Patents

Literature

13015results about "Assembly machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

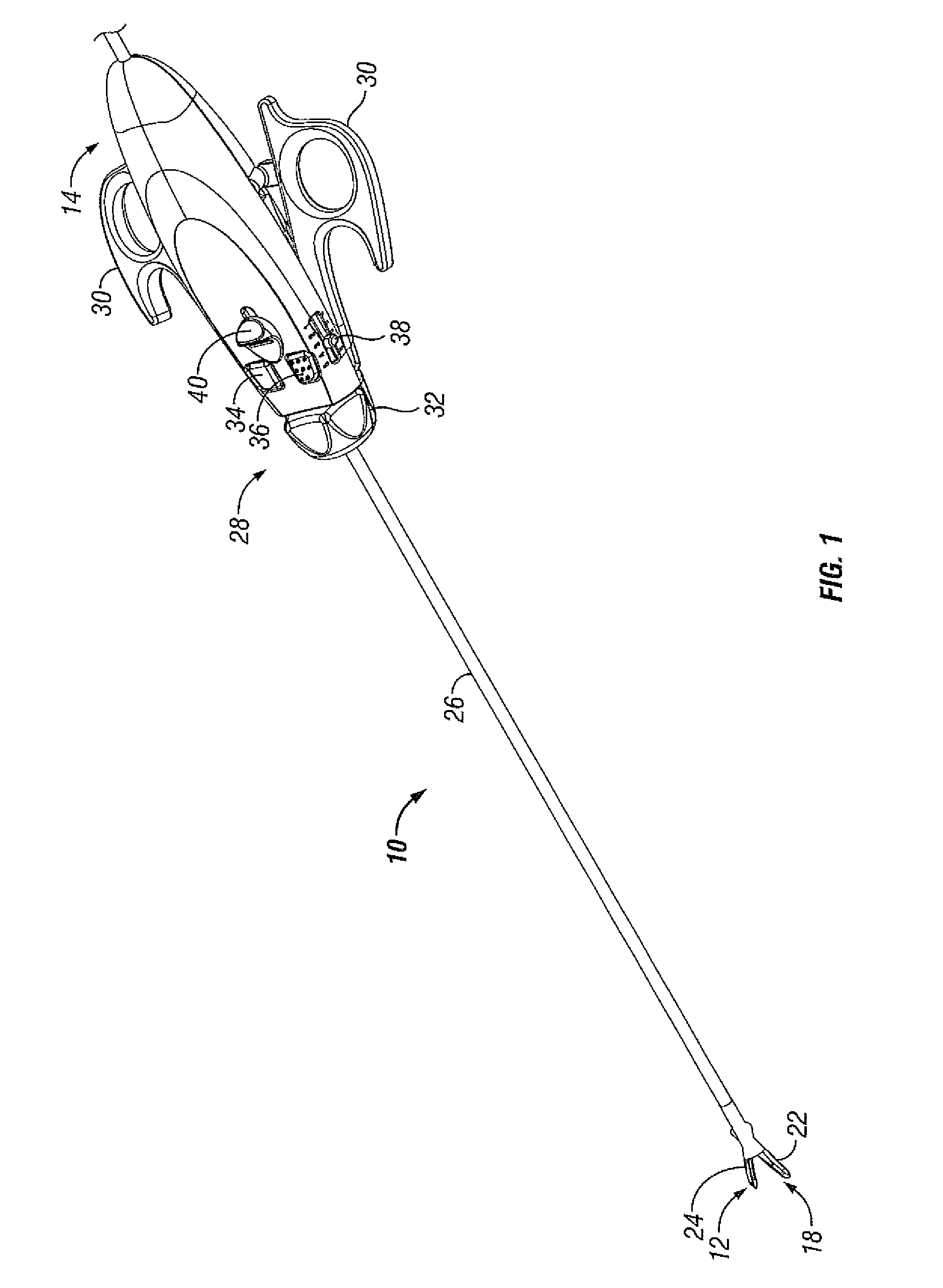

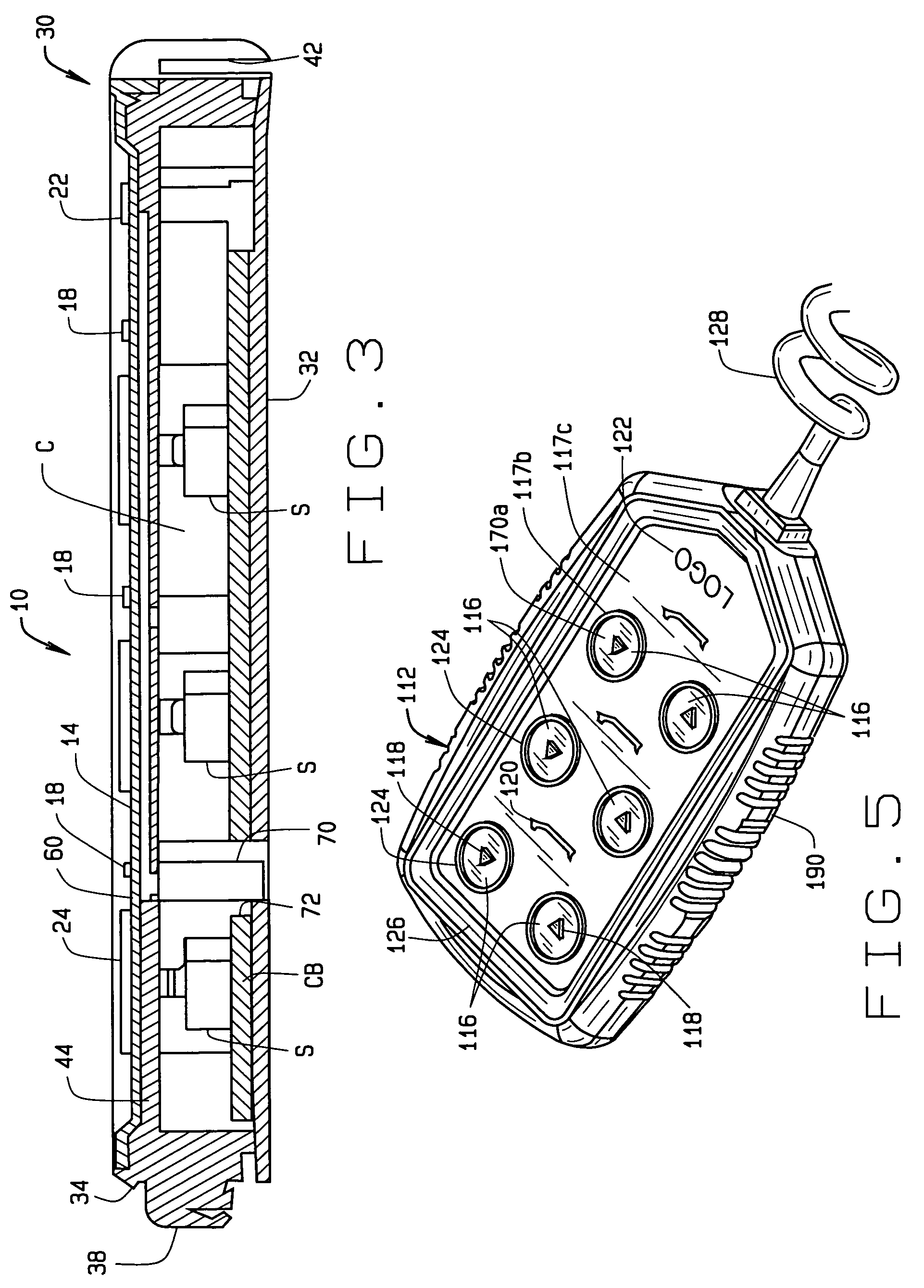

Continuous heart valve support frame and method of manufacture

InactiveUS7137184B2Eliminate unevennessIncrease flexibilityHeart valvesAssembly machinesElgiloyEngineering

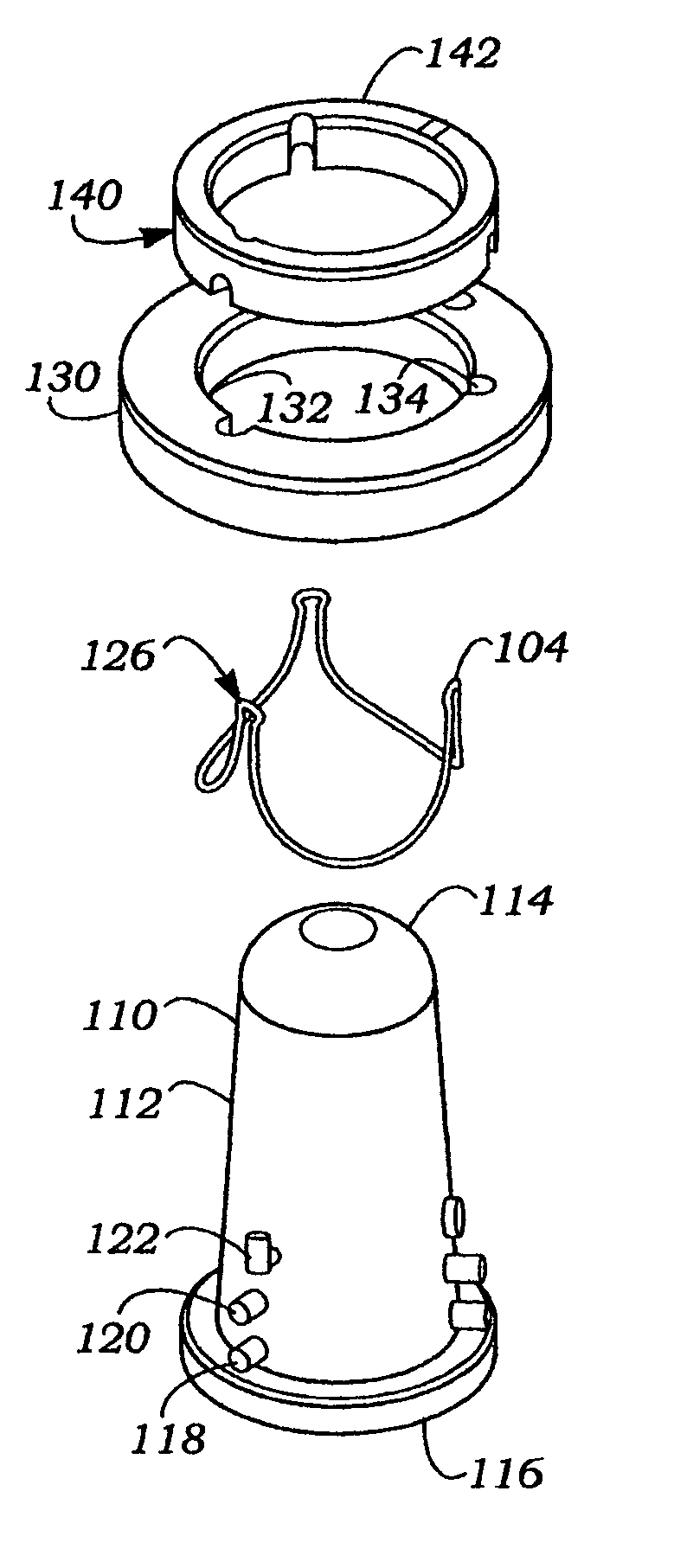

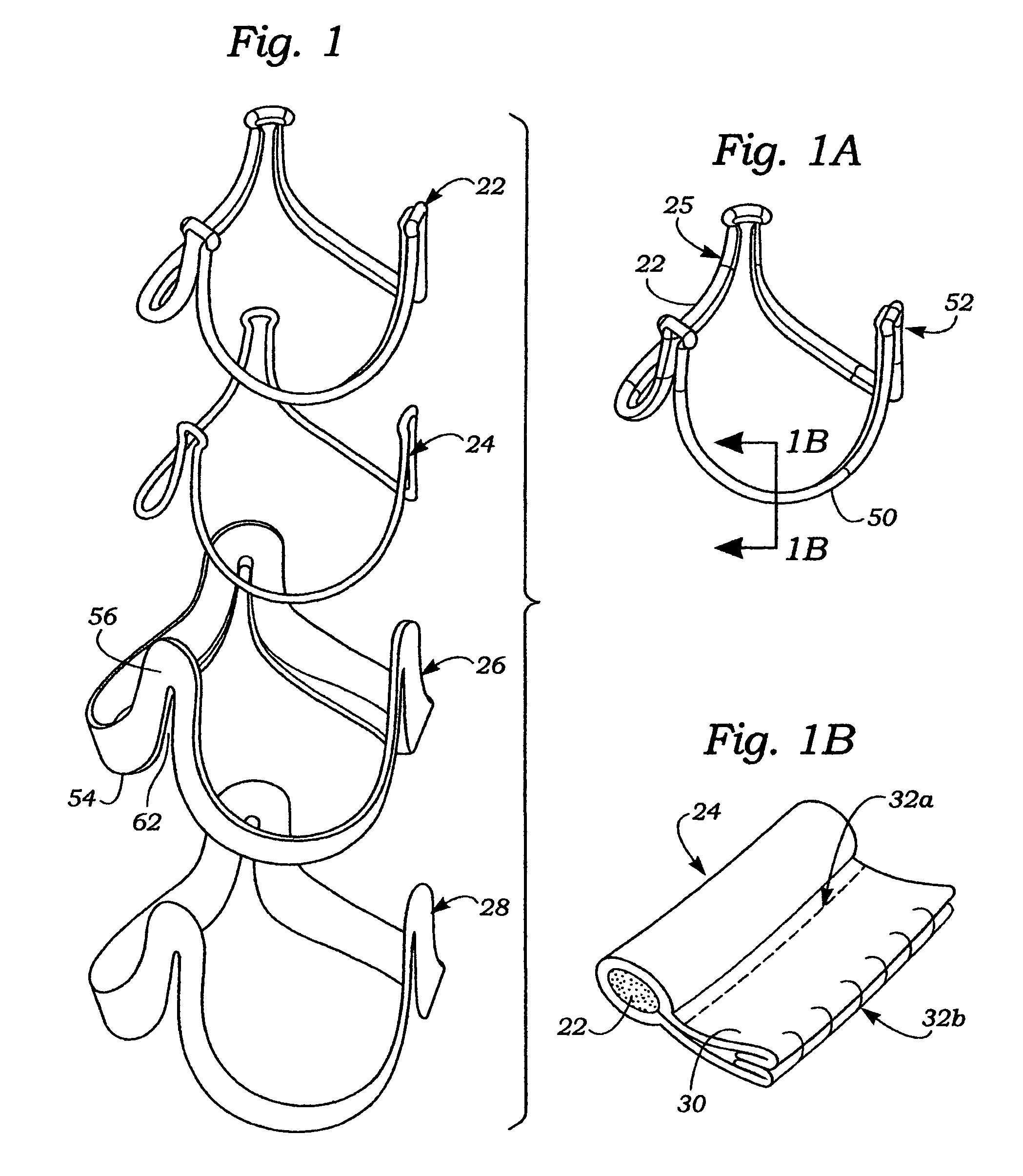

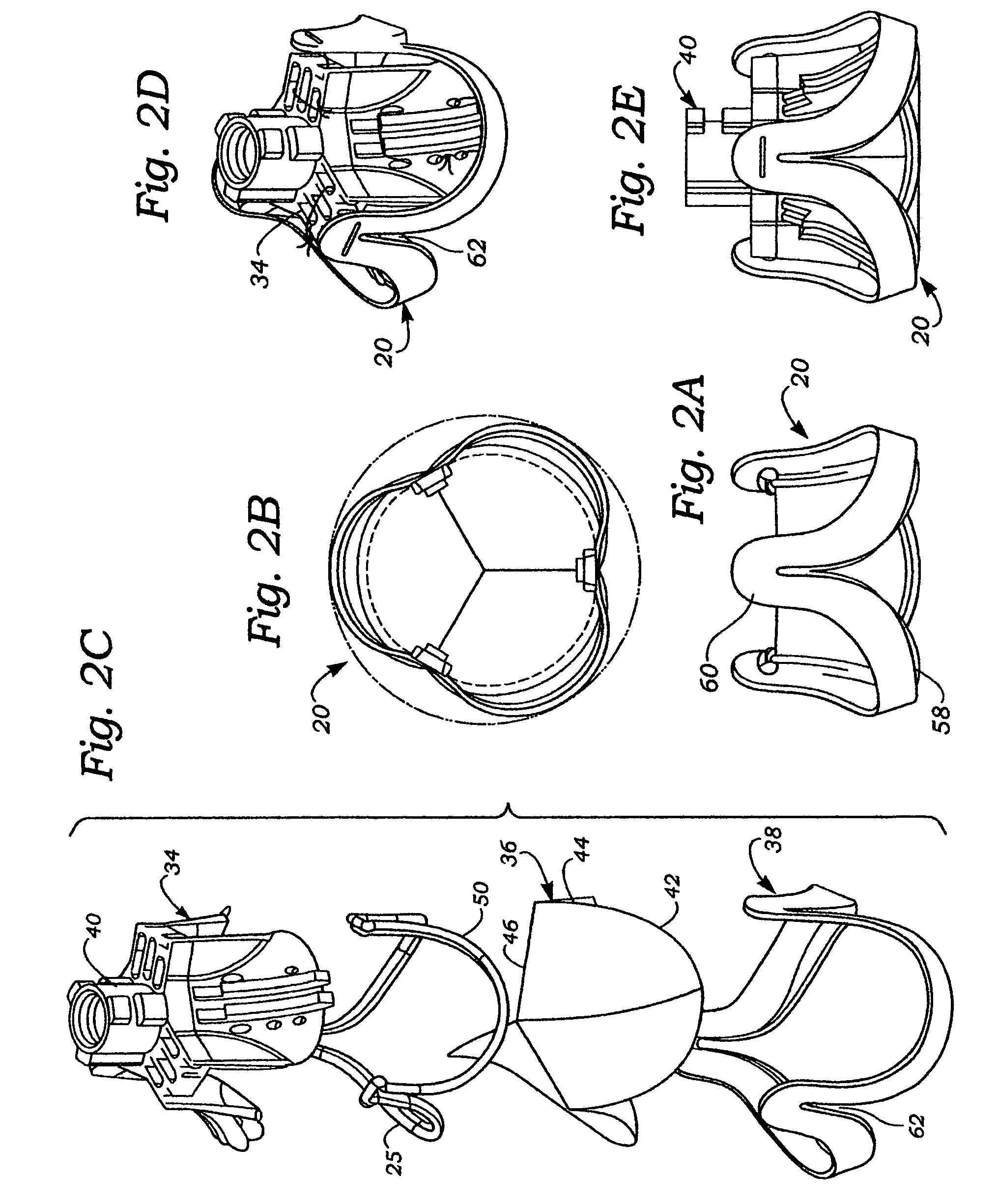

Methods for forming a support frame for flexible leaflet heart valves from a starting blank include converting a two-dimensional starting blank into the three-dimensional support frame. The material may be superelastic, such as NITINOL, and the method may include bending the 2-D blank into the 3-D form and shape setting it. A merely elastic material such as ELGILOY may be used and plastically deformed in stages, possibly accompanied by annealing, to obtain the 3-D shape. Alternatively, a tubular blank could be formed to define a non-tubular shape, typically conical. A method for calculating the precise 2-D blank shape is also disclosed. A mandrel assembly includes a mandrel and ring elements for pressing the blank against the external surface of the mandrel prior to shape setting.

Owner:EDWARDS LIFESCIENCES CORP

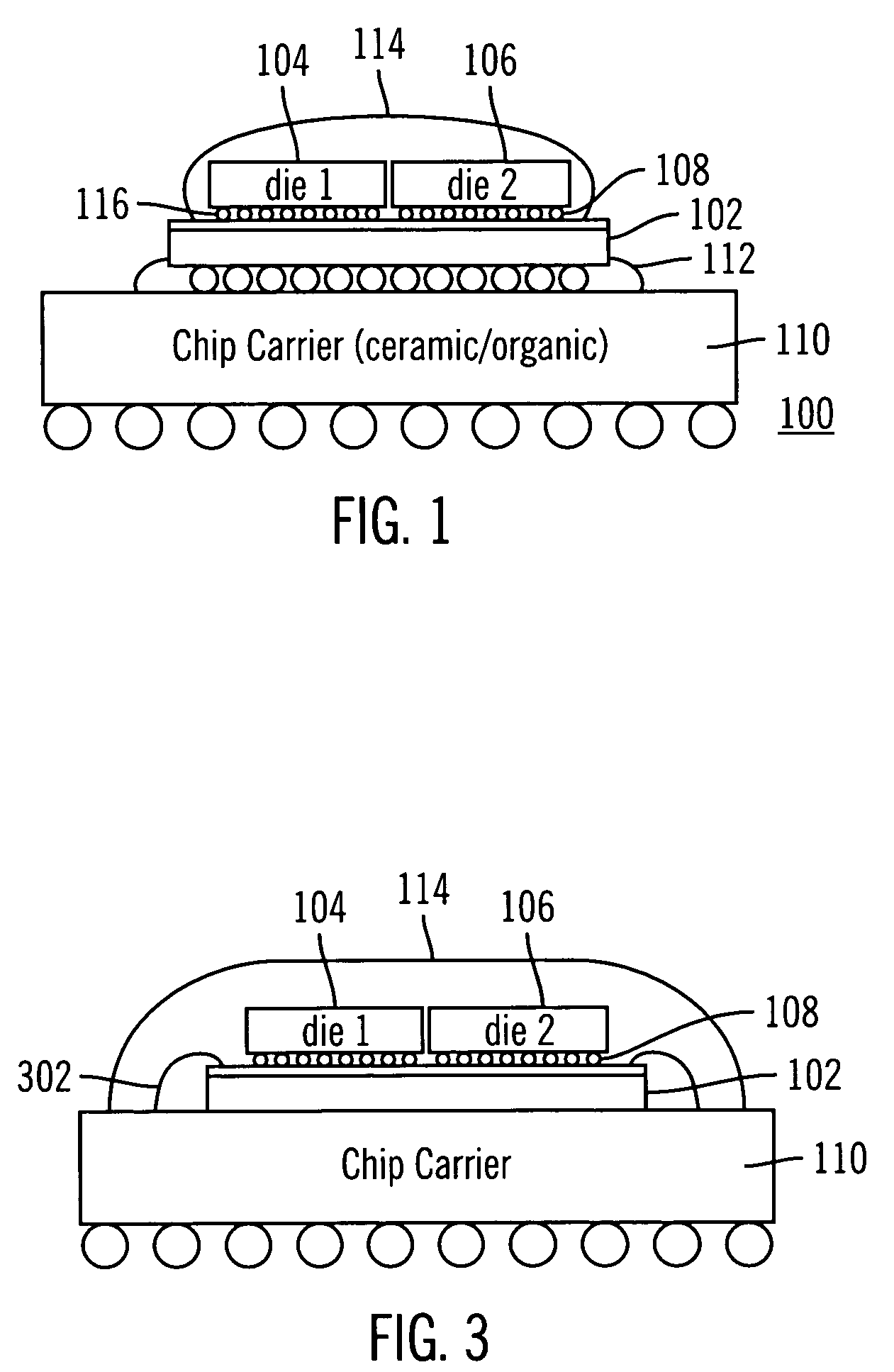

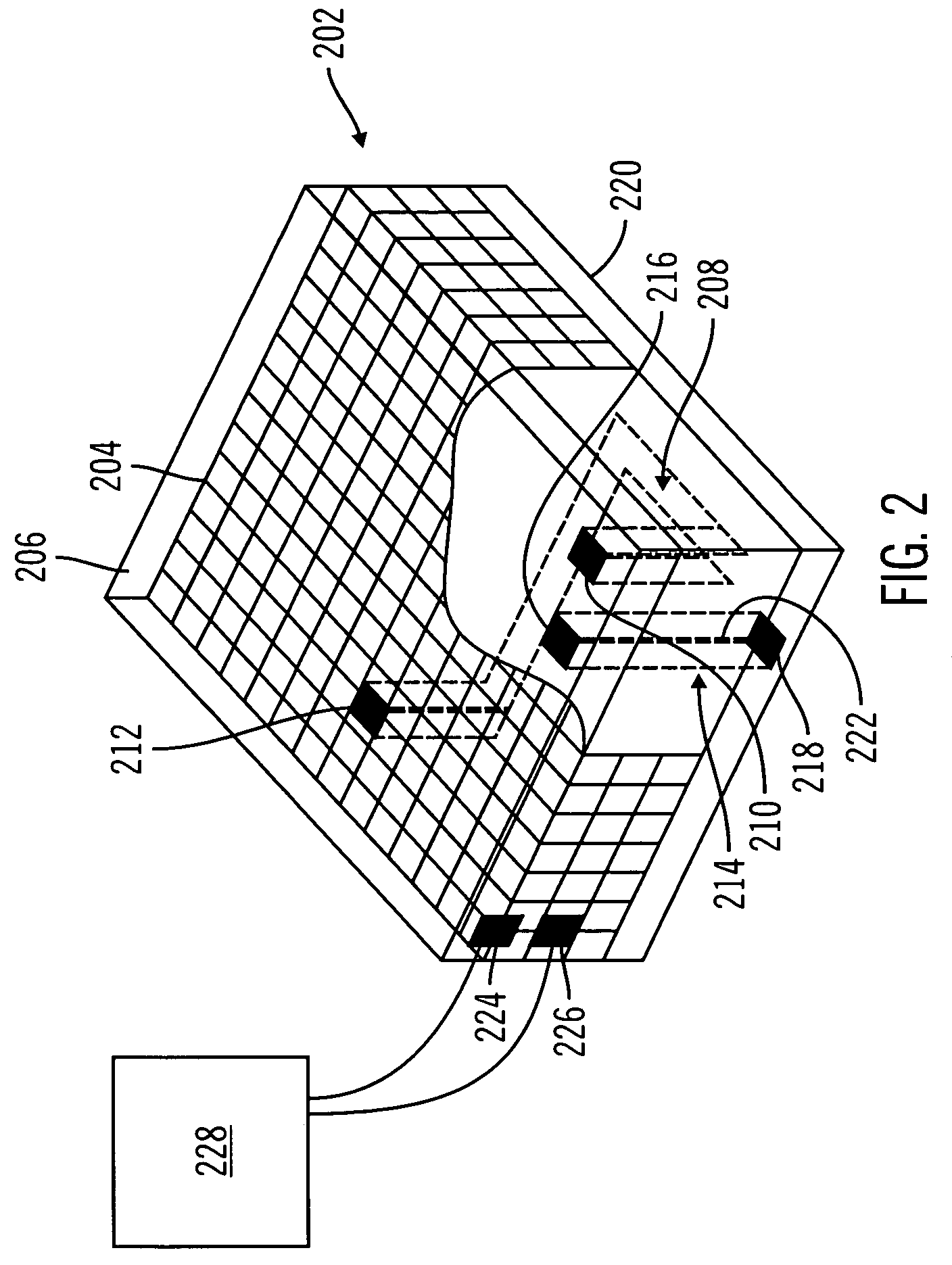

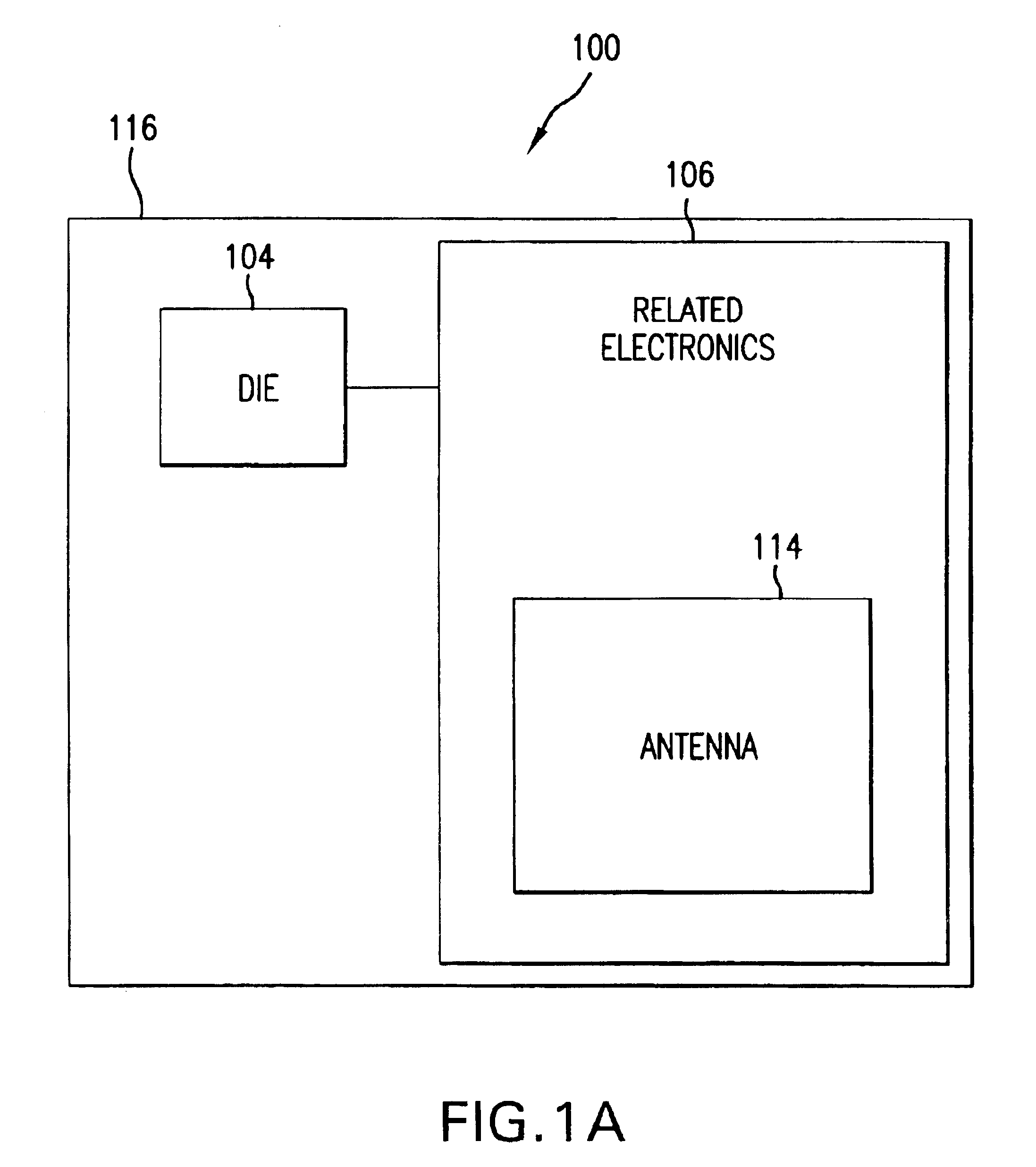

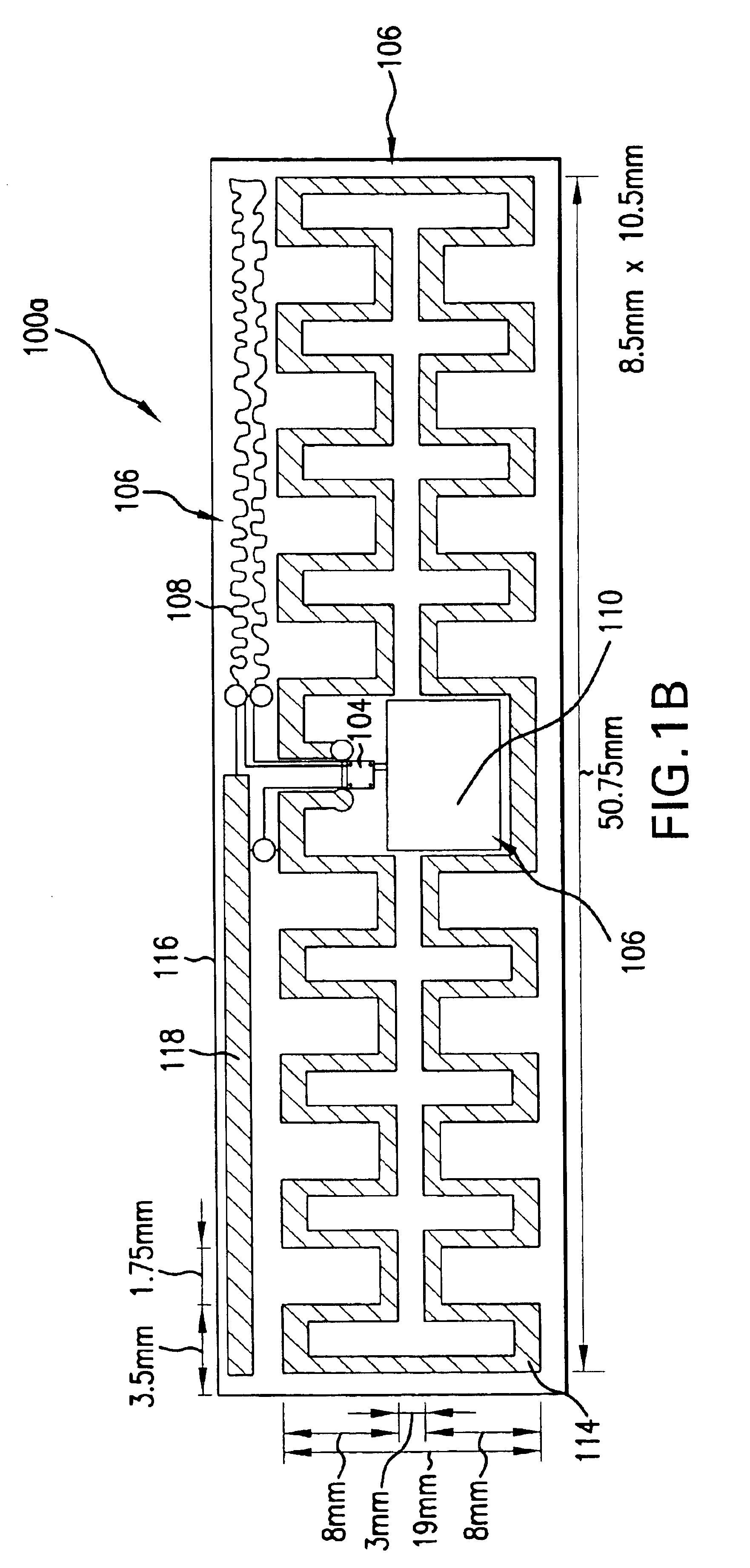

Physically highly secure multi-chip assembly

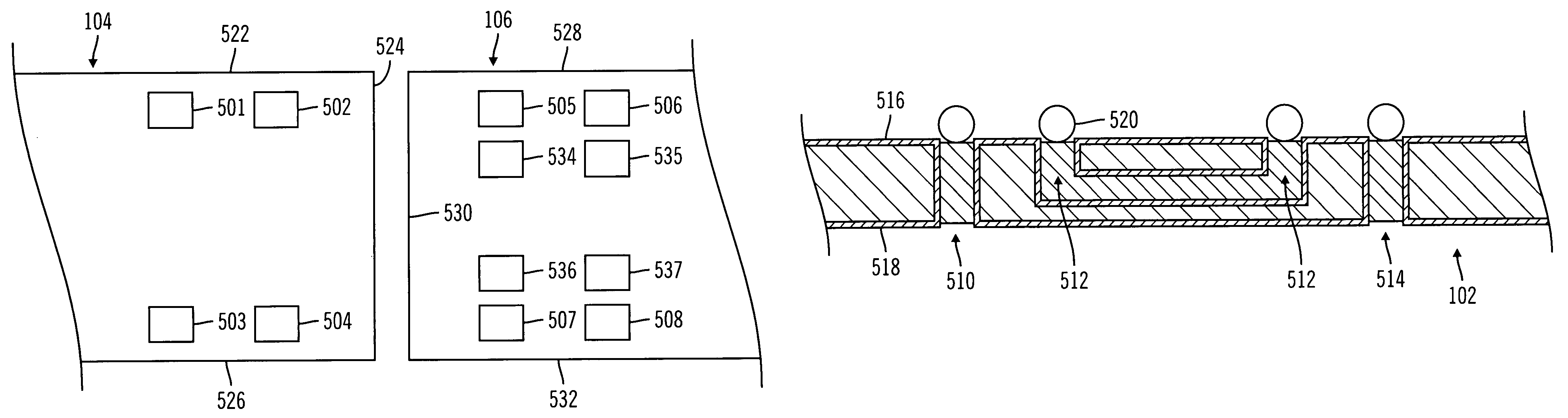

A physically secure processing assembly is provided that includes dies mounted on a substrate so as to sandwich the electrical contacts of the dies between the dies and the substrate. The substrate is provided with substrate contacts and conductive pathways that are electrically coupled to the die contacts and extend through the substrate. Electrical conductors surround the conductive pathways. A monitoring circuit detects a break in continuity of one or more of the electrical conductors, and preferably renders the assembly inoperable. Preferably, an epoxy encapsulation is provided to prevent probing tools from being able to reach the die or substrate contacts.

Owner:BEIJING PIANRUOJINGHONG TECH CO LTD

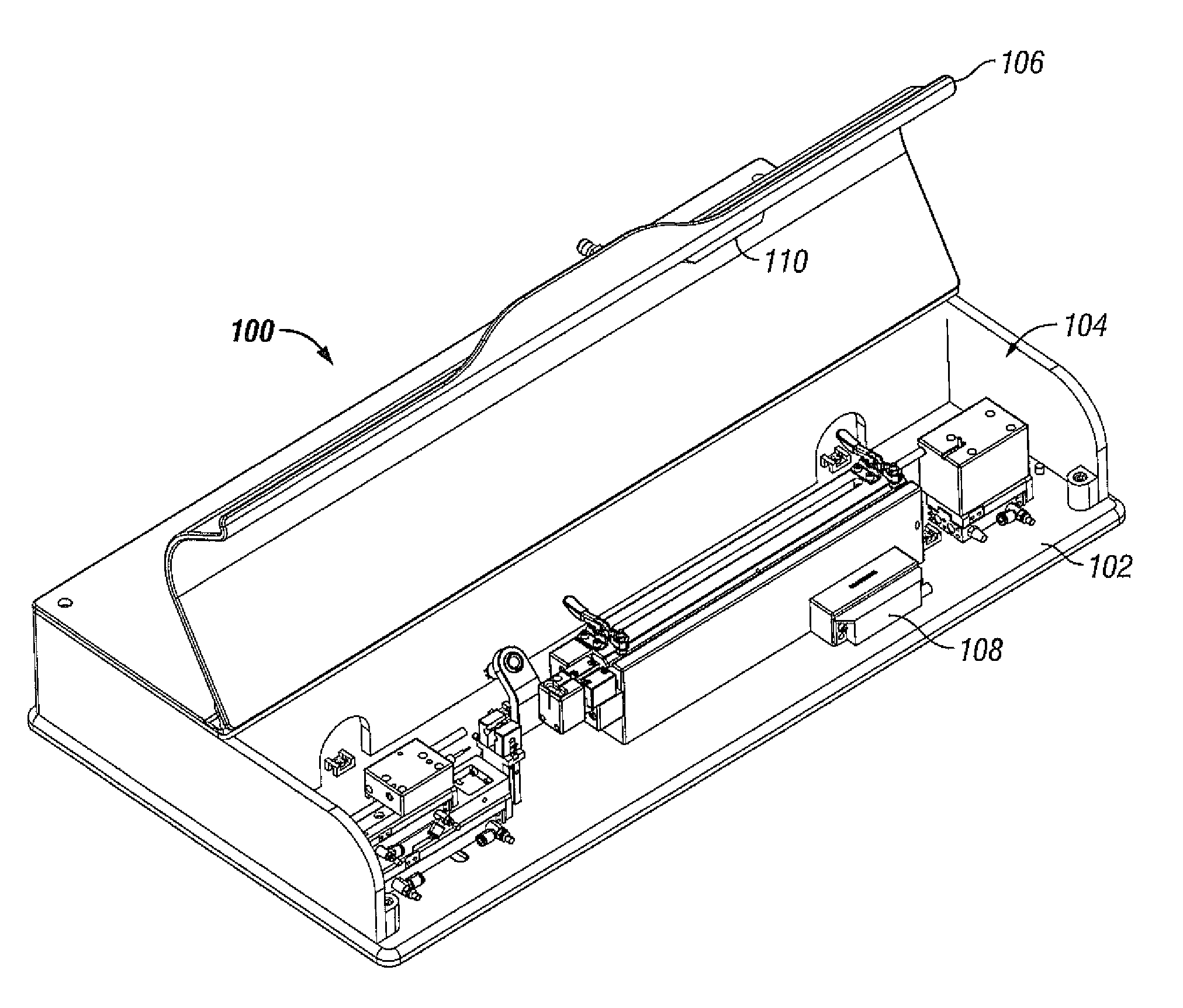

Automated assembly device to tolerate blade variation

An automated device facilitates the assembly a surgical instrument that includes a knife with a high aspect ratio. The automated device includes a fixture for restraining a subassembly of the surgical instrument that includes the knife. A blade grip on the device is movable relative to the fixture, and is configured to urge the knife into a restrained position in the subassembly suitable for the subsequent assembly of an additional instrument component. A grip actuator is provided to move the blade grip.

