Patents

Literature

16873results about "Thermometer details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

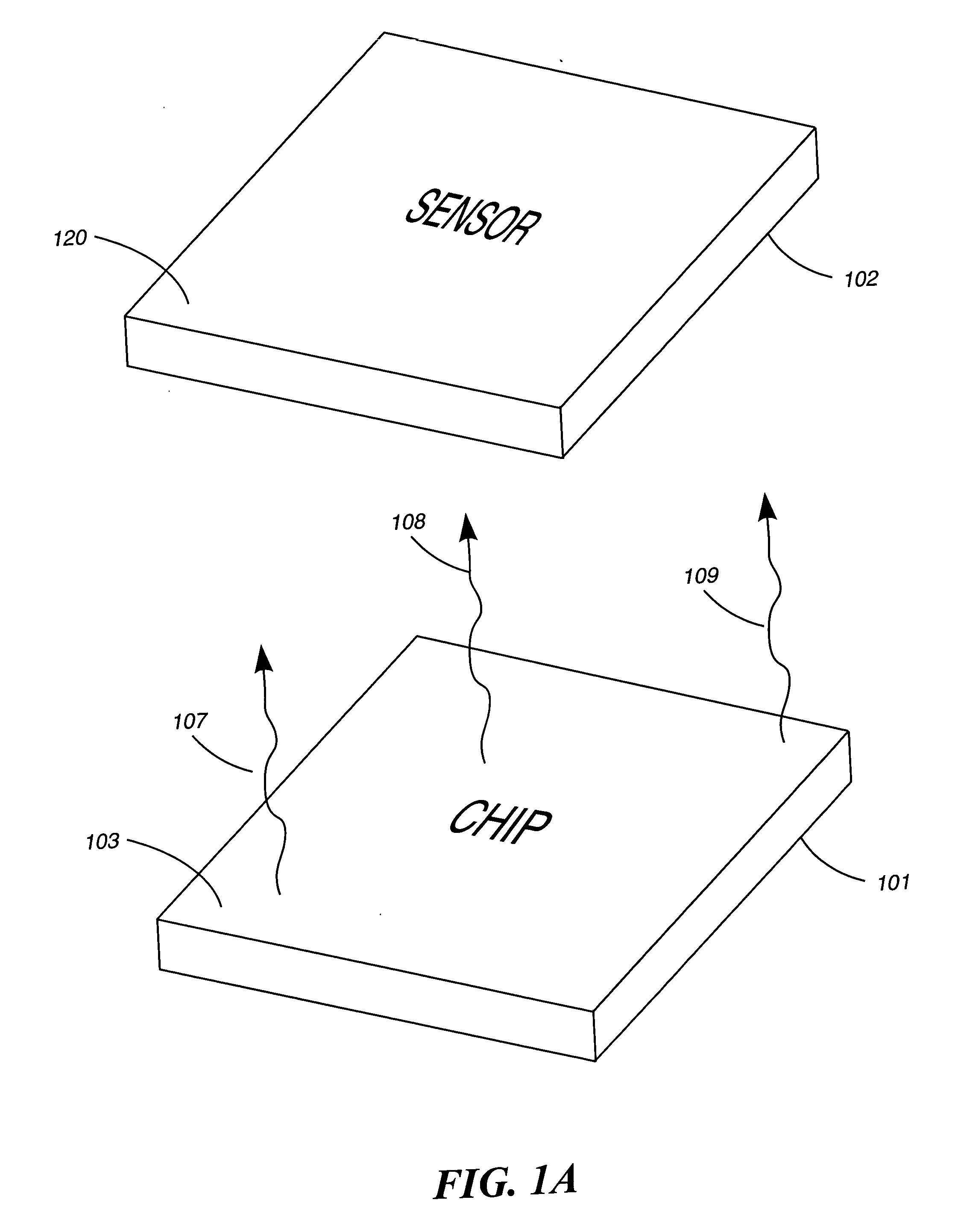

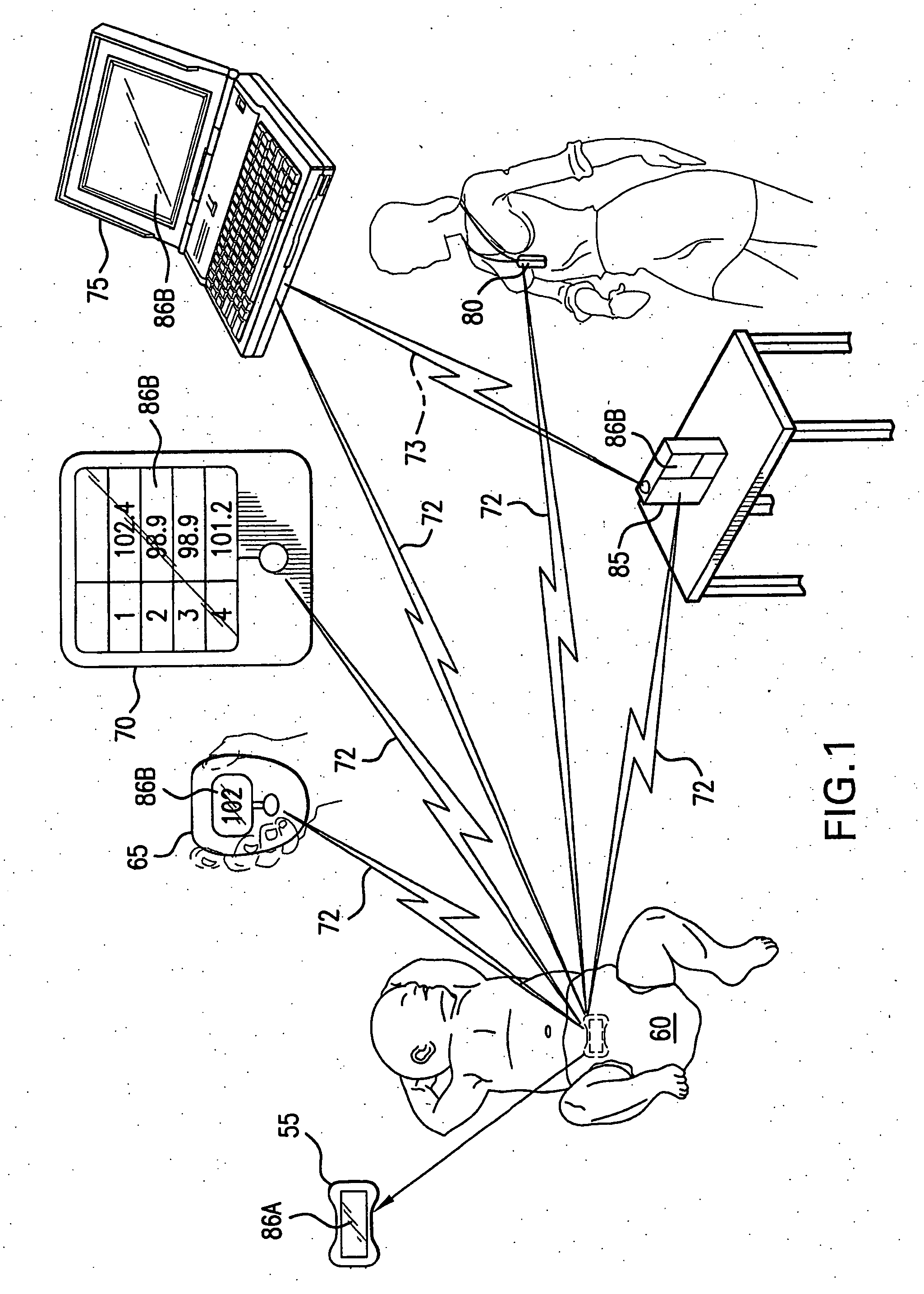

Non-invasive temperature monitoring device

InactiveUS20050245839A1Short-term useLow costThermometer detailsElectrocardiographyMonitoring systemEngineering

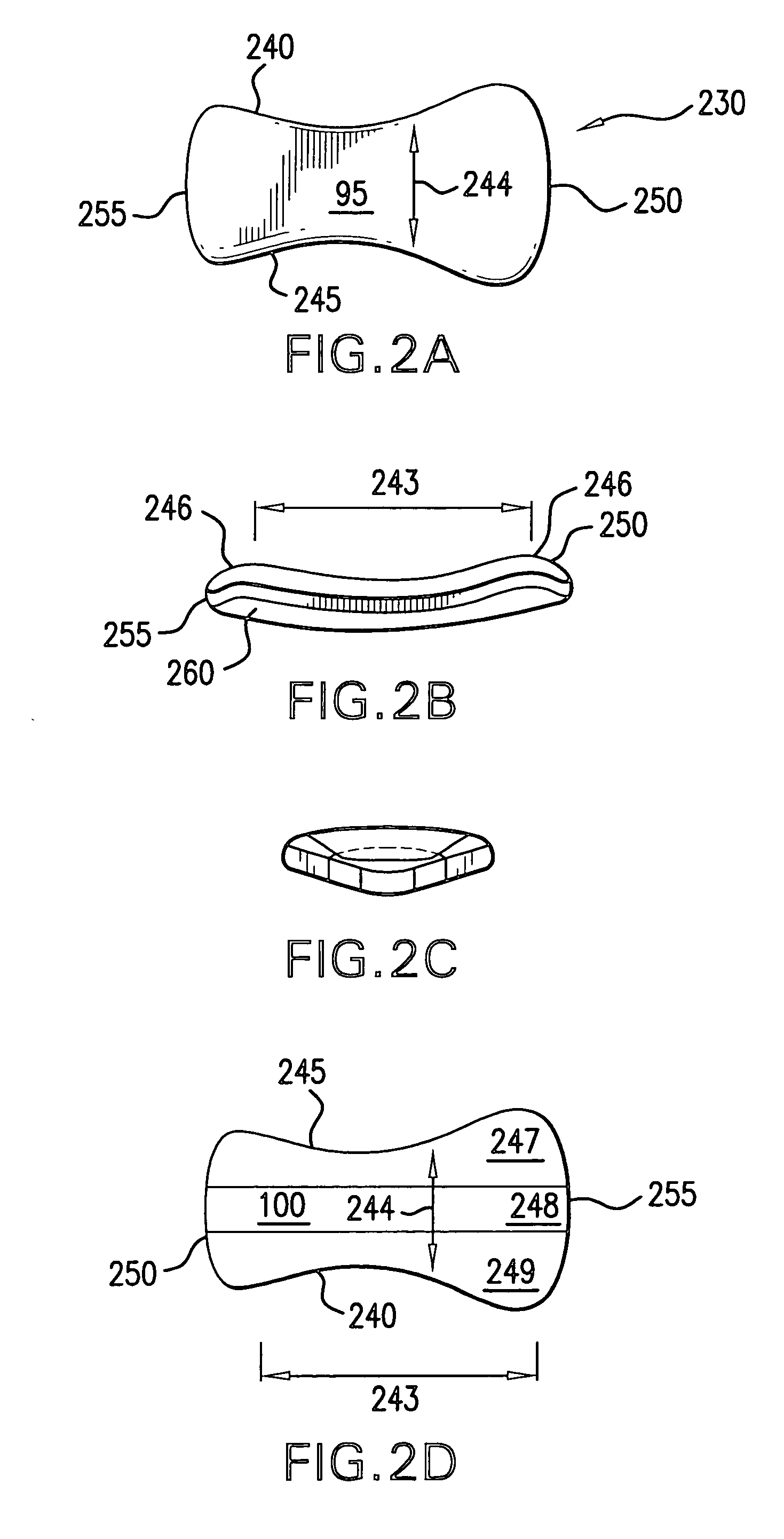

A monitoring system comprises a module having at least one sensor and preferably skin and ambient temperature sensors within a housing. The device may be durable or disposable. The housing may be provided with certain surface features and shapes to facilitate mounting on and interface with the skin of the wearer for more accurate temperature measurement. A receiver may be provided to obtain and display data from the module. The module may also display the output data. The output data comprises both detected and derived data relating to physiological and contextual parameters of the wearer and may be transmitted directly to a local recipient or remotely over a communications network. The system is capable of deriving and predicting the occurrence of a number of physiological and conditional states and events and reporting the same as output data.

Owner:J FITNESS LLC

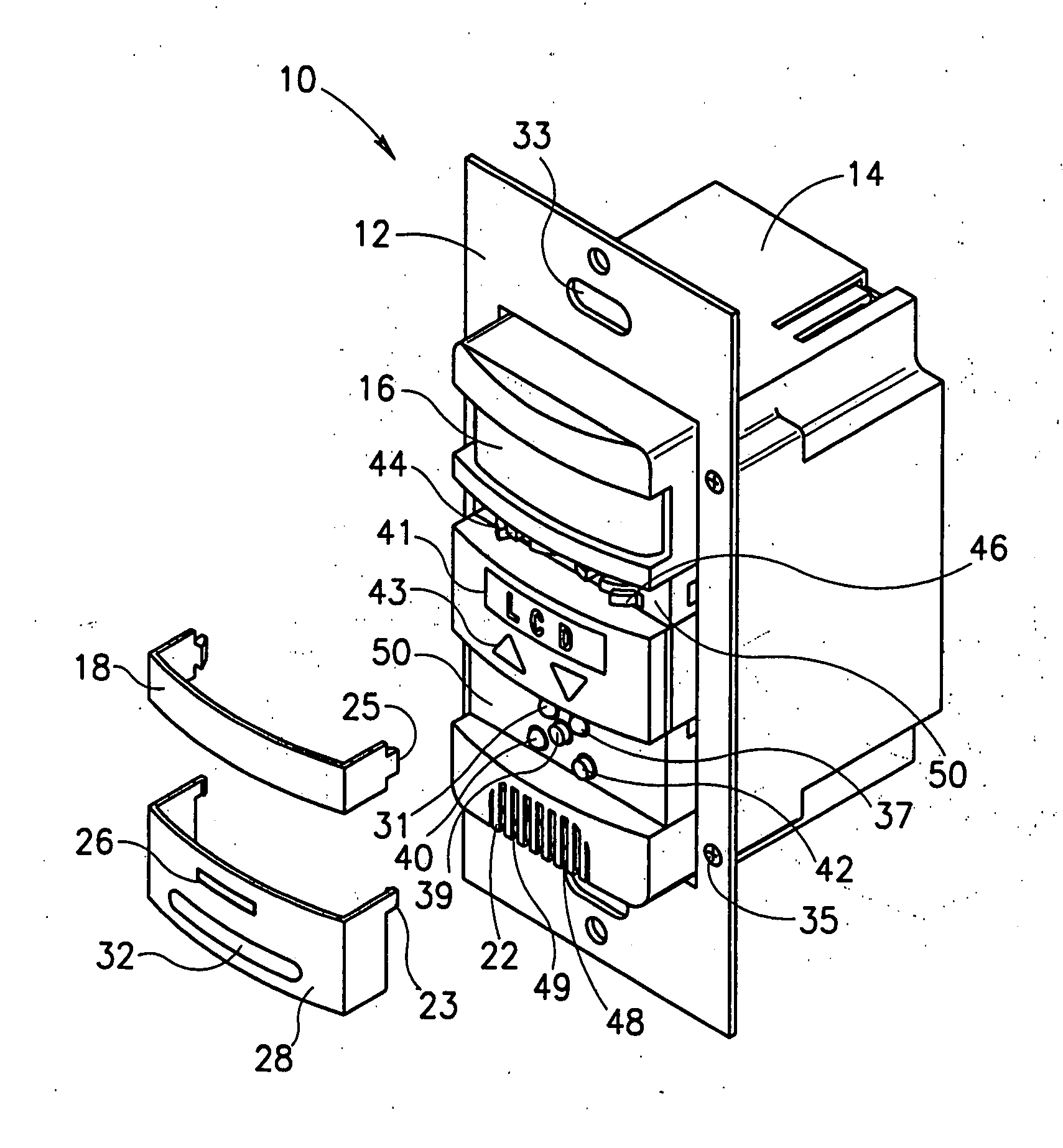

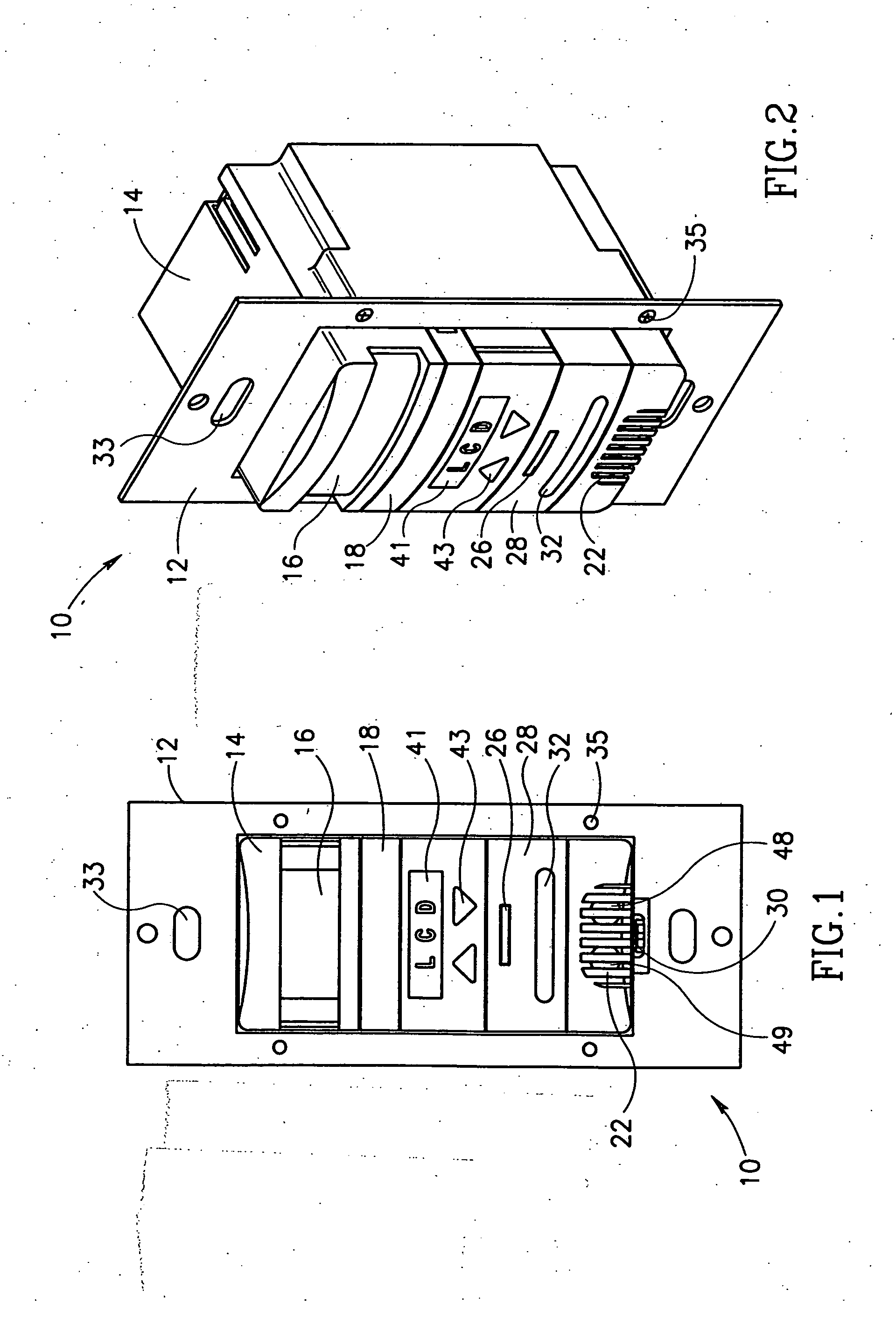

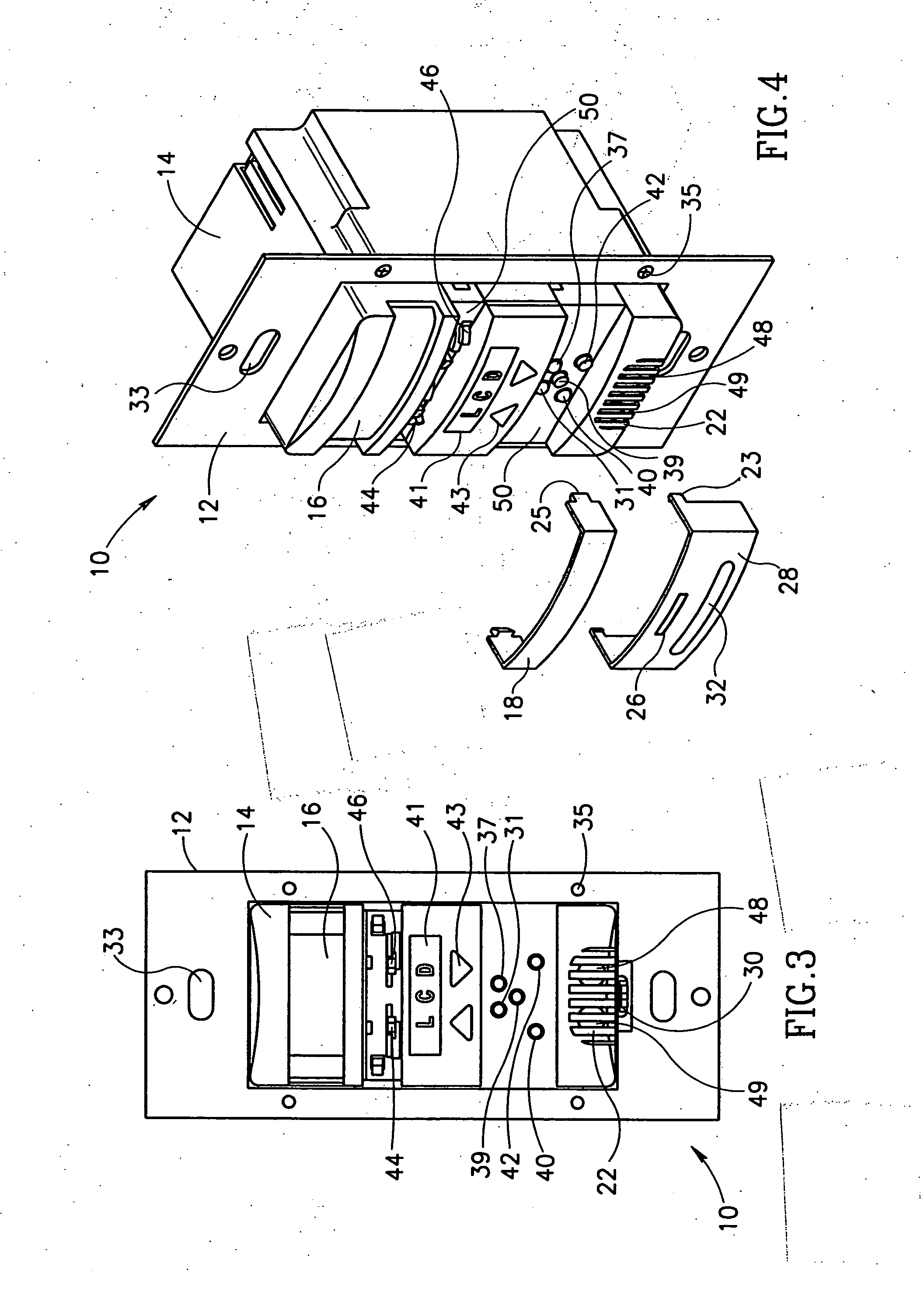

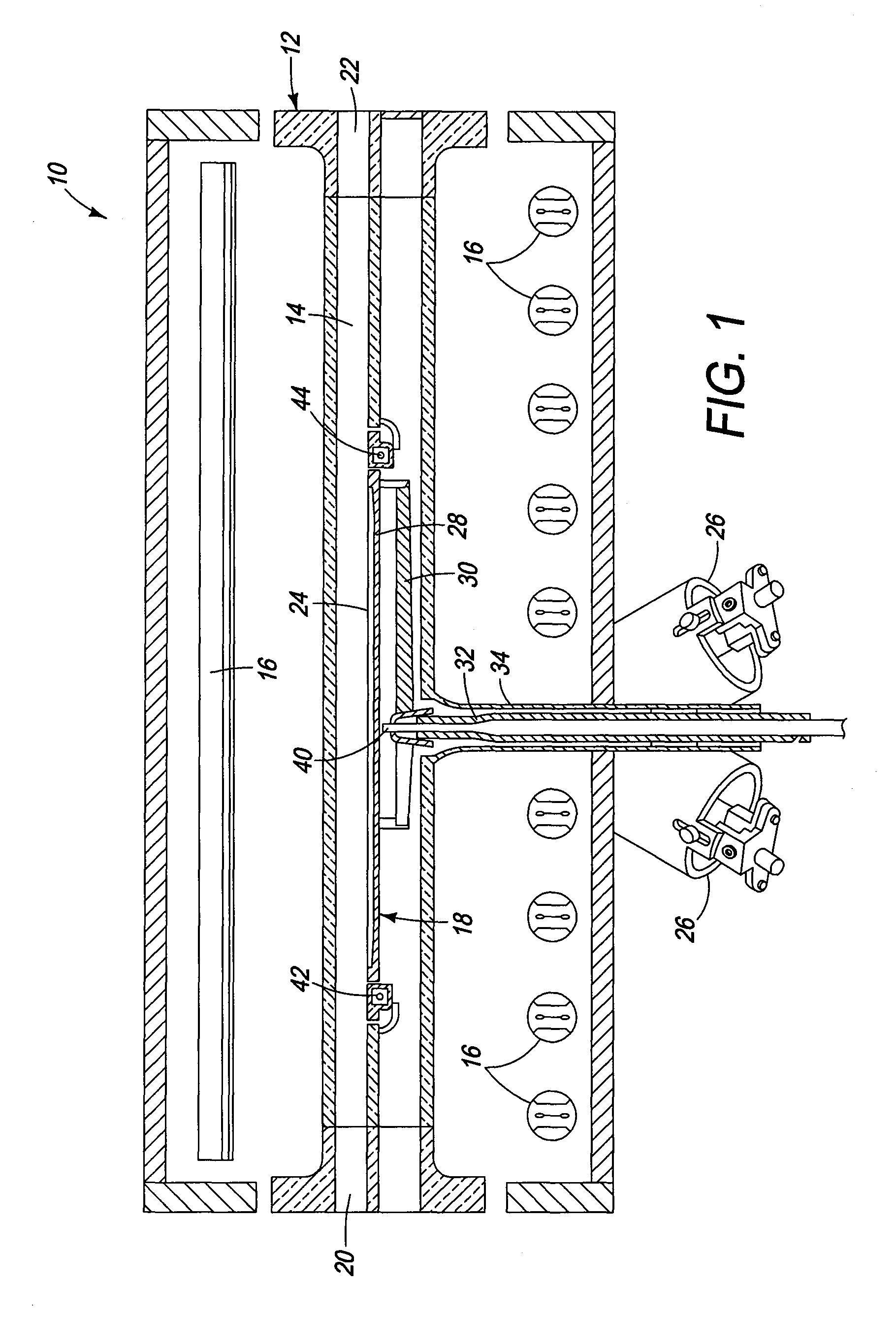

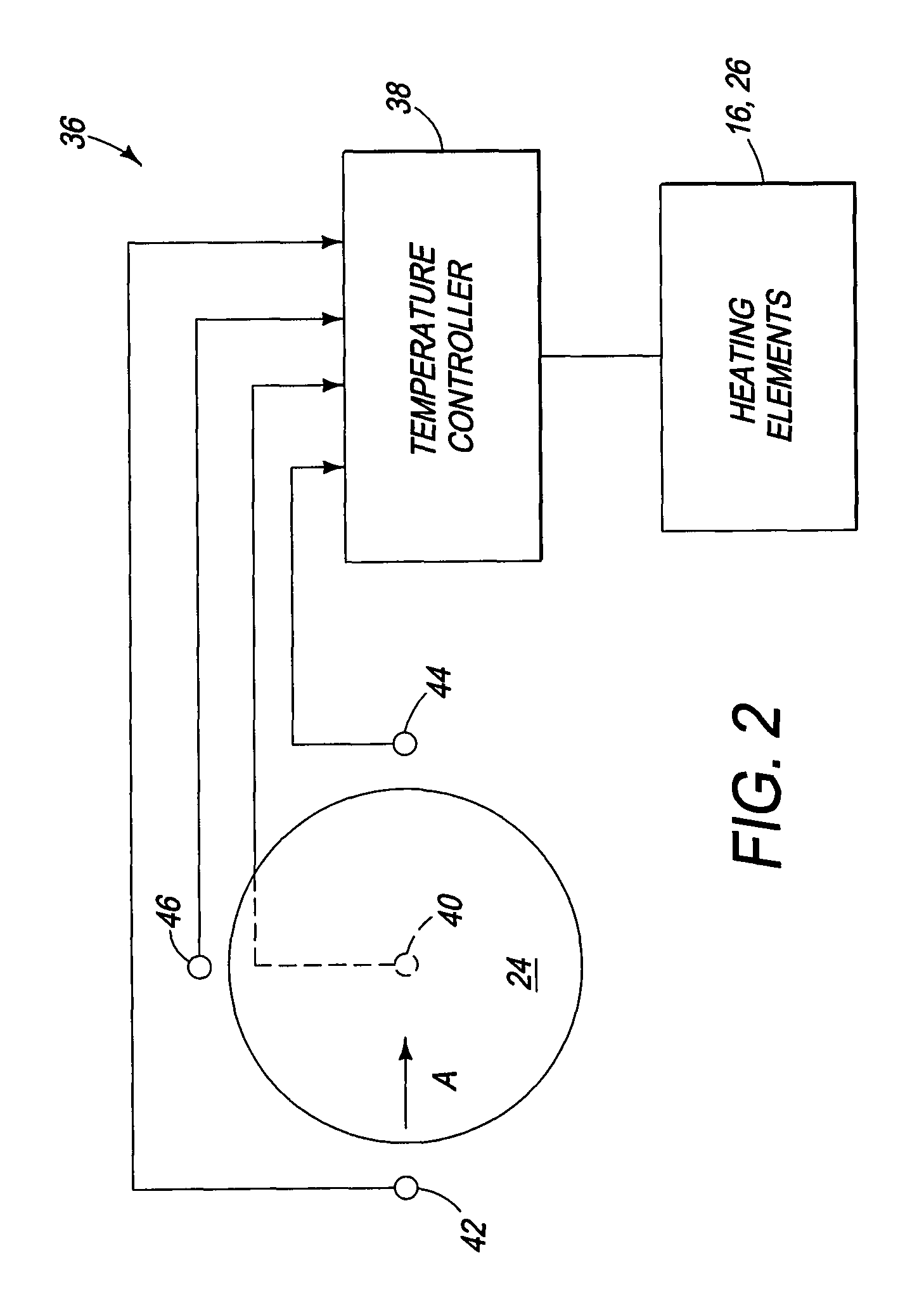

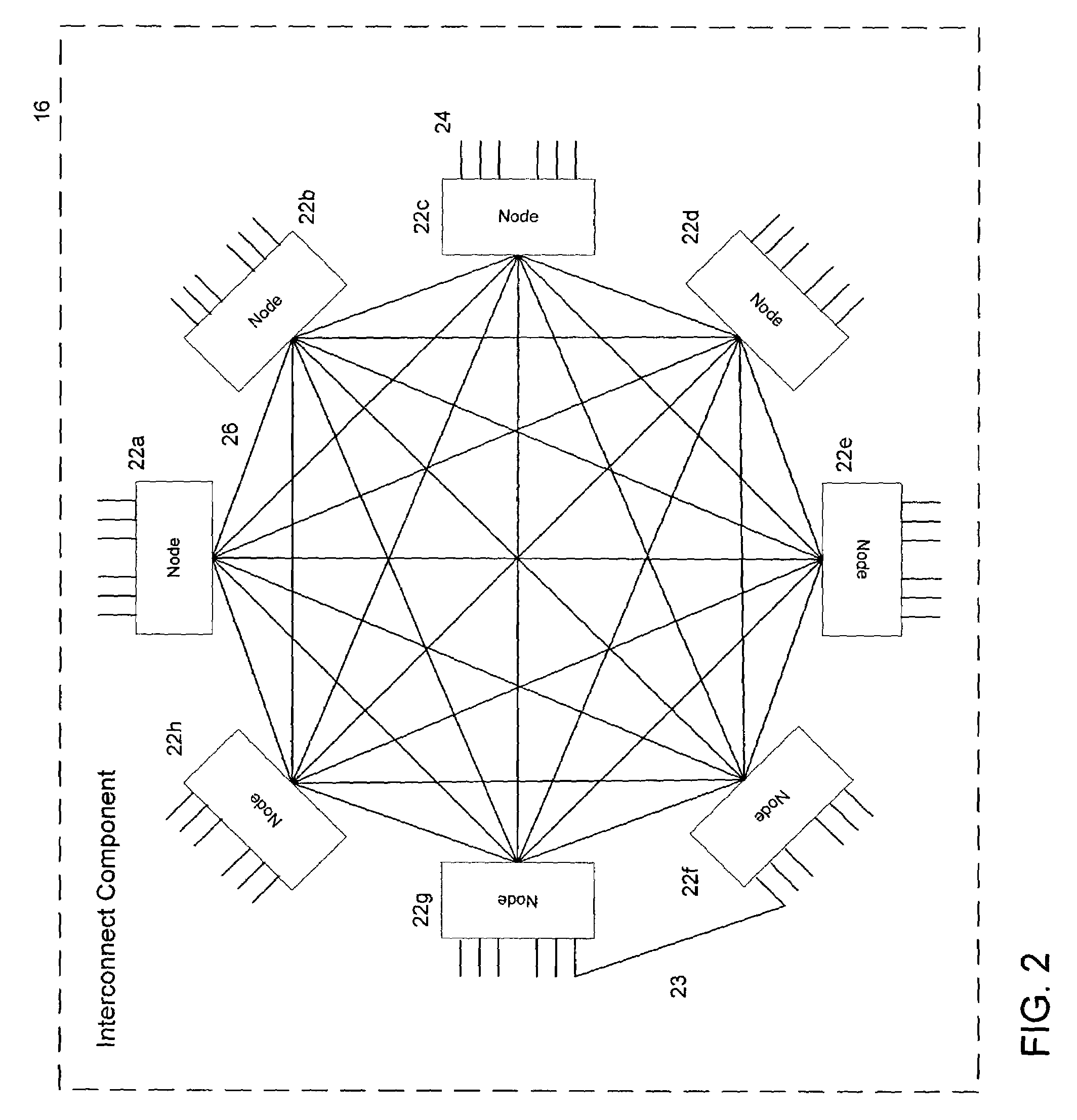

Network based multiple sensor and control device with temperature sensing and control

InactiveUS20050043907A1Minimize adverse effectsPartial latencyThermometer detailsElectric devicesMultiple sensorControl equipment

A multifunction sensor device which provides various transducer functions including means for performing temperature sensing, humidity sensing, ambient light sensing, motion detection, thermostat functions, switching functions, load switching and dimming functions, displaying actual and set temperature values, displaying time of day values and a means to put the device in an on, off or auto mode. The device has utility in environments such as that found in offices, schools, homes, industrial plants or any other type of automated facility in which sensors are utilized for energy monitoring and control, end user convenience or artificial or natural cooling, heating and HVAC control. The device can be used as a switch or dimmer, sensor or thermostat as well as to adjust and control all natural and artificial lighting, temperature and humidity devices. Key elements of the invention include overcoming the difficulty of mounting diverse sensors or transducers within the same device or housing; permitting these various sensors to exist in a single package that can be mounted to a wall in a substantially flush manner; and eliminating the requirement of an air flow channel in the device, thus minimizing any adverse effects on the motion detecting element or sensor as well as providing built in partial hysteresis. The device may include additional transducers or sensors and is constructed such that the temperature and humidity sensors are neither exposed to the flow of air in a room or area nor in an airflow channel whereby a chimney effect may occur. The device can transmit and receive real time data, relative data and actual discrete data in addition to switching and controlling loads locally or remotely. An embodiment utilizing airflow channels to direct air over the temperature and humidity sensors is also disclosed.

