Patents

Literature

1909results about How to "Realize the assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

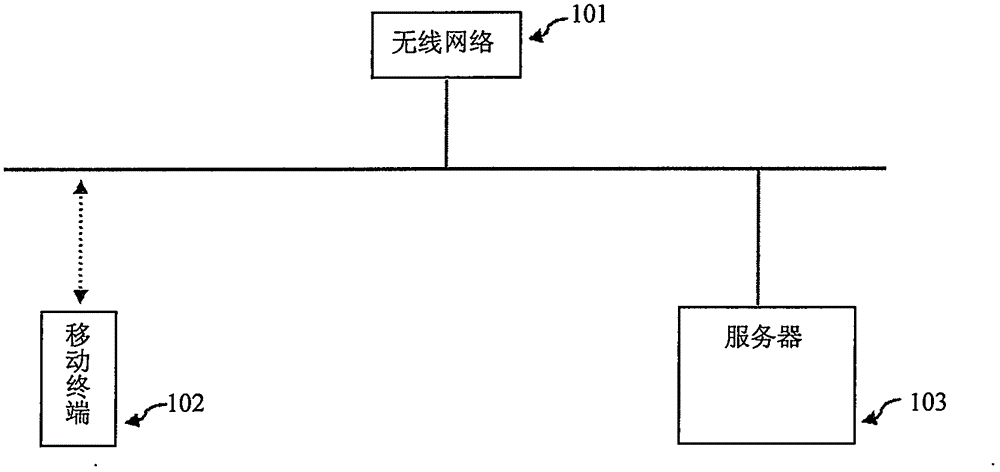

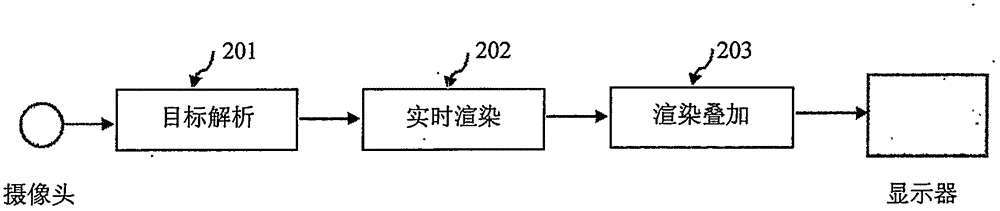

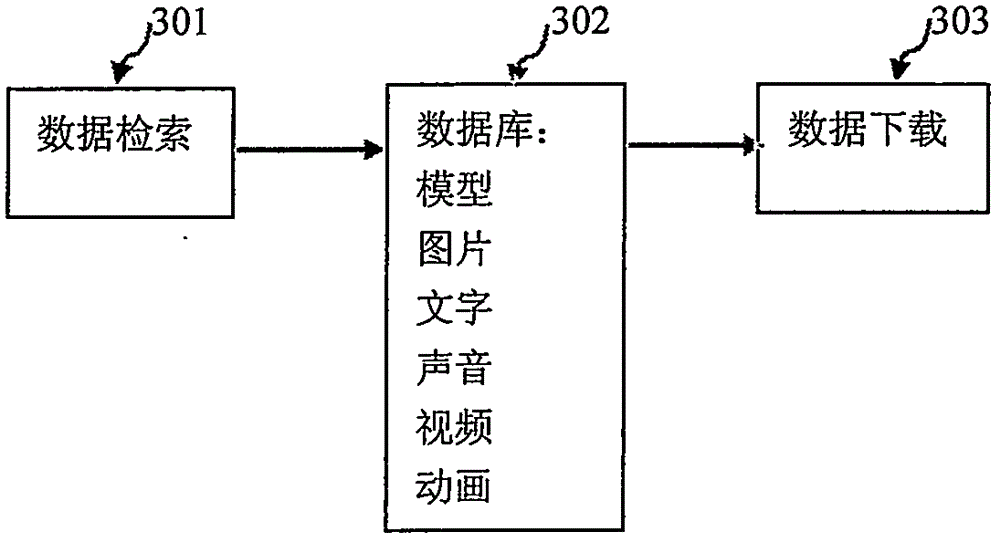

Real-time interaction reality augmenting system and method

The invention discloses a reality augmenting method. The reality augmenting method comprises the steps that a terminal obtains a current scene image through a camera, and detects a recognized target in the image to obtain data information in the recognized target; whether corresponding calling information exists in the terminal or not is checked, if yes, real-time rendering is directly carried out, and virtual information is superimposed on a terminal screen to be displayed in a scene; if the corresponding information does not exist, the information is uploaded to a server, the corresponding information is called from a database and downloaded to the terminal to be rendered in real time, and the effect of augmenting the reality is achieved. Meanwhile, movement, rotation and zooming of a virtual image can be controlled by moving the current scene or a terminal device.

Owner:李成

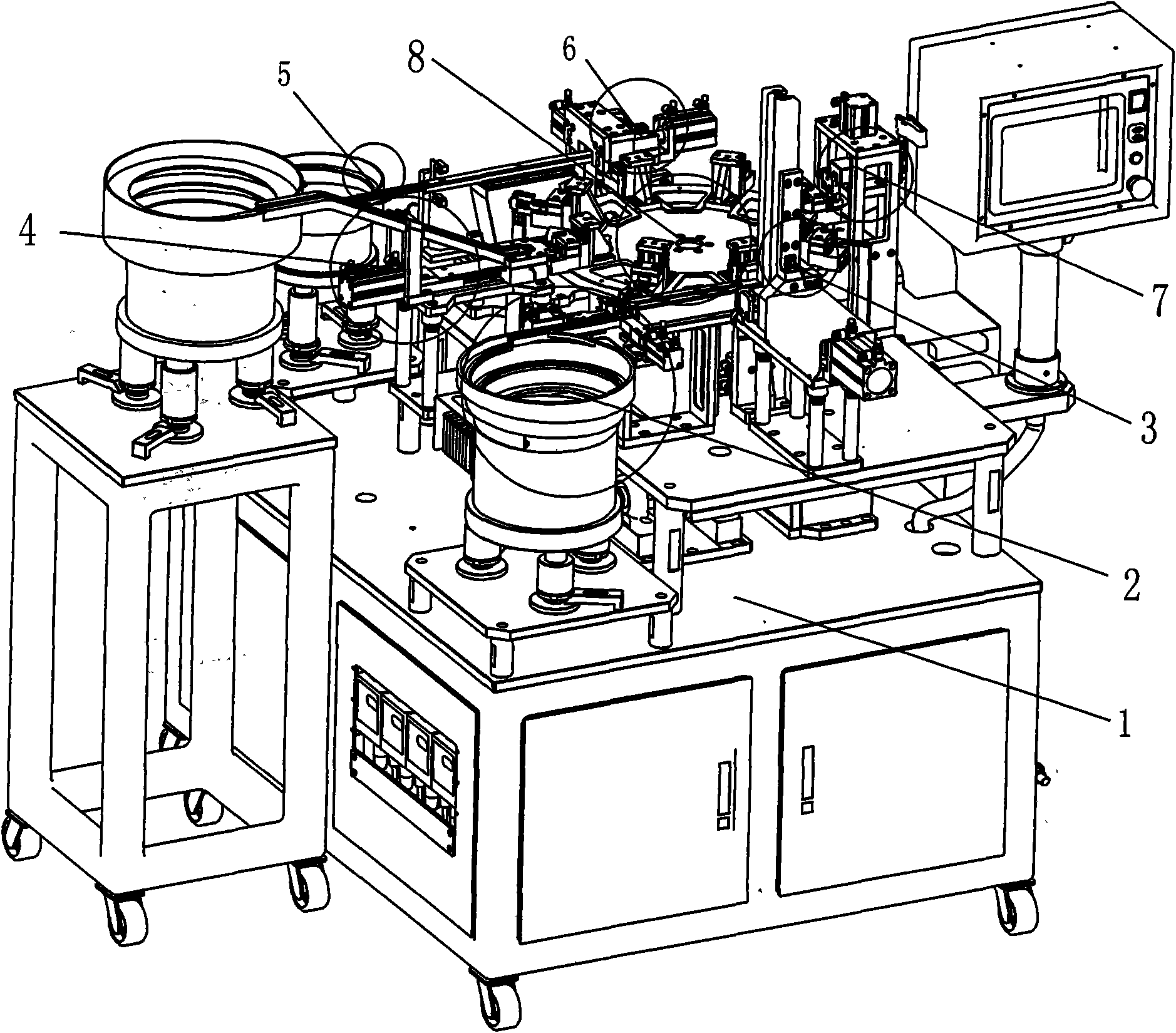

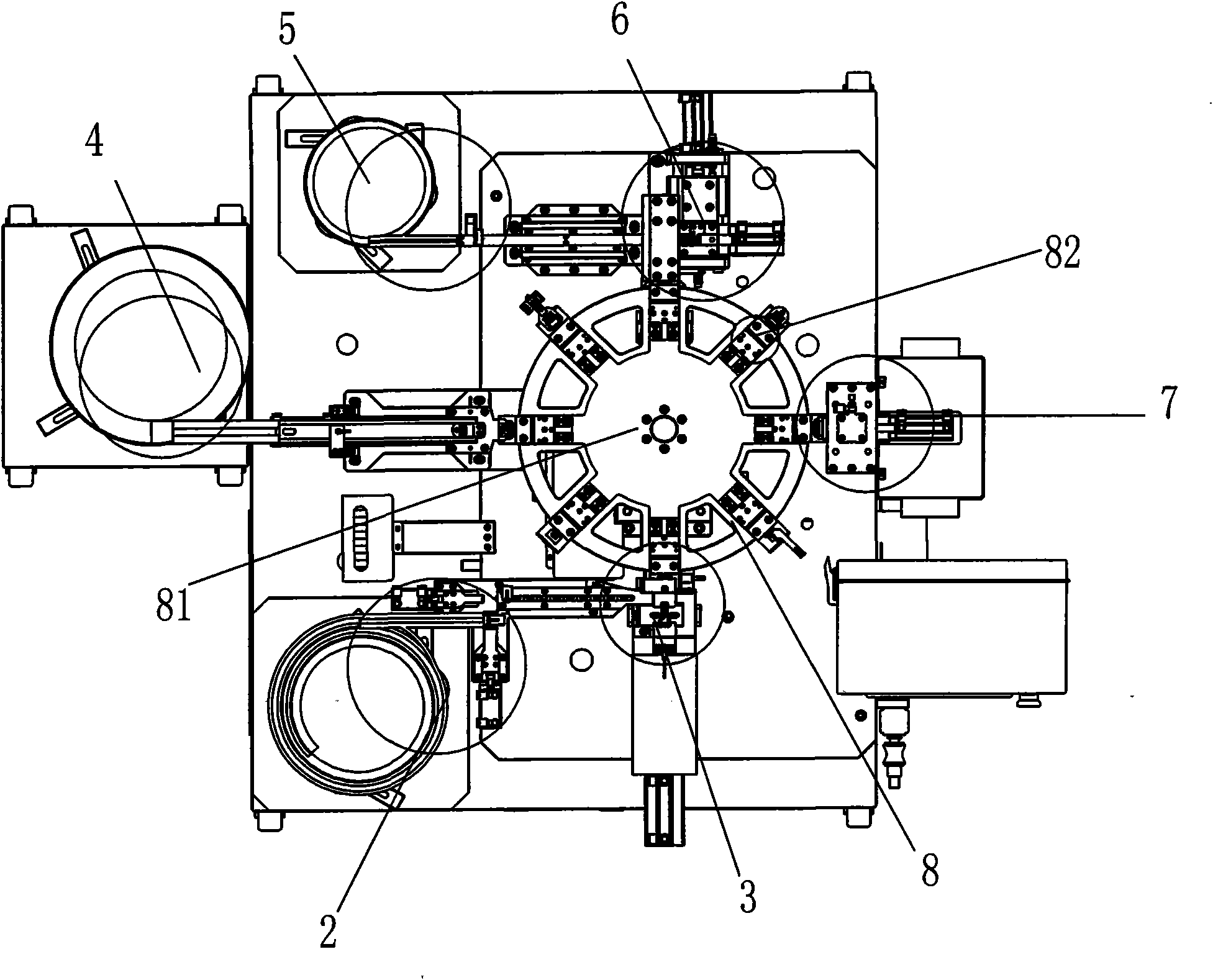

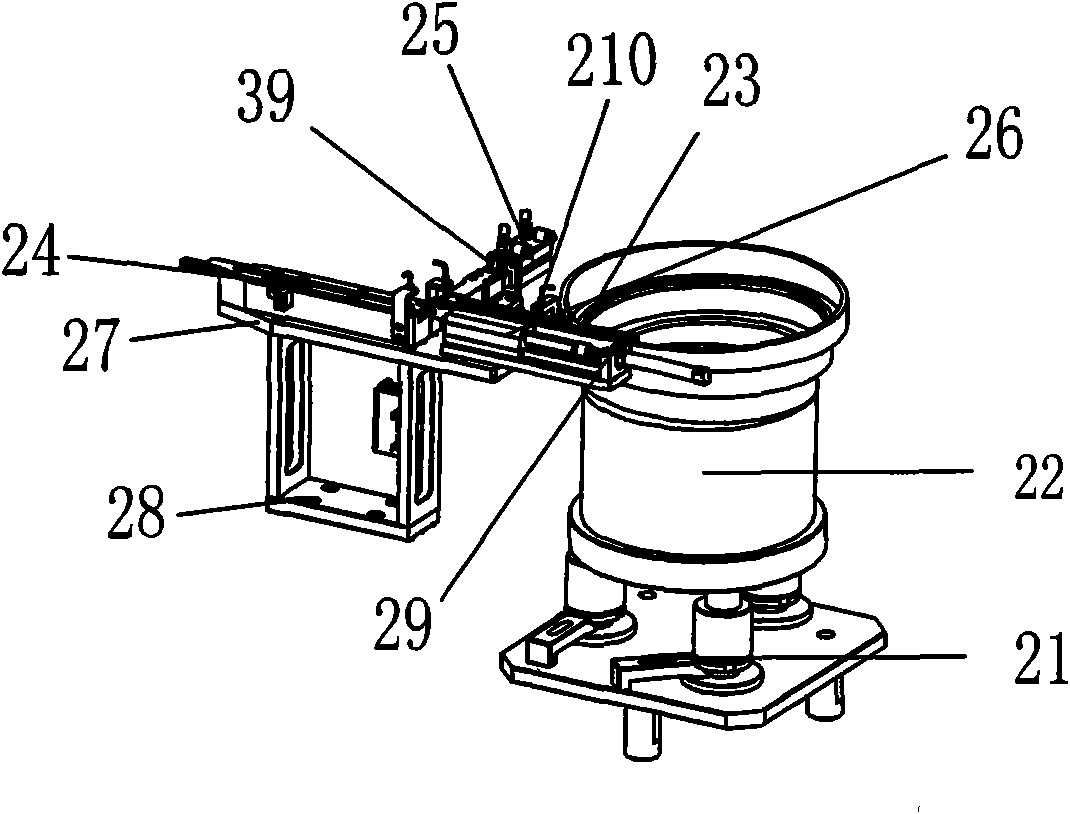

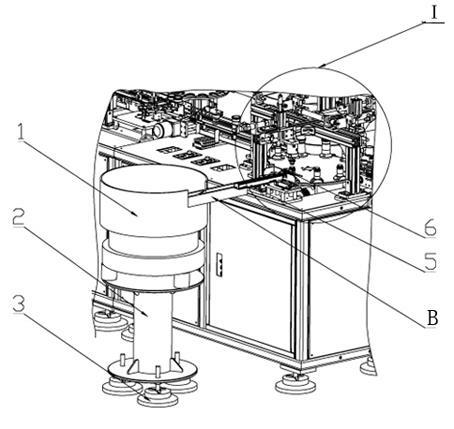

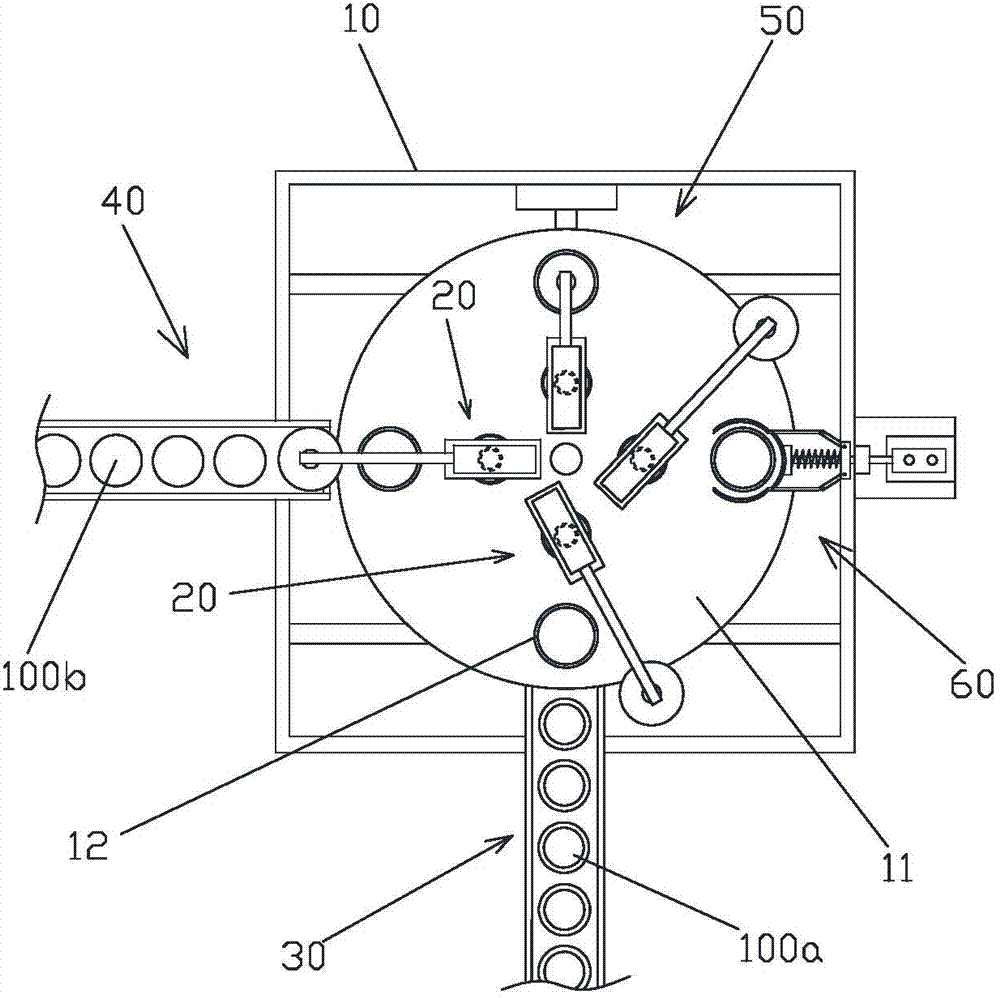

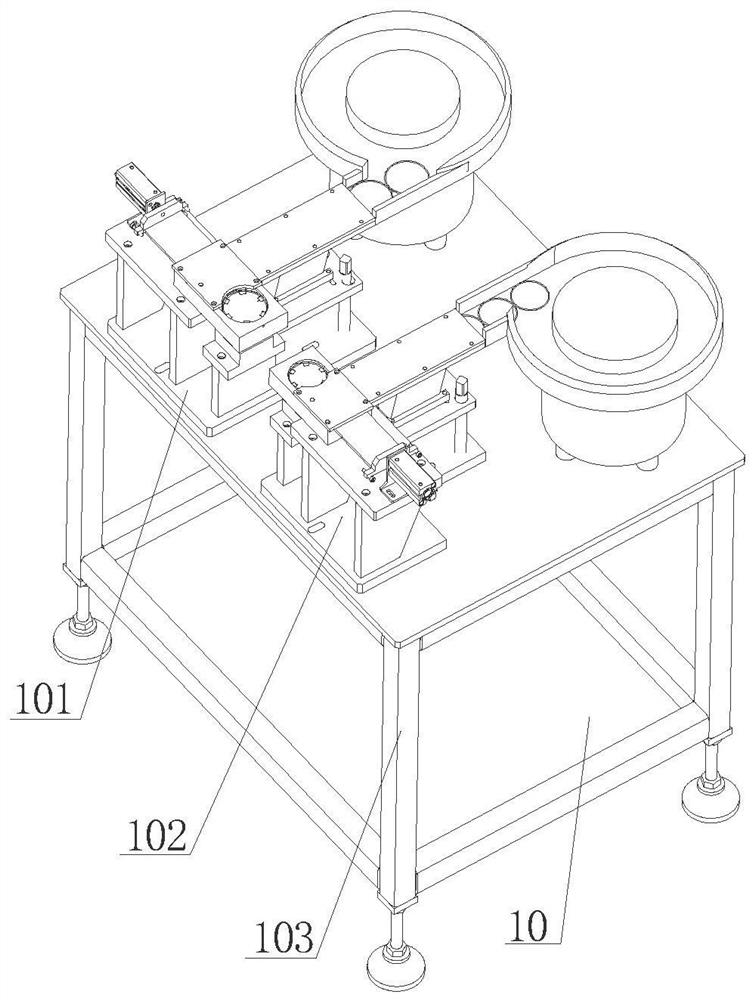

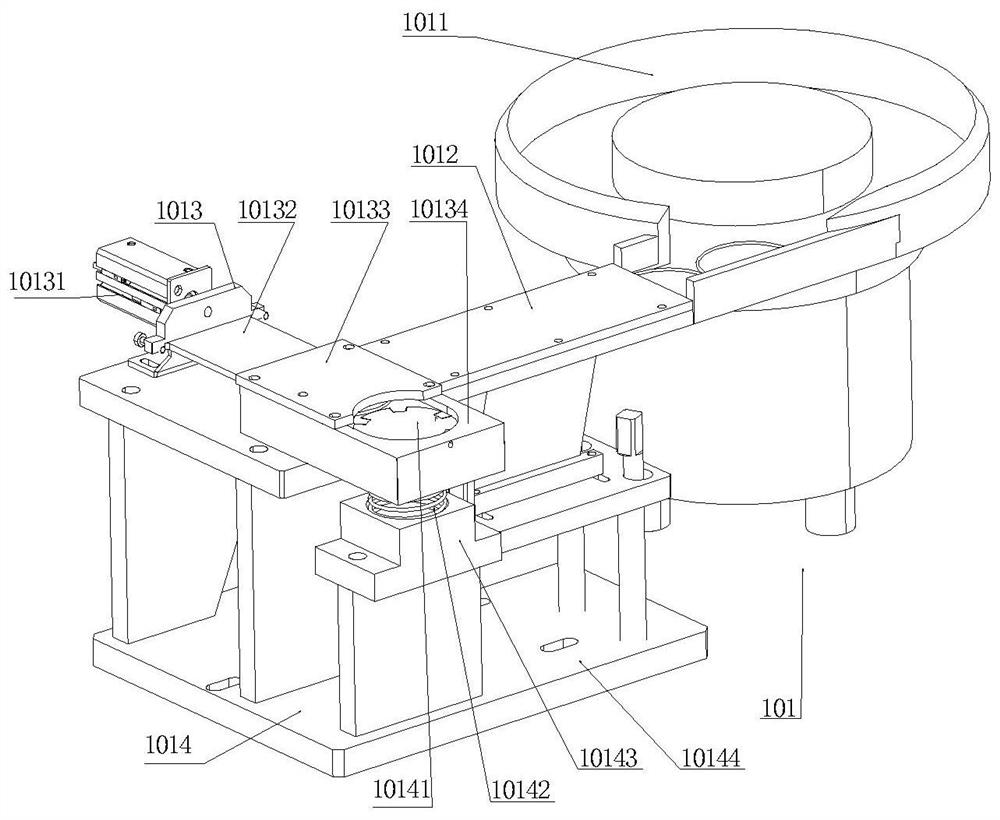

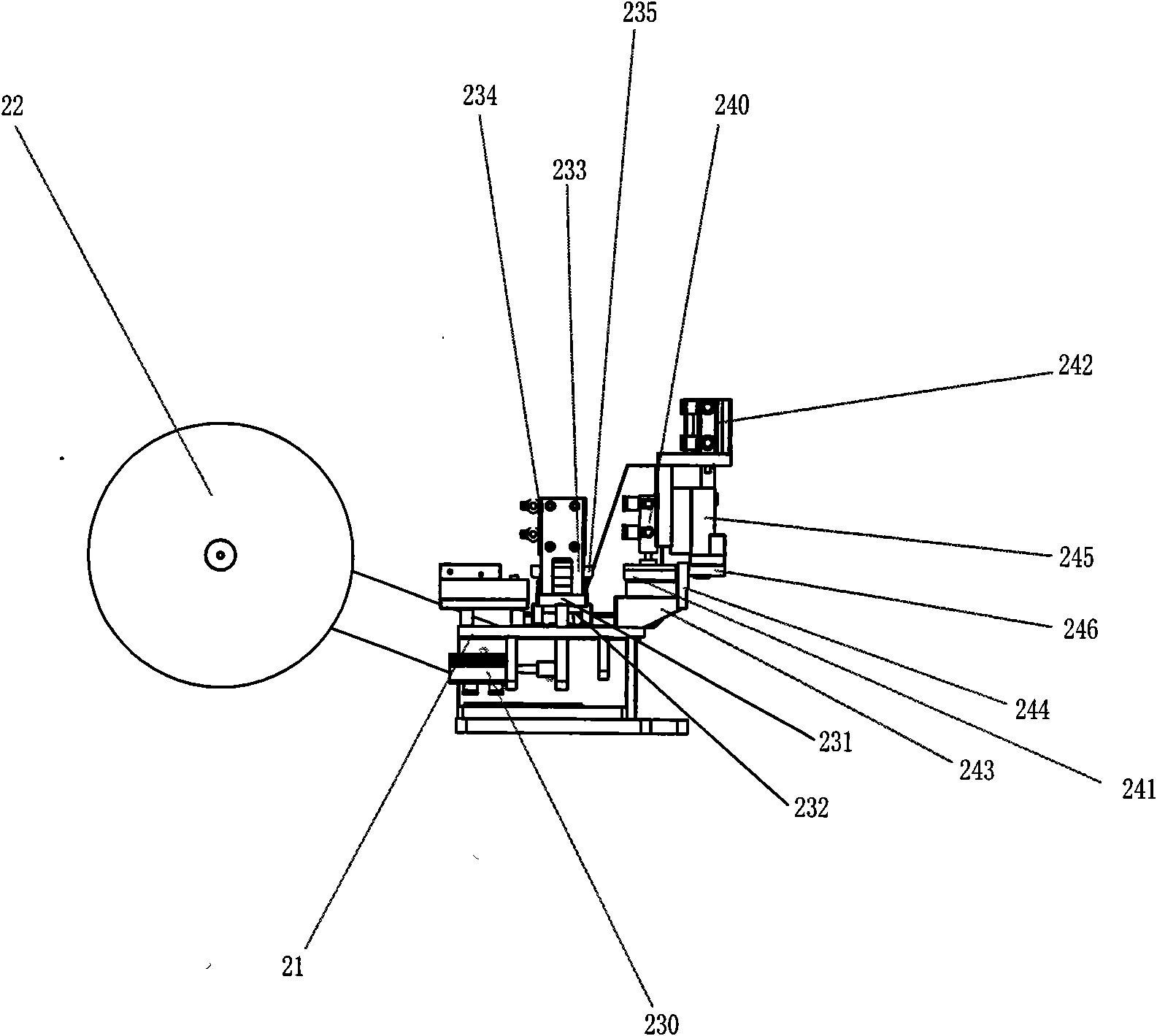

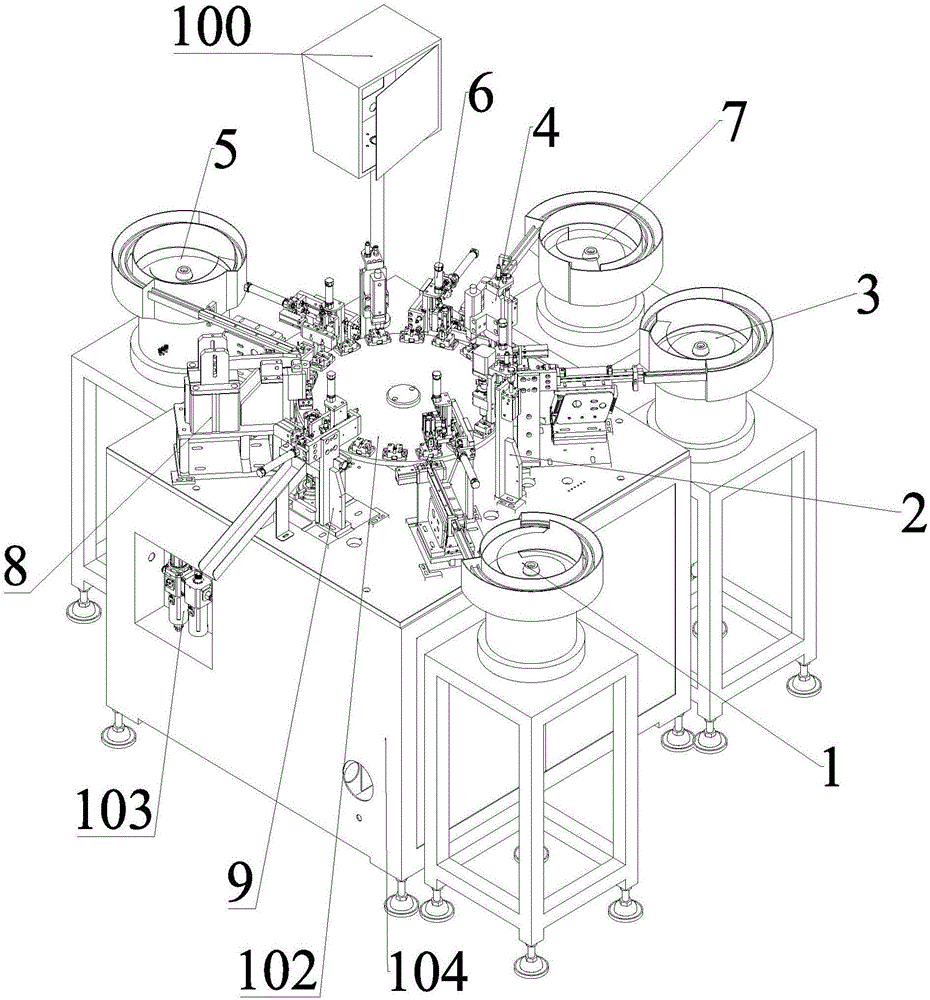

Folding key assembling machine

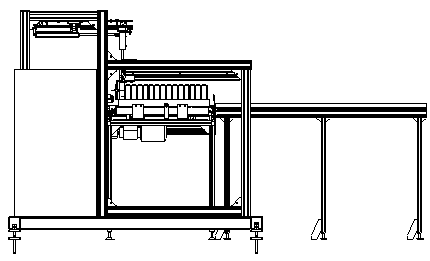

InactiveCN101972932ARealize automatic feedingRealize the assemblyAssembly machinesSemi automaticControl circuit

The invention relates to a folding key assembling machine, which comprises a worktable, and a plastic head feeding mechanism, a hardware press-in mechanism, a key handle feeding mechanism, a pin feeding mechanism, a pin pressing mechanism, a loading mechanism and an assembling and conveying mechanism which are arranged on the worktable, wherein the assembling and conveying mechanism is provided with a key holder; the hardware press-in mechanism, the key handle feeding mechanism and the pin pressing mechanism are connected with the assembling and conveying mechanism in turn; the output end of the plastic head feeding mechanism is connected with the hardware press-in mechanism; the output end of the pin feeding mechanism is connected with the pin pressing mechanism; and the mechanisms are connected with the main control circuit electrically. In the invention, the automatic feeding mechanism and the automatic assembling mechanism are combined scientifically; the operation mechanicals form a continuous operation streamline for automatically feeding and assembling folding keys in place of the manual and semi-automatic ways of assembling the folding keys; thus, the production efficiency of the folding keys is improved obviously, assembly quality is improved, production cost is saved and labor intensity is lowered.

