Patents

Literature

229results about How to "Reduce magnification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

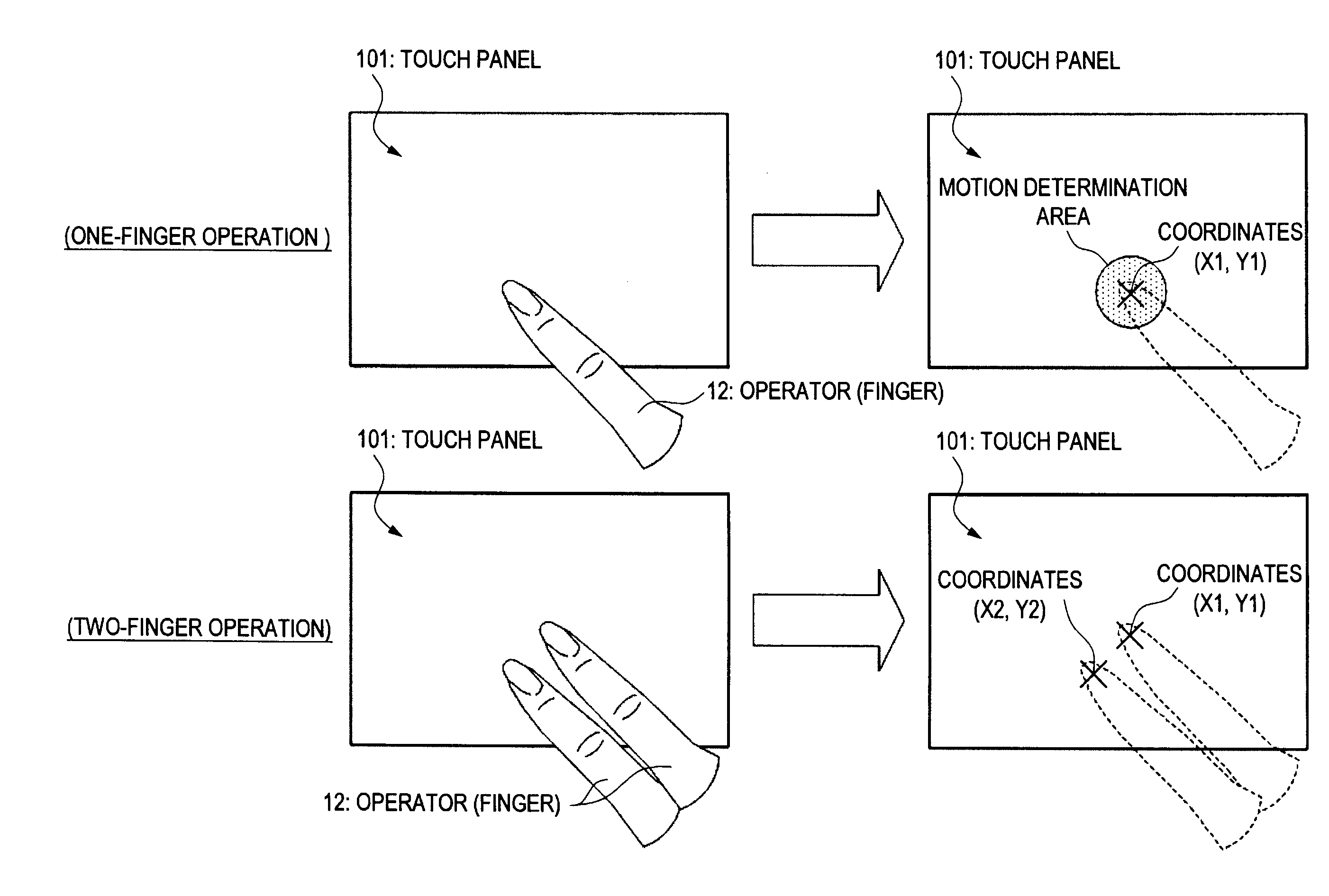

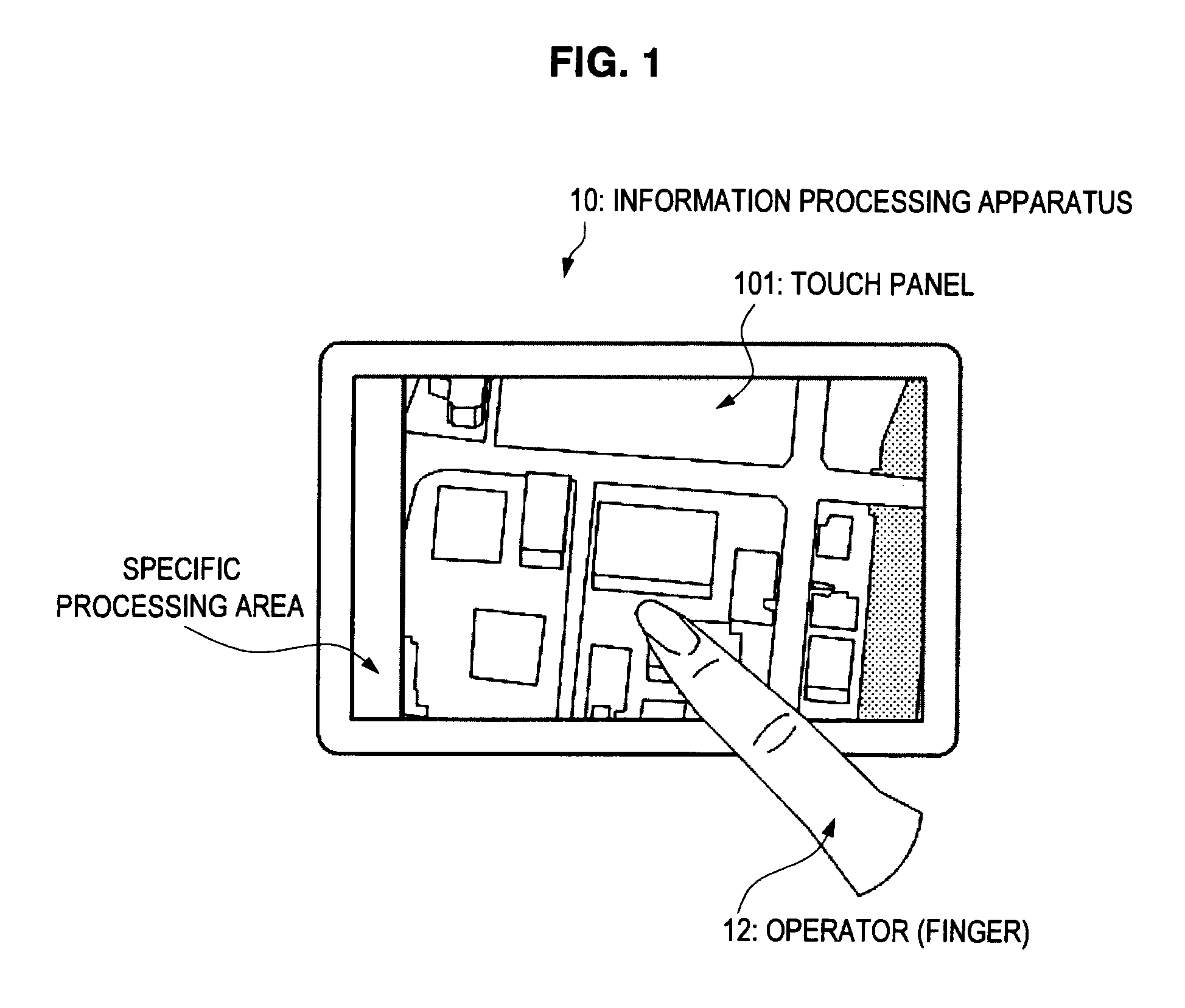

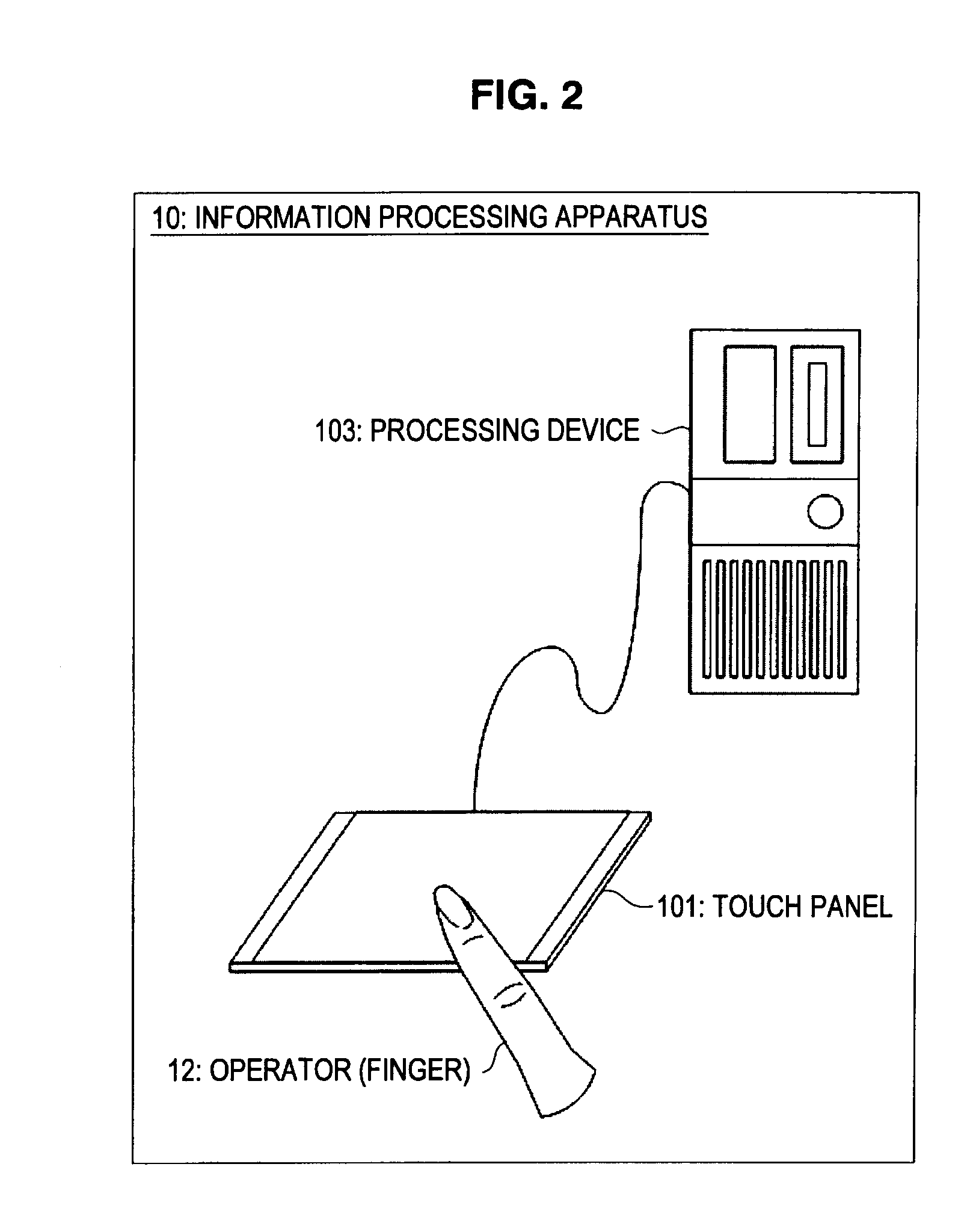

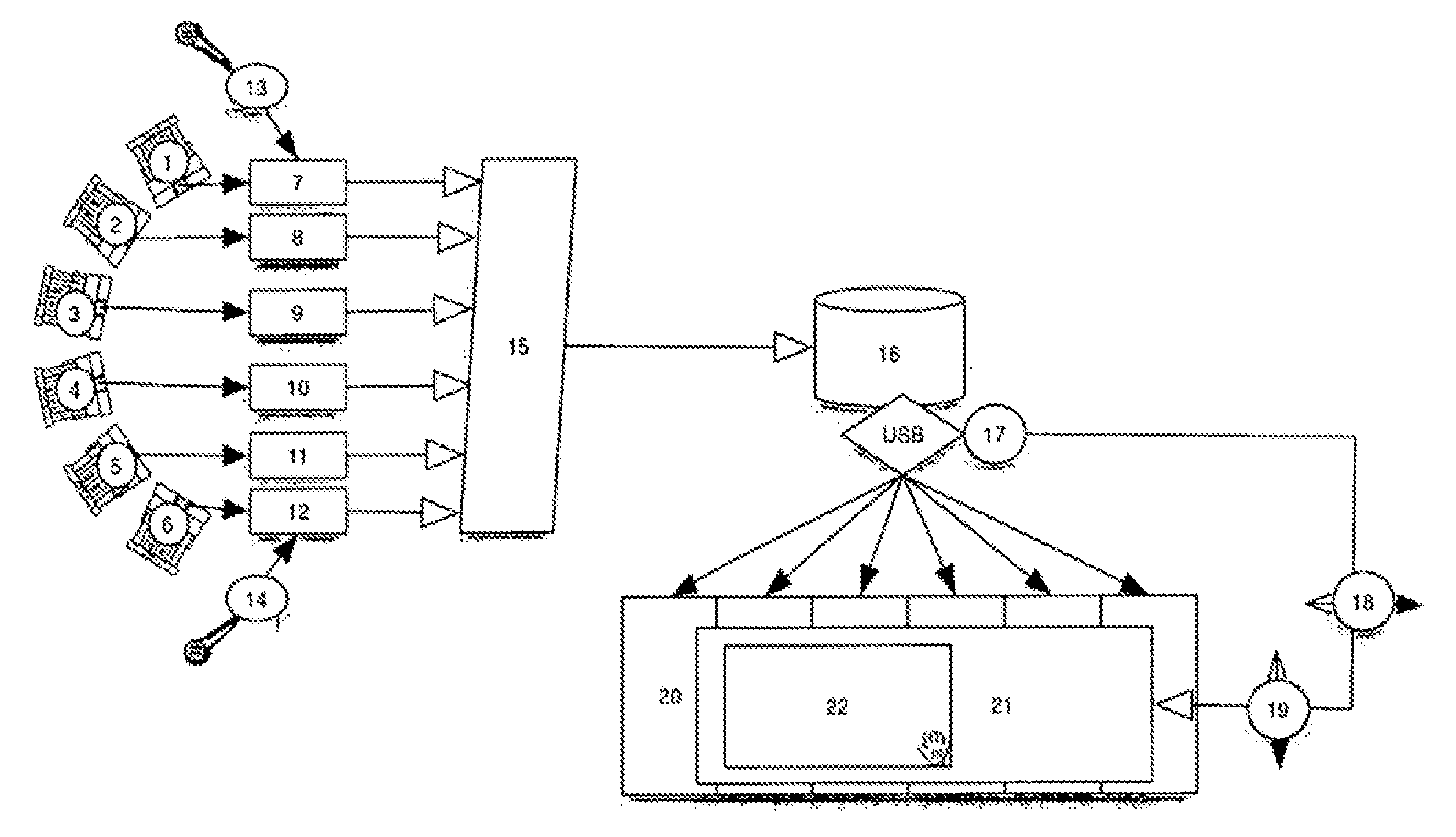

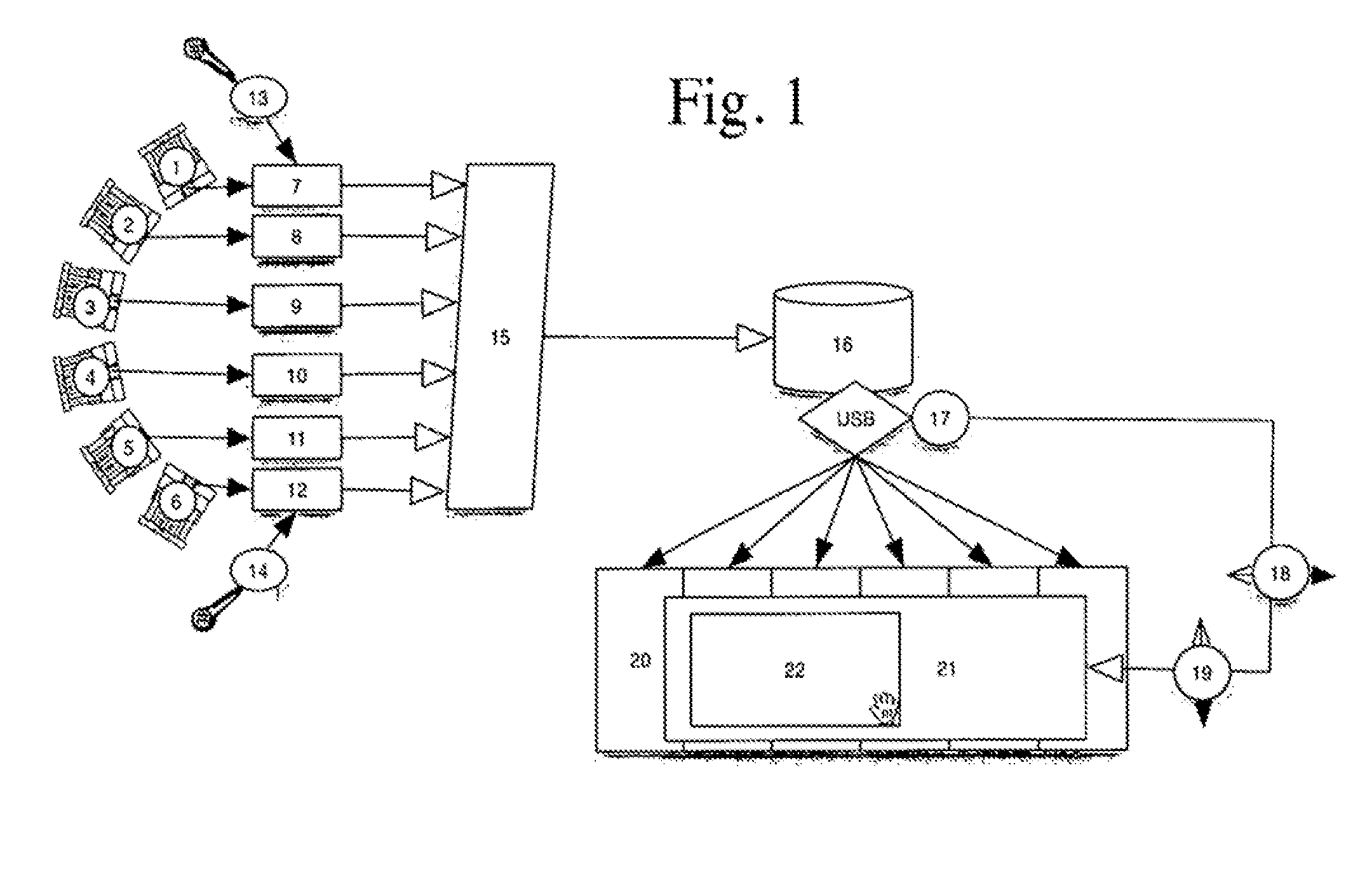

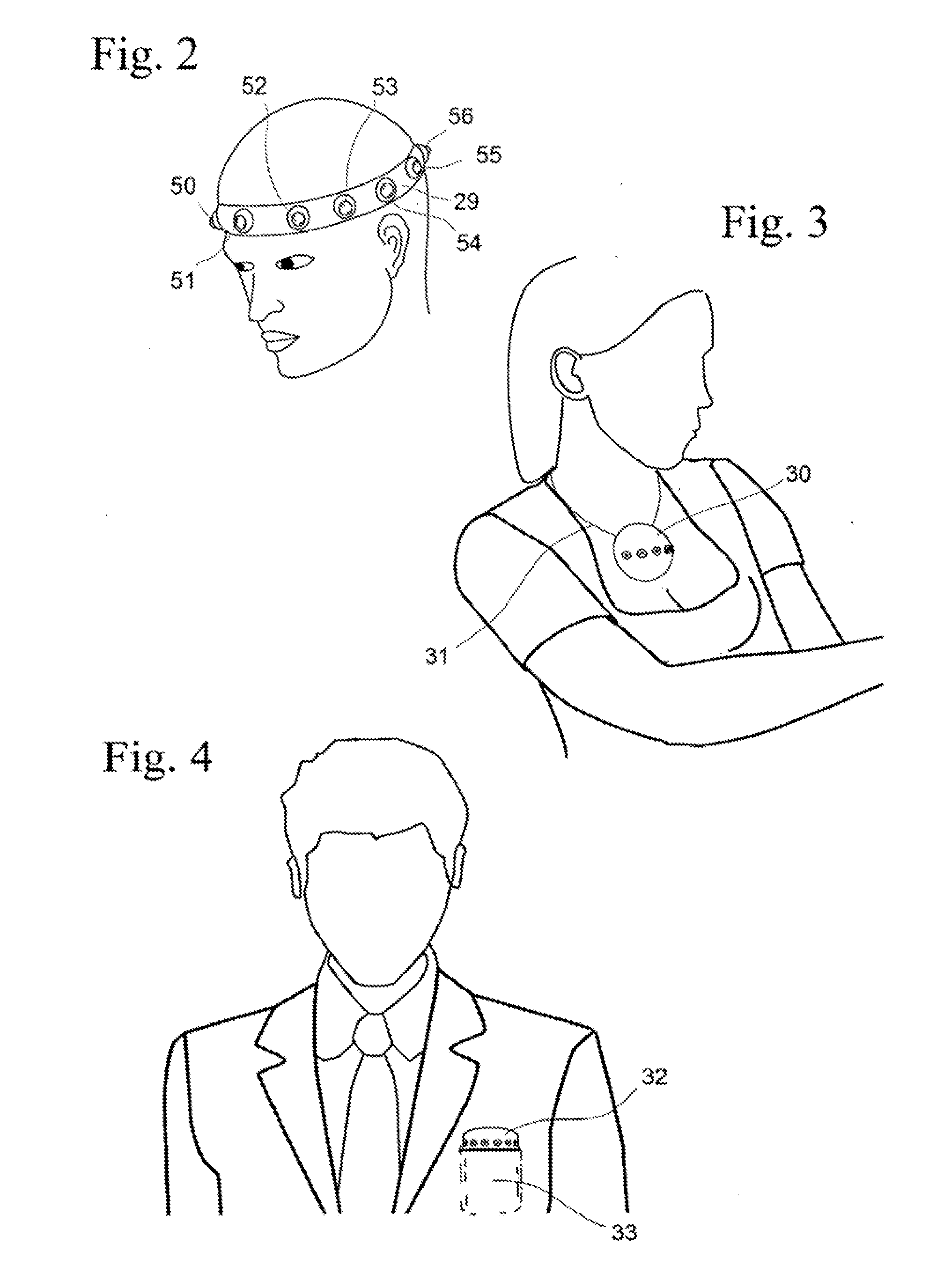

Information Processing Apparatus, Information Processing Method and Program

InactiveUS20100079501A1Easy to operateEasy fine-tuningCathode-ray tube indicatorsNavigation instrumentsInformation processingComputer graphics (images)