Owner:ECKEL DAVID P +2

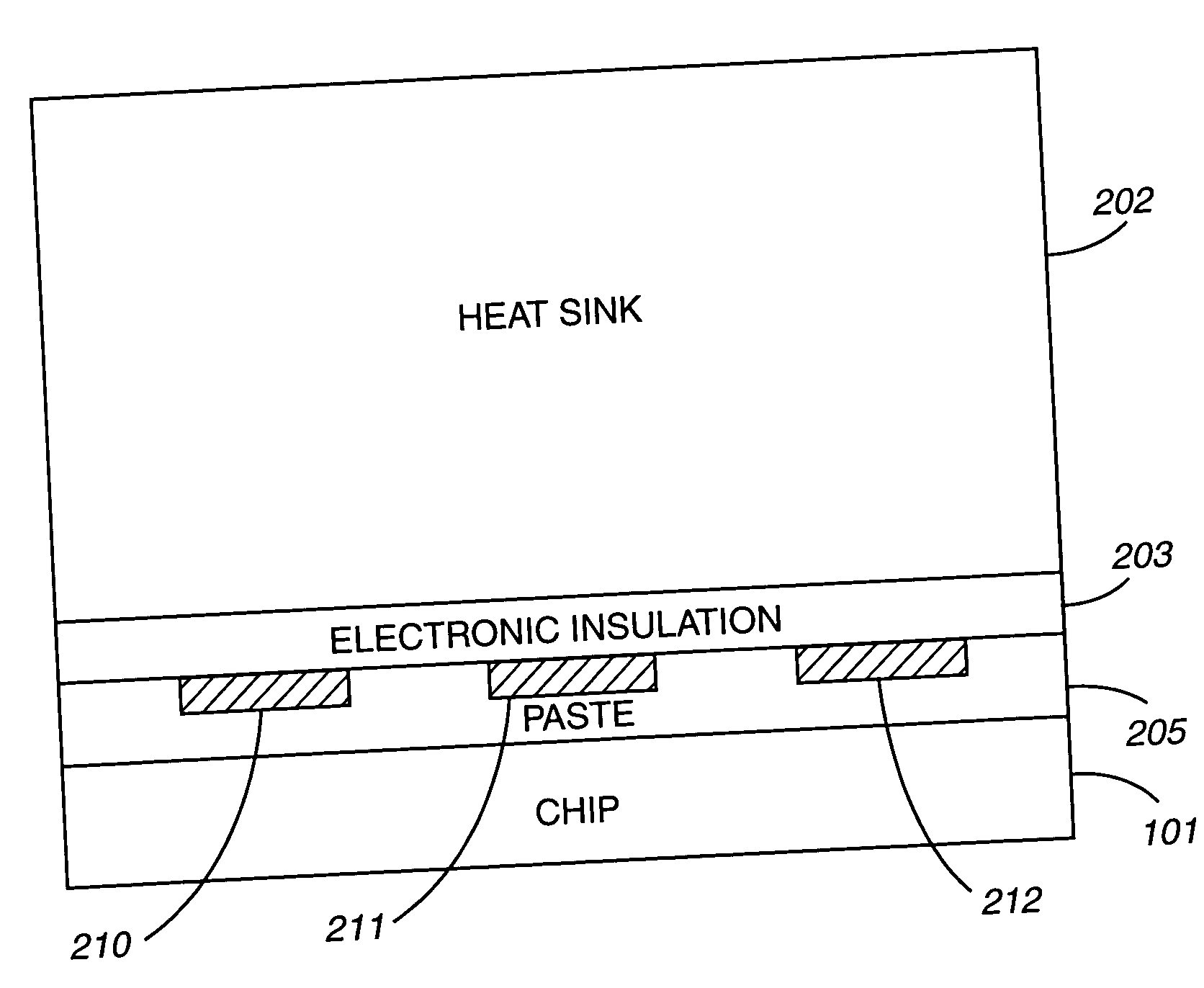

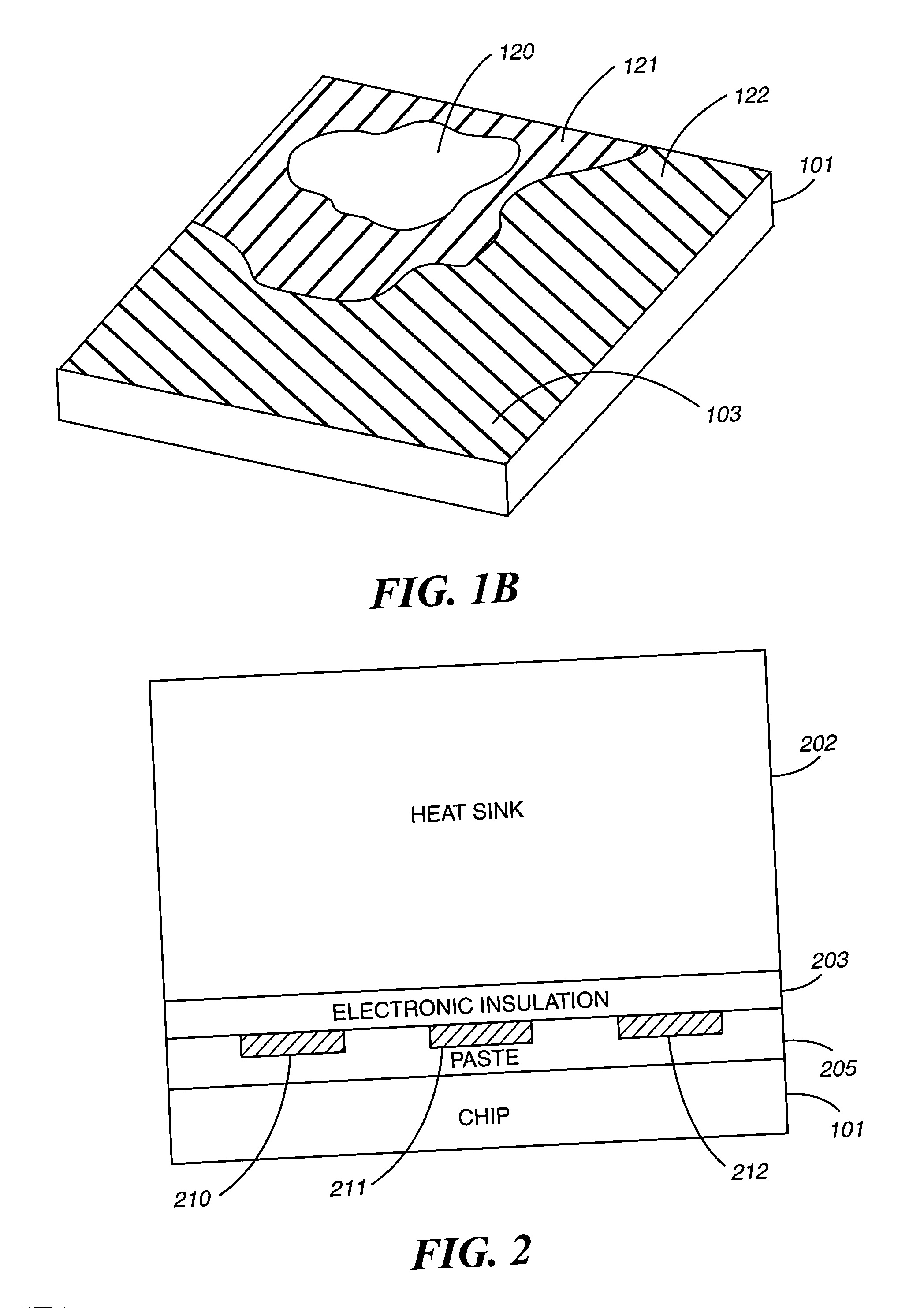

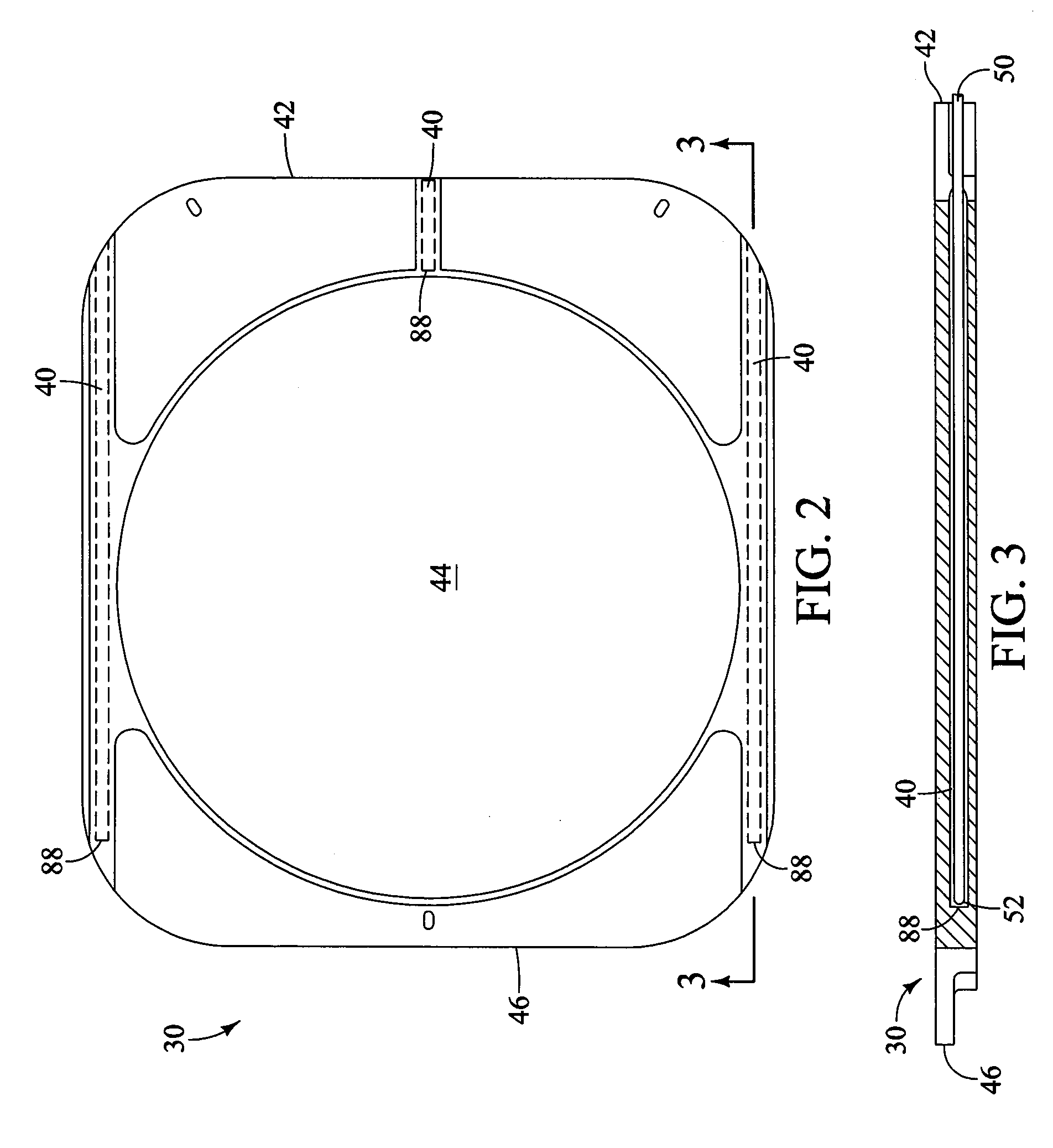

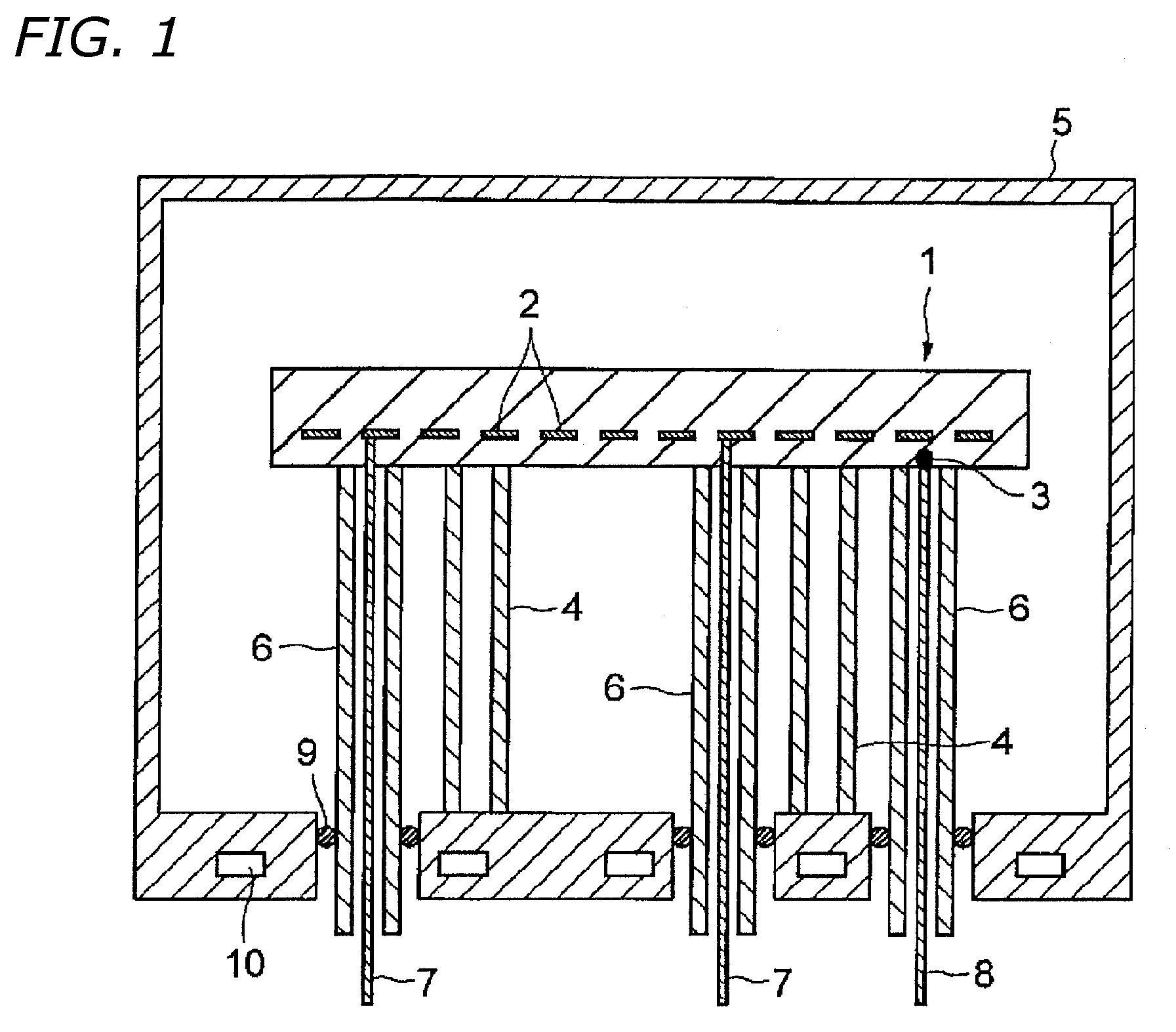

Thermal measurments of electronic devices during operation

InactiveUS20050114068A1Thermometer detailsThermometers using material expansion/contactionElectricityEngineering

A system and method for measuring thermal distributions of an electronic device during operation is disclosed. The system includes an electronic device, a heat sink adjacent to the electronic device and an electrical-insulating layer disposed on the electronic device so as to separate the electronic device and the heat sink. The system further includes a plurality of thermal sensors located on the electrical-insulating layer, each of the plurality of thermal sensors in a different location. The plurality of thermal sensors is located within one or more thin film circuit layers disposed adjacent to the electrical insulating layer. The system further includes a module for receiving thermal information from the plurality of thermal sensors during operation of the electronic device. The system further includes a processor coupled to the module for generating a thermal distribution of the electronic device based on the thermal information received from the plurality of thermal sensors.

Owner:IBM CORP

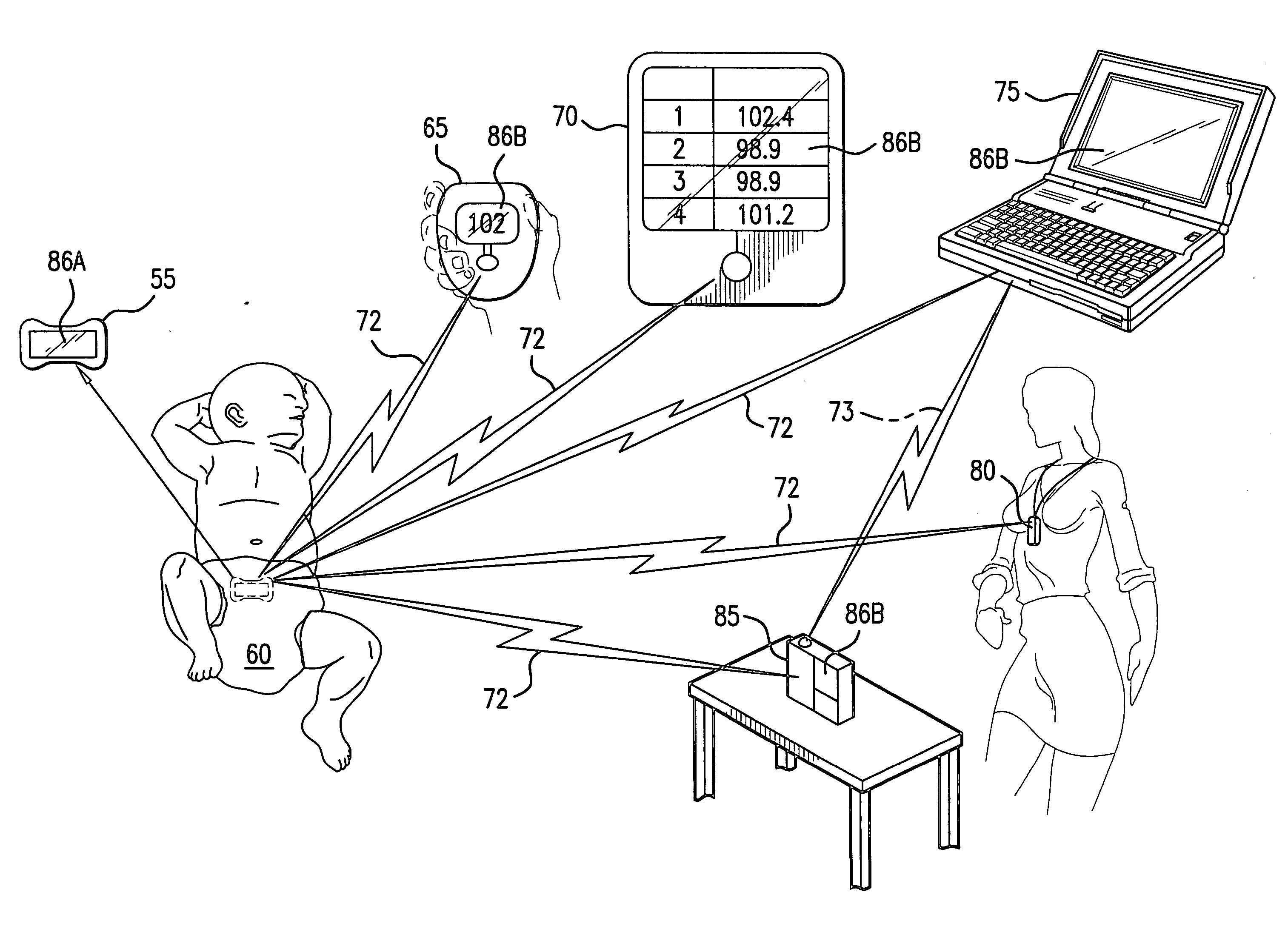

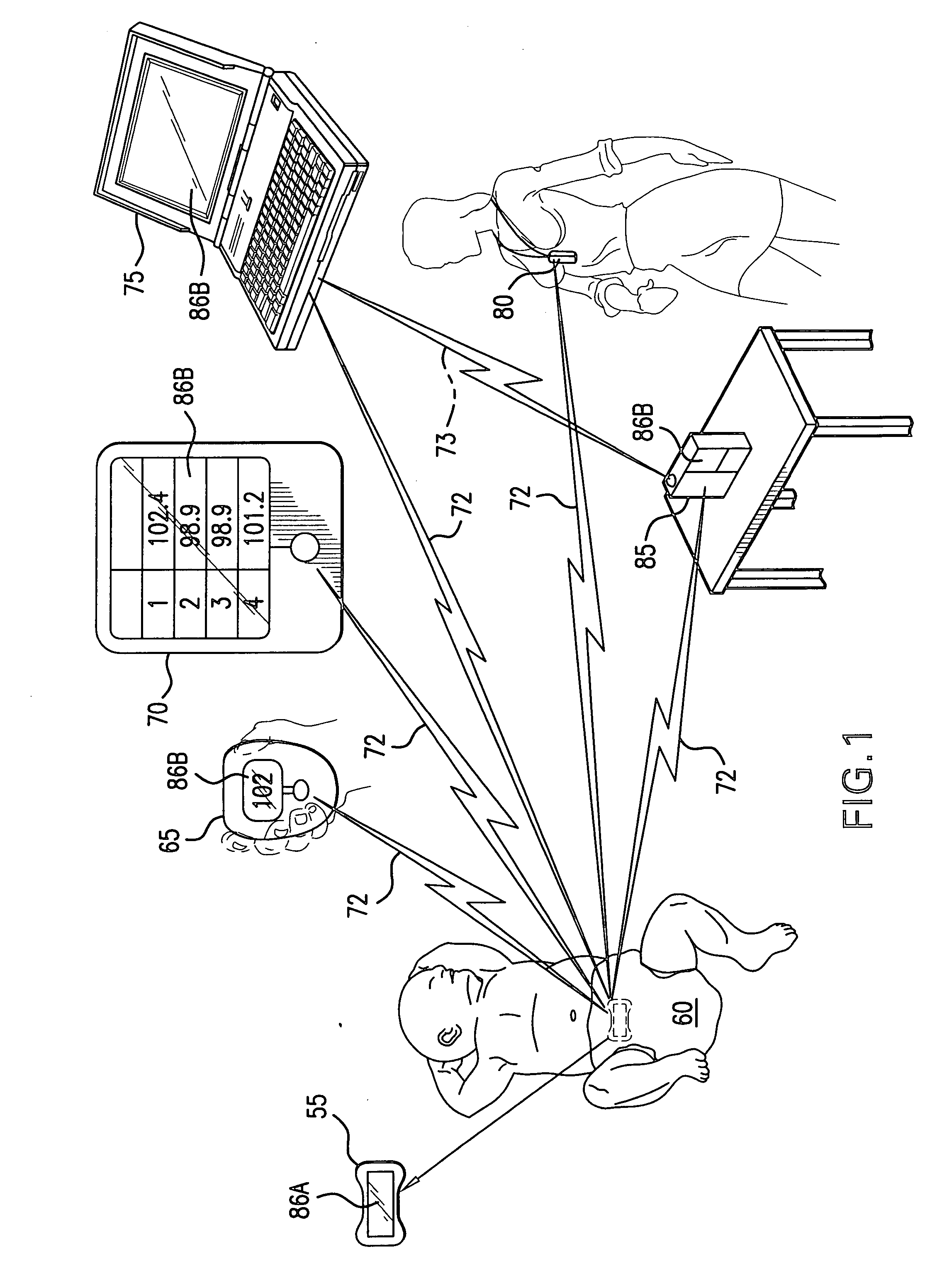

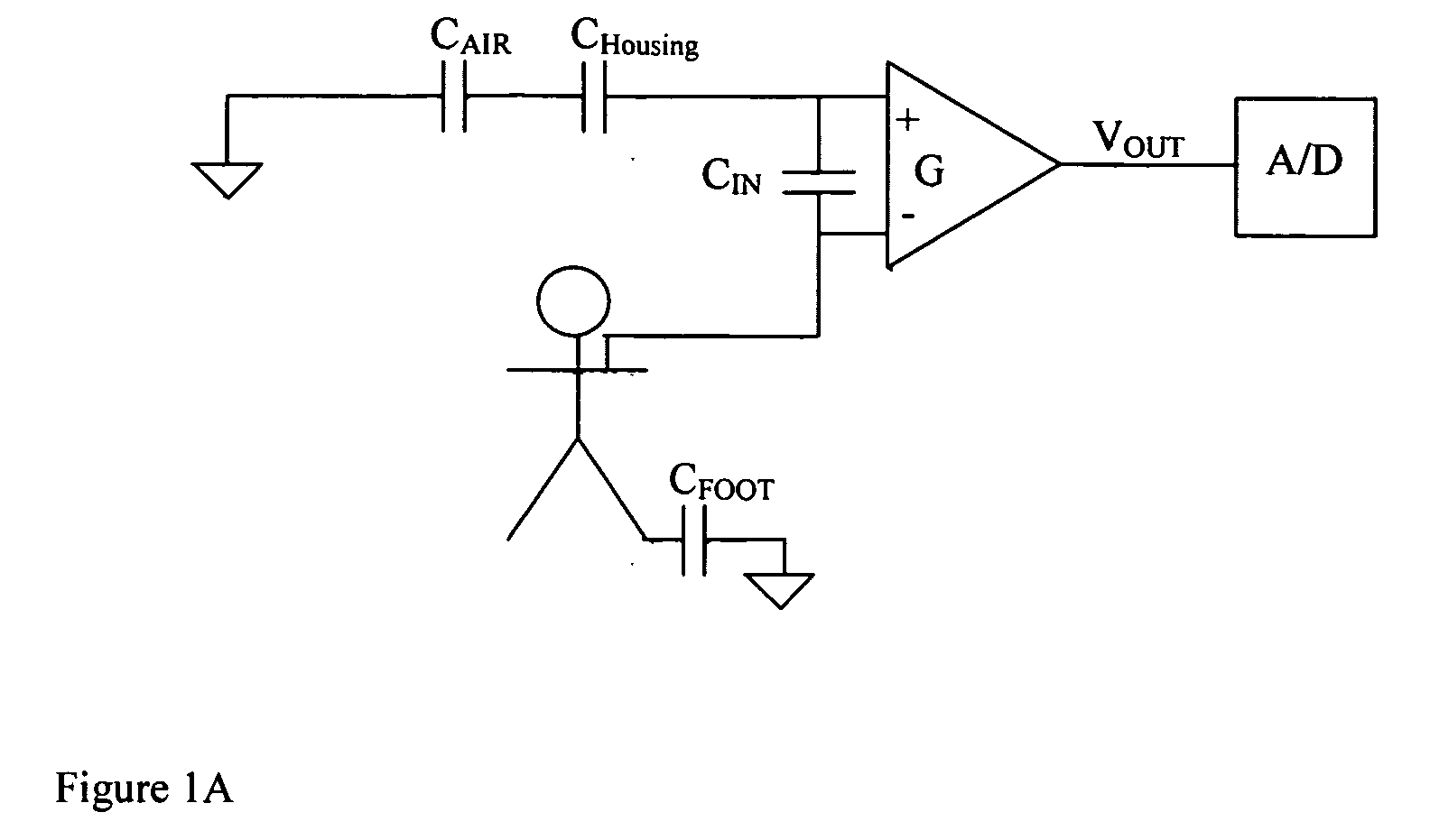

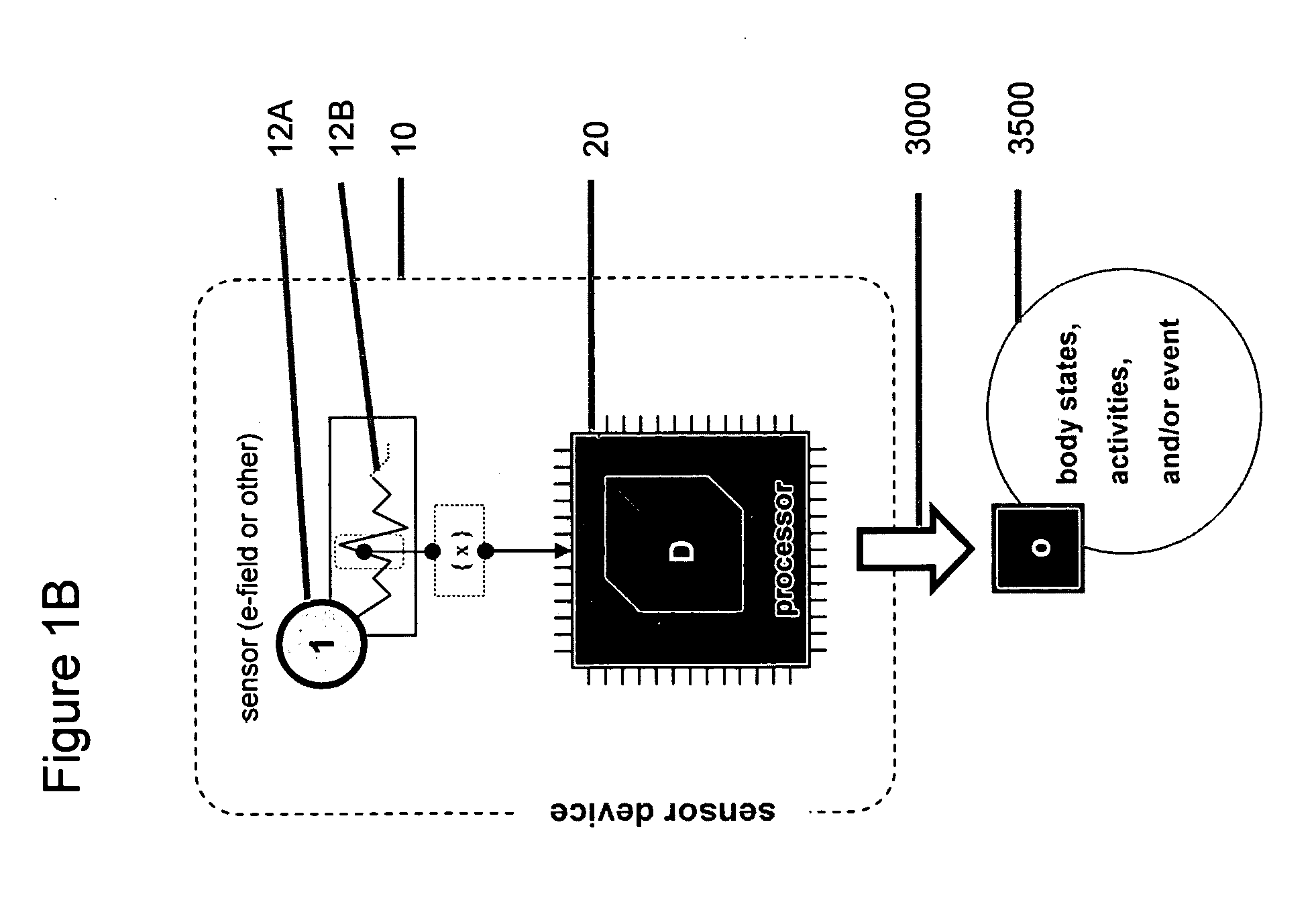

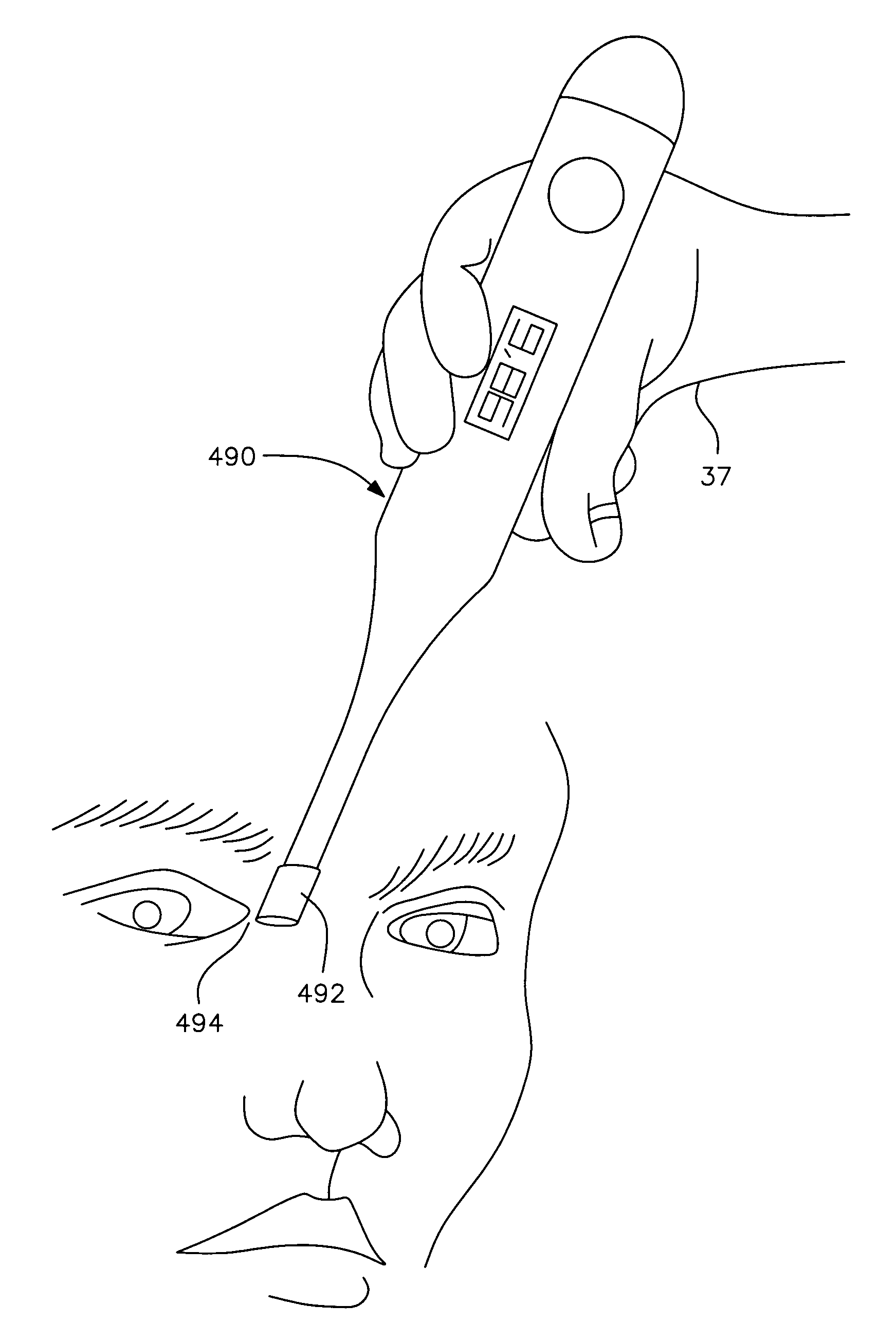

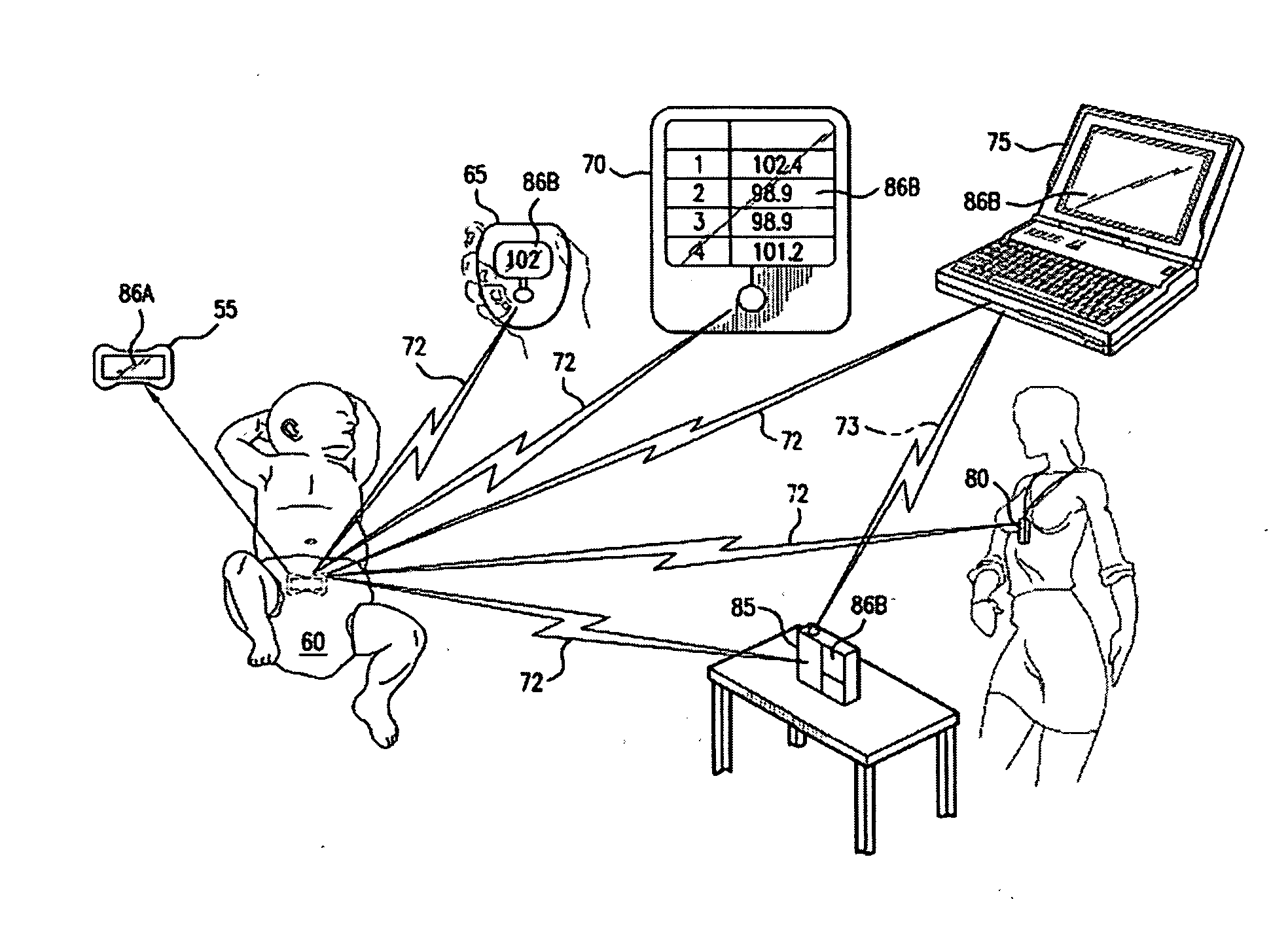

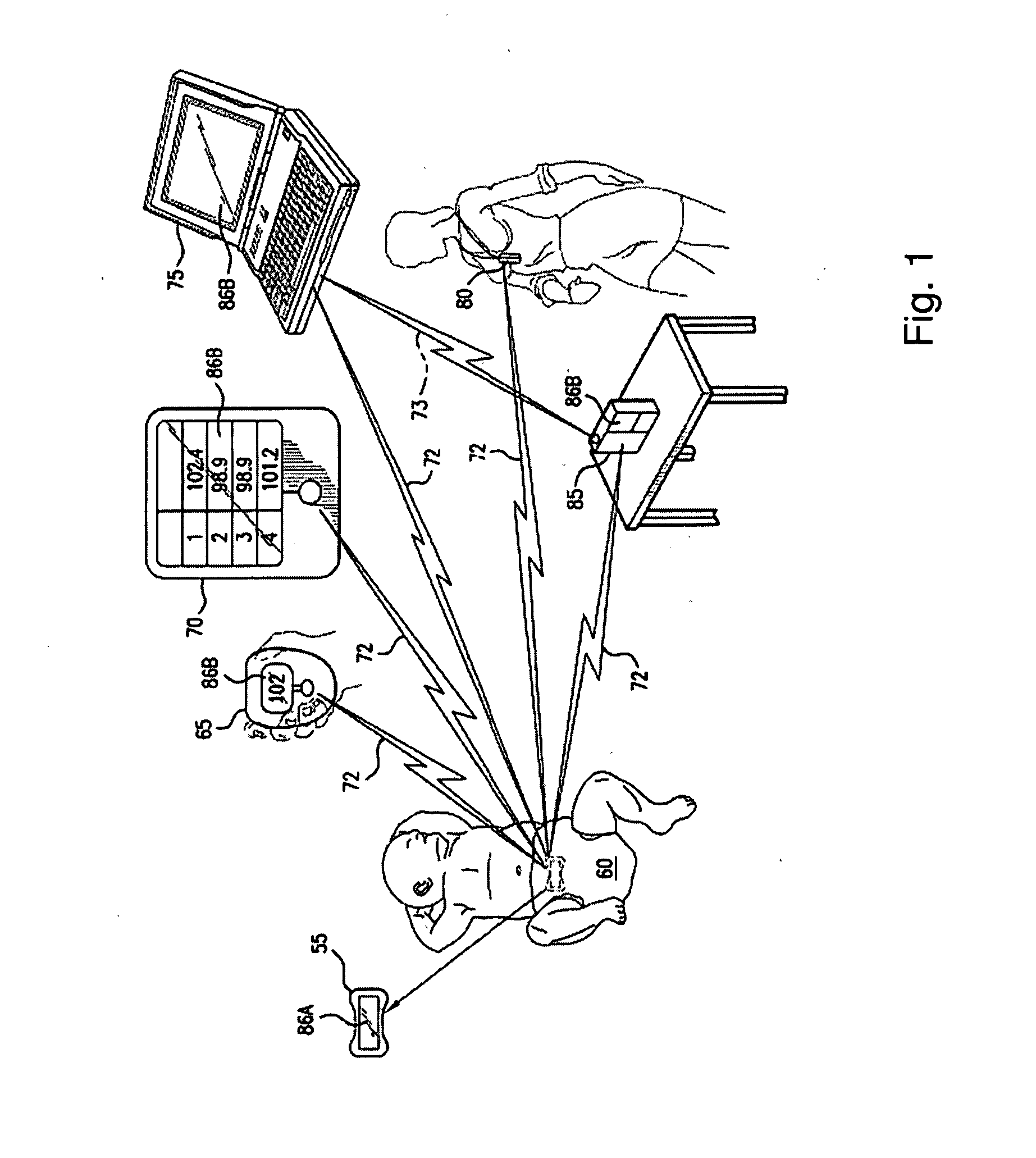

Devices and systems for contextual and physiological-based detection, monitoring, reporting, entertainment, and control of other devices

InactiveUS20070100666A1Short-term useLow costThermometer detailsMechanical apparatusElectric field sensorMonitoring system

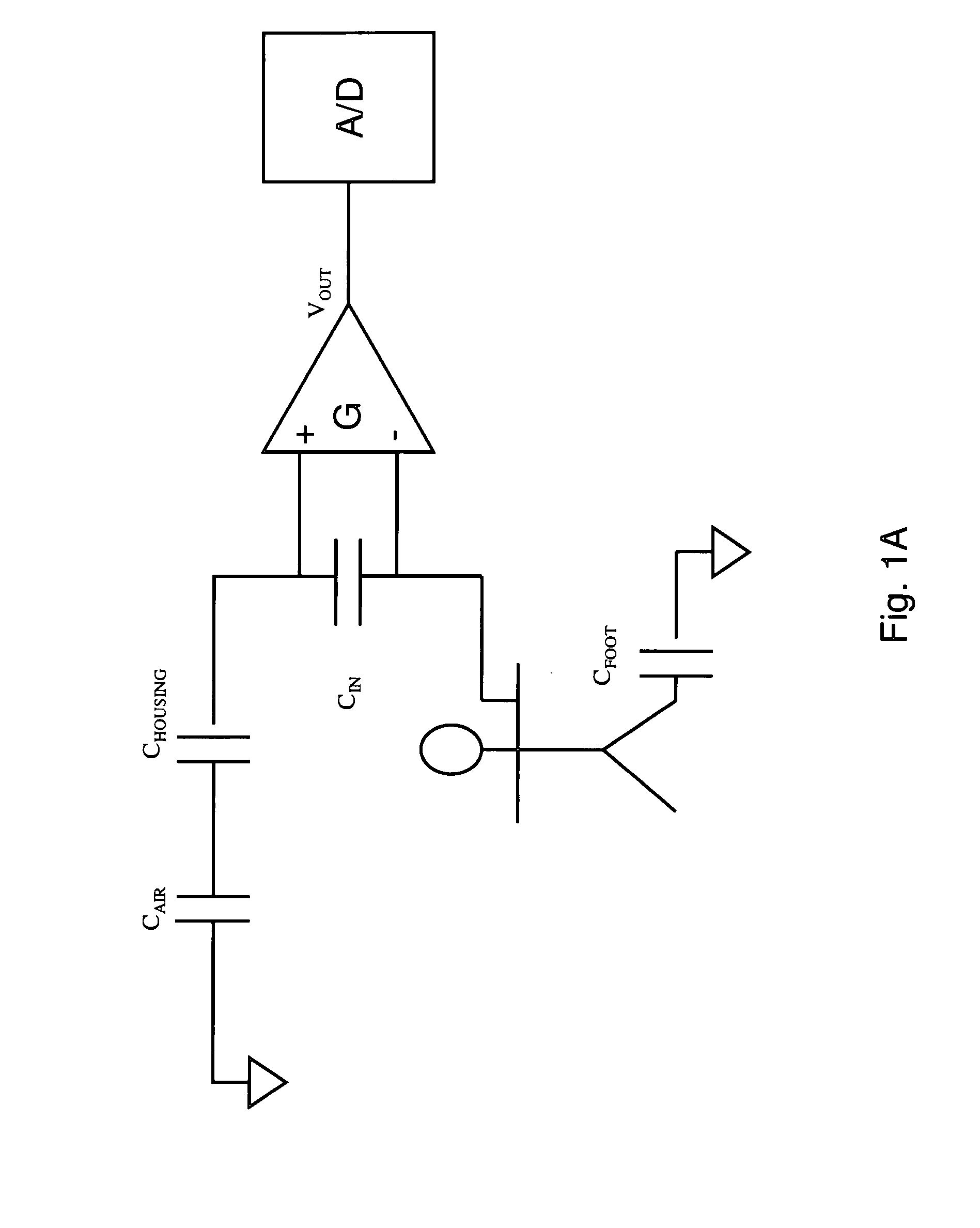

A monitoring system comprises a module having at least one sensor which could be an electric-field sensor within a housing. The device may be durable or disposable. A receiver may be provided to obtain and display data from the module. The module may also display the output data. The output data comprises both detected and derived data relating to physiological and contextual parameters of the wearer and may be transmitted directly to a local recipient or remotely over a communications network. The system is capable of deriving and predicting the occurrence of a number of physiological and conditional states and events and reporting the same as output data.