Owner:周俊雄

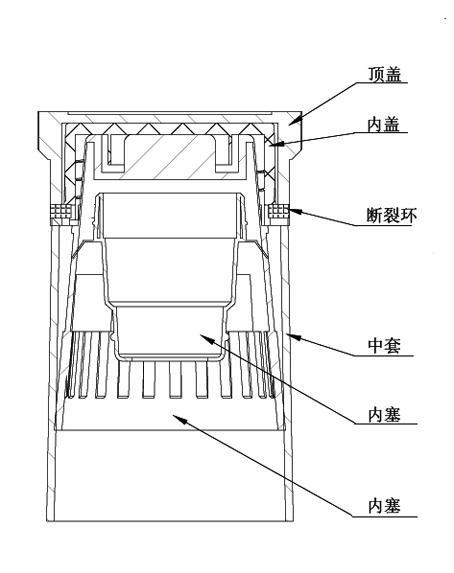

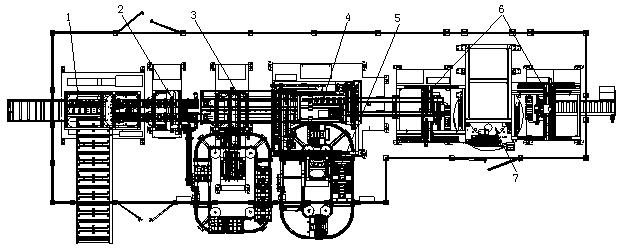

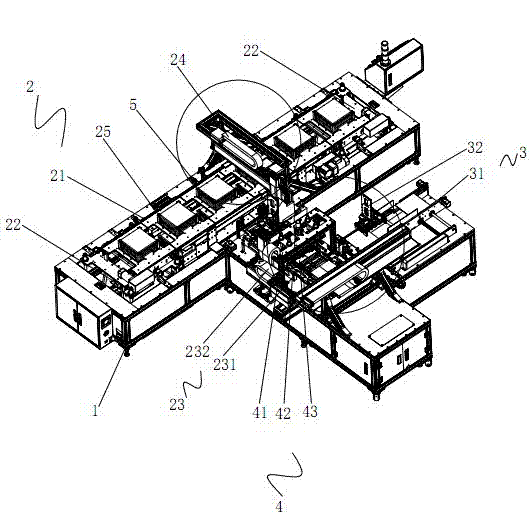

Numerical control bottle cap production line

InactiveCN102248397ARealize the assemblyImprove product qualityAssembly machinesBottle neckManipulator

The invention discloses a numerical control bottle cap production line, which comprises the following processes of: an inner plug feeding unit, an inner assembly unit, a bottle neck feeding unit, a bottle neck assembly unit, a middle sleeve feeding unit, a middle sleeve assembly unit, a middle sleeve stamping unit, a manipulator pick-up unit, an inner cap feeding unit, an inner cap assembly unit,an inner cap screwing unit, a top cap feeding unit and the top cap assembly unit, wherein the inner plug feeding unit is connected with the inner plug assembly unit by an inner plug vibrating plate slideway; the bottle neck feeding unit is connected with the bottle neck assembly unit by a bottle neck slideway and a bottle neck conveying belt; the middle sleeve feeding unit is connected with the middle sleeve assembly unit by a slideway and a middle sleeve conveying belt; the middle sleeve stamping unit is connected with the middle sleeve assembly unit and the manipulator pick-up unit; and theinner cap feeding unit is connected with the inner cap assembly unit by an inner cap conveying belt. In the numerical control bottle cap production line, an integral bottle cap is assembled on the automatic production line to fulfill the aims of improving the production efficiency and the quality of products.

Owner:山东泉舜电子科技有限公司

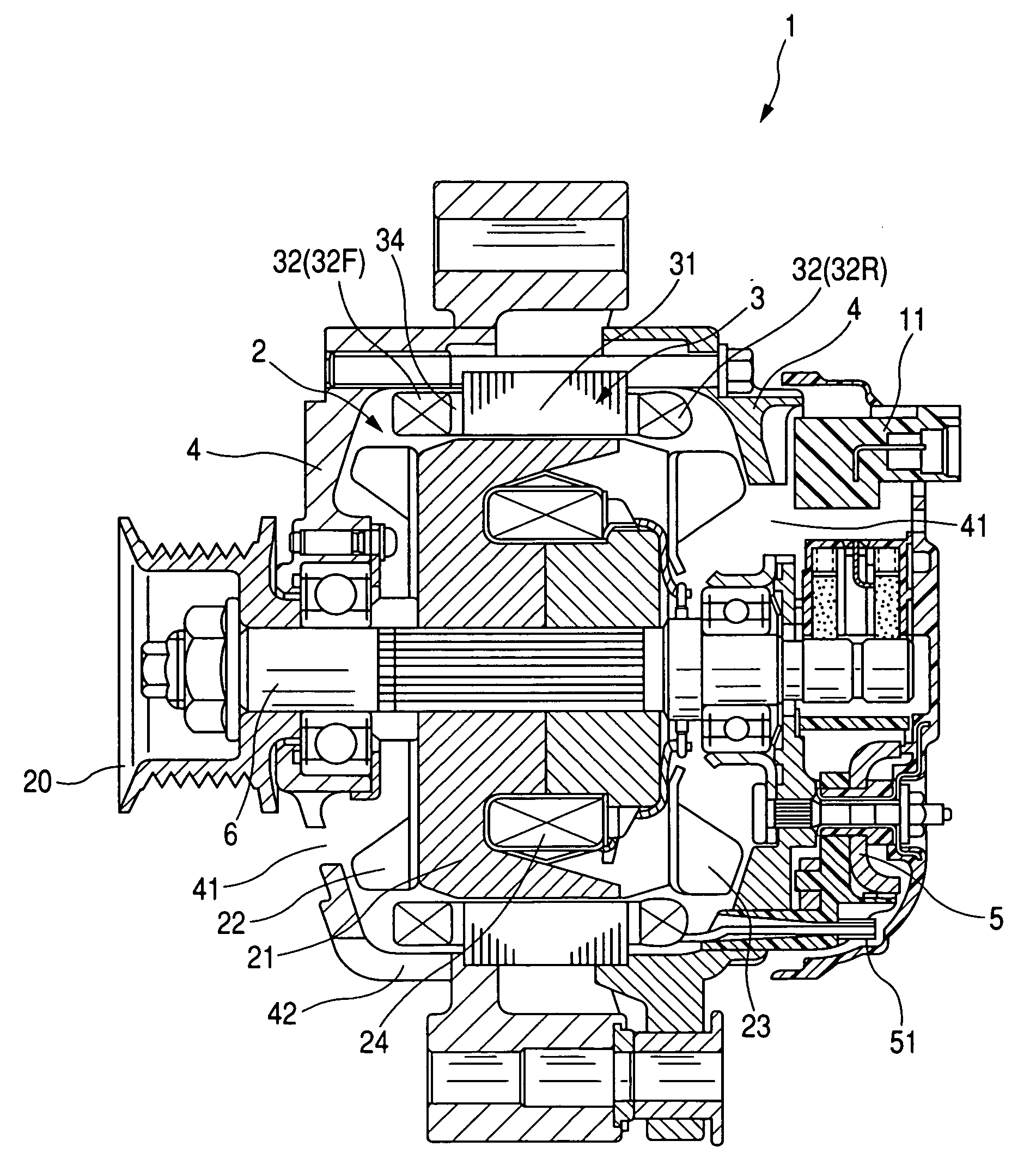

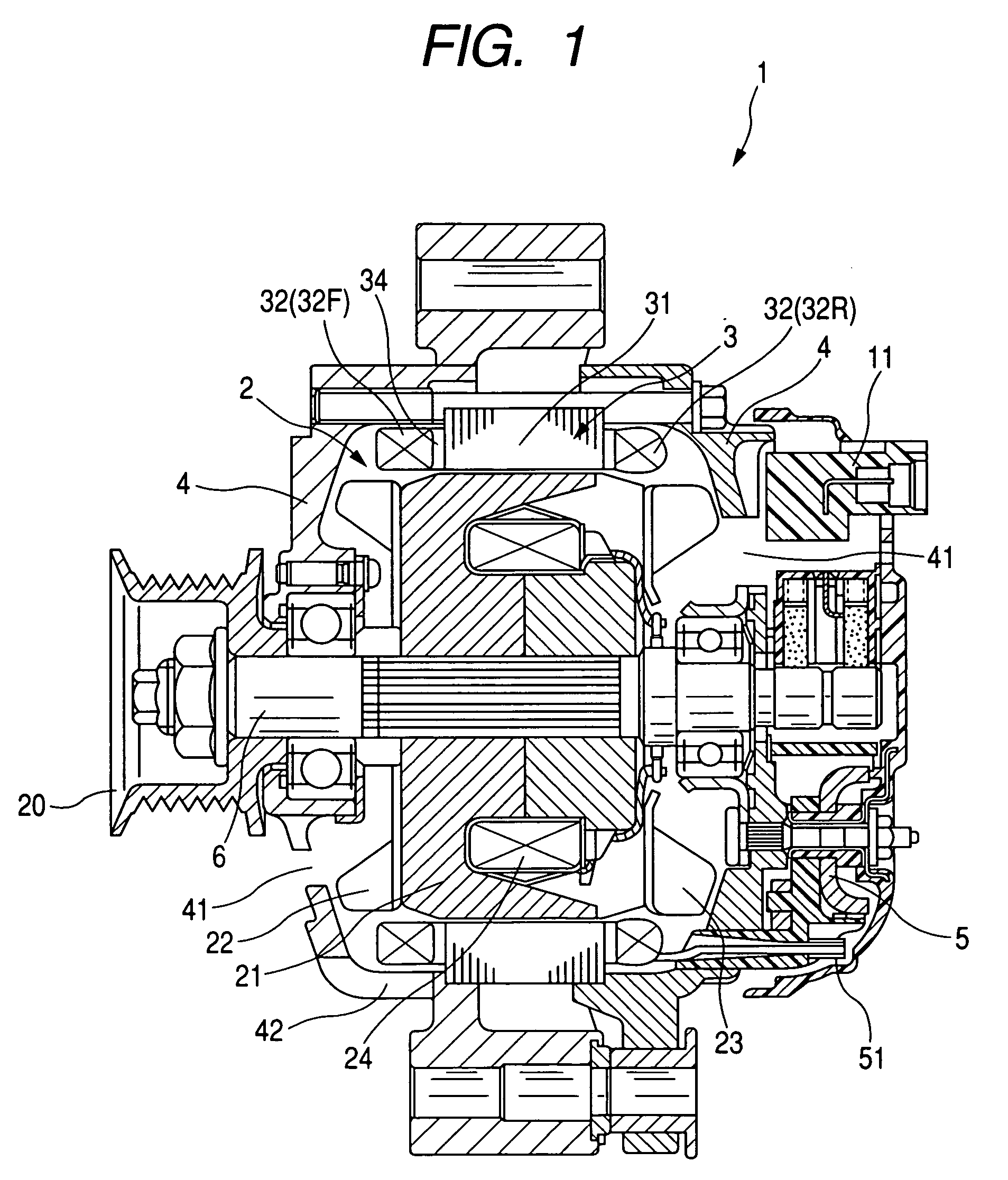

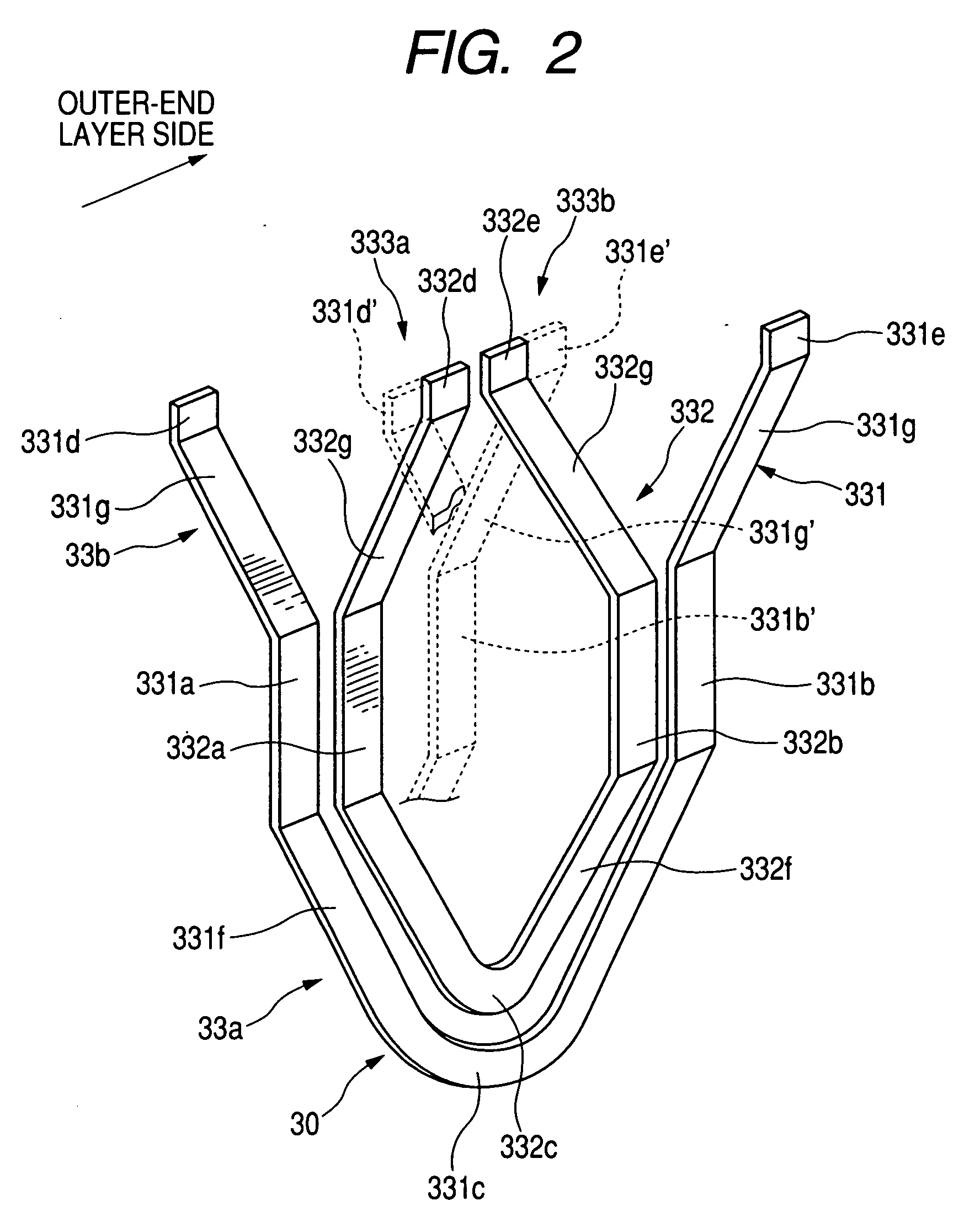

Rotary electric machine for vehicles

InactiveUS20070007843A1Easy to assembleImprove maintainabilitySynchronous generatorsAsynchronous induction motorsElectric machineEngineering

A rotary electric machine, such as a vehicular AC generator, comprises a rotor rotatably driven; and a stator having a stator iron core disposed to face the rotor and stator windings mounted at the stator iron core, the stator windings being composed of a plurality of electric conductors made from aluminum and copper. For example, the plurality of stator windings are different in materials from each other winding by winding, the materials being either the aluminum or the copper. Alternatively, the plurality of stator windings include windings each being made, part by part, from different materials, the different materials being the aluminum and the copper.

Owner:DENSO CORP

System architecture for enterprise integrated information platform and method for implementing the same

ActiveCN102130966AEfficient use ofRealize the assemblyTechnology managementTransmissionComputer architectureManagement unit

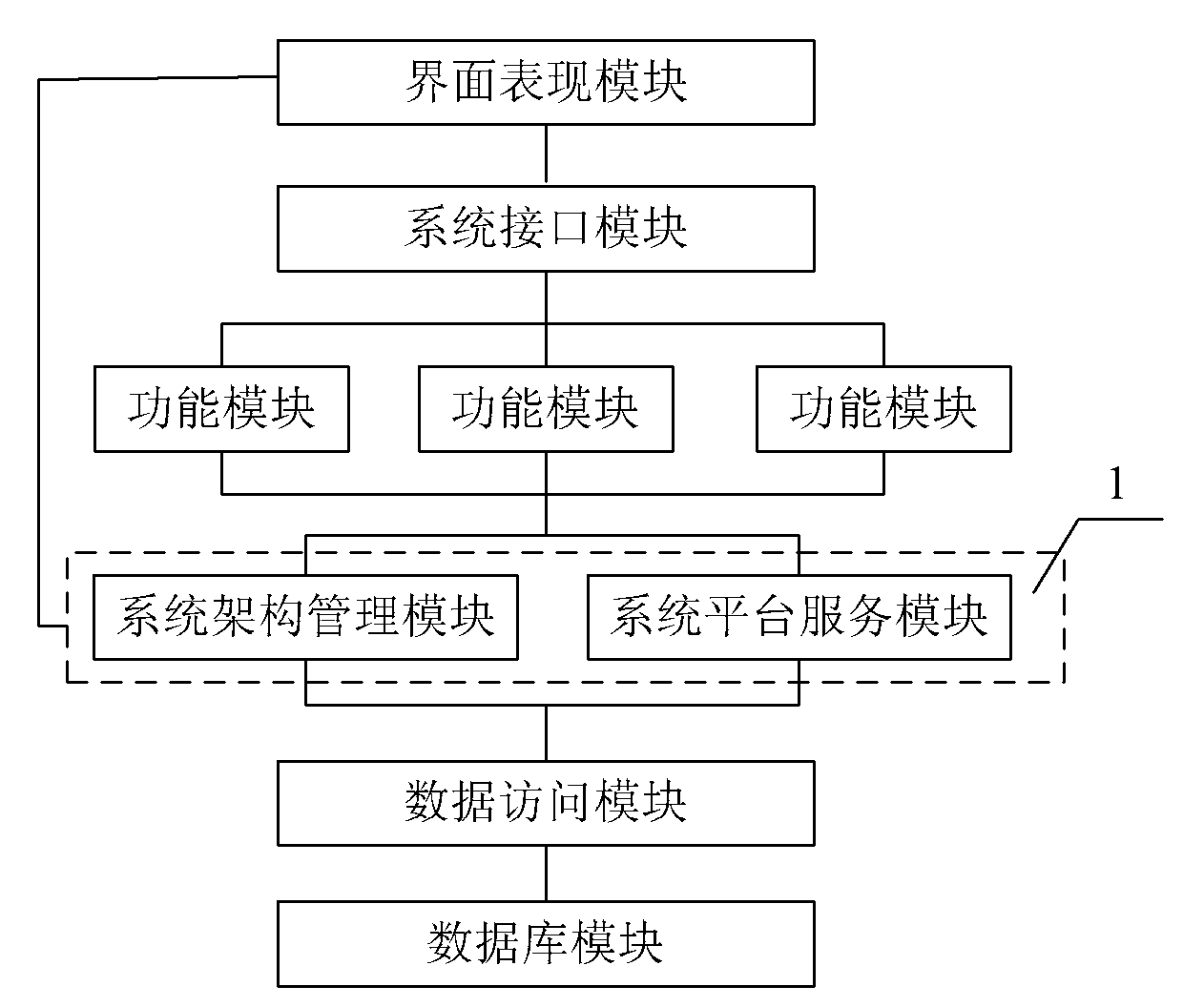

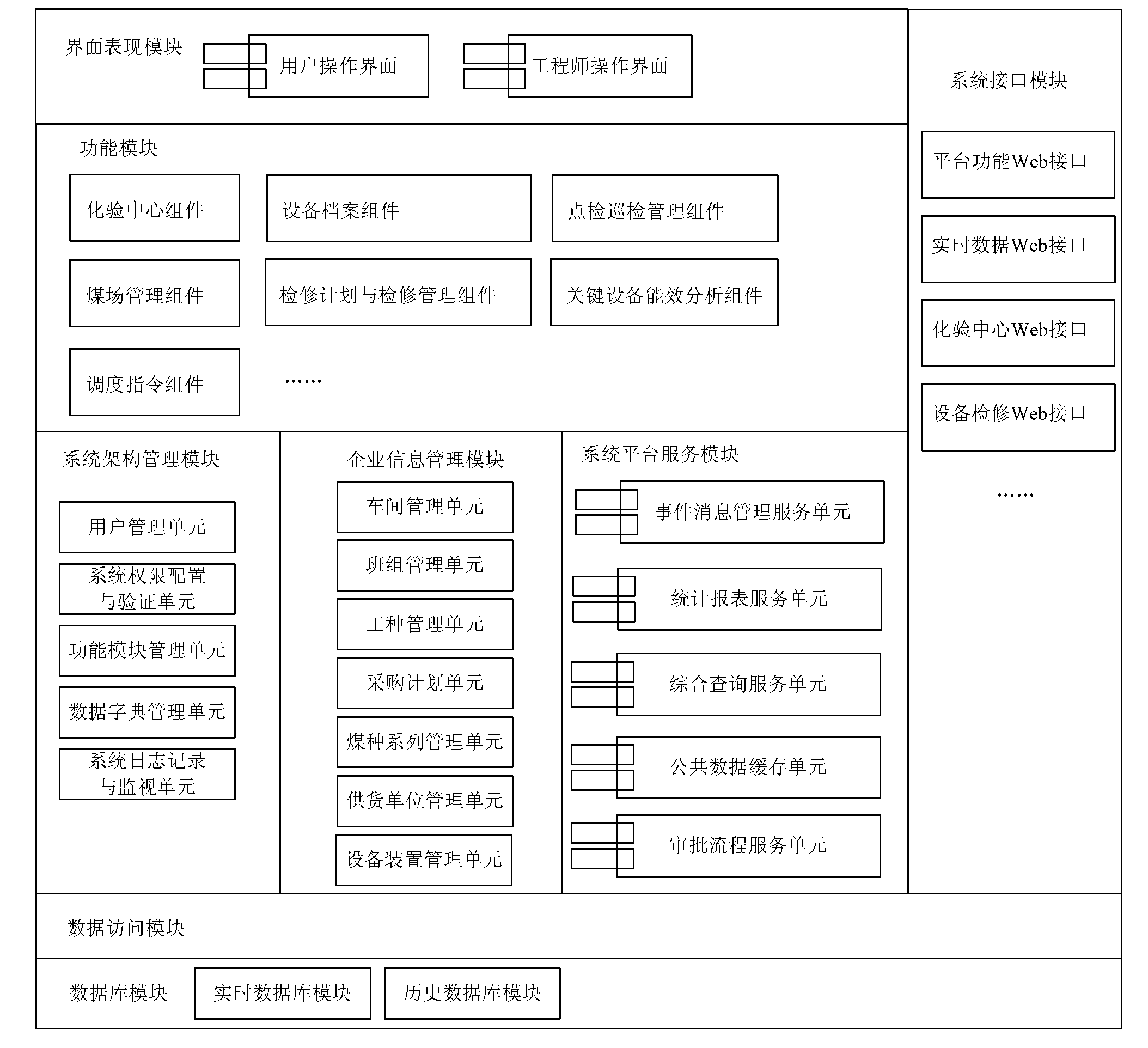

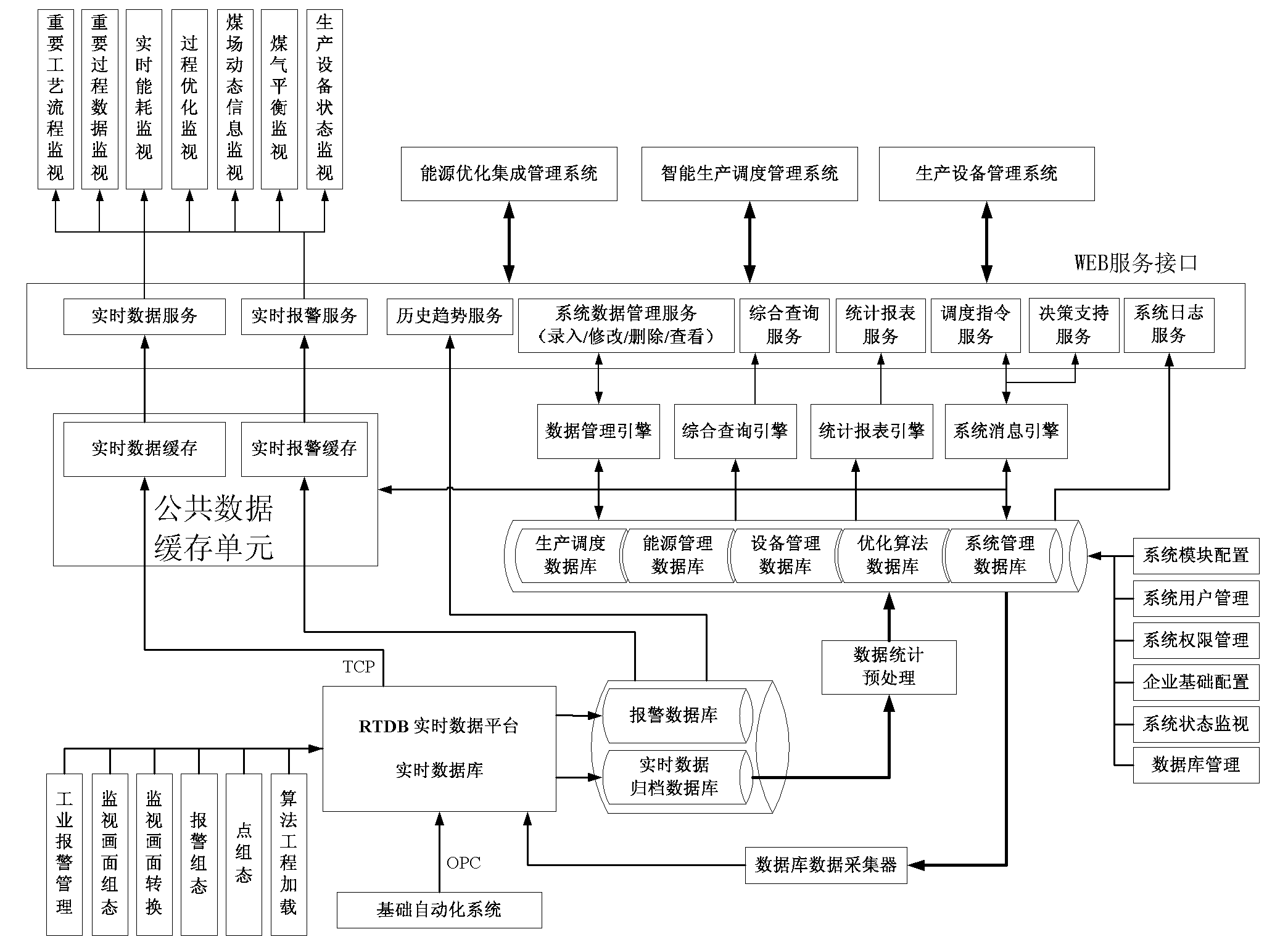

The invention relates to a system architecture for an enterprise integrated information platform and a method for implementing the system architecture. The system architecture comprises a database module, a data access module, a system framework module, two or more than two functional modules, a system interface module and an interface performance module from a bottom layer to the top in sequence; the interface performance module has a multi-level module directory structure built by configuring hierarchies for regulating each functional module; the system framework module comprises a system architecture management module and a system platform service module; the system architecture management module comprises a functional module management unit; the functional module management unit is connected with the functional modules and the interface performance module respectively; the system platform service module comprises an engine unit; and the engine unit transfers data information in the database module to the functional modules and the system interface module via the data access module. By the system architecture disclosed by the invention, the enterprise integrated information is efficiently utilized, the same information is acquired and collected at one time and applied in multiple places, and the maintenance cost is lowered.

Owner:中广核智能科技(深圳)有限责任公司

Air purifying filter element rapid assembling equipment

InactiveCN104741917AIncrease productivityRealize the assemblyWelding/cutting auxillary devicesAssembly machinesAir filterMechanical engineering

The invention relates to air purifying filter element rapid assembling equipment. The air purifying filter element rapid assembling equipment comprises a rotating disk which is rotatably fixed on a rack and is arranged horizontally and a first driving mechanism connected with the rotating disk. The circumference of the rotating disk is provided with clamping devices at intervals, wherein the clamping device are used for clamping air filter element assemblies. The positions, in the rotating direction of the rotating disk, of the periphery of the rotating disk is sequentially provided with a feeding device, a distributing device, an assembling device and an unloading device at intervals, wherein the feeding device is used for conveying filter element bodies to the clamping devices, the distributing device is used for conveying upper end covers and lower end covers to the clamping devices, the assembling device is used for carrying out connecting among the air filter element assemblies, and the unloading device is used for carrying out unloading on assembled air filter elements. According to the technical scheme, assembling and fixed connecting between the upper and lower end covers and the filter element bodies can be rapidly achieved, and the production efficiency of the air filter elements is improved.

Owner:朱玉兵

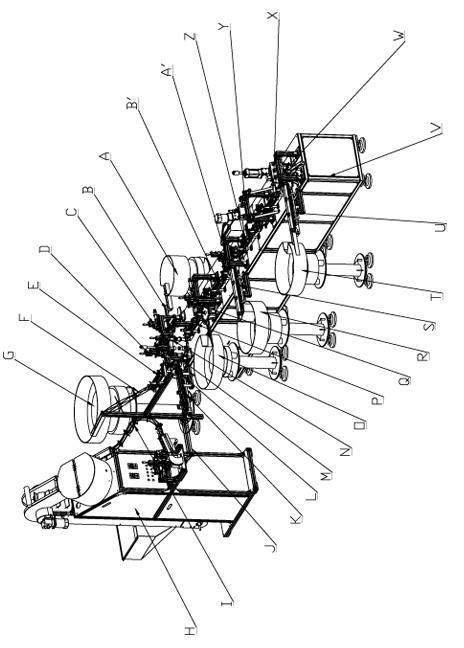

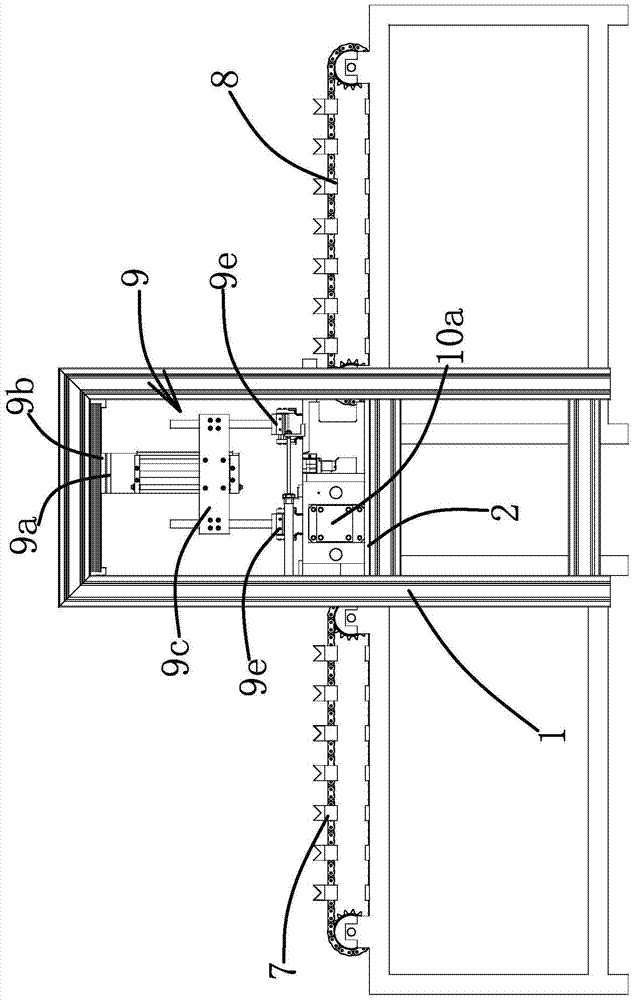

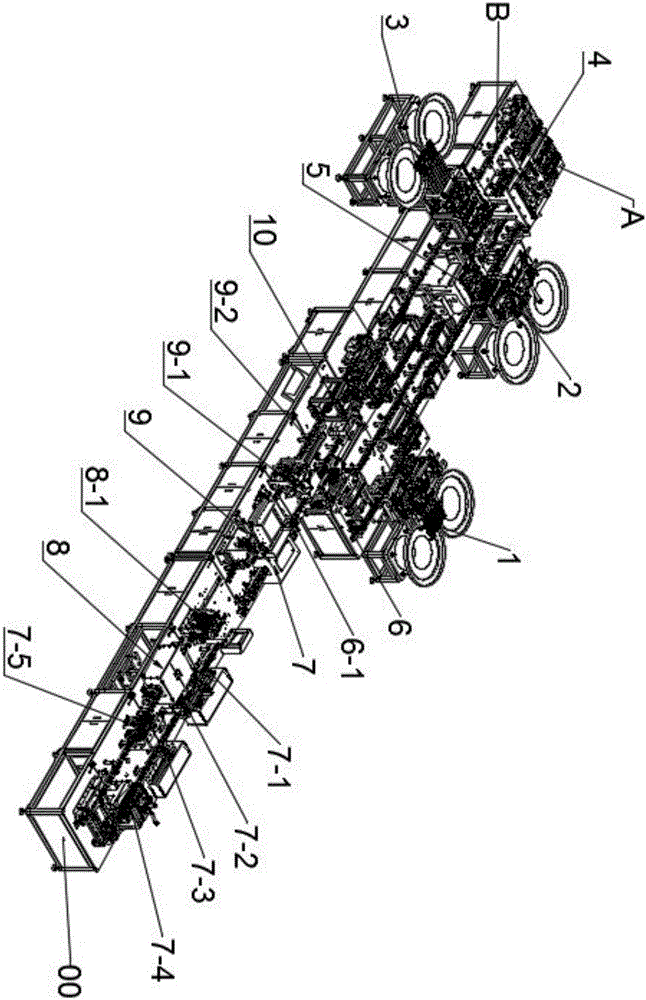

New energy power module assembling line

ActiveCN107819134ARealize the assemblyRealize automatic assemblyPrimary cell manufactureAssembling battery machinesNew energyBattery cell

The invention discloses a new energy power module assembling line relating to the technical field of tools for battery modules. A battery cell detection station is arranged on one side of a battery cell loading assembly, a automatic battery cell frame mounting station is arranged on one side of the battery cell detection station, a battery cell splicing station is arranged on one side of the automatic battery cell frame mounting station, a side loading line of the battery cell splicing station is arranged on one side of the battery cell splicing station, a battery cell module transplanter is arranged on one side of the side loading line of the battery cell splicing station, and a riveting machine is mounted on the battery cell module transplanter. The new energy power module assembling line can achieve assembly of a new energy battery module and can achieve automatic assembling, so that the labor and the time are saved and the efficiency is high.