Owner:COVIDIEN LP

Drug cartridge assembly and method of manufacture

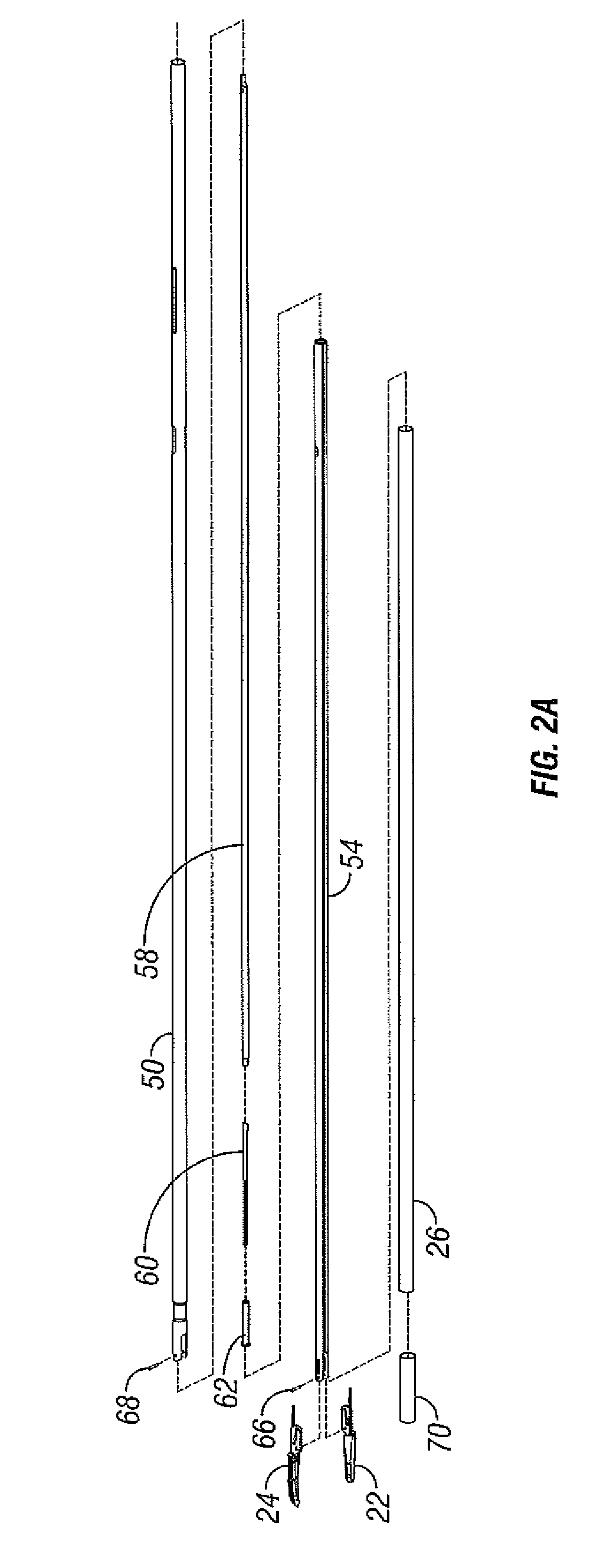

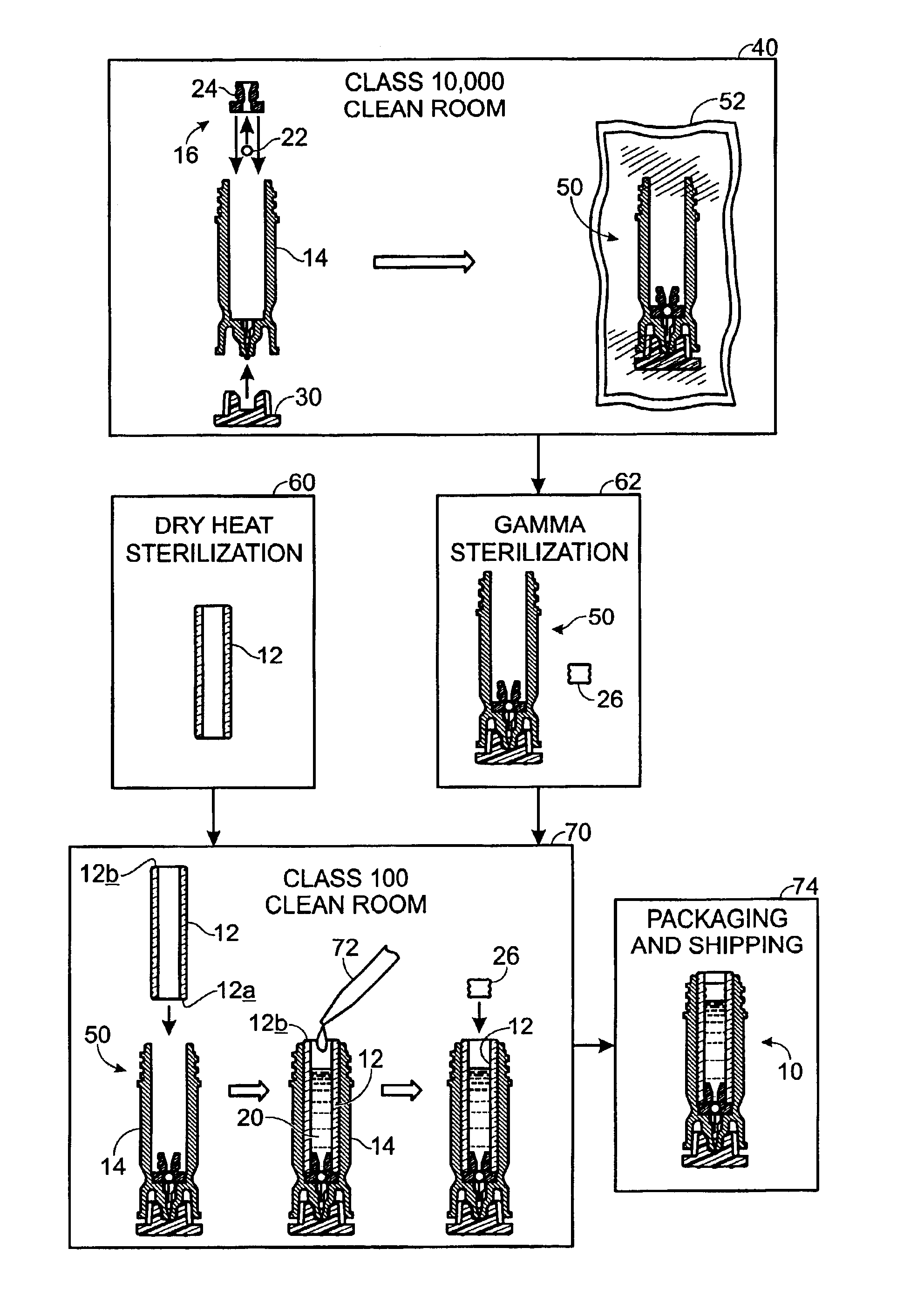

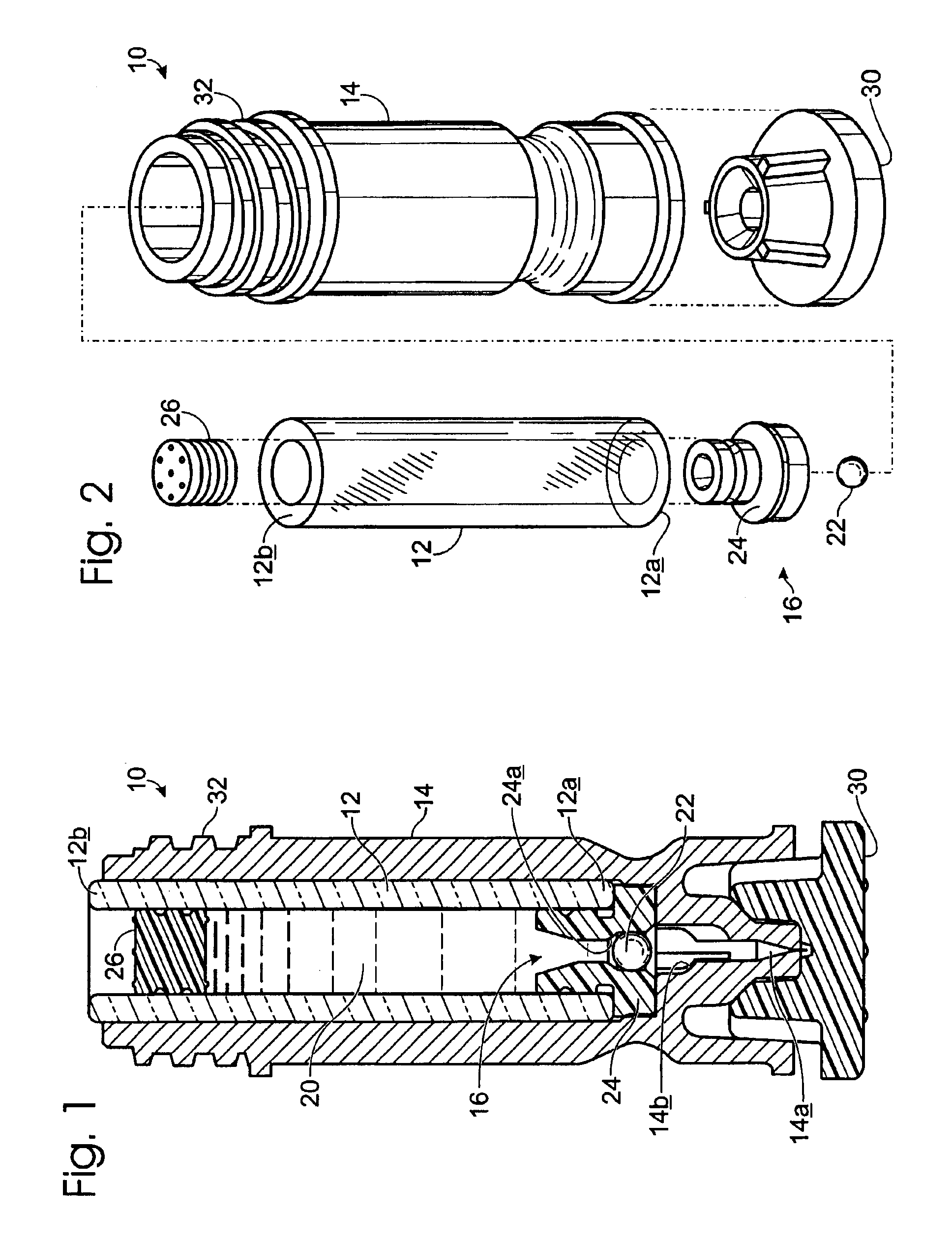

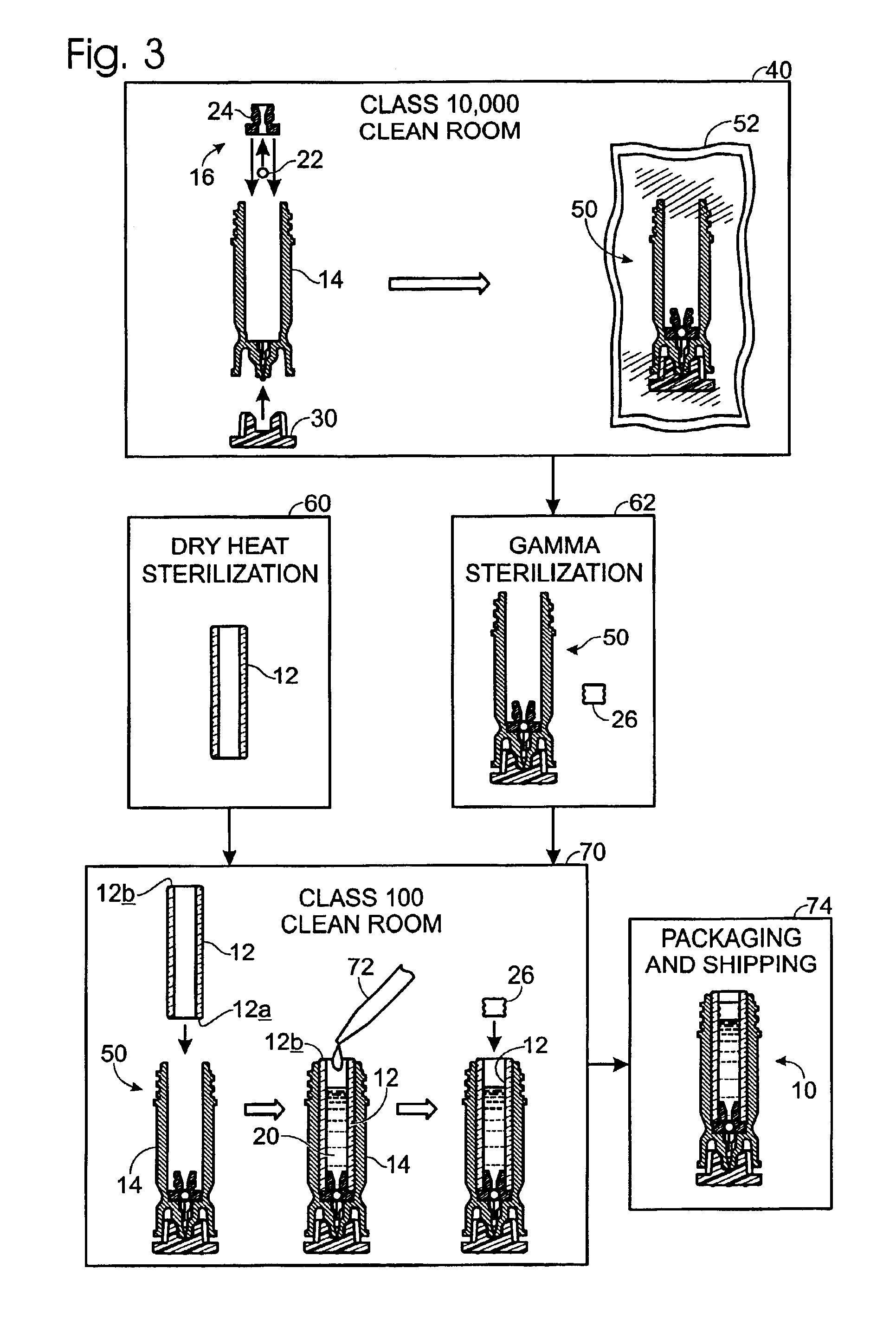

A method of manufacture for a drug cartridge assembly. The method includes providing a drug cartridge, providing a nozzle sub-assembly, and sterilizing the drug cartridge and nozzle sub-assembly. The method further includes assembling the drug cartridge and nozzle sub-assembly together in a configuration that enables ejection of liquid out of the drug cartridge through the nozzle sub-assembly. The method further includes filling the drug cartridge with a liquid, such as an injectable drug. The method may include separate sterilization of the drug cartridge and nozzle sub-assembly, using different sterilization processes. Portions of the method may be performed prior to sterilization within a first cleanroom, with subsequent steps being performed in a second cleanroom having a substantially lower particulate-per-volume rating than the first cleanroom.

Owner:BIOJECT

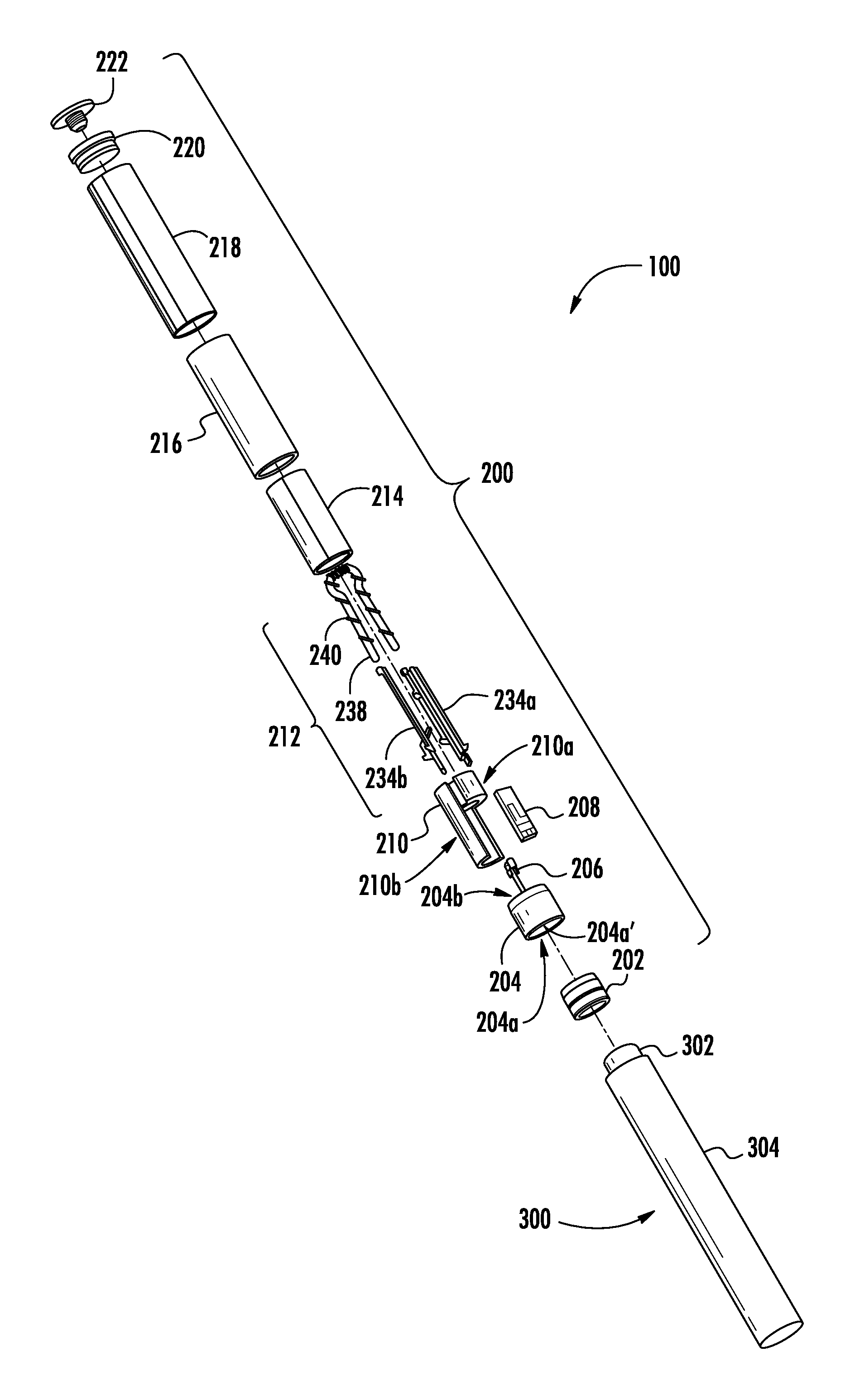

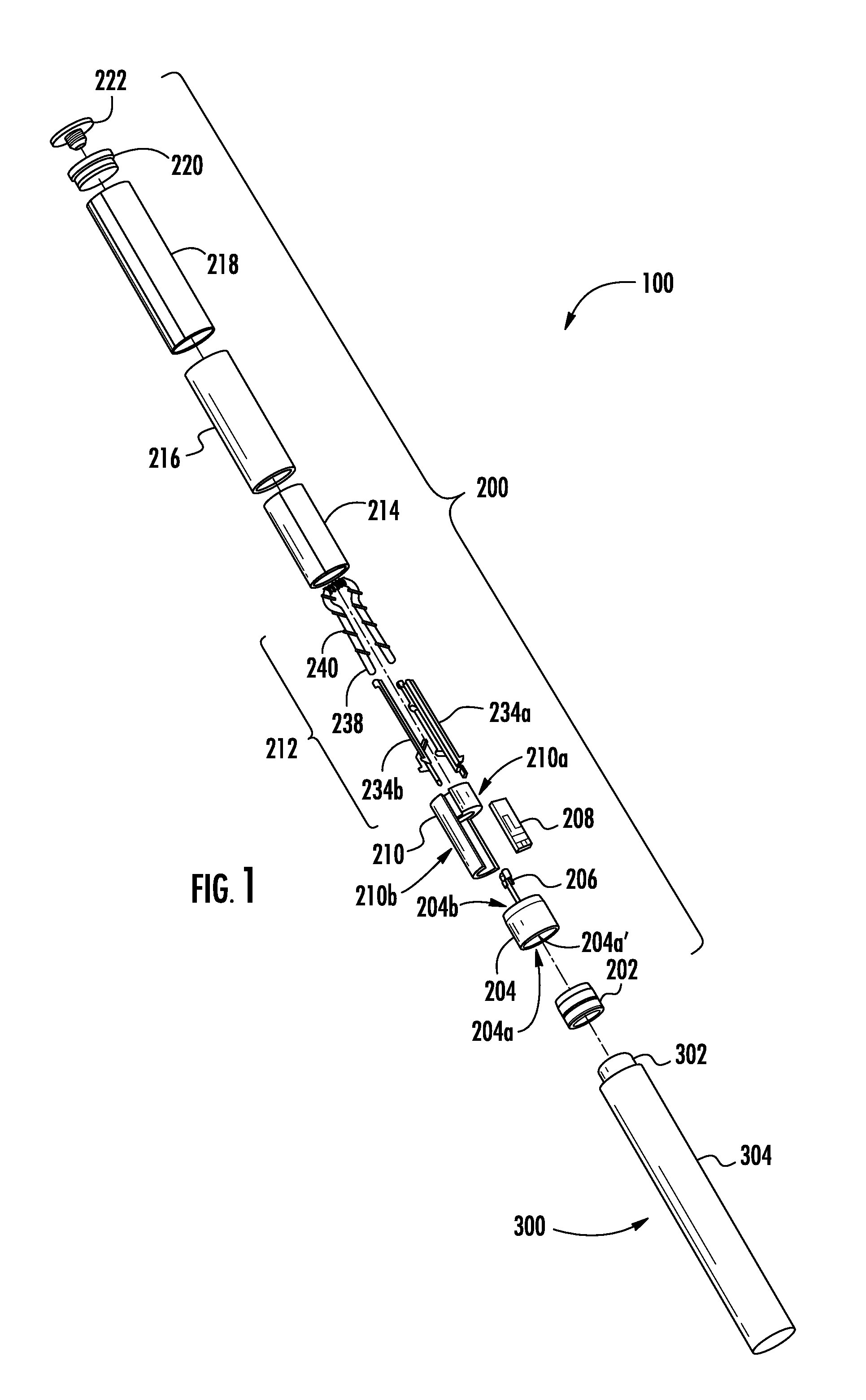

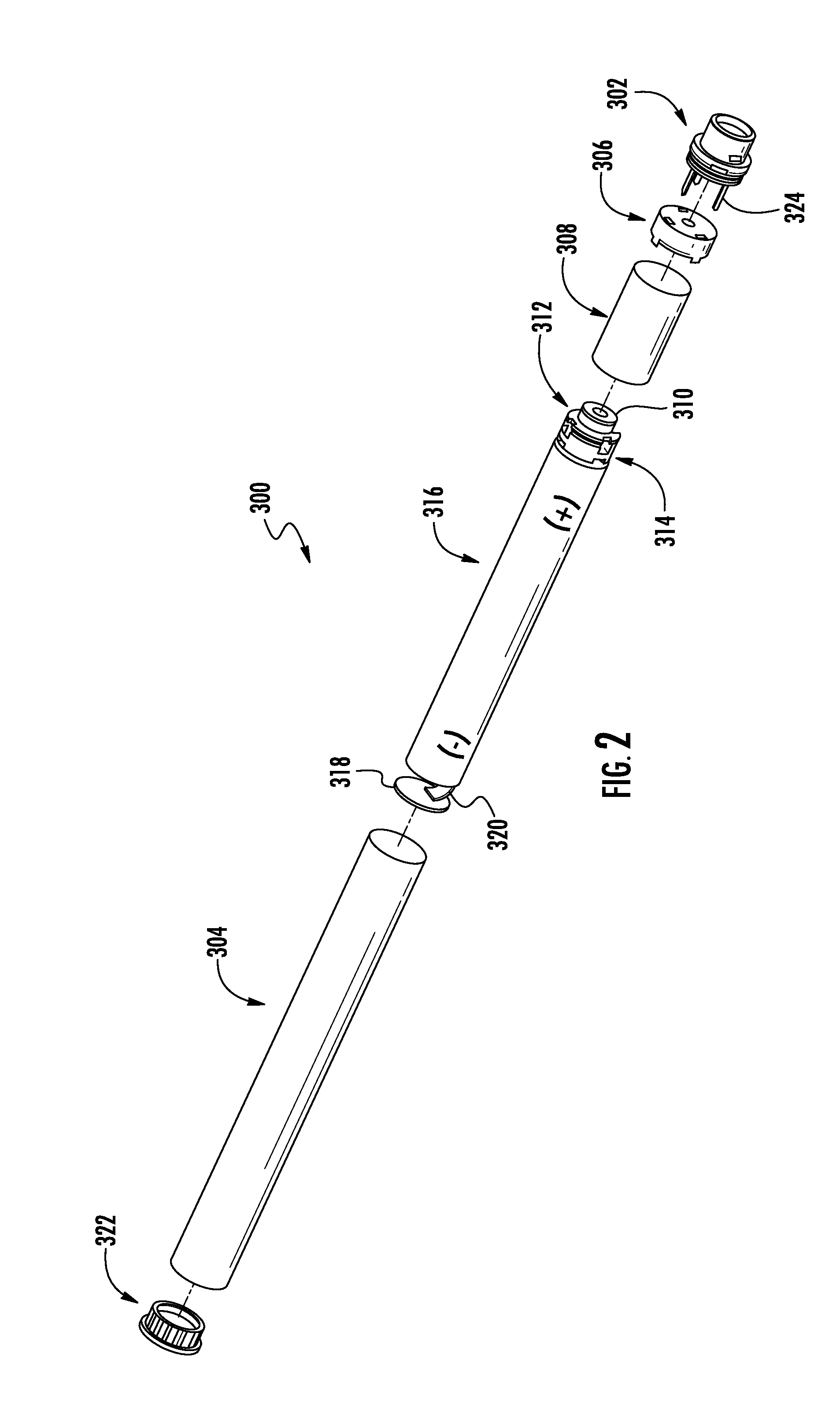

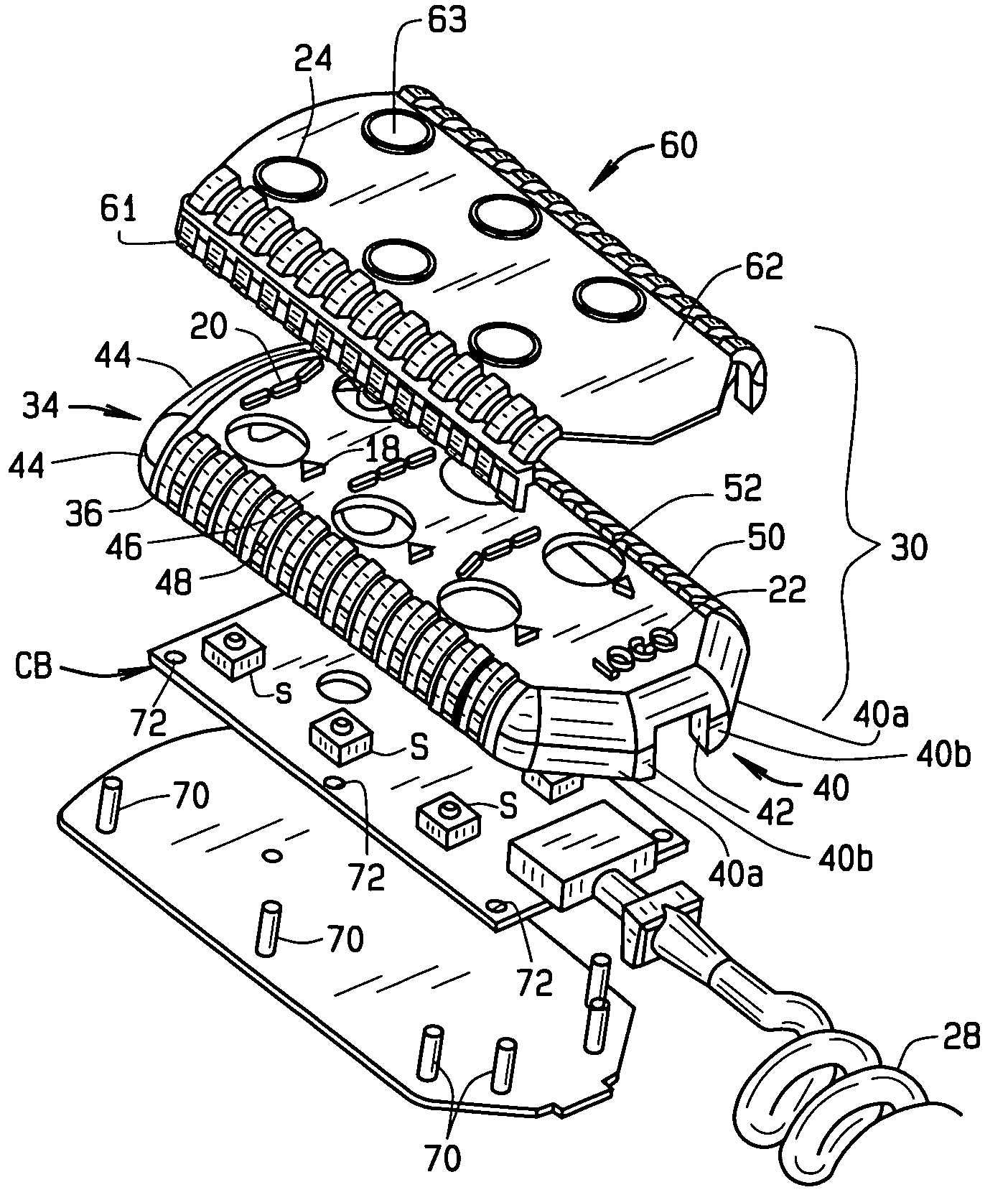

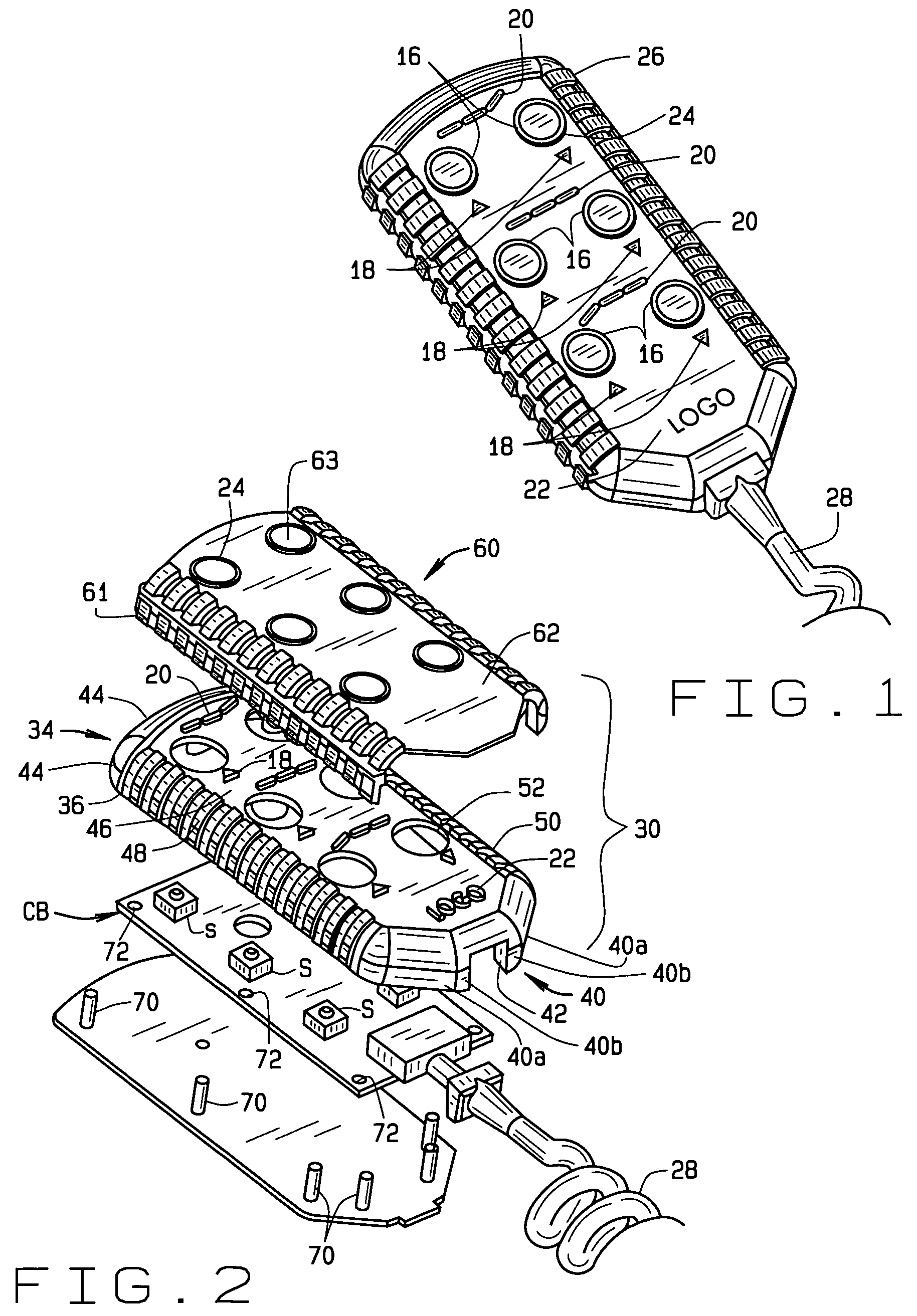

Method for Assembling a Cartridge for a Smoking Article

ActiveUS20150223522A1Easy to insertMonorailsCigarette manufactureAerosol deliveryMechanical engineering

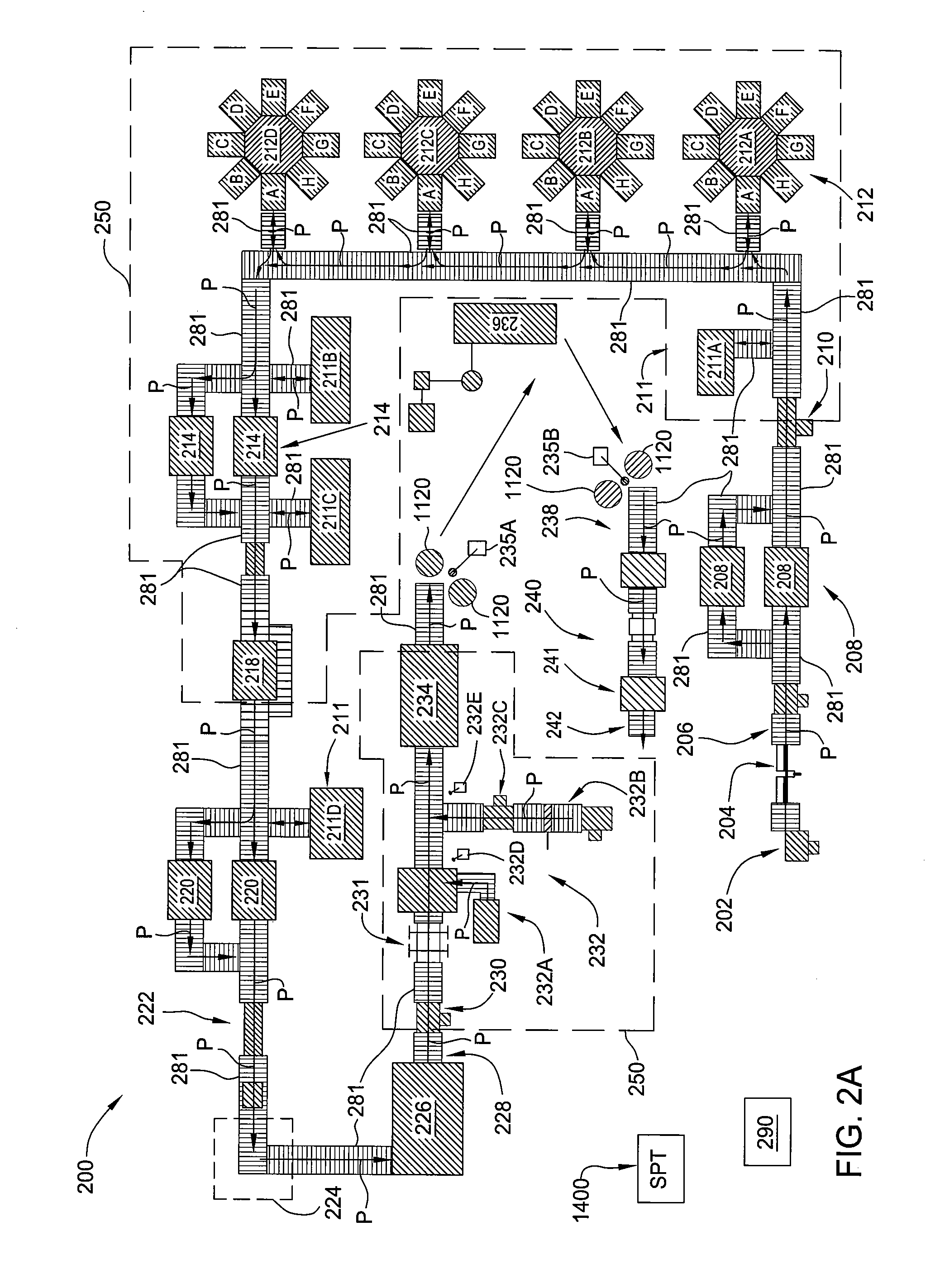

The present disclosure relates to systems, apparatuses, and methods for assembling cartridges for aerosol delivery devices. The cartridges may be assembled by transporting carriages between various substations at which parts are added to a base. In another assembly method, the base may be moved between a plurality of robots which direct the base downwardly into contact with components to couple the components therewith. An inspection system may inspect the cartridges at various stages of completion.

