Patents

Literature

94 results about "Metal forming process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal Forming Process. Metal forming is a manufacturing process in which forces are applied on raw material such that stresses induced in the material are greater than yield stress and less than ultimate stress. The material experiences plastic deformation to change the shape of the component and converted to the desired shape...

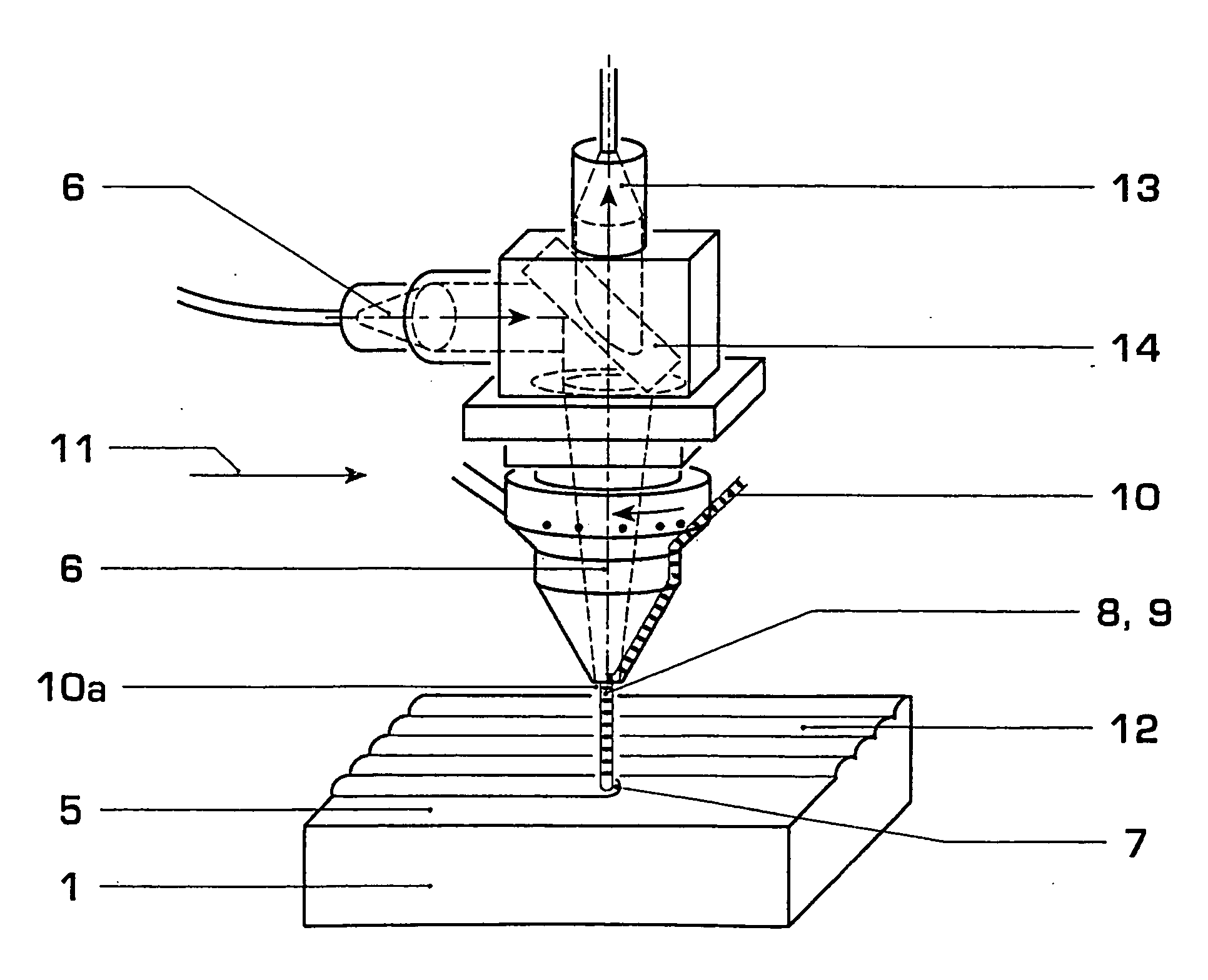

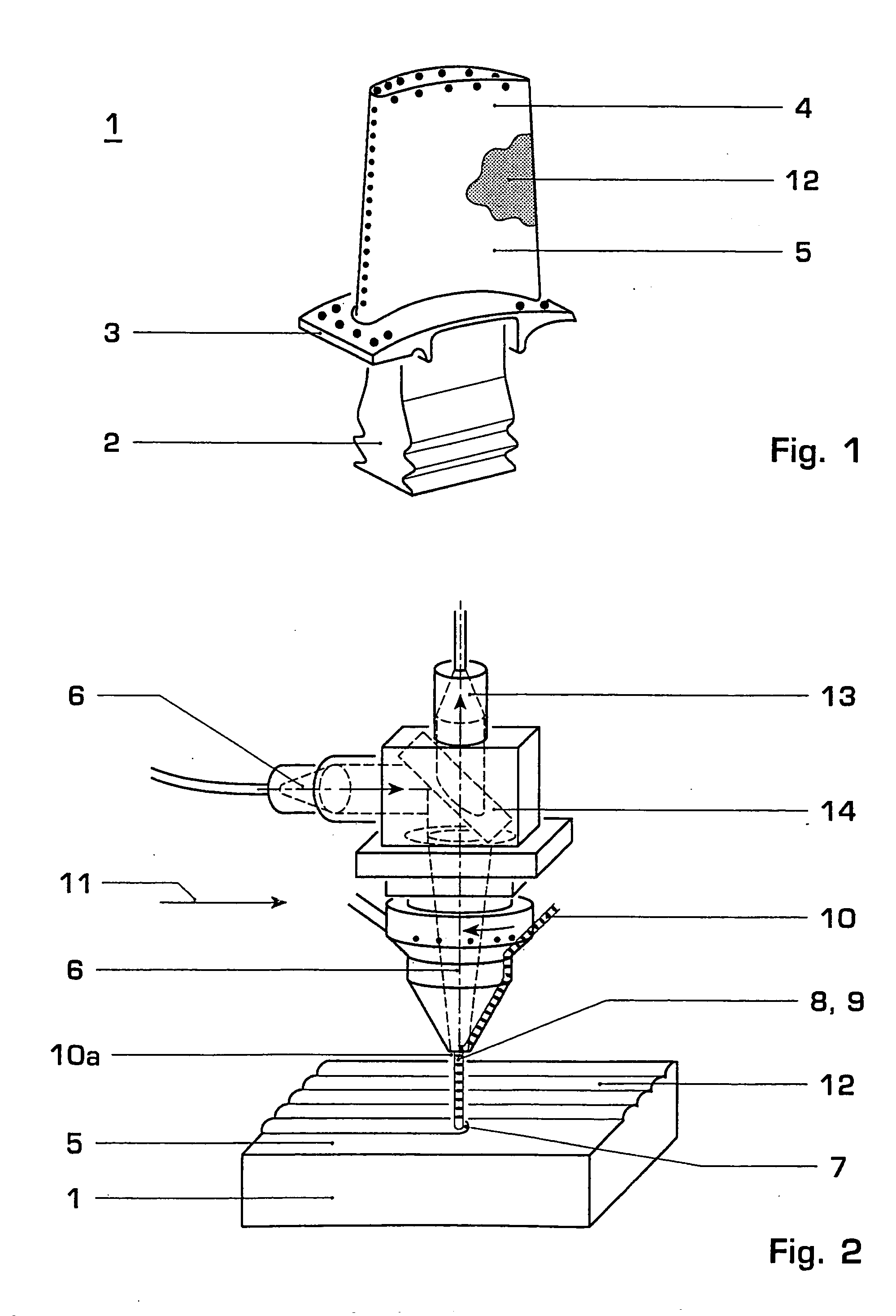

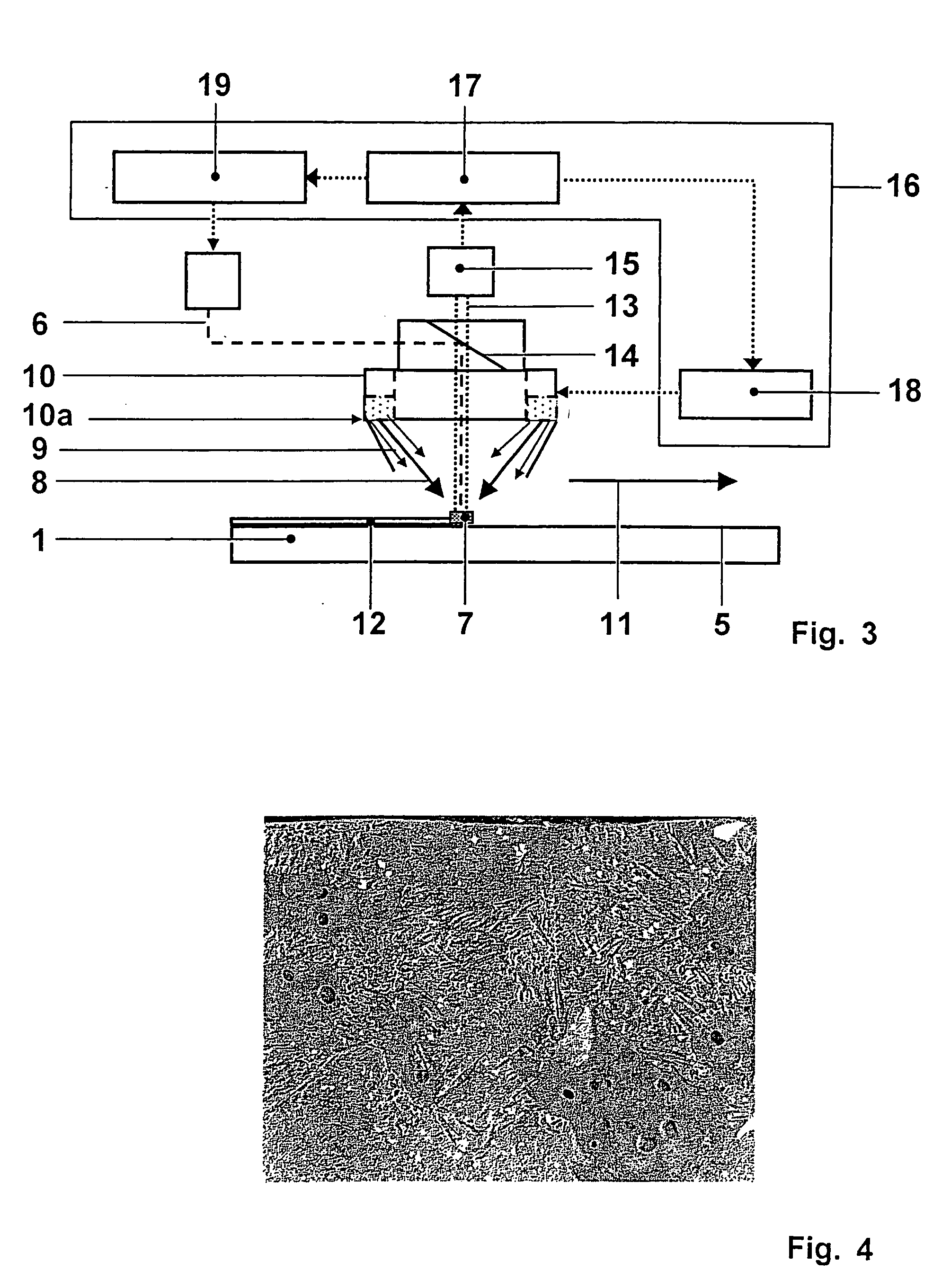

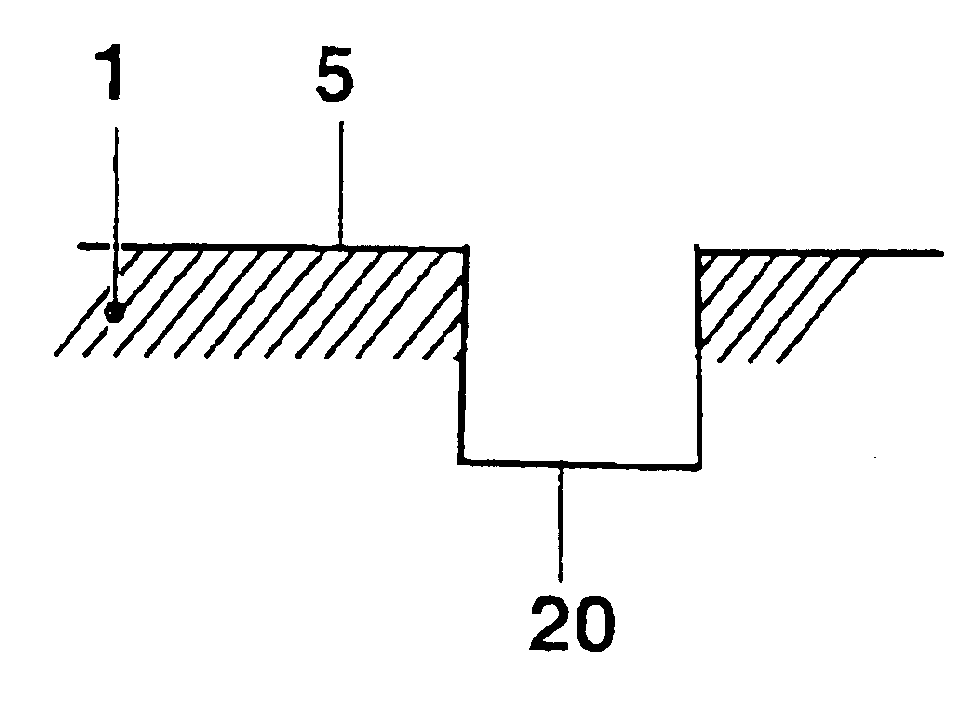

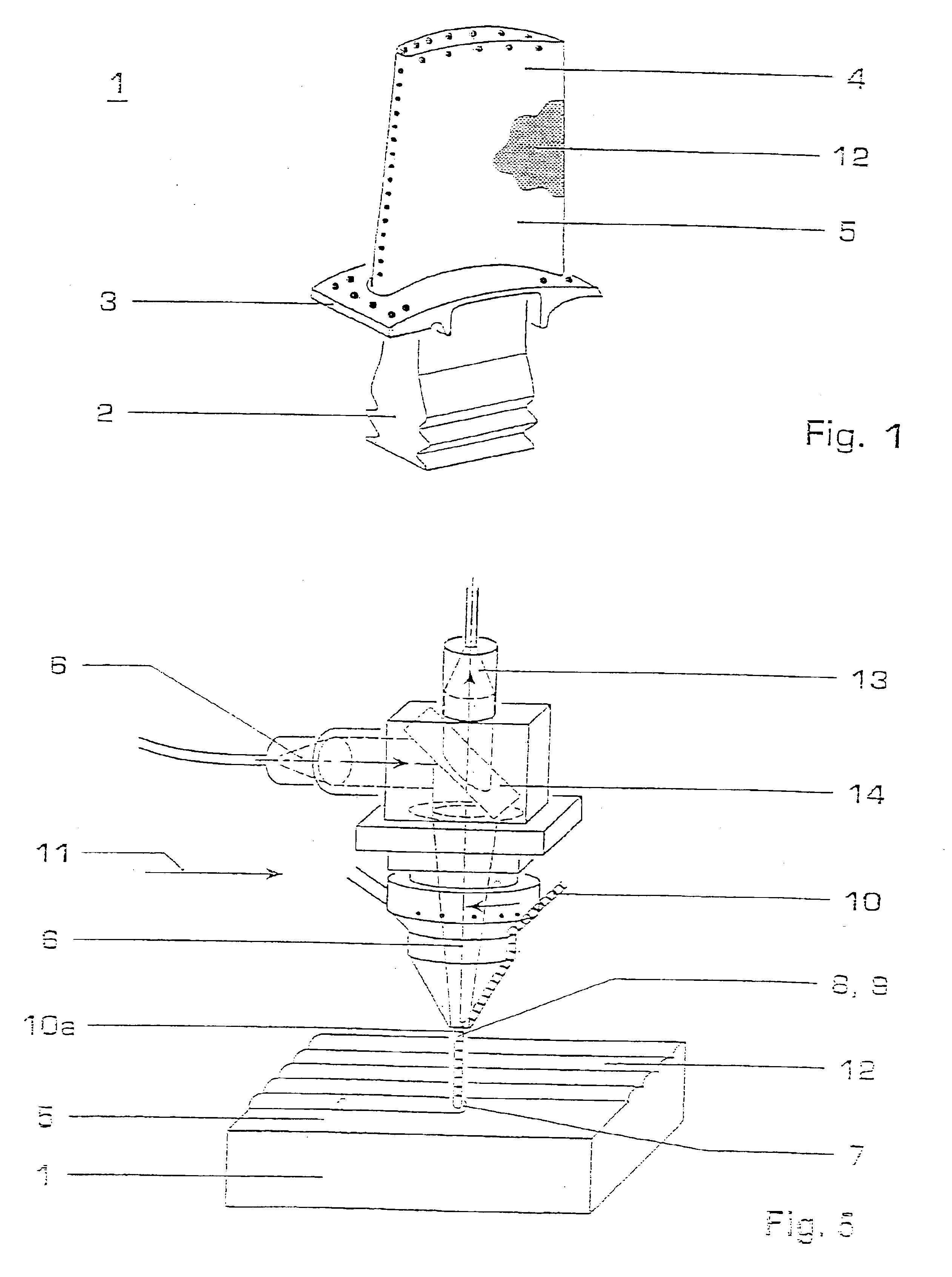

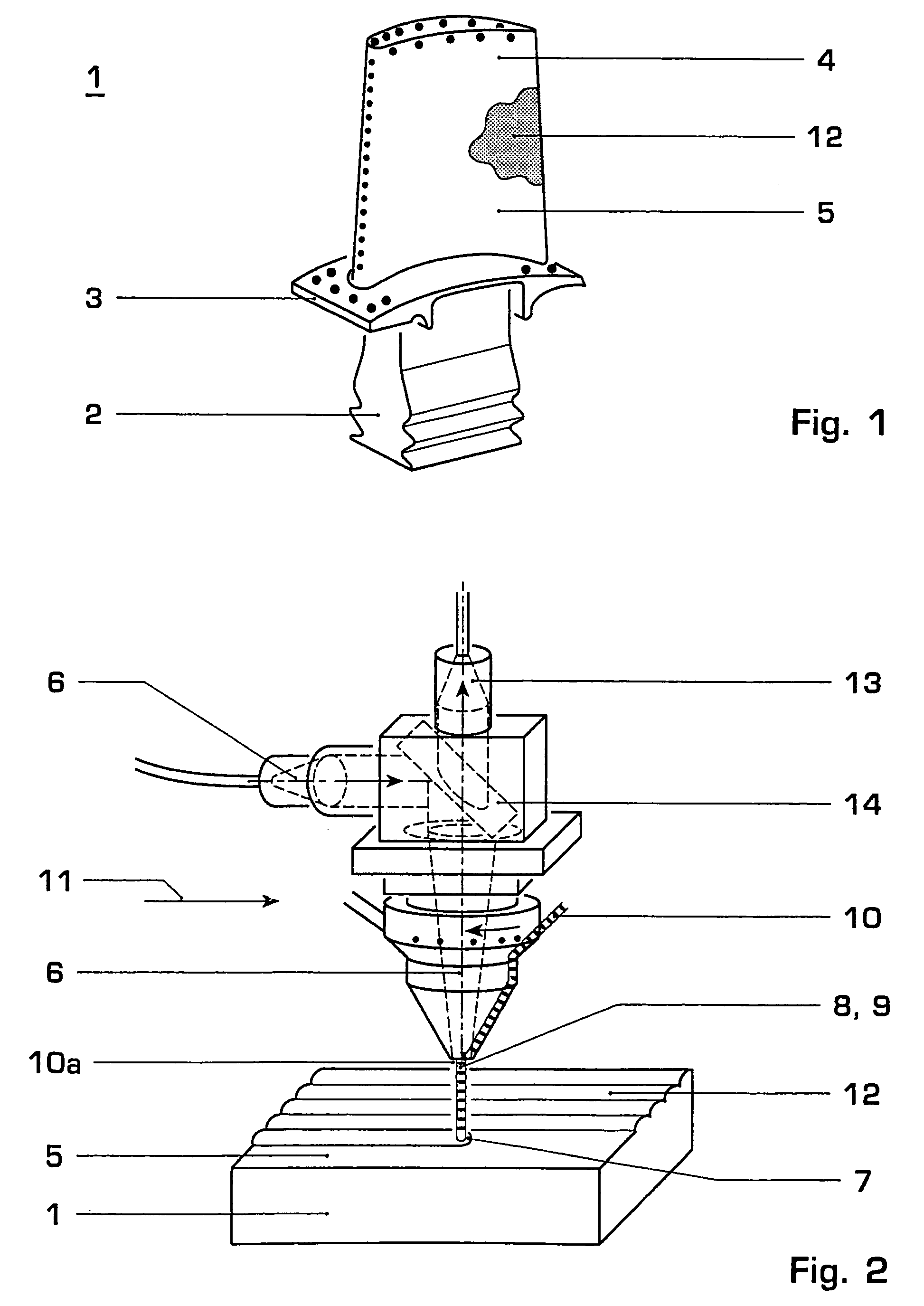

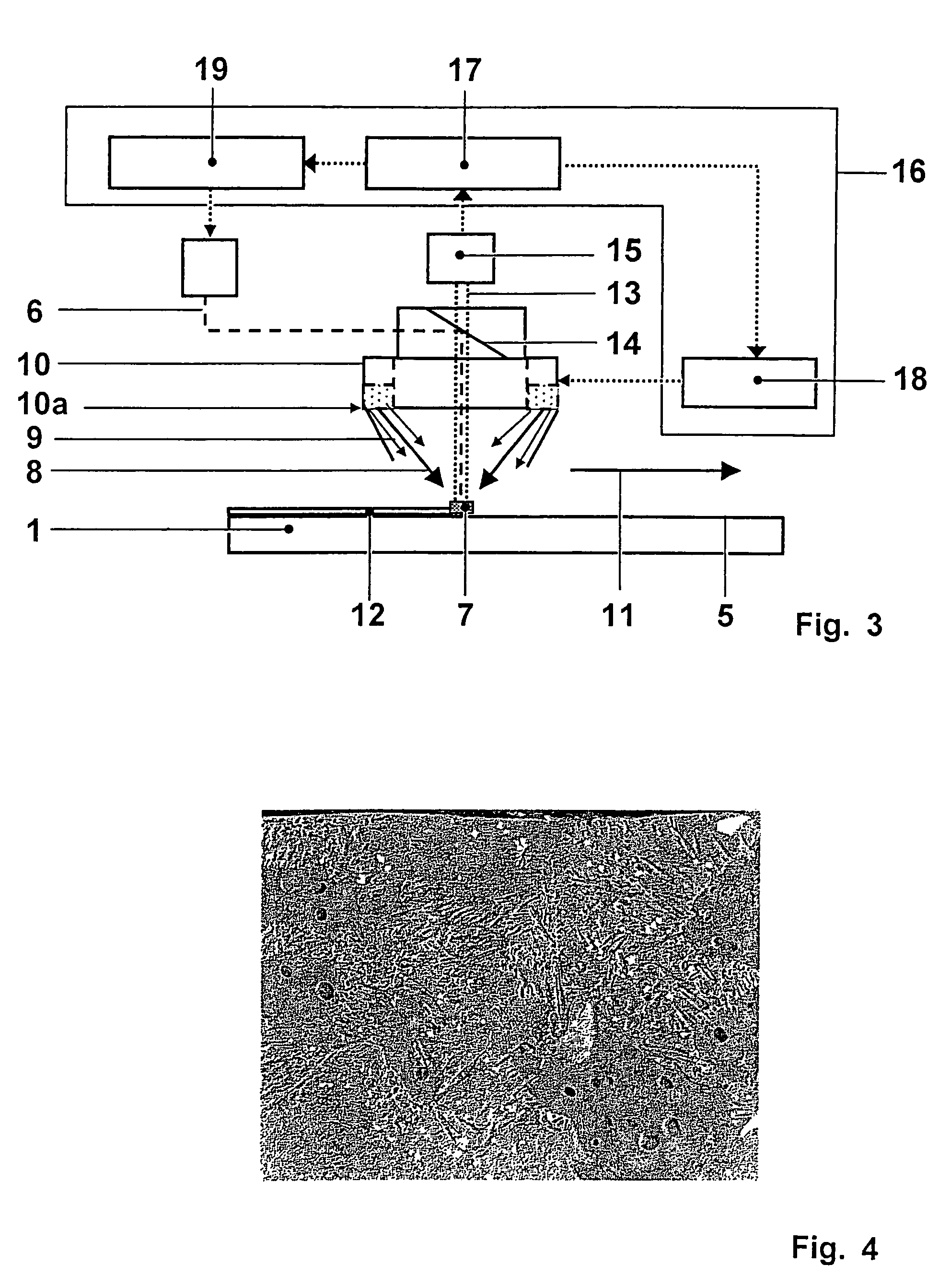

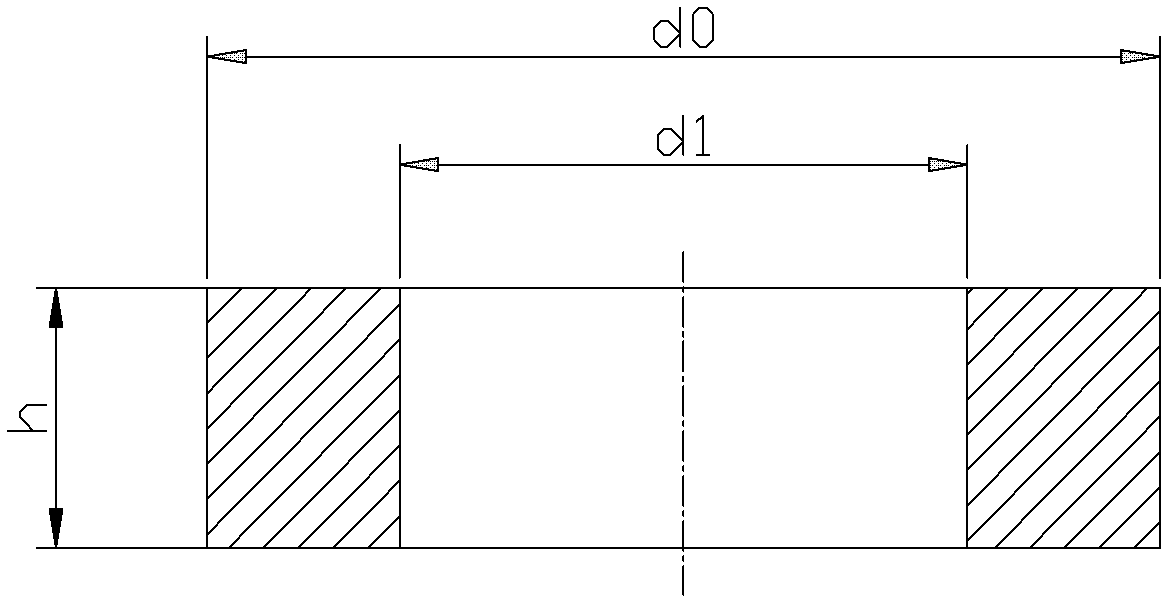

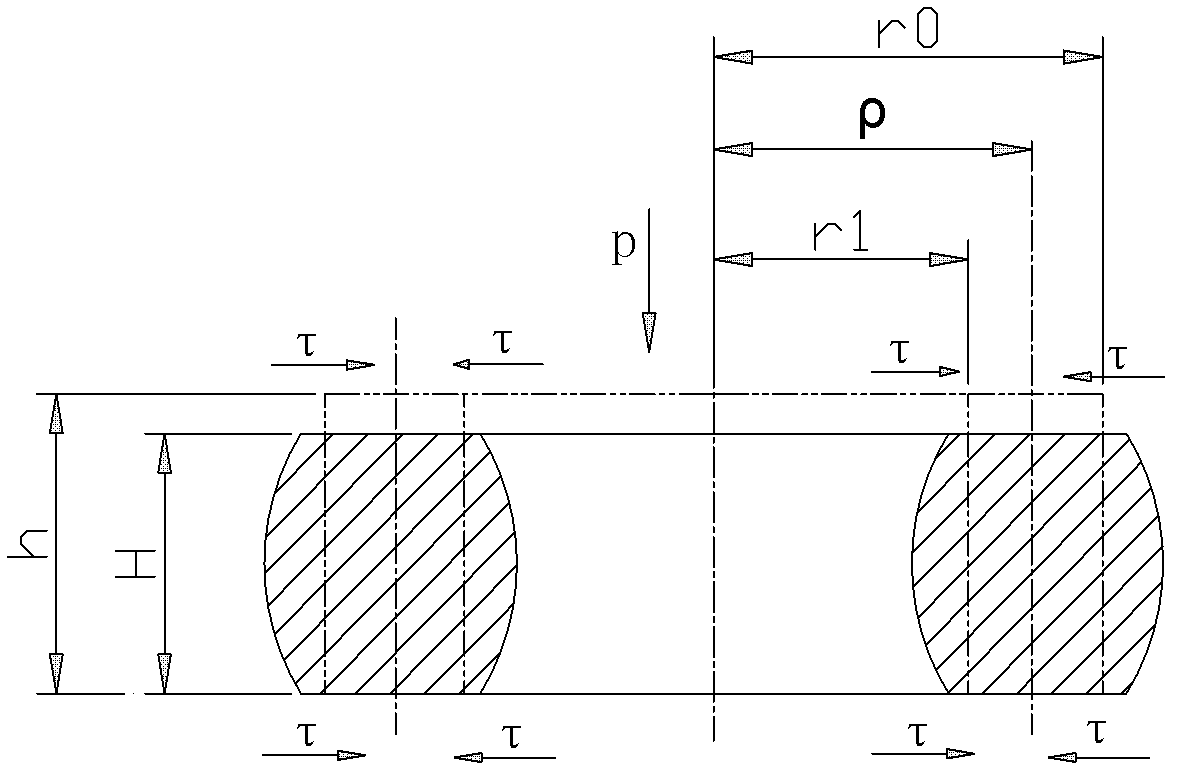

Method for controlling the microstructure of a laser metal formed hard layer

ActiveUS20060081571A1Function increaseShort timeTurbinesAdditive manufacturing apparatusControl systemMetal forming process

It is disclosed a method of applying a coating (12) with a controlled laser metal forming process. A light source with a specific power and a signal capturing apparatus is moved over an article (1) to form locally a melt pool (7) on the surface (5) of the article (1) to which a coating powder (8) is injected. An optical signal (13) is captured from the melt pool (7), and the monitored optical signal (13) is used for the determination of the temperature and temperature fluctuations of the melt pool (7). Furthermore, a control system (16) is used to adjust at least one process parameter such as the power of the light source to obtain desired melt pool properties. Subsequently the melt pool (7) solidifies. The high degree of control over the microstructure provides an efficient tool for generating laser metal formed hard coatings (12) with optimised wear properties.

Owner:ANSALDO ENERGIA IP UK LTD

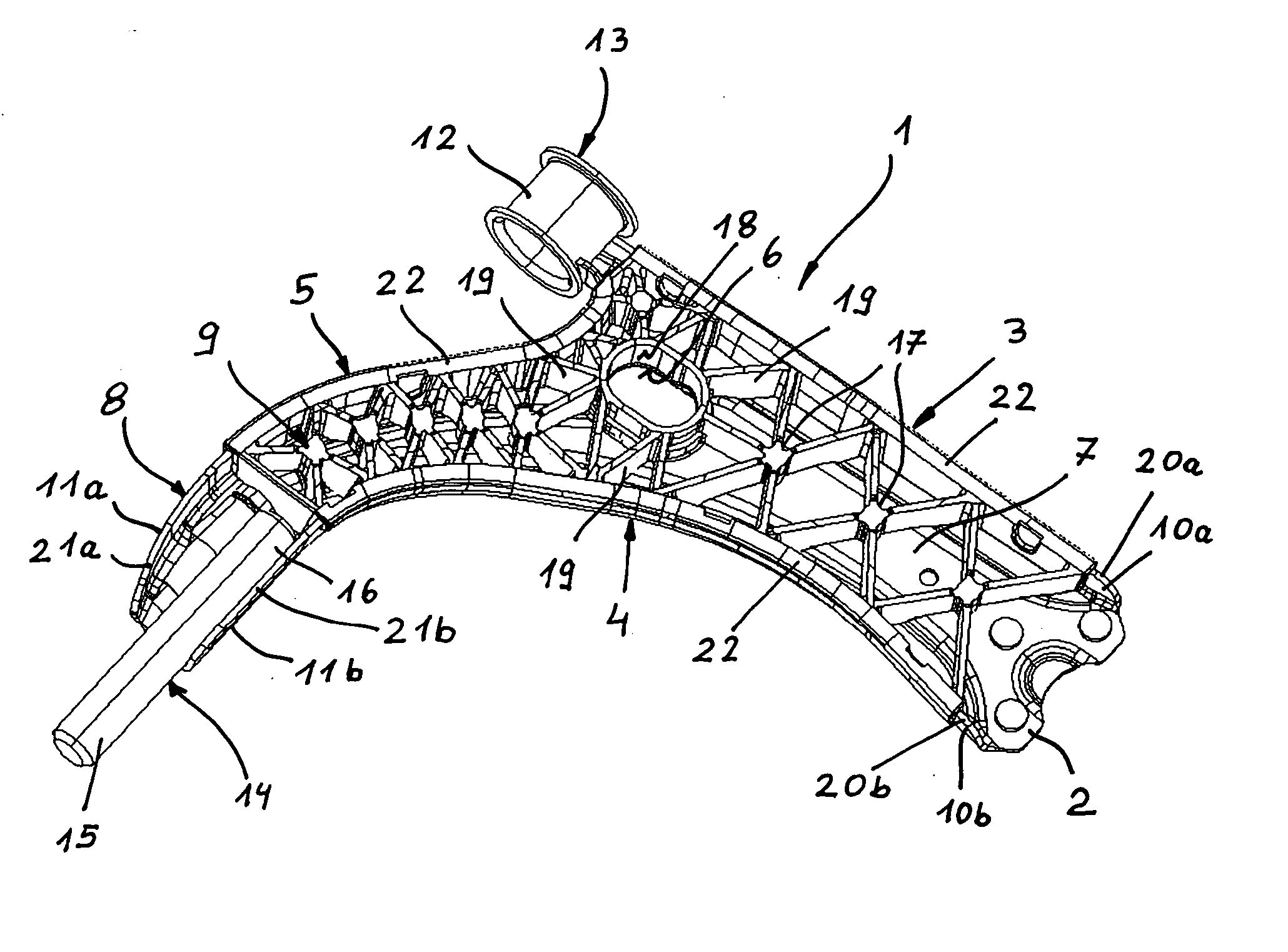

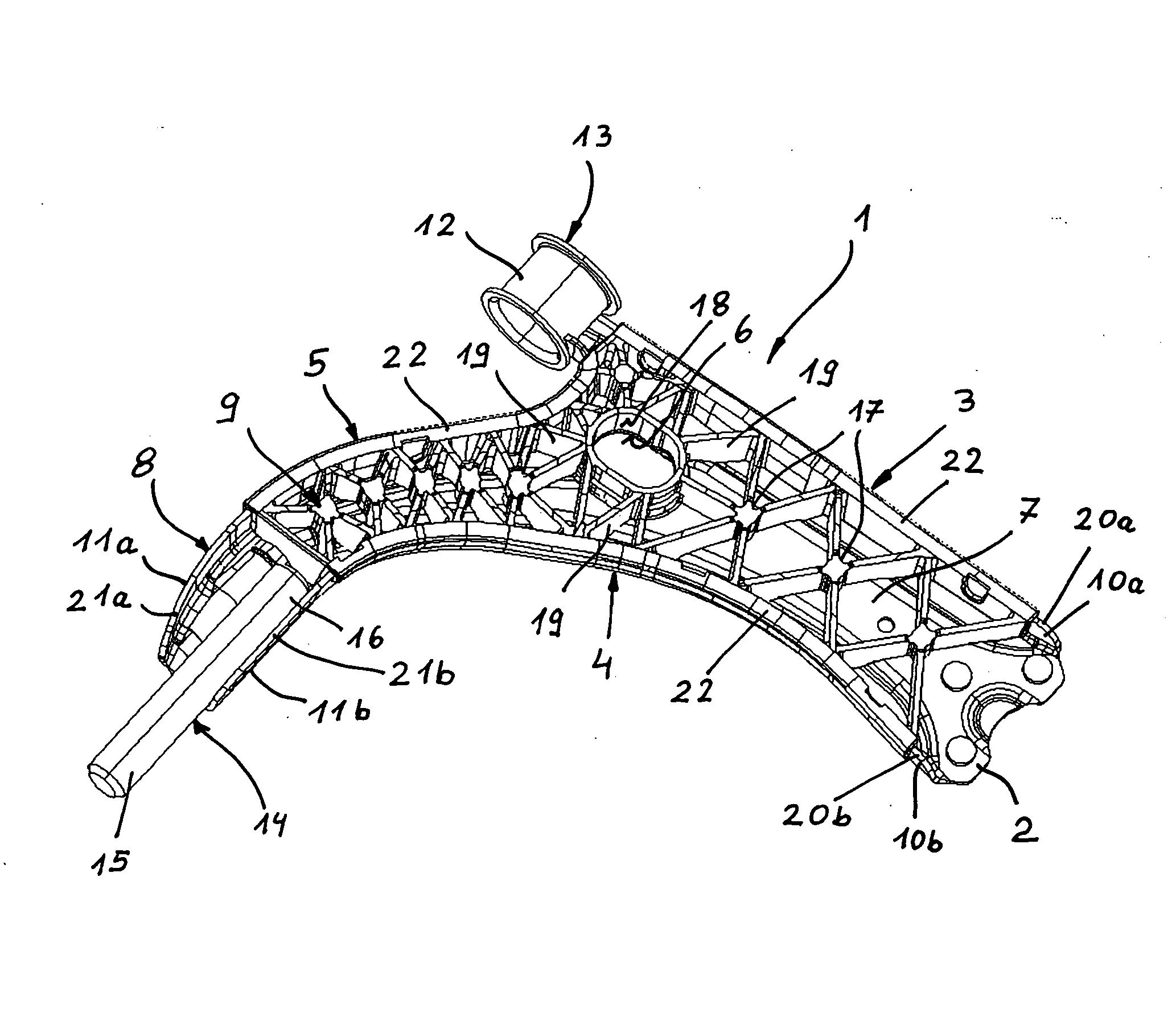

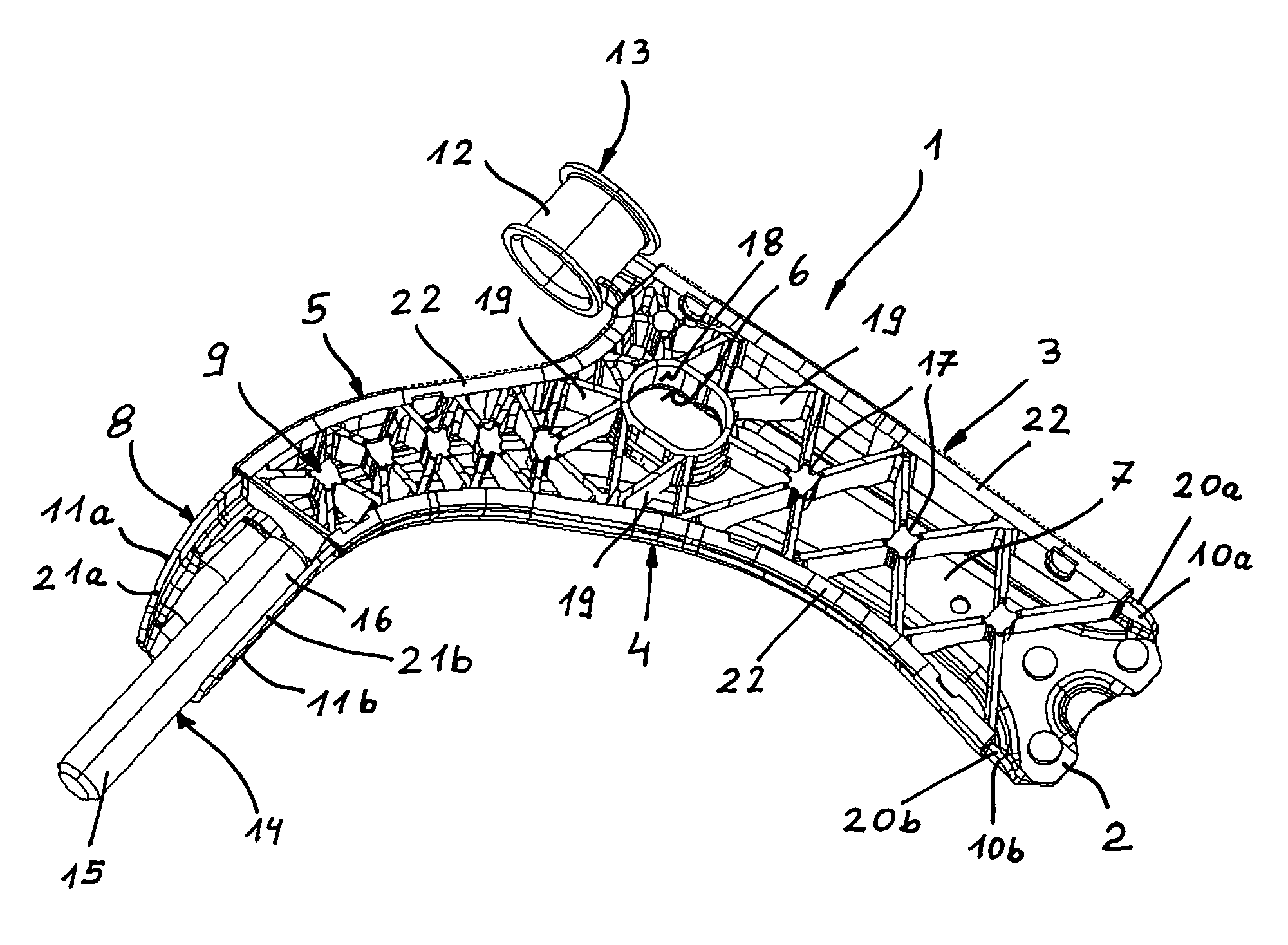

Control arm structure for wheel suspensions of motor vehicles, and method of making such a control arm structure