Owner:丁琛琦

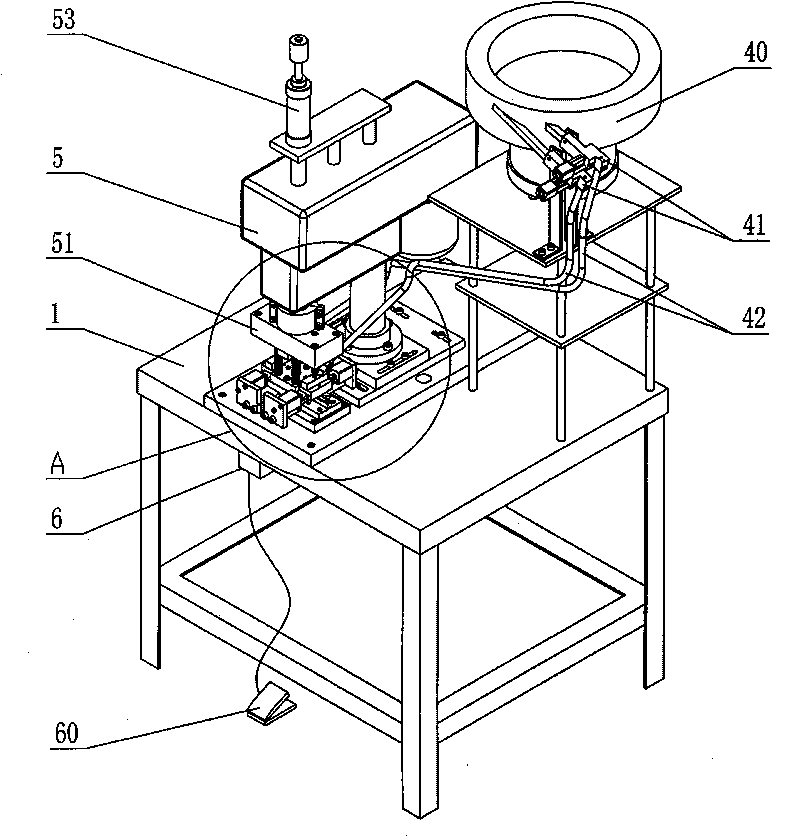

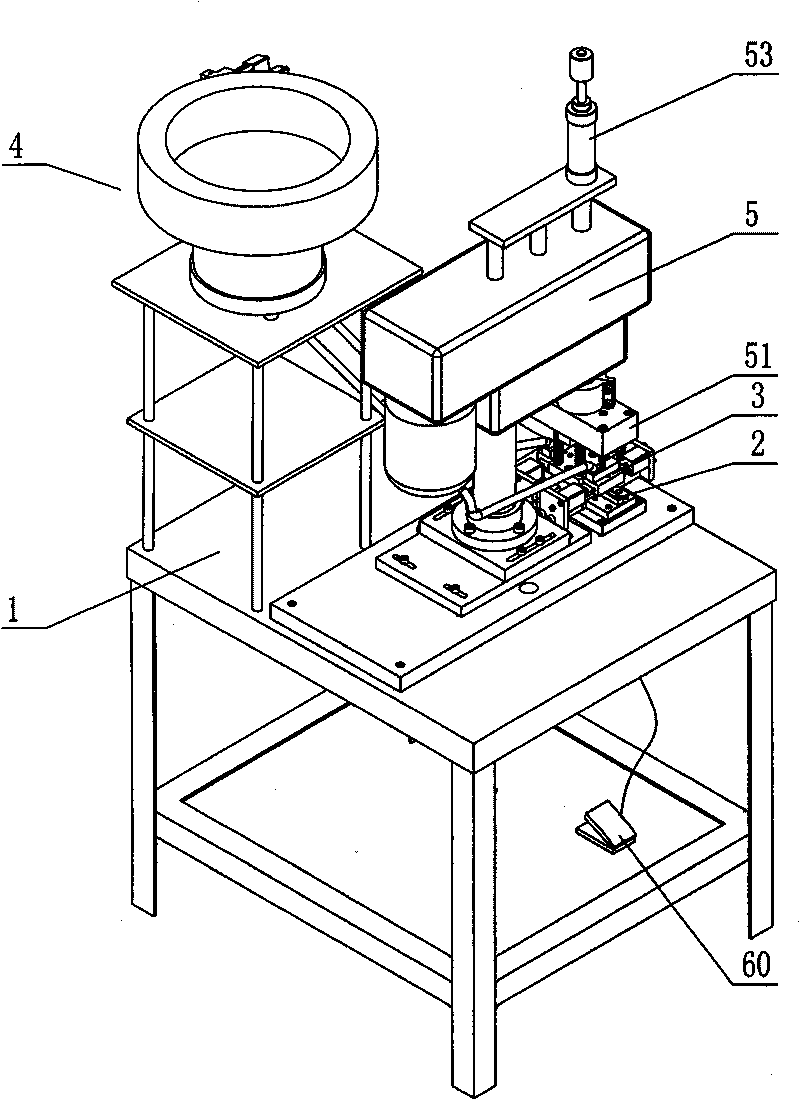

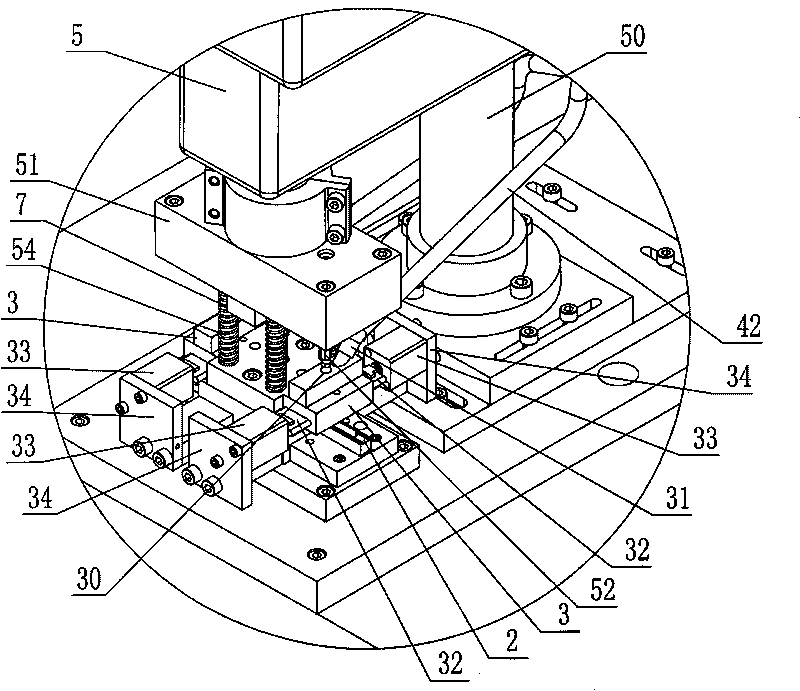

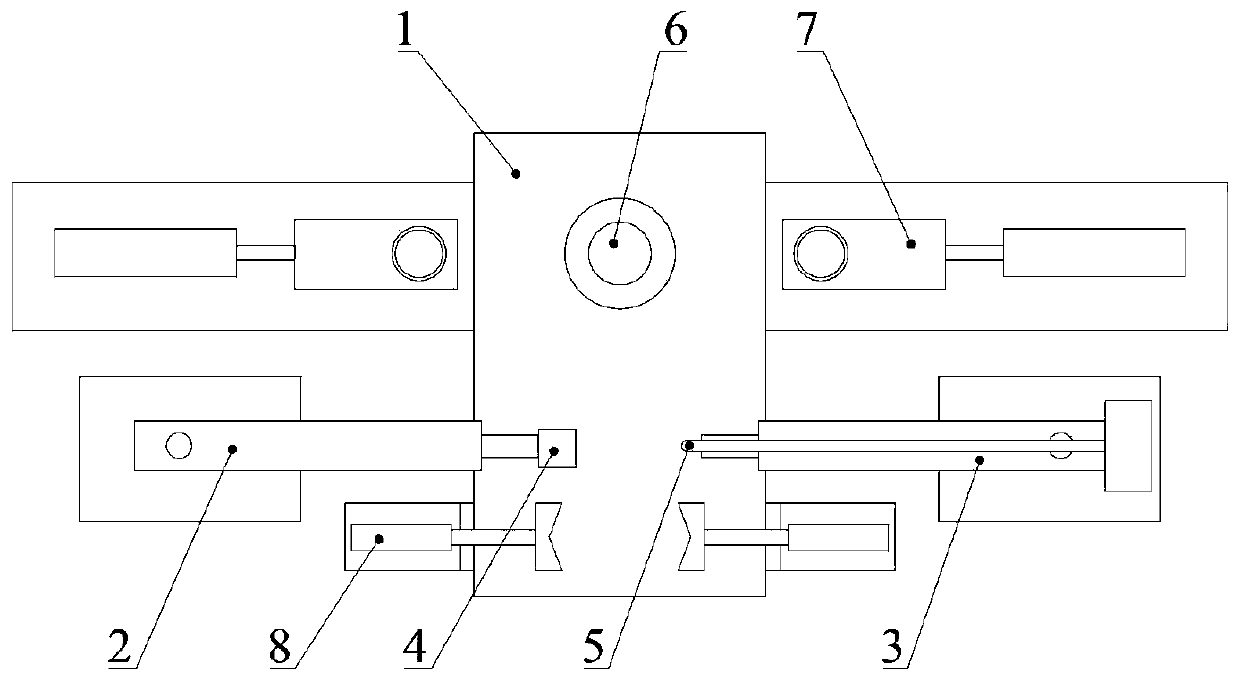

Hinge component assembling machine

ActiveCN101733634AReduce human involvementReduce manufacturing costAssembly machinesWork holdersElectrical controlControl switch

The invention relates to a hinge component assembling machine which assembles a permanent pedestal and a hinge arm component of a hinge together by a bolt. The hinge component assembling machine comprises a pedestal positioning seat arranged on a worktable, a bolt positioning seat positioned positioned above the pedestal positioning seat, a bolt feeding mechanism for transporting the bolt to the bolt positioning seat, a bench drill for assembling the bolt on the permanent pedestal and the hinge arm component, and a control switch connected with an electrical control device; the bolt positioning seat comprises a bolt assembling guide hole which is formed on the bolt positioning seat and is communicated up and down, a blanking port connector which is used for sending the bolt to the bolt assembling guide hole by the bolt feeding mechanism, guide grooves formed on two sides of the bolt positioning seat, bolt aligning splints arranged on the guide grooves, and a cylinder for controlling the bolt aligning splints to close up or separate from the bolt assembling guide hole; and the cylinder is fixed by a fixing plate which is arranged on the worktable. The hinge component assembling machine with the structure can effectively improve production efficiency and reduce production cost.

Owner:GUANGDONG ADAMS METALS FABTE

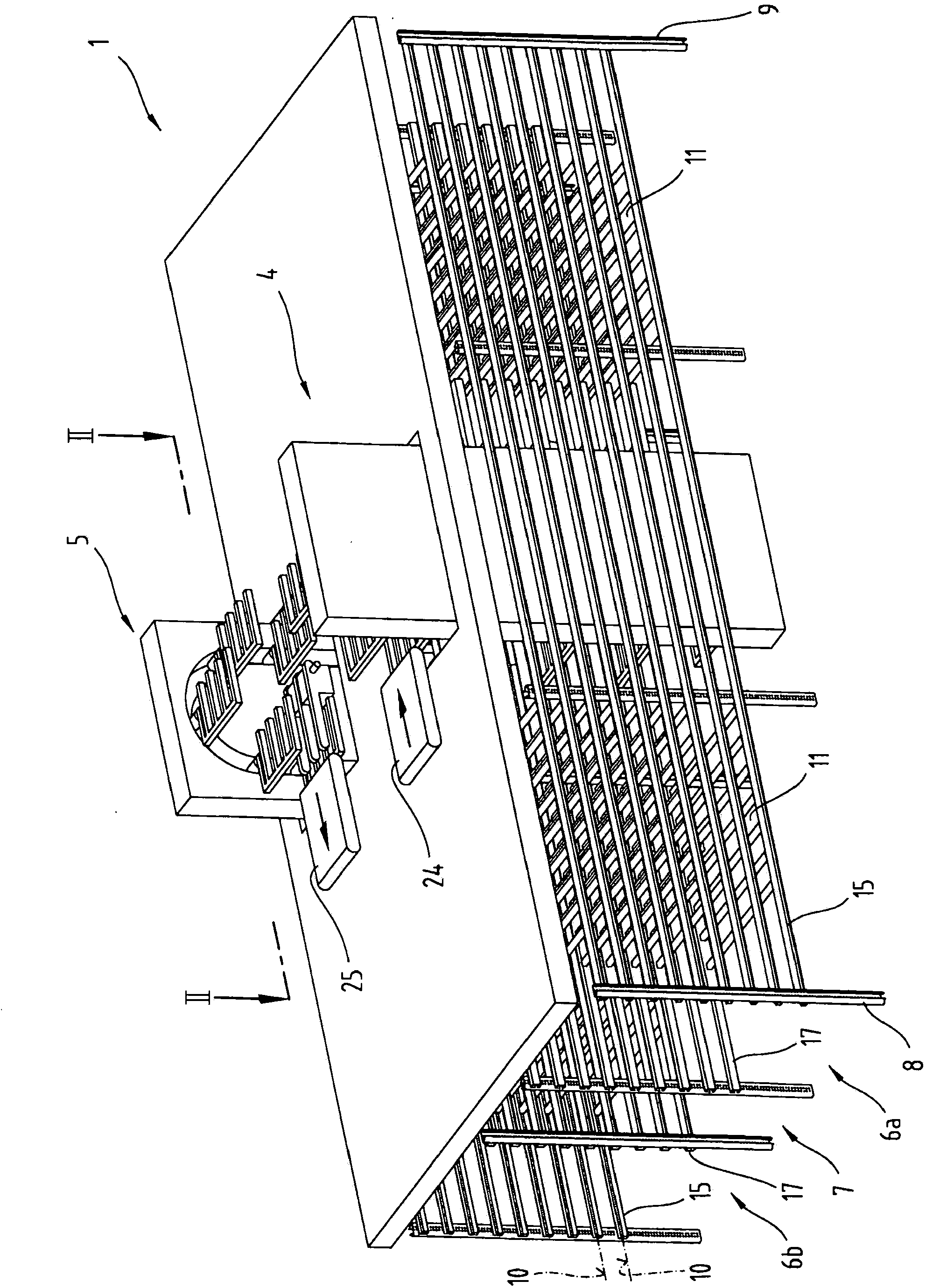

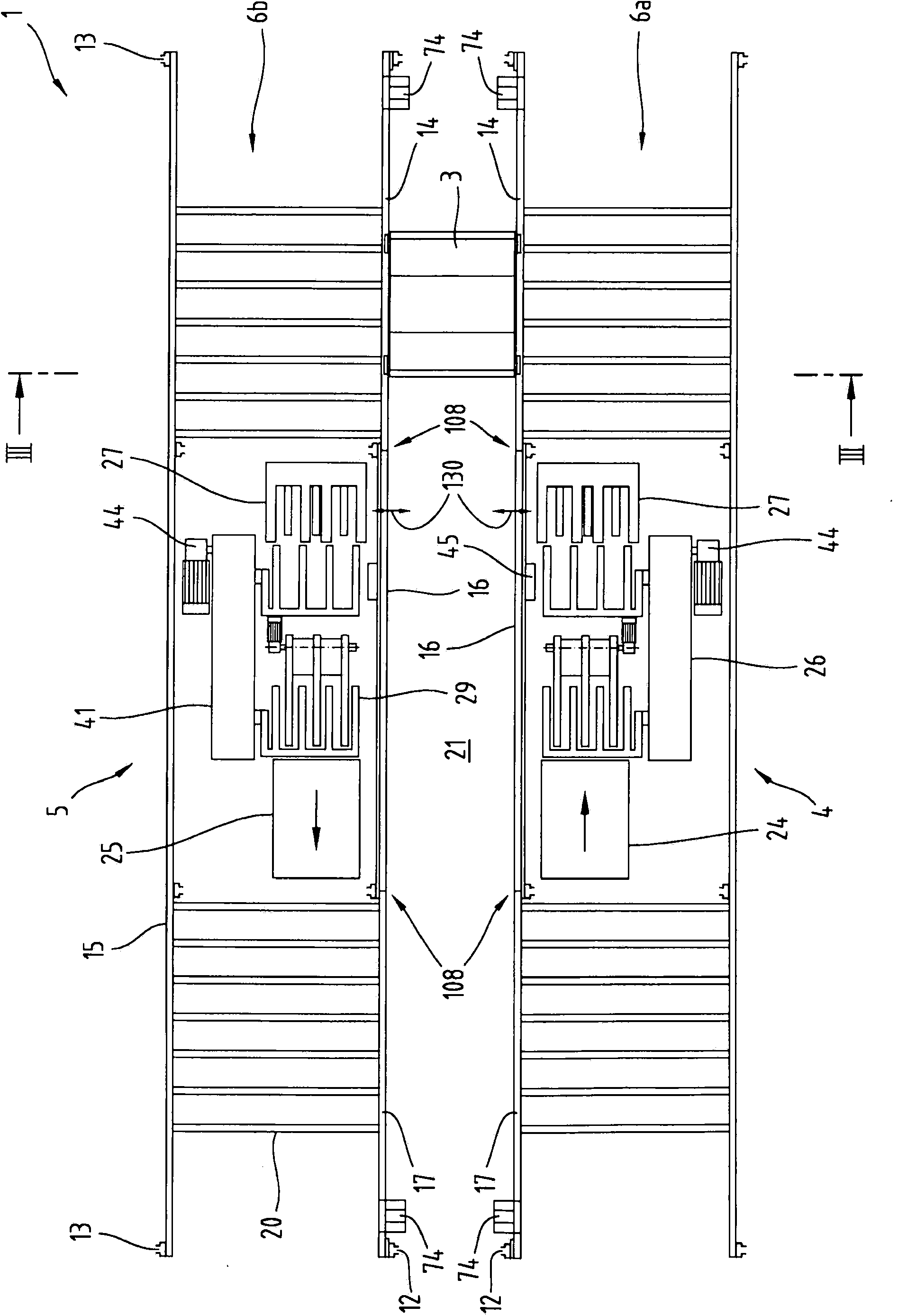

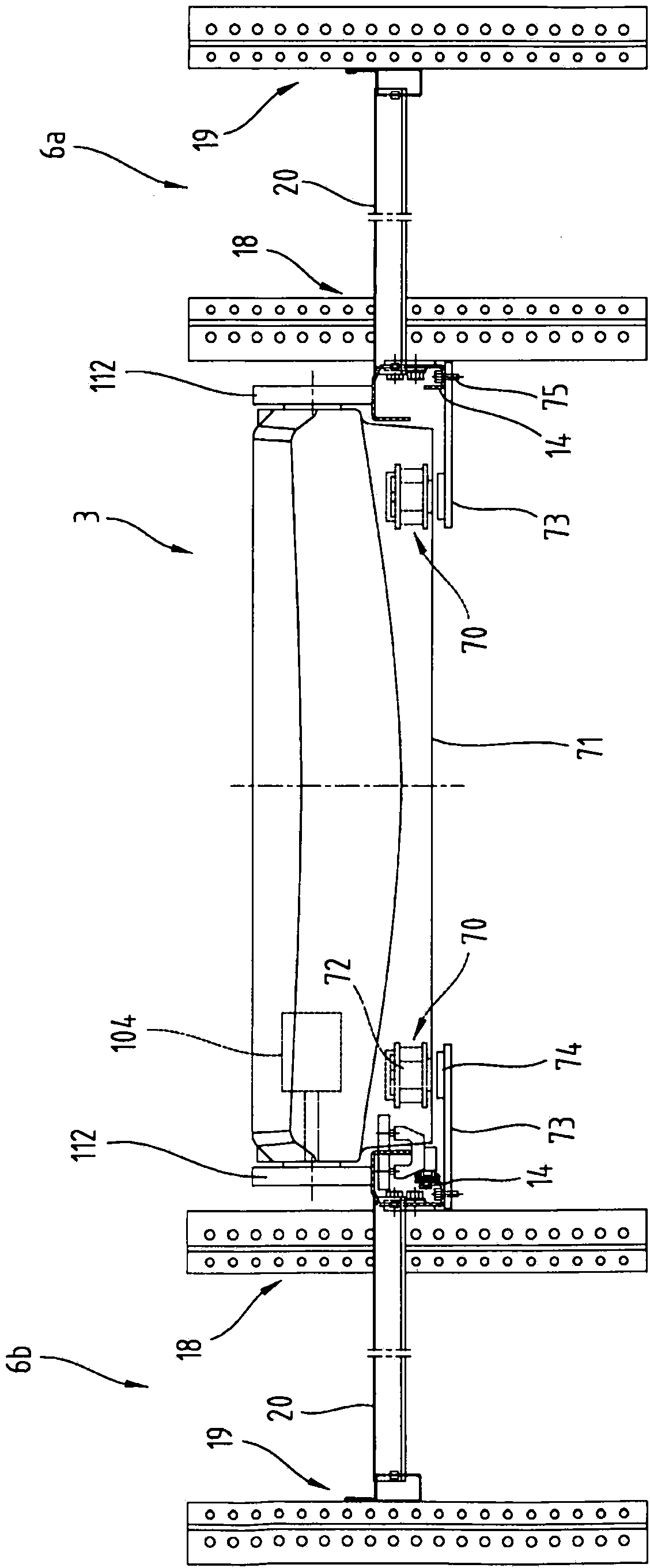

Rack storage system

ActiveCN103648928ARapid responseSave assembly timeConveyorsStorage devicesEngineeringMechanical engineering

The invention relates to a rack storage system (1) having a conveyor vehicle (3) for transporting goods (3) to be stored, parallel storage racks (6a, 6b) and a rack aisle (7) extending therebetween, which storage racks (6a, 6b) each comprise front track posts (12) adjacent to the rack aisle (7), rear rack posts (13) remote from the rack aisle (7) and front and rear horizontal beams (14, 15, 16, 17) extending in the direction of the rack aisle (7) in rack planes (10) that lie one above the other, wherein the autonomous conveyor vehicle (3) is drivable on the front horizontal beams (14, 15, 16, 17) opposite of one another. The front and / or rear horizontal beams (14, 15, 16, 17) in at least one of the rack planes (10) comprise, in the direction of the longitudinal extent thereof, at least one mounting section (66; 76) in which mounting interfaces (67) for fixing at least one function add-on module (57) of the rack storage system (1) and optionally a mounting plane for the function add-on module (57) are formed.

Owner:TGW MECHANICS GMBH

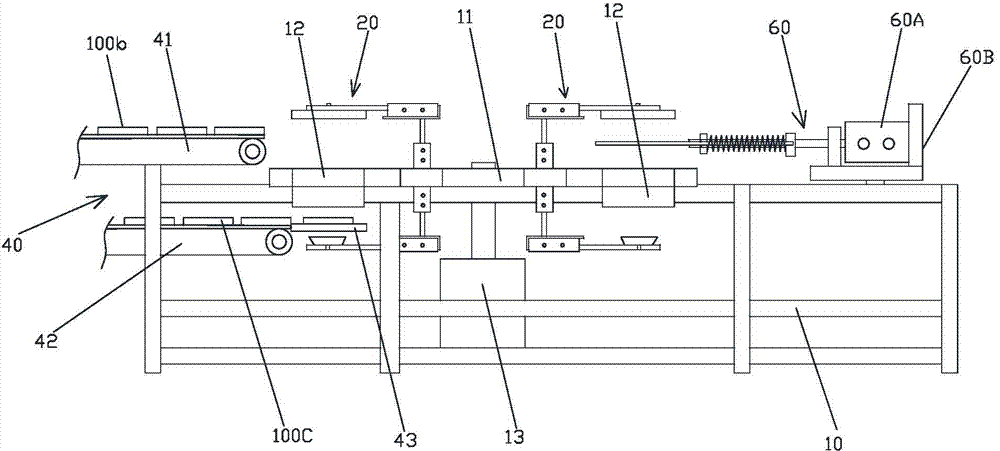

Automatic assembly machine of bottom shell of LED (light-emitting diode) module

InactiveCN102371481ARealize the assemblyConveying many productsMetal working apparatusEngineeringUltimate tensile strength

The invention relates to an automatic assembly machine of a bottom shell of an LED (light-emitting diode) module. The machine comprises a frame and an assembly mechanism, wherein the assembly mechanism is arranged on the frame and used for pressing a PCB (printed circuit board) into the bottom shell, a bottom shell feeding mechanism for conveying the bottom shell to an assembly working position is arranged on one side of the assembly mechanism on the frame, a PCB feeding mechanism for conveying the PCB to the assembly working position is arranged on the other side of the assembly mechanism onthe frame, and each mechanism is respectively connected with a master control circuit. The automatic assembly machine of the bottom shell of the LED module can realize automatic feeding and assembly of the bottom shell and the PCB products, greatly improve the production efficiency and the quality of the assembled products and reduce the labor difficulty and the intensity.

