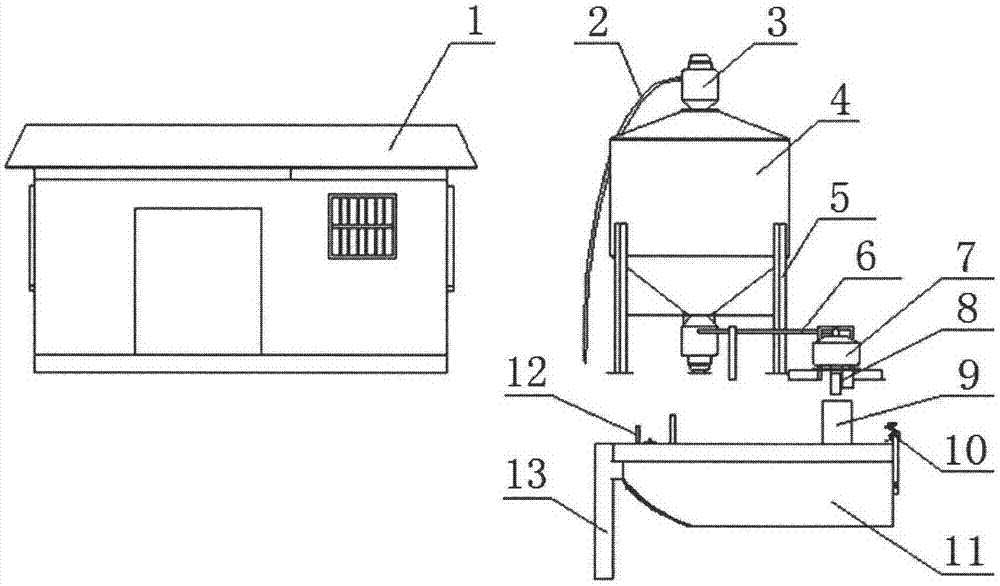

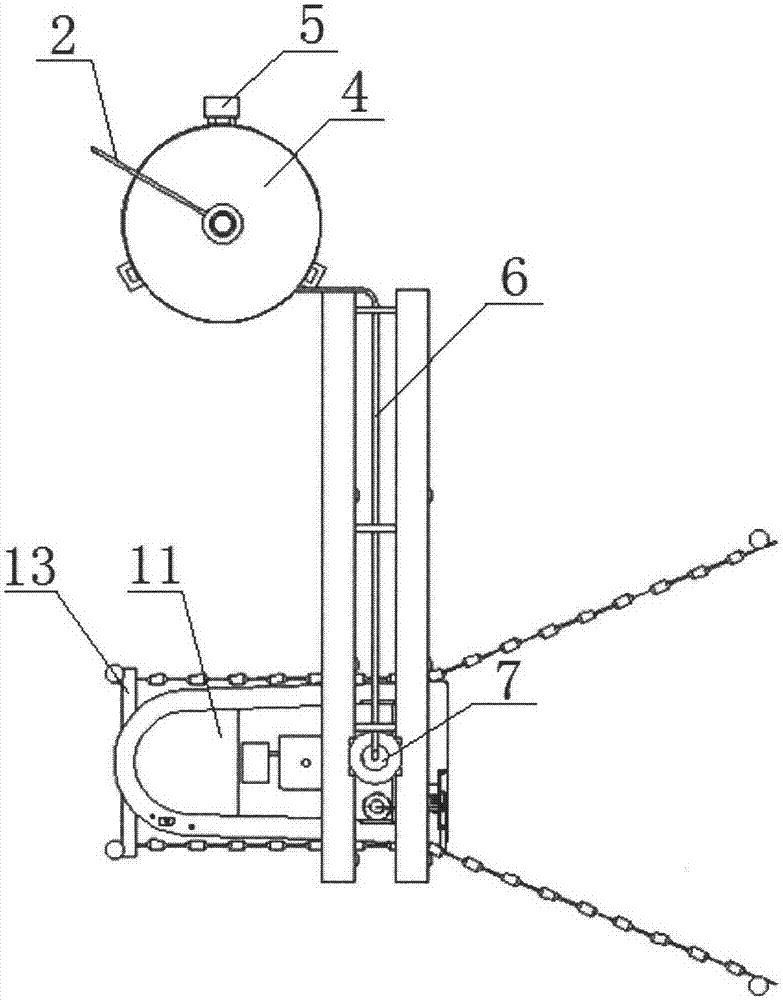

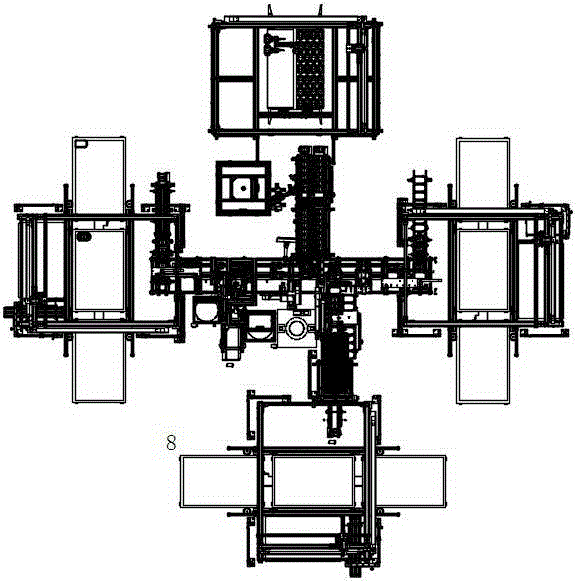

GPS (global positioning system) navigation based intelligent feeding and spraying system and device

InactiveCN103918596AReduce labor intensitySplash evenlyPisciculture and aquariaVeterinary instrumentsShrimpGps navigation

The invention discloses a GPS (global positioning system) navigation based intelligent feeding and spraying system and device, and belongs to the field of aquaculture equipment. A main controller receives a task and an instruction inputted by a man-machine interaction subsystem, and controls a feed subsystem to execute feed action; the feed subsystem feeds back feed information to the main controller, and the feed information is displayed to the man-machine interaction subsystem; a hull controller receives hull movement information inputted by a hull and a movement subsystem and controls the hull to move, and a feeding (spraying) subsystem executes feeding (spraying) action under an instruction of the hull controller; the feeding (spraying) subsystem feeds back feeding (spraying) information to the hall controller; the main controller and the hull controller are wirelessly connected through a communication subsystem. Labor intensity of aquaculture farmers is lowered greatly, accurate feeding of feed and uniform spraying of medicine are realized, use efficiency of the feed and medicine is improved, impact of aquaculture on the environment is reduced, and the system and device is particularly applicable aquaculture of shrimps and crabs.

Owner:常州智能农业装备研究院有限公司

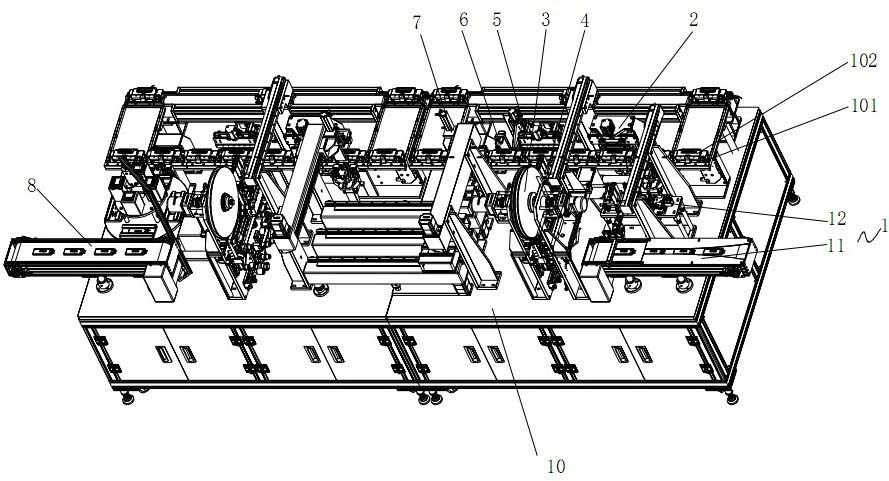

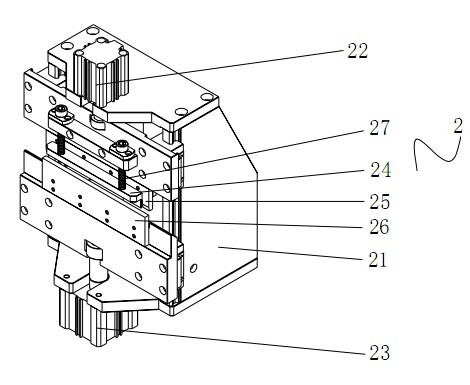

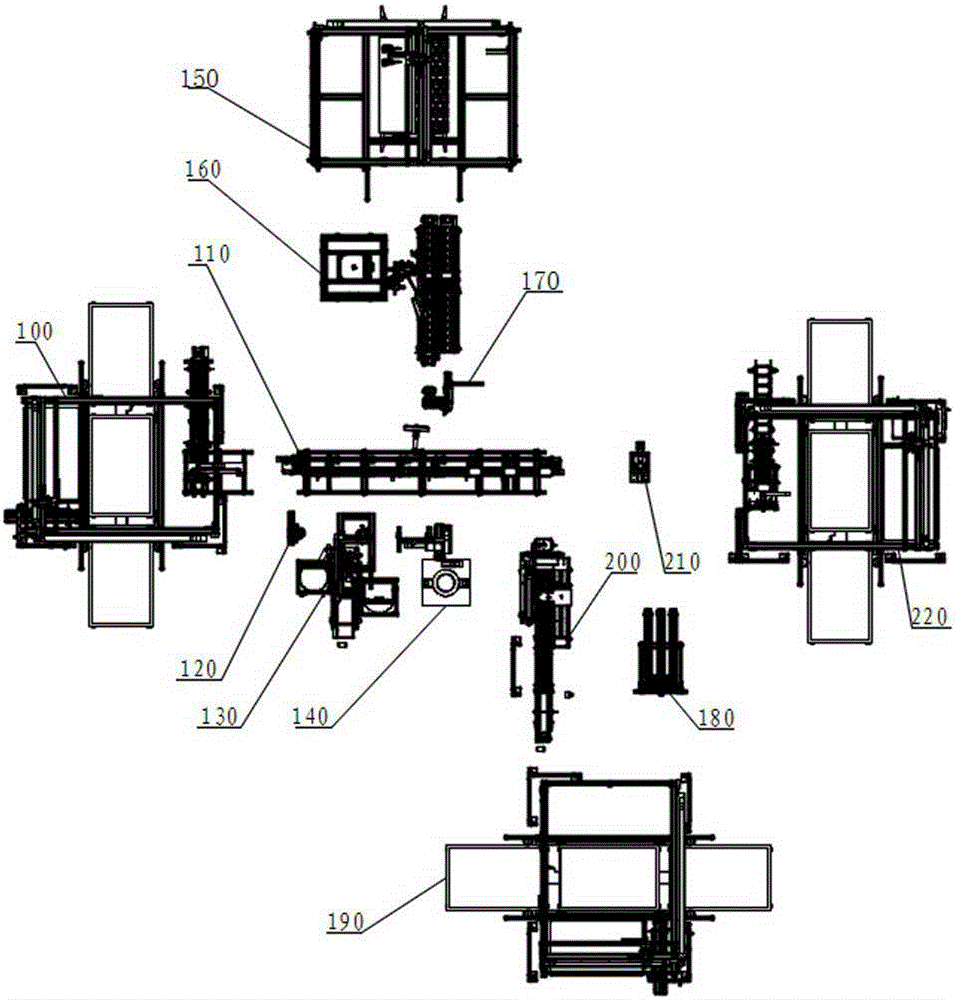

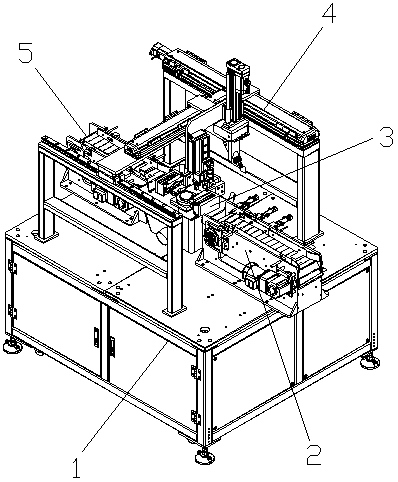

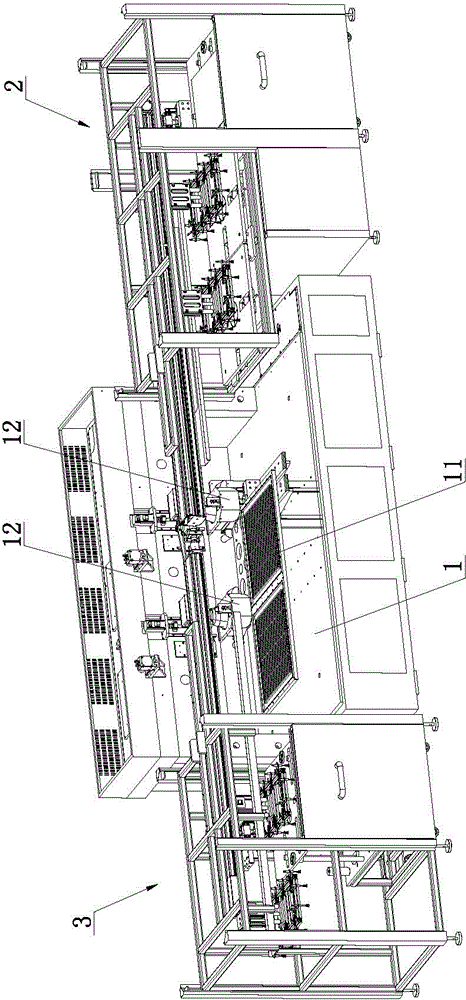

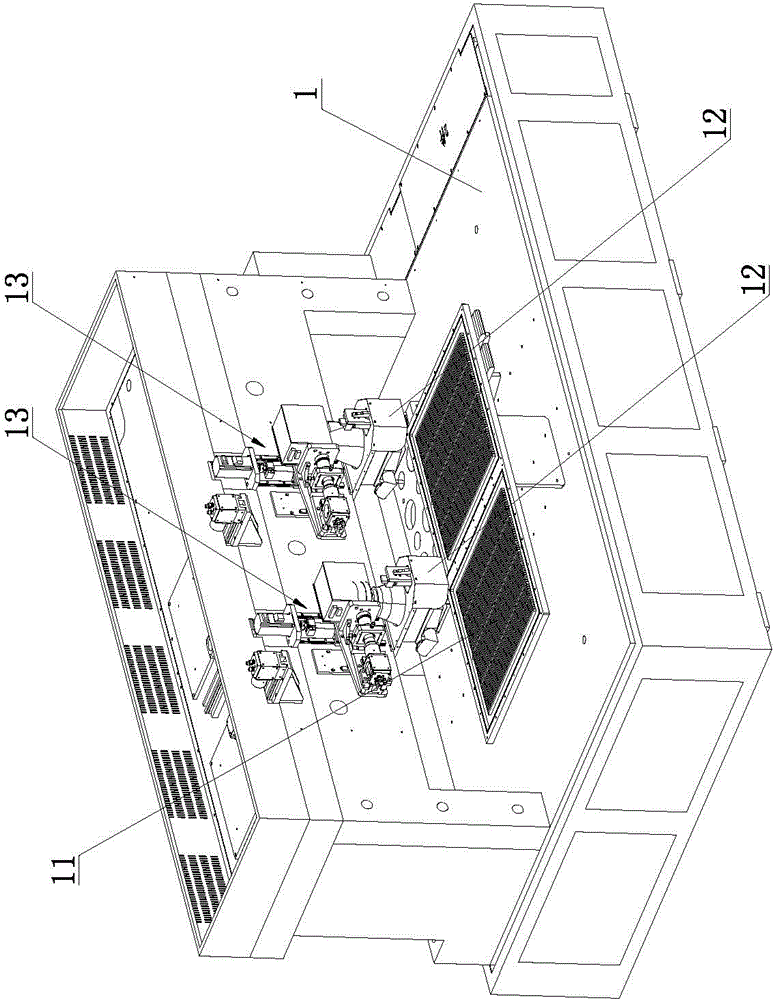

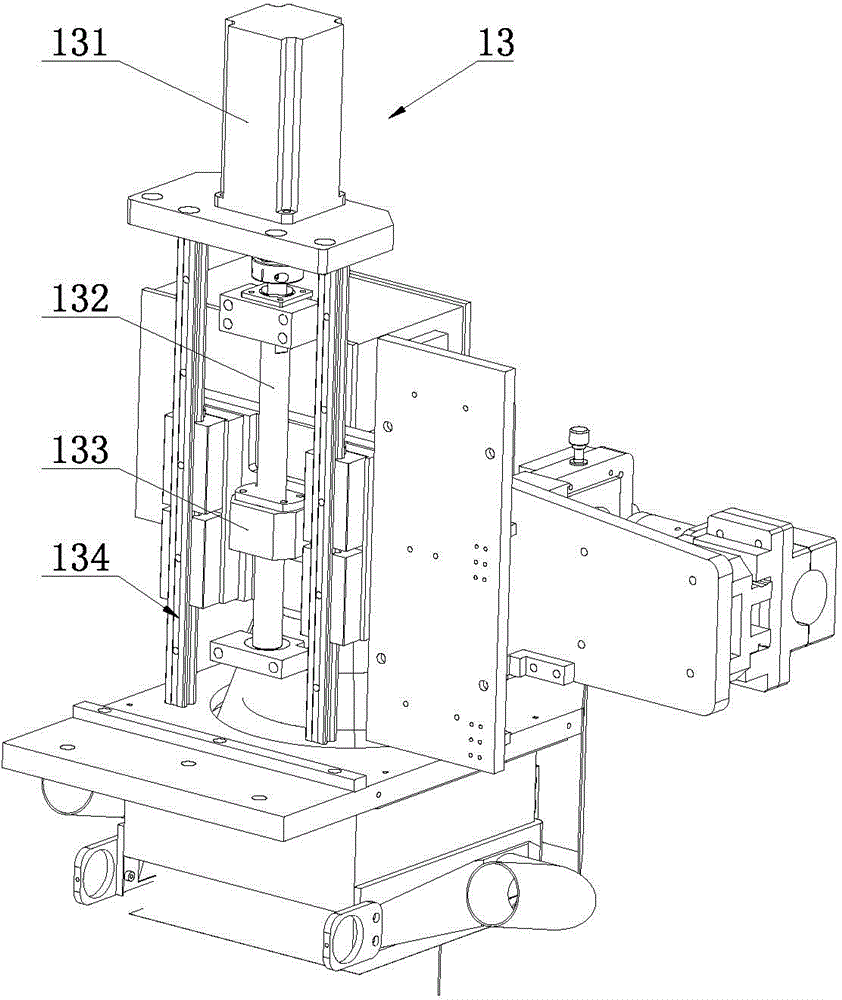

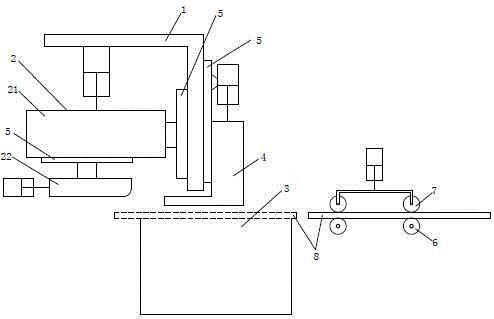

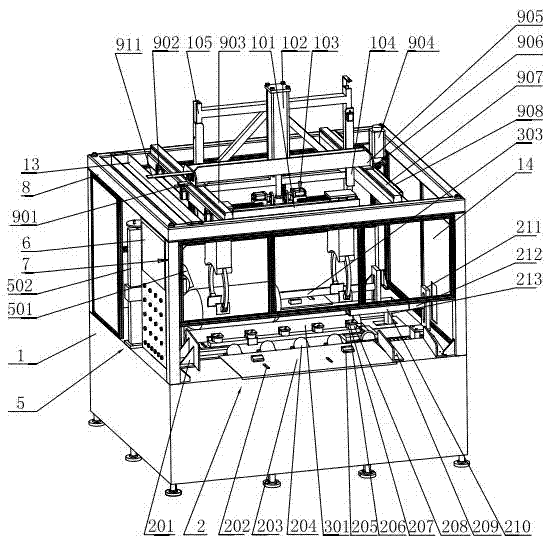

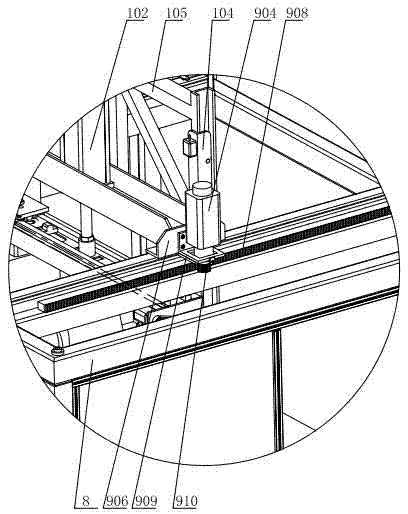

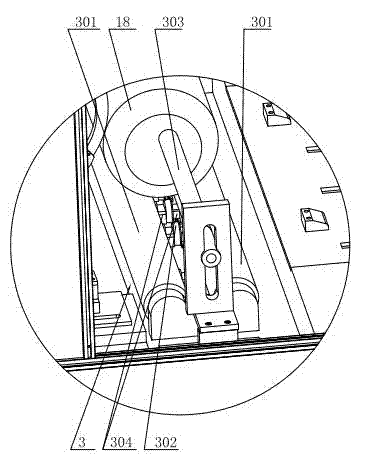

Automatic assembling device for fuel gas meters

ActiveCN105215680AIncrease productivityRealize automatic feedingAssembly machinesEngineeringFully automatic

The invention discloses an automatic assembling device for fuel gas meters. The objective of the invention is to solve the problems that when fuel gas meters are produced by adopting a manual mode at present, the work intensity of operation workers is high, the inconsistency is low, the product quality stability is hard to ensure, and the labor cost is high. The device comprises an upper cover feeding module, an annular guide rail conveying module, an upper cover shaft oil applying module, a magnetic steel group assembling module, an adhesive applying module, a movement feeding module, a gas outlet pipe assembling module, a movement assembling module, a seal ring supply module, a lower cover feeding module, a lower cover assembling module, a seal ring prepressing module and a finished meter discharging module. The automatic assembling device realizes the later fully-automatic assembly of the fuel gas meters and can realize the functions of automatically feeding and assembling movements, upper covers and lower covers, automatically assembling magnetic steels, automatically applying oil on upper cover shafts, automatically assembling gas pipes, automatically assembling and prepressing seal rings and automatically discharging and boxing finished products. No people directly participate in the assembly and production of the fuel gas meters, and the assembled fuel gas meters are high in consistency. Meanwhile, the production efficiency is effectively improved, labor cost and management cost are reduced, and a remarkable effect is played on improving the economical benefit of fuel gas meter production enterprises.

