Patents

Literature

611results about "Forging hammers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

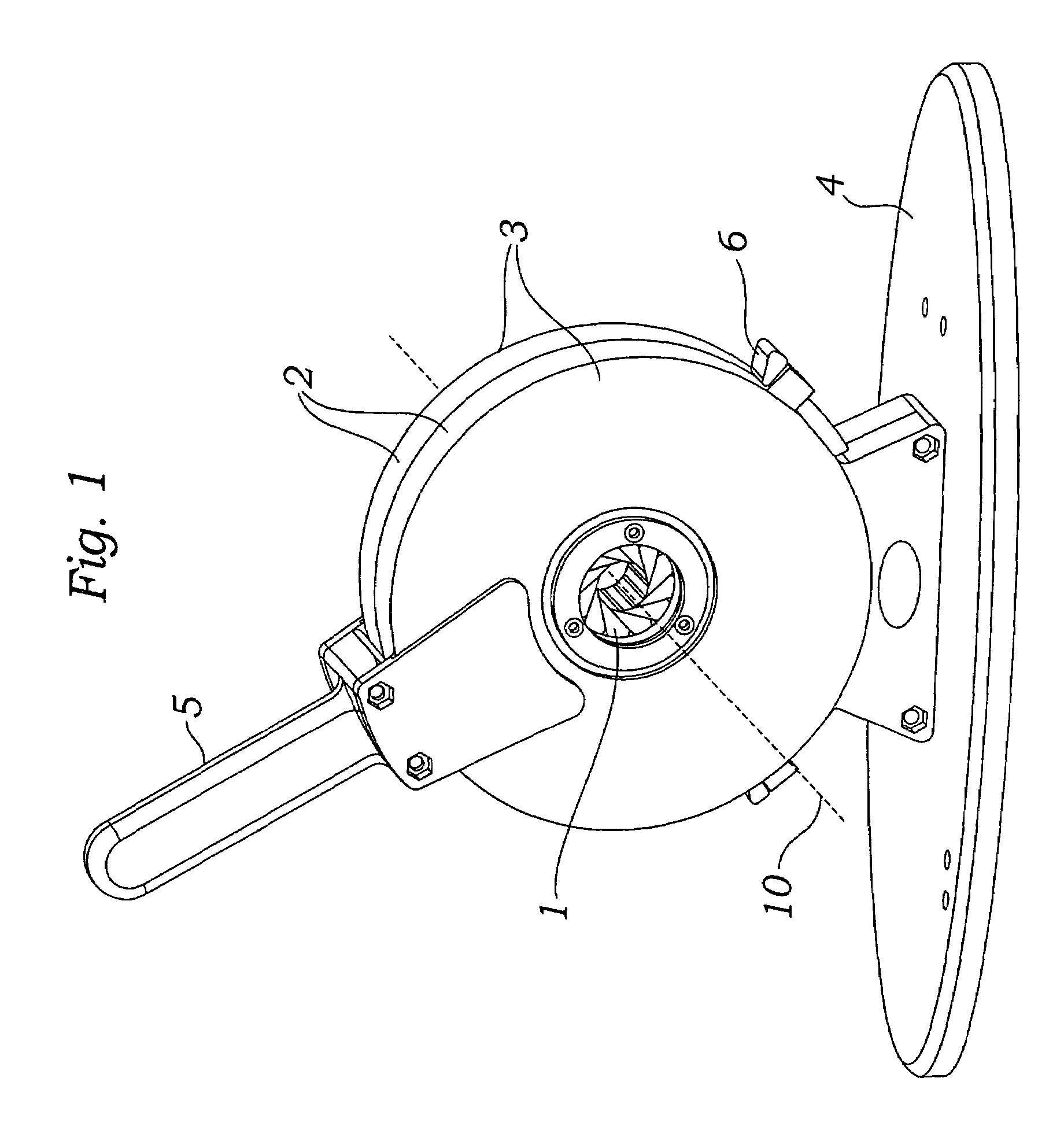

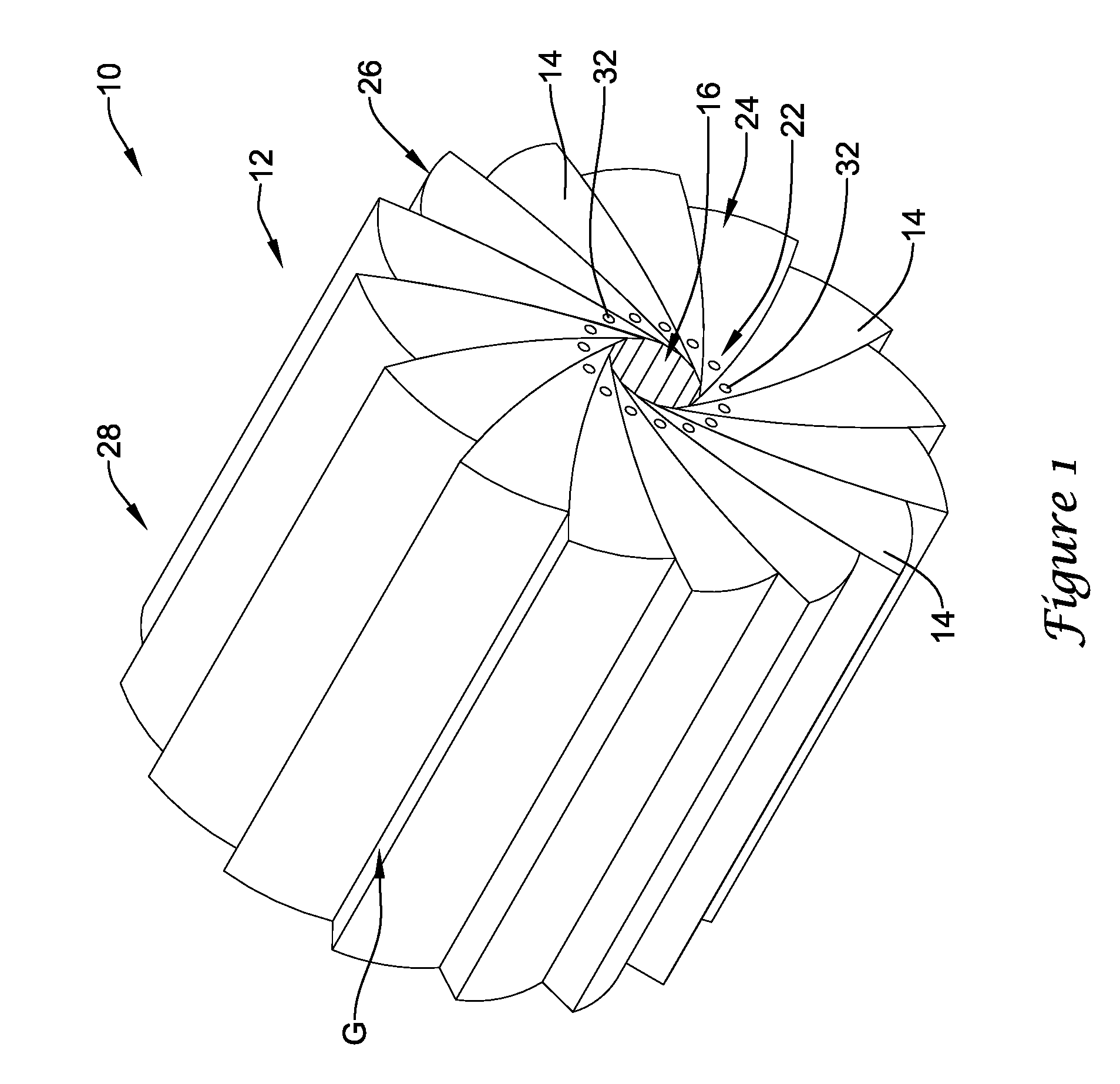

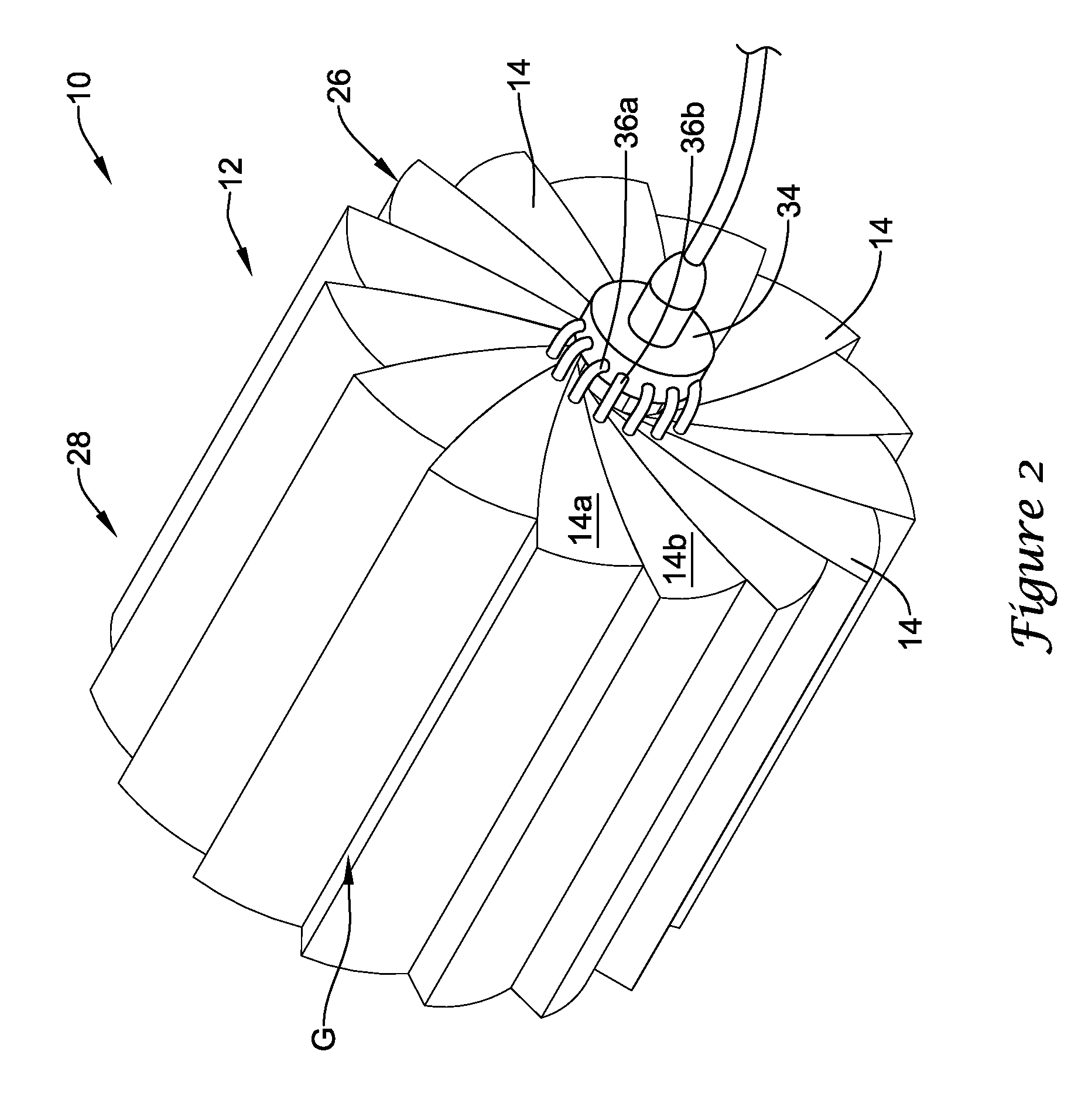

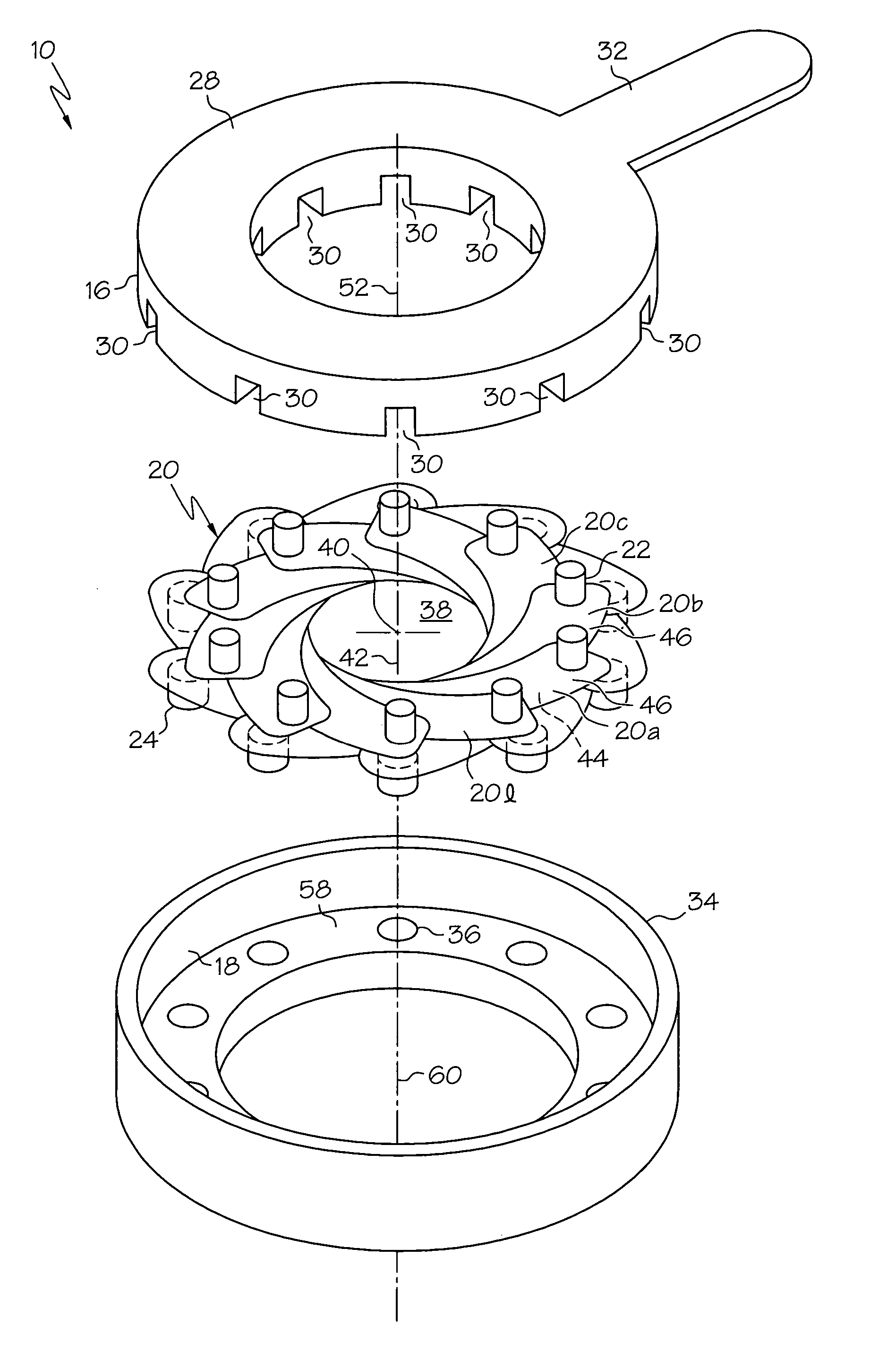

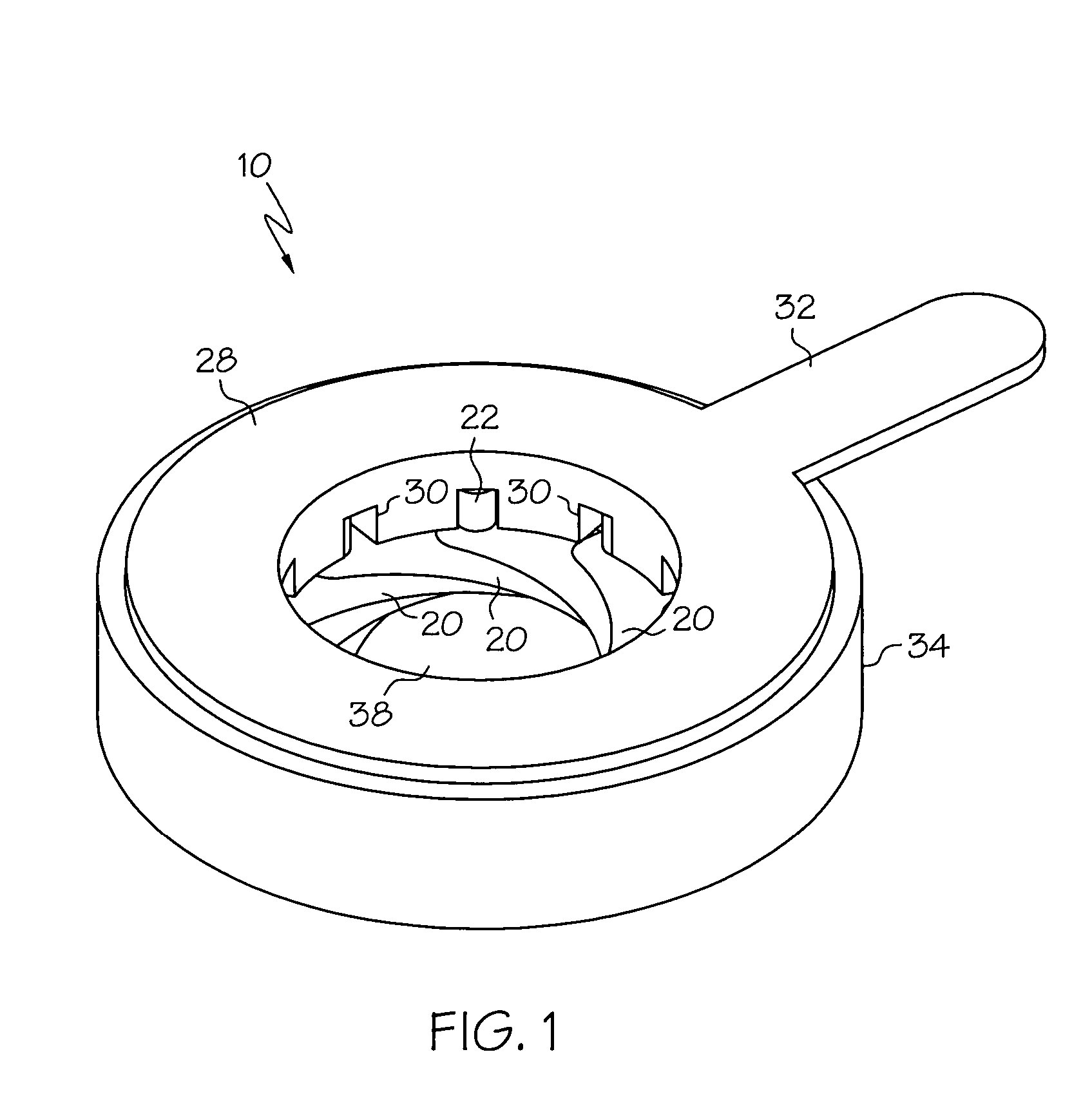

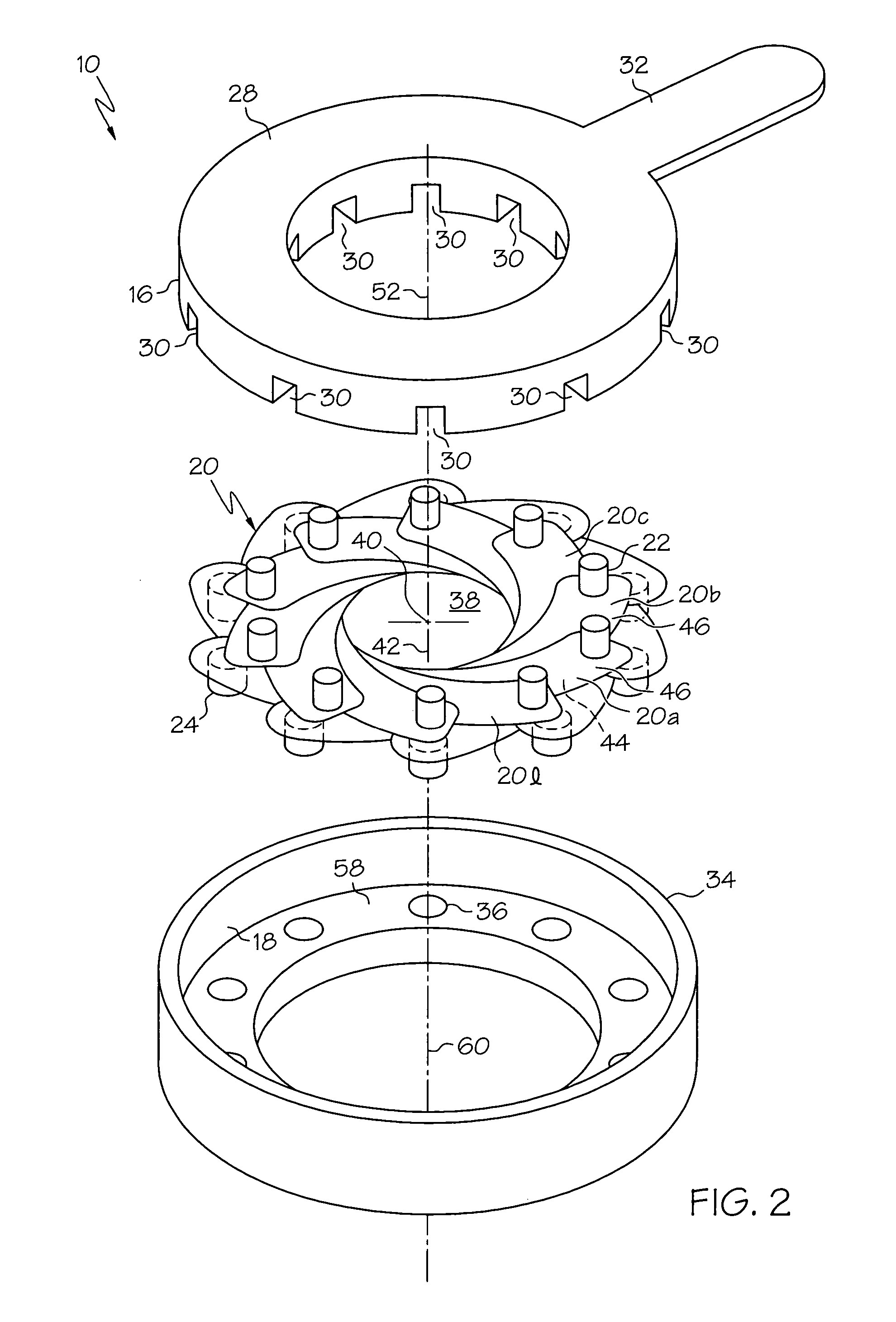

Prosthetic valve crimping device

ActiveUS20070056346A1Prevent rotationMost efficientStentsBalloon catheterProsthetic valveEngineering

