Patents

Literature

4024results about "Scanning probe microscopy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

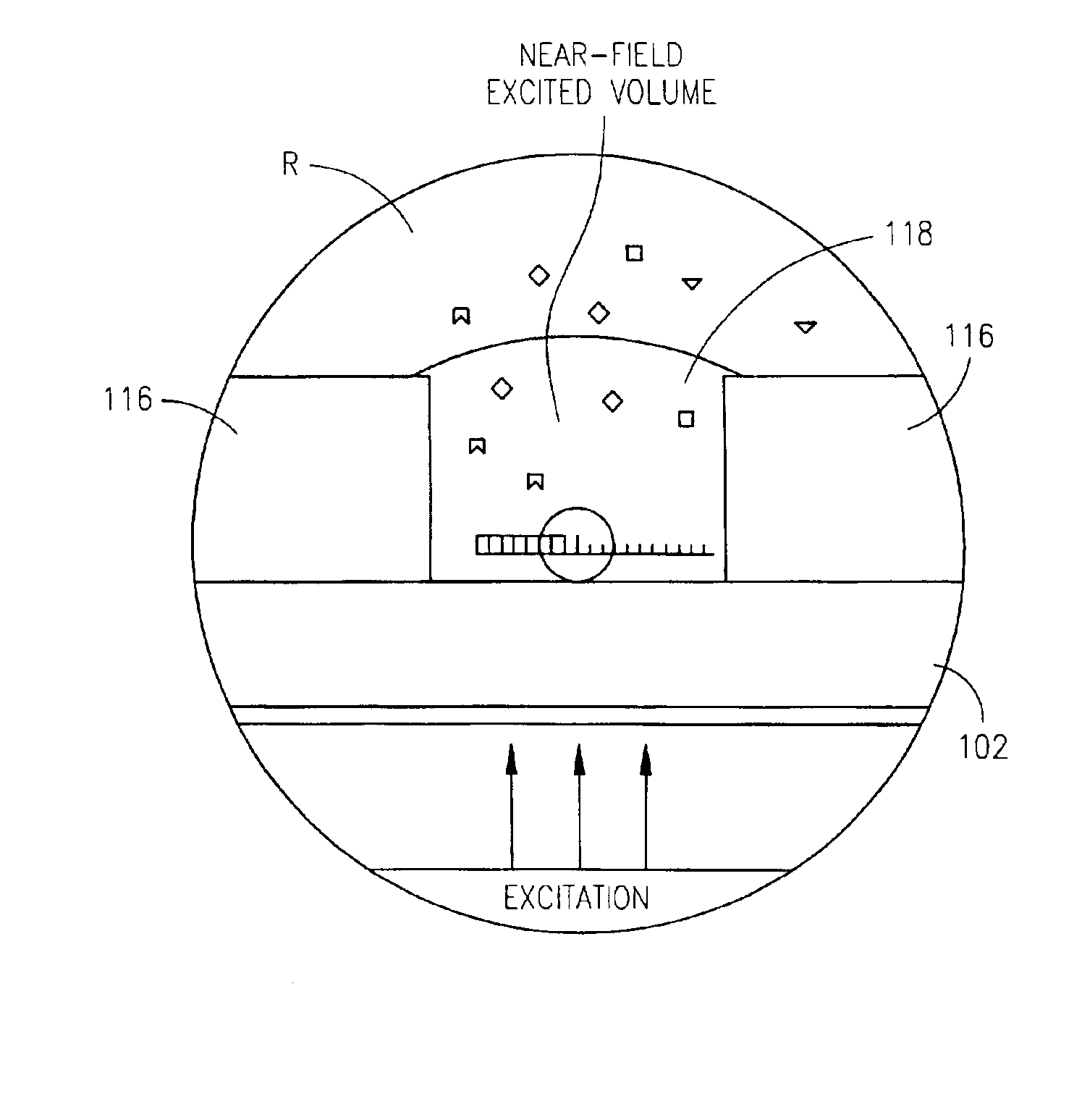

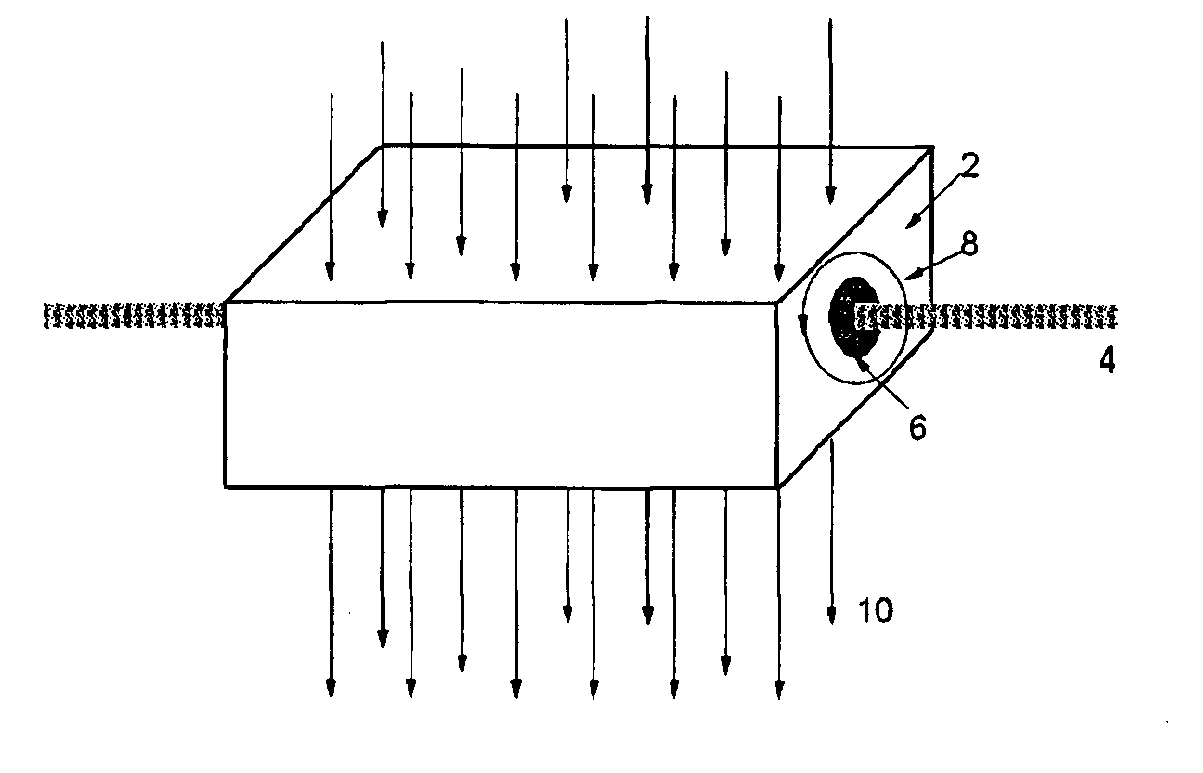

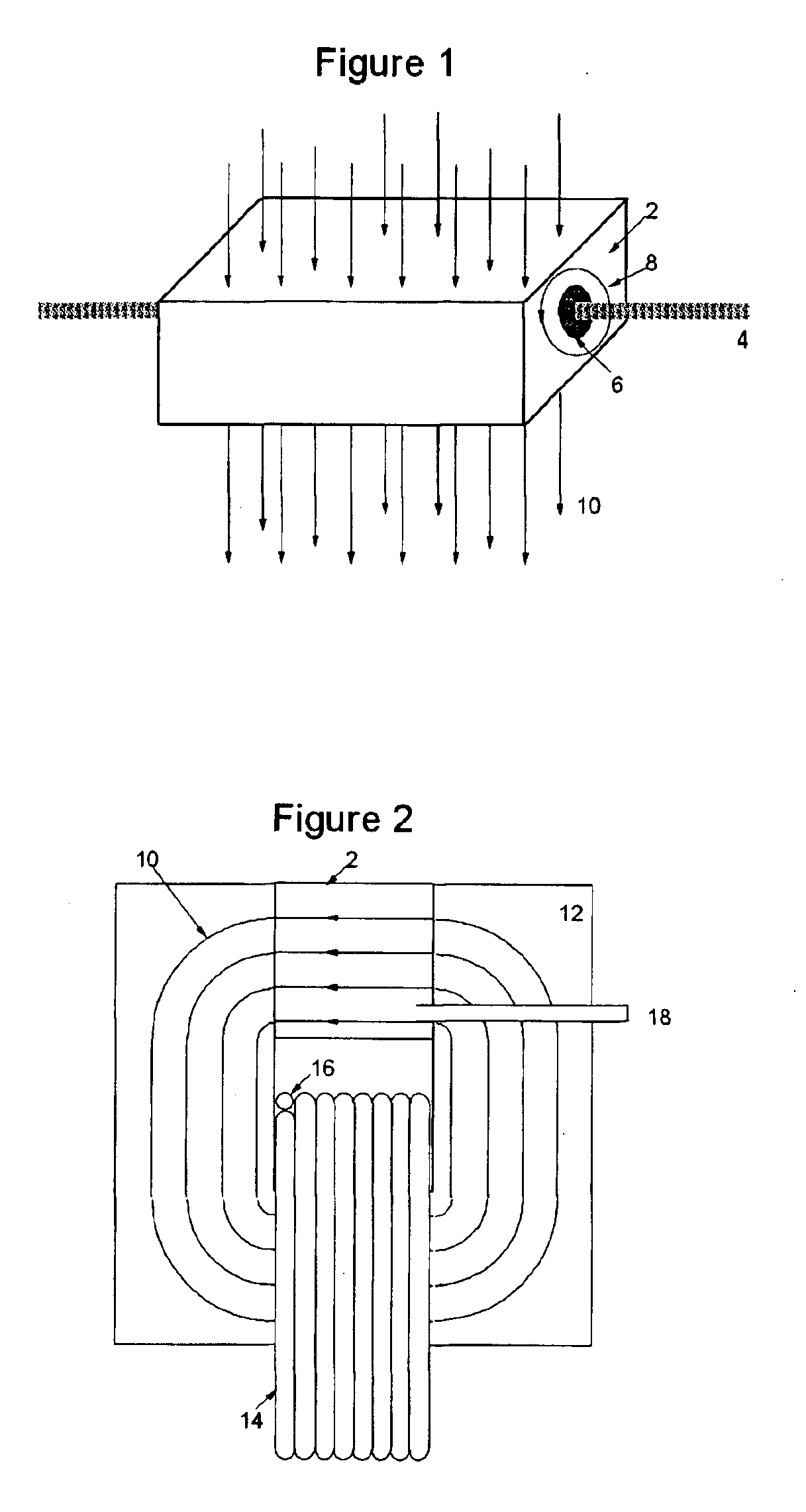

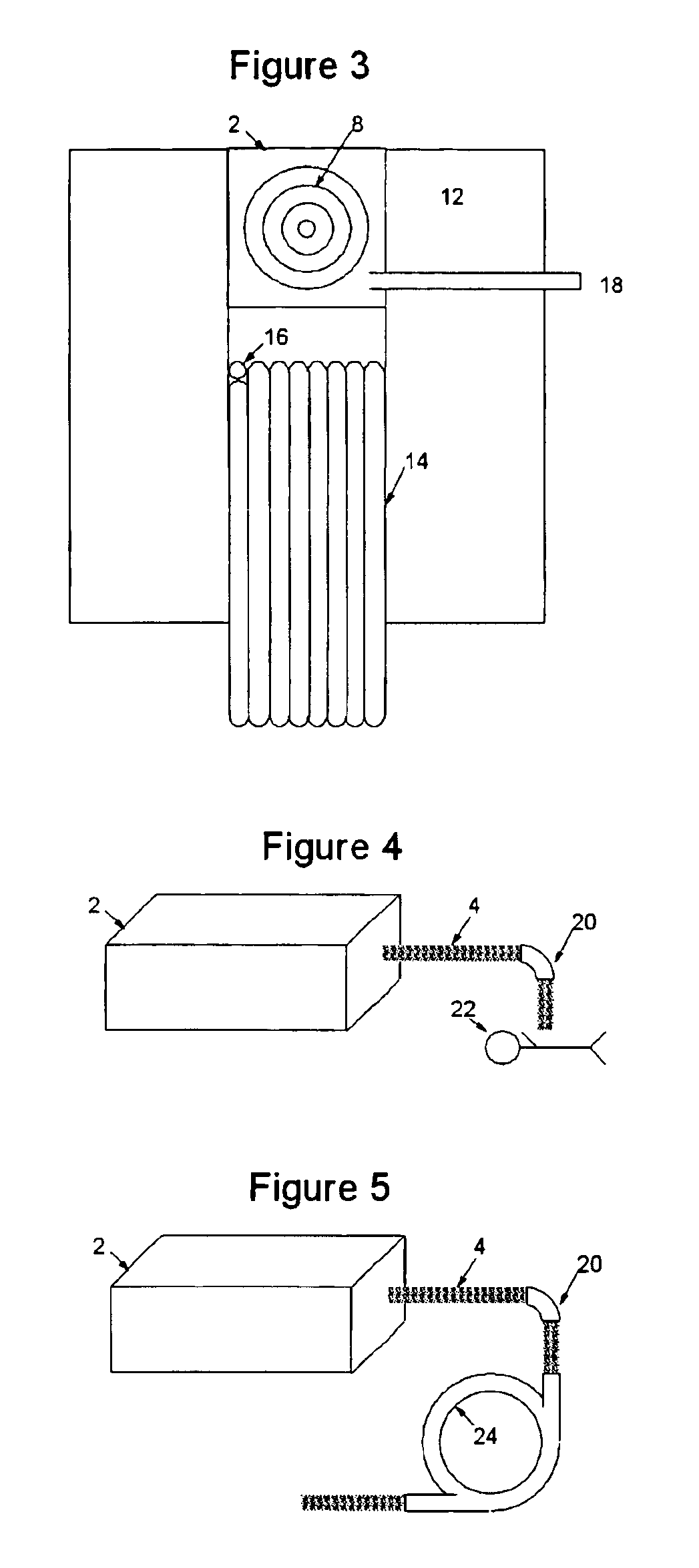

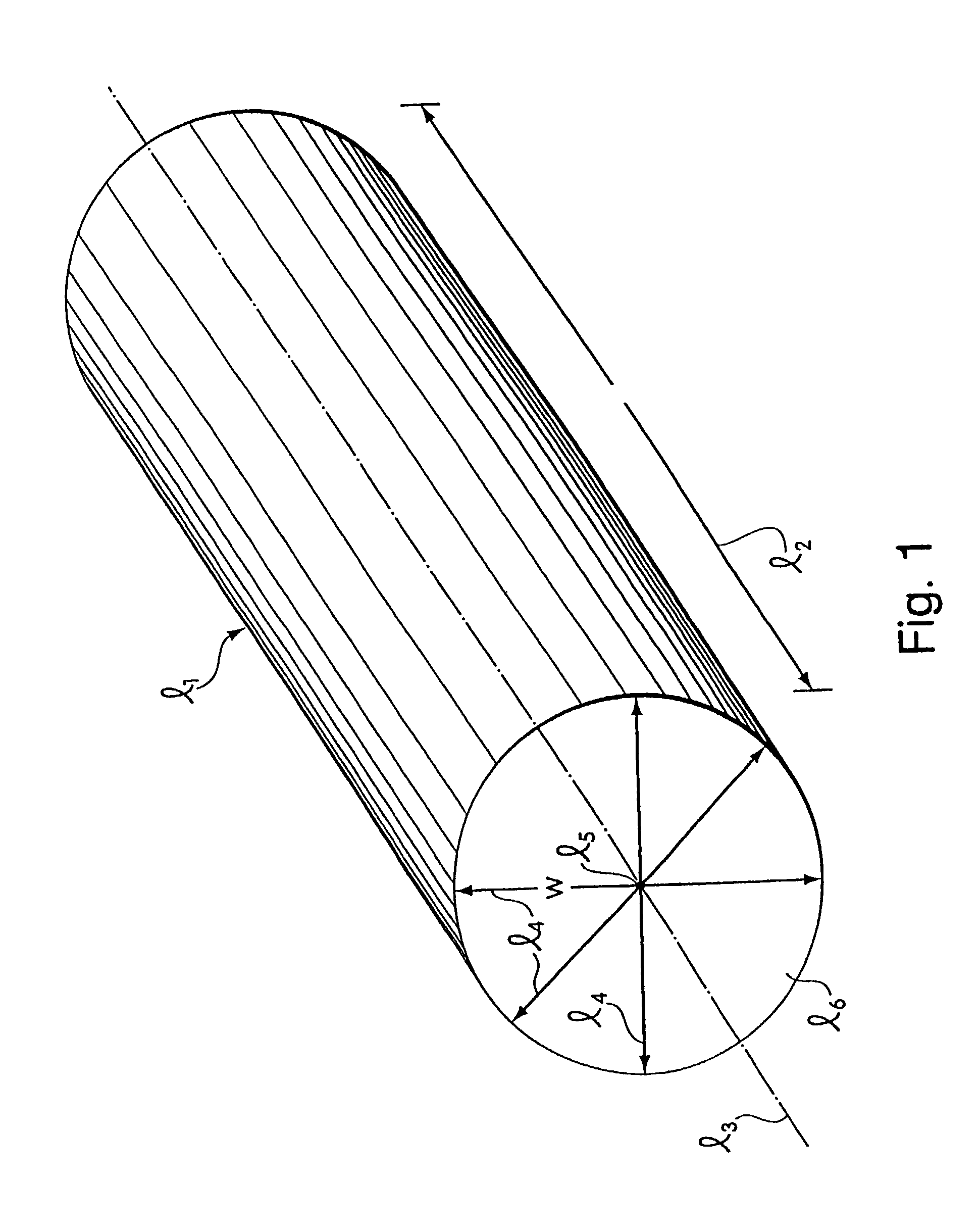

Zero-mode clad waveguides for performing spectroscopy with confined effective observation volumes

InactiveUS6917726B2Effective volumeEasy to useMicrobiological testing/measurementBiological material analysisAnalyteSpectroscopy

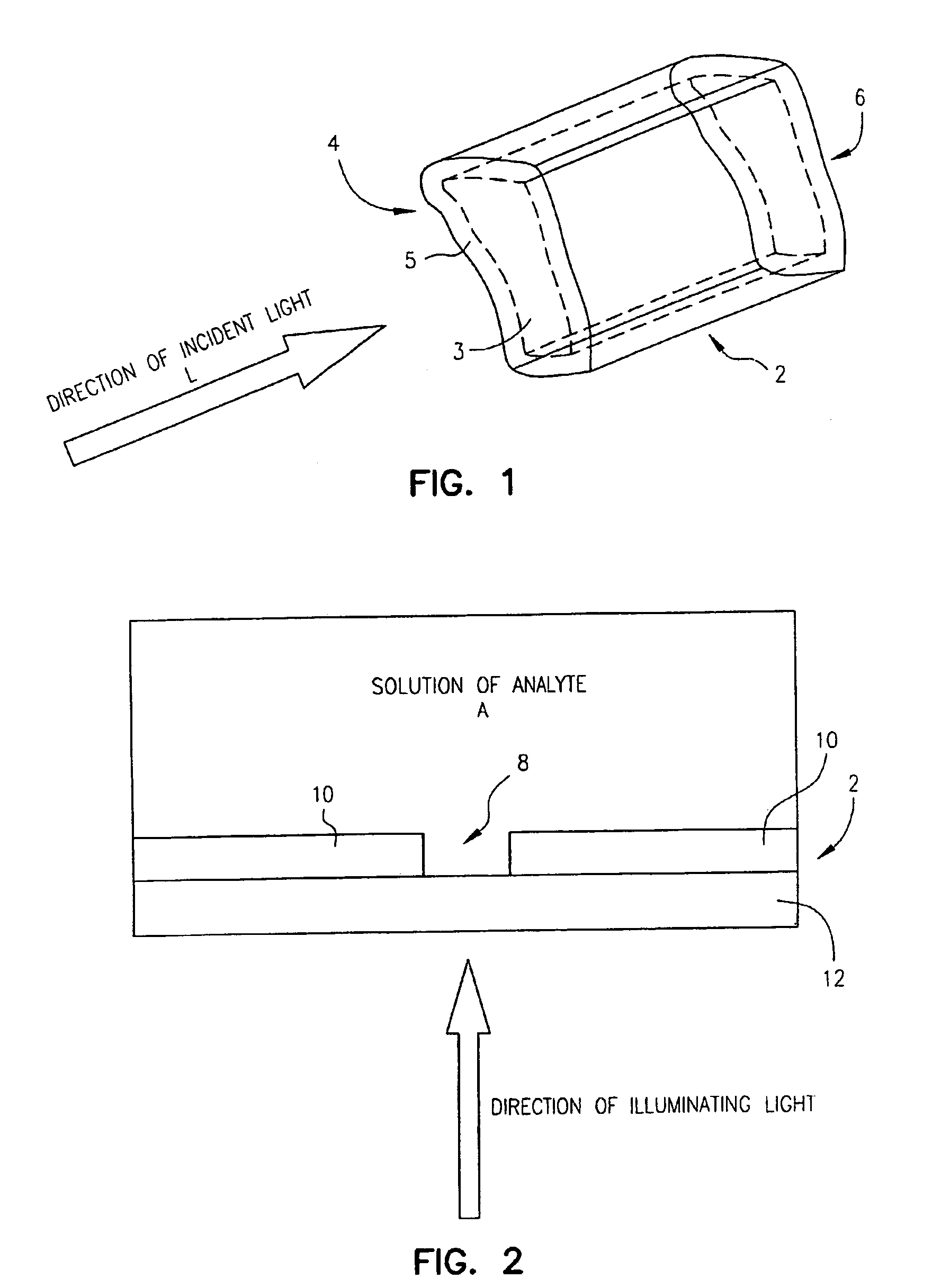

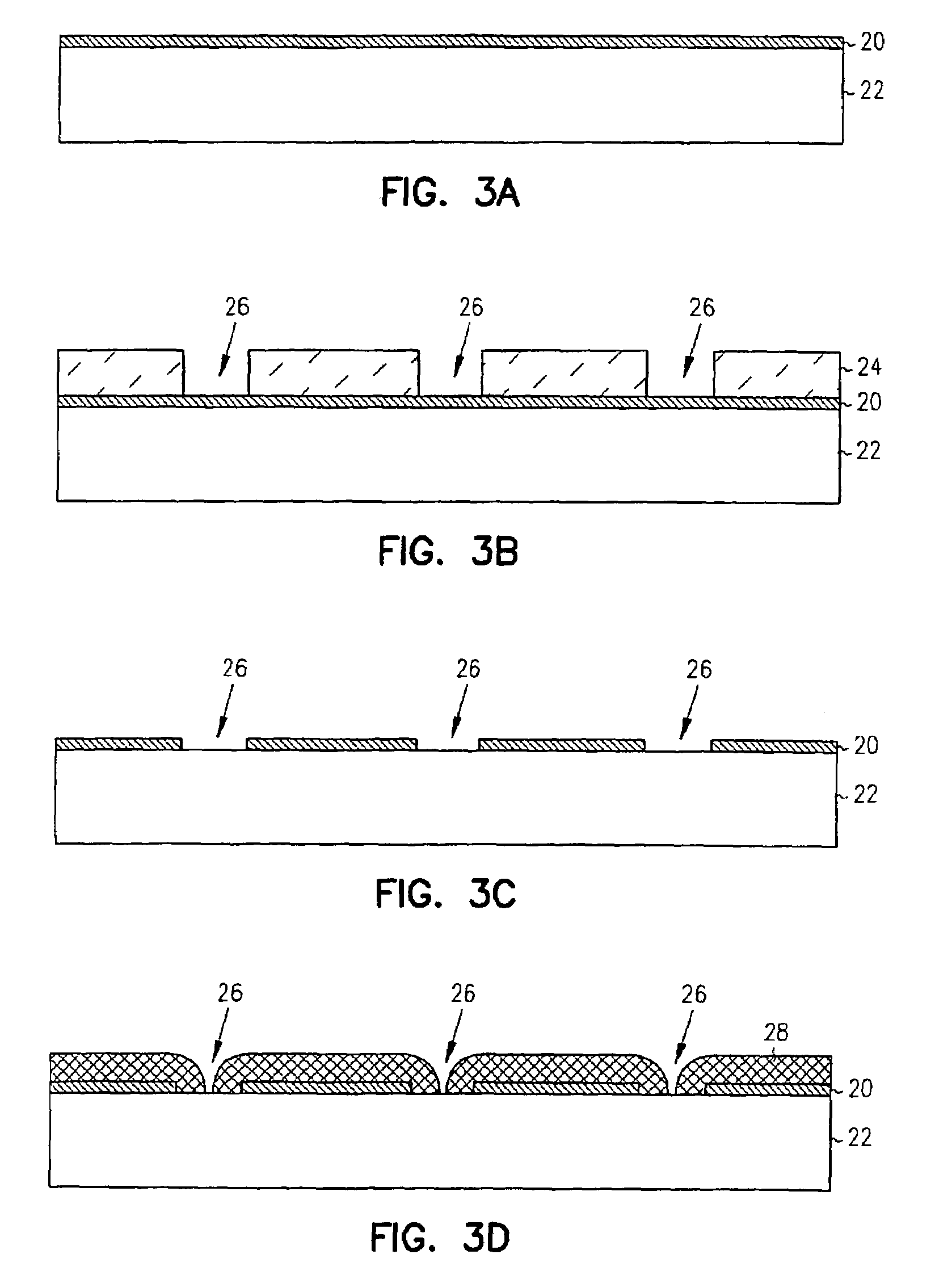

The present invention is directed to a method and an apparatus for analysis of an analyte. The method involves providing a zero-mode waveguide which includes a cladding surrounding a core where the cladding is configured to preclude propagation of electromagnetic energy of a frequency less than a cutoff frequency longitudinally through the core of the zero-mode waveguide. The analyte is positioned in the core of the zero-mode waveguide and is then subjected, in the core of the zero-mode waveguide, to activating electromagnetic radiation of a frequency less than the cut-off frequency under conditions effective to permit analysis of the analyte in an effective observation volume which is more compact than if the analysis were carried out in the absence of the zero-mode waveguide.

Owner:CORNELL RES FOUNDATION INC

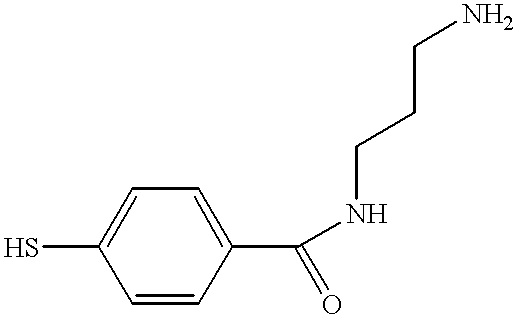

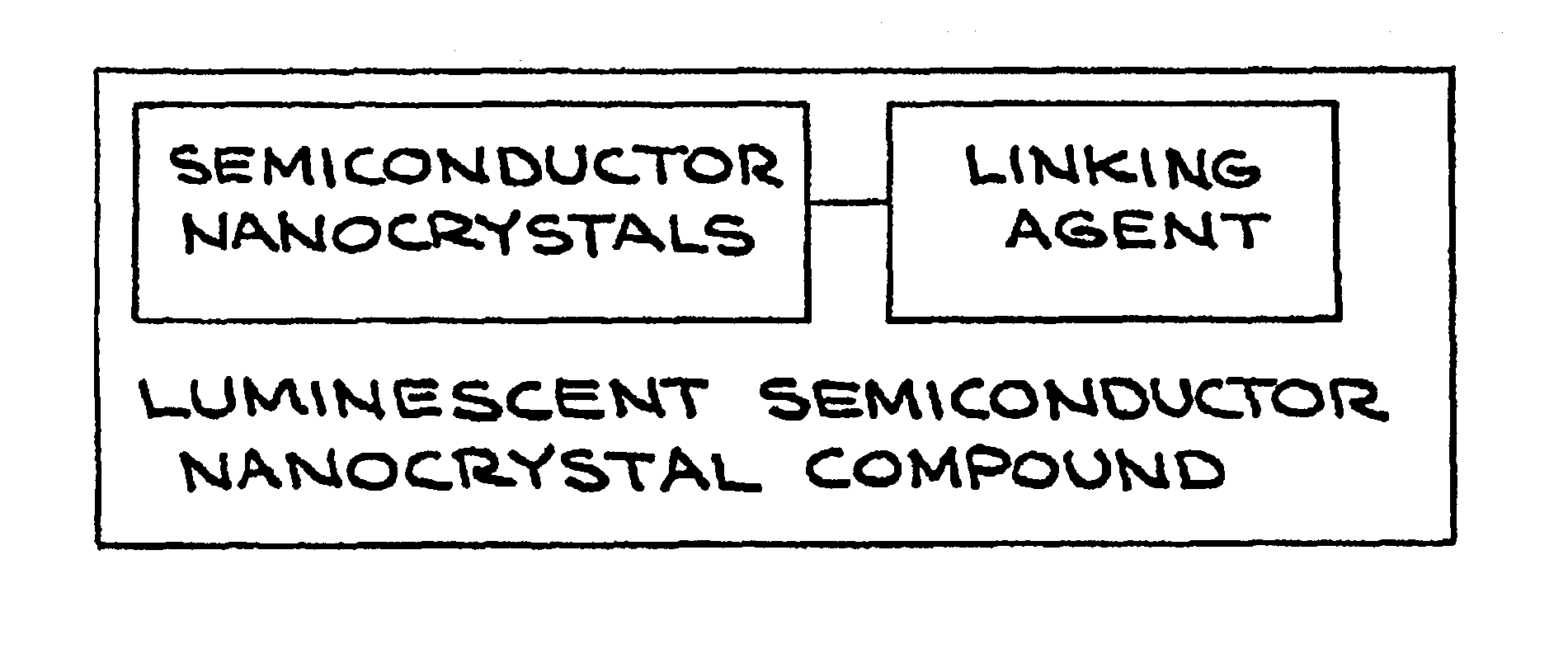

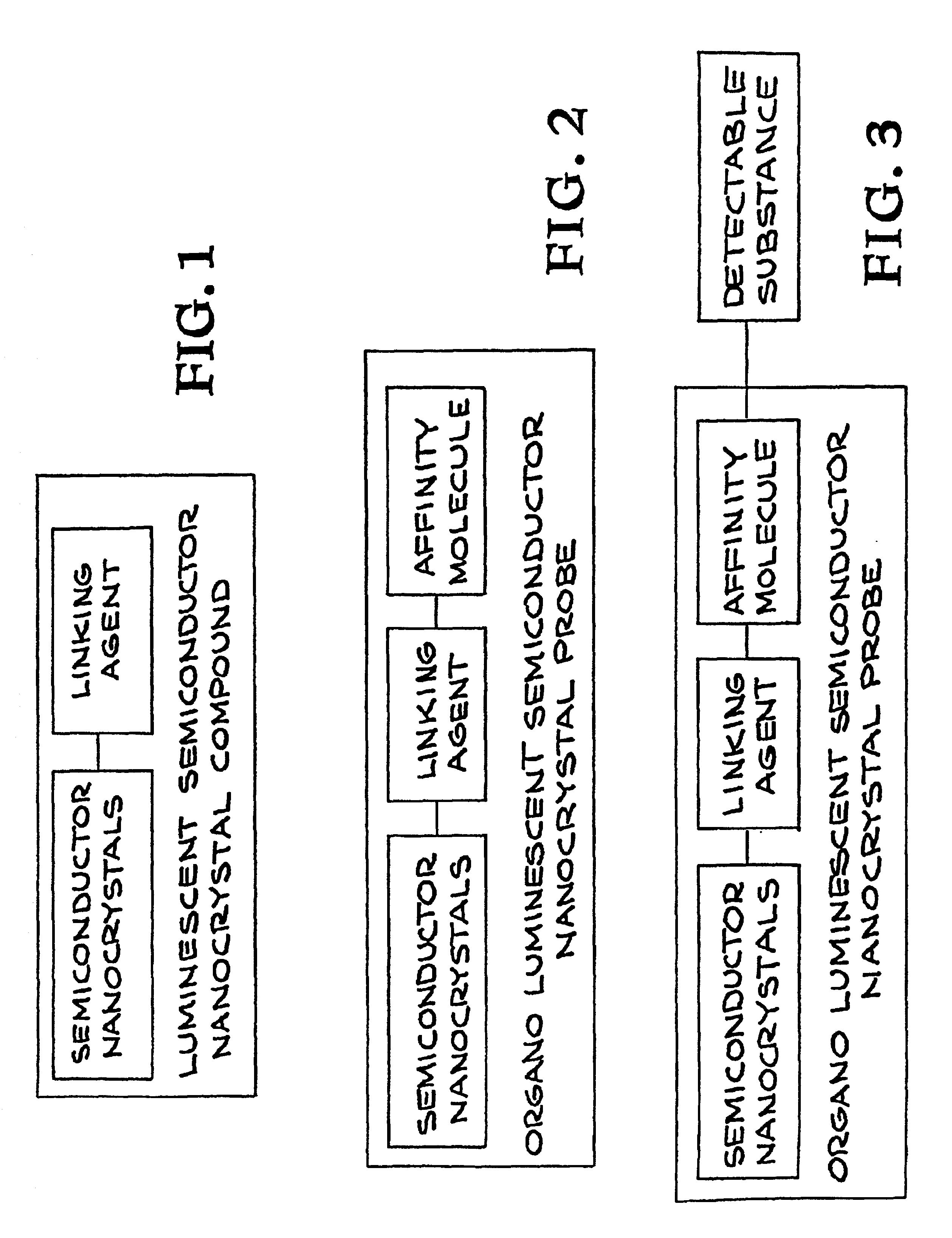

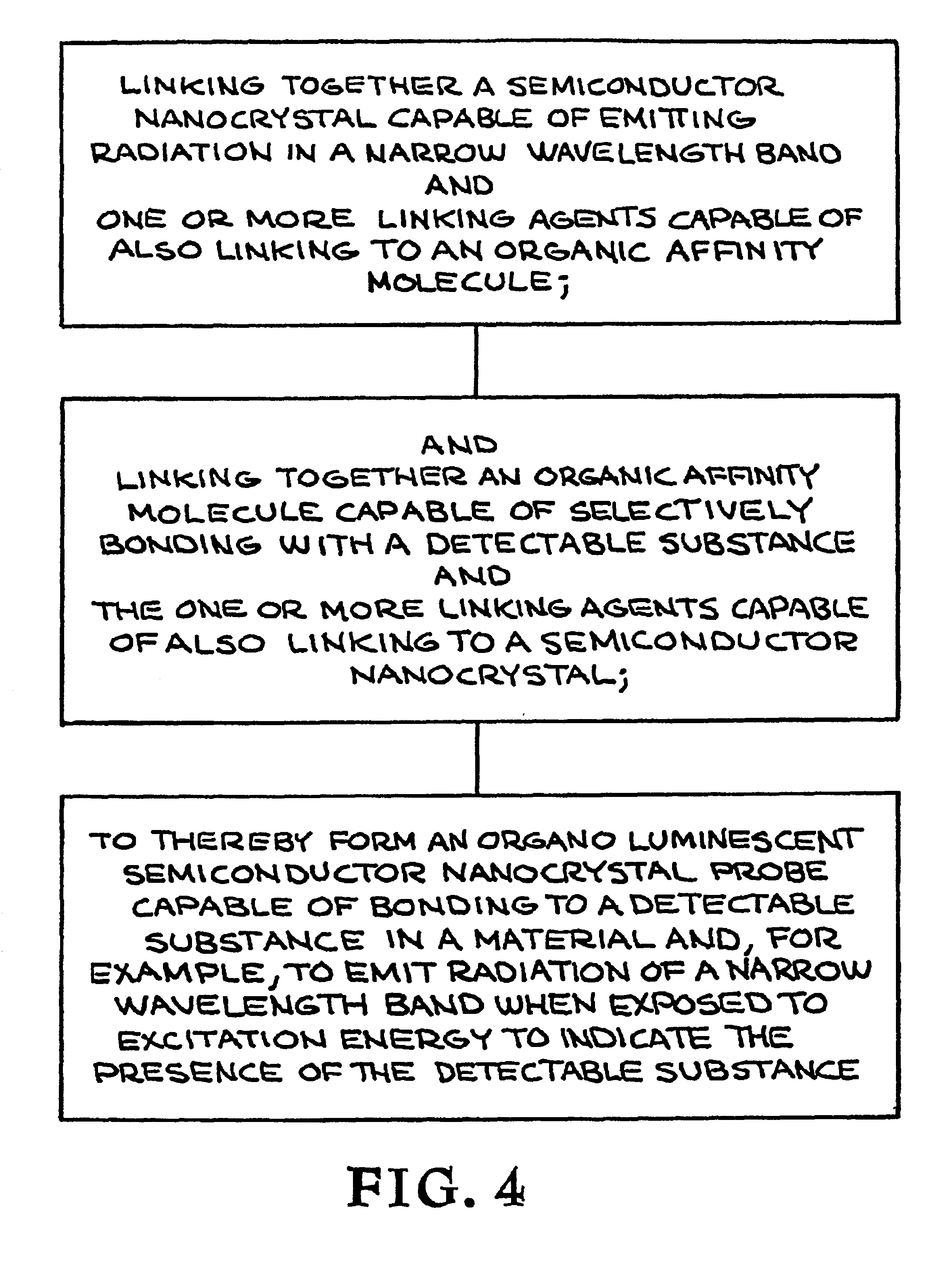

Organo luminescent semiconductor nanocrystal probes for biological applications and process for making and using such probes

A semiconductor nanocrystal compound is described capable of linking to an affinity molecule. The compound comprises (1) a semiconductor nanocrystal capable of emitting electromagnetic radiation and / or absorbing energy, and / or scattering or diffracting electromagnetic radiation-when excited by an electromagnetic radiation source or a particle beam; and (2) at least one linking agent, having a first portion linked to the semiconductor nanocrystal and a second portion capable of linking to an affity molecule. The compound is linked to an affinity molecule to form a semiconductor nanocrystal probe capable of bonding with a detectable substance. Subsequent exposure to excitation energy will excite the semiconductor nanocrystal in he probe, causing the emission of electromagnetic radiation. Further described are processes for respectively: making the semiconductor nanocrystal compound; making the semiconductor nanocrystal probe; and using the probe to determine the presence of a detectable substance in a material.