Owner:SICHUAN FUDE ROBOT

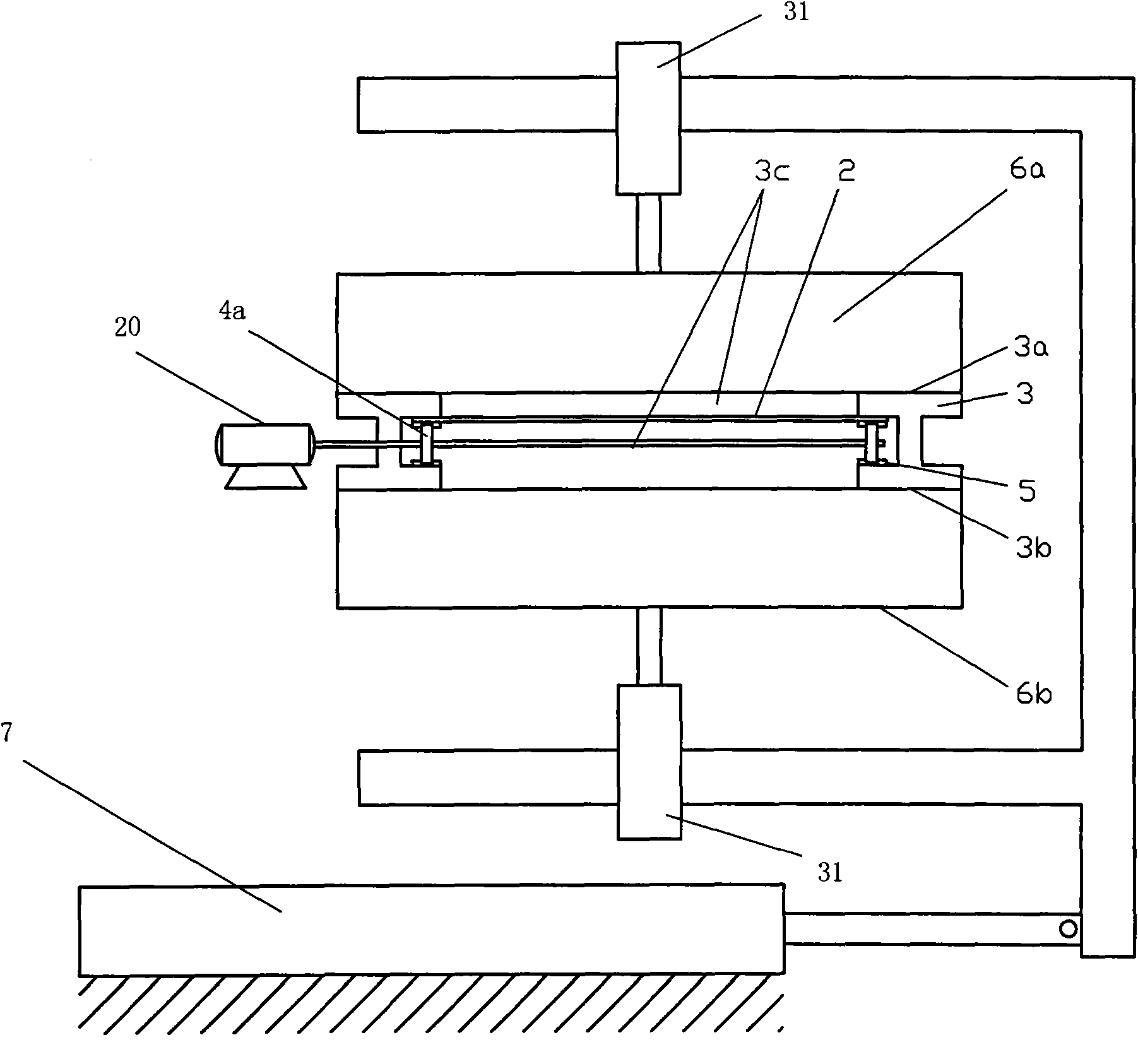

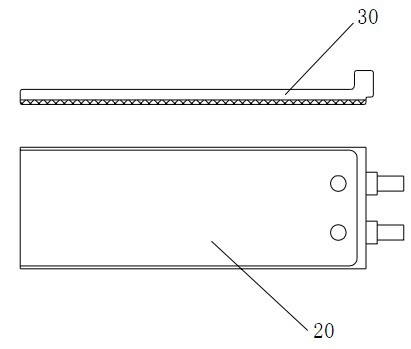

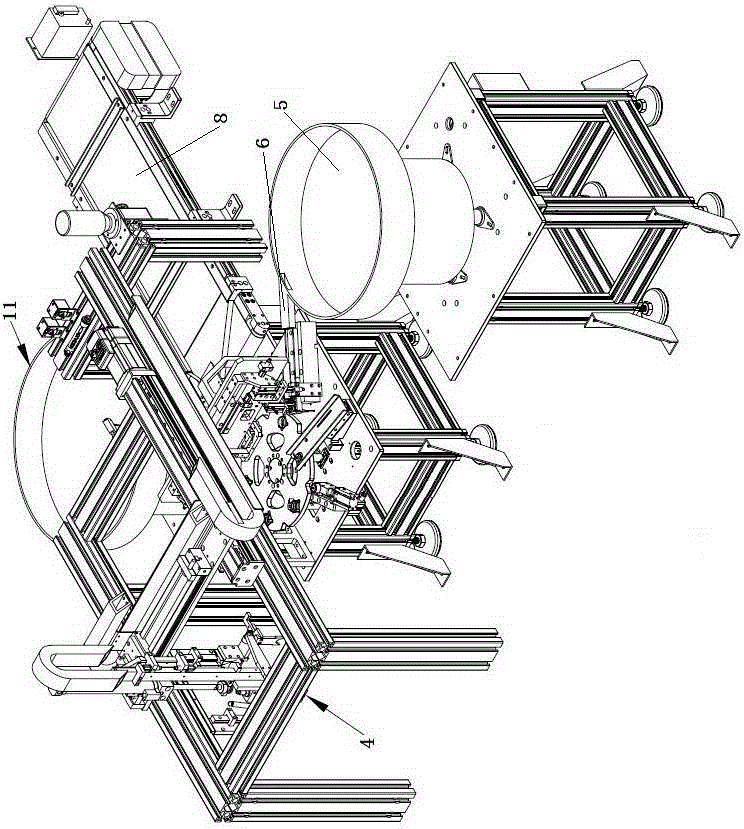

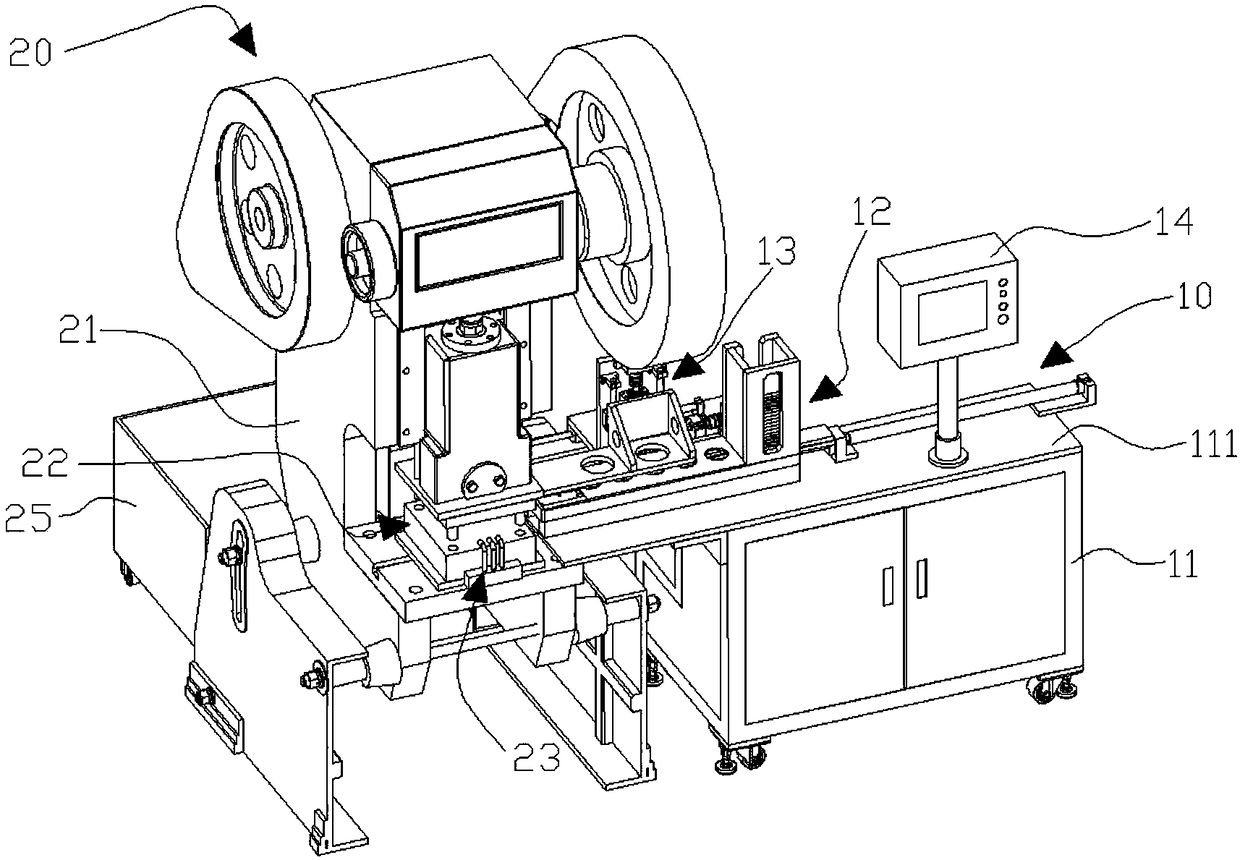

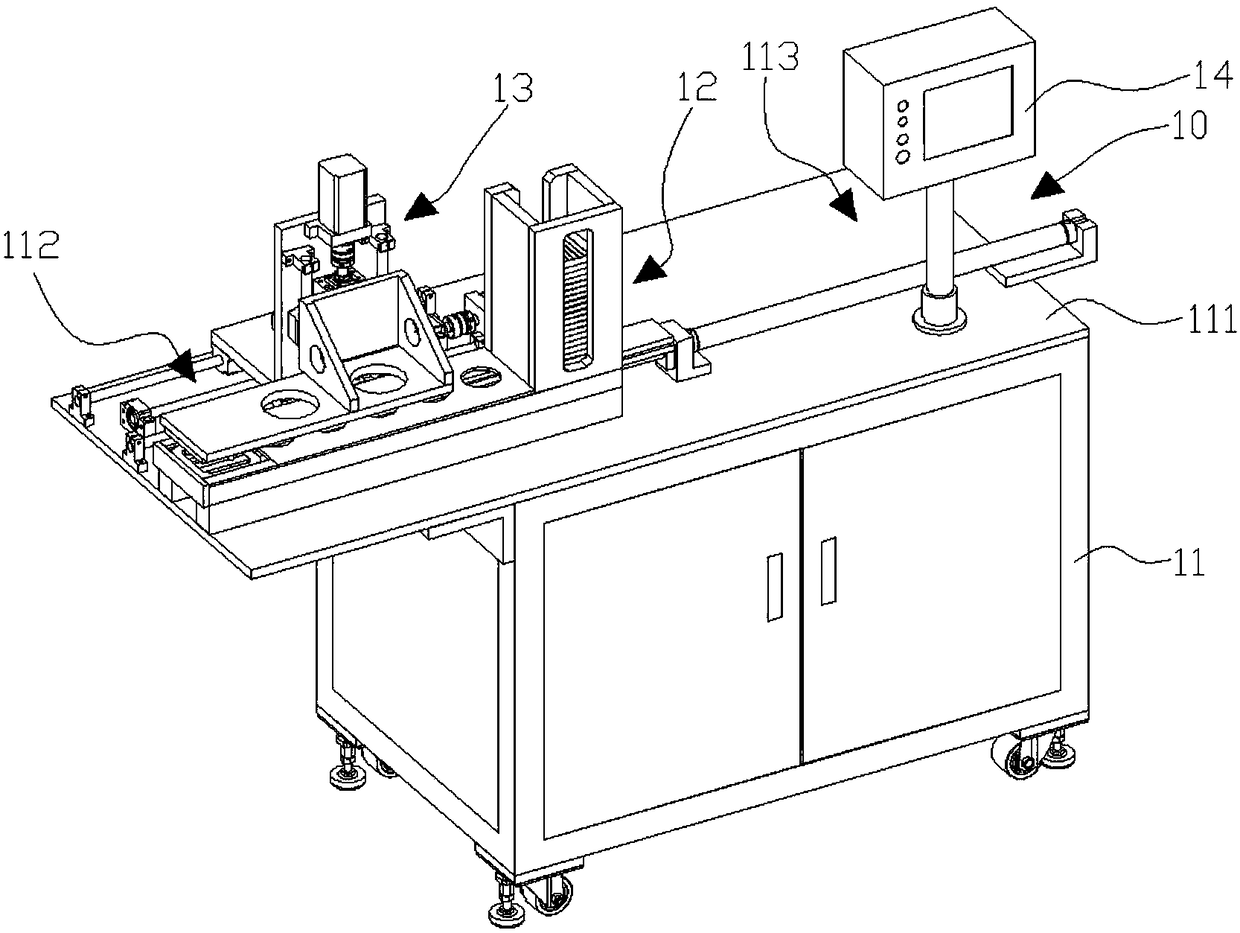

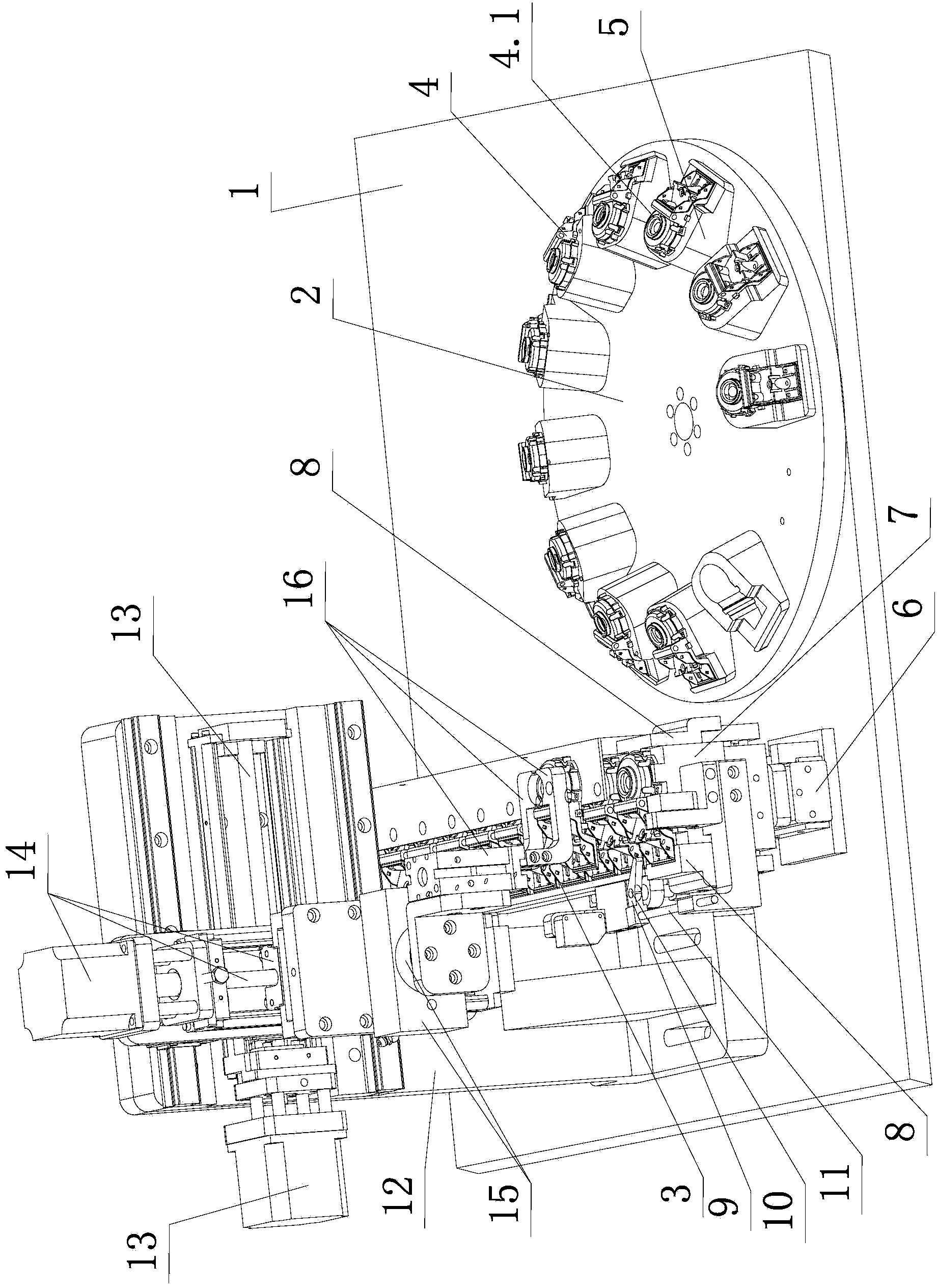

Automatic laminator for flexible-package lithium battery

ActiveCN102582193ARealize automatic feedingQuality improvementLamination ancillary operationsFinal product manufactureElectrical batteryEngineering