Owner:RAI STRATEGIC HLDG INC

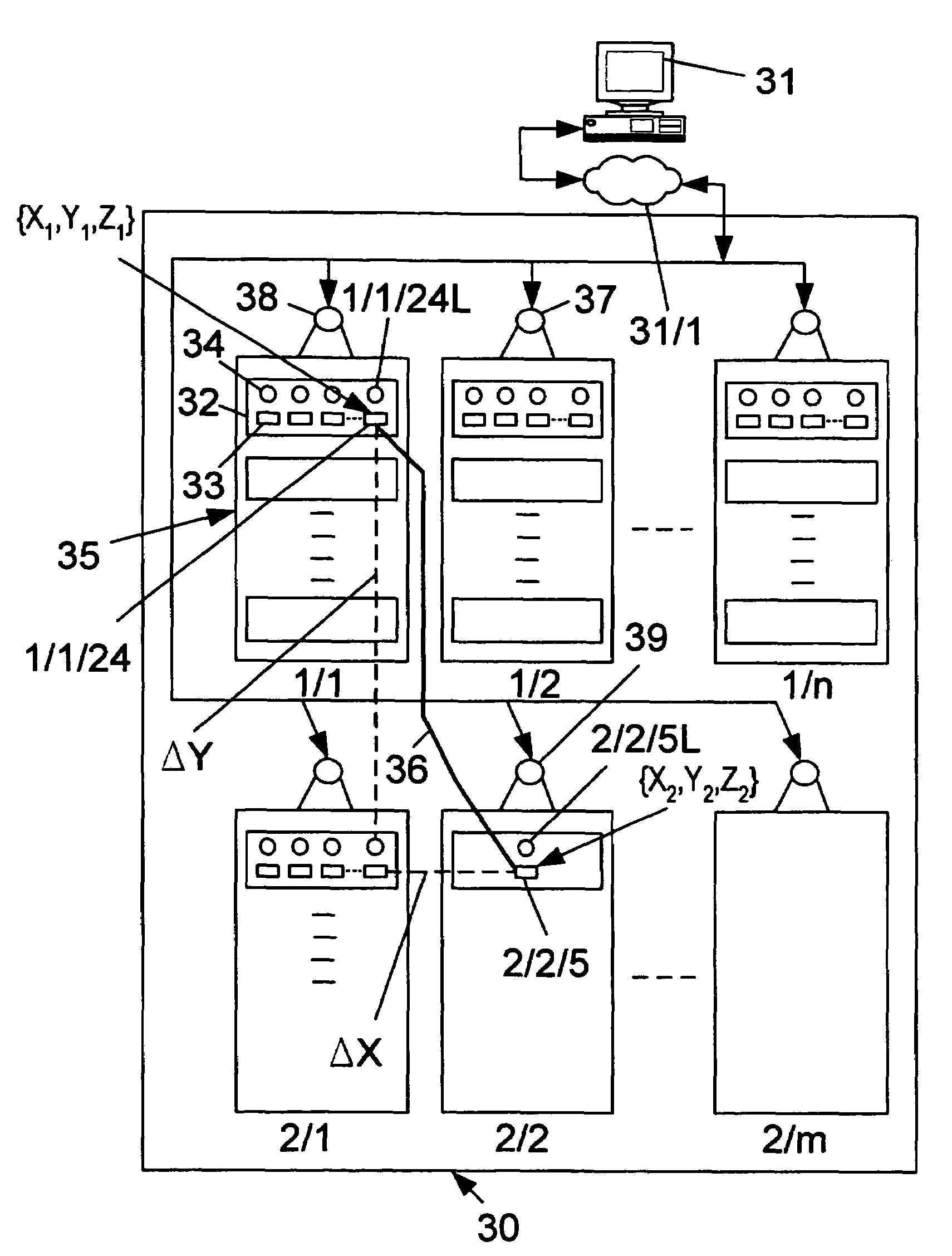

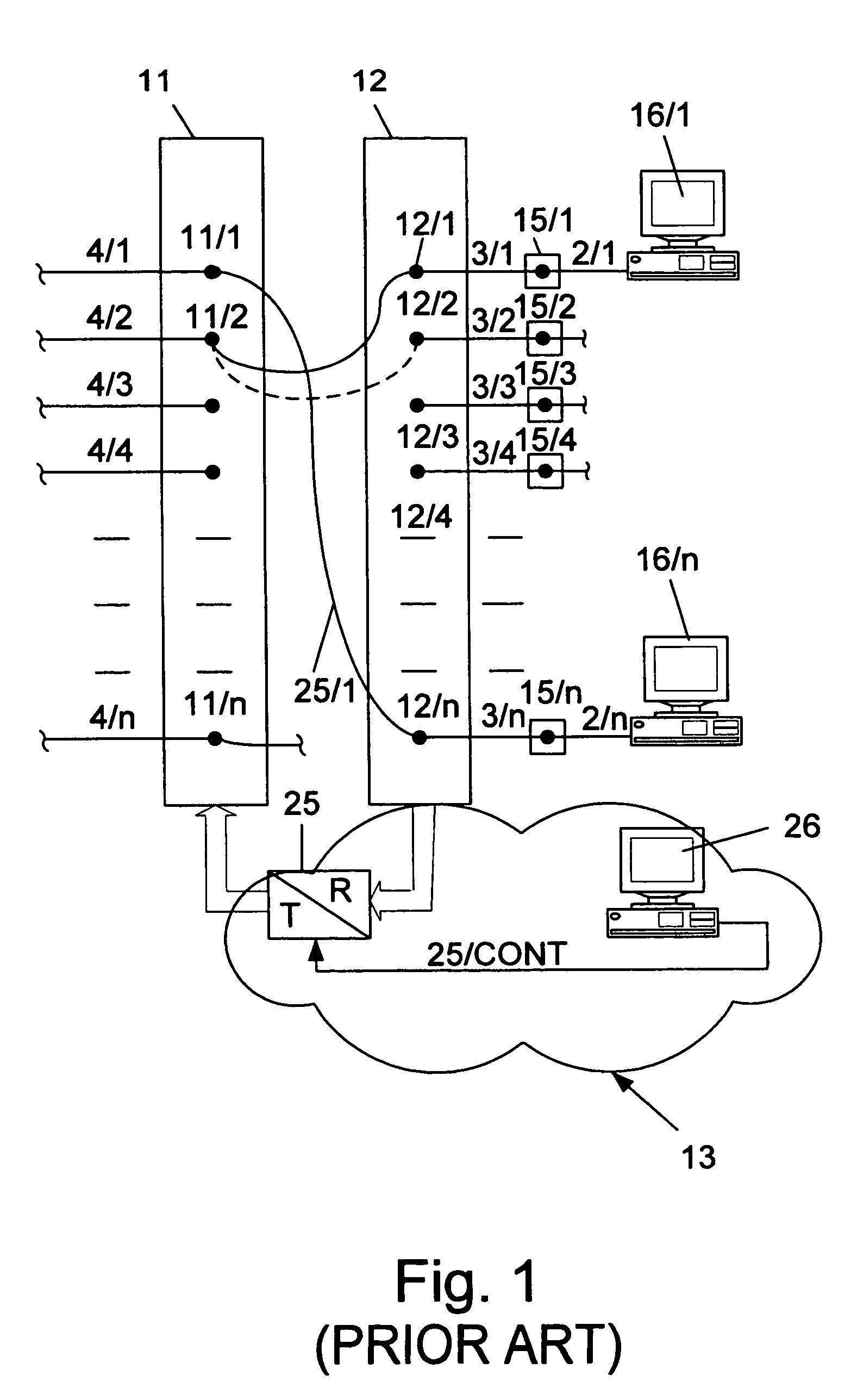

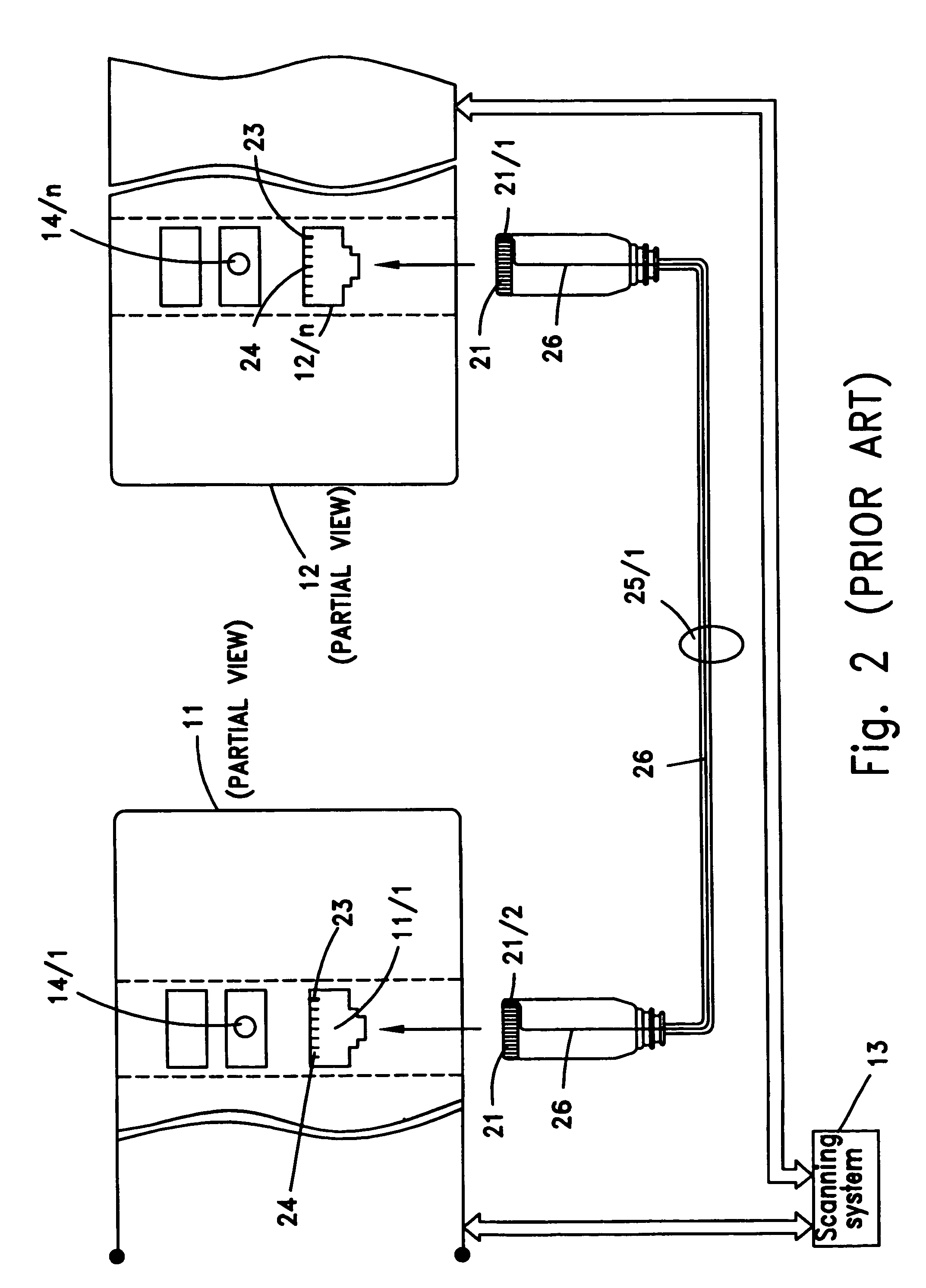

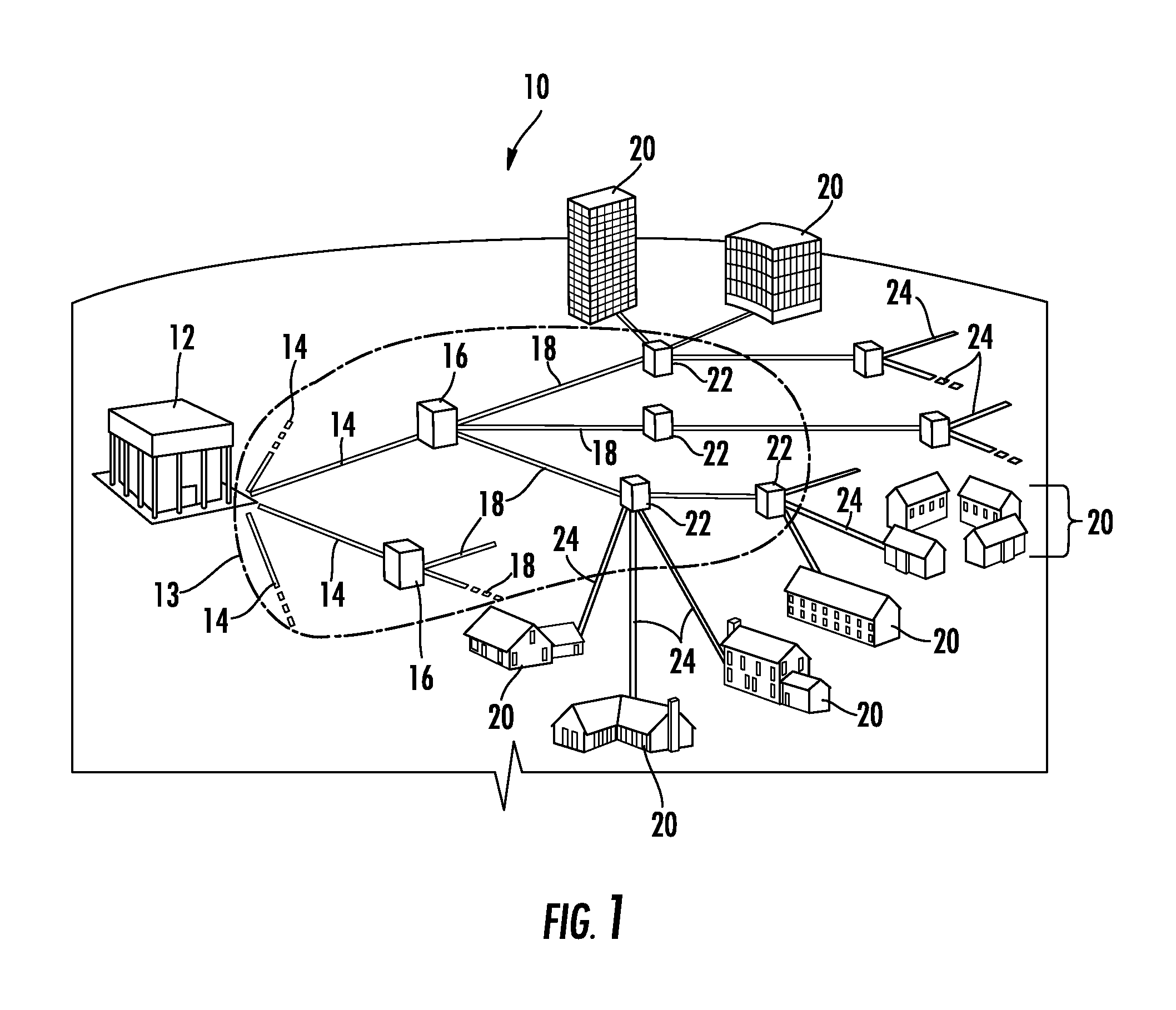

Management of large scale cabling systems

Method and system for managing cabling rooms that include a plurality of communication panels, which are arranged closely to one another. Each cabling room has a plurality of patch panels, structurally connected to form vertical structures. An operator is automatically guided to a communication panel or a plurality of communication panels, in which changes are to be made to modify the connectivity status or to deal with connectivity problems that may arise for any reason. The system automatically indicates to an operator optimal ports that are available and optimal patch cords for connecting them, based on distances between ports and on the electrical characteristics of the electrical signals that it is intended to pass between the ports.

Owner:RIT TECHNOLOGIES

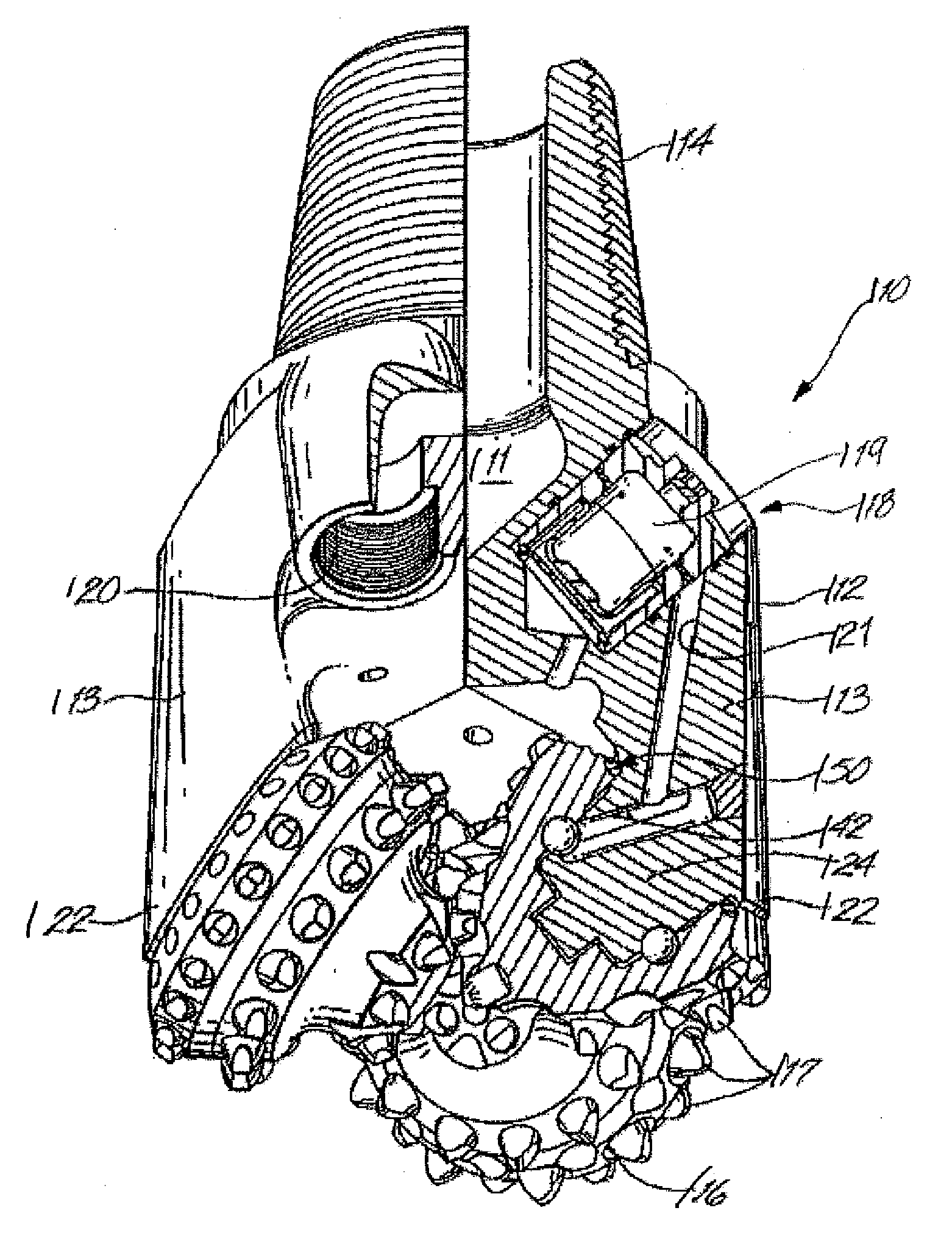

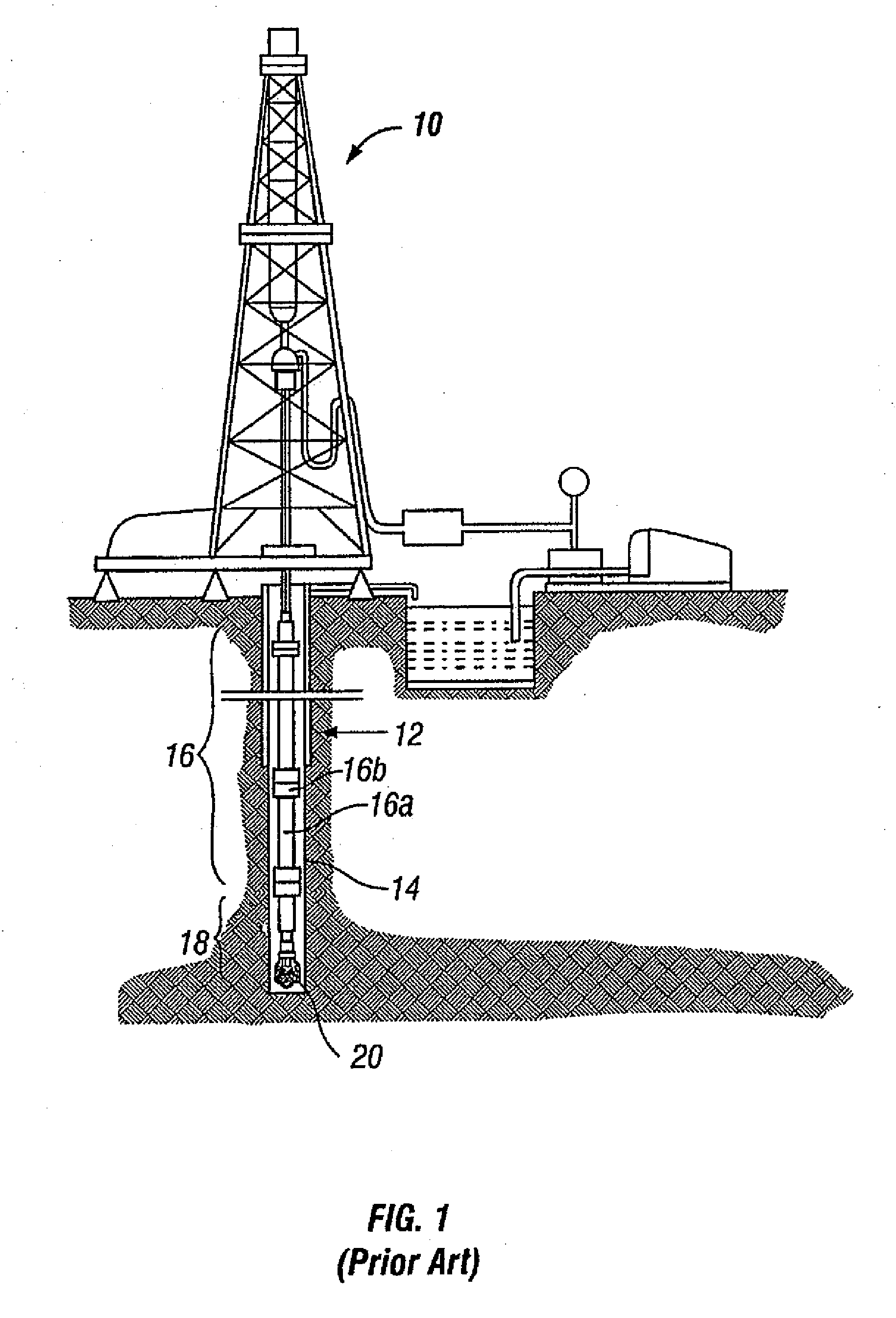

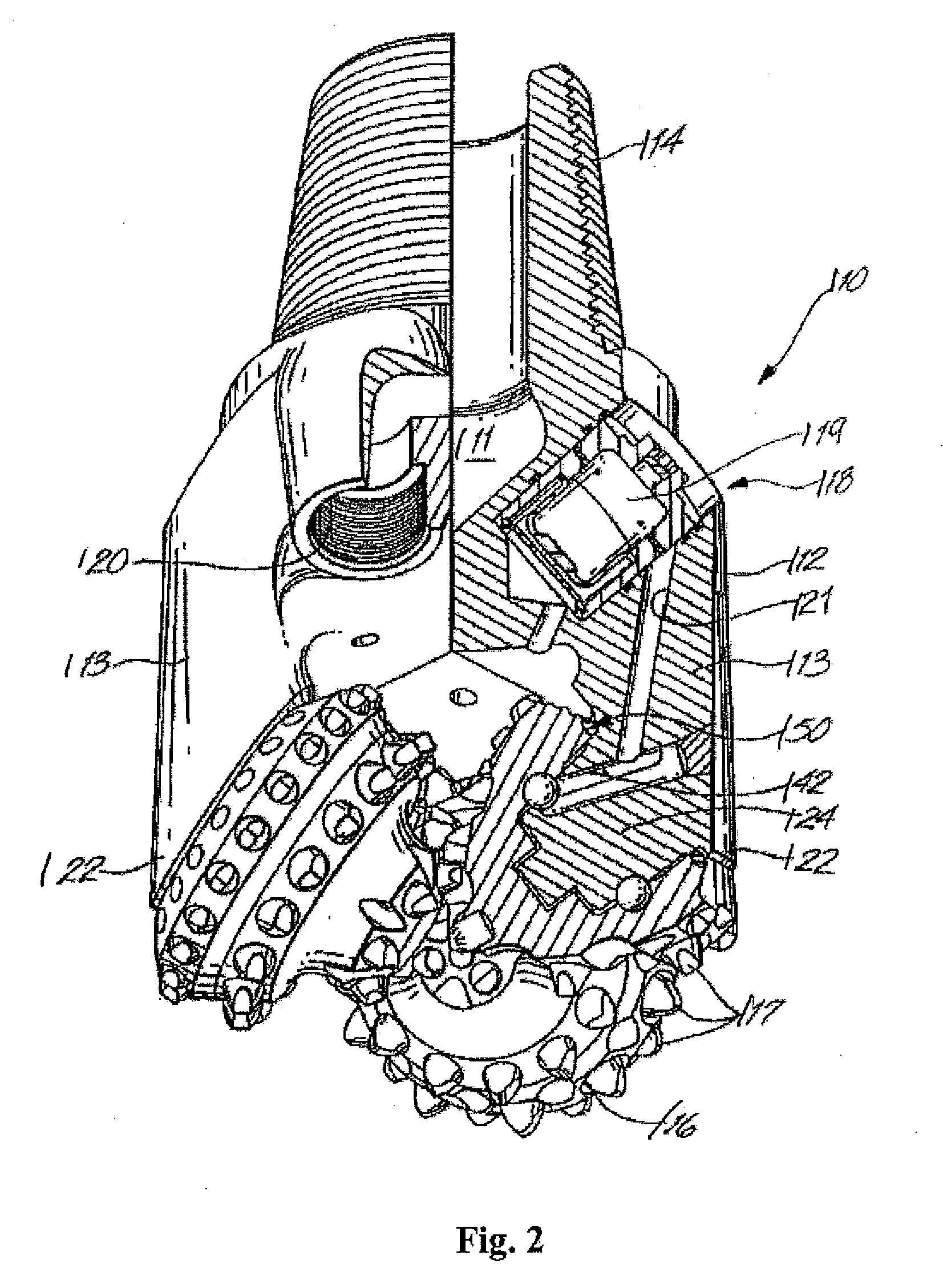

Composite coating with nanoparticles for improved wear and lubricity in down hole tools

Owner:SMITH INT INC

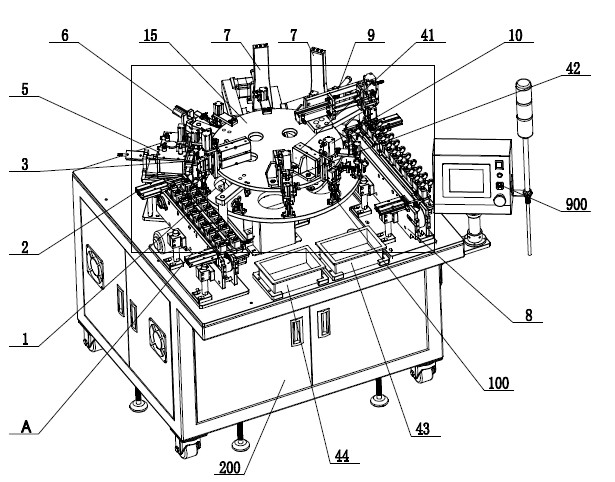

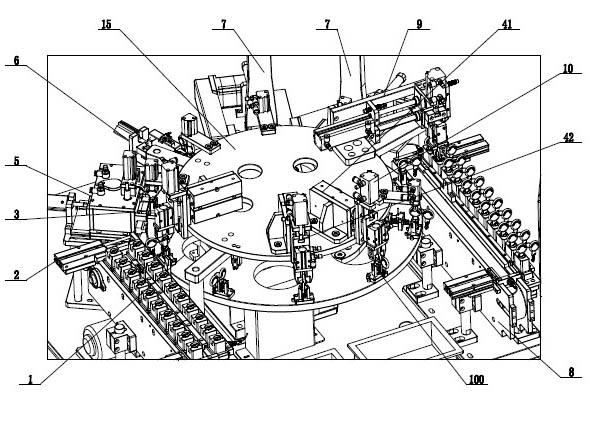

Automatic lock cylinder assembly machine

InactiveCN102009343ASolve the speed problemSolve efficiency problemsAssembly machinesEngineeringControl circuit

The invention discloses an automatic lock cylinder assembly machine which comprises a machine body and a rotating plate assembly with a lock cylinder arranged on the machine body, wherein an upper lock cylinder manipulator assembly, an upper spring assembly, a spring dection assembly, two upper lock plate assemblies, a key inserting manipulator assembly, a lock cylinder detection assembly, and a finish-product grabbing manipulator assembly are successively arranged along the clockwise circumference direction of the rotating plate assembly, wherein the finish-product grabbing manipulator assembly comprises a good product grabbing manipulator assembly and a defective product grabbing manipulator assembly; and the upper lock cylinder manipulator assembly, the key inserting manipulator assembly, the lock cylinder detection assembly, the good product grabbing manipulator assembly and the defective product grabbing manipulator assembly are all arranged on the rotating plate assembly, the rest assemblies are all arranged on the machine body, the machine body is provided with a bracing wire feeding mechanism for conveying the lock cylinder and a key to the corresponding position, and the assemblies are all connected with a master control circuit and are controlled by the master control circuit. The automatic lock cylinder assembly machine provided by the invention not only has the advantages of high production efficiency and low space capacity, but also ensures that the lock cylinder assembling quality is improved.

Owner:周俊雄

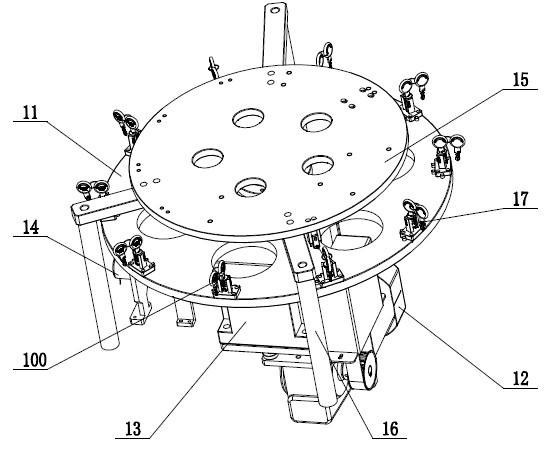

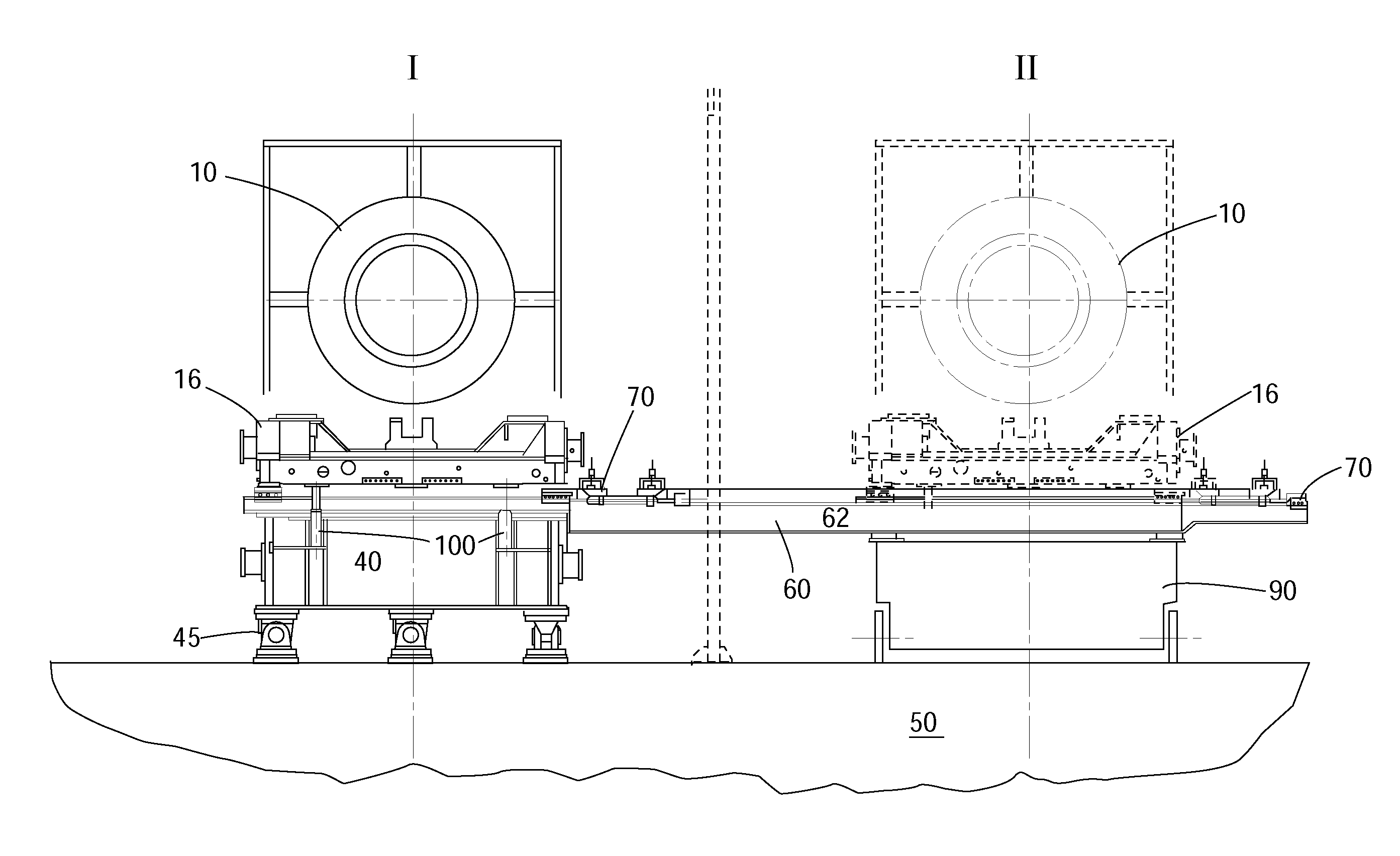

Method for moving and aligning heavy device

ActiveUS9032620B2Assembly machinesSemiconductor/solid-state device manufacturingEngineeringLift system

Method for laterally replacing a heavy component of a plant assembly, the method including disconnecting the heavy component from other components of the plant assembly and from a base plate to which the heavy component is fixed; lifting the heavy component above the base plate with a lifting system provided within the base plate; connecting at least a pair of rails to the base plate, under the lifted heavy component, such that the at least a pair of rails extends at substantially a right angle relative to a longitudinal axis of the heavy component; lowering the heavy component on crawling mechanisms disposed on the at least a pair of rails; and laterally replacing the heavy component from the base plate and the other components of the plant assembly by actuating the crawling mechanisms.