Owner:RGT UNIV OF CALIFORNIA

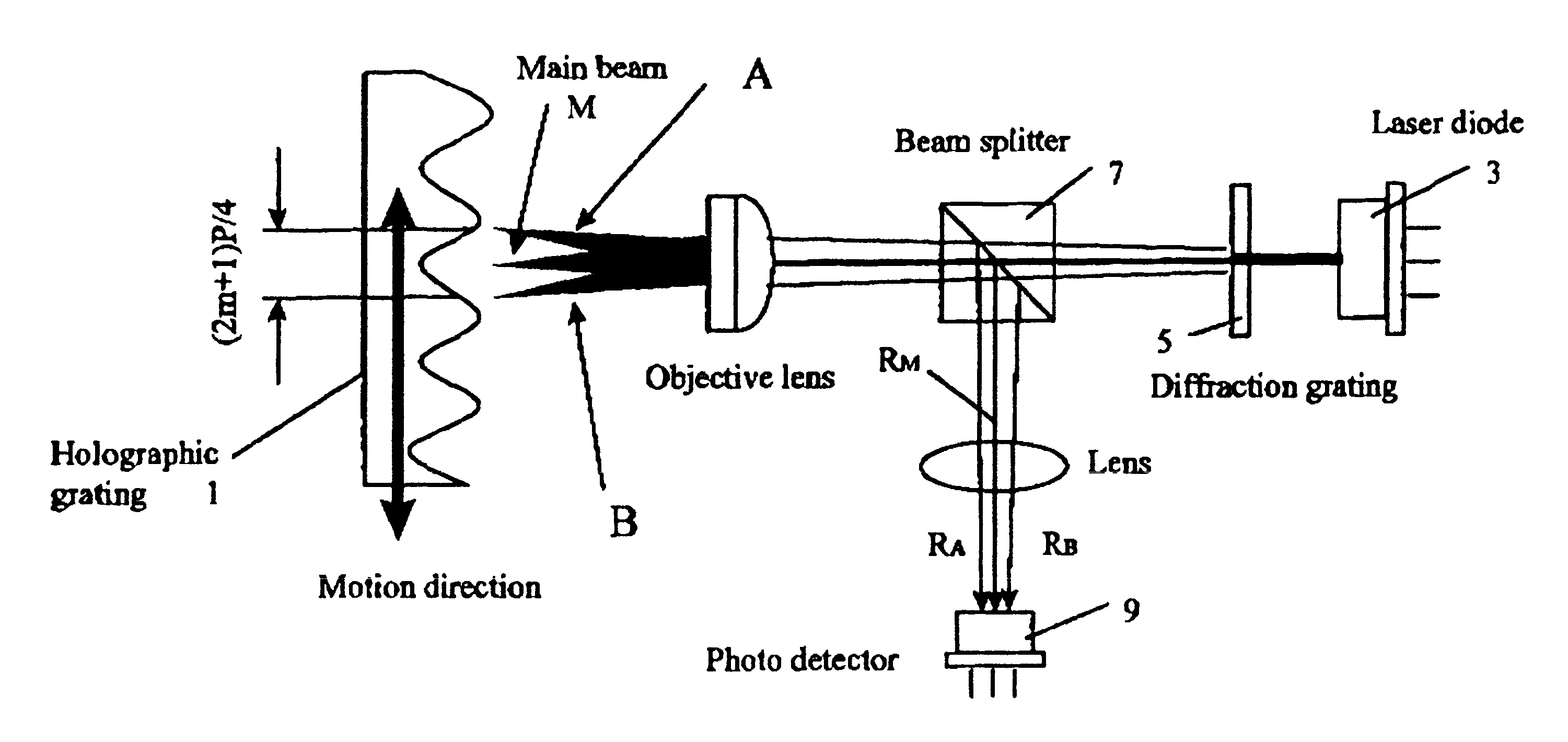

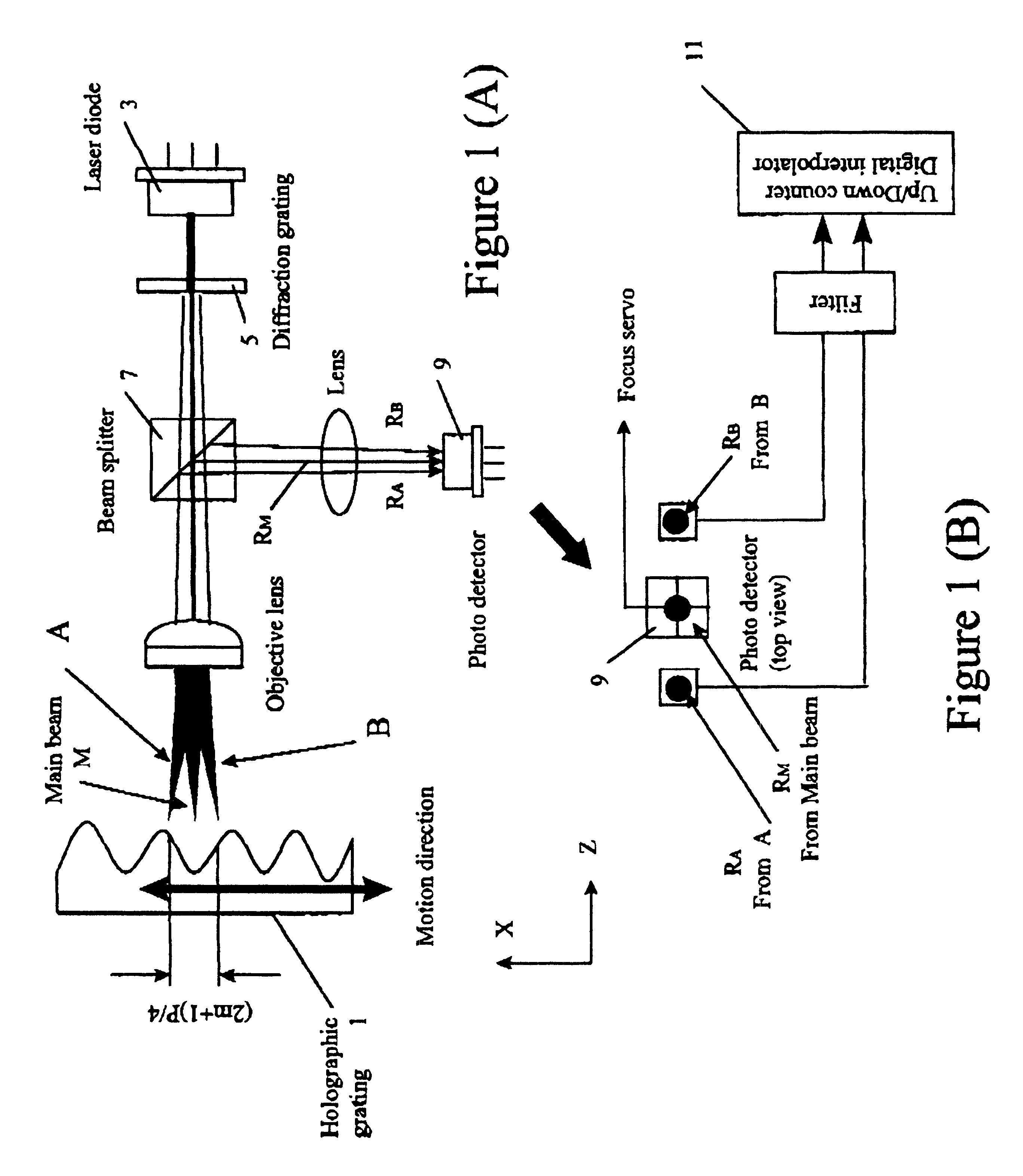

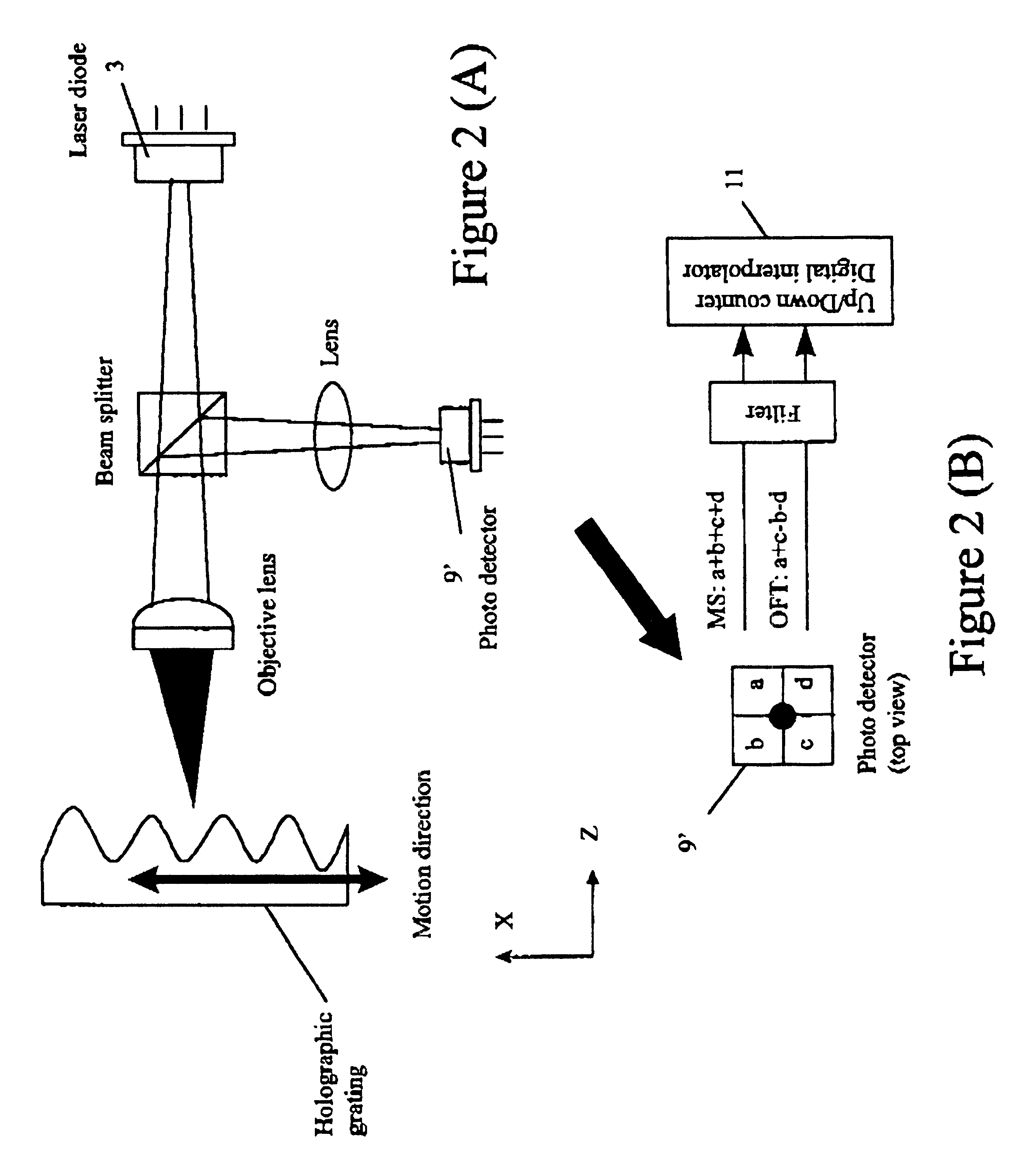

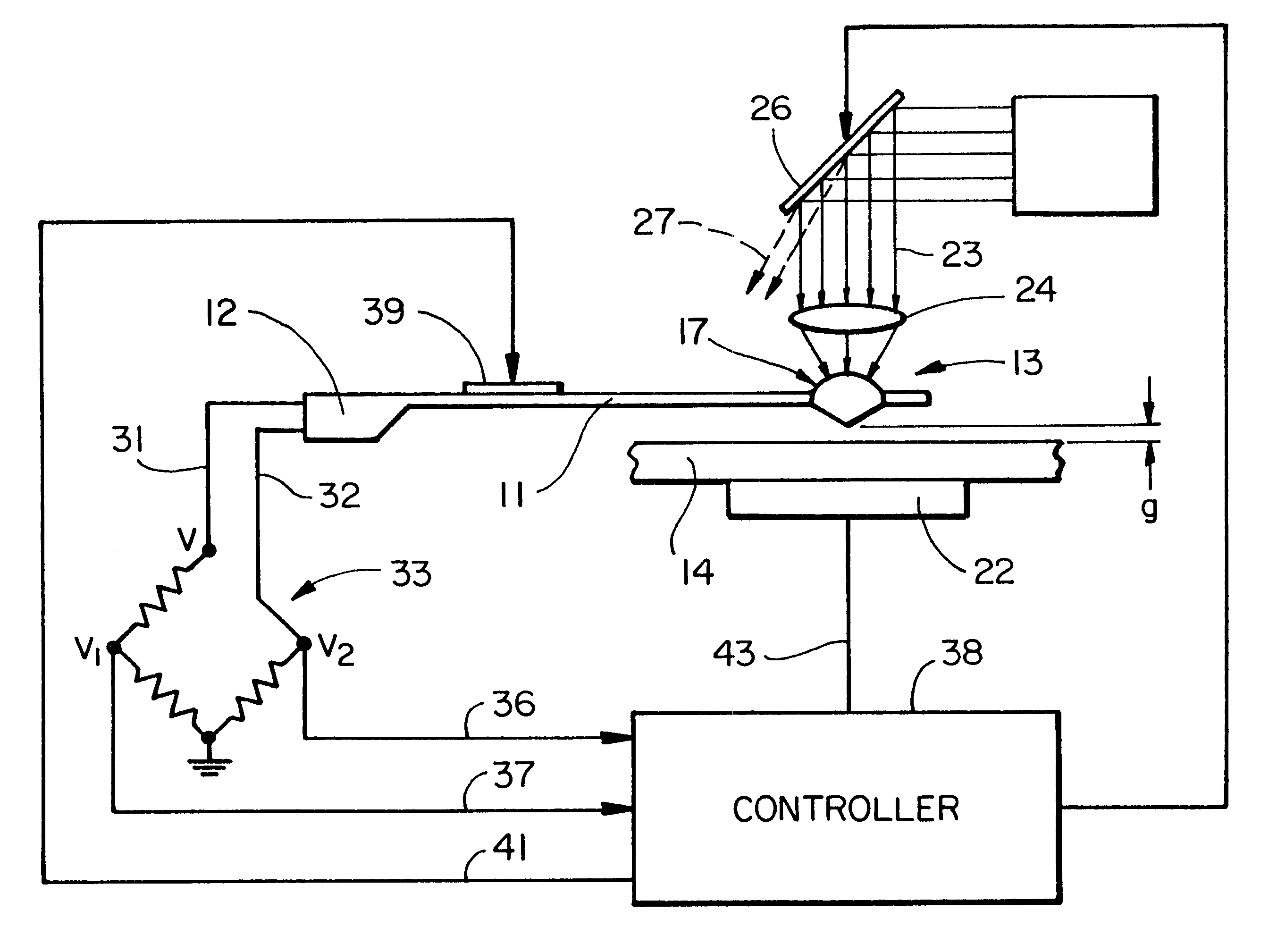

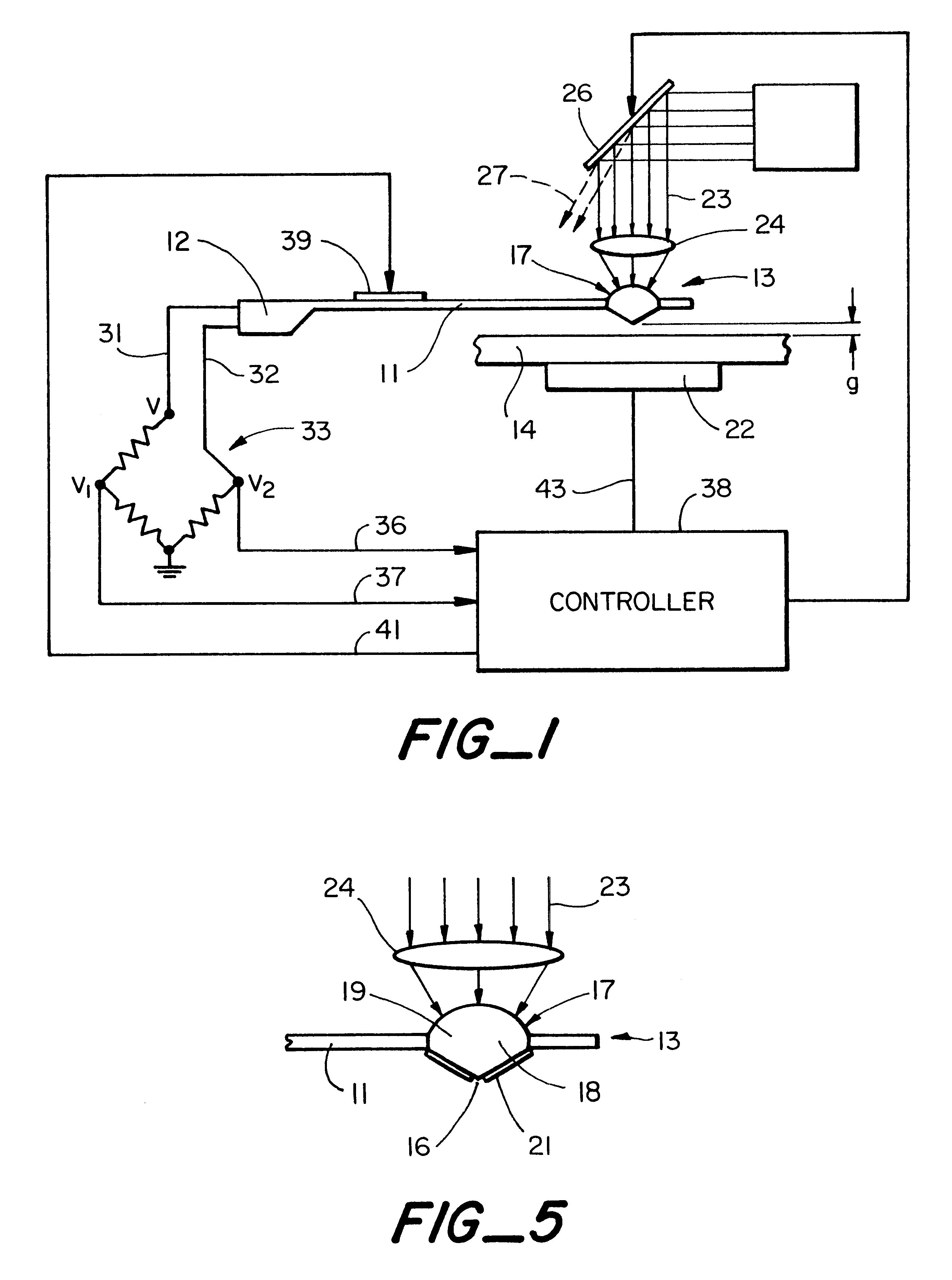

Method of and apparatus for real-time continual nanometer scale position measurement by beam probing as by laser beams and the like of atomic and other undulating surfaces such as gratings or the like relatively moving with respect to the probing beams

InactiveUS6639686B1Improved position sensing responseImprove operationNanoopticsInstrumental componentsGratingLight beam

An improved method of and apparatus for real-time continual nanometer scale position measurement by beam probing as by laser beams and the like, both fixed and oscillating or scanning, over an atomic and other undulating surface such as gratings or the like, relatively moving with respect to the probing beams; and providing, where desired, increased detection speeds, improved positioning sensing response, freedom from or relaxed requirements of strict control on probing oscillation amplitude, and multi-dimensional position measurement with focused beam probes and the like.

Owner:NANOWAVE

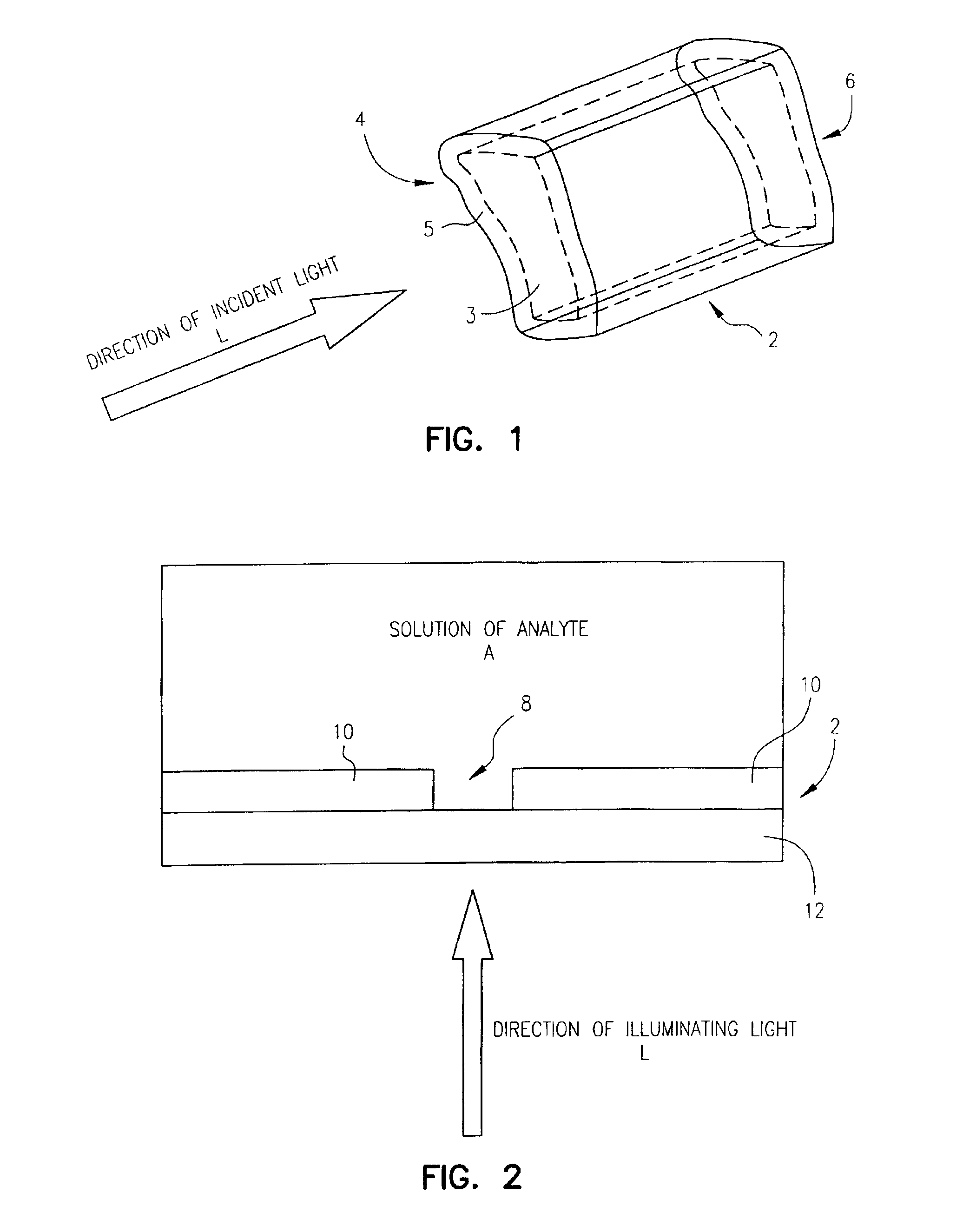

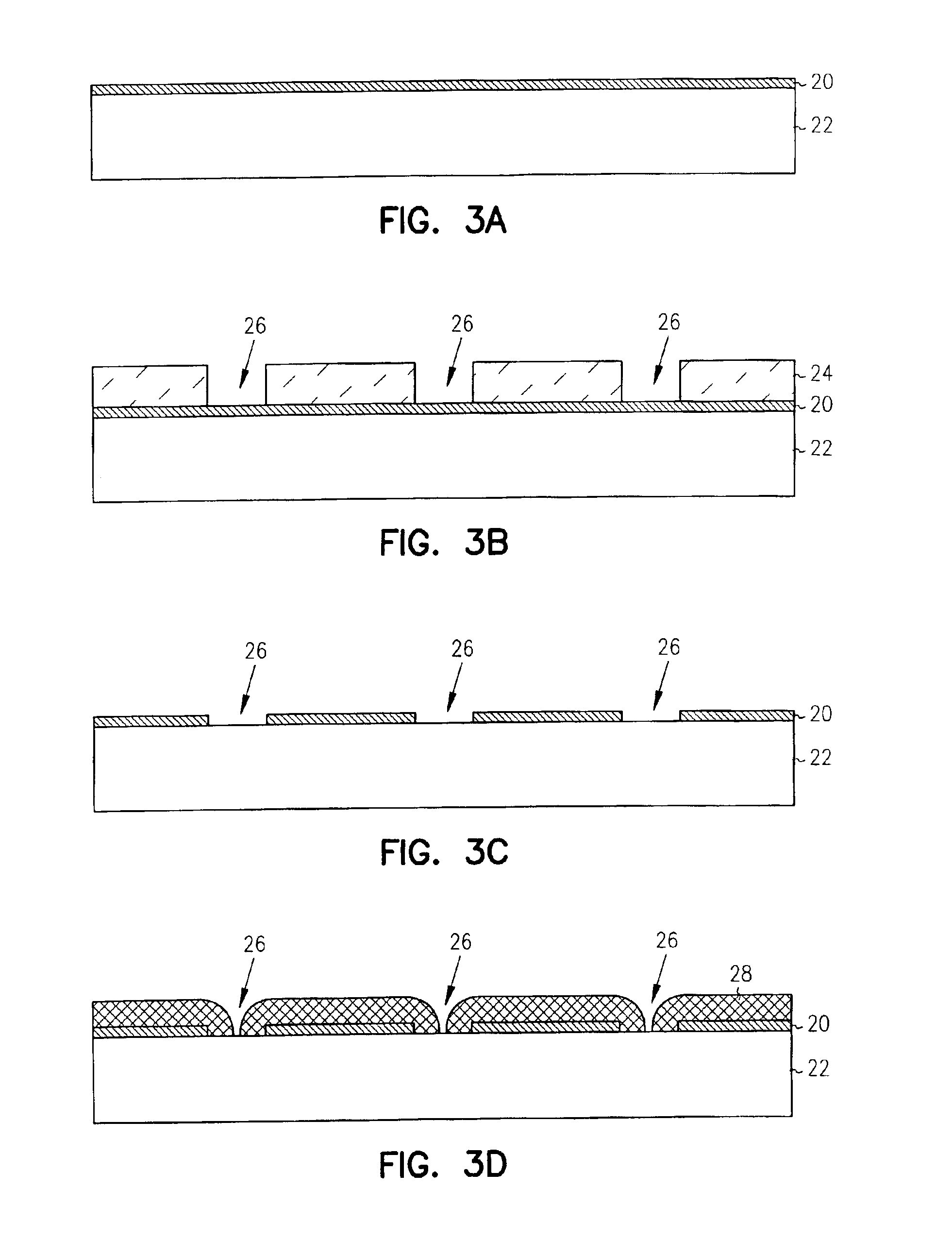

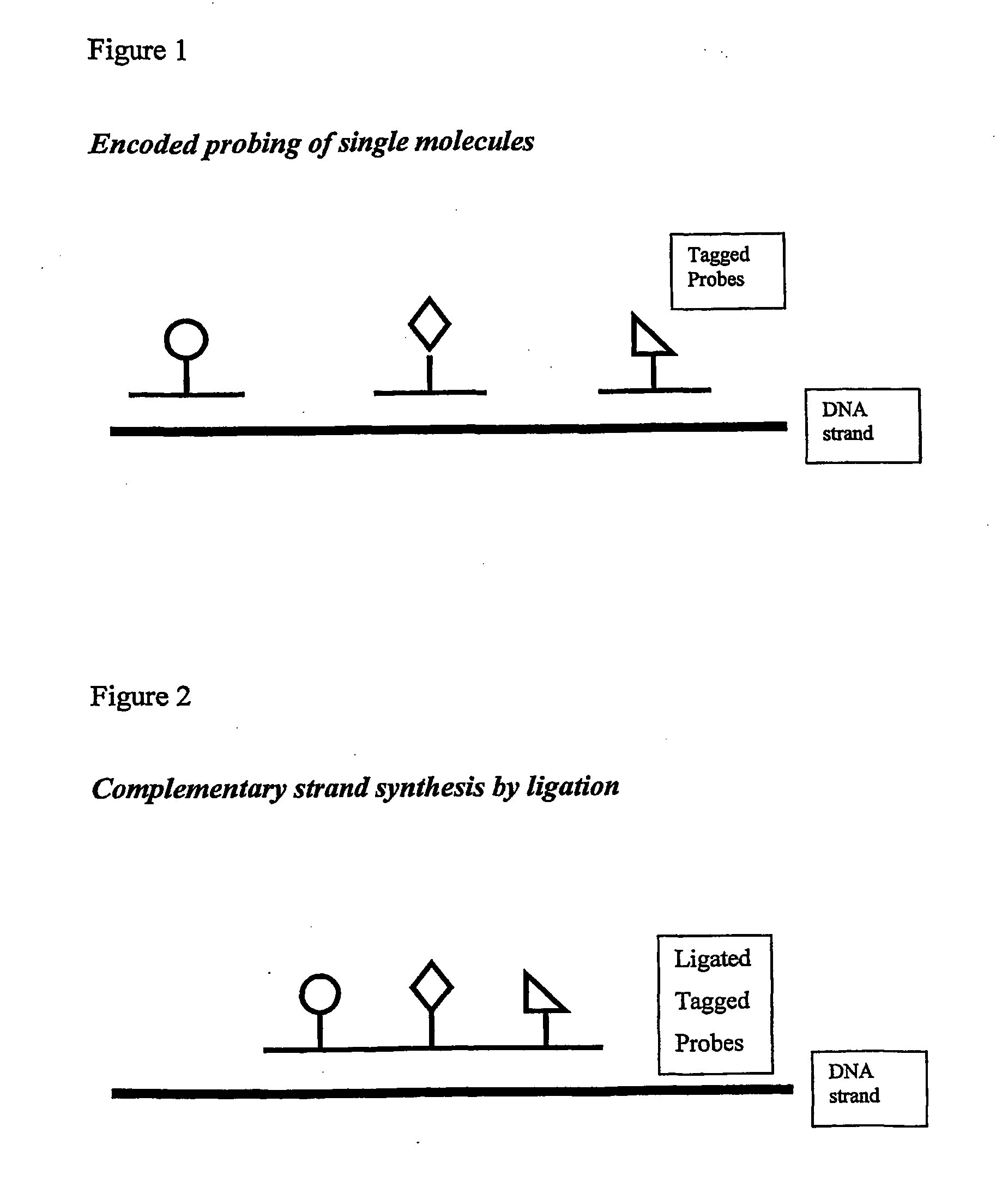

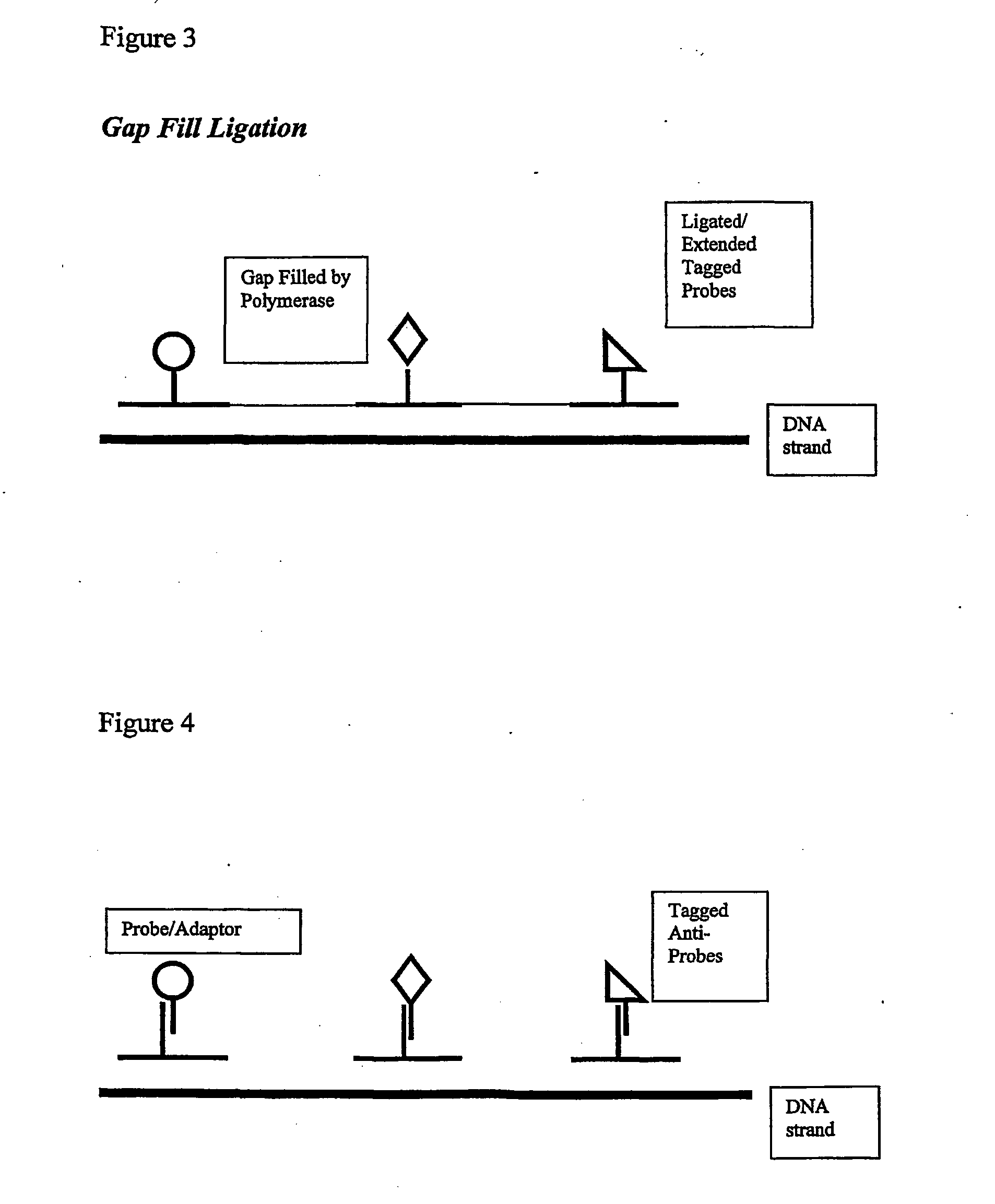

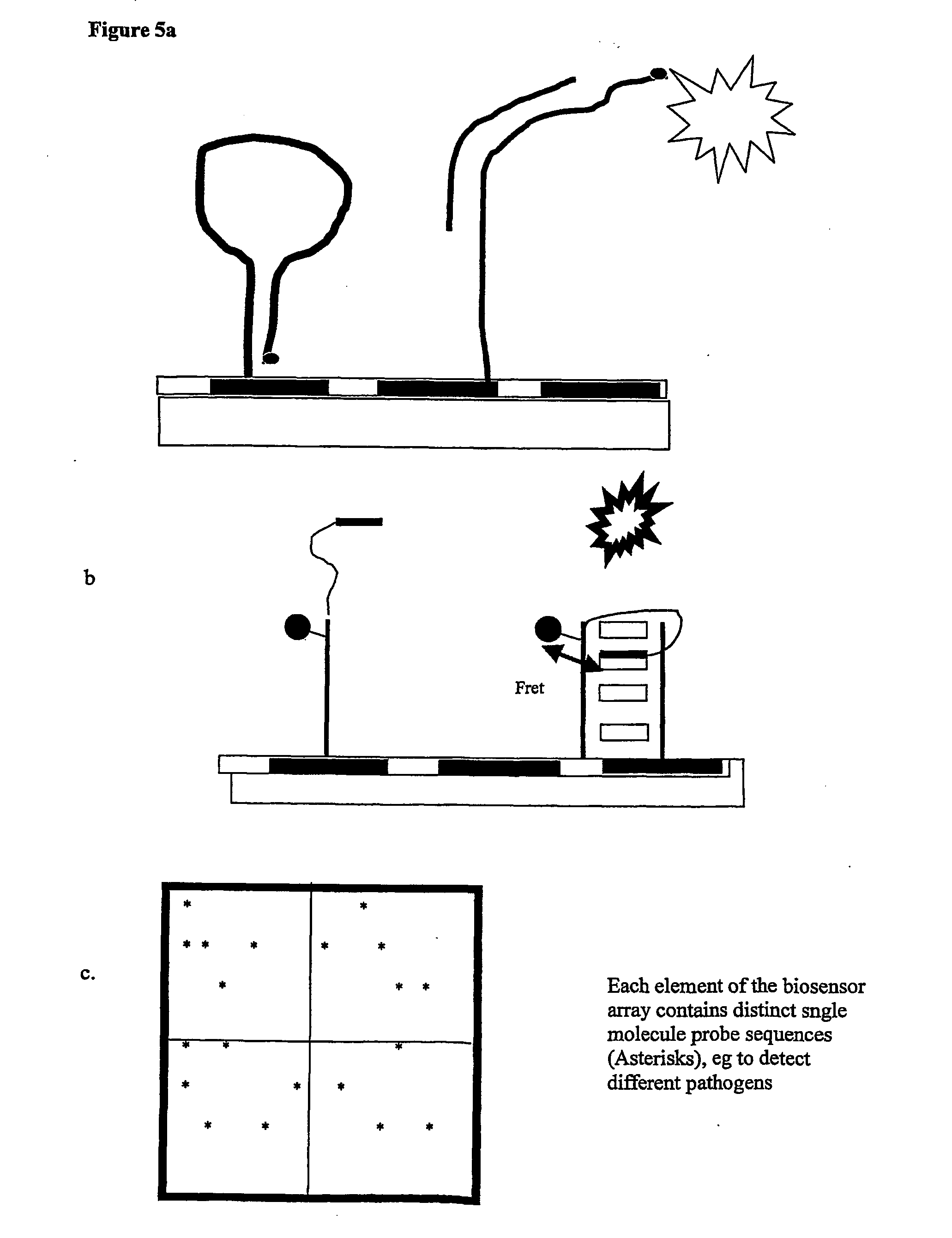

Arrays and methods of use

InactiveUS20040248144A1Minimise photobleachingMinimizing transferMaterial nanotechnologyBioreactor/fermenter combinationsMolecular arrayAssay

Methods are provided for producing a molecular array comprising a plurality of molecules immobilised to a solid substrate at a density which allows individual immobilised molecules to be individually resolved, wherein each individual molecule in the array is spatially addressable and the identity of each molecule is known or determined prior to immobilisation. The use of spatially addressable lowdensity molecular arrays in single molecule detection and analysis techniques is also provided. Novel assays and methods are also provided.

