Patents

Literature

4121 results about "Thermocouple device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thermocouple is an electrical device consisting of two dissimilar electrical conductors forming electrical junctions at differing temperatures. A thermocouple produces a temperature-dependent voltage as a result of the thermoelectric effect, and this voltage can be interpreted to measure temperature.

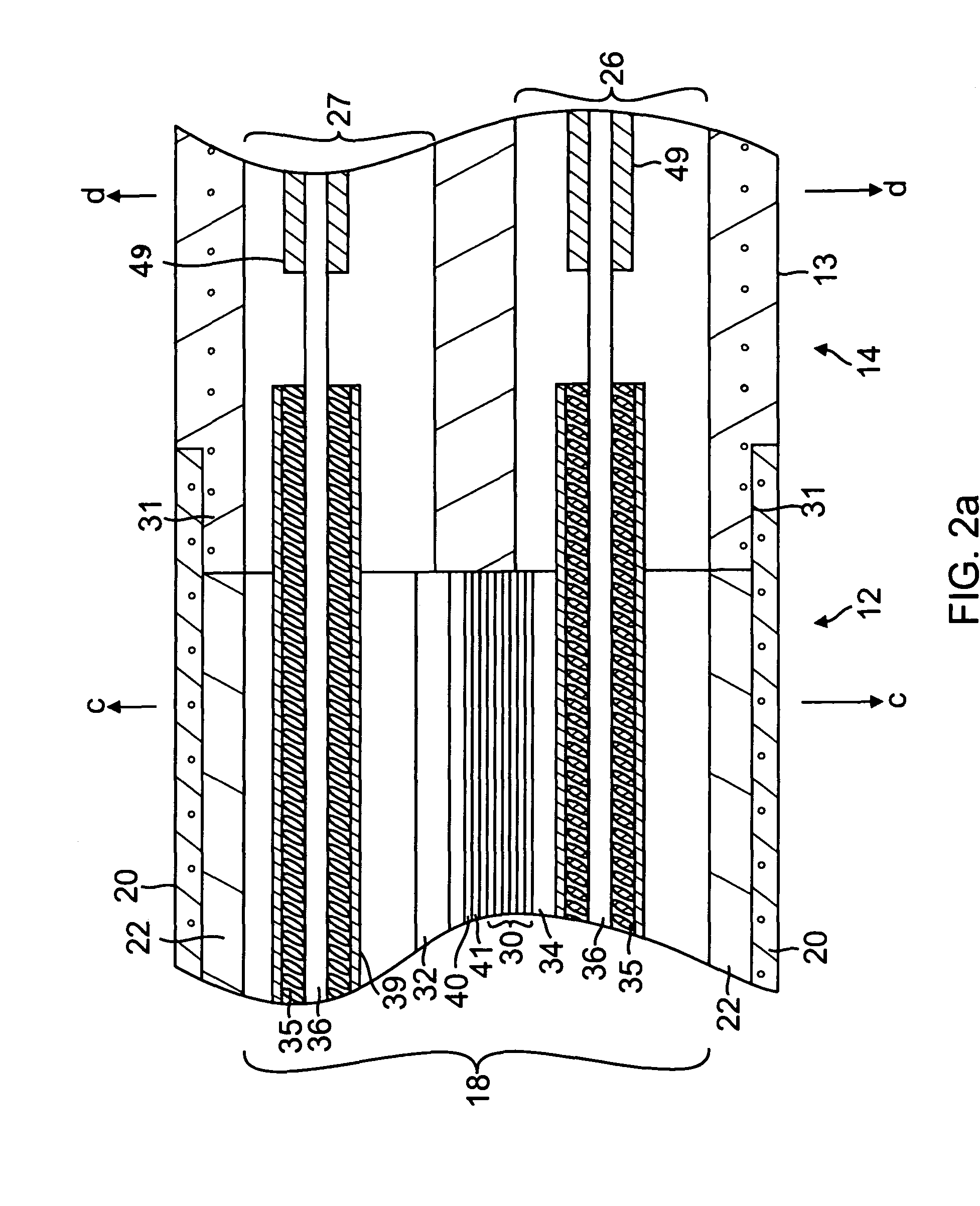

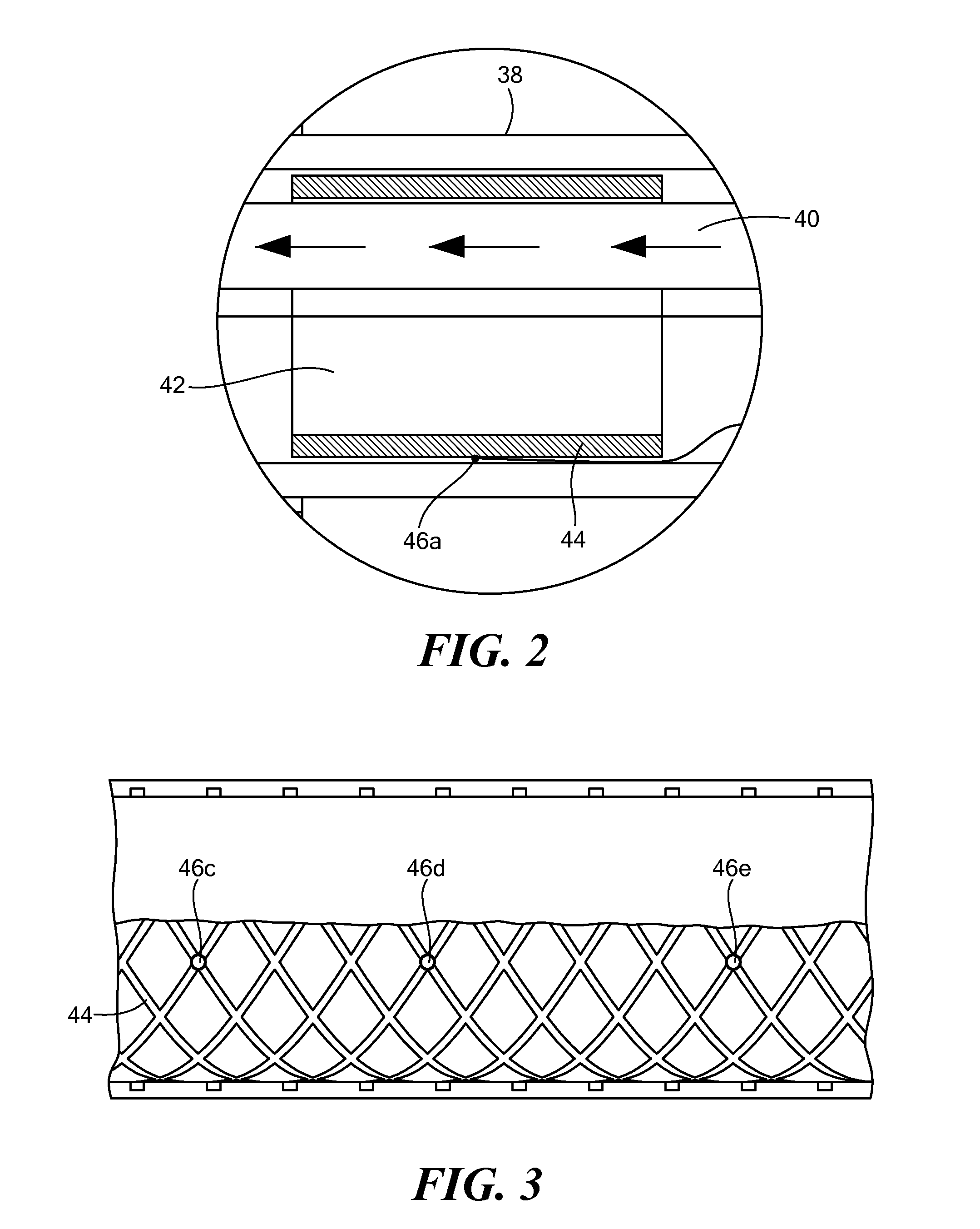

Endoprostheses and methods of manufacture

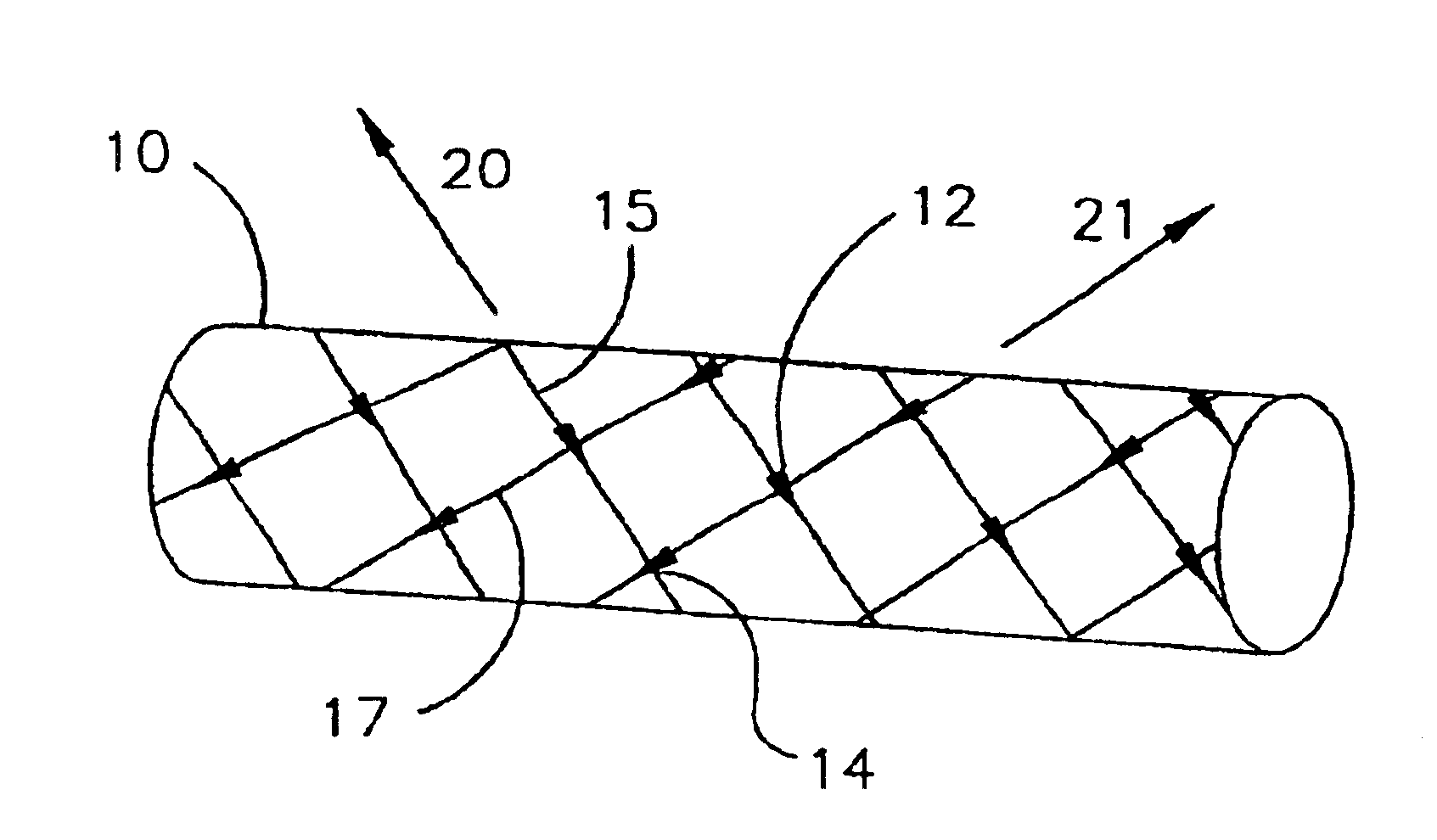

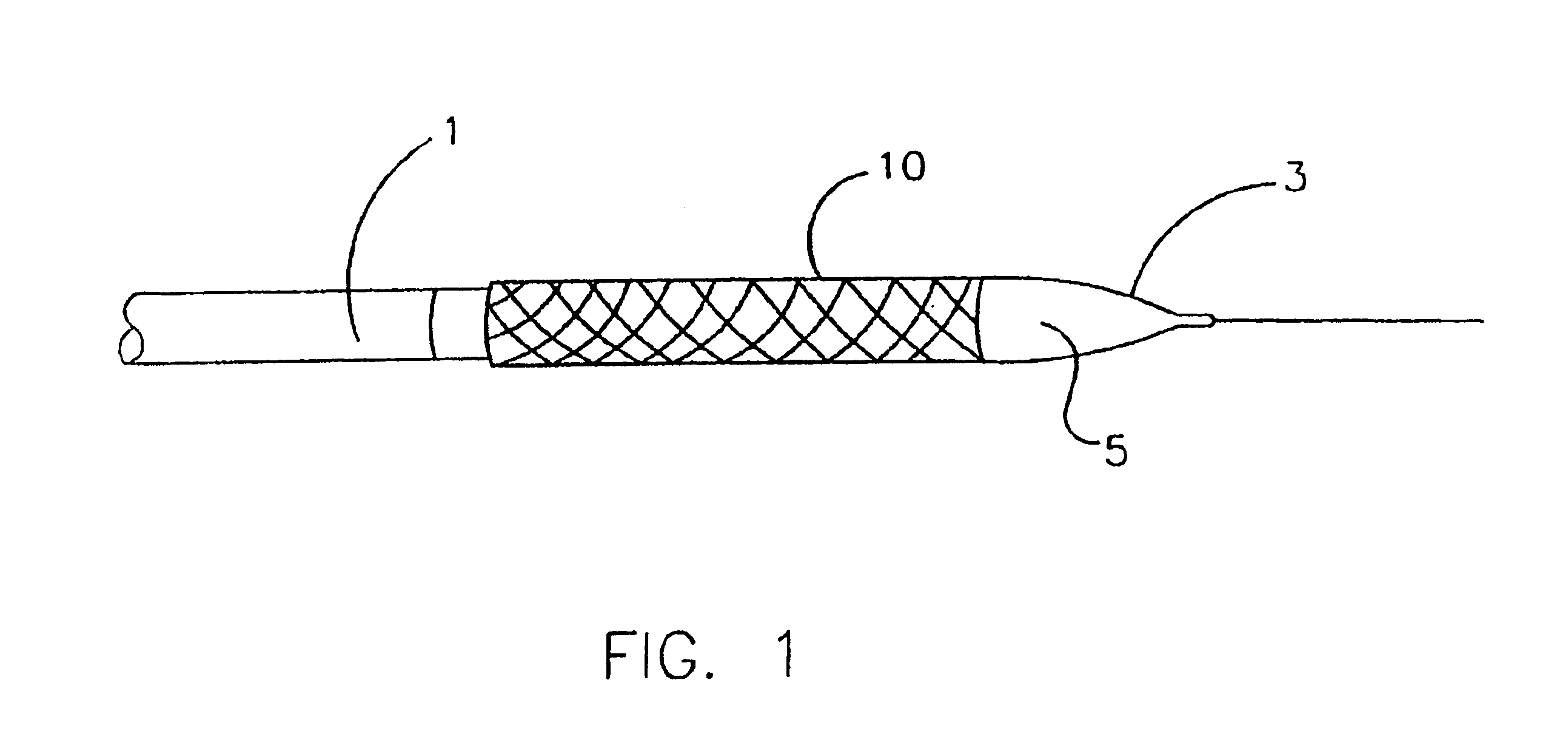

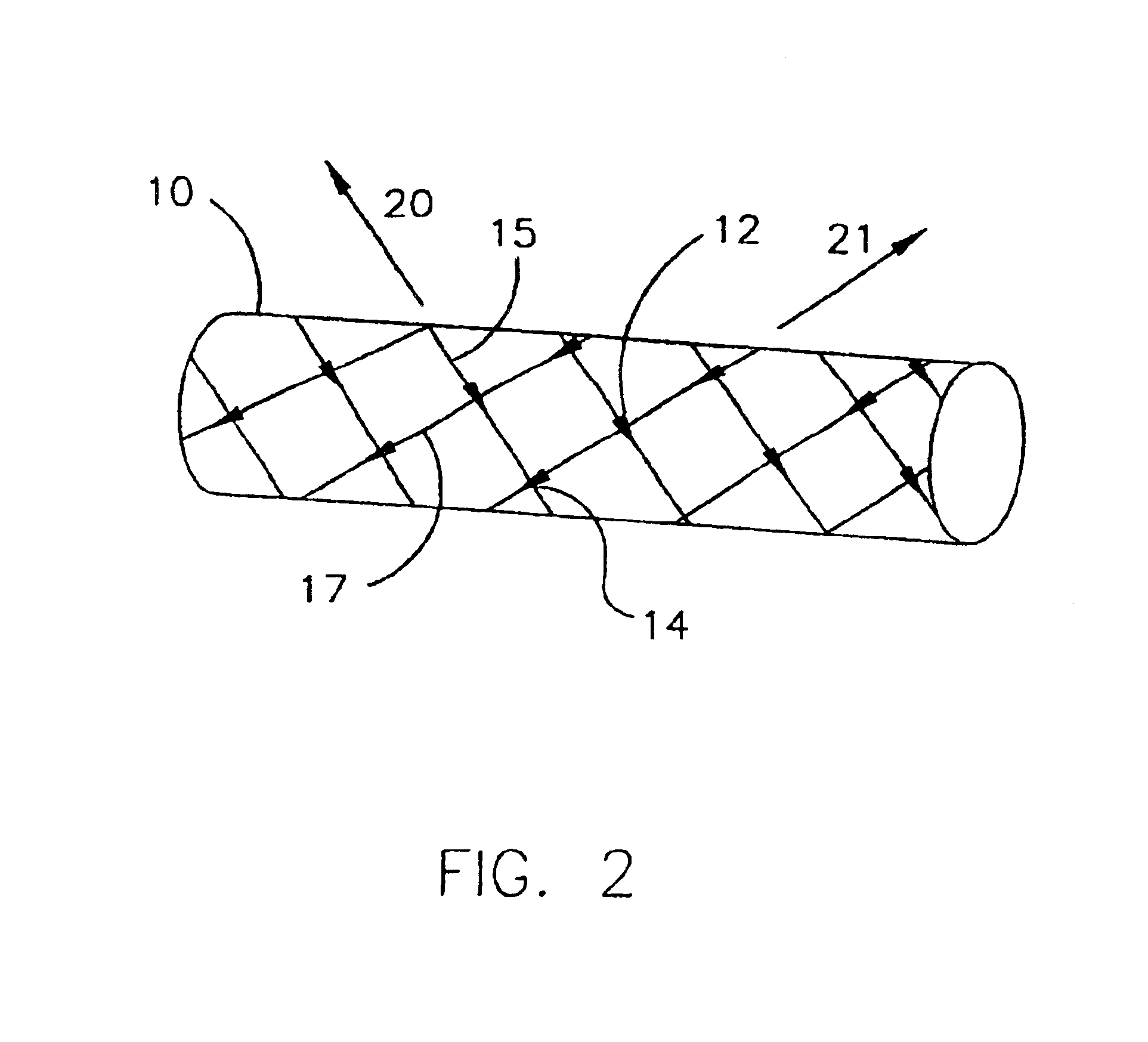

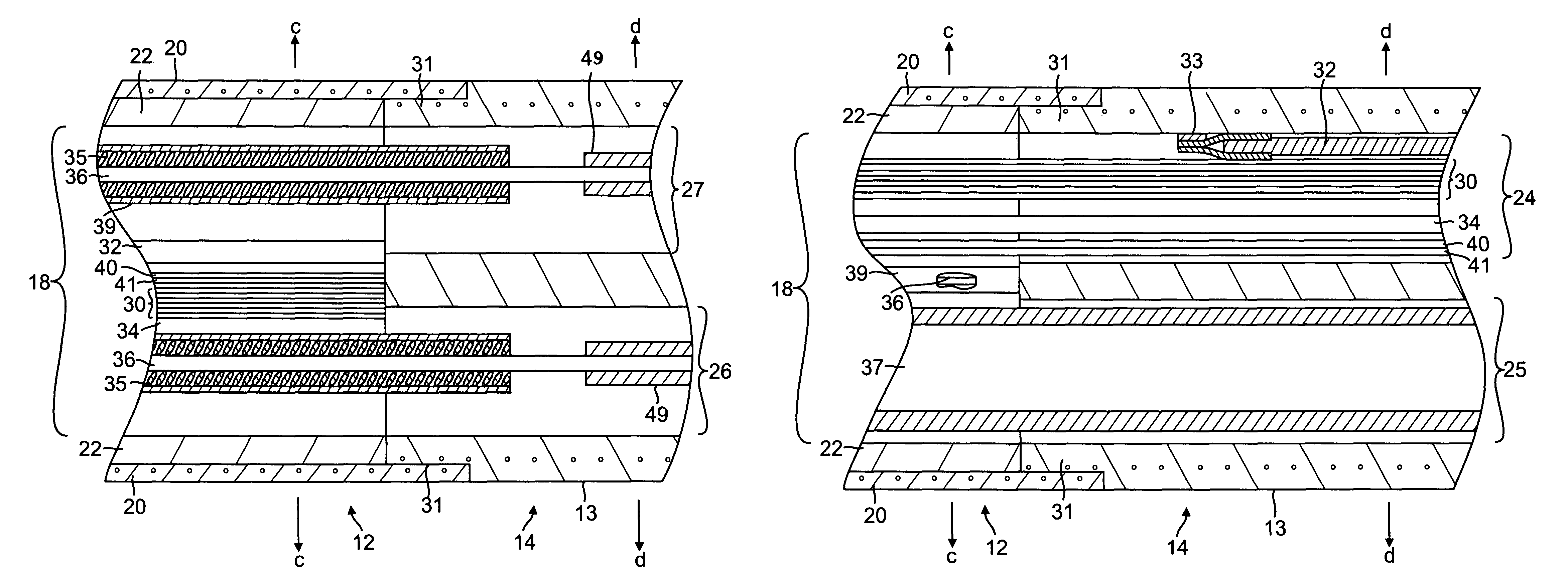

Improved endoprostheses comprising a delivery configuration and a deployed configuration and methods of manufacture are disclosed. Some embodiments according to the invention comprise woven tubular structures and means for maintaining said structures in their expanded configurations. In one embodiment of the invention, locking elements disposed on one or more fibers maintain said endoprosthesis in its deployed configuration. In alternative embodiments, one or more axial members may maintain said endoprosthesis in its deployed configuration. In yet additional alternative embodiments, a chemical bond or thermocouple may maintain said endoprosthesis in its deployed configuration. Some embodiments according to the invention may comprise erodible material.