Owner:J FITNESS LLC

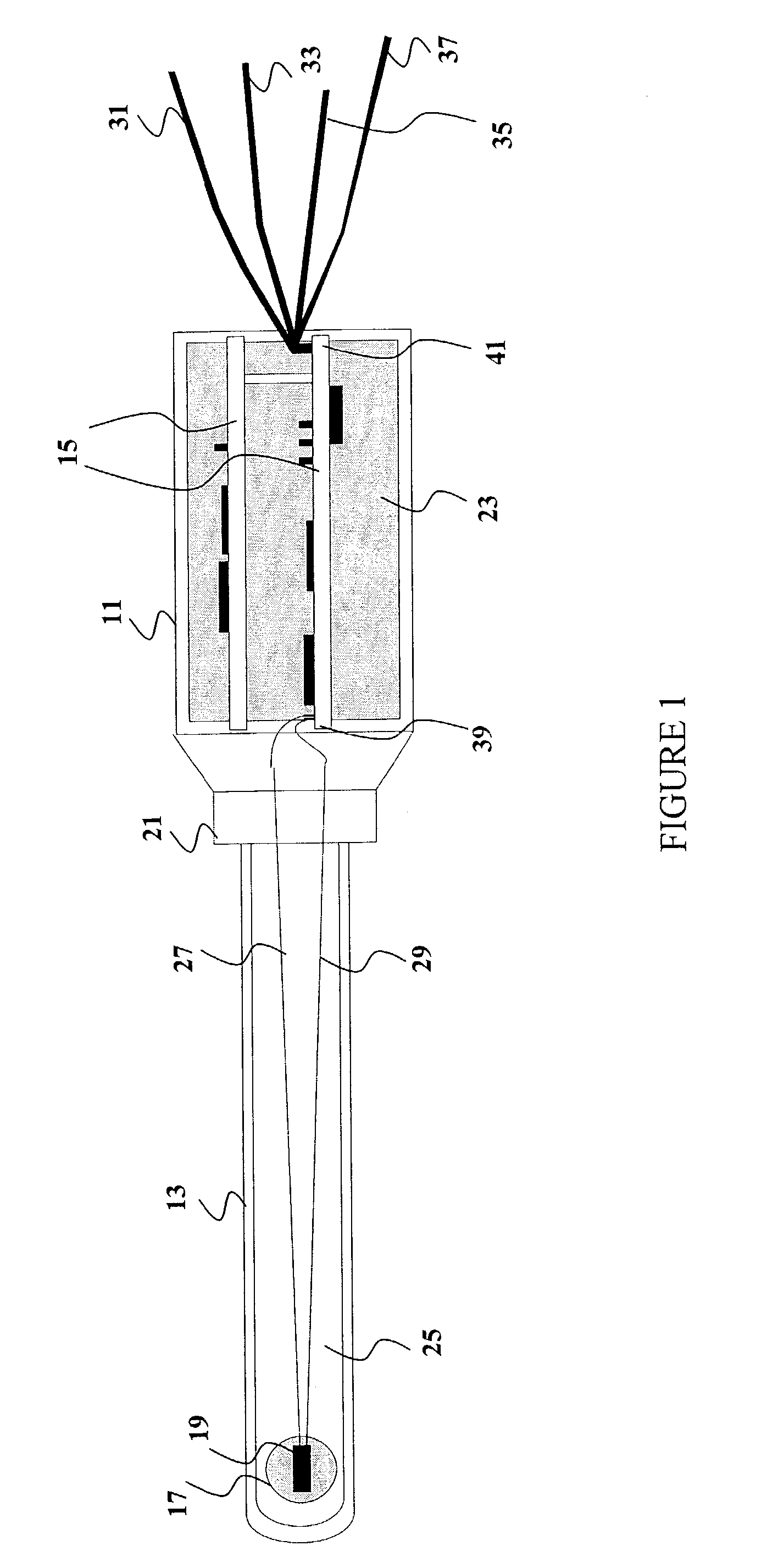

Apparatus and method for measuring biologic parameters

ActiveUS20090105605A1Prevent dehydrationAvoid overhydrationThermometer detailsTelevision system detailsInfraredVideo transmission

Support structures for positioning sensors on a physiologic tunnel for measuring physical, chemical and biological parameters of the body and to produce an action according to the measured value of the parameters. The support structure includes a sensor fitted on the support structures using a special geometry for acquiring continuous and undisturbed data on the physiology of the body. Signals are transmitted to a remote station by wireless transmission such as by electromagnetic waves, radio waves, infrared, sound and the like or by being reported locally by audio or visual transmission. The physical and chemical parameters include brain function, metabolic function, hydrodynamic function, hydration status, levels of chemical compounds in the blood, and the like. The support structure includes patches, clips, eyeglasses, head mounted gear and the like, containing passive or active sensors positioned at the end of the tunnel with sensing systems positioned on and accessing a physiologic tunnel.

Owner:BRAIN TUNNELGENIX TECH CORP

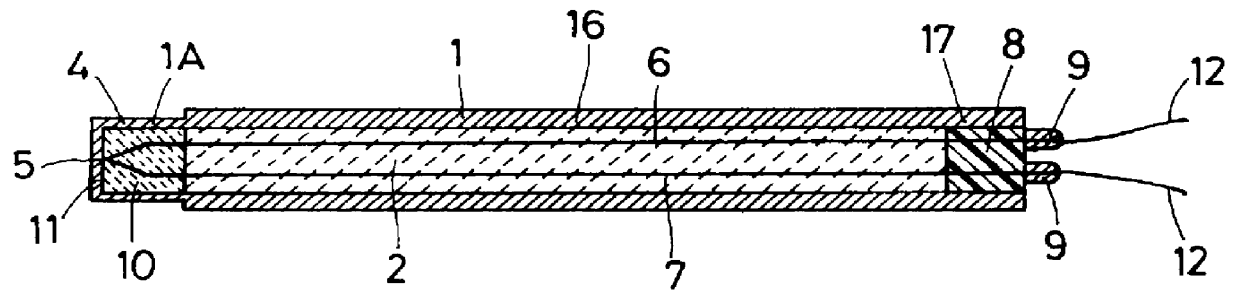

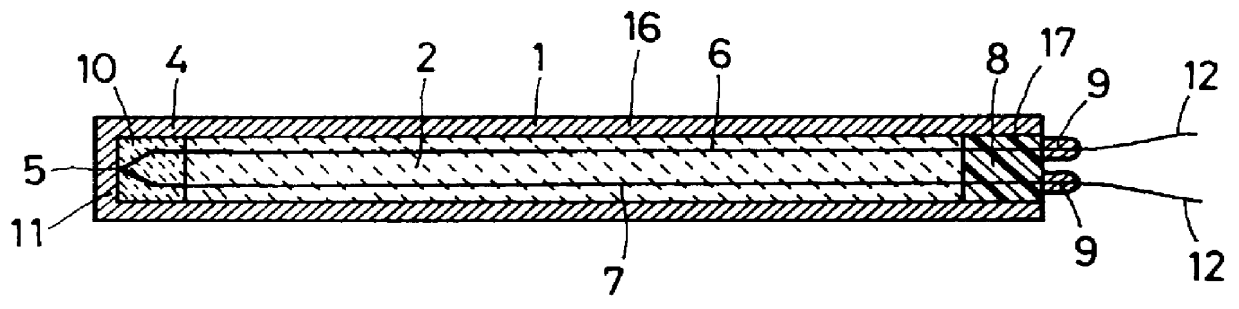

Ceramic sheath type thermocouple

InactiveUS6102565AThermometer detailsThermometers using electric/magnetic elementsHeat resistanceWhiskers

This ceramic sheath type thermocouple has a long service life, an improved temperature measuring responsibility and an improved temperature measuring precision, and enables repetitive use. The ceramic sheath type thermocouple has its protective tube 1 formed of a heat resisting ceramics selected from silicon nitride, sialon and silicon carbide. In the protective tube 1 are installed a pair of W-Re wires that are connected to form a joint portion constituting a temperature measuring point 5. A filler made of Si3N4 reaction-sintered ceramics is loaded into the front end portion of the protective tube to enclose the W-Re wires. Another filler made of SiC whisker with a heat conductivity smaller than that of the filler of the front end portion is loaded into the rear portion of the protective tube. An inert gas is sealed in the protective tube. Alternatively, the temperature measuring portion may be formed by exposing from the front end portion of the protective tube the joint portion where the ends of the W-Re wires are connected. The temperature measuring portion is coated with a cover film that is made of silicon carbide, silicon nitride or a composite of these, all having excellent heat resisting and corrosion resisting properties.

Owner:ISUZU MOTORS LTD

Devices and systems for contextual and physiological-based reporting, entertainment, control of other devices, health assessment and therapy

InactiveUS20080167535A1Short-term useLow costThermometer detailsMechanical apparatusMonitoring systemDerived Data

A monitoring system comprises a module having at least one sensor to determine human status information. The device may be durable or disposable. A receiver may be provided to obtain and display data from the device. The device may also display the output data. The output data comprises both detected and derived data relating to physiological and contextual parameters of the wearer and may be transmitted directly to a local recipient or remotely over a communications network. The system is capable of deriving and predicting the occurrence of a number of physiological and conditional states and events and reporting the same as output data.

Owner:J FITNESS LLC

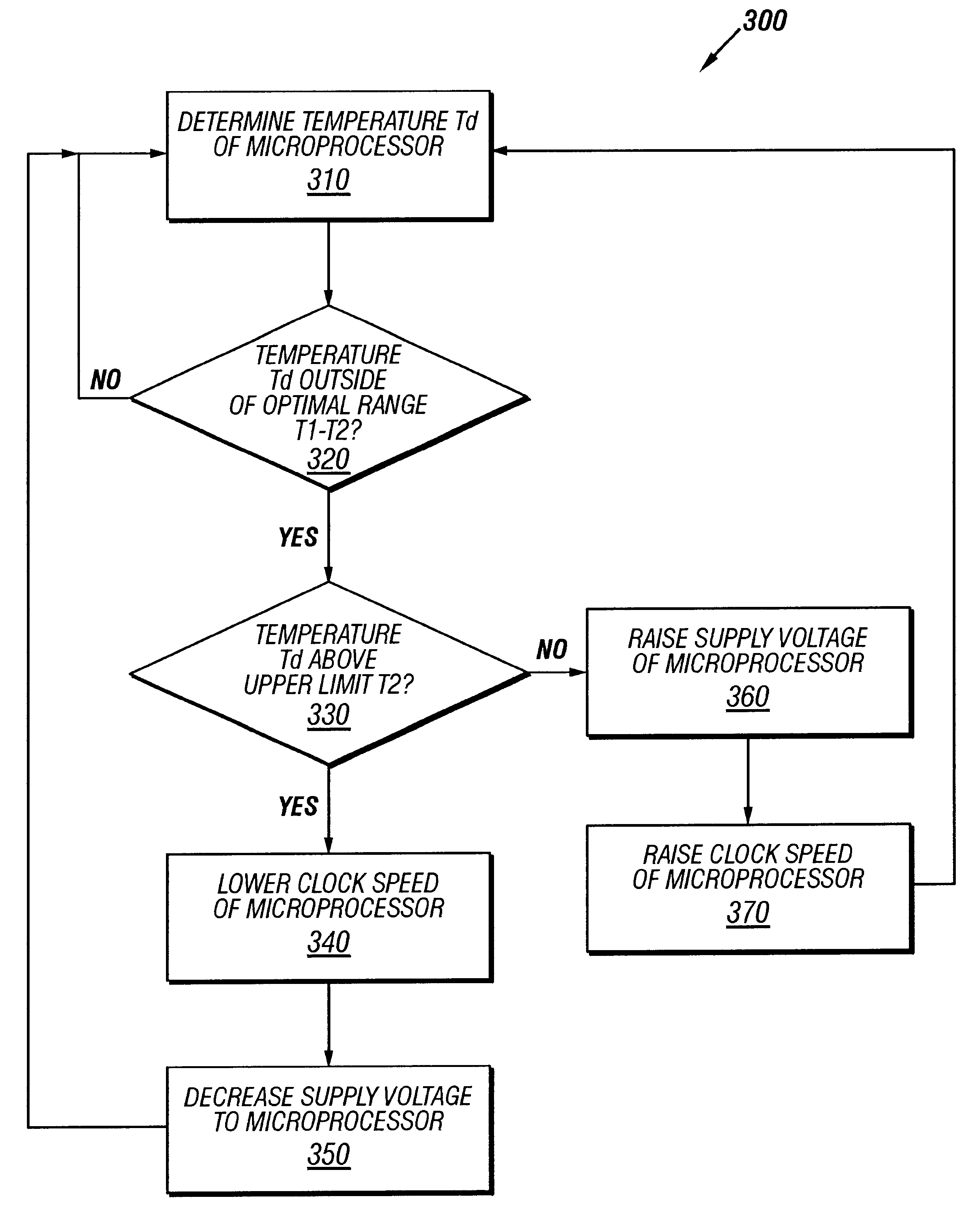

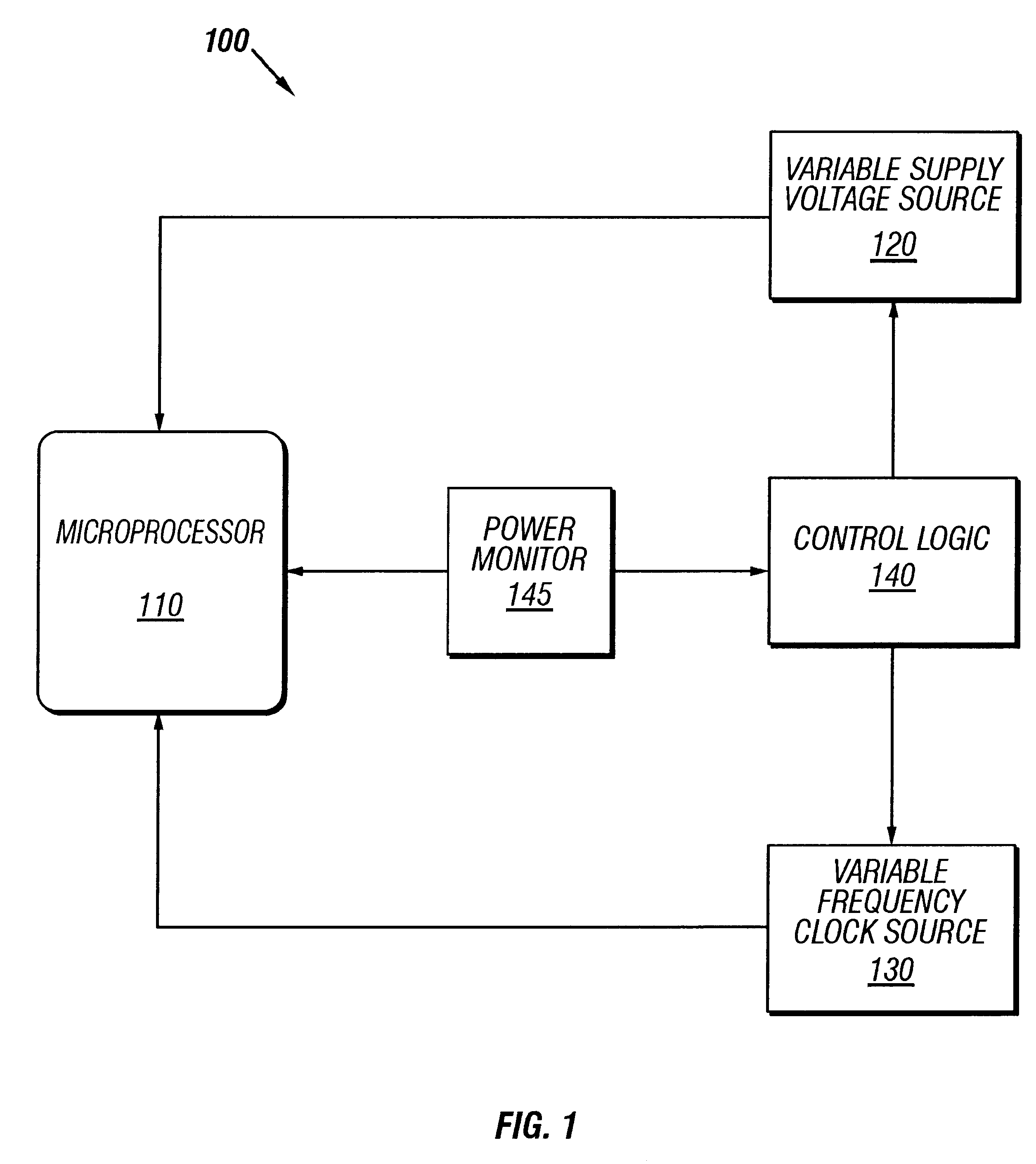

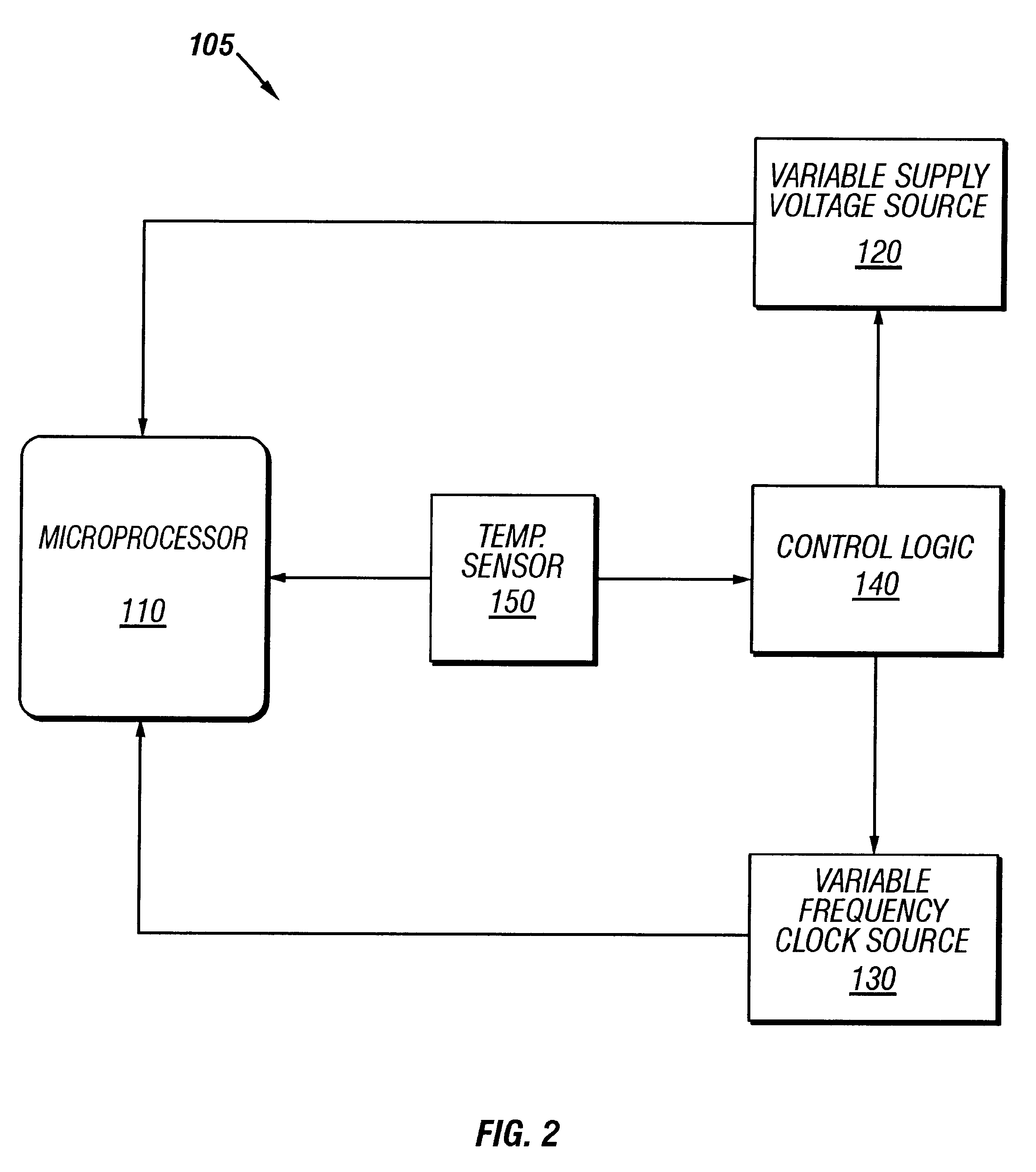

Method and apparatus for power throttling in a microprocessor using a closed loop feedback system

A method and apparatus for power throttling in a microprocessor. A voltage source supplies voltage to the microprocessor, and a clock source operates the microprocessor at a desired frequency. In one embodiment, a power monitor is configured to measure the short term power consumption of the microprocessor. In another embodiment, a temperature sensor measures the temperature of the microprocessor. Control logic is coupled to the voltage source and the clock source. The control logic receives an indication of the power consumption or temperature, as applicable, and compares it to a predetermined value. In response to the comparison, the control logic varies the supply voltage and the frequency.

Owner:INTEL CORP

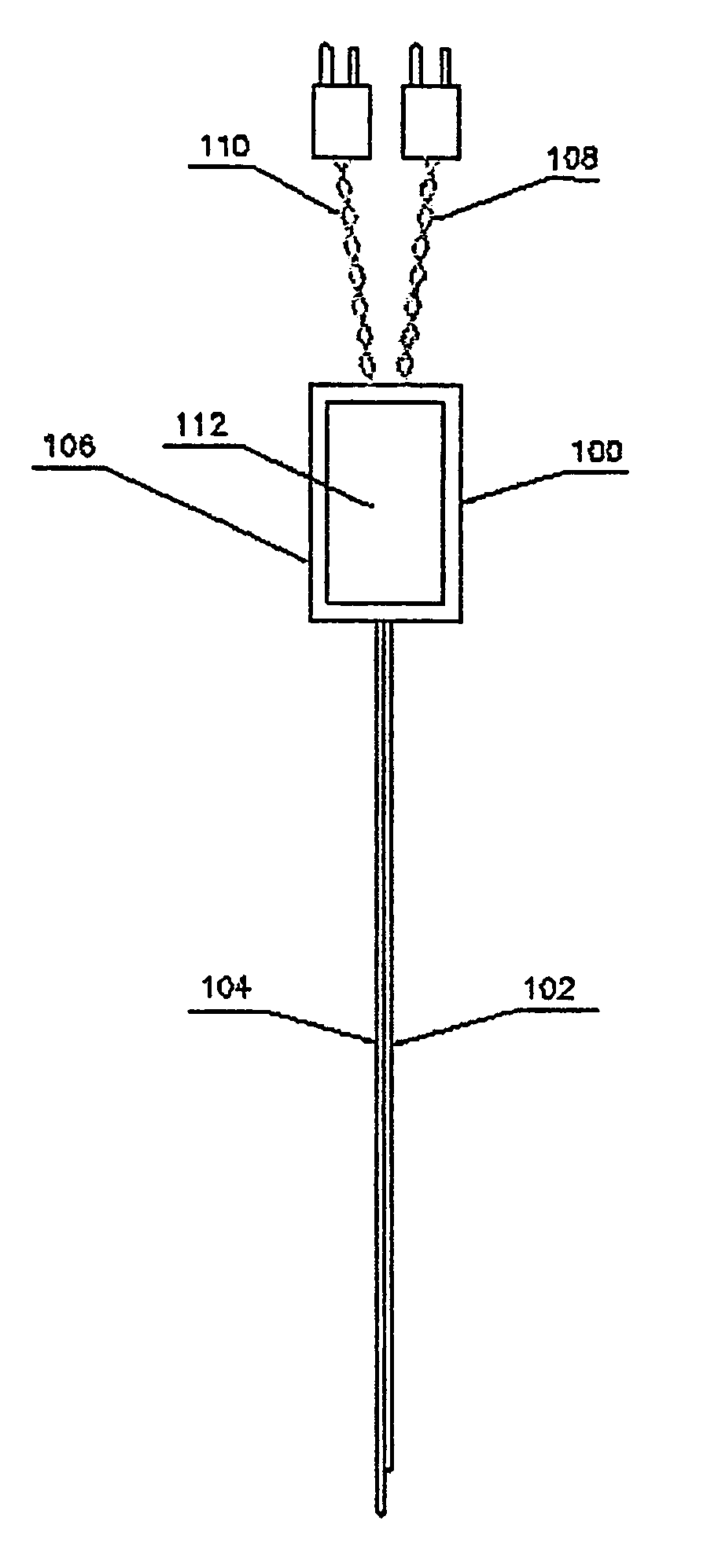

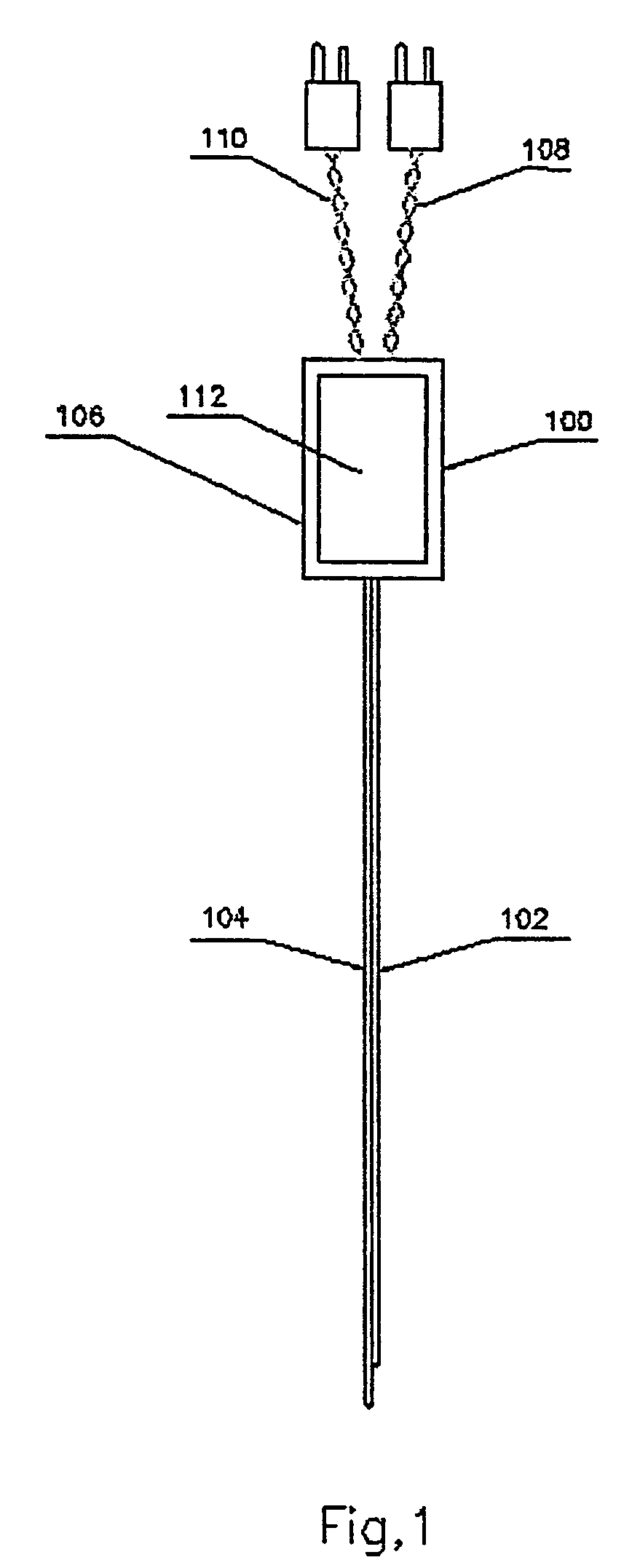

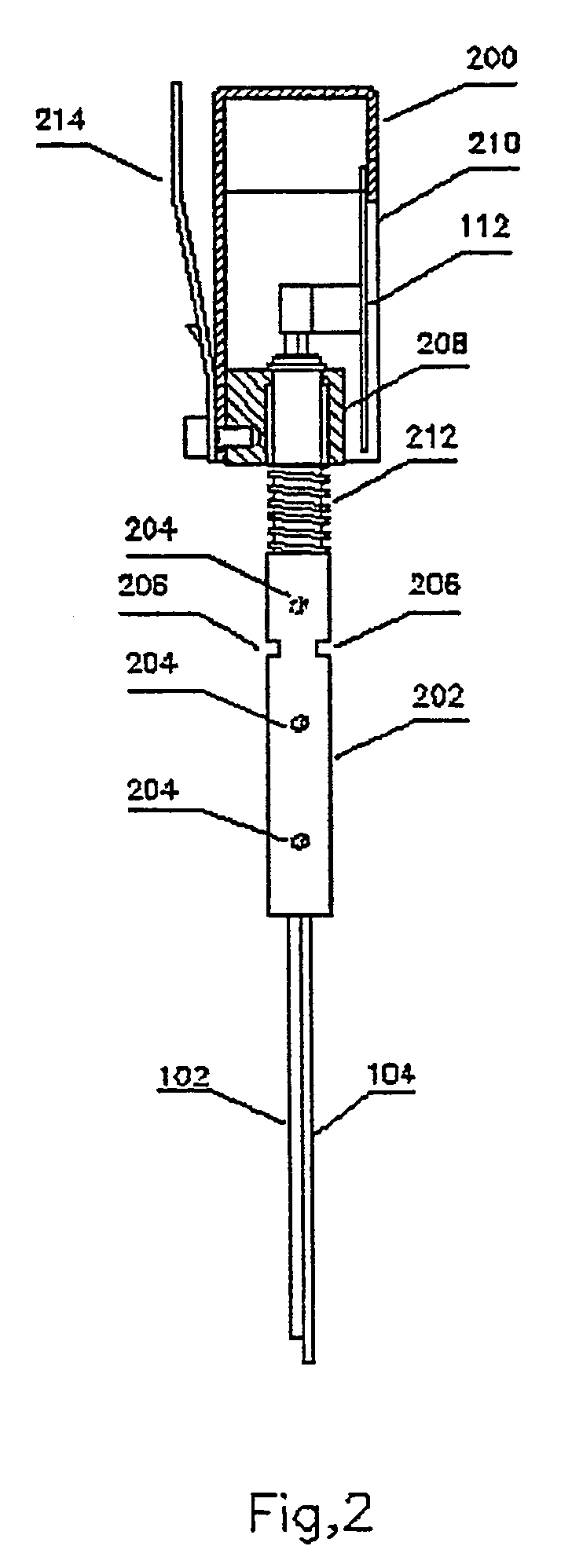

Thermocouple

ActiveUS8100583B2Thermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple device

A thermocouple having at least one inner alignment feature or at least one outer alignment feature, or a combination thereof for positively positioning and aligning at least one thermocouple junction within a bore formed in a susceptor ring of a semiconductor substrate processing reactor. The outer alignment feature is configured to positively align the junction(s) longitudinally within the bore. The inner alignment feature configured to positively position the junction(s) rotationally within the sheath of the thermocouple relative to the bore.