Owner:NUOVO PIGNONE TECH SRL

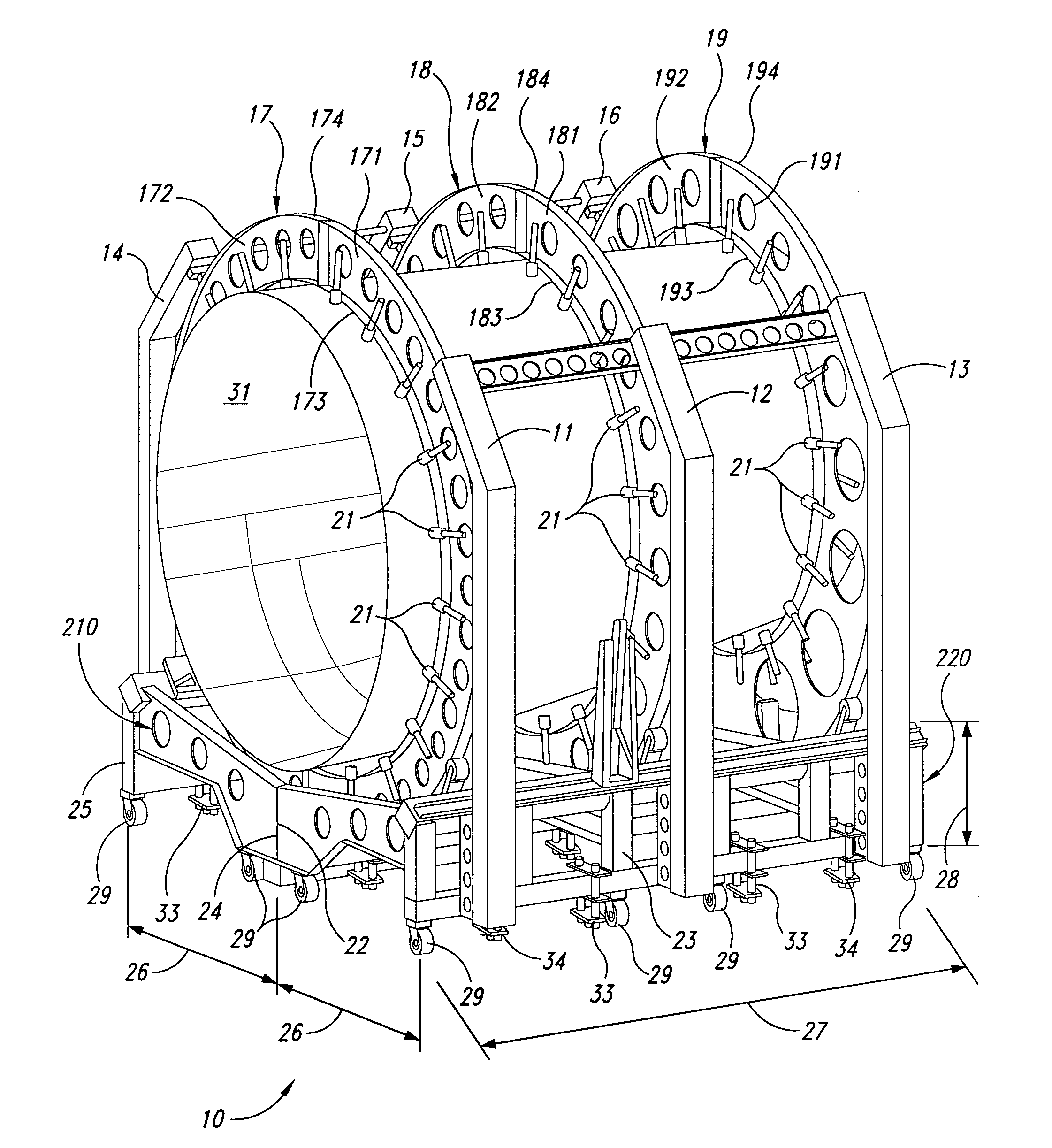

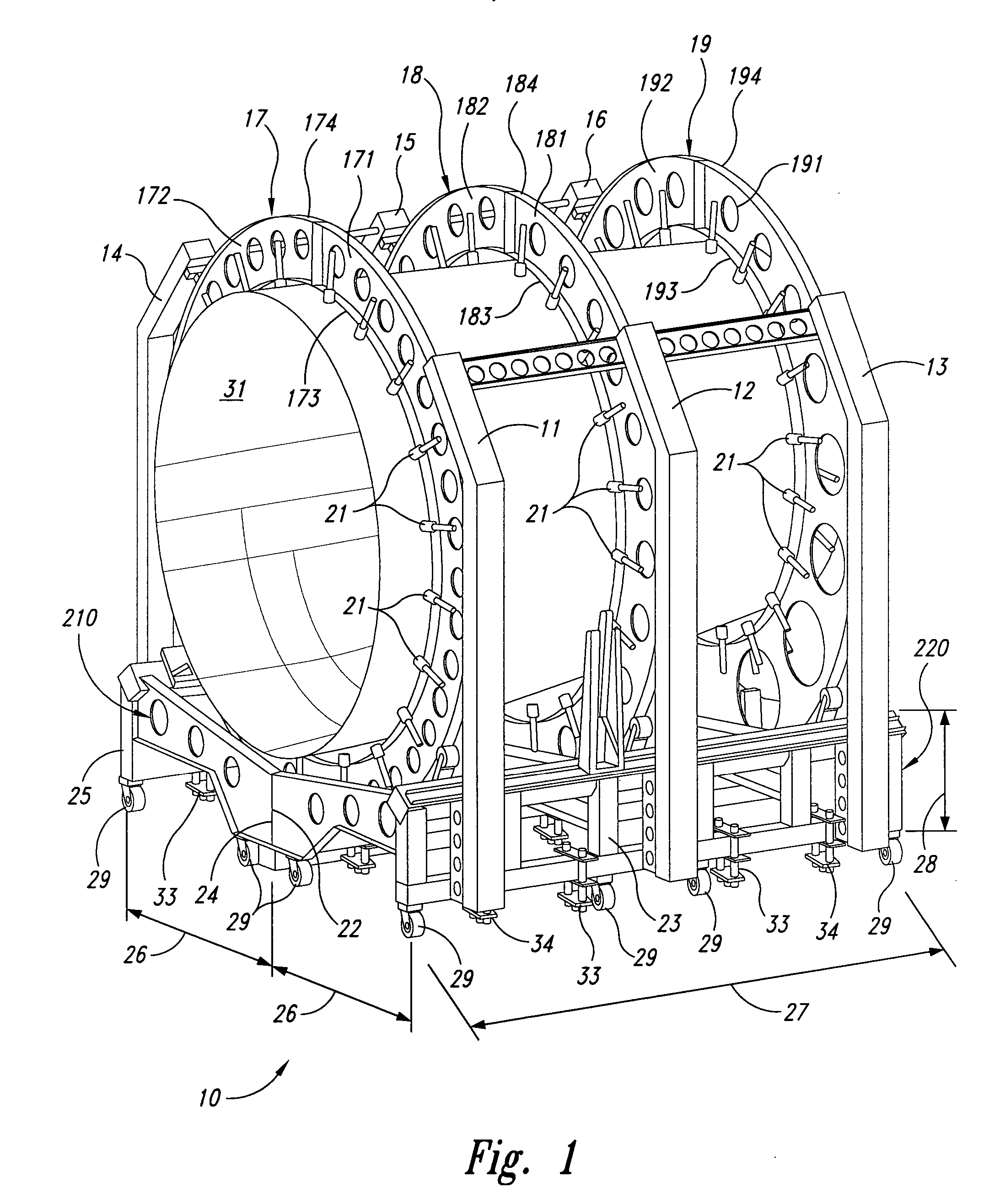

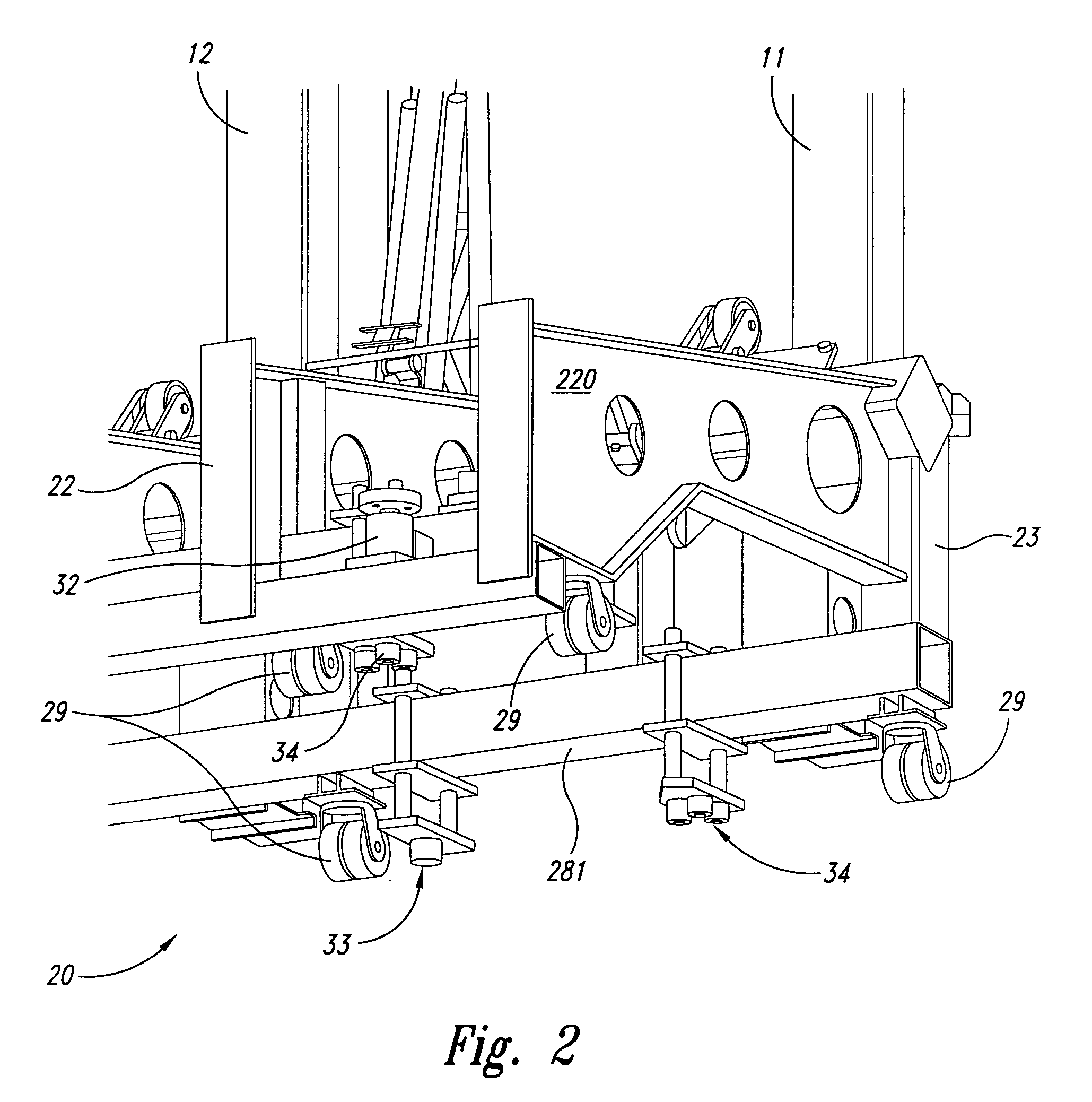

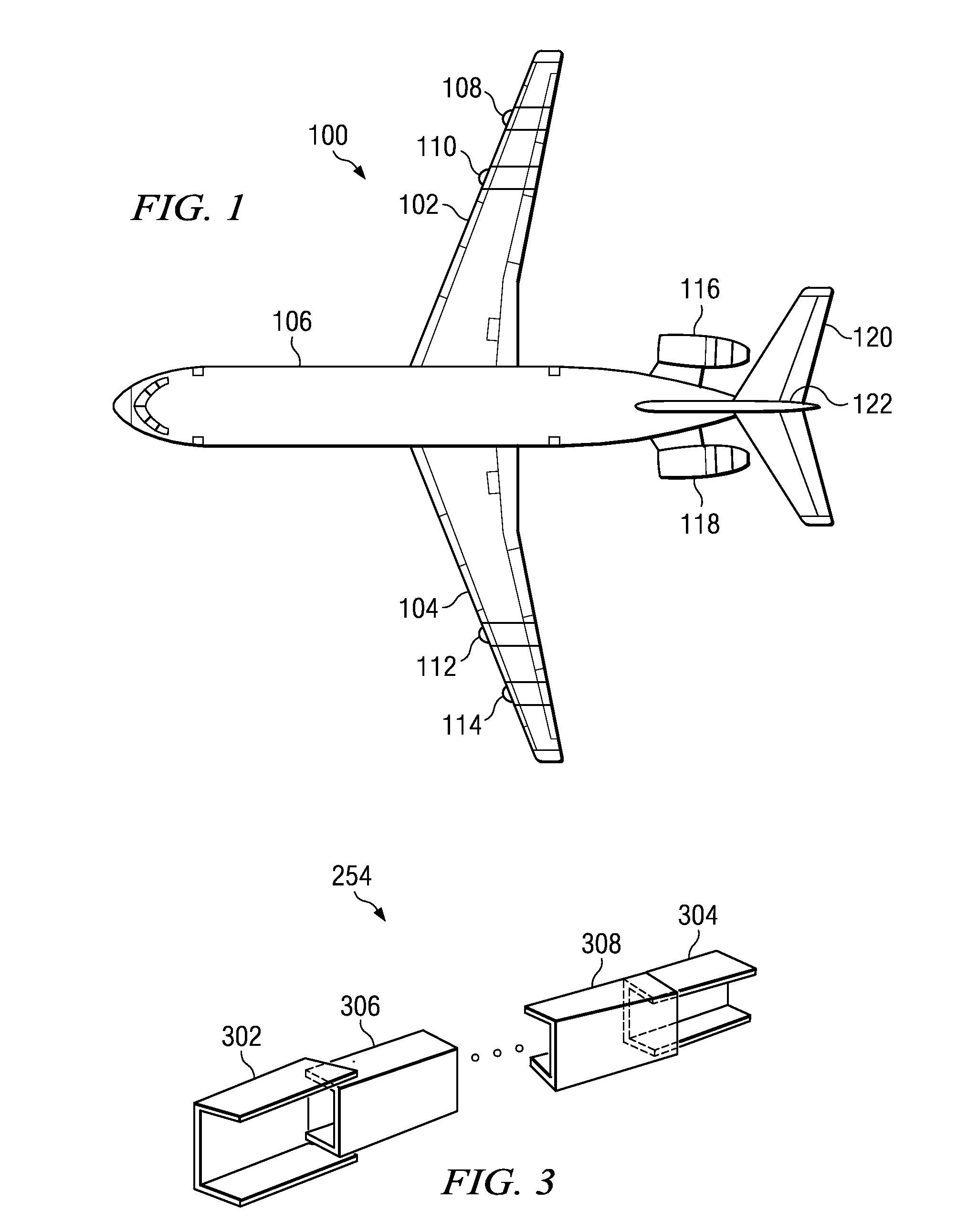

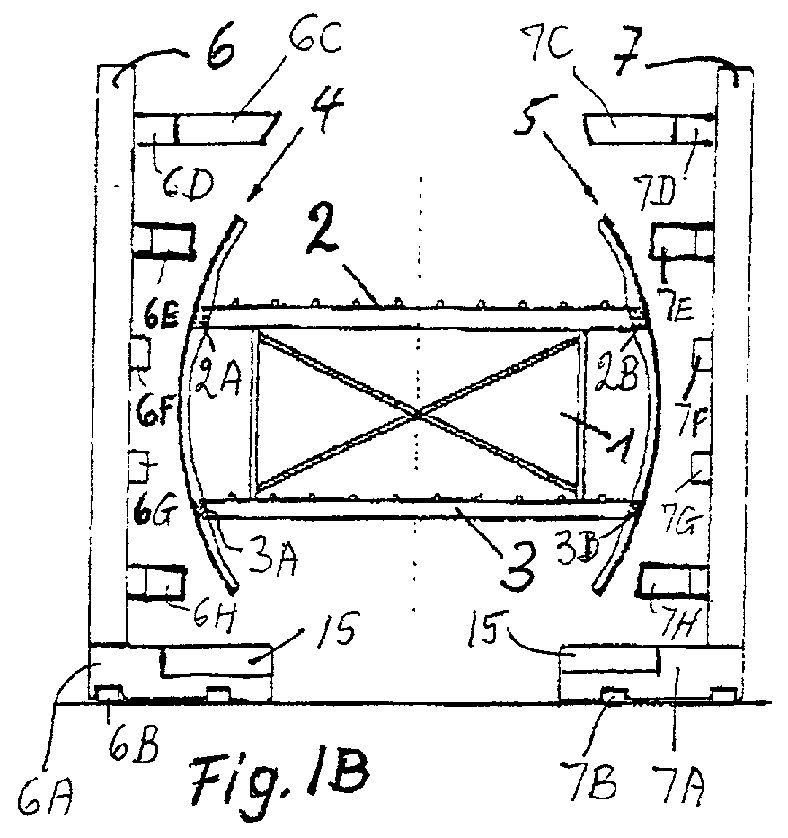

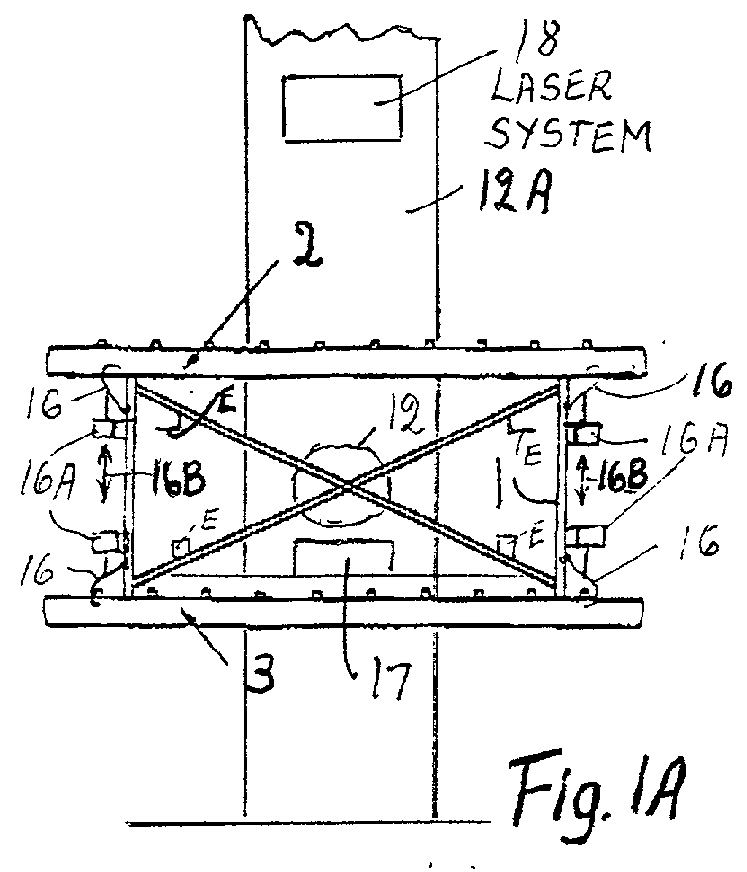

One-piece barrel assembly cart

A one-piece barrel assembly cart includes a right assembly cart base connected with a left assembly cart base and at least three stabilizer rings that are attached to the assembly cart base. The one-piece barrel assembly cart may be used to stabilize a tapered cured composite barrel, for example the large fuselage barrel of the aft section of a large new generation aircraft, such as a 7E7 Boeing airplane. A modular assembly cart includes at least two identical modules. Each of these modules includes a cart base and a stabilizer ring. The diameter of the inner surface of the stabilizer ring may vary as needed. Other modules including a fuselage support may be added. By providing modular assembly carts any shape and size of a one-piece composite barrel may be stabilized after curing of the composite material.

Owner:THE BOEING CO

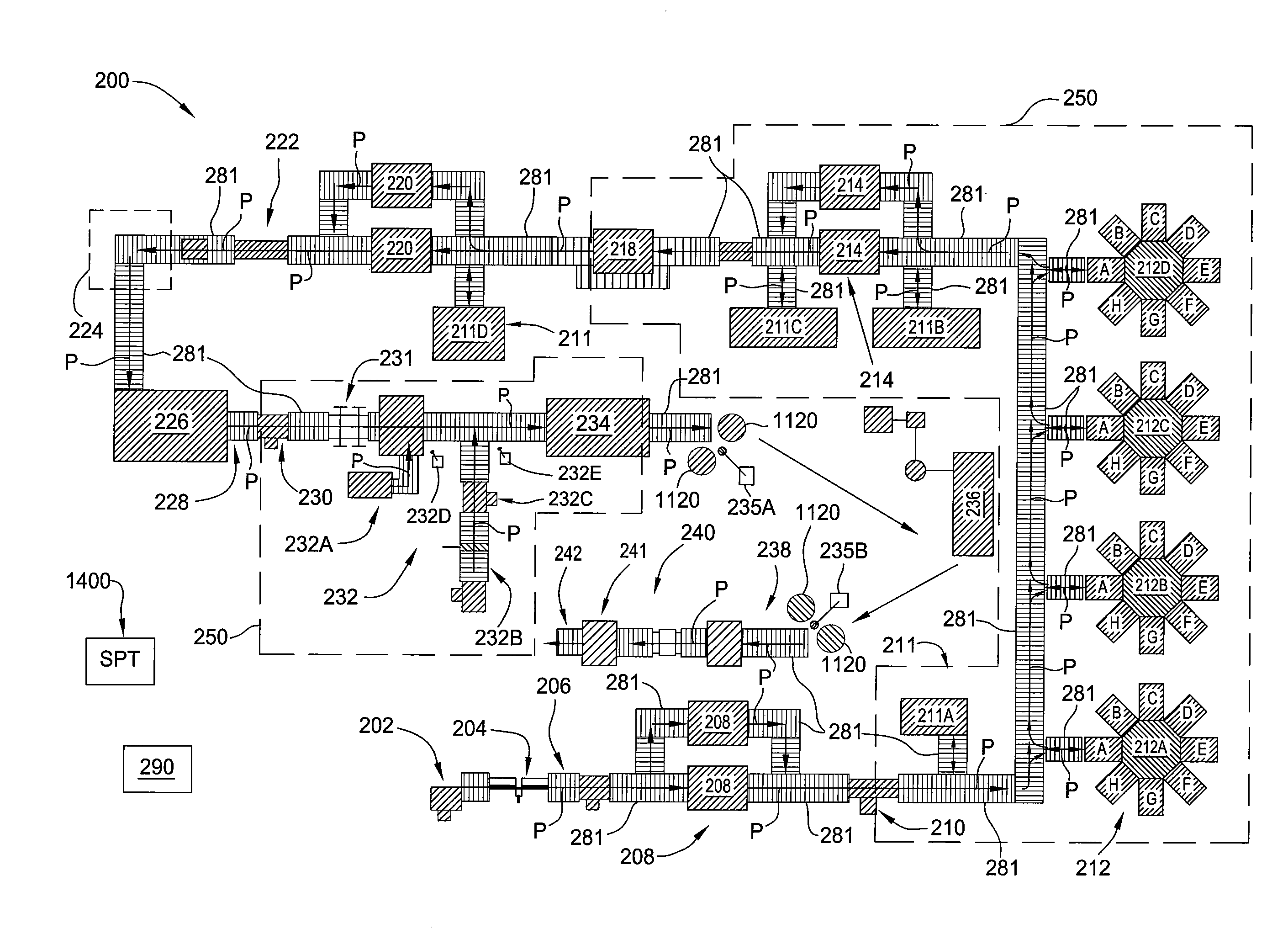

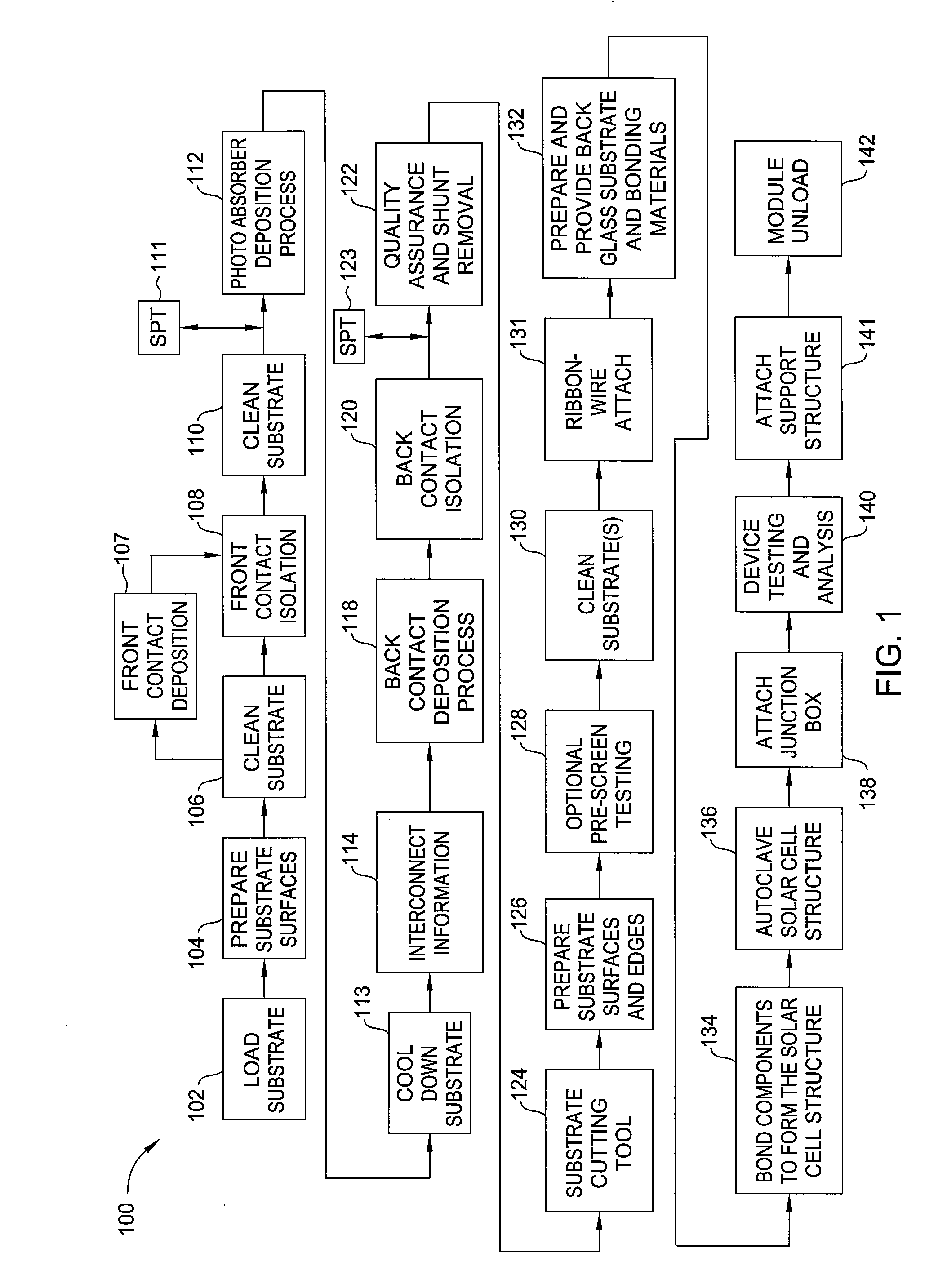

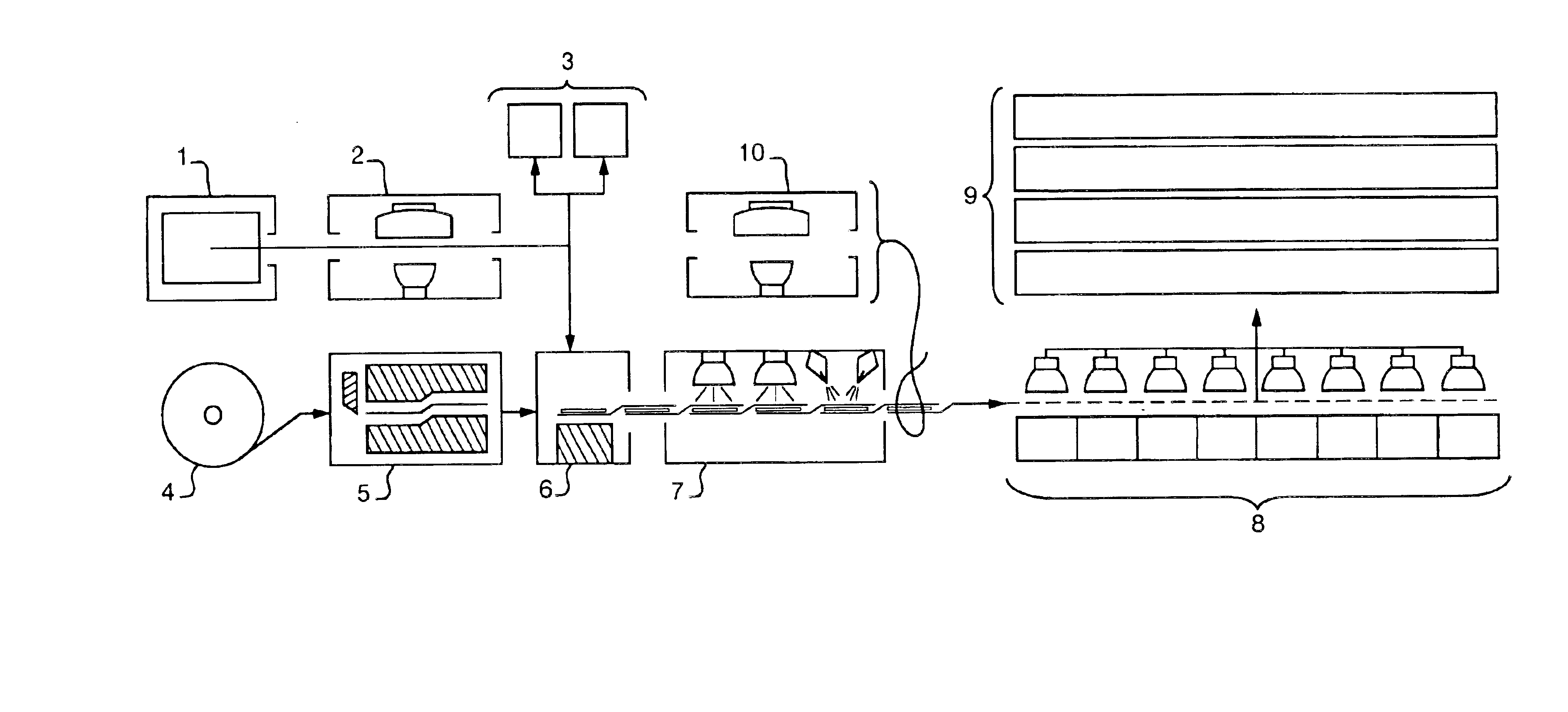

Photovoltaic production line

InactiveUS20090077805A1Improve bindingPhotovoltaic monitoringWave amplification devicesProduction lineQuality assurance

The present invention generally relates to a system that can be used to form a photovoltaic device, or solar cell, using processing modules that are adapted to perform one or more steps in the solar cell formation process. The automated solar cell fab is generally an arrangement of automated processing modules and automation equipment that is used to form solar cell devices. The automated solar fab will thus generally comprise a substrate receiving module that is adapted to receive a substrate, one or more absorbing layer deposition cluster tools having at least one processing chamber that is adapted to deposit a silicon-containing layer on a surface of the substrate, one or more back contact deposition chambers, one or more material removal chambers, a solar cell encapsulation device, an autoclave module, an automated junction box attaching module, and one or more quality assurance modules that are adapted to test and qualify the completely formed solar cell device.

Owner:APPLIED MATERIALS INC

Method of manufacturing electronic device including aligning first substrate, second substrate and mask, and transferring object from first substrate to second substrate, including irradiating object on first substrate with light through mask

ActiveUS7127810B2Easily downsizedEasy to manufactureSolid-state devicesPhotomechanical apparatusOptoelectronicsElectron

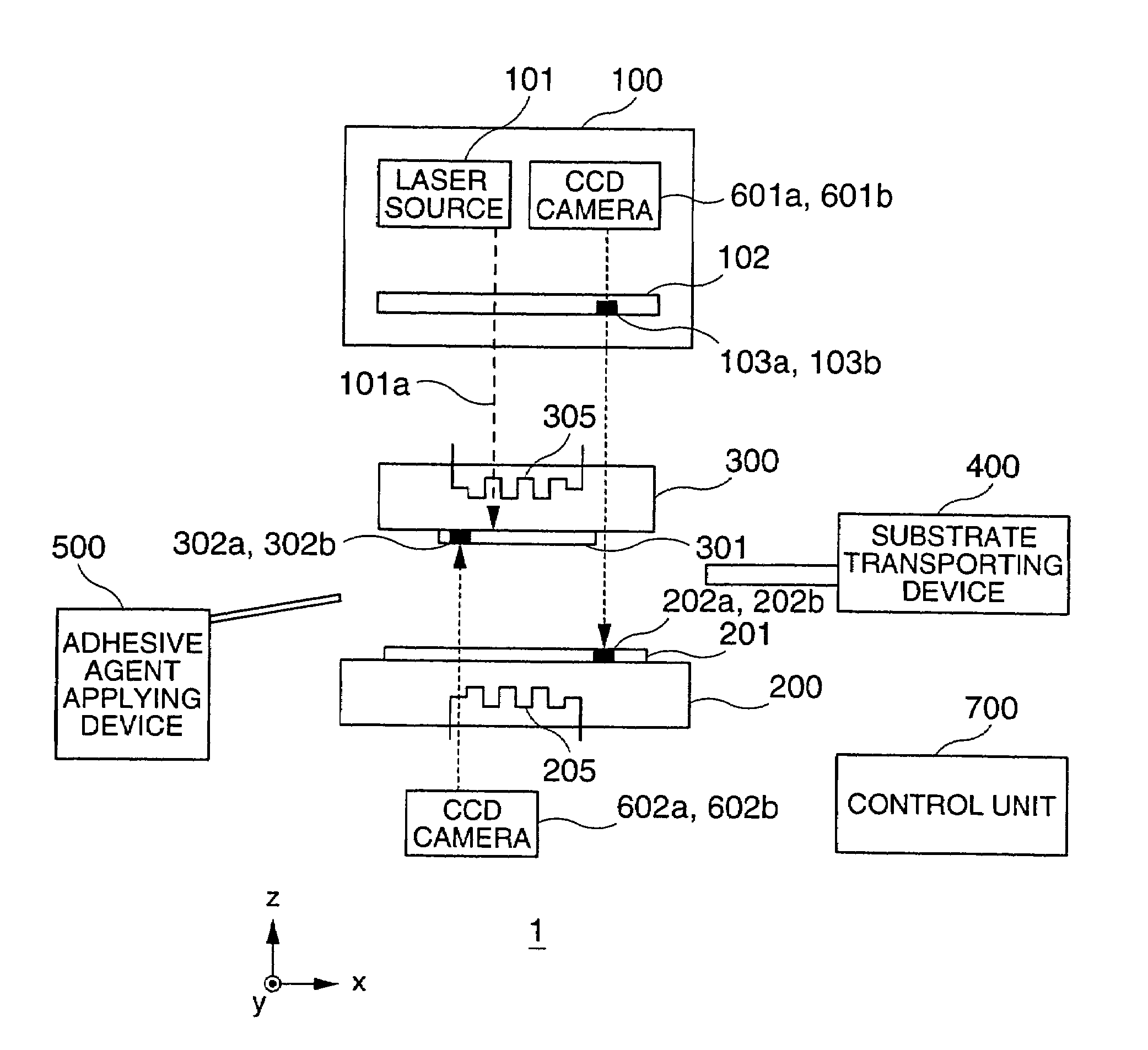

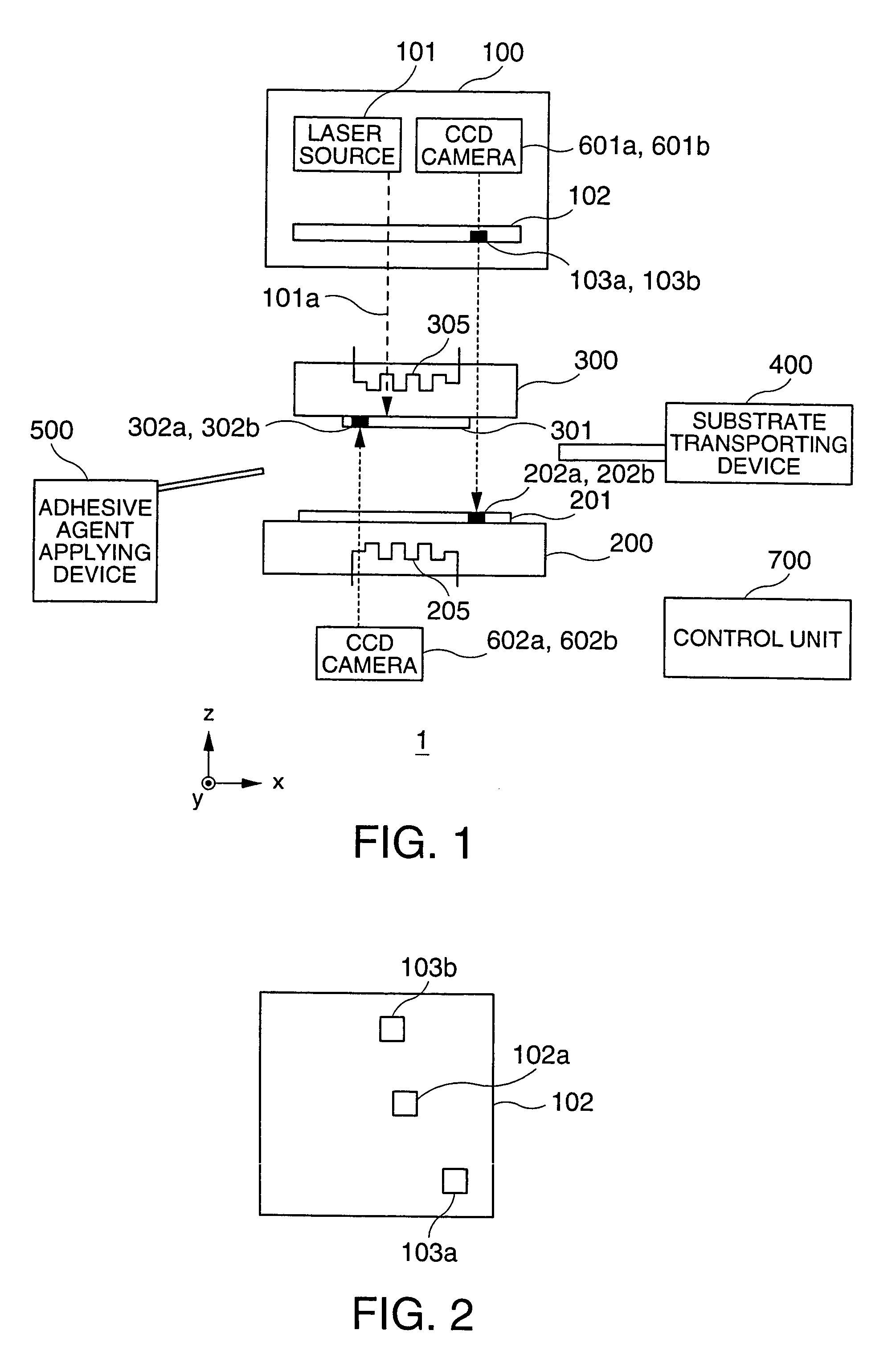

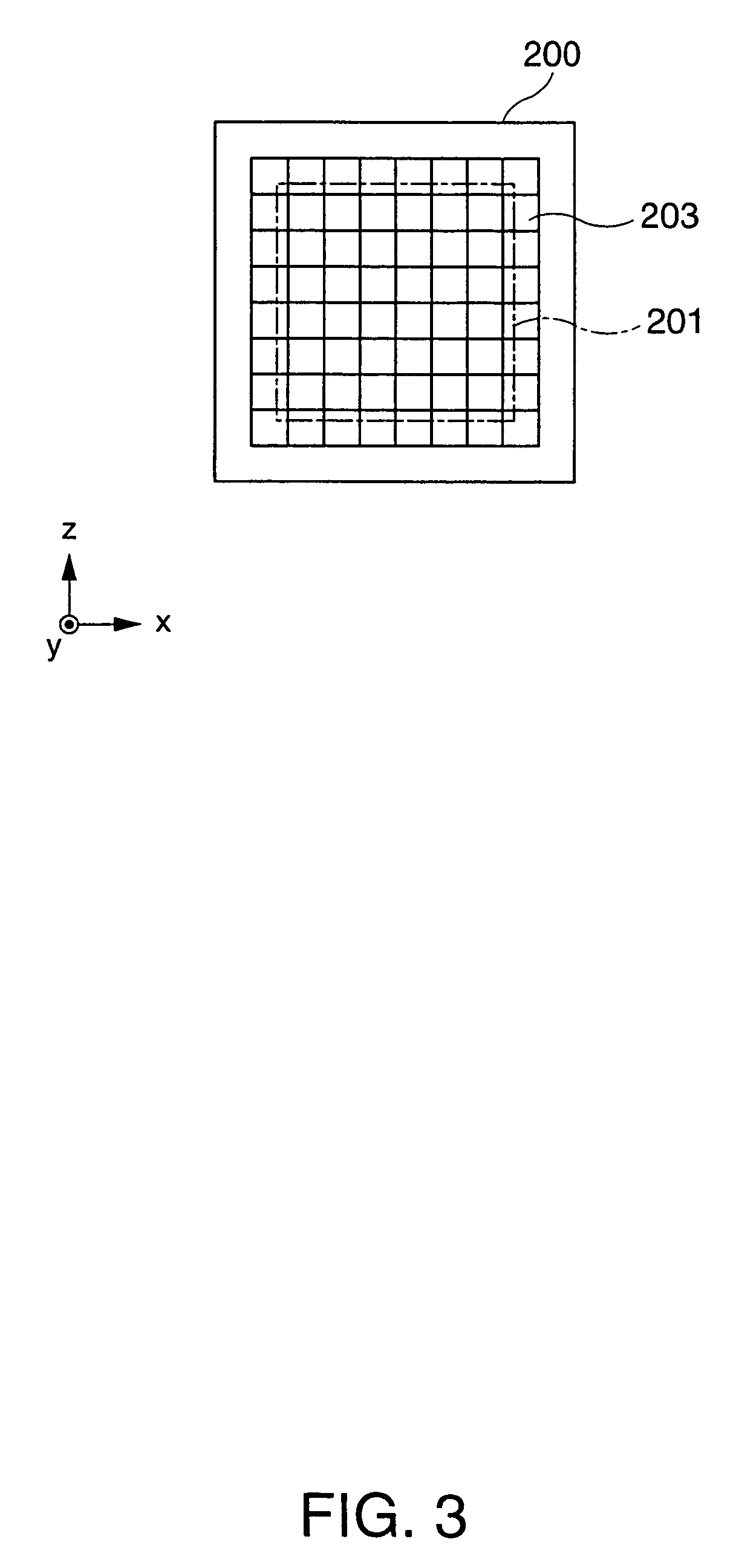

A method of manufacturing an electronic device includes providing a mask substrate, a first substrate on which an object to be transferred is formed, and a second substrate to which the object is to be transferred, adjusting positions of the mask substrate, the first substrate and the second substrate so that an alignment mark formed on one of the substrates (a reference substrate) and alignment marks formed on other two of the substrates are aligned with each other, and transferring the object to be transferred from the first substrate to the second substrate, the transferring step including irradiating the object to be transferred from the first substrate with light transmitted through the mask substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

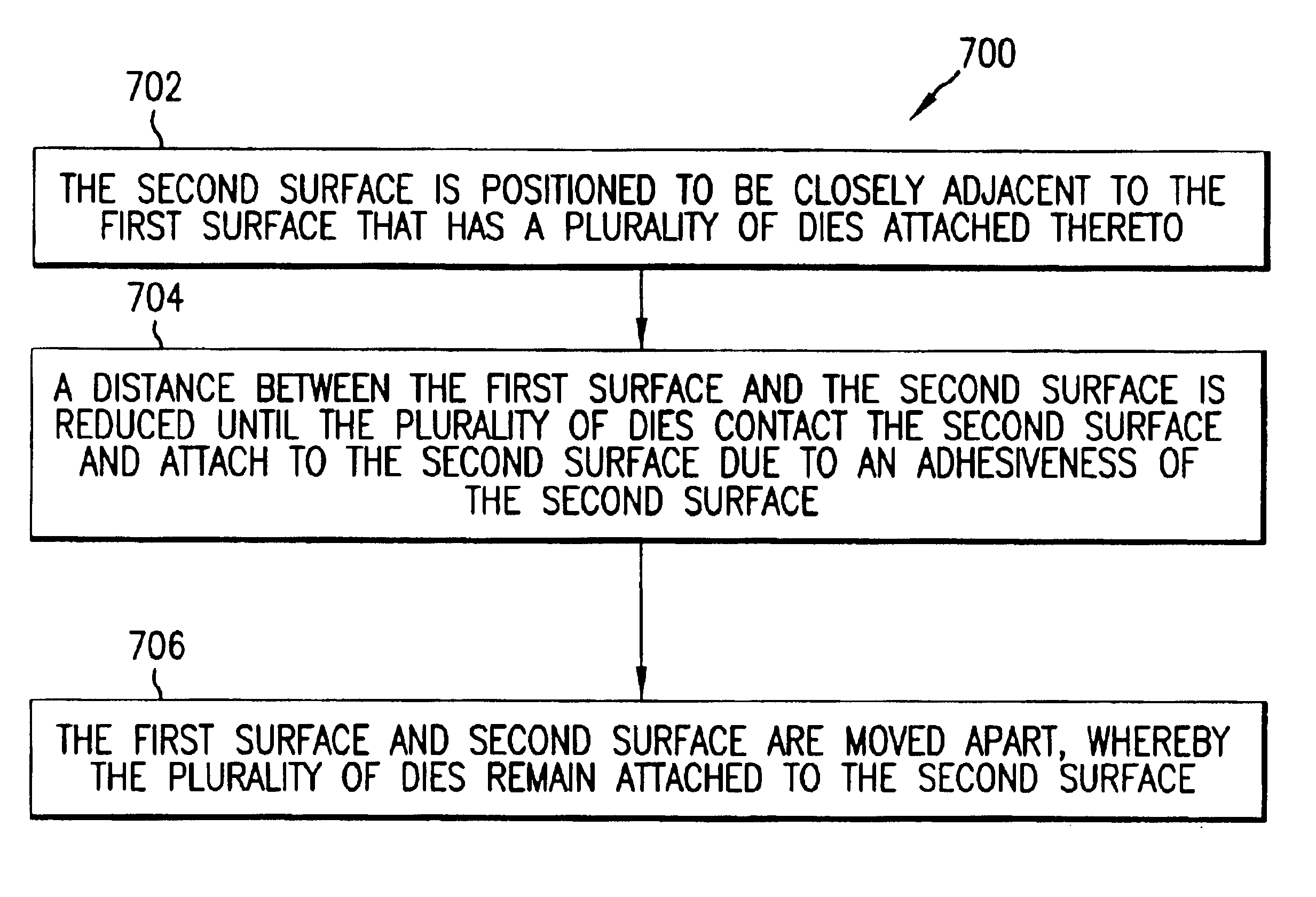

System and method of transferring dies using an adhesive surface

InactiveUS6848162B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringBiomedical engineering

A method and system for transferring a plurality of integrated circuit dies from a first surface to a second surface is described. The second surface is positioned to be closely adjacent to the first surface that has a plurality of dies attached thereto. A distance is reduced between the first surface and the second surface until the plurality of dies contact the second surface and attach to the second surface due to an adhesiveness of the second surface. The first surface and second surface are moved apart. The plurality of dies remain attached to the second surface.