Owner:SYNECOR LLC

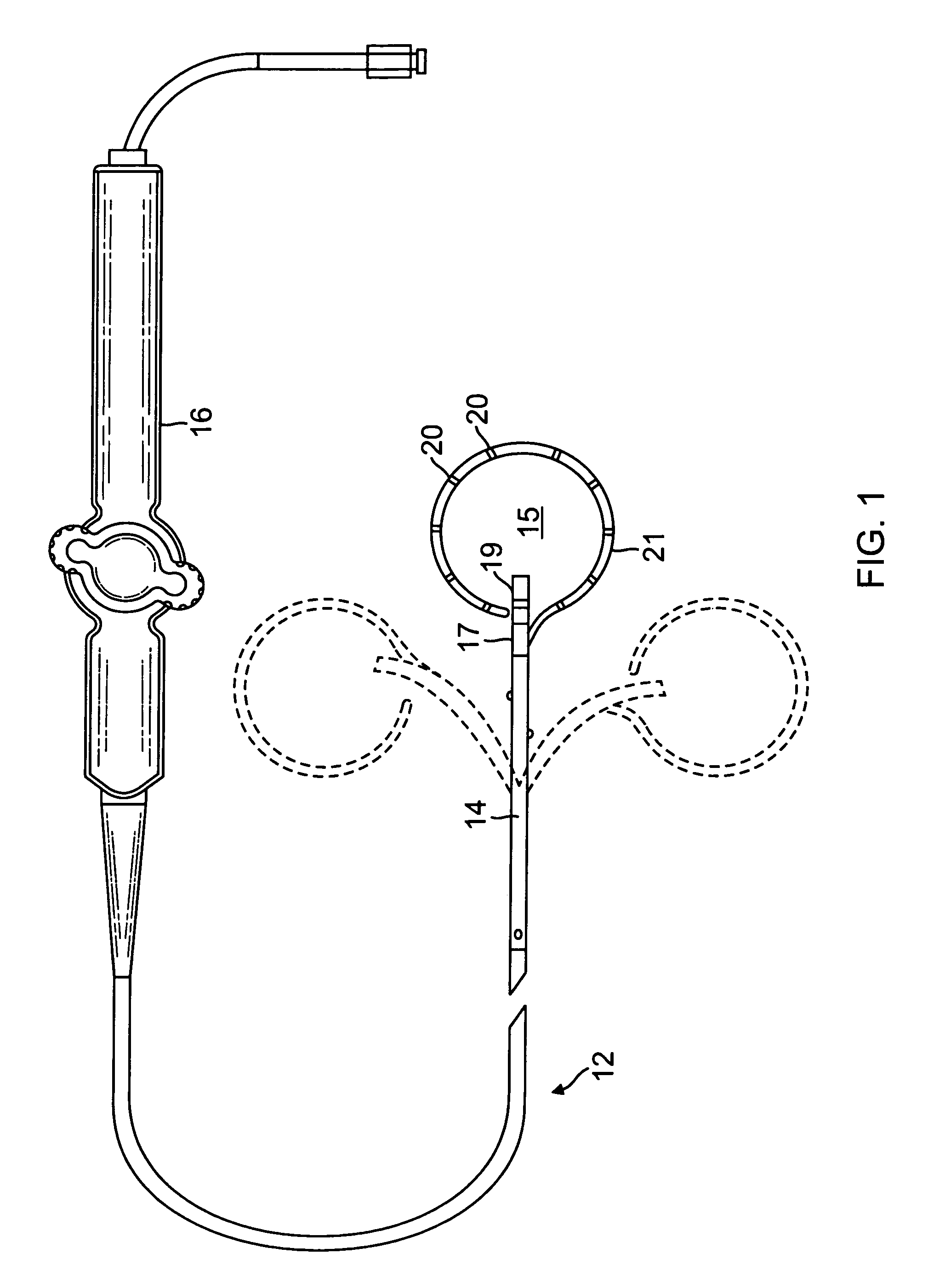

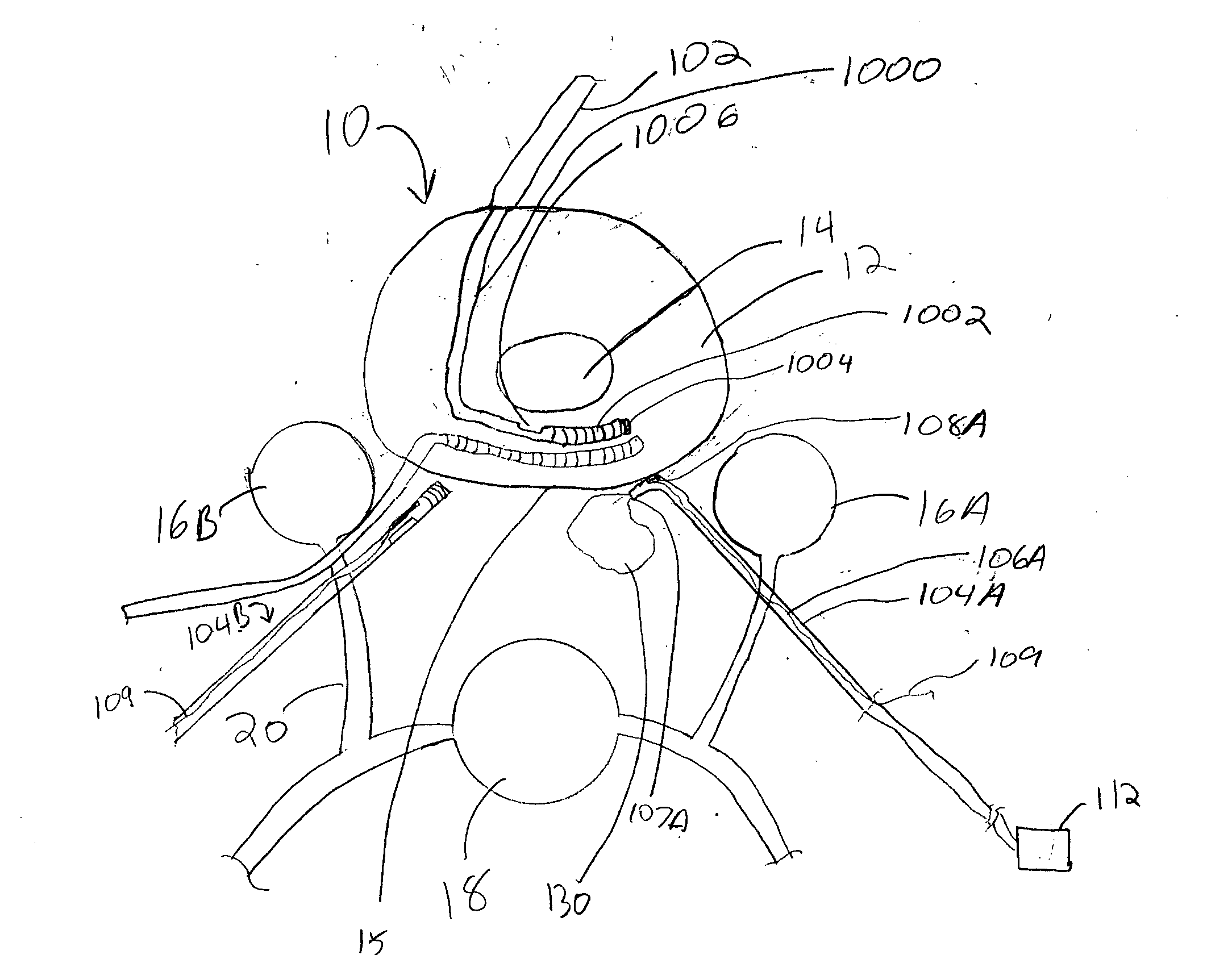

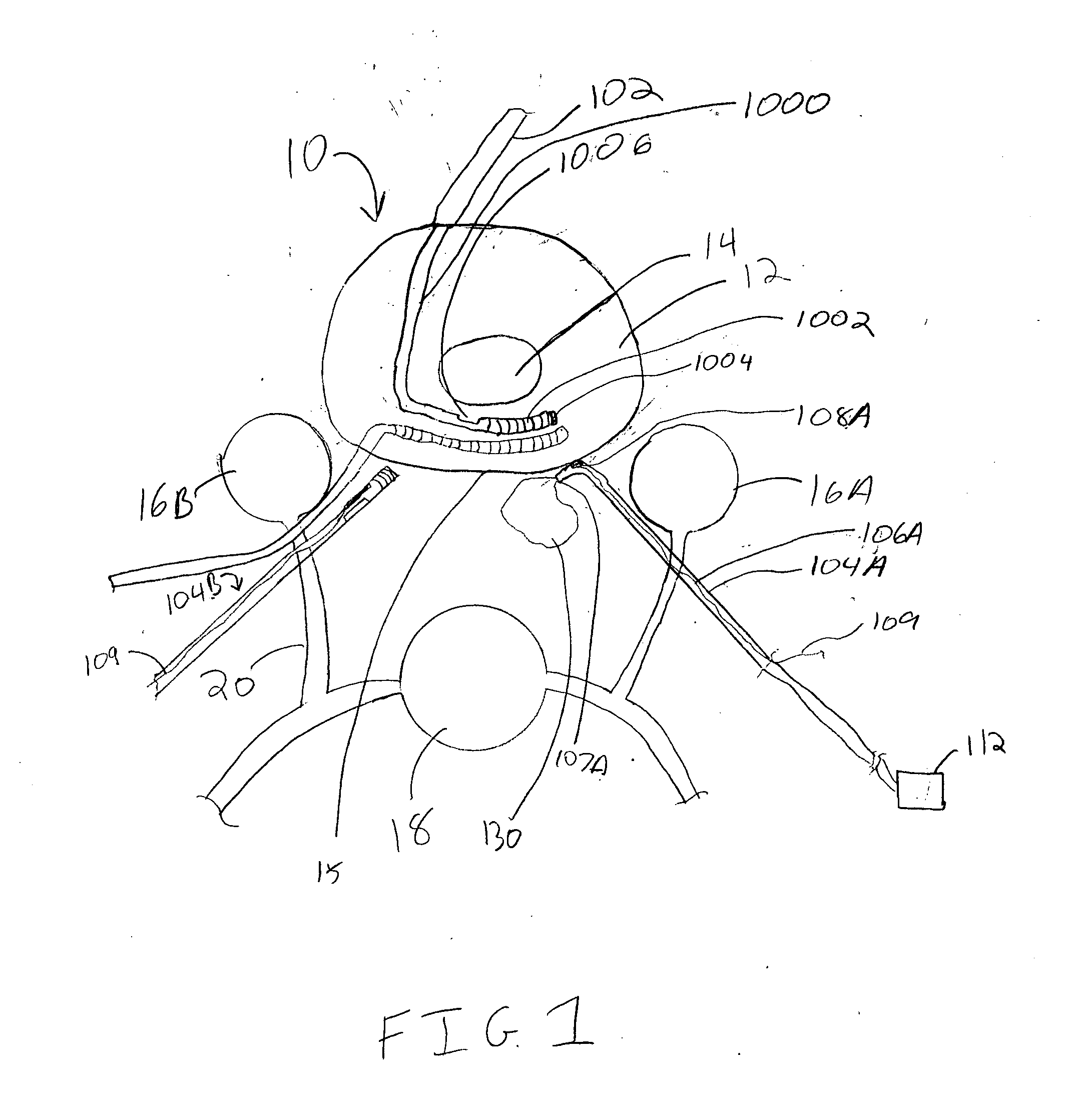

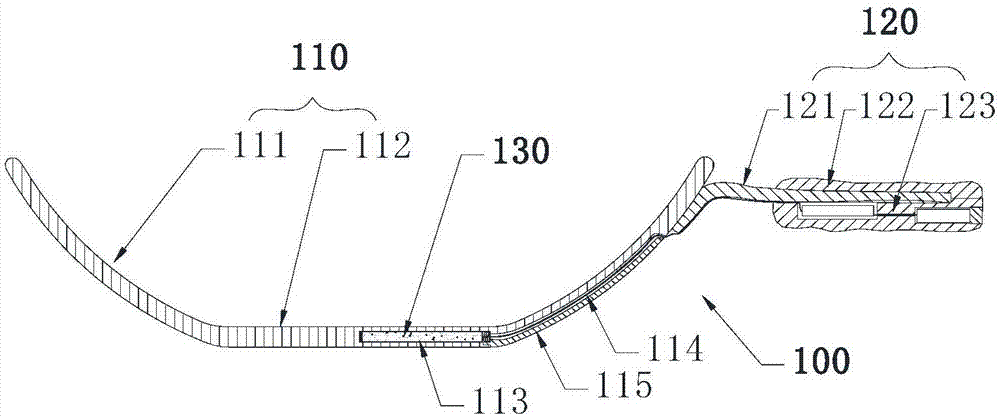

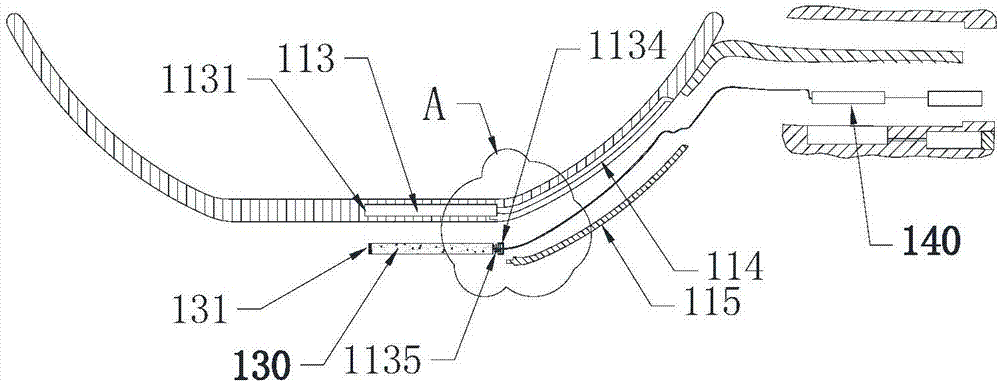

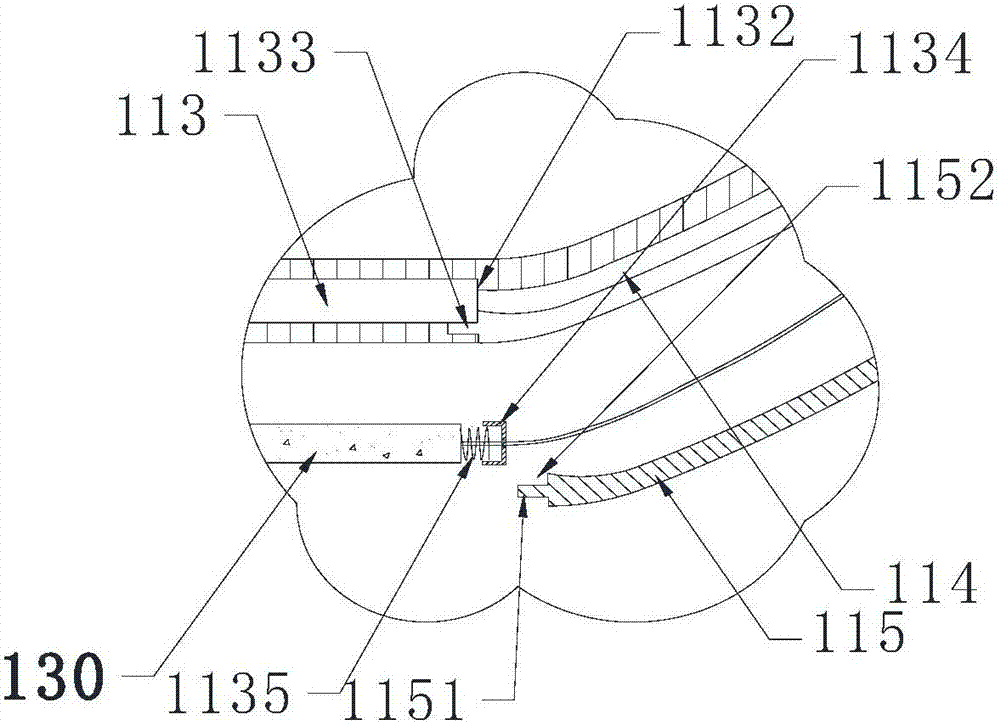

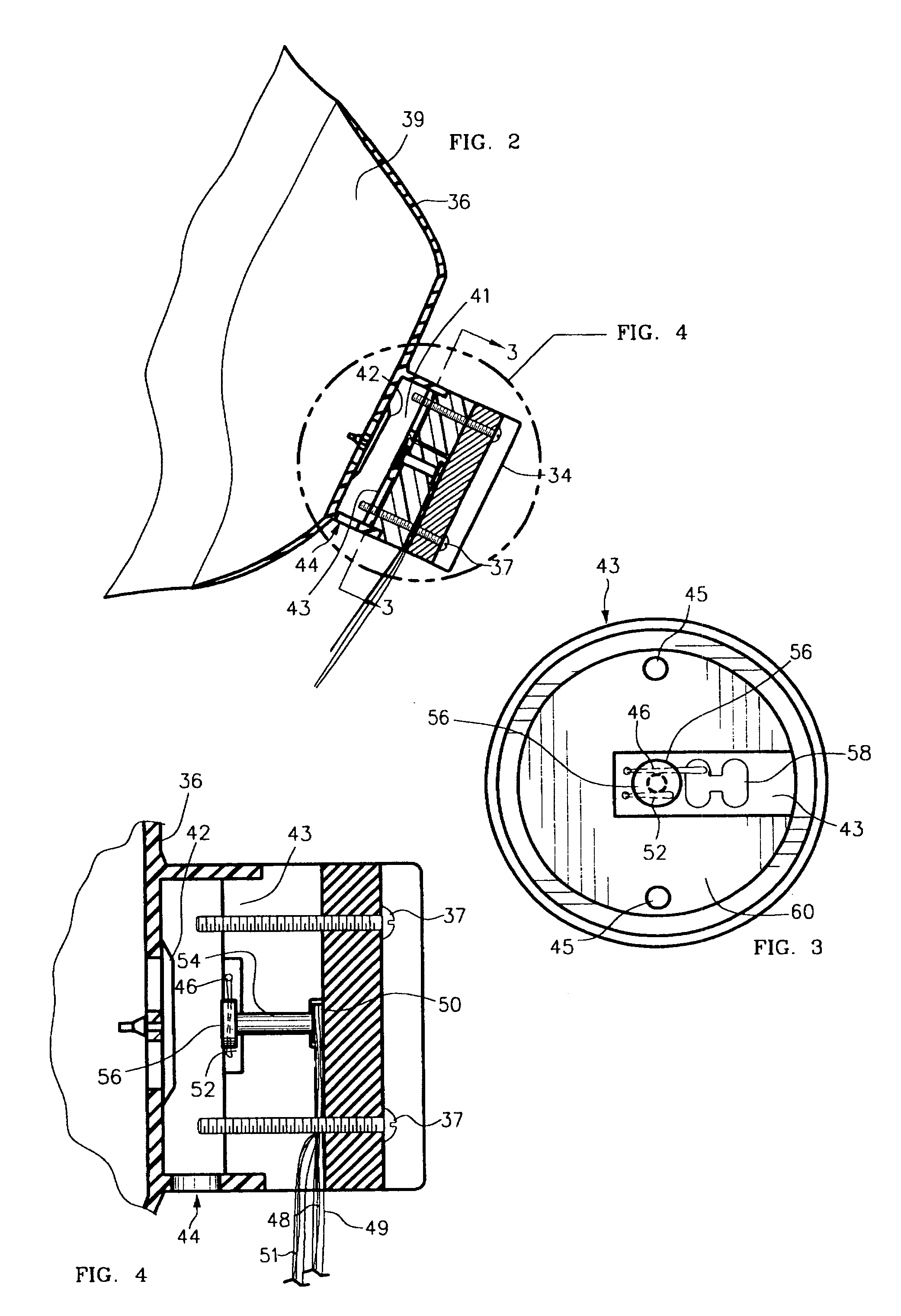

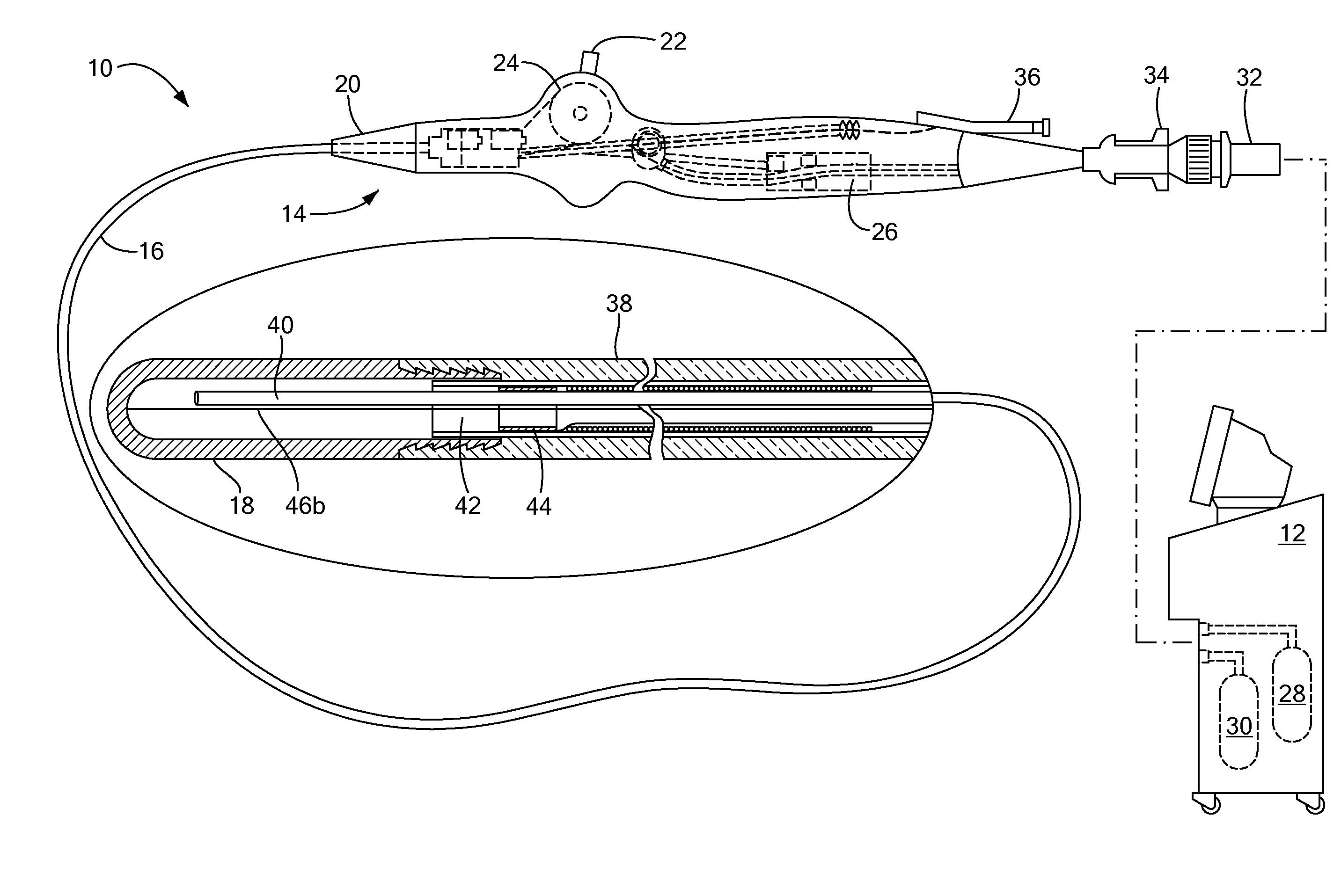

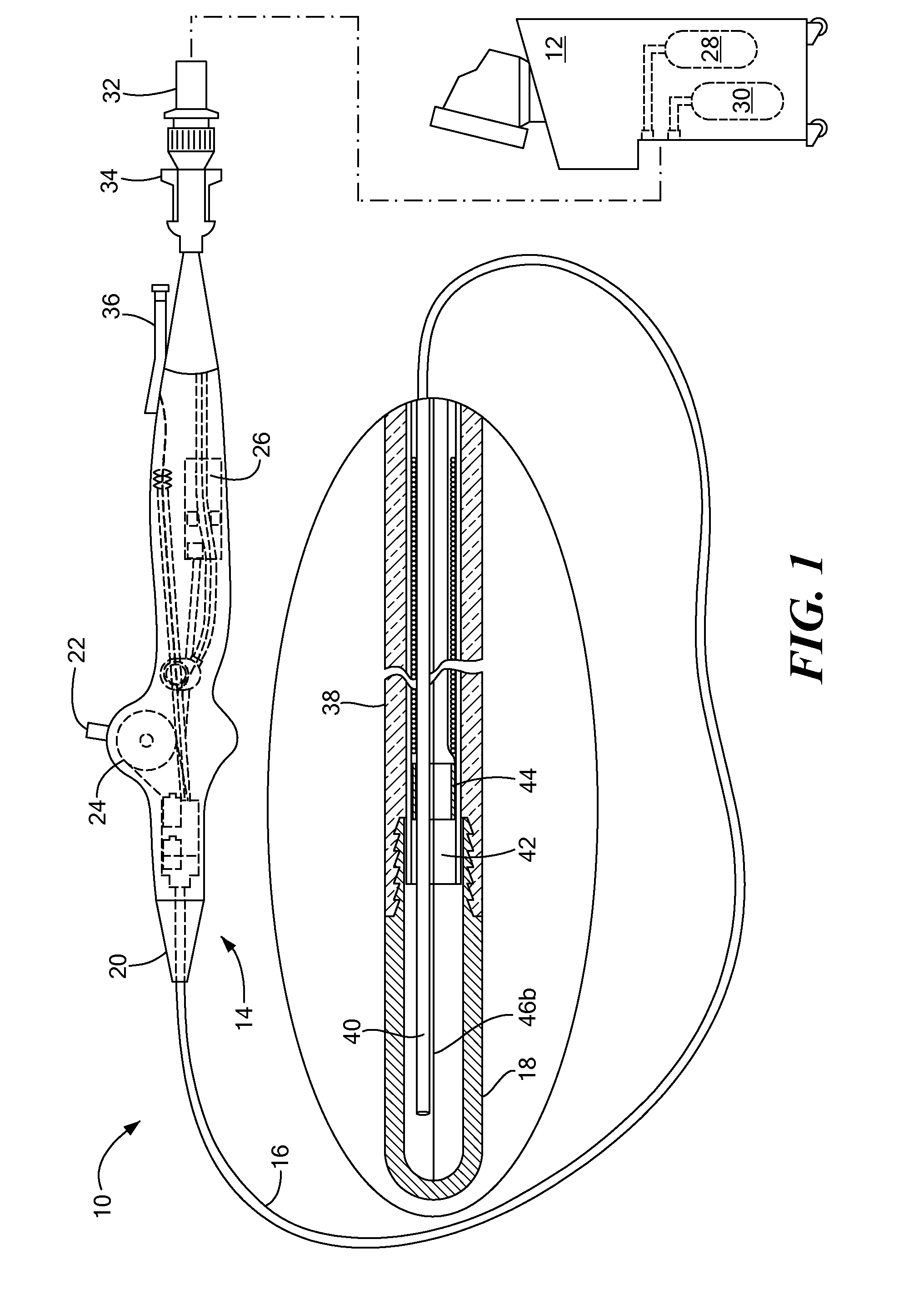

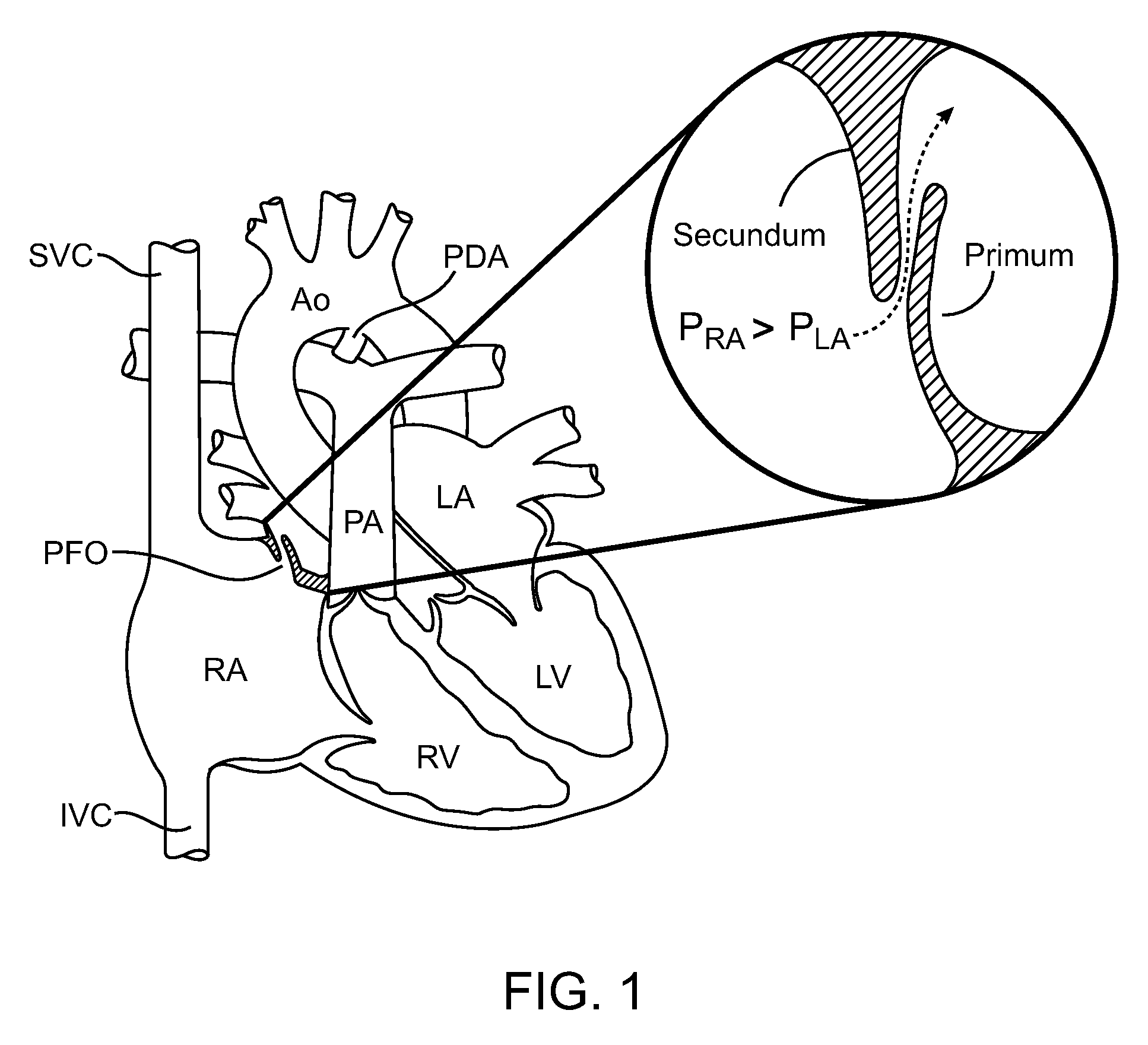

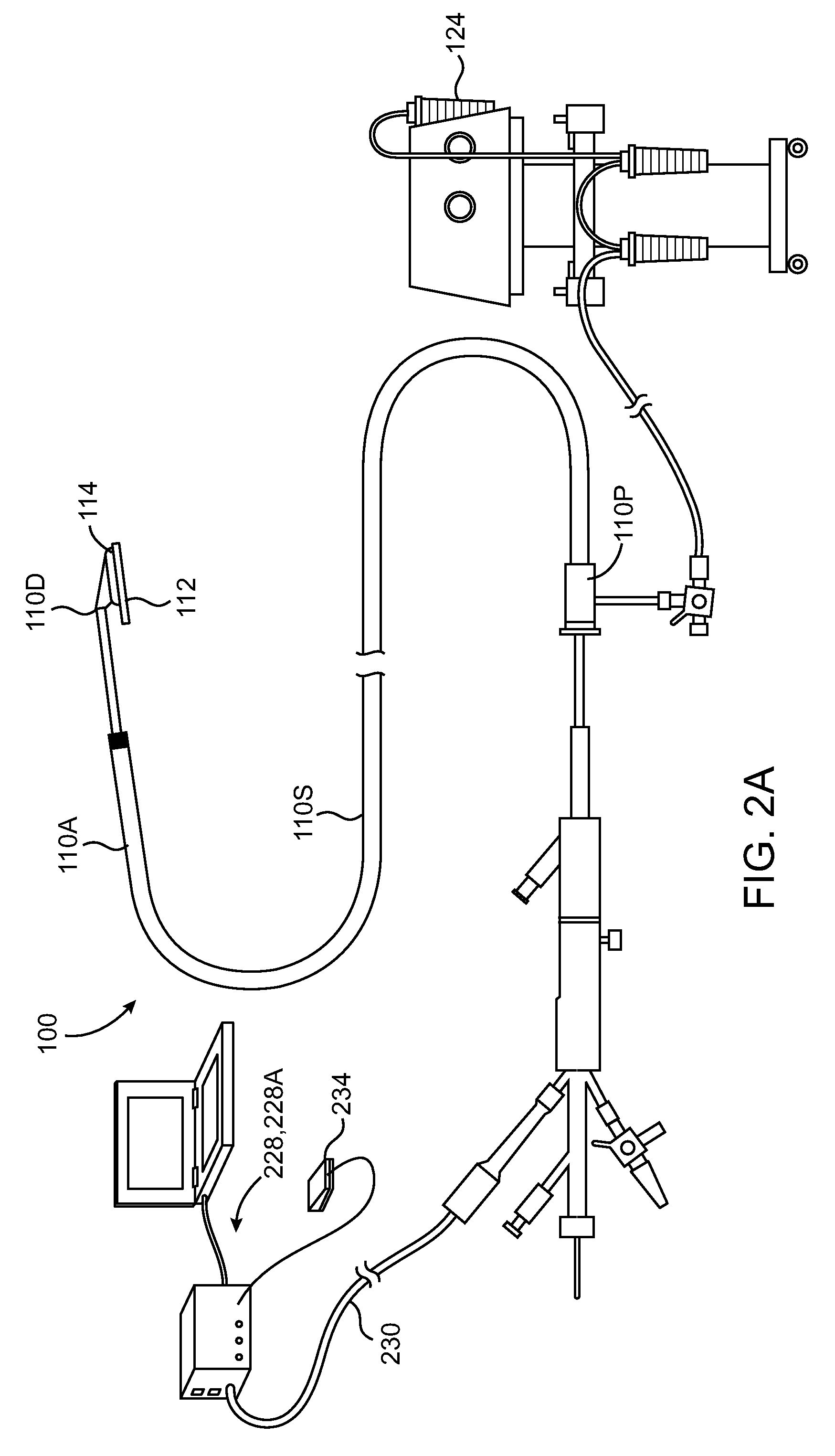

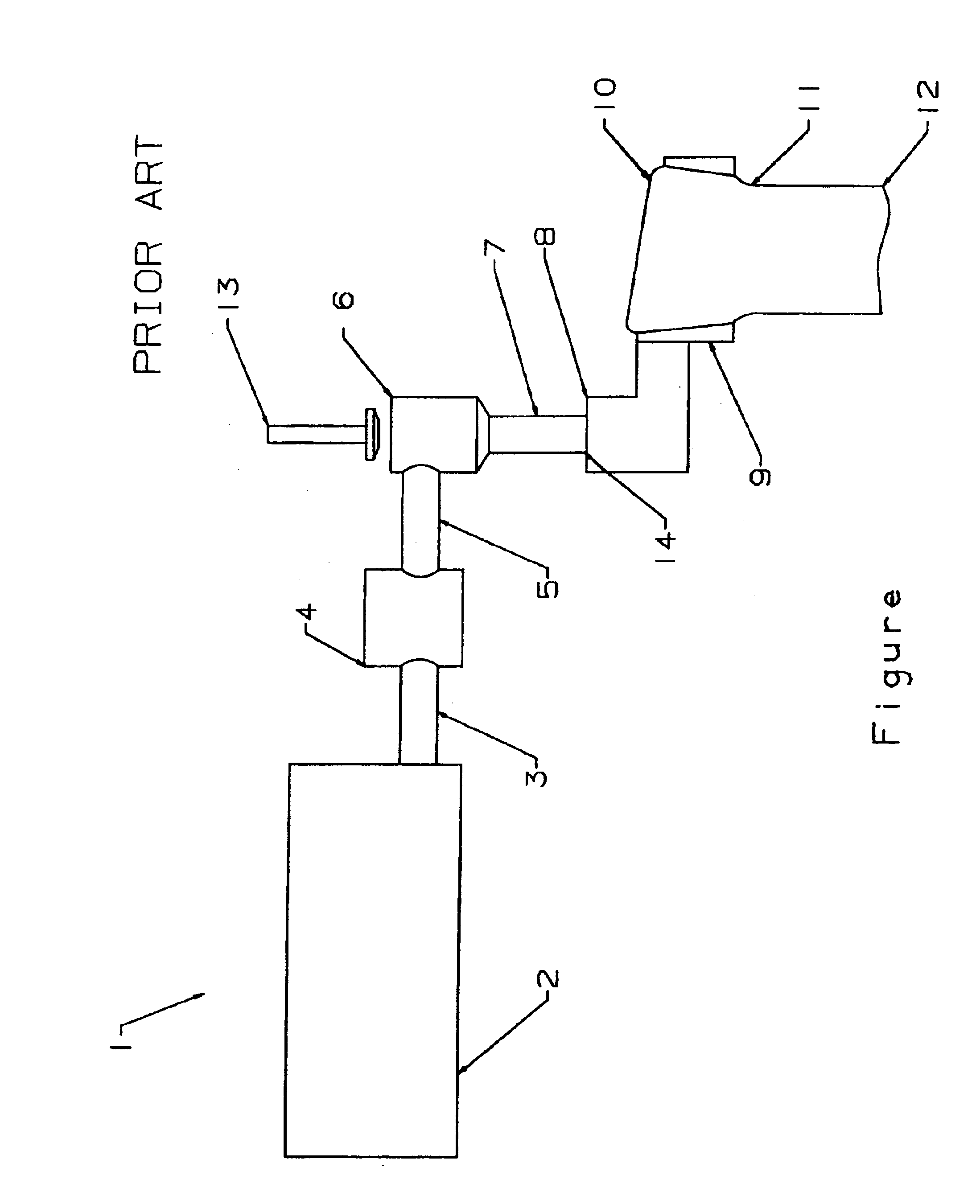

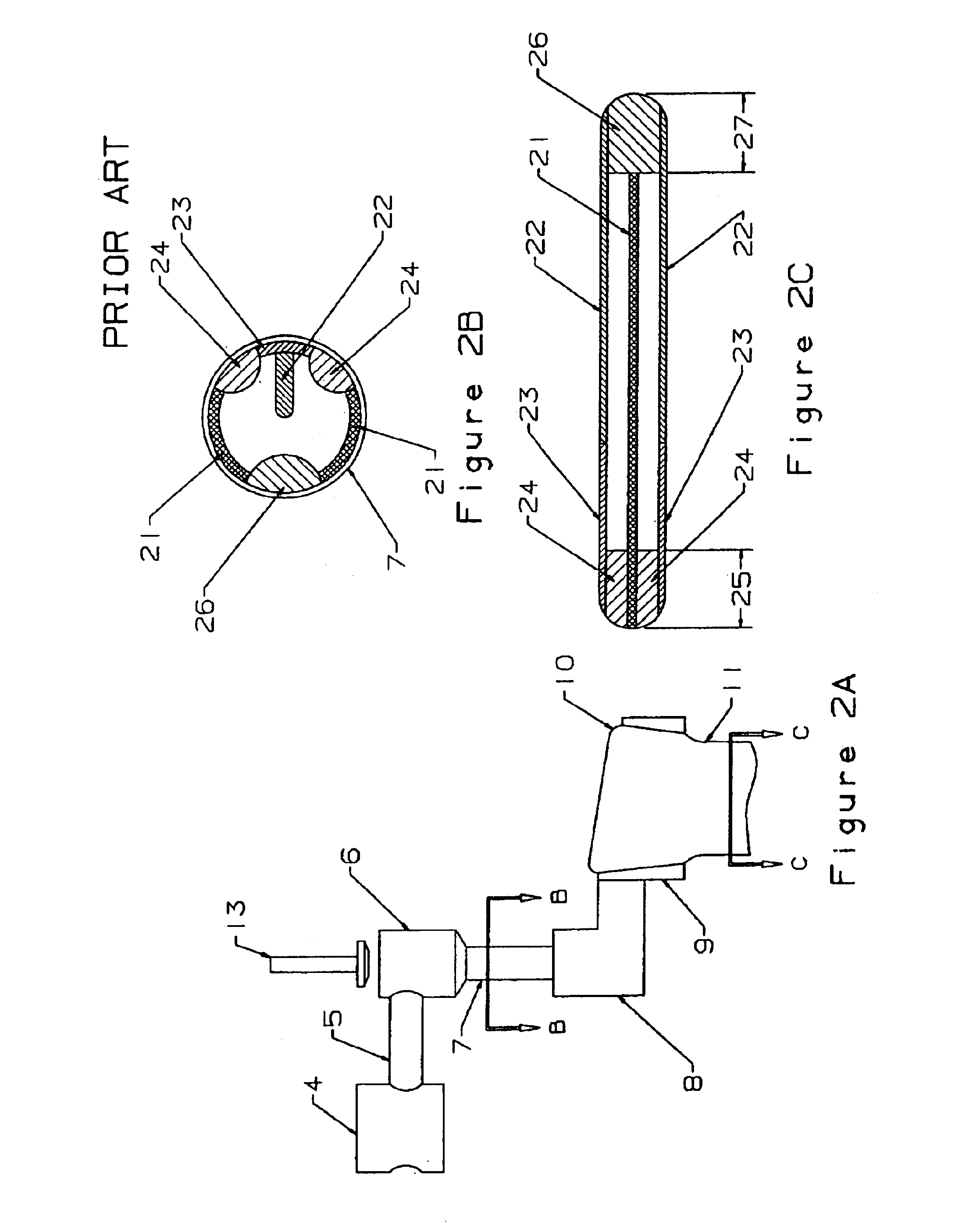

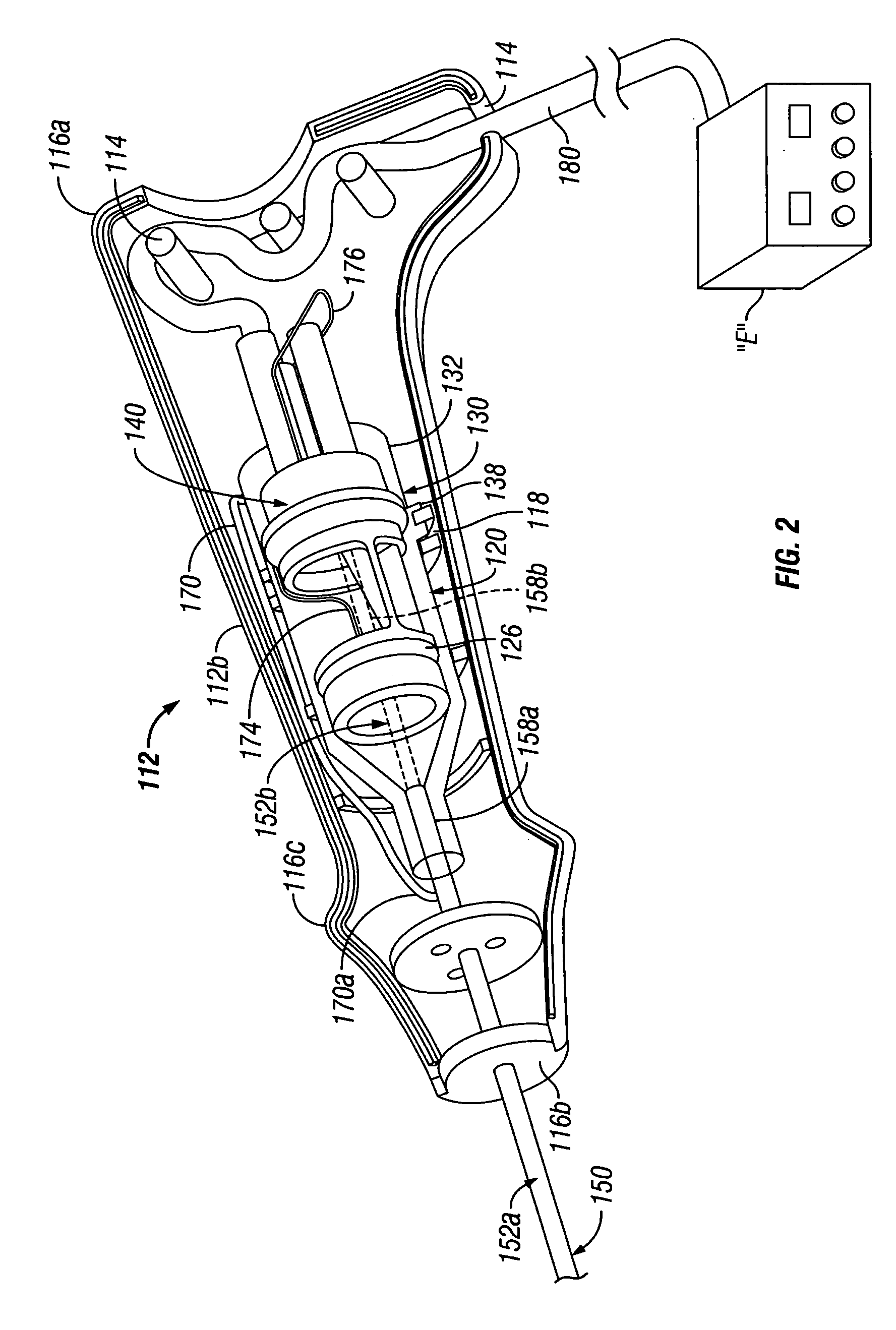

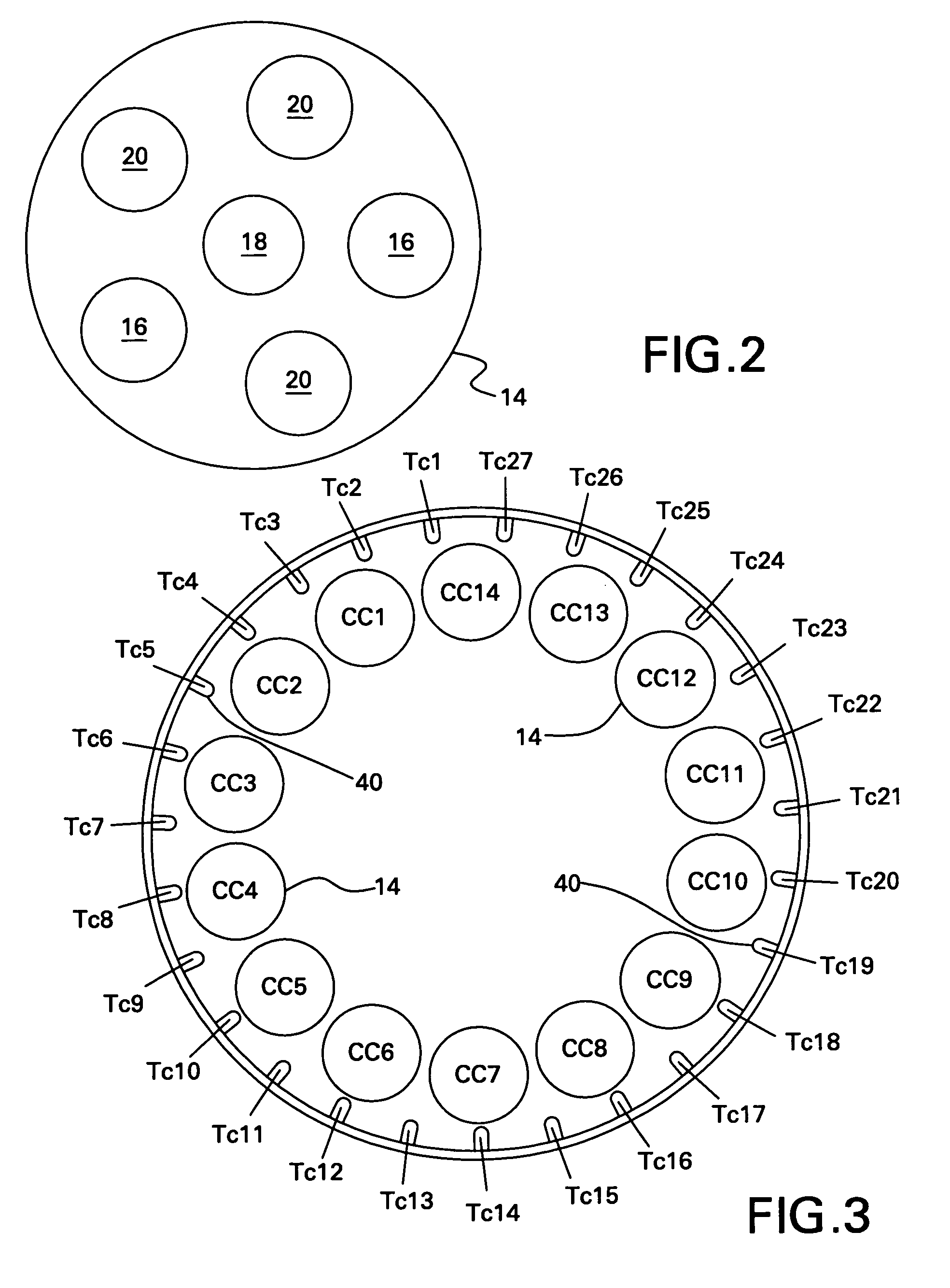

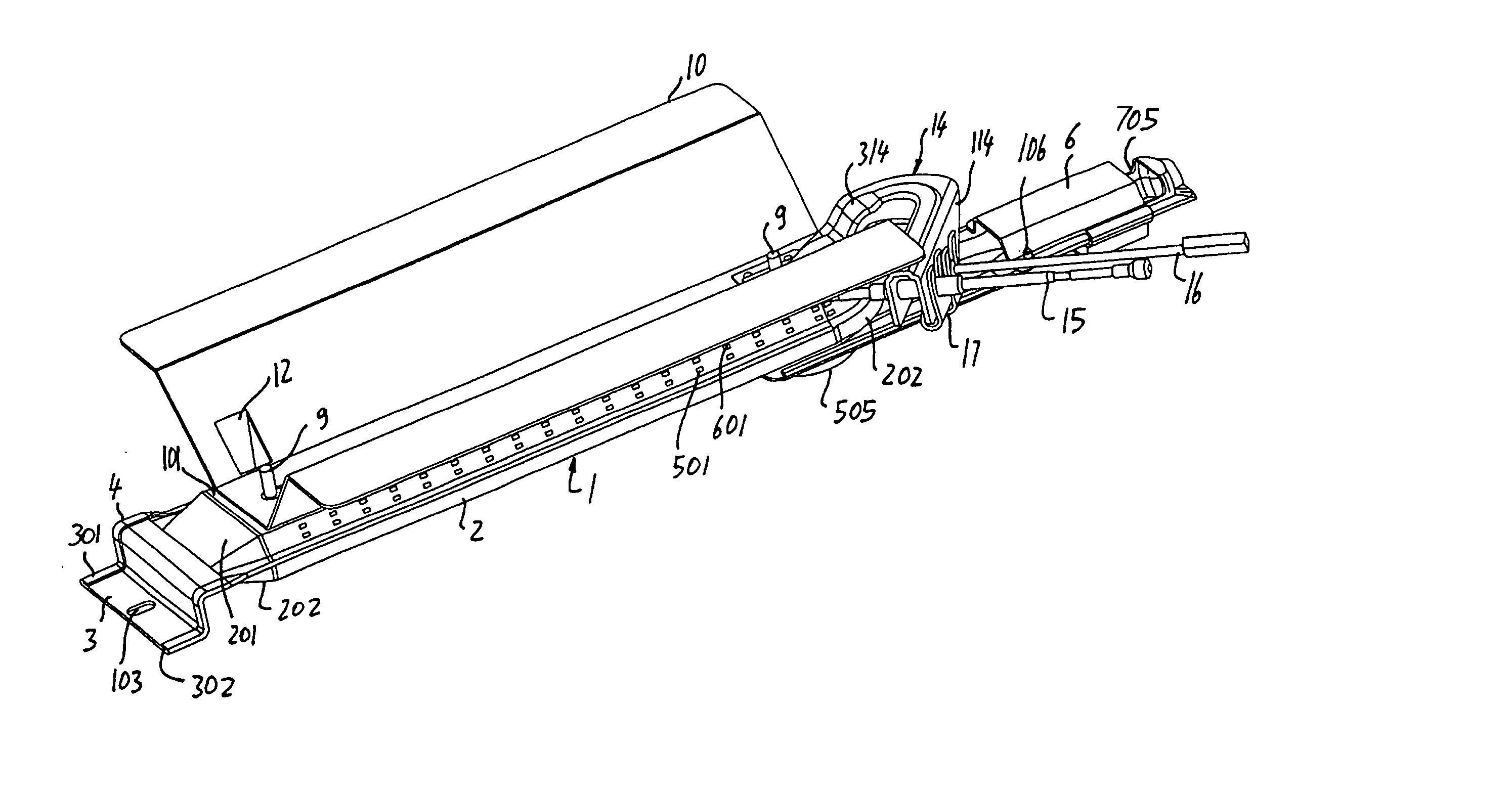

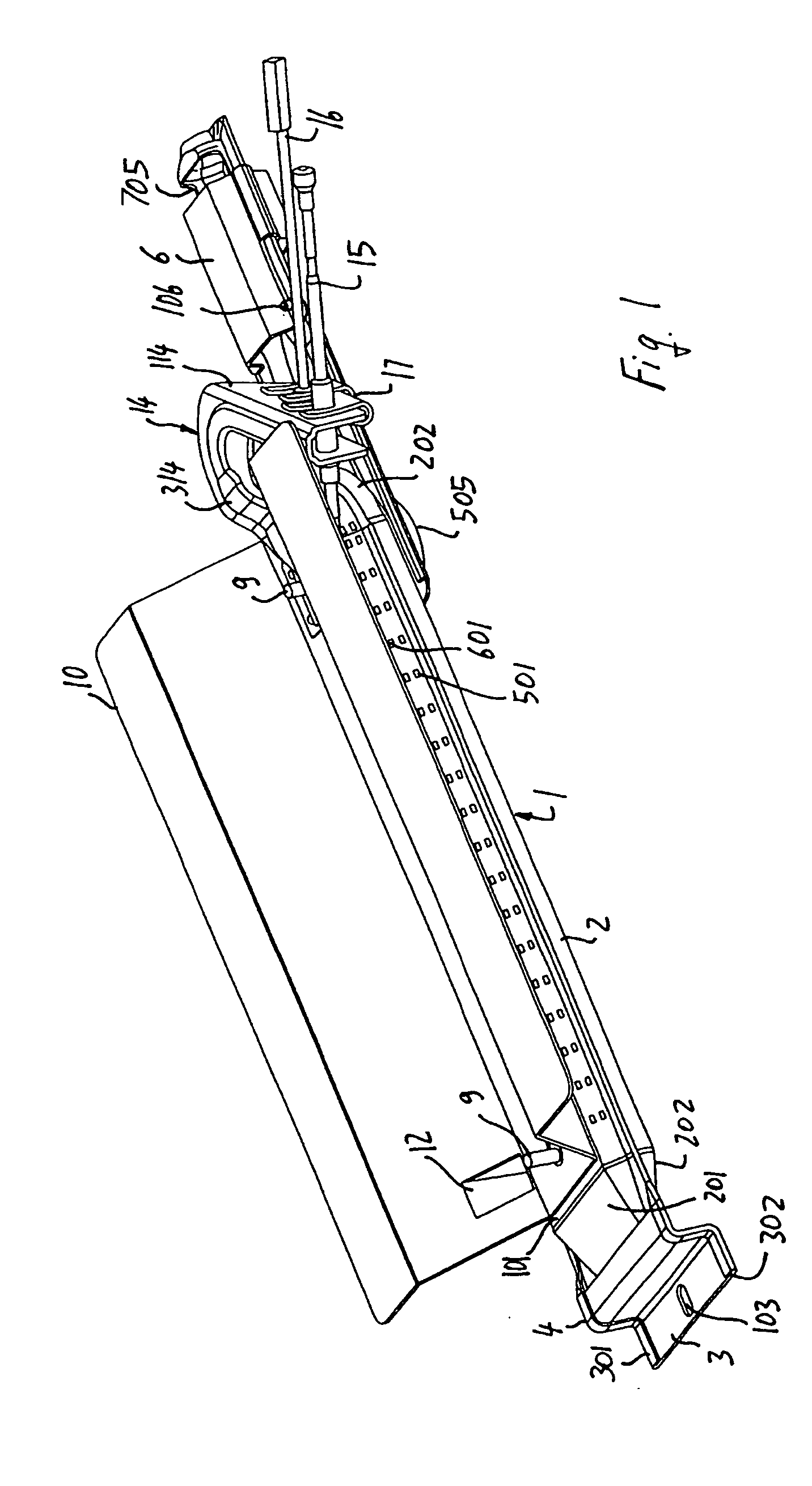

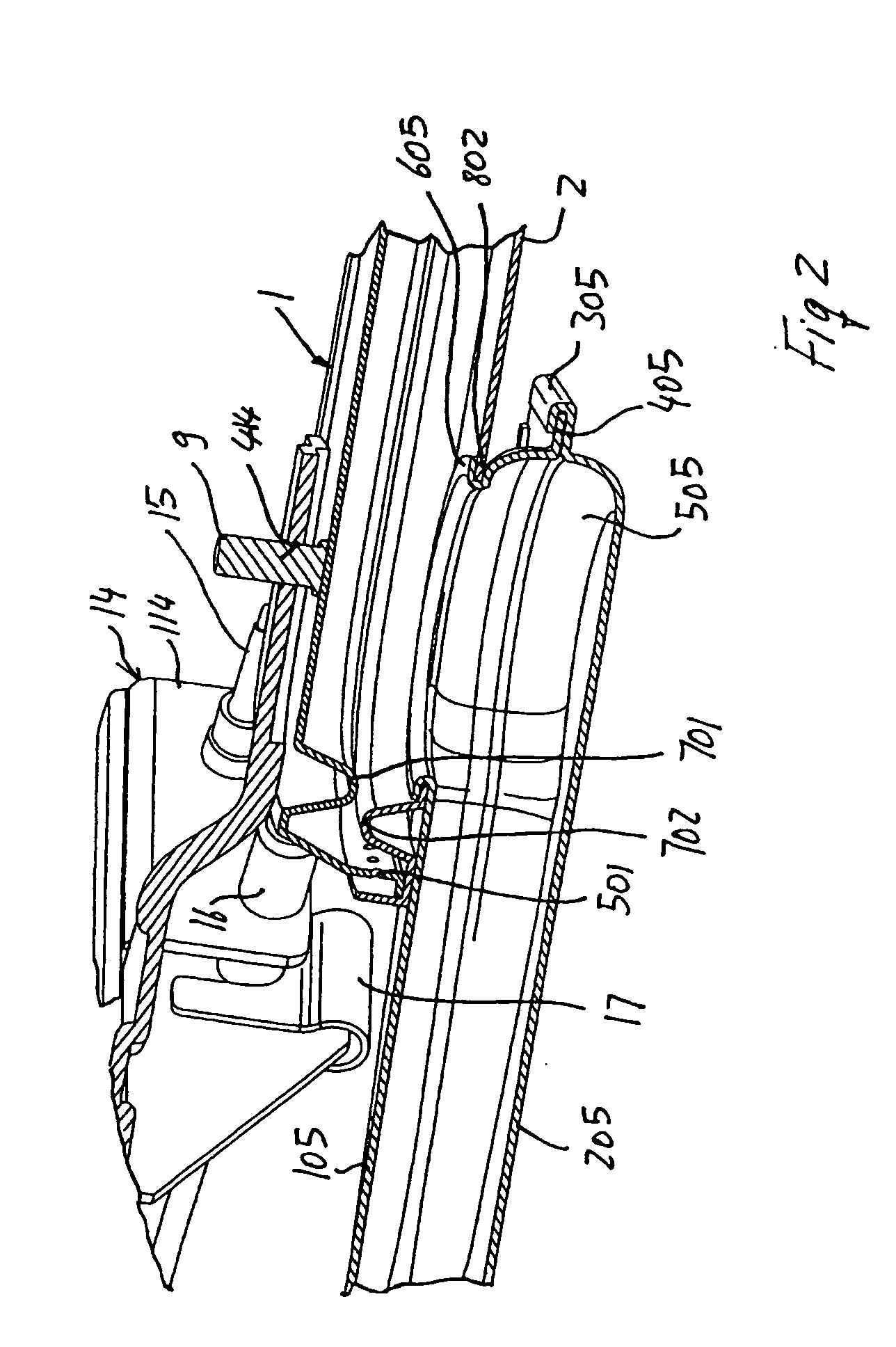

Epicardial mapping and ablation catheter

ActiveUS8287532B2Safely maneuverReliable contactBioelectric signal measurementCatheterEpicardial mappingThermocouple Wire

A catheter adapted for mapping and ablating epicardial tissue from the pericardial cavity includes a catheter body and an electrode assembly that has a tip section and a loop member lying generally within a plane, wherein the tip section includes an ablation electrode exposed on one side of the loop member and an insulation member exposed on an opposite side of the loop member. The catheter also includes a intermediate section between the catheter body and the electrode assembly, wherein the intermediate deflects the loop member and the tip section bi-directionally within the same plane. So arranged, the catheter can be safely maneuvered in the pericardial sac and swept in a side to side motion over the epicardium with the ablation electrode reliably facing and making contact with the epicardium. The tip section can include a balloon that is inflatable to push away surrounding pericardial tissue. The catheter may further include an injection needle whose distal end can extend outside of the tip section to puncture epicardial tissue. A lumen in the injection needle allows for delivery to agents directly to the punctured tissue and thermocouple wires can be carried in the lumen for temperature sensing at the treatment site.