Owner:ASM IP HLDG BV

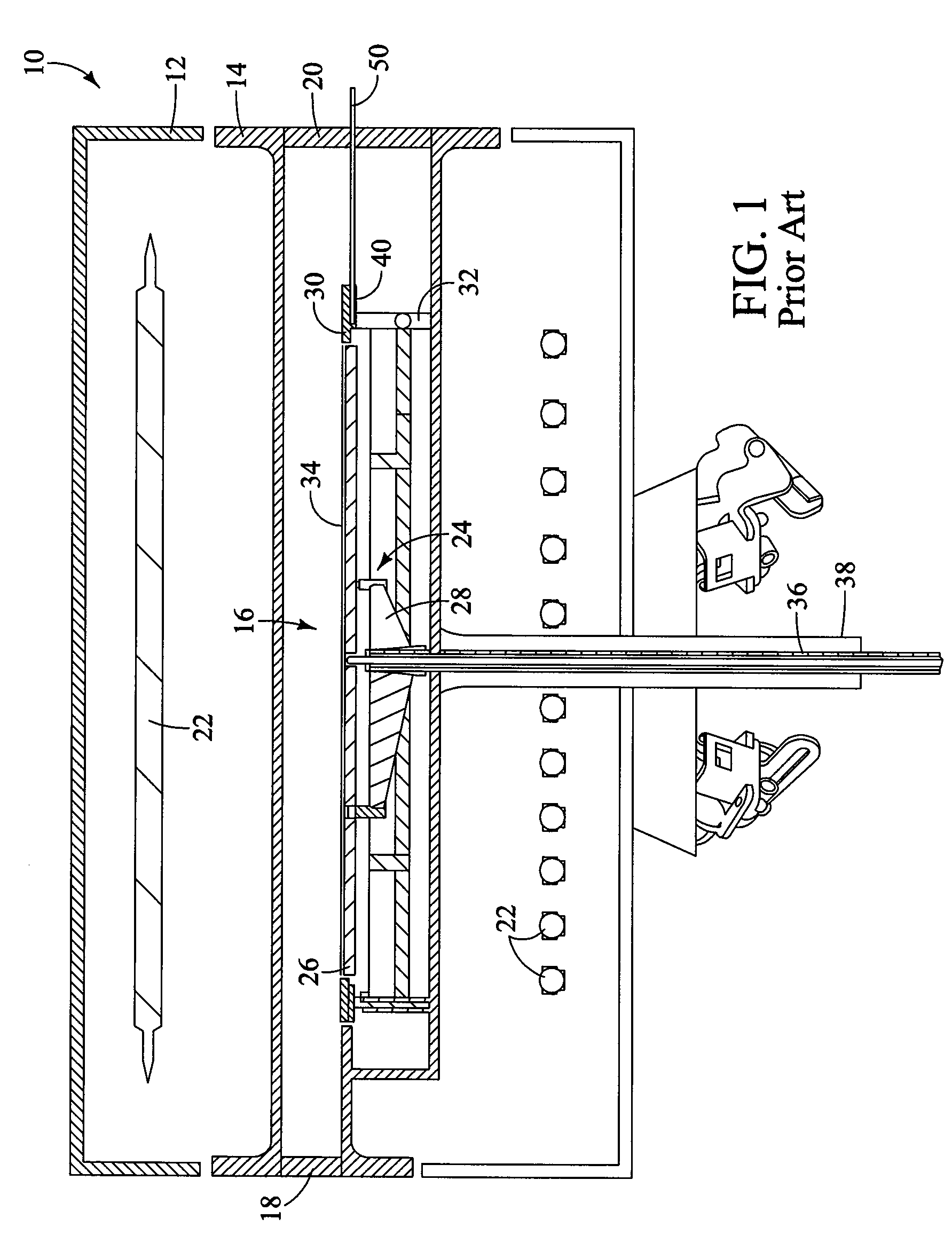

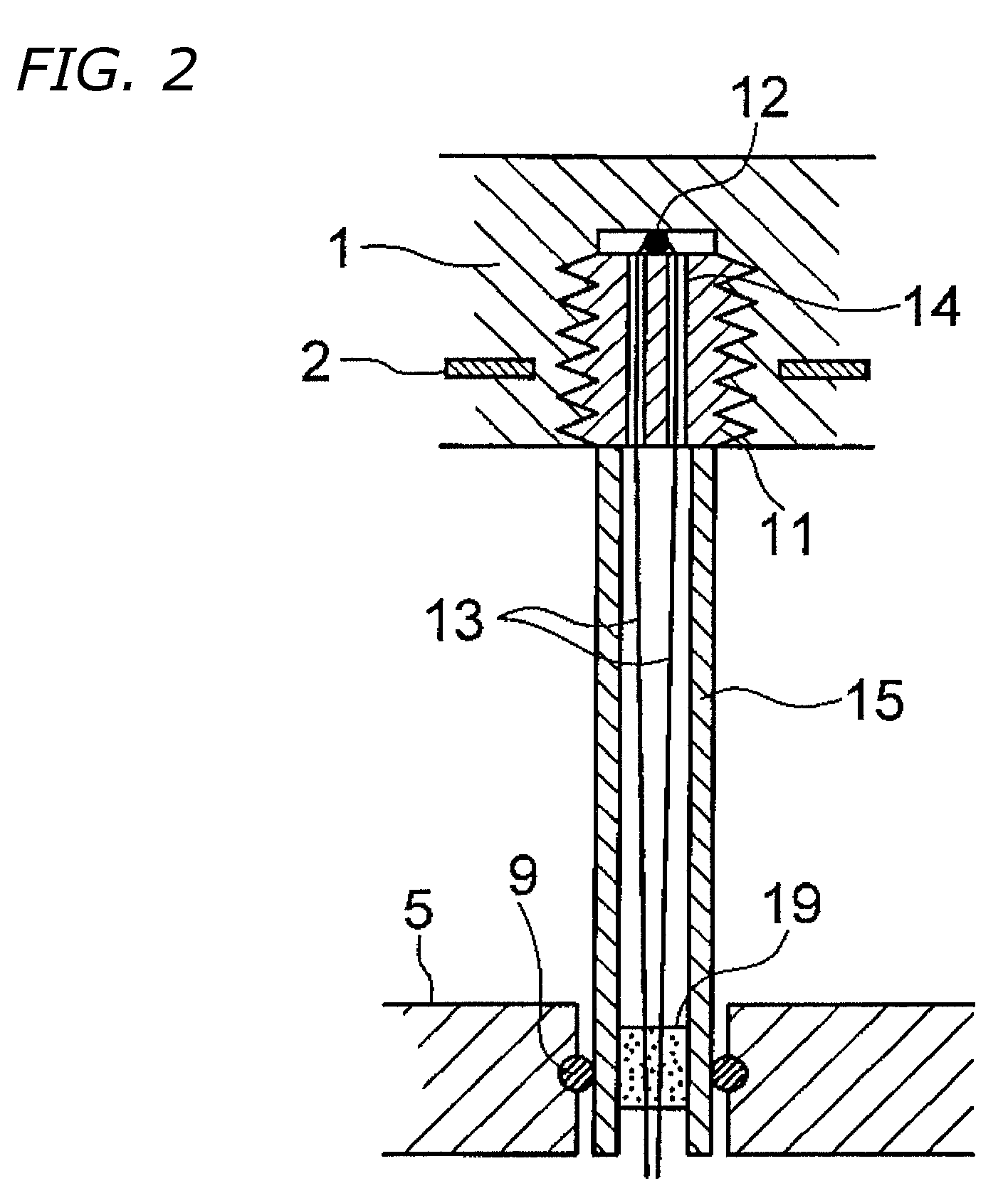

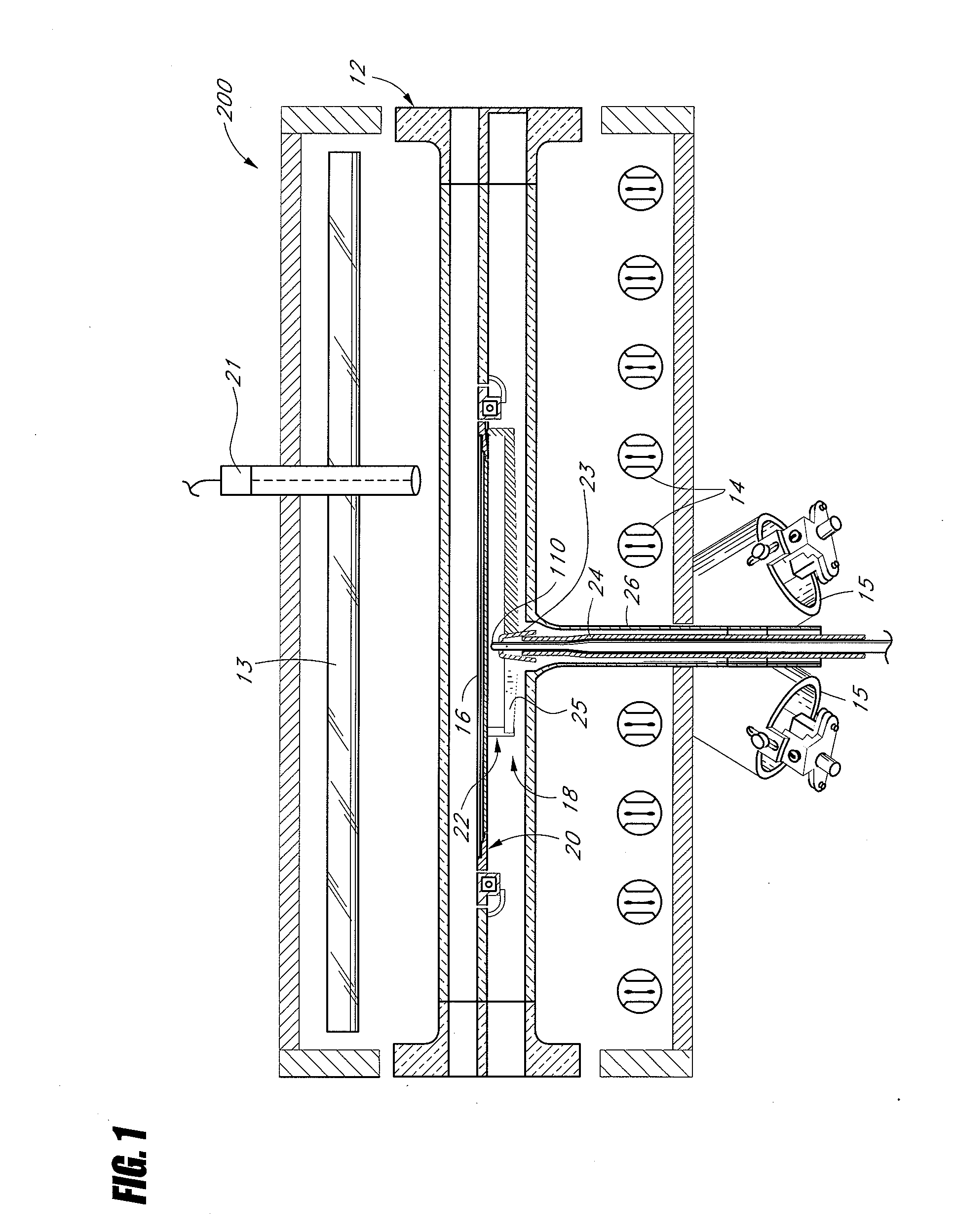

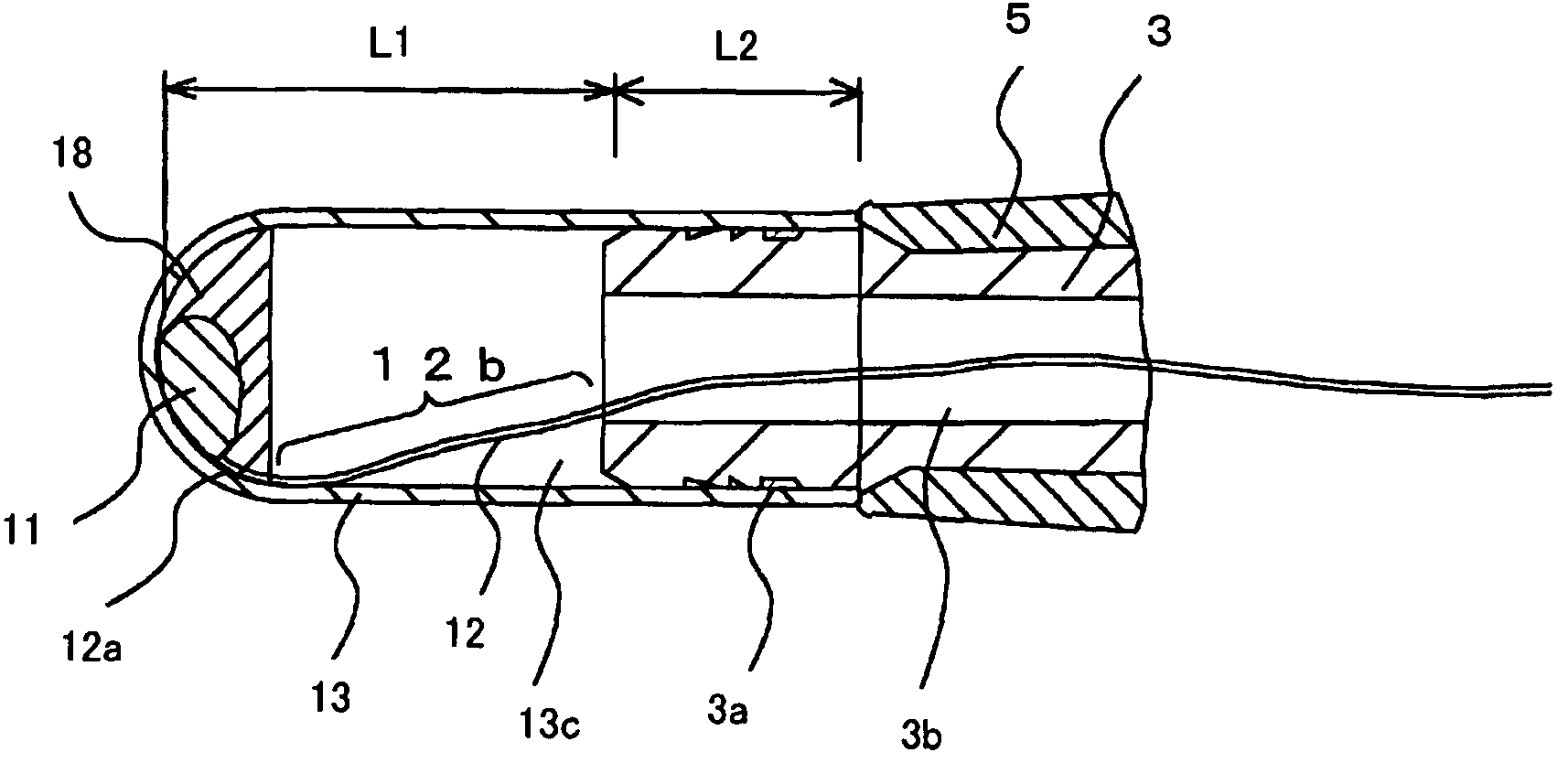

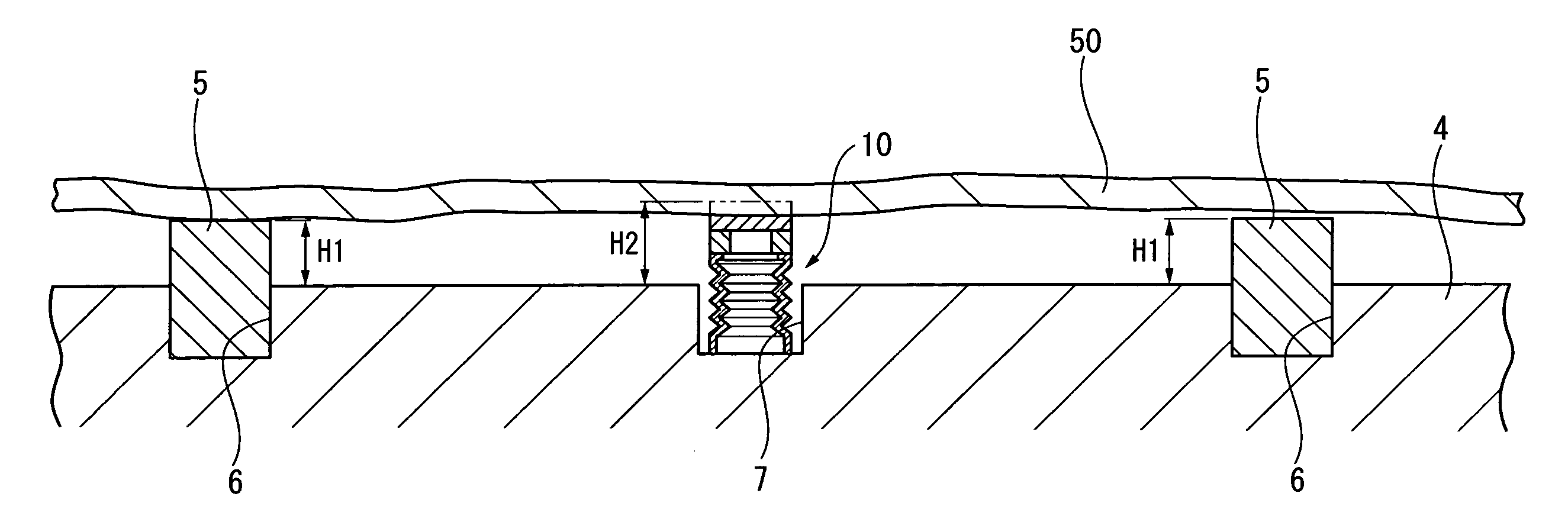

Temperature gauge and ceramic susceptor in which it is utilized

InactiveUS7090394B2Shorten the timeEasy to replaceThermometer detailsThermometers using electric/magnetic elementsSusceptorMetallurgy

Temperature gauge, and ceramic susceptors and semiconductor manufacturing equipment utilizing the temperature gauge, in which the thermocouple may be easily replaced even if damaged, and in which heat from the temperature-gauging site is readily transmitted to the temperature-gauging contact, shortening time until the measurement temperature stabilizes. A temperature-gauging contact (12) in the tip of the thermocouple contacts, in an exposed-as-it-is state, a temperature-gauging site on a ceramic susceptor (1), and by means of a circular cylindrical-shaped retaining member (11) screwed into female threads in the ceramic susceptor (1) is detachably pressed upon and retained against the ceramic susceptor. Thermocouple lead lines (13), passing through a through-hole (14) in the retaining member (11), stretch from one end face to the other end face thereof. The retaining member may be provided with a flange having threaded holes and screwlocked into female screws in the ceramic susceptor.

Owner:SUMITOMO ELECTRIC IND LTD

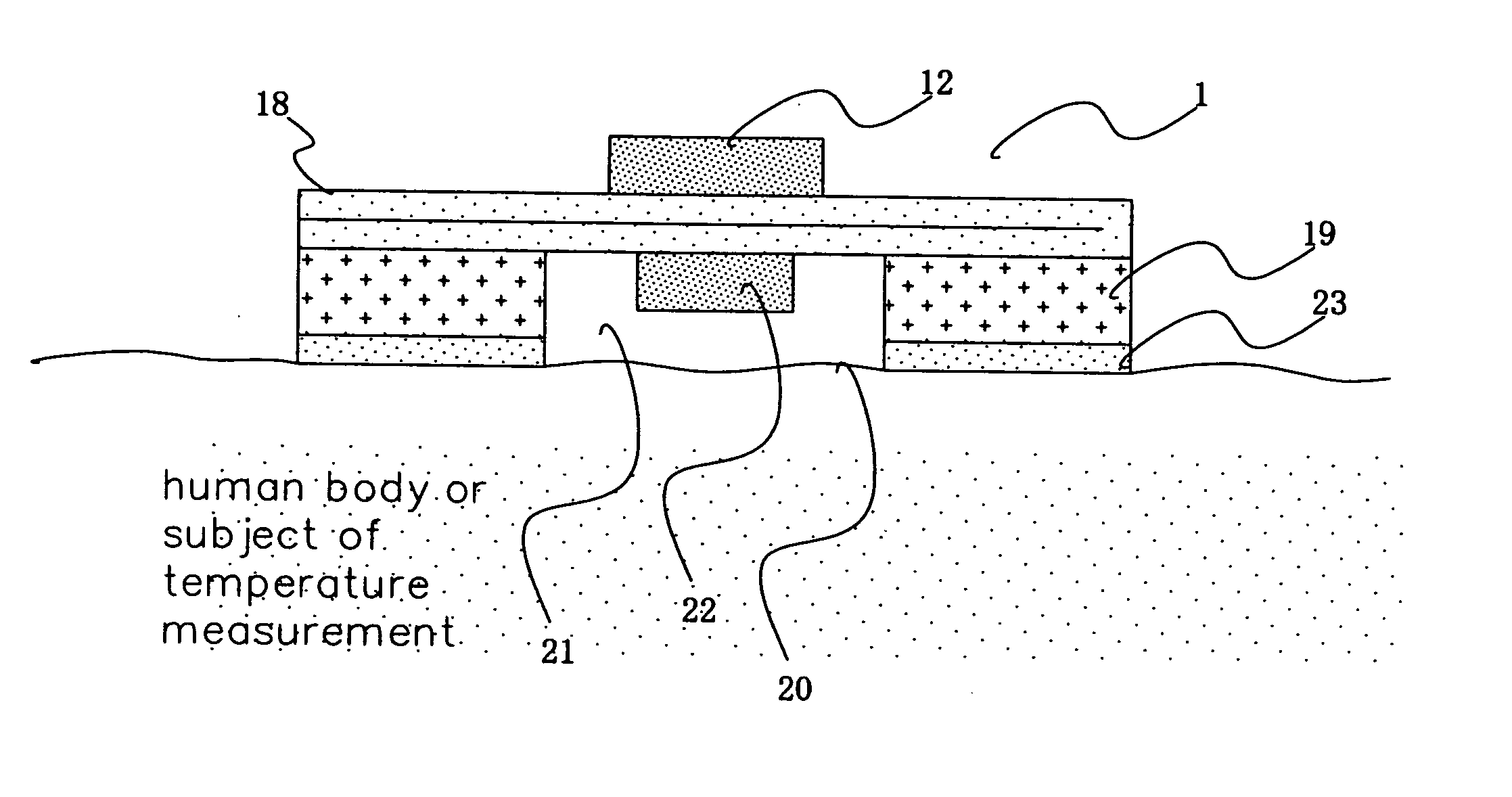

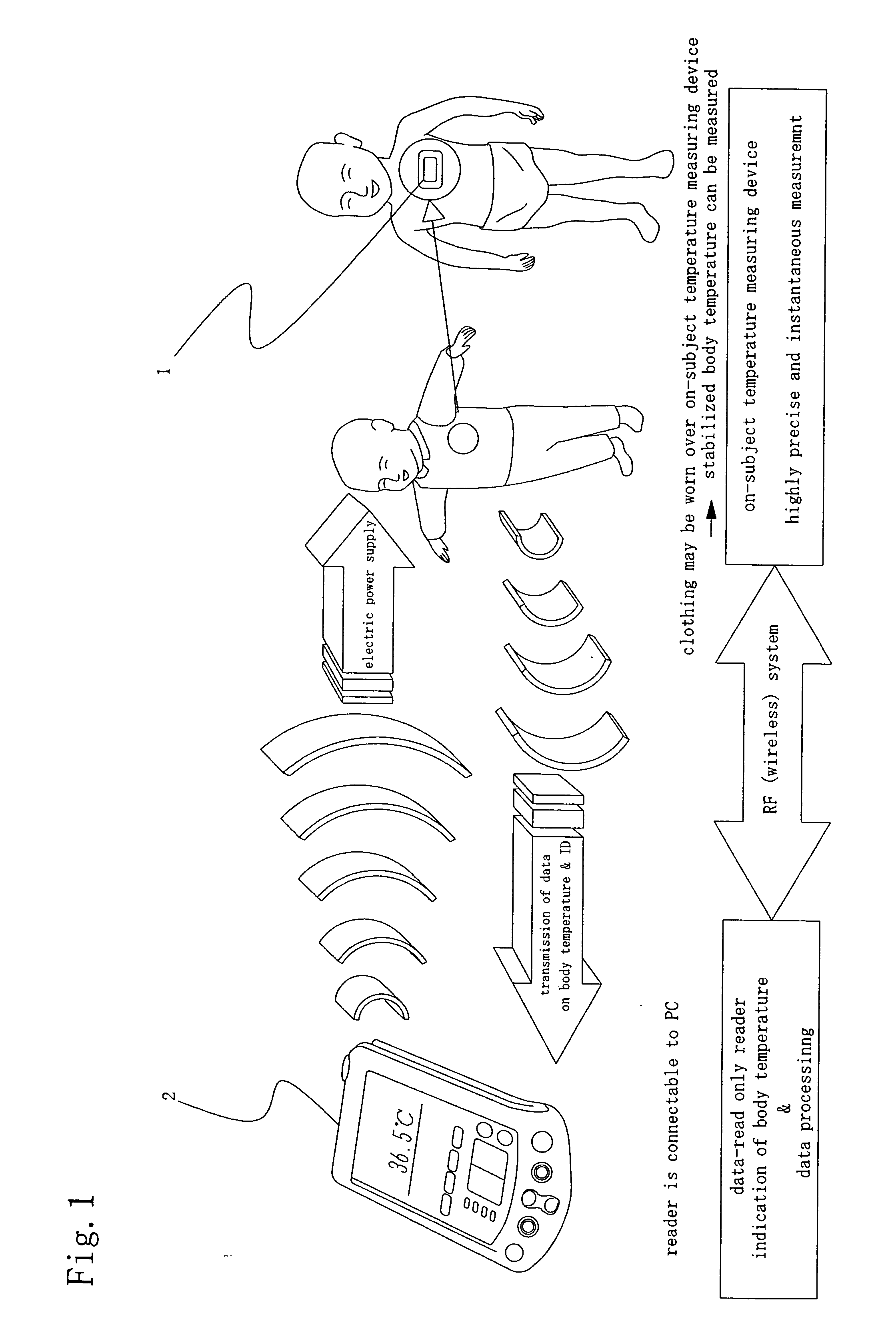

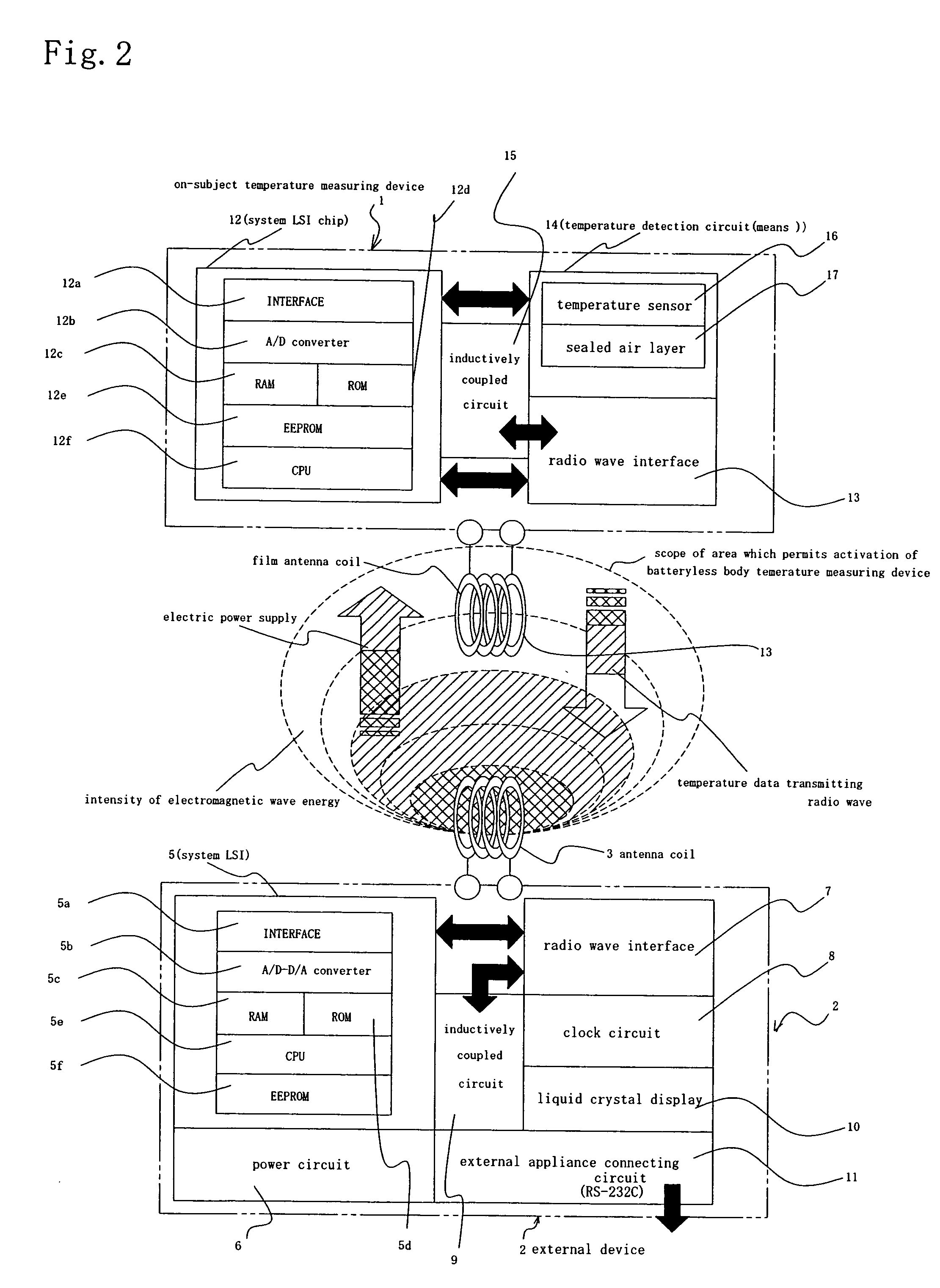

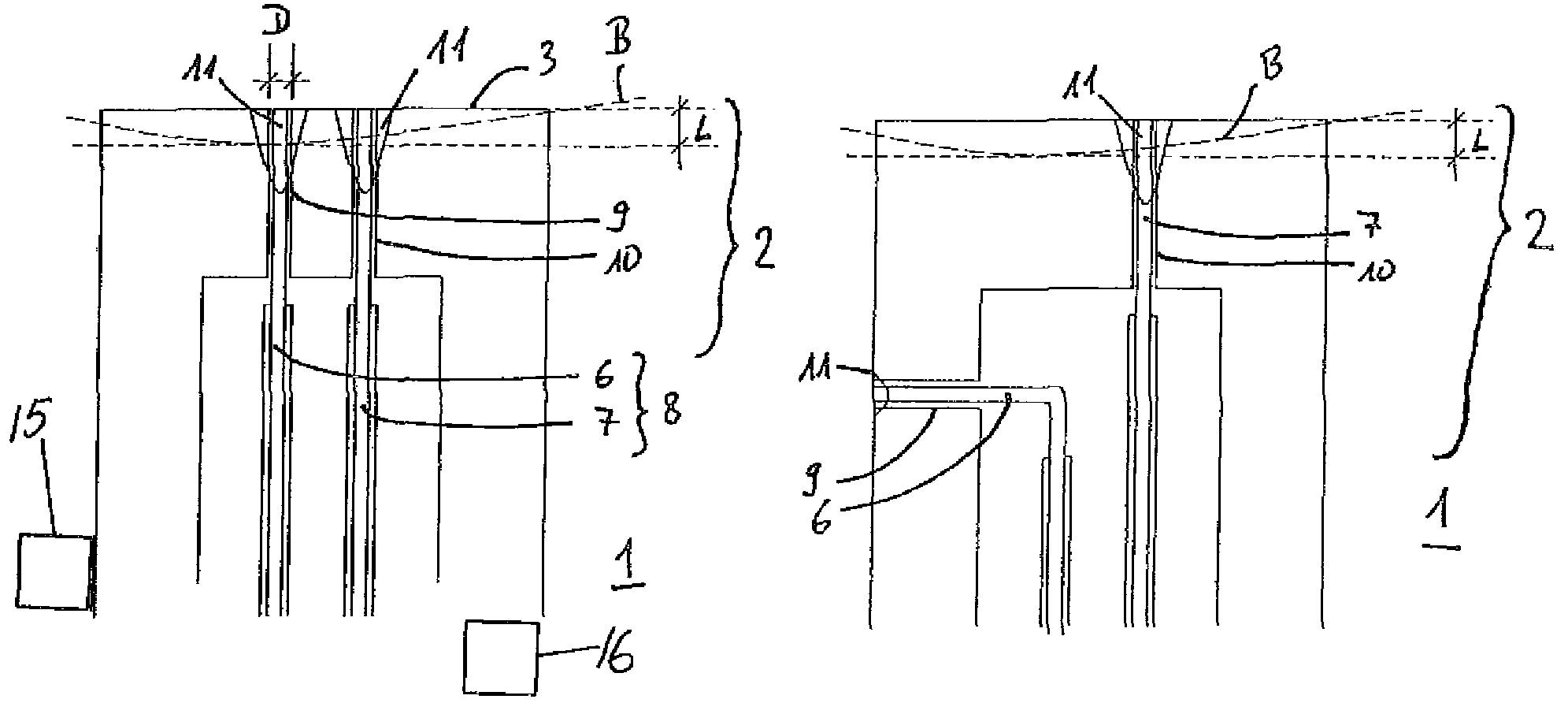

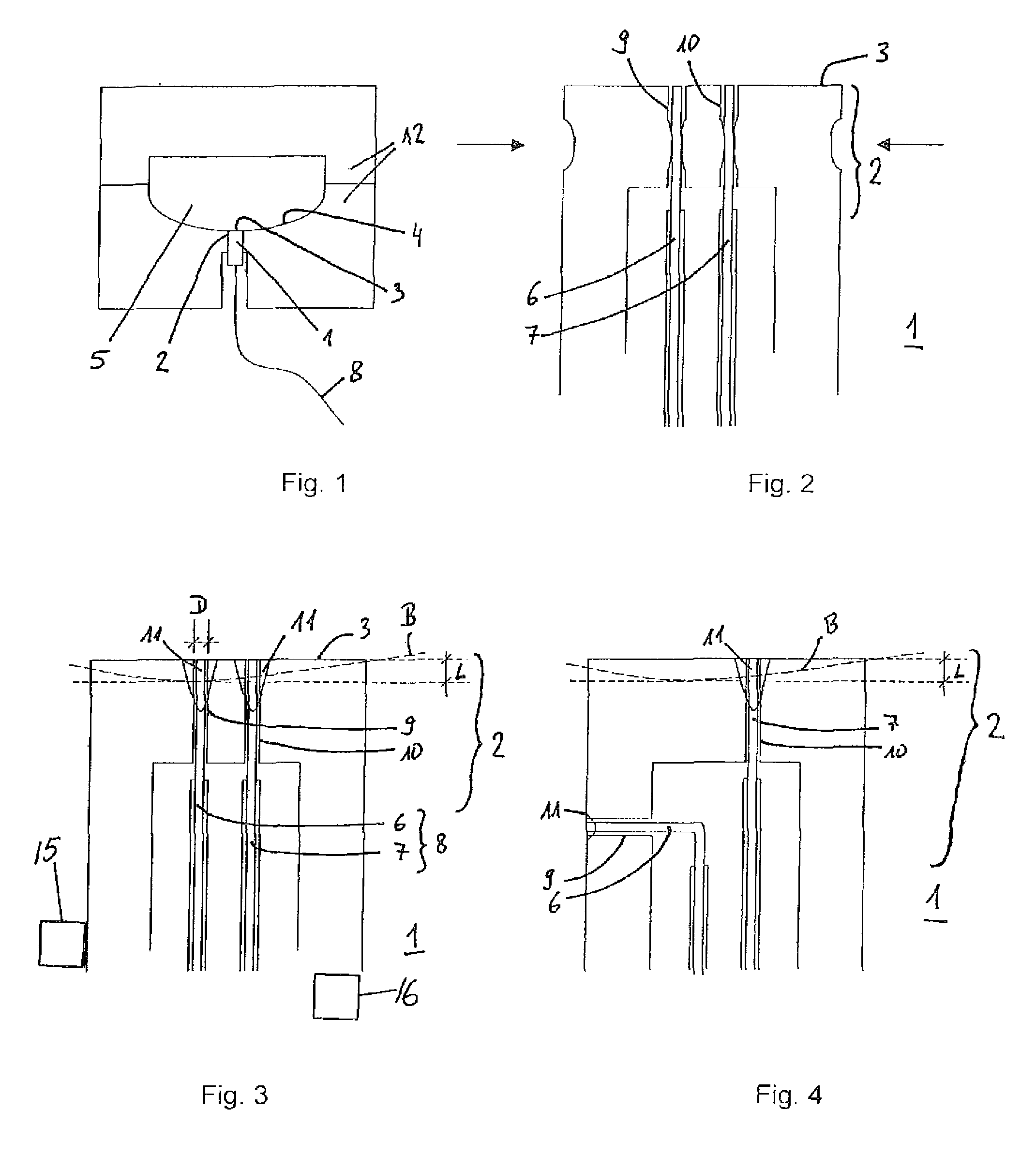

Temperature measuring device and temperature measuring method

InactiveUS20050141591A1Low production costFree replacementThermometer detailsElectric signal transmission systemsSingle-Use DeviceMeasurement device

A temperature measuring device and a temperature measuring method are provided which are capable of obtaining precise measured temperature values with respect even to old persons, sucklings or infants, which device may be formed into a disposable type according to need, which method may be carried out using such a disposable type device according to need, and which enable precise temperature measurement in real time. An on-subject temperature measuring device 1, which is attached to a subject when a temperature of the subject is measured, receives a radio wave from a reader 2 as an external device and is thereby electrically powered. Using the electric power, temperature measurement is performed in the on-subject temperature measuring device 1. The results of the measurement are transmitted through radio waves to the reader 2 in the form of a temperature of the subject and ID data. The reader 2 is so constructed as to be connectable to a personal computer (not shown), and data processing by the personal computer is performed according to need.

Owner:SAKANO KAZUHITO +2

Method and a device for thermal analysis of cast iron

InactiveUS7168852B2Improve accuracyEliminate sourceThermometer detailsWithdrawing sample devicesCooling curveComputer module