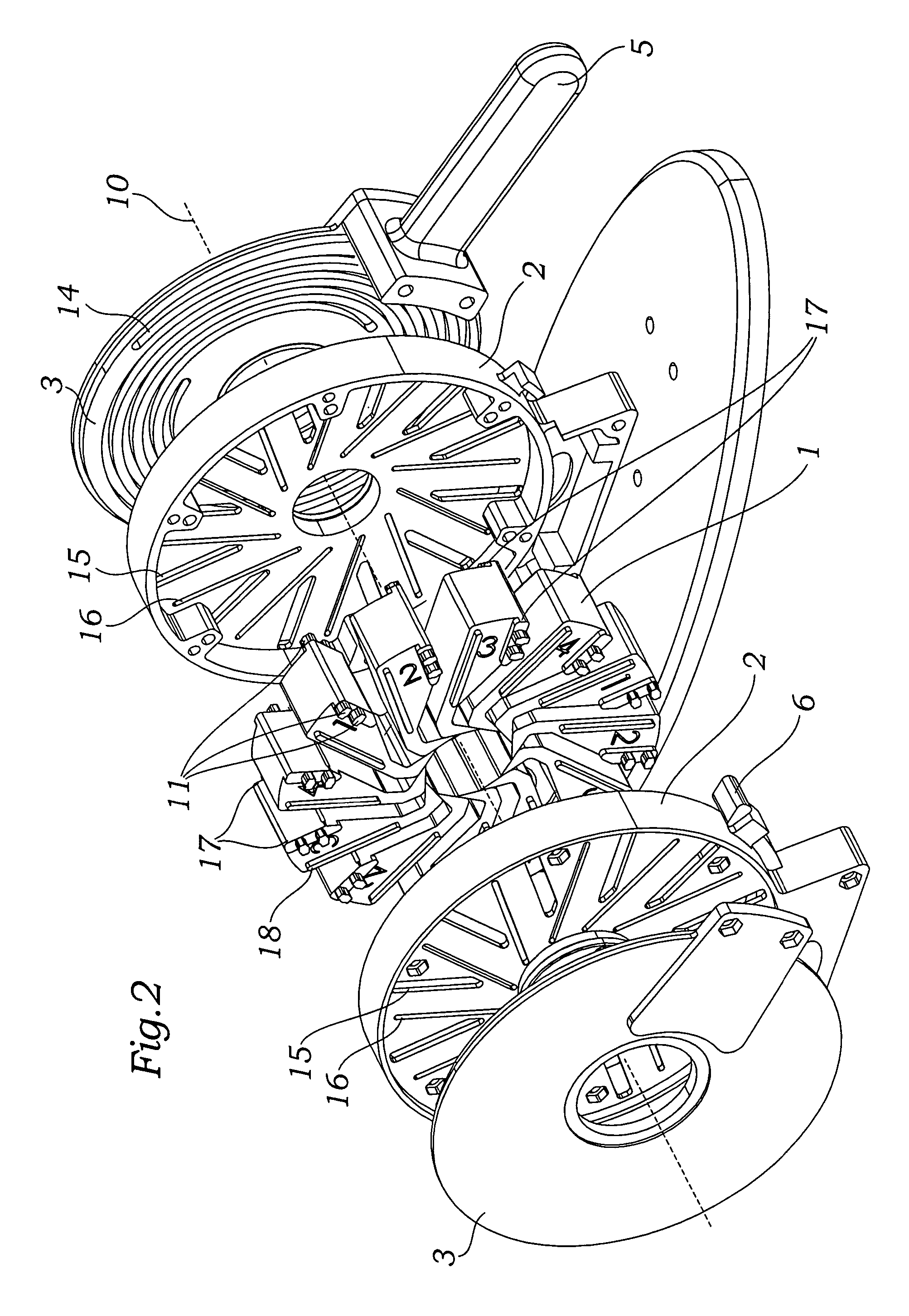

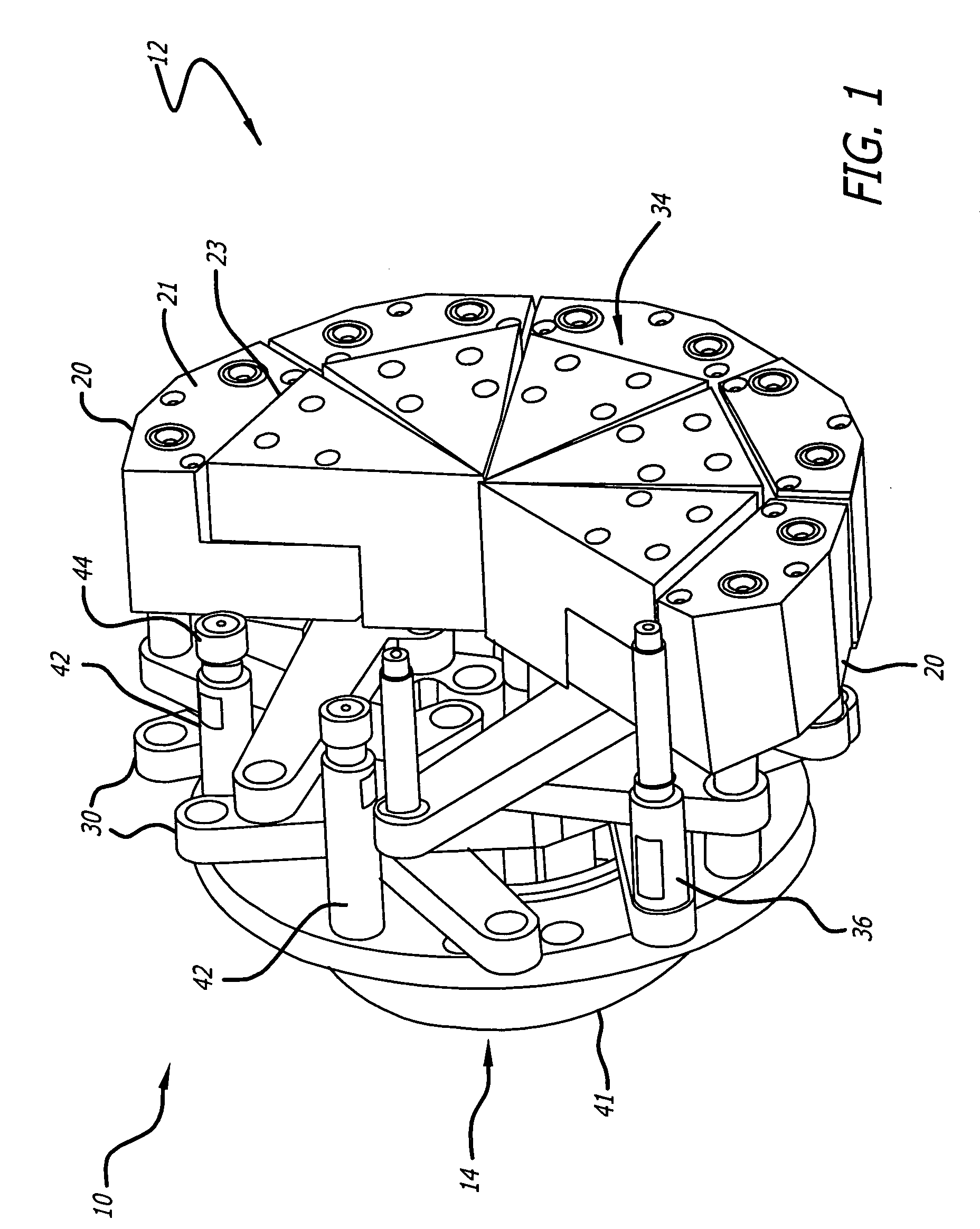

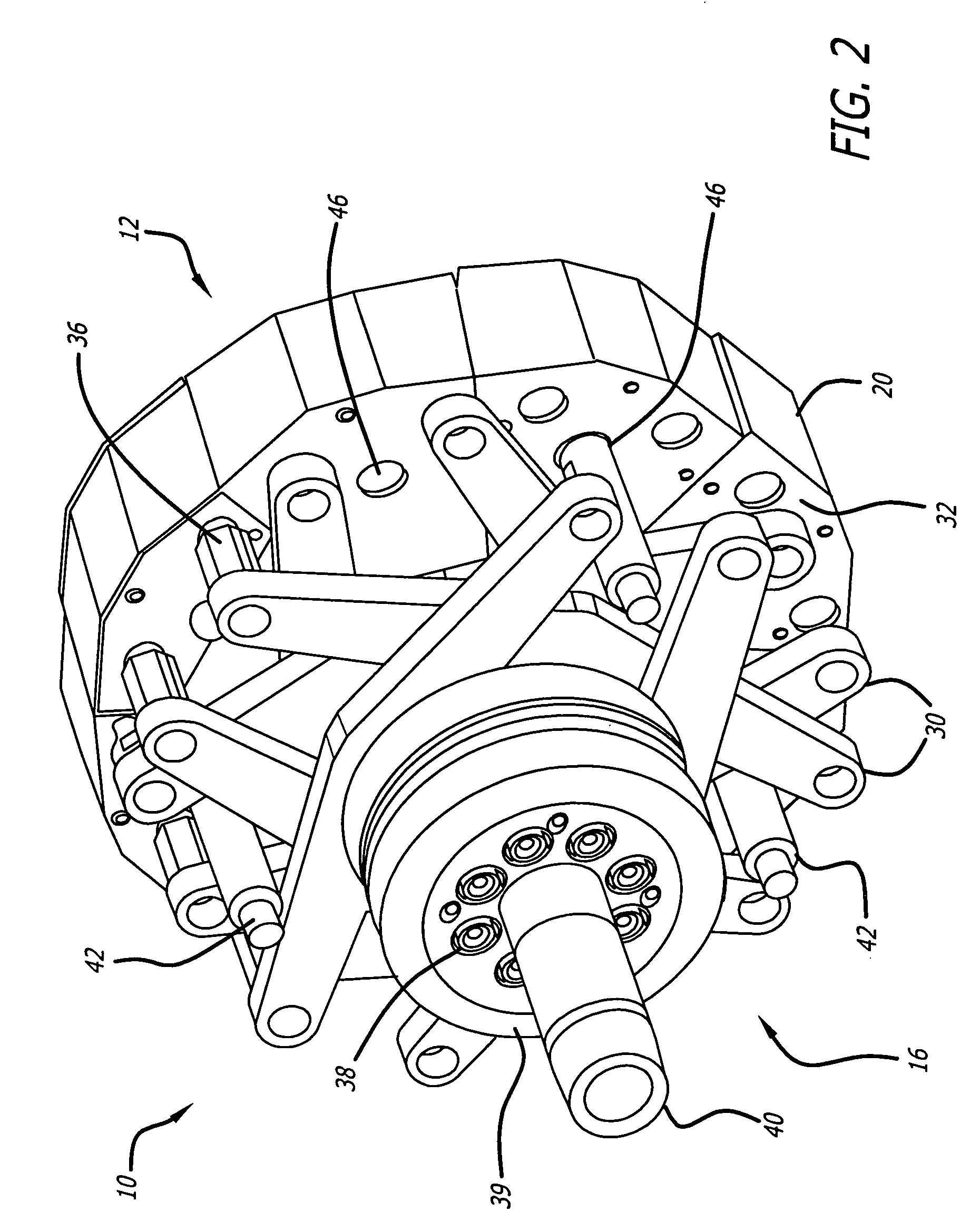

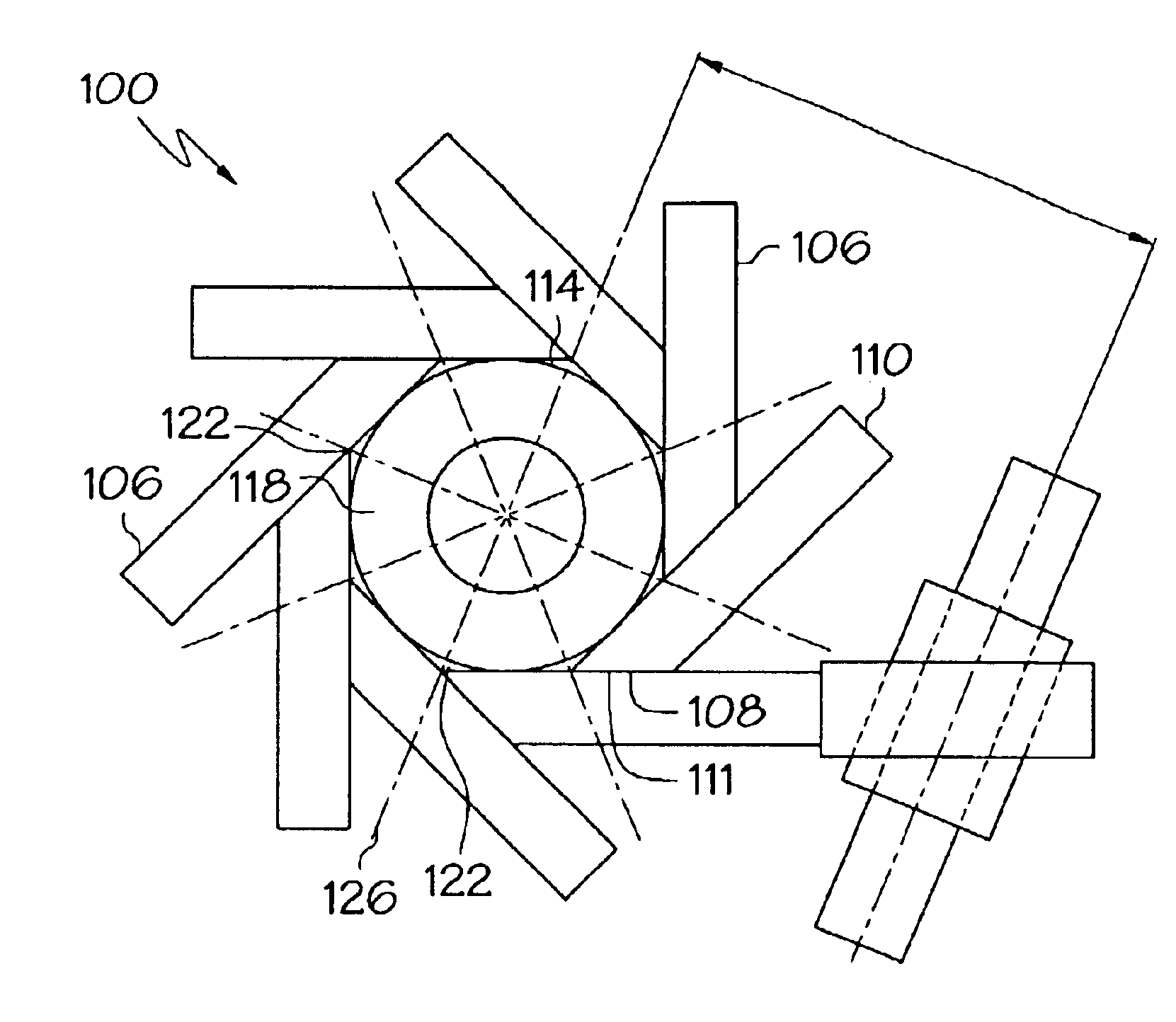

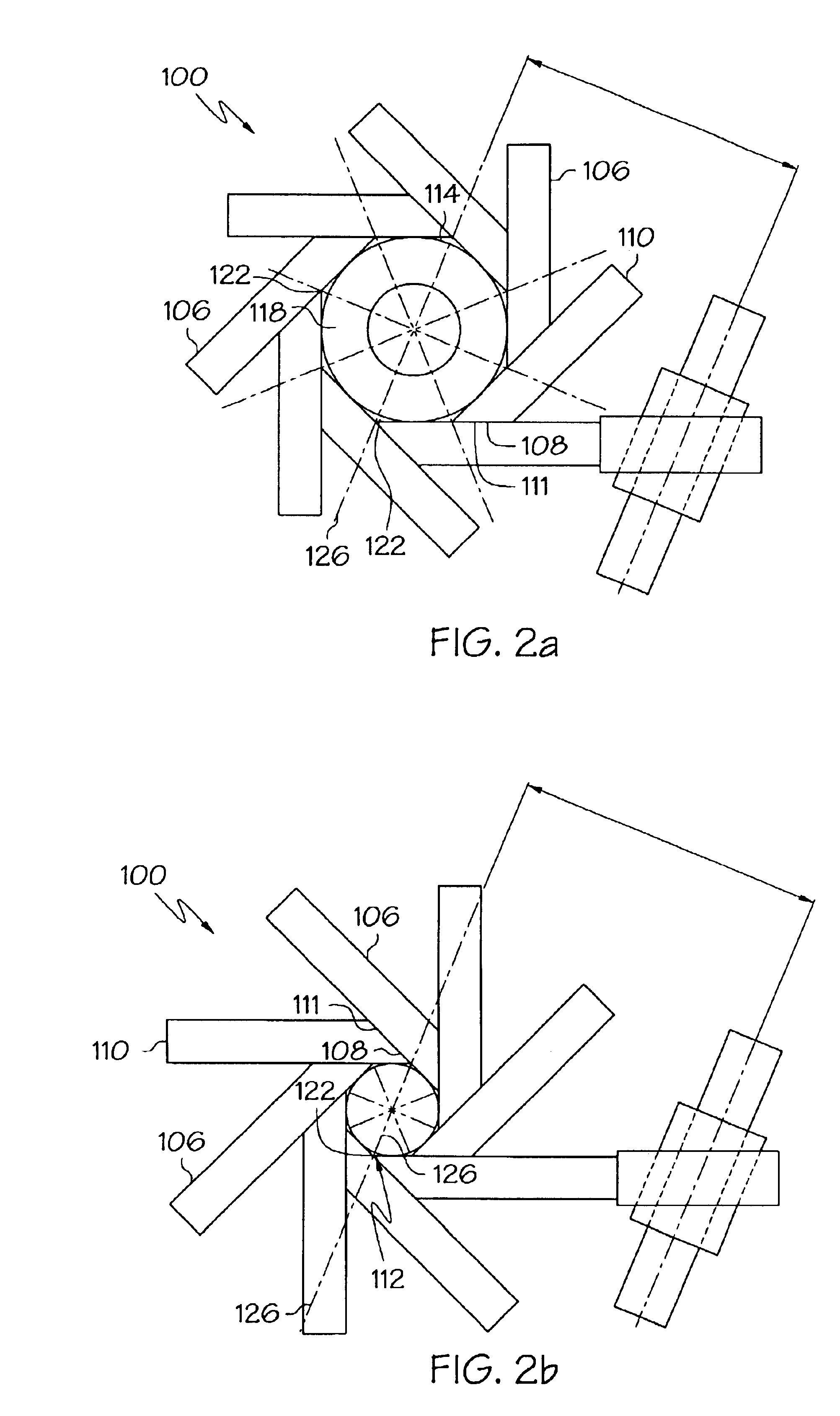

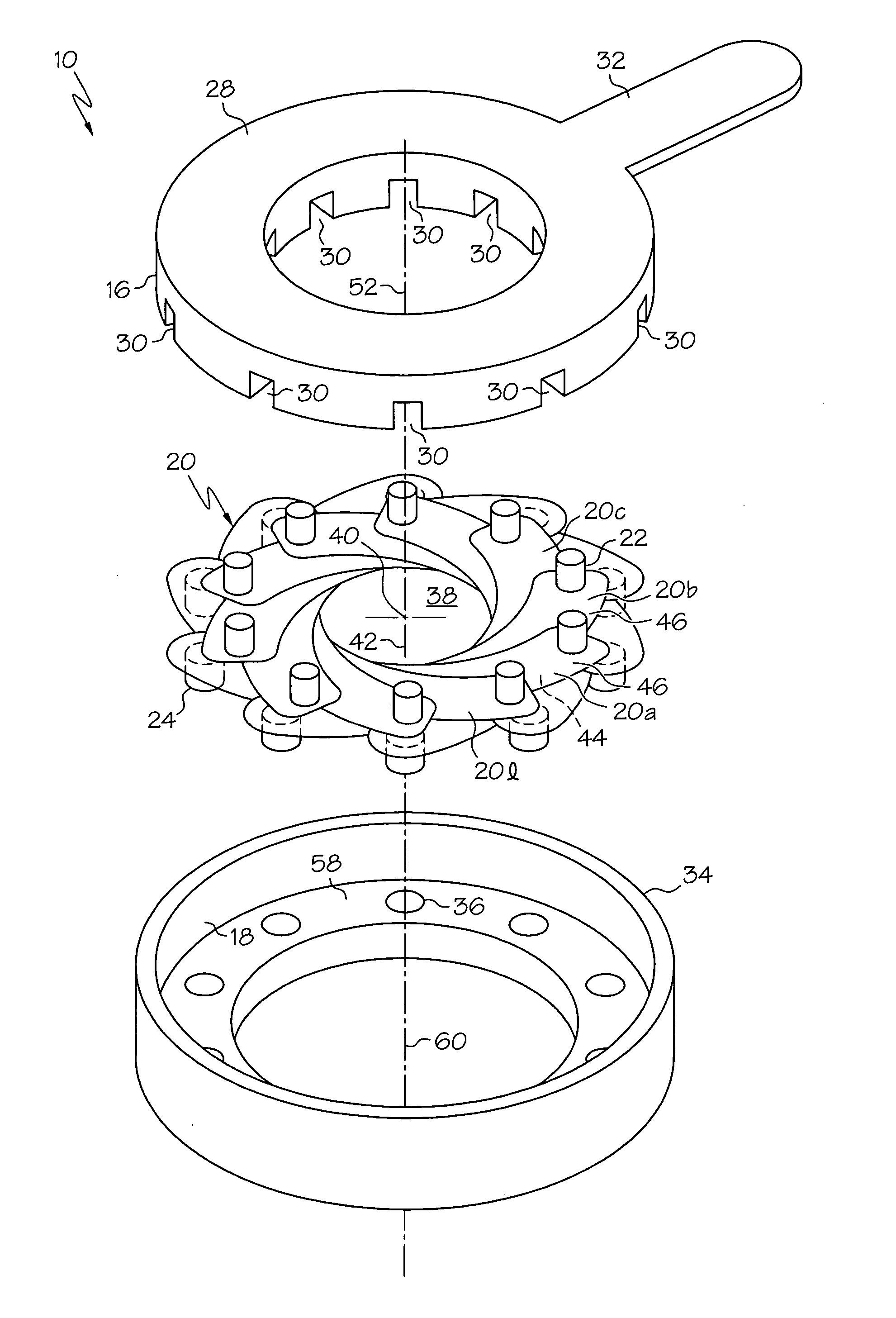

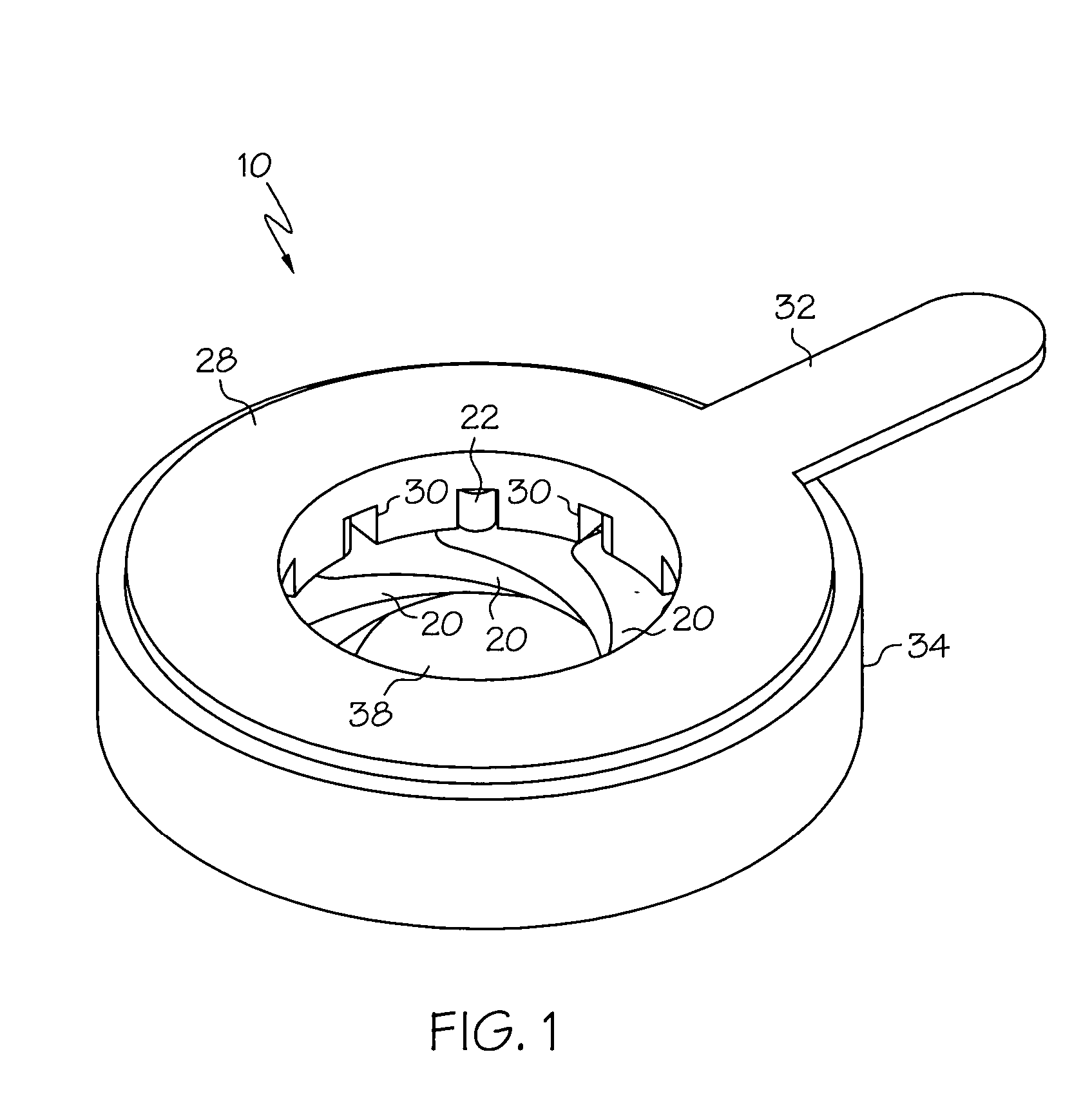

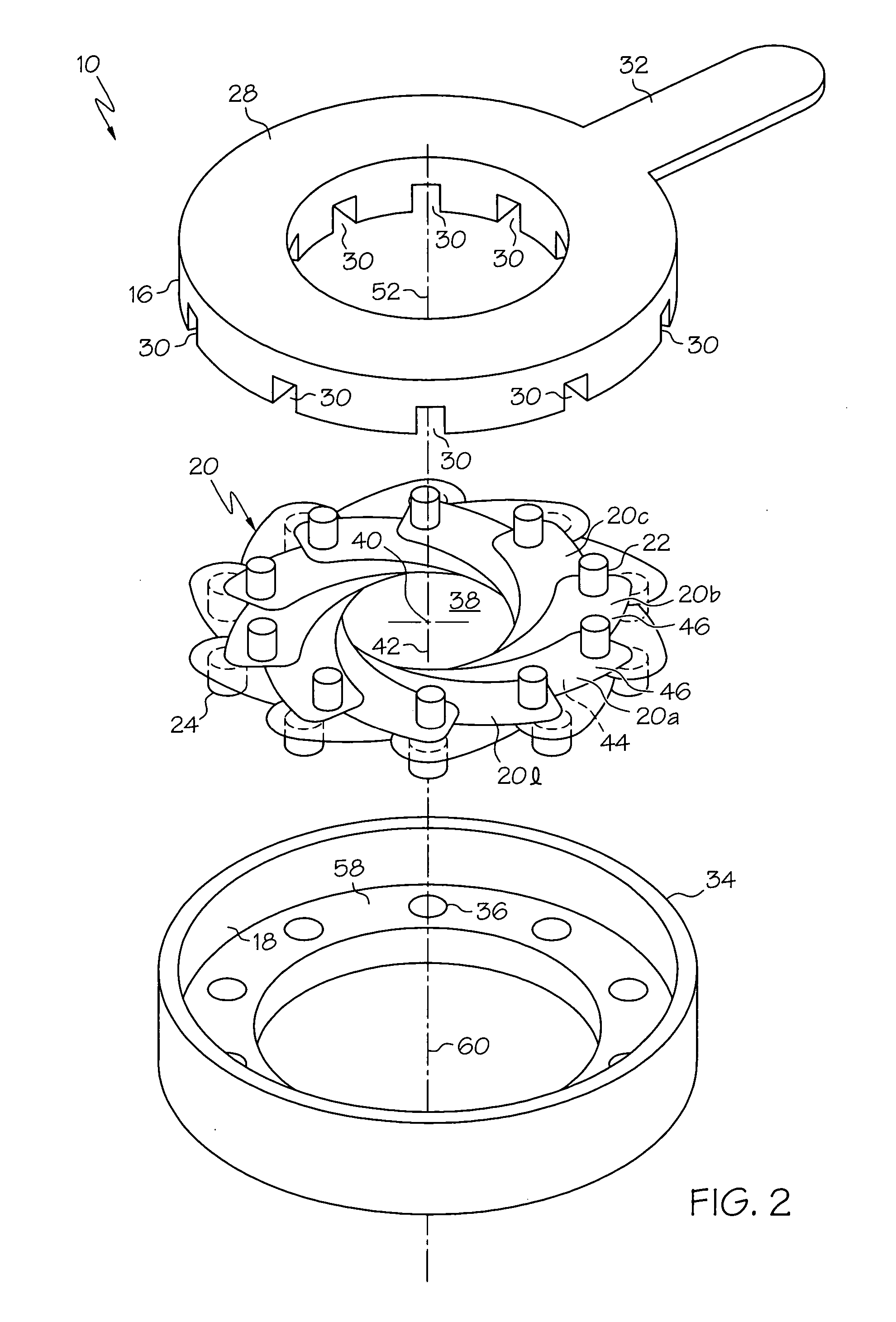

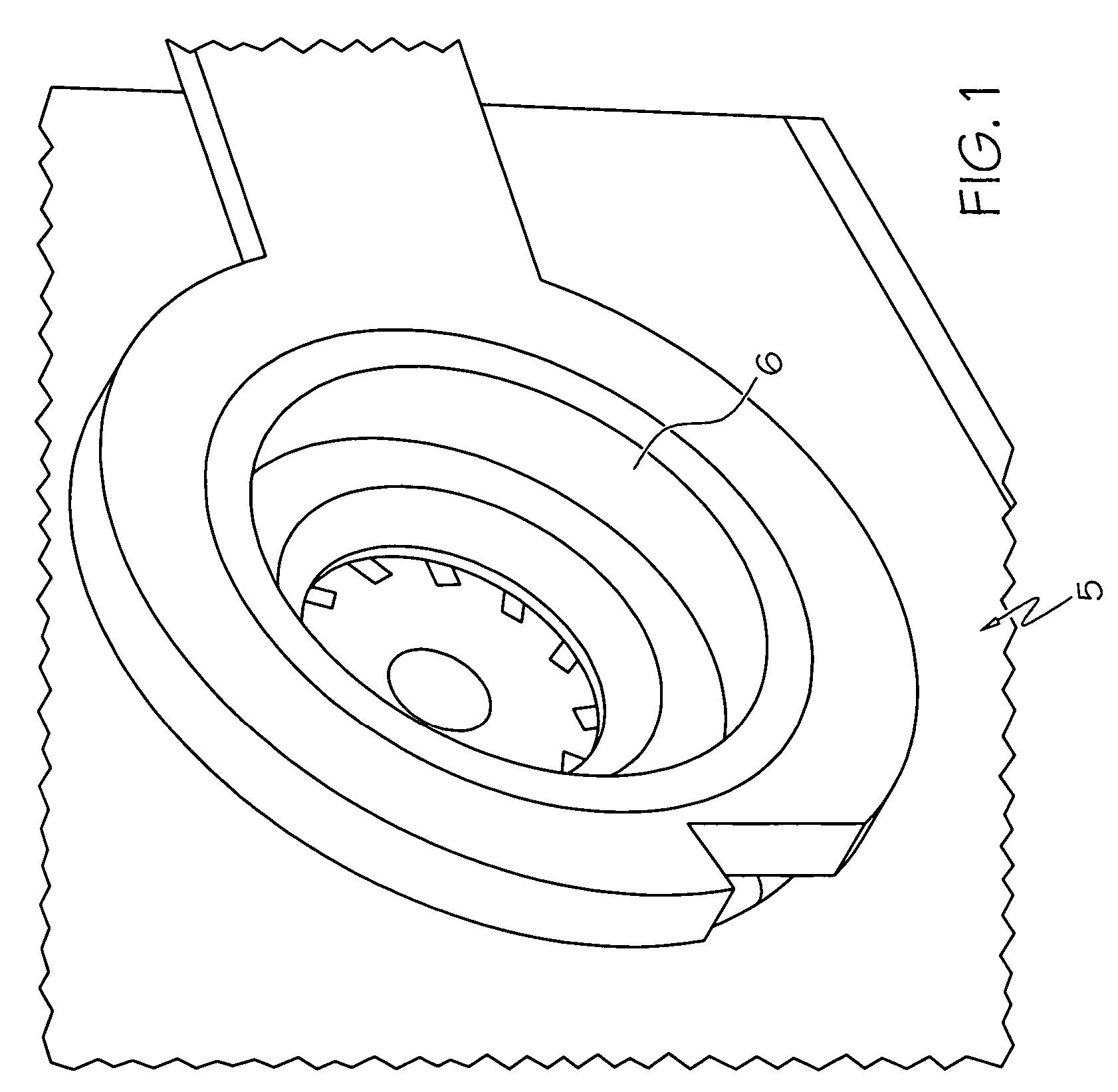

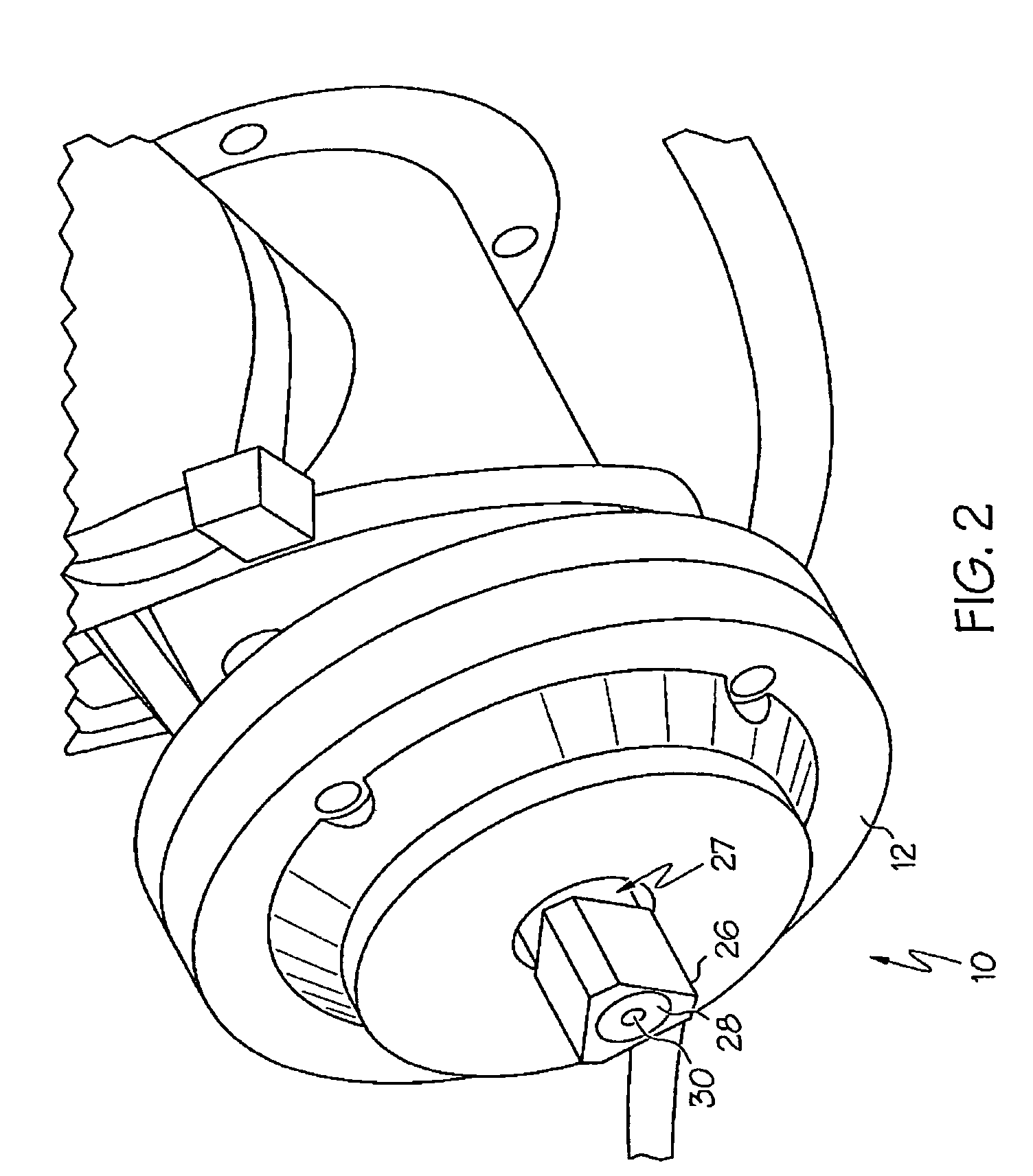

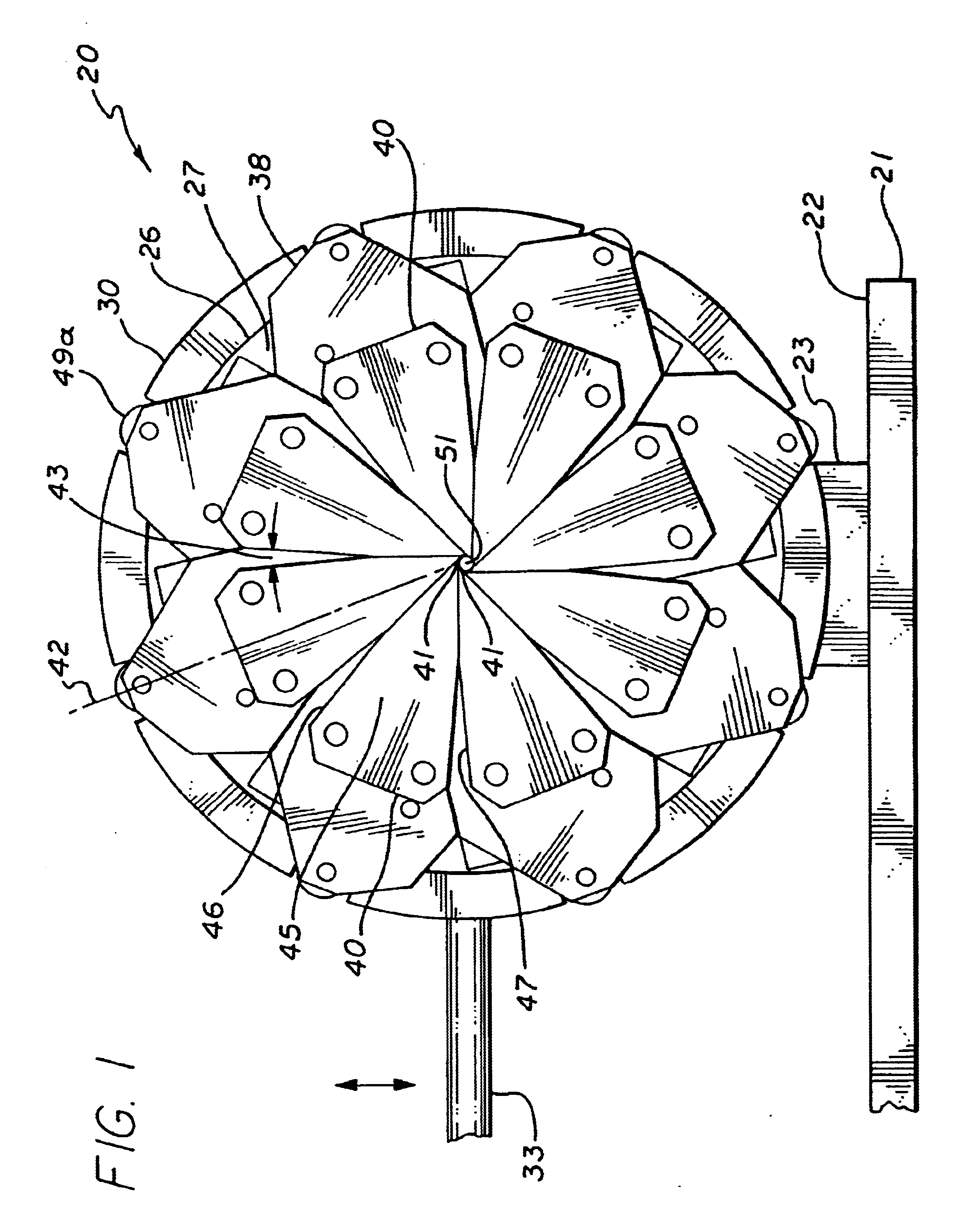

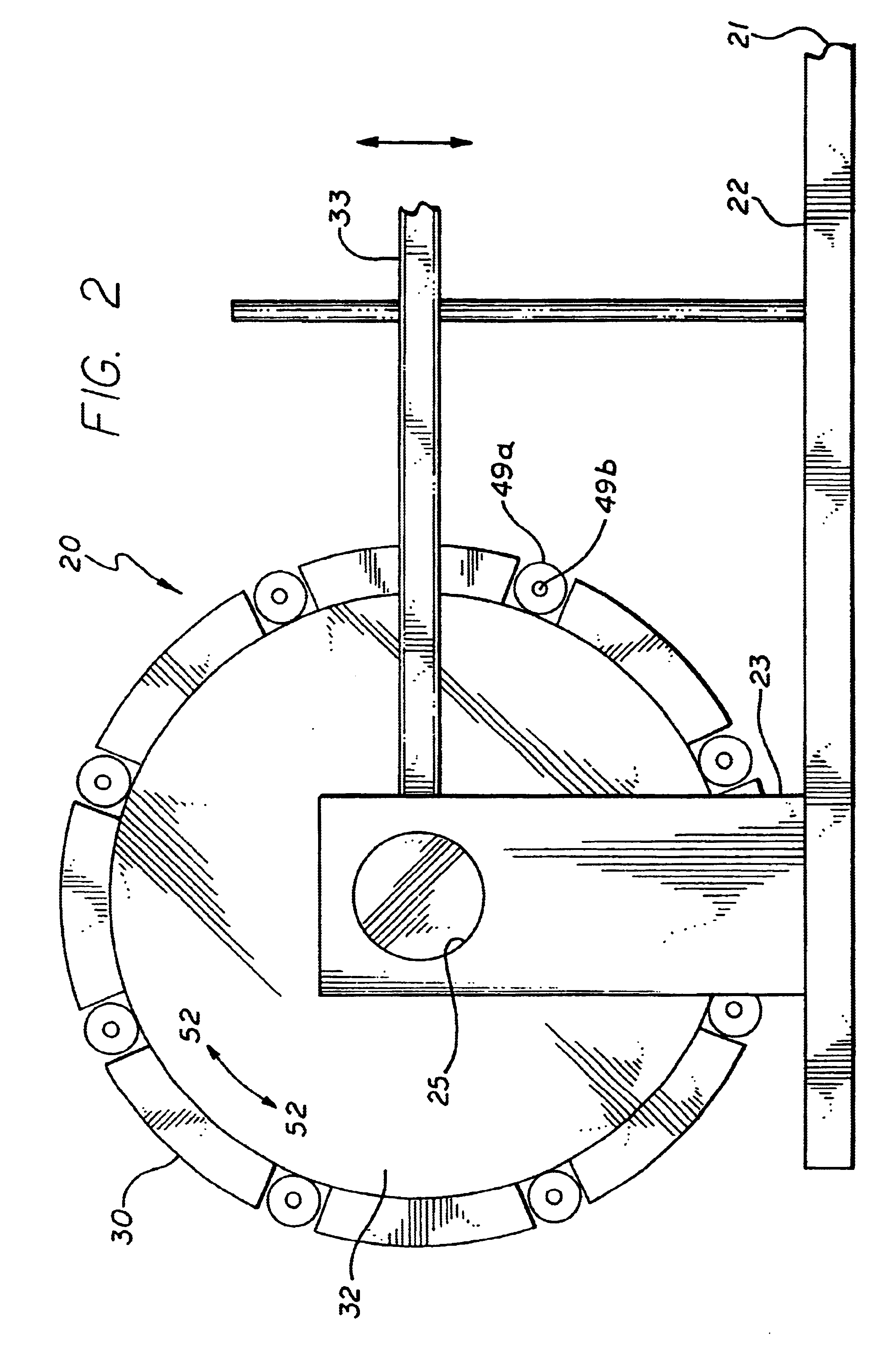

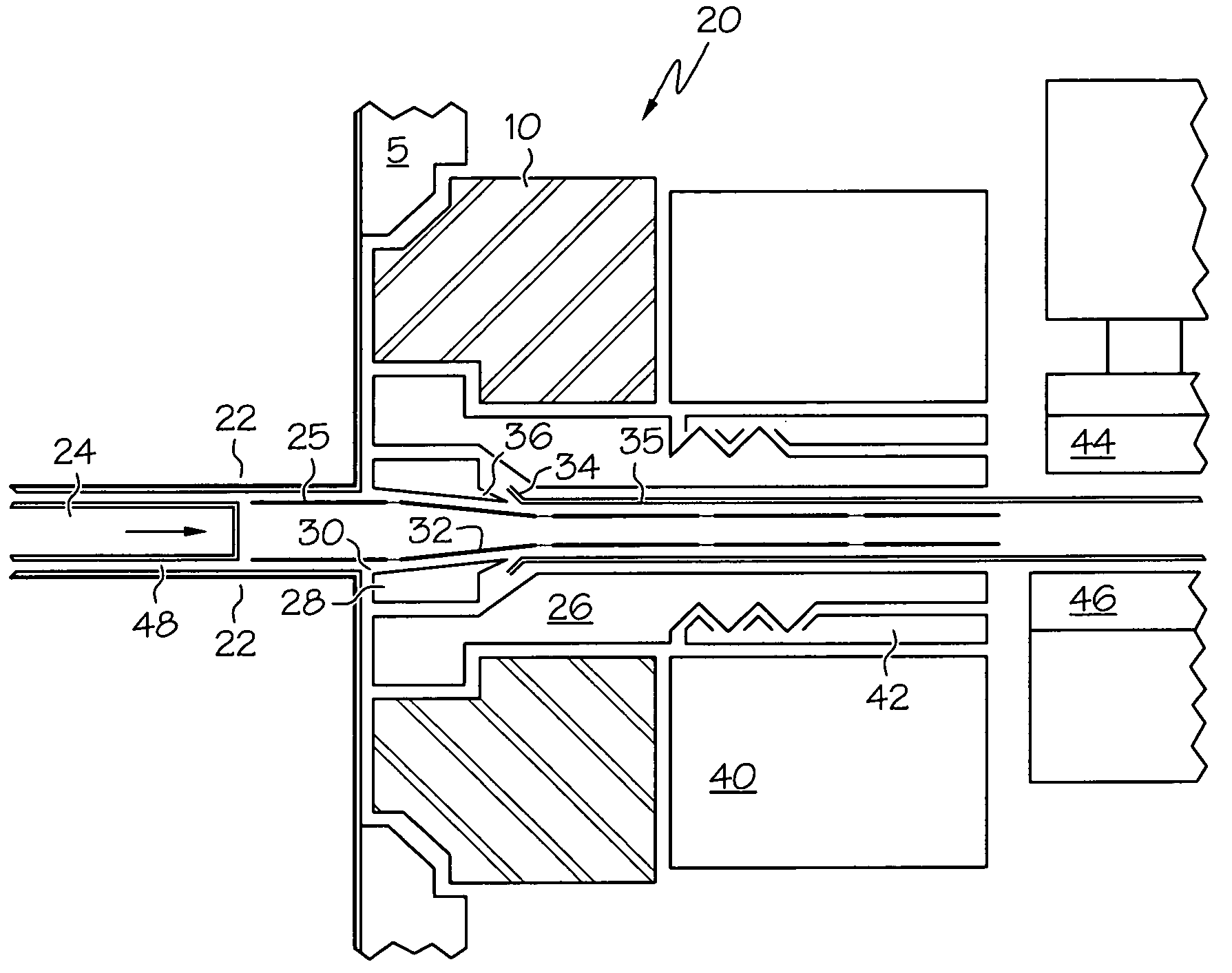

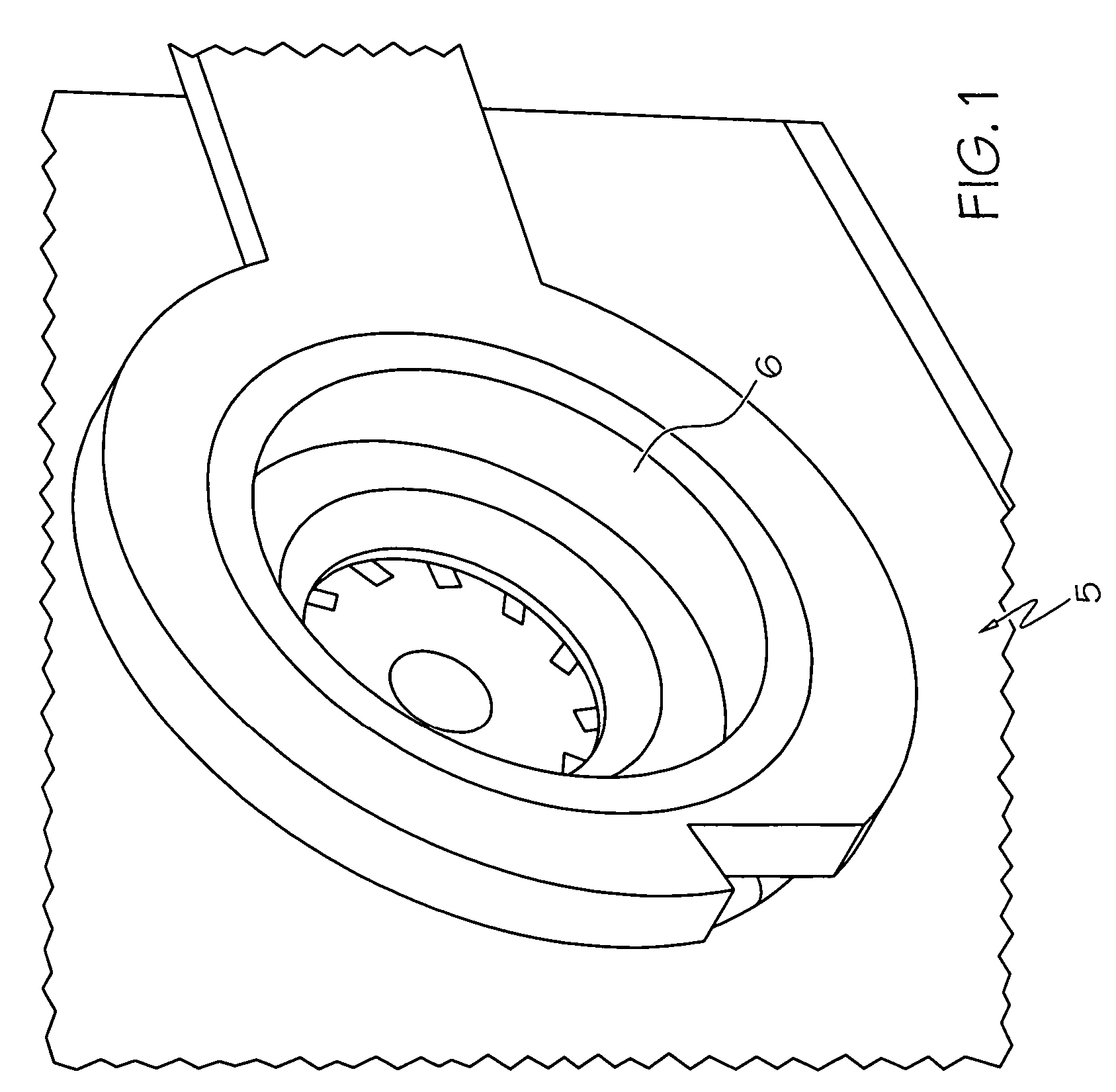

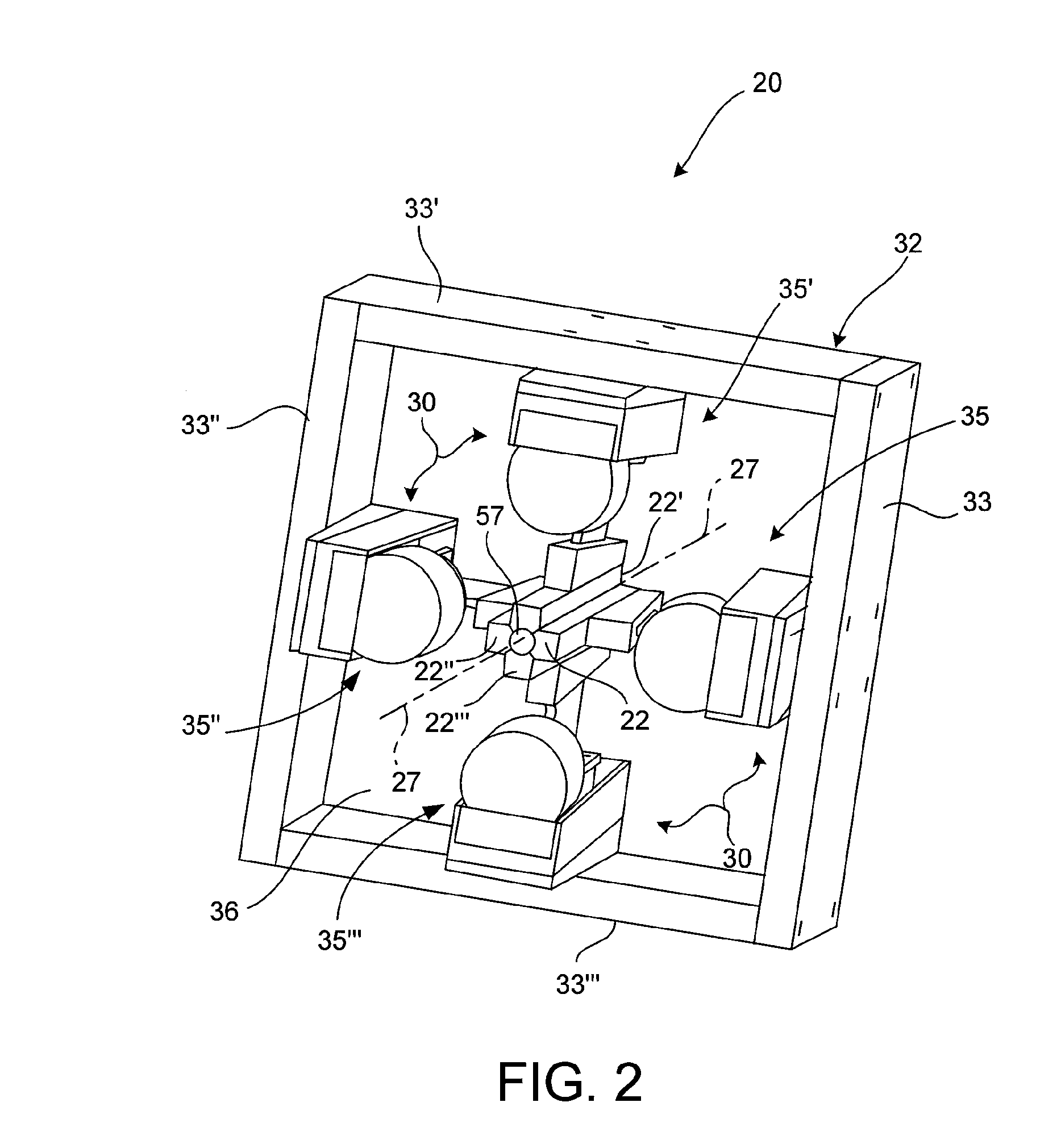

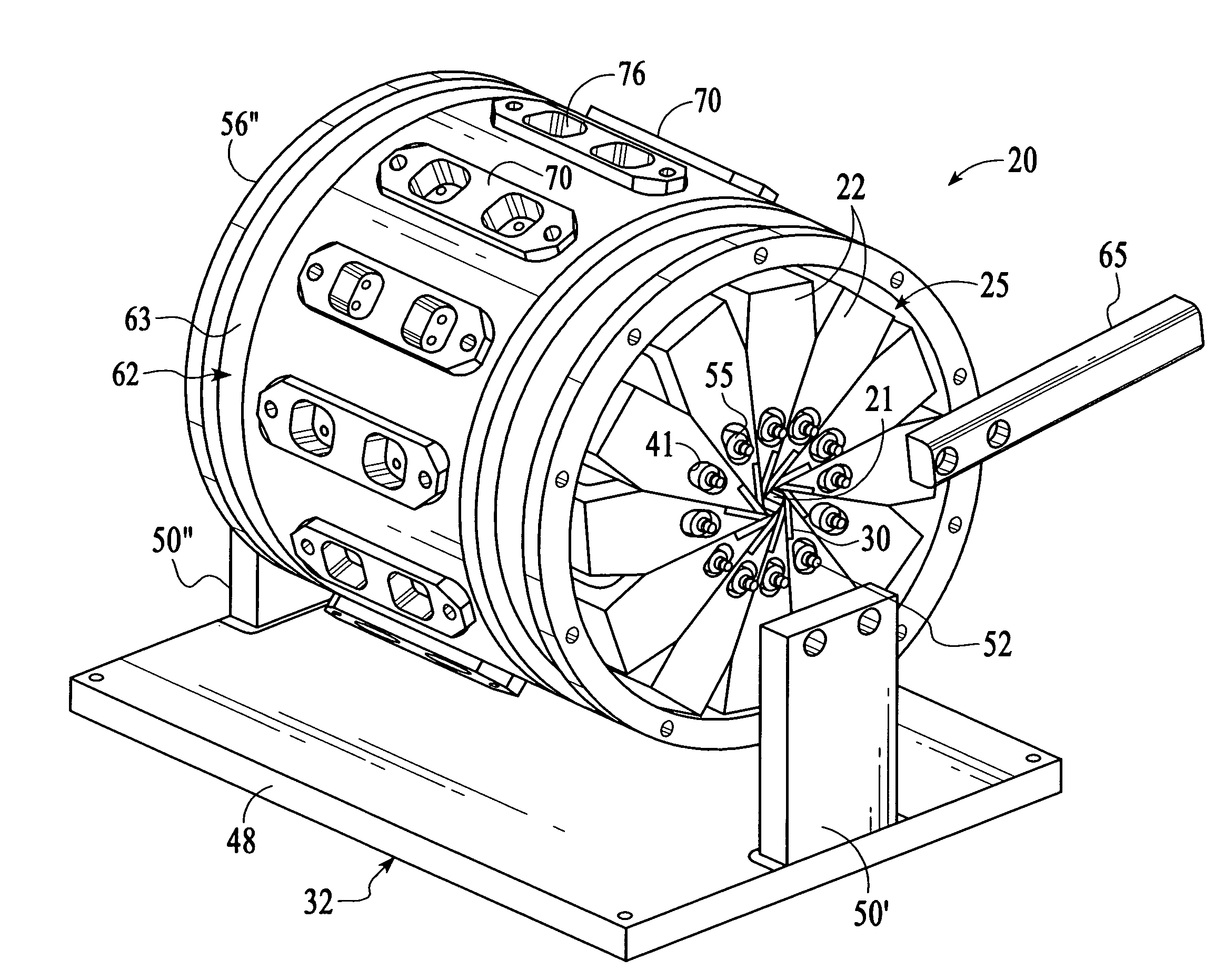

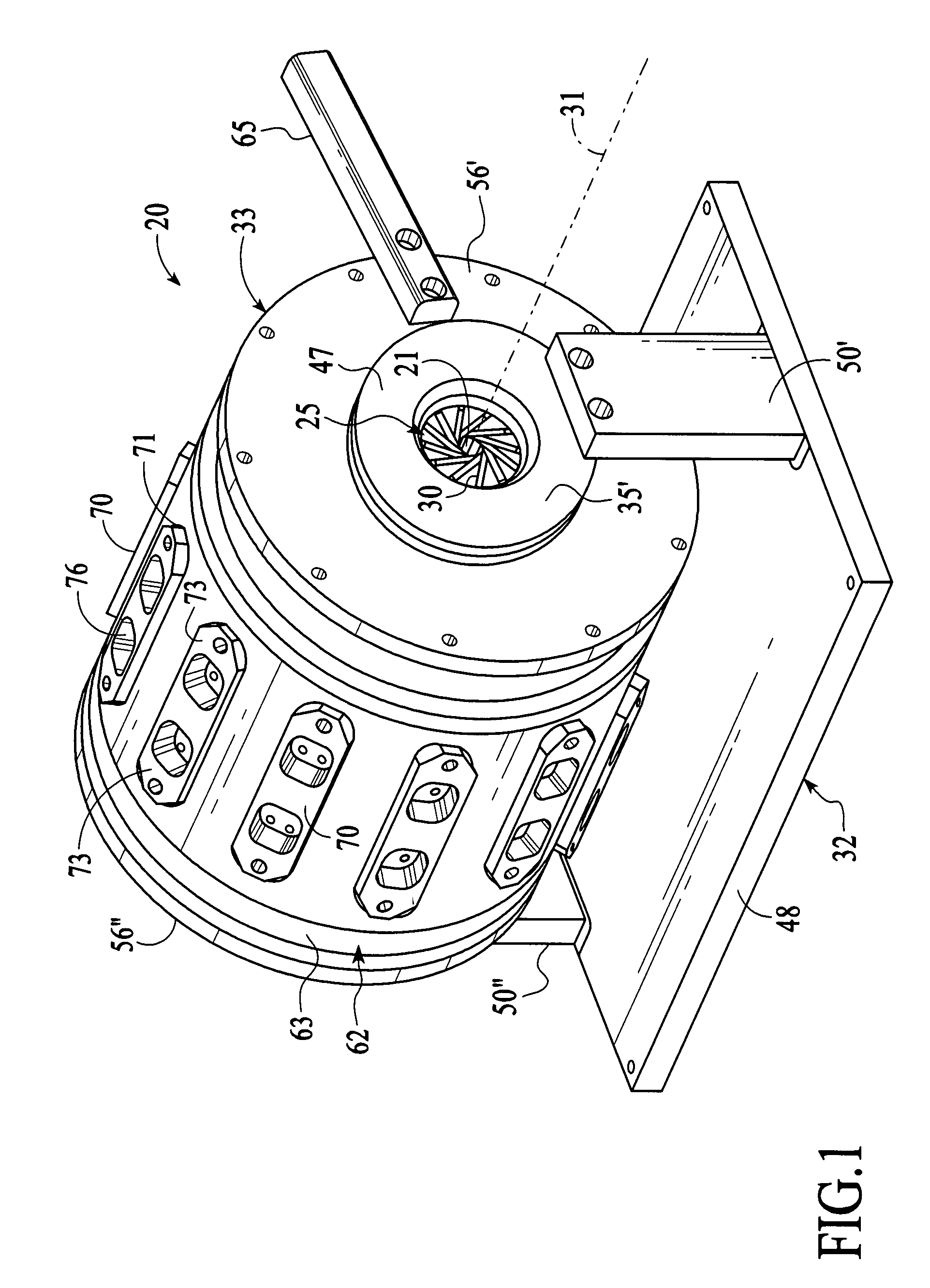

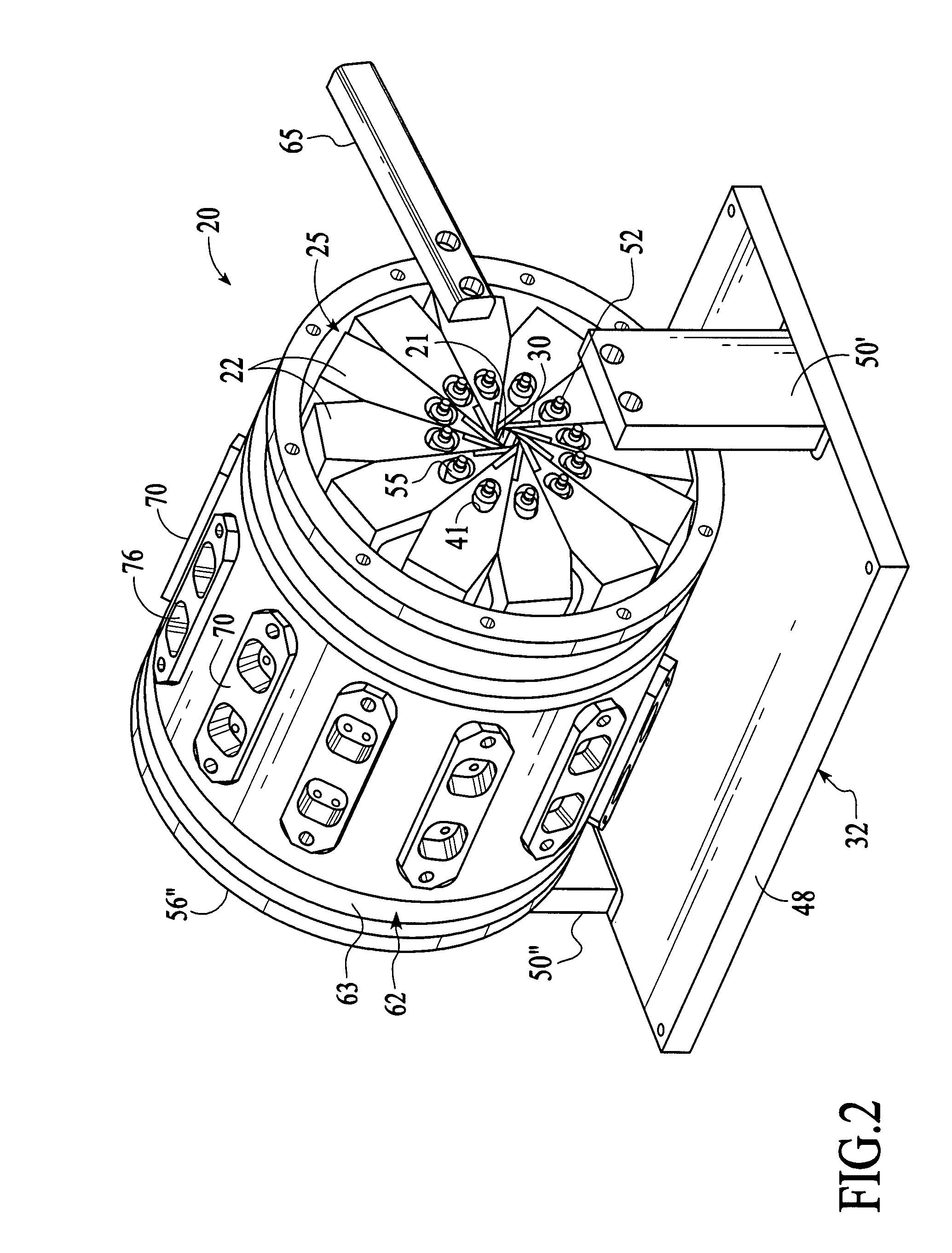

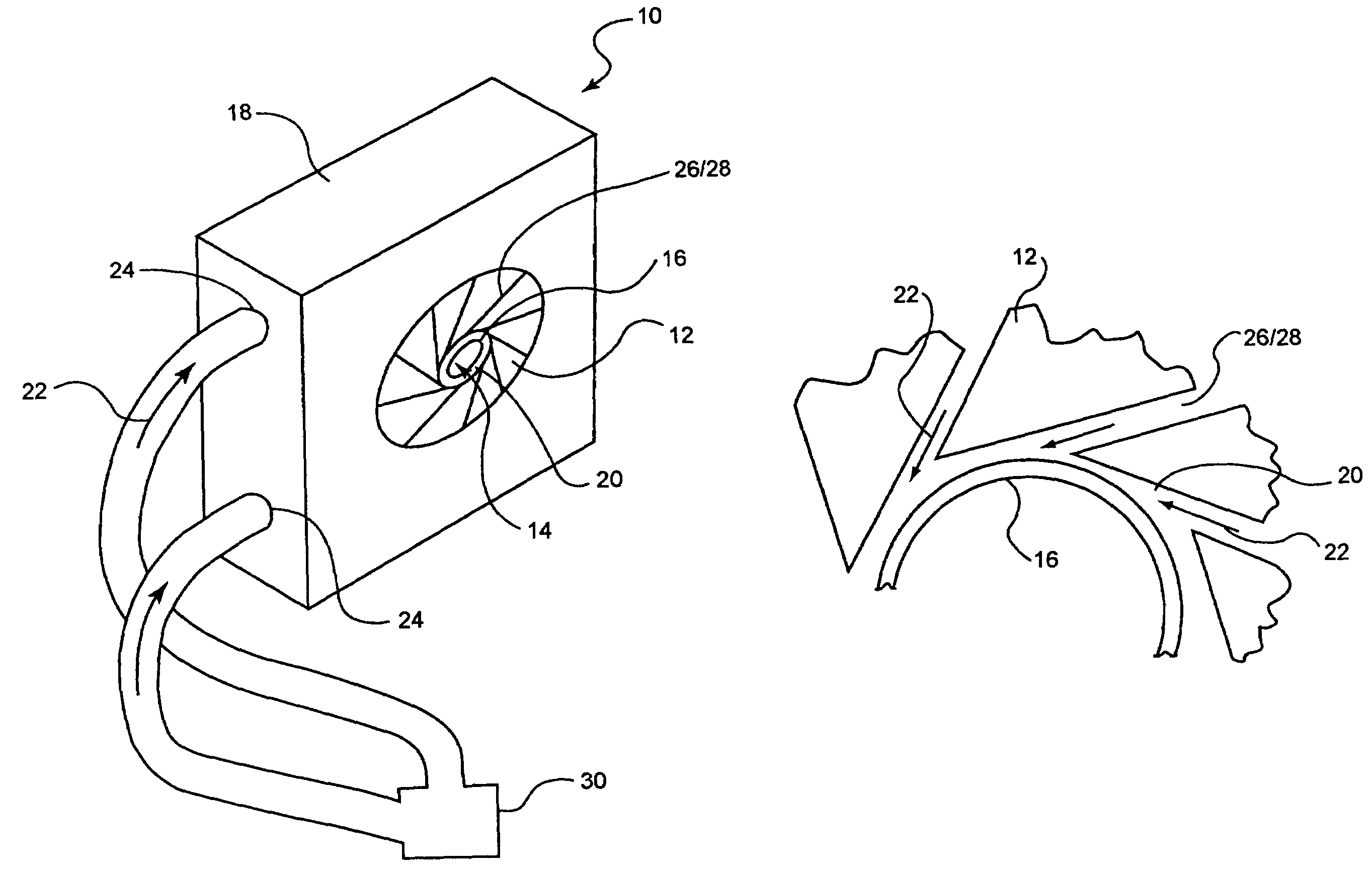

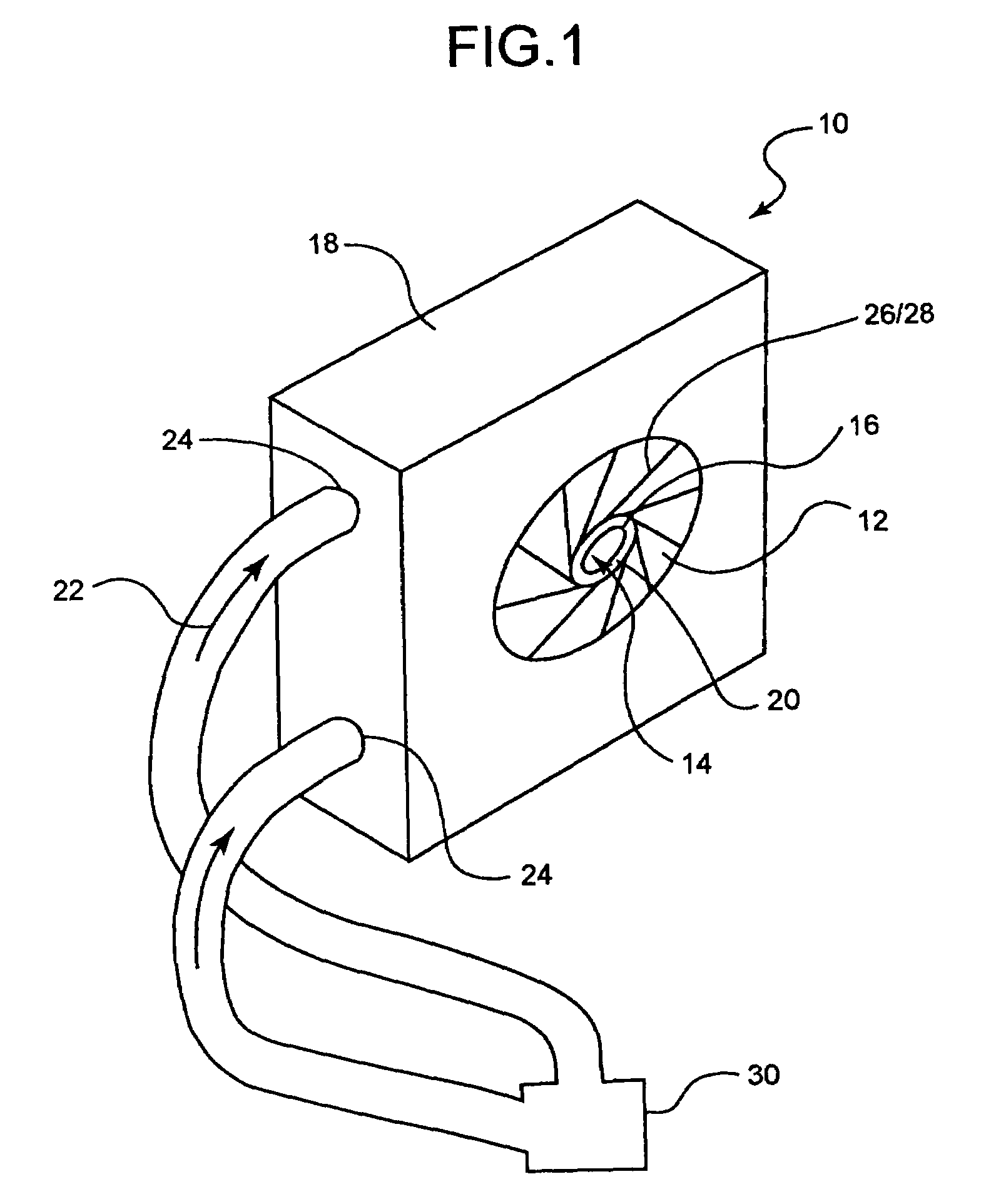

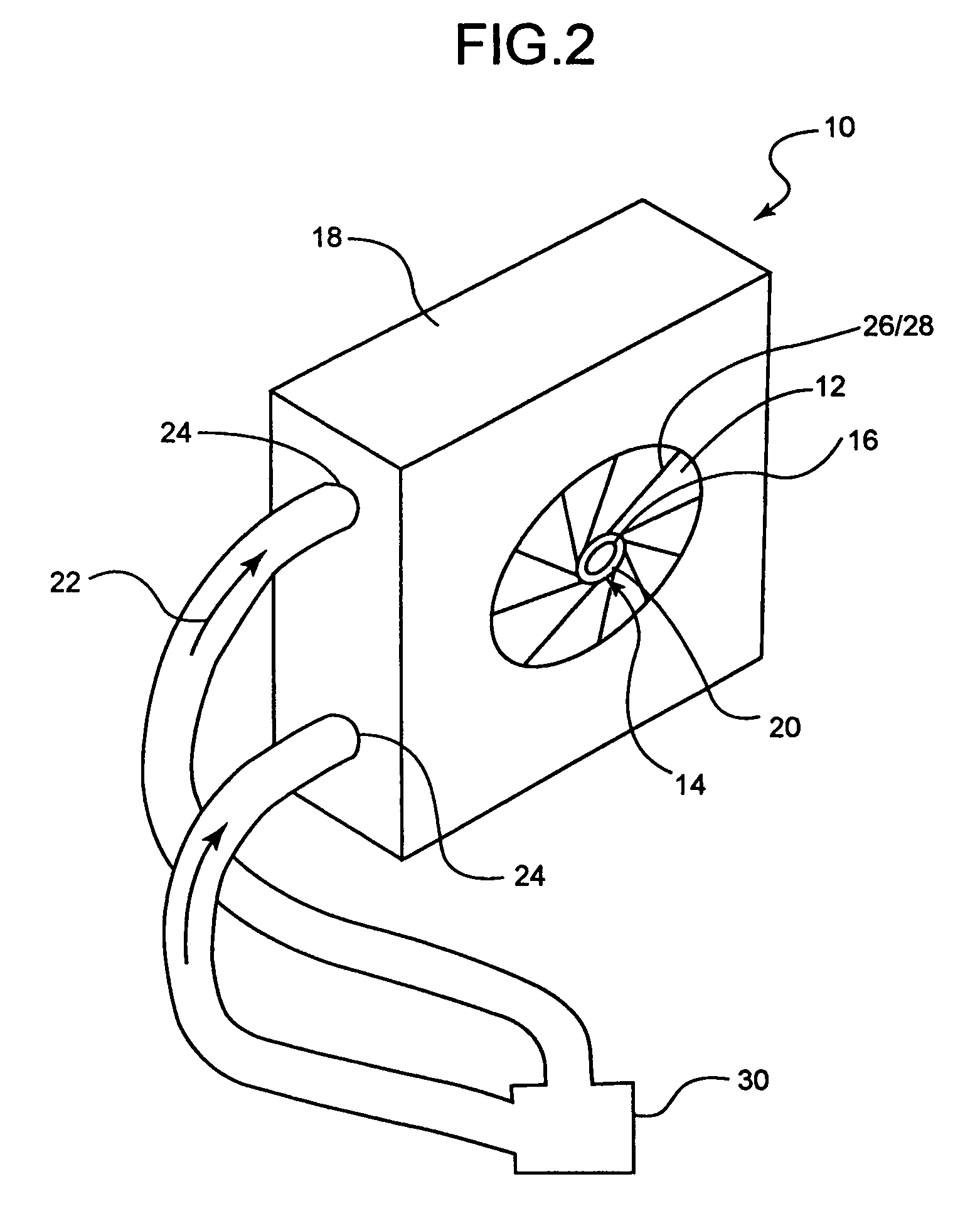

An improved crimping mechanism well-suited for use with stented prosthetic heart valves. The crimping mechanism includes a plurality of jaws configured for linear non-rotational movement toward a central axis. A rotational plate is formed with a plurality of spiral grooves or tracks for engaging the jaws. Rotational movement of the spiral tracks produces linear movement of the jaws. Nesting of the inner ends of the jaws permits each to be acted on along different radial lines while their inner faces move together evenly to reduce the crimping aperture in a smooth fashion. The crimping mechanism is particularly well-suited for use with stented prosthetic heart valves, such as a prosthetic aortic valve, though it can also be applied to other stented heart valves, venous valves, and even stent grafts which tend to be fairly large.

Owner:EDWARDS LIFESCIENCES CORP

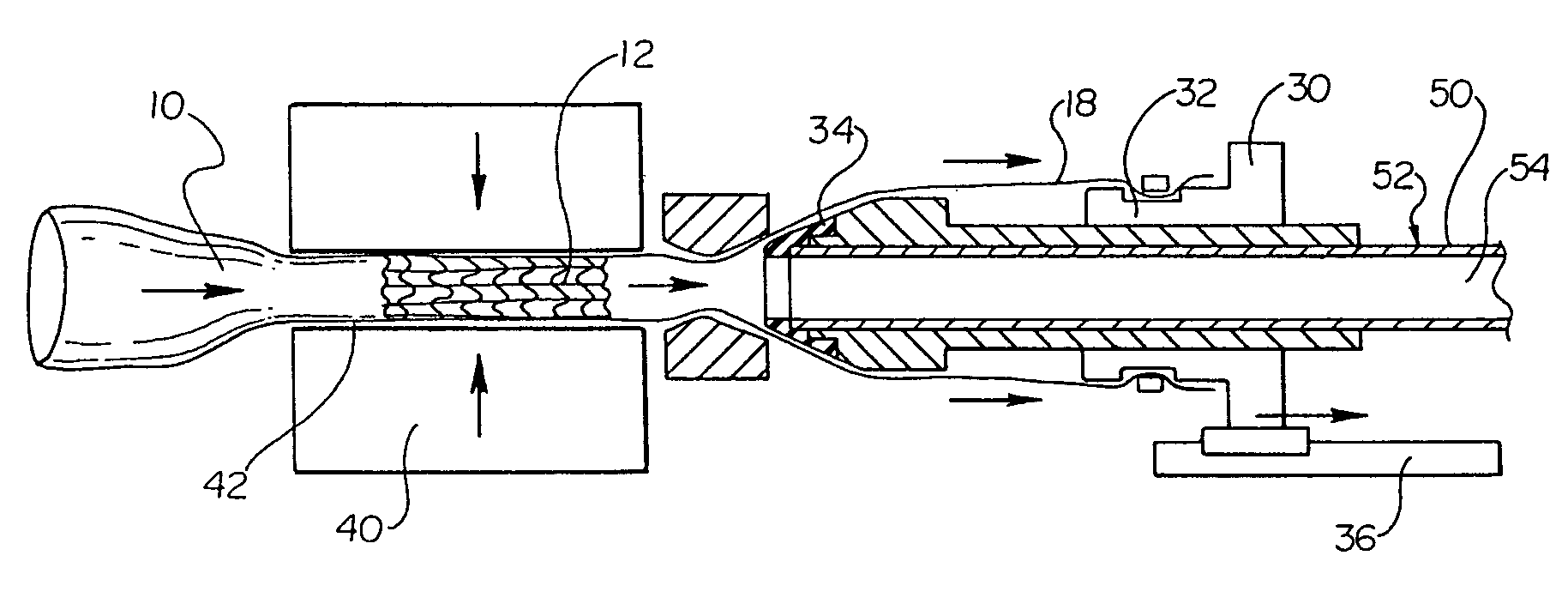

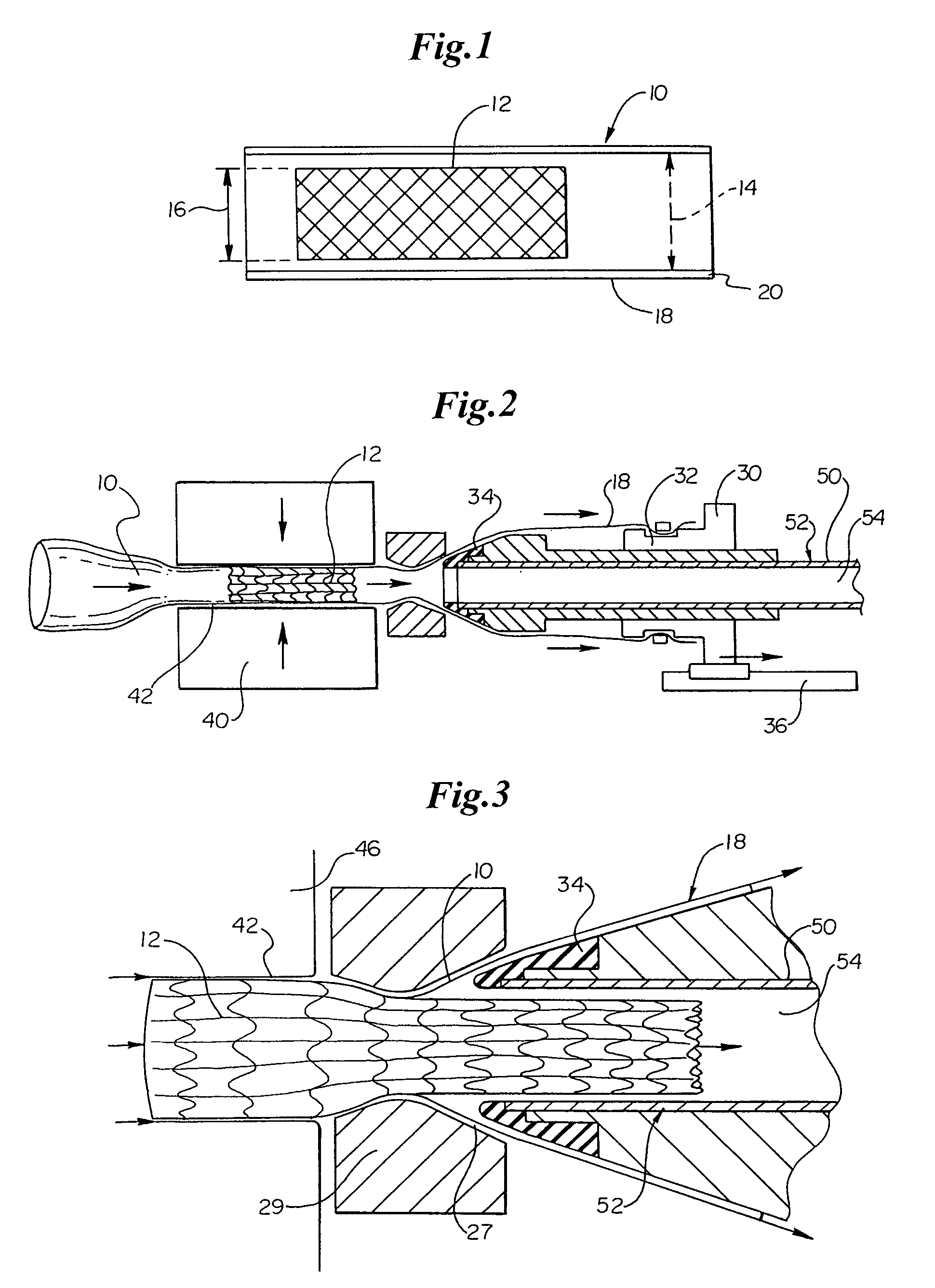

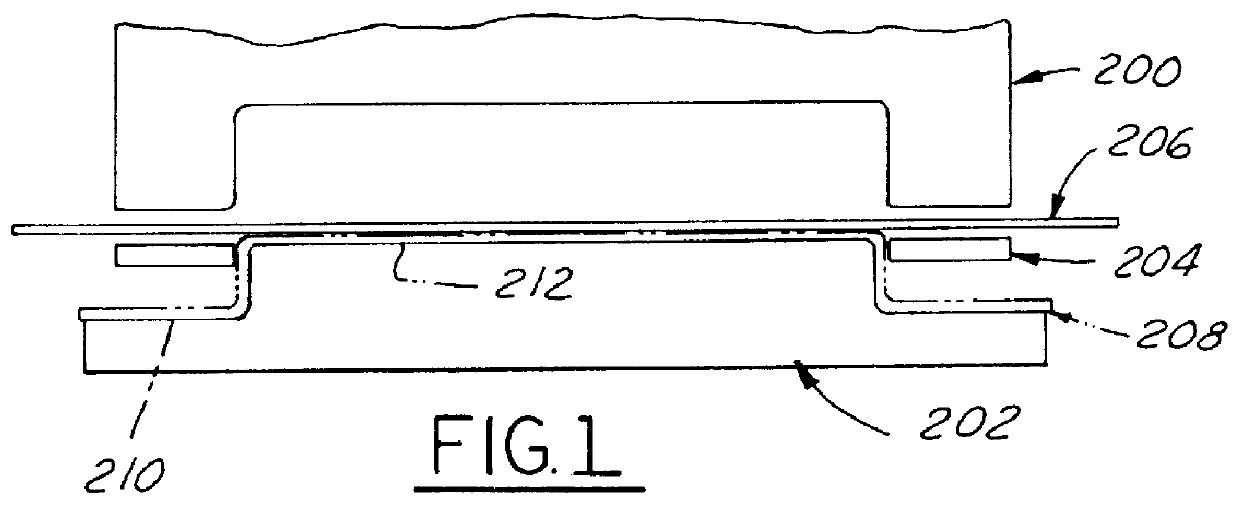

Protective loading of stents

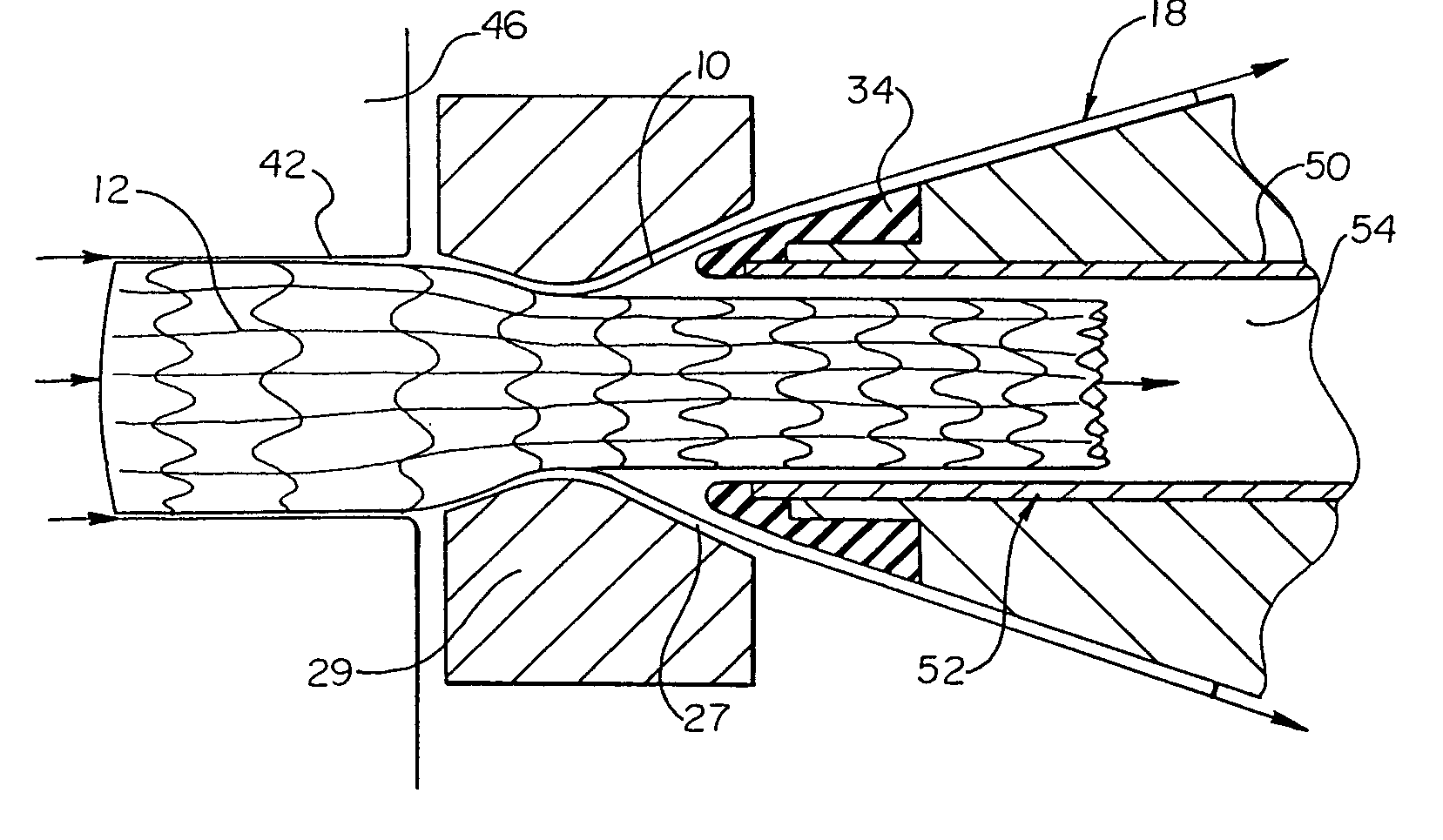

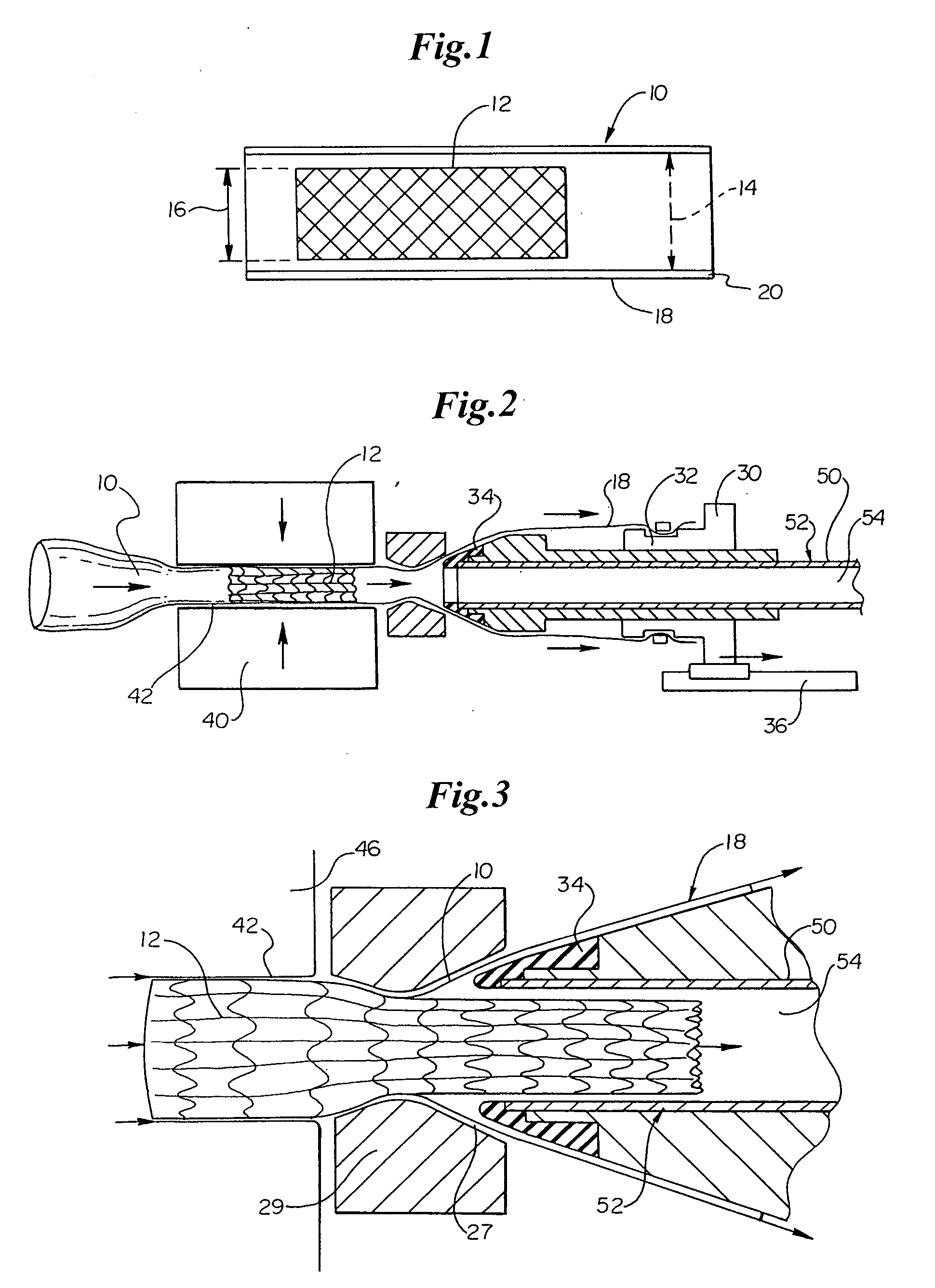

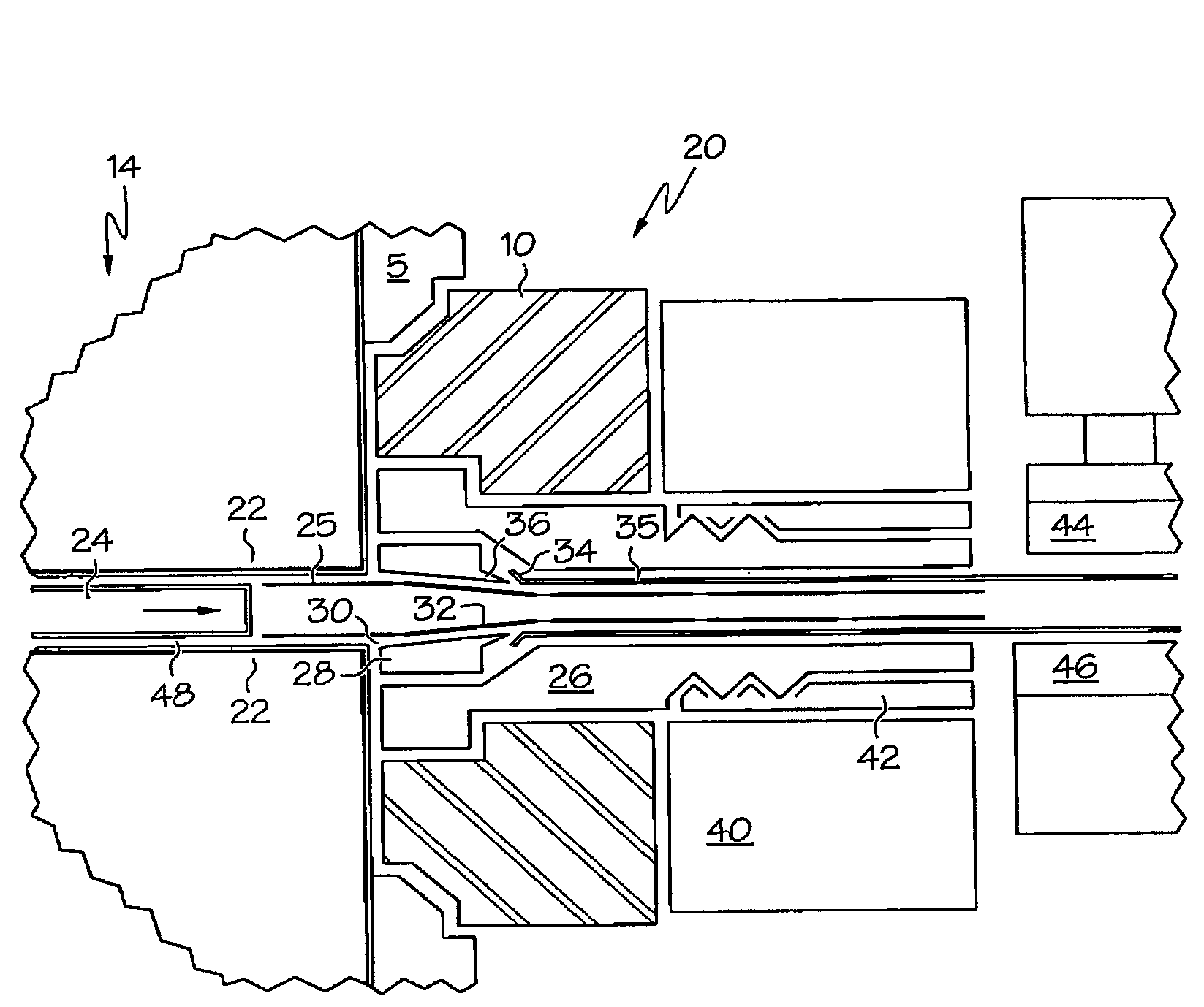