Owner:周俊雄

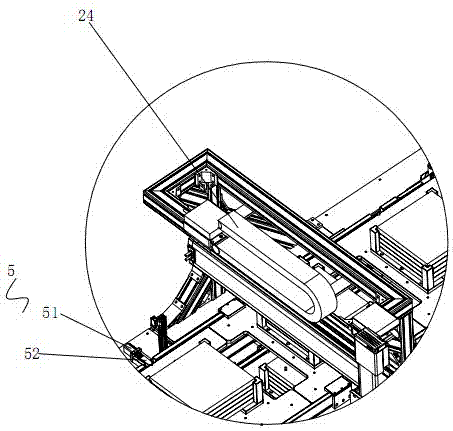

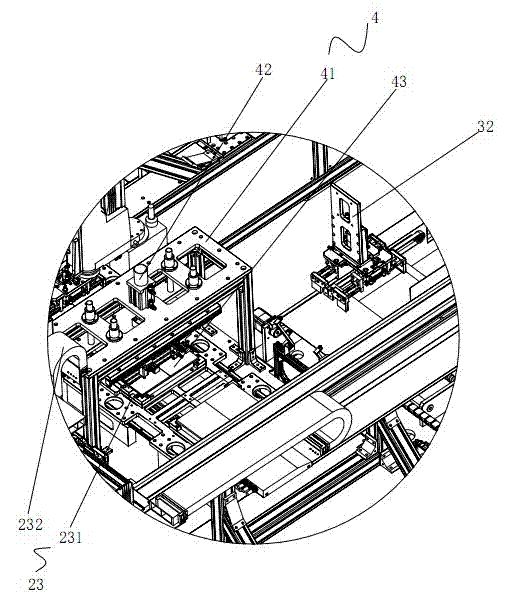

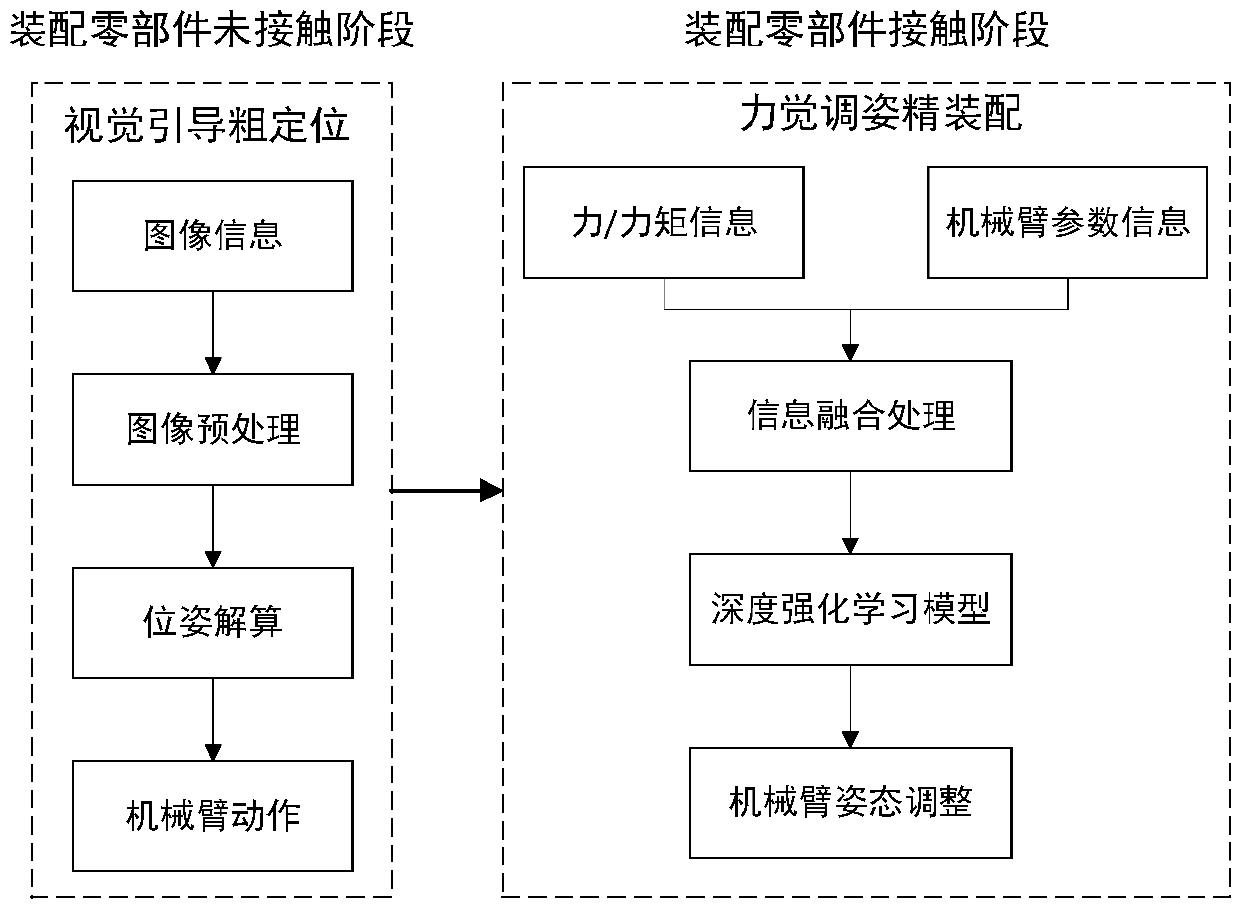

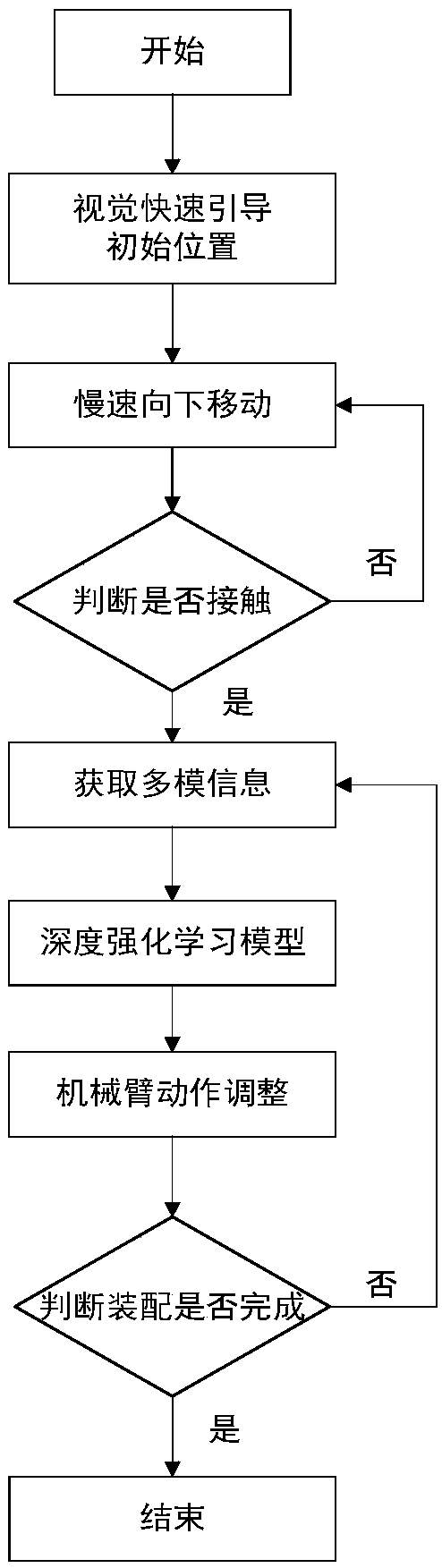

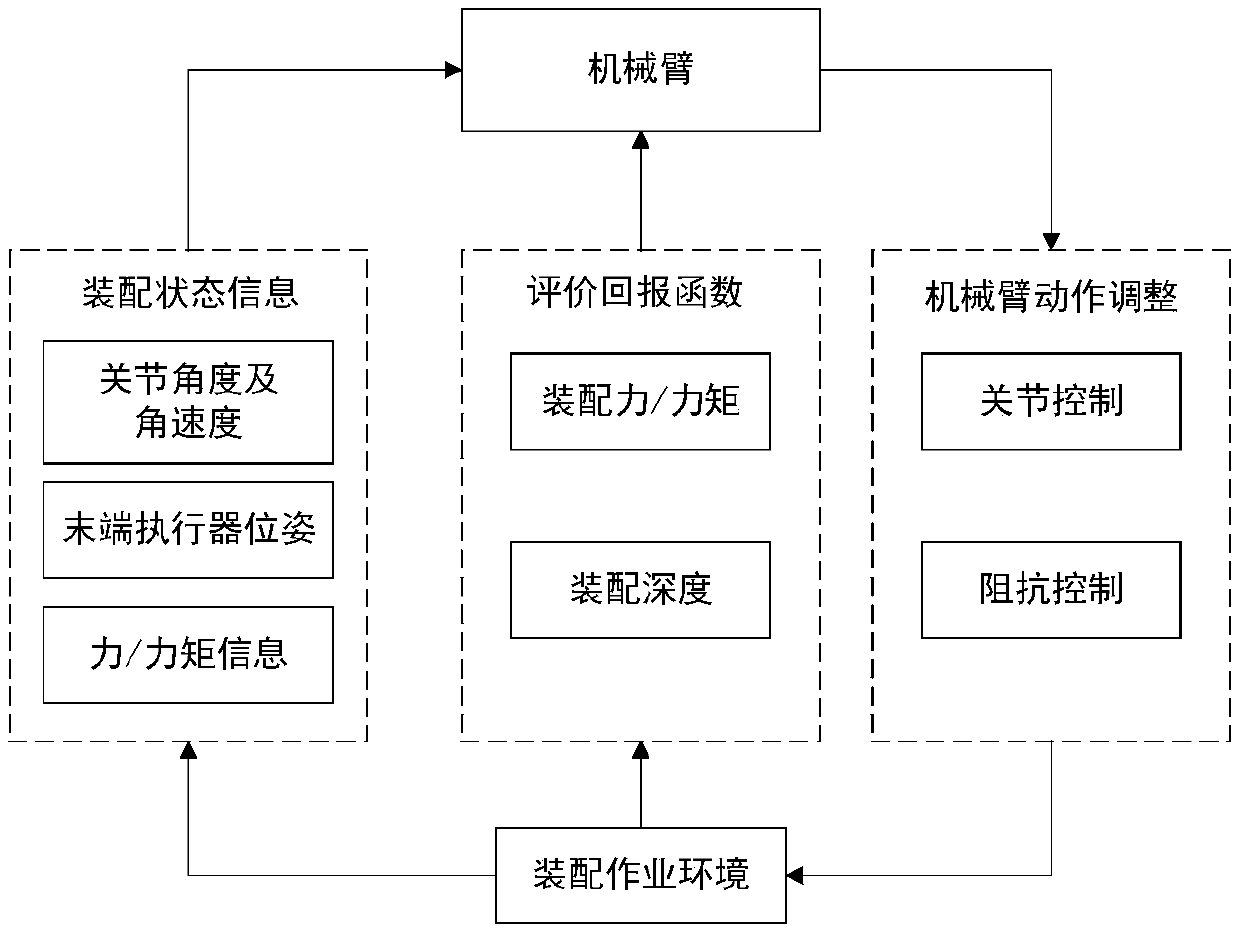

A flexible assembly system and method based on multi-mode information description

ActiveCN109543823ARealize the assemblySolve the problem of low labor efficiencyAssembly machinesNeural architecturesEngineeringStudy methods

The invention discloses a flexible assembly system and method based on multi-mode information description. The flexible assembly method comprise the following steps: in the non-contact stage between the end parts of the manipulator and the parts to be assembled, the manipulator is rapidly positioned near the target position by visual guidance, and the visual guidance rough positioning is realized;When the end parts of the manipulator contact with the parts to be assembled, the multi-mode information description of the assembly state is formed by the force information and the parameters of themanipulator itself, and the posture adjustment is carried out based on the depth reinforcement learning method, so as to realize the precise assembly of the force sense and posture adjustment of theassembled parts. An embodiment of the present disclosure effectively solves the problem of low labor efficiency; The manipulator adapts to the change of environment actively; Visual images, force / moment information and manipulator parameters are used to describe the assembly process.

Owner:SHANDONG UNIV

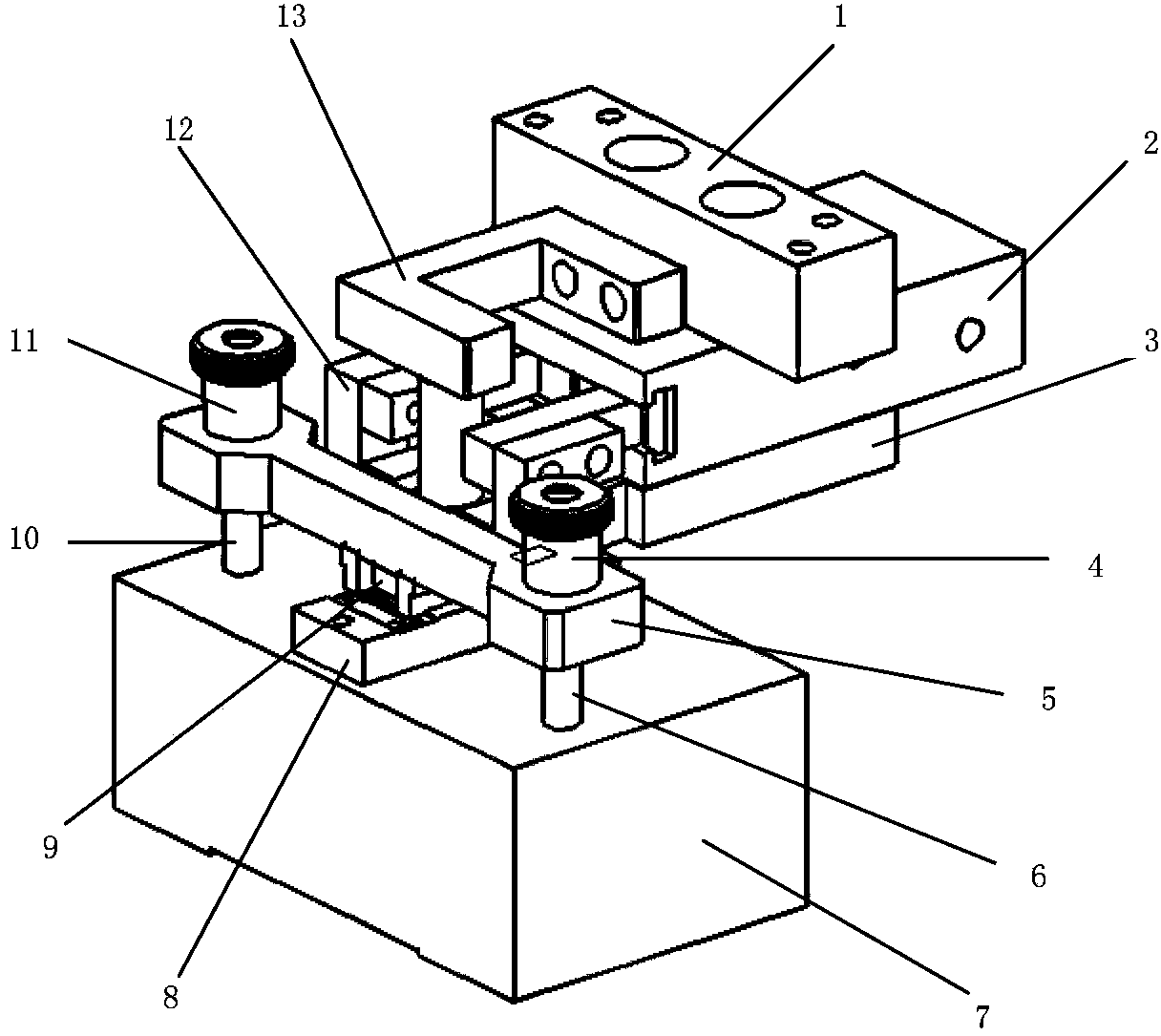

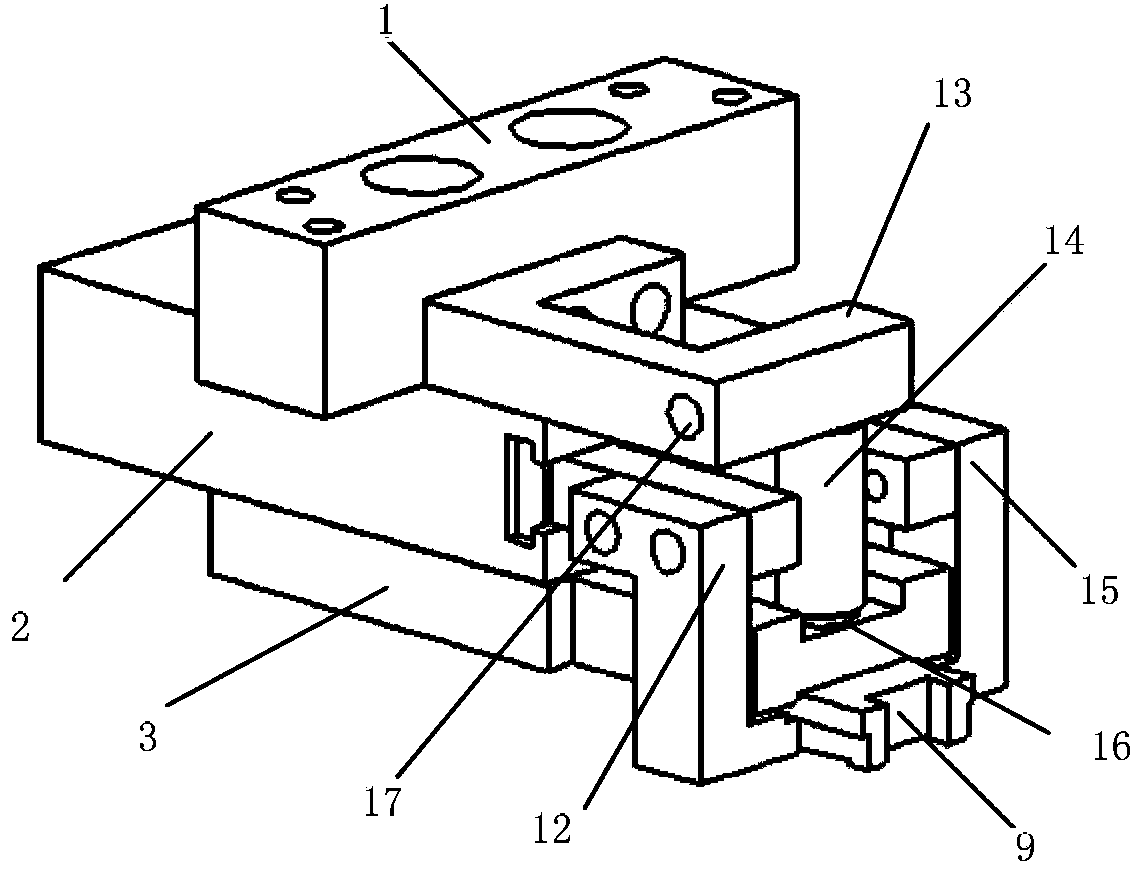

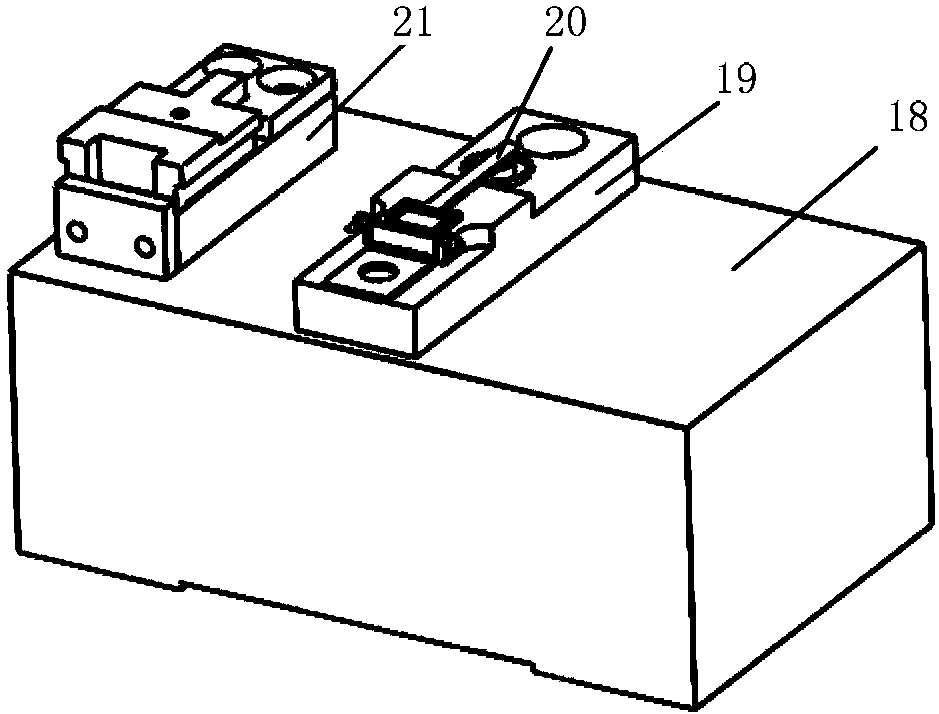

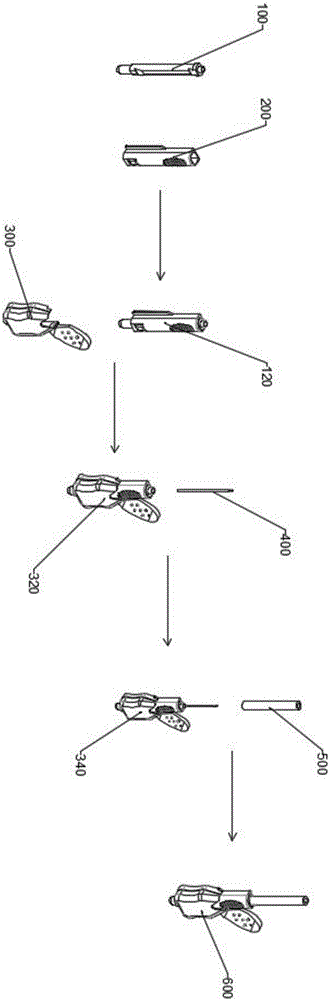

Tiny component assembling device and method

InactiveCN103350333AAchieve adsorptionRealize the assemblyMetal working apparatusMechanical componentsMechanical engineering

The invention relates to the technical field of precision assembly, in particular to a tiny component assembling device and method. The tiny component assembling device is characterized by consisting of a feeding clamp unit, combined adsorbing clamp unit and an assembling clamp unit, wherein the combined adsorbing clamp unit comprises a connecting block, a U-shaped pneumatic connecting block, a sucking disc connecting post, a left clamp finger, a right clamp finger, a sucking disc, a transitional adsorbing block, a positioning block and a pneumatic clamp; the transitional adsorbing block is designed to have a series of different sizes and structures and is used for adsorbing tiny components with various structural characteristics, so that the shift function of a clamp is achieved and the universality of the clamp is improved; the transitional adsorbing block adsorbs, moves and assembles the tiny components in the assembling process, and fixes an assembly after completion of the assembling process, thus ensuring that the assembly precision is not damaged, and achieving precision assembly of the tiny components. The tiny component assembling device and method are applicable to clamping adsorption, movement, assembly and fixation of tiny mechanical components.

Owner:DALIAN UNIV OF TECH

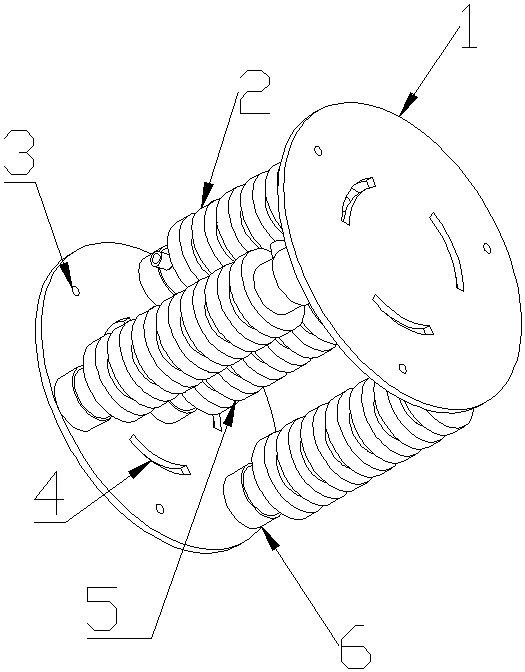

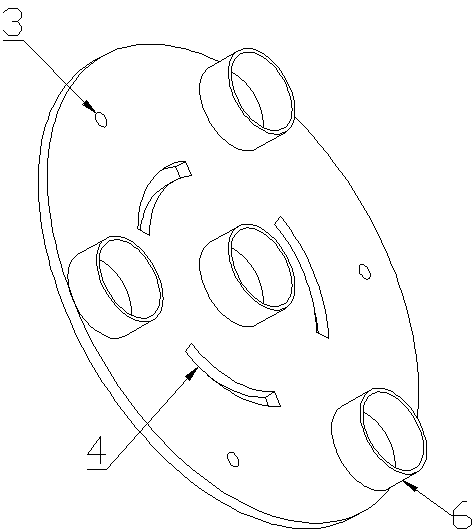

Variable-rigidity flexible mechanical arm module and control method thereof

InactiveCN109648550ARealize modular productionRealize the assemblyProgramme-controlled manipulatorVariable stiffnessButt joint

The invention relates to a variable-rigidity flexible mechanical arm module and a control method thereof. The variable-rigidity flexible mechanical arm module comprises two connecting plates (1) arranged on two sides, and a plurality of silica gel inflatable bags (2) are connected between the two connecting plates (1), wherein the plurality of silica gel inflatable bags (2) comprise variable stiffness silica gel inflatable bags which are used for generating an antagonistic effect and are arranged in the middle of the two connecting plates (1), and further comprise curved silica gel inflatablebags which are uniformly distributed around the two connecting plates (1) and are used for controlling the deformation shape; and each silica gel inflatable bag (2) is connected with an air pipe, theconnecting plates (1) are provided with pipeline passing holes (4) for allowing the air pipes to pass through, and the connecting plates (1) are further provided with connecting structures which can be in butt joint with a connecting plate of other flexible mechanical arm module so that the plurality of flexible mechanical arm modules can be connected in series. The variable-rigidity flexible mechanical arm module is simple in structure, convenient to assemble and flexible in movement; and the control method of the flexible mechanical arm module is efficient in work and the control precision is high.

Owner:FUZHOU UNIV

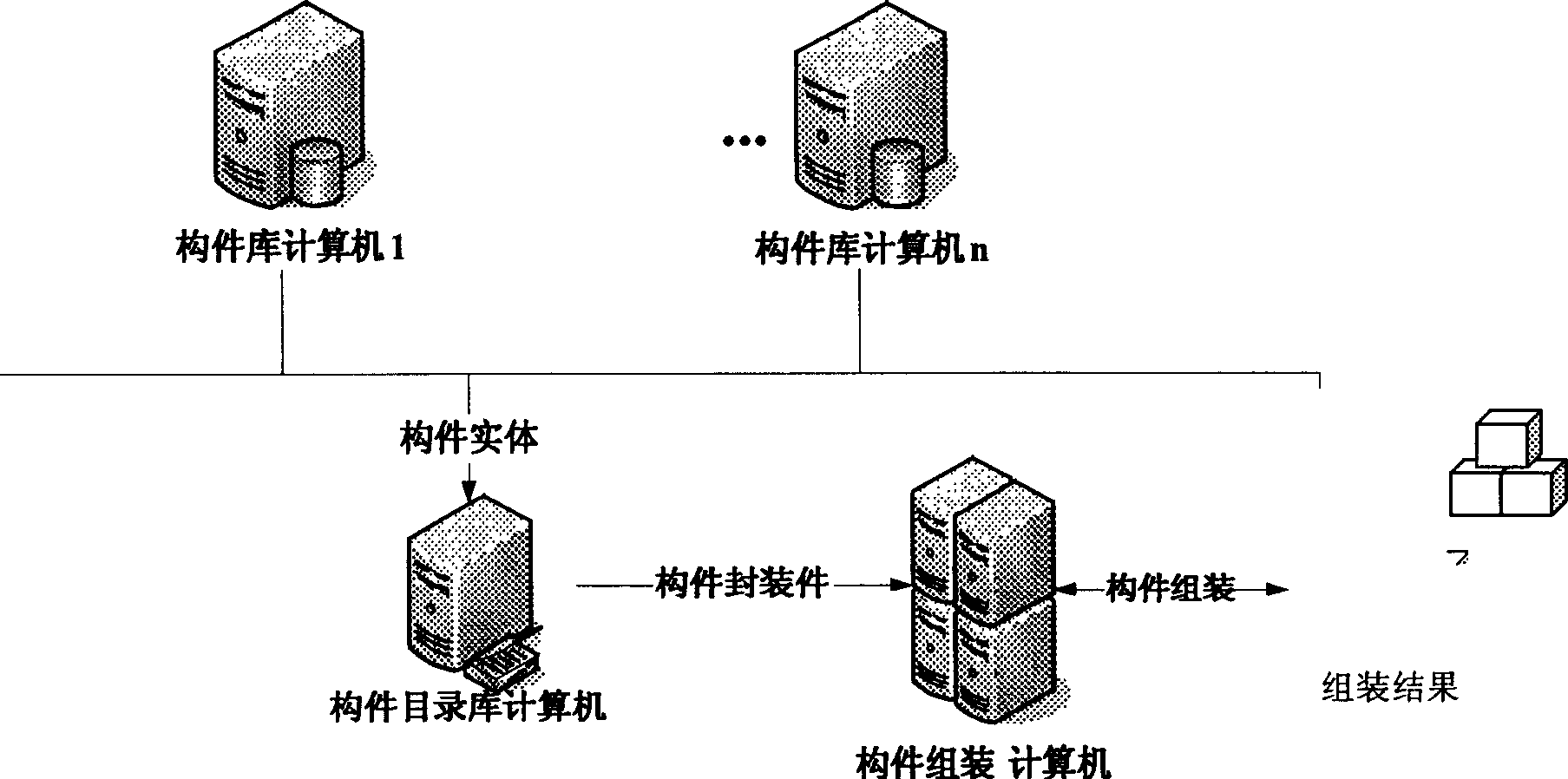

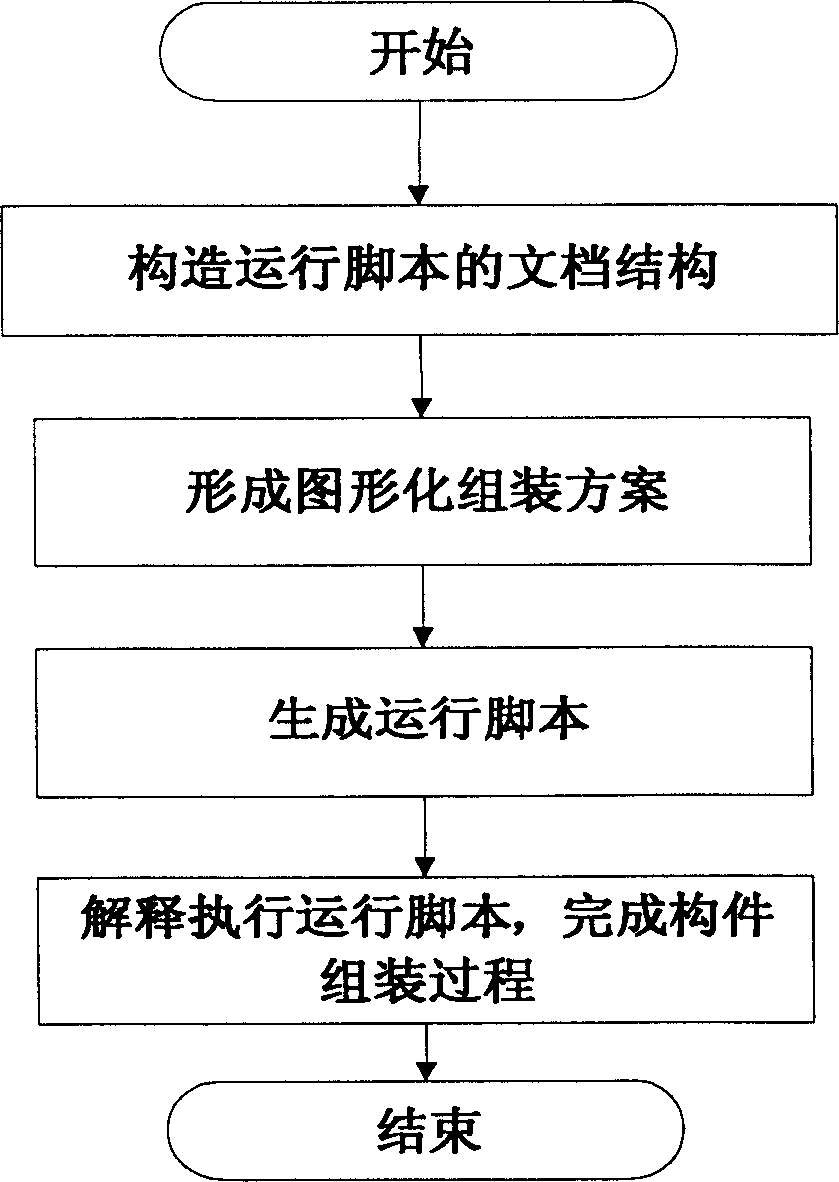

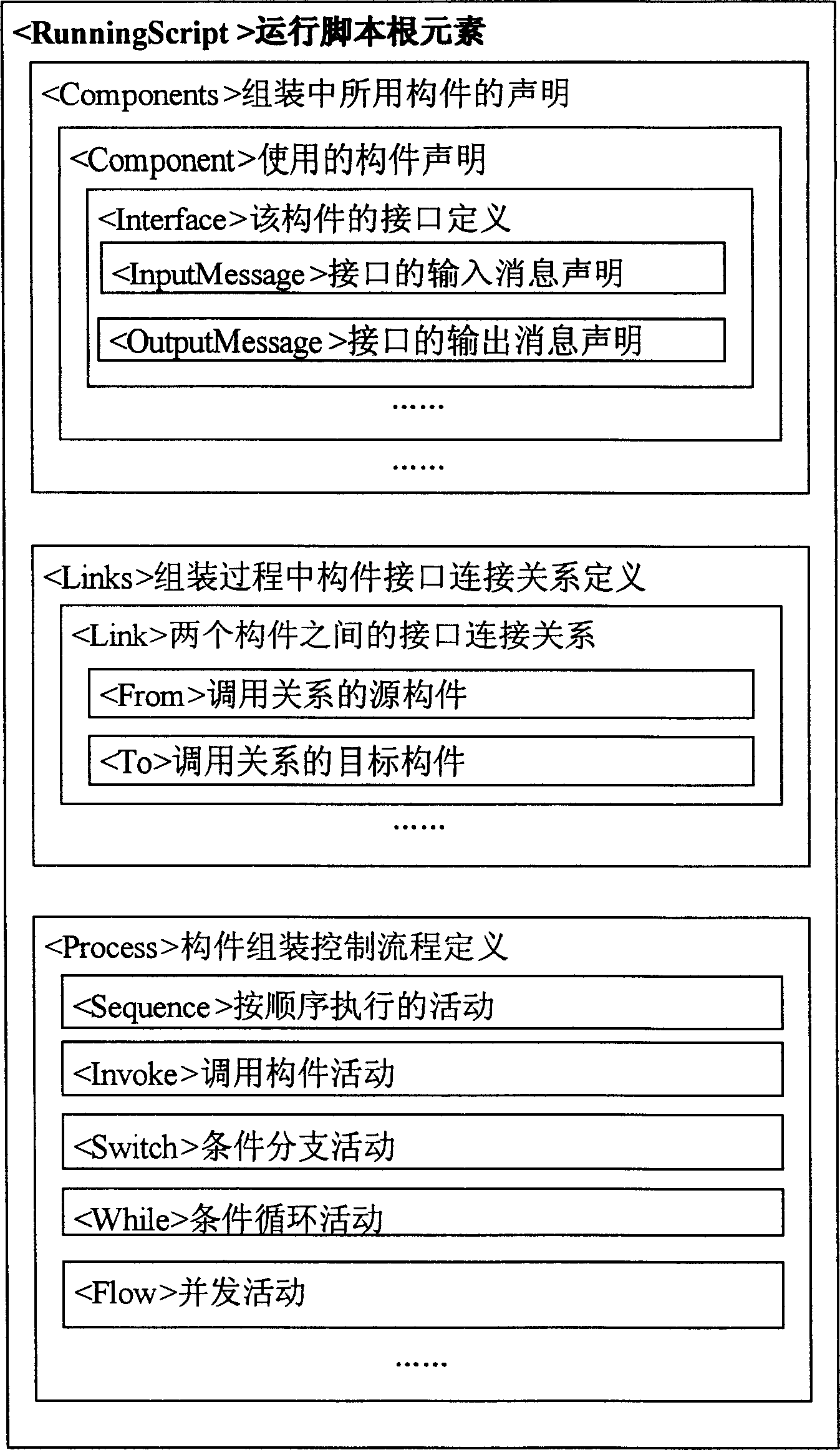

Member assembling method based on united member package structure

InactiveCN1744038ARealize visual programmingRealize the assemblySpecific program execution arrangementsService flowSoftware design

The invention belongs to area of software engineering technique. Component library is setup at one or more computers so as to form computers of component library. User encapsulates components from computers of component library so as to form packages described in unified formalism. The said packages are stored in directory library of component so as to form computers of directory library of component. Software for assembling components is setup in a computer so as to form a computer of component assembly. User picks up a set of package of component to be assembled from computers of directory library of component, and down loads the set of package to the computer of component assembly. Based on information of package of component to be assembled, the computer of component assembly assembles the set of package. Features are: visual programming based on components, supporting integration of service flow for different application areas, customizing and integrating individualized services.