Owner:INVITAE CORP

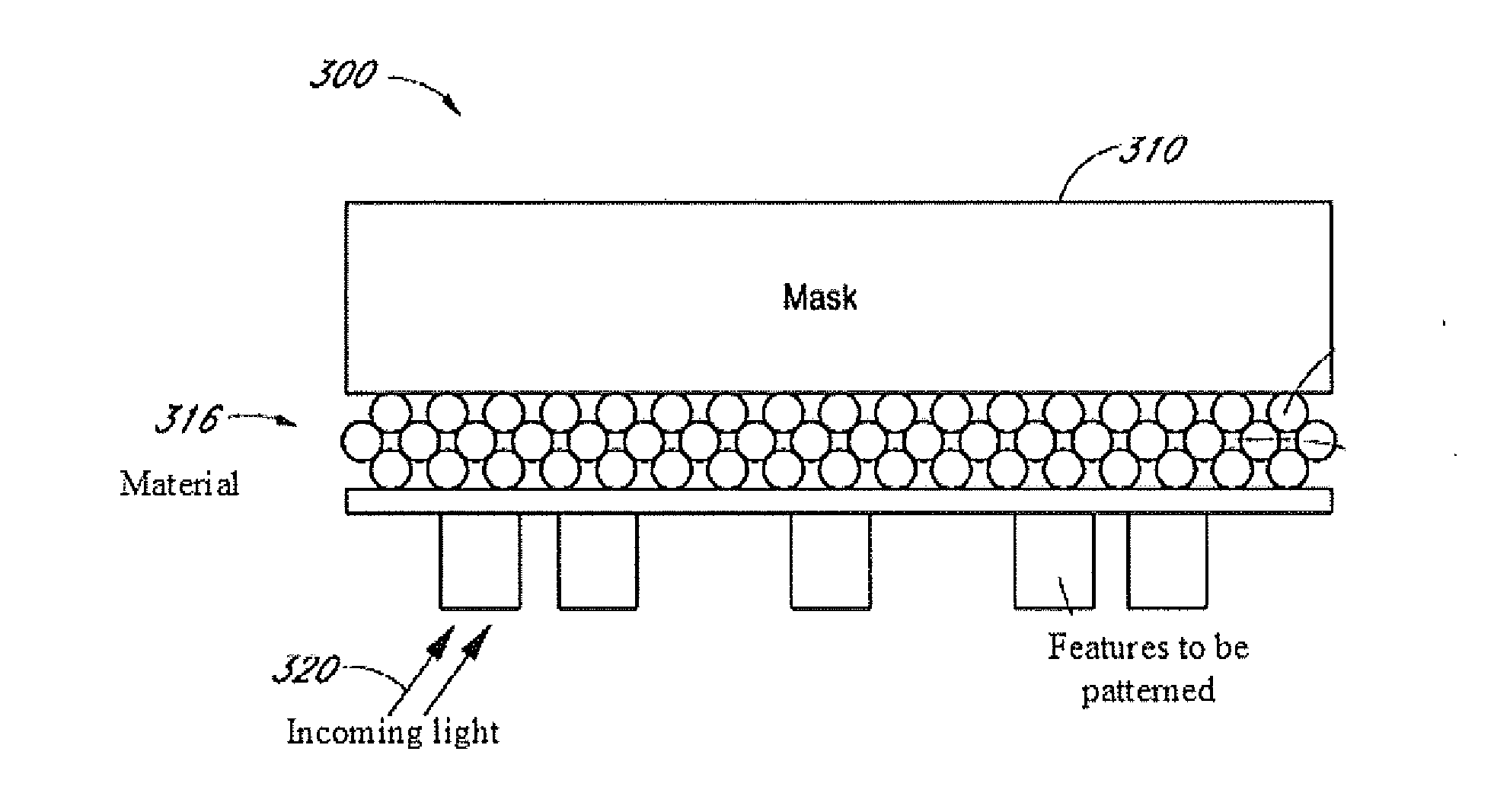

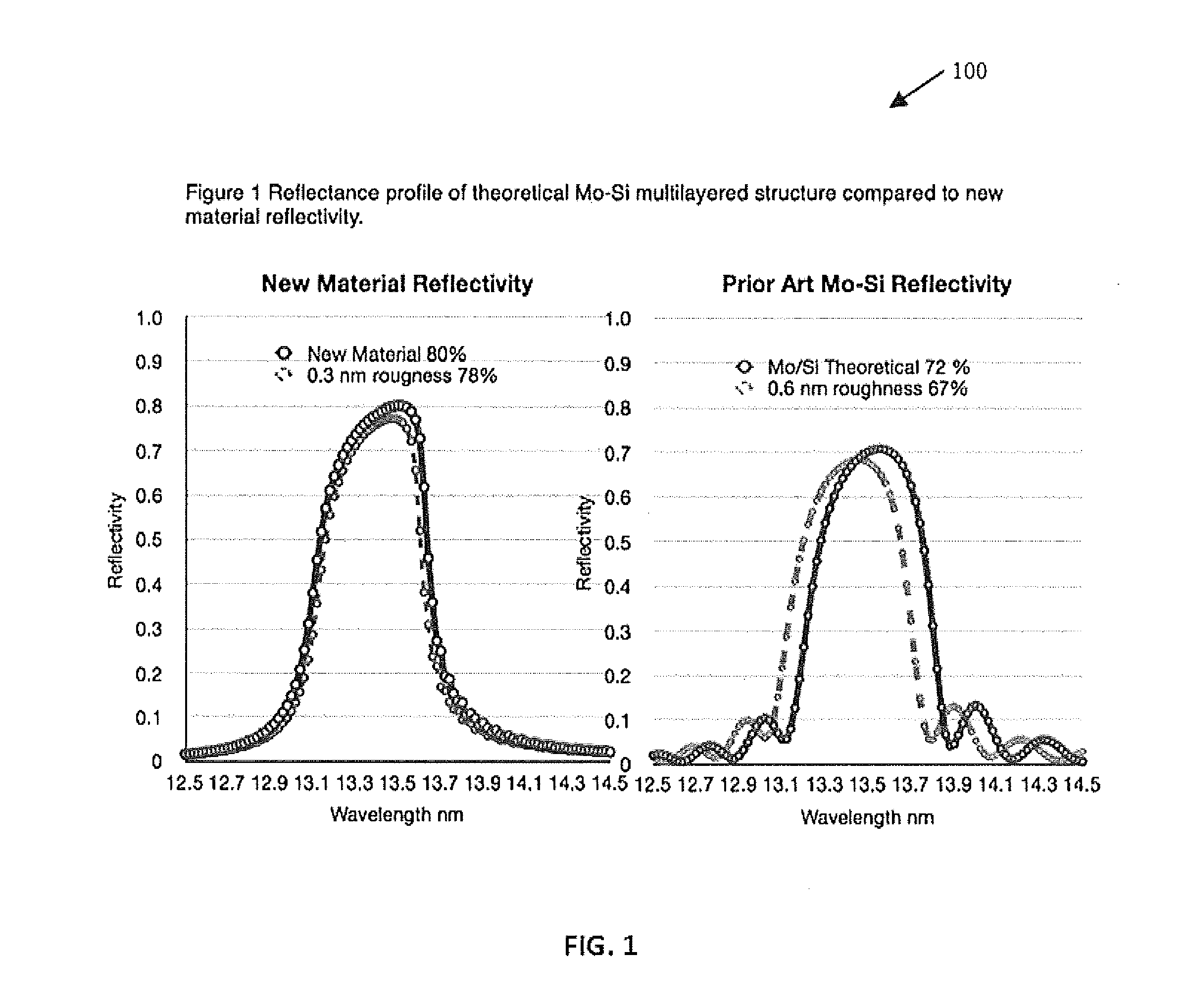

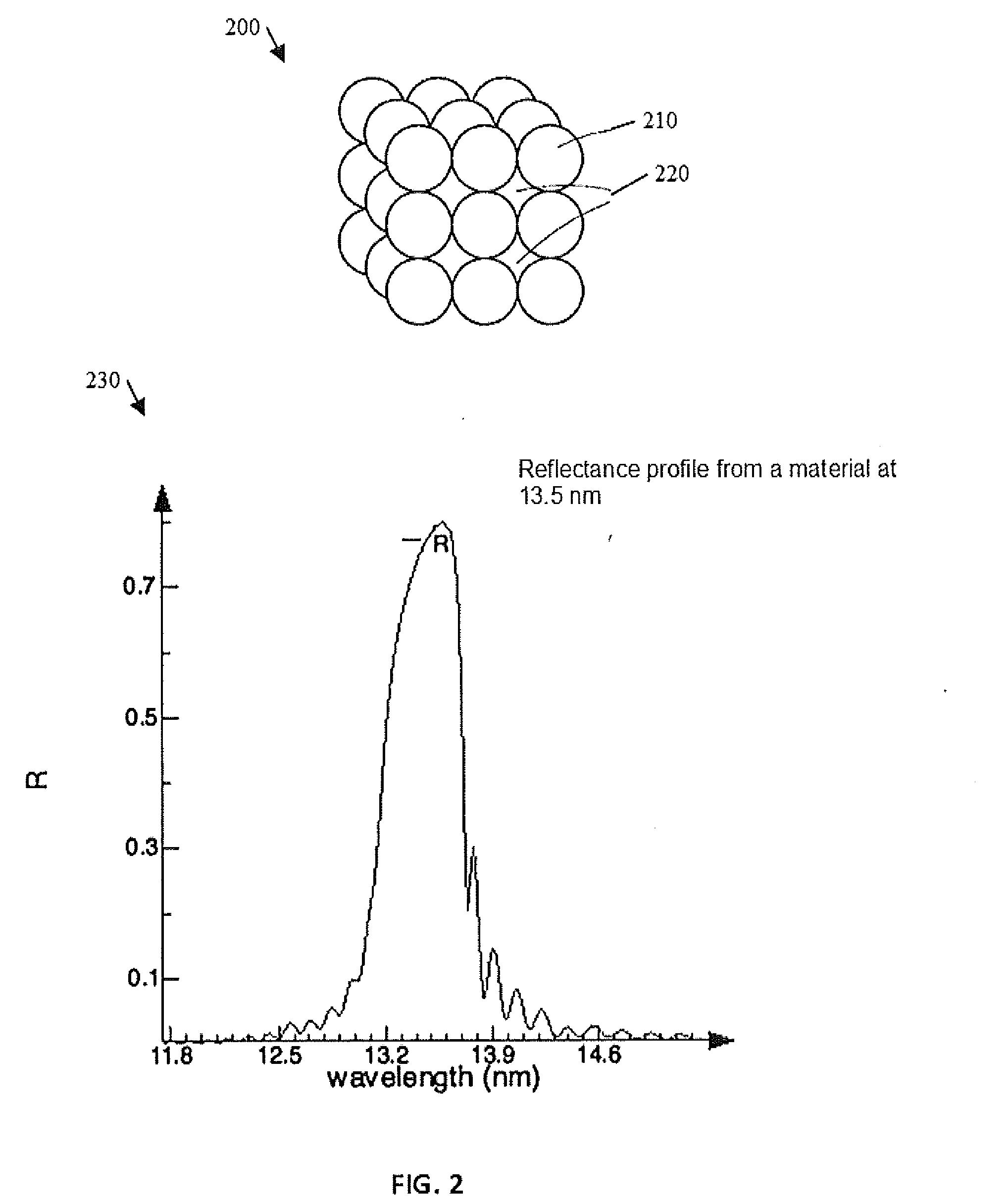

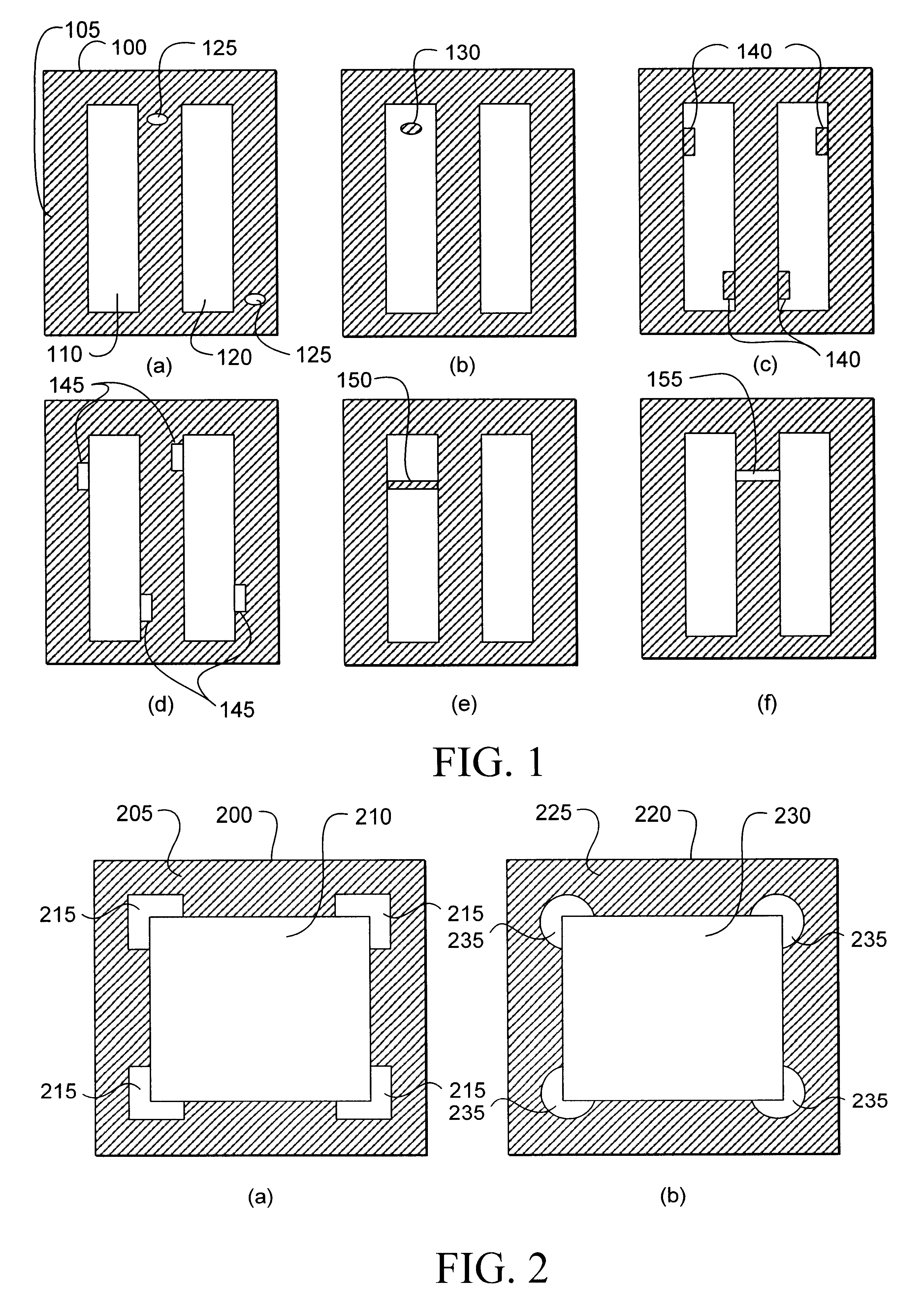

Materials, components, and methods for use with extreme ultraviolet radiation in lithography and other applications

ActiveUS20160085003A1Improve reflectivitySpread the wordMaterial analysis using wave/particle radiationRadiation/particle handlingPhotonicsUltraviolet

Nanostructured photonic materials, and associated components for use in devices and systems operating at ultraviolet (UV), extreme ultraviolet (EUV), and / or soft Xray wavelengths are described. Such a material may be fabricated with nanoscale features tailored for a selected wavelength range, such as at particular UV, EUV, or soft Xray wavelengths or wavelength ranges. Such a material may be used to make components such as mirrors, lenses or other optics, panels, lightsources, masks, photoresists, or other components for use in applications such as lithography, wafer patterning, astronomical and space applications, biomedical applications, biotech or other applications.

Owner:JAISWAL SUPRIYA

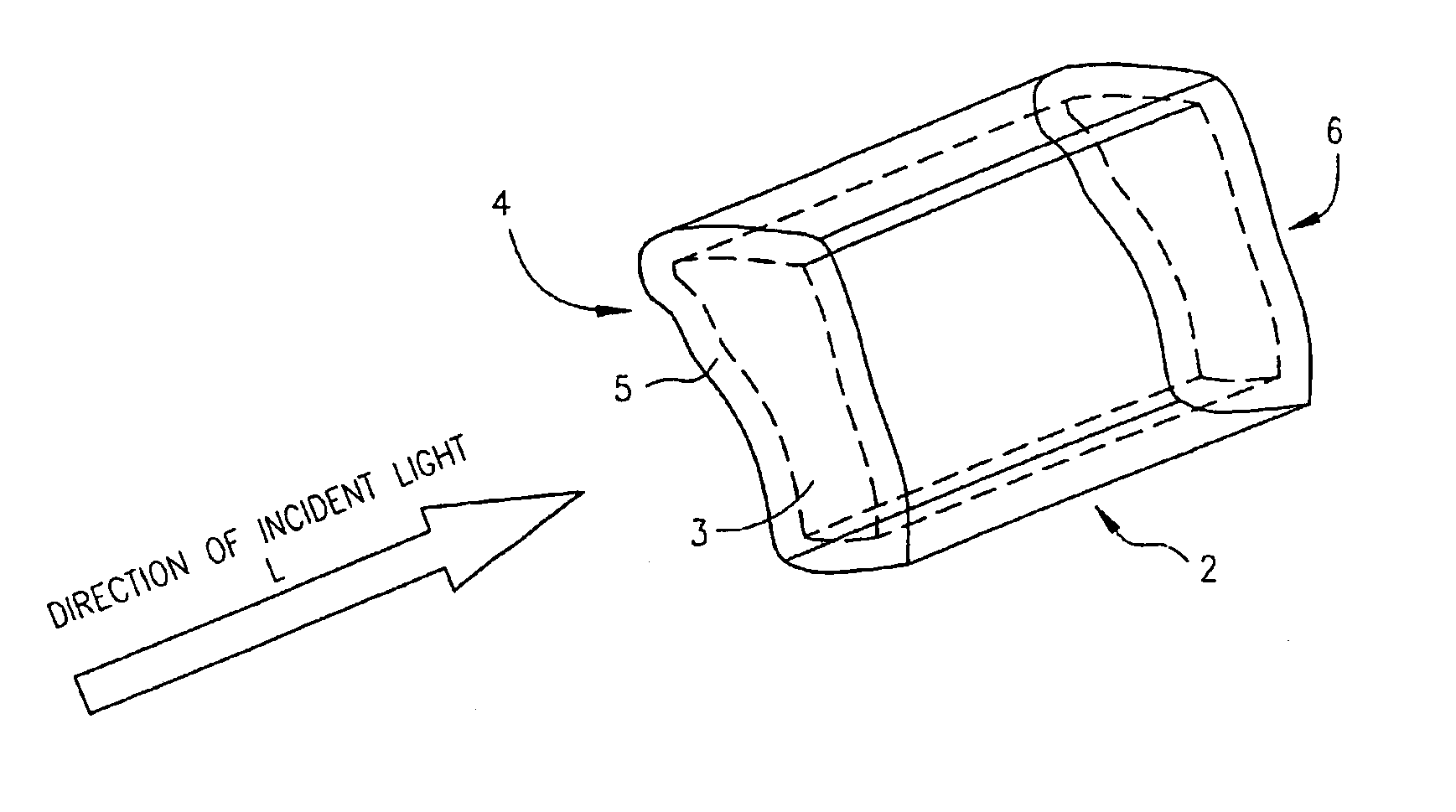

Waveguides for performing spectroscopy with confined effective observation volumes

InactiveUS7013054B2Effective volumeEasy to useCladded optical fibreMicrobiological testing/measurementAnalyteSpectroscopy

The present invention is directed to a method and an apparatus for analysis of an analyte. The method involves providing a zero-mode waveguide which includes a cladding surrounding a core where the cladding is configured to preclude propagation of electromagnetic energy of a frequency less than a cutoff frequency longitudinally through the core of the zero-mode waveguide. The analyte is positioned in the core of the zero-mode waveguide and is then subjected, in the core of the zero-mode waveguide, to activating electromagnetic radiation of a frequency less than the cut-off frequency under conditions effective to permit analysis of the analyte in an effective observation volume which is more compact than if the analysis were carried out in the absence of the zero-mode waveguide.

Owner:CORNELL RES FOUNDATION INC

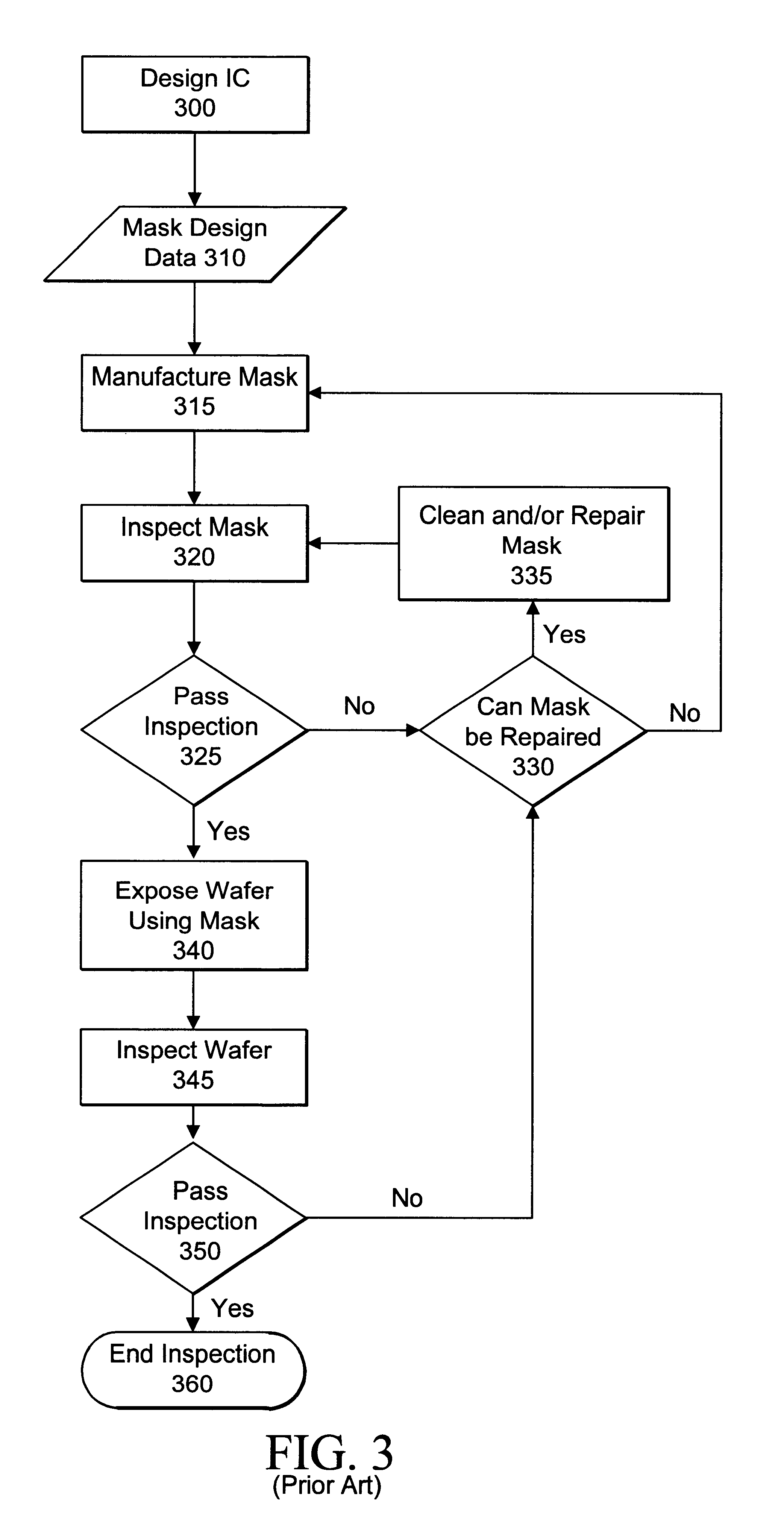

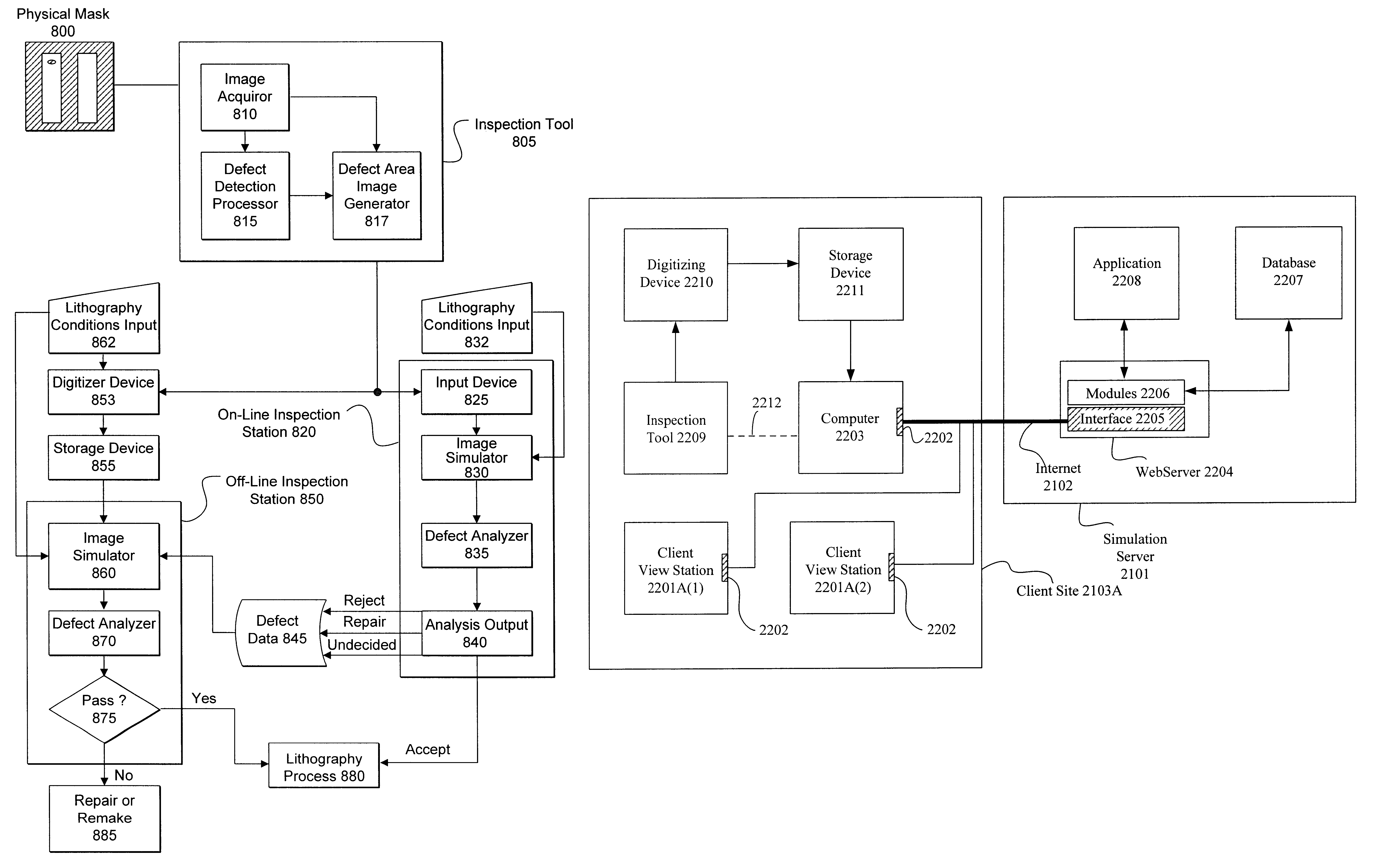

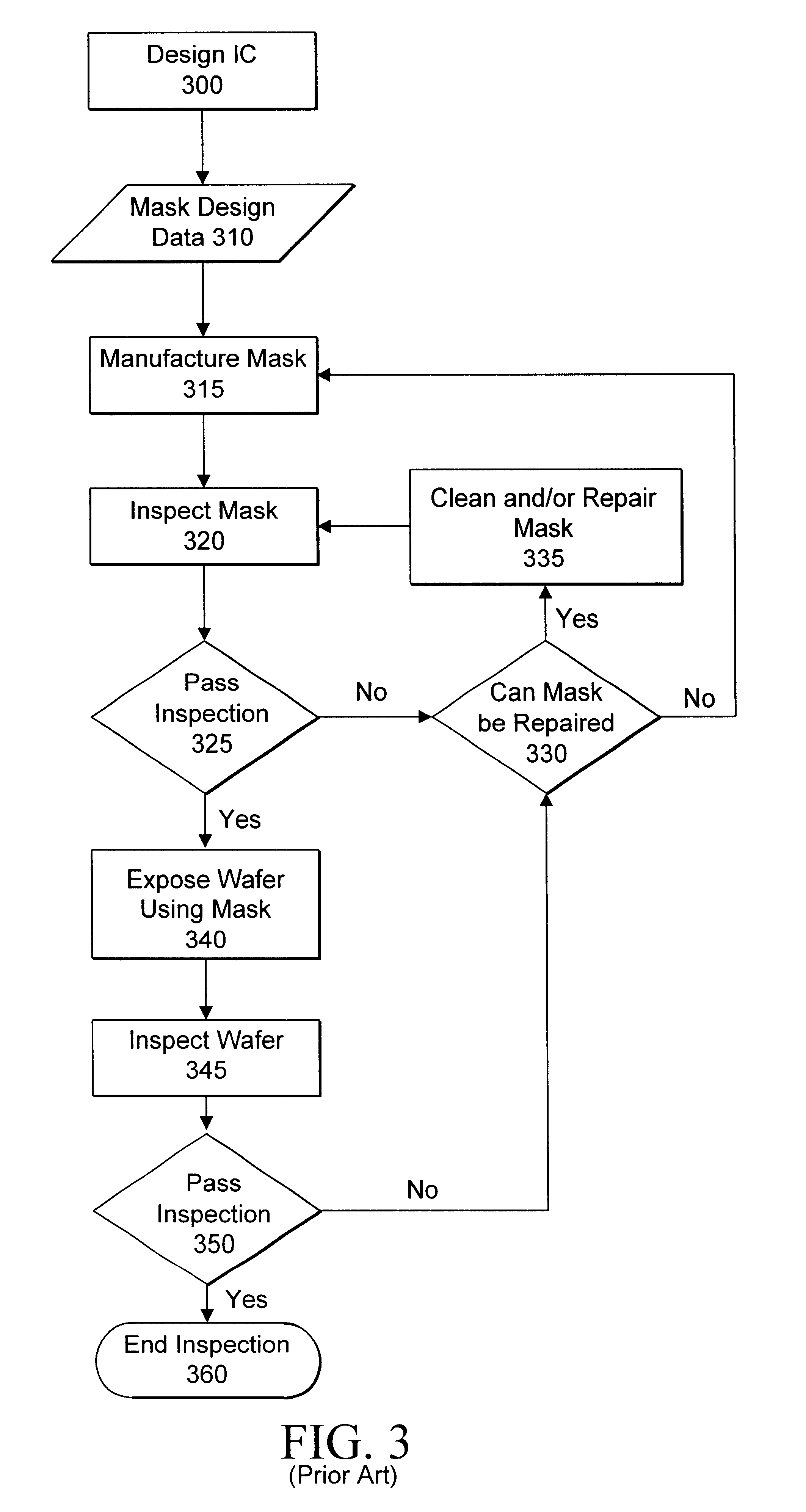

Visual inspection and verification system

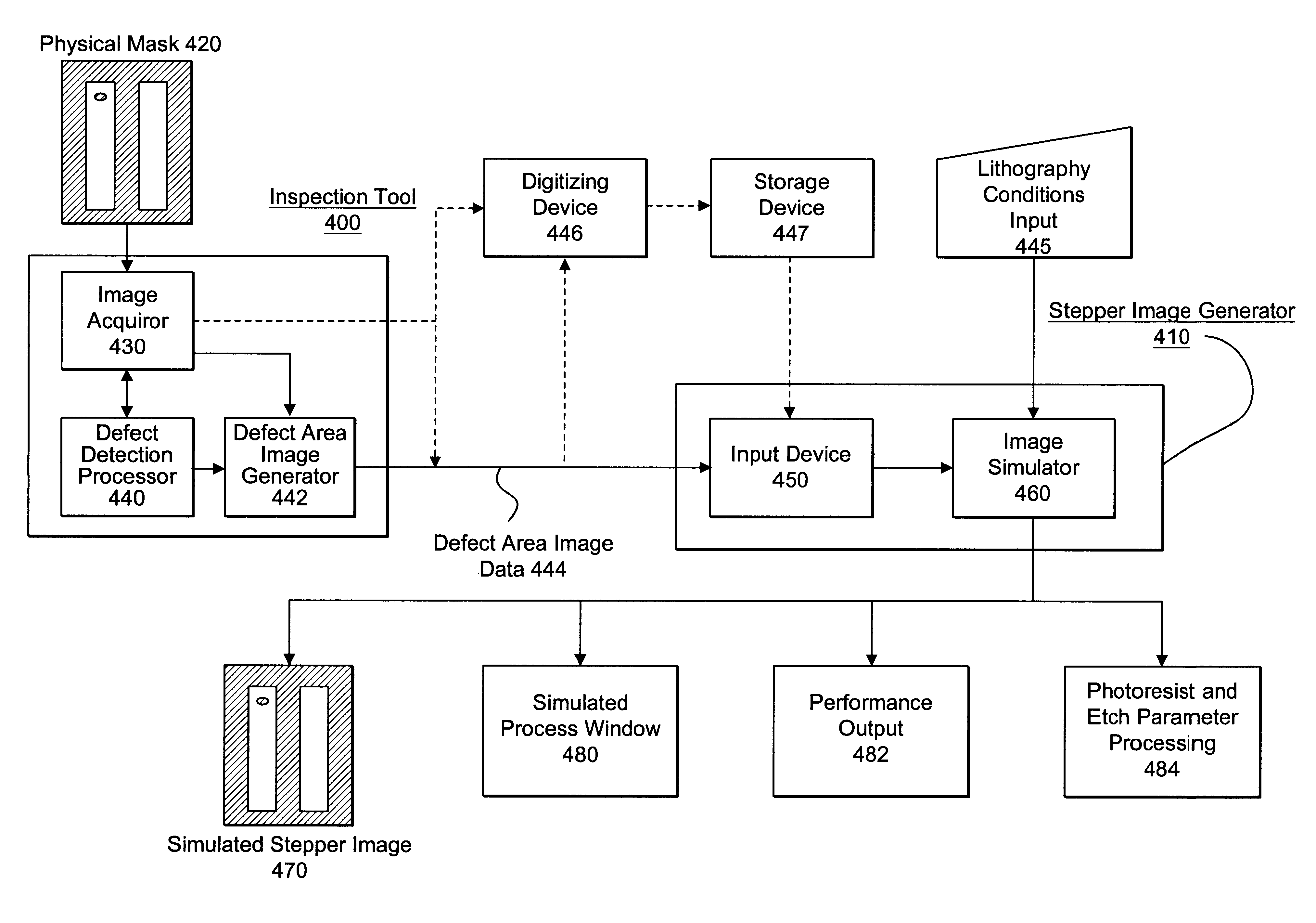

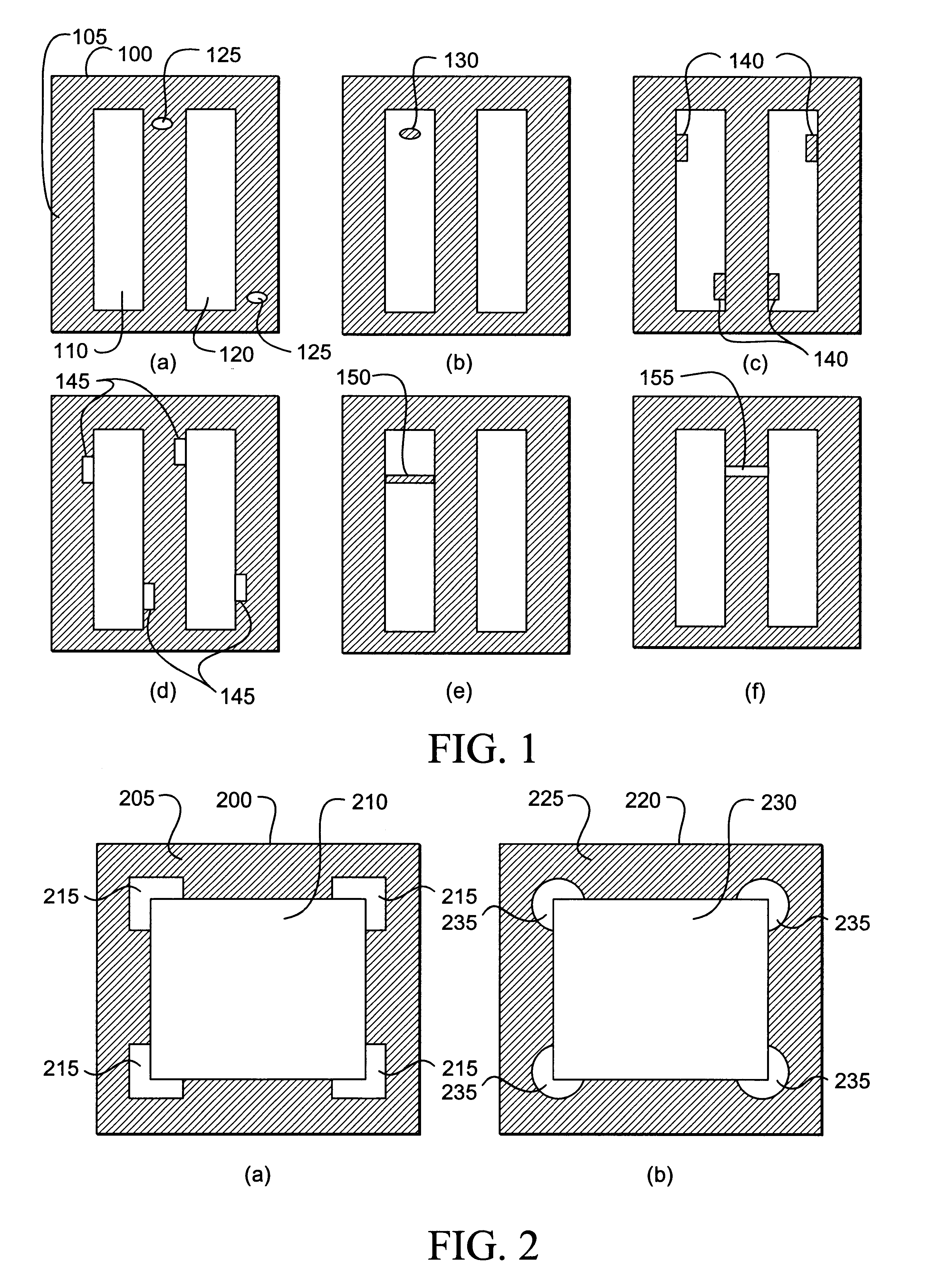

A method and apparatus for inspecting a photolithography mask for defects is provided. The inspection method comprises providing a defect area image to an image simulator wherein the defect area image is an image of a portion of a photolithography mask, and providing a set of lithography parameters as a second input to the image simulator. The defect area image may be provided by an inspection tool which scans the photolithography mask for defects using a high resolution microscope and captures images of areas of the mask around identified potential defects. The image simulator generates a first simulated image in response to the defect area image and the set of lithography parameters. The first simulated image is a simulation of an image which would be printed on a wafer if the wafer were to be exposed to an illumination source directed through the portion of the mask. The method may also include providing a second simulated image which is a simulation of the wafer print of the portion of the design mask which corresponds to the portion represented by the defect area image. The method also provides for the comparison of the first and second simulated images in order to determine the printability of any identified potential defects on the photolithography mask. A method of determining the process window effect of any identified potential defects is also provided for.