Owner:SYMBOL TECH INC

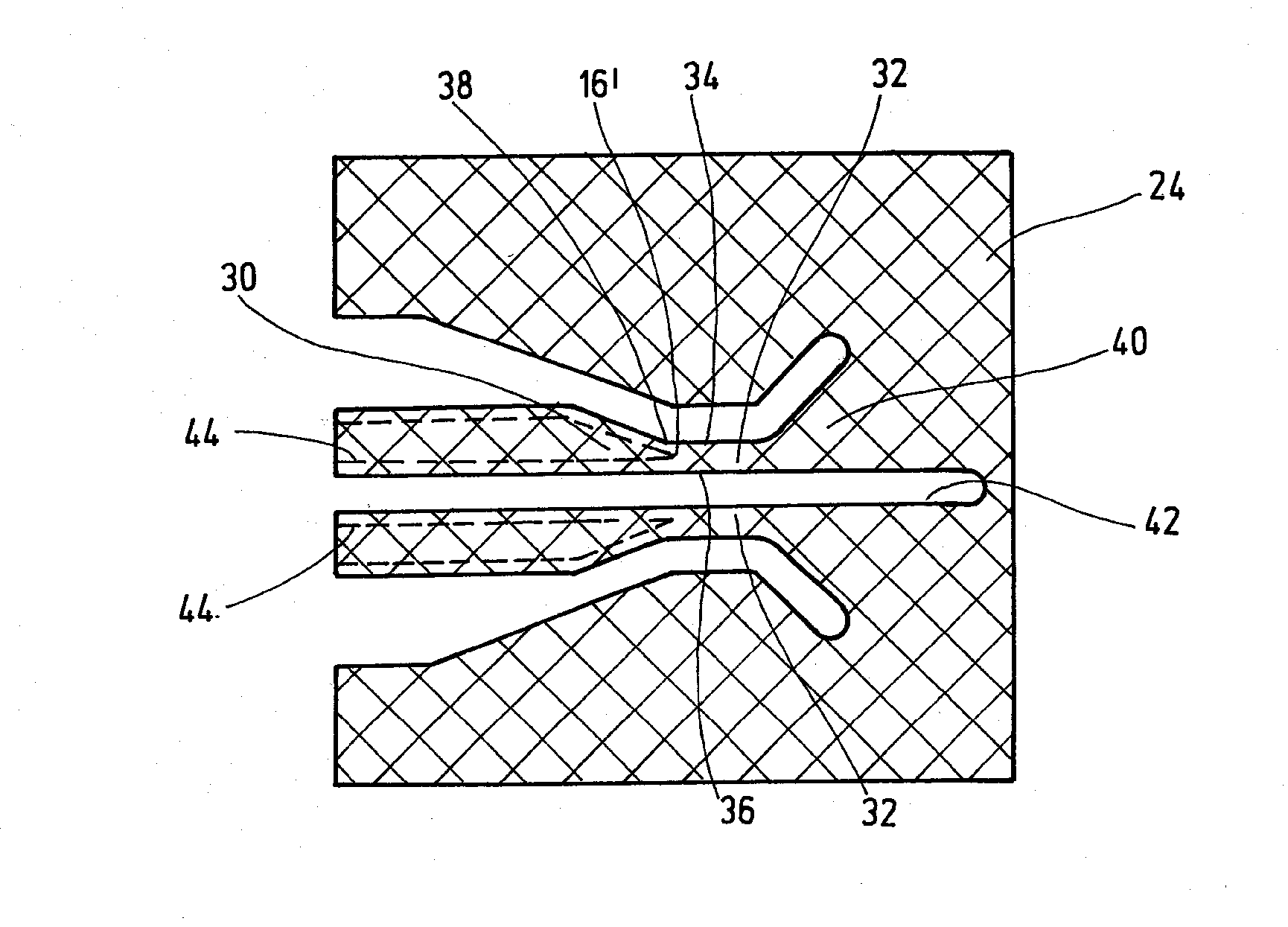

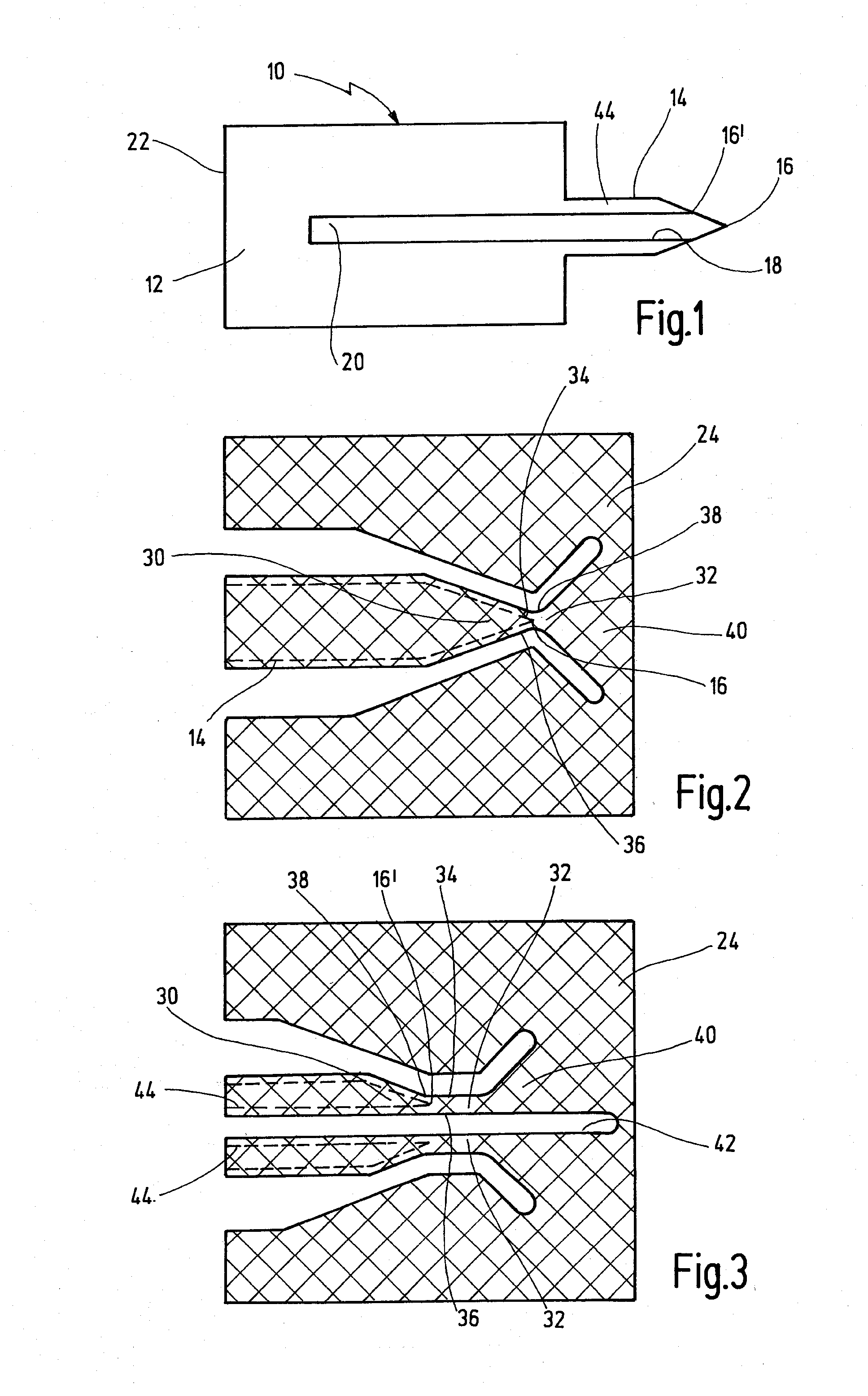

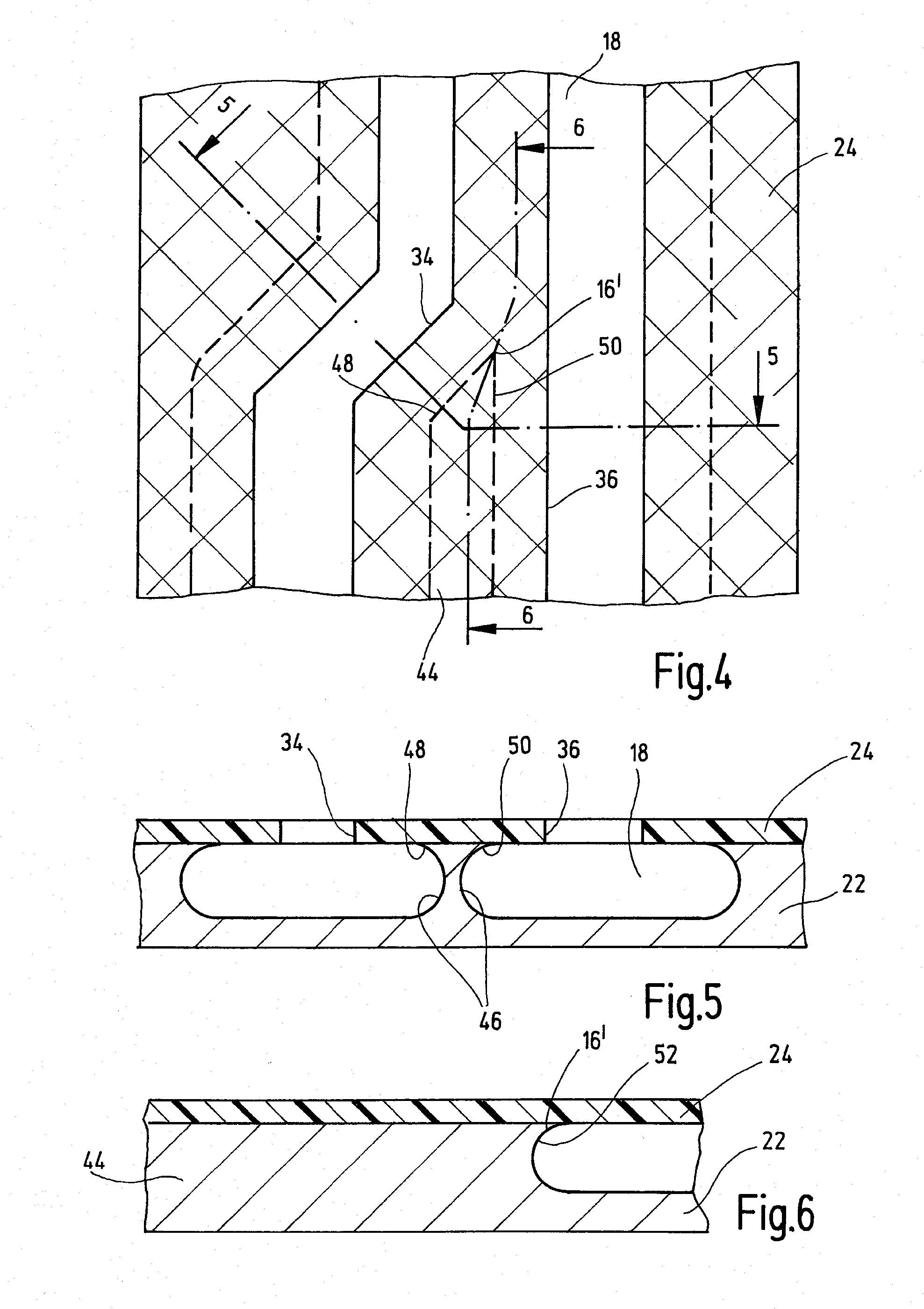

Method for producing a pricking element

ActiveUS20080040919A1Avoid actionSmall possible volumeDecorative surface effectsSurgical needlesElectrical and Electronics engineeringEngineering

The present invention provides a process for producing a lancing element in which a flat-shaped member is formed from a flat material by applying a mask and allowing an etching agent to act upon it, wherein at least a part of the flat-shaped member is shaped as a tip. The mask is provided with a shaping area for the tip to be formed and with a screening area which extends distally beyond this shaping area to prevent the tip from being etched off at the front. A sharp tip is exposed by laterally undercutting the side flanks of the shaping area and screening area.

Owner:ROCHE DIABETES CARE INC

Control housing and method of manufacturing same

InactiveUS7146701B2Easy to cleanFlat surfaceContact surface shape/structureEmergency casingsEngineering

Owner:NEECO TRON

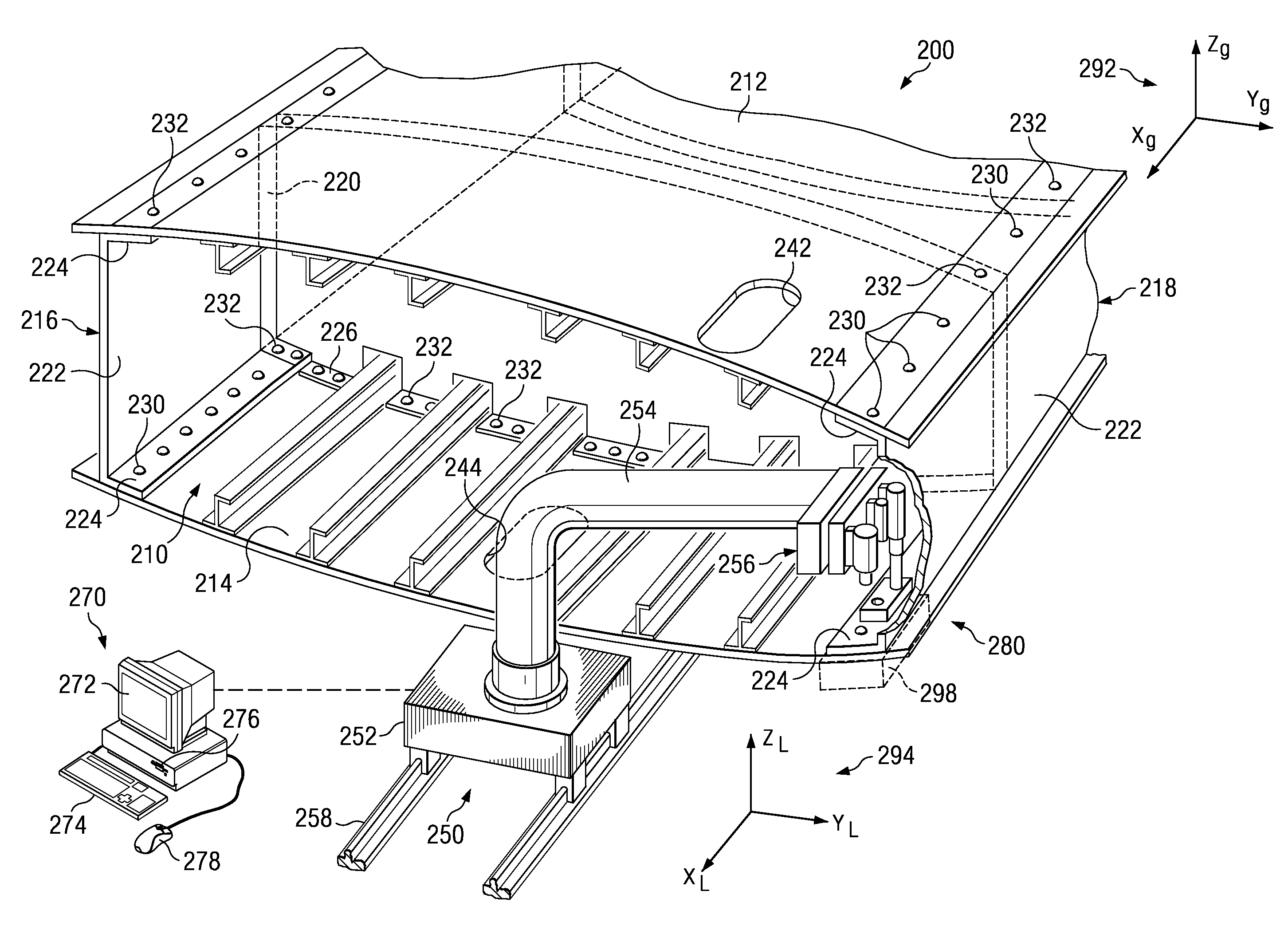

Robot-deployed assembly tool and method for installing fasteners in aircraft structures

ActiveUS20080155807A1Eliminate gapsAircraft componentsAutomatic control devicesFlight vehicleEngineering

An assembly system and method for assembling an aircraft wing box or other structure that may define an interior area accessible through at least one access opening are provided. The method includes inserting a robot having an assembly tool mounted thereto into the interior area through the at least one access opening. The assembly tool may be positioned at a fastener location, and may be clamped to the structure. A hole may be made through the structure, and a fastener may be installed in the hole.

Owner:THE BOEING CO

Solar cell stringing machine

Owner:GTAT CORPORATION

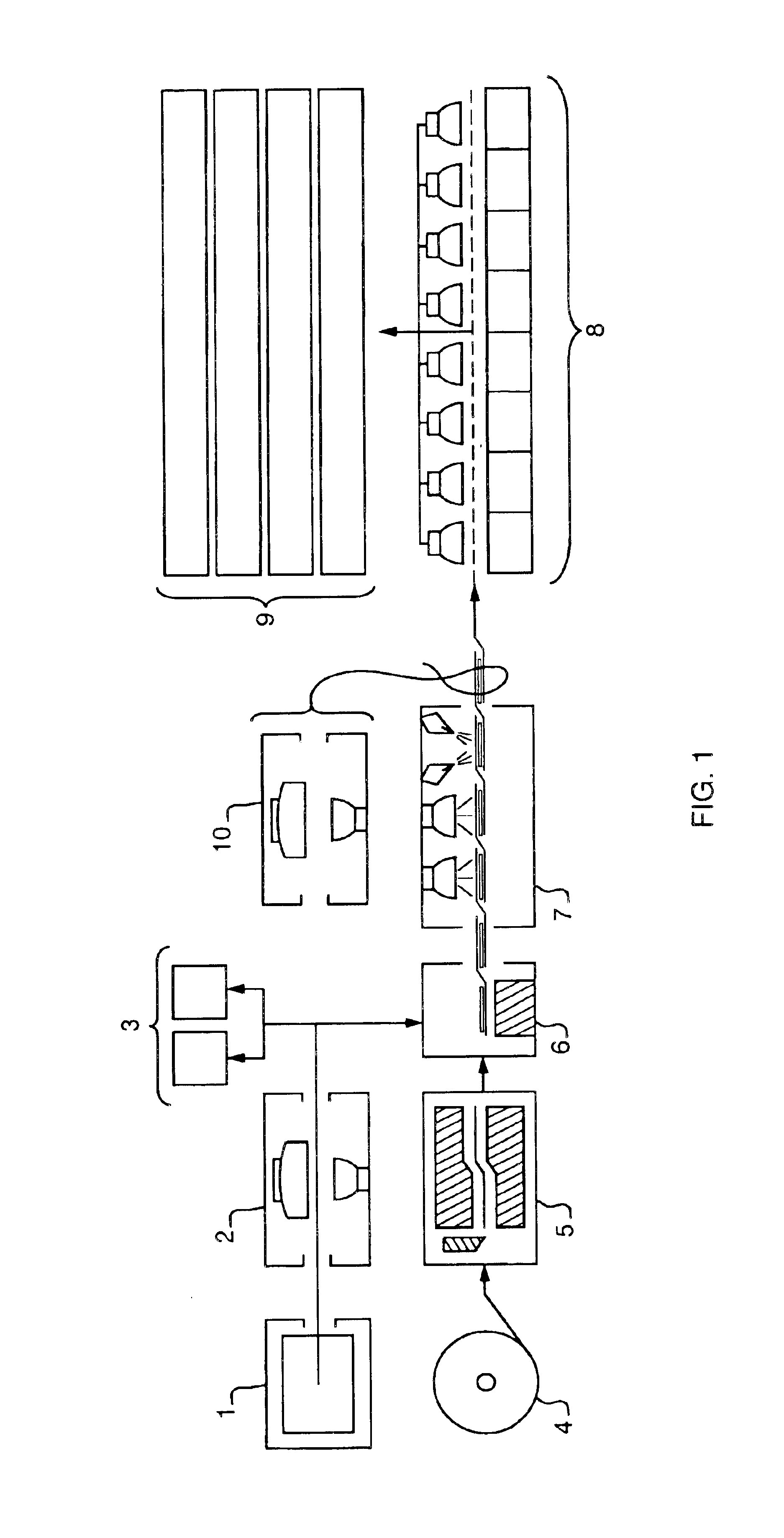

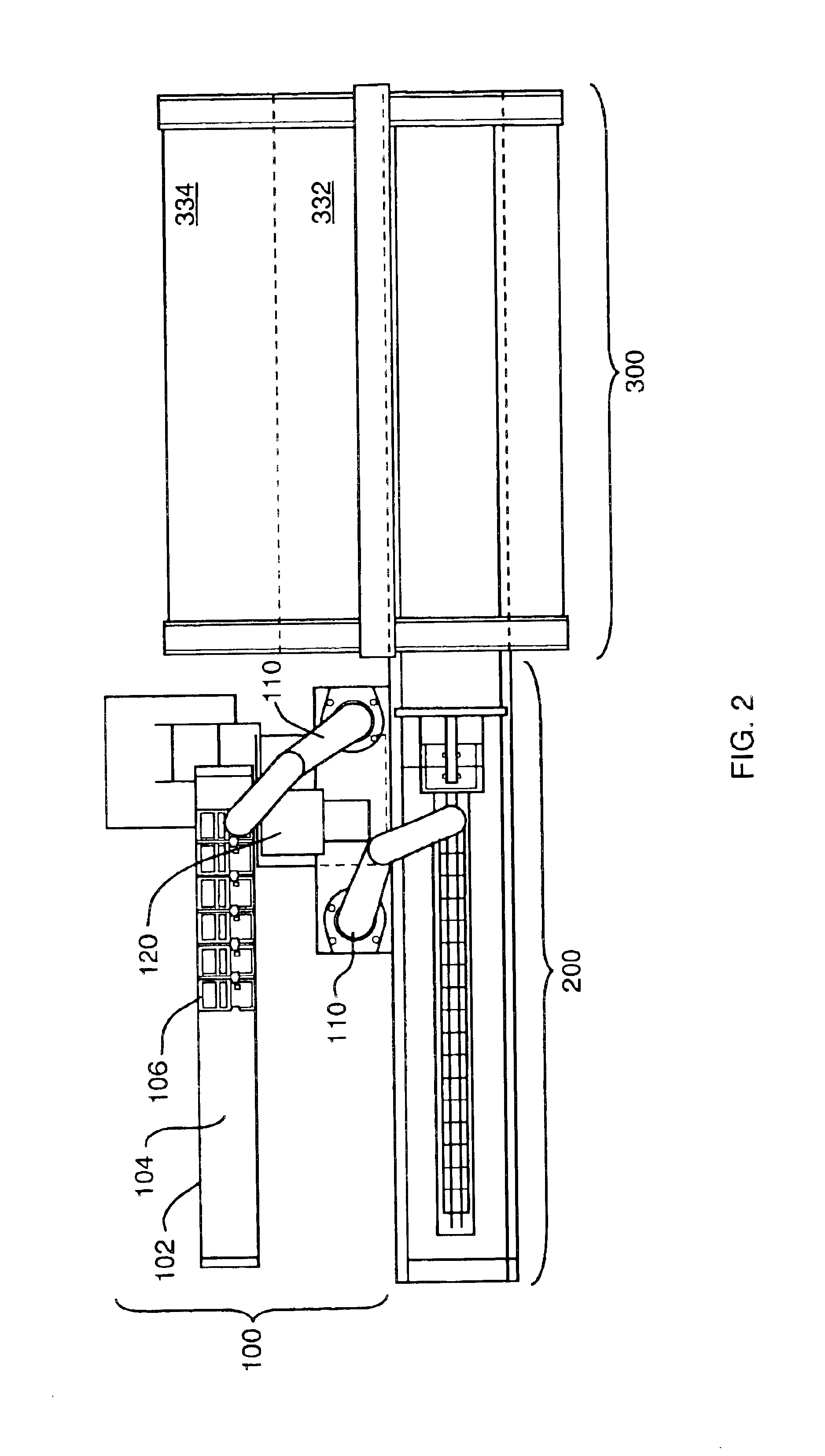

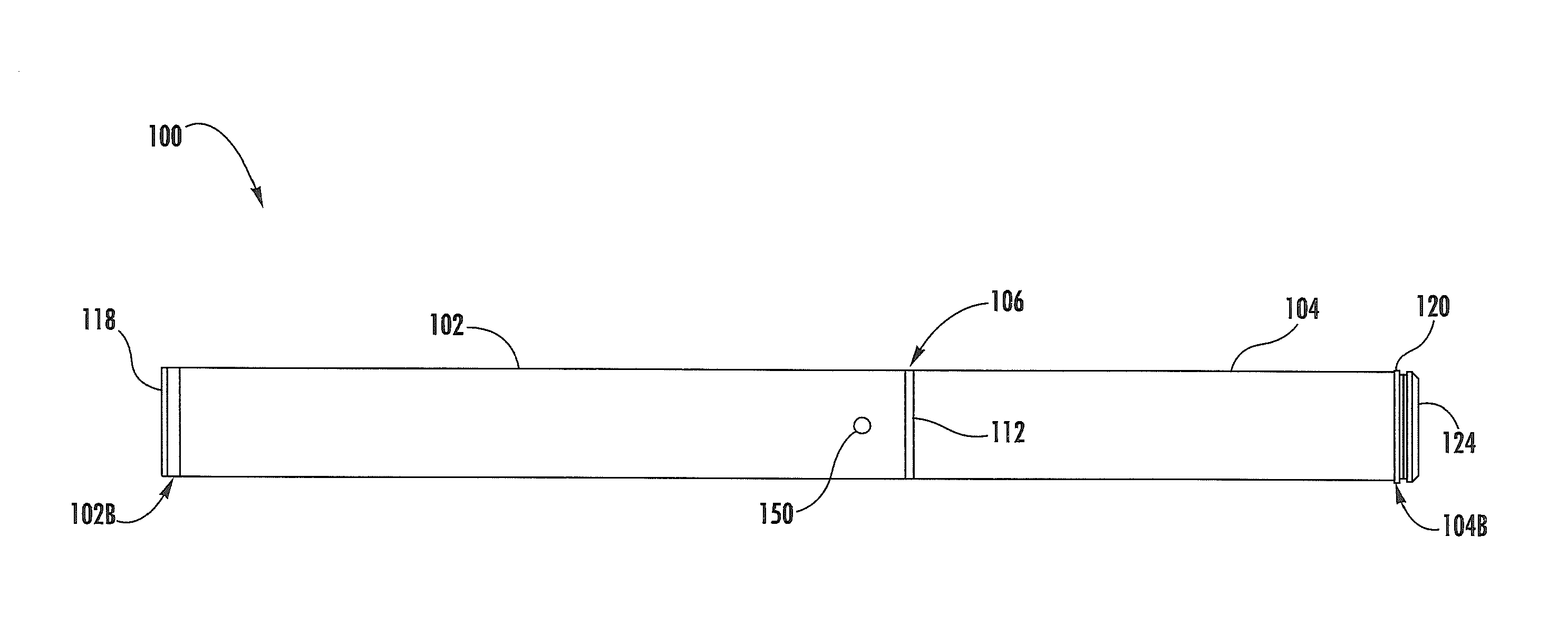

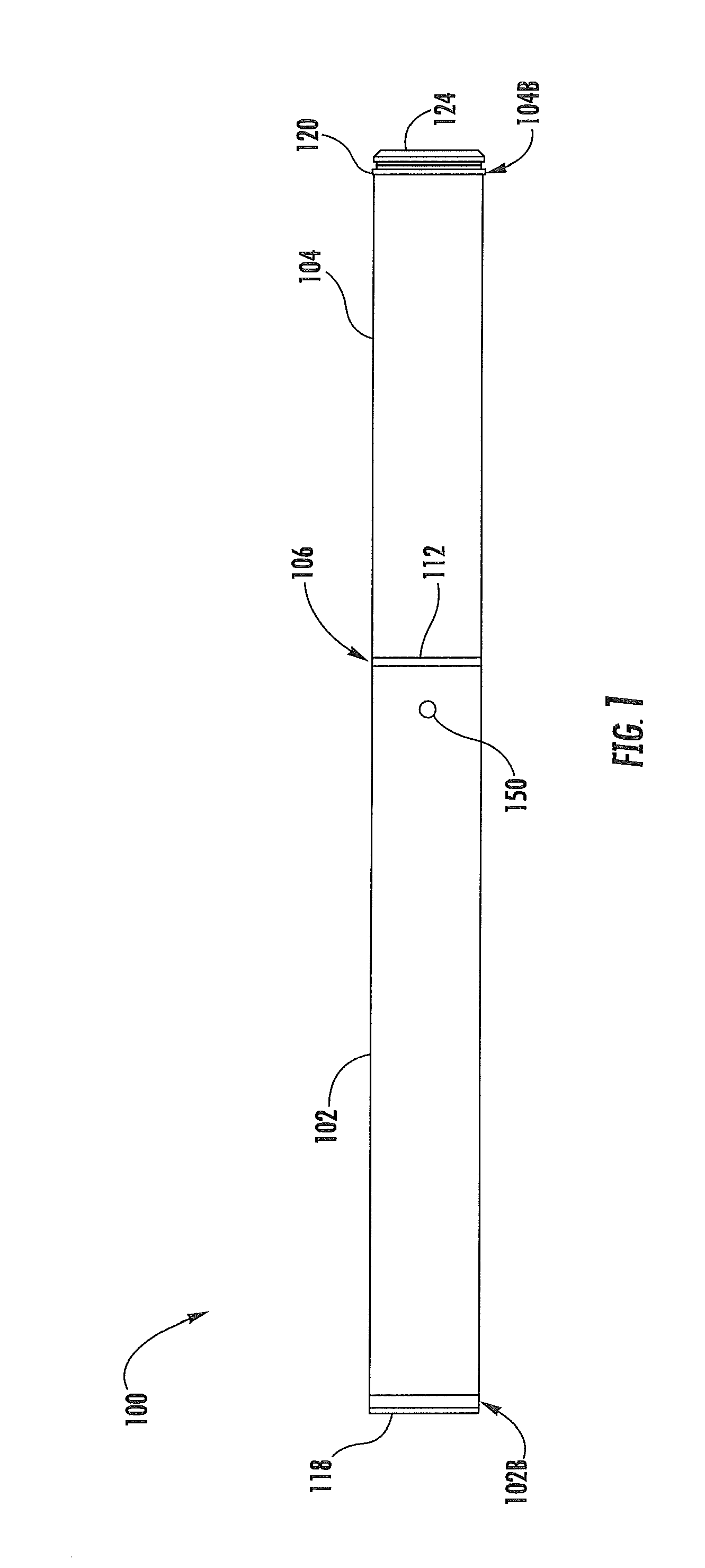

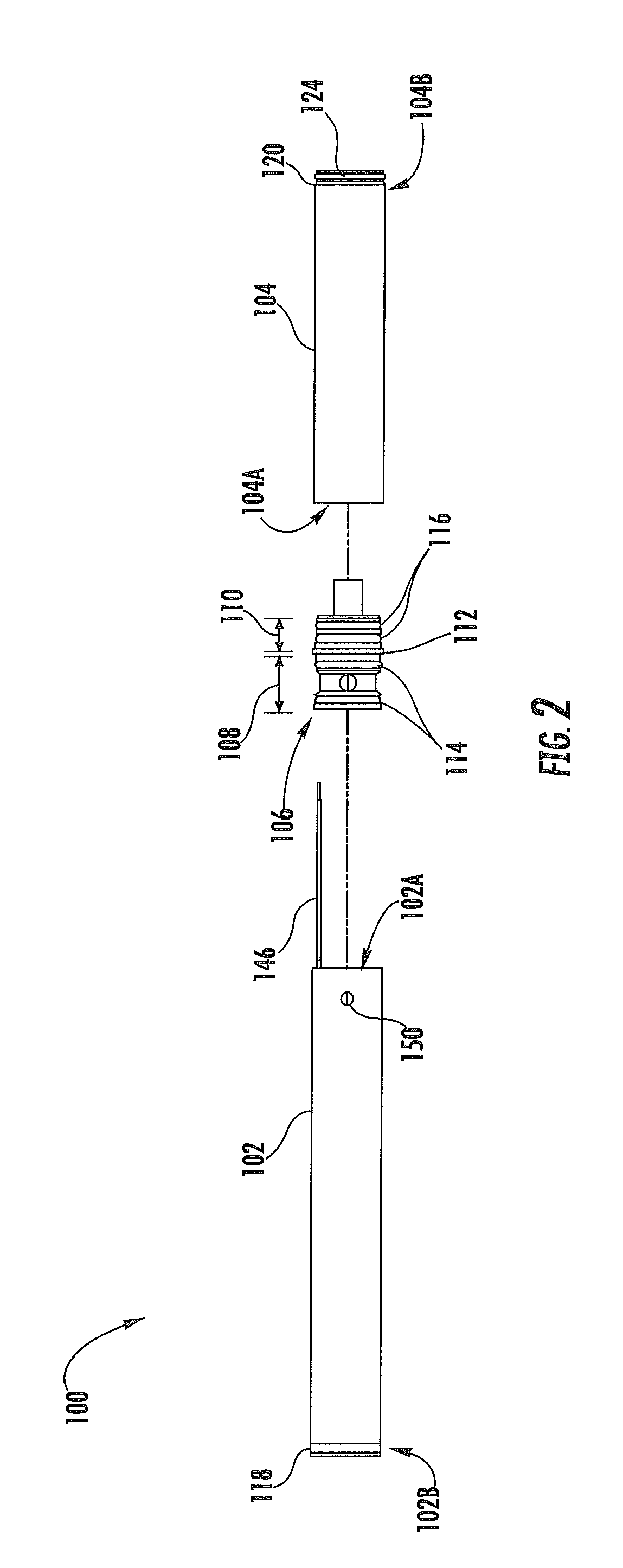

Aerosol Delivery Device Comprising Multiple Outer Bodies and Related Assembly Method

The present disclosure relates to an aerosol delivery device. The aerosol delivery device may include a first outer body, a second outer body, and a coupler received therebetween. A securing mechanism may couple the outer bodies together to retain the aerosol delivery device in an assembled configuration. For example, the coupler may be welded to the first outer body and the second outer body. Related assembly methods are also provided.

Owner:RAI STRATEGIC HLDG INC

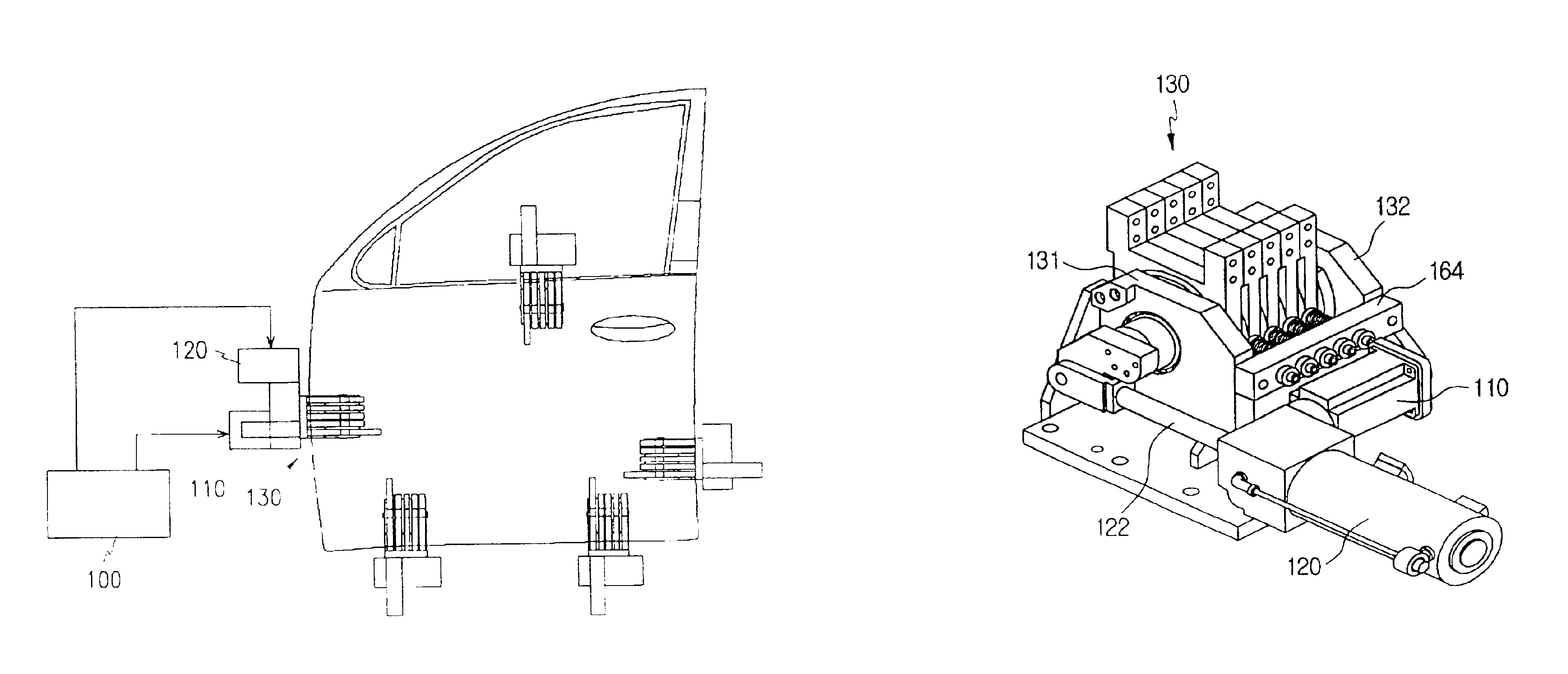

Panel-securing system for various vehicle types

A panel-securing system for various vehicle types is provided, in which various clamps and fingers for different panel shapes may be selected for operation by a single cylinder, the amount of space utilized to install the system is minimized, and parts used in the system are simplified. The panel-securing system for use in a production line for various vehicle types comprises a controller having stored therein panel information for various vehicle types, the controller generating and outputting a locator-selection control signal and a panel-securing control signal corresponding to panel information of the correct vehicle type; a first actuator for selecting a locator corresponding to the locator-selection control signal output by the controller; a second actuator for driving a locator corresponding to the panel-securing control signal output by the controller; and a panel-securing assembly including a plurality of locators, which correspond to panels of the various vehicle types.