Owner:SONY CORP

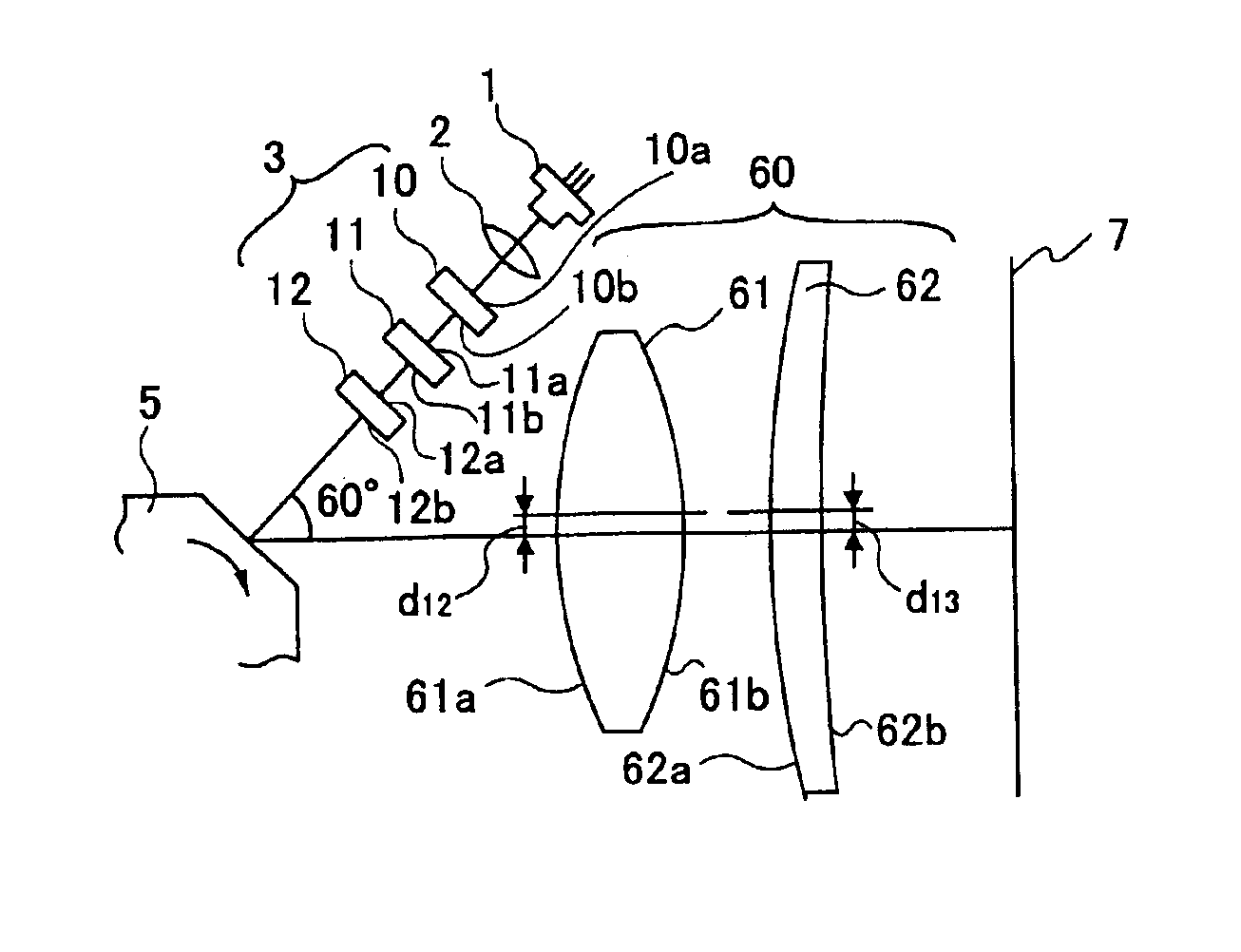

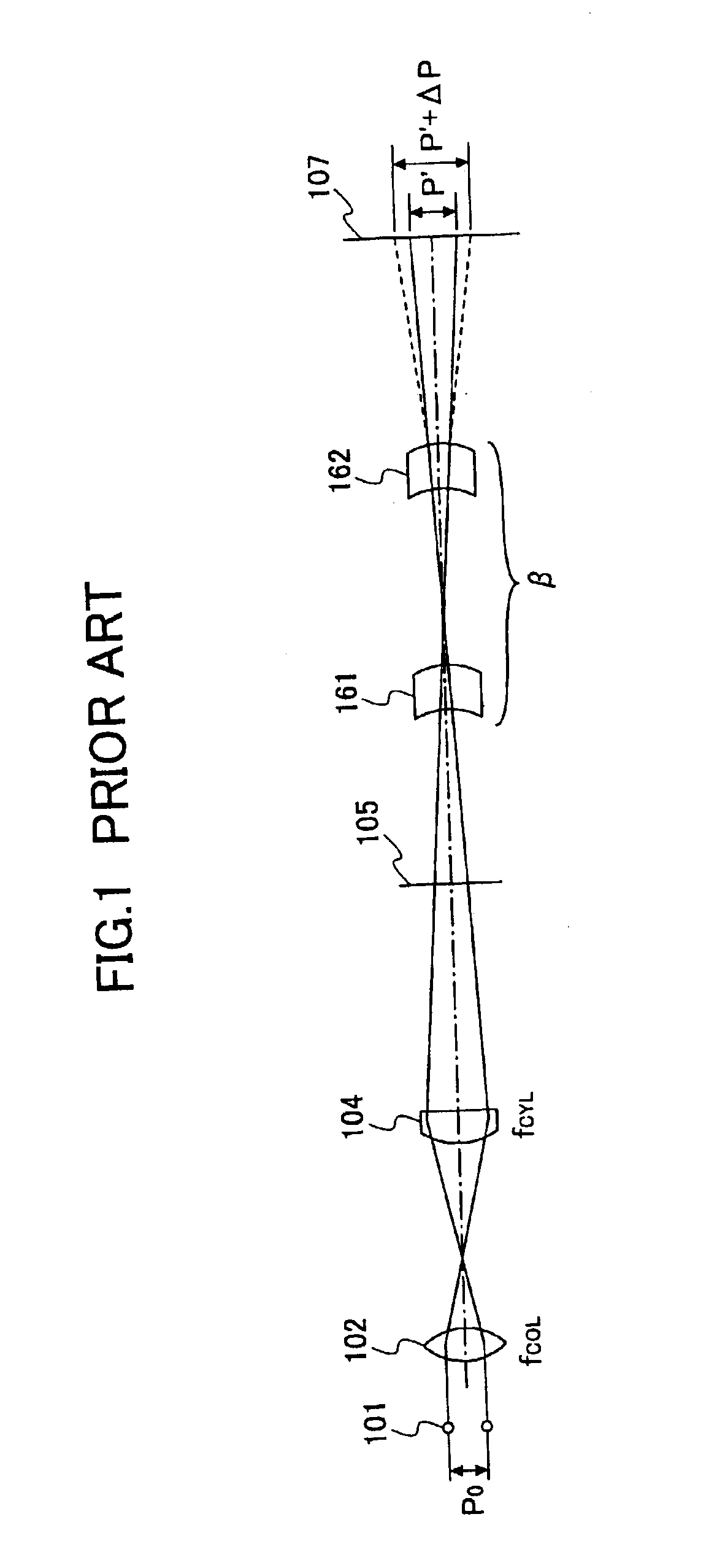

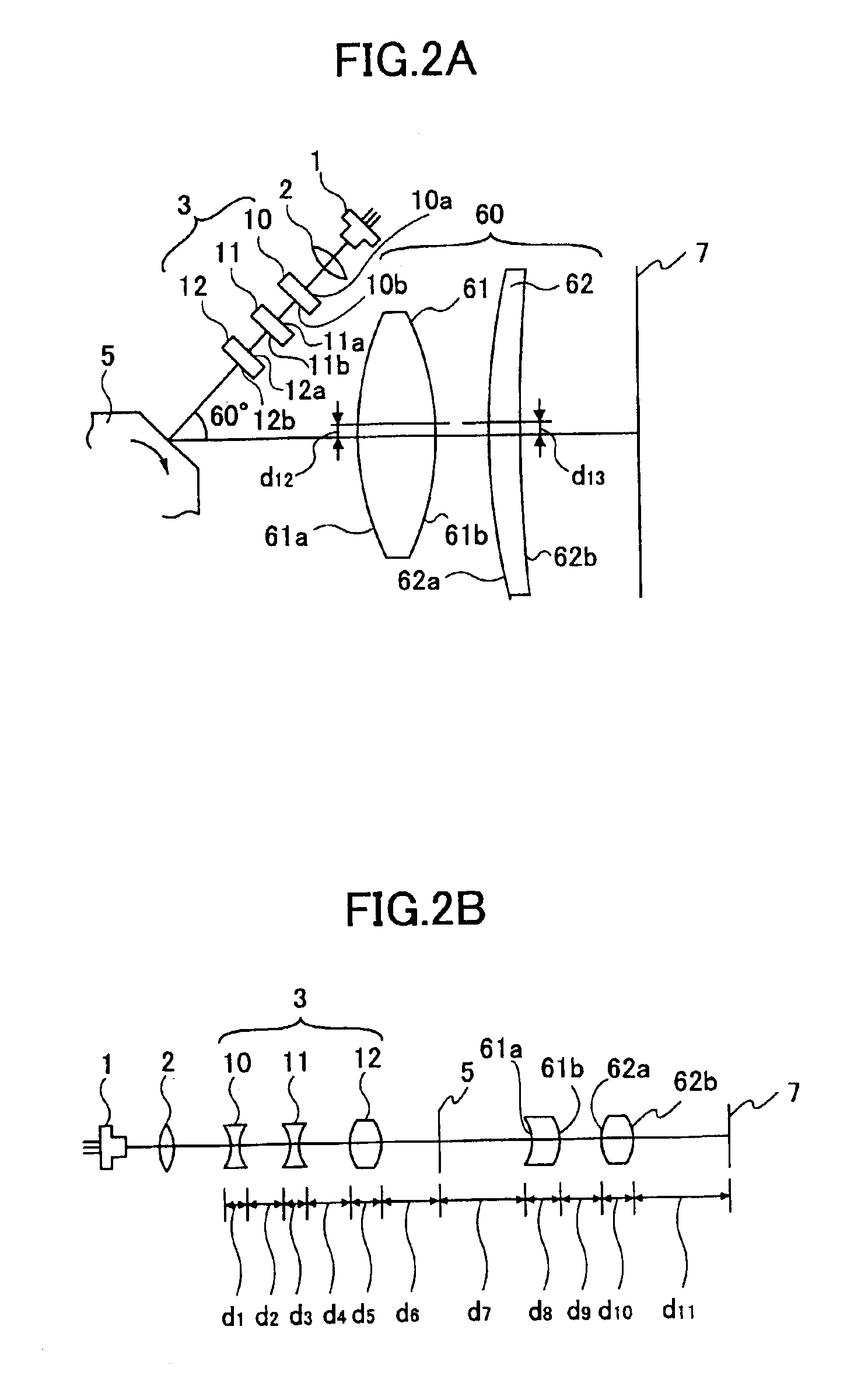

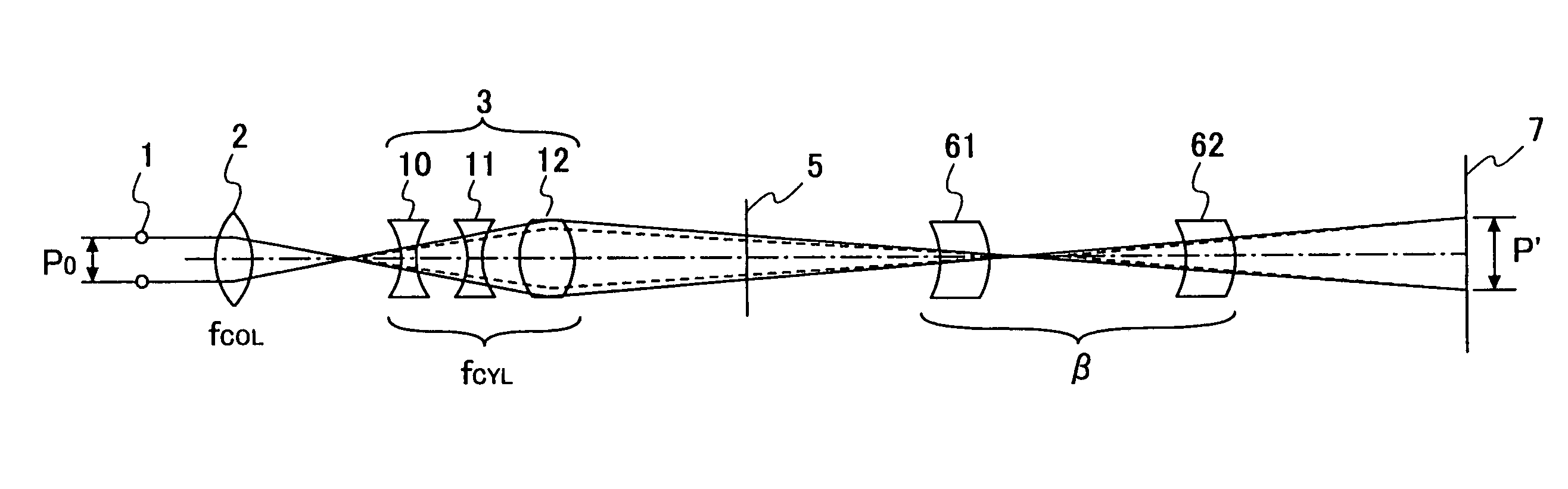

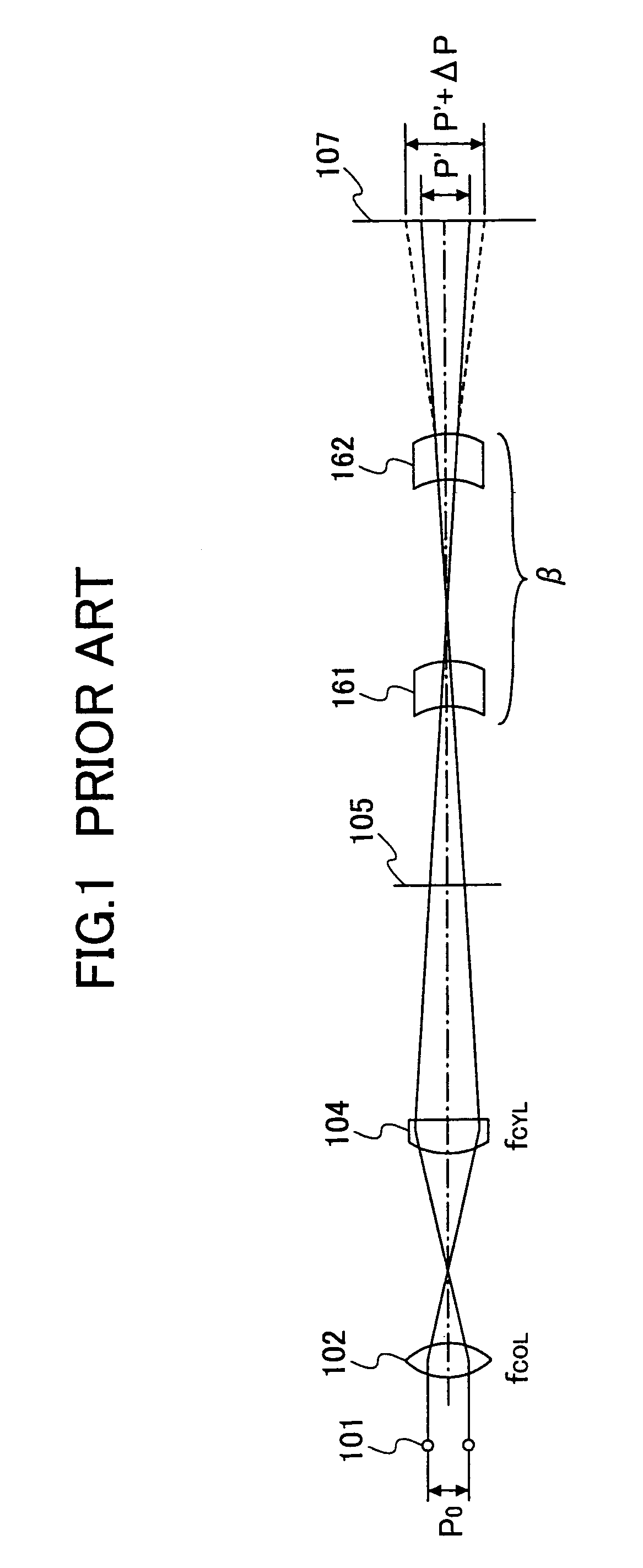

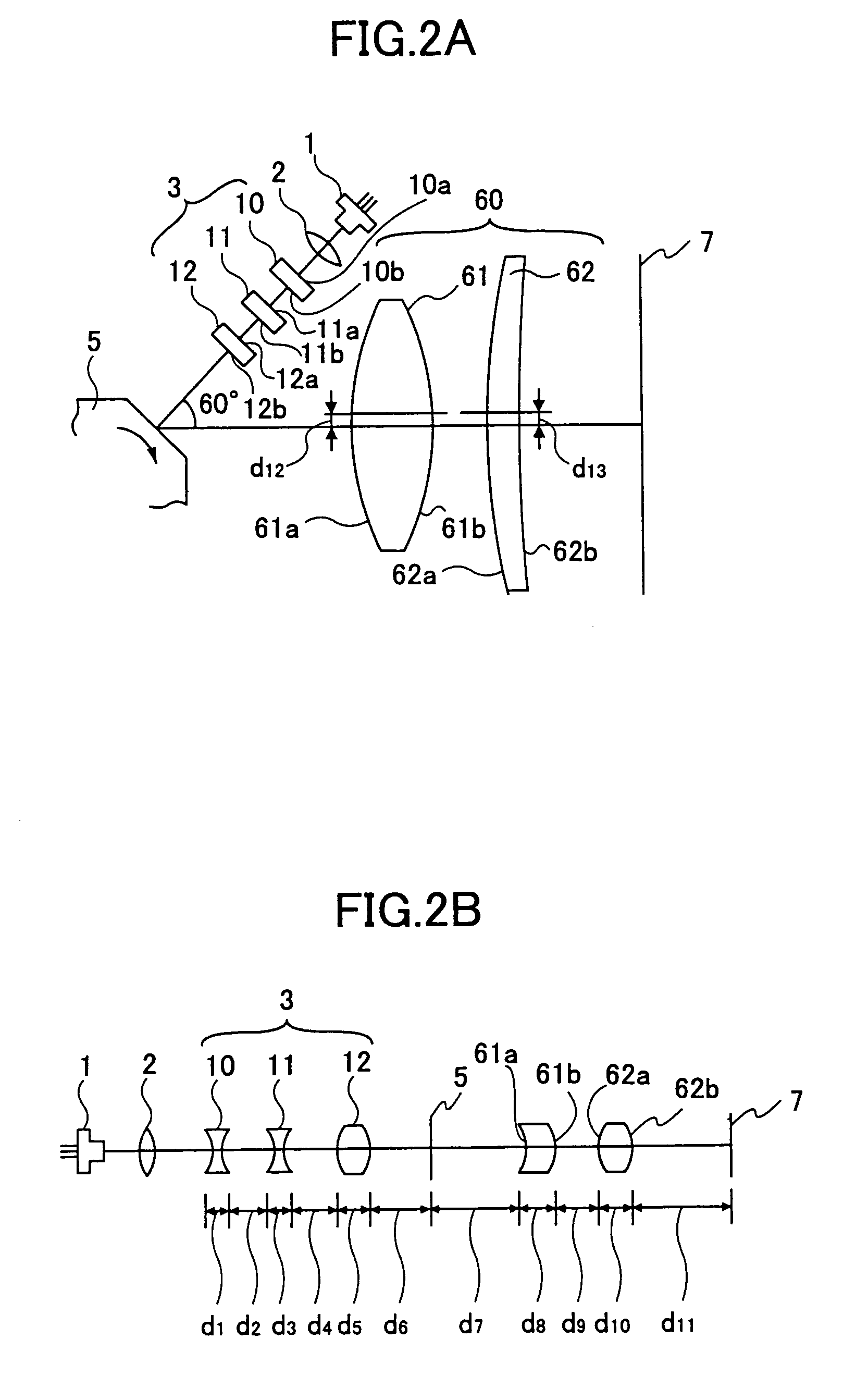

Optical scanning device and imaging apparatus implementing the same

InactiveUS7050210B2Control changesReduce cost and power consumptionInking apparatusPictoral communicationNegative powerLight beam

Owner:RICOH KK

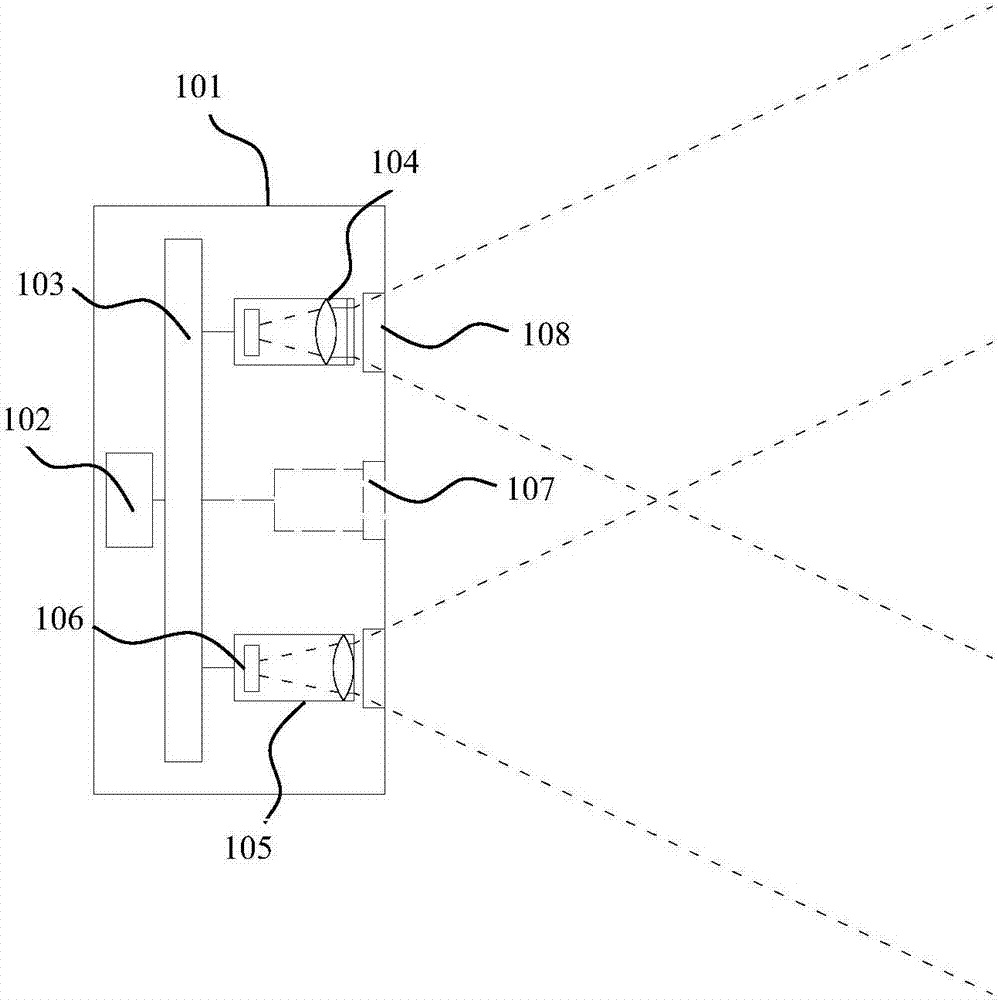

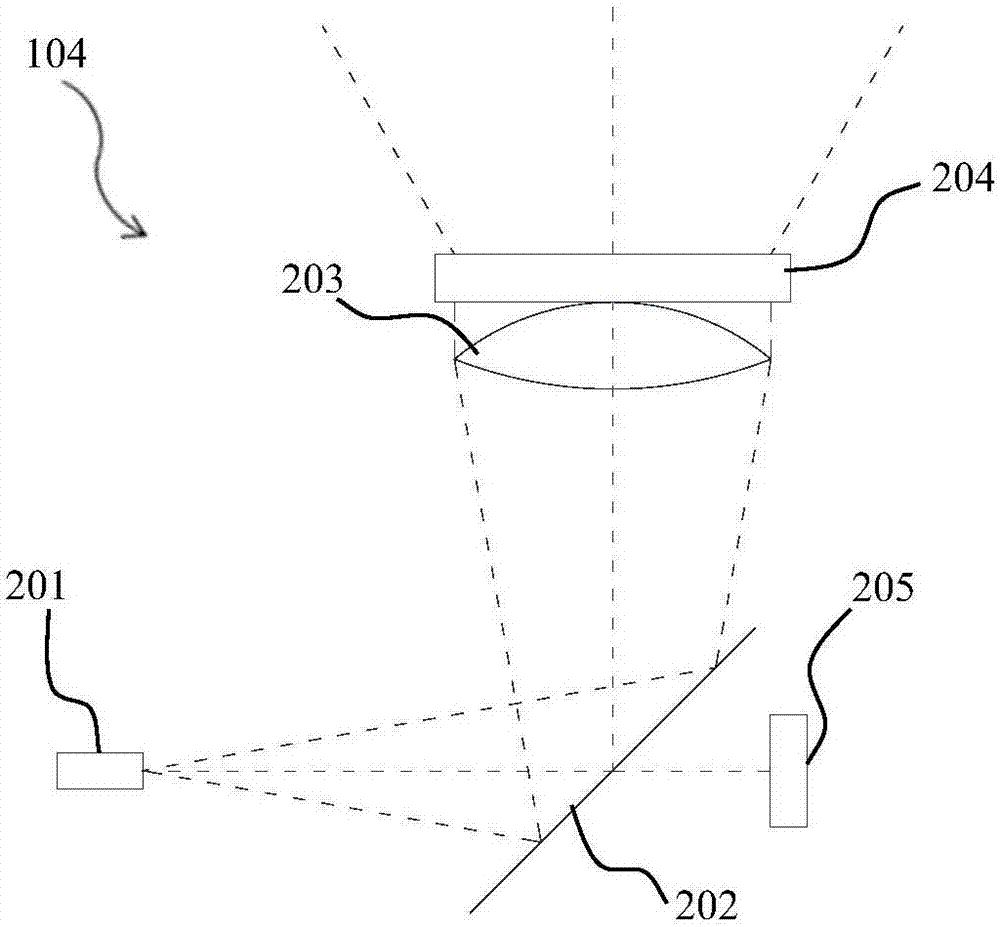

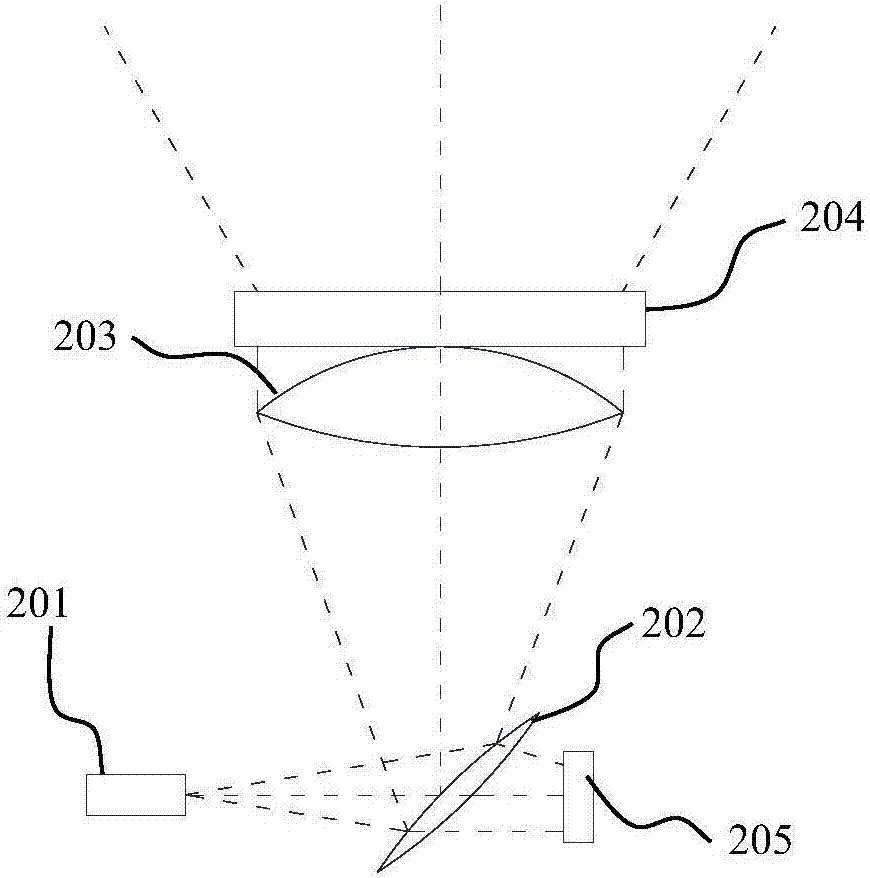

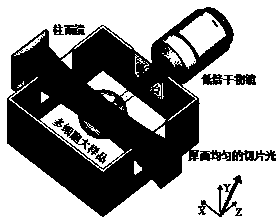

Laser projection module and depth camera

InactiveCN107167997AReduce volumeReduce magnificationProjectorsCamera body detailsLight beamOptoelectronics

The invention provides a laser projection module, which comprises a light source for emitting light beams; a gathering lens used for receiving and gathering the light beams emitted by the light source; a specific optical element, which comprises an optical surface having a reflection function and is used for reflecting at least a part of the light beams; and a pattern generator used for receiving the light beams reflected by the specific optical element and outputting a structured light pattern. The invention also provides a depth camera, which comprises the laser projection module above and is used for projecting a structured light beam image to a target space. According to the laser projection module and the depth camera, by arranging the gathering lens having the gathering function and the specific optical element having the reflection function, the laser projection module and the depth camera are allow to have smaller sizes respectively.

Owner:SHENZHEN ORBBEC CO LTD

Optical scanning device and imaging apparatus implementing the same

InactiveUS7154651B2Control changesReduce cost and power consumptionPrintingPictoral communicationNegative powerLight beam

A multi-beam optical scanning device is disclosed that includes a light source emitting a bundle of rays, a first optical system coupling the rays into diverging rays, a second optical system condensing the diverging rays into linear rays extending in the main scanning direction, a light deflector deflecting the linear rays, and a third optical system condensing the deflected rays onto a scanning surface. The second and third optical systems include resin imaging elements. At least one resin imaging element of the second optical system has a negative power in a sub scanning direction and a surface configuration that is arranged to effectively compensate for a change in field curvature caused by a temperature change in a support member of the first optical system or the resin imaging element of the third optical system. The second optical system as a whole has a positive power in the main scanning direction.

Owner:RICOH KK

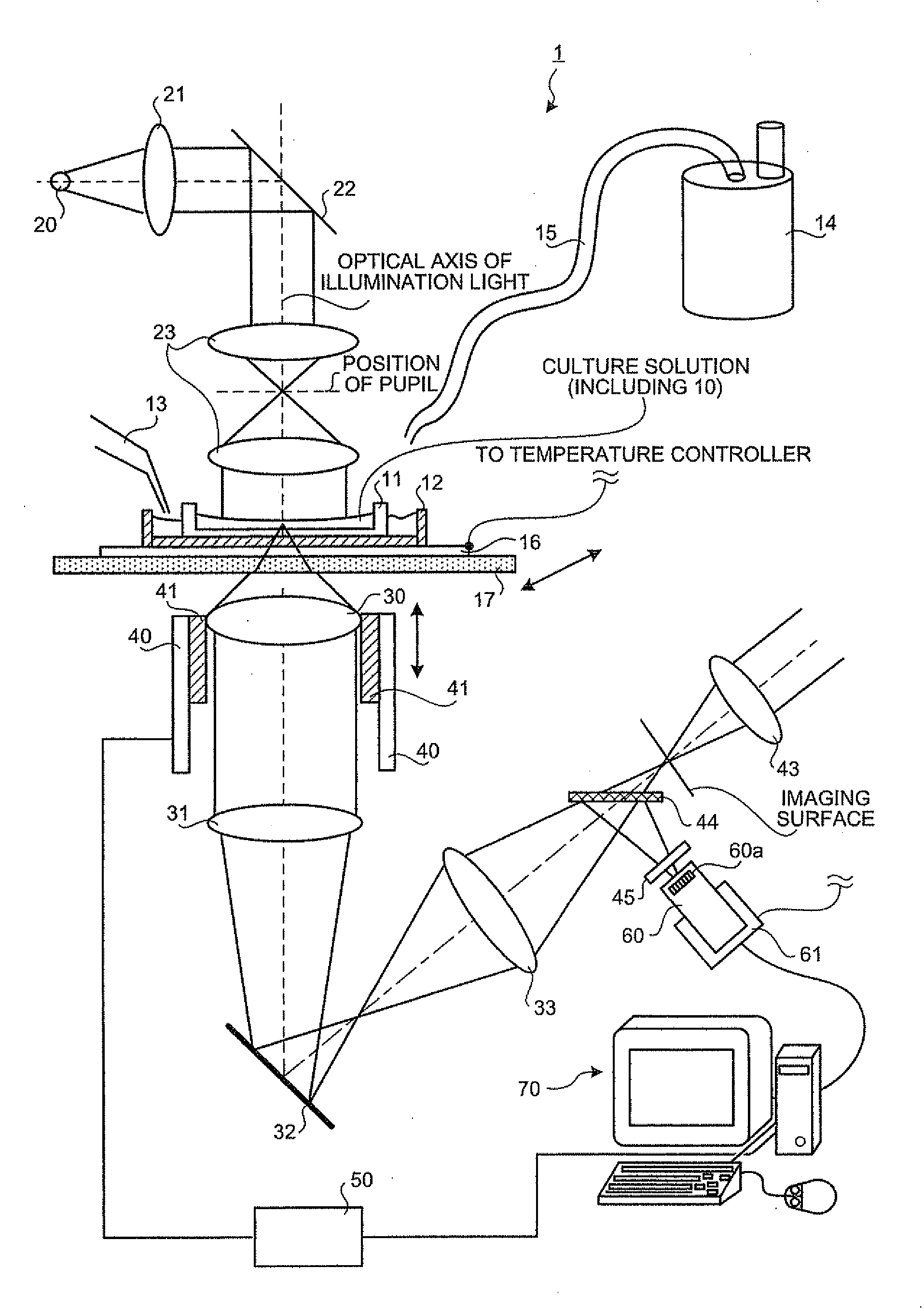

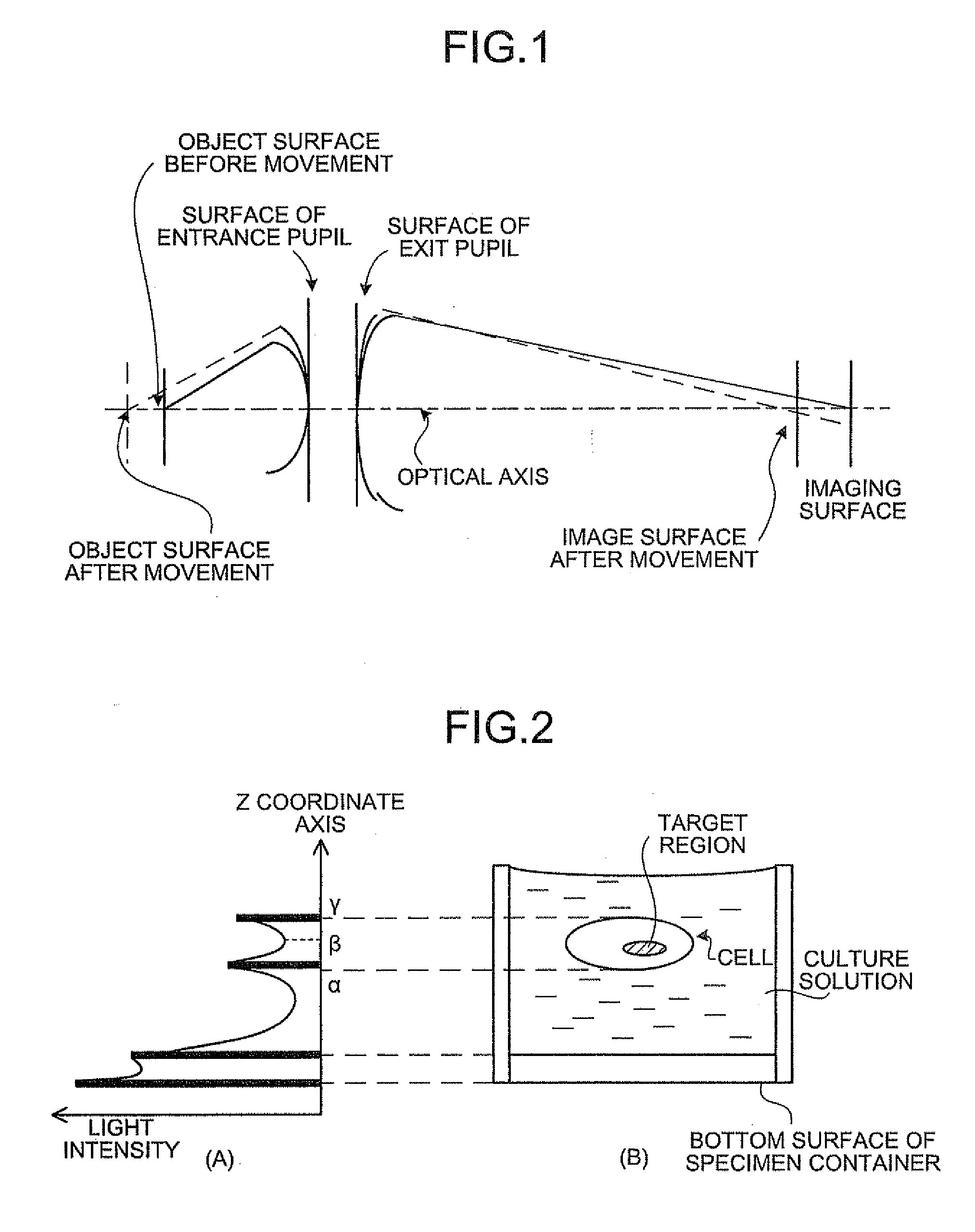

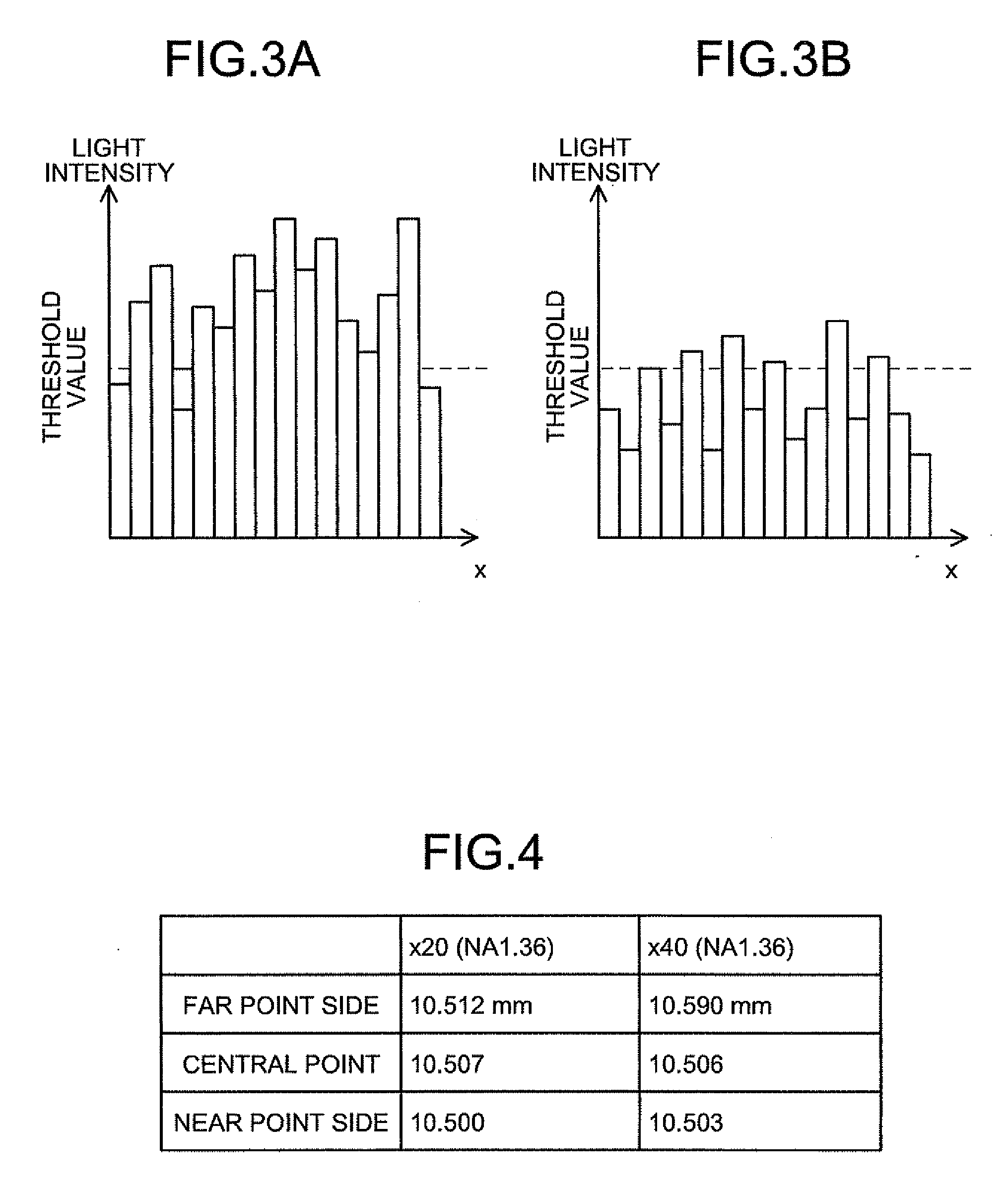

Focal position determining method, focal position determining apparatus, feeble light detecting apparatus and feeble light detecting method

InactiveUS20080225278A1Reduce magnificationLimit angleProjector focusing arrangementMaterial analysis by optical meansFocal positionPhysics

A focal position determining method determines a focal position of an objective lens focused on an observed target region in a specimen. The focal position determining method includes measuring any one of the focal position of the objective lens at a near point and the focal position of the objective lens at a far point or both so as to determine the focal position of the objective lens focused on the observed target region based on the measured focal position.