Owner:SYNOPSYS INC

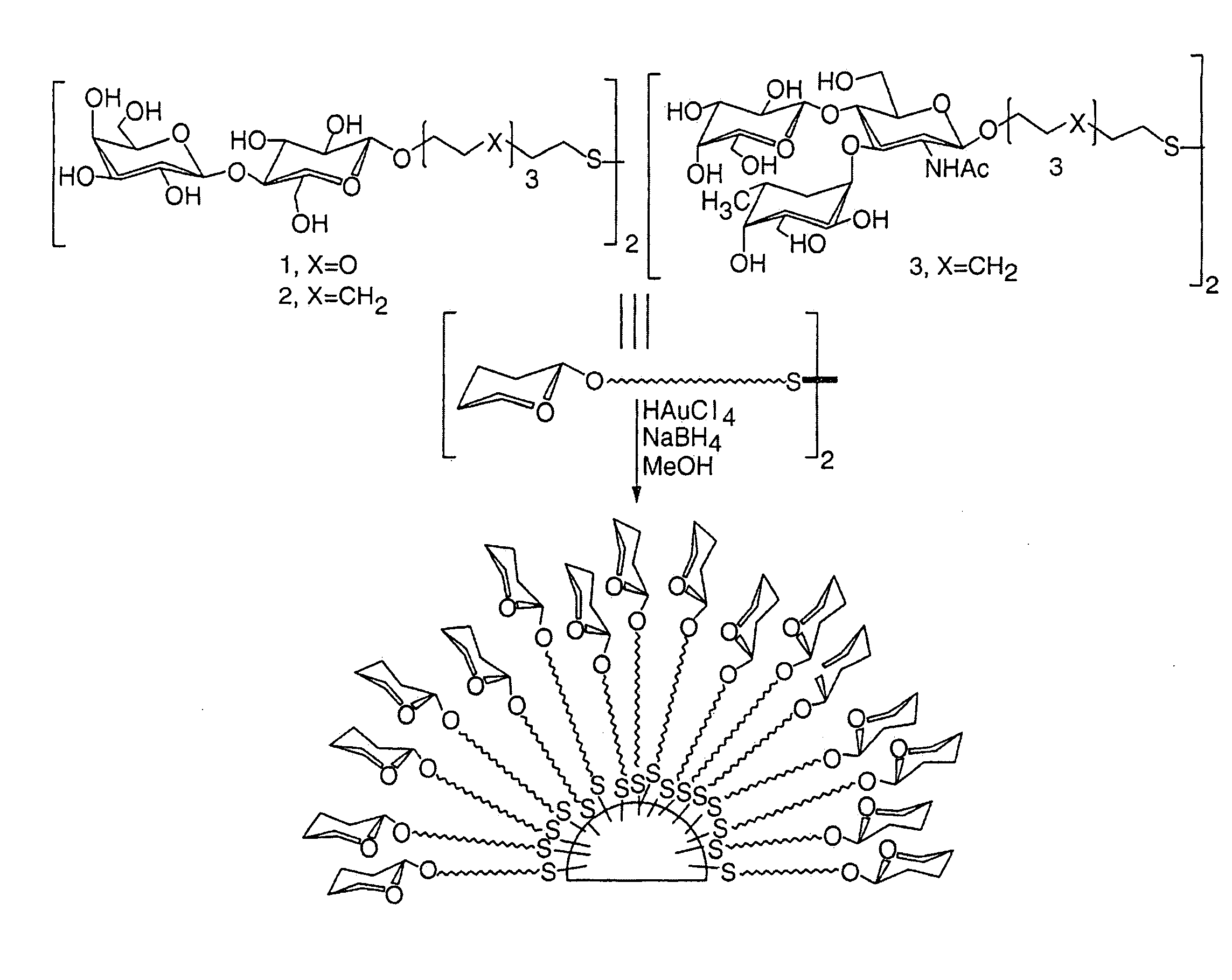

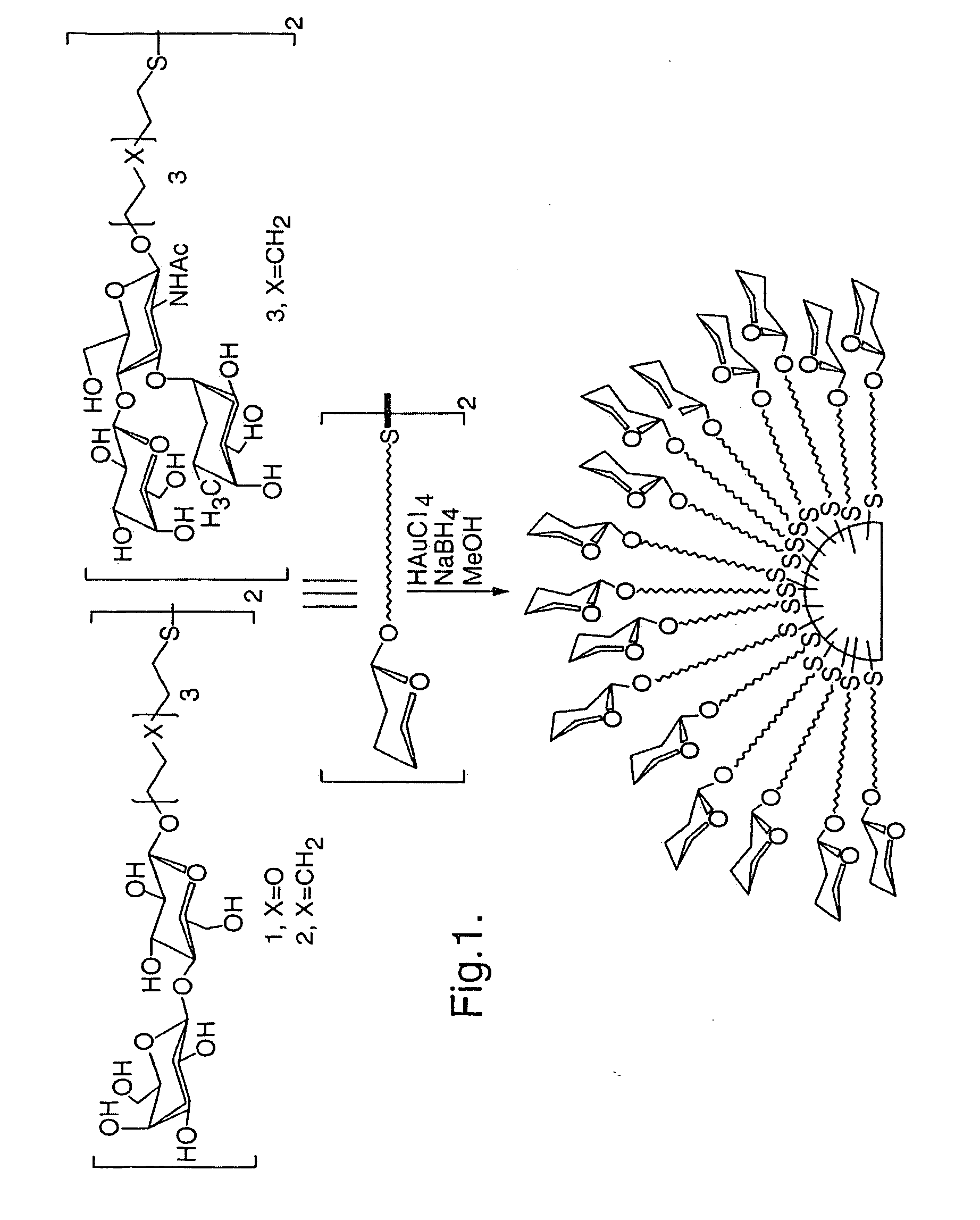

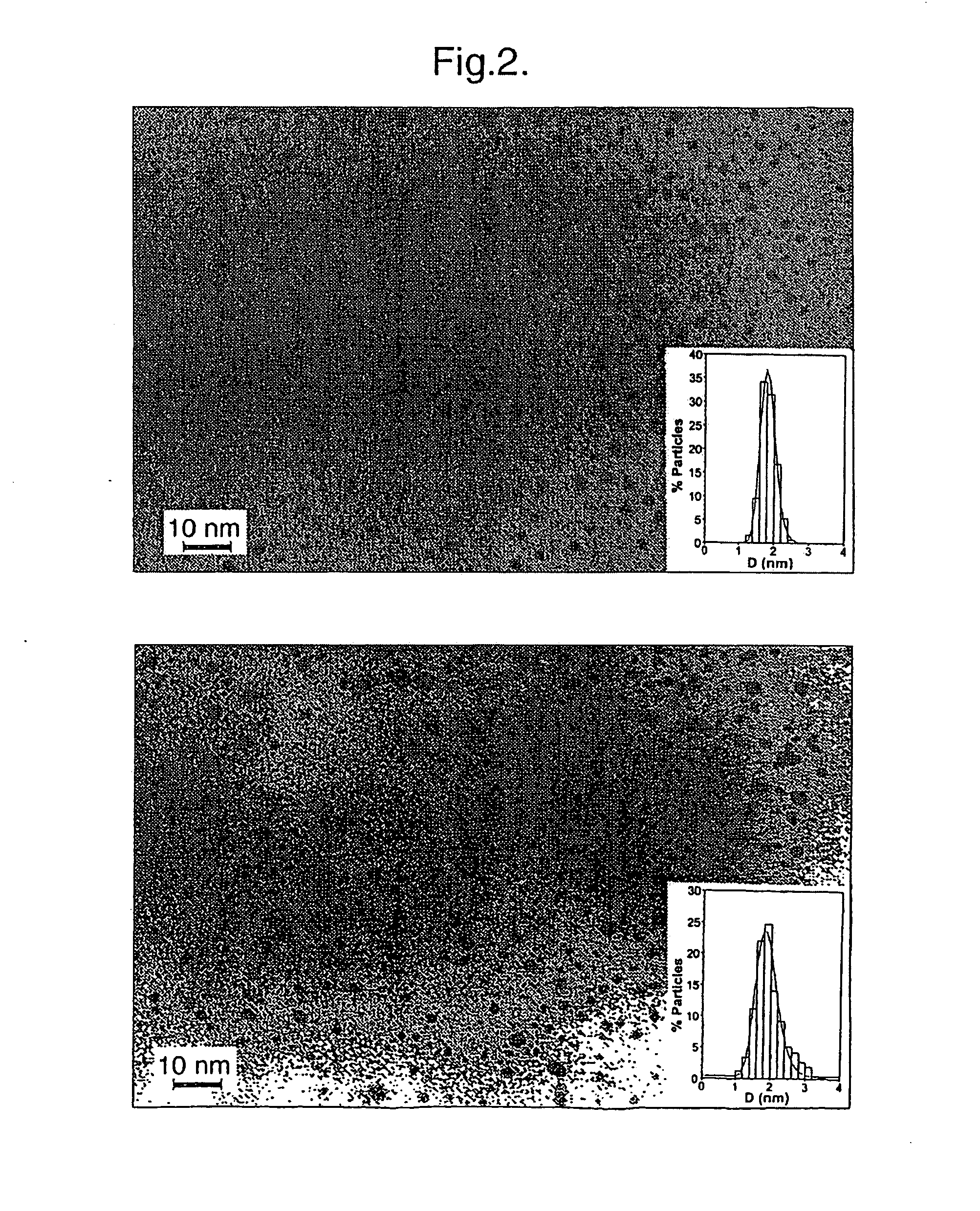

Nanoparticles

InactiveUS20080145441A1Reliably modulatedAntibacterial agentsOrganic active ingredientsMoietyCarbohydrate moiety

Materials and methods for studying and modulating the interaction of carbohydrate-containing moieties with other species are described, in particular, small particles, e.g. clusters of metal or semiconductor atoms, which can be employed as a substrate for immobilising a plurality of ligands comprising carbohydrate groups. These “nanoparticles” can then be used to study carbohydrate mediated interactions, e.g. with other carbohydrates or proteins, and as therapeutics and diagnostic reagents.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

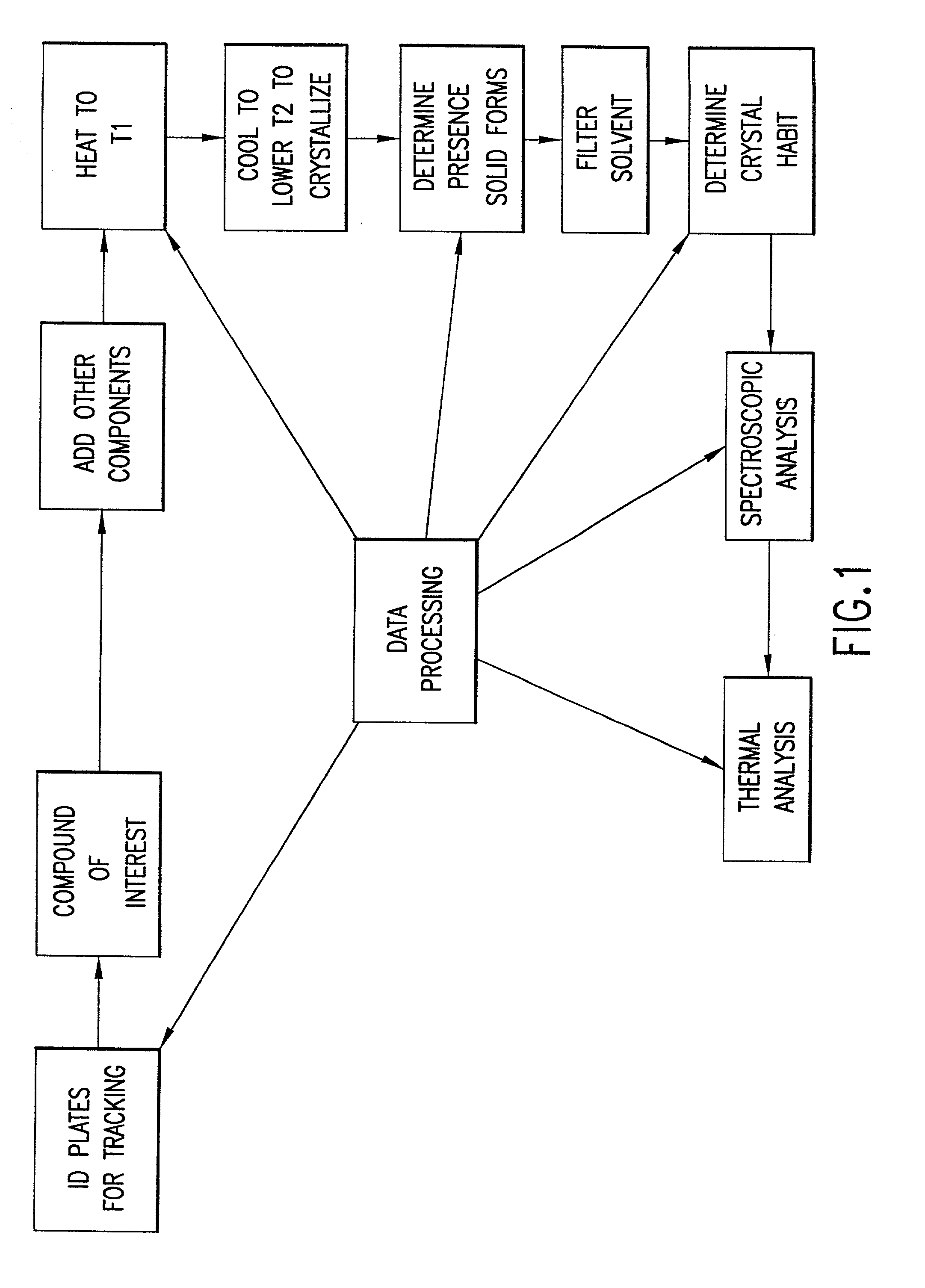

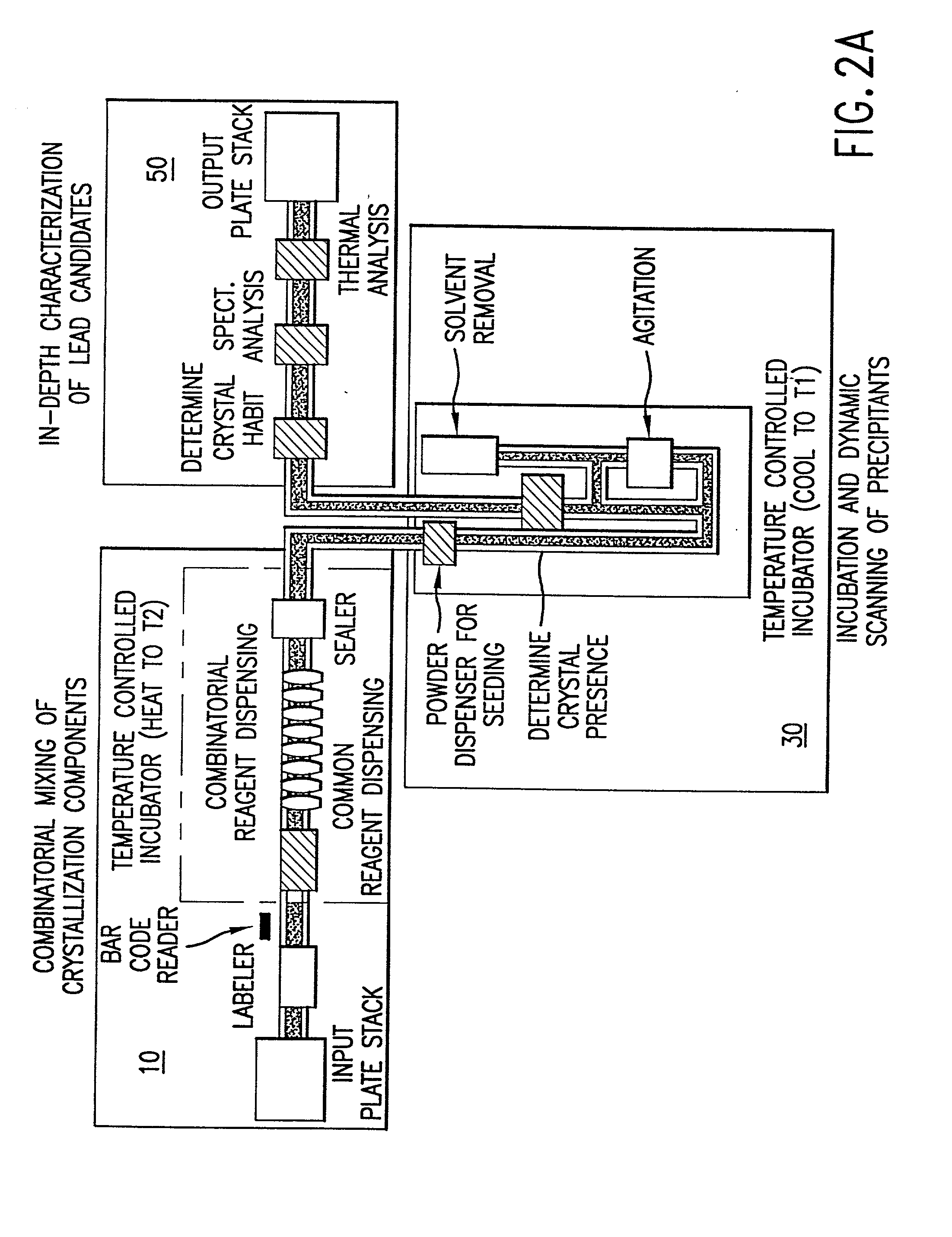

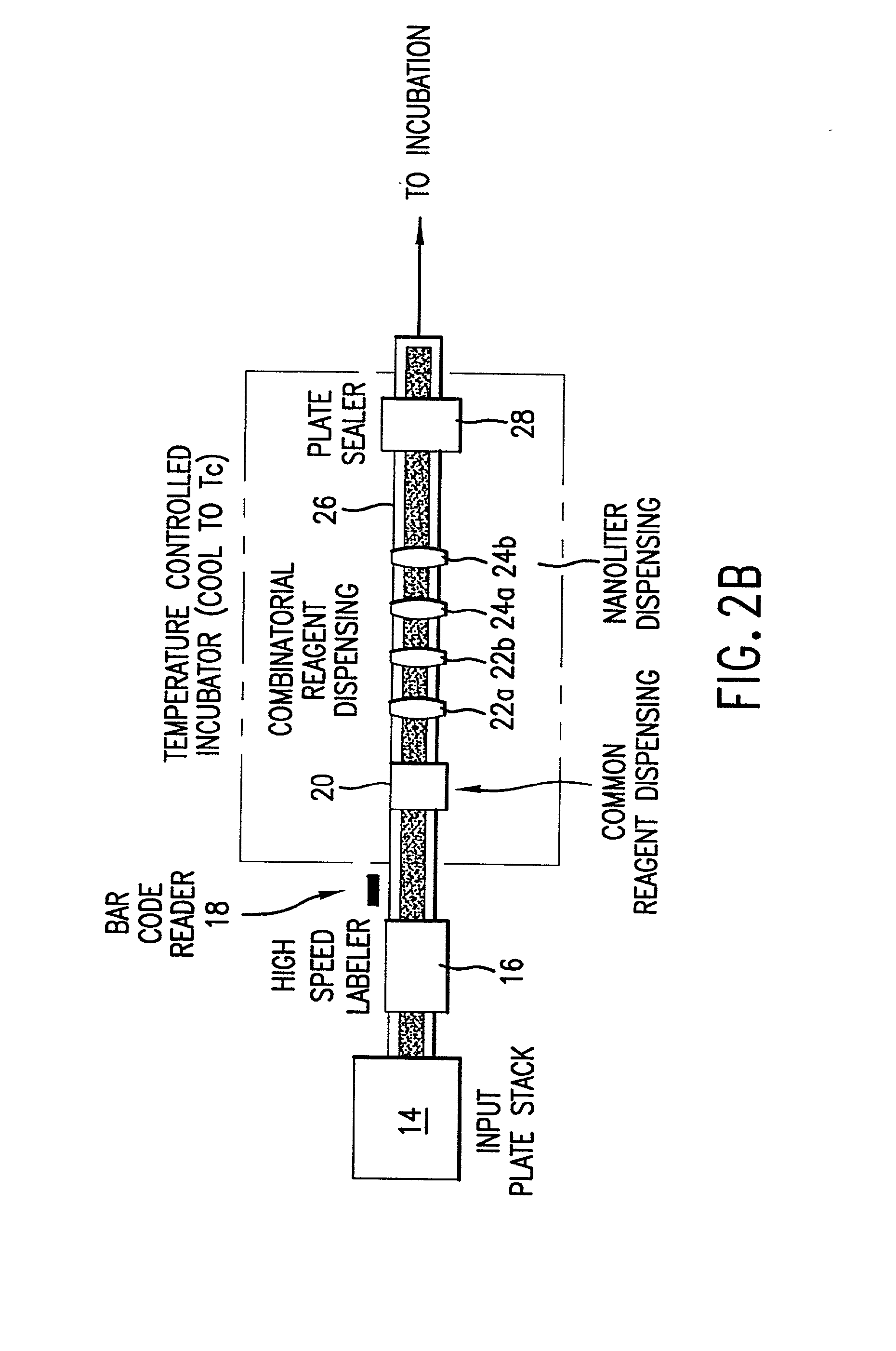

High-throughput formation, identification, and analysis of diverse solid-forms

InactiveUS20020048610A1Cost-effectiveImprove bioavailabilitySequential/parallel process reactionsFrom normal temperature solutionsSolubilitySolid mass

The invention concerns arrays of solid-forms of substances, such as compounds and rapid-screening methods therefor to identify solid-forms, particularly of pharmaceuticals, with enhanced properties. Such properties include improved bioavailability, solubility, stability, delivery, and processing and manufacturing characteristics. The invention relates to a practical and cost-effective method to rapidly screen hundreds to thousands of samples in parallel. The invention further provides methods for determining the conditions and / or ranges of conditions required to produce crystals with desired compositions, particle sizes, habits, or polymorphic forms. In a further aspect, the invention provides high-throughput methods to identify sets of conditions and / or combinations of components compatible with particular solid-forms, for example, conditions and / or components that are compatible with advantageous polymorphs of a particular pharmaceutical.