A system for protecting a stent from contact during loading comprises a stent, a protective sleeve disposed about the stent and a loading tool. The inner diameter of the protective sleeve is greater than the outer diameter of the stent. The protective sleeve has a length longer than that of the stent. The portion of the sleeve extending beyond the length of the stent defines a sleeve extension. The loading tool is positioned about at the stent retaining sleeve of a catheter. The tip region of the loading tool separates the protective sleeve and the stent from one another when the protective sleeve is pulled over the tip region of the loading tool. When the protective sleeve is pulled over the tip region of the loading tool the stent is advanced into a lumen defined by the stent retaining sleeve of the catheter.

Owner:BOSTON SCI SCIMED INC

Prosthetic valve crimping device

ActiveUS7530253B2Most efficientReduce the overall diameterStentsBalloon catheterProsthetic valveEngineering

An improved crimping mechanism well-suited for use with stented prosthetic heart valves. The crimping mechanism includes a plurality of jaws configured for linear non-rotational movement toward a central axis. A rotational plate is formed with a plurality of spiral grooves or tracks for engaging the jaws. Rotational movement of the spiral tracks produces linear movement of the jaws. Nesting of the inner ends of the jaws permits each to be acted on along different radial lines while their inner faces move together evenly to reduce the crimping aperture in a smooth fashion. The crimping mechanism is particularly well-suited for use with stented prosthetic heart valves, such as a prosthetic aortic valve, though it can also be applied to other stented heart valves, venous valves, and even stent grafts which tend to be fairly large.

Owner:EDWARDS LIFESCIENCES CORP

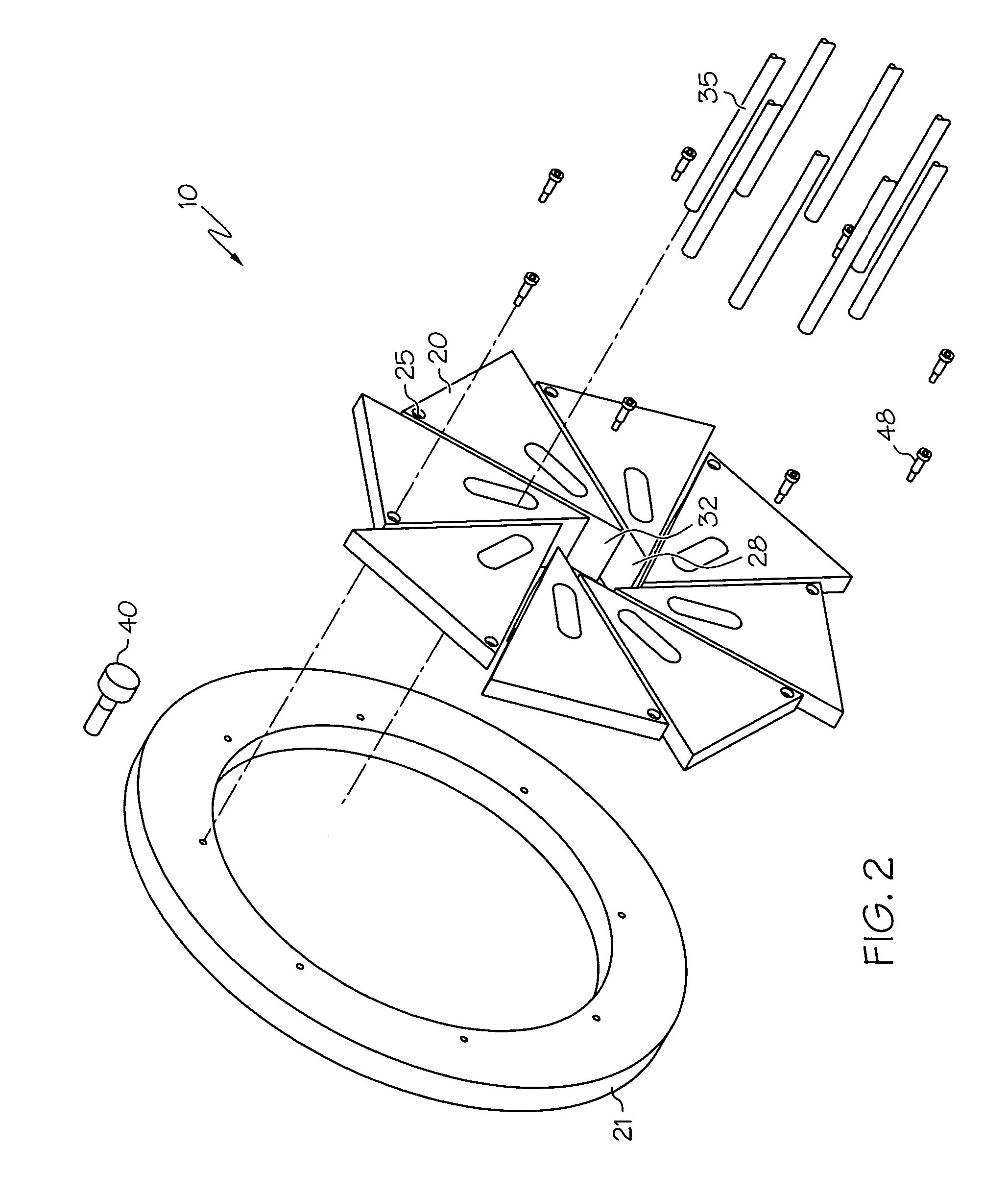

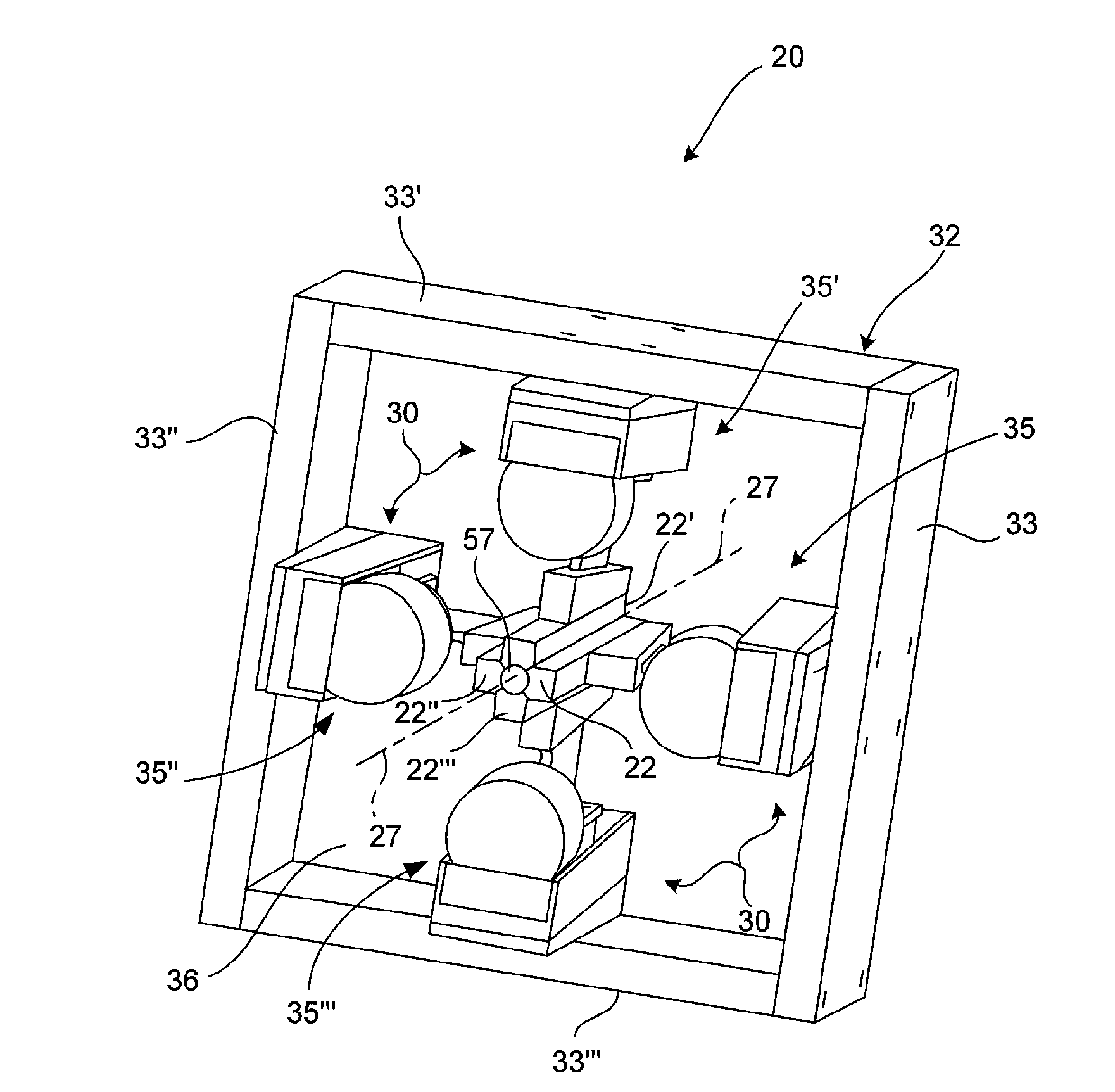

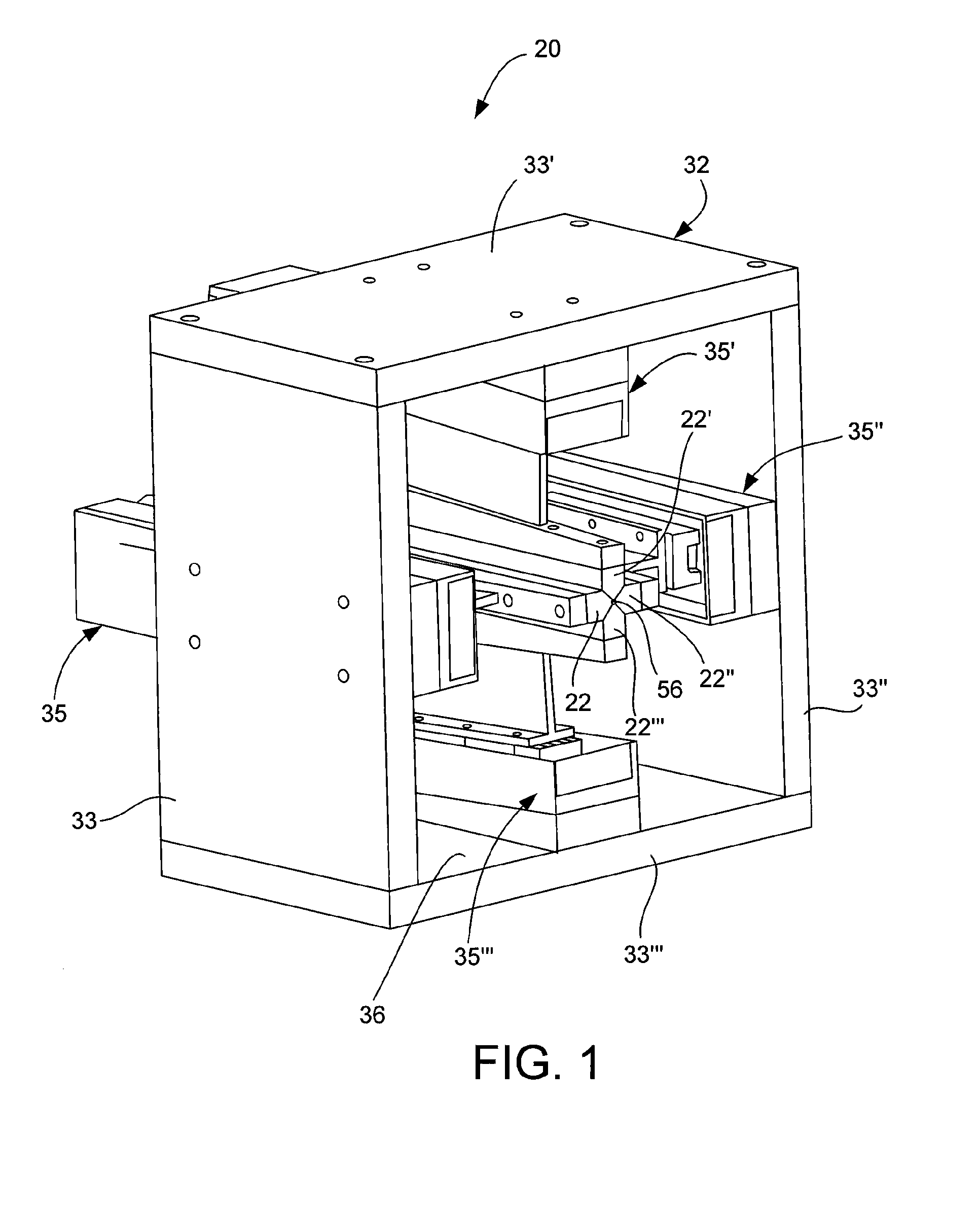

Stent crimper

An apparatus for applying an inward force to a medical device may include at least two independently operable sections. Each section may include a plurality of movable blades arranged to form an aperture or chamber whose size may be varied. Each blade may be pivotally connected to a mount and slidably engaged with a constraining member. The blades are movable so as to allow the aperture to be sized to contain the medical device and to alter the size of the aperture.