Owner:TSINGHUA UNIV

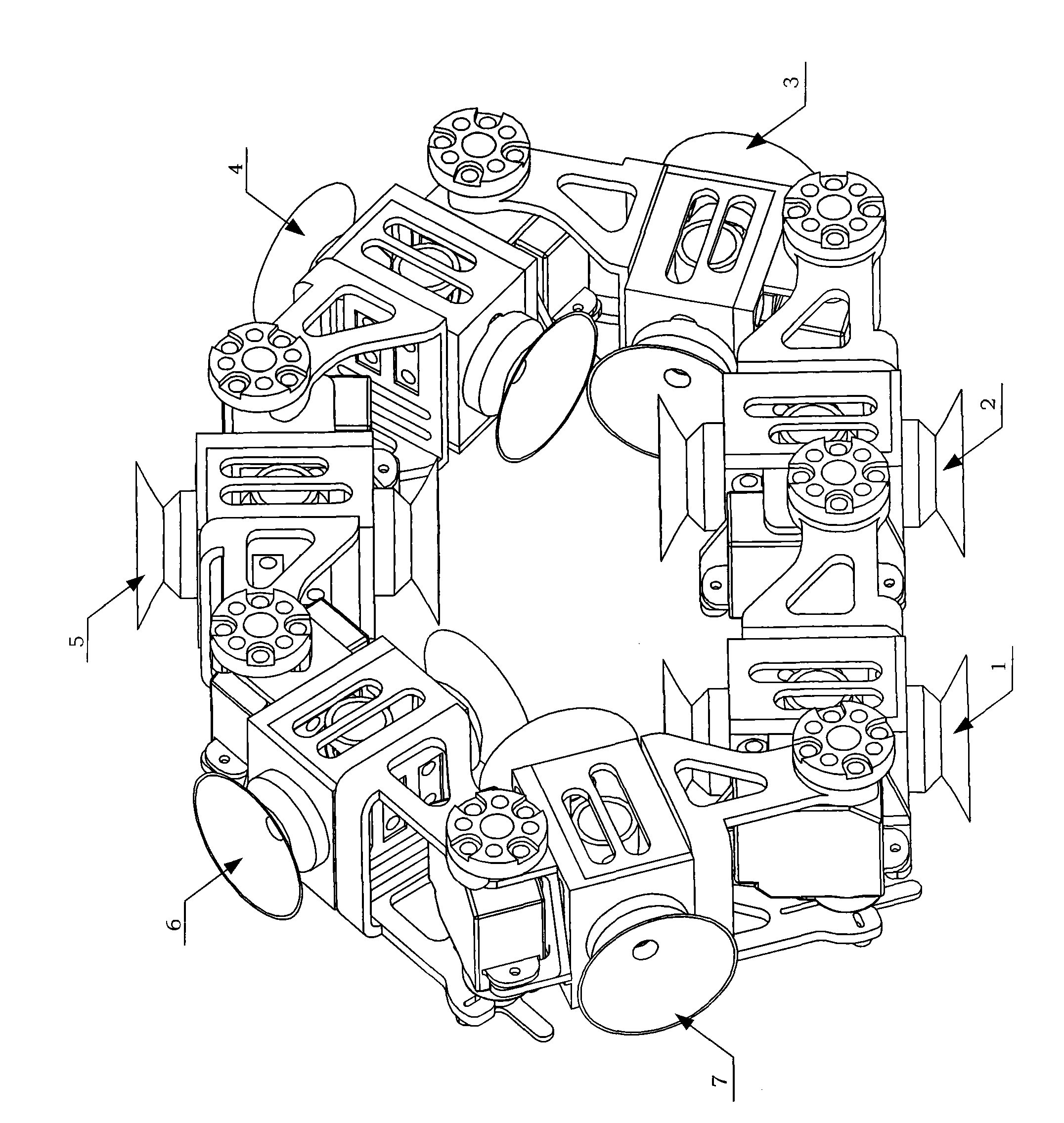

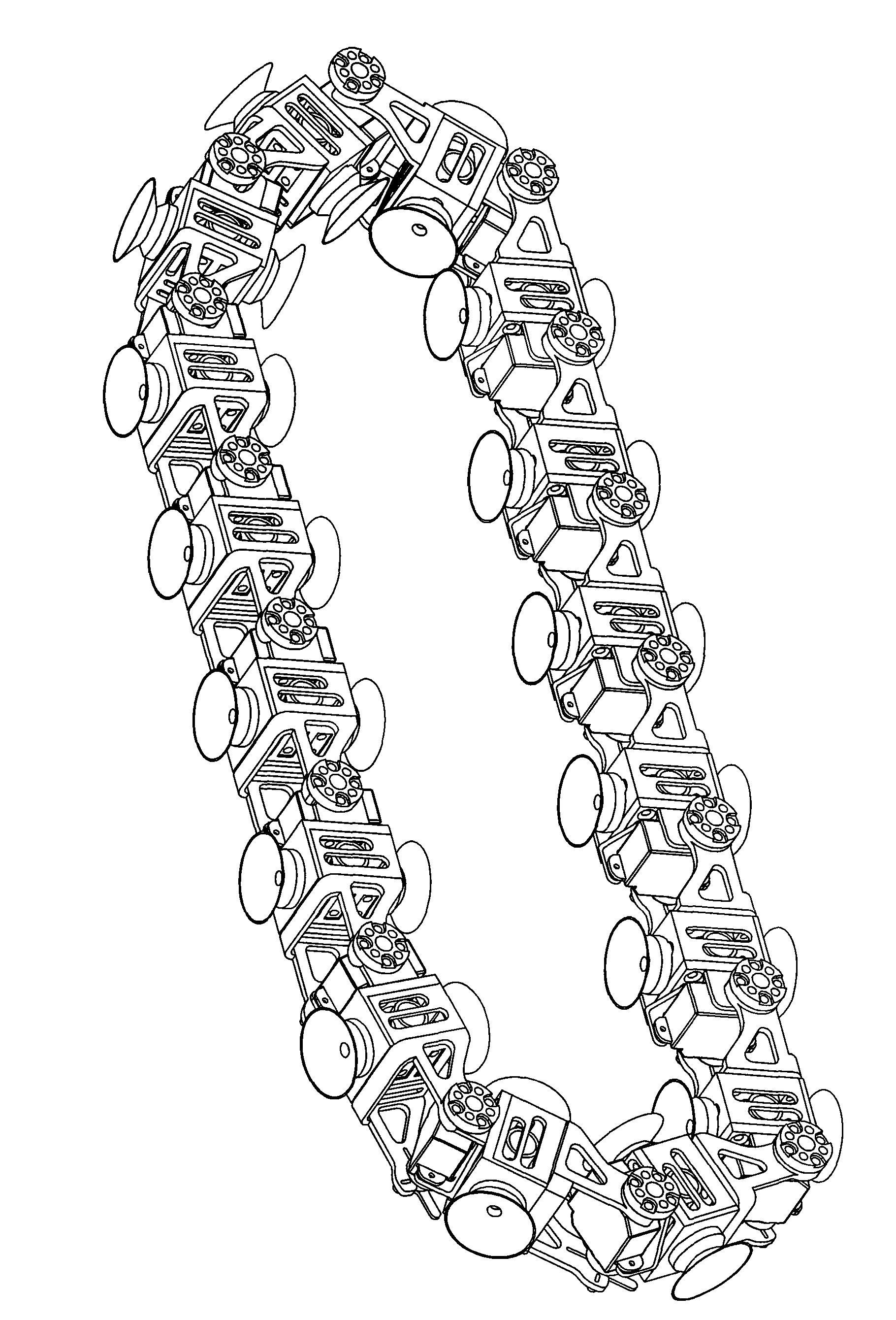

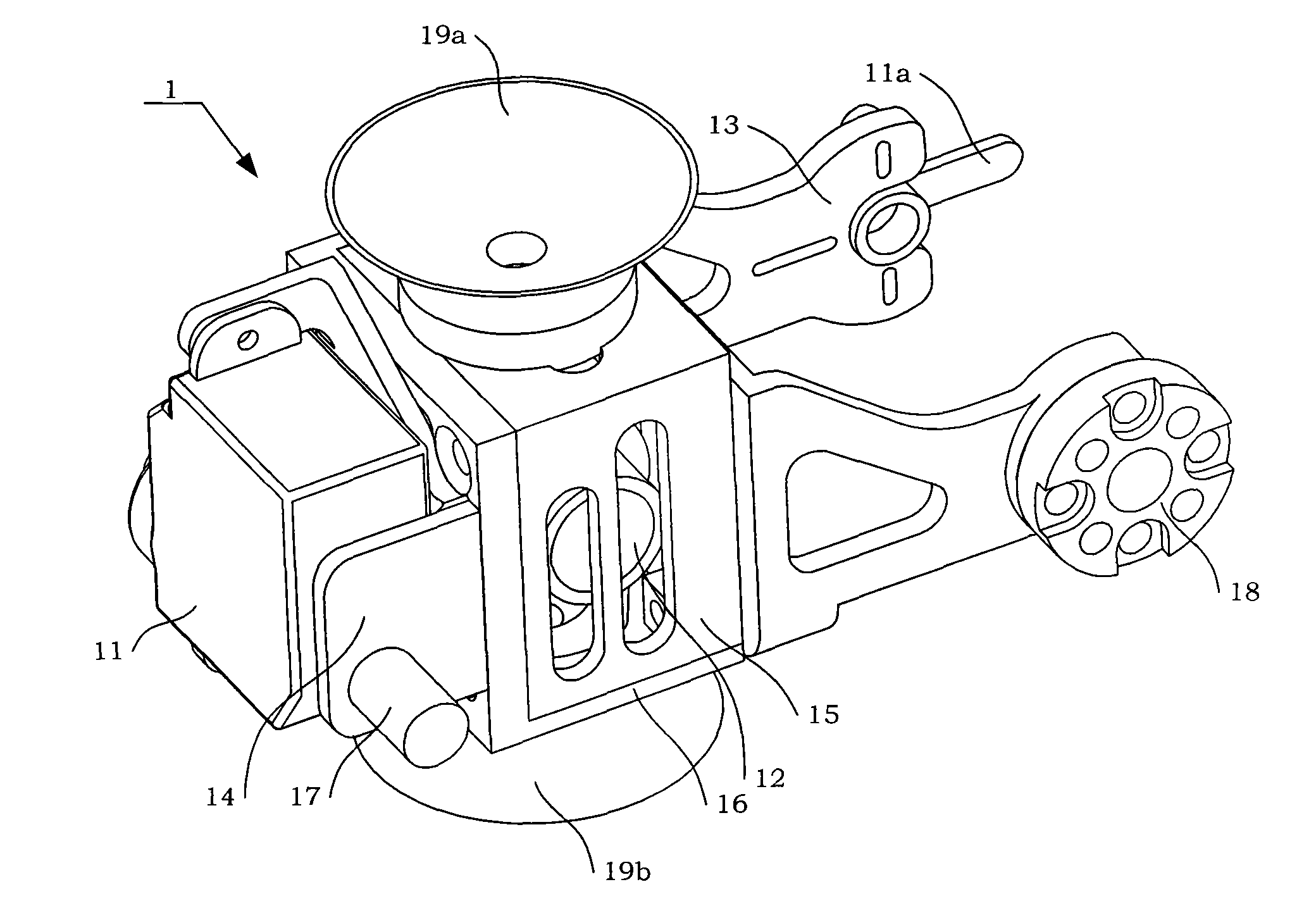

Modular reconfigurable crawler-type wall climbing robot

The invention discloses a modular reconfigurable crawler-type wall climbing robot, consisting of seven or more than seven absorption joints. Each absorption joint comprises a U-shaped frame, a bracket, a shell A, a shell B, a shaft, a shaft sleeve, a steering engine, an electromagnet, a sucker A and a sucker B; the sucker A is arranged on the shell A; the sucker B is arranged on the shell B; the steering engine and the shaft are arranged on the bracket; the shaft sleeve is arranged on the U-shaped frame; the shell A and the shell B are connected and form a cavity used for arranging the electromagnet; the U-shaped frame is connected with the shell A; and the bracket is connected with the shell B. The modular reconfigurable crawler-type wall climbing robot forms a serial crawler-type structure of the robot by the U-shaped frame of the former absorption joint and the output shaft and shaft of the steering engine of the latter absorption joint so as to lead the robot to have the feature of multiple degrees of freedom. The crawler-type robot which is formed by adopting connection of seven or more than seven absorption joints with identical structures enhances the motion flexibility, absorption reliability and obstacle-climbing capability of the robot.

Owner:BEIHANG UNIV

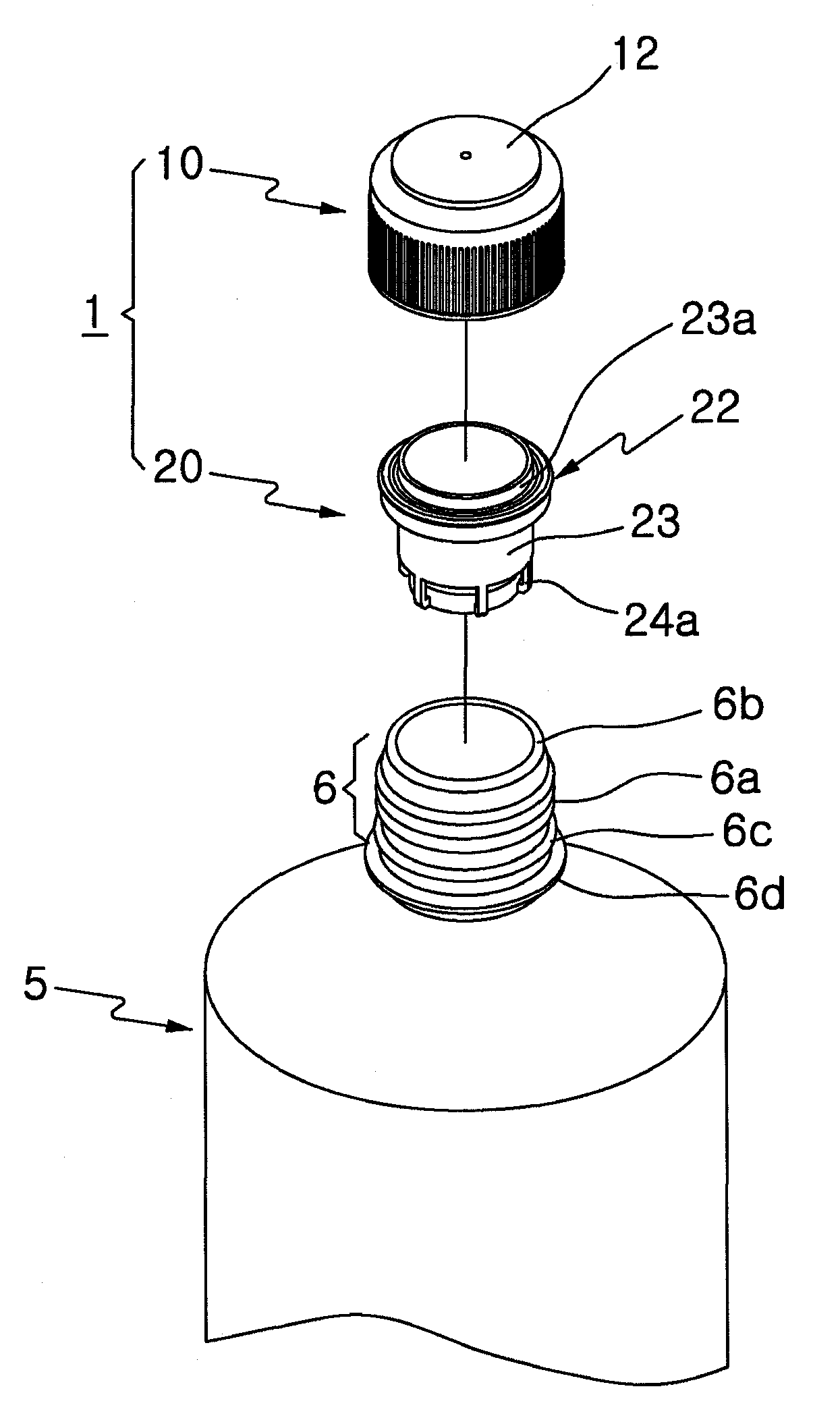

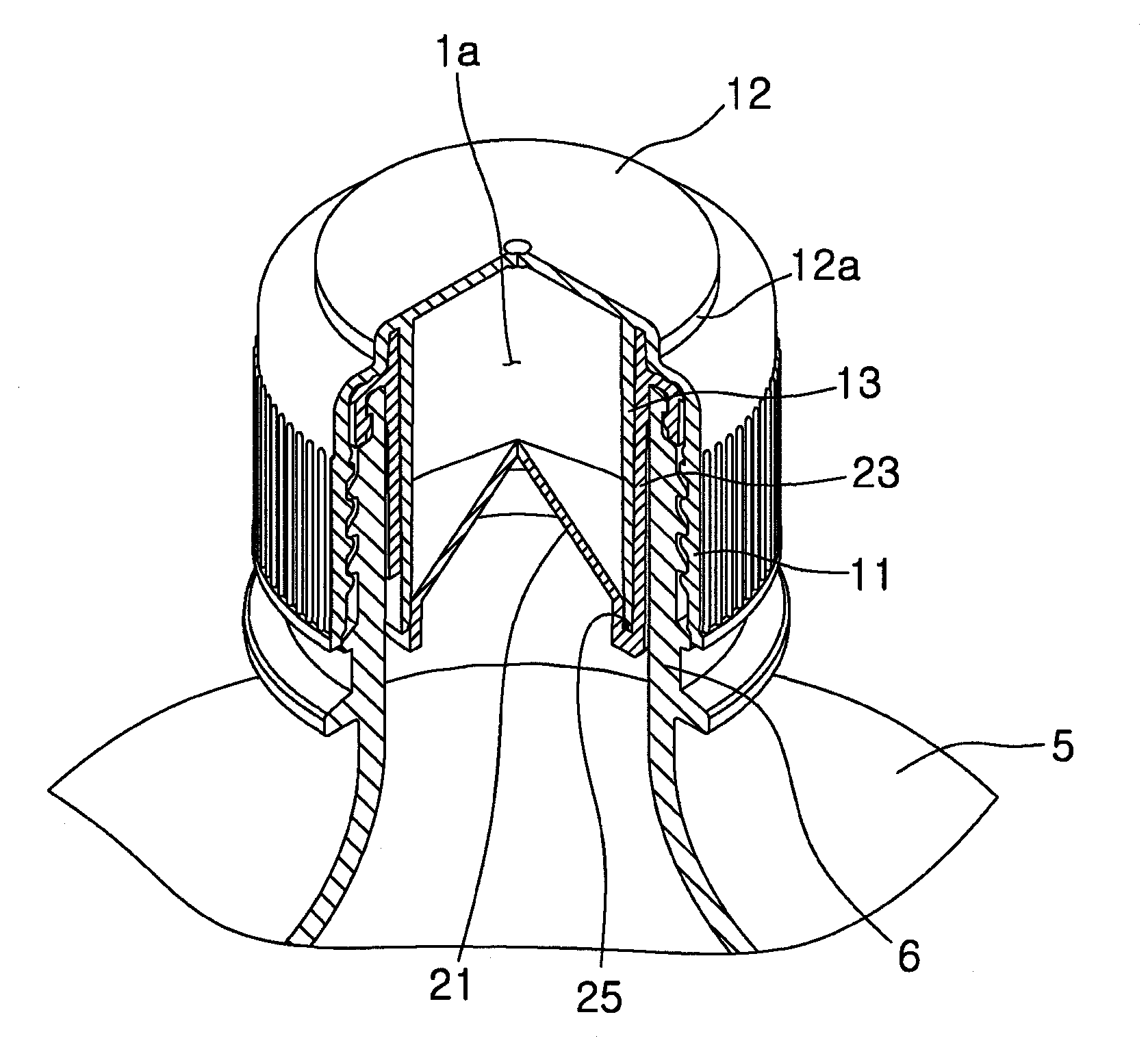

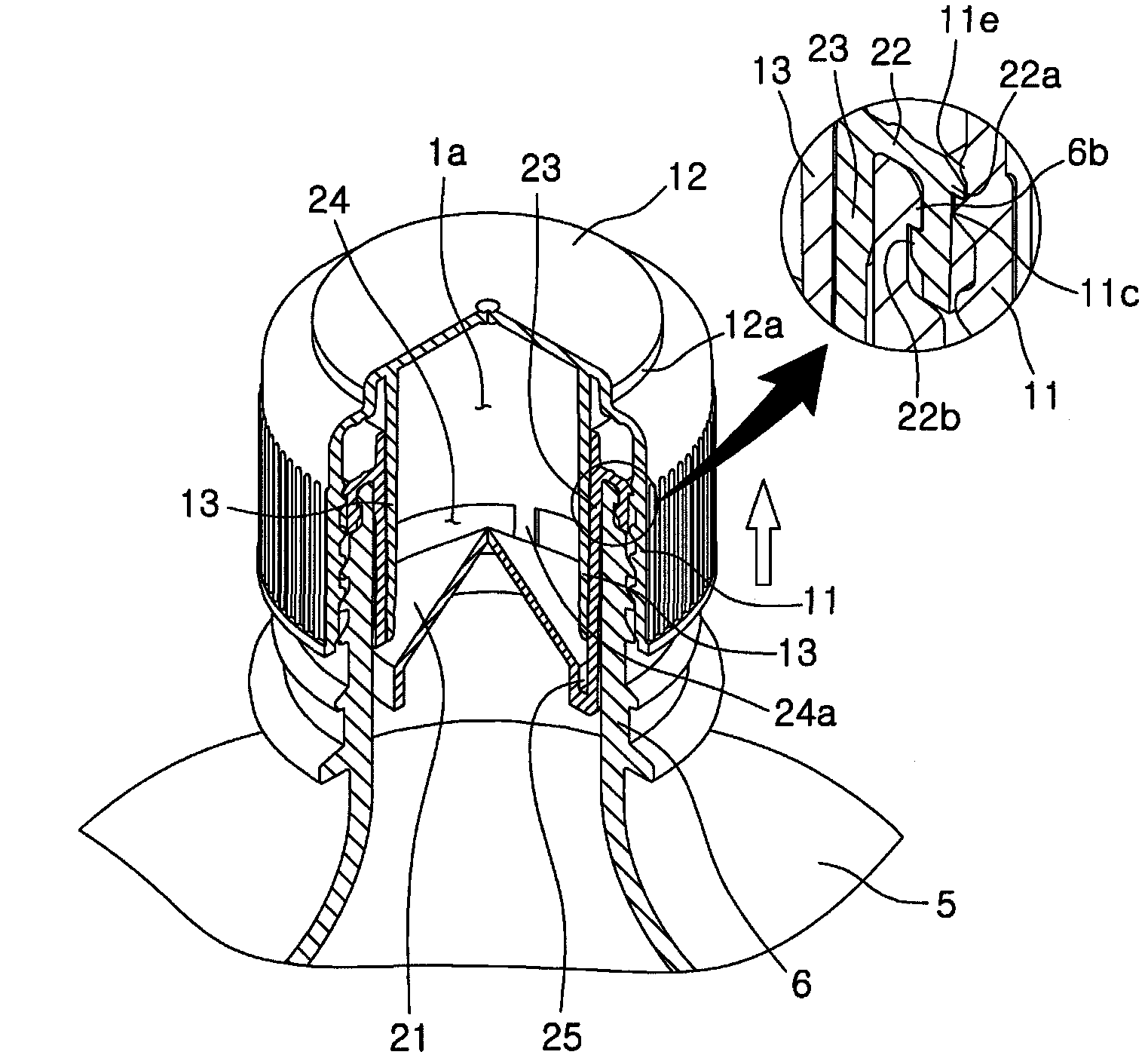

Container cap

InactiveCN102361804ARealize the assemblyEasy to manufactureClosure with auxillary devicesContainers with multiple articlesMechanical engineering

Owner:任孝彬

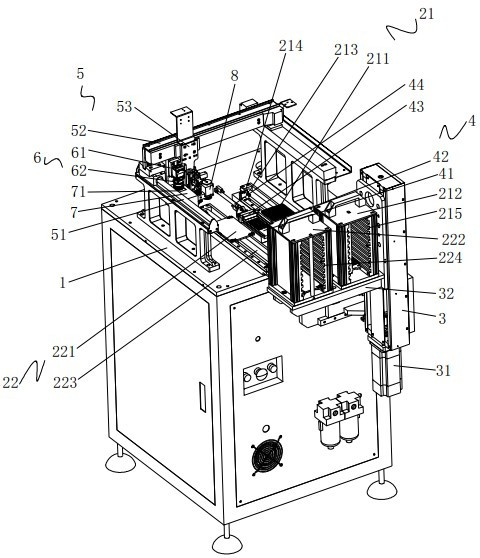

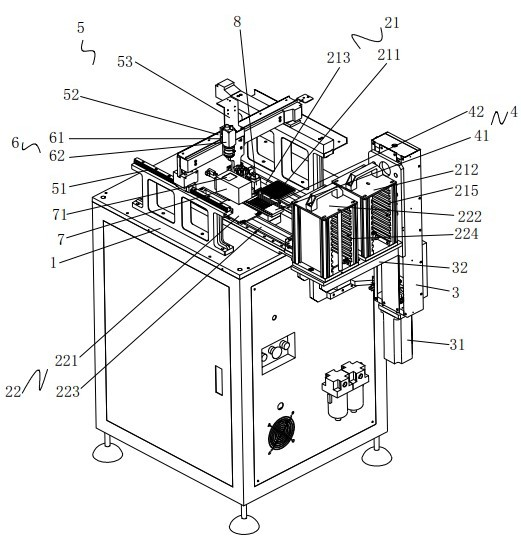

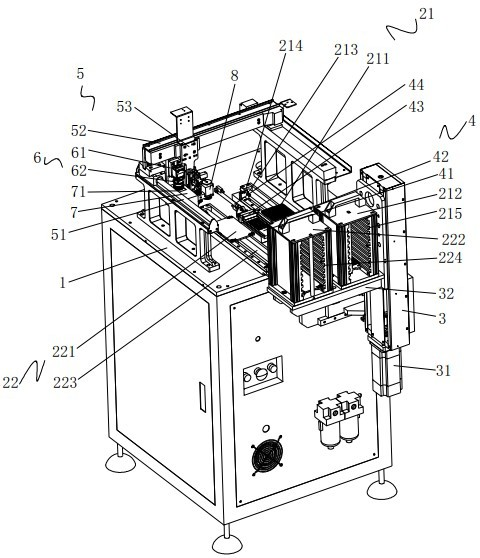

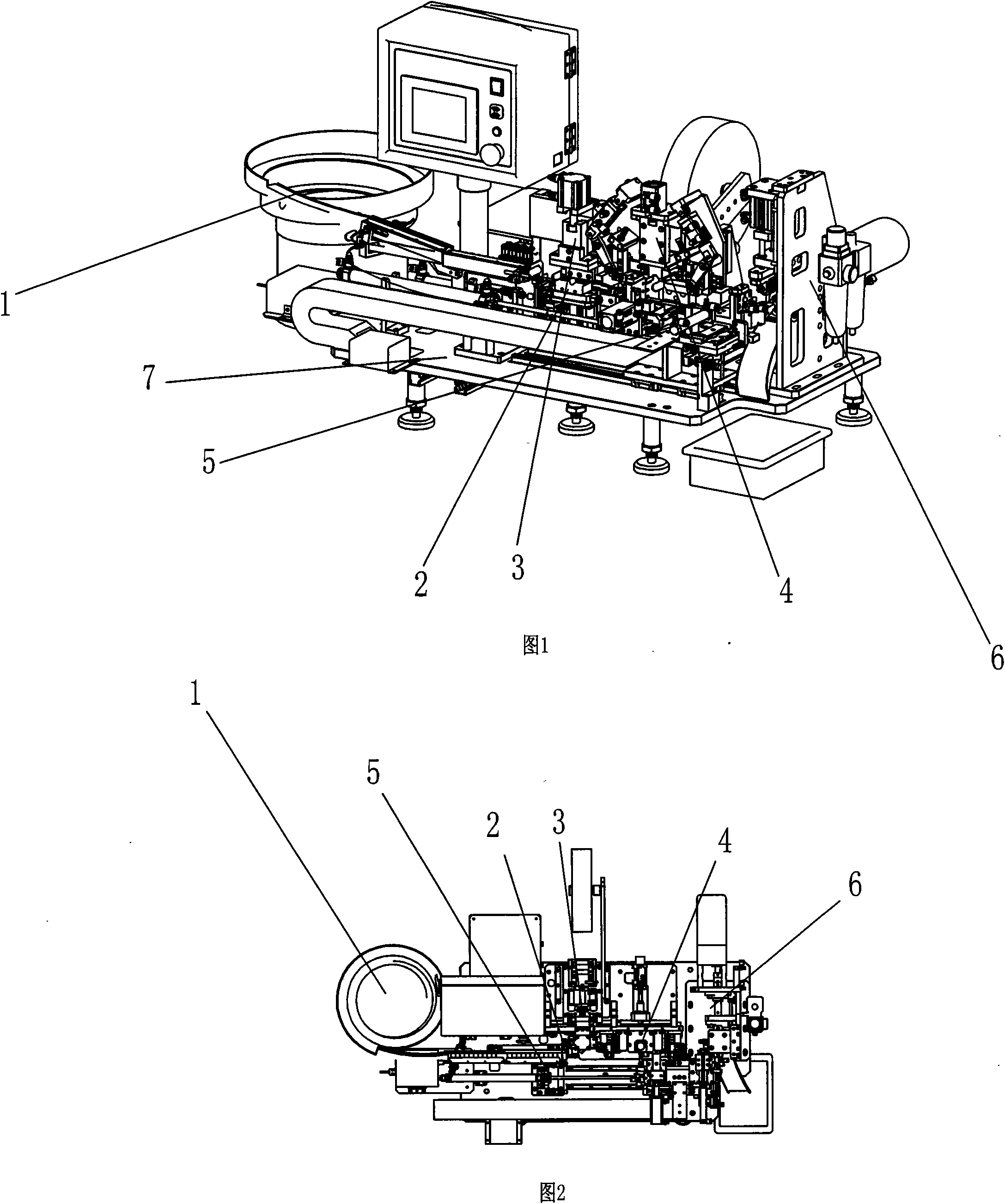

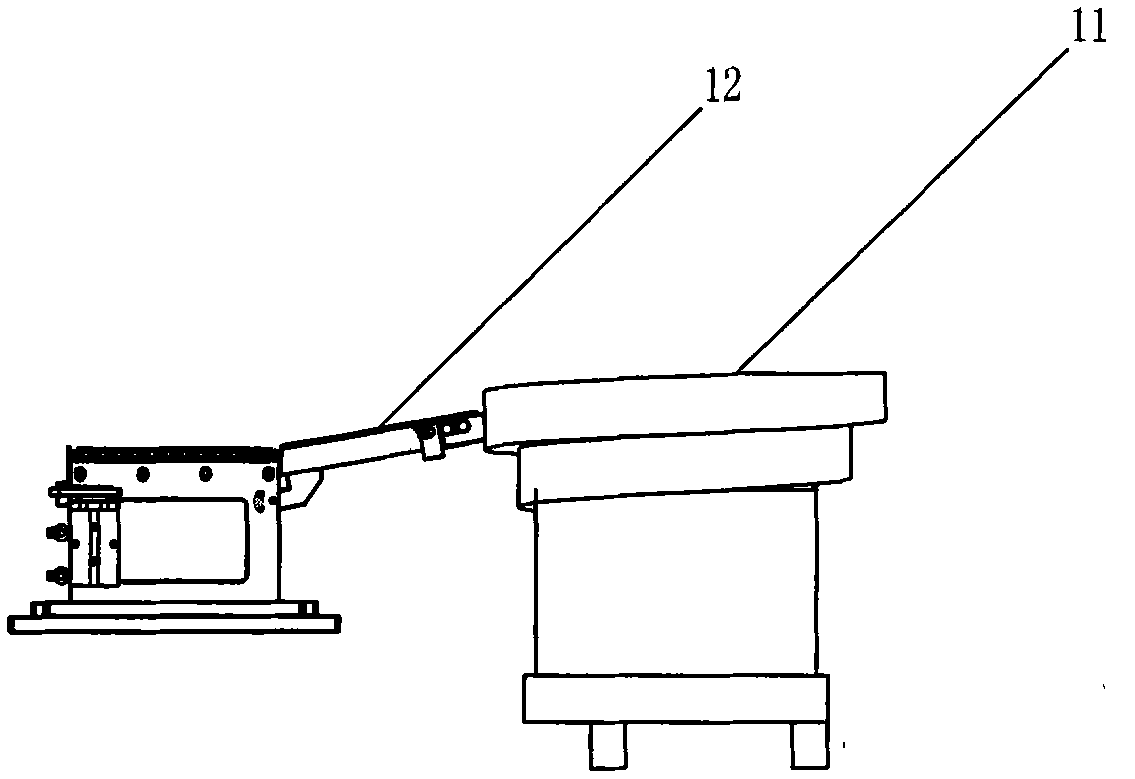

Camera module assembling machine

ActiveCN102606578AReasonable structural designReduce installation processFastening meansEngineeringMechanical engineering

The invention relates to a camera module assembling machine, which comprises a frame and an operating table disposed on the frame. A feeding mechanism, a glue feeding mechanism and an assembly mechanism are arranged on the operating table and respectively connected with a master control circuit, wherein the feeding mechanism is used for respectively conveying camera modules and FPC (flexible printed circuit) flexible substrates to an assembly station, and the assembly mechanism is used for dipping the camera modules into glue and then mounting the same on the FPC flexible substrates. The camera module assembling machine is reasonable in structural design, a camera module feeding mechanism, an FPC flexible substrate feeding mechanism, the glue feeding mechanism and the assembly mechanism are disposed on the operating table, the camera module feeding mechanism and the FPC flexible substrate feeding mechanism convey the camera modules and the FPC flexible substrates to the assembly station respectively, and the assembly mechanism dips the camera modules into glue and then mounts the same on the FPC flexible substrates, so that automatic feeding, glue dipping and assembly of the camera modules and the FPC flexible substrates are realized, mounting procedures are reduced while assembly efficiency is improved, and assembly quality is further guaranteed.

