Air purifying filter element rapid assembling equipment

An assembly equipment and air purification technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low assembly efficiency, accelerated piston group cylinder wear, cylinder scuffing, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objects and advantages of the present invention more clear, the present invention will be specifically described below with reference to the embodiments. It should be understood that the following text is only used to describe one or more specific embodiments of the present invention, and does not strictly limit the protection scope of the specific claims of the present invention.

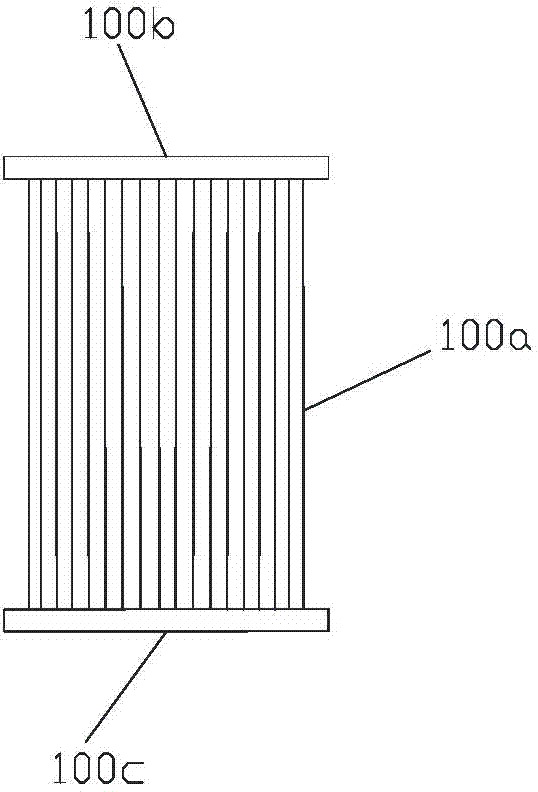

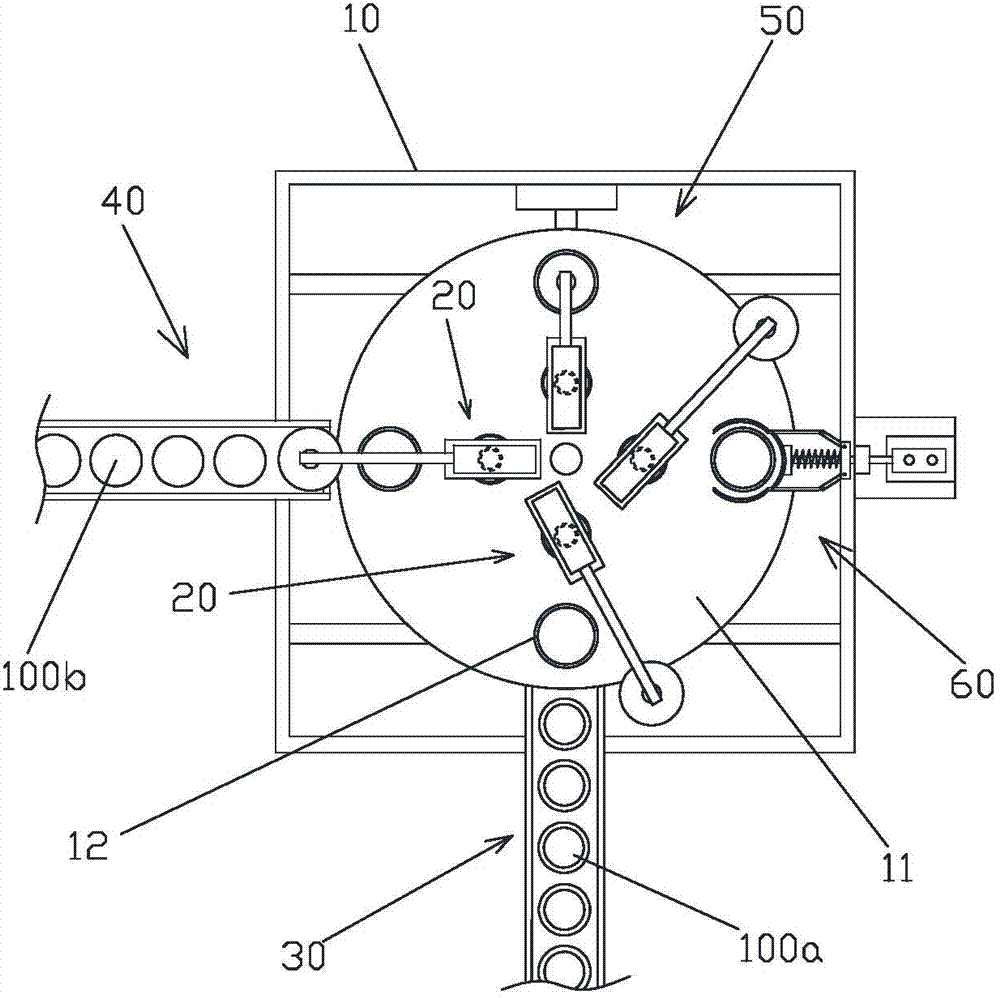

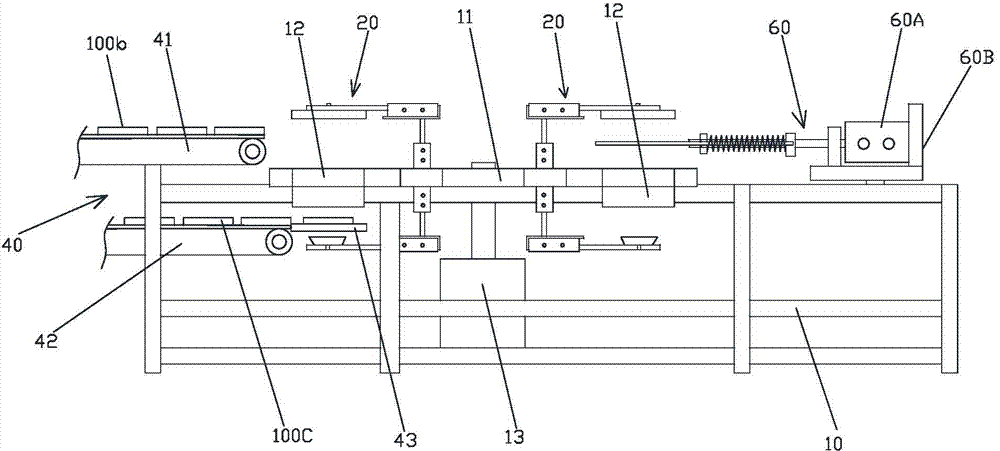

[0017] The technical scheme adopted by the present invention is as follows figure 1 , 2 As shown, an air purification filter element quick assembly equipment includes a turntable 11 rotatably fixed on a frame 10 and arranged horizontally and a first drive mechanism connected to the turntable 11. The first drive mechanism can be formed by a drive motor 13. The turntable A clamping device 20 for clamping the air filter element assembly is arranged at a circumferential interval of 11 , and a feeding device 30 for conveying the filter element body to the clamping device 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com