Owner:BIOSENSE WEBSTER INC

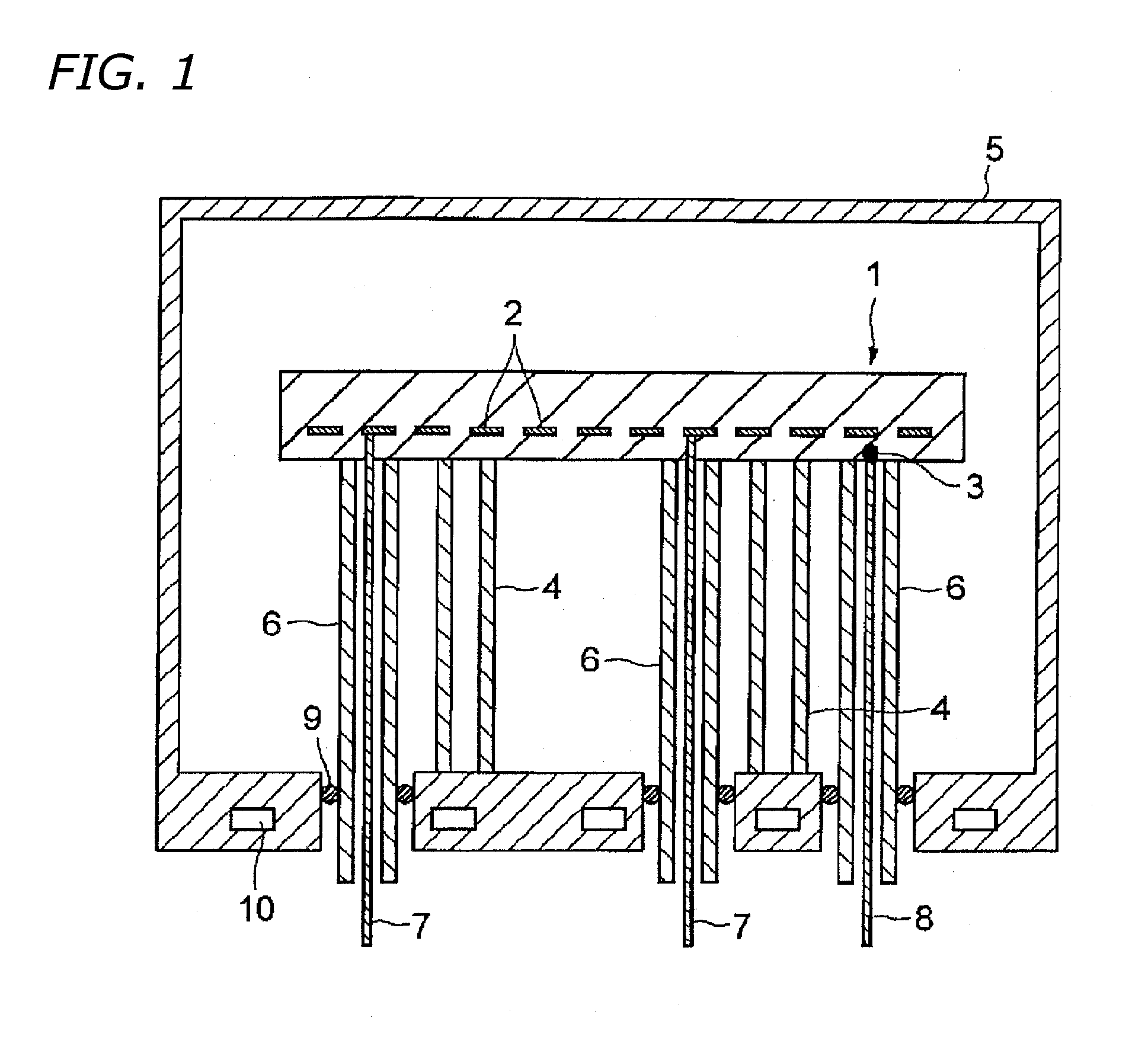

Thermocouple

ActiveUS8100583B2Thermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple device

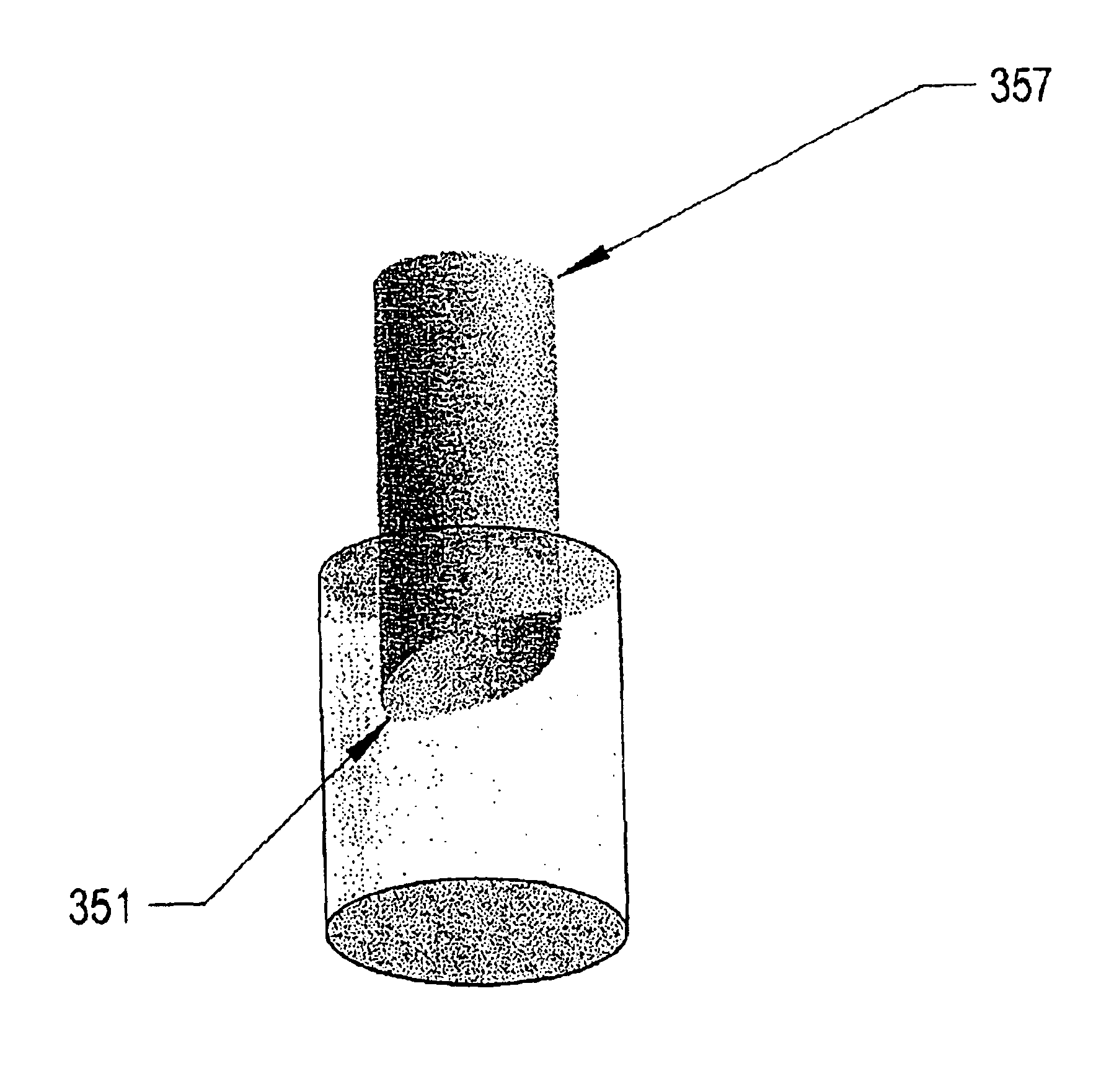

A thermocouple having at least one inner alignment feature or at least one outer alignment feature, or a combination thereof for positively positioning and aligning at least one thermocouple junction within a bore formed in a susceptor ring of a semiconductor substrate processing reactor. The outer alignment feature is configured to positively align the junction(s) longitudinally within the bore. The inner alignment feature configured to positively position the junction(s) rotationally within the sheath of the thermocouple relative to the bore.

Owner:ASM IP HLDG BV

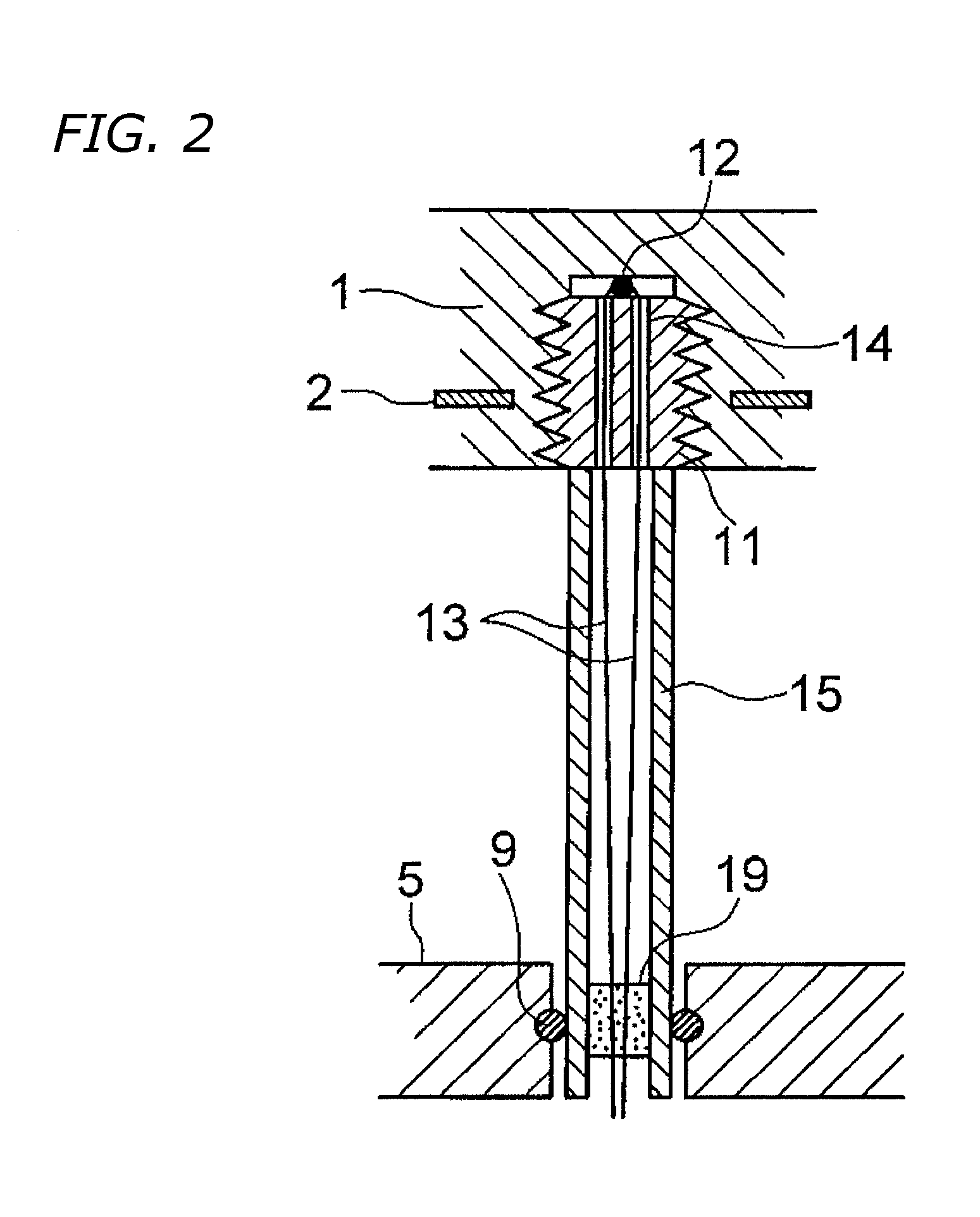

Smart temperature measuring device

ActiveUS9297705B2Avoid data transferThermometer detailsThermometers using electric/magnetic elementsTemperature controlGraphics

A temperature measuring device having a smart chip, or electronic circuit, integrated therein is provided. The smart chip, or electronic circuit, includes at least a unique identification number or data specific to the particular temperature measuring device stored thereon. The electronic circuit further includes calibration data of the temperature measuring device stored thereon. A module controller of a temperature control system is configured to verify the unique identification number of the thermocouple assembly prior to allowing data to be transferred between the temperature measuring device and a temperature controller. A graphical user interface allows an operator to enter the unique identification number or data to verify the temperature measuring device and display an error message if the number or data entered is not equivalent, or does not match, the unique identification number or data stored on the electronic circuit.

Owner:ASM IP HLDG BV

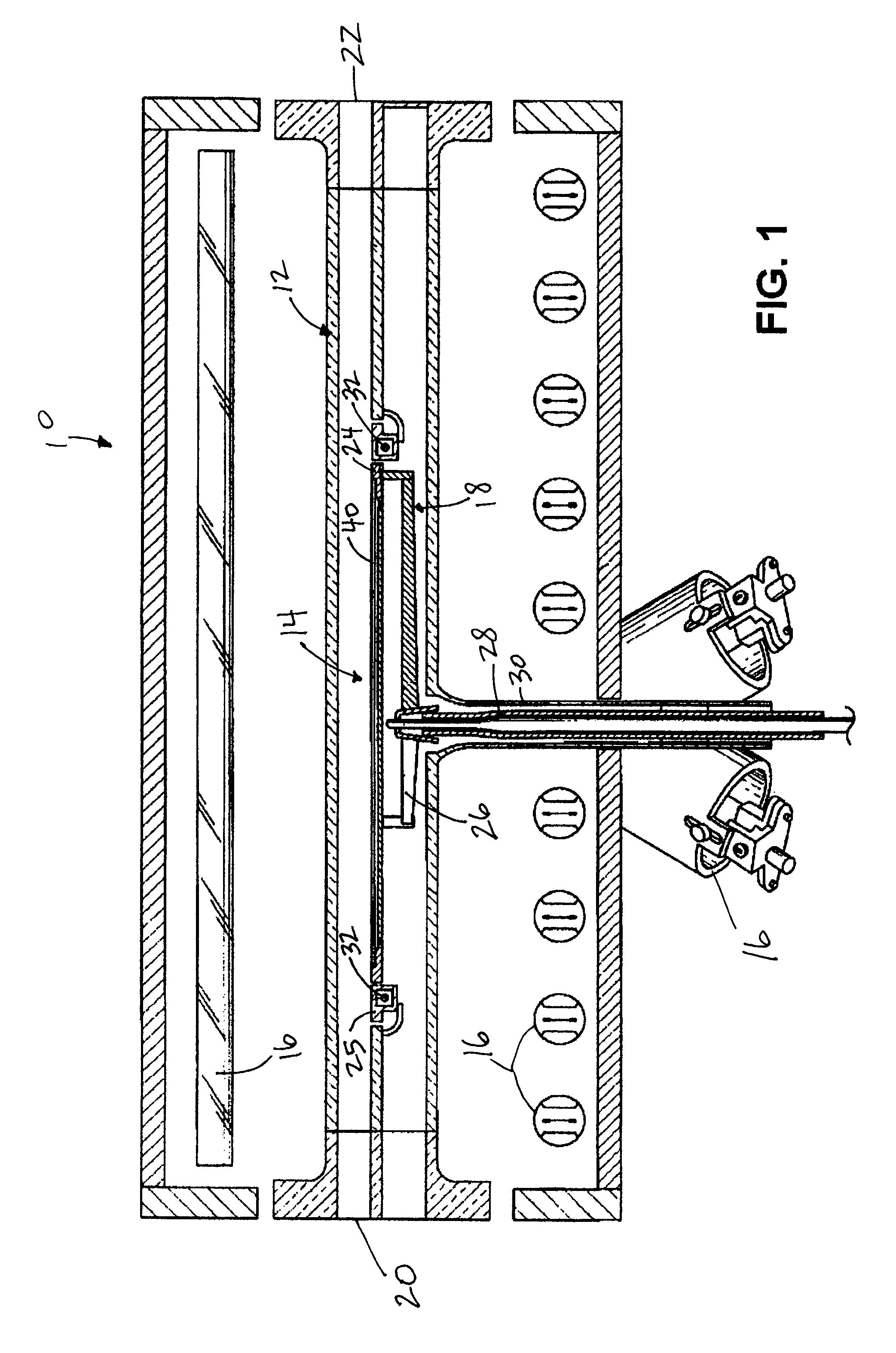

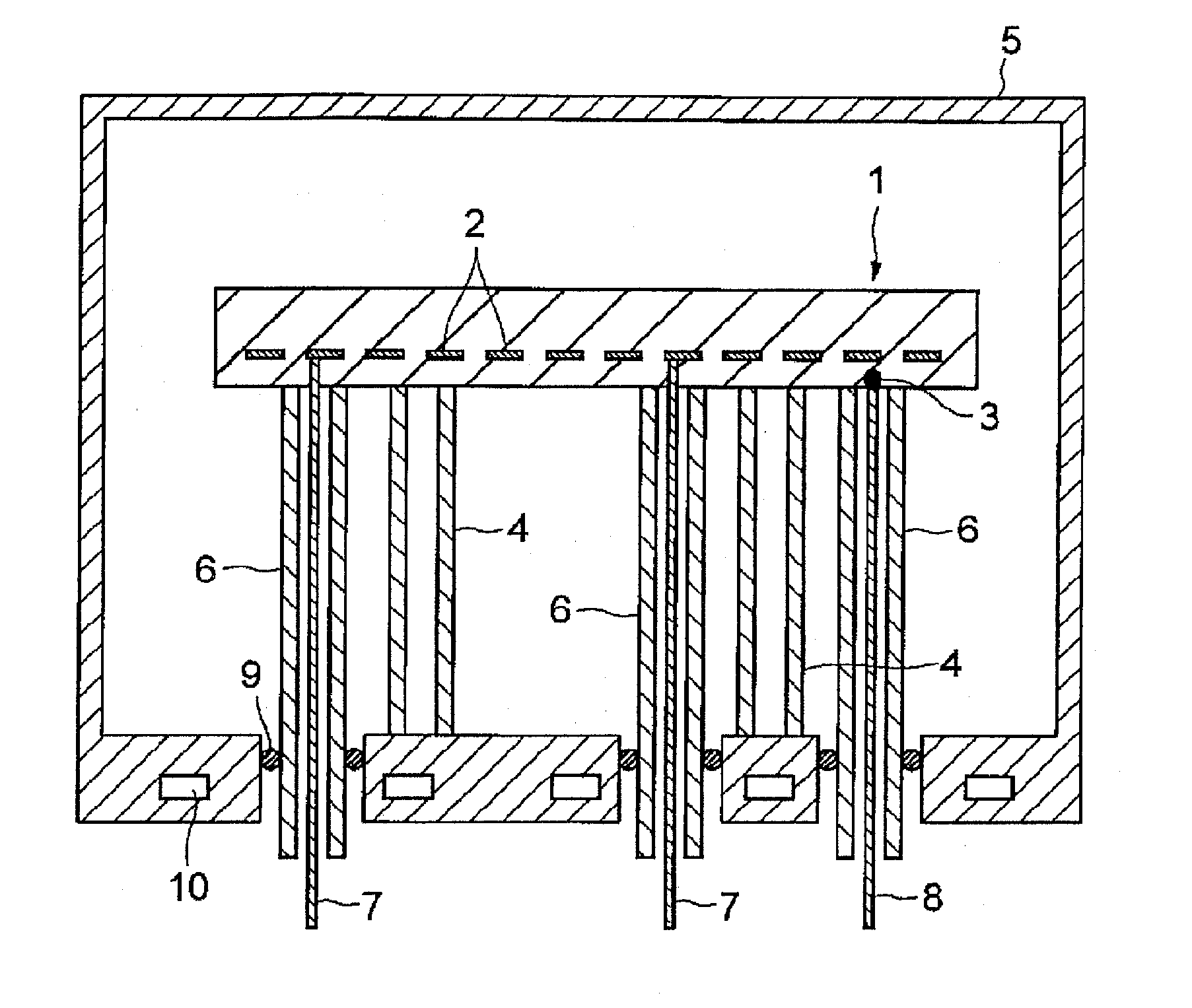

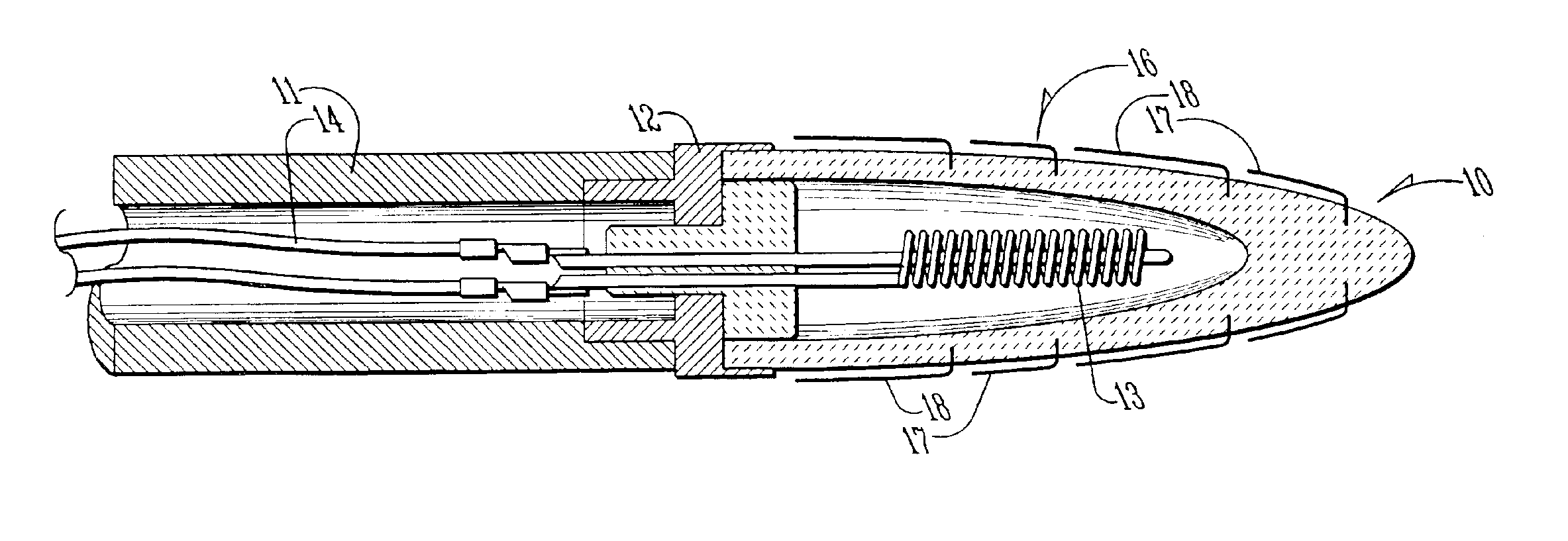

Temperature gauge and ceramic susceptor in which it is utilized

InactiveUS20040208228A1Easy to replaceAccurate temperatureThermometer detailsThermometers using electric/magnetic elementsSusceptorMetallurgy

Temperature gauge, and ceramic susceptors and semiconductor manufacturing equipment utilizing the temperature gauge, in which the thermocouple may be easily replaced even if damaged, and in which heat from the temperature-gauging site is readily transmitted to the temperature-gauging contact, shortening time until the measurement temperature stabilizes. A temperature-gauging contact (12) in the tip of the thermocouple contacts, in an exposed-as-it-is state, a temperature-gauging site on a ceramic susceptor (1), and by means of a circular cylindrical-shaped retaining member (11) screwed into female threads in the ceramic susceptor (1) is detachably pressed upon and retained against the ceramic susceptor. Thermocouple lead lines (13), passing through a through-hole (14) in the retaining member (11), stretch from one end face to the other end face thereof. The retaining member may be provided with a flange having threaded holes and screwlocked into female screws in the ceramic susceptor.

Owner:SUMITOMO ELECTRIC IND LTD

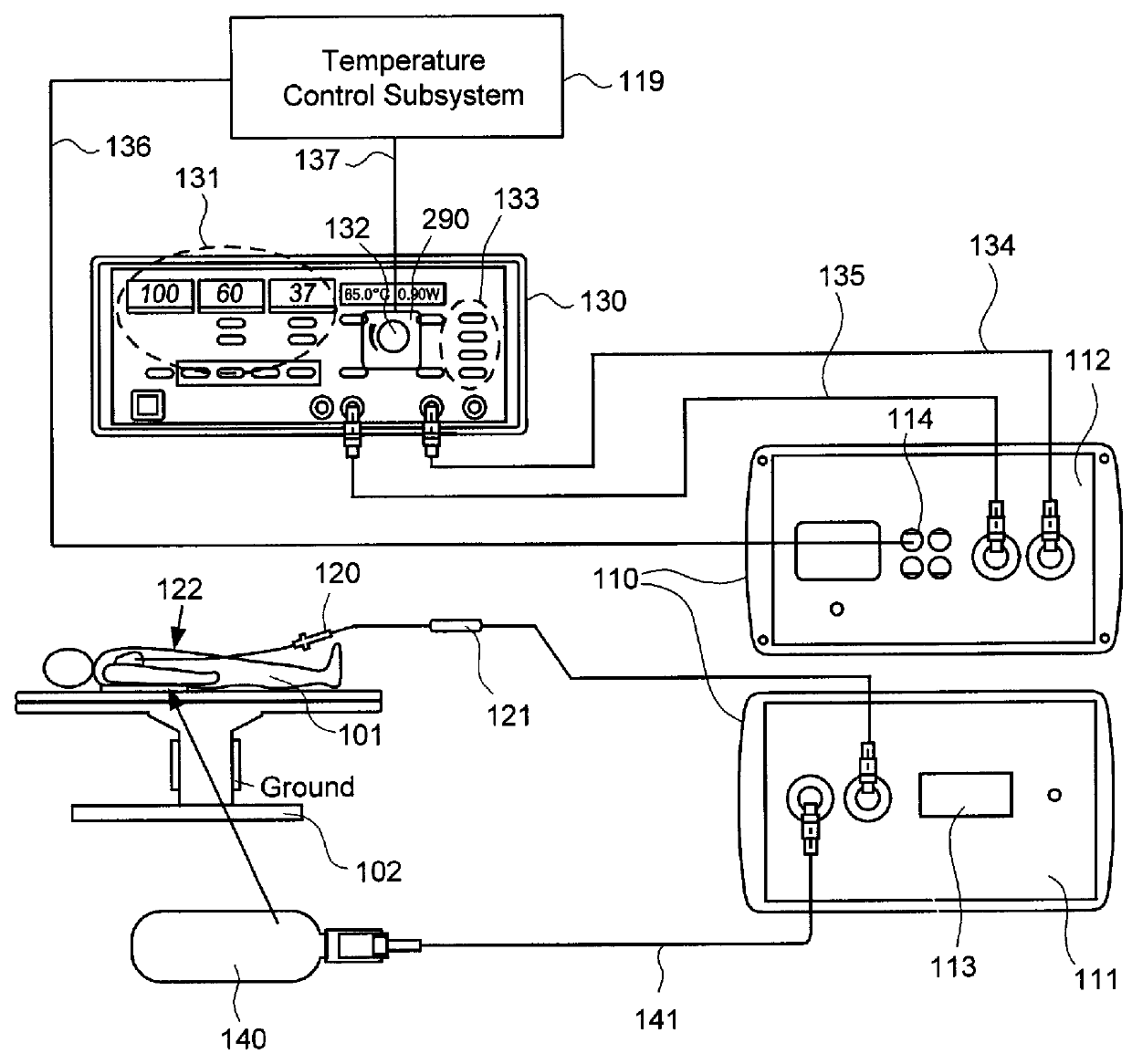

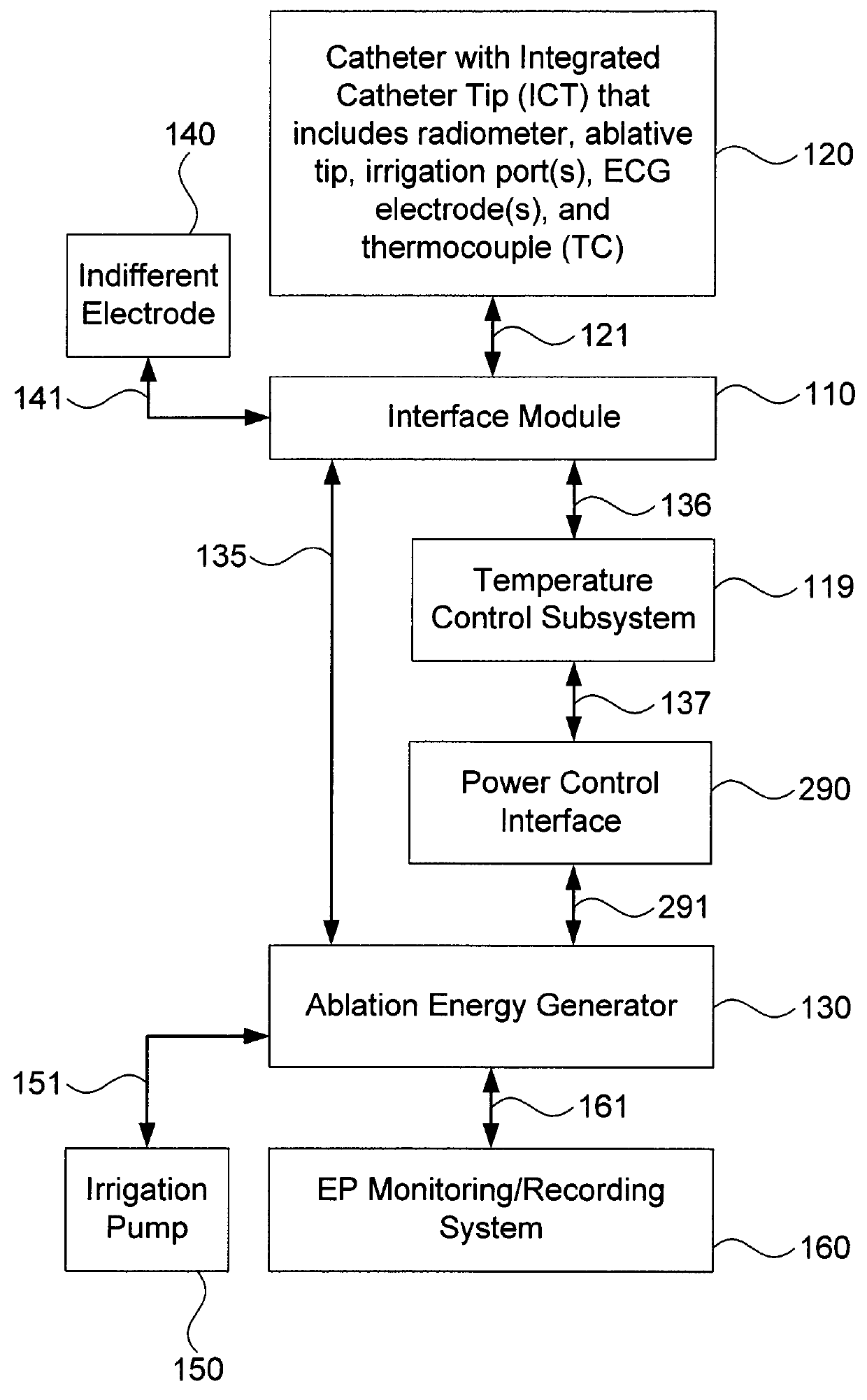

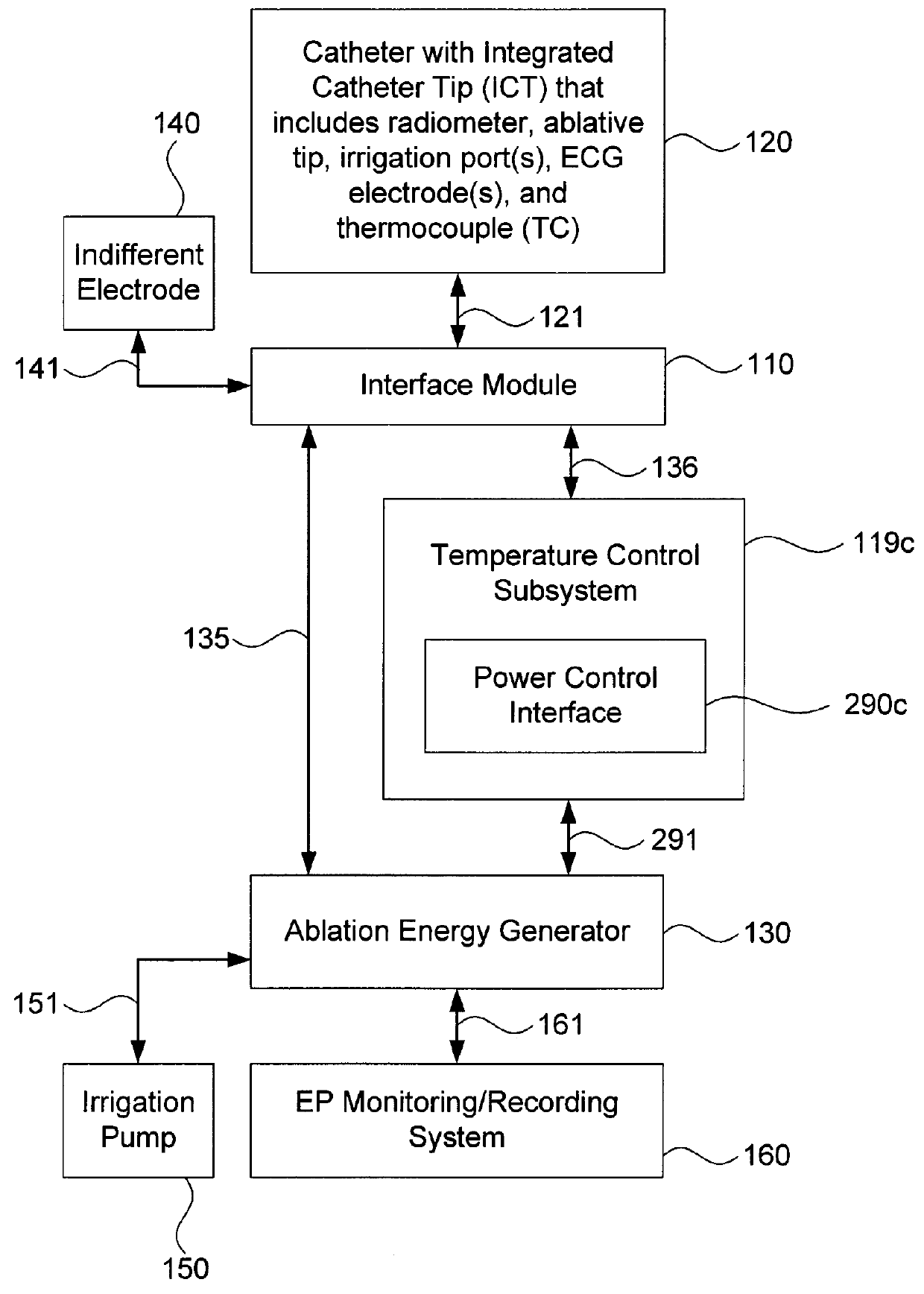

Systems for temperature-controlled ablation using radiometric feedback

ActiveUS9226791B2Sufficient ablationInformation can be usedUltrasound therapySurgical instruments for heatingTemperature controlRadiometer

Owner:CORAL SAND BEACH LLC +1

Apparatus and methods for sensing and cooling during application of thermal energy for treating degenerative spinal discs

InactiveUS20050004563A1Reduce the temperatureAvoid motor nerve damageSurgical needlesSurgical instruments for heatingThermal energySpinal nerve

Apparatus and methods for performing spinal disc lesioning procedures while monitoring the temperature near the spinal nerve roots. A needle containing a thermocouple and an injection bore may be placed between the disc and a nerve root. Temperature near the nerve root may be monitored during the lesioning procedure and if raised to a point where damage to the nerve could occur, the procedure may be stopped before damage is done. Coolant may be injected through the injection bore to lower the temperature near the nerve root. Additional dual purpose needles may be placed on the disc adjacent the opposite nerve root or in the spinal canal at the level of the disc for additional control. A hollow, flexible tip electrode needle may be used to repair and lesion the disc tissue. Prior to lesioning, the electrode may be stimulated to assess motor nerve response and avoid motor nerve damage.