Owner:HUIZHOU DESAY AUTOMATION TECH

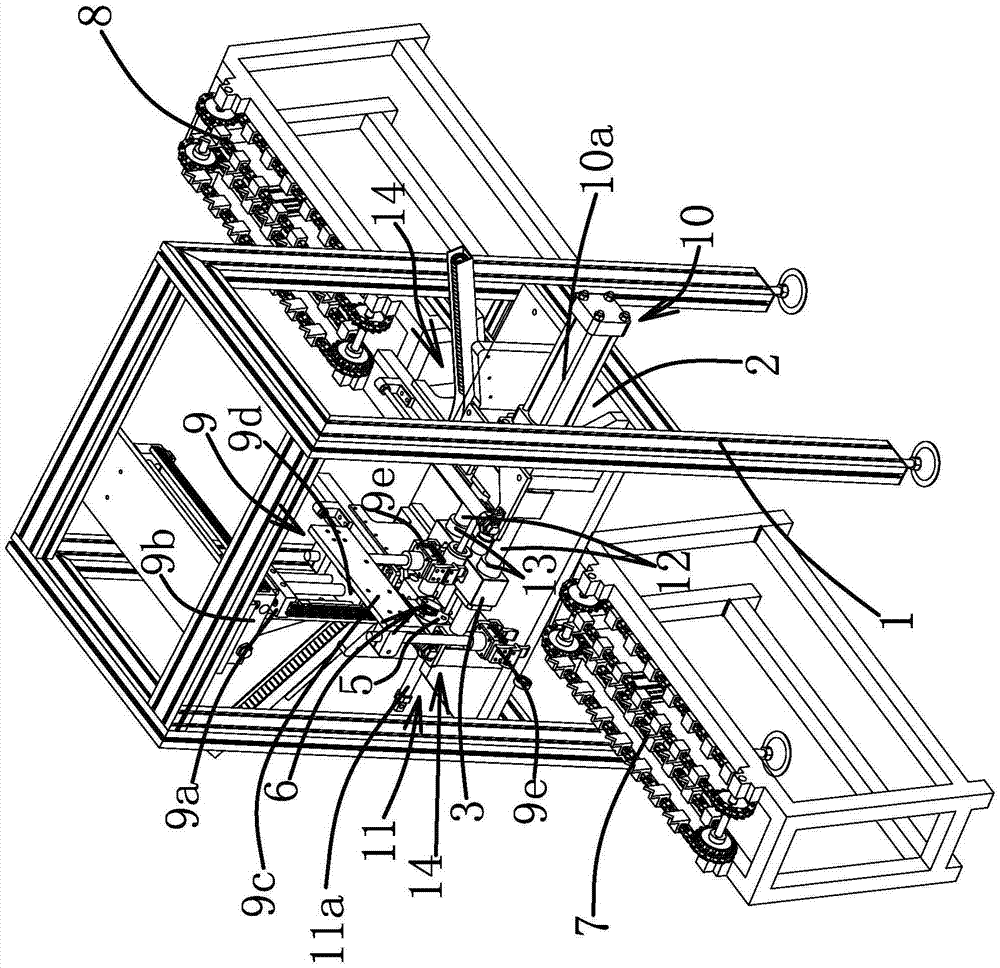

Automatic assembling machine of rotors and bearings of motors

PendingCN105436870ARealize the assemblyGuaranteed smooth assemblyMetal working apparatusMechanical equipmentEngineering

The invention provides an automatic assembling machine of rotors and bearings of motors, belongs to the technical field of mechanical equipment and solves the problem that the rotors and the bearings cannot be assembled smoothly by the existing automatic assembling machine of the rotors and the bearings of the motors. The automatic assembling machine of the rotors and the bearings of the motors comprises a frame and a workbench, wherein a positioning seat is arranged on the workbench; a material receiving block I and a material receiving block II are arranged on two longitudinal sides of the positioning seat; storage slots are formed in the material receiving block I and the material receiving block II; a conveying chain I and a conveying chain II are respectively arranged on two transverse sides of the positioning seat; a mechanical arm assembly is arranged on the workbench; a translation mechanism I capable of driving the material receiving block I to be subjected to longitudinal translation is arranged on the workbench; a resetting mechanism is arranged between the workbench and the positioning seat. The automatic assembling machine of the rotors and the bearings of the motors has the advantage that the rotors and the bearings are smoothly assembled.

Owner:LEO GRP ZHEJIANG PUMP CO LTD

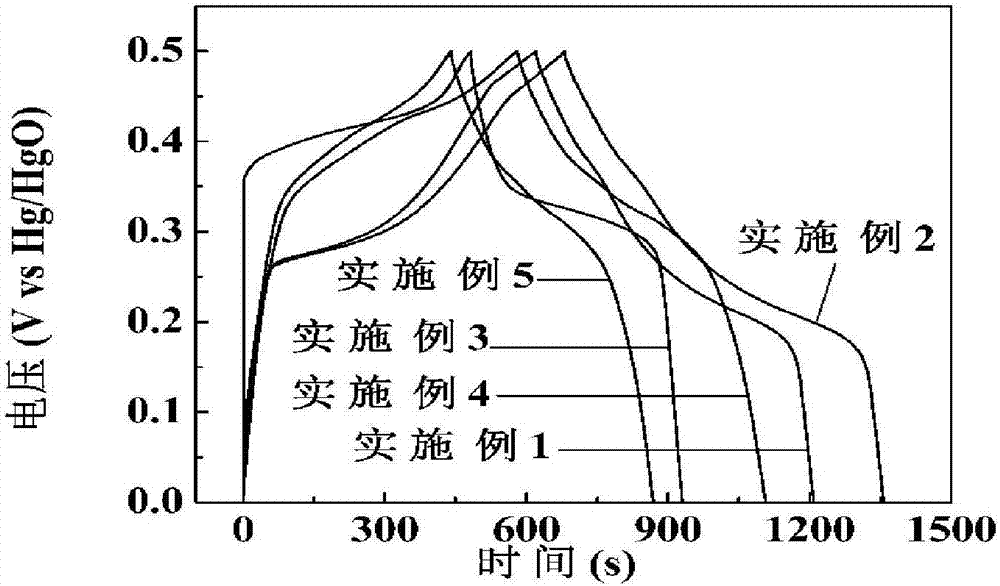

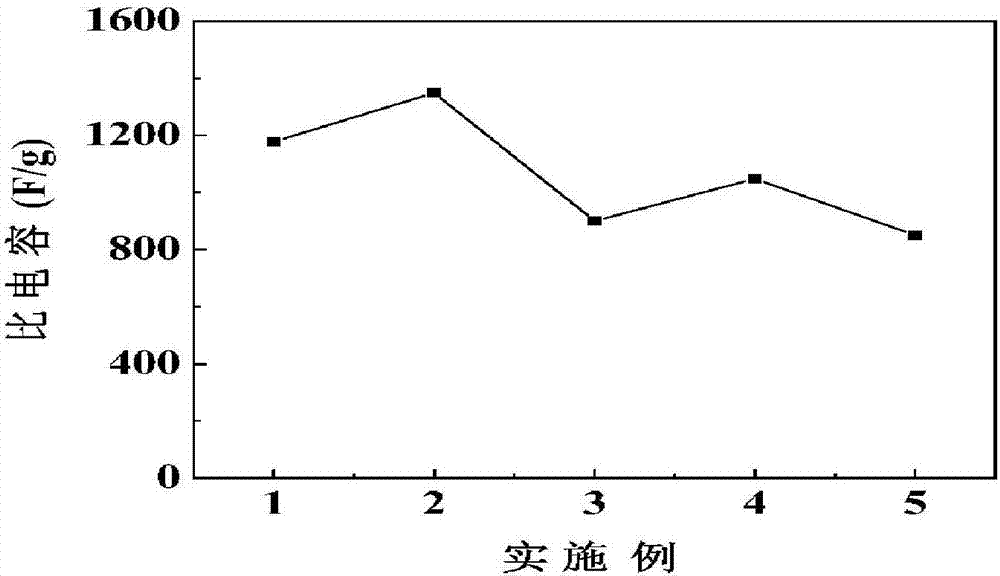

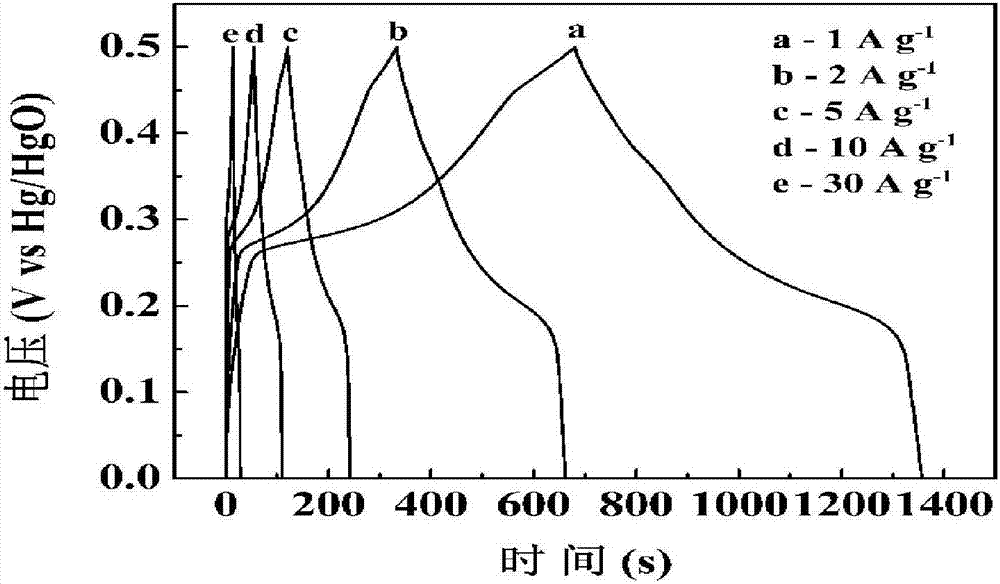

Method for preparing supercapacitor electrode material through cobalt-nickel bimetallic oxide and graphene

InactiveCN106935419ARealize the assemblyOptimal Control StructureHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceGraphene nanocomposites

The invention discloses a method for preparing supercapacitor electrode material through cobalt-nickel bimetallic oxide and graphene. According to the method, cobalt-nickel bimetallic hydroxide is stripped in deionized water, and graphene oxide having negative charges and the cobalt-nickel bimetallic hydroxide having positive charges are heterogeneously assembled so that compounding of the graphene oxide and the cobalt-nickel bimetallic hydroxide at the nanoscale can be realized. The reaction is controllable, and the prepared layered cobalt-nickel oxide and graphene nanocomposite material has great uniformity and has high specific capacitance, great rate performance and ultra-long cycle life when it is used for the supercapacitor electrode material so as to be wide in application prospect.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

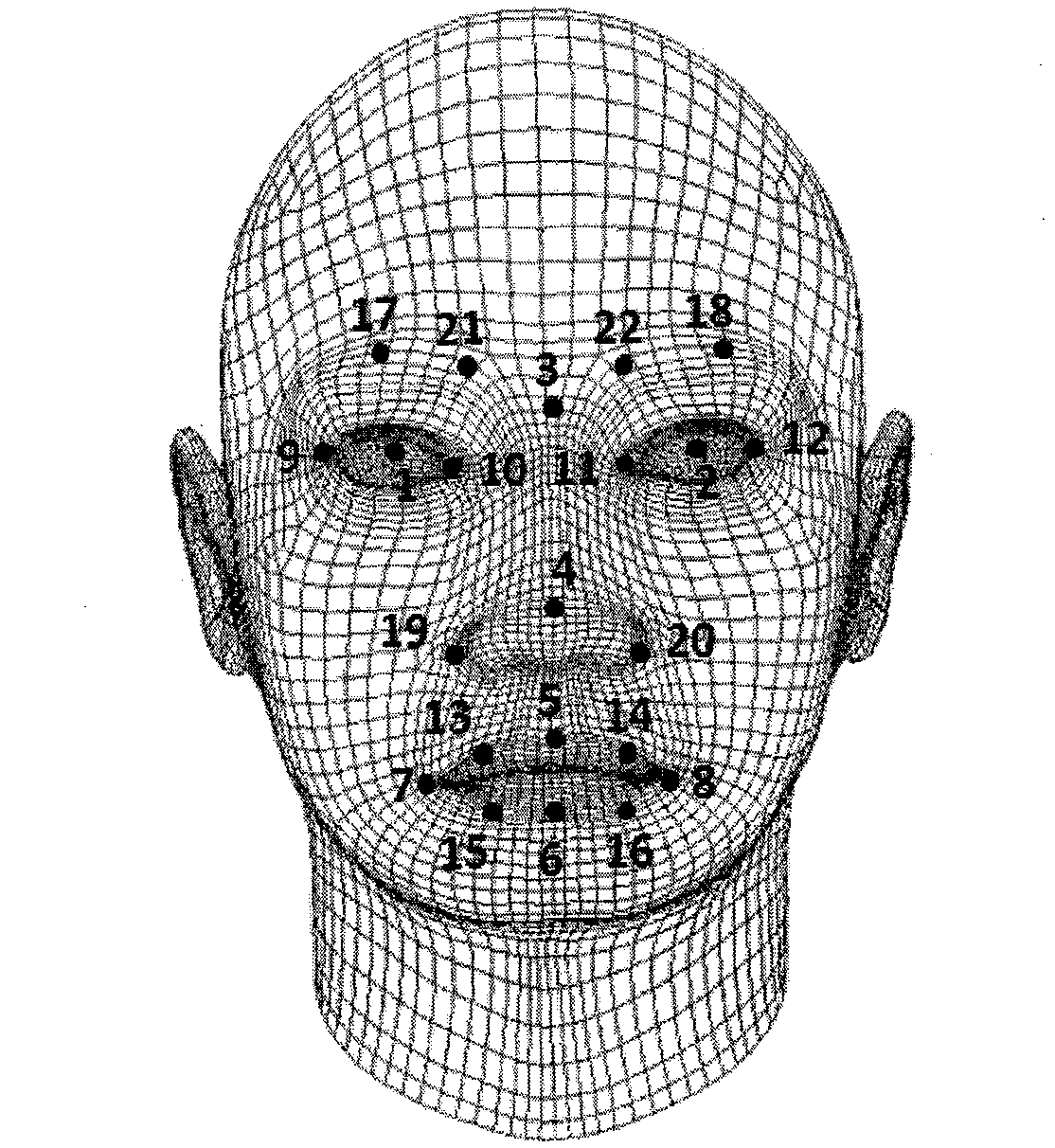

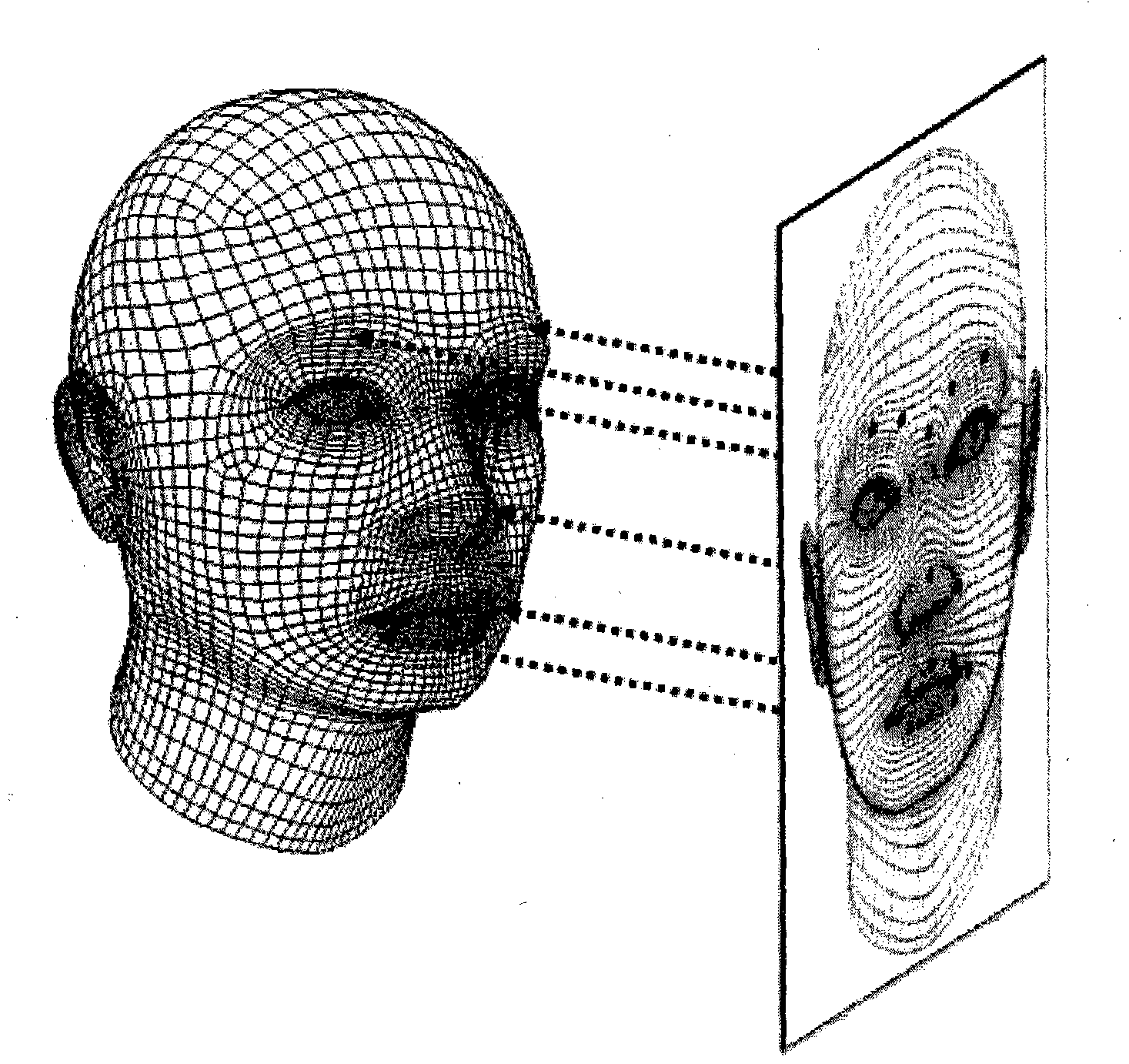

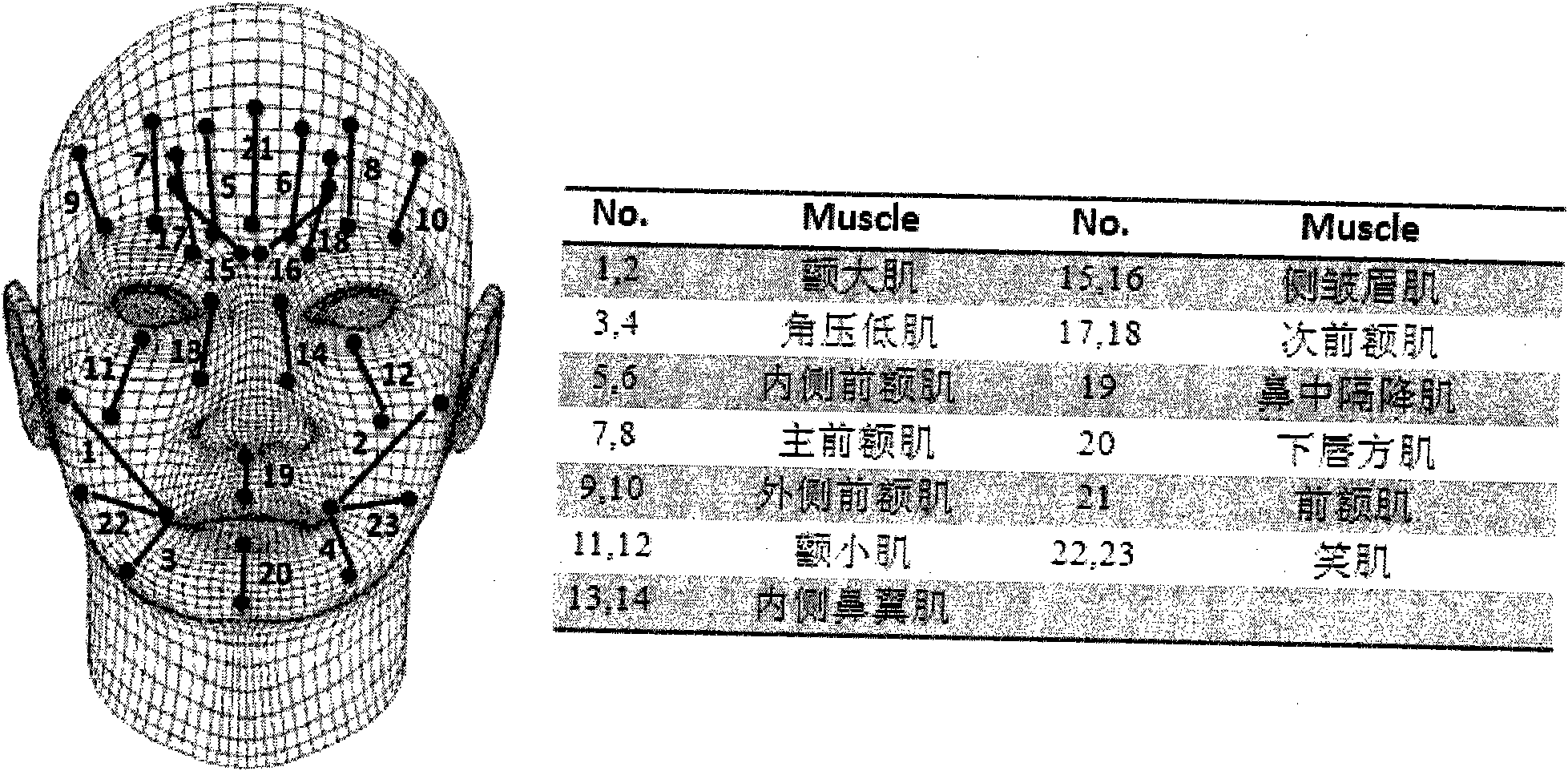

Method for automatically constructing three-dimensional face muscle model

InactiveCN101783026AAccurate locationRealize the assembly3D-image rendering3D modellingMuscle contractionAnimation

The invention provides a method for automatically constructing a three-dimensional face muscle model. The muscle model is the most commonly used facial animation drive model at present, three-dimensional facial expression changes are driven by simulating contraction of the facial muscle; however, an artist spends much time in performing fine adjusting on the construction of the conventional face muscle model, and after the face muscle model is changed at a time, all the construction even needs to do again. Based on the problems, the invention provides the novel method for constructing the face muscle model; the method realizes the automatic construction and the assembly of the face muscle by researching a space position mapping relationship between the three-dimensional face characteristic points and the face muscle; and an experimental result proves that the method makes the artist be free from fussy hand debugging, and enables a normal user to customize a three-dimensional image with various expressions required per se.

Owner:BEIHANG UNIV

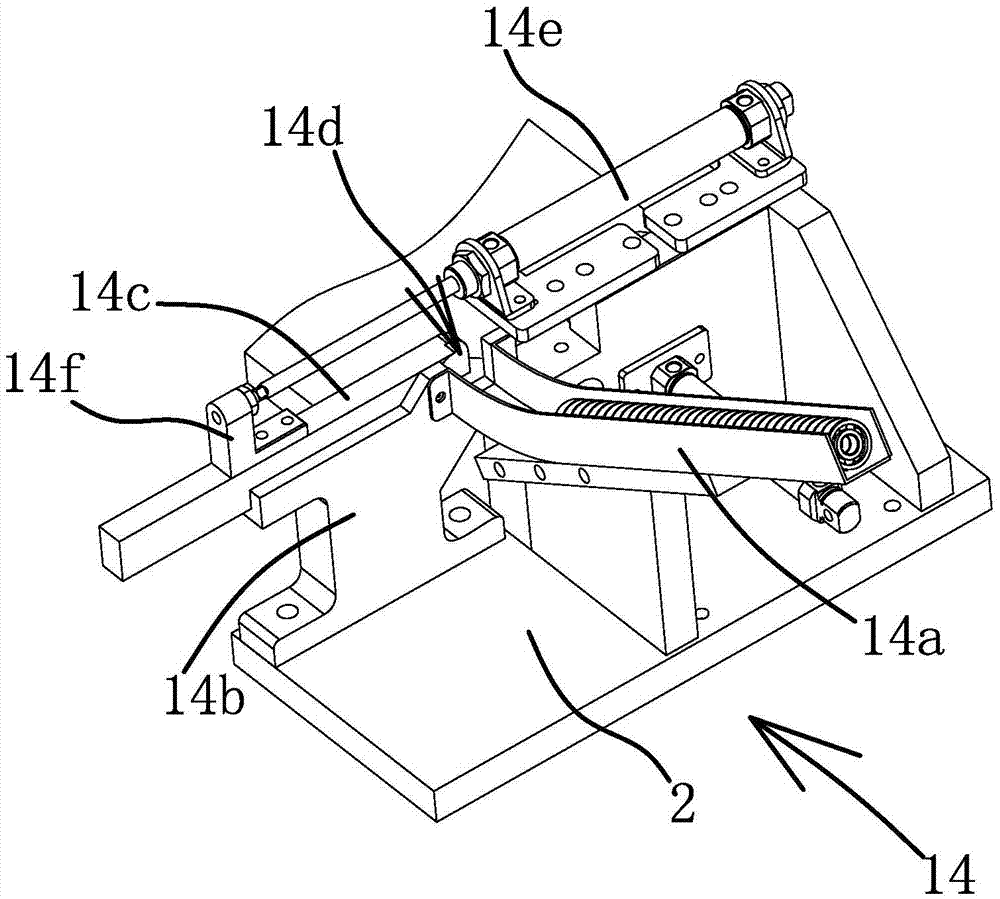

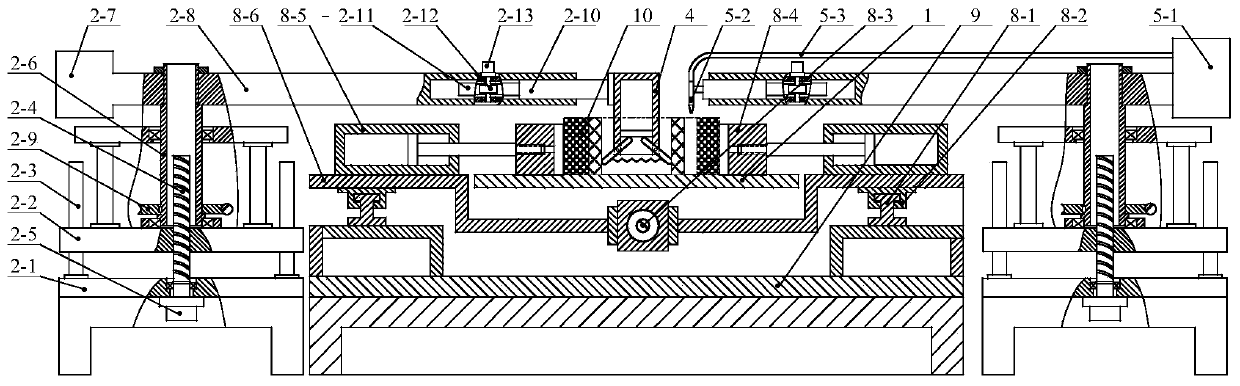

Bearing assembly all-in-one machine and assembly method thereof

ActiveCN110185711AGuaranteed precision and consistencySimple mechanical structureBearing componentsNozzleEngineering

The invention discloses a bearing assembly all-in-one machine and an assembly method thereof. The assembling of bearing balls and press-fitting of a bearing retainer are important processes in the assembly of rolling bearings. The machine comprises an operating platen, a ball loading module, a retainer pressing-in module, a station switching mechanism and a base, wherein the ball loading module comprises an inner ring triaxial mechanical arm, a ball triaxial mechanical arm, an inner ring mounting chuck and a ball blowing mechanism; the retainer pressing-in module comprises a pressing-down mechanism and a retainer pushing mechanism; the ball blowing mechanism comprises an air pressure ball bin, an on-off valve, a nozzle and a ball conveying pipe; and the retainer pushing mechanism comprisesa feeding device seat, a feeding air cylinder, a return spring, a T-shaped locking pin, a feeding bottom plate, a feeding device, a feeding inclined rail and a retainer storage bin. By matching the station switching mechanism, the ball loading module and the retainer pressing-in module, the assembly of an inner ring, an outer ring, the balls and the retainer of the bearing can be completed fullyautomatically, and the assembly precision and uniformity of the bearing are effectively guaranteed.