InactiveUS20060175786A1Low ductility potentialHigh strengthMouldsMetal-working apparatusControl armEngineering

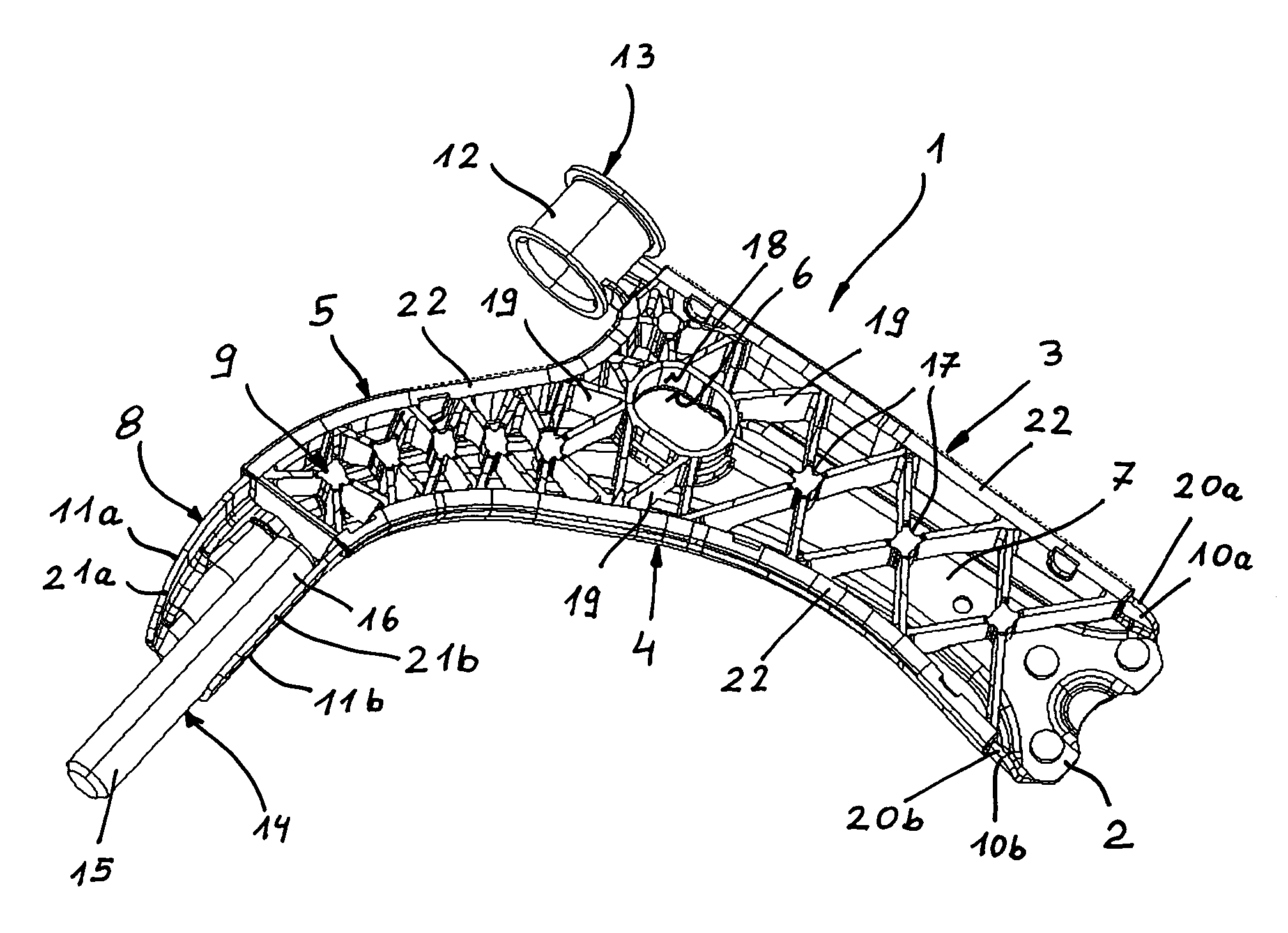

In a method of making a control arm for a wheel suspension of a motor vehicle a blank of steel material having a tensile strength of at least 800 MPa is shaped, using a sheet metal forming process, into a shell body having a center web and plural flank portions extending from the center web in a same direction. The flank portions are connected by a latticed reinforcement made of plastic, without application of a heat treatment process.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

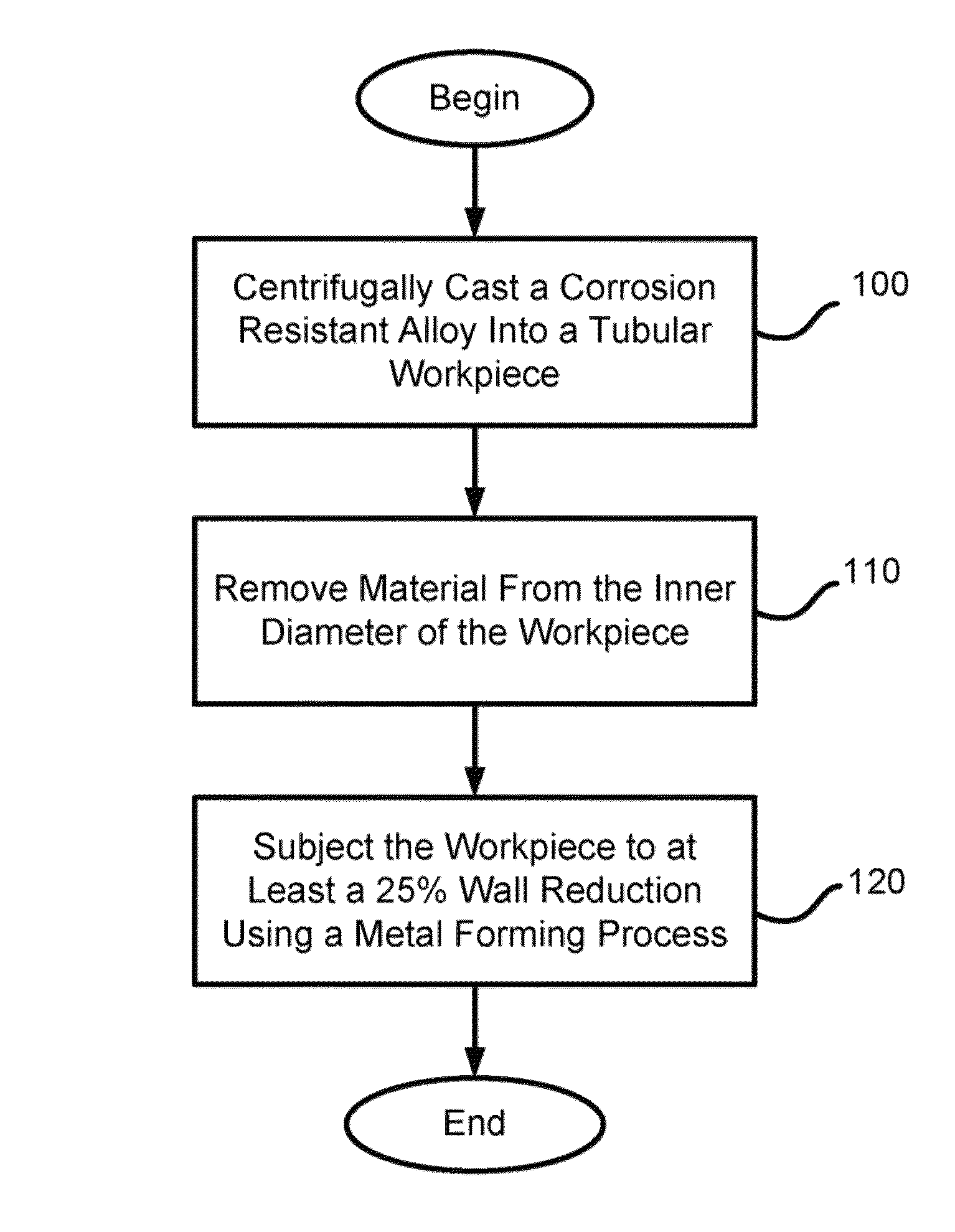

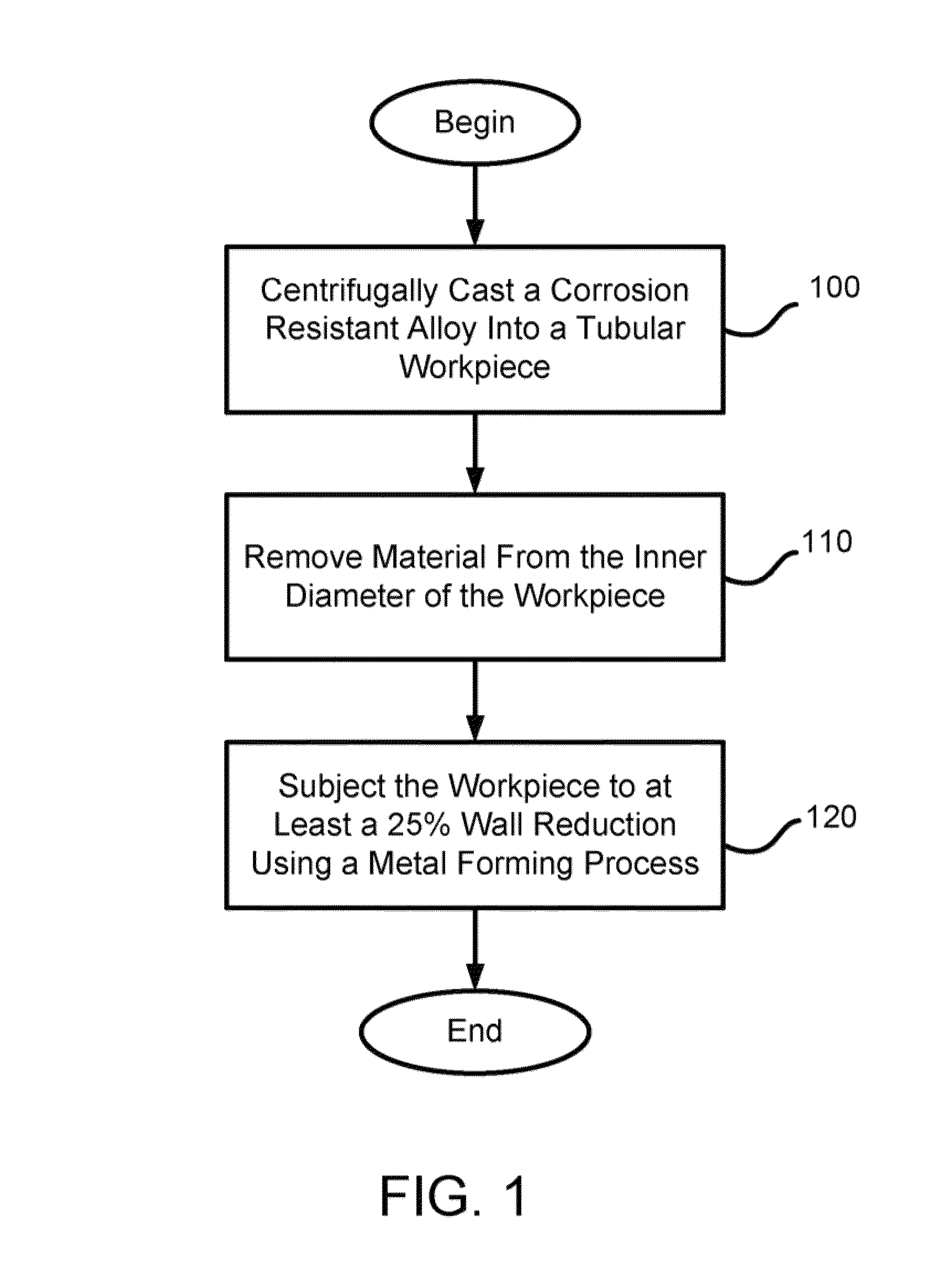

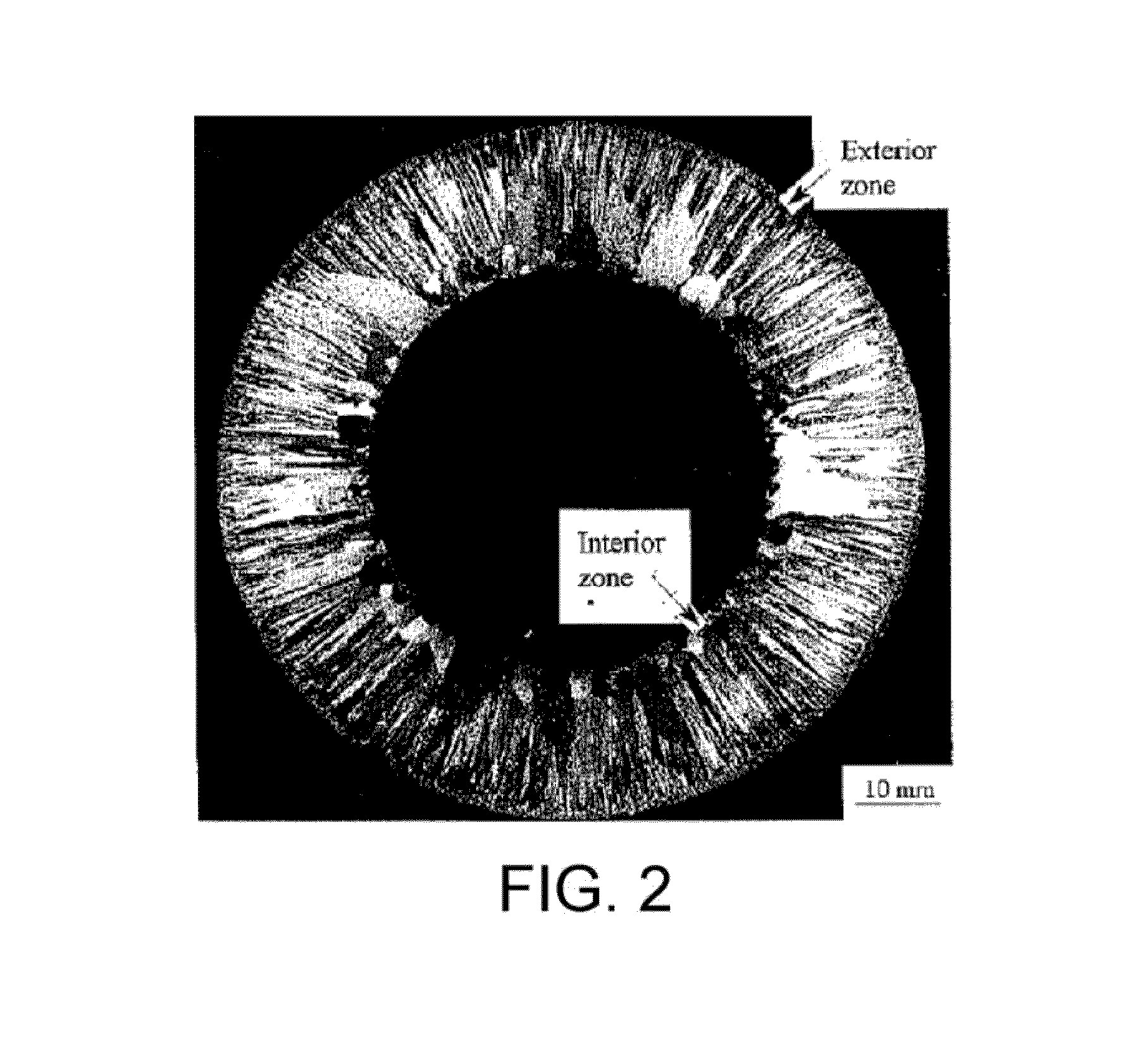

Method of producing cold-worked centrifugal cast tubular products

A method of producing a seamless, tubular product includes centrifugally casting a corrosion resistant alloy into a tubular workpiece having an inner diameter and an outer diameter. The method then removes material from the inner diameter of the workpiece and subjects the workpiece to at least about a 25% wall reduction at a temperature below a recrystallization temperature of the workpiece using a metal forming process. The metal forming process includes radial forging, rolling, pilgering, and / or flowforming.

