Combustible burning rate test device in plateau artificial oxygen-enriched environment

A technology of combustion rate and testing device, which is applied in the field of fire safety, can solve problems affecting the combustion process of samples, oxygen consumption, and experimental results, and achieve stable and reliable test performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

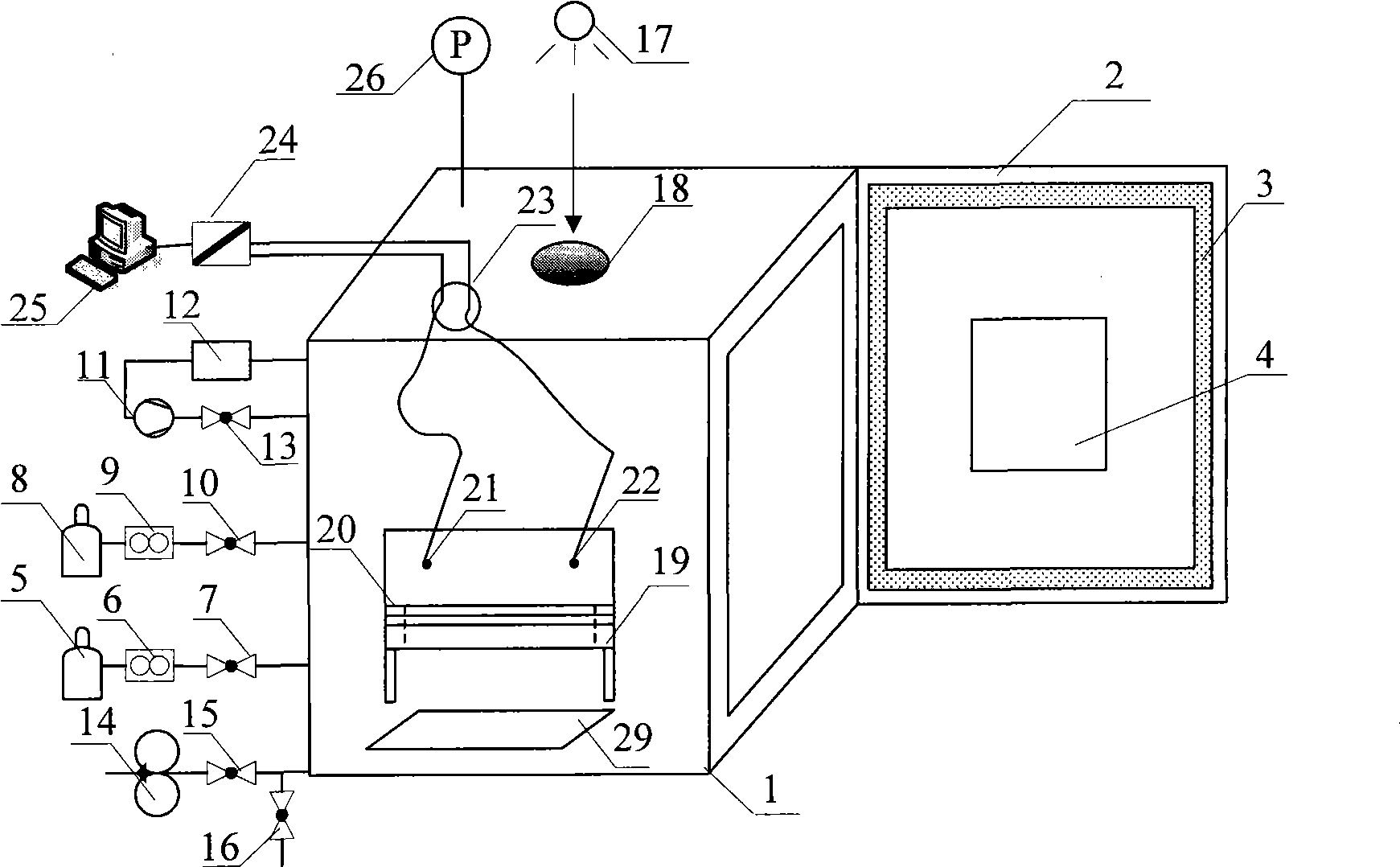

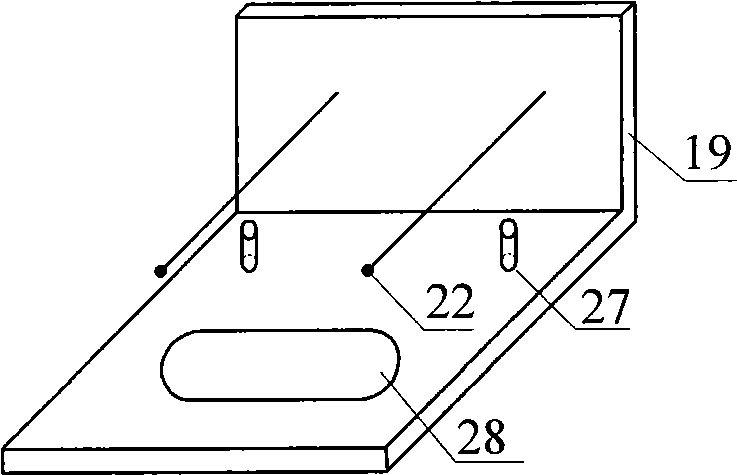

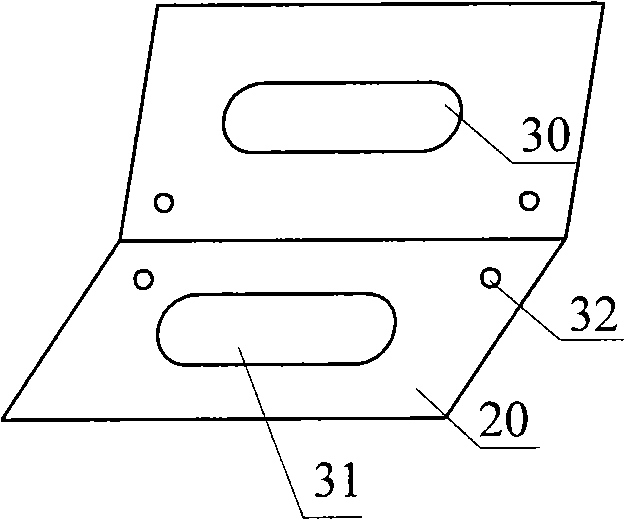

[0022] The implementation example of the present invention carries out the combustion rate test on the combustible filter paper by simulating the atmospheric pressure at different altitudes and different oxygen concentrations at the same atmospheric pressure. Design the volume of the required combustion space according to the amount of oxygen required for complete combustion of the hydrocarbon content in the filter paper and the requirement to maintain a 1% error. In this implementation example, take a piece of filter paper with a diameter of 11.1cm and a mass of 0.7685g, and the size of the filter paper is 10×50mm 2 , its mass is 0.037g and its molar weight is: 0.037 / 163=2.284×10 -4 mol, complete combustion 2.284×10 -4 mol C 6 h 10 o 5 0.00137mol of oxygen is needed, and 1L of standard atmosphere contains oxygen: 0.209 / 22.4=0.00933mol. When the oxygen consumption accounts for the total oxygen content within 1%, regardless of the impact of the reduction of oxygen in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com