The invention relates to an automatic laminator for a flexible-package lithium battery. The automatic laminator comprises a working table and a rotary plate arranged on the working table. A clamp for sucking a battery is arranged on the rotary plate; a battery feeding mechanism for conveying batteries to be laminated to the clamp, a membrane belt feeding mechanism for conveying membrane belts, a lamination mechanism for adhering the membrane belts to the surface of the battery and a battery discharging mechanism are arranged on the working table in sequence. And the mechanisms are respectively connected with a main control circuit. According to the laminator provided by the invention, the battery feeding mechanism, the membrane belt feeding mechanism, the lamination mechanism and the battery discharging mechanism are arranged on the working table in sequence, and are respectively connected with the main control circuit, so that the batteries are automatically fed, laminated and discharged, the production efficiency and the laminated battery quality can be greatly improved, and the labor difficulty and the labor intensity can be reduced.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

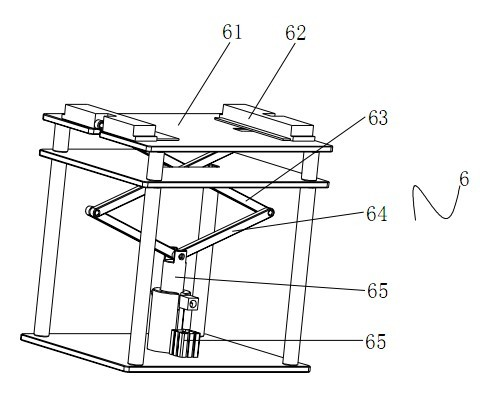

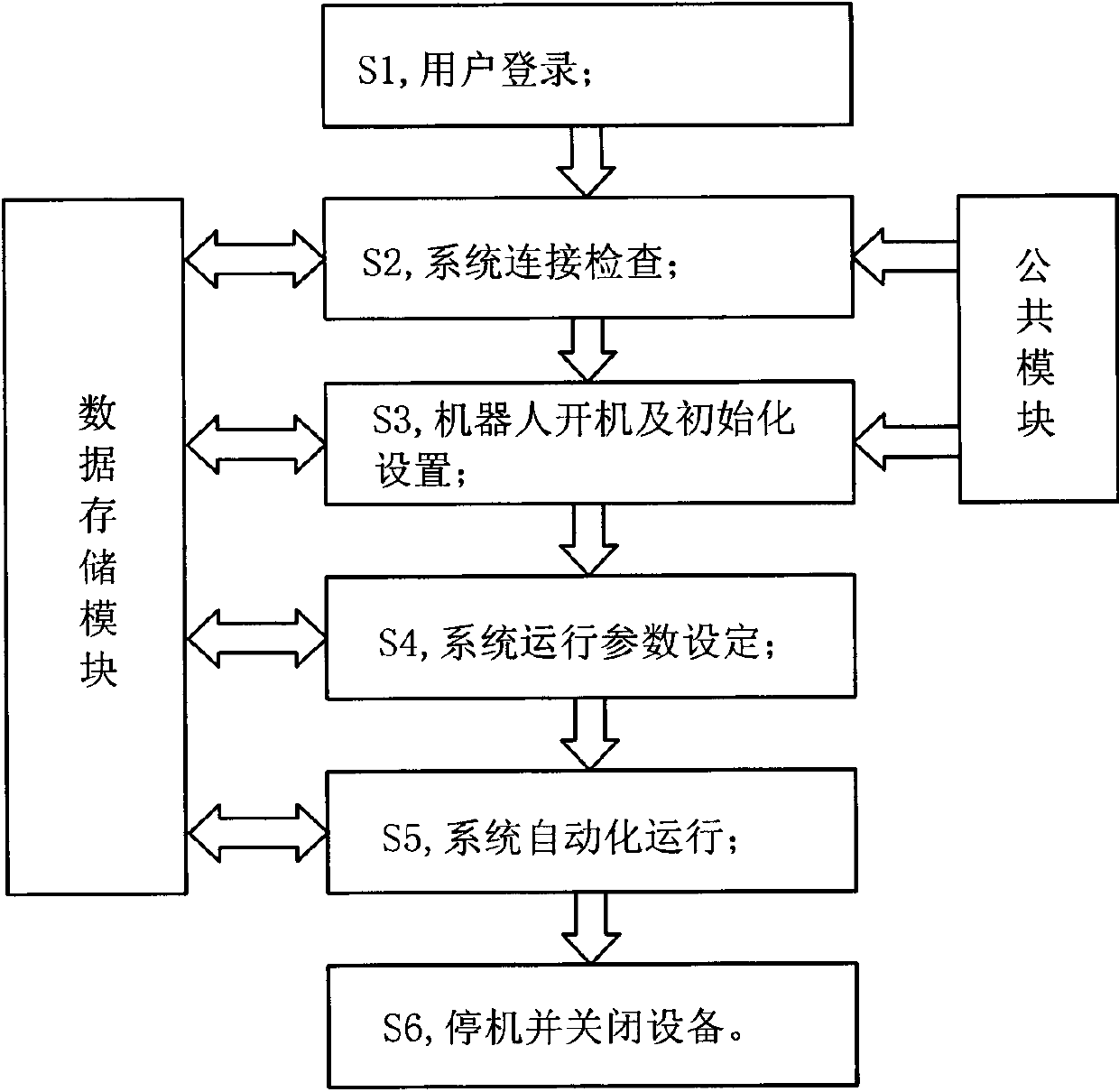

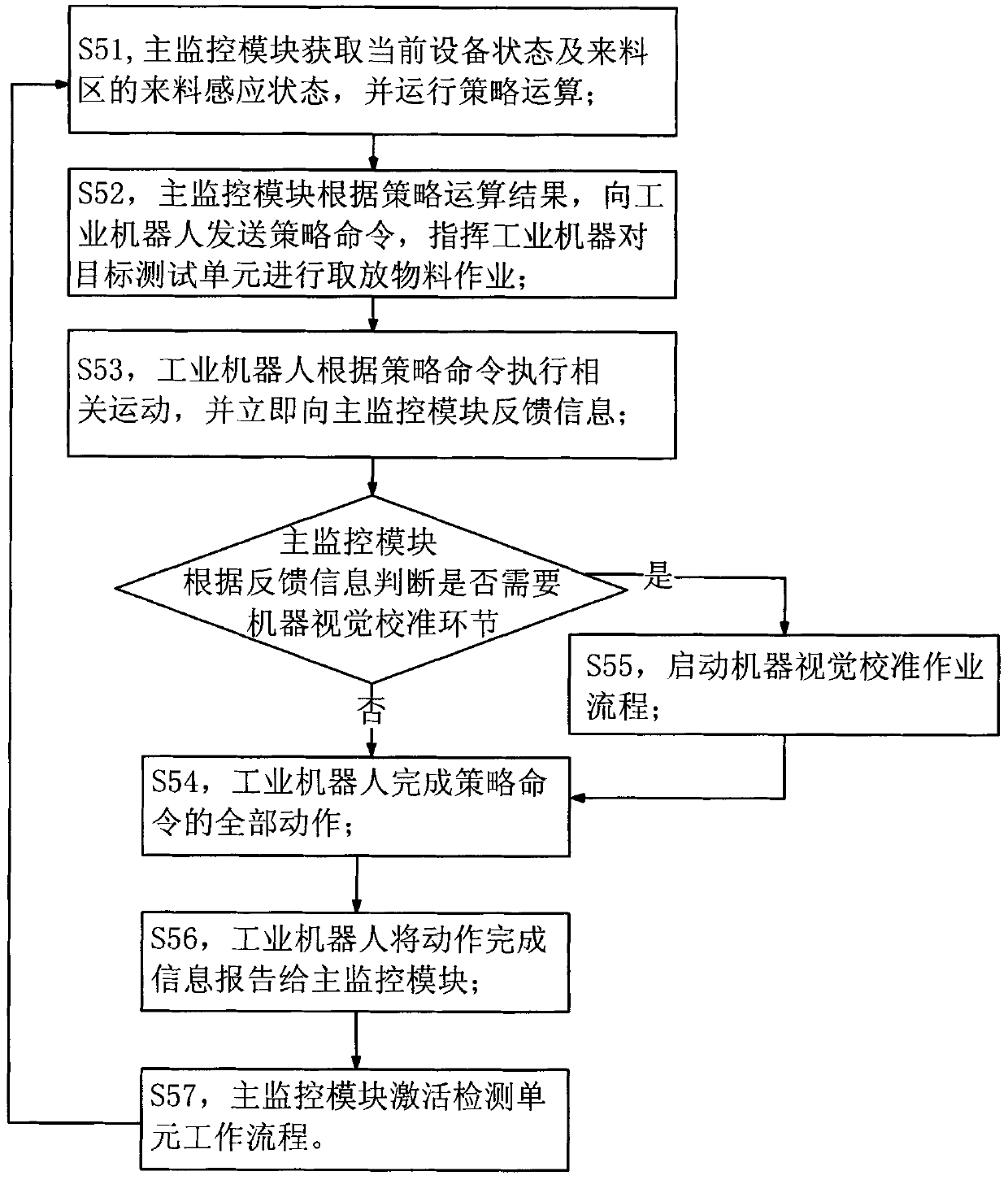

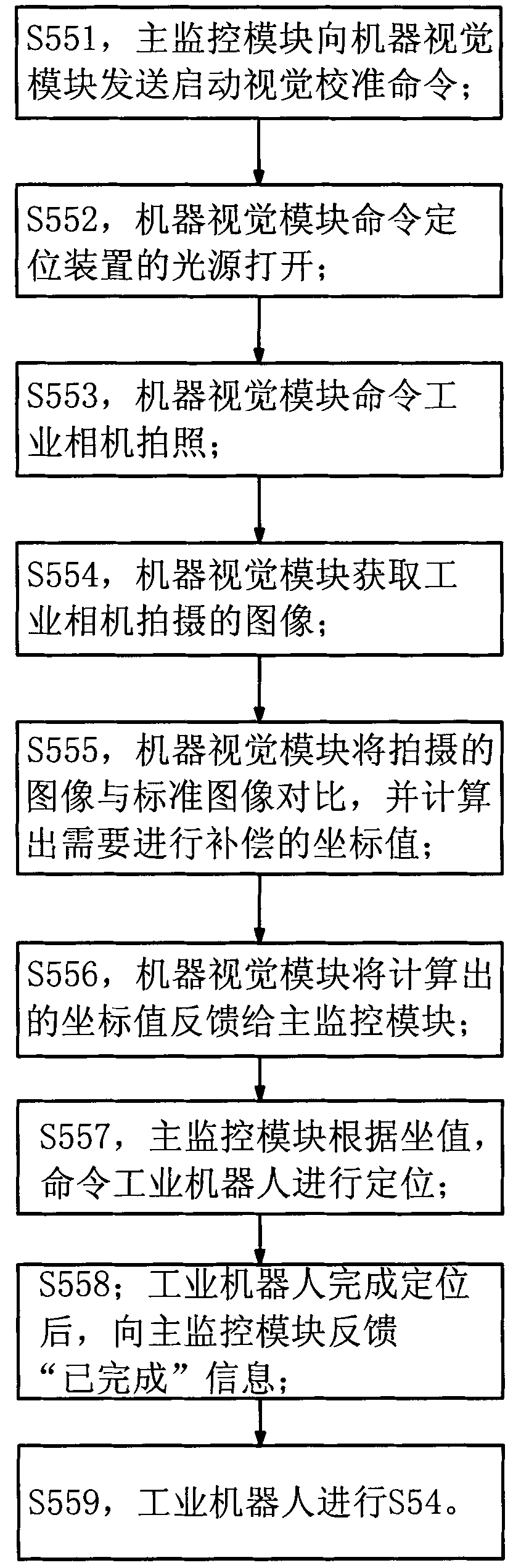

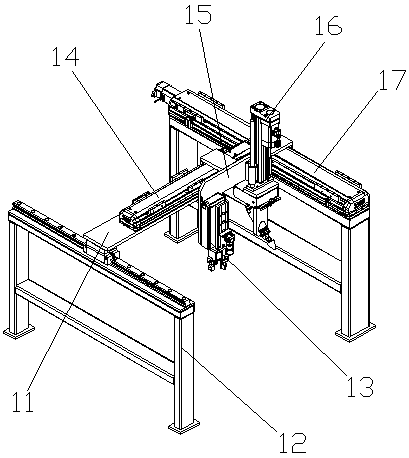

Automatic feeding, testing and sorting system and operation method thereof

ActiveCN103368795ARealize automatic feedingRealize unmannedData switching networksConveyor partsProgrammable logic controllerControl engineering

The invention discloses an automatic feeding, testing and sorting system and an operation method of the system. The operation method comprises the following steps of: S1, user login; S2, system connection checking; S3, robot starting and initialized setting; S4 system operation parameter setting; S5 system automatic operation; S6 stopping and equipment shutting. The operation method provided by the invention realizes organic combination in controlling test units, an industrial robot, a PLC (Programmable Logic Controller) electrical system, an image acquisition module and other peripheral equipment, automation in feeding, starting a test and sorting tested products to corresponding areas, as well as an unmanned testing process. In S2 and S3, required programs can be called from a public module in which global thread programs are stored; in S2, S3, S4 and S5, key variables required during system operation and stored in a data storage document can be called or rewritten so as to greatly improve the calculation efficiency.