Owner:EPIMED INT

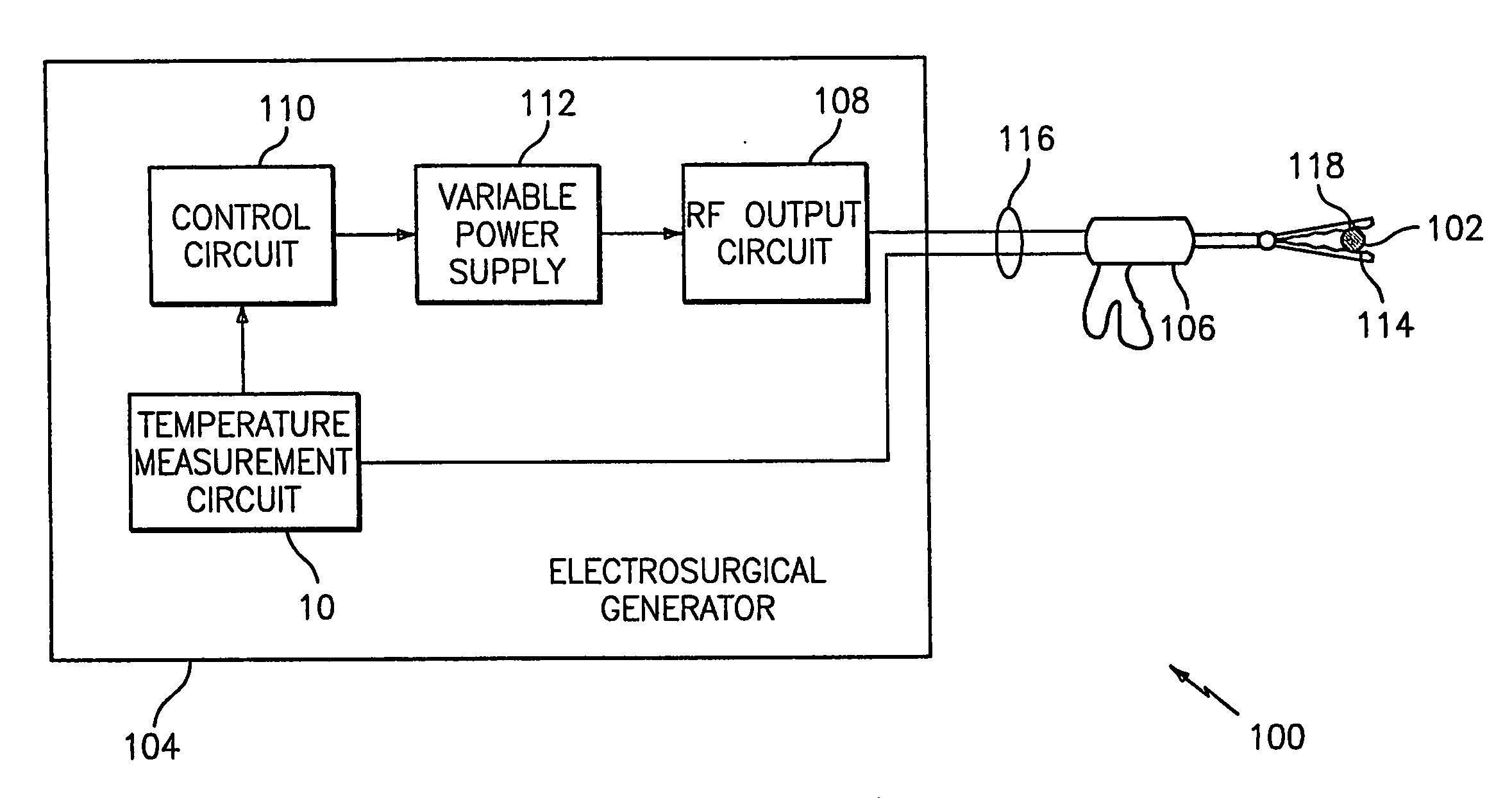

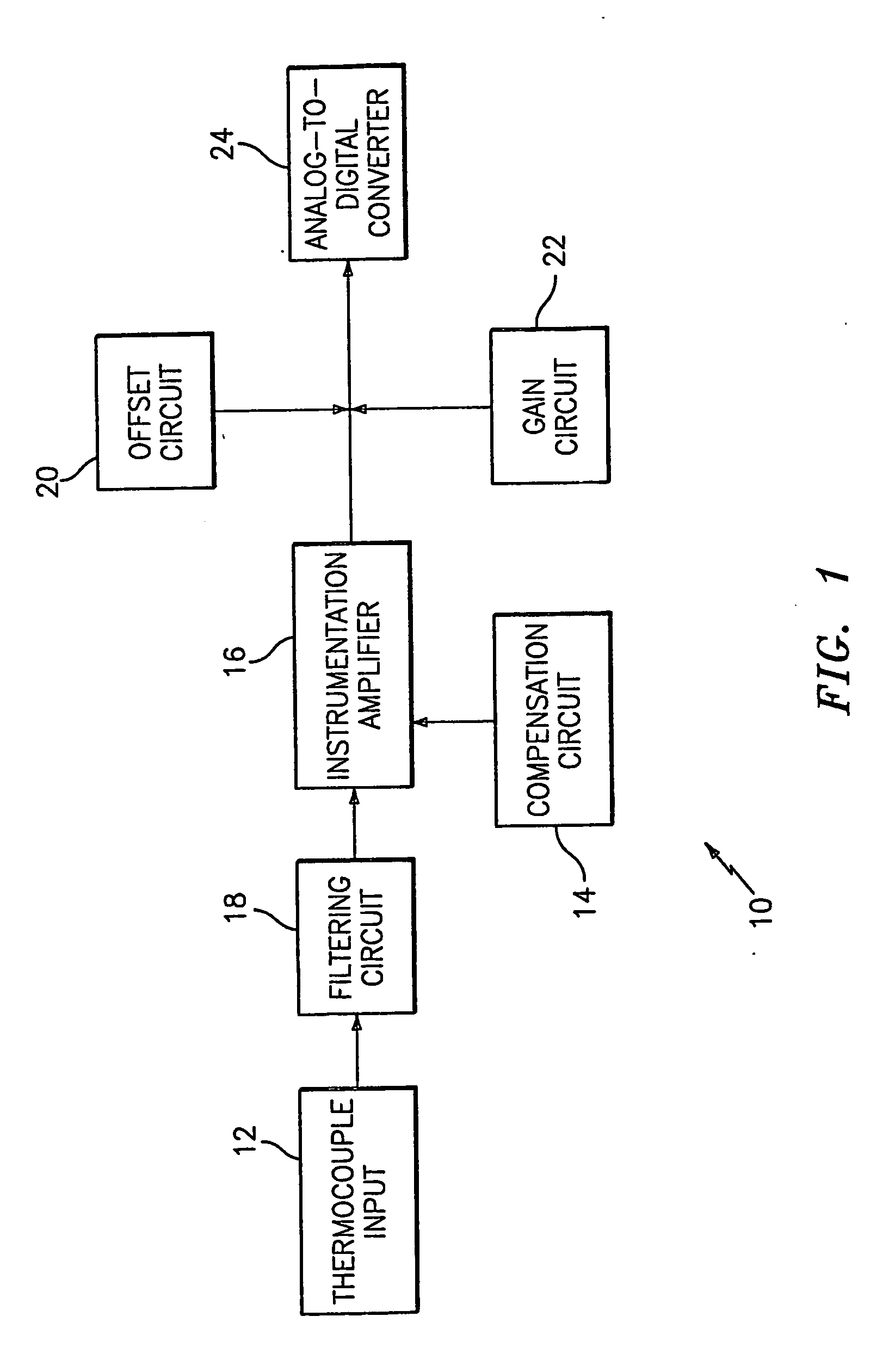

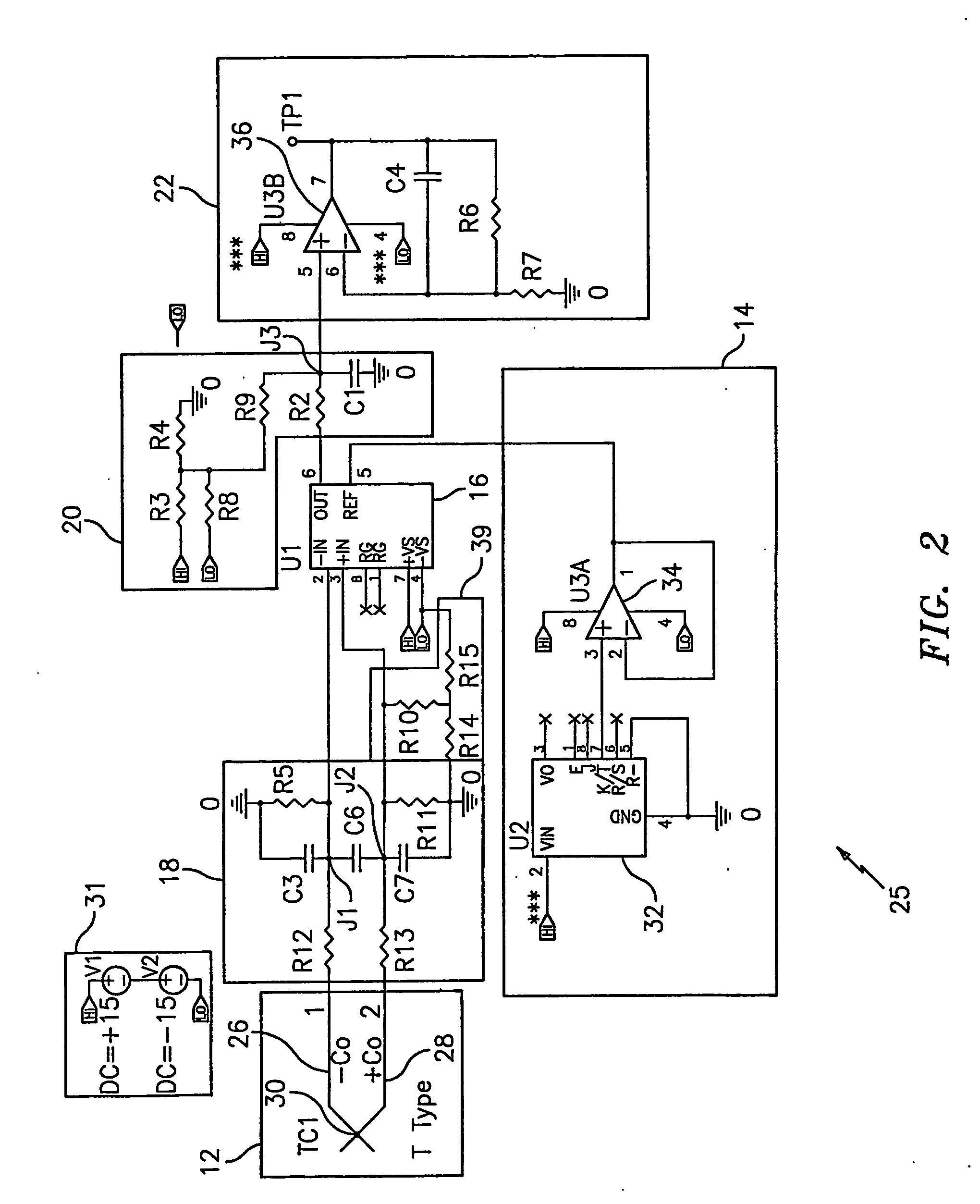

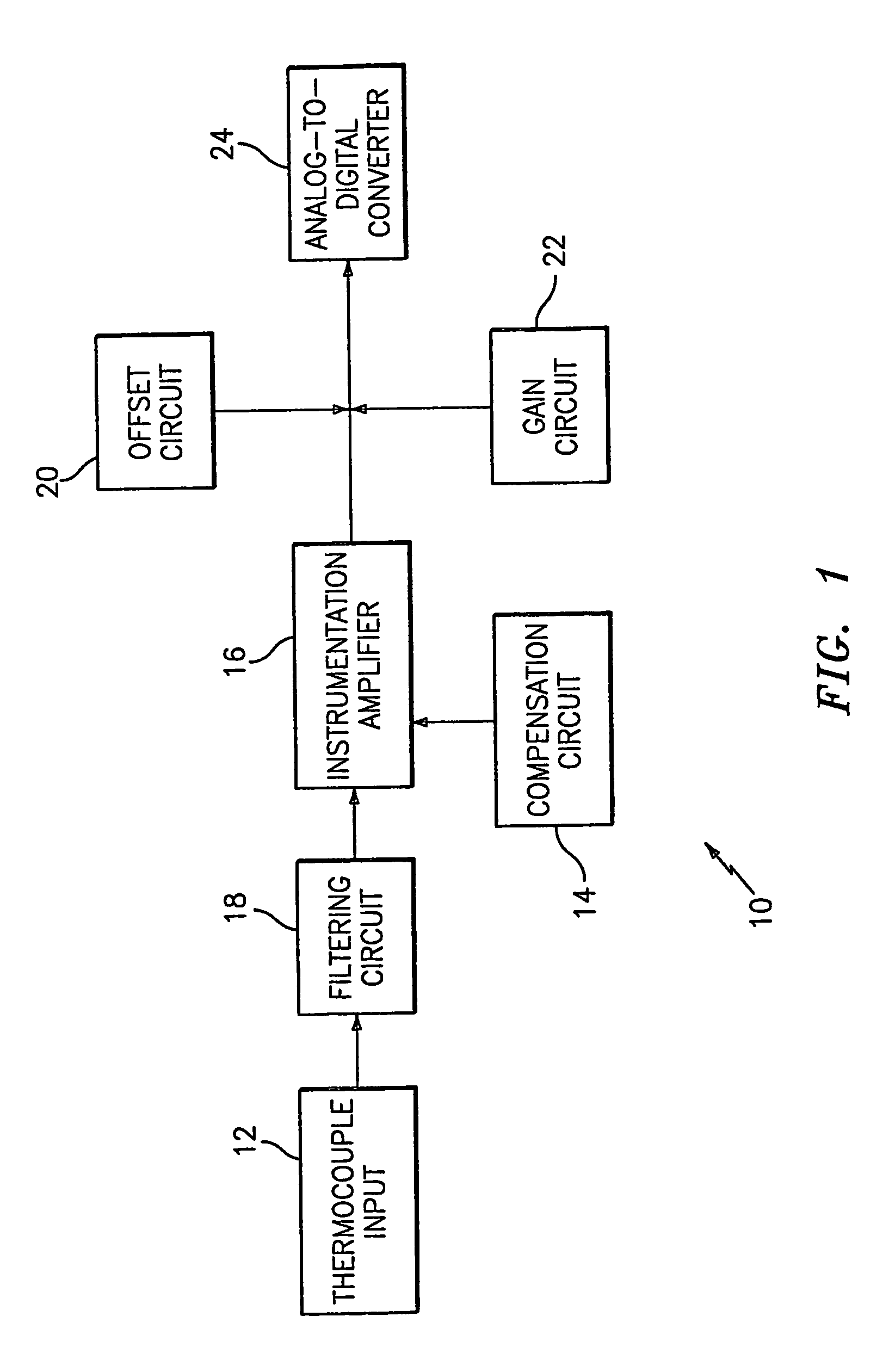

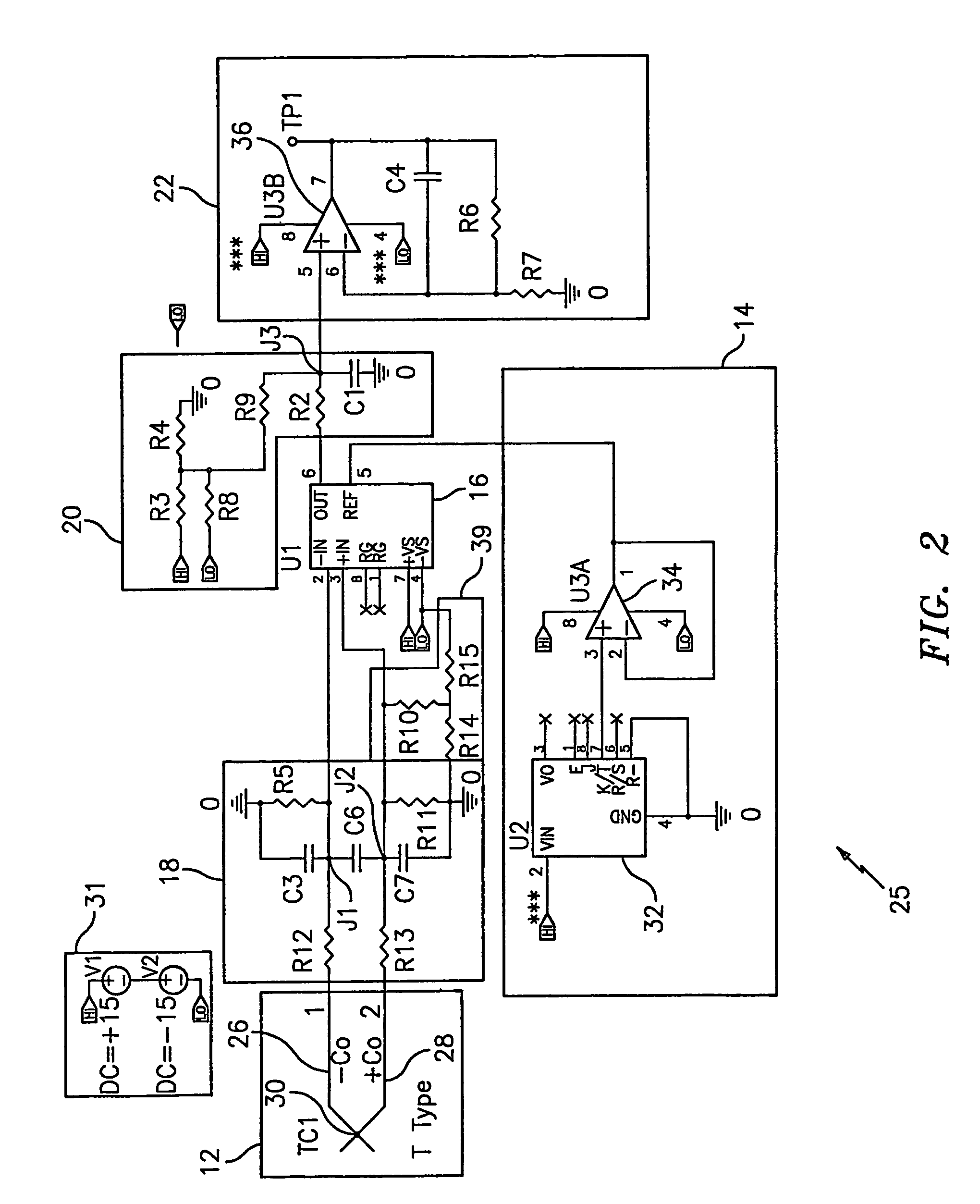

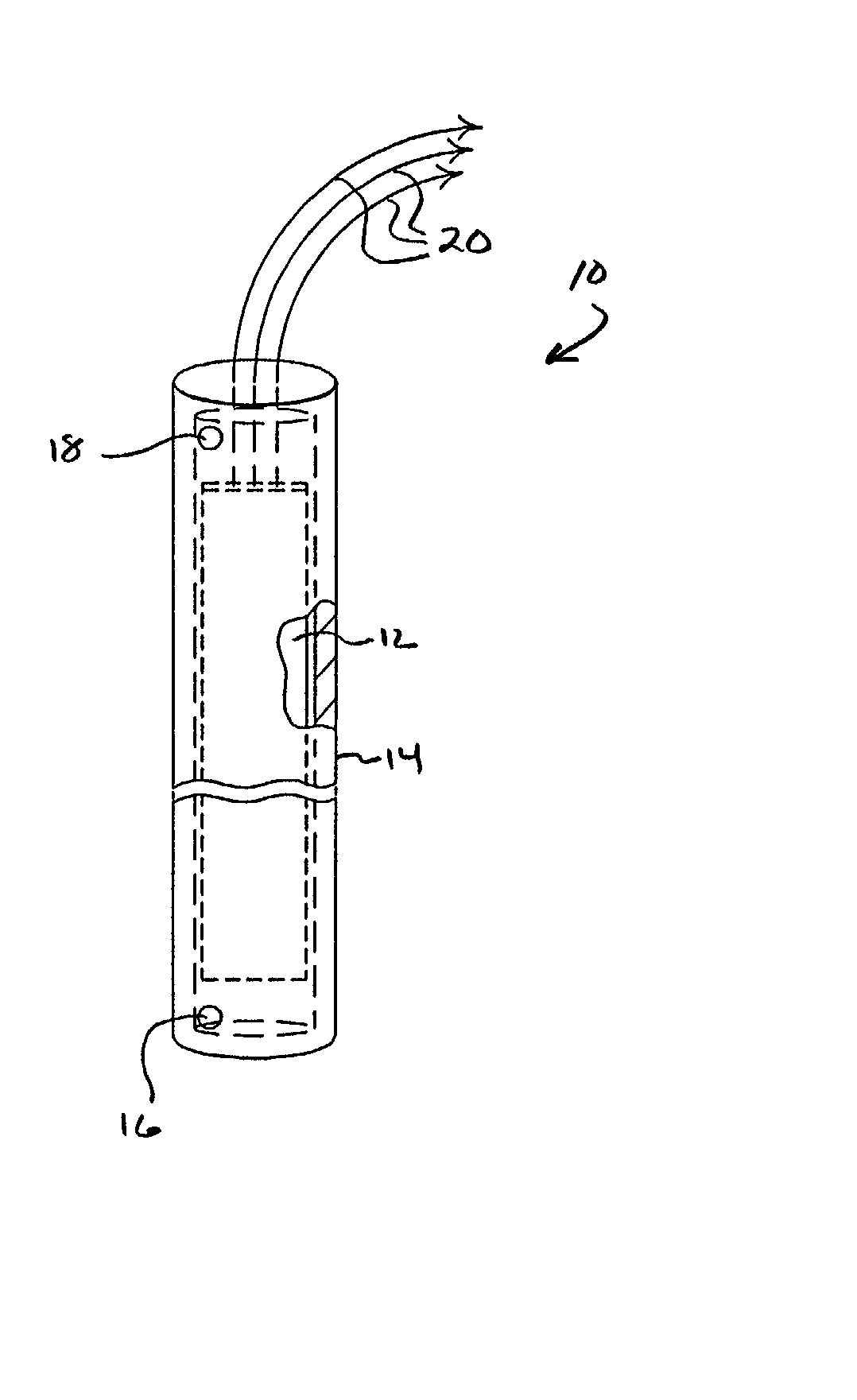

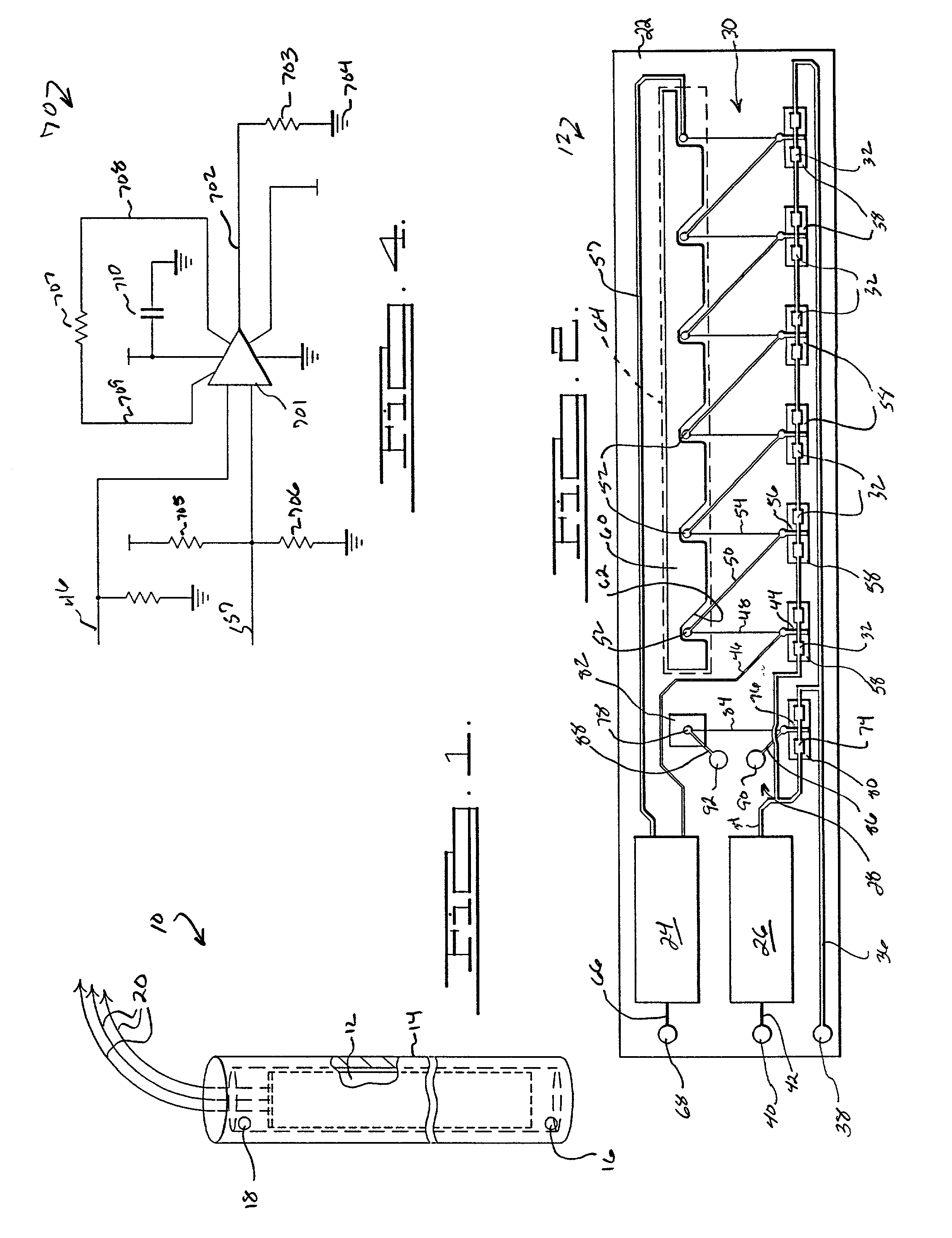

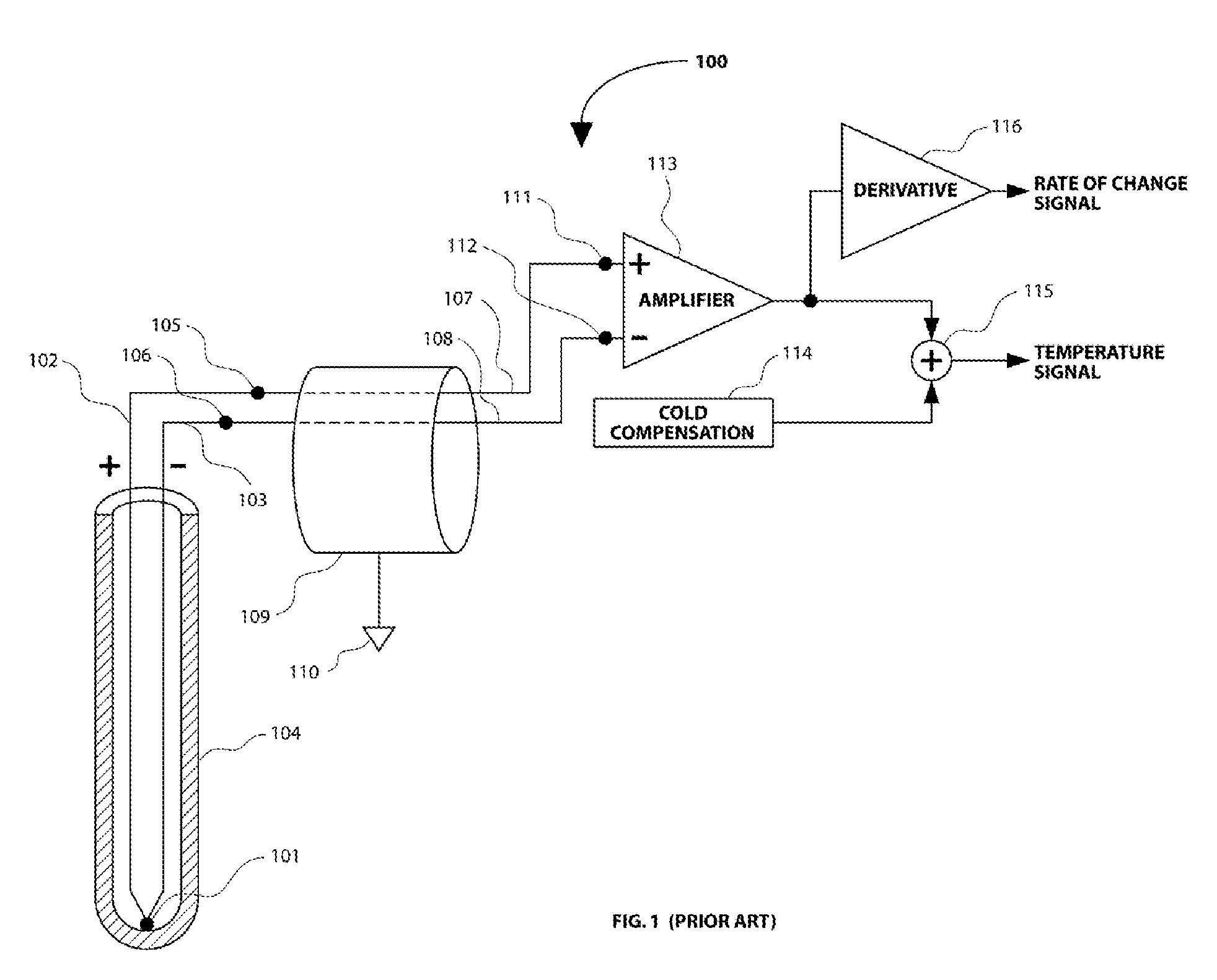

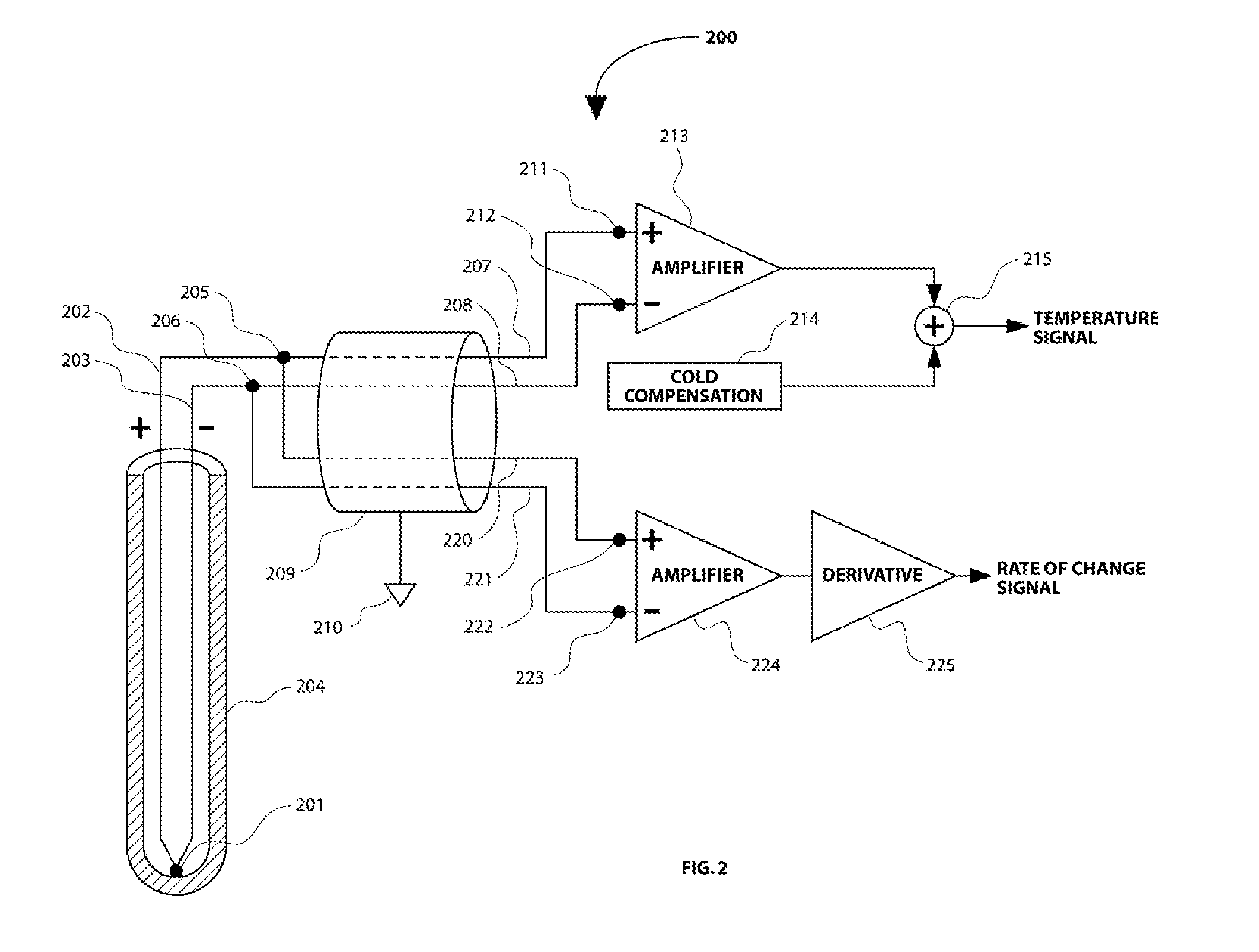

Thermocouple Measurement Circuit

InactiveUS20080125767A1Easy to addThermometers using electric/magnetic elementsUsing electrical meansInstrumentation amplifierAudio power amplifier

A thermocouple measuring circuit for sensing a temperature at a measuring point is provided. The thermocouple measurement circuit (12) includes a thermocouple input for sensing a temperature at a measuring point, a compensation circuit (14) for compensating thermocouple effects of junctions of the thermocouple, and an instrumentation amplifier (16) for summing an output of the thermocouple and an output of the compensation circuit and outputting a voltage indicative of the temperature sensed, wherein the output of the compensation circuit is a reference voltage for the output of the instrumentation amplifier. Various embodiments of the thermocouple measurement circuit may be employed in electrosurgical generators for controlling output power dependent on temperature conditions.

Owner:COVIDIEN AG

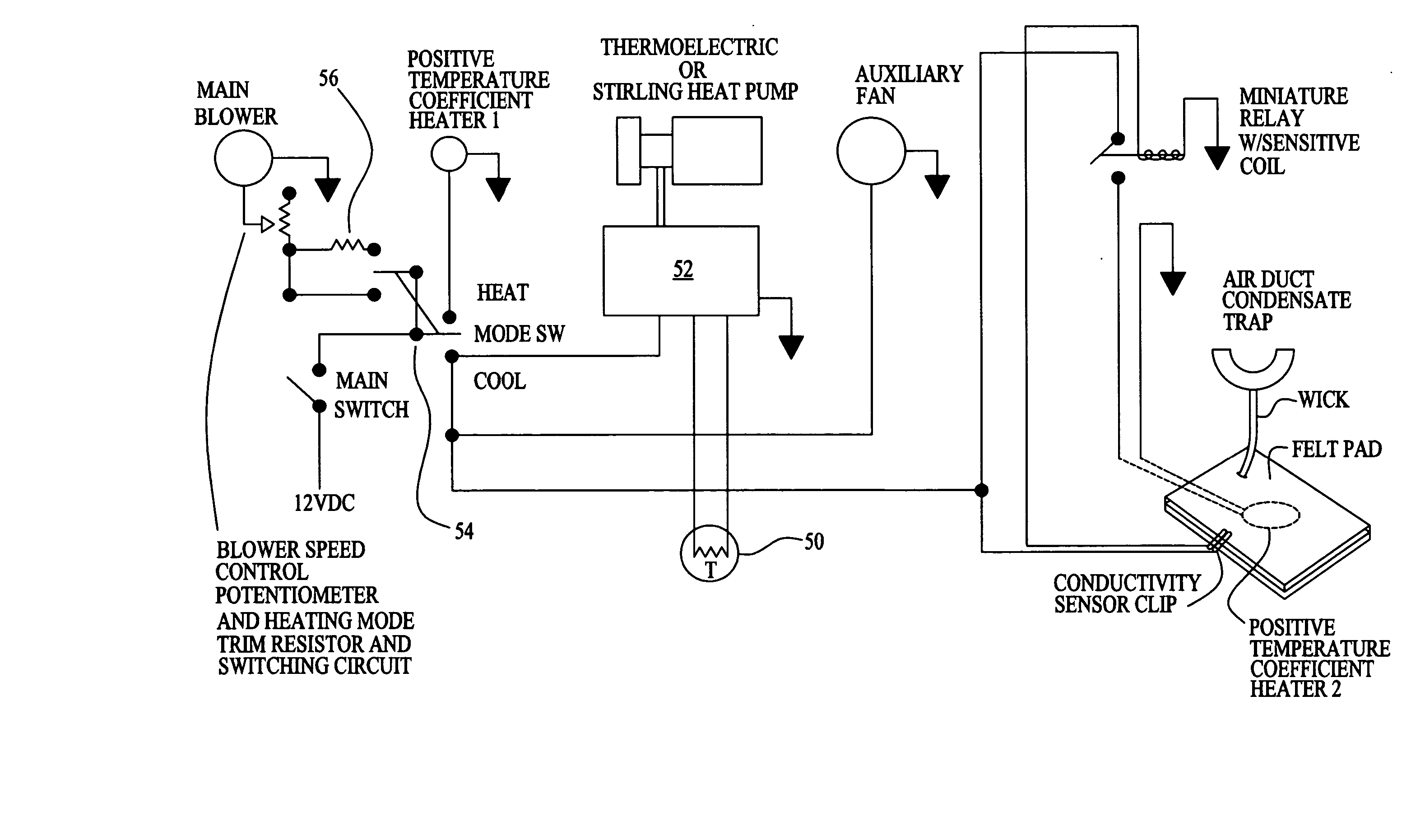

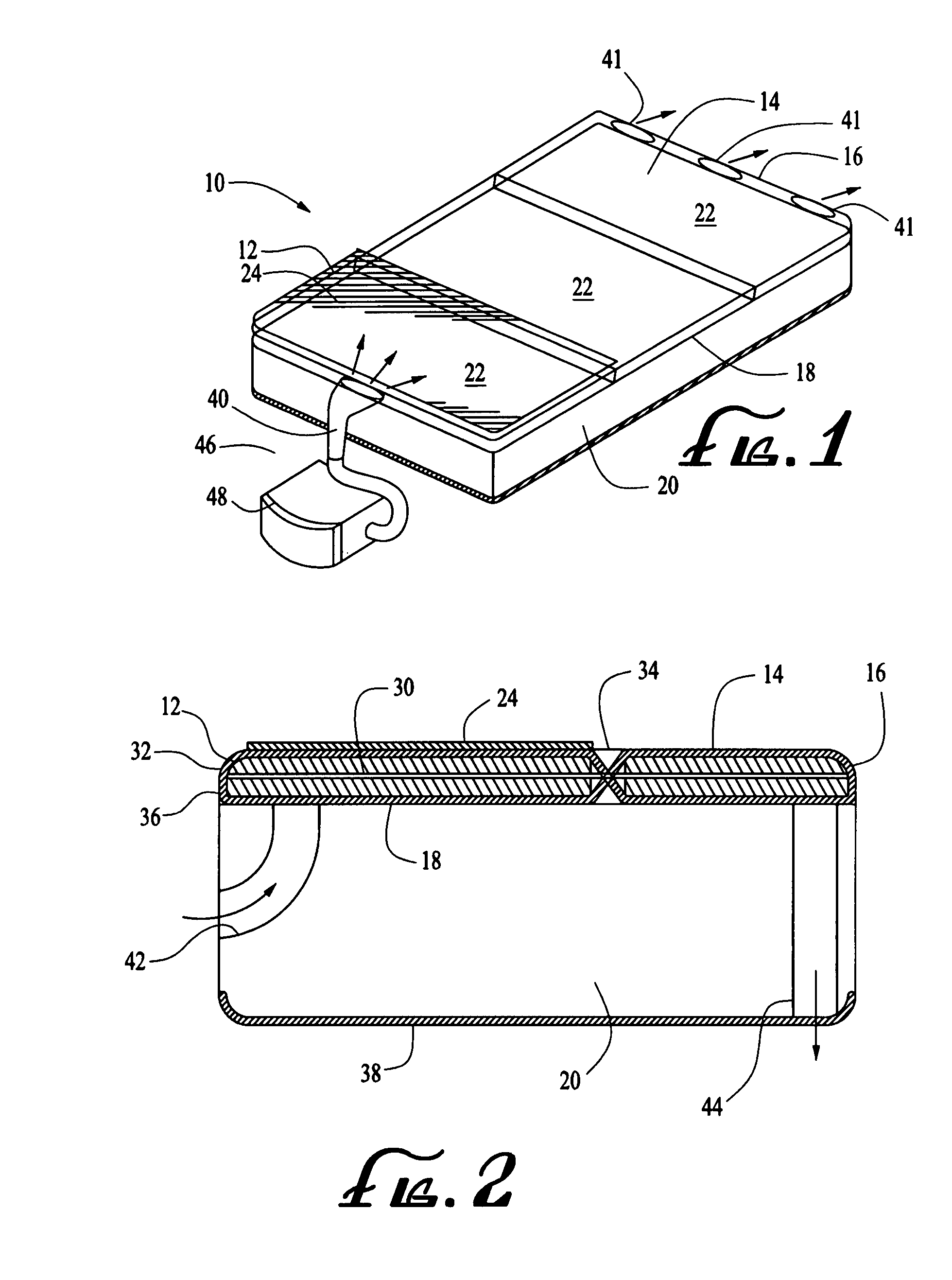

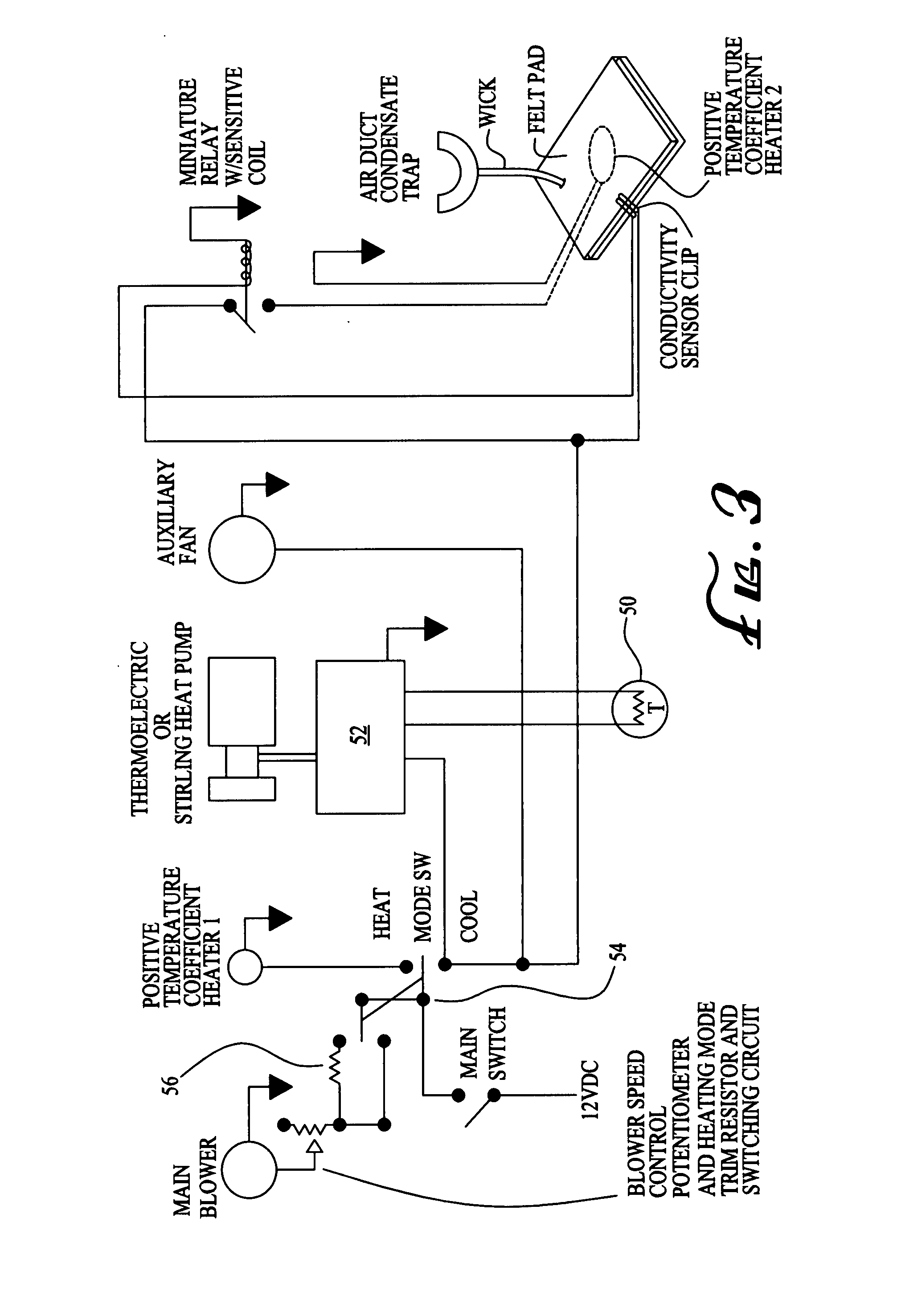

Convective seating and sleeping systems

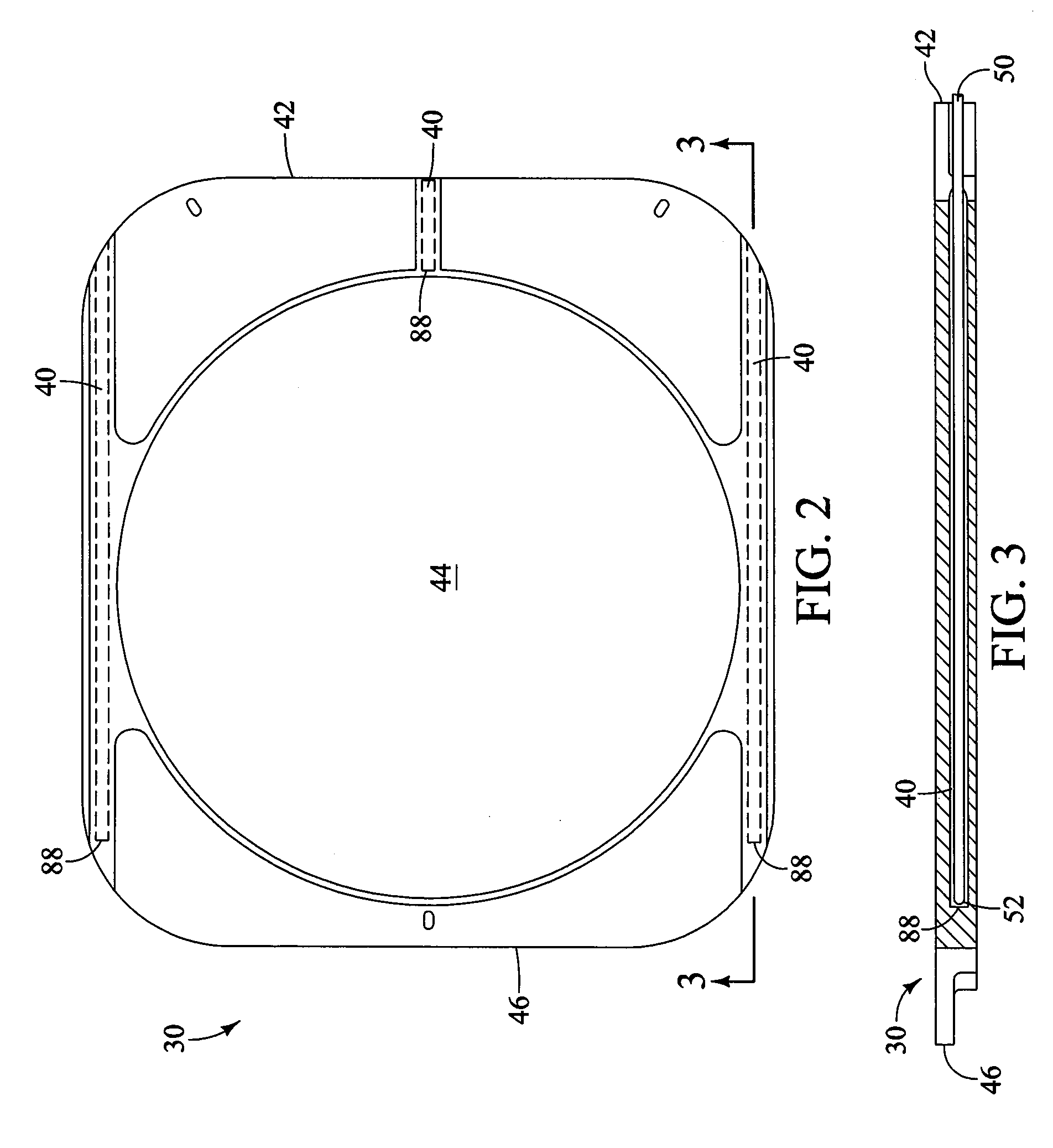

InactiveUS20070251016A1Limit undesired unravelingEliminate requirementsStuffed mattressesSpring mattressesMagnetic bearingControl data

A convective seating and sleeping system with a plenum for use as a mattress, cushion or as part of seat or other structure to deliver air flow to a user or users. The convective cushion includes a modular plenum made of removable pockets and a thermocouple to provide control data to selectively control the temperature and / or quantity of the air delivered to the cushion. The cushion includes the use of tubular spacer material. The cushion has deep styling lateral and longitudinal pleats and air flow structures around the pleats to provide a controlled air flow to the cushion. The invention includes an improved Stirling cycle heat pump with magnetic bearing structures and relative humidity controls and an improved thermoelectric heat pump that selectively controls the relative humidity of the air delivered to the cushion. The cushion can be activated and operated by remote operation from a telecommunications device.