Owner:杭州电子科技大学安吉智能制造技术研究院有限公司 +1

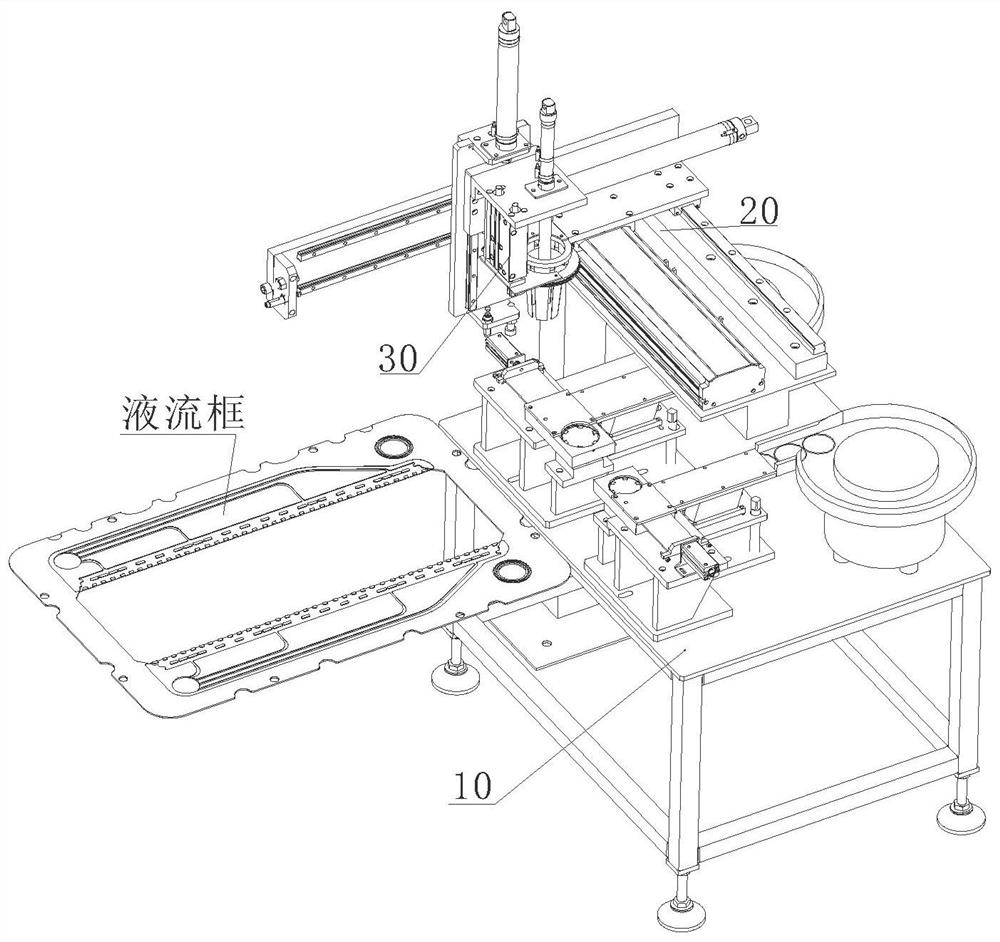

Automatic sealing ring assembling device and automatic assembling method thereof

InactiveCN113084485ASolve the problem of manual assemblyRealize the assemblyMetal working apparatusConveyor partsStructural engineeringMechanical engineering

The invention relates to the field of sealing ring assembling, and discloses an automatic sealing ring assembling device and an automatic assembling method thereof. The automatic sealing ring assembling device comprises a feeding mechanism, a moving mechanism and a taking and unloading mechanism, and the feeding mechanism is used for automatic discharging of the sealing ring. The taking and unloading mechanism is driven by the moving mechanism to assemble the sealing ring on the feeding mechanism onto a to-be-mounted part. A material taking assembly comprises a conical clamping jaw and a fourth driving device, the outer diameter of the conical clamping jaw is increased through driving of the fourth driving device, the conical clamping jaw is sleeved with the sealing ring, and automatic material taking is completed. An unloading assembly comprises an annular movable assembly and a fifth driving device, the annular movable assembly moves on the conical clamping jaw through the fifth driving device, the sealing ring is pushed to be installed on the to-be-mounted part, and automatic assembling is completed. According to the automatic sealing ring assembling device, automatic assembling of a single sealing ring can be achieved, and automatic assembling of a plurality of sealing rings with different inner diameters can be achieved at the same time.

Owner:湖南钒谷新能源技术有限公司

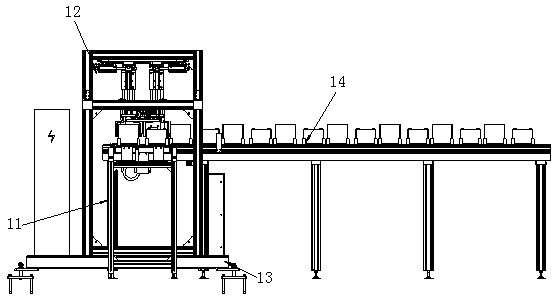

Lithium battery cathode assembling machine

InactiveCN102044663AGood assembly qualityImprove efficiencyCell electrodesOperating environmentEngineering

The invention discloses a lithium battery cathode assembling machine which comprises a working platform, wherein a steel shell feeding device, a lithium sheet feeding and shearing device, a lithium sheet transferring device, a cathode shaping device, a steel shell transferring device and a cathode rolling device are sequentially arranged on the working platform, and all the devices are connected with a main control circuit. The invention solves the problems of low speed and low efficiency for manually assembling the cathode of a lithium battery, has the advantages of good assembling quality and high efficiency, improves the operating environment, and saves the cost. The lithium battery cathode assembling machine has a simple structure; when the cathode is assembled, the lithium sheet is firstly fed, and then sheared; the sheared lithium sheet is fed into a shaping working station, and subjected to low shaping, left and right shaping and upper shaping, and then loaded into a steel shell; and the steel shell loaded with the cathode is fed to a rolling position for rolling, and then the steel shell subjected to the rolling is conveyed and discharged, therefore, the automatic feeding,shaping and assembling of the lithium battery cathode are realized.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

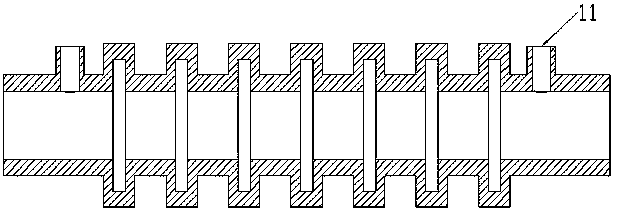

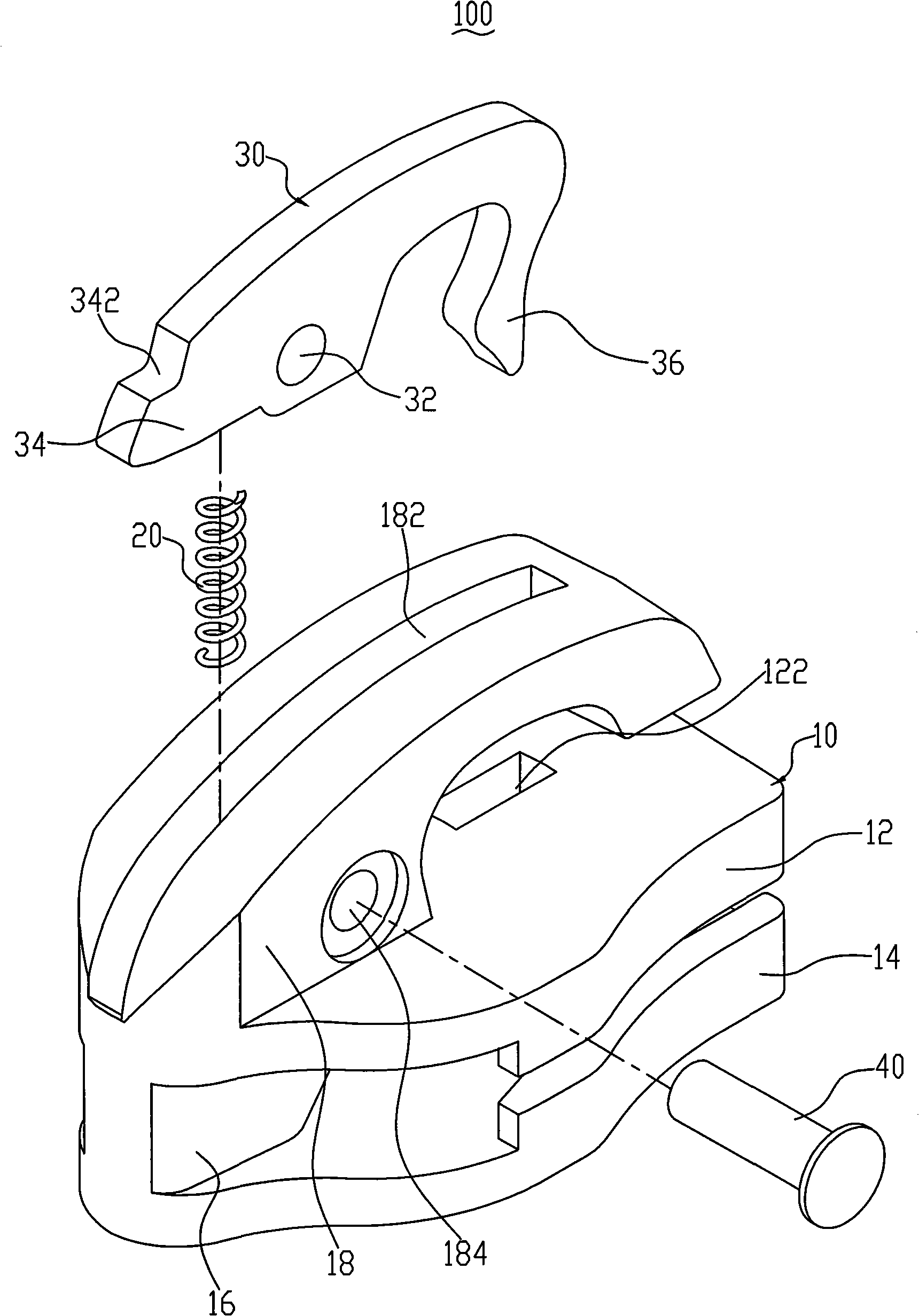

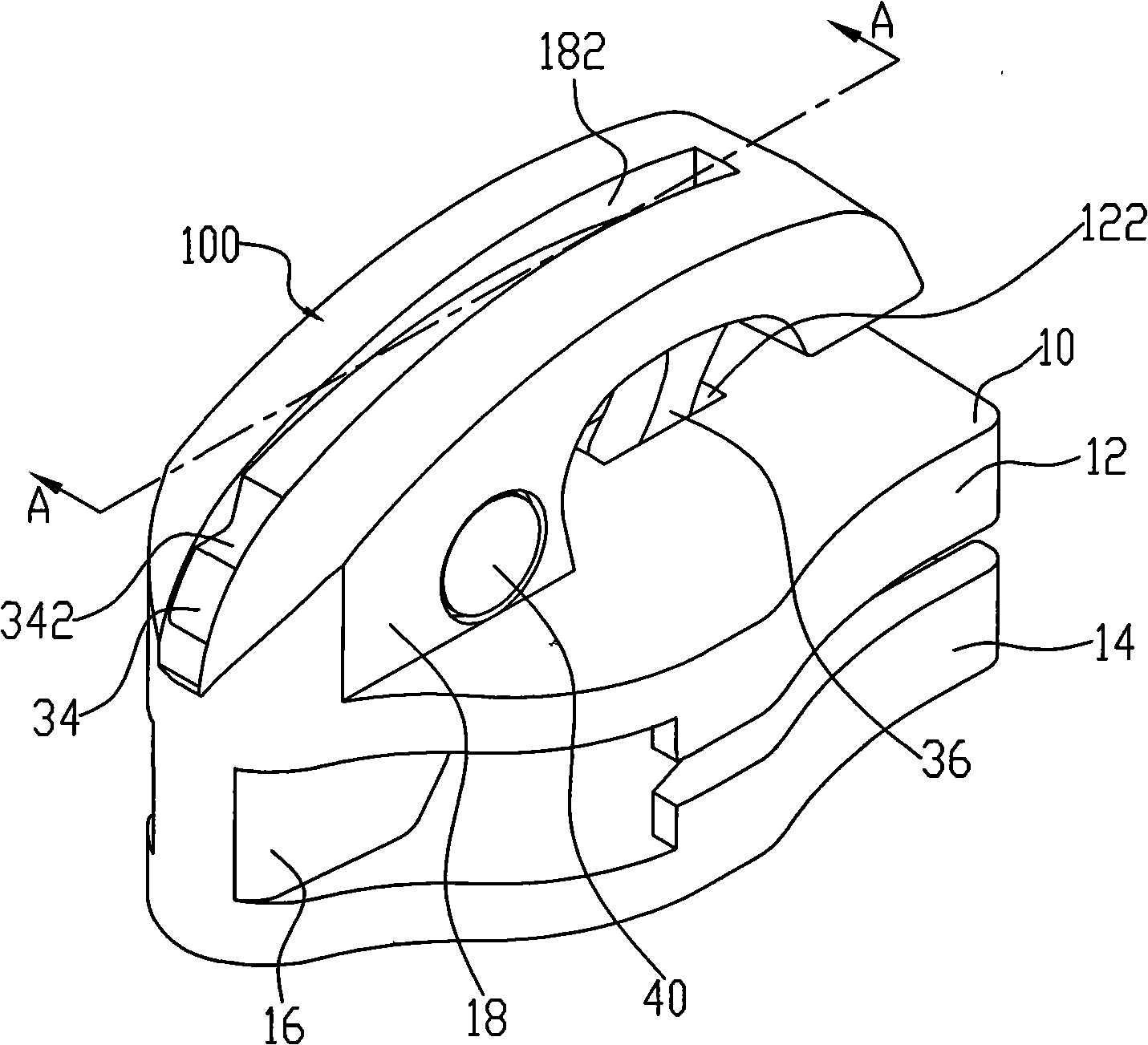

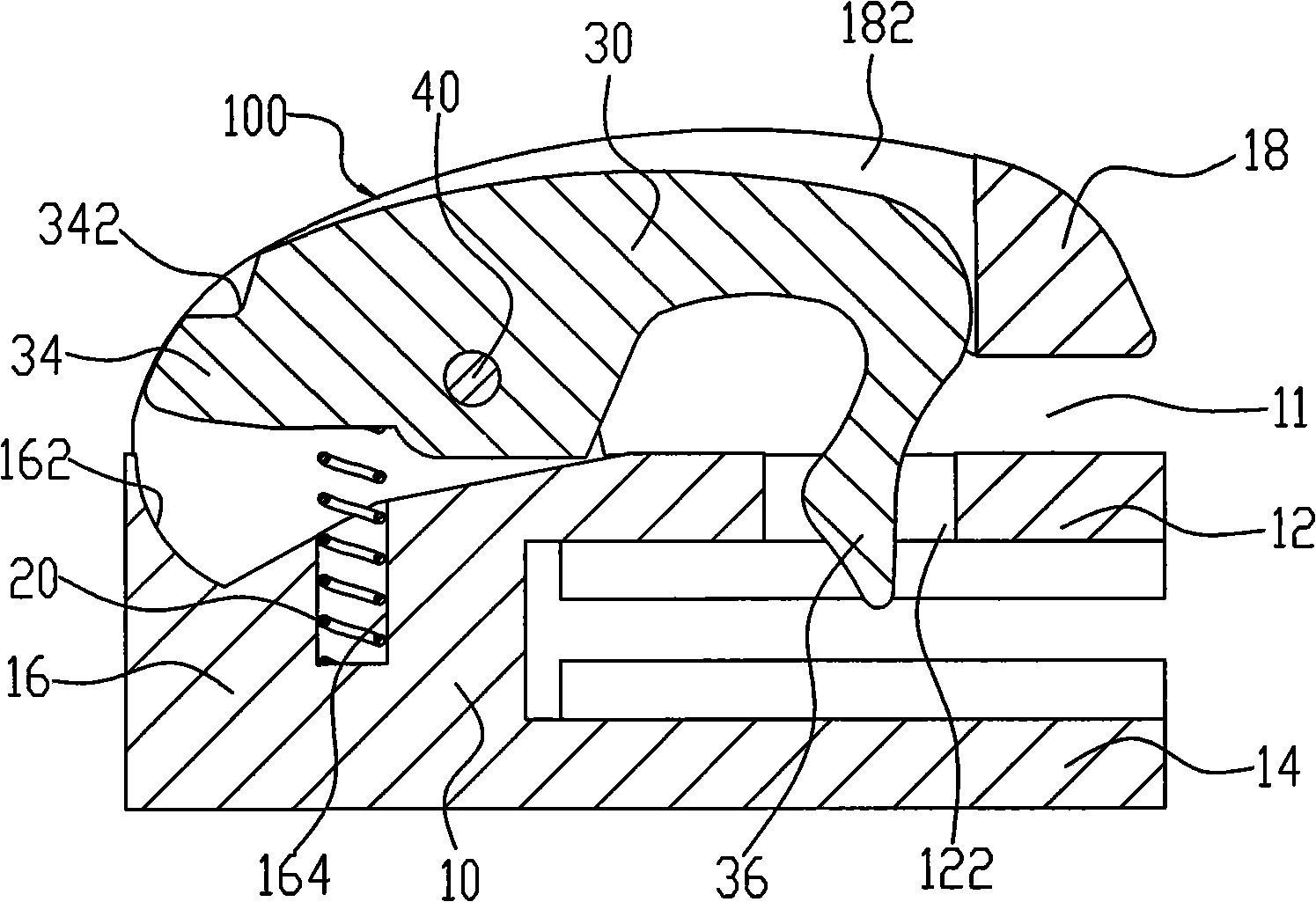

Tension-chain sliding block and tension-chain head using same

The invention relates to a tension-chain sliding block and a tension-chain head using the same. The tension-chain sliding block comprises a sliding block, an elastic element and a self-locking element, wherein the sliding block is provided with a pulling piece block and a through hole, one end of the pulling piece block is connected with the sliding block, and the other end of the pulling piece block and the sliding block form a gap for a pulling rod of a pulling piece to pass through. The pulling piece block is provided with a through hole, the self-locking element is provided with a butt part and a hook part, the self-locking element can be rotatably pivoted into the through hole of the pulling piece block, the elastic element is respectively connected with the sliding block and the butt part of the self-locking element, elastic force is applied to the self-locking element to enable the hook part of the self-locking element to be inserted into the through hole of the sliding block; and in operation, the hook part of the self-locking element can be in the through hole of the sliding block by rotating the self-locking element to enable the pulling rod of the pulling piece to pass through. The tension-chain sliding block has the advantages of simple structure and convenient assembling, and the tension-chain head has the advantage of convenient operation.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

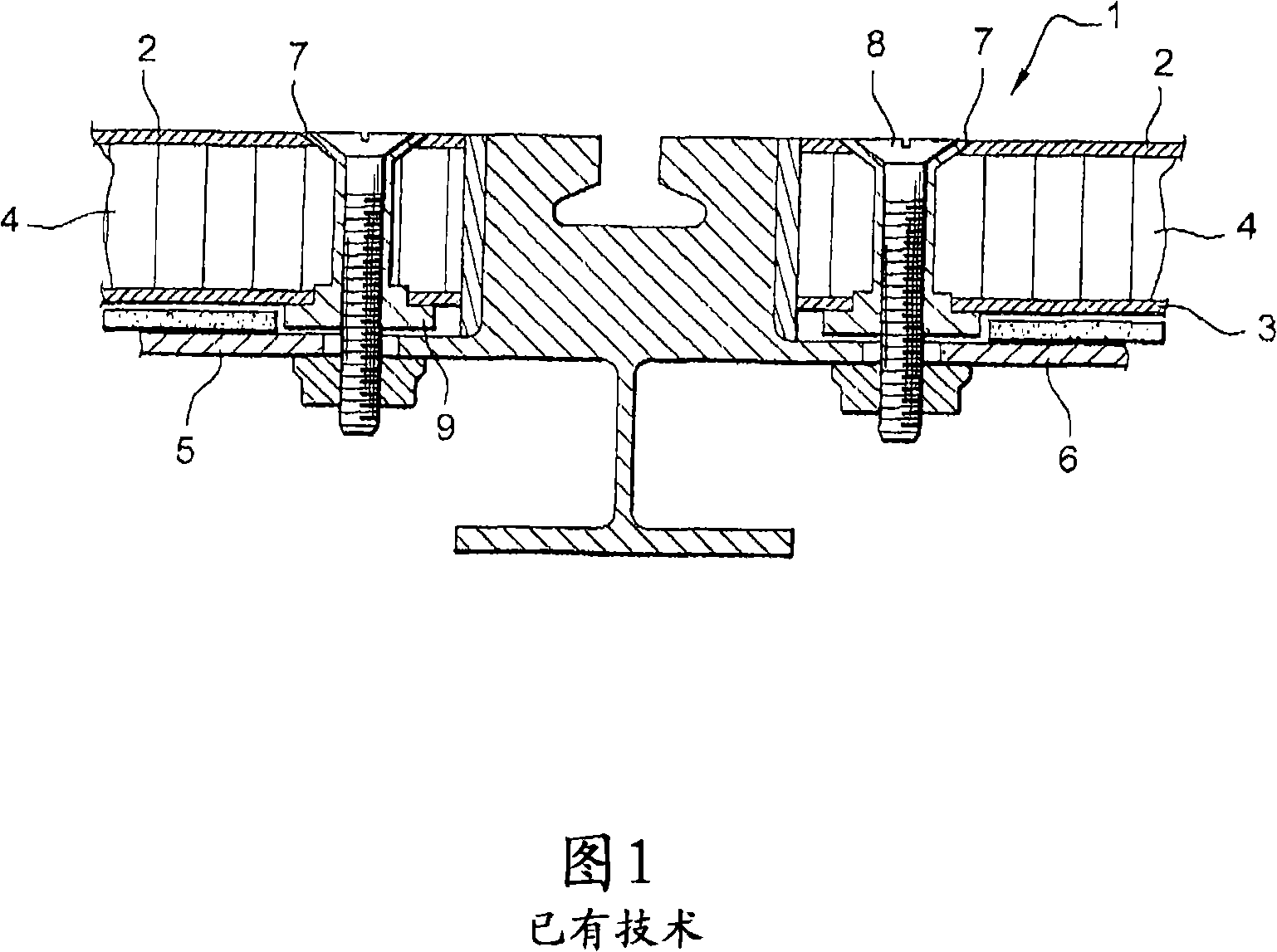

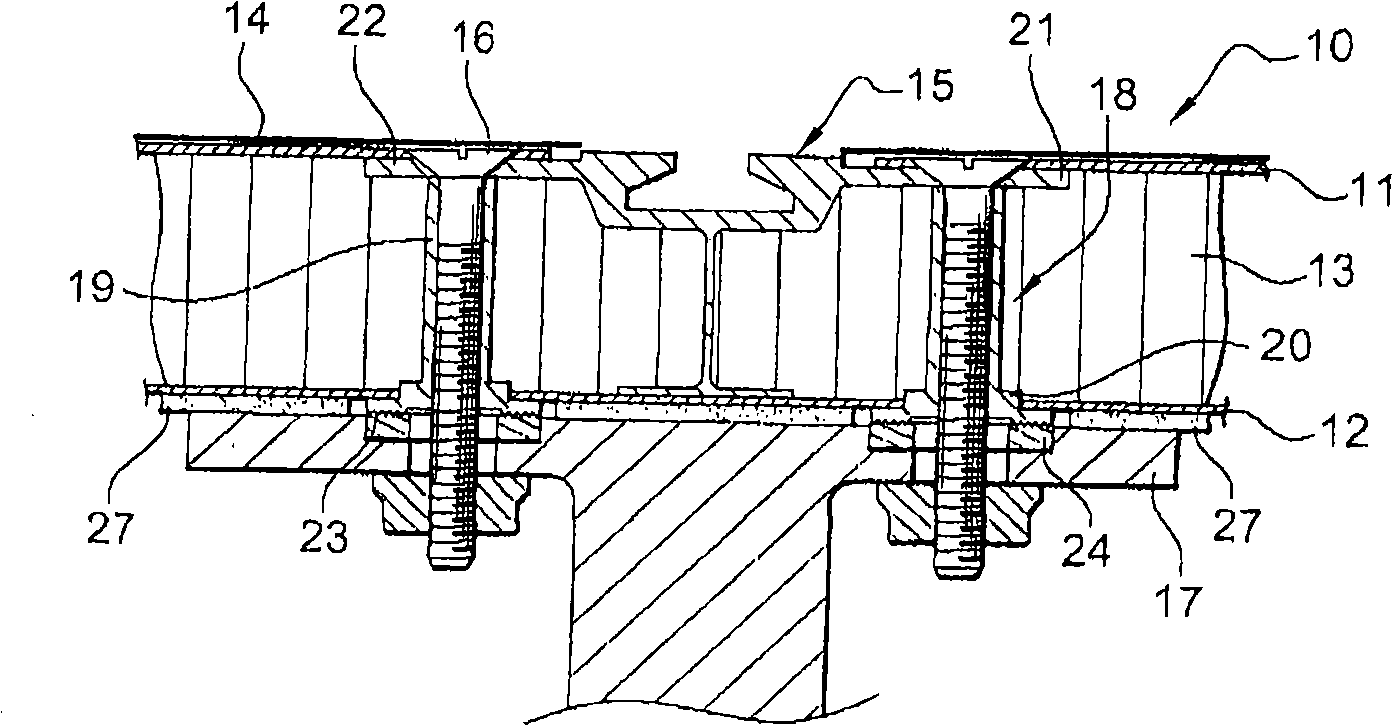

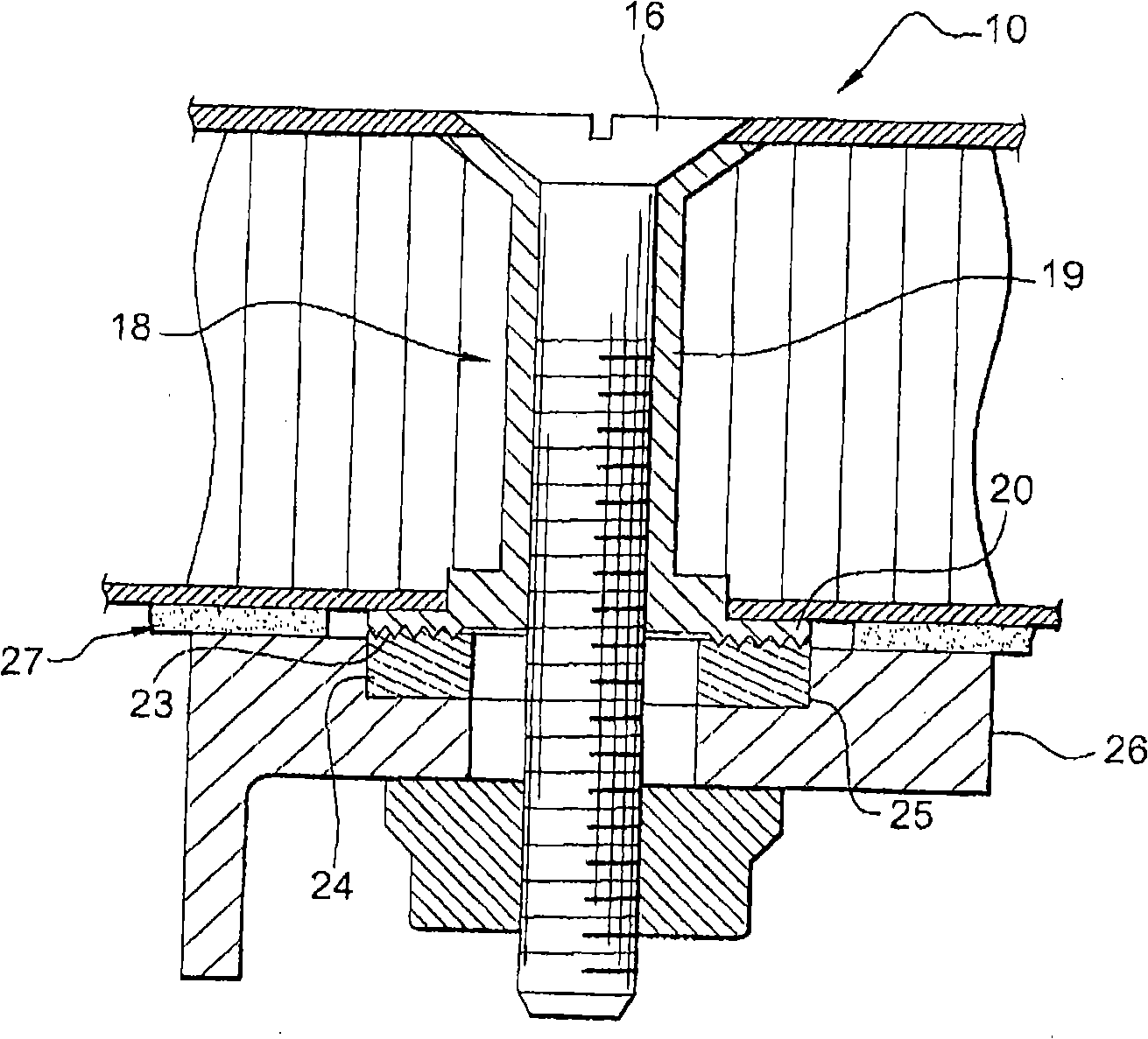

Device for fixing a lightweight panel on a support

InactiveCN101273207ARealize the assemblyFuselage framesEfficient propulsion technologiesBiomedical engineeringFlange

The invention concerns a device for fixing a lightweight panel on a support. Said device comprises an insert (18) including at least one flange (20), said insert being designed to receive a bolt-type fixing member (16). The invention is characterized in that said flange (20) has an outer surface comprising tooth elements (23) and the device comprises a part made of ductile material (24) including an opening for passing through the fixing member (16). The tooth elements (23) are designed to co-operate, when the panel is being fixed on the support, with the ductile part (24) to enable said panel to be fixed without deforming it.