Owner:ATI FLOWFORM PROD

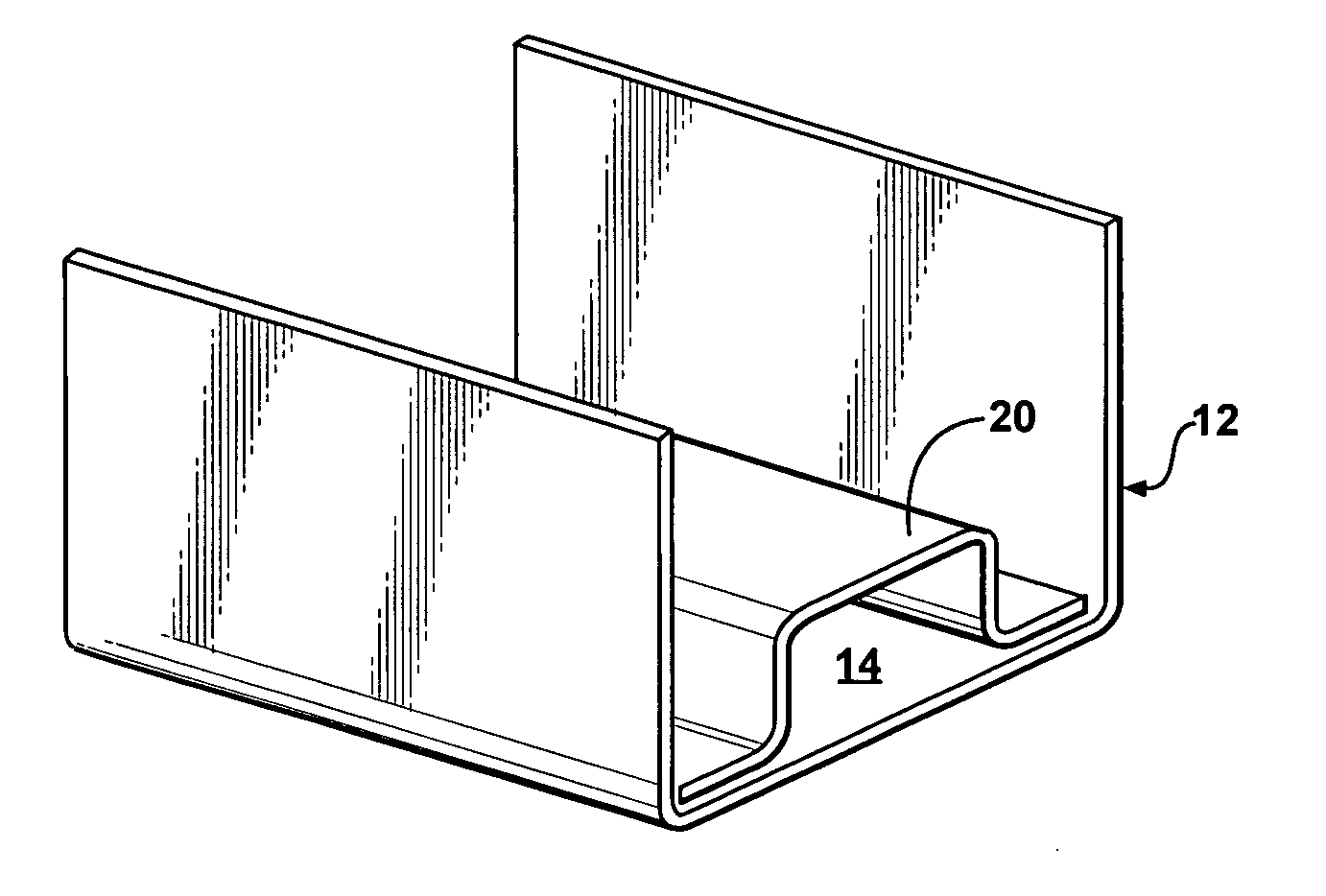

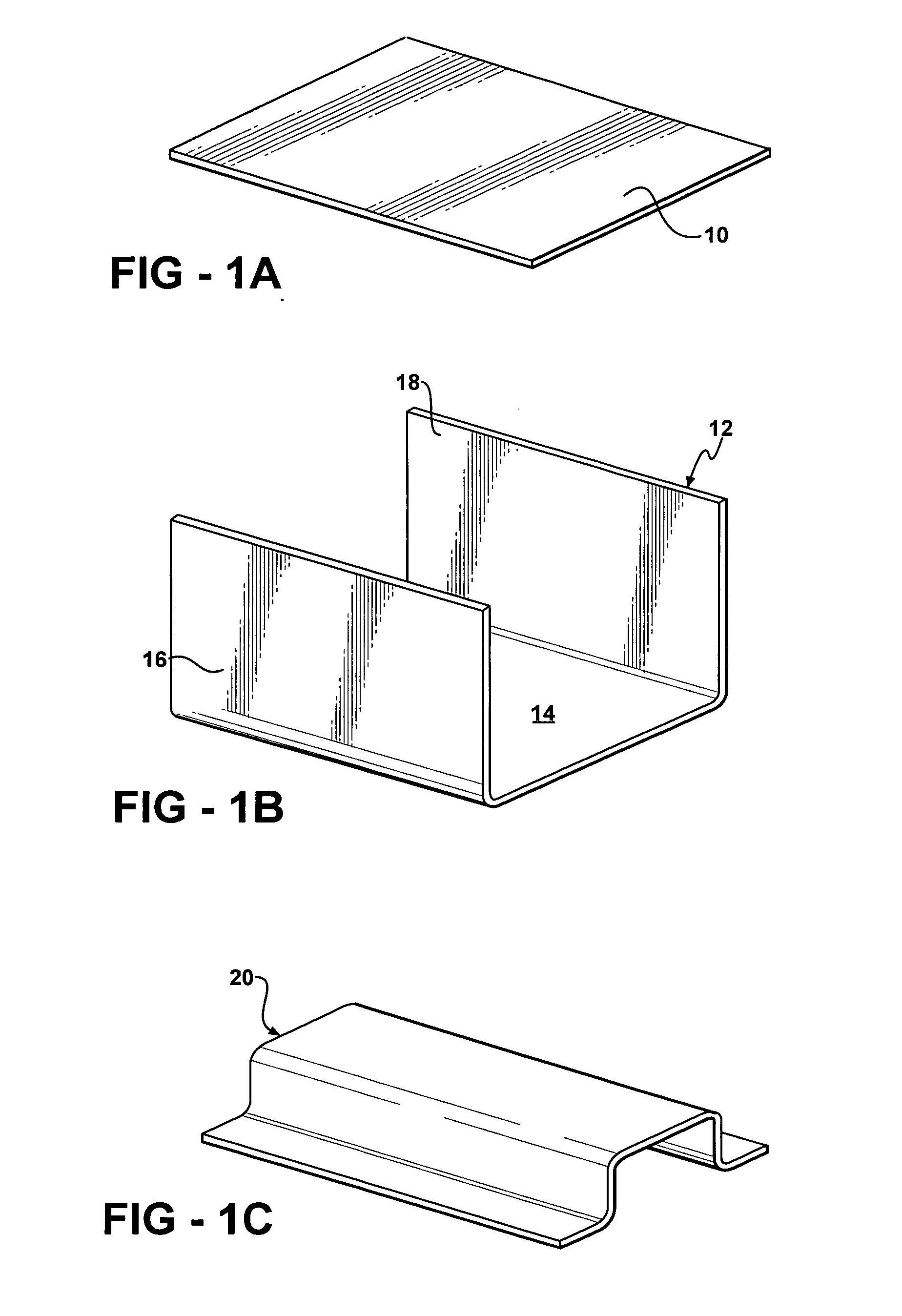

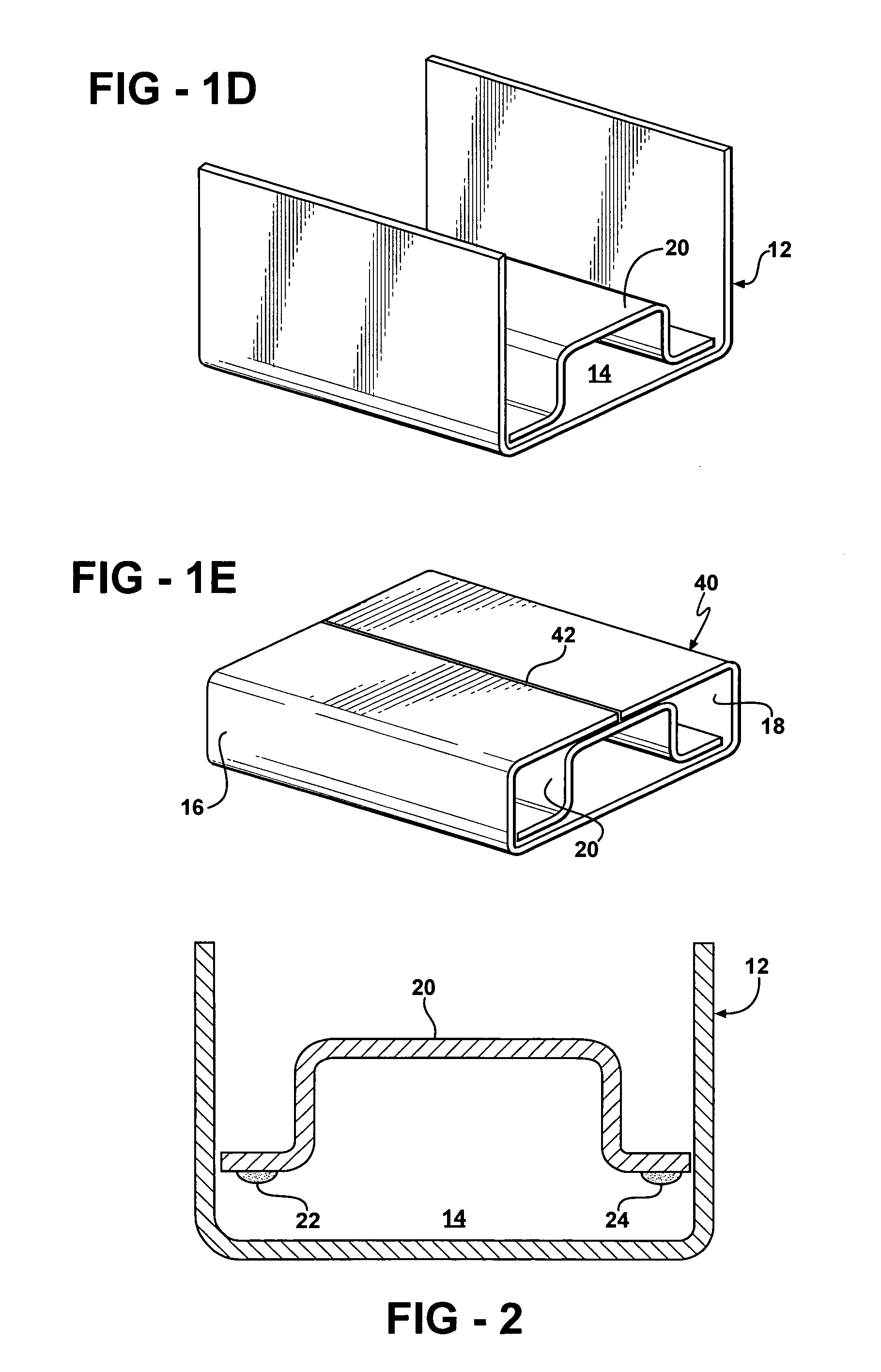

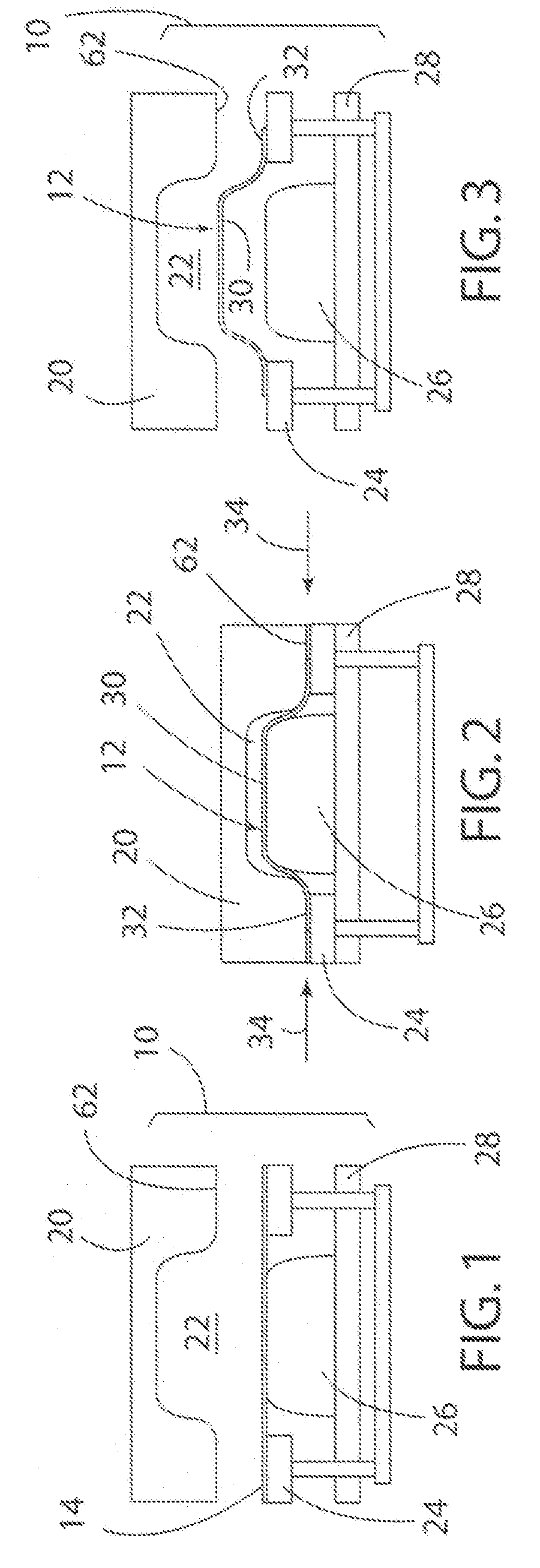

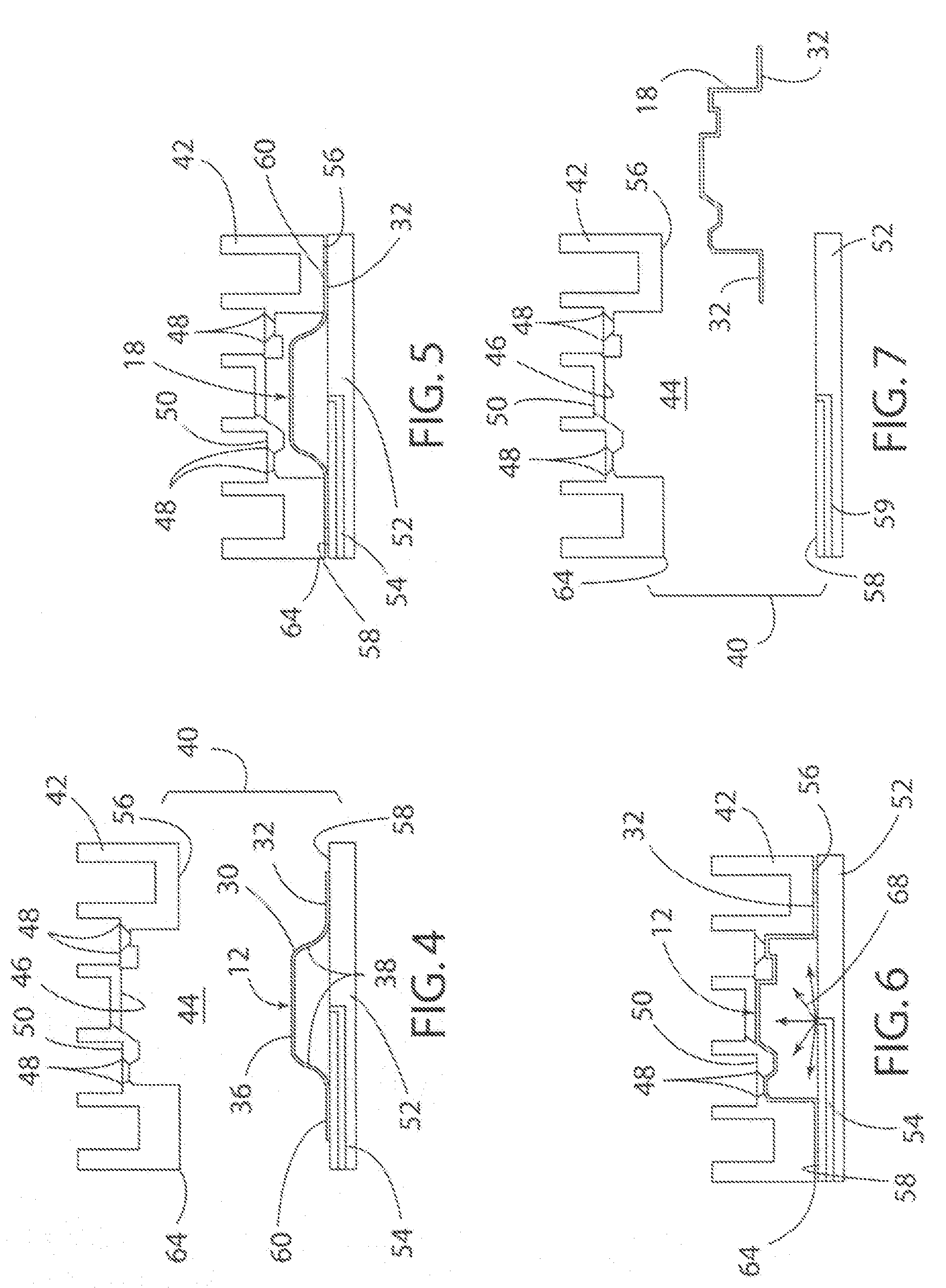

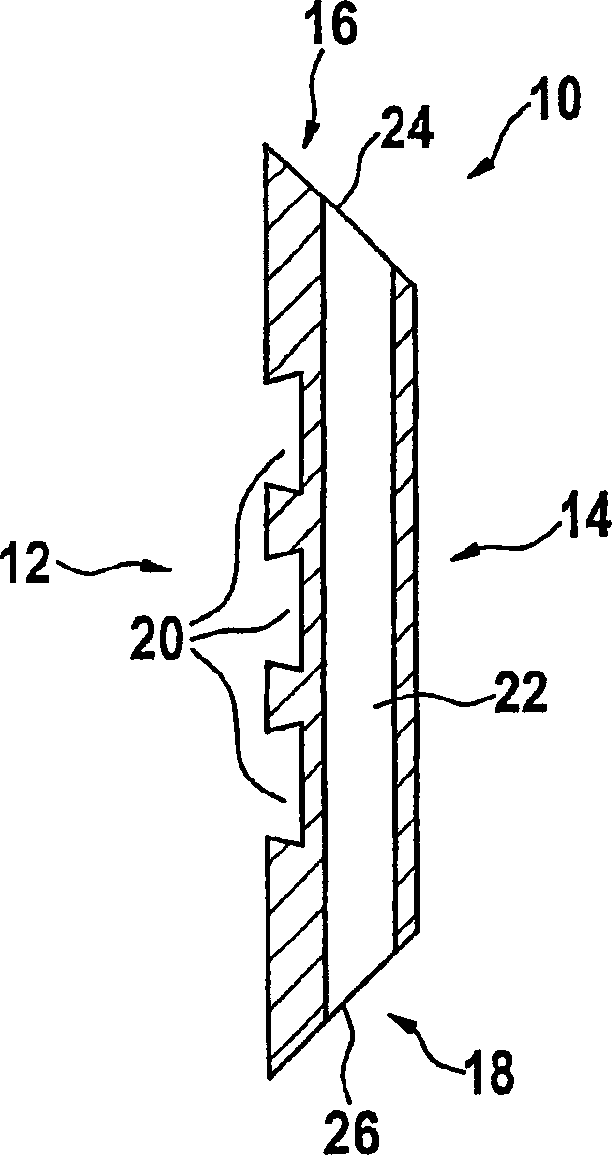

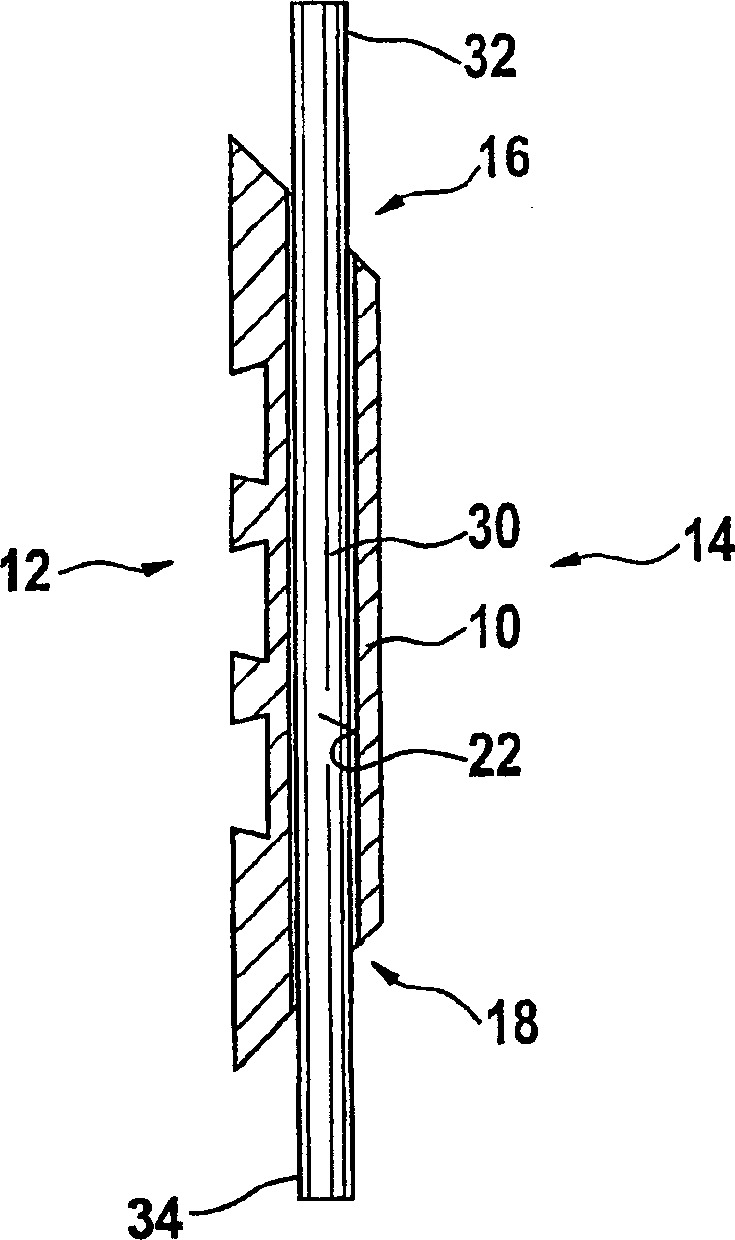

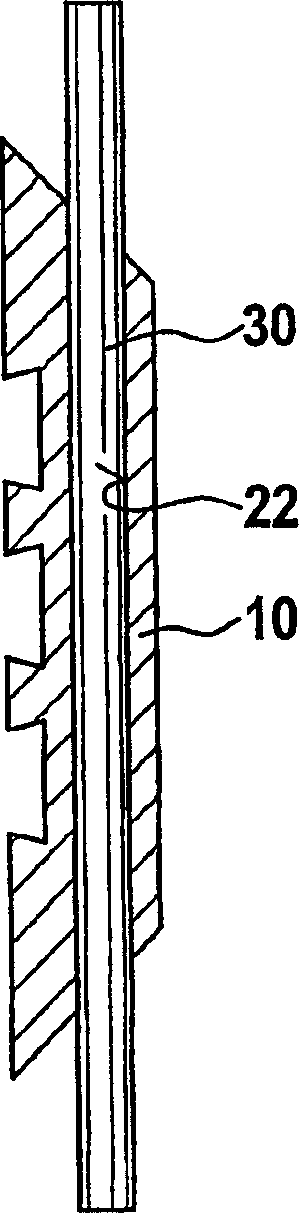

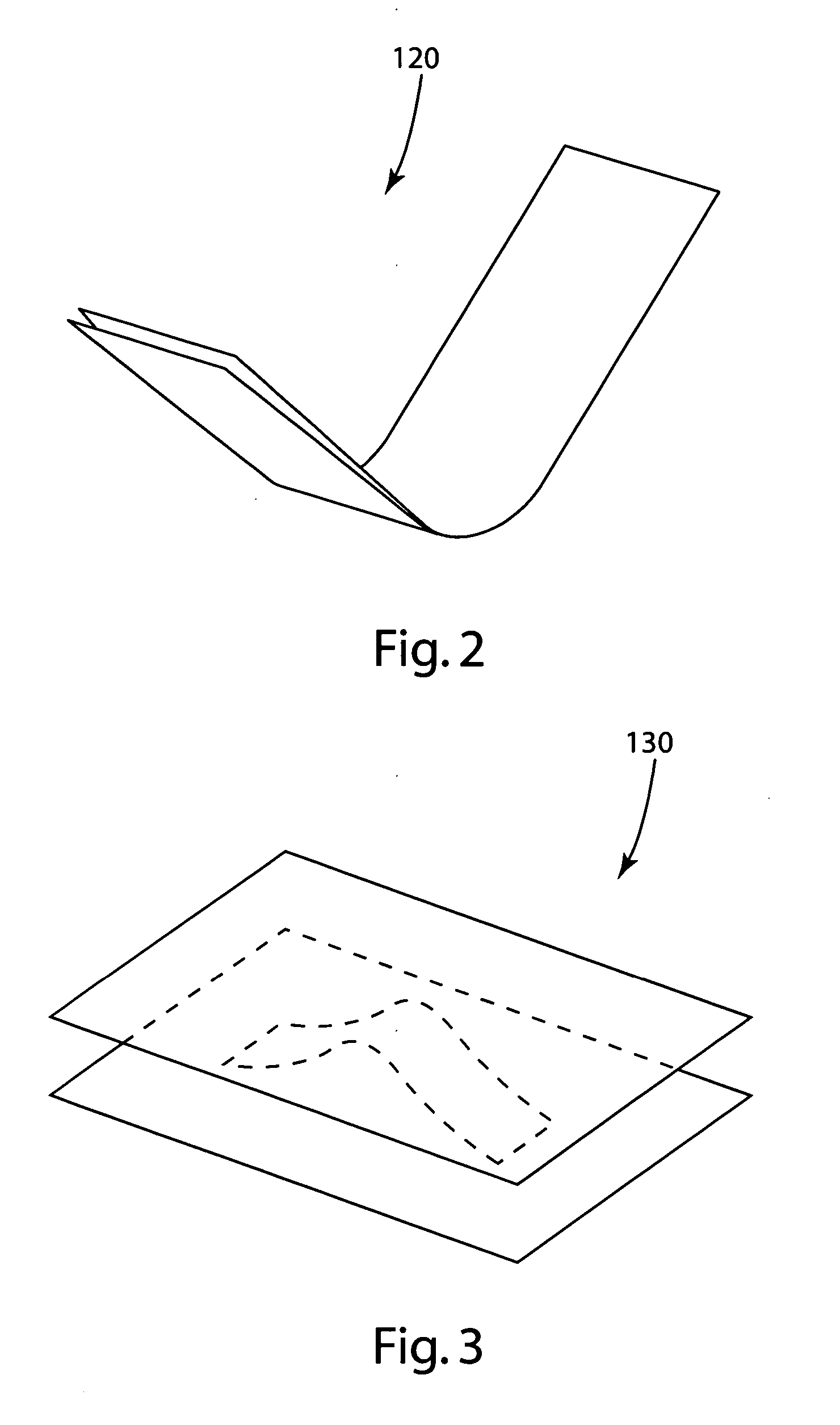

Method for manufacturing a reinforced structural component, and article manufactured thereby

A reinforced structural component is manufactured by forming an intermediate structural member which defines a channel extending along at least a portion of its length. A support member is disposed in the channel and affixed to the intermediate structural member. A second forming operation is carried out on the combination of the intermediate structural member and support member so as to partially enclose and fixedly retain the support member therein. The method may be applied to metallic and nonmetallic structures, and may be utilized in conjunction with high speed metal forming processes such as roll forming. Disclosed herein are structures made according to the method as well as use of the method in the manufacture of structural components for motor vehicles.

Owner:NOBLE ADVANCED TECH

Method for fabricating, modifying or repairing of single crystal or directionally solidified articles

ActiveUS6998568B2Ill effectQuality of jointTurbinesAdditive manufacturing apparatusSingle crystalMetal forming process

It is disclosed a method for fabricating, modifying or repairing of single crystal or directionally solidified articles. Two single crystal or directionally solidified prefabricated parts are joint by isothermally brazing using a brazing material. After that an epitaxial or non-epitaxial layer on the surface of the created article and of the braze joint is applied using a laser metal forming process.

Owner:ANSALDO ENERGIA IP UK LTD

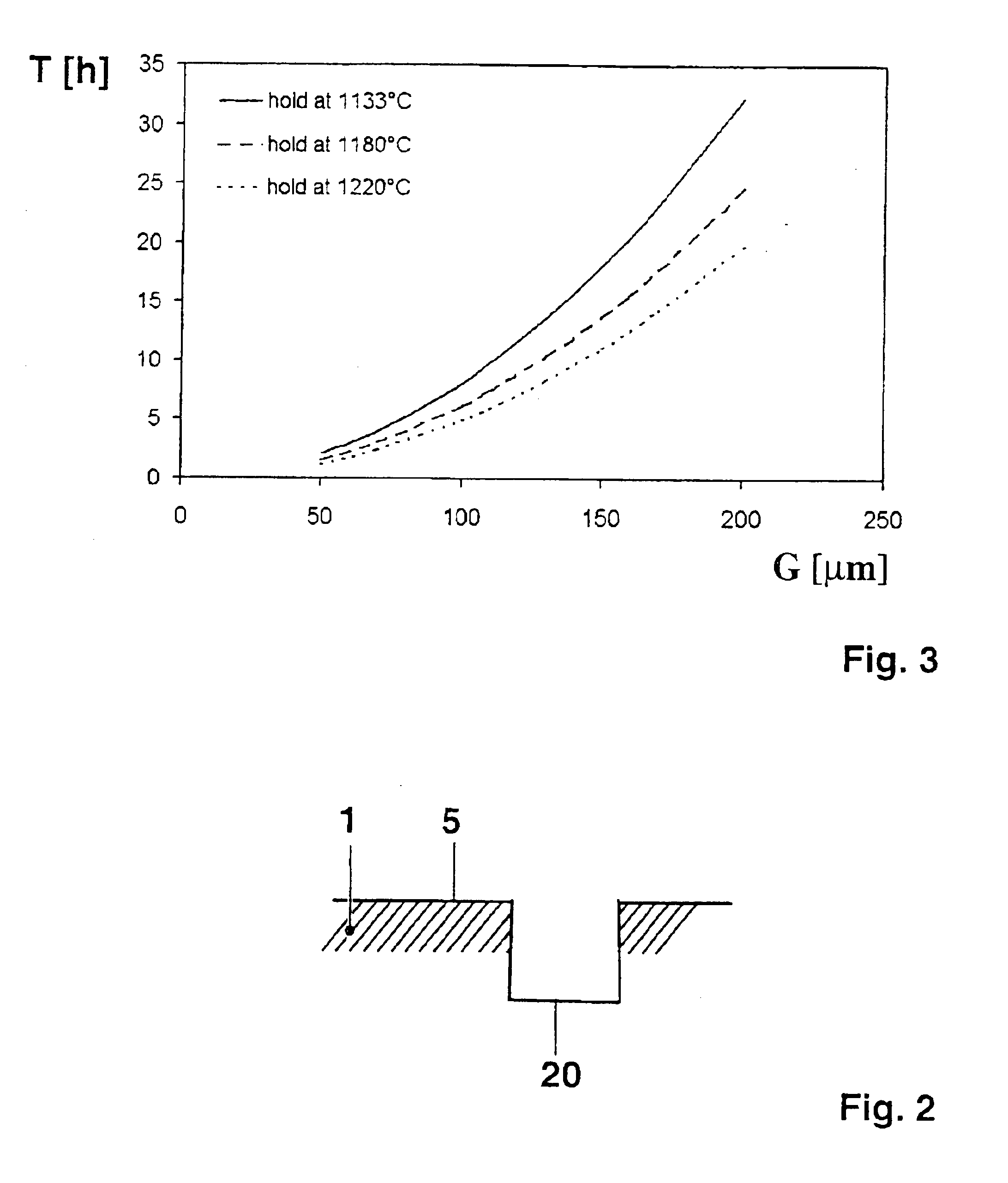

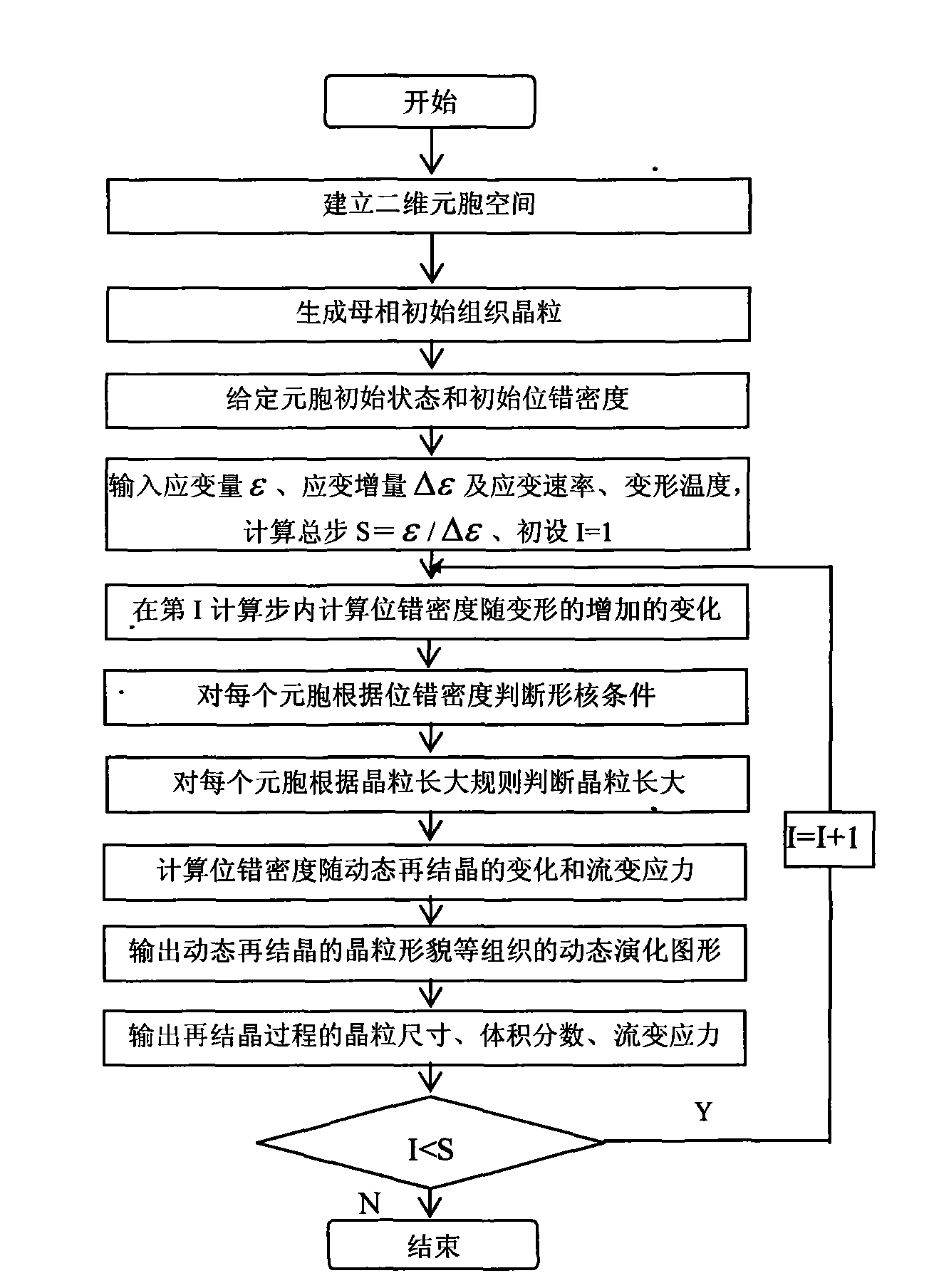

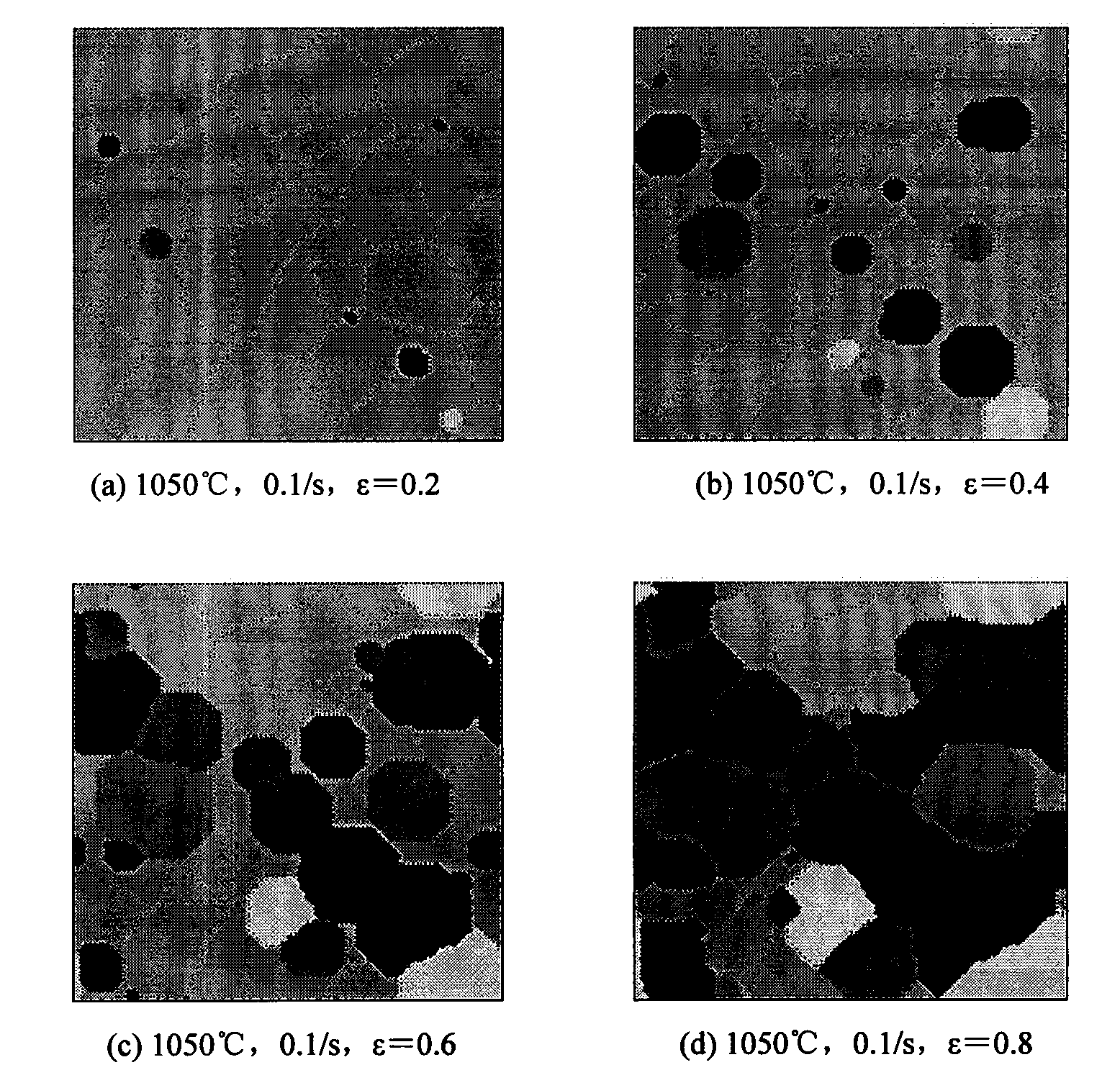

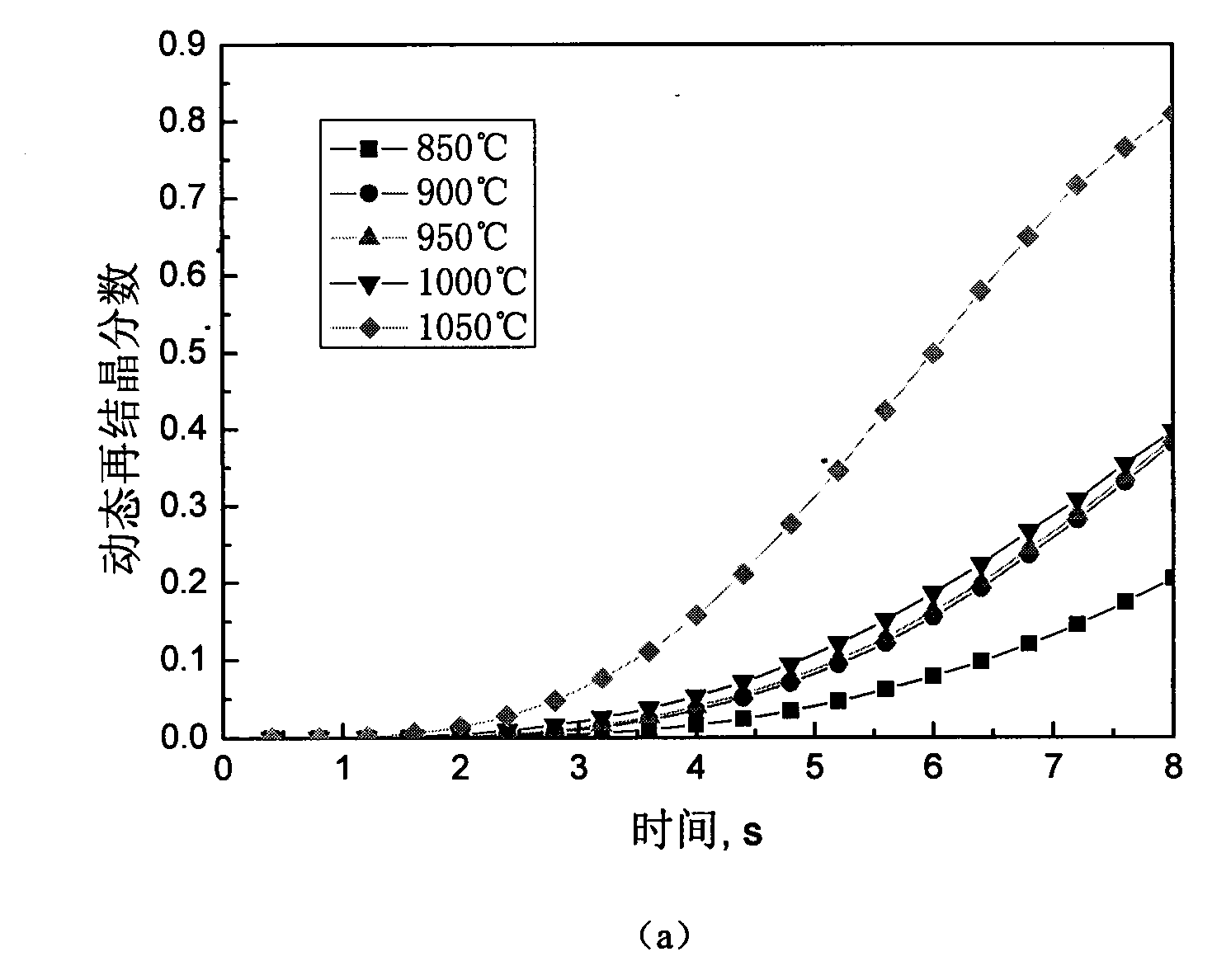

Method for predicting structure evolution of austenite dynamic recrystallization in thermal deformation of plate-strip steel

InactiveCN101591729AAccelerate development cycleQuantitativeHeat treatment process controlFlow stressCellular automation

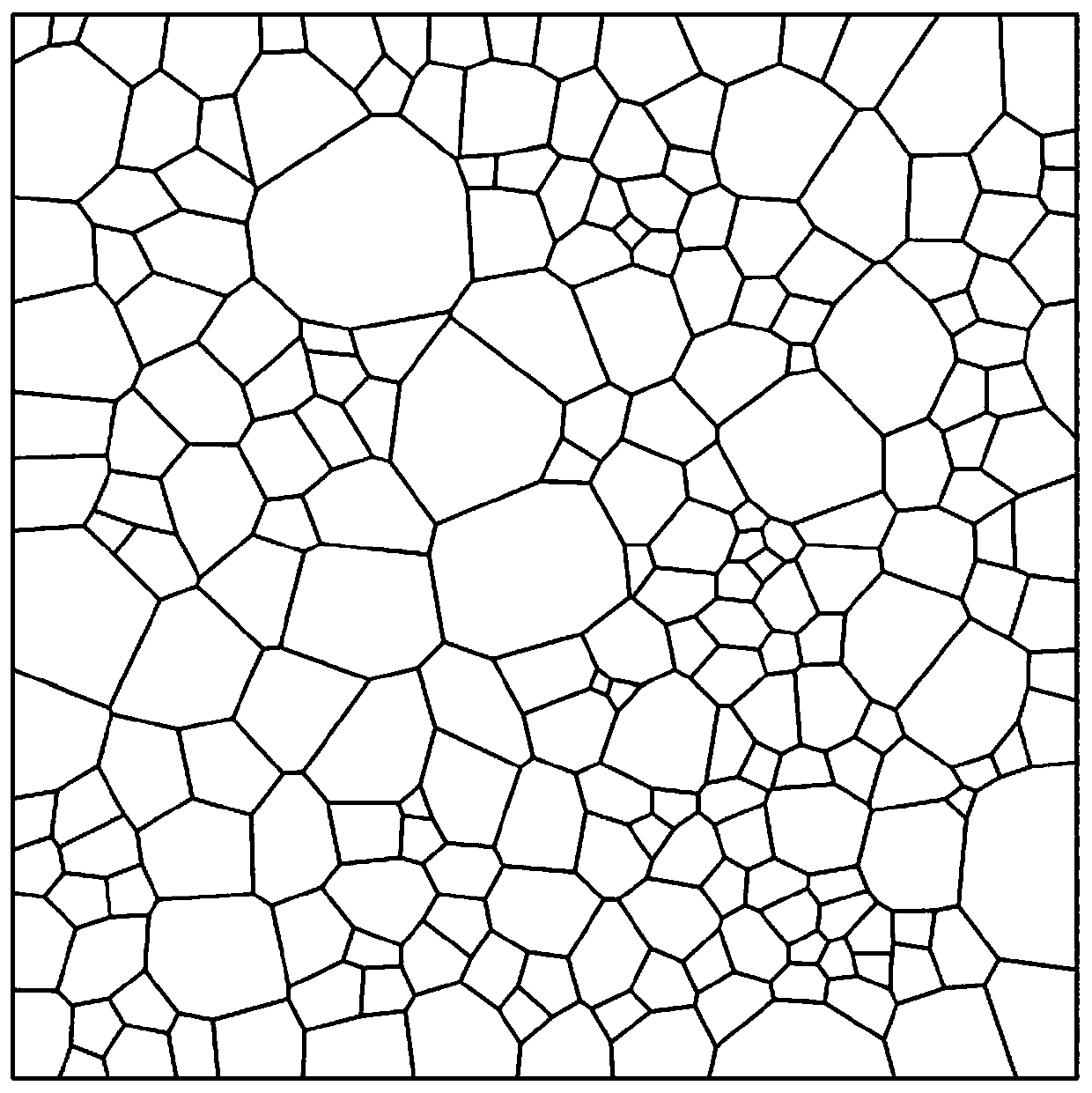

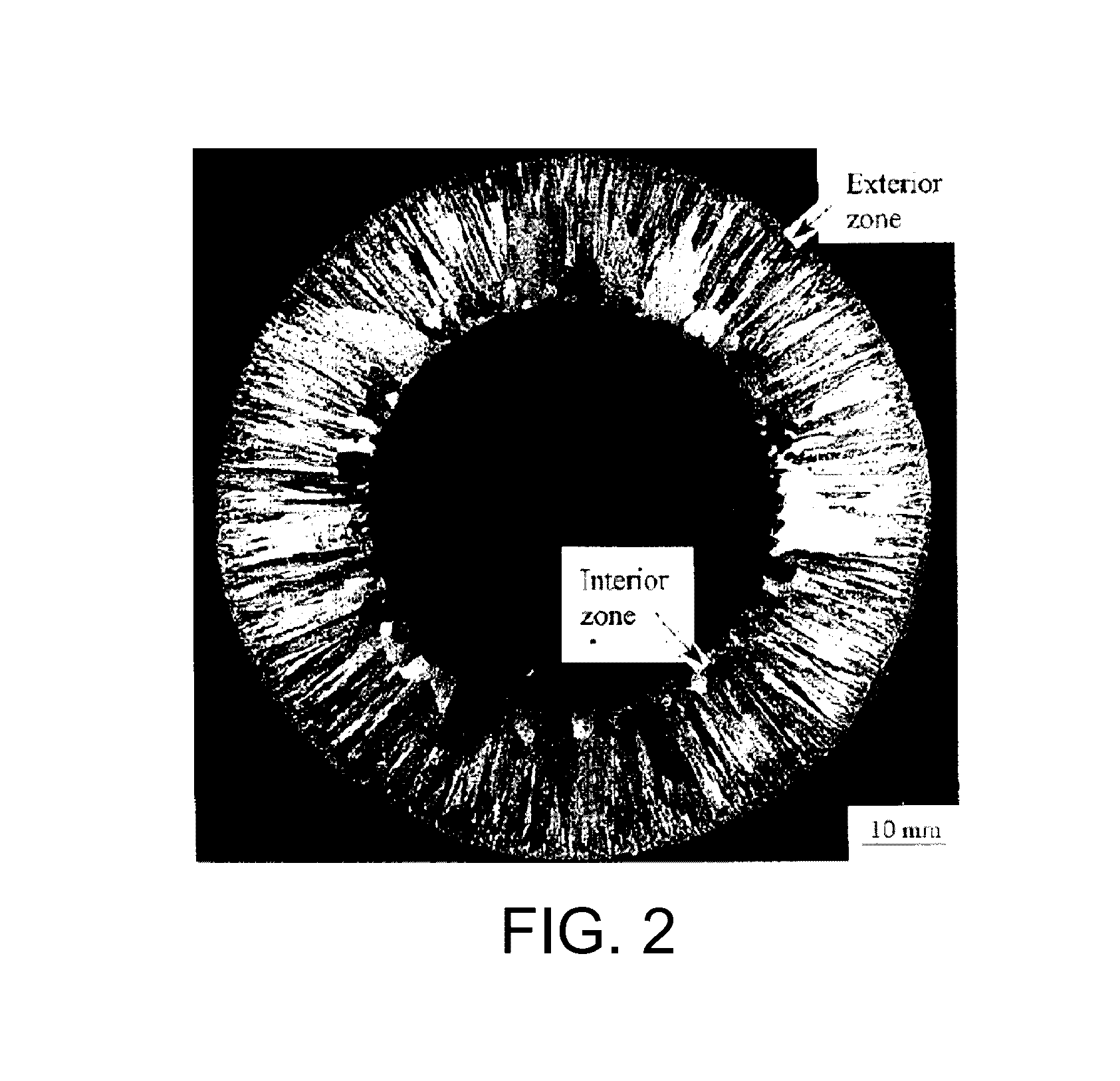

The invention relates to a method for predicting structure evolution of austenite dynamic recrystallization in thermal deformation of plate-strip steel, which belongs to the technical field of steel rolling. The method achieves the predictions of the transformed fraction, the grain size, the grain morphology and the flow stress of dynamic recrystallization by establishing a dynamic recrystallization physical metallurgical model and a dynamic recrystallization cellular automation model. The method achieves the reproduction of the structure evolution of a metal forming process by a computer, not only can save the experimental cost, but also can accelerate the development cycle of a new type of steel. The developed method for predicting the structure evolution of the austenite dynamic recrystallization in the thermal deformation of the plate-strip steel achieves the quantitative, precise and visual descriptions of the grain morphology, the volume fraction and the grain size of the recrystallization process, and can obtain important parameters of the flow stress and the like, thus the method is significant in further analyzing the evolution law of microstructures.