Owner:FEHER STEVE

Liquid sensor and ice detector

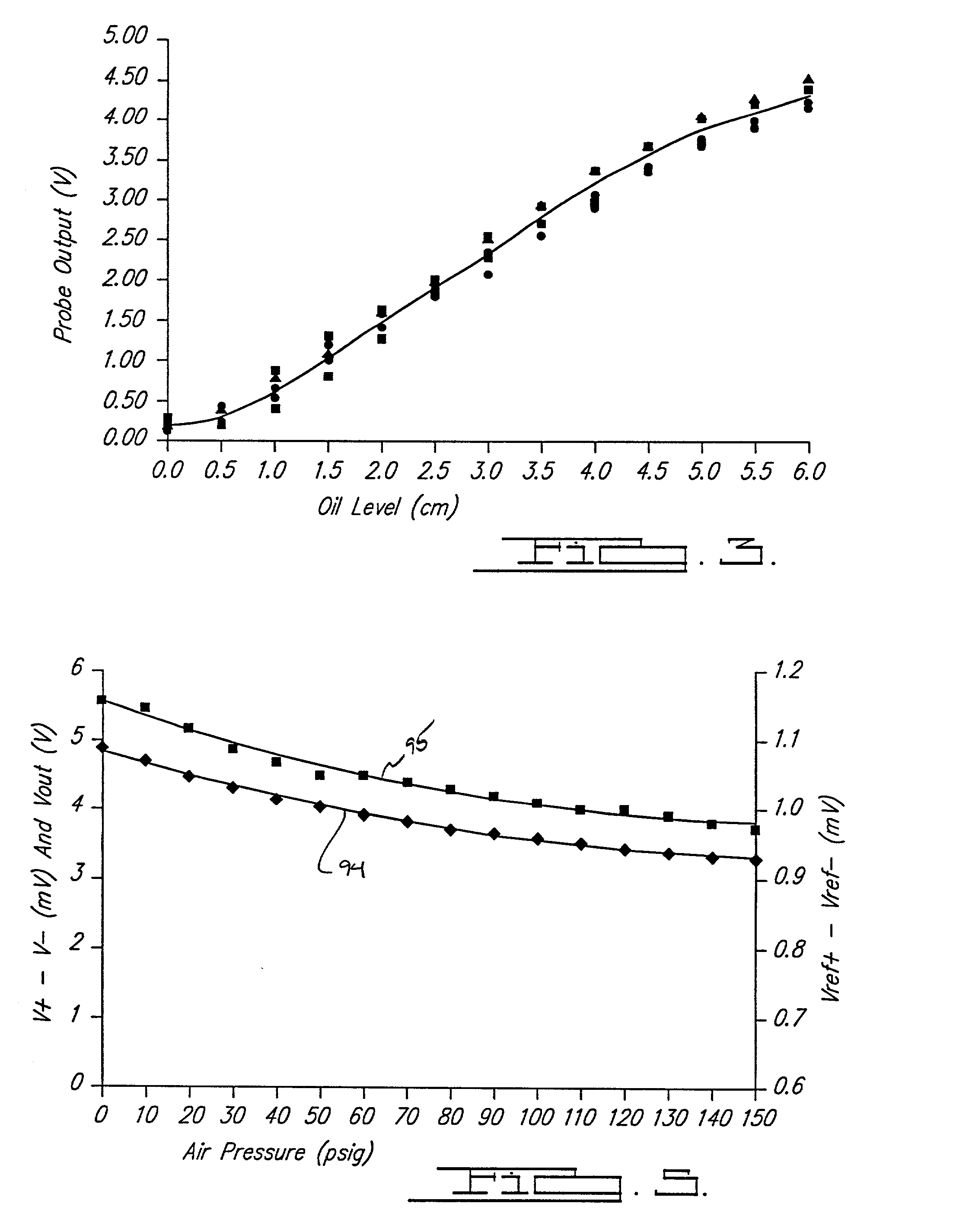

InactiveUS20050126282A1Difference in efficiencyRemove heat moreMachines/enginesLubrication indication devicesScreen printingLiquid temperature

An improved apparatus and a method of measuring and interpreting reliably, simply and accurately the information on continuous liquid level, liquid temperature and other liquid properties within a vessel. The apparatus could be made of a powered heater element and temperature sensors can be screen-printed, vacuum deposited, etched, welded, soldered or plated on one or both sides of a single rigid or a flexible substrate. The geometry of the heater determines the curve shape, such as steepness or shallowness of a temperature profile along a heater. Various parallel and serial configurations of thermocouples or temperature sensors can be used to measure the temperature along a heater. Simultaneous measurements from all the temperature sensors, before and after heat is applied, are used to generate accurate temperature profiles for the entire heater. Different features of the temperature profiles will determine accurately the liquid level, liquid temperature and other liquid properties. Apparatus of the invention may also be used to detect ice formation.

Owner:MAATUK JOSEF

Thermocouple measurement circuit

InactiveUS8104956B2Easy to addThermometers using electric/magnetic elementsUsing electrical meansInstrumentation amplifierAudio power amplifier

A thermocouple measuring circuit for sensing a temperature at a measuring point is provided. The thermocouple measurement circuit (12) includes a thermocouple input for sensing a temperature at a measuring point, a compensation circuit (14) for compensating thermocouple effects of junctions of the thermocouple, and an instrumentation amplifier (16) for summing an output of the thermocouple and an output of the compensation circuit and outputting a voltage indicative of the temperature sensed, wherein the output of the compensation circuit is a reference voltage for the output of the instrumentation amplifier. Various embodiments of the thermocouple measurement circuit may be employed in electrosurgical generators for controlling output power dependent on temperature conditions.

Owner:COVIDIEN AG

Smart pan

InactiveCN107048976AReduce firepowerAvoid spillingBoiling over preventionWarming devicesAutomatic controlControl signal

The invention belongs to the field of pans, and particularly discloses a smart pan comprising a pan body, a handle, a thermocouple and a pan controller. The thermocouple is assembled to the bottom of the pan body, and the pan controller is disposed within the handle. The pan controller acquires the corresponding cooking program, the cooking program is configured with the set value of the pan temperature associated with time, the measured value of the pan temperature based on thermocouple detection and the set value of the pan temperature obtained from the cooking program are processed to generate a control signal for manipulating a heating unit for heating the smart pan and changing the strength of heating power of the heating unit, the measured value of the pan temperature is enabled to reach the set value of the pan temperature till the cooking program is totally executed by the pan controller, and food cooking is finished. Throughout the cooking process, the smart pan manipulates the heating unit based on the acquired cooking program, the temperature of the smart pan is controlled automatically, food cooking is completed without user participation, and users can make delicious food either with or without cooking skills.

Owner:李明守

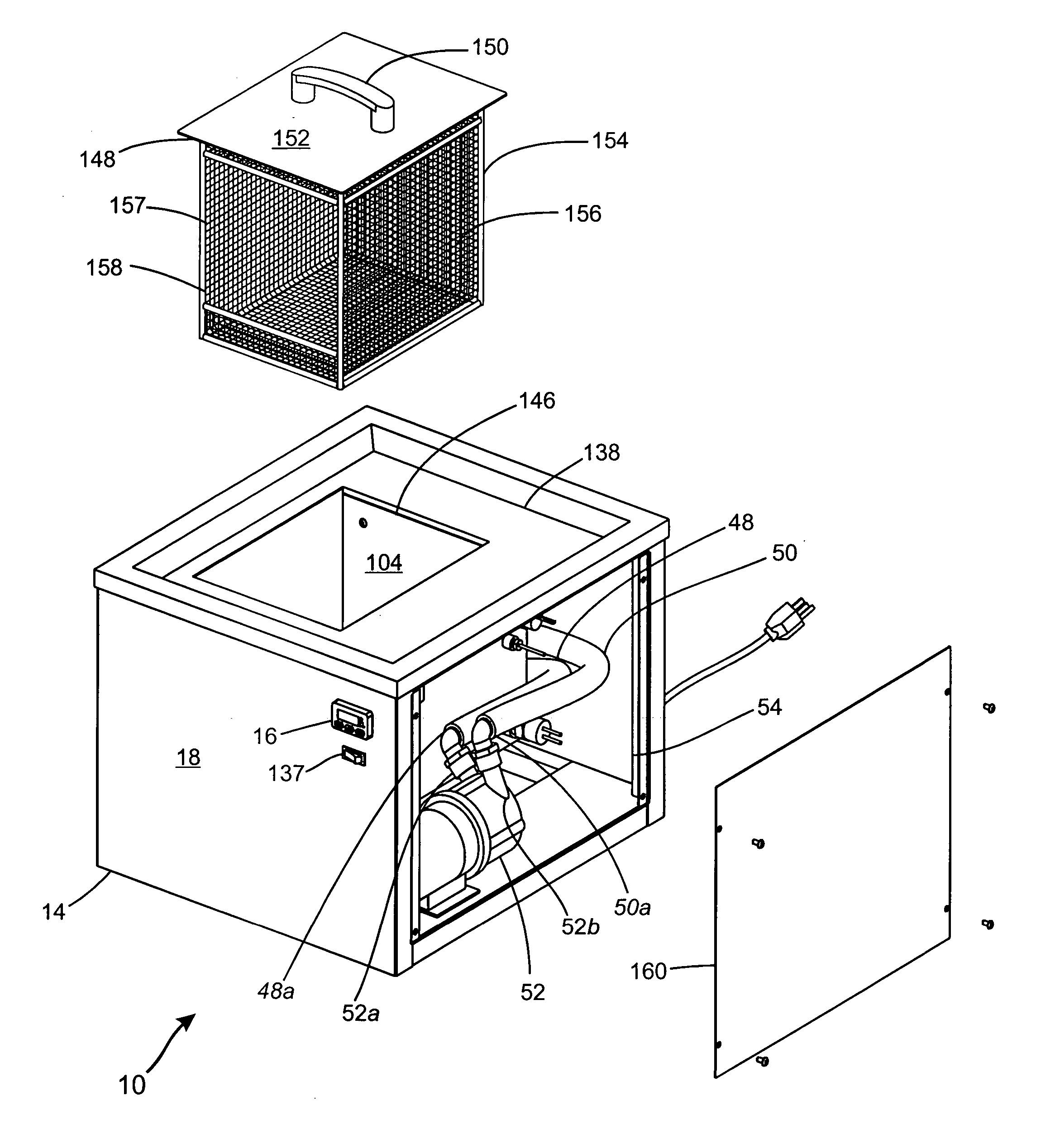

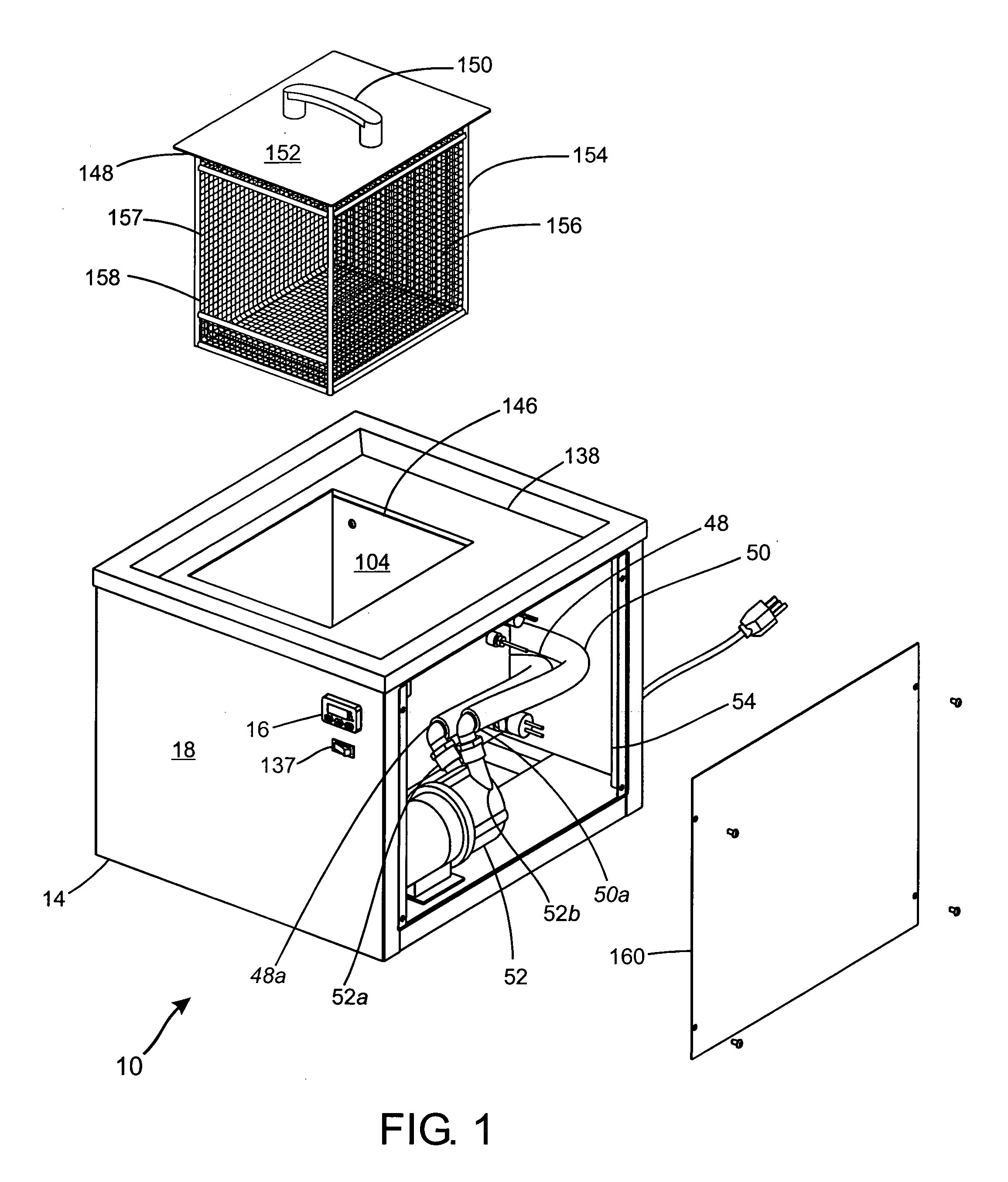

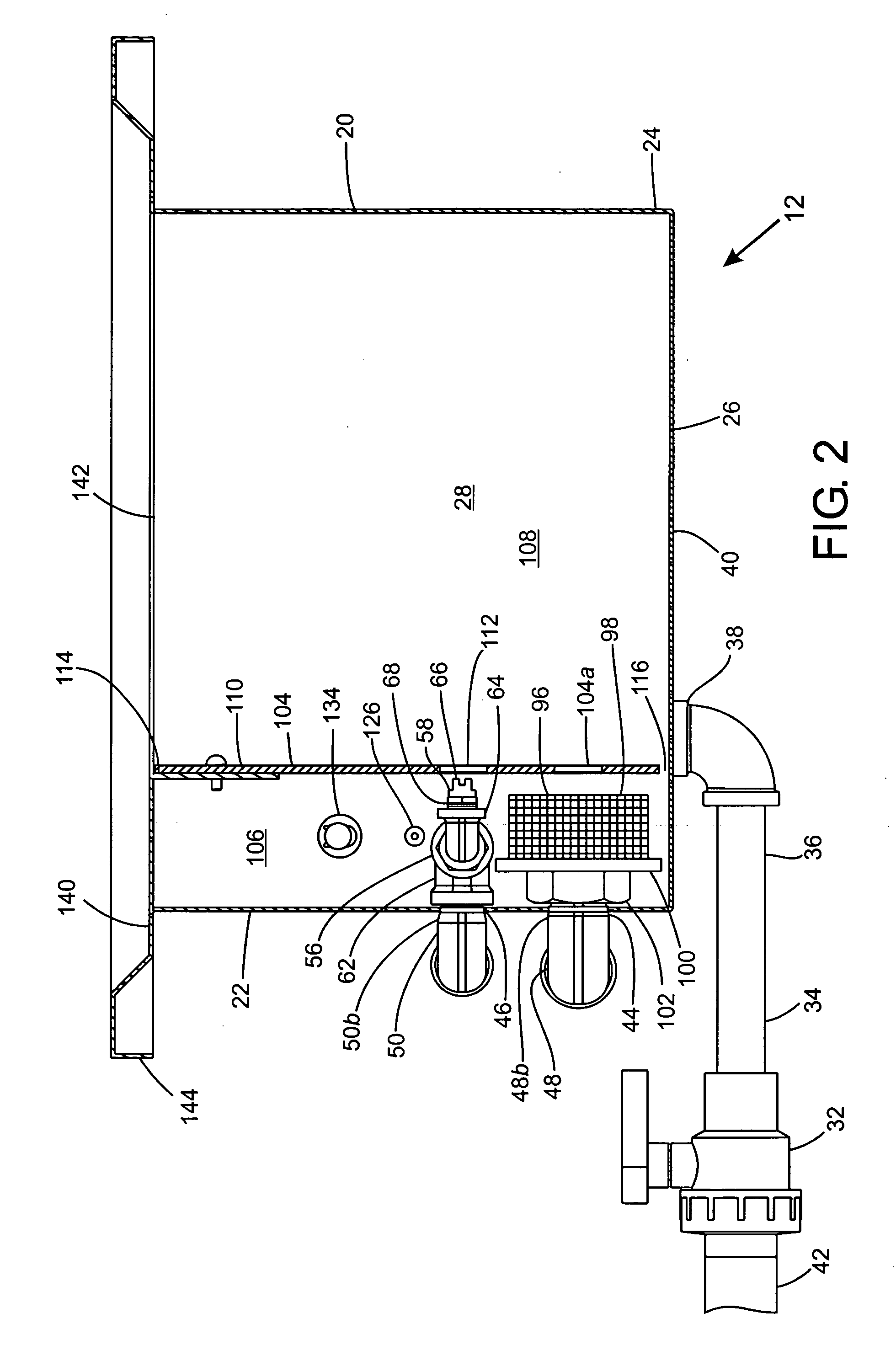

Apparatus and method of removing water soluble support material from a rapid prototype part

ActiveUS20050103360A1Low costEasy to useAdditive manufacturing apparatusHollow article cleaningSupport removalPotassium hydroxide

The support removal apparatus comprising in combination a retention tank having a manifold assembly comprising a plurality of nozzle heads in hydraulic communication with the discharge side of a pump, collectively configured for agitating an aqueous cleaning solution comprised of sodium or potassium hydroxide, sodium or potassium carbonate, and water; a heating element mounted within the retention tank for heating the aqueous cleaning solution to a predetermined temperature set point; a basket strainer mounted within the retention tank in hydraulic communication with the intake side of the pump to mitigate passage of small rapid prototype parts and residual support material therethrough and into the pump and manifold assembly; a work surface mounted atop the retention tank and having a movable lid fitted with a basket for containing small rapid prototype parts; a thermocouple for maintaining the temperature within a tolerable range for optimum removal of support material; a level indicator to ensure adequate solution level in the retention tank for operability of the pump and heating element; a cabinet having interface controller mounted on an exterior panel thereof for setting timer and heat functions; and a microprocessor having capabilities for making minute adjustments to the heating element via feedback from the thermocouple and controlling operation of the pump and heating element for a pre-set time interval.

Owner:TAFOYA DAVID JONATHAN

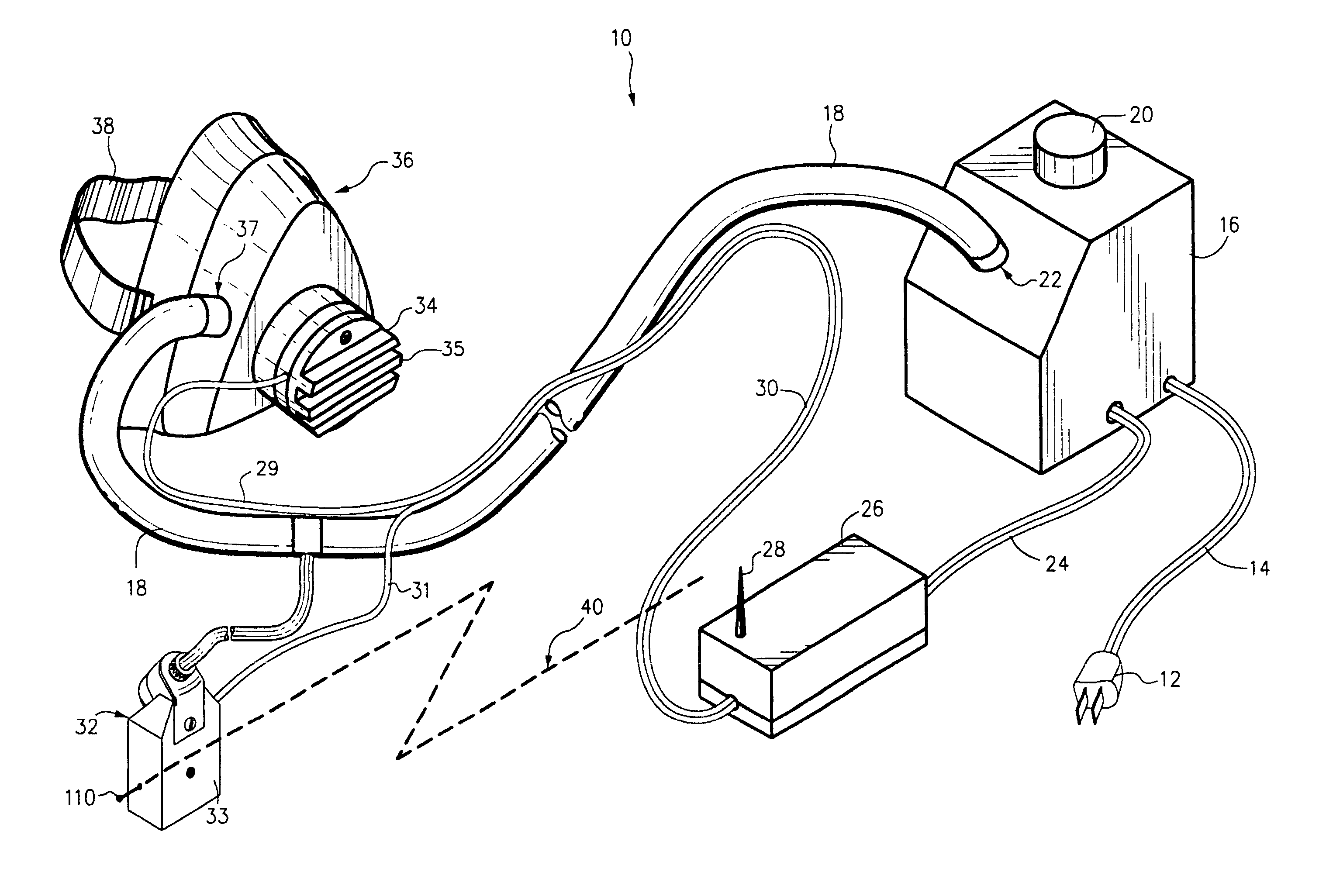

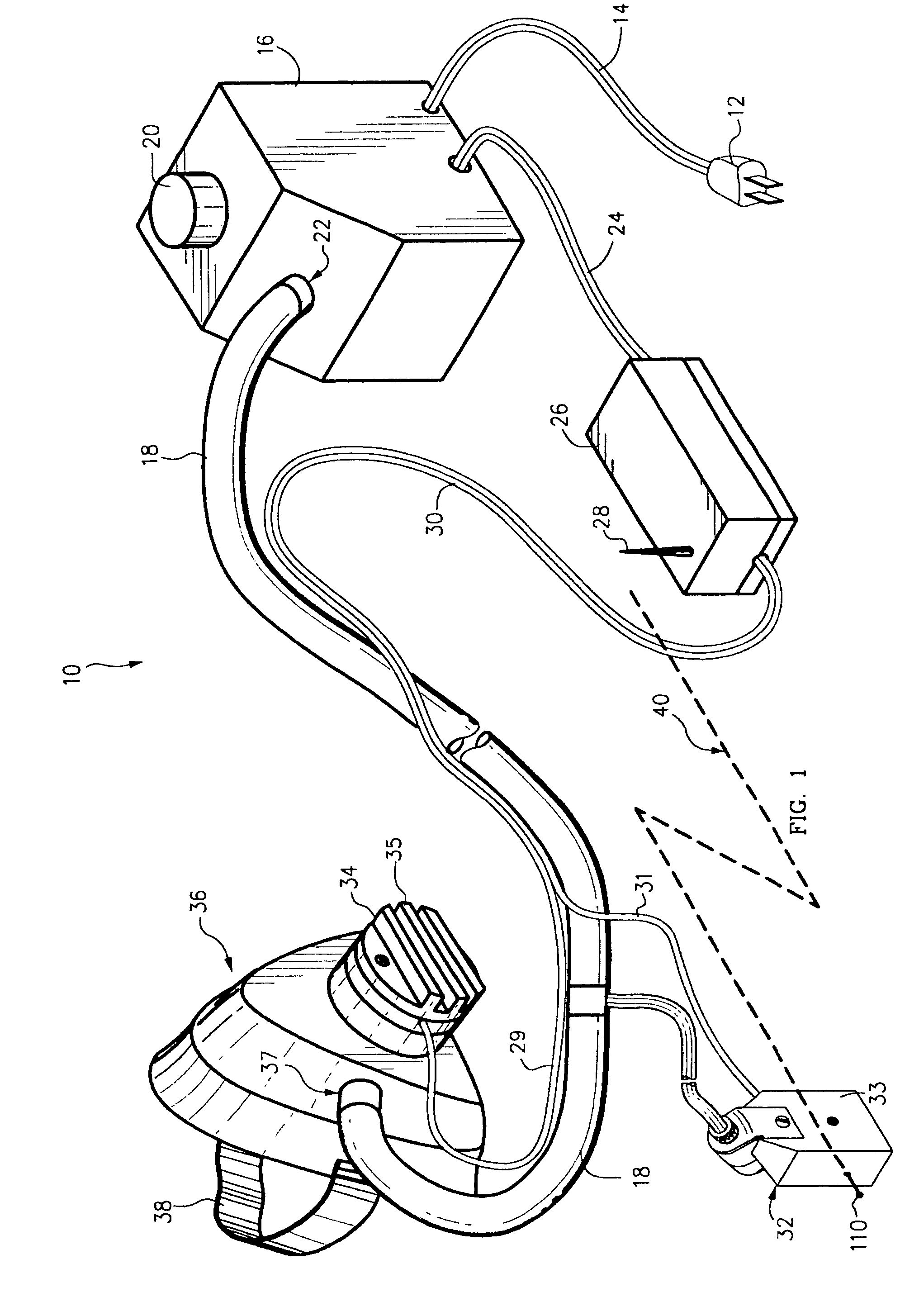

Respiratory monitoring, diagnostic and therapeutic system

ActiveUS7101341B2Accurate calculationAccurate monitoringRespiratory masksWithdrawing sample devicesElectricityNebulizer

Disclosed is a system and method for monitoring, diagnosing, and treating certain respiratory conditions, such as asthma. The system includes a mask apparatus fitted with a pH sensor and thermocouple, a continuous positive airway pressure (CPAP) device, a processing receiver, and a therapeutic nebulizer / atomizer / humidifier device. The mask apparatus, CPAP device and therapeutic nebulizer / atomizer / humidifier device are connected by a pneumatic means. The pH sensor and the thermocouple are in electrical communication with the processing receiver that controls, through an electronic means, the CPAP device and therapeutic nebulizer / atomizer / humidifier device. The electrical communications can be in the form of a plurality of wires or employ wireless means.

Owner:SIERRA MEDICAL TECH

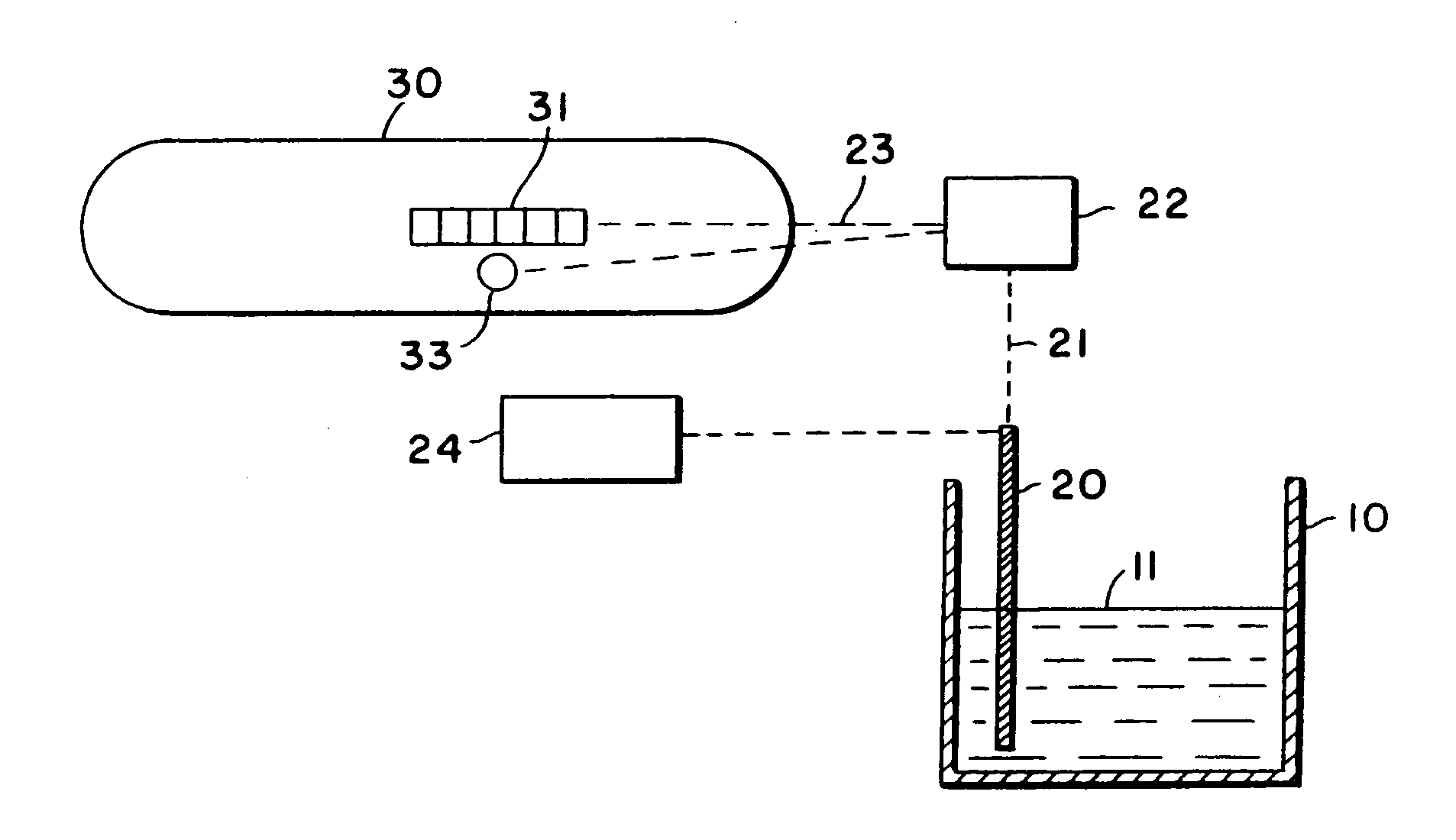

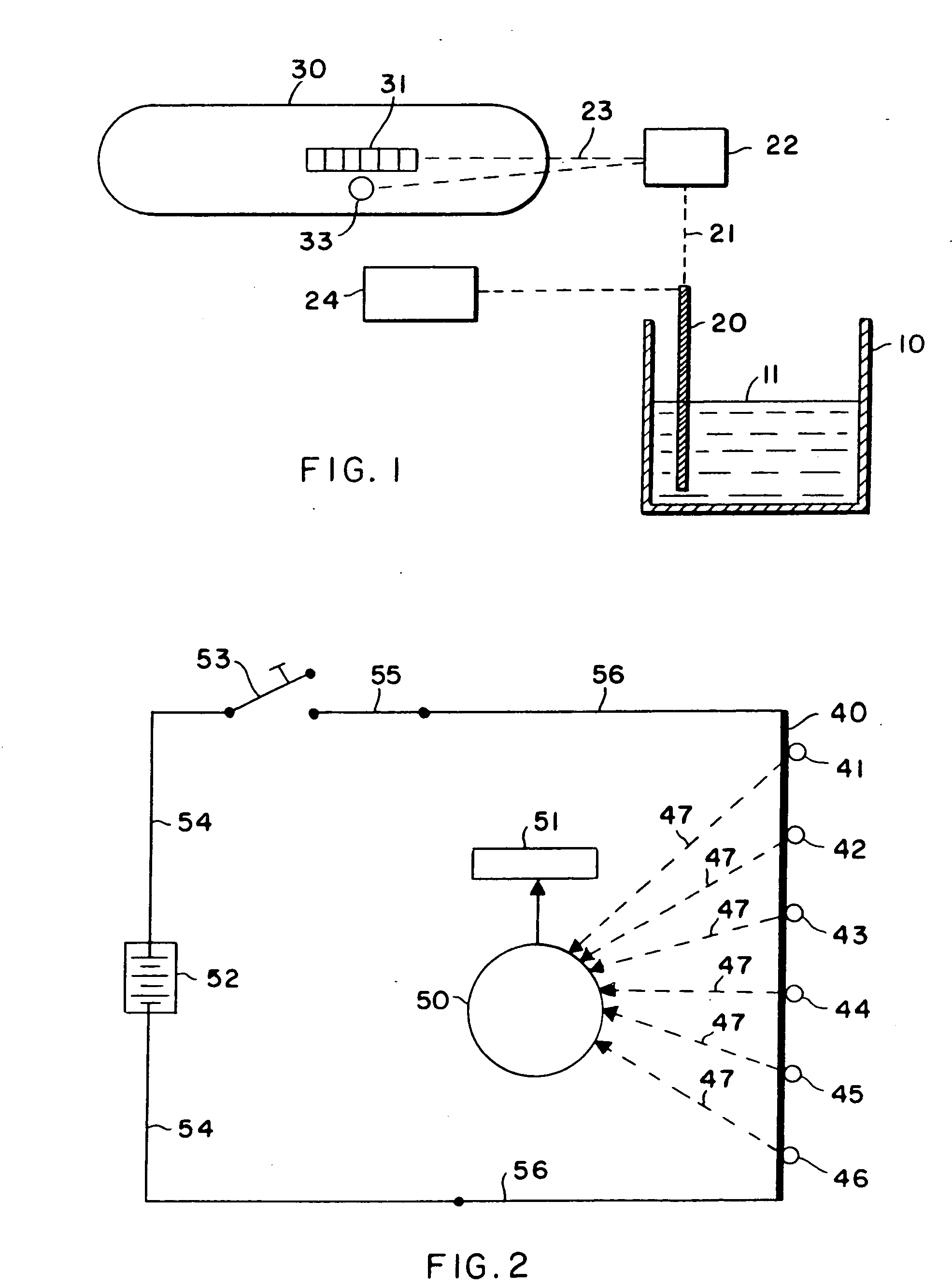

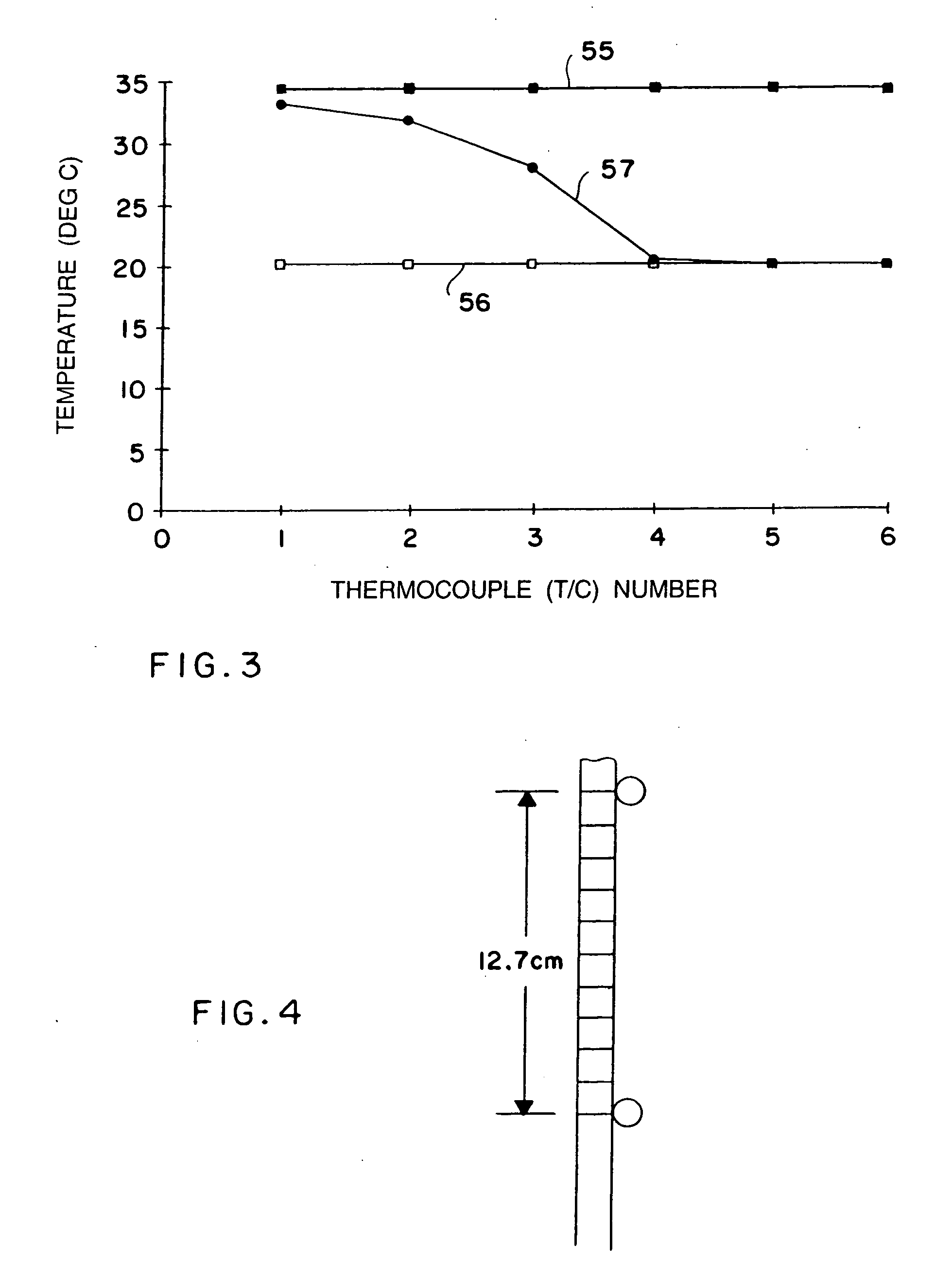

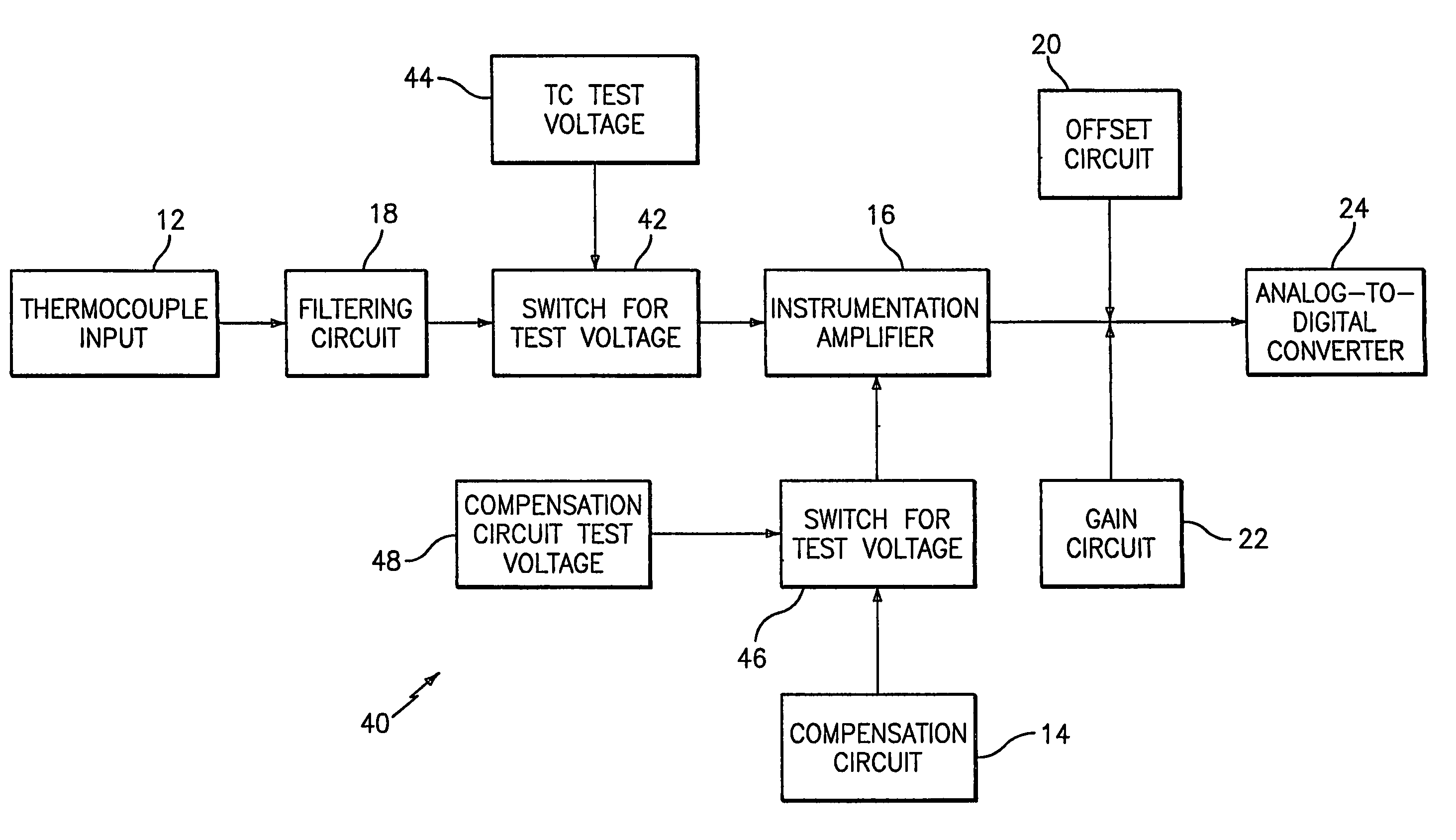

Liquid level sensor

InactiveUS20020129650A1Reduce leakageMinimize numberVolume variation compensation/correction apparatusMachines/enginesEngineeringLiquid level sensor

An improved liquid level sensor is disclosed which provides a reliable and simple device for accurately determining the level of a liquid within a vessel. The sensor of the present invention utilizes a plurality of thermocouples grouped in pairs with the pairs being spaced along a line extending generally in the direction in which the liquid level may vary. A first thermocouple of each pair is located in relatively close thermal proximity to an electrically powered heater and the second of each pair of thermocouples is spaced away from the heater. The thermocouples are connected in series and produce a signal directly indicative of the level of the liquid along the sensor. Additionally, a pressure sensing circuit may also be incorporated with the liquid level sensor.