Owner:OLYMPUS CORP

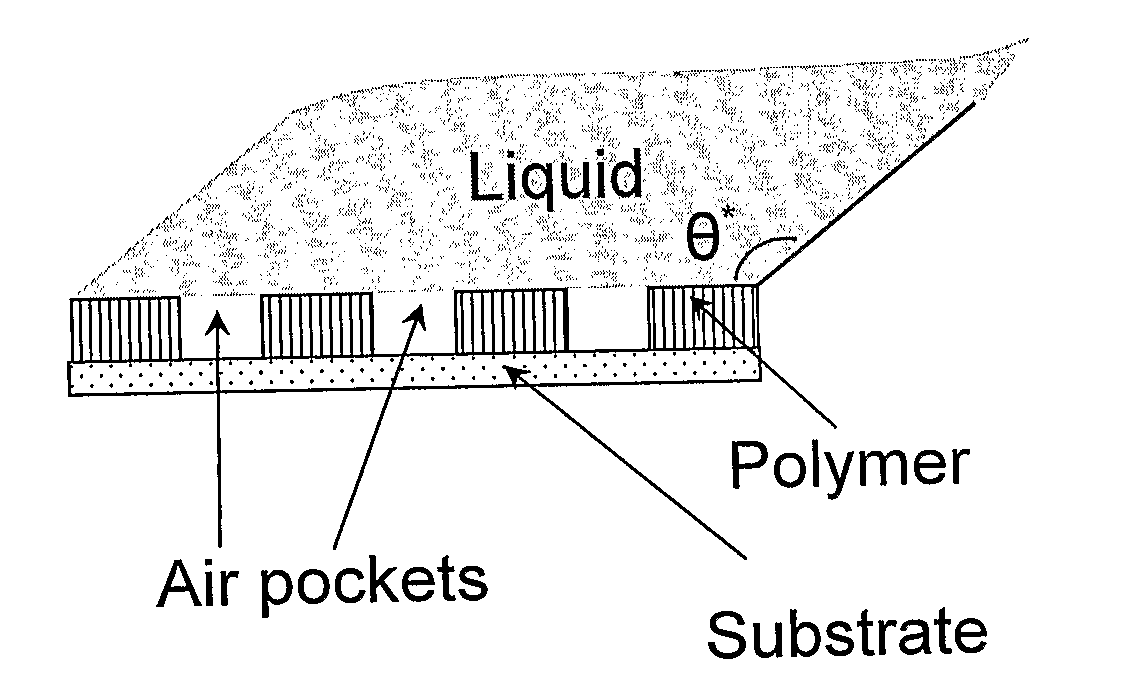

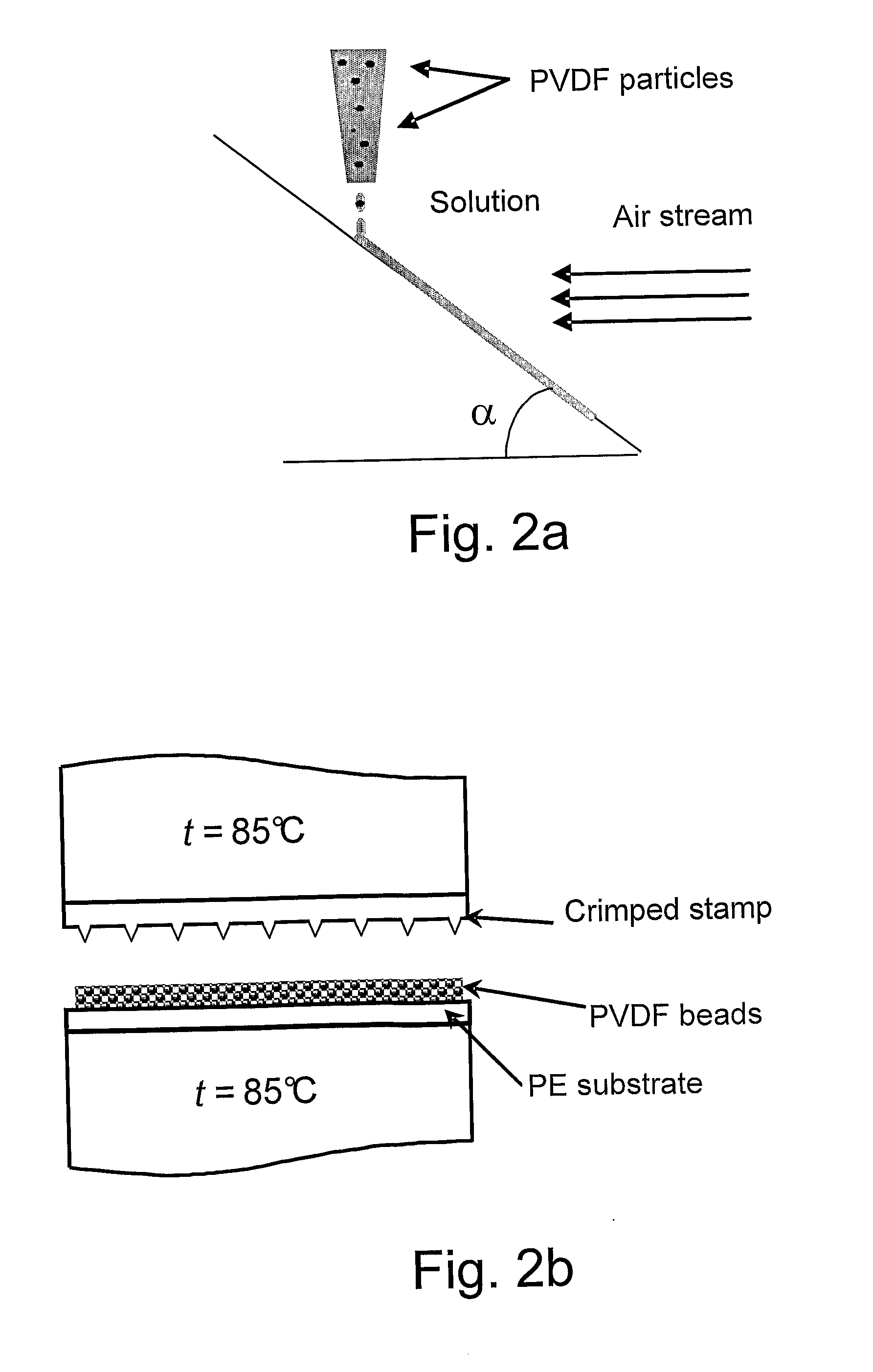

Superhydrophobic nanotextured polymer and metal surfaces

InactiveUS20100021692A1Reduce magnificationHigh magnificationLayered productsVacuum evaporation coatingPolymeric surfaceHydrophobic surfaces

A method of manufacturing a multiscale (hierarchical) superhydrophobic surface is provided. The method includes texturing a polymer surface at three size scales, in a fractal-like or pseudo-fractal-like manner, the lowest scale being nanoscale and the highest microscale. The hydrophobic polymer surface may be converted to hydrophobic metal surface by subsequent deposition of a metal layer onto the polymer surface.

Owner:ARIEL UNIV RES & DEV

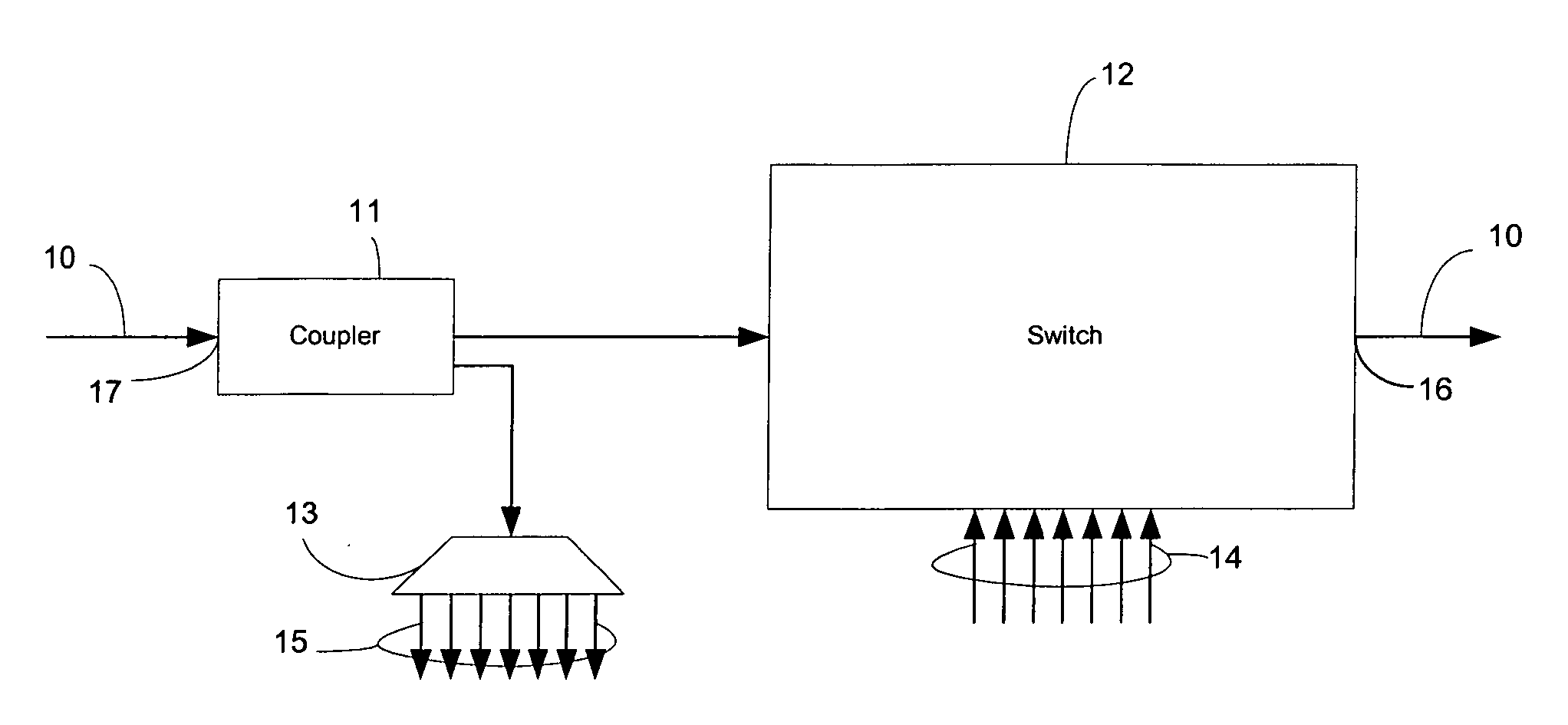

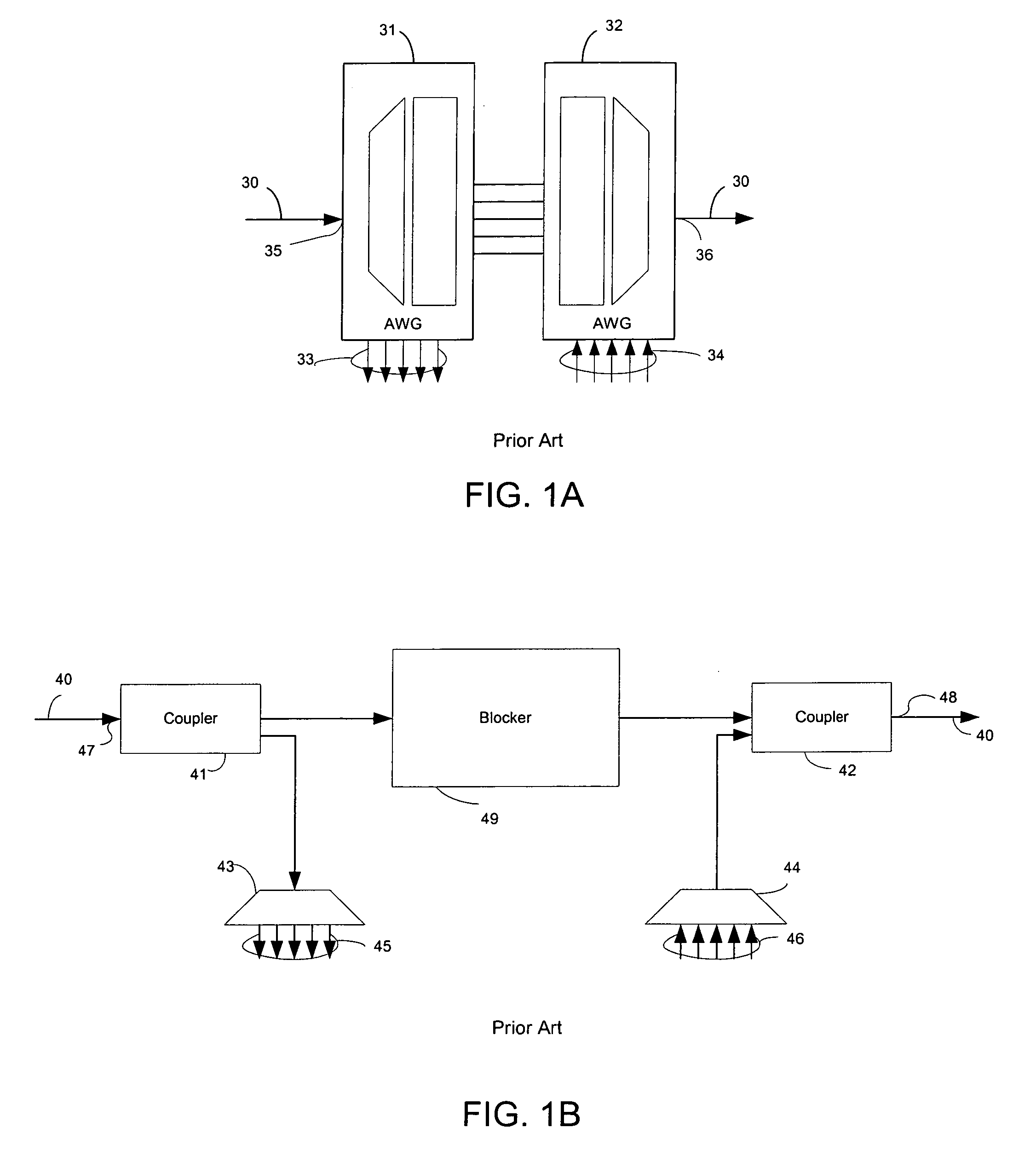

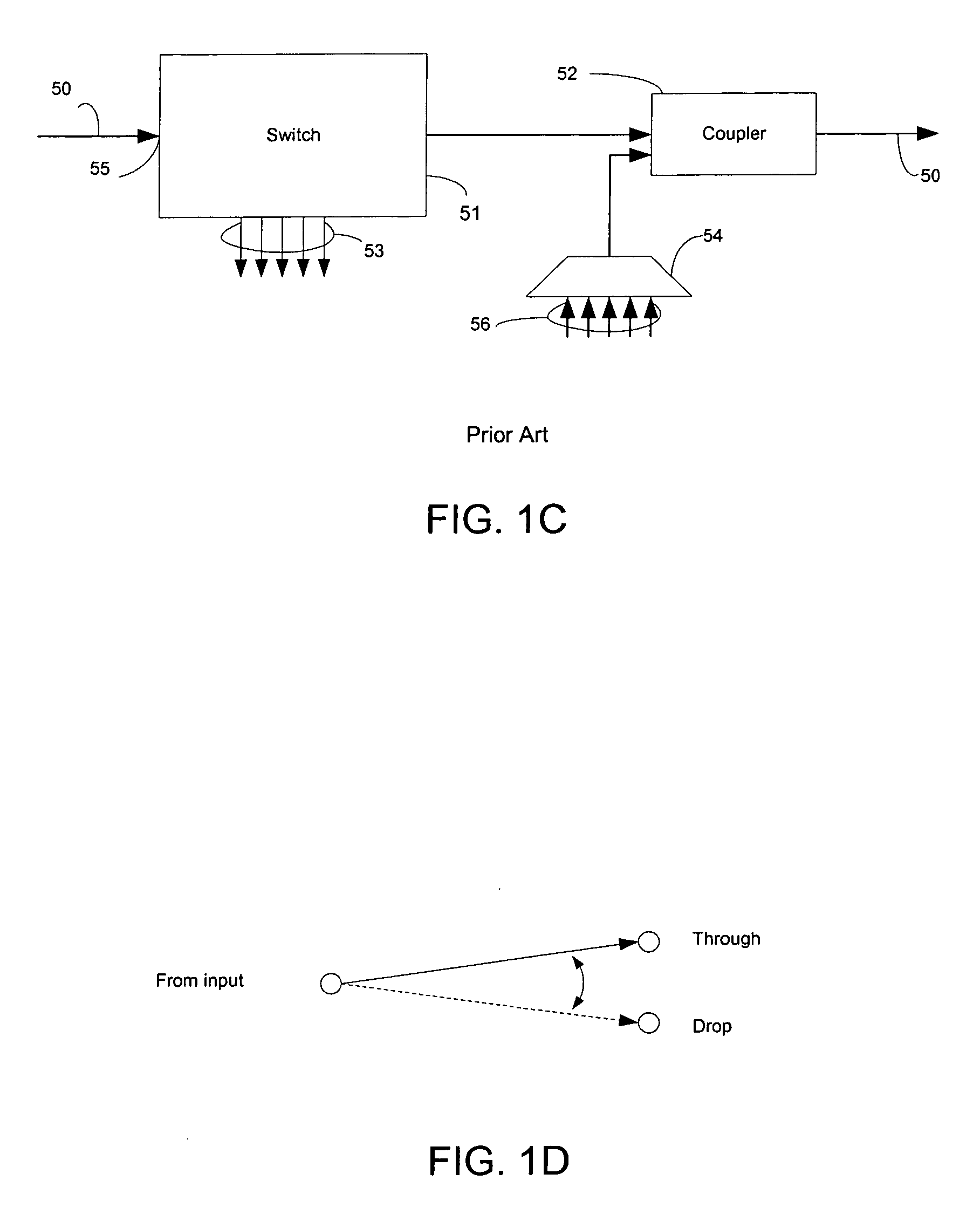

Optical add/drop multiplexer with reconfigurable add wavelength selective switch

ActiveUS20060072918A1Lower requirementReduce magnificationMultiplex system selection arrangementsLaser detailsMultiplexerSignal on

A reconfigurable WDM add / drop multiplexer and its method of operation at an add / drop node on an optical fiber carrying a plurality of WDM signals is described. The WDM add / drop multiplexer has a coupler and a demultiplexer element dropping WDM signals from the optical fiber to a plurality of drop terminals, and a wavelength-selective switch adding WDM signals from a plurality of add terminals onto the optical fiber. The coupler splits the WDM signals received from the optical fiber and passes the split WDM signals to the first and second output terminals. The demultiplexer element separates the split WDM signals at the plurality of drop terminals. The wavelength-selective switch, which has an input terminal for connection to the second coupler output terminal and an output terminal for connection to the optical fiber, selectively adds WDM signals on the plurality of add terminals to the optical fiber responsive to control signals.

Owner:CISCO TECH INC

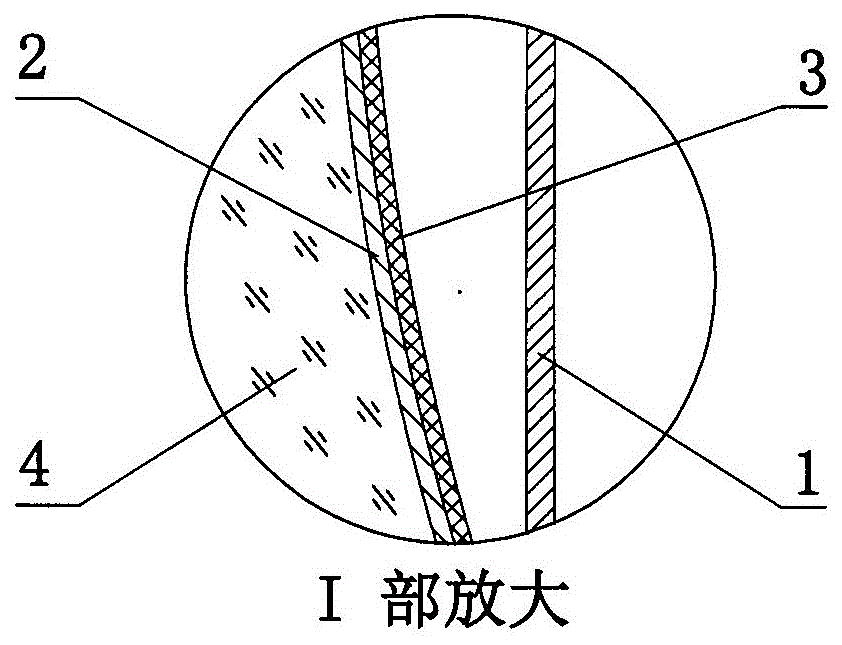

Ophthalmic lens element

Owner:THE VISION CRC LTD

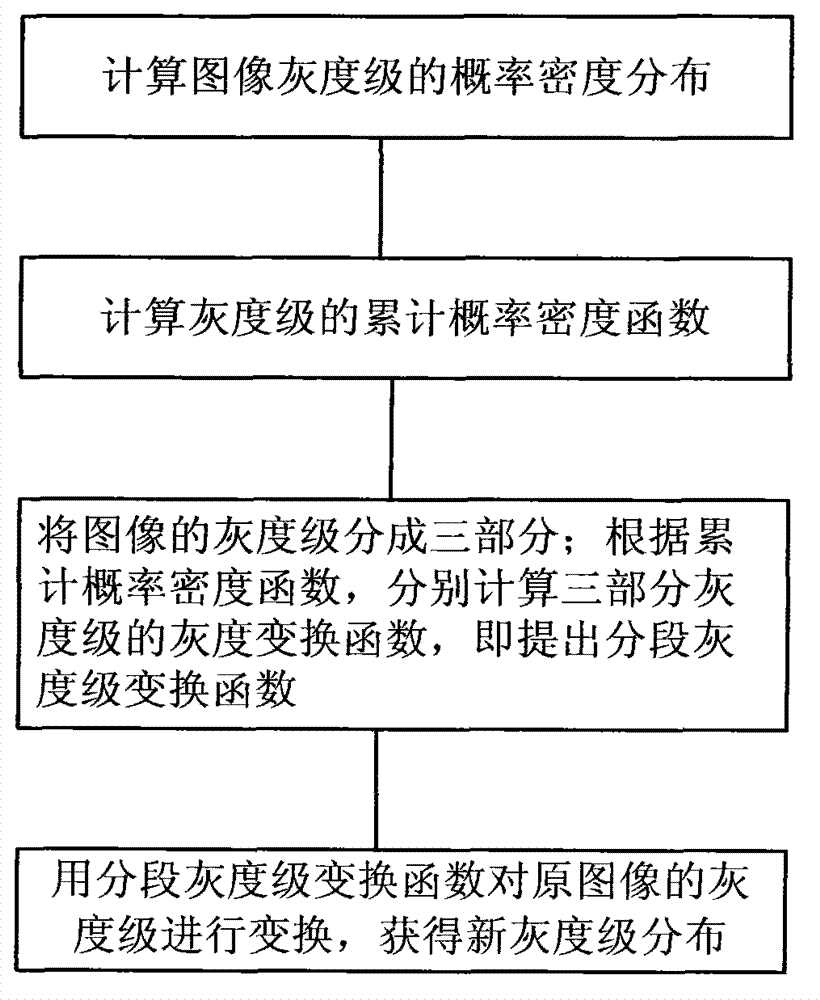

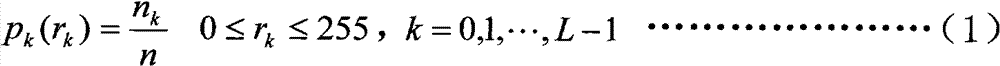

Image nonlinearity enhancement method based on histogram subsection transformation

The invention discloses an image nonlinearity enhancement method based on histogram subsection transformation. The method comprises the following steps of: S1, calculating probability density distribution of image gray levels; S2, calculating accumulated probability density functions of the gray levels; S3, dividing the gray levels of the images into three parts, wherein the first part of gray level range is between 0 and 85, the second part of gray level range is between 86 and 170, and the third part of gray level range is between 171 and 255; respectively calculating gray level transformation functions of the three parts of gray levels according to the accumulated probability density functions, namely proposing sectional gray level transformation functions; and S4, transforming the gray levels of the original images by using the sectional gray level transformation functions to acquire the distribution of new gray levels. By the method, the definition of the image is further improved, the excessive enhancement of the image is avoided, and the image vision effect meets the requirement of an eye vision system.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

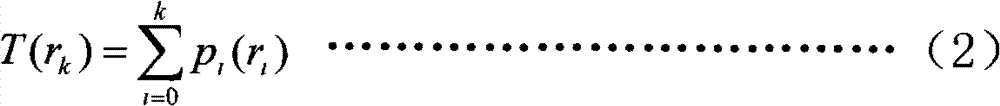

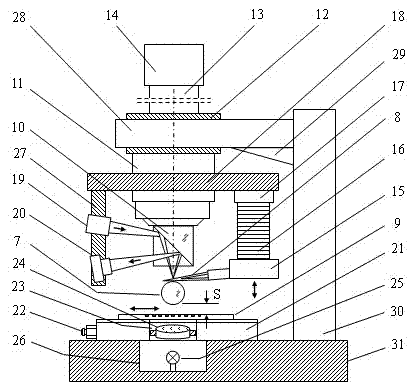

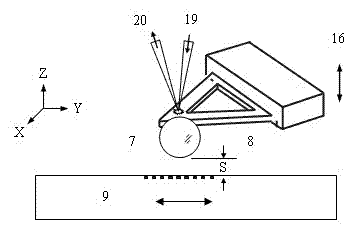

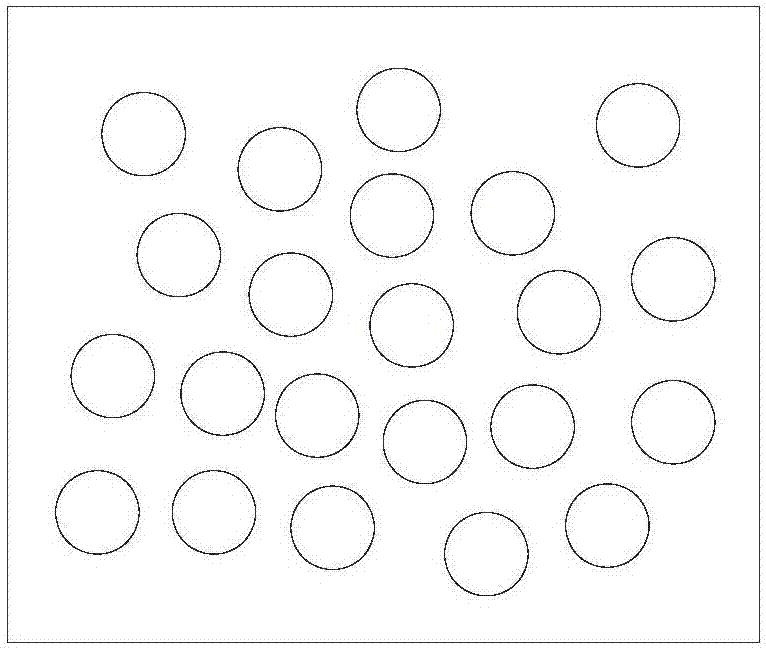

Super-resolution microscopic imaging method and system based on microcantilever and microsphere combined probe

InactiveCN102735878AAchieving lateral adjustmentRealization of super-resolution microscopy imagingScanning probe microscopyMicroscopic imageFull field

The invention discloses a super-resolution microscopic imaging method and a super-resolution microscopic imaging system based on a microcantilever and microsphere combined probe. The system comprises a super-resolution microscopic imaging device which comprises the microcantilever and microsphere combined probe, piezoelectric ceramic, a laser, a transflective prism, a position sensitive element, a stepping movable table, an objective, a charge coupled device (CCD) and the like, and a control system which comprises a current-to-voltage converter, a feedback control module, a high-voltage amplifier, a stepping controller, a computer, an interface and the like. A microsphere is lifted off by the microcantilever and microsphere combined probe and is approximate to the surface of a sample, and an atomic-force-based micro / nano feedback control method is adopted, so that the distance between the microsphere and the sample is controlled in a near-field range, and super-resolution optical microscopic imaging is realized. The new super-resolution microscopic imaging method based on the microcantilever and microsphere probe has the advantages that the multi-zone, full-field and super-resolution optical microscopic imaging of the sample is realized, the limit of optical diffraction is broken, and the defects of the traditional microsphere microscopic imaging technology in many aspects are overcome.

Owner:ZHEJIANG UNIV

Three dimensional pixel super-resolution microscopic imaging method

ActiveCN104111242AReduce magnificationLow priceFluorescence/phosphorescenceSensor planeHigh resolution image

A three dimensional pixel super-resolution microscopic imaging method is characterized by comprising the following steps: carrying out space vector scanning on a sample, wherein the scanning vector can form a non-right-angle spacial deflection angle with the plane horizontal direction X and vertical direction Y of an image collection device sensor or a Z axis direction of a microscope, so as to make that two neighbored image slices can be scanned by a step size of a sub pixel displacement along the X, Y, and Z directions; collecting the original three dimensional image sequence A by the image collecting device, cutting the original image sequence A into a plurality of groups of three dimensional image sequences Bi according to the lossless sampling principle, carrying out a super-resolution treatment on Bi to generate a three dimensional high resolution image E, and carrying out a deblurring treatment on E so as to obtain a clear high resolution image F. The spacial reflection angles formed by the scanning vector with the horizontal direction X, the vertical direction Y, and the Z axis of the microscope can be identical or different.

Owner:HUAZHONG UNIV OF SCI & TECH

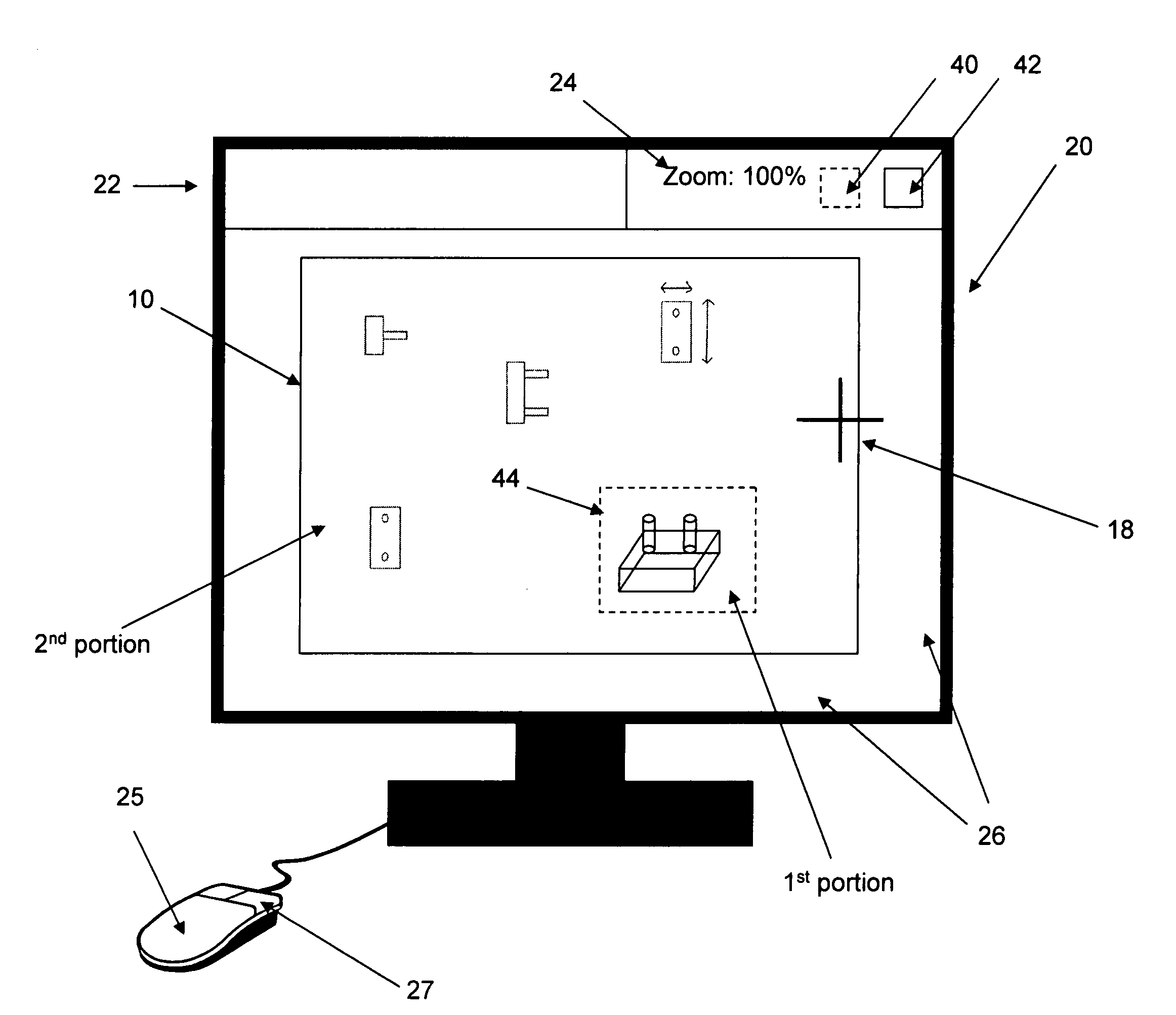

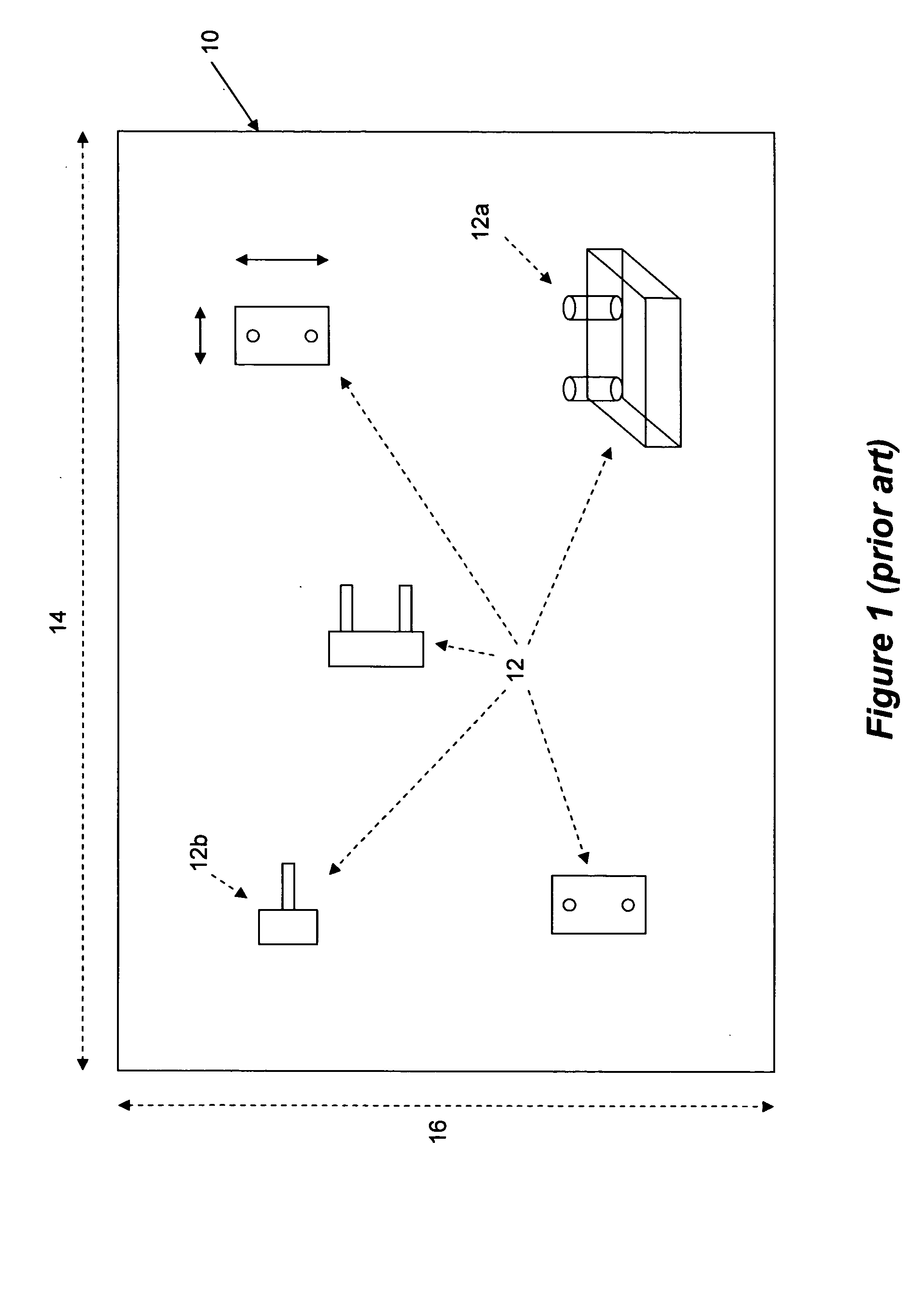

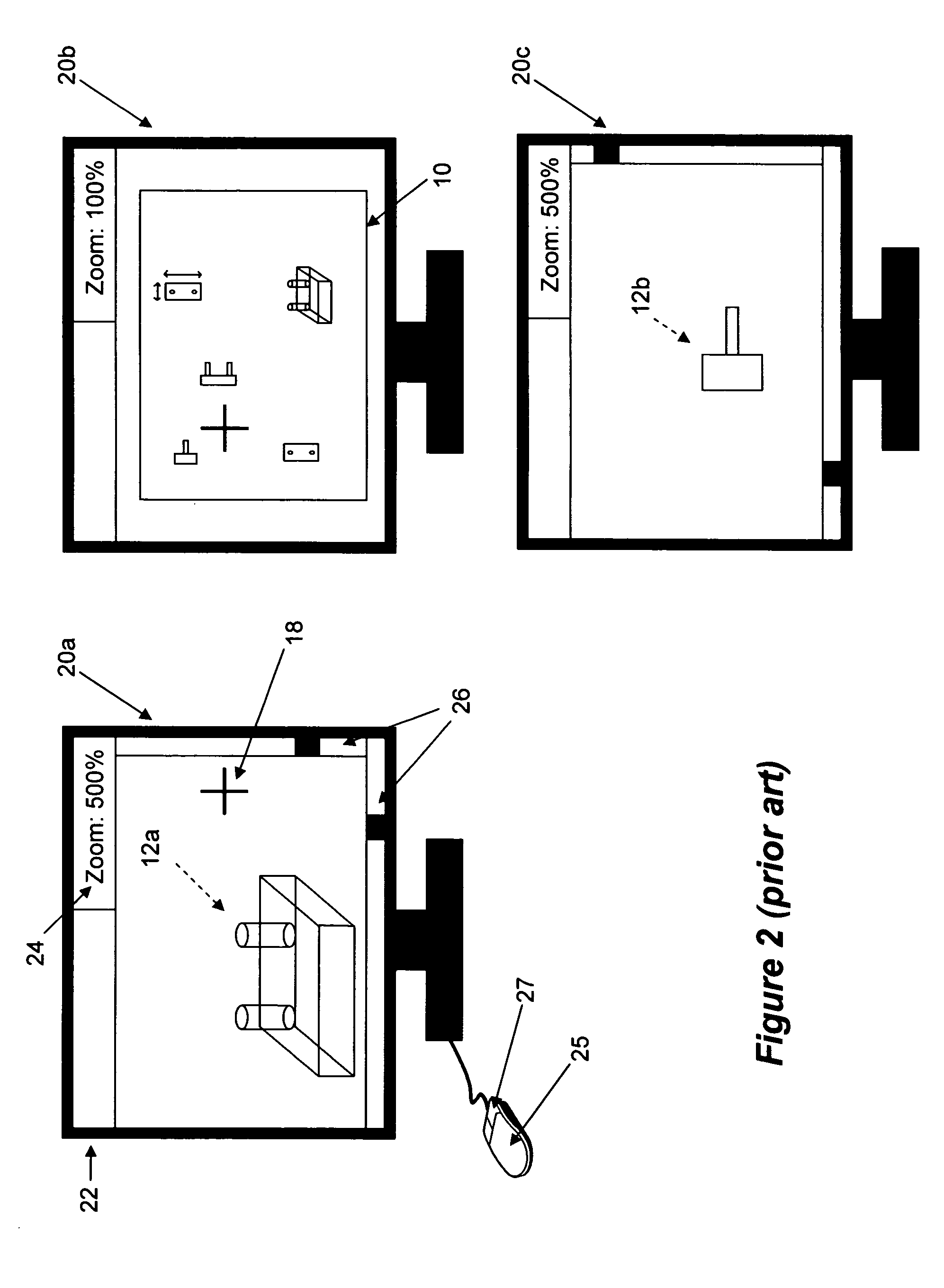

Navigation within a large computer file

InactiveUS20050179705A1Reduce magnification2D-image generationCathode-ray tube indicatorsGraphicsGraphical user interface

Disclosed herein is a method and graphical user interface (GUI) for navigating within the contents of a computer file, and specifically within a large non-paginated graphical file. A first portion of the file is displayed at a first magnification. Thereafter, an option is selected to display a second portion of the contents of the file (preferably the entire file) at a second lower magnification. An area is defined within the displayed second portion that highlights the first portion. This area is moveable, preferably by clicking and dragging the area using a mouse pointer, to a new (third location) on the file. Thereafter, the method allows the third portion to be automatically or manually magnified as was the first portion.