Owner:SINTERCAST

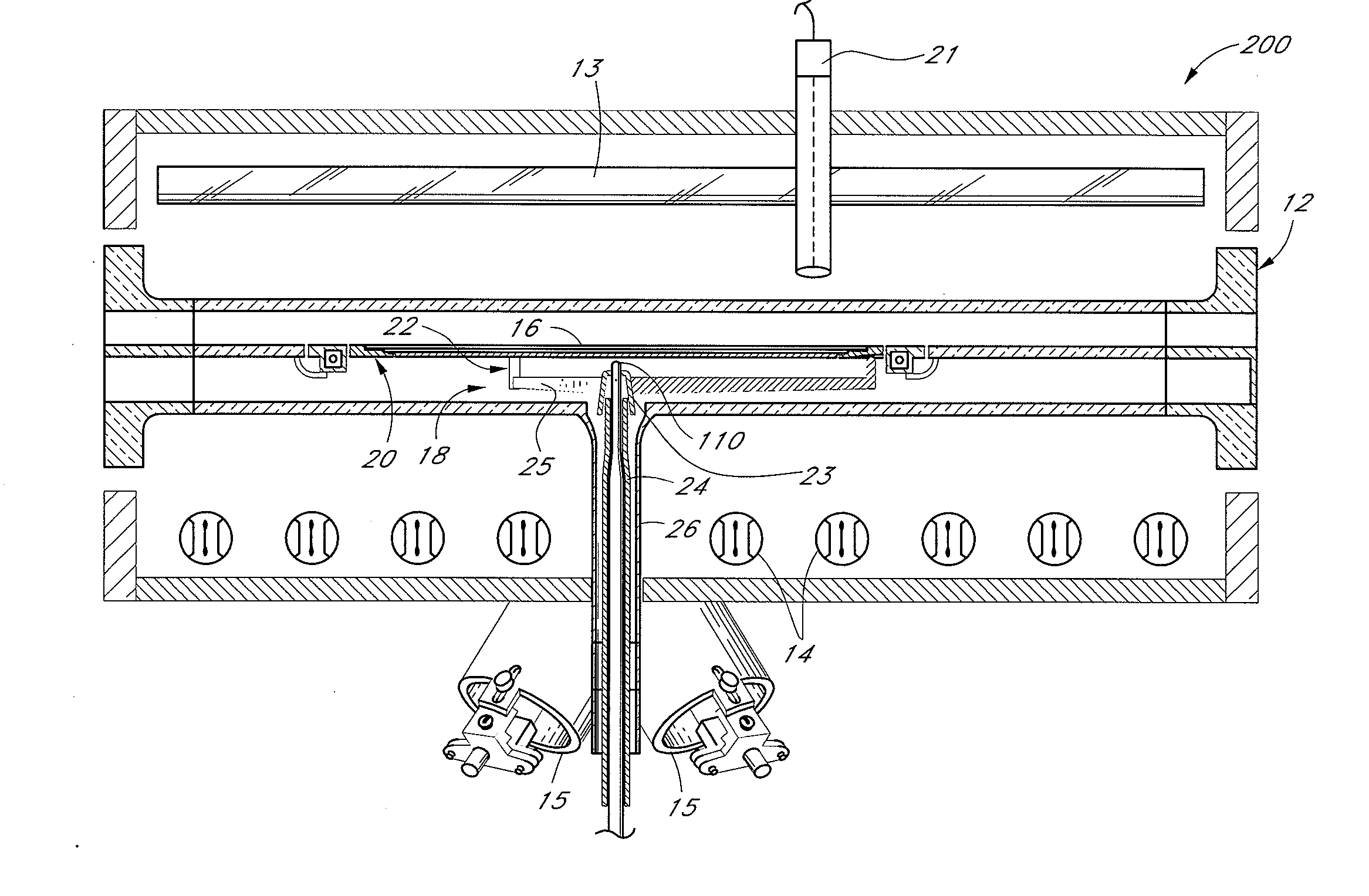

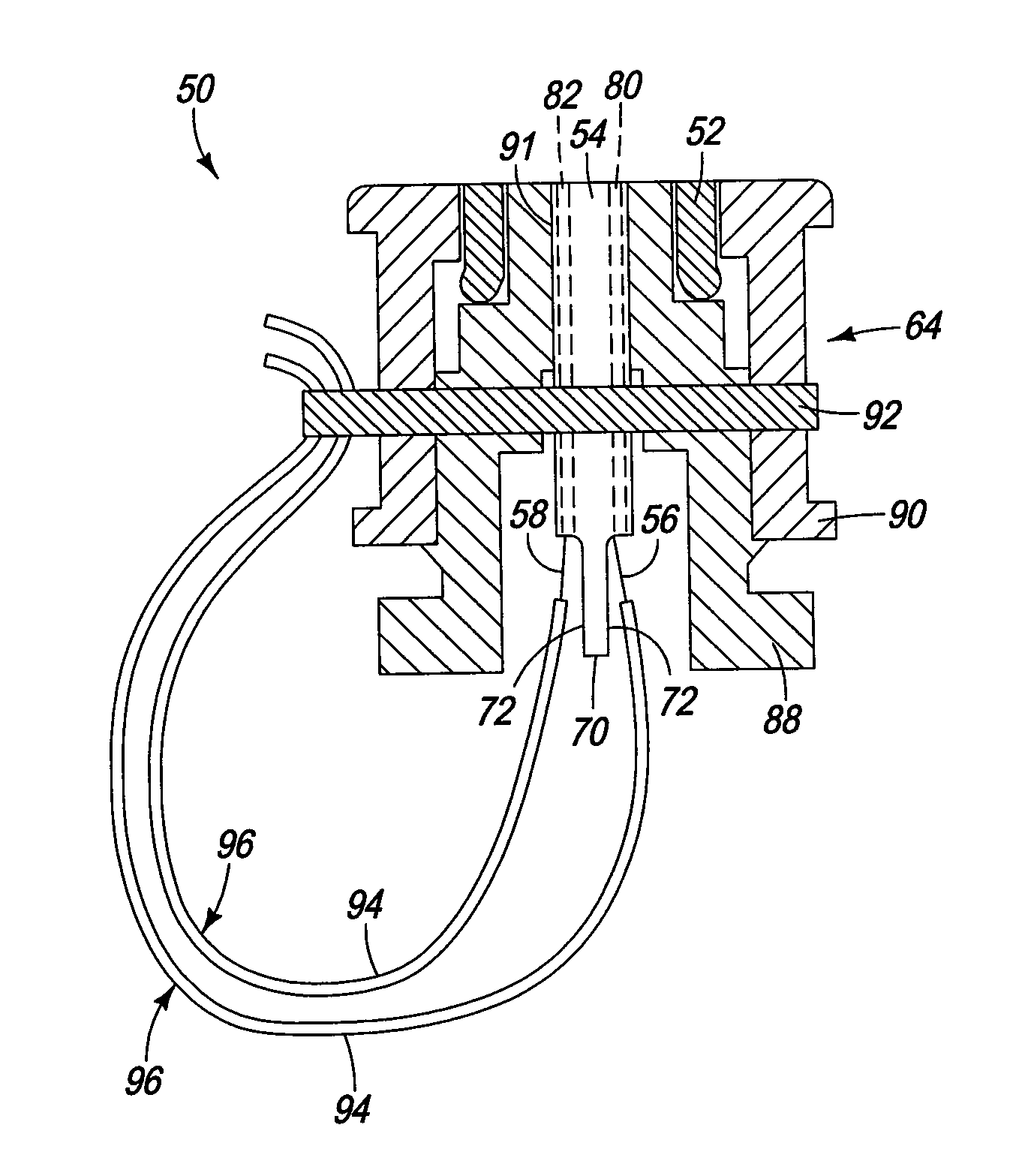

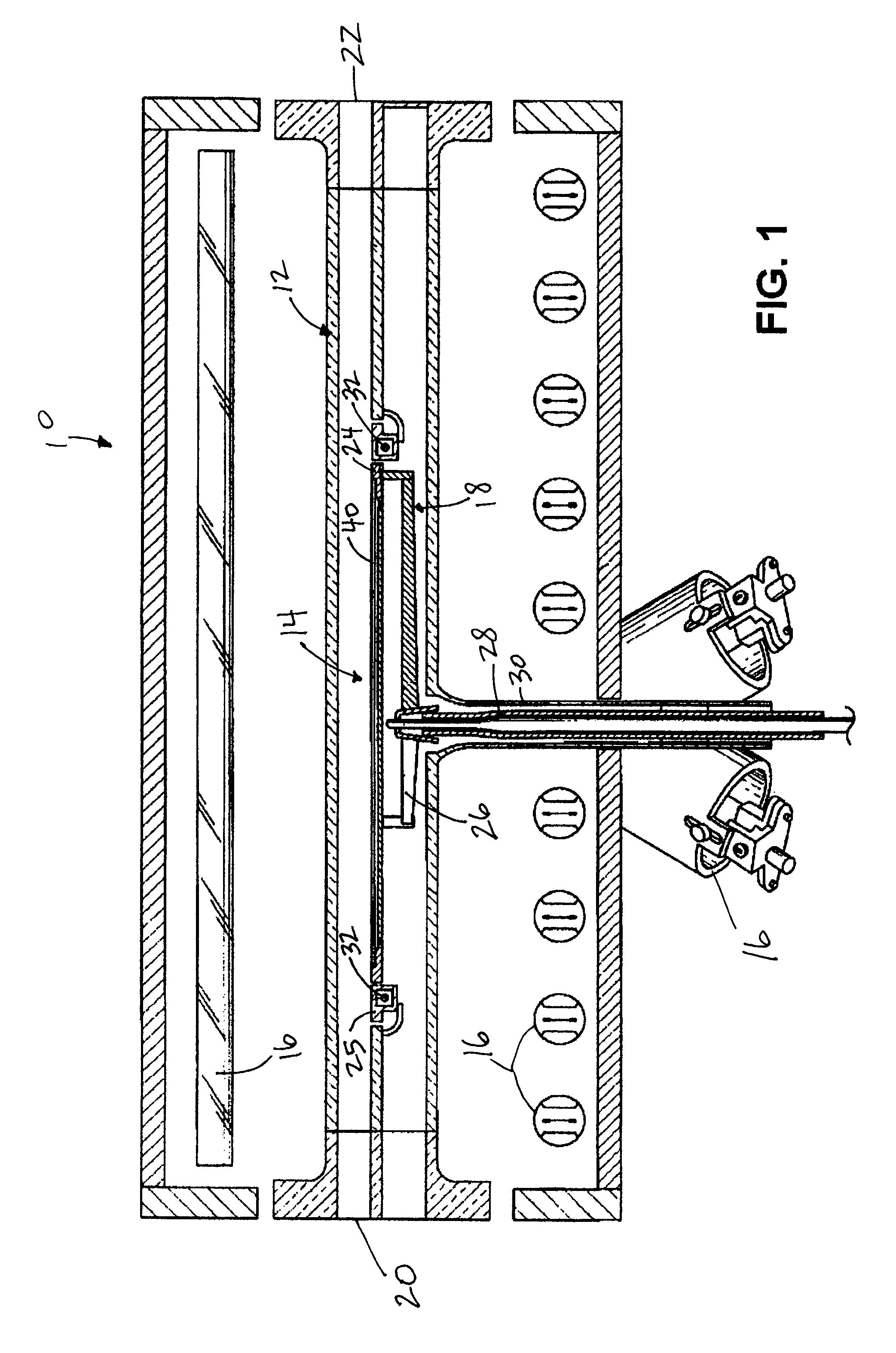

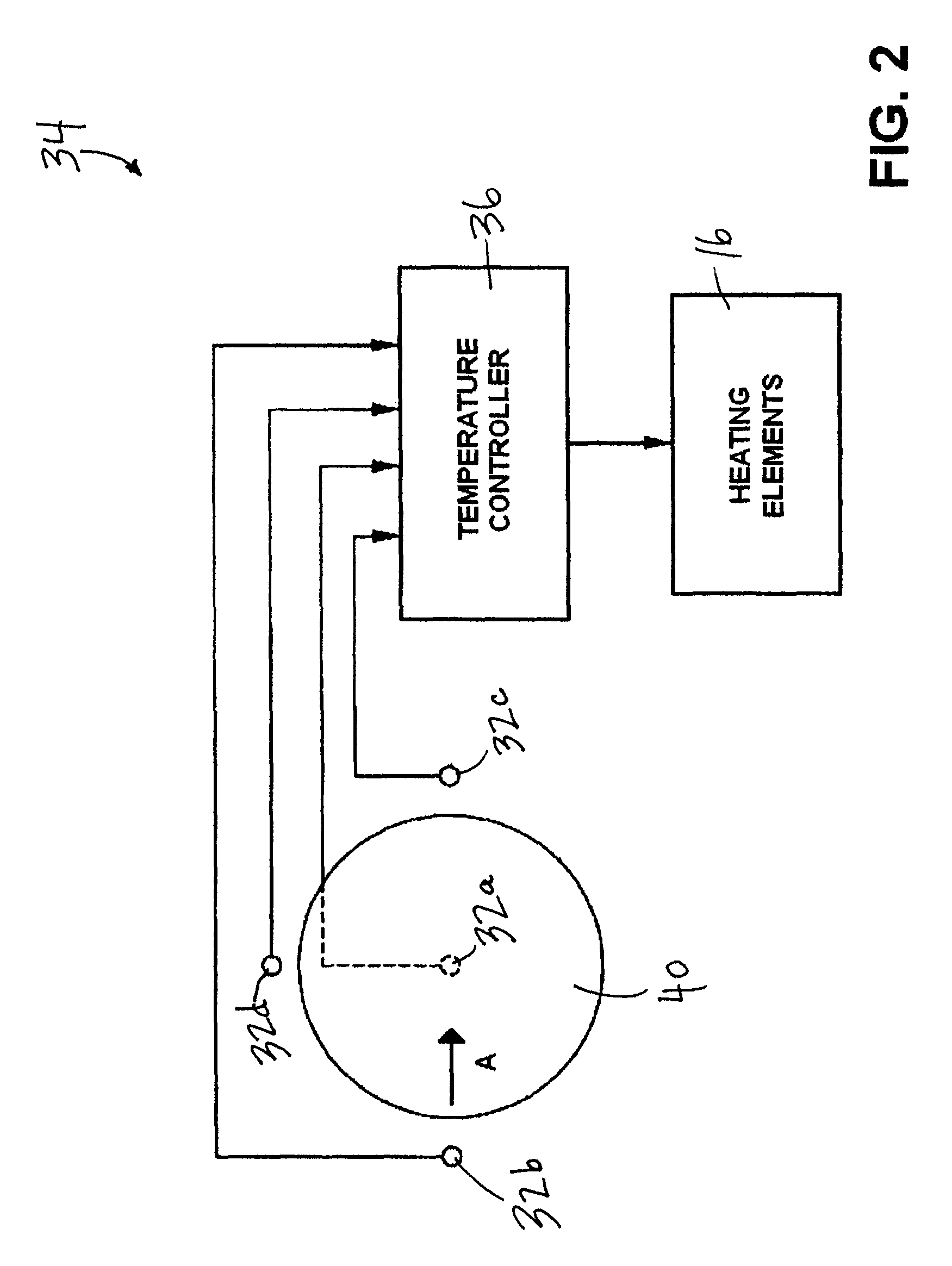

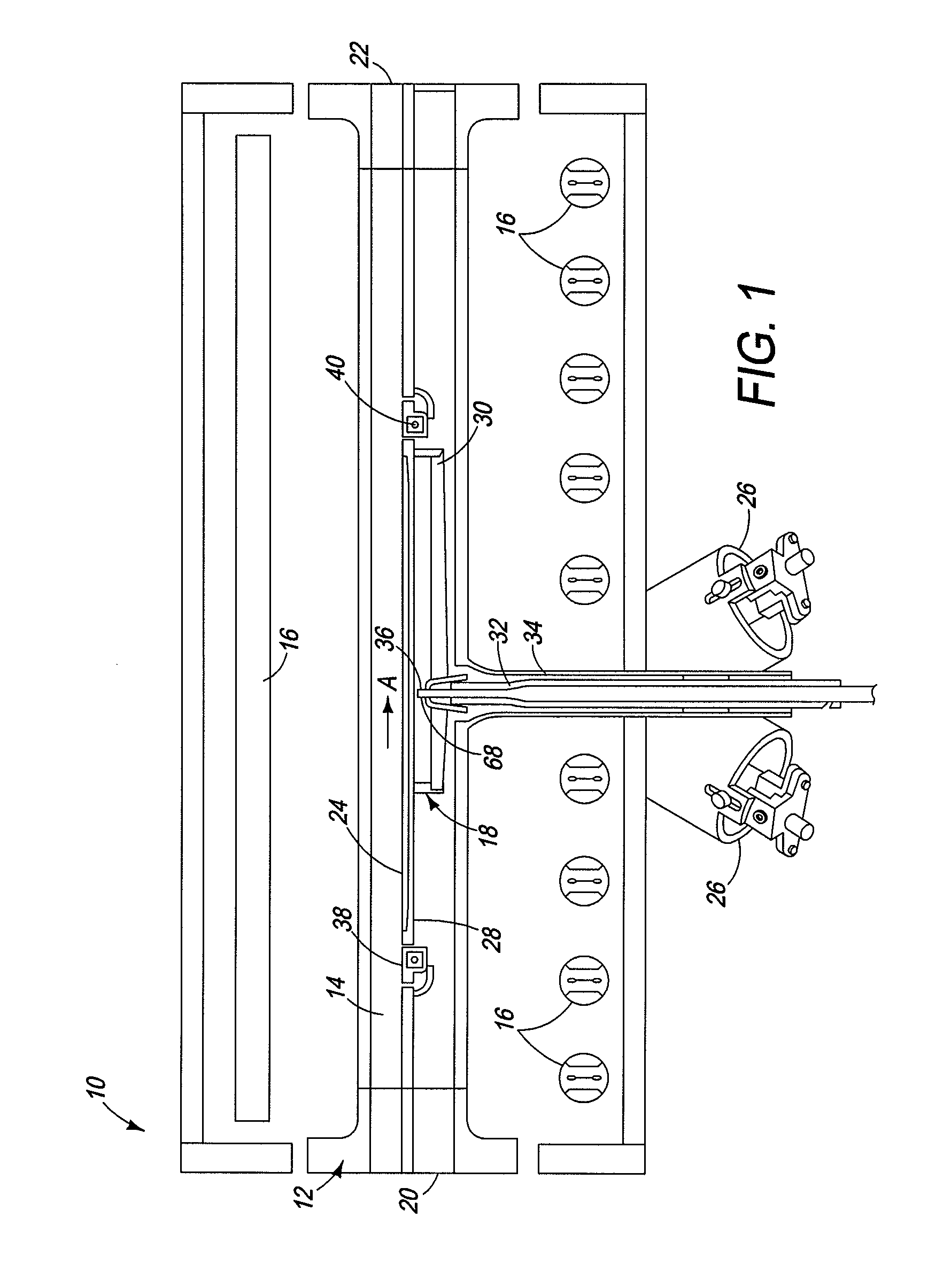

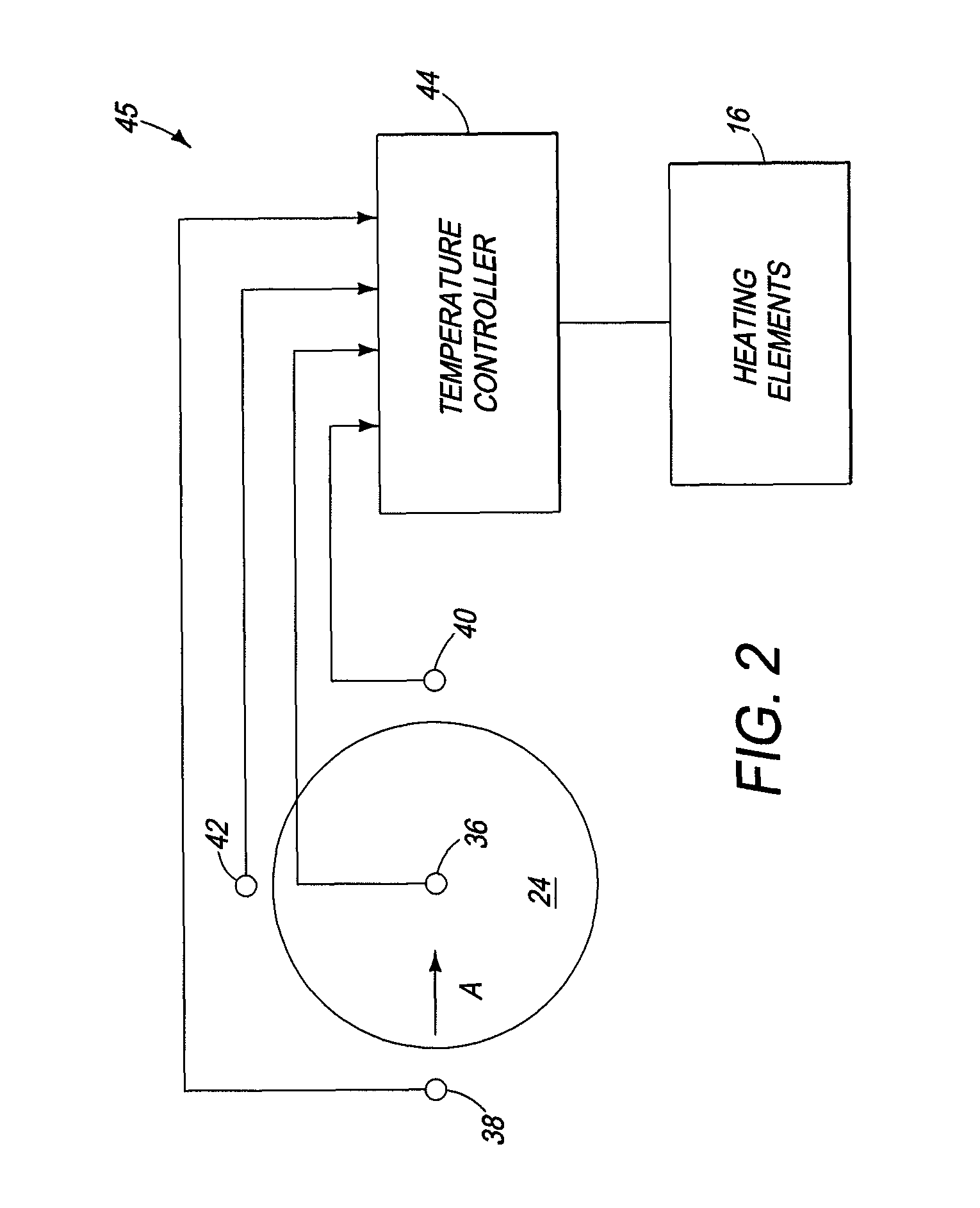

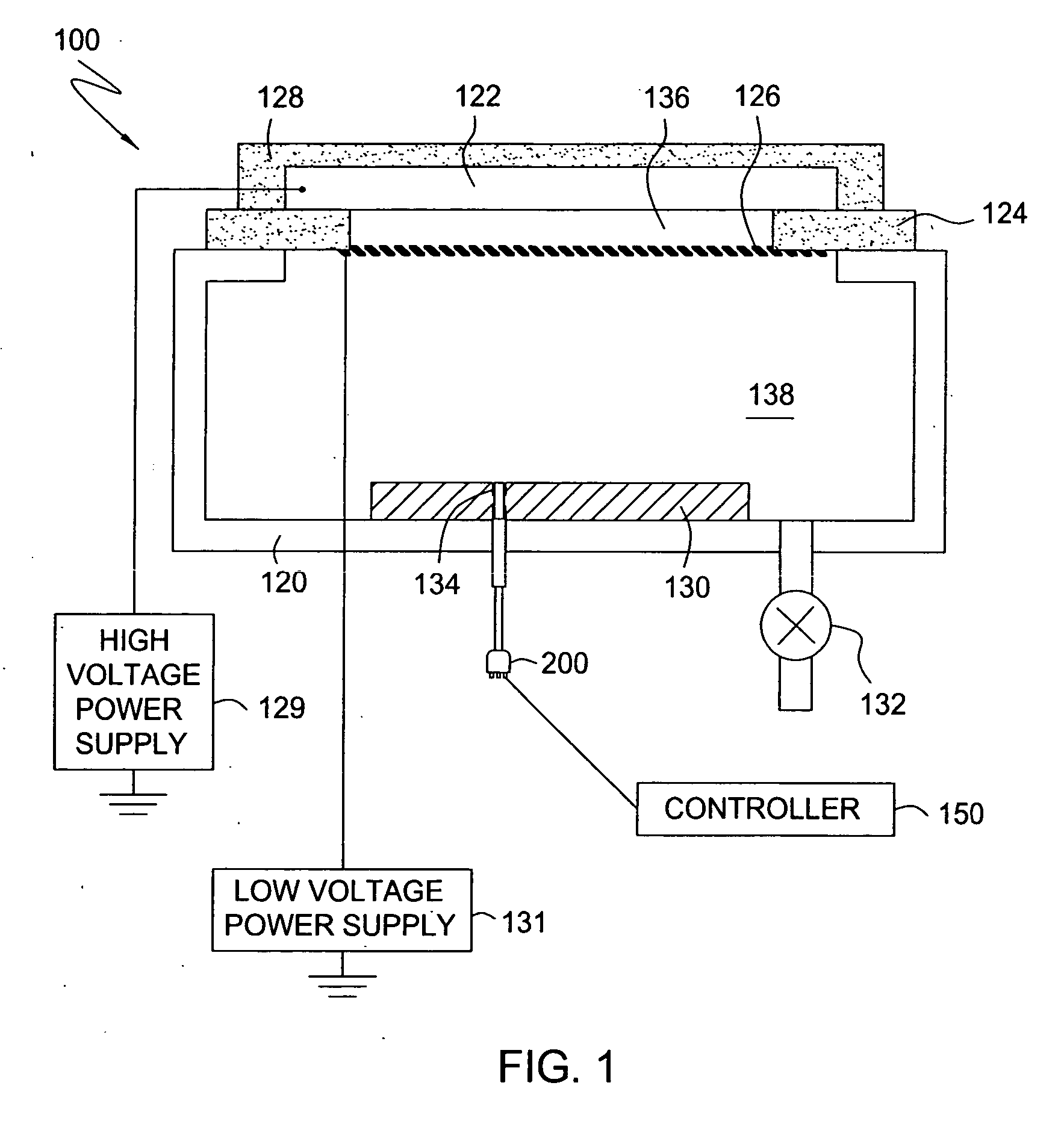

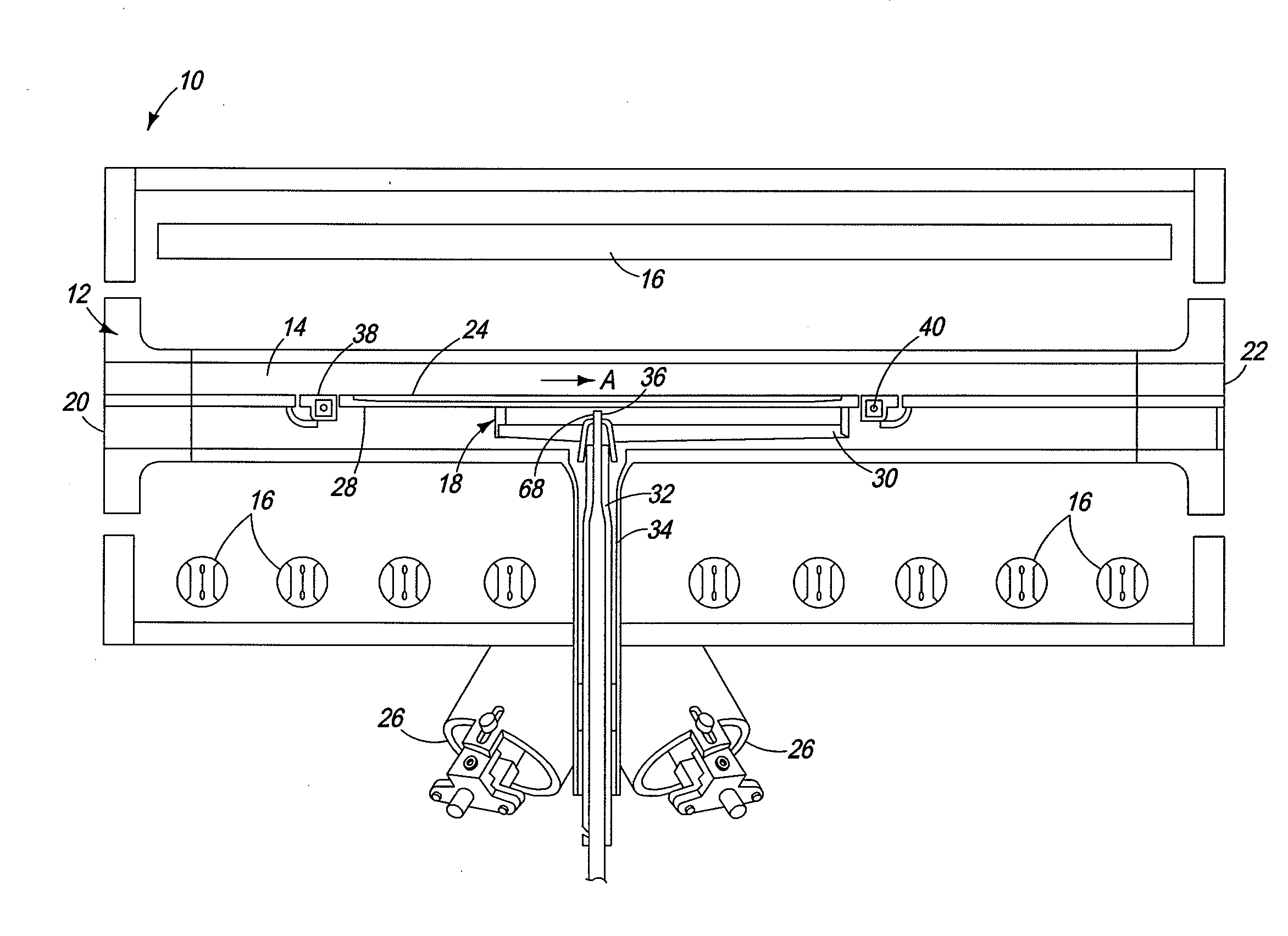

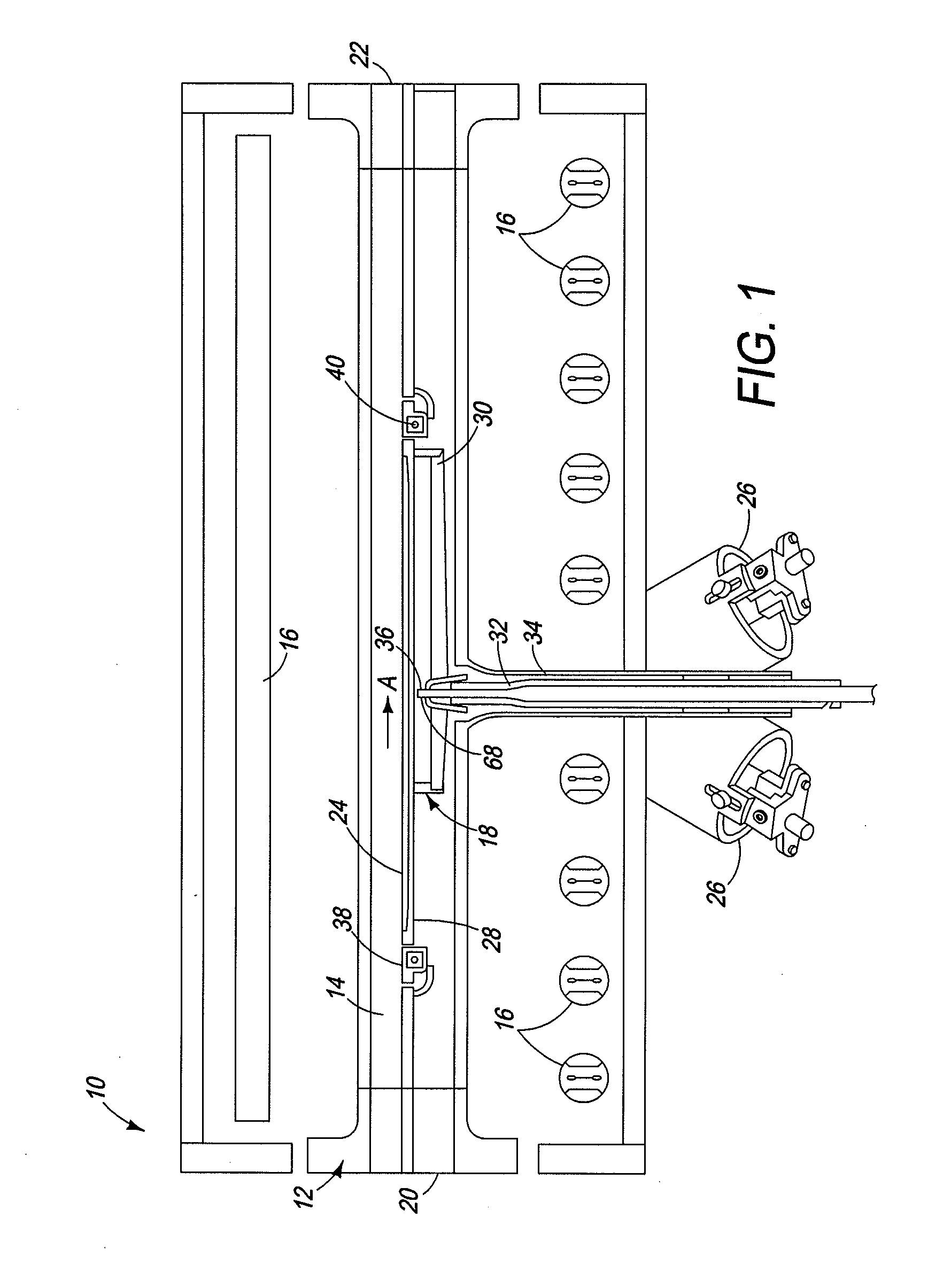

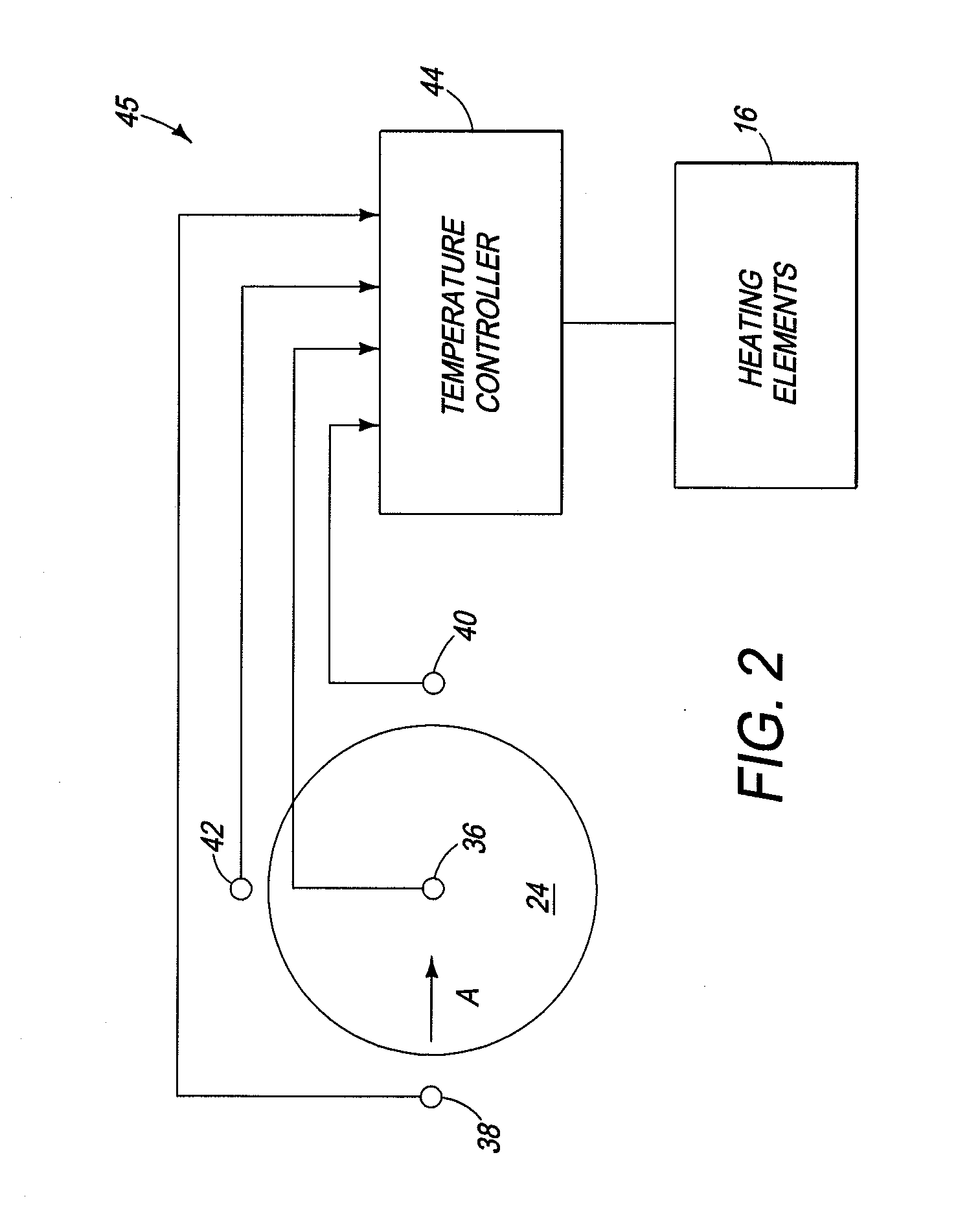

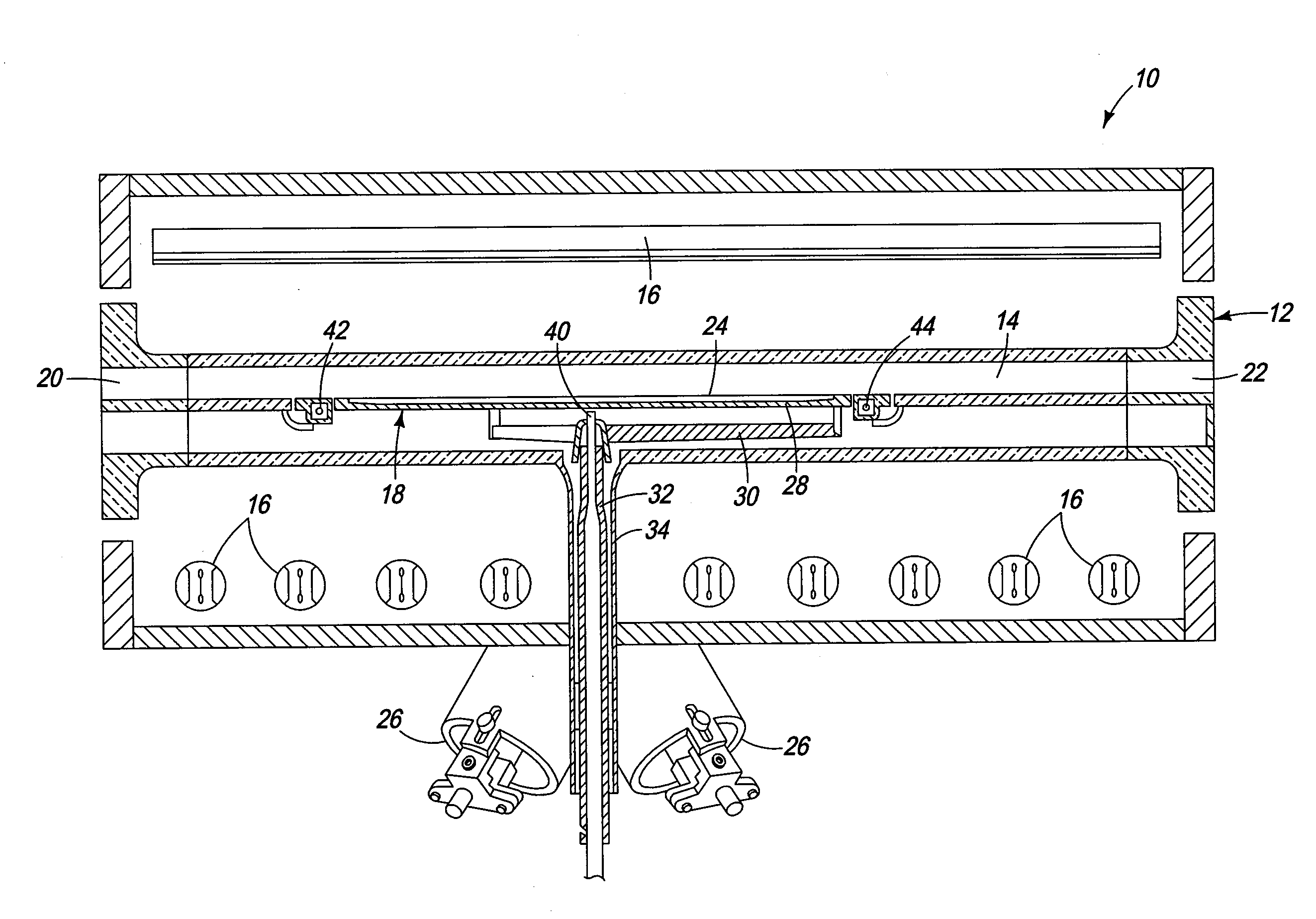

Redundant temperature sensor for semiconductor processing chambers

Systems are provided for measuring temperature in a semiconductor processing chamber. Embodiments provide a multi-junction thermocouple comprising a first junction and a second junction positioned to measure temperature at substantially the same portion of a substrate. A controller may detect failures in the first junction, the second junction, a first wire pair extending from the first junction, or a second wire pair extending from the second junction. The controller desirably responds to a detected failure of the first junction or first wire pair by selecting the second junction and second wire pair. Conversely, the controller desirably responds to a detected failure of the second junction or second wire pair by selecting the first junction and first wire pair. Systems taught herein may permit accurate and substantially uninterrupted temperature measurement despite failure of a junction or wire pair in a thermocouple.

Owner:ASM IP HLDG BV

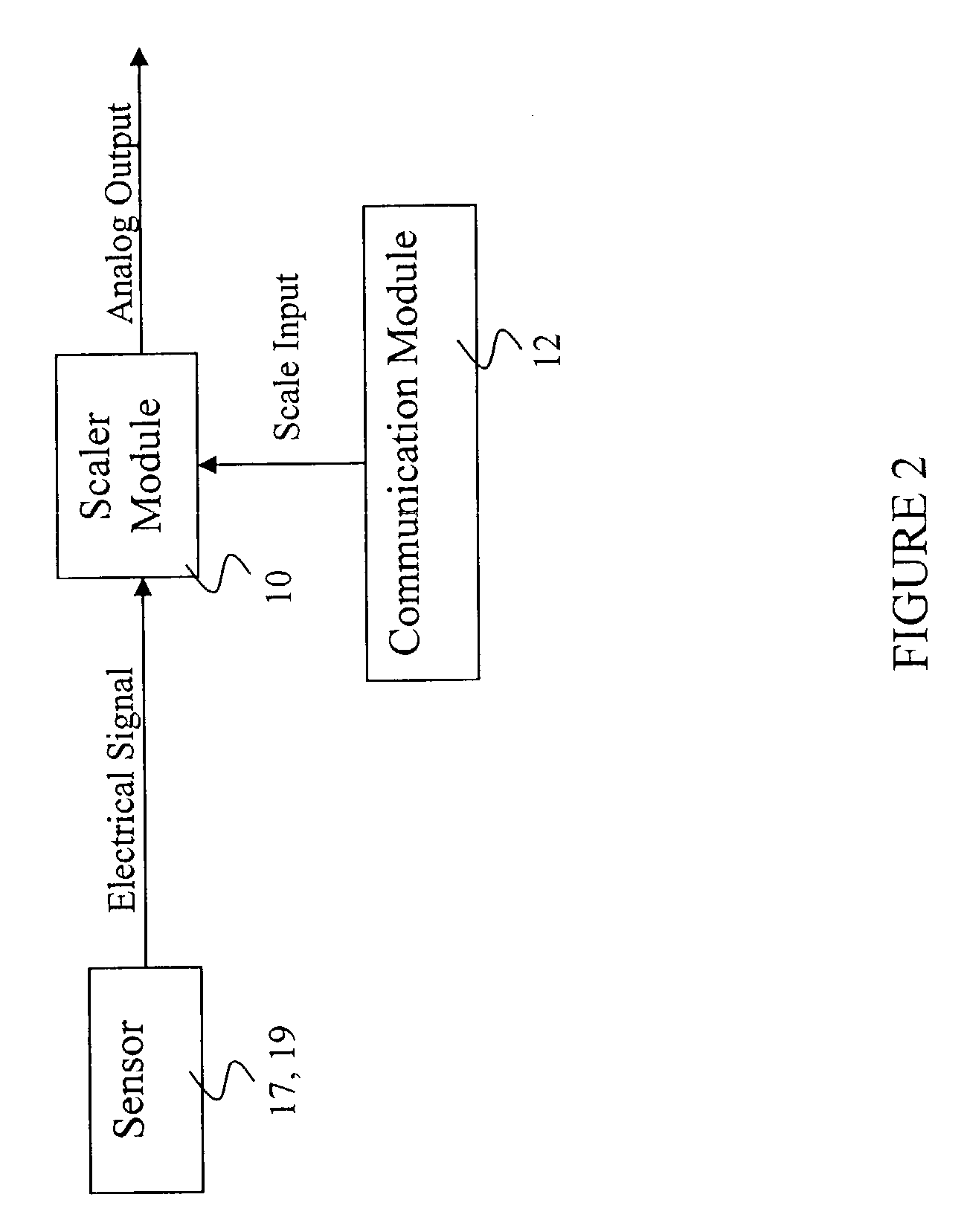

Remotely programmable integrated sensor transmitter

ActiveUS7223014B2Thermometer detailsThermometers using electric/magnetic elementsElectricityAnalog signal

A remotely programmable integrated sensor transmitter device for measuring and reporting a physical quantity of a given medium comprises a sensor for measuring a physical quantity of a medium and providing an electrical output as a function of the property measured, a scaler module for receiving the electrical output and for producing a scaled analog signal as a function of the physical quantity and a scale selection input, and a data interface for receiving programming data from an external computer and for providing the scale selection output to the scaler module.

Owner:INTEMPCO CONTROLS

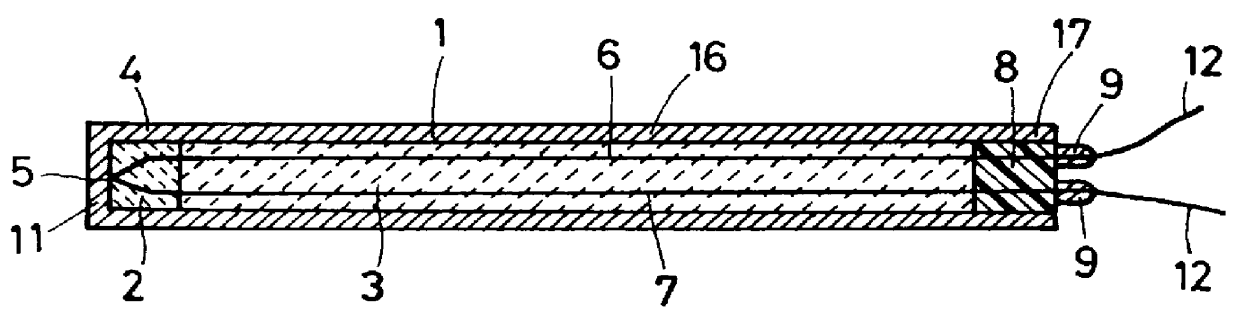

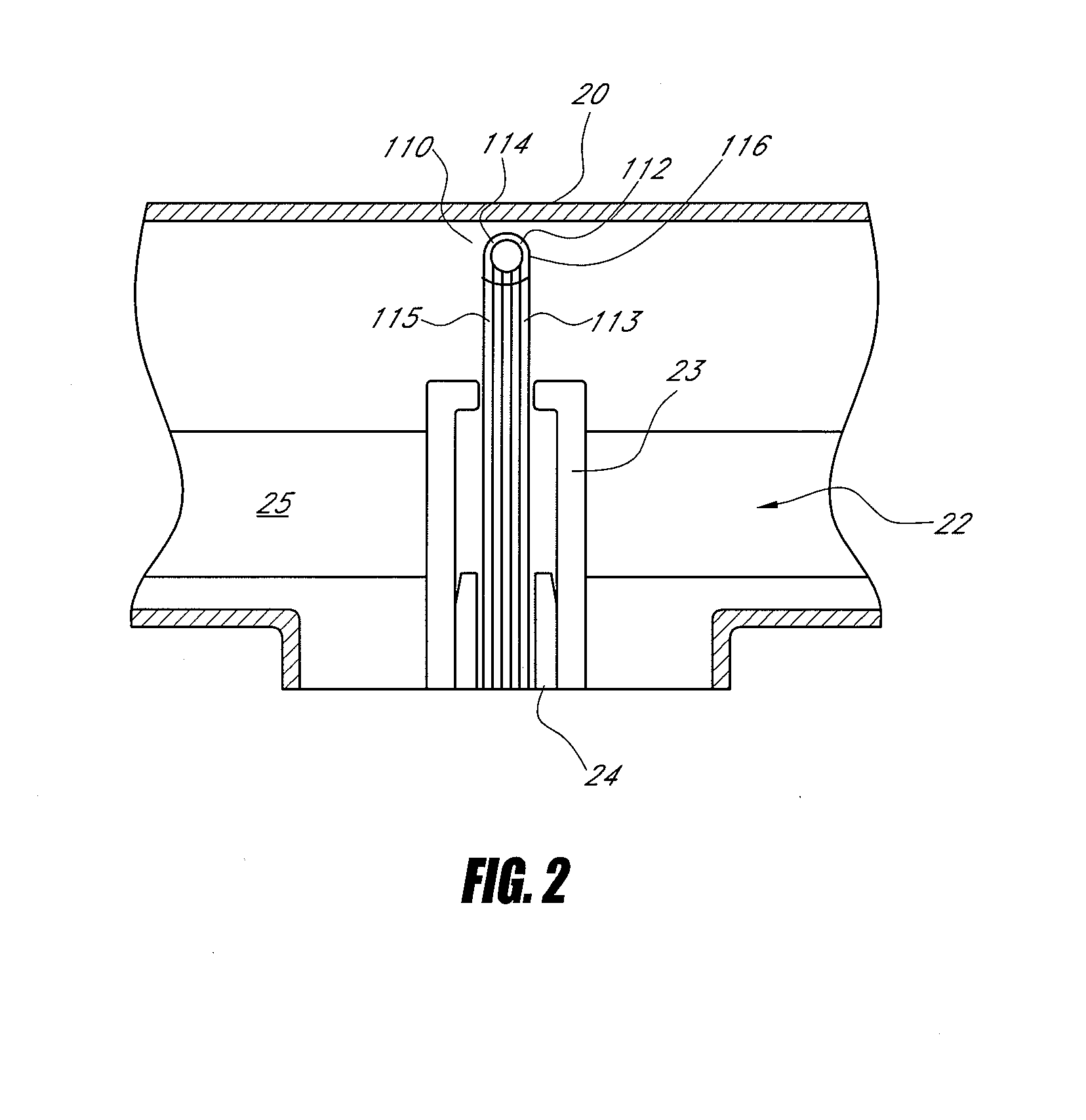

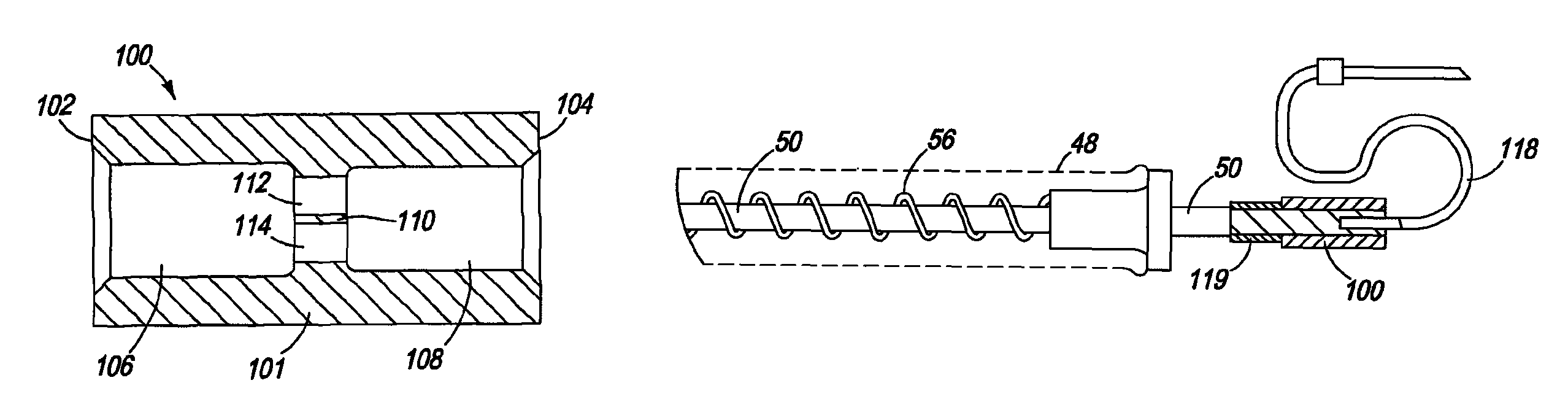

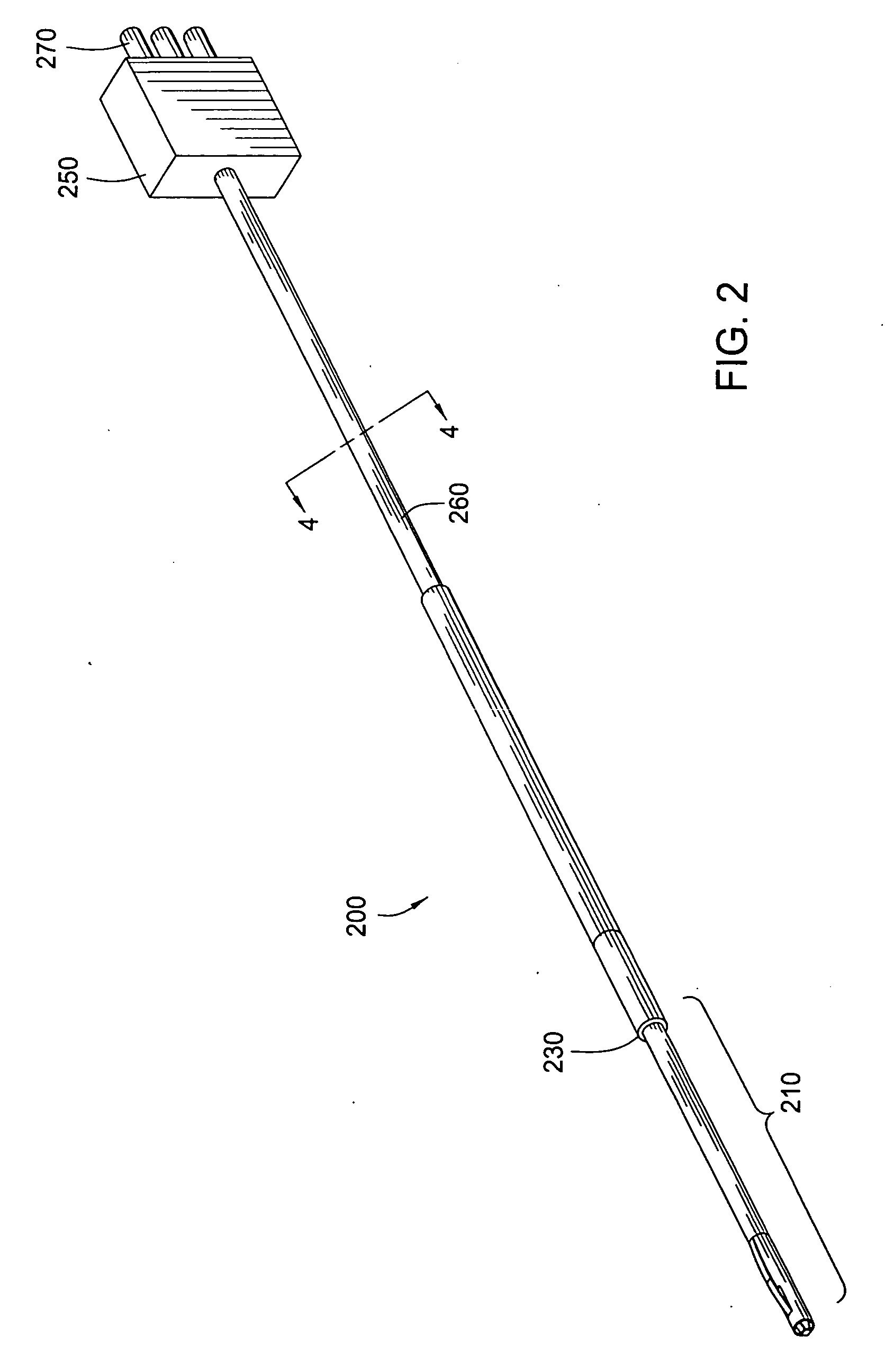

Thermocouple

ActiveUS7946762B2Thermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple

A thermocouple for use in a semiconductor processing reactor is described. The thermocouple includes a sheath having a measuring tip at one end and an opening at the other end. A support member having bores formed along the length is disposed within the sheath. A pair of wires formed of dissimilar metals are disposed within the bores, and one end of the wires is fused together to form a junction. The wires extend along the length of the bores. As the wires exit the bore, they are spatially or physically separated to prevent a short circuit therebetween. The ends of the wires exiting the bore are also free to thermally expand in the longitudinal manner, thereby reducing or eliminating the potential for the wires to fail due to grain slip.