Owner:BOSTON SCI SCIMED INC

Devices and methods for abluminally coating medical devices

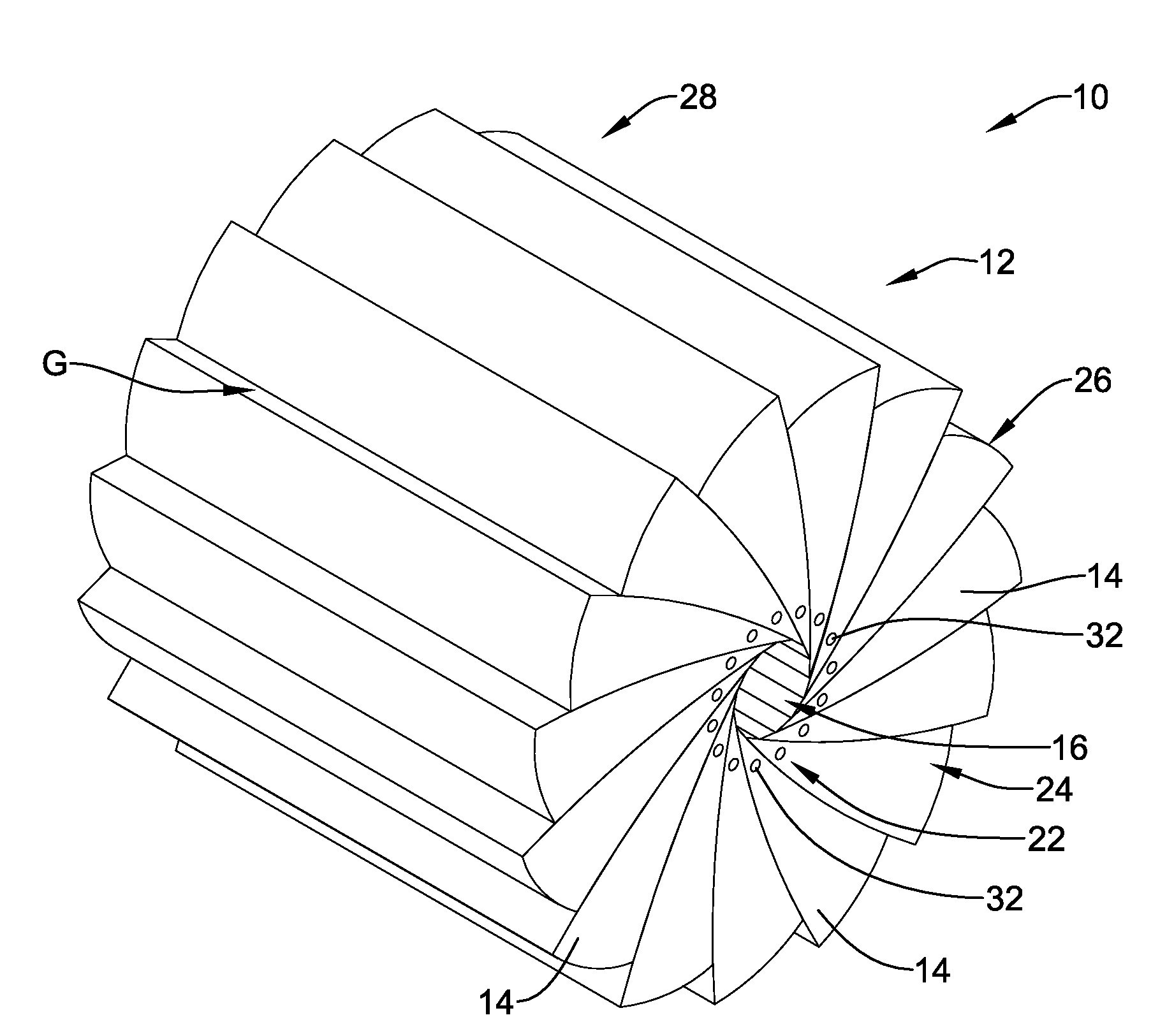

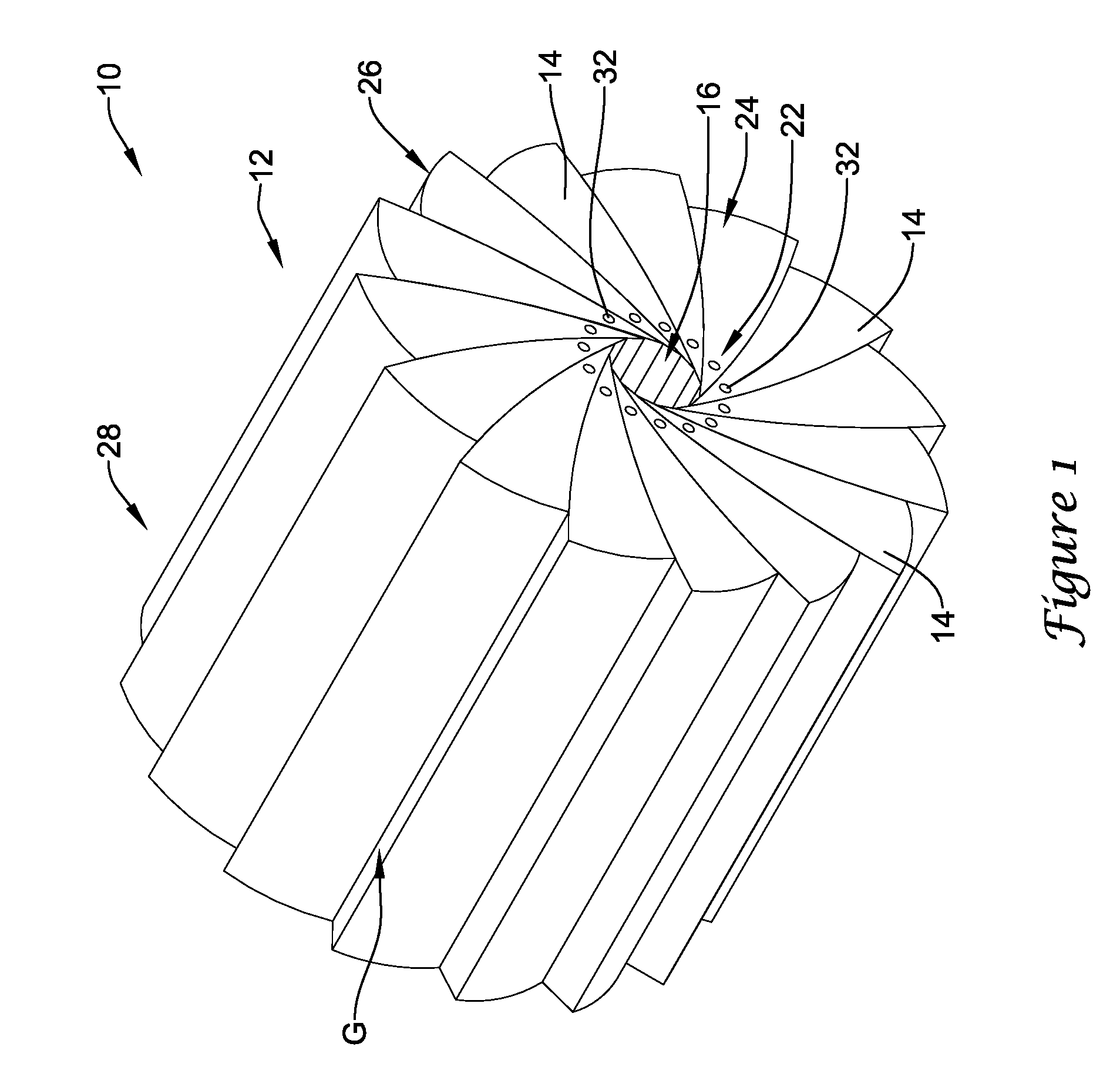

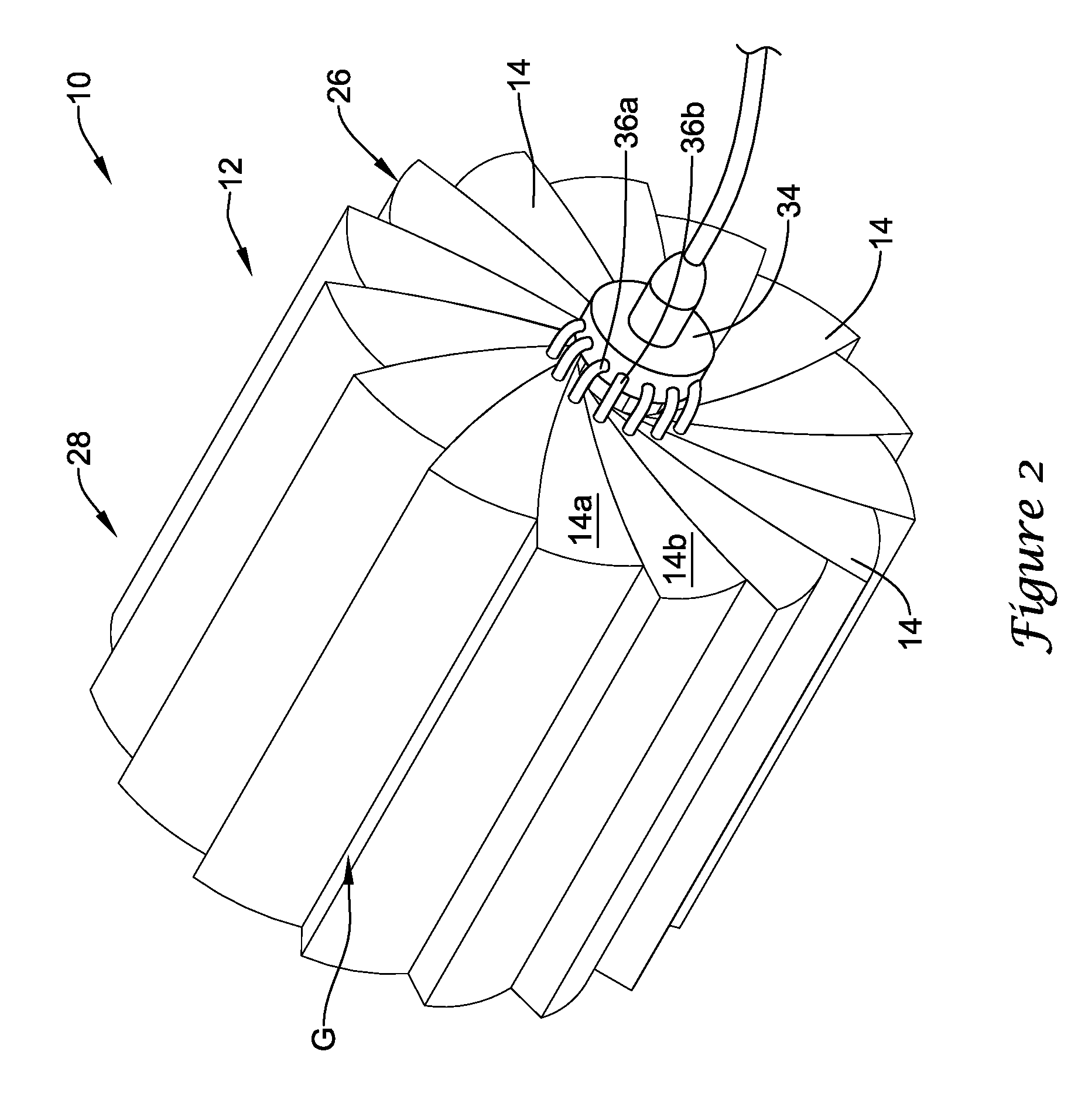

A stent crimping and coating apparatus is disclosed. The apparatus includes a plurality of crimping blades positioned in a radial array and collectively forming a central crimping lumen, wherein the plurality of crimping blades radially movable to alter the diameter of the central crimping lumen. Each of the crimping blades includes a first surface configured to at least in part define the central crimping lumen. One or more of the crimping blades includes a fluid channel extending therein and a plurality of openings in fluid communication with the fluid channel. The plurality of openings are located at the first surface of the one or more crimping blades and adapted to discharge a fluid into the central crimping lumen.

Owner:BOSTON SCI SCIMED INC

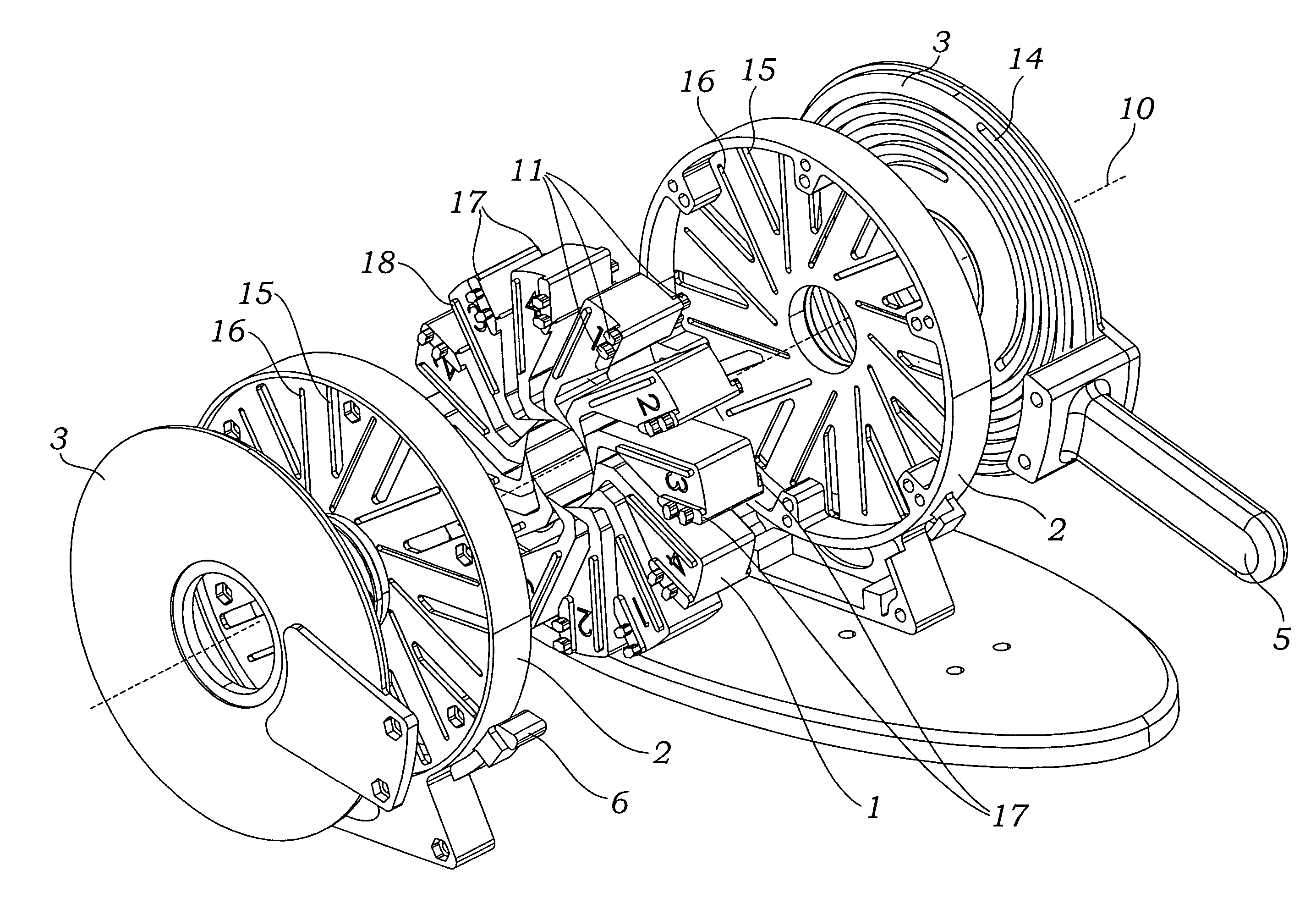

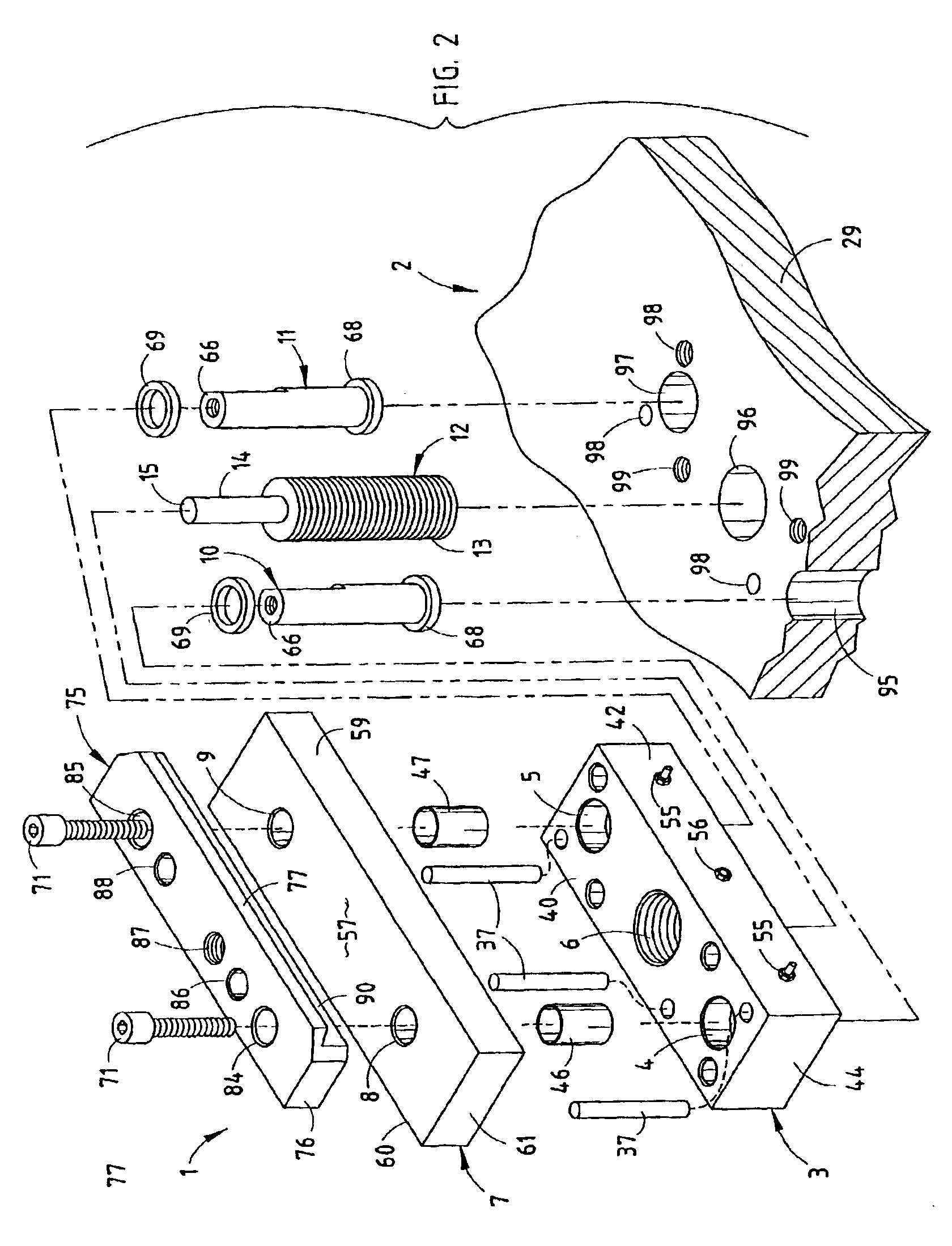

Assembly for crimping an intraluminal device and method of use

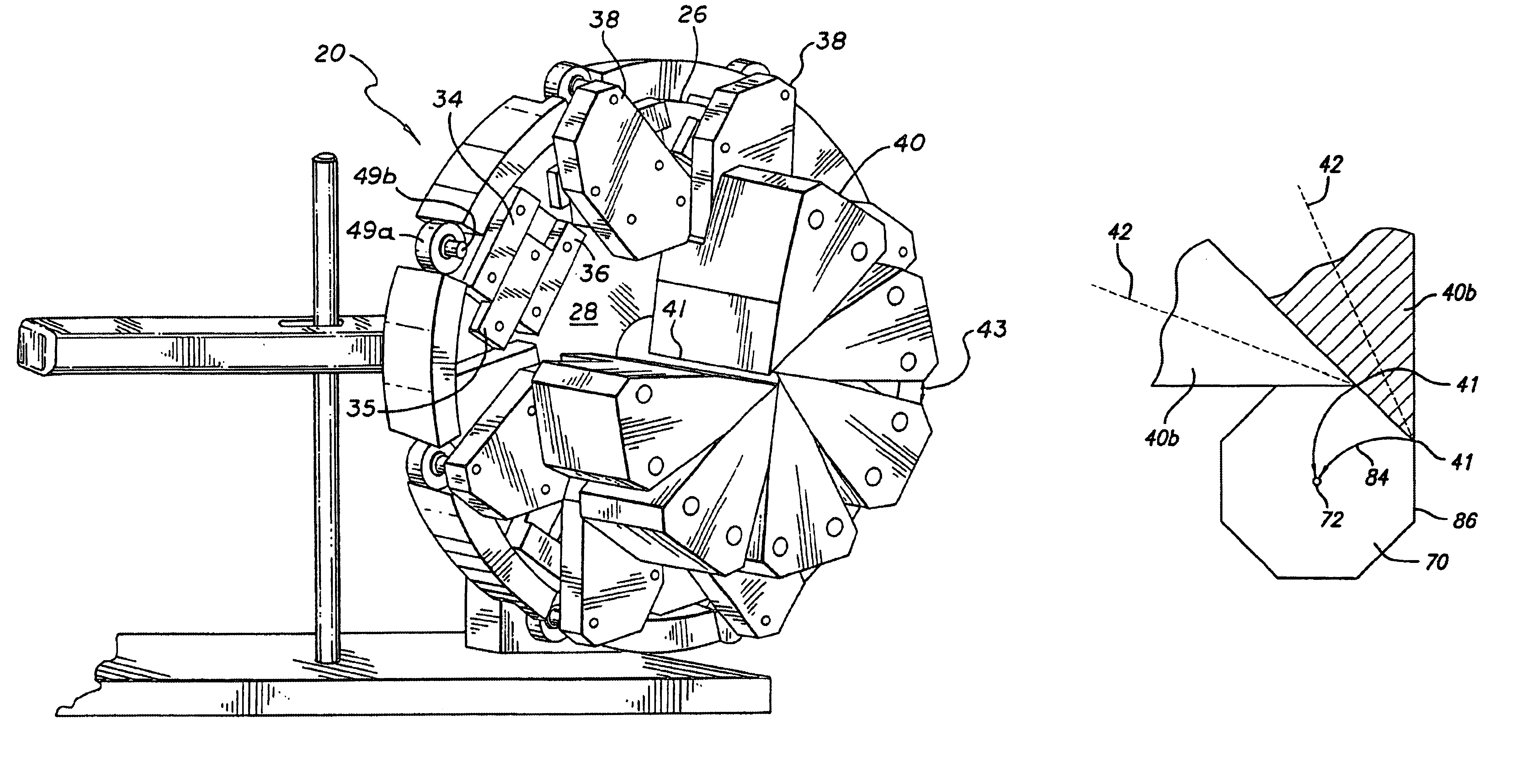

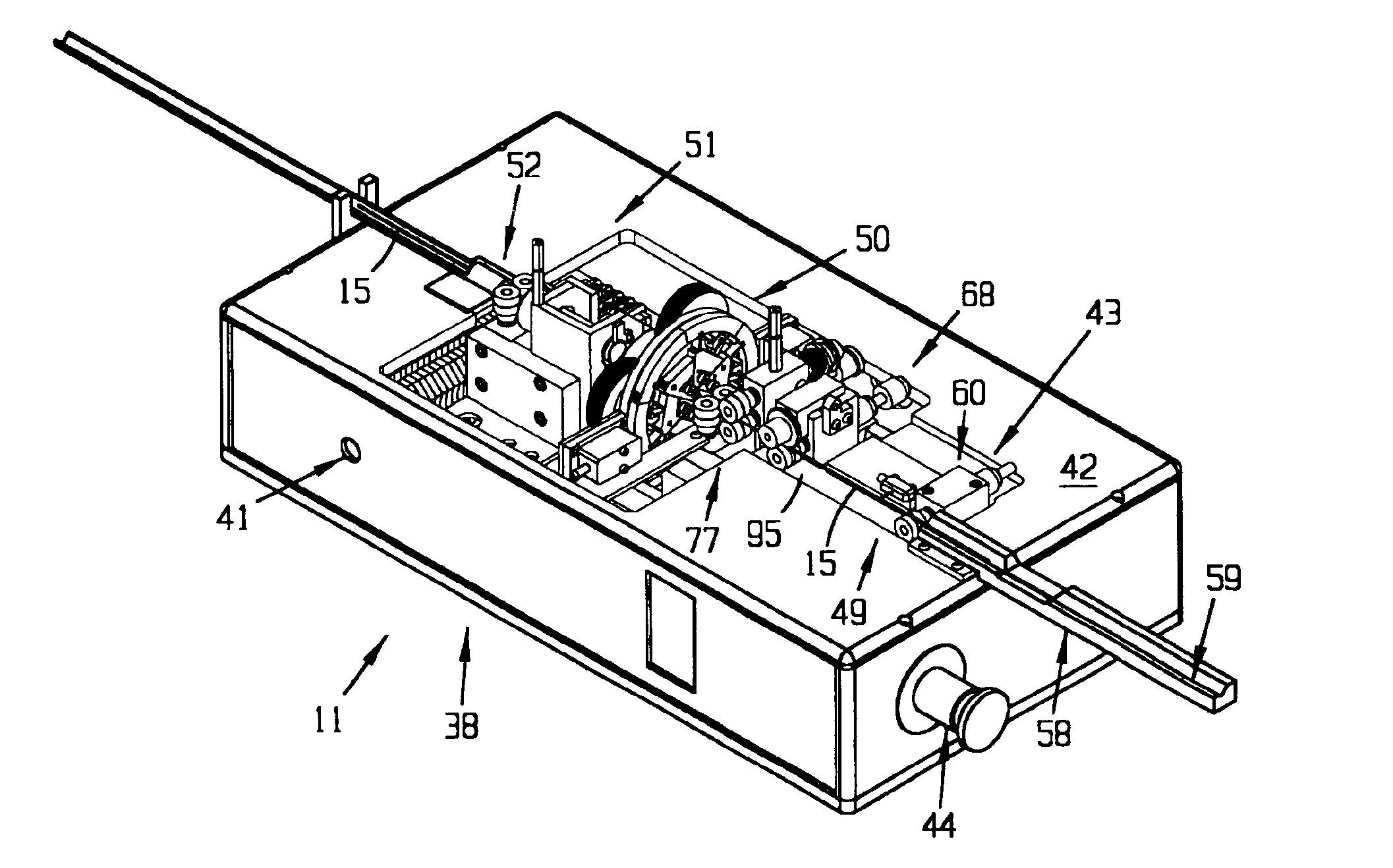

InactiveUS7152452B2Easy to useAccurate measurementStentsForging hammersEngineeringUltimate tensile strength

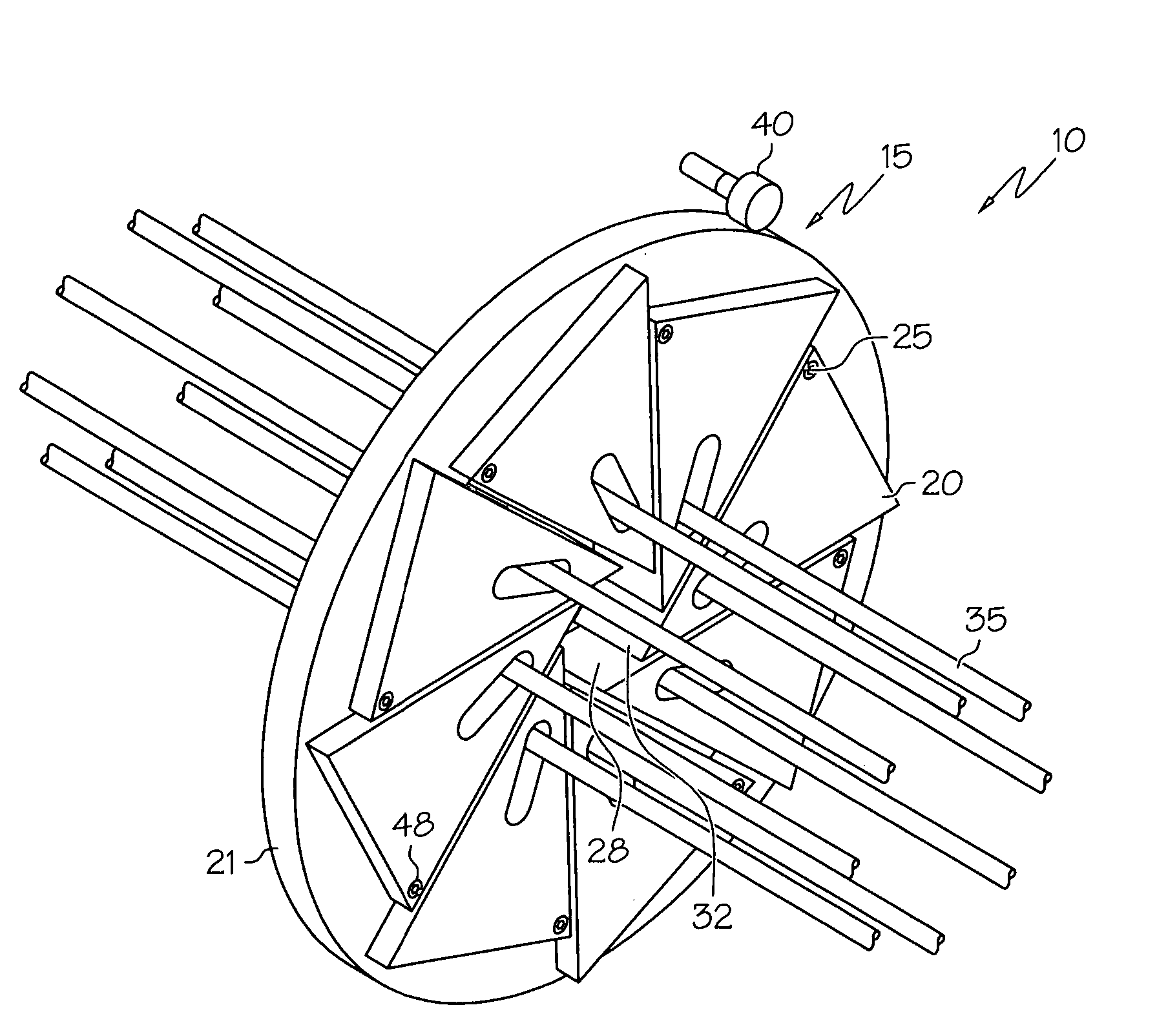

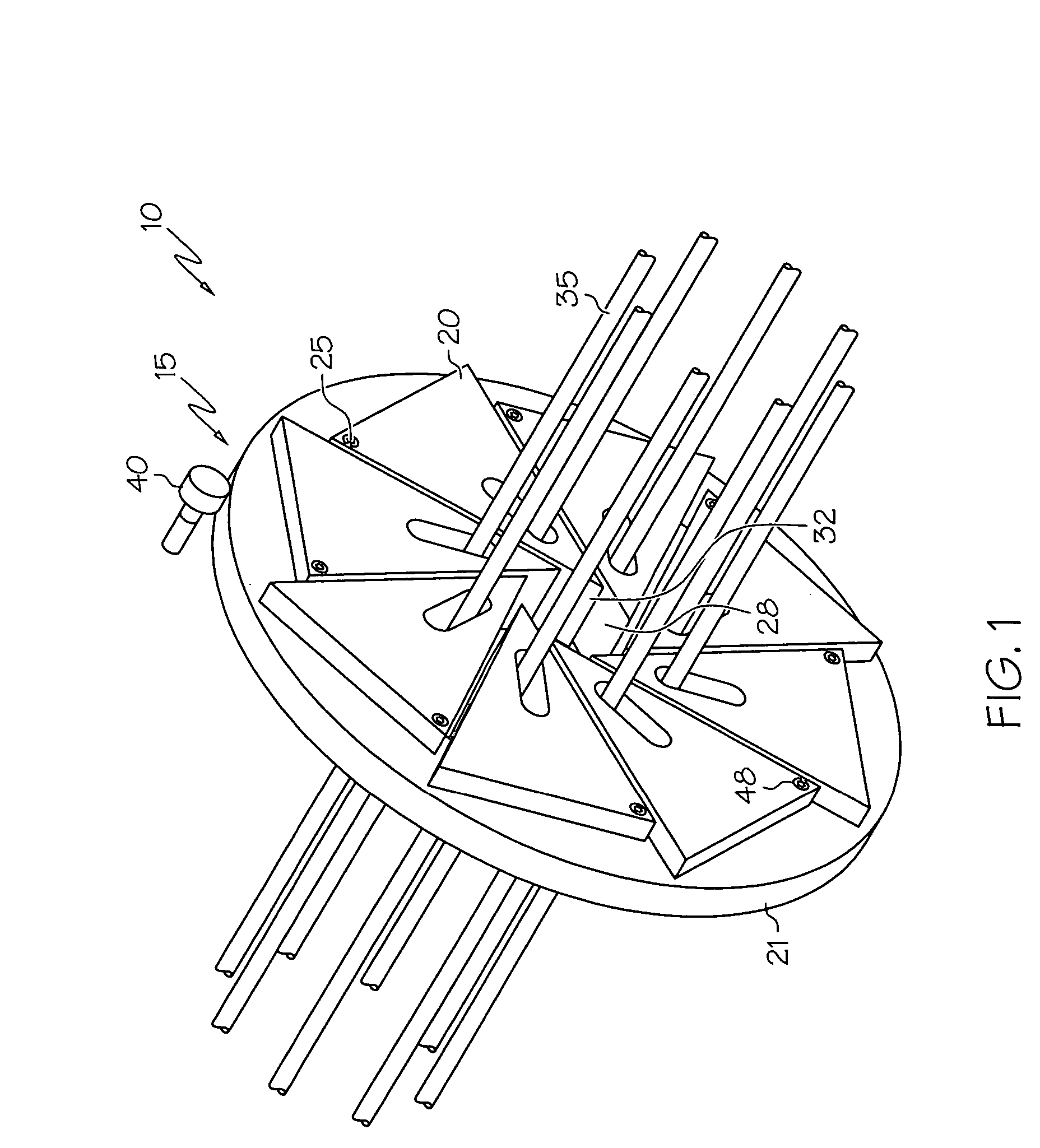

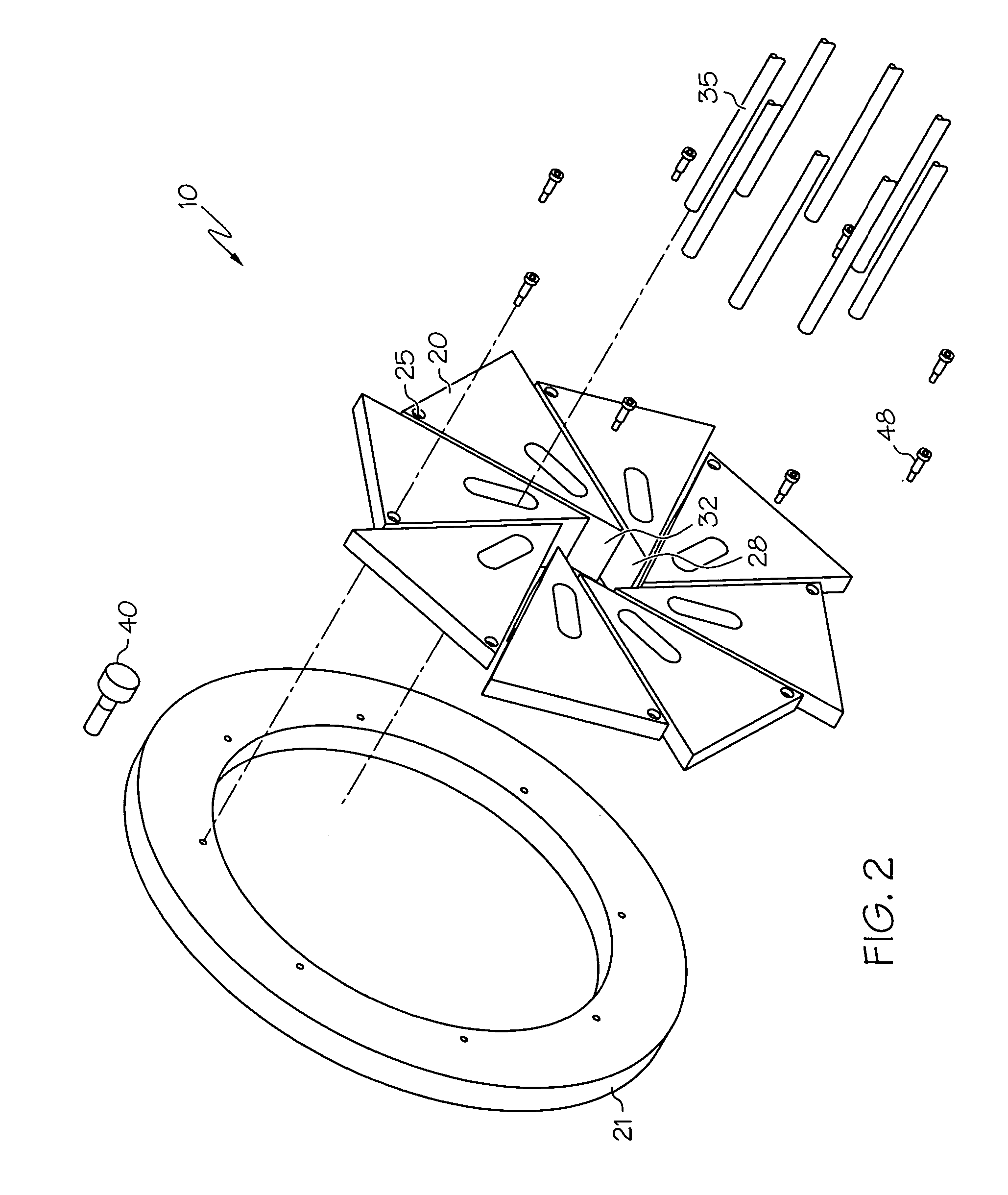

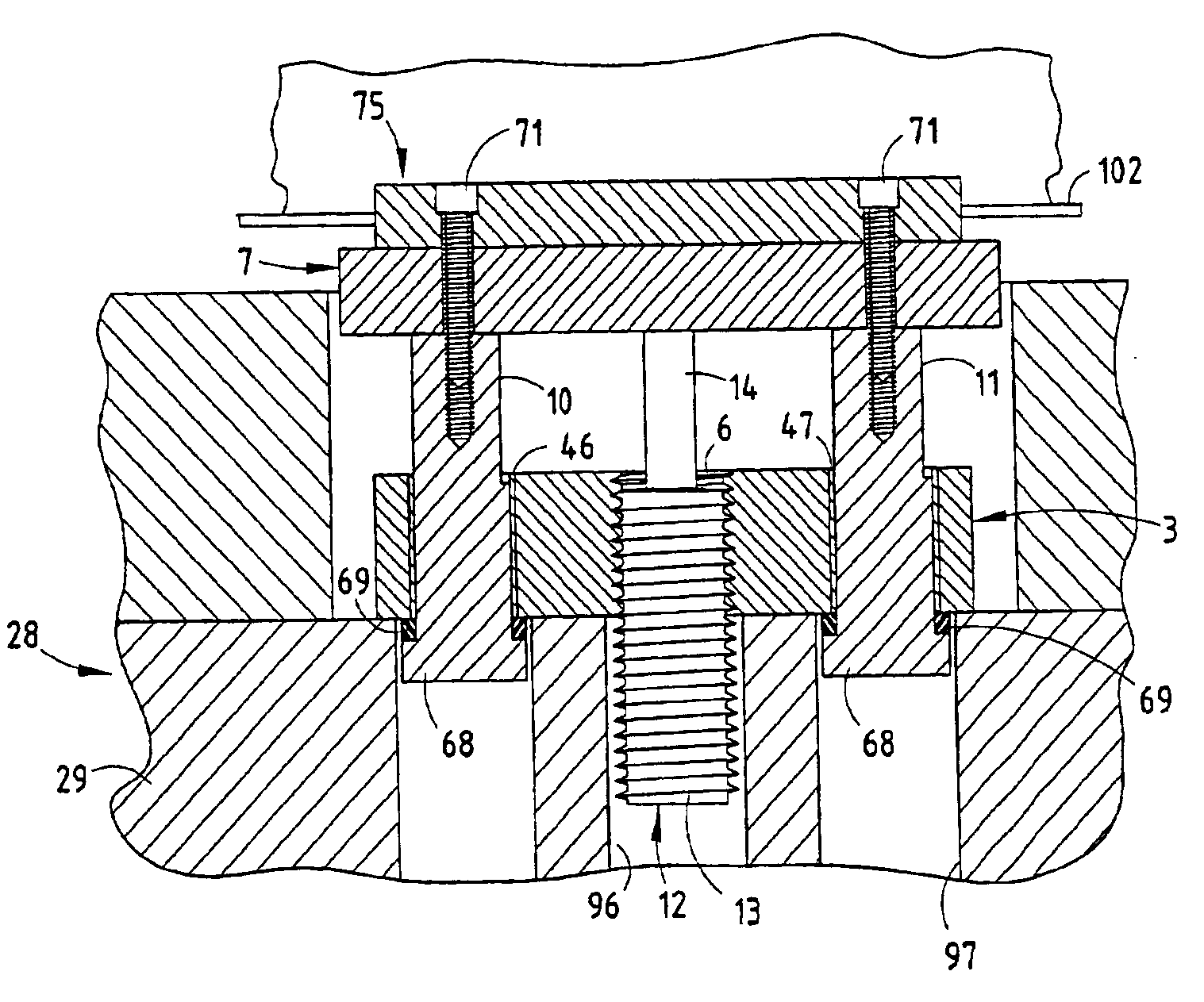

An assembly is provided which can crimp or compress an intraluminal device or measure the radial strength of an intraluminal device. The crimping assembly includes at least two moving-element subassemblies, each with a pair of moving elements. The moving elements having a first side and a second side joining at a tip. The moving-element subassembly is able to move in such a way that the moving elements move relative to each other from a first position with the tips offset from each other by a first distance, to a second position with the tips offset from each other by a second distance different than the first distance. The assembly also includes a movement assembly that interfaces with each of the moving-element subassemblies. The movement assembly moves the pairs of moving elements between the first position and the second position.