Owner:THERM O DISC

Thermocouple-controlled catether cooling system

The present invention provides a medical system, including a catheter defining an injection lumen, a chamber in fluid communication with the injection lumen, and an exhaust lumen in fluid communication with the chamber; a first temperature sensor positioned in the exhaust lumen proximal to the chamber; a second temperature sensor positioned in the chamber; and a console in electrical communication with the first and second temperature sensors, the controller modifying coolant flow through the medical device based at least in part upon a signal received from the first and second temperature sensor. The system may further include a thermally-conductive element circumscribing a substantial portion of the exhaust lumen proximal to the chamber, where the first temperature sensor is mounted to the thermally-conductive element, and the thermally-conductive element may include at least one of a braid, coil, and band.

Owner:MEDTRONIC CRYOCATH LP

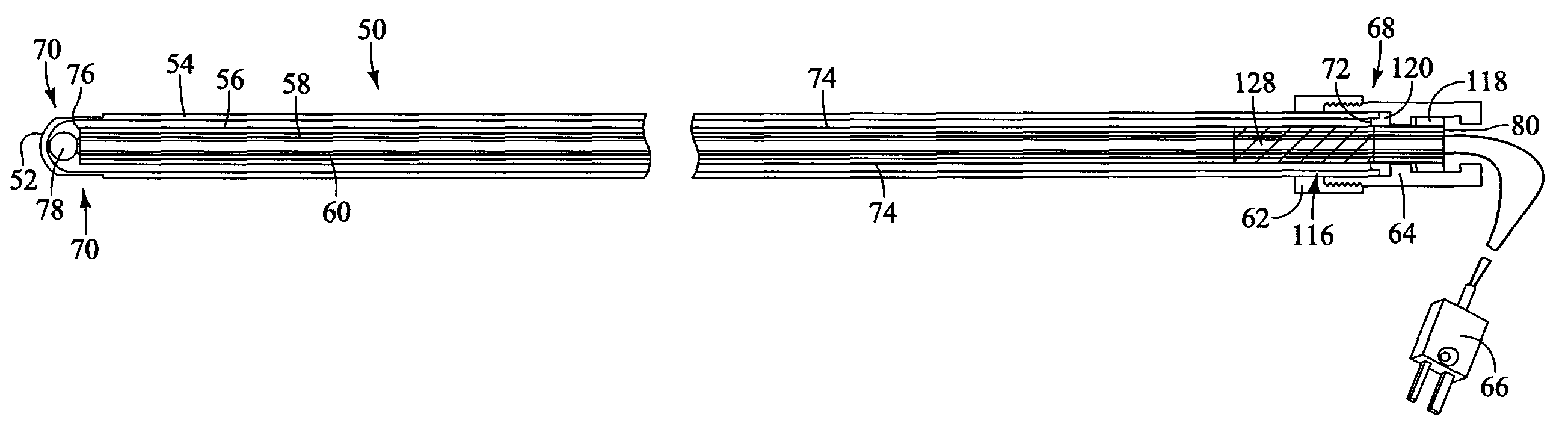

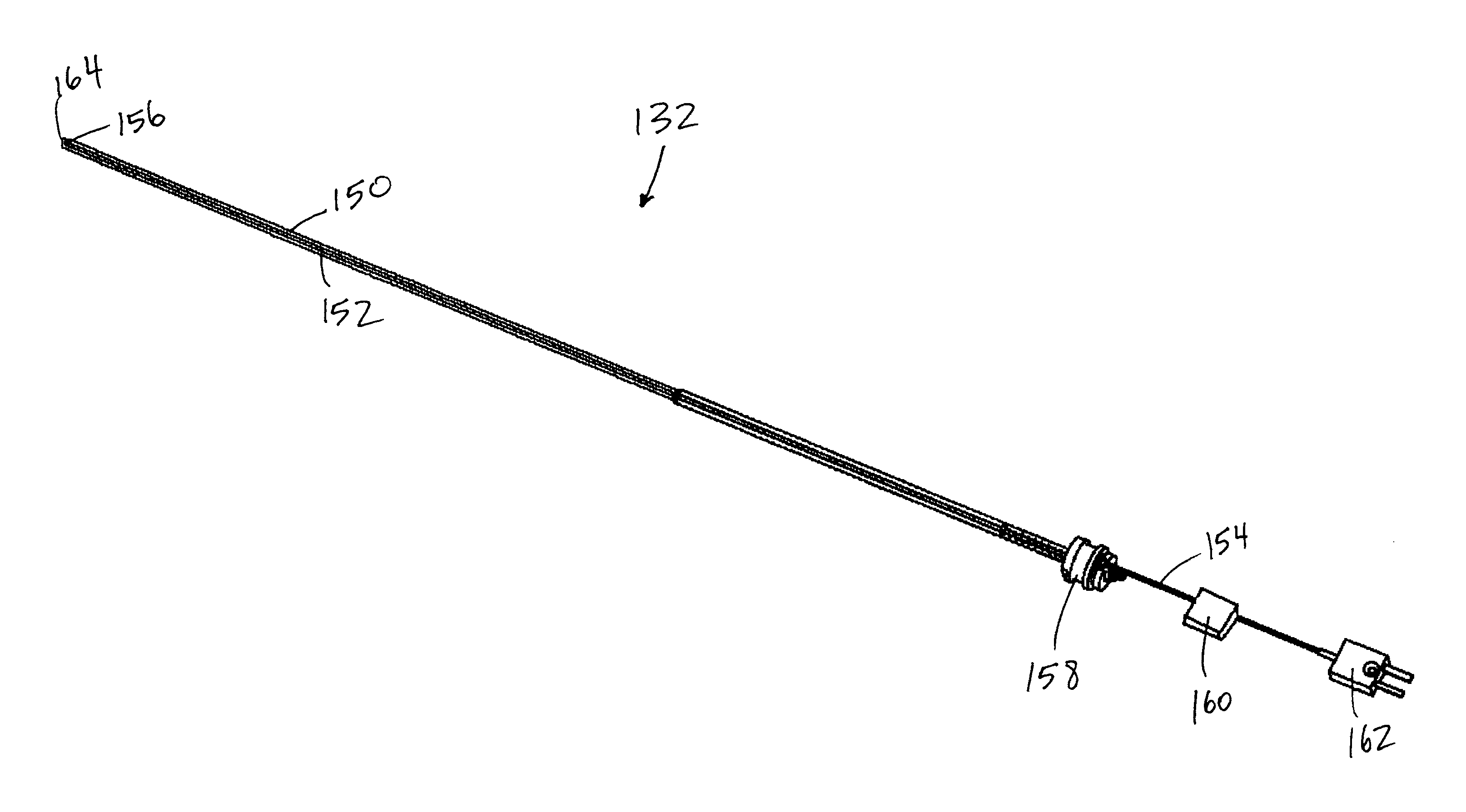

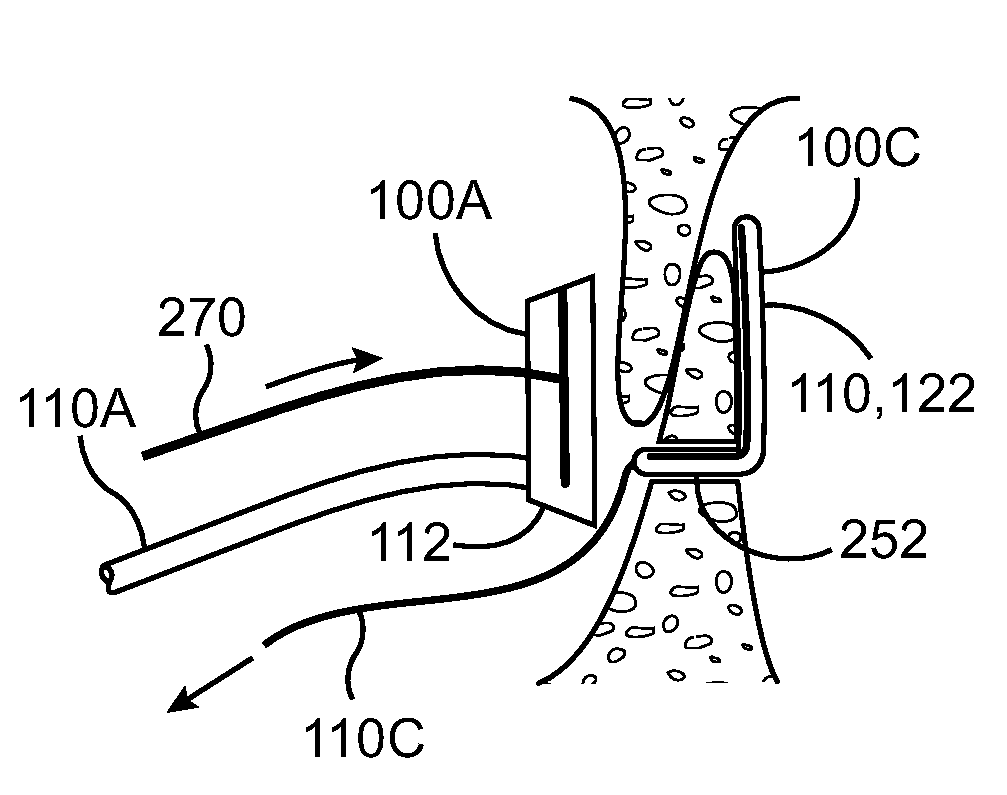

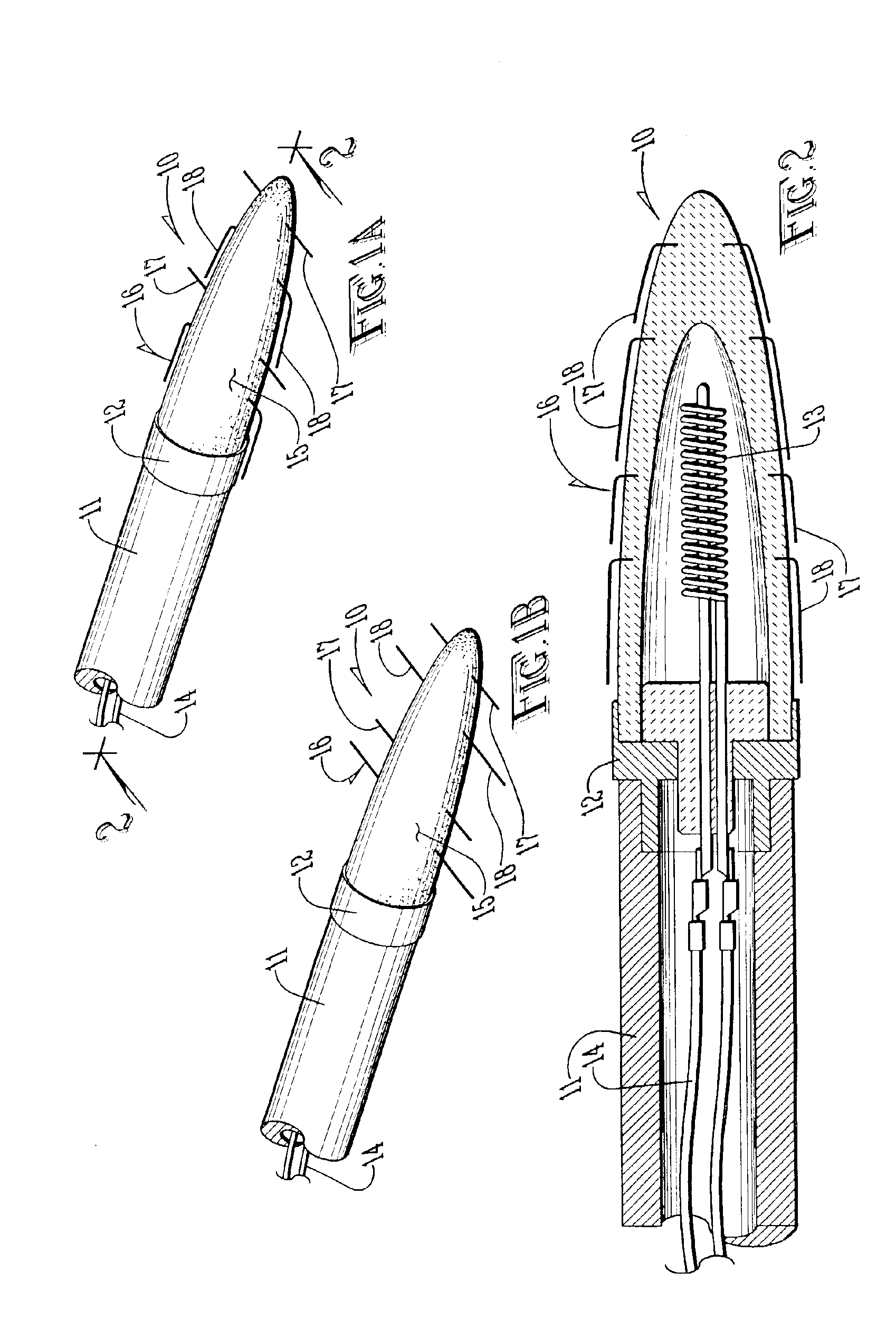

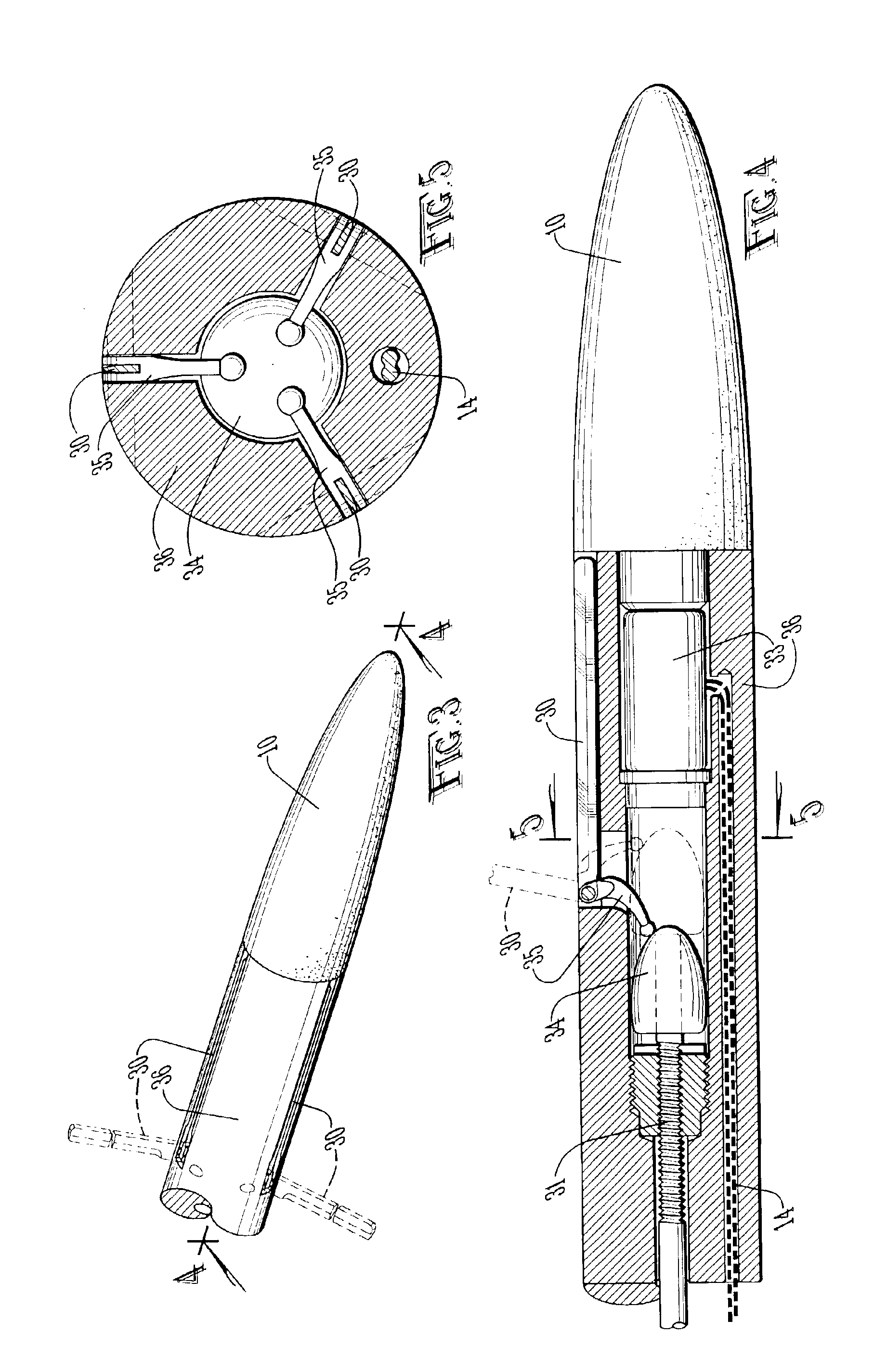

Energy delivery apparatus with tissue piercing thermocouple

A device for delivering energy to tissue, including an elongate flexible shaft having a proximal end and a distal end; at least one energy delivery device operably connected to the distal end of the shaft; a flange protruding from a tissue apposition surface of the energy delivery device; at least one thermocouple proximate said flange, whereby said flange is configured to pierce or displace tissue placed in abutment with the tissue apposition surface, and said thermocouple is configured to measure the temperature of the displaced or pierced tissue.

Owner:TERUMO KK

Conductive interstitial thermal therapy device

InactiveUS6872203B2Highly predictable temperature distributionLimit on maximum temperatureSurgical instruments for heatingThermal probeFiber

An apparatus and method for thermally destroying tumors in which heat is generated by electrical resistance heating conducted to the target tissue. Computerized scanning is used to optimize the geometry of a thermal probe. The probe has a metal tip heated by a remote laser. The metal tip is mounted on the end of a wave guide fiber for transmitting the laser radiation to the metal tip. The tip is coated with a thin layer of biocompatible ceramic to avoid coagulated tissue sticking to the tip. The tip has one or more thin, thermally-conductive elements which deploy in stages to coagulate the tumor. The conductive elements may be thin wires or blades. On one embodiment, the conductive elements are composed of a shape memory material that is folded against the tip at lower temperatures and deploys at selected higher temperatures. In another embodiment, the conductive elements are blades that are deployed mechanically. The tip may be provided with a miniature thermocouple to provide temperature feedback information.

Owner:ARKANSAS CHILDRENS HOSPITAL RES INST +1

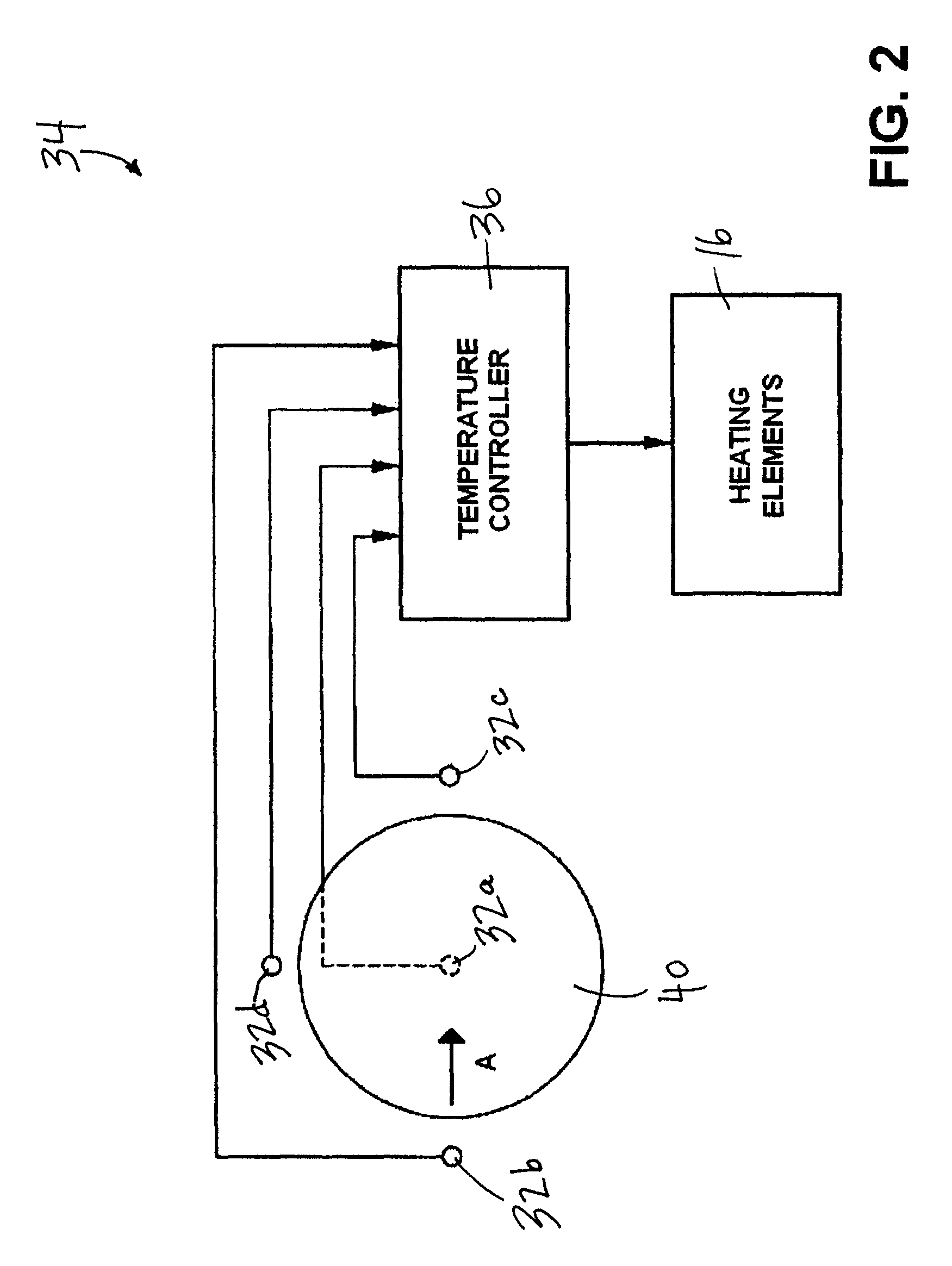

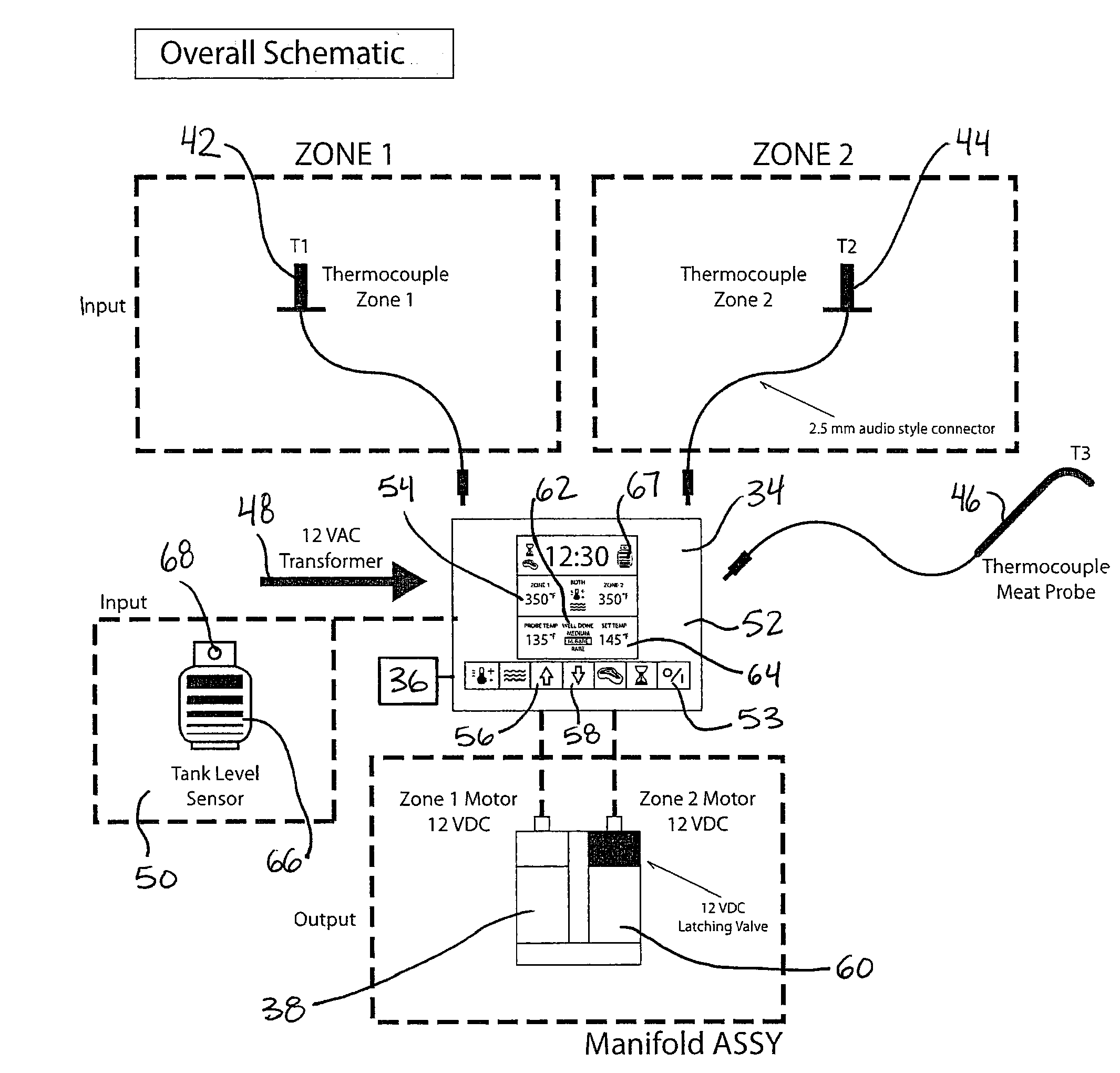

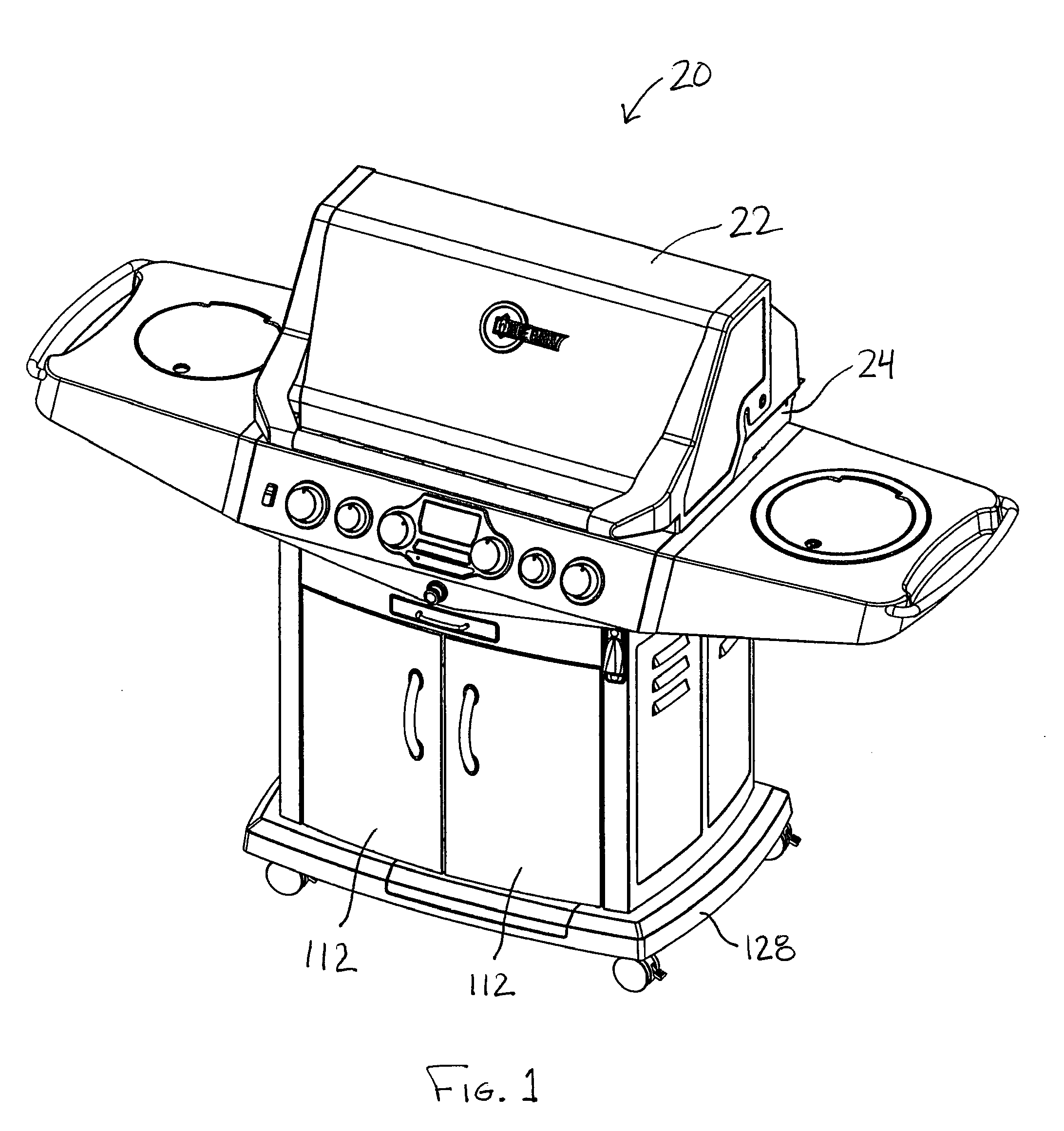

Temperature control device and method

ActiveUS20090183729A1Control flowFuel supply regulationBoiling over preventionElectronic controllerThermal state

A temperature control system for safely controlling the rate of flow of a flammable fluid at generally constant pressure is disclosed. The system may include a flow control apparatus that is free of a regulator mechanism, for affecting the flow of the fluid. The flow control apparatus may be operable between at least a first flow rate and a second flow rate, and may have at least one upstream opening and at least one downstream opening. The system may also include a first burner in fluid communication with the downstream opening of the flow control apparatus and a conduit in fluid communication at one end thereof with the upstream opening of the flow control apparatus, and configured at the other end thereof for connection to a fuel supply. A thermocouple may be located in the vicinity of the burner or an appliance used in conjunction with the burner. The thermocouple converts a sensed thermal state into an electrical signal. An electronic controller, in communication with the flow control apparatus, for activating the flow control apparatus to one of said first and second flow rates, and being in communication with the thermocouple for receiving the electrical signal from the thermocouple is also provided. An interface connected to the controller for manually inputting a desired temperature may be included, wherein the controller is operable to automatically cycle the flow control apparatus between the first and second flow rates until the temperature sensed by the thermocouple is similar to the desired temperature.