Owner:SHENZHEN JIACHEN TECH

Paperboard stacking device and paperboard stacking machine

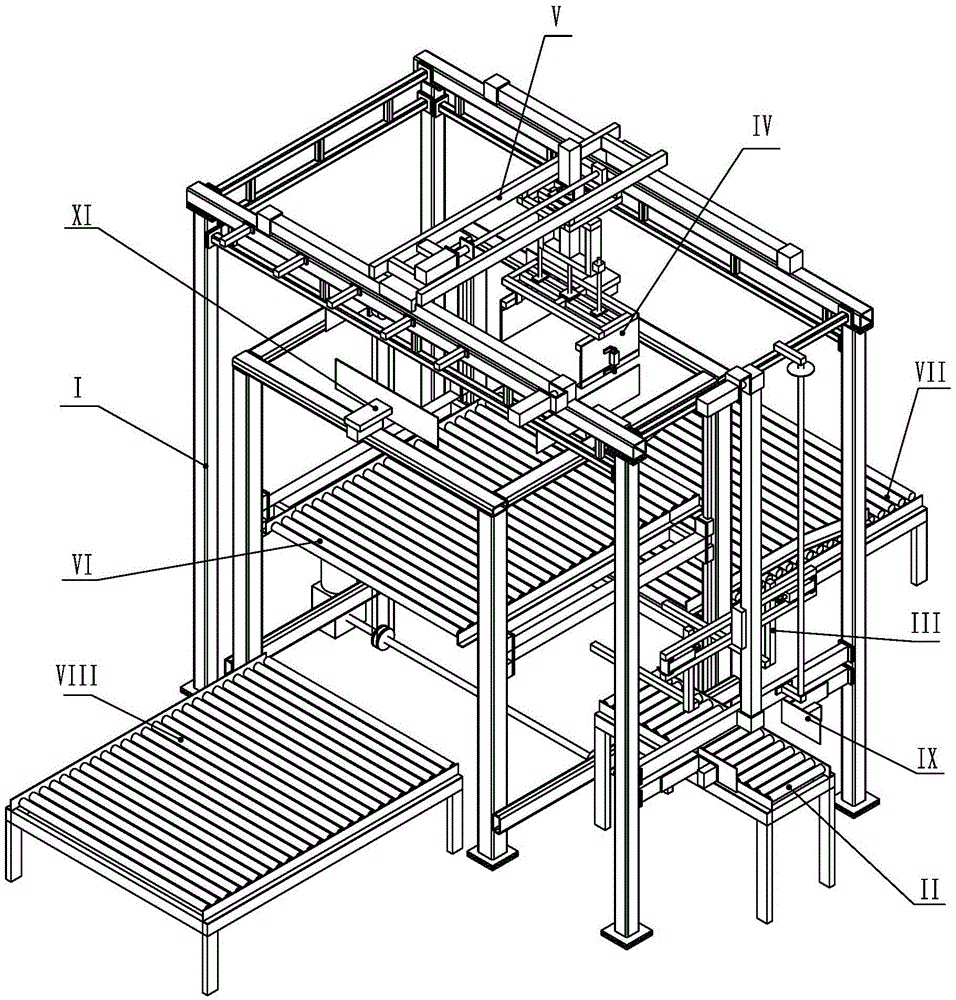

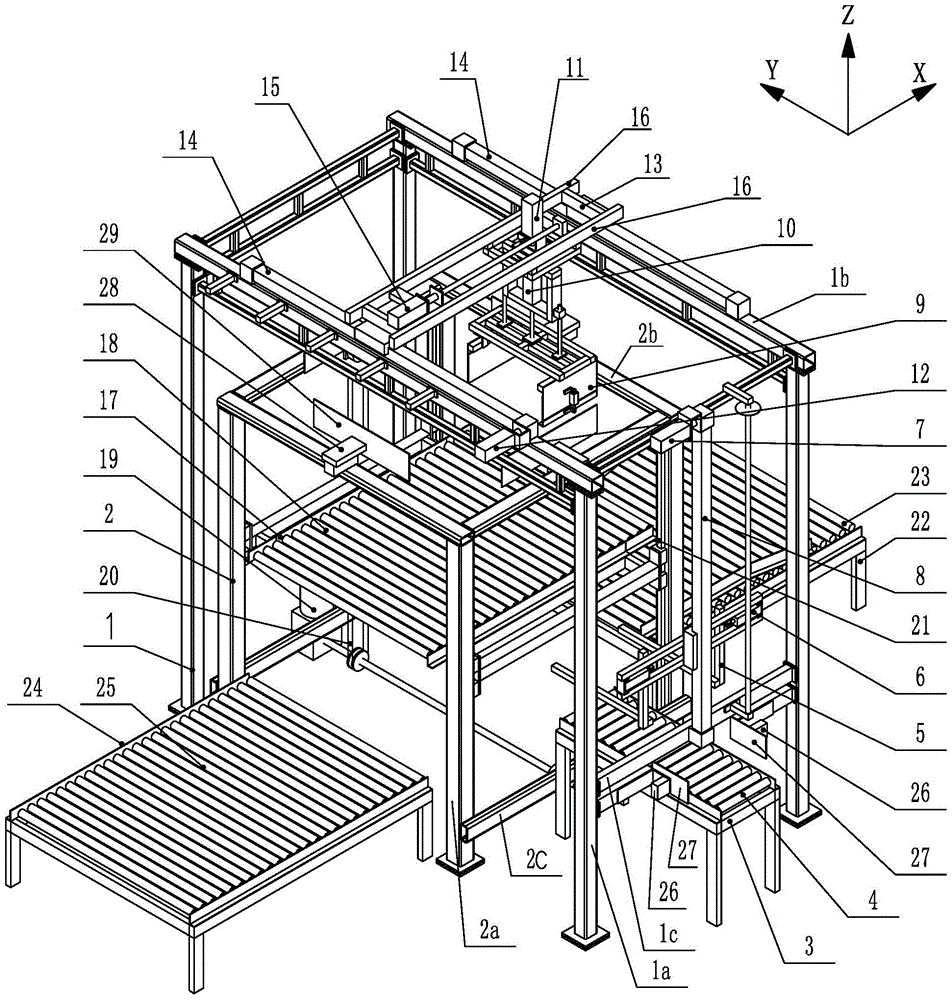

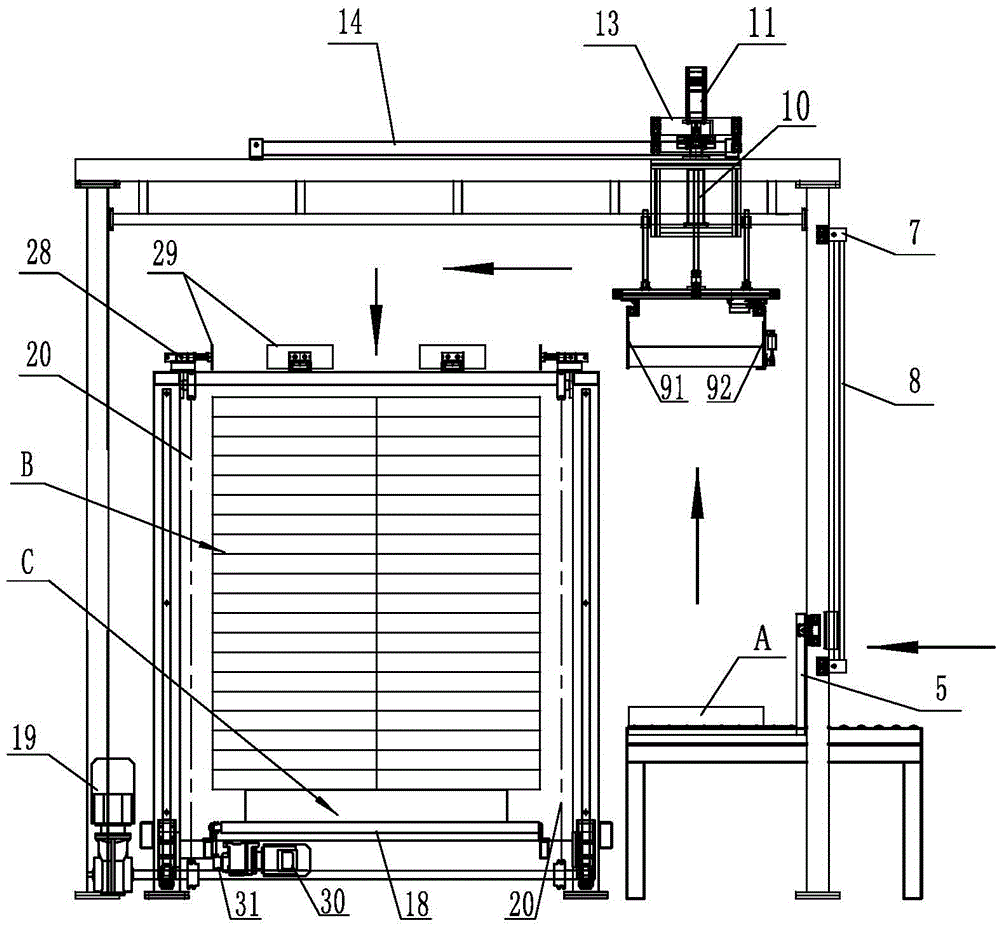

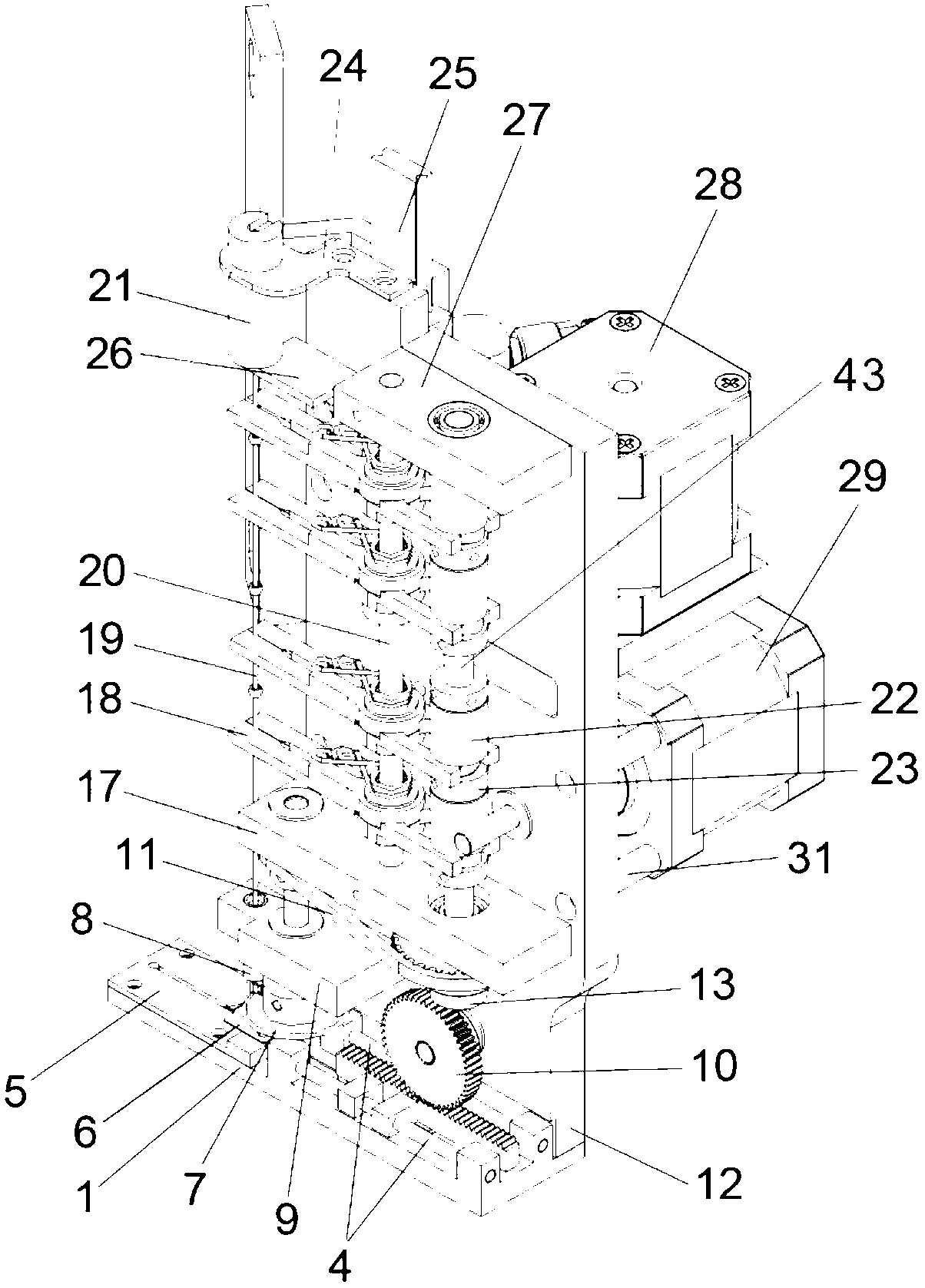

ActiveCN105565017ARealize automatic feedingAutomate operationPile receiversArticle feedersCardboardStack machine

The invention discloses a paperboard stacking machine and a paperboard stacking device. The paperboard stacking machine comprises a paperboard stacking device, a paperboard feeding mechanism, a tray feeding mechanism and a paperboard output mechanism; the paperboard stacking device comprises a main body frame; the main body frame comprises an outer frame and an inner frame; a paperboard lifting mechanism is arranged at one side of the outer frame; a gripper mechanism and a gripper translation mechanism are arranged on a top beam of the outer frame; a paper feeding normalizing mechanism is arranged on a stand column of the outer frame; a tray lifting output mechanism is arranged on the inner frame; and a stacking normalizing mechanism is arranged on a top beam of the inner frame. The paperboard stacking machine realizes automation of automatic feeding and paperboard feeding, paper feeding normalizing, lifting, grabbing, translation, rotating, releasing, stacking normalizing, paper stack descending and paper stack output of the tray, and can trimly stack packaged corrugated paperboards or cartons according to predetermined putting positions and rules, thus realizing automatic operation, being good in stacking quality and high in stacking speed, and saving manpower.

Owner:SHANDONG CENTURY MACHINERY

Embroidery bead feeding apparatus and method

ActiveCN103266434ARealize automatic feedingIngenious structureAutomatic machinesProduction rateElectric machinery

The invention discloses an embroidery bead feeding apparatus, which comprises a bead guiding pipe for guiding embroidery beads to fall down, a time sharing clamping mechanism, an embroidery bead separation mechanism, a feeding mechanism and an automatic feeding mechanism, wherein the time sharing clamping mechanism comprises a plurality of clampers, and a one-way sleeve drives the mutually-spaced clampers to carry out time sharing separation and enclosing under clamping motor driving, such that the bead guiding pipe is always positioned on a fixation position. The present invention further provides an embroidery bead feeding method. According to the present invention, the embroidery beads are conveyed to processing positions one by one through the time sharing clamping mechanism, the embroidery bead separation mechanism and the automatic feeding mechanism so as to achieve automatic embroidery bead feeding. The apparatus has characteristics of ingenious structure, high production rate, high automation degree, easy installation and maintenance, low processing cost and high practical values.

Owner:WENZHOU OULUOHUA INDAL

Automatic feeding device

InactiveCN102029330ARealize automatic feedingRealize stampingMetal-working feeding devicesPositioning devicesEngineeringUltimate tensile strength

The invention relates to an automatic feeding device which comprises a base, a feeding box and a feeding cylinder, wherein the feeding box is vertically arranged on the upper surface of the base, a longitudinal feeding groove is arranged inside the feeding box, a horizontal channel communicated with the feeding groove is formed between the lower bottom surface of the feeding box and the base, the upper surface of the base at one side of the feeding box is provided with the feeding cylinder, the front end of the feeding cylinder is provided with a horizontal push plate moving in the horizontal channel of the feeding box, and the base at the other side of the feeding box is provided with a processing table. The automatic feeding device is a feeding machine with simple structure, simple operation and high automation, can realize automatic feeding and discharging, greatly improves the production efficiency, lowers the labor intensity of workers, and is suitable for being popularized and used in musical instrument industry or other industries.

Owner:TIANJIN JINBAO MUSICAL INSTR

Appearance detection equipment

InactiveCN101865666AHigh degree of automationImprove accuracyUsing optical meansSortingCantileverAutomation

The invention discloses an appearance detection equipment, which comprises a work bench and is characterized in that: the work bench is provided with a feeding device, a detection device and an automatic separation device; the detection device comprises a table-shaped camera station arranged on the work bench; the rear of the camera station is provided with a first support vertical to the work bench; the top of the first support is provided with a second cantilever extending to the camera station; and the second cantilever is provided with a camera aligning with the camera station. The appearance detection equipment realizes automatic feeding, automatic detection and automatic separation, so operators are not required in the whole detection process. The appearance detection equipment has the advantages of high automation degree, high accuracy, high efficiency and the like.

Owner:SIP GOLDWAY TECH

Stamping automatic feeding device and method

ActiveCN104043751ASave the time to returnRealize automatic feedingMetal-working feeding devicesPositioning devicesPunchingMotor drive

The invention discloses a stamping automatic feeding device and a stamping automatic feeding method. The device comprises a pushing mechanism which is located on one side of a punching machine, wherein the structure of the pushing mechanism is that a pushing plate is fixedly mounted on a piston rod of a pushing air cylinder; the pushing air cylinder is fixedly mounted on a nut seat of a pushing ball screw; the nut seat of the pushing ball screw is mounted on a pushing guide rail in a sliding way; a screw of the pushing ball screw is connected with a pushing servo motor; the pushing servo motor is fixedly mounted on a rack; two ends of the pushing ball screw and the pushing guide rail are mounted on the rack by bearing seats. Firstly, materials are pushed to an initial processing position by the pushing air cylinder, and then the pushing servo motor drives the pushing plate to push the materials for one processing position each time, so that the automatic feeding of the materials is realized. According to the stamping automatic feeding device and the stamping automatic feeding method, the combination of the pushing air cylinder which is arranged and a step pushing mechanism which is mounted on the pushing mechanism is adopted, and the automatic feeding of an old-fashioned punching machine is realized.

Owner:宜昌市综艺包装有限公司

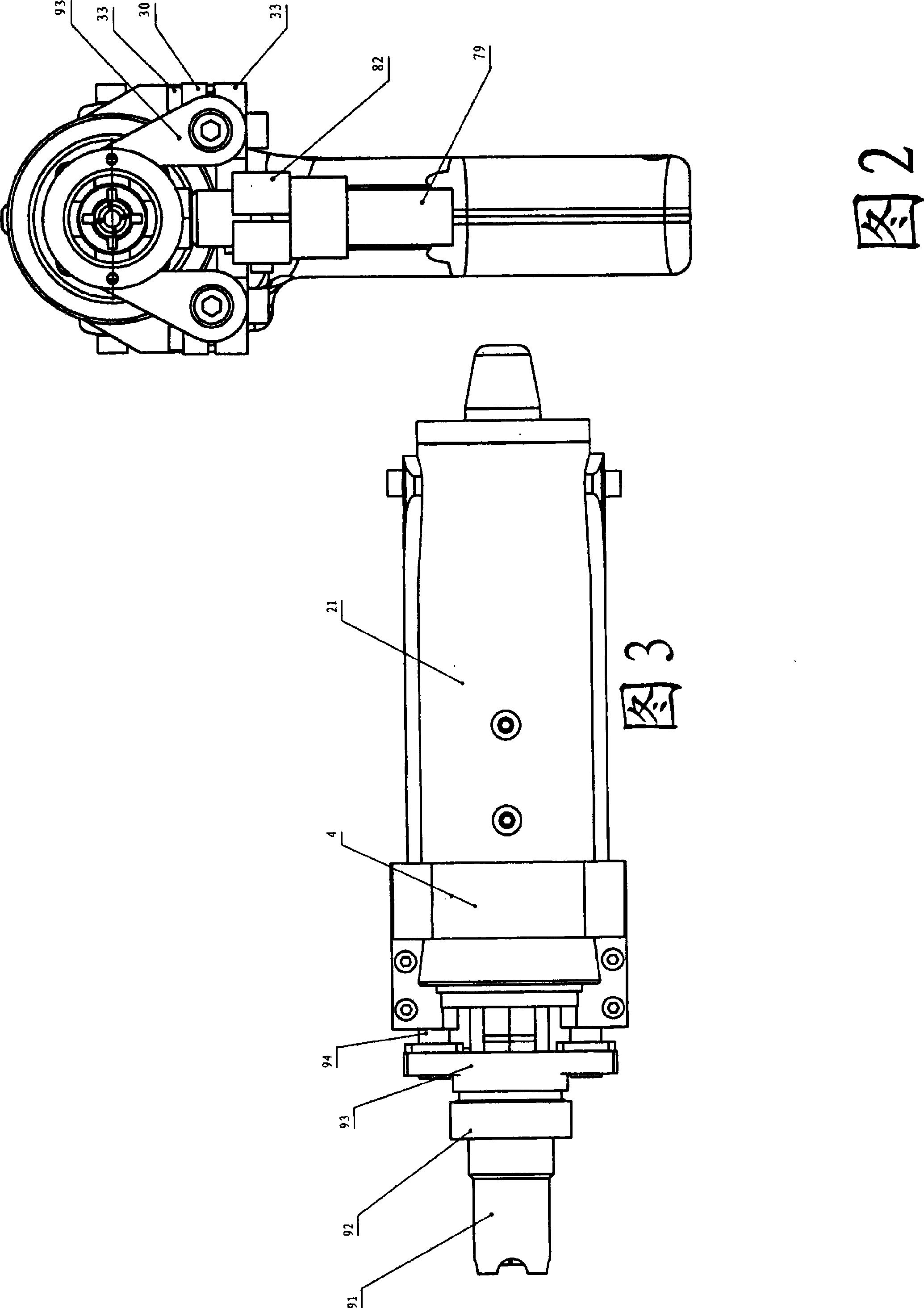

Arc discharge type double-screw bolt welding gun

InactiveCN101376193ARealize automatic feedingRealize chargingElectrode supporting devicesEngineeringStud welding

The invention discloses a drawn-arc type stud welding gun, which comprises a fixed component and a movable component. A stud receiver component and a cylinder piston component are arranged at the middle part of the movable component; the stud receiver component is mounted at the front end of the cylinder piston component, and an arc-shaped screw transporting slide is formed therein; a conducting clamping head of the receiver component is mounted in front of the stud receiver component, the penetrating inner hole thereof is communicated with a screw outlet port of the arc-shaped screw transporting slide and a screw inlet port of the arc-shaped screw transporting slide of the receiver component is communicated with the outside of the welding gun; and a piston rod of the cylinder piston component is coaxial with the inner hole of the conducting clamping head; and when the piston of the cylinder piston component moves forward, the piston rod thereof enters the inner hole of the conducting clamping head through the arc-shaped screw transporting slide of the stud receiver component, and the air passage of the cylinder piston component is communicated with the outside of the welding gun. The drawn-arc type stud welding gun can realize the automatic feeding and loading of the stud welding screws after the automatic feeding device is connected with the stud welding power source, thereby greatly improving the welding speed of the stud welding screws and reducing the labor intensity of workers at the same time.

Owner:SHENZHEN HONGBAI TECH IND

Automatic plate packing machine

ActiveCN102263226AImprove work efficiencyRealize automatic feedingElectrode manufacturing processesEngineeringMechanical engineering

The invention discloses an automatic plate packing machine, which comprises a plate pushing mechanism for pushing a plate, a paper feeding mechanism for feeding partition board paper, a first plate feeding mechanism for feeding a first plate, a second plate feeding mechanism for feeding a second plate and an assembly mechanism, wherein the first plate feeding mechanism, the paper feeding mechanism and the second plate feeding mechanism are sequentially arranged along the pushing direction of the plate pushing mechanism; the assembly mechanism is arranged under the second plate feeding mechanism; the first plate is fed to the plate pushing mechanism by the first plate feeding mechanism; the paper feeding mechanism is in fit with the plate pushing mechanism to finish the packing of the first plate; the second plate is fed to the assembly mechanism by the second plate feeding mechanism; and the first packed plate is pushed to the assembly mechanism by the plate pushing mechanism to be laminated with the second plate. The automatic plate packing machine has a simple and compact structure and high plate packing efficiency, and is convenient to operate.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

Pneumatic polishing machine with conveniently-adjusted polishing angle

InactiveCN108296937AEasy to holdIngenious structural designGrinding drivesGrinding feed controlDistribution controlPower component

The invention relates to a polishing machine, in particular to a pneumatic polishing machine with the conveniently-adjusted polishing angle. The pneumatic polishing machine comprises a rack, a conveying device and a power distribution control cabinet, the conveying device and the power distribution control cabinet are arranged on the rack, the conveying device is composed of a feeding device and adischarging device, a clamping rotation mechanism is arranged between the feeding device and the discharging device, a feeding mechanism is arranged at the position, above the clamping rotation mechanism, of the rack, and power components in the feeding device, the discharging device, the clamping rotation mechanism and the feeding mechanism are electrically connected with the power distributioncontrol cabinet; and automatic feeding and discharging of workpieces are achieved through the feeding device and the discharging device, the clamping rotation mechanism is used for fixing the workpieces and automatically adjusting the polishing angle during polishing, and polishing in different directions is achieved.