Owner:ABBOTT CARDIOVASCULAR

Protective loading of stents

A system for protecting a stent from contact during loading comprises a stent a protective sleeve disposed about the stent and a loading tool. The inner diameter of the protective sleeve is greater than the outer diameter of the stent. The protective sleeve has a length longer than that of the stent. The portion of the sleeve extending beyond the length of the stent defines a sleeve extension. The loading tool is positioned about at the stent retaining sleeve of a catheter. The tip region of the loading tool separates the protective sleeve and the stent from one another when the protective sleeve is pulled over the tip region of the loading tool. When the protective sleeve is pulled over the tip region of the loading tool the stent is advanced into a lumen defined by the stent retaining sleeve of the catheter.

Owner:BOSTON SCI SCIMED INC

Methods for abluminally coating medical devices

A stent crimping and coating apparatus is disclosed. The apparatus includes a plurality of crimping blades positioned in a radial array and collectively forming a central crimping lumen, wherein the plurality of crimping blades radially movable to alter the diameter of the central crimping lumen. Each of the crimping blades includes a first surface configured to at least in part define the central crimping lumen. One or more of the crimping blades includes a fluid channel extending therein and a plurality of openings in fluid communication with the fluid channel. The plurality of openings are located at the first surface of the one or more crimping blades and adapted to discharge a fluid into the central crimping lumen.

Owner:BOSTON SCI SCIMED INC

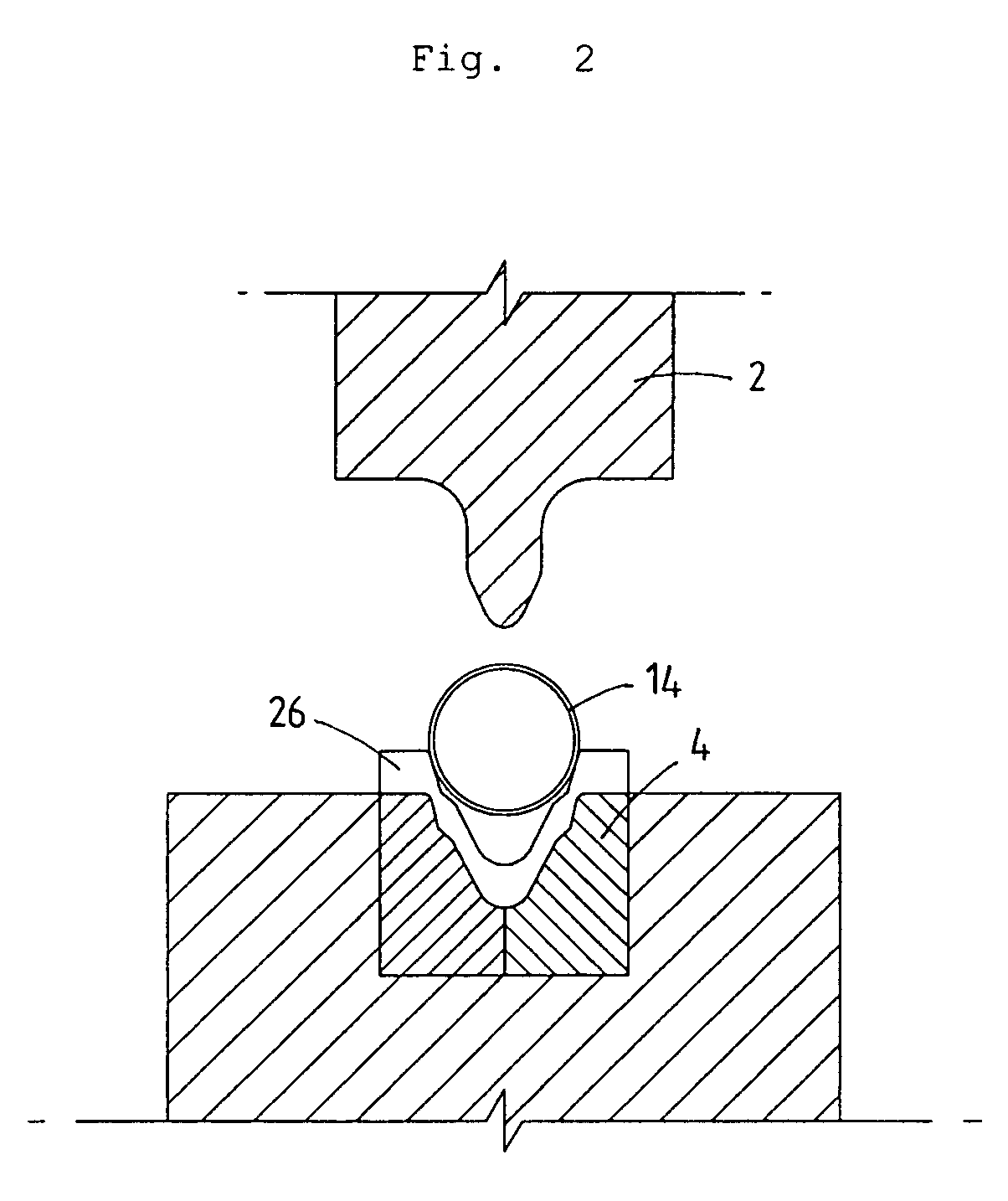

Apparatus for contracting, loading or crimping self-expanding and balloon expandable stent devices

InactiveUS6915560B2Minimizing distortion of and scoringReduce the overall diameterStentsAutomatic control devicesEngineeringKnife blades

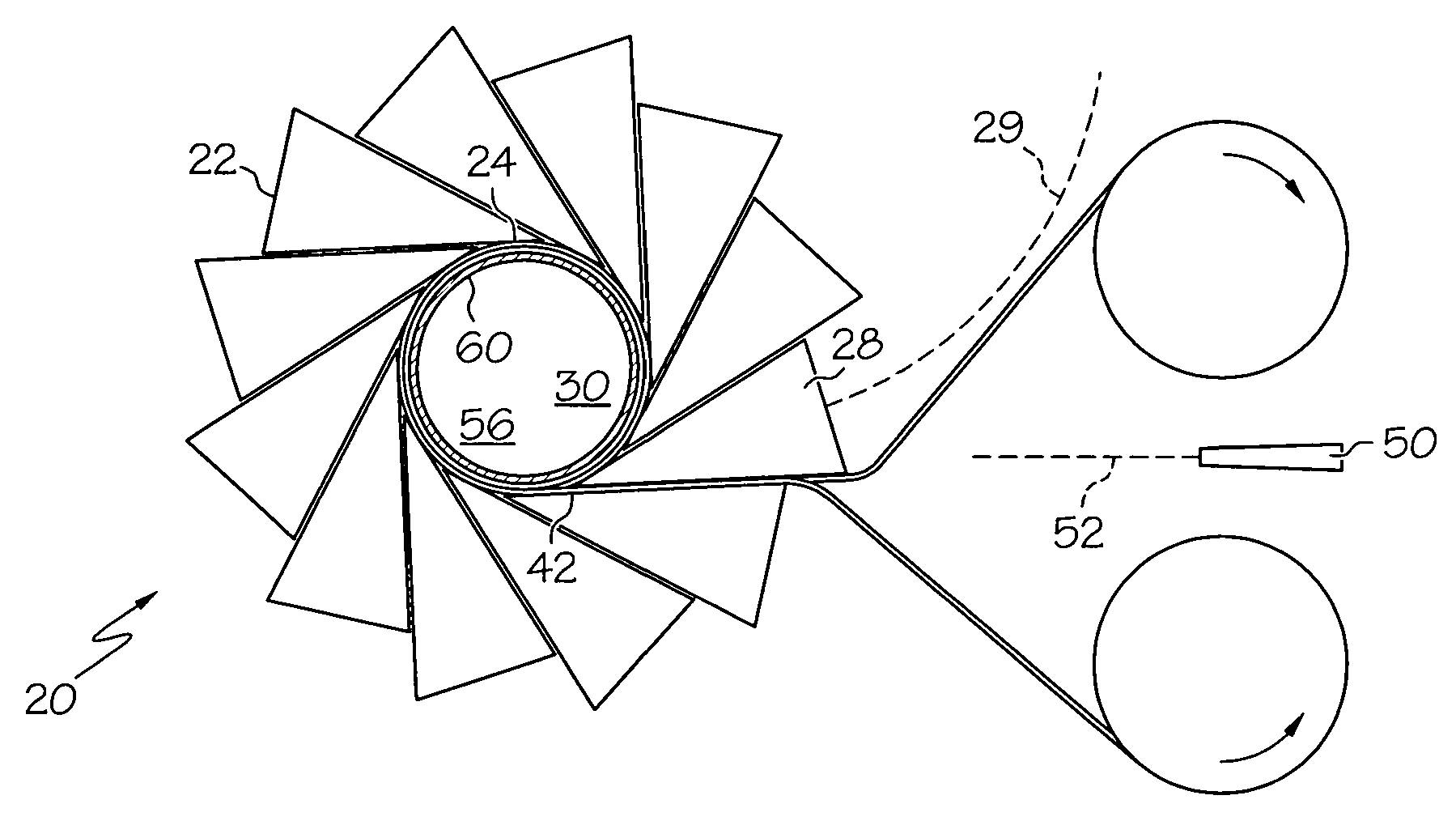

An apparatus for manipulating a medical device is formed of at least three coupled movable blades which are disposed about a reference circle to form an aperture whose size may be varied. The aperture capable of being sized to contain a medical device. Each blade is in communication with an actuation device which is capable of moving the blade to alter the size of the aperture. Each blade includes a single radial point which a) lies on the circumference of the reference circle prior to movement of the blade, and b) may be moved only along a radius of the reference circle on movement of the blade.

Owner:BOSTON SCI SCIMED INC +2

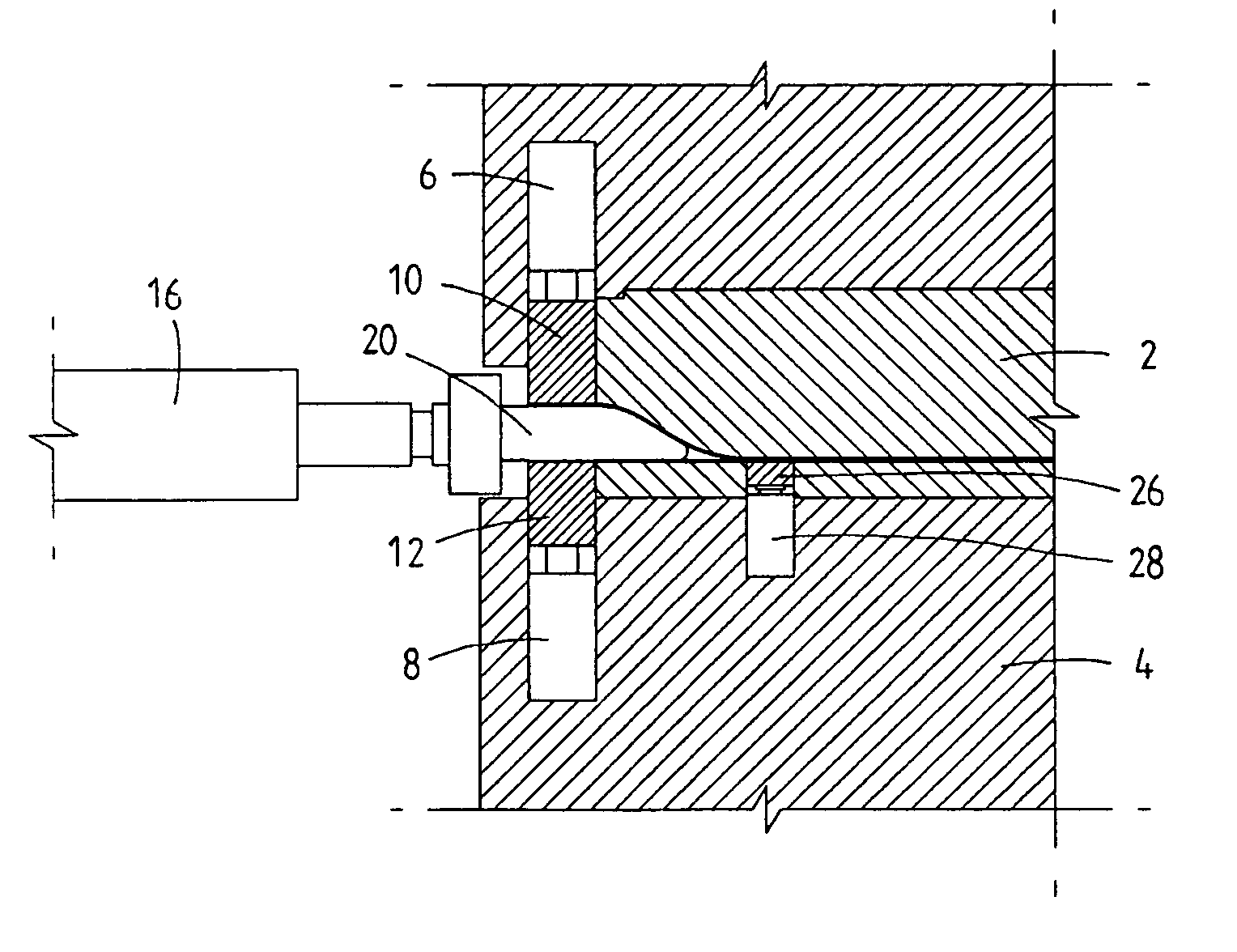

Hemming method and apparatus

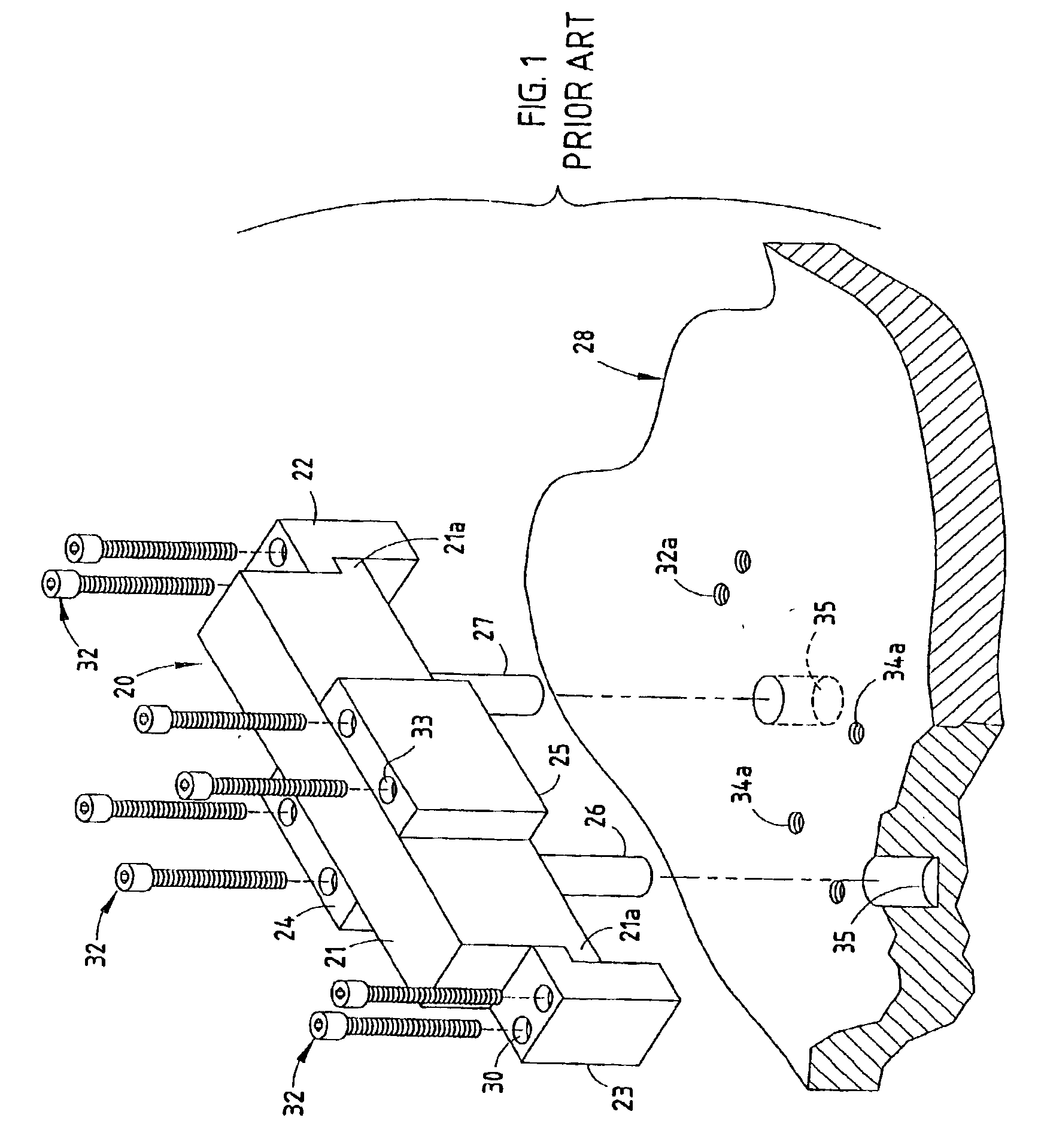

InactiveUS6029334AImprove appearance qualityEliminate the problemForging hammersAssembly machinesEmbedmentRead through

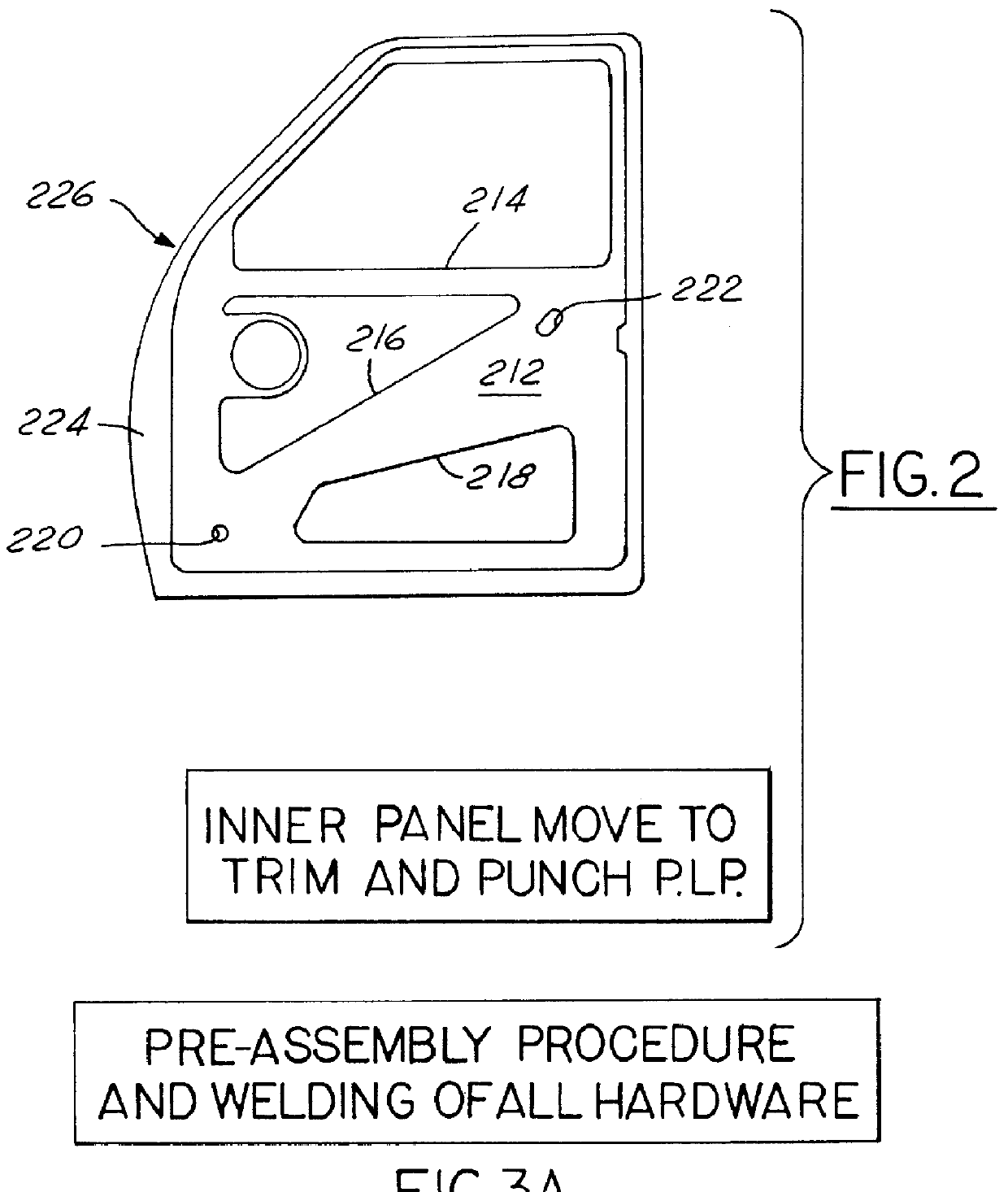

Improved method and apparatus for interlocking hemmed together edges of inner and outer vehicle body panels with an improved interlock joint. The inner panel blank is draw stamped and provided with PLP holes in a stamping press. A plurality of conventional hardware components are then welded to the inner panel. Then interlock holes are formed by a piercing tool moving through the inner panel border from its outboard to its inboard side while the inner panel is held by clamps and PLP pins. The hole piercing punch thus leaves cold worked upset material slightly raised inboard, rather than outboard, around the pierced interlock hole margin. Then the inner panel subassembly is married to the outer panel and transferred to a hemming station and again precisely clamped and positioned by PLP pins, whereupon hemming press gates are operable for hemming the flange lip of the outer panel over the inner panel border. The final hemming steel of each gate carries staking punches that individually strike a precision registered portion of such hemmed lip to deform it into locking engagement with the associated interlock hole. The upset material is thus flattened and accurately worked into embedment into the interior surface of the hemmed flange lip, rather than into the interior surface of the outer panel, thereby avoiding creating read through problems on the outer panel.

Owner:UNOVA IP

Stent crimper

An apparatus for applying an inward force to a medical device may include at least two independently operable sections. Each section may include a plurality of movable blades arranged to form an aperture or chamber whose size may be varied. Each blade may be pivotally connected to a mount and slidably engaged with a constraining member. The blades are movable so as to allow the aperture to be sized to contain the medical device and to alter the size of the aperture.