Owner:HYUNDAI MOTOR CO LTD

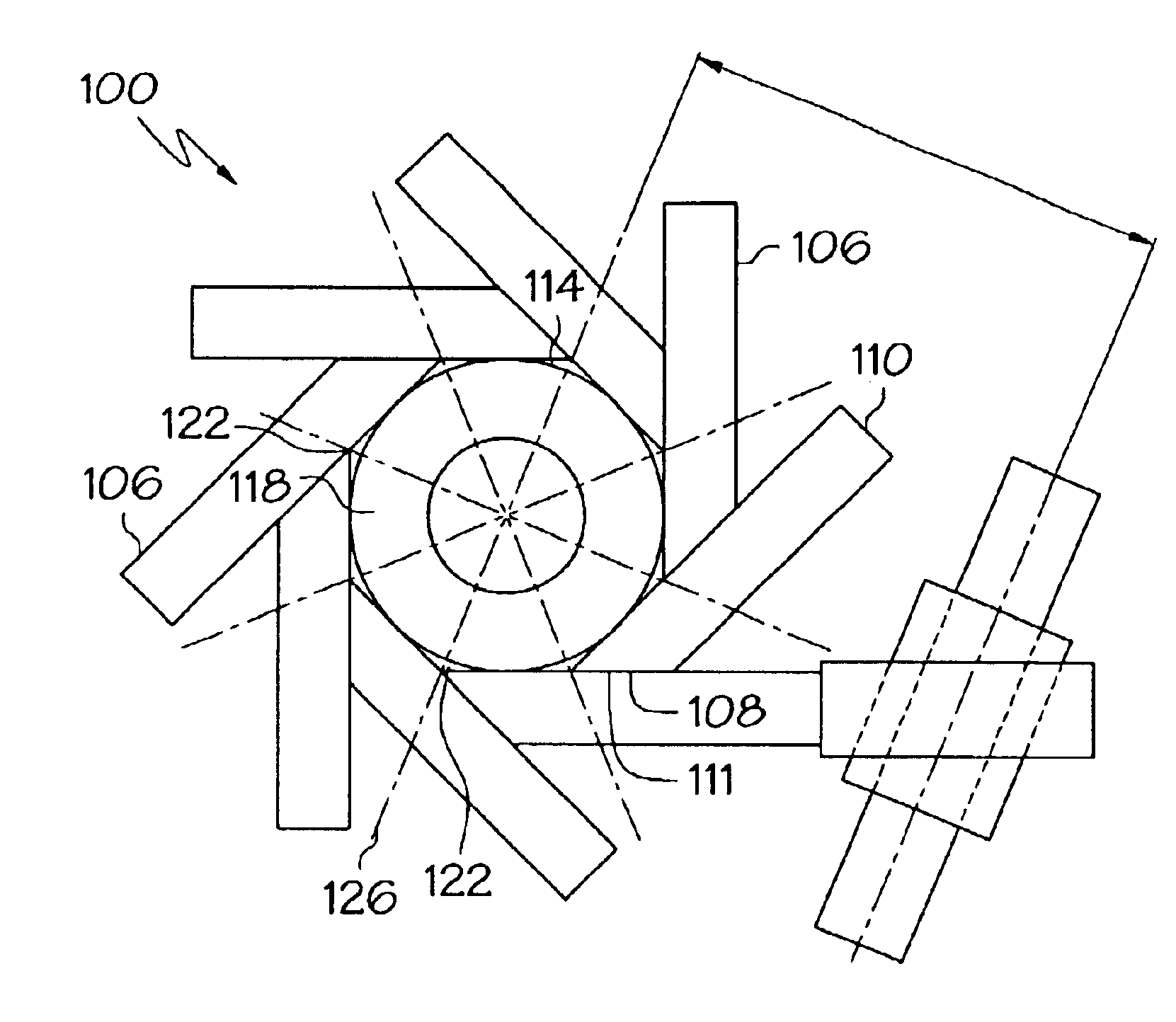

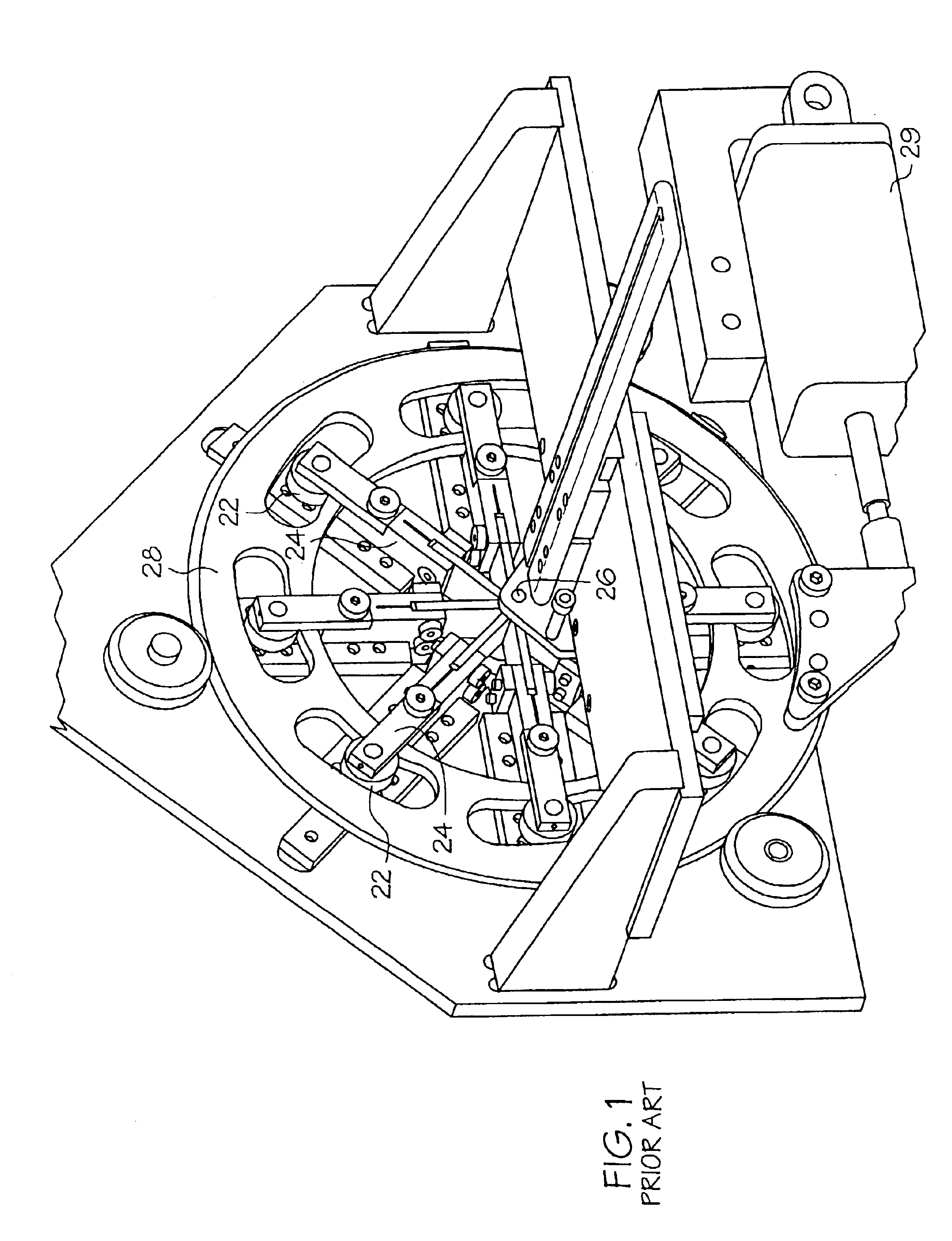

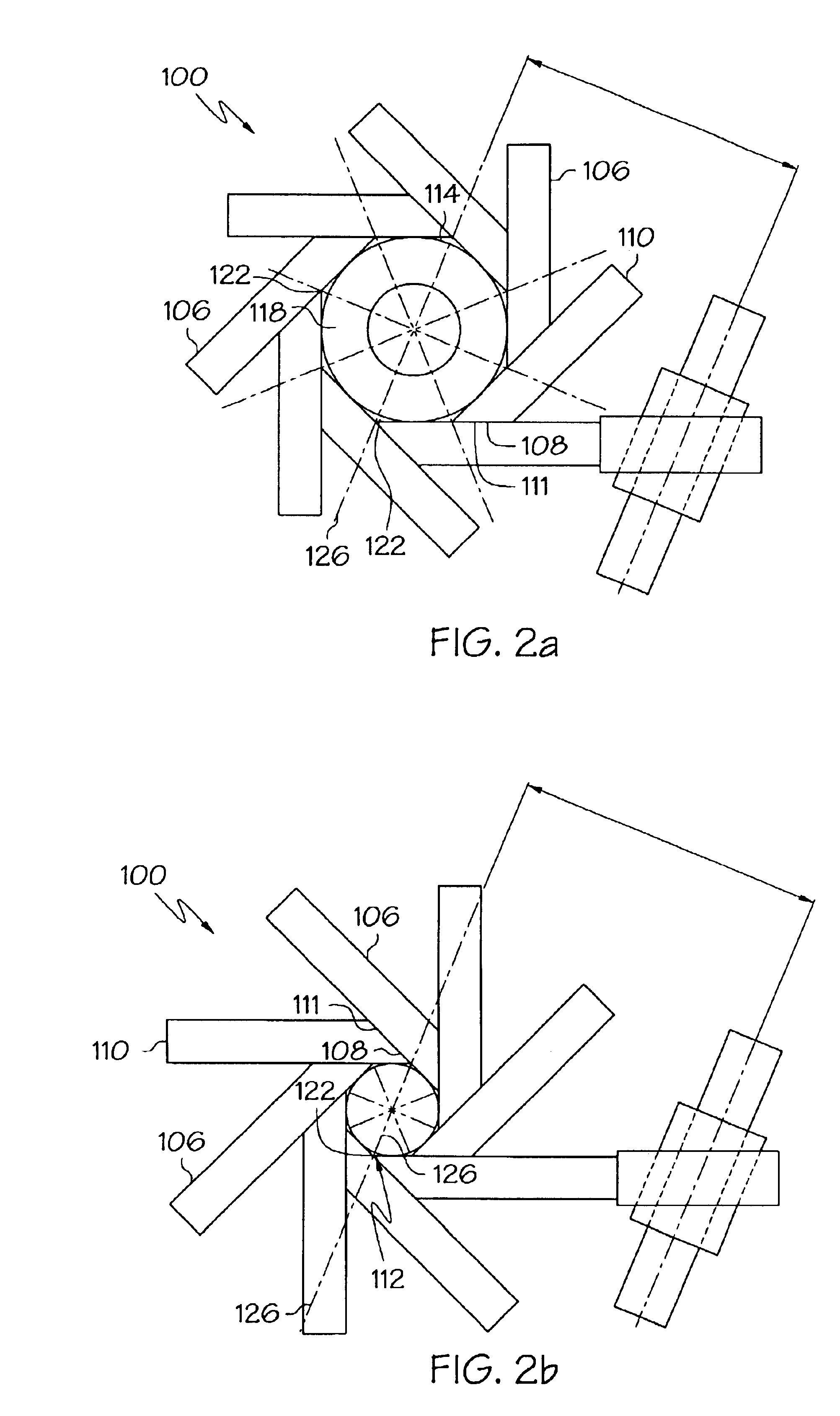

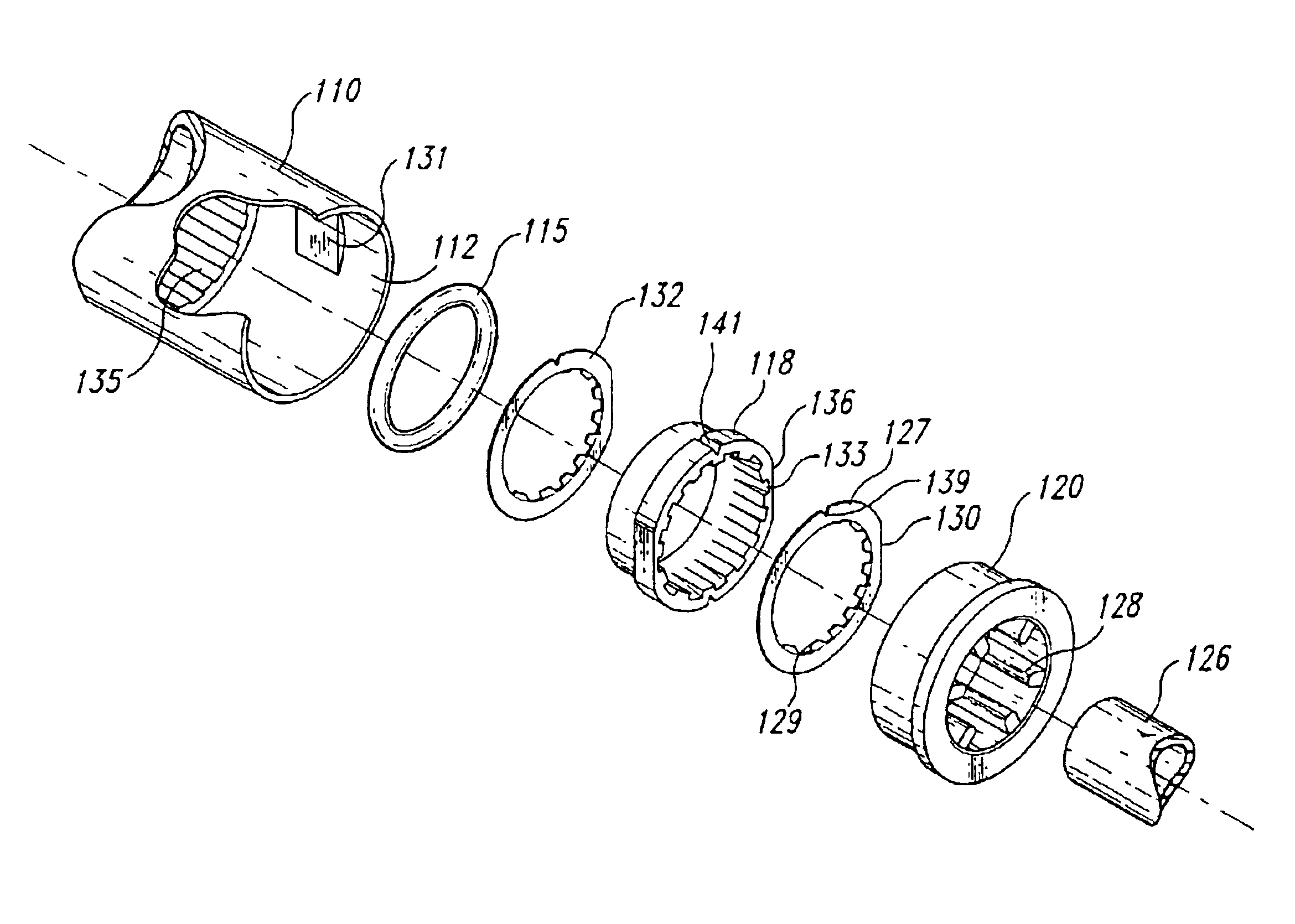

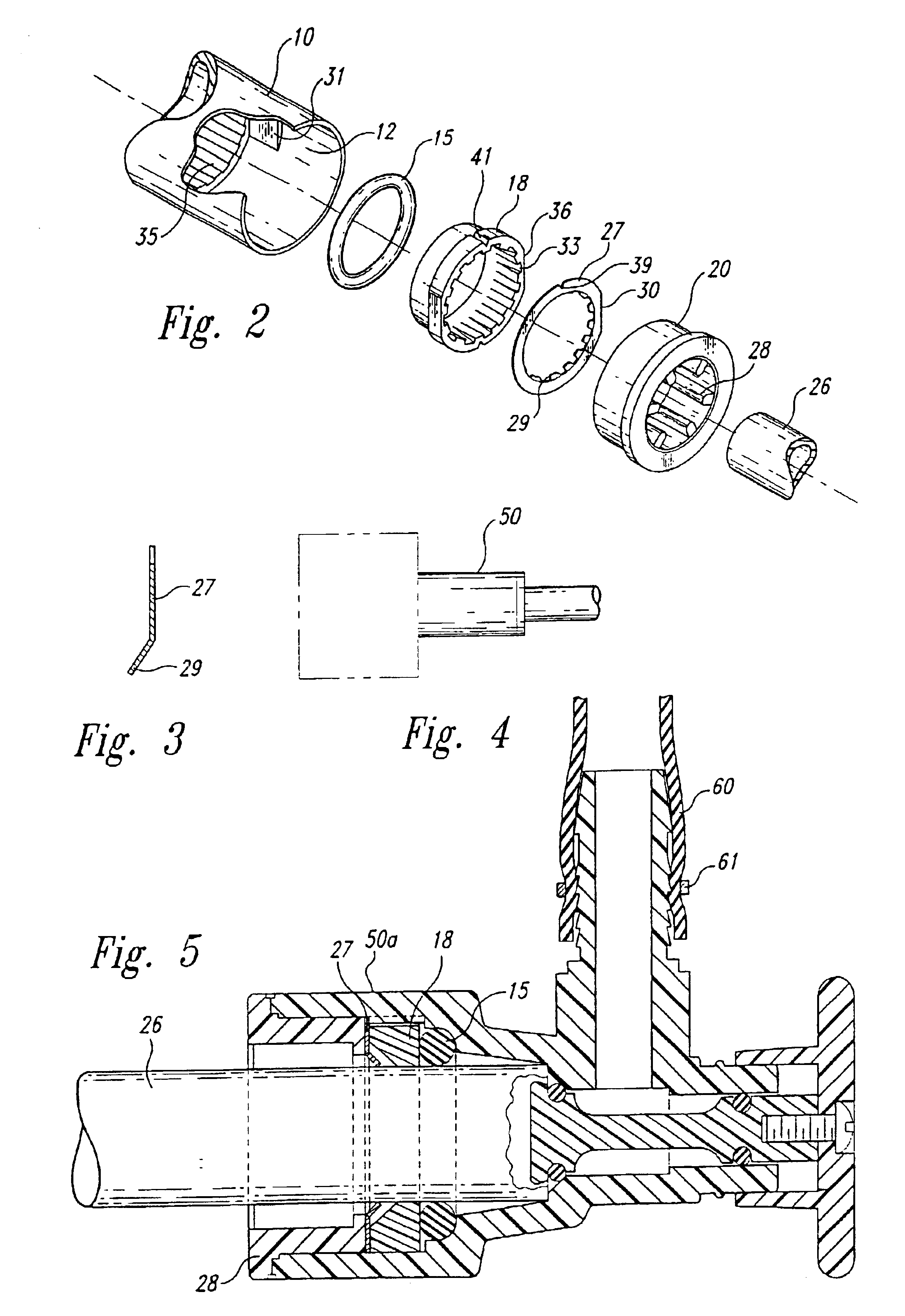

Apparatus for contracting, loading or crimping self-expanding and balloon expandable stent devices

InactiveUS6915560B2Minimizing distortion of and scoringReduce the overall diameterStentsAutomatic control devicesEngineeringKnife blades

An apparatus for manipulating a medical device is formed of at least three coupled movable blades which are disposed about a reference circle to form an aperture whose size may be varied. The aperture capable of being sized to contain a medical device. Each blade is in communication with an actuation device which is capable of moving the blade to alter the size of the aperture. Each blade includes a single radial point which a) lies on the circumference of the reference circle prior to movement of the blade, and b) may be moved only along a radius of the reference circle on movement of the blade.

Owner:BOSTON SCI SCIMED INC +2

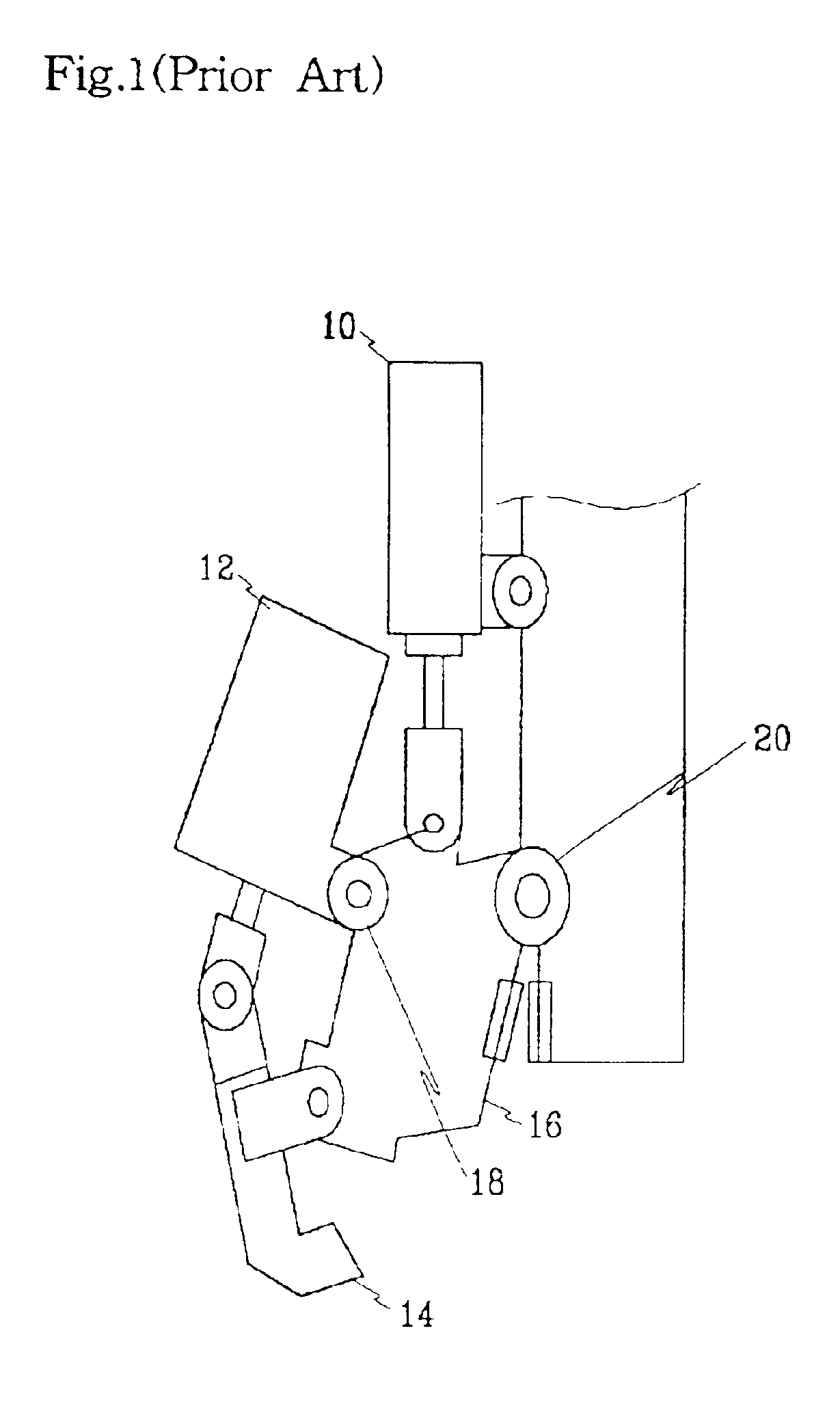

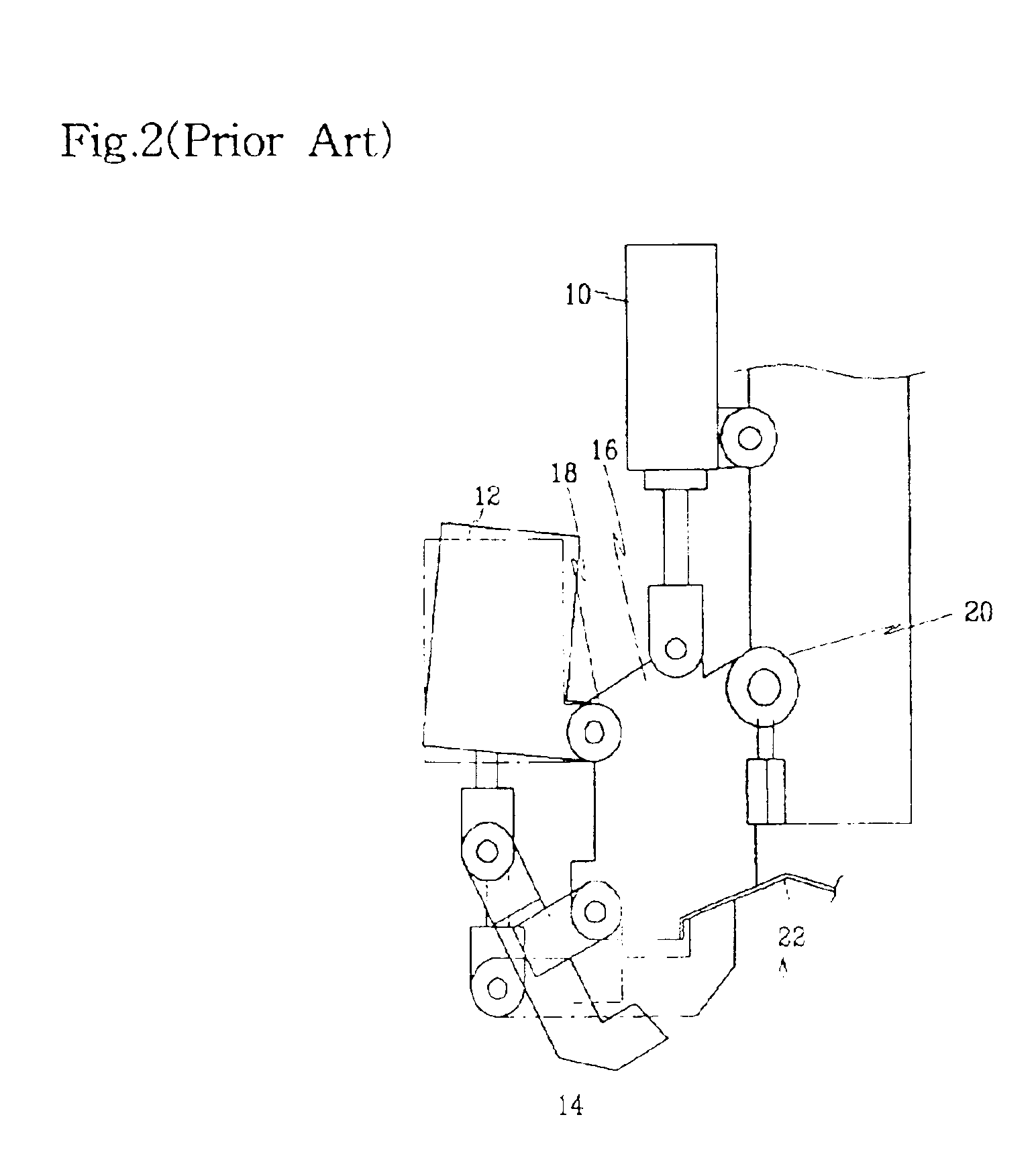

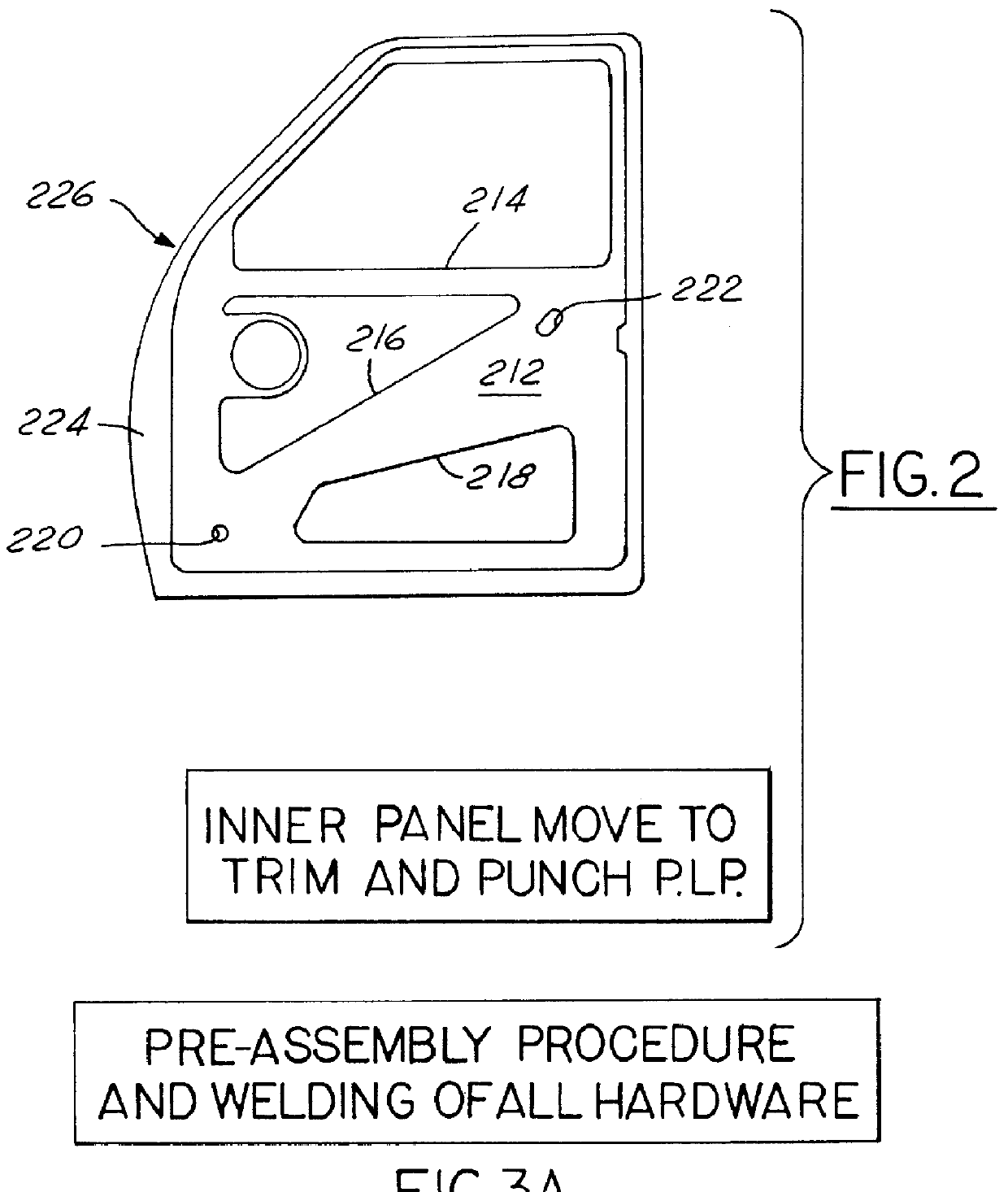

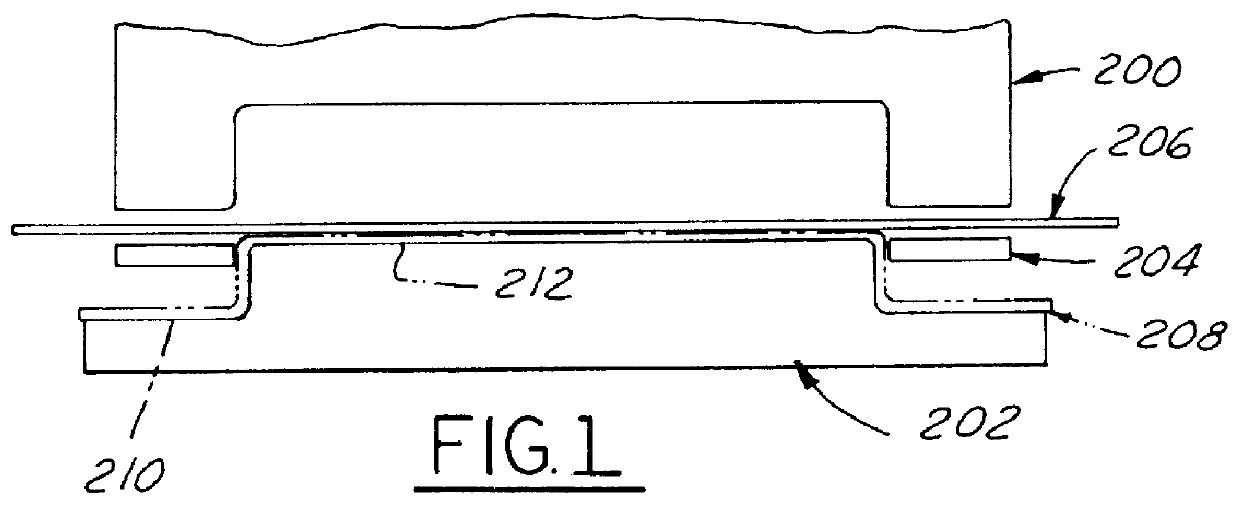

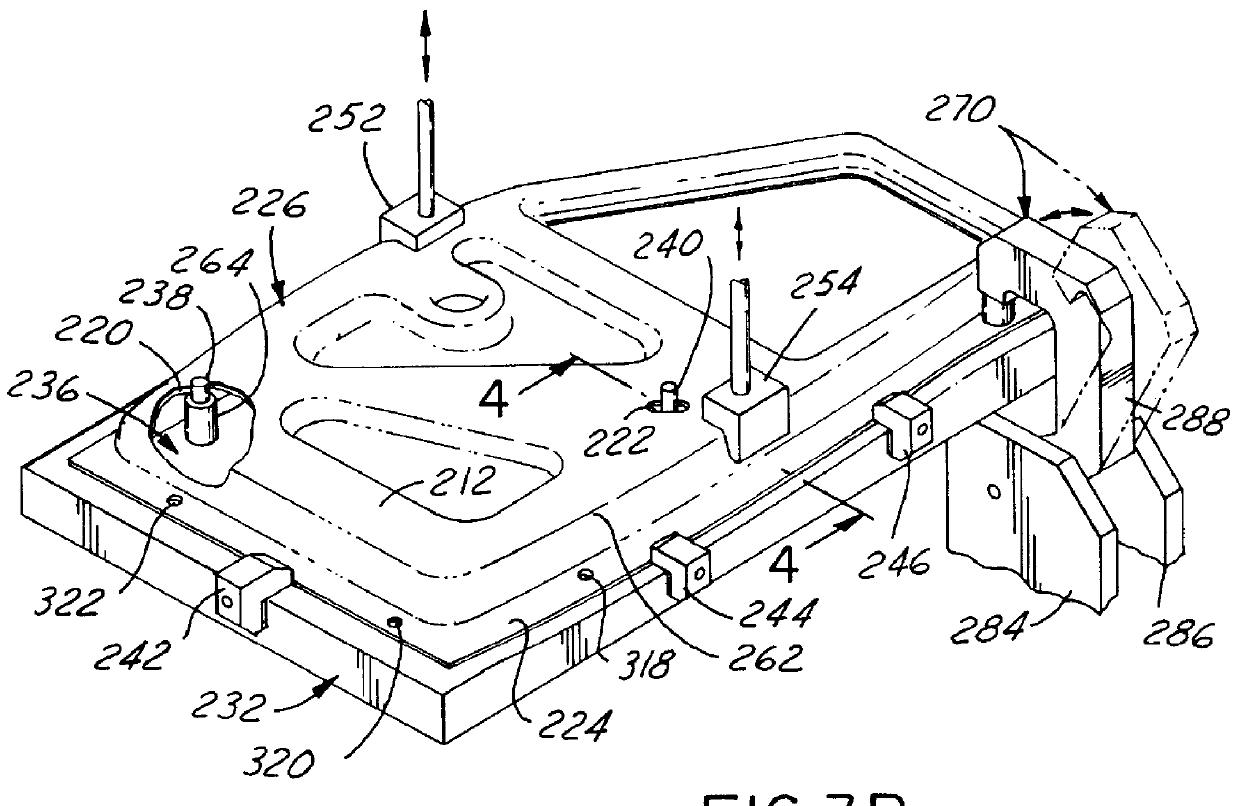

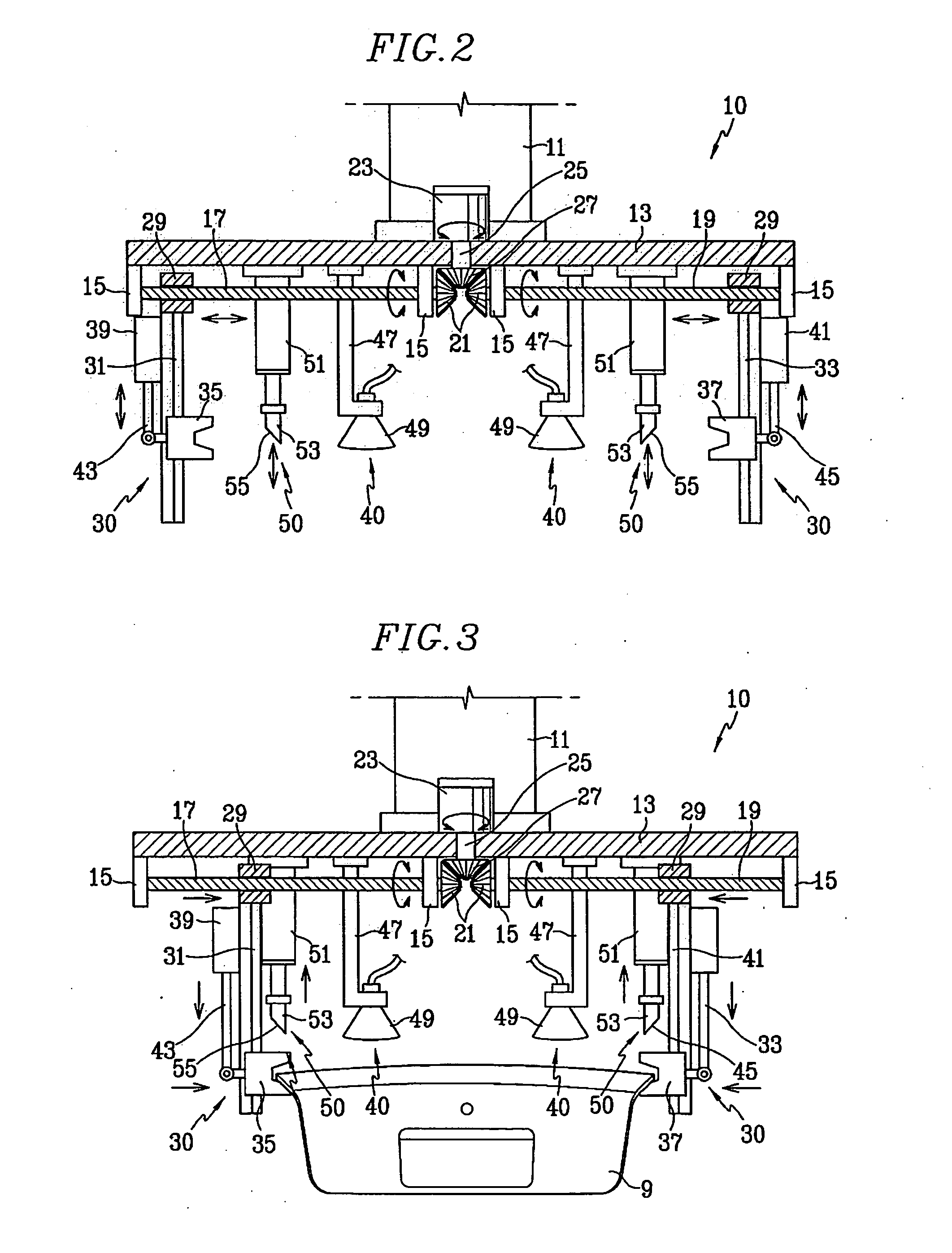

Hemming method and apparatus

InactiveUS6029334AImprove appearance qualityEliminate the problemForging hammersAssembly machinesEmbedmentRead through

Improved method and apparatus for interlocking hemmed together edges of inner and outer vehicle body panels with an improved interlock joint. The inner panel blank is draw stamped and provided with PLP holes in a stamping press. A plurality of conventional hardware components are then welded to the inner panel. Then interlock holes are formed by a piercing tool moving through the inner panel border from its outboard to its inboard side while the inner panel is held by clamps and PLP pins. The hole piercing punch thus leaves cold worked upset material slightly raised inboard, rather than outboard, around the pierced interlock hole margin. Then the inner panel subassembly is married to the outer panel and transferred to a hemming station and again precisely clamped and positioned by PLP pins, whereupon hemming press gates are operable for hemming the flange lip of the outer panel over the inner panel border. The final hemming steel of each gate carries staking punches that individually strike a precision registered portion of such hemmed lip to deform it into locking engagement with the associated interlock hole. The upset material is thus flattened and accurately worked into embedment into the interior surface of the hemmed flange lip, rather than into the interior surface of the outer panel, thereby avoiding creating read through problems on the outer panel.