Owner:APPLE INC

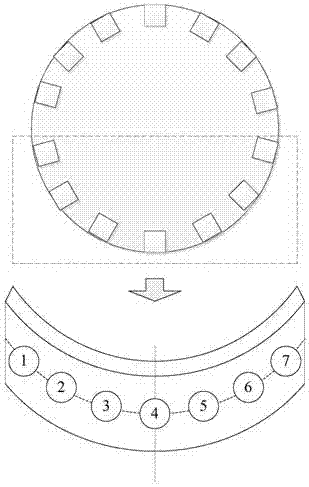

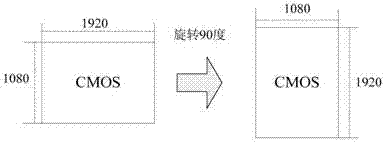

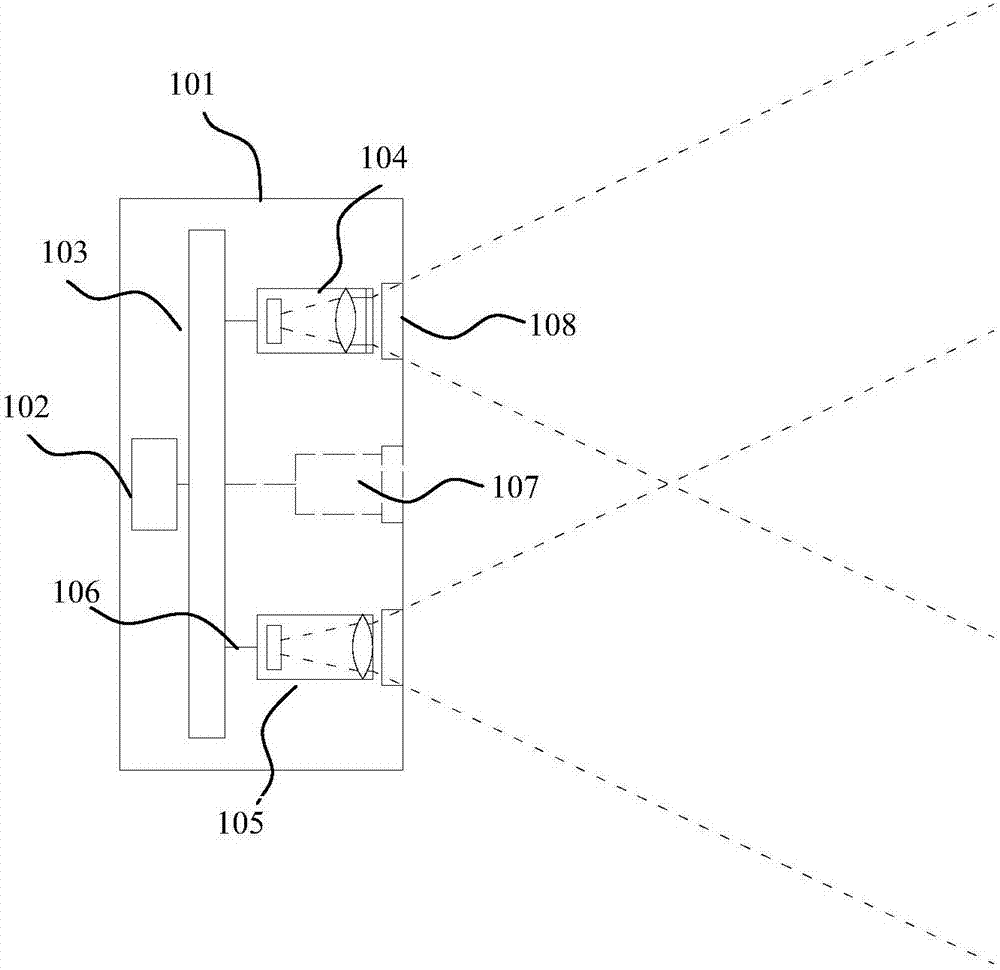

Ultrahigh resolution panorama speed dome AIO (All-In-One) system

ActiveCN103501409ASolve the contradictions that cannot be obtained at the same timeFast and precise focus positioningTelevision system detailsImage analysisInformation processingSpatial registration

The invention relates to an image information processing technology, and provides an ultrahigh resolution panorama speed dome AIO (All-In-One) system, a video stitching method and a spatial registration method of the ultrahigh resolution panorama speed dome AIO system. A device comprises an engine base element, a panorama stitching video camera comprising multiple cameras, a speed dome, a controller, a shell and a support. The video stitching method comprises the steps of lookup table calculation, stitching line calculation, image fusion and the like. The spatial registration method comprises the steps of establishing a panorama stitching image coordinate system, uniformly dividing a panorama stitching image into a plurality of rectangular regions, sampling, calculating a mapping relation of sampling points and calculating a non-sampling point mapping relation by adopting a bilinear interpolation method. According to the ultrahigh resolution panorama speed dome AIO system, the video stitching method and the spatial registration method, provided by the invention, not only can panorama monitoring be realized, but also a high-resolution monitoring scene can be provided at the same time, and quick and accurate focus location, zoom out and zoom in and quick and stable browsing of an interested target can be realized through registration linkage between a panorama real-time stitching camera and the speed dome.

Owner:NAT UNIV OF DEFENSE TECH +1

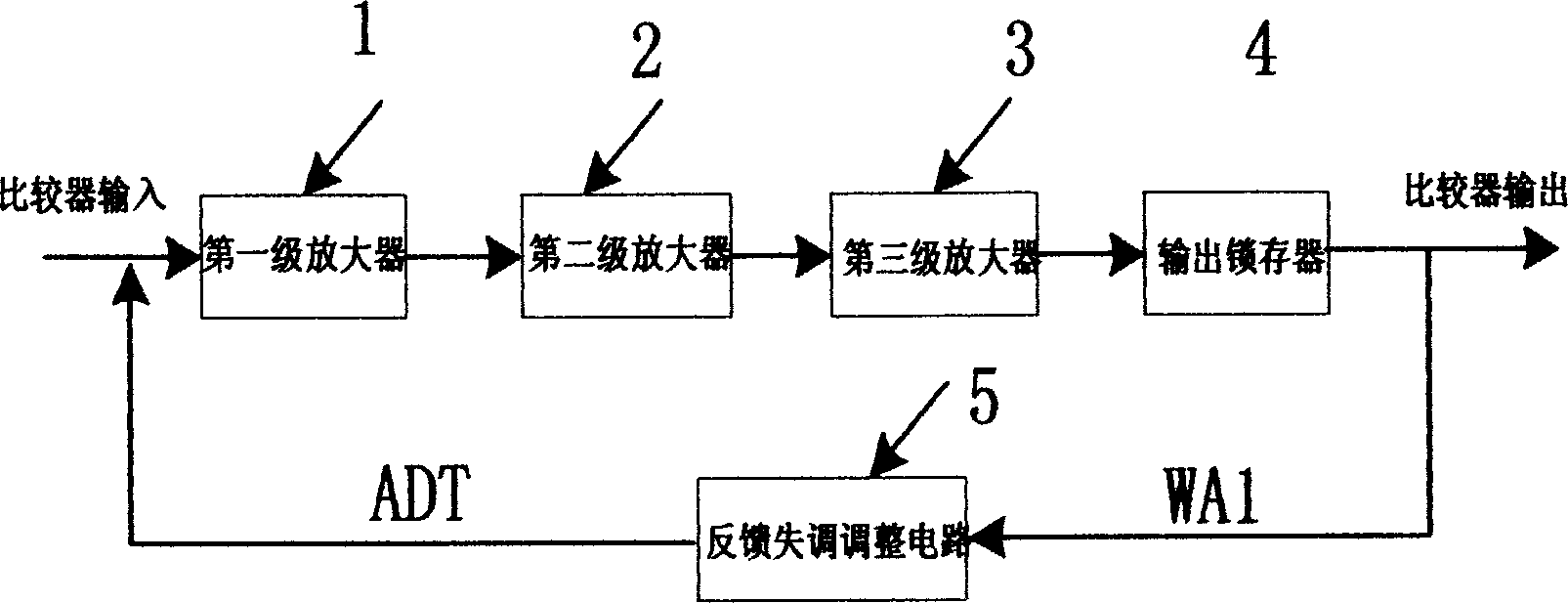

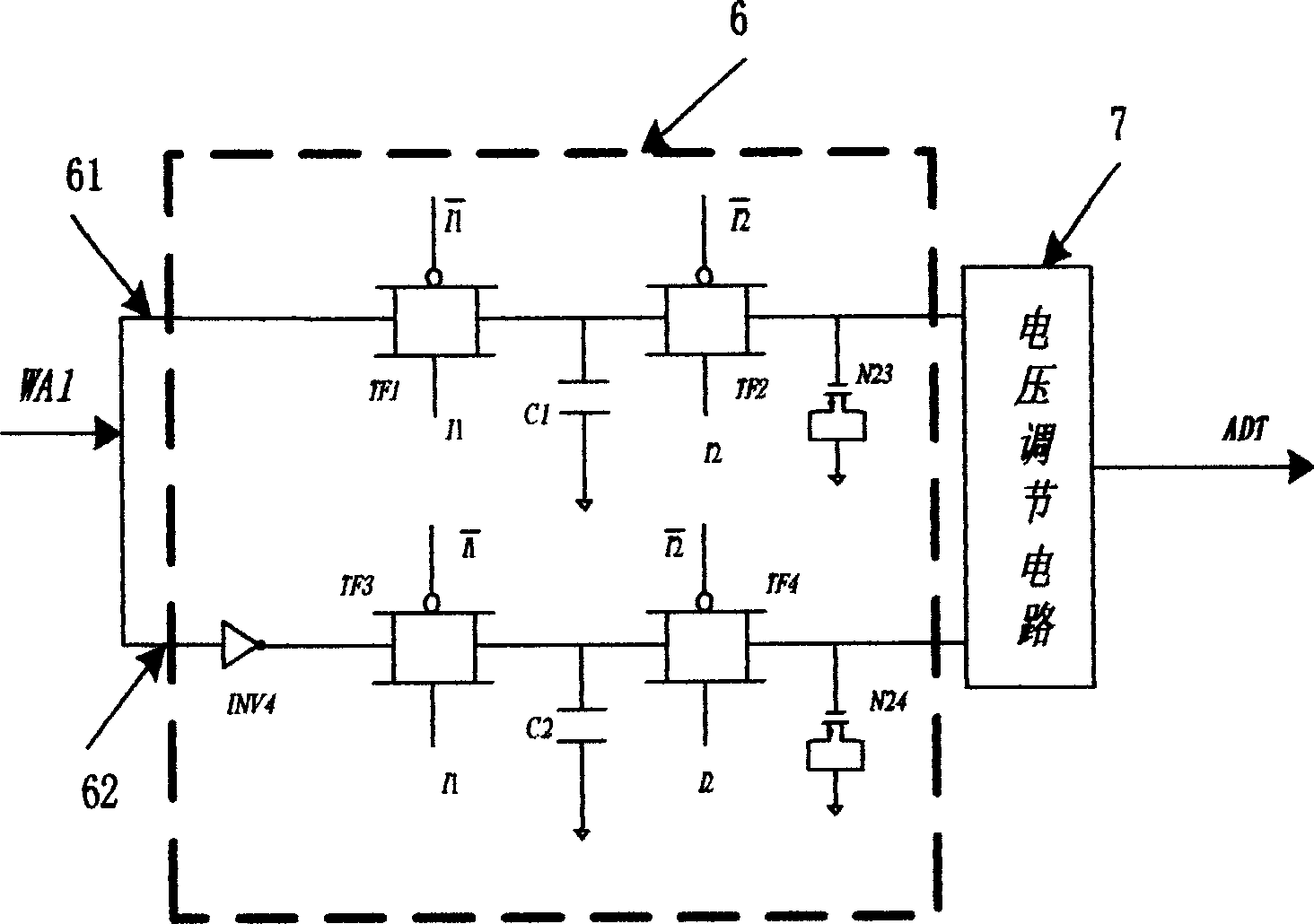

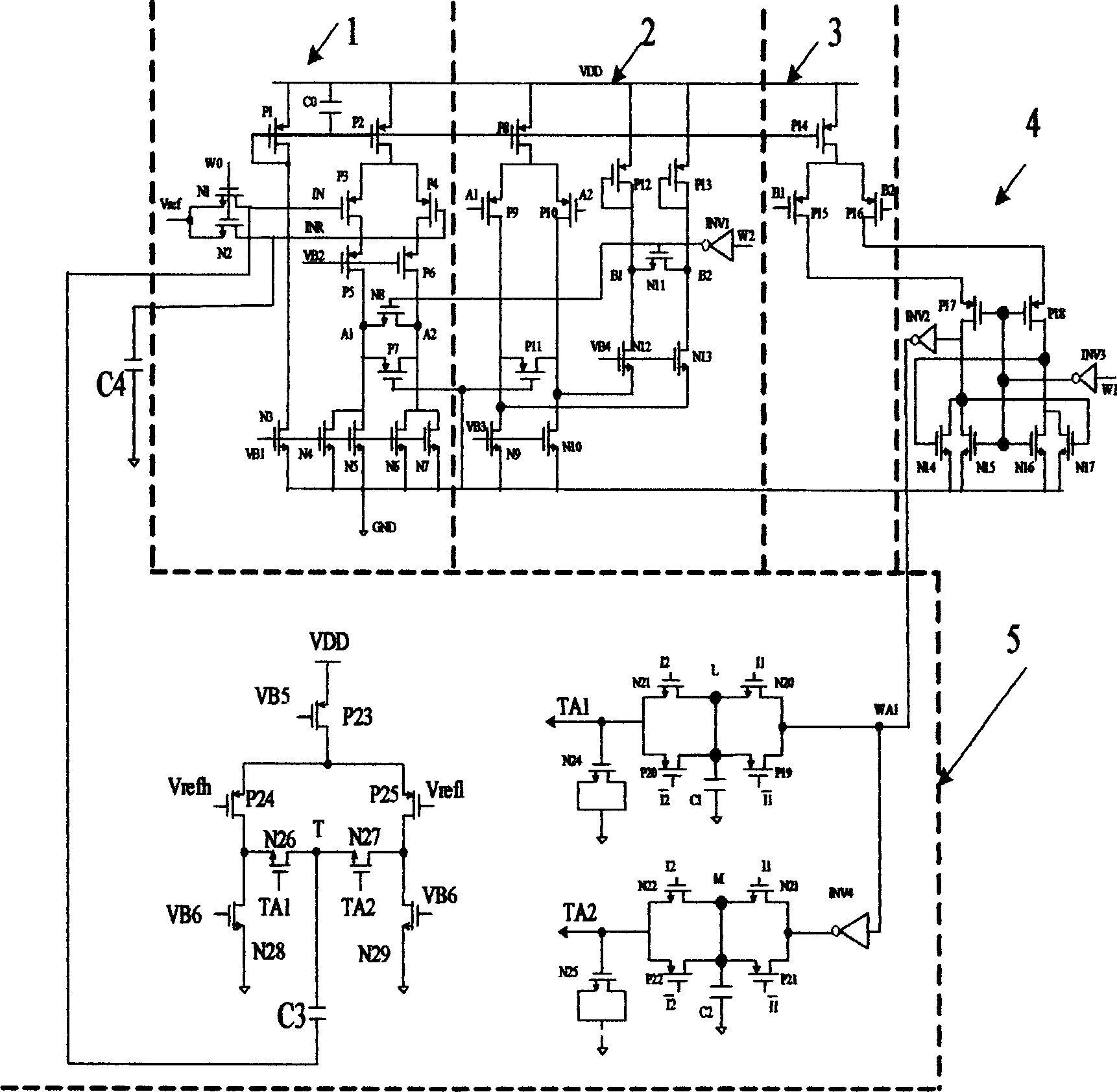

CMOS comparator

InactiveCN1622459AHigh precisionHigh speedAnalogue/digital conversionElectric signal transmission systemsCmos comparatorCapacitance

The CMOS comparator has feedback offset regulating circuit comprising switching capacitor filter and voltage regulating circuit, output latch with output connected to the input of the switching capacitor, the output of the switching capacitor filter connected to the input of the voltage regulating circuit, the output of voltage regulating circuit connected to one end of the comparator offset correcting capacitor C3, the other end of C3 connected to the non-inversion input of the first amplifier, and the capacitor C4 as the capacitor of C3 with one end connected to the inversion input of the first amplifier and the other end grounded. The switching capacitor filter consists of the first branch and the second branch, the first branch consists of two transmission gates, the second branch consists of one inverter and two other transmission gates, and the inverter has its input connected to the output of the output latch.