Owner:DONGGUAN UNIV OF TECH

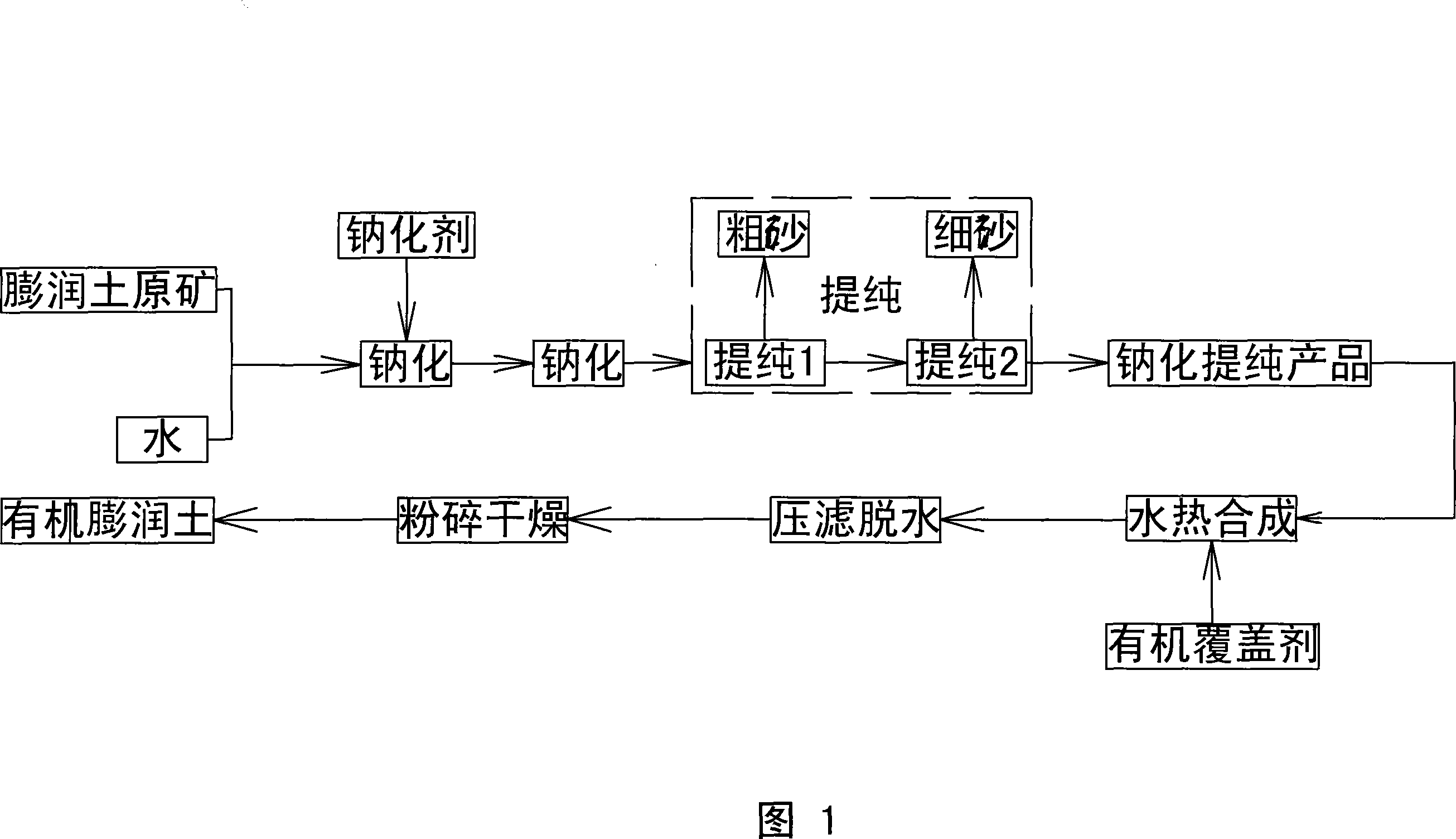

Method for preparing heavy-viscous organophilic bentonite

InactiveCN101224894AContinuously workingImprove stabilityPigmenting treatmentSilicon compoundsSodium BentonitePrinting ink

The invention provides a method for preparing high viscosity organophilic bentonite, which carries out steps of sodium treatment, purification, hydrothermal synthesis, dewatering by filter pressing, crashing and drying operation to bentonite raw ore to obtain the high viscosity organophilic bentonite. The invention can be directly applied to oil paint, printing ink, petroleum drilling slurry and heavy polymer and so on as a thickening suspension agent, a fluid deformation agent and an anti-sagging agent. Through systematic study on technologies of the sodium treatment modification, purification, organic compound and so on of the bentonite, the invention prepares organophilic bentonite jelly glue with stable product quality and excellent performance and determines a proper technical process flow and technical parameters.