Owner:WOLFEDALE ENG

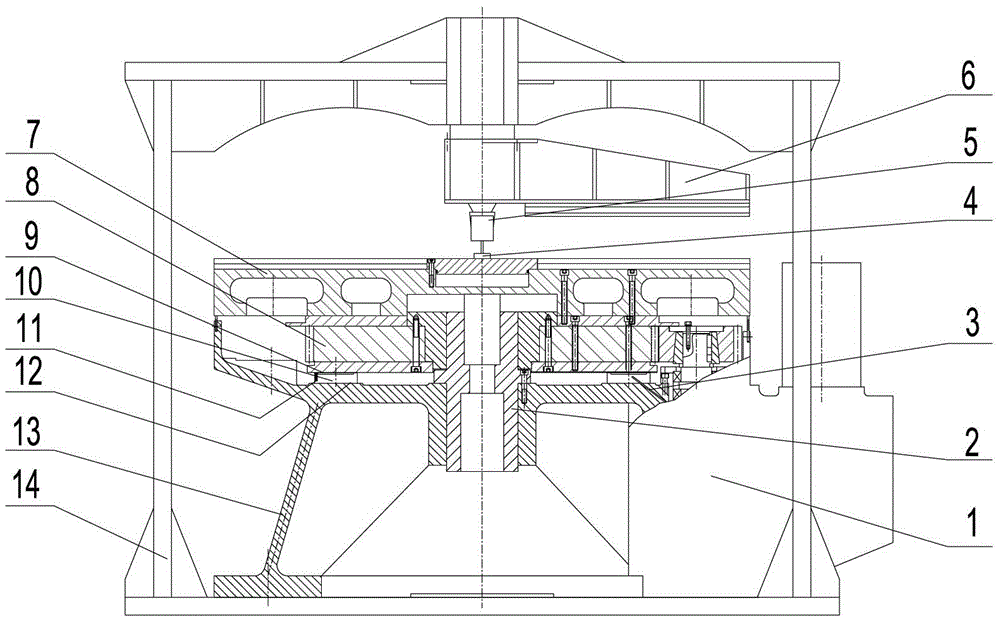

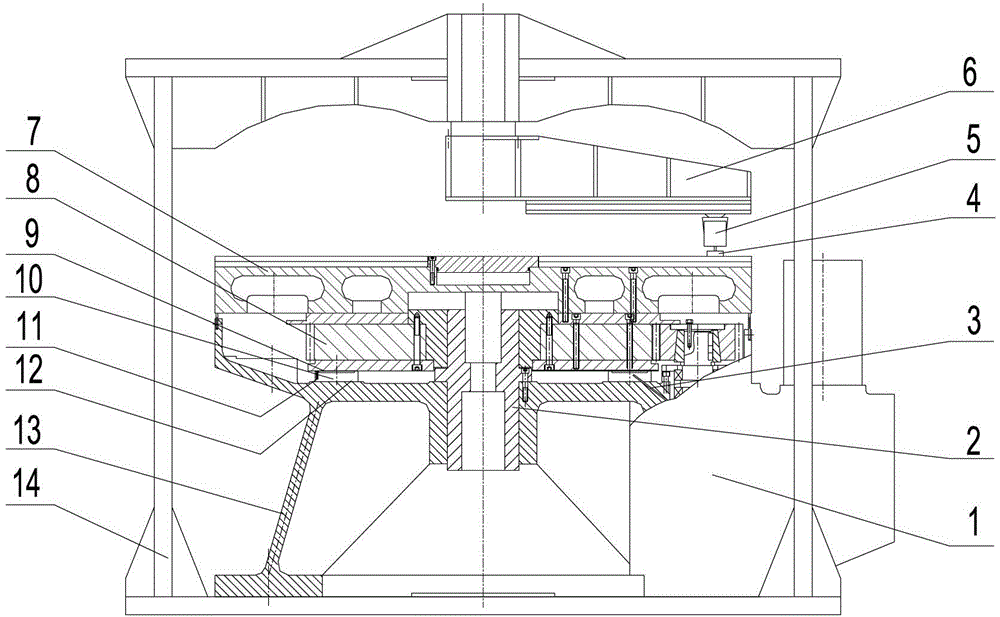

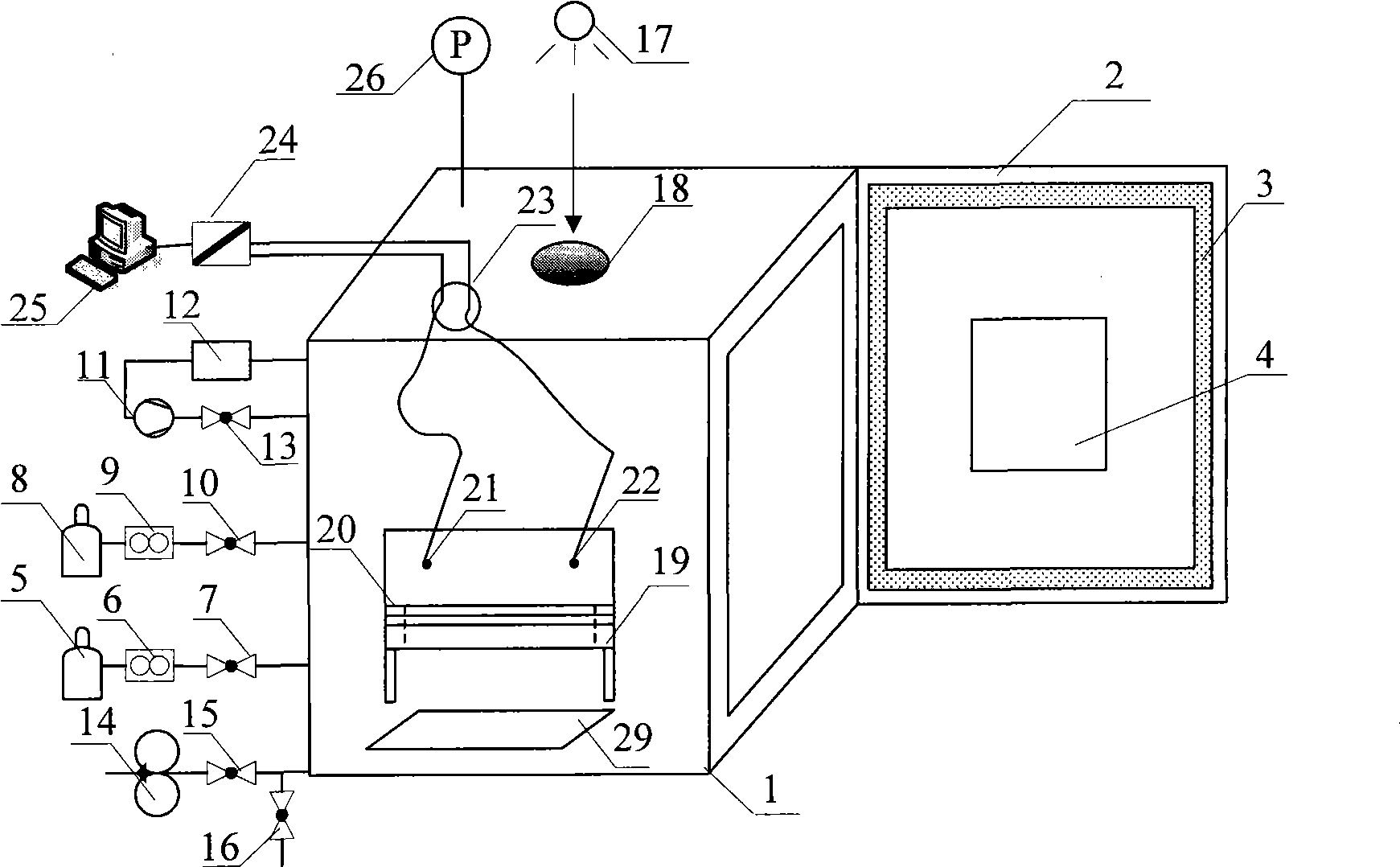

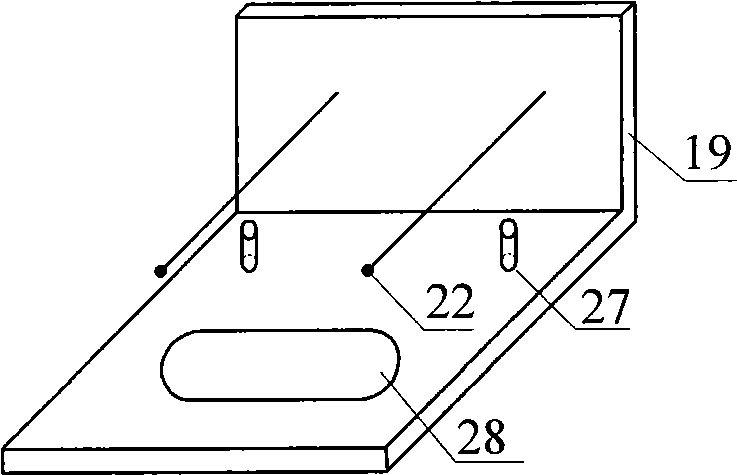

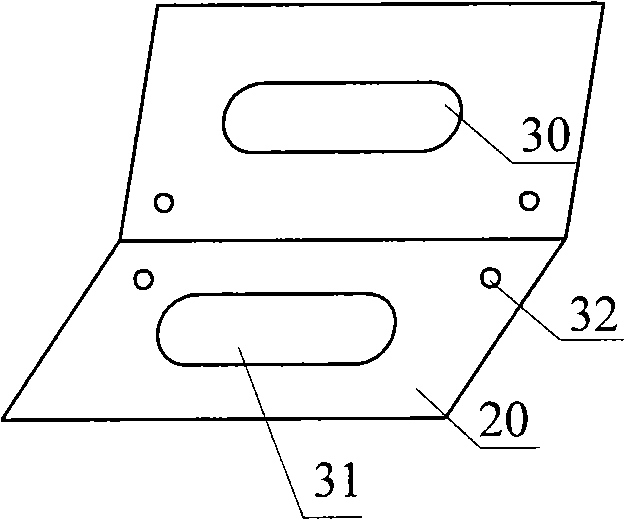

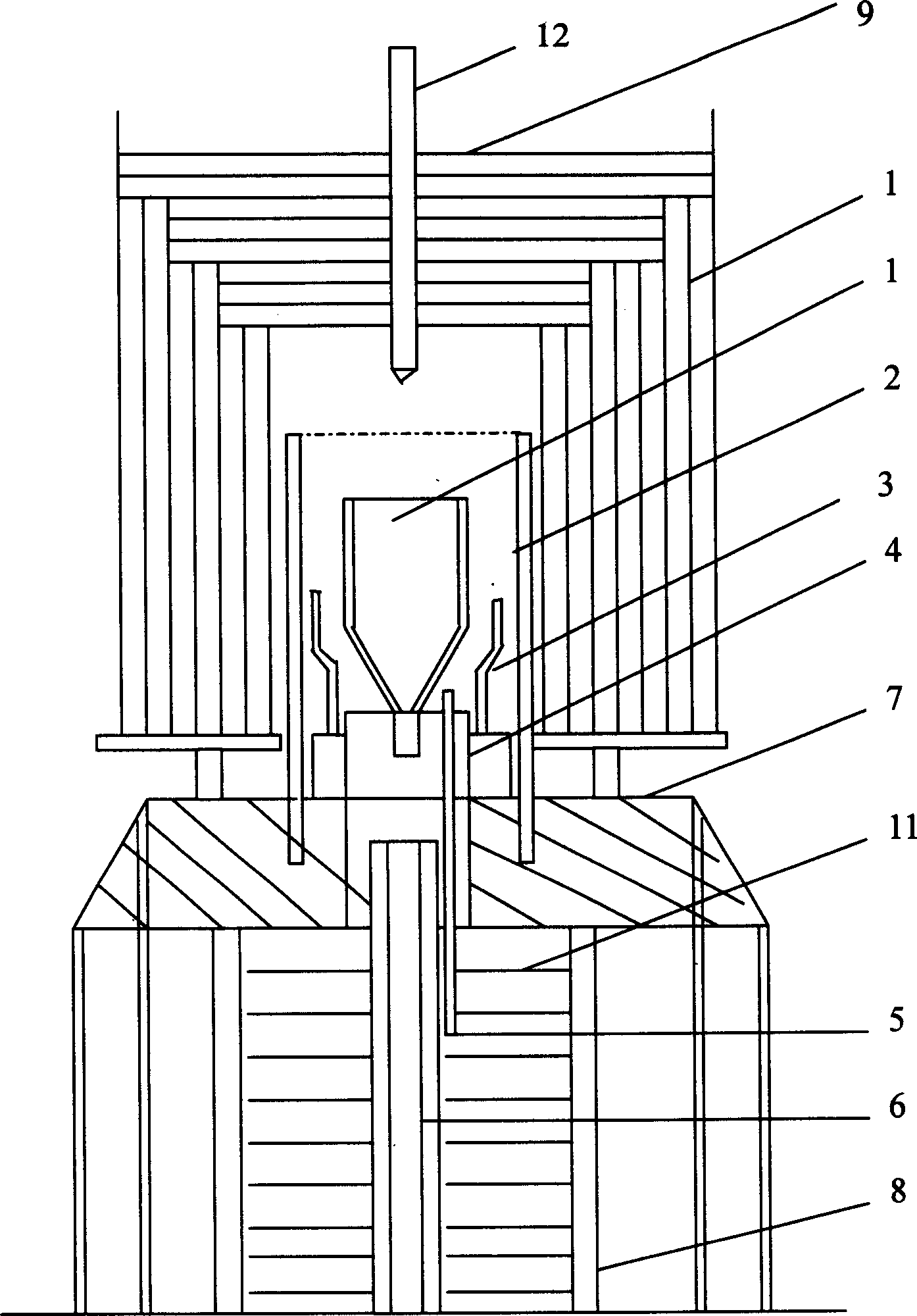

Quantitive type experimental device for dynamic and static performances of static-pressure rotary table

ActiveCN102980755AStructural parameter optimizationImprove machining accuracyMachine part testingElectricityEddy current

The invention provides a quantitive type experimental device for dynamic and static performances of a static-pressure rotary table, and belongs to the field of machinery design and manufacture. According to the experimental device, a loading device (5) and a loading arm (6) are used for changing magnitude of loads or changing oil supply pressure to control the distance between a static-pressure oil cushion (10) and a rotary table disc chuck (7), a pressure sensor (12) is used for measuring pressure in an oil cavity, an eddy current displacement sensor (11) is used for measuring the thickness of an oil film, a thermocouple temperature sensor (3) is used for measuring oil temperature, a force sensor (4) is used for obtaining magnitude of loading force, a pressure gauge a (15) on a multi-head pump at an oil inlet in the oil cavity is used for measuring pressure of the oil inlet of the oil cavity, and a pressure gauge b (16) arranged between an oil pump and the multi-head pump is used for measuring the oil supply pressure of the static-pressure rotary table. By means of the experimental device, a test of the dynamic and static performances of the static-pressure rotary table is carried out under the condition that temperature is between minus 10 DEG C and 60 DEG C and pressure is not more than 100 MPa, and the experimental device provides guarantee for solving problems in engineering, optimizing structural parameters of the rotary table, and improving machining precision of the rotary table.

Owner:BEIJING UNIV OF TECH

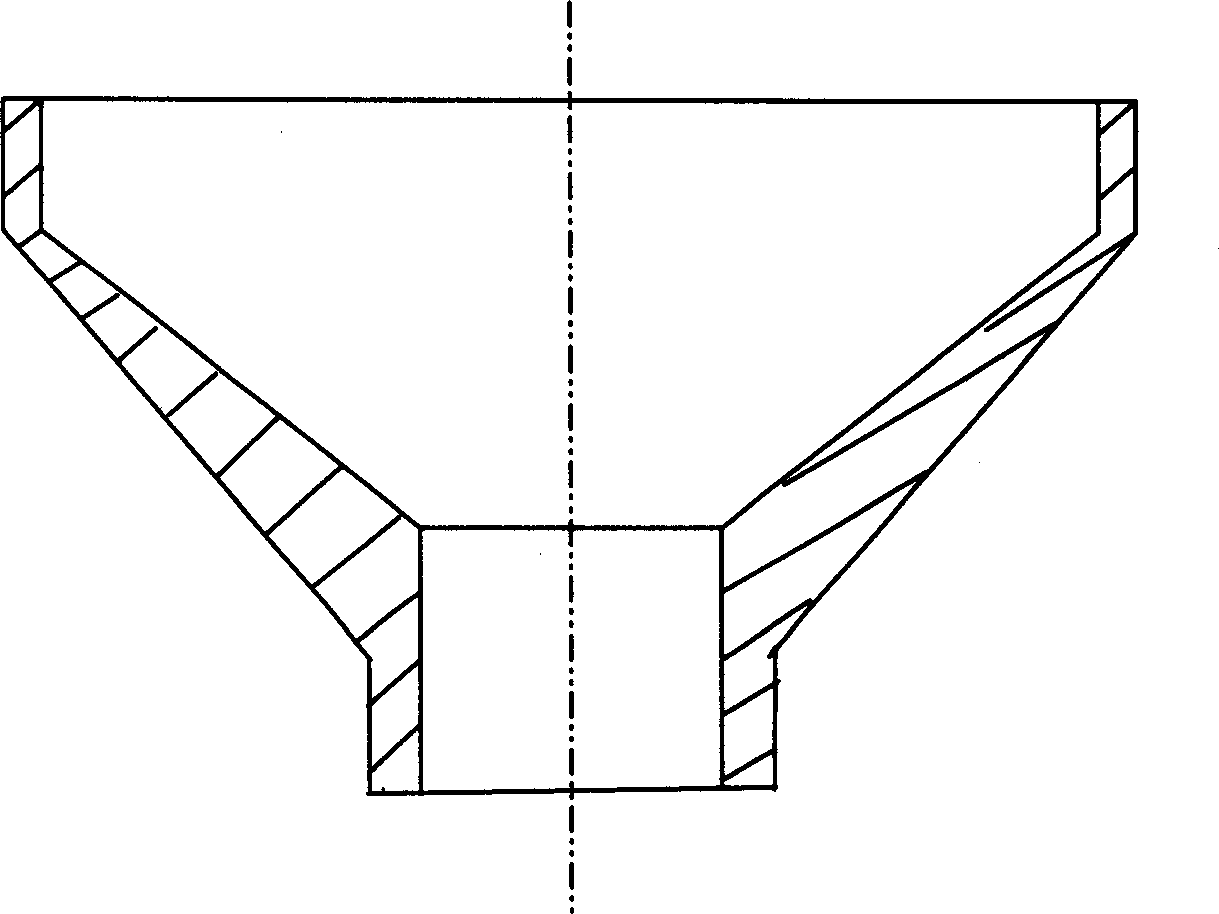

Overflow downdrawn glass forming method and apparatus

InactiveUS6895782B2Reduce unevennessGlass furnace apparatusGlass drawing apparatusFlat glassThermal creep

The present invention alters the flow path at the inlet of the sheet glass forming apparatus to improve quality. The bottom of the downcomer pipe is preferably shaped to alter the character of the vortex flow in the quiescent flow zone between the pipes. In another embodiment, a bead guide provides hydraulic stresses that are in opposition to the surface tension stress and thus reduces the influence of surface tension on the formation of thick beads on the edges of the sheet. The present invention also measures the temperature of the glass by immersing thermocouples in the glass, at locations where any defects caused by the immersion are in the glass that forms the unusable edges of the sheet. In another embodiment, the support structure for the trough is altered to substantially reduce the aging of the trough due to thermal creep.

Owner:CORNING INC

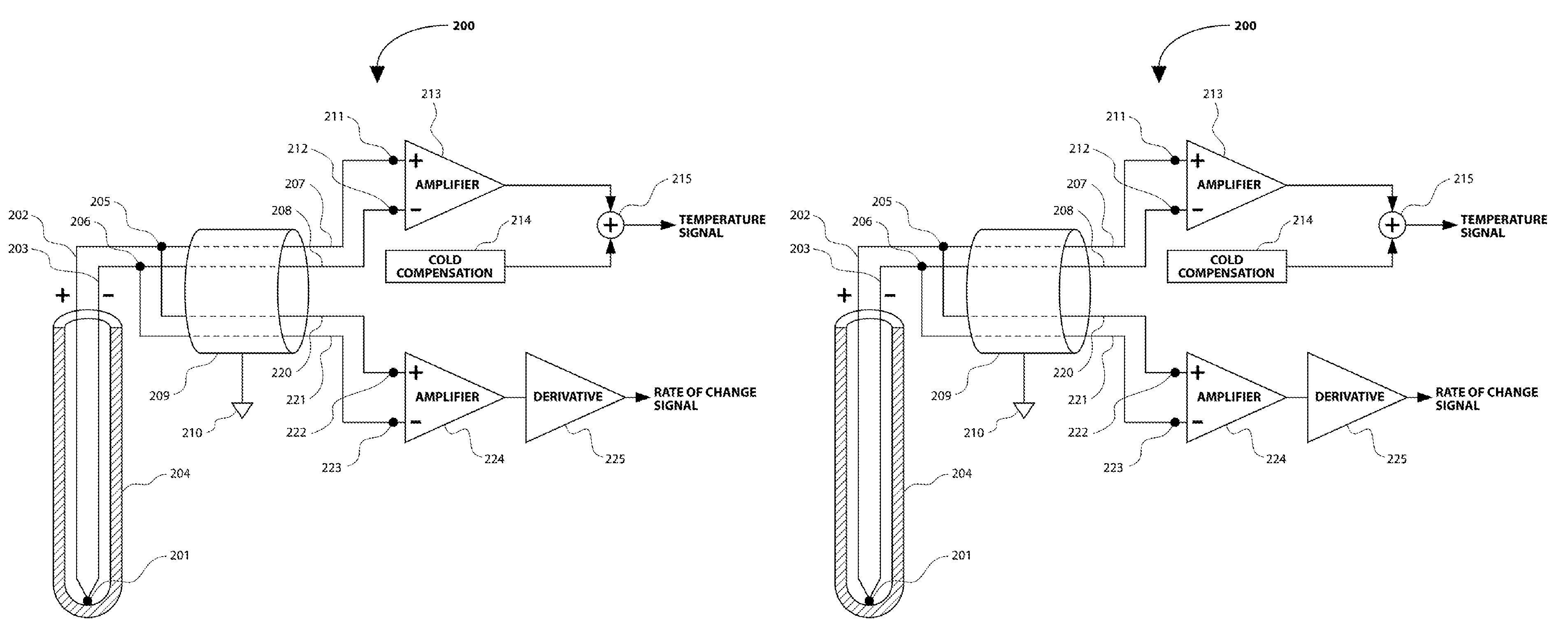

Method and apparatus for measurement of temperature and rate of change of temperature

InactiveUS8602643B2Accurate measurementHigh fidelity measurementThermometers using value differencesThermometers using electric/magnetic elementsElectrical conductorAlloy

A method and apparatus is presented for obtaining of accurate measurements of the temperature of a thermocouple and high fidelity measurements of the rate of change of the temperature of a thermocouple. A first sub-circuit is connected to the thermocouple with two conductors made of two different thermocouple alloys which are substantially the same as the alloys used in the construction of the thermocouple. A second sub-circuit is connected to the thermocouple with two conductors made of substantially identical material, such as copper. The first sub-circuit provides an accurate measurement of the temperature of the thermocouple. The second sub-circuit provides a high fidelity measurement of the rate of change of the temperature of the thermocouple.

Owner:GARDINER DAVID PHILLIP

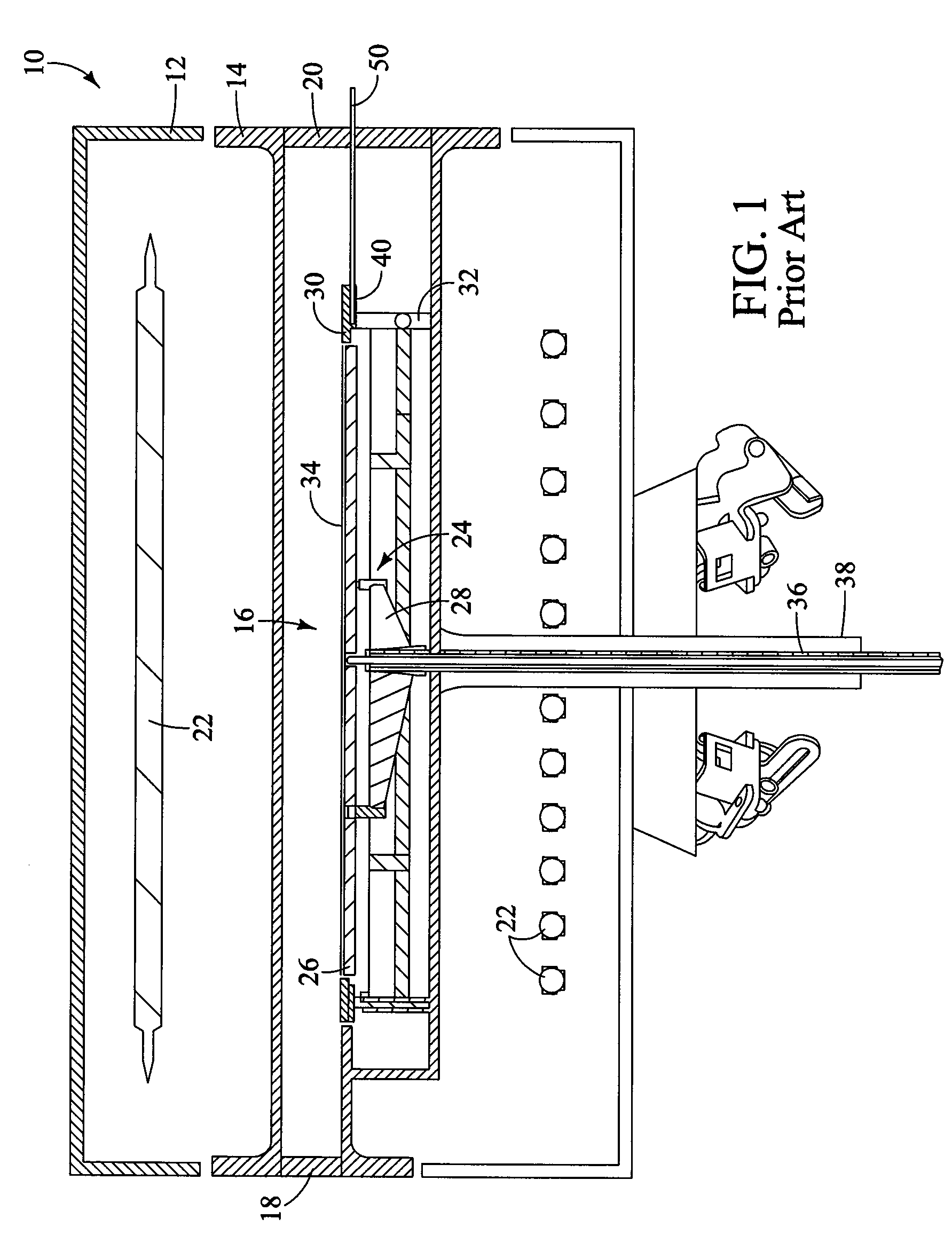

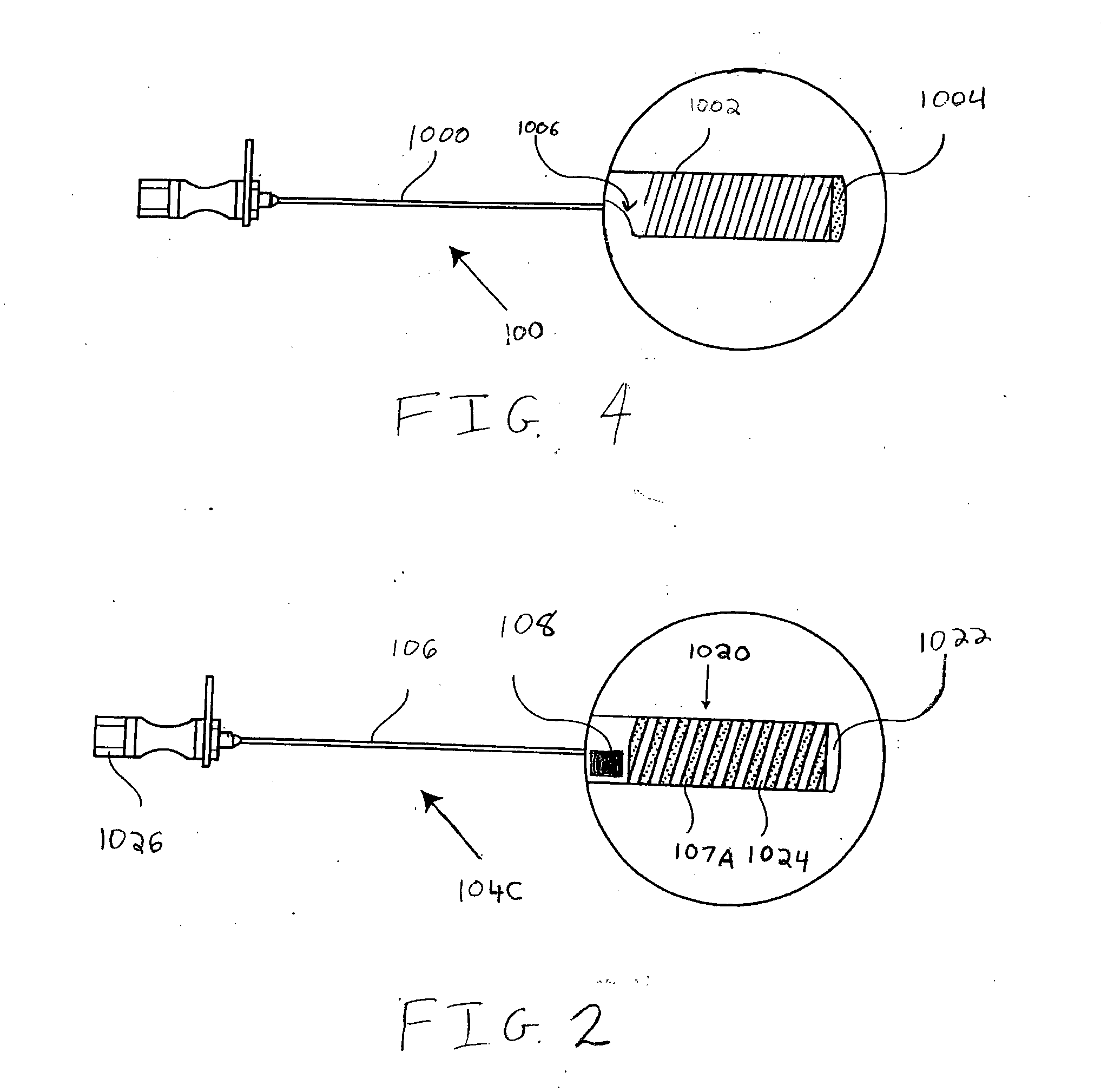

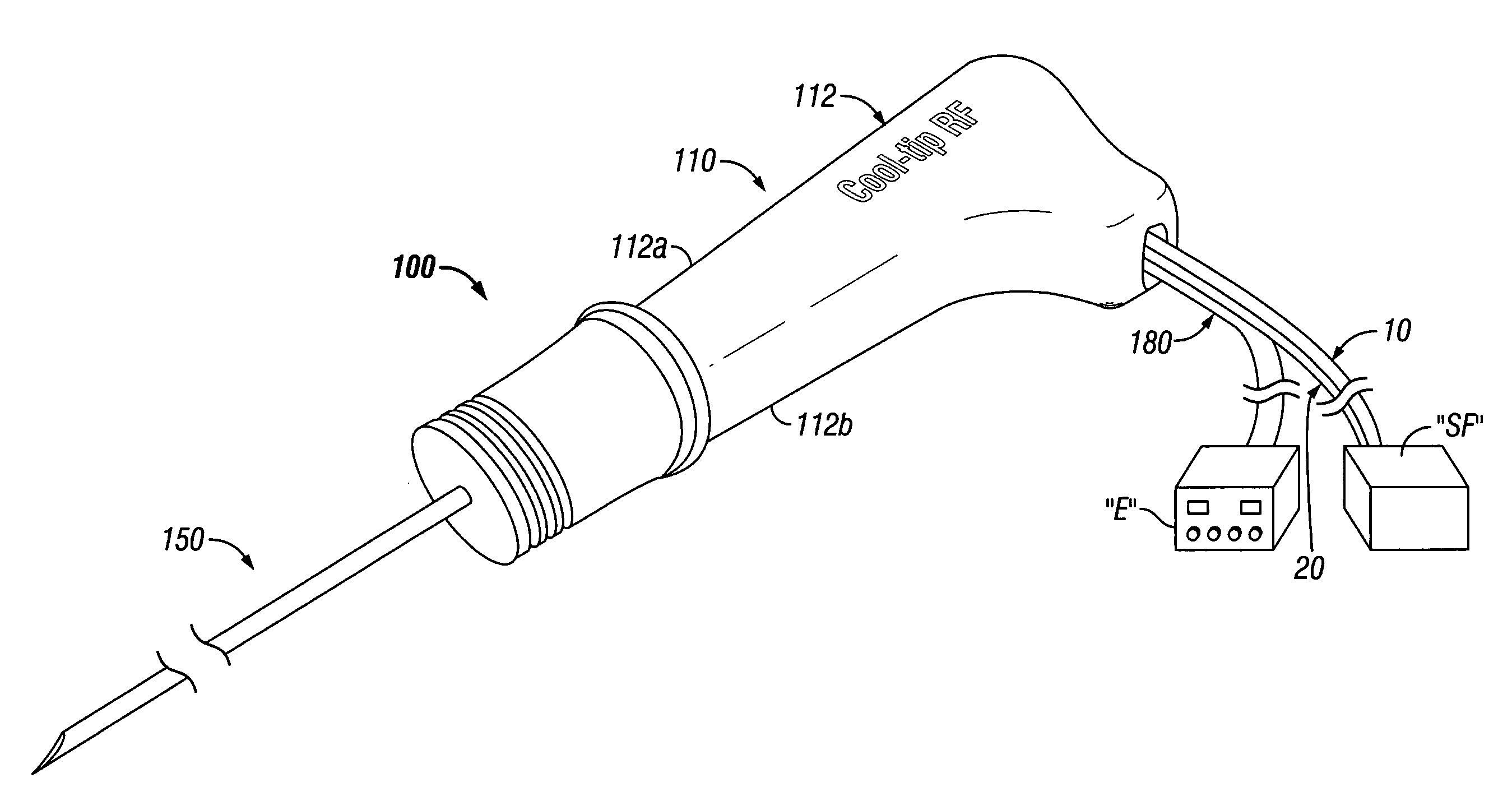

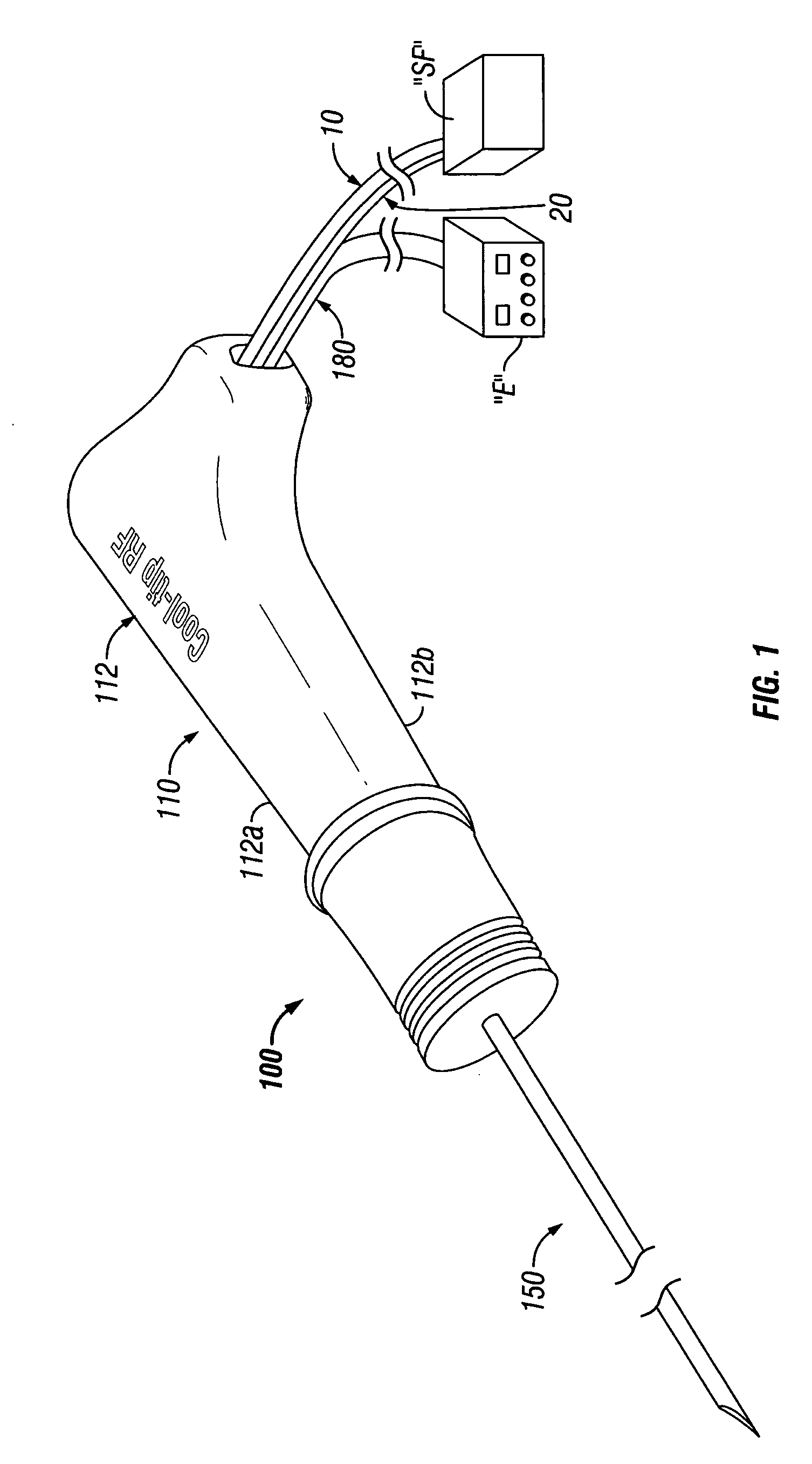

Cool-tip thermocouple including two-piece hub

An ablation electrode system includes a handle assembly; a needle electrode assembly supported in and extending from the handle assembly. The needle electrode assembly includes an outer tube having at least a conductive distal tip and defining a cavity therein; and an inner tube disposed at least partially within the cavity of the outer tube and defining a lumen therein. The ablation electrode assembly includes a hub assembly fluidly connected to the needle electrode assembly. The hub assembly defines a first chamber and a second chamber; wherein the proximal end portion of the inner tube is in fluid communication with the first chamber and the proximal end portion of the outer tube is in fluid communication with the second chamber. The ablation electrode assembly includes a first fluid conduit fluidly connected to the first chamber; and a second fluid conduit fluidly connected to the second chamber.

Owner:COVIDIEN AG

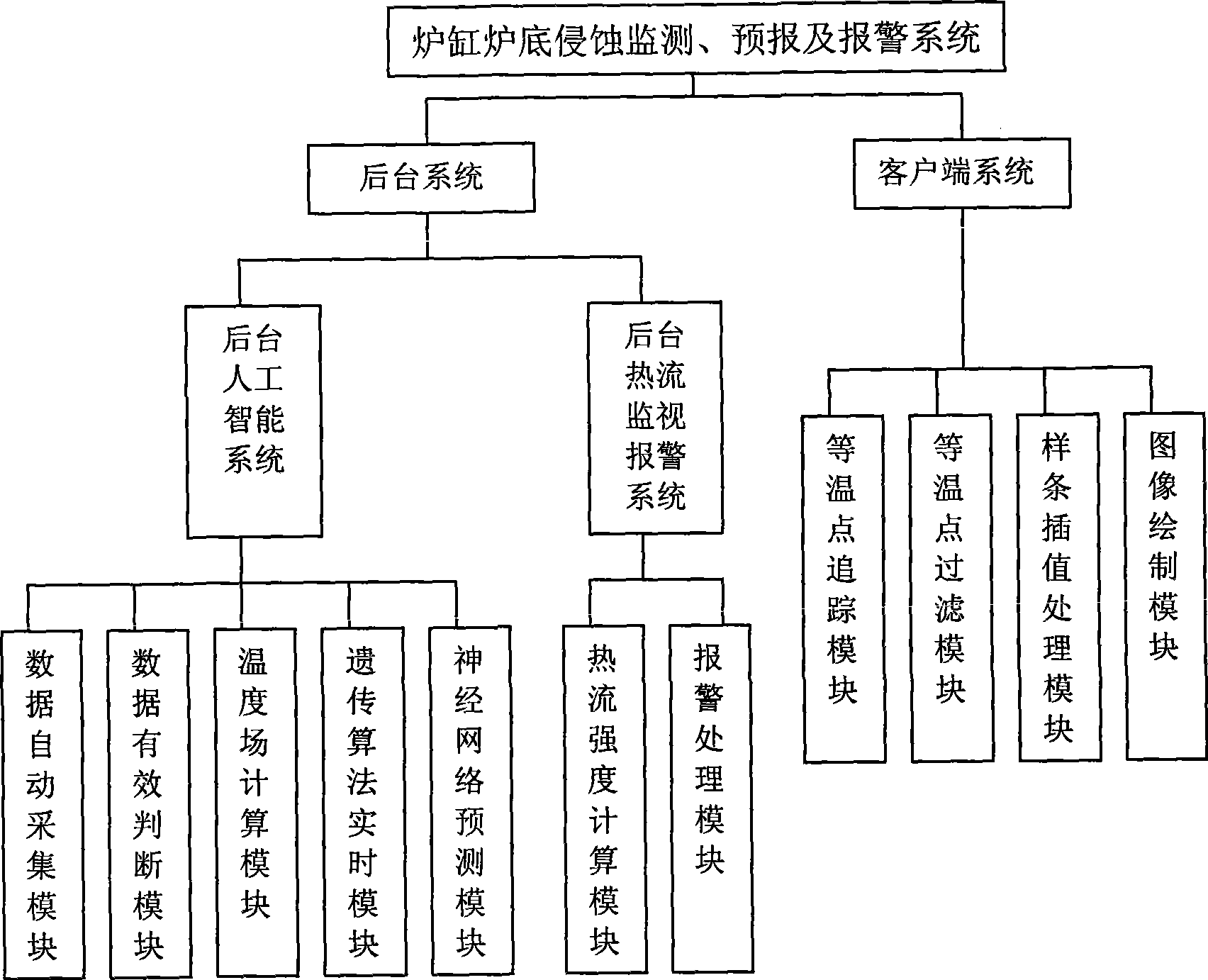

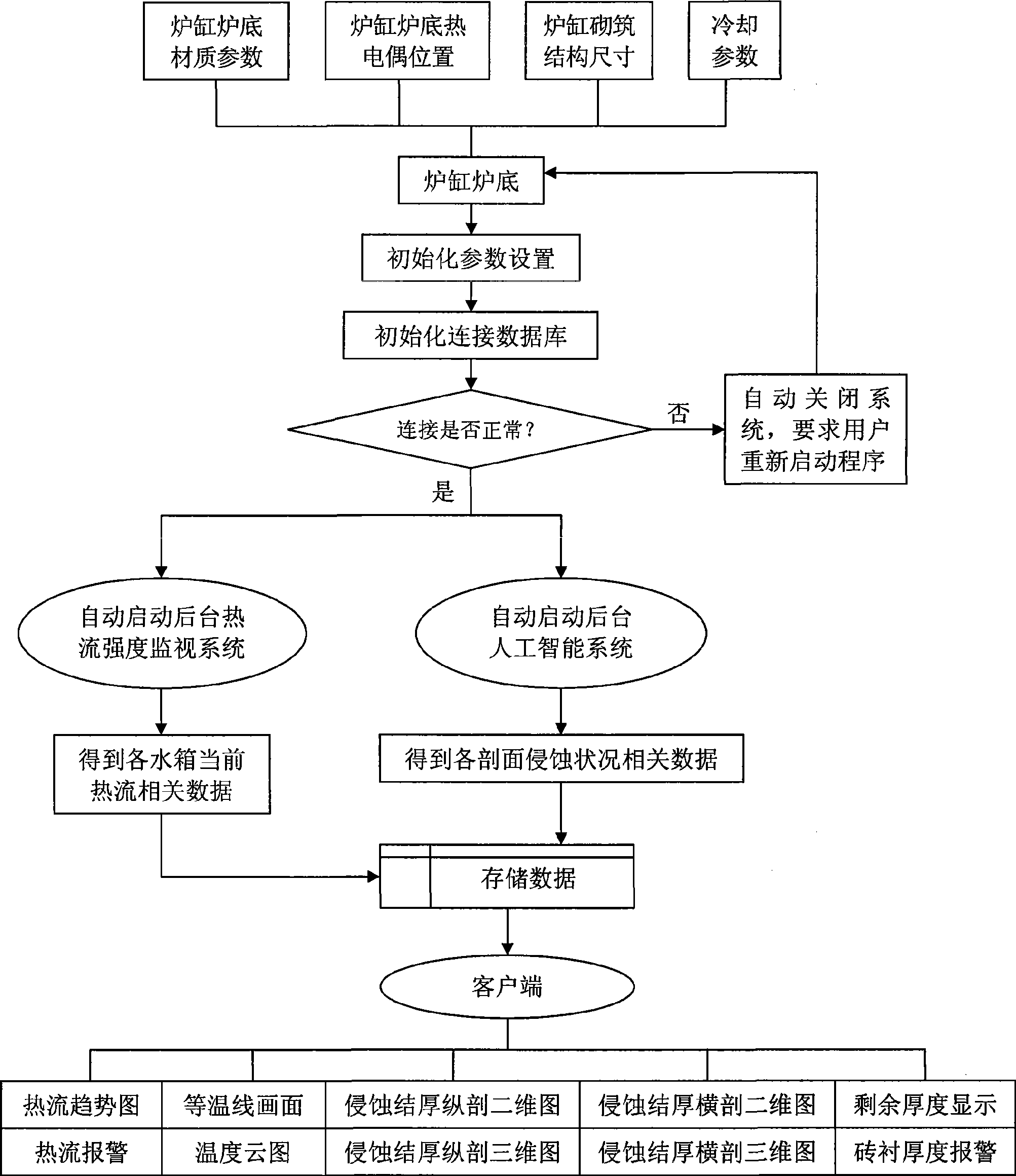

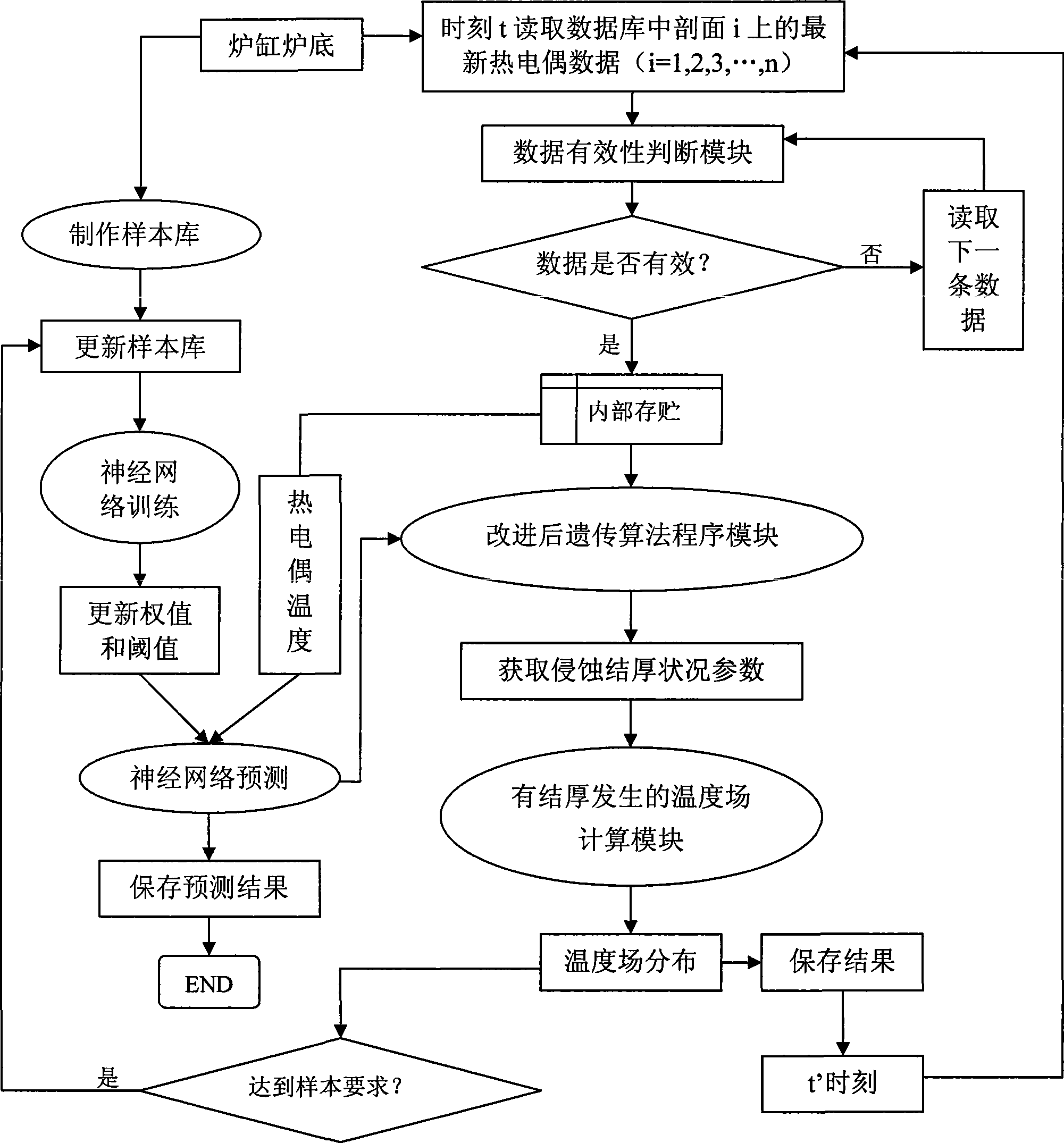

Monitoring, prediction and alarm system for blast furnace hearth and bottom

InactiveCN101457268ARealize online monitoring and alarmImplement storageThermometers using electric/magnetic elementsUsing electrical means3d imageData acquisition