Owner:SOUTHEAST UNIV

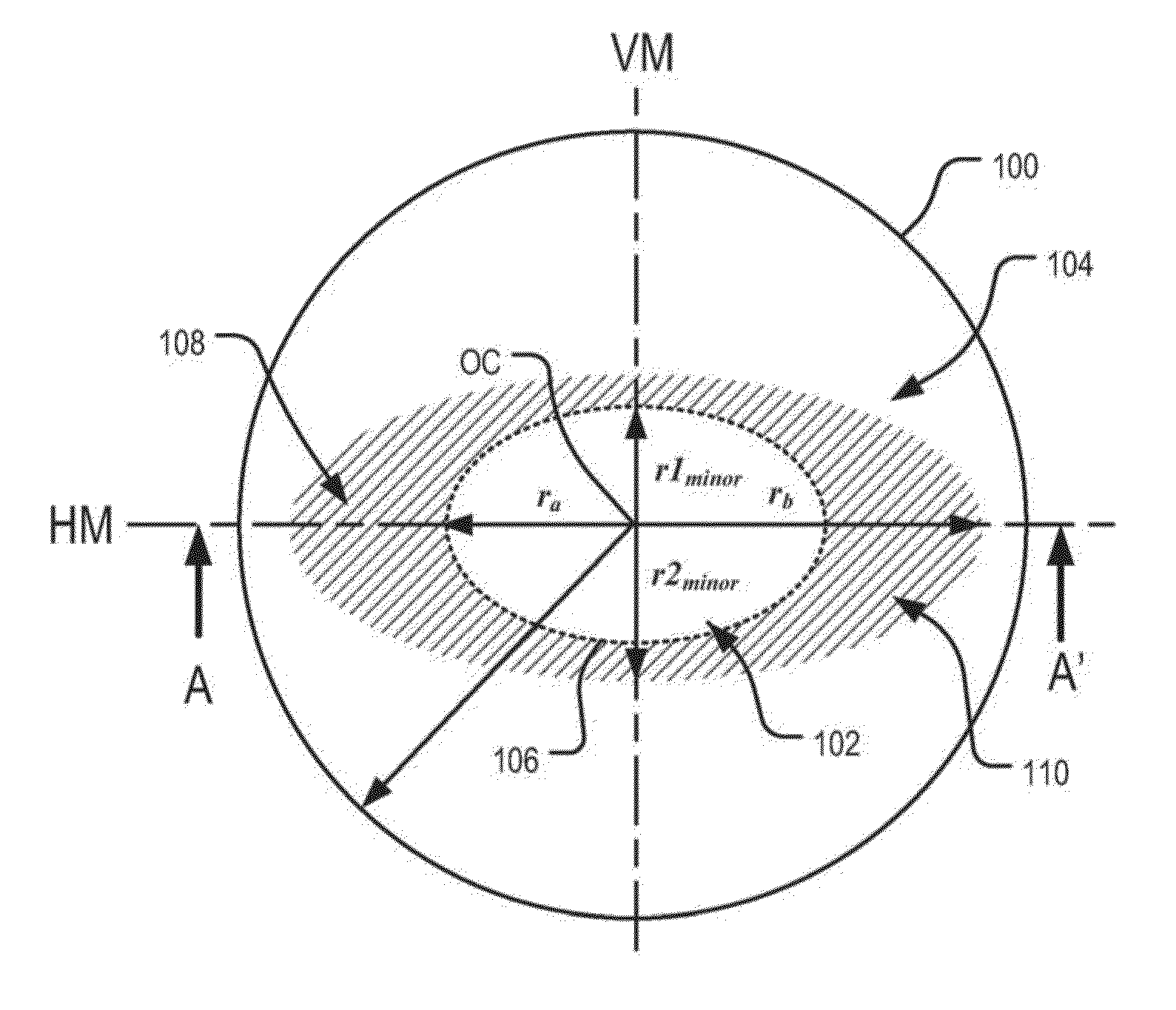

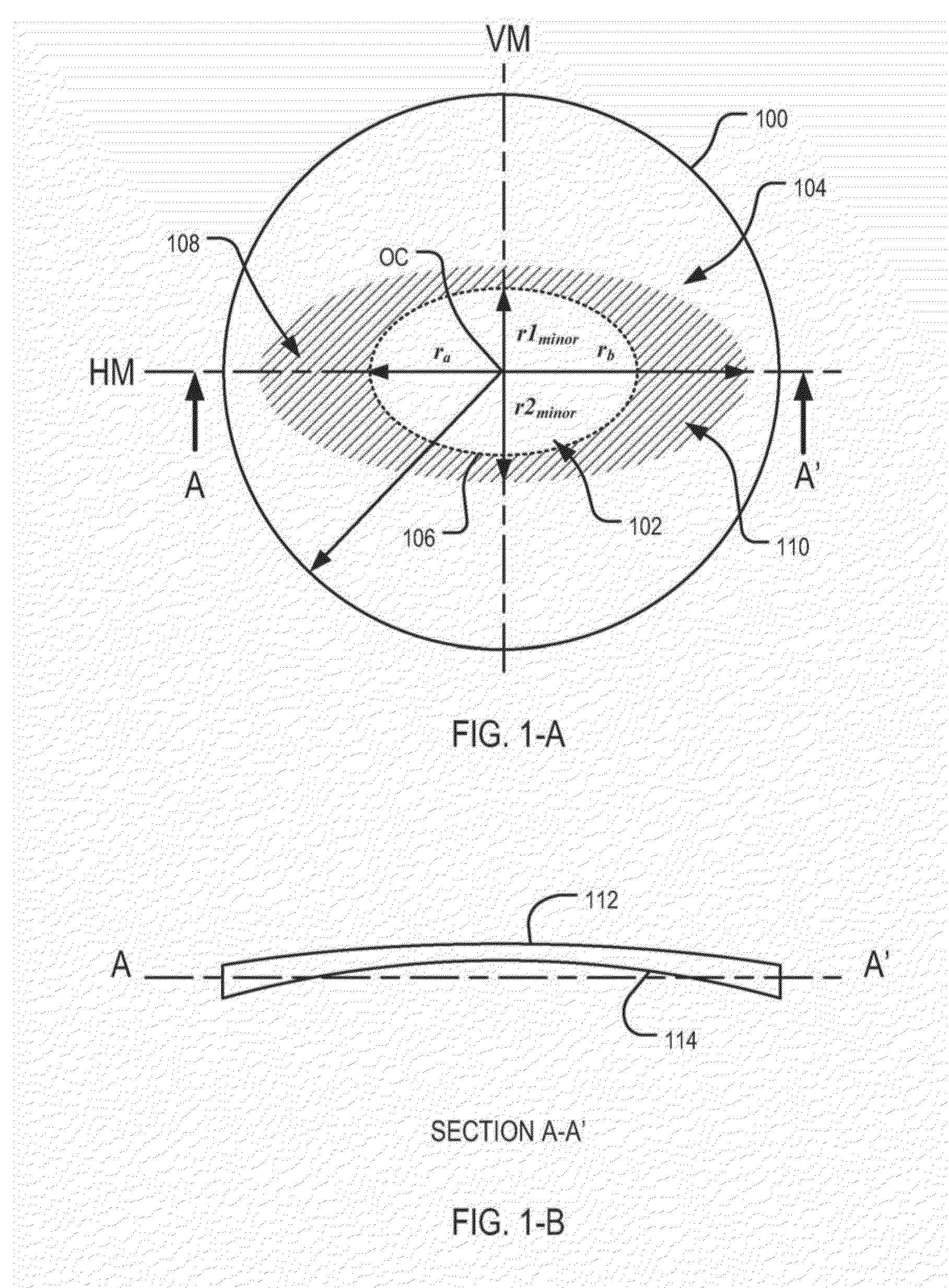

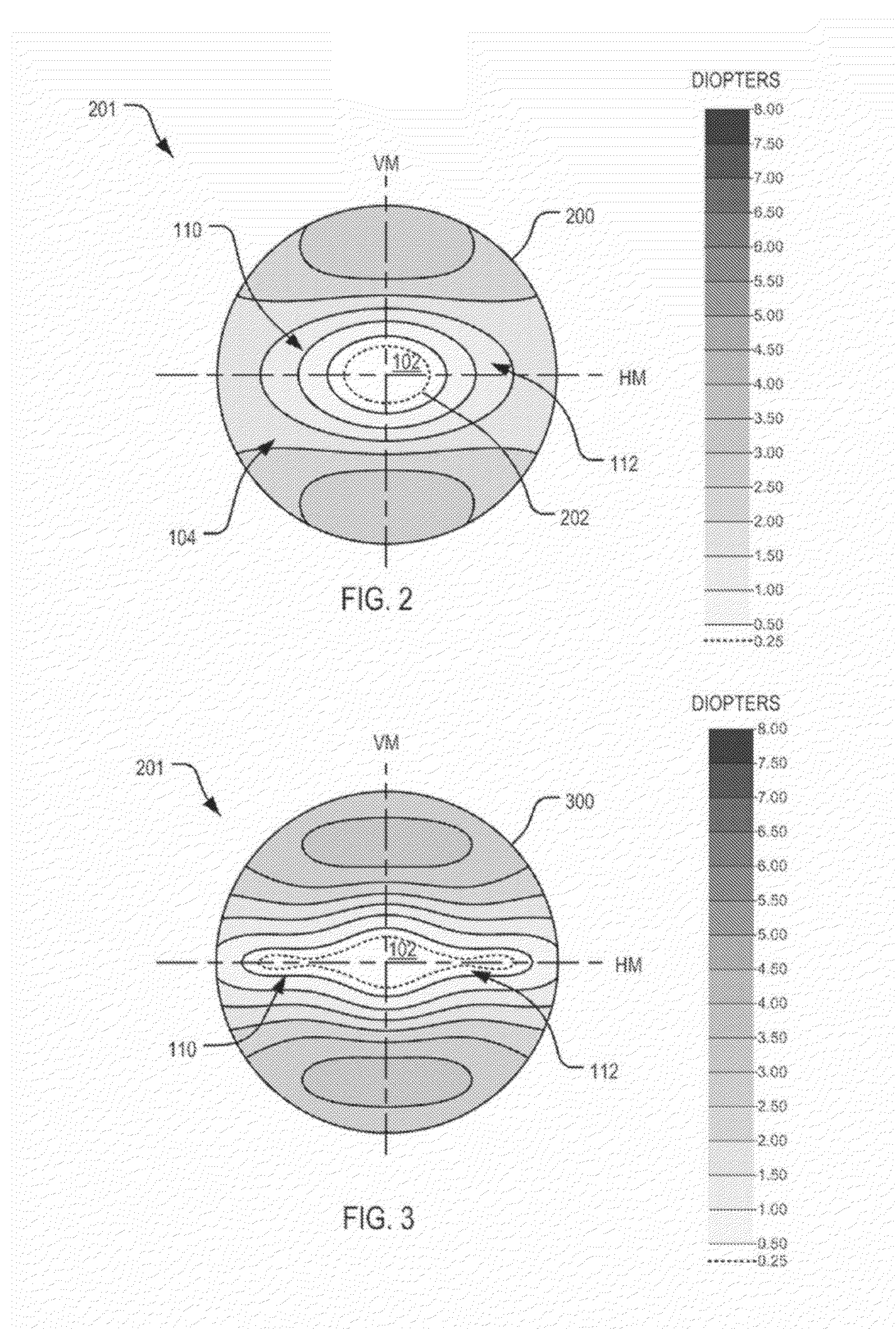

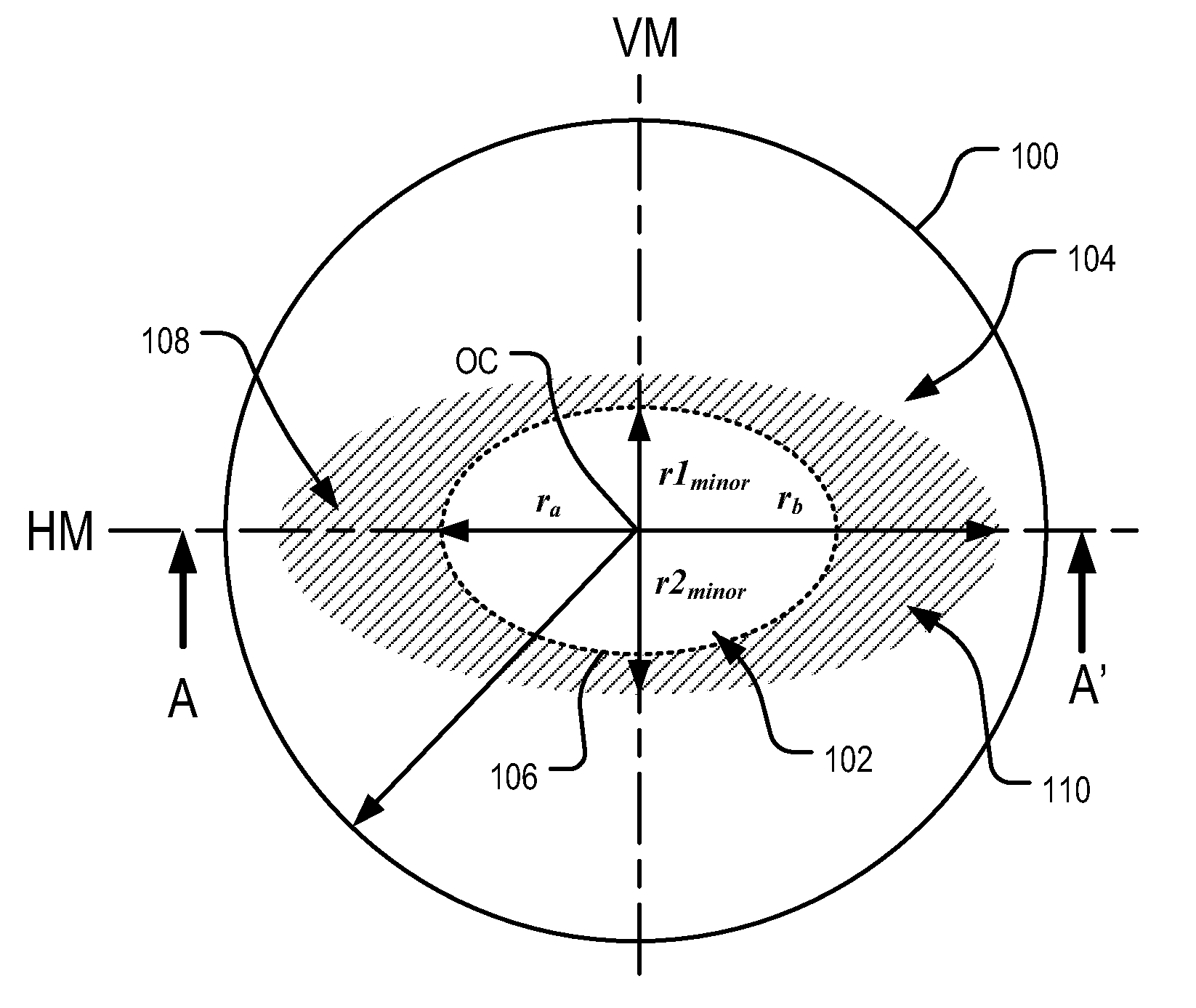

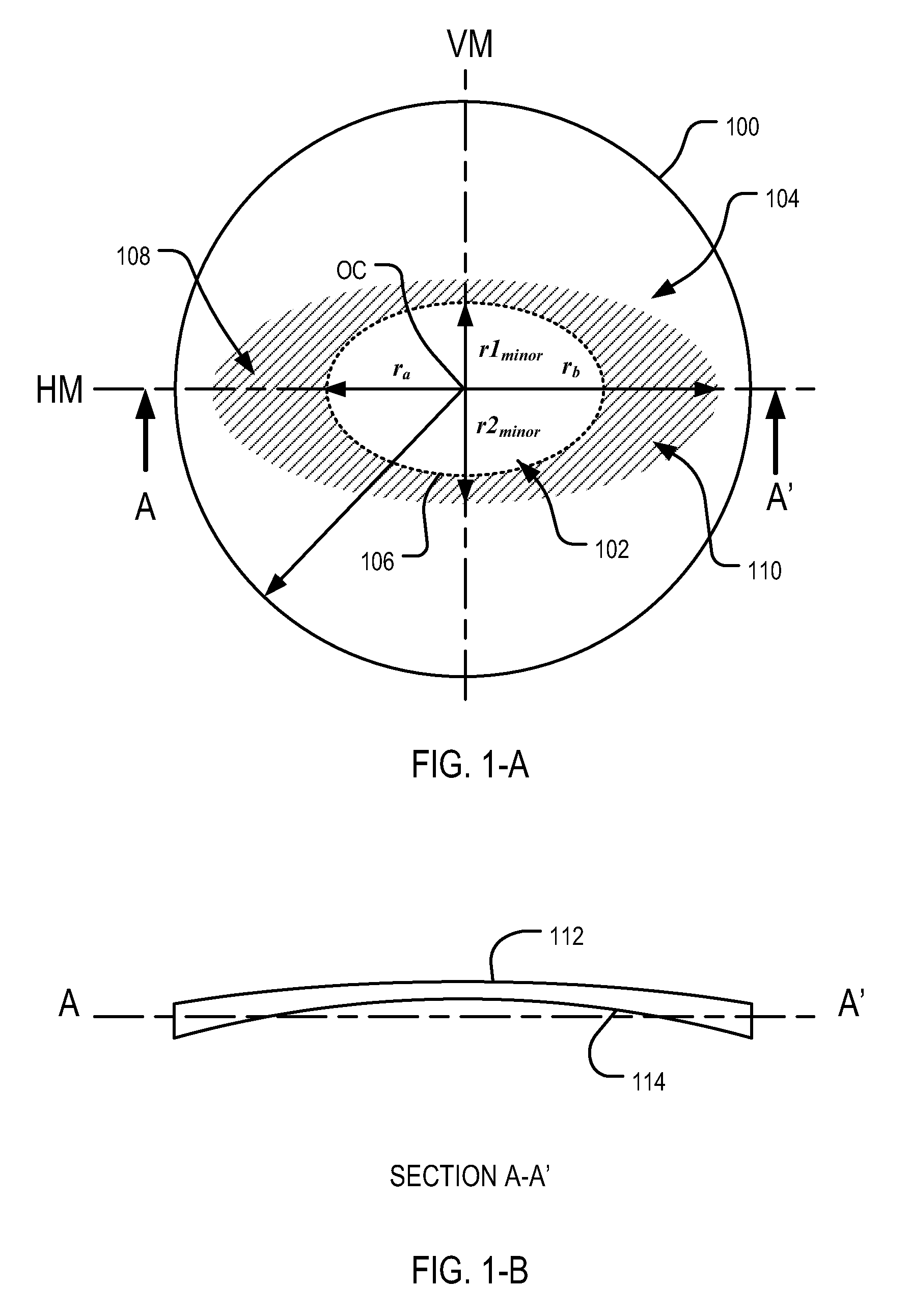

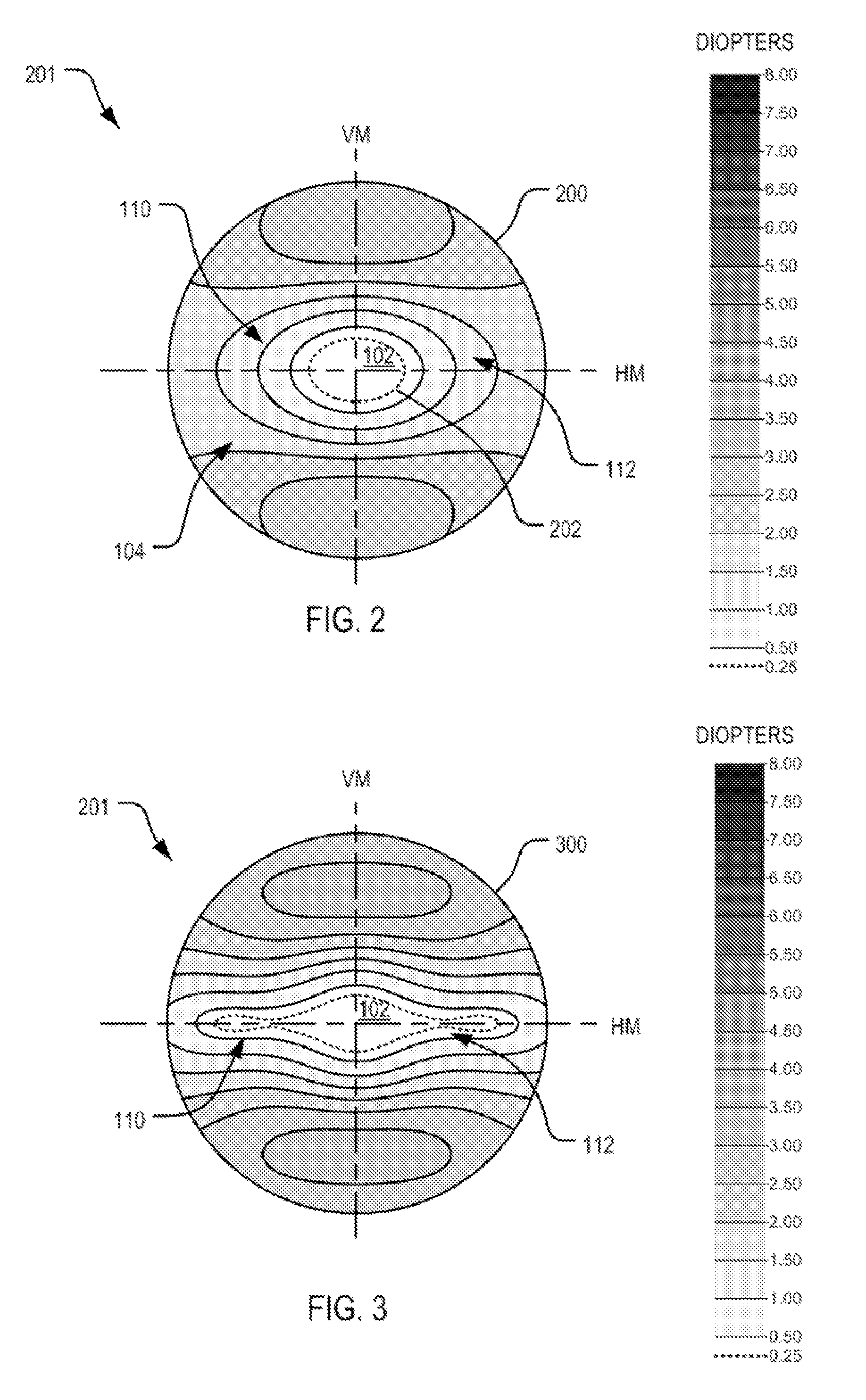

Ophthalmic lens element

ActiveUS20110037944A1Clear visionLower surfaceSpectales/gogglesOptical partsCentral foveal visionLens plate

An ophthalmic lens element is disclosed. The lens element includes a front surface and a rear surface, at least one which includes a horizontal meridian and a vertical meridian. A central region of the lens element includes a foveal vision zone providing a first power for providing clear foveal vision for a wearer. A peripheral region of positive power relative to the first power is also included. The peripheral region includes dual progressive zones located bilaterally of the vertical meridian and extending radially outwardly from the central region. The lens element provides a distribution of surface astigmatism which provides, on the horizontal meridian, a relatively low surface astigmatism in the central region and the progressive zones.

Owner:THE VISION CRC LTD

Portable wide-angle video recording system

InactiveUS20130050401A1Reduce magnificationAvoiding smearing effectTelevision system detailsImage data processing detailsSystem of recordCamera module

A portable video recording system is disclosed, comprising an array of camera modules. The set is equipped with gyroscopes, to allow the extrapolation of the camera's movement from a stitched wide-angle reproduction.From a composed series of master images, picture format and focus can be selected in post production, which avoids sighting and manual settings during recording.

Owner:BREITBLICK

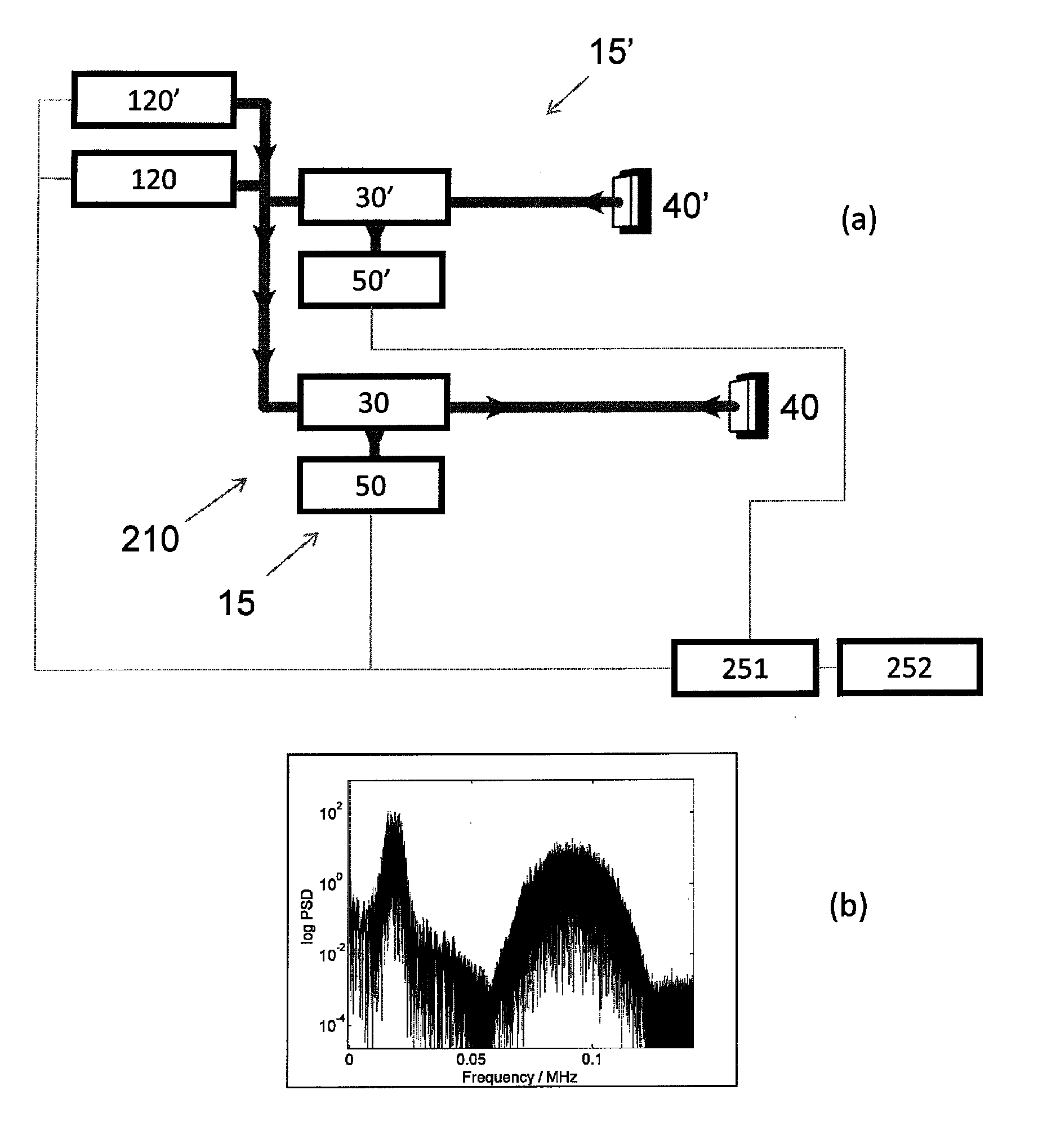

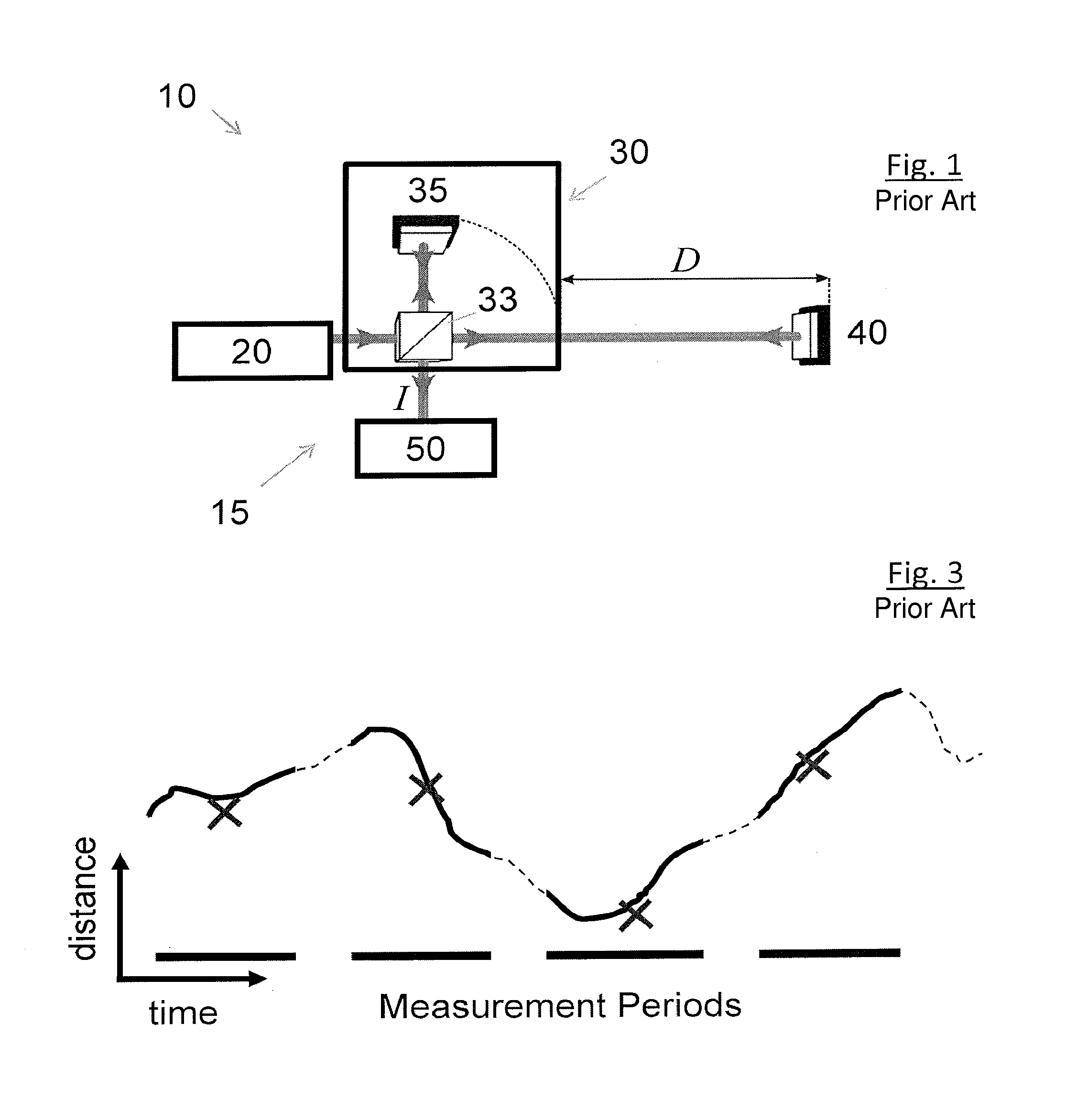

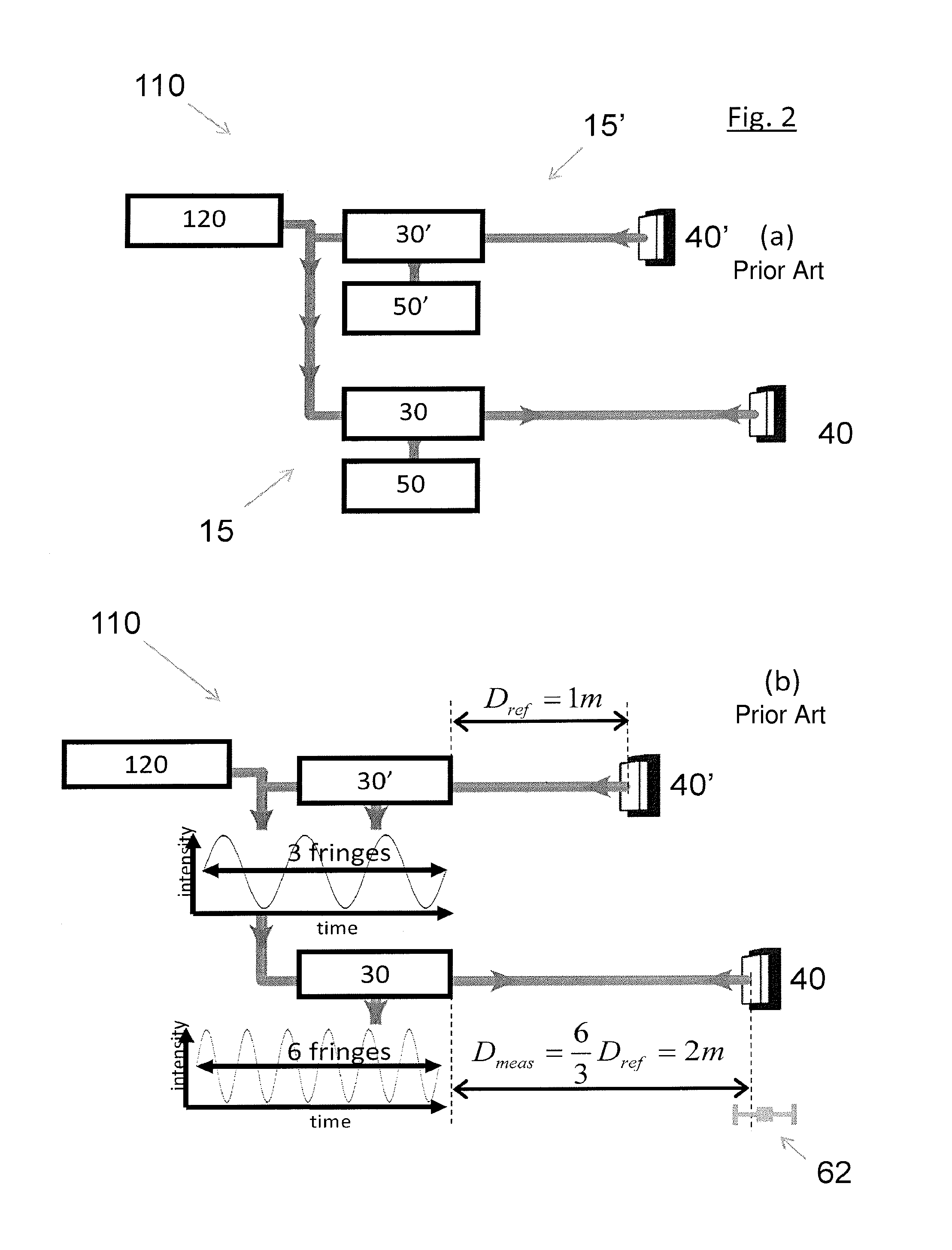

Apparatus and method for measuring distance

ActiveUS9030670B2Error minimizationLow technical requirementsInterferometersUsing optical meansLight beamOptical path length

A method of tracking the position of an object, comprising using reference interference data from first output beam, reference interference data from a second output beam, measurement interference data from the first output beam, measurement interference data from the second output beam, and knowledge of the difference between the absolute phase offset of the first output beam and the absolute phase offset of the second output beam for both a reference interferometer (15′) and a measurement interferometer (15) to calculate a parameter indicative of the absolute phase offset of the measurement interferometer (15) for the first output beam. The calculated parameter is used to calculate the ratio of the optical path differences of the measurement interferometer (15) and the reference interferometer (15′).

Owner:OXFORD UNIV INNOVATION LTD

Parallelly connected capacitance type capacitance pressure sensor

InactiveCN106289592ARelative change increasesHigh sensitivityForce measurementRapid change measurementSignal-to-noise ratio (imaging)Internal resistance

The invention aims to provide a parallelly connected capacitance type capacitance pressure sensor which effectively solves the problems that a single capacitance pressure sensor fails to effectively increase capacitance relative variation due to limit on geometric dimensioning and has too large internal resistance and small SNR (signal to noise ratio) and the like. The sensor comprises a matched shell, a fixed electrode assembled with the matched shell, pipe-shaped extraction electrode, a moving electrode and a pressure extraction opening. The sensor is characterized in that the pressure extraction opening is one with a public welding base, two fixed electrodes and moving electrodes with the same specification assembled in the matched shell and a capacitance pressure sensor of the pipe-shaped extraction electrode are connected with one public welding base pressure extraction opening, the fixed electrode is connected with a lead wire to form the capacitance pressure sensor parallelly connected with two capacitance pressure sensors. The parallelly connected capacitance type capacitance pressure sensor has a rational structure design, multiples capacitance relative variation, remarkably improves sensitivity and SNR, is good in stability and high in measuring accuracy and reduces internal resistance, which enables the measuring range, compared with a single one, a constant upper limit and substantial extension in small and micro direction.

Owner:SHENYANG SENSOR TECH INST

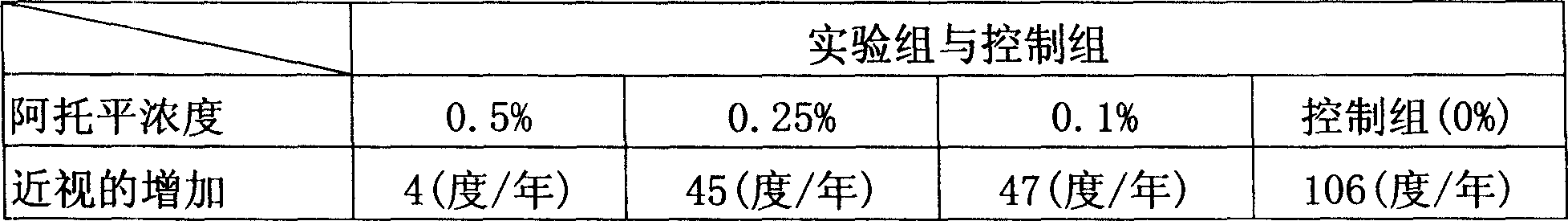

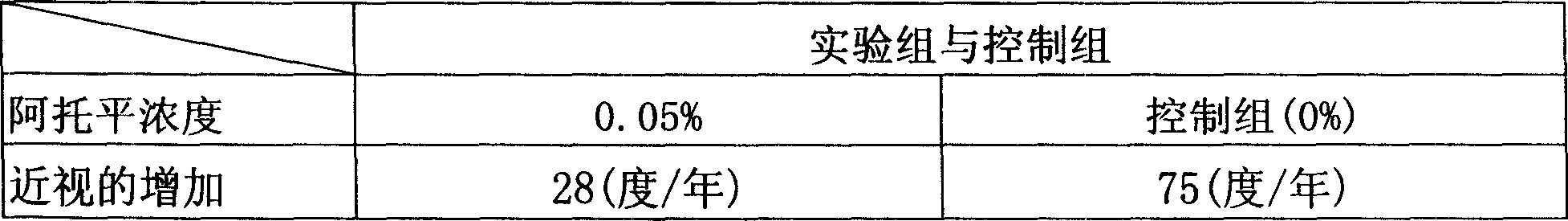

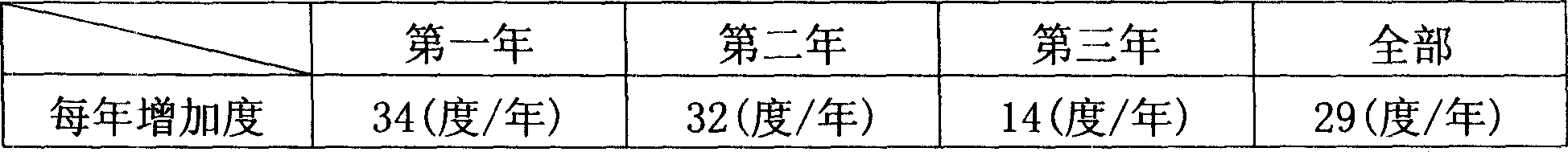

Atropine eyewater in low concentration for restraining increase of degree of short sight and preparing method

InactiveCN101049287AImprove pupil dilationImprove photophobia and other side effectsSenses disorderPharmaceutical delivery mechanismMedicineUltraviolet

Owner:CHANG GUNG MEMORIAL HOSPITAL

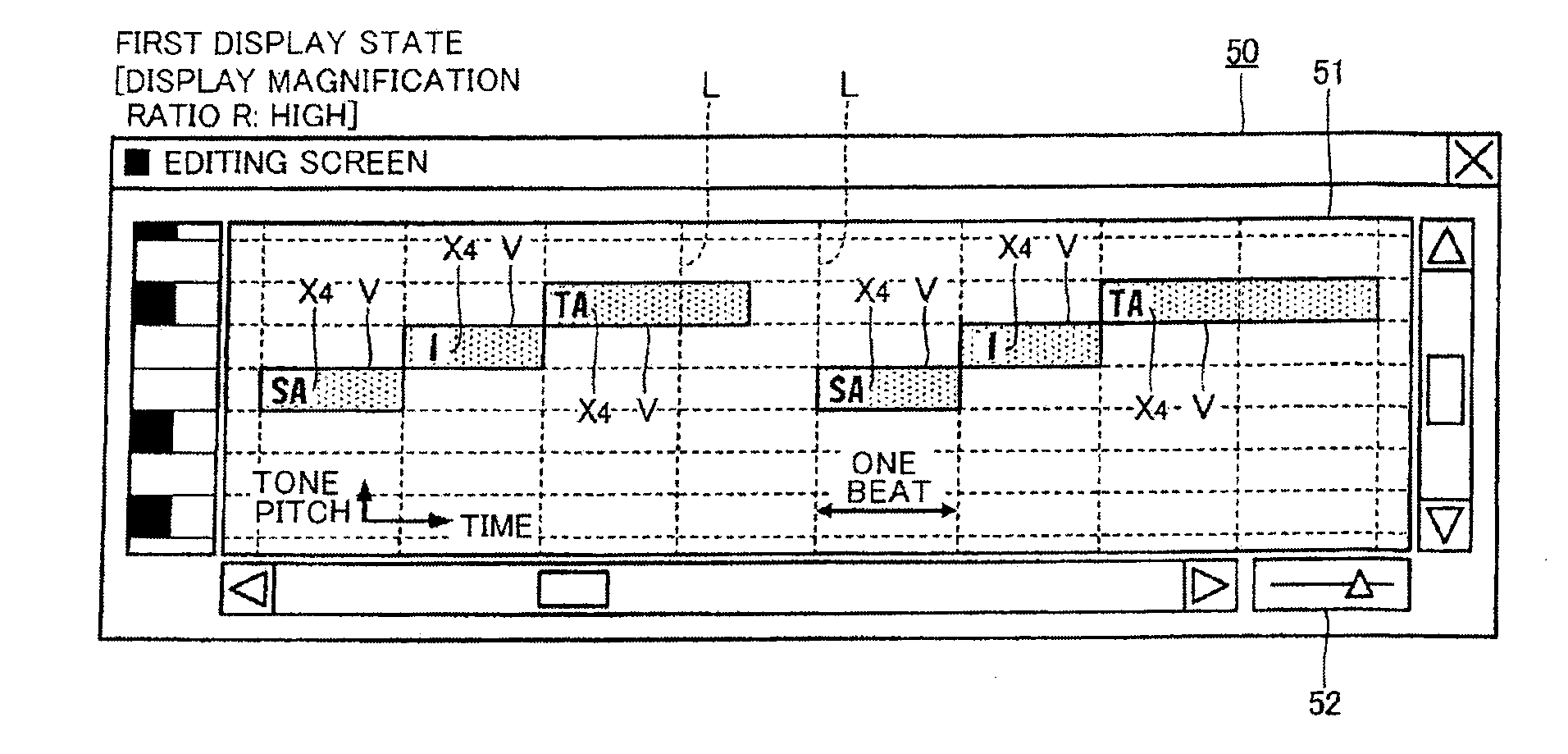

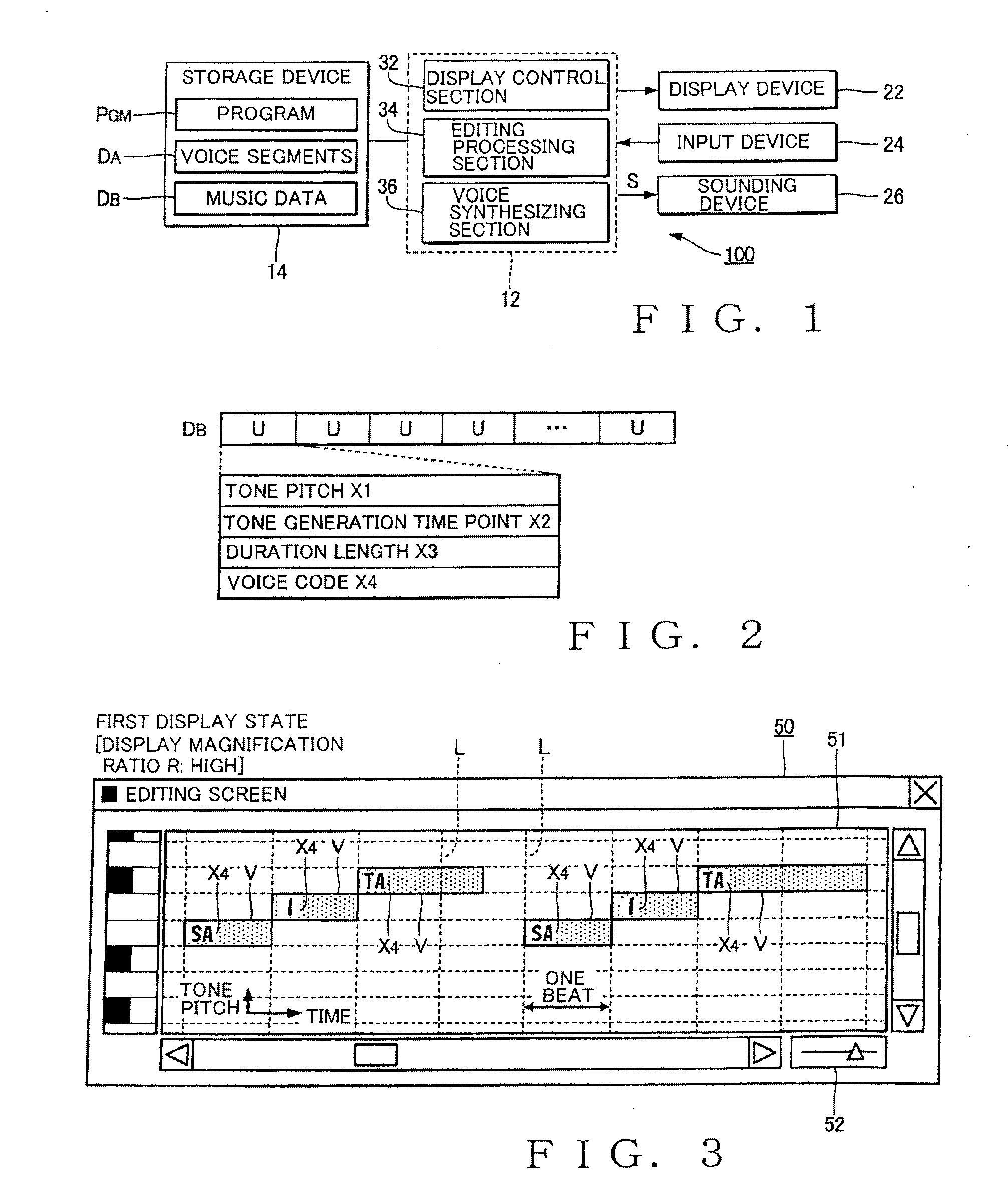

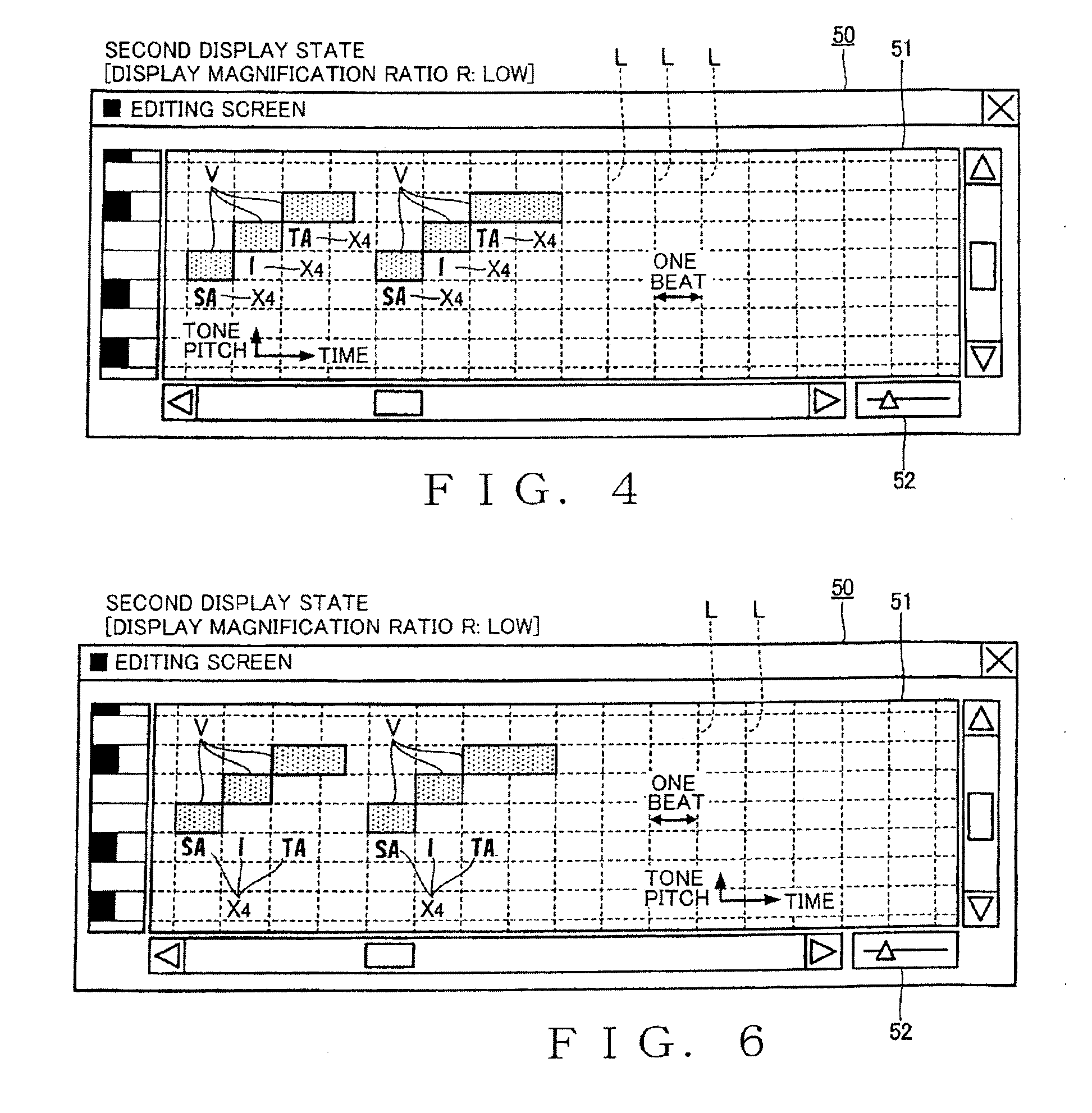

Music data display control apparatus and method

ActiveUS20130112062A1Ensure visibilityEasy to understandElectrophonic musical instrumentsWind musical instrumentsData displayRelevant information

A display area, in which a note is displayed on two-axis coordinates configured by a tone pitch axis and a time axis, is displayed on a display device. A display magnification ratio used in the display area is variable. A note image of a given note is displayed in the display area to be arranged in correspondence with a tone pitch and a tone generation time of the note. The size of the note image is varied with the display magnification ratio. Relevant information is displayed in association with the note image displayed in the display area in such a manner that the relevant information is arranged inside the note image of the note in a first display state and the relevant information is arranged outside the note image of the note in a second display state with a display magnification ratio lower than that of the first display state.