Owner:MILLENNIUM PHARMA INC +1

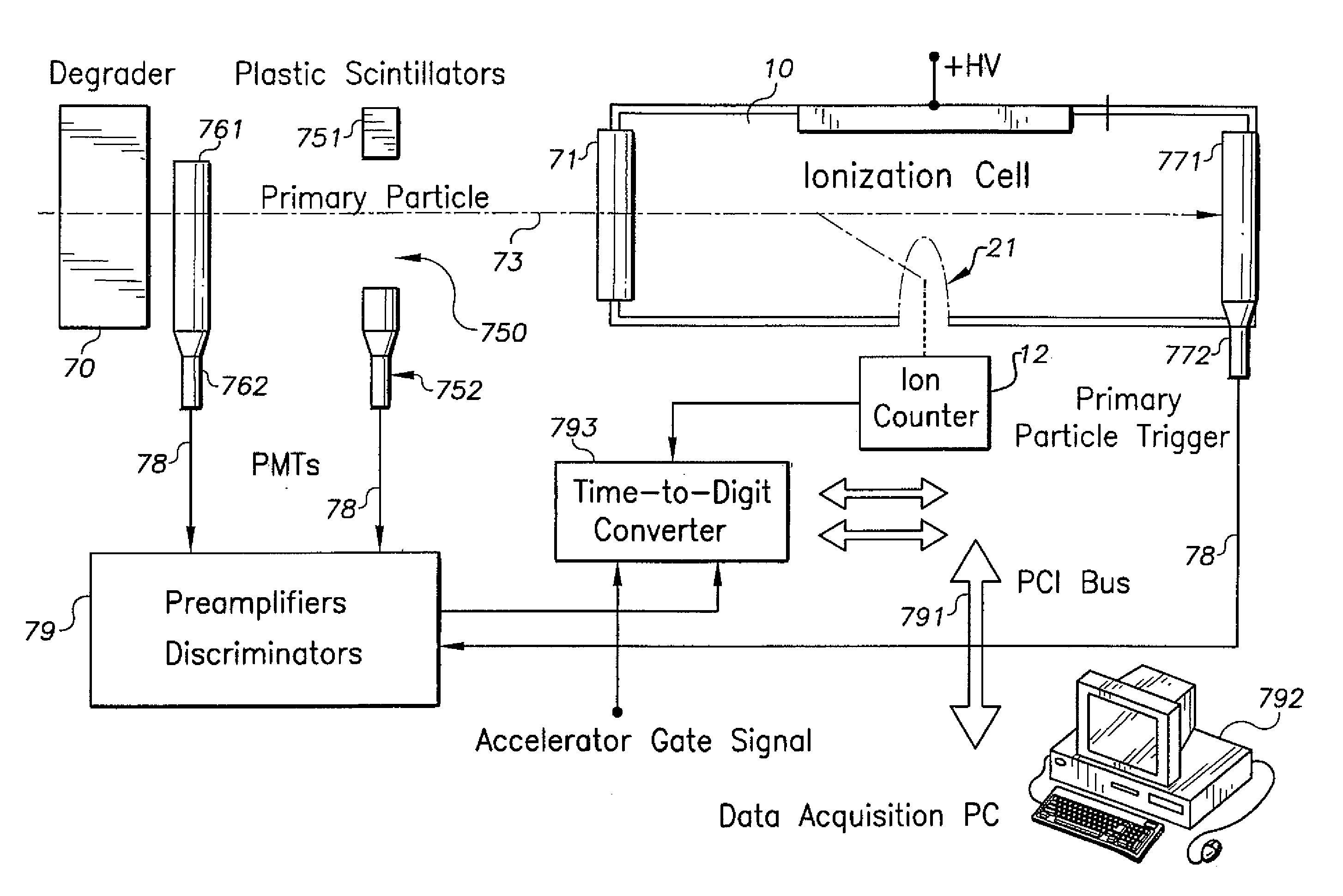

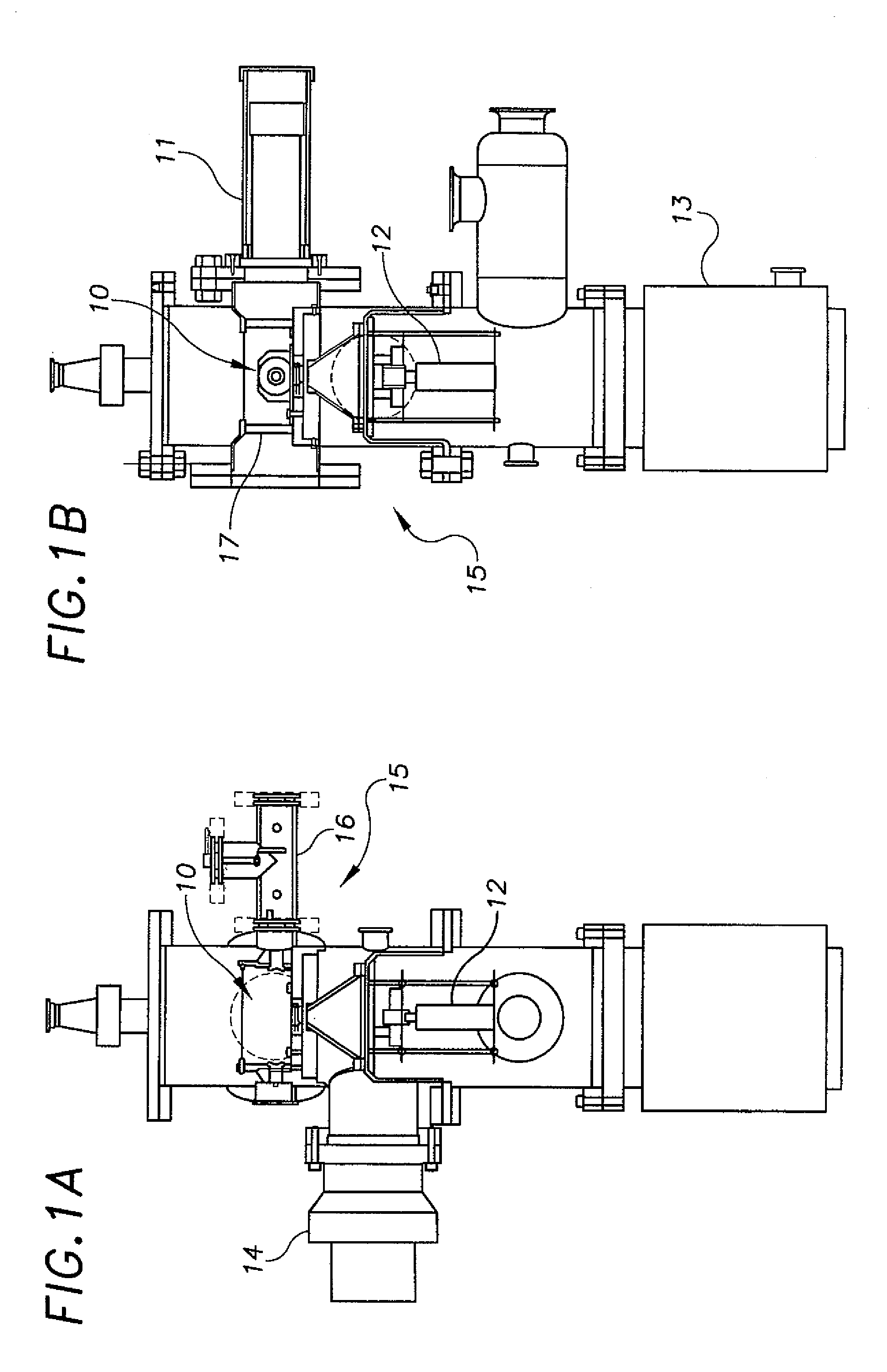

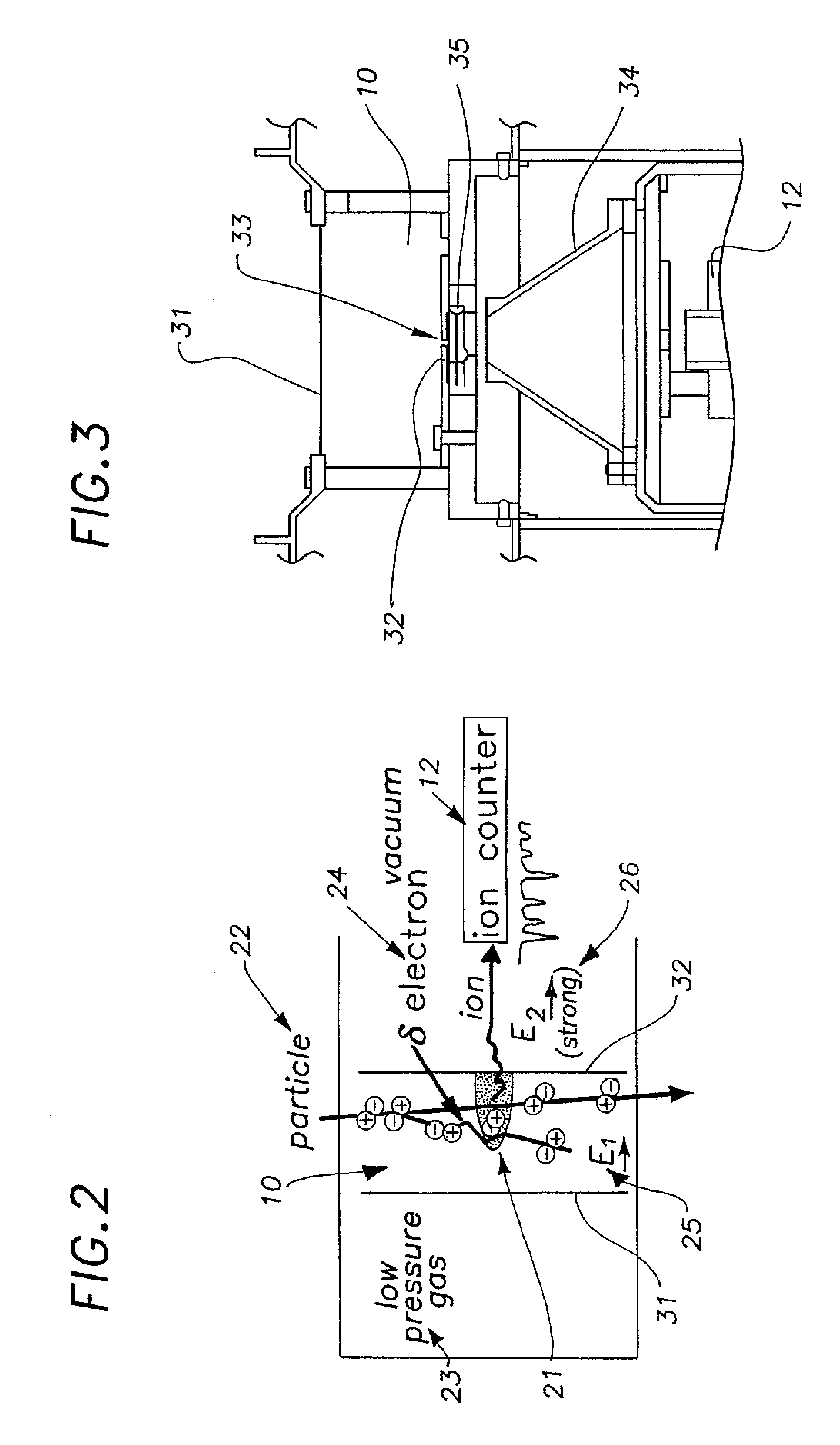

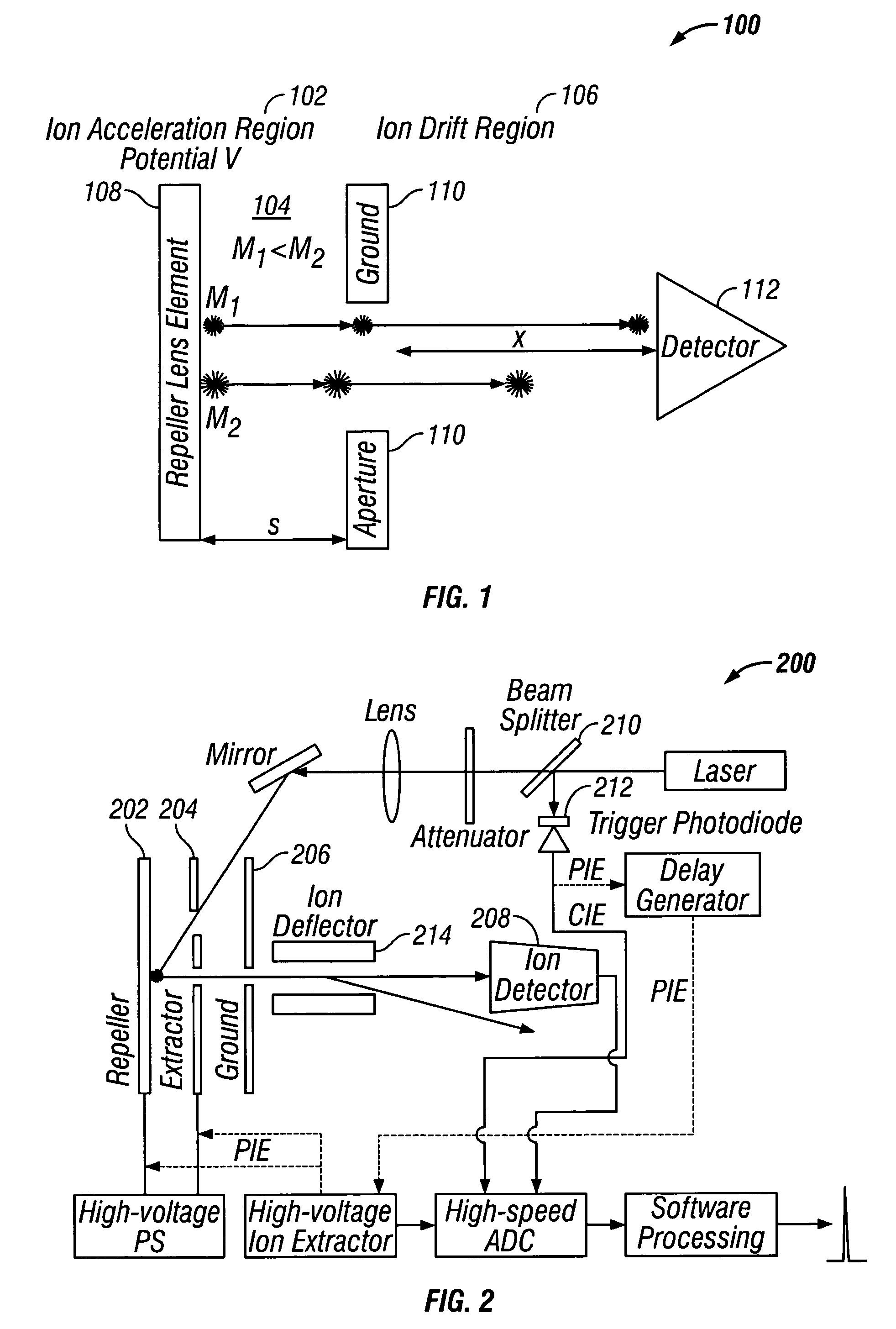

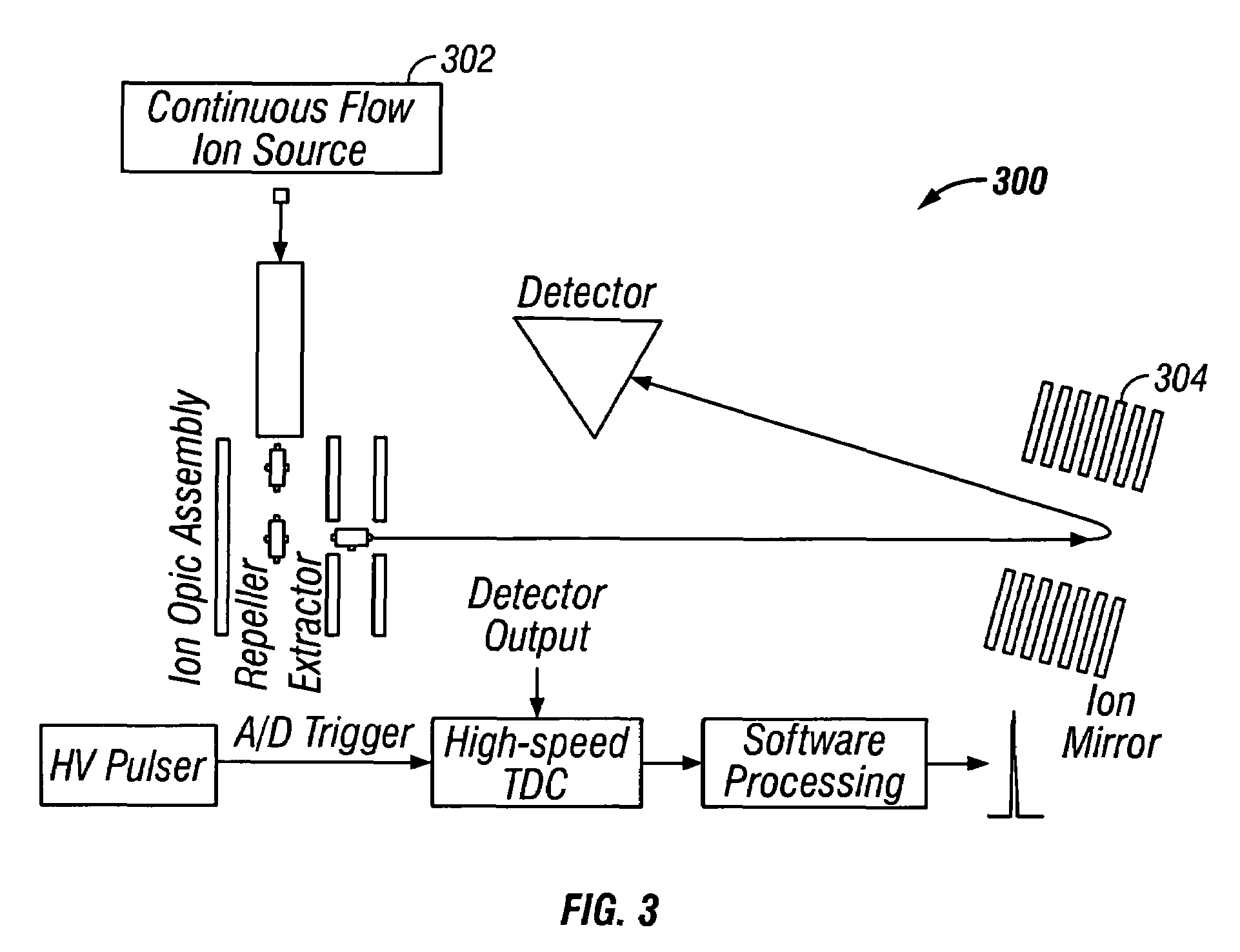

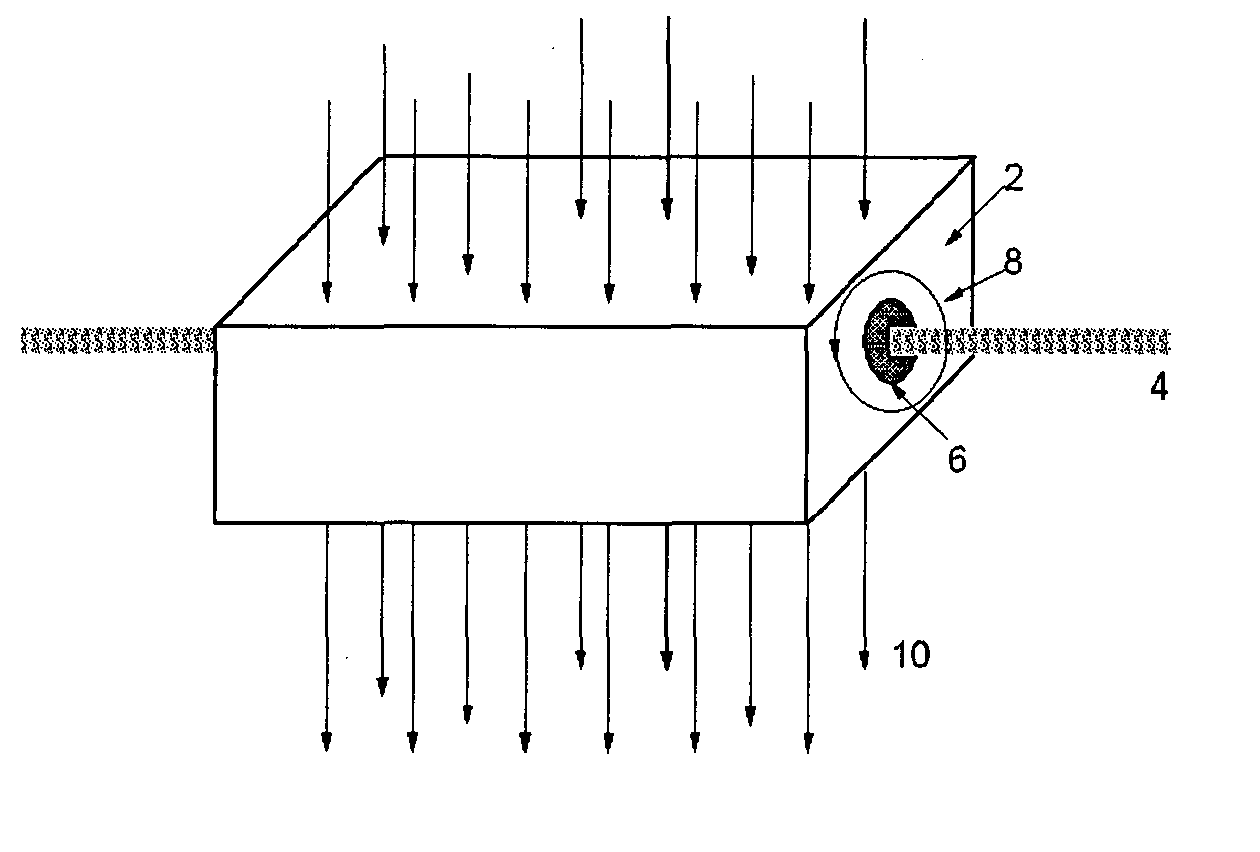

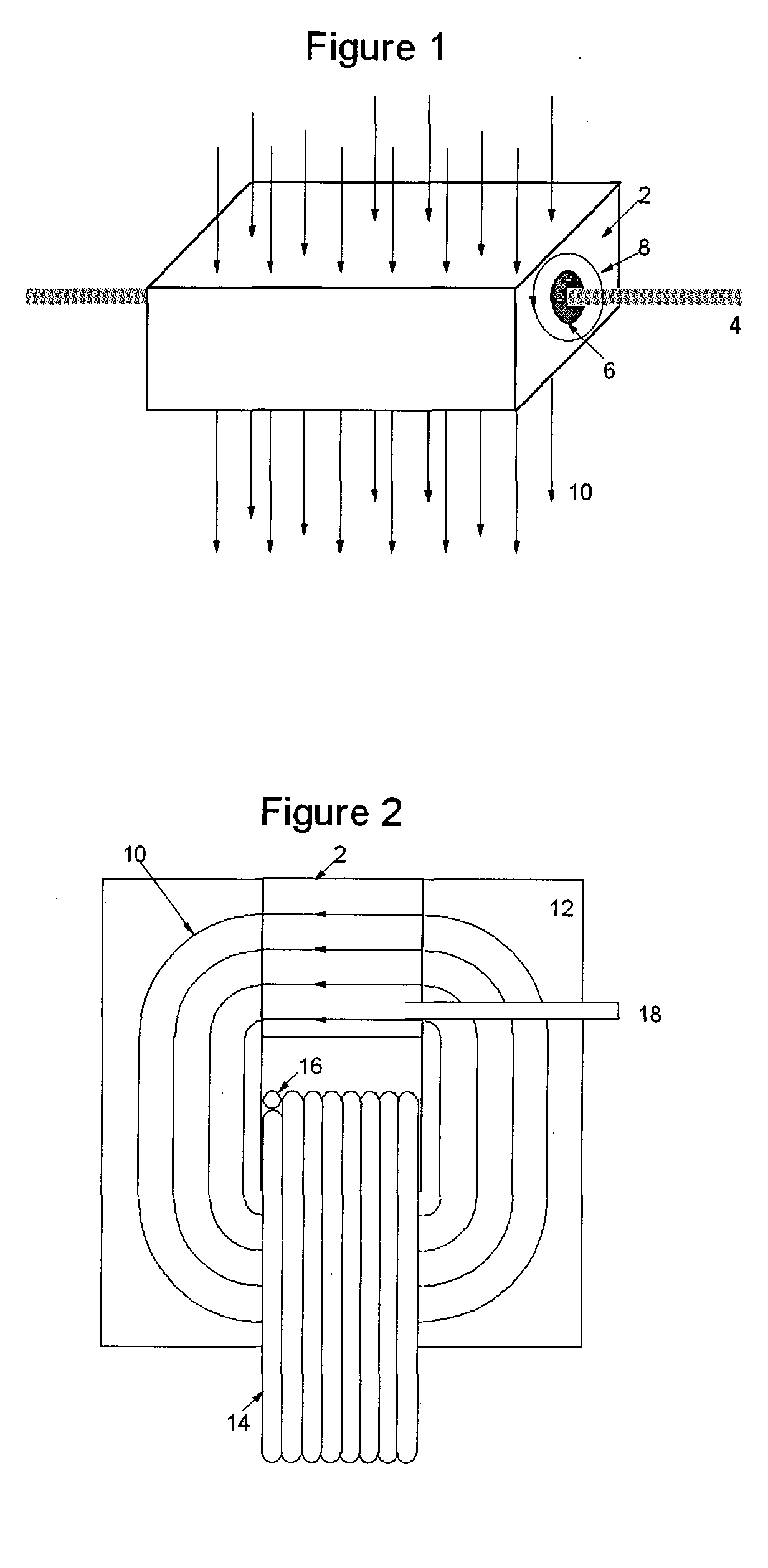

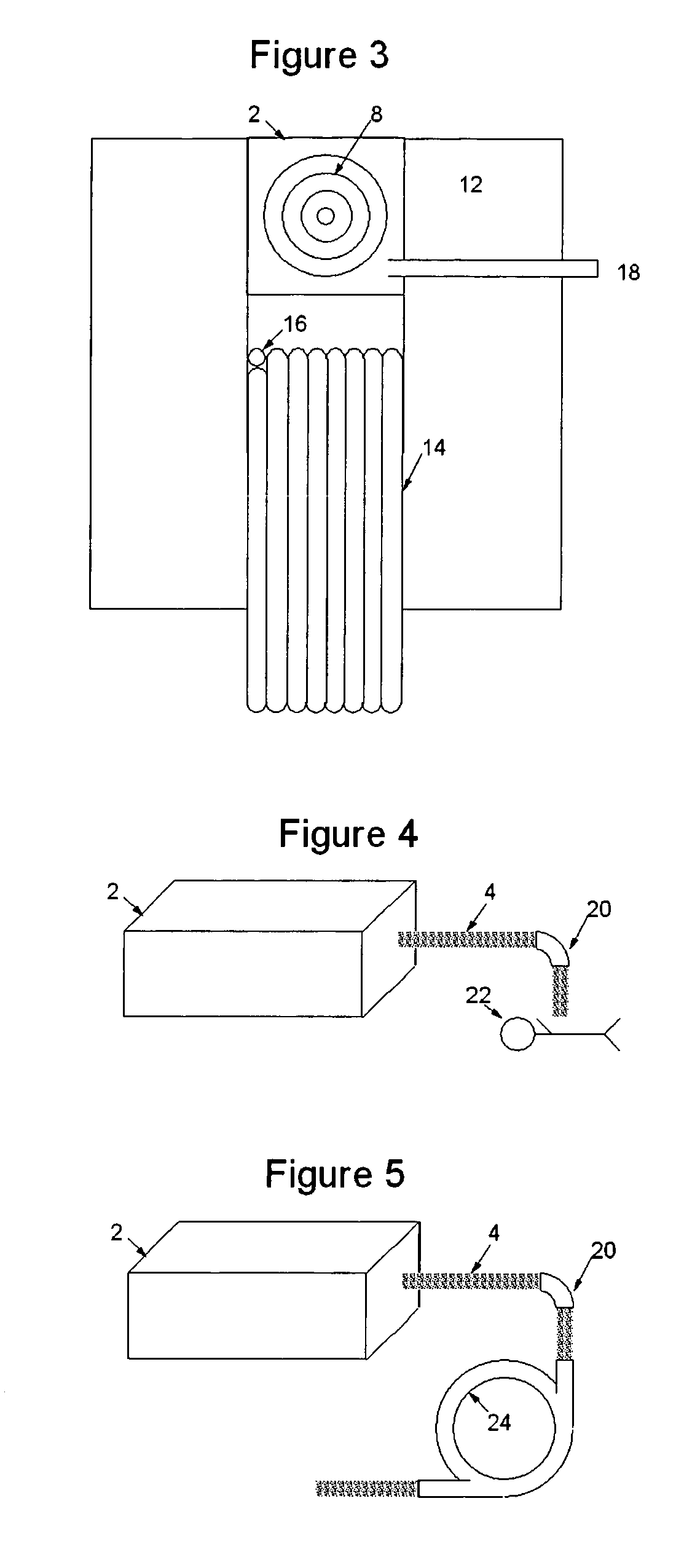

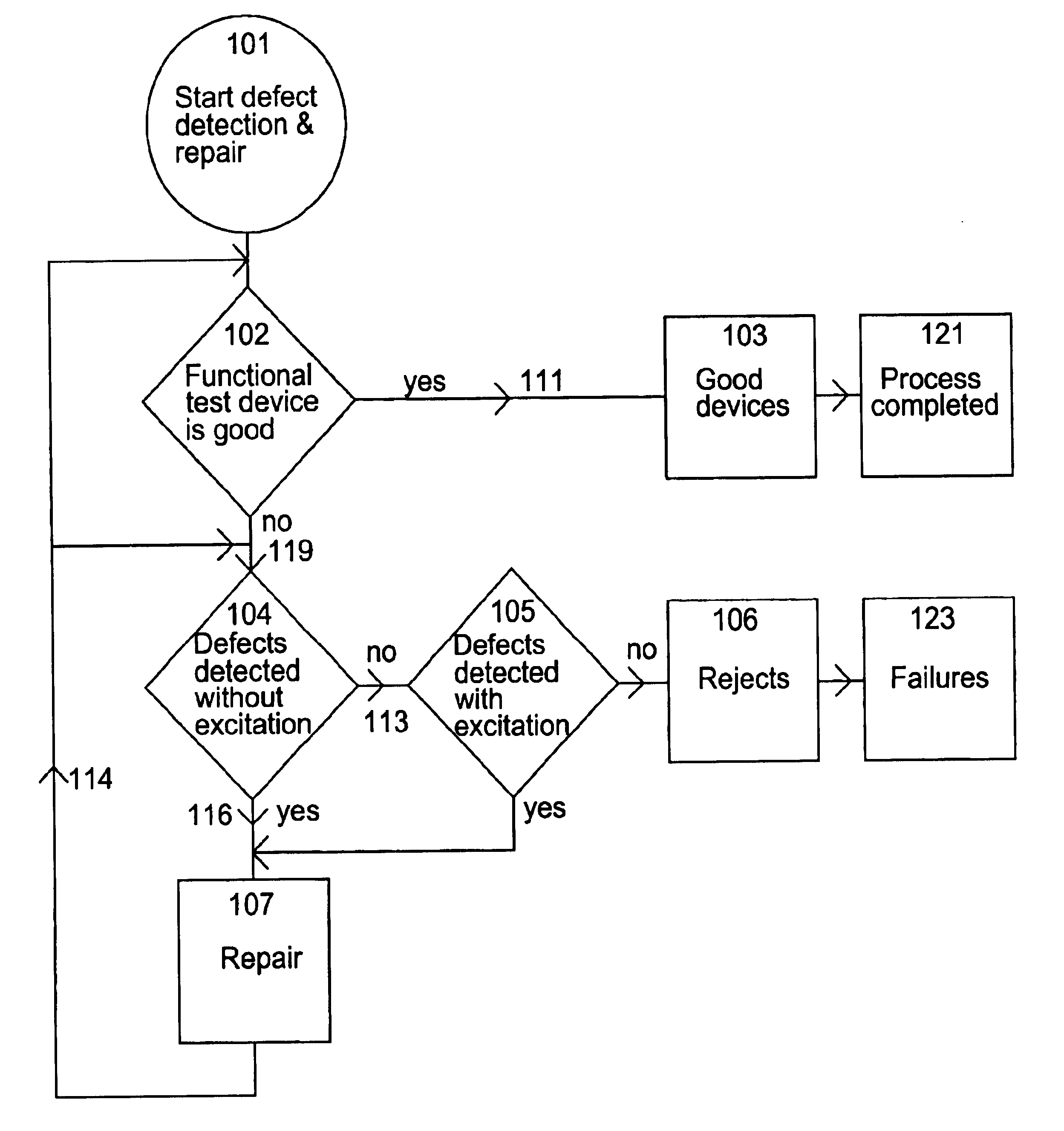

Nanodosimeter based on single ion detection

InactiveUS7081619B2Time-of-flight spectrometersMaterial analysis by electric/magnetic meansFluenceDosimeter

A nanodosimeter device (15) for detecting positive ions induced in a sensitive gas volume by a radiation field of primary particle, comprising an ionization chamber (10) for holding the sensitive gas volume to be irradiated by the radiation field of primary particles; an ion counter system connected to the ionization chamber (10) for detecting the positive ions which pass through the aperture opening and arrive at the ion counter (12) at an arrival time; a particle tracking system for position-sensitive detection of the primary particles passing through the sensitive gas volume; and a data acquisition system capable of coordinating the readout of all data signals and of performing data analysis correlating the arrival time of the positive ions detected by the ion counter system relative to the position sensitive data of primary particles detected by the particle tracking system. The invention further includes the use of the nanodosimeter for method of calibrating radiation exposure with damage to a nucleic acid within a sample. A volume of tissue-equivalent gas is radiated with a radiation field to induce positive ions. The resulting positive ions are measured and compared with a determination of presence or extent of damage resulting from irradiating a nucleic acid sample with an equivalent dose of radiation.

Owner:LOMA LINDA UNIVERSITY +1

Particle beam processing system

InactiveUS6838676B1Decreased beam sizeLow costStability-of-path spectrometersMaterial analysis by optical meansParticle beamParticle physics

A method for slowing and controlling a beam of charged particles includes the steps of superimposing at least one magnetic field on a mass and passing the beam through the mass and at least one magnetic field such that the beam and the mass slows but does not stop the particles. An apparatus for slowing and controlling a beam of charged particles includes a bending magnetic field superimposed on a focusing magnetic field within a mass.

Owner:HBAR TECH LC

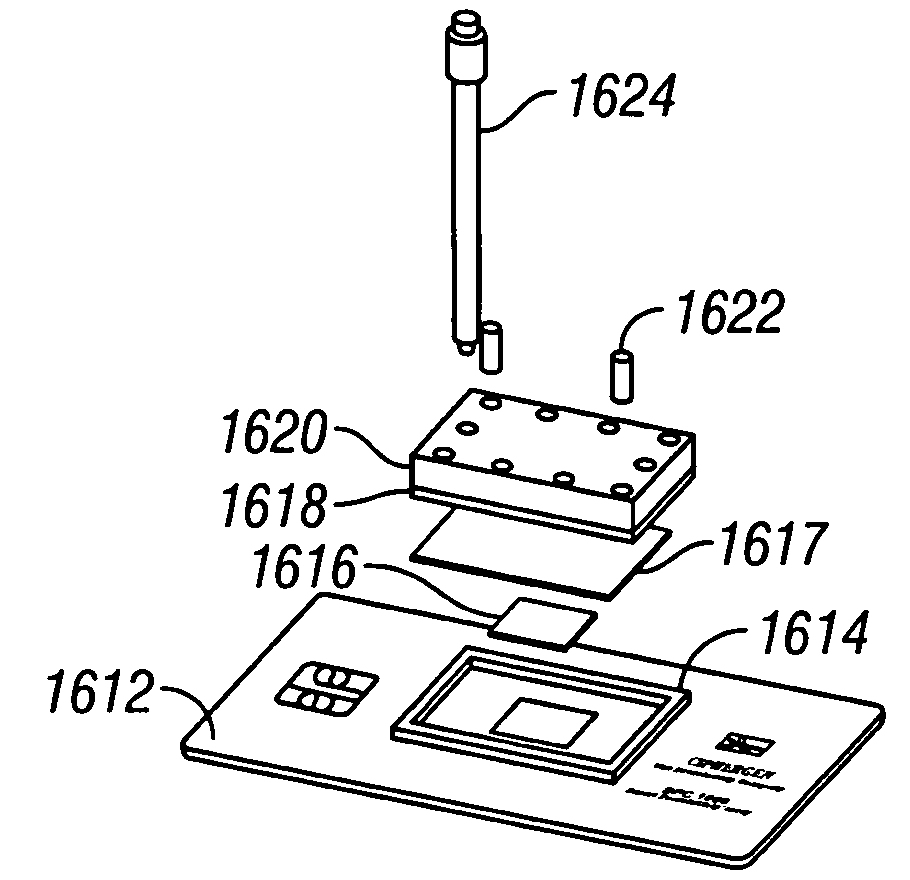

Apparatus for microfluidic processing and reading of biochip arrays

InactiveUS7046357B2Improve performanceParticle separator tubesBeam/ray focussing/reflecting arrangementsAnalyteAnalysis tools

A method and a device for detecting an analyte, including a substrate having a chemically selective surface; and a fluidic system disposed on the substrate, the manifold having at least one fluid path in communication with at least a discrete region of the surface, wherein the one fluid path and the discrete region together define a contained sample region on the surface. The fluidic system has a removable portion, wherein the removal of the removable portion of the fluidic system renders the discrete region directly interrogatable by a surface-based analytical tool.

Owner:BIO RAD LAB INC

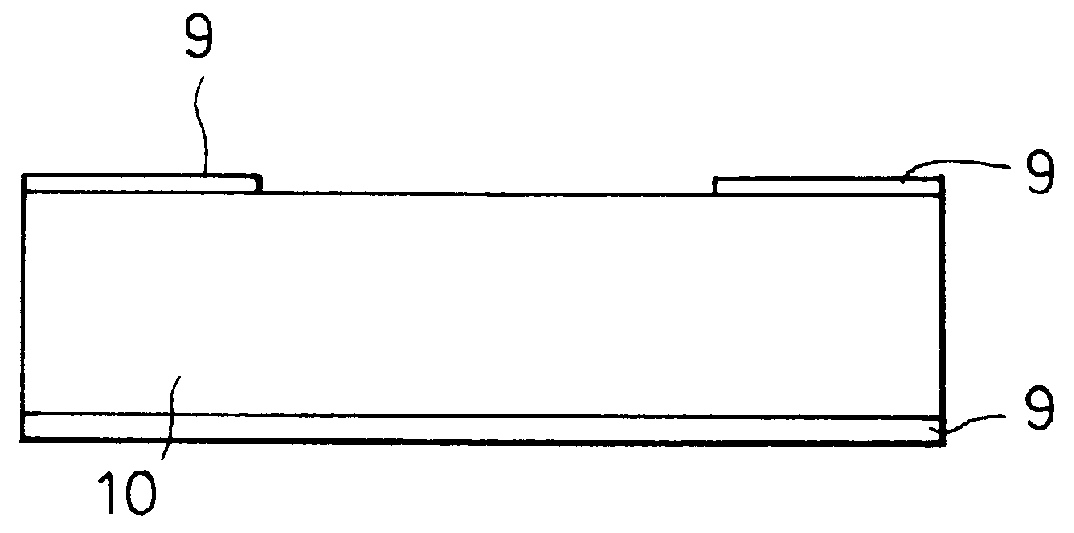

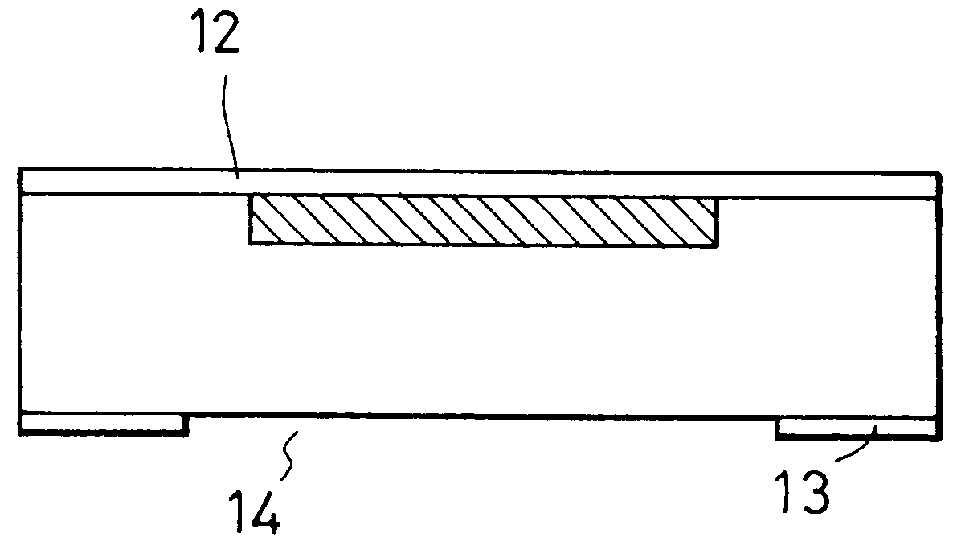

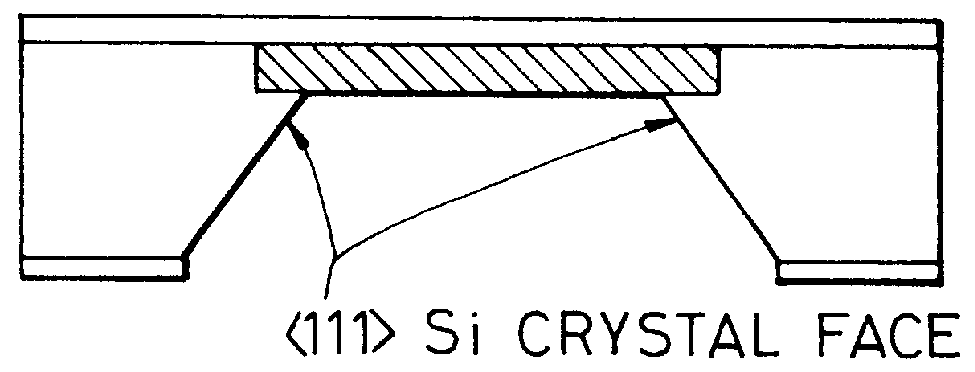

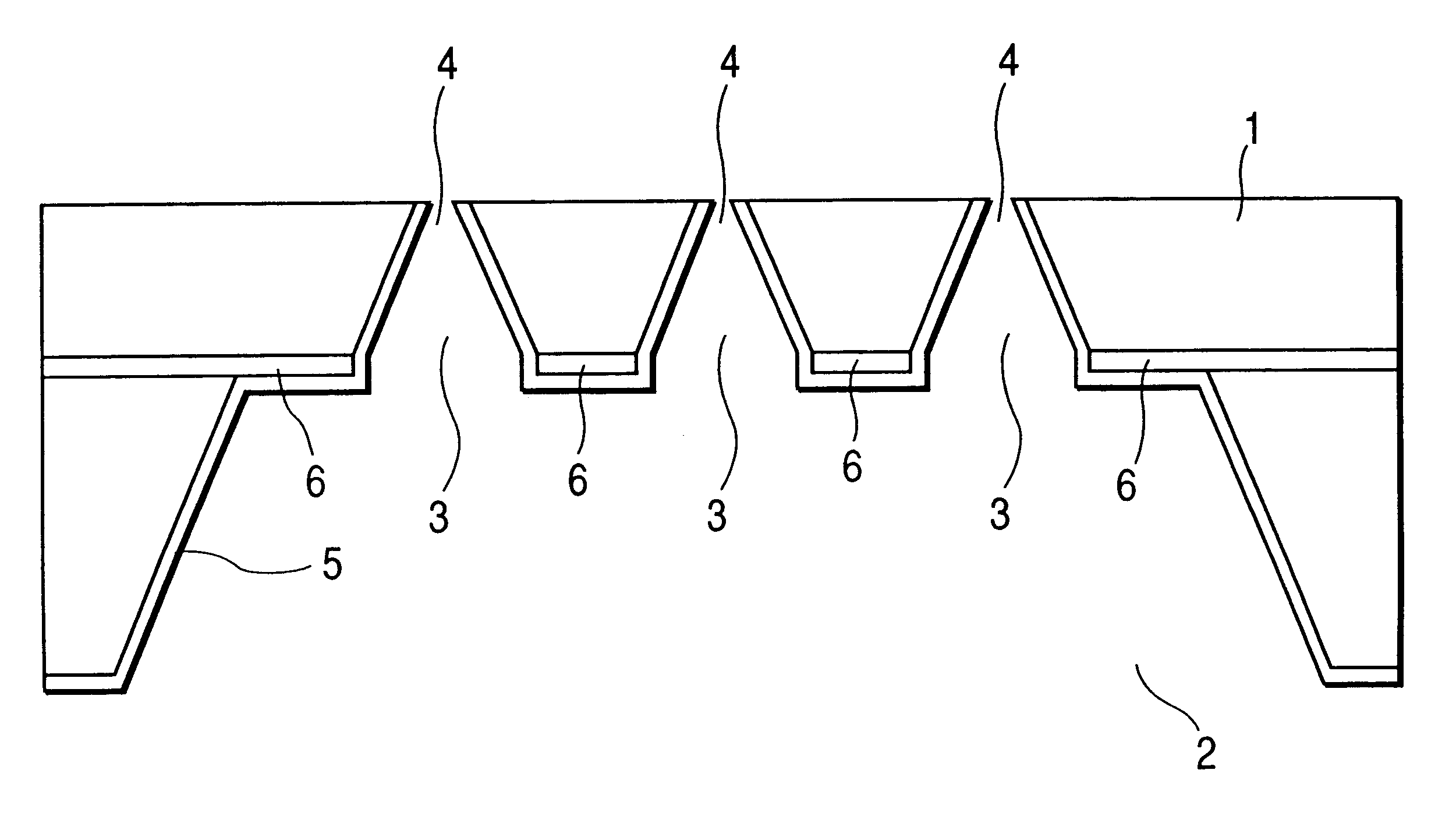

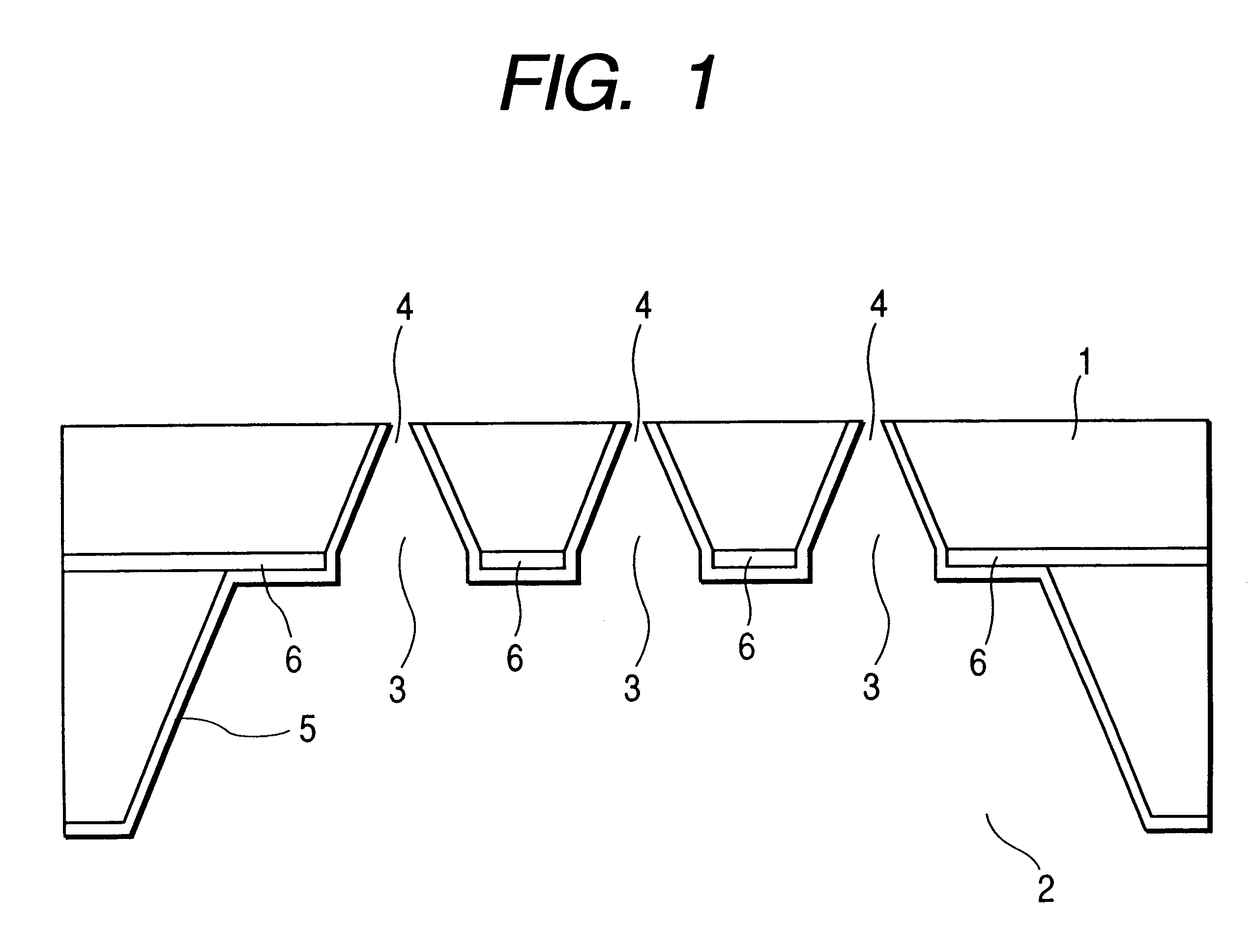

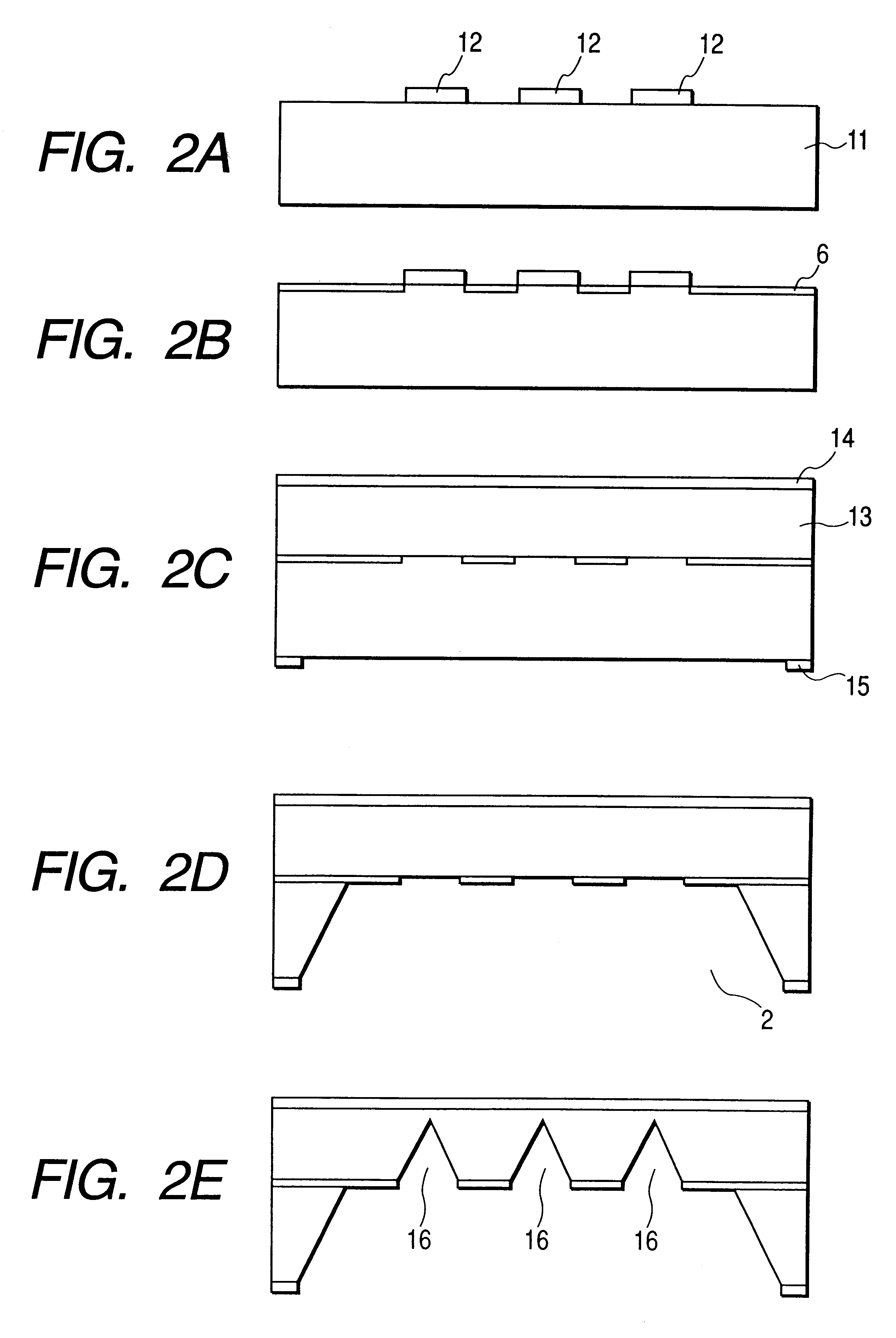

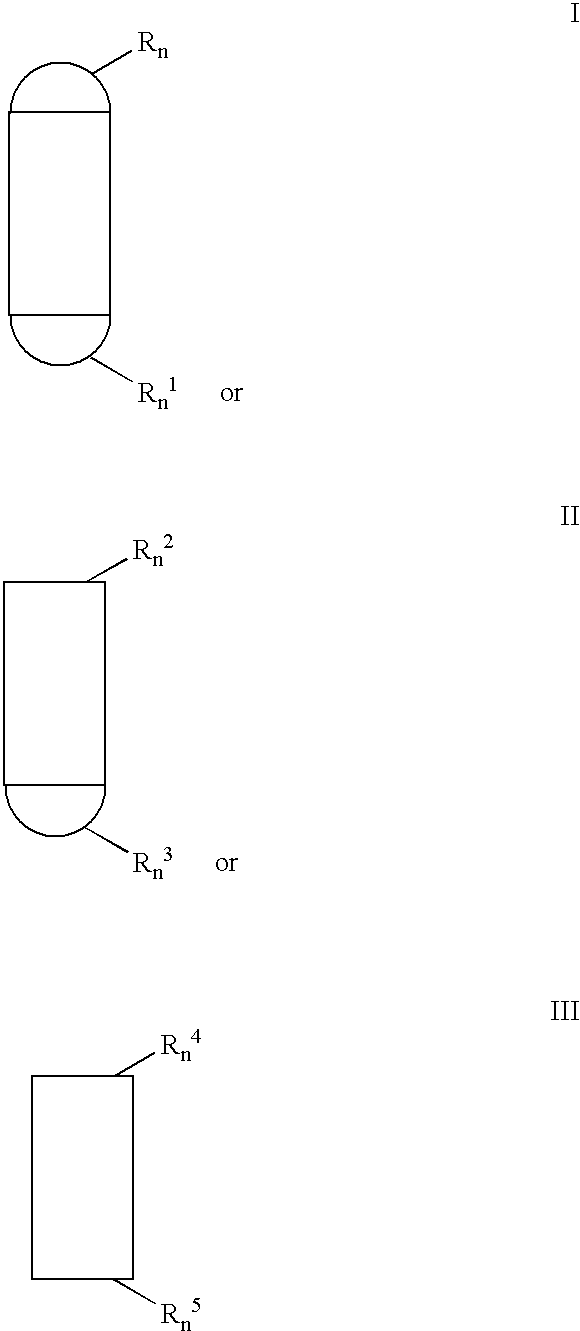

Method of producing a through-hole, silicon substrate having a through-hole, device using such a substrate, method of producing an ink-jet print head, and ink-jet print head

The invention provides a method of producing a through-hole, a substrate used to produce a through-hole, a substrate having a through-hole, and a device using such a through-hole or a substrate having such a through-hole, which are characterized in that: a through-hole can be produced only by etching a silicon substrate from its back side; the opening length d can be precisely controlled to a desired value regardless of the variations in the silicon wafer thickness, and the orientation flat angle, and also regardless of the type of a silicon crystal orientation-dependent anisotropic etchant employed; high productivity, high production reproducibility, and ease of production can be achieved; a high-liberality can be achieved in the shape of the opening end even if temperature treatment is performed at a high temperature for a long time; and a high-precision through-hole can be produced regardless of the shape of a device formed on the surface of a substrate.