Owner:苏州中材非金属矿工业设计研究院有限公司

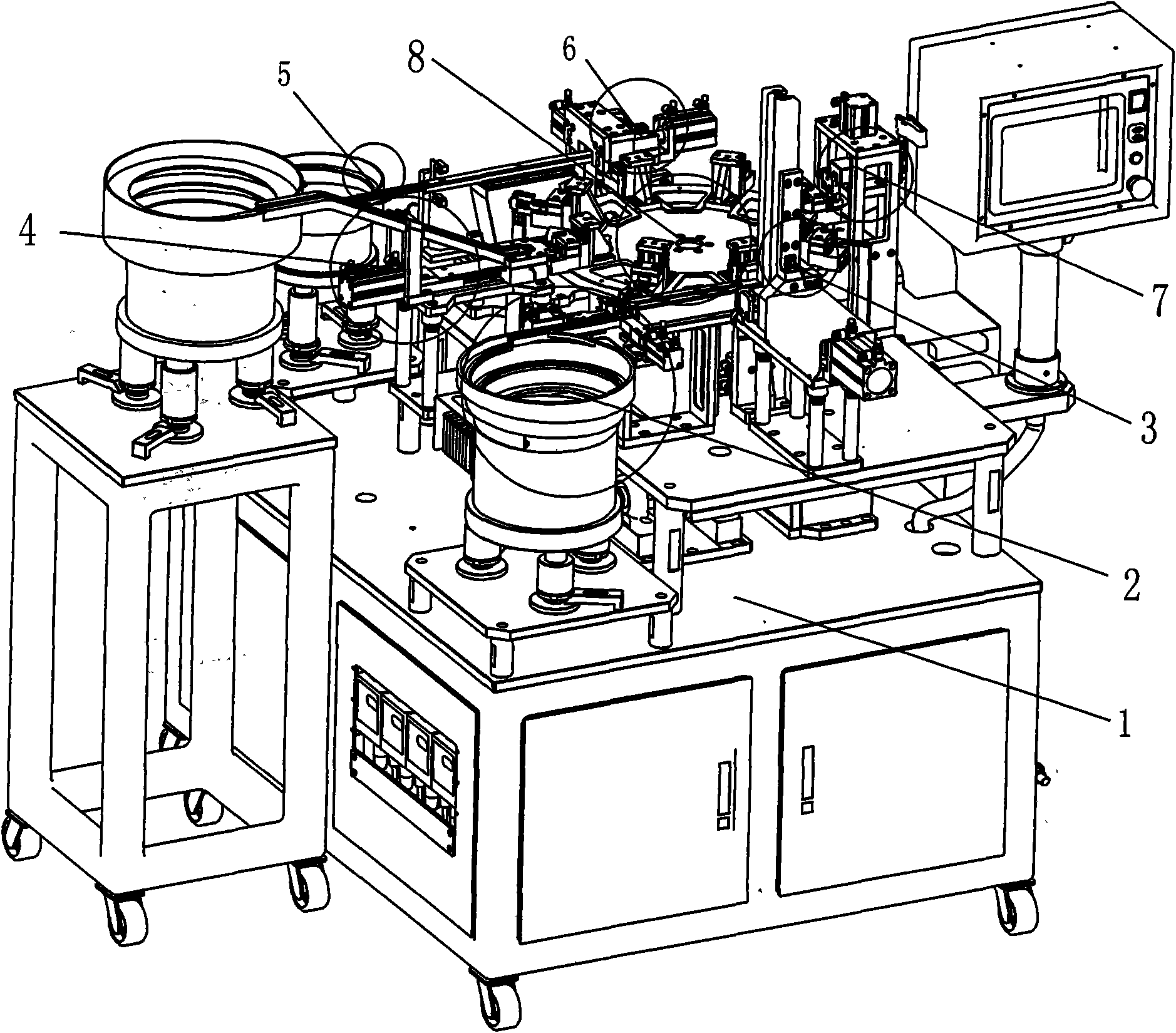

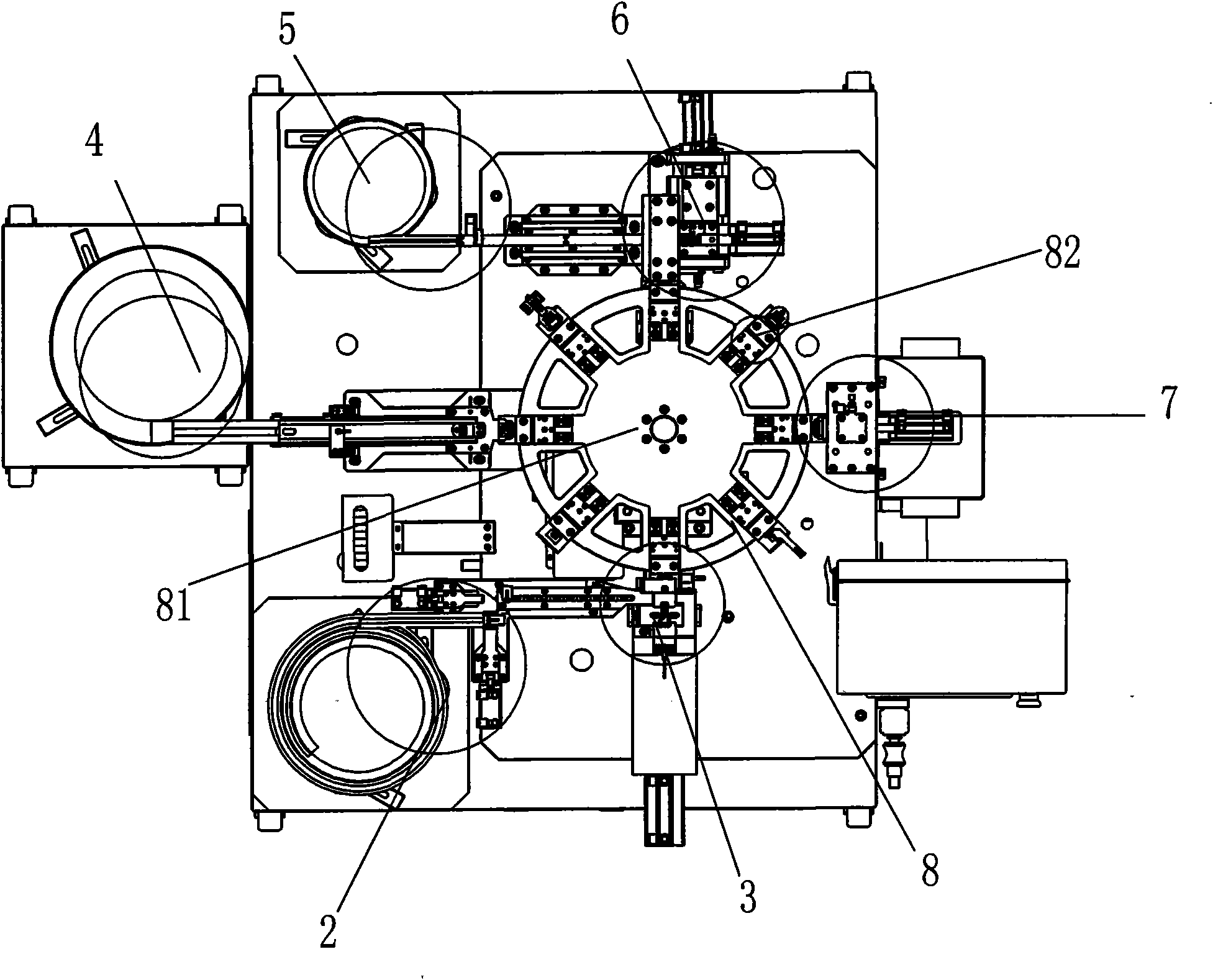

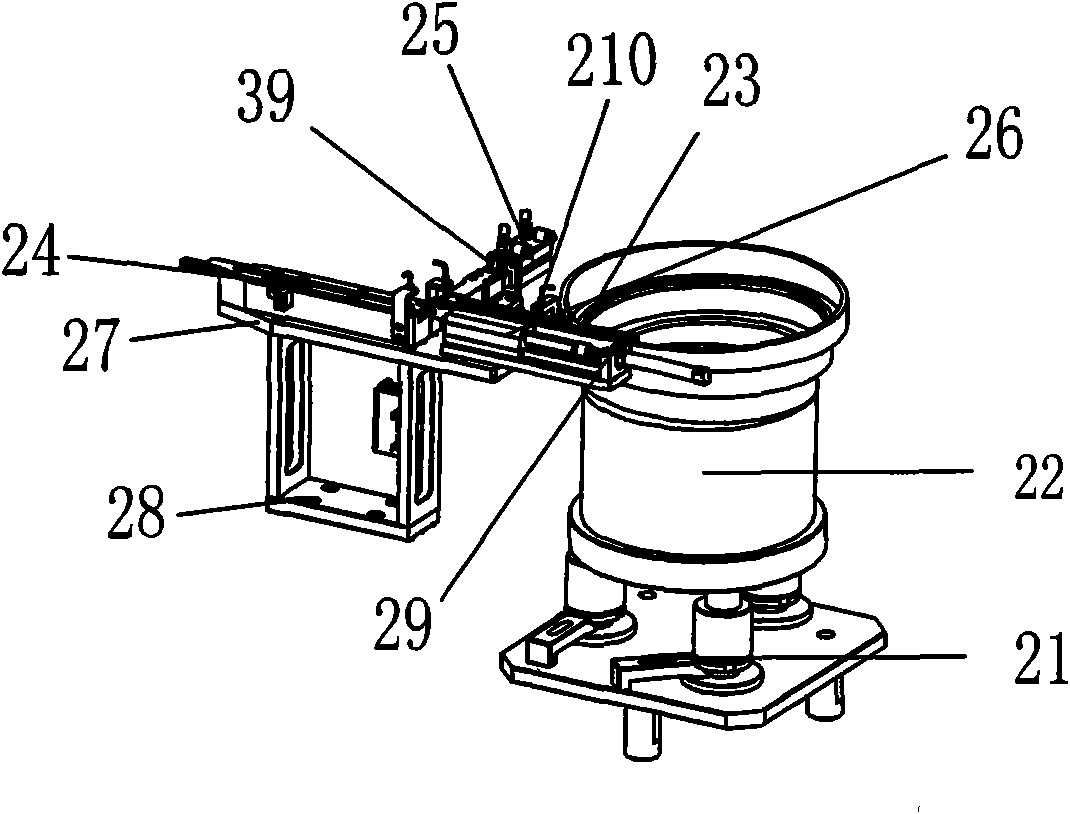

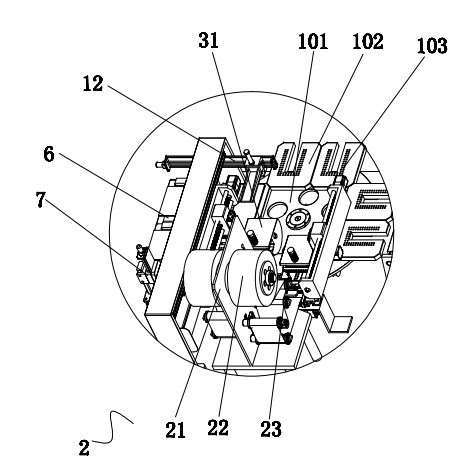

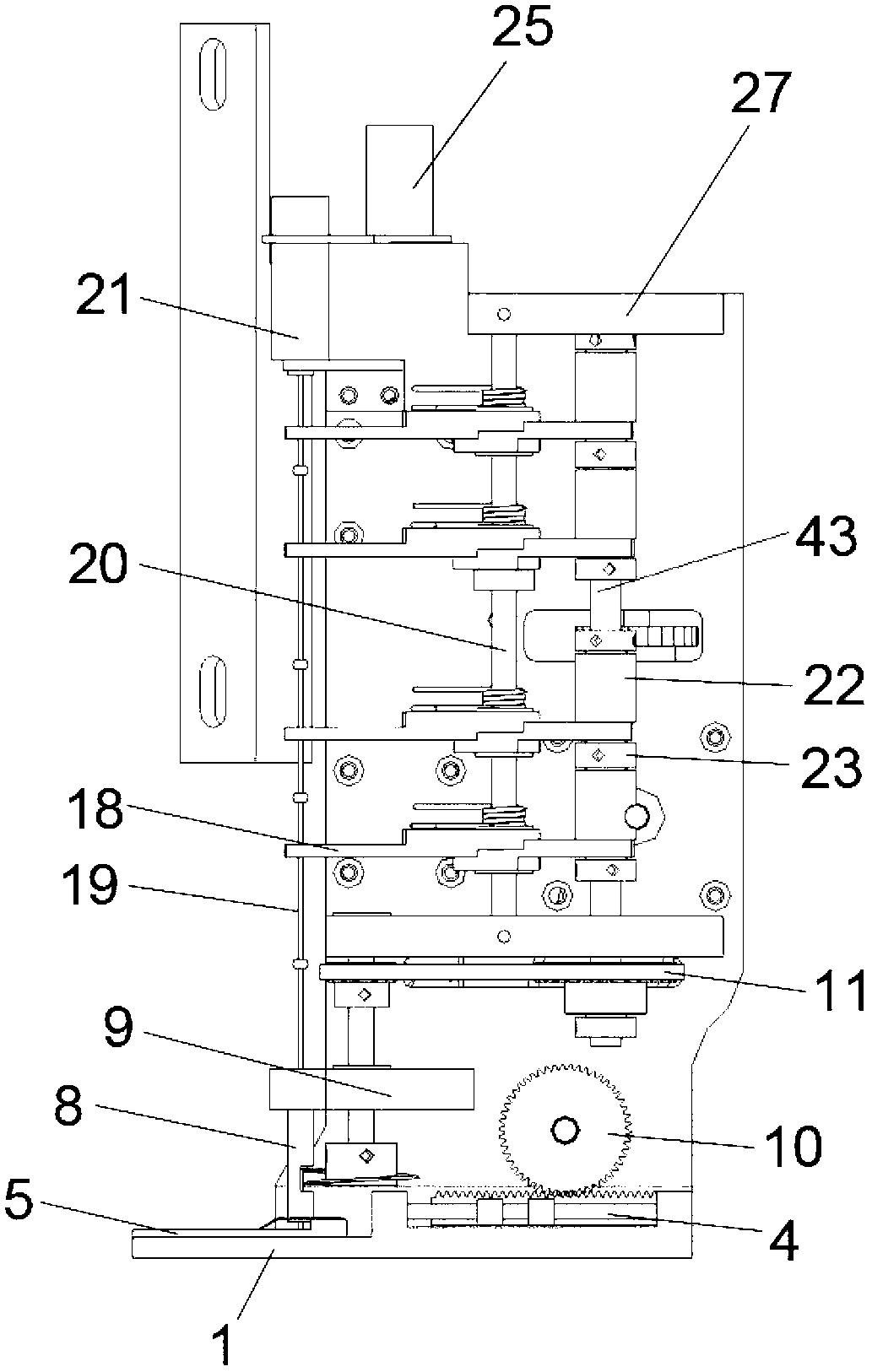

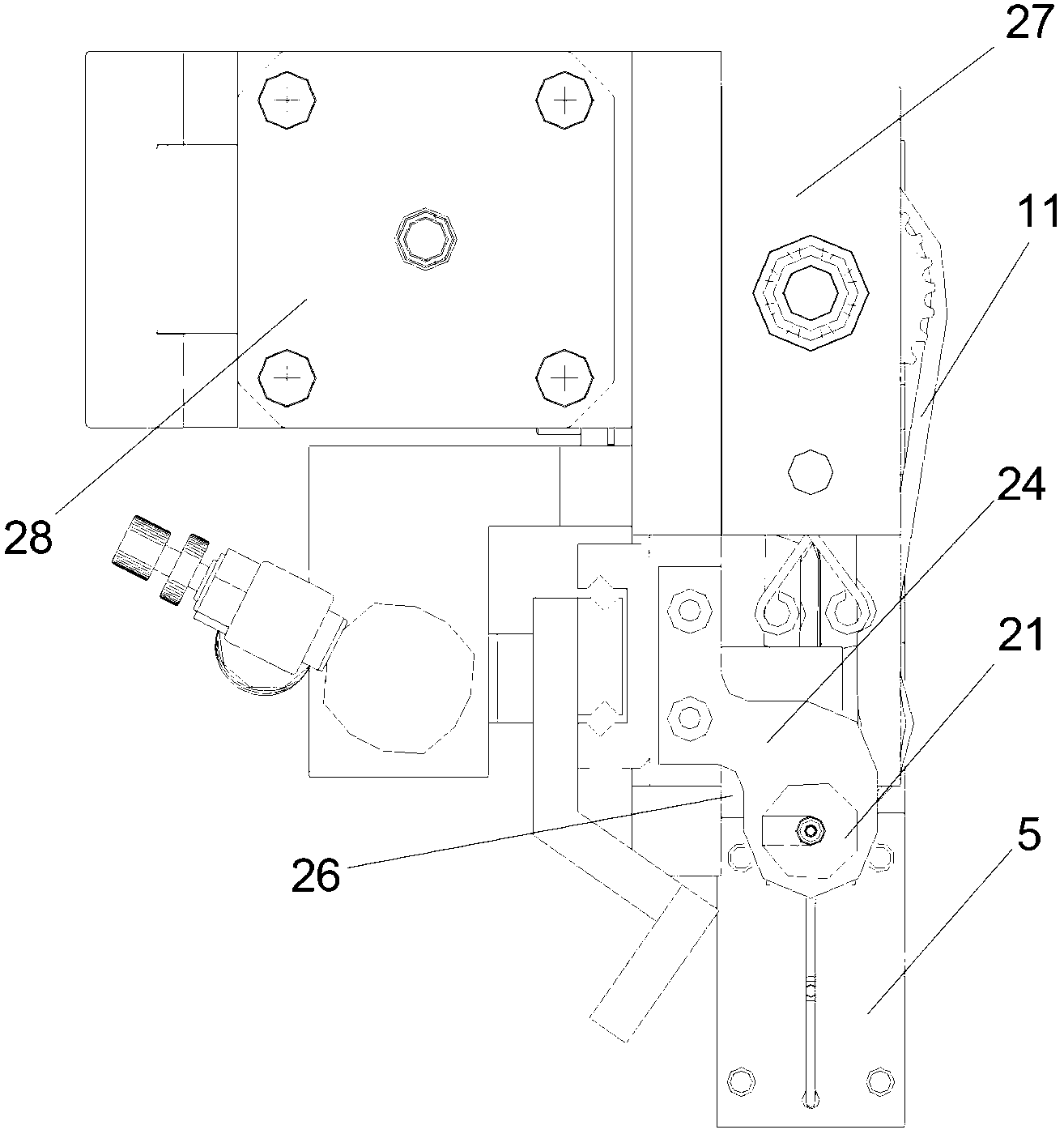

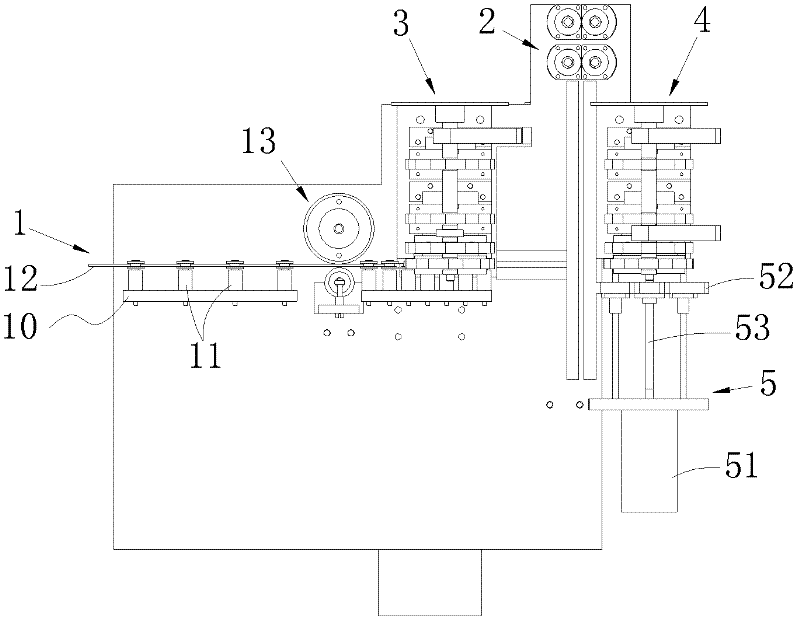

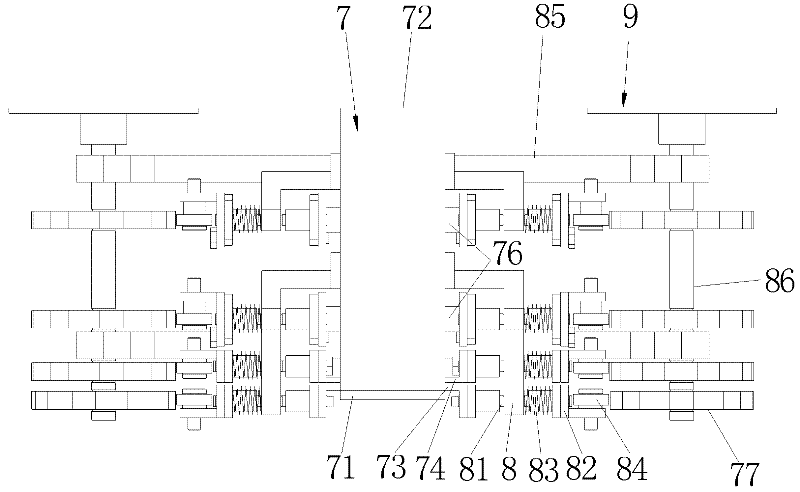

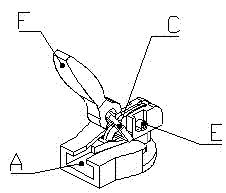

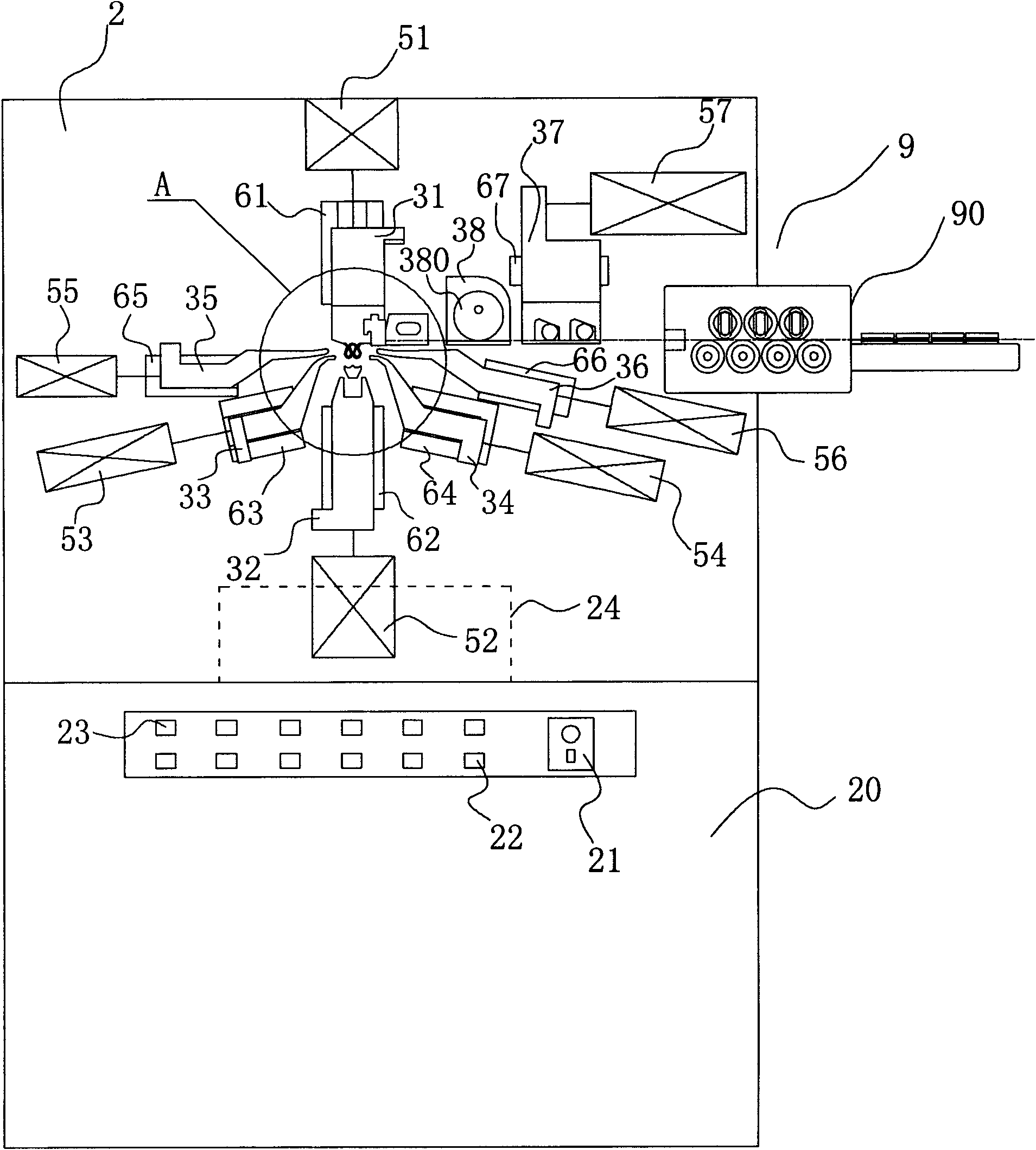

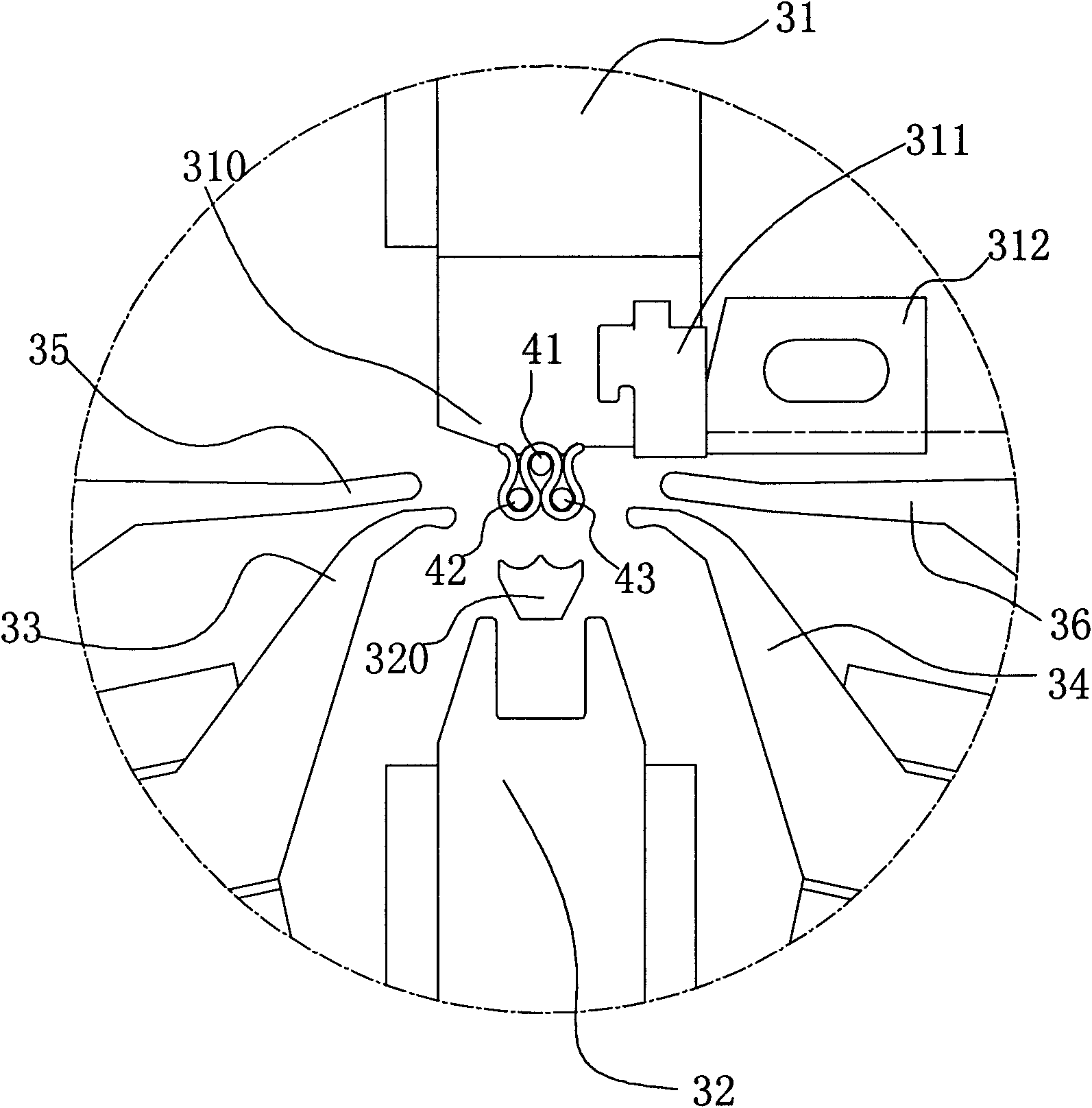

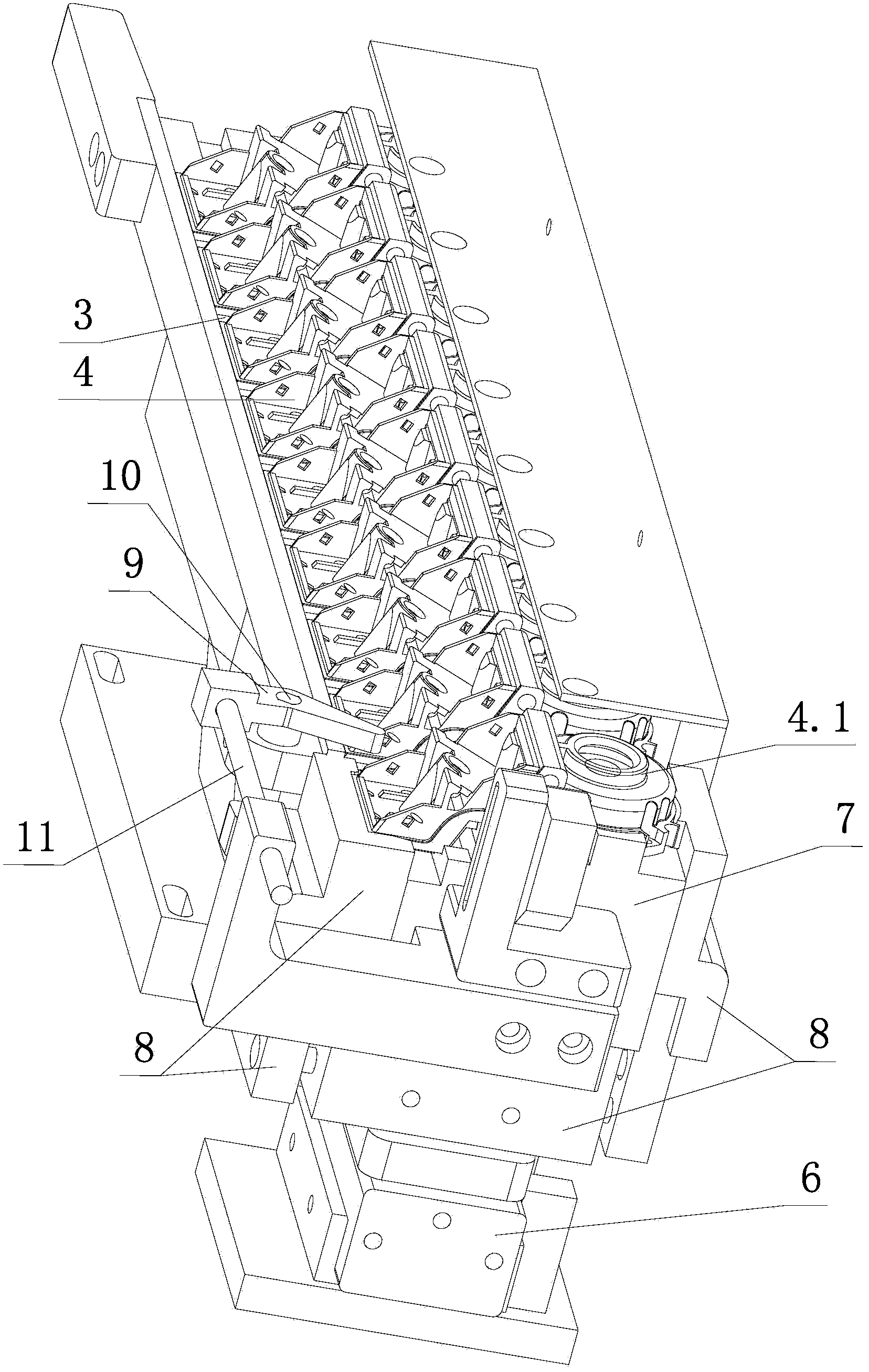

Six-part full-automatic assembly machine for invisible zipper puller

InactiveCN102525044AHigh degree of automationRealize automatic feedingSlide fastenersEngineeringStructural engineering

The invention discloses a six-part full-automatic assembly machine for invisible zipper puller and is characterized in that a moving assembly that is connected with a power device is arranged at the table top of a frame; twelve die cavities for fixing zipper pullers are arranged at equal intervals on the margin of the division main rotor plate of the moving assembly; and a zipper puller feeding mechanism, a zipper puller detection mechanism, a zipper puller spring feeding mechanism, a spring detection mechanism, a triangular collar feeding mechanism, a triangular collar detection mechanism, a horse hooker feeding mechanism, a copper pin feeding mechanism, a copper pin detection mechanism, a puller detection mechanism, a puller detection mechanism rejected puller discharge mechanism, and a qualified product discharge mechanism are arranged on the frame and used for assembling zipper pullers. The six-part full-automatic assembly machine integrates the functions of two machines, the detection mechanisms are arranged behind the corresponding feeding mechanism to automatically identify parts in the die cavities, and the start-up or shut-down of the assembly machine is automatically controlled according to the assembly information of parts, so as to prevent defected parts from entering the next procedure or prevent idle running of the assembly machine, as a result, the rate of rejected products is reduced and the assembly machine is guaranteed to run safely and reliably.

Owner:义乌市振宏机械科技有限公司

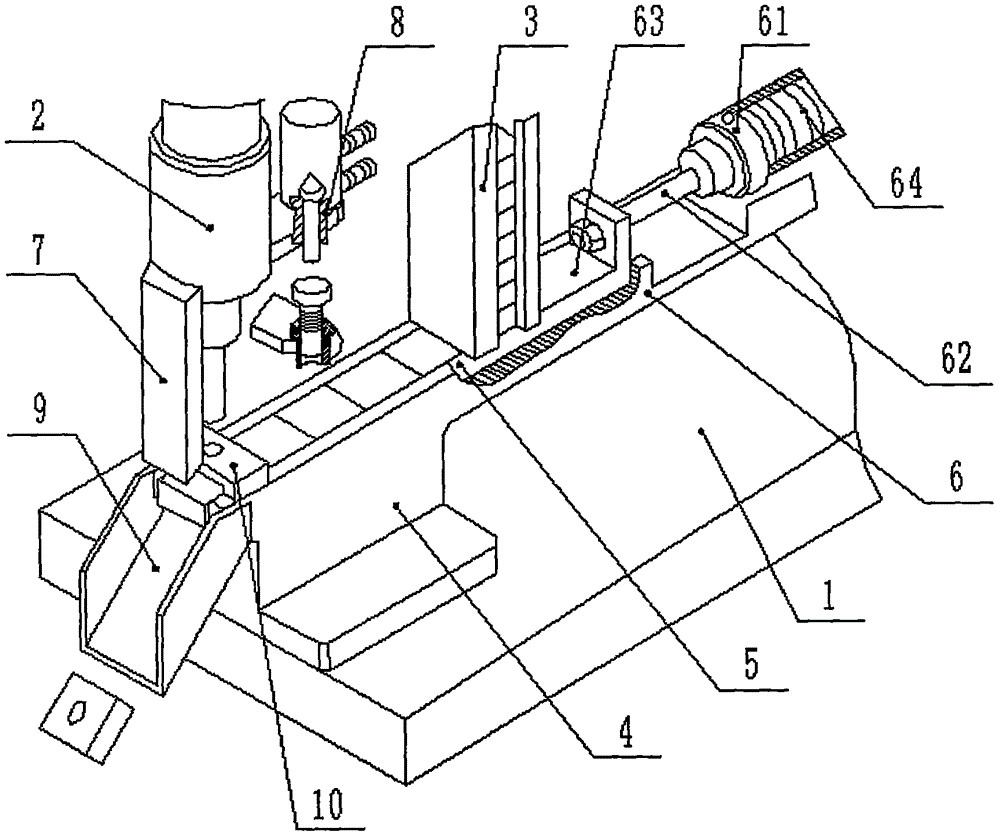

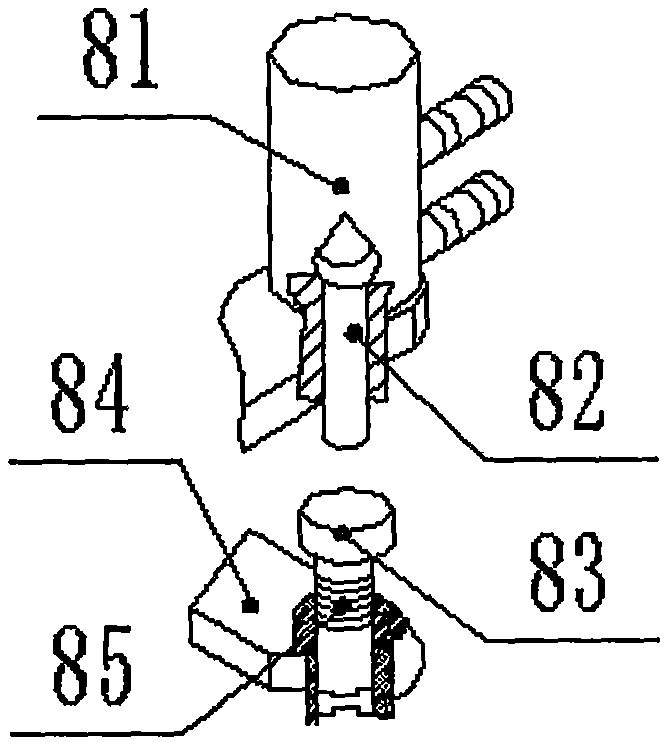

Drilling machine provided with automatic feeding device

InactiveCN105798689ARealize automatic feedingImprove clamping efficiencyMetal working apparatusEngineeringDrilling machines

The invention discloses a drilling machine provided with an automatic feeding device, belongs to the field of automatic drilling machines and solves problems that existing drilling machines cannot feed materials automatically and are low in drilling efficiency. The technical scheme is as follows: the drilling machine comprises a workbench and a drilling machine spindle, wherein a storage tank is fixedly arranged on one side of the drilling machine spindle, a feeding base is fixedly mounted on the workbench below the storage tank, a delivery guiding groove is formed in the feeding base in advance, a discharging port of the storage tank directly faces the delivery guiding groove, one side of the delivery guiding groove extends right below the drilling machine spindle, a push device is mounted on the other side of the delivery guiding groove, and a workpiece stop block is fixedly arranged on the drilling machine spindle, can slide up and down along the outer side surface of the drilling machine spindle and is located at the tail end of the delivery guiding groove after vertically falling.