Owner:BOSTON SCI SCIMED INC

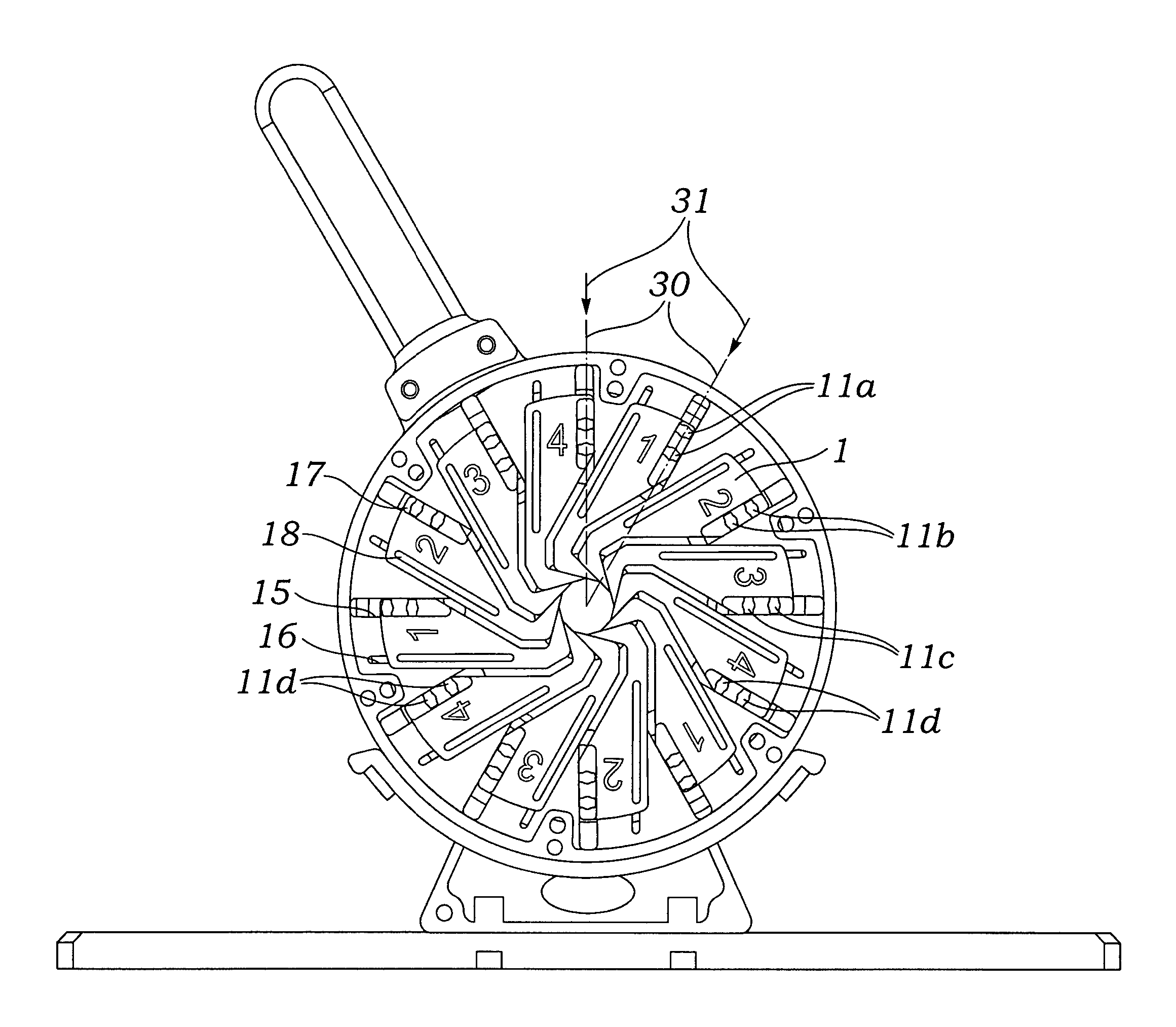

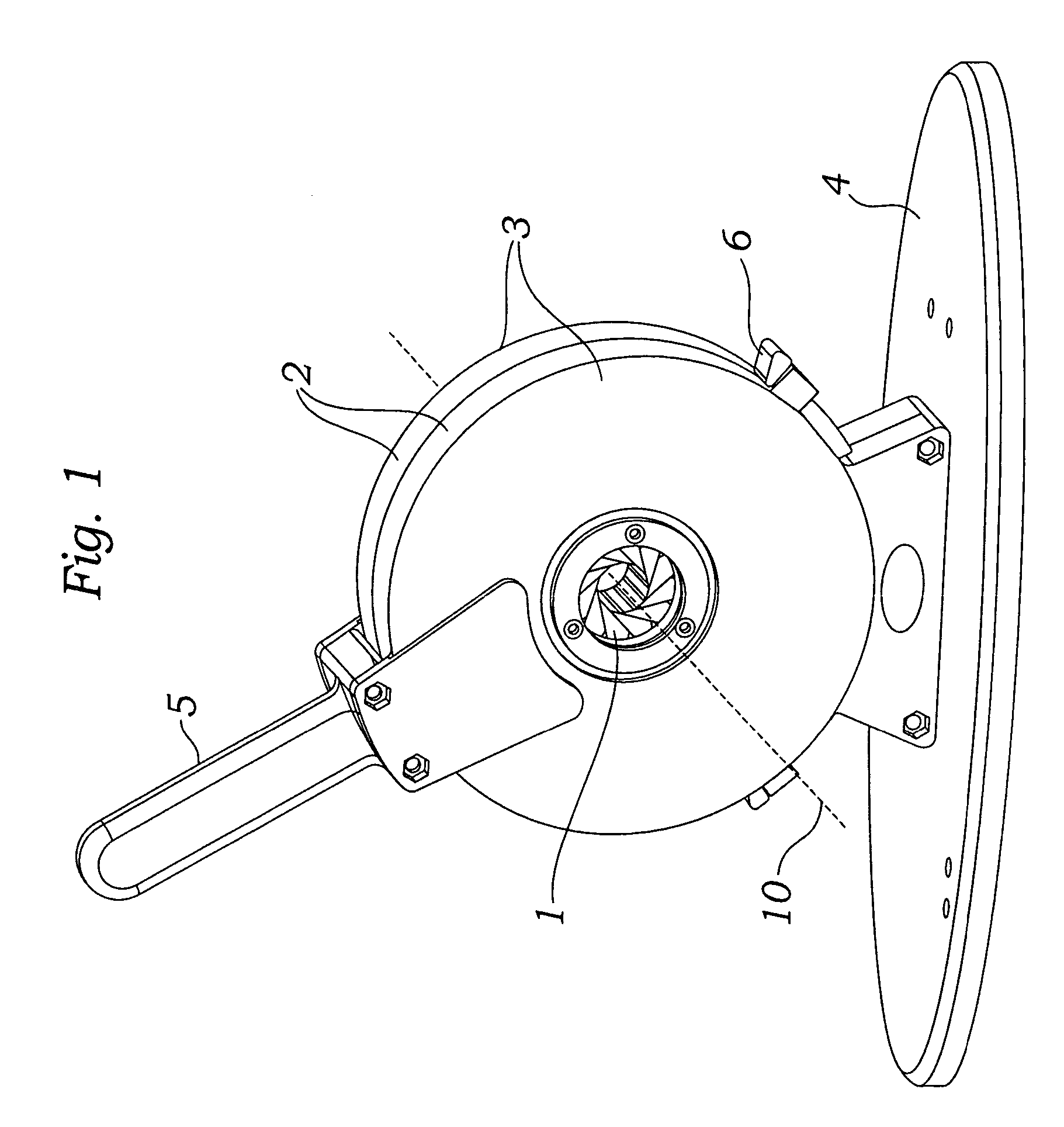

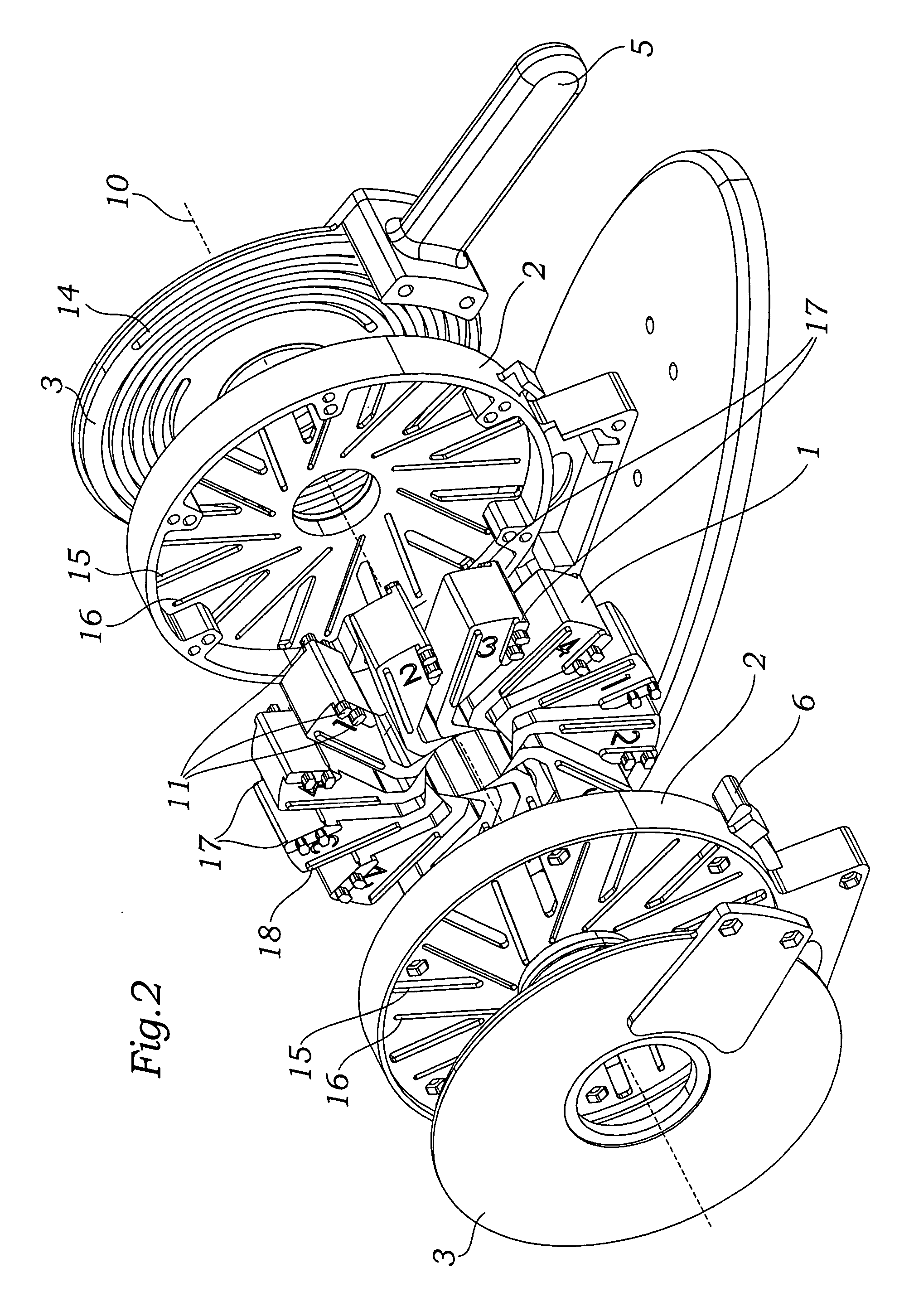

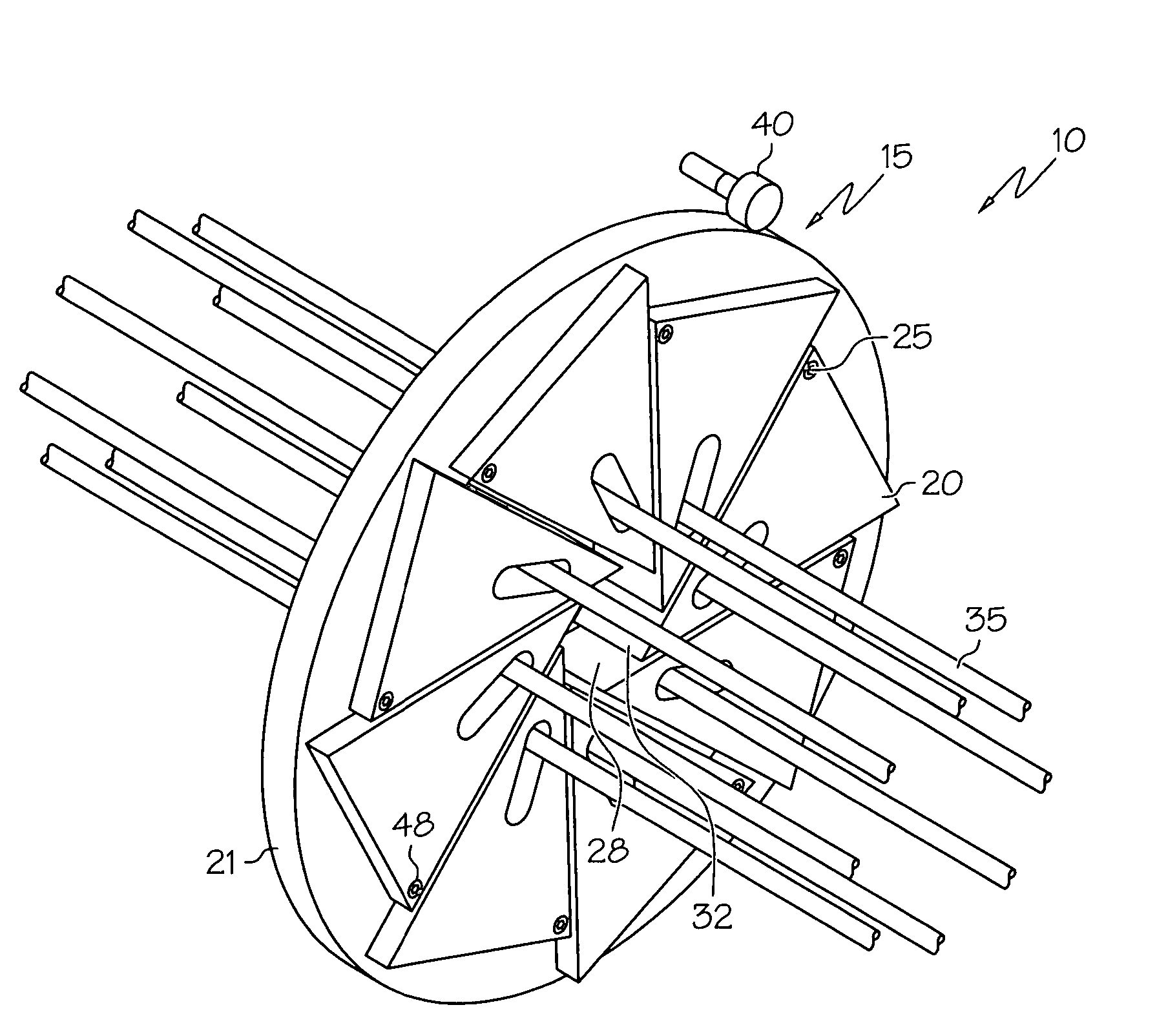

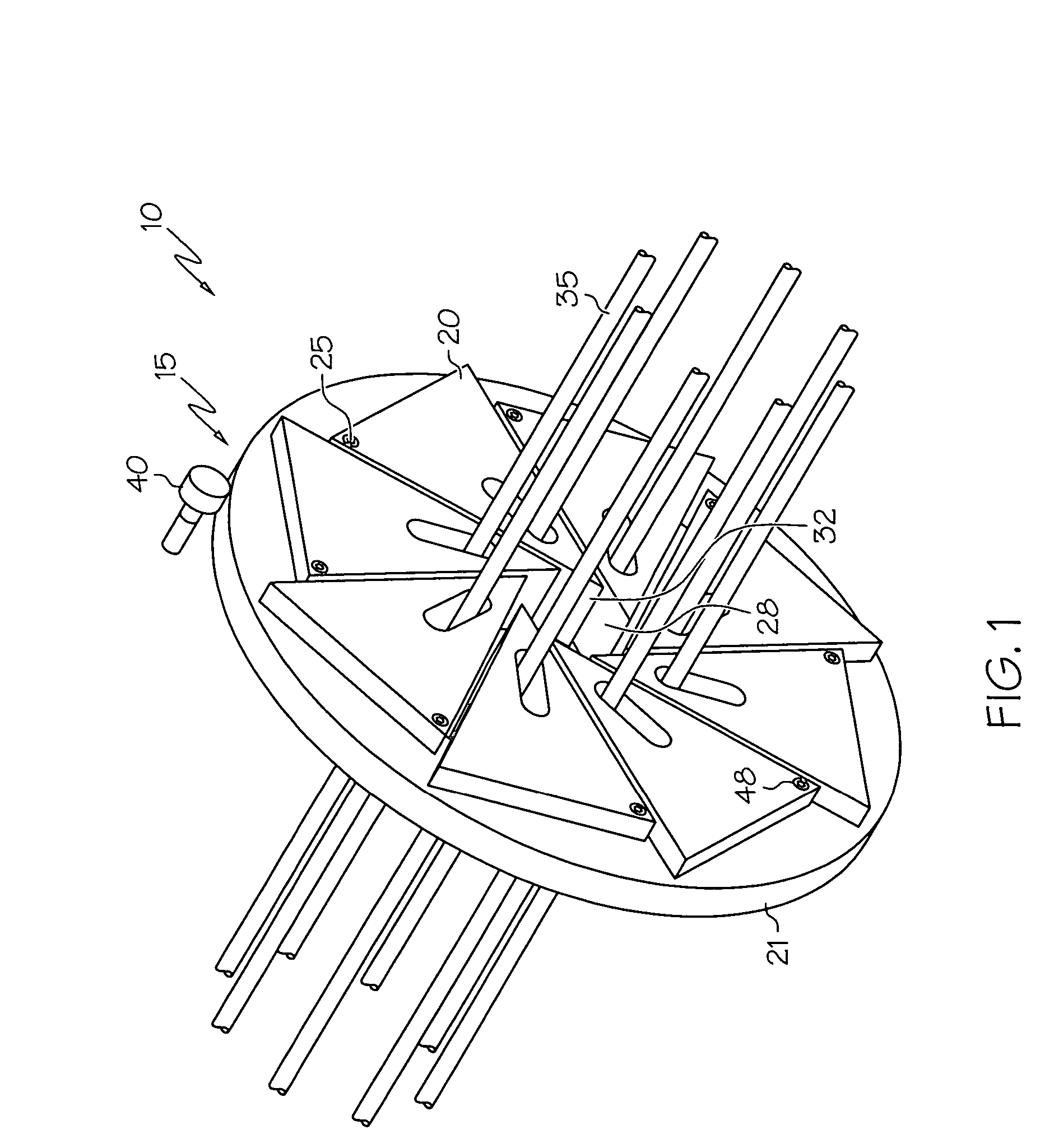

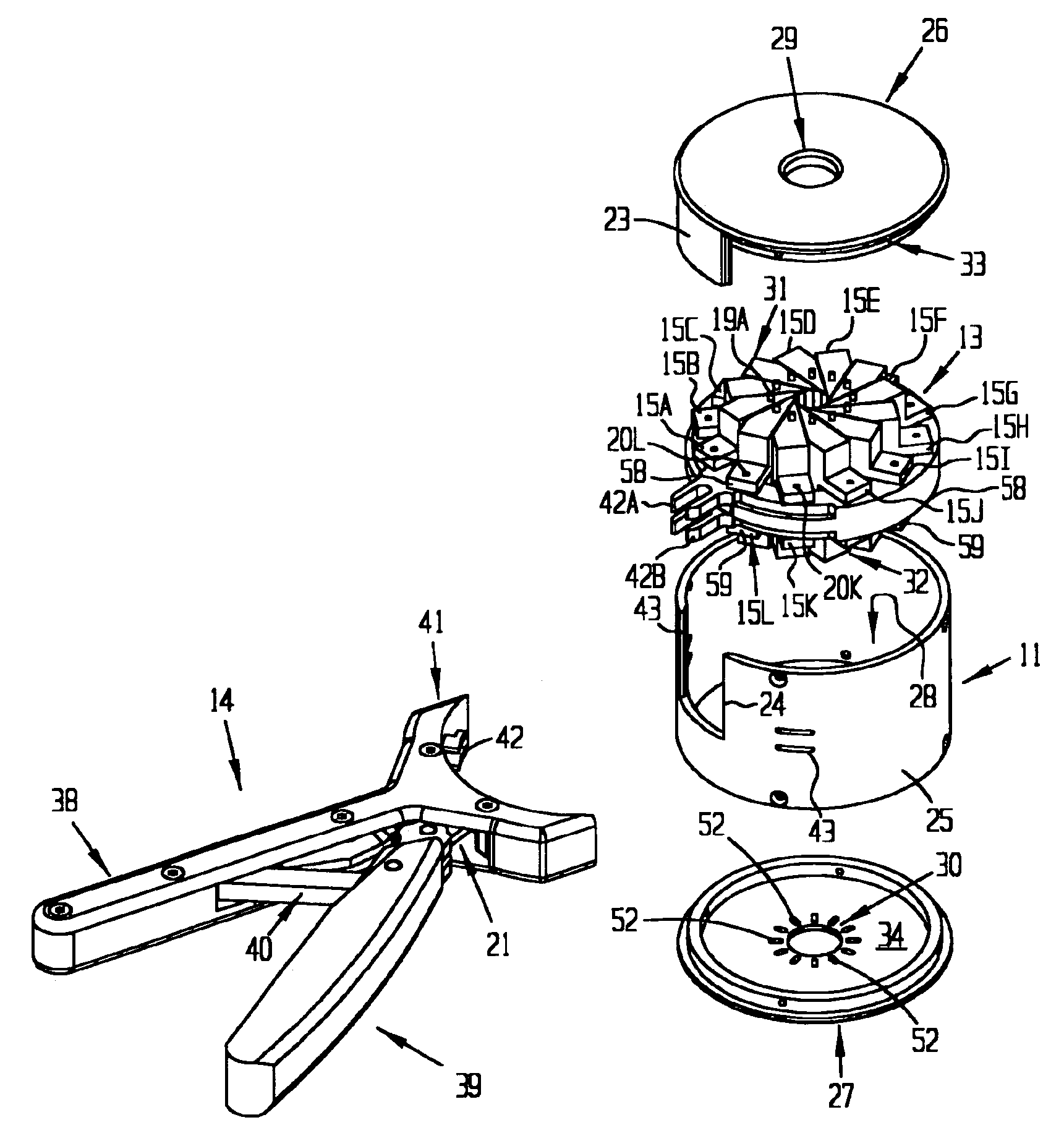

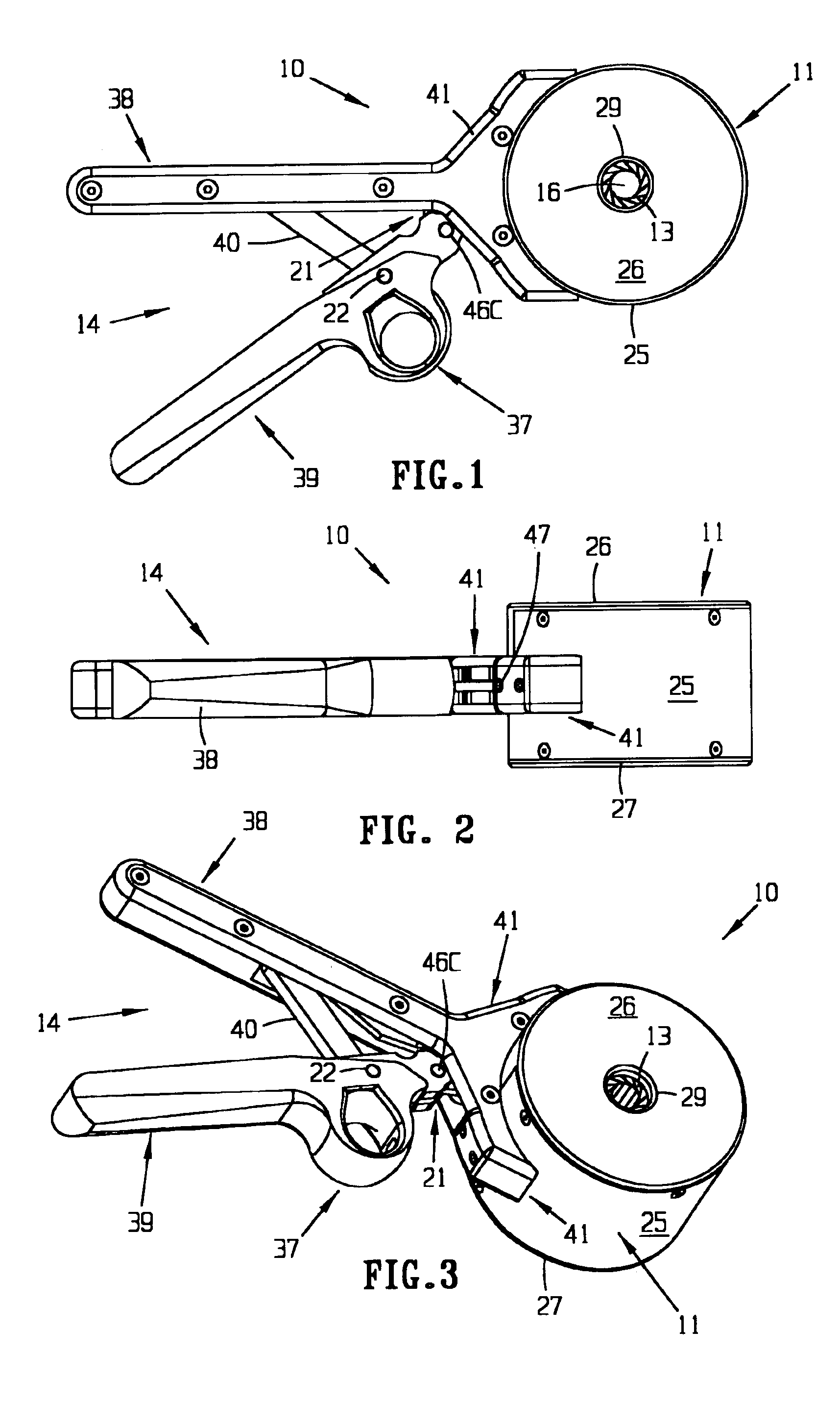

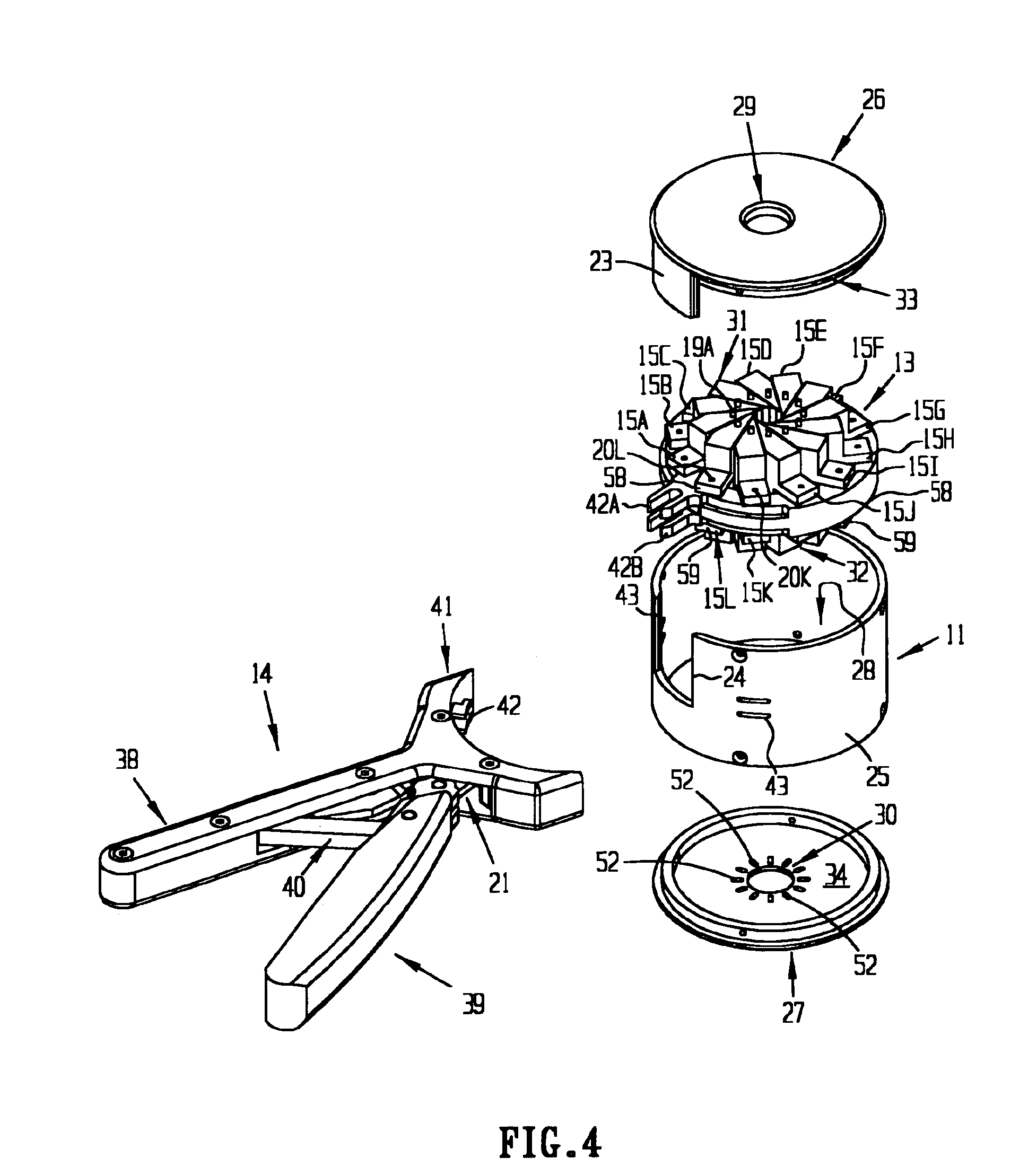

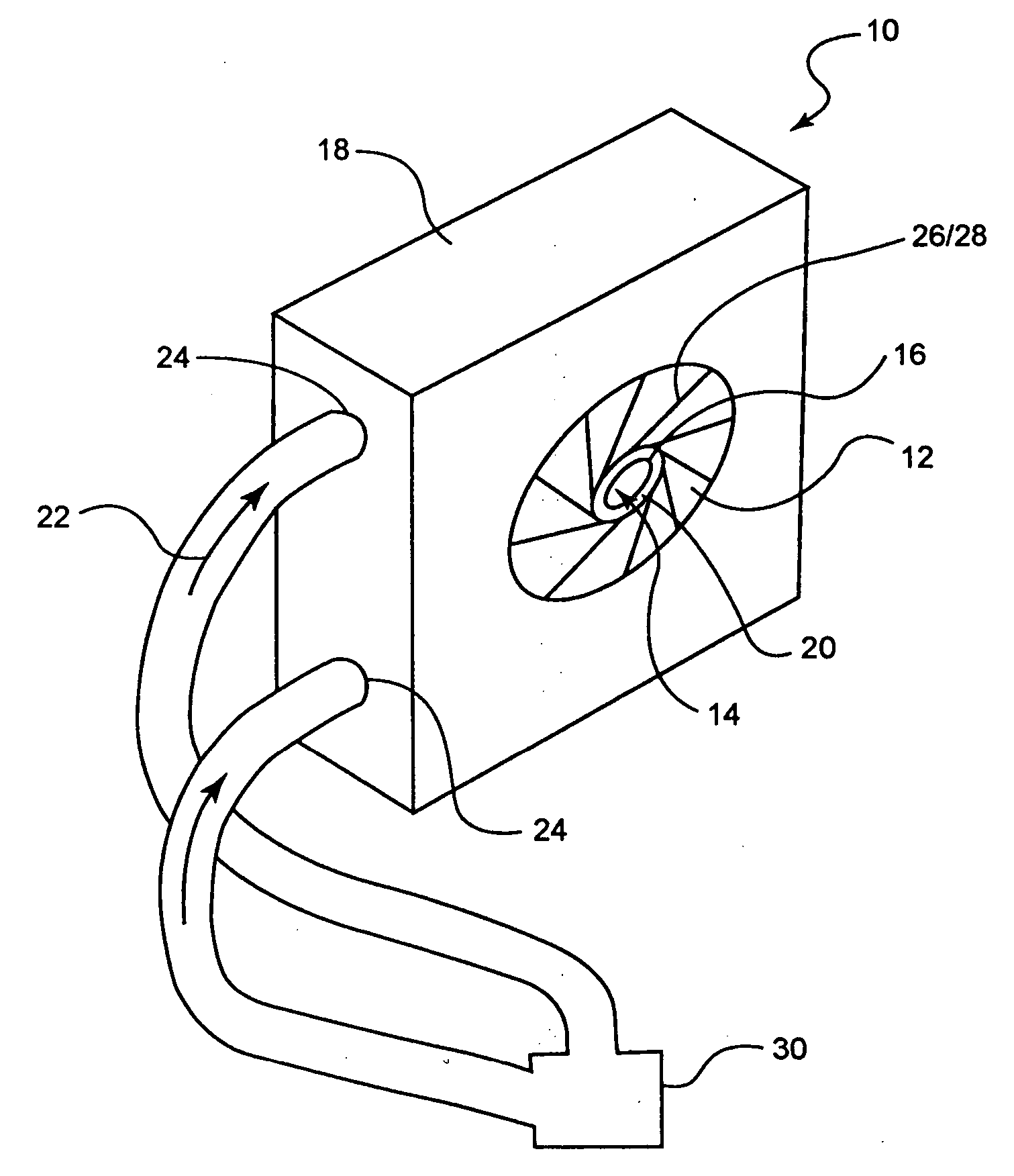

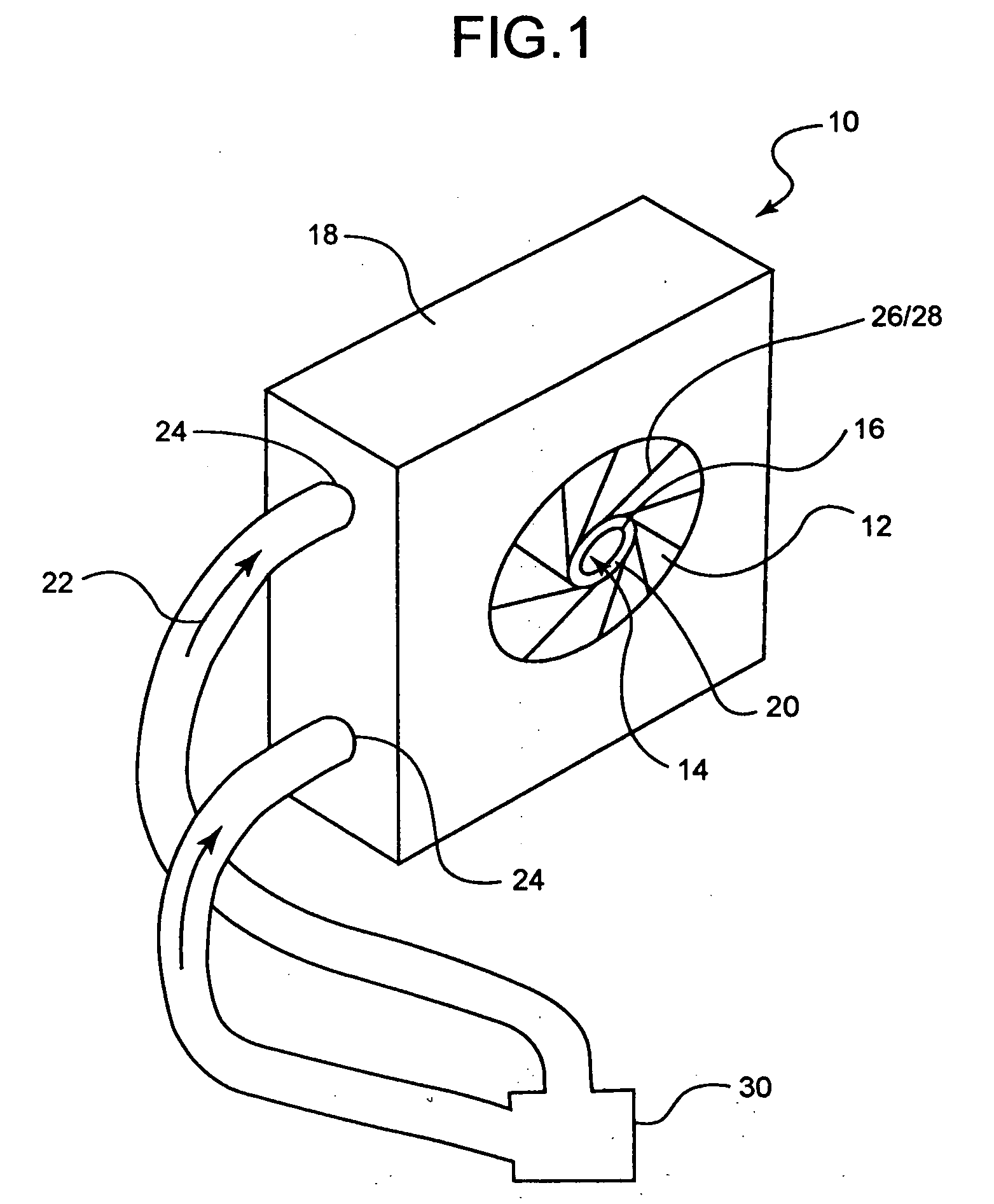

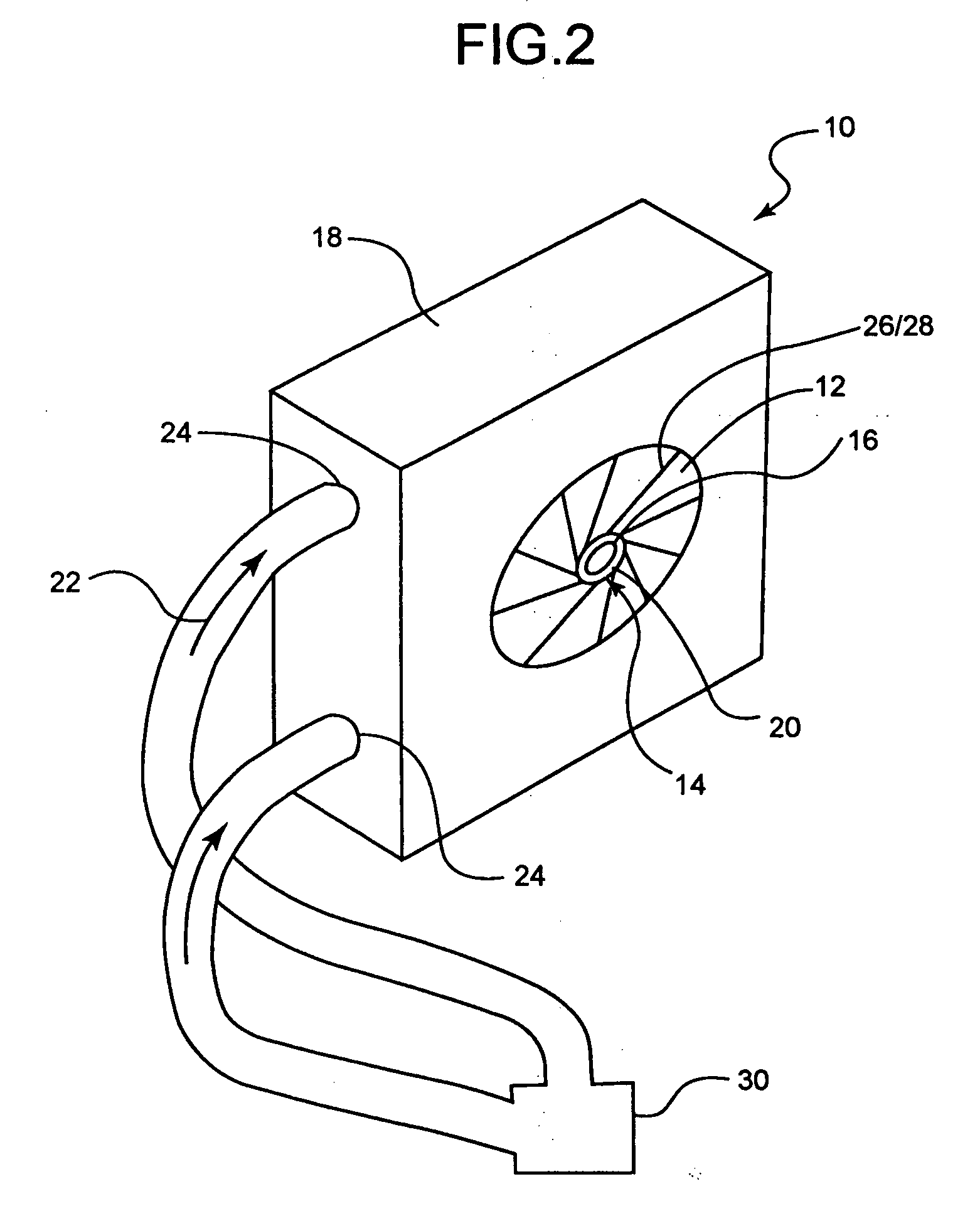

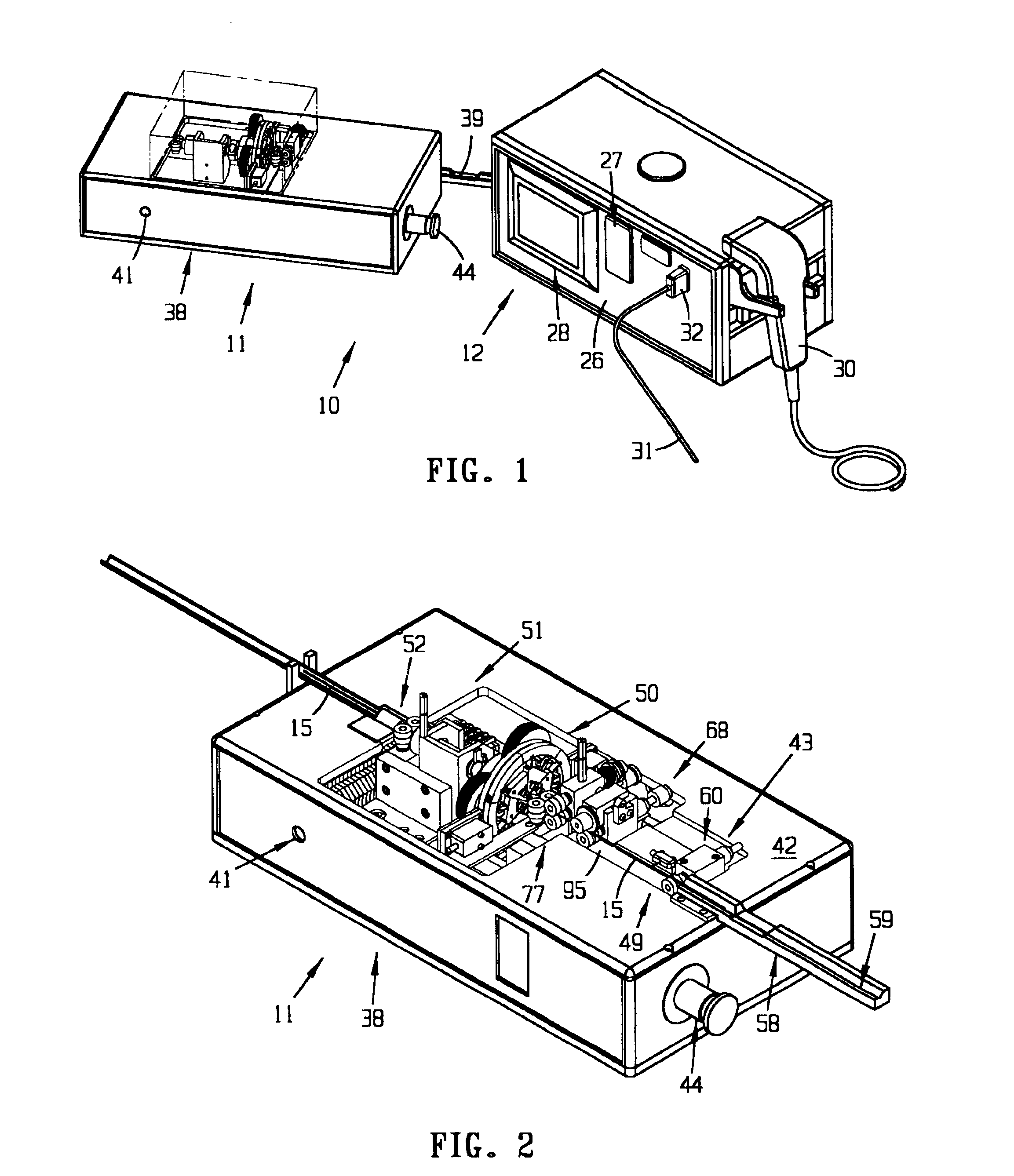

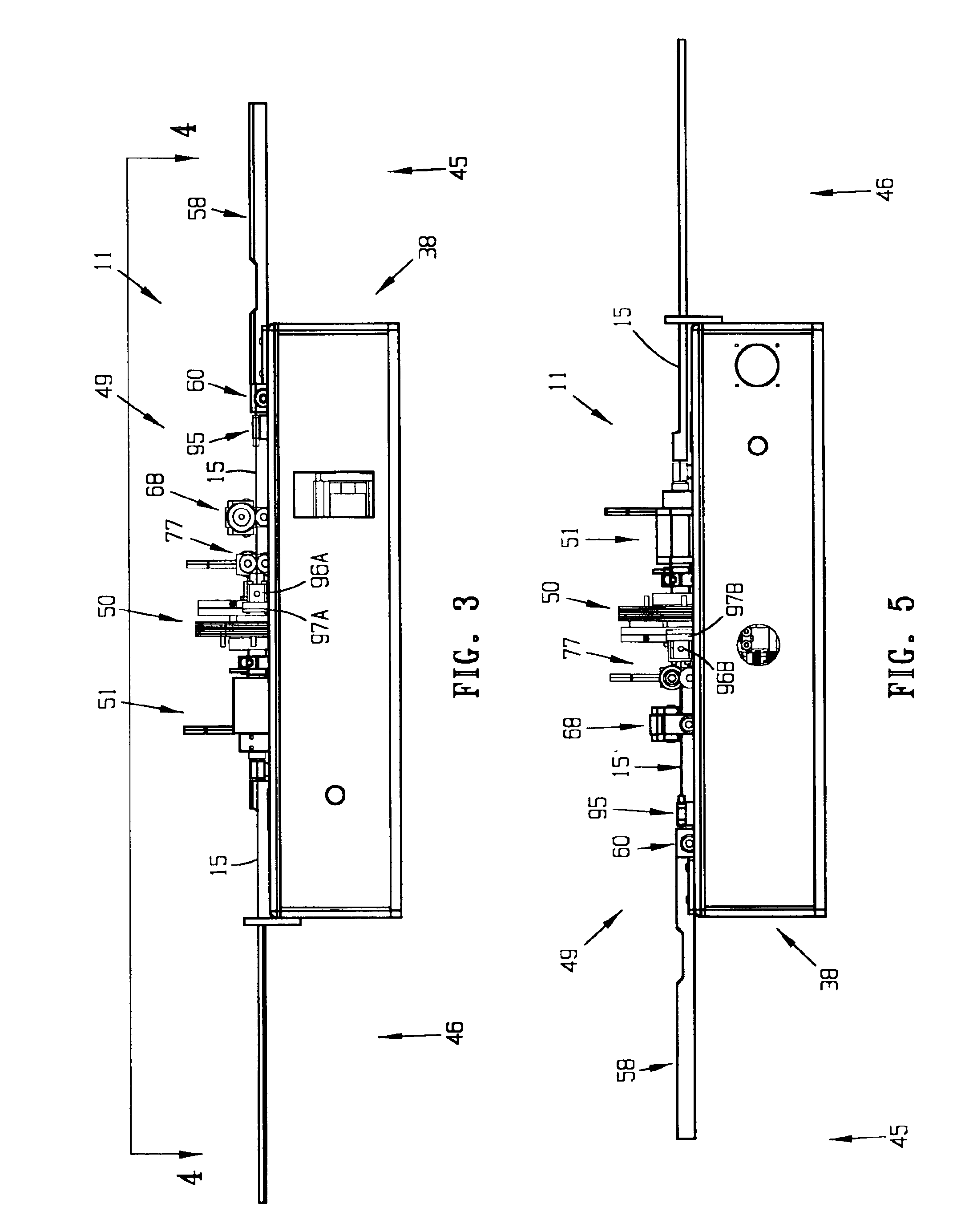

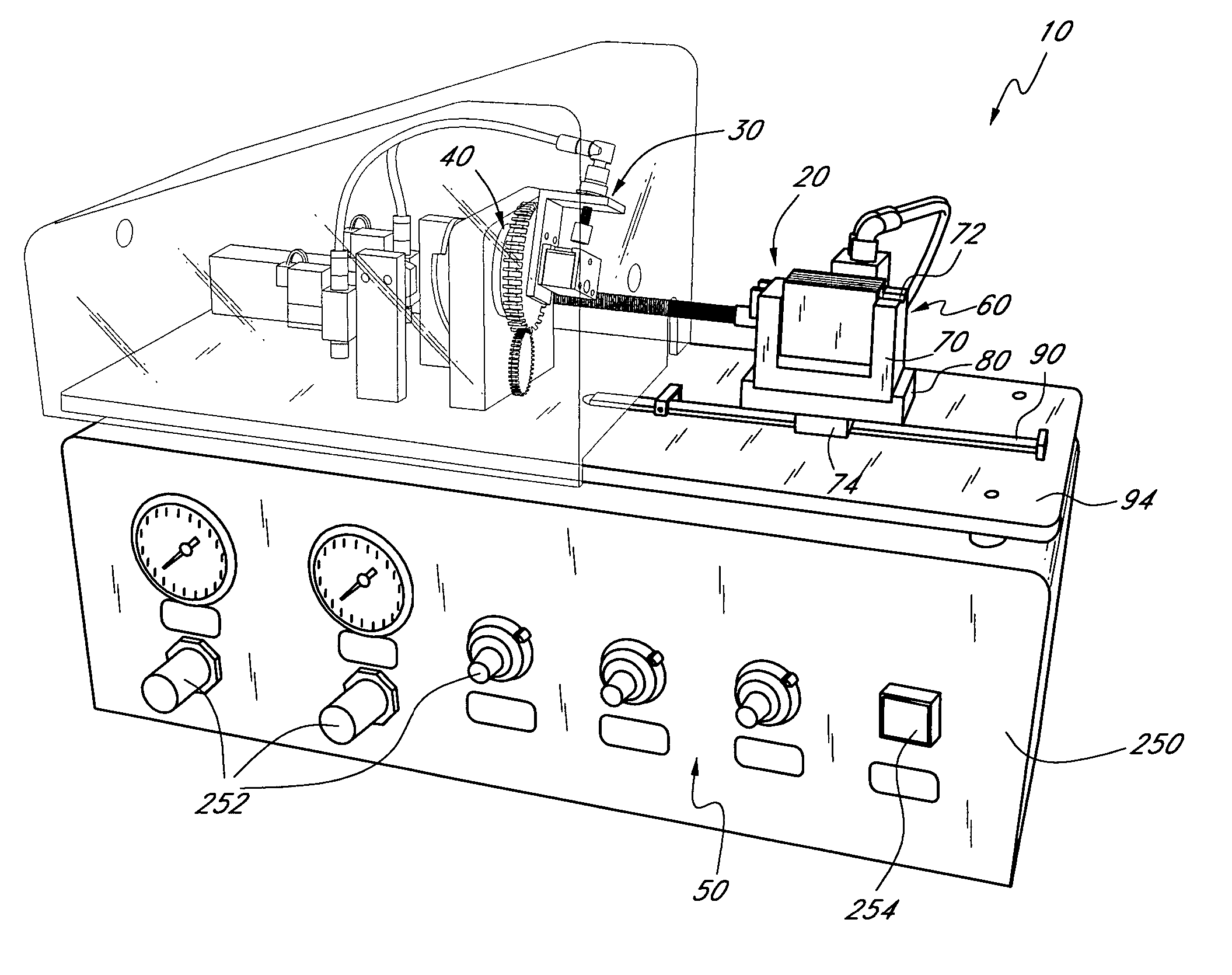

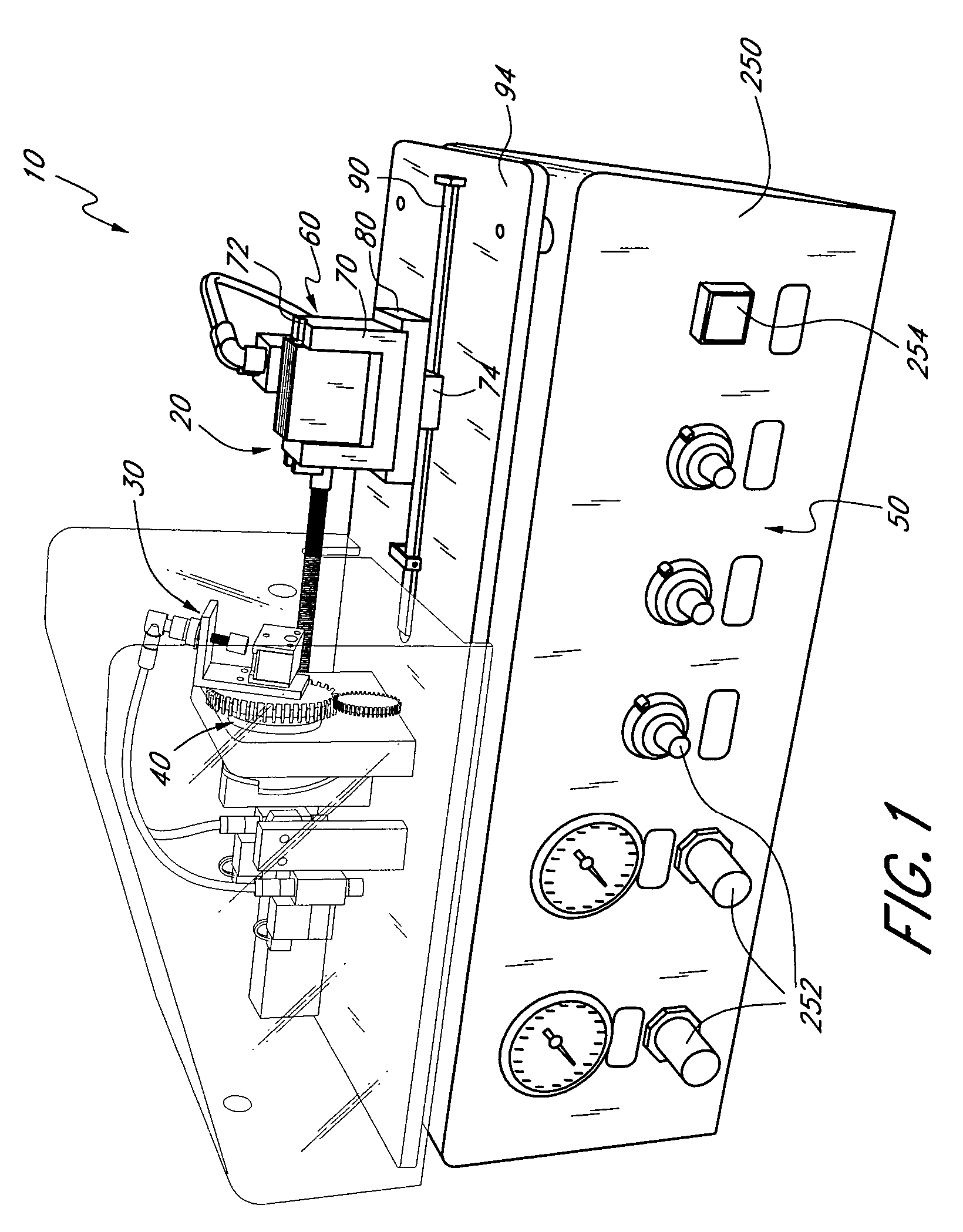

Hand held stent crimping apparatus and method

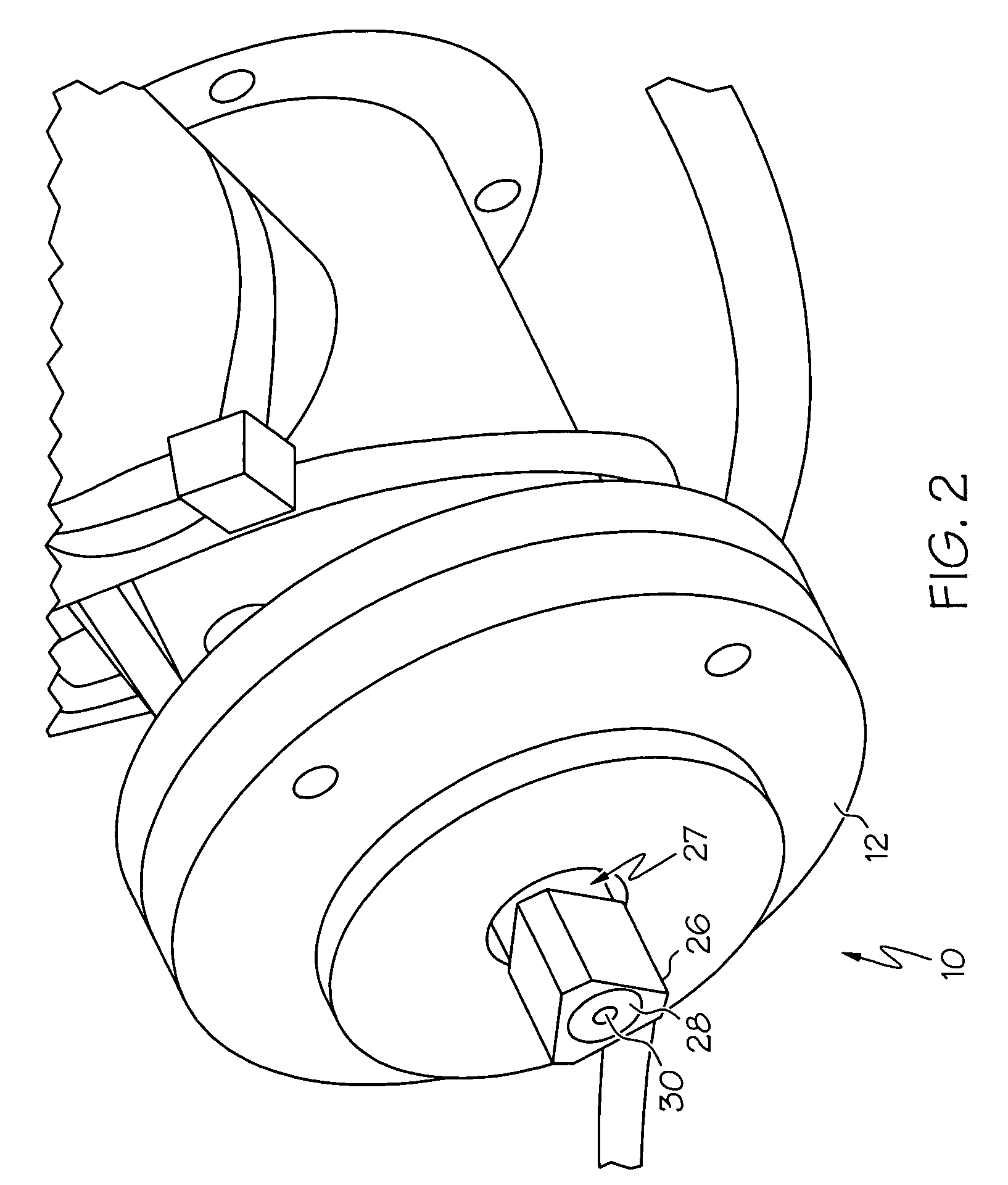

A hand actuatable apparatus and method for crimping a stent or processing other articles by segmental radial compression. The apparatus includes a stationary base housing; a rotatable drive hub which is moveable in relation to the base housing; a crimping head communicatively coupled to the base housing and to the drive hub; and an actuator handle connected to the base housing and to the drive hub. The crimping head includes a plurality of segments oriented about a center aperture which receives a stent or article to be compressed. The segments each have a proximal end and an angled distal end with at least one angled side face terminating in an edge of a predetermined length and defining the center aperture. Actuation of the handle rotates the drive hub, which causes the segments to move and pivot, resulting in closure of the center aperture and compression of the stent or other article.