Owner:NORTHEASTERN UNIV

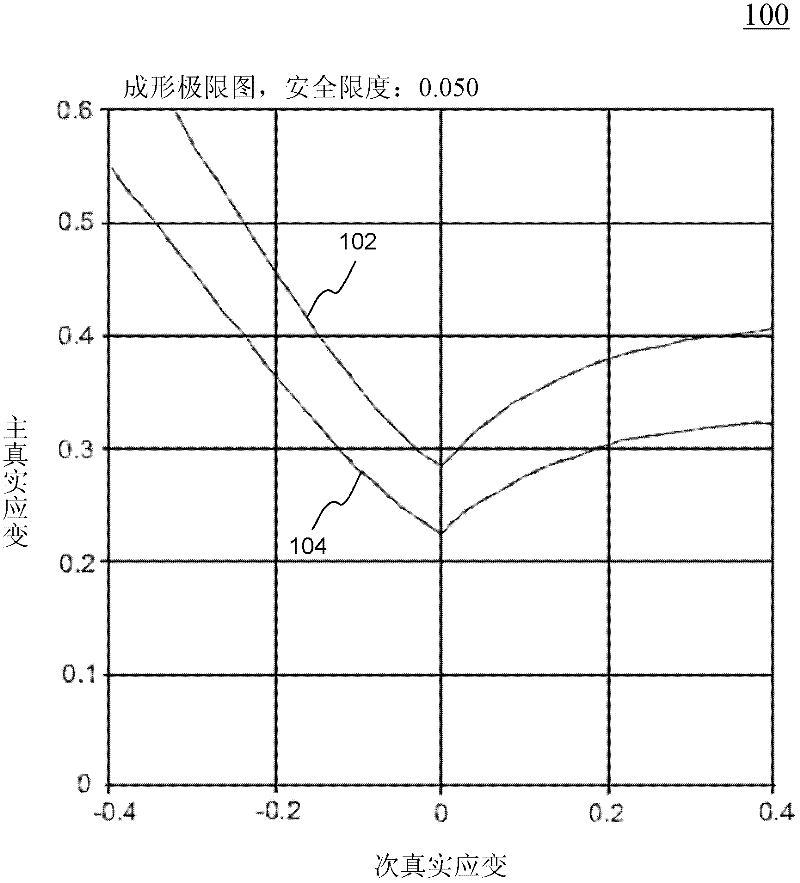

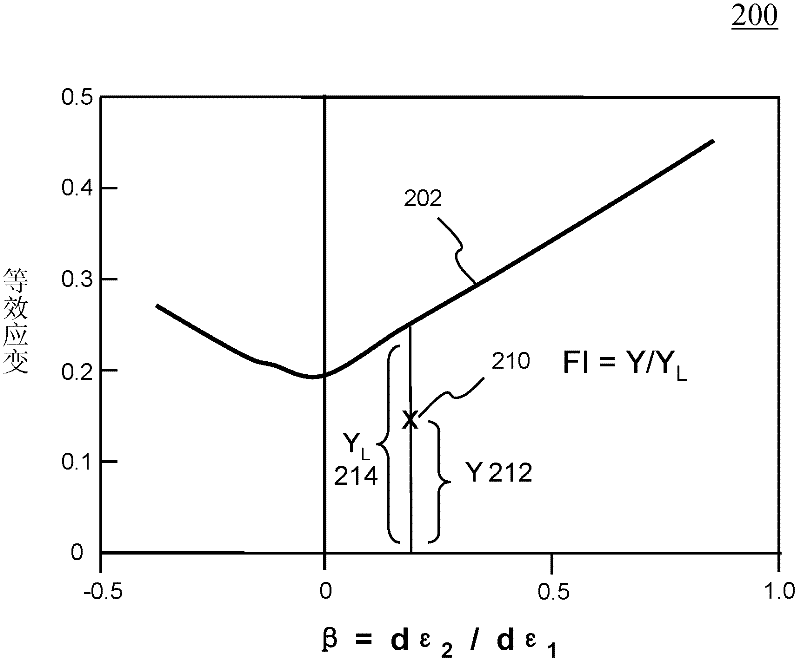

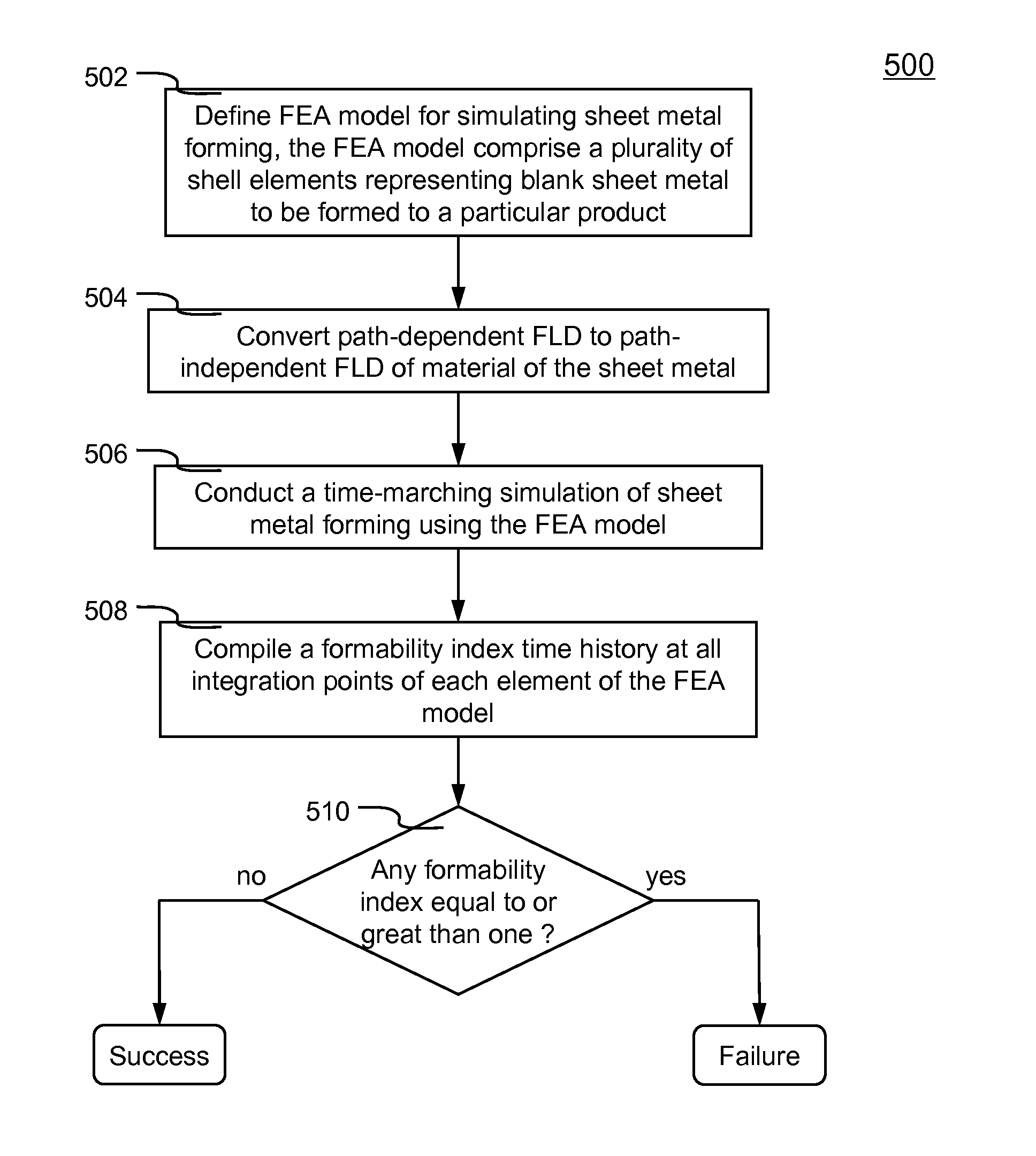

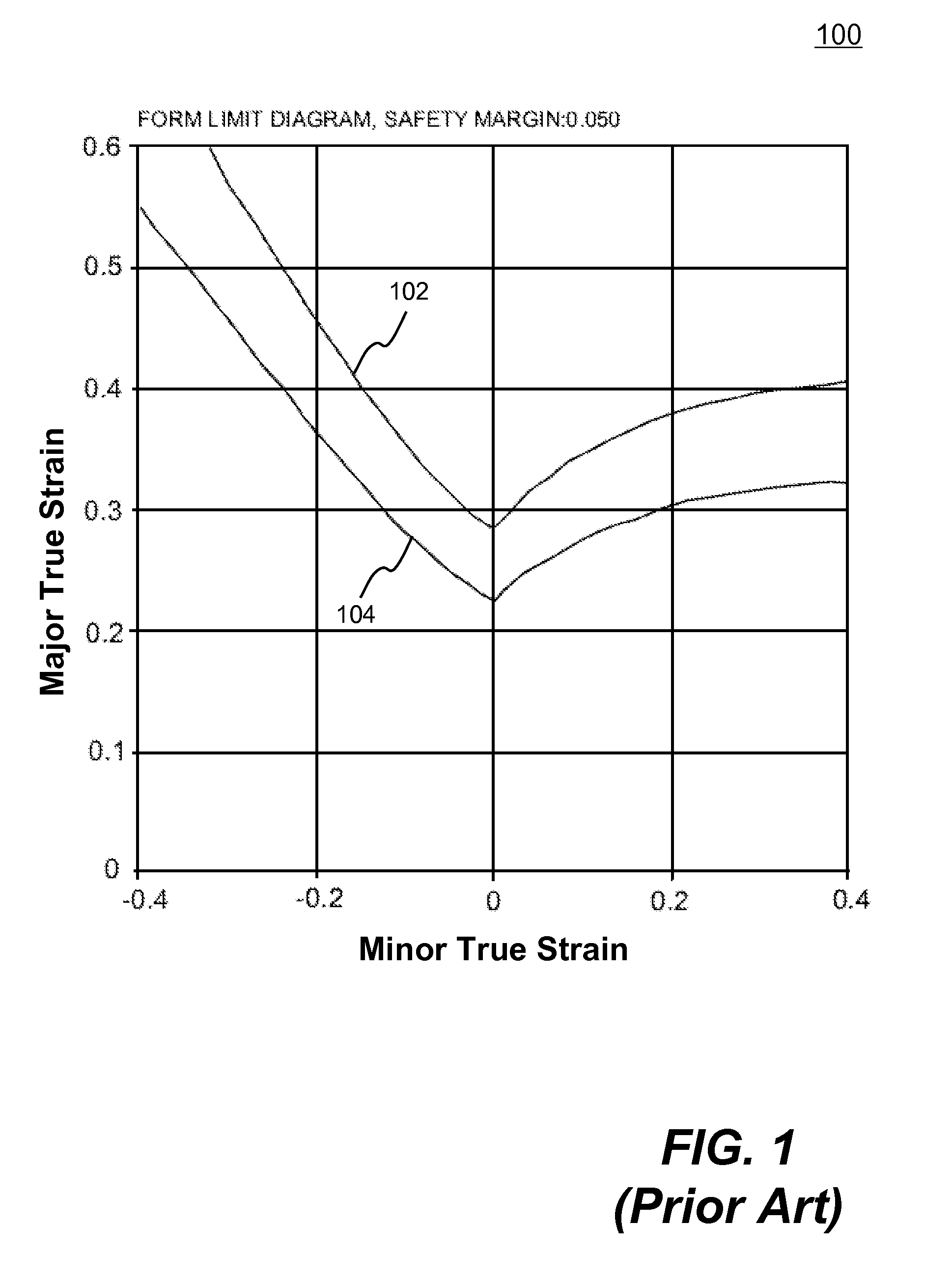

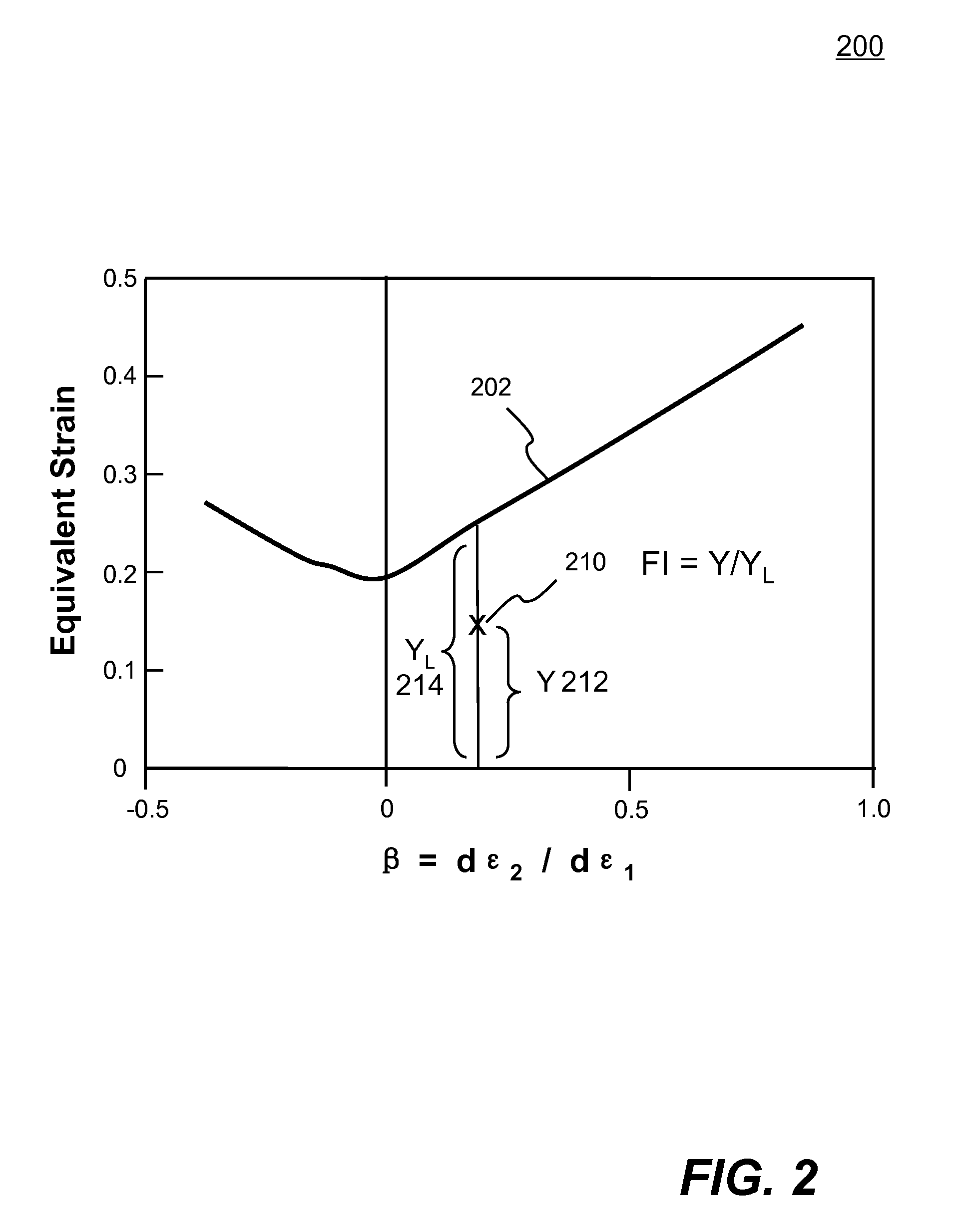

Method and system for numerically simulating and predicting necking failure in sheet metal forming

InactiveCN102262688AEasy to useEasy to observeDesign optimisation/simulationAerodynamics improvementForming limit diagramElement analysis

Systems and methods of predicting sheet metal forming failure using numerical simulations (e.g., finite element analysis) are disclosed. A FEA model is defined for a particular sheet metal forming process. Blank sheet metal is modeled with a plurality of shell elements. Additionally, a deformation path-dependent forming limit diagram (FLD) is converted to a path-independent FLD. A time-marching simulation of the sheet metal forming process is conducted using the FEA model. At each solution cycle, equivalent strain at each integration point of shell element is checked against the corresponding forming limit strain value of the path-independent FLD. The ratio of the equivalent strain and the forming limit strain is defined as formability index. A time history of the formability index of each shell element is saved into a file and displayed to a monitor upon user's instructions. When a particular element's formability index reaches one or higher, a localized necking is predicted.

Owner:LIVERMORE SOFTWARE TECH

Method and computing system for designing a sheet-metal-forming process

ActiveUS20120123579A1Reduce and eliminate possibilityEasy for users to understandDesign optimisation/simulationTotal factory controlDisplay deviceMetal forming process

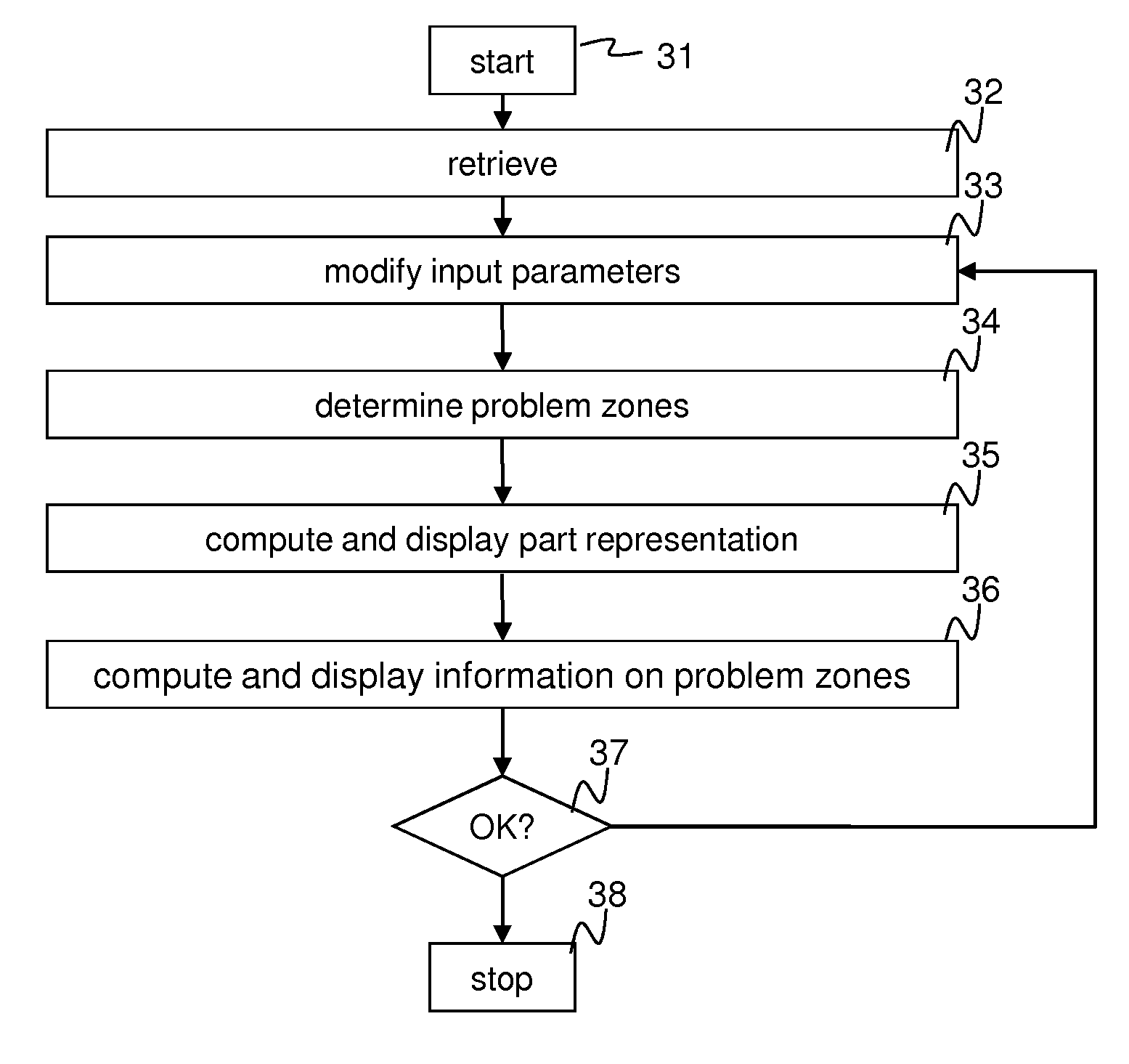

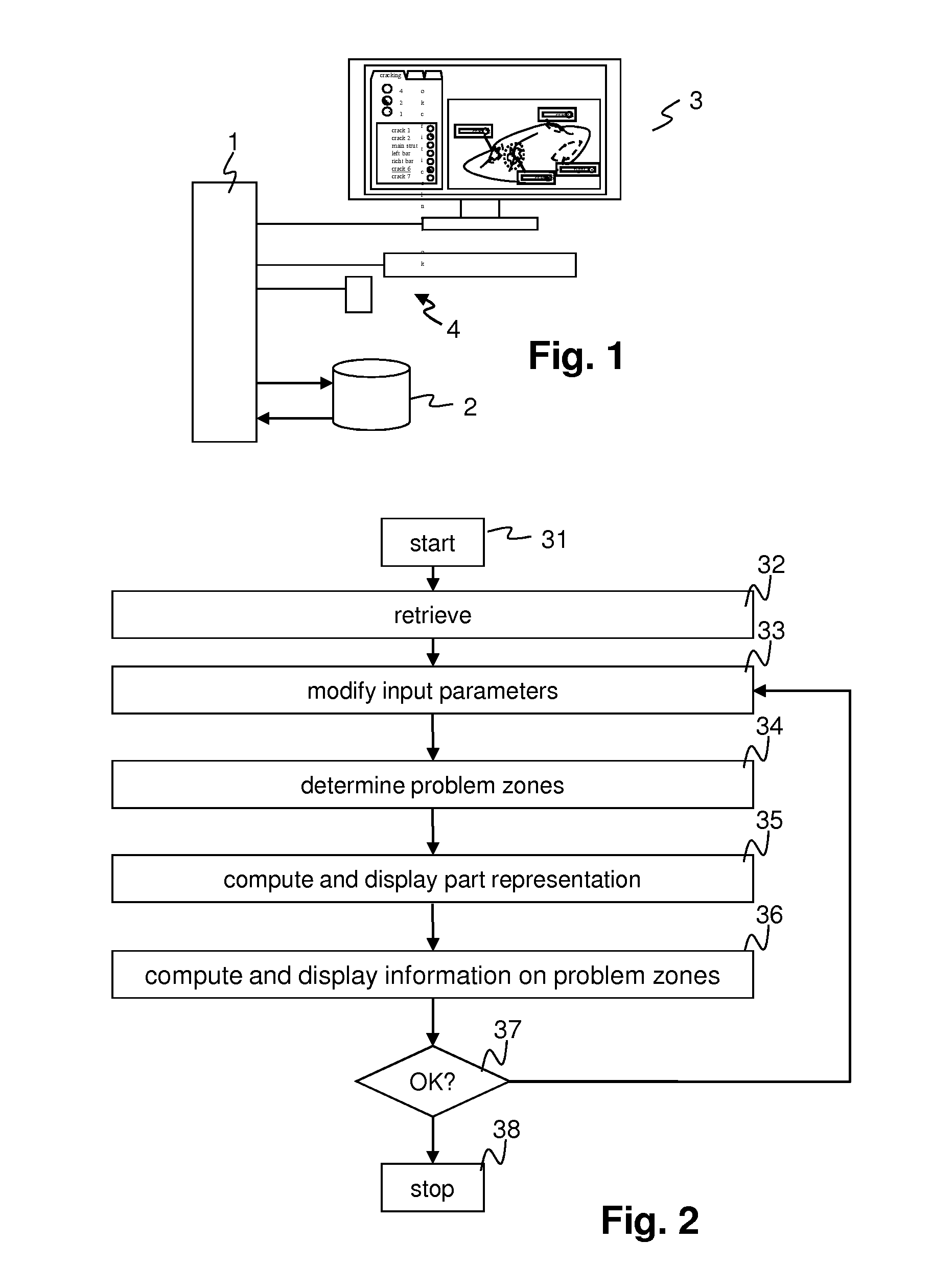

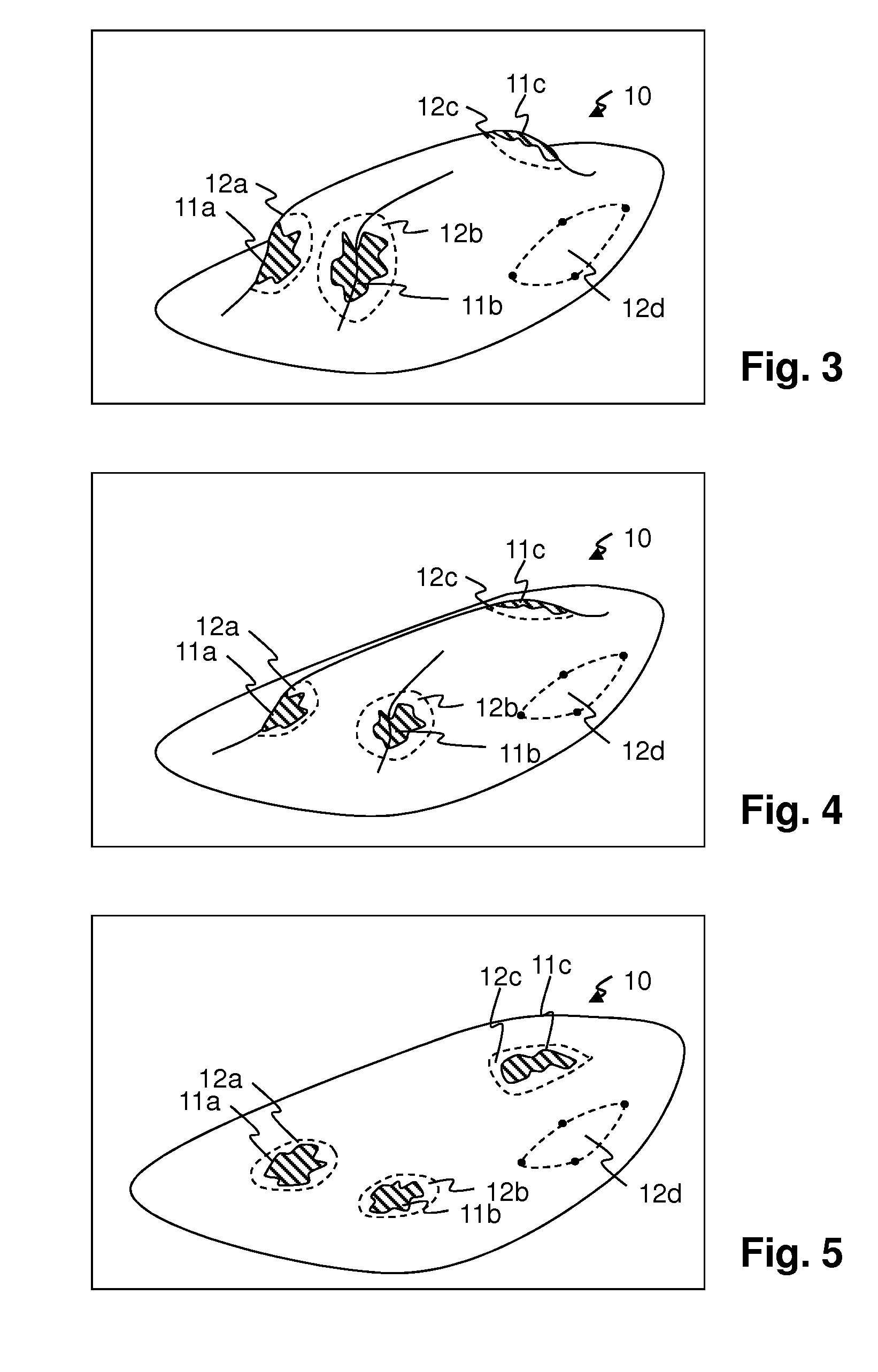

In a method for designing a formed sheet-metal part performed by a processor of a computing system, by means of:a numerical model of a geometry of the part,a numerical simulation of a forming process, andlocal property variables associated with points of the part and computed from results of the numerical simulation,a method for managing problem zones of the formed sheet-metal part comprises the steps of:determining problem zones of the sheet-metal part based on the results of the numerical simulation;determining a visual representation of the sheet-metal part, and displaying this visual representation on a display operatively coupled to the processor; indicating the location of the problem zones on the sheet-metal part; anddisplaying on the display device information associated with the at least one problem zone whose location is indicated.

Owner:NETABTAL MASCHEN

Control arm structure for wheel suspensions of motor vehicles, and method of making such a control arm structure

InactiveUS7556273B2Low ductility potentialHigh strengthBuilding roofsMetal-working apparatusMobile vehicleControl arm

In a method of making a control arm for a wheel suspension of a motor vehicle a blank of steel material having a tensile strength of at least 800 MPa is shaped, using a sheet metal forming process, into a shell body having a center web and plural flank portions extending from the center web in a same direction. The flank portions are connected by a latticed reinforcement made of plastic, without application of a heat treatment process.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

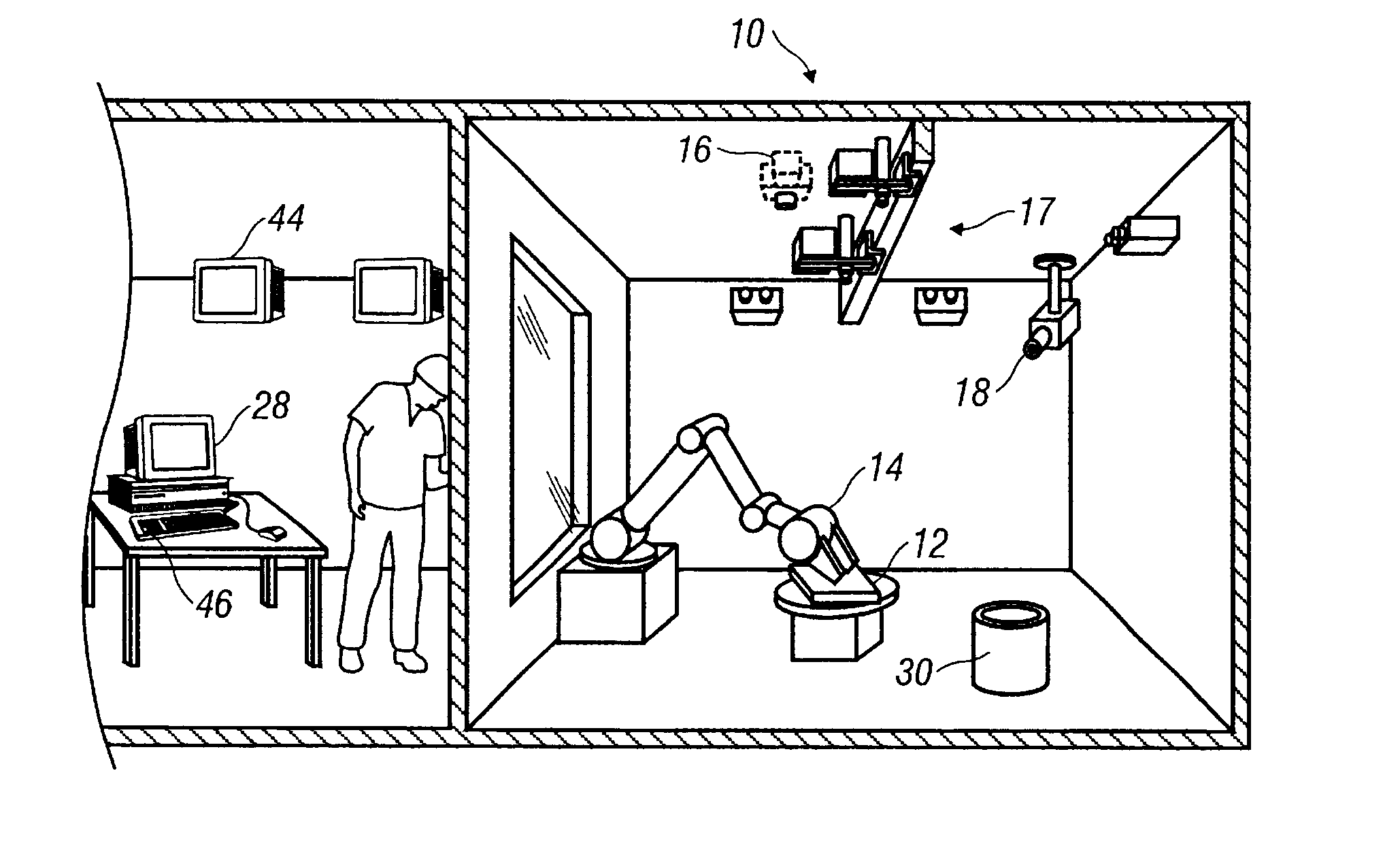

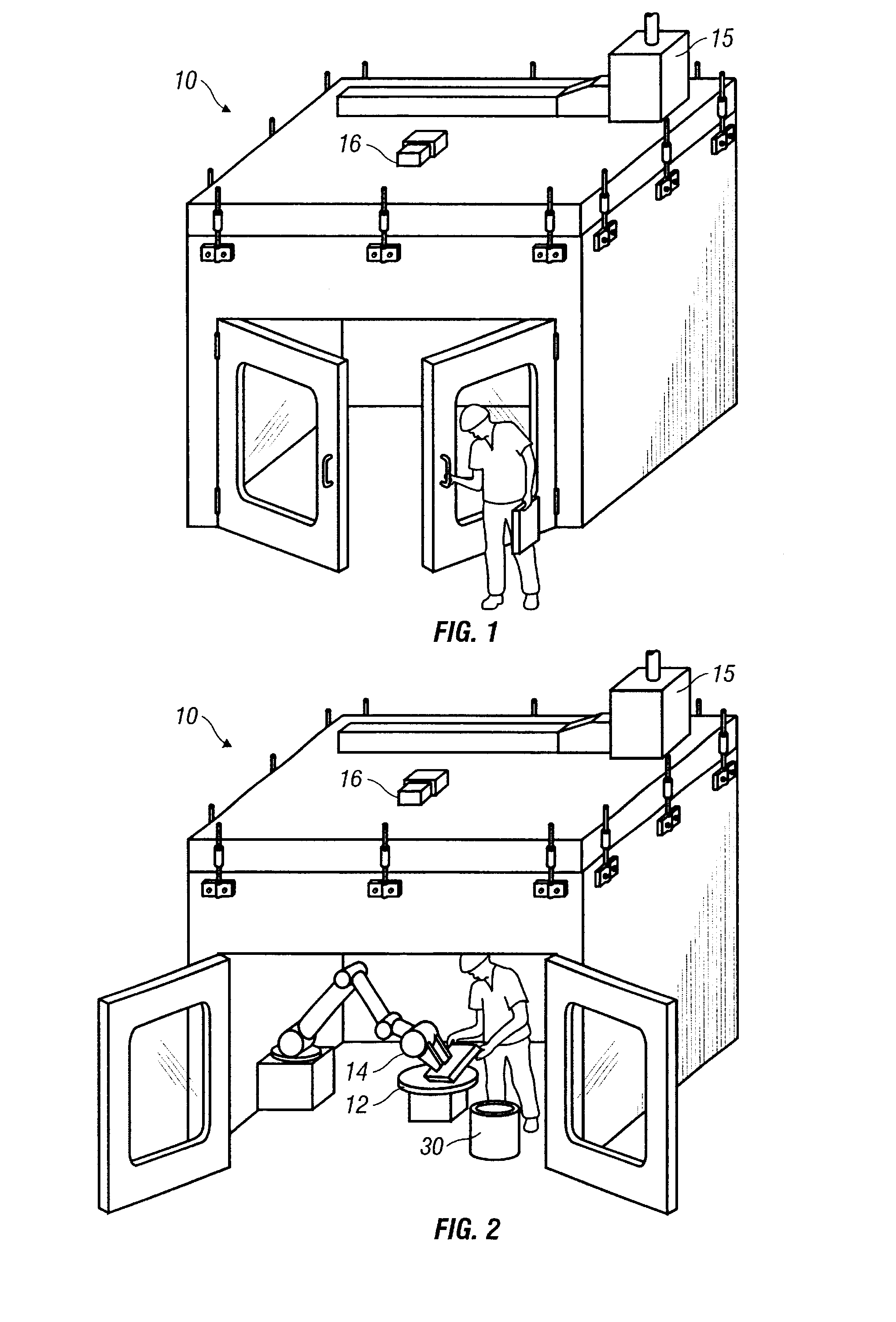

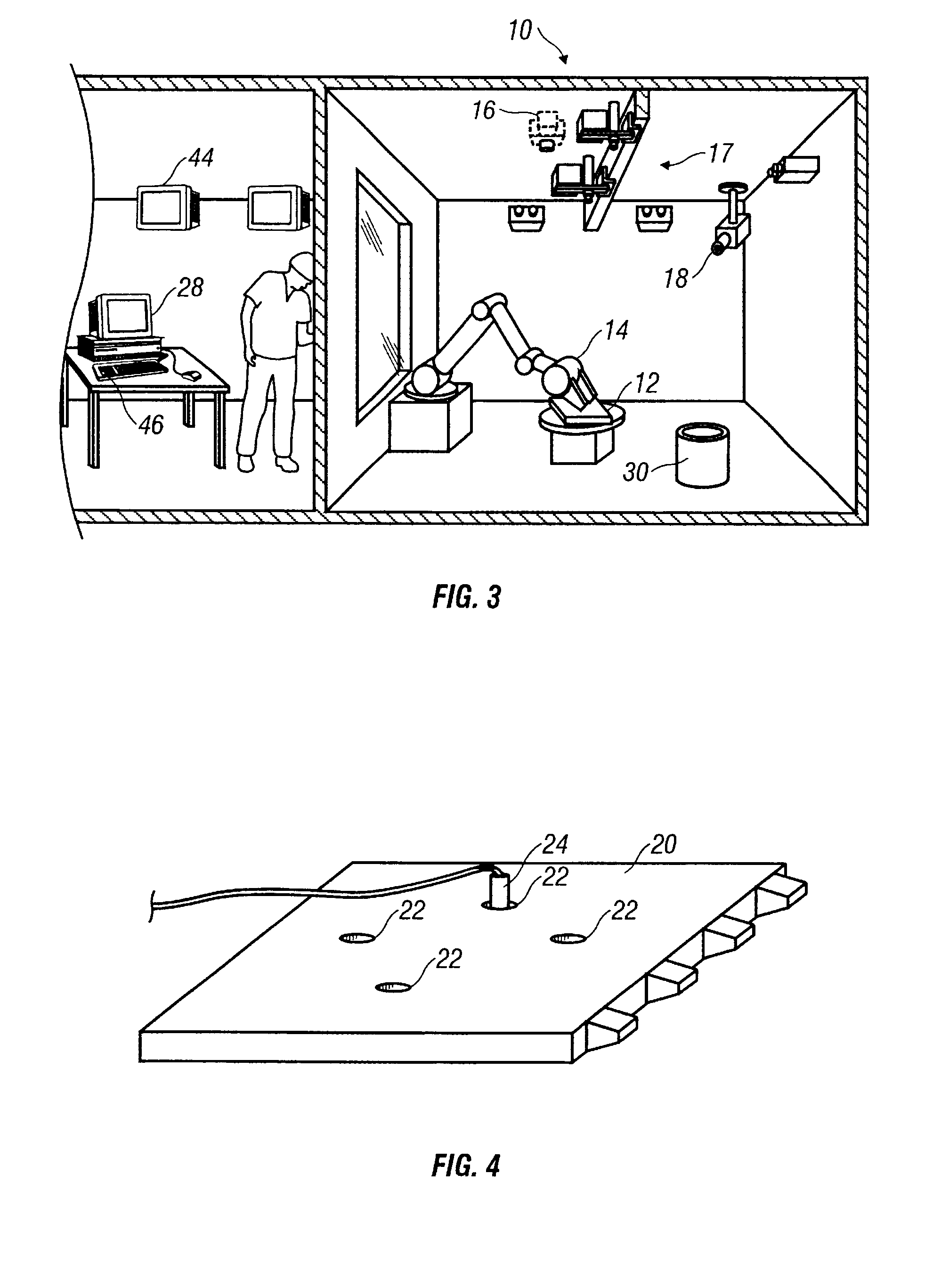

Automated spray form cell

InactiveUS6640878B2High sensitivityAccurate distributionMolten spray coatingCasting safety devicesStress inducedAutomotive industry