Owner:UNOVA IP

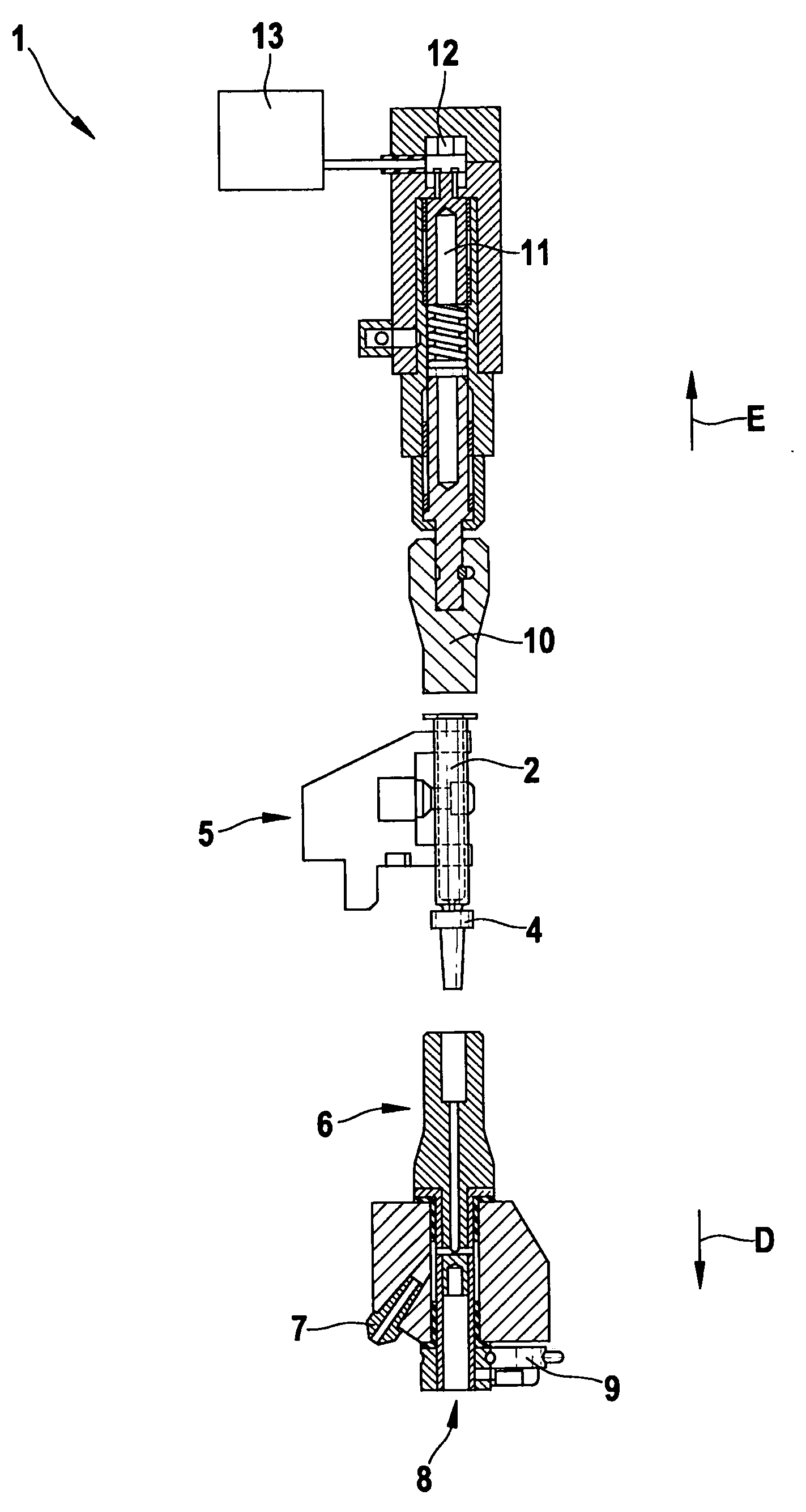

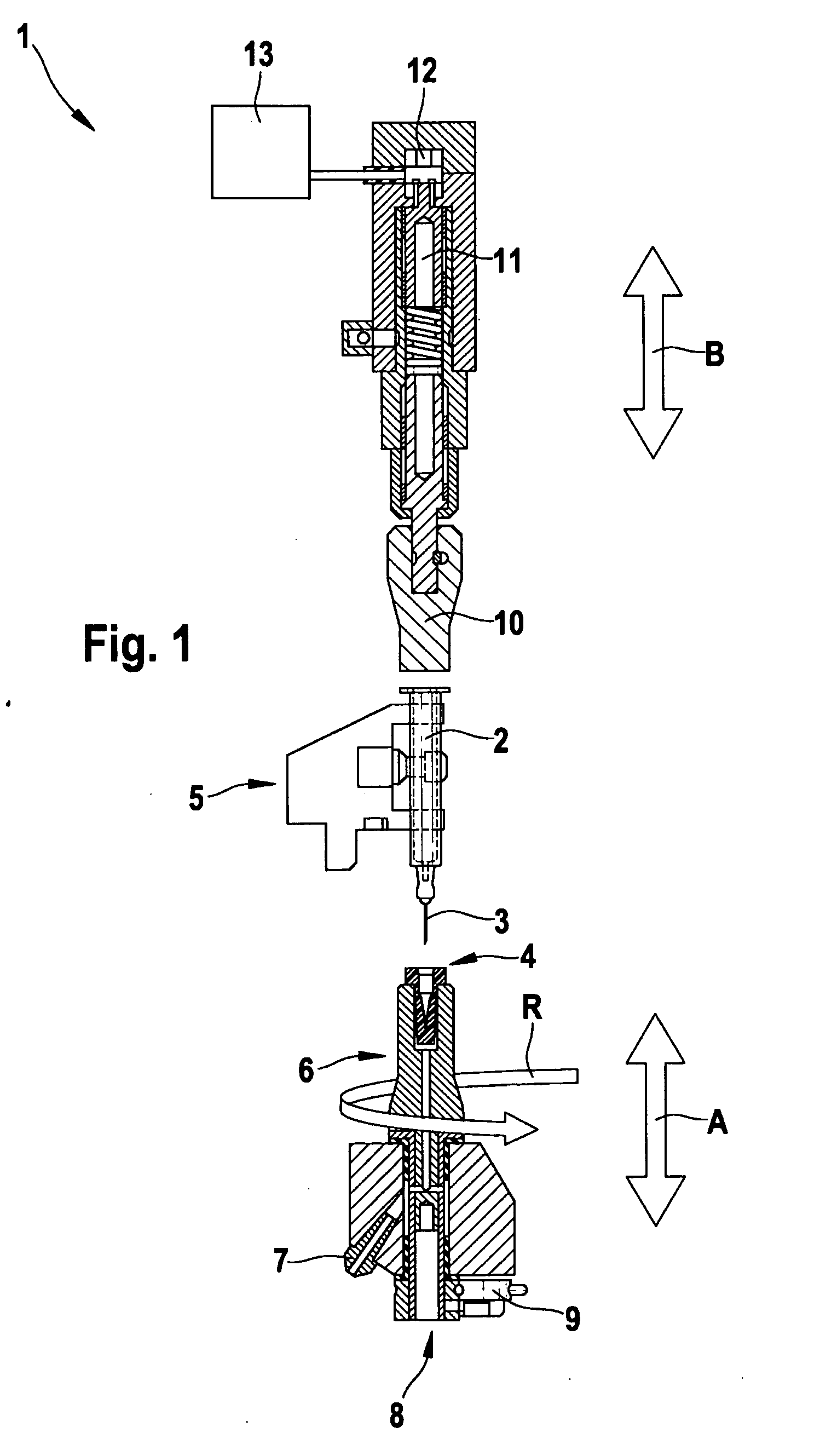

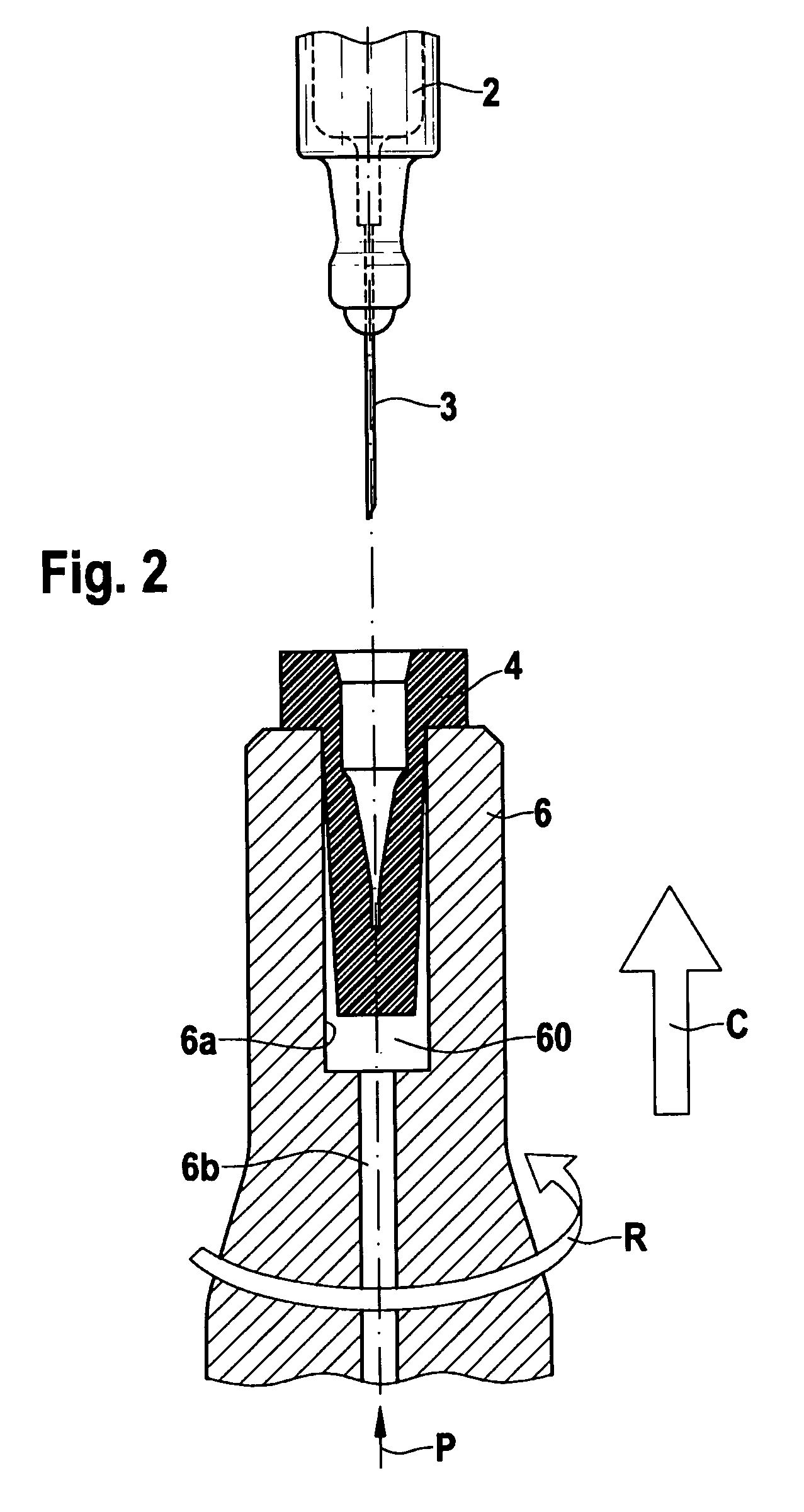

Device and method for mounting a needle guard on a syringe body

InactiveUS20100162548A1Force is smallShort timeAutomatic control devicesMedical devicesNeedle guardCompressed air

The invention relates to a device for mounting a needle guard (4) onto a syringe body (2) that is provided with a needle (3), comprising a retaining device (5) for retaining the syringe body (2), a needle guard receptacle (6) for receiving the needle guard (4), a compressed air system (7) for providing compressed air, a first displacement device (8) for displacing the needle guard receptacle (6) in a vertical direction (A), and a rotation device (9) for at least partially rotating the needle guard receptacle (6), wherein the needle guard receptacle (6) is disposed beneath the retaining device (5), the compressed air being fed to the needle guard receptacle (6) such that the needle guard (4) is suspended on an air cushion (60) in a floating manner, and wherein the needle guard receptacle (6) can be displaced in a vertical direction (A) by means of the first displacement device (8). The invention further relates to a method for mounting the needle guard (4) onto the syringe body (2).

Owner:ROBERT BOSCH GMBH

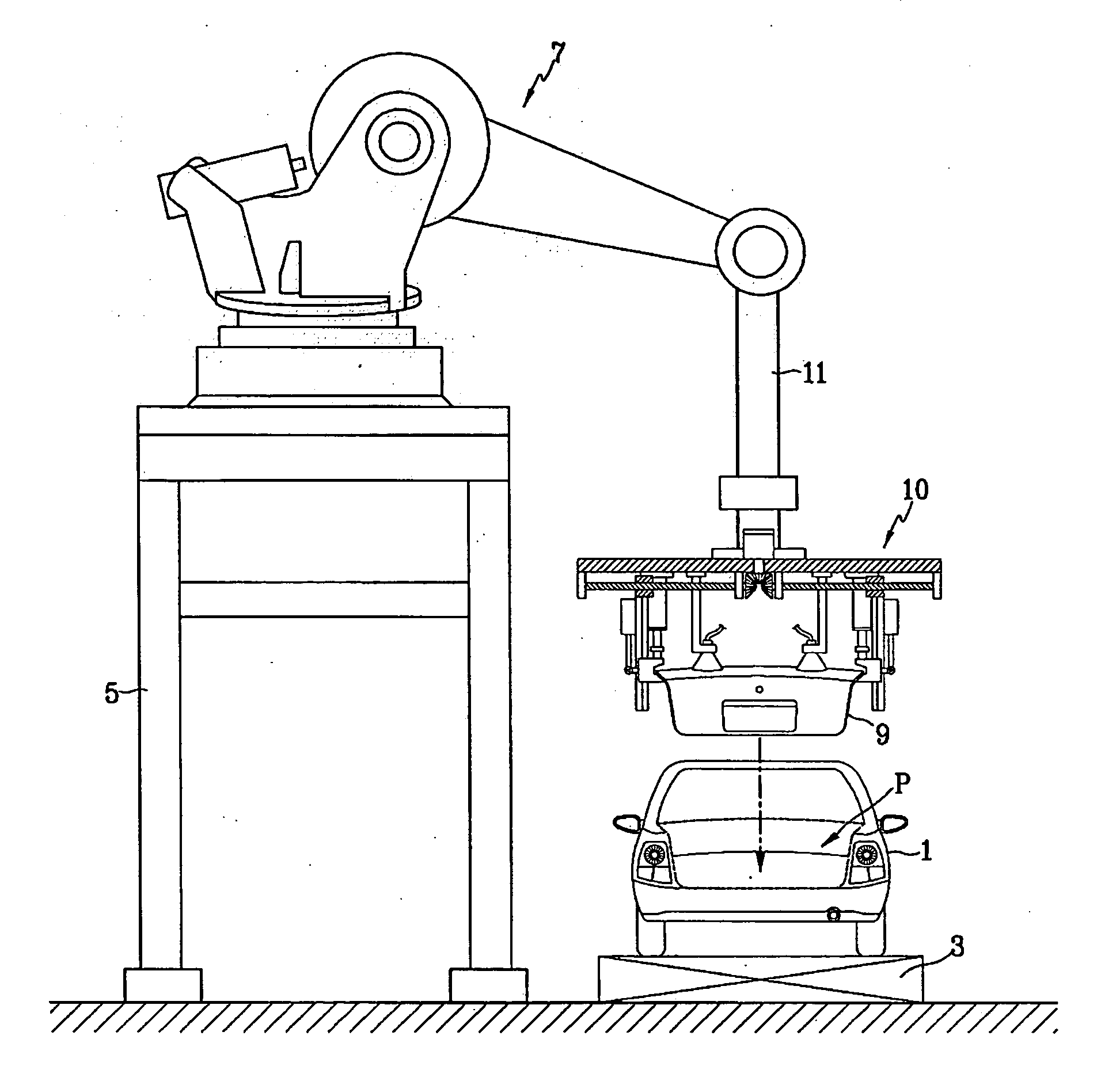

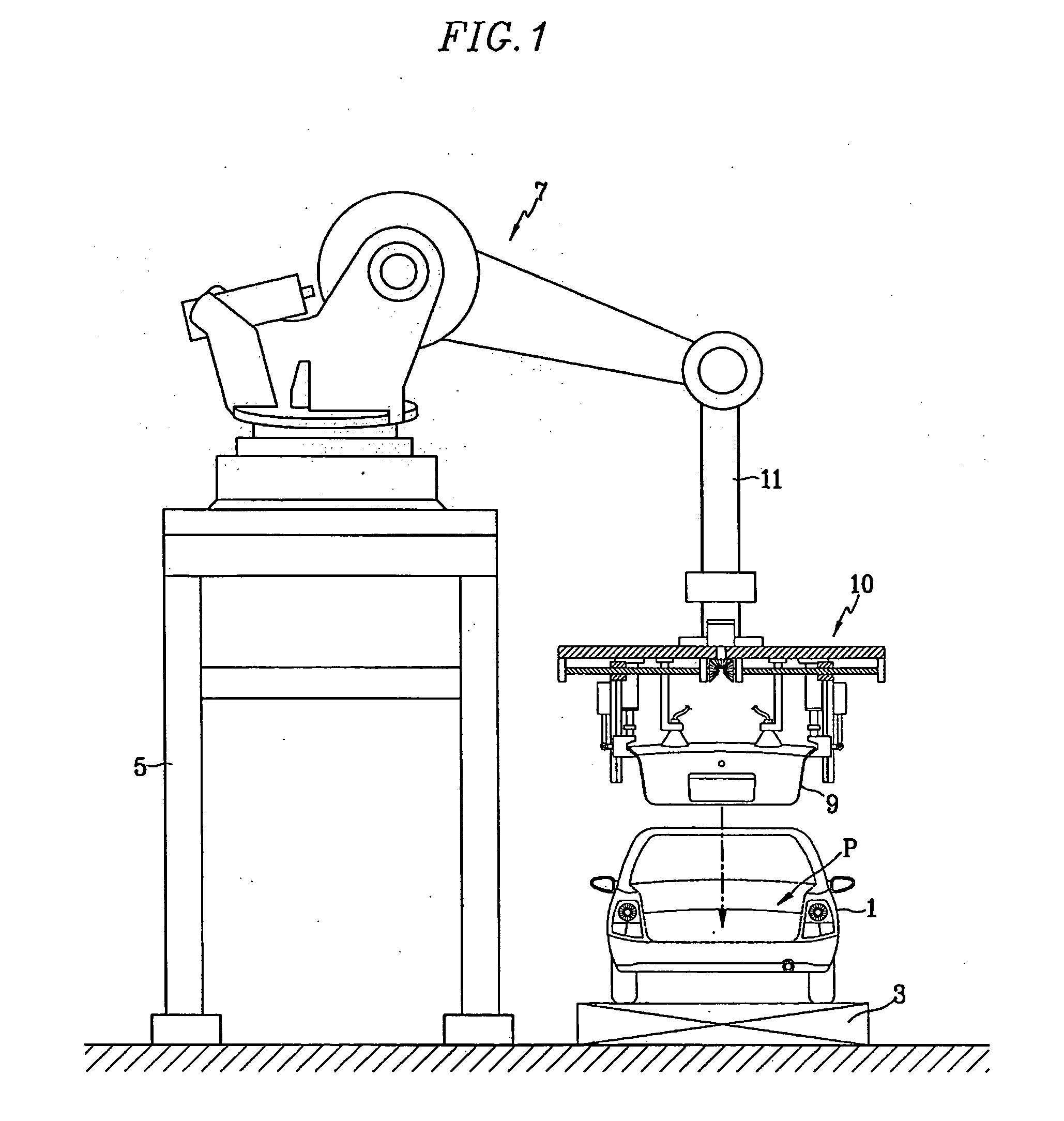

Apparatus for manipulating a vehicle body panel

Manipulating a vehicle body panel includes utilizing a base plate, left and right screw rods, a motor, and clamping units. The base plate is connected to the arm of the robot. The left and right screw rods are rotatably mounted below the base plate by bearing blocks and each of the screw rods has a driven helical gear at an interior end thereof. The motor is disposed central to and above the base plate and has a rotating shaft. A driving helical gear is formed at an end of the rotating shaft and is engaged with both of the driven helical gears. The clamping units are respectively mounted to the left and right screw rods by a screw block. The clamping units clamp the vehicle body panel by laterally moving with respect to the base plate and move the vehicle body panel up and down.

Owner:HYUNDAI MOTOR CO LTD

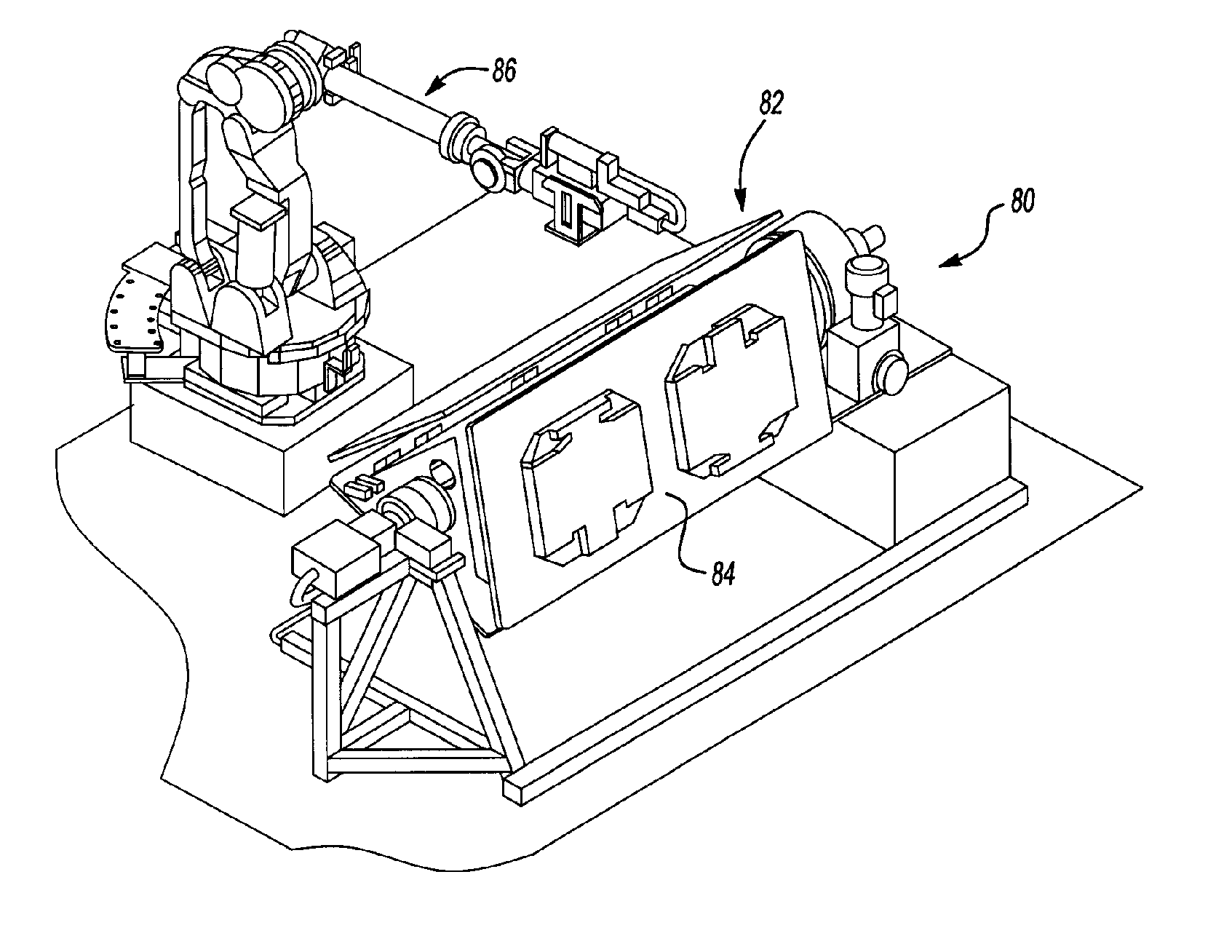

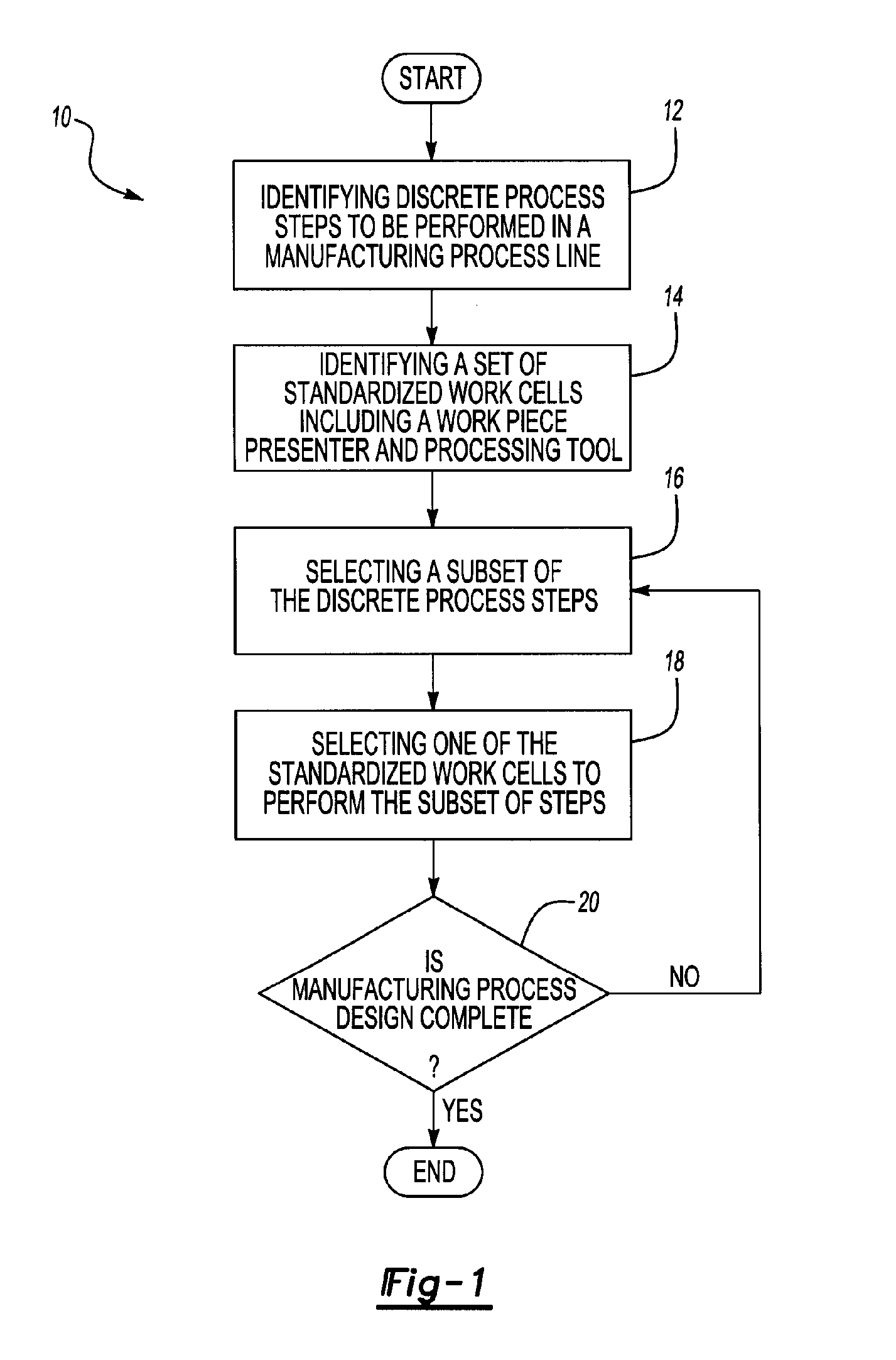

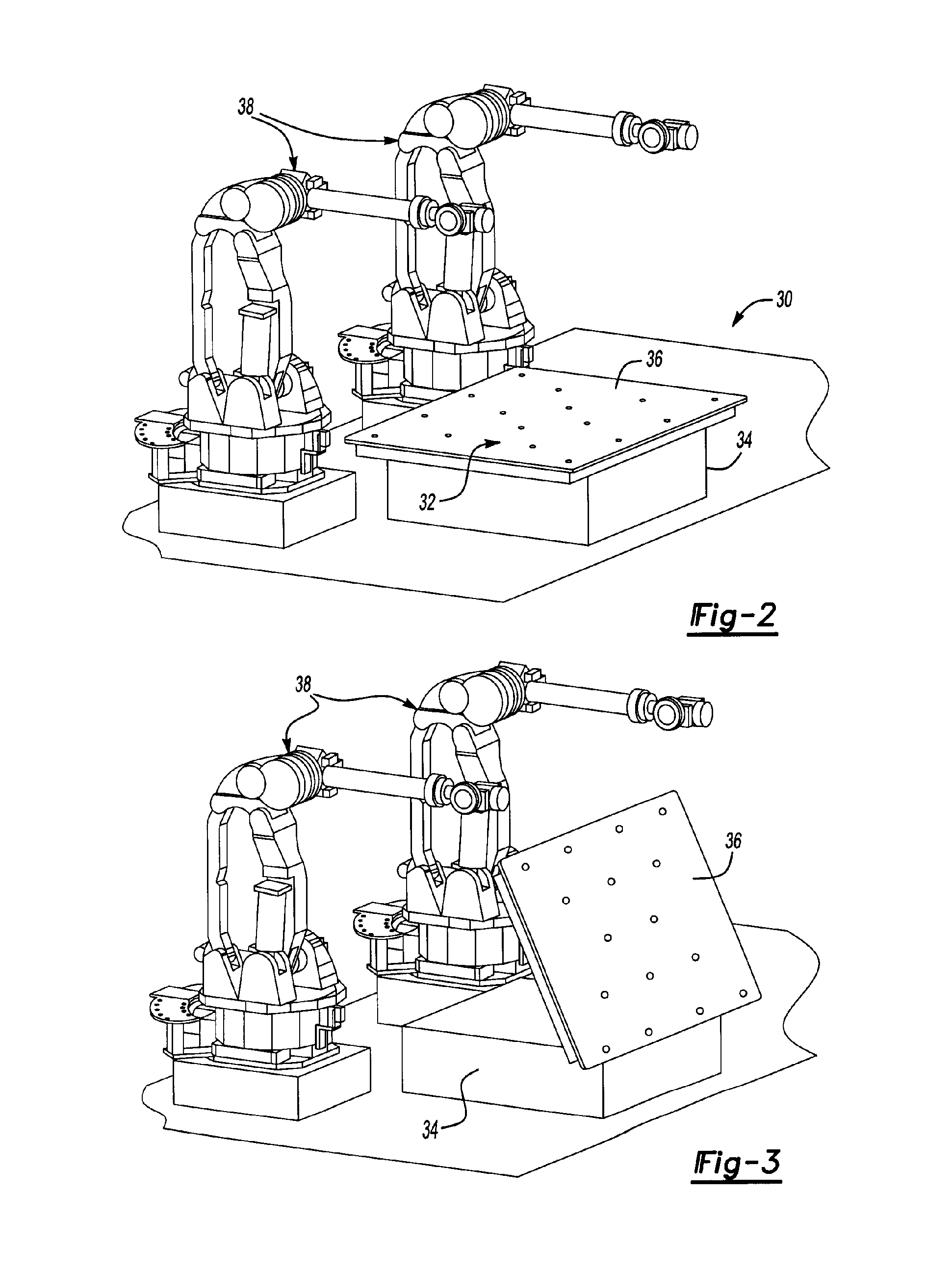

Manufacturing assembly line and a method of designing a manufacturing assembly line

InactiveUS20050044700A1Easy to adjustOptimal quality levelVehicle seatsPrecision positioning equipmentManufacturing technologyEngineering

A method of designing a manufacturing process line. A process is identified as a set of discrete steps. A subset of steps is assigned to one of a plurality of standardized work cells. The work cells include a standardized workpiece presenter and a standardized processing tool. Additional subsets of discrete steps are assigned to a standardized work cell until the design for the manufacturing process is completed.

Owner:FORD MOTOR CO

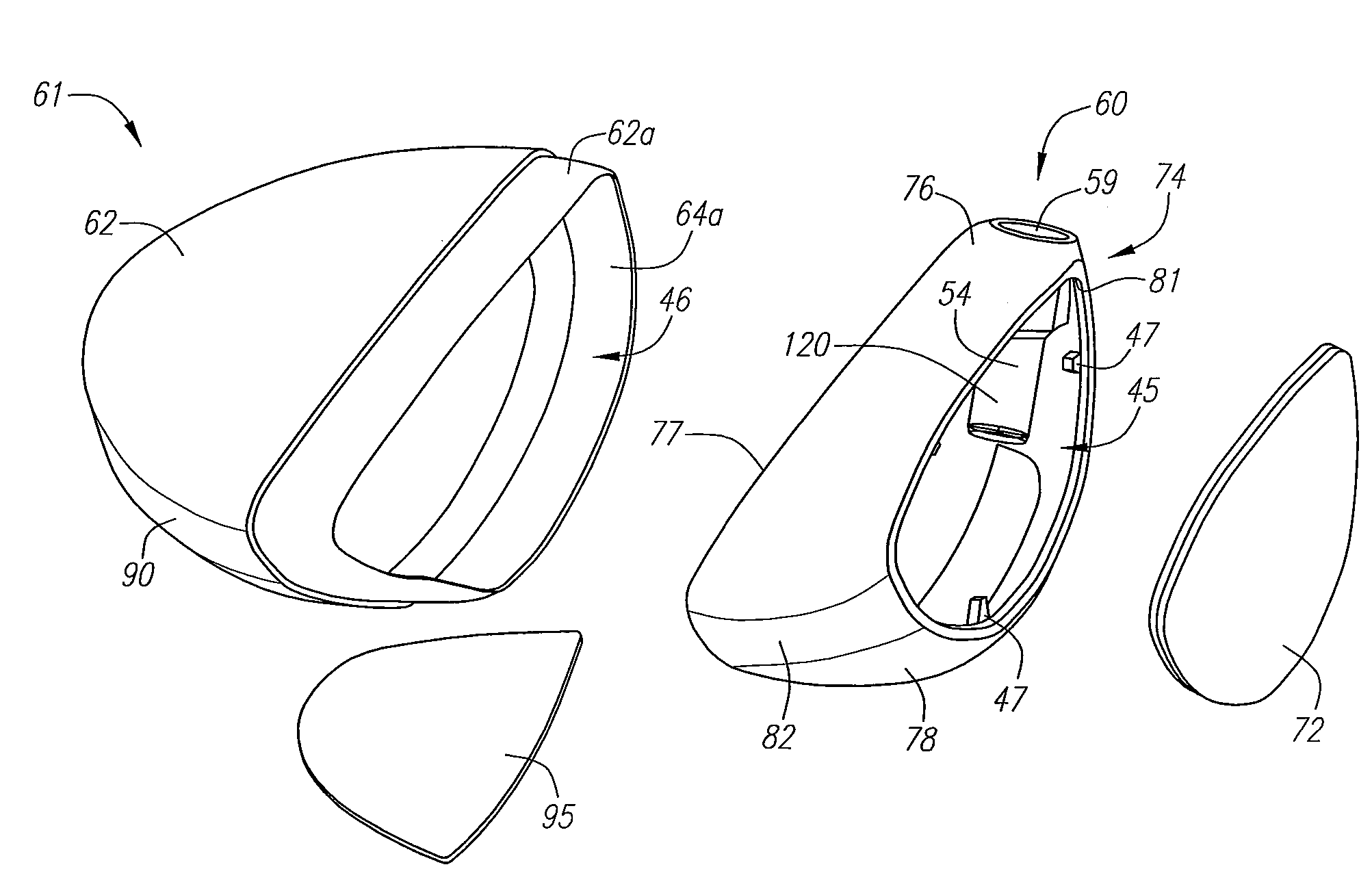

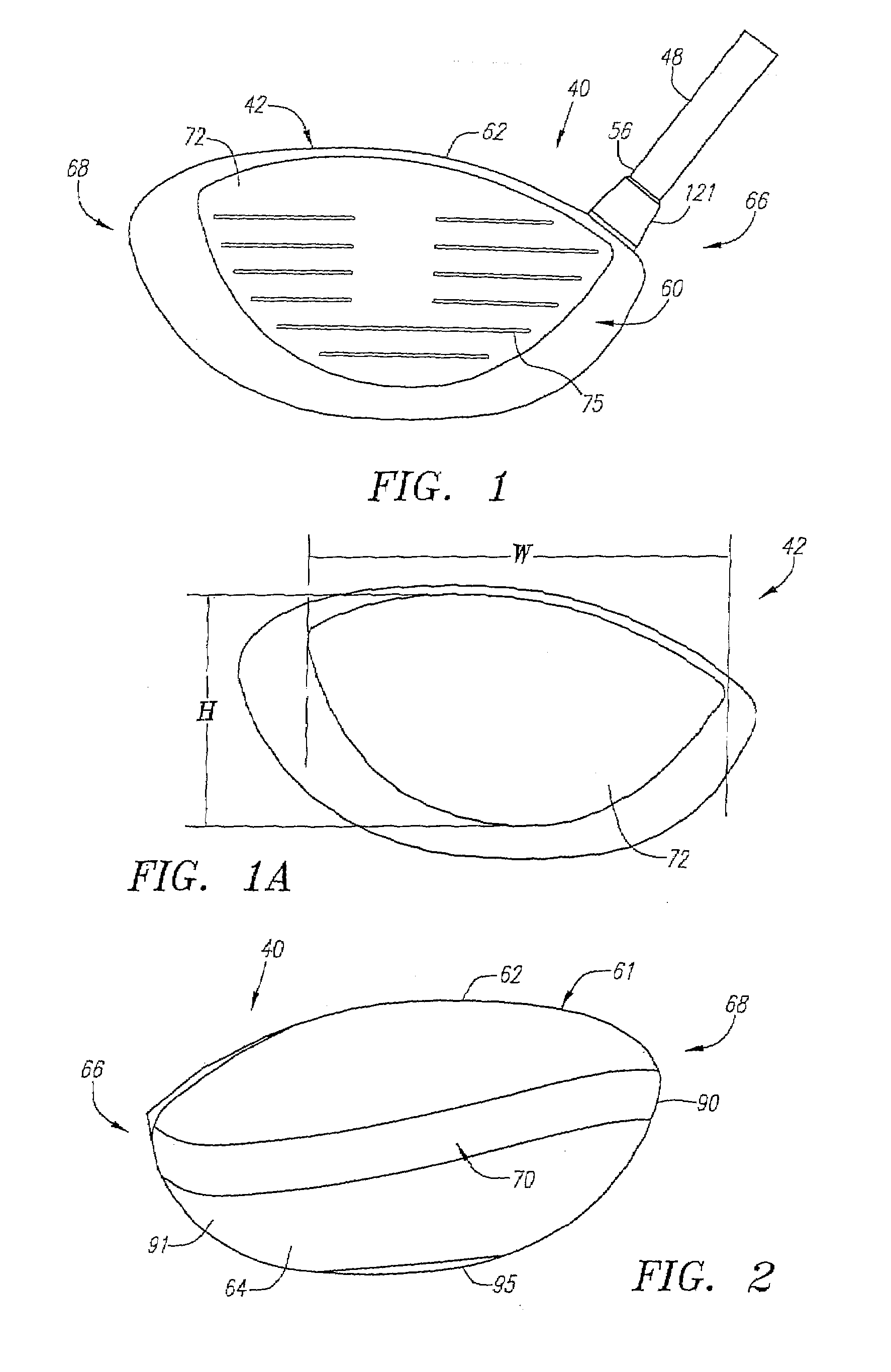

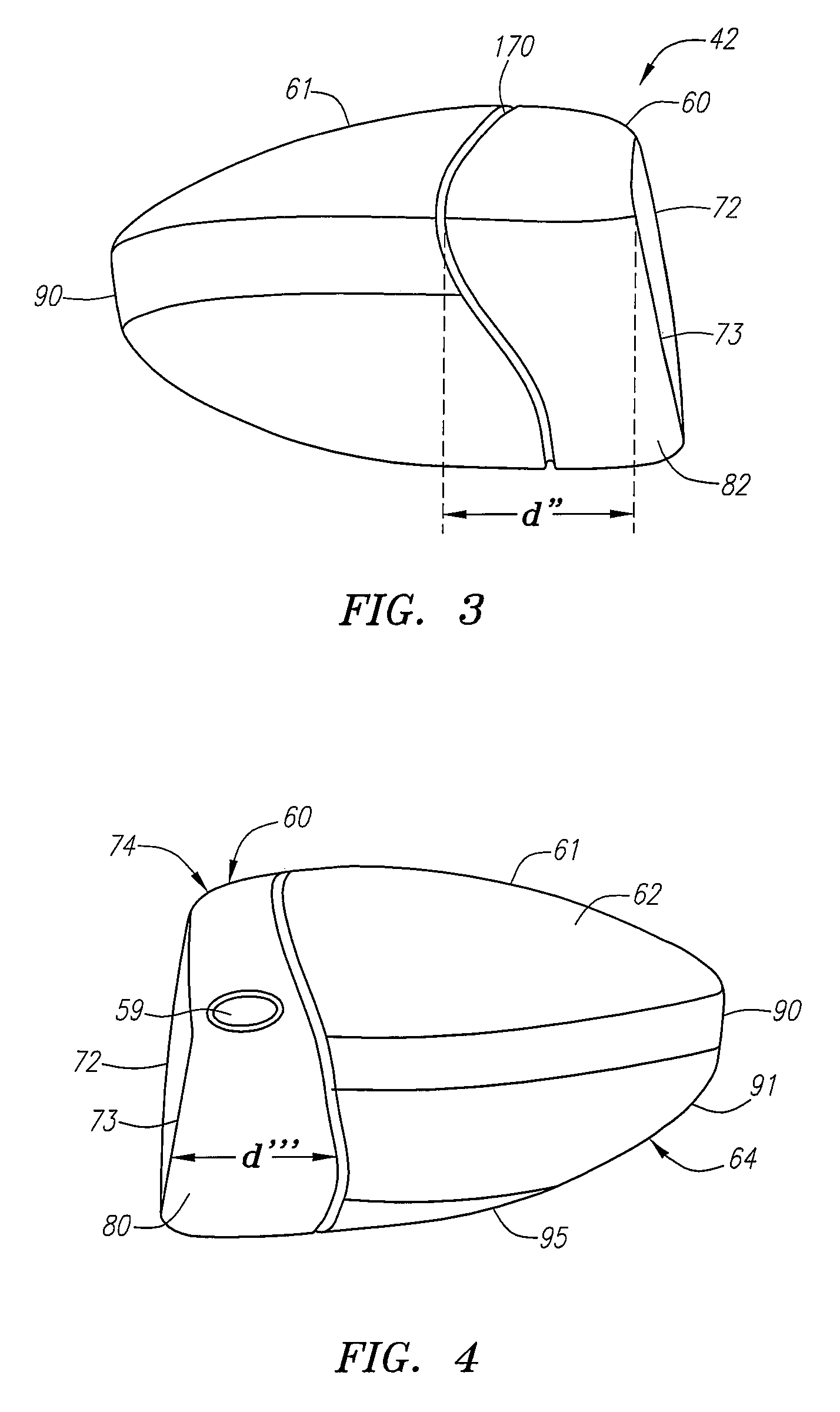

Method for processing a golf club head with cup shaped face component

ActiveUS7082665B2Improve complianceReduce weightMetal rolling stand detailsAssembly machinesEngineeringGolf Ball

A method for producing a golf club head (42) with a two-piece face component (60) and an aft-body (61) is disclosed herein. The face component (60) includes a formed or forged striking face insert (72) and a cast face cup (74) with a front face (81) and a return portion (77) and separately forming the striking face insert (72). The striking face insert (72) is then pressed or swaged into an opening in the front face (81) of the cast face cup (74) while at the same time the cast face cup (74) is coined. The striking face insert (72) is then welded to the face cup (74) on the interior surface of the face component (60). The assembled face component (60) is then attached to the aft-body (61).