Owner:MACHINE SOLUTIONS

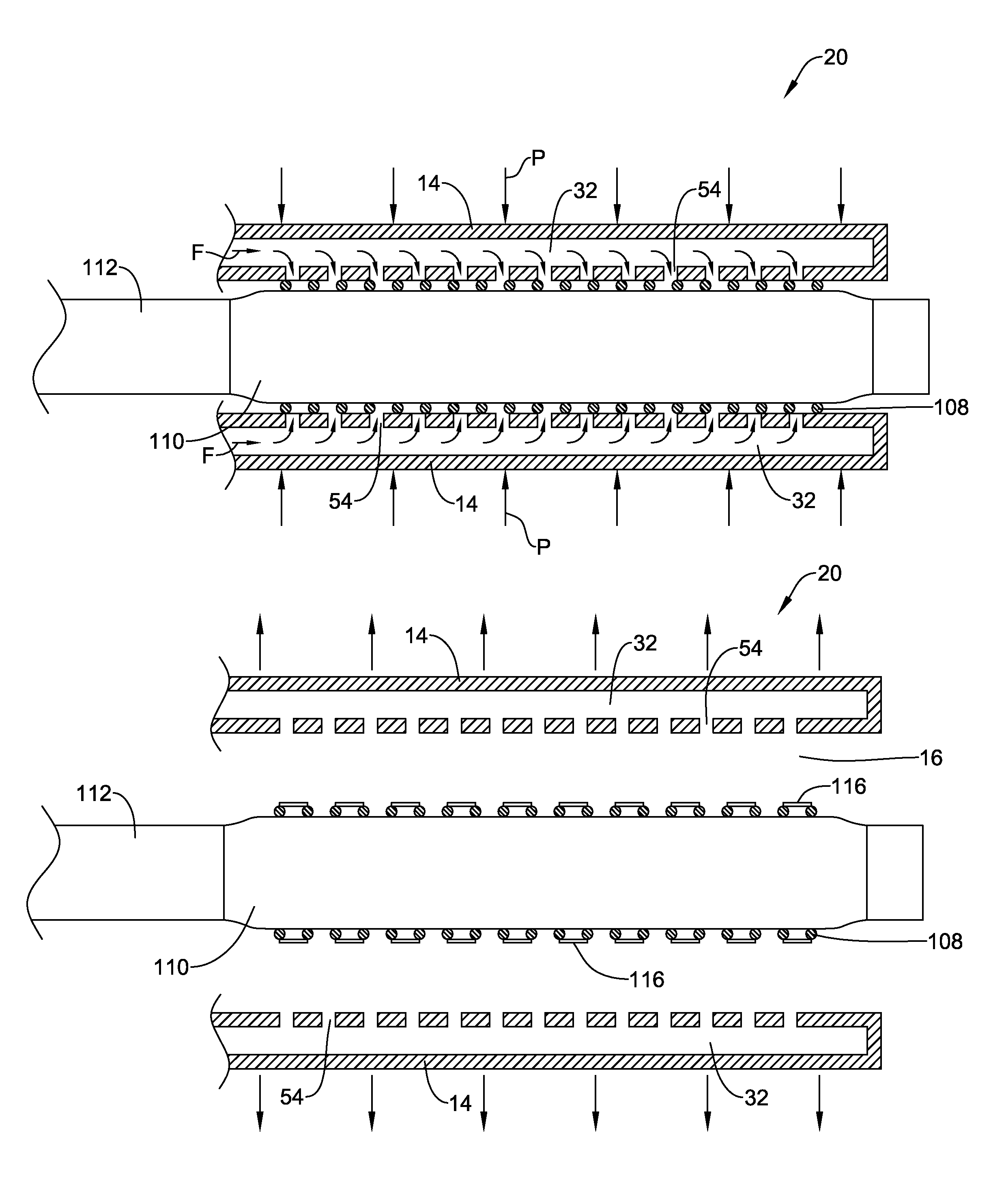

Stent reducing system and device

ActiveUS20050154450A1Reduce frictionMinimize adhesionStentsForging hammersInsertion stent% diameter reduction

A system for reducing the diameter of a stent comprises a stent contracting assembly and a fluid source. The assembly comprises a plurality of contracting members that define a diameter reduction chamber for receiving a stent. When the chamber is in a pre-reduction configuration the stent has a first diameter and when the chamber is in a reduced configuration the stent has a second diameter. The second diameter is less than the first diameter. The fluid source is in fluid communication with the chamber and is constructed and arranged to inject a fluid therein. The fluid forms a fluid bearing between the contracting members and the stent which prevents the contracting members from contacting the stent in the reduced diameter configuration.

Owner:BOSTON SCI SCIMED INC

Edge curling tool

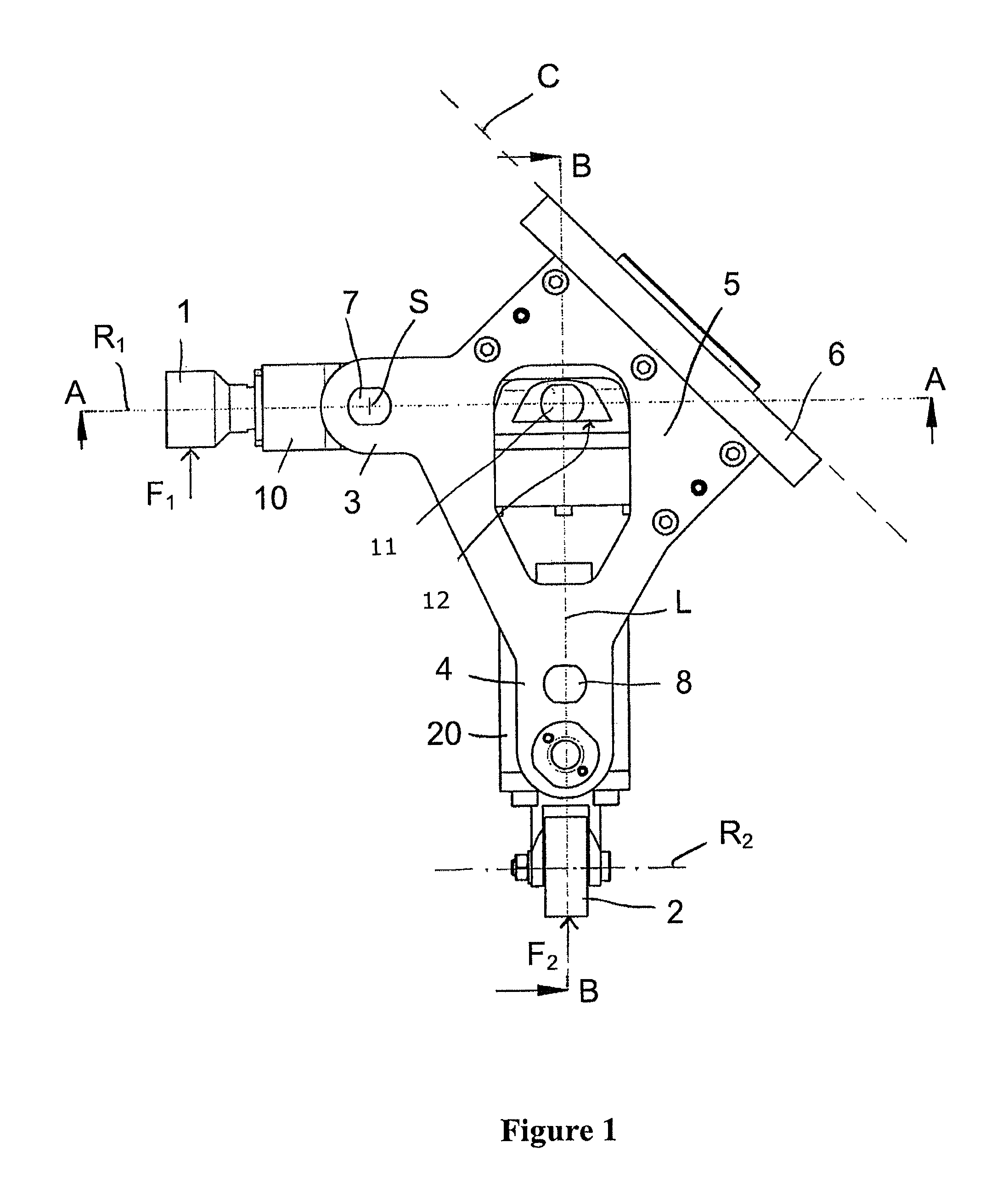

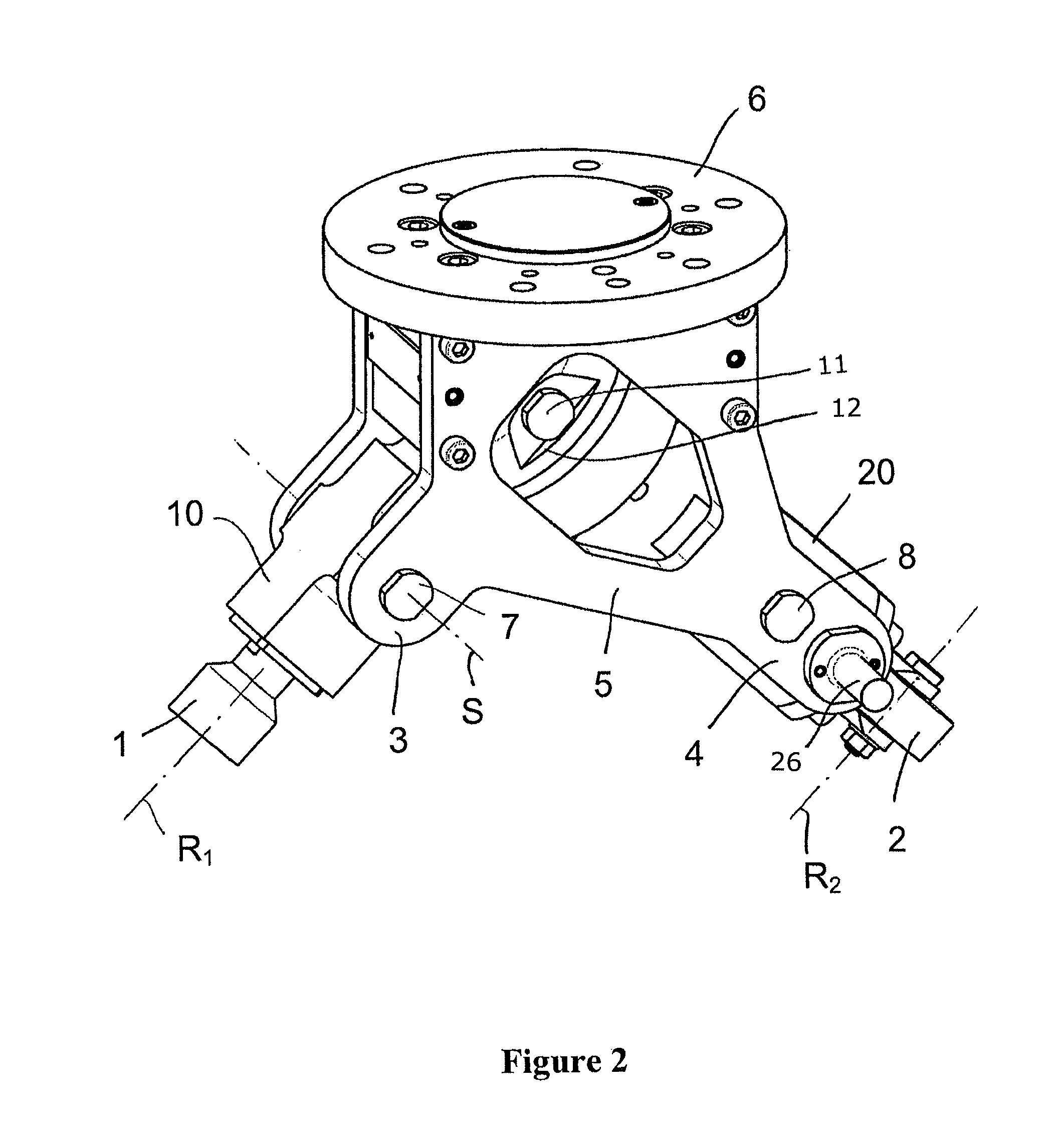

A roll-flanging tool, including a bearing structure having a connector, by which the tool can be connected via a connection plane to an actuator which can be moved spatially. A first arm and a second arm are spread apart from each other and connected to each other in a connection portion which includes the connector. A first flanging roller is mounted on an end of the first arm which faces away from the connection plane, such that it can be rotated about a first rotational axis which extends along the first arm and pierces the connection plane. A second flanging roller is mounted on an end of the second arm which faces away from the connection plane, such that it can be rotated about a second rotational axis. The first rotational axis intersects or crosses a perpendicular dropped onto the second rotational axis, in or on the roll-flanging tool.

Owner:FFT PRODIONSSYST

Stent crimper

InactiveUS20050234537A1Minimize distortionReduce coefficient of frictionStentsShaping toolsStent crimperMedical device

An apparatus for reducing the size of a medical device, the apparatus including at least one independently operable discrete section which can reduce the diameter of the medical device, the independently operable discrete section including a plurality of coupled movable blades arranged to form an aperture whose size may be varied, the blades movable so as to allow the aperture to be sized to contain a medical device and to alter the size of the aperture. The blades may be curved and / or overlapping. Each blade may be pivotally connected to a first member or mount and slidably engaged with a second member or collar. The size of the aperture may be adjusted by rotating the collar relative to the mount.

Owner:BOSTON SCI SCIMED INC

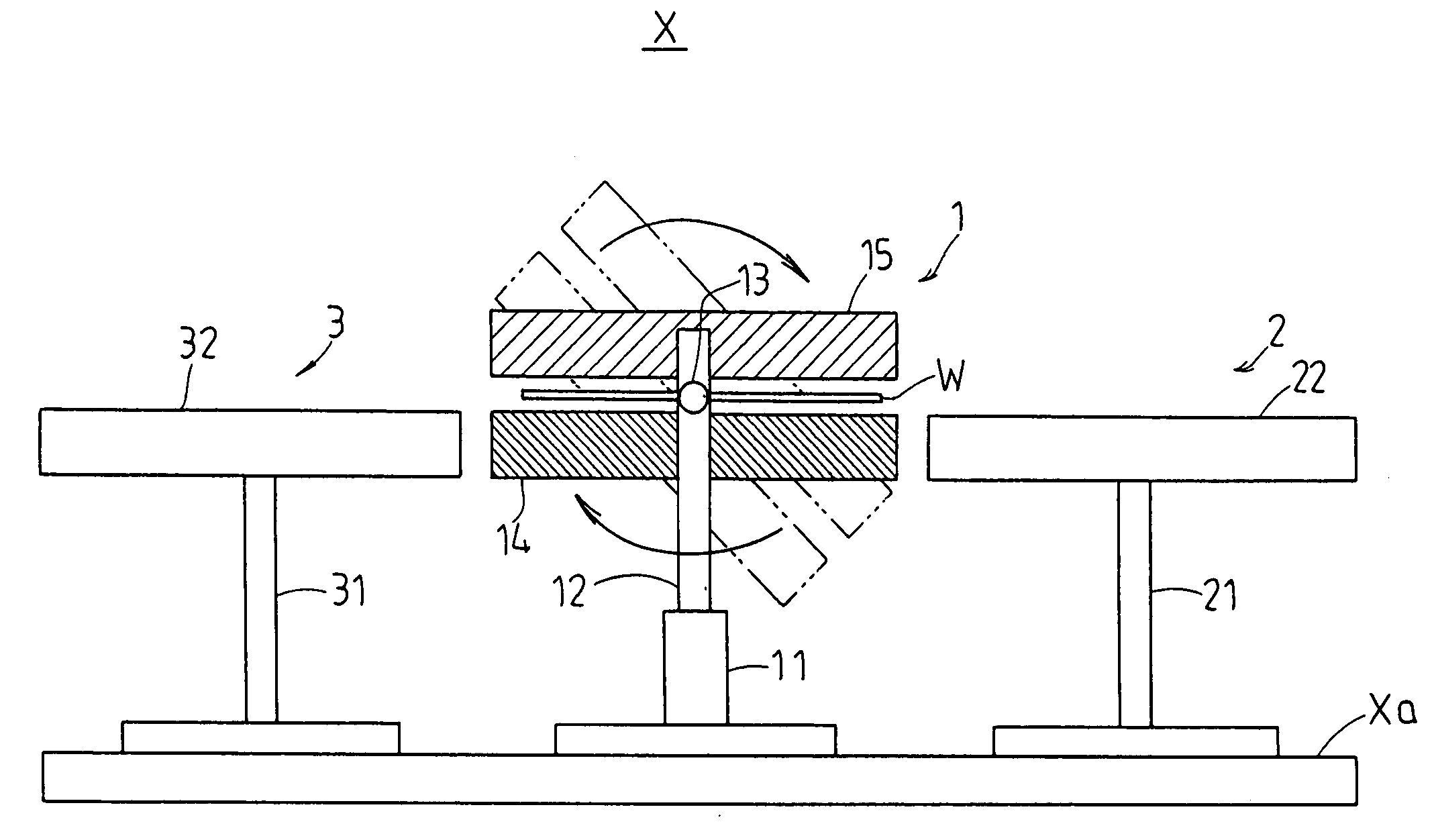

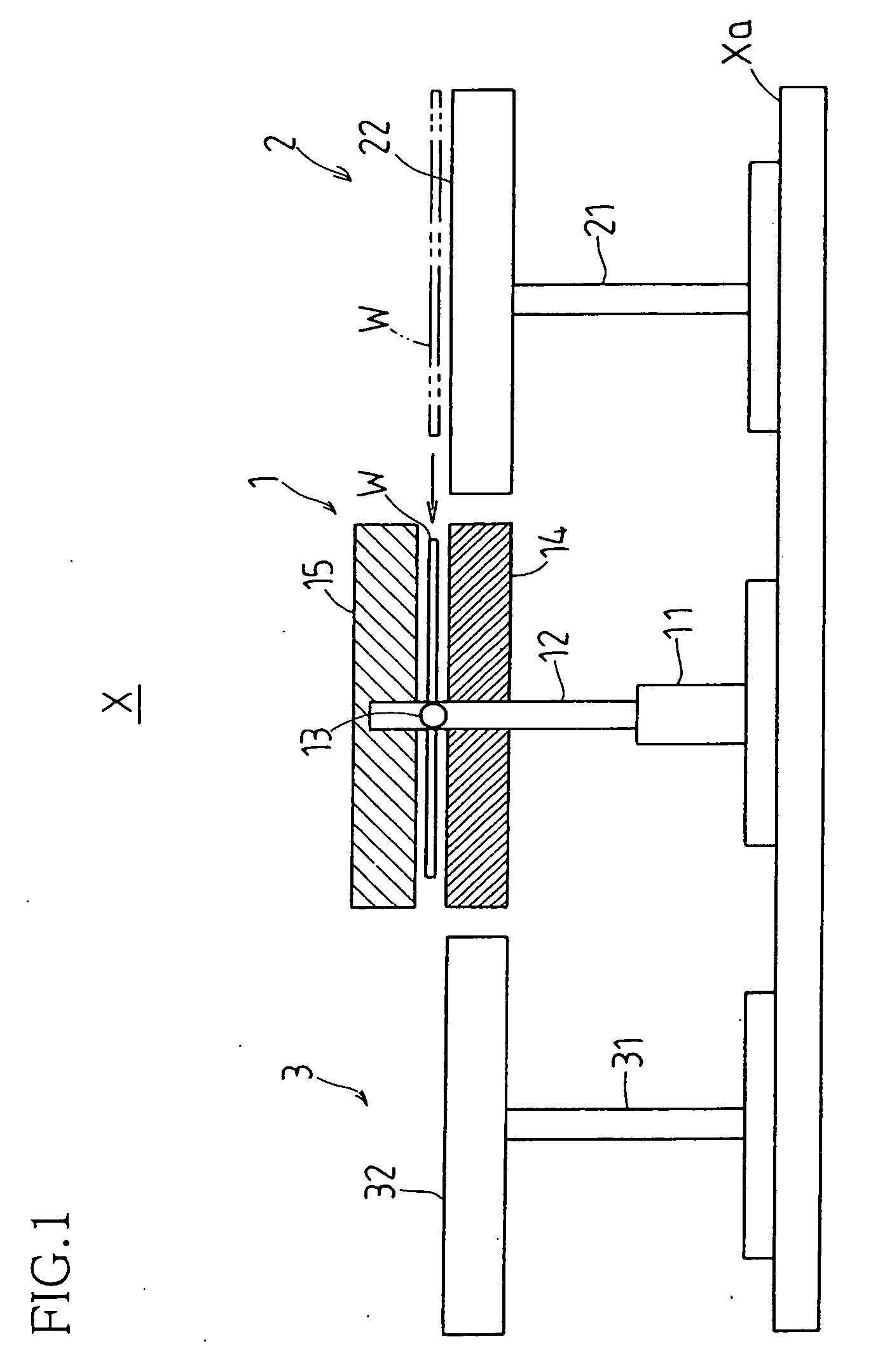

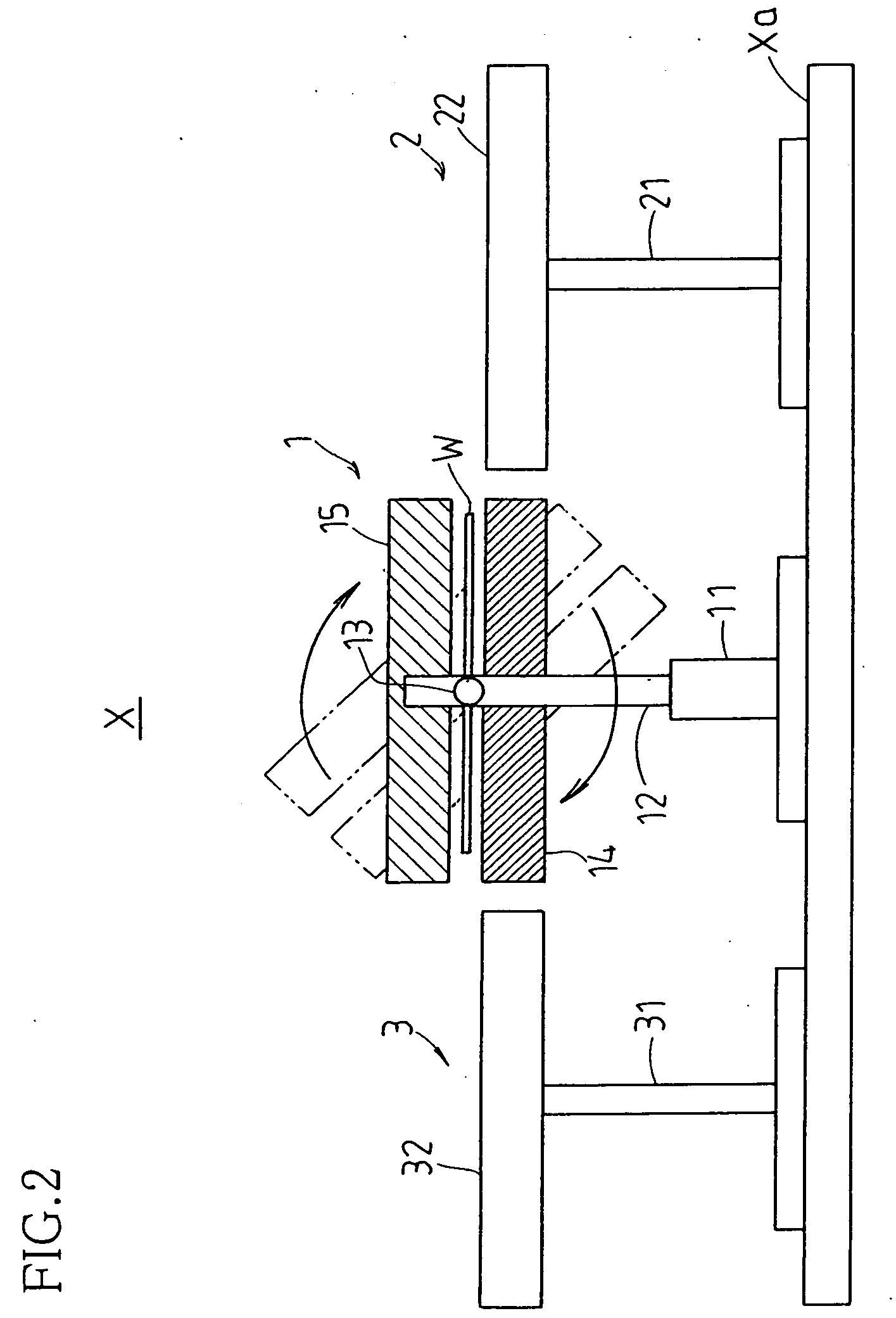

Workpiece transport apparatus

InactiveUS20040197184A1Reduce Particle GenerationEliminate mechanical partForging hammersSemiconductor/solid-state device manufacturingTransport engineering

While periphery or peripheries of workpiece(s) W lifted in floating fashion by simultaneous suction and expulsion of gas(es) between pair(s) of first and second, or upper and lower, transport stages 14, 15 is / are retained by plurality of elevator pins 16, respective transport stage(s) is / are inverted vertically and workpiece(s) is / are transferred from upper first transport stage(s) to lower second transport stage(s) such that workpiece(s) W is / are lifted in floating fashion thereabove by simultaneous suction and expulsion of gas(es) in accompaniment to lowering of respective elevator pin(s) at said first transport stage(s).

Owner:SHARP KK

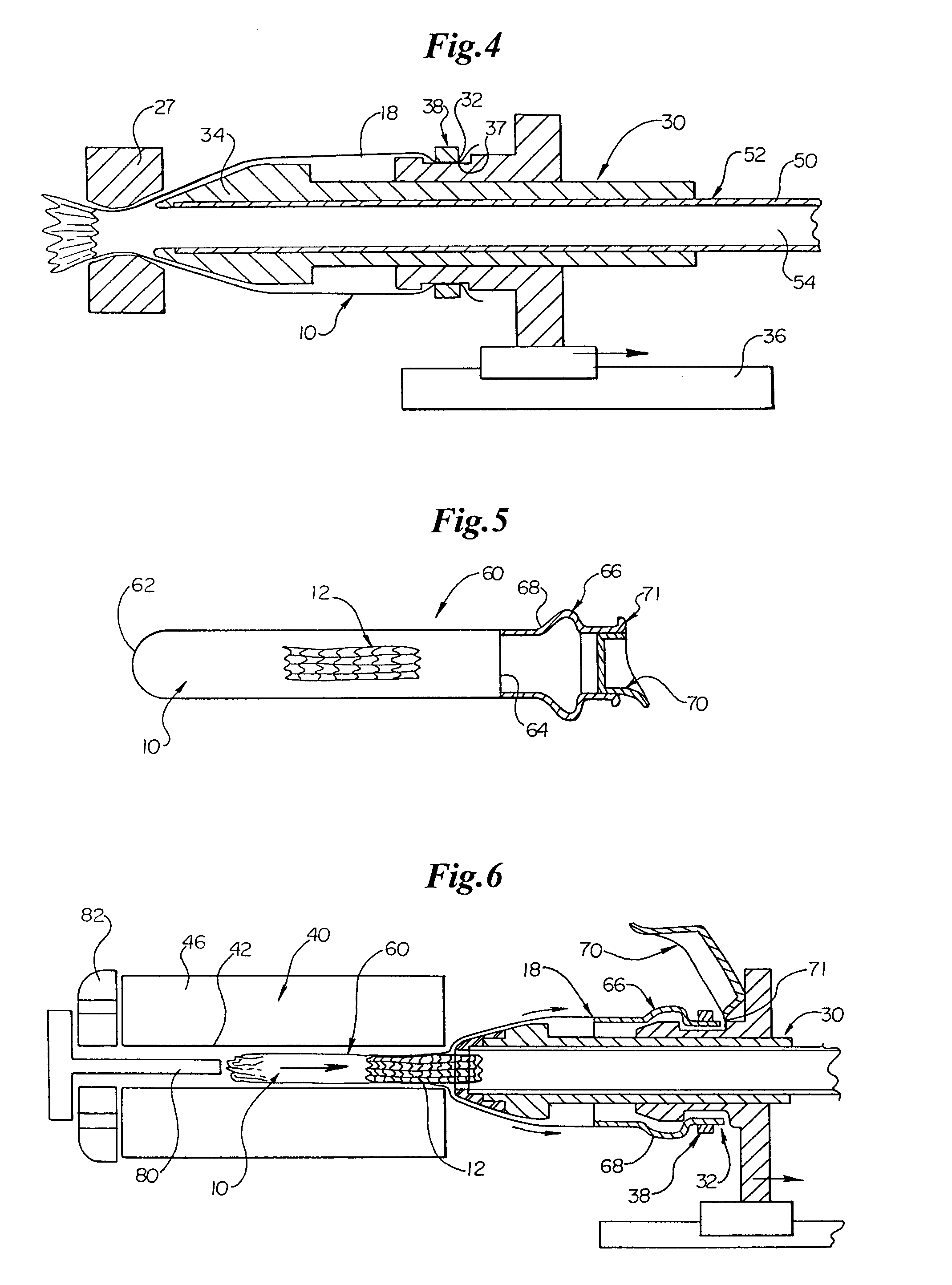

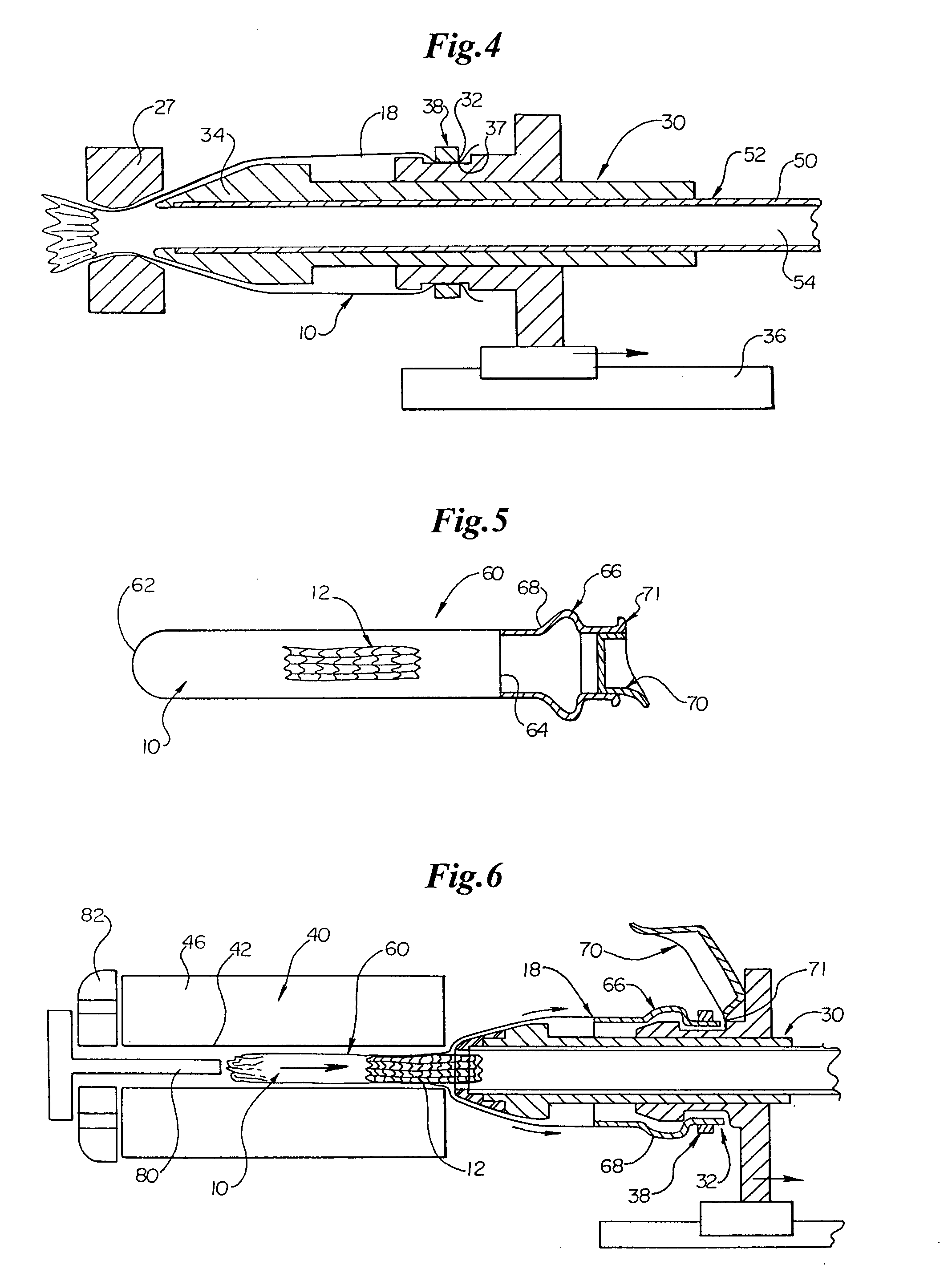

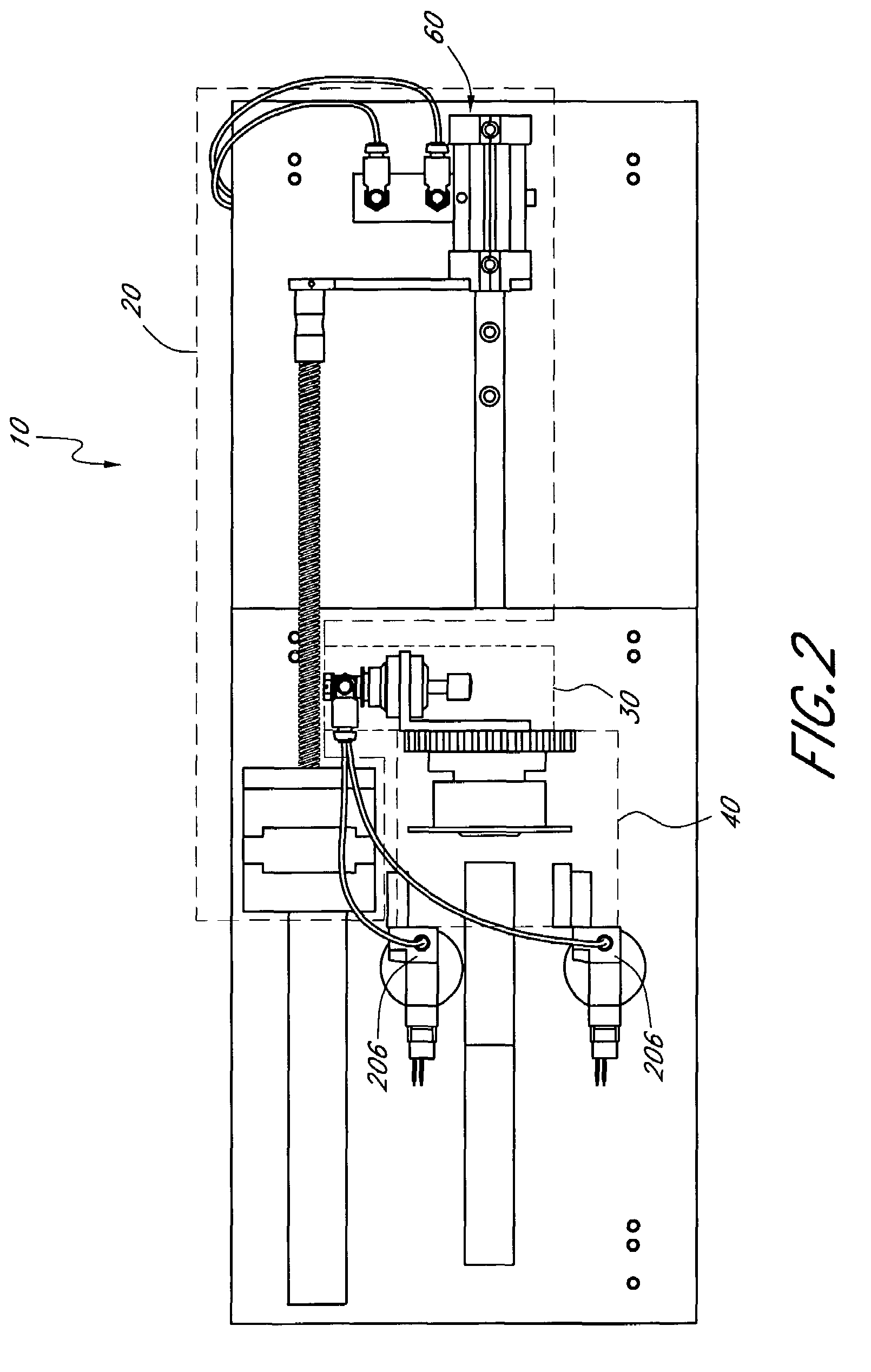

Apparatuses for crimping and loading of intraluminal medical devices

ActiveUS7316147B2Small sizeVaries in sizeStentsAutomatic control devicesMedical deviceDelivery system

Crimping apparatuses for reducing the diameter of an intraluminal medical device from a first diameter to a second diameter prior to loading the medical device into a catheter delivery system and loading apparatuses for introducing the medical device into a catheter delivery system, the devices constructed and arranged for matingly engaging one another, combinations thereof, and methods of using the devices.

Owner:BOSTON SCI SCIMED INC

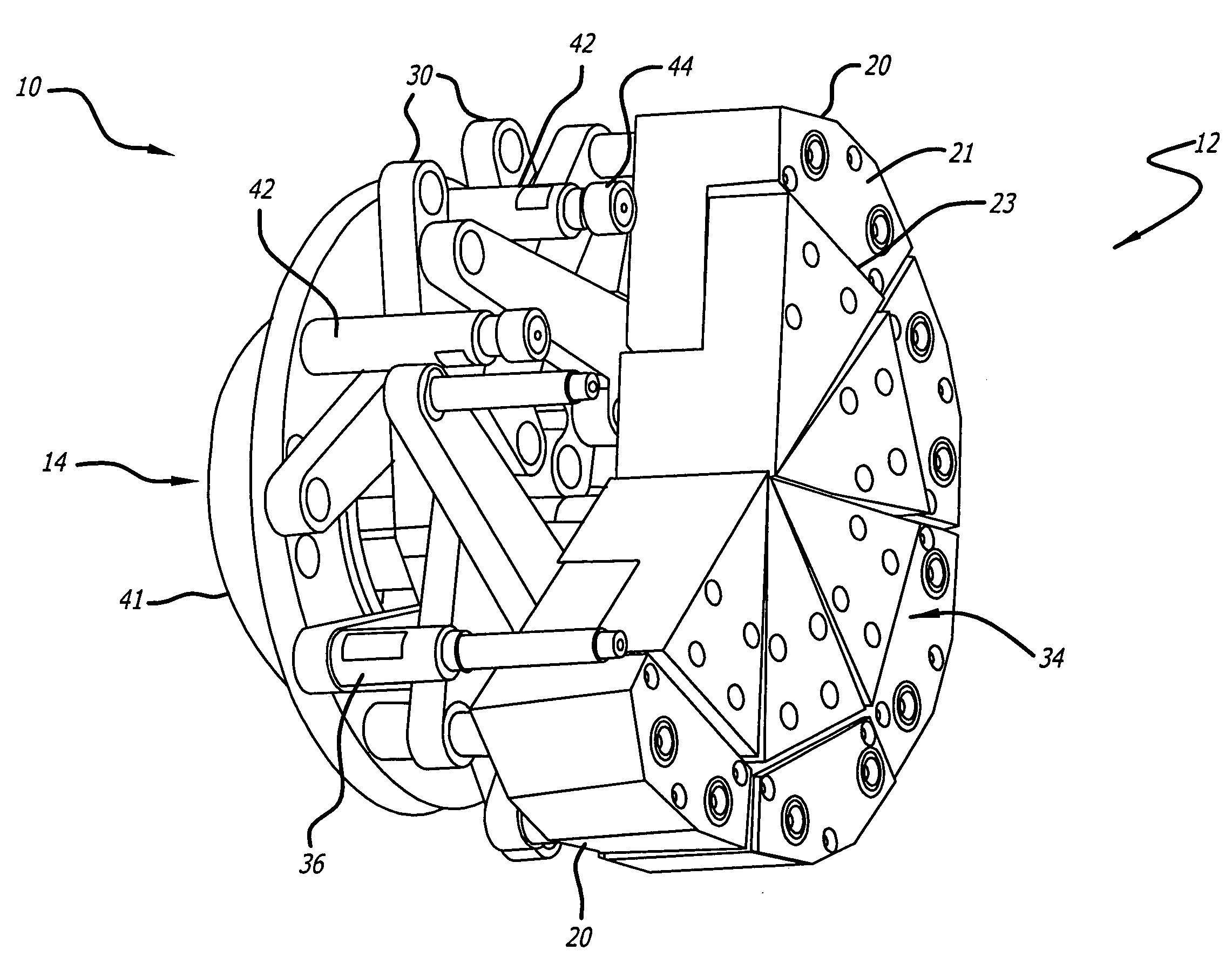

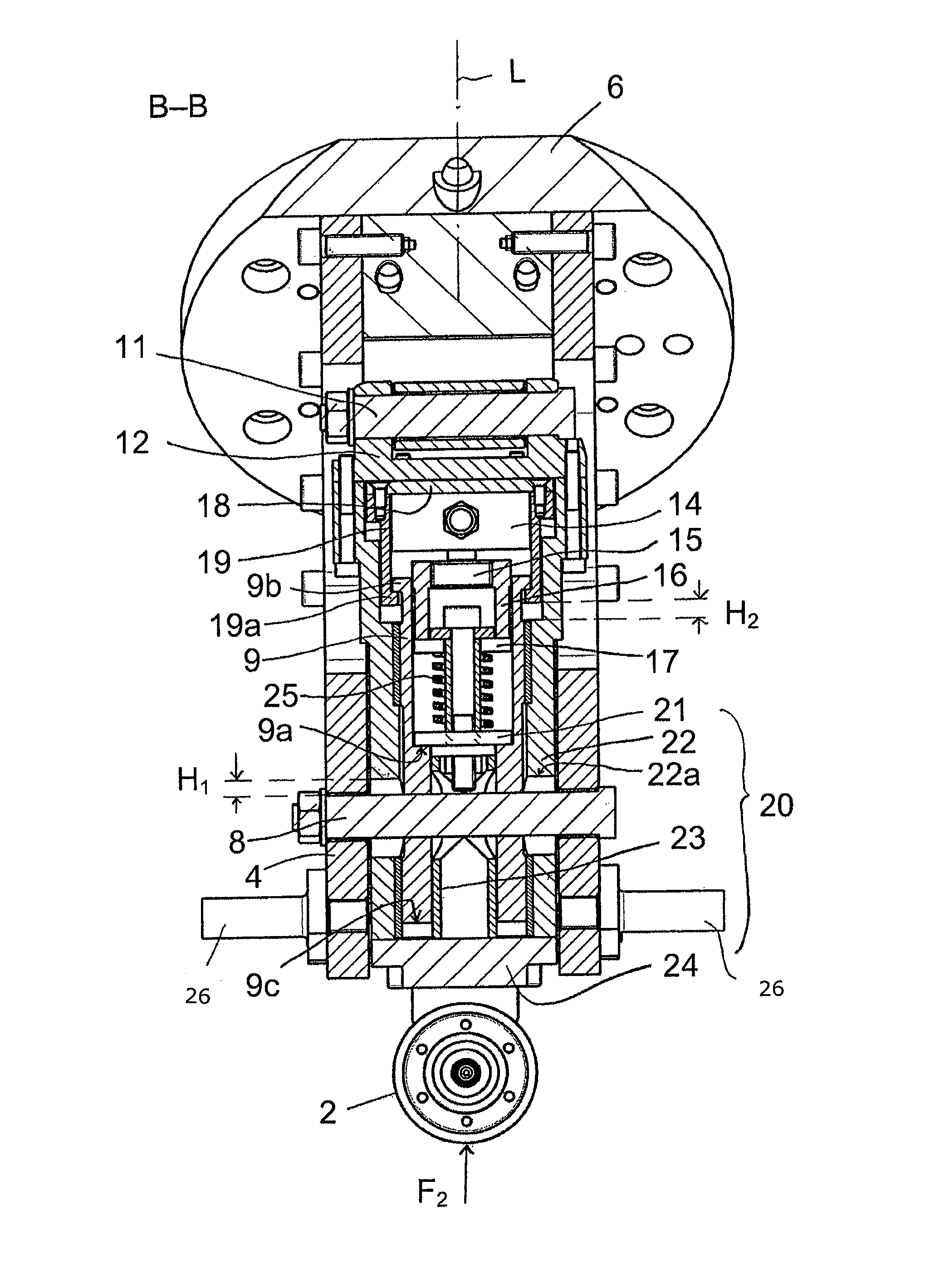

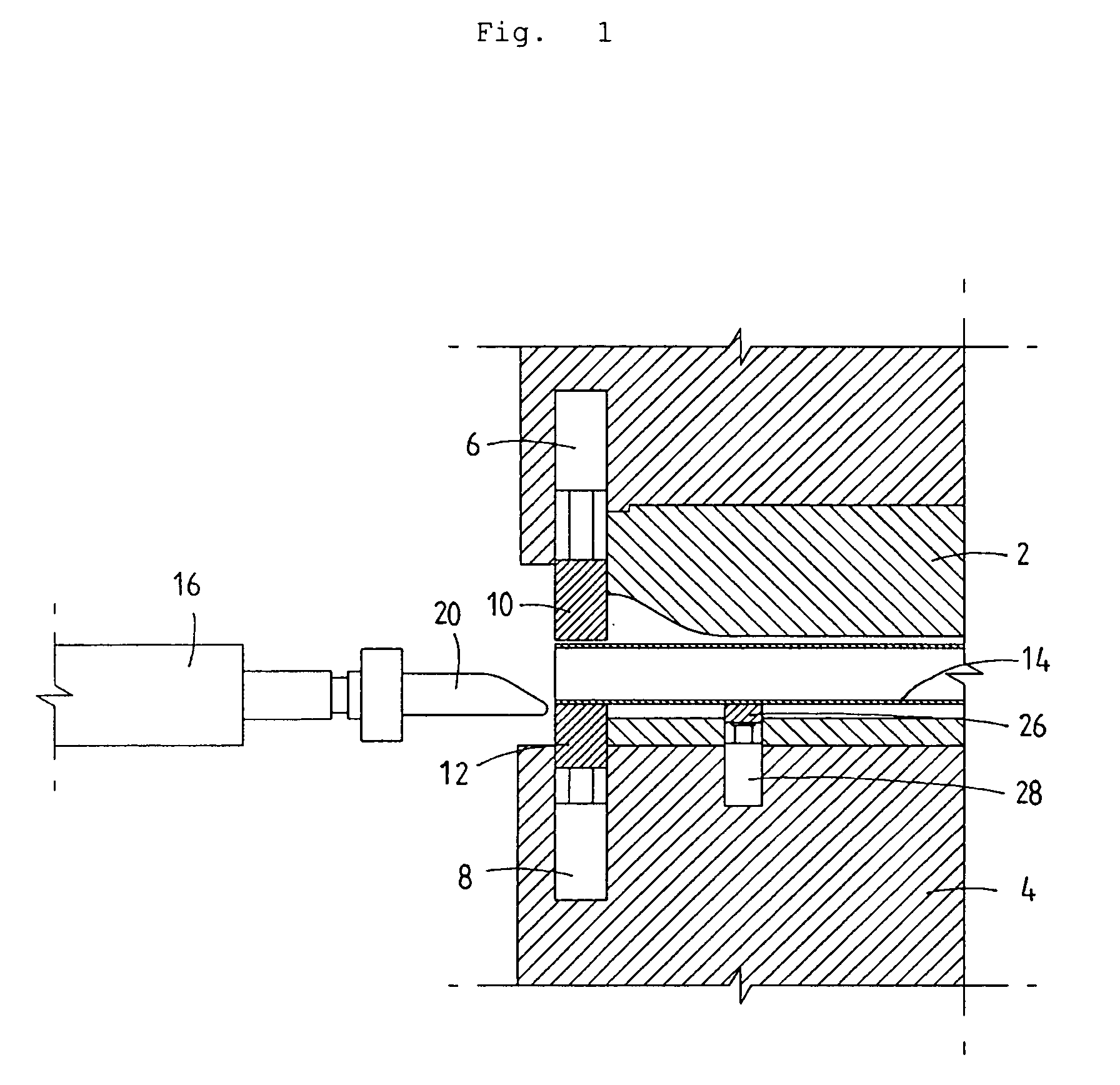

Assembly for crimping an intraluminal device or measuring the radial strength of the intraluminal device and method of use