Owner:ASM IP HLDG BV

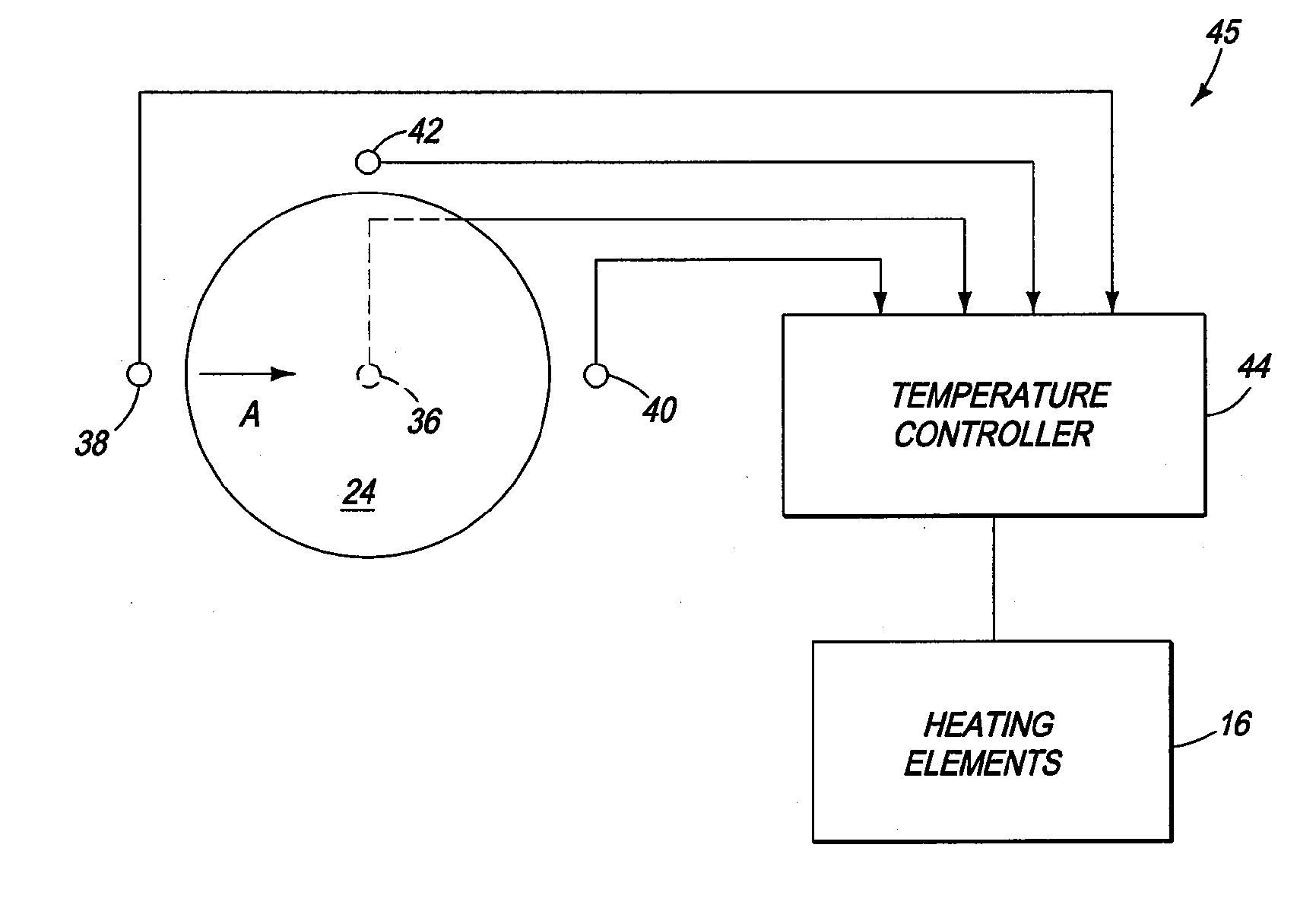

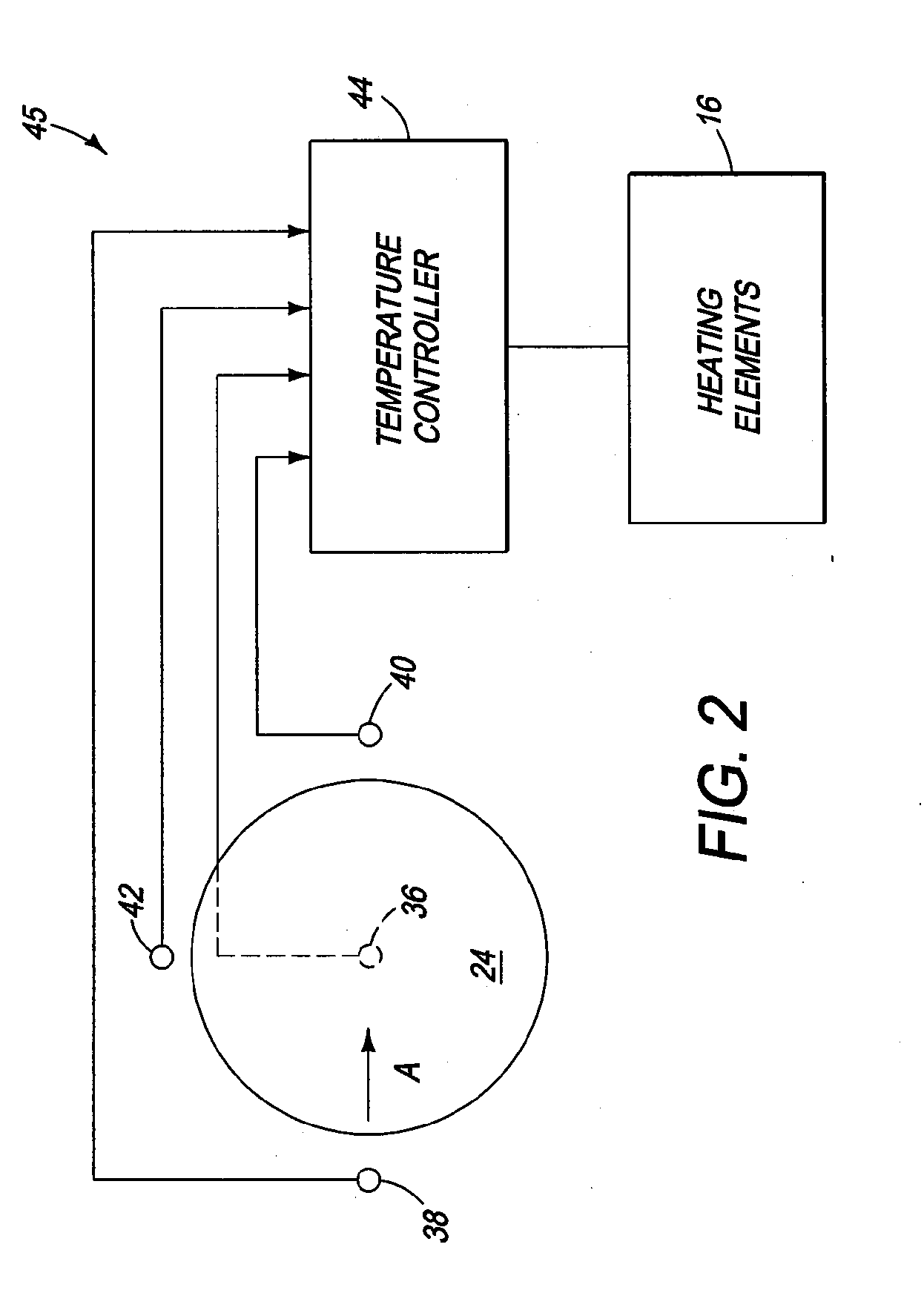

Smart temperature measuring device

ActiveUS9297705B2Avoid data transferThermometer detailsThermometers using electric/magnetic elementsTemperature controlGraphics

A temperature measuring device having a smart chip, or electronic circuit, integrated therein is provided. The smart chip, or electronic circuit, includes at least a unique identification number or data specific to the particular temperature measuring device stored thereon. The electronic circuit further includes calibration data of the temperature measuring device stored thereon. A module controller of a temperature control system is configured to verify the unique identification number of the thermocouple assembly prior to allowing data to be transferred between the temperature measuring device and a temperature controller. A graphical user interface allows an operator to enter the unique identification number or data to verify the temperature measuring device and display an error message if the number or data entered is not equivalent, or does not match, the unique identification number or data stored on the electronic circuit.

Owner:ASM IP HLDG BV

Thermocouple

ActiveUS7874726B2Thermometer detailsThermometers using electric/magnetic elementsThermal expansionEngineering

A thermocouple having a support tube configured to receive a pair of wires of dissimilar metals. The pair of wires of the thermocouple connected at a junction adjacent to one end of the support tube. The thermocouple further including a cap attached to the opposing end of the support tube, wherein the cap receives the free ends of the pair of wires. The cap allowing the pair of wires to translate freely therethrough to accommodate the difference in thermal expansion and contraction of the pair of wires relative to the thermal expansion and contraction of the support tube.

Owner:ASM IP HLDG BV

Temperature sensor with processable front

ActiveUS7789559B2Thermometer detailsThermometers using electric/magnetic elementsThermocouple WireBiomedical engineering

A temperature sensor has a sensor tip and a front for measuring the temperature of the inner walls of tools, particularly inner walls of injection molding tools. The tip of the temperature sensor has two thermocouple wires of a thermocouple. Each thermocouple wire of the thermocouple guided to the front is welded to the sensor tip up to a depth which is larger than the total processing depth behind the front. The sensor tip is processable by removing of material at the front up to that processing depth.

Owner:KISTLER HLDG AG

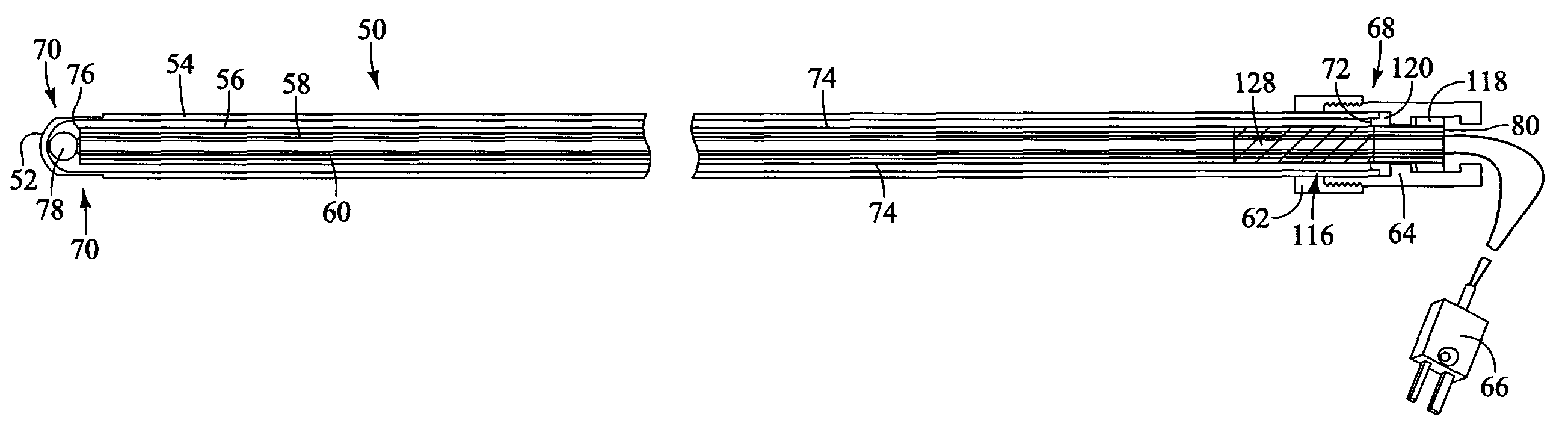

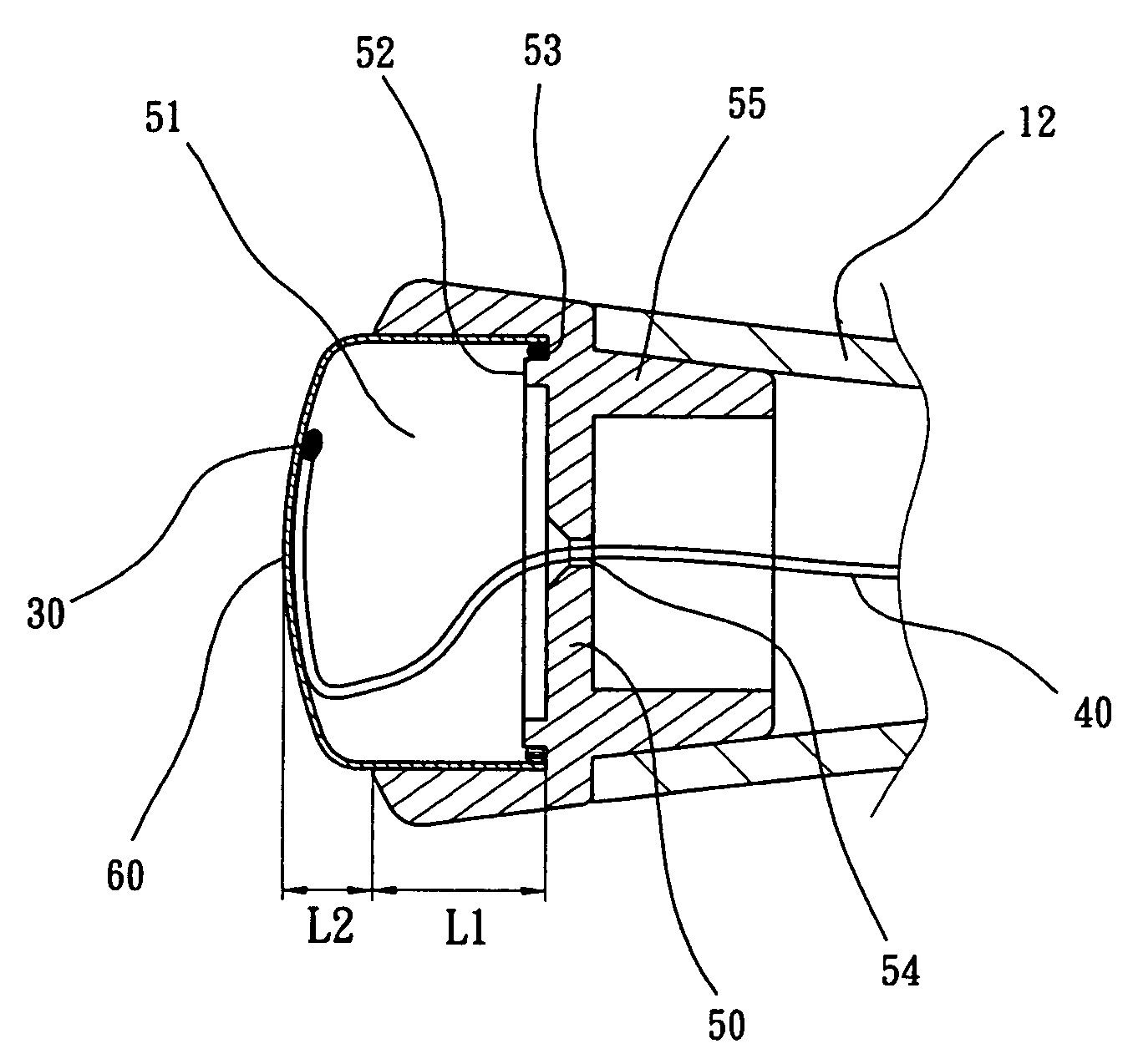

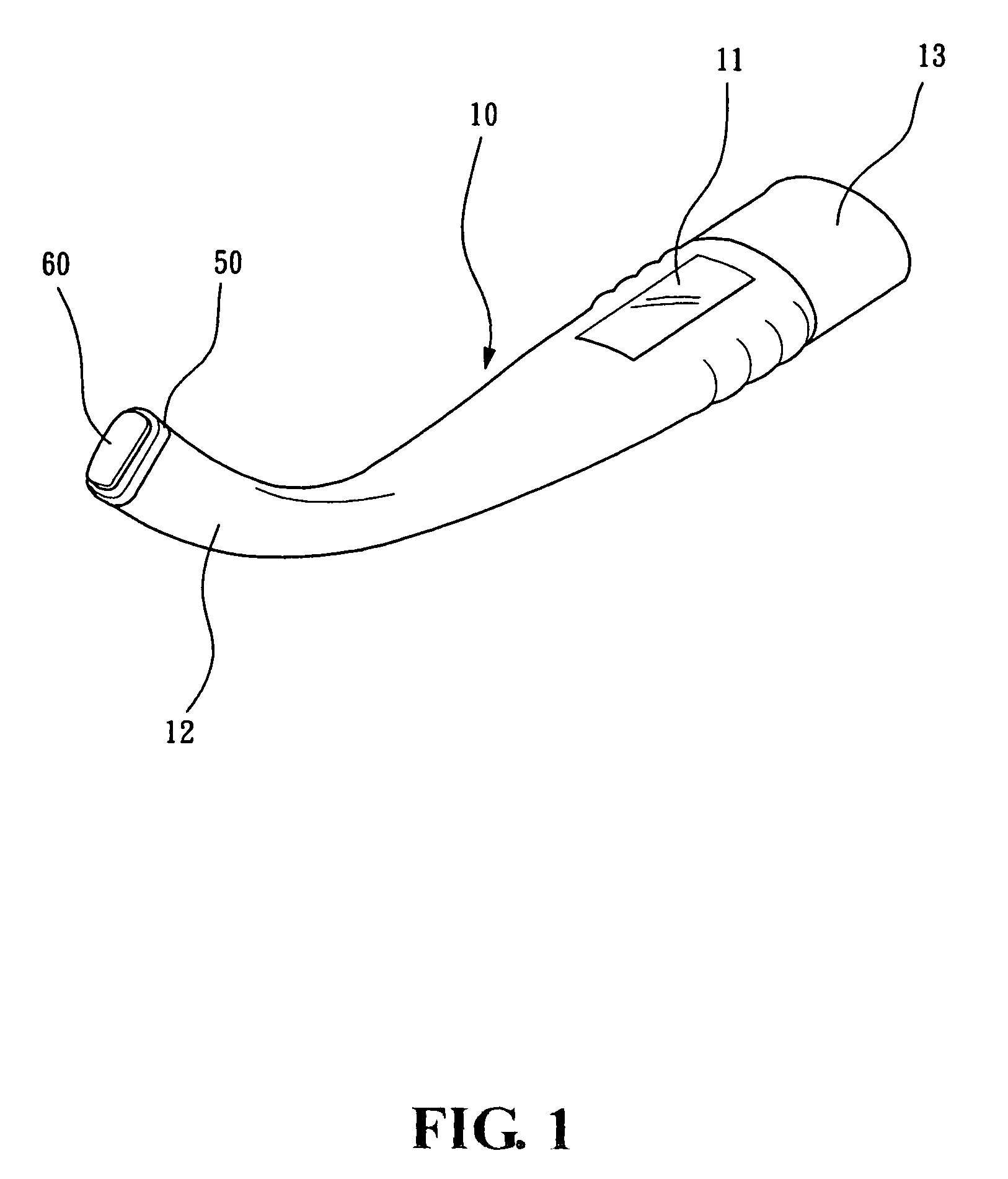

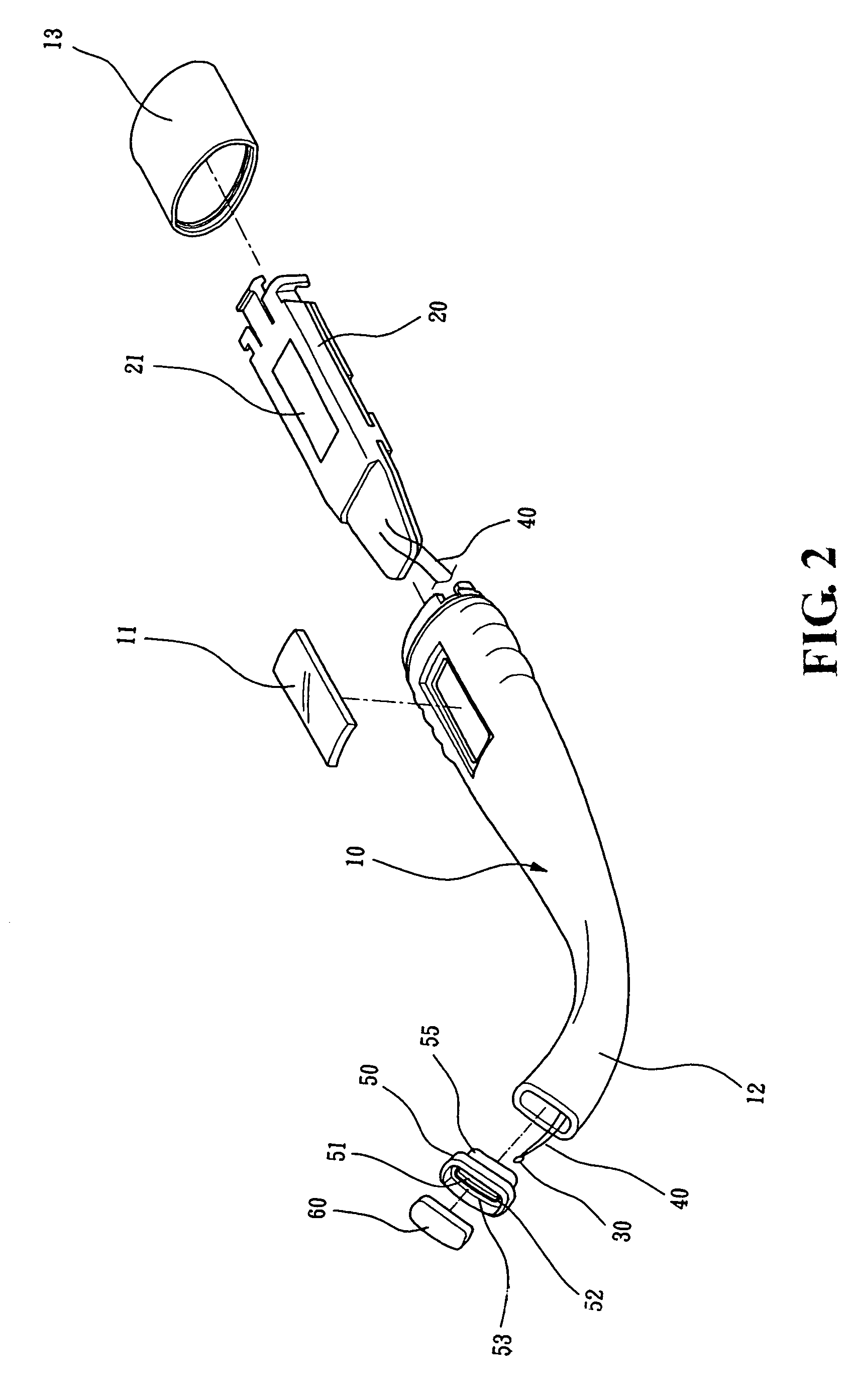

Conducting structure and electronic clinical thermometer embodying the structure

InactiveUS7320544B2Fully contactedHeld easily and comfortablyThermometer detailsThermometers using electric/magnetic elementsHeat balanceEngineering

A conducting structure and an electronic clinical thermometer, wherein the conducting structure is provided on the measuring end of the clinical thermometer, and the measuring end has a recess, a temperature sensor and conducting wires fitted in the recess, and a contact member having a curved top and made of metallic conductive material and having a predetermined length embedded in the recess thereby providing the contact member with a large temperature sensing contact area but only with a small portion protruded out of the measuring end, and therefore enabling the thermometer to be fully in contact with a certain portion of the human body such as the armpit, preventing the thermometer from being broken, and achieving heat balance rapidly. The measuring end of the thermometer may be bent at a predetermined angle or the contact member may be arranged at either side of the measuring end as required.

Owner:ACTHERM INC

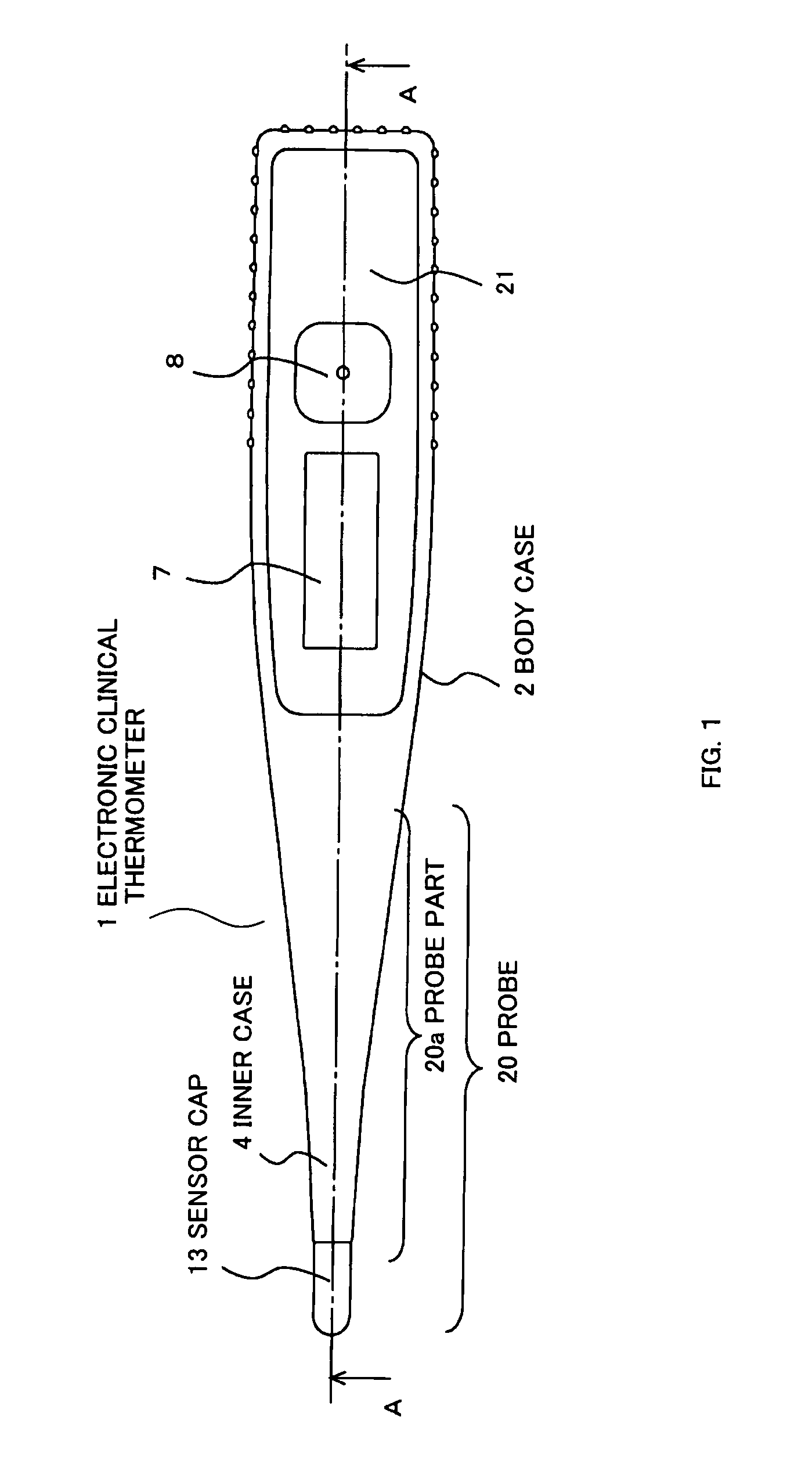

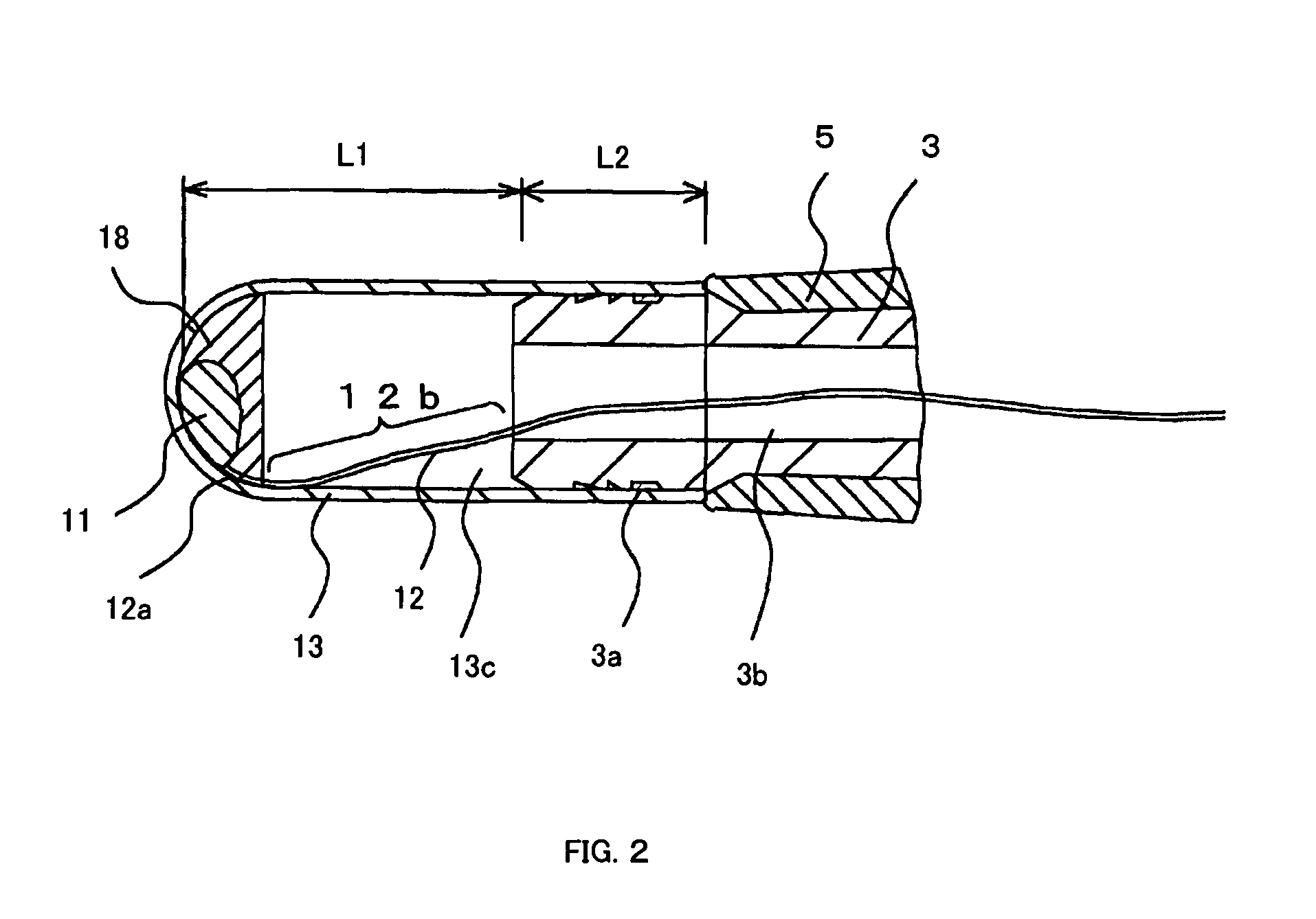

Electronic clinical thermometer and method of producing the same

InactiveUS7806587B2Thermometer detailsThermometers using electric/magnetic elementsBiomedical engineeringTemperature sensitive

A method of producing an electronic clinical thermometer is disclosed, the electronic clinical thermometer including a temperature-sensitive element, lead wire that is connected to the temperature-sensitive element, a body case having a probe part in which an insertion path for the lead wire to be inserted is formed, and a sensor cap having a cavity one end of which is opened and the other end is closed, both the lead wire projecting from the insertion path and the temperature-sensitive element being stored within the sensor cap, and the method includes a step for mounting the sensor cap on the probe part, in a state where the lead wire having the temperature-sensitive element mounted on the tip thereof projects from the insertion path of the probe part.

Owner:A STUCKI CO +1

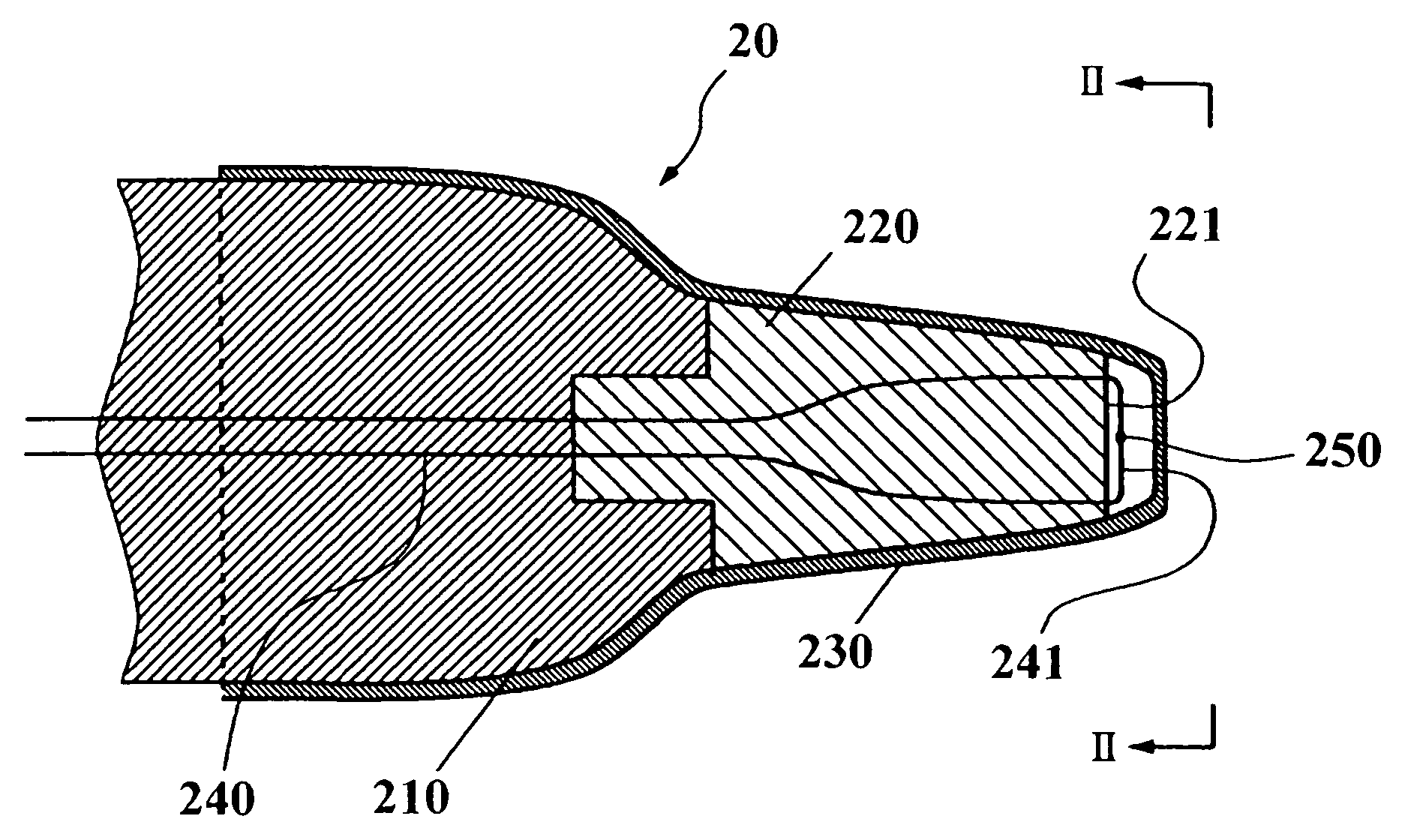

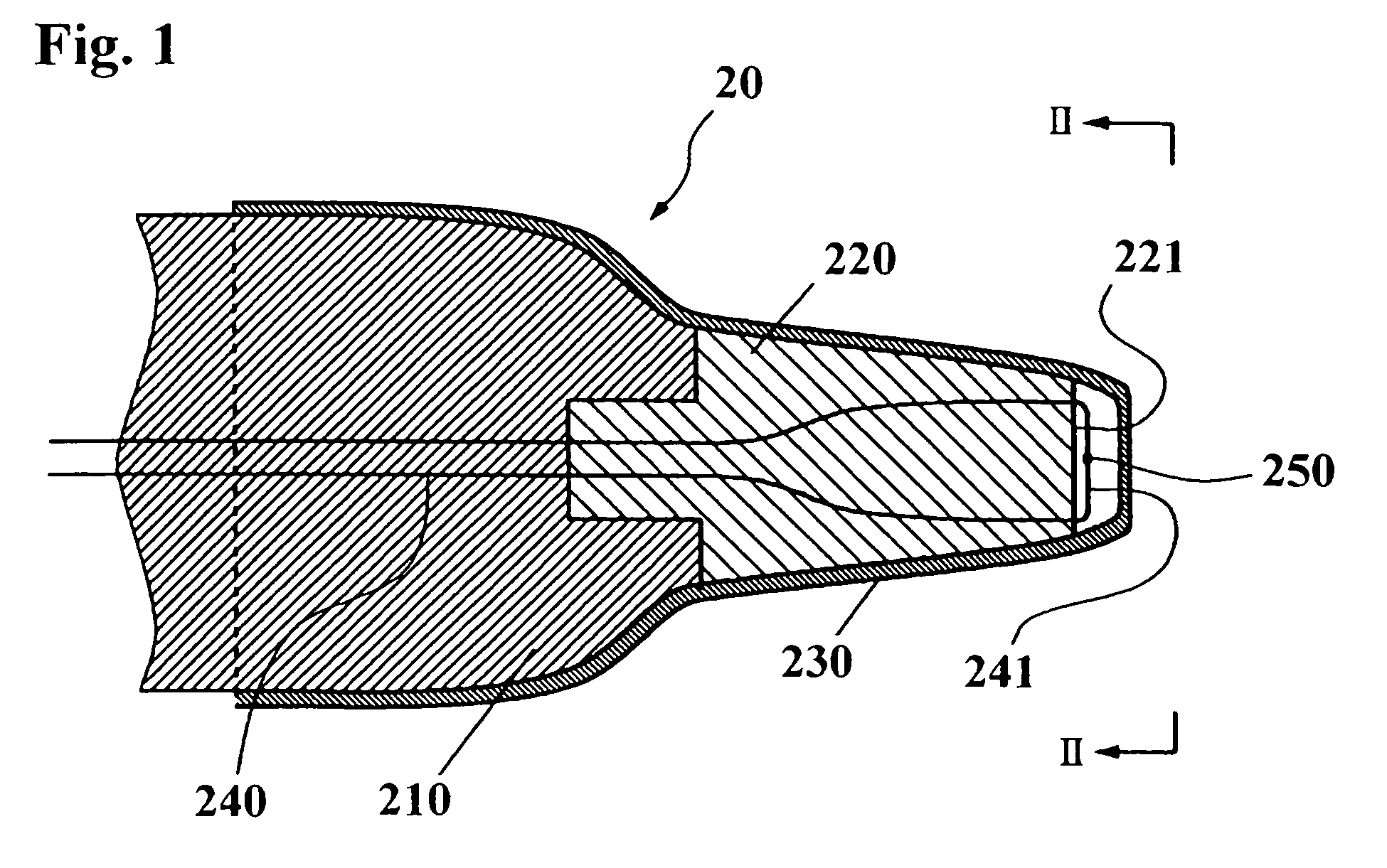

Ear-type clinical thermometer

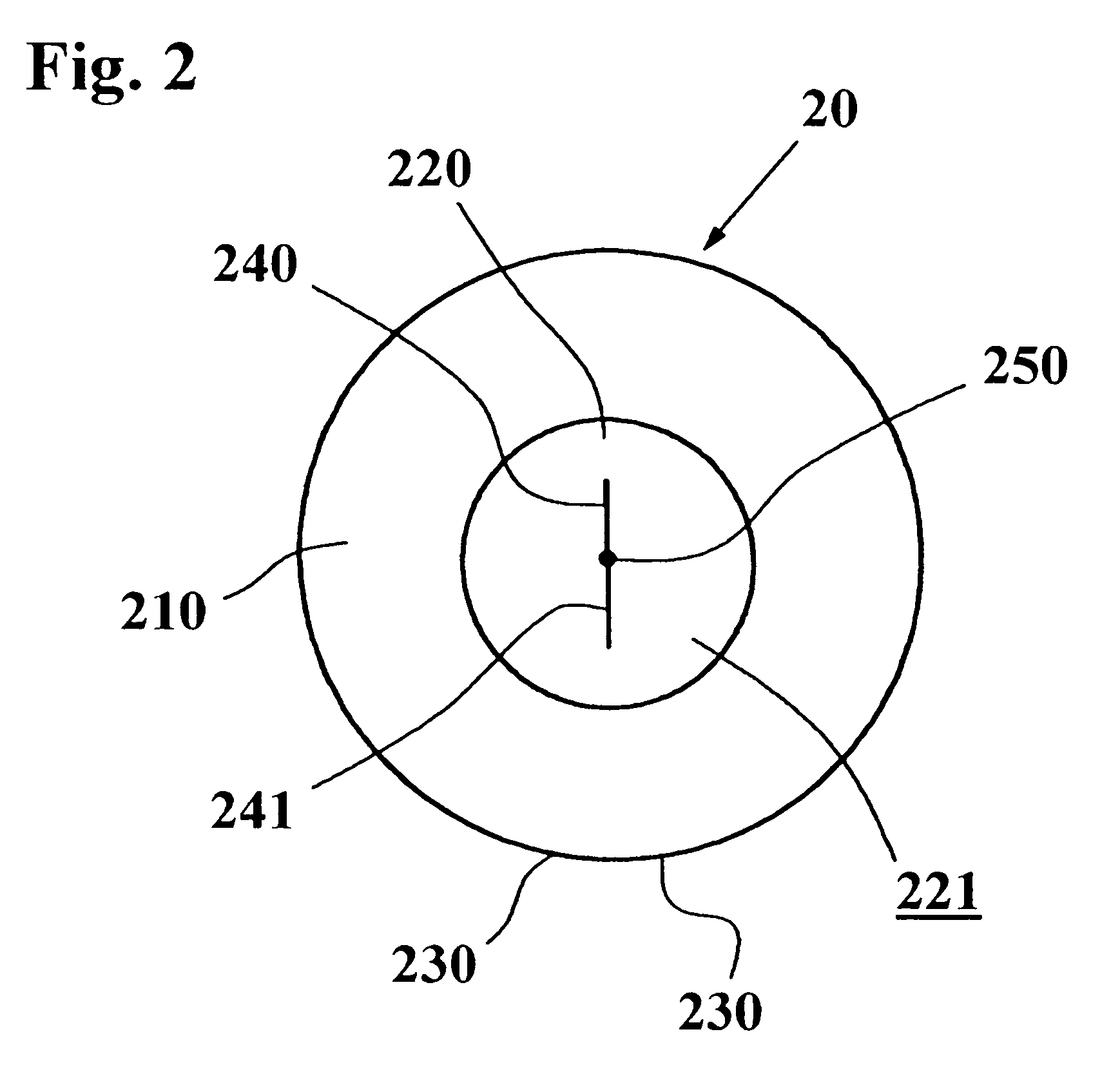

ActiveUS7410290B2Shorten the time periodConvenience to workThermometer detailsThermometers using electric/magnetic elementsCouplingResponsivity

A probe of an ear-type clinical thermometer 20 comprises a first heat insulation member 210 made of a resin material and a second high heat insulation member 220 made of a resin material that is connected to a distal end of the first heat insulation member 210 by conventional coupling means. The second high heat insulation member 220 is tapered forwardly and is provided on the distal end with a concave surface 221. A protection cover 230 sheathes the first heat insulation member 210 and second high heat insulation member 220. A thermistor fine lead wire 240 is embedded in the first heat insulation member 210 and second high heat insulation member 220 so that a turning end portion 241 of the wire 240 is bridged over the concave surface 221 of the second high heat insulation member 220 to be exposed above the concave surface 221. An ultrafast responsivity thermistor 250 is mounted substantially on a center of the turning end portion 241 of the thermistor fine lead wire 240.