Owner:CANON KK

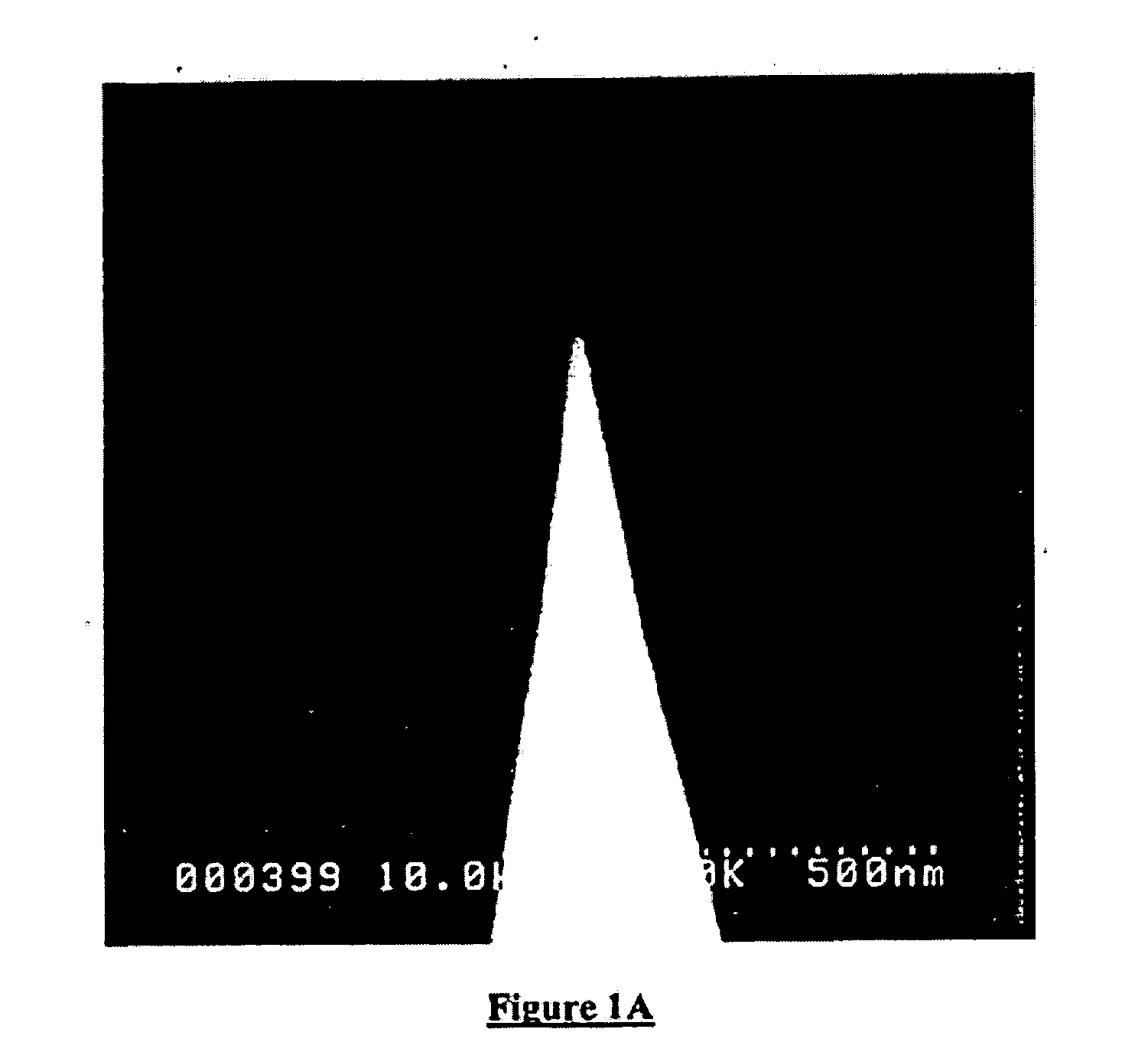

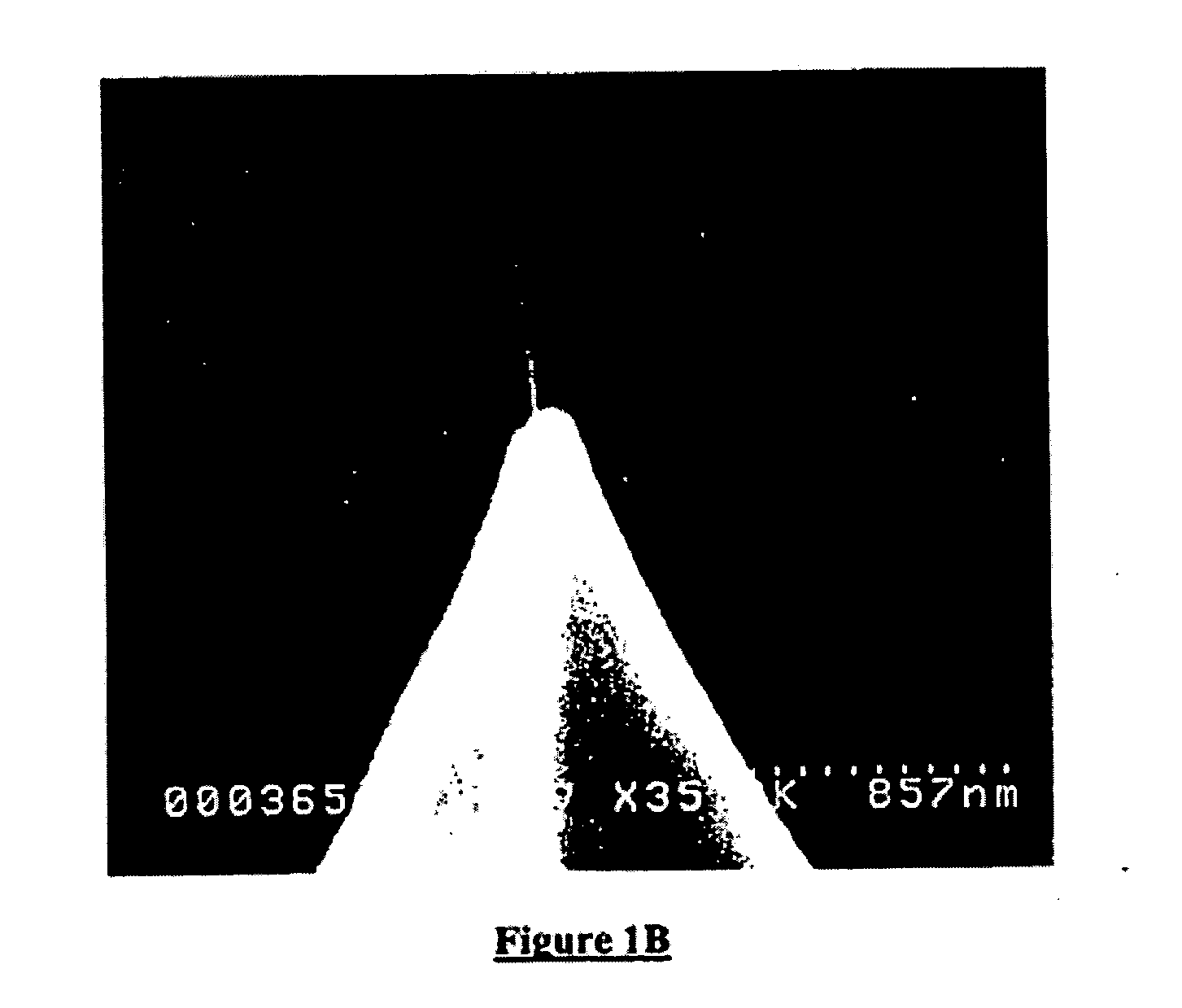

Optical probe for detecting or irradiating light and near-field optical microscope having such probe and manufacturing method of such probe

InactiveUS6215114B1Beam/ray focussing/reflecting arrangementsMaterial analysis by optical meansLight irradiationNear field optical microscope

An optical prove for detecting or irradiating evanescent light is manufactured by forming a film having a regulated film thickness on a substrate, then forming a recess from the rear surface of the substrate, and forming a through hole in the film from the side of the recess by etching. The obtained optical probe has a micro-aperture at the tip of the through hole and usually, a plurality of optical probes each having a micro-aperture of uniform profile are formed on a single substrate. In the recess, light-receiving or light-irradiating means may be provided.

Owner:CANON KK

Method and apparatus for a network-based mask defect printability analysis system

InactiveUS6578188B1Minimal additional costCode for implementing the network server is extremely robustImage enhancementNanotechThe InternetSimulation

A mask defect printability simulation server provides simulations, one-dimensional analysis, and reports to multiple clients over a wide area network, such as the Internet. This network-based simulation server allows a client to leverage a core of highly-trained engineers. Additionally, the network-based simulation server can be easily supported since only a single source for the tools associated with the simulation server is necessary for multiple clients. A client can access the simulation server using a standard personal computer having a browser, thereby eliminating the need for client to maintain an expensive database for the server. Finally, in the network-based simulation server, multiple users can view the same mask defect image and provide real-time comments to each other as simulation and analysis are performed on the defect image, thereby encouraging problem solving and decision-making dialogue among the users.

Owner:SYNOPSYS INC

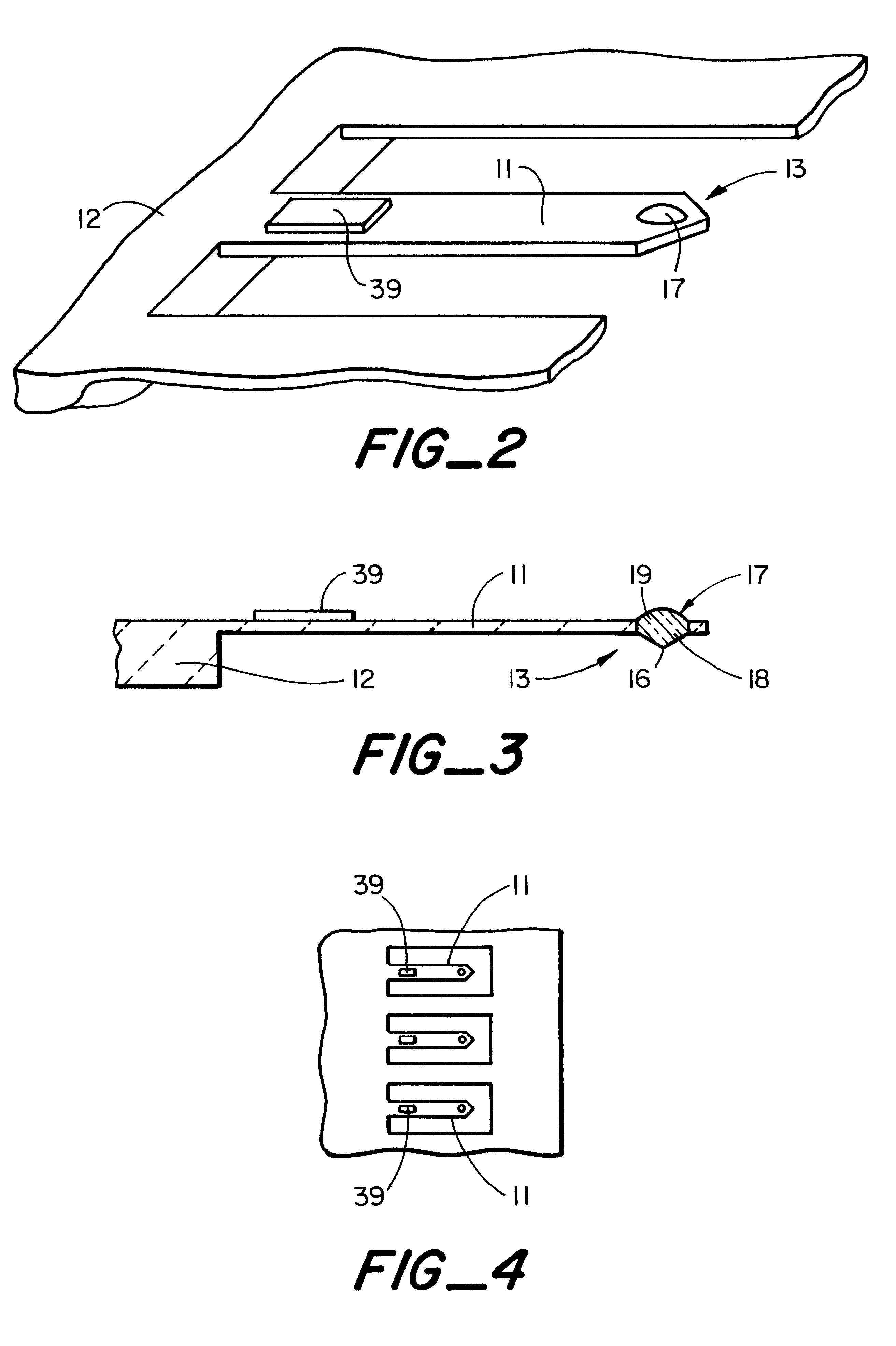

Near field optical scanning system employing microfabricated solid immersion lens

A solid immersion lens integrated on a flexible support such as a cantilever or membrane is described, together with a method of forming the integrated structure.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

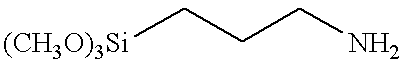

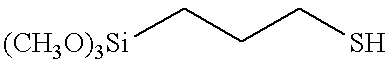

Organo luminescent semiconductor nanocrystal probes for biological applications and process for making and using such probes

A semiconductor nanocrystal compound is described capable of linking to an affinity molecule. The compound comprises (1) a semiconductor nanocrystal capable of emitting electromagnetic radiation and / or absorbing energy, and / or scattering or diffracting electromagnetic radiation—when excited by an electromagnetic radiation source or a particle beam; and (2) at least one linking agent, having a first portion linked to the semiconductor nanocrystal and a second portion capable of linking to an affinity molecule. The compound is linked to an affinity molecule to form a semiconductor nanocrystal probe capable of bonding with a detectable substance. Subsequent exposure to excitation energy will excite the semiconductor nanocrystal in the probe causing the emission of electromagnetic radiation. Further described are processes for respectively: making the luminescent semiconductor nanocrystal compound; making the semiconductor nanocrystal probe; and using the probe to determine the presence of a detectable substance in a material.