Owner:WUXI INST OF COMMERCE

Punching device for automatic loading and unloading

The invention discloses a punching device for automatic loading and unloading. The punching device comprises an automatic loading mechanism and an automatic unloading and punching mechanism; the automatic loading mechanism is used for conveying metal sheets to the automatic unloading and punching mechanism, and comprises a mounting base, a pushing structure and a feeding structure; the pushing structure is mounted at the front end of the top surface of a mounting plate, and comprises a pushing cylinder, a push plate, a storage box and a pushing guide rail; the pushing cylinder, the push plate,the storage box and the pushing guide rail are arranged on the same straight line; the pushing cylinder and the push plate push the metal sheets, positioned at the bottommost part in the storage box,into the pushing guide rail to convey from the end near the pushing cylinder to the other end; the feeding structure is arranged at the back end of the top surface of the mounting plate, and is usedfor conveying the metal sheets, conveyed to the end far from the pushing cylinder of the pushing guide rail, from the pushing structure to the automatic unloading and punching mechanism; and the automatic unloading and punching mechanism is used for punching and automatically unloading the metal sheets. The punching device realizes automatic loading and unloading.

Owner:HONORFAITH FURNITURE

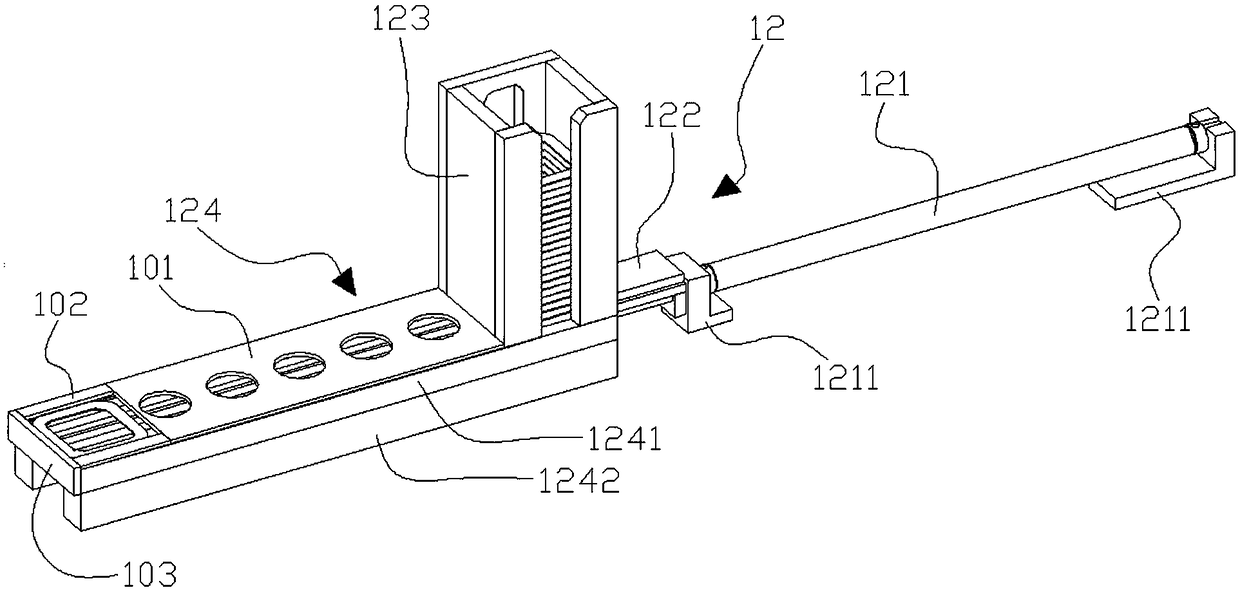

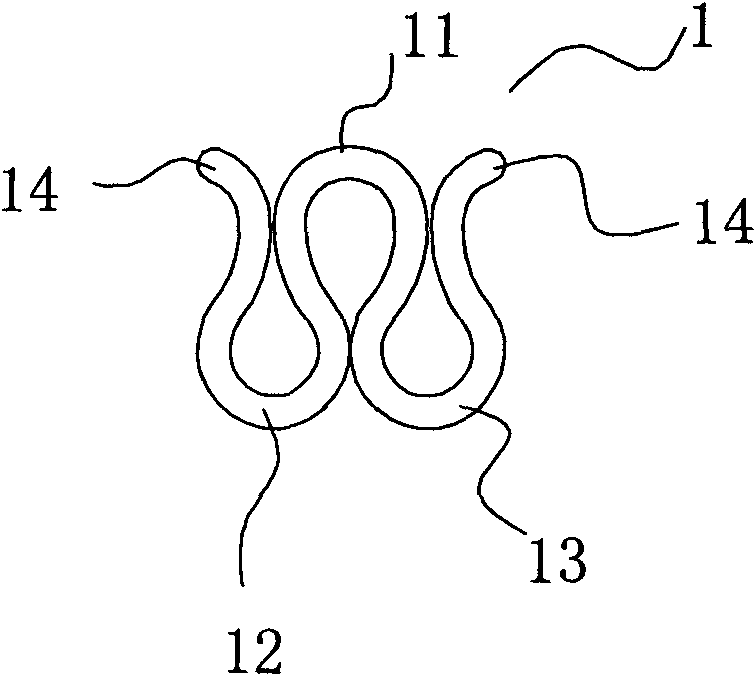

Automatic shaping device and automatic shaping method of W-shaped necklace buckle

InactiveCN101987341ARealize automatic feedingConform to size standardWire articlesWatch chainsMechanical engineeringLinear object

The invention discloses an automatic shaping device and an automatic shaping method of a W-shaped necklace buckle. The automatic shaping device comprises a template, a feeding mechanism, a first mold core, a cutting and bending die, an extrusion die, a second mold core and a third mold core, wherein the feeding mechanism is arranged at one side of the template, the first mold core is arranged on the template, the cutting and bending die is arranged above the first mold core, the extrusion die is arranged just below the first mold core, and the second mold core and the third mold core are arranged at the left side and the right side between the first mold core and the extrusion die; the template is provided with a first left outer die and a first right outer die at the left side and the right side of the first mold core and is also provided with a second outer die and a third outer die. The invention also discloses the automatic shaping method of the W-shaped necklace buckle. In the device, a mechanized structure is adopted so as to realize automatically feeding, cutting, bending, blanking and the other working procedures of the necklace buckle, thus, the yield is increased by multiple times as compared with the original manual operation and the shape of each necklace buckle conforms to the dimension standard because a mechanical mould is used for extruding and shaping. The device and method not only can be used for automatically shaping the necklace buckle but also can be used for the bending and shaping technology of the W-shaped small linear objects.

Owner:SHENZHEN FUQI JEWELRY

Programmable automatic welding system

ActiveCN101456107ARealize automatic feedingRealize automatic clampingWelding/cutting auxillary devicesAuxillary welding devicesSlide plateEngineering

The invention provides a programmable automatic welding system, which comprises a feed cylinder component, a main machine bedplate, a feeding component, a workpiece holding component, a welding gun holder, an electric control system, an air channel and a programmable controller, wherein the feed cylinder component comprises a feed cylinder and a T-shaped discharge oblique path for through which a workpiece enters the feed cylinder is arranged above the feed cylinder component; and the feeding component comprises a feeding bedplate and is fixed on the machine bedplate, two sides of the feeding component are provided feeding slide rails with a square notch respectively, and two sides of the feeding bedplate are fixed with feeding sliding plates which are matched with the slide rails respectively. The programmable automatic welding system can realize automatic feeding, automatic holding, automatic welling and automatic material retuning, sets free workers from complex manual labour, controls multi-direction operations and time through programs and is suitable for welding products of various sizes.

Owner:NINGBO XULI METAL PROD

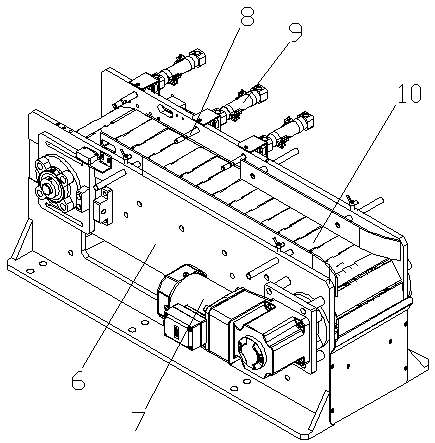

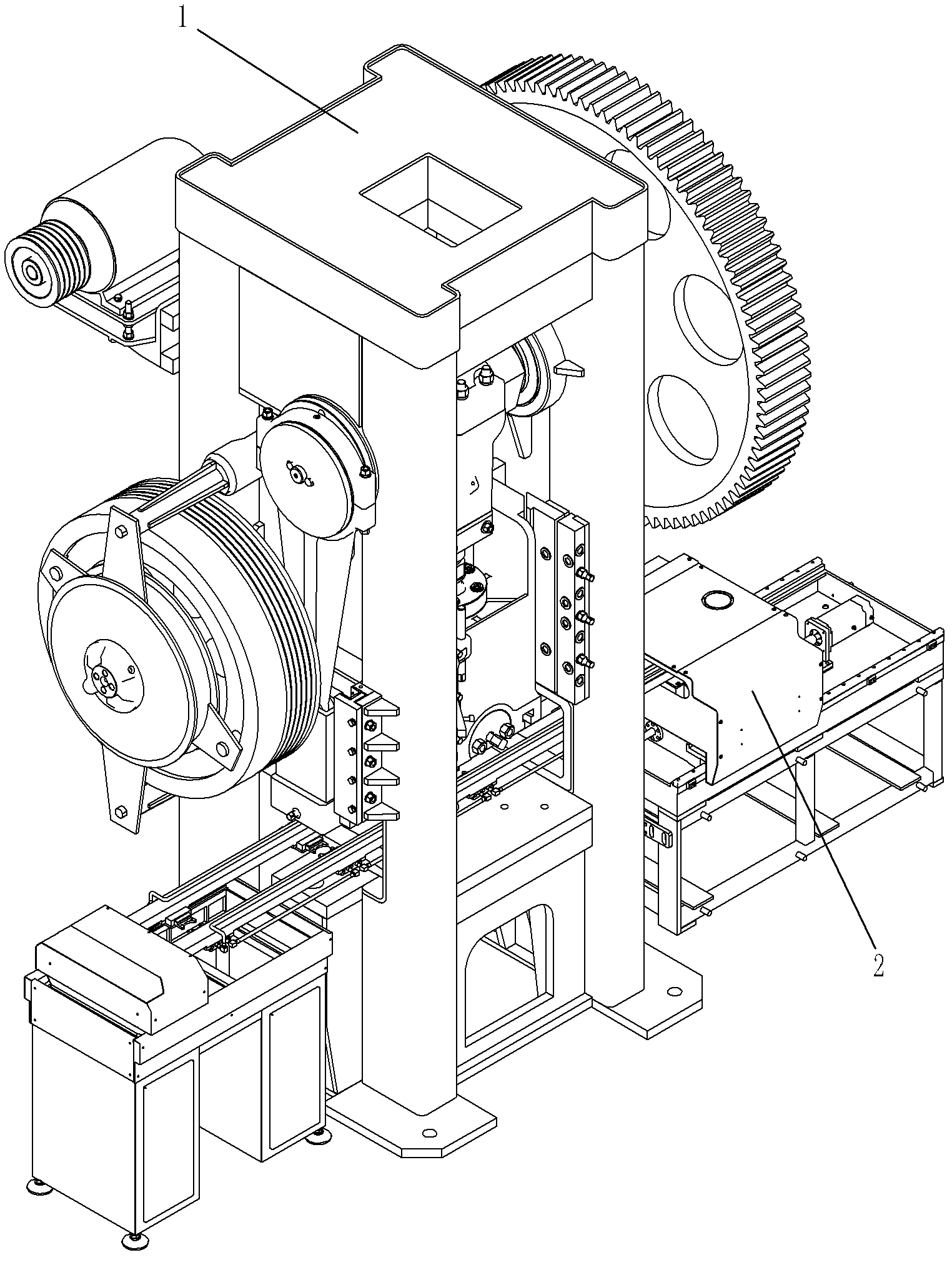

High-speed laser drilling machine capable of charging and discharging automatically

ActiveCN104551418AAvoid damageImprove loading and unloading efficiencyWelding/cutting auxillary devicesAuxillary welding devicesGalvanometerEngineering

The invention relates to the technical field of laser drilling equipment, and particularly relates to a high-speed laser drilling machine capable of charging and discharging automatically. The high-speed laser drilling machine comprises a cabinet, a charging device and a discharging device, wherein the cabinet is provided with a vacuum adsorption platform, a high-speed laser galvanometer and a drilling linear module which is used for driving the high-speed laser galvanometer to move along the z-axis direction; the charging device comprises a charging rack, a charging box, a charging component and a charging vacuum suction disc; the charging rack is provided with a charging movable plate and a charging linear module; the charging component is connected with the charging movable plate; the charging box is provided with a charging bearing plate; a charging lifting component is arranged at the rear side of the charging box; the discharging device comprises a discharging rack, a discharging box, a discharging component and a discharging vacuum suction disc; the discharging rack is provided with a discharging movable plate and a discharging linear module; the discharging component is connected with the discharging movable plate; the discharging box is internally provided with a discharging bearing plate; the discharging box is provided with a discharging lifting component. According to the high-speed laser drilling machine, the automatic charging and discharging can be realized; the charging and discharging efficiency is high; materials can be prevented from being damaged.

Owner:鞍山盛雄激光设备有限公司

Bending machine used for bending plates

ActiveCN105013887ARealize automatic feedingRealize the defect that the bending is not in placeMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention discloses a bending machine used for bending plates and belongs to the technical field of machining. The bending machine comprises a rack, an upper bending part, a lower bending part and a feeding mechanism. The lower bending part is fixedly arranged, and the upper bending part is arranged in a vertical sliding mode. A material pressing plate is correspondingly arranged above the lower bending part. The material pressing plate is arranged in a vertical sliding mode. The upper bending part comprises an ejecting block and a sliding pressing plate. The ejecting block is arranged in a vertical sliding mode. The sliding pressing plate is located on the lower surface of the ejecting block and is arranged in a reciprocating sliding mode in the feeding direction. The sliding pressing plate is provided with a sliding driving device in a matched mode. A round corner is arranged on the side, matched with the lower bending part, of the sliding pressing plate. A bending gap is reserved between the sliding pressing plate and the lower bending part. The feeding mechanism comprises driving rollers and driven rollers located above the driving rollers, and the driven rollers are connected with a lifting driving device. The bending machine ensures the bending precision and is capable of improving efficiency, simple, practical and obvious in effect.

Owner:CHANGSHA CITY WANZHENG LORRY CARRIAGE

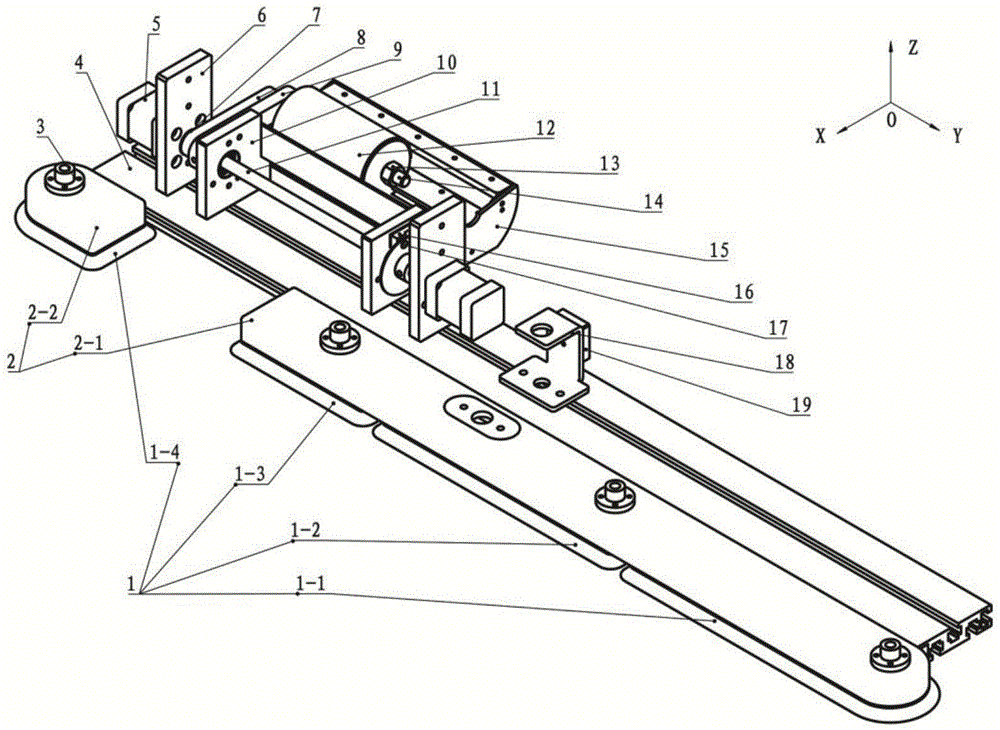

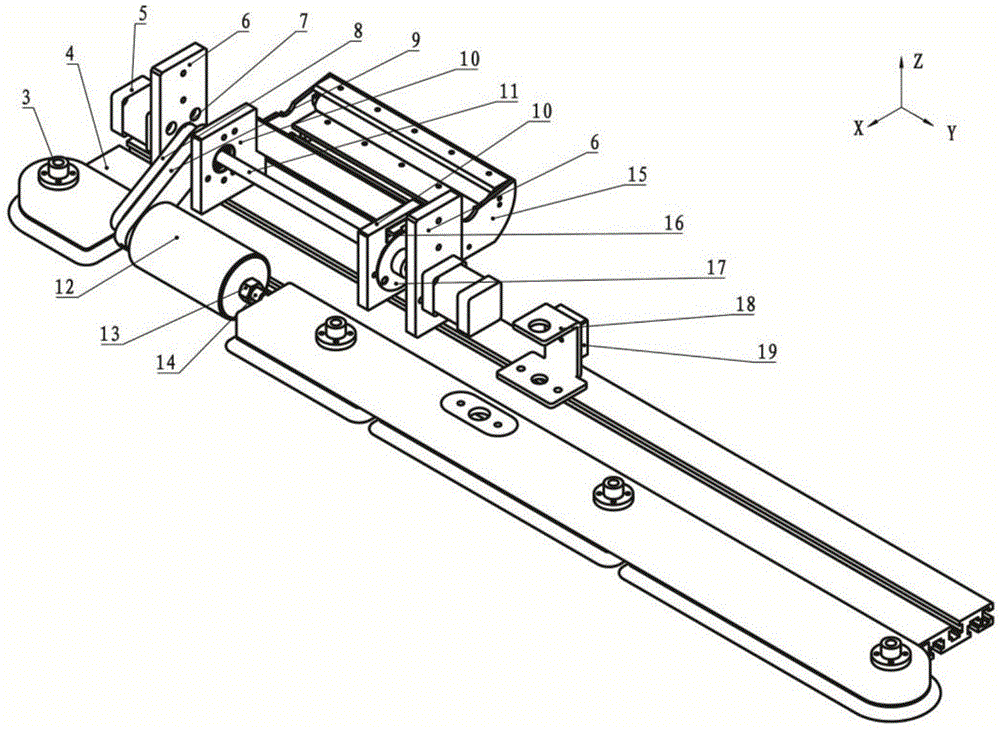

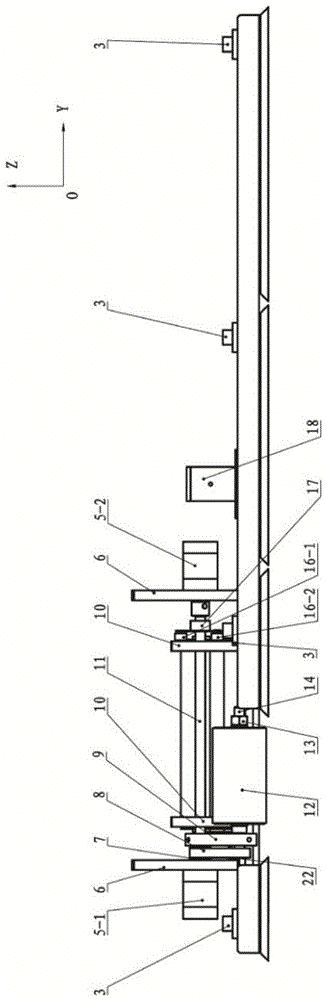

Feeding manipulator used for hot forging production line

InactiveCN102581197ARealize automatic feedingSimple structureForging/hammering/pressing machinesProduction lineEngineering