Owner:BIO ECHO NET

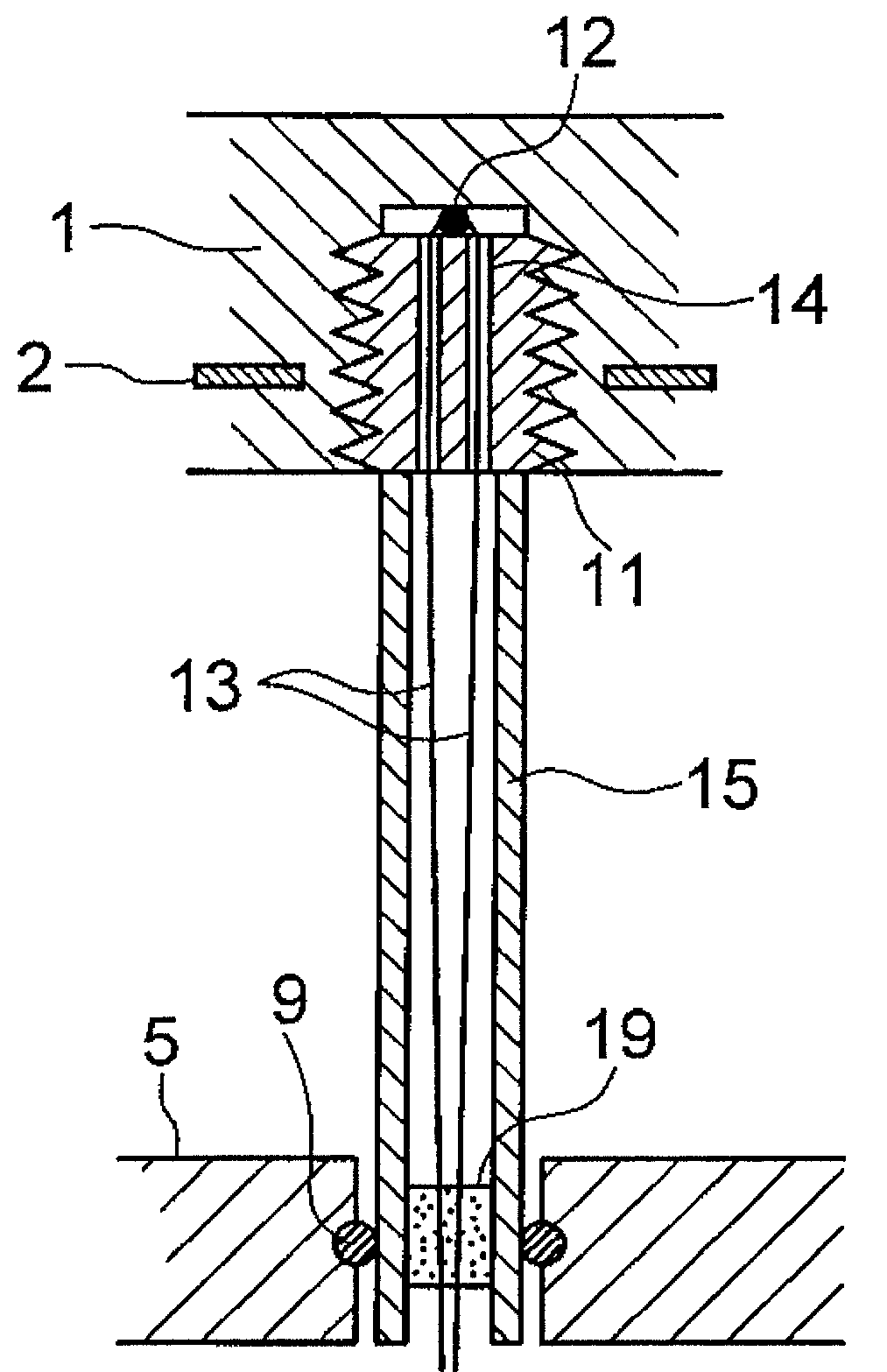

Thermally conductive ceramic tipped contact thermocouple

InactiveUS20060275933A1Thermometer detailsSemiconductor/solid-state device testing/measurementThermocoupleMaterials science

An apparatus for processing a substrate. The apparatus comprising a tubular member with a first end and a second end. The first end comprising an opening; and a temperature sensor disposed in the opening. The temperature sensor comprising a resilient member. The resilient member comprising a surface made of a ceramic material wherein the surface made of a ceramic material extends through the opening to provide a substrate contact surface.

Owner:APPLIED MATERIALS INC

Thermocouple

A thermocouple having a support tube configured to receive a pair of wires of dissimilar metals. The pair of wires of the thermocouple connected at a junction adjacent to one end of the support tube. The thermocouple further including a cap attached to the opposing end of the support tube, wherein the cap receives the free ends of the pair of wires. The cap allowing the pair of wires to translate freely therethrough to accommodate the difference in thermal expansion and contraction of the pair of wires relative to the thermal expansion and contraction of the support tube.

Owner:ASM IP HLDG BV

Thermocouple

ActiveUS20090308425A1Thermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple

A thermocouple for use in a semiconductor processing reactor is described. The thermocouple includes a sheath having a measuring tip at one end and an opening at the other end. A support member having bores formed along the length is disposed within the sheath. A pair of wires formed of dissimilar metals are disposed within the bores, and one end of the wires is fused together to form a junction. The wires extend along the length of the bores. As the wires exit the bore, they are spatially or physically separated to prevent a short circuit therebetween. The ends of the wires exiting the bore are also free to thermally expand in the longitudinal manner, thereby reducing or eliminating the potential for the wires to fail due to grain slip.

Owner:ASM IP HLDG BV

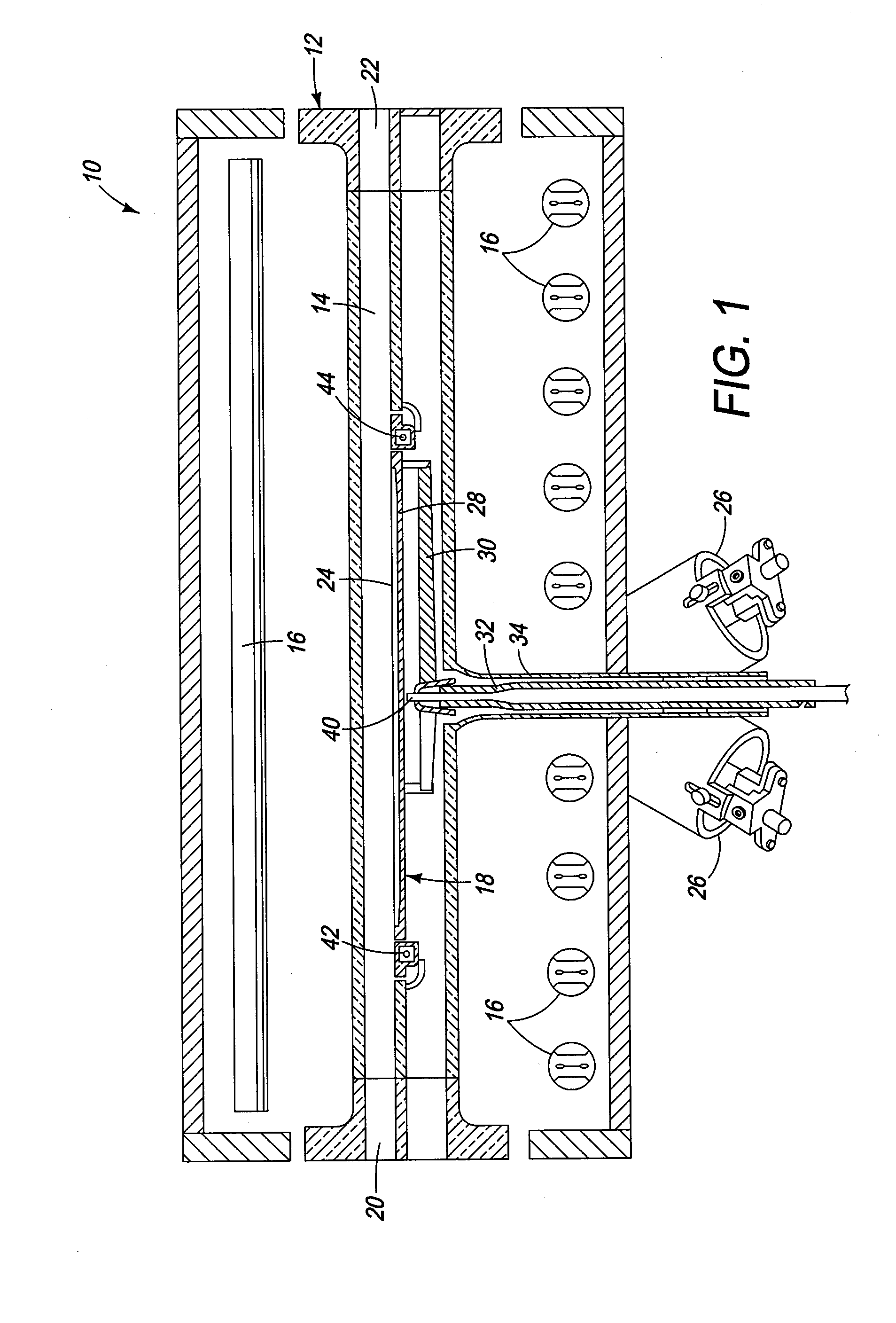

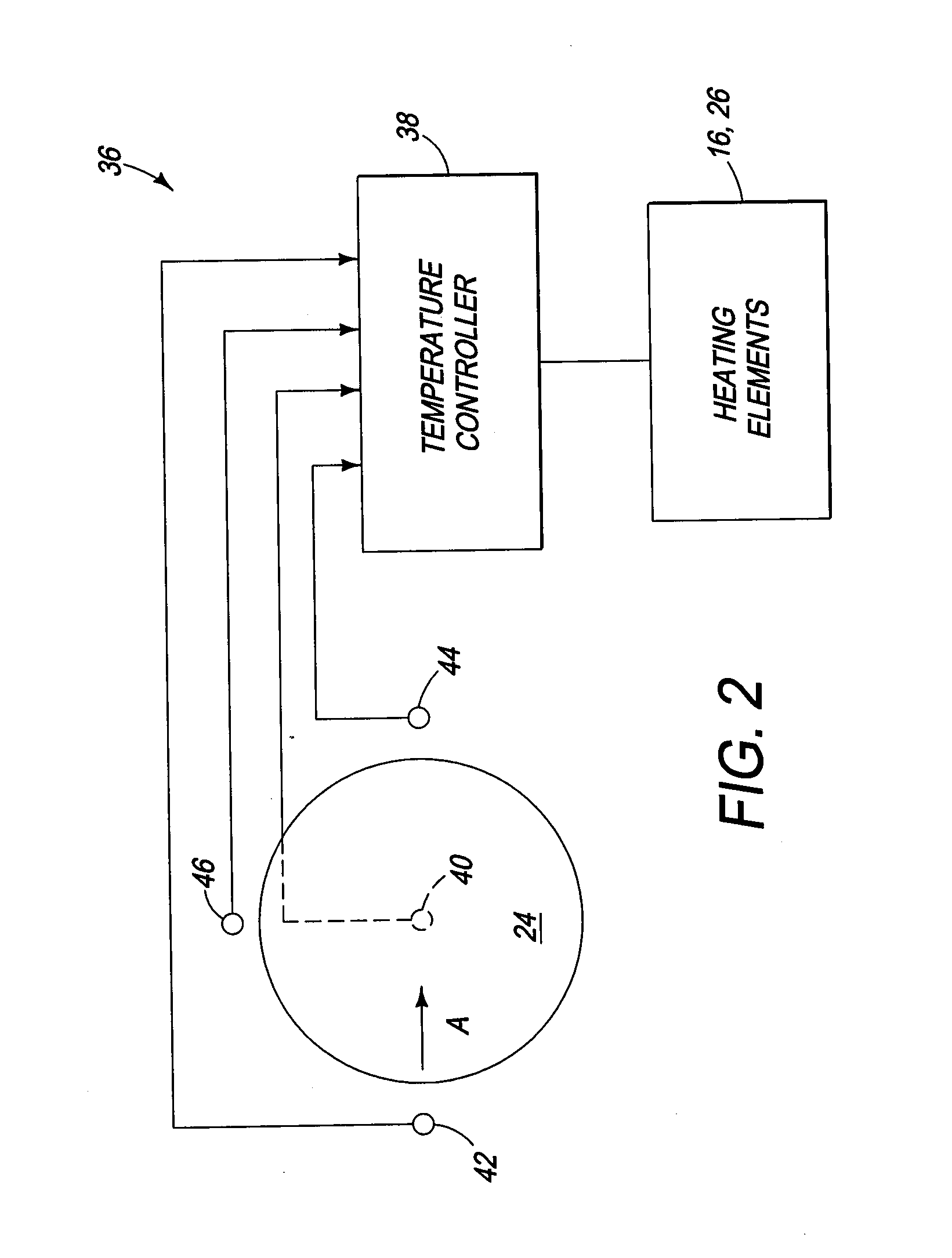

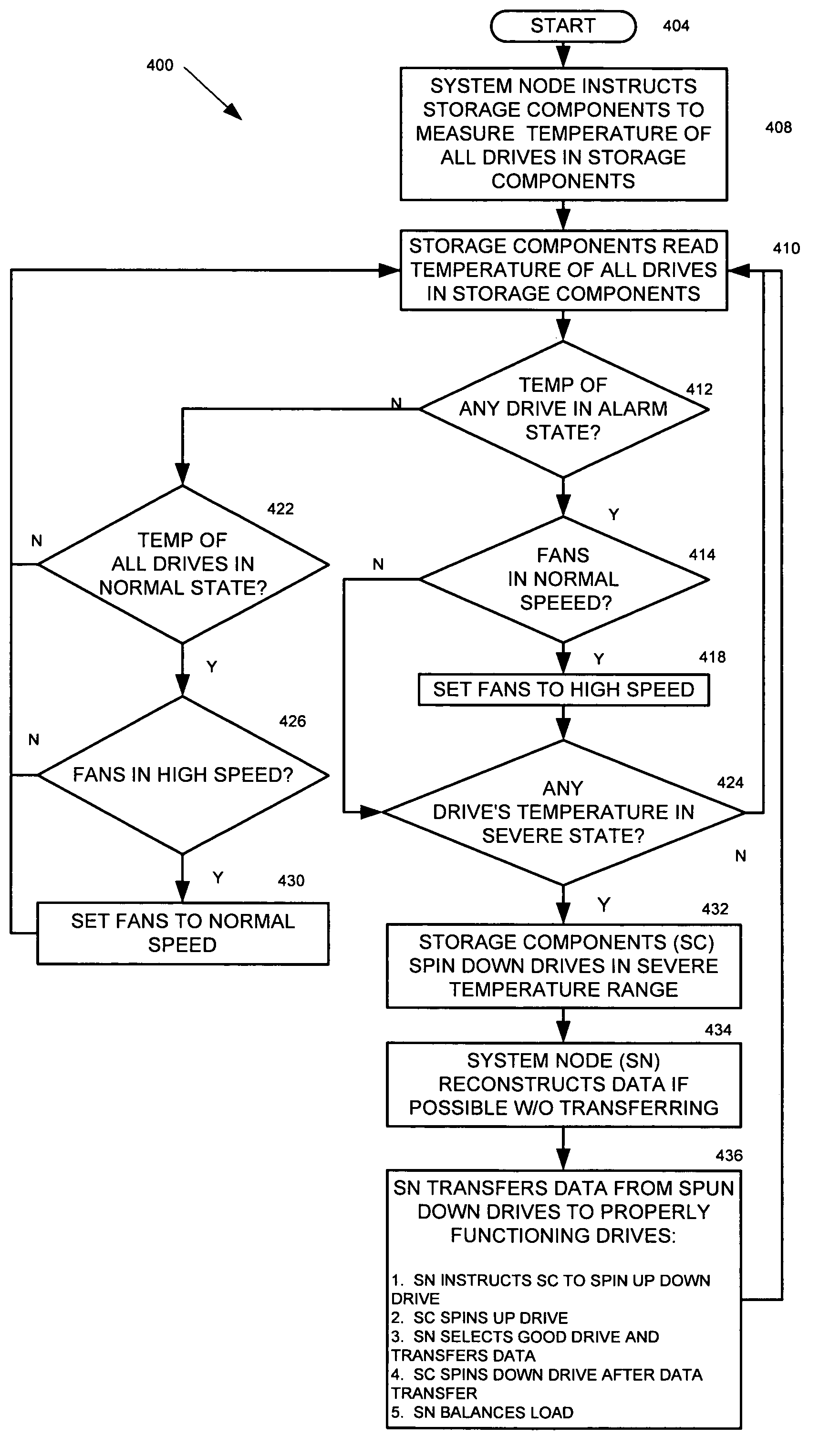

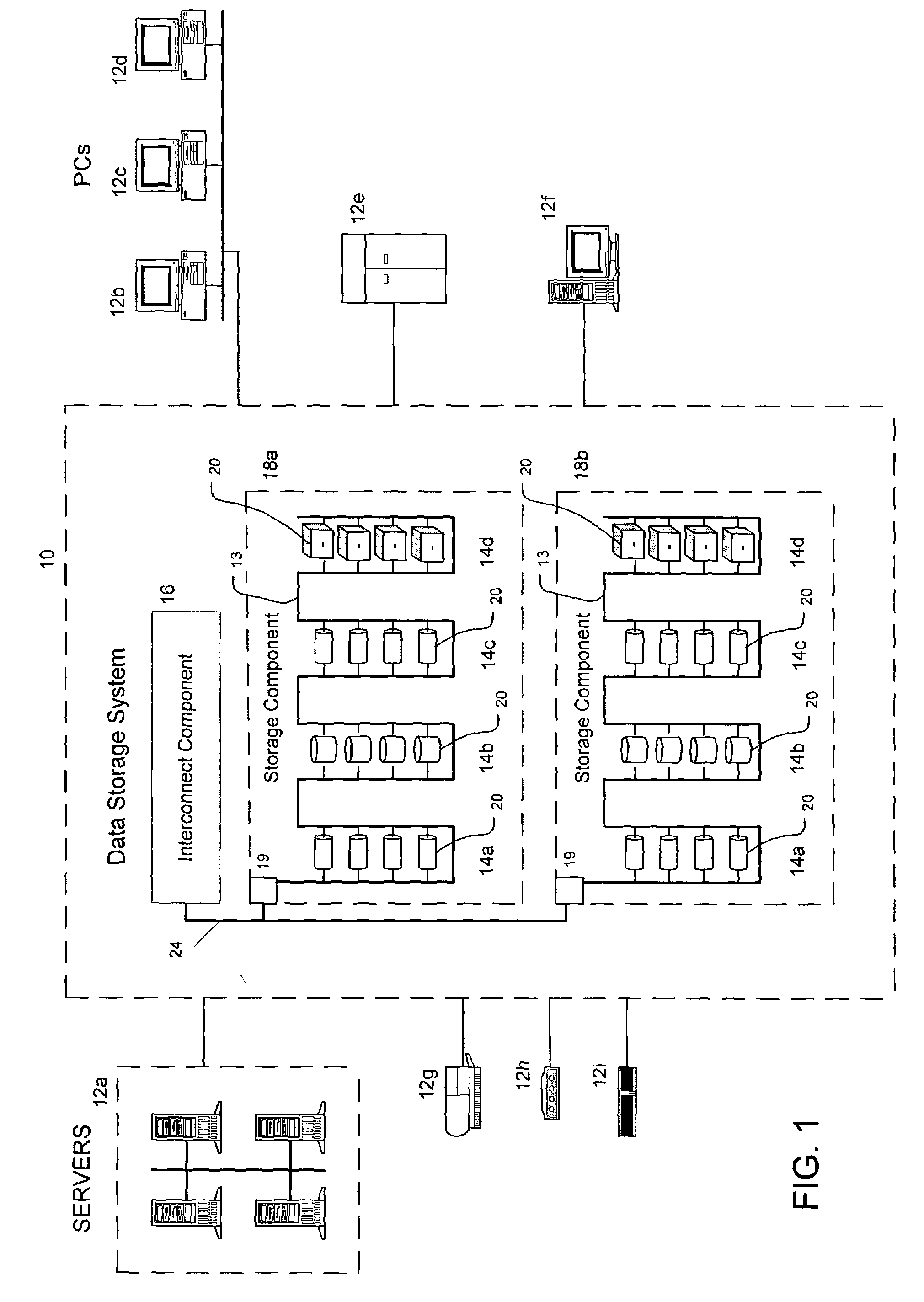

Preventing damage of storage devices and data loss in a data storage system

ActiveUS7146521B1Prolong lifeAvoid data lossThermometer detailsEnergy efficient ICTData CorruptionData loss

A data storage system and method capable of reducing the operating temperature of the data storage system, removing any overheating storage devices from operation, reconstructing data, and evacuating data from the overheating storage devices before the devices and the data are damaged or lost.

Owner:VALTRUS INNOVATIONS LTD

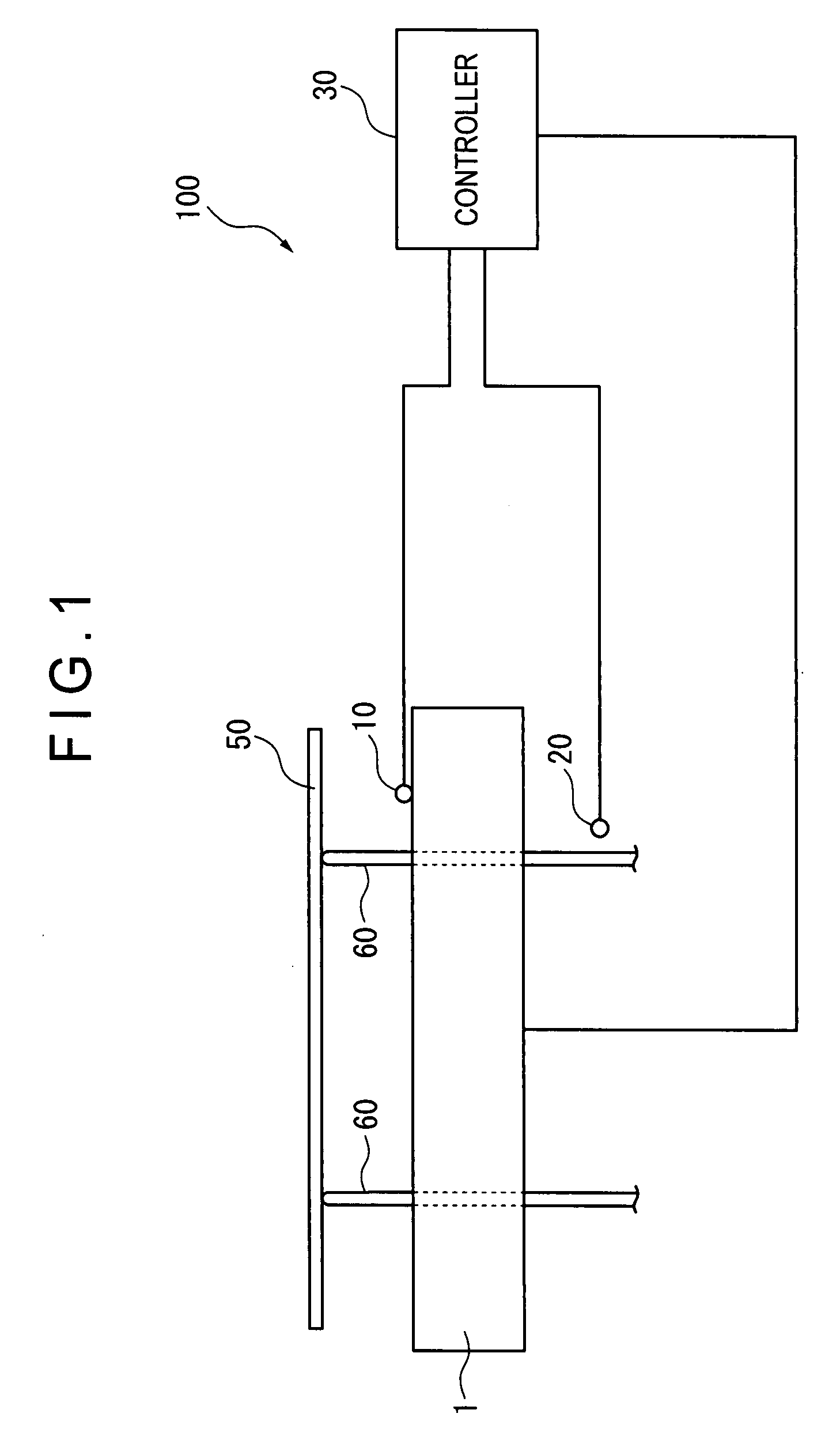

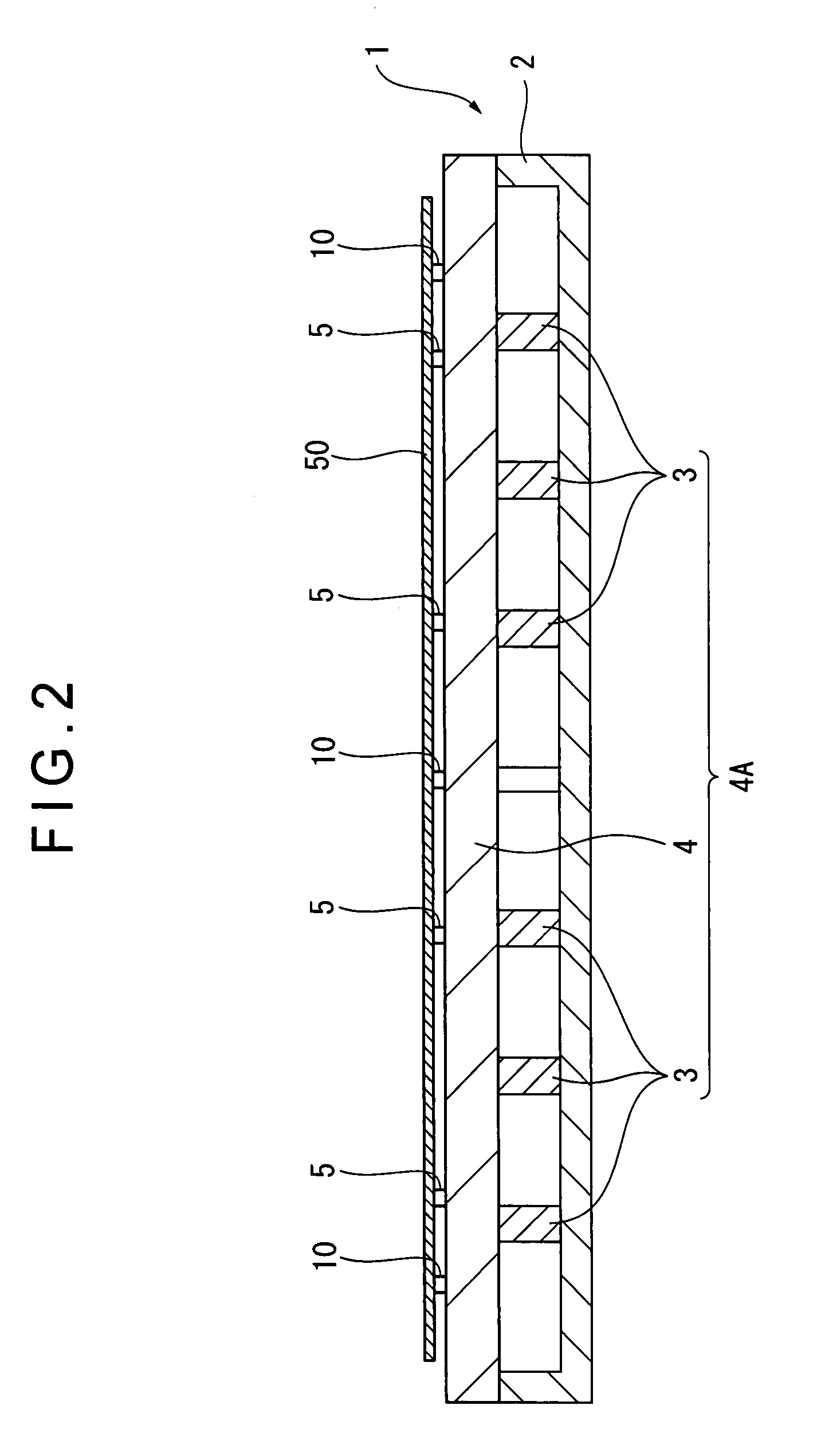

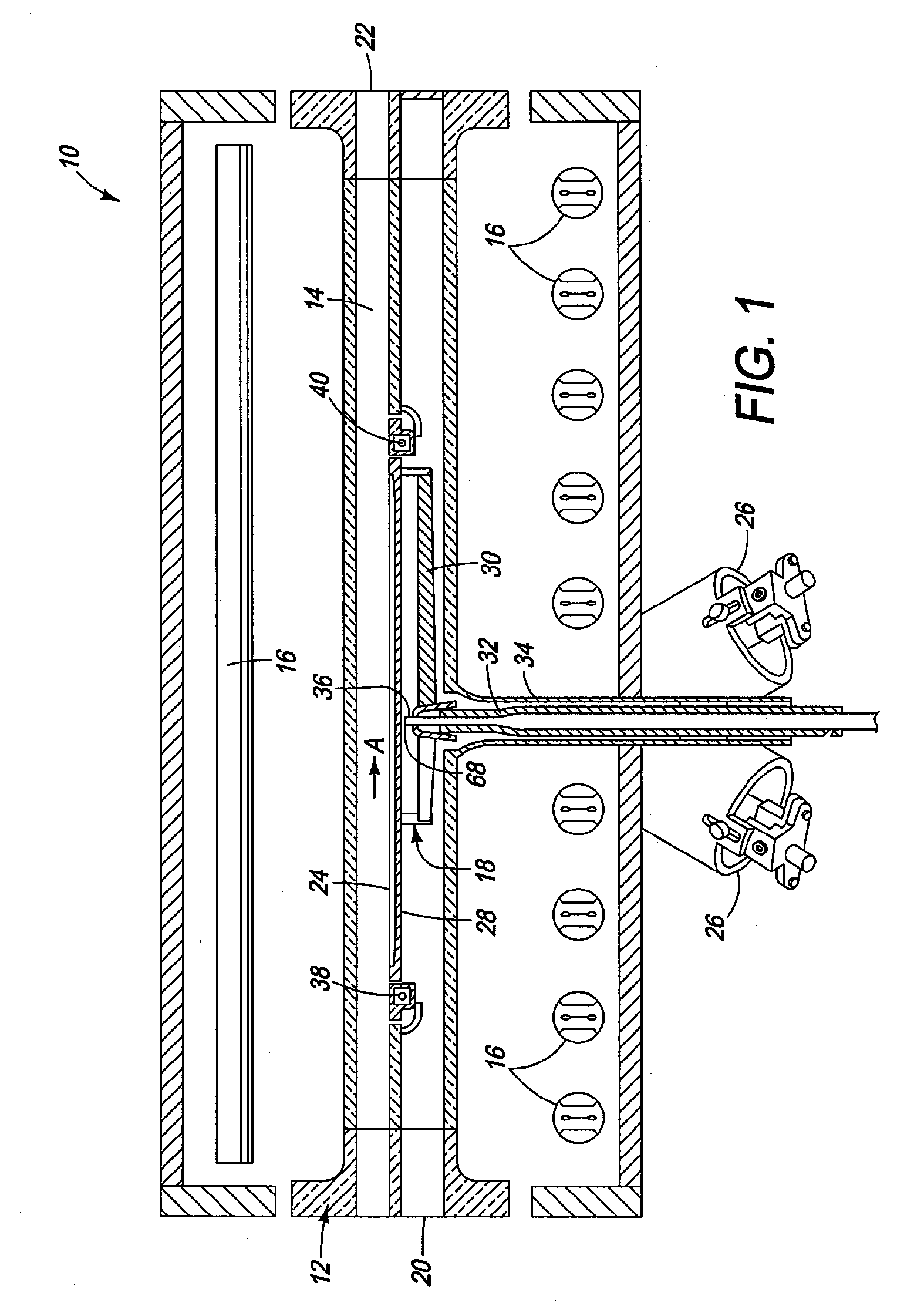

Temperature sensor, temperature control device, temperature controller and temperature-control method

ActiveUS20080043803A1High measurement accuracyThermometer detailsMechanical apparatusTemperature controlEngineering

A temperature sensor (10) includes: a temperature-sensing portion for measuring a temperature of an object (50) by contacting the object; and a supporting portion for supporting the temperature-sensing portion from a side opposite to a contact surface, the supporting portion having a space at a portion partially corresponding to the temperature-sensing portion. A temperature controller includes: a temperature control device; the temperature sensor (10) for measuring the temperature by contacting the object (50); and a controller for controlling the temperature control device. The controller includes: a mounting-state judging means for judging a mounting-state of the object (50); a switching means for switching a control gain and a target temperature of the temperature control device based on the judging result; and a control-command generating means for generating a control command based on the control gain, the target temperature and a measurement value of the temperature sensor (10).

Owner:KOMATSU LTD

Thermocouple

A thermocouple for use in a semiconductor processing reaction is described. The thermocouple includes a sheath having a measuring tip and an opening at the opposing end. A support member that receives a portion of a first wire and a second wire is received within the sheath. The first and second wires form a junction that contacts the inner surface of the sheath at the measuring tip. A spacing member is secured at the opening of the sheath and receives the support member. The spacing member allows the support member, first wire, and second wire to freely thermally expand relative to each other without introducing compression or tension stresses therein.