Owner:FORD MOTOR CO

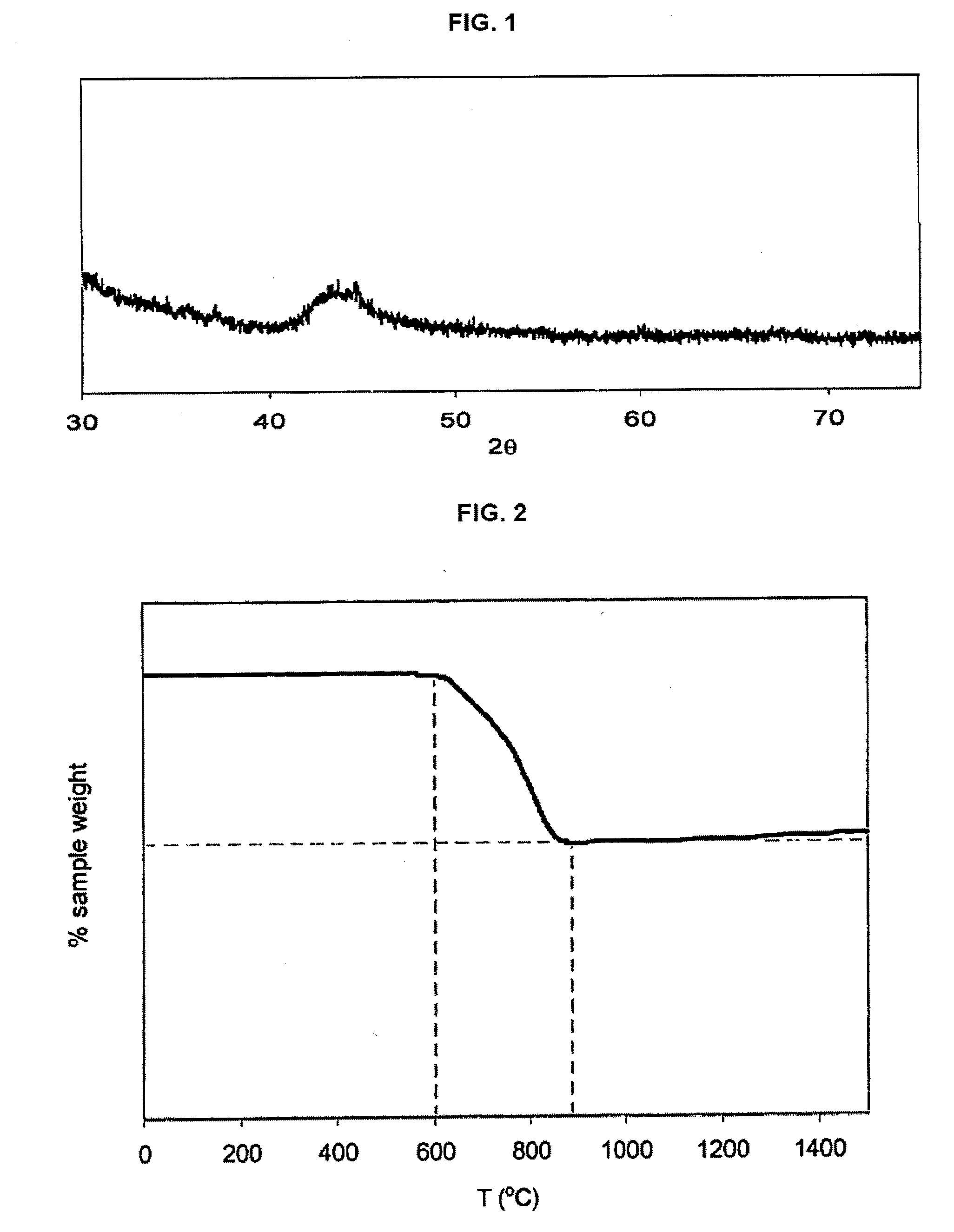

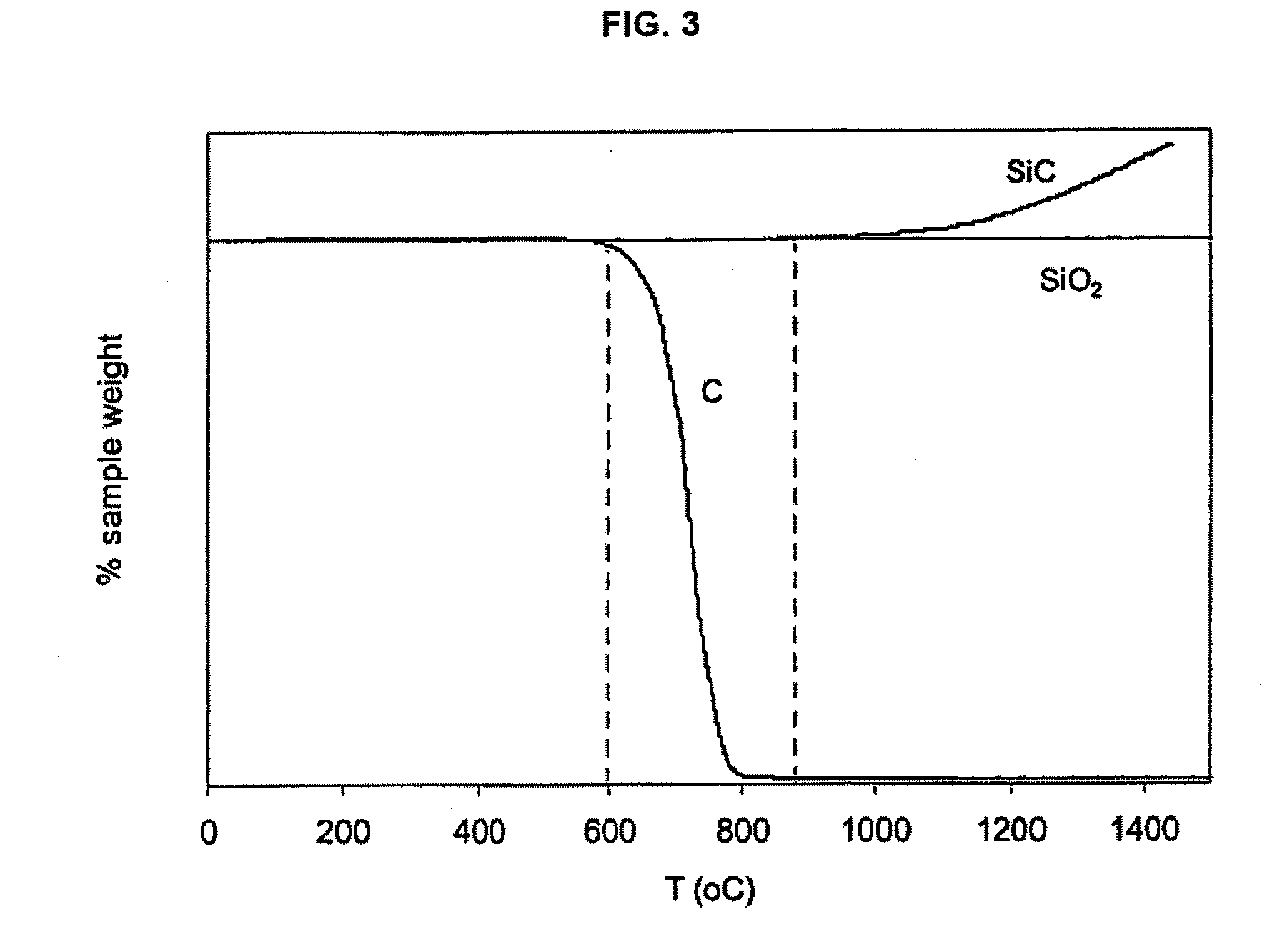

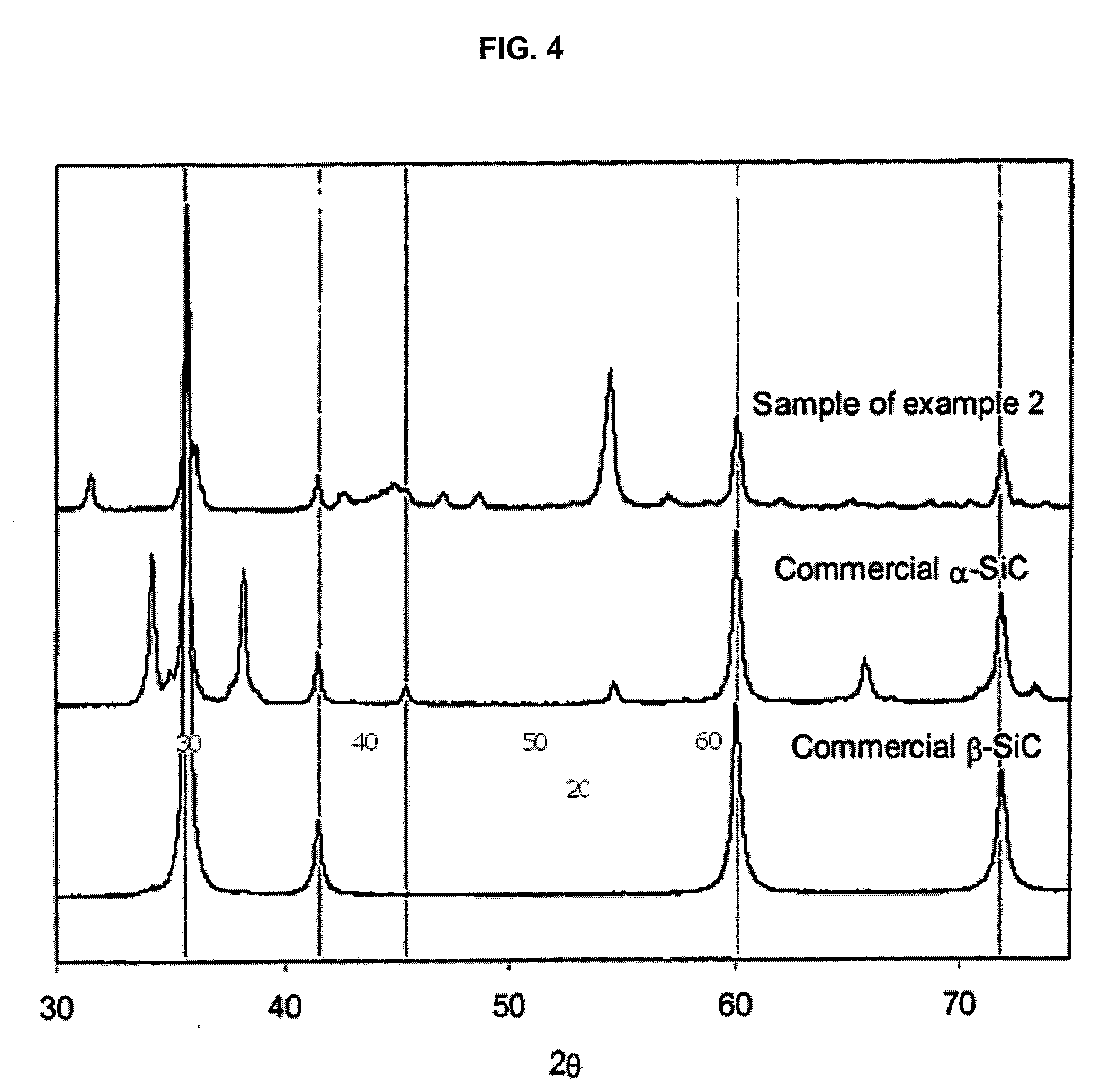

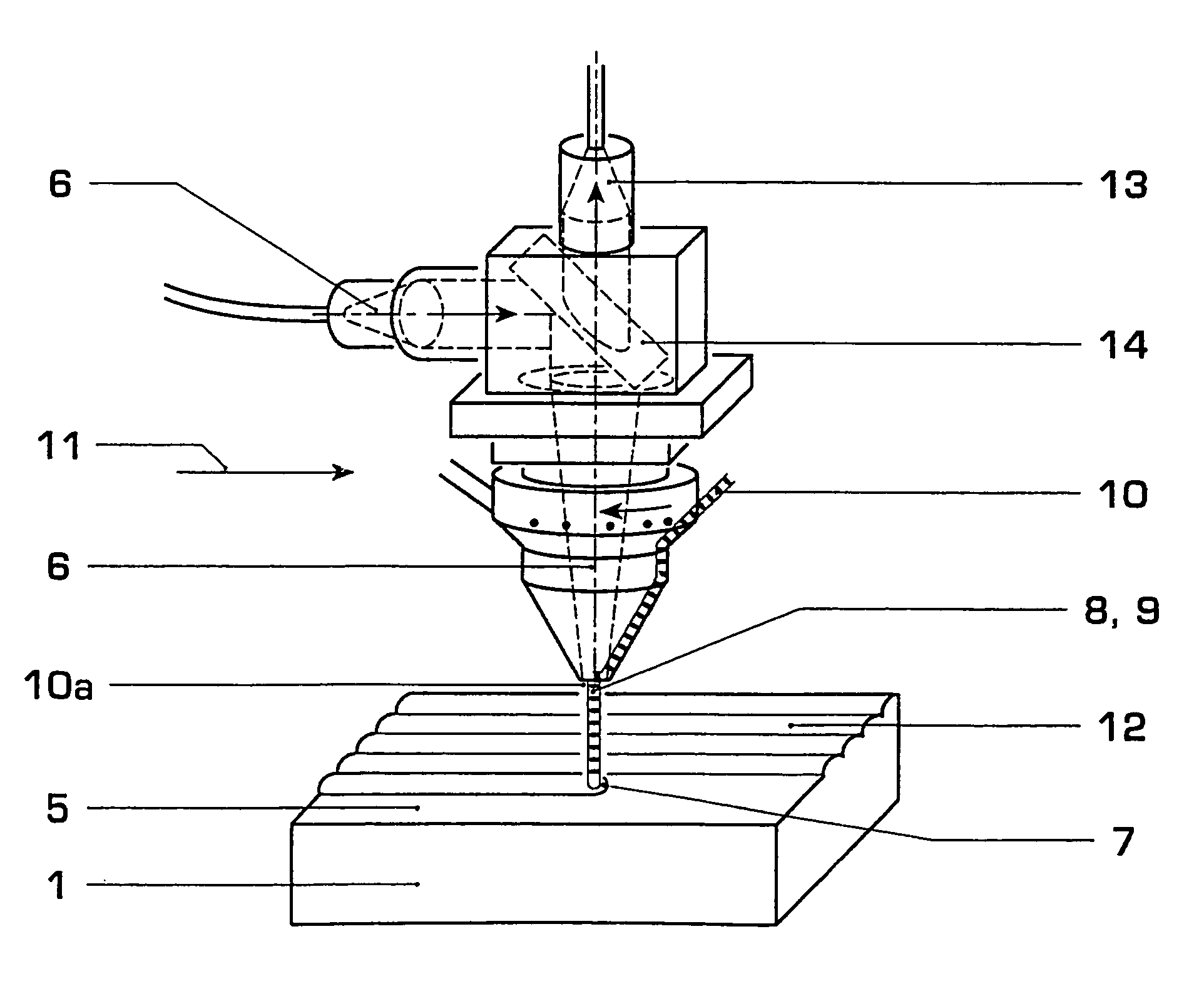

Manufacture and use of engineered carbide and nitride composites

Carbides and nitrides are provided containing a controlled amount of pre-determined diluents and methods for their manufacture and use are disclosed. The pre-determined diluents include at least one of the silica, silicon metal, carbon, alumina, boron oxide, alkaline earth oxides such as calcium oxide, magnesium oxide, alkali oxides such as sodium oxide, potassium oxide, iron oxide, titanium oxide, and other components typically present in glass, ceramics, or metals. The carbides and nitrides with pre-determined diluents are formed by optionally pyrolyzing a precursor material to form a carboneous mixture and heat treating the carboneous mixture for a pre-determined time and at an elevated temperature during which carbon and / or nitrogen reacts with silica in the mixture to form carbides and / or nitrides and controlled amounts of pre-determined diluents. The carbides and nitrides disclosed herein may be used as blowing agents in a glass, ceramic, or metal forming processes or for promoting dispersion of the carbides and nitrides throughout a glass, ceramic, or metal composite.

Owner:JAMES HARDIE INT FINANCE BV

Method for controlling the microstructure of a laser metal formed hard layer

ActiveUS7705264B2Easy to controlReliable manufacturingTurbinesAdditive manufacturing apparatusControl systemMetal forming process

It is disclosed a method of applying a coating (12) with a controlled laser metal forming process. A light source with a specific power and a signal capturing apparatus is moved over an article (1) to form locally a melt pool (7) on the surface (5) of the article (1) to which a coating powder (8) is injected. An optical signal (13) is captured from the melt pool (7), and the monitored optical signal (13) is used for the determination of the temperature and temperature fluctuations of the melt pool (7). Furthermore, a control system (16) is used to adjust at least one process parameter such as the power of the light source to obtain desired melt pool properties. Subsequently the melt pool (7) solidifies. The high degree of control over the microstructure provides an efficient tool for generating laser metal formed hard coatings (12) with optimised wear properties.

Owner:ANSALDO ENERGIA IP UK LTD

Method for quickly and accurately confirming friction coefficient in metal forming processes

InactiveCN102539315AIncrease coefficient of frictionSimple methodUsing mechanical meansMaterial analysisMetal forming processMaterials science

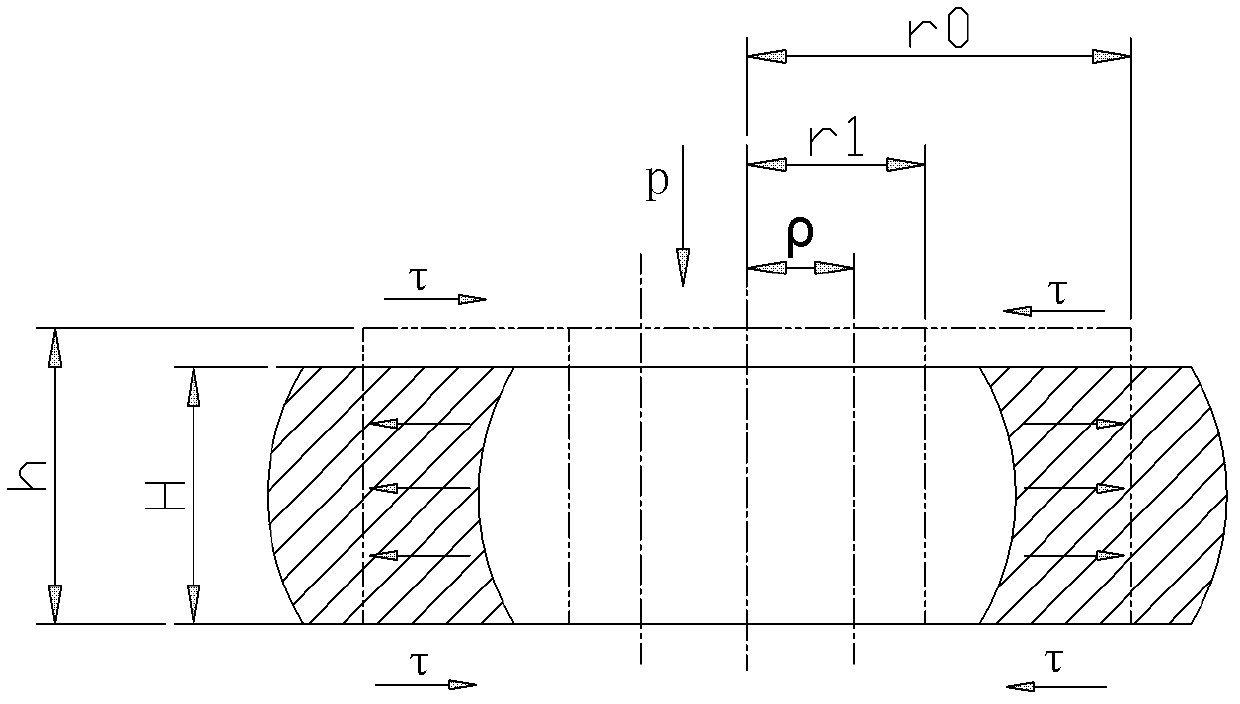

The invention relates to the field of metal forming manufacturing, in particular to a method for quickly and accurately confirming friction coefficient in metal forming processes. The method comprises n groups of ring upsetting tests: a first group of ring upsetting tests contain three samples, the dimensional proportion of the outer diameter, the inner diameter and the height of a ring sample is 3:2:1, the press-down rate is smaller than 50%, the inner diameter, the outer diameter and the height of the deformed ring sample is measured, each size is measured from three different directions and obtained from the average, the average inner diameter, the outer diameter and the height of the three samples are calculated, the radius of a neutral layer is calculated, friction factor m is calculated, and the best friction factor mi is obtained by calculation. The method is simple and practical, and simultaneously takes bulging and material hardening in the ring sample upsetting test into consideration. Thus, the defect that an existing analytic method cannot simultaneously take bulging and material hardening into consideration is overcome, and complex data processing caused by using a rating curve method is avoided.

Owner:SHANGHAI UNIV OF ENG SCI

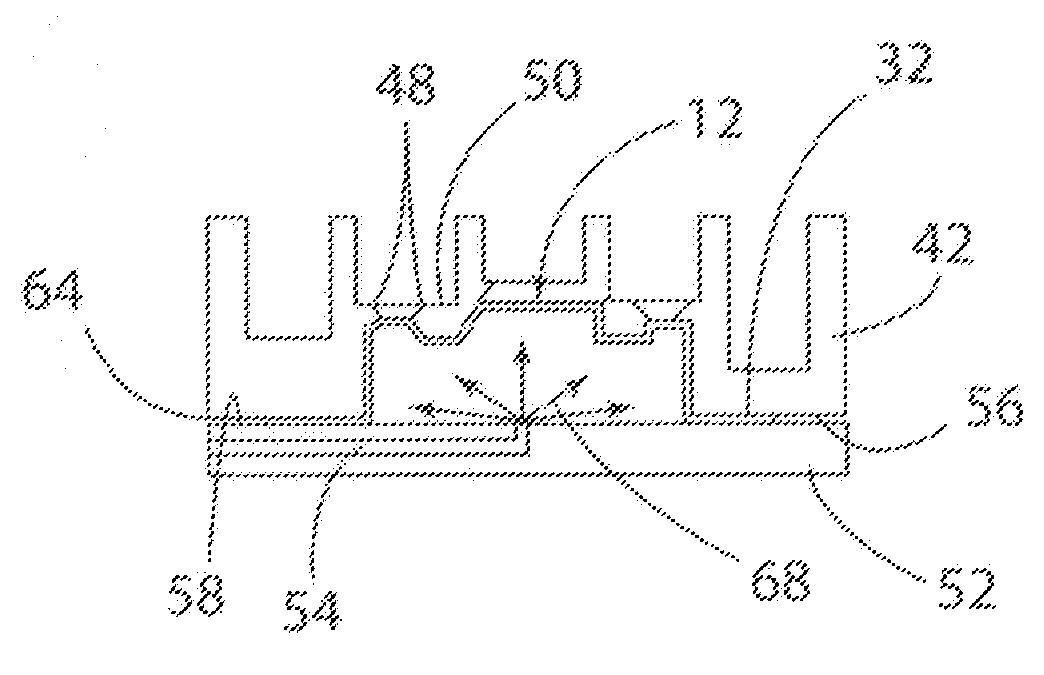

Sheet metal forming process

InactiveUS20080127697A1Shorten molding timeImprove mobilityShaping toolsMetal forming processMaterials science

A sheet metal forming process and apparatus using both a mechanical forming step and a superplastic forming step. The mechanical forming step includes using a double-action draw die to create a preform. The preform is then transferred to a superplastic forming tool that uses a superplastic forming process to complete the forming process and create a finished workpiece. Using the mechanical forming step enables rapid creation of a preform having a geometry that reduces overall forming time and provides the ability to draw in additional material to reduce part thinning.