The invention discloses a feeding manipulator used for a hot forging production line, which comprises a left rack, a right rack and two clamping arms, wherein the two clamping arms straddle on the left rack and the right rack and are used in pair. A lower carriage is horizontally and glidingly arranged on the right rack and is driven by a driving device A to move left and right, and an upper carriage is vertically and glidingly arranged on the lower carriage and is driven by a driving device B to move up and down. An auxiliary lower carriage is arranged on the left rack in a left-and-right gliding mode, and an auxiliary upper carriage is vertically and glidingly arranged on the auxiliary lower carriage. The right ends of the two clamping arms are respectively connected with the upper carriage in a front-and-back gliding mode and are driven by a driving device C installed on the upper carriage to relatively move to join or separate, and the left ends of the two clamping arms are respectively connected with the auxiliary upper carriage in a front-and-back gliding mode and are relatively fixed in a vertical direction. A plurality of pairs of clamping jaws used for clamping blanks are relatively arranged on the two clamping arms. According to the feeding manipulator, automatic feeding among multi-stations of a press can be realized. The feeding manipulator has the advantages of being simple in structure, reliable in operation and high in efficiency.

Owner:浙江博雷重型机床制造有限公司

Full-automatic plate wrapping machine

InactiveCN102780048ACompact structureImprove work efficiencyFinal product manufactureLead-acid accumulators constructionCamEngineering

The invention discloses a full-automatic plate wrapping machine which comprises a body. A plate push rail, a plate push device, a paper sending device, a plate wrapping device, a first plate dropping frame, a second plate dropping frame and a lifting mechanism are arranged in the body. The plate push device, the first plate dropping frame, the paper sending device, the plate wrapping device and the second plate dropping frame are sequentially arranged along the propelling direction of the plate push rail. The lifting mechanism is arranged right below the second plate dropping frame, and each of the first plate dropping frame and the second plate dropping plate is provided with a clamping part, a plate holding part and a cam driving device which drives the clamping part and the plate holding part to move. A polar plate at the lowest end is released by the plate holding part when the clamping part is in a clamped state, and supported and held by the plate holding part when the clamping part is in a loosened state. An existing plate wrapping machine is improved, auxiliary transferring devices are not needed during plate wrapping, and the full-automatic plate wrapping machine is more compact and higher in operating efficiency.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

High-efficiency crusher for ceramic production

The invention discloses a high-efficiency crusher for ceramic production. The crusher comprises a conveying cylinder, a hydraulic cylinder and a vibrating motor, wherein the outer wall of the conveying cylinder is covered with an electric heating layer; a feed funnel is arranged at the upper side of the left end of the conveying cylinder; a first rotating shaft is horizontally arranged in the internal axes place of the conveying cylinder; and multiple spiral blades are uniformly arranged on the first rotating shaft from left to right. The high-efficiency crusher for ceramic production can crush and dry raw materials for ceramic production, adopts two crushing modes of the spiral blades and crushing rollers to greatly improve the crushing efficiency, can screen materials with unqualified particle size to convey into a crushing cavity for circularly crushing, adopts the vibrating motor to drive a screen to vibrate so as to improve the screening efficiency and effect, guarantees the crushing effect and the finished product quality, improves the adjustment of a gap between the upper and lower crushing rollers to realize the particle size adjustment of the crushed materials, and improves the practicability.

Owner:顾广才

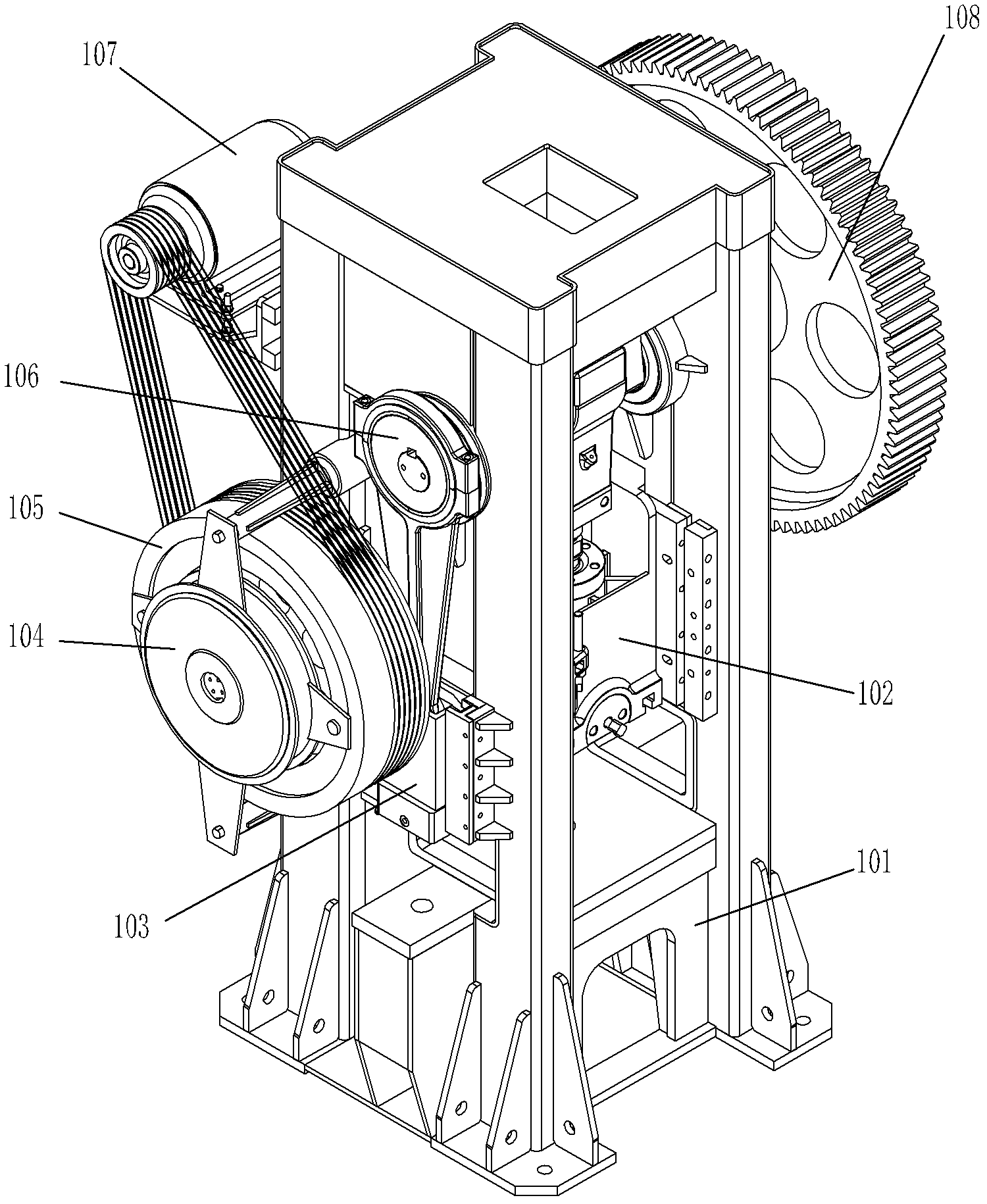

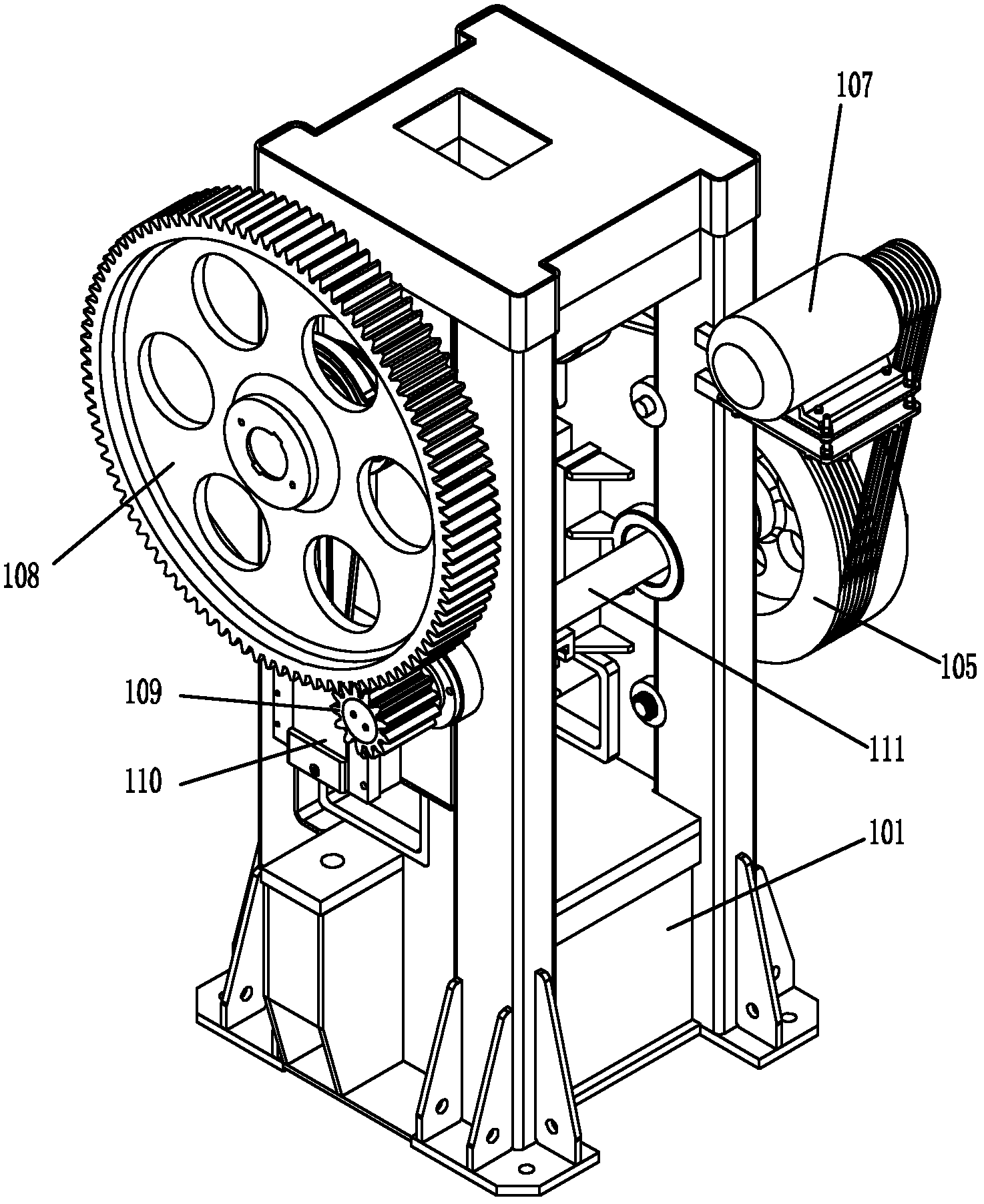

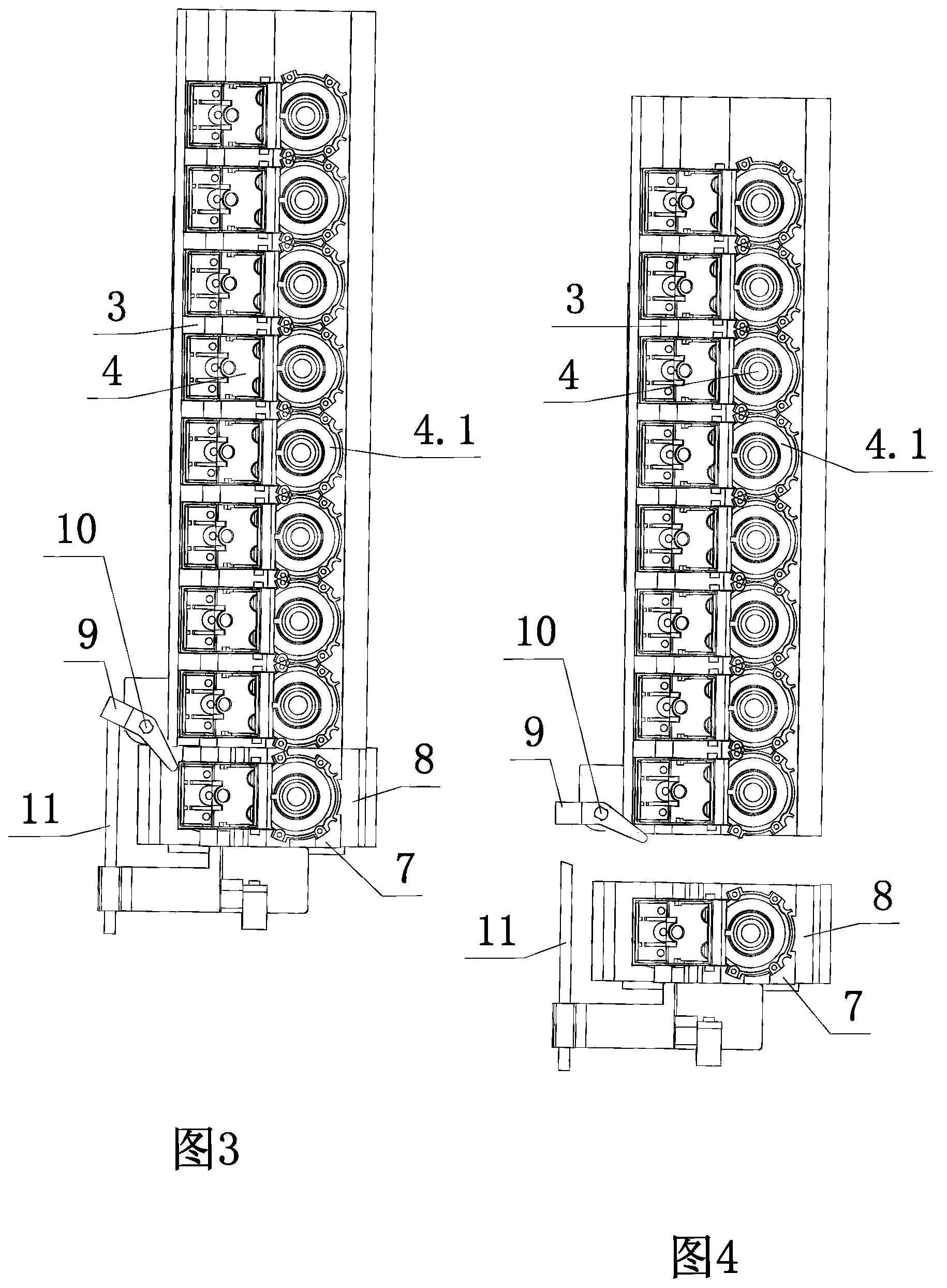

Full-automatic steel ball assembling machine

ActiveCN104015040AAchieve separationPrecise positioningMetal working apparatusEngine lubricationSteel ballEngineering

The invention discloses a full-automatic steel ball assembling machine which comprises a machine frame (1). A transition section material groove (7) is formed in the machine frame (1). The tail end of an automatic feeding groove channel (3) is hinged with a blocking plate (9). When the transition section material groove (7) is separated from the tail end of the automatic feeding groove channel (3), the front end of the blocking plate (9) abuts against a workpiece (4) at the forefront end on the automatic feeding groove channel (3). When the transition section material groove (7) abuts against the tail end of the automatic feeding groove channel (3), a top rod (11) of the transition section material groove (7) stops the front end of the blocking plate (9) from preventing the workpiece (4) from moving forward. A feeding arm is arranged on the machine frame (1). The machine further comprises a steel ball discharging device, a down-pressing device and an oil injection device. The machine can achieve automatic feeding of the workpiece (4), the workpiece is conveyed to a down-pressign working position quickly, accurately and efficiently, a steel ball can be automatically conveyed into a mounting hole of the workpiece (4), the steel ball can be pressed automatically, and automatic oil injection can be carried out to the steel ball.

Owner:NINGBO JINGCHENG CAR IND

Marking machine

ActiveCN103042836ARealize automatic feedingAchieving stationarityTypewritersBiochemical engineeringGas cylinder

The invention relates to a marking machine. The marking machine comprises a bed body, wherein a feeding unit, a fixing unit and a discharging unit are sequentially arranged on the bed body, and a marking unit and a control panel are further arranged at one side of the bed body; and upright posts are arranged at the periphery of the bed body, a frame is arranged on the upright posts, a walking unit is arranged on the frame, and a lifting translation unit is arranged on the walking unit and is connected with a clamping unit. According to the marking machine, the structure is simple, the operation is convenient, the full-automatic operations such as automatic feeding, marking and automatic discharging of an air bottle are realized, the stability of air bottle grabbing is realized by using pincers, the safety and the convenience can be realized, the automation degree is high, the tedious process that the air bottle requires to be manually carried in the prior art is avoided, the time and the labor are saved, not only is the cost saved, and but also the production efficiency is improved.

Owner:XINGUANG NUMERICAL CONTROL TECH

Automatic cloth single-layered separation and fetching method and mechanism of sewing machine

The invention relates to an automatic cloth single-layered separation and fetching method of a sewing machine. In a working process, a cloth sticking wheel and a cloth fetching device are pressed down together; firstly, the cloth sticking wheel is in contact with cloth; when pressure reaches a pre-set value of a pressure sensor, the cloth fetching device stops pressing down and the cloth sticking wheel is spliced with the cloth; after the cloth is stuck, the cloth fetching device ascends for a proper height; meanwhile, when the cloth sticking wheel swings upwards to be parallel to a fetching movement part, the cloth is separated in a singe layer to be fetched; the cloth sticking wheel continually ascends to be released from the cloth to be ready for secondary layering work; after each time of layering is finished, the cloth sticking wheel is driven by a sticking wheel stepping motor to roll for a certain angle to keep a new sticking surface; when the cloth sticking wheel is detected by a sensor assembly to rotate for one circle, a swinging motor drives the cloth sticking wheel to wholly swing to enter a cloth sticking wheel washing device to be washed; after the washing is finished, the cloth sticking wheel is oppositely driven by the swinging motor to wholly swing, and is detected by the sensor assembly to swing in place so as to enter a to-be-layered working state.

Owner:上海富山精密机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com