InactiveUS6840081B2Easy to useAccurate measurementStentsForging hammersEngineeringUltimate tensile strength

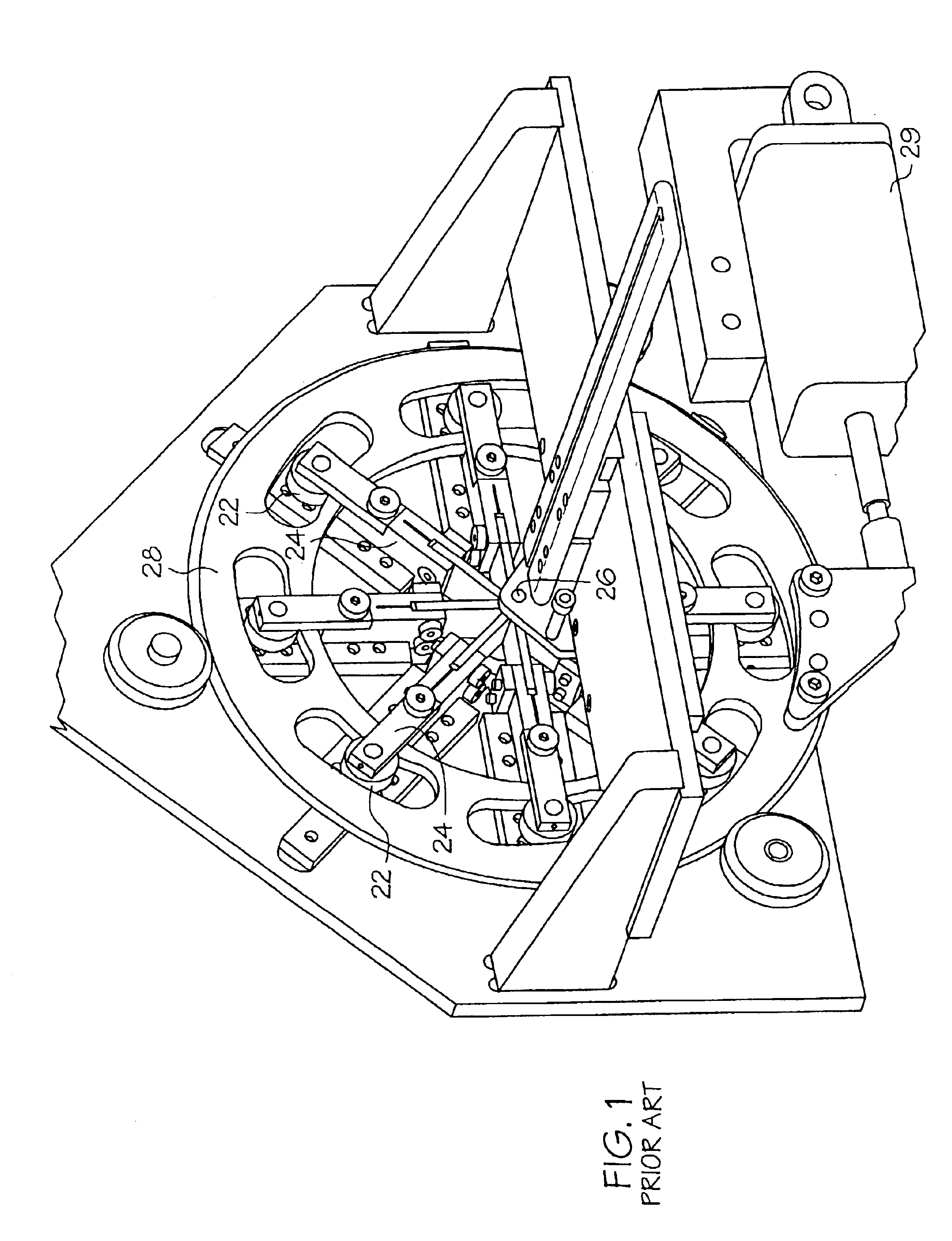

An assembly is provided which can crimp or compress an intraluminal device or measure the radial strength of an intraluminal device. The device includes a first disk and a second disk for imparting movement to a number of spaced apart moving elements attached to linear sliders on the first disk. In one configuration, rotational movement is imparted to the second disk which causes the tips of the moving elements to move is a linear direction toward the center of the opening formed by the elements thereby closing in on the device. In another configuration, rotational movement is imparted to the first disk and the tips move along an arcuate path from the perimeter of the opening toward the center of the opening.

Owner:ABBOTT CARDIOVASCULAR

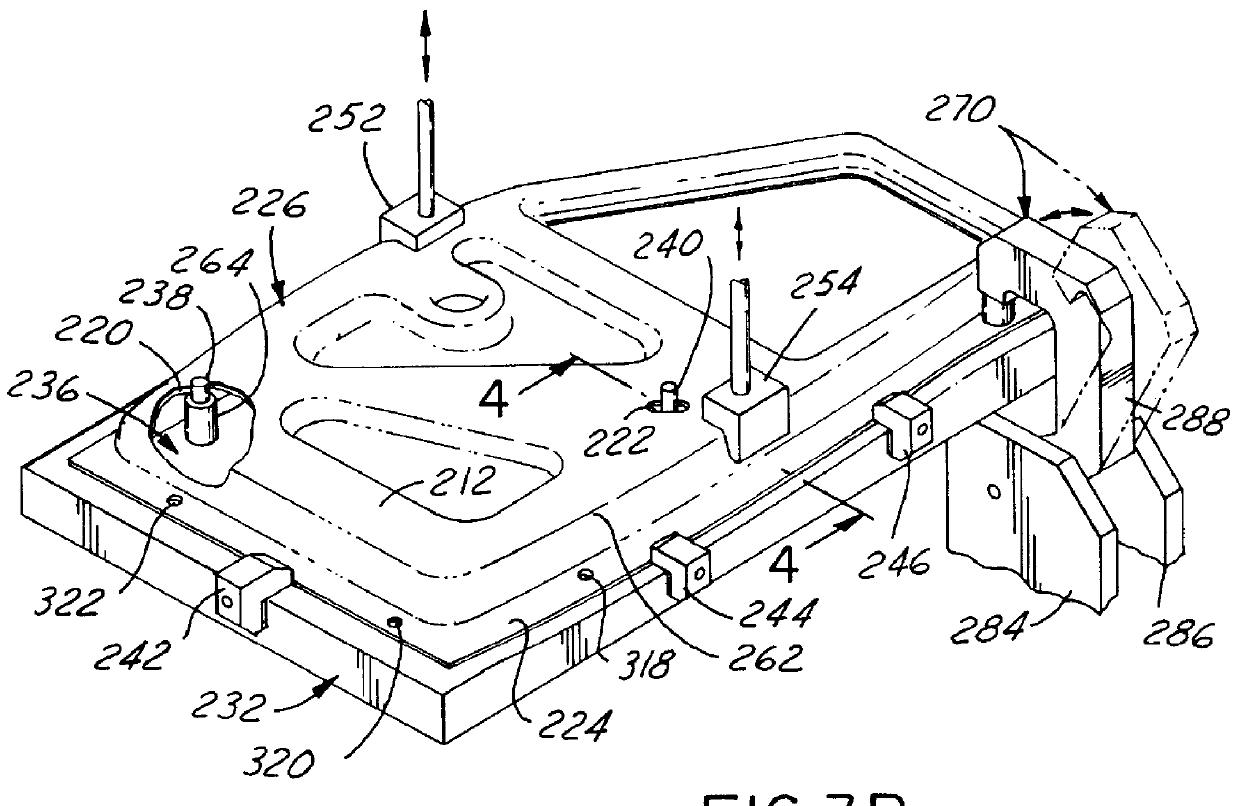

Stock lifter for metal forming dies and method for making the same

InactiveUS6848290B2Reduce design costReduce manufacturing costShaping toolsMetal-working feeding devicesMetal formingReciprocating motion

A self-contained stock lifter is particularly adapted for use in multiple station, progressive metal forming dies and the like, and includes a base plate with two vertical through holes adjacent opposite sides, and a vertical spring unit aperture located between the through holes. The stock lifter also includes a lifter bar having two vertical through holes in vertical registry with the base plate through holes. Two rigid guide shafts are mounted in the base plate through holes to permit the lifter bar to reciprocate in a manner which selectively lifts stock in the die to permit longitudinal shifting of the stock along the multiple die stations. A spring unit has a base retained in the spring unit aperture, and a reciprocating rod biased outwardly, with a free end abutting a central portion of the lifter bar to shift the lifter bar to an extended position, thereby defining a fully self-contained unit that can be readily mounted in and removed from the die to reduce manufacturing and repair costs.

Owner:PYPER TOOL & ENG

Stent crimper

InactiveUS7143625B2Minimize distortionReduce coefficient of frictionStentsShaping toolsStent crimperMedical device

Owner:BOSTON SCI SCIMED INC

Apparatuses for crimping and loading of intraluminal medical devices

ActiveUS20050166389A1Easy alignmentReduce needStentsAutomatic control devicesMedical deviceBiomedical engineering

Crimping apparatuses for reducing the diameter of an intraluminal medical device from a first diameter to a second diameter prior to loading the medical device into a catheter delivery system and loading apparatuses for introducing the medical device into a catheter delivery system, the devices constructed and arranged for matingly engaging one another, combinations thereof, and methods of using the devices.

Owner:BOSTON SCI SCIMED INC

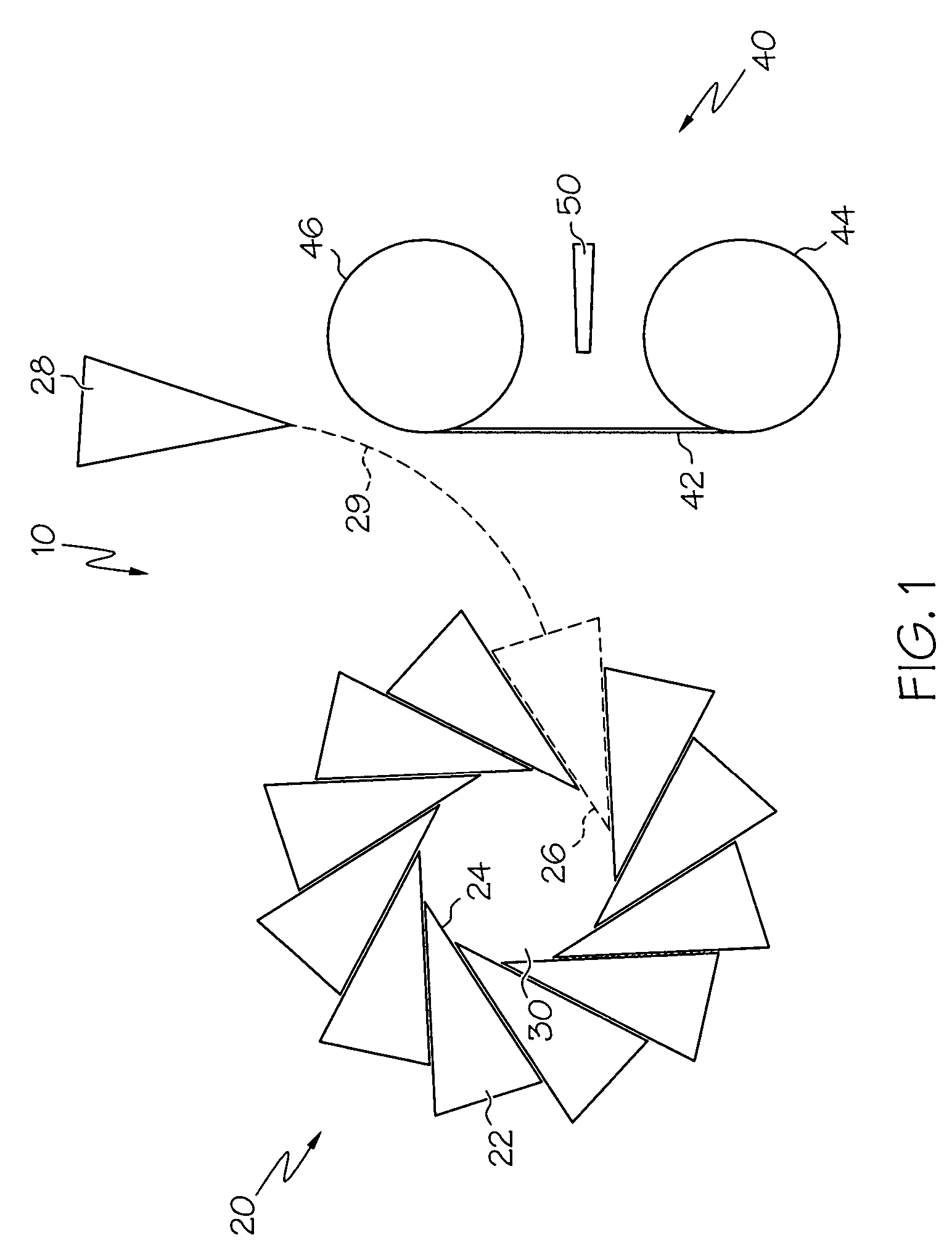

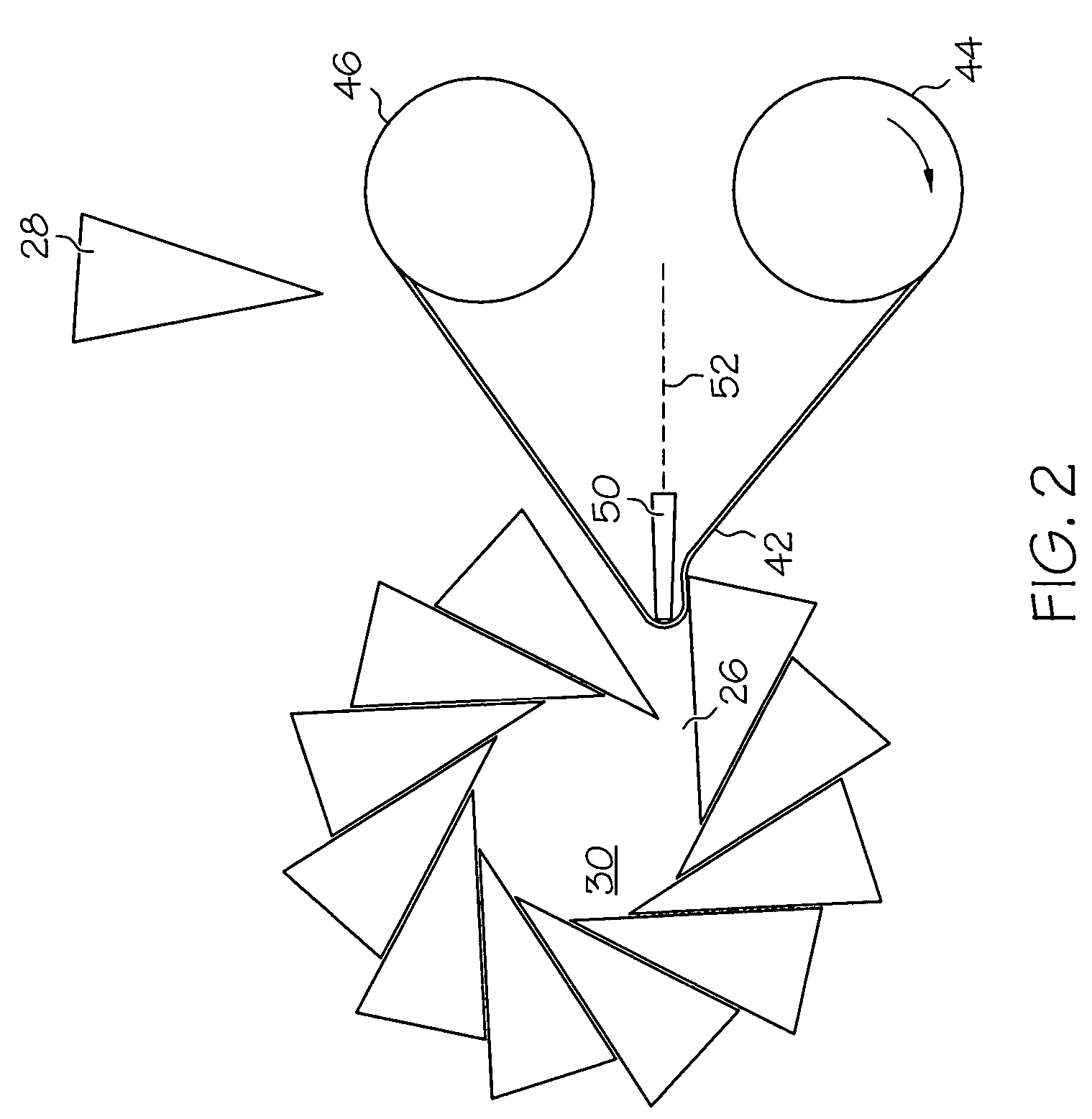

Protective sheet loader

A protective sheet loader may comprise a first roller, a second roller, a sheet of material spanning between the first and second rollers, and a loading mechanism. A portion of the sheet of material may be loaded into the crimping chamber of an apparatus for reducing the size of a medical device. A medical device may be placed within the crimping chamber such that the sheet of material forms a barrier between the walls of the crimping chamber and the medical device and prevents cross-contamination between the medical device and the crimping device. After a crimping step is completed, the medical device and the contaminated portion of the sheet of material may be removed from the crimping chamber, and a clean portion of the sheet of material may be loaded into the crimping chamber.

Owner:BOSTON SCI SCIMED INC

Stent crimping assembly and method

A stent crimping assembly is provided for crimping a stent from a first diameter to a reduced second diameter. The assembly includes a set of two or more blade devices each having a proximal portion, a downstream distal portion, and a respective edge wall extending from the proximal portion to the distal portion. Each respective edge wall is oriented relative to one another, in a respective crimp position, to collectively define an elongated conical-shaped crimp aperture. The conical-shaped crimp aperture at the respective proximal portion of each blade is formed for receipt of at least a portion of the stent in the first diameter. The crimping assembly further includes a drive assembly associated with each blade device and configured to independently displace each blade edge wall in a manner substantially along a respective predetermined first path from the respective crimp position to a respective retracted position, oriented a predetermined incremental distance from the crimp position in a respective proximal direction.

Owner:ABBOTT LAB INC

Swaging technology

InactiveUS6931899B2Practical and reliable and accurate and efficientForging hammersShaping safety devicesEngineeringCatheter

A swager for swaging marker bands to a medical catheter, comprises an article input mechanism, the article input mechanism having a first input roller assembly for receiving and conveying an article, a first sensor for detecting a predetermined aspect of the article, a second input roller assembly for receiving and conveying the article, a positioning roller assembly for precisely aligning the article with respect to the swaging head, and a second sensor all constructed and arranged in a streamwise orientation. The swager also has a radial compression swaging head with a central swaging aperture, the swaging head being aligned and communicatively coupled with the input mechanism to receive an input article from the article input mechanism and to swage the article, the swaging head being rotatable and including (i.) a unitary die plate including a plurality of die segments movably coupled to each other to provide a radial compressive force to the article disposed in the central swaging aperture; and (ii.) a closing plate pivotally coupled with respect to each other. The swager also has an output mechanism aligned and communicatively coupled with the swaging head to receive the swaged article. A swaging head and die are also disclosed.

Owner:MACHINE SOLUTIONS

Stent crimping system

A stent crimping assembly is provided for crimping a stent from a first diameter to a reduced second diameter. The crimping assembly includes a plurality of movable wedges disposed about a rotational axis to form a wedge assembly. Each wedge includes a respective first side and a second side converging to form a tip portion. The tip portions are arranged to collectively form an iris about the rotational axis thereof. The iris defining a crimp aperture about which the movable wedges are disposed. Each wedge is associated with a stationary structure and an rotational actuation unit such that during rotation of the actuation unit about the rotational axis, the iris is caused to rotate about the rotational axis, relative the stationary structure, for inward movement of the wedges to decrease the size of the aperture and outward movement of the wedges to increase the size of the aperture.

Owner:ABBOTT LAB INC

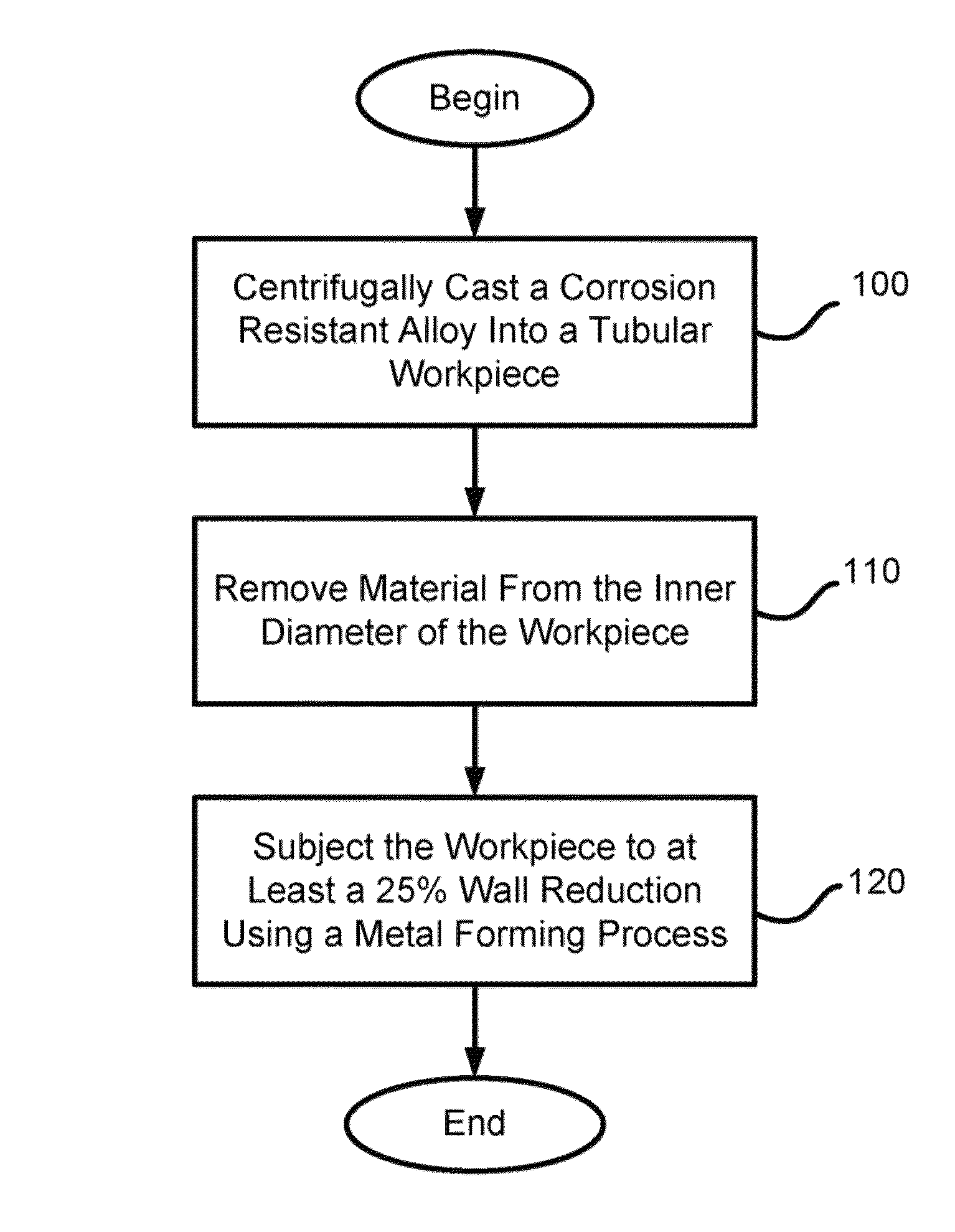

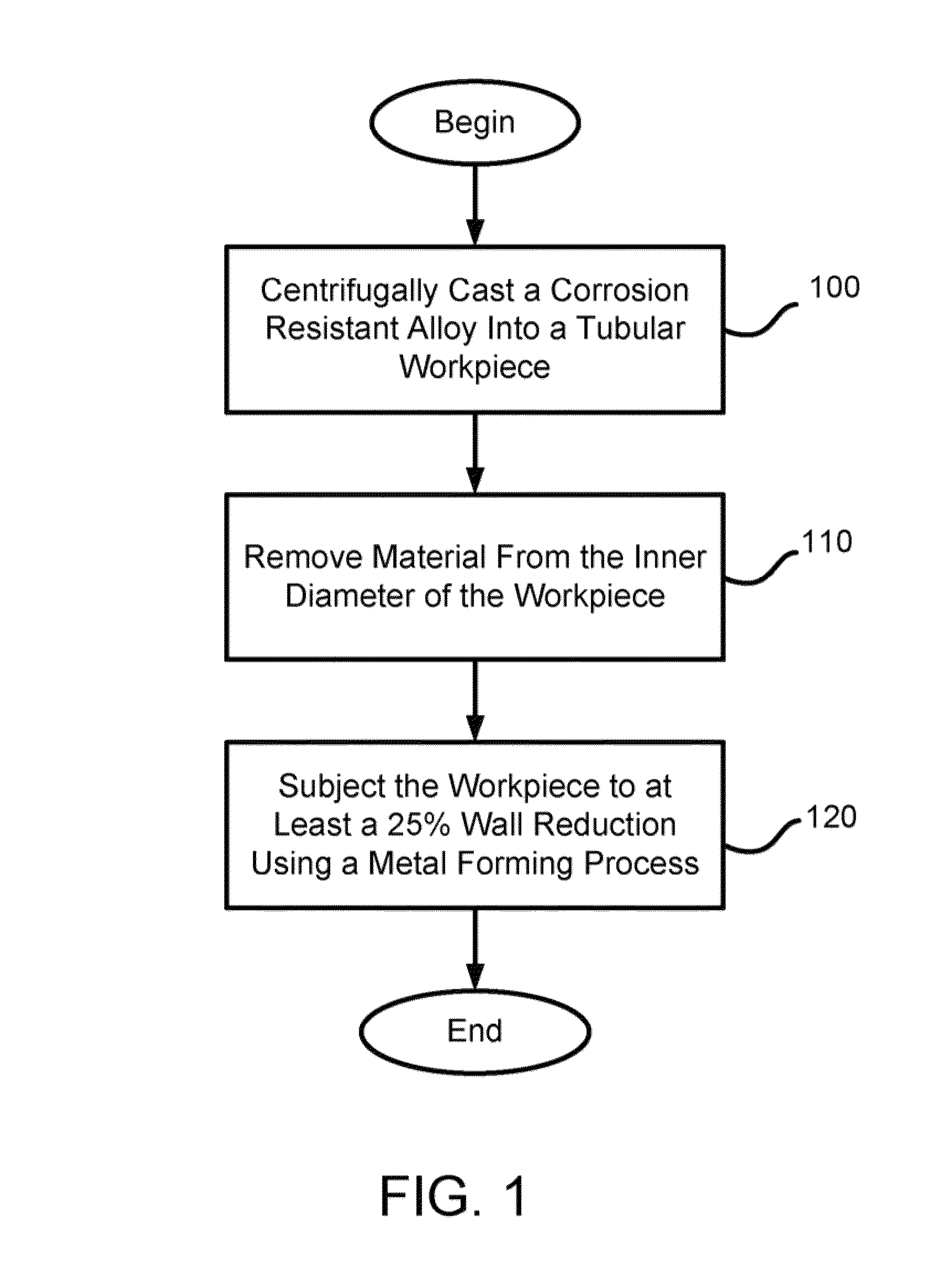

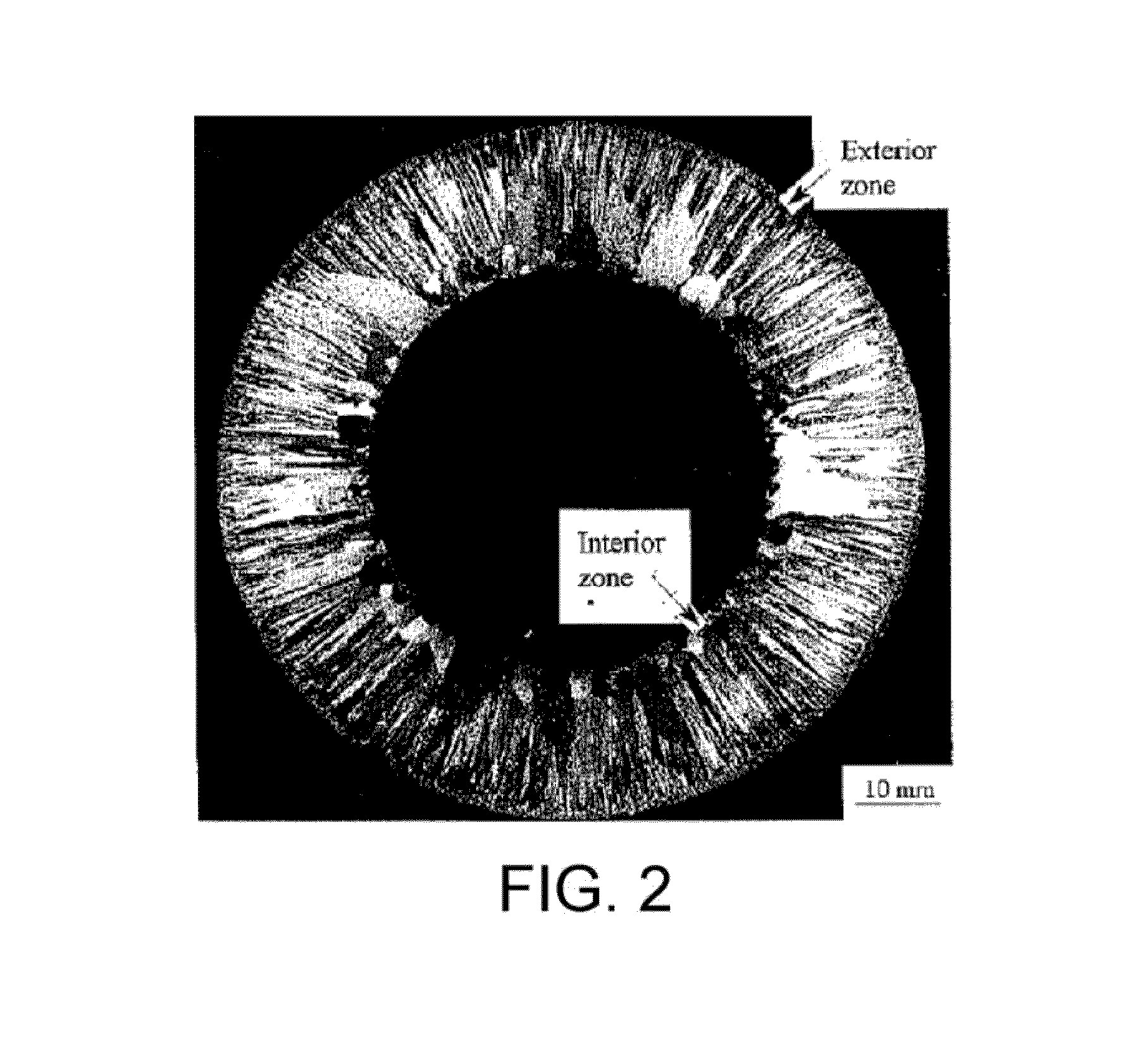

Method of producing cold-worked centrifugal cast tubular products

A method of producing a seamless, tubular product includes centrifugally casting a corrosion resistant alloy into a tubular workpiece having an inner diameter and an outer diameter. The method then removes material from the inner diameter of the workpiece and subjects the workpiece to at least about a 25% wall reduction at a temperature below a recrystallization temperature of the workpiece using a metal forming process. The metal forming process includes radial forging, rolling, pilgering, and / or flowforming.

Owner:ATI FLOWFORM PROD

Swaging machine and method of use

Owner:CONFLUENT MEDICAL TECH INC

Apparatus for forming beam member used for torsion beam for rear wheel suspension of automobile

Disclosed herein is an apparatus for forming a beam member for a torsion beam in a rear wheel suspension system of an automobile. The apparatus comprises top and bottom dies for forming a U-shaped or V-shaped section and an extension section of the beam member, upper and lower pad-dies coupled to top and bottom dies for forming a rectangular section of the beam member before operation of the top and bottom dies, and left and right cams installed at both sides of a pipe so as to be horizontally inserted into the pipe by a hydraulic cylinder for maintaining inner shapes of the extension section and the rectangular section. The cams prevent both distortion and wrinkling from occurring on the rectangular section and the extension section upon operation of the top and bottom dies, thereby allowing the beam member to be formed to have different cross sections at different portions with a complete symmetry by a single process.

Owner:HWASHIN CO LTD

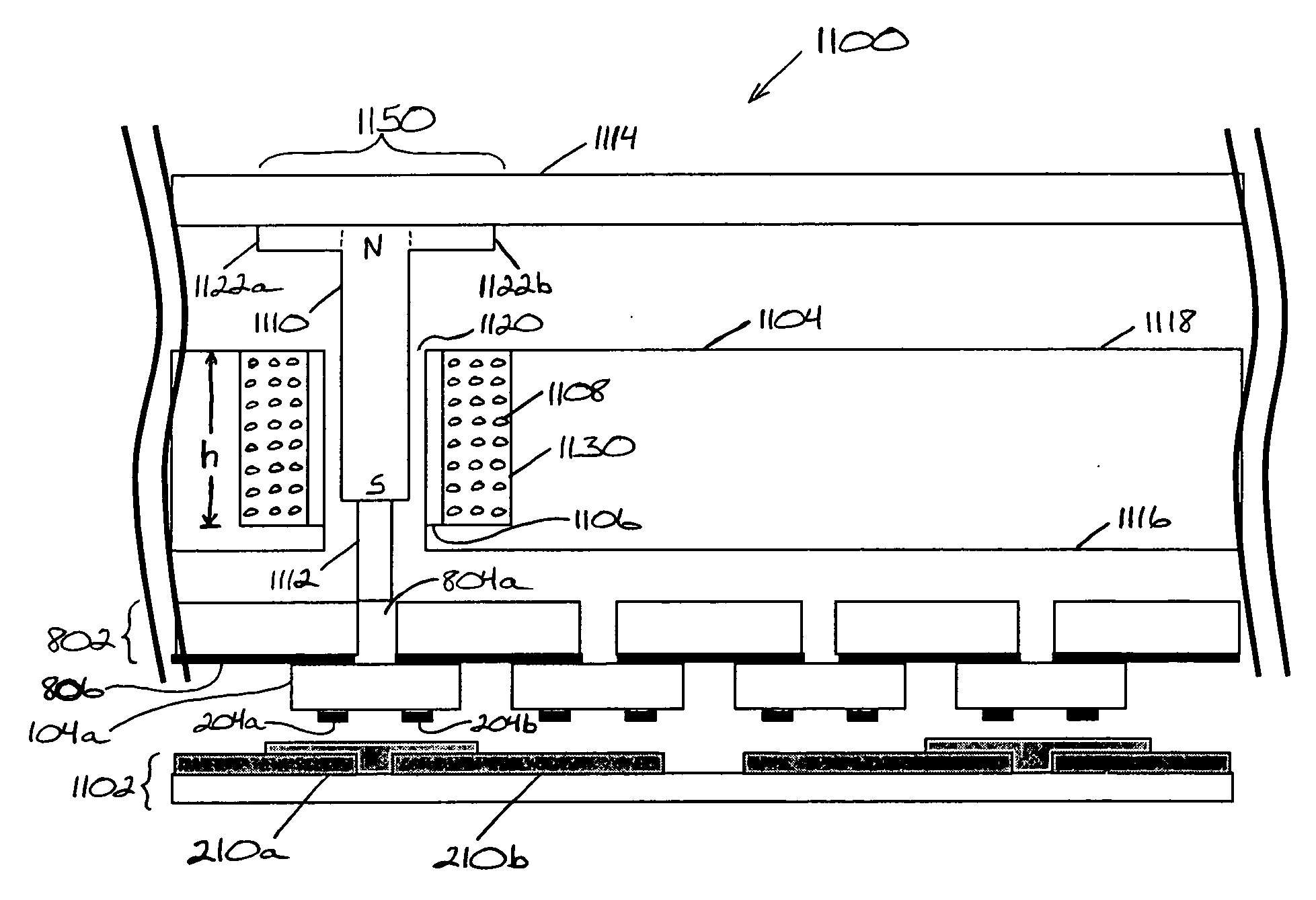

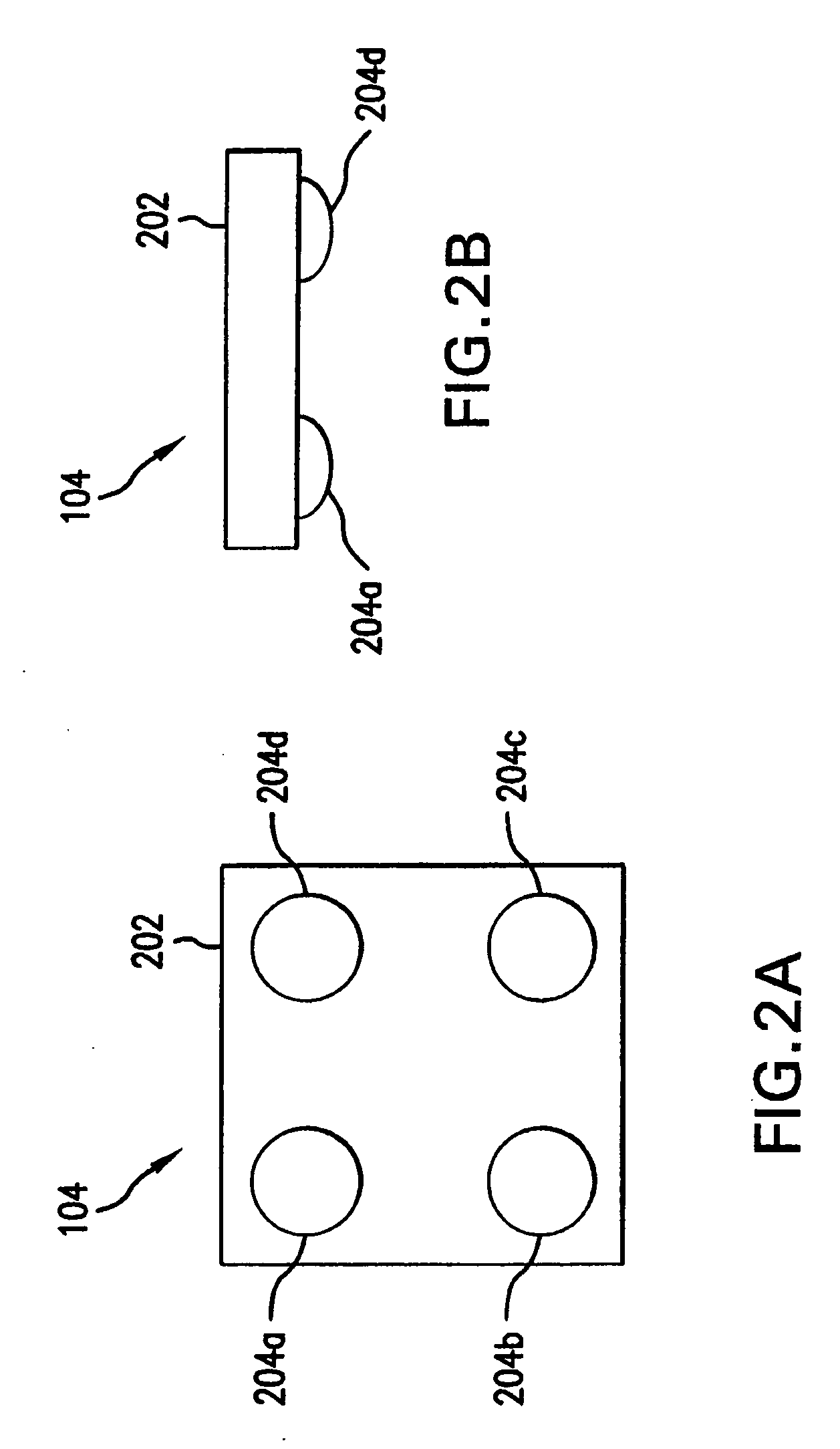

Transferring die(s) from an intermediate surface to a substrate

Dies that are attached to a die plate can be transferred to a substrate. An actuator can be used to cause a die to be released from the die plate and to come into contact with the substrate. For example, the die may cover a corresponding hole in the die plate. The actuator can move a pin into the hole in the die plate, thereby pushing the die from the die plate. The actuator may be actuated by an electromagnetic stimulus. For instance, a solenoid having windings around a tubular core may provide the electromagnetic stimulus to the actuator. Current may be provided to the windings of the solenoid to generate the electromagnetic stimulus that actuates the actuator. The actuator may be provided in the tubular core of the solenoid.

Owner:SYMBOL TECH INC

Stent reducing system and device

ActiveUS7284401B2Reduce frictionMinimize adhesionShaping toolsStentsFluid bearing% diameter reduction

Owner:BOSTON SCI SCIMED INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com