Owner:FORD GLOBAL TECH LLC +2

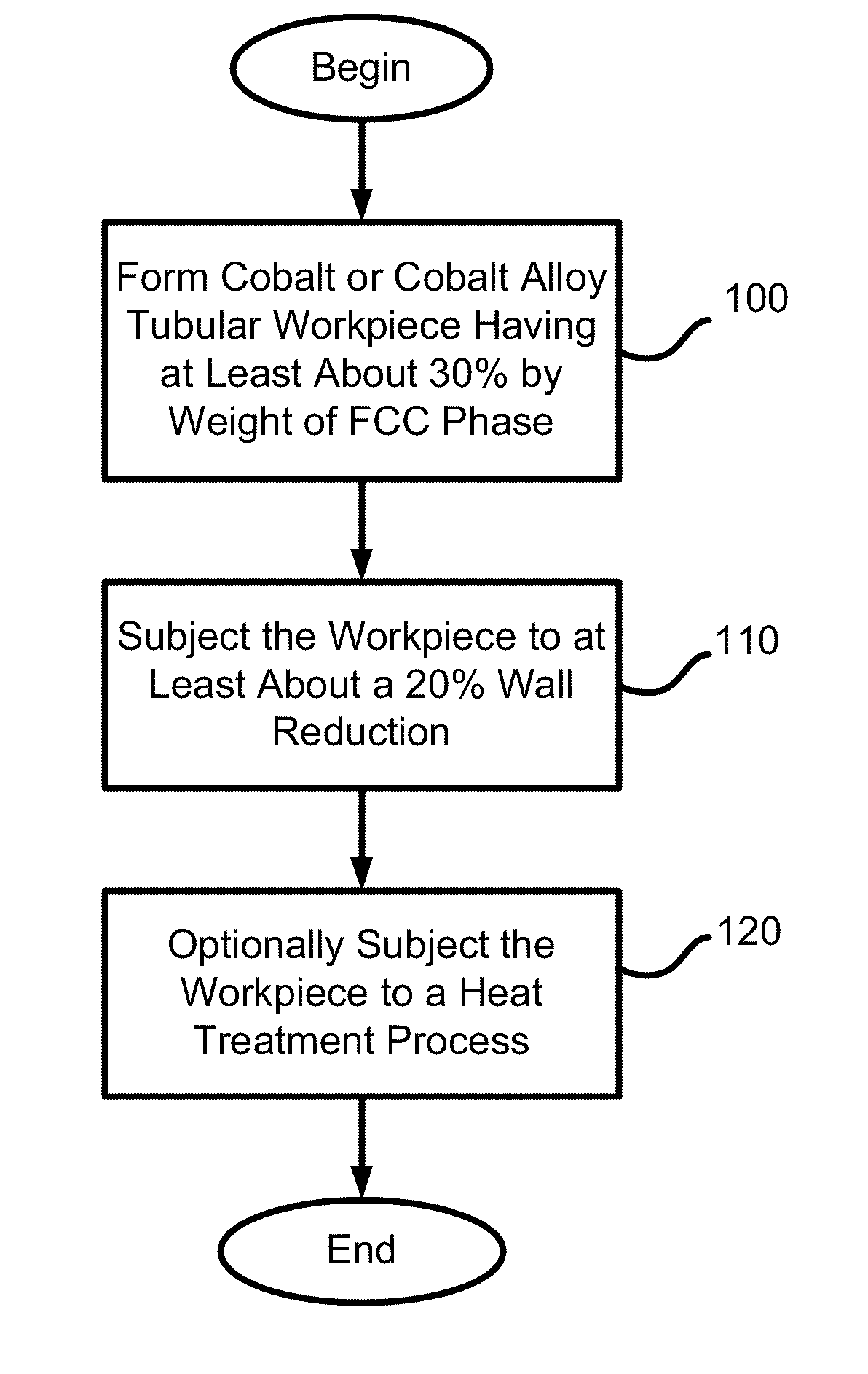

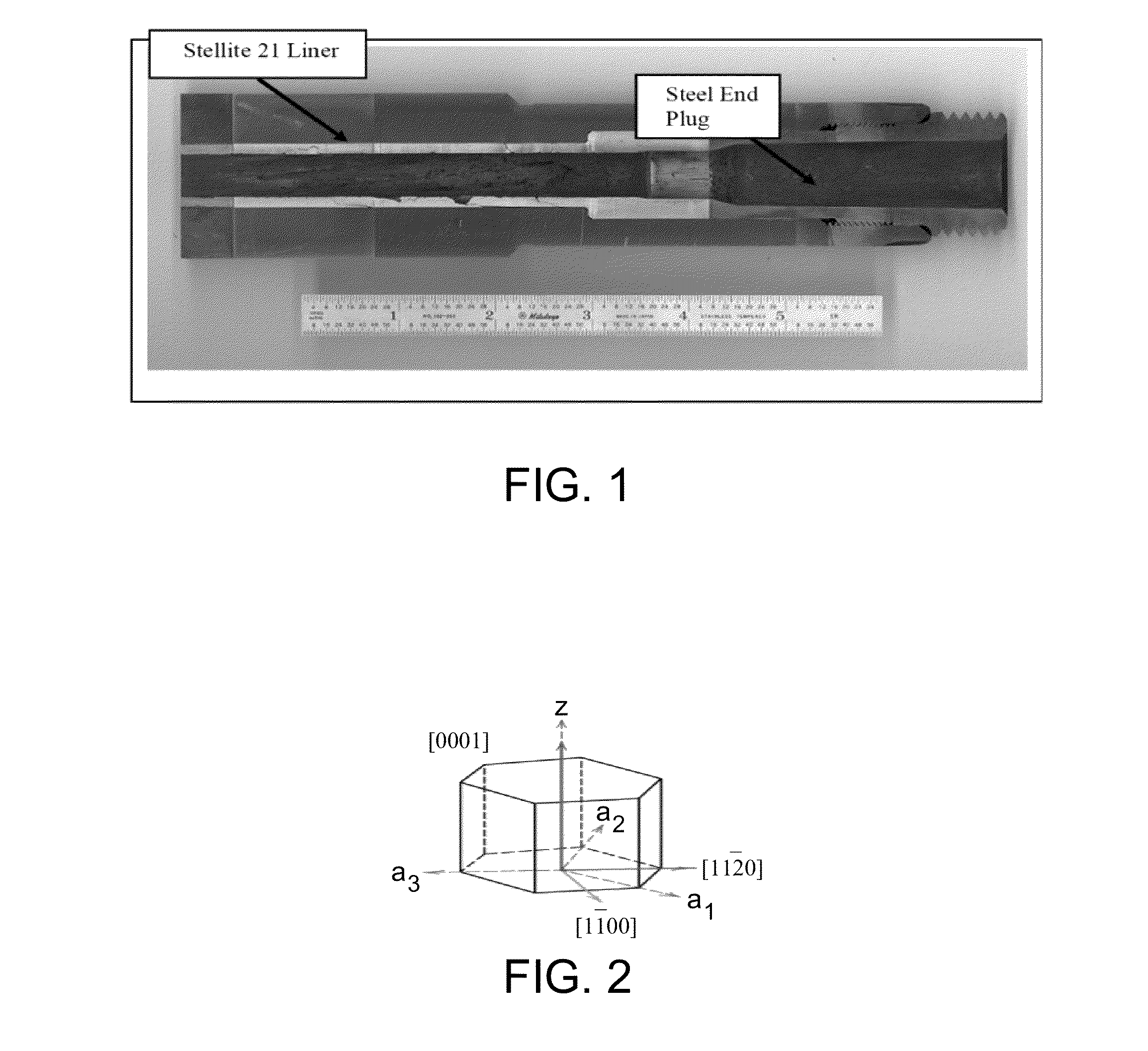

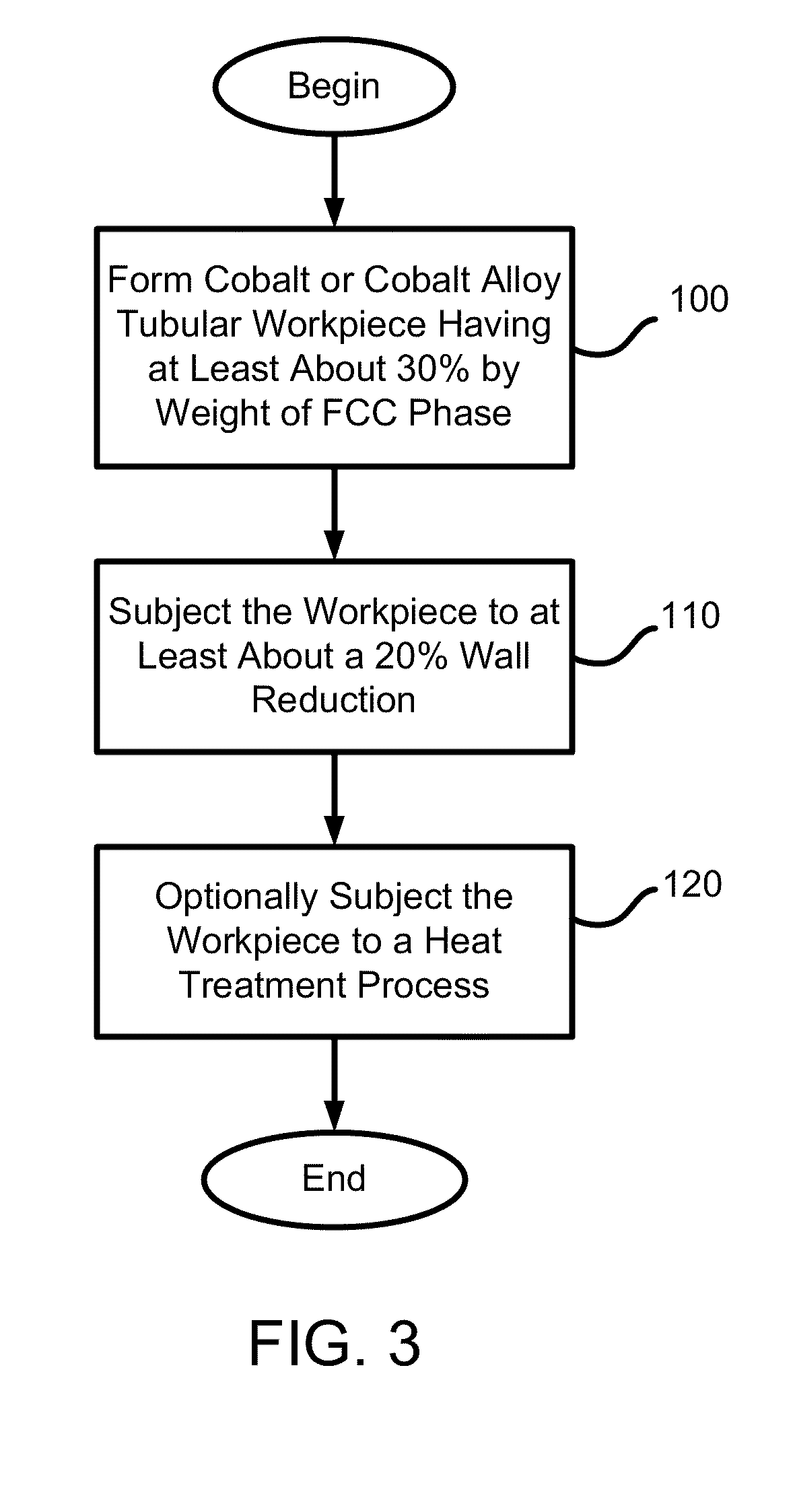

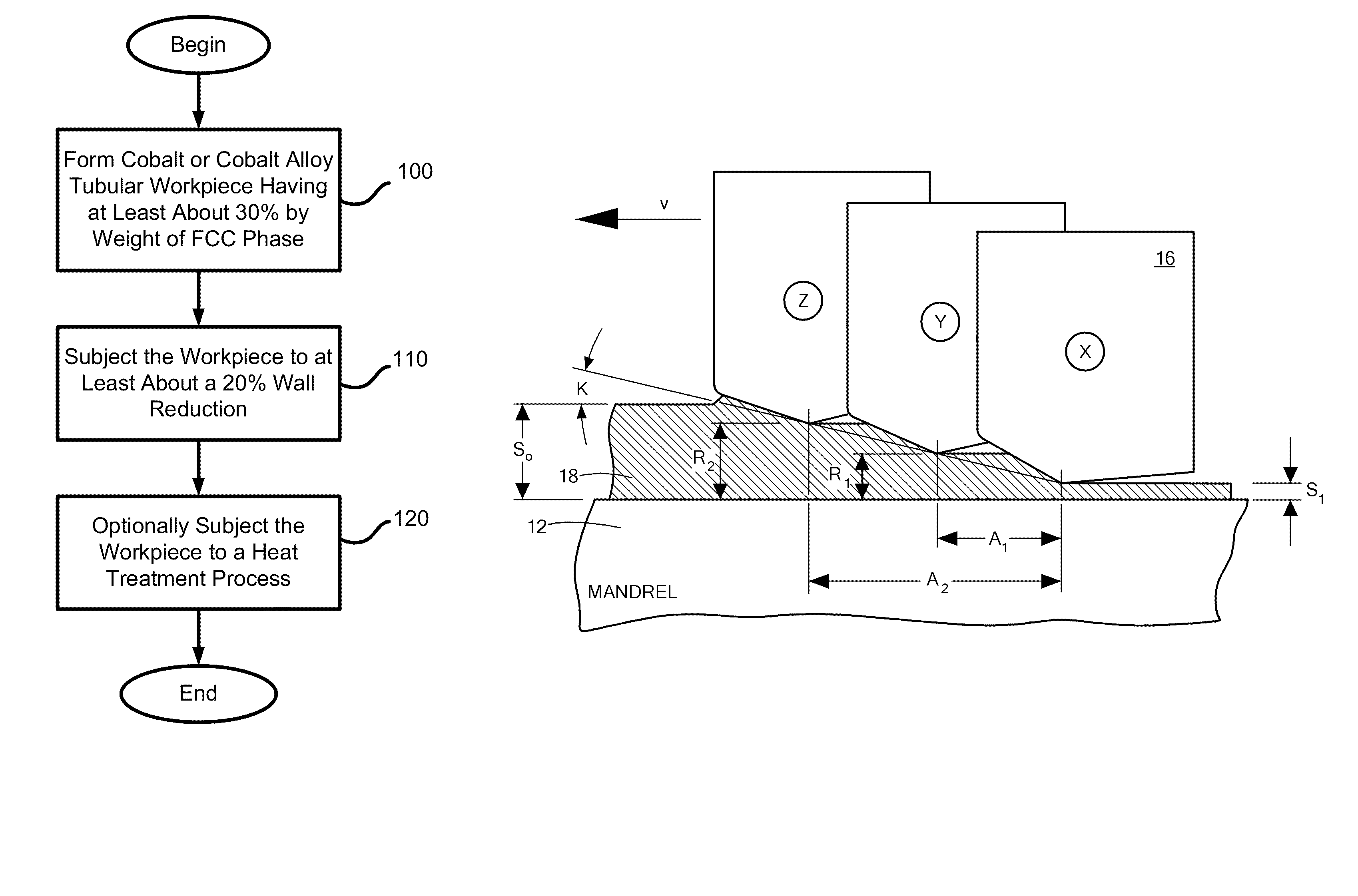

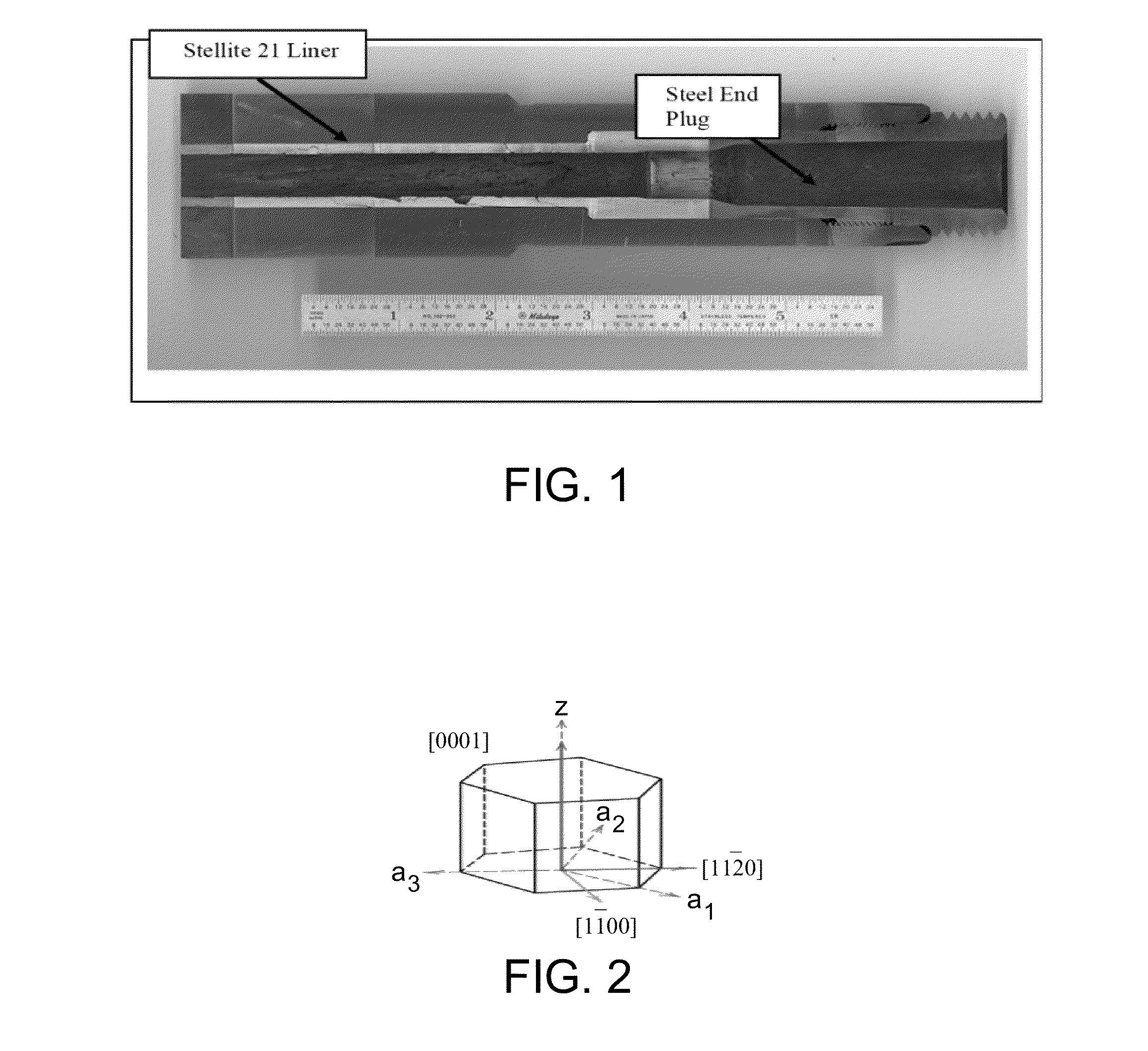

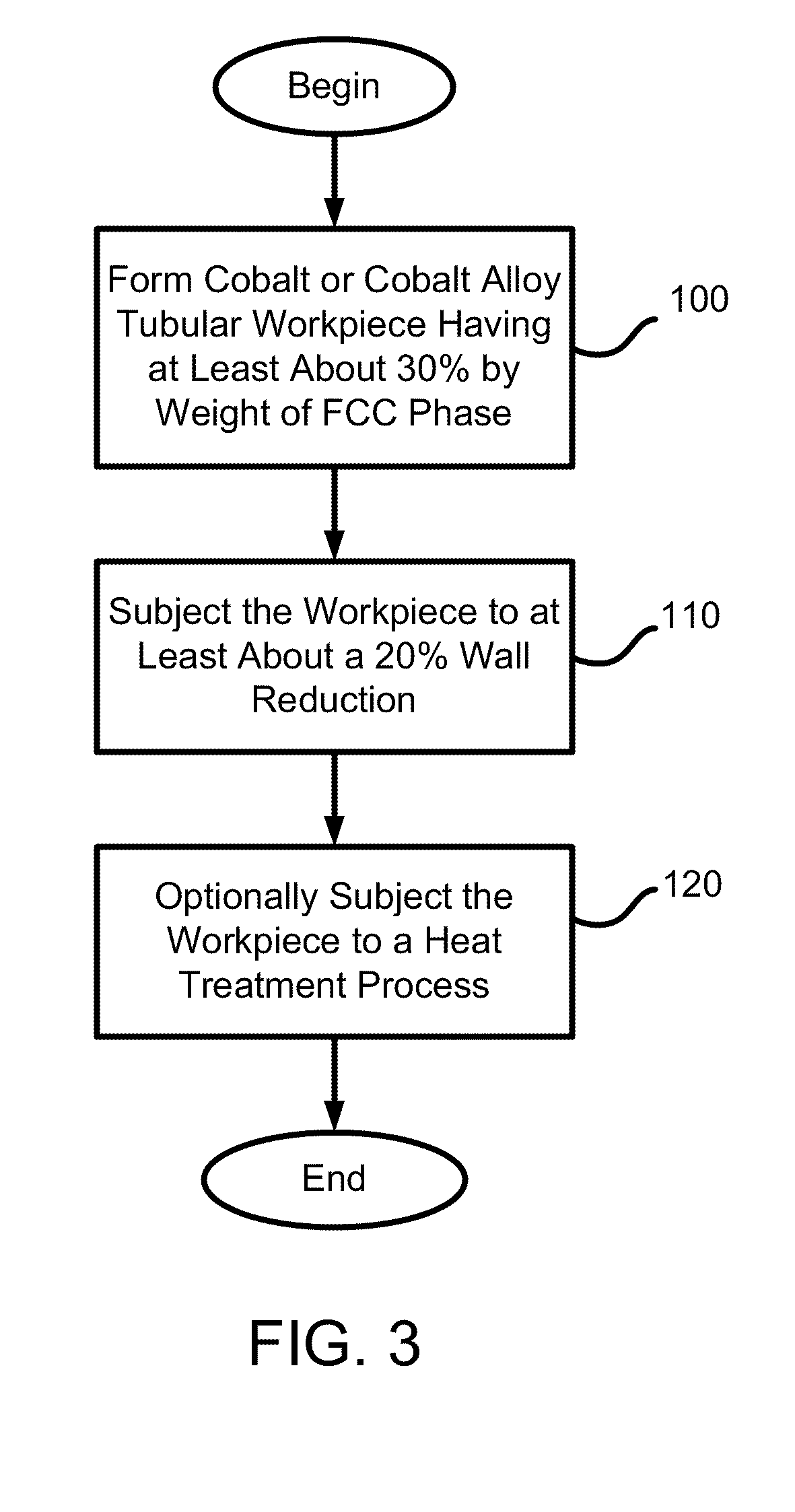

Stress Induced Crystallographic Phase Transformation and Texturing in Tubular Products Made of Cobalt and Cobalt Alloys

A method of producing a cobalt-based tubular product includes forming a cobalt or cobalt alloy tubular workpiece having at least about 30% by weight of fcc phase and subjecting the workpiece to at least about a 20% wall reduction at a temperature below a recrystallization temperature of the workpiece using a metal forming process. The metal forming process may include radial forging, rotary swaging, pilgering and / or flowforming. A gun barrel includes a tubular component made of a cobalt-based superalloy material. The component has at least about 25% by weight of hcp phase with basal planes radially oriented perpendicular to an inner diameter of the component.

Owner:ATI FLOWFORM PROD

Sheet Metal Forming Failure Prediction Using Numerical Simulations

InactiveUS20110295570A1Computation using non-denominational number representationDesign optimisation/simulationForming limit diagramElement analysis

Systems and methods of predicting sheet metal forming failure using numerical simulations (e.g., finite element analysis) are disclosed. A FEA model is defined for a particular sheet metal forming process. Blank sheet metal is modeled with a plurality of shell elements. Additionally, a deformation path-dependent forming limit diagram (FLD) is converted to a path-independent FLD. A time-marching simulation of the sheet metal forming process is conducted using the FEA model. At each solution cycle, equivalent strain at each integration point of shell element is checked against the corresponding forming limit strain value of the path-independent FLD. The ratio of the equivalent strain and the forming limit strain is defined as formability index. A time history of the formability index of each shell element is saved into a file and displayed to a monitor upon user's instructions. When a particular element's formability index reaches one or higher, a localized necking is predicted.

Owner:LIVERMORE SOFTWARE TECH

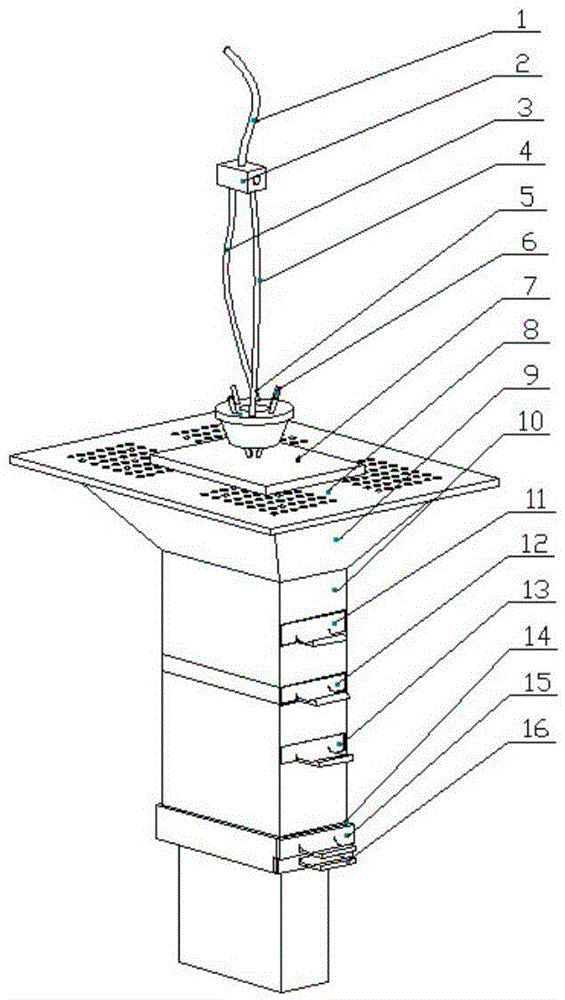

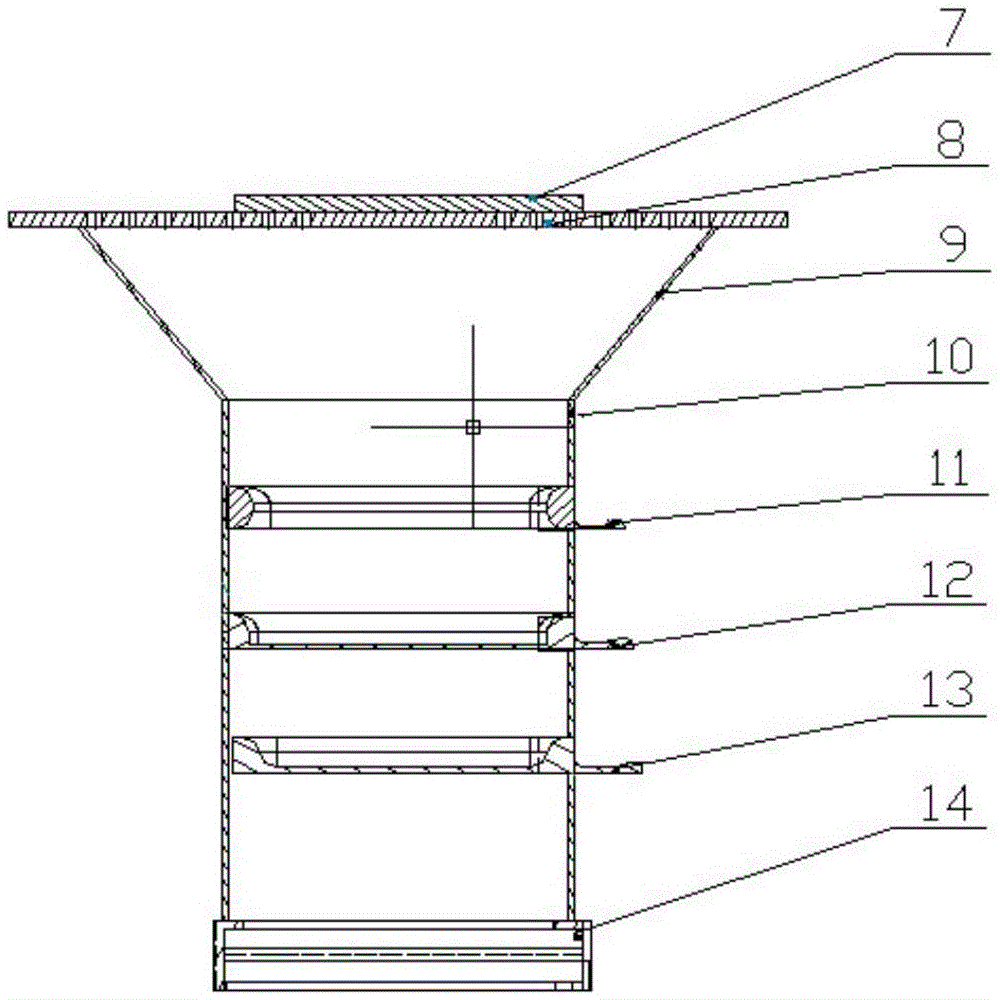

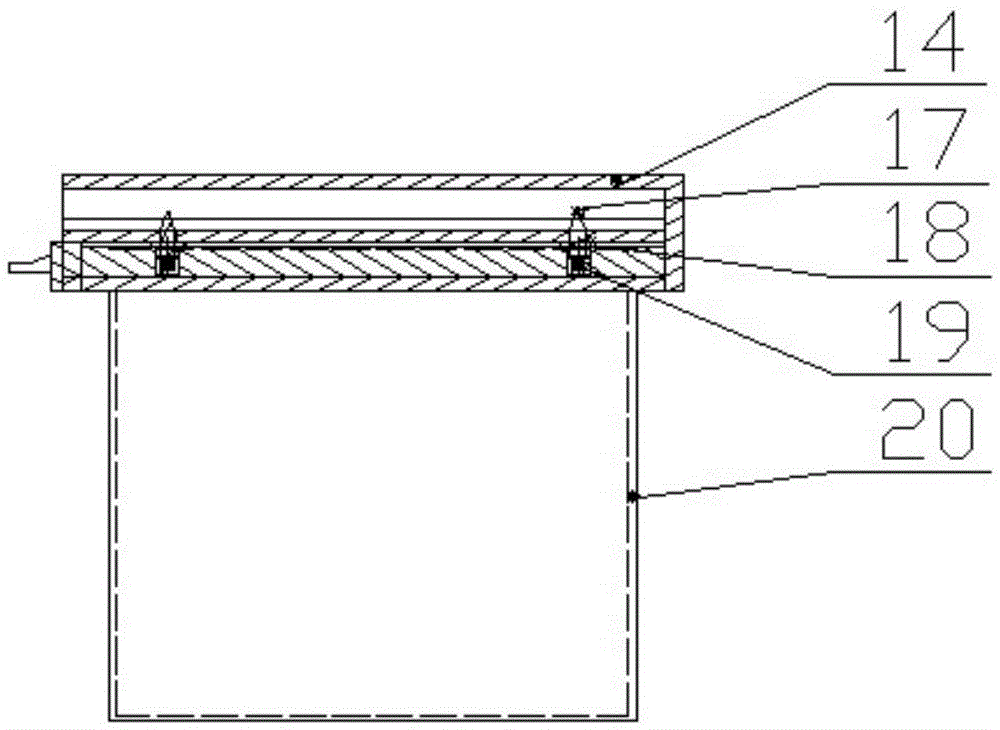

Powder recovery device suitable for laser metal forming process

ActiveCN105598452AAvoid harmReduce volumeAdditive manufacturing apparatusIncreasing energy efficiencySolenoid valveMetal forming process

The invention discloses a powder recovery device suitable for the laser metal forming process. One route of powder clearing gas of a powder clearing module is divided into two routes of gas after passing through a three-position two-way solenoid valve and enters a powder clearing gas passage of a powder feeding nozzle; a forming substrate is installed on a porous working table of a powder conveying and filtering module, a powder recovery funnel is installed on the lower portion of the porous working table, a powder recovery passage is installed on the lower portion of the funnel, and a drawer-type bladeless fan, a low-number mesh screen and a high-number mesh screen are detachably installed in the recovery passage in sequence; a powder recovery bag installation seat, a powder blocking plate and a powder recovery bag of a powder collecting module are installed at the tail end of the recovery passage. The powder recovery device suitable for the laser metal forming process can be used for the field of laser metal forming, integration of powder collecting, screening and recycling in the laser metal forming process is achieved, the powder utilization rate is increased, and the cost of the laser metal forming technology is reduced; the probability that people make contact with powder during powder cleaning after processing is completed is reduced, and the safety of operators during processing is guaranteed.

Owner:XI AN JIAOTONG UNIV

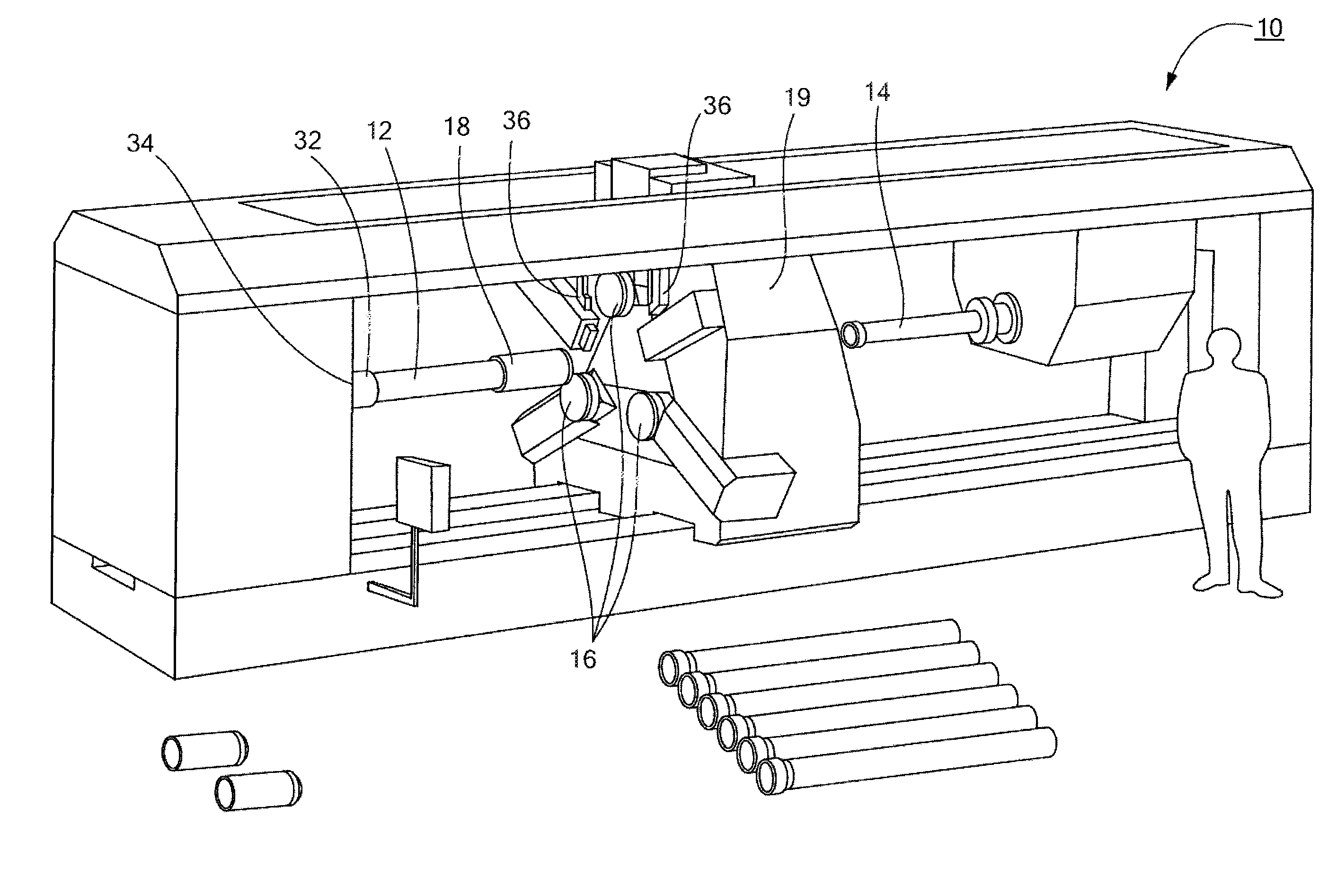

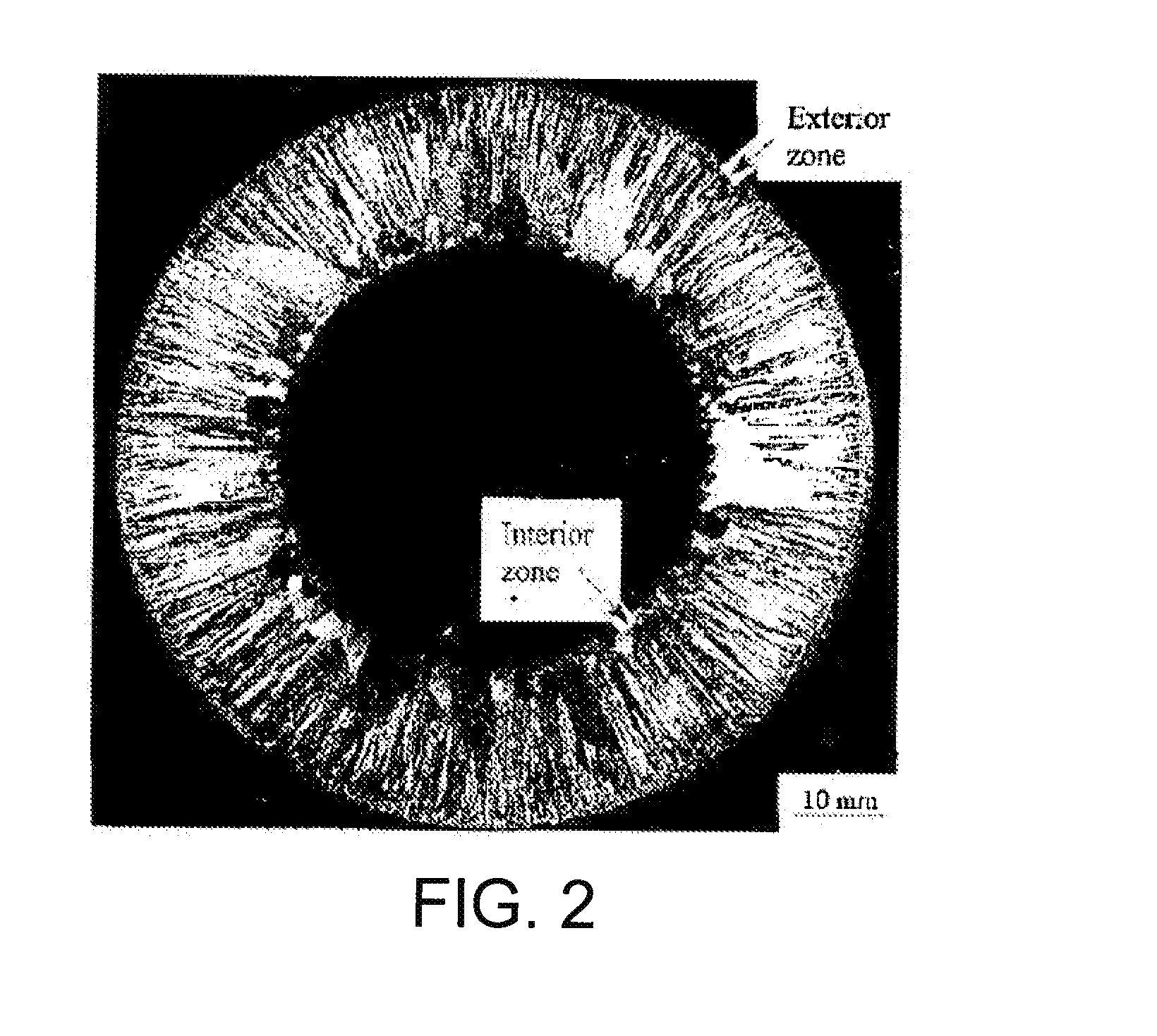

Method of Producing Cold-Worked Centrifugal Cast Tubular Products

ActiveUS20150183015A1Rigid pipesMetal rolling arrangementsCorrosion resistant alloyMetal forming process

A method of making a seamless, tubular article comprises subjecting a cast tubular workpiece of a corrosion resistant alloy to at least about a 25% wall reduction at a temperature below a recrystallization temperature of the workpiece using a metal forming process comprising at least one of radial forging, rolling, pilgering, and flowforming. The cast tubular workpiece is a centrifugally cast tubular workpiece comprising an inner diameter and an outer diameter.

Owner:ATI FLOWFORM PROD

Method of manufacturing a cooling plate and a cooling plate manufactured with this method

InactiveCN1886522AEasy to produceQuality improvementFurnace cooling arrangementsCooling devicesMetal forming processMechanical engineering

Owner:PAUL WURTH SA

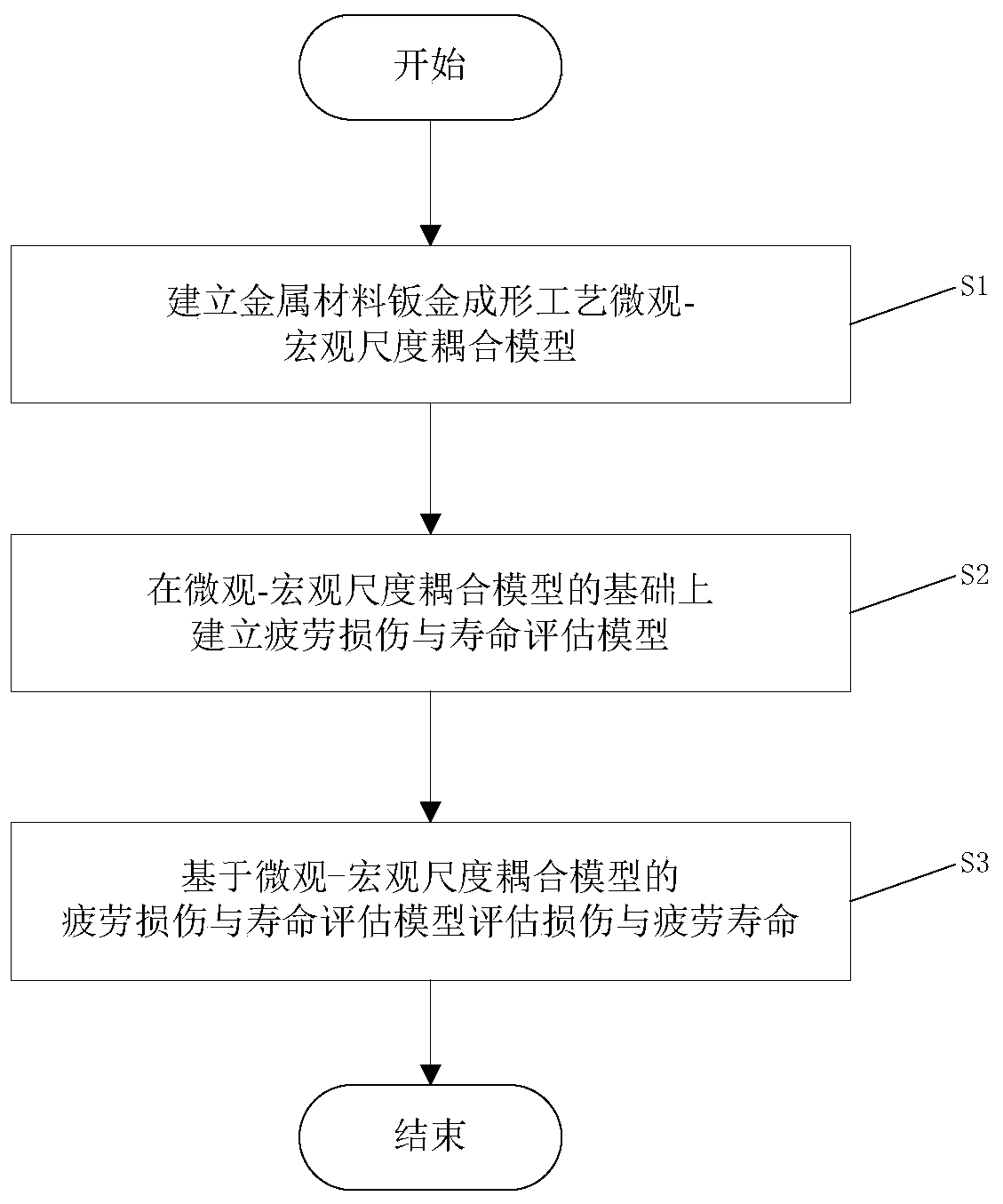

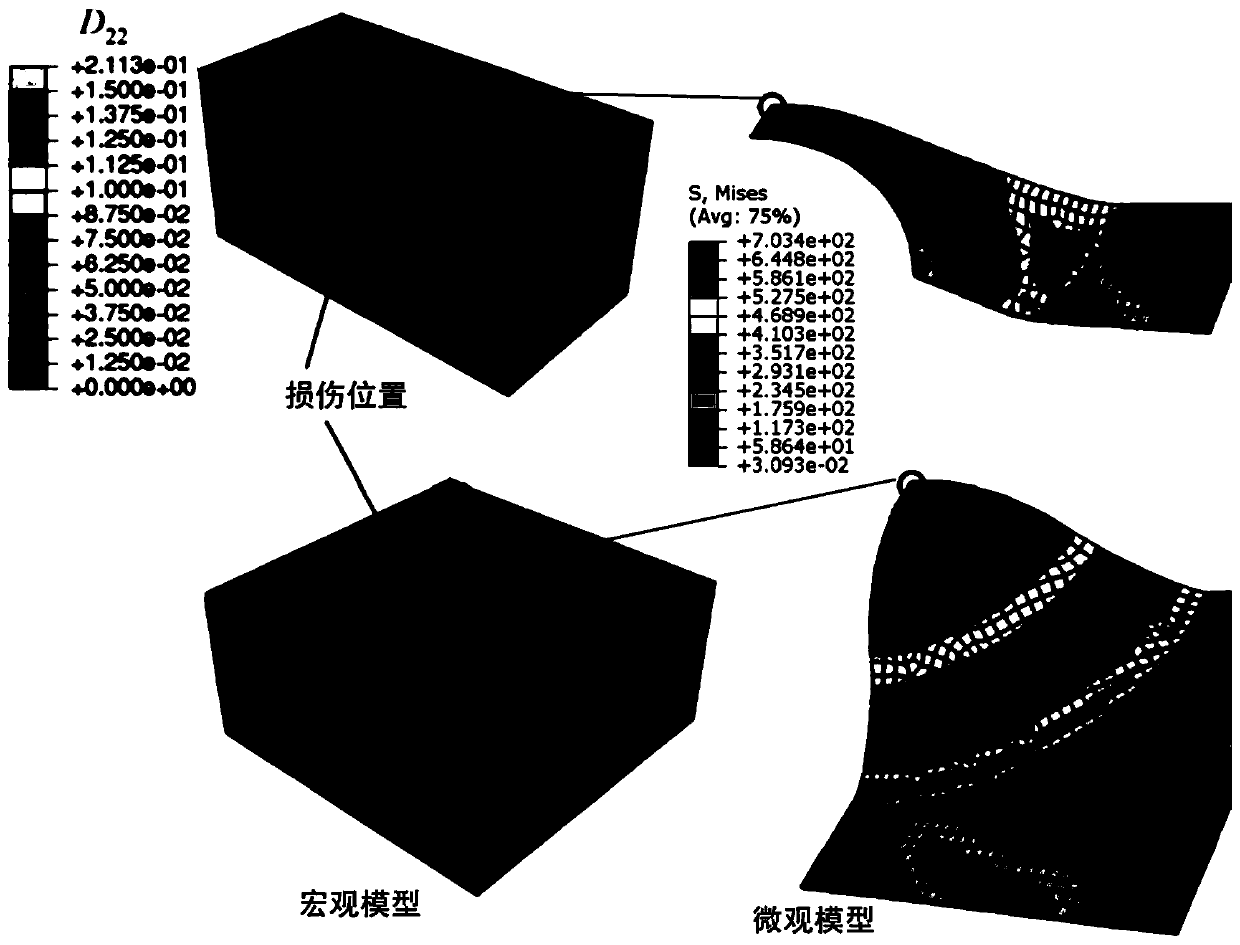

Method for evaluating damage and fatigue life of microscopic-macroscopic scale sheet metal forming process model

ActiveCN110211645ADesign optimisation/simulationChemical data visualisationFatigue damageMacroscopic scale

The invention discloses a method for evaluating damage and fatigue life of a microscopic-macroscopic scale sheet metal forming process model. According to the method of the invention, a microscopic plastic constitutive model is established and macro geometry is coupled; furthermore sheet metal forming process simulation is performed; based on sheet metal forming process simulation, a microscopic-macroscopic coupling fatigue damage model is established for performing fatigue life simulation; a sheet metal forming process and a fatigue failure mechanism are researched, thereby supplying theoretical guidance and technology optimization basis for engineering application. Sheet metal forming process material performance and plastic deformation evolution distribution are researched in a microscopic aspect. Influence and contribution degree of microscopic characteristics such as crystal grain size and orientation distribution and precipitated phase distribution to the sheet metal forming process are researched. Furthermore the macroscopic model and process researching fatigue damage are coupled, and the component fatigue life is evaluated. The invention provides the reliable high-efficiency calculating model and the evaluating method. Establishment of the related model and the algorithm has important science innovation and high engineering application value.

Owner:SICHUAN UNIV

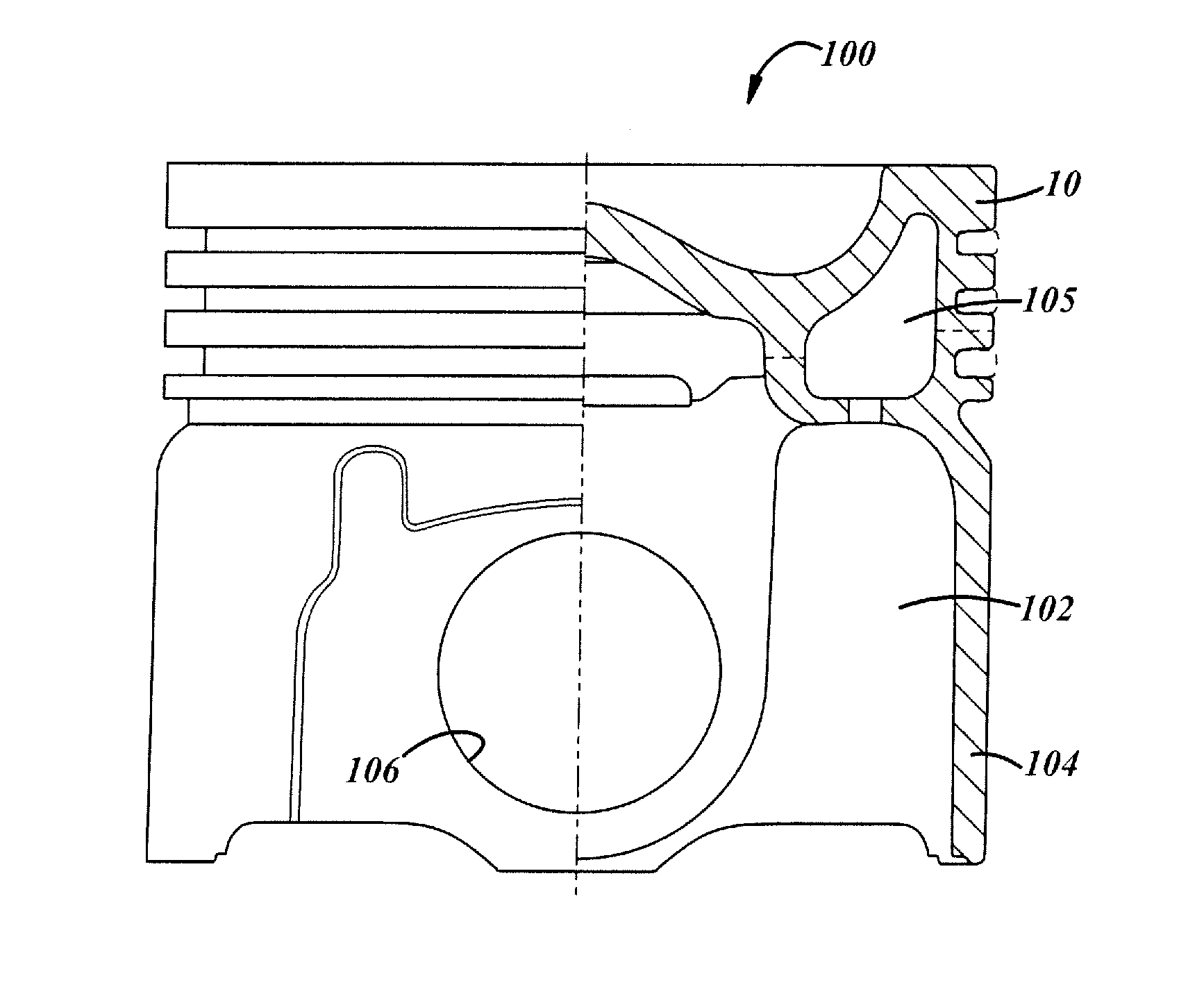

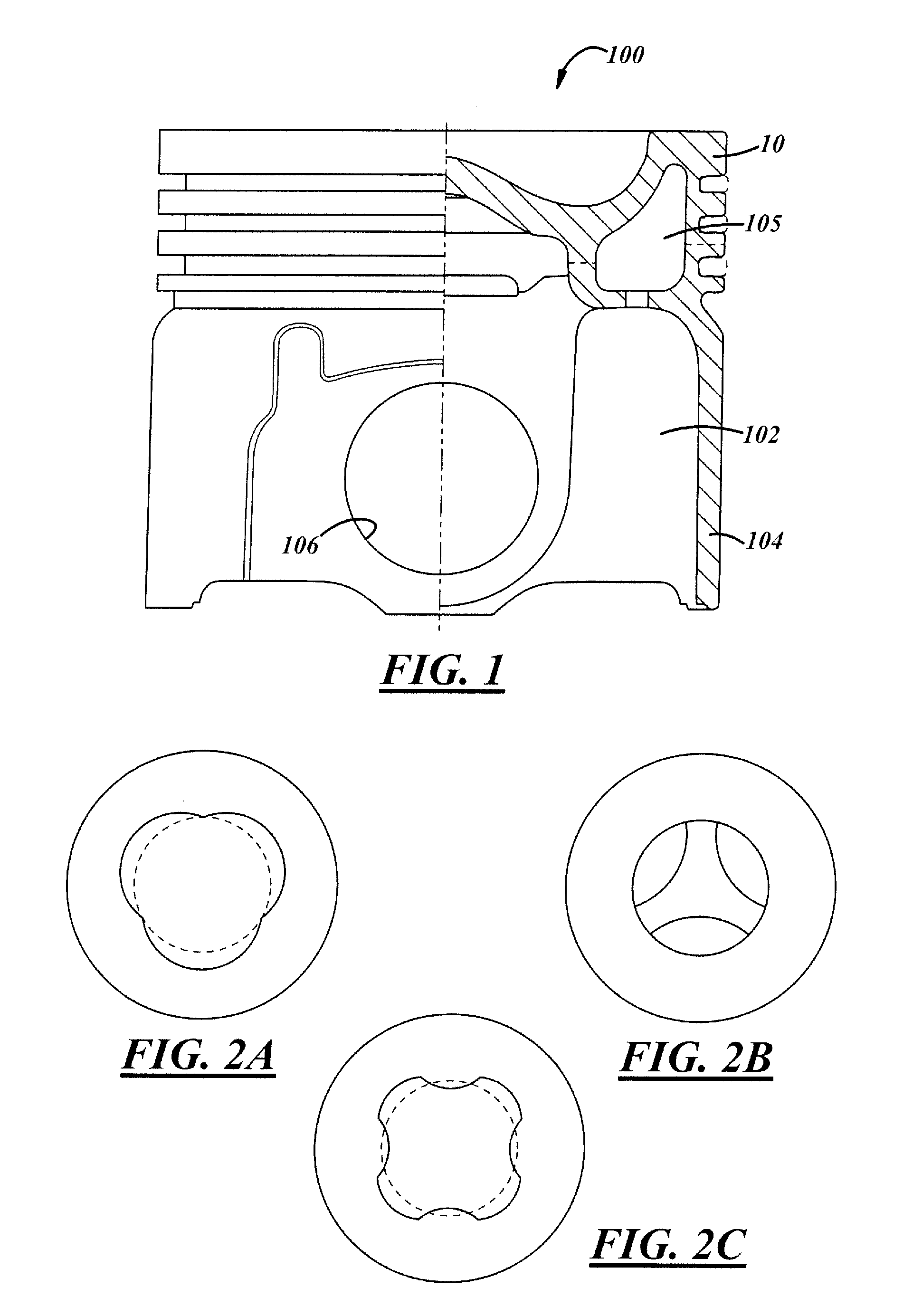

Complex-Shaped Piston Oil Galleries With Piston Crowns Made By Cast Metal or Powder Metal Processes

ActiveUS20140230774A1Uniform wall thicknessMinimizes and eliminates hot spotInternal combustion piston enginesPlungersCombustionMetallurgy

A steel piston with an oil gallery, and process for forming a steel piston oil gallery channel, which corresponds to the complex shape of the combustion bowl in the piston crown. The piston crown is made by a cast metal or powder metal forming process. The oil gallery channel is formed to the basic shape that corresponds to the shape of the walls of the combustion bowl. Machine-turning surfaces in the oil gallery channel can be machine-finished as desired. Surfaces in the oil gallery which cannot be machined with conventional turning operations, such as recesses and protrusions into the channel, are left in the original as-formed condition.