Owner:YAMAHA CORP

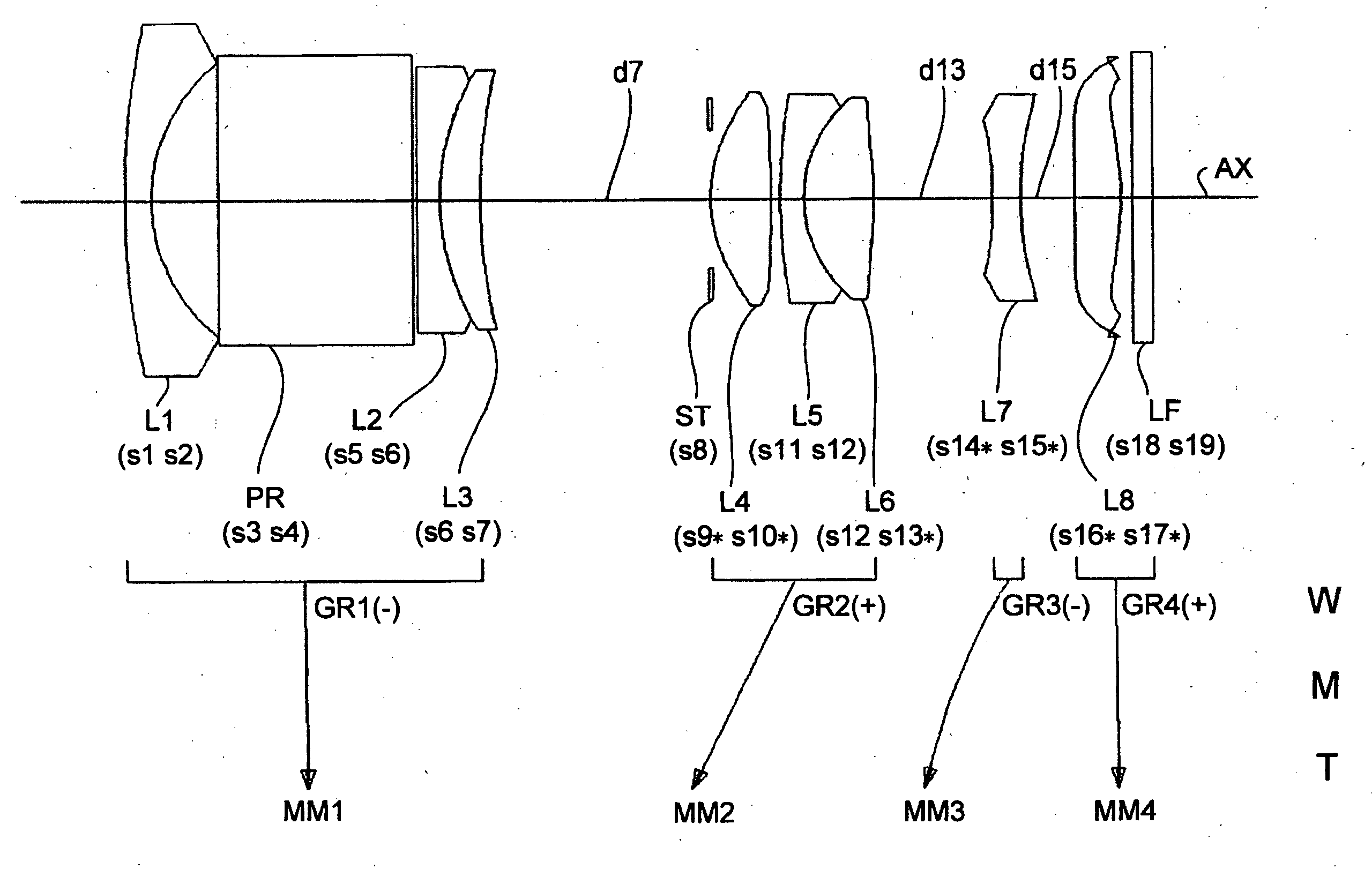

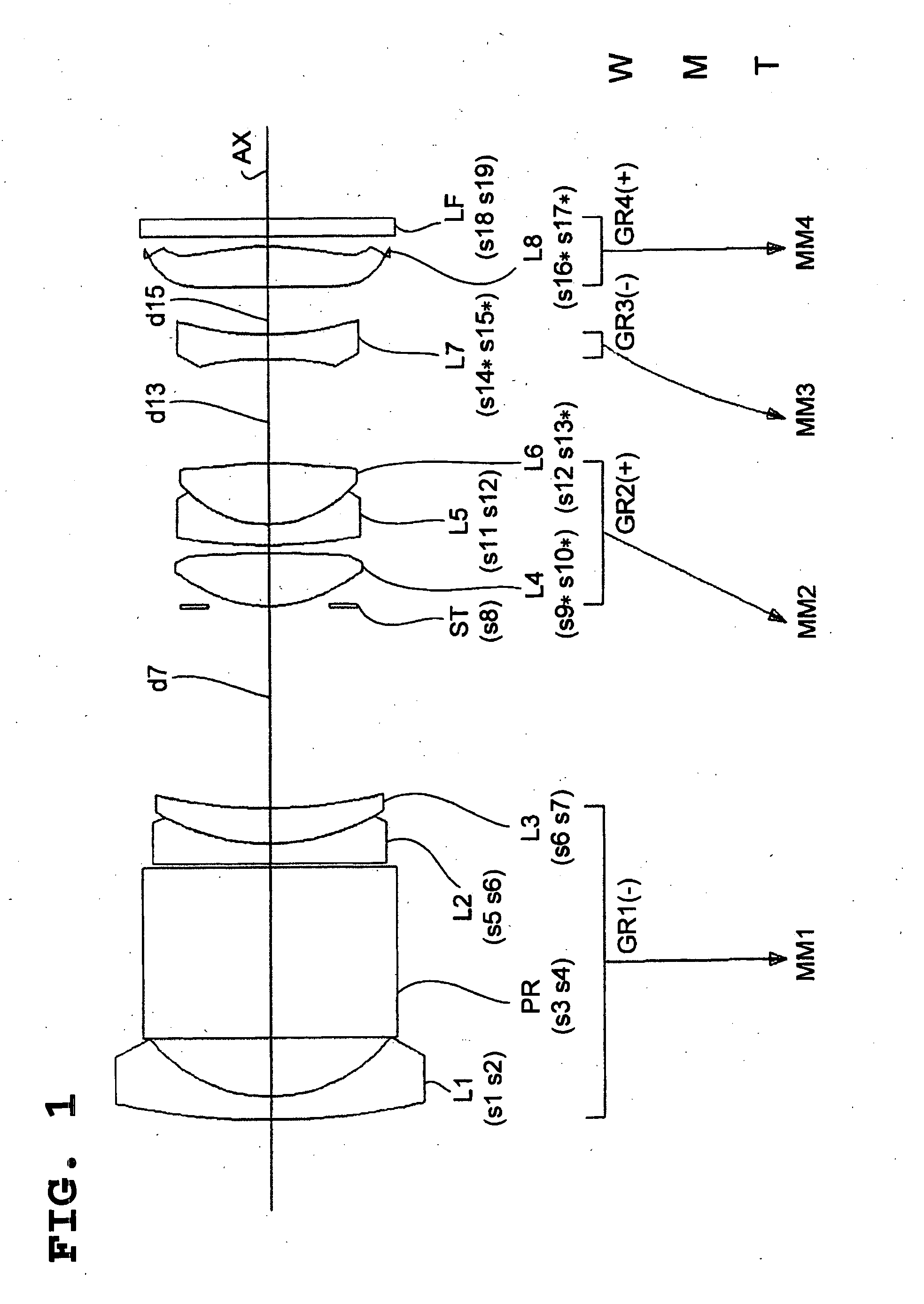

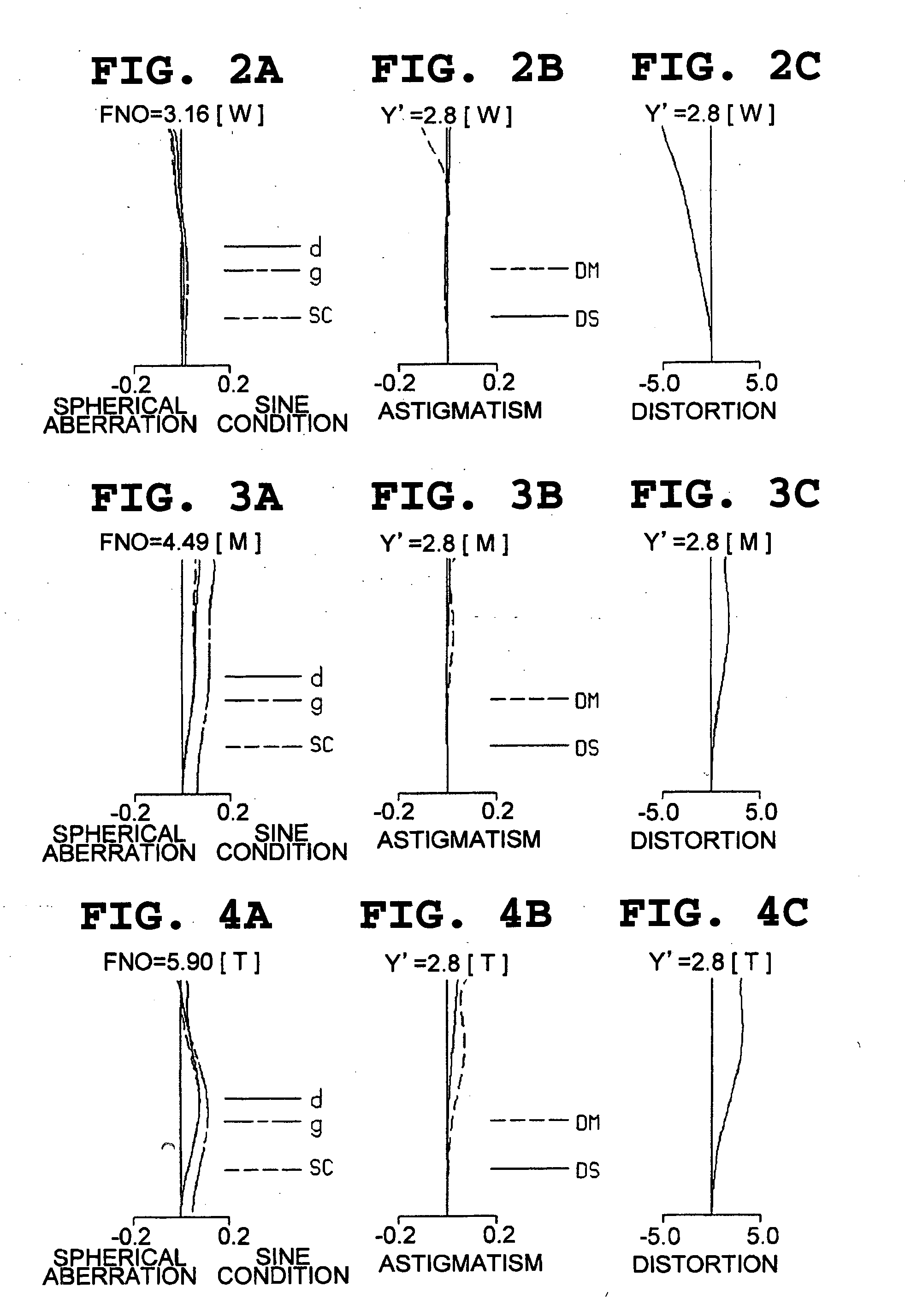

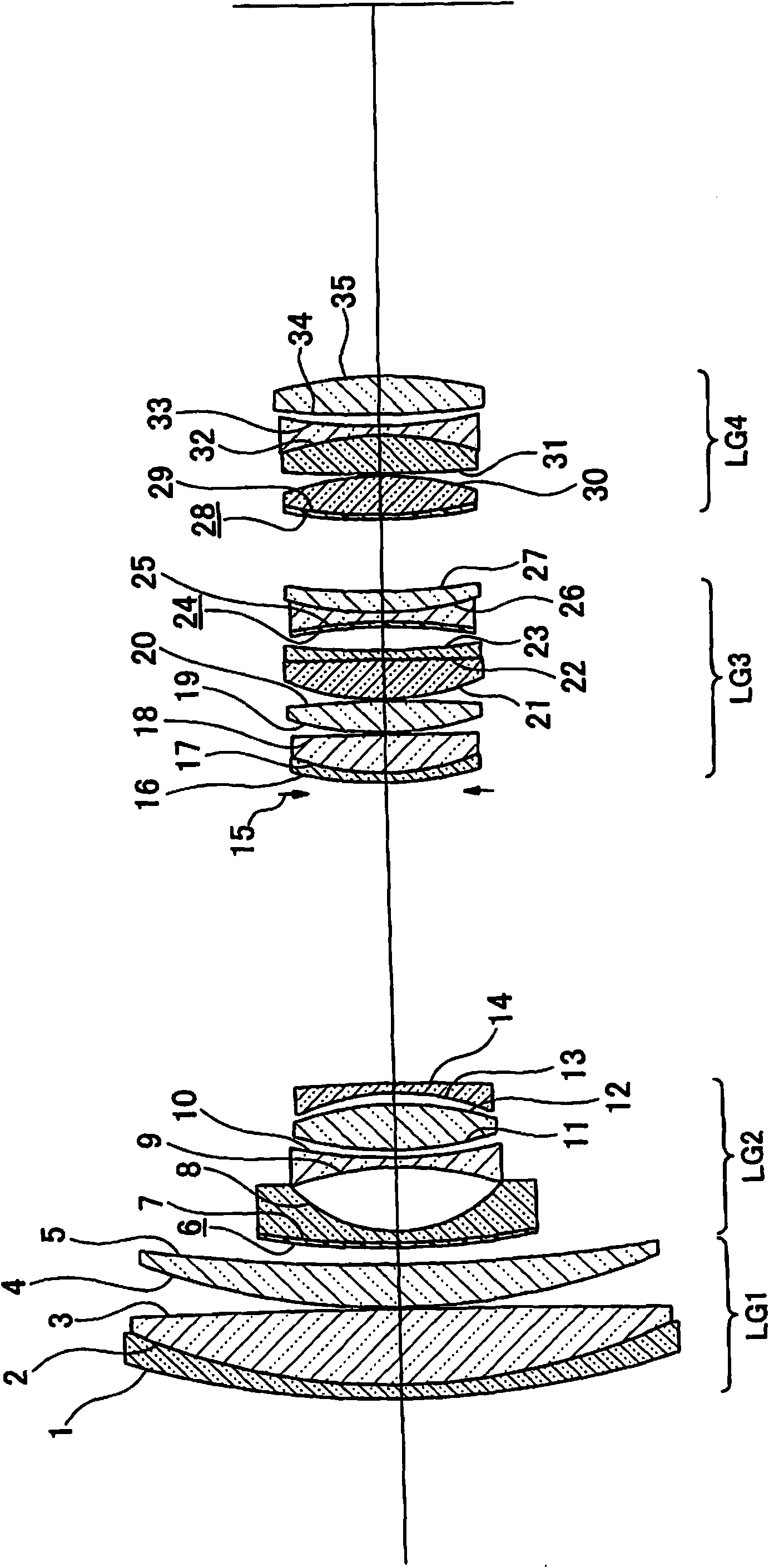

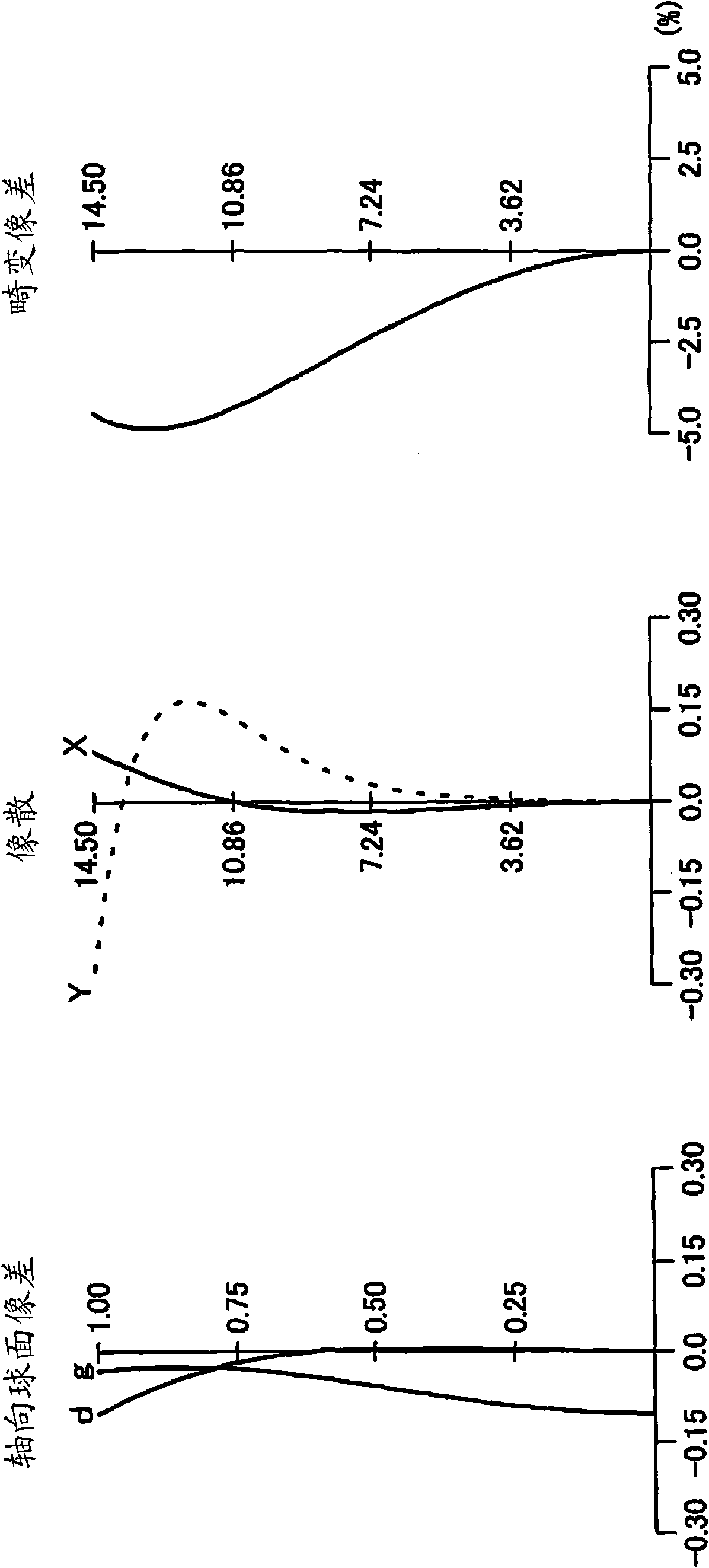

Magnification varying optical system and image taking apparatus

ActiveUS20070201143A1Reduce magnificationDownsized magnification varying opticalLensOptical axisOptical power

A magnification varying optical system that directs light from an object to an image sensor includes in order from the object side: a first lens unit having negative optical power and including an optical axis changing element that changes the optical axis; a second lens unit having positive optical power and including three lens elements; a third lens unit having negative optical power; and a fourth lens unit having positive optical power. In this magnification varying optical system, in magnification varying from the wide-angle end to the telephoto end, the first lens unit is stationary, the distance from the first lens unit to the second lens unit decreases, and the distance from the third lens unit to the fourth lens unit increases. The magnification varying optical system satisfies the specified conditions.

Owner:KONICA MINOLTA OPTO

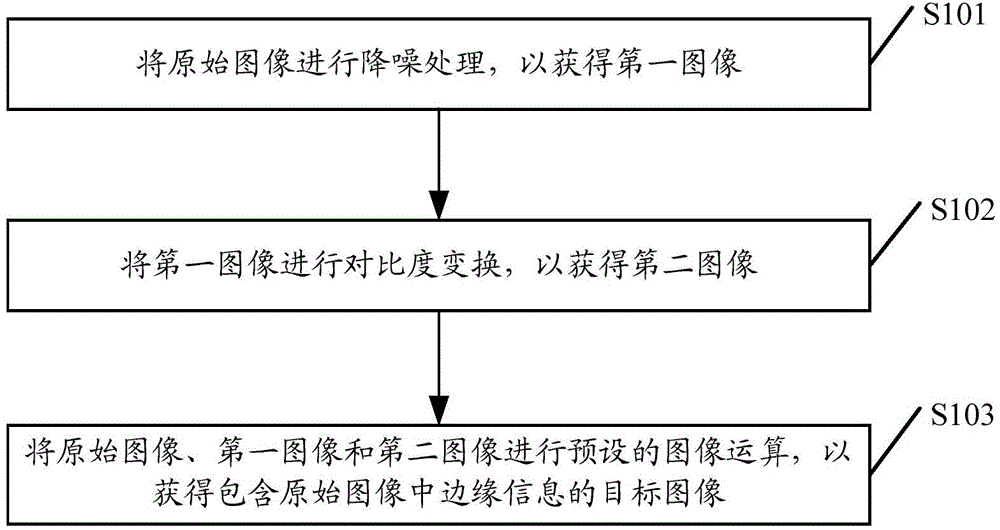

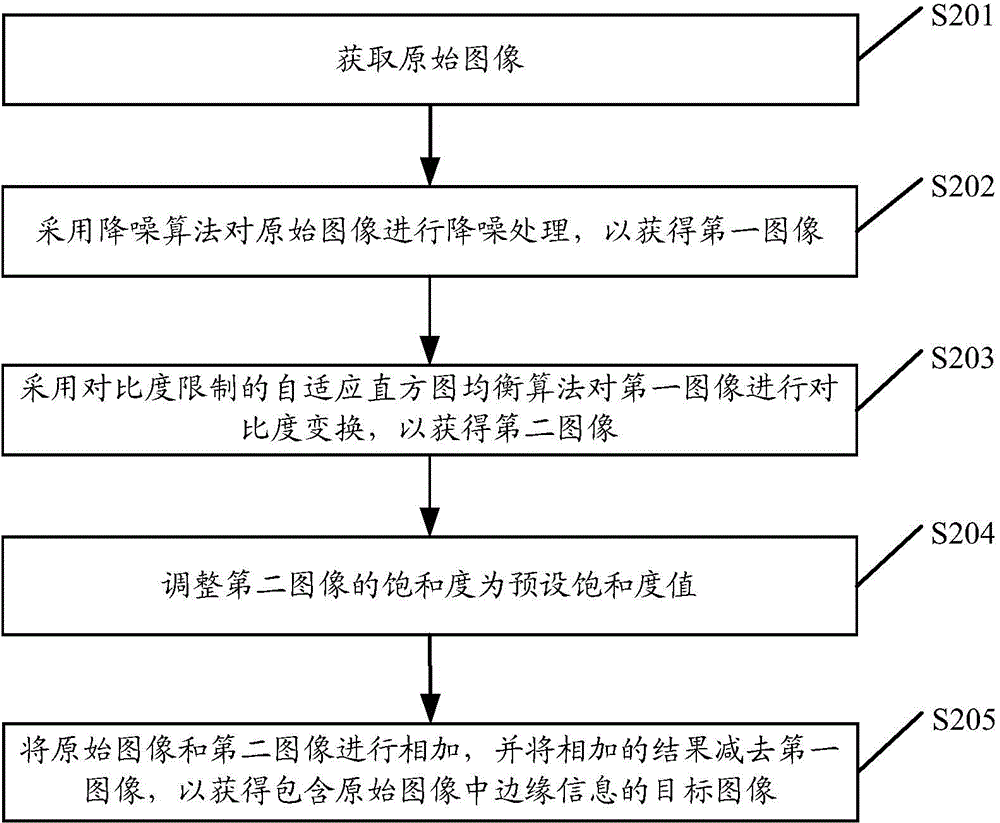

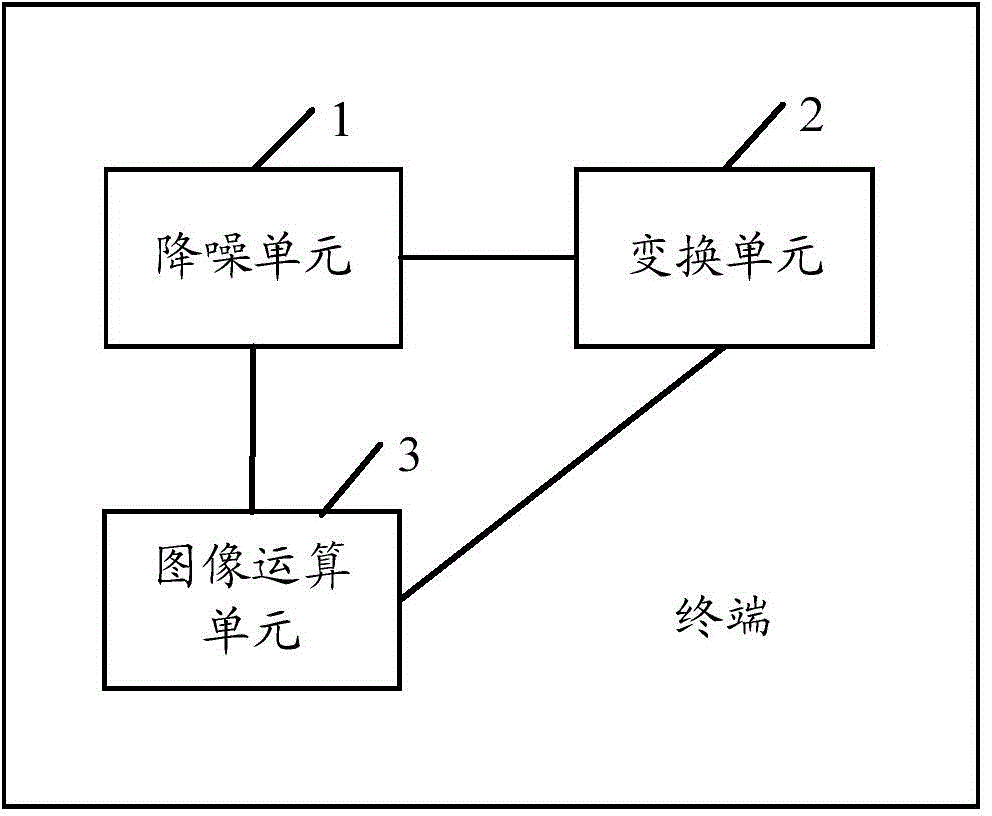

Image enhancement method

ActiveCN104376542AImprove visual effectsReduce magnificationImage enhancementImage enhancementComputer science

The embodiment of the invention discloses an image enhancement method. The image enhancement method comprises the steps that denoising treatment is conducted on an original image, so that a first image is obtained; contrast conversion is conducted on the first image, so that a second image is obtained; preset image operation is conducted on the original image, the first image and the second image, so that a target image containing the edge information of the original image is obtained. By the adoption of the image enhancement method, when contrast conversion is conducted on the first image which is obtained after denoising treatment, the amplification degree of noisy points in the original image can be reduced, the target image can contain the edge information of the original image through image calculation, and therefore the sense of reality of an enhanced image can be kept.