Owner:RGT UNIV OF CALIFORNIA

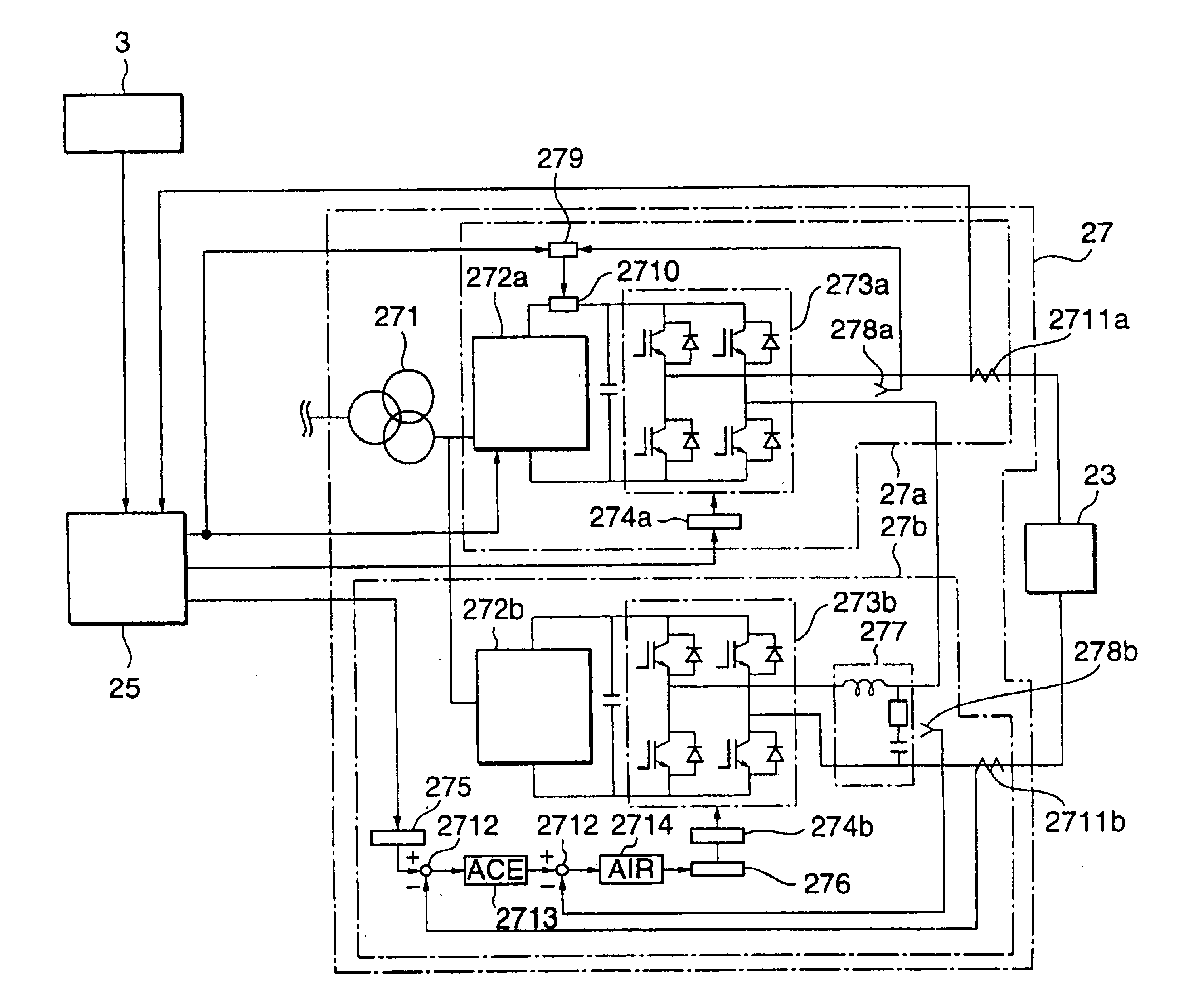

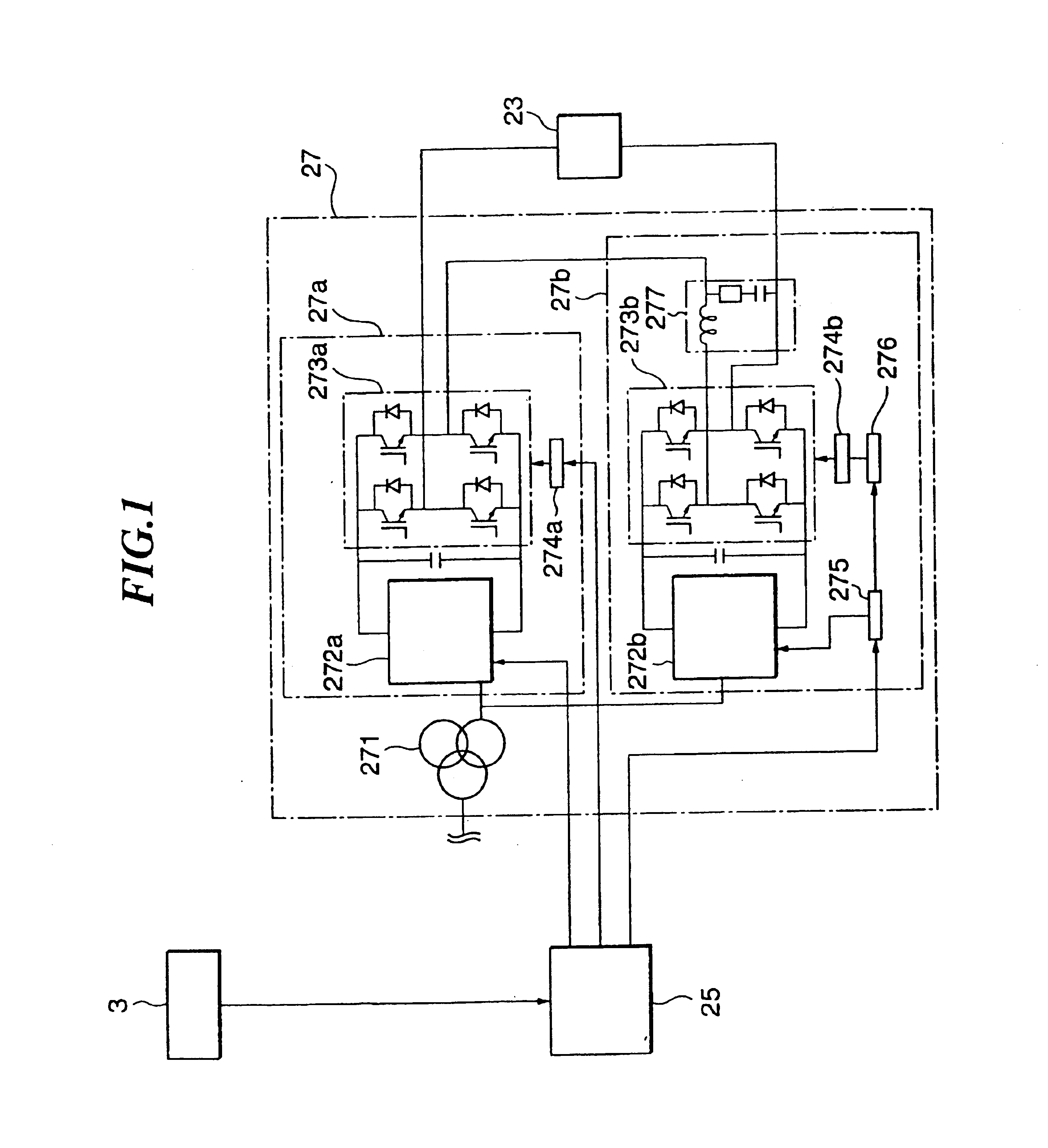

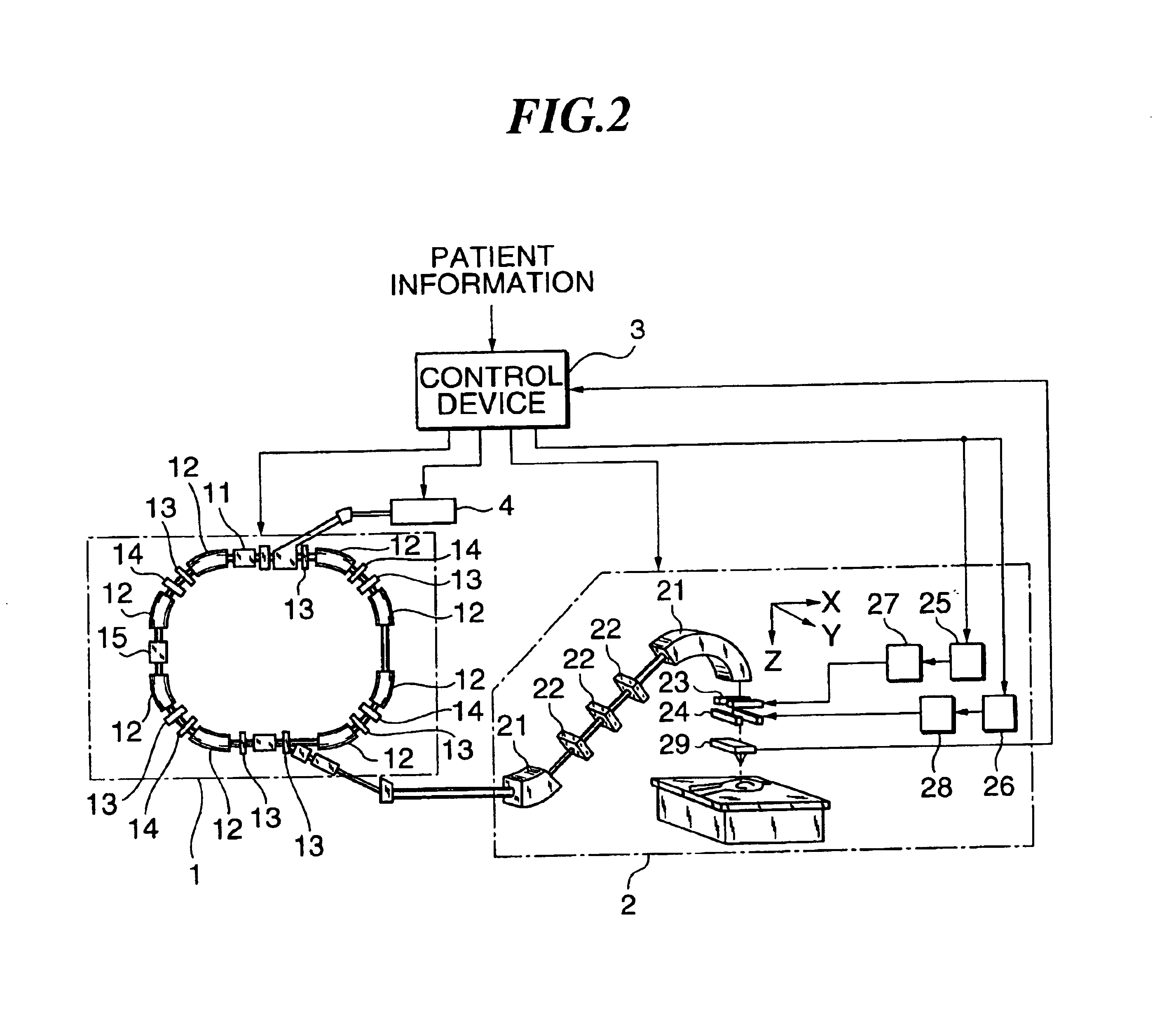

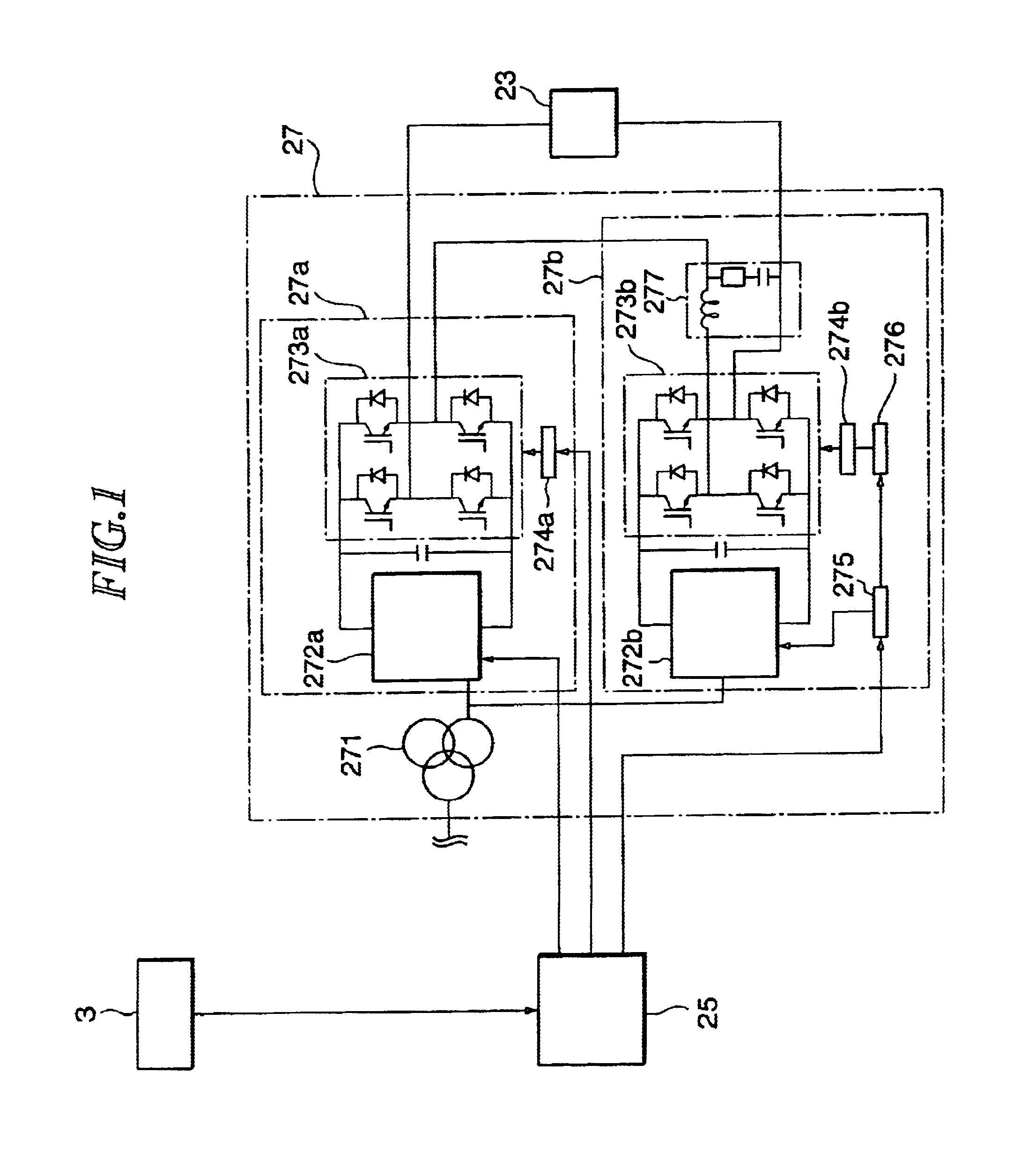

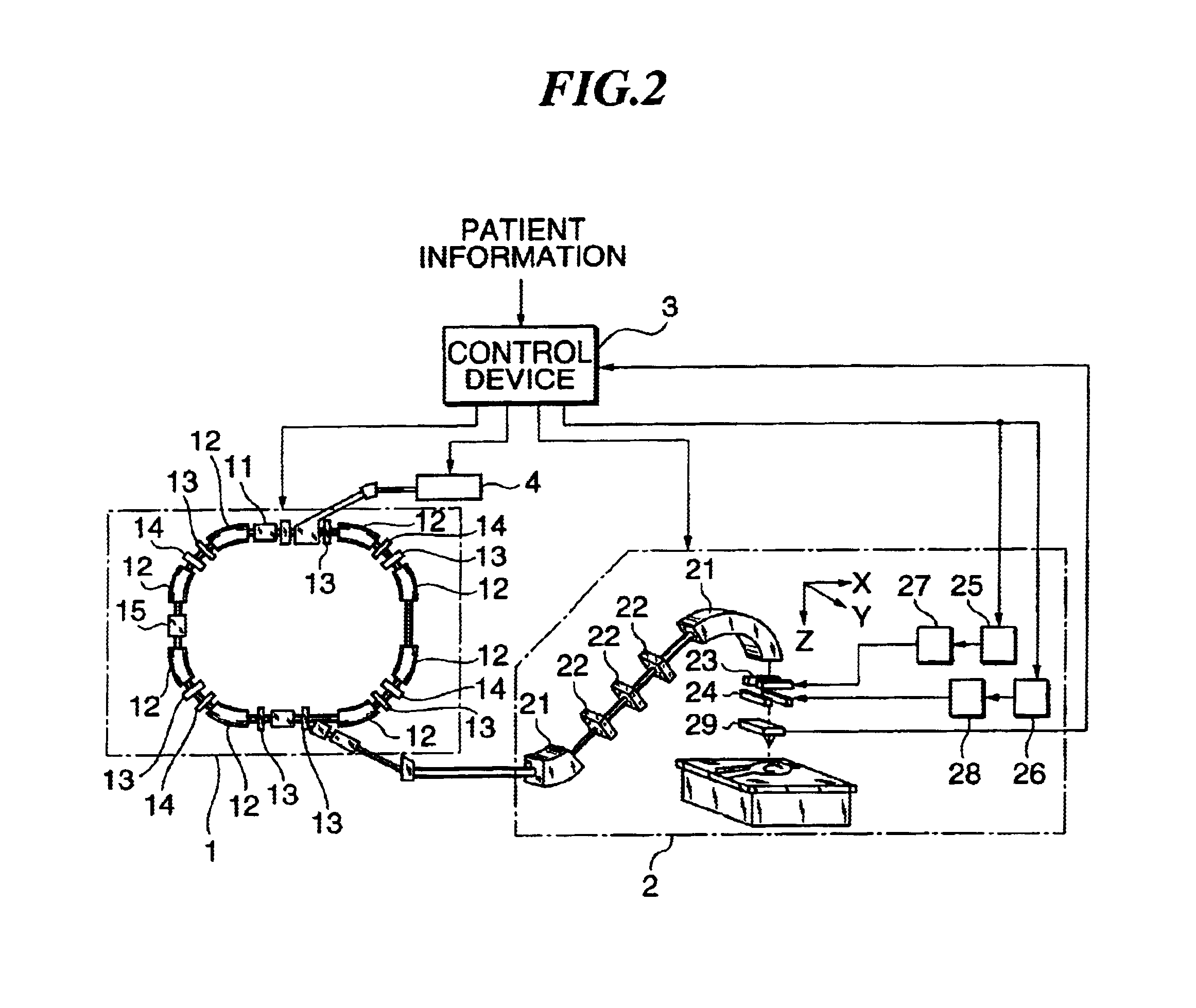

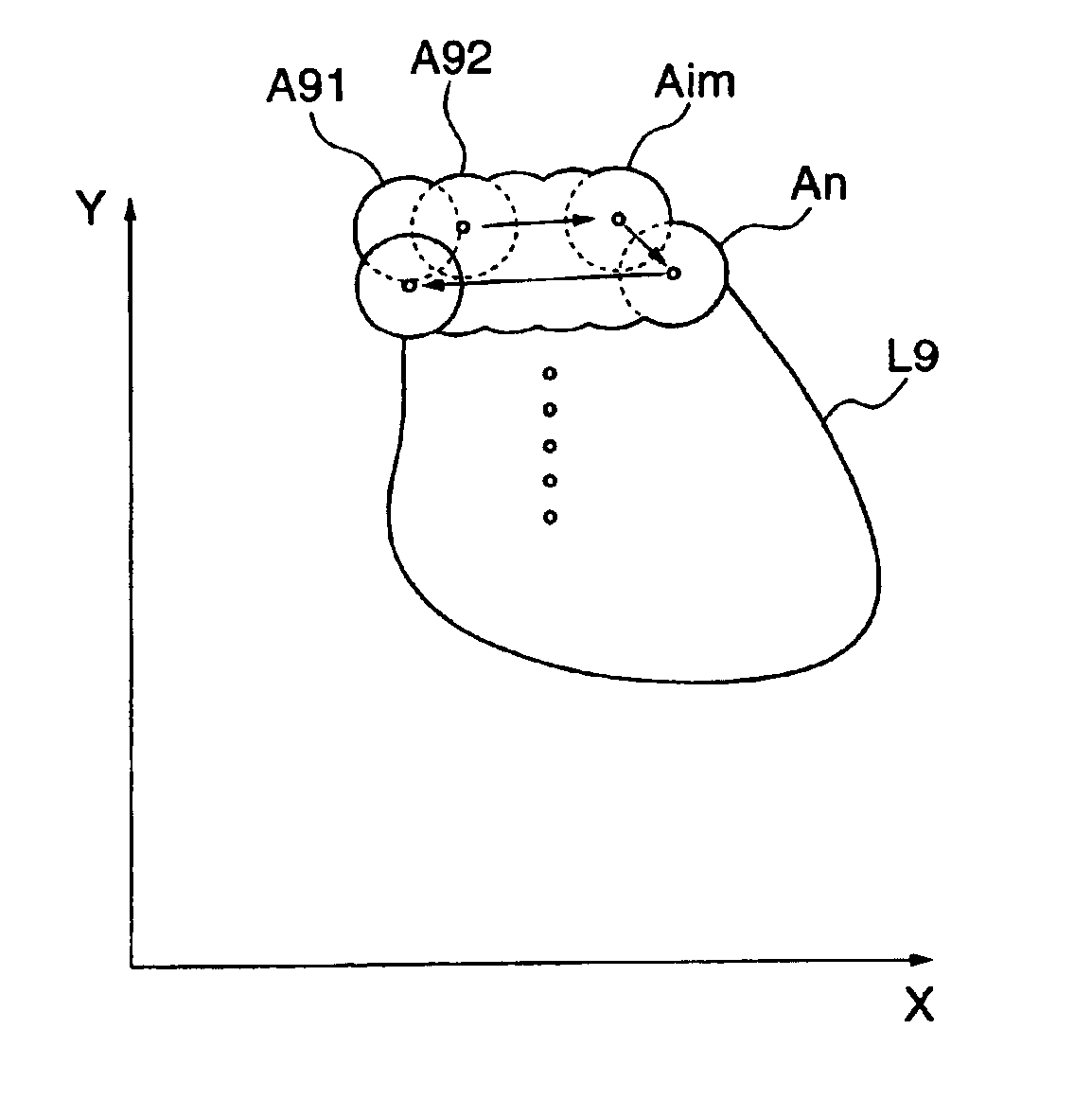

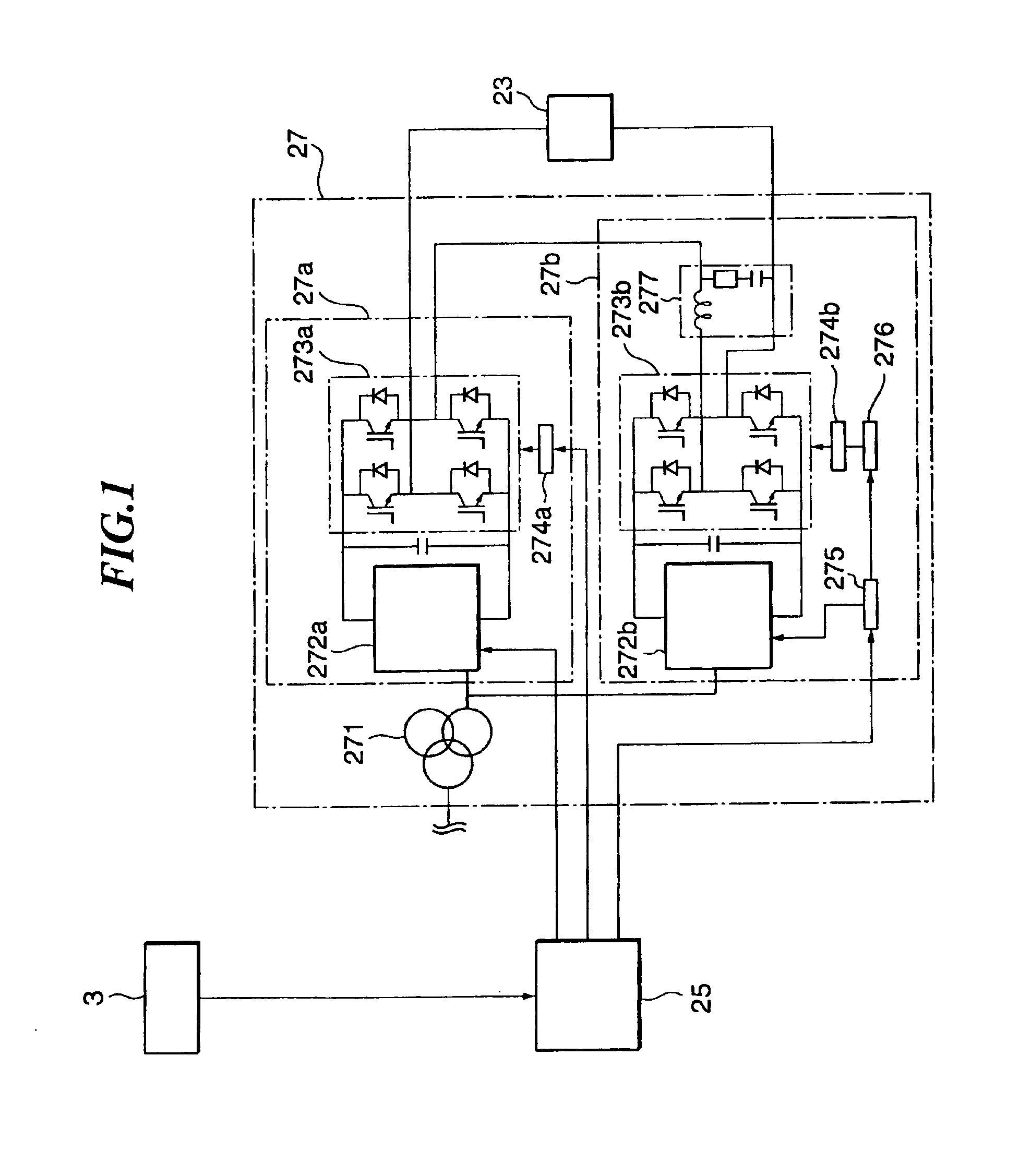

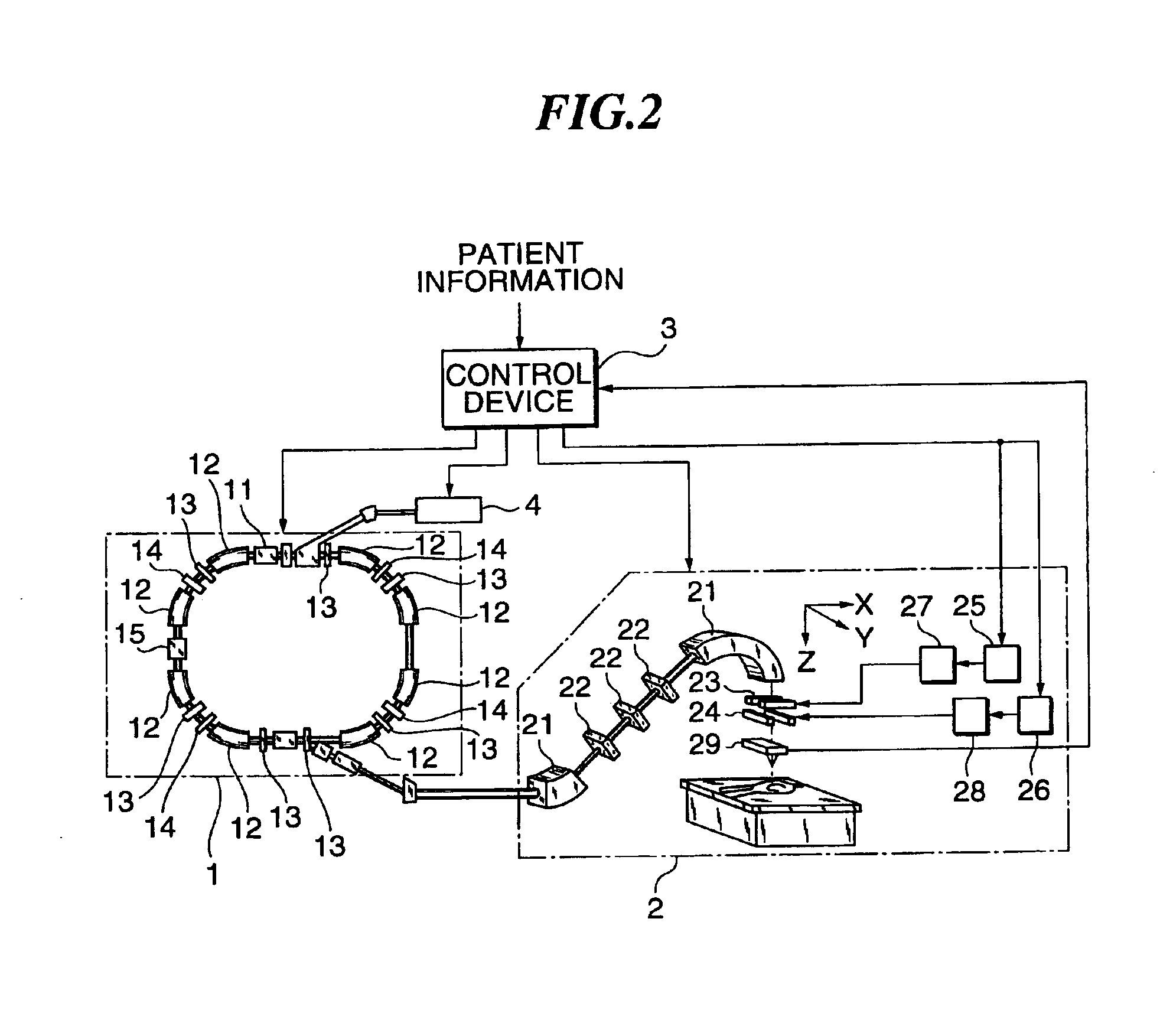

Charged particle beam irradiation equipment and control method thereof

InactiveUS6881970B2Short timeIrradiation time can be shortenedThermometer detailsStability-of-path spectrometersParticle physicsElectrical current

A power supply for applying a voltage to a scanning electromagnet for deflecting a charged particle beam has a first power supply unit having no filter and a second power supply unit having a filter. When an irradiation position of the charged particle beam in an irradiation object is moved, the first power supply unit, namely a power supply unit having no filter, is used to apply the voltage to the scanning electromagnet, so that an exciting current flowing in the scanning electromagnet can be changed in a short time. Further, when the irradiation position of the charged particle beam is maintained, the second power supply is used to apply a voltage whose pulsating component was removed to the scanning electromagnet, so that the exciting current flowing in the scanning electromagnet can be controlled precisely. Consequently, the charged particle beam can be applied uniformly to the irradiation object and an irradiation time of the charged particle beam to the irradiation object can be curtailed.

Owner:HITACHI LTD

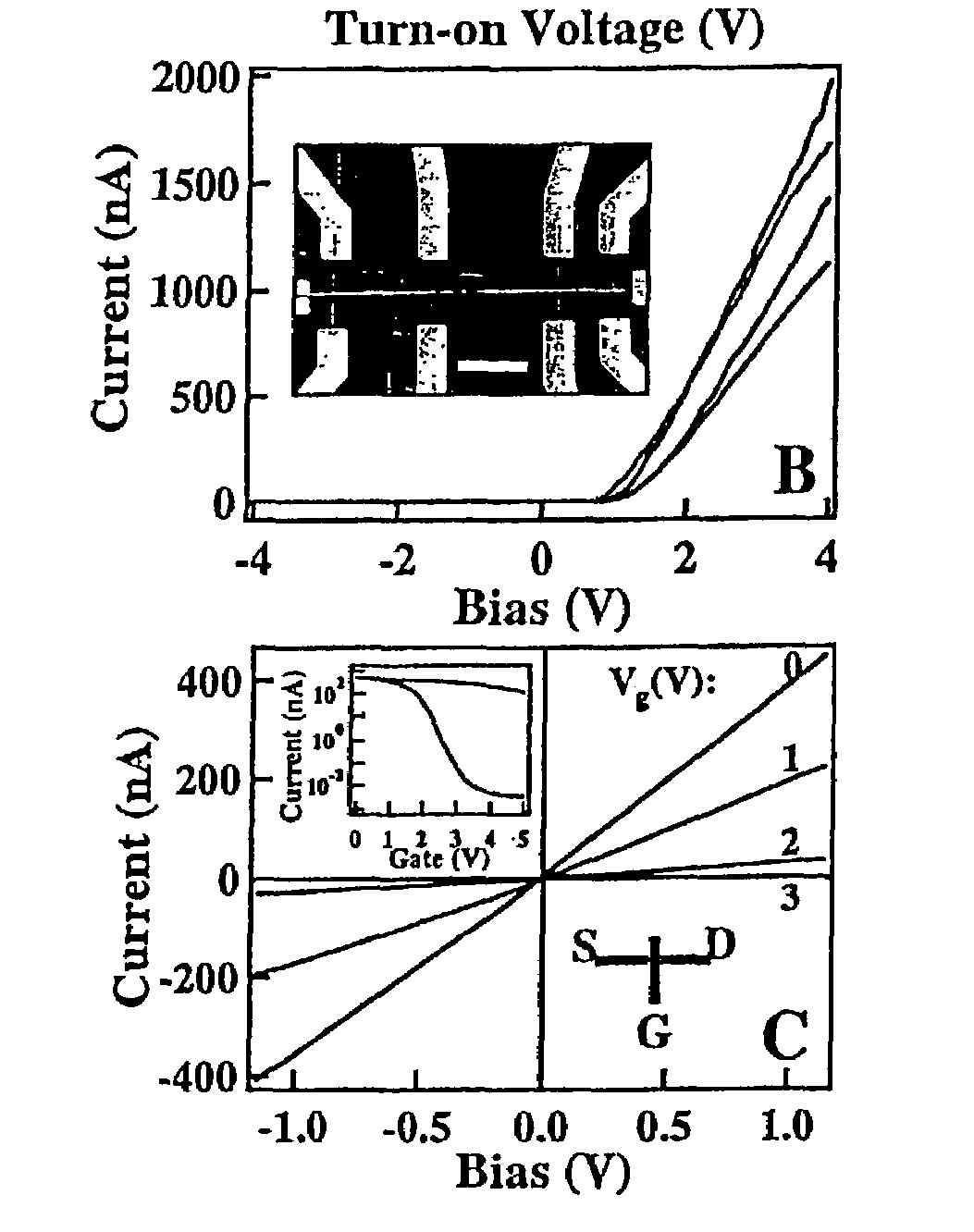

Nanoscale wires and related devices

InactiveUS7301199B2Material nanotechnologySemiconductor/solid-state device detailsDopantTunnel diode

The present invention relates generally to sub-microelectronic circuitry, and more particularly to nanometer-scale articles, including nanoscale wires which can be selectively doped at various locations and at various levels. In some cases, the articles may be single crystals. The nanoscale wires can be doped, for example, differentially along their length, or radially, and either in terms of identity of dopant, concentration of dopant, or both. This may be used to provide both n-type and p-type conductivity in a single item, or in different items in close proximity to each other, such as in a crossbar array. The fabrication and growth of such articles is described, and the arrangement of such articles to fabricate electronic, optoelectronic, or spintronic devices and components. For example, semiconductor materials can be doped to form n-type and p-type semiconductor regions for making a variety of devices such as field effect transistors, bipolar transistors, complementary inverters, tunnel diodes, light emitting diodes, sensors, and the like.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

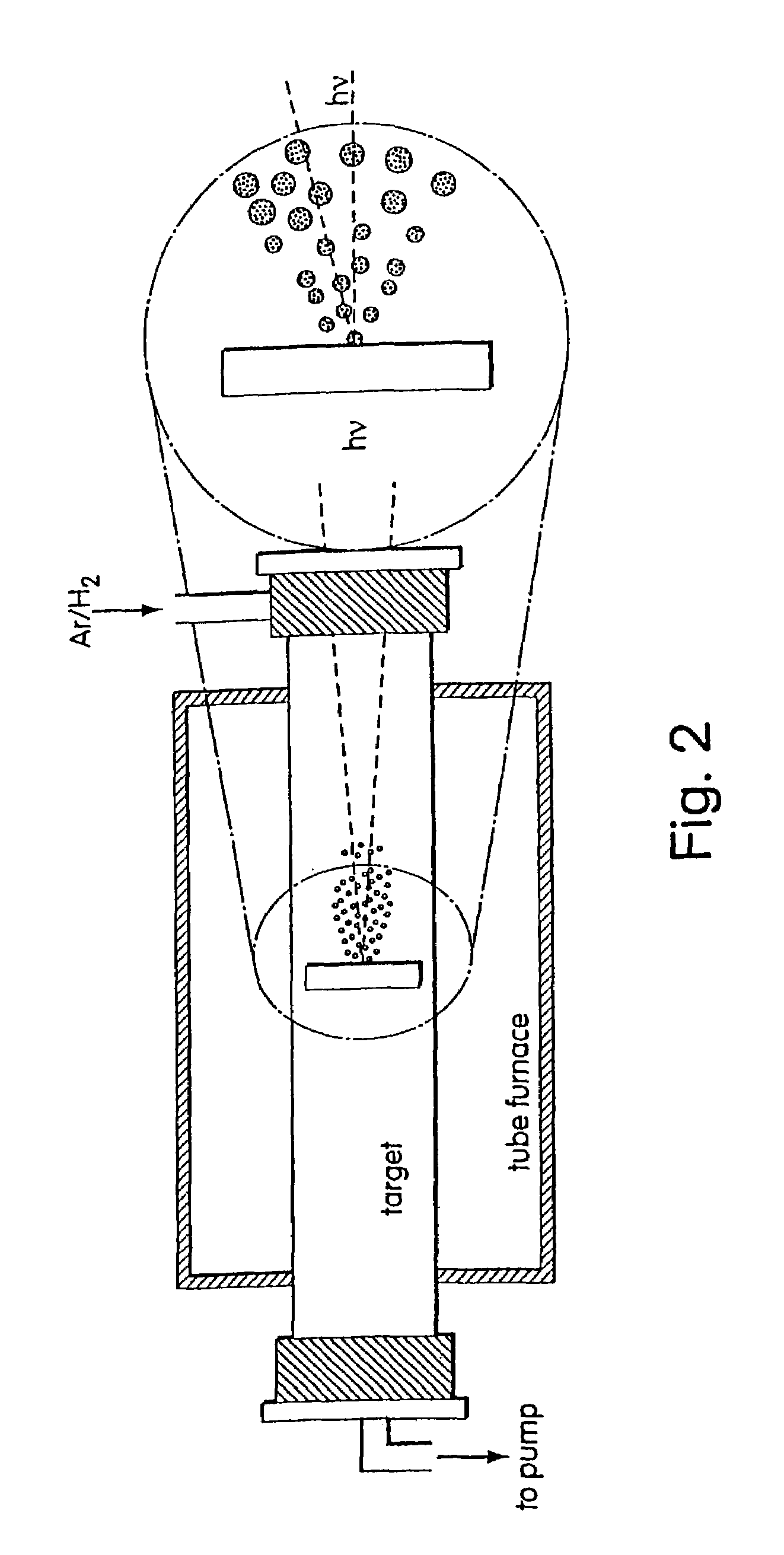

Method for purification of as-produced single-wall carbon nanotubes

InactiveUS20020127169A1High yieldNanostructure manufactureSpecial paperSolar cellSingle-Walled Nanotube

A method for purifying a mixture comprising single-wall carbon nanotubes and amorphous carbon contaminate is disclosed. The method includes the steps of heating the mixture under oxidizing conditions sufficient to remove the amorphous carbon, followed by recovering a product comprising at least about 80% by weight of single-wall carbon nanotubes. A method for producing tubular carbon molecules of about 5 to 500 nm in length is also disclosed. The method includes the steps of cutting single-wall nanotube containing-material to form a mixture of tubular carbon molecules having lengths in the range of 5-500 nm and isolating a fraction of the molecules having substantially equal lengths. The nanotubes may be used, singularly or in multiples, in power transmission cables, in solar cells, in batteries, as antennas, as molecular electronics, as probes and manipulators, and in composites.

Owner:RICE UNIV

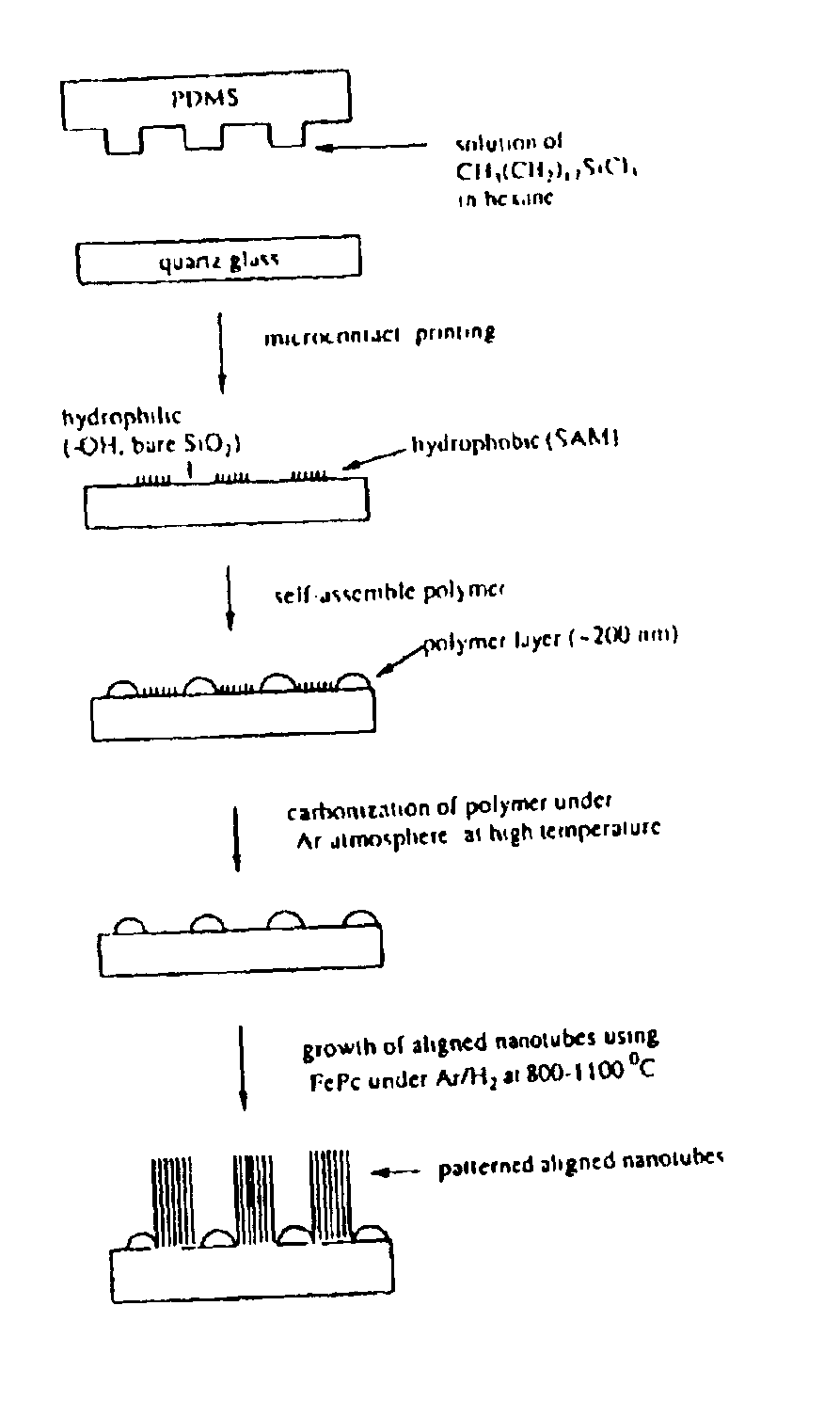

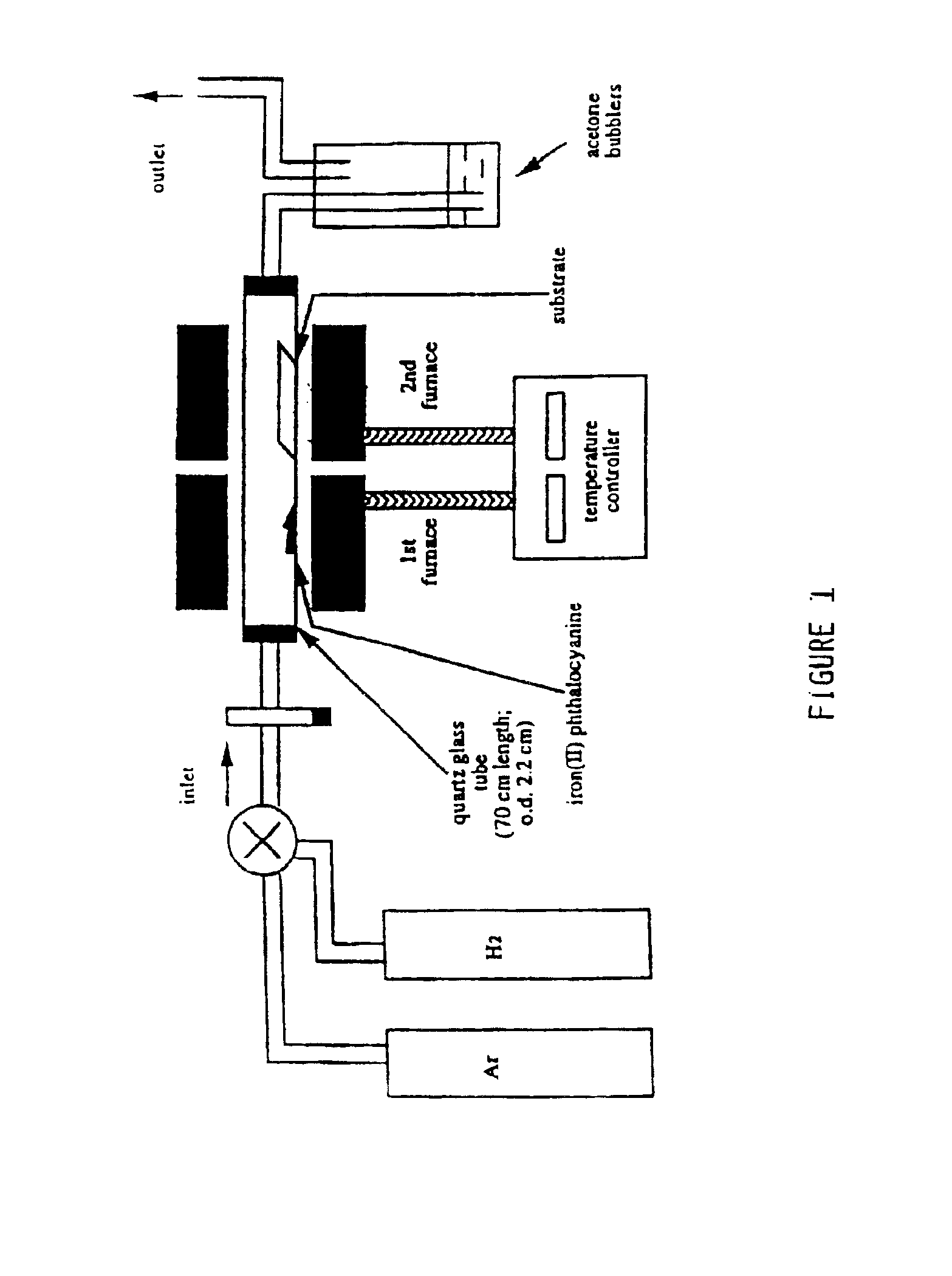

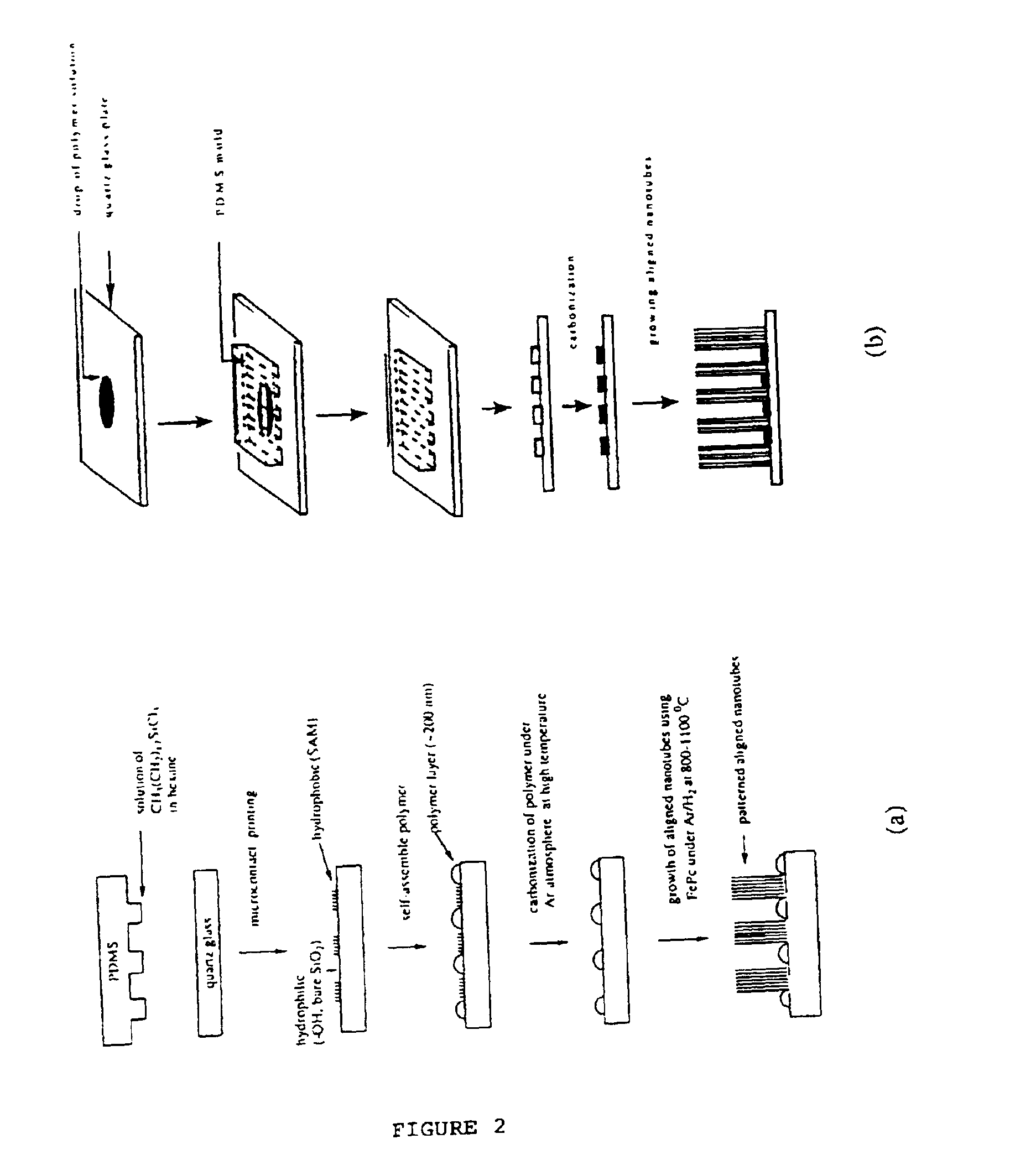

Process for making aligned carbon nanotubes

A process for preparing a patterned layer of aligned carbon nanotubes on a substrate including: applying a pattern of polymeric material to the surface of a substrate capable of supporting nanotube growth using a soft-lithographic technique; subjecting said polymeric material to carbonization to form a patterned layer of carbonized polymer on the surface of the substrate; synthesising a layer of aligned carbon nanotubes on regions of said substrate to which carbonized polymer is not attached to provide a patterned layer of aligned carbon nanotubes on said substrate.

Owner:UNIV OF DAYTON

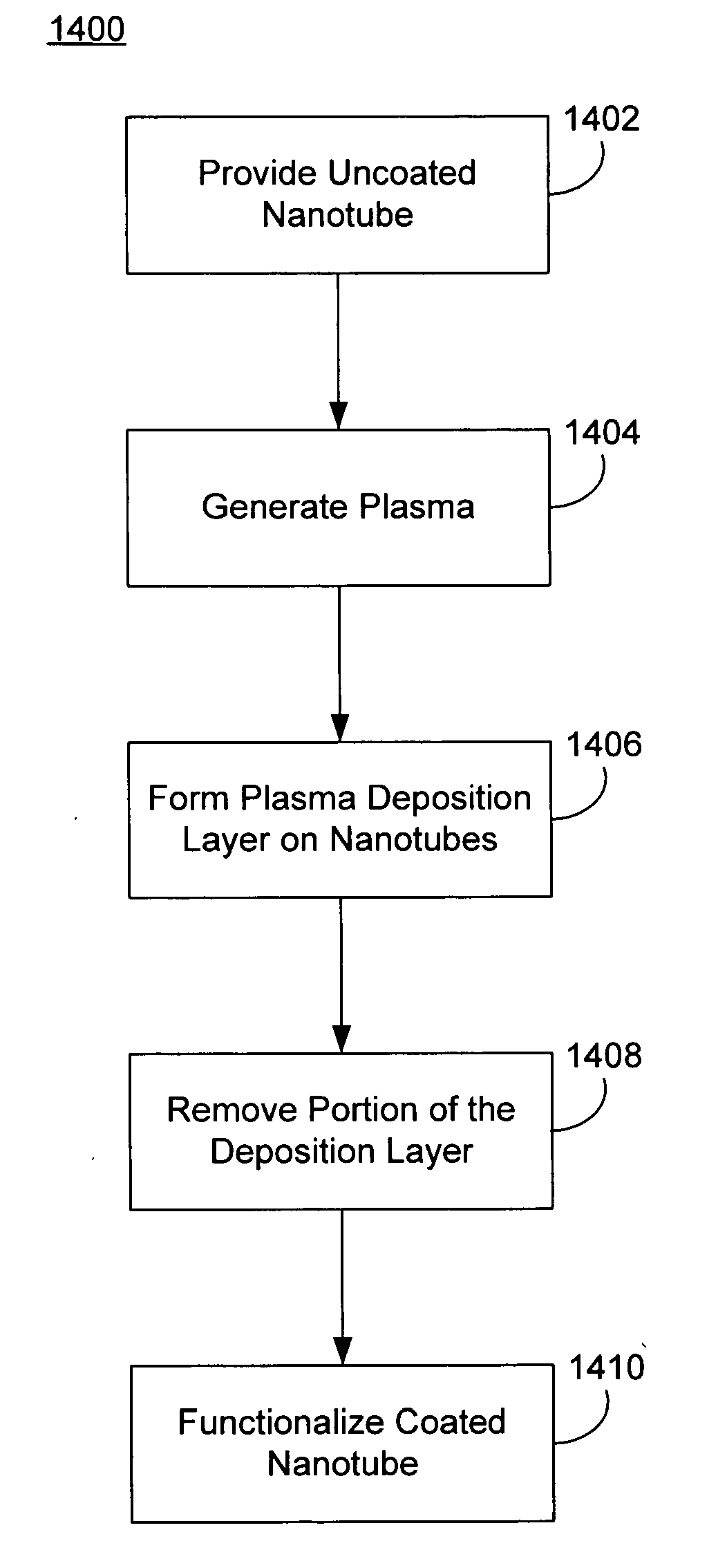

Coatings for carbon nanotubes

A coated nanotube that includes an inner nanotube having an exterior surface, and a plasma deposited layer covering at least part of the exterior surface of the inner nanotube. Also, a method of making a coated nanotube, the method where the method includes the steps of generating a plasma from a coating precursor, and exposing an inner nanotube to the plasma, where a plasma deposited layer is formed on at least a portion of the inner nanotube. Additionally, a method of making a coated nanotube that includes the steps of providing an inner nanotube, and evaporating a metal into the inner nanotube, where the metal forms a coating layer on at least a portion of the inner nanotube.

Owner:CALIFORNIA INST OF TECH

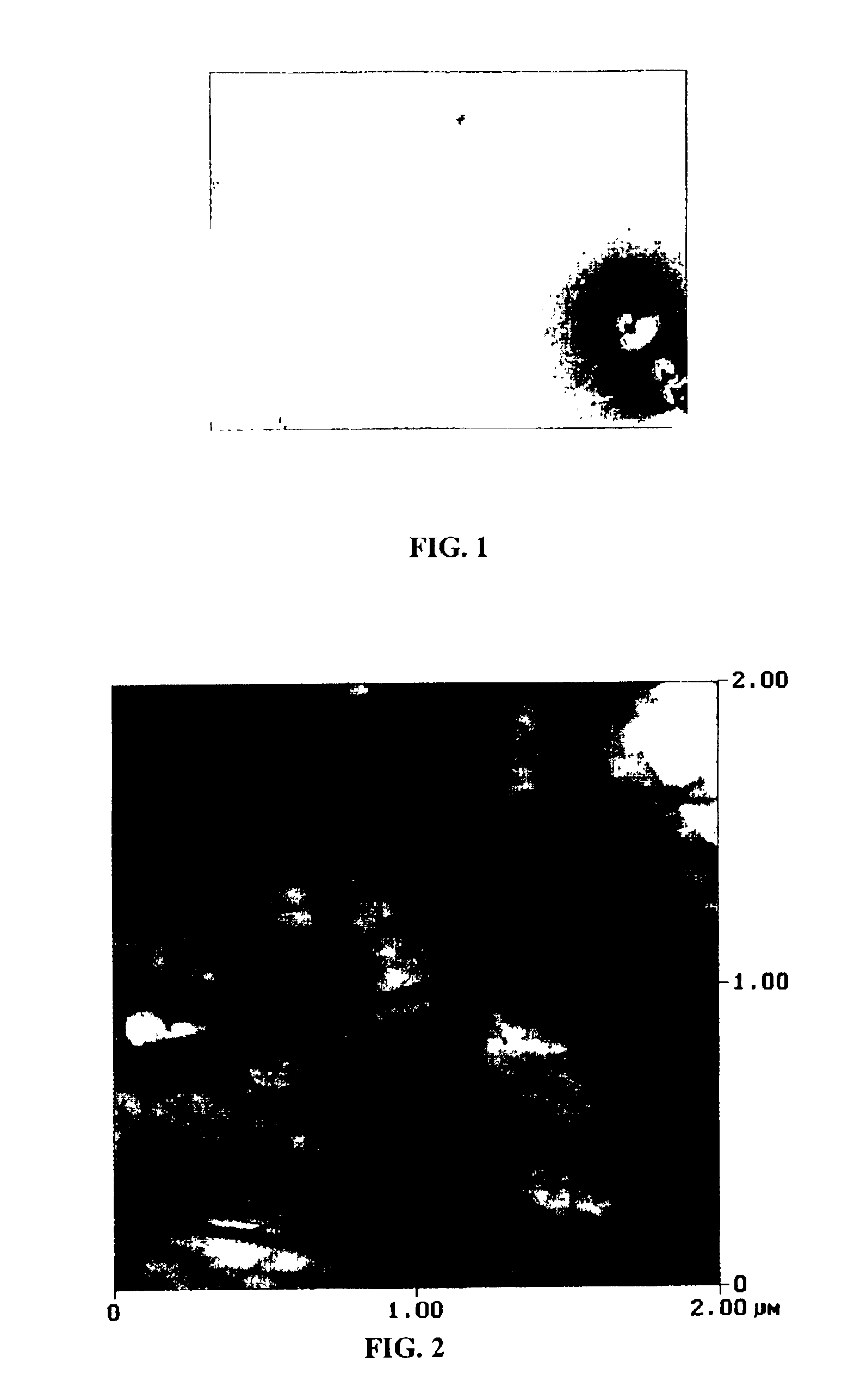

High surface quality GaN wafer and method of fabricating same

InactiveUS6951695B2Improve surface qualityPolycrystalline material growthAfter-treatment detailsSurface roughnessHigh surface

AlxGayInzN, wherein 0≦x≦1, 0≦y≦1, 0≦z≦1, and x+y+z=1, characterized by a root mean square surface roughness of less than 1 nm in a 10×10 μm2 area. The AlxGayInzN may be in the form of a wafer, which is chemically mechanically polished (CMP) using a CMP slurry comprising abrasive particles, such as silica or alumina, and an acid or a base. High quality AlxGayInzN wafers can be fabricated by steps including lapping, mechanical polishing, and reducing internal stress of said wafer by thermal annealing or chemical etching for further enhancement of its surface quality. CMP processing may be usefully employed to highlight crystal defects of an AlxGayInzN wafer.