Owner:TENNECO

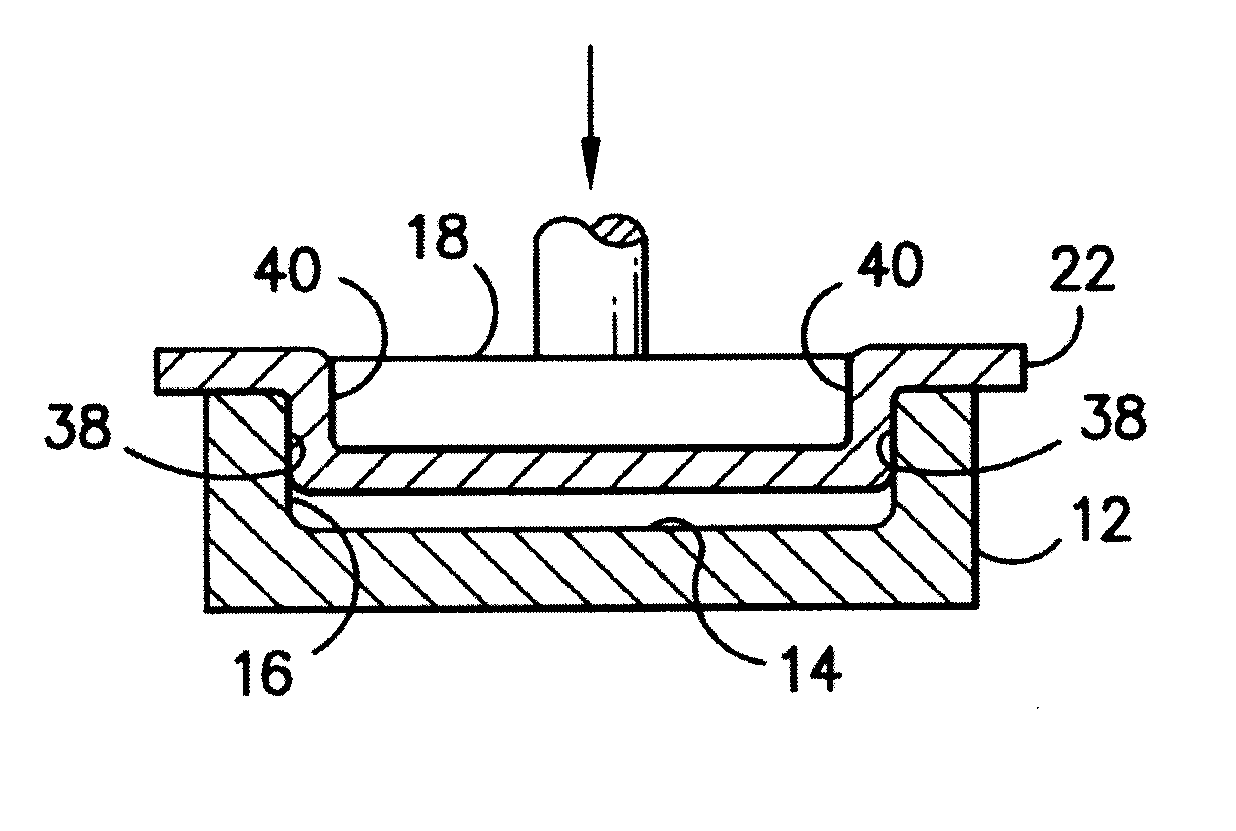

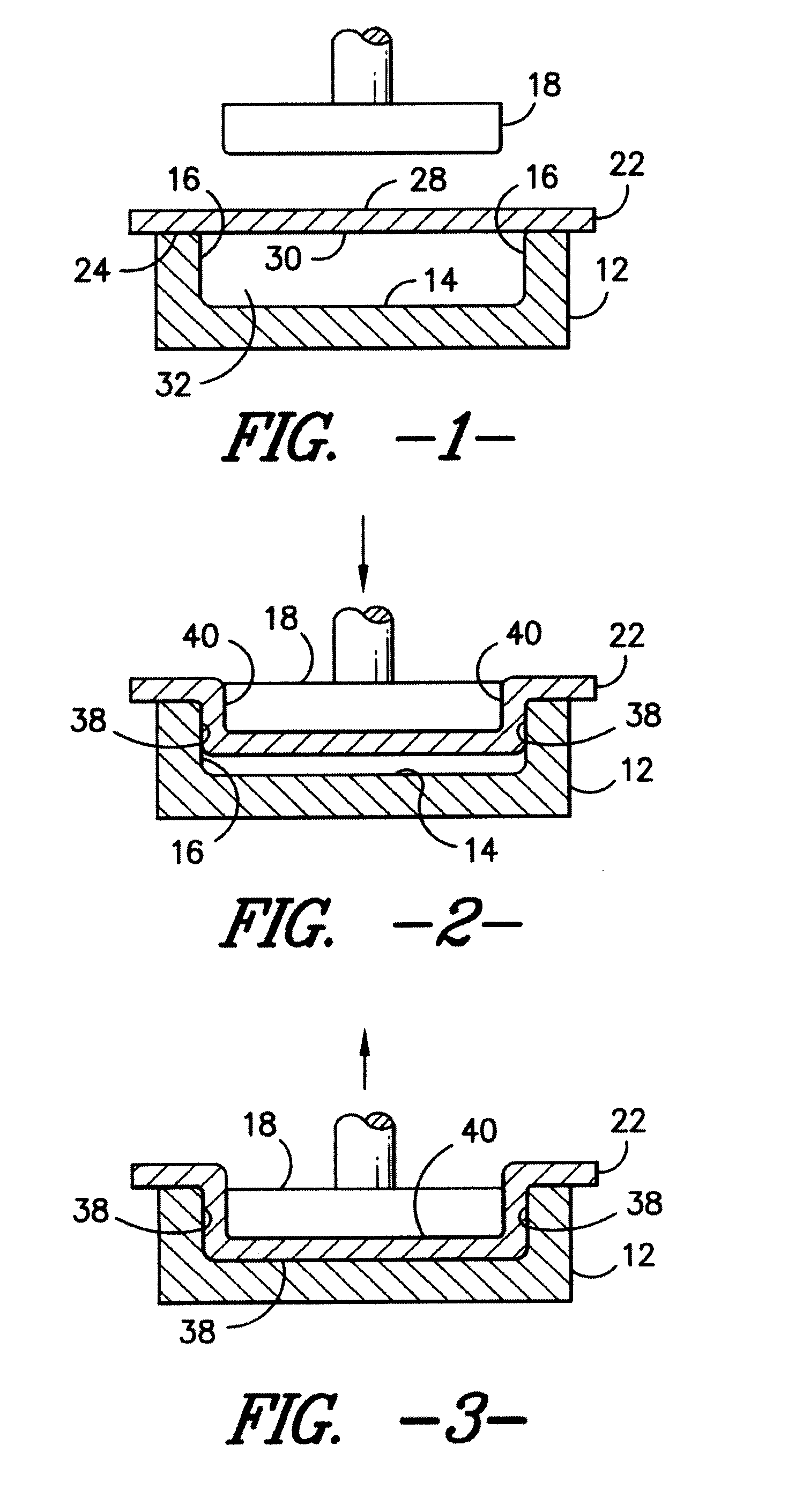

Linear actuator

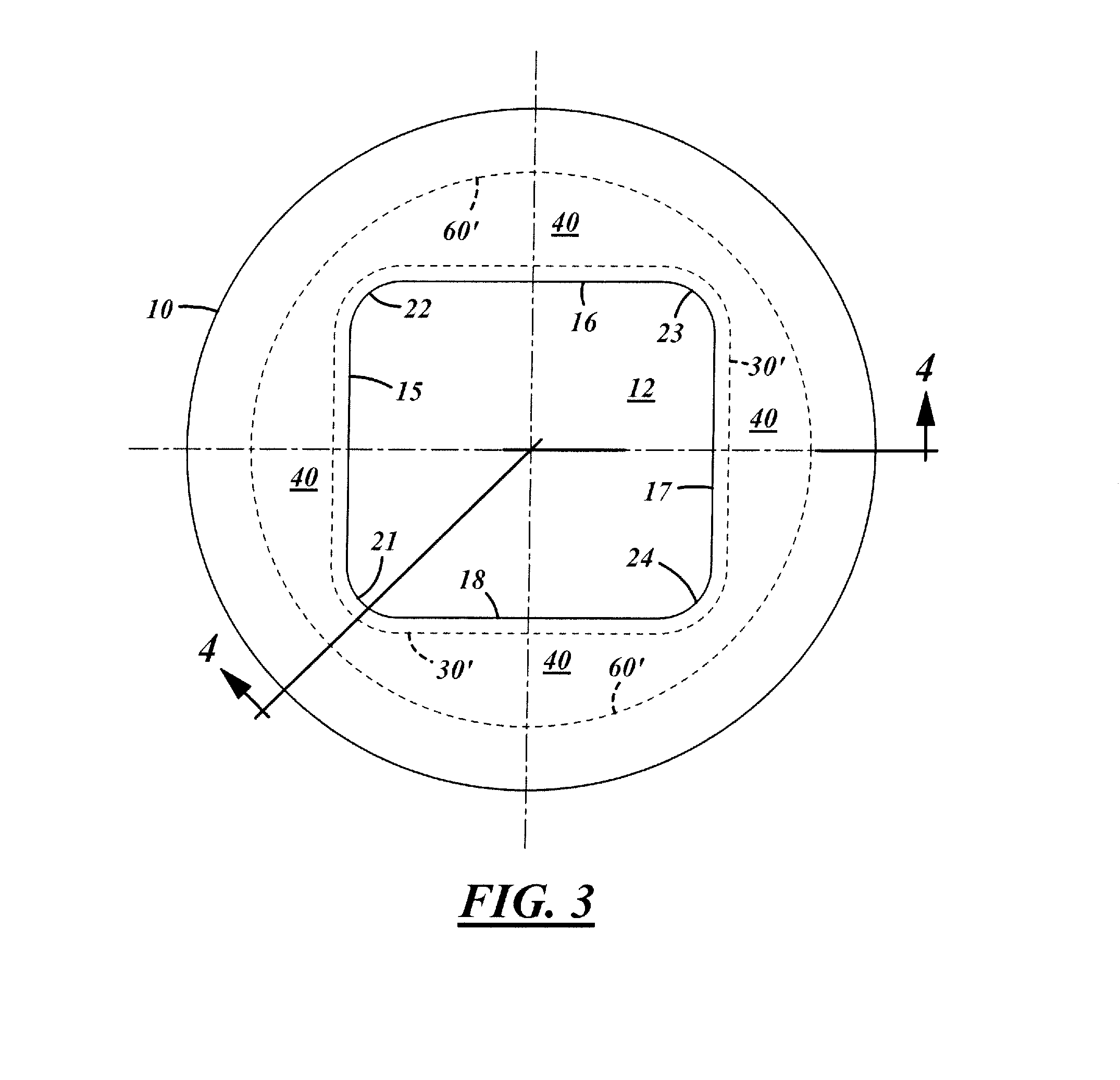

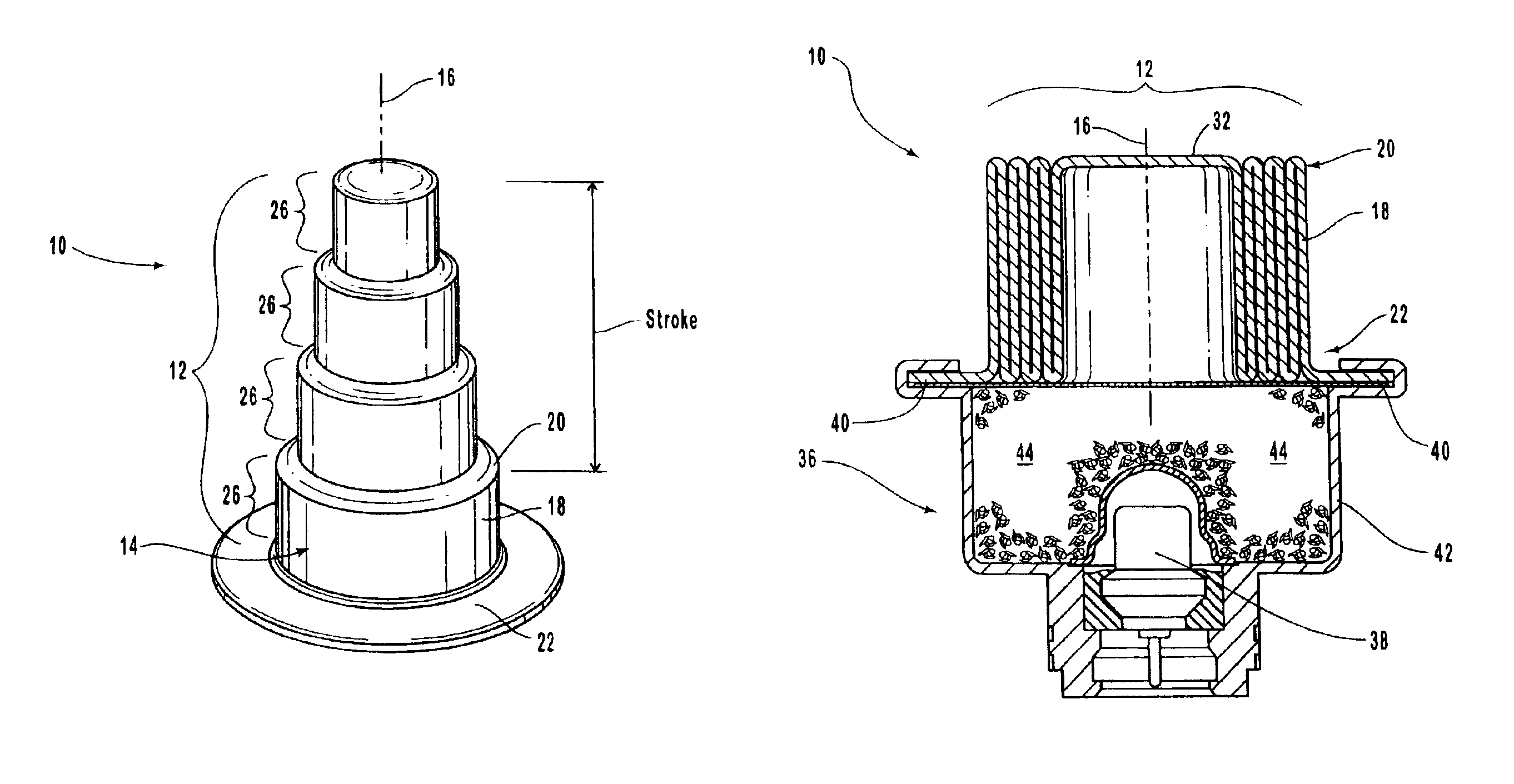

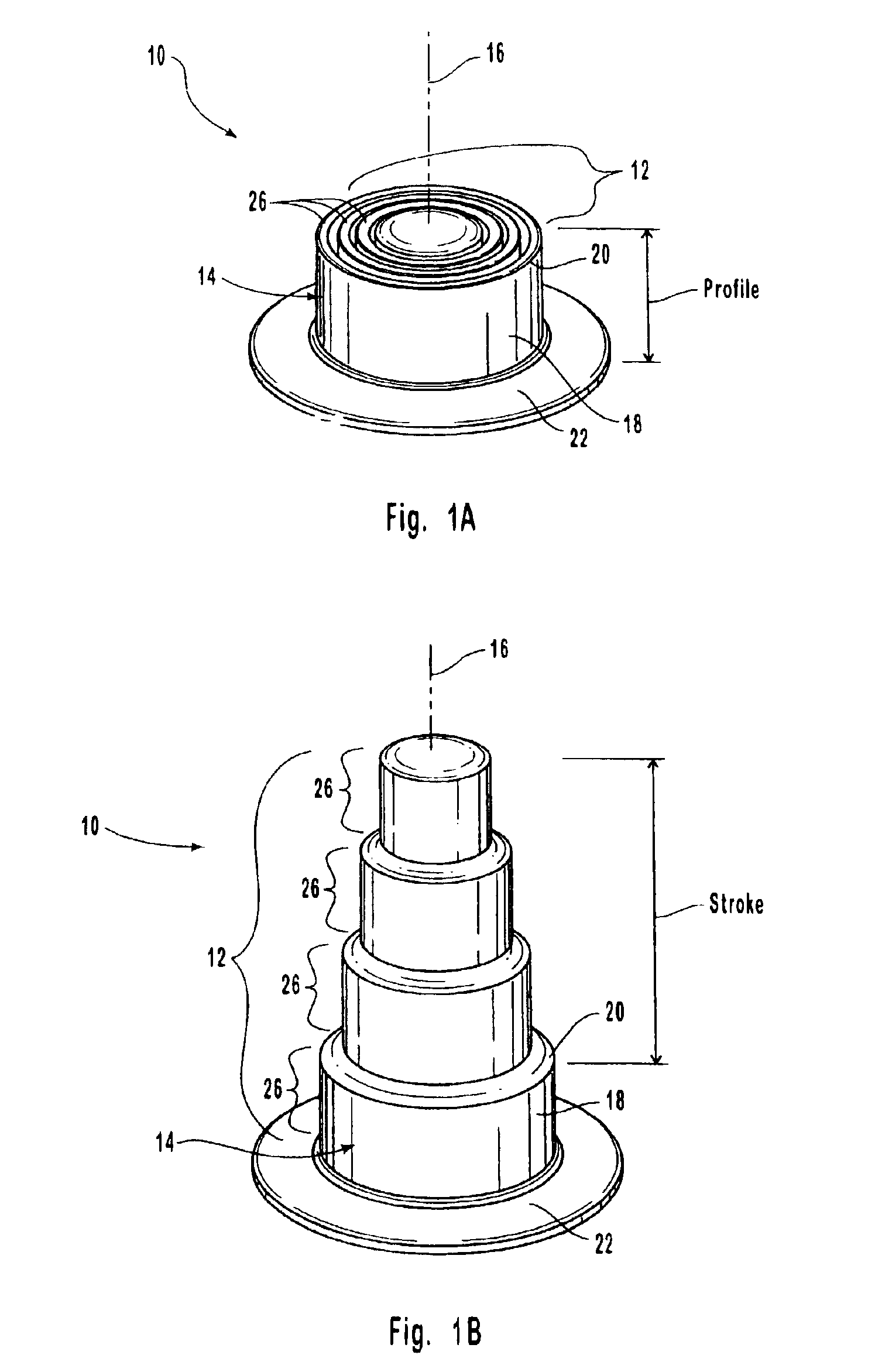

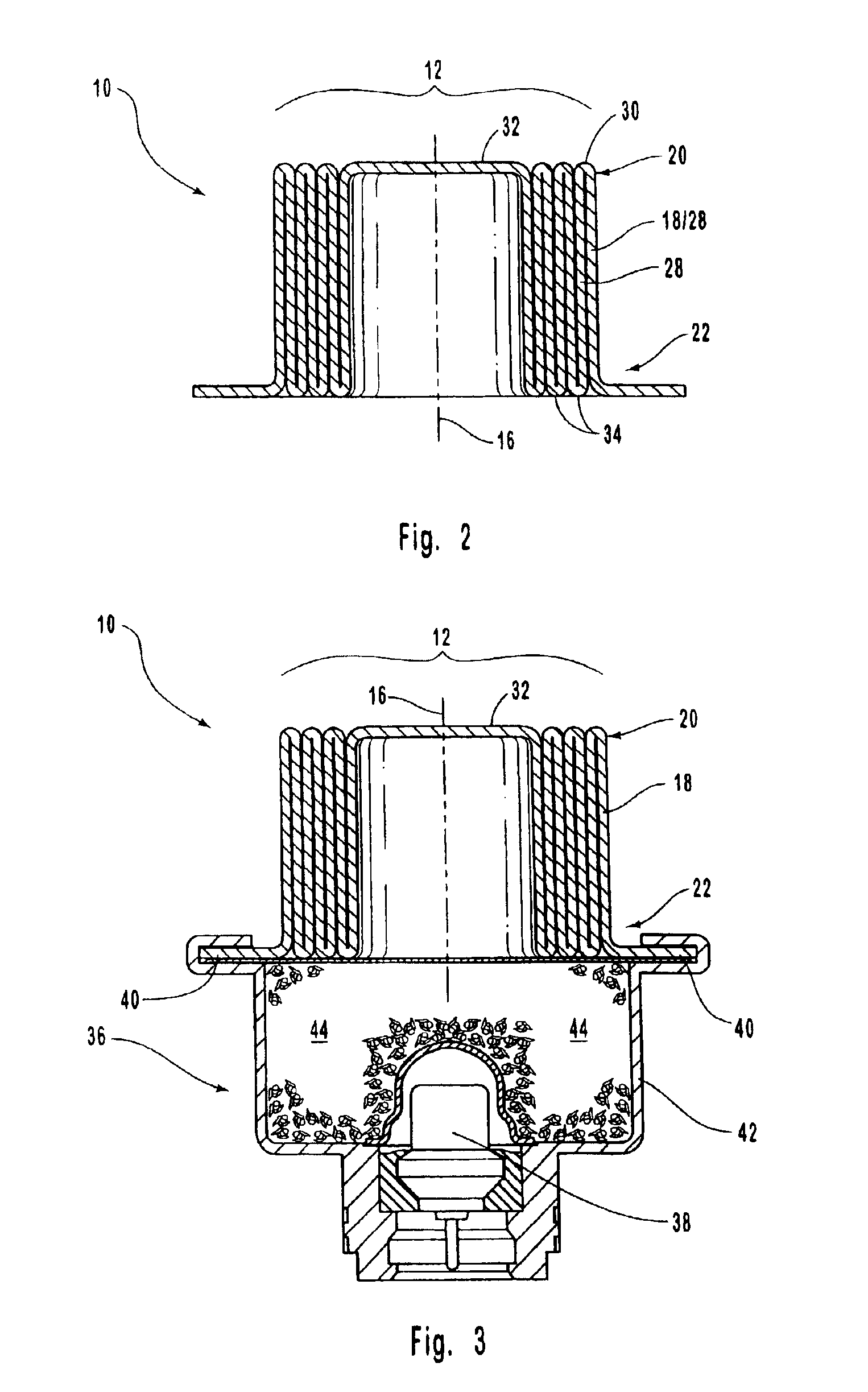

InactiveUS6907817B2Small shapeLong strokeFlexible wall reciprocating enginesPyrotechnical actuatorsMetal forming processStamping process

A linear actuator having a low profile and a long stroke is provided. The actuator includes a housing integrally connected to a telescoping piston. The piston may be extended by a fluid such as inflation gas provided by an inflation gas generator in fluid communication with the piston. The piston extends rapidly through a one-shot stroke. The extending piston converts energy in the fluid into motion for performing linear work. The linear actuator may be formed from a single piece of parent material through stamping processes including deep draw stamping. Alternatively, other metal forming processes may be used to form the linear actuator.

Owner:AUTOLIV ASP INC

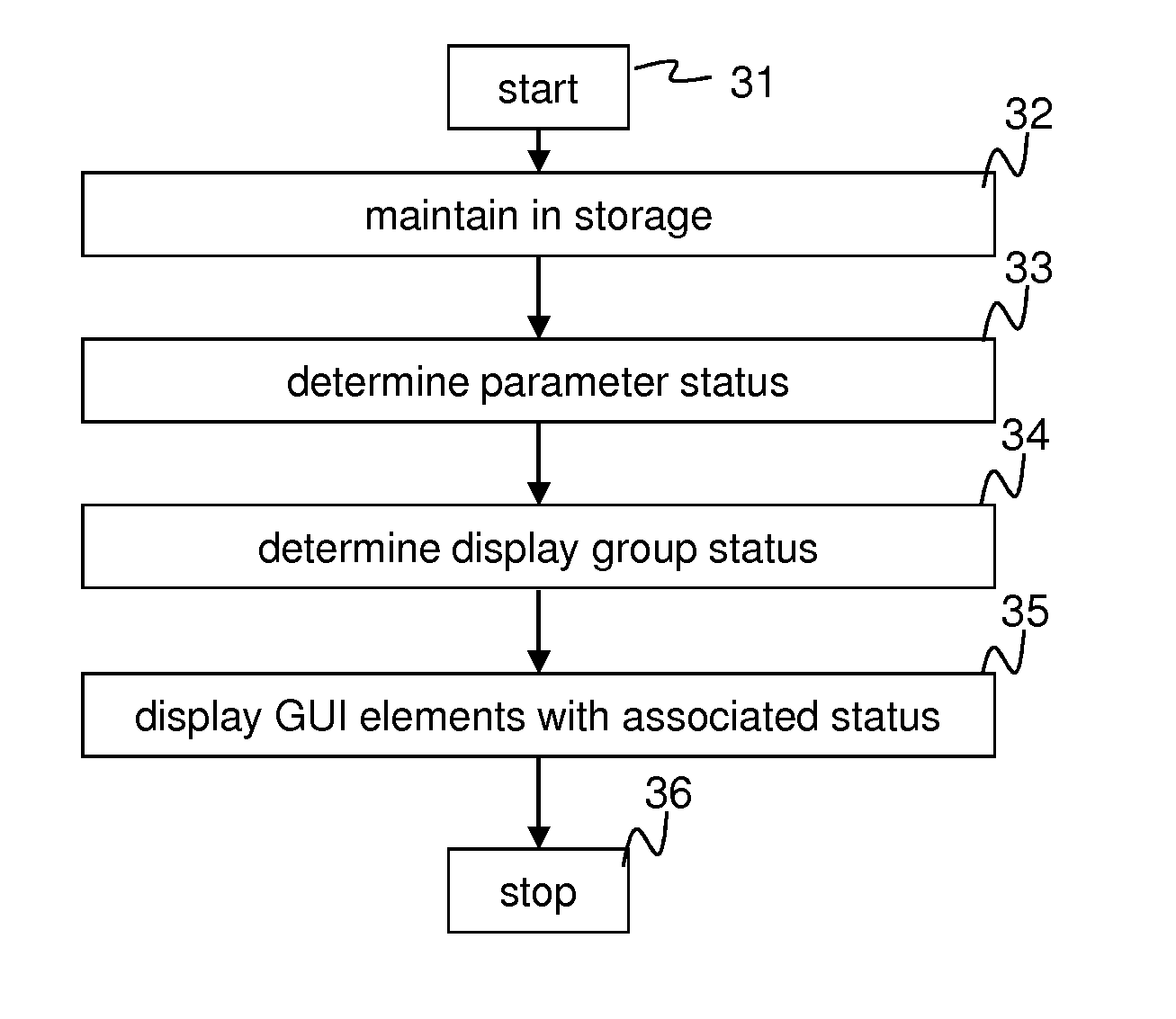

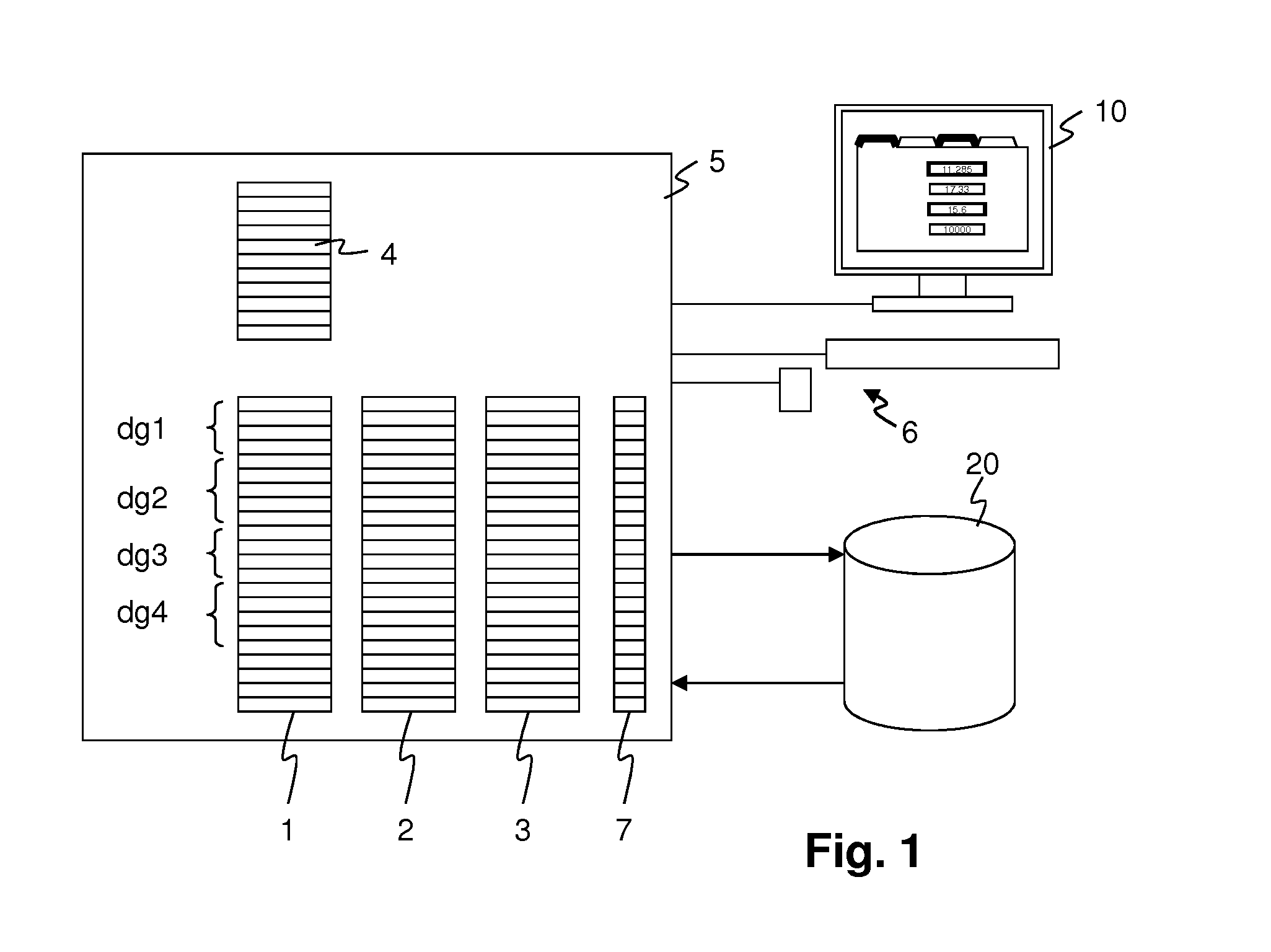

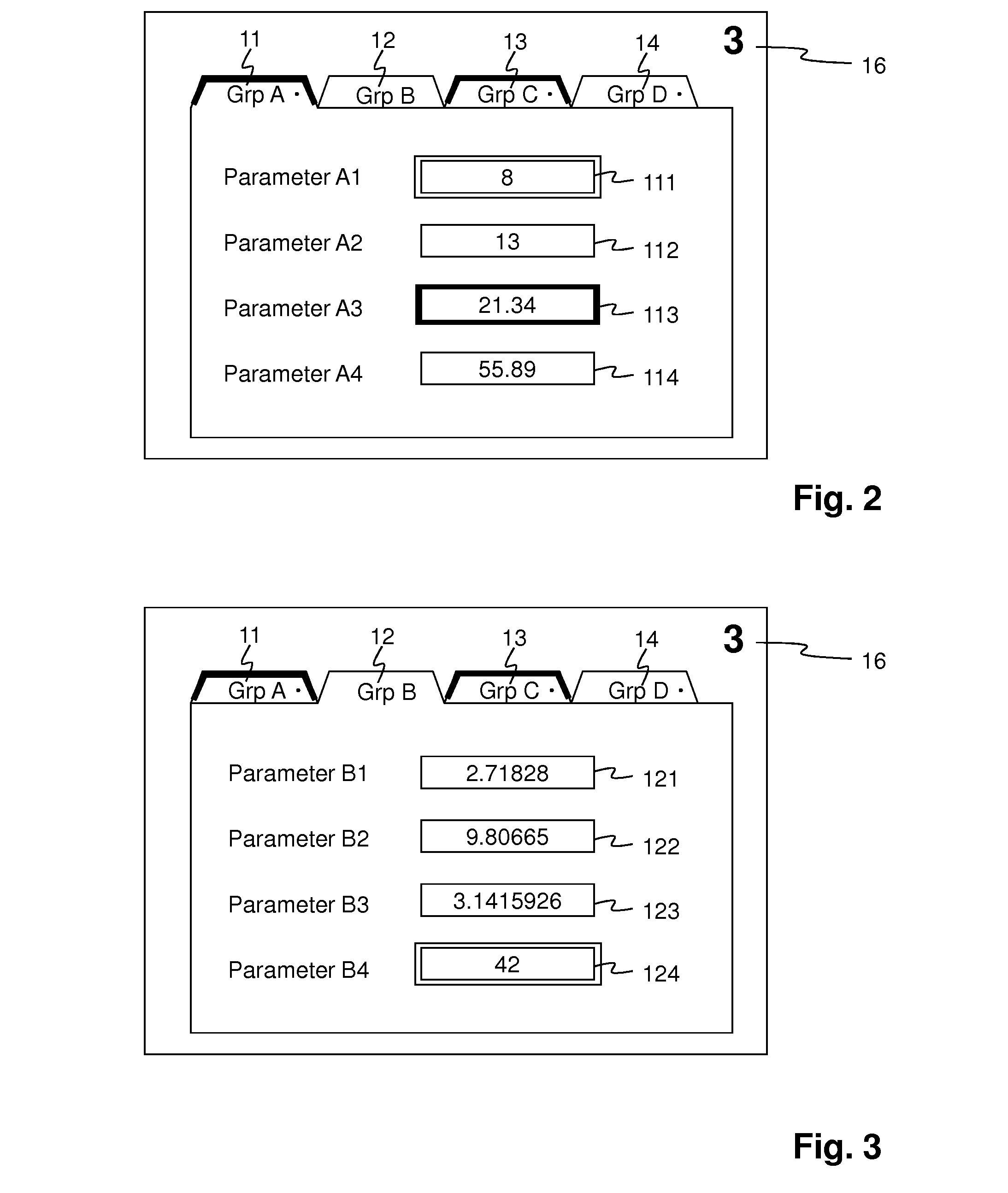

Method and system for processing and displaying sheet-metal-forming simulation parameters

ActiveUS20120123747A1Easy for to orient herselfConvenient visualComputation using non-denominational number representationDesign optimisation/simulationSimulationMetal forming process

In a method for the numerical simulation of sheet-metal-forming processes, forming simulation parameters are visually displayed by:maintaining active values of the simulation-program-control parameters and standard values of the parameters that can be, used as a reference;determining a status of each parameter as being “noncompliant” if and only if the active value of the parameter is not equal to the standard value of the parameter;grouping parameters into display groups, and determining the status of a display group as being “noncompliant” if and only if the status of at least one of the parameters or other display groups assigned to the display group is “noncompliant”;displaying GUI elements showing the active values of the parameters, and GUI elements associated with a display group; anddisplaying, for each of the GUI elements, a visual indication of the status of the corresponding parameter or display group.