Owner:TOPGOLF CALLAWAY BRANDS CORP

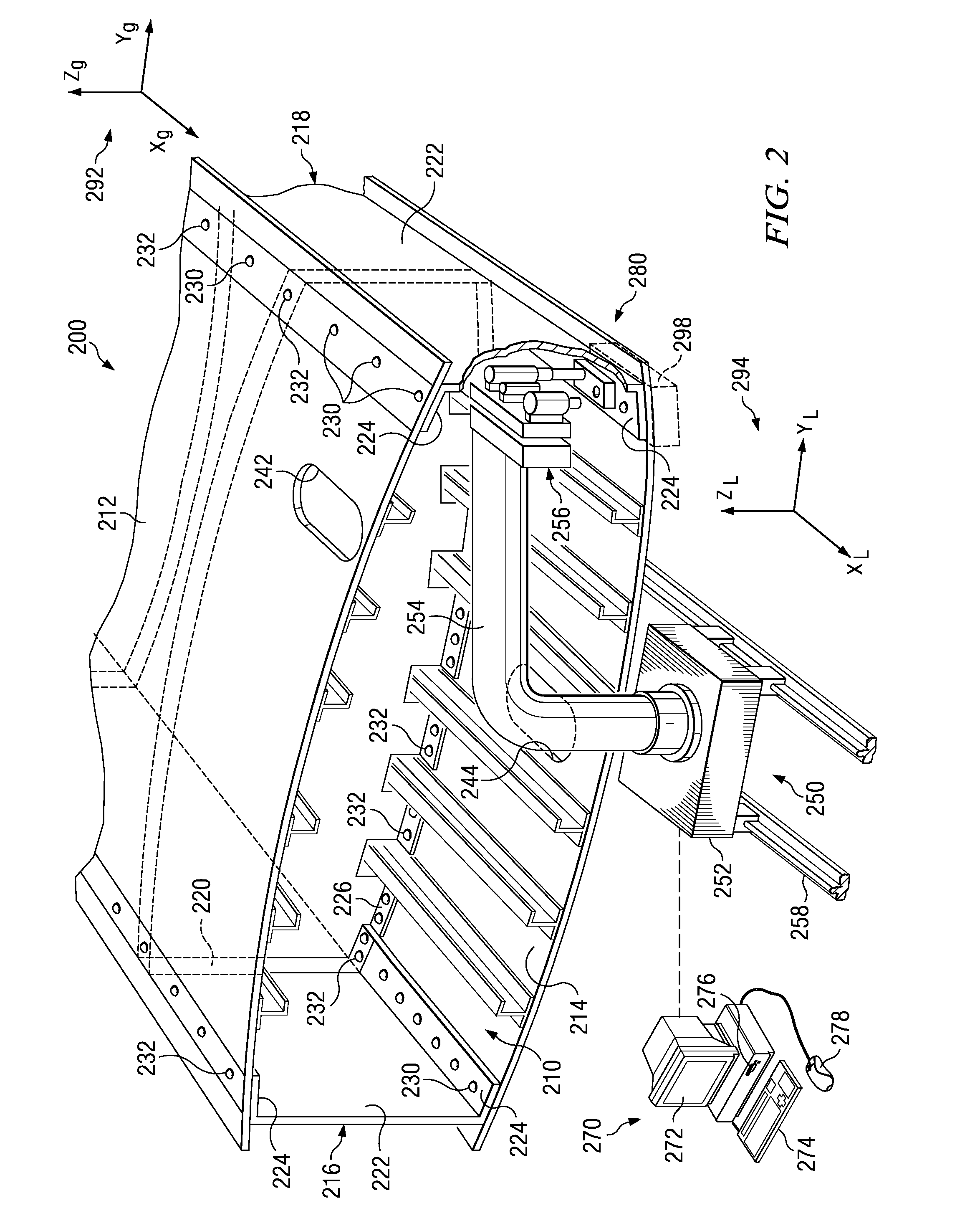

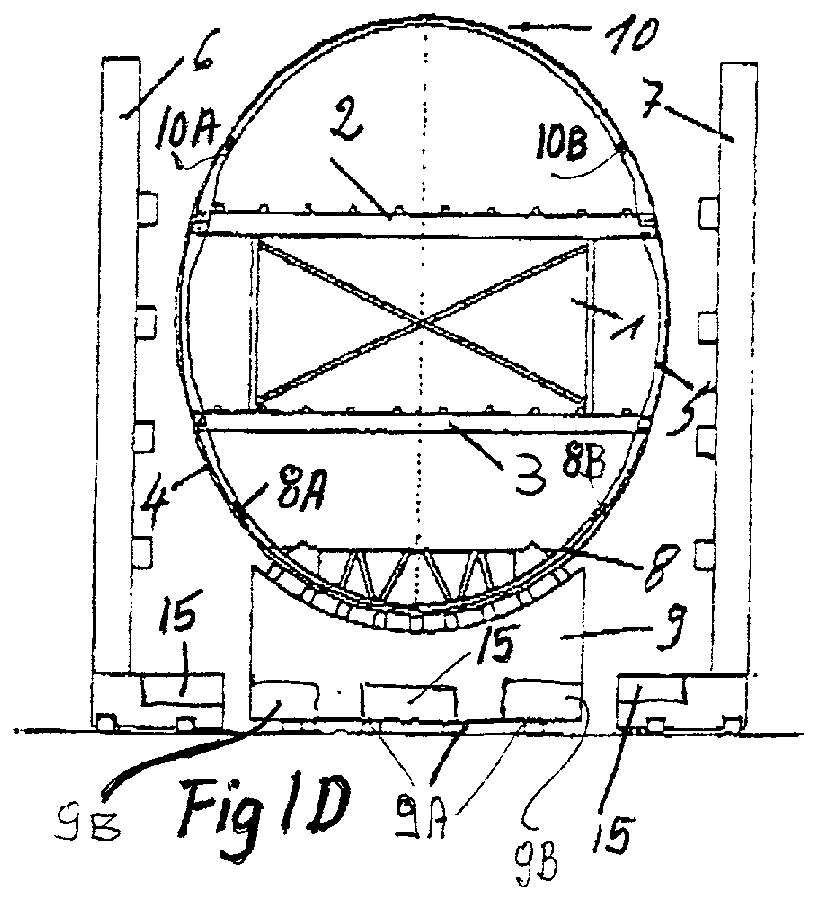

Method and apparatus for assembling a three-dimensional structural component

InactiveUS20010054228A1Precise tolerance rangeExact rangeFuselage framesAutomatic control devicesClassical mechanicsMechanical engineering

Three-dimensional large scale bodies such as jumbo aircraft fuselages (14) are assembled in body sections around a central longitudinal assembly core (1) which itself is mounted at its ends and accessible all around along its length. Robots carrying tools for holding, transporting and precisely positioning preassembled wall shell sections, are movable along the central core (1). First, at least one floor grid (2 or 3) is releasably mounted to the core. Then, side wall shell sections (4, 5) are secured to the floor grids. Then, top and bottom wall shell sections (10, 8) are secured to the side wall shell sections (4, 5) to form a body section (BS) of the large scale body (14). Neighboring body sections are secured to each other along cross-seams. Upon completion, the floor grids are released from the core (1) and the core is removed preferably withdrawn longitudinally from the assembled large component or body.

Owner:AIRBUS OPERATIONS GMBH

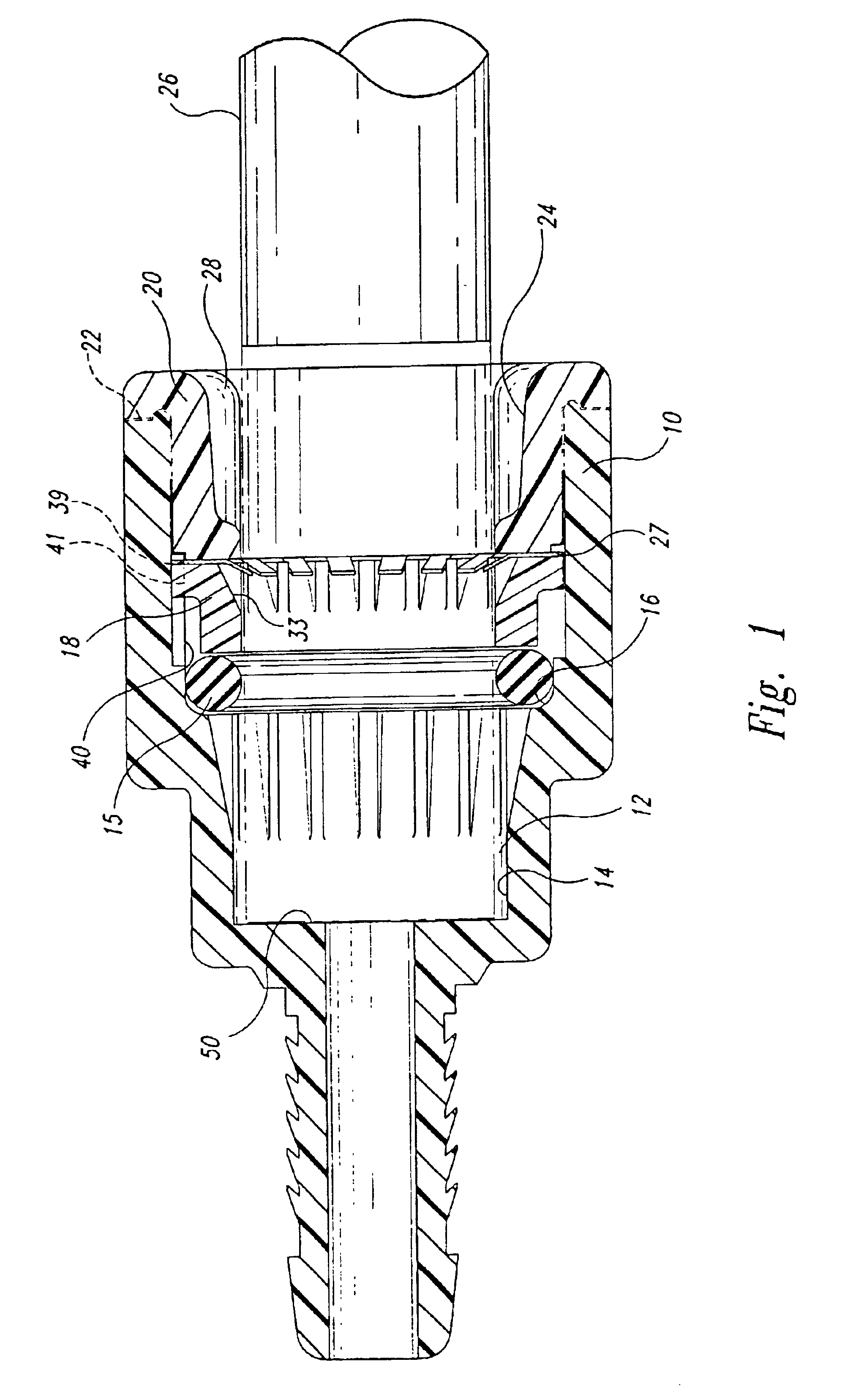

Tube coupling

InactiveUS6860523B2Enabling detectionImprove gripSleeve/socket jointsFluid pressure sealed jointsFluid couplingEngineering

A fluid coupling having an outer housing with an internal bore, an O-ring fitted within the bore, a spacer bushing fitted against the O-ring, a gripper ring fitted against the axially outer side of the spacer ring, the gripper ring having axially and radially inwardly protruding circumferentially spaced gripping teeth, the teeth arranged for providing a twist when subjected to simultaneous rearward axial and rotational forces, and an end bushing holding the gripper ring, spacer bushing, and O-ring within the outer housing. A fluid coupling having an outer housing with an internal bore, an O-ring seal fitted within the bore, a spacer bushing fitted against the seal, a first gripper ring fitted against the axially outer side of the spacer ring, a second gripper ring fitted against the O-ring seal, the gripper rings having axially and radially inwardly protruding circumferentially spaced gripping teeth, in one embodiment the teeth arranged for providing a twist when subjected to simultaneous rearward axial and rotational forces, and an end bushing holding the gripper rings, spacer bushing, and O-ring within the outer housing.

Owner:ACCOR TECH

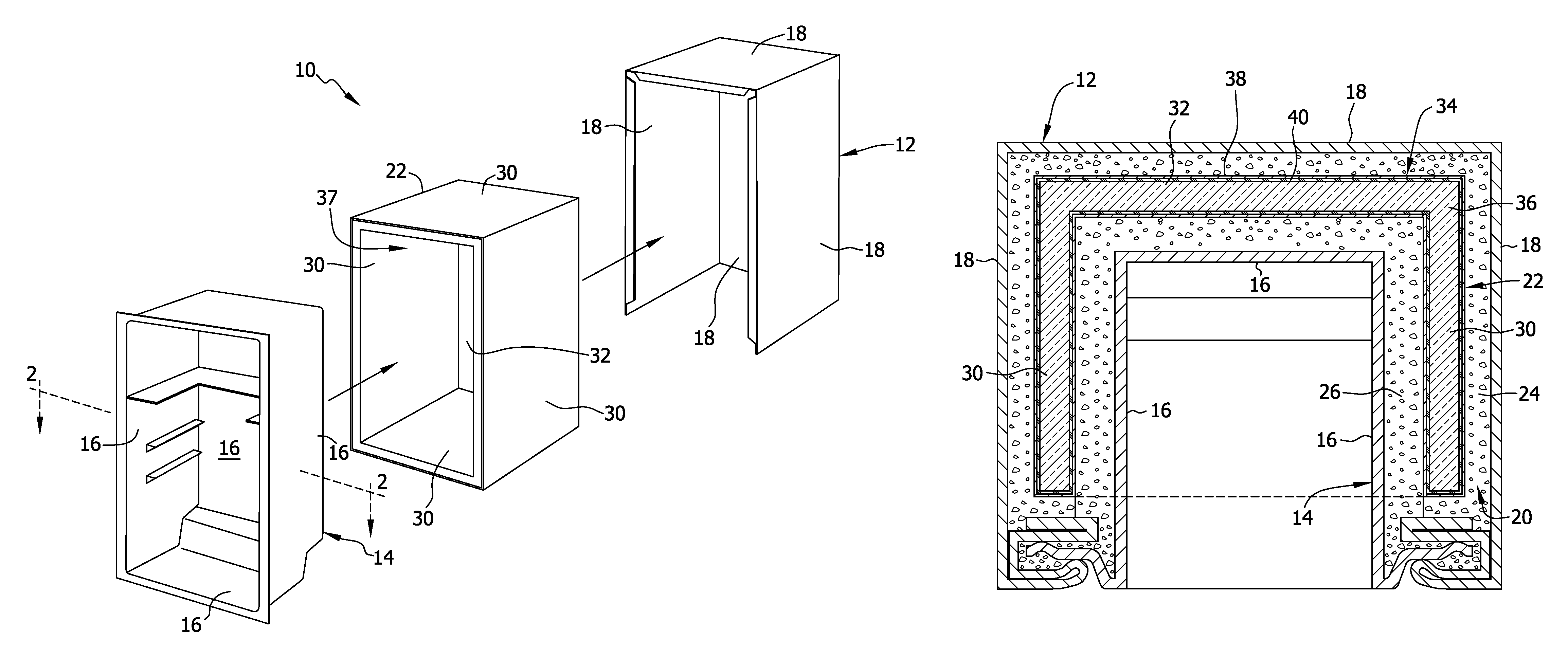

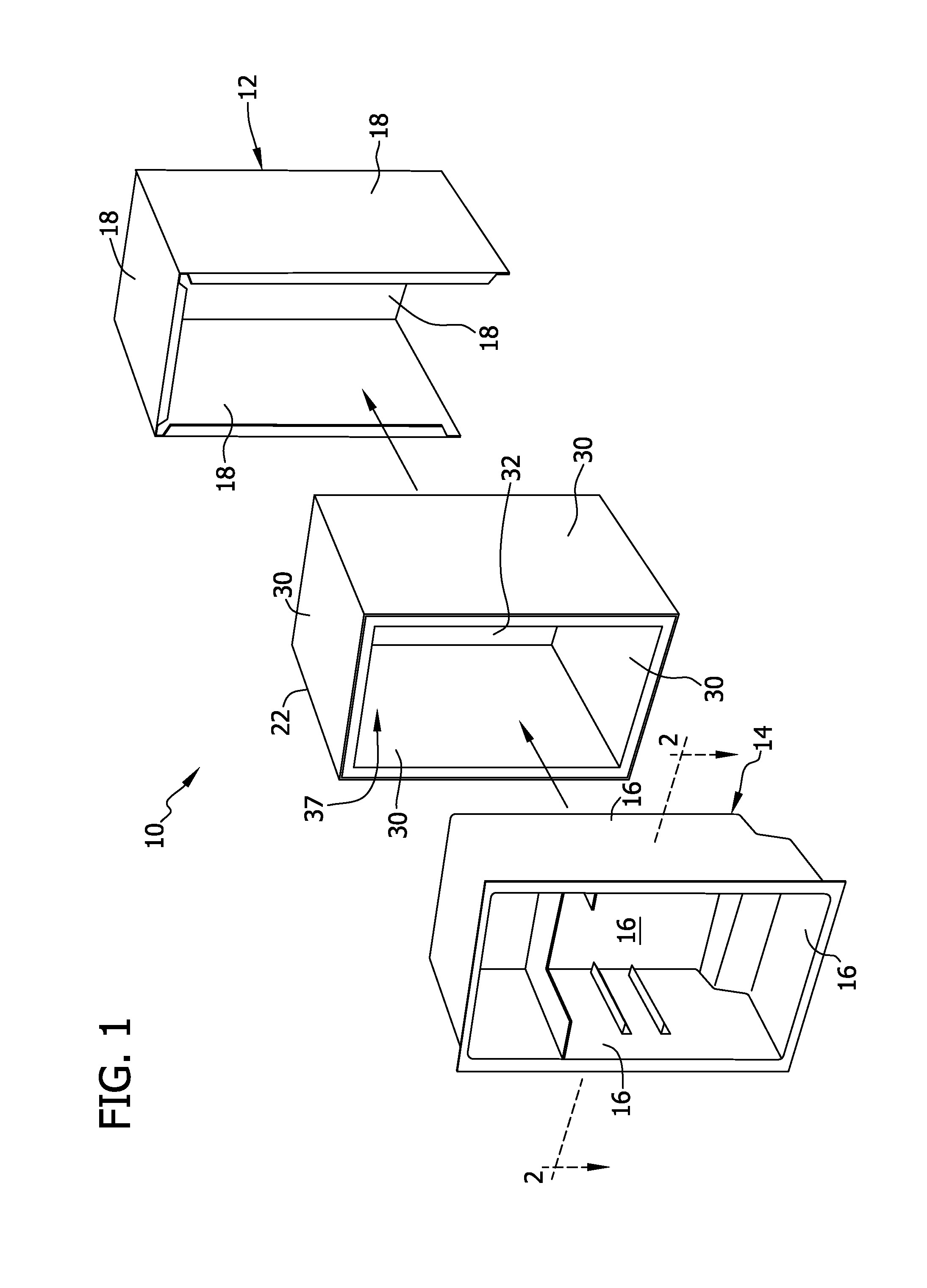

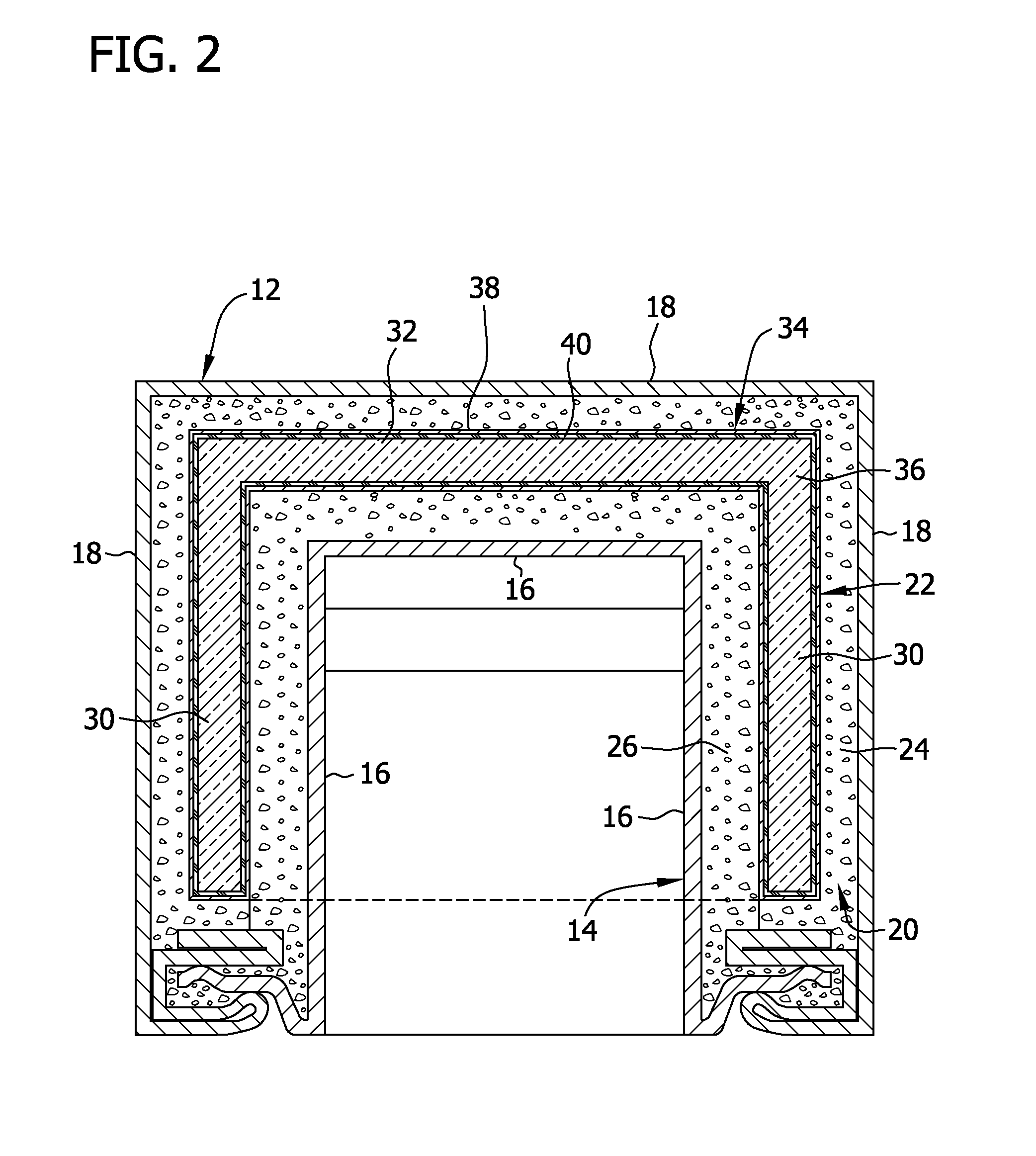

Method and apparatus for insulating a refrigeration appliance

ActiveUS8881398B2Envelopes/bags making machineryThermal insulationRefrigerationElectrical and Electronics engineering

A method of insulating a refrigeration appliance. The refrigeration appliance includes a case, a liner, and a five-sided, box like vacuum panel. The liner is formed to be inserted into the case forming a chamber between the liner and the case. The five sides of the vacuum panel define a cavity. The method includes in one embodiment, positioning the five-sided vacuum panel in the chamber between the case and the liner, injecting foam into the chamber, and curing the foam to attach the five sided vacuum panel to the case and the liner.

Owner:HAIER US APPLIANCE SOLUTIONS INC

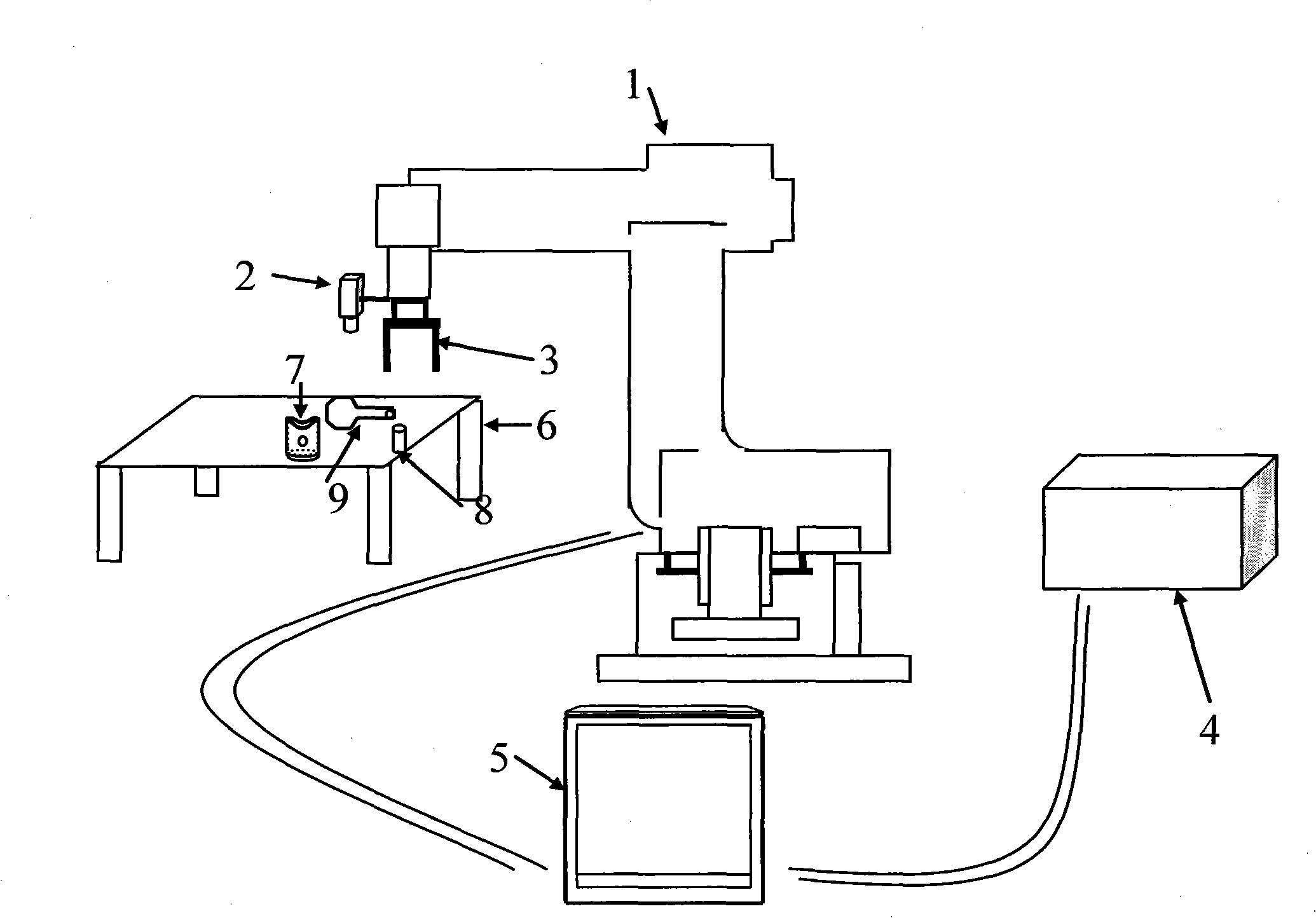

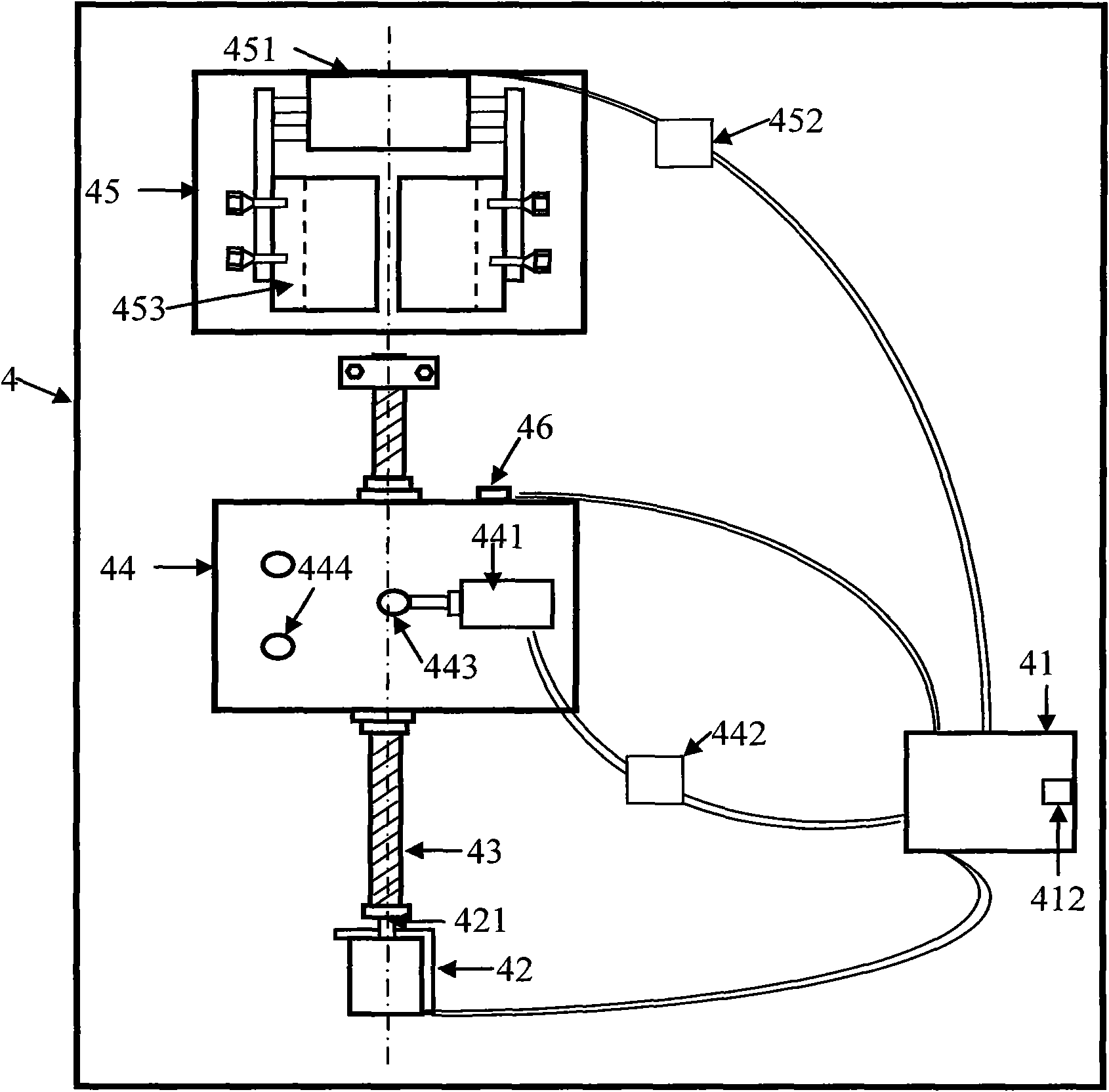

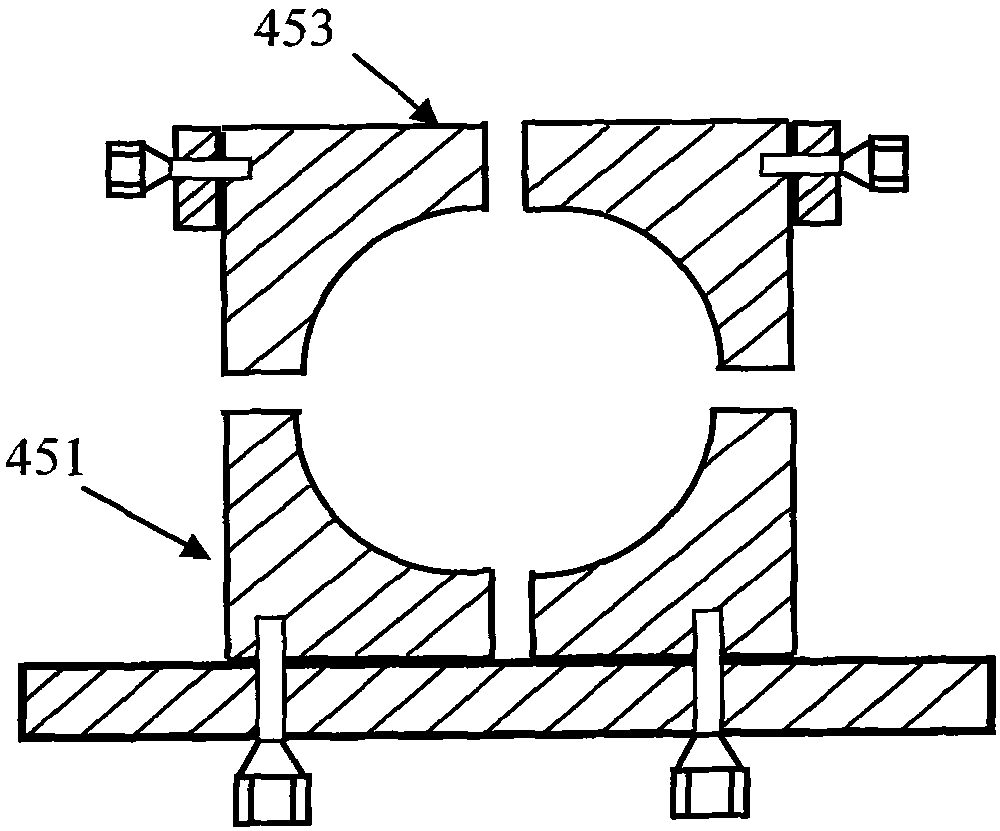

Industrial robot-based assembly method and device of piston, piston pin and connecting rod

ActiveCN101913076AImplement automatic assemblyImprove assembly efficiencyProgramme-controlled manipulatorAssembly machinesData terminalControl circuit

The invention relates to an industrial robot-based assembly method and device of a piston, a piston pin and a connecting rod. The method of the invention comprises the following steps: a vision camera is used to identify the positions and directions of the piston, piston pin and connecting rod, the grabing positions are calculated by a computer, a mechanical paw grabs the piston, the piston pin and the connecting rod to place on an intelligent assembly table; the connecting rod is inserted in the piston under the control of the intelligent assembly table; an industrial robot places the piston pin in a piston assembly hole; the vision camera in the device identifies and positions the piston, piston pin and connecting rod on a work platform; the data terminal of the industrial robot is connected with the data terminal of the computer; the vision camera is connected with the computer; the industrial robot controls the mechanical paw to grab the piston, piston pin and connecting rod and place on the intelligent assembly table; the serial signal line of the intelligent assembly table is connected with the computer, the control circuit board of the intelligent assembly table controls a connecting rod jig to insert the connecting rod in the piston; and the industrial robot assembles the piston pin in the piston assembly hole according to the sensorless assembly method.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

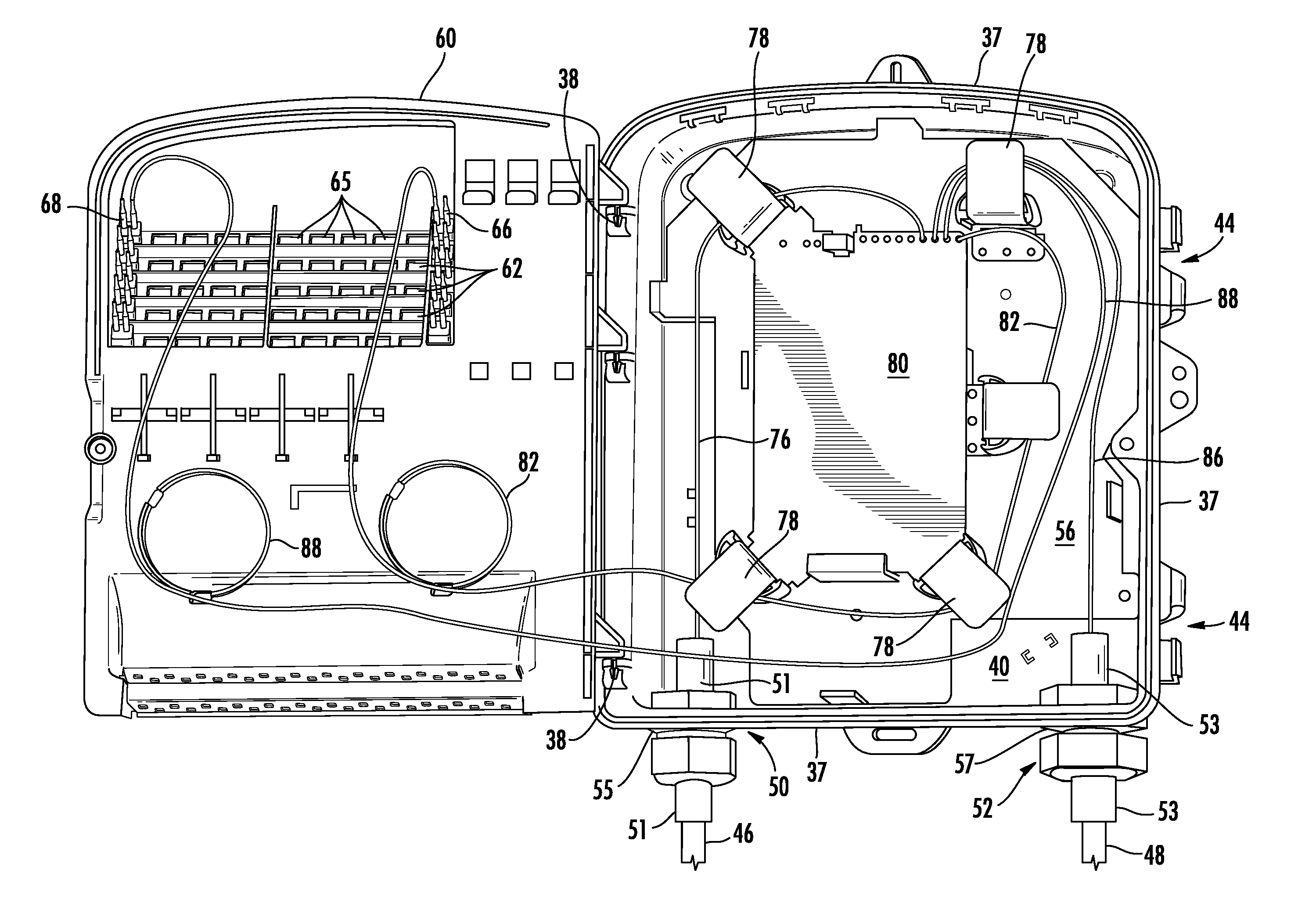

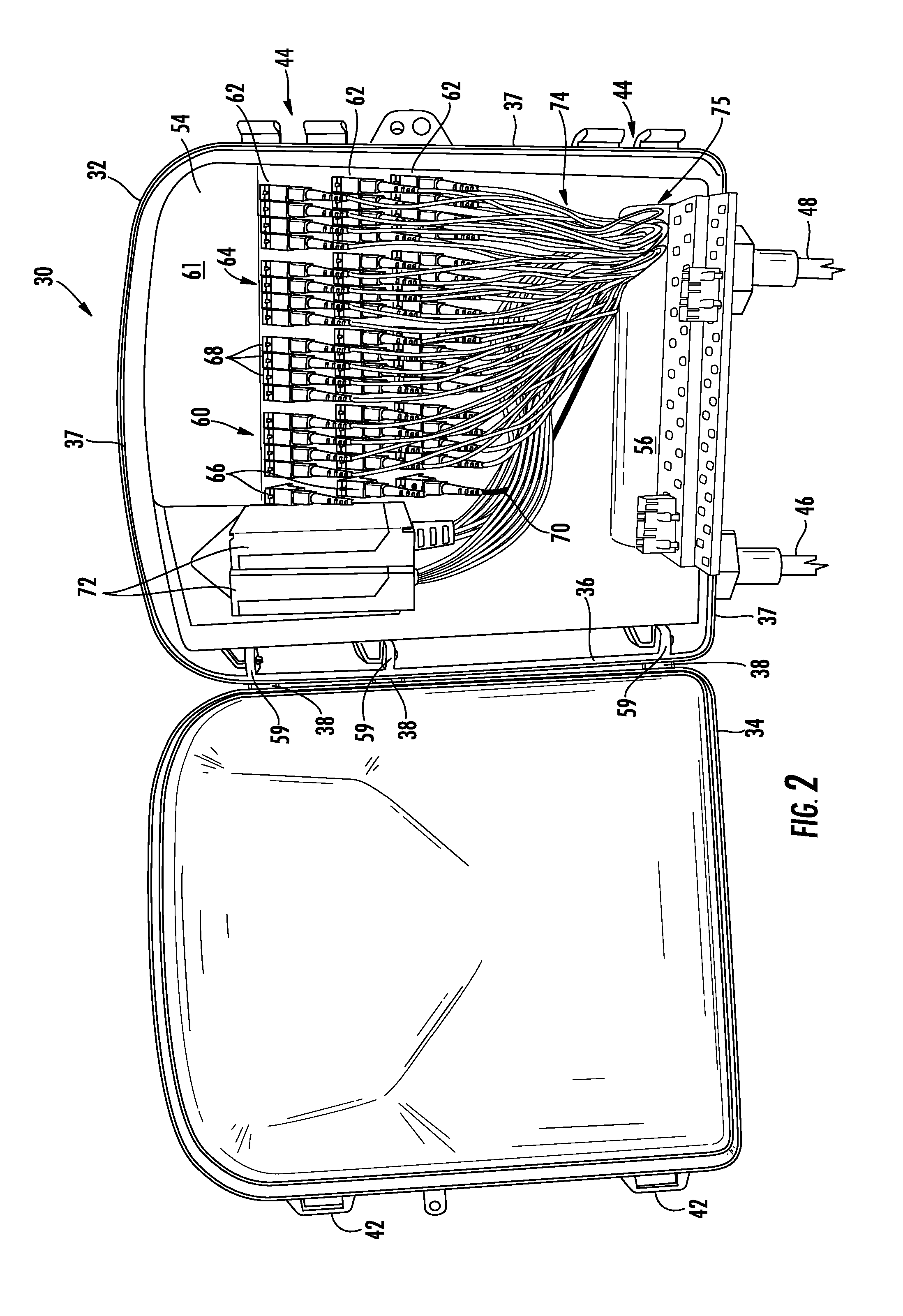

Methods, Apparatuses for Providing Secure Fiber Optic Connections

Methods and apparatuses for providing secure fiber optic connections are disclosed. In one embodiment, a locking apparatus comprising a locking plate to secure fiber optic connections is disclosed. The locking plate is configured to be attached to a fiber optic adapter panel and adjustably positioned to a selected position such that when a fiber optic connector on the end of a fiber optic cable is connected to a fiber optic adapter on the fiber optic adapter panel, the fiber optic cable is allowed to pass through a cut-out area of the locking plate but a finger portion of the locking plate does not allow the fiber optic connector to pass through the cut-out area. A lock disposed on the locking plate is configured to keep the locking plate in the selected position. The locking apparatus may also be used to securely store unused or unconnected ports of an optical splitter in a separate enclosure, such as a parking lot compartment.

Owner:CORNING OPTICAL COMM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com