Owner:AIRBUS OPERATIONS (SAS)

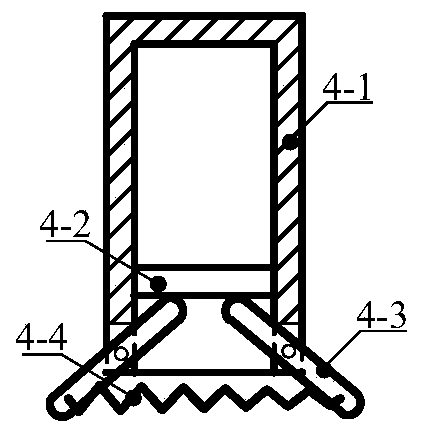

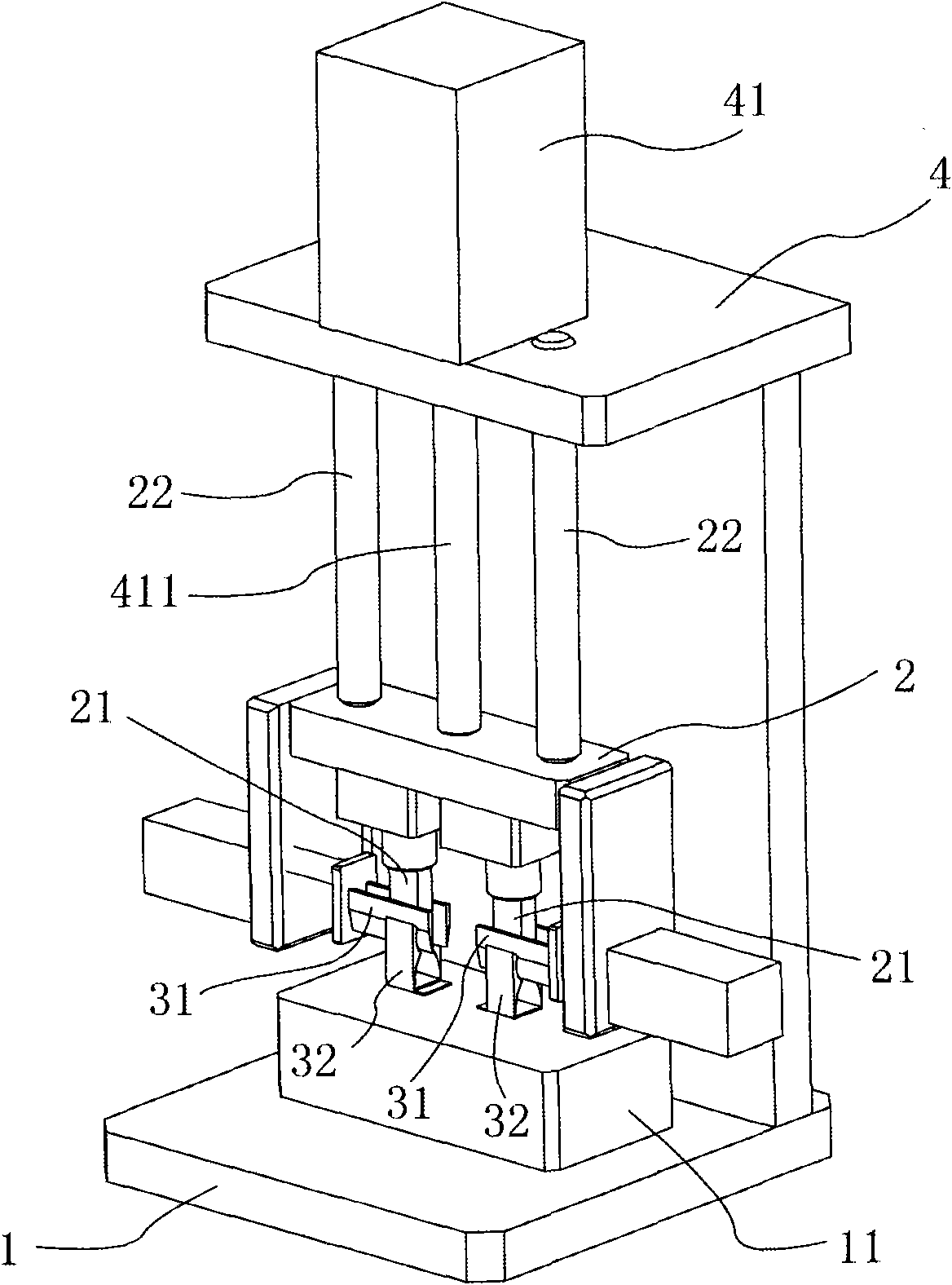

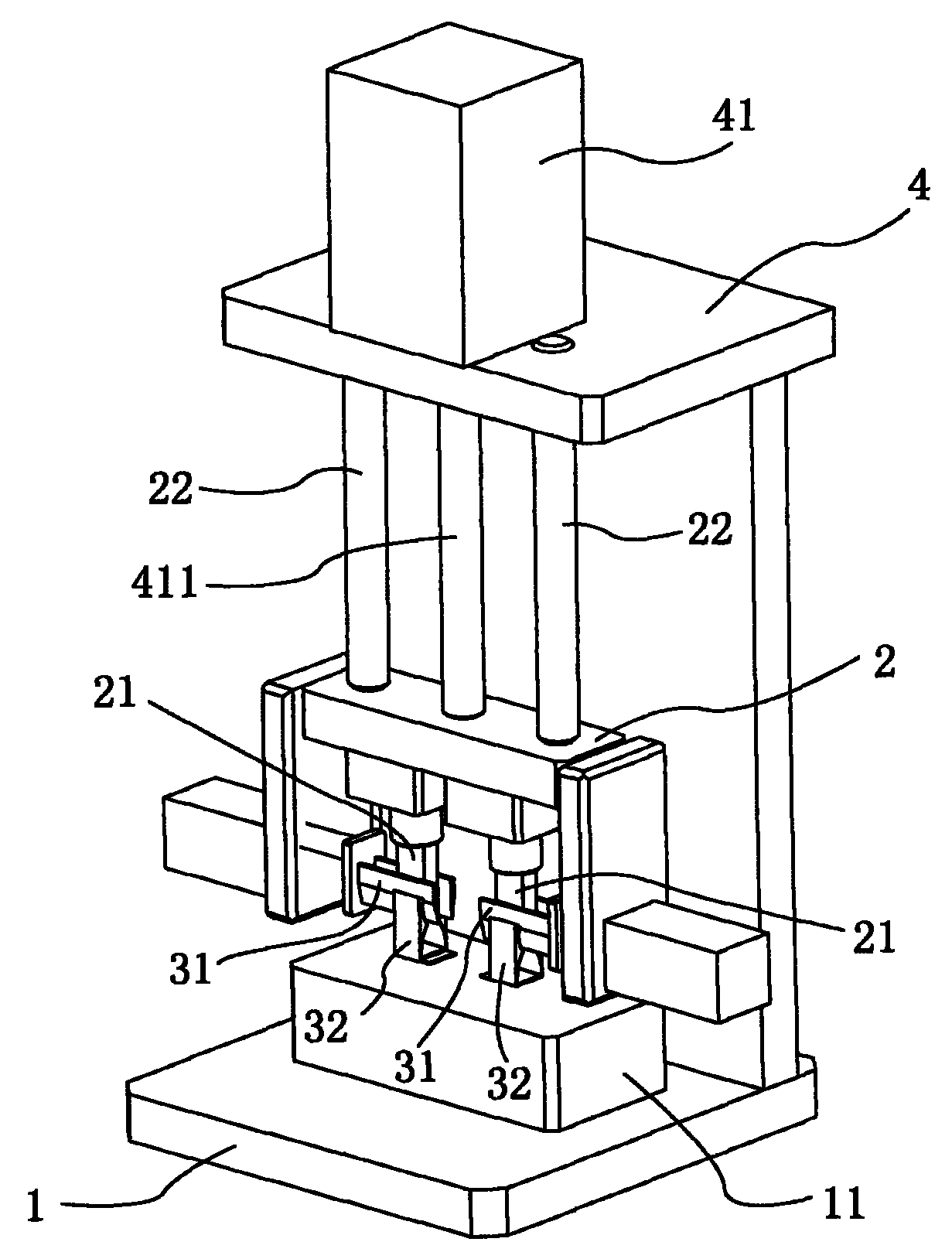

Pressure assembly mechanism

The invention relates to a pressure assembly mechanism, which is used for pressing small products or parts in corresponding cavities of large products or parts. The pressure assembly mechanism comprises an upper punch arranged on an upper die fixed plate and a lower die fixed plate arranged on a base, wherein a guiding sleeve is also arranged on the upper die fixed plate; a guiding rod is arranged in the guiding sleeve; the upper die fixed plate is connected with the head part of a piston rod for driving an air cylinder; the piston rod is parallel to the guiding rod; a clamp for clamping the large products or parts is arranged on the lower die fixed plate; and at least part of the lateral surface of the upper punch along the feeding direction is an inclined plane.

Owner:SUZHOU NEW DISTRICT KEXING WILL ELECTRONICS

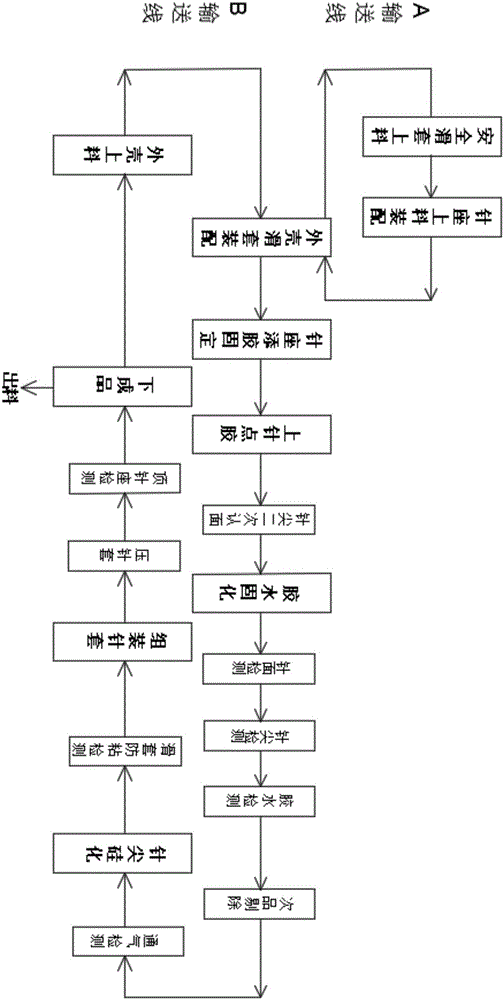

Safe intravenous needle assembling machine

PendingCN106041523ARealize the assemblyImprove yield rateAssembly machinesFinal product manufactureIntravenous needlesEngineering

The invention provides a safe intravenous needle assembling machine, and belongs to the technical field of medical apparatuses and instruments. The safe intravenous needle assembling machine solves the problems that an existing assembling machine is incomplete in assembling and not high in yield of finished products. The assembling machine comprises a machine frame, and is characterized in that two carrier circulation conveying lines are arranged on the machine frame in parallel and include the sliding sleeve carrier conveying line and the outer shell carrier conveying line; the sliding sleeve carrier conveying line is sequentially provided with a safe sliding sleeve feeding mechanism for feeding corresponding assemblies to an assembling station and a needle base feeding and assembling mechanism in the conveying direction; the outer shell carrier conveying line is sequentially provided with an outer shell feeding mechanism, an outer shell and sliding sleeve assembling mechanism, a needle base glue adding fixing mechanism, a needle feeding and dispensing mechanism, a glue curing device, a needle tip silicification mechanism, a needle sleeve assembling mechanism and a finished product discharging mechanism in the conveying direction; and the outer shell and sliding sleeve assembling mechanism is located between the sliding sleeve carrier conveying line and the outer shell carrier conveying line and located behind the needle base feeding and assembling mechanism of the sliding sleeve carrier conveying line in the conveying direction. According to the safe intravenous needle assembling machine, assembling of the accessories in a safe intravenous needle can be successfully achieved; the accessories are subject to staggered and repeated receiving, so that the production efficiency can be greatly improved; and a plurality of inspection items are additionally carried out in the assembling process, and inferior-quality product screening is carried out on the accessories and middle assemblies in an all-around manner, so that discharging of inferior-quality products is reduced, and the yield of the finished products is improved.

Owner:梁启明

Shaft core assembler

ActiveCN106736536AQuality improvementRealize automatic feeding processAssembly machinesControl systemDisplay device

The invention discloses a shaft core assembler. The shaft core assembler comprises a shaft core mounting mechanism, a direction adjusting mechanism, a lower gasket assembly mechanism, an oil dispensing mechanism, an upper gasket assembly mechanism, a second oil dispensing mechanism, a gear assembly mechanism, a riveting mechanism and a finished product detecting mechanism; the shaft core mounting mechanism, the direction adjusting mechanism, the lower gasket assembly mechanism, the oil dispensing mechanism, the upper gasket assembly mechanism, the second oil dispensing mechanism, the gear assembly mechanism, the riveting mechanism and the finished product detecting mechanism are fixedly mounted on a frame in sequence in the clockwise direction; a cutter is arranged on the frame; a turntable is rotationally mounted on the upper side of the cutter; tools are uniformly distributed on the edge of the turntable; and a display is arranged on the frame, and is connected to a control system. The shaft core assembler realizes automatic loading, assembly and detection of all parts of a shaft core, realizes automatic production, and improves the production efficiency and the quality of the shaft core.

Owner:DONGGUAN XINLIANGDIAN AUTOMATION EQUIP TECH

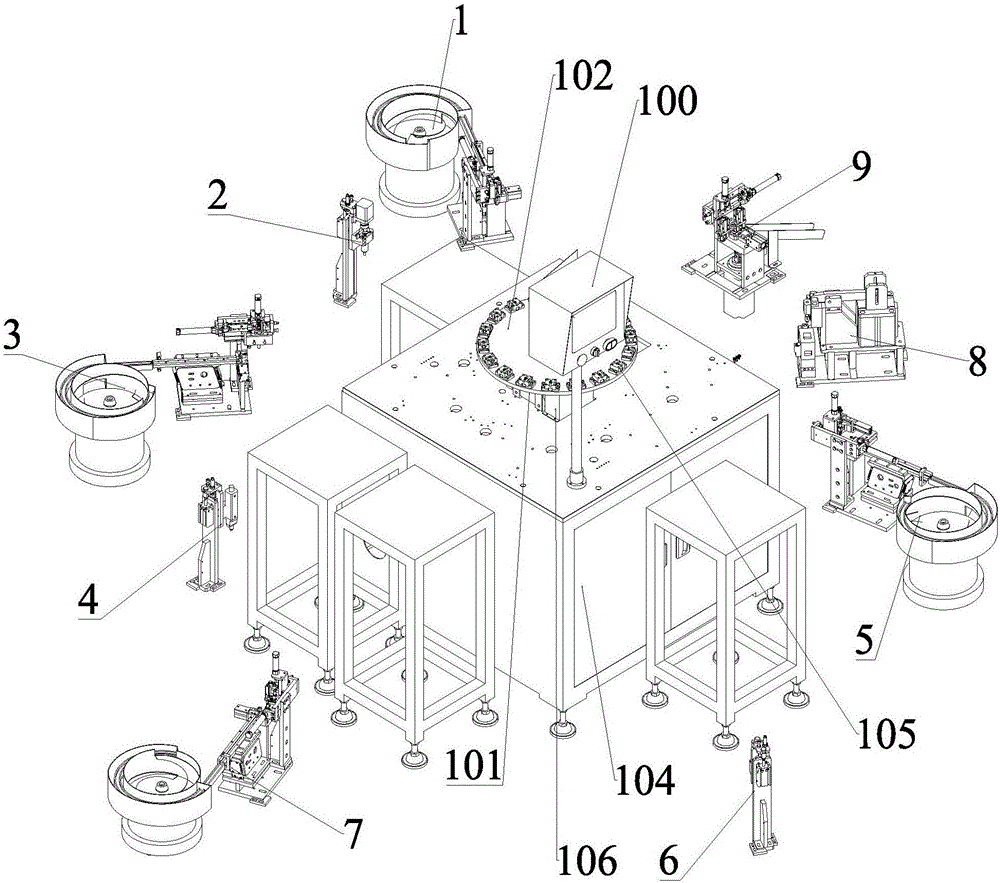

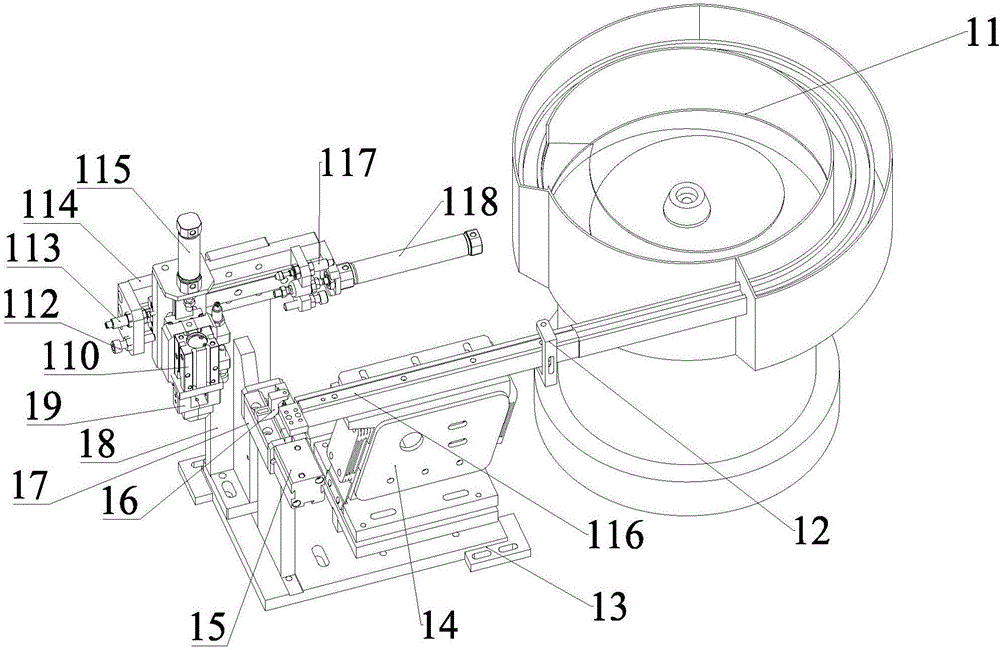

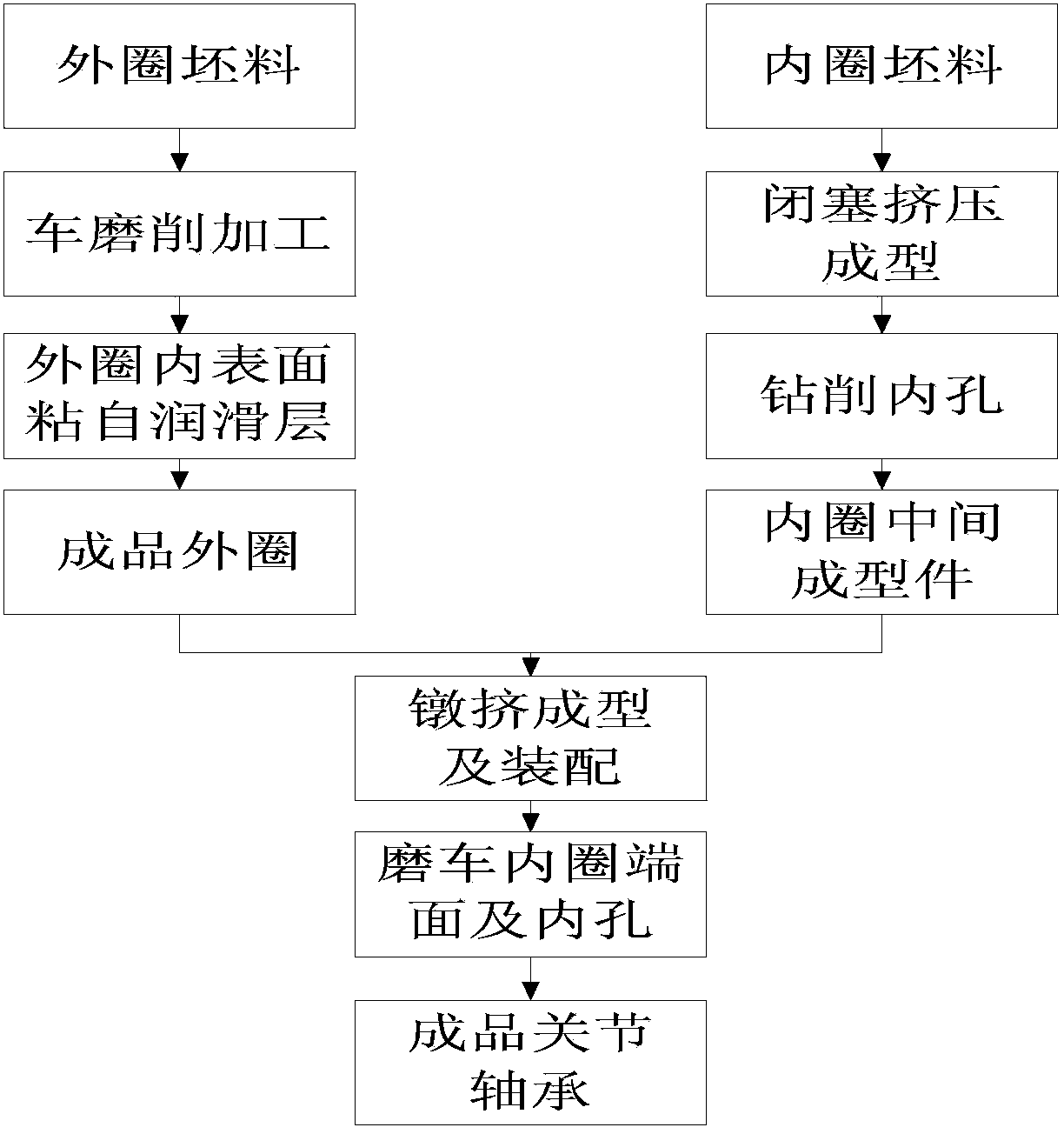

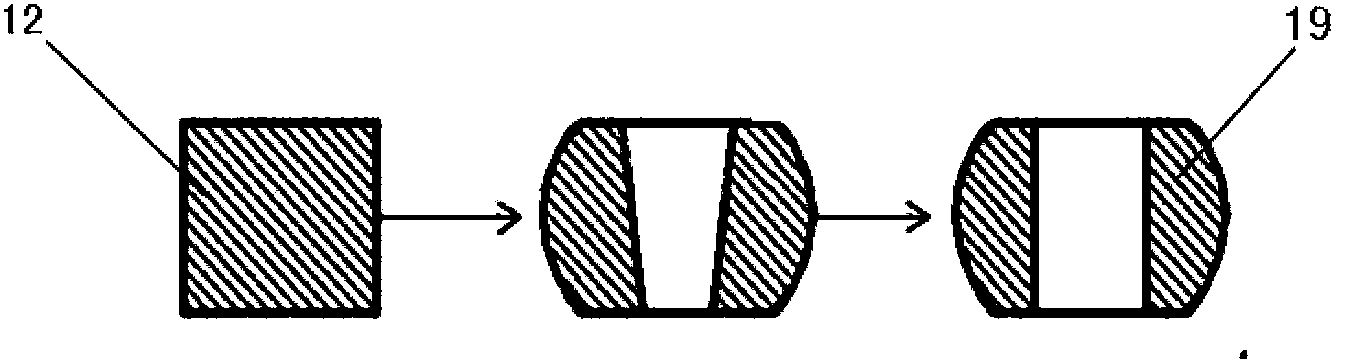

Extrusion forming manufacturing method for inner race of integral type titanium alloy self-lubricating spherical plain bearing

ActiveCN103357810AHigh precisionExtend your lifeForging/hammering/pressing machinesEngine componentsTitanium alloyCopper alloy

The invention discloses an extrusion forming manufacturing method for an inner race of an integral type titanium alloy self-lubricating spherical plain bearing. The method comprises the following steps: firstly machining a titanium outer race for the spherical plain bearing according to the requirement, and adhering a self-lubricating layer on the inner surface of the outer race to form a finished bearing outer face; secondly, conducting obturated-extrusion forming on a blank of the bearing inner race through an obturated-extrusion die; thirdly, machining a workpiece into an inner race middle forming piece which is provided with a cylindrical hole of certain size, wherein the diameter of the hole is smaller than that of an inner hole of a finished spherical plain bearing inner race; fourthly, conducting upset-extrusion forming on the inner race middle forming piece through an upset-extrusion die, and assembling the inner race and the outer race while conducting the upset-extrusion forming; and fifthly, grinding two end faces and the cylindrical hole of the inner race for assembling the inner race and the outer race of the bearing to obtain the finished self-lubricating spherical plain bearing. The extrusion forming manufacturing method is applicable to the self-lubricating spherical plain bearing with the titanium alloy outer race and the copper alloy inner race, and the manufactured bearing is long in service life and high in reliability.

Owner:QINHUANGDAO HUALIN PRECISION BEARING TECH

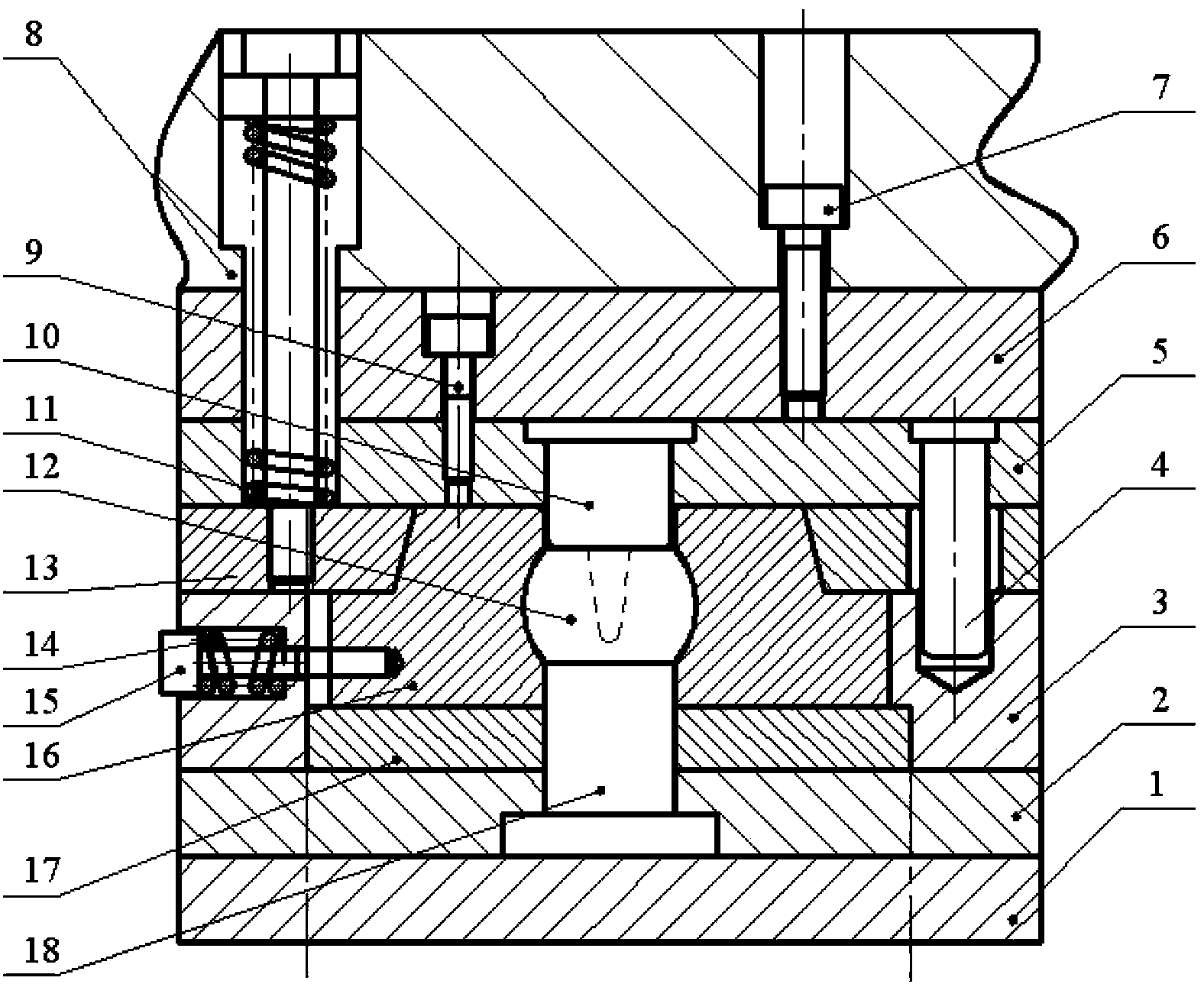

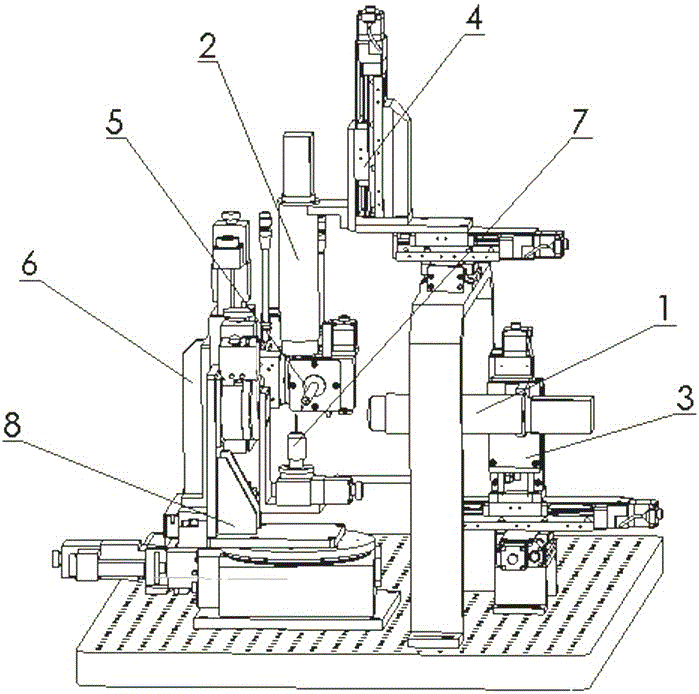

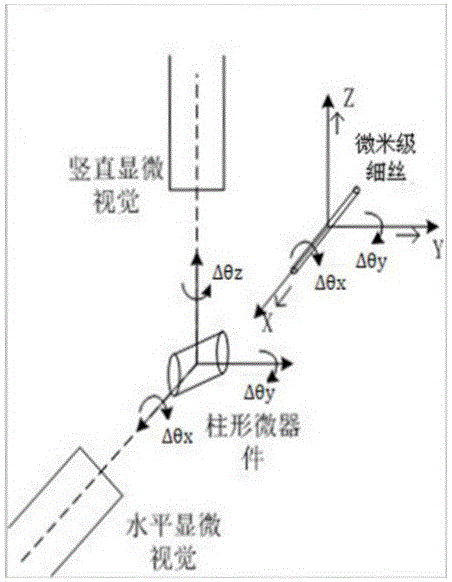

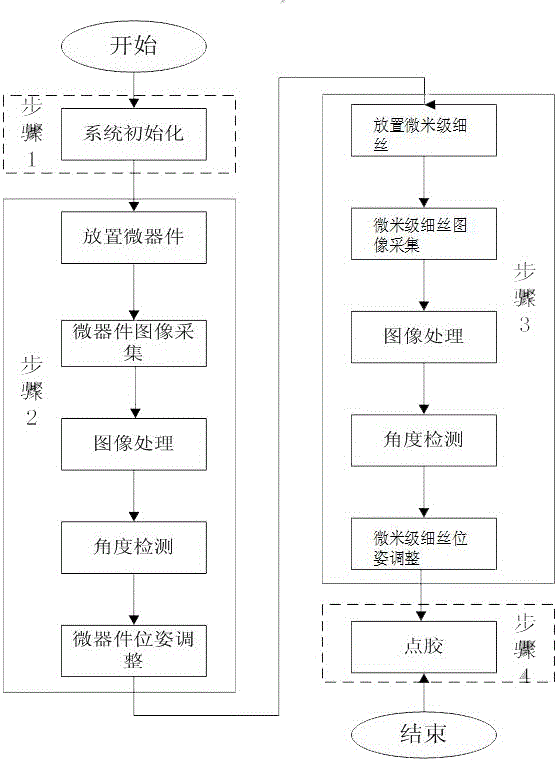

Spatial and angular assembling device for micro-devices

InactiveCN106271587AReal-time monitoringAchieve registrationAssembly machinesMetal working apparatusRotational axisMicro devices

The invention discloses a spatial and angular assembling device for micro-devices. The spatial and angular assembling device is used for spatially and angularly assembling micron-grade fine filaments and the cylindrical micro-devices and comprises a control host, a two-dimensional orthogonal microscopic vision observing device, a cylindrical micro-device attitude adjusting device and a thin filament pose adjusting device. The spatial and angular assembling device has the advantages that the cylindrical micro-device attitude adjusting device has three rotational degrees of freedom, three rotary shafts intersect with one another at a point owing to structural designs, the geometric centers of the cylindrical micro-devices are positioned at the intersection point of the three rotary shafts, accordingly, the micro-devices are assuredly always positioned in microscopic vision fields of view when attitudes of the cylindrical micro-devices are adjusted, the random attitudes of the cylindrical micro-devices can be adjusted in three-dimensional spaces, and various spatial and angular assembly requirements can be met; a fine filament pose adjusting mechanism has five degrees of freedom and is used for positioning spatial poses of the micron-grade fine filaments and fittingly assembling the micron-grade fine filaments; the micron-grade fine filaments and the cylindrical micro-devices can be spatially and angularly assembled under high-precision conditions by the spatial and angular assembling device, and the assembly precision can reach 0.3 degree.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com