Owner:SHENZHEN TRANSSION HLDG CO LTD

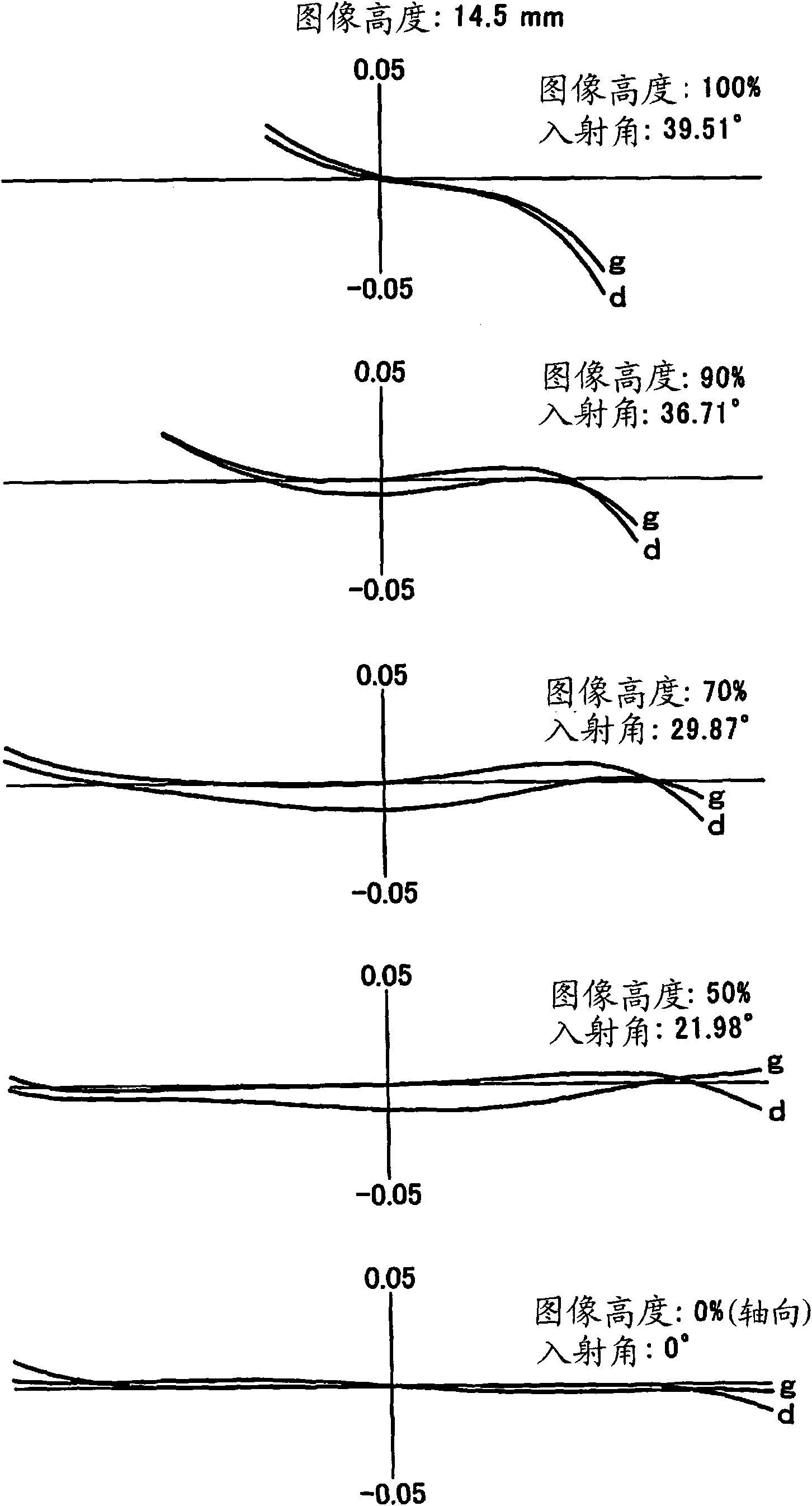

High variable power zoom lens

A compact and lightweight, high variable power zoom lens especially suitable for single-lens reflex digital cameras, which is 75 degrees or even wider in field angle at the wide-angle end, approximately 3 to 4 in F-number at the wide-angle end and approximately 6 to 7 at the telephoto end, and about 15x in variable power ratio. The zoom lens of four groups of lens pieces respectively exerting positive, negative, positive, and positive refractivities varies the power from the wide-angle end to the telephoto end as a result of the 1st and 2nd lens groups being split more, the 2nd and 3rd lens groups coming closer to each other, and the 3rd and 4th lens groups also coming closer to each other. The 3rd lens group has the leading set of lens pieces of positive refractivity closer to objects andthe trailing set of lens pieces of negative refractivity, and the trailing set alone are moved to be orthogonal to the optical axis to compensate for defocus in the imaging plane caused by a tremor of the user's hand(s). The 2nd lens group are displaced closer to objects for the focusing.

Owner:TAMRON

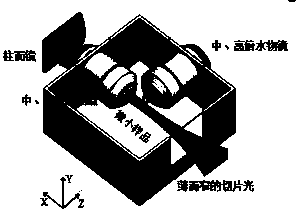

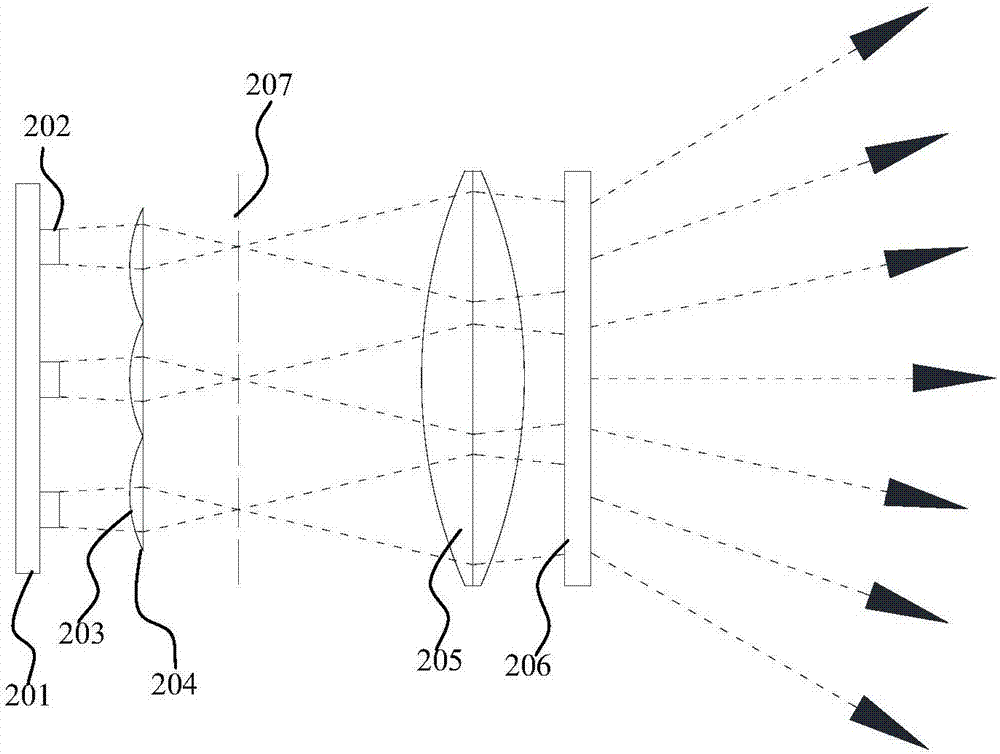

Laser projection device

InactiveCN106990659AReduce magnificationImprove pattern qualityProjectorsOptical pathImaging quality

The invention provides a laser projection device and a depth camera thereof. The laser projection device comprises a VCSEL array, a micro-lens array, a main lens and a pattern generation optical element. Micro-lens units receive and focus light beams emitted by corresponding VCSEL units. The main lens carries out secondary focusing imaging on the light beams of the micro-lens array. Through a secondary imaging optical path consisting of the micro-lens array and the main lens, quite low magnification times is achieved, so imaging quality of a laser projection module is improved and the laser projection device is quite small in size. In addition, according to the difference application scene requirements, the distance between the micro-lens array and the main lens can be adjusted in the installation to increase or decrease the magnification times, thereby satisfying the size of required spot patterns at a long distance or a small distance.

Owner:SHENZHEN ORBBEC CO LTD

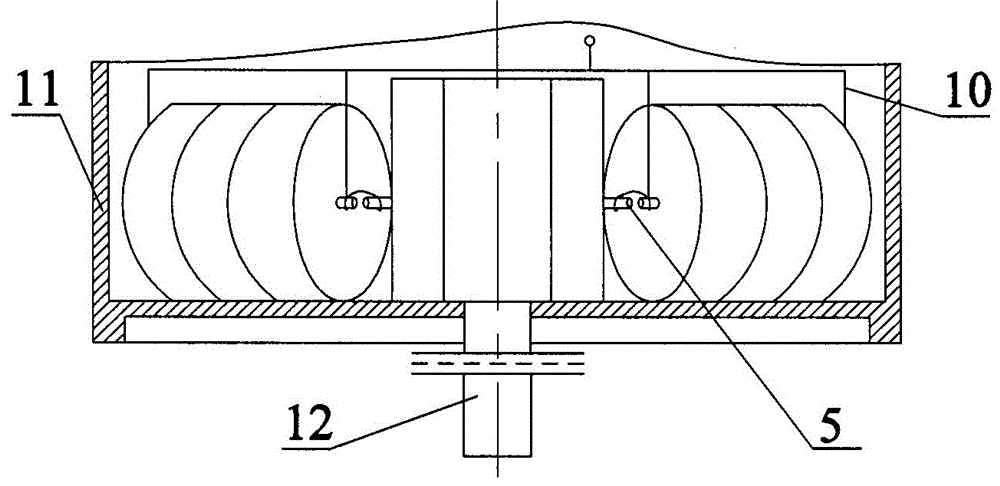

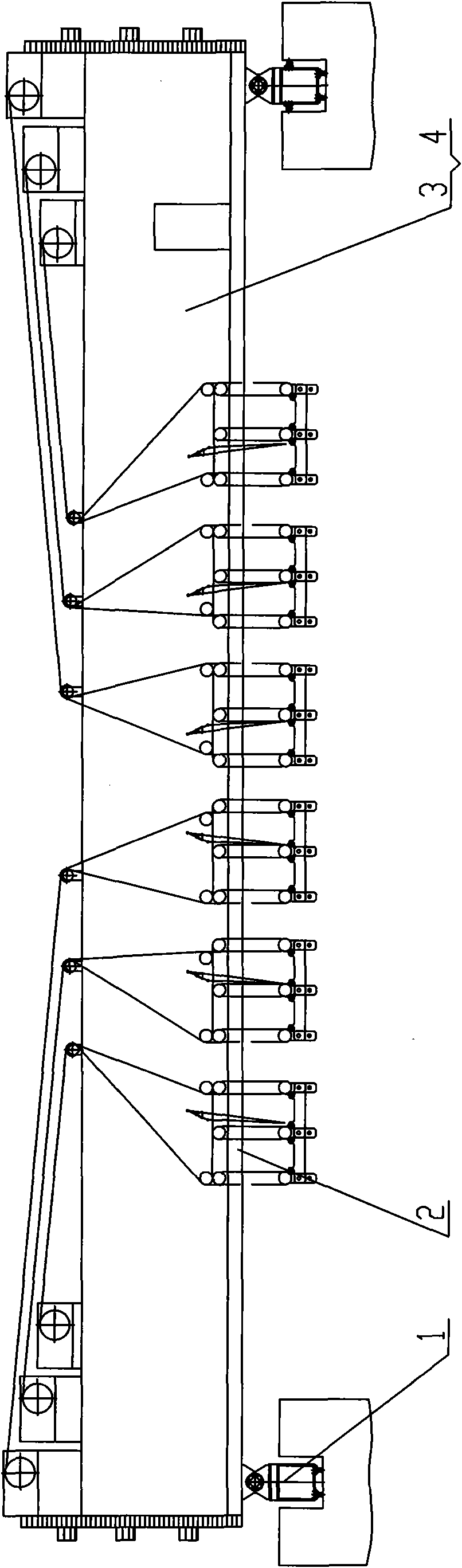

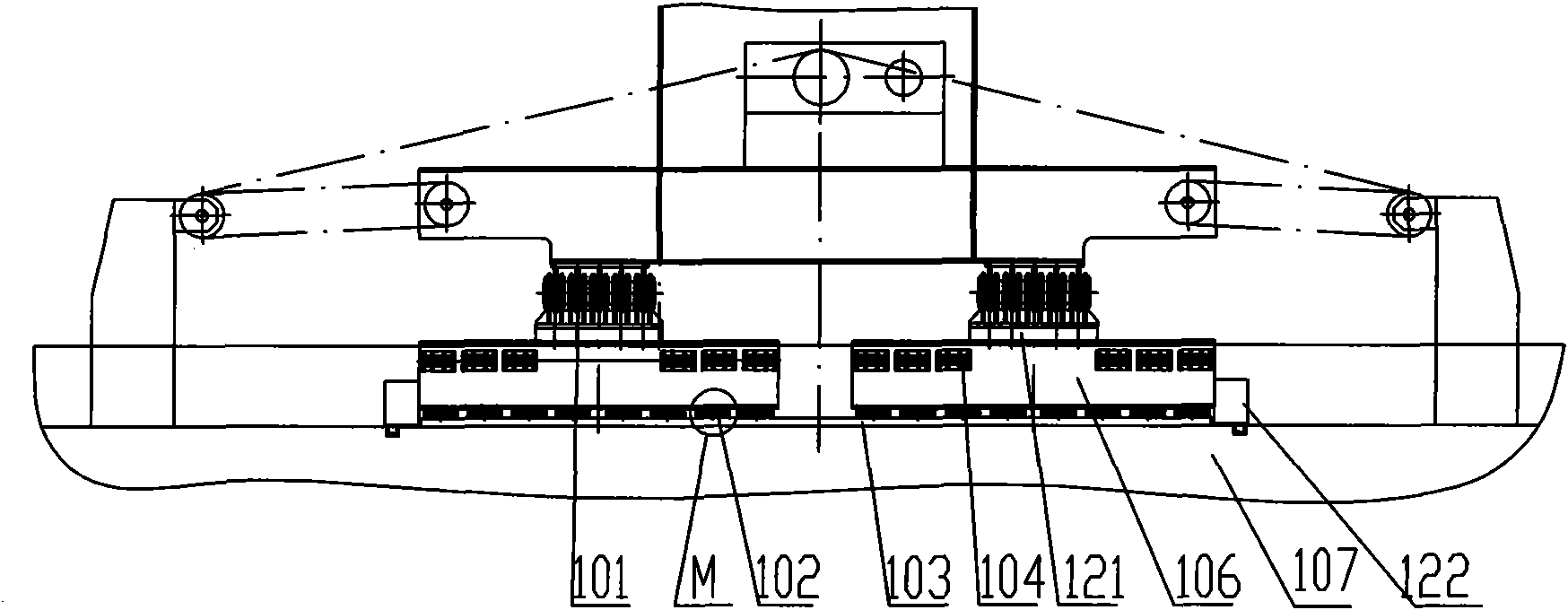

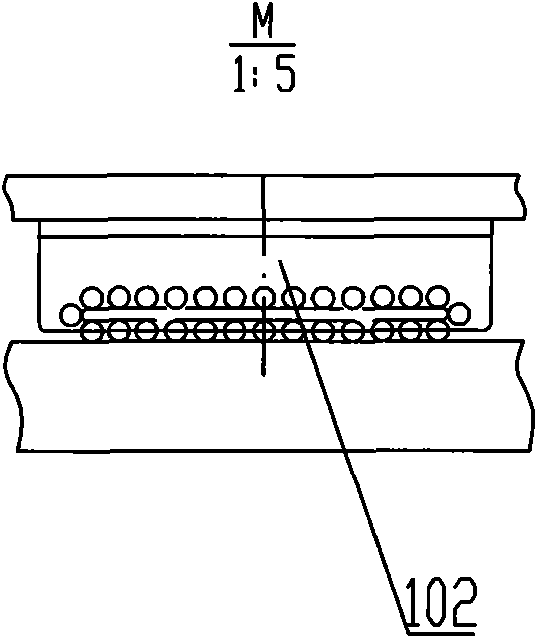

Multi-suspension-centres crane

ActiveCN101607676AImprove the forceEven by forceTravelling cranesWinding mechanismsWinding machineReduction drive

The invention discloses a multi-suspension-centres crane which comprises main beams, an operating mechanism, a lifting mechanism and an electric control system, wherein the operating mechanism comprises a bearing mechanism composed of an idle wheel device and an elastic body, and a drive mechanism composed of a motor, a reducer, a winding drum group, two groups of steel ropes, a pulley block and a pulley bracket, wherein the lifting mechanism comprises more than 2 sets of winding machines on each main beam, adopts a multilayer winding and symmetrical rope mode of duplex winding drums and steel ropes, and adopts a mode that a hook connecting piece is respectively hinged or fixedly connected with a corresponding hook group through a pin roll. The multi-suspension-centres crane has the characteristics of safety and reliability, strong practicability and the like through the self-set corresponding control method, is suitable to a crane with ultra-high lifting load, especially the multi-suspension-centres crane for lifting by sections on an offshore drilling platform.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

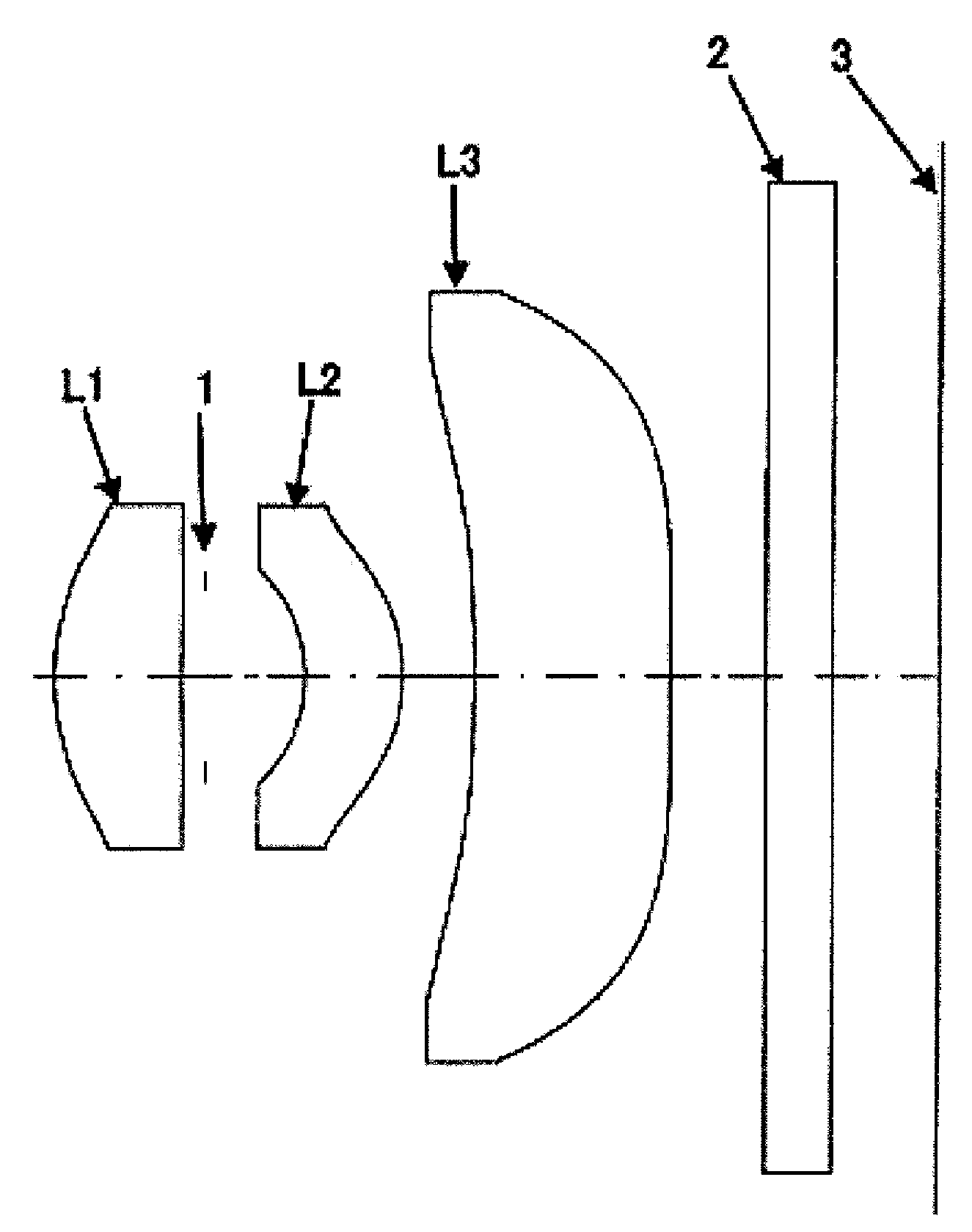

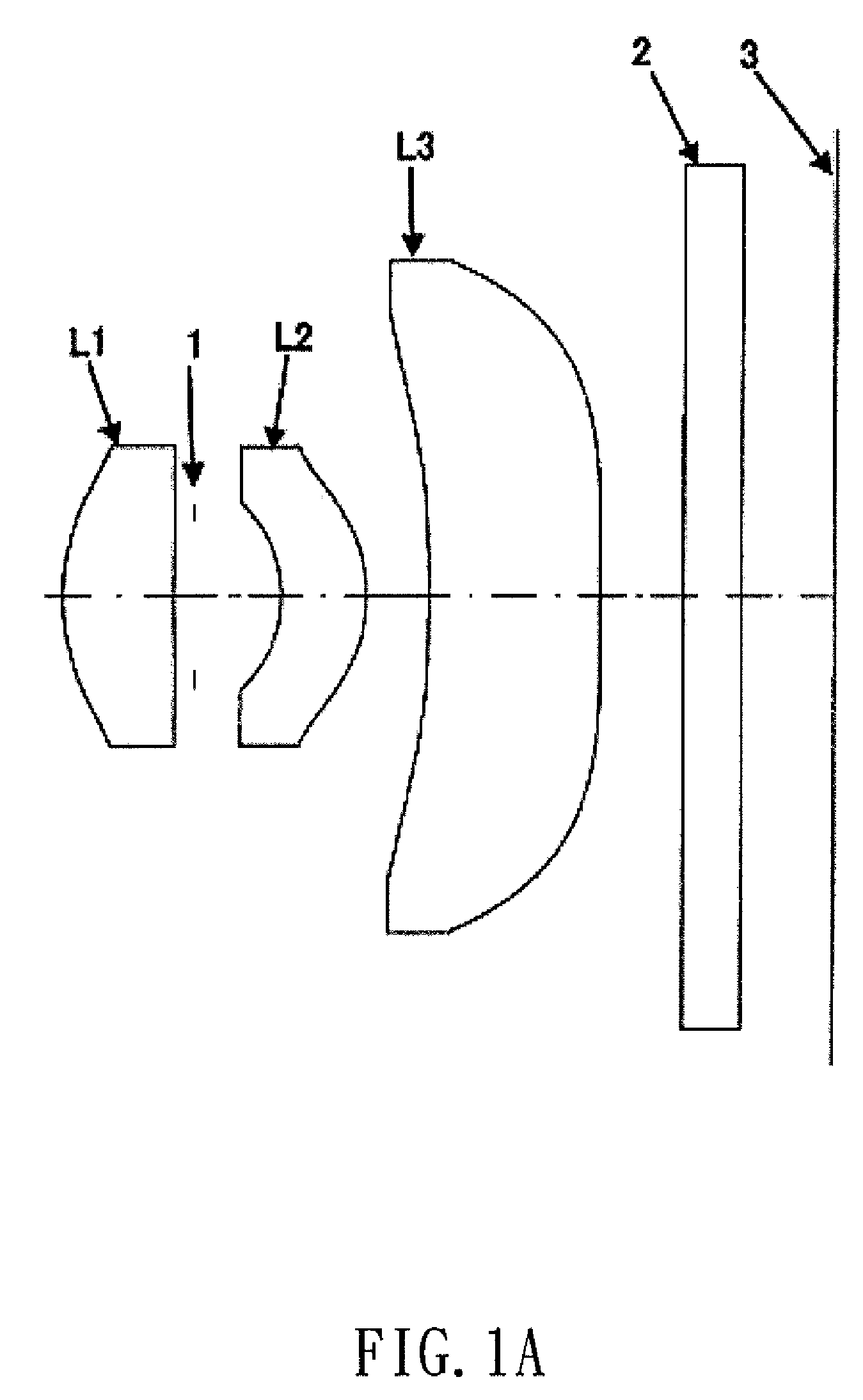

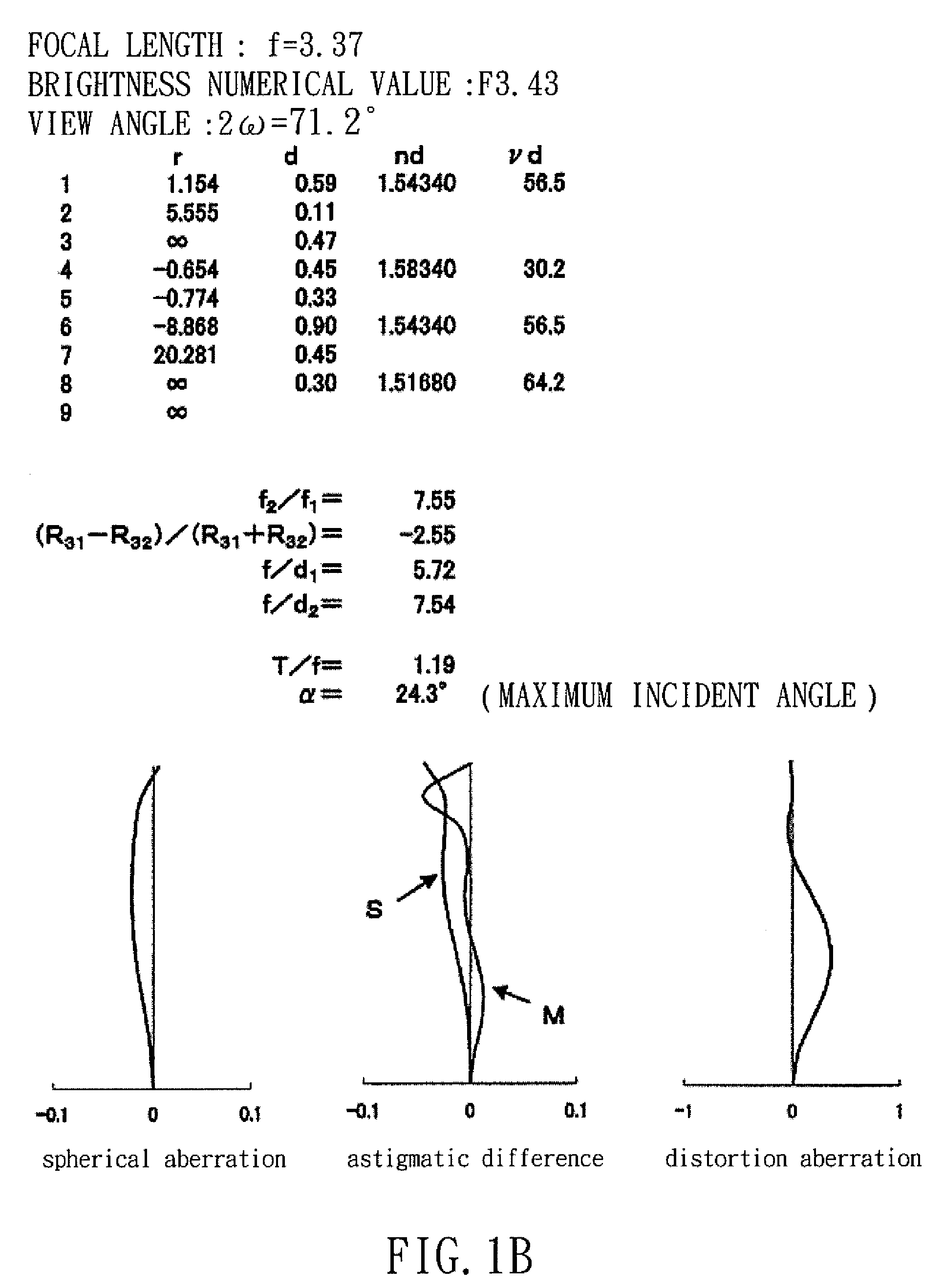

Three-piece lens assembly

ActiveUS7443613B2Wide viewing angleGood performance of aberration compensationOptical elementsPlastic materialsOptoelectronics

A three-piece lens assembly comprises: a first lens group, a second lens group, a third lens group and an aperture. The first lens group is a positive meniscus lens with a convex surface facing the object side and with another surface facing an aperture. The second lens group is a positive meniscus lens with a concave surface facing the aperture and the object side. The third lens group is a biconcave lens with a concave surface facing the second lens and the object side and with another surface facing the image side, and the concave surface of the third lens facing the object side is greater than the another surface of the third lens facing the image side in radius of curvature. Both sides of the first, second and third lens groups are aspheric and are all made of plastic material.

Owner:LARGAN PRECISION

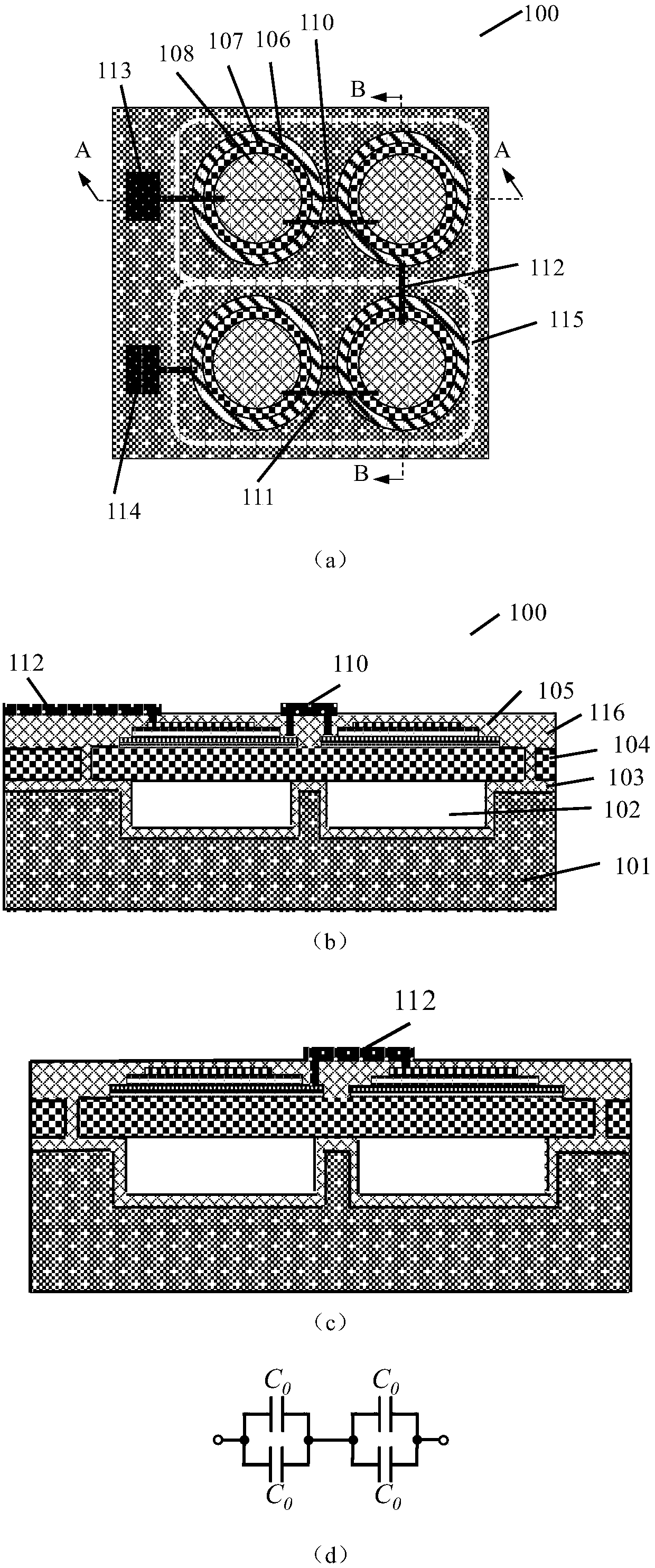

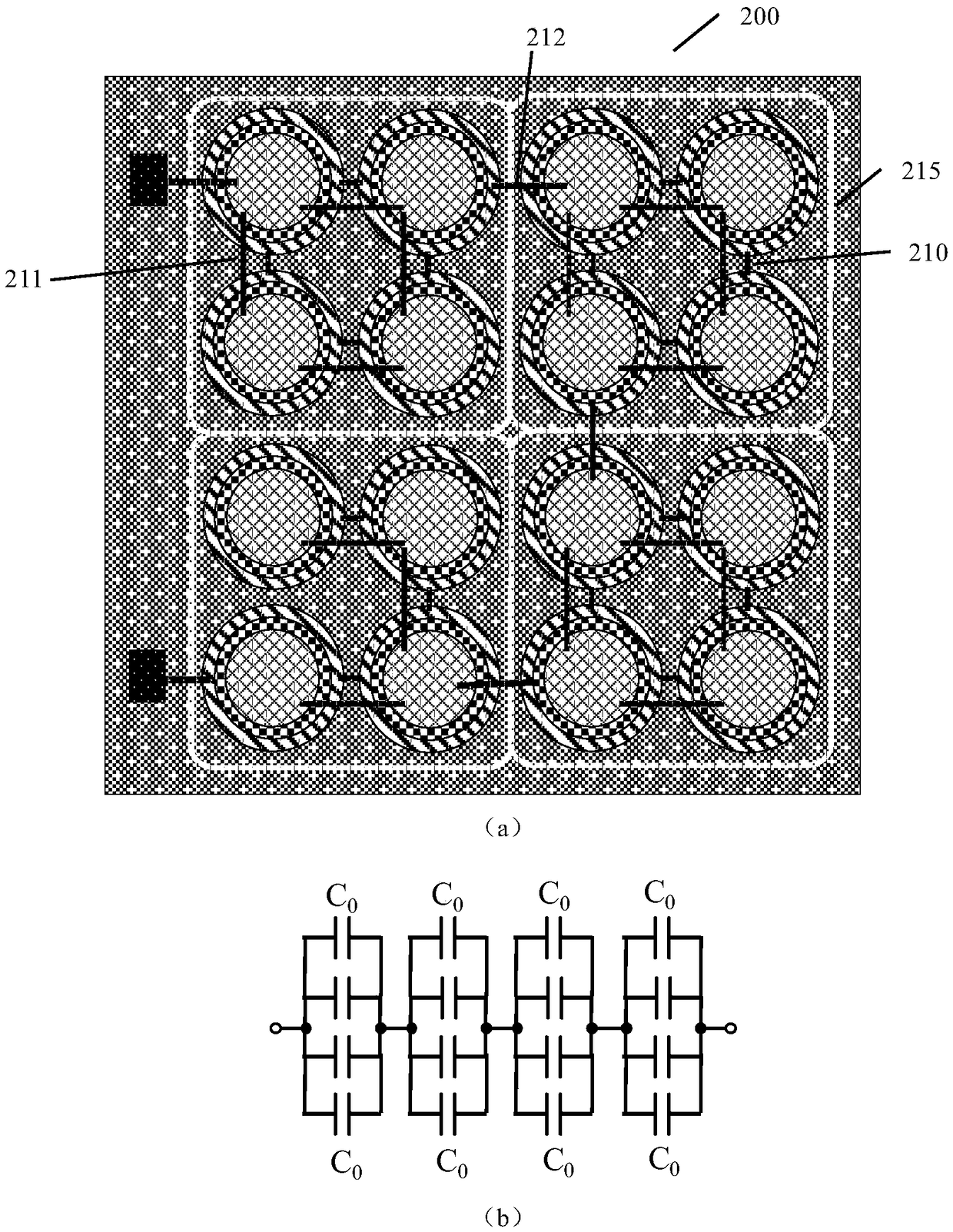

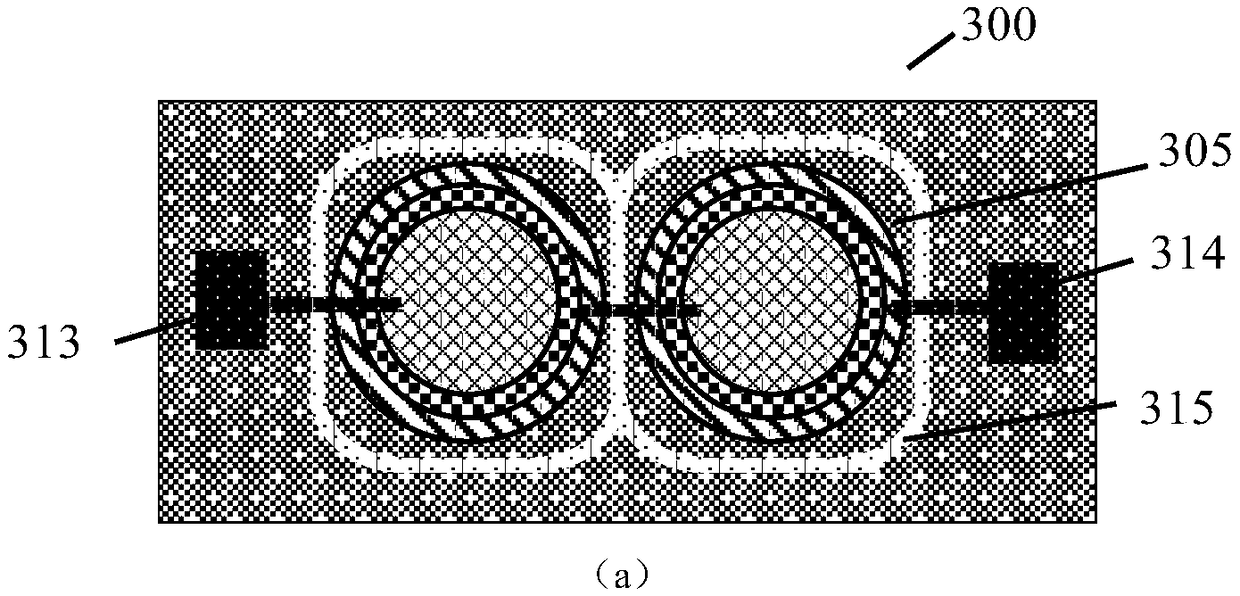

Micro electromechanical system piezoelectric transducer and manufacturing method thereof

ActiveCN109244232AHigh sensitivityAvoid the influence of parasitic capacitancePiezoelectric/electrostrictive device manufacture/assemblyFinal product manufactureElectricitySignal-to-noise ratio (imaging)

The invention discloses a micro-electromechanical system piezoelectric transducer and a manufacturing method thereof, in particular an array piezoelectric transducer and a manufacturing method, and belongs to the micro-electromechanical system field. The transducer adopts array design and is composed of at least two array elements. The wafer-level electrical series connection or parallel connection between the array elements is realized by a micro-electromechanical system (MEMS) process compatible with the semiconductor process, but at least one electrical series connection is provided; Semiconductor MEMS process can effectively control the parasitic capacitance generated by electrical series and parallel connection, thus effectively improve the sensitivity. The invention improves the sensitivity of the transducer through the wafer-level electric series and parallel connection between the array elements. Compared with the traditional piezoelectric ceramic transducer, the parasitic capacitance caused by the following circuit string and parallel connection is avoided. A wafer-level array MEMS transducer is proposed. The array transducer can be connected in series with different arrayelements according to the needs, so that the sensitivity of the transducer can be defined independently. The transducer also has the advantages of high signal-to-noise ratio, low cost, low electricalnoise and high signal-to-noise ratio.