Owner:NETABTAL MASCHEN

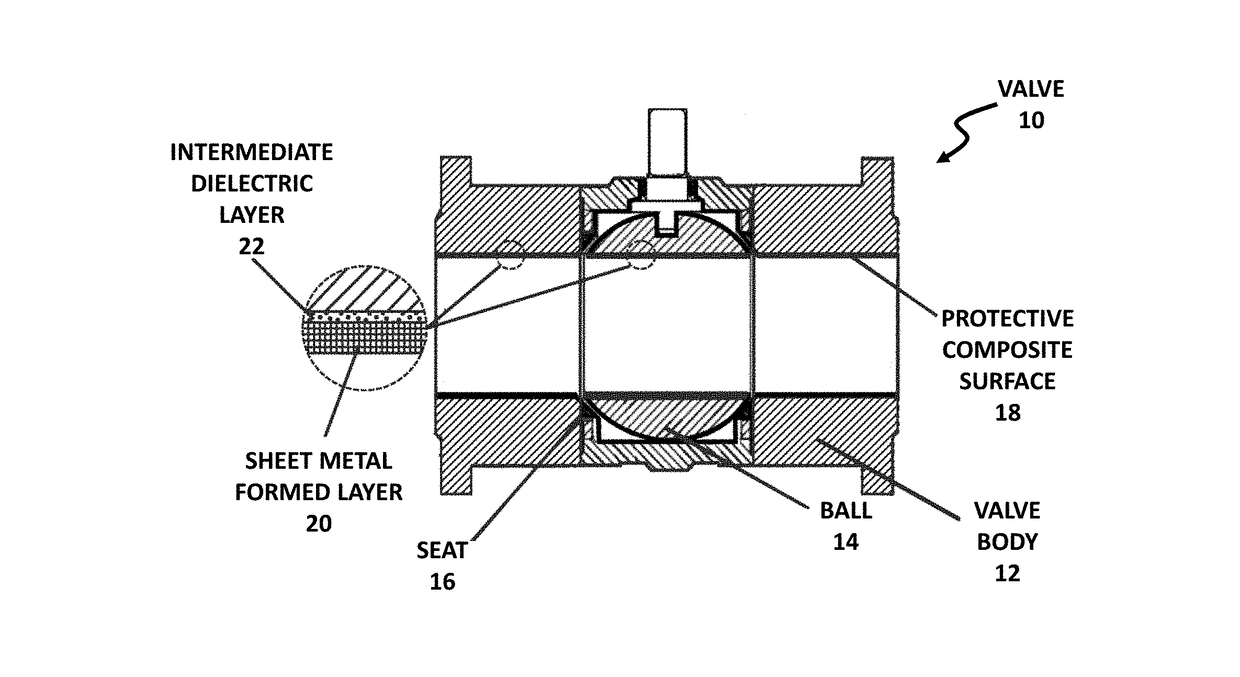

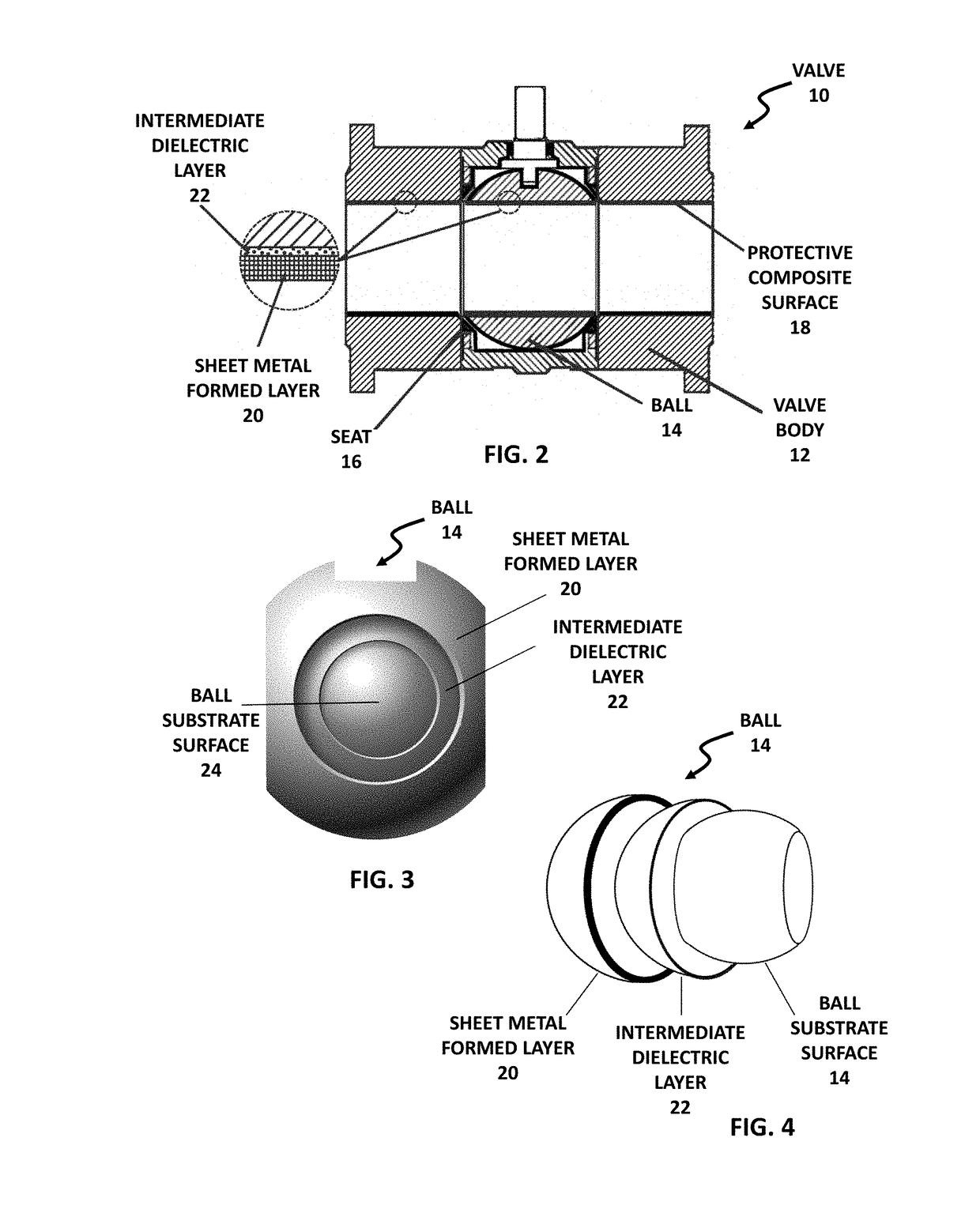

Protective composite surfaces

A machine component at least partially covered with a protective composite surface for providing corrosion protection and wear resistance comprises: a first layer of dielectric ceramic and / or polymer material in contact with an outer surface of the machine component; and a second layer of monolithic metal, reinforced metal, or metal alloy formed over the first layer by a sheet metal forming process.

Owner:KIM GEORGE

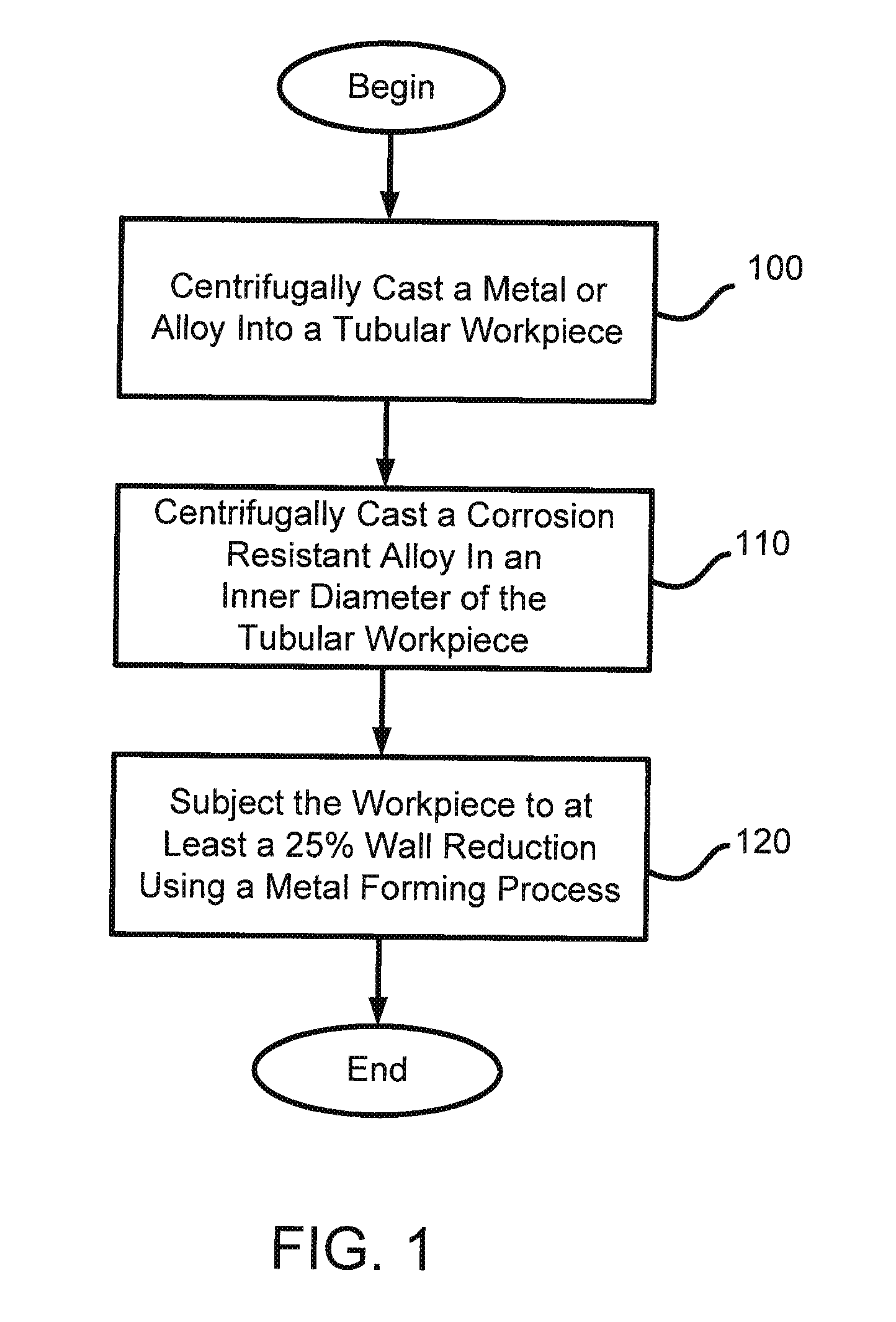

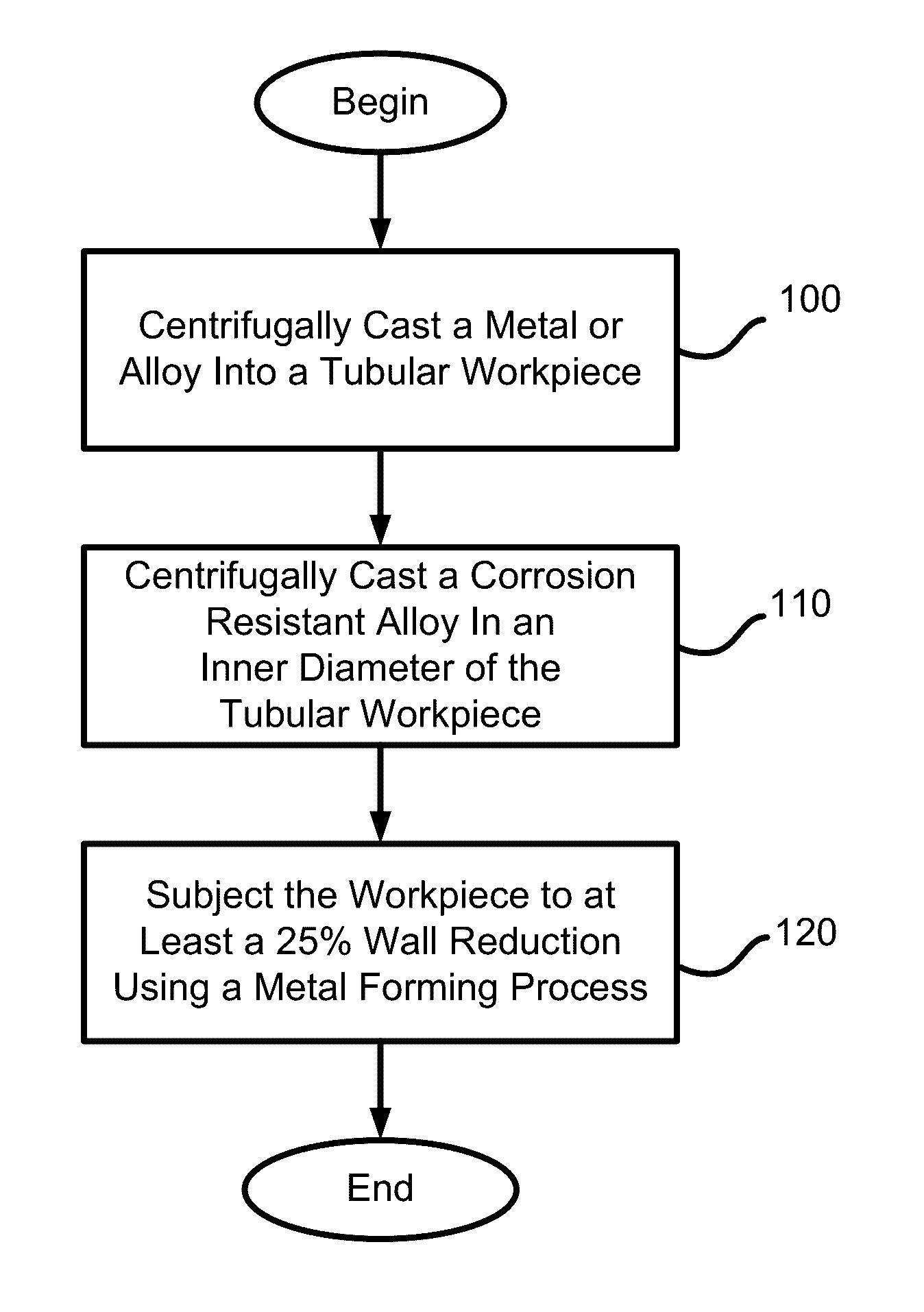

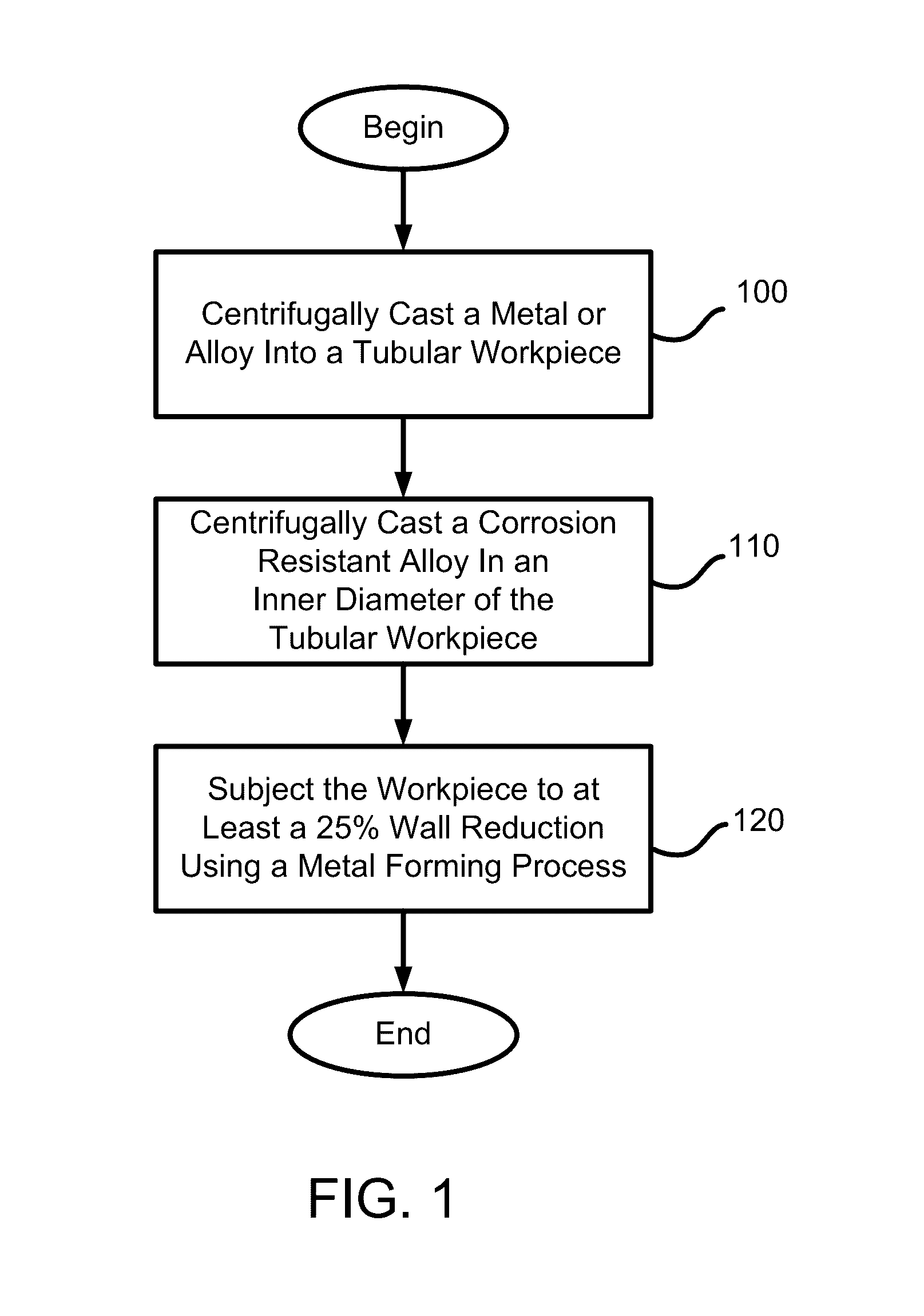

Method for producing cold-worked centrifugal cast composite tubular products

A method of producing a seamless, composite tubular product includes centrifugally casting a metal or alloy into a tubular workpiece having an inner diameter. The method then centrifugally casts a corrosion resistant alloy in the inner diameter of the tubular workpiece to form a composite tubular workpiece having an inner diameter and an outer diameter. The inner diameter of the composite tubular workpiece is formed of the corrosion resistant alloy, and the outer diameter is formed of the metal or alloy. The method then subjects the composite tubular workpiece to at least about a 25% wall reduction at a temperature below a recrystallization temperature of the workpiece using a metal forming process. The metal forming process includes radial forging, rolling, pilgering, and / or flowforming.

Owner:ATI FLOWFORM PROD

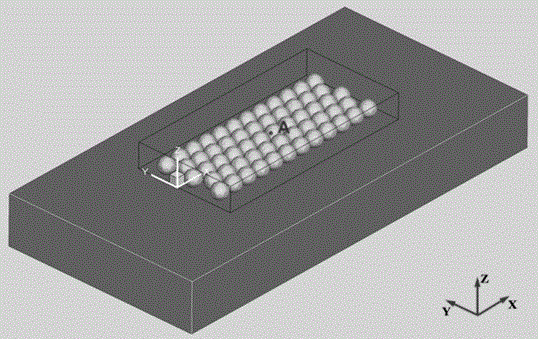

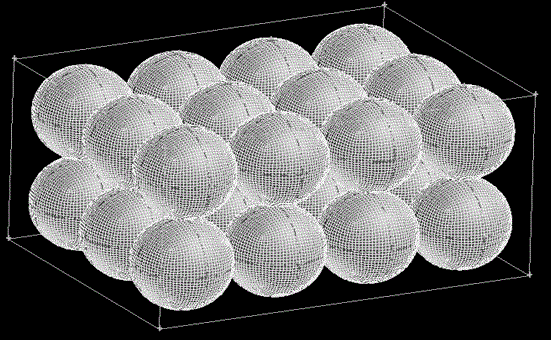

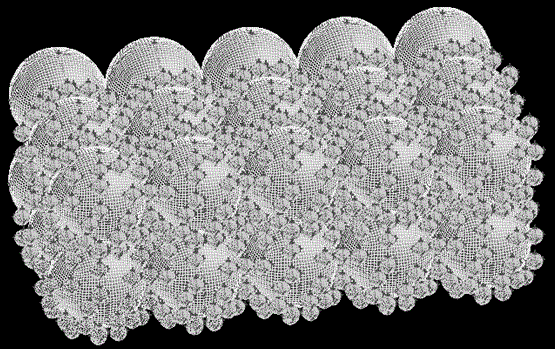

Mesoscopic simulating method for light-solid coupling process of laser beam and powder particles

The present invention discloses a mesoscopic simulating method for the light-solid coupling process of a laser beam and powder particles, and belongs to the technical field of a laser metal forming process. The method comprises: building a three-dimensional randomly-distributed particle accumulation model of a powder bed in a mesoscale; building a control equation of the three-dimensional randomly-distributed particle accumulation model; and resolving the three-dimensional randomly-distributed particle accumulation model by using a multi-phase flow algorithm under the constraint of the control equation so as to acquire a melting flow process. According to the mesoscopic simulating method for the light-solid coupling process of the laser beam and the powder particles, an effect of a powder particle stacking structure on laser absorption is considered; a coupling process of the powder particles and the laser is simulated; the temperature of the coupling process is numerically simulated to record a powder particle melting process; a temperature field and changes do not need to be observed after processing parameters are changed; a melting bath model is avoided being built on a macroscopic level; and the effect of the powder particle stacking structure on the light-solid coupling process is not considered.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Lubricant formulation for high temperature metal forming processes

InactiveUS20080078225A1Improve surface adhesionImprove the lubrication effectShaping toolsWork treatment devicesBoron nitrideMetal forming process

Owner:GM GLOBAL TECH OPERATIONS LLC

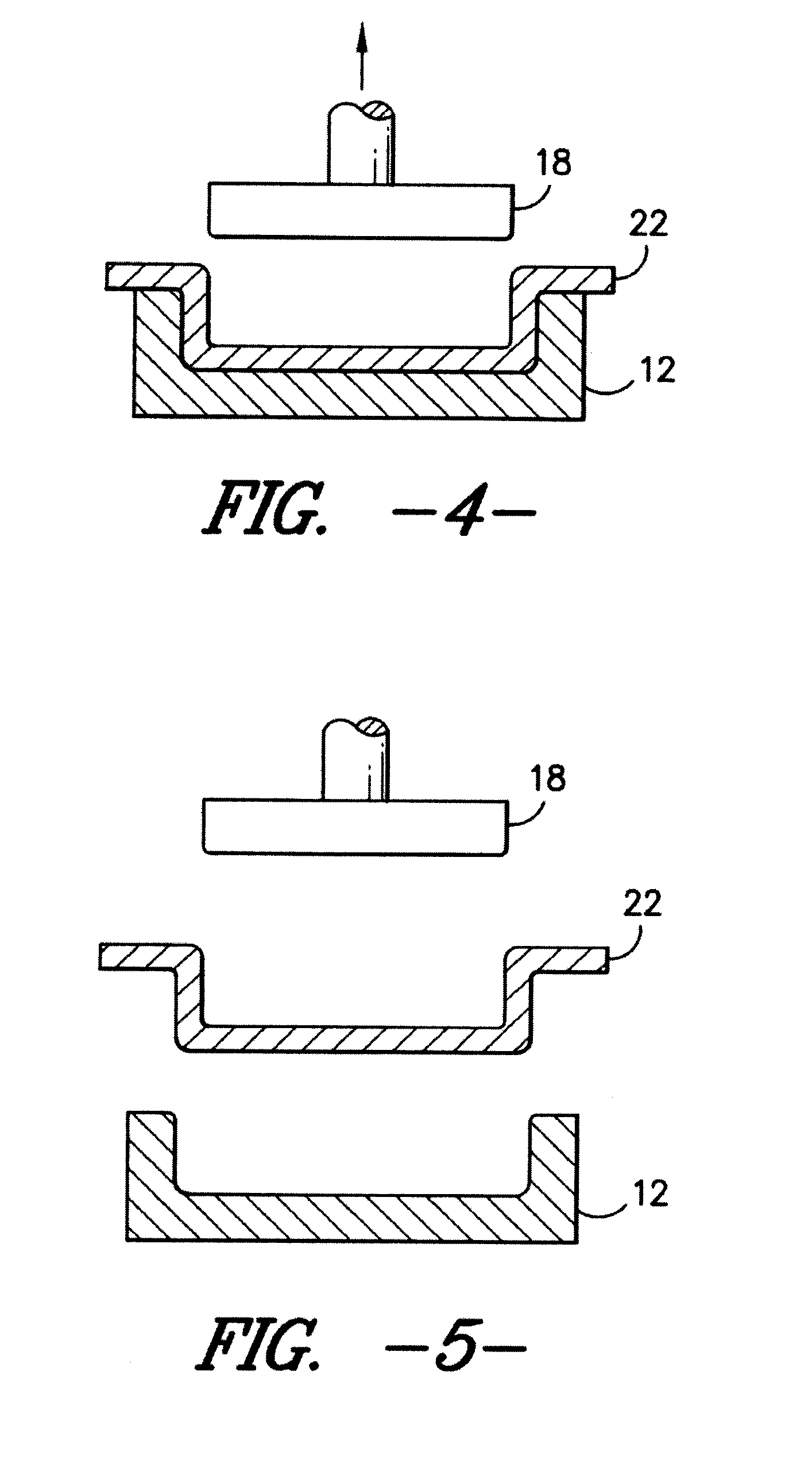

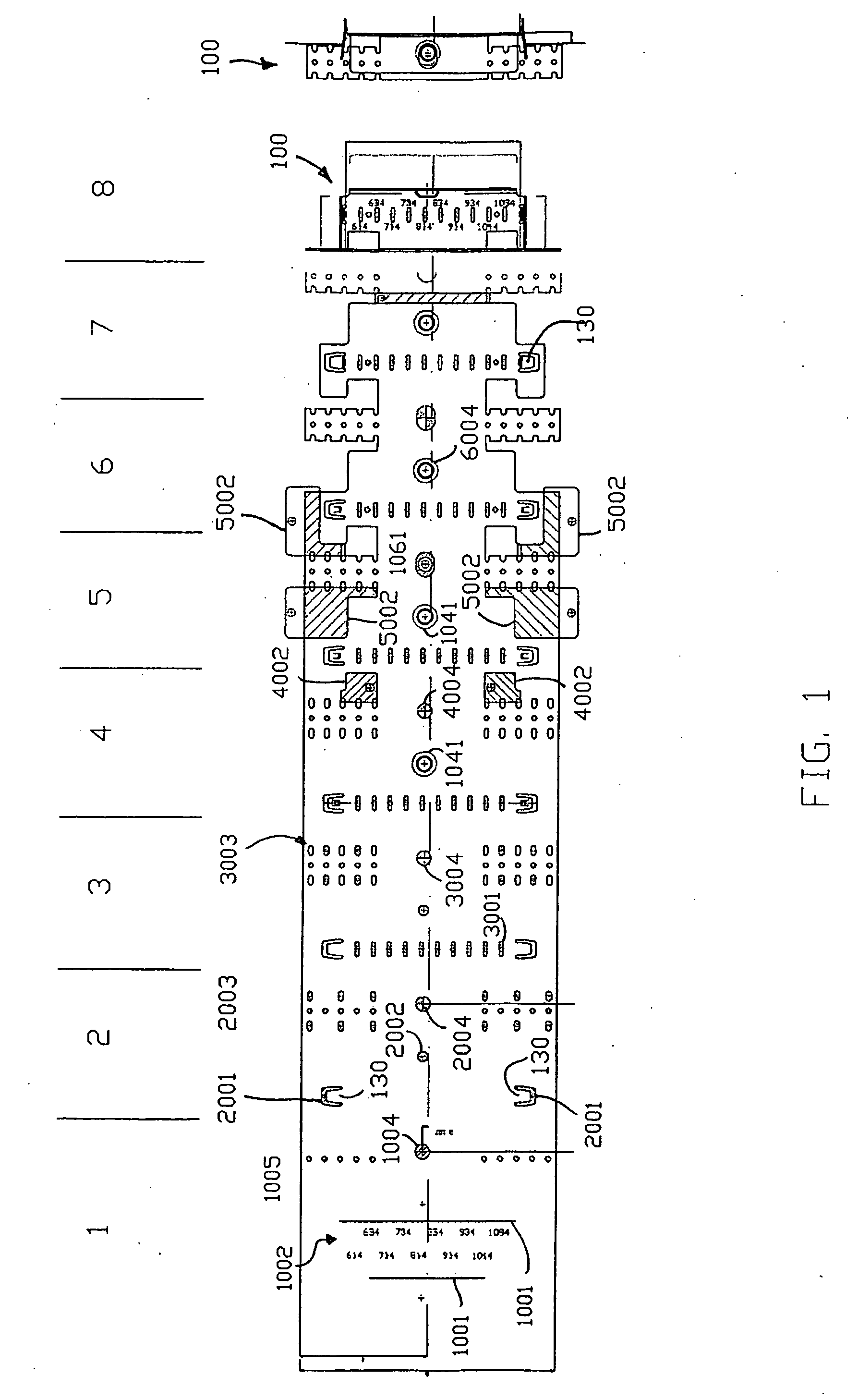

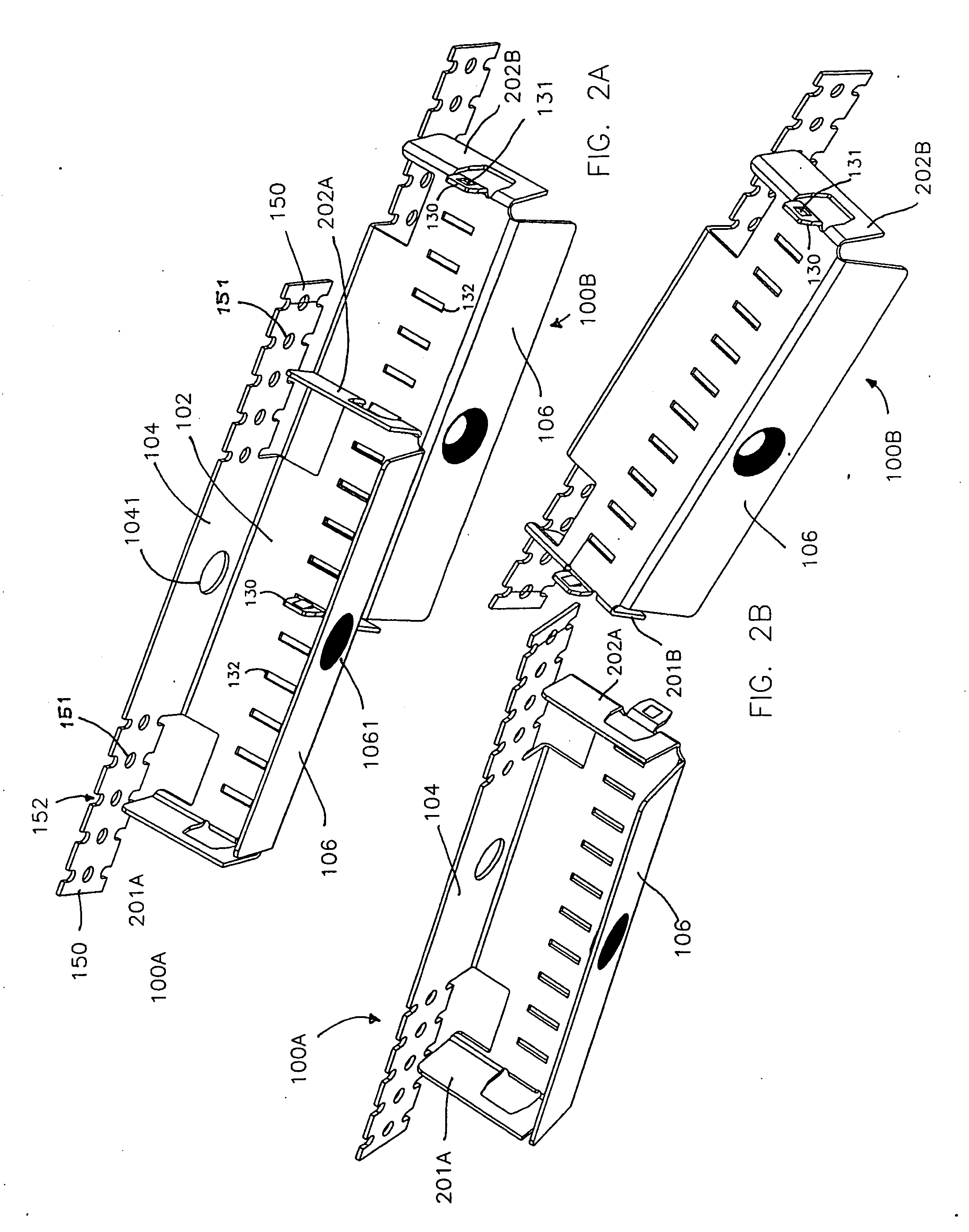

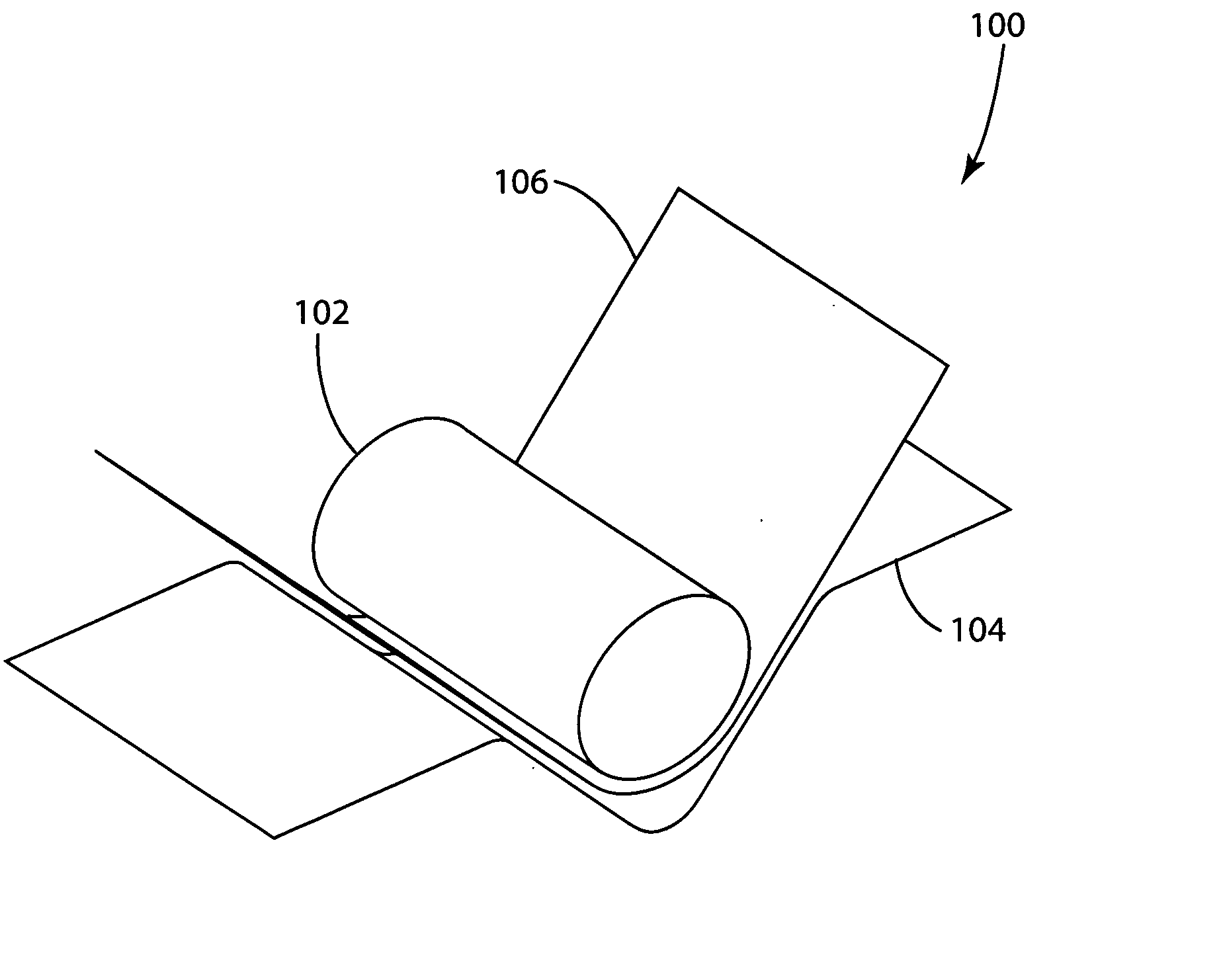

Frame member fastening device and method of manufacture

A frame member fastening device and method of manufacture provides a single configuration fastening device which can be used singly in connection with a frame member, or which can be combined with another identical fastening device to form a fastening device assembly for use with frame members of different internal widths, by interlocking two identical fastening devices in an opposed, base-to-base assembly configuration. The fastening device is manufactured in a progressive metal forming process with successive stages in which the features of the device are formed.

Owner:QUINTILE MARK +2

Crash analysis through estimation of residual strains resulting from metal formation

InactiveUS20070251327A1Increase speedForce measurementUsing electrical meansResidual strainCollision analysis

A method is disclosed for estimating or predicting residual strains resulting from metal formation. The method includes determining parameters indicative of physical and spatial characteristics of elements representing a formed metal part. A maximum plastic strain resulting from the metal forming processes is then estimated, as a function of the physical and spatial characteristics of a first one of the elements and a subset of the elements.

Owner:BROWN CORP OF AMERICA INC

Stress induced crystallographic phase transformation and texturing in tubular products made of cobalt and cobalt alloys

A method of producing a cobalt-based tubular product includes forming a cobalt or cobalt alloy tubular workpiece having at least about 30% by weight of fcc phase and subjecting the workpiece to at least about a 20% wall reduction at a temperature below a recrystallization temperature of the workpiece using a metal forming process. The metal forming process may include radial forging, rotary swaging, pilgering and / or flowforming. A gun barrel includes a tubular component made of a cobalt-based superalloy material. The component has at least about 25% by weight of hcp phase with basal planes radially oriented perpendicular to an inner diameter of the component.

Owner:ATI FLOWFORM PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com