A monitoring, forecasting and alarm system of the bottom and hearth of a blast furnace belongs to the longevity technical field of blast furnaces. The system comprises online monitoring and forecasting hardware and software processing modules; the online monitoring and forecasting hardware consists of a thermocouple and a cooling system which are laid at the furnace hearth and the furnace bottom, and a database of the blast furnace production process is connected by the Ethernet; the software processing modules comprise a data acquisition module, a data validity judgment module, a temperature field computation module, an improved genetic algorithm module, a B-P neural network module, a database, an isotherm, an erosion and thickening image display module, a 3D imaging module, a heat flow monitoring and alarm module and a historical data query module; and the software processing modules are operated on an industrial control computer. The monitoring, forecasting and alarm system has the advantages of low investment, reliability and visualization. The system provides an objective and quantized basis for the erosion and thickening erosion condition of the furnace hearth and the furnace bottom in the blast furnace ironmaking process, and helps a blast furnace operator timely know the condition of the furnace hearth and the furnace bottom and take effective furnace protection measures so as to prolong the service life of the blast furnace.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

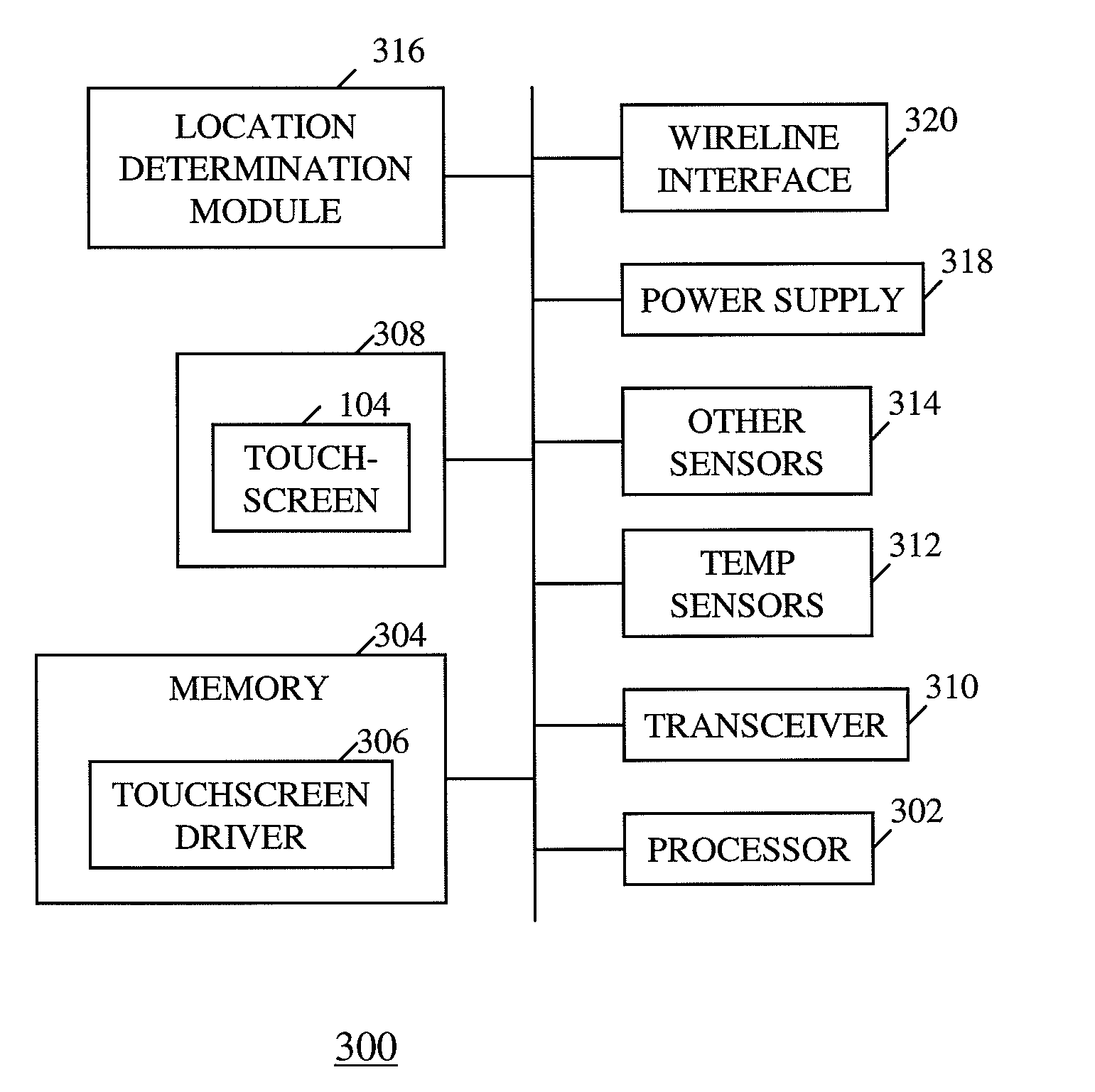

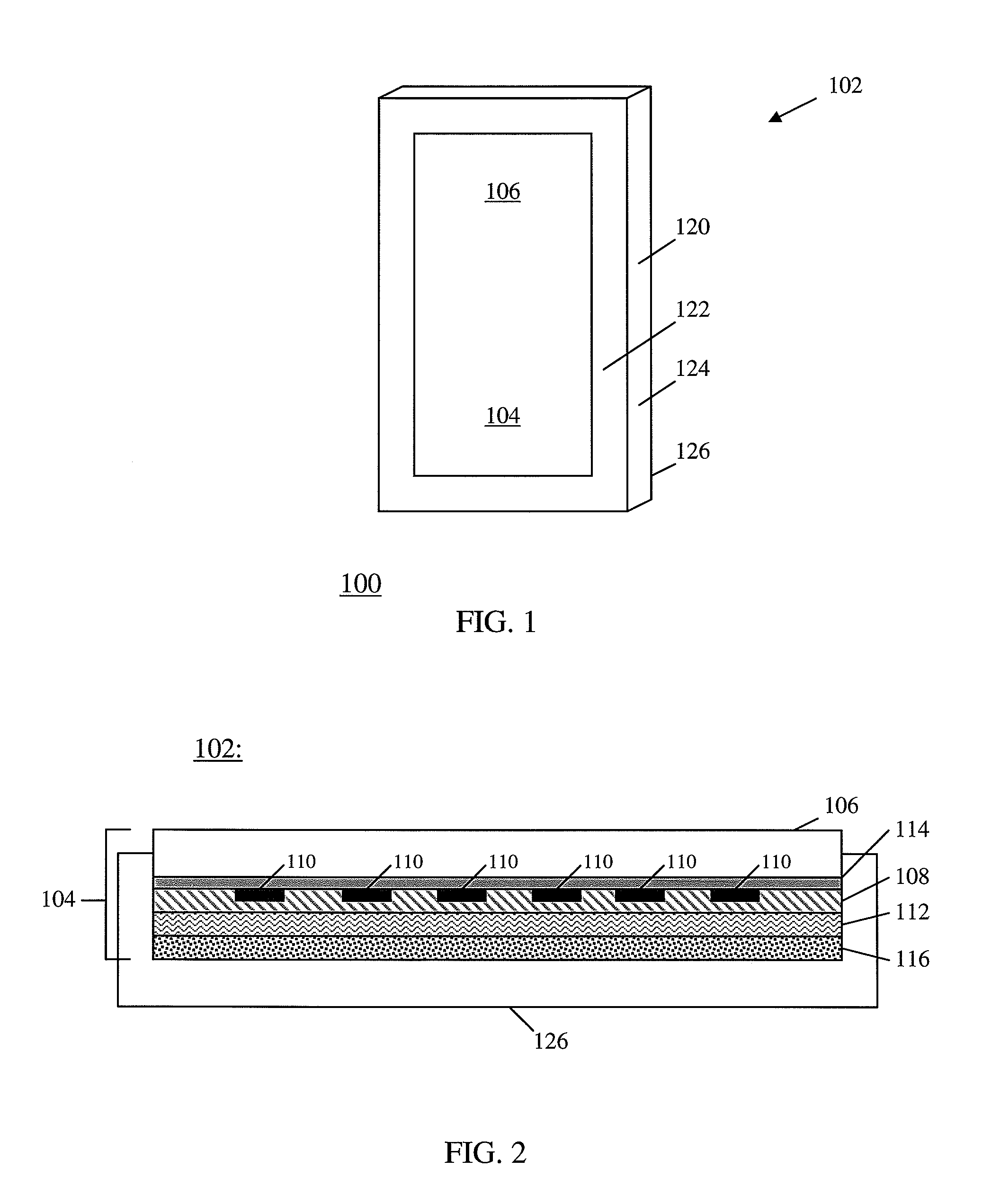

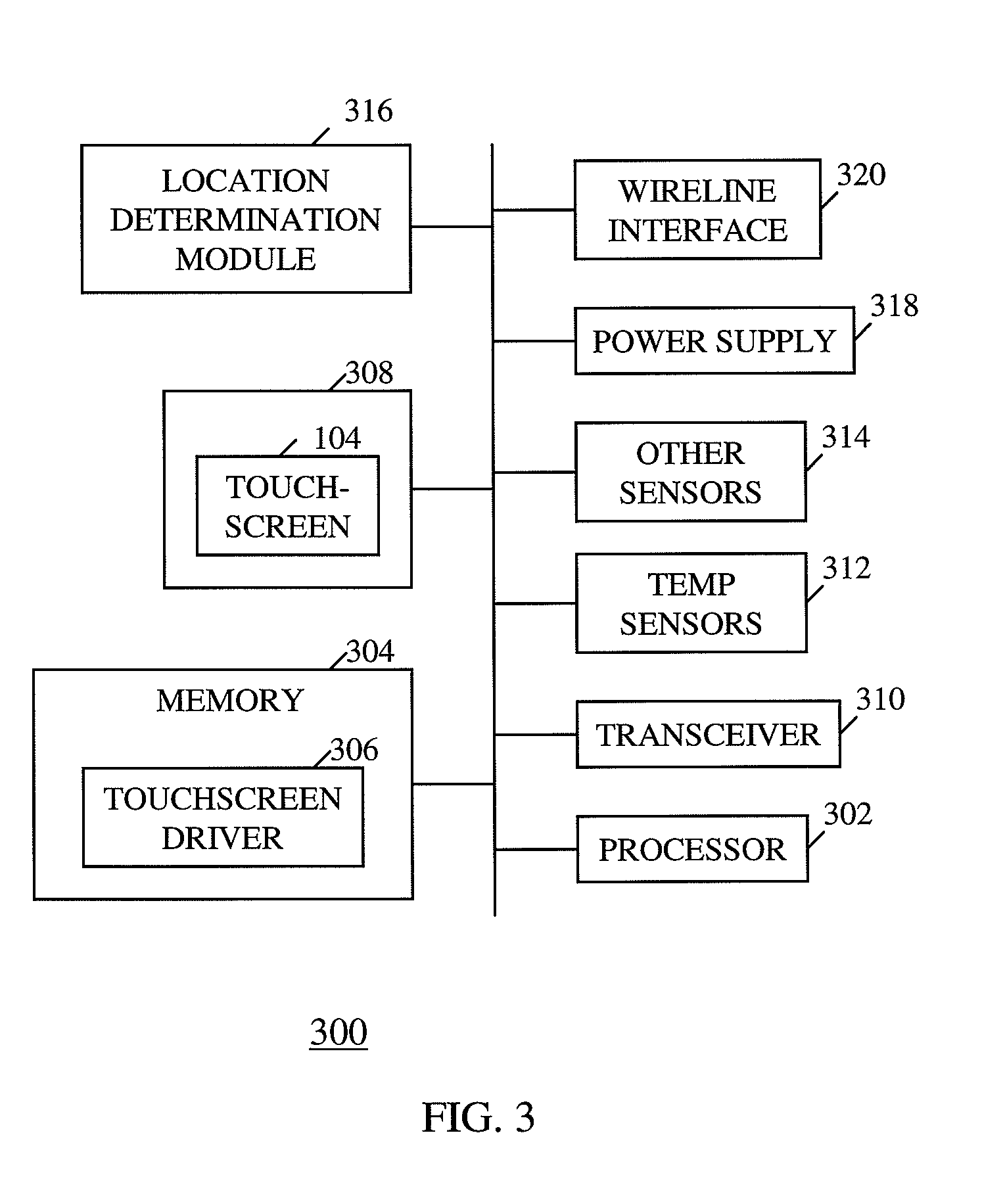

User computer device with temperature sensing capabilities and method of operating same

InactiveUS20120068952A1Digital data processing detailsThermometers using electric/magnetic elementsThermal energyDocking station

A user computer device is provided that comprises a temperature sensitive touchscreen having a temperature sensitive user interface comprising multiple thermal energy emitter / detector devices, such as thermocouples. The multiple thermal energy emitter / detector devices are capable both of detecting thermal energy and emitting thermal energy. The temperature sensitive user interface generates thermal patterns that may be transferred to other thermally sensitive electronic devices or that may be used to authenticate the user computer device. The user computer device also can detect and thermally communicate with a thermal energy docking station and, based on thermal recognition, activate applications displayed on the temperature sensitive touchscreen. Further, the user computer device can auto-bias a temperature of the temperature sensitive user interface in order to better assure proper operation of the temperature sensitive user interface in all operating conditions.

Owner:GOOGLE TECH HLDG LLC

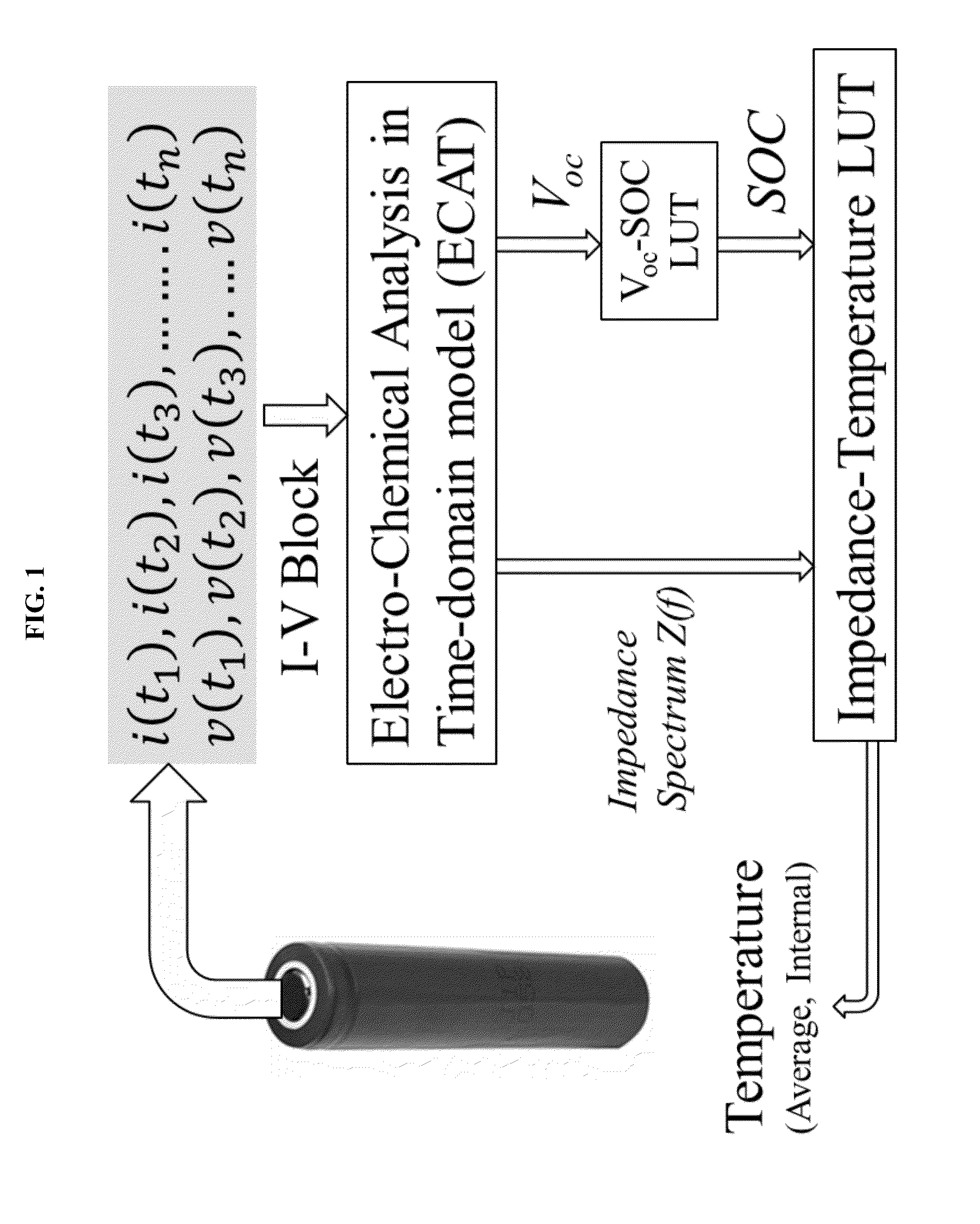

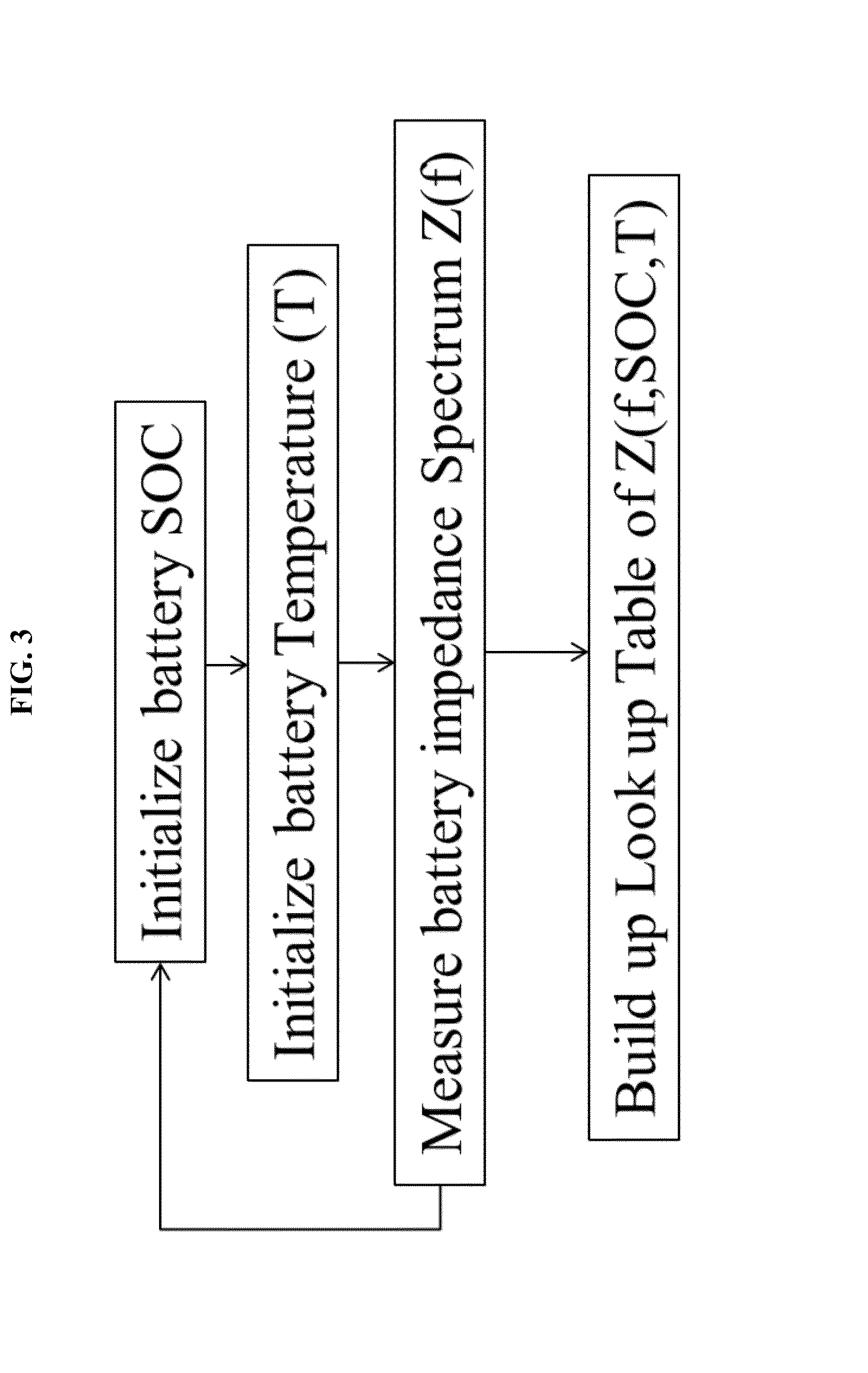

Methods and apparatus for sensing the internal temperature of an electrochemical device

ActiveUS20140372055A1Improve accuracy and reliabilityImprove battery safetyElectric devicesThermometers using electric/magnetic elementsElectrical batteryEngineering

The internal temperature of an electrochemical device may be probed without a thermocouple, infrared detector, or other auxiliary device to measure temperature. Some methods include exciting an electrochemical device with a driving profile; acquiring voltage and current data from the electrochemical device, in response to the driving profile; calculating an impulse response from the current and voltage data; calculating an impedance spectrum of the electrochemical device from the impulse response; calculating a state-of-charge of the electrochemical device; and then estimating internal temperature of the electrochemical device based on a temperature-impedance-state-of-charge relationship. The electrochemical device may be a battery, fuel cell, electrolytic cell, or capacitor, for example. The procedure is useful for on-line applications which benefit from real-time temperature sensing capabilities during operations. These methods may be readily implemented as part of a device management and safety system.

Owner:HRL LAB

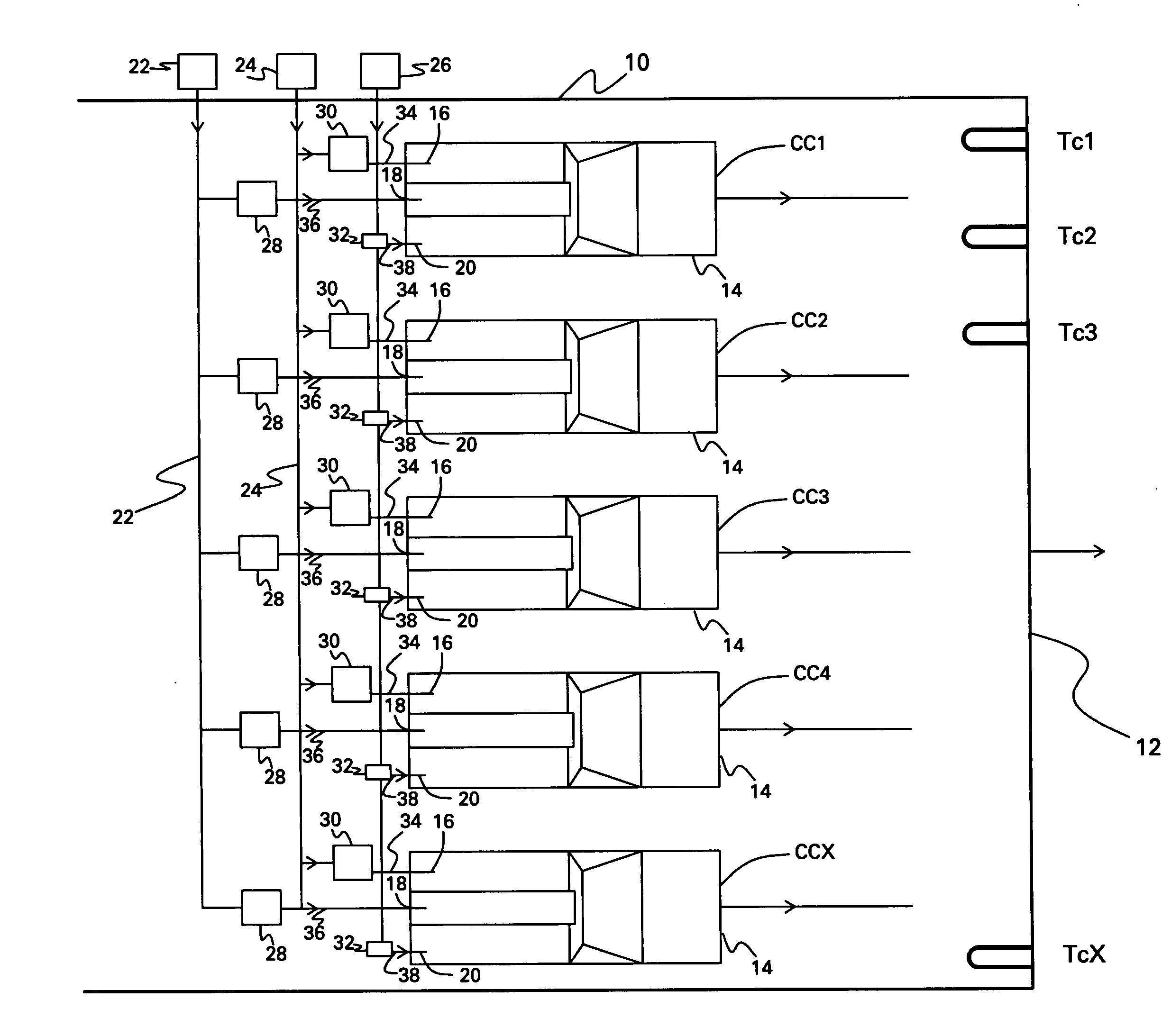

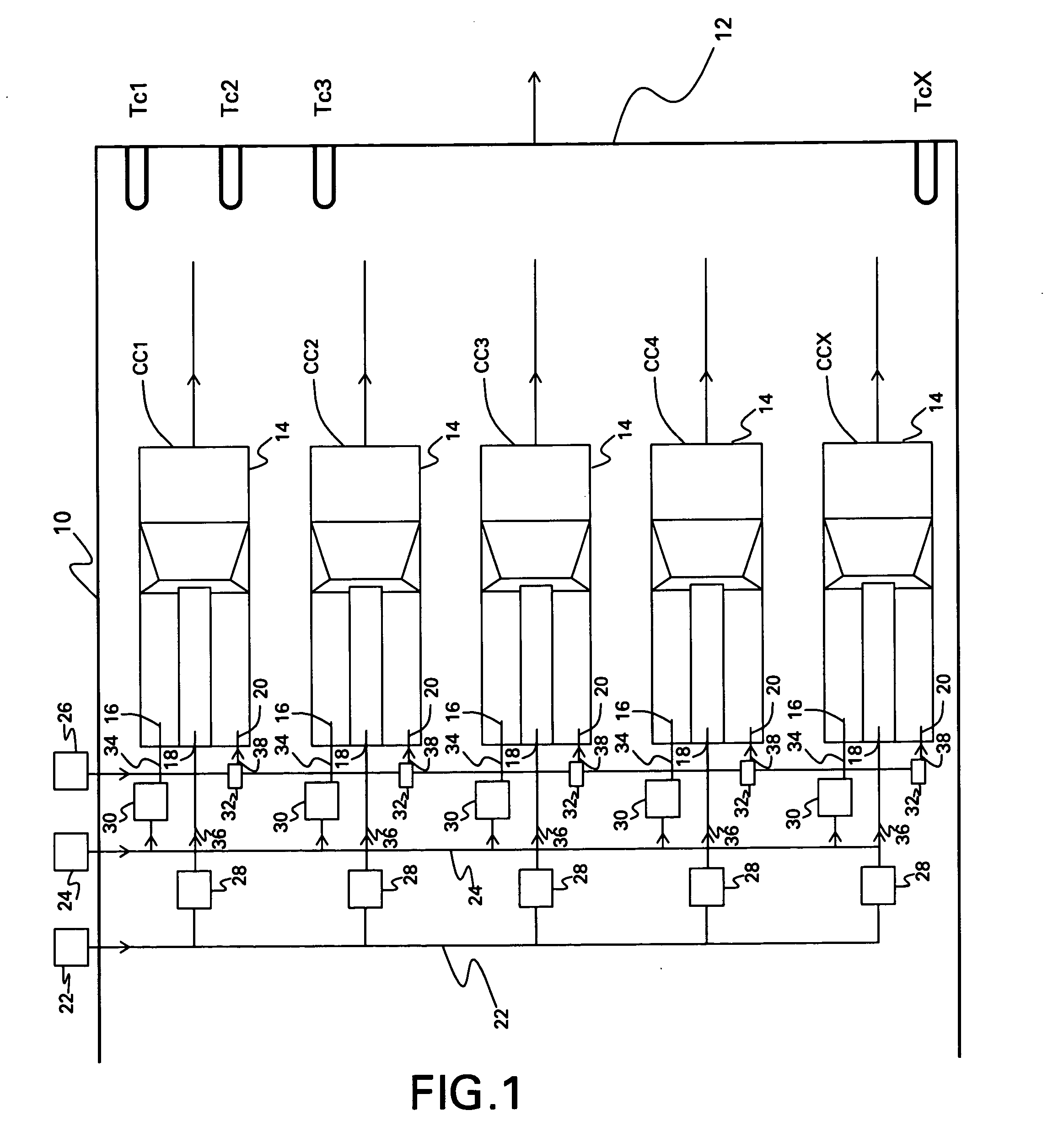

Method and apparatus for actuating fuel trim valves in a gas turbine

ActiveUS20050097895A1Minimized pressure dropOvercomes shortcomingFuel supply regulationContinuous combustion chamberCombustion chamberNitrous oxide

The gas turbines of the present invention have multiple combustion chambers, and within each chamber are multiple fuel nozzles. Each nozzle has its own fuel control valve to control the fuel flowing to the nozzles. To minimize the pressure drop through the fuel control valves, multiple manifolds are employed. Each manifold supplies at least one fuel nozzle in multiple combustion chambers with fuel. The fuel control valves are mounted on the manifolds such that the weight of the fuel control valves and nozzles are carried by the manifolds, not the multiple combustion chambers. A plurality of thermocouples for measuring exhaust gas from said multiple combustion chambers are employed to sense gas exhaust temperature. In carrying out the methods of the present invention for tuning a gas turbine, it is essential to note that the most efficient gas turbine is one which has the least nitrous oxides, the least amount of unburned hydrocarbons, and the least amount of carbon monoxide for a specified energy output. In order to tune the gas turbine to accomplish these objectives, it is desirable that each combustion chamber in the gas turbine be well balanced relative to the remaining combustion chambers. It is an aim of the present invention to tune each of the multiple combustion chambers such that no specific combustion chamber is rich or lean, and all are operating within about 1% of the remaining combustion chambers.

Owner:GENERAL ELECTRIC CO

Combustible burning rate test device in plateau artificial oxygen-enriched environment

InactiveCN101509908AStable and reliable test performanceChemical analysis using combustionMaterial heat developmentCombustion chamberGas composition

The invention provides a testing device for the combustion rate of combustibles in a plateau artificial oxygen-enriched environment, belonging to a field of fire safety. The testing device consists of the following seven parts: a combustion chamber, a positioning mechanism, an air distribution system, an airflow-circulation and concentration-monitoring system, a vacuum-pumping system, an ignition system and a data acquisition system. A sample is arranged on a sample support by a sample clamper, and then vacuum-pumping is carried out to a sealed chamber by the vacuum-pumping system; each single high-purity gases are mixed in the sealed chamber after passing through a mass flowmeter and a flow regulating valve; the total pressure of the gases is displayed by a high-precision vacuum manometer; when the requirements of the total pressure of the gases and gas compositions are met, a micro-air pump is started to mix the airflow in the sealed chamber; a laser light source is started to ignite the sample after the concentration of the gas compositions is steady; the sample combustion flame passes through two thermocouples sequentially; temperature change curves of the thermocouples are obtained by A / D conversion and the data acquisition system; and the time between two maximum temperature points of the curves corresponding to the two thermocouples is taken as the combustion time of the sample between the thermocouples with fixed distance, thus obtaining the combustion rate of the sample under the total pressure of the gases and the concentration of the gas compositions. The testing device has stable and reliable testing performance, and is simple and convenient.

Owner:UNIV OF SCI & TECH BEIJING

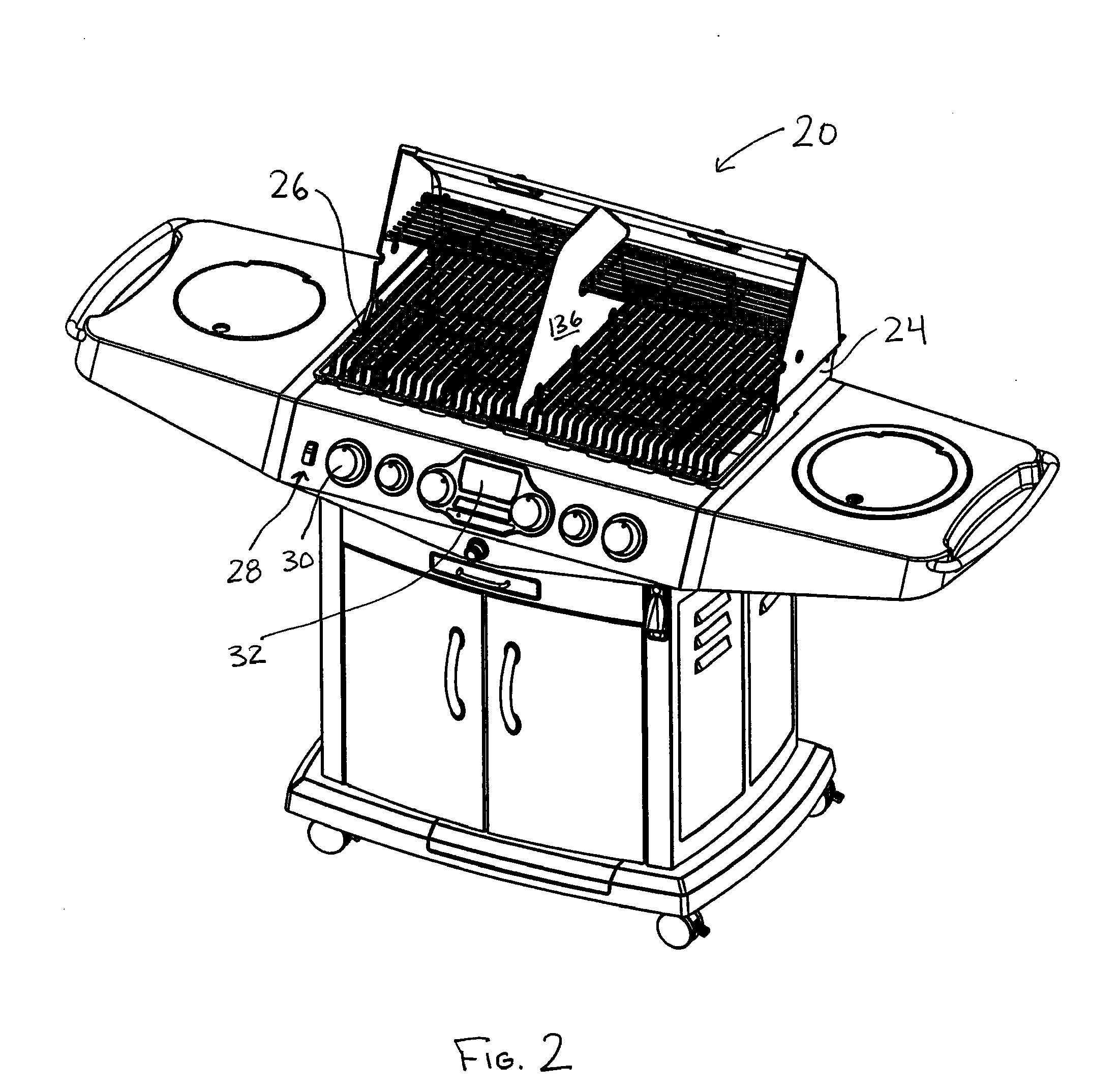

Oven or grill burner, venturi tube, mounting for a thermocouple and/or an igniter, and process for fabricating said burner

ActiveUS20050138789A1Function increaseStrong construction adaptabilityDomestic stoves or rangesBurner manufactureCombustorCoupling

The invention relates to a burner comprising two half shells, one of which is perforated, that are tightly joined together along at least a portion of their edges, so as to form a tubular body communicating with a venturi tube. At least two corresponding ends of the two half shells have a truncated profile, providing the tubular body has at least one truncated end. The invention also relates to a venturi tube for said burner that is composed of two half shells The invention further relates to a mounting for a thermocouple and for an igniter of said burner, the mounting having coupling means that cause mutual contact surfaces to be oriented in at least three non-parallel planes and that prevent mounting rotation, so that the position thereof is accurately defined. The invention also relates to a process for fabricating said burner.

Owner:CAST SPA

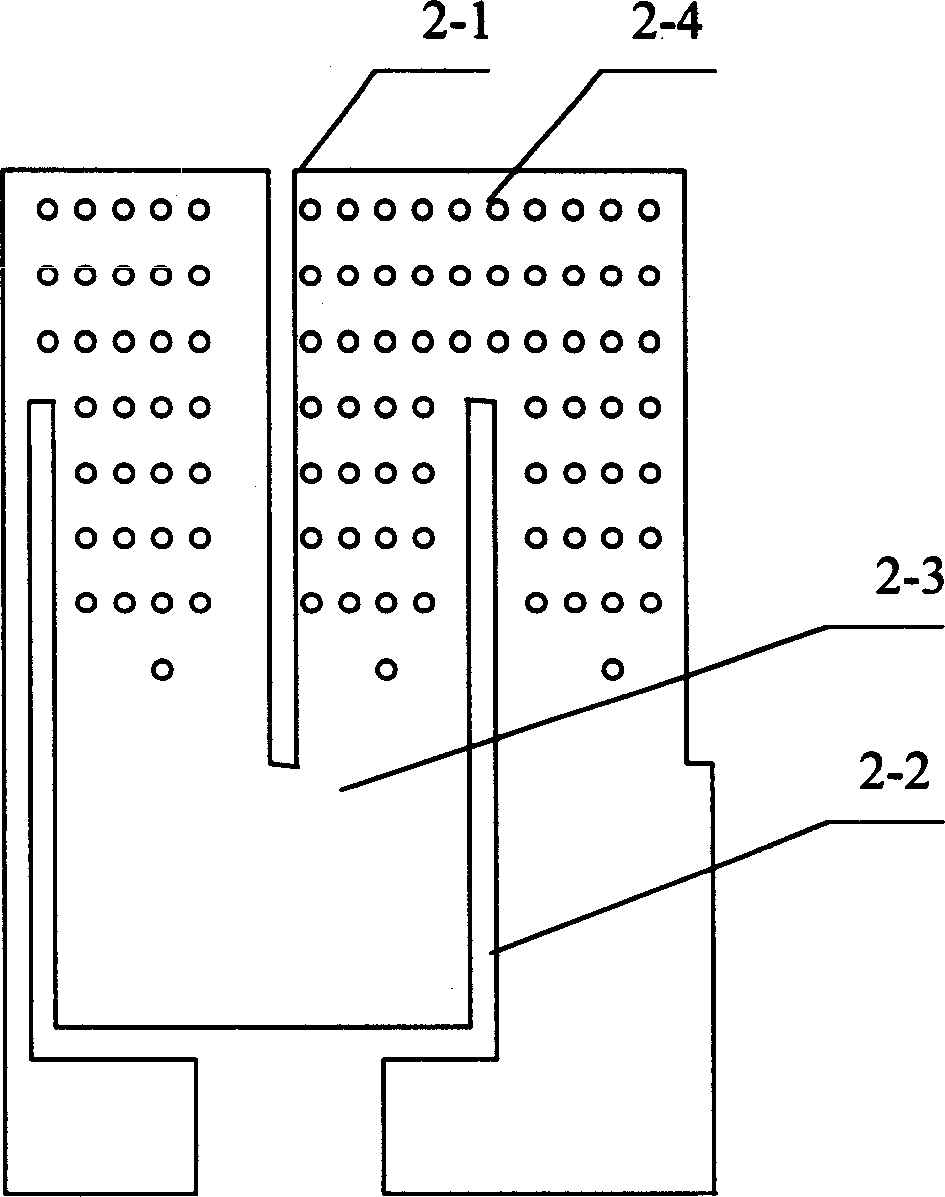

Growth apparatus for large-areaed crystal by temperature gradient technique and crystal growth method thereof

InactiveCN1485467AIn-situ annealingDynamic adjustment of temperature gradientFrom frozen solutionsEngineeringAbnormal shaped

A temperature-gradient device for growing crystals with large area and a method of growing crystals. The device comprises a bell-like vacuum resistance oven, cone crucible and a heater in the oven, the crucible at the center of the oven, the heater comprising main cylinder heater of graphite and auxiliary cone heater with an irregular shape, vacuum system, UPS regulated power supply, two sets of controllable silicon trigger circuits, two sets of temperature controllers. The device could adjust automatically temperature gradient in growing crystals.The invention could grow complete nonsplitingcrystals with the size of more than 5 inch.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com