Owner:徐景辉

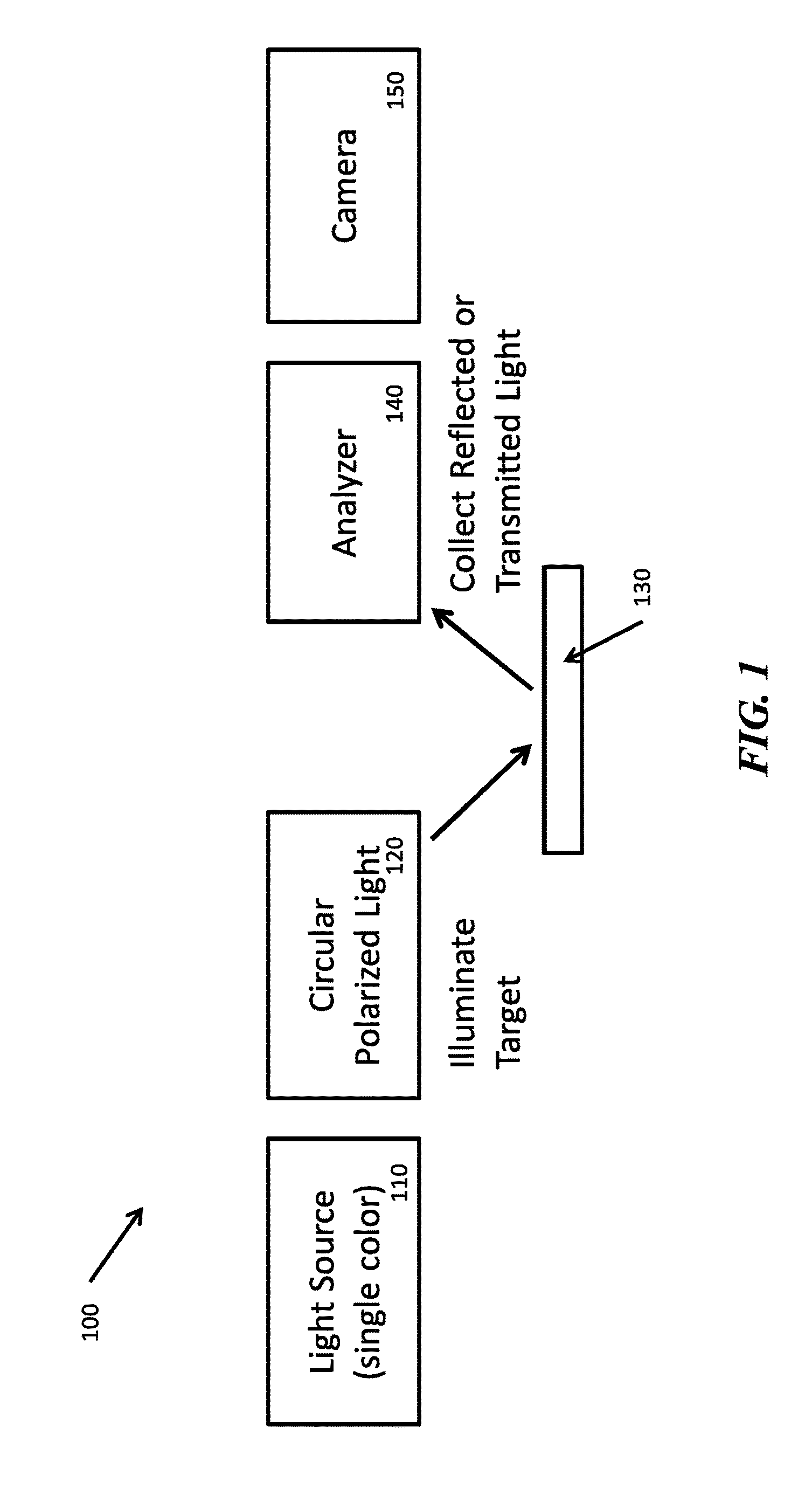

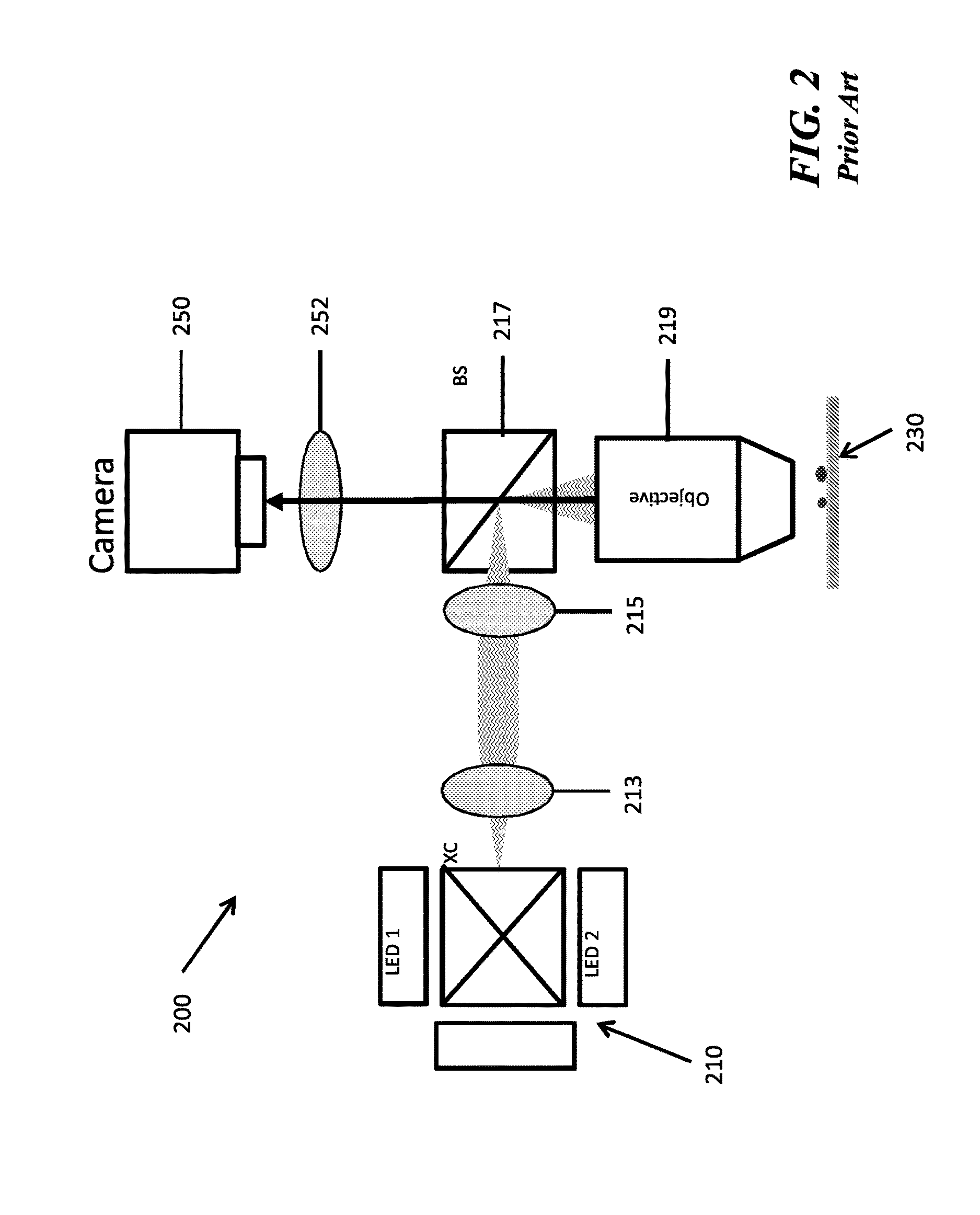

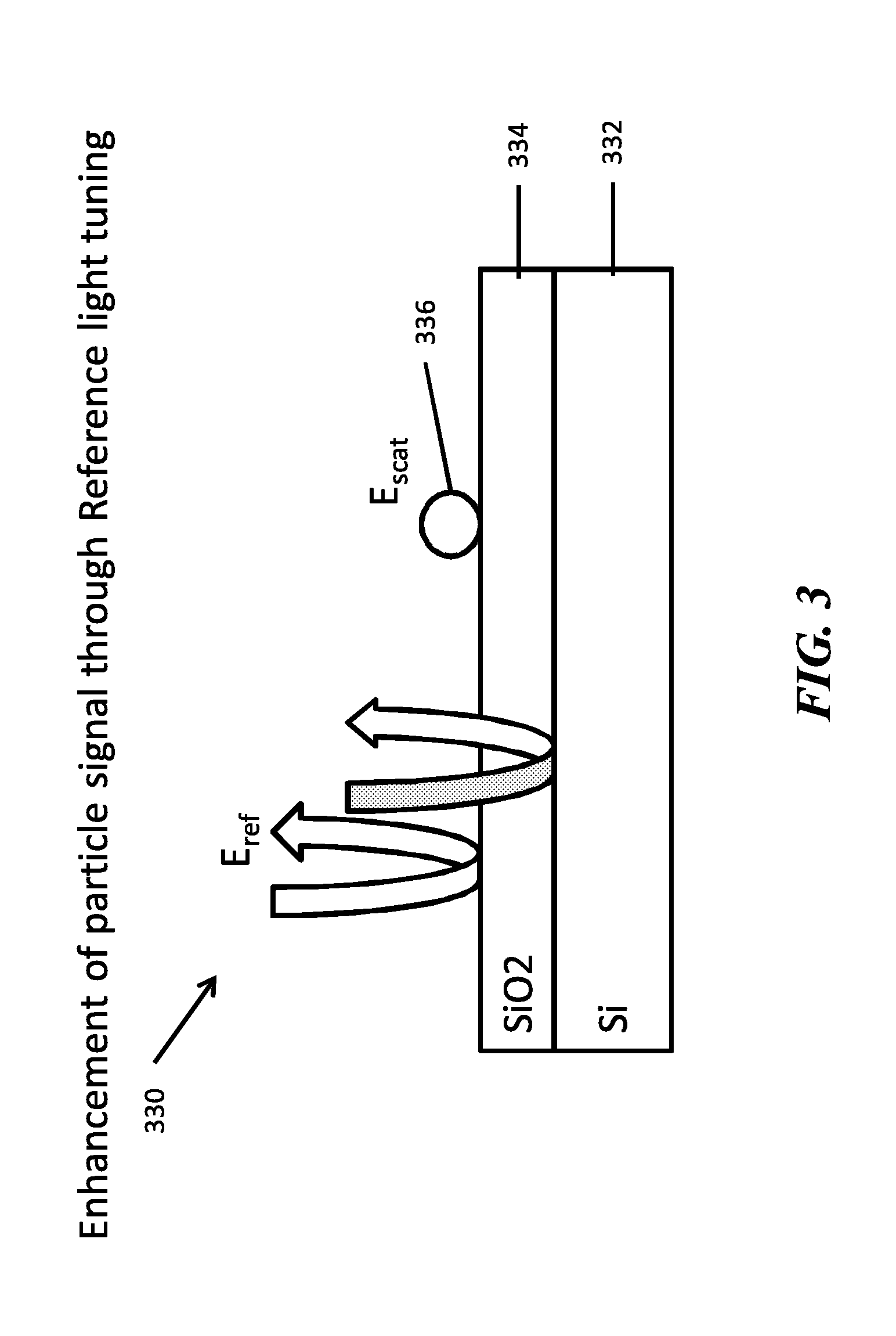

Polarization enhanced interferometric imaging

ActiveUS20170016821A1High sensitivityIncrease costPolarisation-affecting propertiesInterferometersNanoparticleInterferometric imaging

An imaging system uses polarized light to illuminate the target and then uses a polarization filter to remove the light that is reflected from the target without modification. The target can include one or more anisotropic objects that scatter the light and alter the polarization state of the reflected light and causing it to be selectively transmitted to the imaging device which can record the transmitted light through the filter. The illuminating light can be circularly polarized and the filter can remove the circularly polarized light. The target can include asymmetric nanoparticles, such as nanorods that alter the amplitude or phase of the scattered light enabling pass through the filter to be detected by the imaging device.

Owner:TRUSTEES OF BOSTON UNIV

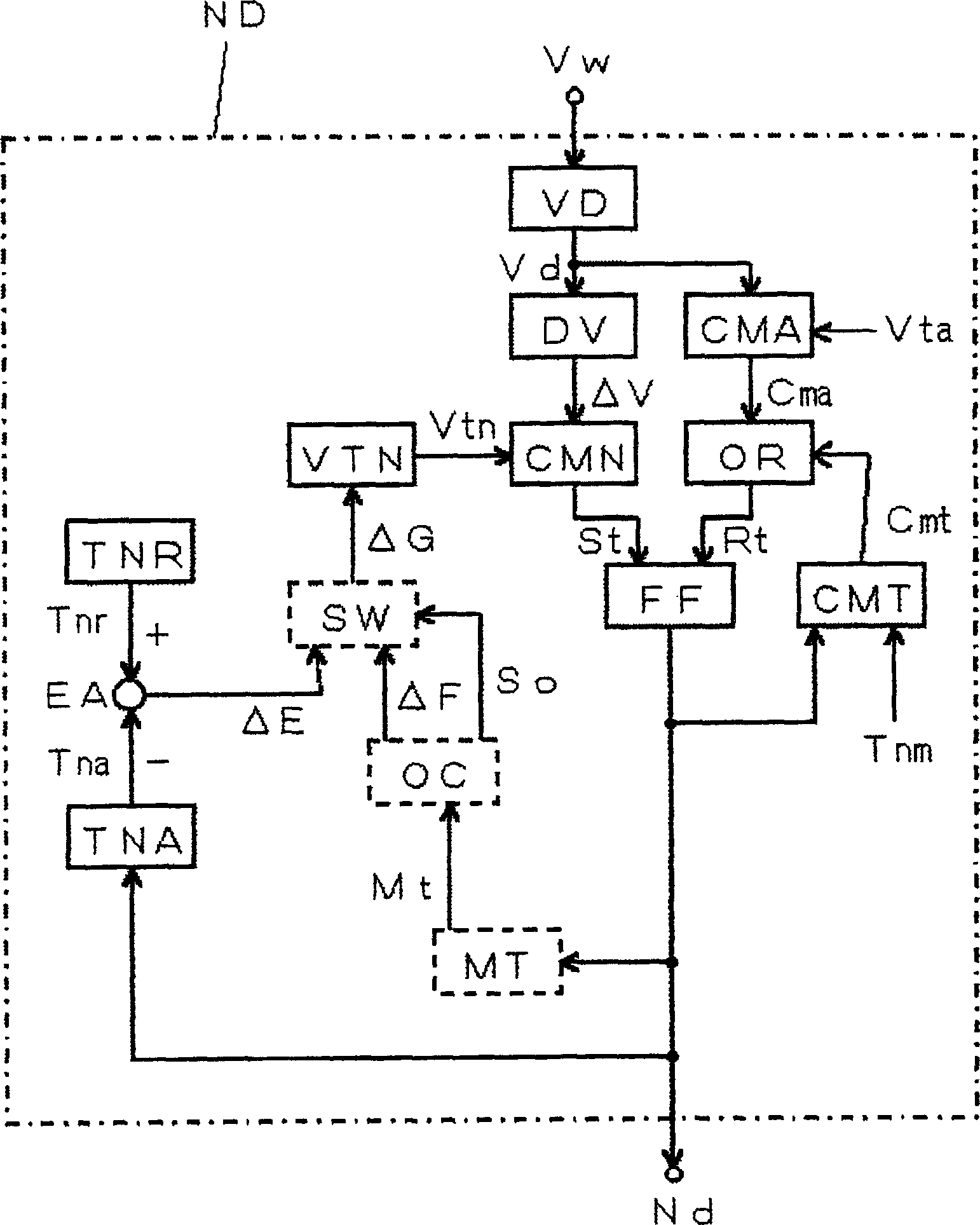

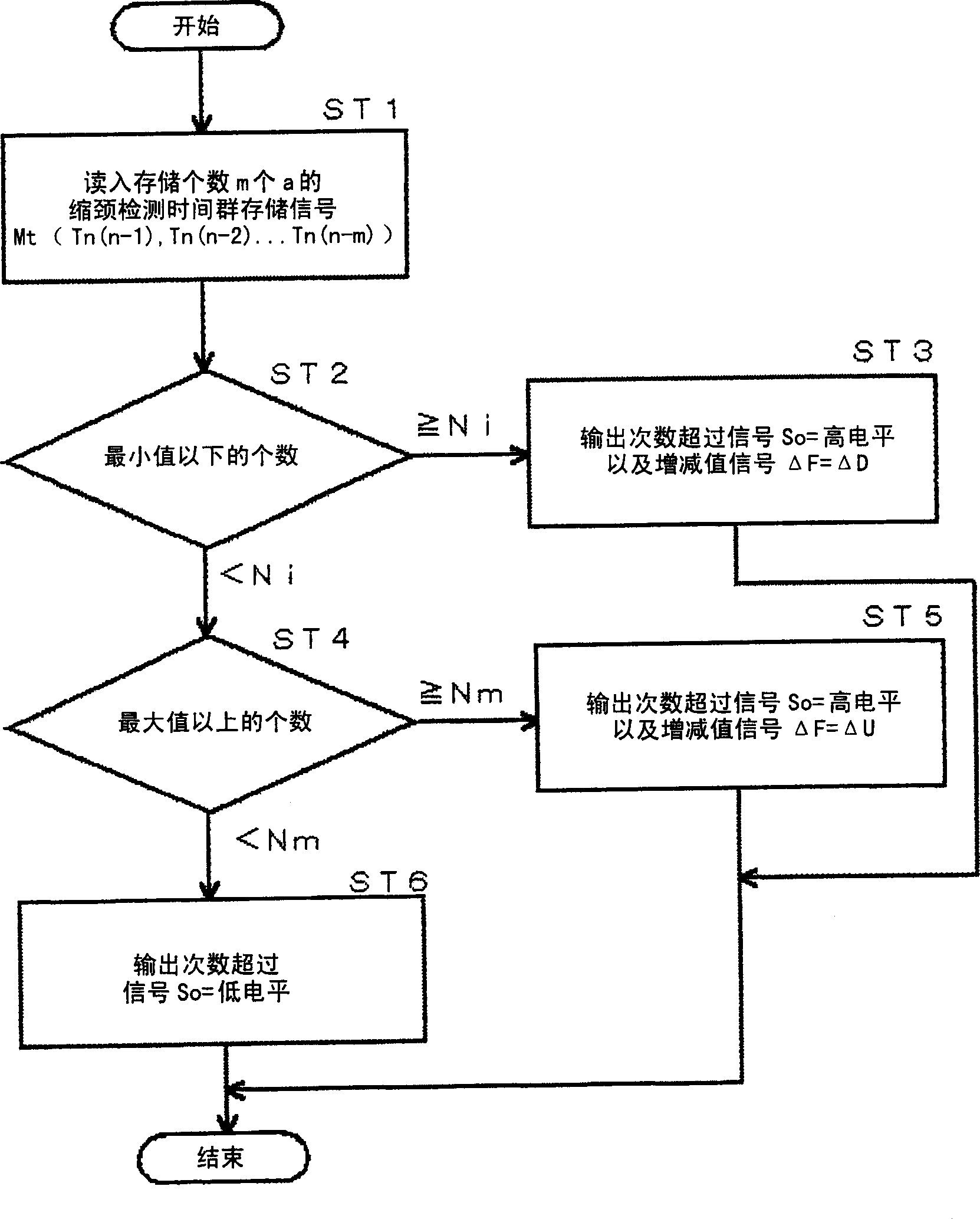

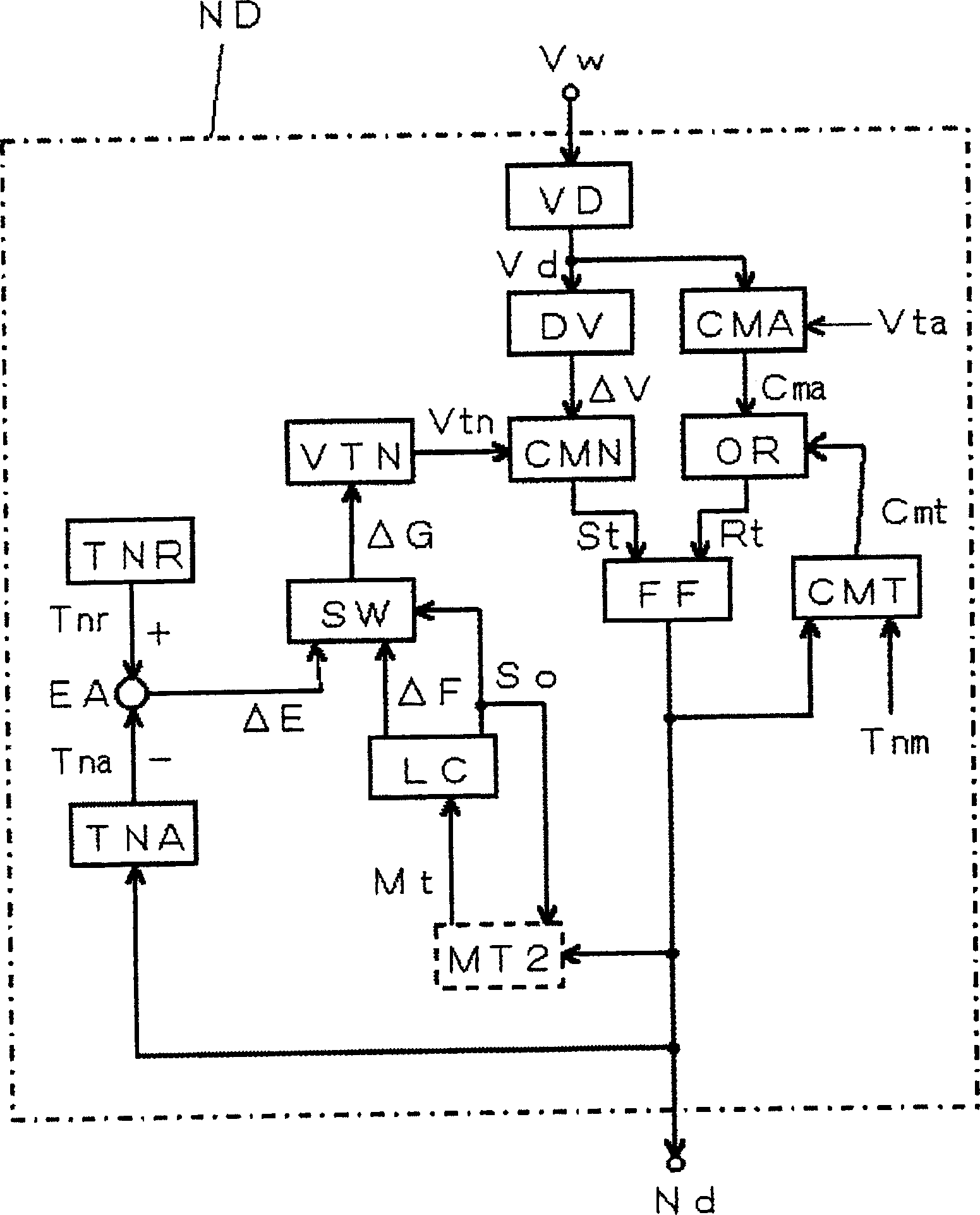

Necking checking and control method for melted electrode arc welding

ActiveCN1840277ACorrection will not be excessiveThe control system is stableArc welding apparatusElectrical resistance and conductancePower flow

The present invention purposes to improve accuracy of detecting constriction in a method for detecting / controlling constriction in consumable electrode arc welding attended with a short circuit. In this method for detecting / controlling constriction in consumable electrode arc welding, the constrictive phenomenon of a droplet as a sign phenomenon of regeneration of arc from a short-circuit state is detected by that a change in a voltage or resistance value between a consumable electrode and a base metal reaches a reference value Vtn for detecting the constriction, thereby a welding current is rapidly reduced. The constriction detecting time is detected for each short-circuit, storing the detecting time from the current point of time retroactively to the prescribed number of time in the past (MT). When the number of each stored constriction detecting time (Mt) below the minimum value inclusive is not less than the minimum number, the reference value Vtn for detecting the constriction is decreased by the variation [Delta]F. When the number of each stored constriction detecting time (Mt) above the maximum value inclusive is not less than the maximum number, the reference value Vtn for detecting the constriction is increased by the variation [Delta]F. Thus, the reference value Vtn for detecting the constriction is optimized.

Owner:DAIHEN CORP

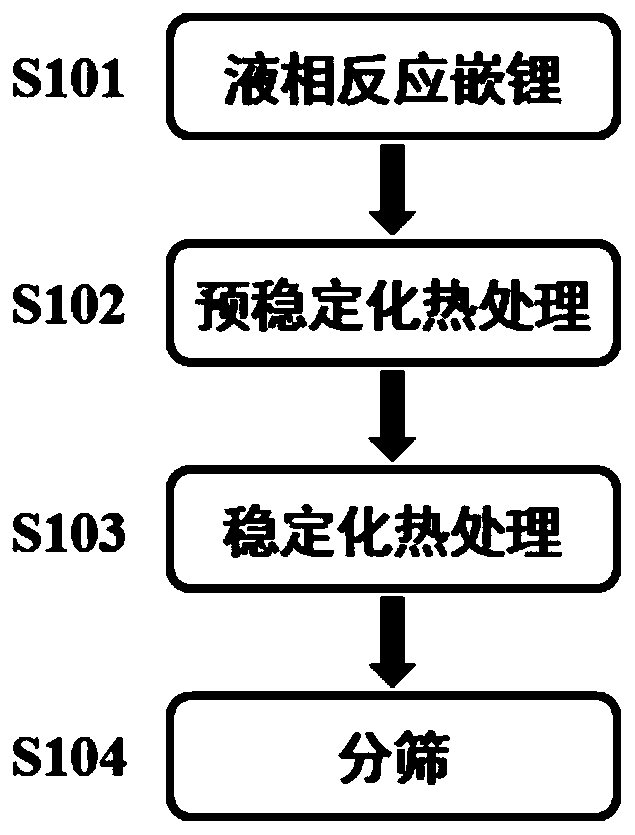

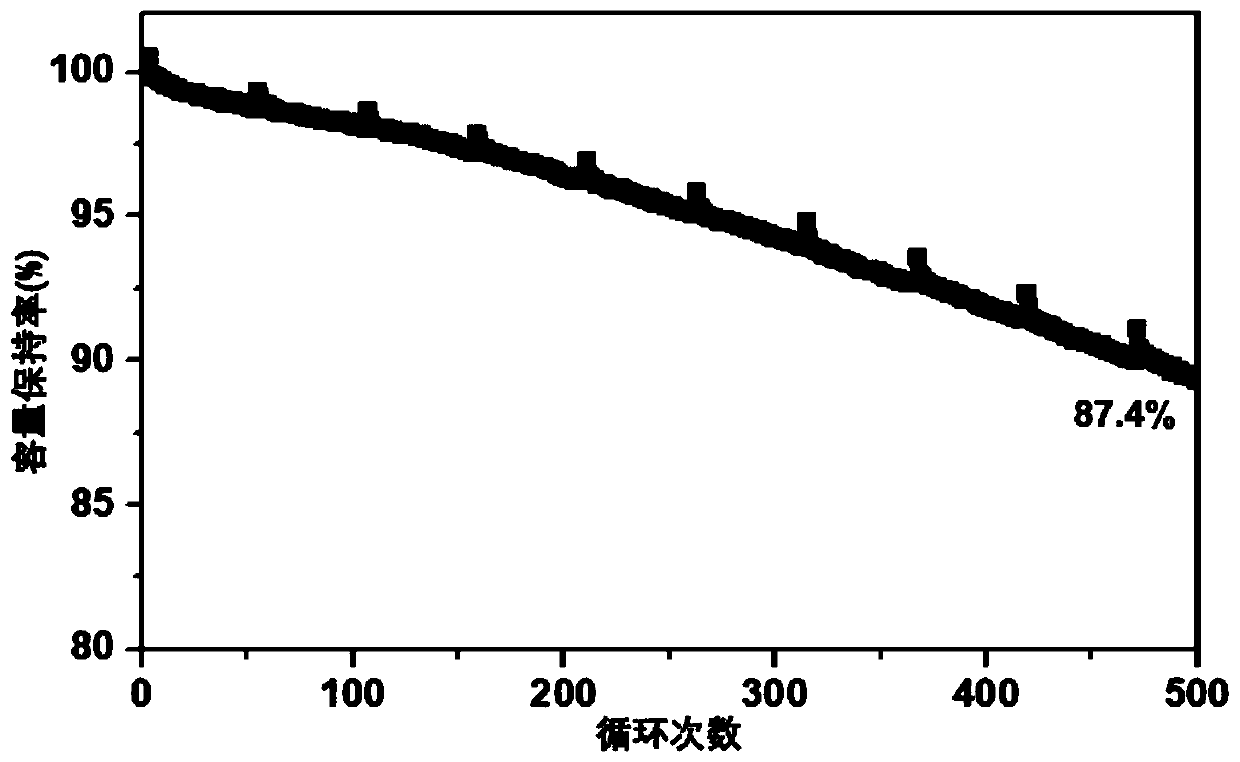

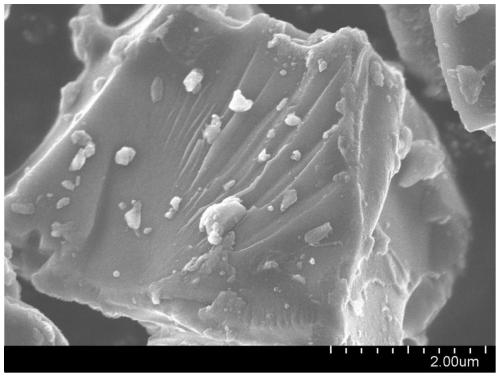

Anode active material and preparation method and application thereof

ActiveCN111180693AIncrease capacityImprove Coulombic efficiencyCell electrodesSecondary cellsPhysical chemistrySilicon oxide

The invention relates to an anode active material and a preparation method and application thereof. The anode active material includes: silicon oxide particles; and elemental silicon nanoparticles dispersed in the silicon oxide particles, wherein the median particle size of the monatomic silicon nanoparticles is 0.2-20 nm; the silicon oxide particles comprise lithium, the lithium in the silicon oxide particles comprises a lithium silicate compound, and the lithium silicate compound comprises one or more of Li2Si2O5, Li6Si2O7, Li2SiO3, Li8SiO6 and Li4SiO4. The anode active material disclosed bythe invention has the advantages of high capacity and coulombic efficiency, good multiplying power and cycle performance, the low expansion rate and the like when being used in a secondary battery. The preparation method is good in repeatability and high in safety. The secondary battery provided by the invention has the characteristics of high volume energy density, good rate capability, good cycling stability, low expansion rate and the like.

Owner:BERZELIUS (NANJING) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com