Owner:ASM IP HLDG BV

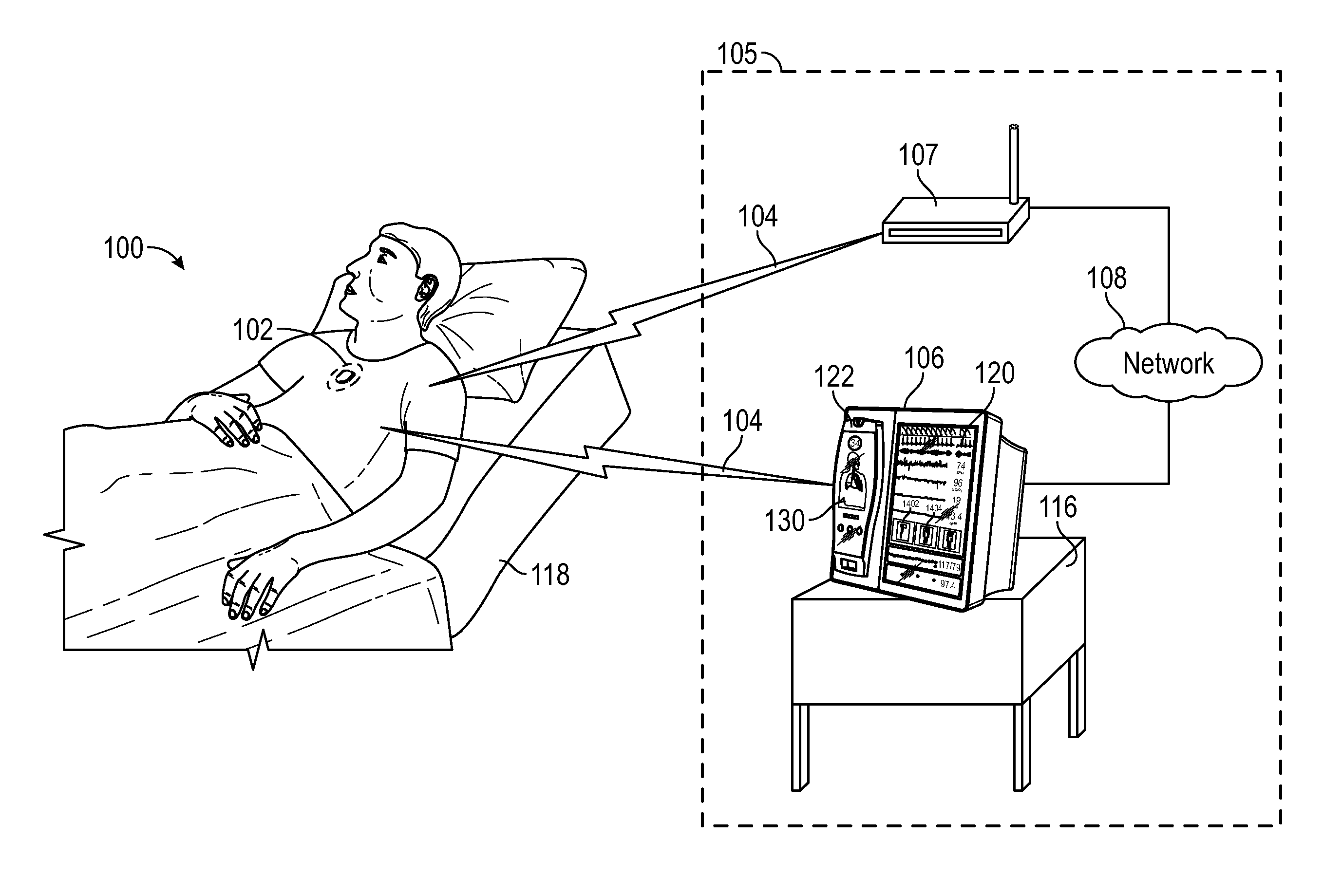

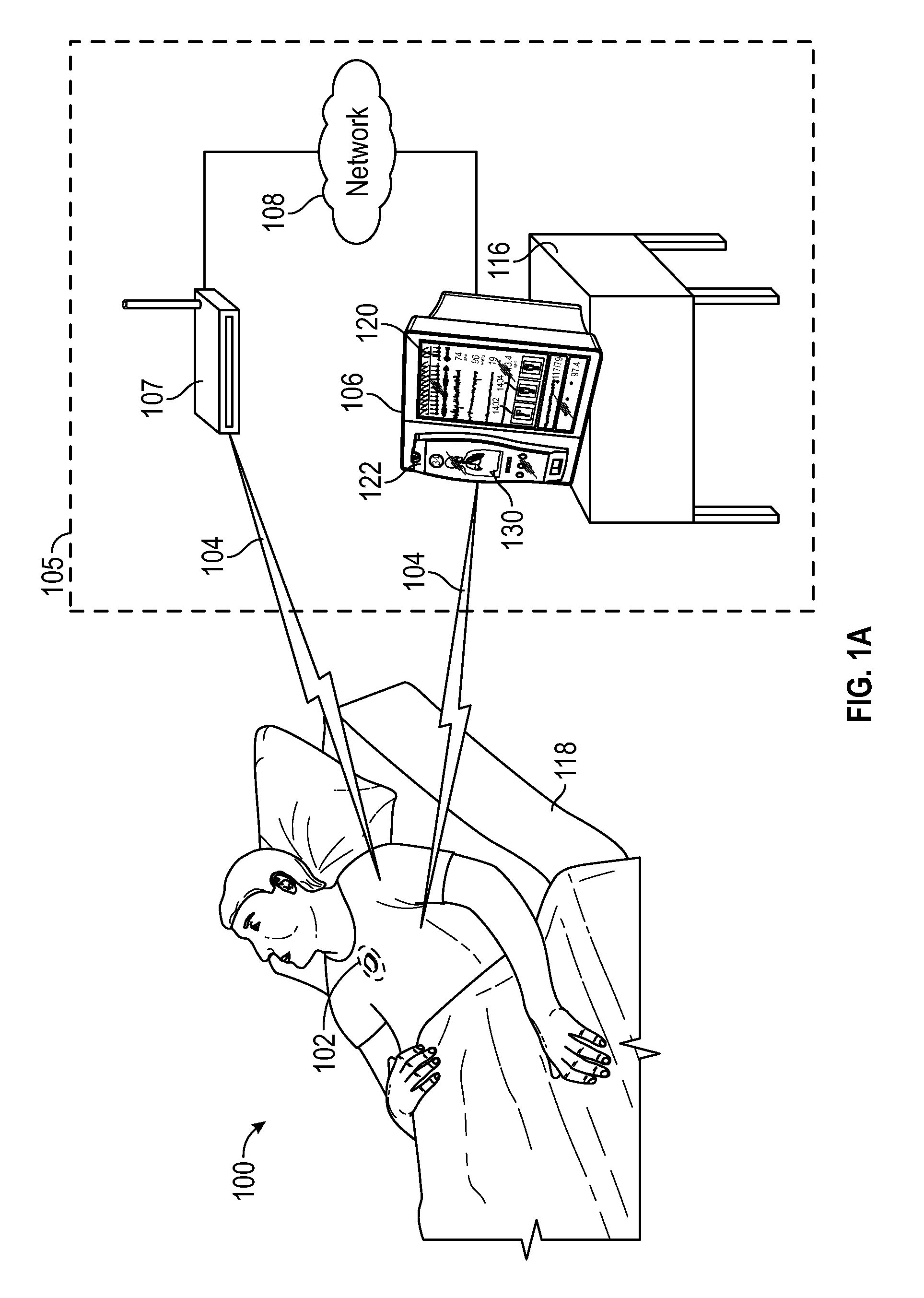

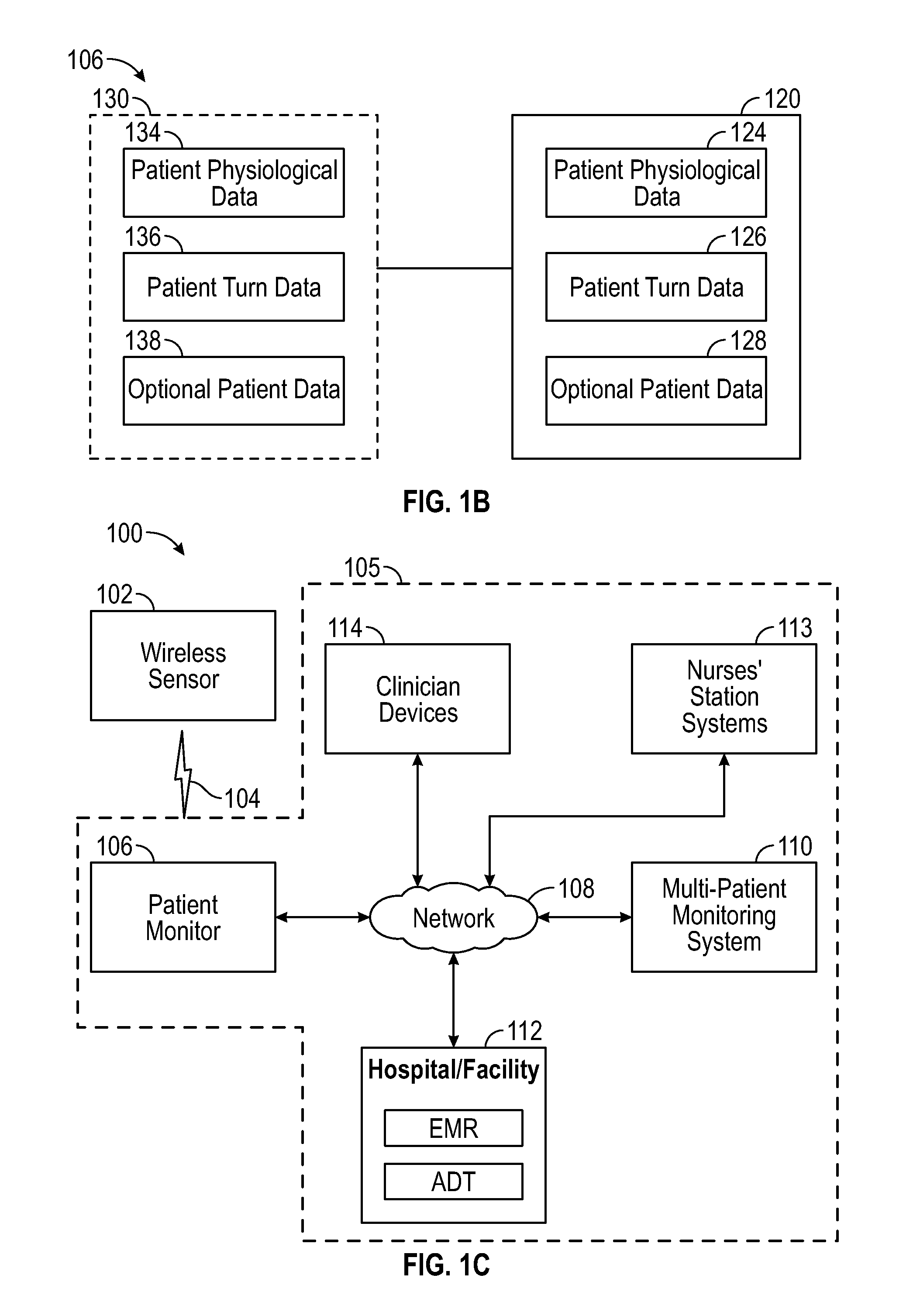

Wireless patient monitoring systems and methods

A patient monitoring system to help manage a patient that is at risk of forming one or more pressure ulcers is disclosed. The system includes a patient-worn wireless sensor that senses the patient's orientation and wirelessly transmits information indicative of the sensed orientation to a patient monitor. The patient monitor receives, stores, and processes the transmitted information. It also displays and transmits information indicative of the patient's orientation to help caregivers manage the patient's risk of formation of one or more pressure ulcers. The system can identify the present orientation of the patient and determine how long the patient has been in the present orientation. If the patient remains in an orientation beyond a predefined duration, the system can notify the patient and / or caretakers that the patient is due to be repositioned.

Owner:MASIMO CORP

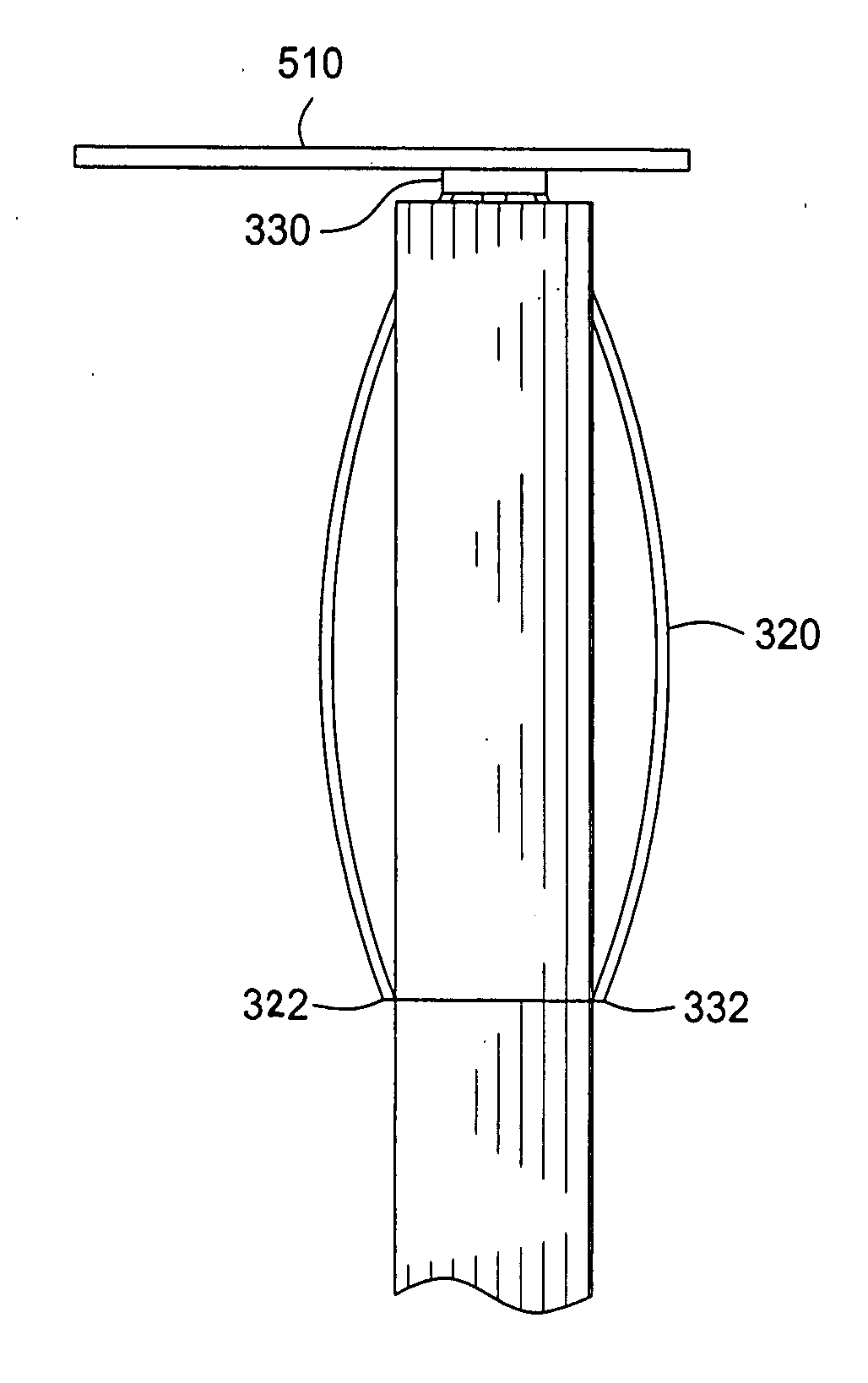

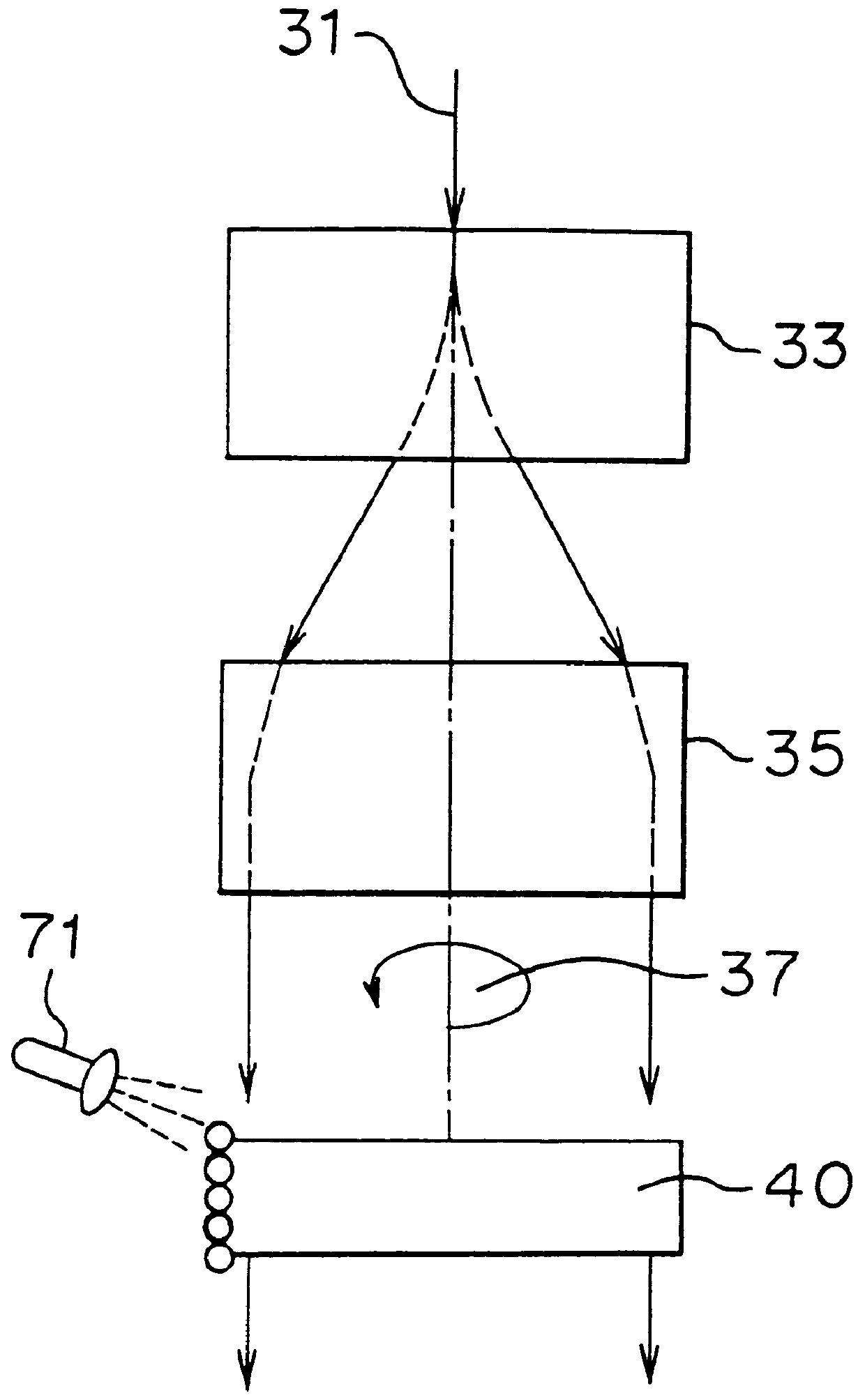

Charged particle beam irradiation apparatus and method of irradiation with charged particle beam

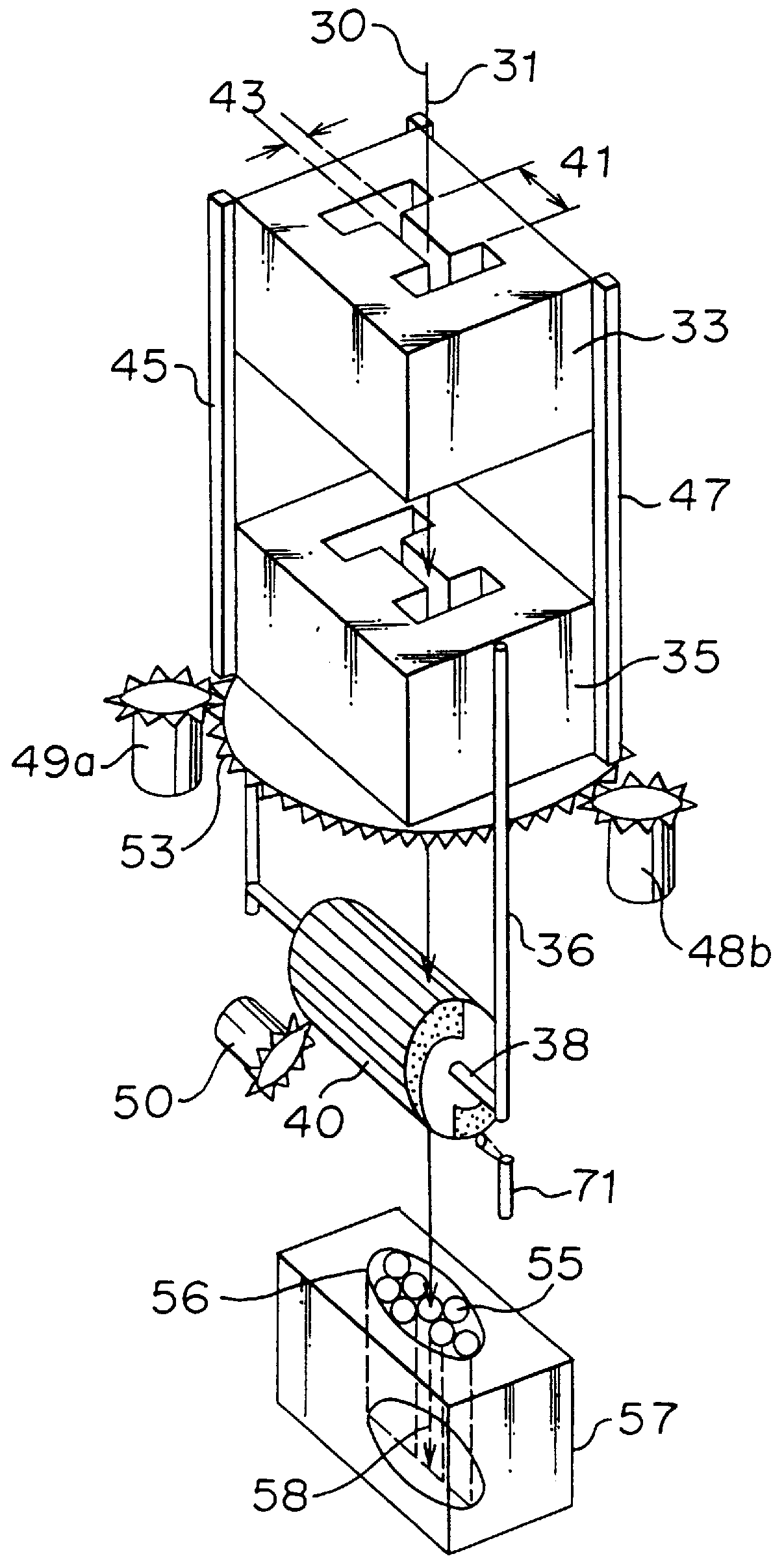

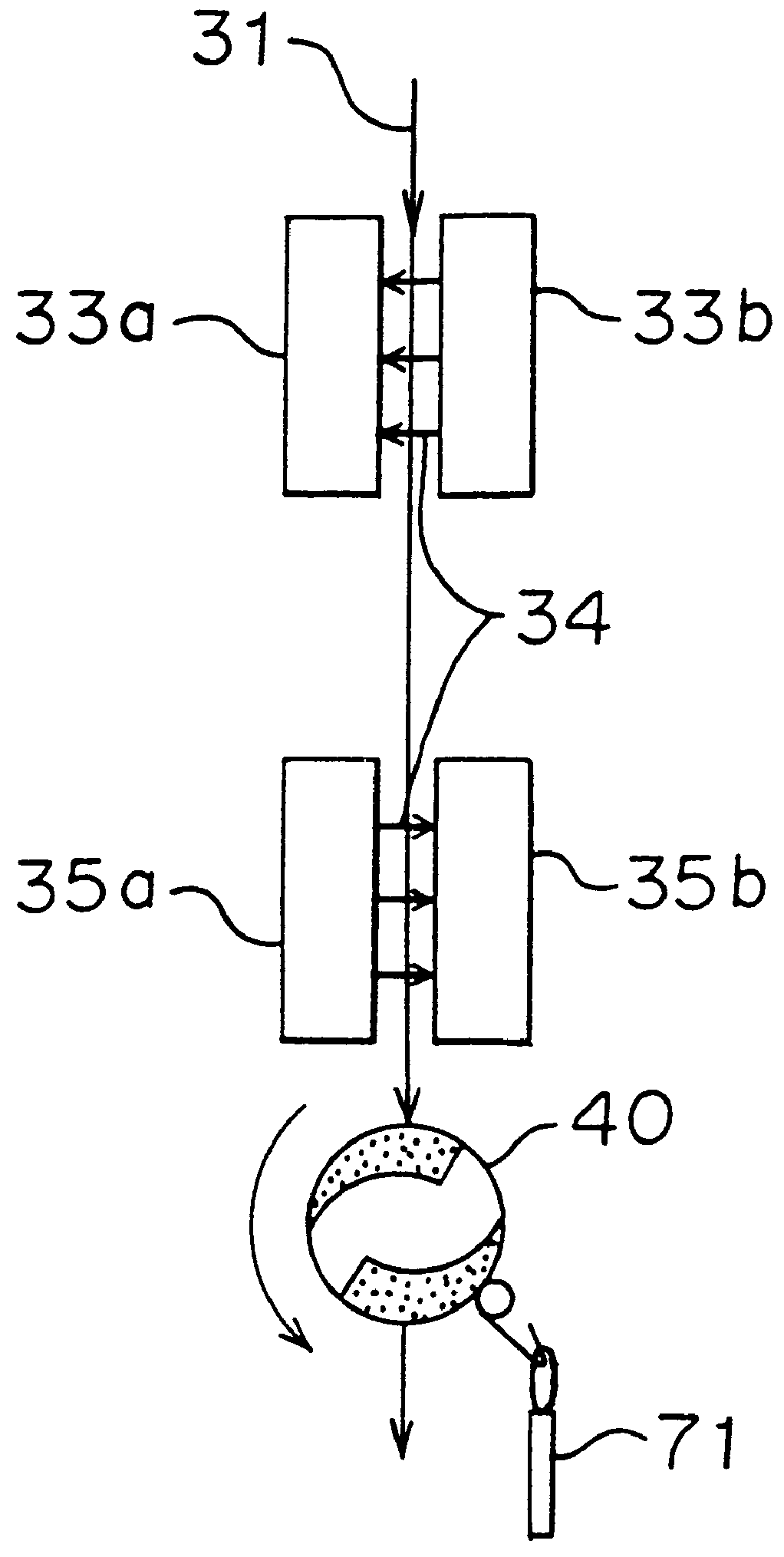

InactiveUS6034377AThermometer detailsBeam/ray focussing/reflecting arrangementsCharged particle beamAtomic physics

A charged particle beam irradiation apparatus includes two electromagnets arranged in series along a direction of an incident axis of a charged particle beam, for deflecting the charged particle beam in opposite directions, an energy modulator including a cylindrical member having a length and a distribution of wall thickness in a circumferential direction, a first rotational drive for rotating the cylindrical member around a rotation axis, and a detector for detecting the angular position of the cylindrical member. The energy modulator is disposed at a downstream side of the scanning electromagnets so that the deflected charged particle beam passes through the rotation axis. The apparatus includes an energy degrader for limiting energy of the charged particle beam, and a second rotational drive for rotating the scanning electromagnets and the energy modulator together around the incident axis of the charged particle beam.

Owner:MITSUBISHI ELECTRIC CORP

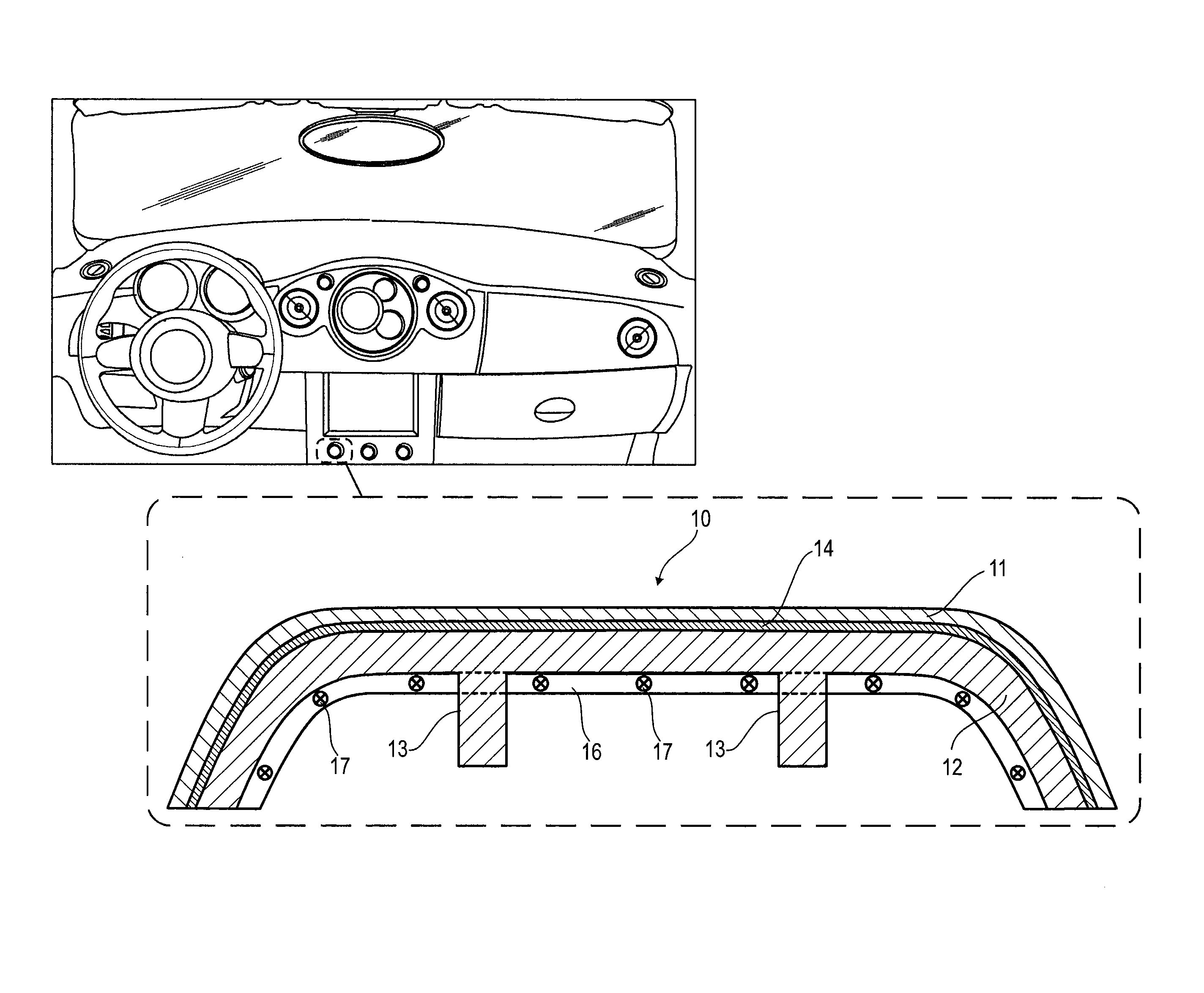

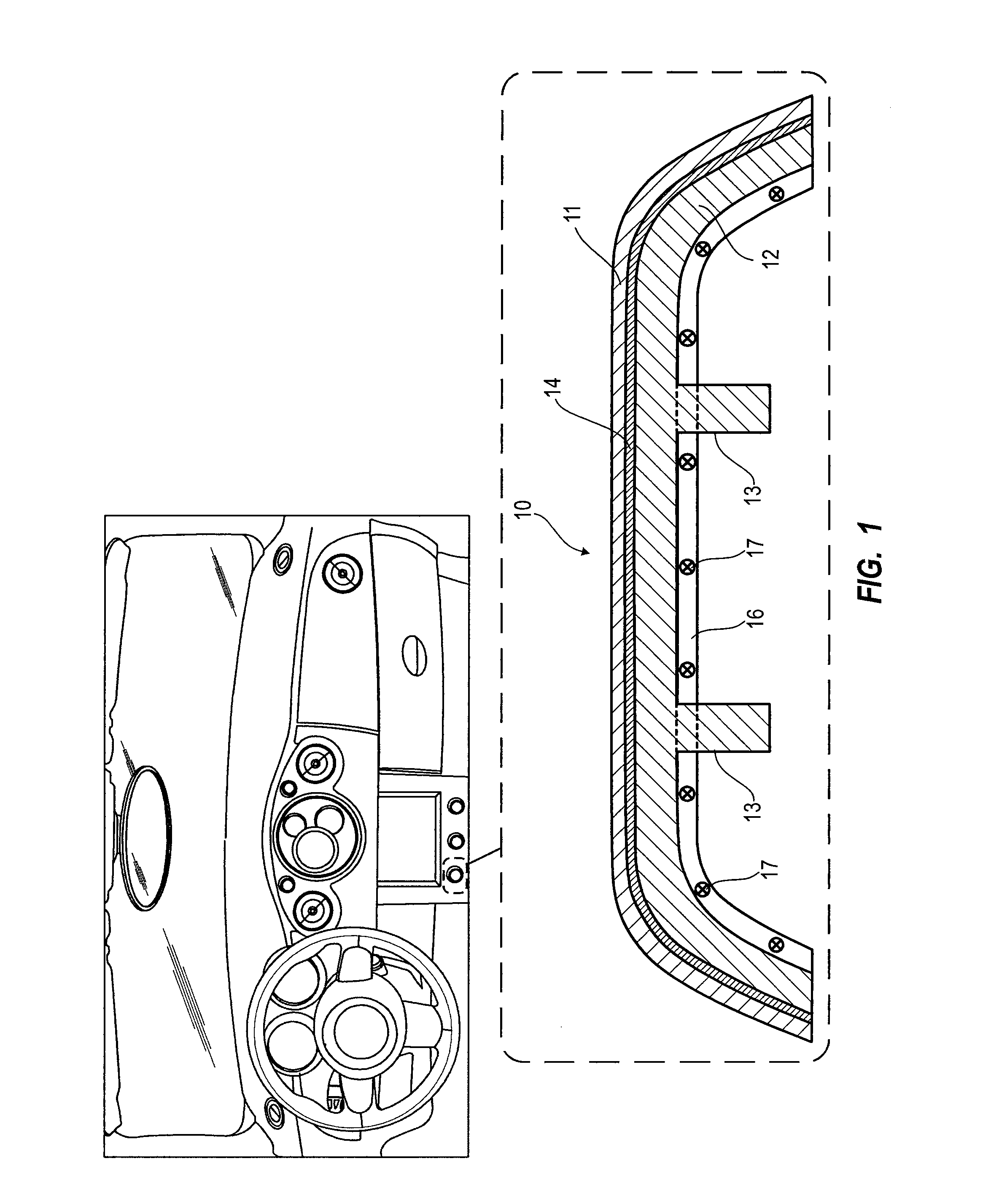

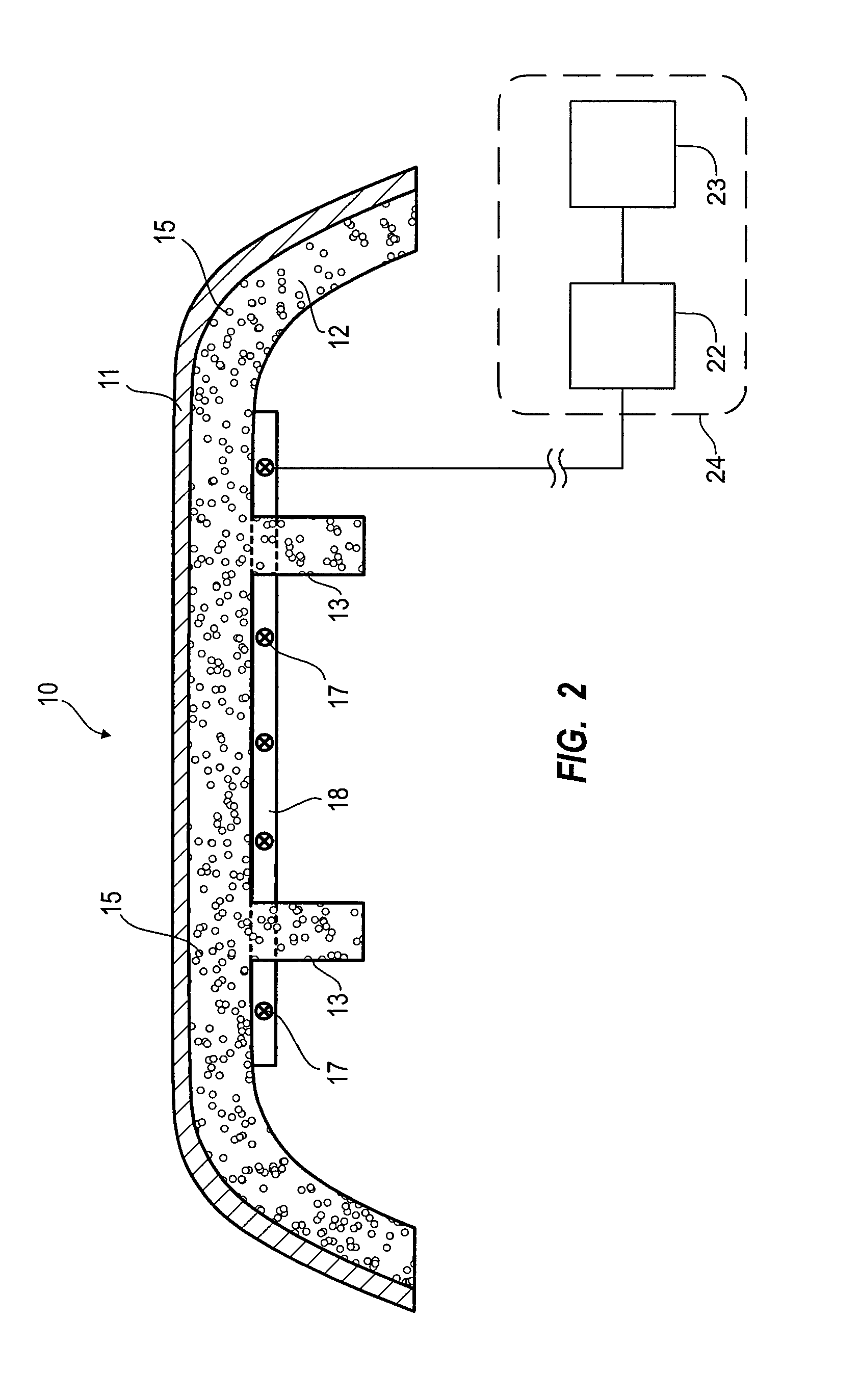

Luminous molded part, in particular a decorative part and/or trim part for a vehicle interior

InactiveUS8016465B2Decorative effectInhibition effectThermometer detailsUV light devicesLuminescent materialVisible range

The invention relates to a molded part, in particular a decorative part and / or a trim part for a vehicle interior. According to the invention, the molded part comprises at least one excitation source for emitting electromagnetic waves and at least one luminescent material which is excitable or excited by the electromagnetic waves emerging from the excitation source or sources to emit light in the visible range.

Owner:NOVEM CAR INTERIOR DESIGN GMBH

Features

- R&D

- Intellectual Property

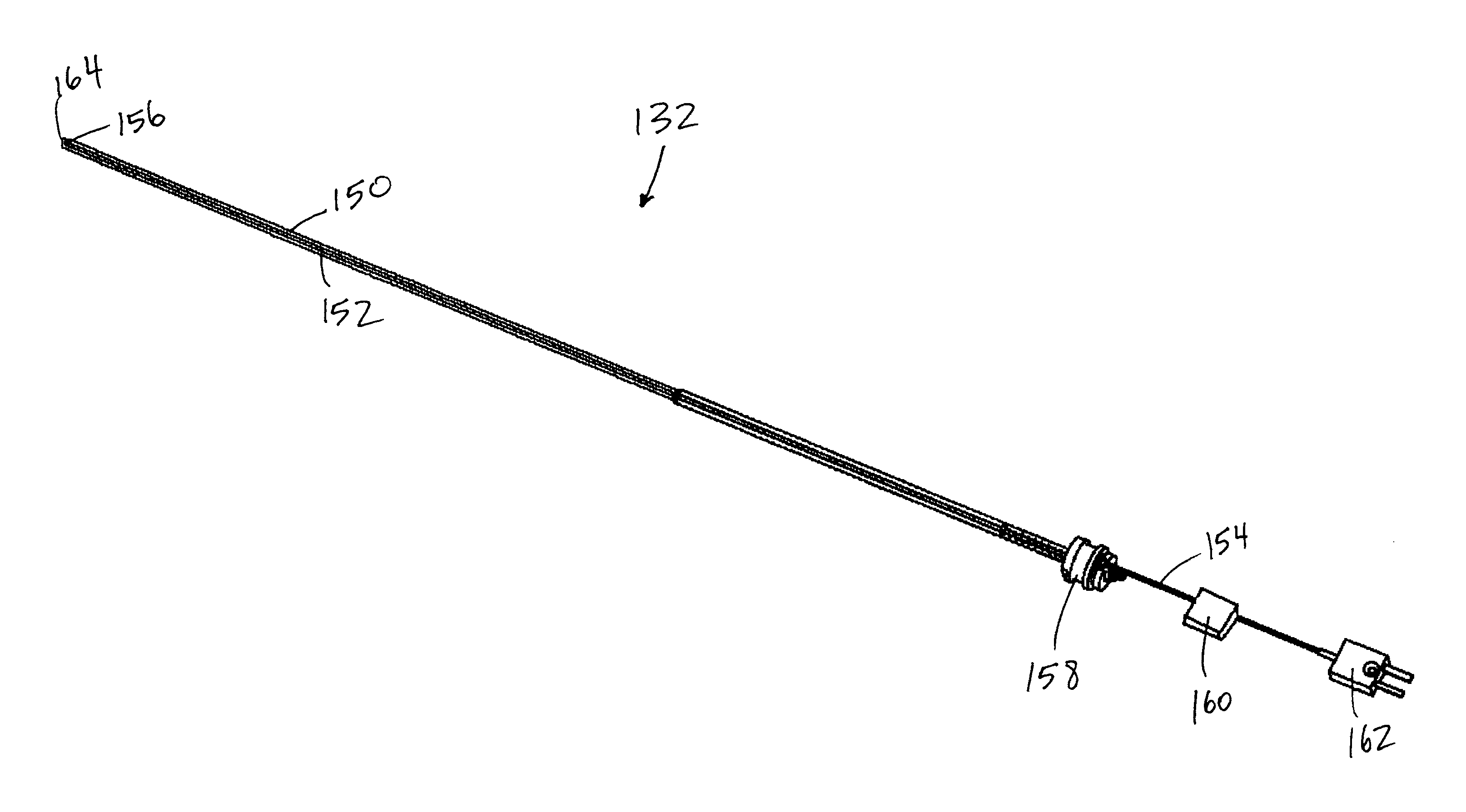

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com