Owner:WOLFSPEED INC

Charged particle beam irradiation equipment having scanning electromagnet power supplies

InactiveUS6903351B1Irradiation time can be shortenedShort timeThermometer detailsStability-of-path spectrometersExcitation currentElectrical current

A power supply for applying a voltage to a scanning electromagnet for deflecting a charged particle beam has a first power supply unit having no filter and a second power supply unit having a filter. When an irradiation position of the charged particle beam in an irradiation object is moved, the first power supply unit, namely a power supply unit having no filter, is used to apply the voltage to the scanning electromagnet, so that an exciting current flowing in the scanning electromagnet can be changed in a short time. Further, when the irradiation position of the charged particle beam is maintained, the second power supply is used to apply a voltage whose pulsating component was removed to the scanning electromagnet, so that the exciting current flowing in the scanning electromagnet can be controlled precisely. Consequently, the charged particle beam can be applied uniformly to the irradiation object and an irradiation time of the charged particle beam to the irradiation object can be curtailed.

Owner:HITACHI LTD

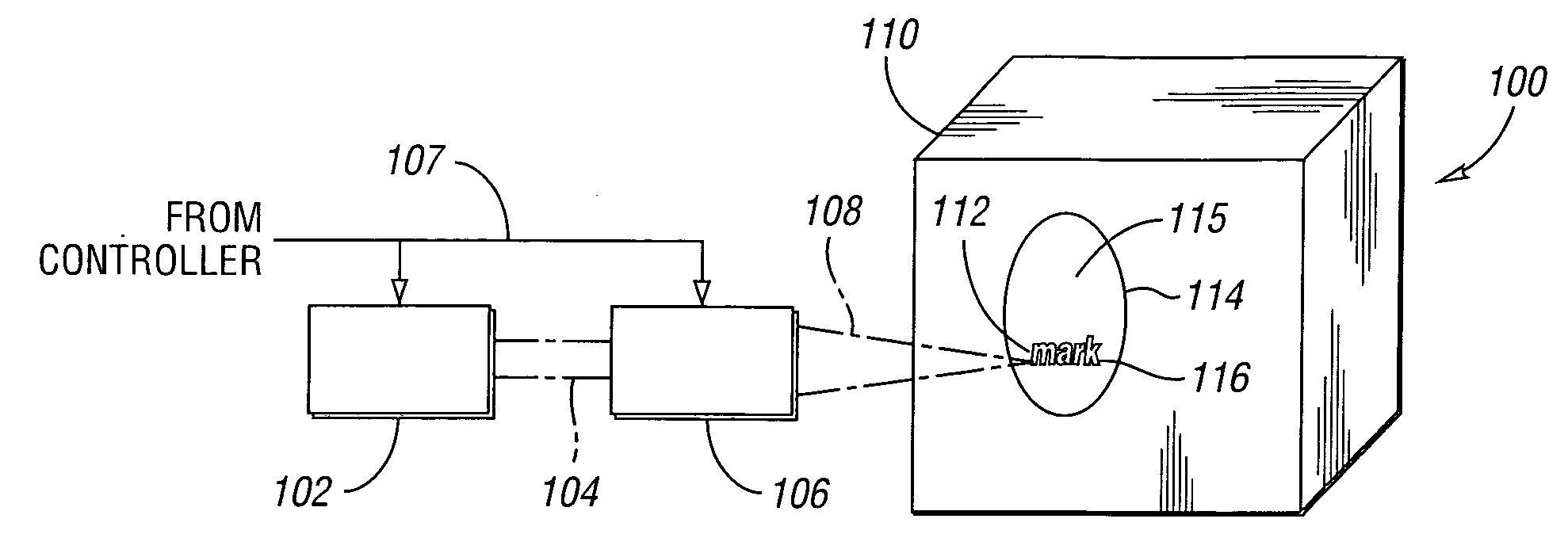

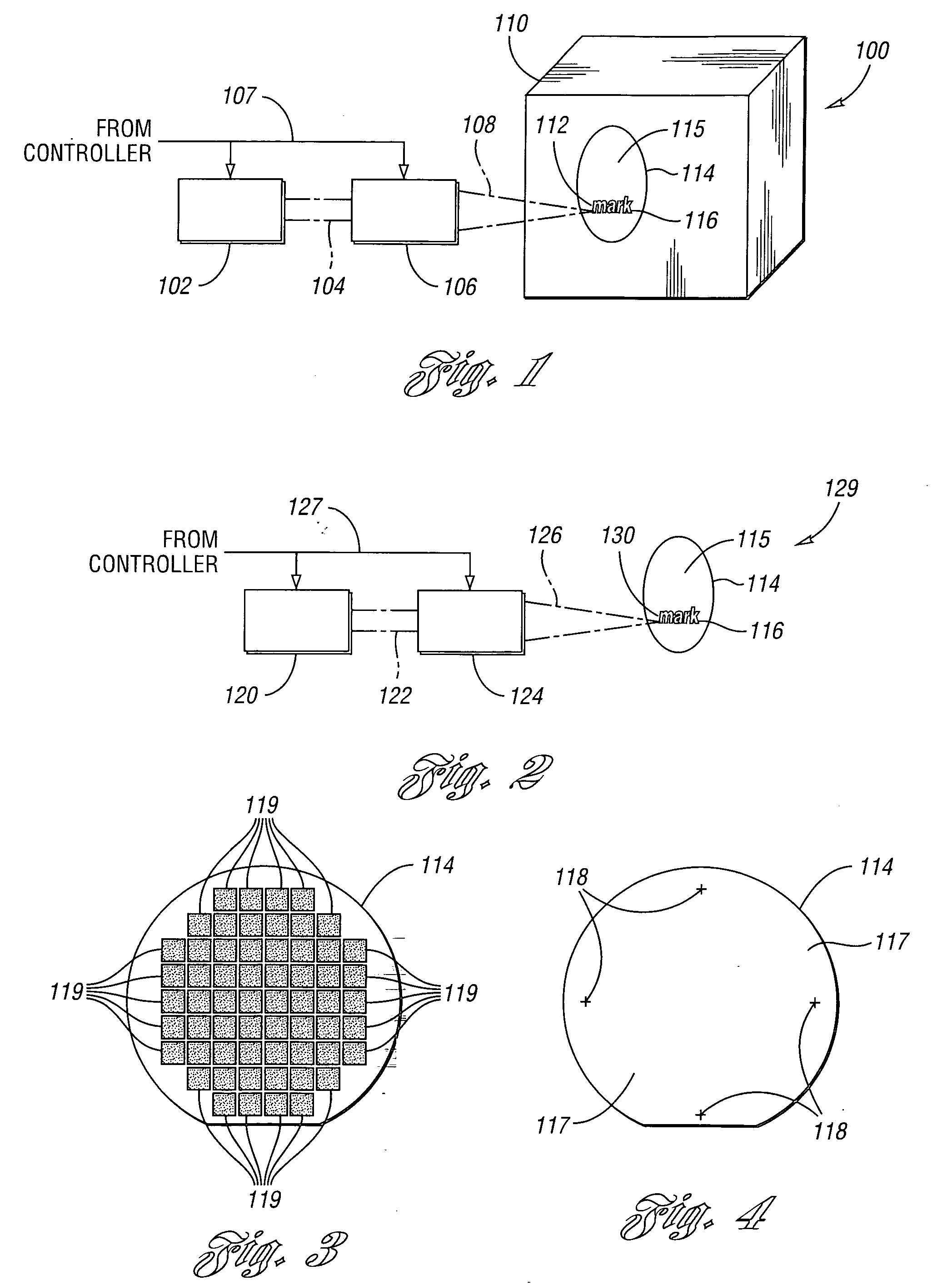

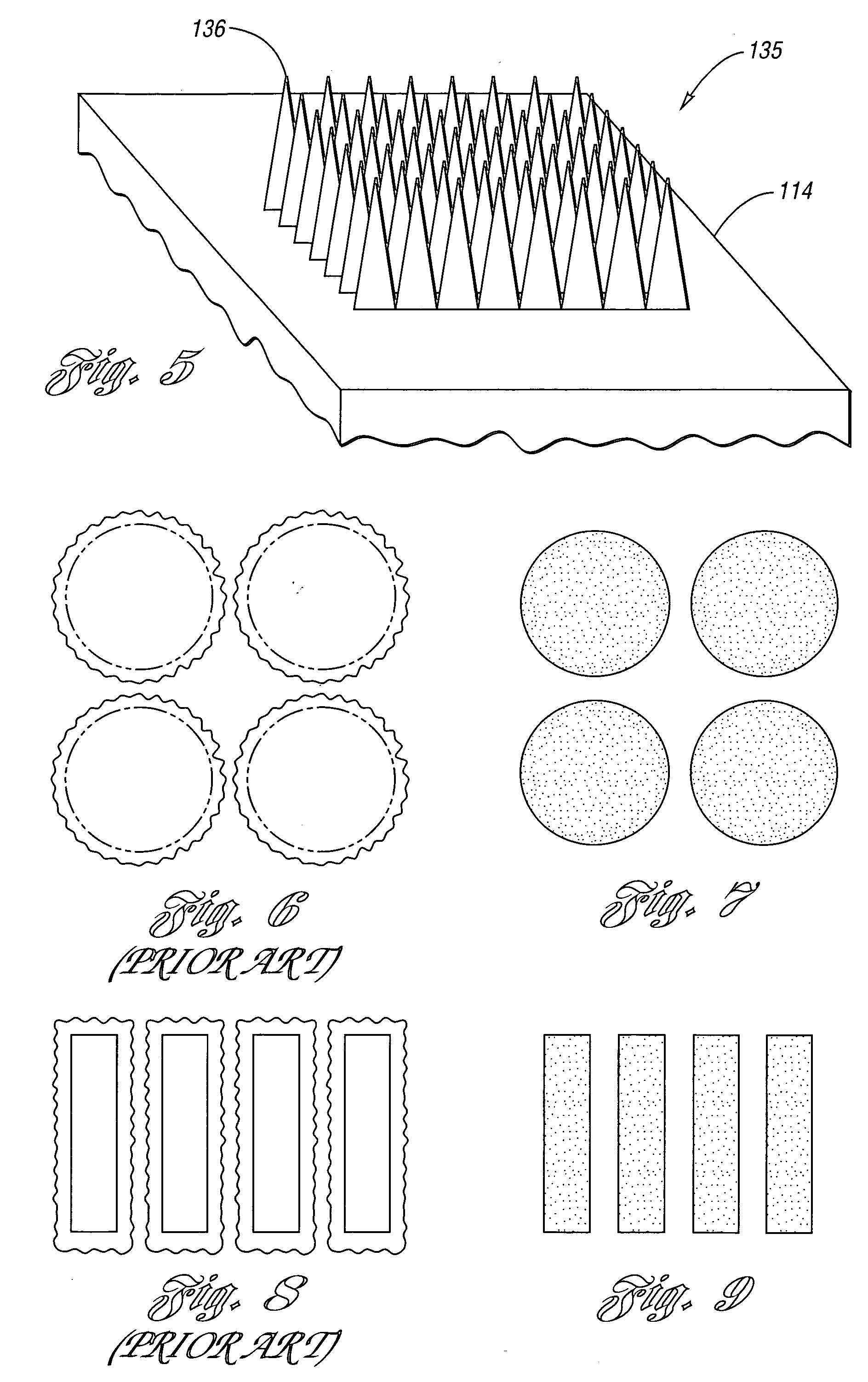

Laser-based method and system for processing targeted surface material and article produced thereby

InactiveUS20060000814A1Prevent unwanted changesSufficient total fluenceAdditive manufacturing apparatusSemiconductor/solid-state device detailsTarget surfaceSlag

A laser-based method and system for processing targeted surface material and article produced thereby are provided. The system processes the targeted surface material within a region of a workpiece while avoiding undesirable changes to adjacent non-targeted material. The system includes a primary laser subsystem including a primary laser source for generating a pulsed laser output including at least one pulse having a wavelength and a pulse width less than 1 ns. A delivery subsystem irradiates the targeted surface material of the workpiece with the pulsed laser output including the at least one pulse to texture the targeted surface material. The pulsed laser output has sufficient total fluence to initiate ablation within at least a portion of the targeted surface material and the pulse width is short enough such that the region and the non-targeted material surrounding the material are substantially free of slag.

Owner:ELECTRO SCI IND INC

Dynamically adjustable probe tips

ActiveUS7022976B1Beam/ray focussing/reflecting arrangementsMaterial analysis by optical meansEngineeringActuator

Various probe systems and probes are provided. In one aspect, a probe is provided that includes a base and a first member coupled to the base. The first member has a first tip for probing a circuit device. A first actuator is coupled to the first member for moving the first member relative to the base. Electrical and / or topographical probing is possible.

Owner:GLOBALFOUNDRIES US INC

Charged particle beam irradiation equipment and control method thereof

InactiveUS6900446B2Irradiation time can be shortenedShort timeStability-of-path spectrometersStatic indicating devicesParticle physicsElectrical current

A power supply for applying a voltage to a scanning electromagnet for deflecting a charged particle beam has a first power supply unit having no filter and a second power supply unit having a filter. When an irradiation position of the charged particle beam in an irradiation object is moved, the first power supply unit, namely a power supply unit having no filter, is used to apply the voltage to the scanning electromagnet, so that an exciting current flowing in the scanning electromagnet can be changed in a short time. Further, when the irradiation position of the charged particle beam is maintained, the second power supply is used to apply a voltage whose pulsating component was removed to the scanning electromagnet, so that the exciting current flowing in the scanning electromagnet can be controlled precisely. Consequently, the charged particle beam can be applied uniformly to the irradiation object and an irradiation time of the charged particle beam to the irradiation object can be curtailed.

Owner:HITACHI LTD

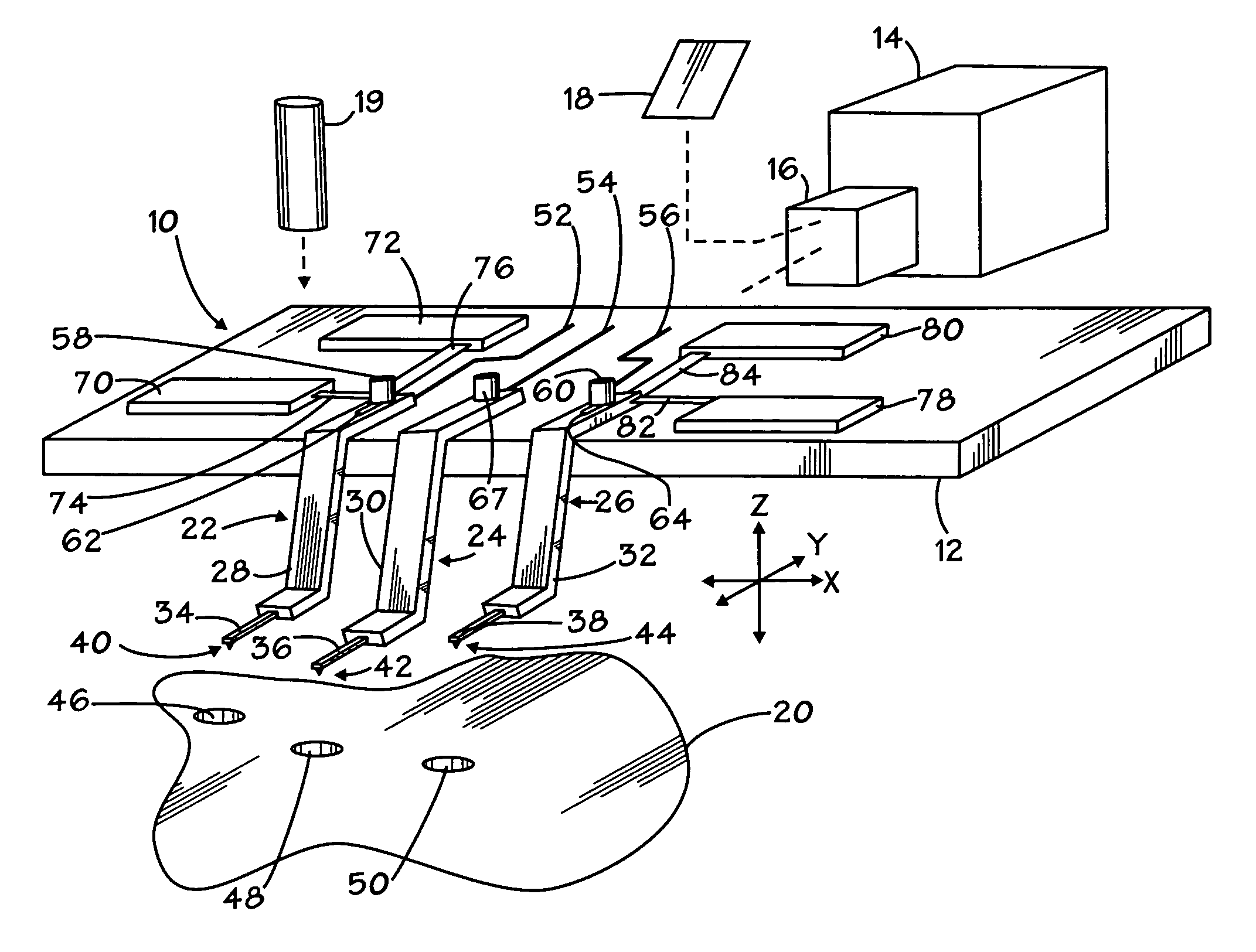

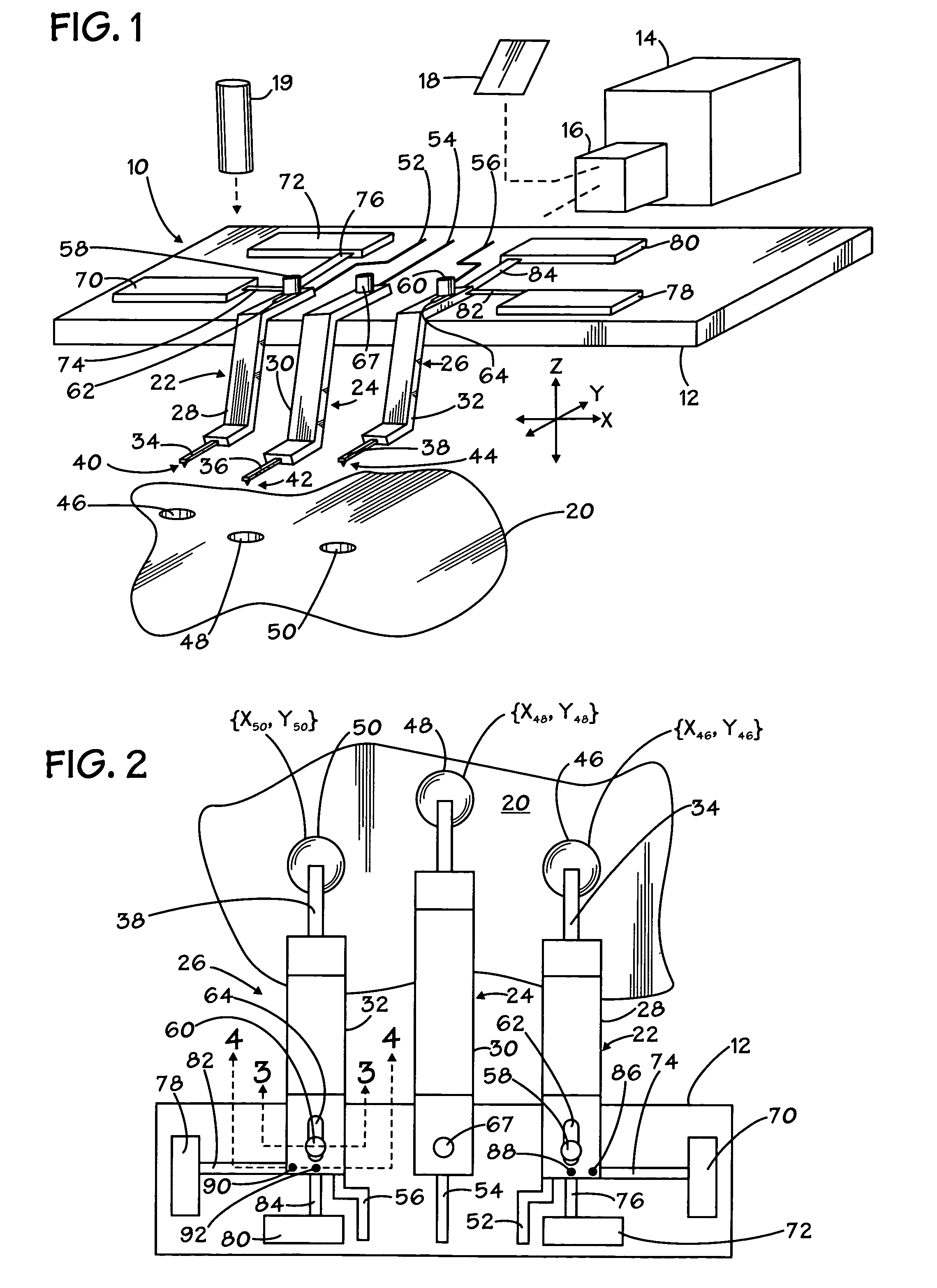

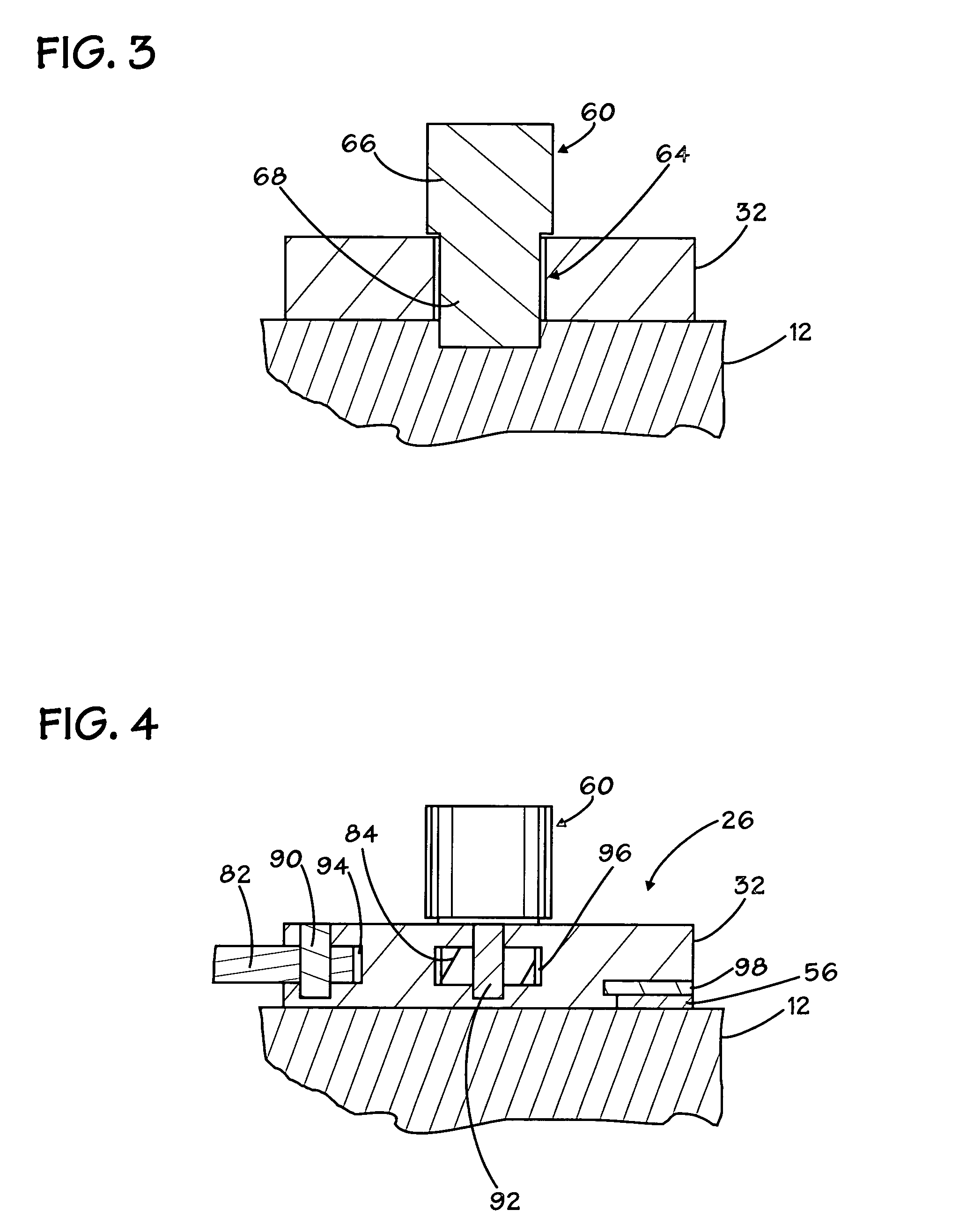

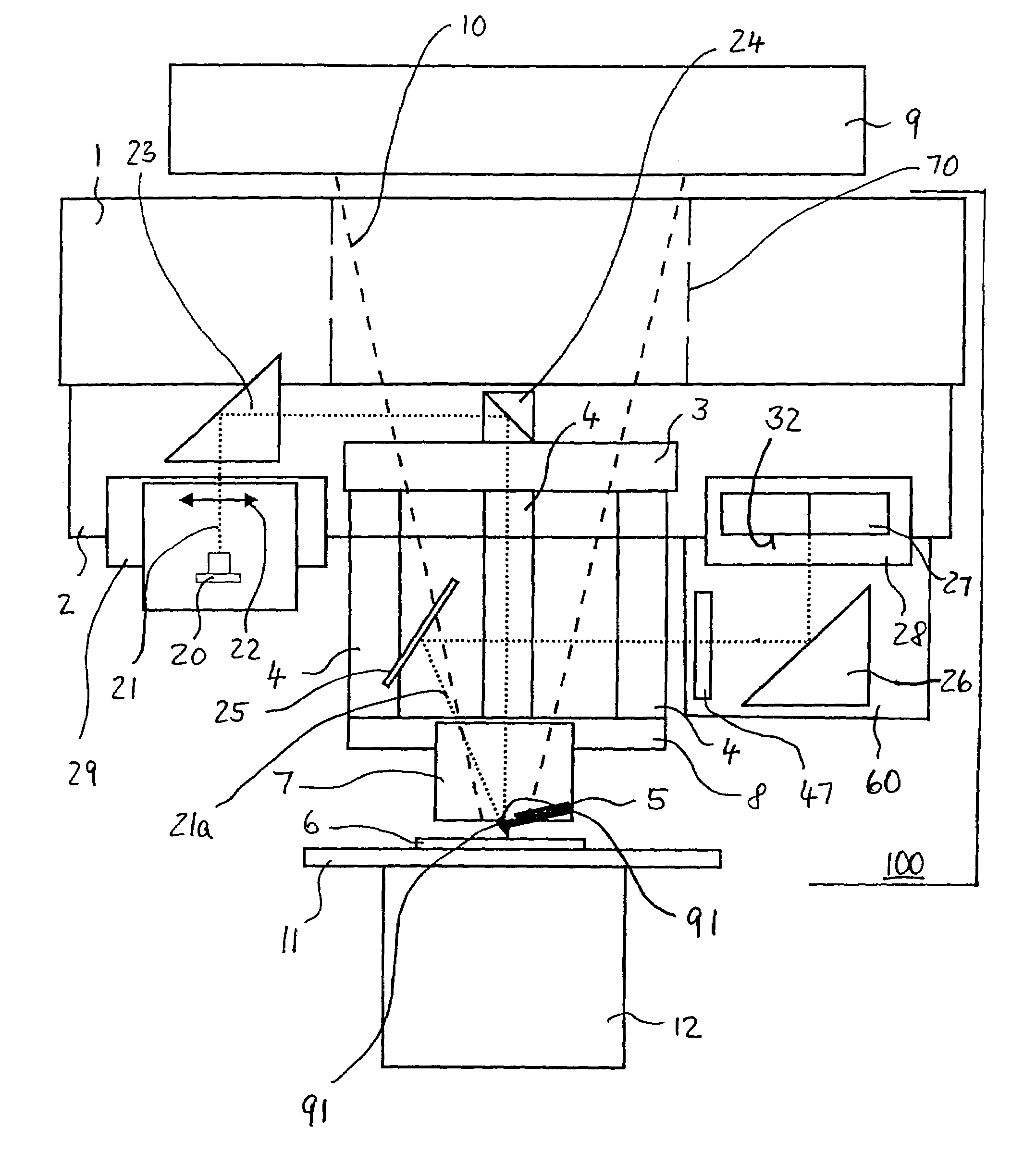

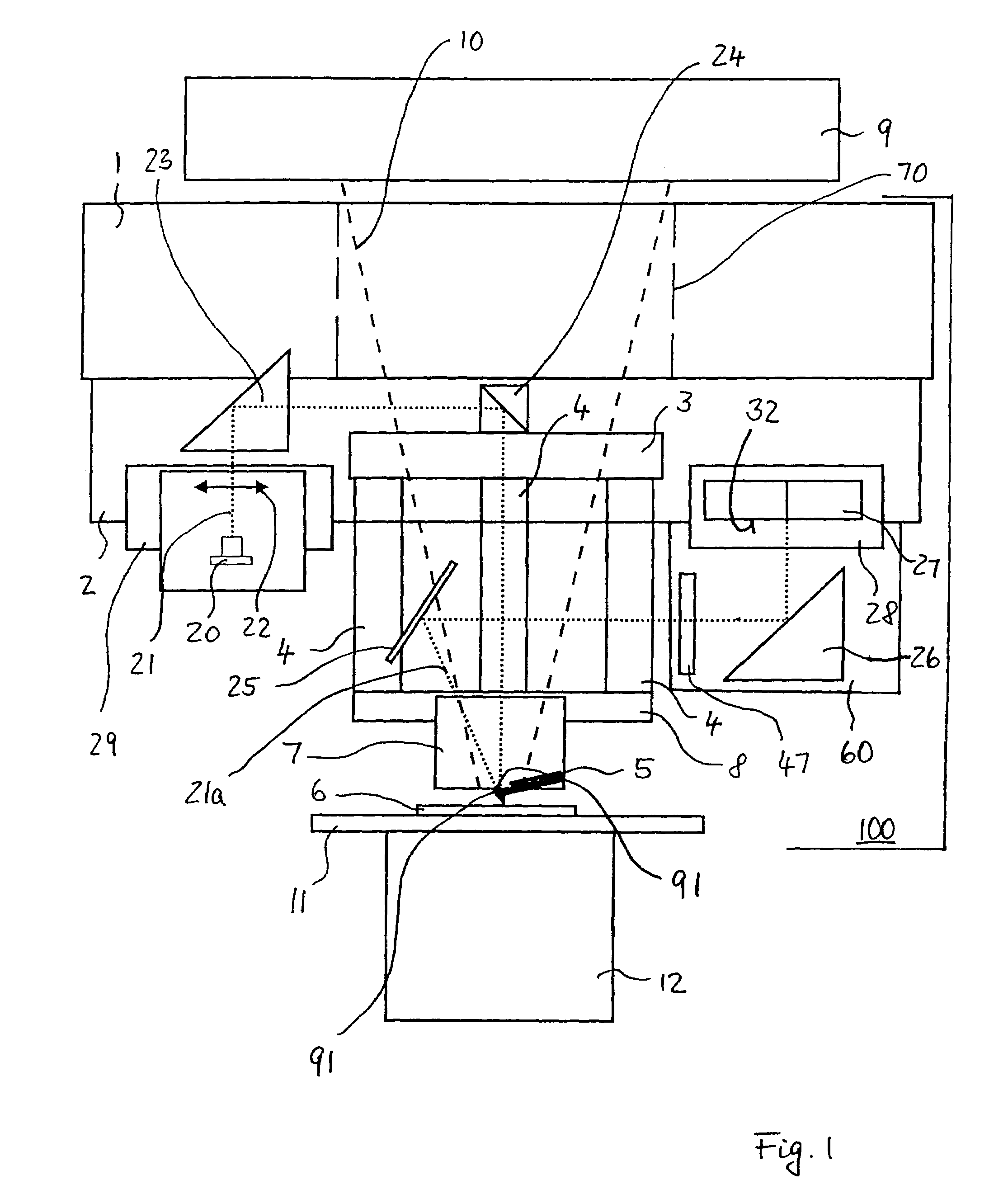

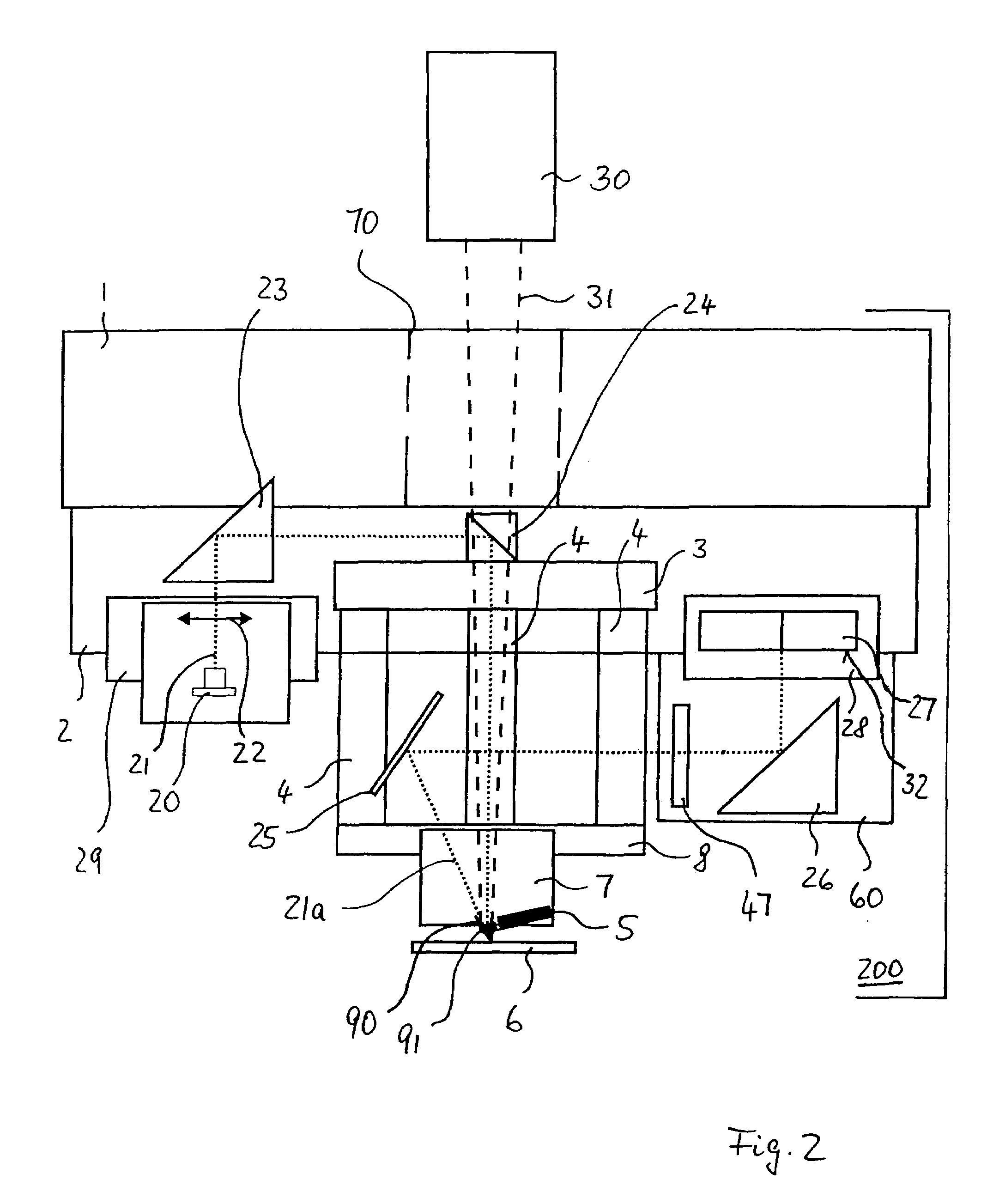

Apparatus and method for a scanning probe microscope

InactiveUS7022985B2Easy to modifyImprove measurement stabilityNanotechMaterial analysis using wave/particle radiationScanning electron microscopeScanning probe microscopy

The invention relates to an apparatus and a method for a scanning probe microscope, comprising a measuring assembly which includes a lateral shifting unit to displace a probe in a plane, a vertical shifting unit to displace the probe in a direction perpendicular to the plane, and a specimen support to receive a specimen. A condenser light path is formed through the measuring assembly so that the specimen support is located in the area of an end of the condenser light path.

Owner:JPK INSTR

Particle beam processing system

InactiveUS20050017193A1Small sizeLow costStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsParticle beamLight beam

Owner:HBAR TECH LC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com