Powder recovery device suitable for laser metal forming process

A metal forming and recycling device technology, applied in the direction of process efficiency improvement, energy efficiency improvement, additive manufacturing, etc., can solve problems such as difficult protection, metal powder human health hazards, etc., achieve small size, avoid spillage and pollution, energy consumption, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

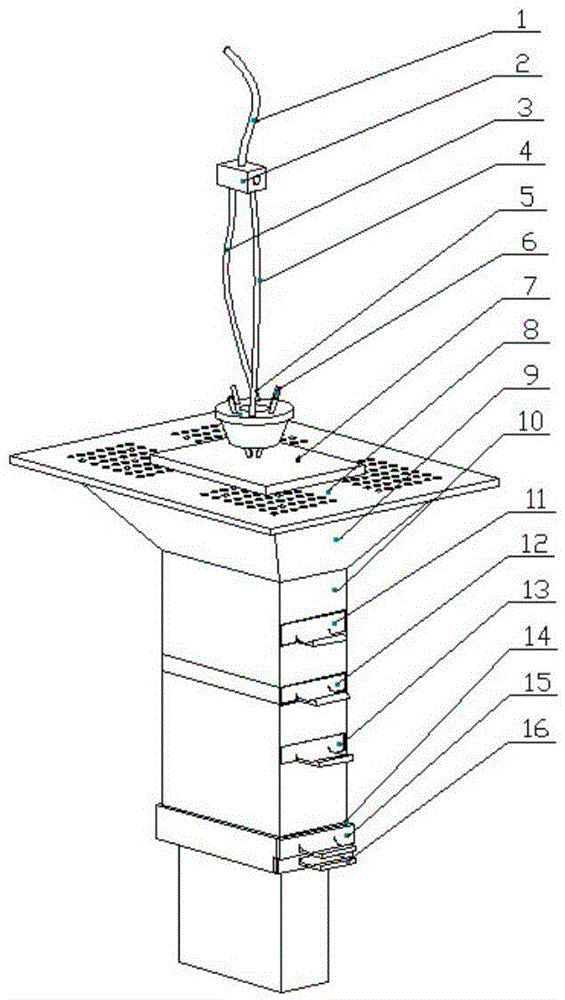

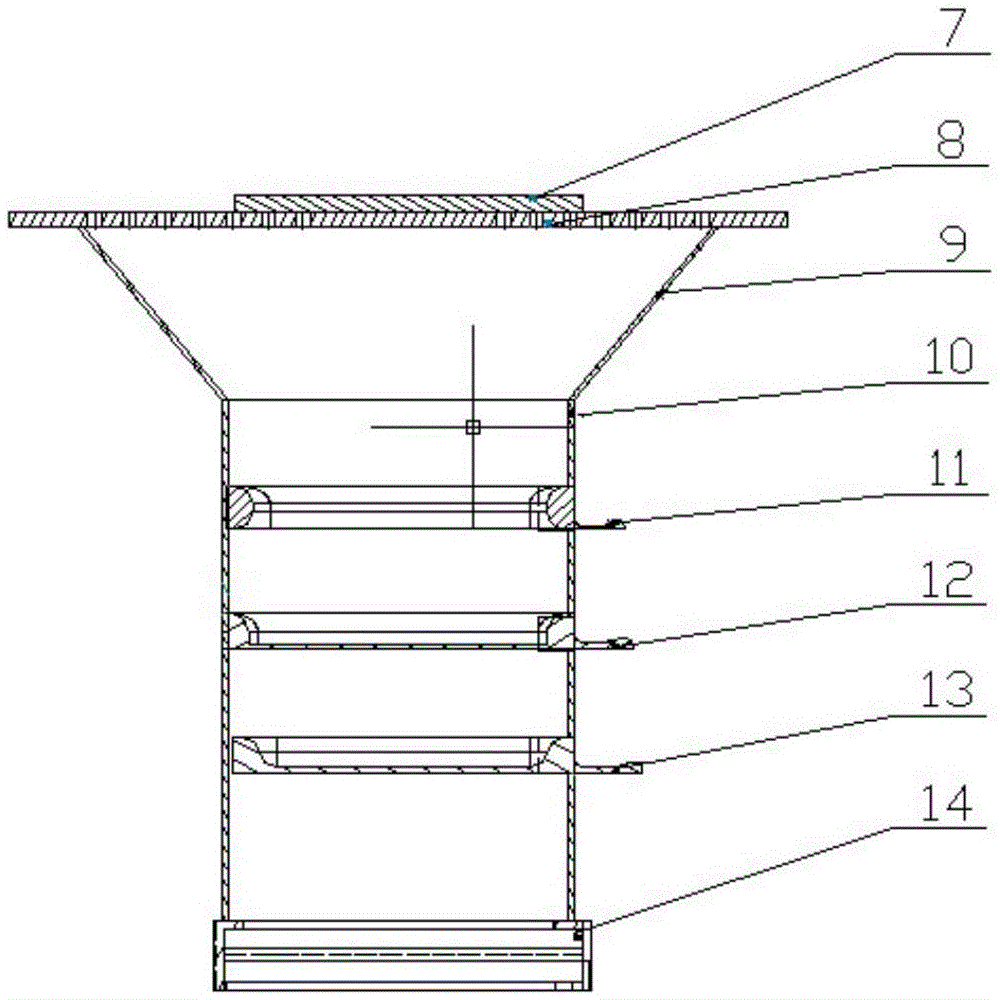

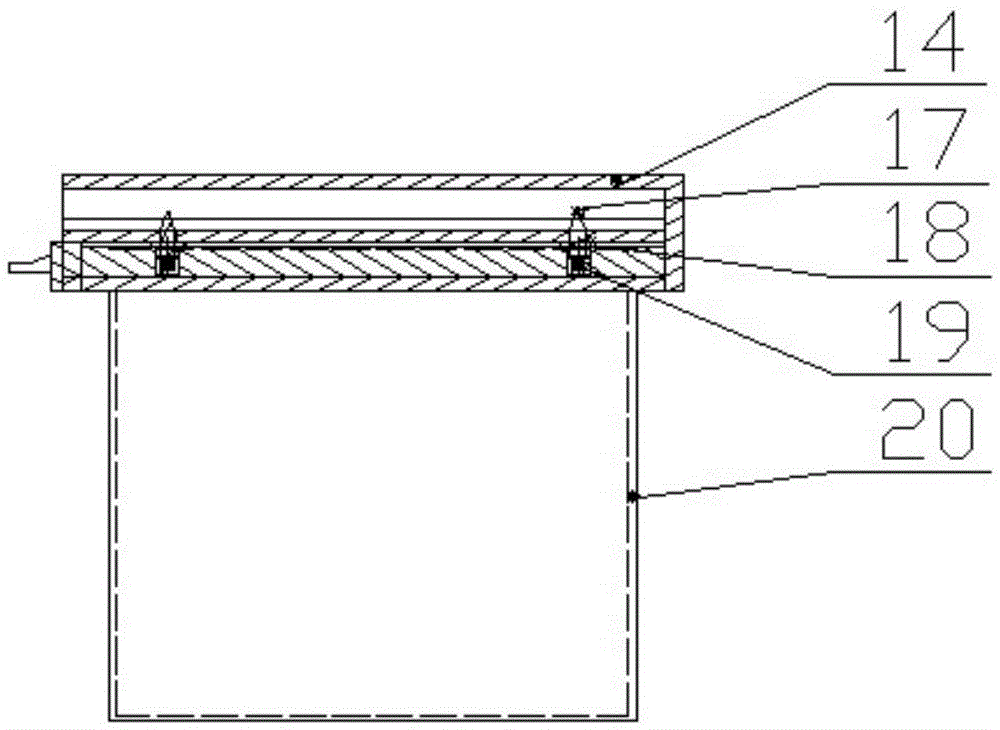

[0018] Refer to the overall structure diagram of a metal powder recovery device used in laser metal forming process figure 1 , the powder recovery channel and the structure diagram of the recovery bag refer to the reference respectively figure 2 , image 3 , the end of powder recycling put away the powder recycling bag for reference Figure 4 , including powder cleaning module, powder collection and delivery module, powder collection module.

[0019] refer to figure 1 , the powder recovery unit consists of figure 1 1 to 6 in the middle, 1 is the three-position two-way solenoid valve for the powder cleaning gas to enter, and then divided into two gas channels 3 and 4 that can be opened independently and simultaneously, and the powder cleaning gas enters the powder feeding nozzle 5 along the pipeline In the powder cleaning gas channel, the moving platform drives the nozzle to move above the workbench, and the solenoid valve controls the start and stop of the two paths of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com